Patents

Literature

1657results about How to "Fully dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

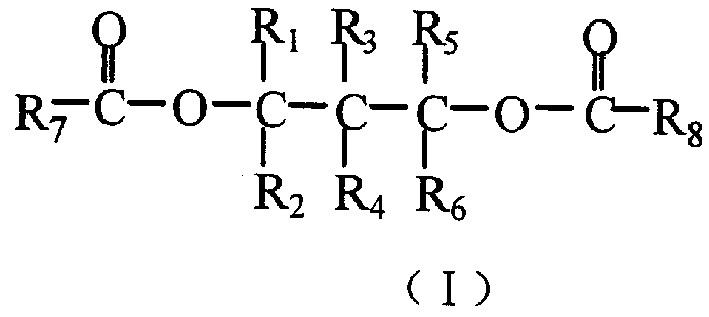

Catalyst for olefine polymerizing reaction and its components

The present invention provides one kind catalyst component for CH2=CHR olifine polymerization, where R is H or alkyl radical or aryl radical of C1-C6. The catalyst component contains Mg, Ti, halogenand electron donor.

Owner:CHINA PETROLEUM & CHEM CORP +1

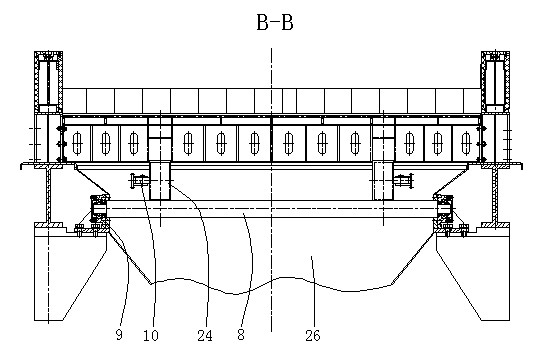

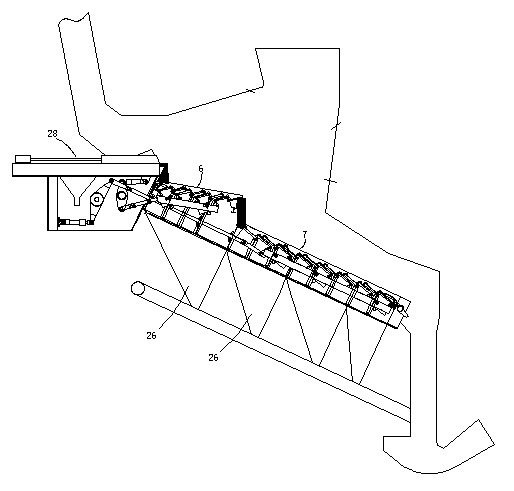

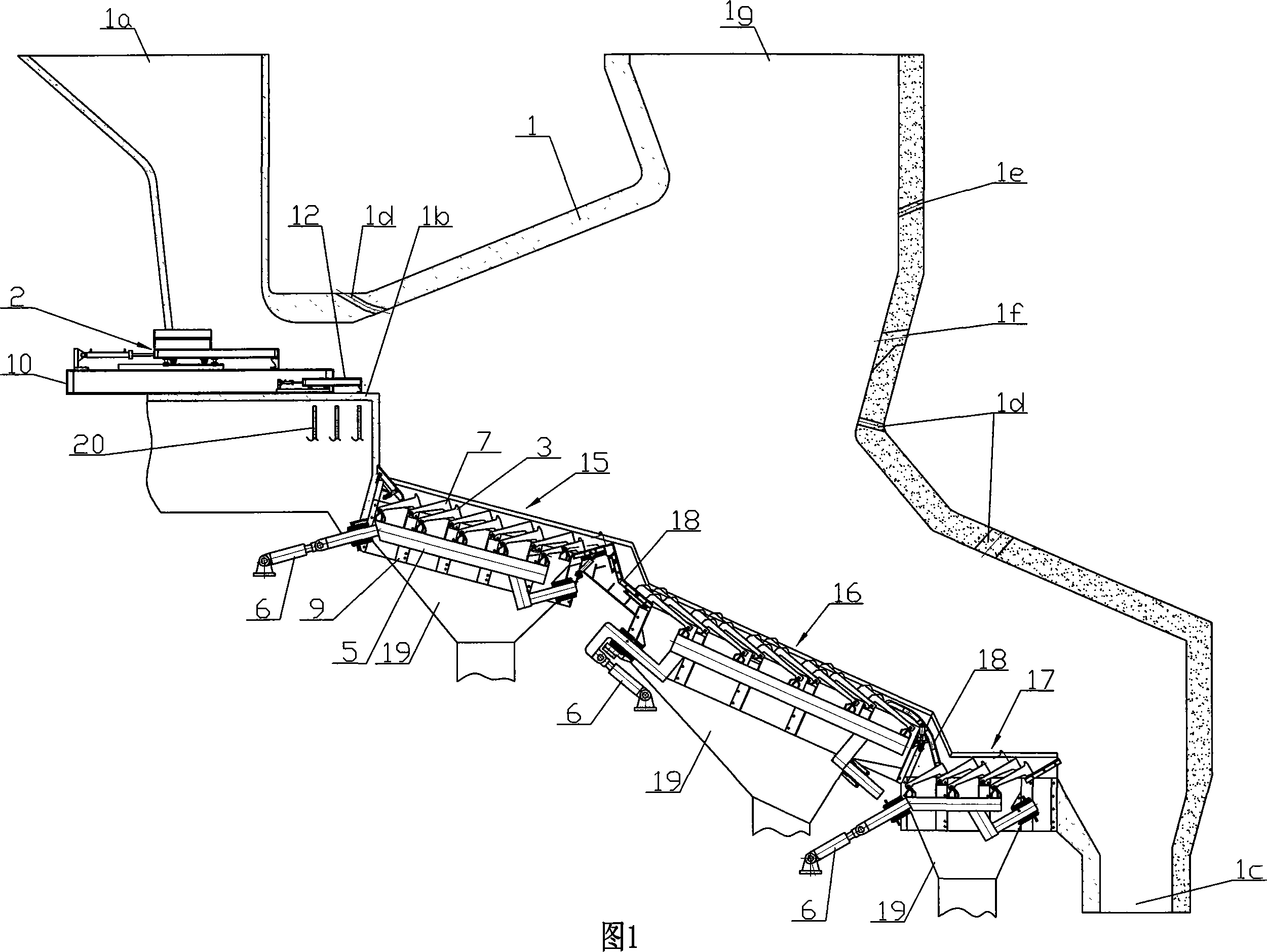

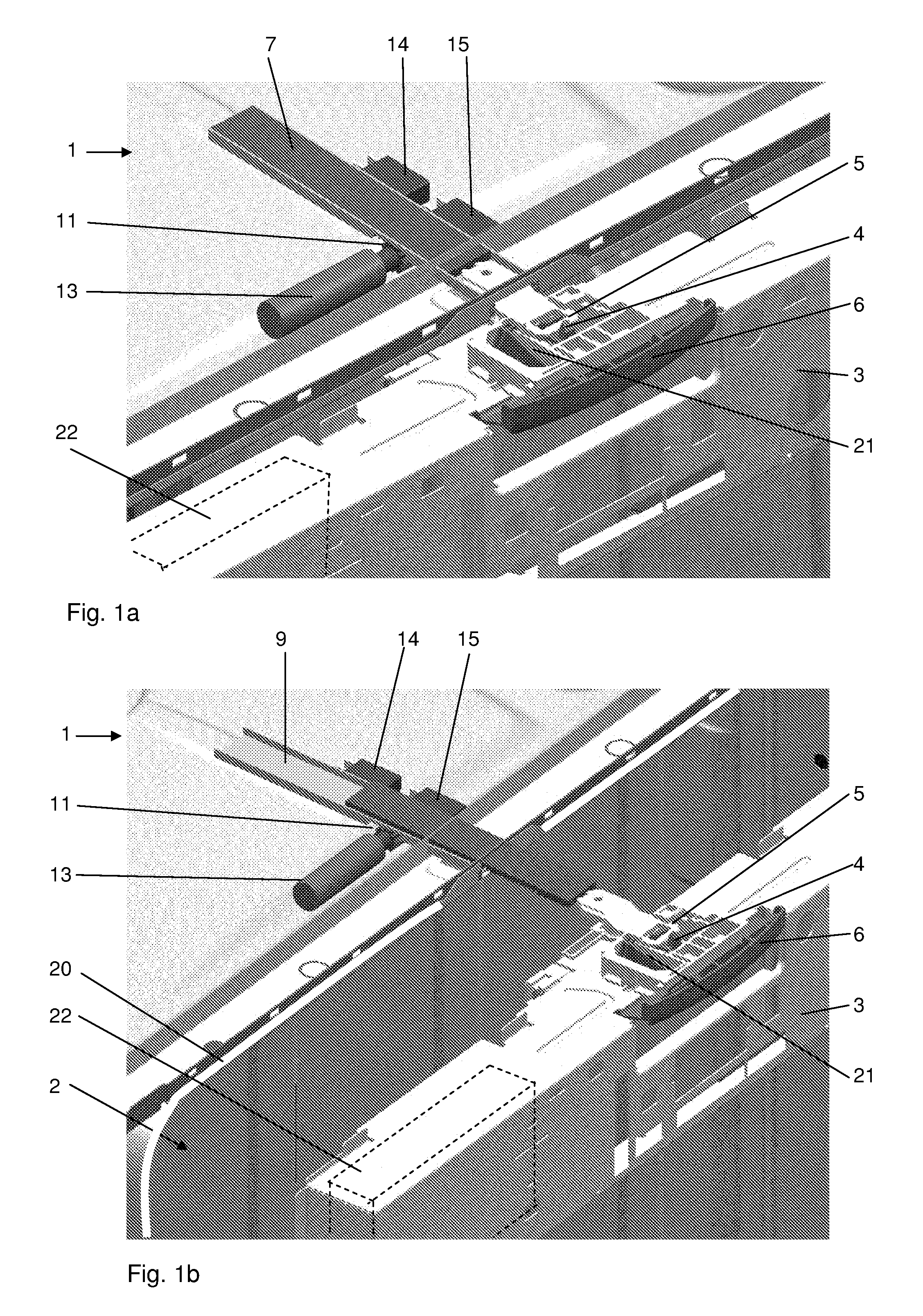

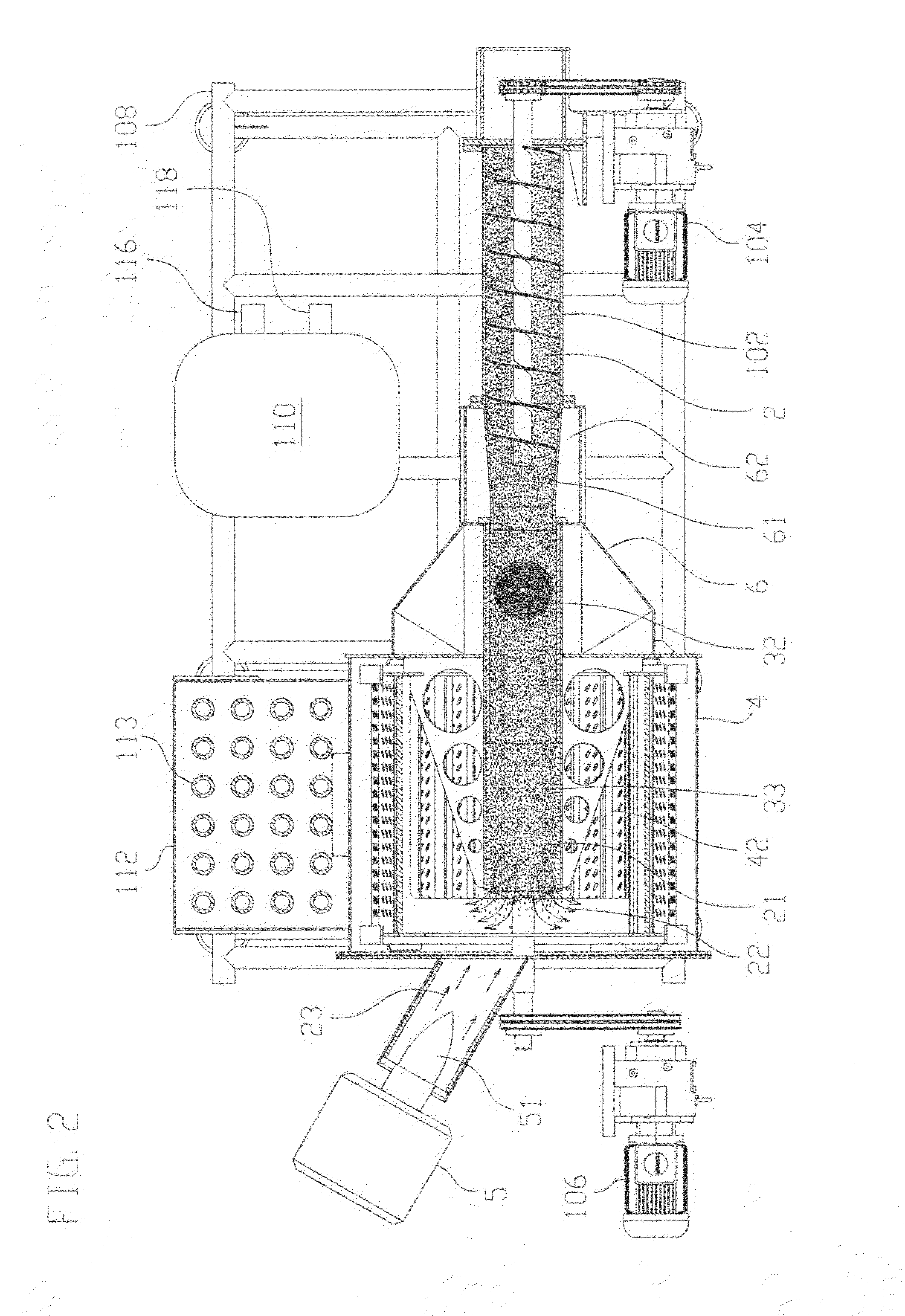

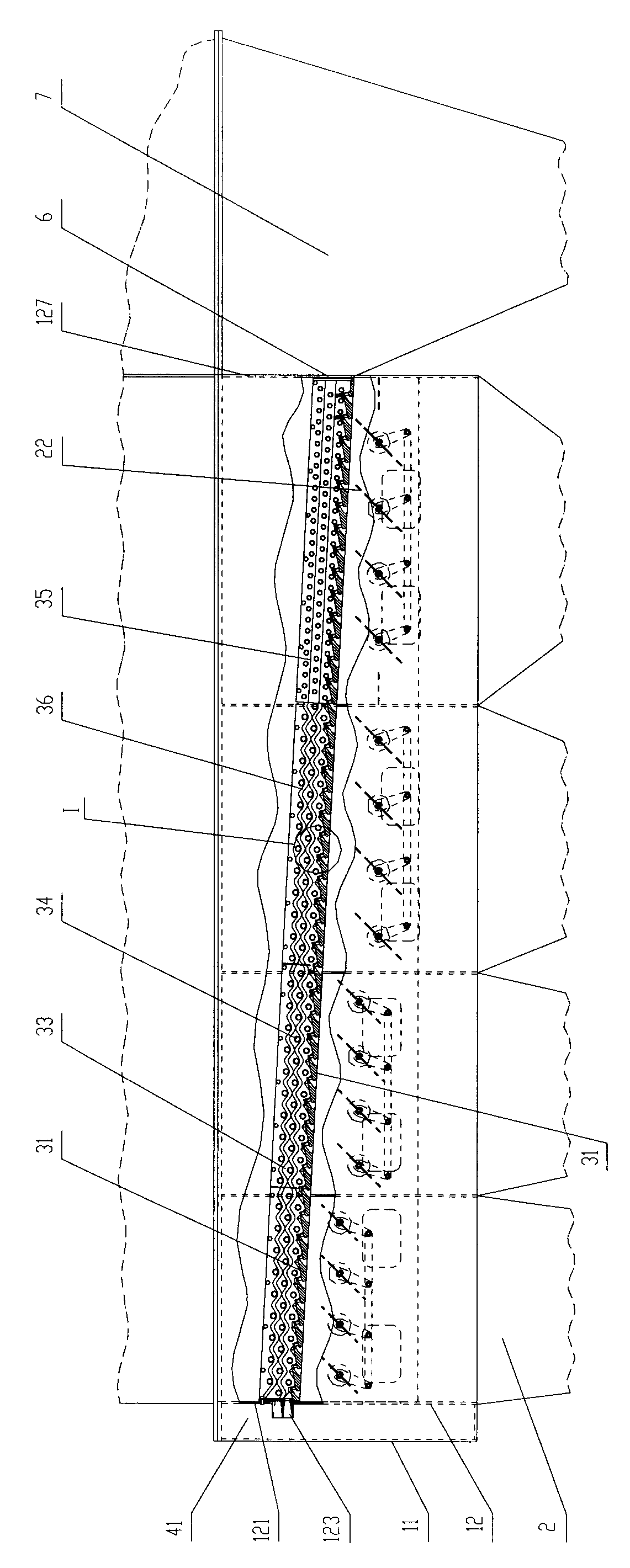

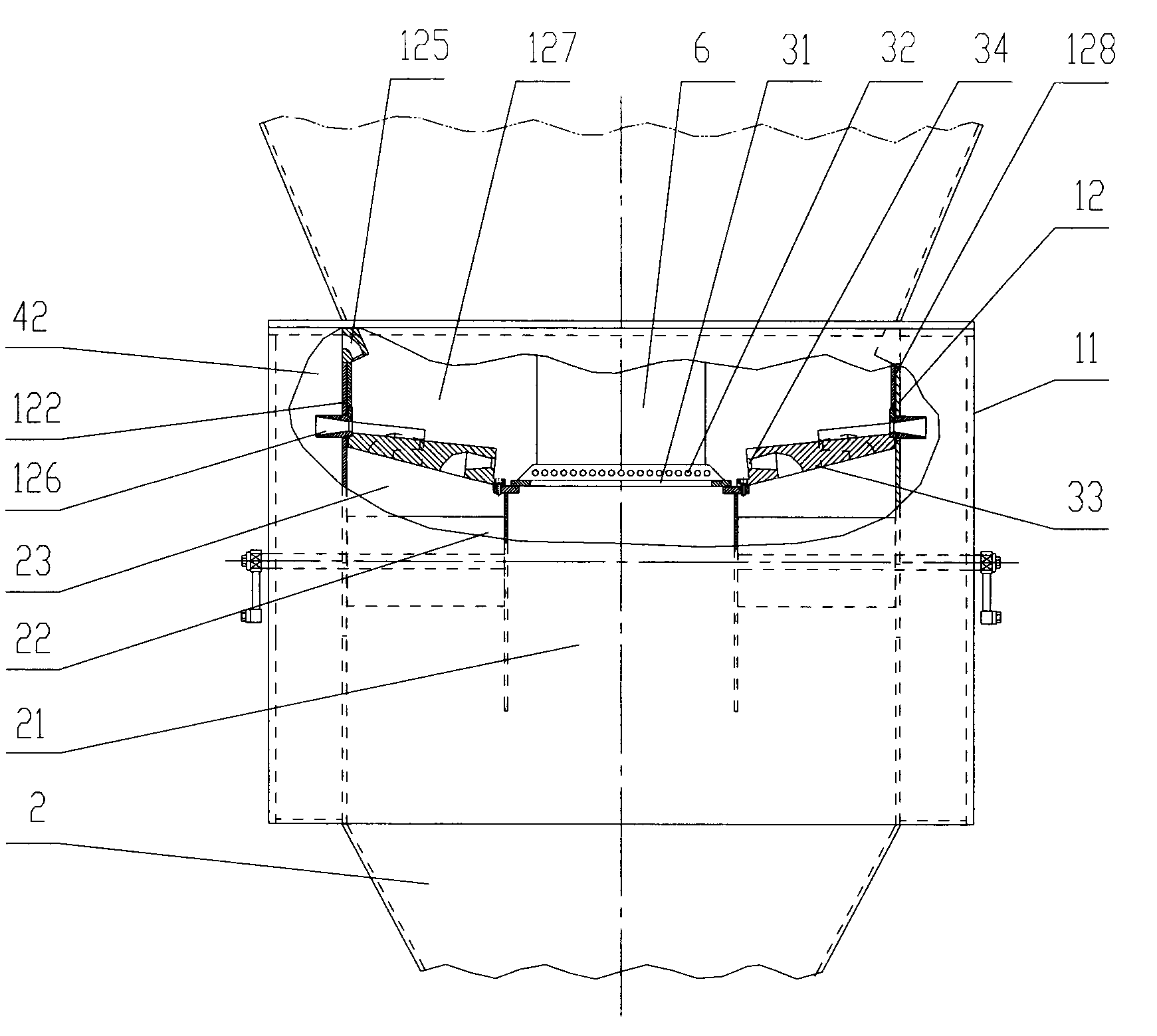

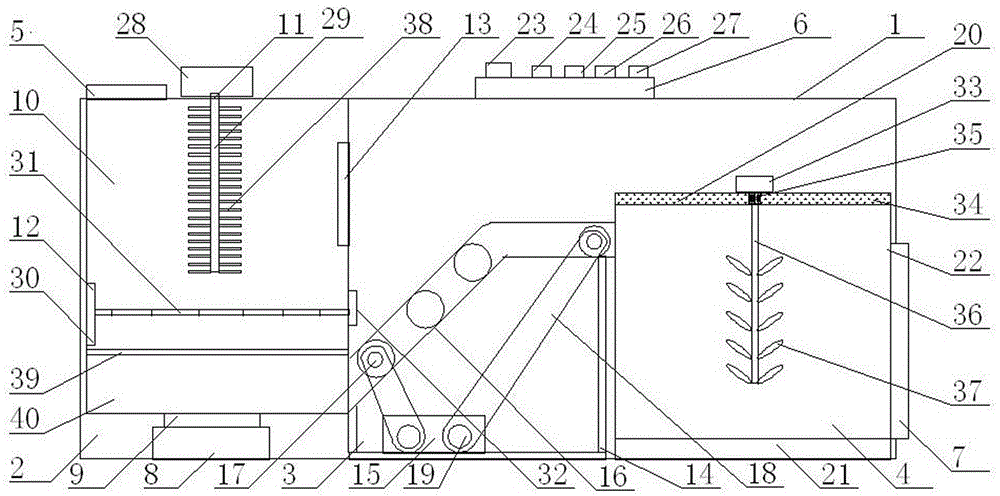

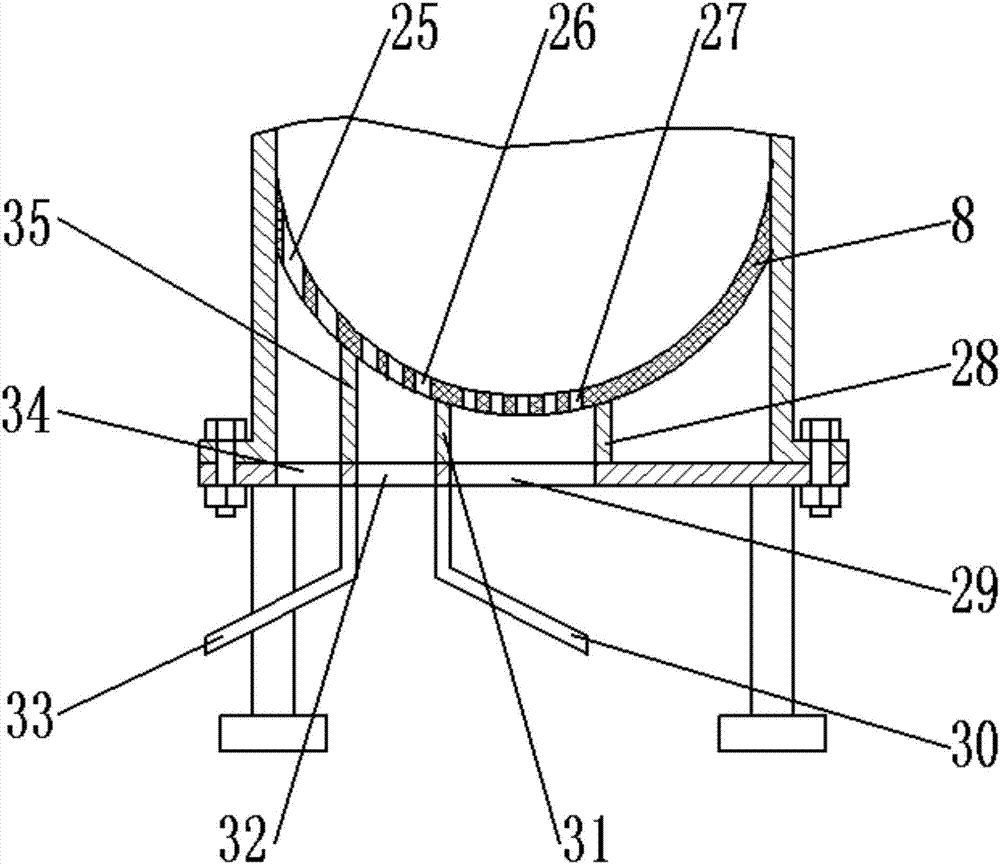

Two-stage garbage incinerator

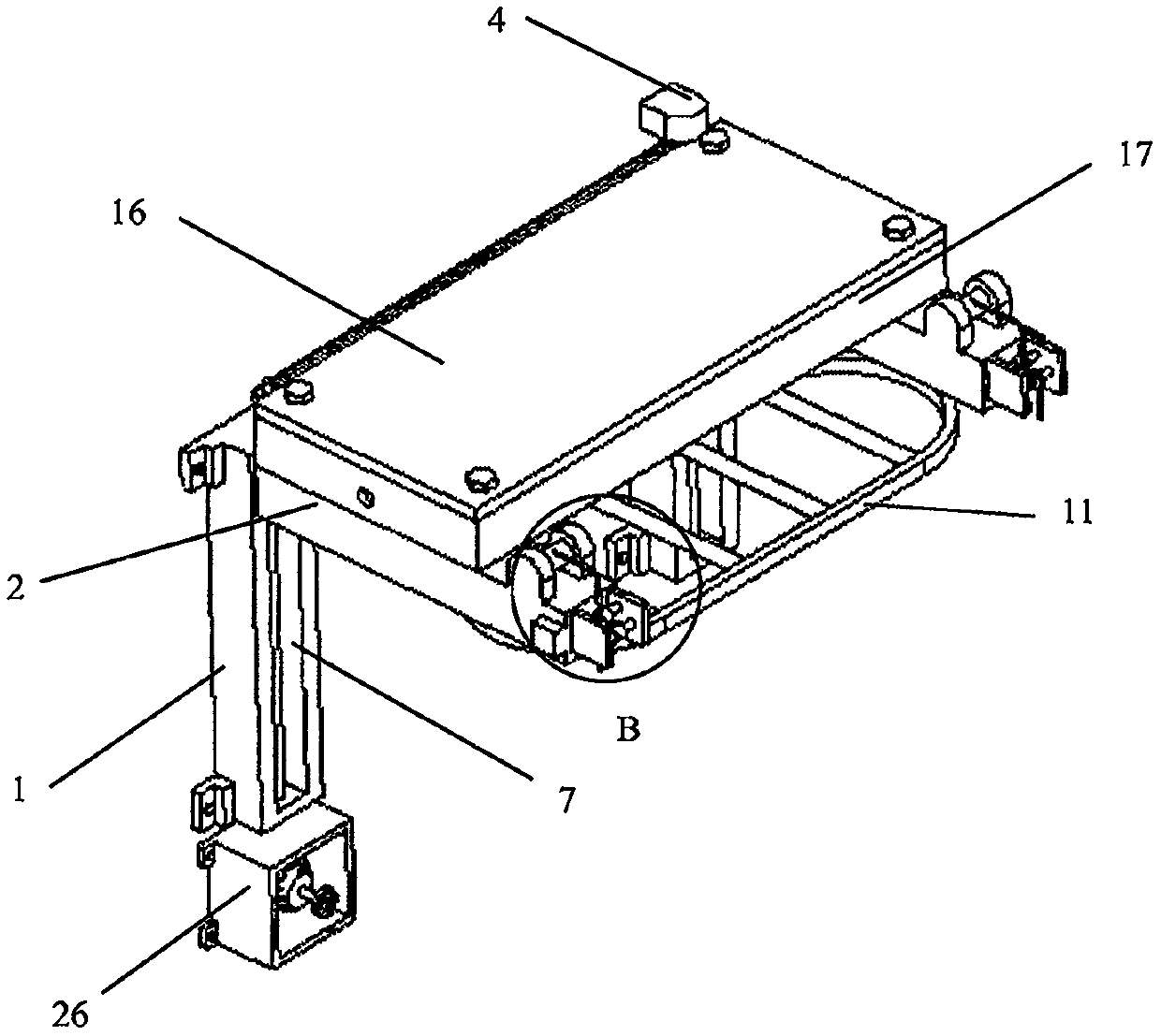

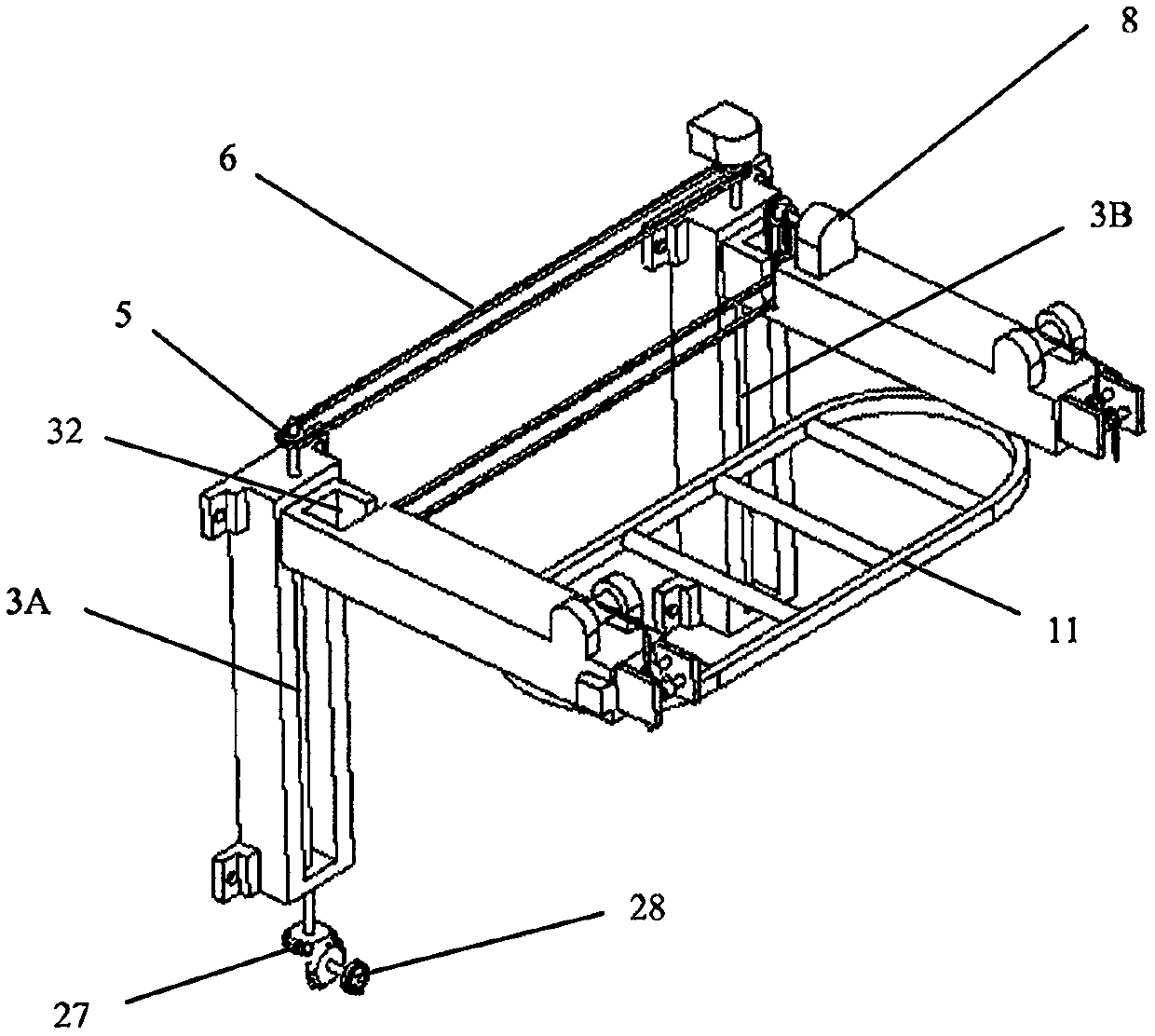

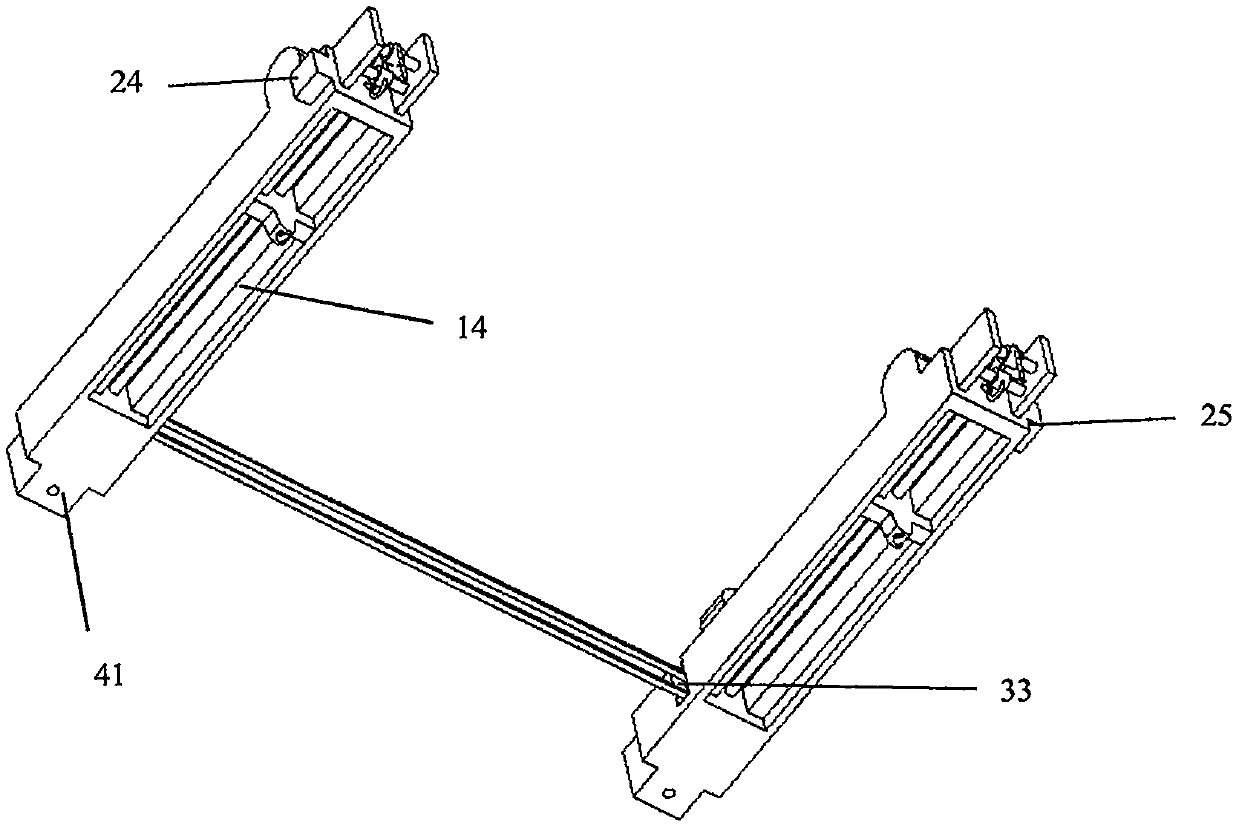

ActiveCN101922715AGuaranteed incineration effectFully dryInclined grateIncinerator apparatusLoss rateCombustion

