Patents

Literature

596results about How to "Improve contact efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

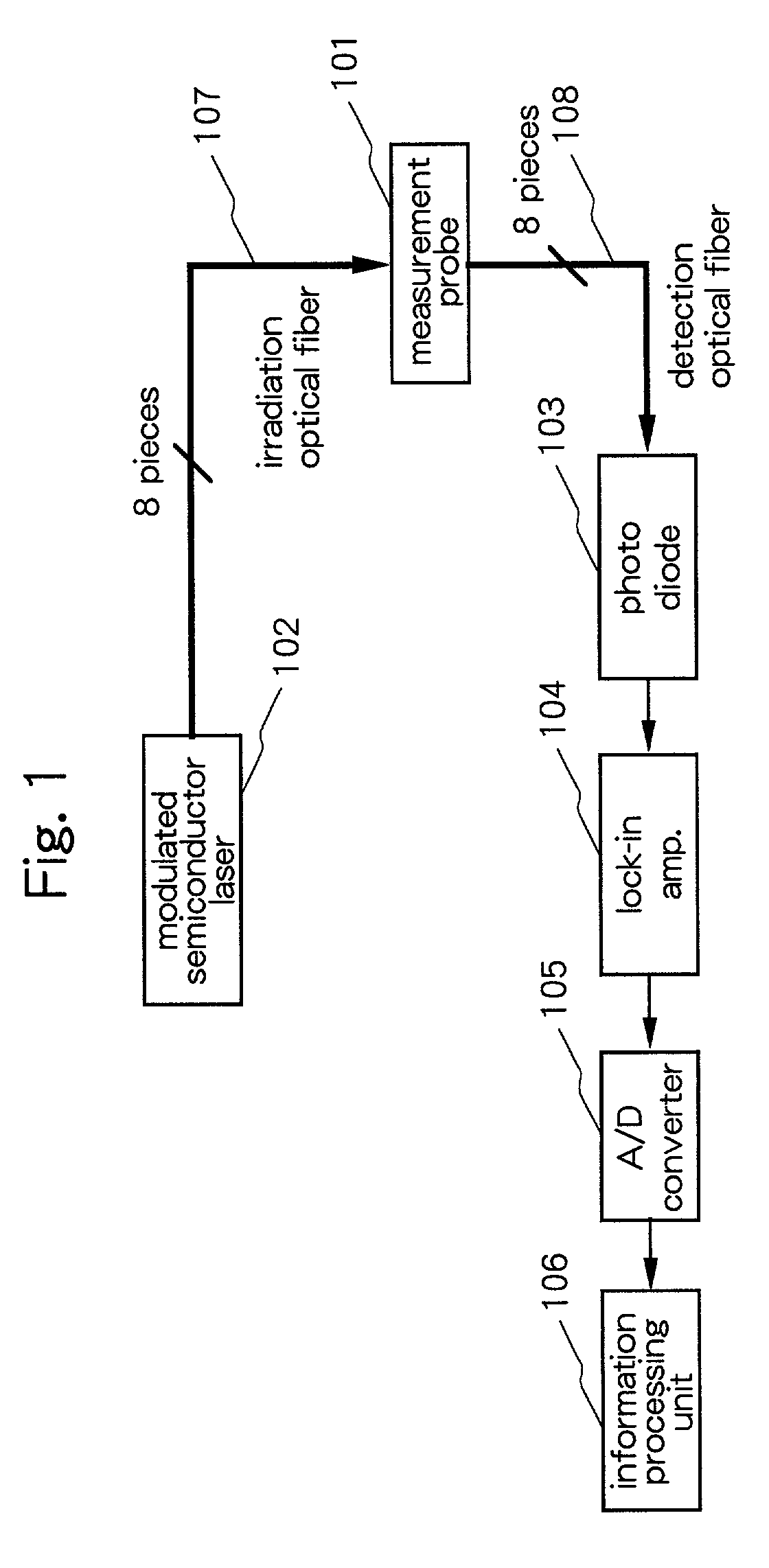

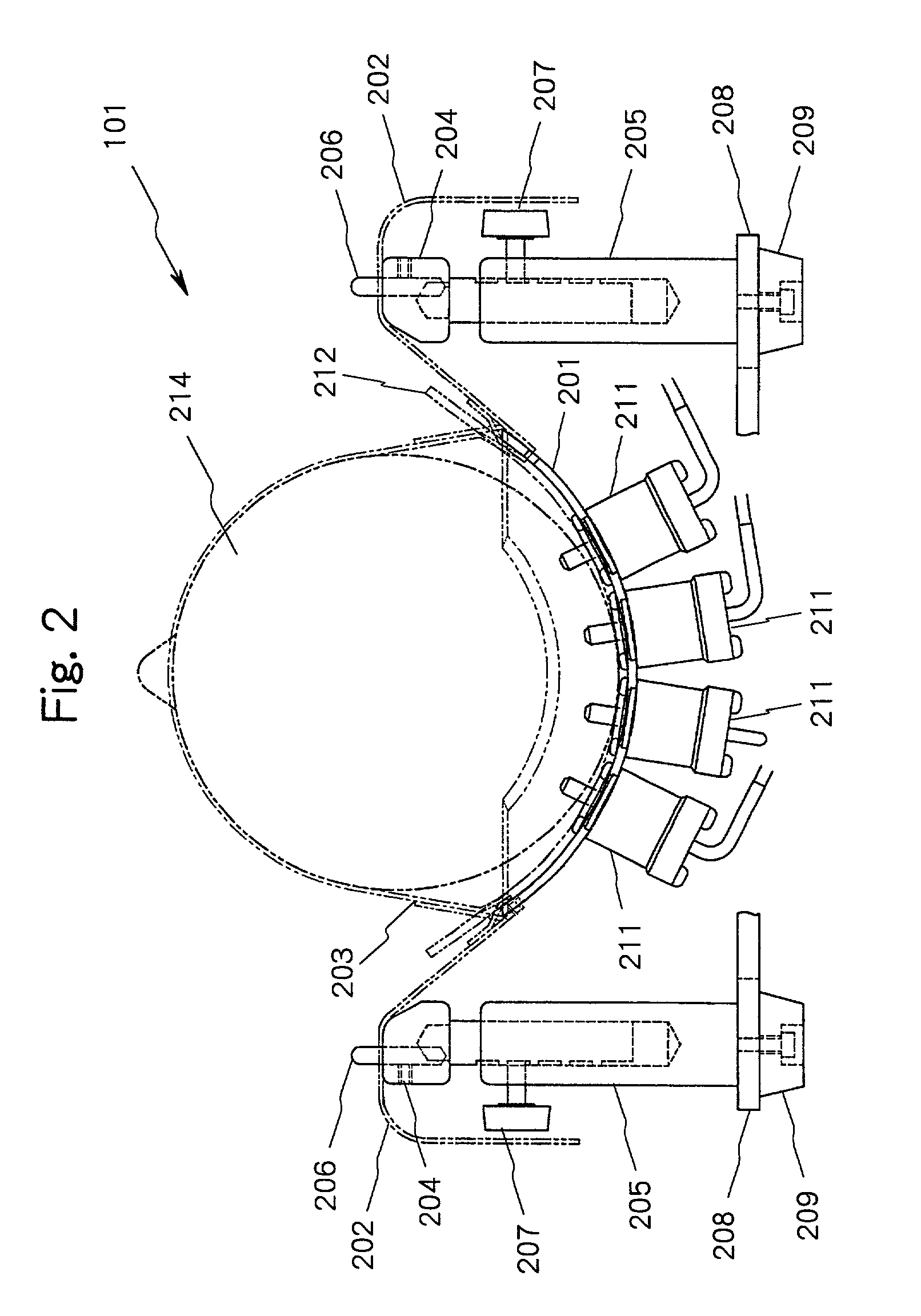

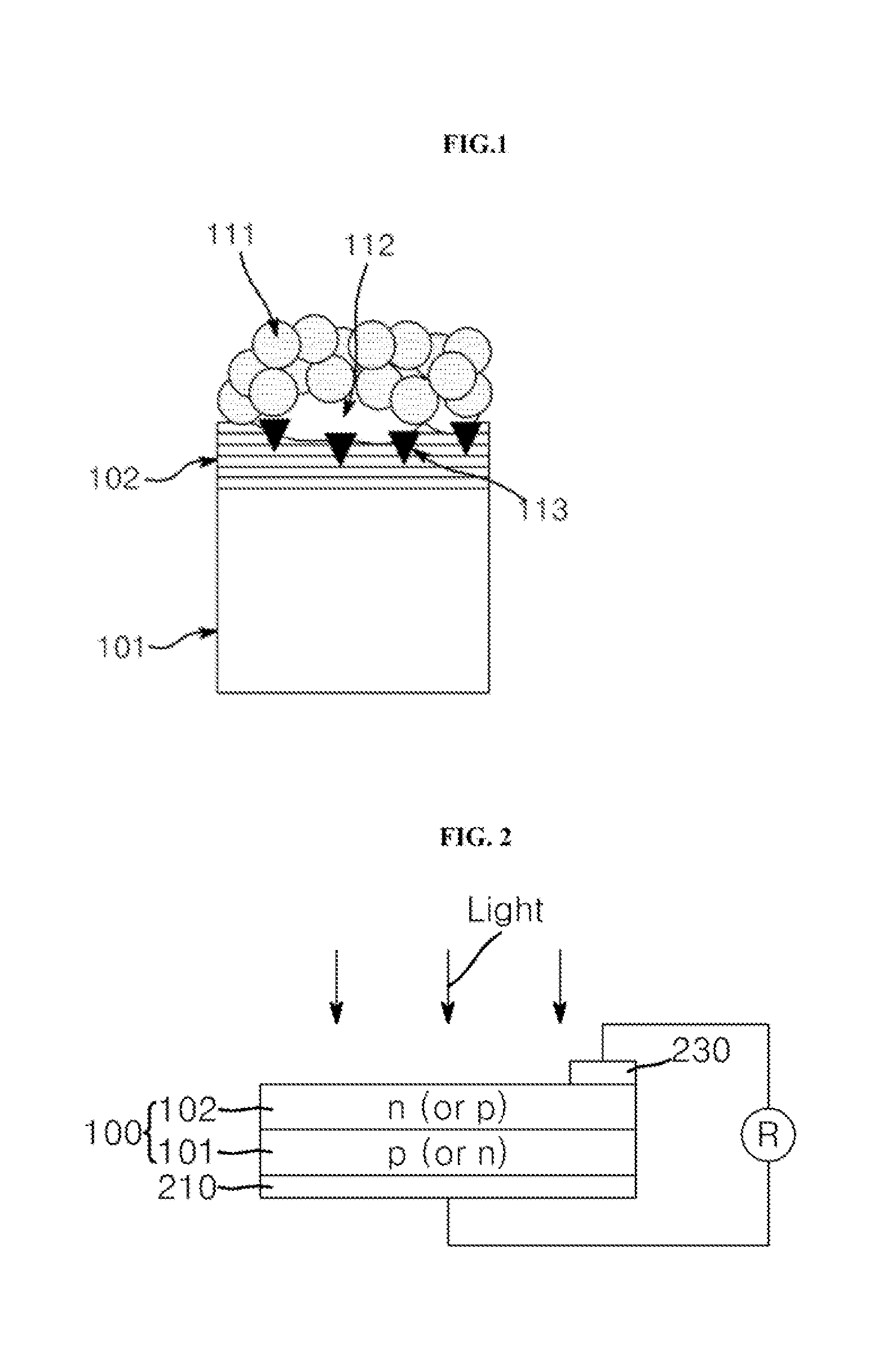

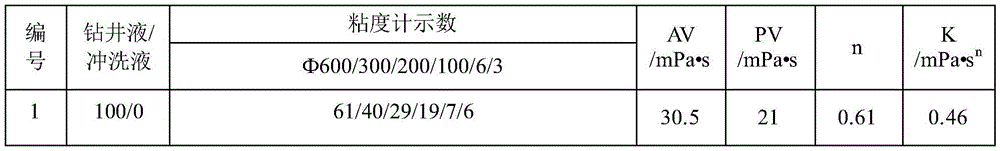

Biological optical measuring instrument

InactiveUS7039454B1Ensure correct executionIncrease contactScattering properties measurementsElectrical testingBiological bodyMeasuring instrument

A biological optical measuring instrument comprising a measuring probe (101) for collecting light from a plurality of portions of a subject (214) transmitted through the subject (214) by means of an optical fiber (108) by guiding light emitted from a light source (102) by an optical fiber (107), and irradiating the light to the subject (214) so as to create a living body transmitted light intensity image of the subject (214) from the transmitted and collected light. The measuring probe (101) further comprises optical fiber fixing members (201, 210, 211) for fixing the optical fibers (107, 108) at a predetermined interval and support members (202, 204, 205) for rockably supporting the optical fiber fixing members. Thus, it is possible to provide a technique of performing living body optical measurement while the living body lies in lateral decubitus.

