Patents

Literature

74results about How to "Improve the magnetocaloric effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced magnetocaloric effect material

InactiveUS7076959B2Efficient amplificationWithout adversely affecting the functionality of the materialLiquid fillingEnergy efficient heating/coolingCore ParticleAtomic physics

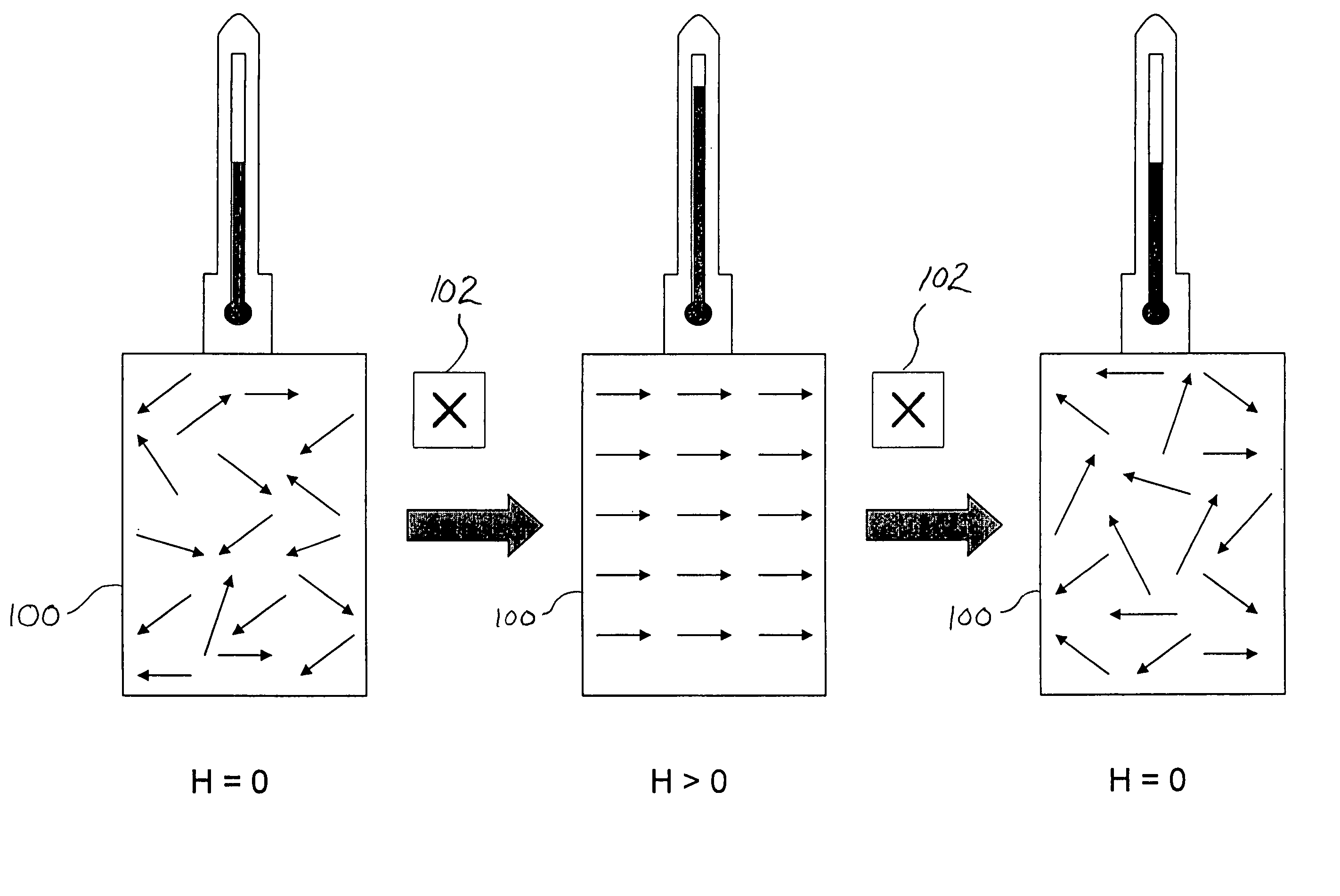

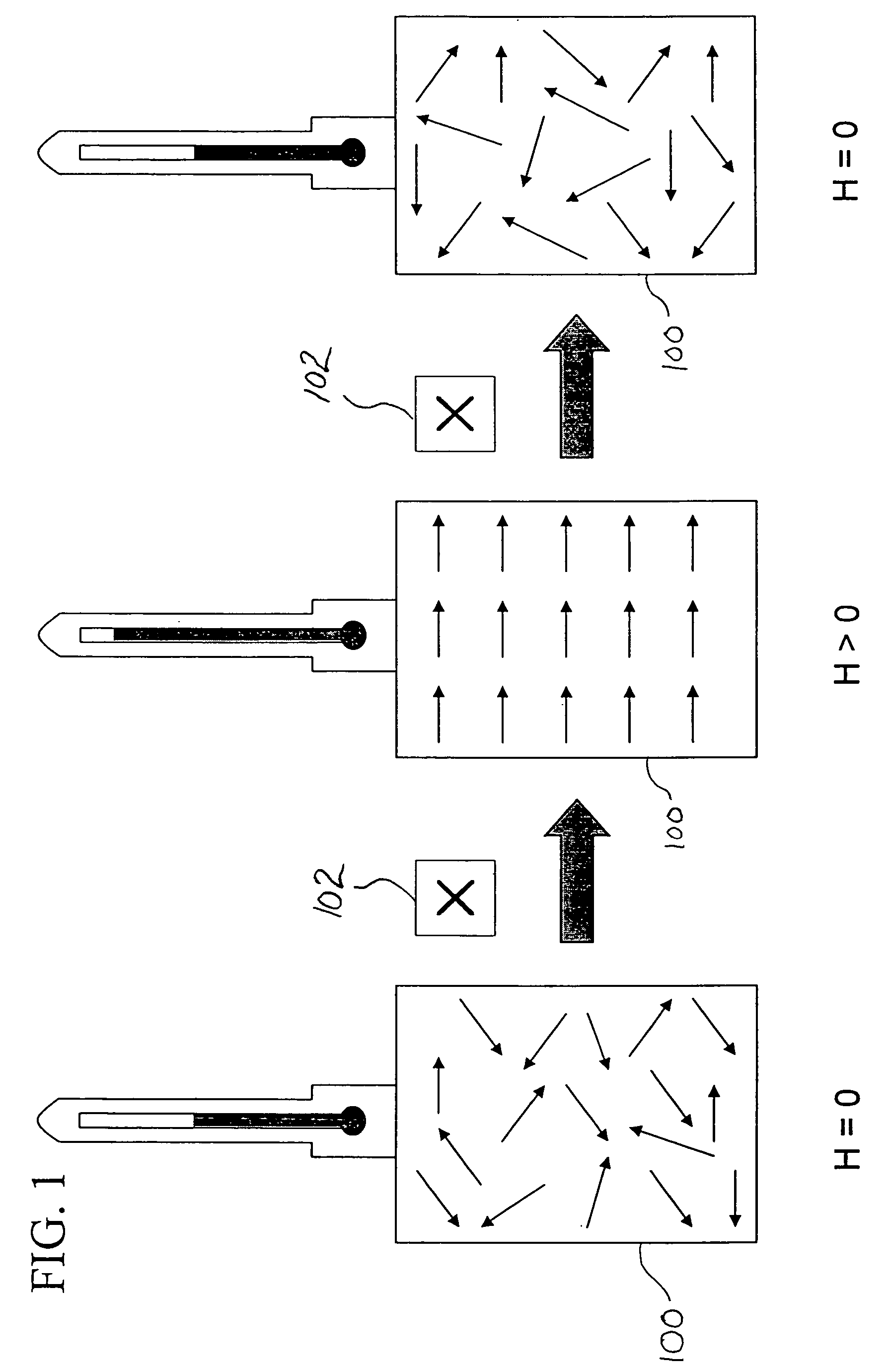

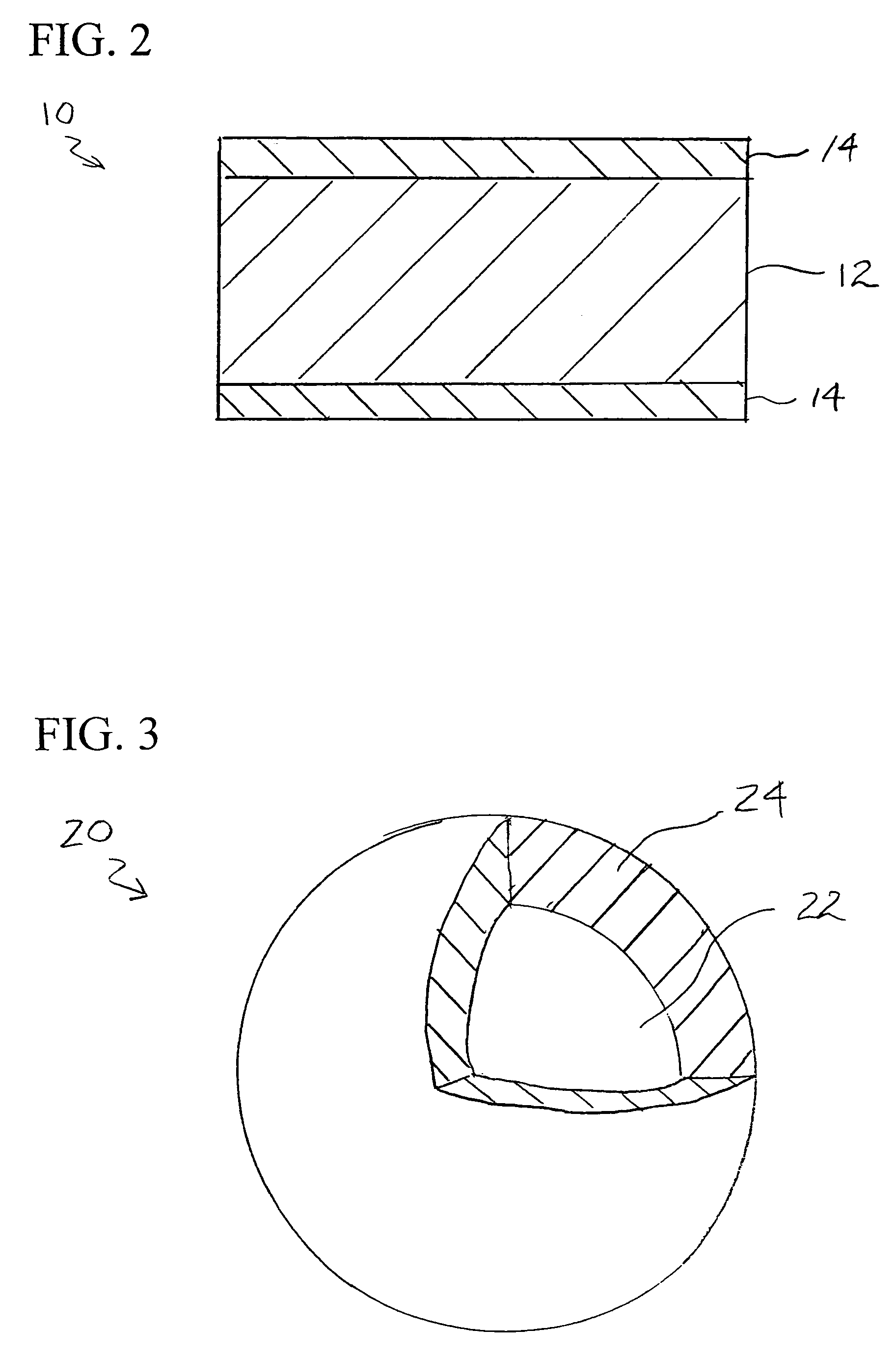

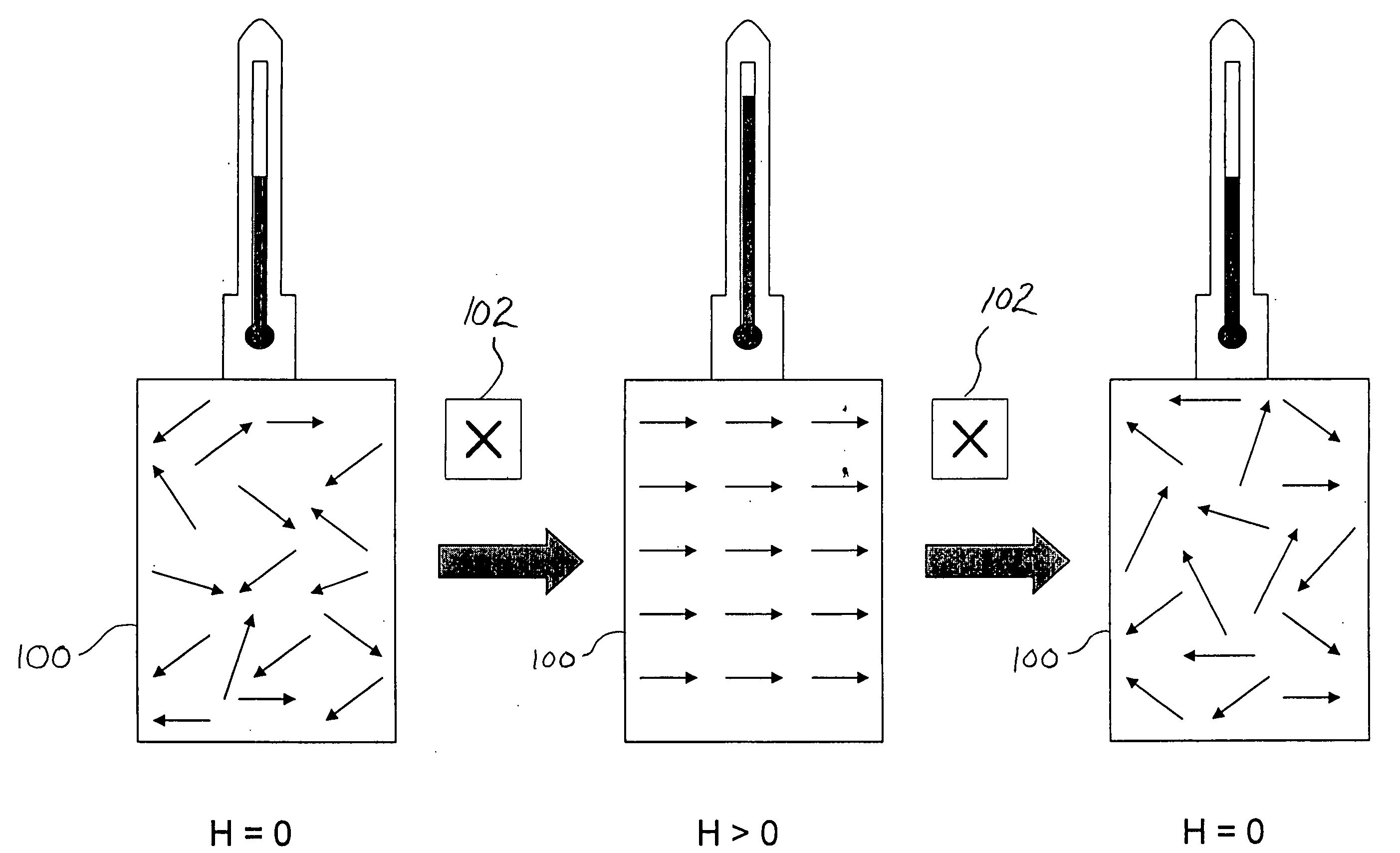

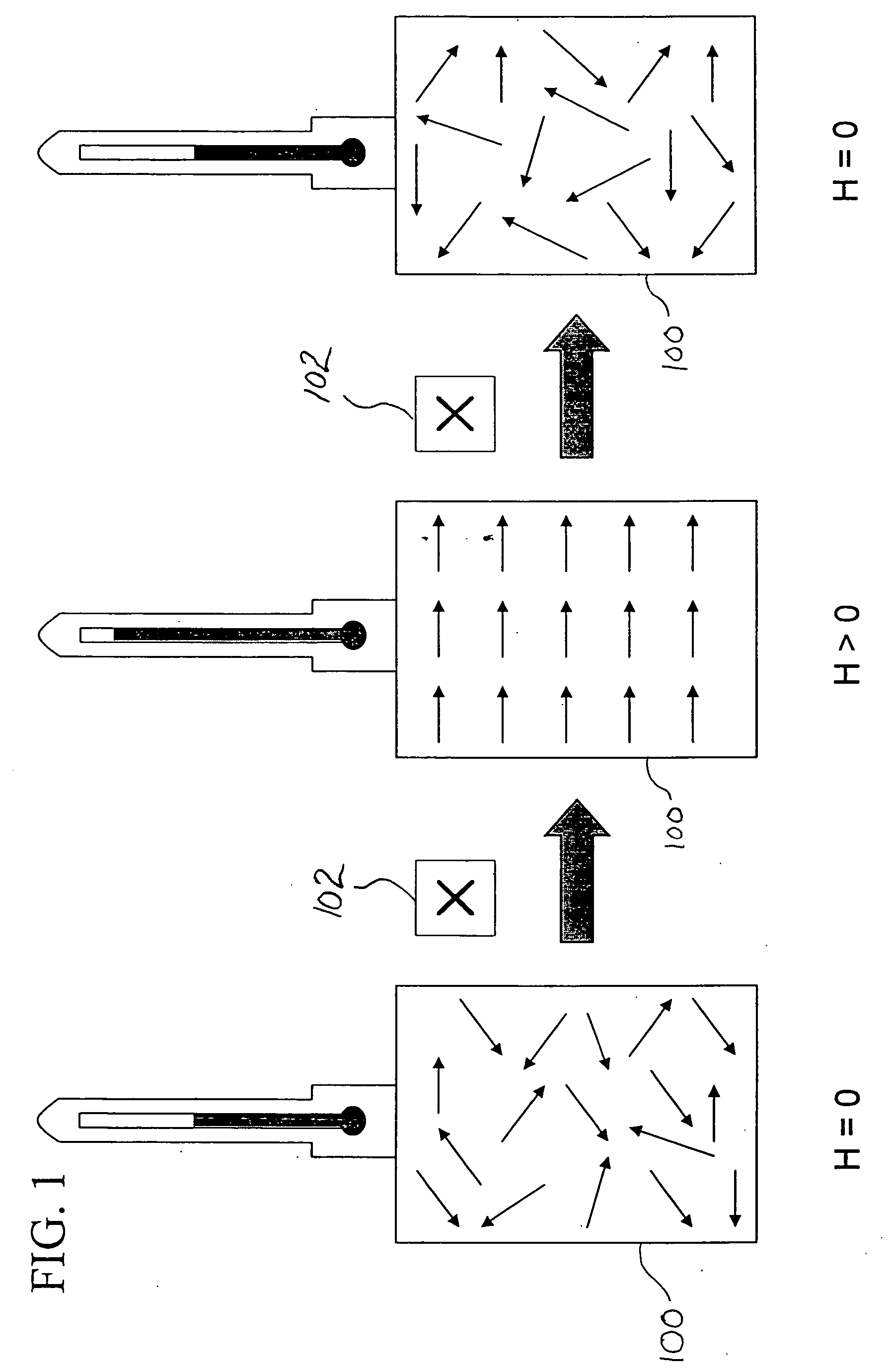

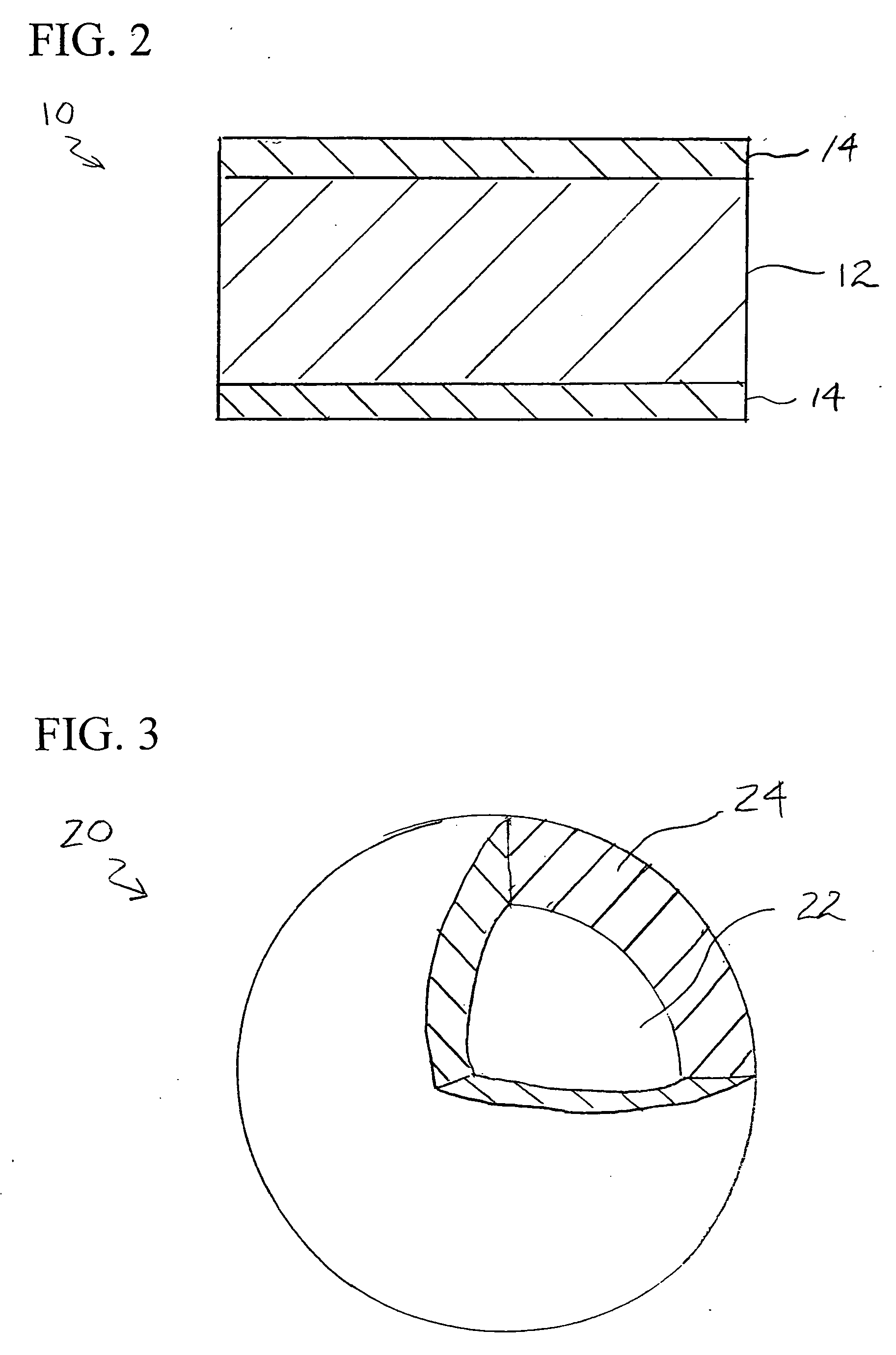

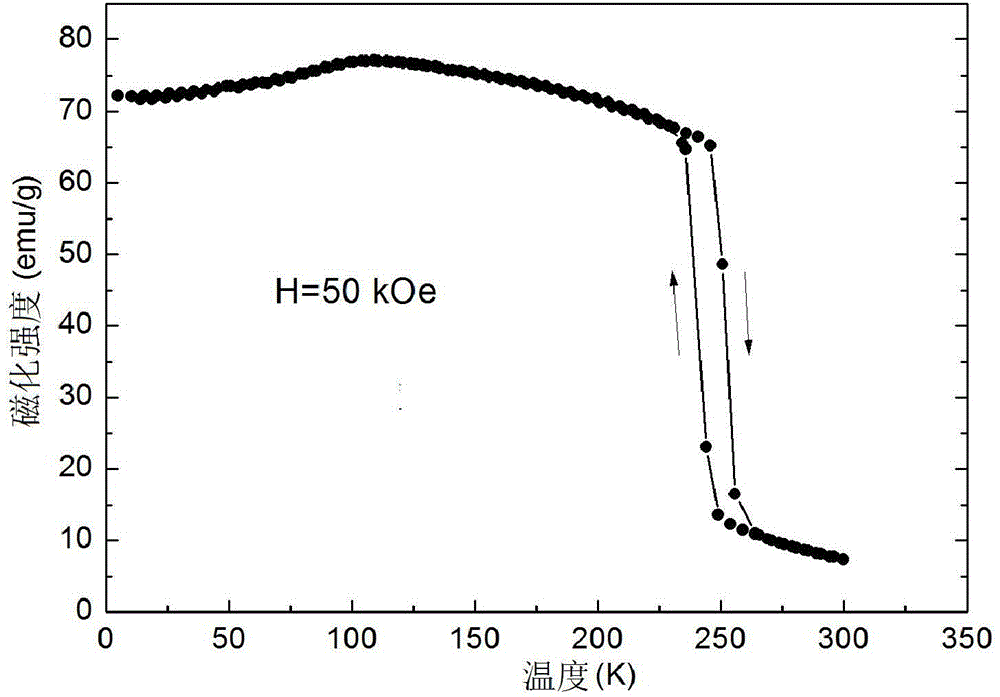

A magnetocaloric effect heterostructure having a core layer of a magnetostructural material with a giant magnetocaloric effect having a magnetic transition temperature equal to or greater than 150 K, and a constricting material layer coated on at least one surface of the magnetocaloric material core layer. The constricting material layer may enhance the magnetocaloric effect by restriction of volume changes of the core layer during application of a magnetic field to the heterostructure. A magnetocaloric effect heterostructure powder comprising a plurality of core particles of a magnetostructural material with a giant magnetocaloric effect having a magnetic transition temperature equal to or greater than 150 K, wherein each of the core particles is encapsulated within a coating of a constricting material is also disclosed. A method for enhancing the magnetocaloric effect within a giant magnetocaloric material including the step of coating a surface of the magnetocaloric material with a constricting material is disclosed.