A two-stage garbage incinerator is characterized in that secondary air supply holes are arranged on front and rear arches of a furnace body and an ignition combustion-supporting hole is arranged on the rear arch; a grate in the furnace body is divided into two stages from top to bottom; the upper stage is a forward pushing stage and the lower stage is a backward pushing stage; an independent primary air chamber is arranged below each stage; the heads of the grates on the forward pushing stage face the low point direction of the grates; the heads of the grates on the backward pushing stage face the high point direction of the grates; moving beams of the grates on the same stage are equipped with left and right draw bars arranged side by side; the left and right draw bars are supported by supporting roller devices and are connected with the moving beams to form draw bar frames; and the ends of the draw bar frames are connected with front rocker arm driving mechanisms, lateral rocker arm driving mechanisms or front straight driving mechanisms. The incinerator can realize full drying of the whole garbage material, ensure complete combustion and ensure the garbage incineration effect and hot ignition loss rate. At the same time, the incinerator has less spare parts and spare part specifications, good quick-wear part interchangeability and low manufacture and maintenance costs.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

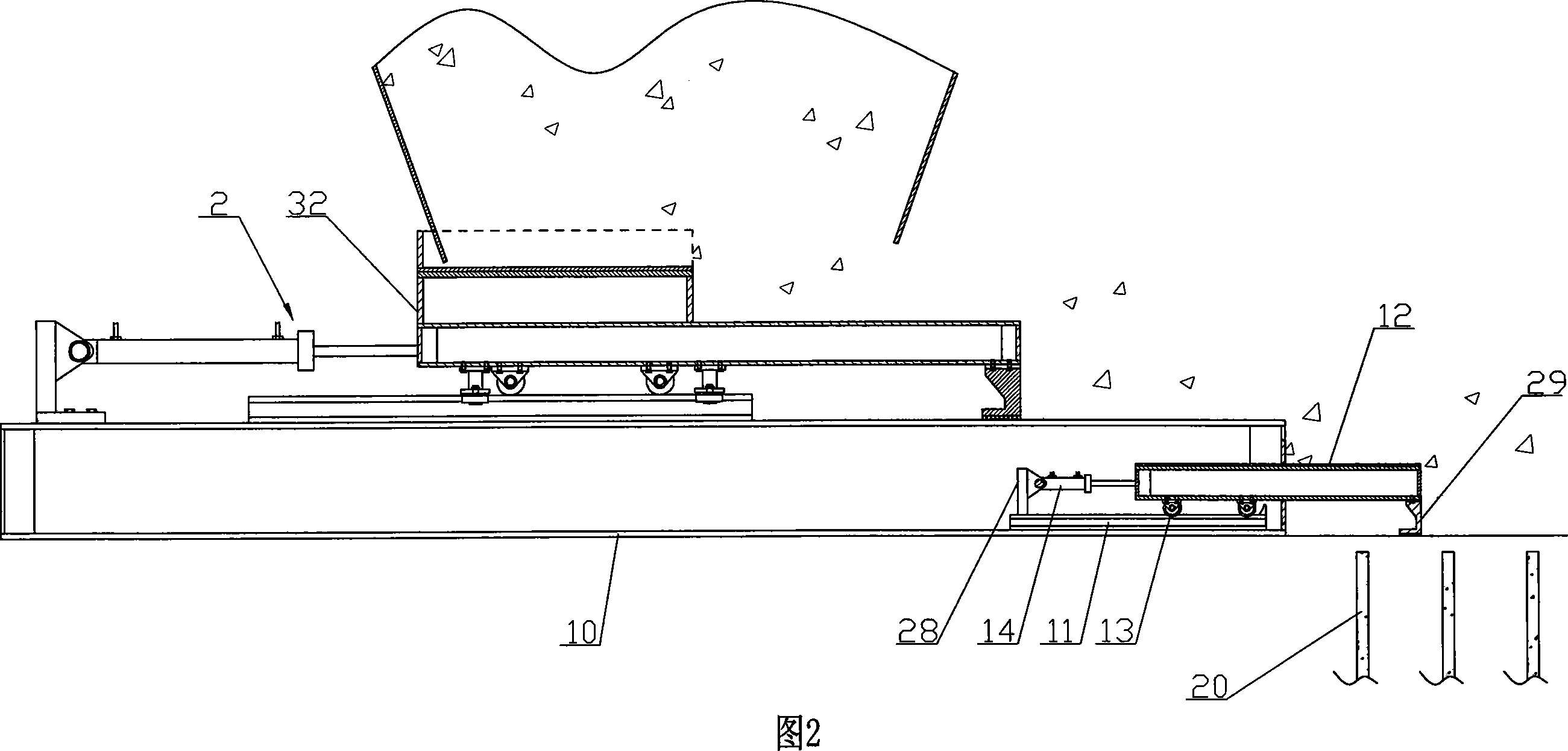

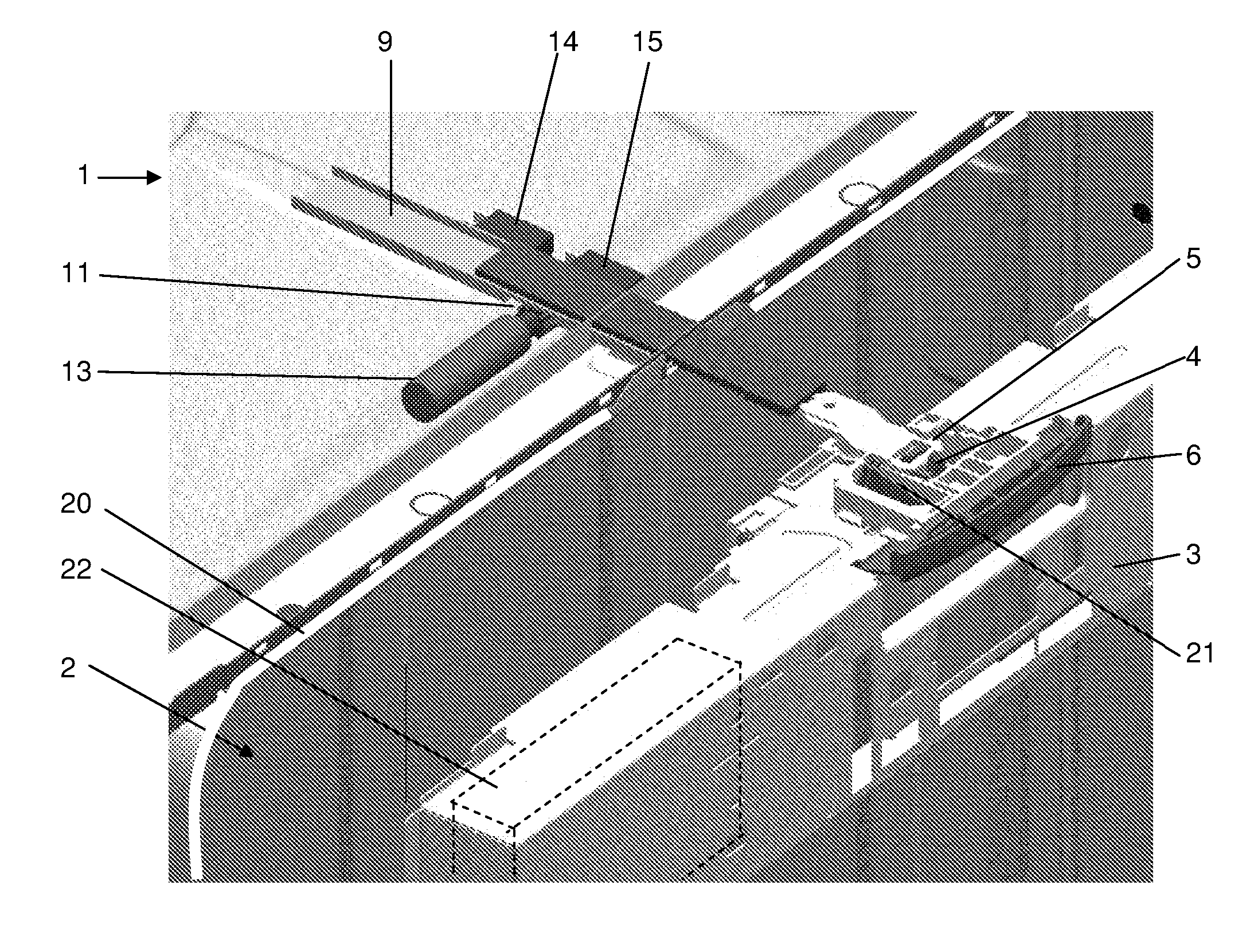

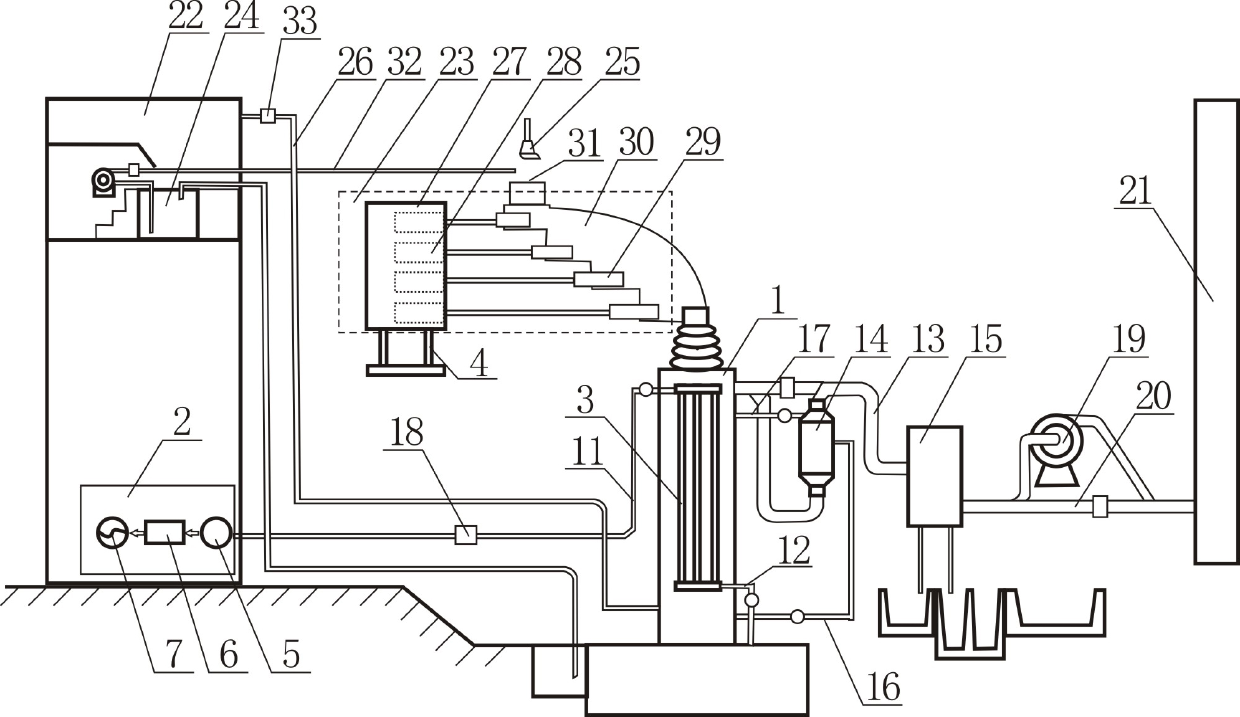

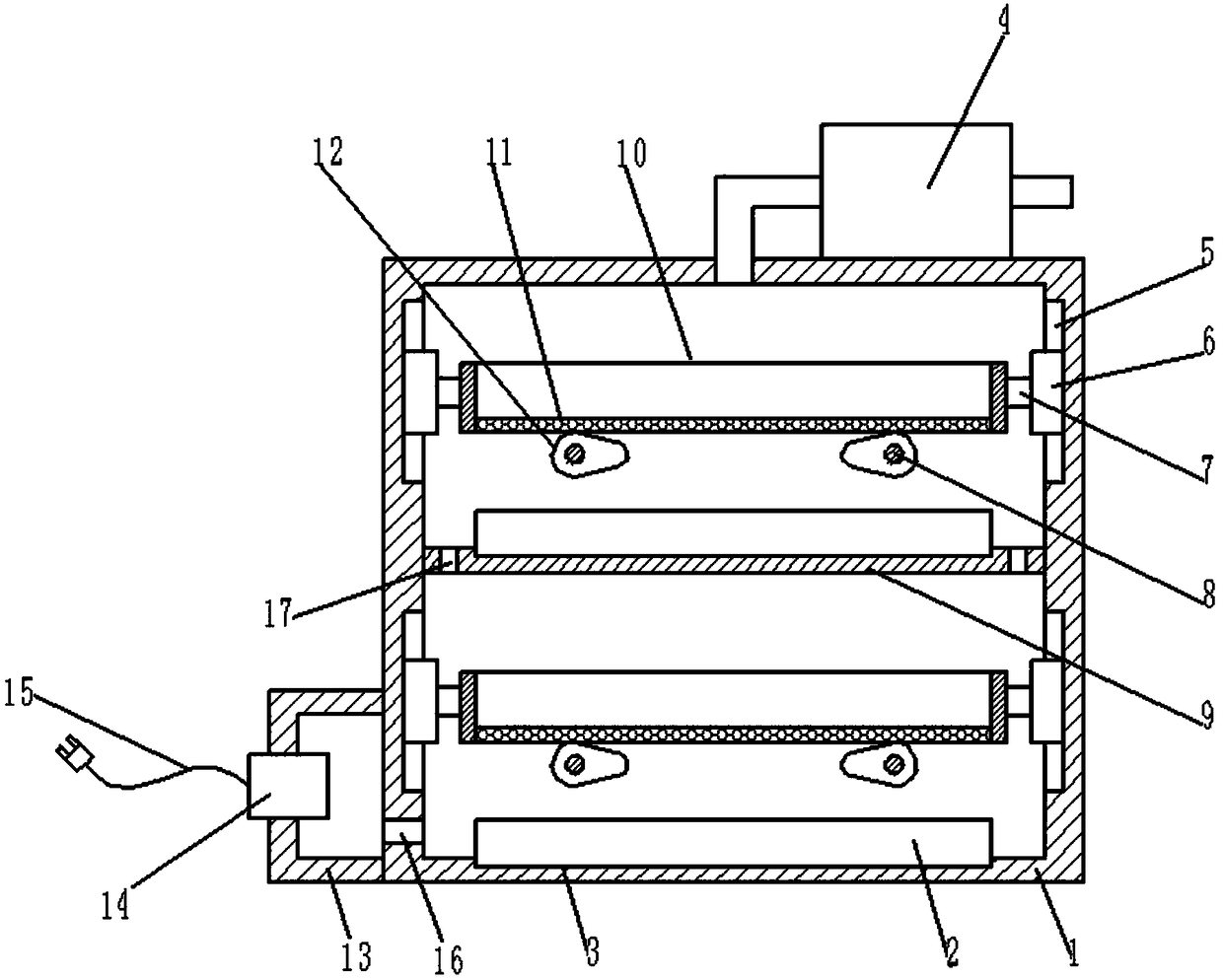

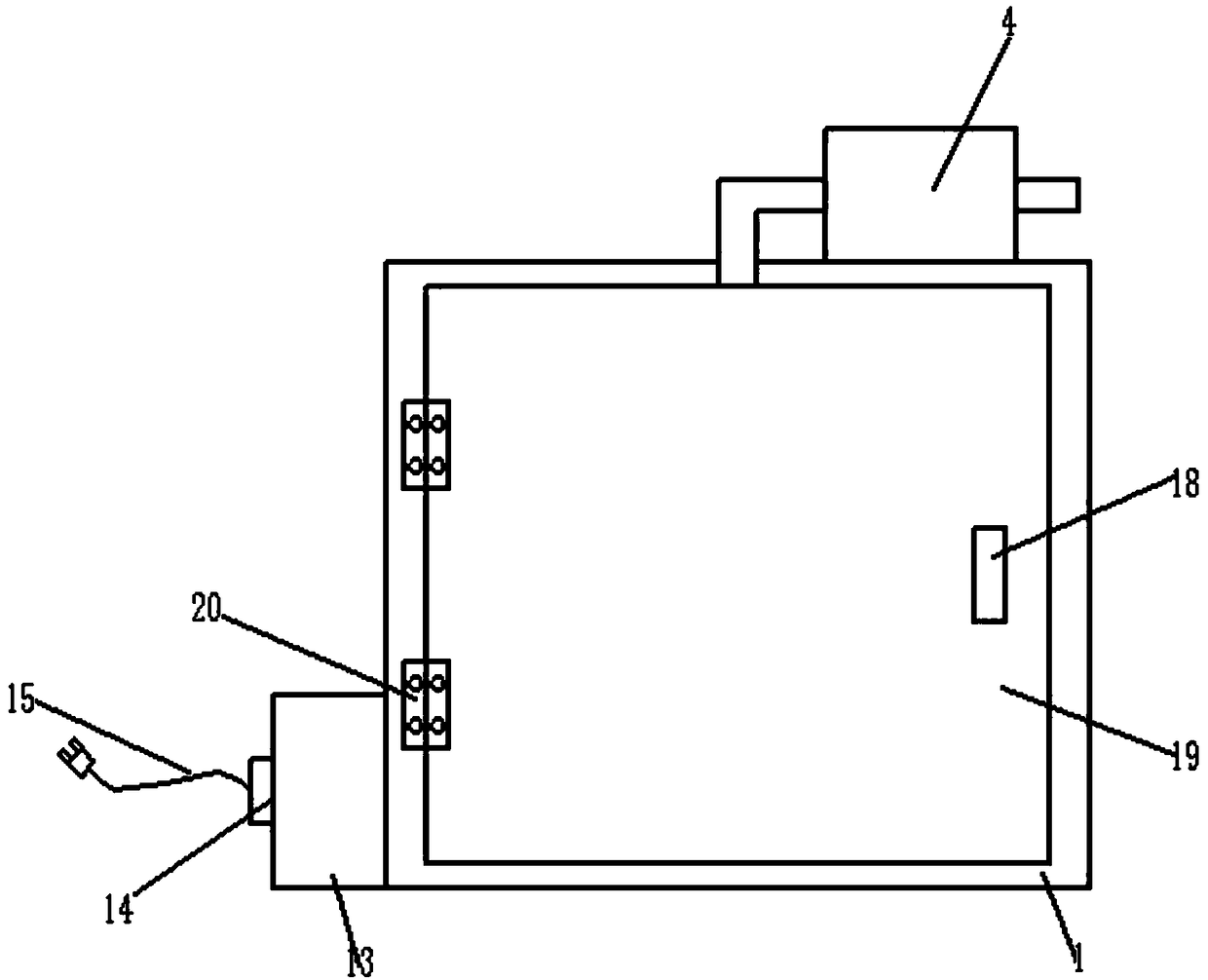

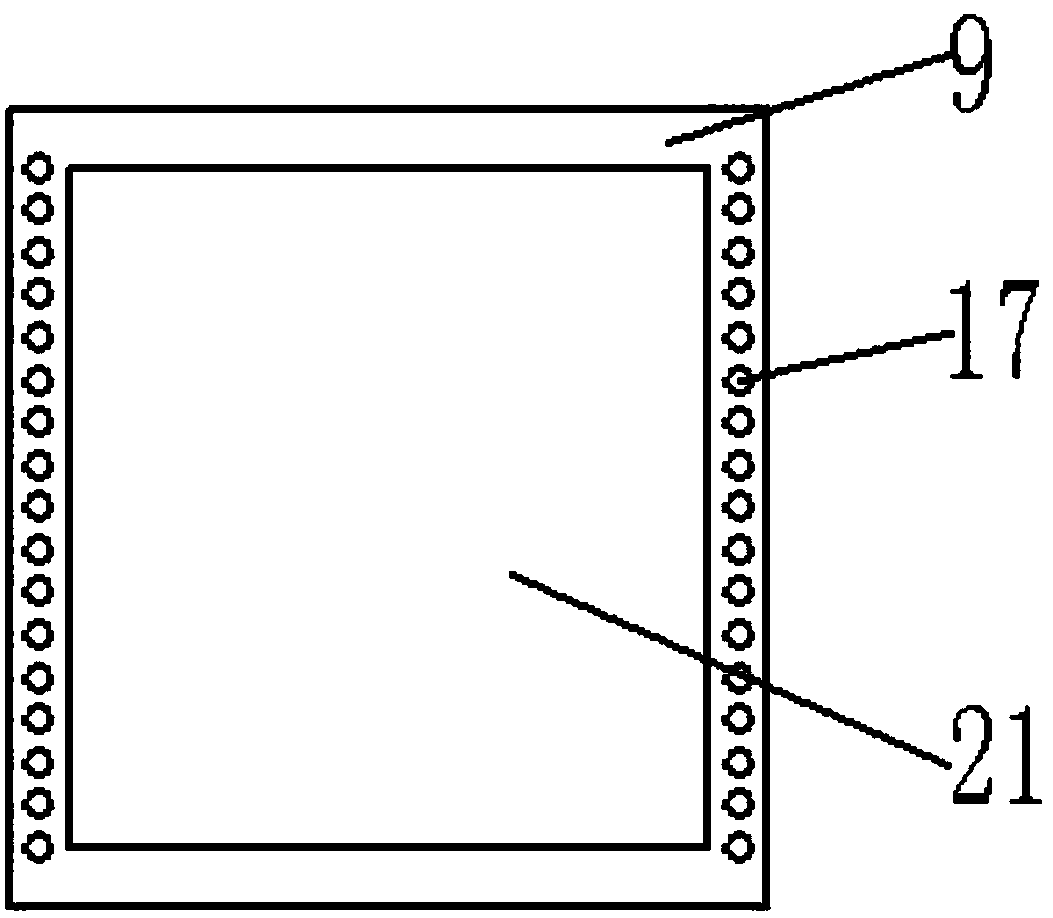

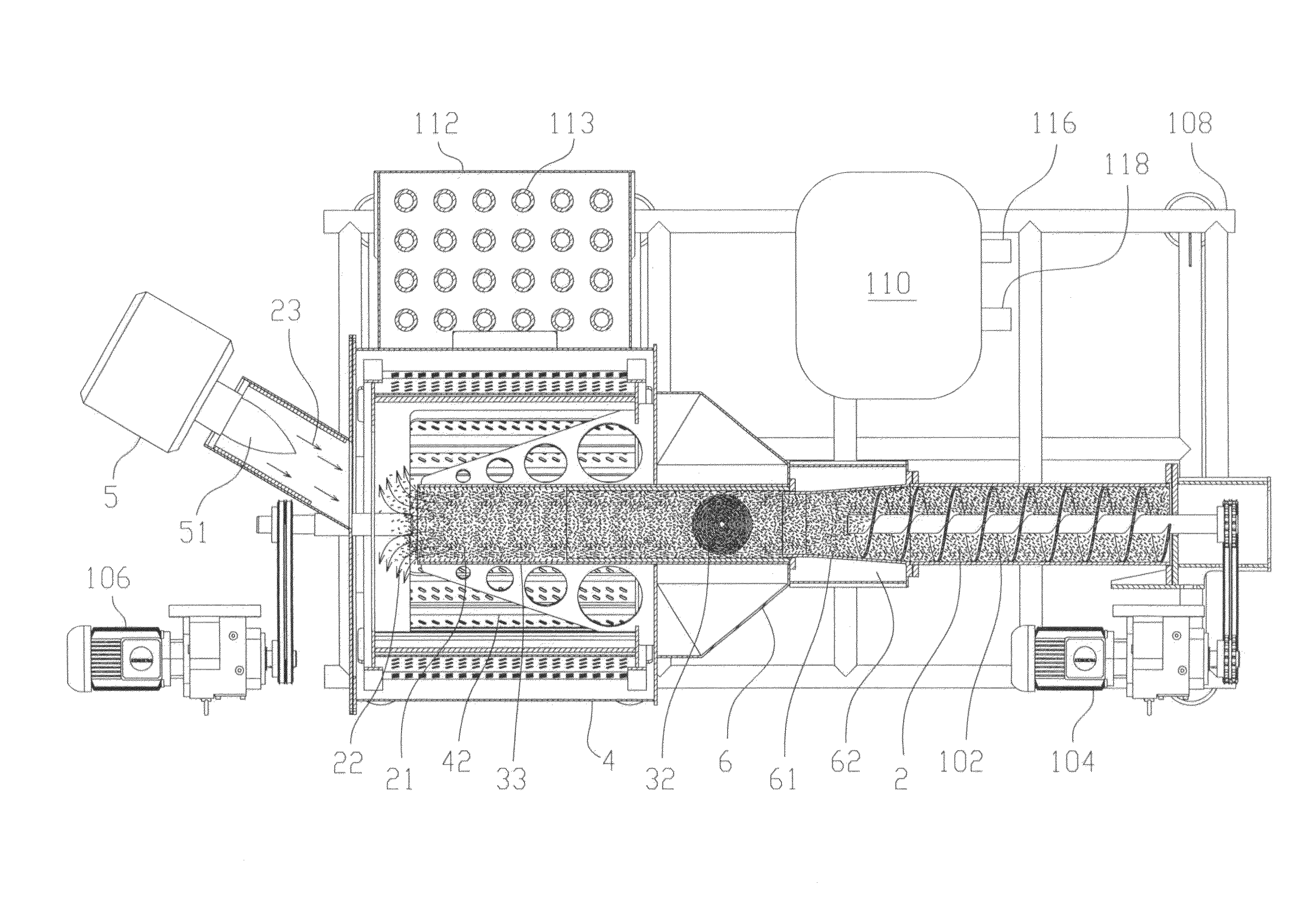

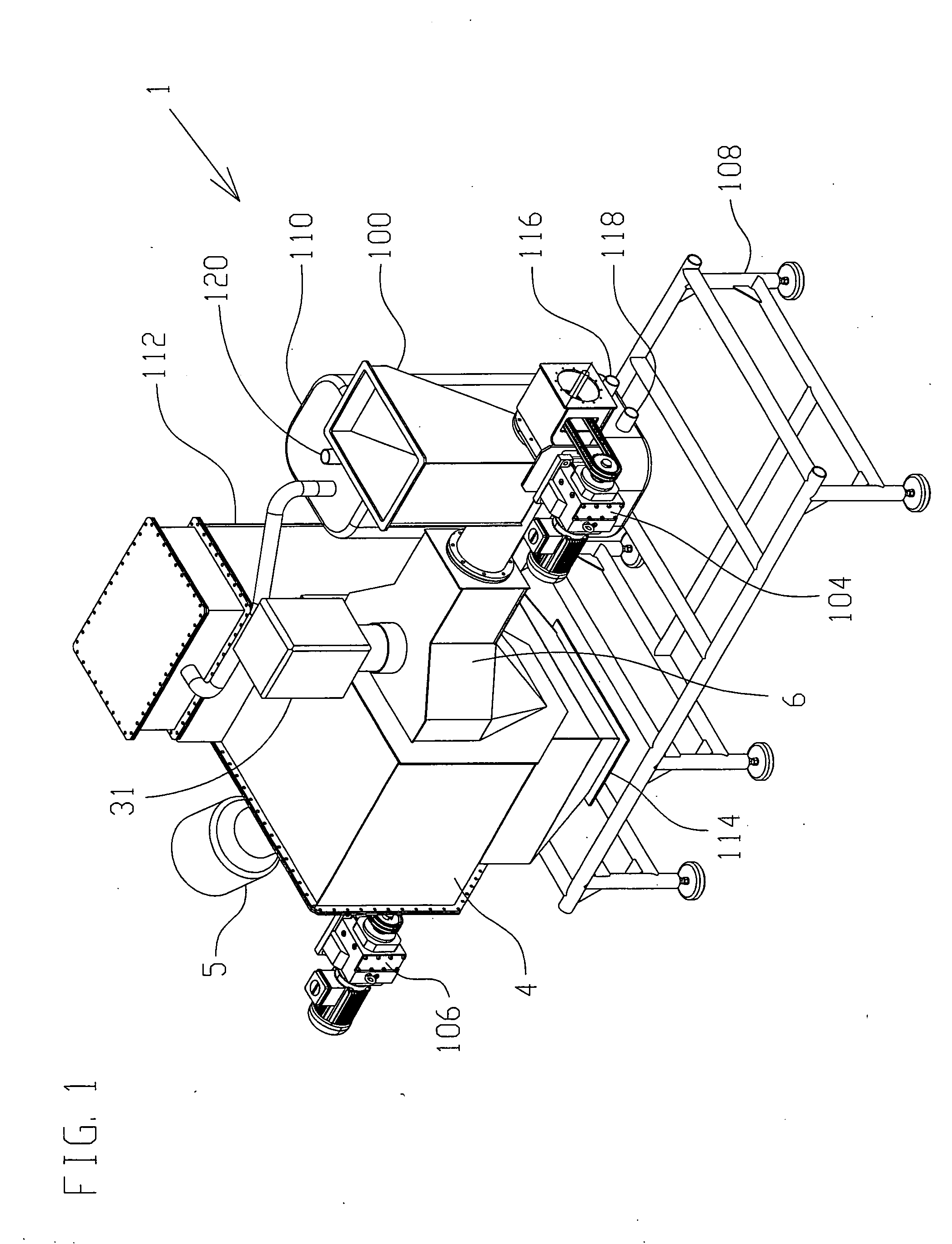

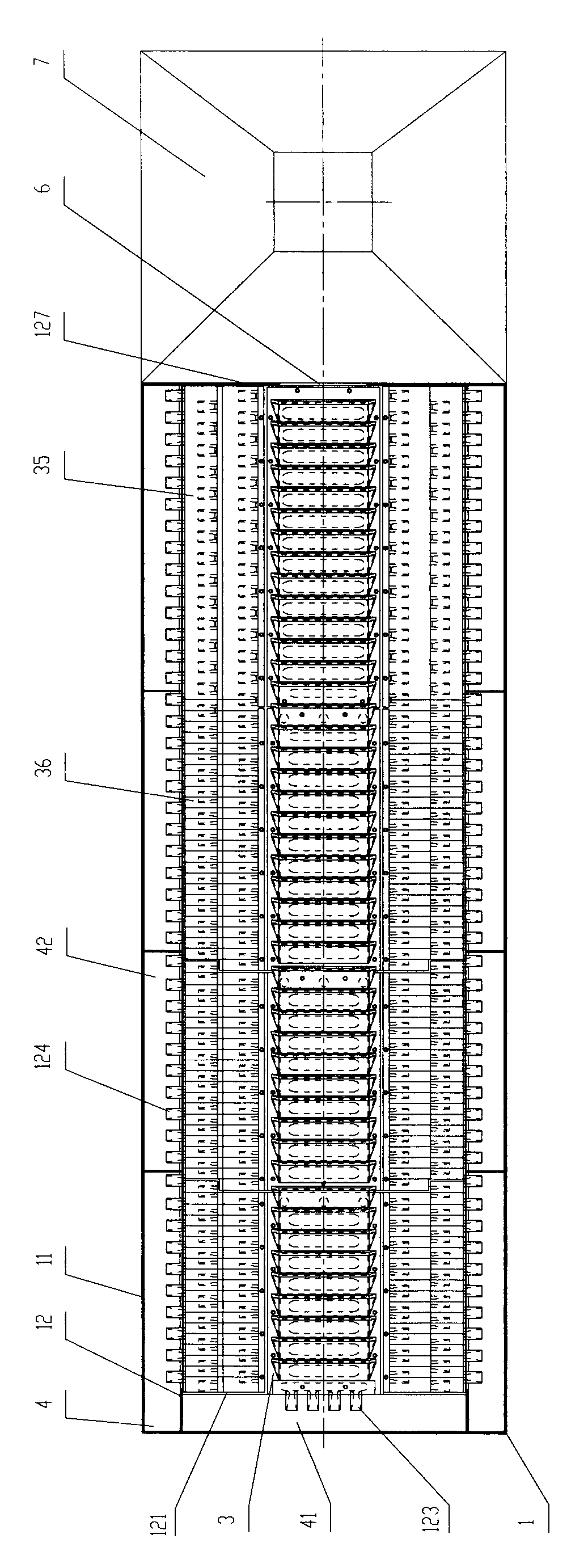

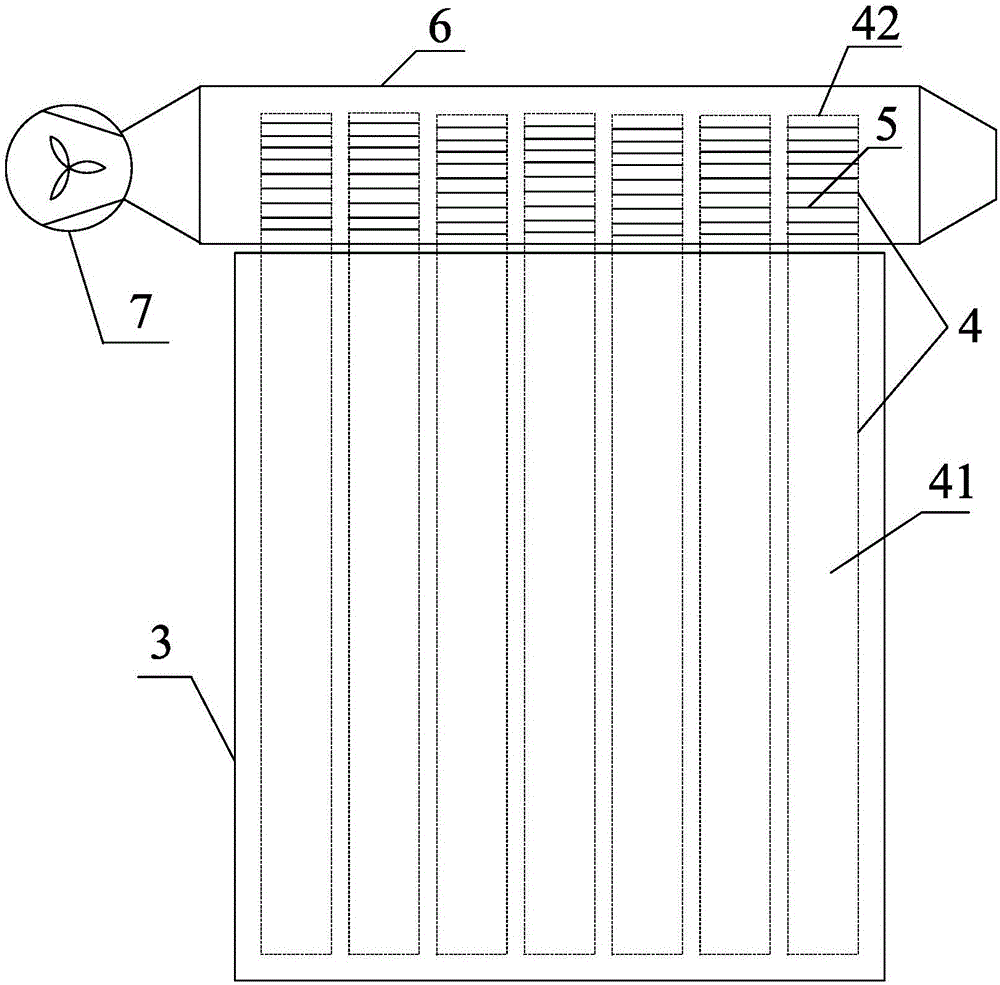

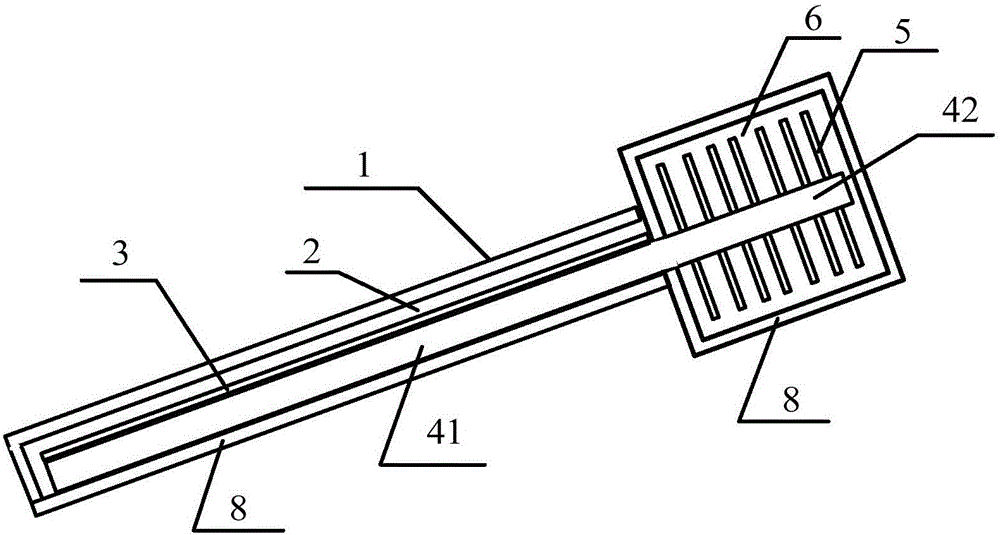

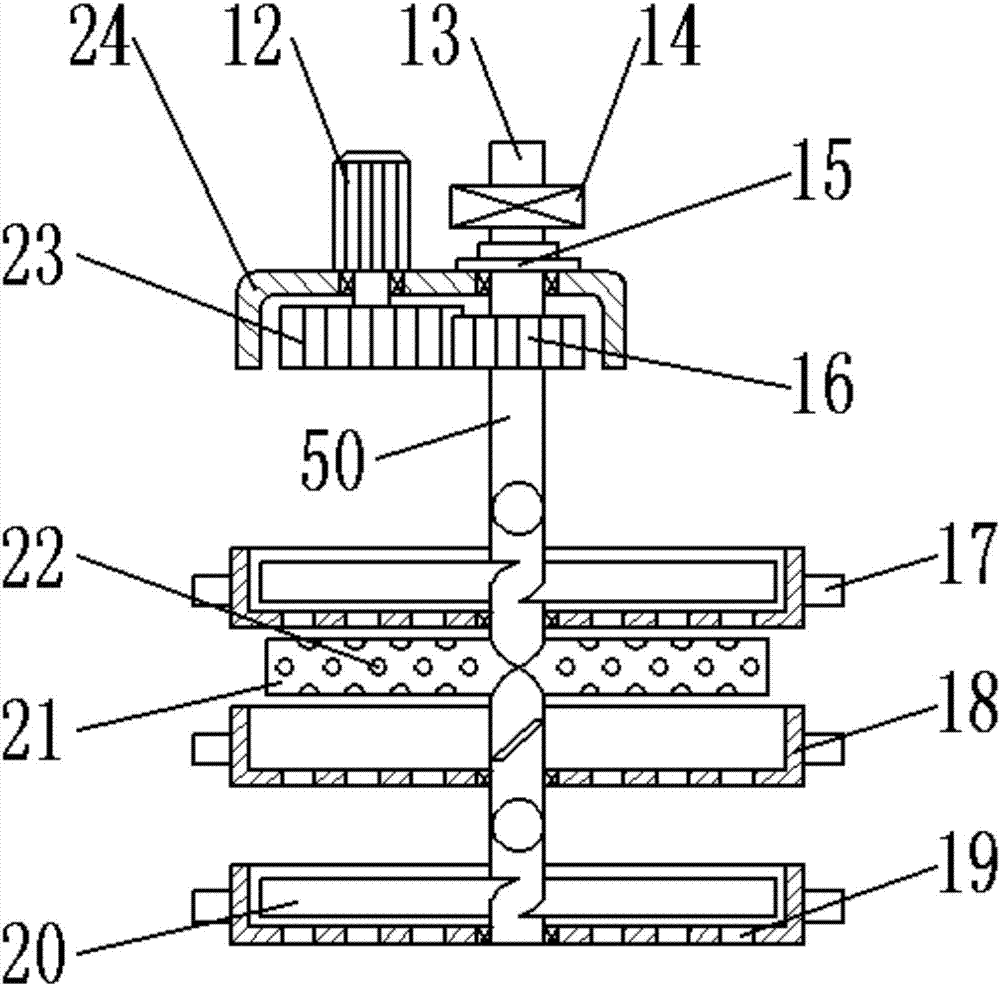

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

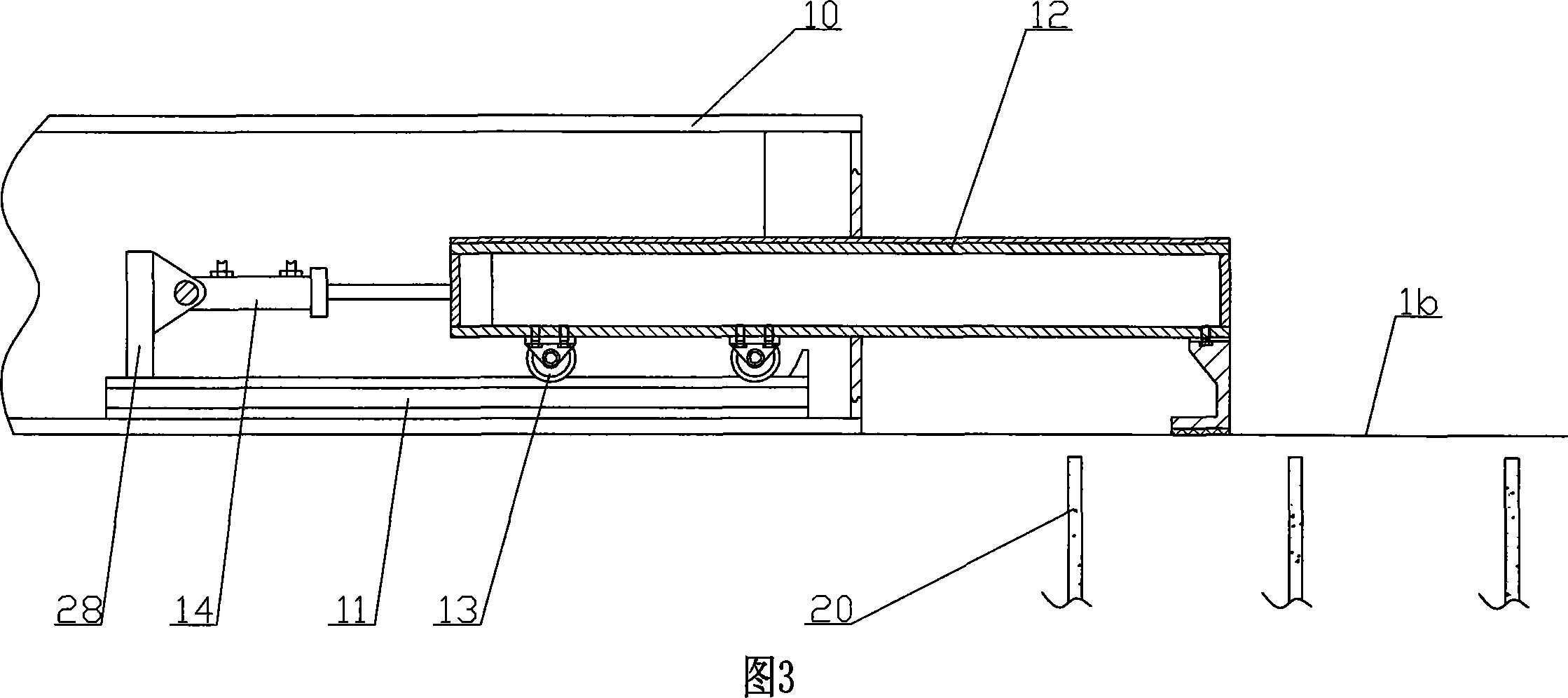

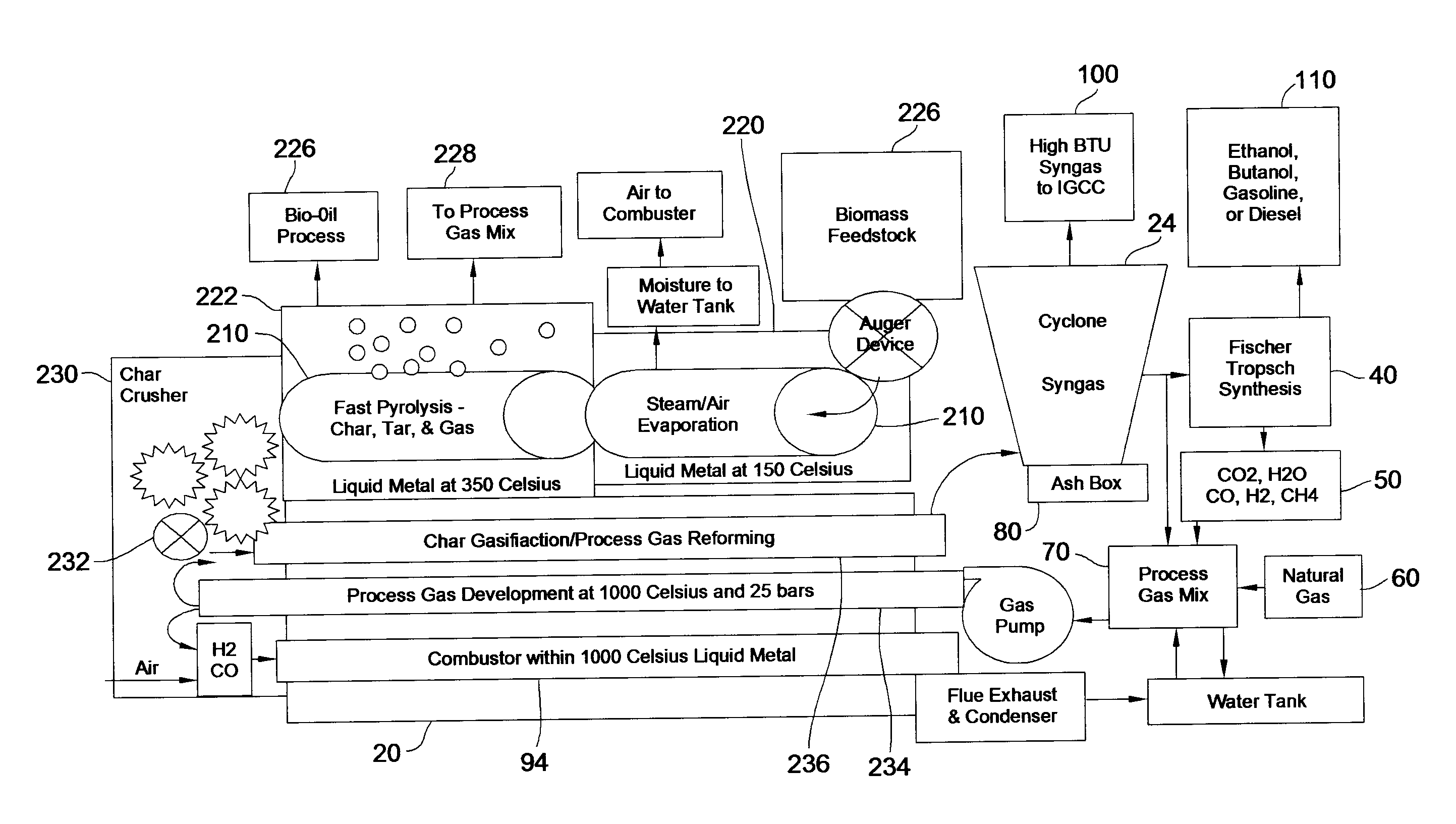

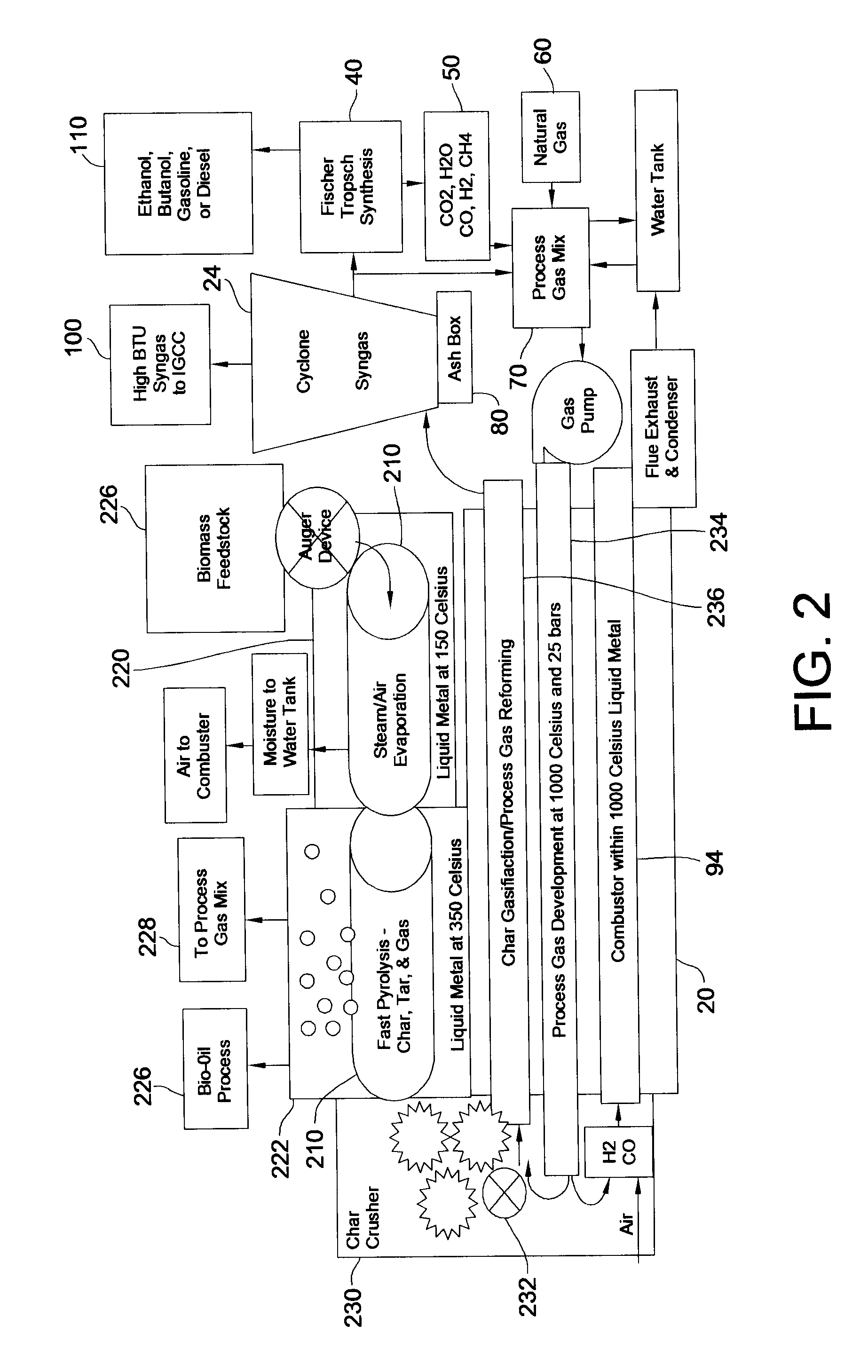

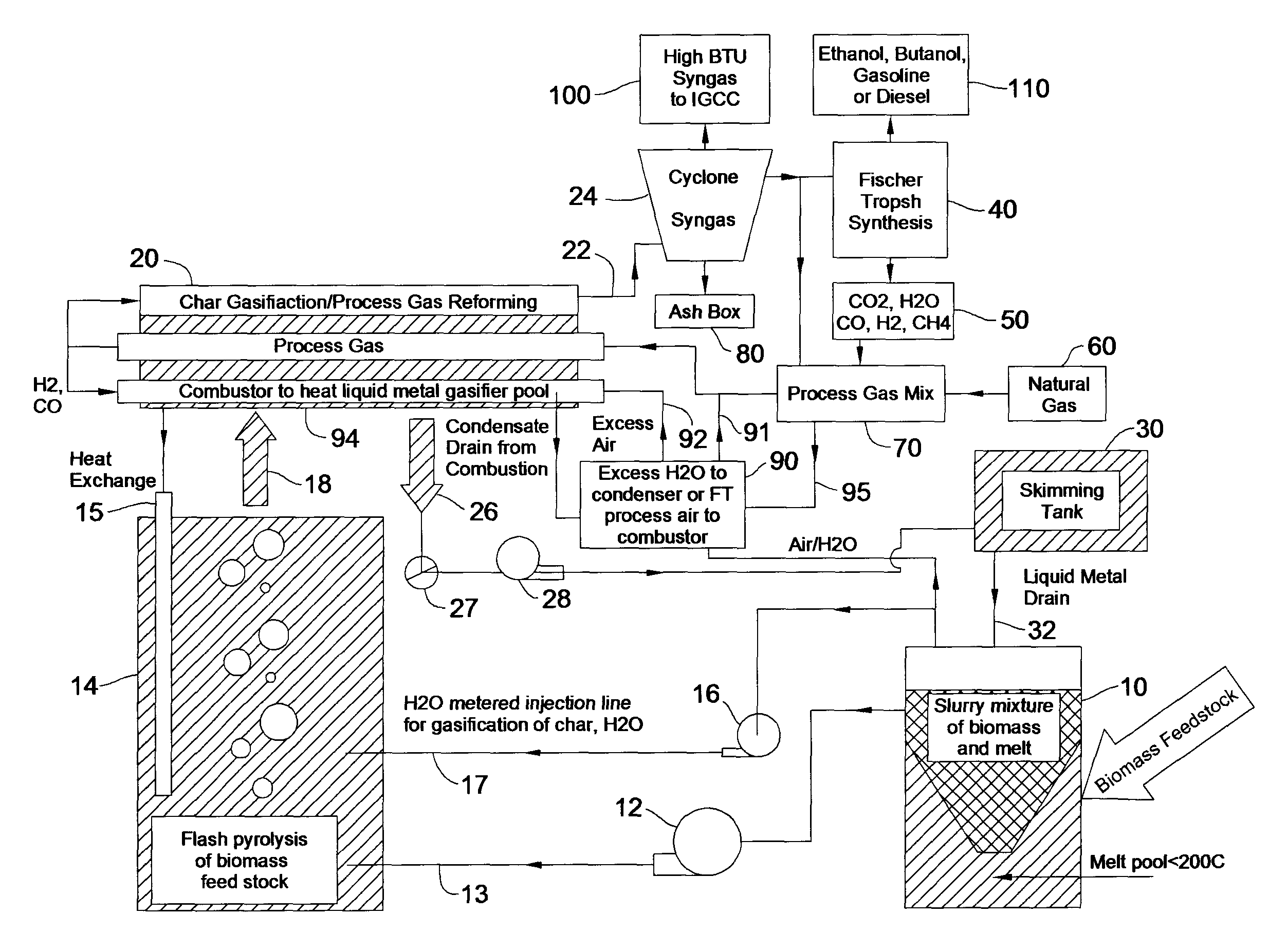

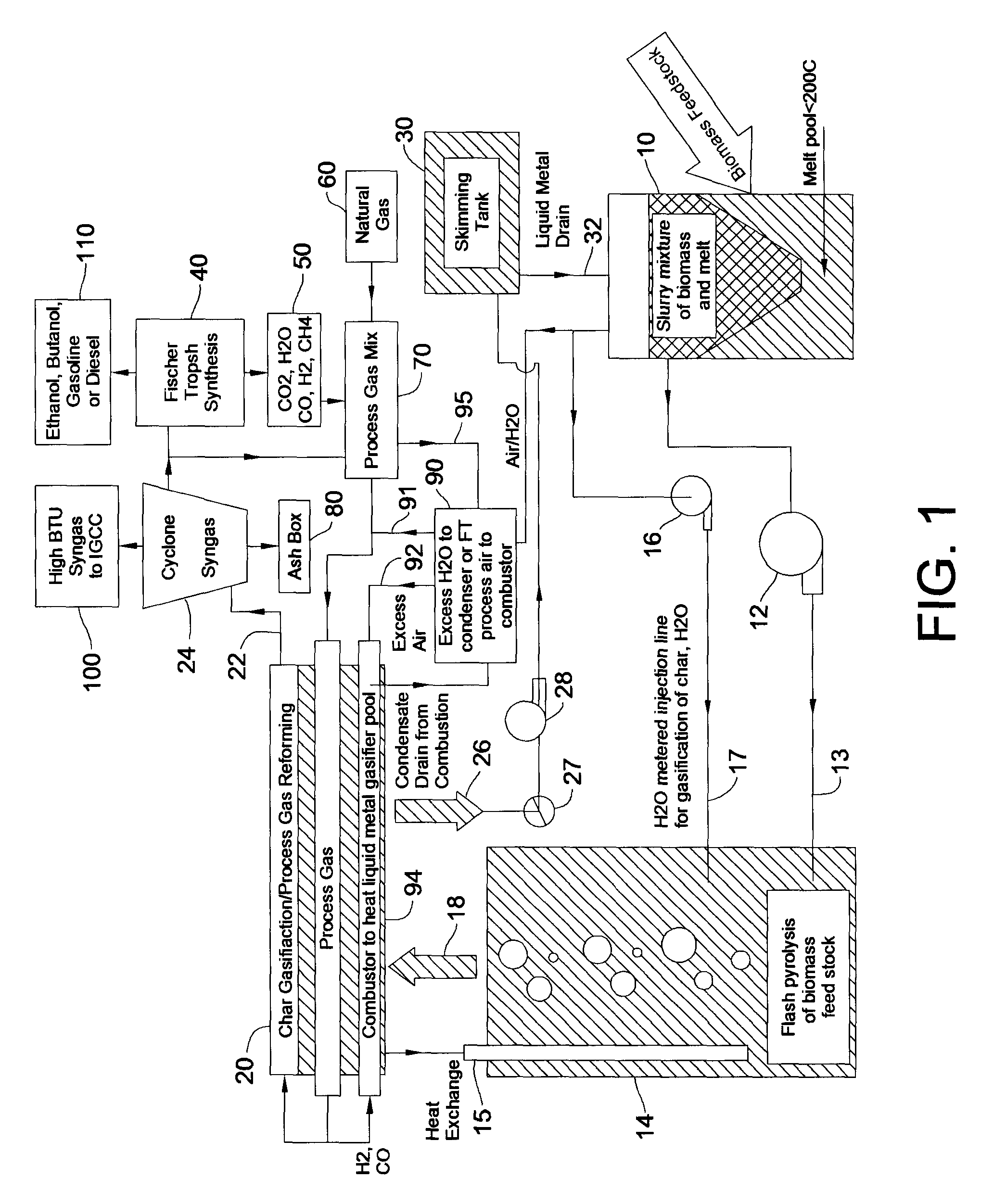

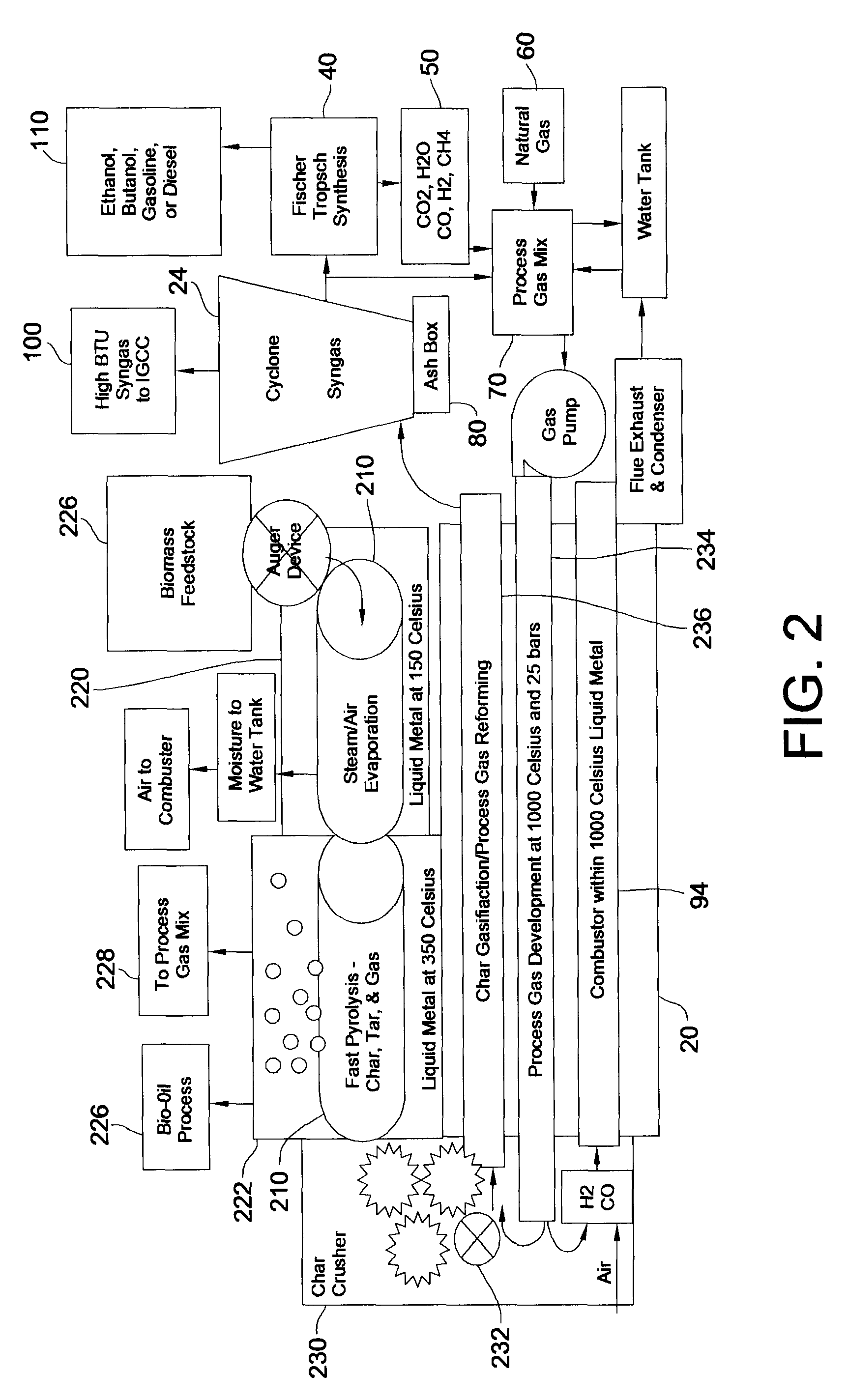

Method and apparatus to protect synthesis gas via flash pyrolysis and gasification in a molten liquid