Owner:HITACHI LTD

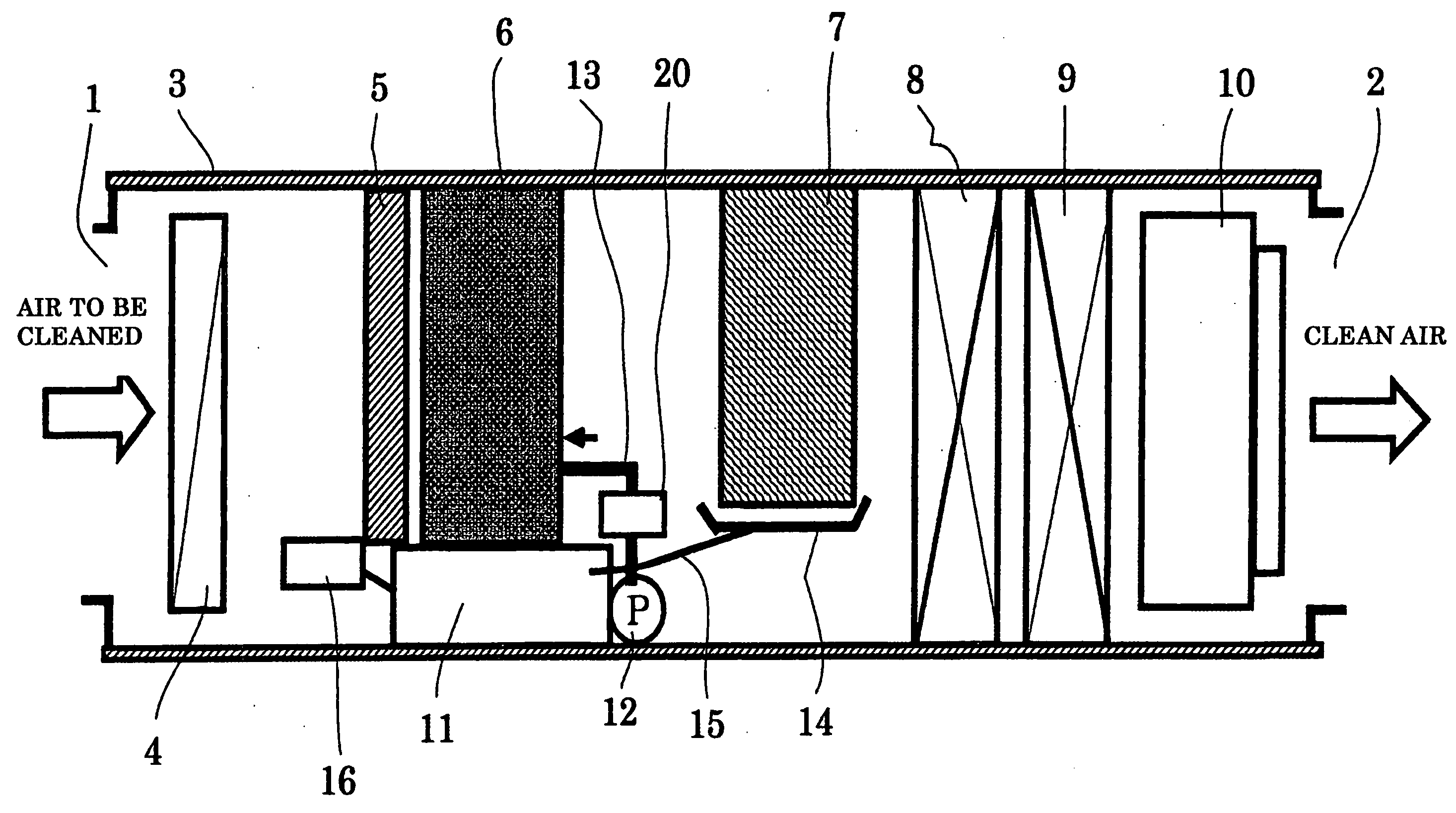

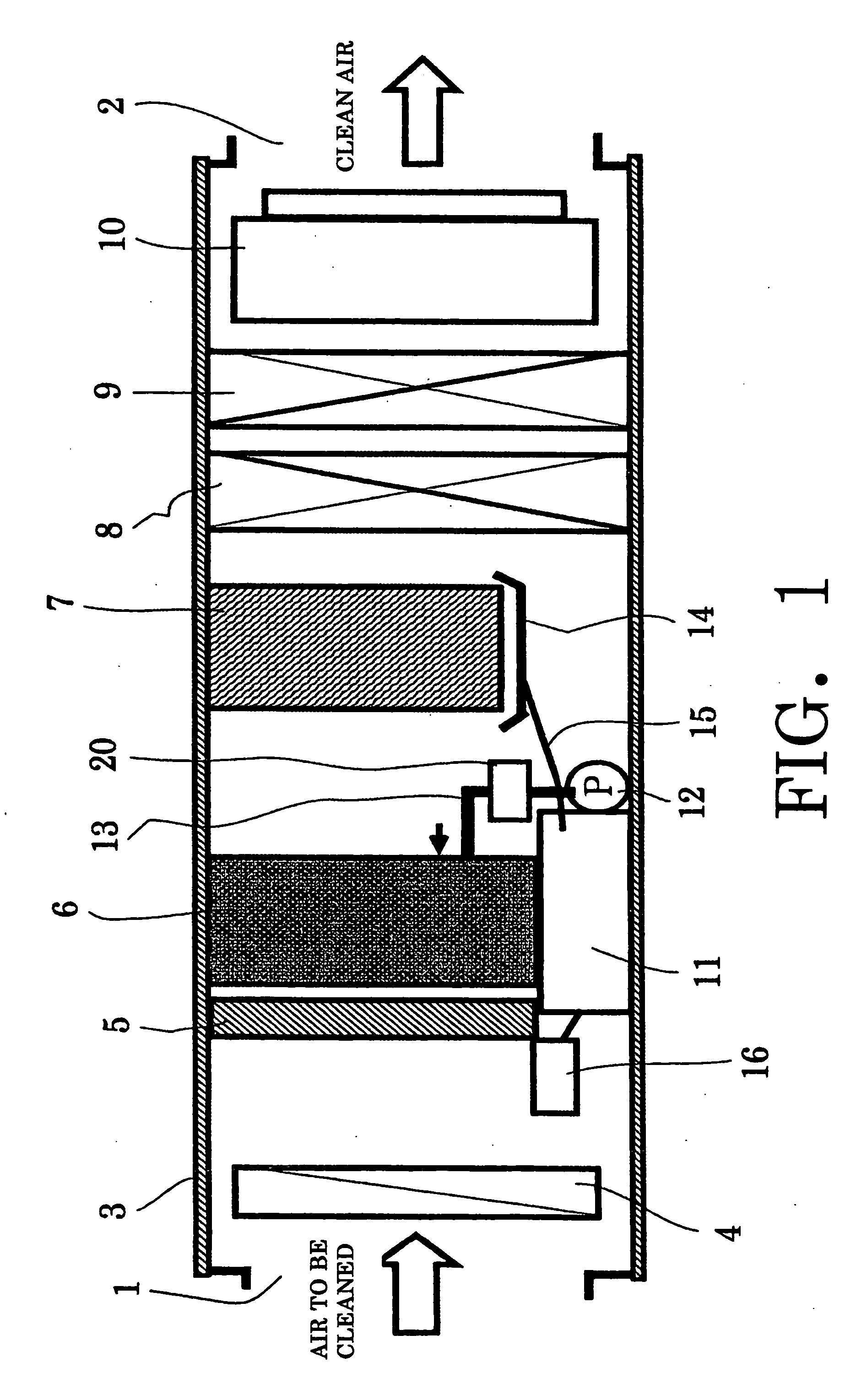

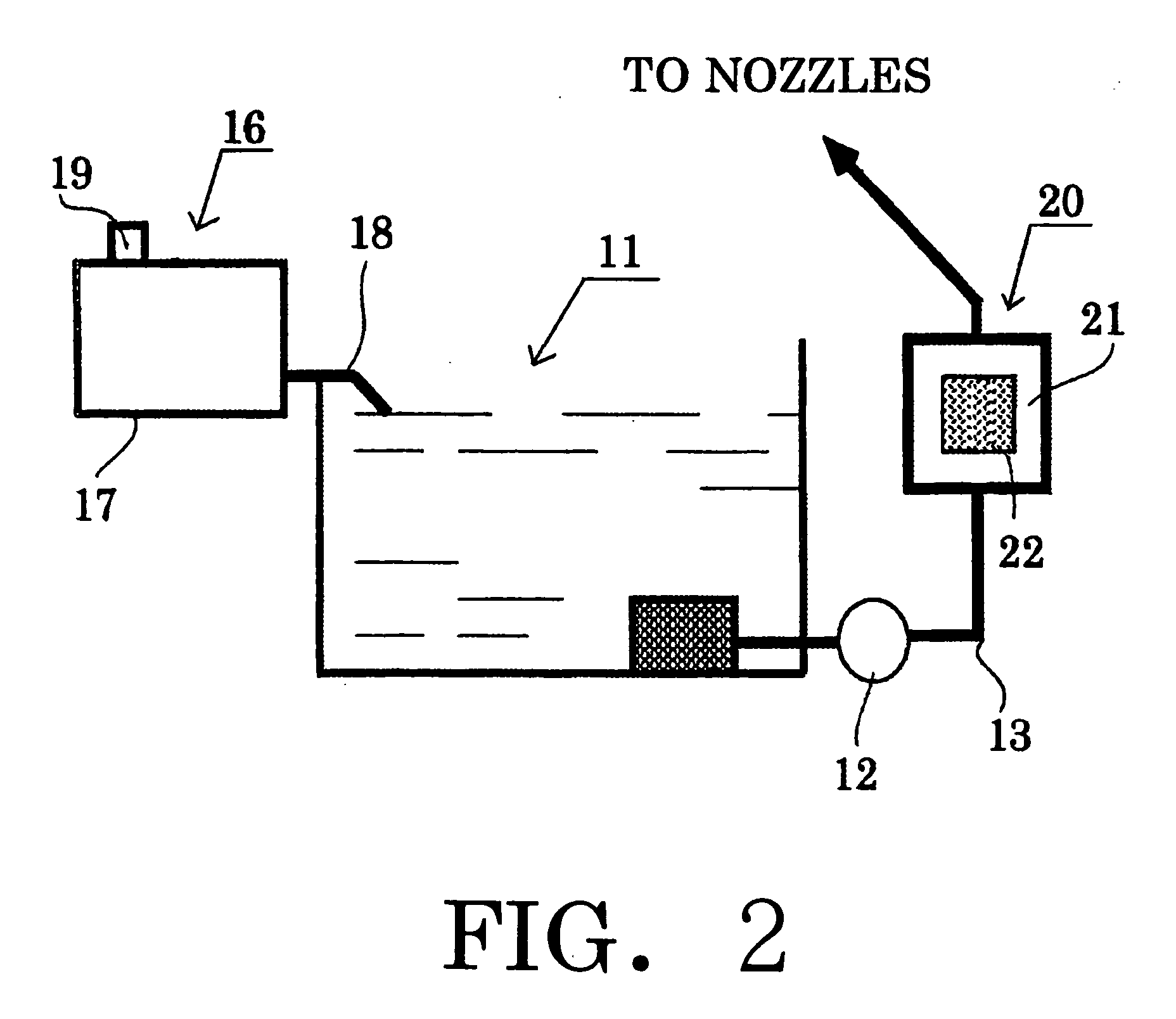

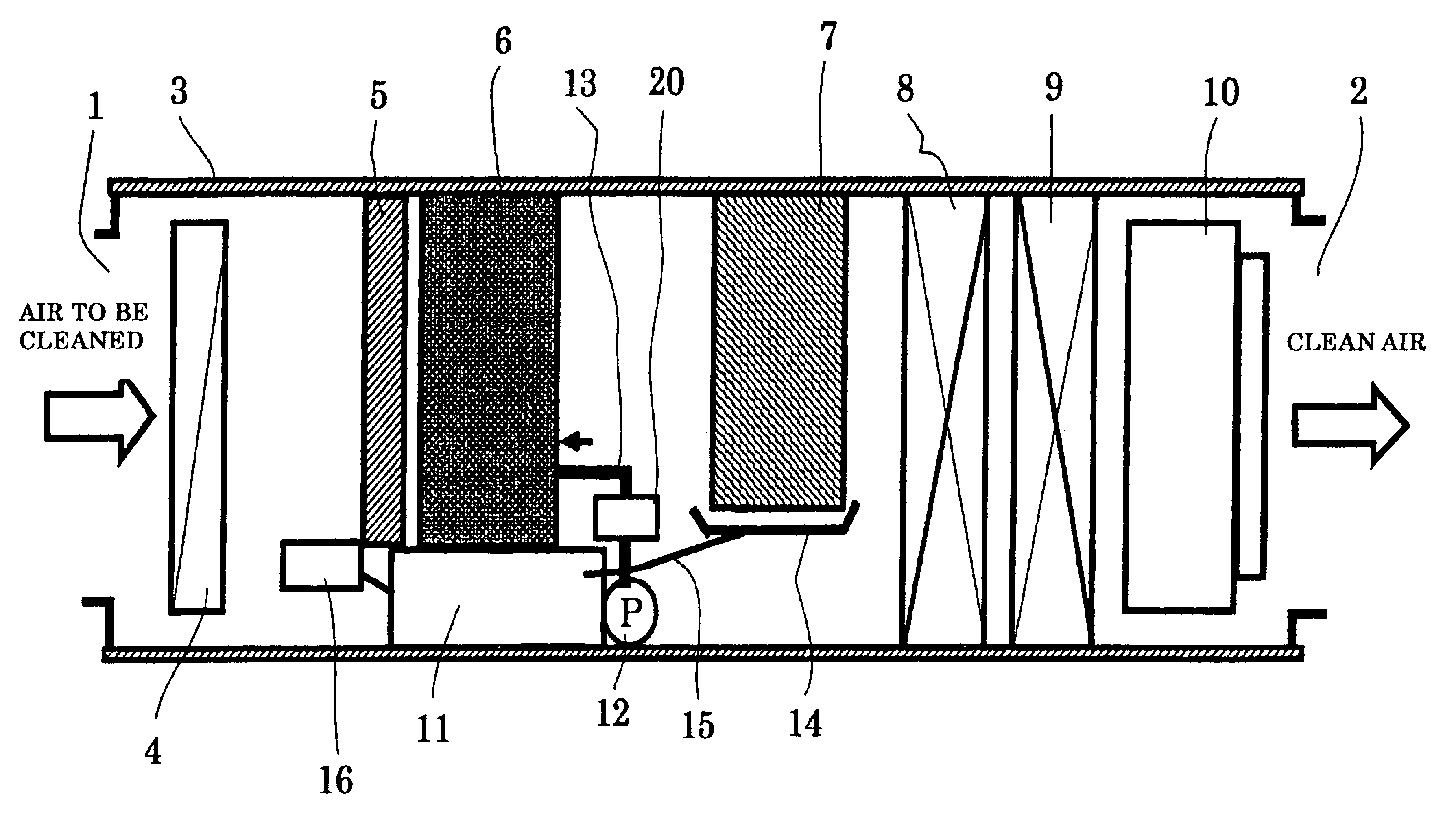

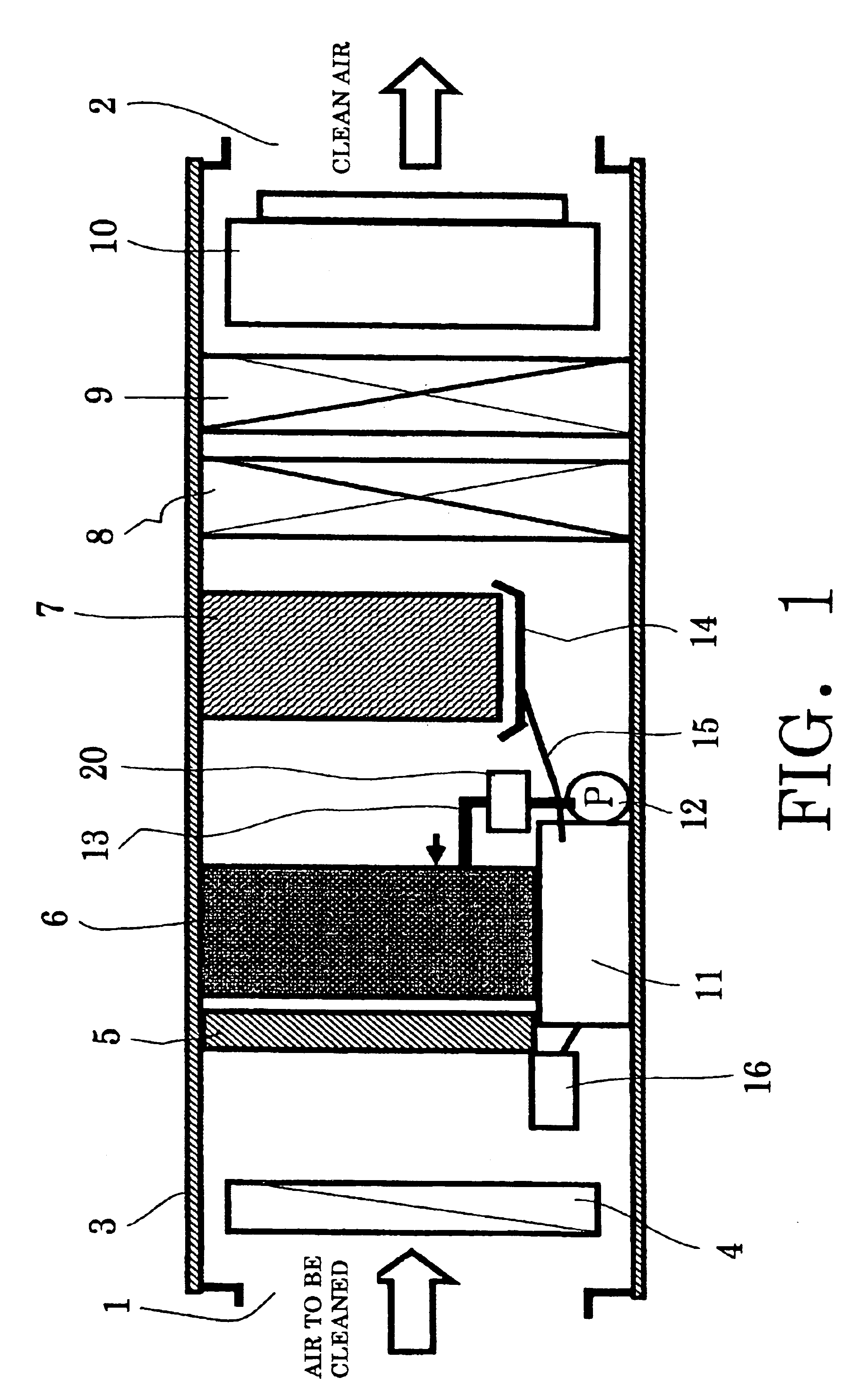

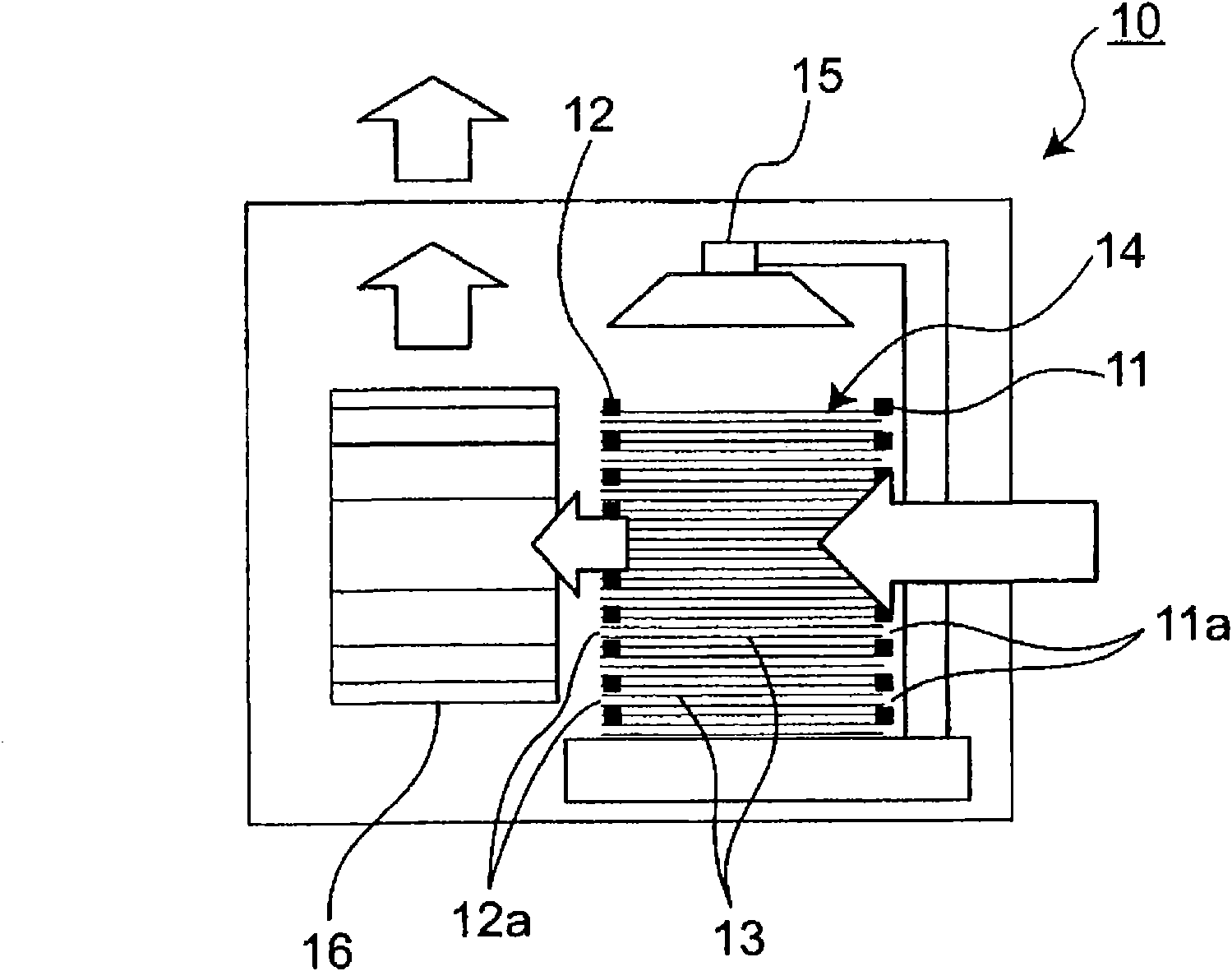

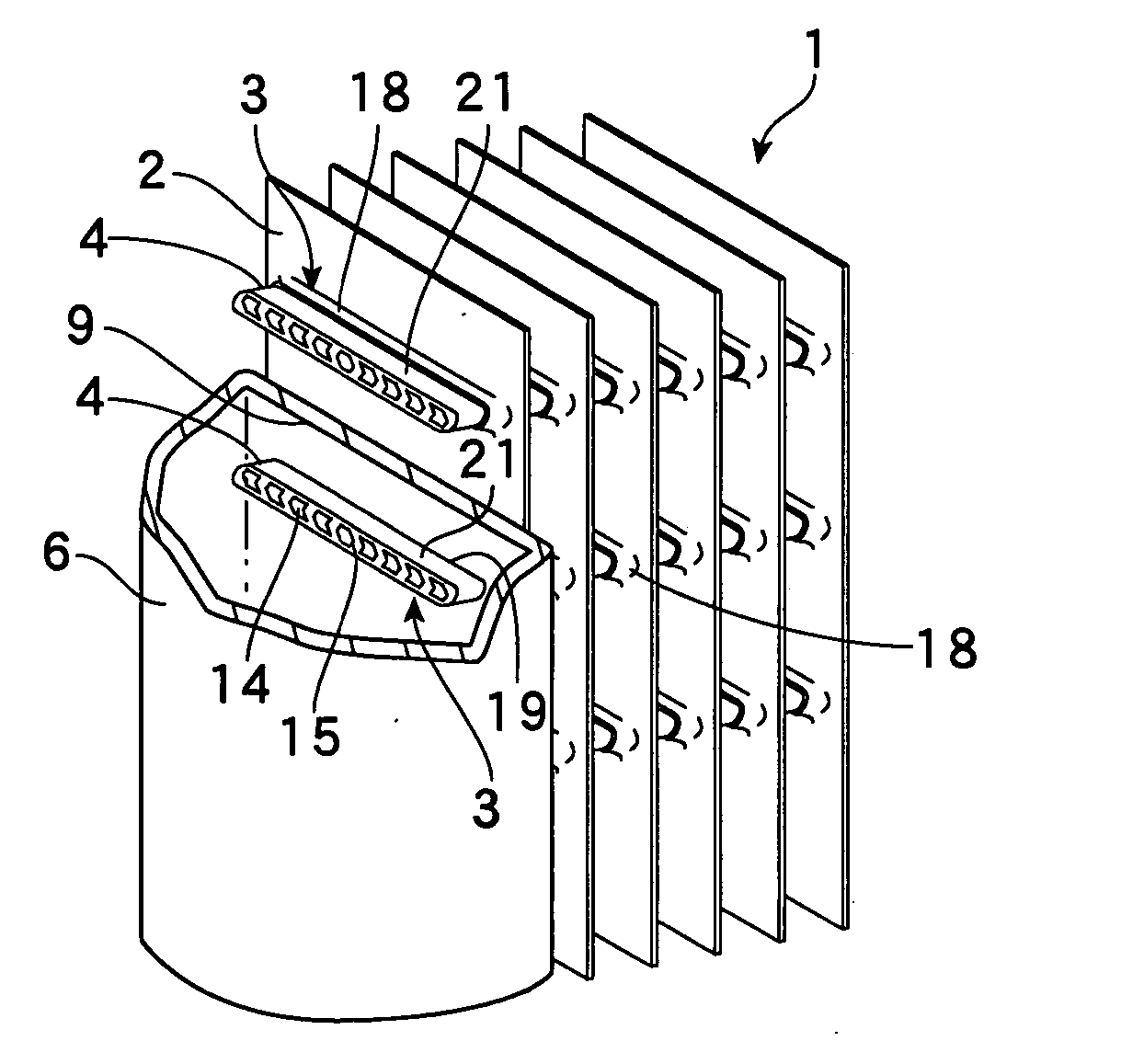

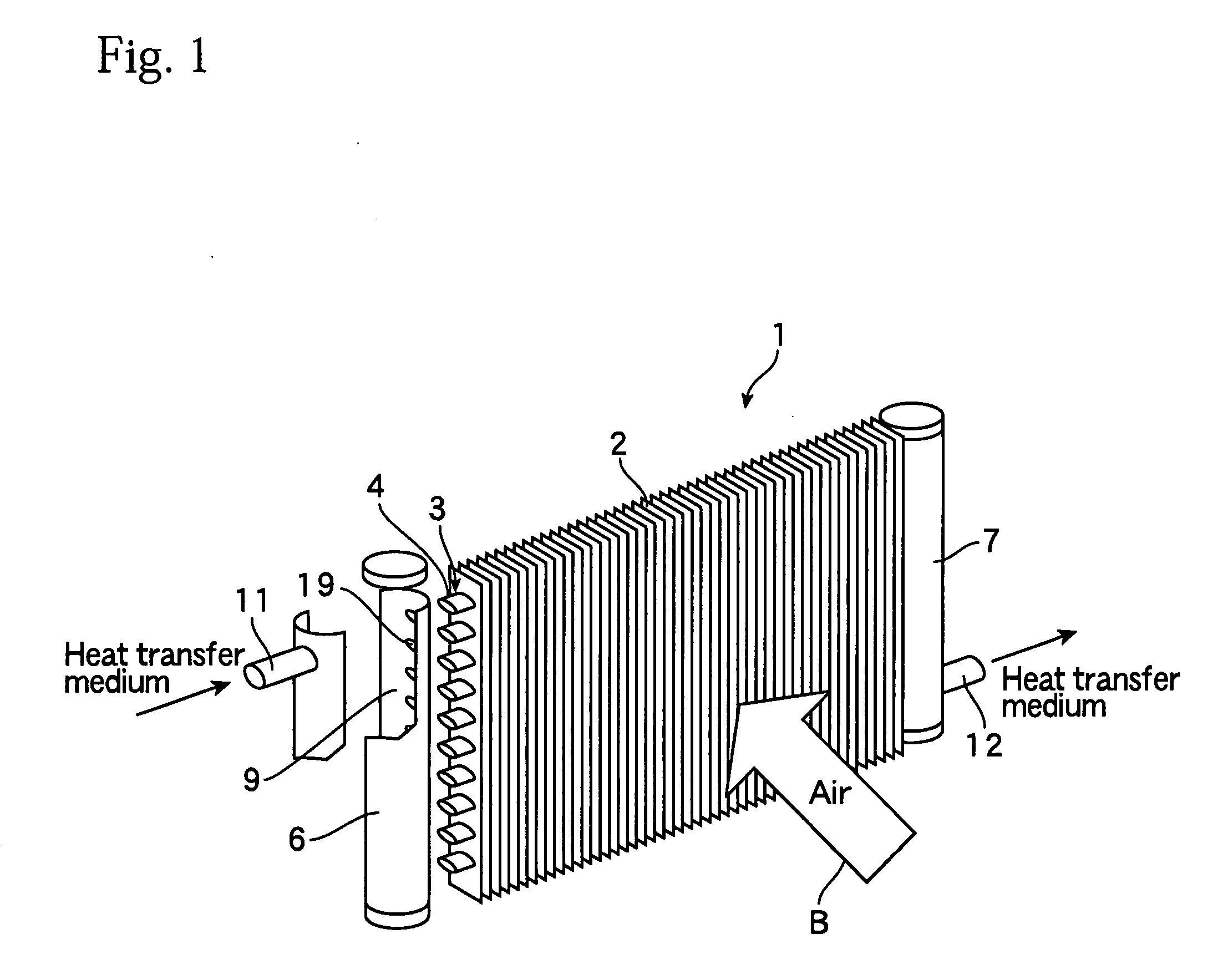

Air cleaner

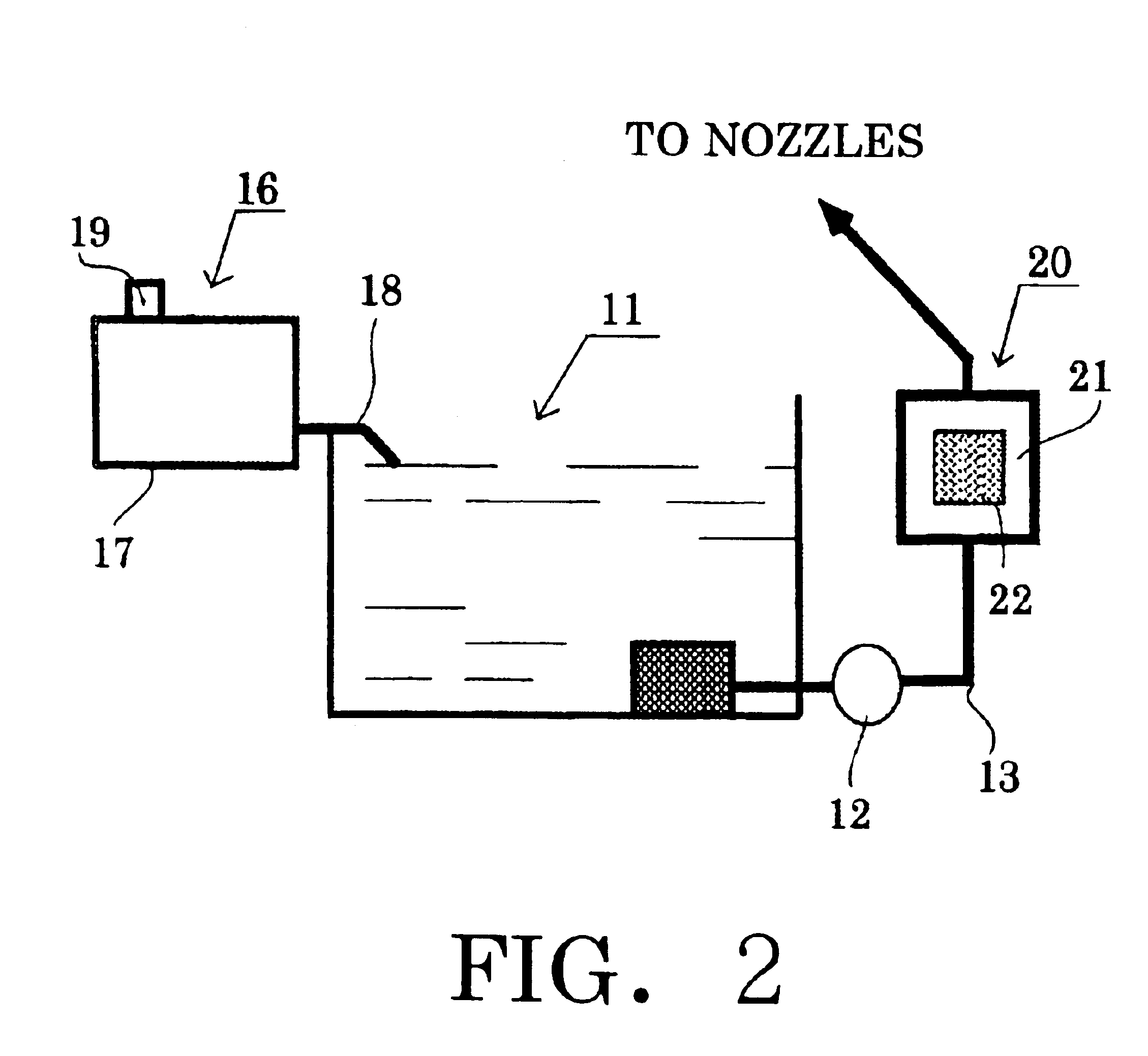

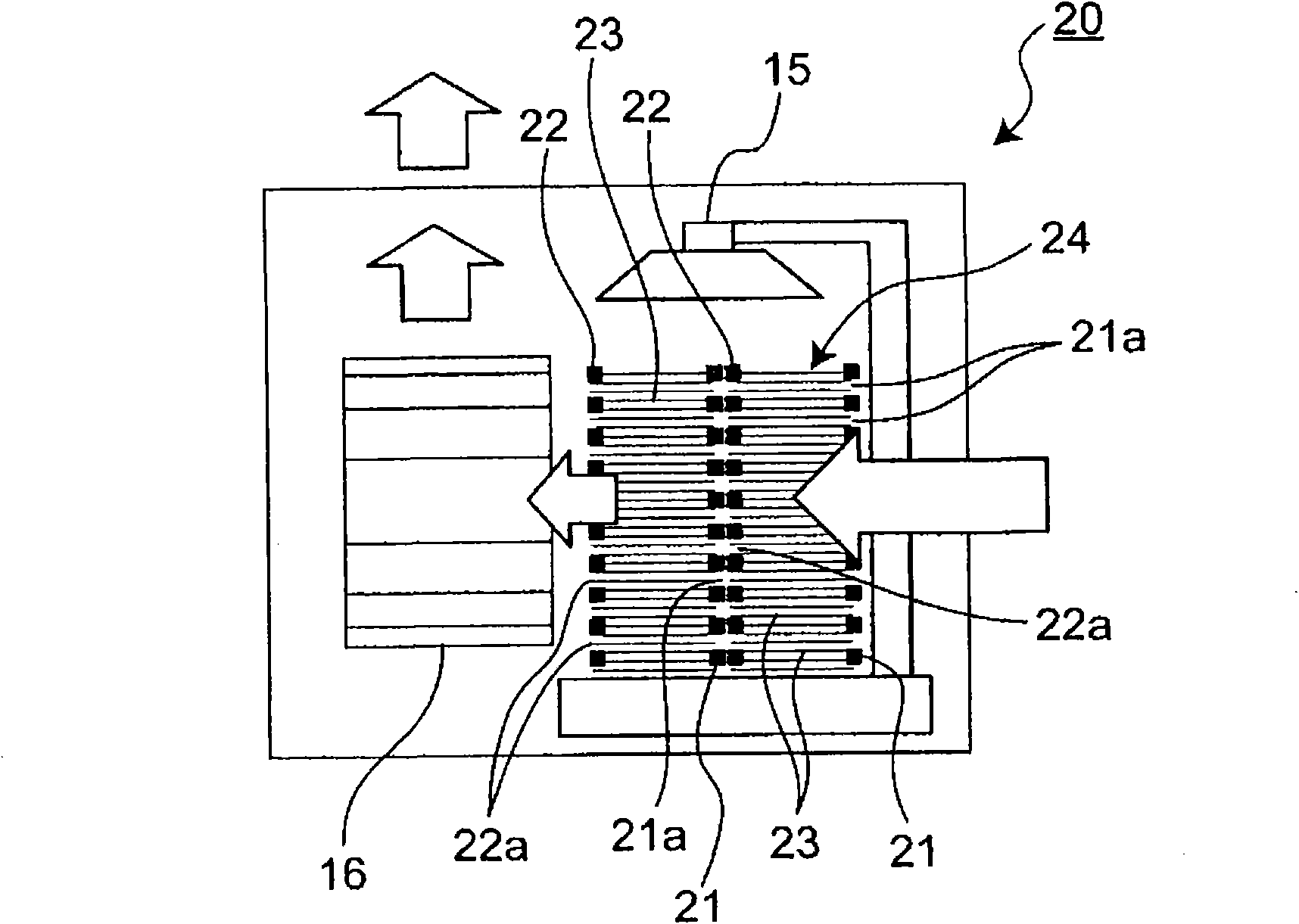

ActiveUS20050072308A1Improve contact efficiencyEasy to handleCombination devicesMechanical apparatusForeign matterChlorine dioxide

An air cleaner for cleaning air and for providing sterilization and deodorization effects, includes an air-liquid contact part, for bringing the air into contact with a water screen formed by spraying, using nozzles, pressurized circulating water, and for removing foreign materials from the air; a liquid separating part for separating from the air, tiny water droplets that are included in the air passing through the air-liquid contact part; a cylindrical body into which air to be cleaned is guided, and in which the air-liquid contact part and the liquid separating part are arranged in order; a chlorine dioxide addition unit, for adding a stabilized chlorine dioxide solution to a water tank for the water that is circulated; and a chlorine dioxide activation unit, for activating chlorine dioxide added to the circulating water, that is arranged in a circulating water pipe that extends from the water tank to the spray nozzles.

Owner:FM IWATE

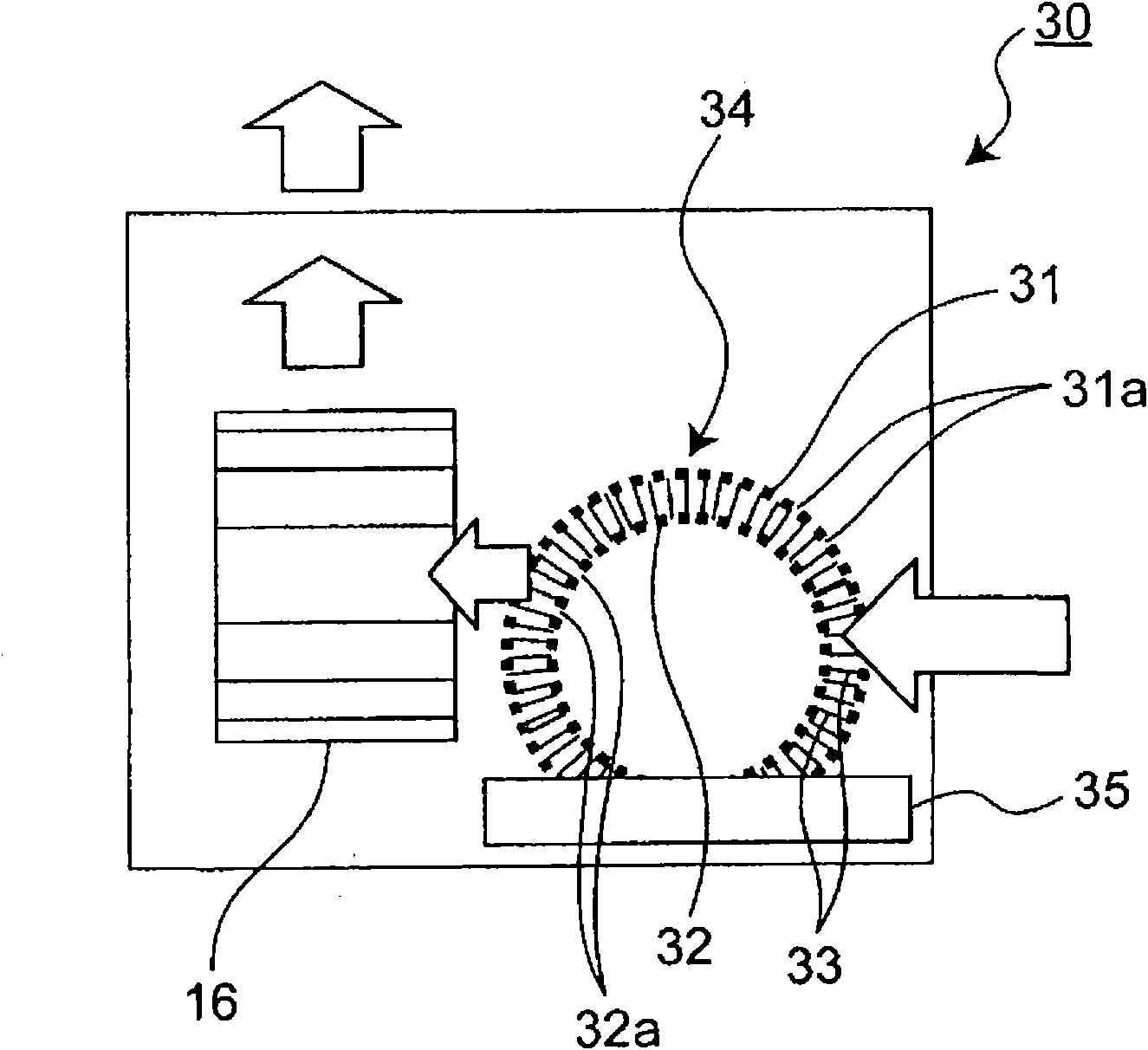

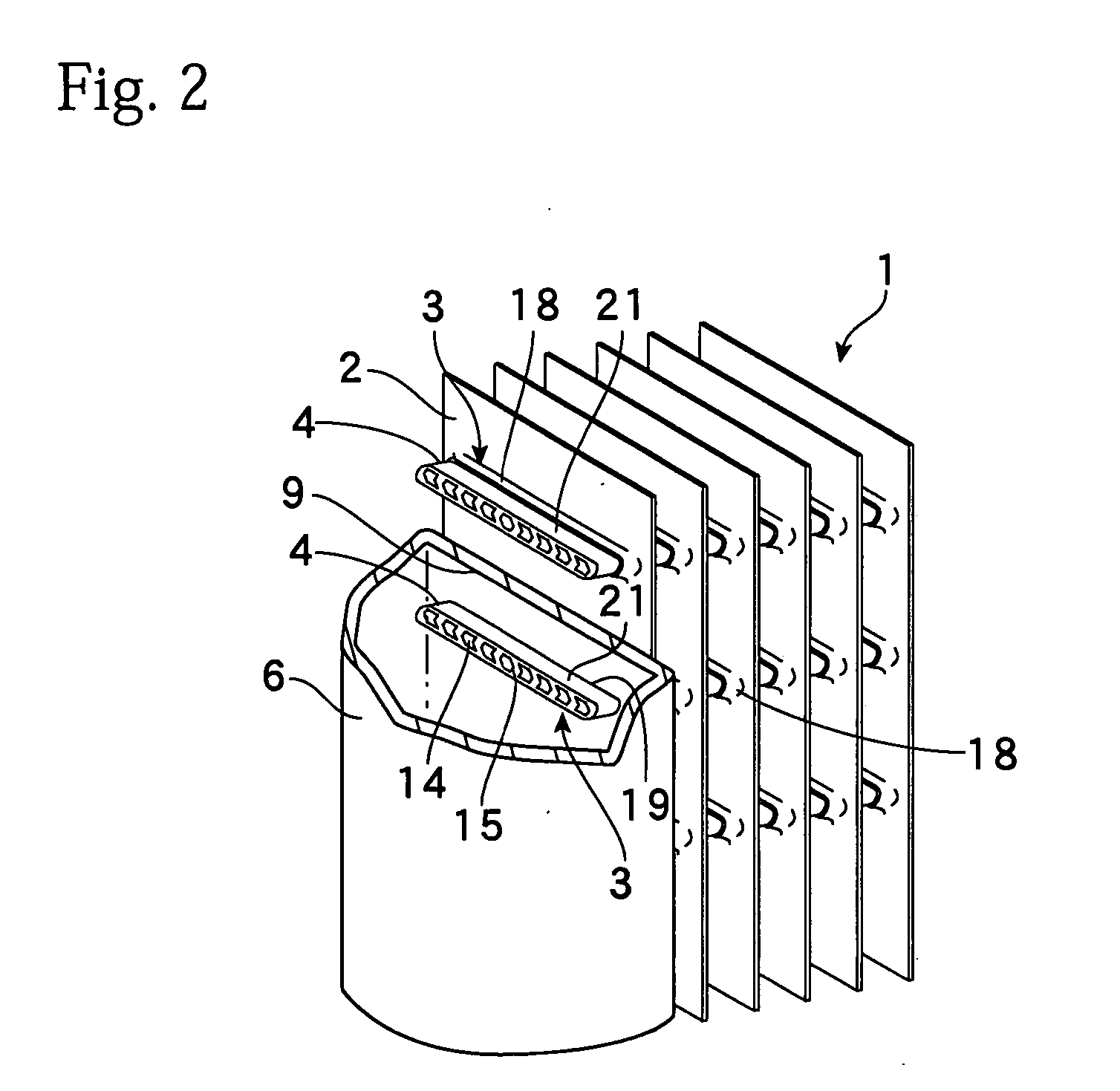

Air cleaner

ActiveUS6946021B2Improve contact efficiencyEasy to handleCombination devicesMechanical apparatusForeign matterChlorine dioxide

An air cleaner for cleaning air and for providing sterilization and deodorization effects, includes an air-liquid contact part, for bringing the air into contact with a water screen formed by spraying, using nozzles, pressurized circulating water, and for removing foreign materials from the air; a liquid separating part for separating from the air, tiny water droplets that are included in the air passing through the air-liquid contact part; a cylindrical body into which air to be cleaned is guided, and in which the air-liquid contact part and the liquid separating part are arranged in order; a chlorine dioxide addition unit, for adding a stabilized chlorine dioxide solution to a water tank for the water that is circulated; and a chlorine dioxide activation unit, for activating chlorine dioxide added to the circulating water, that is arranged in a circulating water pipe that extends from the water tank to the spray nozzles.

Owner:FM IWATE

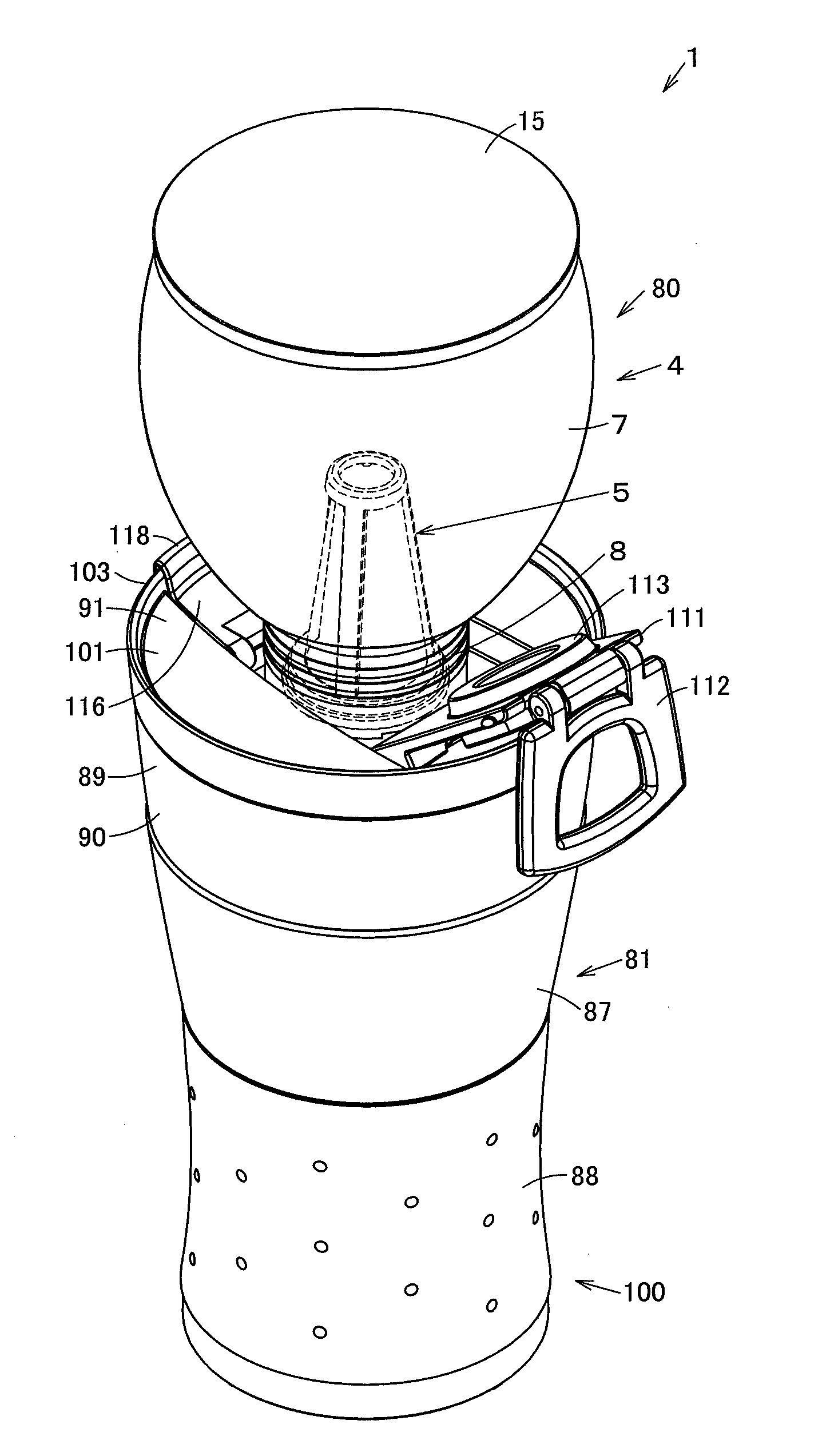

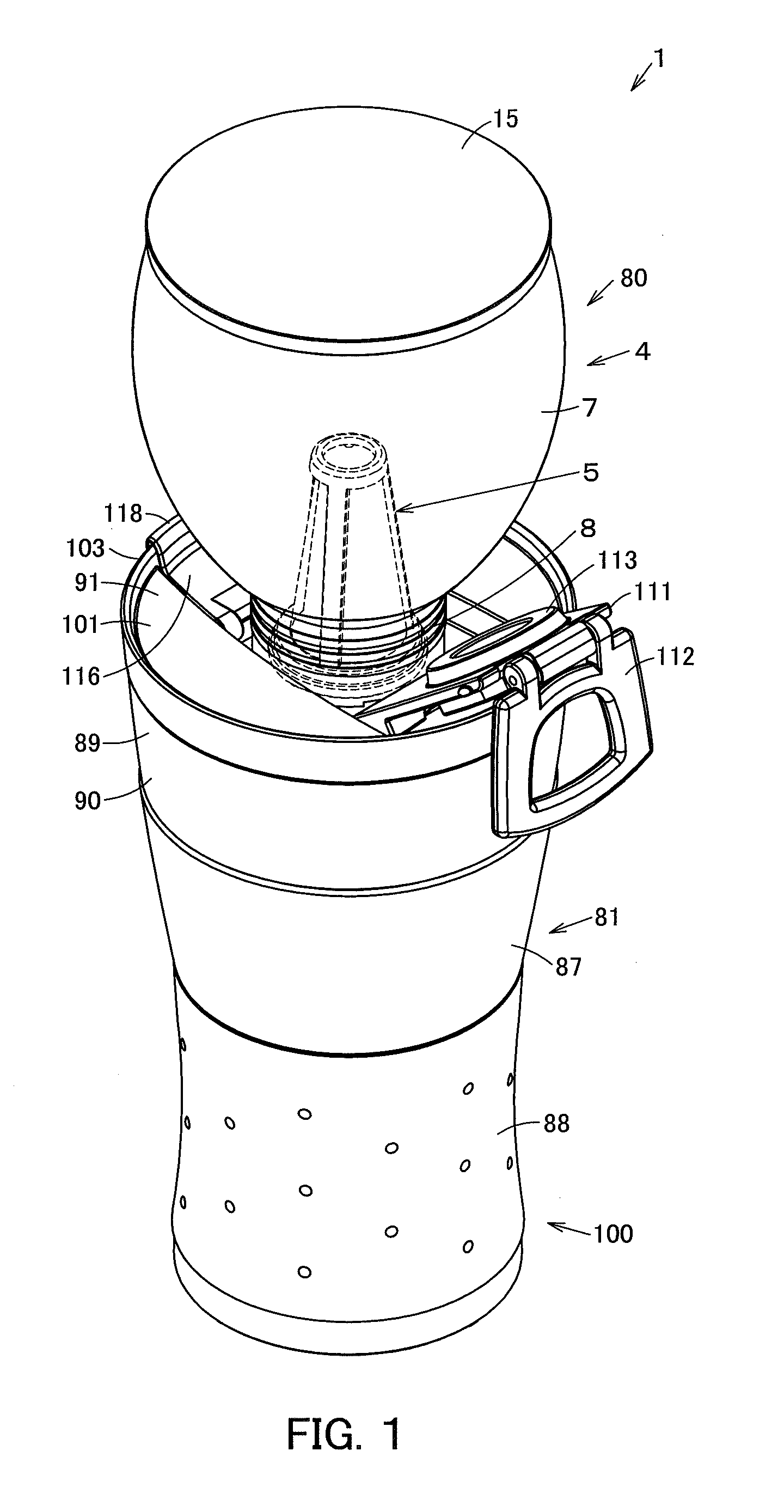

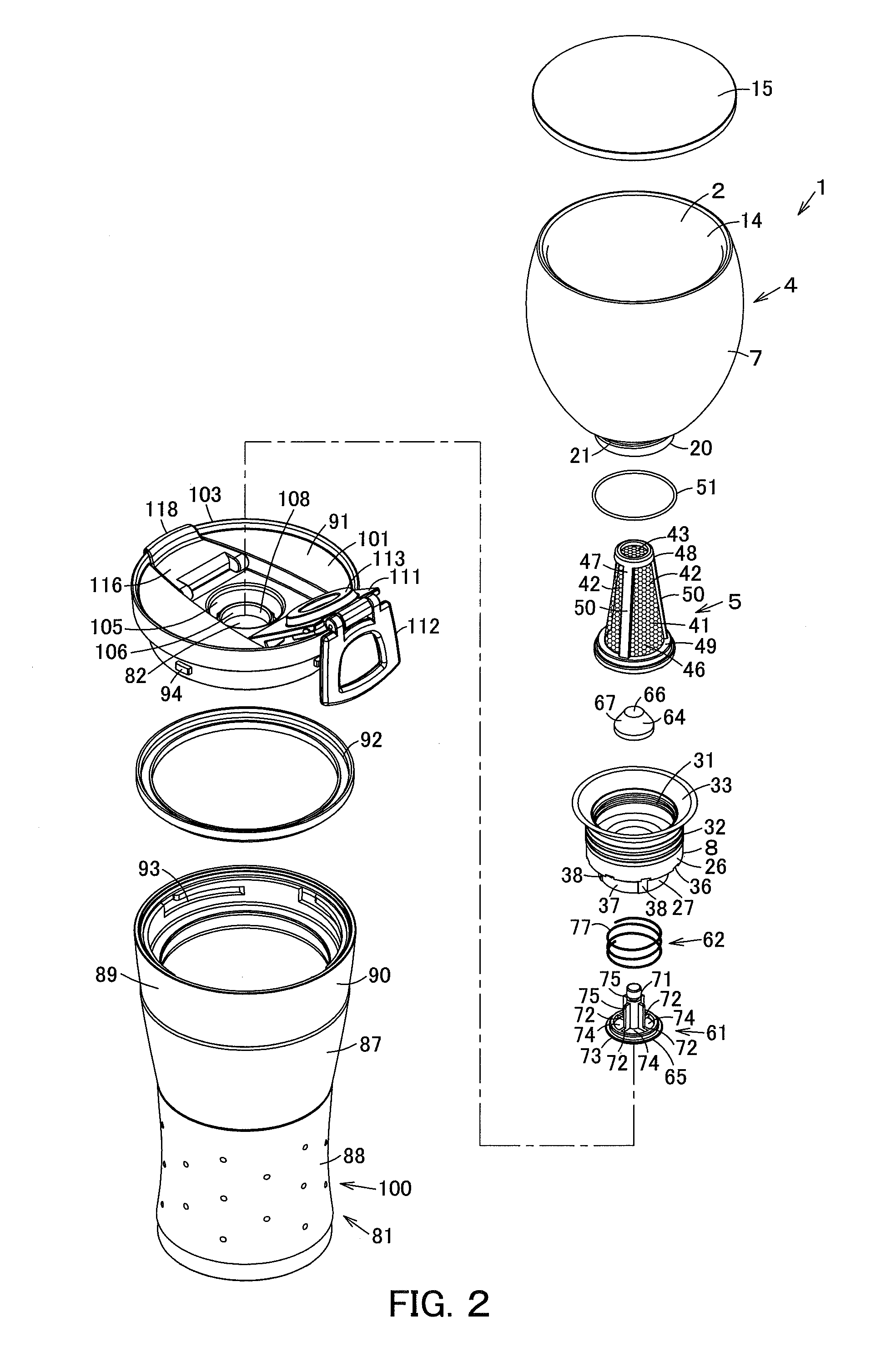

Drink extracting apparatus

InactiveUS20100263548A1Improve contact efficiencyFully extractedBeverage vesselsThermally-insulated vesselsEngineeringMechanical engineering