Owner:BROOKHAVEN SCI ASSOCS

Enhanced magnetocaloric effect material

InactiveUS20050172643A1Efficient amplificationWithout adversely affecting the functionality of the materialLiquid fillingEnergy efficient heating/coolingCore ParticleAtomic physics

A magnetocaloric effect heterostructure having a core layer of a magnetostructural material with a giant magnetocaloric effect having a magnetic transition temperature equal to or greater than 150 K, and a constricting material layer coated on at least one surface of the magnetocaloric material core layer. The constricting material layer may enhance the magnetocaloric effect by restriction of volume changes of the core layer during application of a magnetic field to the heterostructure. A magnetocaloric effect heterostructure powder comprising a plurality of core particles of a magnetostructural material with a giant magnetocaloric effect having a magnetic transition temperature equal to or greater than 150 K, wherein each of the core particles is encapsulated within a coating of a constricting material is also disclosed. A method for enhancing the magnetocaloric effect within a giant magnetocaloric material including the step of coating a surface of the magnetocaloric material with a constricting material is disclosed.

Owner:BROOKHAVEN SCI ASSOCS

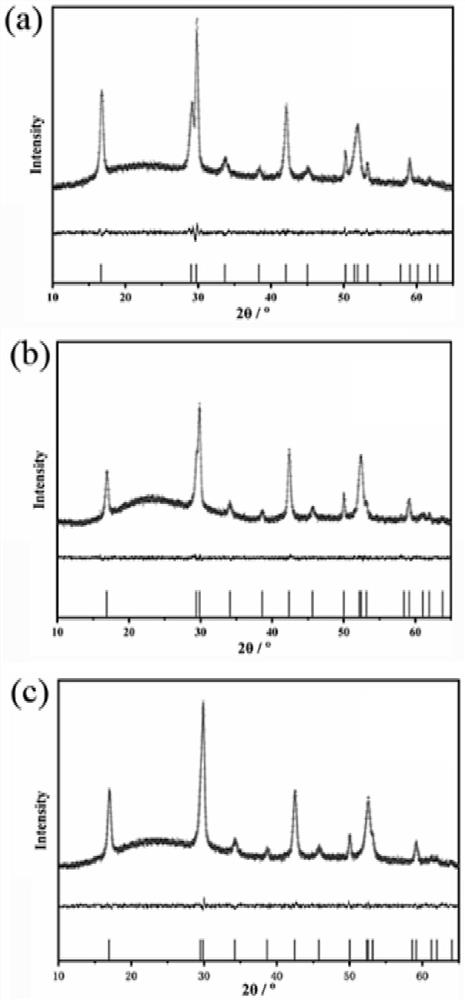

Magnetic composite material and method for producing the same

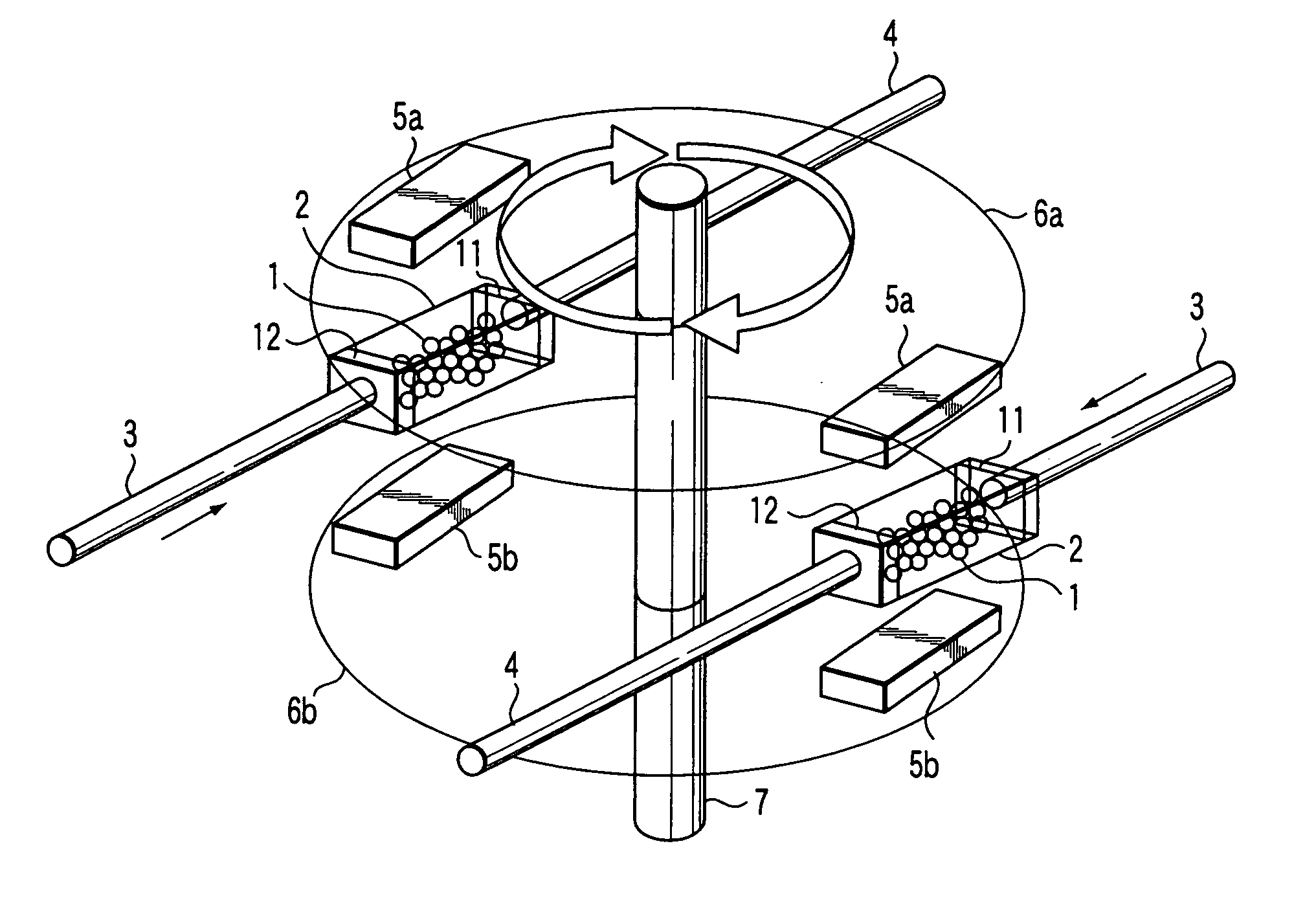

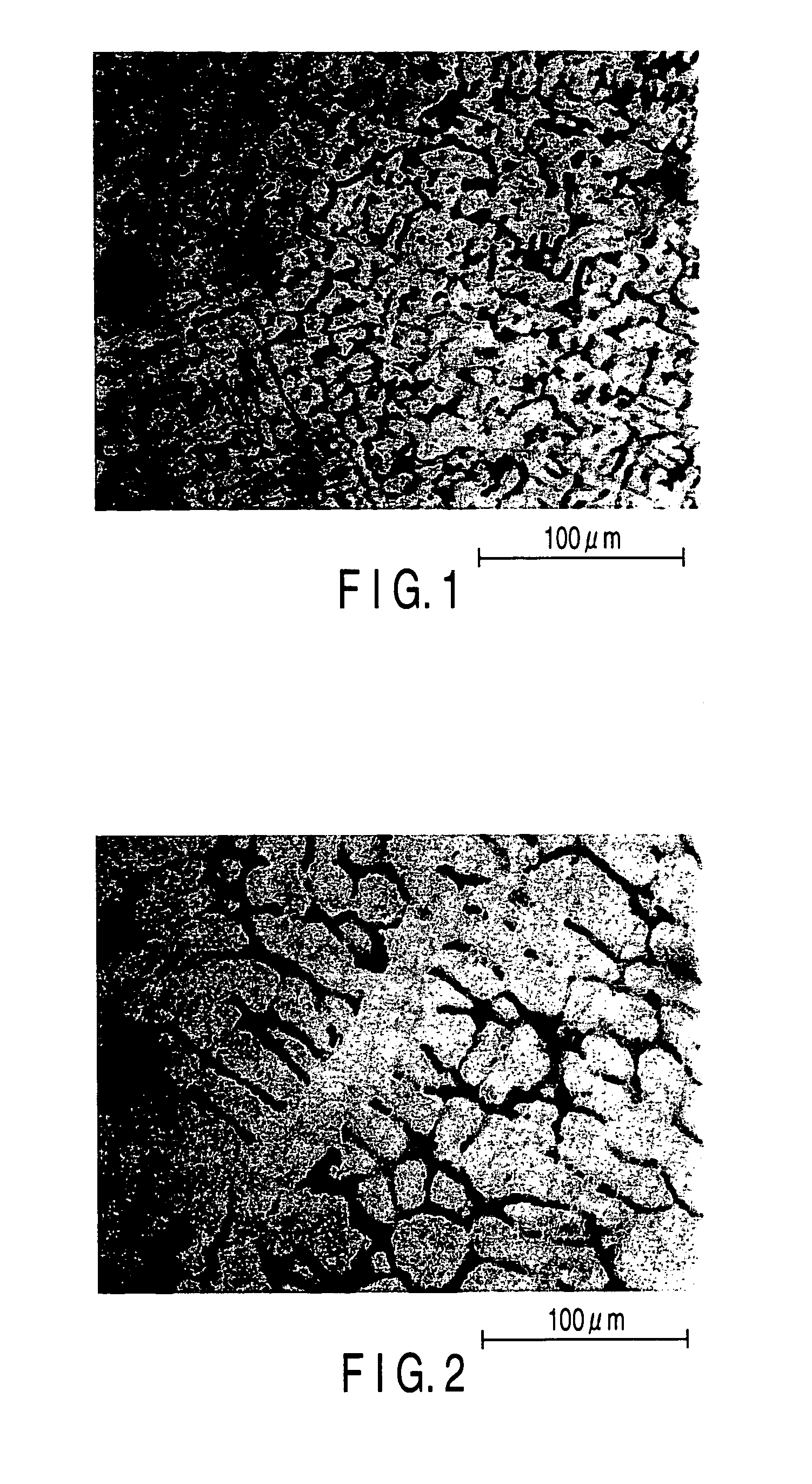

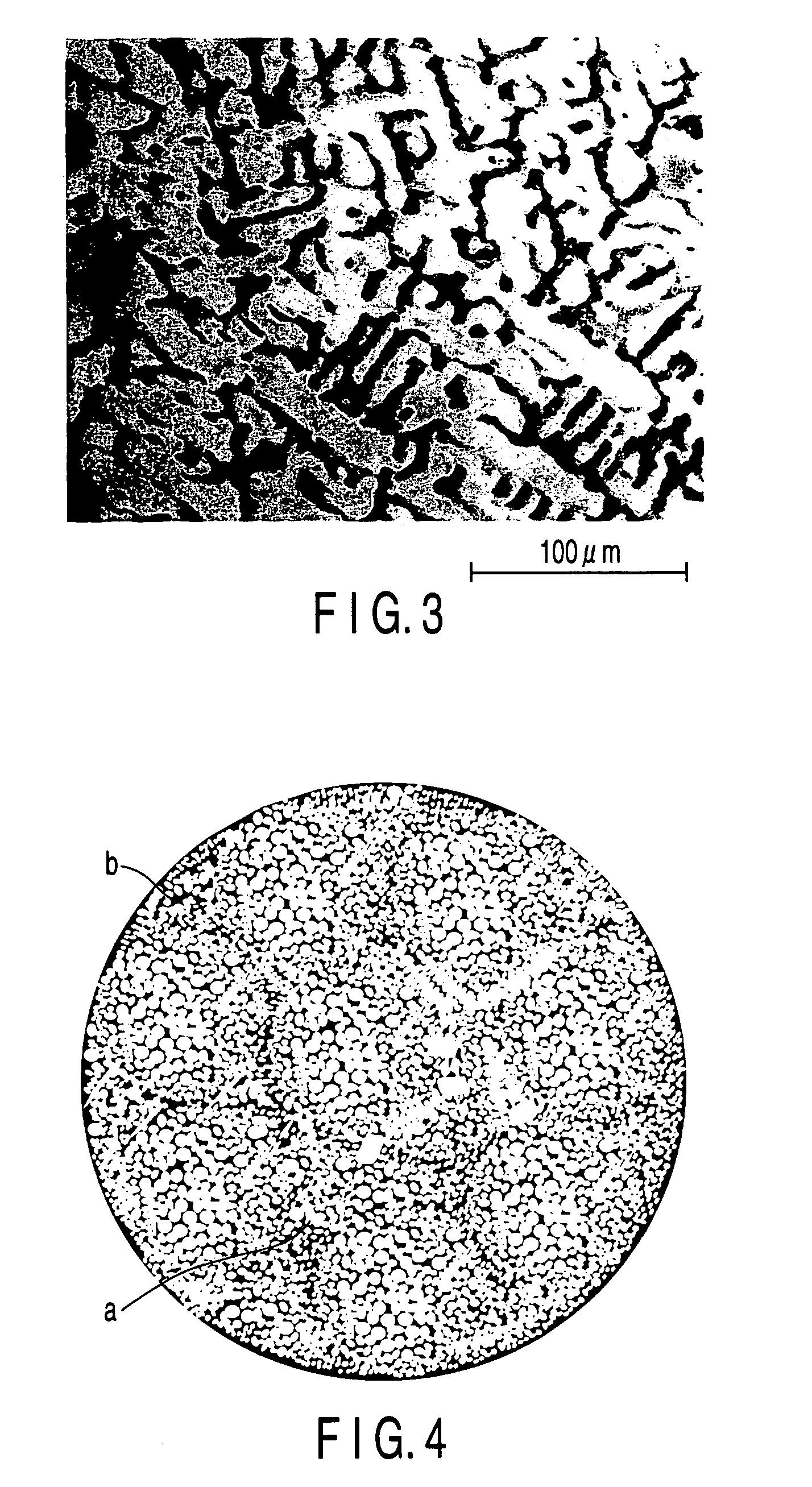

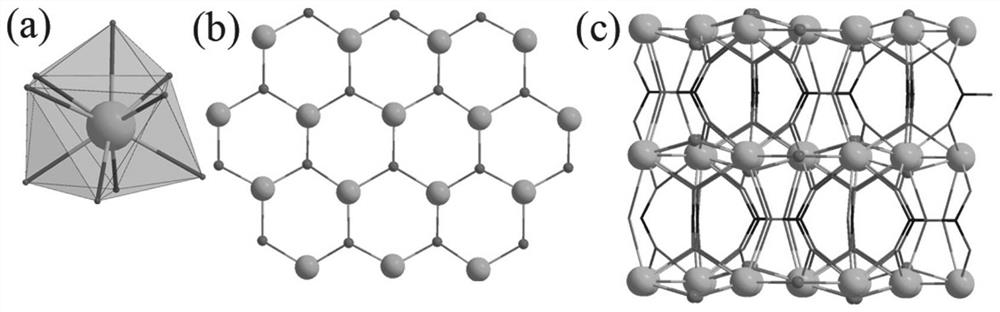

ActiveUS7168255B2Reduce generationSuppress pressure lossEnergy efficient heating/coolingInorganic material magnetismCrystal structureMagnetic refrigeration

The magnetic composite material of the present invention is used as a working substance in the magnetic refrigeration system and comprising at least two phases, including, a first phase composed of an intermetallic compound represented by a general formula: La(Fe(Co, Ni)Si)13, having an NaZn13 type crystal structure, and a second phase is composed of an iron alloy containing Si. The first phase is precipitated in an expansion size of 100 μm or less in average. Preferably, the magnetic composite material contains Fe as a principal component, La in an amount from 4 atomic % to 12 atomic %, Si in an amount from 2 atomic % to 21 atomic %, and Co and Ni in a total amount from 0 atomic % to 11 atomic %, and the total amount of Fe, Co and Ni being from 75 atomic % to 92 atomic %.

Owner:KK TOSHIBA

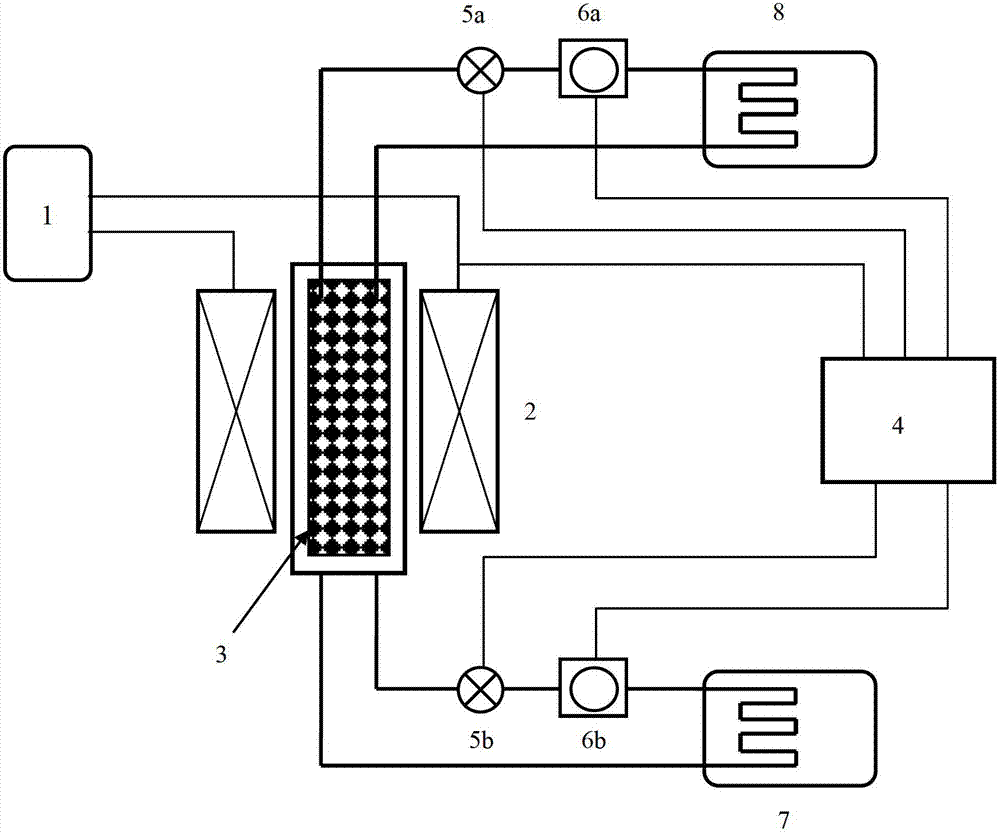

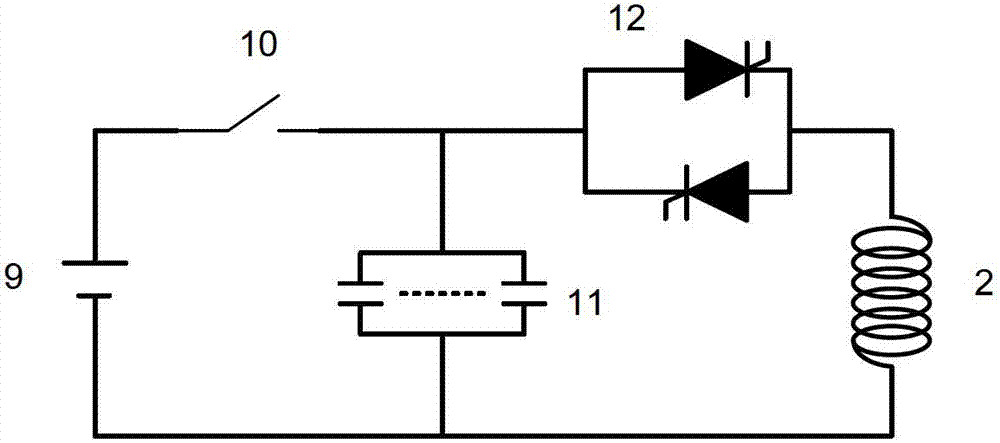

Magnetic refrigerating device based on repetitive pulsed magnetic field

InactiveCN102734977AImprove the magnetocaloric effectAchieving Static Magnetic RefrigerationEnergy efficient heating/coolingMachines using electric/magnetic effectsEngineeringEnergy recovery

The invention discloses a magnetic refrigerating device based on a pulsed magnetic field. The device comprises a repetitive pulsed power supply without a continuous loop, a pulsed magnet, a magnetic refrigeration working medium, a hot end heat exchange unit and a cold end heat exchange unit, wherein the repetitive pulsed power supply discharges to the pulsed magnet, and part of electric energy flows back to the repetitive pulsed power supply to achieve energy recovery; during the discharge process, the pulsed magnet generates the pulsed magnetic field and causes the refrigeration working medium to magnetize and release heat, and the heat generated by the magnetic working medium is transferred to a high-temperature heat source through the hot end heat exchange unit; after the discharge is finished, the repetitive pulsed power supply is shut off, and the pulsed magnet stops generating the pulsed magnetic field, and the magnetic refrigeration working medium demagnetizes and absorbs the heat, and through heat absorption of a low-temperature heat source by the cold end heat exchange unit, the temperature of the low-temperature heat source is lowered, thus completing a discharge refrigeration cycle; and the discharge refrigeration cycle is circulated in a manner above to realize continuous refrigeration. According to the scheme disclosed by the invention, the controllable pulsed magnet generates the intermittent repetitive pulsed magnetic field to achieve the magnetic refrigeration, and the magnetic refrigerating device has the characteristics of high magnetic field intensity, no moving part, convenience and fastness of control, high efficiency and high refrigeration power.

