Patents

Literature

123results about How to "Improve quality ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

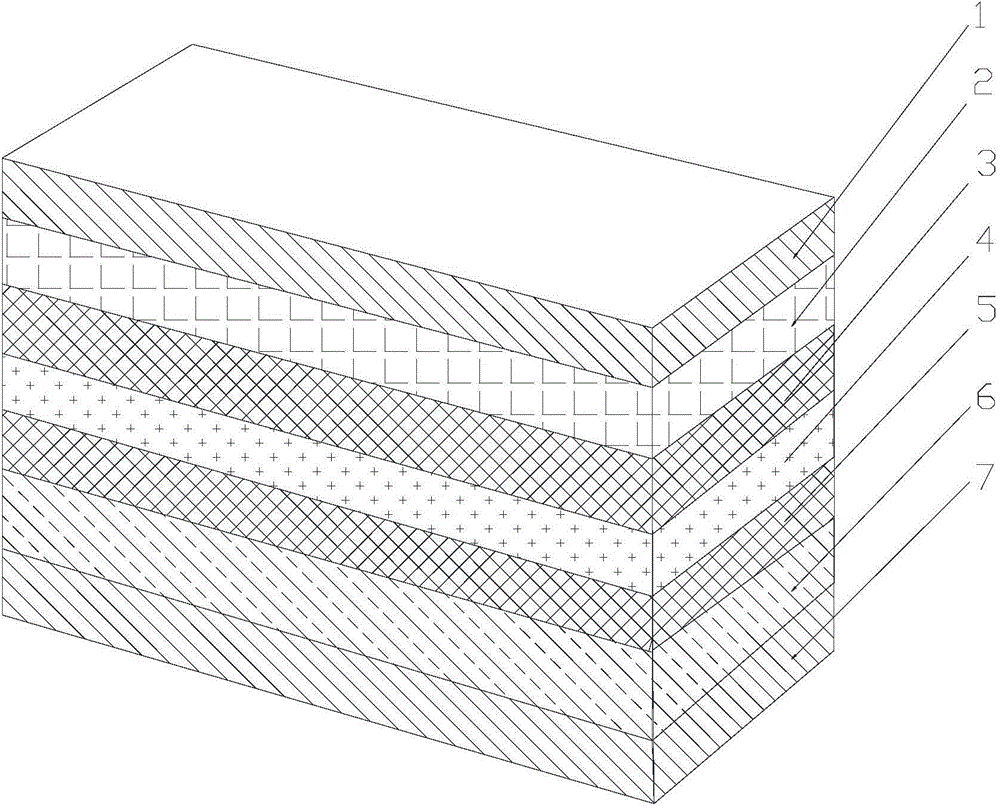

Composite diaphragm as well as preparation method and application thereof

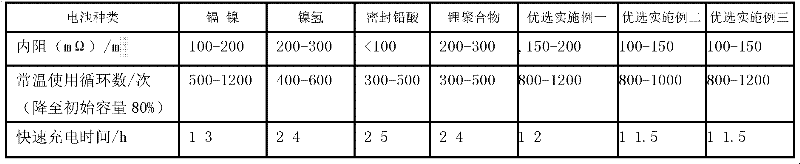

InactiveCN104064713ALarge specific surface areaImprove thermal stabilitySecondary cellsCell component detailsSolventWater soluble

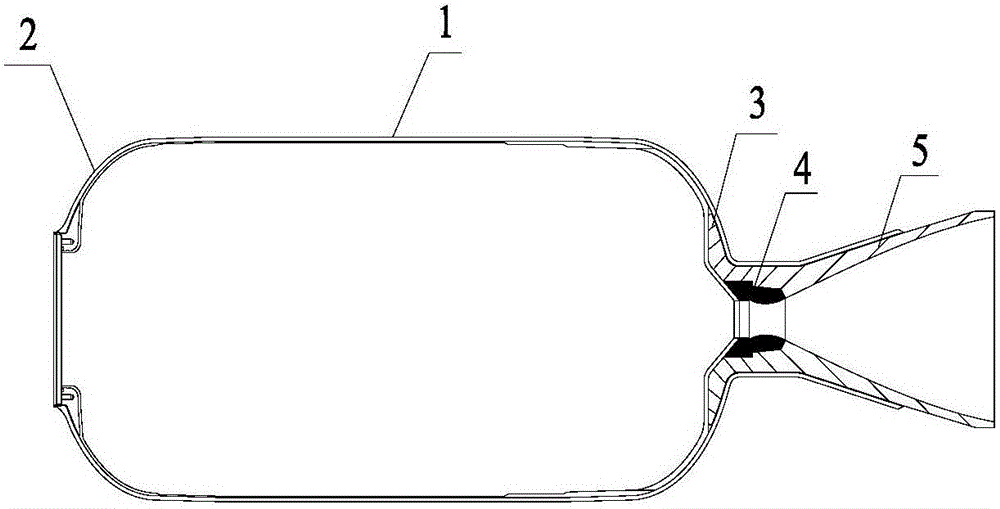

The invention provides a composite diaphragm as well as a preparation method and application thereof, and relates to a lithium ion battery. The composite diaphragm comprises a base diaphragm material; a protective layer coats the surface of the base diaphragm material and adopts a water-soluble bonding agent; a solvent used by slurry of the protective layer is water. The preparation method of the composite diaphragm comprises the steps of (1) evenly mixing inorganic particle powder, the water-soluble bonding agent and the solvent to obtain mixed powder; and (2) coating the single or double surfaces of a common commercially available diaphragm with the mixed powder obtained in the step (1) by a film applicator, carrying out vacuum drying, and removing the solvent to obtain the composite diaphragm, wherein the thickness of the composite diaphragm can be adjusted by controlling the concentration of the slurry and the parameters of the film applicator. The composite diaphragm can be applied to the preparation of a secondary battery and can be used for replacing an existing ceramic diaphragm, wherein the secondary battery comprises but not limited to a lithium ion battery.

Owner:XIAMEN UNIV +1

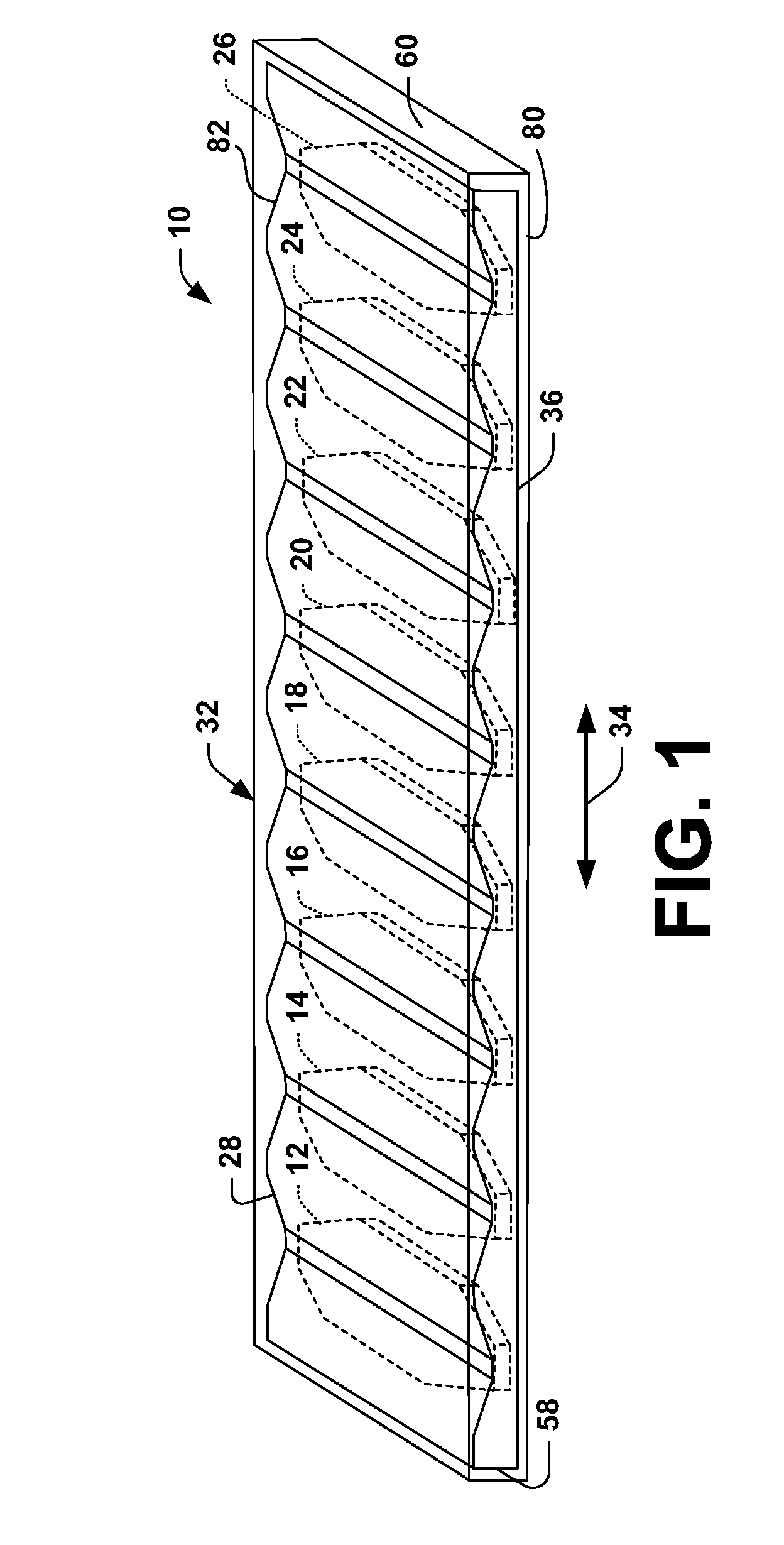

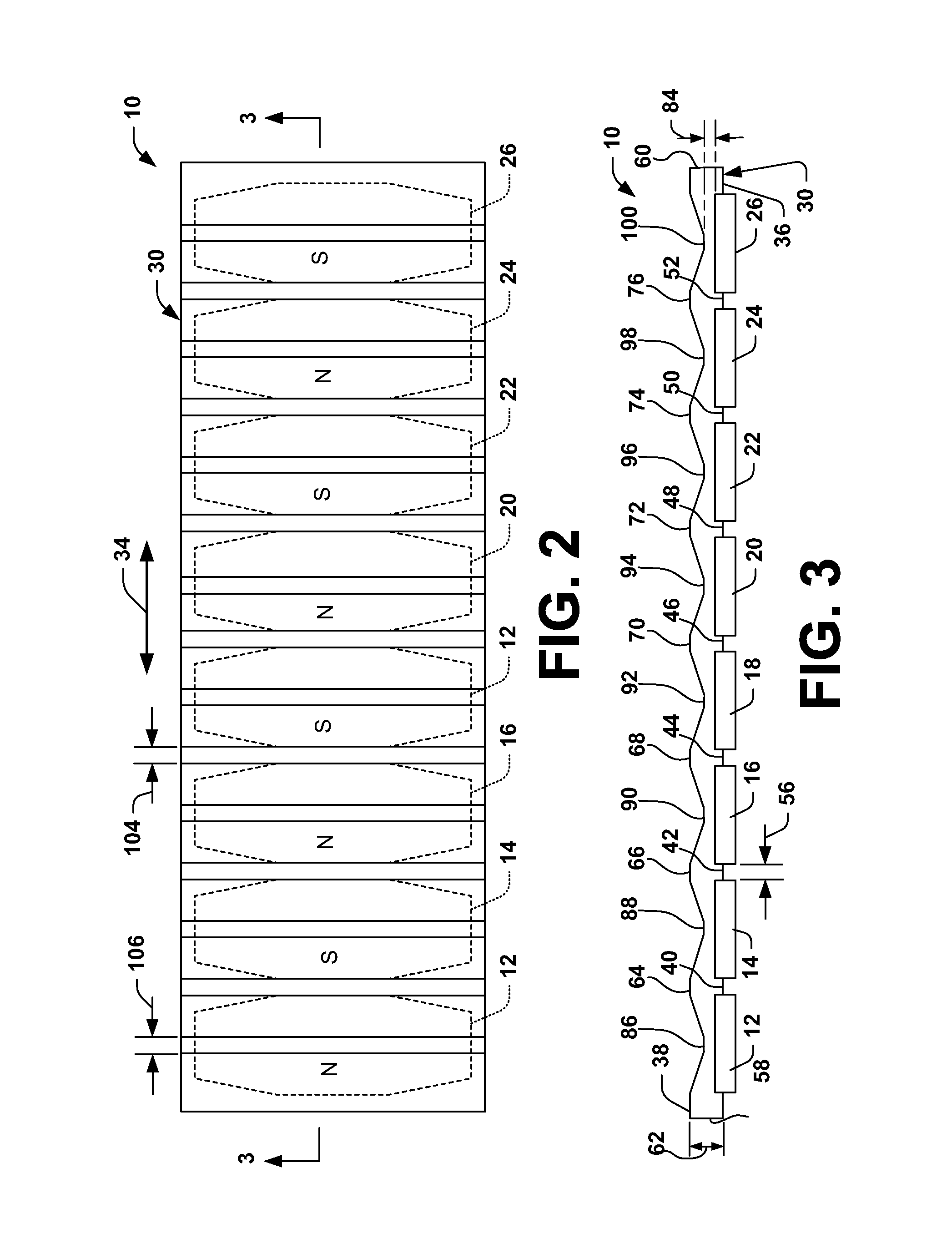

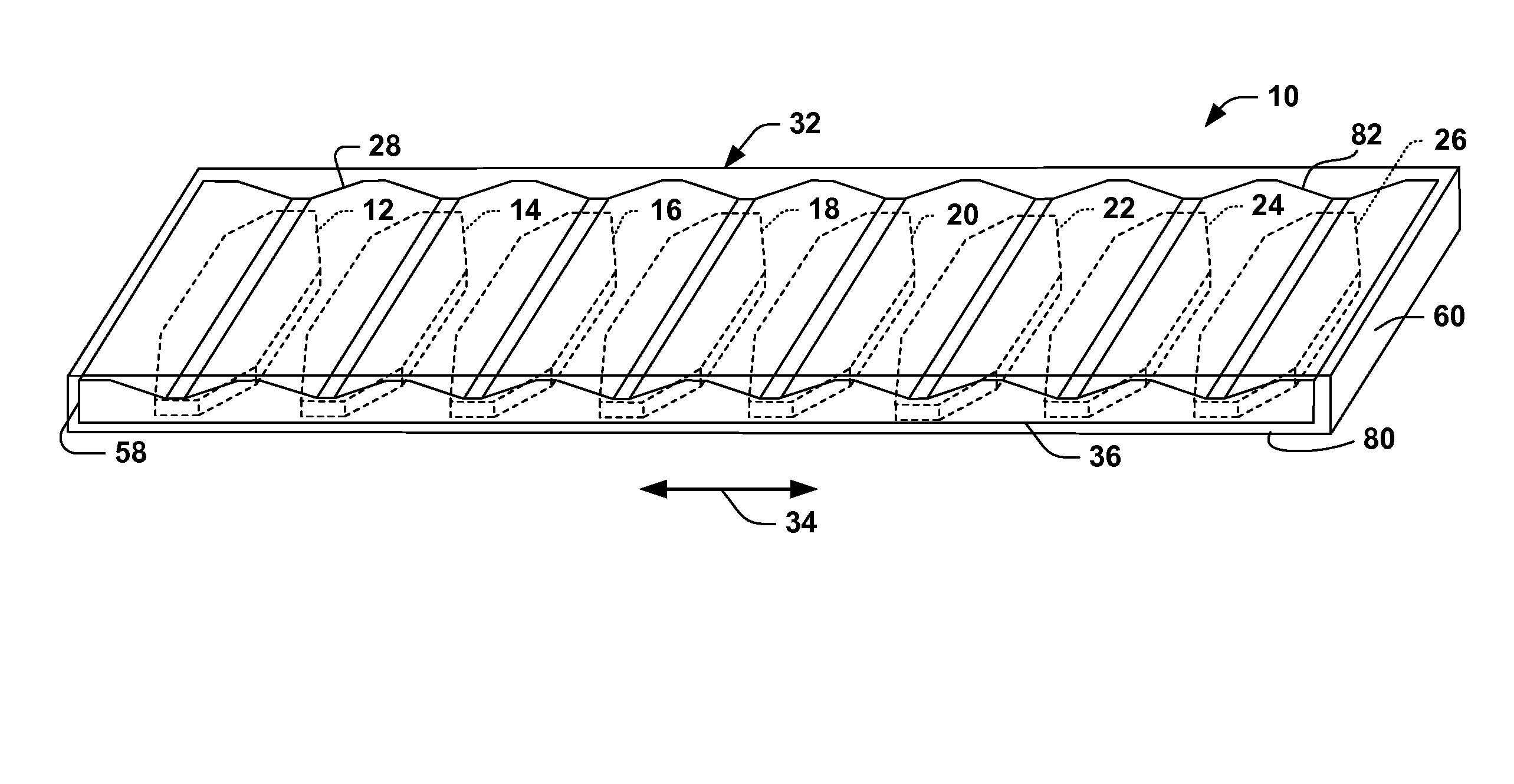

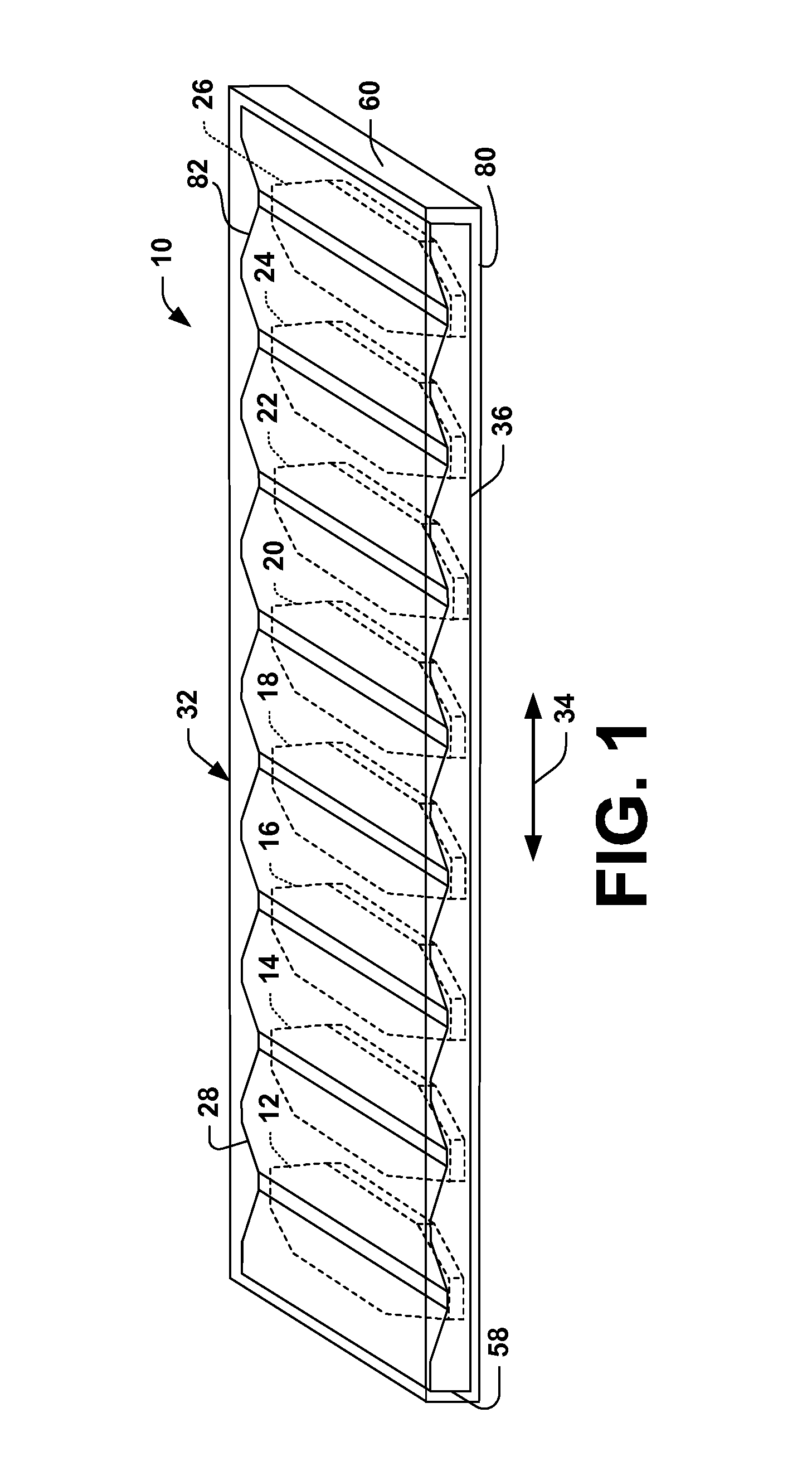

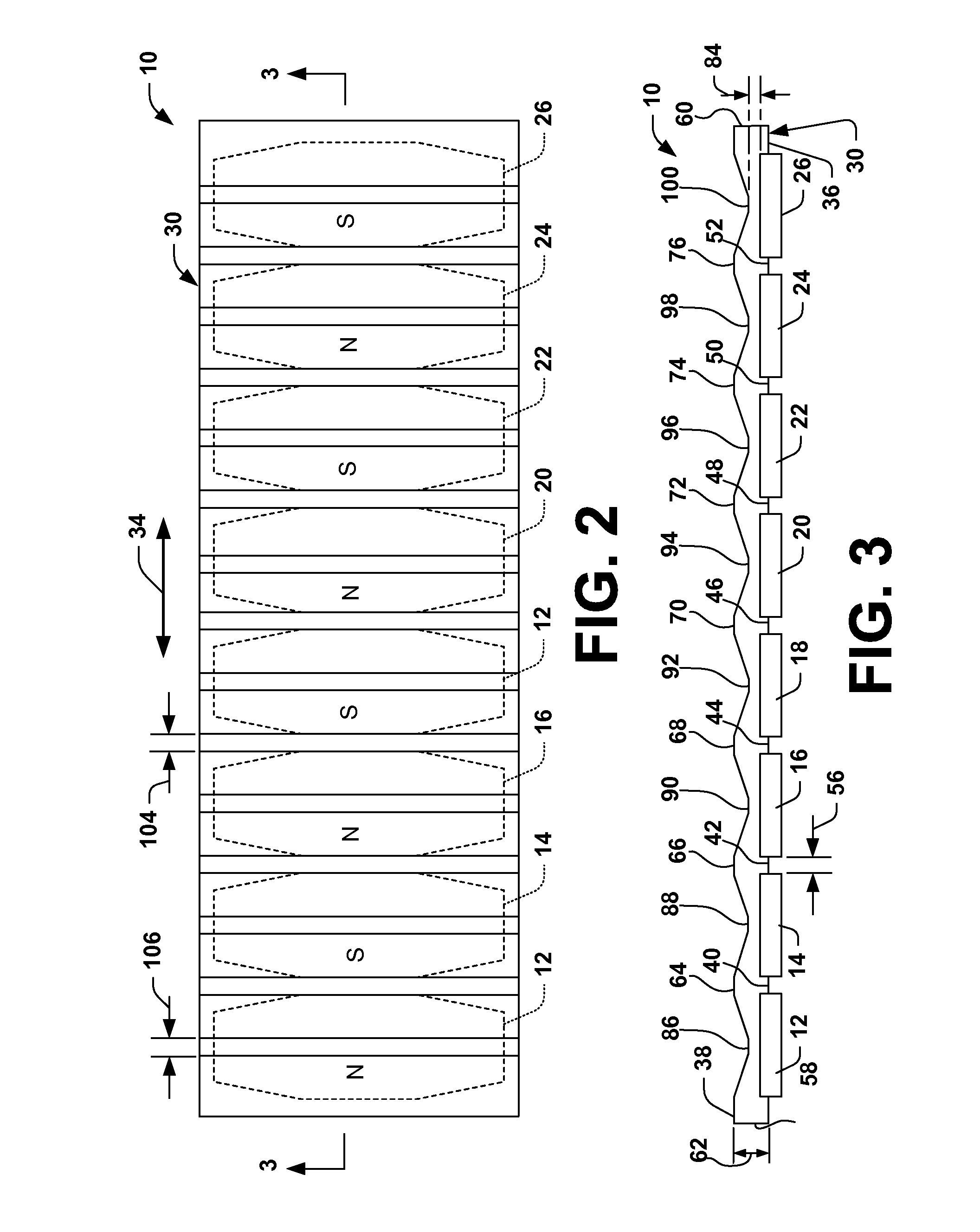

High performance motor and magnet assembly therefor

InactiveUS7586217B1Improve performanceIncrease forceMagnetic circuit rotating partsPropulsion systemsVariable thicknessHigh flux