Owner:FINESKY

Composition for forming solar cell electrode and electrode produced from same

ActiveUS20150364622A1Good ohmic contactMinimize serial resistanceConductive materialNon-conductive material with dispersed conductive materialFritFill factor

A composition for solar cell electrodes and electrodes fabricated using the same. The composition includes silver powder; fumed silica; a glass frit; and an organic vehicle. The composition has improved contact efficiency between electrodes and a silicon wafer by introducing specific fumed silica. Solar cell electrodes fabricated using the composition exhibit minimized serial resistance, thereby providing excellent fill factor and conversion efficiency.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD

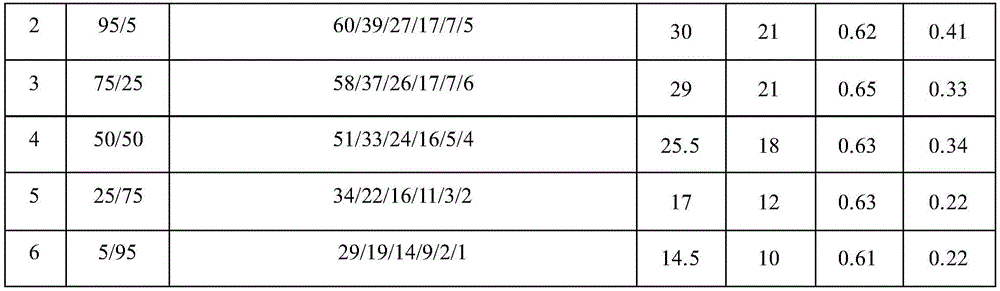

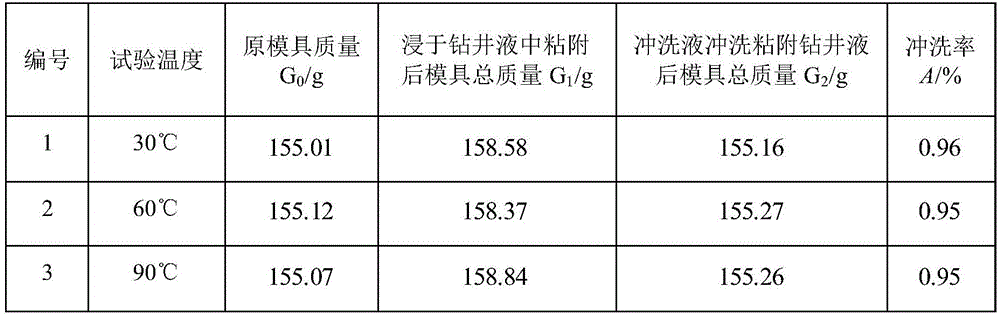

Well cementation flushing liquid system suitable for oil-based drilling fluid and preparation method thereof

InactiveCN105419758AReduce interfacial tensionImprove flushing effectDrilling compositionEngineeringVolumetric Mass Density

A well cementation flushing liquid system suitable for an oil-based drilling fluid and a preparation method thereof. The invention mainly solves the defects of low flushing efficiency, poor wetting conversion capability and poor interface cementing quality in the flushing liquids in the prior art. The flushing liquid system comprises the following components, by weight: 100 parts of clear water, 0.8-1.2 parts of an anionic surfactant, 0.6-0.8 parts of a nonionic surfactant, 0.7-1.0 part of a cosurfactant, 6.0-10.0 parts of an oil phase, 8.0-12.0 parts of a salt water phase, 0.15-5.0 parts of a polymer, 0.0-150 parts of a weighting agent and 1.0-2.5 parts of salt. The flushing liquid system is adjustable in density within 1.01-1.90 g / cm<3> and is 20-130 DEG C in available temperature range. The flushing liquid system can quickly remove residual oil-based drilling fluid, is strong in wetting conversion capability, ensures cementation between cement rings and an annular space, and is wide in application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

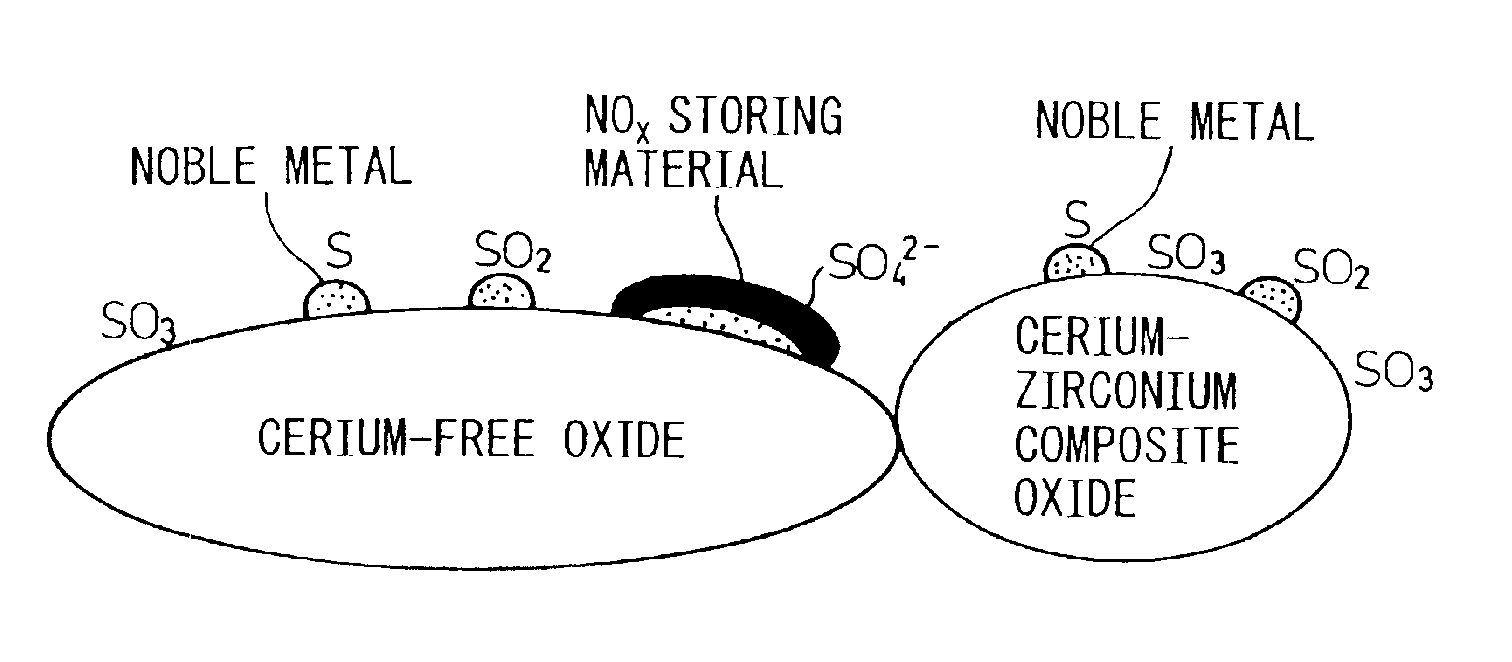

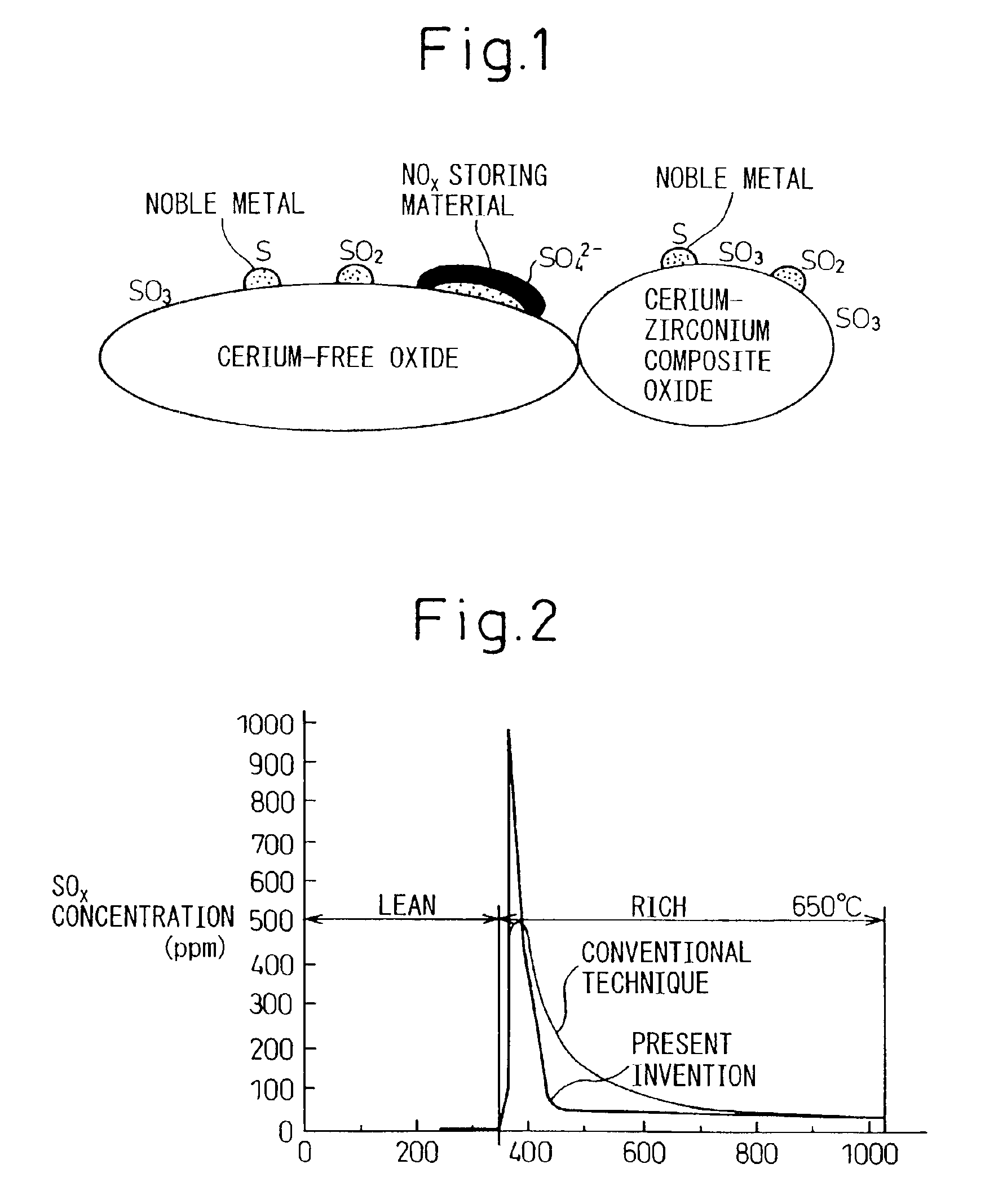

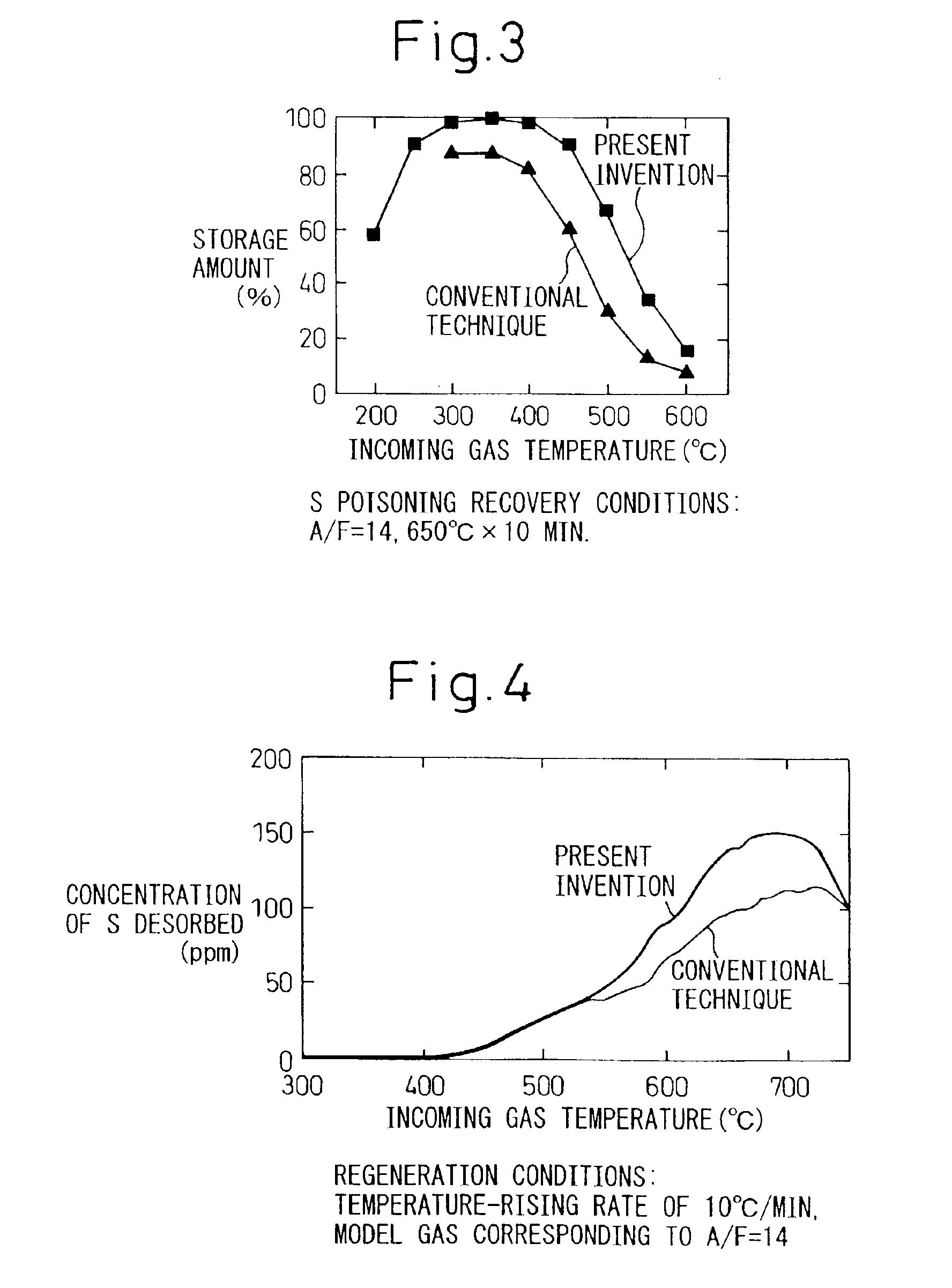

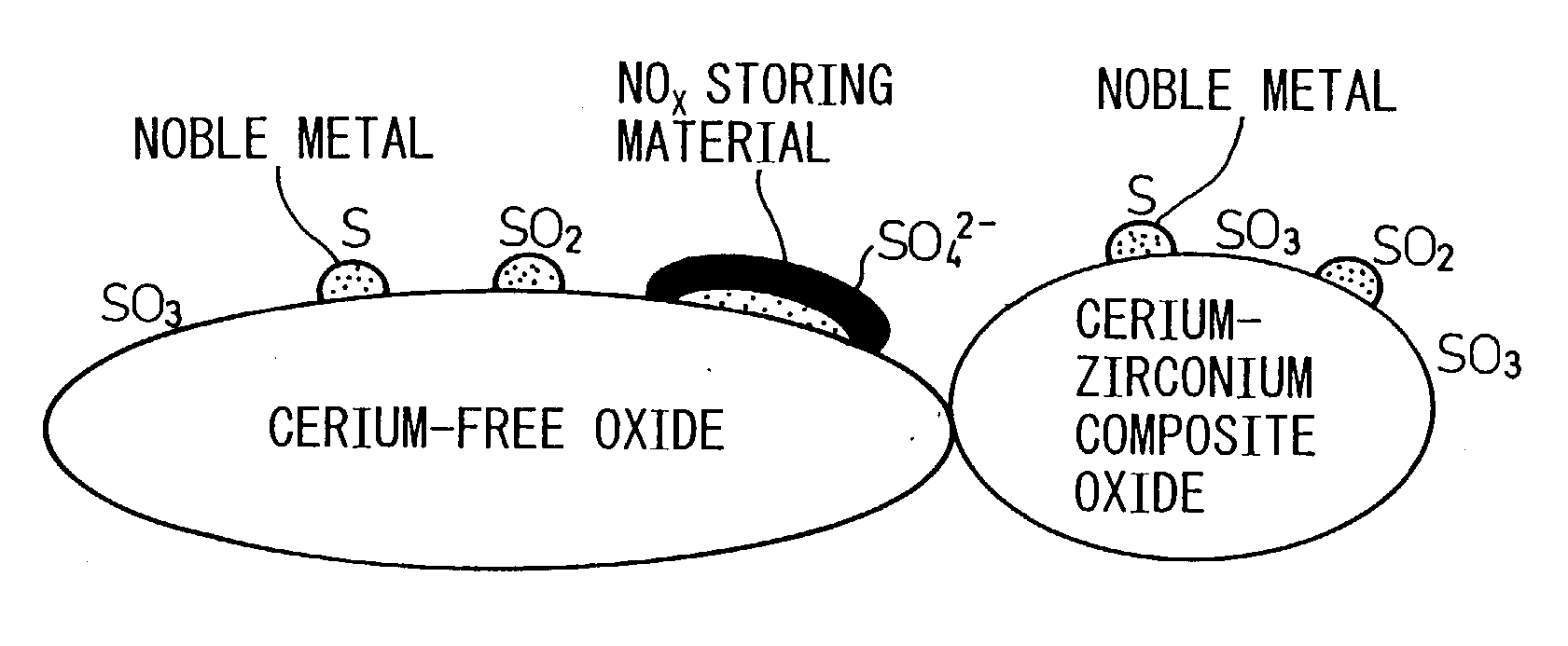

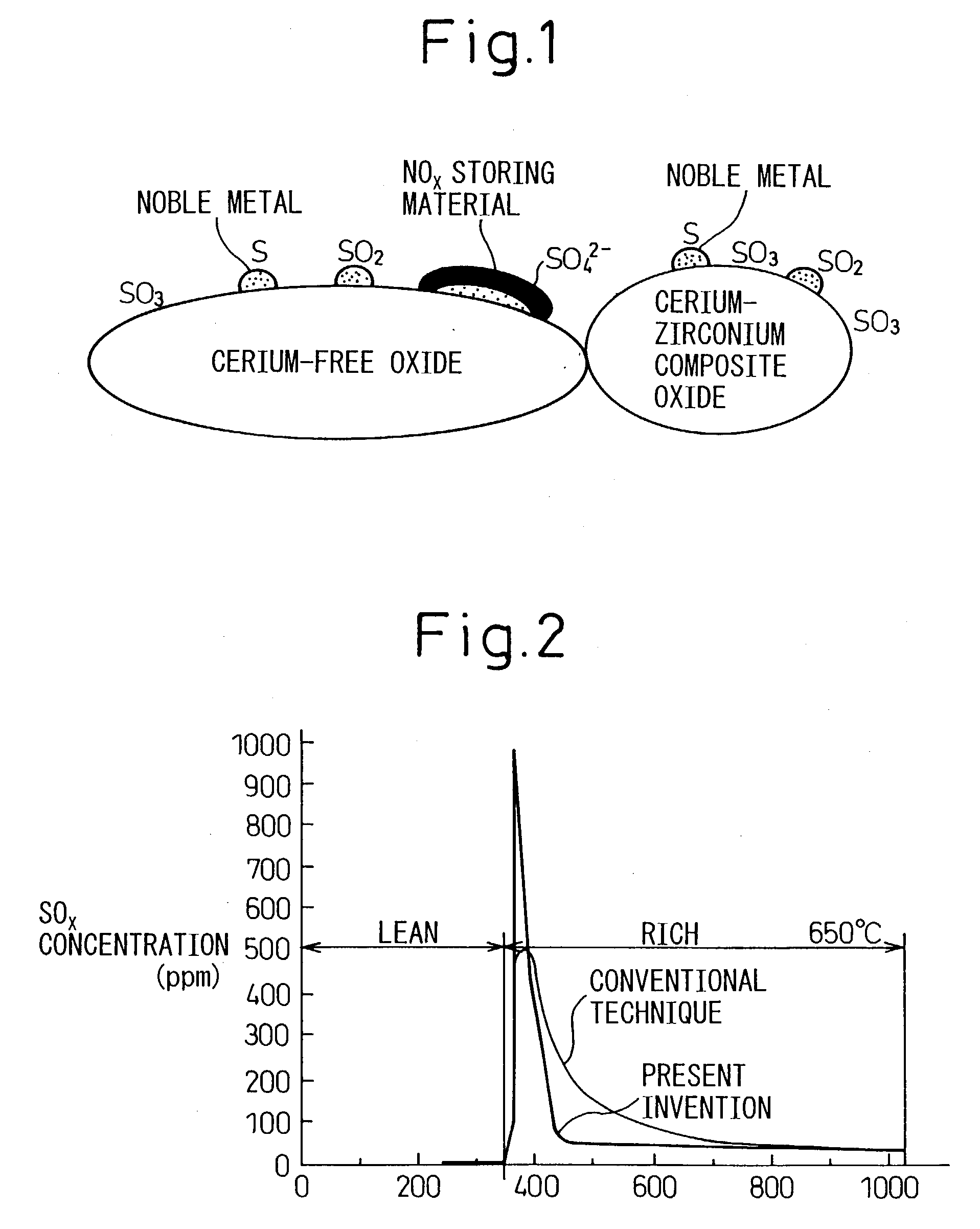

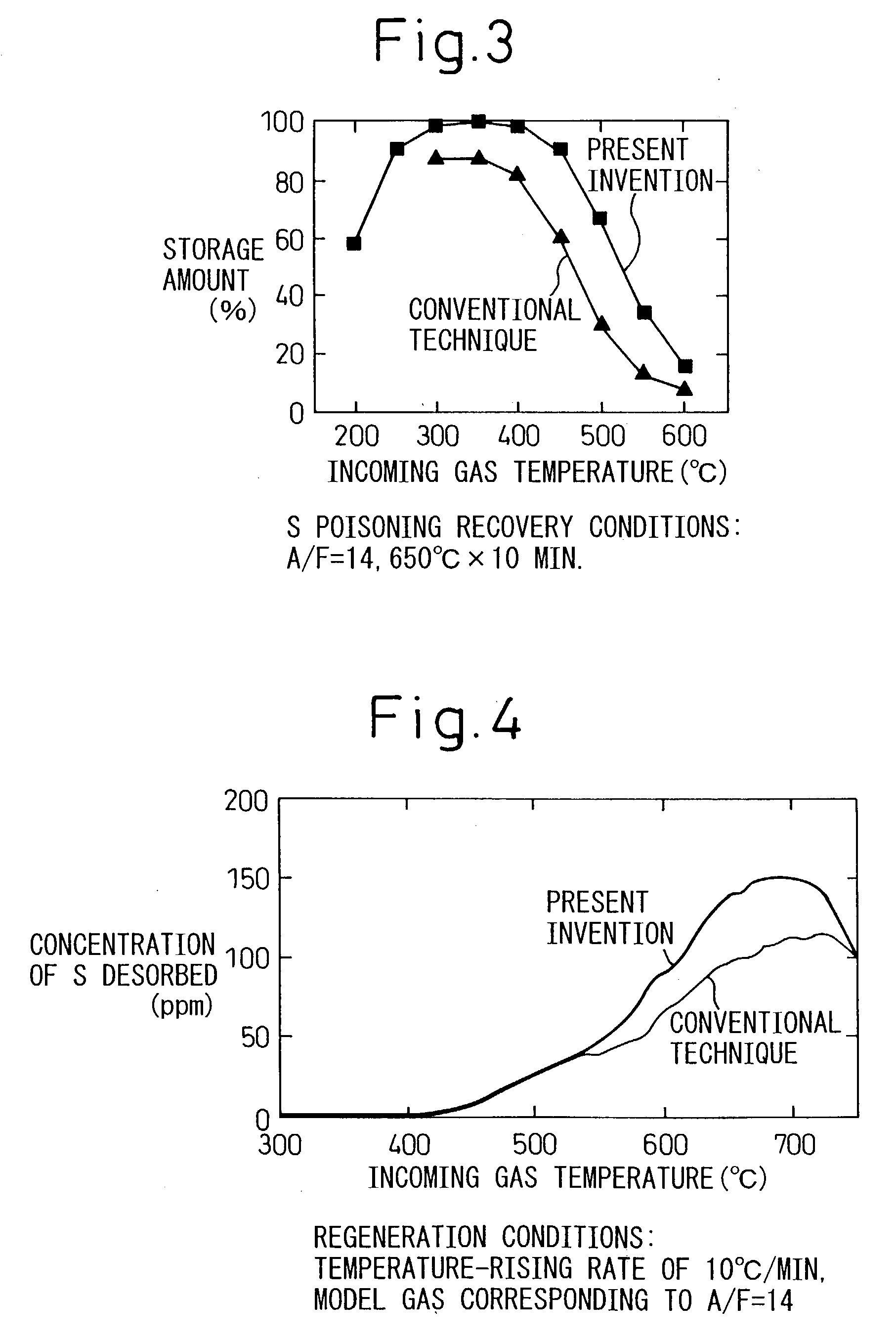

Storage-reduction type NOx purifying catalyst

InactiveUS6956008B2Improve contact efficiencyExhaust gas purifying performanceGas treatmentOther chemical processesCeriumCe element

A storage-reduction type NOx purifying catalyst includes a monolith substrate having formed thereon a coat layer containing a cerium-zirconium composite oxide and a cerium-free oxide, a noble metal and an NOx storing material being supported on the coat layer and the cerium content of the cerium-zirconium composite oxide being less than 30 mol % based on the total molar number of metal atoms contained.