Owner:HUAZHONG UNIV OF SCI & TECH

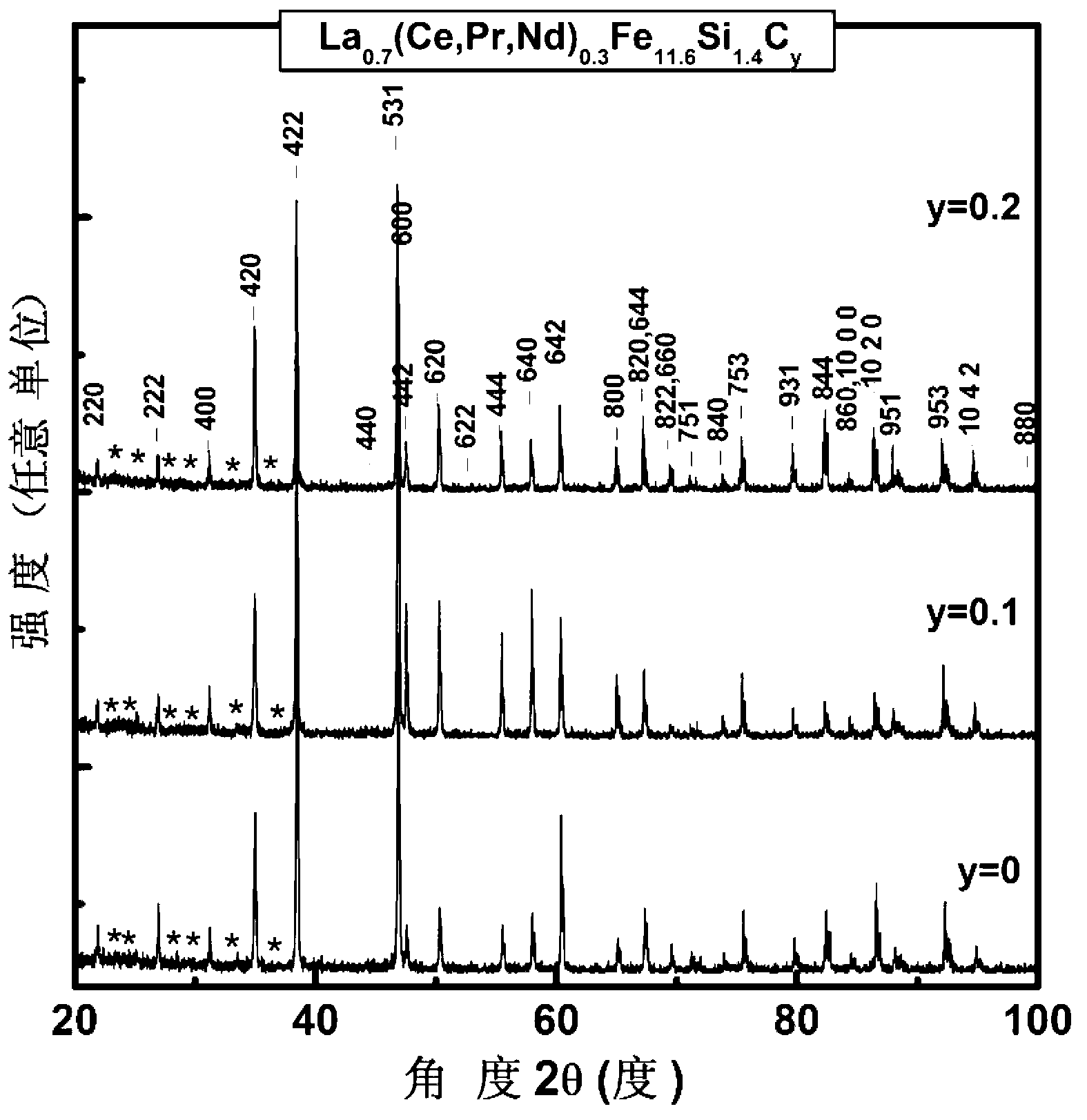

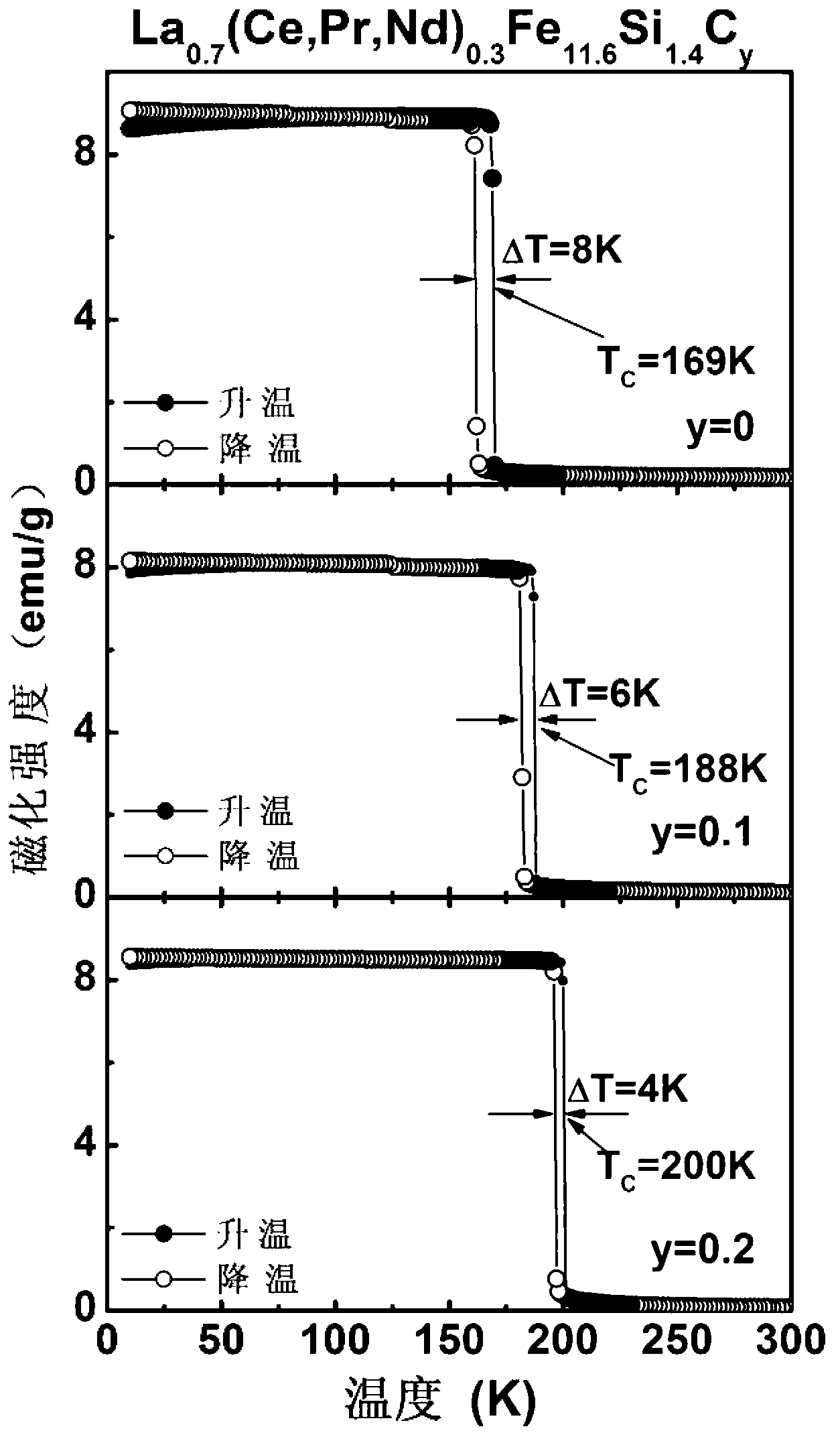

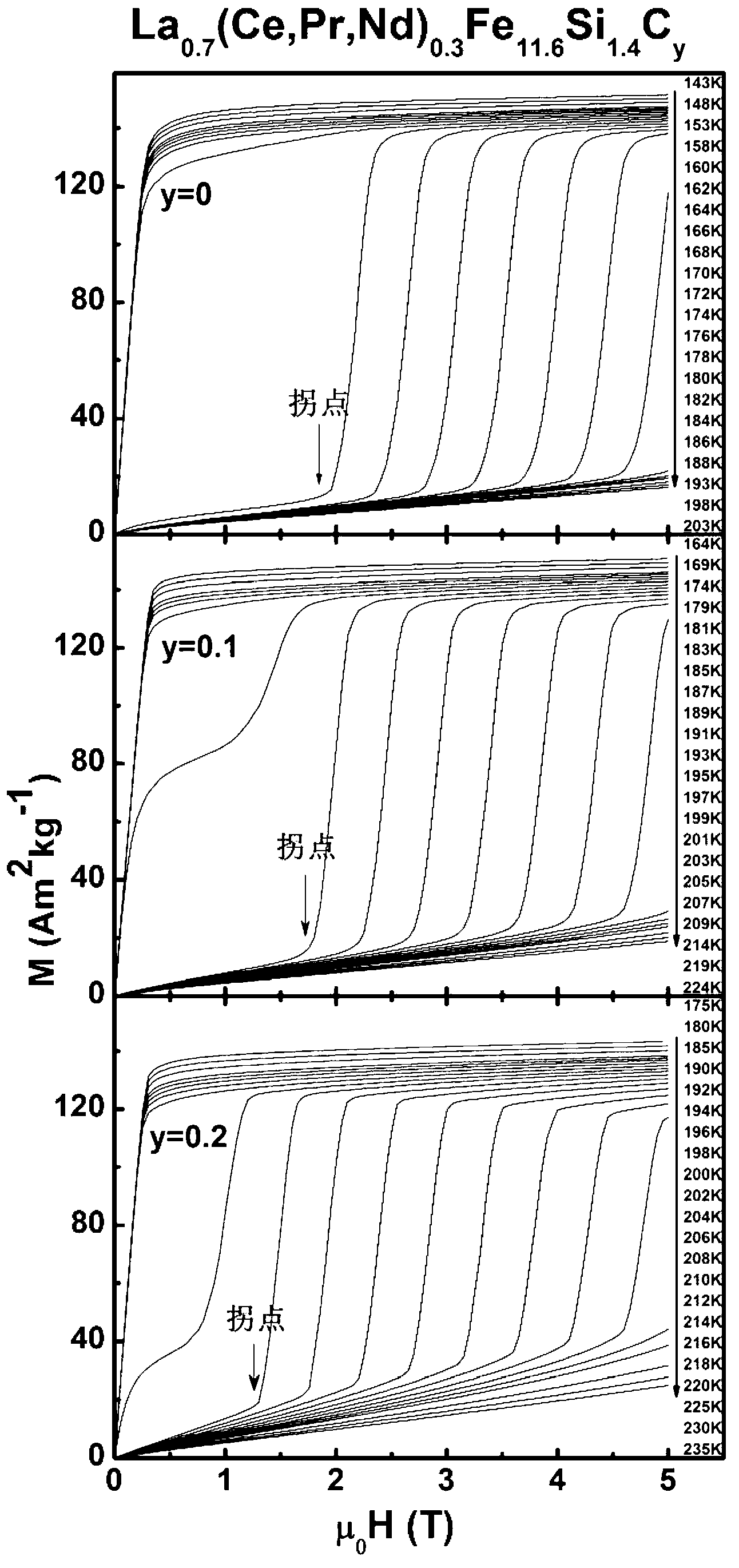

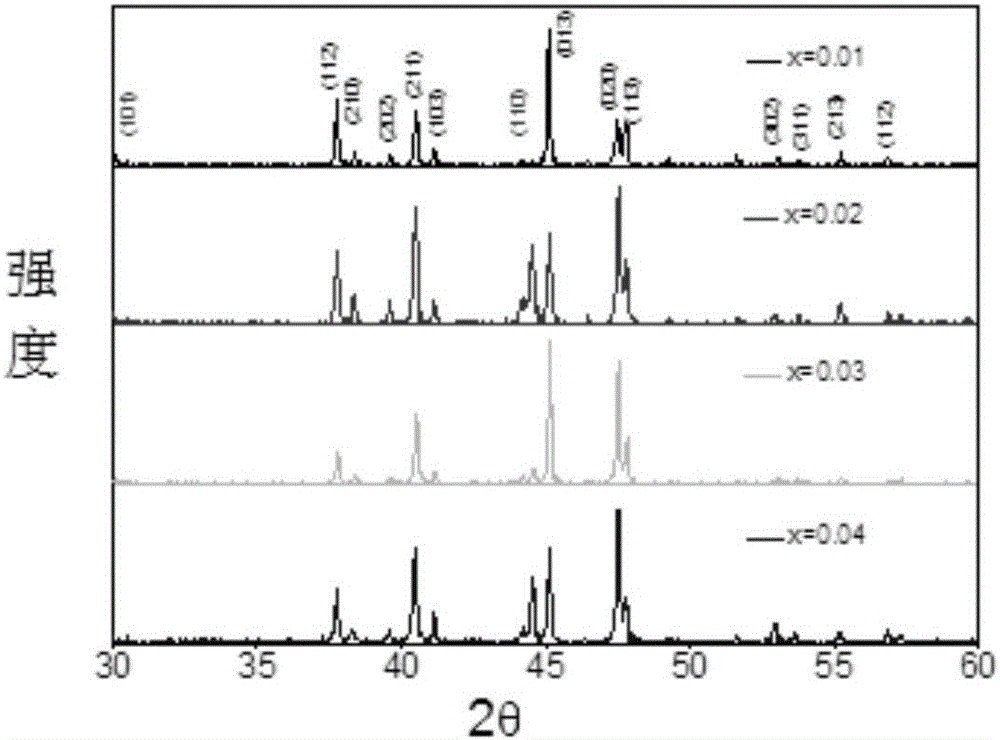

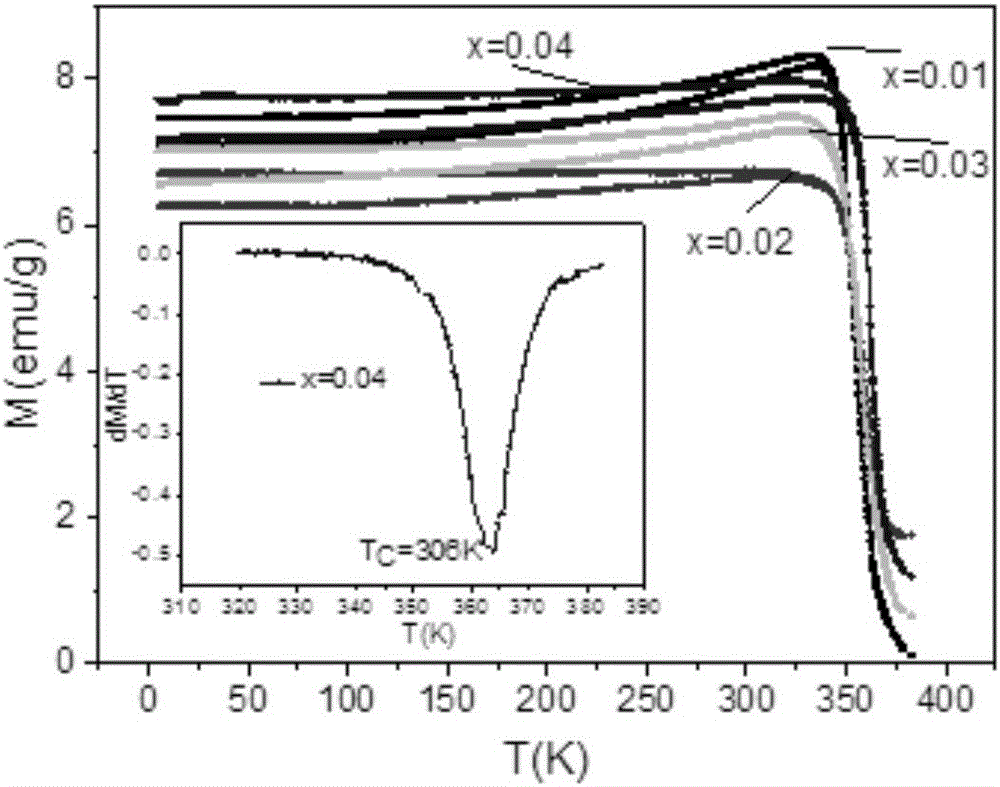

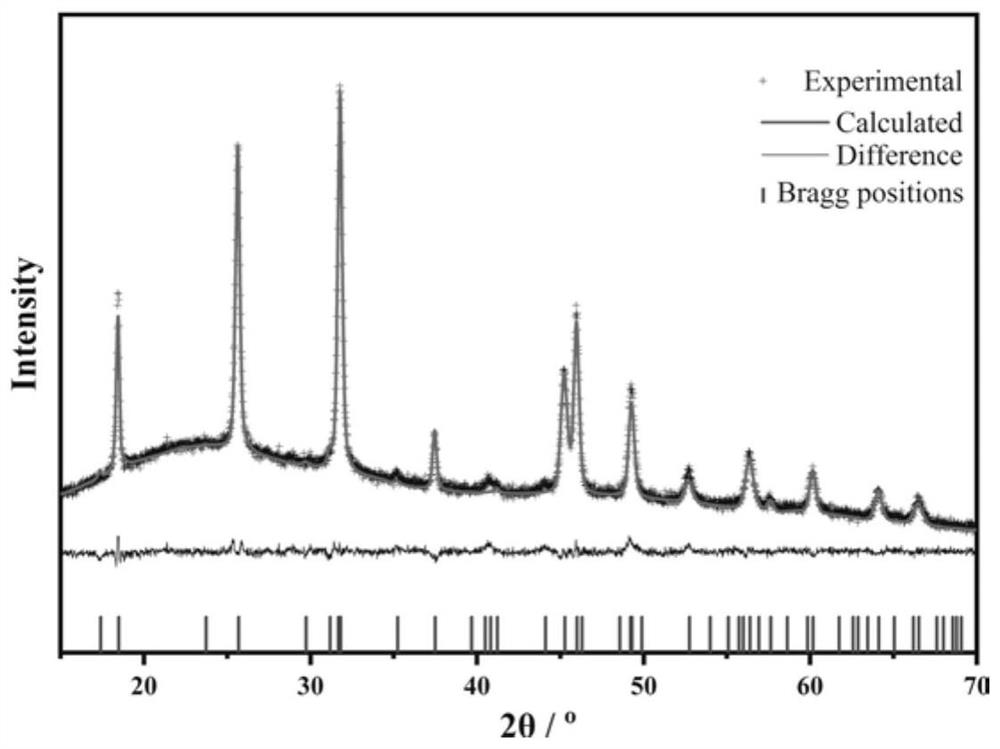

La(Fe,Si)13 based magnetic refrigeration material by taking high-Ce industrial pure mixed rare earth as raw material as well as preparation method and application thereof

ActiveCN103045177AReduce manufacturing costReduce dependenceHeat-exchange elementsMagnetic transitionsSingle substance

The invention provides a La(Fe,Si)13 based magnetic refrigeration material by taking high-Ce industrial pure mixed rare earth as a raw material. The chemical formula is La1-x(Ce,Pr,Nd)x(Fe1-p-qCopMnq)13-ySiyaalpha and is provided with an NaZn12 type structure. The invention further provides a preparation method and an application of the material. The preparation method comprises the following steps: smelting and annealing to prepare the La1-x(Ce,Pr,Nd)x(Fe1-p-qCopMnq)13-ySiyaalpha magnetic refrigeration material by taking the high-Ce industrial pure mixed rare earth as the raw material. Impurities in the raw material high-Ce industrial pure mixed rare earth do not influence the generation of a 1: 13 phase and the appearance of first order phase transformation and variable magnetic transition behavior, so that the dependence on a high-purity single-substance rare earth raw material is reduced, the preparation cost of the material is reduced, and the La(Fe,Si)13 based magnetic refrigeration material has important actual meanings on developing the magnetic refrigeration application of the material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