Owner:ANORAD

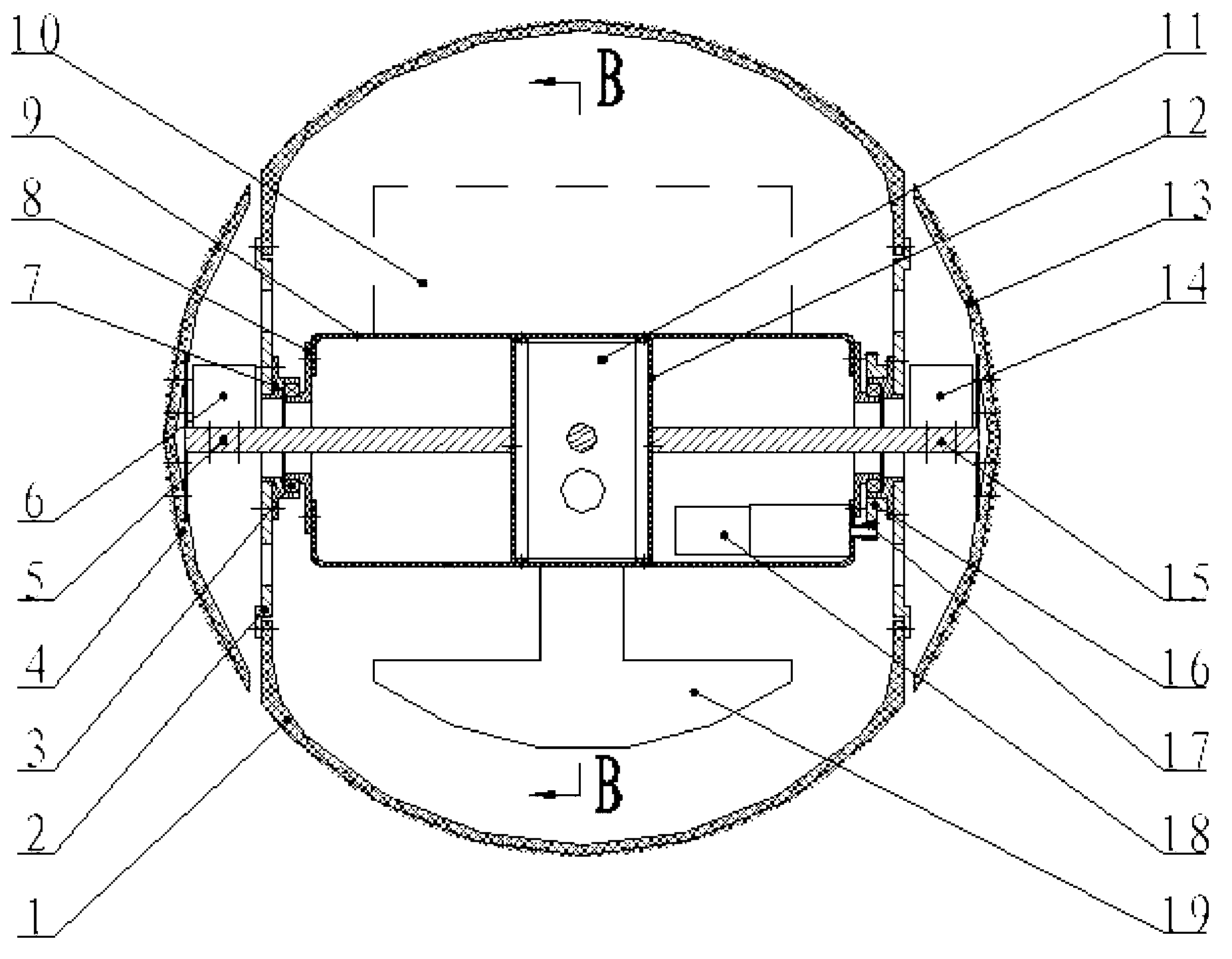

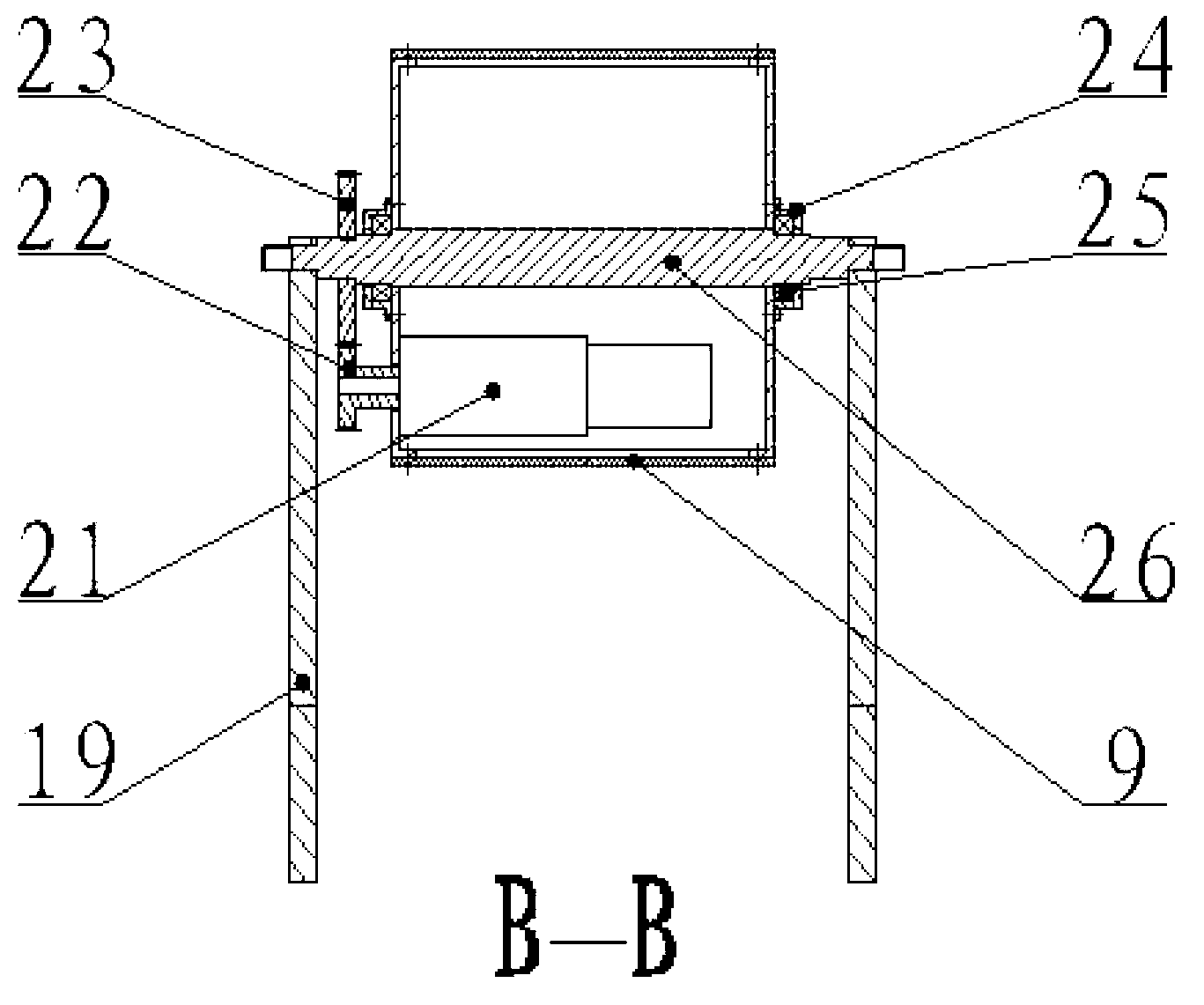

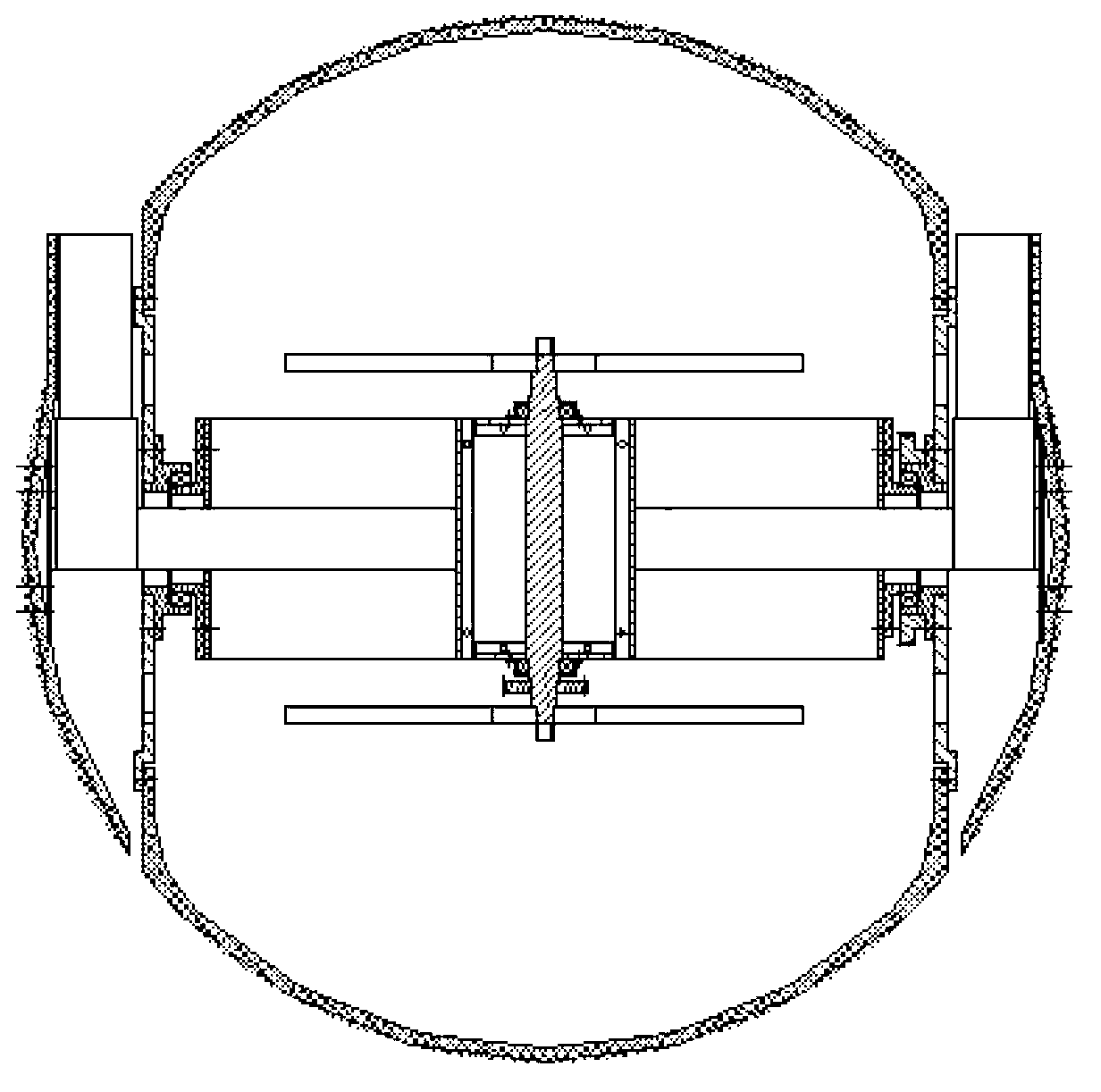

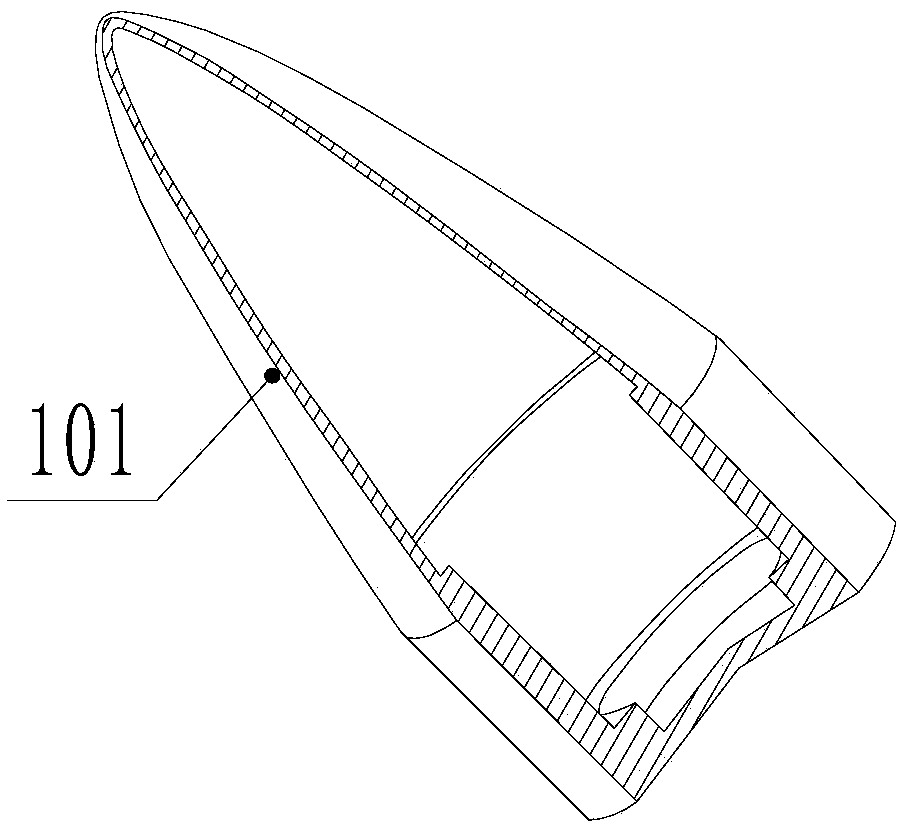

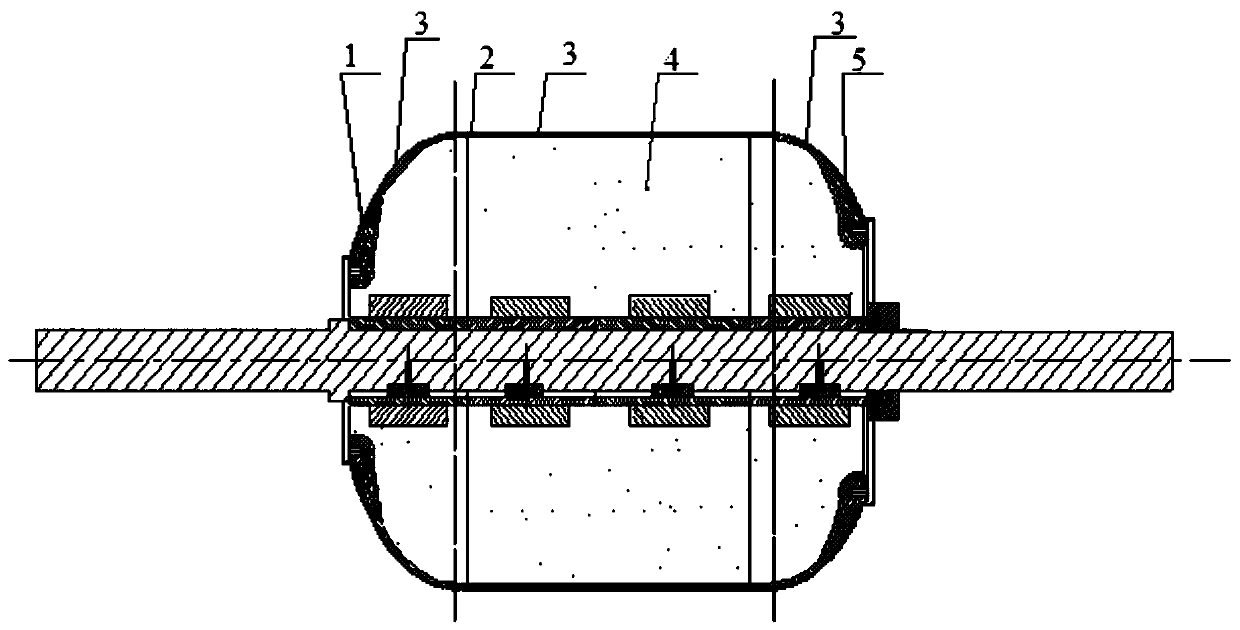

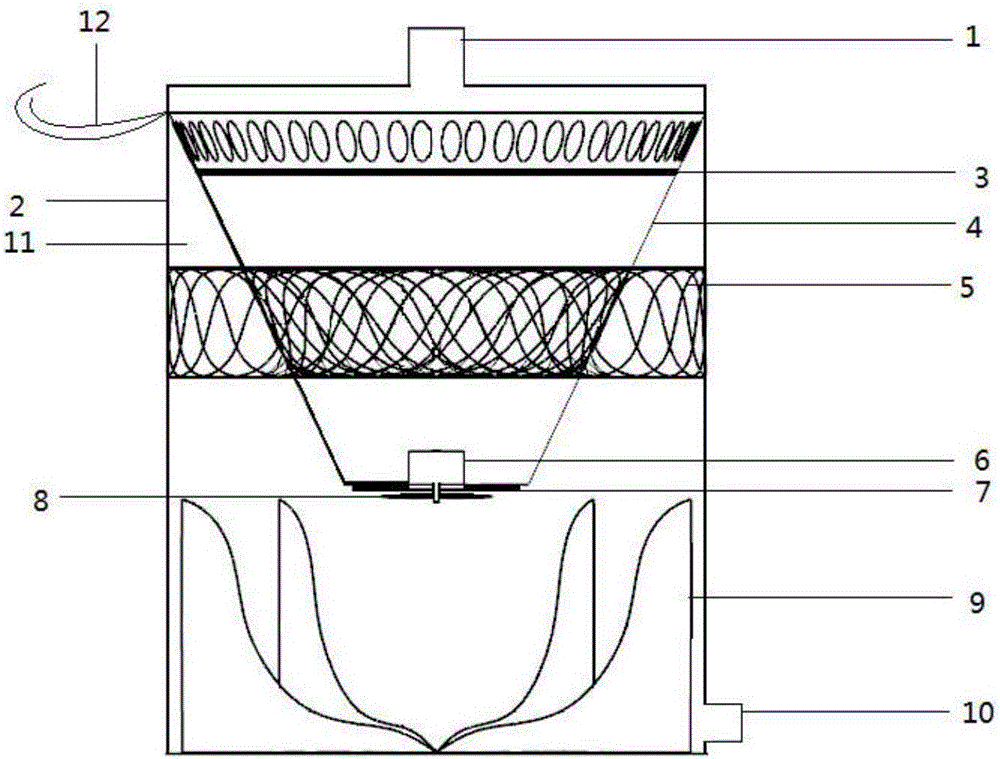

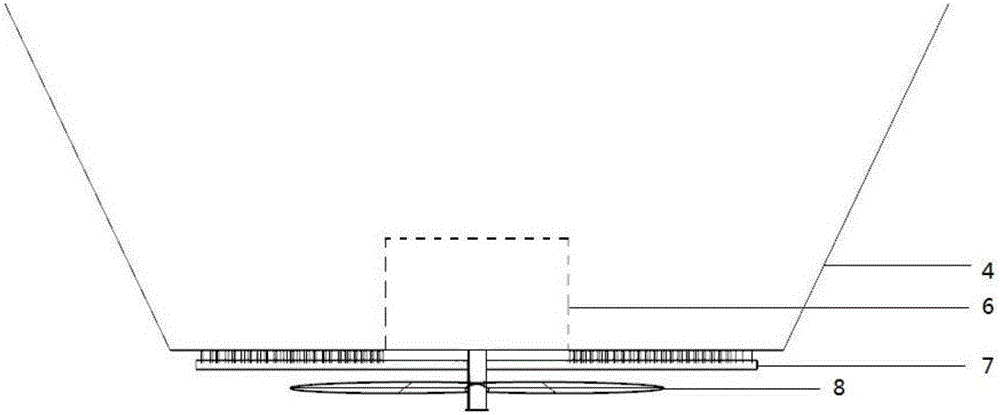

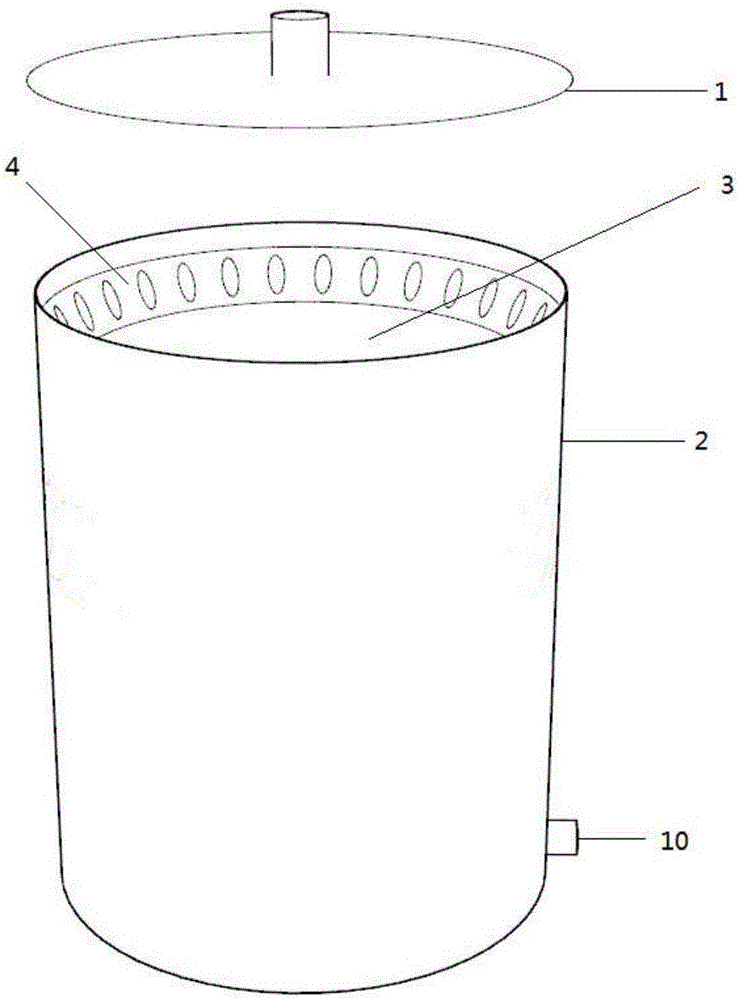

Spherical robot with binocular stereoscopic vision

InactiveCN103171638AWith binocular stereo visionAccurate collectionVehicle body stabilisationVehiclesBinocular distanceSpherical robot

The invention discloses a spherical robot with binocular stereoscopic vision. The spherical robot with the binocular stereoscopic vision comprises a visual camera support structure, a straight line and turning driving mechanism, a novel spherical shell and balance weights. The spherical shell is a whole formed by three portions, the spherical crowns of a left spherical shell and a right spherical shell are cut to form a through hole, a long shaft which cannot rotate with the spherical shell is arranged, the installation of a visual camera sensor is convenient, a visual camera can stretch out of the spherical shell through the through hole of the spherical shell, and the limitation of the spherical shell is avoided. A movement mechanism is provided to enable the spherical robot with the binocular stereoscopic vision to have the capacity of being flexible in turning.