Owner:TOYOTA JIDOSHA KK

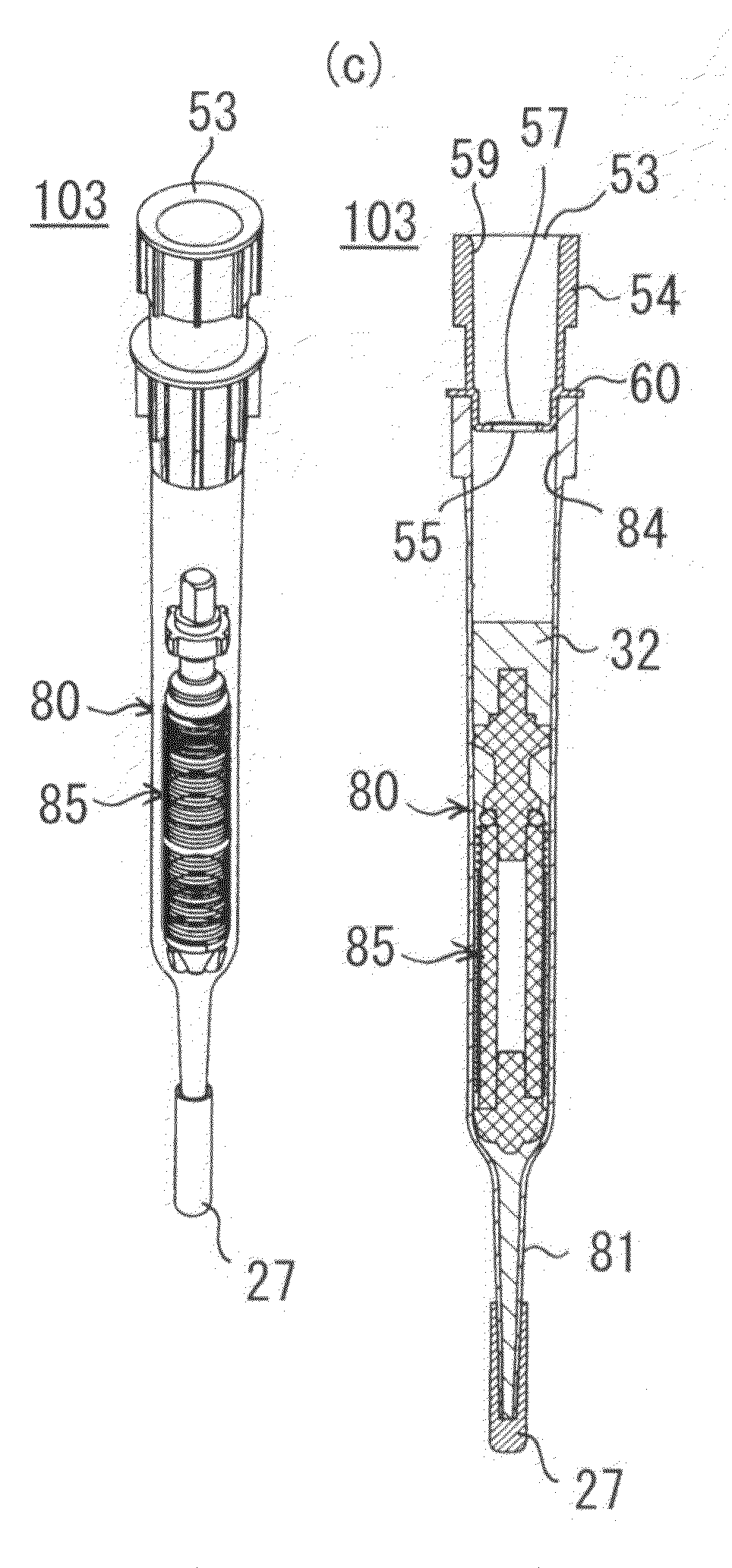

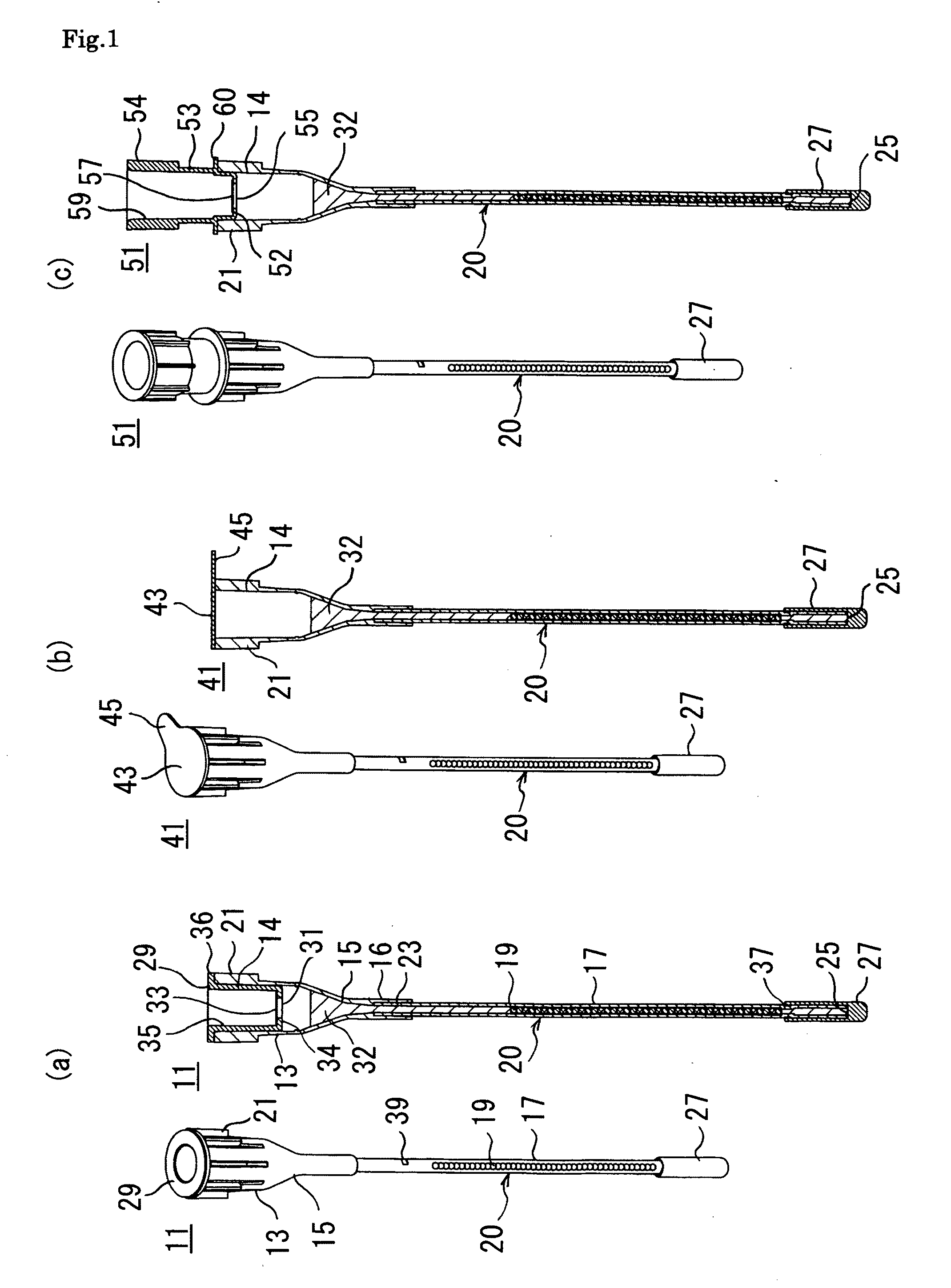

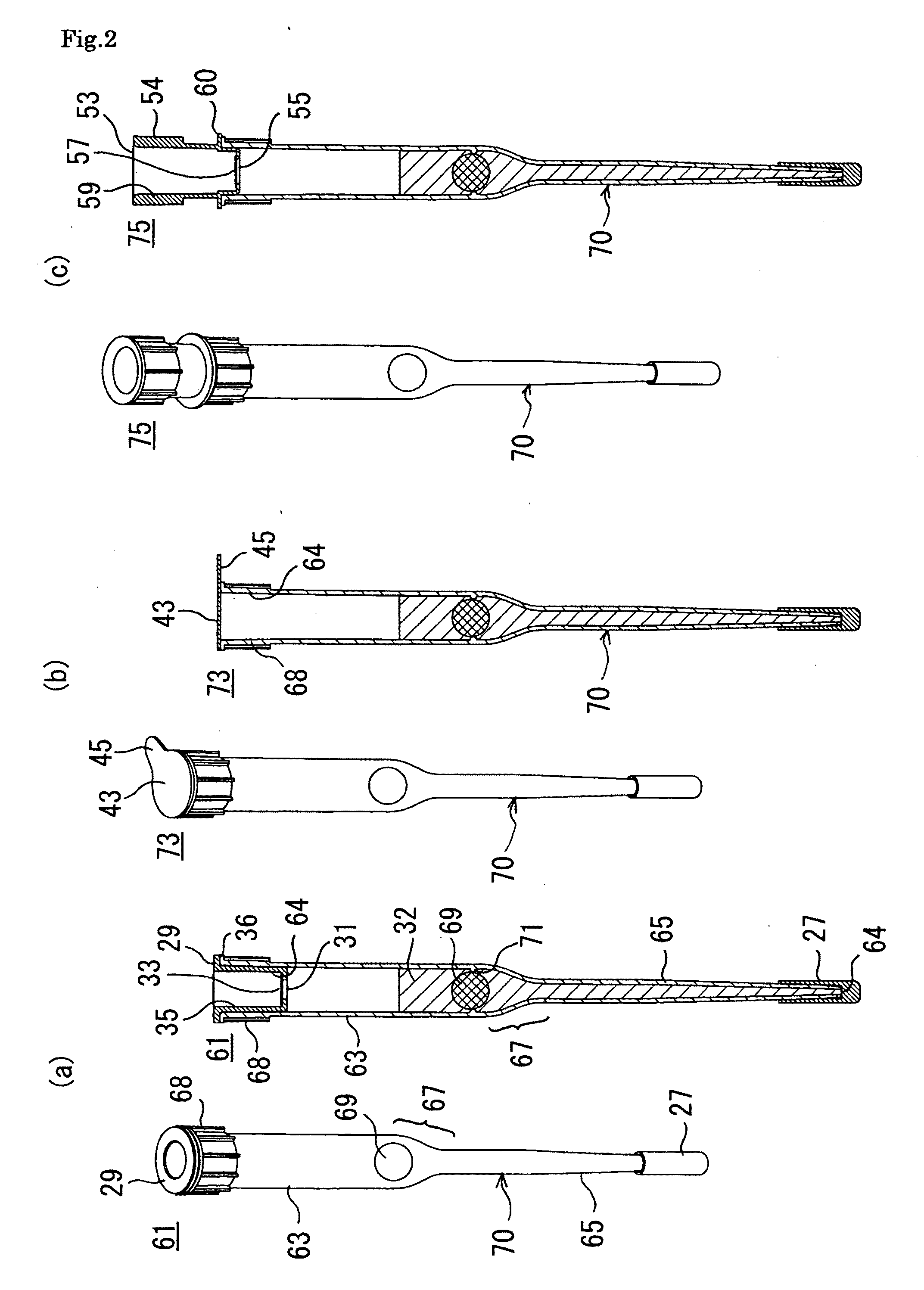

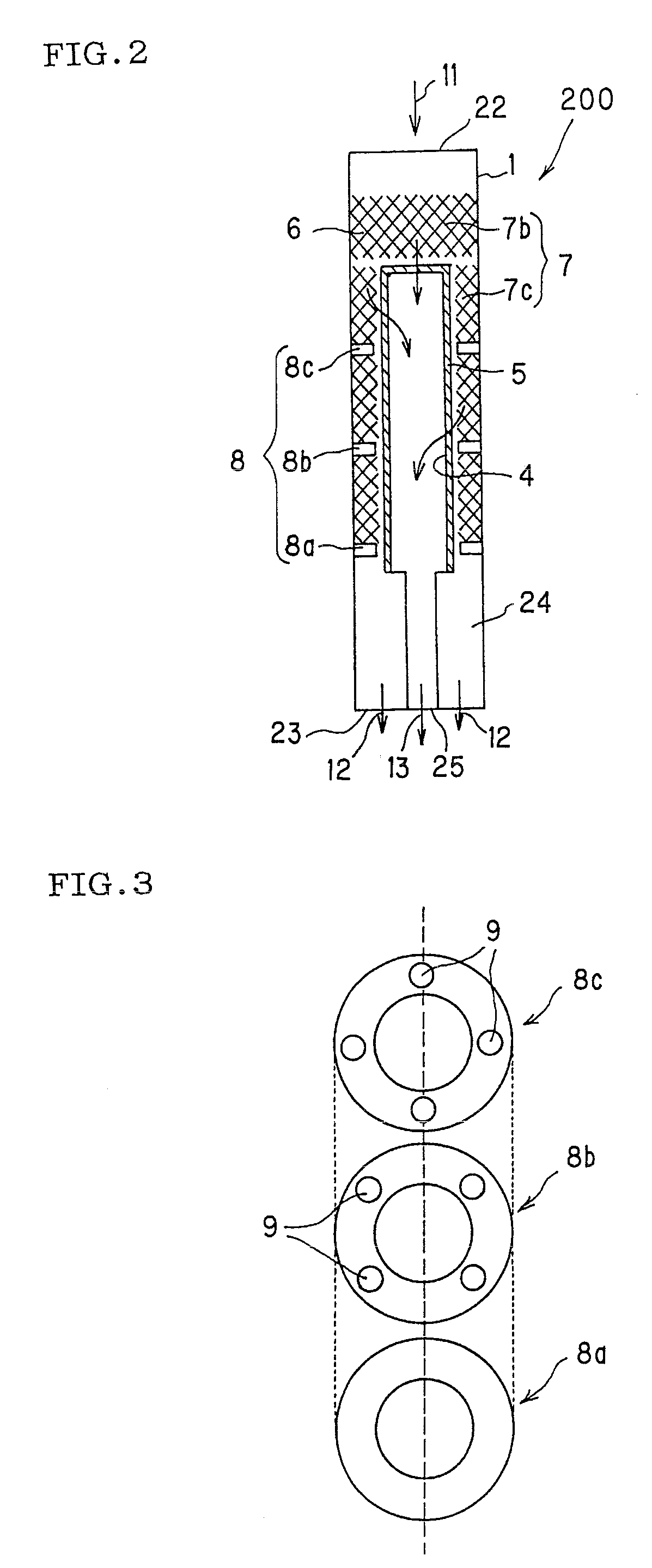

Pipette tip having carrier/fluid enclosed therein, apparatus for treating pipette tip having carrier/fluid enclosed therein and method of treating pipette tip having carrier/fluid enclosed therein

ActiveUS20100043575A1Pass smoothlyImprove reaction efficiencyAnalysis using chemical indicatorsComponent separationPipetteEngineering

The present invention relates to a pipette tip having a support and a fluid enclosed therein, an apparatus for treating the pipette tip having a support and a fluid enclosed therein, and a method of treating the pipette tip having a support and a fluid enclosed therein. The present invention aims at providing separation and purification that may be performed more efficiently and rapidly than the treatments using a conventional treatment using liquid chromatograph or a filter, and constituted to have a function for sustainedly activating the support by comprising a pipette tip comprising an attachment opening that is to be attached to a nozzle for sucking and discharging a gas or to a connecting tube attachable to the nozzle and may be communicated with the nozzle, and an opening that allows flow-in and flow-out of a liquid in response to the suction and discharging of the gas; a support enclosed in the pipette tip, which may adsorb or capture a biological material in the liquid or react with or bond to the biological material; and a fluid for sustainedly activating the support, which comprises a predetermined liquid or a predetermined gas that is enclosed in the pipette tip in a breakable state and comes into contact with the support.

Owner:UNIVERSAL BIO RESEARCH CO LTD

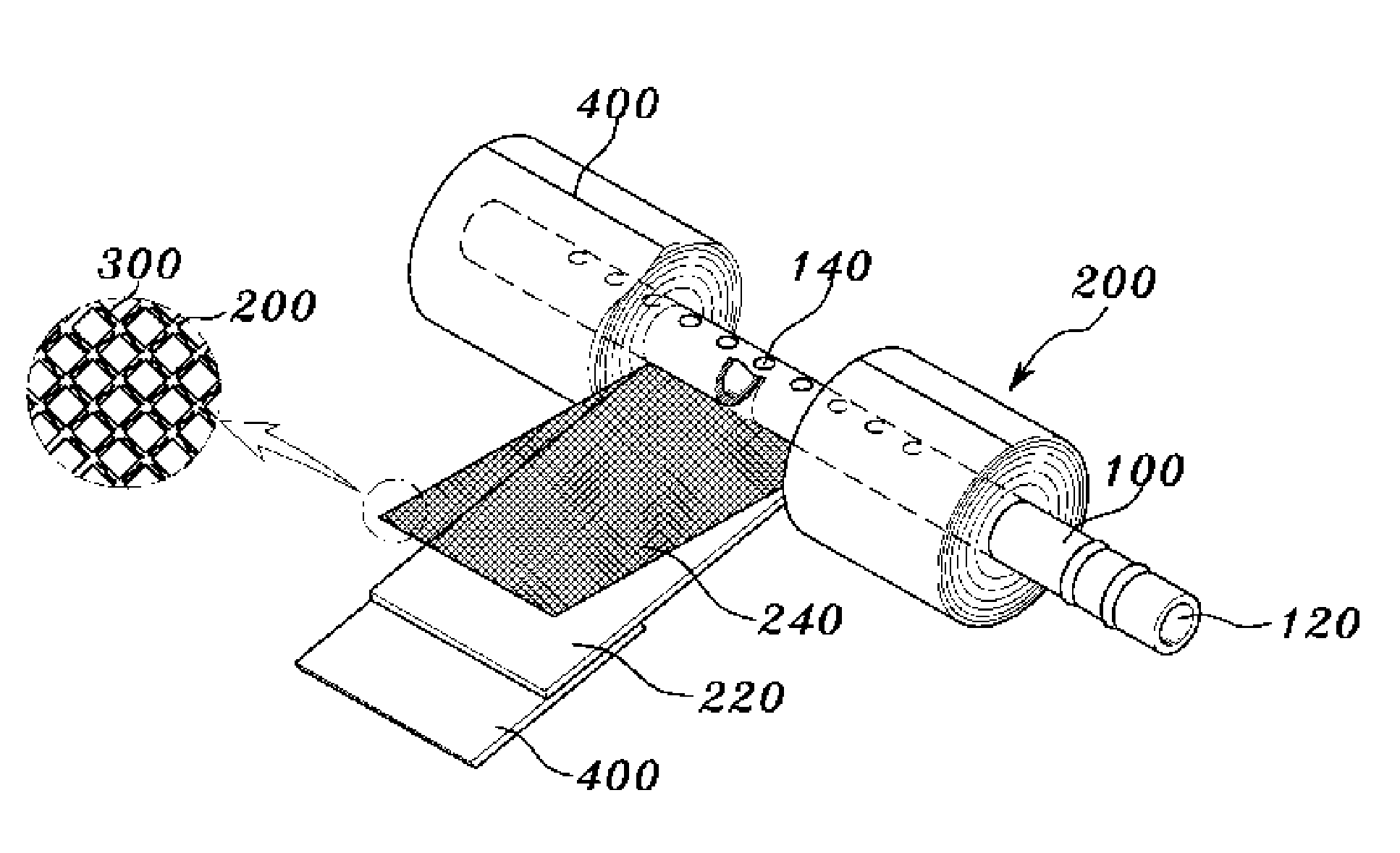

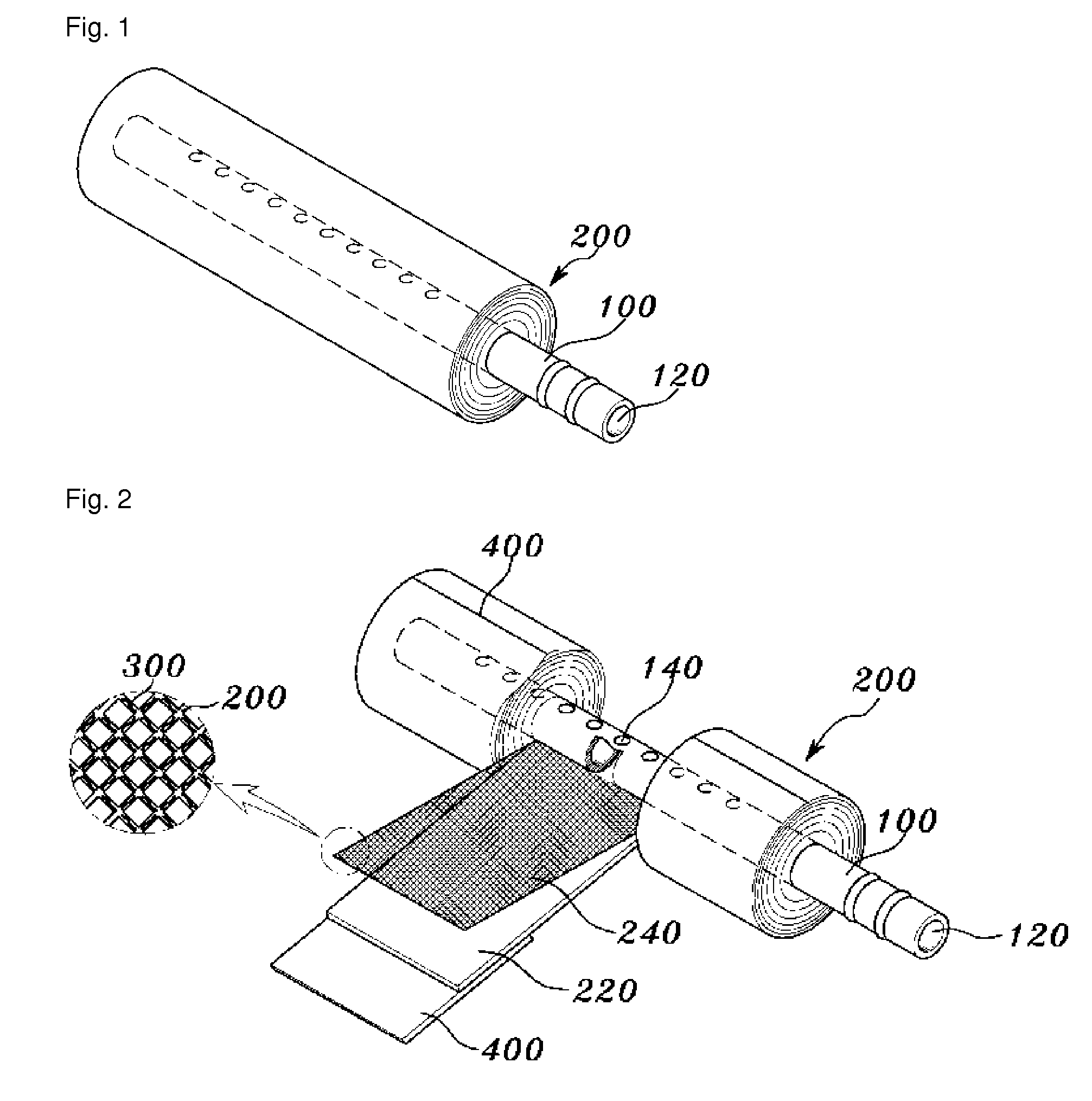

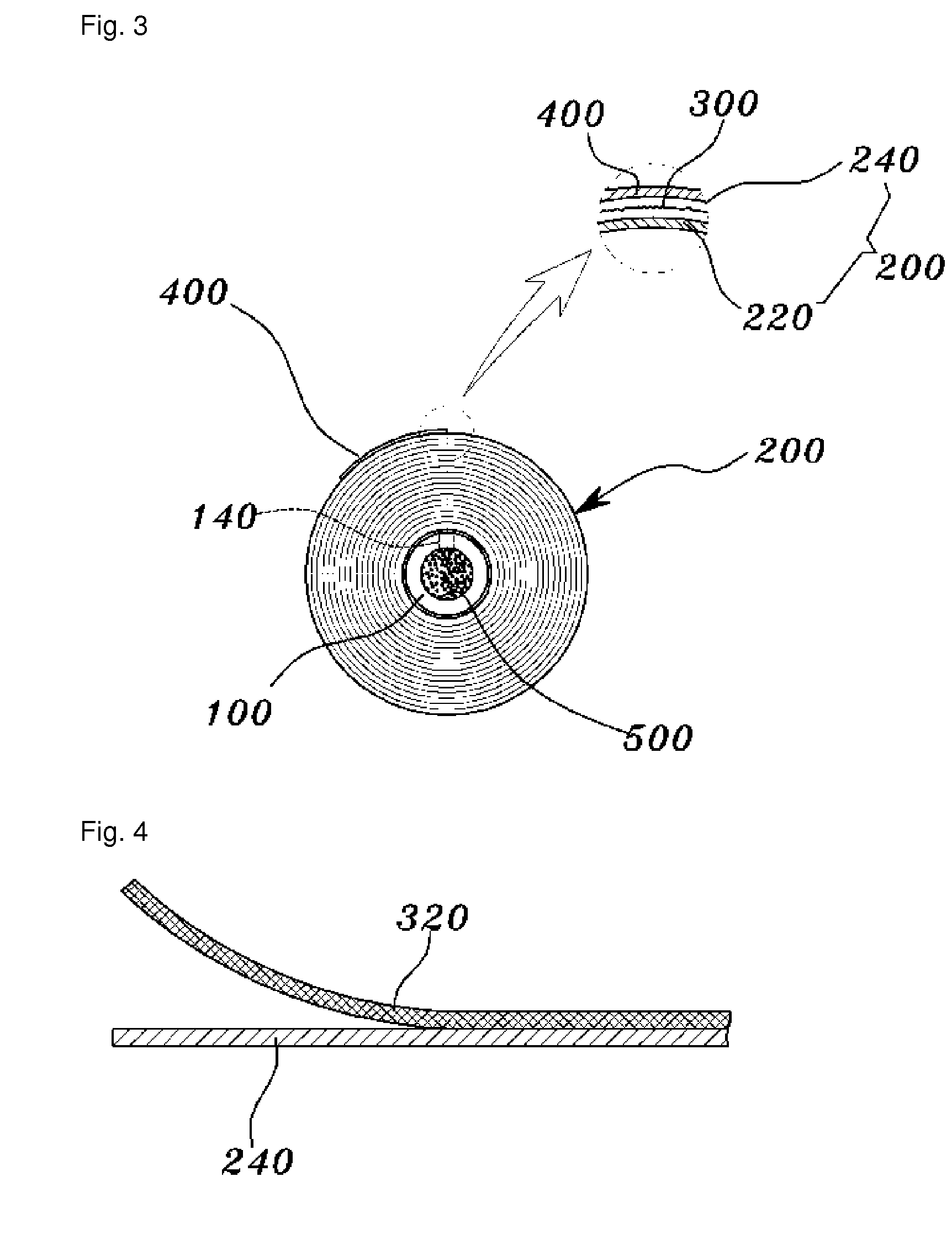

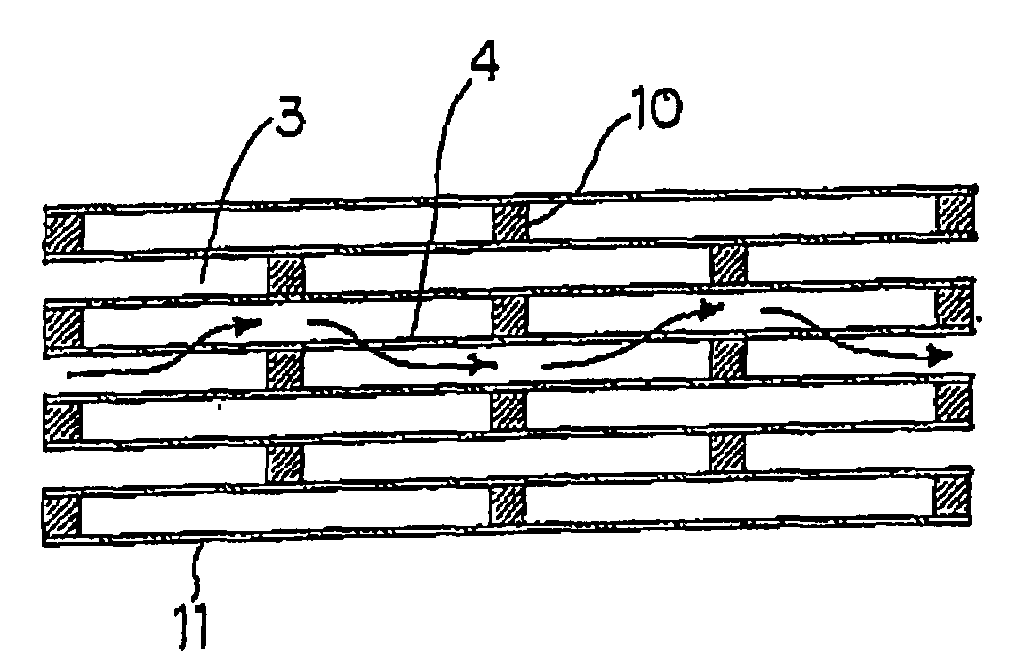

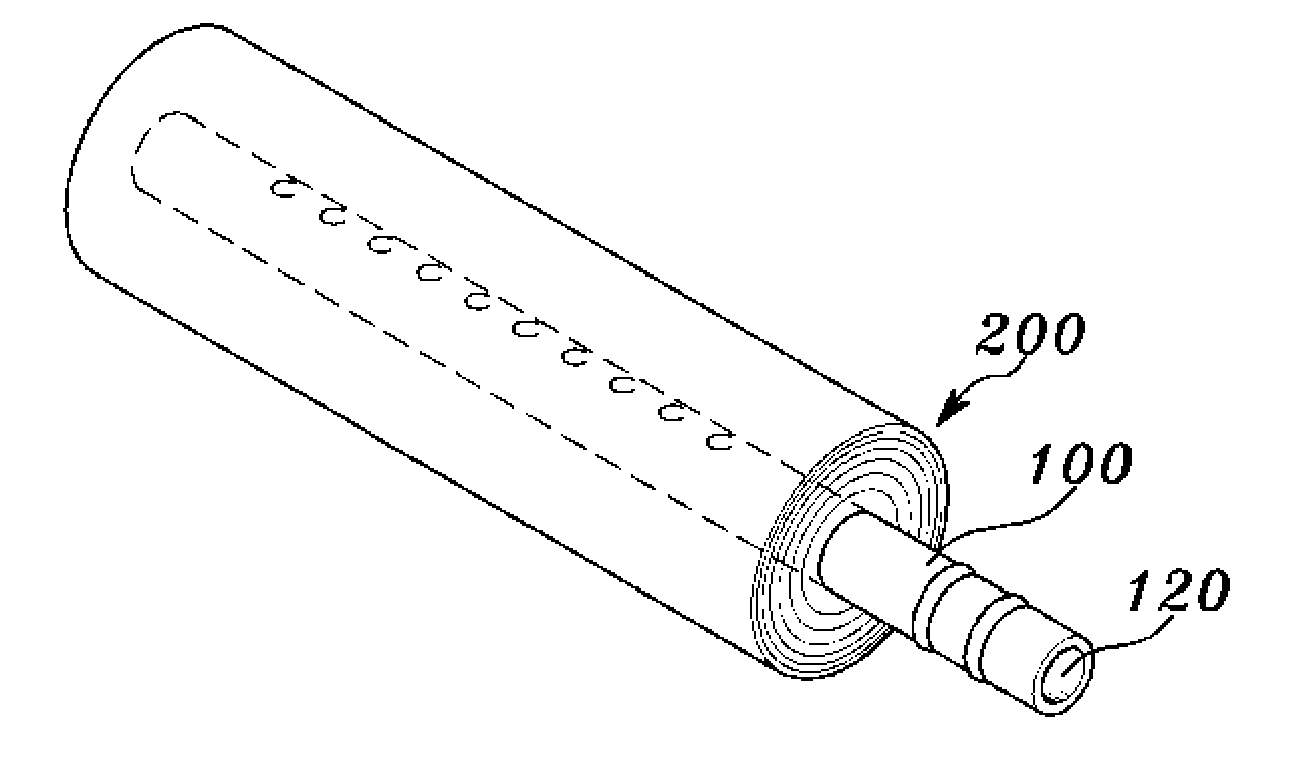

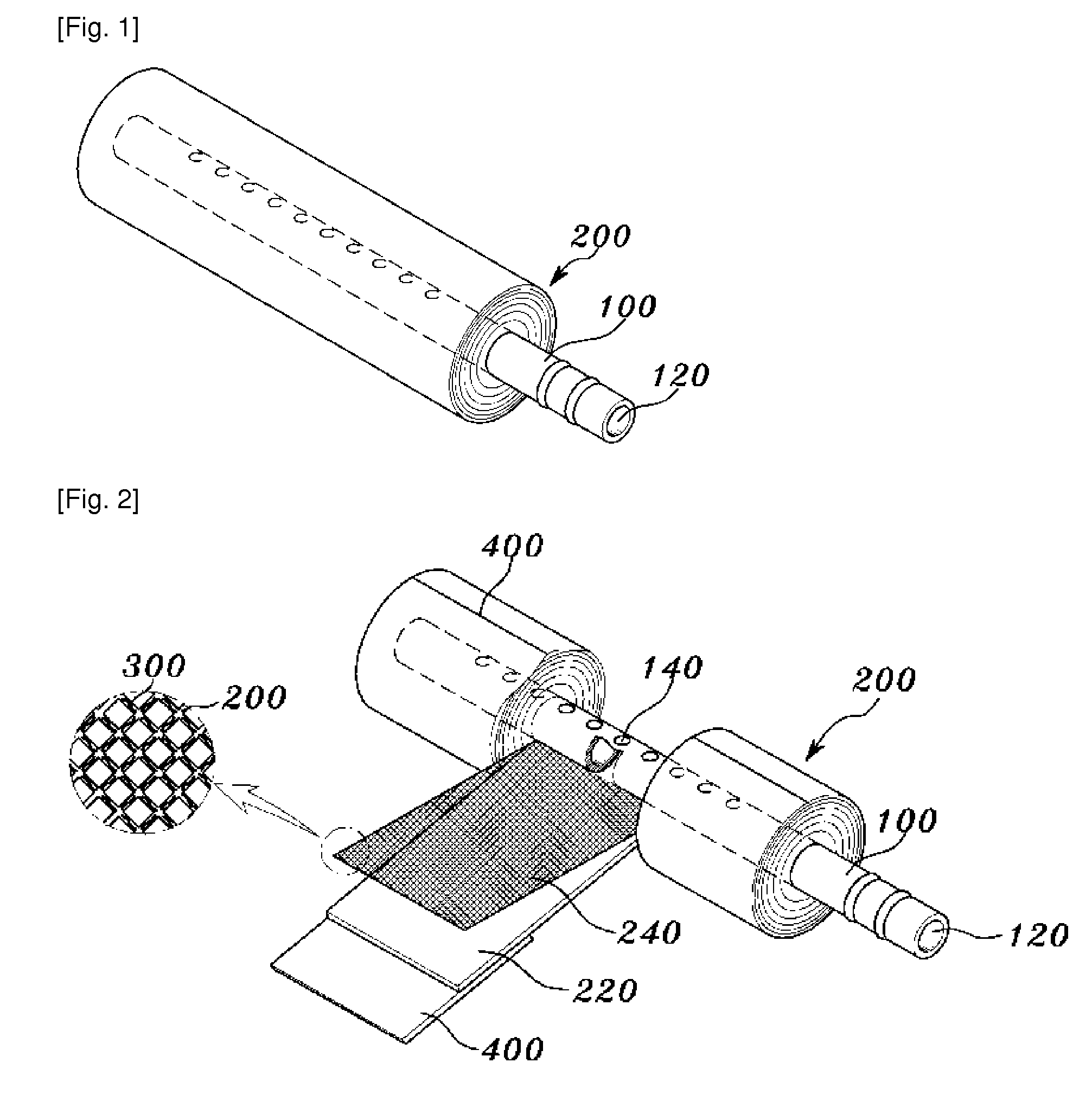

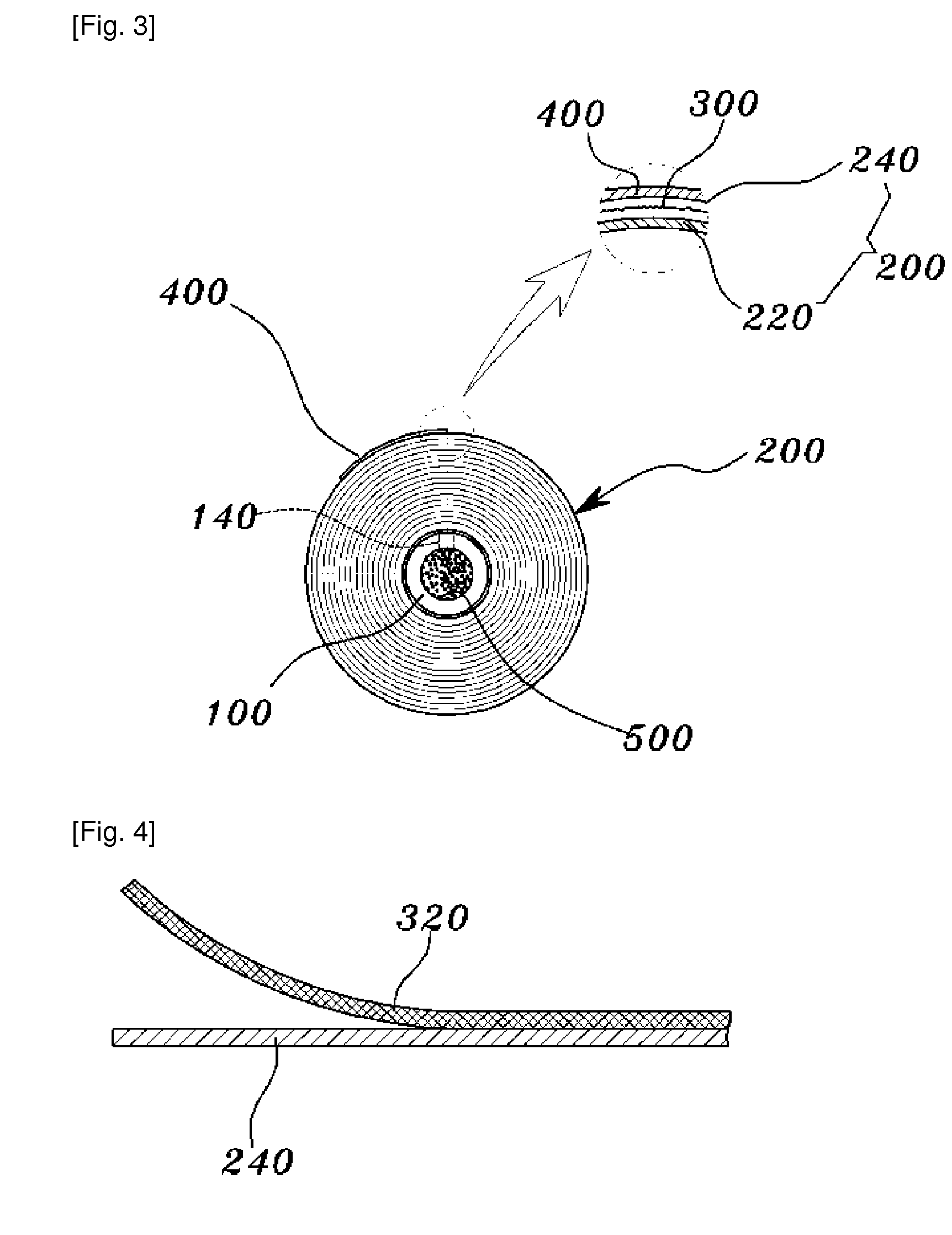

Spiral wound type filter cartridge

Disclosed herein is a spiral wound type filter cartridge and more specifically, a spiral wound type filter cartridge in which activated carbon fiber is provided. The inside of spiral wound type filter cartridge is capable of serving as a carbon filter in a water purifier, thus eliminating the necessity of the use of any carbon filter for pre- or post-treatment in the process of purifying raw water, reducing an overall size of the water purifier and considerably reducing costs associated therewith.