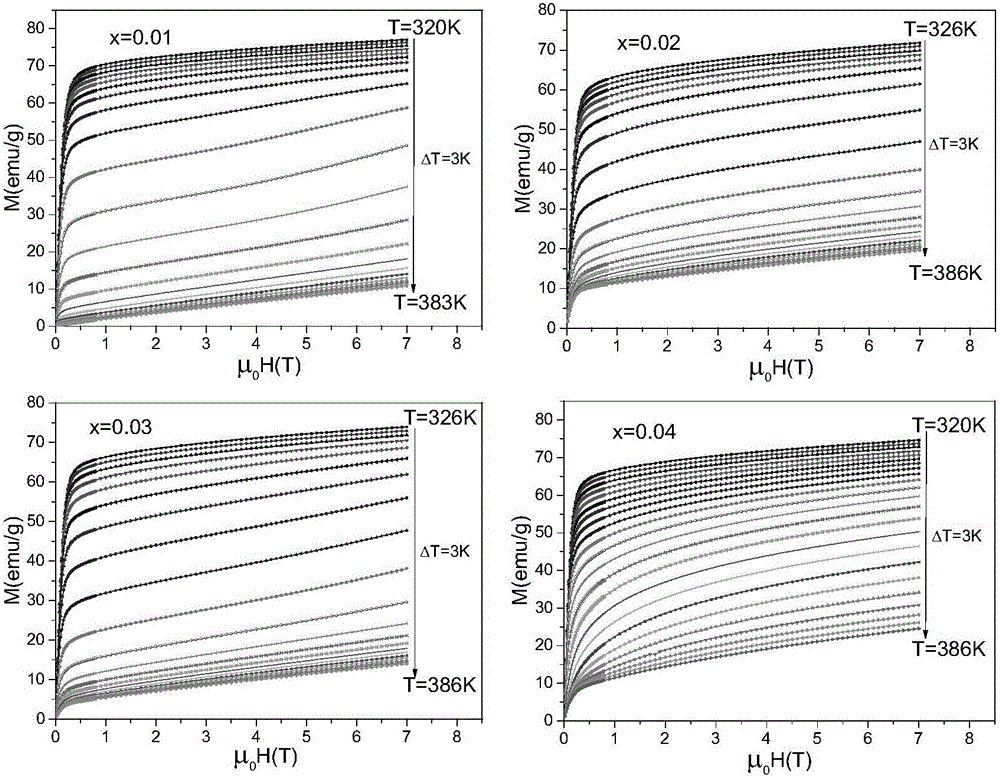

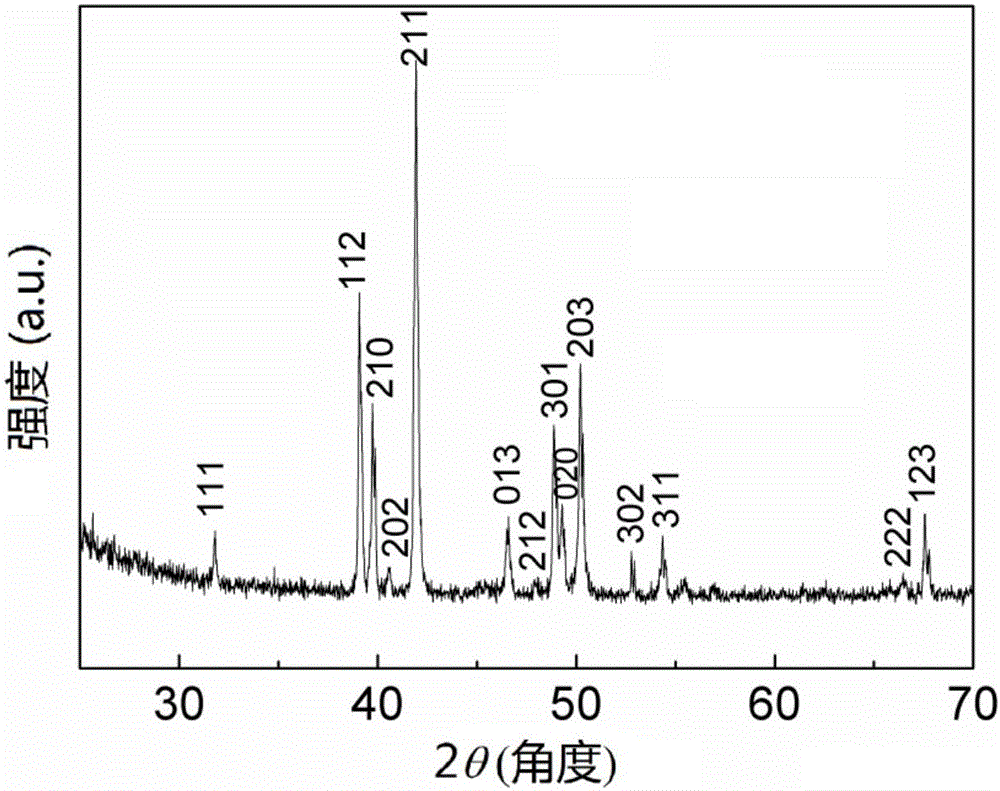

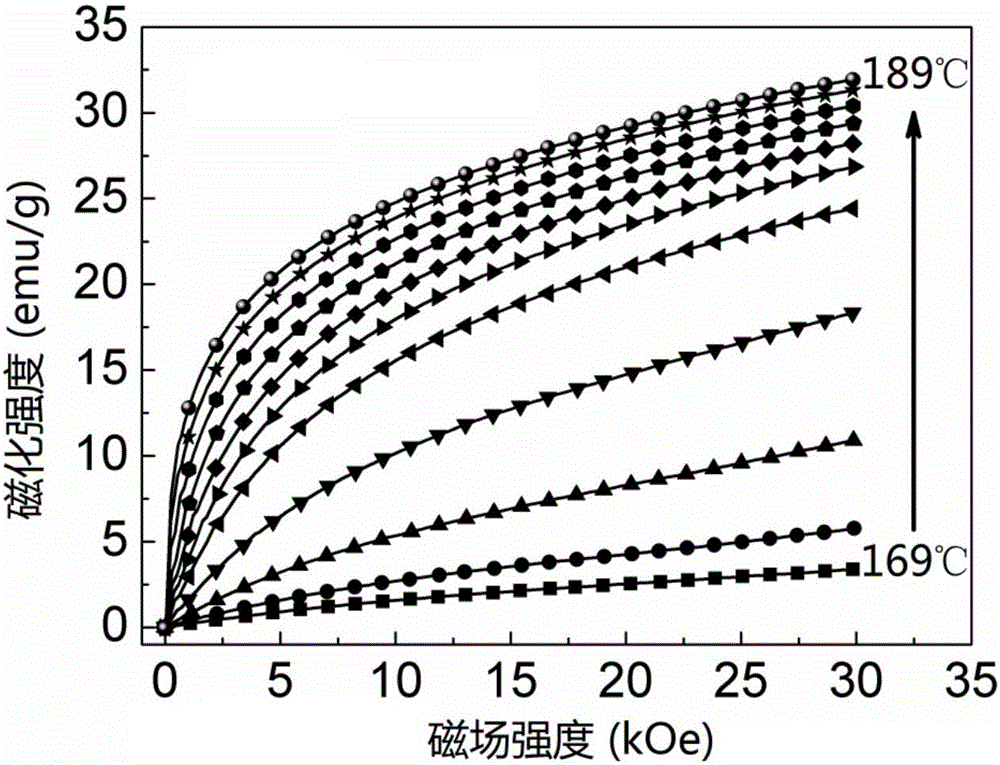

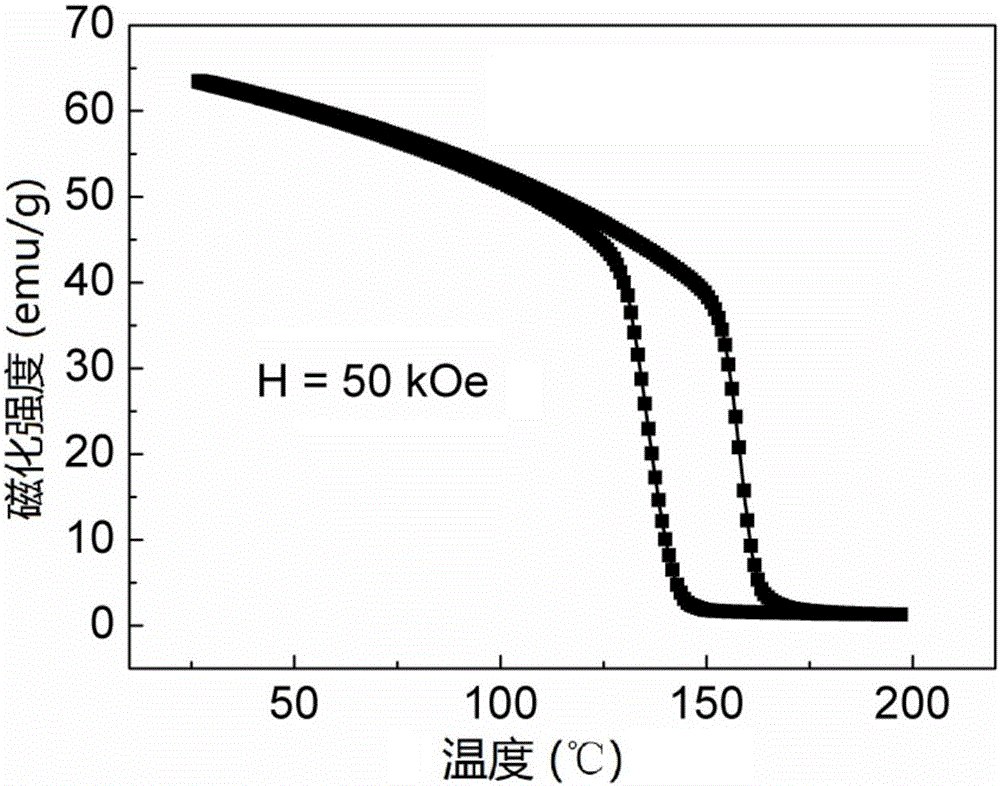

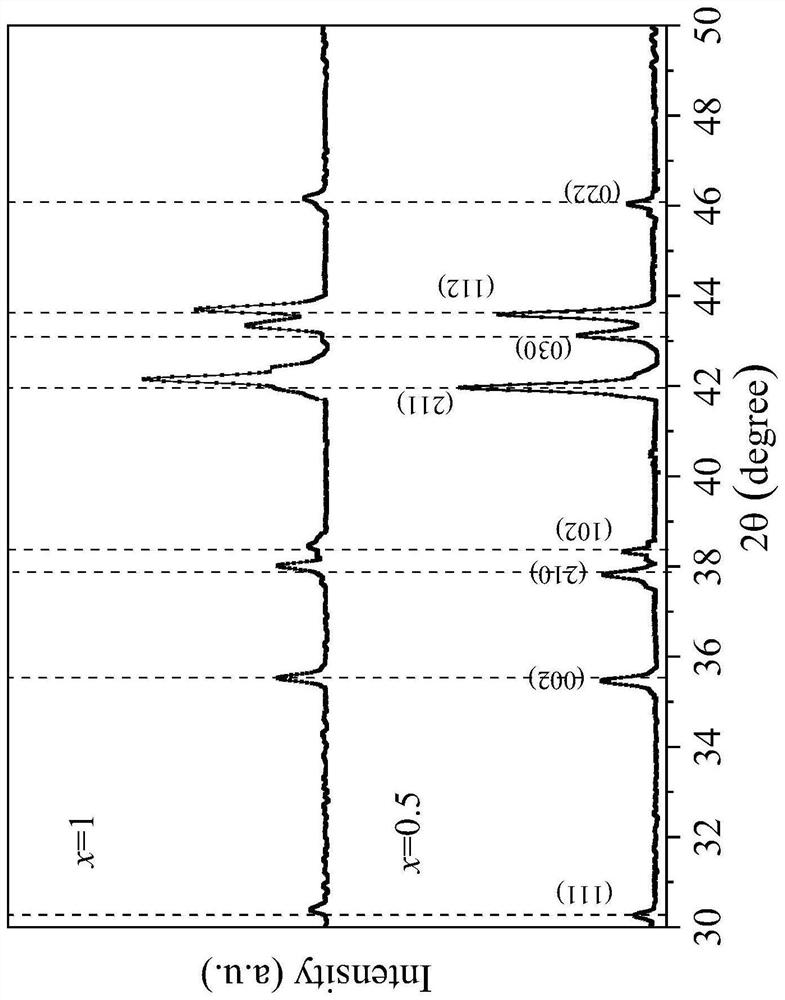

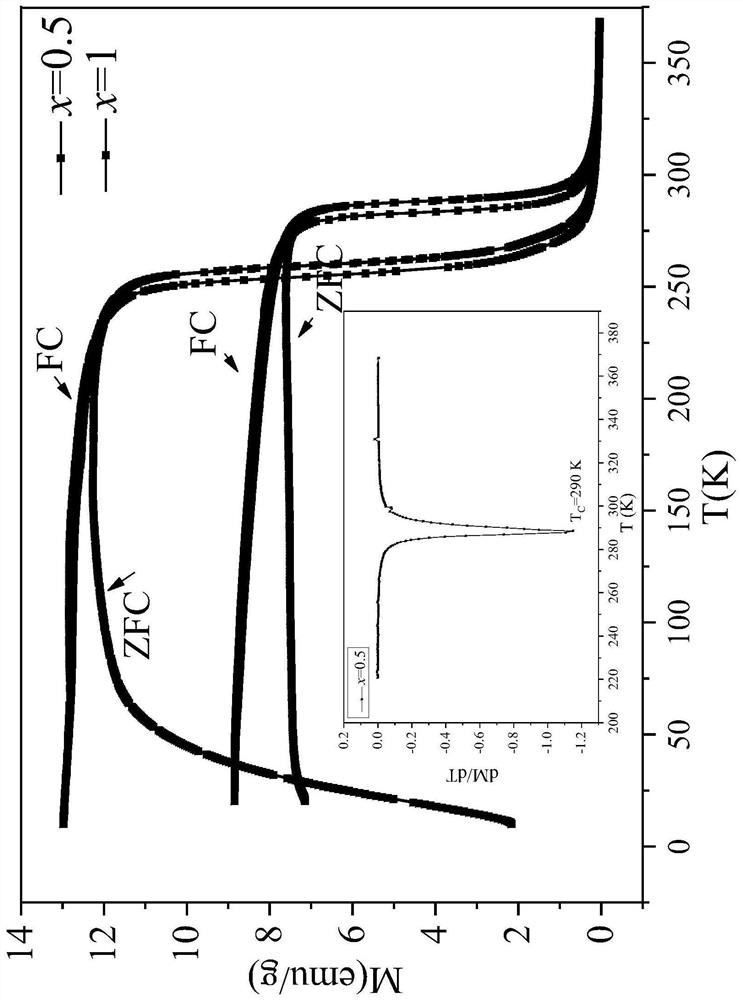

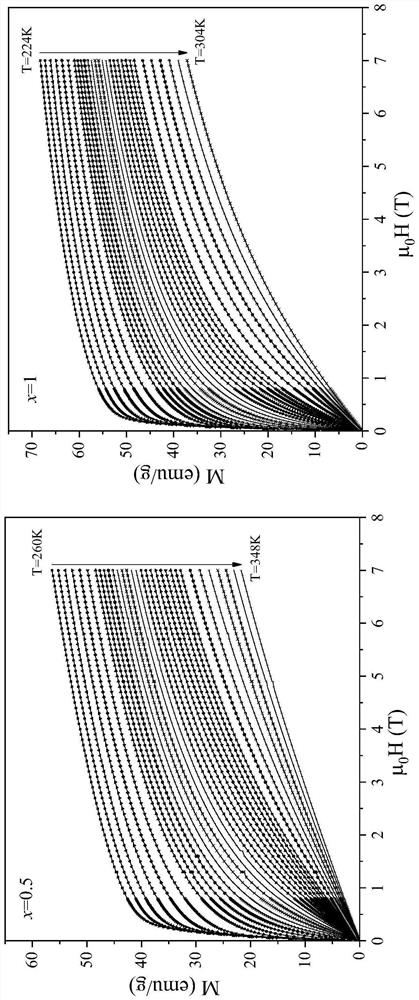

Manganese-cobalt-germanium-base alloy magnetic refrigeration material and preparing method thereof

ActiveCN105714173AHigh curie temperatureImprove the magnetocaloric effectHeat-exchange elementsManganeseCurie temperature

The invention relates to a manganese-cobalt-germanium-base alloy magnetic refrigeration material and a preparing method thereof. The molecule general formula of the magnetic refrigeration material is MnCoGe1-xCux, wherein the value of x ranges from 0.005 to 0.05. The manganese-cobalt-germanium-base alloy magnetic refrigeration material is prepared by the following steps that firstly, a manganese material, a cobalt material, a germanium material and a copper material are weighed according to the molar ratio of 1:1:(1-x): x, heating, fusing and even mixing are conducted under the inert gas shielding, and a mixed sample is obtained; and secondly, the mixed sample is taken out, annealing treatment is conducted, and a target product is obtained. Compared with the prior art, the magnetic refrigeration material has the beneficial effects that the magnetic refrigeration material is good in Curie temperature and magnetocaloric effect, the magnetic refrigeration material is a second-order phase change material, the problem of heat stagnation brought by a first-order phase change material is effectively solved, and preparing is simple and feasible.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

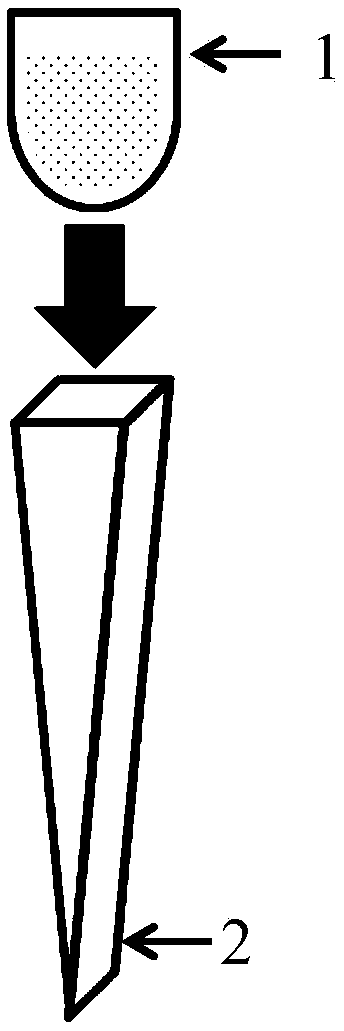

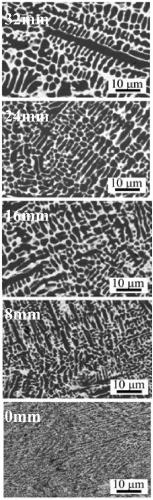

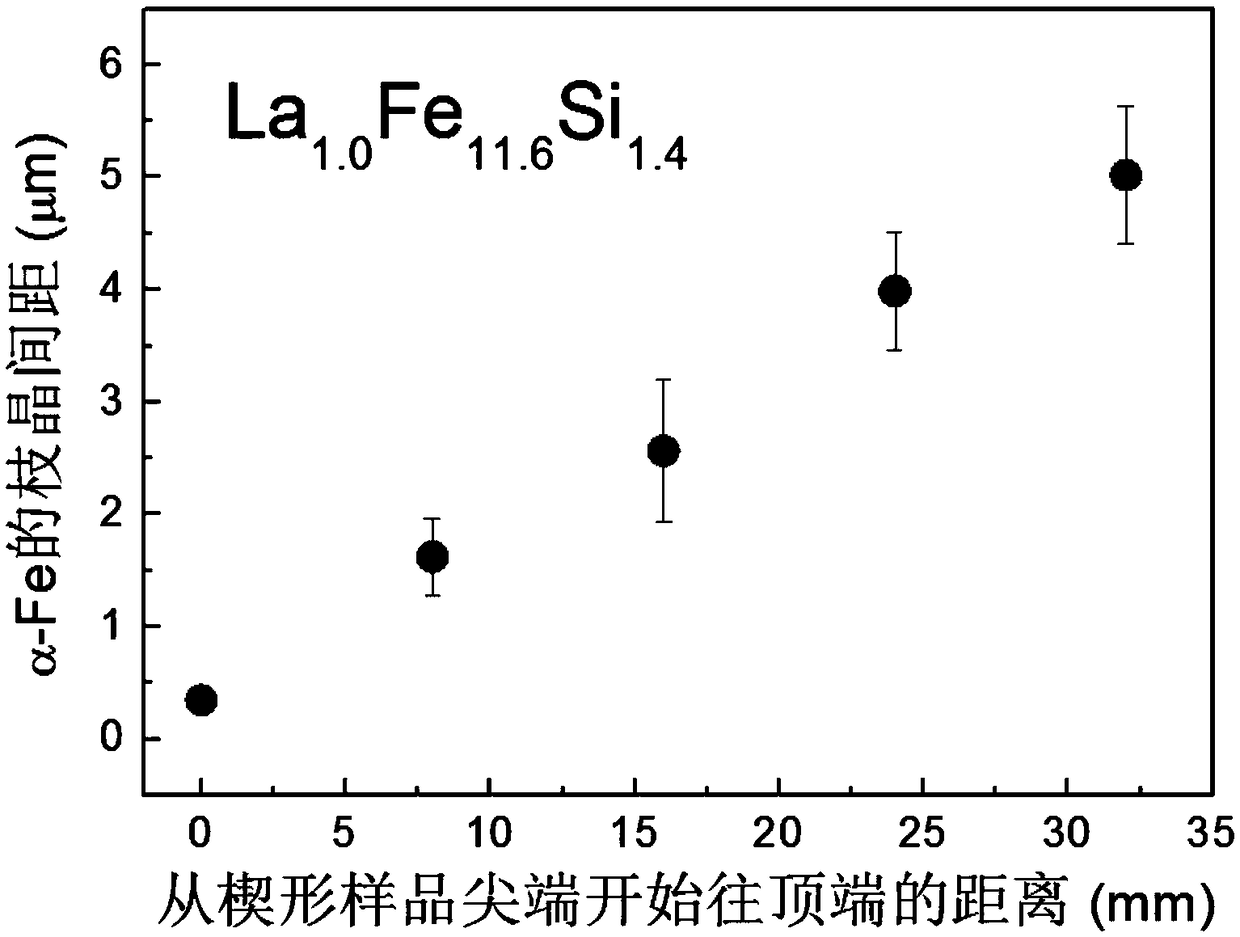

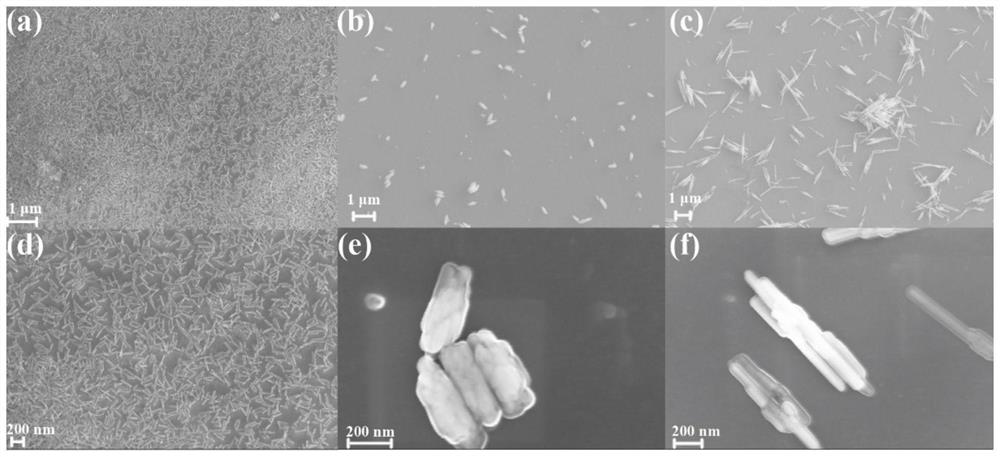

High-throughput preparation method for LaFeSi-based magnetic refrigeration material