Owner:BEIJING UNIV OF POSTS & TELECOMM

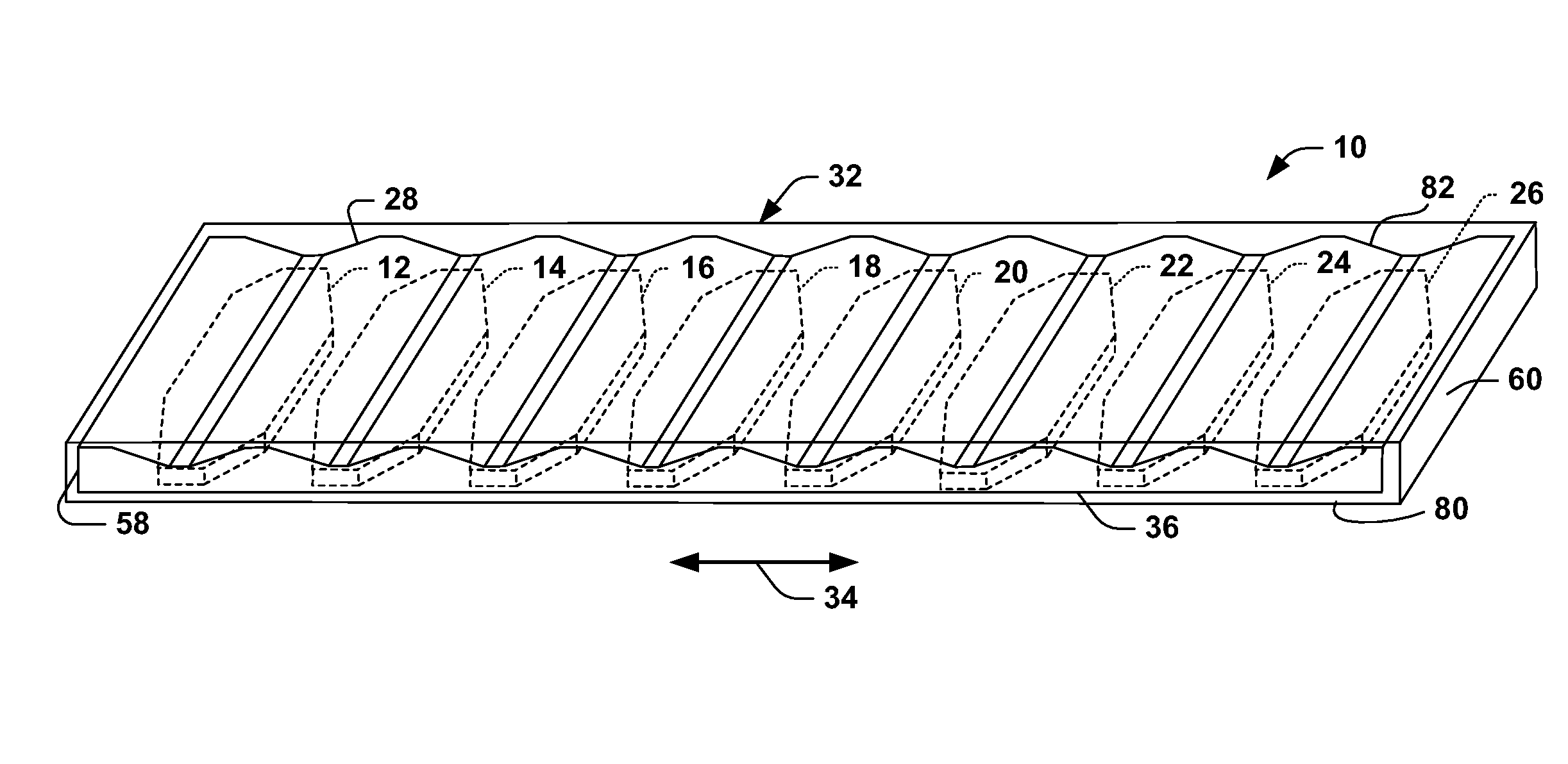

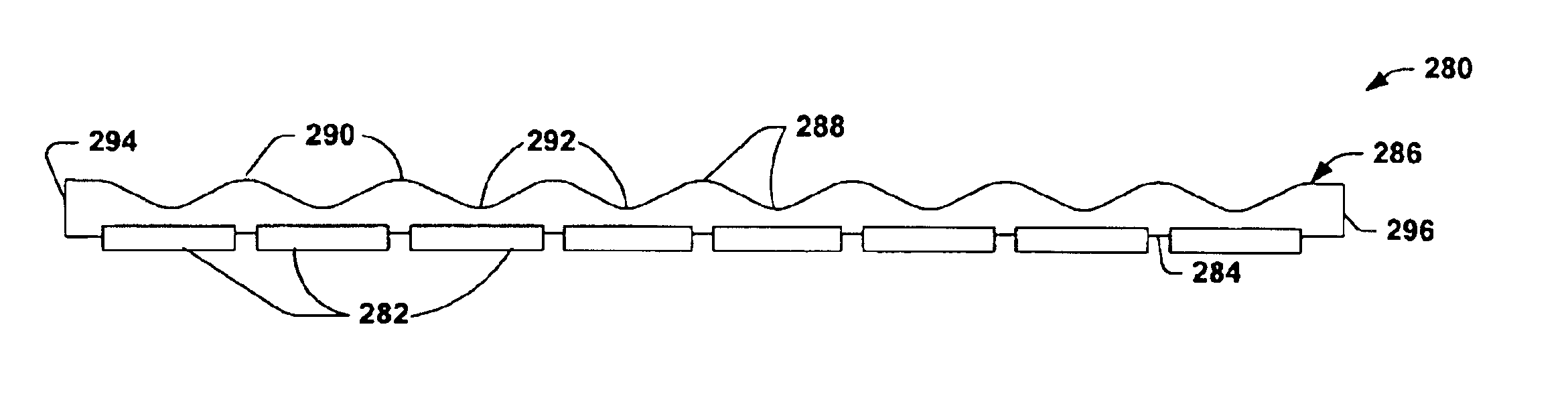

High performance motor and magnet assembly therefor

InactiveUS7291953B1High performanceReduce leakage fluxSynchronous generatorsWindingsMagnetVariable length

A magnet assembly includes a back iron and an array of magnets. The back iron is in the form of a plate having opposed surfaces. The magnets are arranged along one of the surfaces, with the other surface being dimensioned and configured according to the magnetic field distribution associated with the magnets. The back iron geometry provides for reduced mass, reduced leakage flux, and high flux densities to improve performance of a linear motor that employs such a magnet assembly. Additionally, the back iron can be a magnetically conductive annular ring, such as is employed in a rotary motor. Moreover, the magnets can be arranged in a manner that generates a Halbach array to increase force output in a desired direction while canceling stray magnetic fields in other directions. Similar reduced-mass designs can be employed in conjunction with a back iron of a fixed cross-section and magnets of variable thicknesses, variable lengths, and / or variable widths. In a case where the arrangement is employed in a platen and forcer system, plates on both the platen and forcer may be scalloped to reduce mass.

Owner:ANORAD

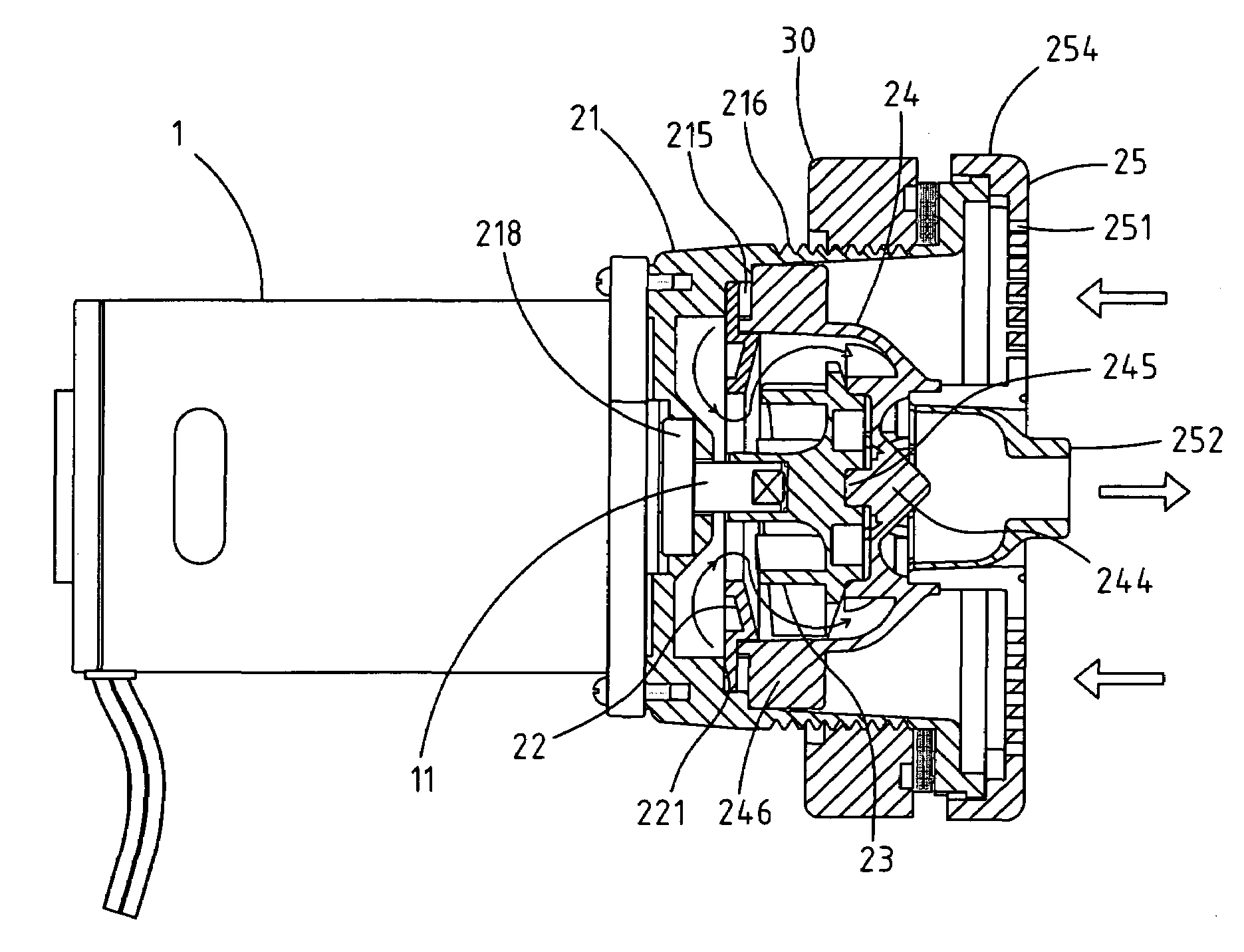

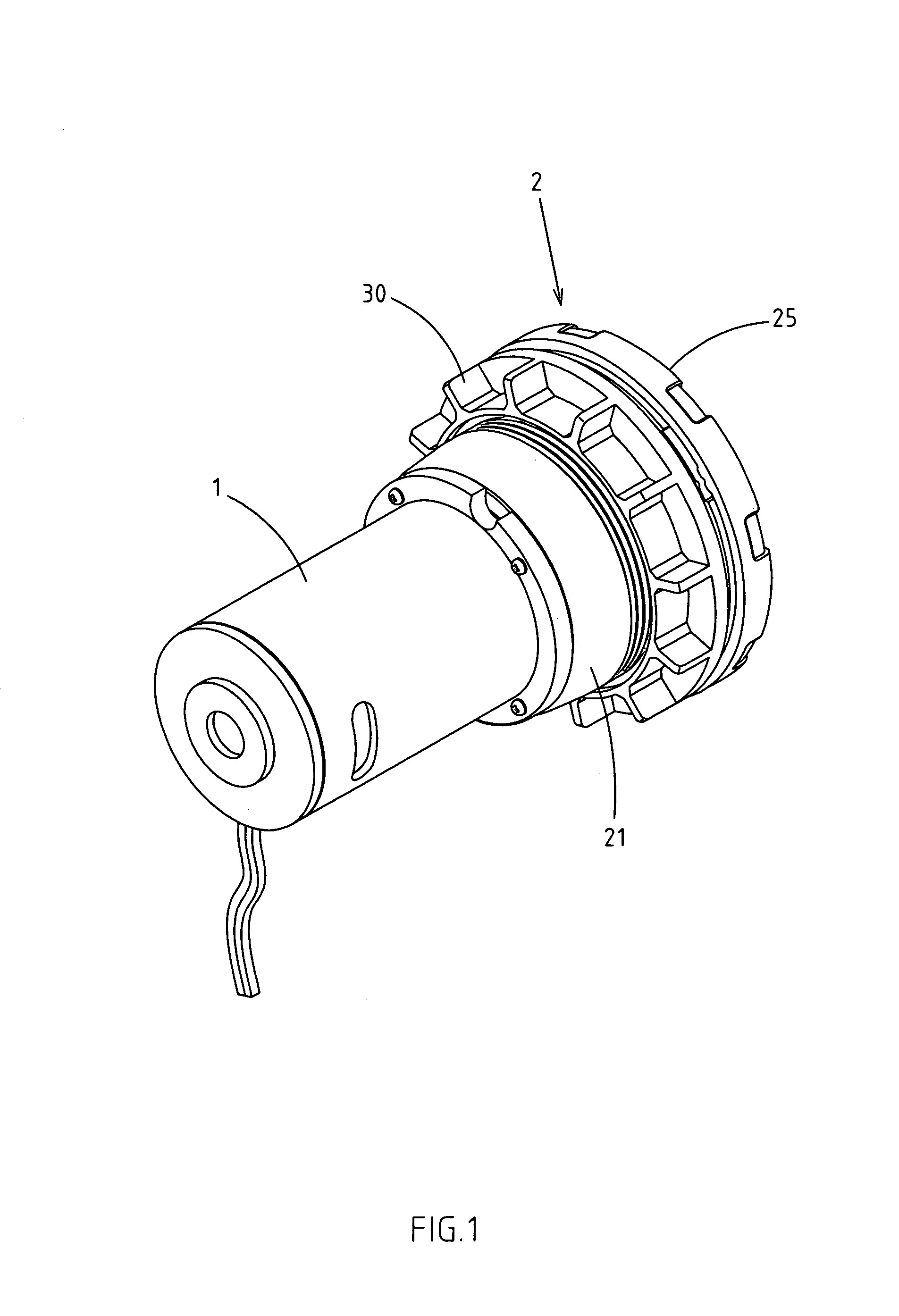

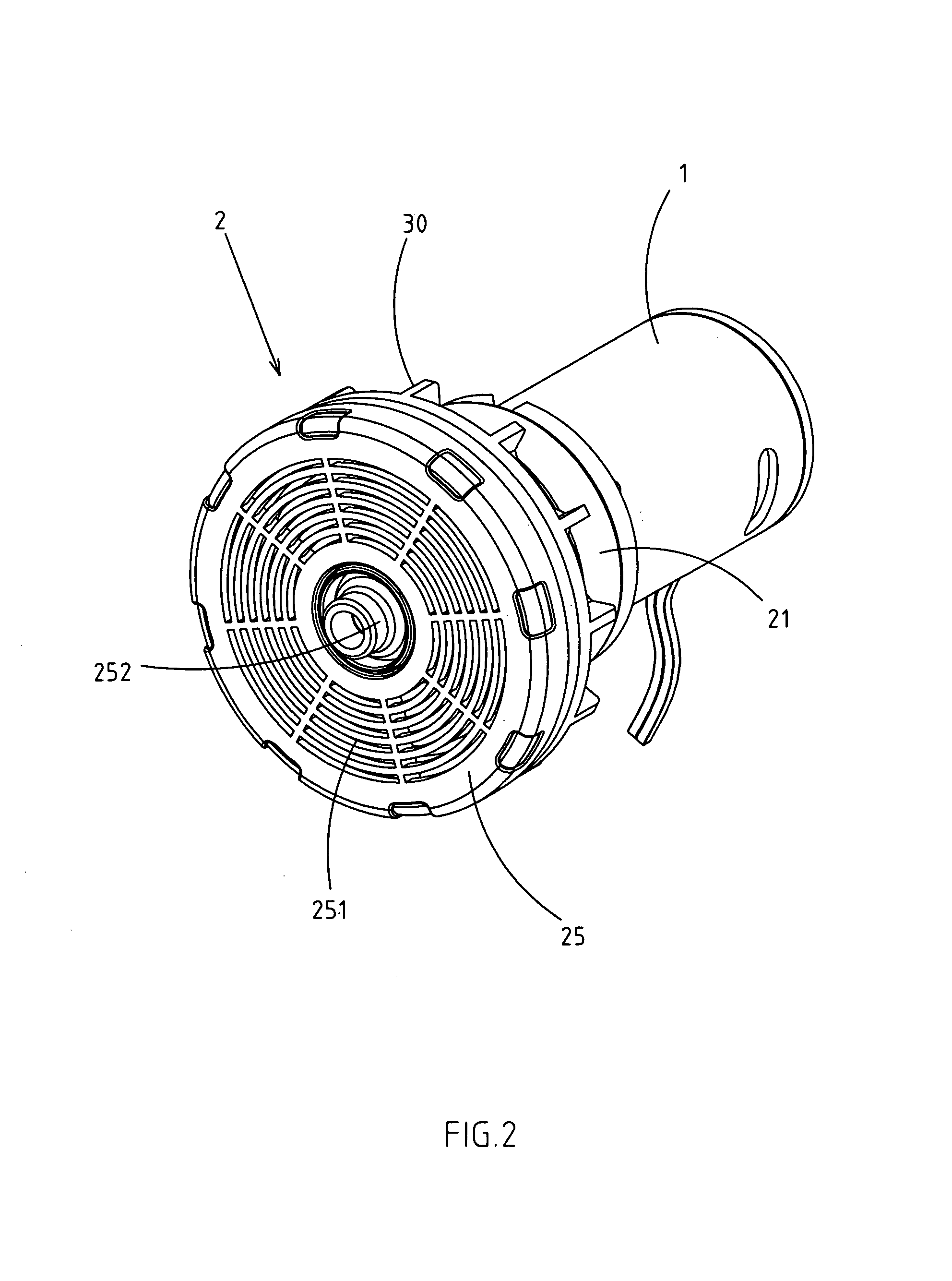

Structure of a swirl generator for liquid

The structure of swirl generator for liquid includes a motor with a head affixed to a swirl generator. The bearing seat of the swirl generator forms a fixation section, allowing the swirl extension to be affixed to the inside of the bearing seat easier and quicker, and installing the water guide cover at the opening of the bearing seat. Therefore, the swirl generator structure has advantages of easy assembly and decomposition for repair.

Owner:CHANG HONG JUN

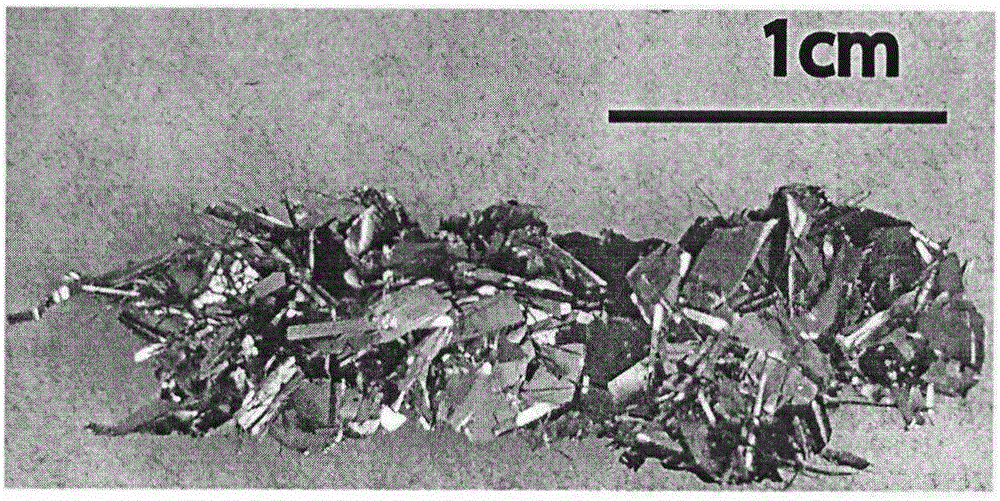

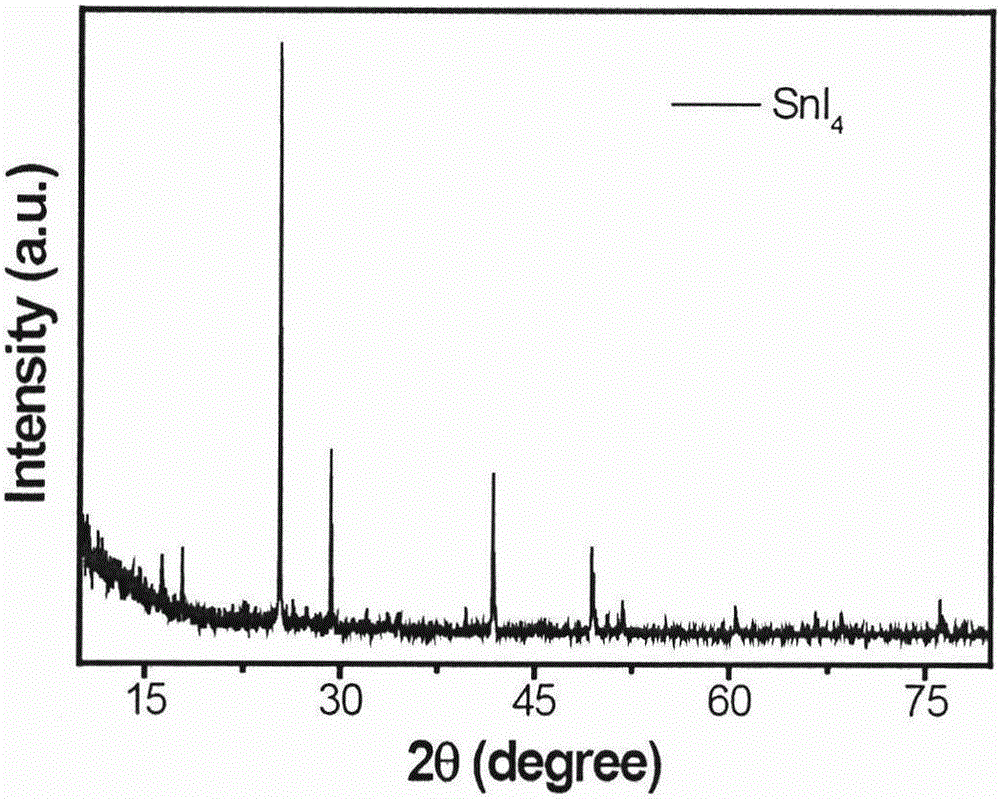

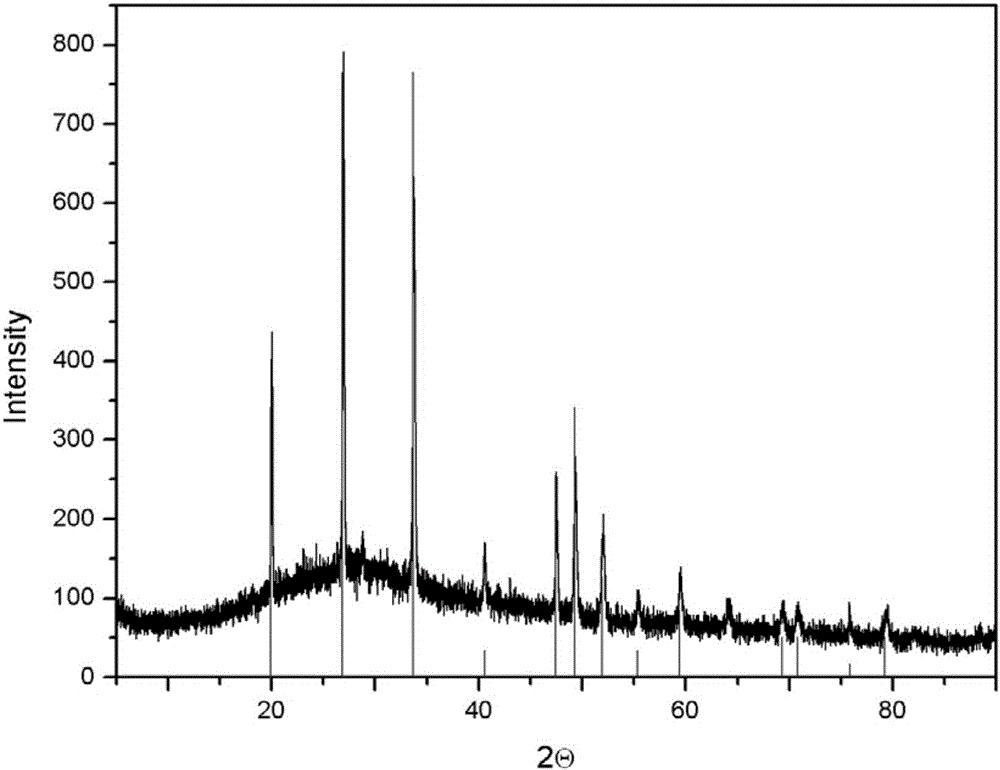

Method for preparing orthorhombic black phosphors monocrystals at low pressure

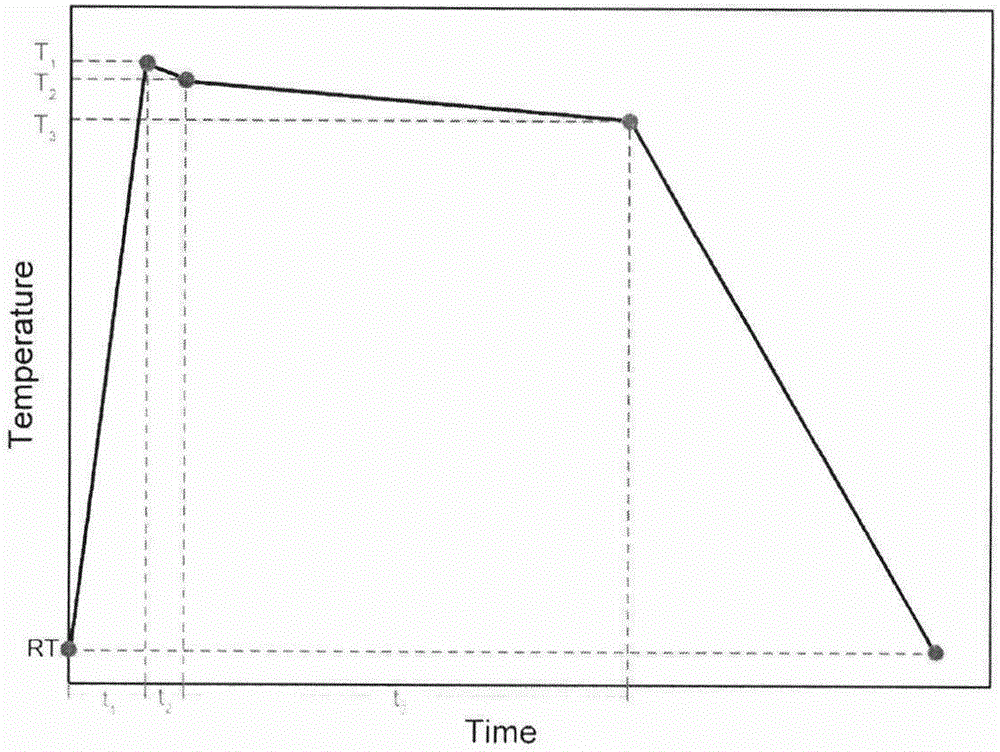

InactiveCN106087050AImprove quality ratioOptimizing the Reaction TemperaturePolycrystalline material growthFrom condensed vaporsSingle crystalMuffle furnace

The invention relates to a method for preparing orthorhombic black phosphors monocrystals. The method comprises the following steps: mixing a phosphorus raw material, elemental Sn and a mineralizer SnI4, placing the obtained mixture in a quartz tube, carrying out vacuum pumping and high temperature sealing, placing the sealed quartz tube in a muffle furnace, and carrying out optimized temperature programming and cooling to prepare black phosphorus. Black phosphorscrystals obtained in the invention have the advantages of large size, good crystallization performance and high purity, and the preparation method has the advantages of low device requirements, easy realization, and provision of great convenience for subsequent black phosphorus application and development.

