Efficient tea leaf drying device

A tea drying device and high-efficiency technology, applied in the directions of tea drying, drying, drying machine, etc., can solve the problems of slow drying speed, difficult uniform contact, and accumulation of tea leaves, so as to achieve sufficient drying and improve drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

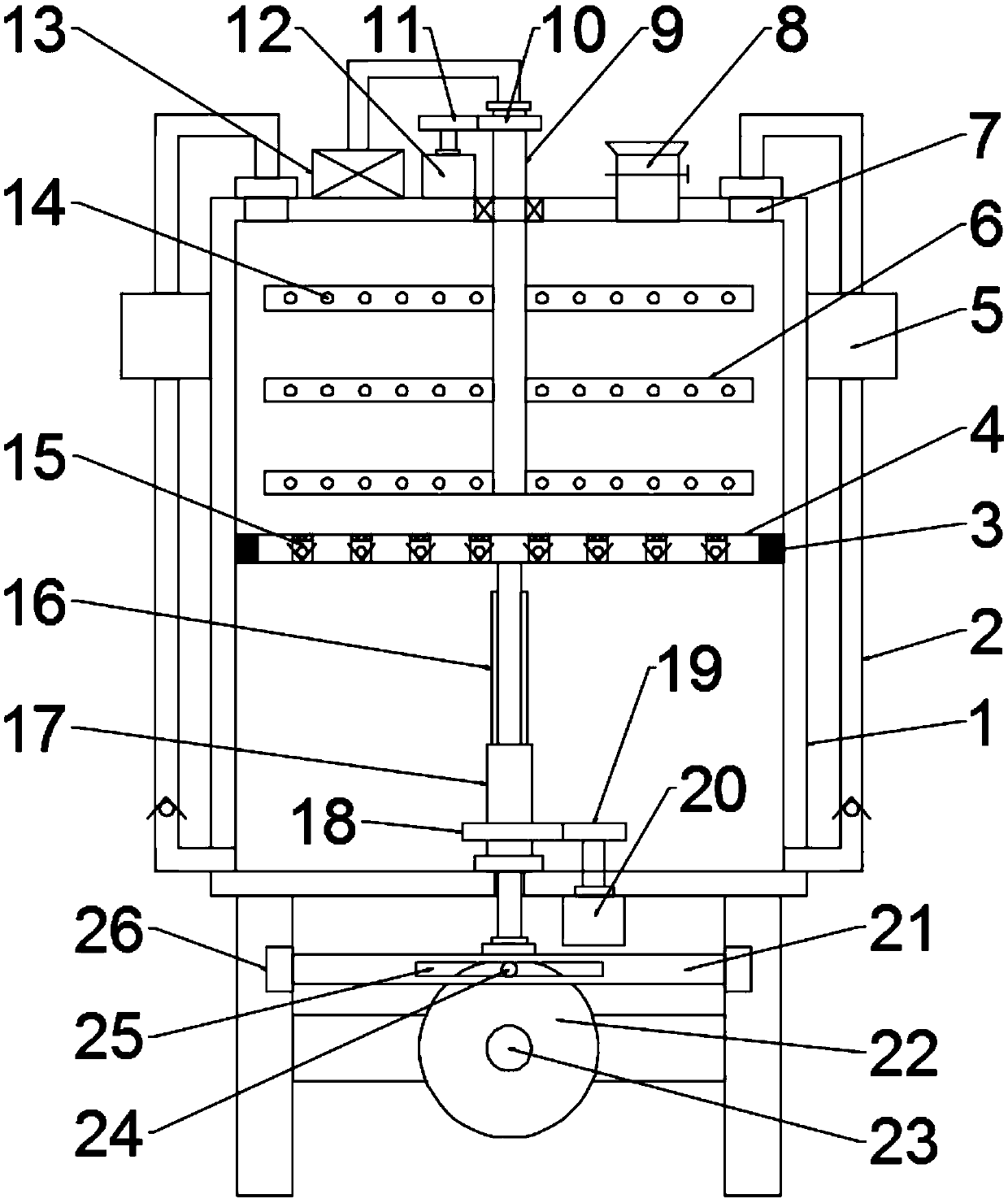

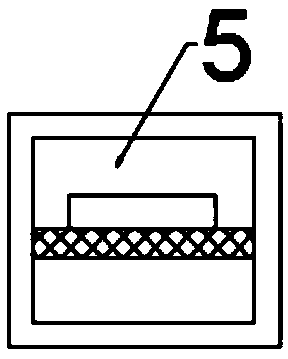

[0021] see Figure 1-2 , in an embodiment of the present invention, a high-efficiency tea drying device includes a cylinder body 1, a hot air blower 13, a hollow stirring shaft 9 and a hollow stirring rod 14, and support plates are installed on both sides of the bottom of the cylinder body 1, and the cylinder body 1 A feed hopper 8 is installed on one side of the top, and a valve is installed on the feed hopper 8. A drum door is installed on the upper part of the cylinder body 1 through hinges and buckles. Sealing strips are adhered around the cylinder door. The hollow stirring shaft 9 is rotationally connected with the top of the cylinder body 1 through bearings. The hollow stirring shaft 9 is located on the shaft section inside the cylinder body 1 and is welded and fixed with a plurality of hollow stirring rods 6. The surface of the hollow stirring rods 6 is uniformly provided with A plurality of air jet pores 14, the hot air blower 13 is installed on the top of the cylinder...