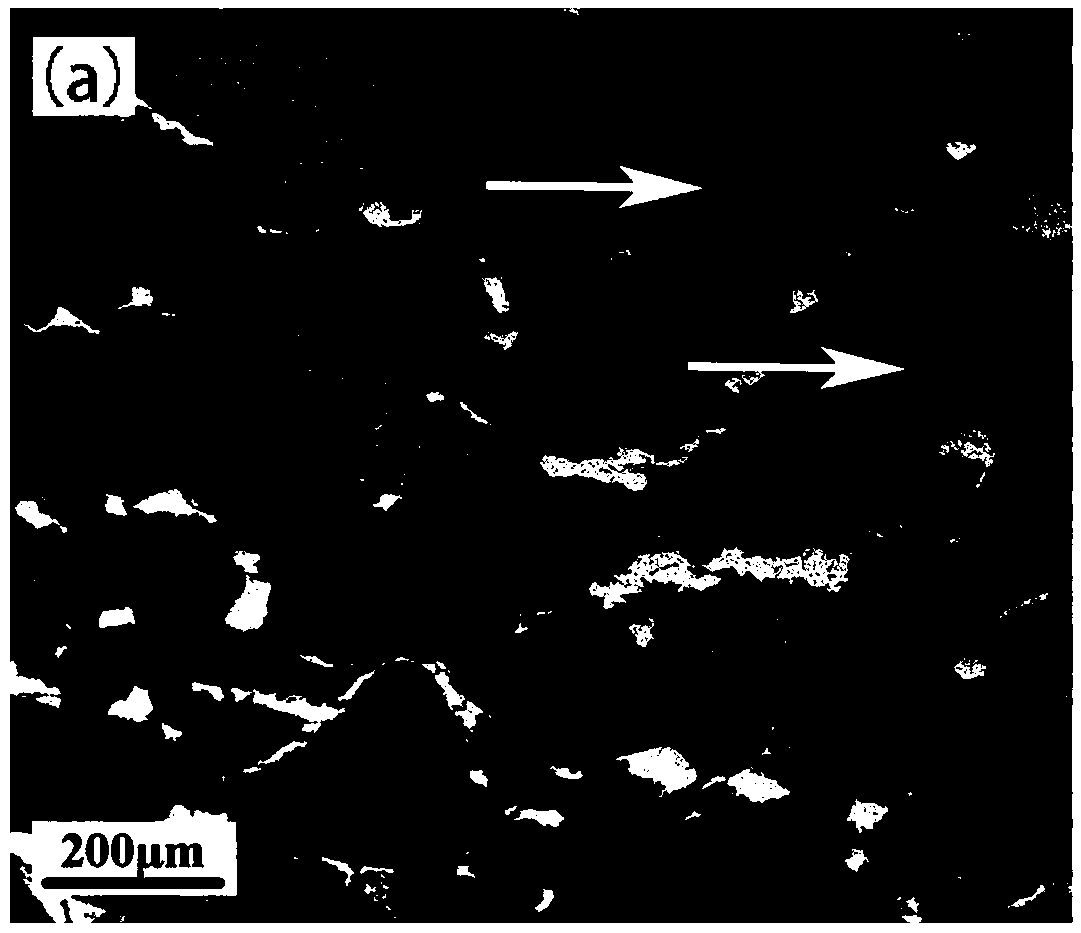

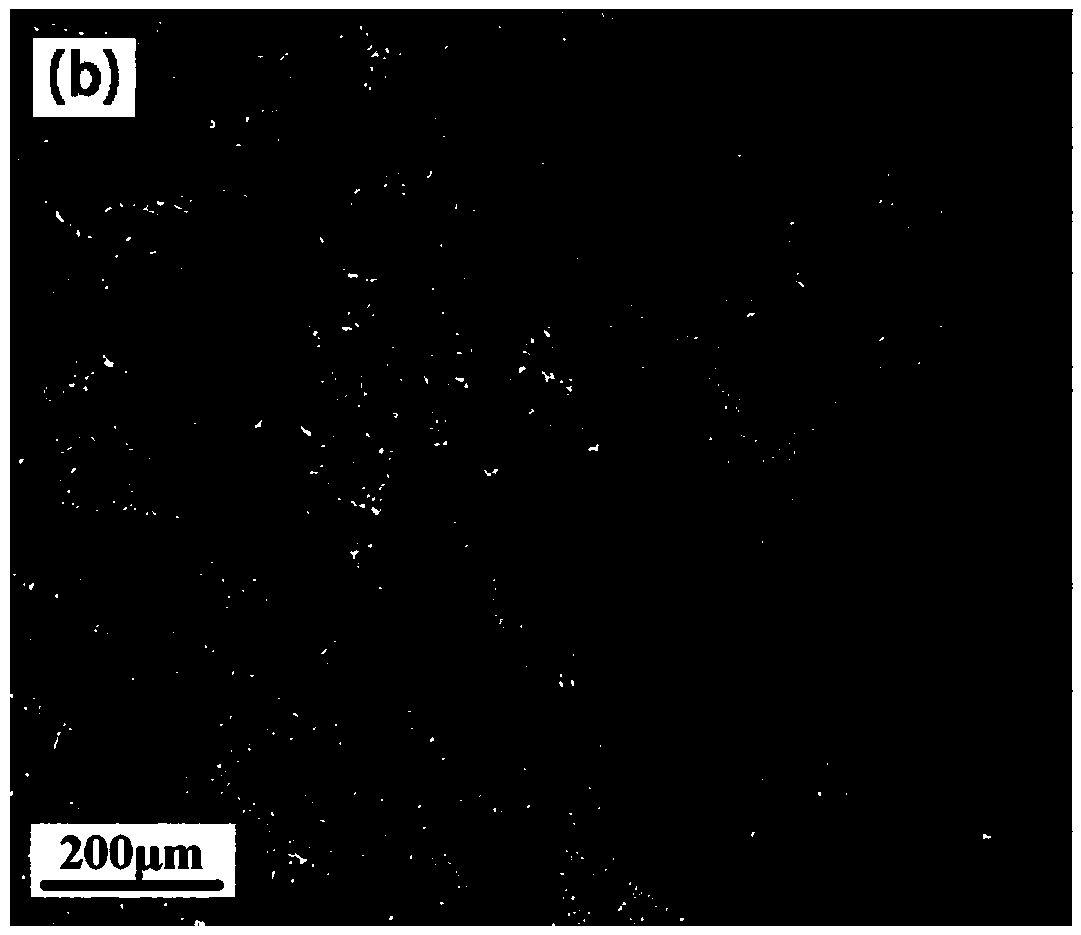

ActiveCN109108227AImprove the magnetocaloric effectFoundry mouldsFurnace typesHigh fluxScanning electron microscope

The invention discloses a high-throughput preparation method for a LaFeSi-based magnetic refrigeration material. According to the method, in the process of casting an alloy ingot from material melt, awedged copper mold is adopted, so the cooling rate of the melt along the height direction is in gradient change, the wedged alloy ingot with a solidified alloy structure gradient is obtained; and annealing is then carried out, and the magnetothermal effect of the obtained LaFeSi-based blocky magnetic refrigeration material with a NaZn13 structure has a gradient. Preferably, by utilizing microstructures obtained by a scanning electron microscope characterizing different cooling rates in the same sample at high throughput, in combination with a magnetothermal performance test, a corresponding relation between different structures, magnetothermal effect and copper mold width is obtained, which can be used for rapidly screening needed sample preparation parameters and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Magnetic phase change alloy

ActiveCN106191616AImprove thermal effectIncreased magnetic heating or energy conversion efficiencyInorganic material magnetismInductances/transformers/magnets manufactureMagnetic phaseHeat pump

The invention discloses a magnetic phase change alloy. The magnetic phase change alloy has a formula of (Mn1-alpha M alpha)xNiy(Ge1-beta Si beta)z; M=Fe or Co; x is not more than 36 and not less than 30; y is not more than 36 and not less than 30; z is not more than 36 and not less than 30; x+y+z=100; alpha is more than 0 and less than 0.8; and beta is not more than 1 and not less than 0. The magnetic phase change alloy has high-temperature huge magnetic heat effect, and widens the temperature range of a magnetic heating material; needed raw materials are rich in storage, easy to store and low in cost; and a preparation process is simple and reliable, is excellent in stability, and is easy to industrial produce. The magnetic phase change alloy is excellent in comprehensive performance, and is an ideal Mn base non-rare earth magnetic heat pump and thermomagnetic power generation candidate material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

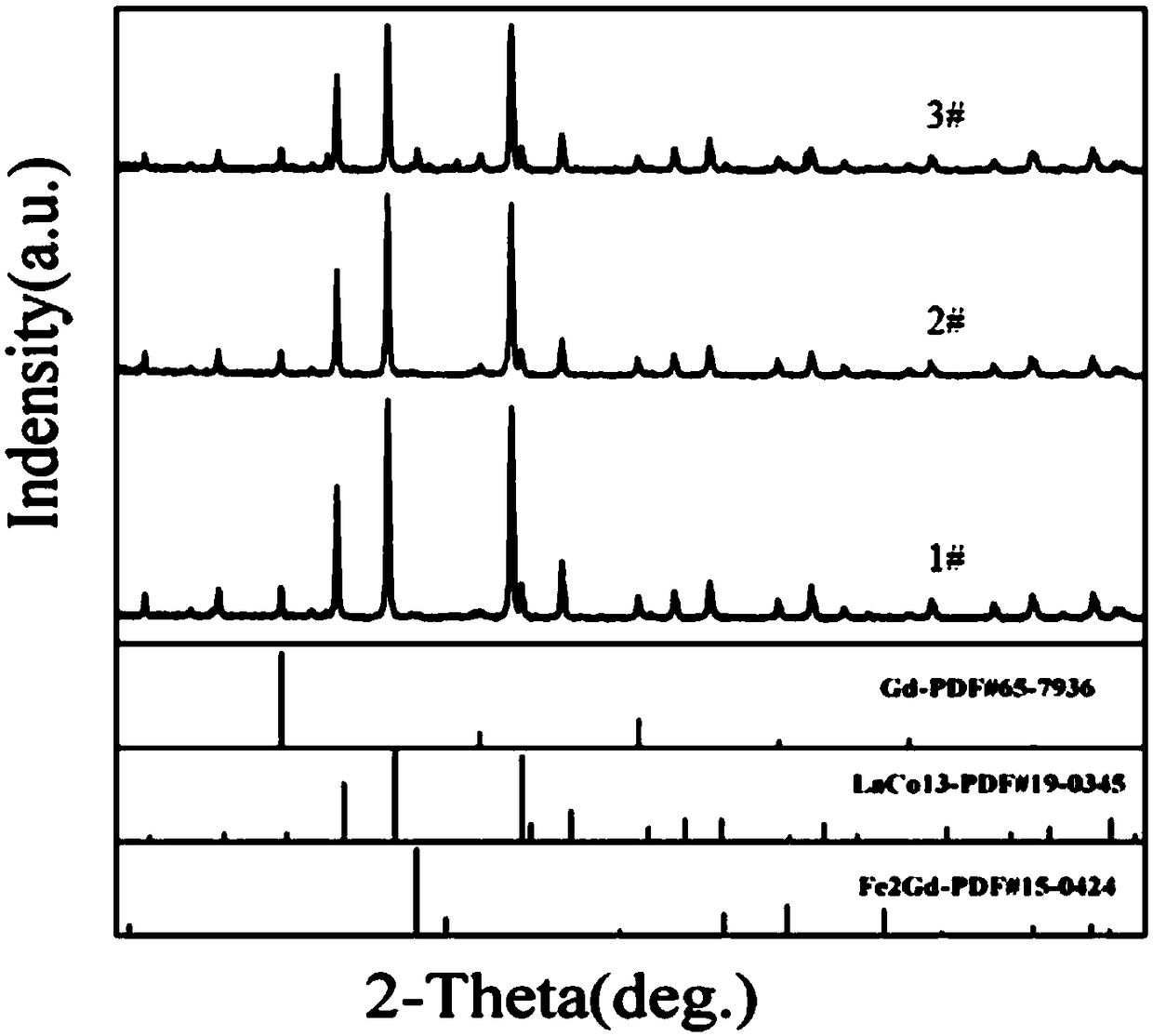

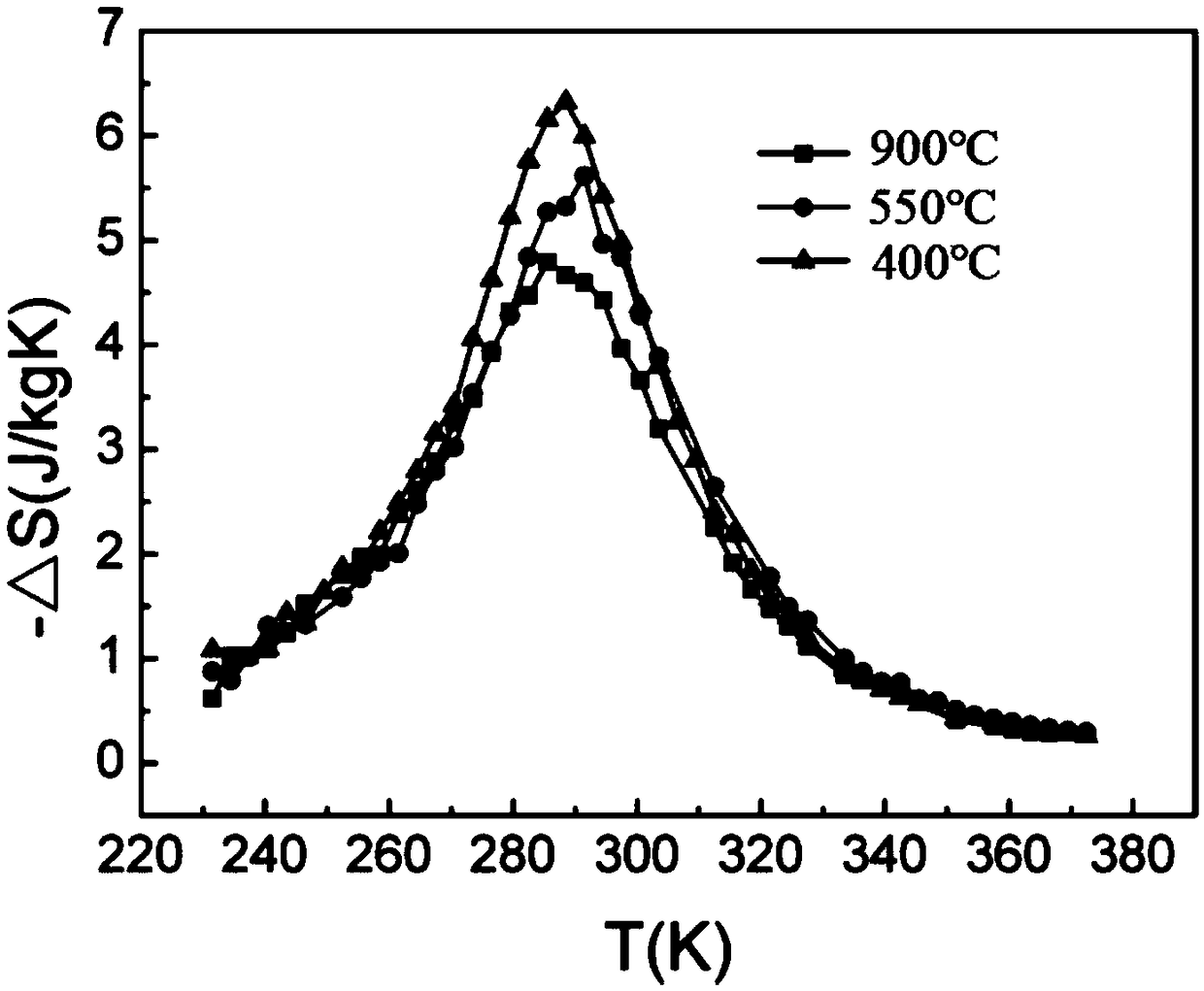

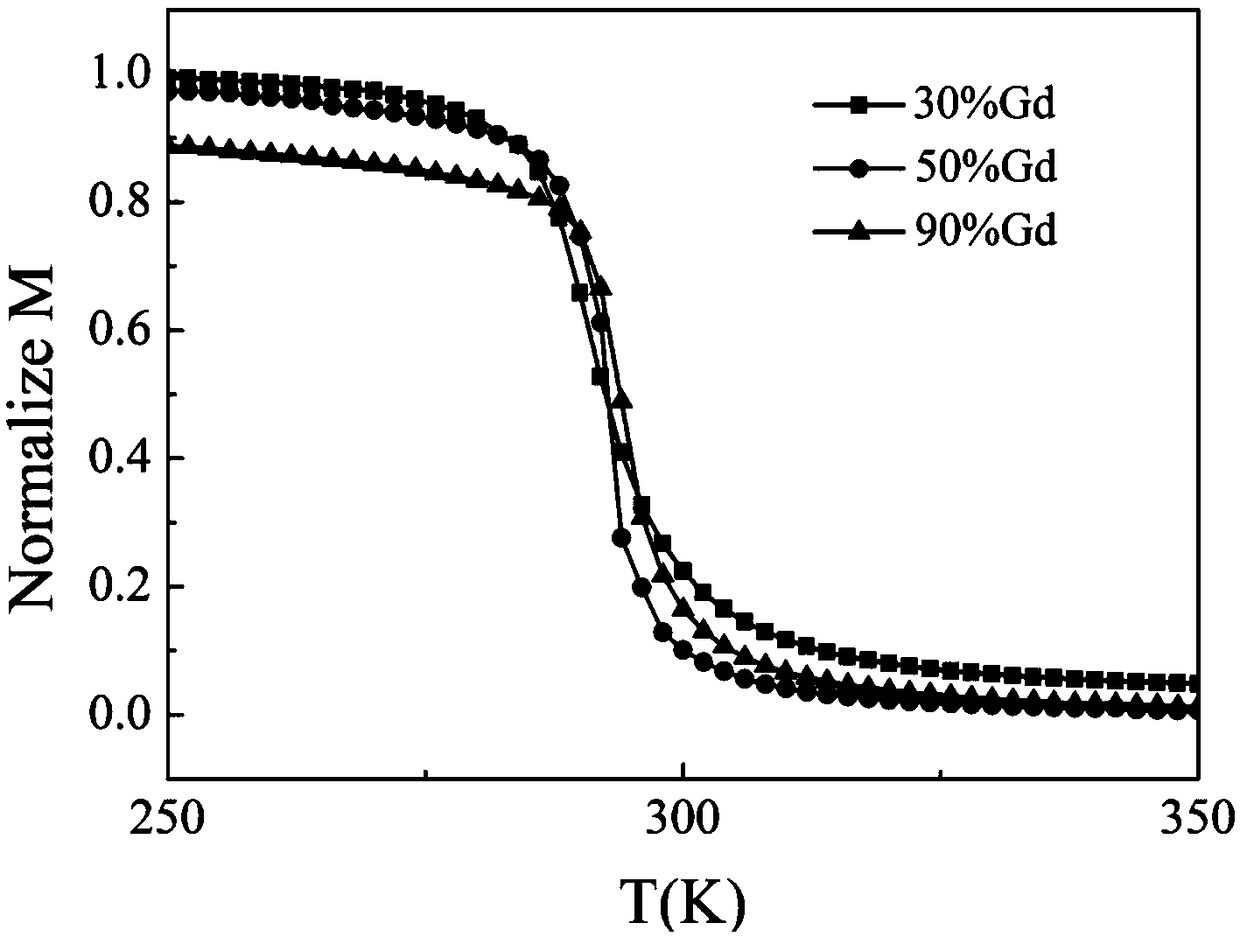

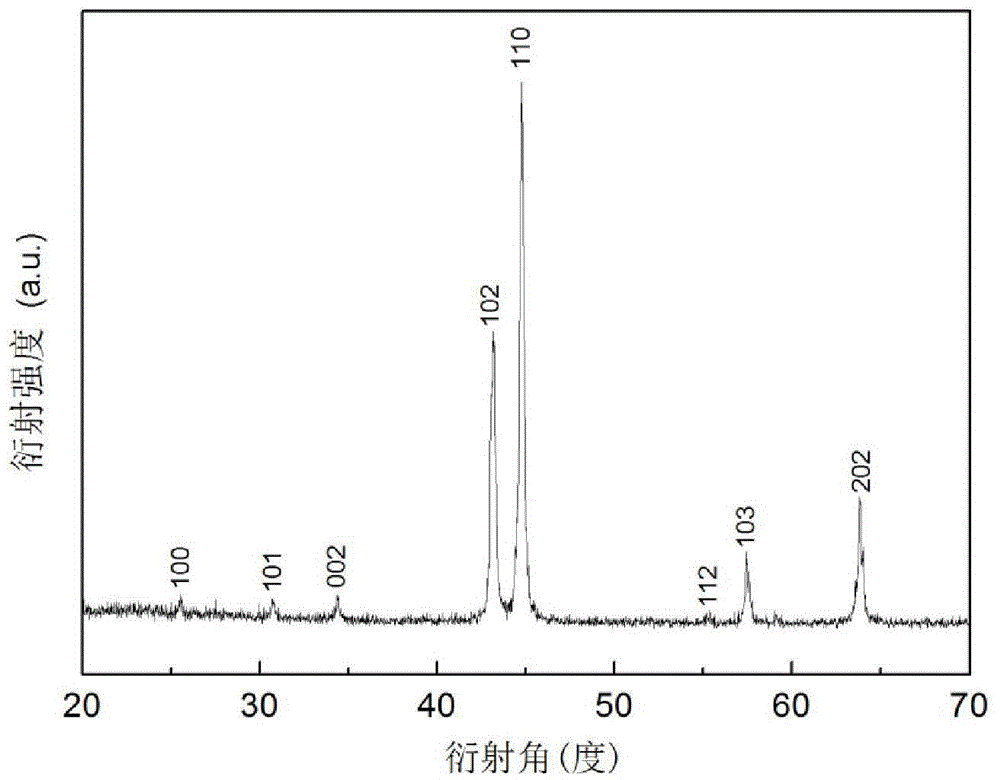

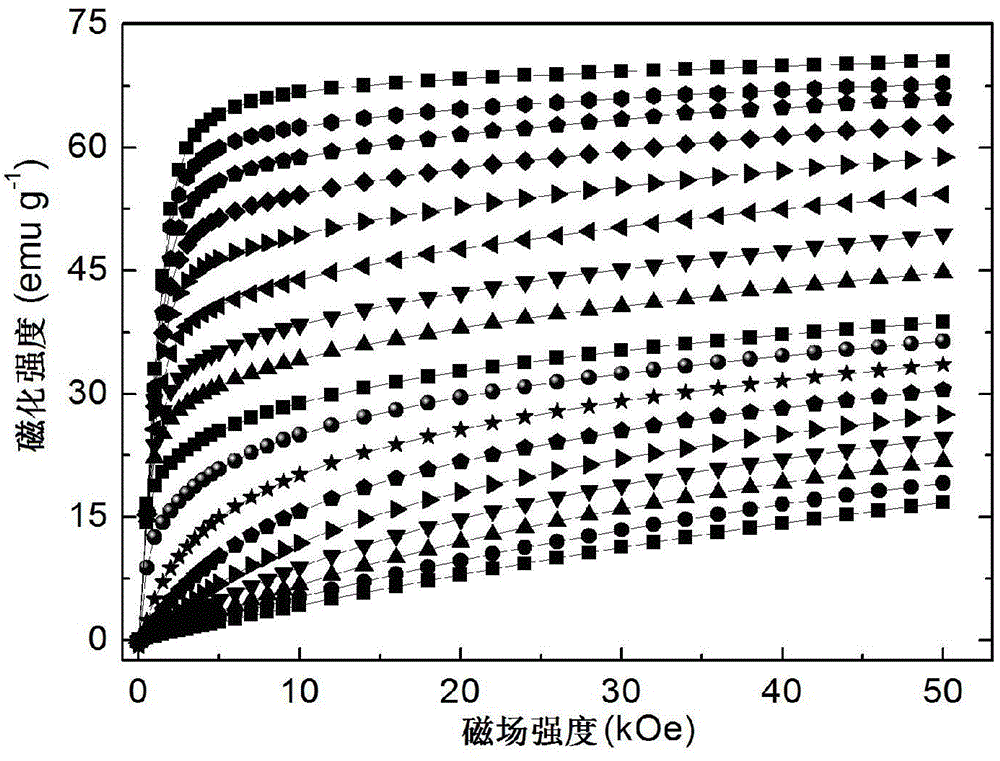

Lanthanum-iron-silicon/gadolinium composite magnetic refrigeration material and preparation technology thereof

ActiveCN108735411AImprove mechanical propertiesAvoid destructionInorganic material magnetismIncreasing energy efficiencyLanthanumMagnetic refrigeration

The invention discloses a lanthanum-iron-silicon / gadolinium composite magnetic refrigeration material and a preparation technology thereof and belongs to the field of magnetic refrigeration materialsin magnetic functional materials. A La-Fe-Si / Gd composite magnetic refrigeration material with high strength and high performance is obtained by adopting metal Gd particles as a second magnetic refrigeration material of playing a bonding role and La-Fe-Si series alloy through hot pressing sintering. The invention further discloses a preparation method and application of the La-Fe-Si / Gd composite magnetic refrigeration material. The La-Fe-Si series alloy and Gd are magnetic refrigeration materials with excellent performance, so that the mechanical properties are complementary. Through additionof Gd elemental particles, the mechanical property of the La-Fe-Si series alloy is greatly strengthened, and furthermore, the damage to the magnetic refrigeration performance caused by use of other binders is avoided. The obtained magnet has good magnetic refrigeration performance and relatively high strength, is simple in equipment, simple in operation and relatively low in cost in an implementation process, is high in economic value and has important application significance in the field of magnetic refrigeration, and mass production is easy to implement.