Owner:NANJING UNIV OF TECH

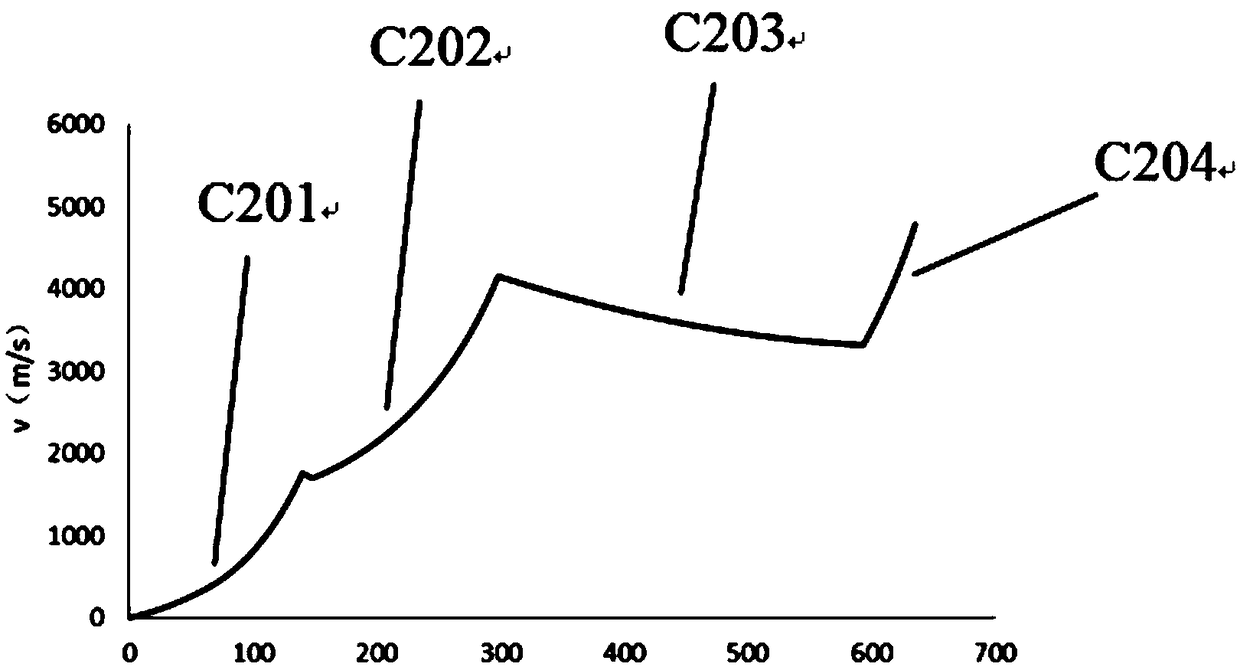

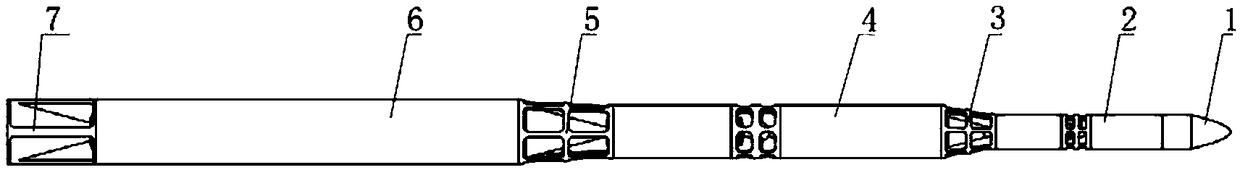

Small Satellite carrier

ActiveCN109018445ASmall scaleGuaranteed business valueCosmonautic vehiclesCosmonautic propulsion system apparatusAviationSolid fuel

The invention relates to the technical field of aerospace, in particular to a small satellite carrier. The utility model comprises a fairing cabin, three sub-cabins, two sub-cabins, two sub-cabins, one sub-cabin and a tail section which are serially connected in series. The power of the first sub-stage and the second sub-stage are both solid-liquid hybrid rocket motors, and the power of the thirdsub-stage is solid rocket motors. The small satellite carrier provided by the invention adopts a solid-liquid hybrid rocket engine for the power of the first sub-stage and the second sub-stage, the liquid oxidant is physically isolated from the solid fuel before ignition, the safety is high, and the maintenance cost is reduced; the solid-liquid hybrid rocket engine is used for the power of the first sub-stage and the second sub-stage. The third stage is powered by solid rocket motor with high mass ratio, low dead weight and the same payload, which effectively reduces the size of the small satellite carrier and improves the quick response capability. The small satellite carrier provided by the invention can ensure the commercial value and economic benefit, and also has the quick response ability.

Owner:BEIHANG UNIV

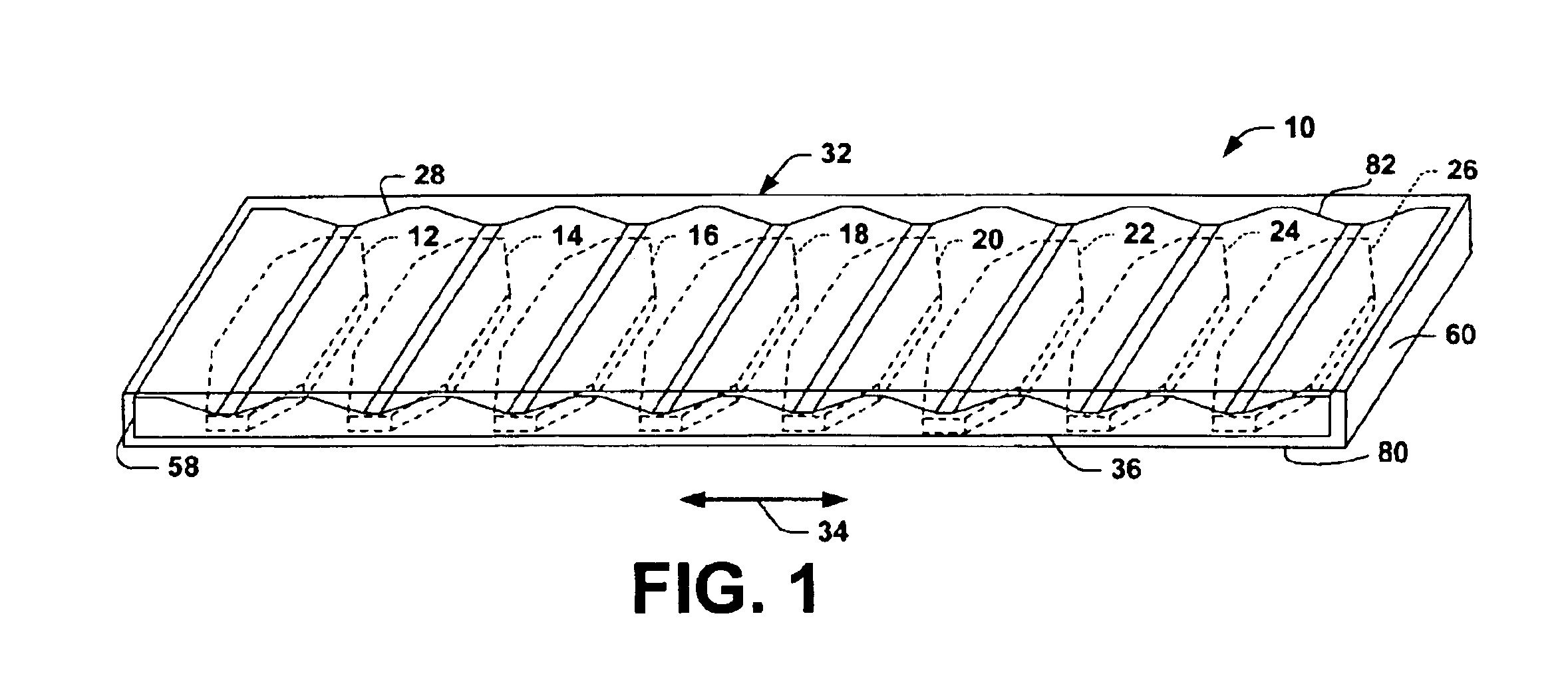

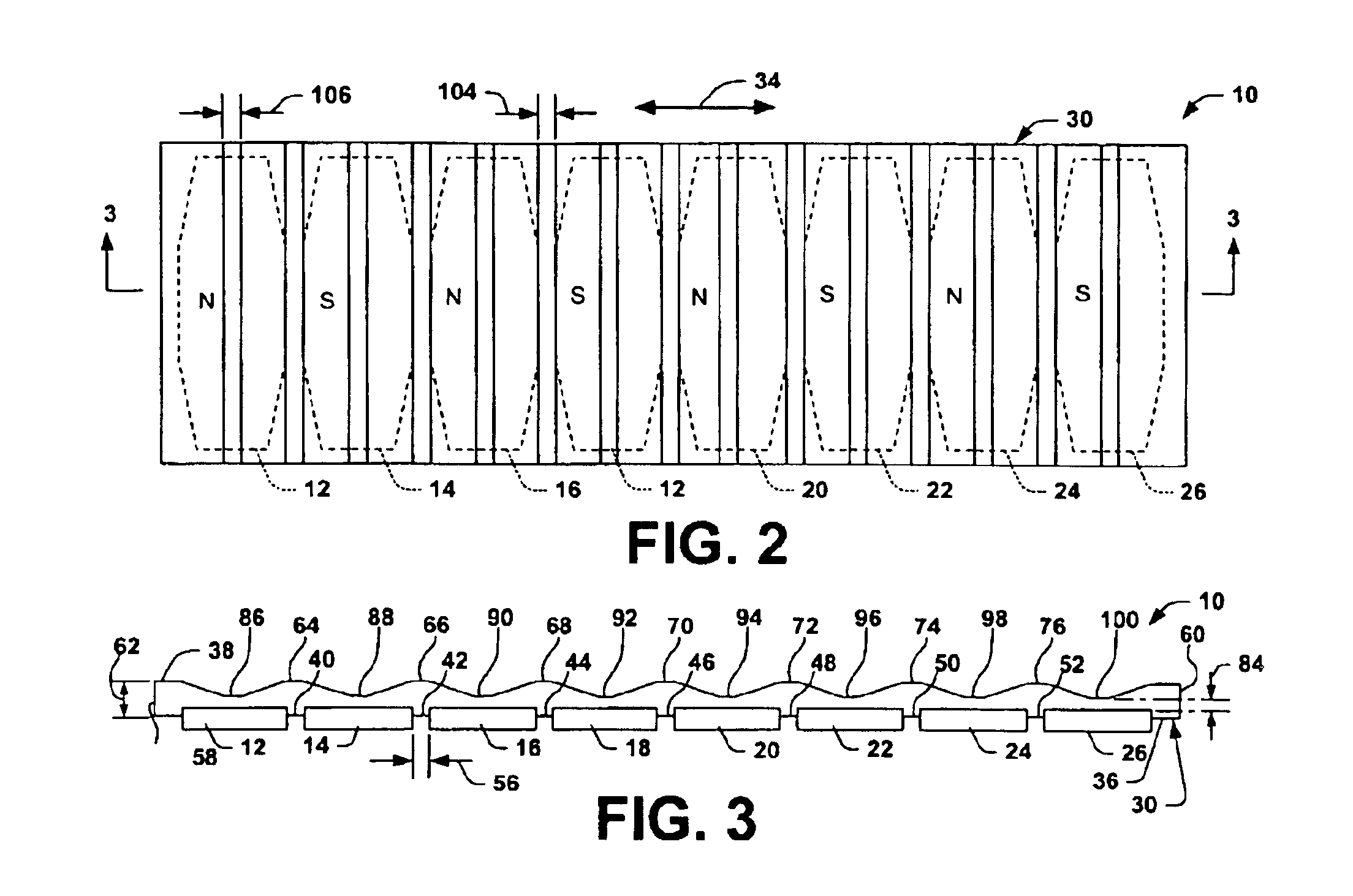

High performance linear motor and magnet assembly therefor

InactiveUS6919653B2High performanceReduce leakage fluxMagnetic circuit rotating partsPropulsion systemsMagnetReduced mass

A magnet assembly includes a back iron and an array of magnets. The back iron is in the form of a plate having opposed surfaces. The magnets are arranged along one of the surfaces, with the other surface being dimensioned and configured according to the magnetic field distribution associated with the magnets. The back iron geometry provides for reduced mass, reduced leakage flux, and high flux densities to improve performance of a linear motor that employs such a magnet assembly.

Owner:ROCKWELL AUTOMATION

Flexible lead-acid battery core easy to recycle, and preparation method of flexible lead-acid battery core

ActiveCN103560252AIncrease profitImprove quality ratioCell seperators/membranes/diaphragms/spacersFinal product manufactureCapacitanceFiber

The invention relates to a preparation method of a flexible lead-acid battery core easy to recycle. The preparation method of the flexible lead-acid battery core is characterized by taking porous glass fiber cloth made of compound sodium alginate fiber as a supporting layer, and comprises the following steps: applying metal flow collection layers to two surfaces of the supporting layer by adopting a vacuum sputtering or vacuum evaporation coating method, coating positive and negative electrode active substances respectively, and drying; spraying a sodium alginate solution on the dried surface, so as to form an isolating layer; and drying so as to obtain the flexible lead-acid battery core capable of being wound. The assembling is performed according to required capacitances, shapes and sizes, electrode leading-out terminals are connected and are pressed in a shell, then an electrolyte is filled in the shell, and the sealing is performed, so that the flexible lead-acid battery core easy to recycle is obtained.