InactiveUS20080307703A1Improve efficiencyLittle heating lossWaste based fuelRetortsSyngasThermodynamics

Disclosed are a method and a corresponding apparatus for converting a biomass reactant into synthesis gas. The method includes the steps of (1) heating biomass in a first molten liquid bath at a first temperature, wherein the first temperature is at least about 100° C., but less than the decomposition temperature of the biomass, wherein gas comprising water is evaporated and air is pressed from the biomass, thereby yielding dried biomass with minimal air content. (2) Recapturing the moisture evaporated from the biomass in step 1 for use in the process gas. (3) Heating the dried biomass in a second molten liquid bath at a second temperature, wherein the second temperature is sufficiently high to cause flash pyrolysis of the dried biomass, thereby yielding product gases, tar, and char. (4) Inserting recaptured steam into the process gas, which may optionally include external natural gas or hydrogen gas or recycled syngas for mixing and reforming with tar and non-condensable gases. (5) Further reacting the product gases, tar, and char with the process gas within a third molten liquid bath at a third temperature which is equal to or greater than the second temperature within the second molten liquid bath, thereby yielding high quality and relatively clean synthesis gas after a relatively long residence time needed for char gasification. A portion of the synthesis gas so formed is combusted to heat the first, second, and third molten liquid baths, unless external natural or hydrogen gas is available for this use.

Owner:US SEC AGRI +1

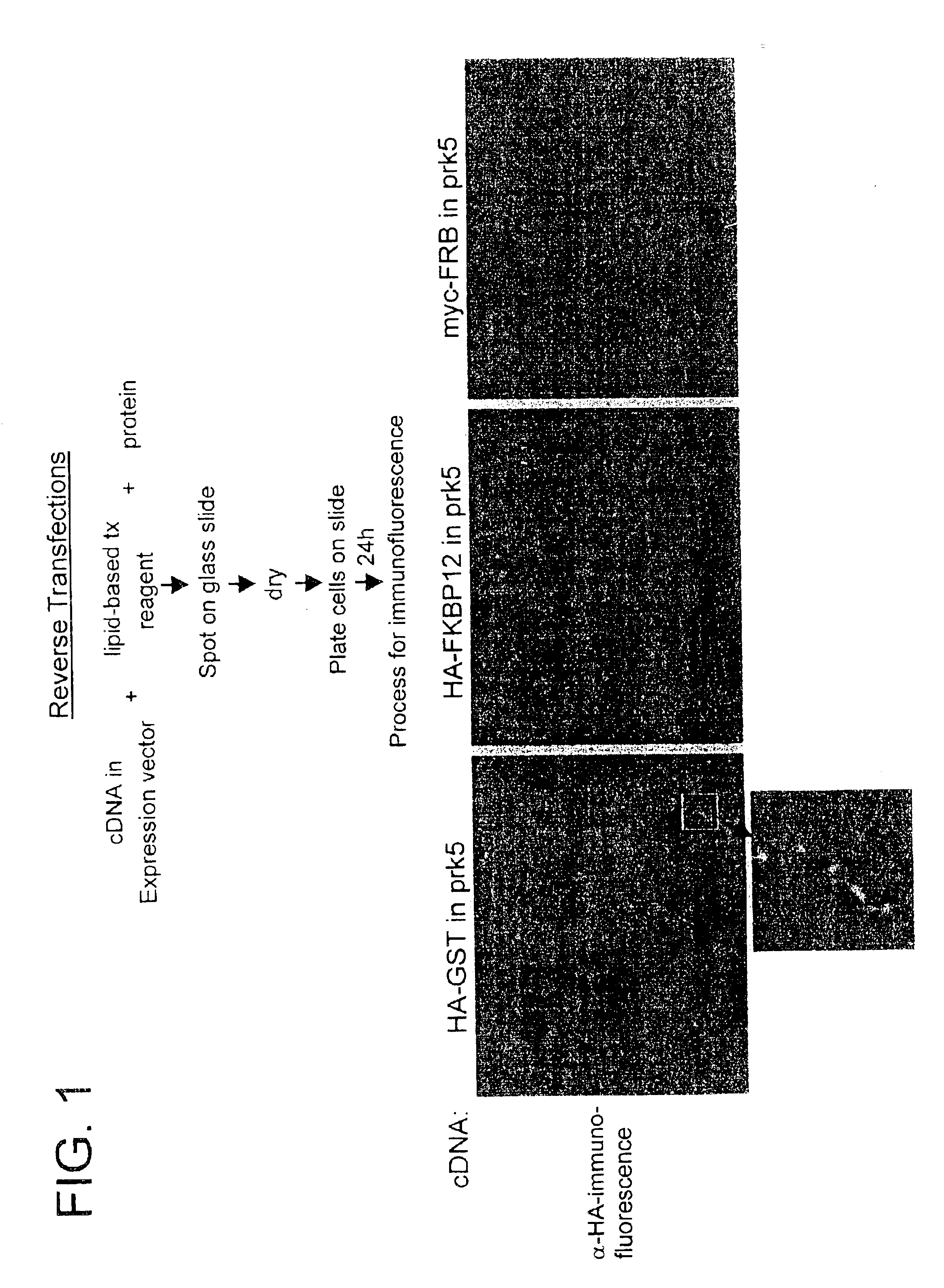

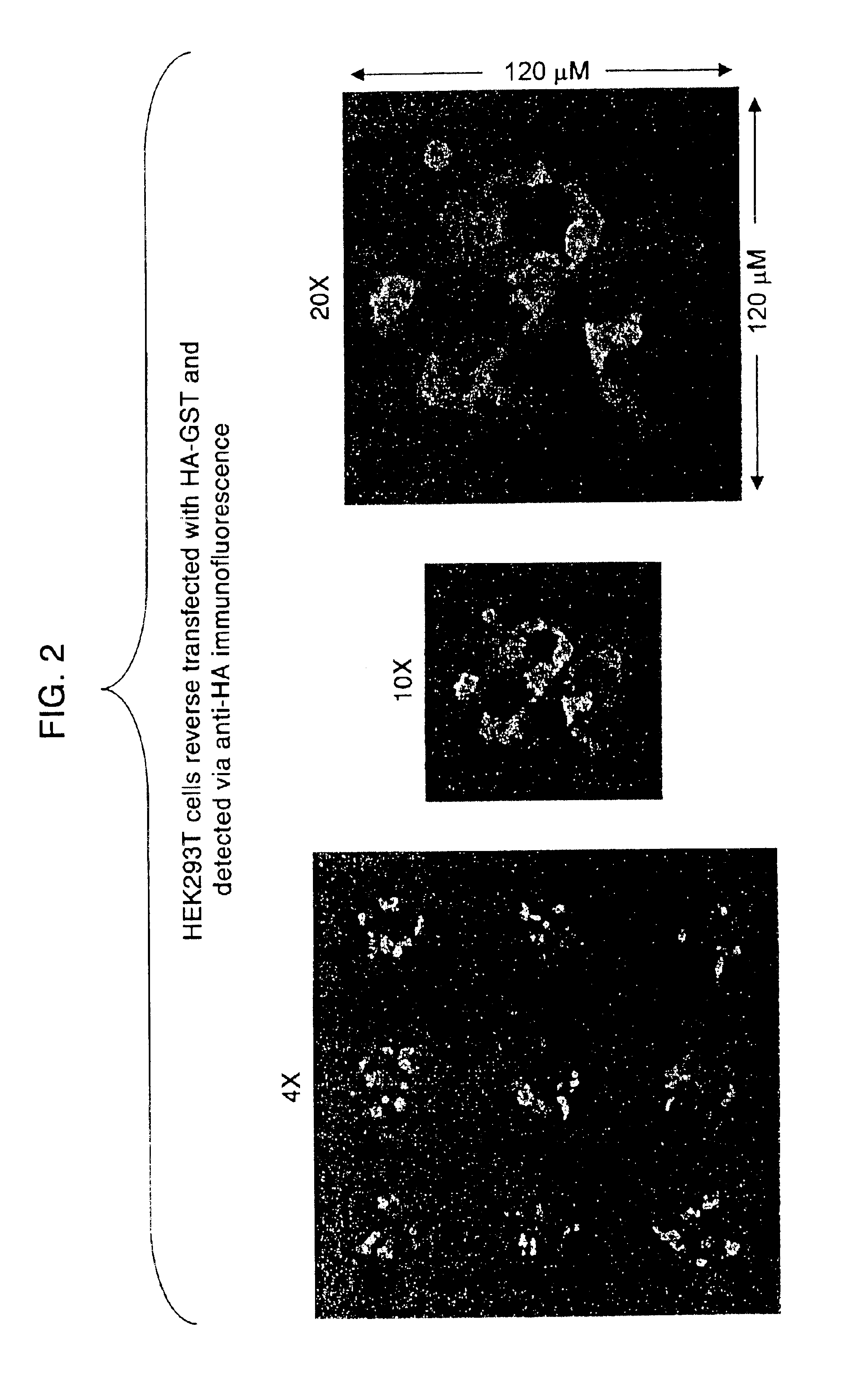

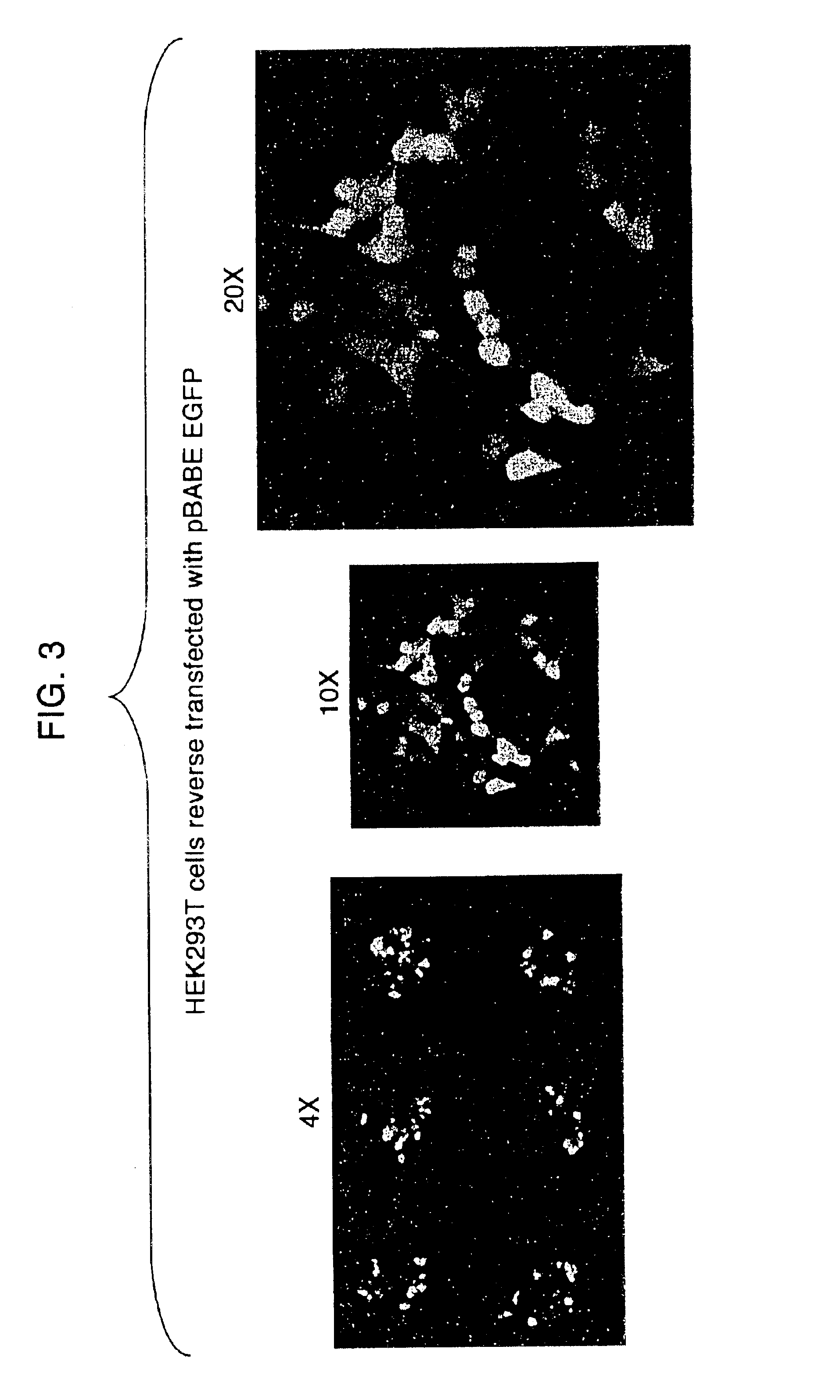

Transfection method and uses related thereto

InactiveUS6951757B2Easy to identifyFully dryBioreactor/fermenter combinationsBiological substance pretreatmentsTransfectionEukaryotic cell

The invention features a method of introducing nucleic acid molecules into eukaryotic cells by (a) depositing a nucleic acid molecule-containing mixture onto a surface, (b) affixing the nucleic acid molecule-containing mixture to the surface, and (c) plating eukaryotic cells onto the surface under appropriate conditions for entry of the nucleic acid molecules into the cells.

Owner:WHITEHEAD INST FOR BIOMEDICAL RES

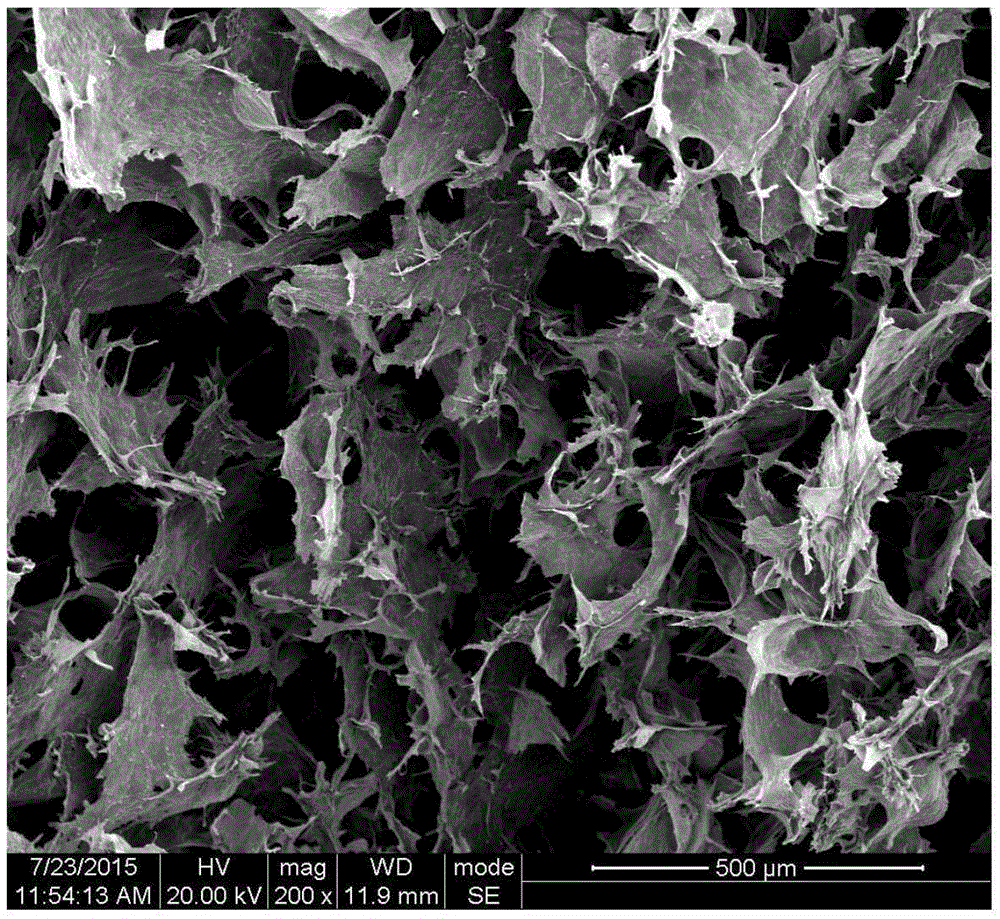

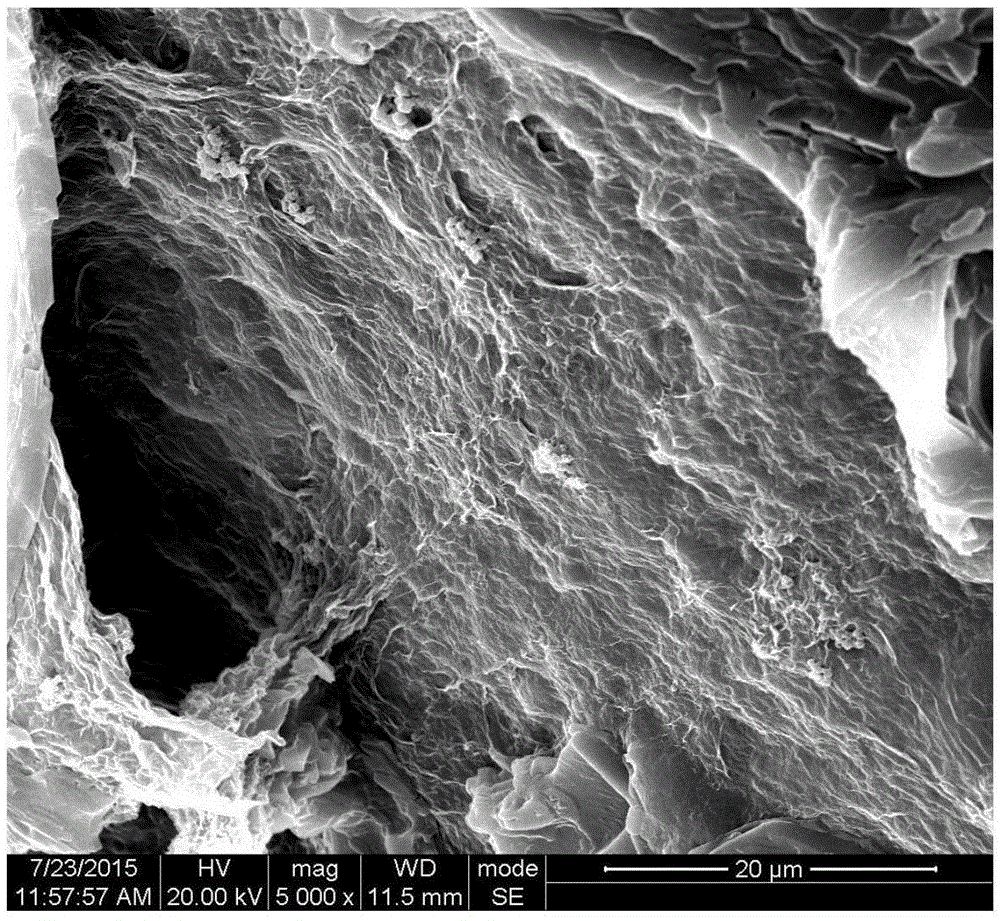

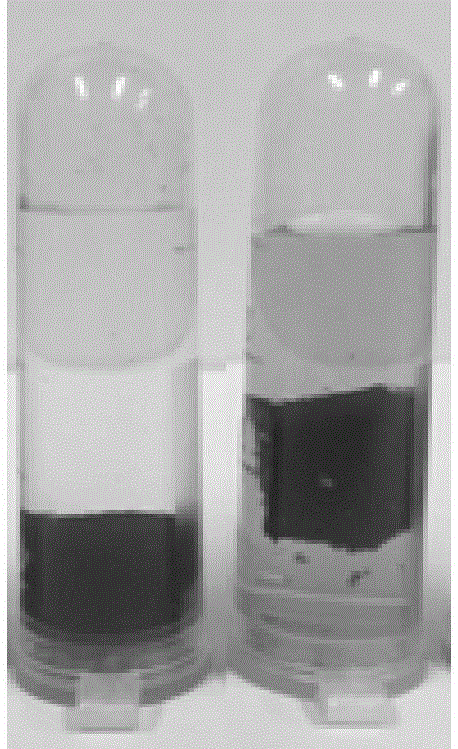

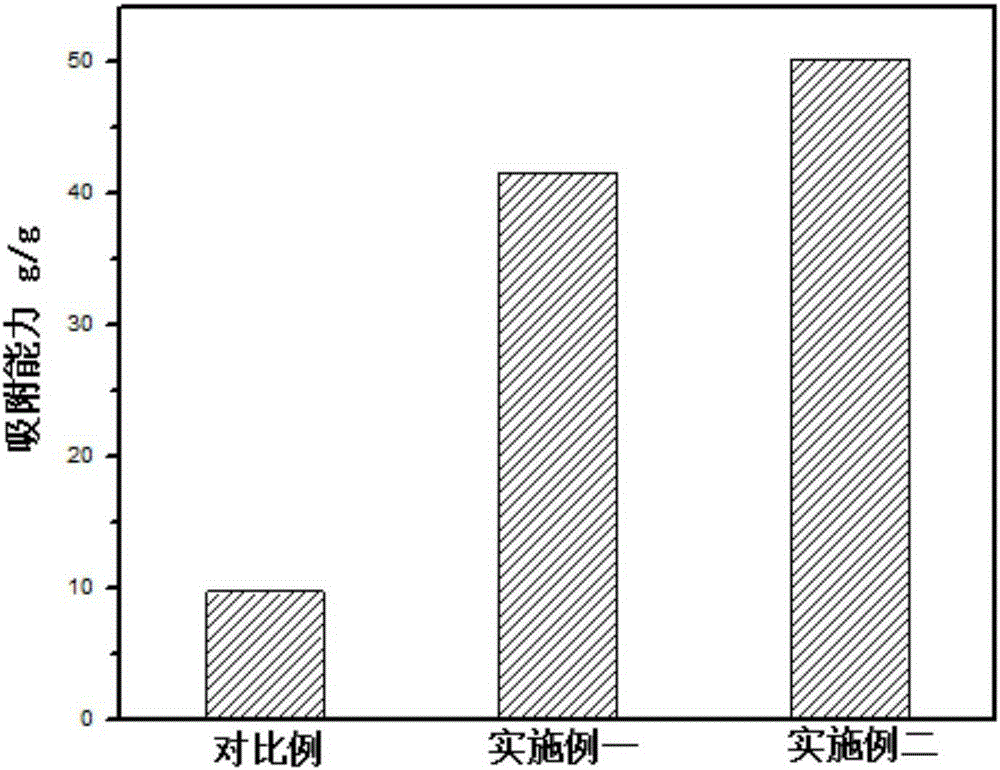

Preparation method for oxidized graphene-poly-dopamine composite aerogel

InactiveCN105254916AIntegrity guaranteedGuaranteed stabilityOther chemical processesAlkali metal oxides/hydroxidesPorosityFreeze-drying

The invention provides a preparation method for oxidized graphene-poly-dopamine composite aerogel. The preparation method comprises the following steps that 1, 0.15-0.7 g of dopamine powder is dissolved in 10-18 ml of distilled water, the dopamine aqueous solutions are mixed with 50-60 ml of oxidized graphene aqueous solutions with the concentration of 5-6 mg / ml, and stirring is performed to obtain oxidized graphene-dopamine mixed solutions; 2, 3-9 ml of tris aminomethane buffer solutions with the concentration of 0.1-0.12 mol / L are dropwise added into the mixed solutions while stirring is performed, stirring is continuously performed for 2-2.5 h, and standing is performed to enable the dopamine to be fully polymerized to obtain oxidized graphene-poly-dopamine composite aquogel; 3, after being placed in an environment with the temperature ranging from minus 20 DEG C to minus 10 DEG C to be frozen for 24-30 h, the composite aquogel is processed through freeze drying, and then the oxidized graphene-poly-dopamine composite aerogel is obtained. The method is simple in technology, and the prepared composite aerogel has the advantages of being high in porosity, excellent in adsorptivity, high in strength and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of graphene oxide/silicon dioxide hybrid aerogel

A preparation method of graphene oxide / silicon dioxide hybrid aerogel comprises the following steps: A, adding 0.05-0.1 mol of a precursor into 9-18 ml of distilled water and dropwise adding a hydrolyst with its concentration of 0.2-0.6 mol / L into the precursor aqueous solution, wherein molar ratio of the hydrolyst to the precursor is 1:20-1:100; stirring at 20-30 DEG C for 5-8 h; adjusting pH value to 6-7 and stirring for 5-45 min so as to obtain a dispersion containing silicon dioxide microspheres; B, adding water to dilute the silicon dioxide microsphere dispersion by 5-50 times, carrying out iso-volume mixing on the diluted silicon dioxide microsphere dispersion and a graphene oxide dispersion with its concentration being 0.6-2 mg / ml, stirring for 10-30 min, carrying out ultrasonic treatment for 10-30 min so as to obtain graphene oxide / silicon dioxide hybrid aerogel; and C, freezing the hybrid aerogel under liquid nitrogen for 5-10 min, freeze-drying and dewatering to obtain the graphene oxide / silicon dioxide hybrid aerogel. The method is environmentally friendly, and the technology is simple. The prepared hybrid aerogel has advantages of complete gel network structure, high porosity, good adsorptivity, high strength, low density and the like.

Owner:SOUTHWEST JIAOTONG UNIV

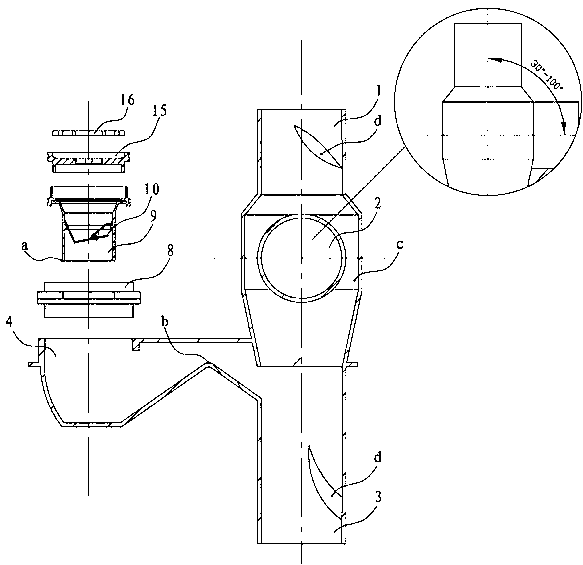

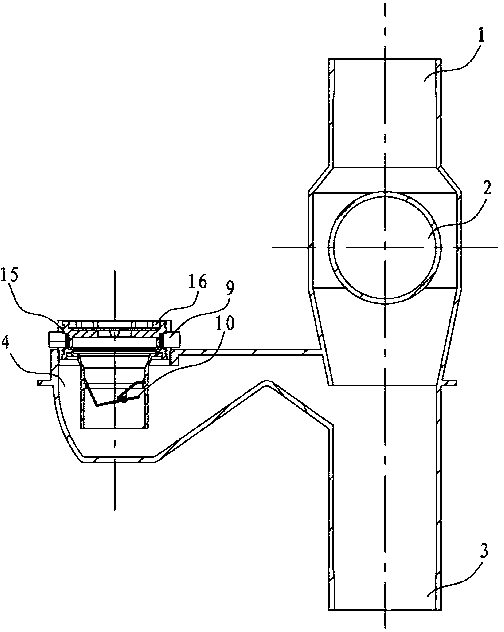

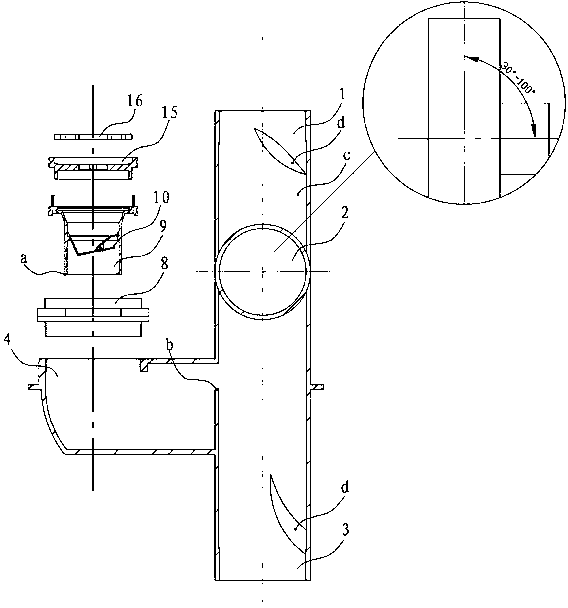

Same floor draining joint for building

InactiveCN102839724AIncrease drainage flowTo achieve the separation effectDomestic plumbingToiletCivil engineering

The invention relates to a same floor draining joint for a building, in particular to a same floor draining joint for a toilet, which consists of an upper vertical pipe draining port, a lower vertical pipe draining port and at least two transverse pipe draining ports; the upper vertical pipe draining port is communicated with the upper end and the lower end of the lower vertical pipe draining port; the at least two transverse pipe draining ports are staggered in position and are arranged between the upper vertical pipe draining port and the lower vertical pipe draining port; the orientation of the inlet of at least one of the transverse pipe draining ports is equal to or nearly equal to the orientation of the upper vertical pipe draining port, and the orientation of the inlet of at least one of the transverse pipe draining ports forms an included angle of 30-100 degrees with the orientation of the upper vertical pipe draining port. The same floor draining joint is rational and scientific in structure, and is capable of realizing the same floor draining and the same floor maintenance when the draining joint is adopted in the same floor draining of the non-falling plate or falling plate; the draining is more safe; the water is not easy to accumulate in the falling plate layer even the way of the falling plate is adopted, and the accumulated water is safely and completely discharged, so as to avoid the foreign smell in the room.