Owner:WOONGJIN COWAY

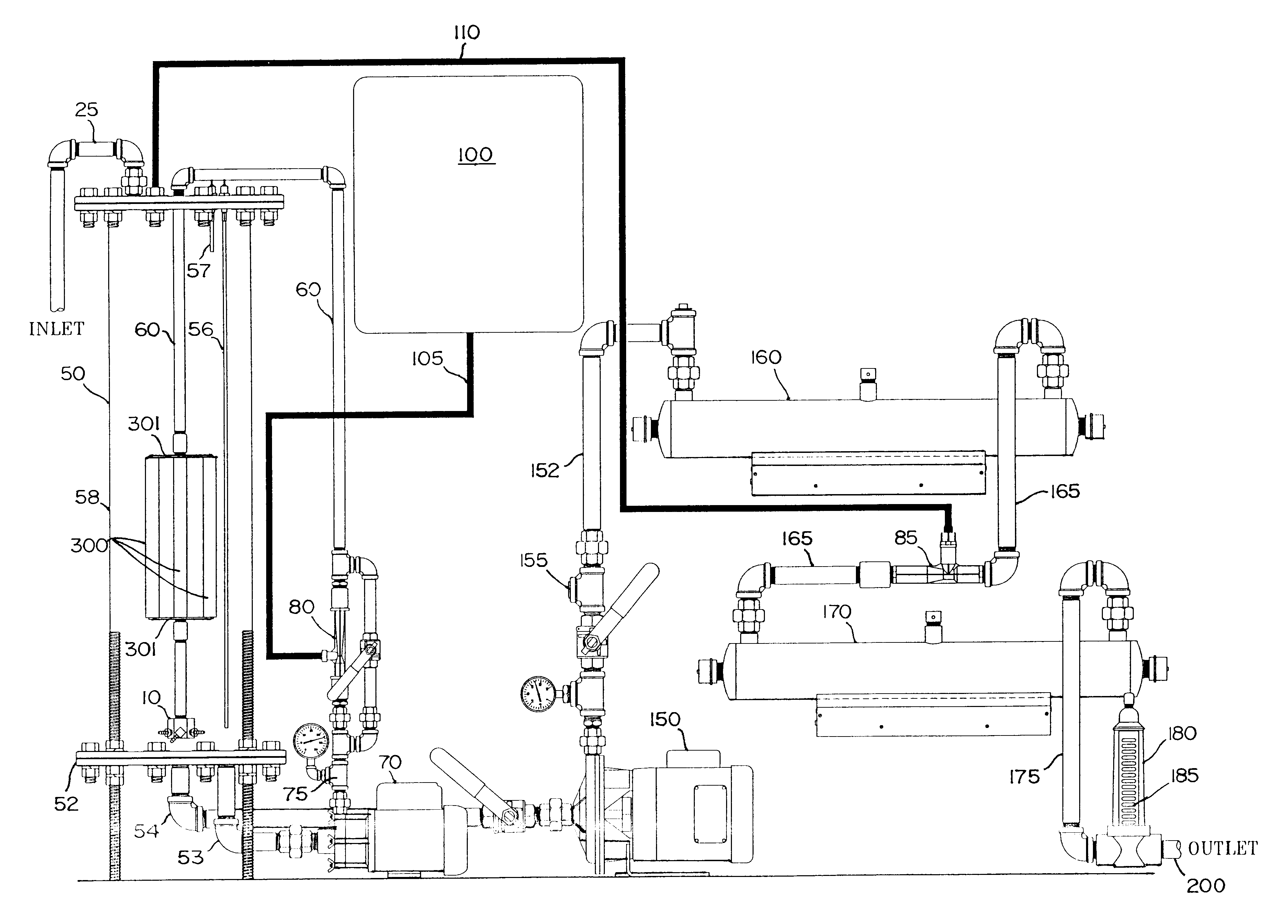

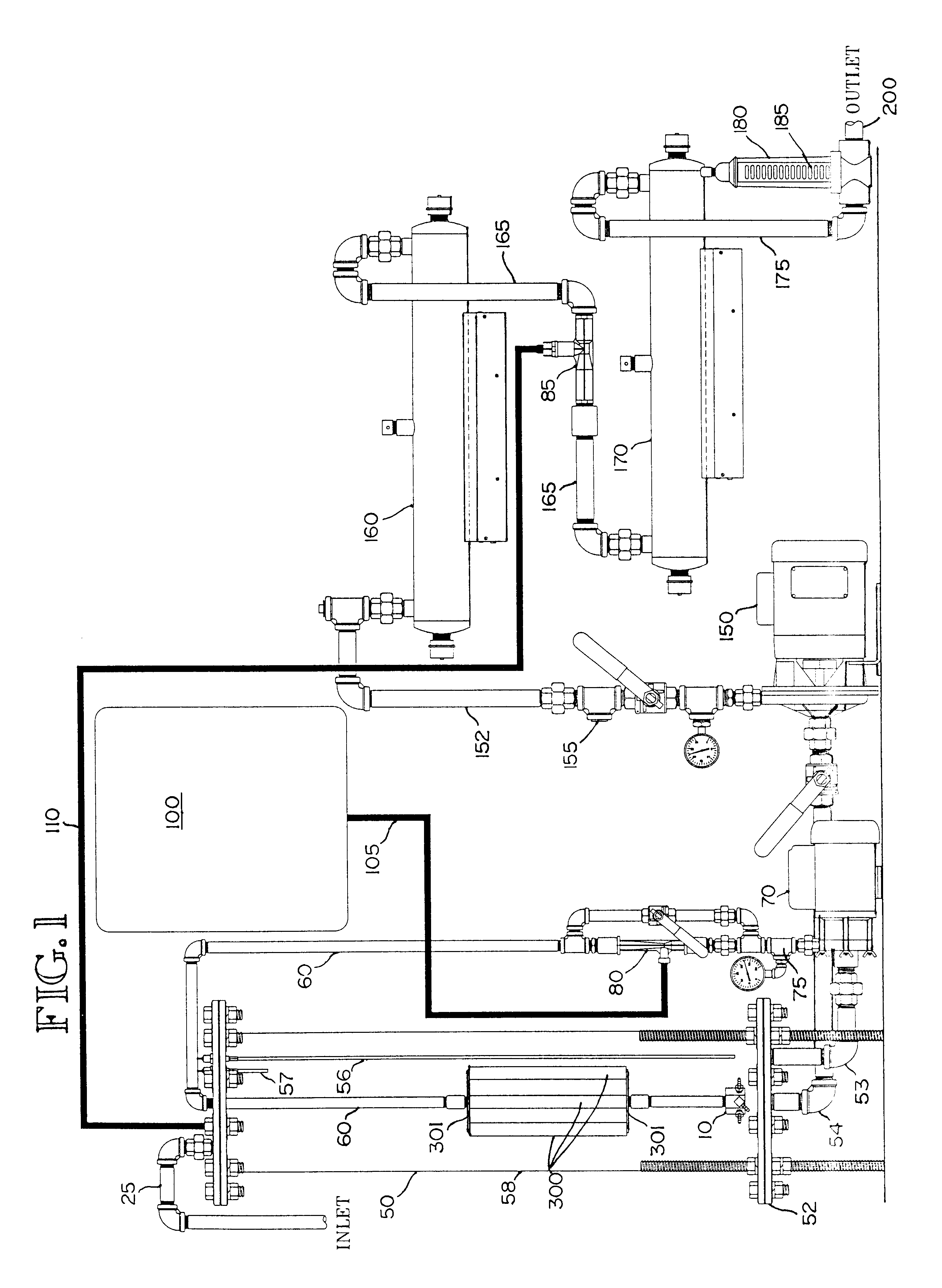

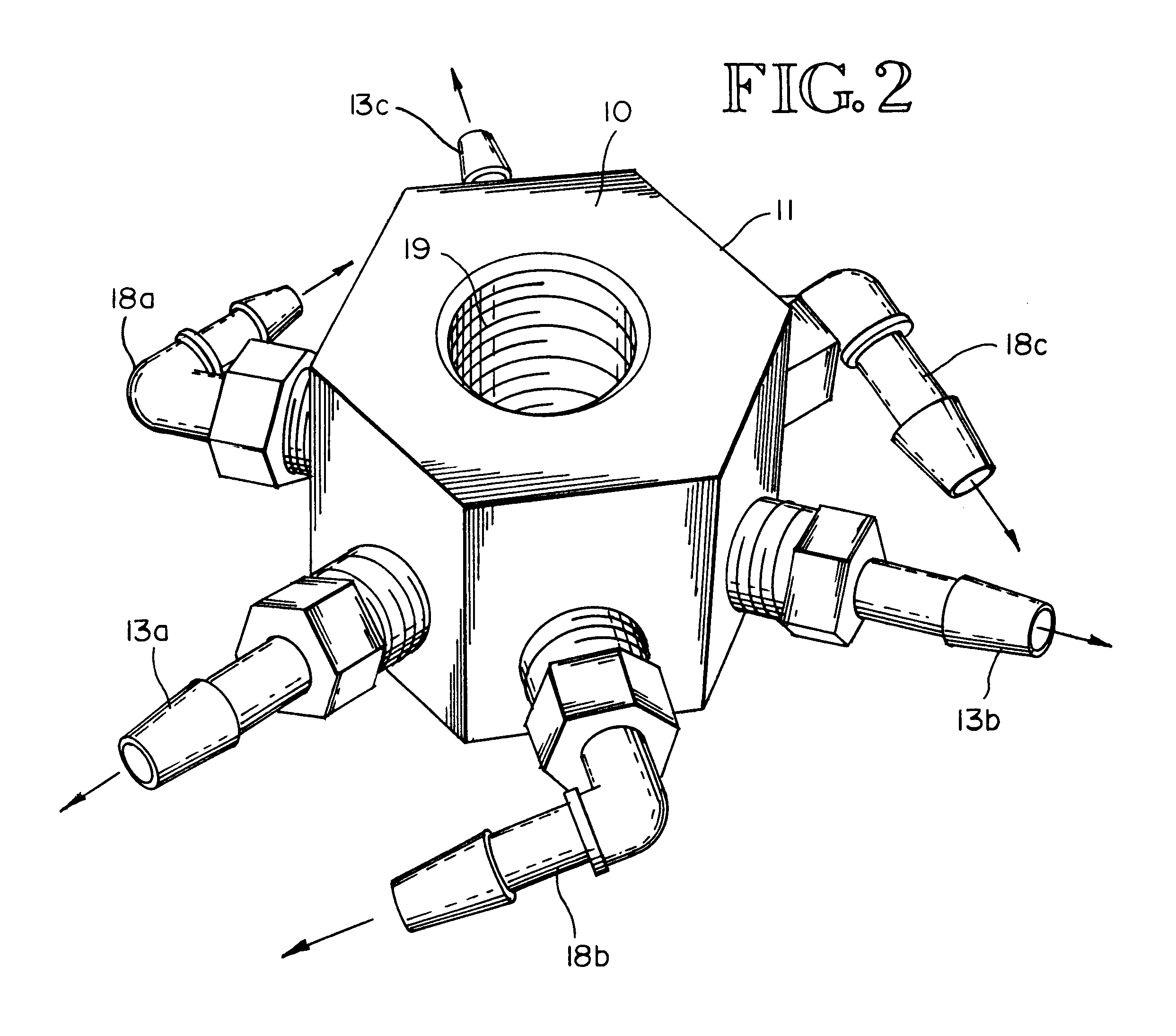

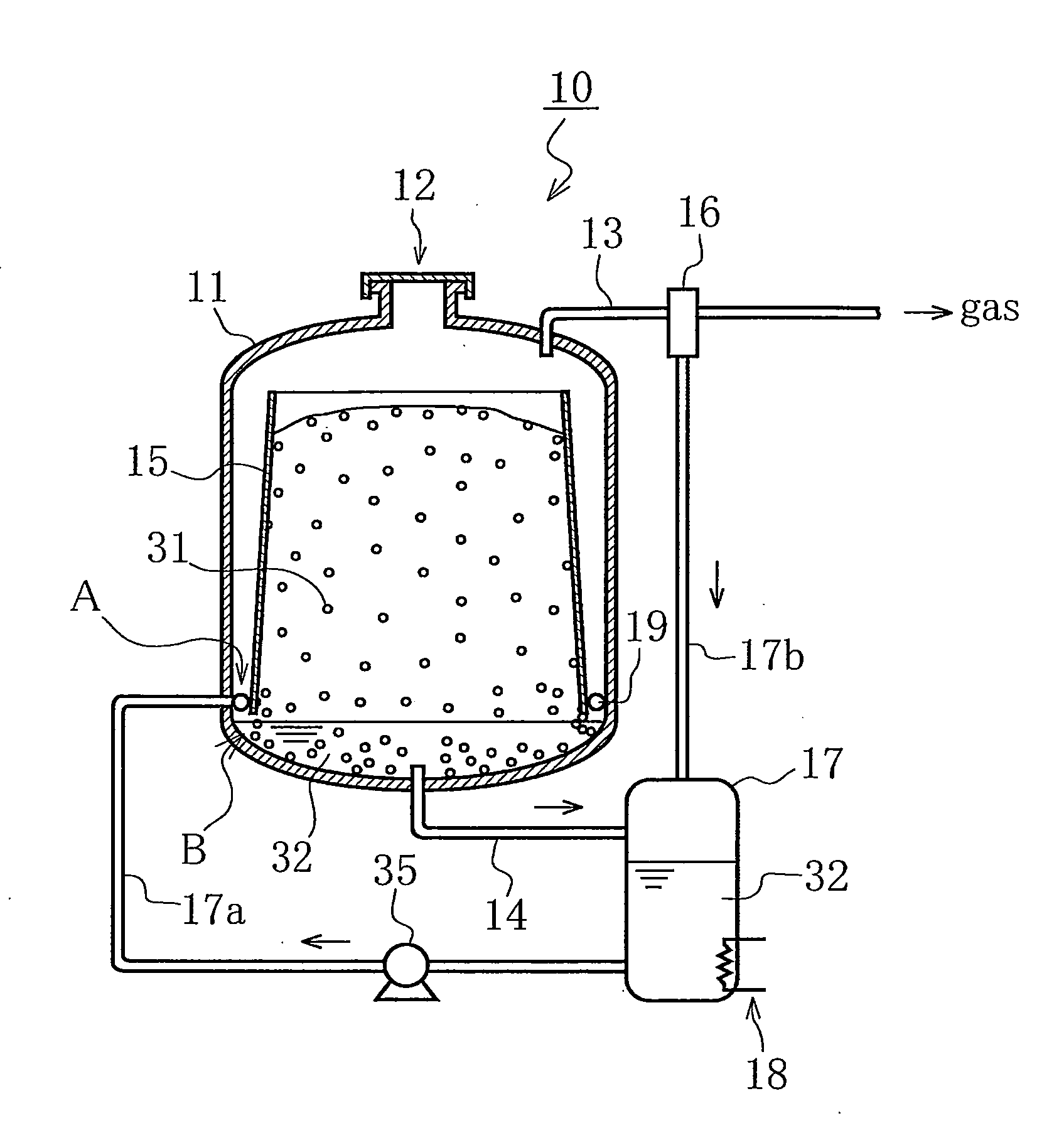

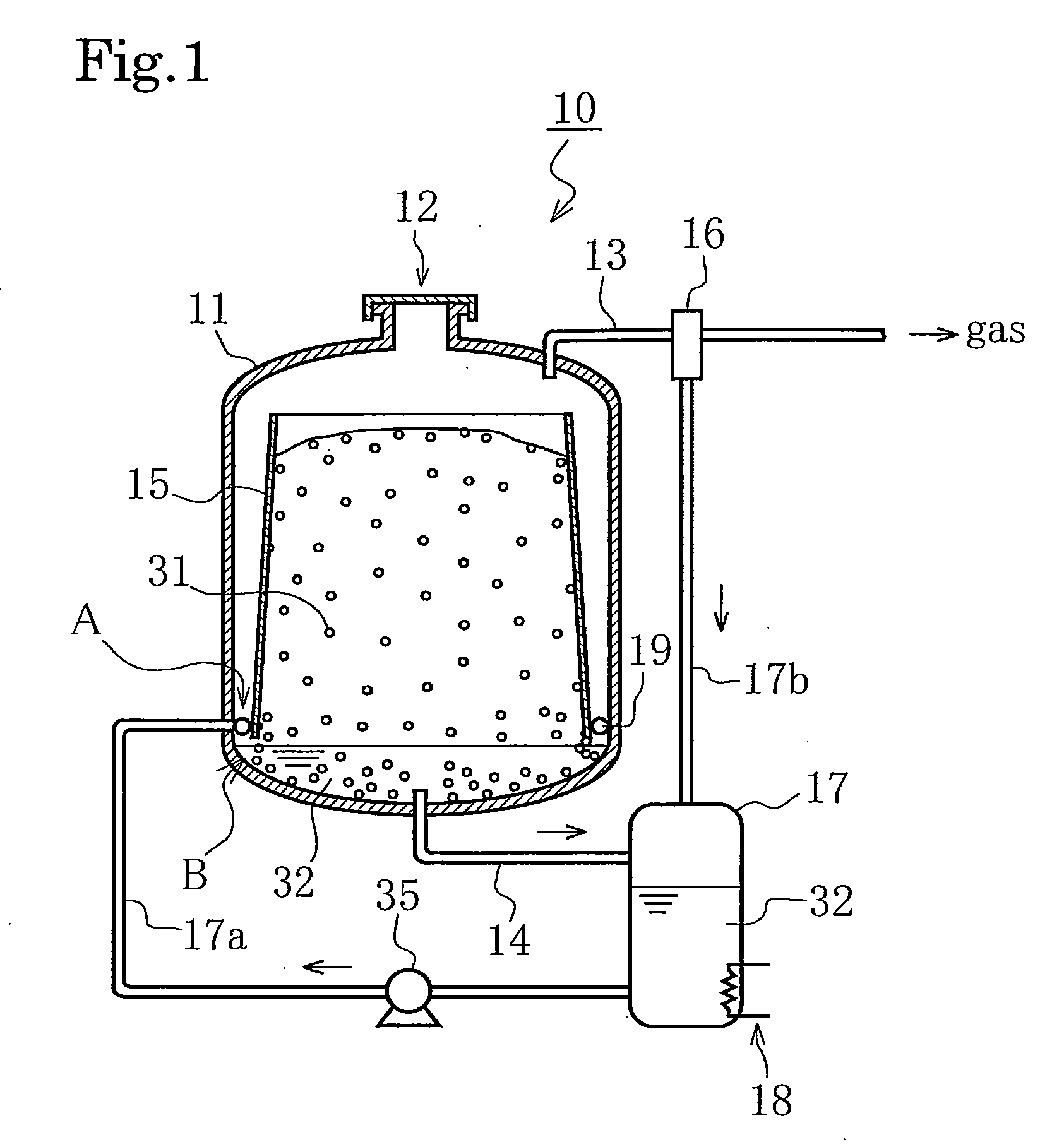

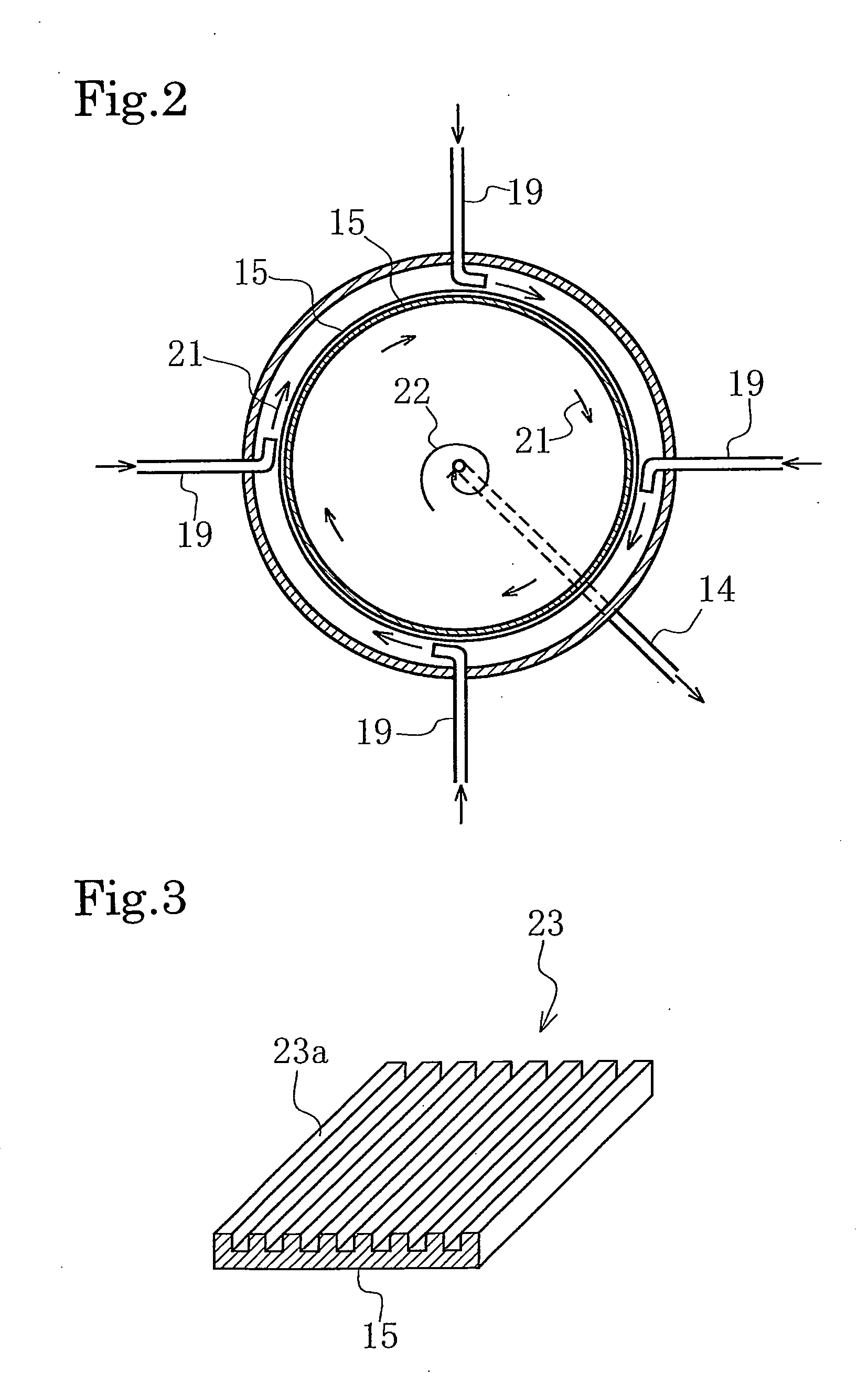

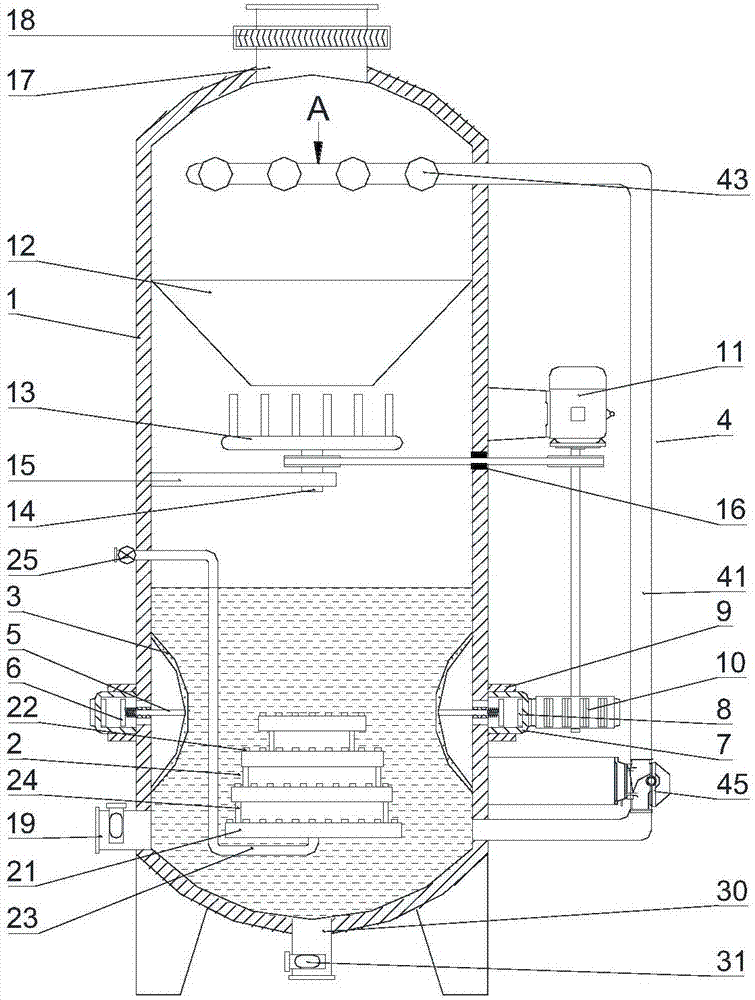

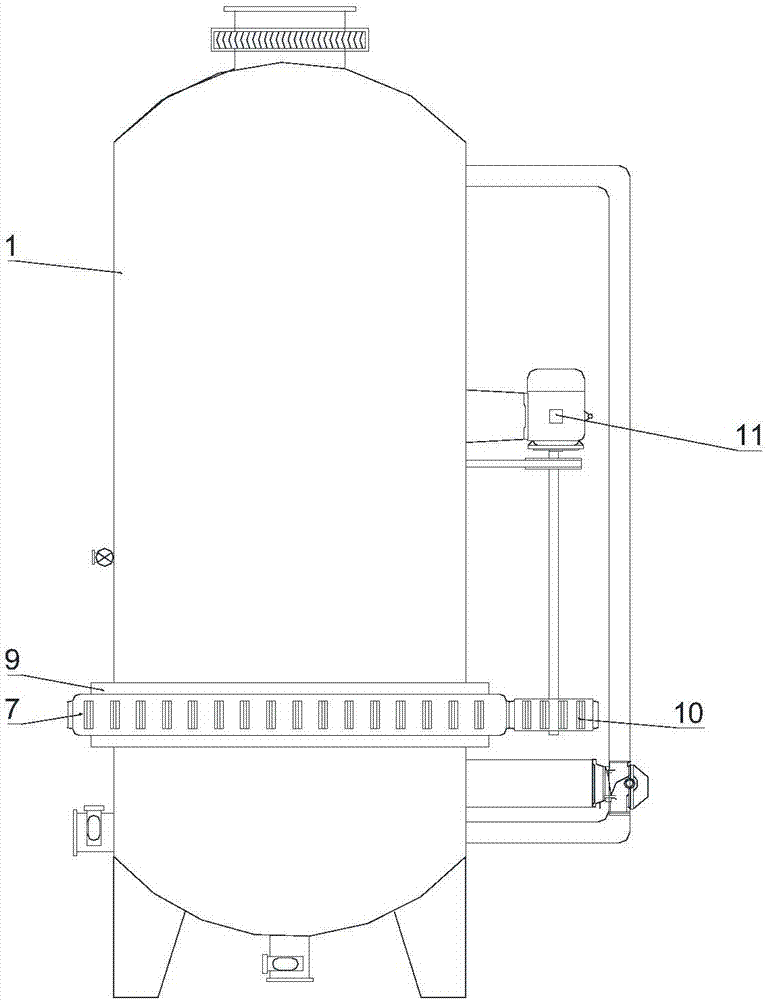

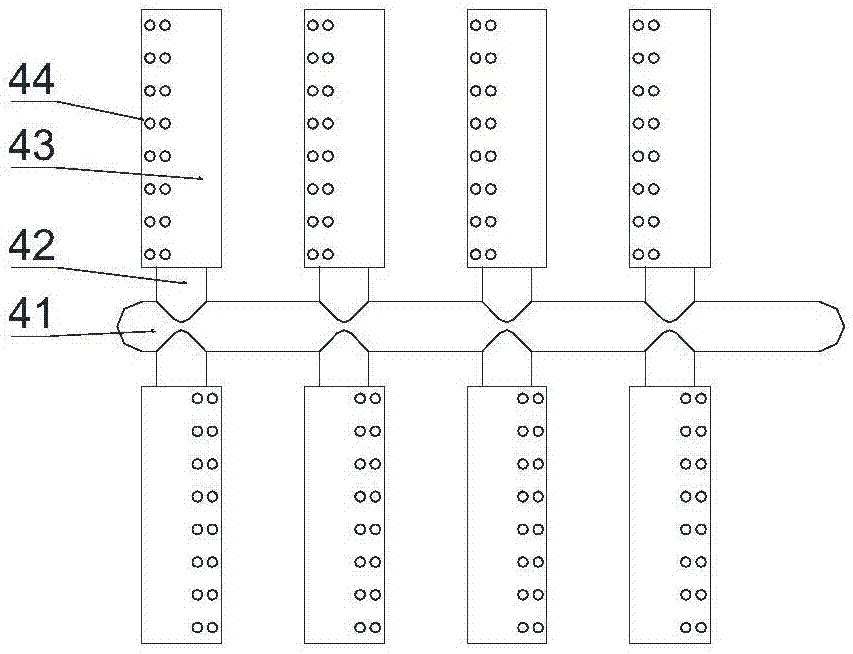

Gas-liquid contact apparatus

InactiveUS6503403B2Improve contact efficiencySmall bubbleUsing liquid separation agentMixing methodsDecompositionDissolution

An apparatus and method for enhancing dissolution of gases in liquids by ejecting the gas-liquid mixture through nozzles in a reaction vessel. The nozzles are pressurized, sized and directed to produce micro-fine gas bubbles in the liquid and to initiate rotational flow of the gas-liquid mixture in the reaction vessel. The small bubble size and rotational flow maximizes the time the gas is in contact with the liquid. The apparatus and method are used to increase the dissolution of ozone gas into aqueous solutions to increase the decomposition of aqueous-based organic compounds, precipitation of heavy metals, and destruct and / or deactivate enteric viruses, enteric bacteria, and protozoans. An alternative embodiment mixes the gas with the liquid prior to ejection through the nozzles.

Owner:SANITROL SYST

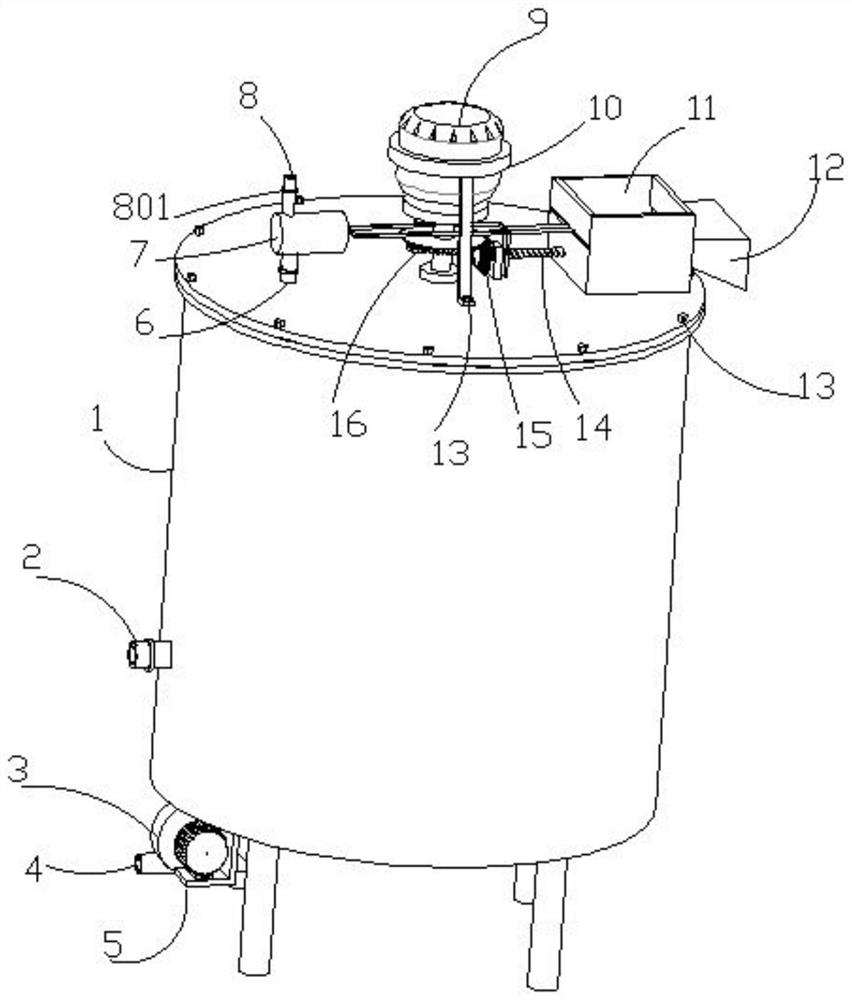

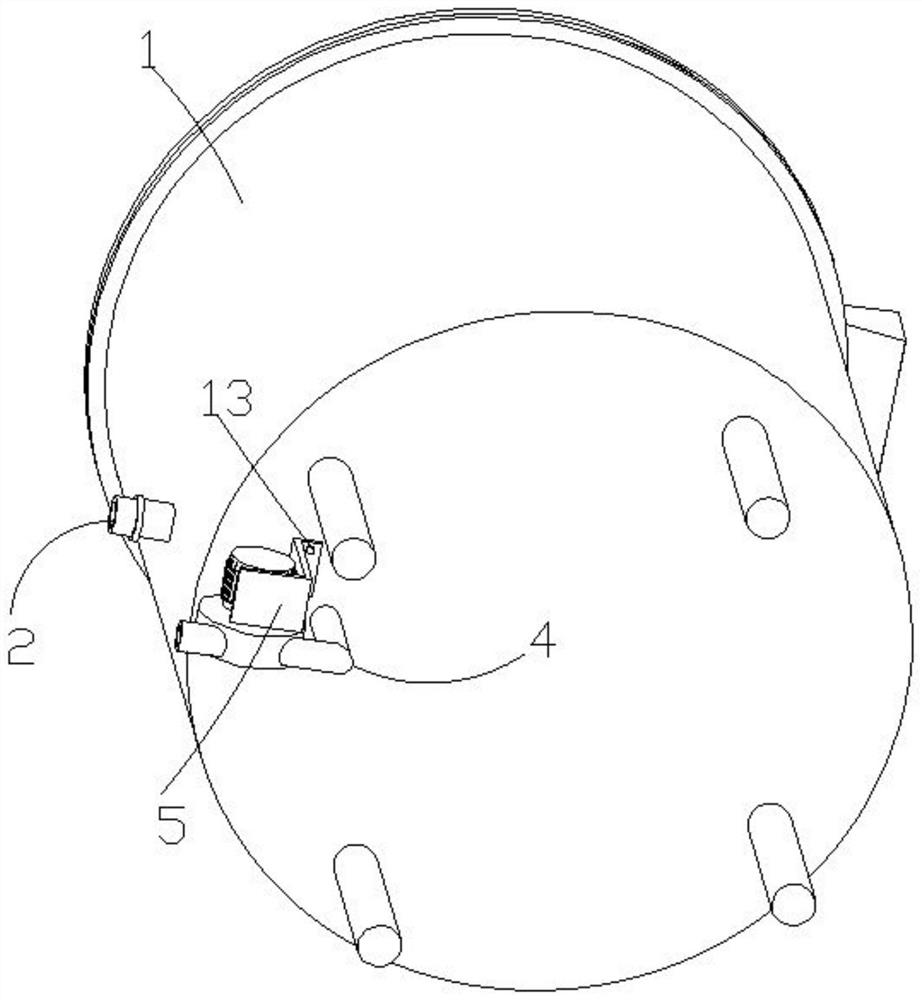

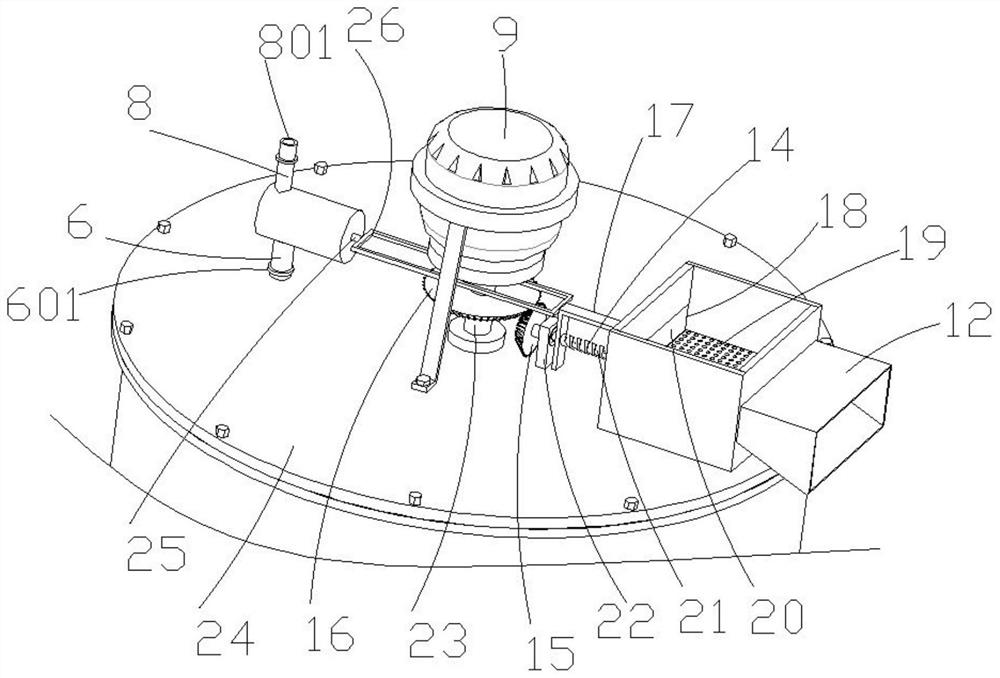

Environment-friendly sewage treatment device and sewage treatment method

InactiveCN111620471AIncrease the degree of mixingOpposite direction of rotationRotary stirring mixersTransportation and packagingSludgeElectric machine

The invention relates to an environment-friendly sewage treatment device and a sewage treatment method in the technical field of sewage treatment. The environment-friendly sewage treatment device comprises a box body, the box body is provided with a cover plate, the cover plate is provided with a mounting frame and a square water inlet cylinder, the water inlet cylinder is provided with a supporting plate, the supporting plate is provided with a filter plate, the mounting frame is provided with a rotating motor, the rotating motor is provided with an upper rotating shaft, the upper rotating shaft is provided with a second bevel gear, and the second bevel gear is provided with a cleaning structure; the cleaning structure is provided with a flocculant uniform spraying structure; the upper rotating shaft is provided with a third bevel gear, the third bevel gear is provided with a fourth bevel gear, the fourth bevel gear is provided with a cross rod, the cross rod is connected with the boxbody, the fourth bevel gear is provided with a fifth bevel gear, the fifth bevel gear is provided with a lower rotating shaft, the lower rotating shaft and the upper rotating shaft are provided withstirring frames, each stirring frame is provided with a straight scraper blade, the straight scraper blade at the lowest end is provided with a transverse scraper blade, the box body is provided witha water outlet pipe with a control valve, and the box body is provided with a sludge pipe, so that the sewage stirring directions in the box body are opposite, the sewage stirring mixing degree is improved, and rapid flocculation treatment is realized.