Owner:FUJIAN REIDA PRECISION

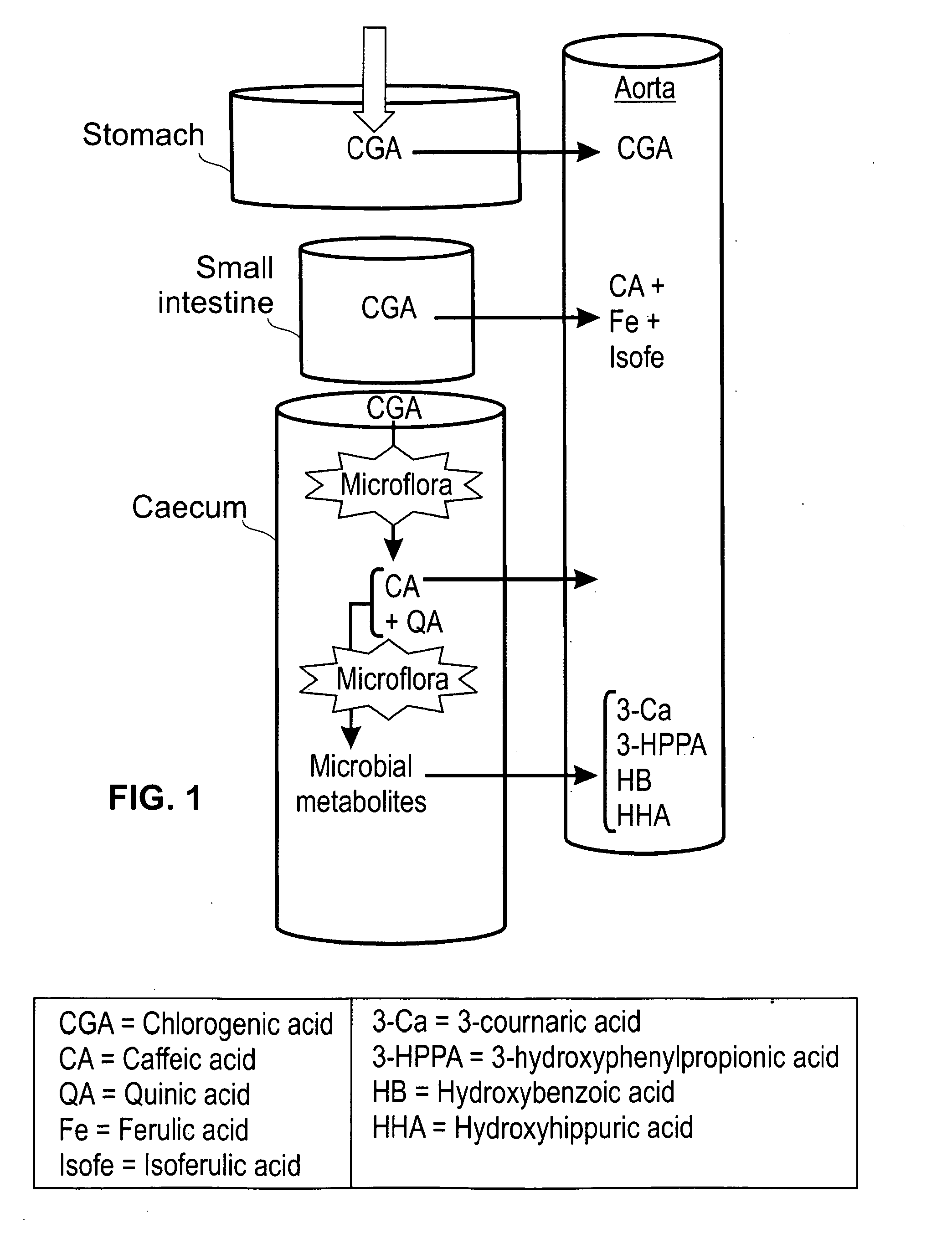

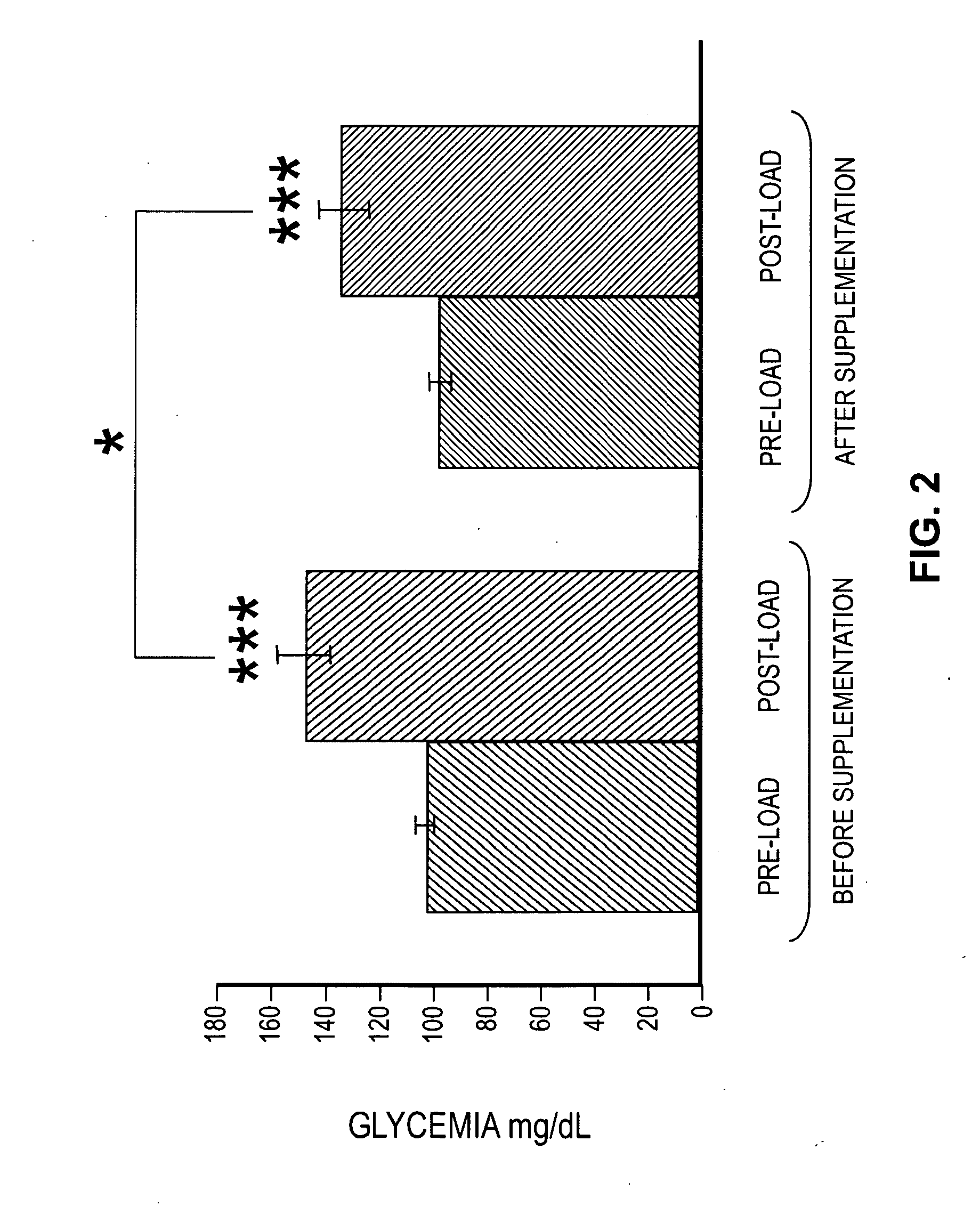

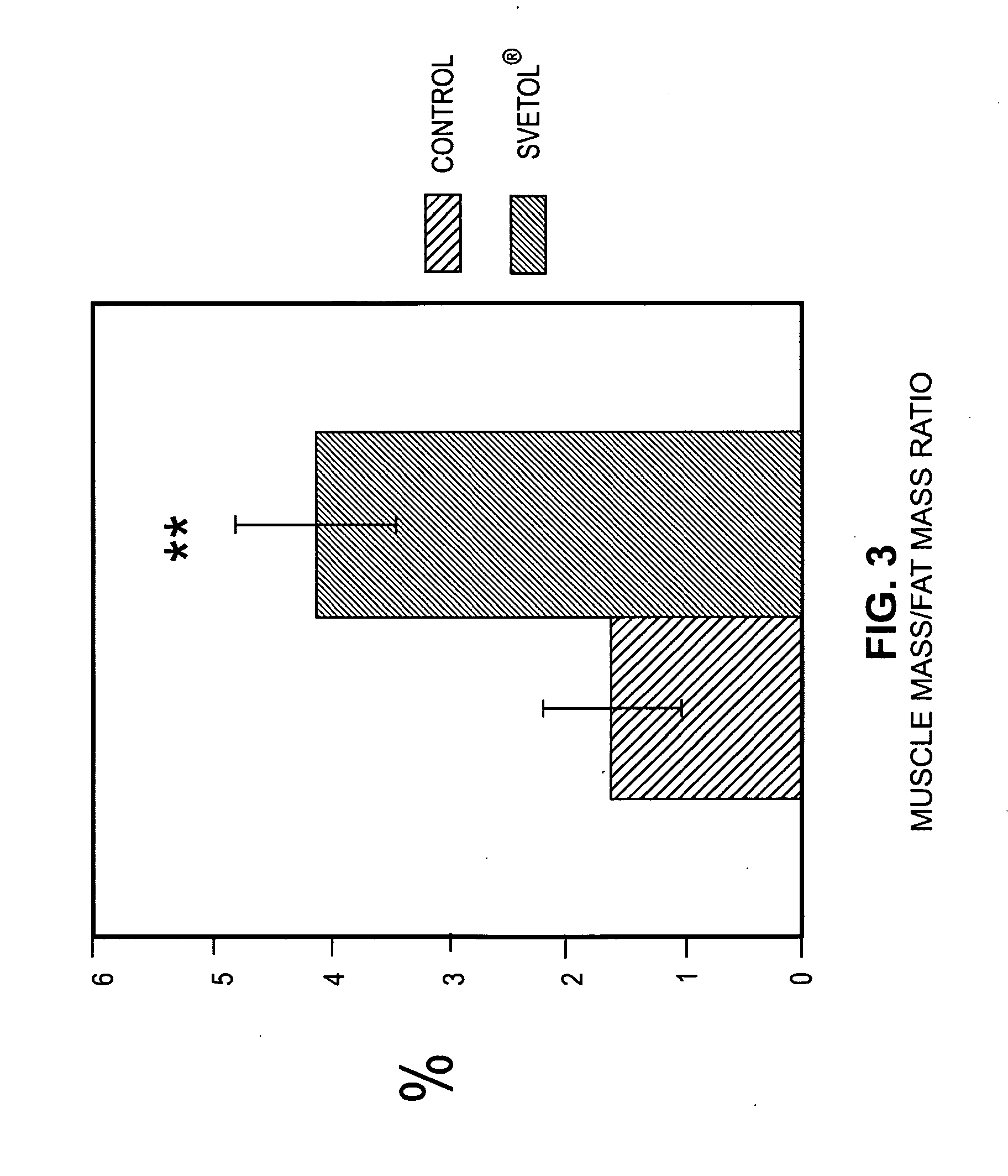

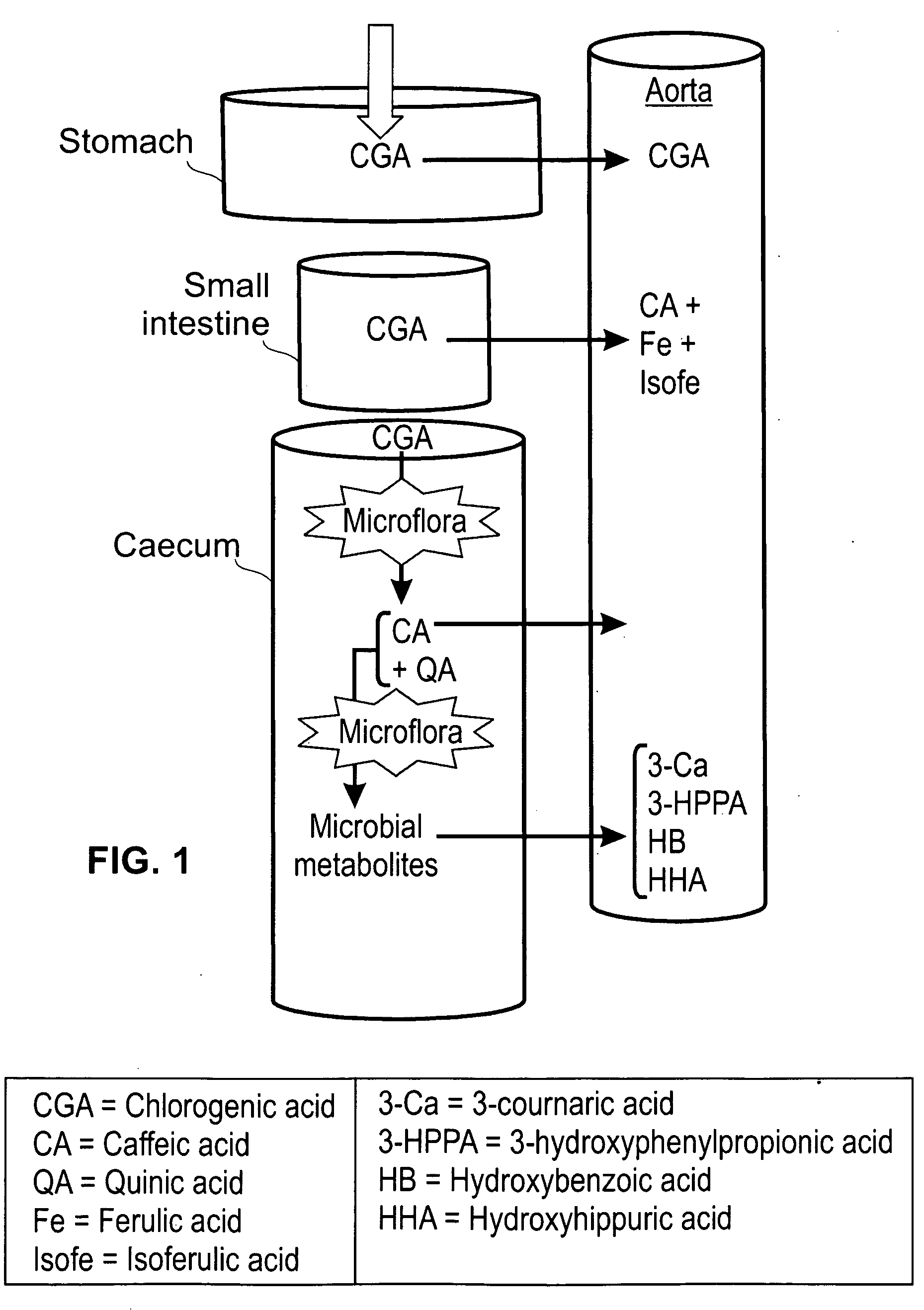

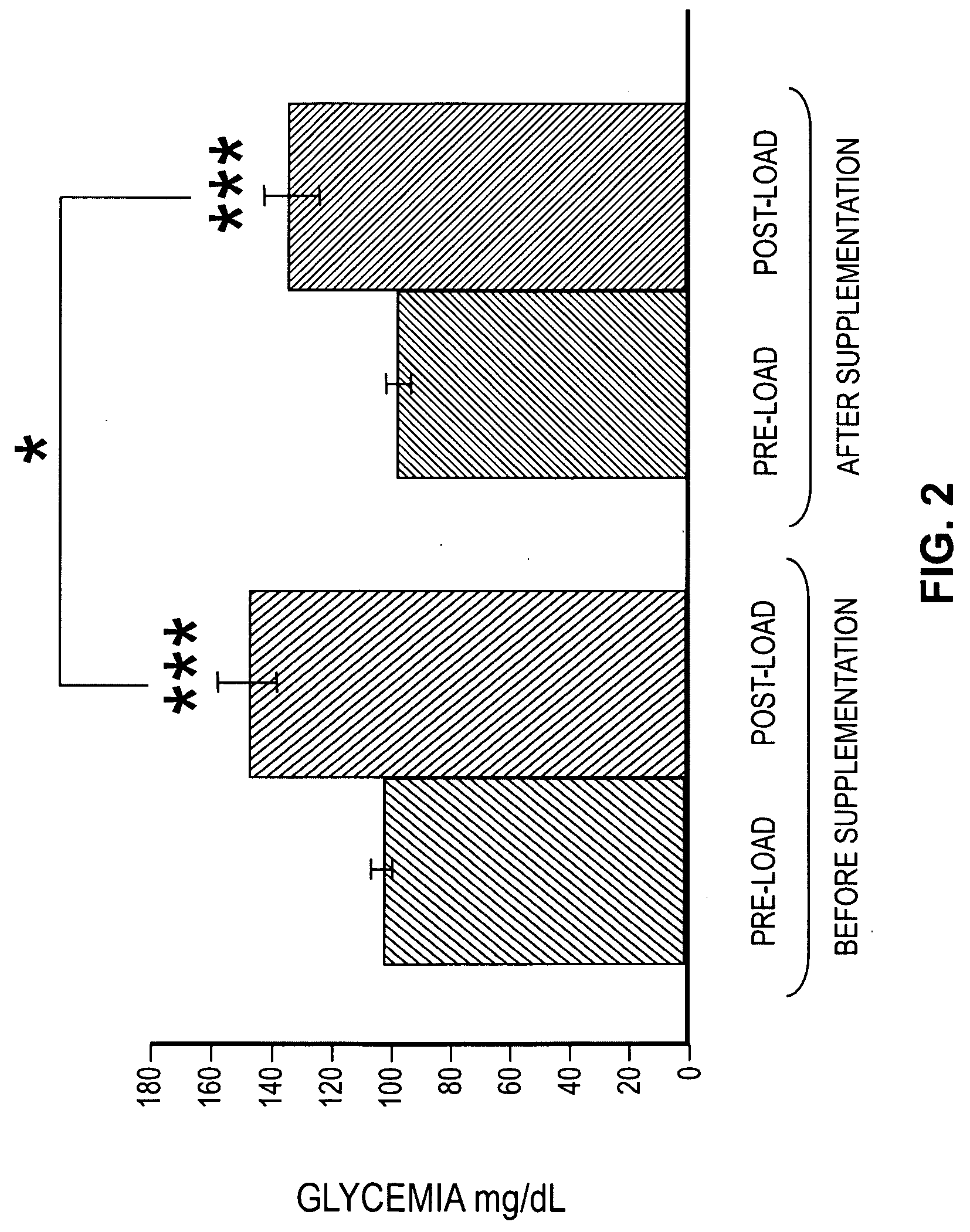

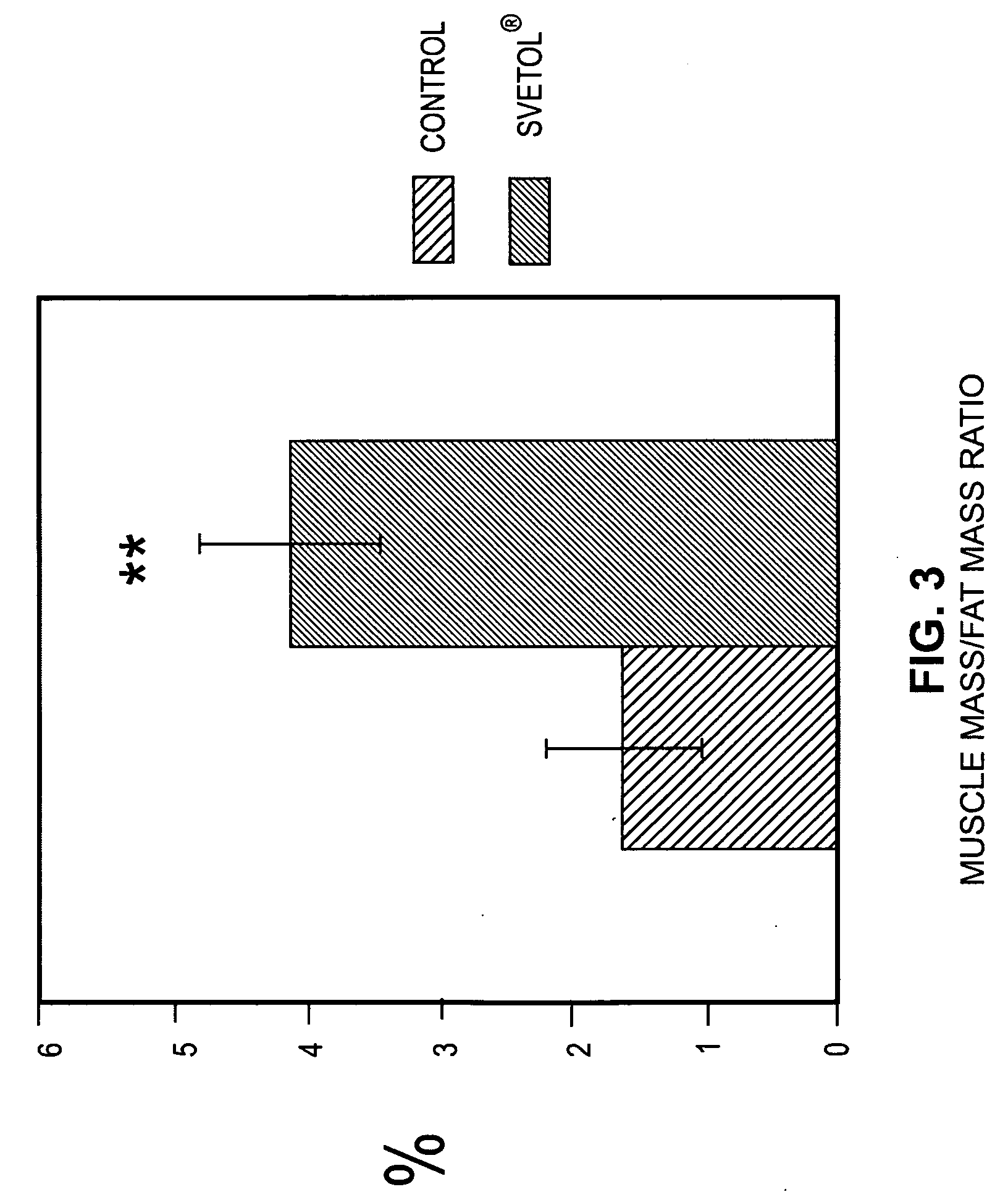

Effects of a decaffeinated green coffee extract on body weight control by regulation of glucose metabolism

ActiveUS20110223281A1BioavailabilityInhibitory activityOrganic active ingredientsAnimal feeding stuffCaffeineStomach

A method of controlling body weight in humans by administering an amount of decaffeinated green coffee extract effective to treat a subject. A preferred green coffee extract contains a ratio of 4-caffeoylquinic acid (4-CQA) to total chlorogenic acids (tCGA) (5-CQA / tCGA) of from about 0.1 to about 0.2. More preferably, the green coffee extract comprises from about 6% to about 8% of 4-caffeoylquinic acid and has a total chlorgenic acid concentration that exceeds about 45%. A preferred method of administration consists of administering the green coffee extracts is a dosage of about 200 mg twice a day prior to meals on an empty stomach.

Owner:NATUREX INC

Preparation method of carbon nitride/microporous molecular sieve composite material

InactiveCN103381371AEffective coverageHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsMolecular sieveCarbon nitride

The invention relates to a preparation method of a carbon nitride / microporous molecular sieve composite material. The method takes the microporous molecular sieve ZSM-5 or MCM-22 as a matrix, and adopts melamine as a precursor. The carbon nitride (C3N4) is loaded to the external surface of the microporous molecular sieve by means of mechanical grinding method and temperature programmed calcinations. The melamine and the microporous molecular sieve are in a mass ratio of 0.1:1-1:1. The composite material obtained by the invention has very good shape selective catalysis on a toluene disproportionation process. Also, the preparation method is simple, and the cost is low.

Owner:CHANGZHOU UNIV

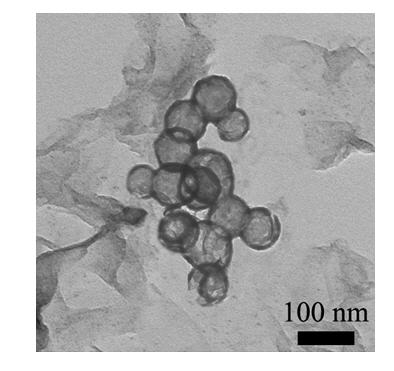

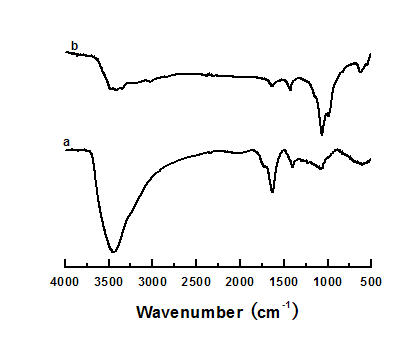

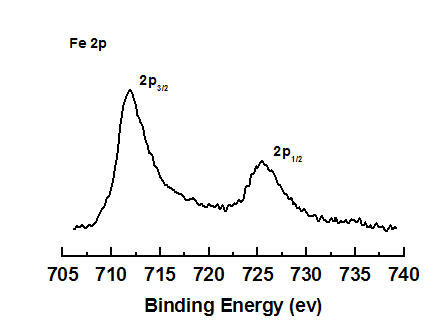

Nano iron phosphate hollow sphere/graphene composite material and preparation method thereof

InactiveCN102185147AGood electrical conductivityGood discharge stabilityCell electrodesCvd grapheneUrea

The invention relates to a nano iron phosphate hollow sphere / graphene composite material with graphene as a carrier, and the nano iron phosphate of a hollow spherical structure with the particle size 50-100nm grows on the graphene. The preparation method of the composite material provided by the invention comprises the following steps: carrying out a hydro-thermal reaction on a mixed liquid containing oxidized graphene, hexahydrate ammonium ferrous sulfate and phosphoric acid at 60-120 DEG C by using urea as a precipitator and adding a surfactant (lauryl sodium sulfate); washing the products;and carrying out vacuum drying, obtaining the nano iron phosphate hollow sphere / graphene composite material. The nano iron phosphate hollow sphere / graphene composite material provided by the invention has the advantages of unique nano hollow structure, excellent electrical conductivity and discharge stability, small particle size, good dispersity and suitability for the anode material of a lithium ion secondary electrode; and the preparation method based on a low-temperature hydro-thermal method is simple and economic, thereby being suitable for realization of industrial large-scale production.

Owner:NANJING NORMAL UNIVERSITY

Effects of a decaffeinated green coffee extract on body weight control by regulation of glucose metabolism

InactiveUS20100112098A1Reduce glycemiaImprove quality ratioOrganic active ingredientsBiocidePhysiologyCaffeoylquinic acid

A method of controlling body weight in humans by administering an amount of decaffeinated green coffee extract effective to treat a subject. A preferred green coffee extract contains a ratio of 5-caffeoylquinic acid (5-CQA) and total chlorogenic acids (tCGA) (5-CQA / tCGA) of between about 0.2 and 0.3. More preferably, the concentration of tCGA is greater than about 45% and the concentration of 5-CQA is less than about 10%. A preferred method of administration consists of administering between about 200 mg and about 1,000 mg per day, more preferably administering about 400 mg per day.