Owner:KUNMING QUNZHIYING TECH

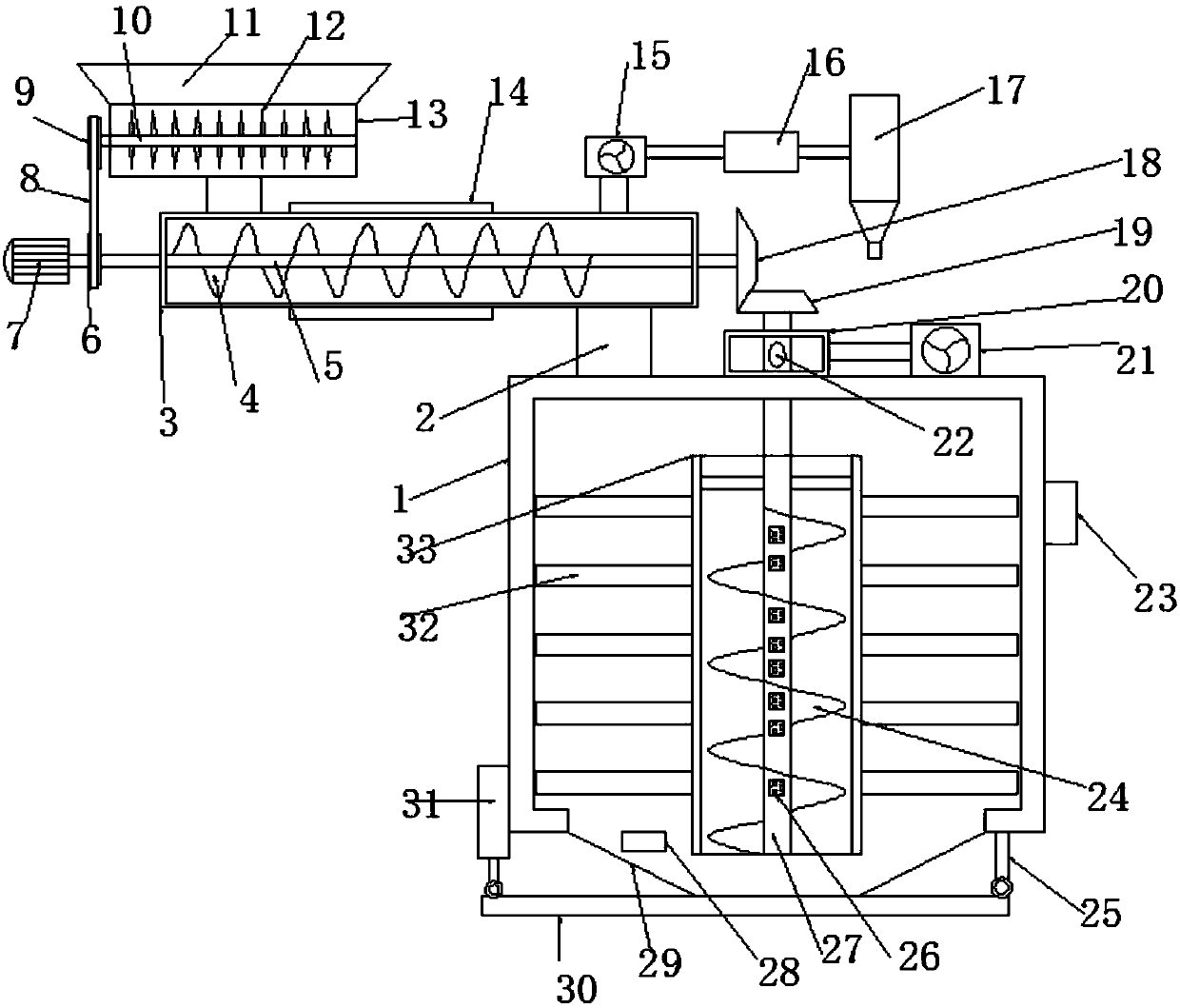

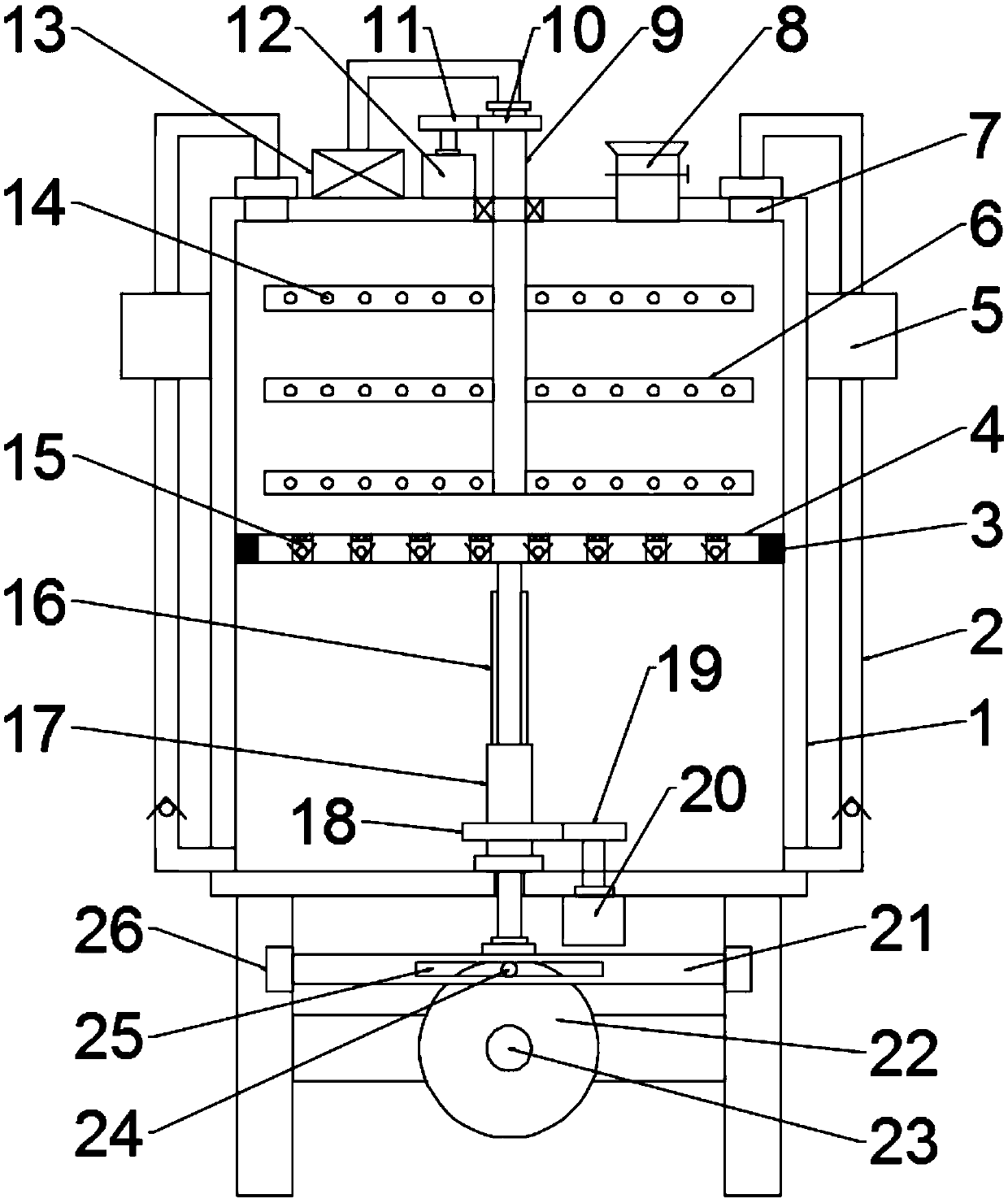

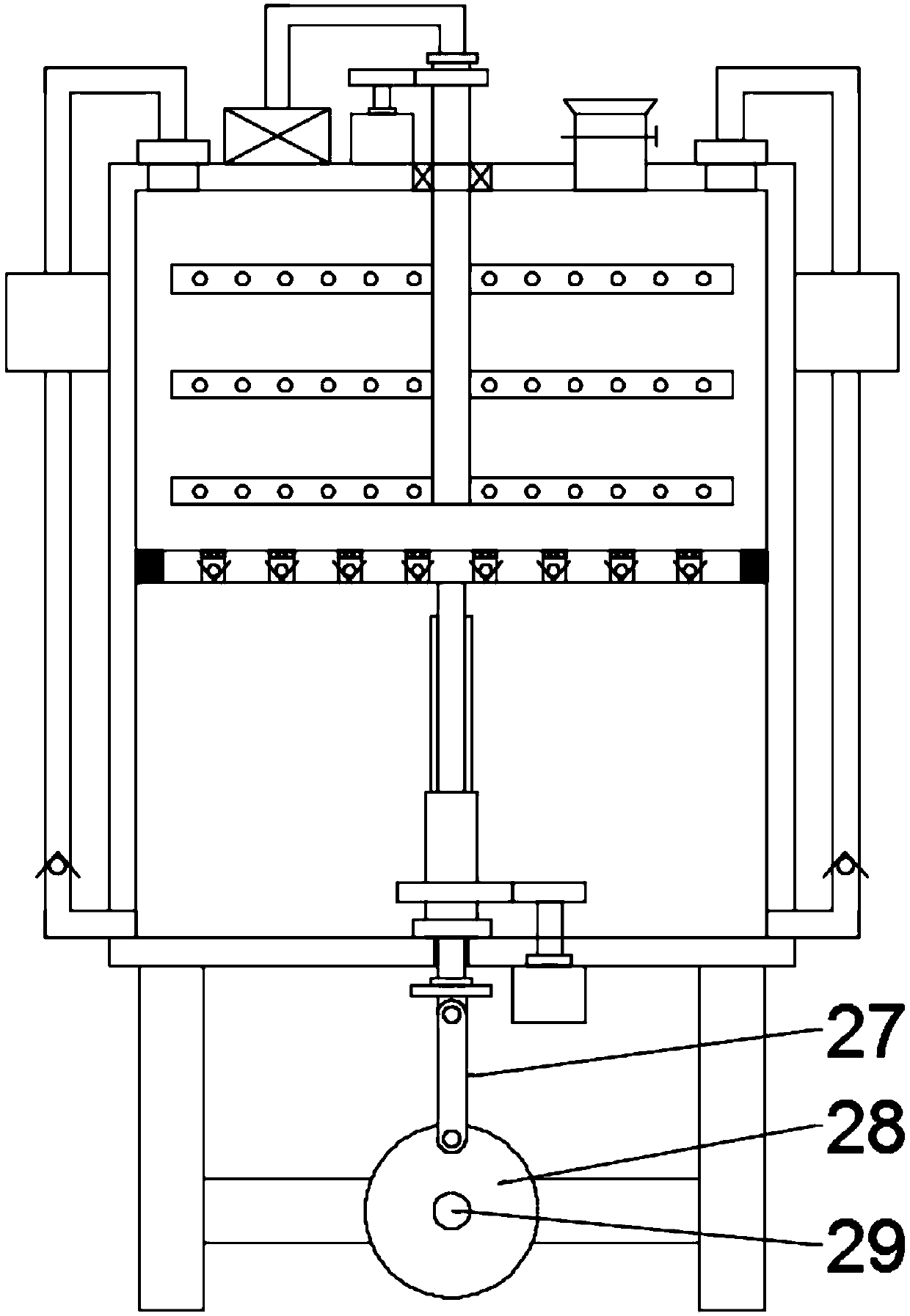

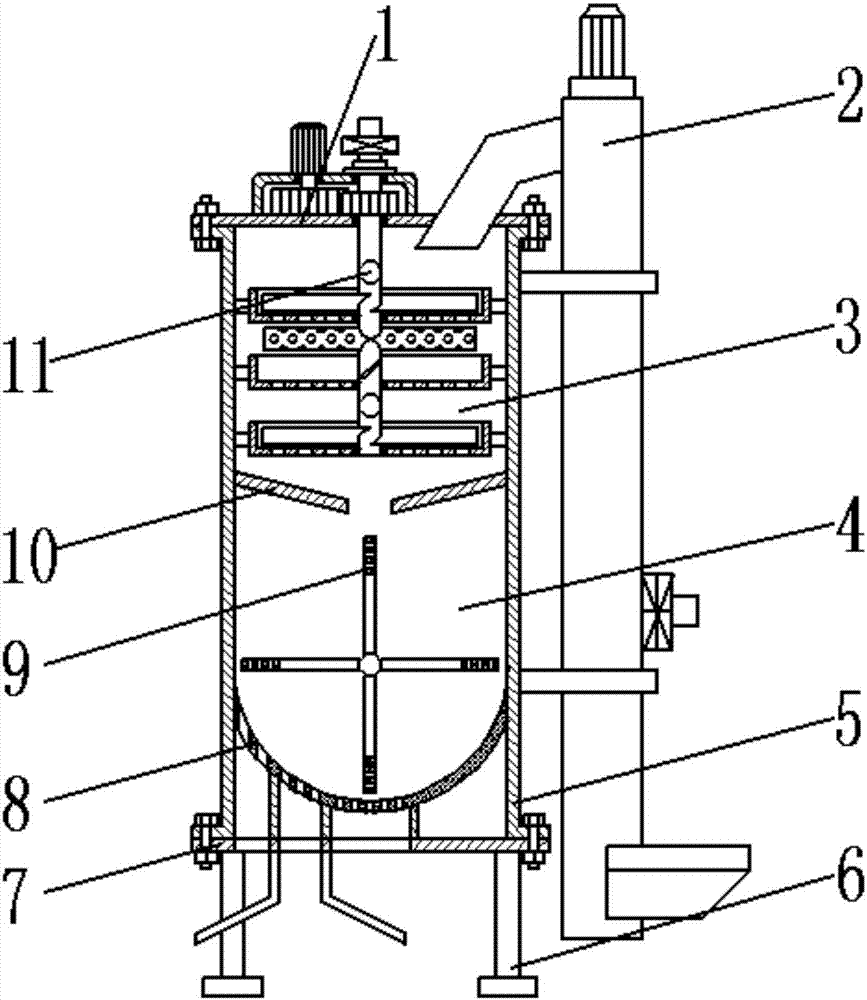

Internal circulation type traditional Chinese medicine drying equipment

InactiveCN107940974AReduce volumeFully dryDrying machine combinationsDrying gas arrangementsSpiral bladeBiochemical engineering

The invention discloses internal circulation type traditional Chinese medicine drying equipment. The equipment comprises a processing box, a connecting channel and a feeding cylinder; the connecting channel is formed in the left upper end of the processing box, and the upper end of the connecting channel is connected with and fixed to the feeding cylinder, a pushing shaft is arranged in the feeding cylinder in a penetrating mode, and a spiral blade is arranged on the pushing shaft; a heating block sleeves the outer side of the feeding cylinder and is used for heating materials in the feeding cylinder, the two ends of the pushing shaft penetrate through the feeding cylinder, the left end of the pushing shaft is fixedly connected with the output end of a driving motor, and a driving gear isarranged at the right end of the pushing shaft; and a driving belt wheel is arranged on the part, close to the driving motor, of the pushing shaft, a feeding pipe is arranged on the upper left side ofthe feeding cylinder, and a crushing box is arranged at the upper end of the feeding pipe. According to the equipment, the structure is simple and reasonable; the materials are crushed in advance sothat the size of the materials can be reduced, and later drying can be facilitated; and meanwhile, circulation drying of the materials in the processing box can be realized through the equipment so that the materials can be fully dried, and the equipment is high in practicability.