Owner:BEIJING UNIV OF TECH

Magnetic alloy serving as magnetic refrigeration material

ActiveCN103334043ALarge magnetic differenceImprove the magnetocaloric effectHeat-exchange elementsRare earthMagnetic refrigeration

The invention discloses a magnetic alloy. The chemical general formula of the magnetic alloy is (Mn100-deltaCodelta) alphaNibetaGegamma, wherein alpha is more than or equal to 25 and less than or equal to 40, beta is more than or equal to 25 and less than or equal to 40, gamma is more than or equal to 25 and less than or equal to 40, alpha+beta+gamma is equal to 100, delta is more than 0 and less than 50, and alpha, beta, gamma and delta refer to the atomic percent content. The magnetic alloy has a huge magnetocaloric effect and high magnetic refrigeration efficiency and can stably operate in a wide temperature range temperature area by serving as a magnetic refrigeration working medium. The required raw materials Mn, Co, Ni and Ge are the conventional metal elements which are low in price, rich in reserves and easy to store. The material is simple and reliable in preparation process, high in process stability and easy to industrially produce. The provided magnetic material (Mn100-deltaCodelta) alphaNibetaGegamma with the huge magnetocaloric effect has excellent comprehensive performance and is an ideal Mn-based non-rare earth magnetic refrigeration candidate material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

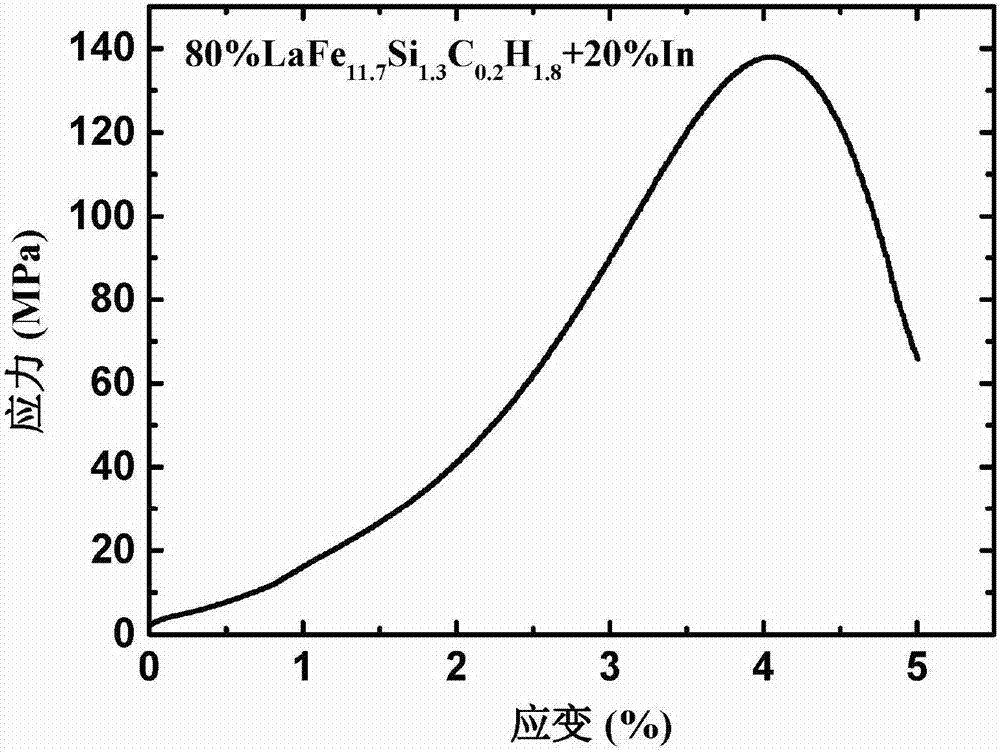

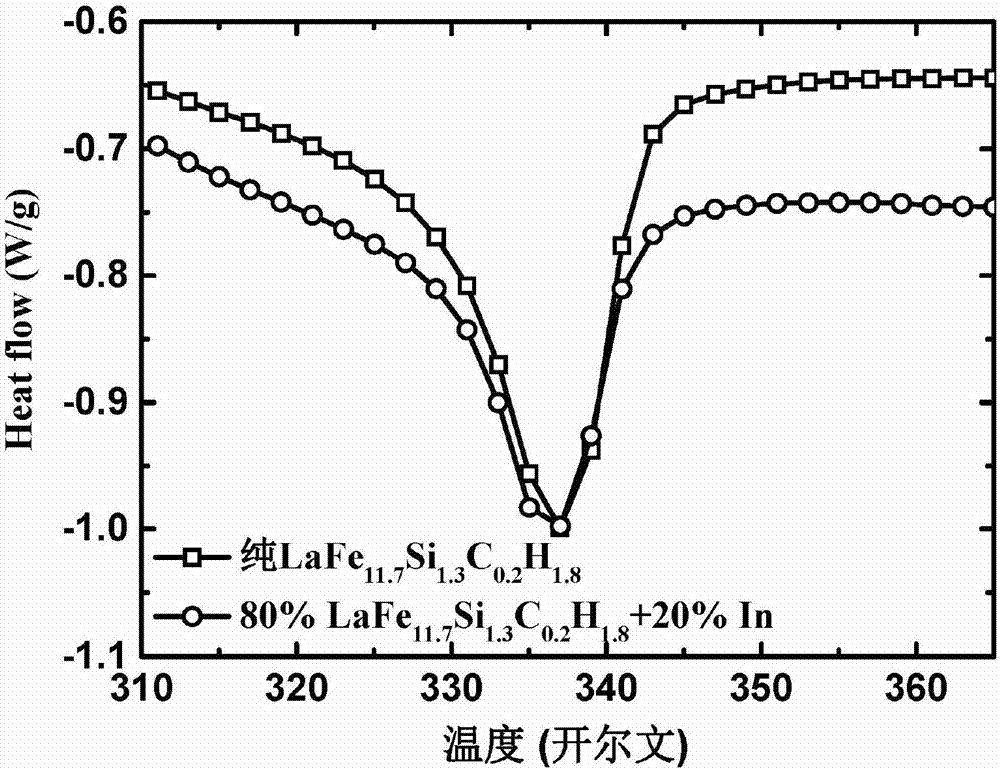

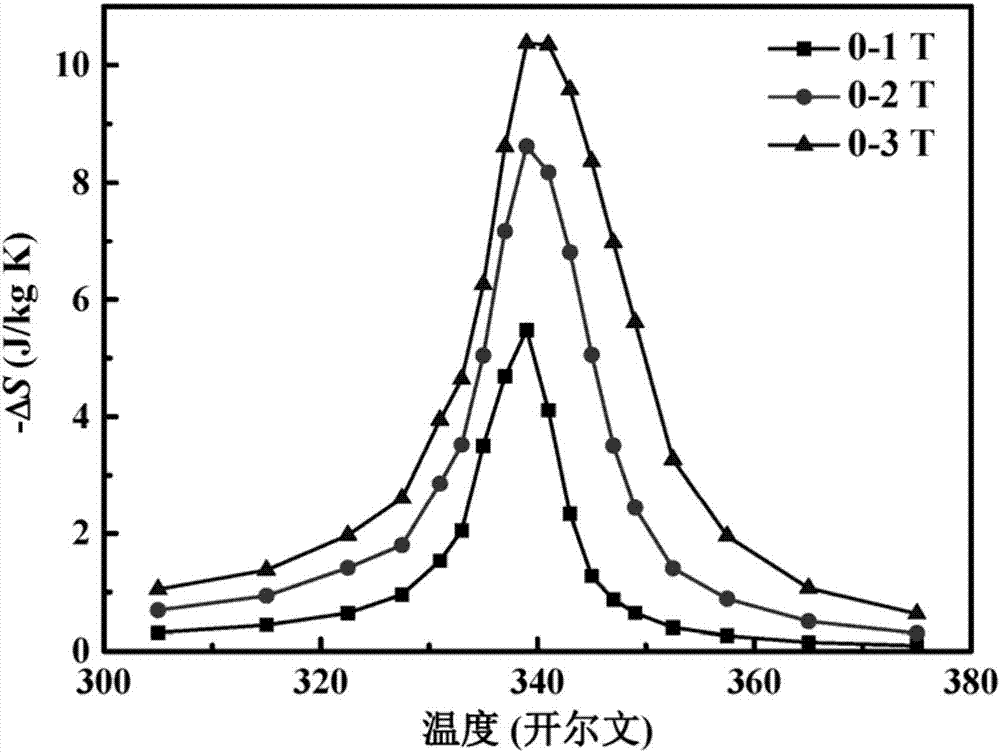

Composite magnetic refrigeration material and preparation method and application thereof

InactiveCN106967923AImprove mechanical propertiesImprove the magnetocaloric effectTransportation and packagingMetal-working apparatusAlloyMagnetic refrigeration

The invention provides a composite magnetic refrigeration material and a preparation method and application thereof. The composite magnetic refrigeration material is specifically composed of X, Y and Z, wherein X is one or more of magnetic refrigeration materials; Y is alloy of one or more elements of IB group, IIB group, IIIA group and IVA group; and Z is one or more of various binding agents frequently used in the prior art. The composite magnetic refrigeration material provided by the invention has higher mechanical performance compared with traditional magnetic refrigeration materials, has an excellent magnetocaloric effect and can be well applied to the field of magnetic refrigeration. The invention further discloses the preparation method of the composite magnetic refrigeration material. By means of the preparation method, composite magnetic refrigeration materials in any shape and with any dimension can be prepared according to actual requirements. In addition, the preparation method has the advantages that raw materials are rich, cost is low, the preparation process is simple, implementation is easy, and industrial production is achieved, and is of great significance on actual application.

Owner:UNIV OF SCI & TECH BEIJING

La-Fe-Si base room-temperature magnetic refrigeration composite material and preparing method thereof

The invention discloses a La-Fe-Si base room-temperature magnetic refrigeration composite material and a preparing method thereof. A La-Fe-Si base magnetic refrigeration material and Ce-Co alloy powder are evenly mixed, low-temperature hot press sintering and subsequent high-temperature diffusion heat treatment are conducted, finally, rapid quenching is conducted to the room temperature, and a cylindrical composite magnetic refrigeration material is prepared; and the La-Fe-Si base magnetic refrigeration material is formed by mixing particles with the granularity being 100-300 microns and the granularity smaller than 46 microns. The composite material is composed of a magnetic heat working medium and a bonding agent. On one hand, the material porosity is reduced through the bonding agent, so that good density and excellent mechanical performance are achieved; and on the other hand, bonding agent atoms enter main phase particles through heat diffusion, a large-platform-shaped magnetic entropy change and high-refrigerating-capacity La-Fe-Si base magnetic refrigeration composite material can be better obtained. The problem that the La-Fe-Si is large in brittleness and is large in heat / magnetic lagging accompanying the first-level phase change, and the La-Fe-Si is difficultly used in the magnetic refrigeration cycle is solved.

Owner:SOUTH CHINA UNIV OF TECH

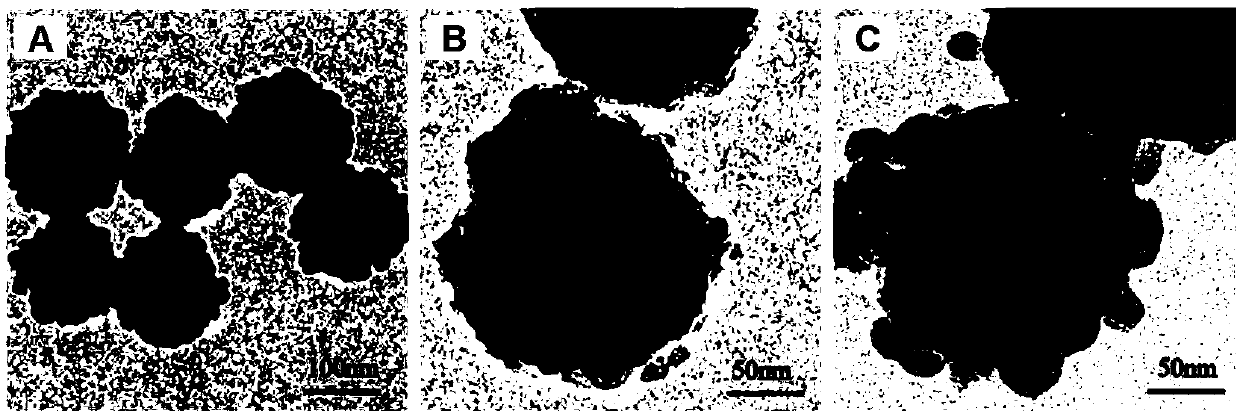

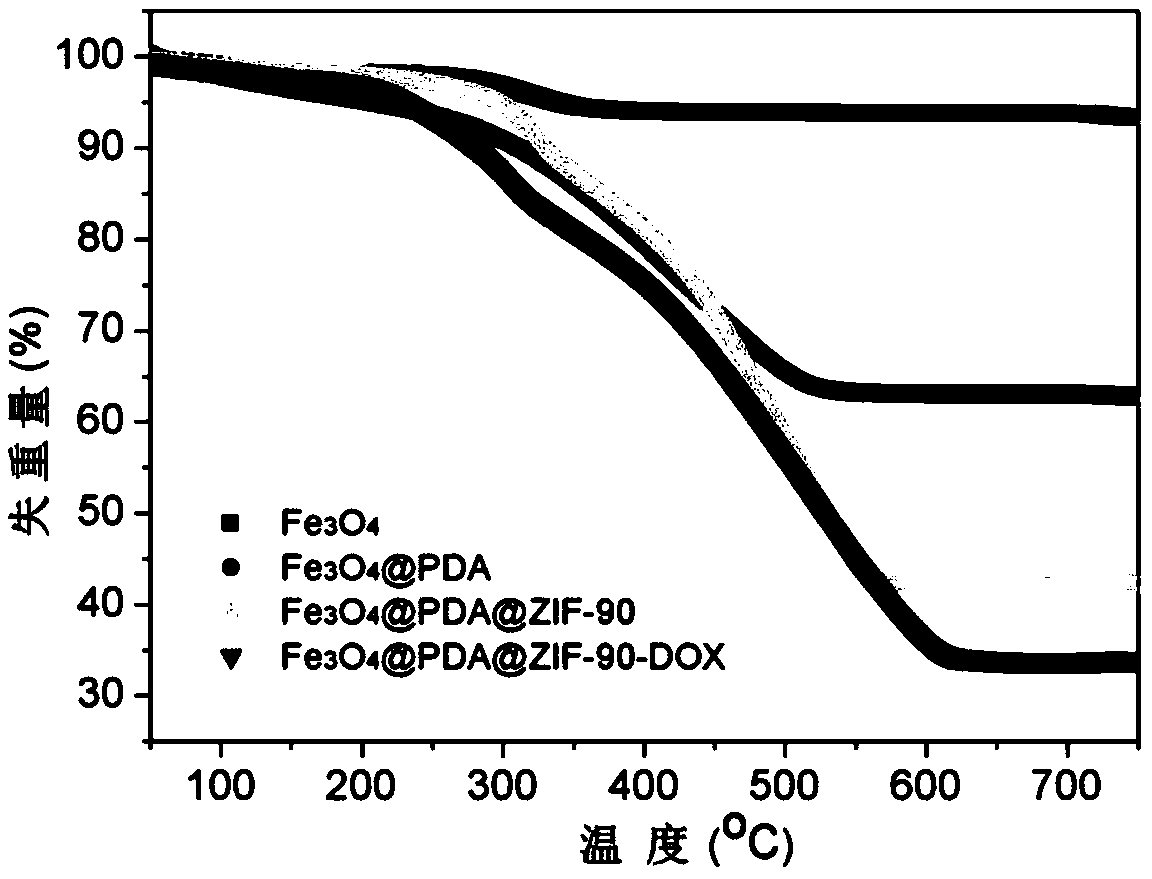

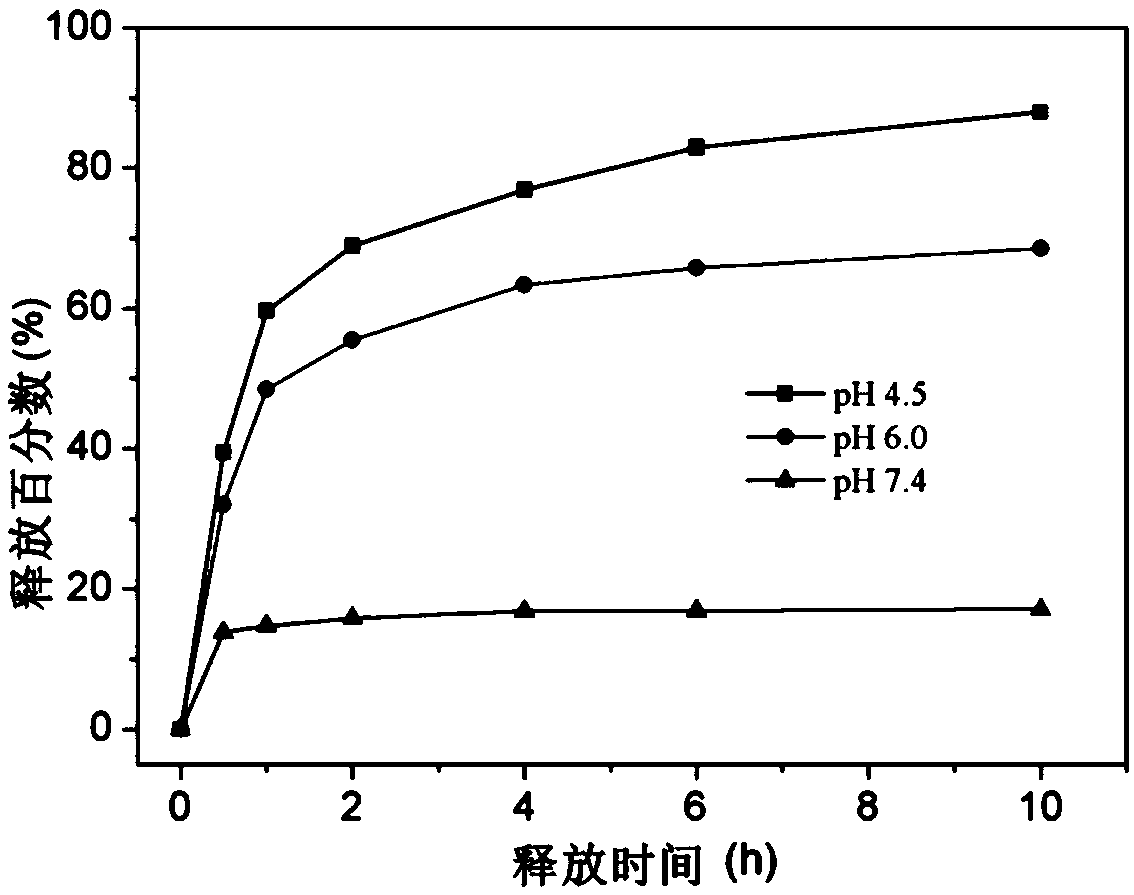

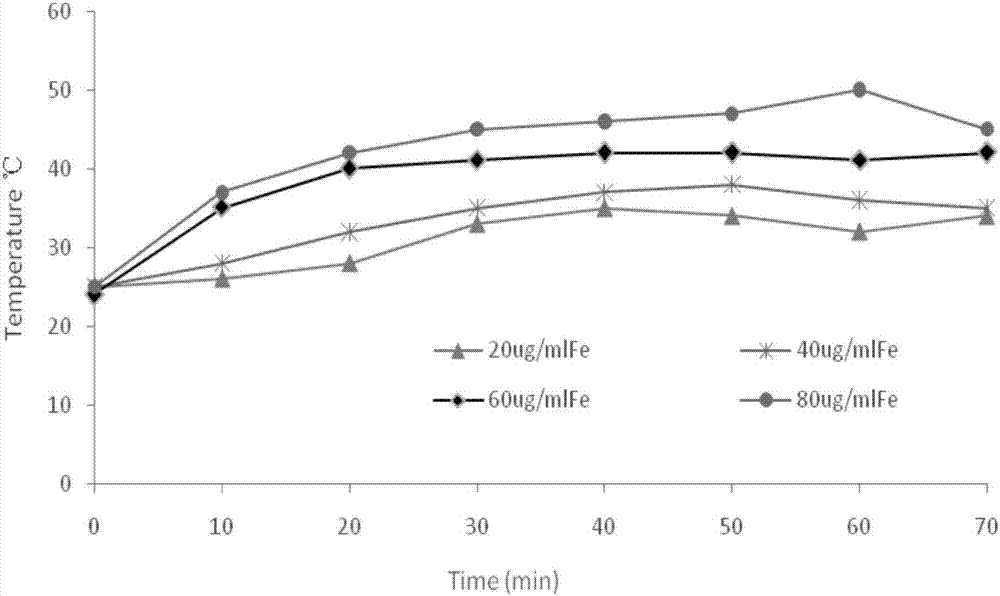

Multifunctional drug carrier, and preparation method and application thereof

ActiveCN109091674AFacilitated releaseNeutral environment stableOrganic active ingredientsEnergy modified materialsPolymerizationIon

The invention discloses a multifunctional drug carrier, and a preparation method and application thereof, and belongs to the field of materialogy. The multifunctional drug carrier has the functions ofmagnetic heat therapy and photo-thermal therapy, and comprises a metal organic frame ZIF-90 outer layer, a polydopamine interlayer and a Fe3O4 particle core. Superpara magnetism Fe3O4 particles are taken as a core, polydopamine coated Fe3O4 particles (Fe3O4@PDA) are formed through auto polymerization in a dopamine alkaline condition, and Zn<2+> is taken as metal ions to be assembled with organicligand imidazole-2-formaldehyde (ICA) to compound Fe3O4@PDA particles so as to prepare the multifunctional drug carrier Fe3O4@PDA@ZIF-90 particles. According to the multifunctional drug carrier disclosed by the invention, anti-cancer drugs can be loaded at high content, and the cancer therapy of drug chemotherapy with the functions of magnetic heat therapy and photo-thermal therapy can be realized.