Owner:NATUREX INC

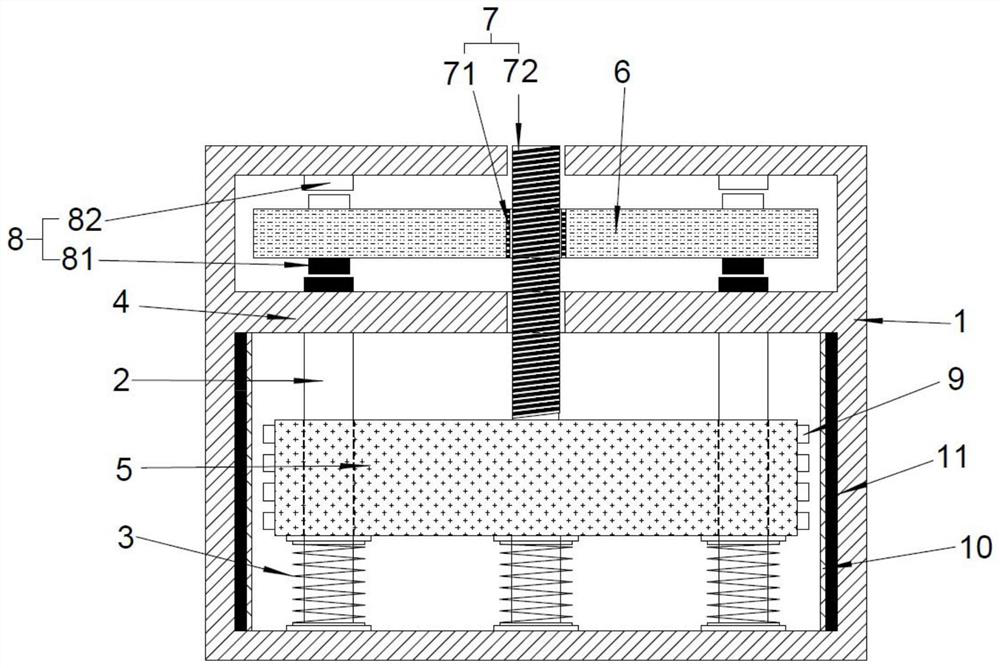

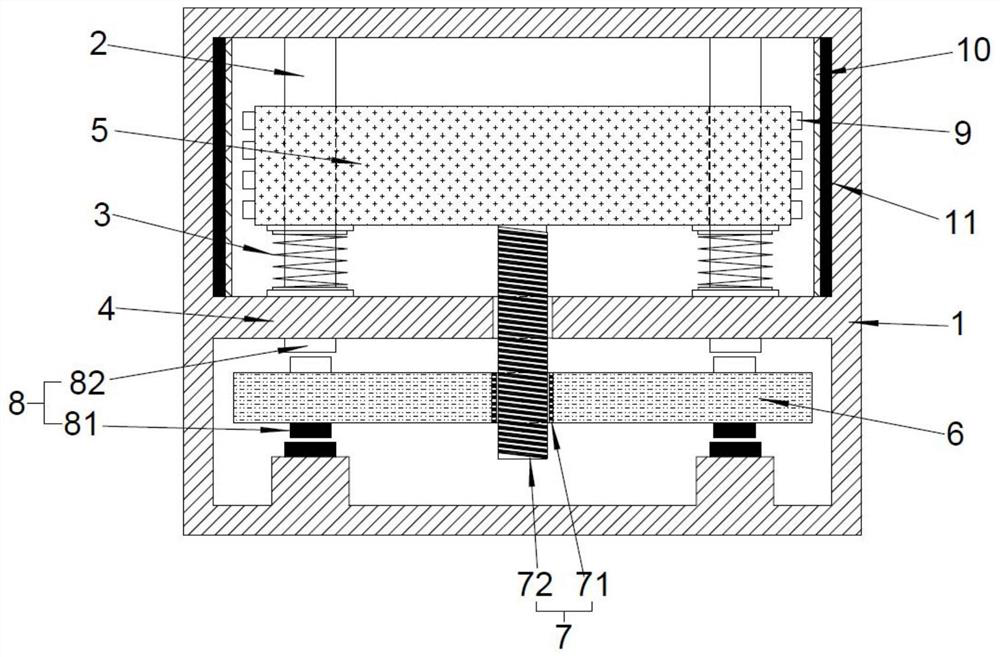

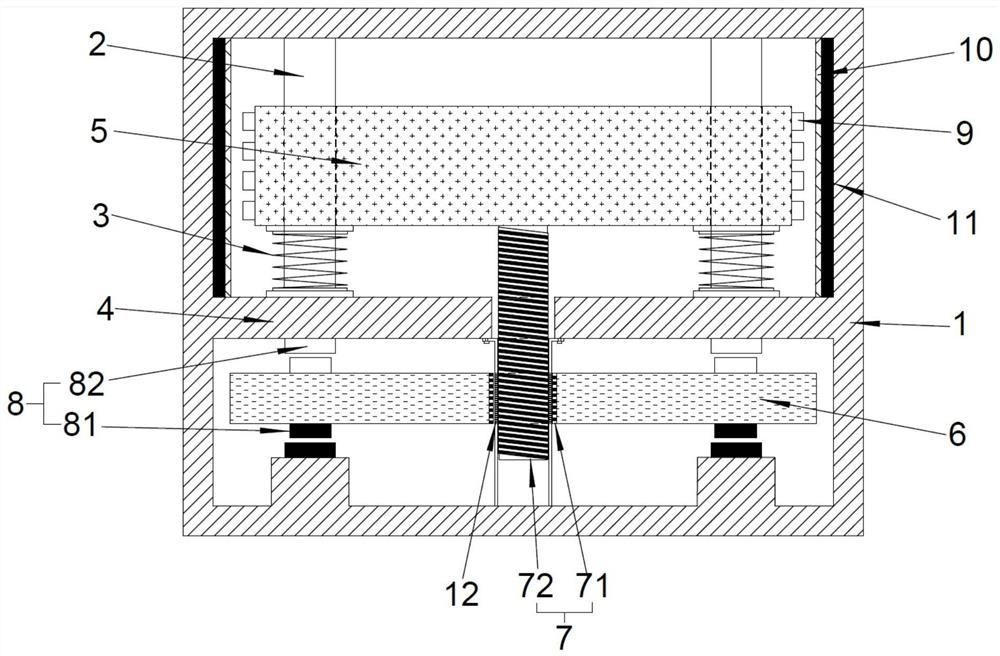

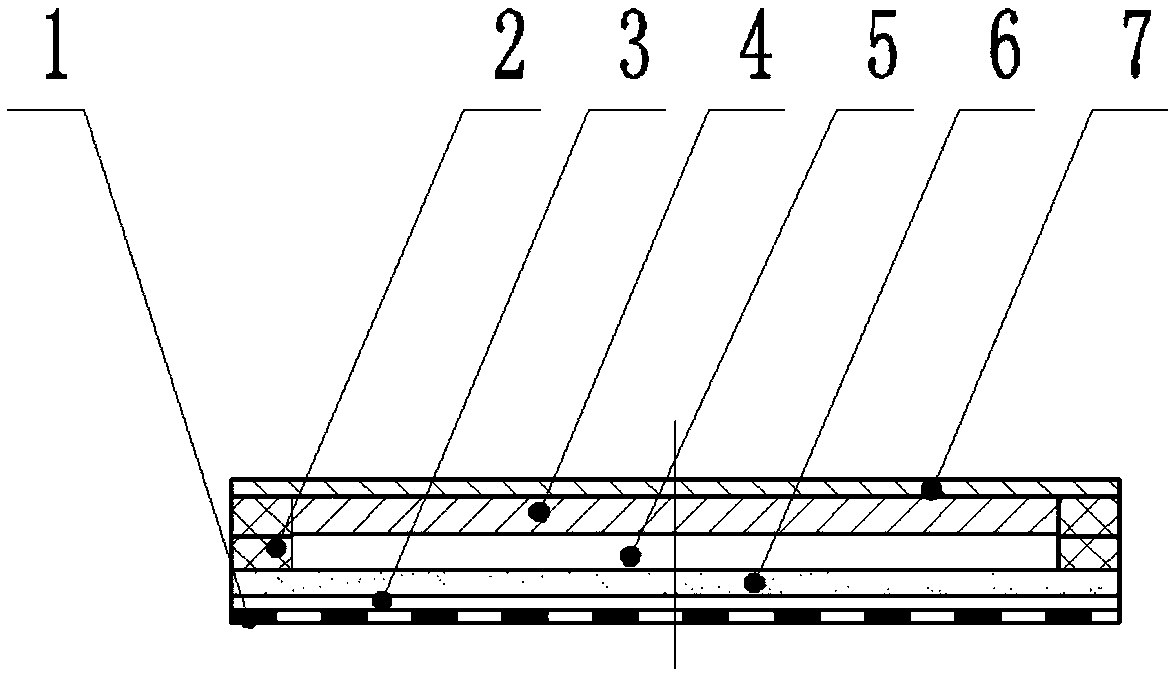

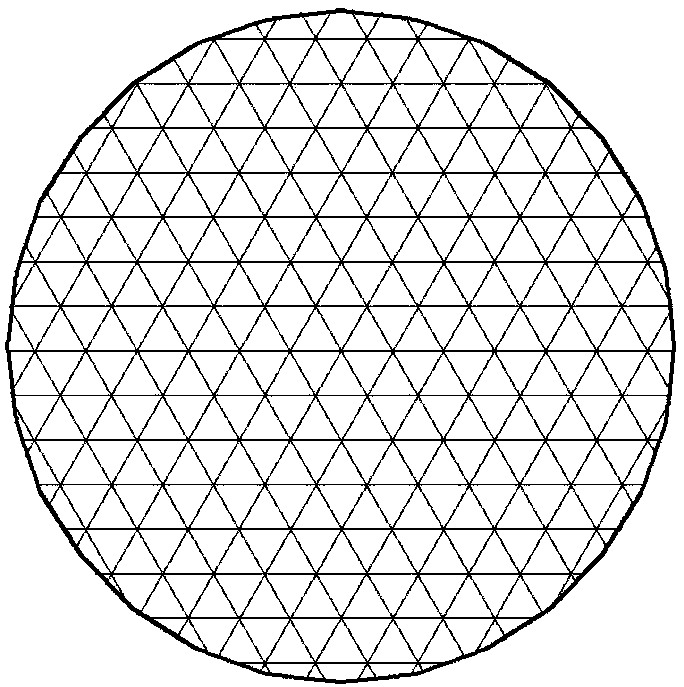

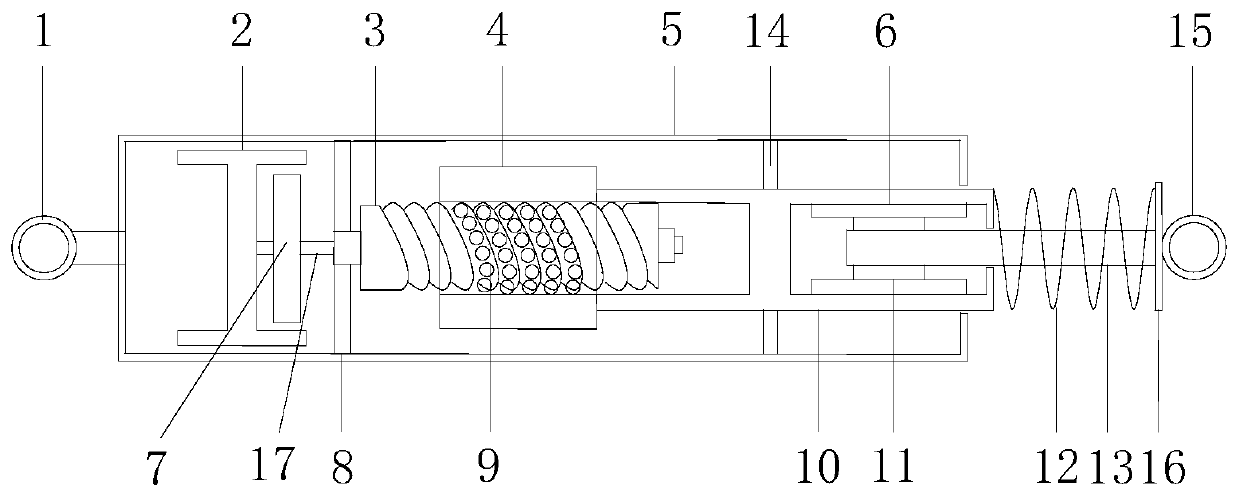

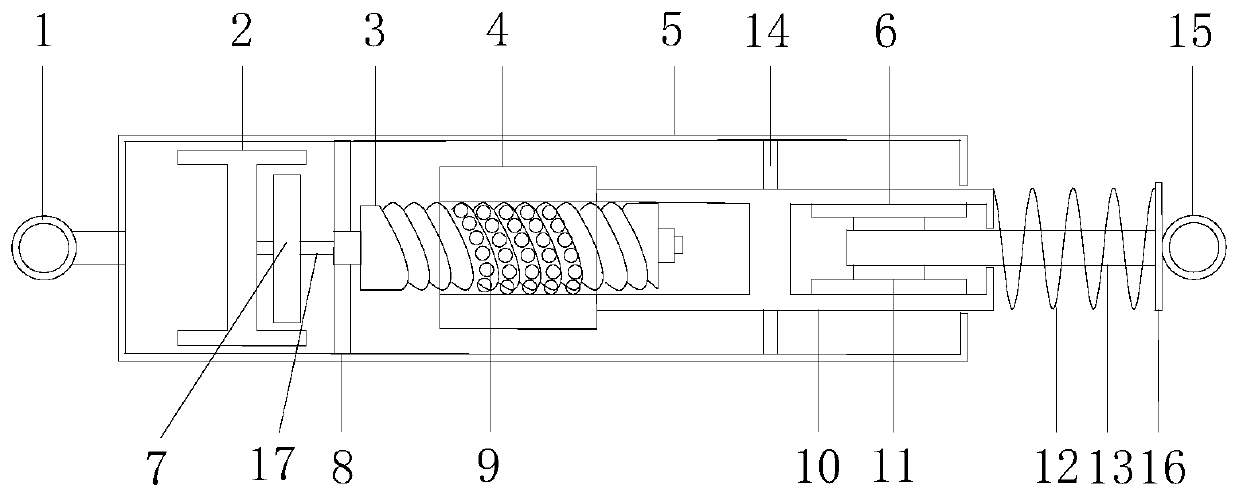

Vertical tuned mass magnetic lead screw type inerter eddy current damper

ActiveCN112128285ALower net elongationReduce physical weightRotating vibration suppressionVibration dampersSupporting systemElectrical conductor

The invention relates to a vertical tuned mass magnetic lead screw type inerter eddy current damper. The vertical tuned mass magnetic lead screw type inerter eddy current damper comprises a spring mass system, an inertia mass system, an eddy current damping system and a supporting system; the spring mass system comprises a spring and a clump weight; the inertia mass system comprises a flywheel, amagnetic lead screw nut pair and a magnetic suspension thrust bearing; the eddy current damping system comprises a straight-strip-shaped permanent magnet, a conductor plate and back iron; and the supporting system comprises guide rods, a supporting bracket and an outer frame. According to the damper, the inerter principle is introduced, physical balance weight is reduced, the net elongation of thespring of a low-frequency structure controlled by the device is reduced while the mass ratio of the device is increased; by adopting the magnetic lead screw nut pair, the friction between a lead screw and a nut is eliminated, and the working efficiency is improved; meanwhile, the magnetic suspension thrust bearing is used cooperatively to ensure that the flywheel is suspended in a flywheel chamber to work normally; and the overall friction of the damper is greatly reduced, and the service life is prolonged.

Owner:湖南省潇振工程科技有限公司

Single battery being capable of resisting overloading and high-spinning and being high in capacity

InactiveCN108232222AIncrease positive conductivityReduce thermal shockDeferred-action cellsCell electrodesCurrent collectorAsbestos

The invention provides a single battery being capable of resisting overloading and high-spinning and being high in capacity. A preparation method includes the steps of: successively tightly laminatinga nickel square-mesh net, a graphite sheet, positive powder, insulation powder, a negative pole sheet and a current collector; surrounding and compacting the outer rings of the insulation powder andthe negative pole sheet by a current blocking ring which is produced by mixing and pulping MgO and asbestos according to mass ratio of 2:1 and punching the mixture into a ring; the insulation powder is a mixture of LiCl-LiBr-LiF ternary eutectic substance and MgO according to the mass ratio of 1:1-1:1.5, wherein the mixture is compressed to form an insulation layer being 0.4-0.6 mm in thickness; the positive powder is a CoS2 / FeS2 mixture according to the mass ratio of 1:1, wherein the positive powder also contains insulation powder accounting for 15-18% by mass of the positive powder and lithium oxide accounting for 2-5% by mass of the positive powder. The single battery has strong anti-severe environment capability, can output stable voltage and is high in specific energy, and also satisfies the demand of resisting overloading and high-spinning and being long in service life.

Owner:北方特种能源集团有限公司西安庆华公司

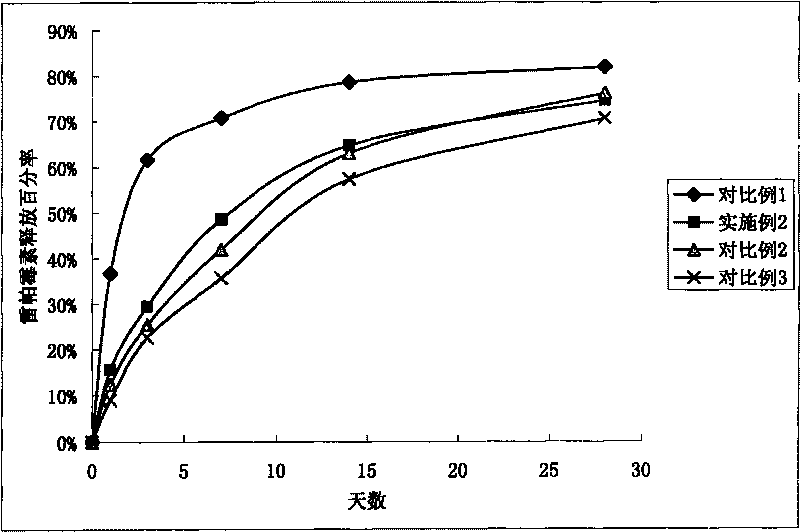

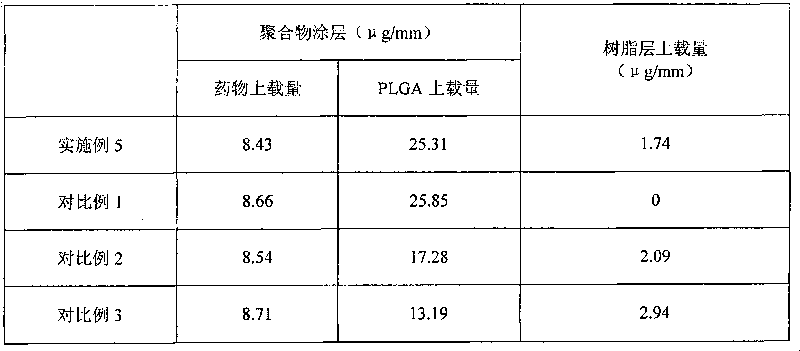

Medicament eluting stent and preparation method thereof

ActiveCN101711710AReduce dosageReduce adverse reactions such as restenosisStentsMedical devicesGlycolic acidMedicine

The invention relates to a medicament eluting stent, which consists of a bare stent and a coating coated on the bare stent. The medicament eluting stent is characterized in that the coating at least comprises a polymer layer and a resin layer, wherein the polymer layer comprises polylactic-co-glycolic acid (PLGA) and medicaments; and the resin layer is coated on the surface of the polymer layer. A resin of the invention is coated on the surface of the medicament-loaded polymer coating. Due to the sustained release effect of the resin, on the premise of guaranteeing medicament dosage, the dosage of the polymer is reduced so as to obvious reduce an inflammatory reaction, reduce the generation of adverse reactions such as late intravascular restenosis and the like, and avoid forming late thrombosis.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

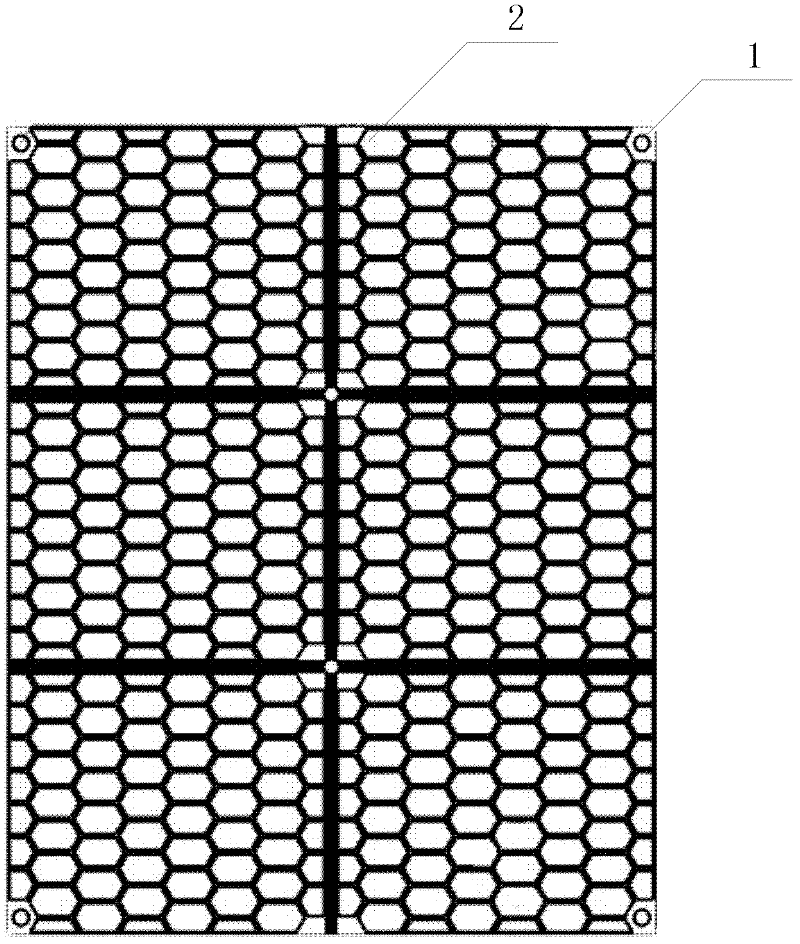

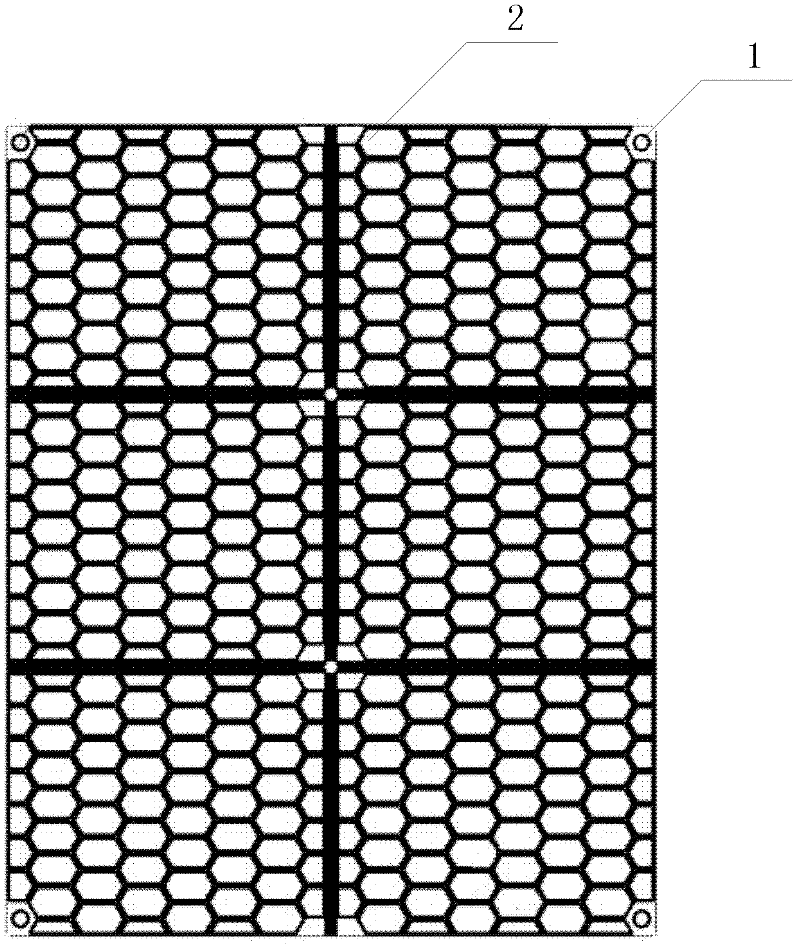

Storage battery grid

InactiveCN102522566AReduce dosageImprove firm performanceElectrode carriers/collectorsCeramic compositeGraphite

The invention discloses a storage battery grid. The storage battery grid comprises a lug or at least one lug hole for installing the lug, wherein the storage battery grid is integrally a polygonal honeycomb structure; the storage battery grid is processed from graphite metal eutectic ceramic, wherein the graphite metal eutectic ceramic comprises conductive agent, ceramic composite material and medium material; the graphite metal eutectic ceramic comprises the following in part by weight: 5-20 parts of conductive agent, 55-70 parts of ceramic composite material, and 5-15 parts of medium material. The storage battery grid is used to substitute a calcium lead alloy storage battery grid in a lead-acid storage battery, and simultaneously substitute a lead metal bus bar, so that the dosage (saved about 50-70%) of heavy metal lead in the lead-acid storage battery is reduced, and lead pollution in the production process of the lead-acid storage battery is relieved. The mass of the storage battery grid is 20% of that of the calcium lead alloy storage battery grid, so that the mass ratio of the polar plate reaction substance to the storage battery grid for carrying and conducting is greatly improved.

Owner:BEIJING HONGYUAN NENGXIN TECH

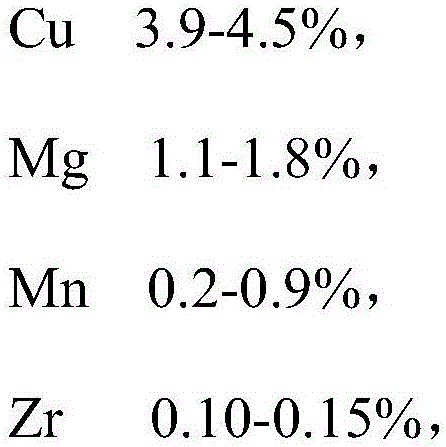

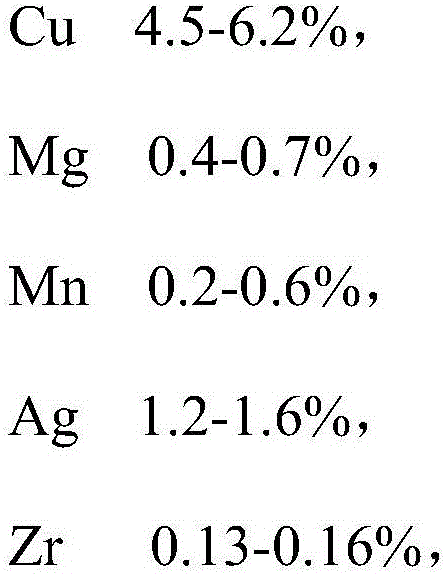

Method for improving damage tolerance performance of Al-Cu-Mg alloy

InactiveCN105734469AImproved resistance to fatigue damage toleranceImproved damage tolerance performanceFatigue damageCrazing

A method for improving the damage tolerance performance of an Al-Cu-Mg alloy is to carry out a solid solution + water quenching treatment on an Al-Cu-Mg alloy plate, and then perform a cold rolling pre-deformation treatment with a deformation amount of 6-15%, and then Perform aging treatment. The process of the invention is simple and reasonable, through cold rolling with small deformation amount after solid solution quenching, a certain compressive stress layer is generated on the surface of the plate, and the formation and expansion of cracks under the action of fatigue stress are effectively inhibited. With the natural aging treatment, the surface layer has a large density of dislocations due to the pre-deformation of cold rolling, which makes the alloy precipitate large-sized Cu-Mg atomic clusters during the natural aging process, and increases the Cu / Mg mass ratio of the clusters, so that The surface layer of the plate produces a large order strengthening effect and modulus strengthening effect; artificial aging treatment can cause the plate to precipitate a fine and dispersed second phase, and at the same time, the higher density dislocations on the surface can form a finer and dispersed second phase on the surface of the plate. Two phases, thereby hindering the formation and propagation of fatigue cracks in the surface area, and improving the fatigue resistance damage tolerance performance of the plate. This surface-hard-core-tough structure can effectively improve the damage tolerance performance of the plate, and is suitable for industrial applications.

Owner:CENT SOUTH UNIV

Glass ceramics generated by taking granite tailings as main raw material, and preparation method for glass ceramics

The invention discloses glass ceramics generated by taking granite tailings as a main raw material and a preparation method for the glass ceramics. The glass ceramics comprises the following components in percentage by mass: 4.2 to 4.4 percent of Na2O, 7.0 to 7.3 percent of MgO, 25 to 26 percent of Al2O3, 42 to 47 percent of SiO2, 4.0 to 4.5 percent of TiO2, 2.9 to 3.1 percent of K2O, 7.9 to 8.2 percent of CaO, 0 to 4 percent of MnO2, and 0.5 to 0.6 percent of Fe2O3. According to the glass ceramics, the granite tailings, dolomite, caustic calcined magnesite, aluminum hydroxide, titanium dioxide, sodium carbonate and manganese ore are utilized as raw materials; through a formula design, the content of each component is within the range above; the using amounts of the TiO2, the MnO2 and the Fe2O3 are adjusted, so that the glass ceramics of multiple colors, such as blue grey, brown and dark yellow, can be obtained; the glass ceramics takes diopside as a primary crystalline phase, takes spinel as a secondary crystalline phase, and is high in mechanical property.

Owner:四川一名微晶科技股份有限公司

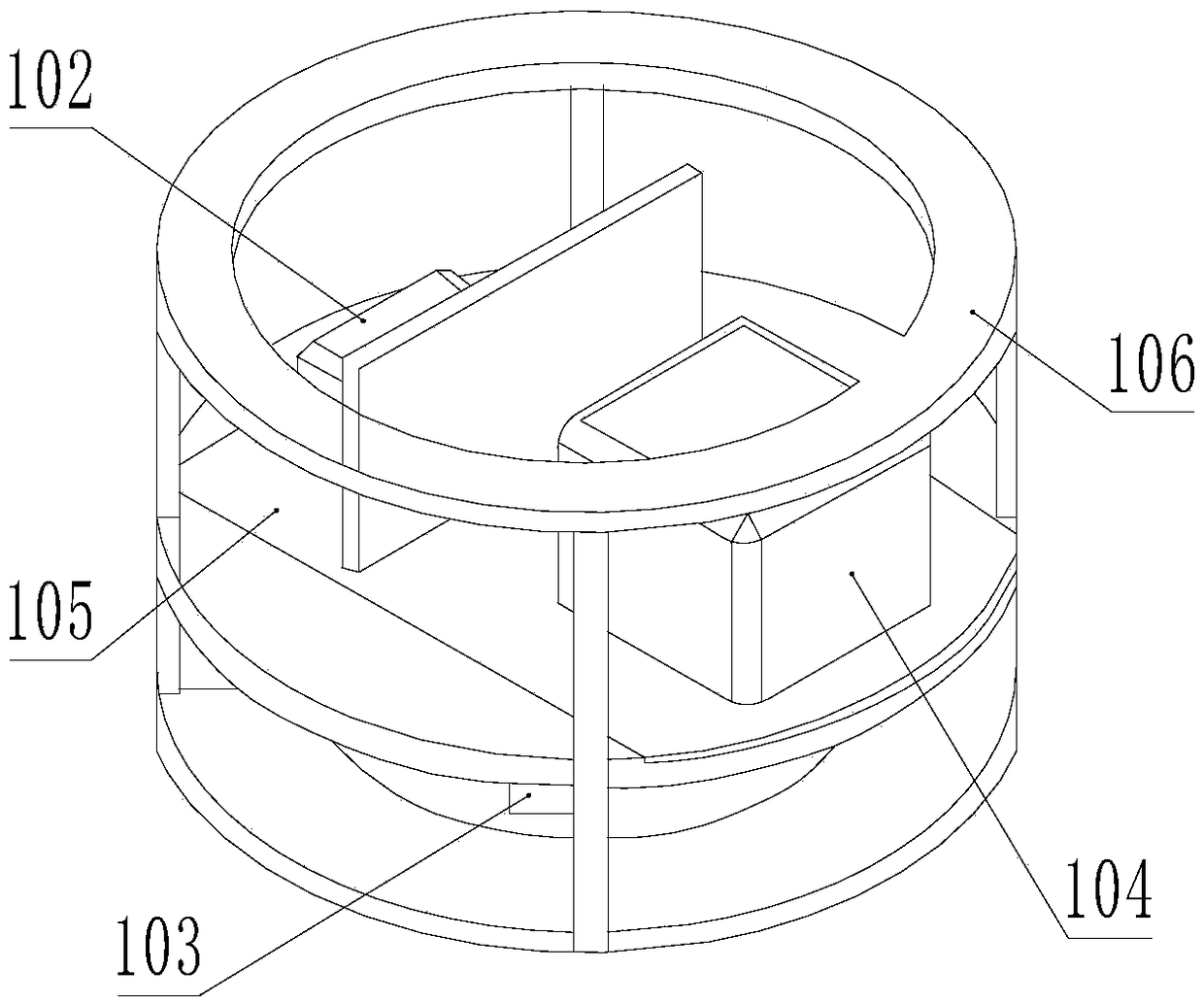

Tuned electromagnetic inertial mass damper

PendingCN109972762AImprove performanceImprove quality ratioProtective buildings/sheltersShock proofingRelative displacementFlywheel

The invention discloses a tuned electromagnetic inertial mass damper, which mainly comprises a ball screw mechanism arranged in an outer barrel. The upper end of the ball screw mechanism is connectedwith a gearbox and a rotary flywheel, and the gearbox is fixed by an upper limit device; the tuned electromagnetic inertial mass damper further comprises an inner barrel arranged at the lower end of the interior of the outer barrel, a lower limit device is arranged on the outer part of the inner barrel, and the inner tube can linearly move up and down in the lower limit device; the upper end of the inner barrel is fixedly connected with the ball screw mechanism to drive the ball screw mechanism to linearly move up and down; and a coil and a permanent magnet are arranged in sequence from the outer side to the inner side of the lower part inside the inner barrel, the permanent magnet is internally and fixedly connected with a magnetic conductor capable of linearly moving up and down, the magnetic conductor extends to the outer sides of the lower ends of the inner barrel and the outer barrel, the lower end of the magnetic conductor body is fixedly connected with the lower part connectionpart and a connection plate of the lower part connection part, and a spring and the connecting plate are fixedly connected with the lower end partof the inner barrel and are mounted outside the magnetic conductor in a sleeving mode. The tuned electromagnetic inertial mass damper is suitable for civil engineering structures with relative displacement, such as stay cable, long span bridge beam and tower beam connection positions, and displacement positions among high-rise buildings.