Owner:马良彬

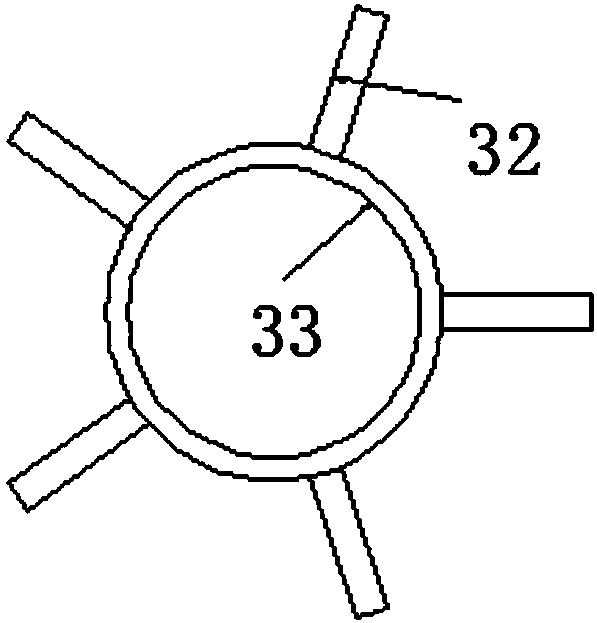

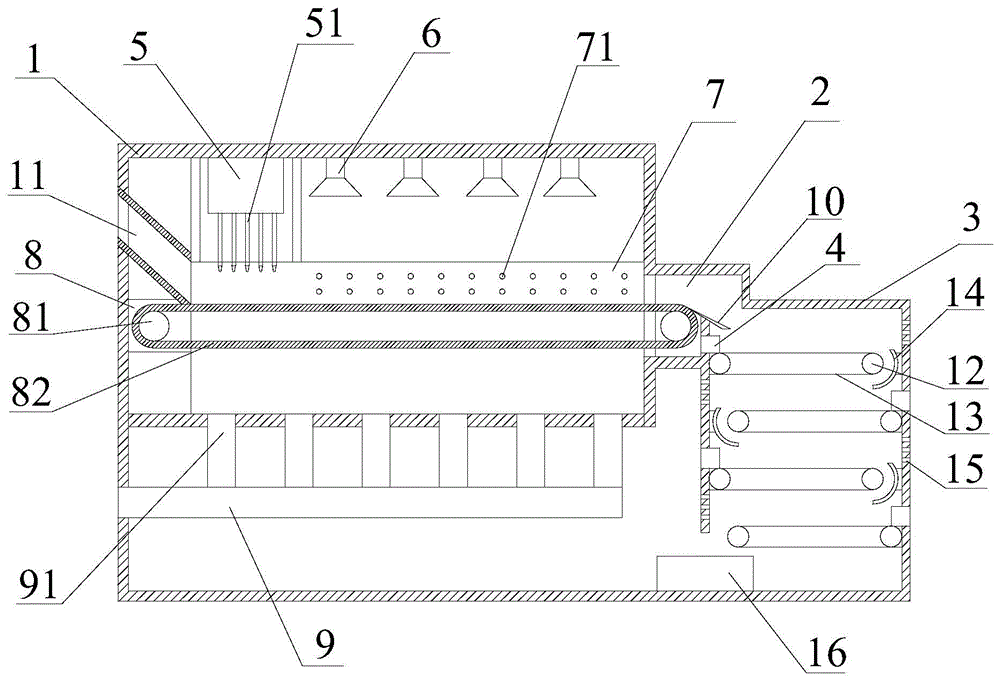

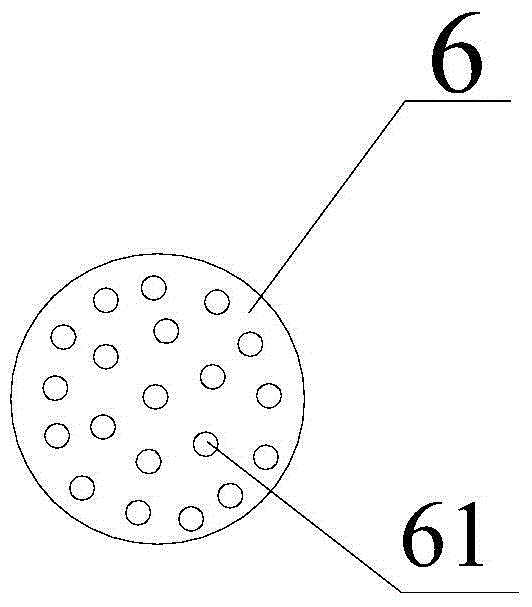

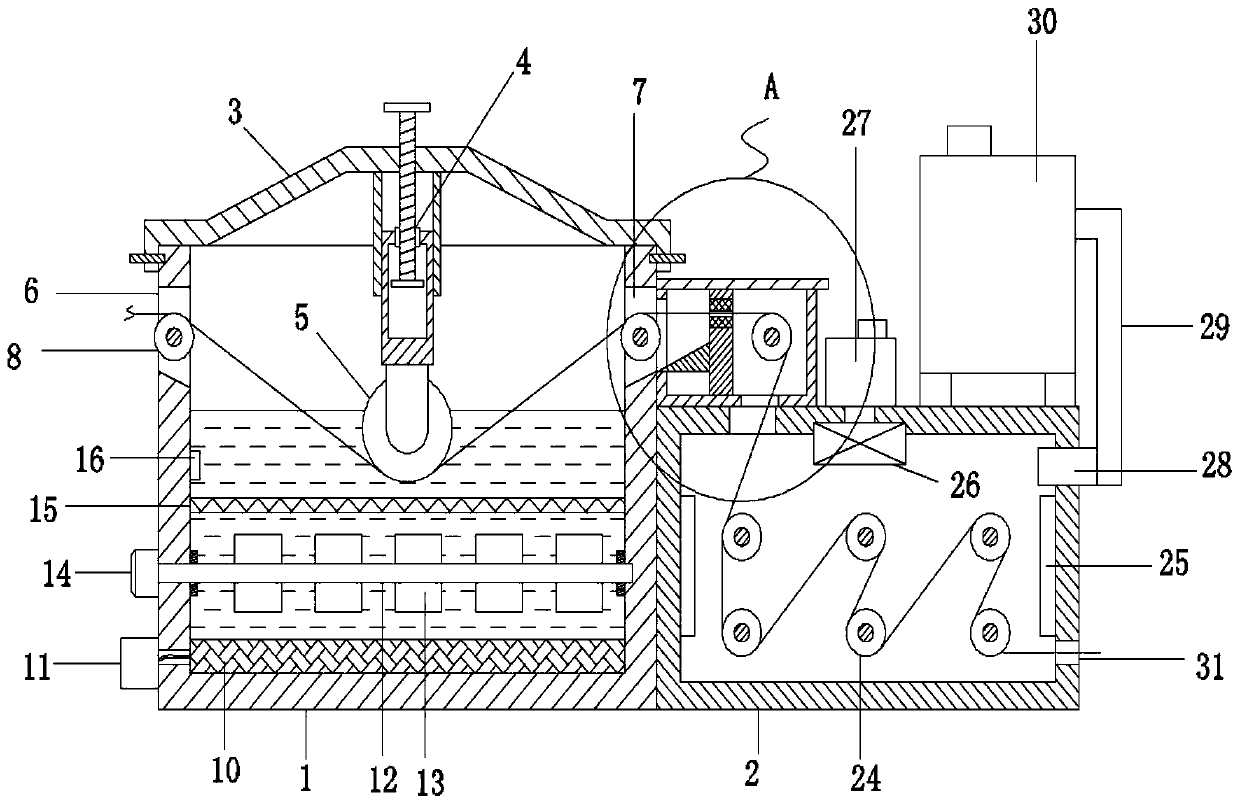

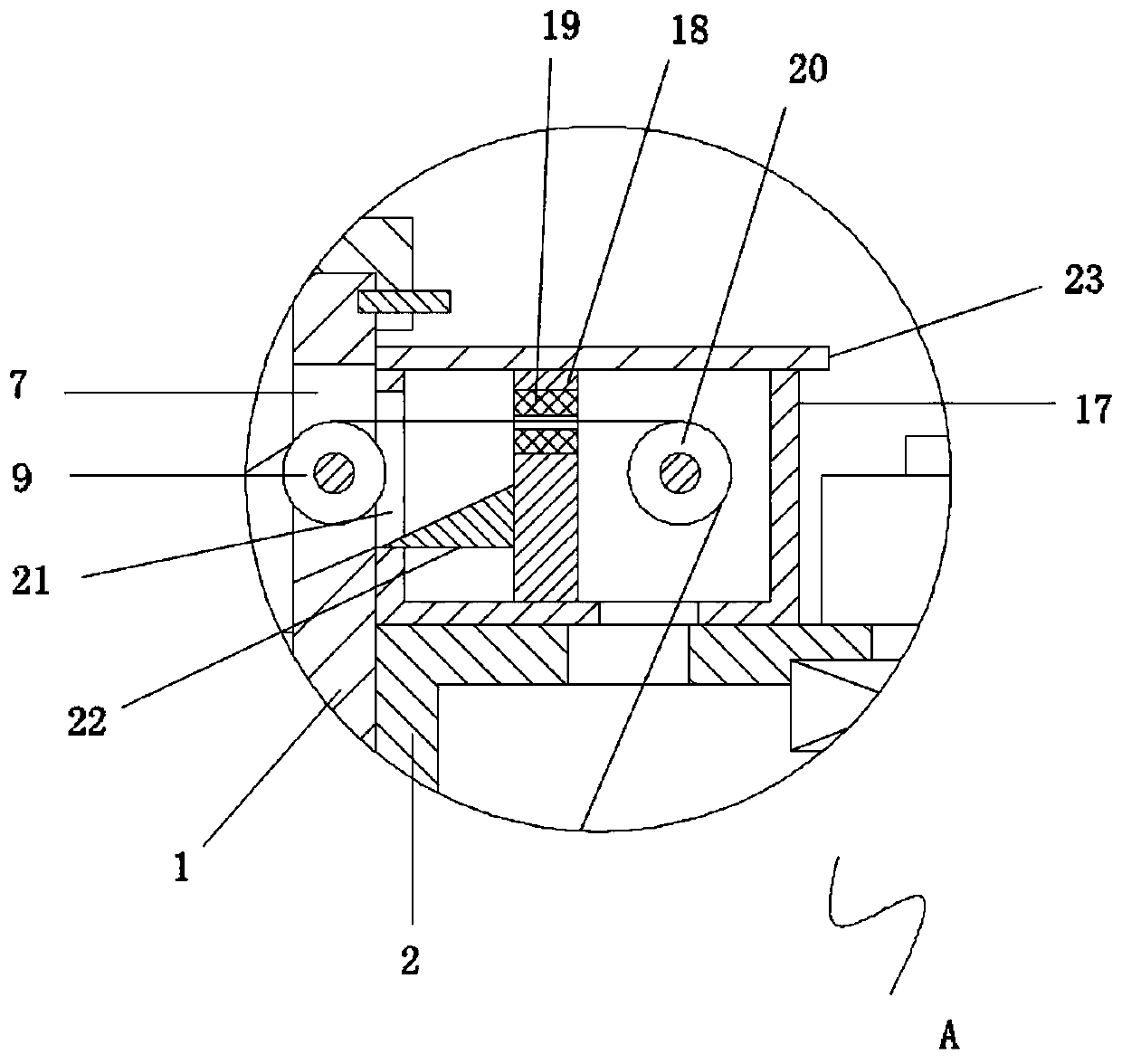

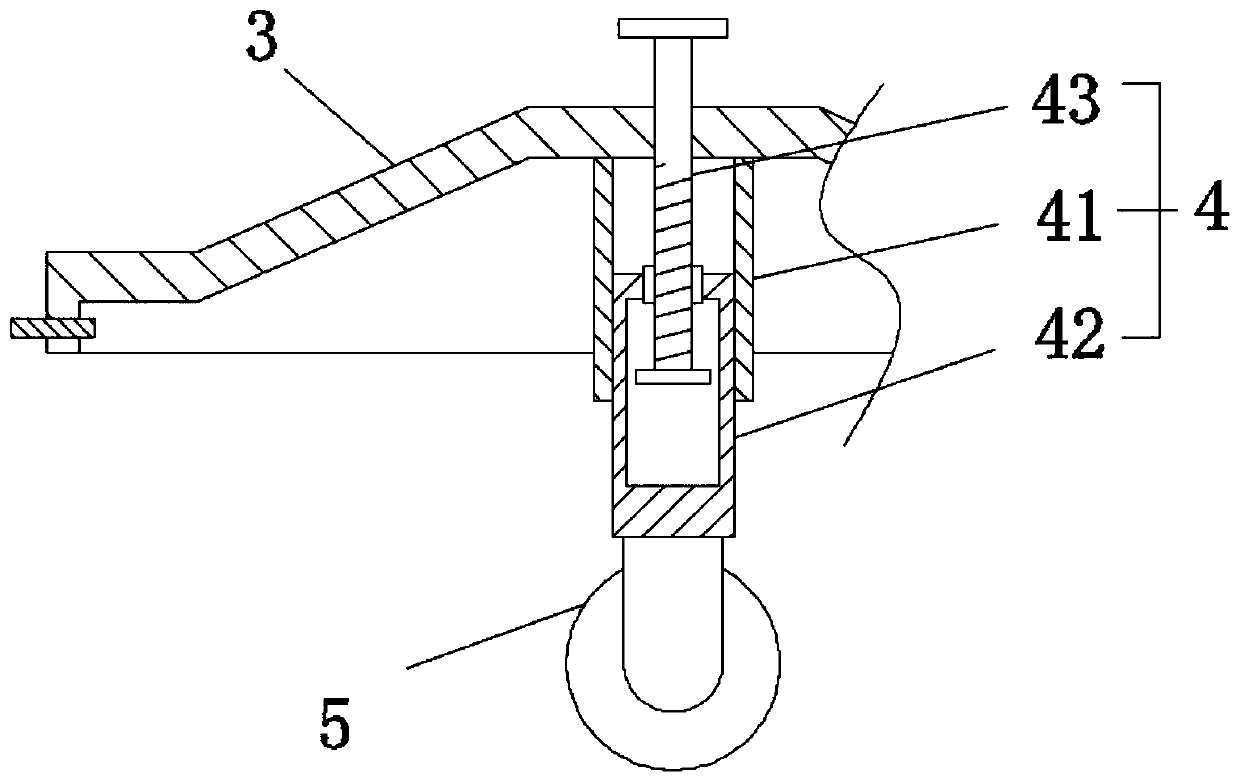

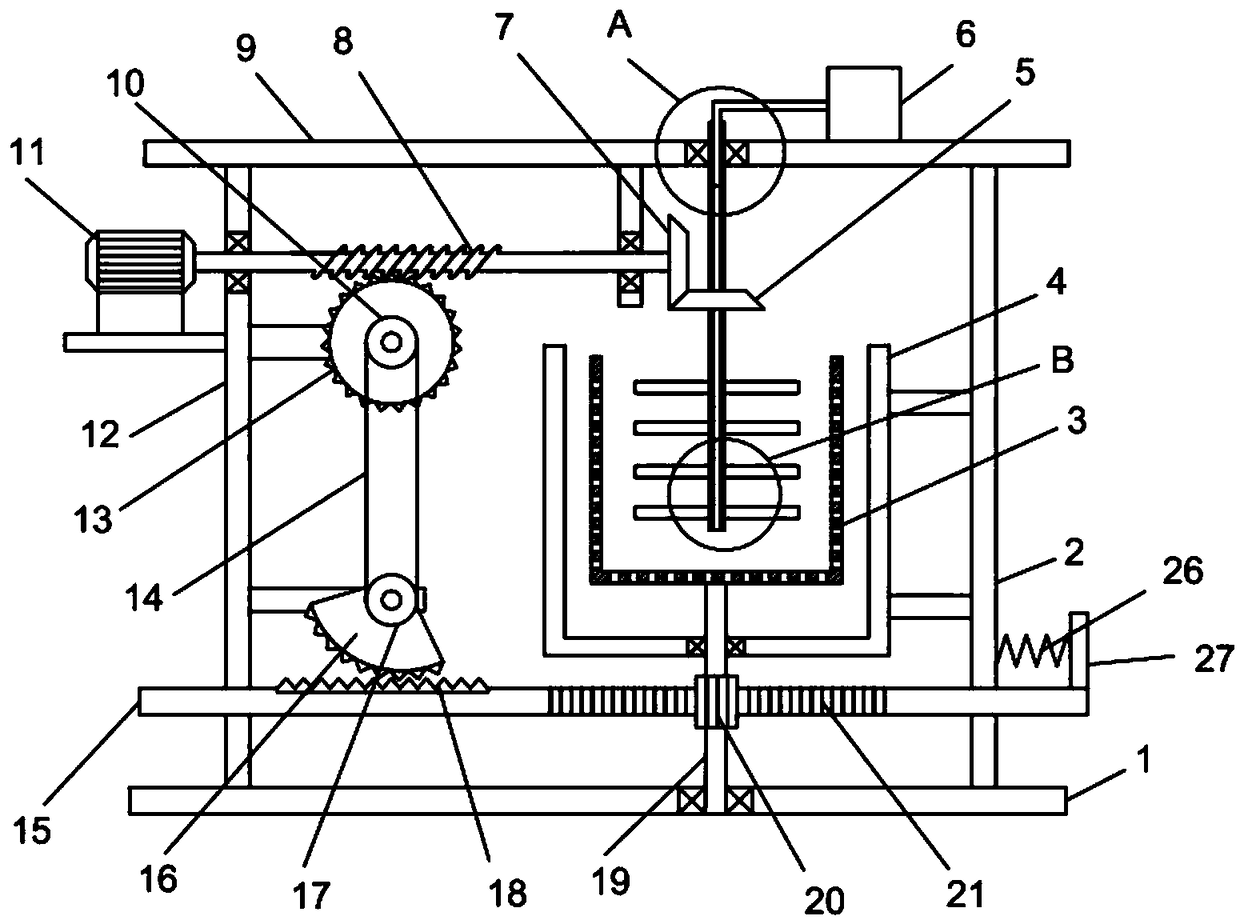

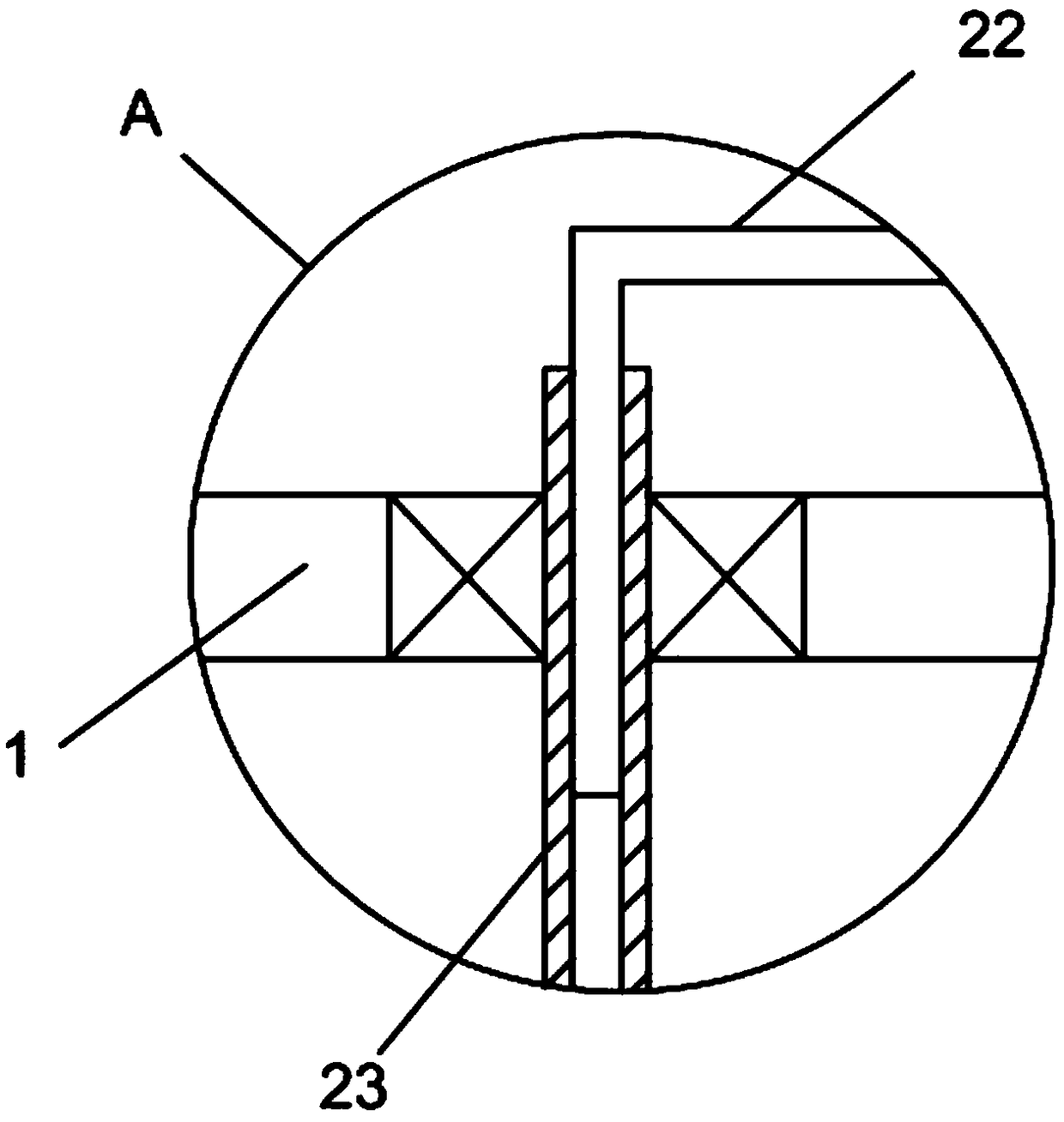

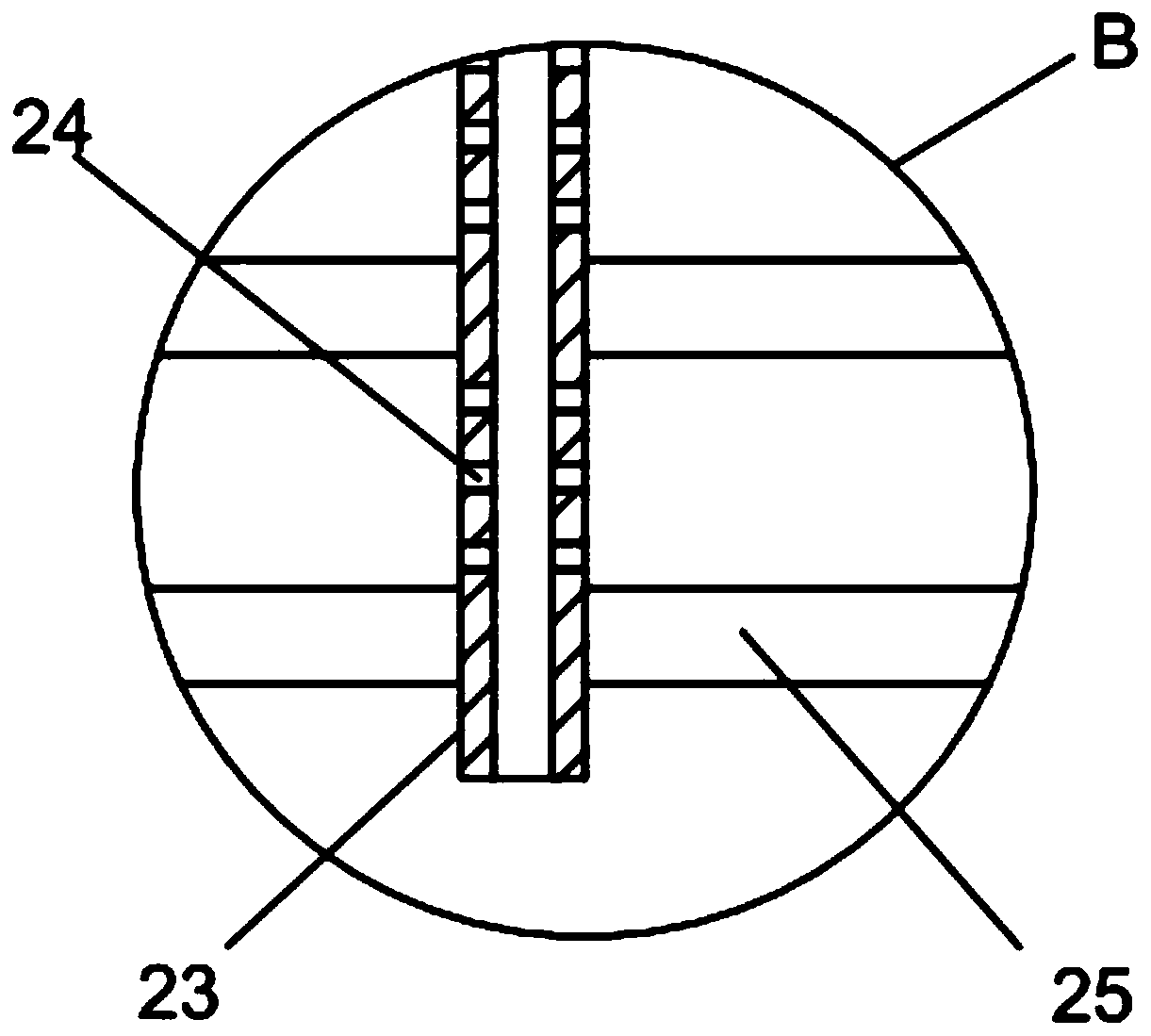

Bearing washing and drying integration device

InactiveCN104550087AReduce the intensity of manual operationImprove work efficiencyDrying gas arrangementsDrying machines with progressive movementsHigh pressureProduction effect

The invention discloses a bearing washing and drying integration device. The bearing washing and drying integration device comprises a washing machine body, a connecting part and a drying machine body, wherein the washing machine body and the drying machine body are communicated with each other through the connecting part to form a whole body, the washing machine body comprises a washing liquid storage box, a high pressure spray head, a baffle plate, a transmission device and a water discharge device, the transmission device is installed inside the washing machine body, the tail end of the transmission device is arranged on the junction of the connecting part and the drying machine body, a discharge baffle plate is arranged in the connecting part, the drying machine body comprises a drying device, conveyor belts, a roller, steering devices and a receiving box, four conveyor belts are arranged inside the drying machine body, each conveyor belt is installed on the roller, the drying device is correspondently installed on the junction of each conveyor belt and the drying machine body, and the steering device is arranged on the steering position of each conveyor belt. By adopting the bearing washing and drying integration device, the washing and drying of a bearing can be completed in one machine, so that the working efficiency is improved, the production effect of the bearing is guaranteed, and the floor occupation area of the machine is reduced.

Owner:XINCHANG LONG HAO BEARING CO LTD

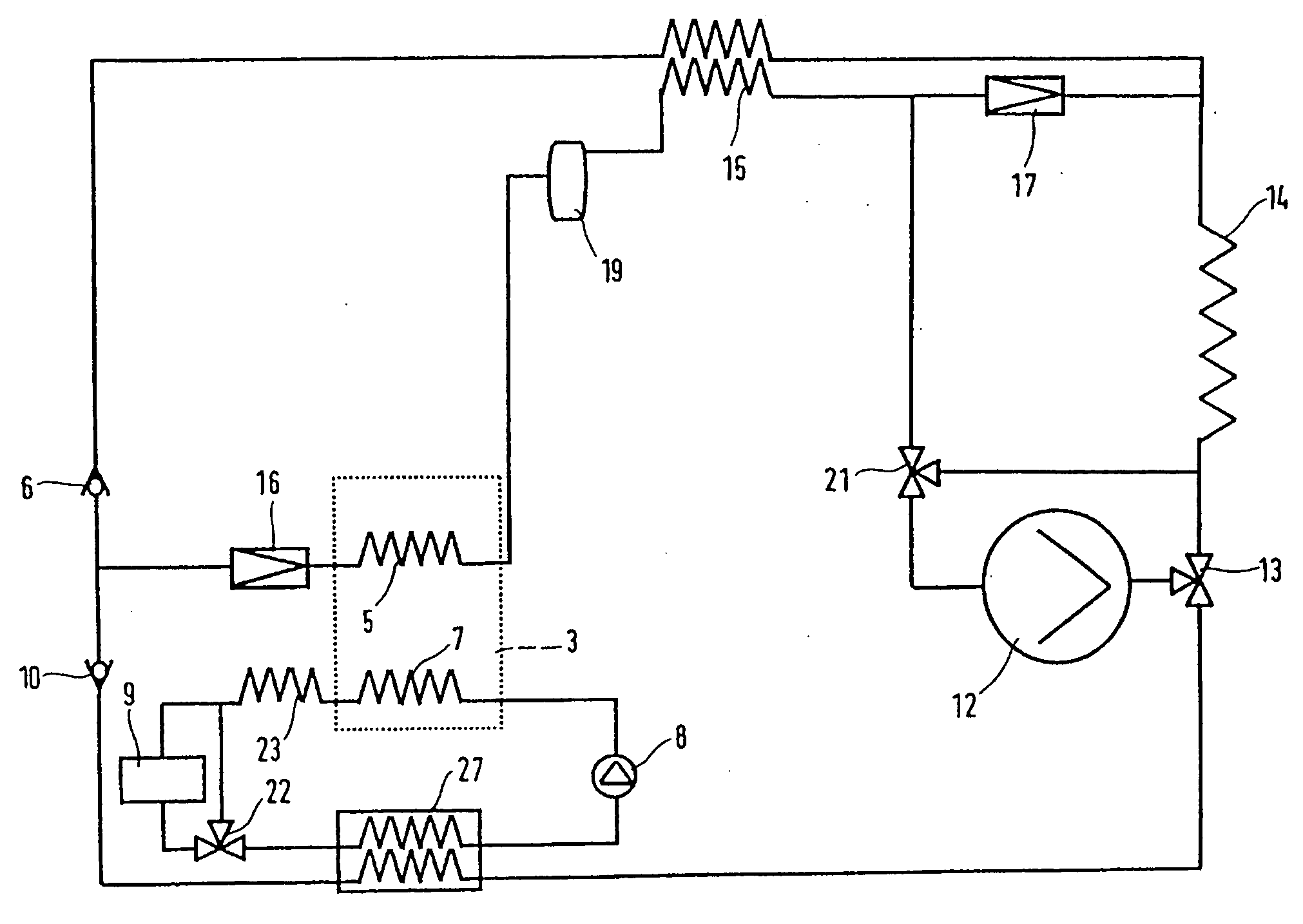

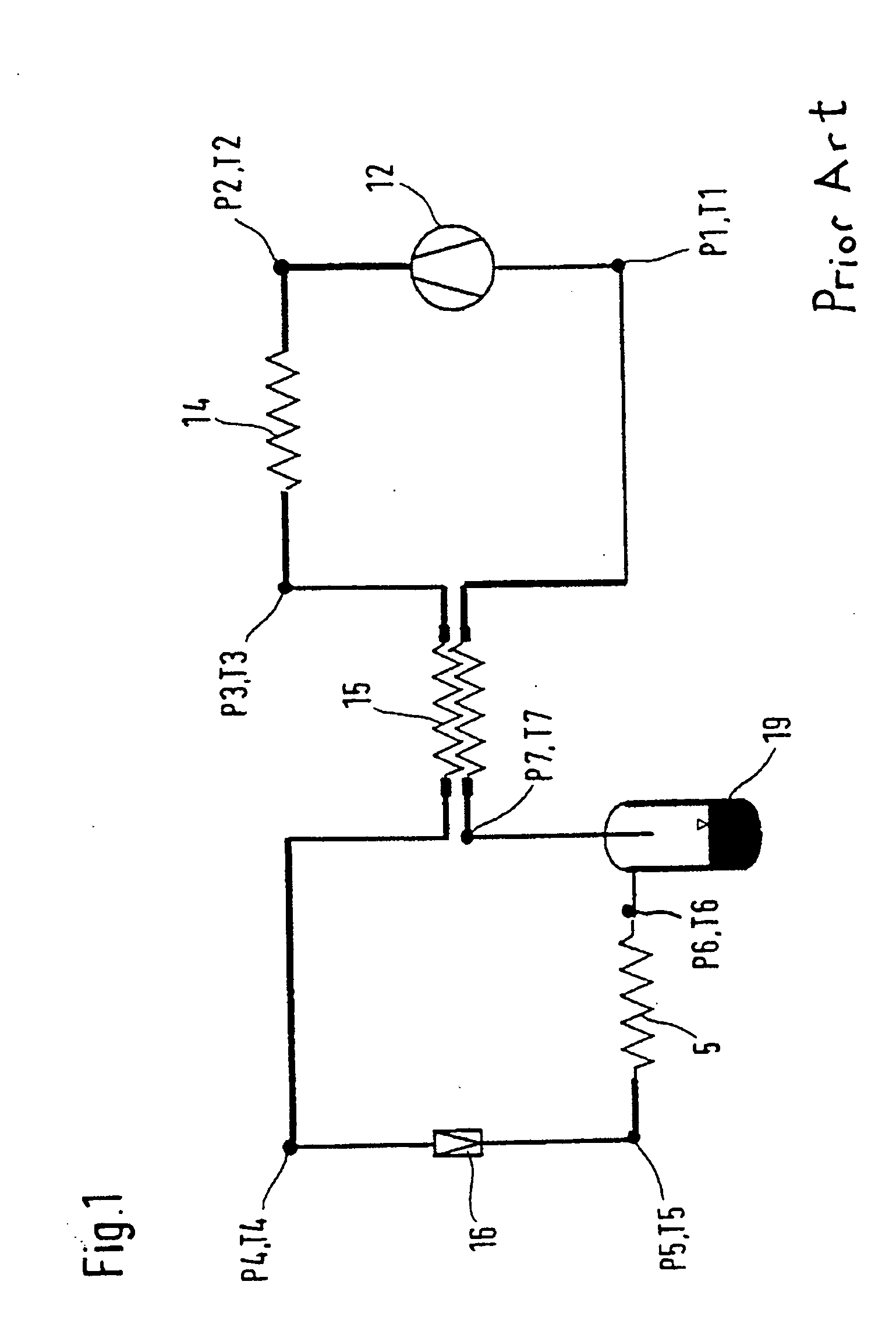

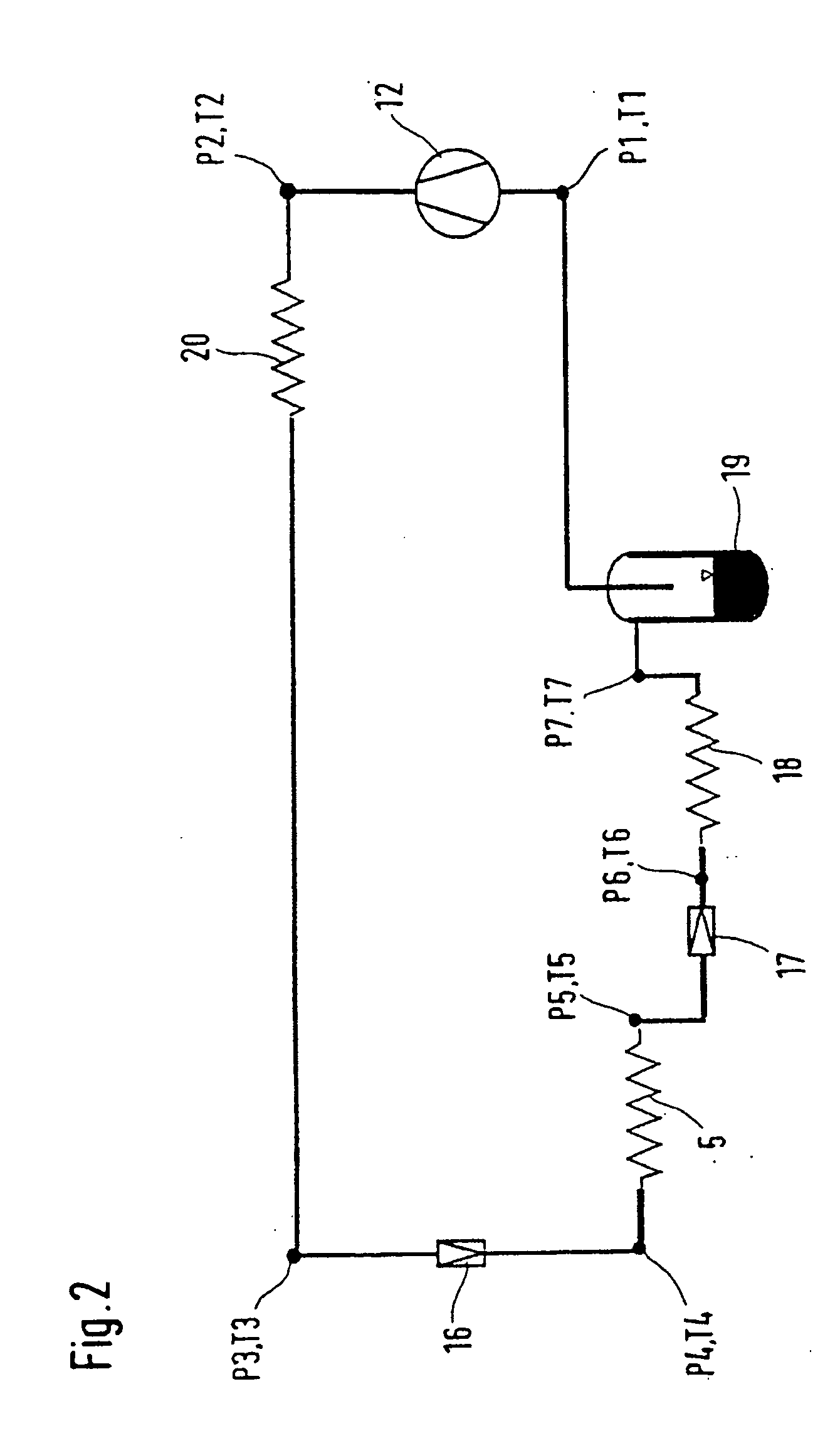

Air-conditioning system for a motor vehicle

InactiveUS20050034473A1Reduce fuel consumptionReduce pollutant emissionsAir-treating devicesMechanical apparatusAir conditioningMotorized vehicle

In an air-conditioning system for a motor vehicle having an integrated heat pump for cooling and heating, in which refrigerant is circulated and which allows heat exchange with the incoming air for the interior compartment of the motor vehicle, the heat transfer is effected either directly, by means of a refrigerant / air heat exchanger through which the air for the interior compartment is conducted, or by means of a secondary refrigerant circuit, which includes two expansion devices and three heat exchangers provided in the refrigerant circuit of the system.

Owner:HANON SYST

Dishwasher having a flushing container with a lockable door and method for performing a dishwashing program in such dishwasher

ActiveUS20060283482A1Simplify operating proceduresSimple actionAutomatic washing/rinsing machine detectionWing accessoriesEngineeringGap width

A dishwasher includes a tub, a hinged door for closing the tub, a sealing gasket disposed between the tub and the door, a device control unit, a closing plate connected to the tub and movable by a motor, a latching element disposed on the door, and a closing tab disposed on the closing plate for engaging with the latching element for closing the door and enabling the device control unit to partially open the door. The closing plate is movable into first and second positions to bring the door into respective first and second partially open positions with respective first and second gap widths. The second gap width is larger than the first gap width.

Owner:MIELE & CO KG

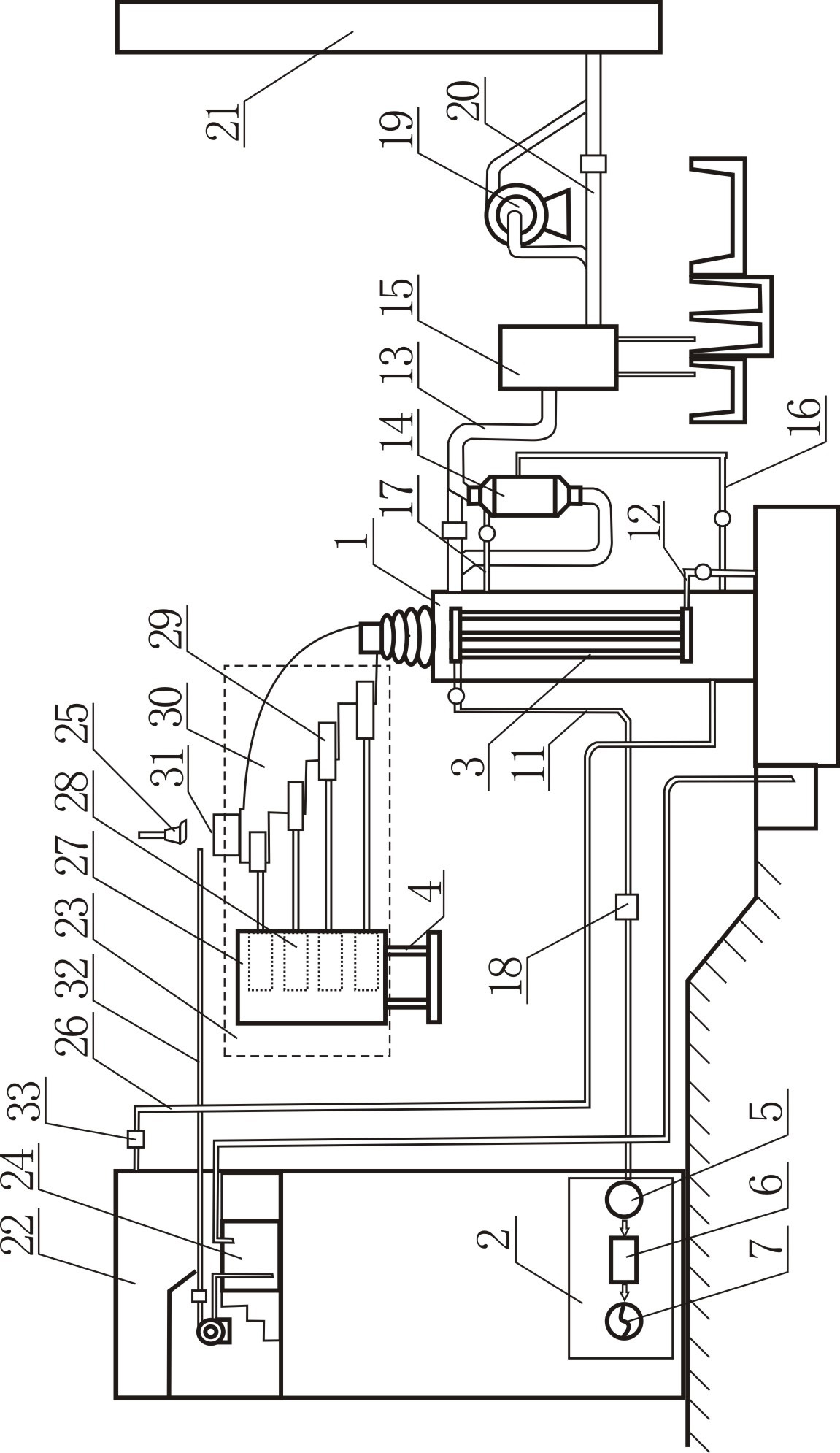

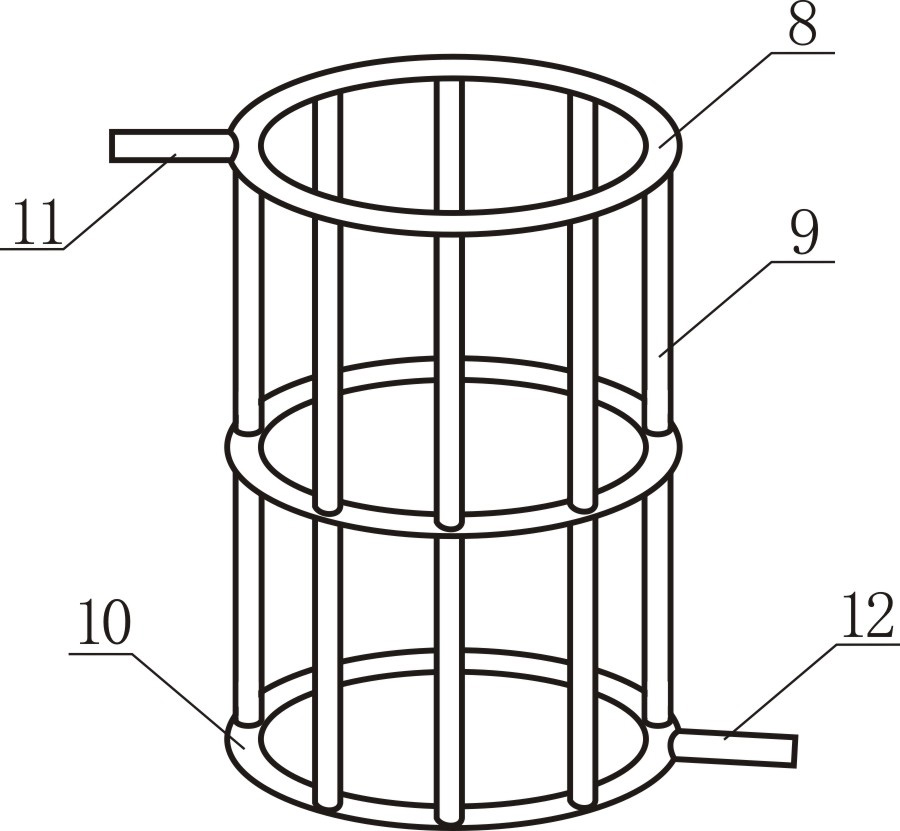

Garbage disposal waste heat power generation system with internal steam pipe

InactiveCN102606236AMaximize recoverySimple structure and processEnergy inputSteam engine plantsFlue gasSteam power

The invention discloses a garbage disposal waste heat power generation system with an internal steam pipe, which comprises a garbage gasifier and a turbine steam power generation device. The turbine steam power generation device comprises a steam generator, a steam discharge pipe, a steam drum, a steam turbine and a power generator, wherein the steam drum, the steam turbine and the power generator are sequentially connected, and the steam generator is arranged in the garbage gasifier and is of a cylindrical cage type structure comprising an upper annular pipe, a plurality of straight pipes and a lower annular pipe. As the steam generator is arranged in the garbage gasifier to realize primary heat exchange and a heat exchanger is additionally arranged in a flue gas channel to realize secondary utilization, heat generated in garbage disposal is used to the maximum extent, the technique with low heat utilization rate of a waste heat boiler for traditional garbage disposal steam power generation in the past is thoroughly changed, and garbage disposal heat recovery is maximized. Owing to a four-step hydraulic pusher, garbage is increasingly looser in the process of entering the garbage gasifier, and is not blocked.