Owner:HUANGGANG NORMAL UNIV

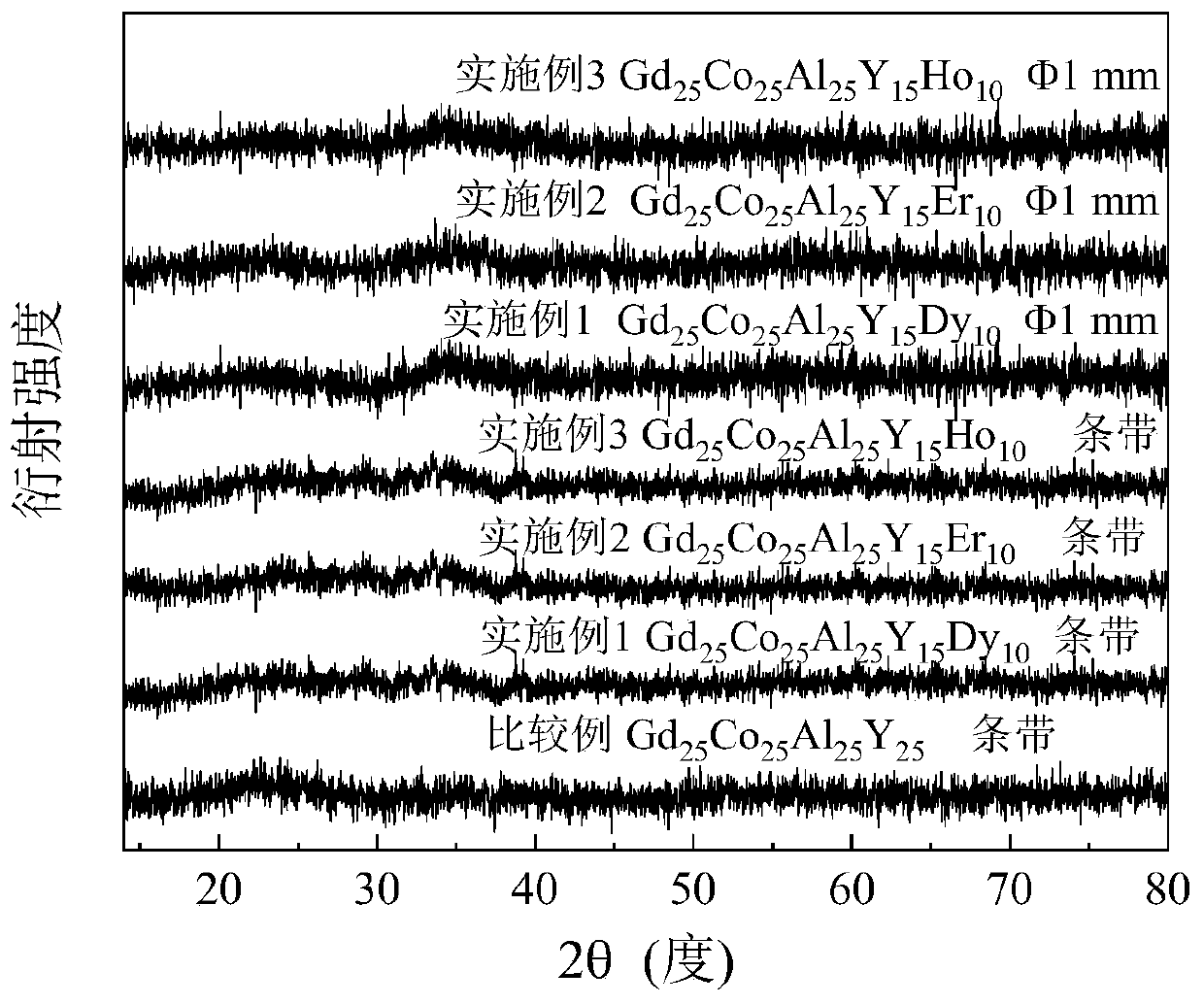

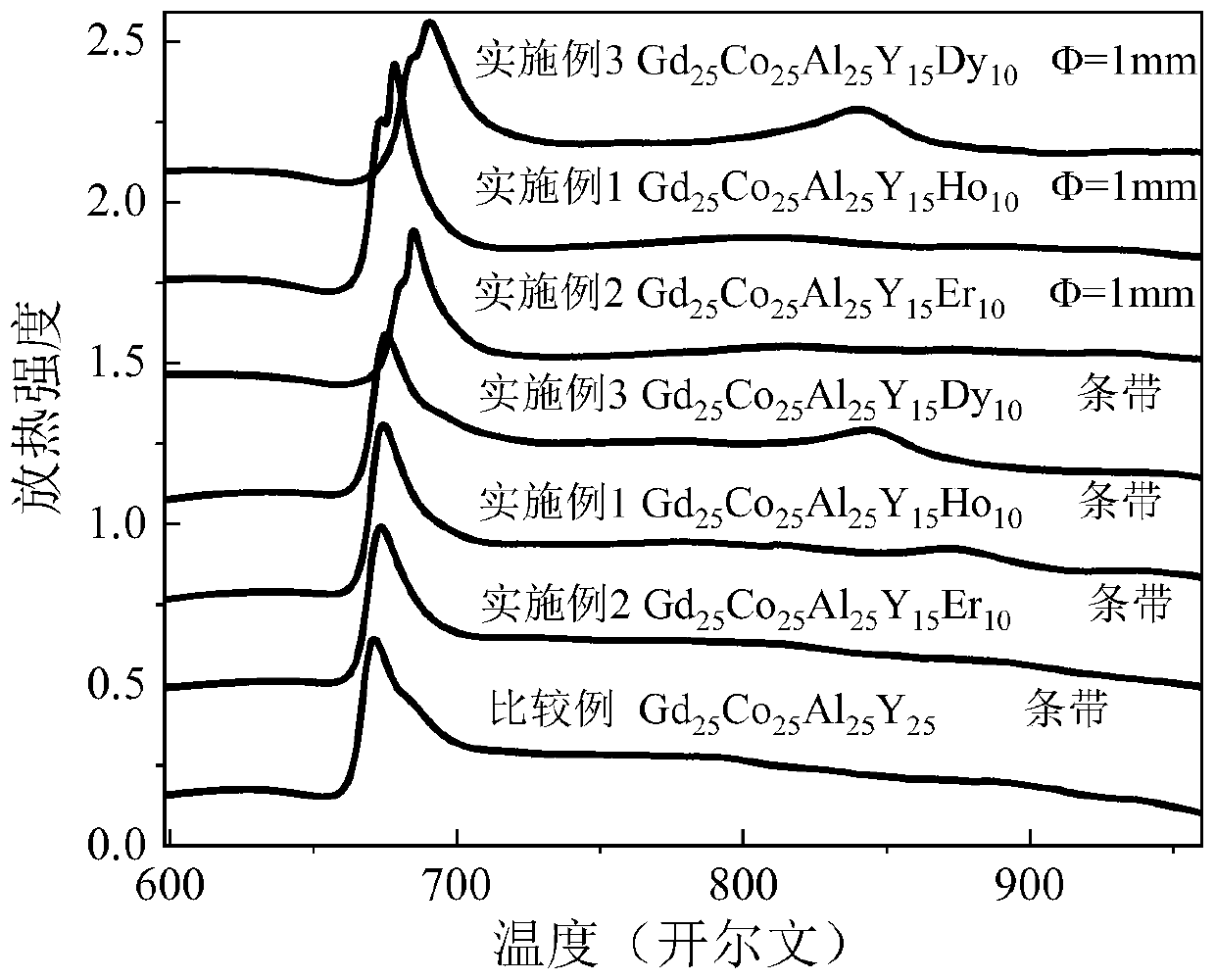

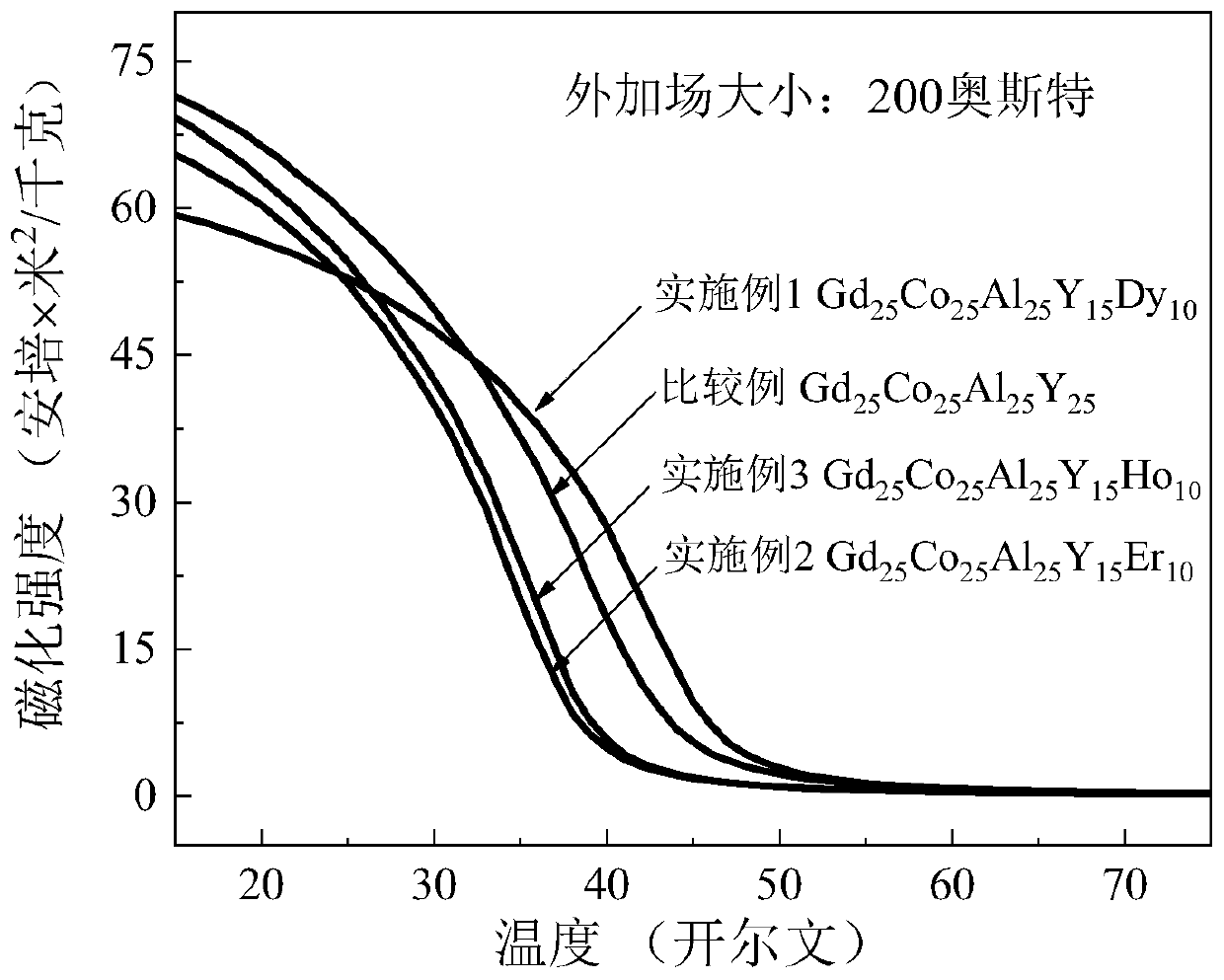

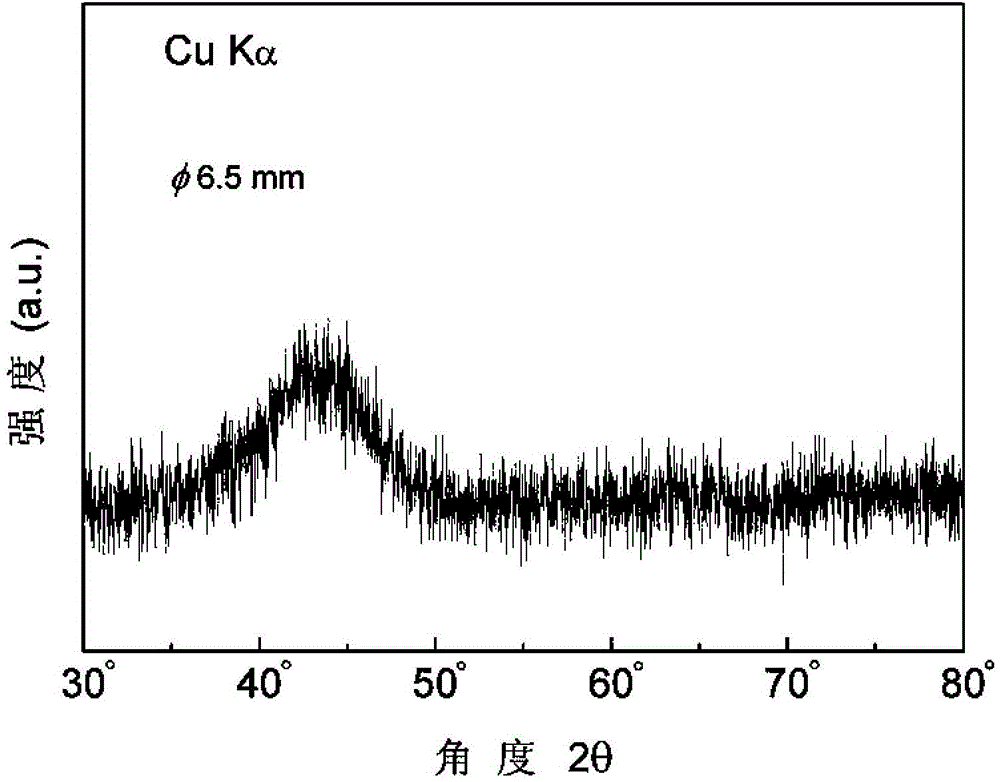

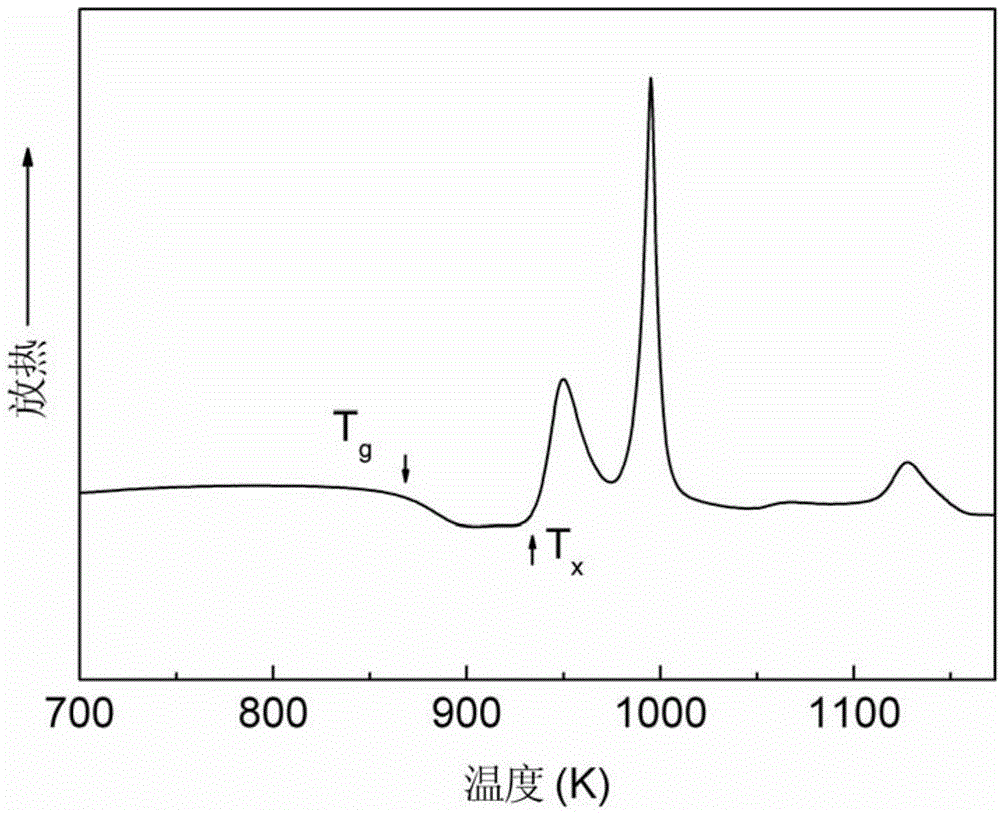

Rare-earth-based high-entropy amorphous alloy high in magnetocaloric effect and preparation method thereof

The invention discloses a rare-earth-based high-entropy amorphous alloy material high in magnetocaloric effect. The molecular formula of the rare-earth-based high-entropy amorphous alloy is GdaCobAlcYdMe, wherein a, b, c, d and e represent the atom percentage content of the corresponding element, a is larger than or equal to 24.8 and smaller than or equal to 25, b is larger than or equal to 8 andsmaller than or equal to 25.4, c is larger than or equal to 24.8 and smaller than or equal to 25.4, d is larger than or equal to 5 and smaller than or equal to 15, e is larger than or equal to 10 andsmaller than or equal to 20, a+b+c+d+e is equal to 100, and M is one of Dy, Er and Ho. On the basis of a GdCoAly high-entropy amorphous alloy, M is used for replacing Y, the high-entropy amorphous alloy high in magnetocaloric effect is obtained, the alloy is stable in magnetocaloric performance, the magnetic variation temperature range is wide, and elements likely to volatile or oxidize are not included. In addition, the completely amorphous structure of the high-entropy amorphous alloy needs no crystallization heat treatment, the preparation process is simple, and the high-entropy amorphous alloy material has good magnetocaloric performance and has good application prospects in the technical field of magnetic refrigeration.

Owner:SOUTHEAST UNIV

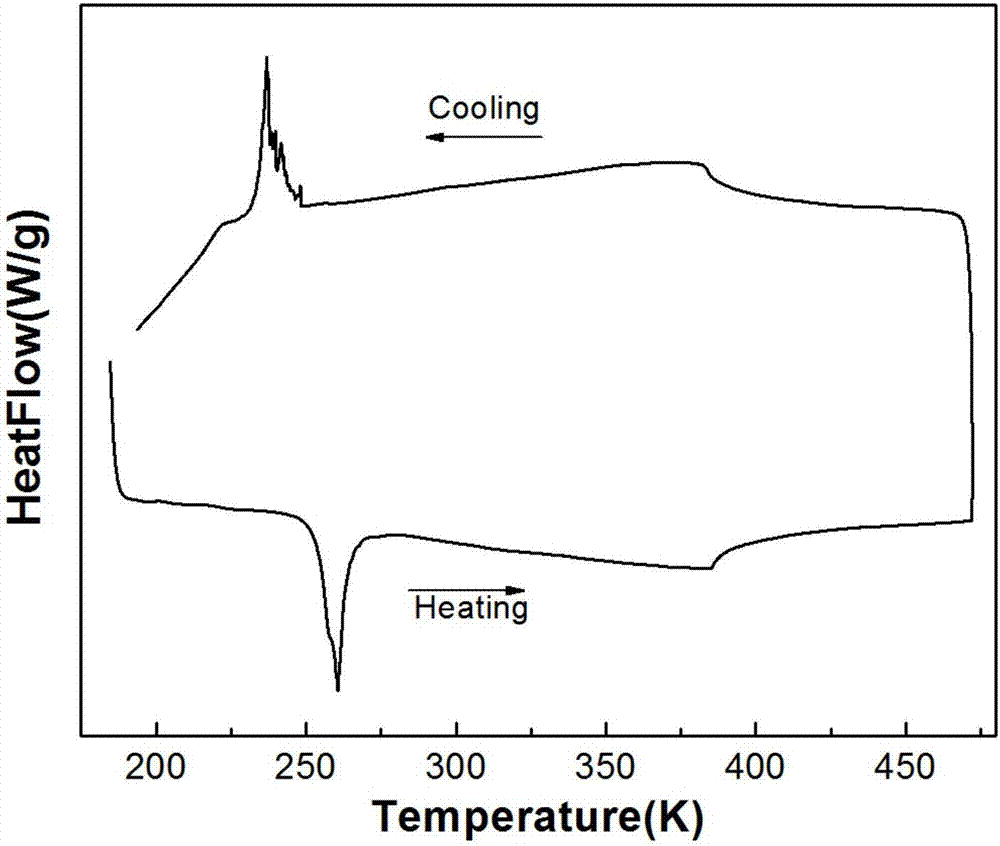

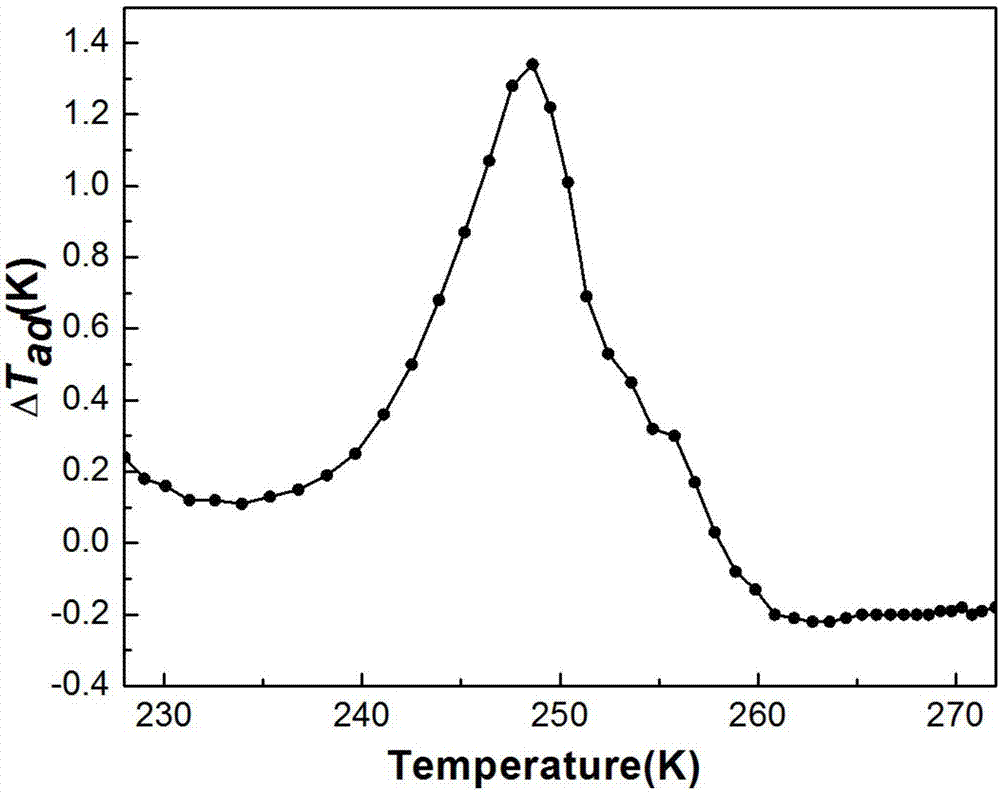

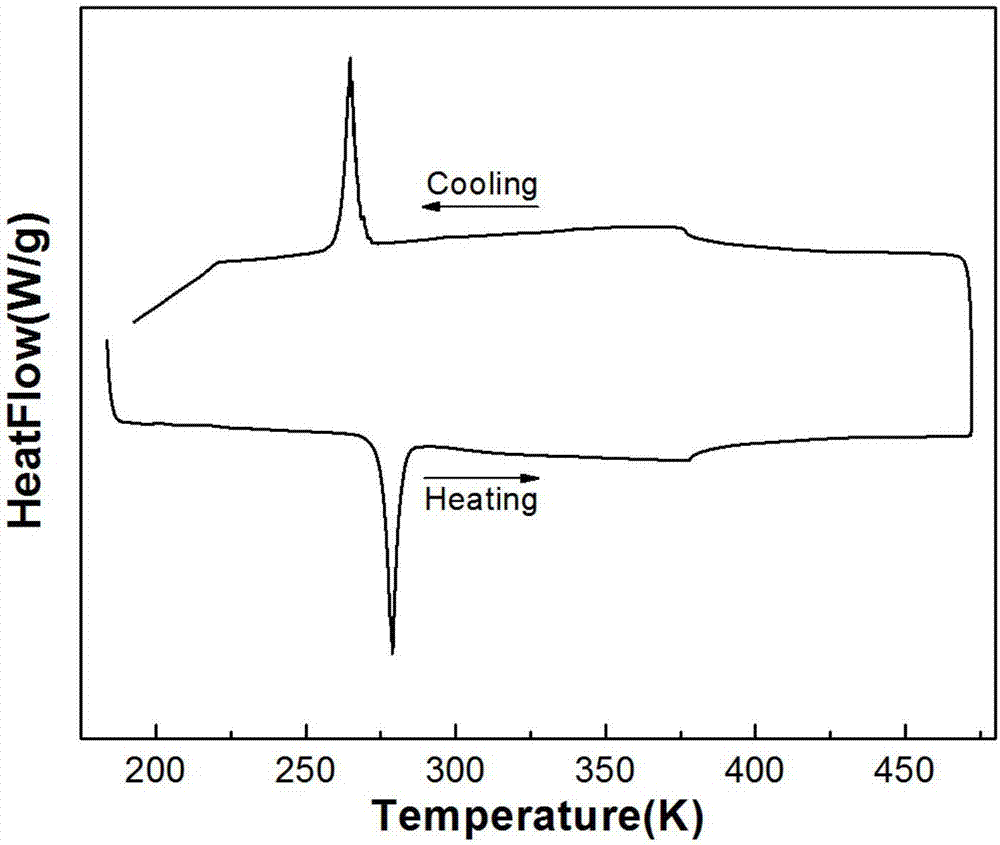

Ni-Co-Mn-In-Ge magnetic refrigeration alloy material and preparing method thereof

ActiveCN107881394ALarge magnetocaloric effectRealize single temperature zone coolingInorganic material magnetismMagnetic refrigerationVacuum arc

A Ni-Co-Mn-In-Ge magnetic refrigeration alloy material and a preparing method thereof belong to the technical field of magnetic refrigeration materials. The chemical molecular formula of the Ni-Co-Mn-In-Ge magnetic refrigeration alloy material is Ni45Co5Mn36.5In<13.5-x>Gex, and the molar number sum of elements in the alloy is 100, wherein x is greater than or equal to 1 and smaller than or equal to 4. In the invention, a poly-crystal ingot is prepared through raw material proportioning and vacuum arc repeated smelting, annealing is carried out under high-purity inert gas protection, and then,rapid water-cooling is carried out, so that a blocky blank of the Ni-Co-Mn-In-Ge magnetic refrigeration alloy is prepared. Under a 1.5T external magnetic field, through a heating magnetizing mode, theadiabatic temperature change range of the alloy block is 1.34-2.69K. The magnetic alloy material can have large adiabatic temperature change near a room temperature, and can be used as a magnetic refrigerating working medium in the working range of a wide temperature range with a great magnetothermal effect.