Owner:CRYSTAL WATER & BLUE SKY ENVIRONMENTAL ENG

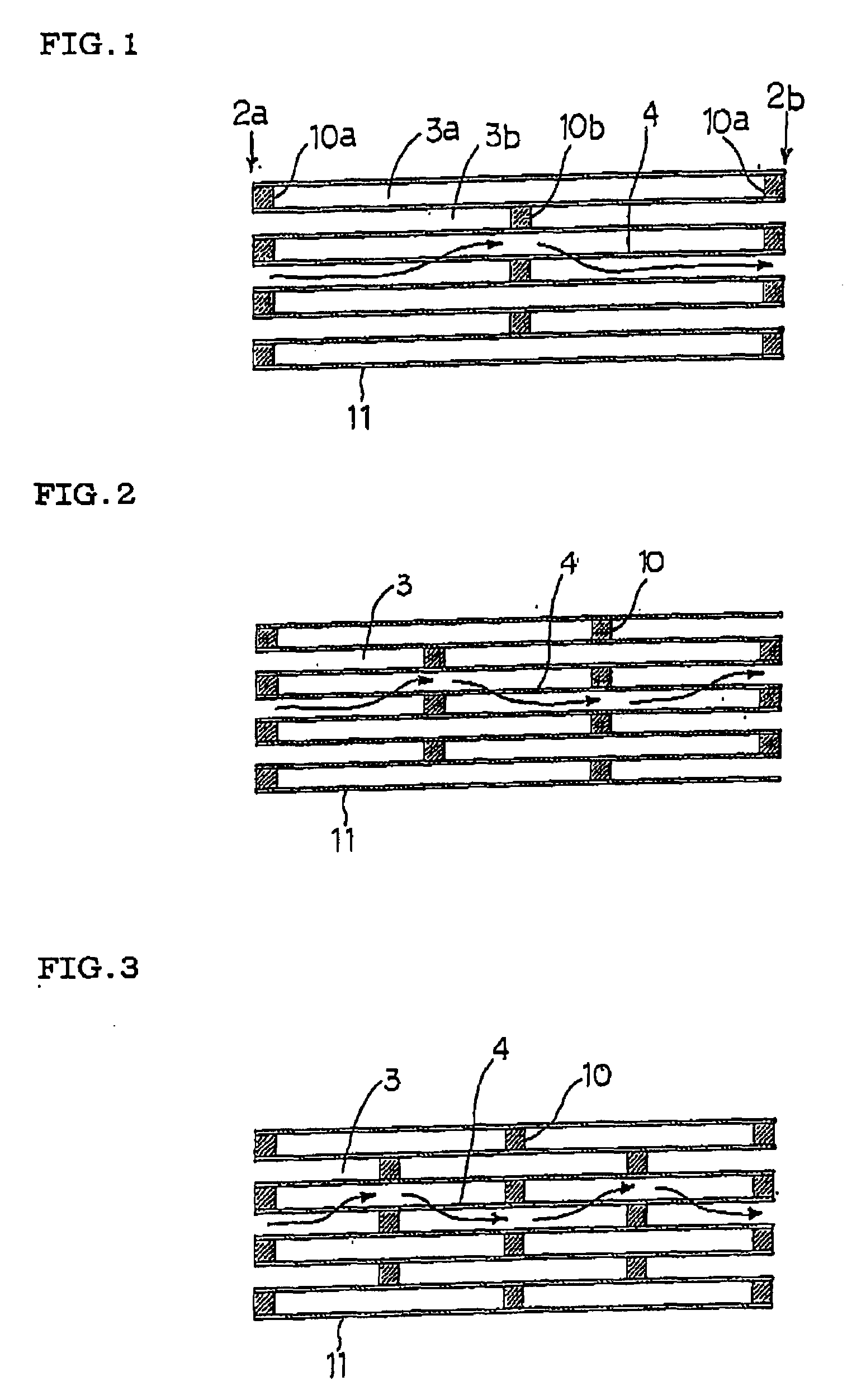

Honeycomb structure and honeycomb catalytic body

InactiveUS20070231539A1High contact efficiencyAmount of catalyst can be reducedInternal combustion piston enginesDispersed particle filtrationStructural engineeringHoneycomb like

There are disclosed a honeycomb catalytic body to which a wall flow structure is applied so that a fluid such as an exhaust gas passes through a partition wall twice or more, and a honeycomb structure for use as a catalyst carrier of the honeycomb catalytic body in which a pore characteristic and the like are appropriately adjusted as the catalytic body. In a honeycomb structure 11 including porous partition walls 4 arranged so as to form a plurality of cells 3 which communicate between two end surfaces of the honeycomb structure and having a large number of pores; and plugging portions 10 arranged so as to plug at least a part of the plurality of cells 3 at any position in a length direction of the cells, an average maximum image distance of the partition walls is larger than 40 μm, and the plugging portions 10 are arranged so that at least a part of a fluid which has entered the cells from one end surface passes through the partition wall 4 twice or more, and is then discharged from the other end portion.

Owner:NGK INSULATORS LTD

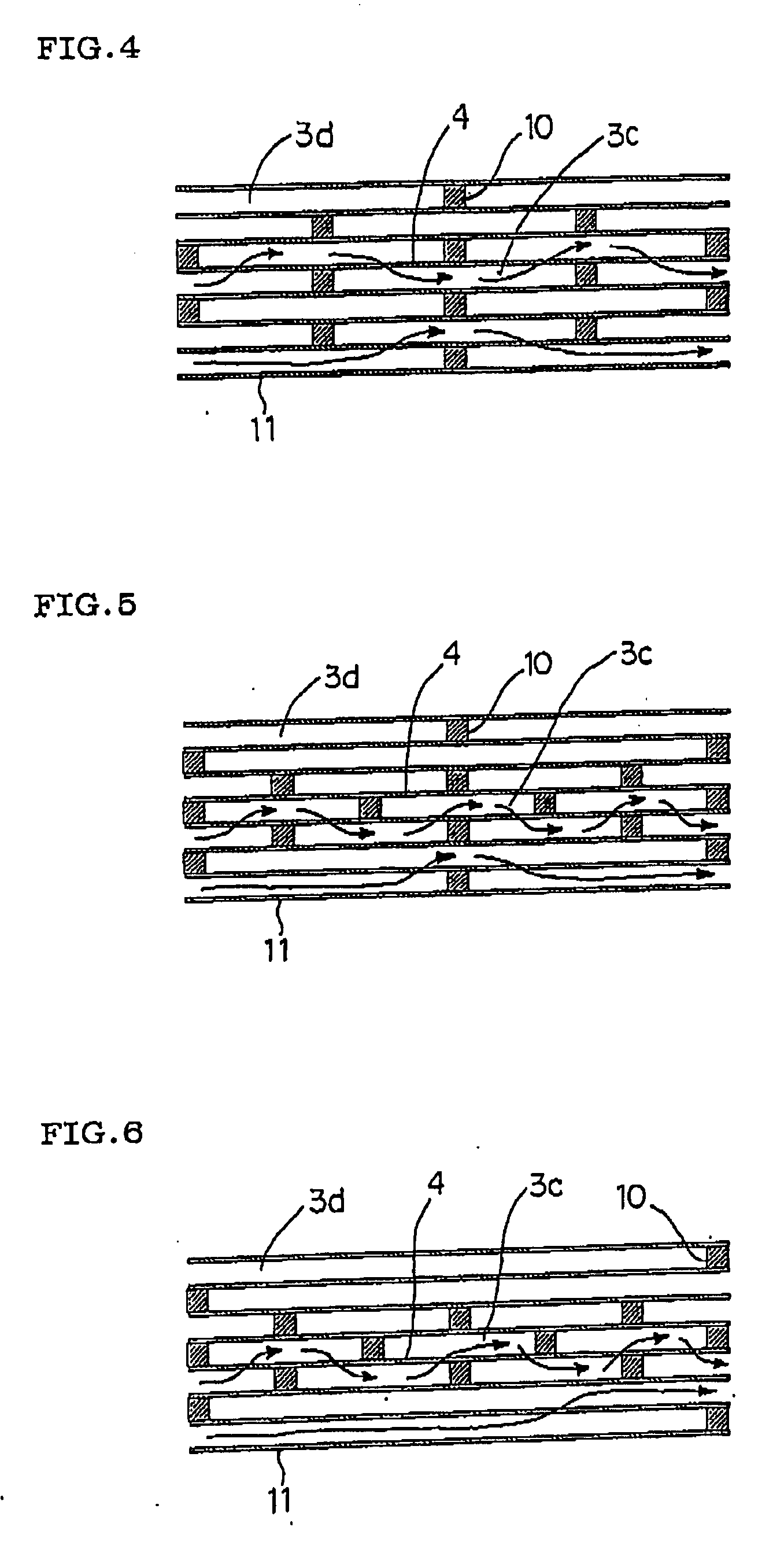

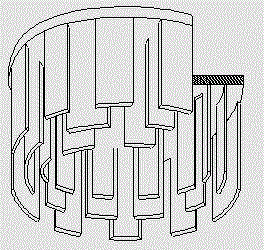

Sectional feeding type alkylation reactor and alkylation reaction method

ActiveCN104549087AEliminate concentration differencesImprove product qualityLiquid hydrocarbon mixtures productionMixersEmulsionSulfuric acid

The invention discloses a sectional feeding type alkylation reactor and an alkylation reaction method. The reactor comprises a reactor barrel body, a seal head, a separating plate, an upper bed layer, a lower bed layer, a feeding pipe, a fed material distributing pipe, a rotating shaft, a supplementing material inlet, a discharging opening, a circulating cooling air inlet and a circulating cooling air outlet. The invention further provides the alkylation reaction method adopting the sectional feeding type alkylation reactor. The alkylation reaction method comprises the following steps: preparing acid hydrocarbon emulsion through iso-butane and concentrated sulfuric acid in the upper bed layer, and then entering a rotating bed at the lower bed layer together with mixed hydrocarbon which enters through a supplemented material inlet, so as to perform alkylation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Storage-reduction type NOx purifying catalyst

InactiveUS20030216254A1Improve contact efficiencyExhaust gas purifying performanceGas treatmentExhaust apparatusCeriumCe element

A storage-reduction type NOx purifying catalyst is disclosed, comprising a monolith substrate having formed thereon a coat layer containing a cerium-zirconium composite oxide and a cerium-free oxide, a noble metal and an NOx storing material being supported on the coat layer and the cerium content of the cerium-zirconium composite oxide being less than 30 mol % based on the total molar number of metal atoms contained.

Owner:TOYOTA JIDOSHA KK

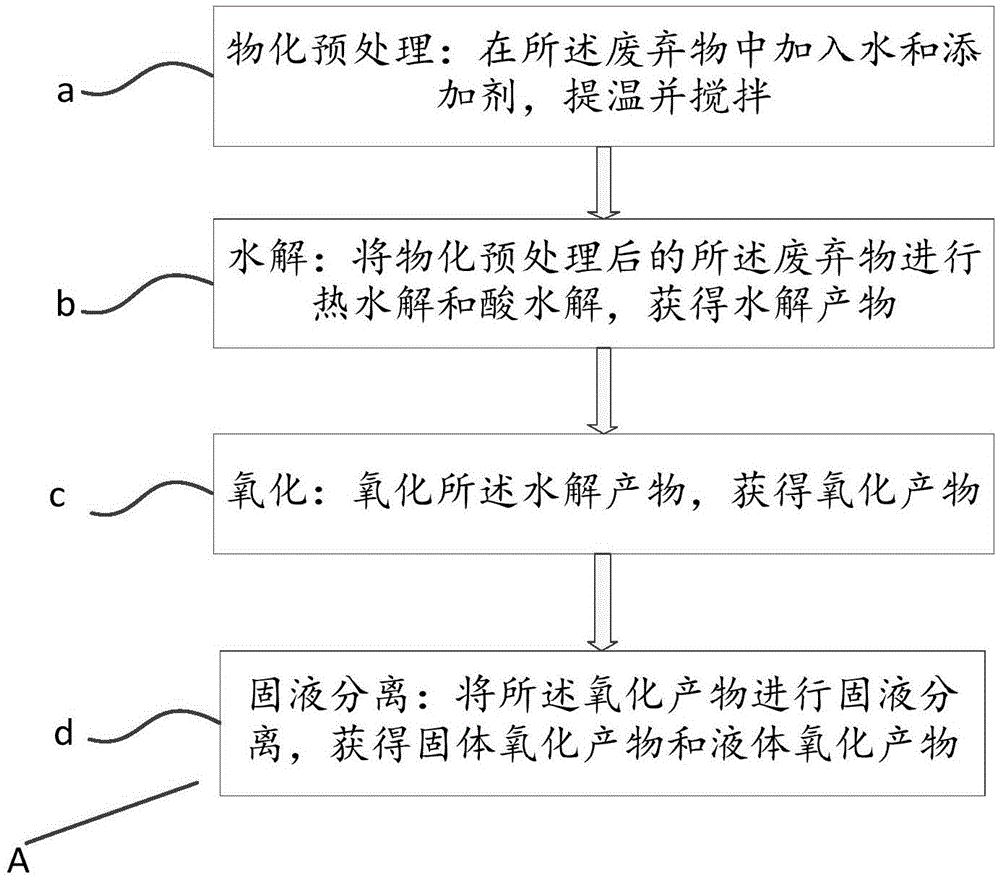

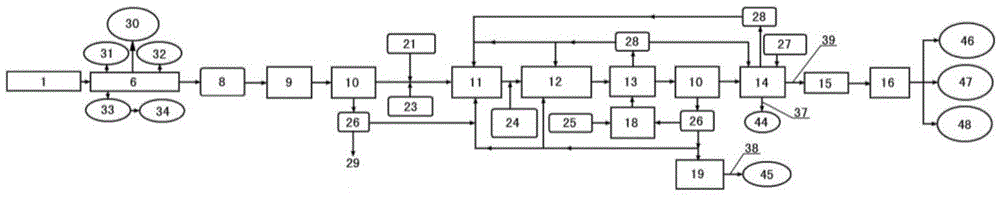

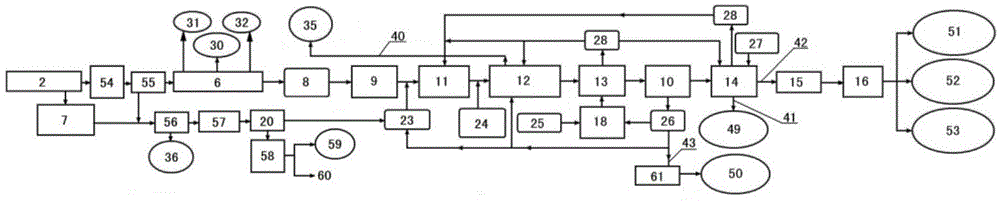

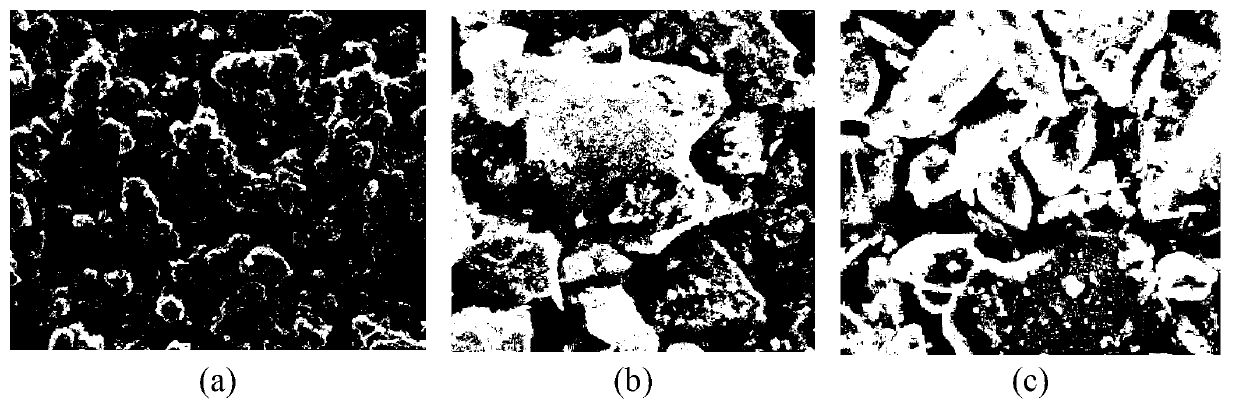

Method and device for treating organic solid waste

ActiveCN104148357AAvoid unfit problemsImprove efficiencySolid waste disposalAcid hydrolysisCompound (substance)

The invention discloses a method and device for treating organic solid waste. The method comprises the steps: (a) carrying out physico-chemical pretreatment, namely adding water and additives into the waste, and heating and stirring; (b) carrying out hydrolysis, namely carrying out thermal hydrolysis and acid hydrolysis on the waste which is subjected to physico-chemical pretreatment, so as to obtain a hydrolyzate; (c) carrying out oxidization, namely oxidizing the hydrolyzate, so as to obtain an oxidization product; and (d) carrying out solid-liquid separation namely carrying out solid-liquid separation on the oxidization product, so as to obtain a solid oxidization product and a liquid oxidization product.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

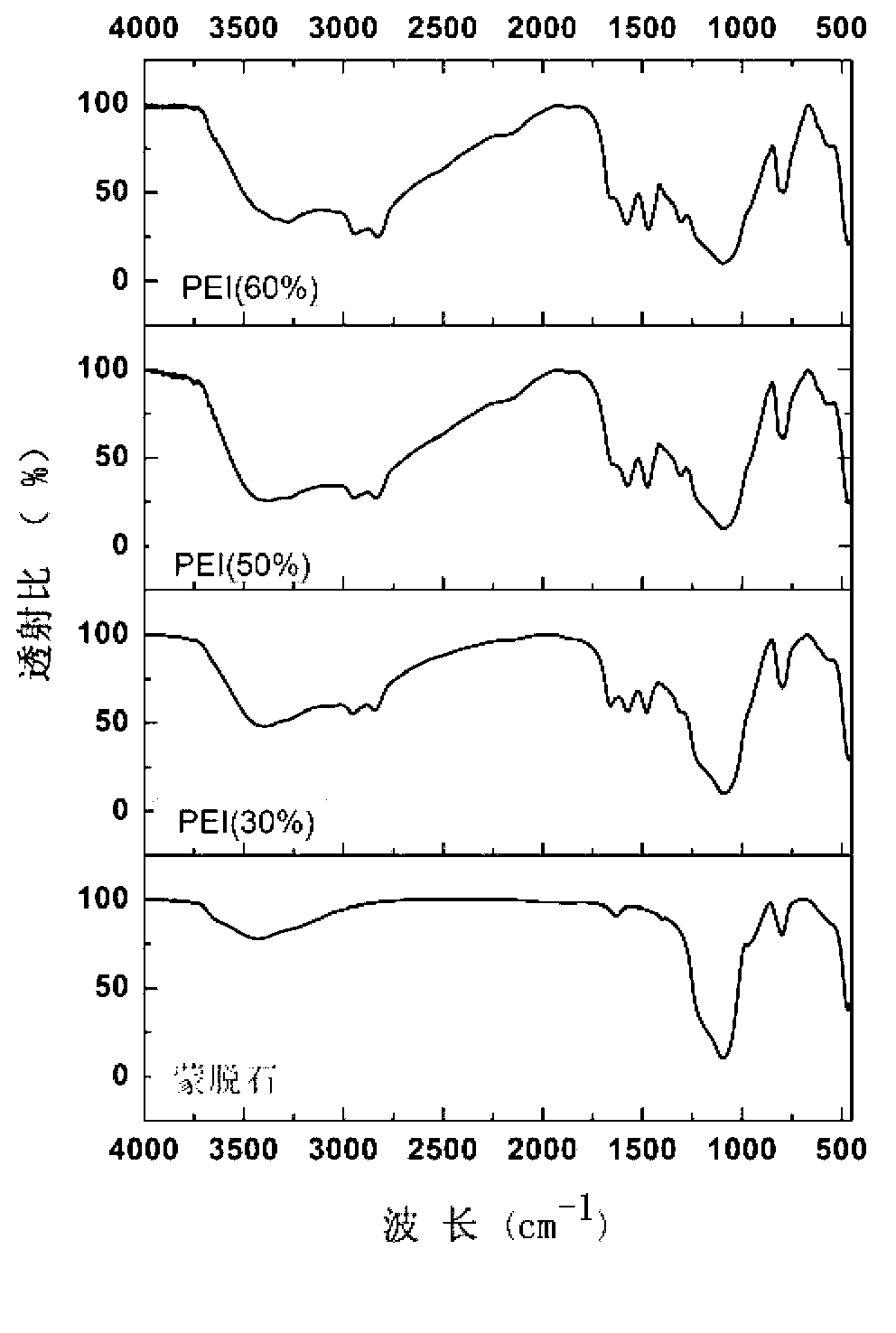

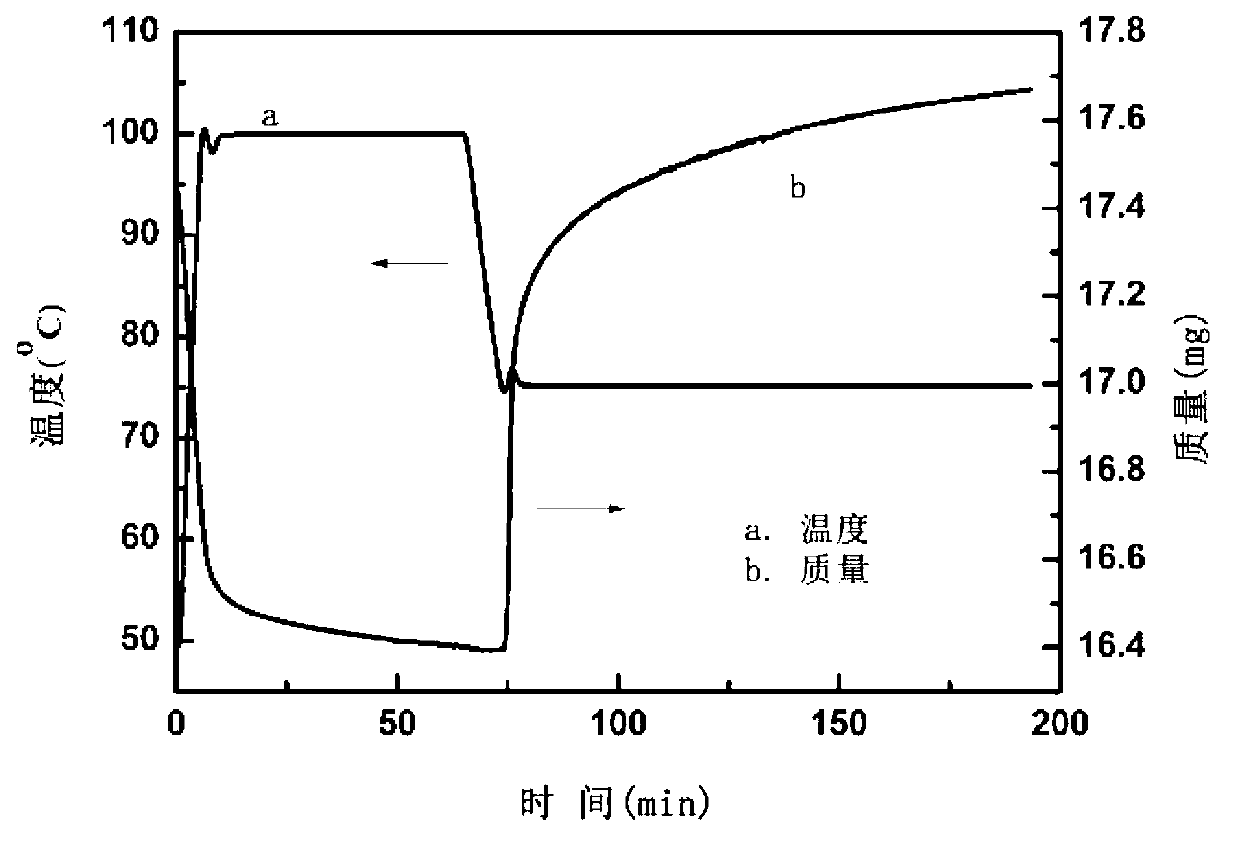

Cage type carbon dioxide adsorption material as well as preparation method and application thereof

InactiveCN103120931ALow priceEffectively fixedOther chemical processesDispersed particle separationMolecular sieveFlue gas

The invention discloses a cage type carbon dioxide adsorption material as well as a preparation method and an application thereof. The preparation method comprises acidation modification of montmorillonite and synthesis of the cage type carbon dioxide adsorption material. In a preparation process of the cage type adsorption material, an impregnation method is adopted, organic matter is directly covered on the inner surface of a mesoporous molecular sieve, the preparation method is simpler in process and low in energy consumption, desorption and regeneration are easy, and energy consumption and cost in an industrial application process can be greatly reduced. Effective loading capacity of organic amine in the composite material is 10-60%, the composite material has good adsorption and desorption capabilities and good stability, as acidified montmorillonite is adopted as a base material, cost is greatly reduced compared with other molecular sieve porous materials, and the requirement of an industrial process, especially removal of carbon dioxide gas in flue gas, to adsorbent material can be met.

Owner:SUN YAT SEN UNIV +1

Alkylation reactor and alkylation reaction method

ActiveCN104667856ASmall scaleFast scaleLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPtru catalystEmulsion

The invention discloses a sectional feeding alkylation reactor and an alkylation reaction method. The reactor comprises a reactor barrel, seal heads, a partition plate, an upper bed layer, a lower bed layer, a feeding pipe, a feeding distributing pipe, a rotary shaft, a supplementing material inlet, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas refrigerating system and a circulating cool gas outlet. The invention further provides the alkylation reaction method. The method comprises the following steps: as the sectional feeding alkylation reactor is adopted, firstly forming an acidic hydrocarbon emulsion in the upper bed layer from iso-butane and concentrated sulfuric acid; and then carrying alkylation reaction on the acidic hydrocarbon emulsion and mixed hydrocarbon entering from the supplementing material inlet in a lower bed layer rotary bed. According to the alkylation method disclosed by the invention, by taking the concentrated sulfuric acid as a catalyst and the iso-butane and olefin as raw materials, the alkylation reaction is carried out. The alkylation reaction disclosed by the invention can be carried out at a low temperature, so that the reactor is low in acid consumption and small in equipment scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