Owner:SHENZHEN JUNENG BIOMASS GASIFICATION TECH

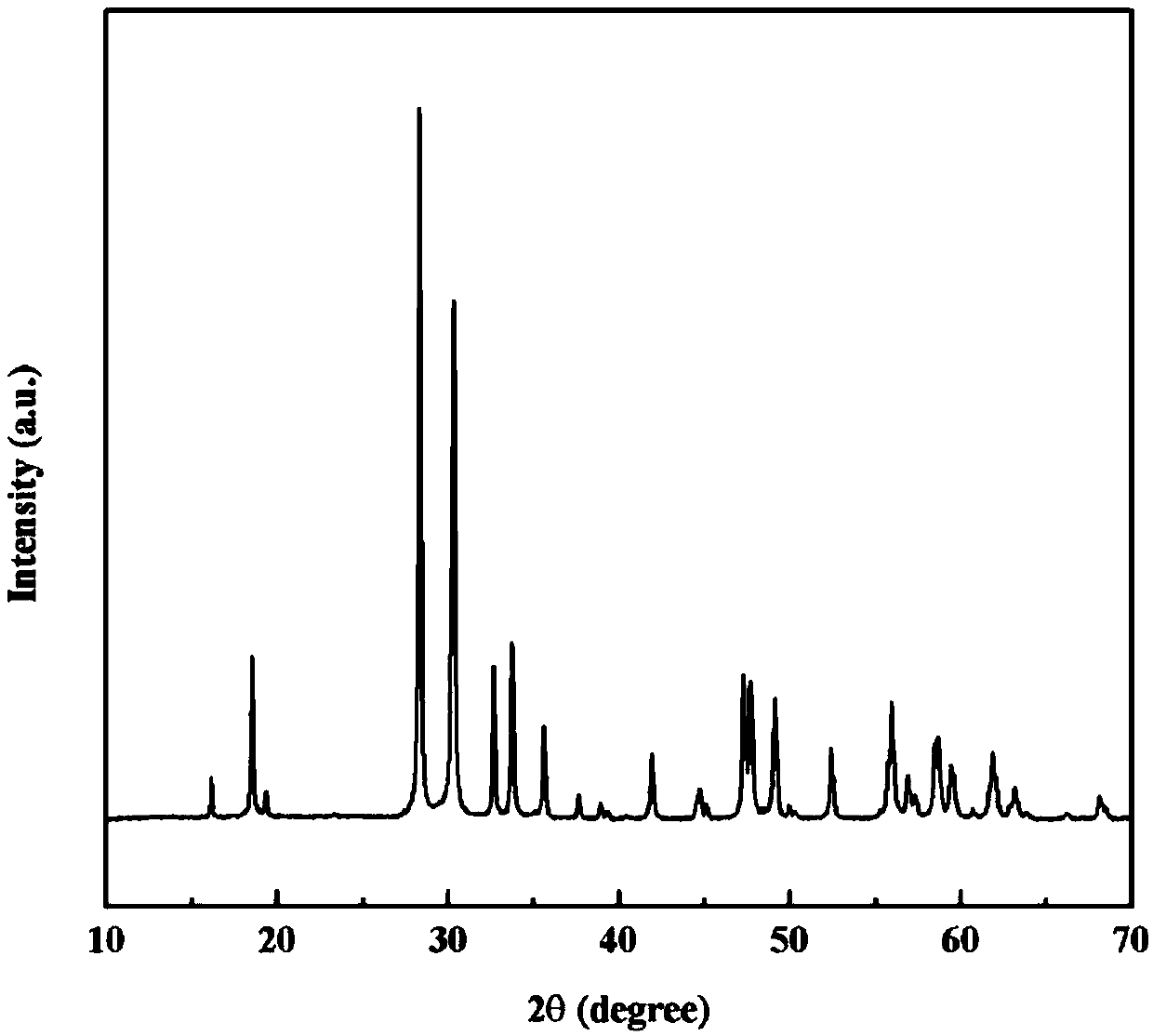

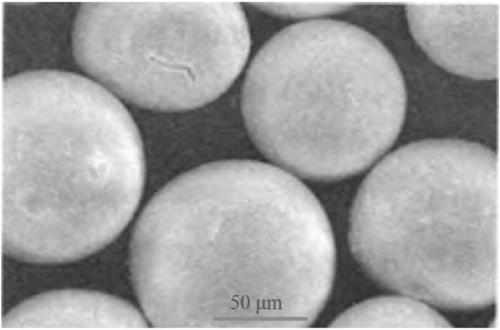

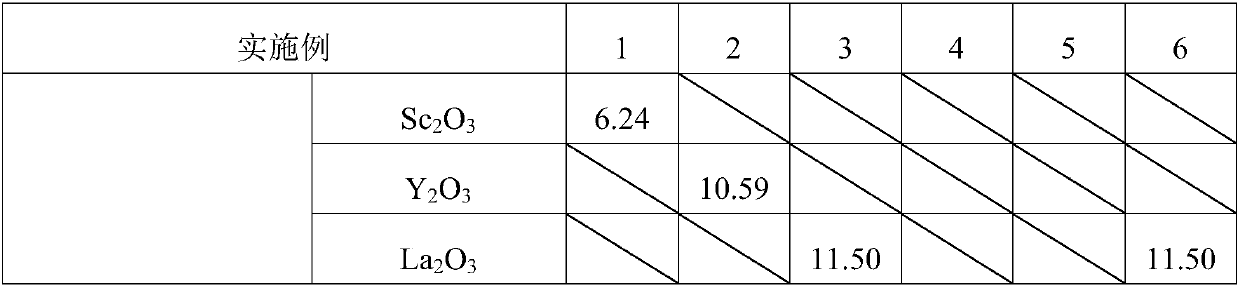

Rare earth tantalum/niobate (RETa/NbO4) ceramic powder and preparation method thereof

The invention relates to the technical field of preparation of ceramic powder, and discloses rare earth tantalum / niobate (RETa / NbO4) ceramic powder and a preparation method thereof. The chemical general formula of the rare earth tantalum / niobate (RETa / NbO4) ceramic powder is RETa / RENbO4, the crystal structure of the ceramic powder is the orthorhombic phase, the crystal lattice space group is C2221, the particle size is 10-70 microns, and the ceramic powder is spherical. In the preparation process, raw materials are subjected to ball milling, after a high temperature solid phase method is adopted for a reaction the processed raw materials, a solvent and an organic adhesive are mixed to obtain paste C, after centrifugal atomization, dry material particles are obtained, resintering is conducted, and the rare earth tantalum / niobate (RETa / NbO4) ceramic powder meeting the requirements of an APS technology for ceramic powder is obtained.

Owner:KUNMING UNIV OF SCI & TECH

Nonwoven fabric dyeing device for clothing production

InactiveCN110004622AAvoid layered settlementImprove dyeing effectTextile treatment containersSucessive textile treatmentsLiquid temperatureDyeing

The invention discloses a nonwoven fabric dyeing device for clothing production in the technical field of nonwoven fabric production. The nonwoven fabric dyeing device comprises a dyeing tank and a drying tank, and the drying tank is fixedly connected to the right side wall of the dyeing tank. Dyeing liquid can be stirred by a stirring mechanism to avoid layered settlement; by arrangement of a heating plate and a component thereof, dyeing liquid temperature can be changed; by arrangement of an end cover and a telescopic mechanism, convenience in mounting of a nonwoven fabric in the dyeing tankis achieved; by arrangement of a protective screen, the problem of fabric loss caused by contact of the nonwoven fabric and the stirring mechanism can be avoided; by the drying tank and dyeing tank integrated structure, fabric dyeing and drying processes are integrated, a fabric dyeing process is simplified, and processing cost is reduced; by arrangement of array cloth rollers, two surfaces of the nonwoven fabric can be dried completely, and drying effects are improved; by arrangement of a filter tank, waste gas generated in dyeing and drying can be purified.

Owner:安徽职业技术学院

Traditional Chinese medicine up-and-down vibration drying device

The invention provides a traditional Chinese medicine up-and-down vibration drying device, and belongs to the field of traditional Chinese medicines. The traditional Chinese medicine up-and-down vibration drying device comprises a medicine drying cabinet, a dehumidification device, a sliding block, a separating plate, a bearing drying box, a cam, an electric heating fan and a cabinet door; the medicine drying cabinet is arranged to be a square cabinet and is arranged on a horizontal working face, the separating plate is welded to the inner wall of the medicine drying cabinet, the medicine drying cabinet is divided by the separating plate into an upper cavity and a lower cavity, the sliding block is arranged in a sliding groove, the bearing drying box is welded to two fixed rods and is arranged at the upper end of the cam, the cam is fixedly arranged on a transmission shaft, the electric heating fan is fixedly arranged in a radiating cover, the dehumidification device is fixedly arranged on the upper end wall of the medicine drying cabinet, the cabinet door is fixedly arranged on the medicine drying cabinet through a hinge, and a sealing strip is arranged on the edge wall of the cabinet door so as to achieve sealing. The traditional Chinese medicine up-and-down vibration drying device is reasonable in design, medicine up-and-down vibration drying is achieved through rotation ofthe cam, drying is sufficient, and follow-up medicine processing is facilitated.

Owner:郑州莉迪亚医药科技有限公司

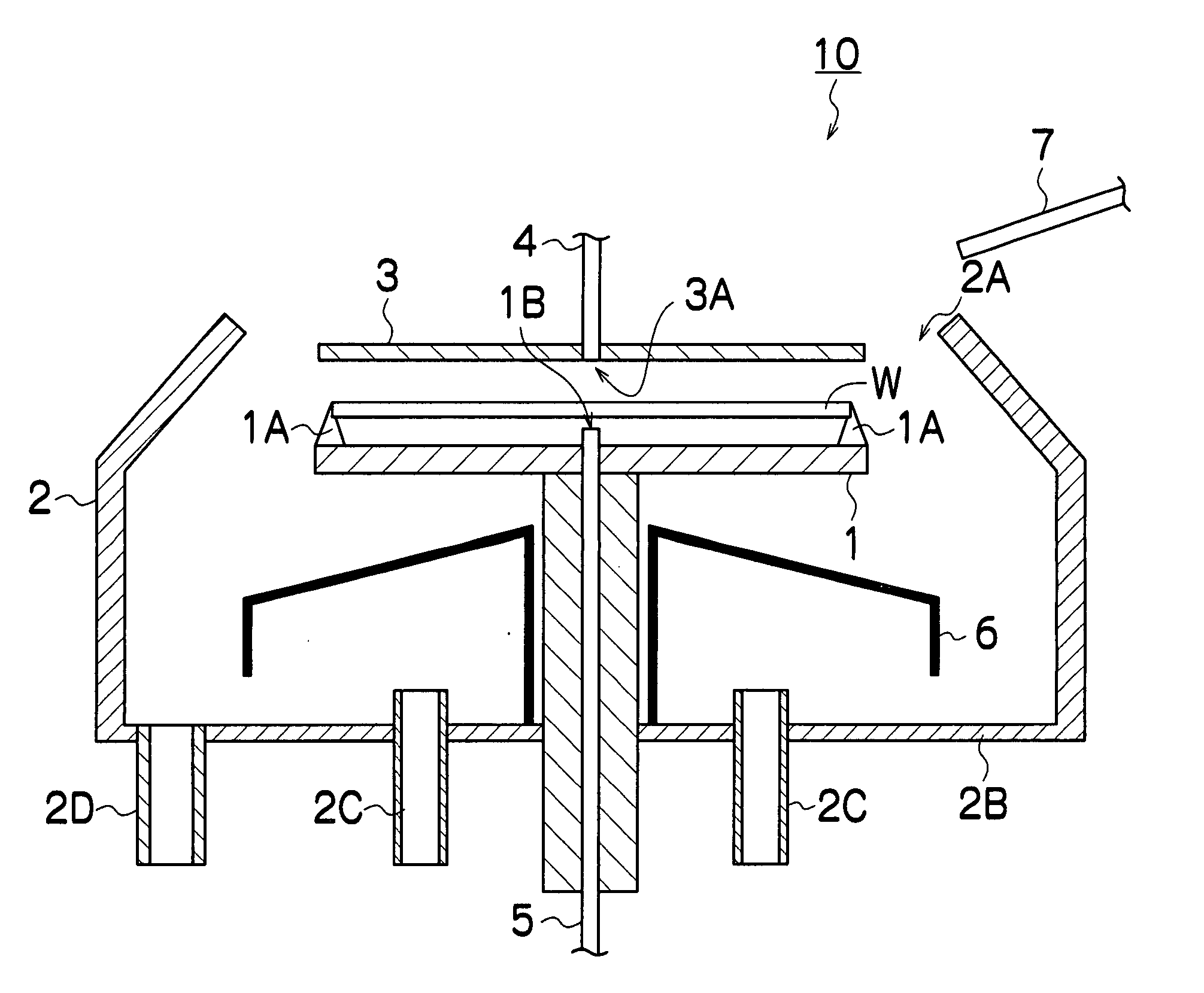

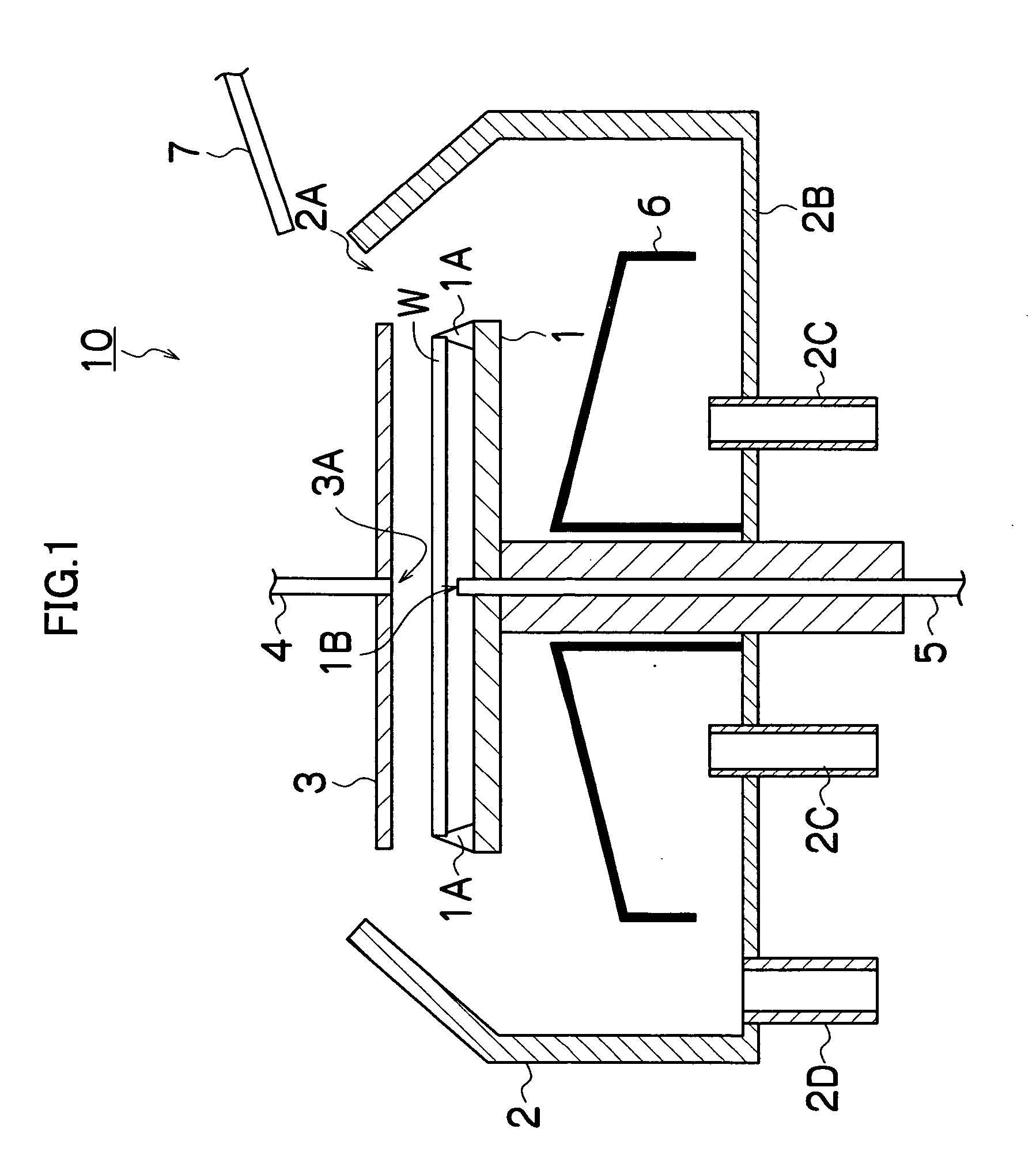

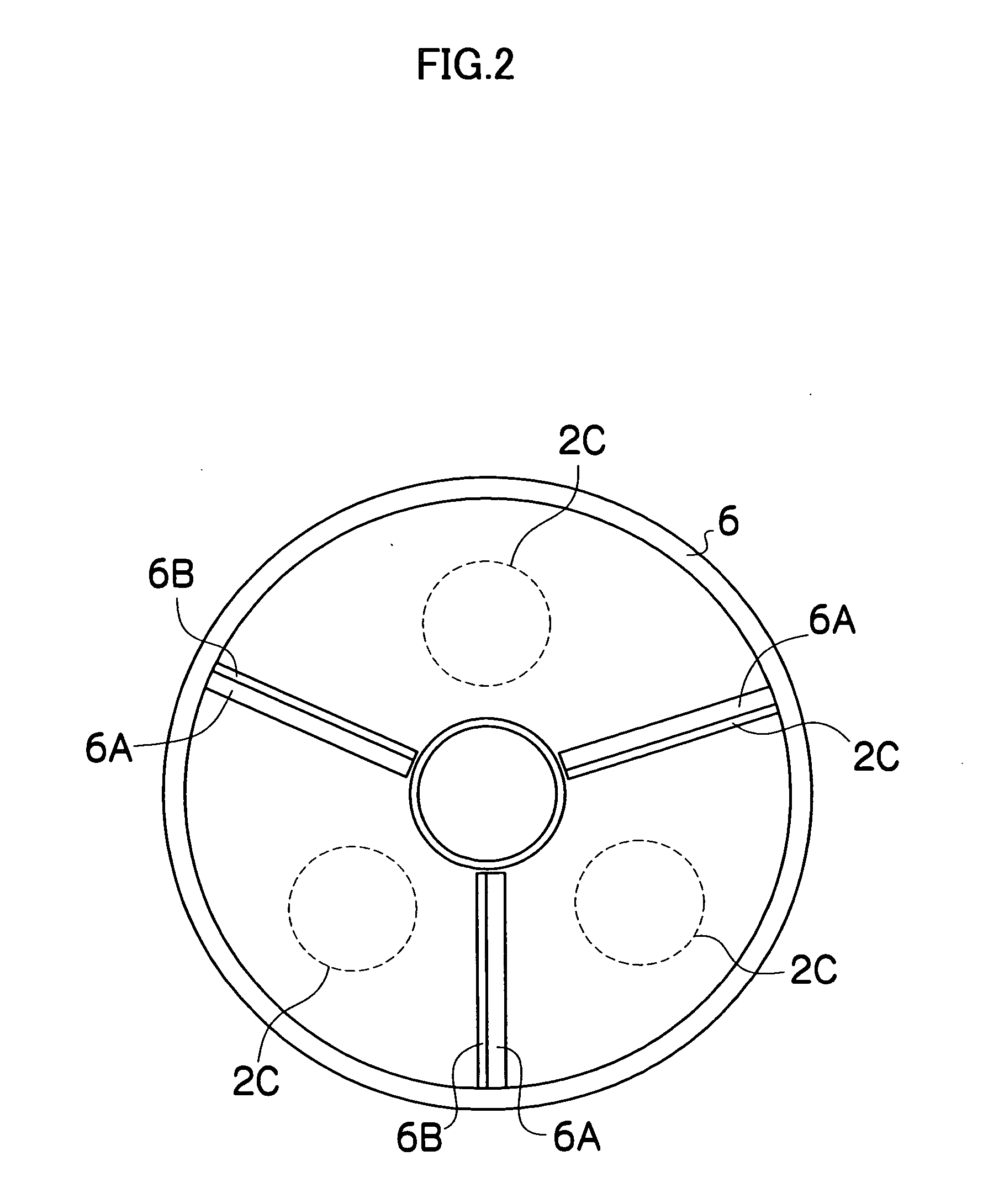

Spin cleaning and drying apparatus and method of spin cleaning and drying

InactiveUS20060042666A1Fully drySemiconductor/solid-state device manufacturingElectrostatic cleaningProcessing typeInjection port

The present invention provides a spin cleaning and drying apparatus of single-wafer processing type which cleans a substrate with a cleaning liquid from a rinse nozzle while rotating the substrate and dries the substrate after cleaning while rotating the substrate, comprising: a spin chuck which holds and rotates the substrates; a cup which has an opening on an upper side, a water discharge port and an exhaust gas port in a bottom portion, and encloses the spin chuck; a flow regulating plate which has a gas injection port in a middle and is provided so as to be able to move backward and forward to a position opposed to the substrate and spaced therefrom at a prescribed distance and to an upward or sideward retracted position; and an exhaust cover, having multiple slit holes each with a hood which opens to an upper surface, is provided below the spin chuck.