Owner:HUNAN UNIV OF SCI & TECH

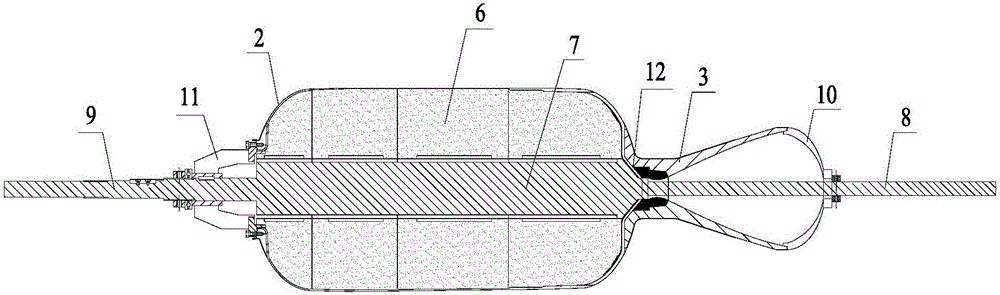

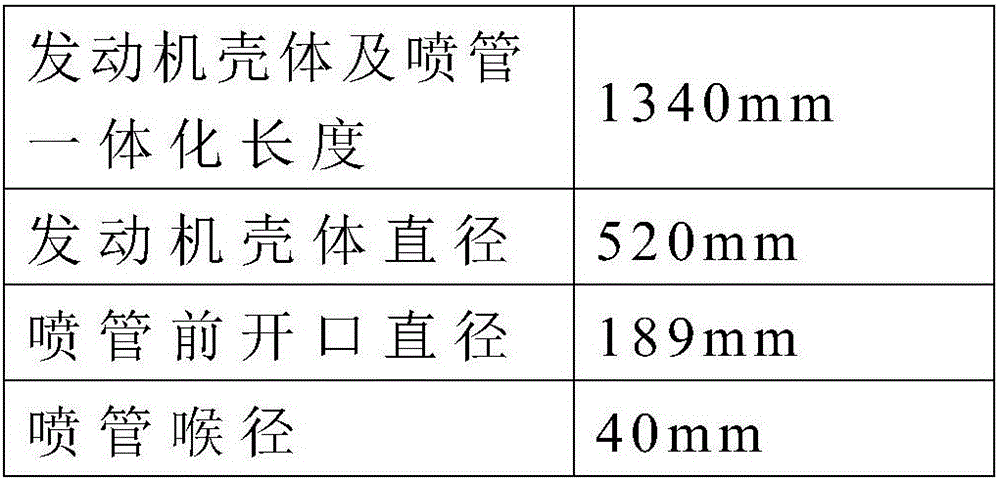

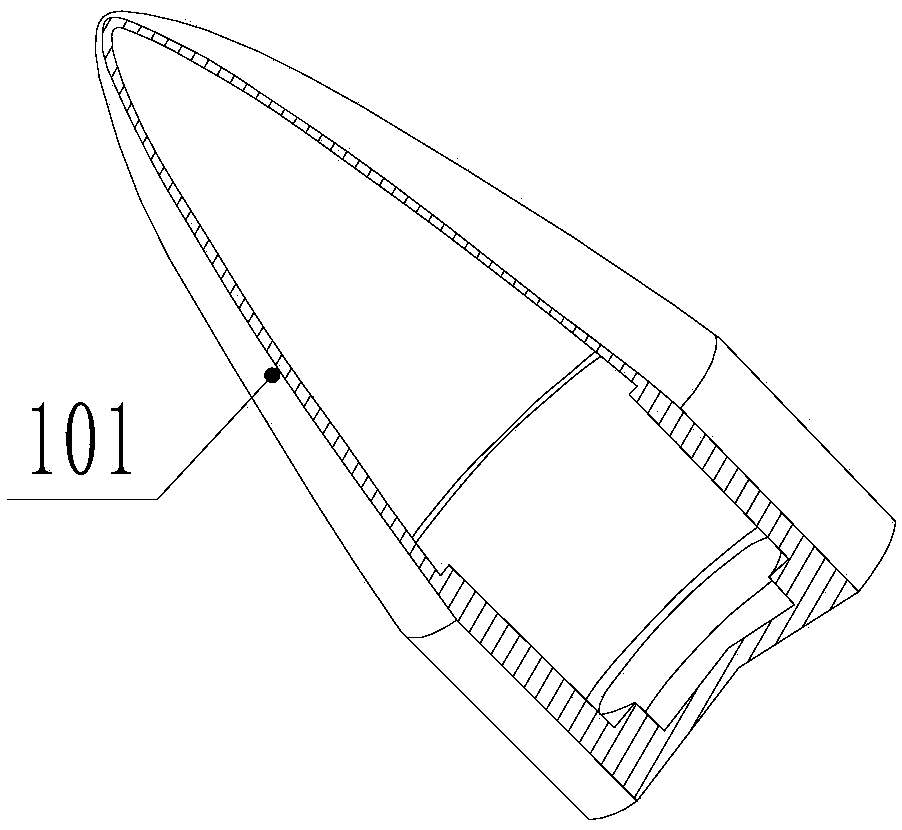

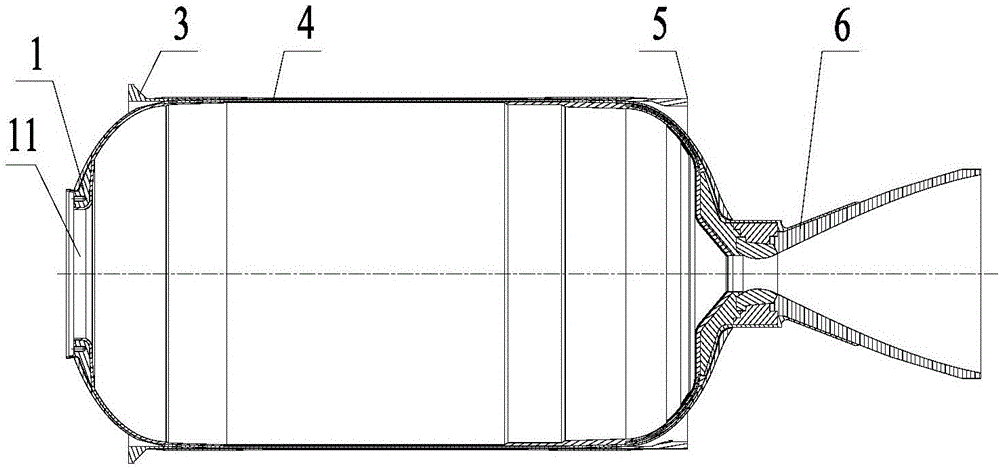

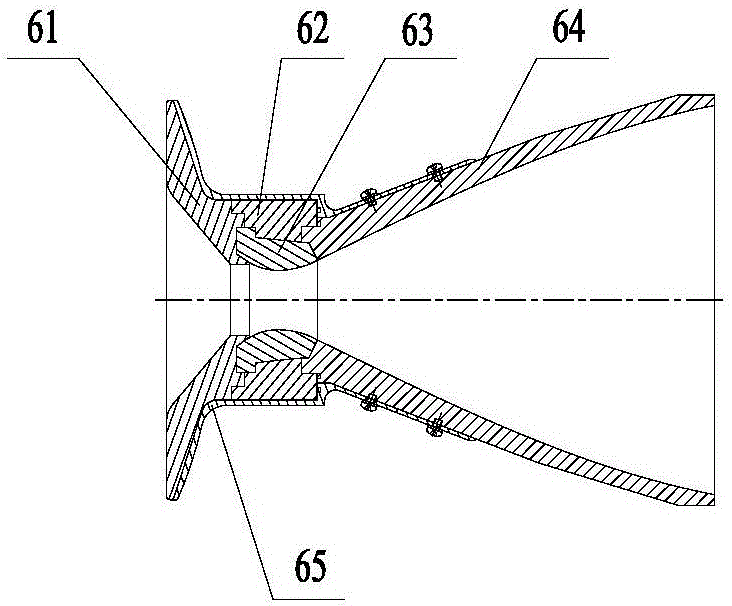

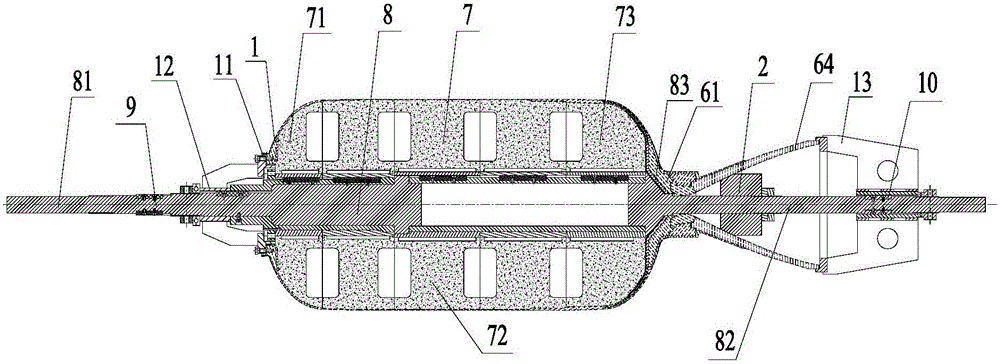

Integral forming method for engine case and spraying pipe

ActiveCN105965866AImprove quality ratioOne-piece molding method is simpleDomestic articlesMass ratioEngineering

The invention discloses an integral forming method for an engine case and a spraying pipe, and relates to a process of integrating the spraying pipe and the engine case rapidly and efficiently. The engine case comprises an engine case body and a front end socket connected with the front end of the engine case body, the structure that an engine case and a spraying pipe are formed independently and then connected through metal in the prior art is eliminated, instead, the spraying pipe and an engine case rear connector are combined into a whole, and formed along with the engine case in a winding mode together after the spraying pipe is assembled in place. A winding layer replaces an original spraying pipe metal shell body, the engine case rear connector, the spraying pipe metal shell body, a connector and the like are omitted, and the mass ratio of an engine can be effectively improved. In addition, the integral forming method is simple, short in period, low in price and particularly suitable for the engine case wound by fibers.

Owner:湖北三江航天江北机械工程有限公司

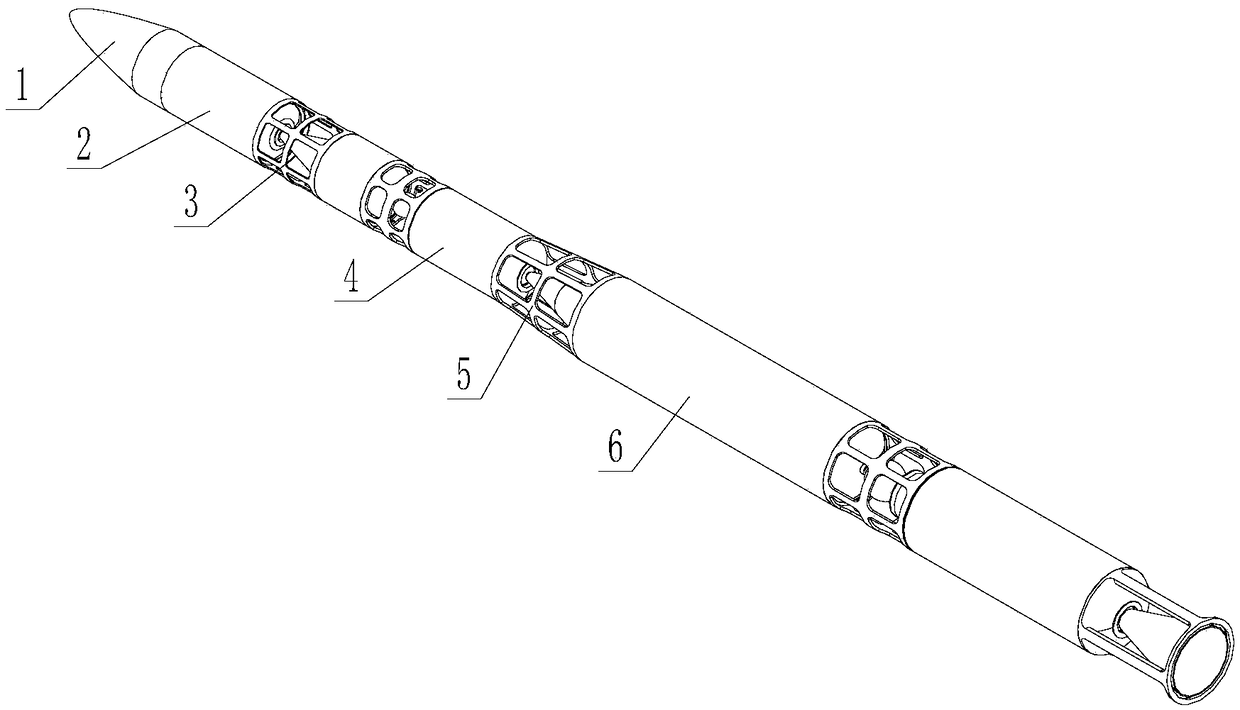

Small Satellite Vehicle

ActiveCN109018446ASmall scaleGuaranteed business valueCosmonautic vehiclesCosmonautic propulsion system apparatusAviationEconomic benefits

The invention relates to the technical field of aerospace, in particular to a small satellite carrier. The utility model comprises a fairing cabin, three sub-cabins, two sub-cabins, two sub-cabins, one sub-cabin and a tail section which are serially connected in series. The power of the first sub-stage is a solid rocket motor, and the power of the second sub-stage and the third sub-stage are bothsolid-liquid hybrid rocket motors. The power of the third stage and the second stage of the small satellite carrier provided by the invention adopts a solid-liquid hybrid rocket engine, the liquid oxidant is physically isolated from the solid fuel before ignition, the safety is high, and the maintenance cost is reduced; The first sub-stage is powered by solid rocket motor with high mass ratio, lowdead weight and the same payload, which effectively reduces the size of small satellite launch vehicle and improves the quick response capability. The small satellite carrier provided by the invention can ensure the commercial value and economic benefit, and also has the quick response ability.

Owner:BEIHANG UNIV

Integral forming method for engine composite shell and spray pipe

ActiveCN106273599AImprove quality ratioImprove performanceDomestic articlesAgricultural engineeringConductor Coil

The invention discloses an integral forming method for an engine composite shell and a spray pipe. The integral forming method refers to the process of rapidly and efficiently combining the spray pipe and the engine composite shell into a whole. The engine composite shell comprises a shell main body part and a front connector connected to the front end of the shell main body part. An engine shell and spray pipe flange connecting structure in the prior art is omitted. After assembled in place, a spray pipe assembly is formed together with the engine composite shell in a winding and curing mode. Metal components such as a rear connector, a connecting piece and the like are omitted. The mass ratio of an engine can be increased effectively. Meanwhile, the assembling procedure of the engine composite shell and the spray pipe is omitted, and the assembling and manufacturing period of the engine composite shell and the spray pipe is effectively shortened.

Owner:湖北三江航天江北机械工程有限公司

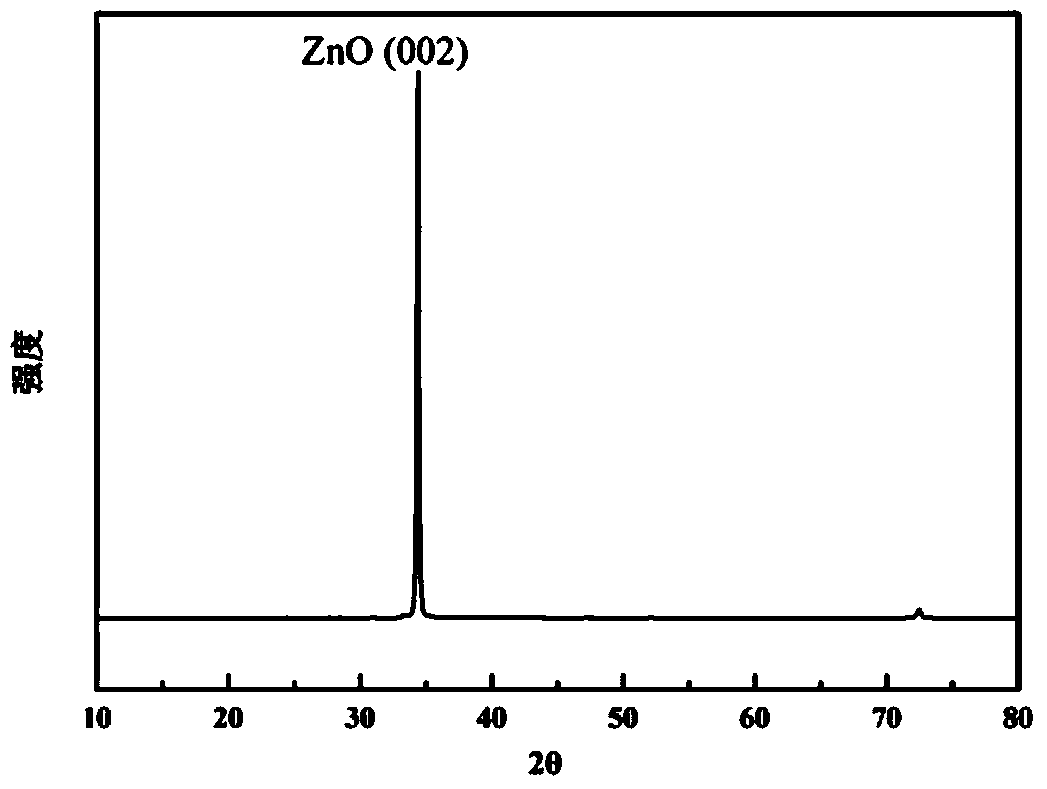

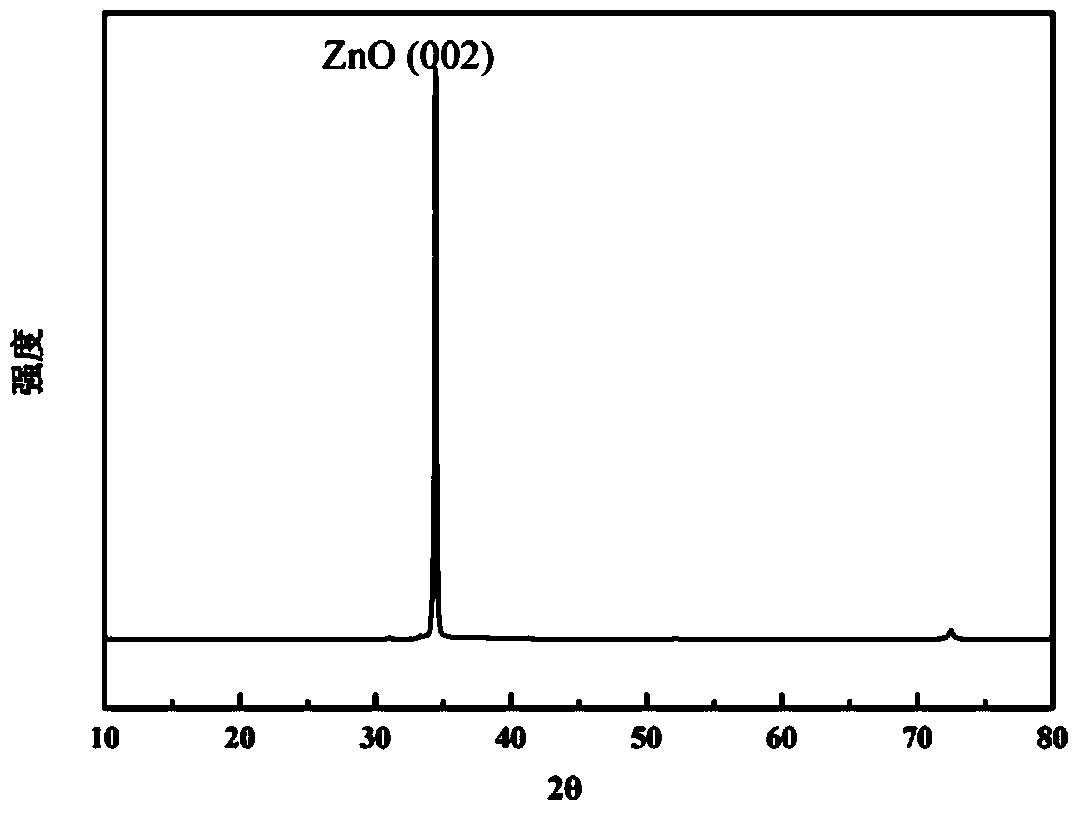

High-mobility ratio aluminum-doped zinc oxide transparent conductive thin film and preparation method thereof

ActiveCN103617831AEasy to handleSputtering pressureConductive layers on insulating-supportsVacuum evaporation coatingHigh concentrationHigh volume manufacturing

The invention discloses a high-mobility ratio aluminum-doped zinc oxide transparent conductive thin film and a preparation method of the high-mobility ratio aluminum-doped zinc oxide transparent conductive thin film. The high-mobility ratio aluminum-doped zinc oxide transparent conductive thin film comprises a glass substrate, an AZO seed layer and an AZO main part layer from bottom to top in sequence, wherein the thickness of the AZO seed layer ranges from 50nm to 200nm, and the thickness of the AZO main part layer ranges from 800nm to 1300nm; the mobility ratio of the aluminum-doped zinc oxide transparent conductive thin film is 40-60cm2V-1s-1, the electrical resistivity of the aluminum-doped zinc oxide transparent conductive thin film ranges from 2*10-4 omega centimeters to 5*10-4 omega centimeters, and the average transmittance of the aluminum-doped zinc oxide transparent conductive thin film within a wavelength range of 400nm to 1200nm is higher than 80%. According to the high-mobility ratio aluminum-doped zinc oxide transparent conductive thin film and the preparation method of the high-mobility ratio aluminum-doped zinc oxide transparent conductive thin film, high-concentration aluminum oxide-doped AZO is used as the seed player, heat treatment is conducted in a short time through a rapid thermal annealing method, as a result, processes are simple, consumed time is short, consumed energy is little, cost is low, and the high-mobility ratio aluminum-doped zinc oxide transparent conductive thin film is suitable for industrial production and application on a large scale.

Owner:ZAOZHUANG VISIONOX ELECTRONICS TECH CO LTD

Molding method for graphene modified epoxy resin fiber wound shell

The invention discloses a molding method for a graphene modified epoxy resin high-strength fiber wound shell. The molding method for the graphene modified epoxy resin high-strength fiber wound shell comprises the following steps that firstly, oxidized graphene is modified; secondly, modified graphene-enhanced epoxy resin is adopted; thirdly, components and parts of the wound shell are molded; fourthly, graphene modified epoxy resin is adopted, and the composite material shell is molded through wet wrapping of graphene modified epoxy resin; fifthly, the shell is solidified; and sixthly, the shell is demolded, and high-strength graphene modified epoxy resin fiber wound shell is acquired. According to the molding method for the graphene modified epoxy resin high-strength fiber wound shell, graphene is modified so that graphene is fully fused with epoxy resin, then the fiber wound shell is molded through wet wrapping of graphene modified epoxy resin; and the special structural property ofgraphene is utilized to fully strengthen the fiber wound composite material.