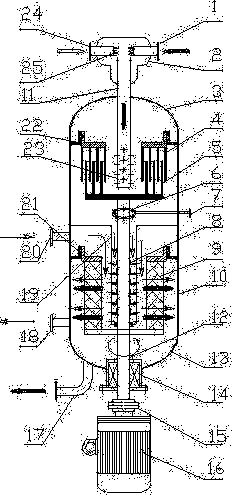

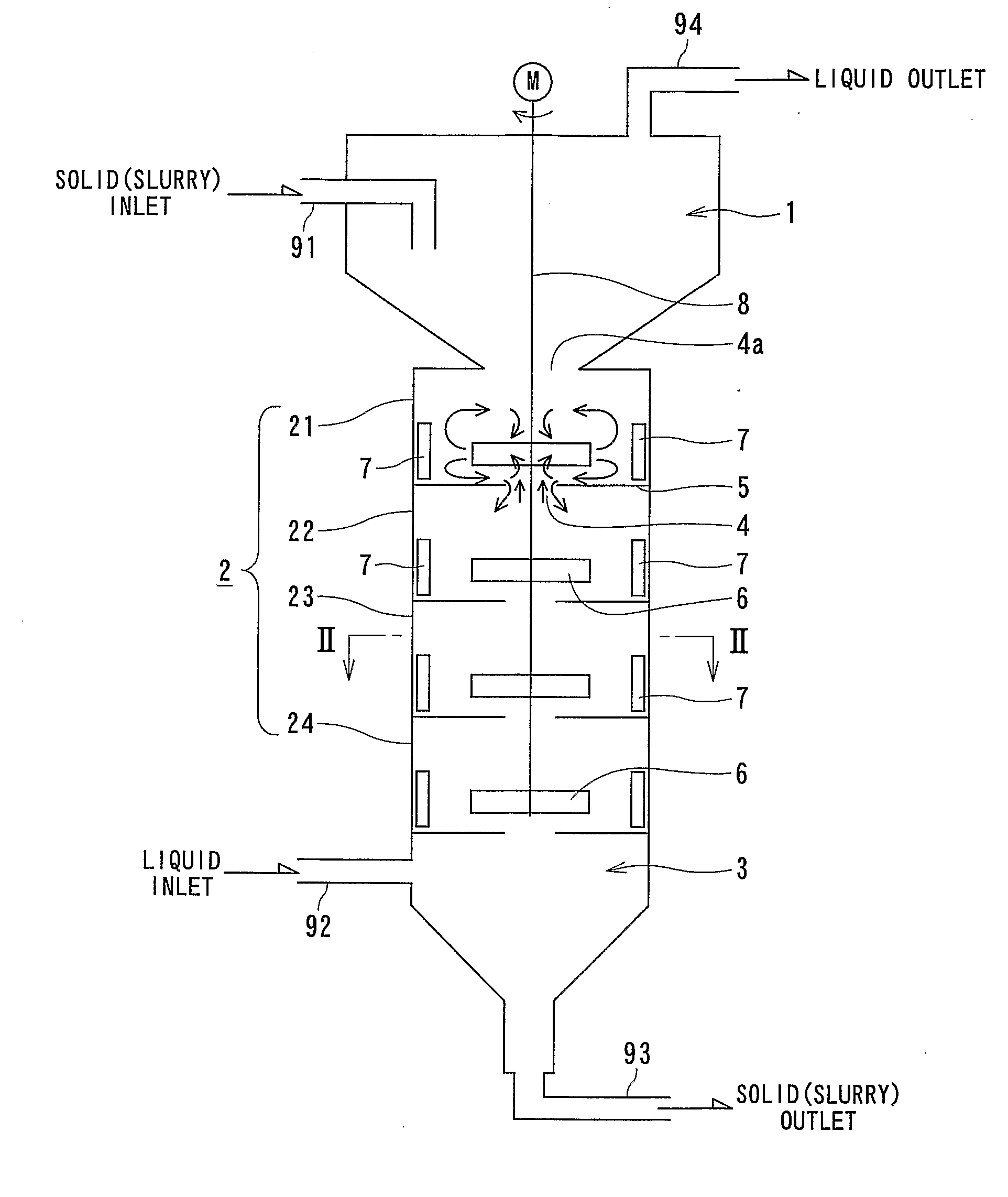

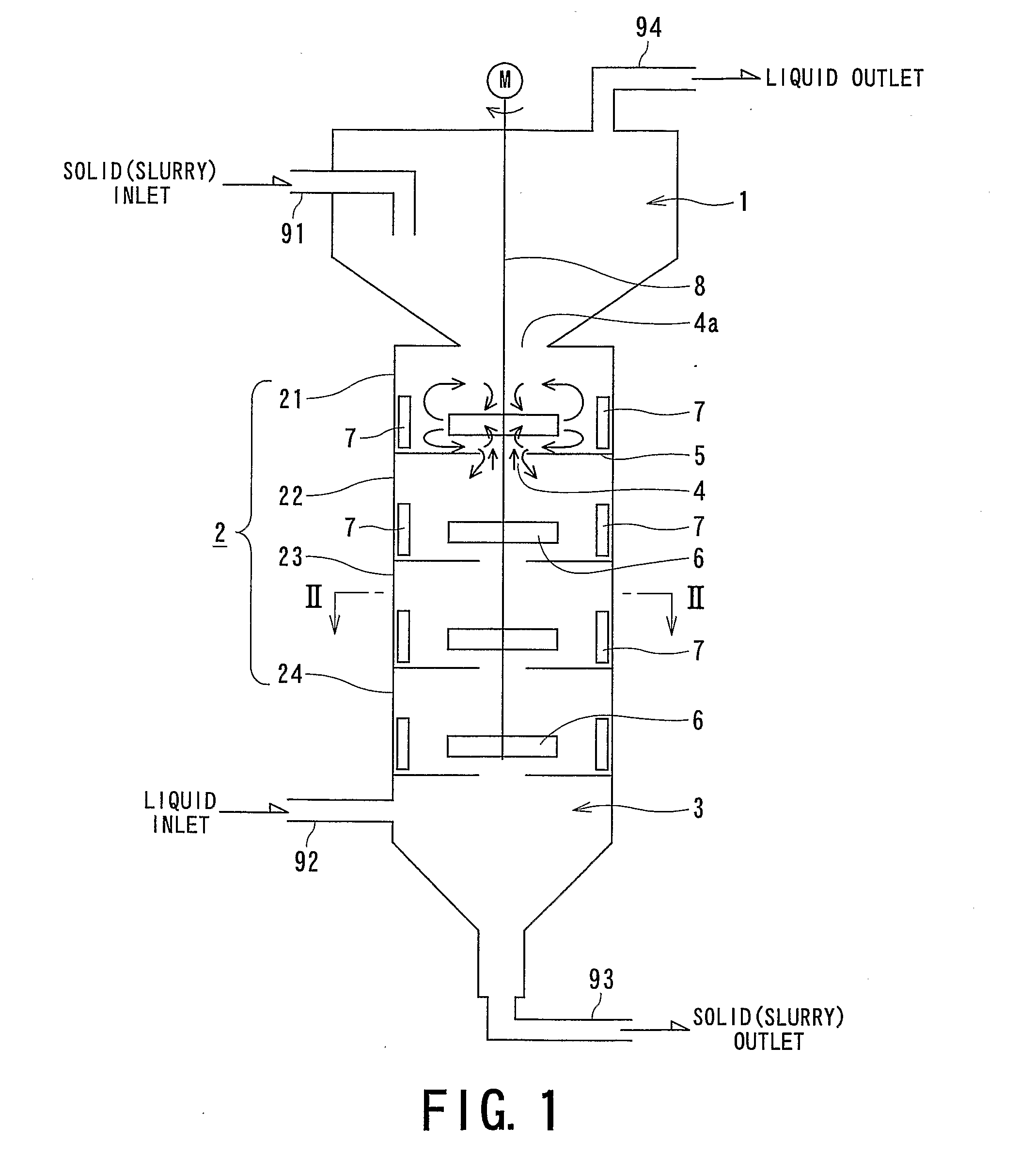

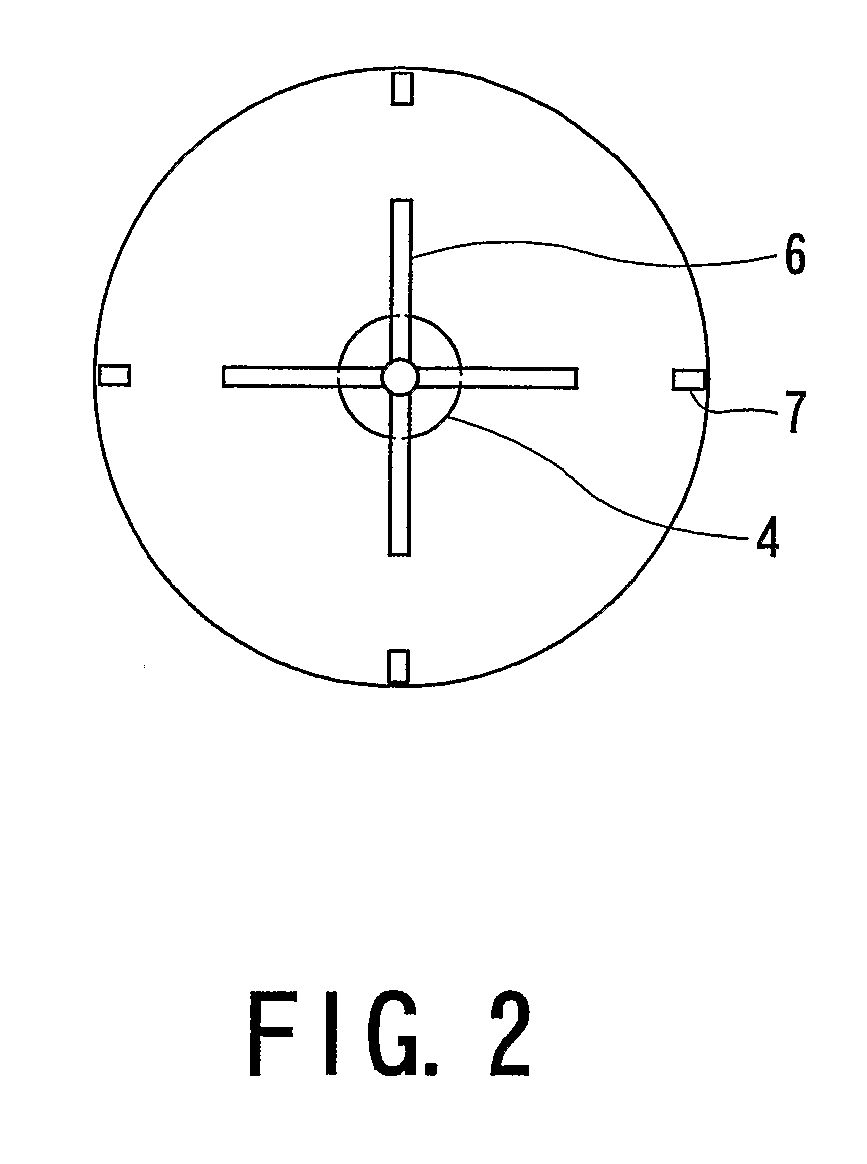

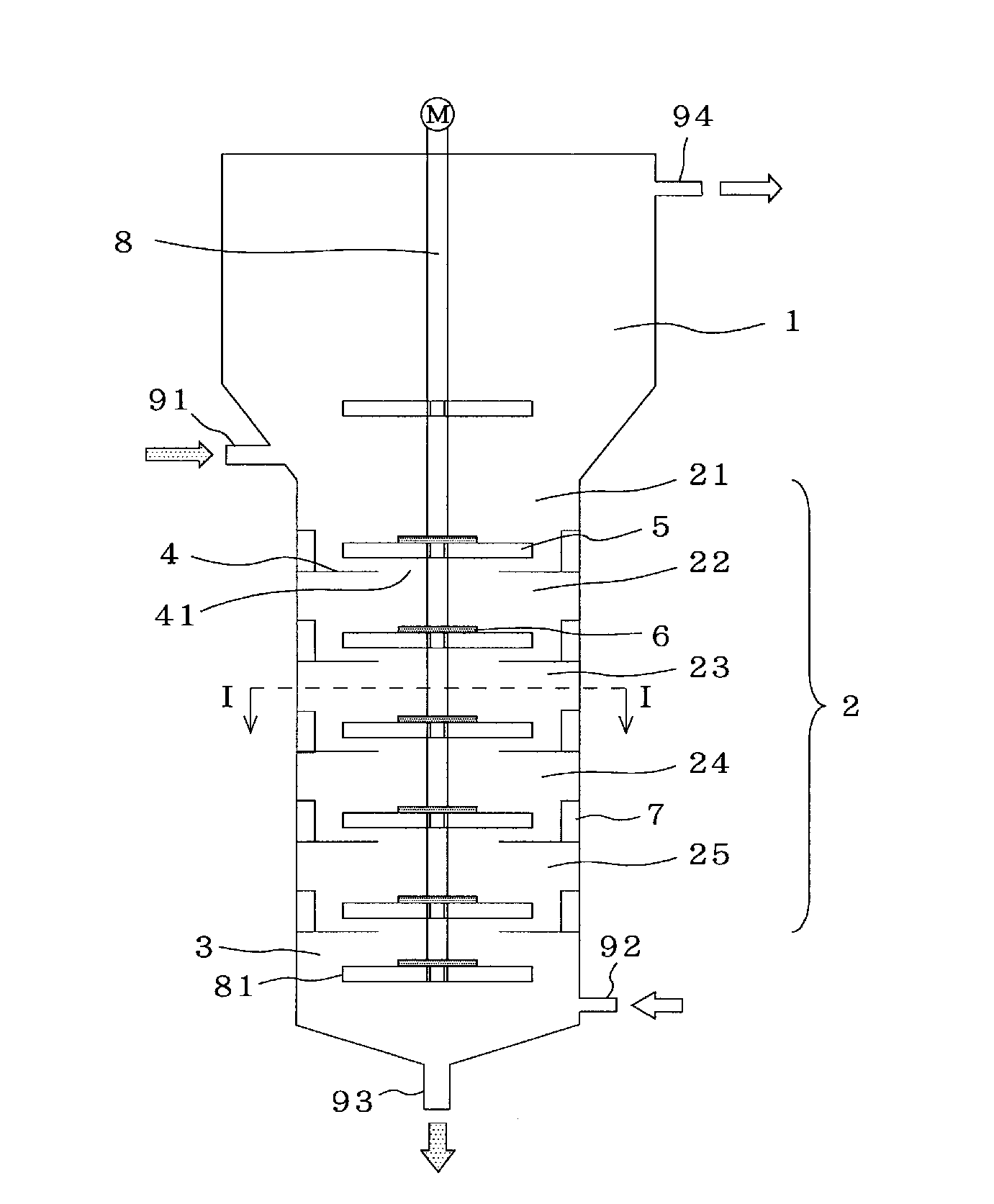

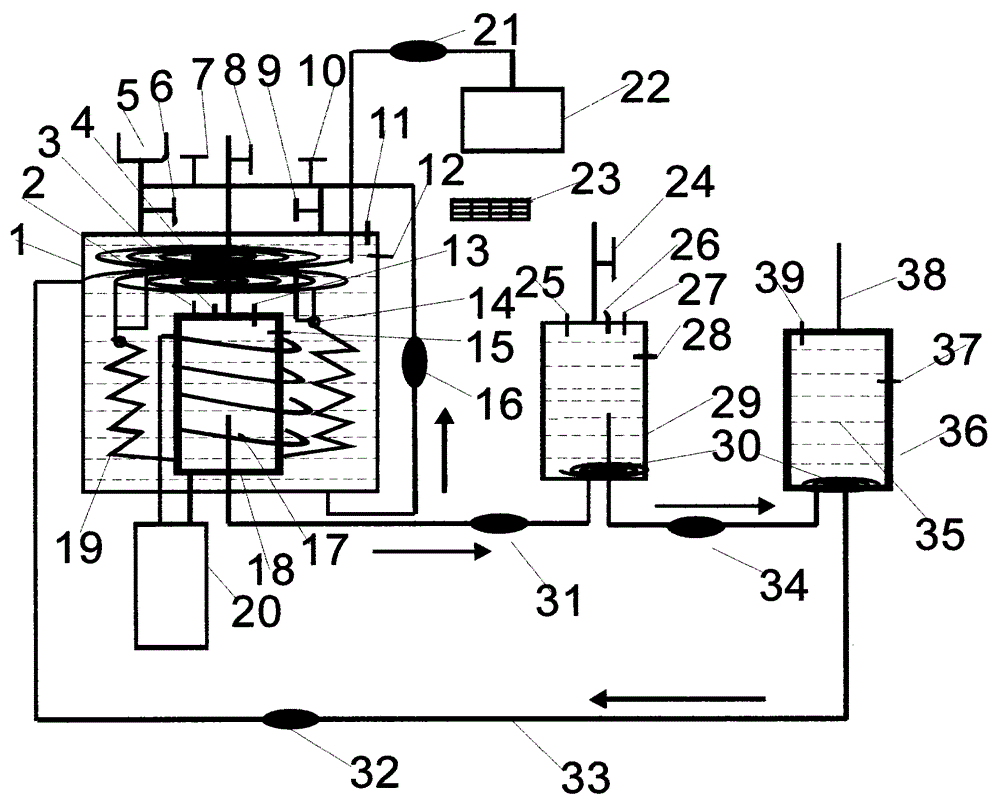

Apparatus and Method for Solid-Liquid Contact

ActiveUS20080025143A1Improve efficiencyImprove uniformityRotary stirring mixersTransportation and packagingChemical industryUnit operation

A vertical solid-liquid contact apparatus, comprising: a plurality of stirring chambers disposed vertically adjacent to each other in series, a plurality of partitioning plates each partitioning an adjacent pair of the stirring chambers and provided with a communicating hole for communication between the adjacent pair of the stirring chambers, and a liquid inlet and a solid inlet provided at an upper part and a lower part of the apparatus. Each stirring chamber has an inner side wall defining the stirring chamber, a radially ejecting stirring blade, and at least one baffle fixed on the inner side wall so as to extend vertically. The stirring blade and the baffle are positionally biased to a lower side of the stirring chamber. The apparatus exhibits a good uniformity of solid-liquid flows and a high contact efficiency, is also simple in structure and allows easy scale-up. The apparatus can be widely applied to unit operations in the chemical industry. The apparatus exhibits a particularly good solid-liquid contact efficiency when operated in the neighborhood of its maximum load.

Owner:KUREHA KAGAKU KOGYO KK

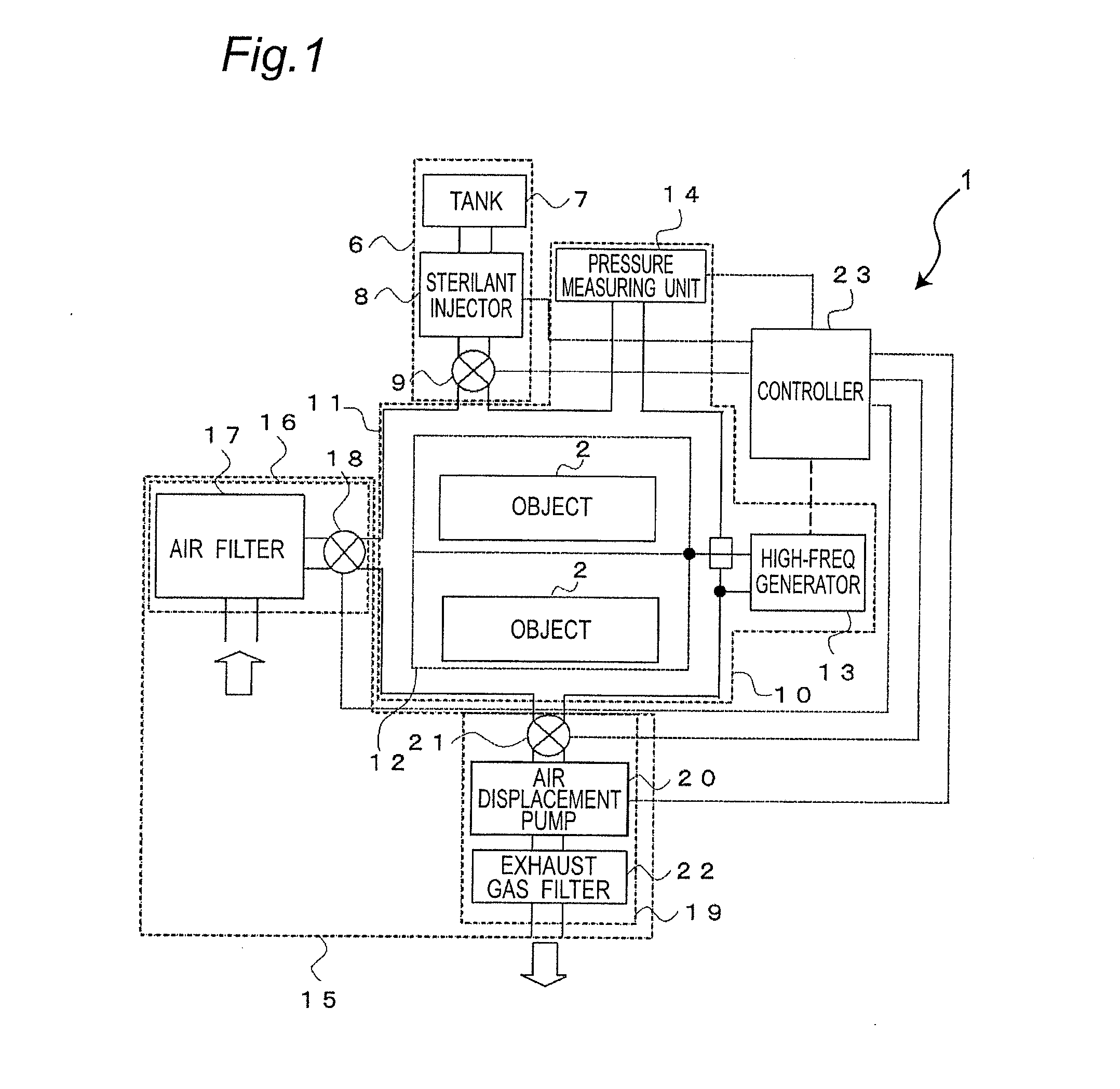

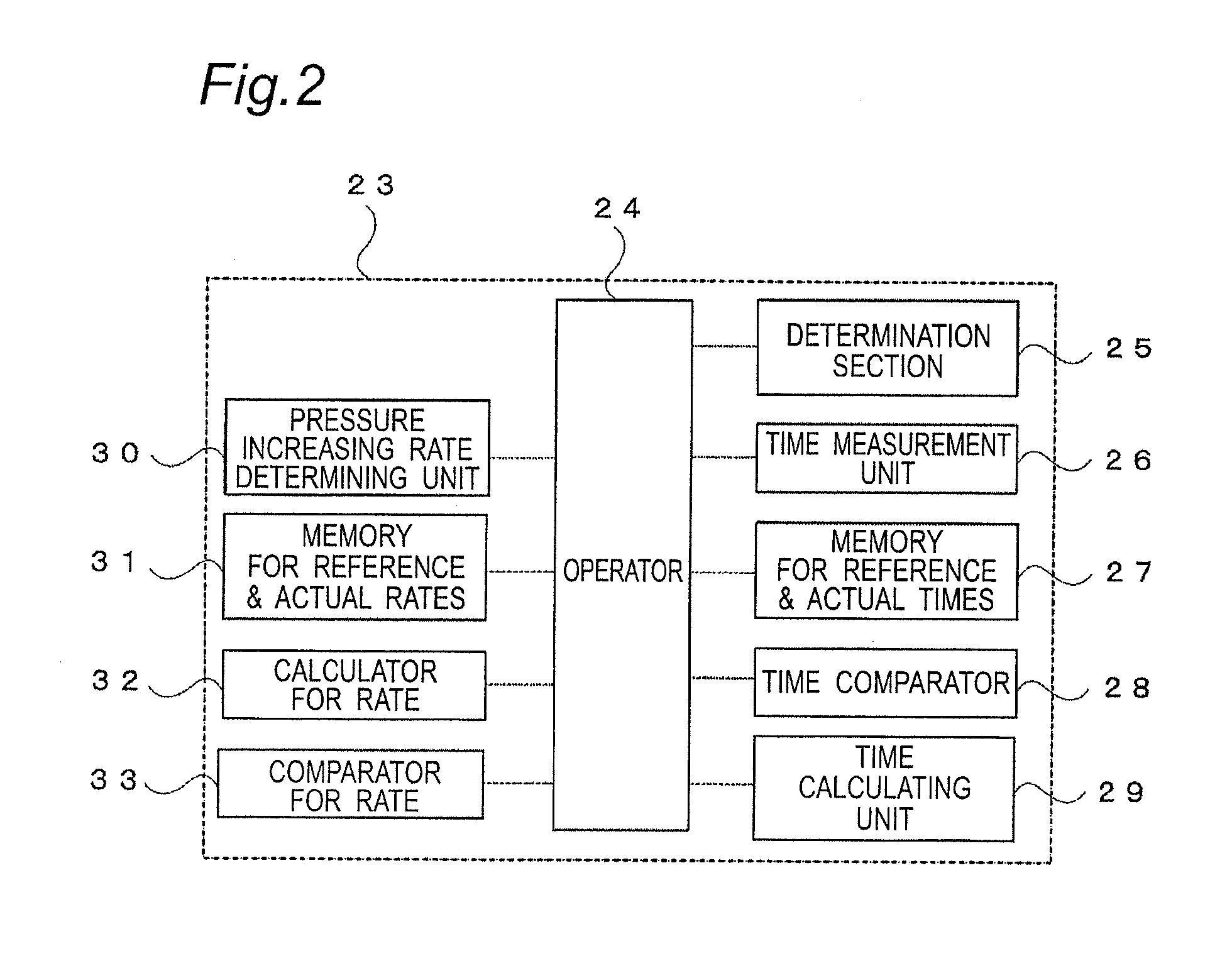

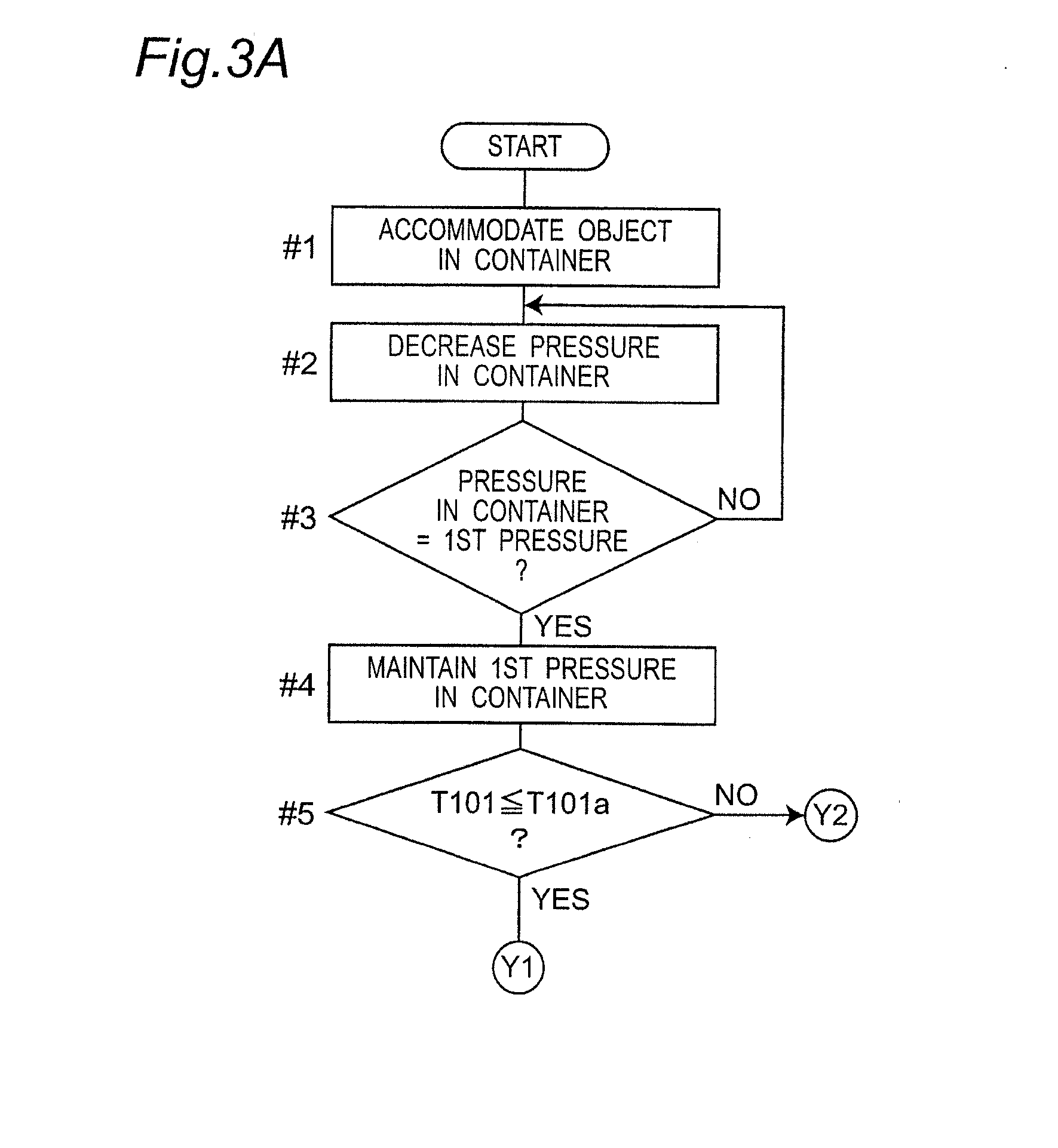

Sterilization method and device

ActiveUS20150313250A1Improve contact efficiencyFully dryExhaust apparatusElement comparisonPressure decreaseProcess engineering

According to the present invention, a sterilant can be injected into a container without residual water on an object to be sterilized. The method includes decreasing a pressure in the container to a pressure higher than the triple point pressure at which water freezes. The method further includes comparing an actual time required for decreasing the pressure and a reference time, or comparing an actual rate of pressure increase and a reference rate to detect residual water on the object. If the residual water is detected, the pressure in the container is increased to the atmospheric pressure or the quasi-atmospheric pressure and the object is heated, and then the pressure is decreased to drain the residual water through the decompression boiling. The step of draining the residual water is repeatedly performed until no residual water is detected on the object and subsequently the sterilant is injected into the container.

Owner:SARAYA CO LTD

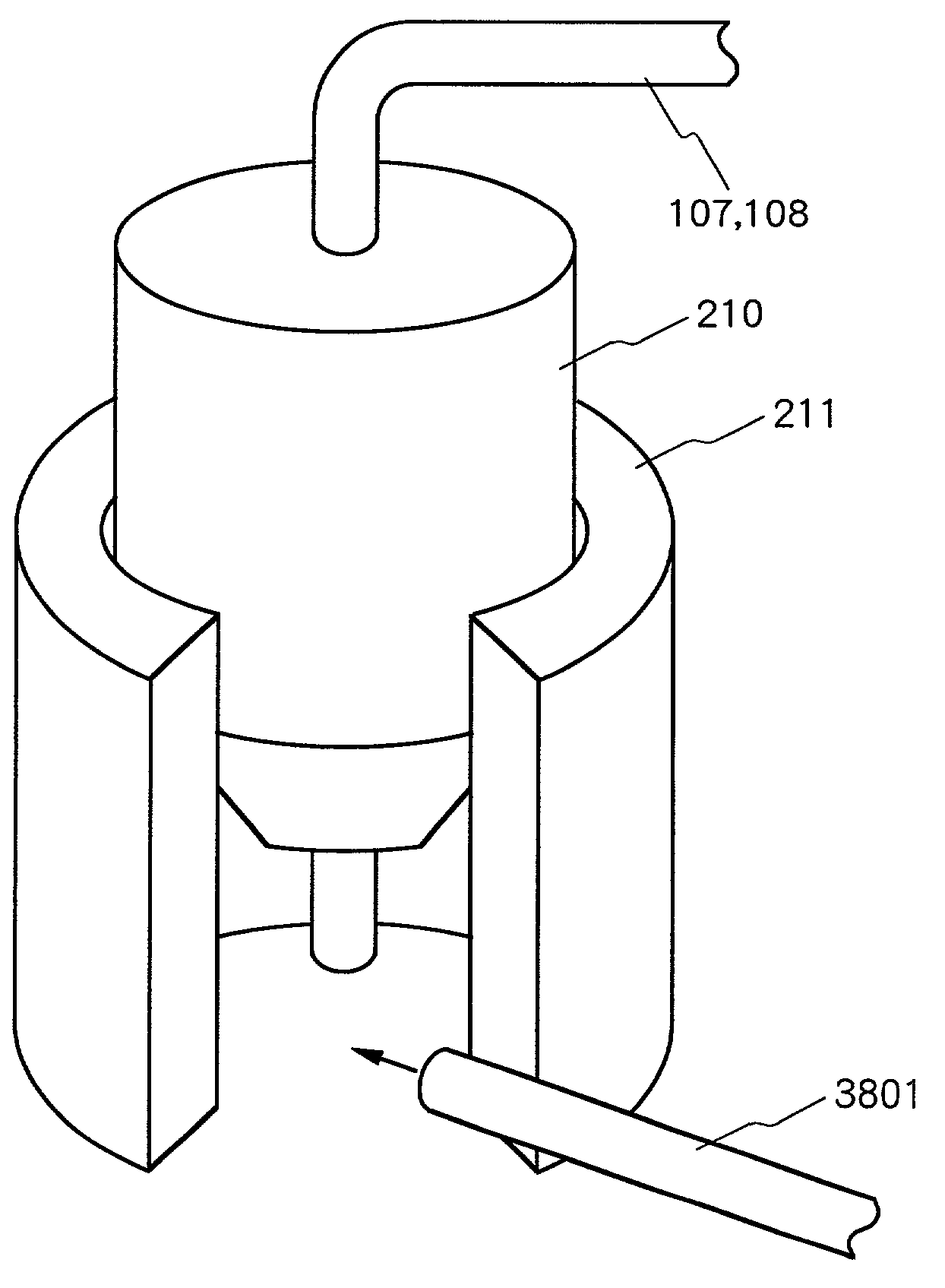

Apparatus and method for gasifying gas hydrate pellet

InactiveUS20100325955A1Eliminates formation of bridgeTransmission very difficultHydrogenOrganic chemistryCompression moldingHydration reaction

A gasification apparatus is provided which enables gas hydrate pellets to be transported and gasified in the same vessel and enables a gas to be generated by pellet decomposition in a controlled amount. The apparatus is free from bridging. The apparatus includes a heat-in-saluted vessel main body and, disposed therein, a tubular structure which is open at the top and bottom. This tubular structure holds therein gas hydrate pellets obtained by compression-molding a gas hydrate produced by the hydration reaction of a raw-material gas with raw-material water. The tubular structure becomes wider in diameter from the upper opening toward the lower opening. A channel for passing a heat carrier therethrough has been disposed between the lower end of the tubular structure and the inner bottom surface of the vessel main body. The apparatus is further equipped, between the tubular structure and the inner wall surface of the vessel main body, with a nozzle which ejects the heat carrier in a circumferential direction for the vessel main body. The vessel main body has a discharge pipe for discharging the heat carrier ejected from the nozzle, the discharge pipe projecting upright from the inner bottom surface of the vessel main body.