Owner:TOKYO SEIMITSU

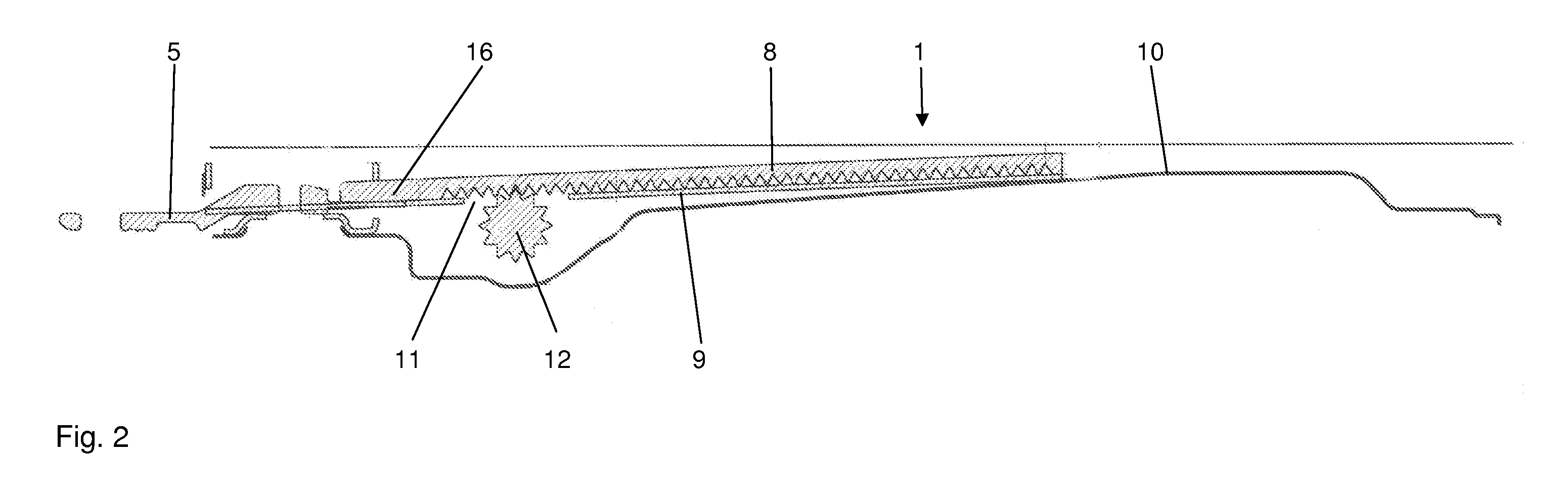

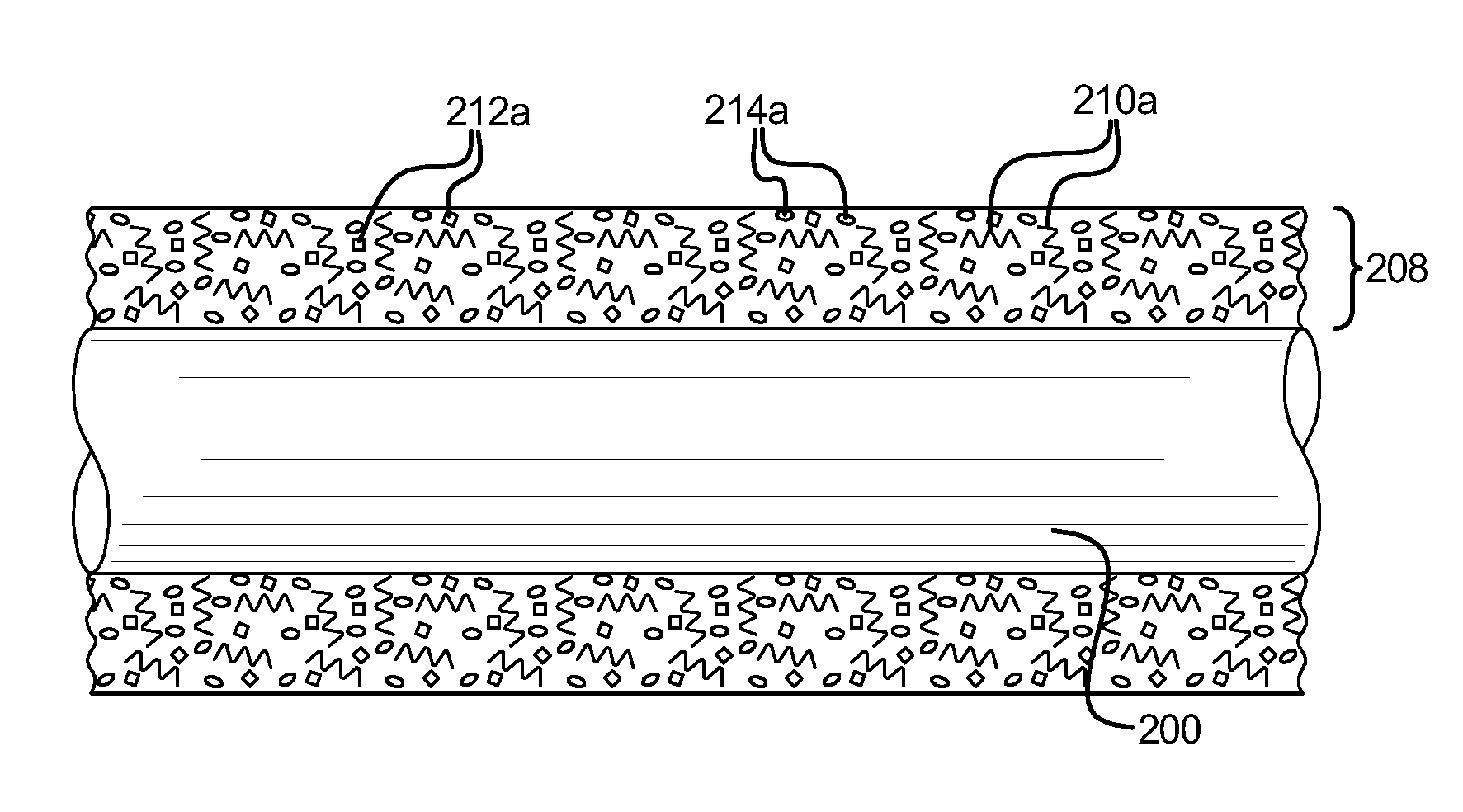

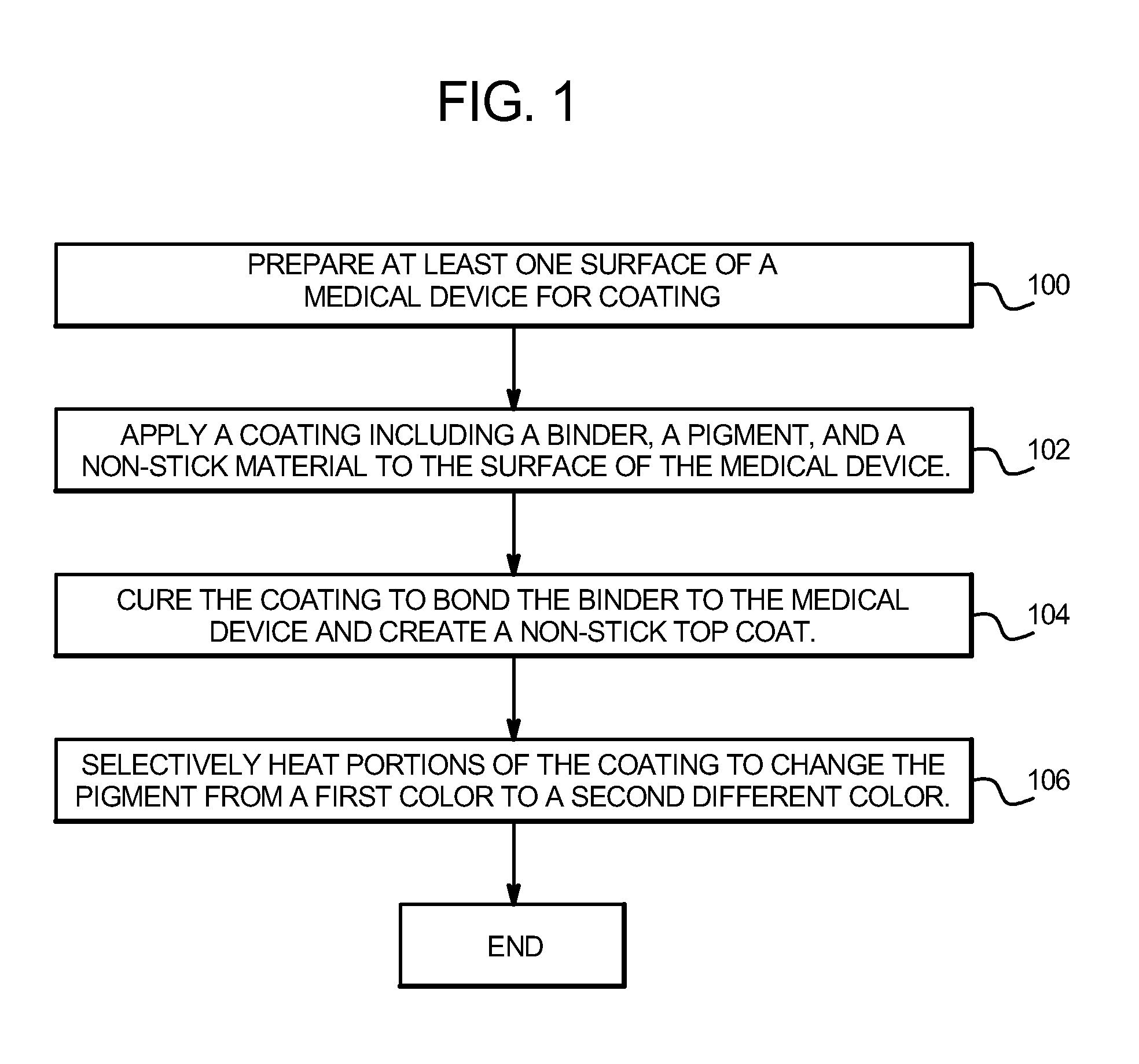

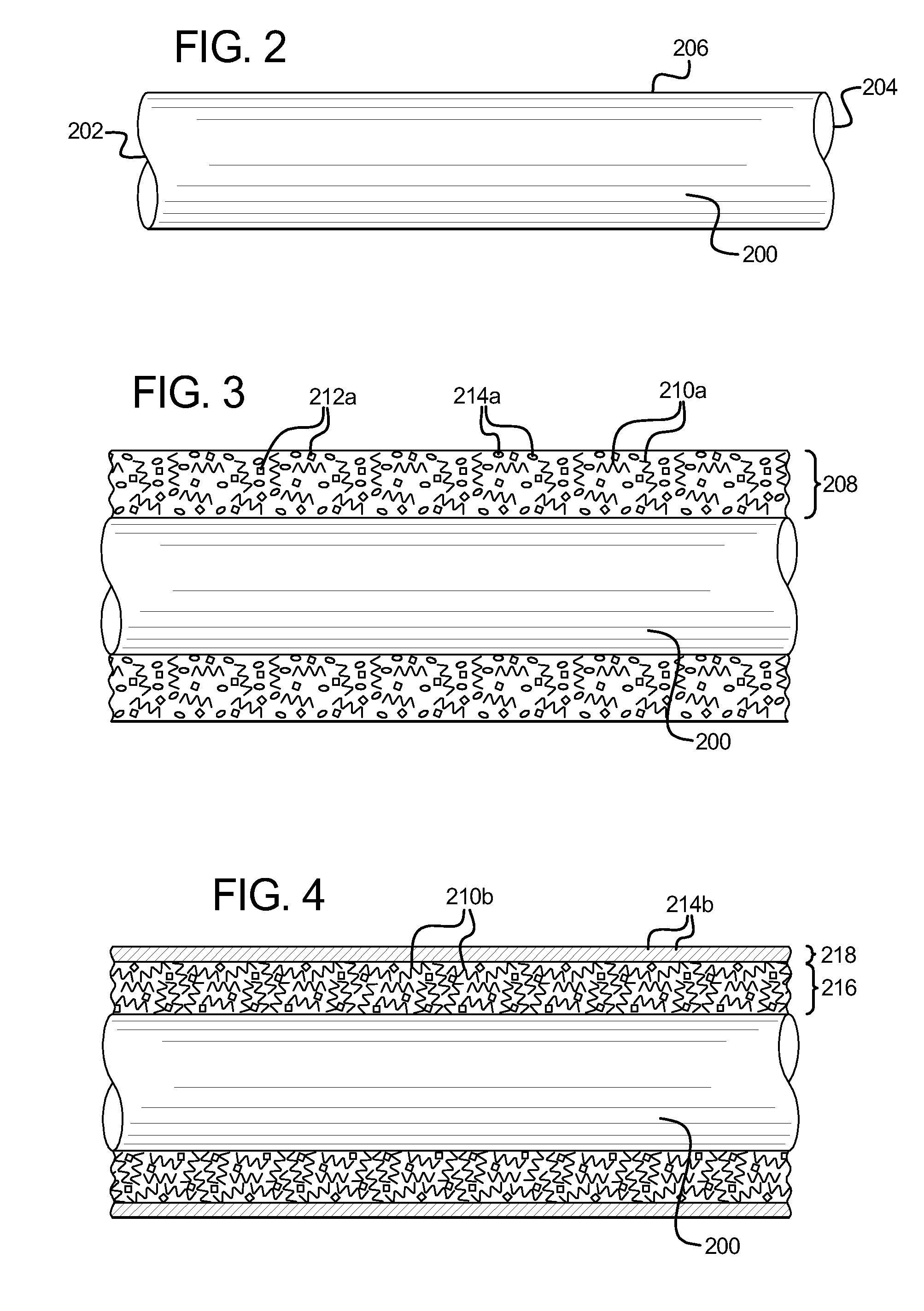

Marked precoated medical device and method of manufacturing same

InactiveUS20120271248A1Fully dryConstant diameterSurgeryPretreated surfacesCoated surfaceGuide wires

A method of manufacturing a coated medical device, such as a medical guide wire, including at least applying a first colored coating to at least a first portion of an outer surface of a medical guide wire, securing a first end of the medical guide wire, and for each a designated quantity of turns, turn a second end of the medical guide wire upon a longitudinal axis of the medical guide wire. The method of manufacturing also includes securing the second end of the medical guide wire, blocking at least a first portion of the coated surface of the medical guide wire, applying a second contrasting colored coating to at least a second, unblocked portion of the outer surface of the medical guide wire and releasing the first end and the second end of the medical guide wire to display at least one spiral marking formed along a length of the medical guide wire.

Owner:INNOVATECH

Process and Device for Generating Gas From Carbonaceous Material

InactiveUS20100154728A1Shorten the timeImprove energy balanceElectrical coke oven heatingGasifier mechanical detailsThermal radiationIrradiation

To gasify carbonaceous material into gas containing CO and H2, the drying and / or the heating and the pyrolysis of the carbonaceous material are performed using microwave irradiation and thermal irradiation and the pyrolysis products and / or the carbonaceous material are then gasified. For this purpose the carbonaceous material is irradiated in a microwave station with a heating unit, and then passed on into a reactor for gasification. The gasification occurs with the aid of a water-steam plasma source.

Owner:ME MUNSTERLAND ENERGY

Drying method for Chinese medical extract

InactiveCN106123496AKeep the fragranceModerate colorDrying solid materials with heatDrying solid materials without heatMedicinal herbsMedicine

The invention relates to a drying method for Chinese medical extract, in particular to a vacuum drying method for Shouhui cathartic extract. The vacuum drying method adopts circulating hot water with the temperature being controlled automatically to serve as a medium for heating of the Chinese medical extract, and the purpose of low-temperature drying of the Chinese medical extract is achieved. Through the method, the defects, occurring to traditional vacuum drying and the like, that thermosensitive components of extract are decomposed due to high temperature, the energy consumption is high, the heat efficiency is low, the extract is dried and burnt, drying is insufficient can be overcome. According to the dried Chinese medical extract obtained through the drying method, the content of effective components is high, the quality of finished products is good, the water content is low, and preparation processing and storage of the finished products are facilitated; fresh scent of medicinal materials is maintained, the color and lustre are natural, the texture is loose and uniform, the extract is easy to crush; and continuous and automatic production can be achieved, and the method has quite high operability and practicability.

Owner:LUNAN PHARMA GROUP CORPORATION

Efficient tea leaf drying device

ActiveCN109612234AFully dryDry evenlyPre-extraction tea treatmentTea dryingWater vaporAgricultural engineering

The invention discloses an efficient tea leaf drying device and relates to the technical field of tea production. The efficient tea leaf drying device aims at solving the problems that an existing device causes tea leaf accumulation and is low in drying speed. The efficient tea leaf drying device comprises a barrel body, a hot air blower, a hollow stirring shaft and hollow stirring rods. A pistondisc is mounted at the position, located below the hollow stirring shaft, inside the barrel body. The bottom end of a spline shaft is provided with a first driving mechanism. The first driving mechanism comprises a third motor, a disc and a movable rod. An air suction pipe is connected to an exhaust opening. The other end of the air suction pipe communicates with the bottom of an inner chamber ofthe barrel body. The piston disc is uniformly provided with multiple air outlet through holes. A one-way valve is mounted in each air outlet through hole. The efficient tea leaf drying device is provided with the hollow stirring shaft, the hollow stirring rods, the hot air blower, the piston disc, the spline shaft, a sleeve and the first driving mechanism; tea leaves are dried while being stirred;drying is conducted more thoroughly and more uniformly; the drying efficiency is improved; drying vapor is continuously pumped out through the piston disc, and after drying, the tea leaves are driedfrom the bottom in a whirlwind manner; and the drying efficiency is further improved.

Owner:徐州青钱柳农业科技有限公司

Multifunctional intelligent clothes hanger

PendingCN109518435AAchieve liftingAchieve scaleBuilding rescueOther drying apparatusFire - disastersSprocket

The invention discloses a multifunctional intelligent clothes hanger. The multifunctional intelligent clothes hanger comprises a lifting assembly, a telescopic assembly, a functional box and an auxiliary escaping assembly. The lifting assembly is composed of a first motor, fixed bases, movable sliding tables, rotating lead screws, a hand cranking assembly, chain wheels and a chain; the telescopicassembly is composed of a second motor, rotating lead screws, a drive assembly, sliding blocks, a clothes airing pole, chain wheels and a chain; the functional box is composed of a box cover, a main box body, an airing device, a sterilizing device, a drying device, illuminating lamps and sensors. The clothes hanger can ascend, descend, retract and stretch, and can automatically take back clothes in wind-blowing and rainy days or under strong sunlight and conduct drying treatment and sterilizing treatment on the clothes. Meanwhile, the auxiliary escaping assembly is arranged so that people canescape conveniently when encountering the emergency condition of fire disasters.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Method for preparing pig plasma protein powder with low ash content

The invention relates to a plasma protein concentrating and drying technology, in particular to a method for preparing pig plasma protein powder with low ash content. In the invention, waste, namely pig blood left after pigs are killed is used as a raw material, and novel plasma protein powder is prepared by centrifugal separation, ultrafiltration concentration and spray drying technologies. The plasma protein powder prepared by using the method has low ash content, low volatile basic nitrogen content, high immune globulin content, high digestion rate, good solubility, good palatability, highsafety, balance nutrients and remarkable effects for promoting weaned pigs to grow, and can be used as a supplement source of feed protein. Through the effective utilization on the pig blood, not only the waste is turned into a valuable thing and benefits are brought to the society, but also the environments can be protected and the current green development tendency is met.

Owner:成都天屹生物科技有限公司

Method and apparatus to produce synthesis gas via flash pyrolysis and gasification in a molten liquid

InactiveUS7875090B2Improve efficiencyControlled heatingWaste based fuelRetortsFlash vacuum pyrolysisDecomposition

Disclosed are a method and a corresponding apparatus for converting a biomass reactant into synthesis gas. The method includes the steps of (1) heating biomass in a first molten liquid bath at a first temperature, wherein the first temperature is at least about 100° C., but less than the decomposition temperature of the biomass, wherein gas comprising water is evaporated and air is pressed from the biomass, thereby yielding dried biomass with minimal air content. (2) Recapturing the moisture evaporated from the biomass in step 1 for use in the process gas. (3) Heating the dried biomass in a second molten liquid bath at a second temperature, wherein the second temperature is sufficiently high to cause flash pyrolysis of the dried biomass, thereby yielding product gases, tar, and char. (4) Inserting recaptured steam into the process gas, which may optionally include external natural gas or hydrogen gas or recycled syngas for mixing and reforming with tar and non-condensable gases. (5) Further reacting the product gases, tar, and char with the process gas within a third molten liquid bath at a third temperature which is equal to or greater than the second temperature within the second molten liquid bath, thereby yielding high quality and relatively clean synthesis gas after a relatively long residence time needed for char gasification. A portion of the synthesis gas so formed is combusted to heat the first, second, and third molten liquid baths, unless external natural or hydrogen gas is available for this use.

Owner:US SEC AGRI +1

Body structure of boiling rotating fluidized bed

ActiveCN102230717ASmooth bed surfaceImprove the flow fieldDrying solid materials with heatHearth type furnacesWave shapeFluidized bed

The invention discloses a body structure of a boiling rotating fluidized bed, which comprises an outer housing and an air distributor. Due to the coverage of the outer housing and the air distributor, an accommodation chamber of the fluidized bed is formed. The air distributor is like a groove and tilts from the feeding end of the bed body to the discharging end. The air distributor mainly comprises an air distributor bottom board configured in the middle and air distributor sideboards configured on the two sides. A blowing bottom hole communicated with a sectionalized wind box is configured on the air distributor bottom board, and a blowing side hole communicated with the sectionalized wind box is configured on the air distributor sideboard. The air distributor is tooth-shaped or wave-shaped, the blowing bottom hole is configured between the teeth of a tooth-shaped air distributor bottom board or at the wave trough of a wave-shaped air distributor bottom board, and the opening of the blowing bottom hole faces the discharging end of the bed body. The opening of the blowing side hole on the air distributor sideboard faces the air distributor bottom board. The invention has the advantages of simple body structure, smooth bed surface and optimized flow field and can greatly improve the boiling rotating fluidized status. In addition, the invention can reduce more energy consumption.

Owner:长沙通发高新技术开发有限公司

Seed screening and drying device for forestry planting

InactiveCN108816726AGood dispersionImprove screening effectSievingSeed and root treatmentAgricultural engineeringDrive motor

The invention discloses a seed screening and drying device for forestry planting. The seed screening and drying device comprises a bearing bottom plate. A left vertical plate and a right vertical plate are fixedly installed on the bearing bottom plate vertically. A top plate is fixedly installed at the upper end of the left vertical plate and the upper end of the right vertical plate horizontally.A drive motor is fixedly installed on the left side of the left vertical plate. A cylinder spur gear is fixedly installed on the surface of a rotating shaft in a sleeving manner and connected with asecond rack in an engaged manner. A screening net basket located in a collecting tank is fixedly installed at the upper end of the rotating shaft. According to the seed screening and drying device, arotating pipe drives stirring blades to rotate to screen forestry seeds in the screening net basket, the screening net basket rotates clockwise and anticlockwise in an alternating manner under drivingof the rotating shaft, dispersing of seeds is promoted, and the seed screening function of the screening net basket is accelerated; and in the screening process, hot air sprayed out by air outlets inthe rotating pipe and the dispersed seeds can be mixed fully, the seeds can be dried fully and fast, screening and drying of the seeds are carried out synchronously, and the working efficiency is improved greatly.

Owner:王丽萍 +4

Cleaning device for traditional Chinese medicines

InactiveCN105478396AEfficient removalEasy to storeCleaning using toolsChemicalsElectric machineryEngineering

A cleaning device for traditional Chinese medicines comprises a housing, a cleaning chamber, a conveying device and a drying chamber, wherein the housing is that the left side of the top end is provided with a feeding port, the middle of the top end is provided with a main controller, the lower end of the right side is provided with a discharging door, the inner left end is provided with the cleaning chamber, the middle end is provided with the conveying device, and the right end is provided with the drying chamber; a rotating motor is mounted at the bottom end of the cleaning chamber and connected to the bottom end of a cleaning barrel through a rotating device; the cleaning barrel is that the inner middle end is provided with a cleaning device, the lower end is provided with a medicine discharging device and a stainless steel filter screen, the bottom end is provided with a sewage chamber, and the inner wall of the right side is provided with an ozone generator; the conveying device comprises a bracket, a conveying motor and a conveyor belt; the conveyor belt is mounted at the upper end of the bracket; transmission shafts at two ends of the conveyor belt are connected to rotating wheels of the conveying motor through belts; the drying chamber is that the inner top end is provided with a sliding device, the inner bottom end is provided with a microwave drying device, and the right side is connected to the discharging door through a discharging port. The cleaning device integrates the cleaning function and the drying function, is simple and convenient to operate, and can save both time and labor.

Owner:南京恒誉名翔科技有限公司

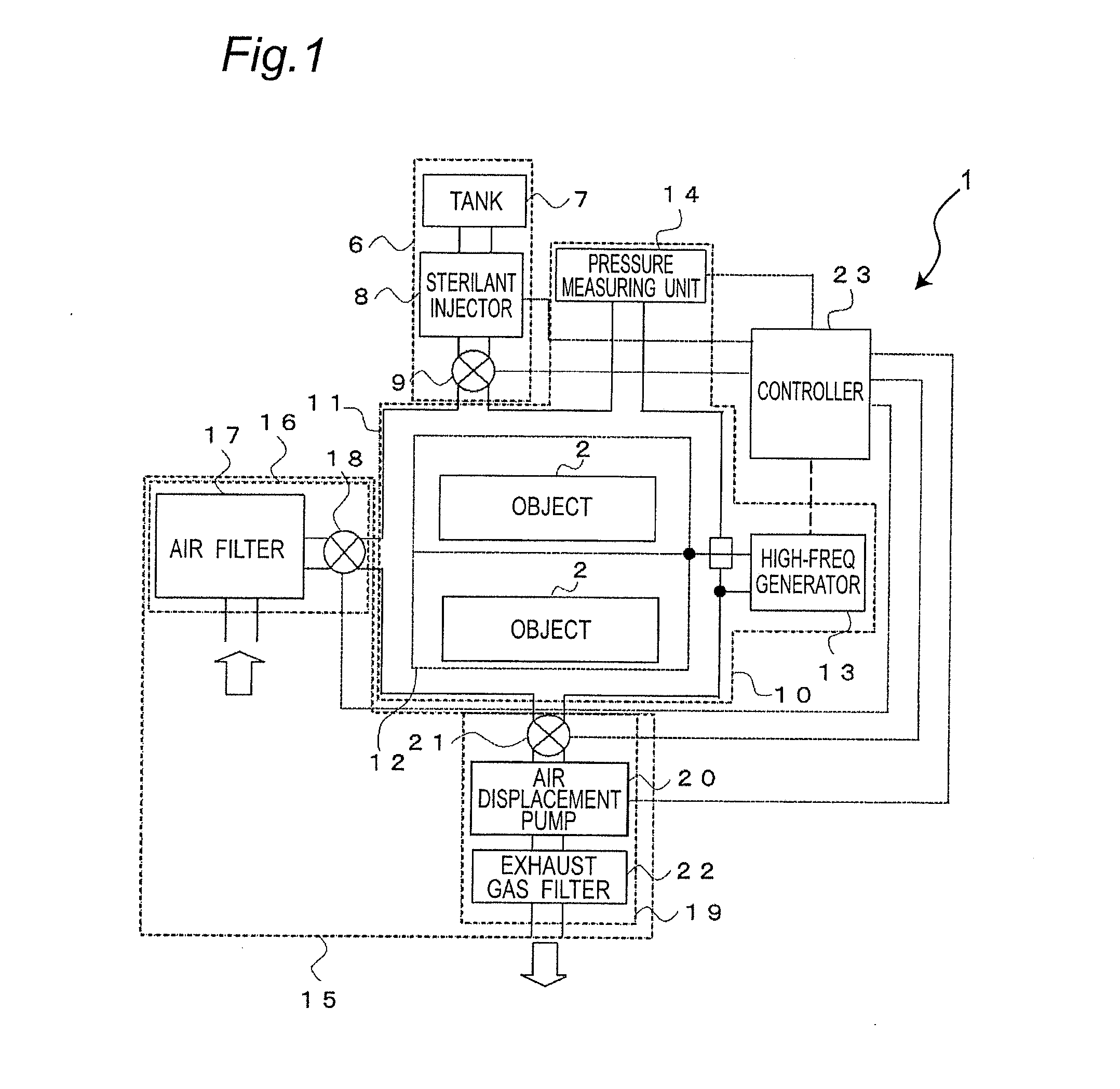

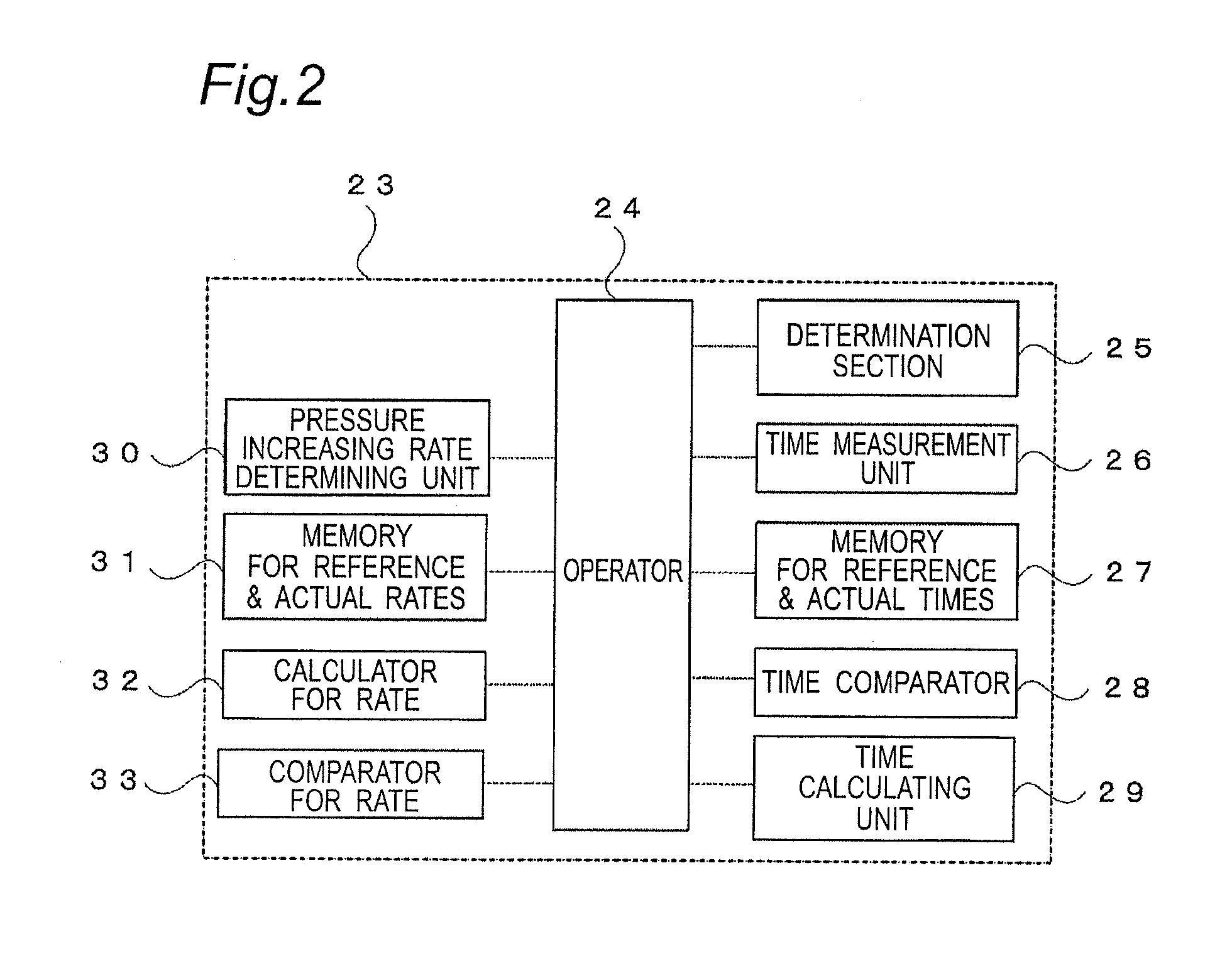

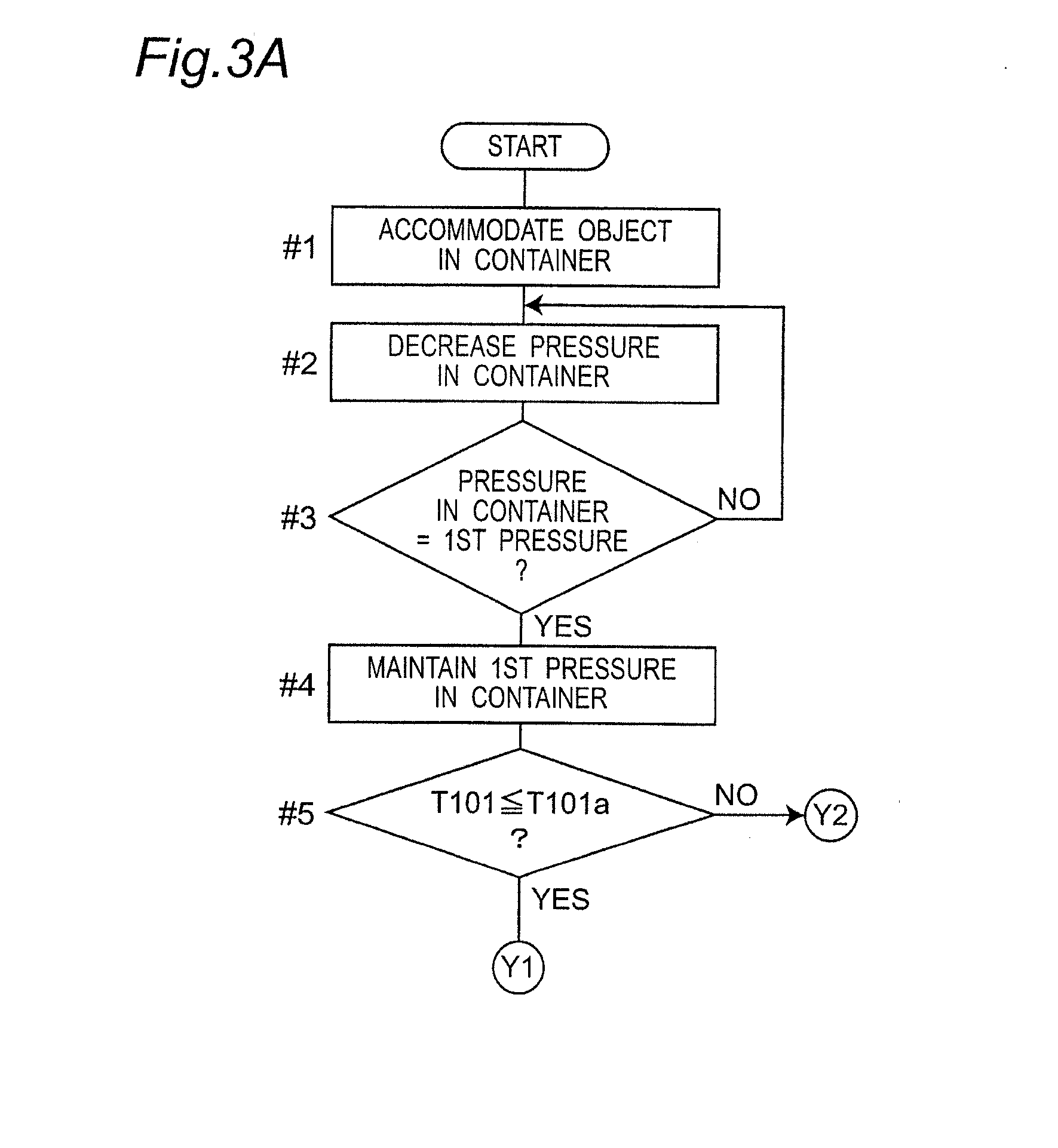

Sterilization method and device

ActiveUS20150313250A1Improve contact efficiencyFully dryExhaust apparatusElement comparisonPressure decreaseProcess engineering

According to the present invention, a sterilant can be injected into a container without residual water on an object to be sterilized. The method includes decreasing a pressure in the container to a pressure higher than the triple point pressure at which water freezes. The method further includes comparing an actual time required for decreasing the pressure and a reference time, or comparing an actual rate of pressure increase and a reference rate to detect residual water on the object. If the residual water is detected, the pressure in the container is increased to the atmospheric pressure or the quasi-atmospheric pressure and the object is heated, and then the pressure is decreased to drain the residual water through the decompression boiling. The step of draining the residual water is repeatedly performed until no residual water is detected on the object and subsequently the sterilant is injected into the container.

Owner:SARAYA CO LTD

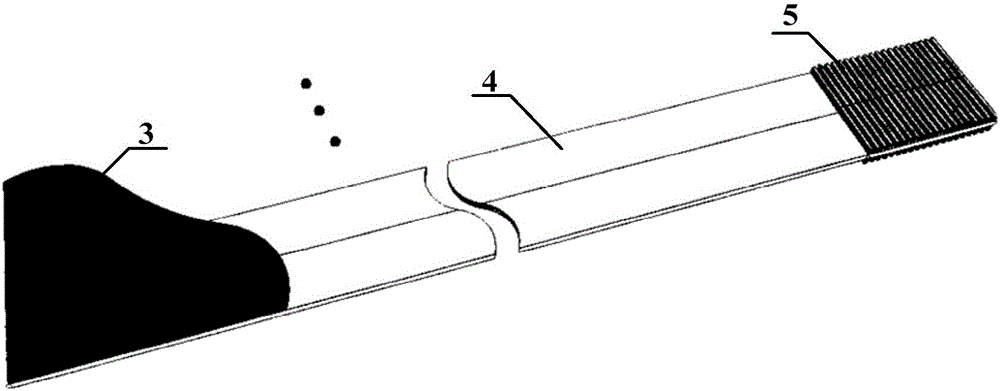

Heat-pipe type panel solar air collector and heating method thereof

InactiveCN105066471AImprove transfer efficiencyEfficient heat transportSolar heating energySolar heat devicesGlass coverSolar air collector

The invention relates to a heat-pipe type panel solar air collector and a heating method thereof. The collector comprises a solar panel heat collection and heat transmission section and an air ventilation heat exchange section. The solar panel heat collection and heat transmission section comprises tempered glass, an efficient heat absorption coating, a heat insulation air layer and a panel heat pipe evaporation section. The back of the efficient heat absorption coating and the obverse side of the panel heat pipe evaporation section are combined organically. The tempered glass covers the outer surface of the panel heat pipe evaporation section organically combined with the efficient heat absorption coating. The heat insulation air layer is arranged between the efficient heat absorption coating and the tempered glass, and the distance from the front of the efficient heat absorption coating to the inner surface of the tempered glass ranges from 20 mm to 50 mm. The air ventilation heat exchange section comprises an air duct, a fan and a panel heat pipe condensation section. The panel heat pipe condensation section is arranged in the air duct, and the fan is arranged on one side of the air duct. The collector has the advantages of being high in heat exchange efficiency, high in reliability, simple in structure, convenient to mount, free of maintenance and long in service life.

Owner:赵耀华

Grading sand screening device for building construction

InactiveCN107252765AKeep dryEasy to move with each otherSievingSand dryingSquare cross sectionEngineering

The invention provides a kind of grading and sand screening equipment for building construction, which comprises a tank body; the tank body is set as a hollow cuboid with a square cross section, an upper cover is set at the top opening of the tank body, and a bottom opening is set at the bottom opening of the tank body. cover; the middle part of the tank body is divided into a drying chamber and a screening chamber by a partition; a drying device is provided in the drying chamber; a screening plate and a screening device are provided in the screening chamber; feeding device; the present invention adds the sand added by the feeding hopper into the tank body at a uniform speed through the feeding device, which is also beneficial to reduce the labor intensity of the workers; through the setting of the drying device, the three-layer rotating material guide plate is used to control the sand falling on the guide The sand in the material tray is turned over, and the hot air blown by the hot air blower is used to evenly distribute the hot air blown in by the three-layer rotating air distribution pipe, so as to facilitate the full drying of the sand; The sand is graded and screened to improve the screening quality.

Owner:合肥多智科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com