Embodiment 2

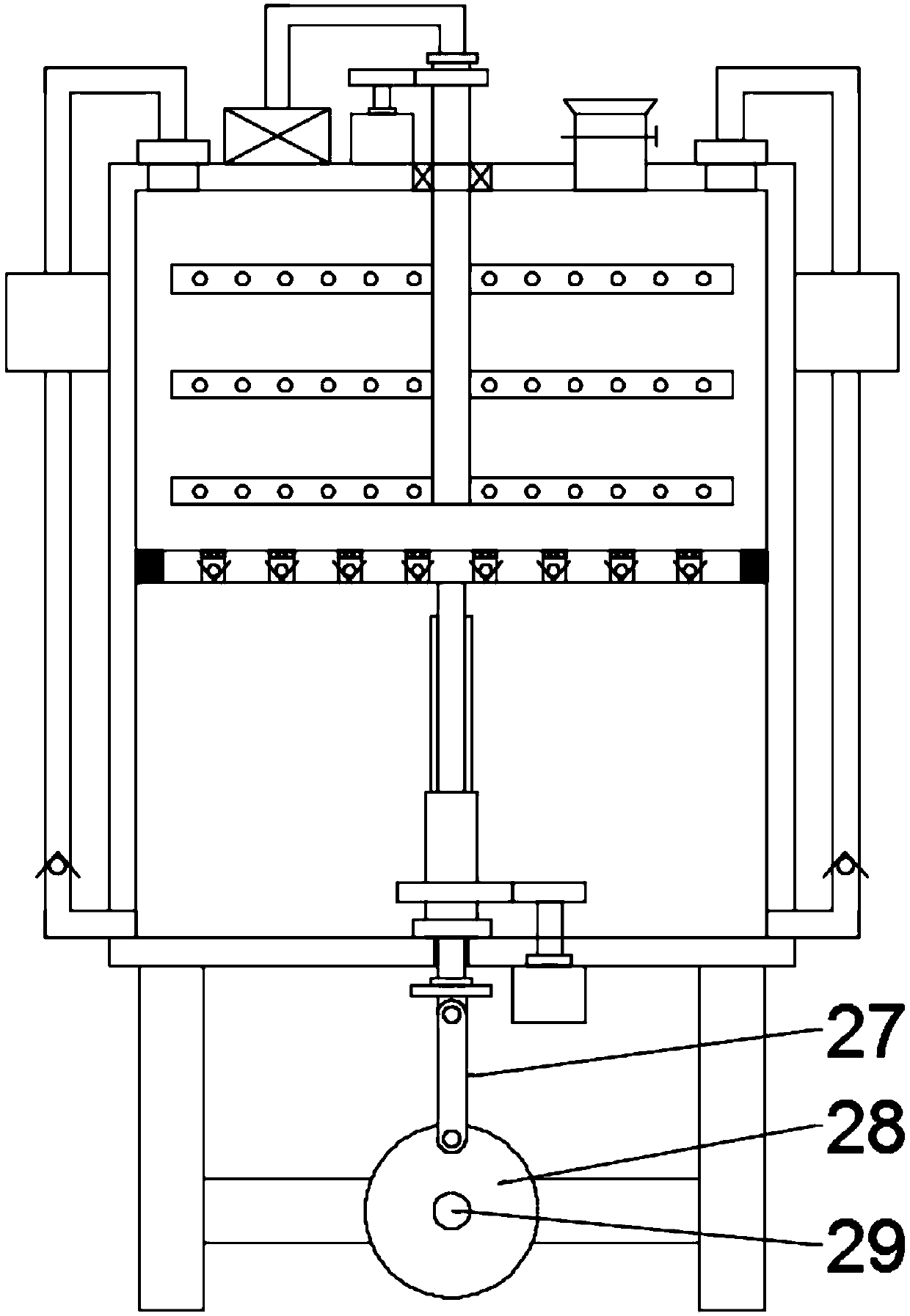

[0023] see image 3, the difference between this embodiment and Embodiment 2 is that the first driving mechanism is replaced by a second driving mechanism, and the second driving mechanism includes a fourth motor 29, a second disk 28 and a connecting rod 27, and the first driving mechanism Four motors 29 are installed on the support plate by the mounting plate, the output shaft end of the fourth motor 29 is equipped with a second disc 28, the outer side of the front end of the second disc 28 is hinged with a connecting rod 27, and the other end of the connecting rod 27 is hinged with a The fixed plate, the bottom end of the spline shaft 16 is rotationally connected with the fixed plate through a bearing and a bearing seat, the fourth motor 29 is started, and the fourth motor 29 drives the second disc 28 to rotate, and the second disc 28 is driven by the connecting rod 27 The spline shaft 16 moves up and down.

[0024] The working principle of the present invention is: when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com