Owner:MITSUI ENG & SHIPBUILD CO LTD +1

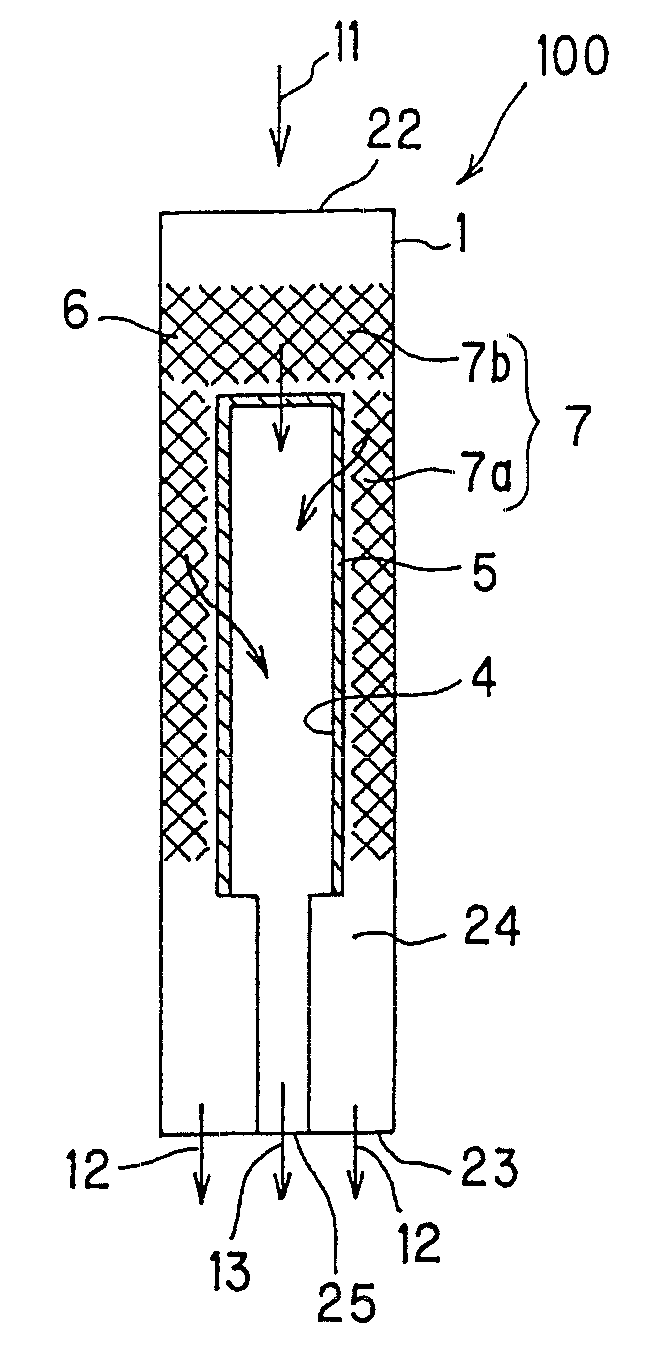

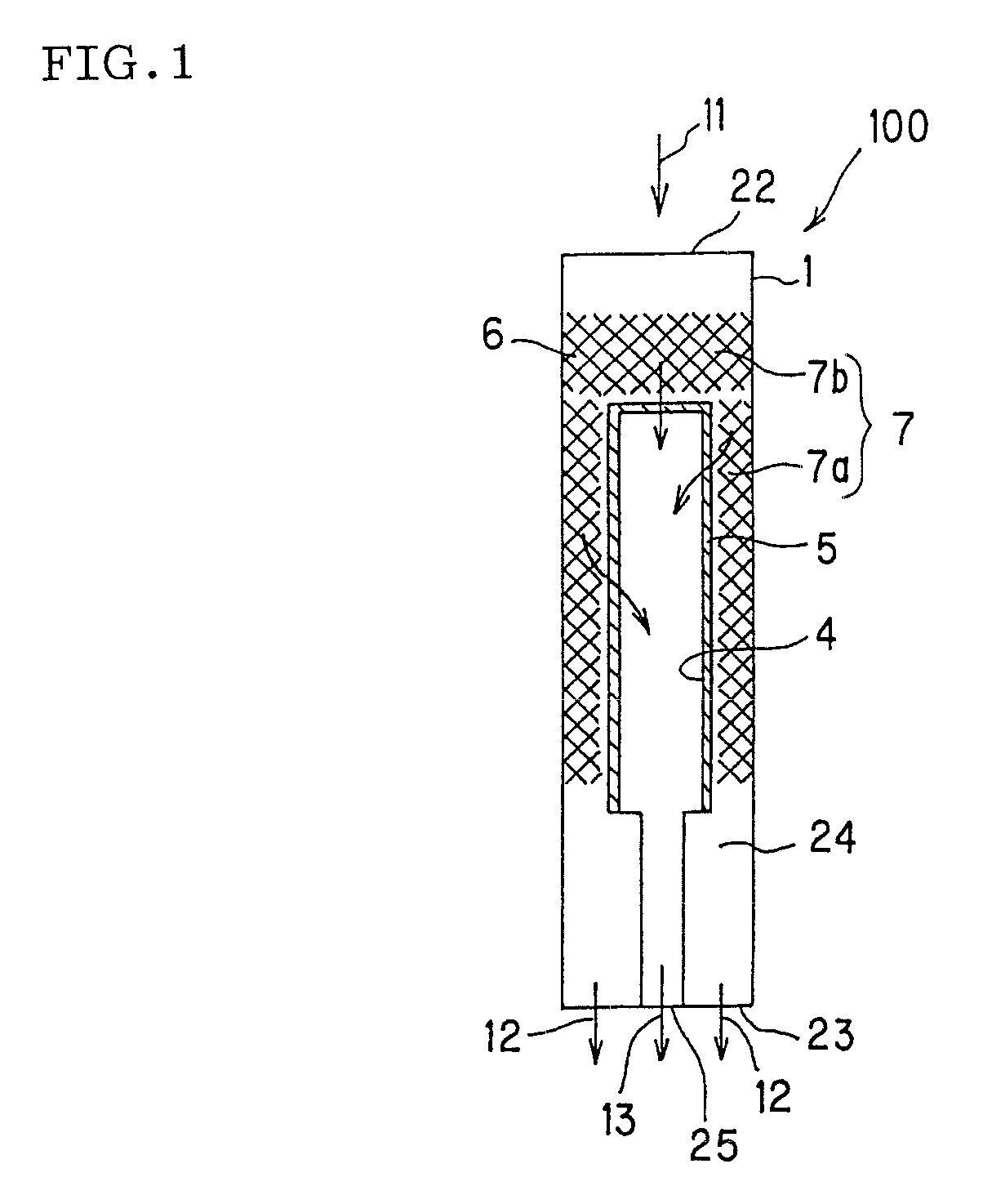

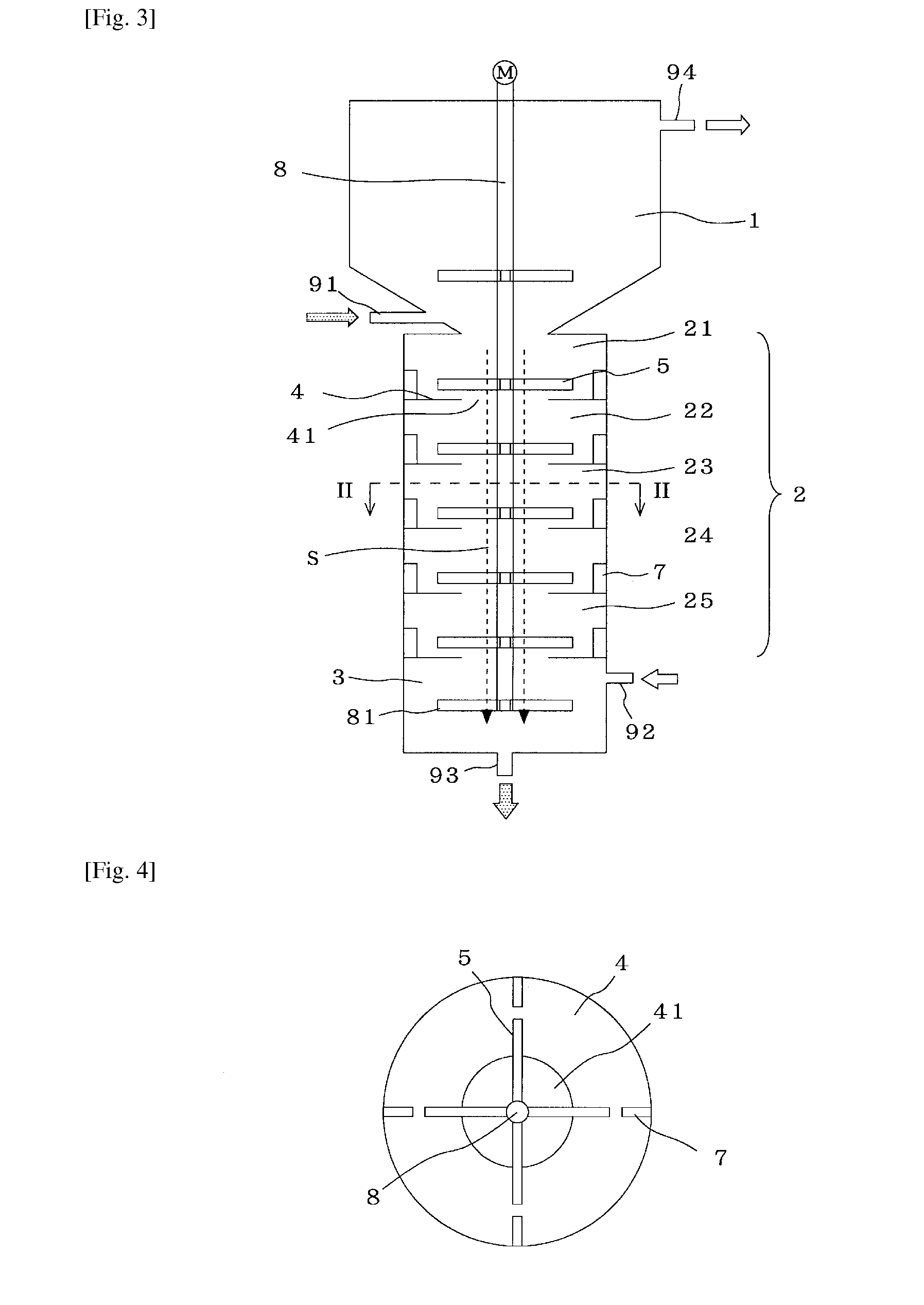

Reactor of selective-permeation membrane type

ActiveUS20070269356A1Improve contact efficiencyEffective contactCombination devicesSemi-permeable membranesChemical reactionEngineering

A selectively permeable membrane reactor 100 includes a reaction tube 1 including an internal space 24 having a supply port 22 as an inlet port for a raw material gas 11 and a discharge port 23 as an outlet port for an unseparated gas 12, and a separation tube 4 inserted into the internal space 24 of the reaction tube 1. The separation tube 4 includes a selectively permeable membrane 5 exhibiting selective permeability for a specific component on a surface facing the internal space 24 of the reaction tube 1, and a process port 25 as an outlet port for a separated gas 13 which has passed through the selectively permeable membrane 5, and a catalyst for promoting a chemical reaction is provided in the internal space 24 of the reaction tube 1 excluding the separation tube 4. The selectively permeable membrane reactor 100 is characterized in that a catalyst is carried by a foamed body 7 having porous structure to form a foam-molded product and suppresses physical and chemical deterioration in the selectively permeable membrane and allows a mixed gas produced by a catalytic reaction to be efficiently separated and taken out through the selectively permeable membrane.

Owner:NGK INSULATORS LTD

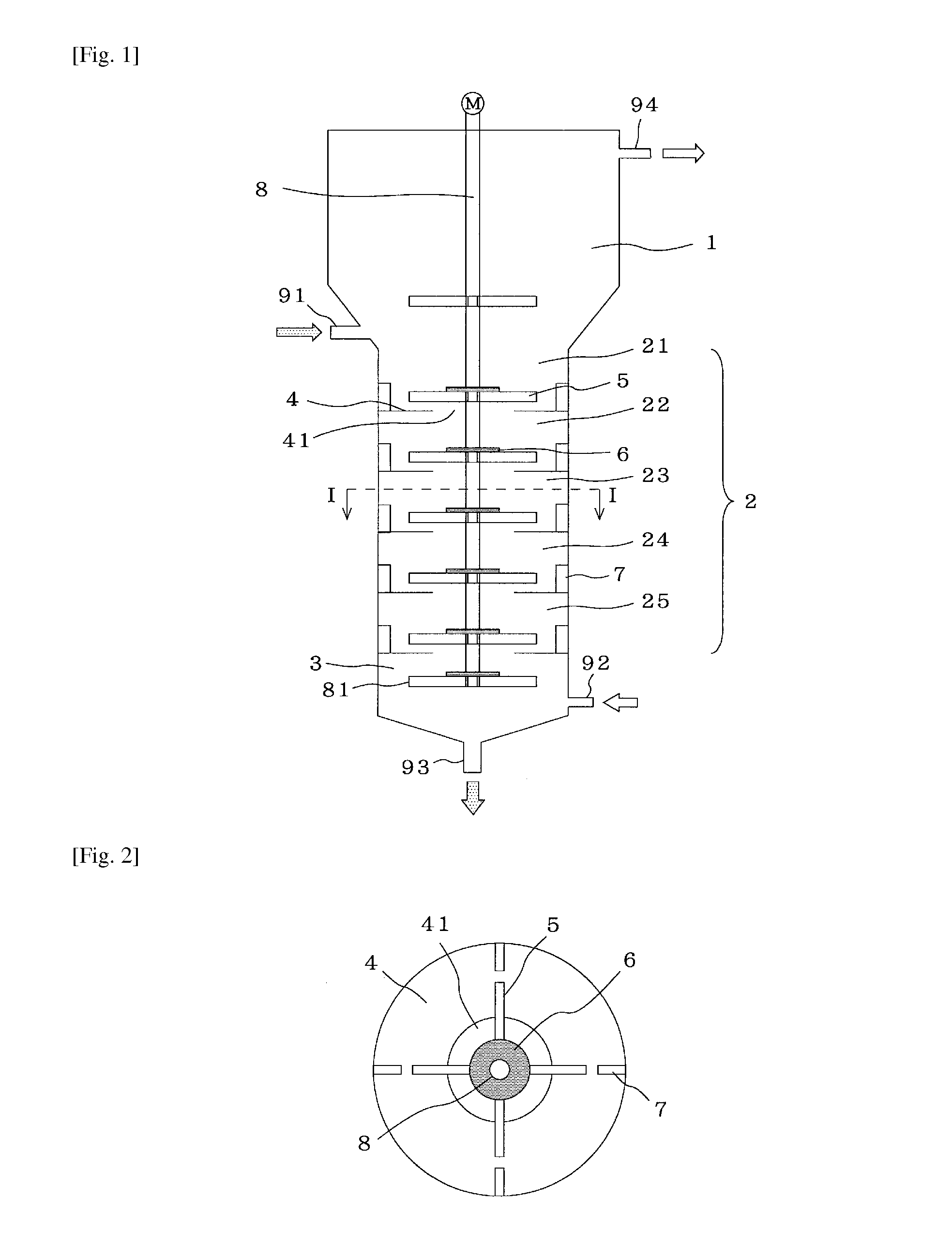

Column-Type Solid-Liquid Countercurrent Contact Apparatus, Solid Particle Washing Apparatus, and Method

ActiveUS20120322972A1Improve contact efficiencyEasy to useRotary stirring mixersTransportation and packagingSolid particleEngineering

A column-type solid-liquid countercurrent contact apparatus, a washing apparatus for solid particles such as poly(arylene sulfide) (PAS) particles, a PAS manufacturing apparatus, a method of solid-liquid countercurrent contact, a method of washing solid particles such as PAS particles, and a method of manufacturing PAS, wherein a column top part, a column body part, and a column bottom part are included, the column body part is provided with a plurality of stirring chambers connected in the vertical direction and mutually divided by a ring-shaped partitioning plate, a paddle blade (a blade diameter / a diameter of the stirring chamber≧0.65 and the blade diameter / the diameter of the stirring chamber≦0.10) and a baffle are disposed at each of the plurality of stirring chambers, and a disc having a size covering at least a part of a communication opening positioned below the paddle blade is attached to a rotating shaft or to the paddle blade.

Owner:KUREHA KAGAKU KOGYO KK

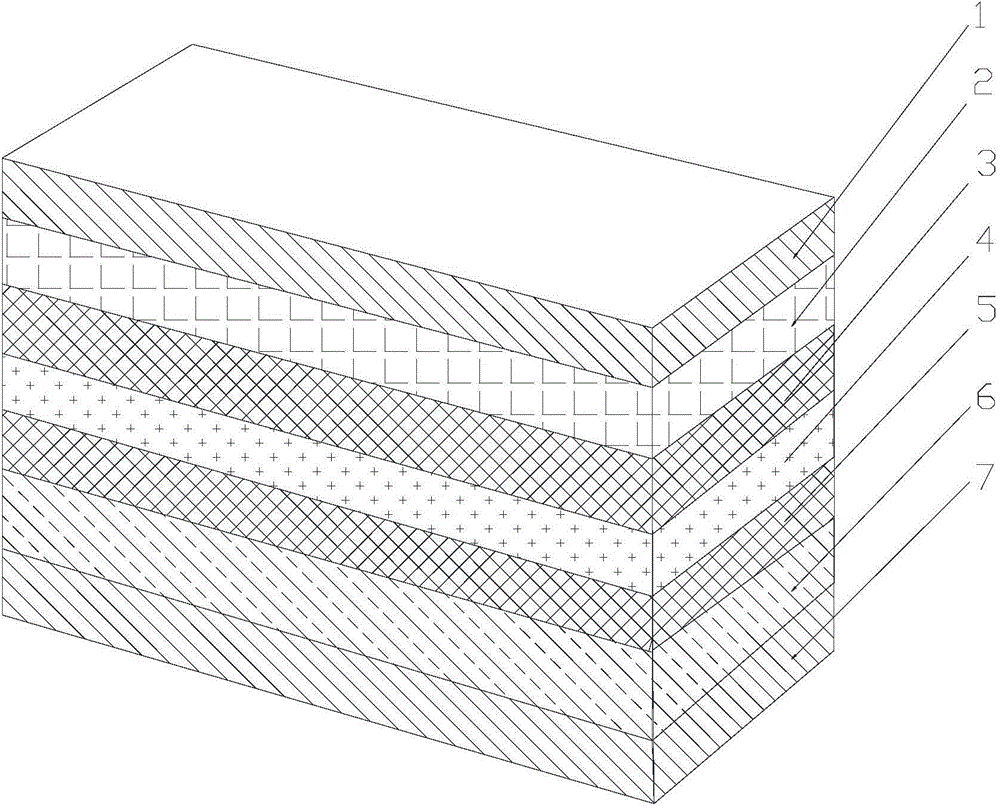

Flexible lead-acid battery core easy to recycle, and preparation method of flexible lead-acid battery core

ActiveCN103560252AIncrease profitImprove quality ratioCell seperators/membranes/diaphragms/spacersFinal product manufactureCapacitanceFiber

The invention relates to a preparation method of a flexible lead-acid battery core easy to recycle. The preparation method of the flexible lead-acid battery core is characterized by taking porous glass fiber cloth made of compound sodium alginate fiber as a supporting layer, and comprises the following steps: applying metal flow collection layers to two surfaces of the supporting layer by adopting a vacuum sputtering or vacuum evaporation coating method, coating positive and negative electrode active substances respectively, and drying; spraying a sodium alginate solution on the dried surface, so as to form an isolating layer; and drying so as to obtain the flexible lead-acid battery core capable of being wound. The assembling is performed according to required capacitances, shapes and sizes, electrode leading-out terminals are connected and are pressed in a shell, then an electrolyte is filled in the shell, and the sealing is performed, so that the flexible lead-acid battery core easy to recycle is obtained.

Owner:FUJIAN REIDA PRECISION

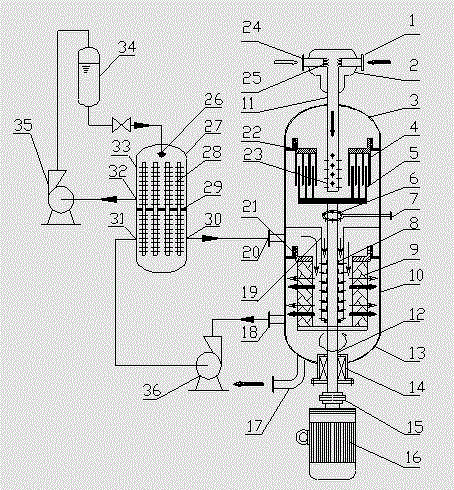

Method and device for continuous separation of methane, carbon dioxide and hydrogen sulfide from biogas by hydrate method

ActiveCN105087093ARealize automatic controlImprove contact efficiencyHydrogen sulfidesHydrocarbon purification/separationHydrate decompositionHigh pressure

The present invention provides a method for continuous separation of methane, carbon dioxide and hydrogen sulfide from biogas by hydrate method, and a three-stage gas separation device for implementing the method. High purity methane is separated by a first stage hydrate dissociation tower working at the temperature of 273.7K-283.1K and under the pressure of 1.324MPa-4.502MPa, high-purity carbon dioxide is separated by a second stage hydrate dissociation tower working at the temperature above 272.8K-288.7K and under the pressure of 0.093MPa-0.499MPa; high-purity hydrogen sulfide is separated by a third stage hydrate dissociation tower working at the temperature above room temperature and under the pressure above atmospheric pressure, and the three-stage gas separation device can be controlled by a written program by a computer to run automatically and select the proper working condition. The gas-liquid contact efficiency, hydrate formation rate, separation process target gas recovery rate and gaseous product purity are improved, hydrate formation heat removal is enhanced, high pressure hydrate system gas, liquid and solid three-phase automatic separation can be achieved, and the method can replace the existing technology, and can be used in production of continuous separation of methane, carbon dioxide and hydrogen sulfide from biogas by industrialized hydrate method.

Owner:肇庆高新区伙伴汽车技术有限公司

Method for remediating PAEs polluted soil by using microwave enhanced calcium peroxide

InactiveCN106493162AStay acidicPromote degradationContaminated soil reclamationSlurryBarium peroxide

The invention belongs to the technical field of organic polluted soil remediation and discloses a method for remediating phthalic acid esters (PAEs) polluted soil by using microwave enhanced calcium peroxide. The method comprises the steps of preparing a slurry soil mixed solution from the PAEs polluted soil according to a certain liquid-solid ratio; adding a certain quantity of citric acid, ferrous sulfate and calcium peroxide into the solution; and carrying out microwave treatment and standing to enable the degradation rate of PAEs in the soil to reach more than 80%. The method has the advantages of simple process condition, low operation requirement, high treatment efficiency, low oxidizing agent waste and the like and is suitable for remediating the PAEs polluted soil.

Owner:CHANGZHOU UNIV

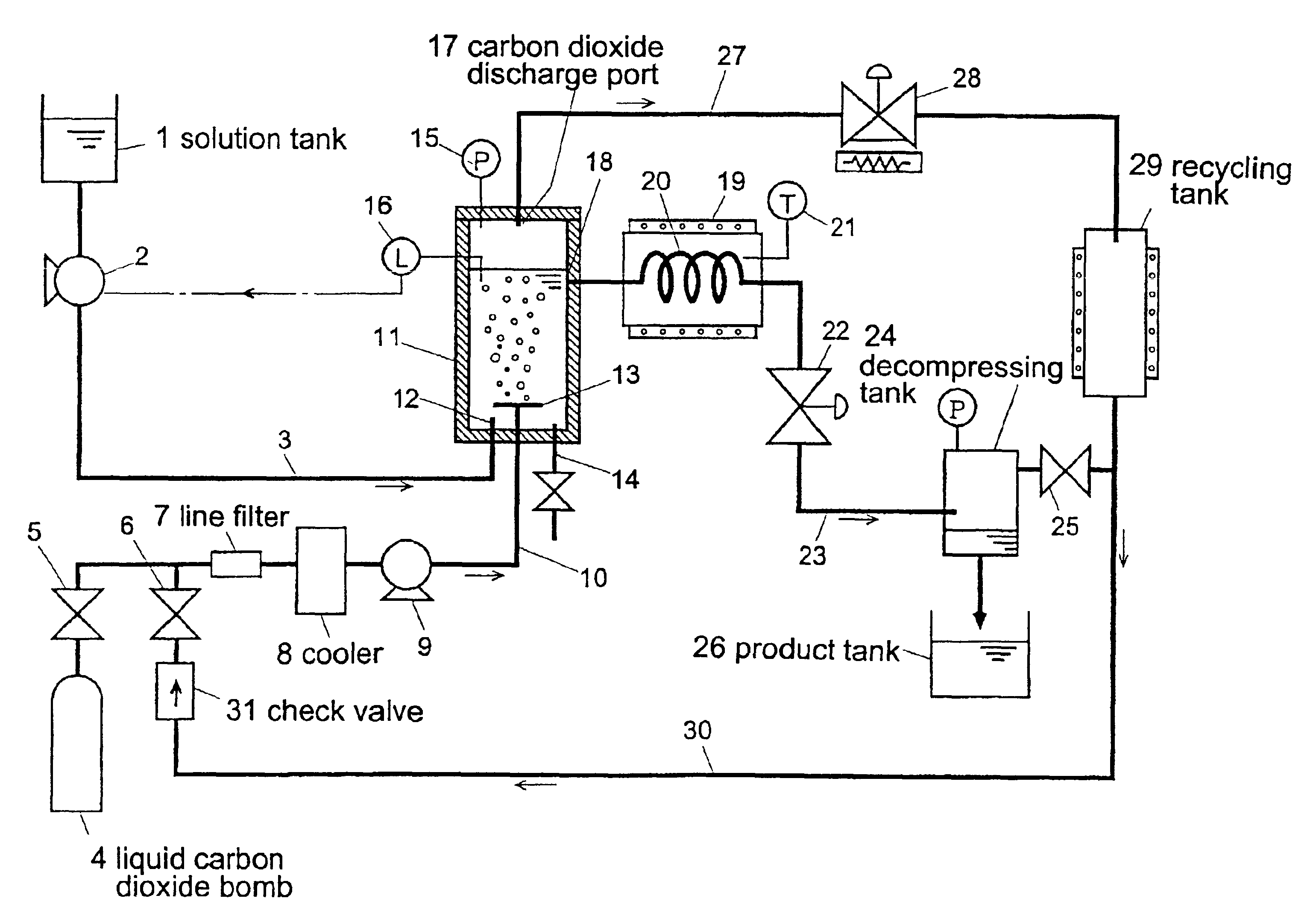

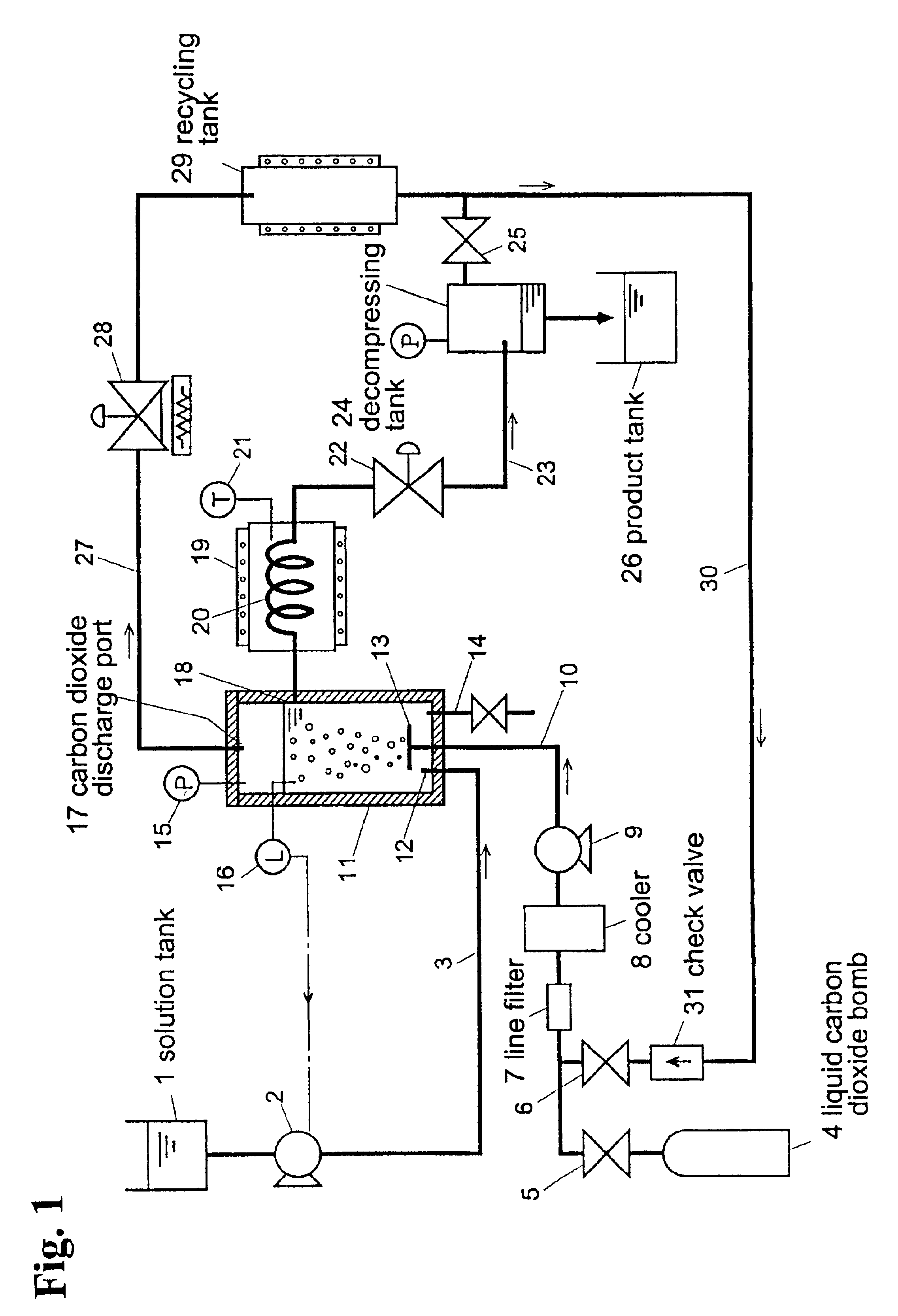

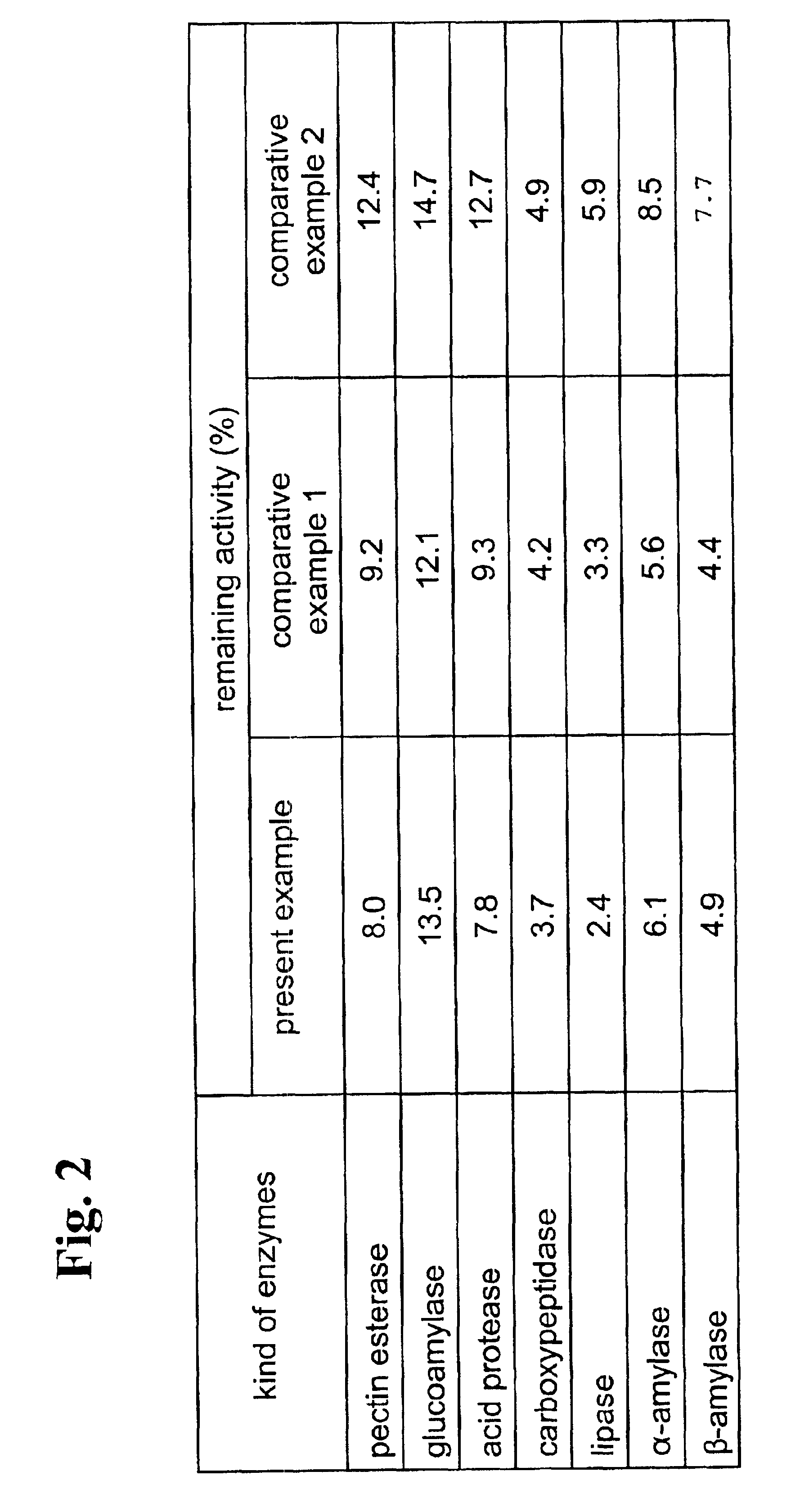

Continuous processing method and continuous processing apparatus for liquid-form substance, and liquid-form substance processed thereby

InactiveUS6821481B1Increase contactSimple materialPressurized chemical processMixing methodsLiquid stateLiquid carbon

A continuous processing apparatus includes a dissolution section for dissolving liquid carbon dioxide into a continuously supplied liquid-form raw material, and a processing section for holding the liquid-form raw material with liquid carbon dioxide dissolved therein under predetermined temperature and pressure to thereby transform carbon dioxide into a supercritical or subcritical state. Thus, bacteria, enzyme and the like contained in the liquid-form raw material can be effectively killed or decreased.

Owner:SHIMADZU CORP

Immersed multi-stage flue gas environment-friendly desulfurization tower

InactiveCN107875828AImprove contact efficiencyFast contact efficiencyGas treatmentUsing liquid separation agentParticulatesFlue gas

The invention discloses a submerged multi-stage flue gas environmental protection desulfurization tower, which comprises a tower body, the inner lower side of the tower body is equipped with an alkaline absorbent, and the inner lower side of the tower body is provided with a ring-shaped flue gas overflow device; the beneficial effect of the present invention is: because the flue gas overflow device includes several layers of annular pipes, the flue gas overflows evenly through the branch pipes on the annular pipes, so that the flue gas bubbles rise evenly, and the suspended particles in the flue gas absorb And sulfur oxides are adsorbed by the alkaline absorbent with high efficiency, and the vibrating membrane vibrates, so that the alkaline absorbent vibrates in transverse ripples, making the flue gas bubbles easily dispersed into multiple small bubbles, and improving the interaction between the flue gas and the alkaline absorbent Contact efficiency, the alkaline absorbent is sprayed on the upper side of the tower body through the spray device, and the alkaline absorbent falling on the throwing plate is thrown out, which further improves the adsorption effect on flue gas, so the desulfurization efficiency of this device is high , the desulfurization efficiency is fast, and the height of the tower body is effectively reduced to save costs.

Owner:王宏亮

Spiral wound type filter cartridge

Disclosed herein is a spiral wound type filter cartridge and more specifically, a spiral wound type filter cartridge in which activated carbon fiber is provided. The inside of spiral wound type filter cartridge is capable of serving as a carbon filter in a water purifier, thus eliminating the necessity of the use of any carbon filter for pre- or post-treatment in the process of purifying raw water, reducing an overall size of the water purifier and considerably reducing costs associated therewith.

Owner:WOONGJIN COWAY

Humidification device and air purifier with humidification function

ActiveCN101680672AWater retention or air permeability is not easily reducedSmall pressure lossMechanical apparatusLighting and heating apparatusWater supplyFiber

A humidification device has an evaporation filter, a water supply device, and a fan device. The evaporation filter uses as a filter base material a three-dimensional structure formed by interconnecting, by connection fibers, a first base material having openings and a second base material having openings, and the first and second base materials are interconnected such that the openings of both the base materials communicate with each other. The water supply device supplies water to the evaporation filter to wet the filter base material. The fan device sends air to the wet filter base material, allows the air to pass through the communicated openings, and sends humidified air out of the evaporation filter. A decrease in humidification ability of the humidification device is suppressed evenif scale is deposited on the evaporation filter. Further, contact efficiency between passing air and water present on the evaporation filter is enhanced, and as a result, although compact in size, the humidification device has high humidification performance.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com