Owner:湖北三江航天江北机械工程有限公司

Hydrogen generation apparatus for chemically producing hydrogen

ActiveCN105836704ASolve problems that don't respond adequatelyImprove quality ratioHydrogen productionEngineeringSieve

Owner:GUANGXI UNIV

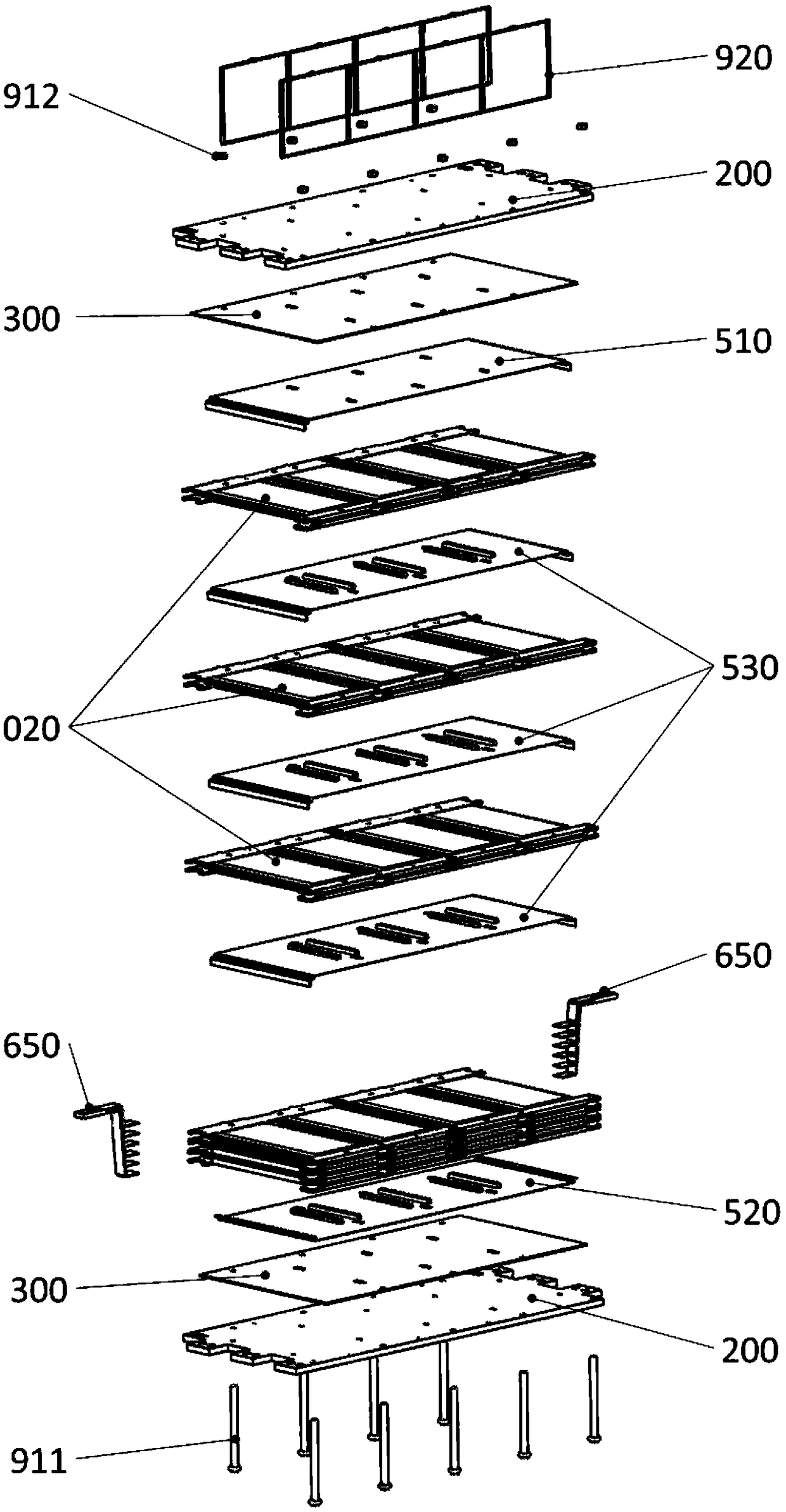

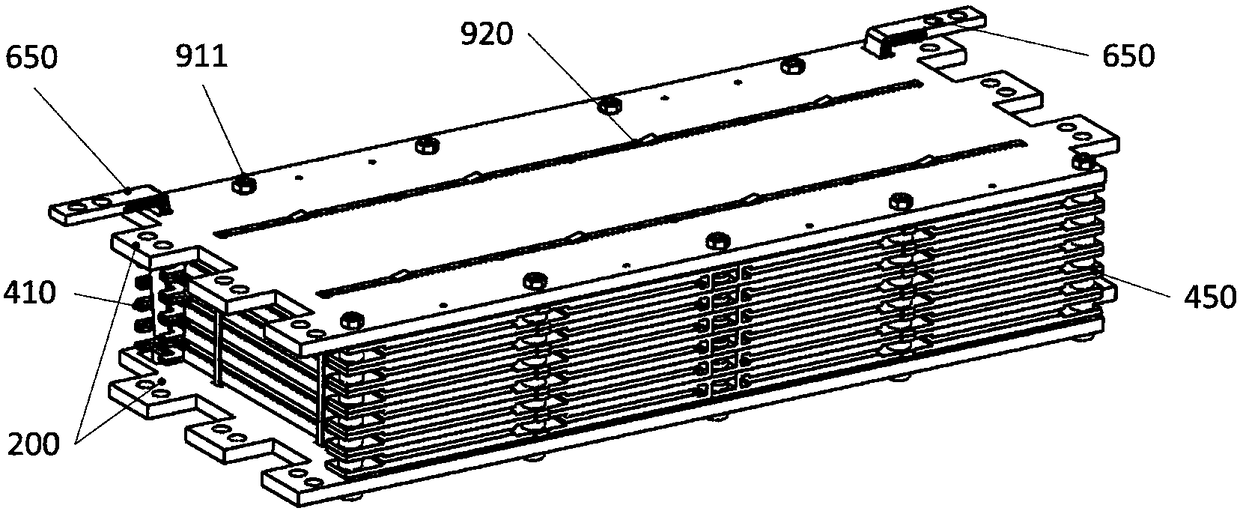

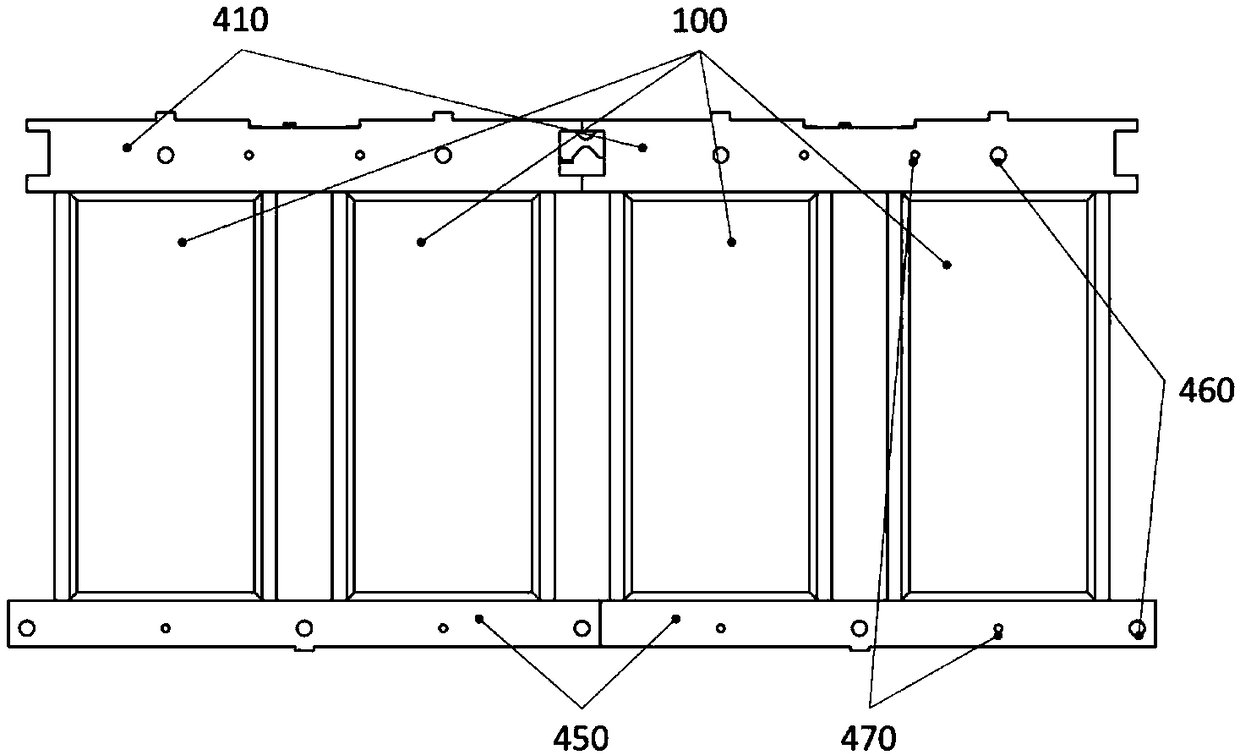

Soft-clad lithium battery module applied to an electric vehicle

ActiveCN109192913ASmall and compact sizeImprove quality ratioSecondary cellsCell component detailsElectricityHigh energy

The invention provides a soft-clad lithium battery module applied to an electric vehicle, the module comprises a soft-packed lithium battery, Side panel, foam, Heat sink, battery holder, Connecting tabs, bus tabs, fastening parts and other structures. The use of unique safety-type tabs improves electrical connection safety and reduces battery positioning accuracy requirements. The flexible busbarcan be bent freely to enlarge the use condition of the connecting piece, the module expansion can be realized relatively easily by using the modular bracket, the module structure is simplified by using the composite radiating plate, and so on, so that the soft-packaged lithium battery module has the advantages of compact structure, safety, stability, easy expansion and higher energy density.

Owner:湖南隆玛科技有限公司

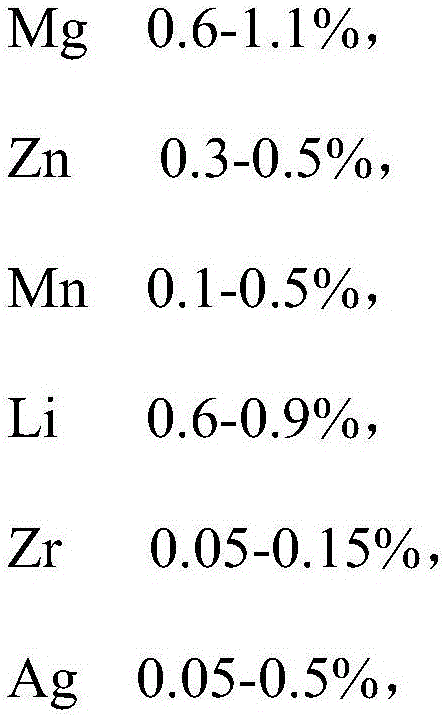

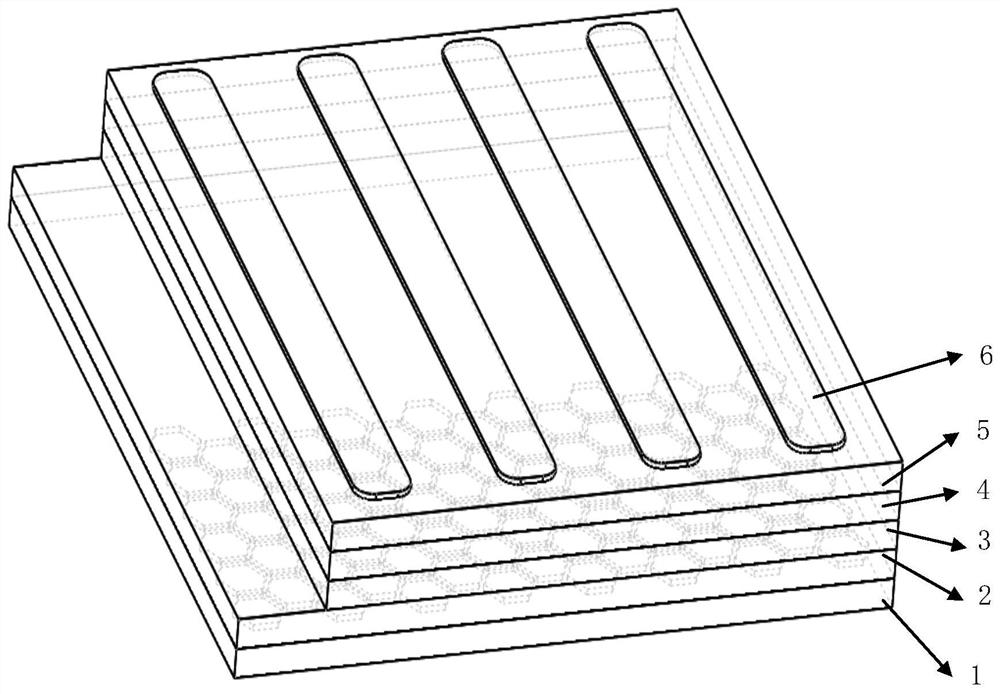

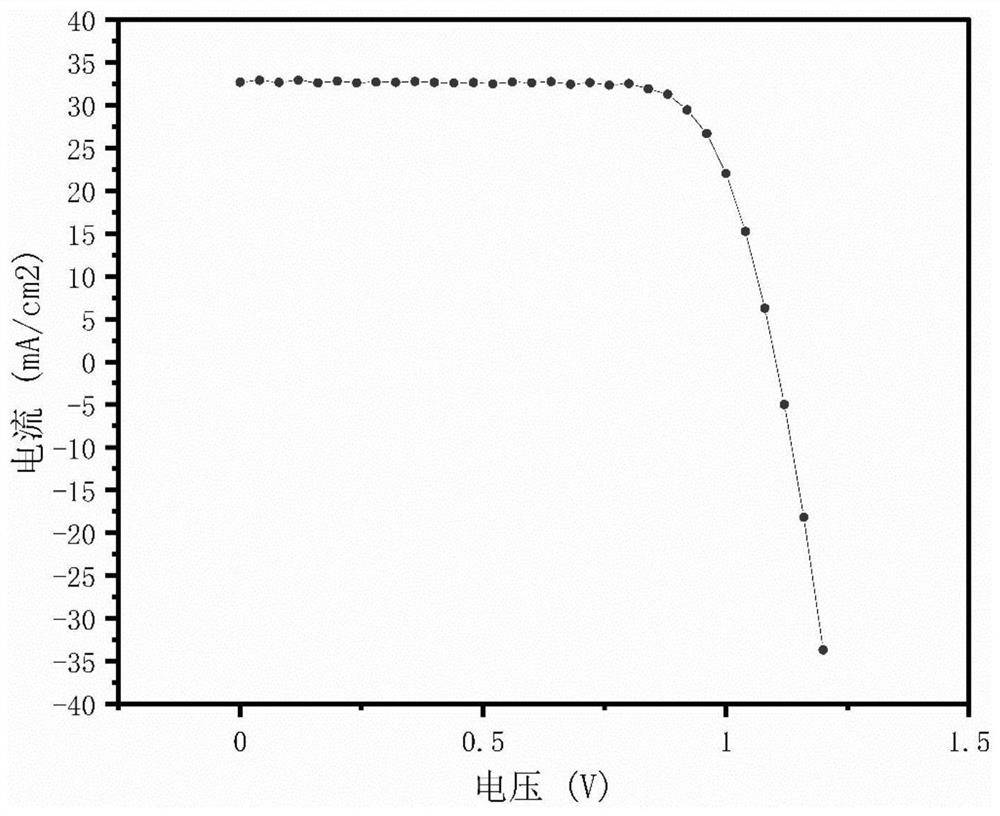

Flexible perovskite solar cell with high power mass ratio and preparation method thereof

ActiveCN113193125AImprove power-to-mass ratioFlexibility with high power-to-mass ratioFinal product manufactureSolid-state devicesEngineeringChemical vapor deposition

The invention discloses a flexible perovskite solar cell with a high power mass ratio and a preparation method thereof. According to the invention, a Palilin film with a thickness of less than 5 [mu]m is prepared by using a chemical vapor deposition method and an ion beam polishing technology to serve as a flexible substrate, and then a transparent conductive functional layer composed of a metal grid and a transparent conductive oxide and other functional layers of the perovskite solar cell are prepared on the flexible substrate; the photoelectric conversion efficiency of the obtained flexible perovskite solar cell can exceed 20%, the power mass ratio can exceed 30 W / g, the bending radius can be smaller than 1 mm, and the performance degradation of the cell after 300 cycles of bending is smaller than 5%. The flexible perovskite solar cell with the high power mass ratio provided by the invention has the characteristics of small mass, high flexibility and very high power mass ratio, has great application potential in the fields of aerospace and the like, and also has unique advantages in the fields of intelligent equipment, wearable equipment and the like.

Owner:PEKING UNIV

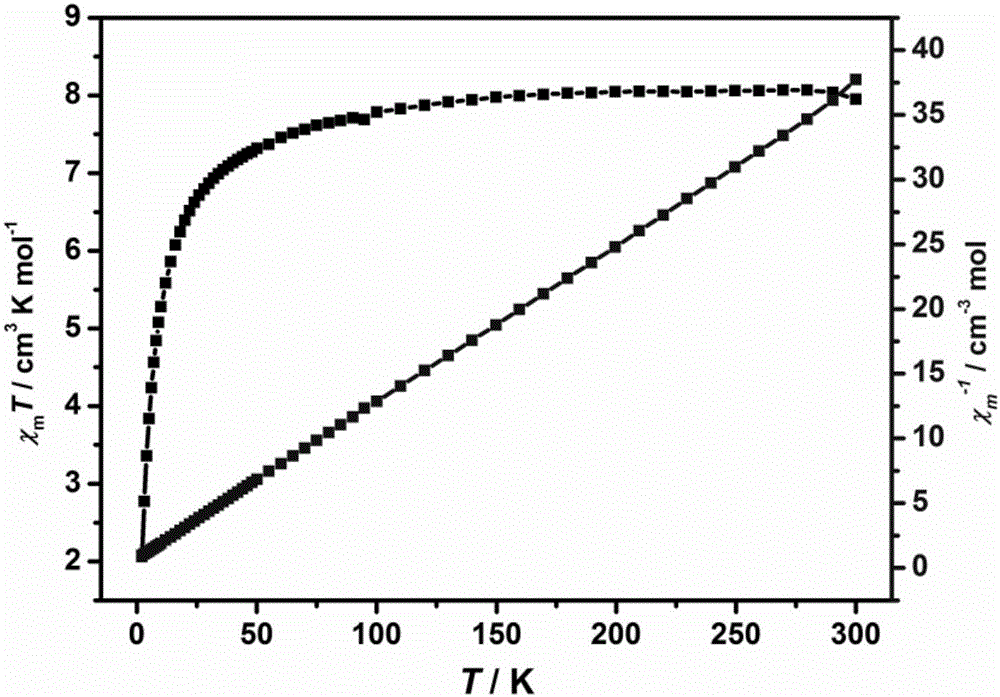

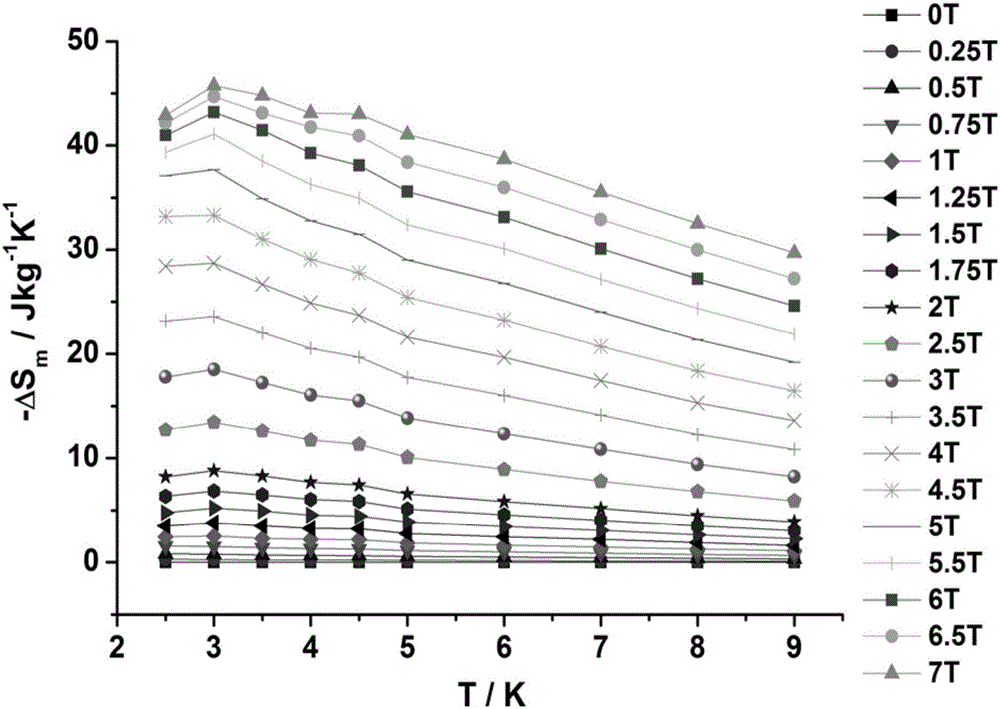

Gadolinium borate and preparation method and application thereof

InactiveCN105836755AImprove the magnetocaloric effectFast preparation methodInorganic material magnetismBoratesFiltrationStrong acids

The invention relates to gadolinium borate and a preparation method and application thereof. According to preparation of gadolinium borate, Gd<3+> is used as a raw material, and small molecular weight BO3<3-> is used as a ligand. The preparation method comprises the following steps: placing gadolinium oxide and boric acid into a quartz porcelain boat, grinding solids into powders, uniformly mixing, drying, transferring the quartz porcelain boat into a quartz tube furnace, heating to 400 DEG C and keeping the temperature for 10 h, heating to 1000 DEG C and keeping the temperature for 6h, cooling to room temperature to obtain a white powdery solid, washing and carrying out suction filtration, and drying to obtain gadolinium borate. The gadolinium borate which is white powdery crystal can be applied in preparation of magnetic refrigeration materials. Synthetic equipment is simple, and the preparation method is fast and easy to operate. The gadolinium borate is a borate compound and has very strong stability and good heat stability from a strong acid environment to a strong base environment. By raising mass ratio of rare earth to the ligand, magnetic density is raised, and magnetic refrigeration effect of the material is greatly enhanced.

Owner:XIAMEN UNIV

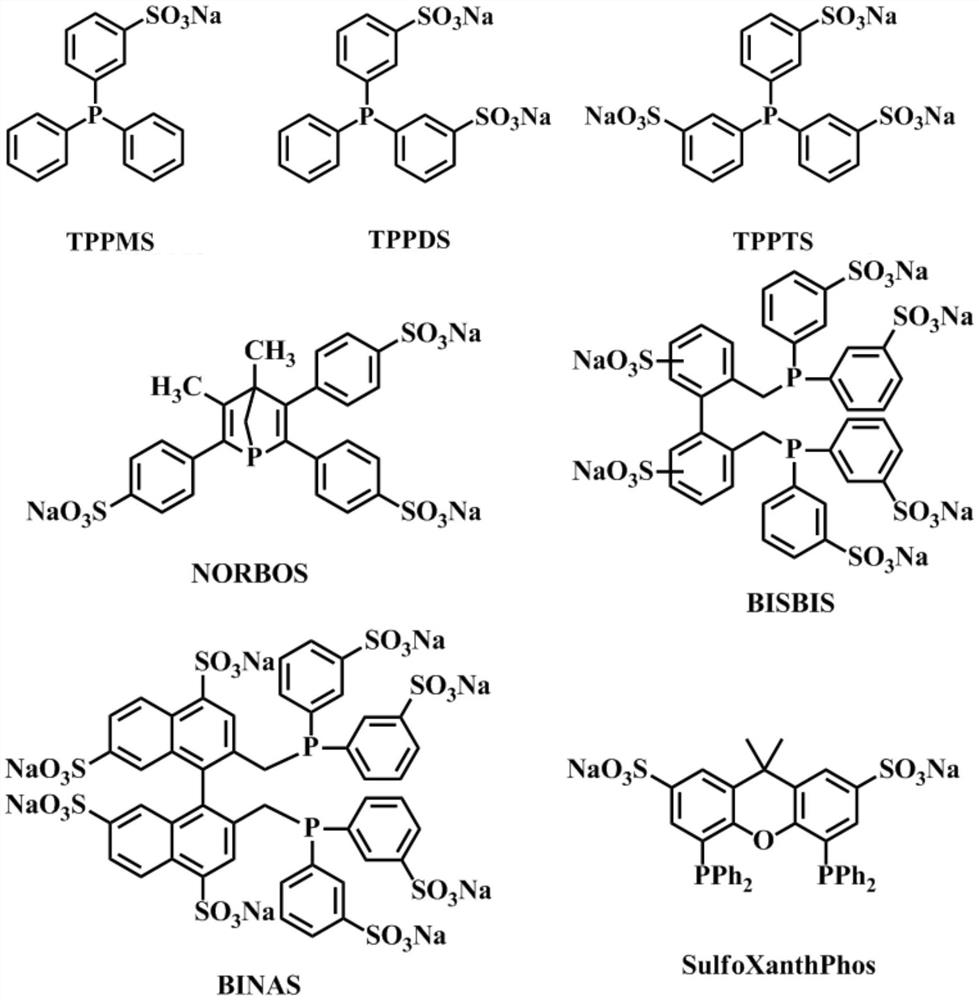

Method for preparing high-carbon aldehyde

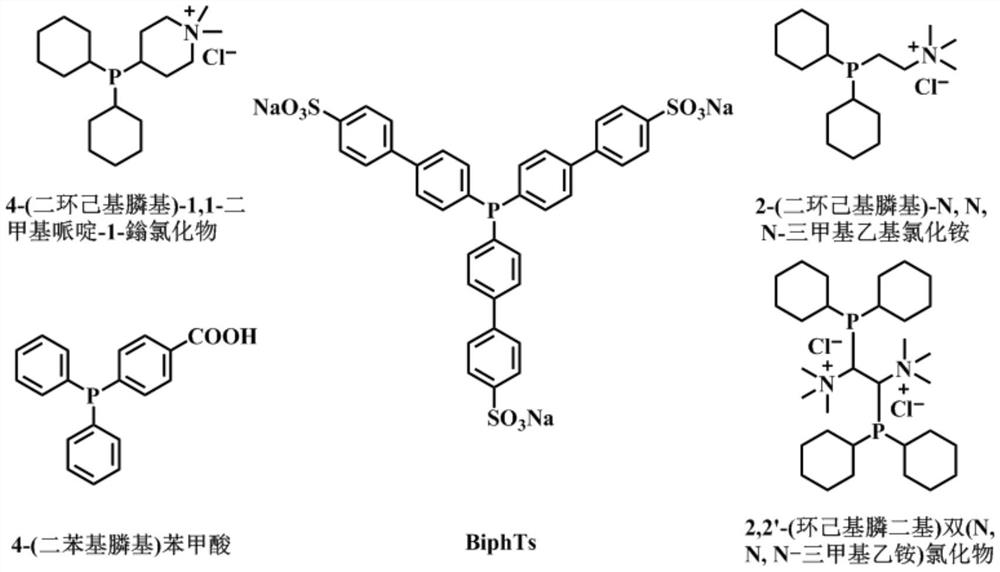

ActiveCN111606792AImprove quality ratioReduce loadOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTPPTSPtru catalyst

The invention discloses a method for preparing a high-carbon aldehyde. Water, diethylene glycol, triethylene glycol or PEG is used as a solvent; the method comprises steps: taking a low-boiling-pointpolar solvent as a solvent system; taking a rhodium monophosphine water-soluble catalyst such as TPPTS / Rh or a rhodium diphosphine water-soluble catalyst such as BISBIS / Rh as a reaction system of thecatalyst, so that the reaction rate is greatly improved, the single conversion frequency (TOF) can reach 20000 h <-1 > or above, the catalyst and the high-carbon aldehyde can be conveniently separated, and the catalyst and the low-boiling-point polar solvent can be repeatedly utilized for multiple times; the reaction selectivity is good, the raw material conversion rate is up to 98% or above, theselectivity of the product aldehyde is 95% or above, and the selectivity of normal aldehyde generated through catalysis of the rhodium diphosphine water-soluble catalyst is 95.0% or above. The methodis simple in process, the production cost is effectively reduced, and the method has great industrial application value.

Owner:成都欣华源科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com