Owner:NORTHEASTERN UNIV

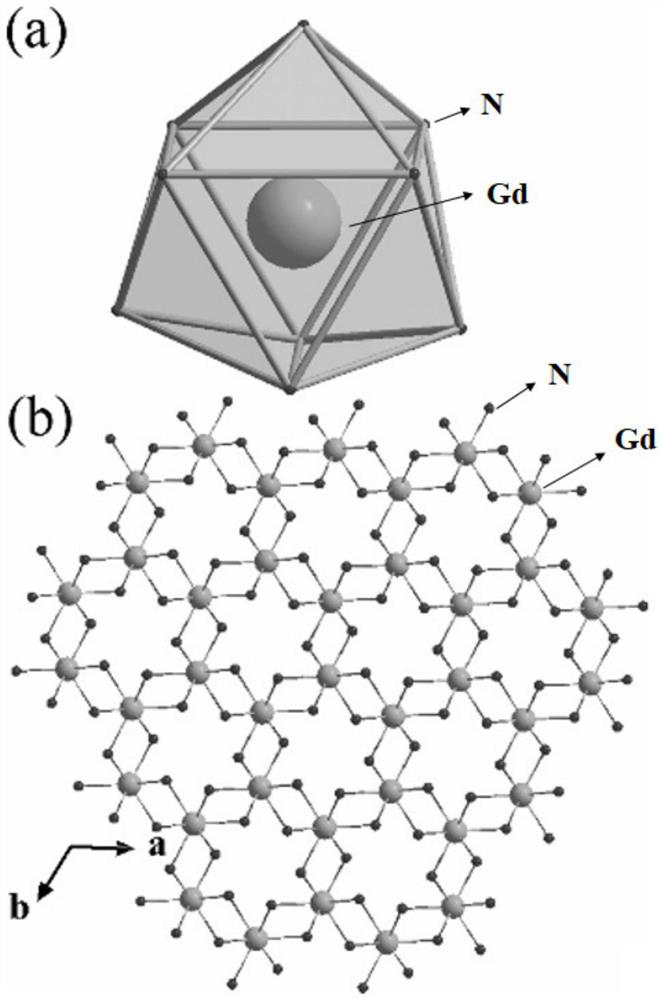

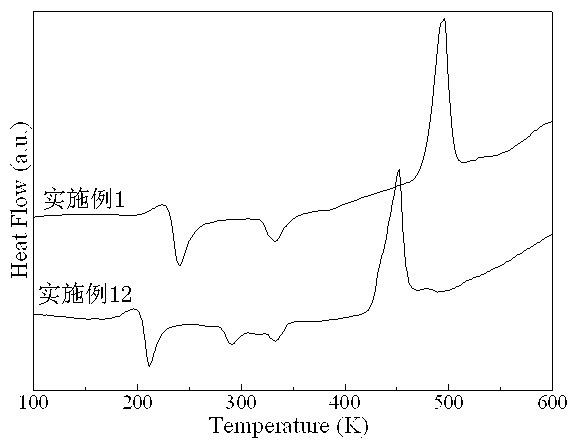

Gadolinium borate and preparation method and application thereof

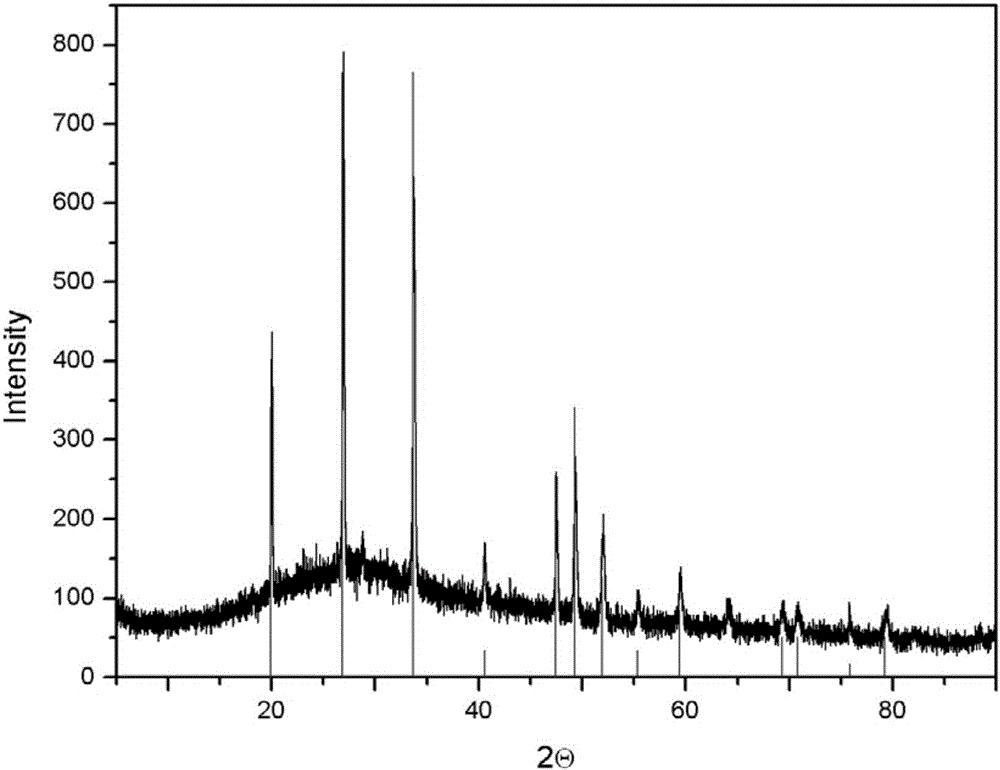

InactiveCN105836755AImprove the magnetocaloric effectFast preparation methodInorganic material magnetismBoratesFiltrationStrong acids

The invention relates to gadolinium borate and a preparation method and application thereof. According to preparation of gadolinium borate, Gd<3+> is used as a raw material, and small molecular weight BO3<3-> is used as a ligand. The preparation method comprises the following steps: placing gadolinium oxide and boric acid into a quartz porcelain boat, grinding solids into powders, uniformly mixing, drying, transferring the quartz porcelain boat into a quartz tube furnace, heating to 400 DEG C and keeping the temperature for 10 h, heating to 1000 DEG C and keeping the temperature for 6h, cooling to room temperature to obtain a white powdery solid, washing and carrying out suction filtration, and drying to obtain gadolinium borate. The gadolinium borate which is white powdery crystal can be applied in preparation of magnetic refrigeration materials. Synthetic equipment is simple, and the preparation method is fast and easy to operate. The gadolinium borate is a borate compound and has very strong stability and good heat stability from a strong acid environment to a strong base environment. By raising mass ratio of rare earth to the ligand, magnetic density is raised, and magnetic refrigeration effect of the material is greatly enhanced.

Owner:XIAMEN UNIV

Iron-based amorphous alloy having magnetothermal effect as well as application of iron-based amorphous alloy and method for regulating and controlling magnetic transition temperature of iron-based amorphous alloy

InactiveCN104313513AImprove the magnetocaloric effectControlling the magnetic transition temperatureMagnetic materialsRare-earth elementMagnetic transitions

The invention discloses an iron-based amorphous alloy having a magnetothermal effect. The iron-based amorphous alloy has a chemical formula of FeaREbBcNbd, wherein RE is one or more rare earth elements selected from Gd, Tb, Dy, Ho, Er and Tm; a, b, c and d are atomic percentages, a is equal to or greater than 50 and less than or equal to 75, b is greater than 0 and less than or equal to 30, c is equal to or greater than 20 and less than or equal to 25, d is equal to or greater than 3 and less than or equal to 5 and the sum of a, b, c and d is equal to 100. The iron-based amorphous alloy has good magnetothermal effect as well as high glass forming capability, is a good magnetothermal material and can be applied as a magnetic refrigerant. In addition, by regulating and controlling types of the rare earth elements in the amorphous alloy and content of the rare earth elements, the magnetic transition temperature of the iron-based amorphous alloy can be regulated and controlled and thus the magnetic transition region can be widened and the iron-based amorphous alloy has large magnetothermal effect in a wider temperature range.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Hydrogen fluoride gadolinium oxide as well as preparation method and application thereof

InactiveCN112456535ASynthetic method is convenientEasy to operateMachines using electric/magnetic effectsRare earth metal compounds preparation/treatmentHydrogen fluorideGadolinium oxide

The invention relates to hydrogen fluoride gadolinium oxide as well as a preparation method and application thereof. The gadolinium oxyfluoride has the following general formula: Gd (OH) yF3-y, wherein y is equal to 0.5-2.5.

Owner:XIAMEN UNIV

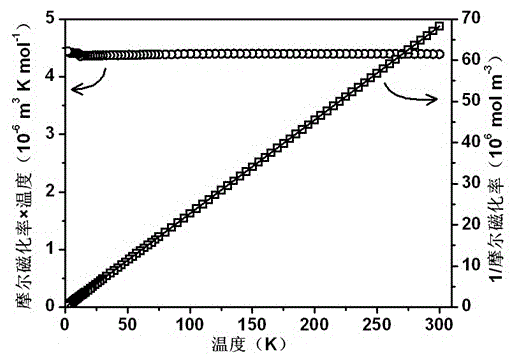

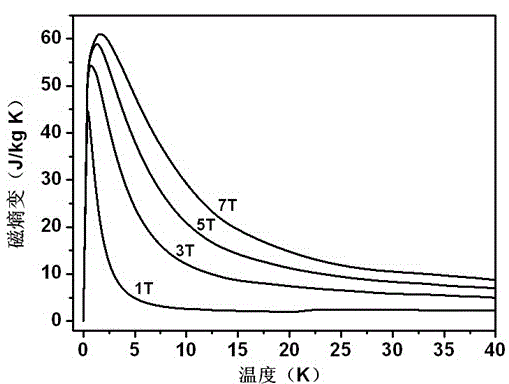

Application of coordination compound in low temperature magnetic refrigeration

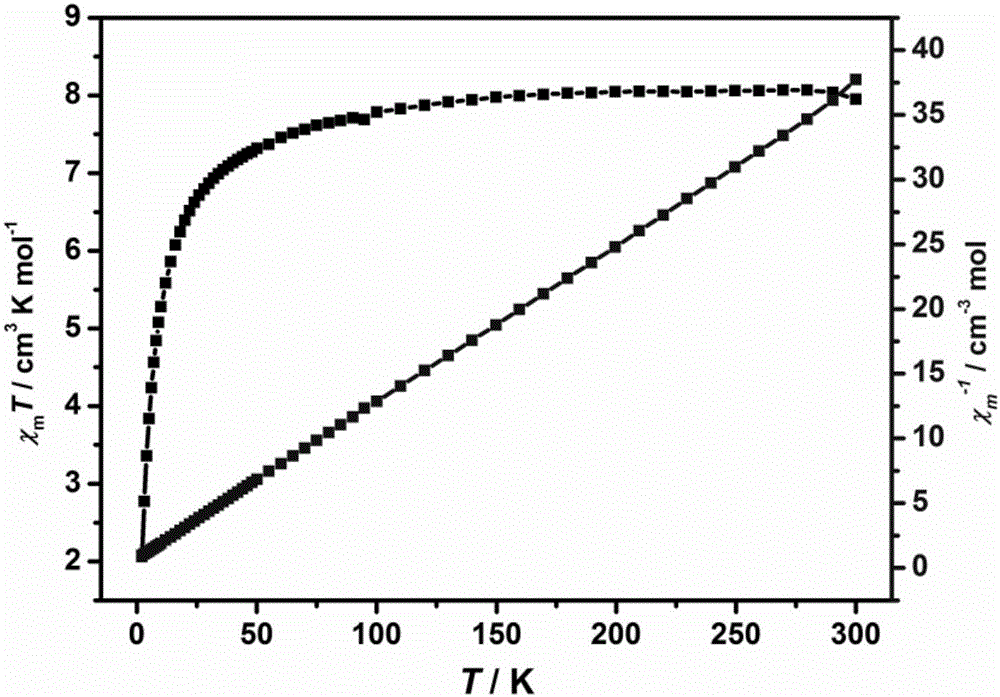

InactiveCN103146352AHigh magnetic entropy changeGood effectHeat-exchange elementsChemistryMagnetic refrigeration

The invention relates to an application of a coordination compound in low temperature magnetic refrigeration. The coordination compound is two-water two (glycolic acid) and manganese (II). The invention belongs to the technical field of manganese application. The application of coordination compound in low temperature magnetic refrigeration aims to provide a magnetic refrigeration working substance with a high refrigeration effect in a low temperature area. The temperature range of the two-water two (glycolic acid) and manganese (II) is 0.3K-40K. The magnetic field exerted in the magnetization stage when the coordination compound is used is 1T-7T. The two-water two (glycolic acid) and manganese (II) of 1kg is magnetized with isothermality when the temperature is 1.7K in the optimized implementation scheme. Obtained magnetic entropy change is 61.2J / K when the magnetic field exerted outside is 7T.

Owner:SUN YAT SEN UNIV

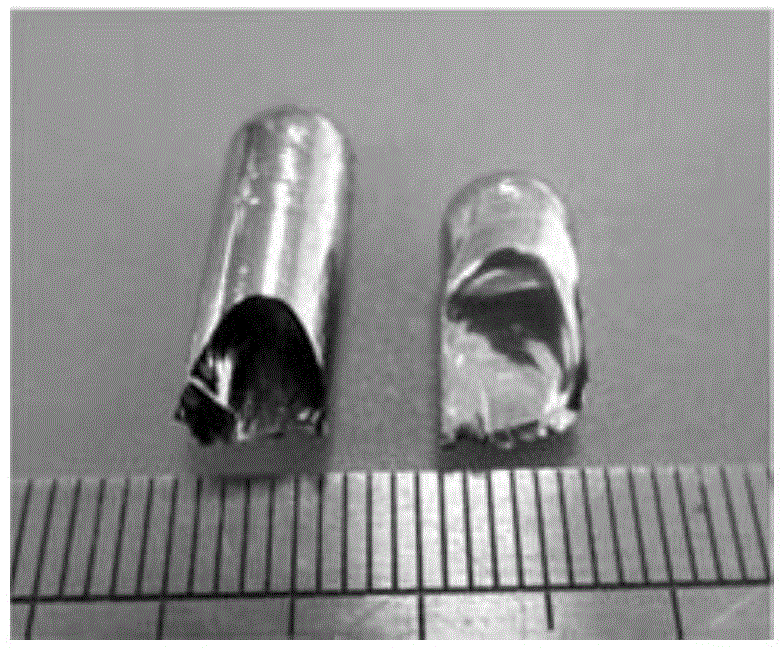

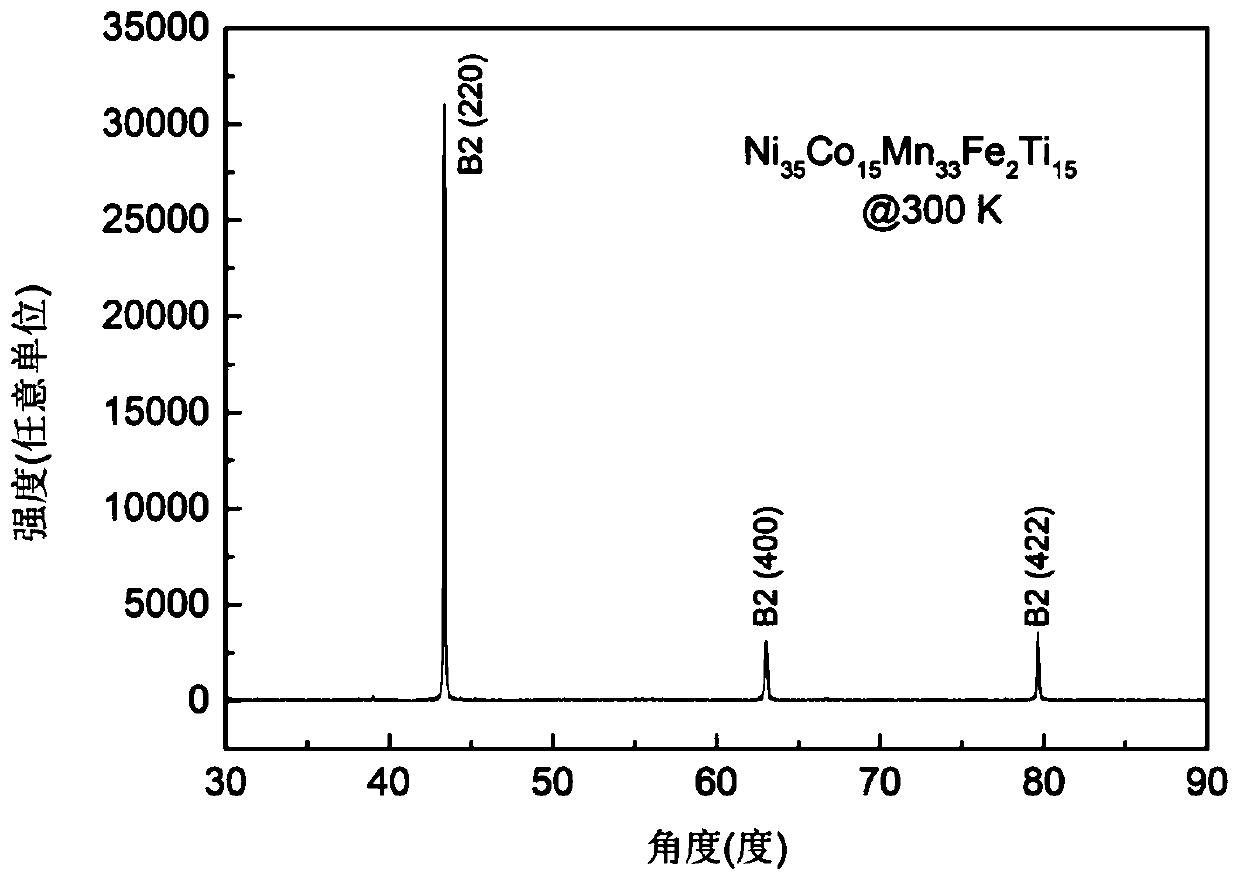

Material capable of regulating and controlling magnetism and related magnetic effects through bending or twisting, preparation method of material and application of material

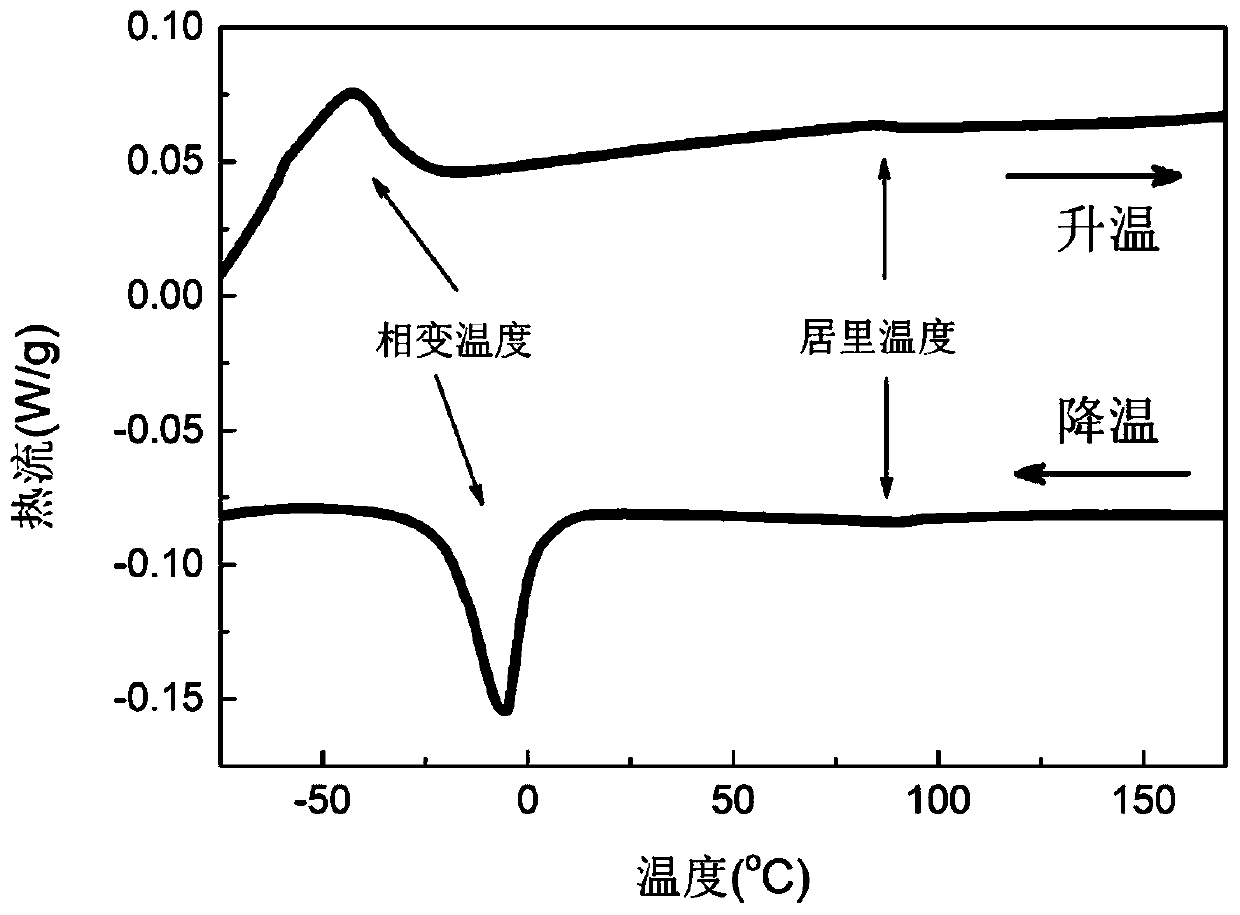

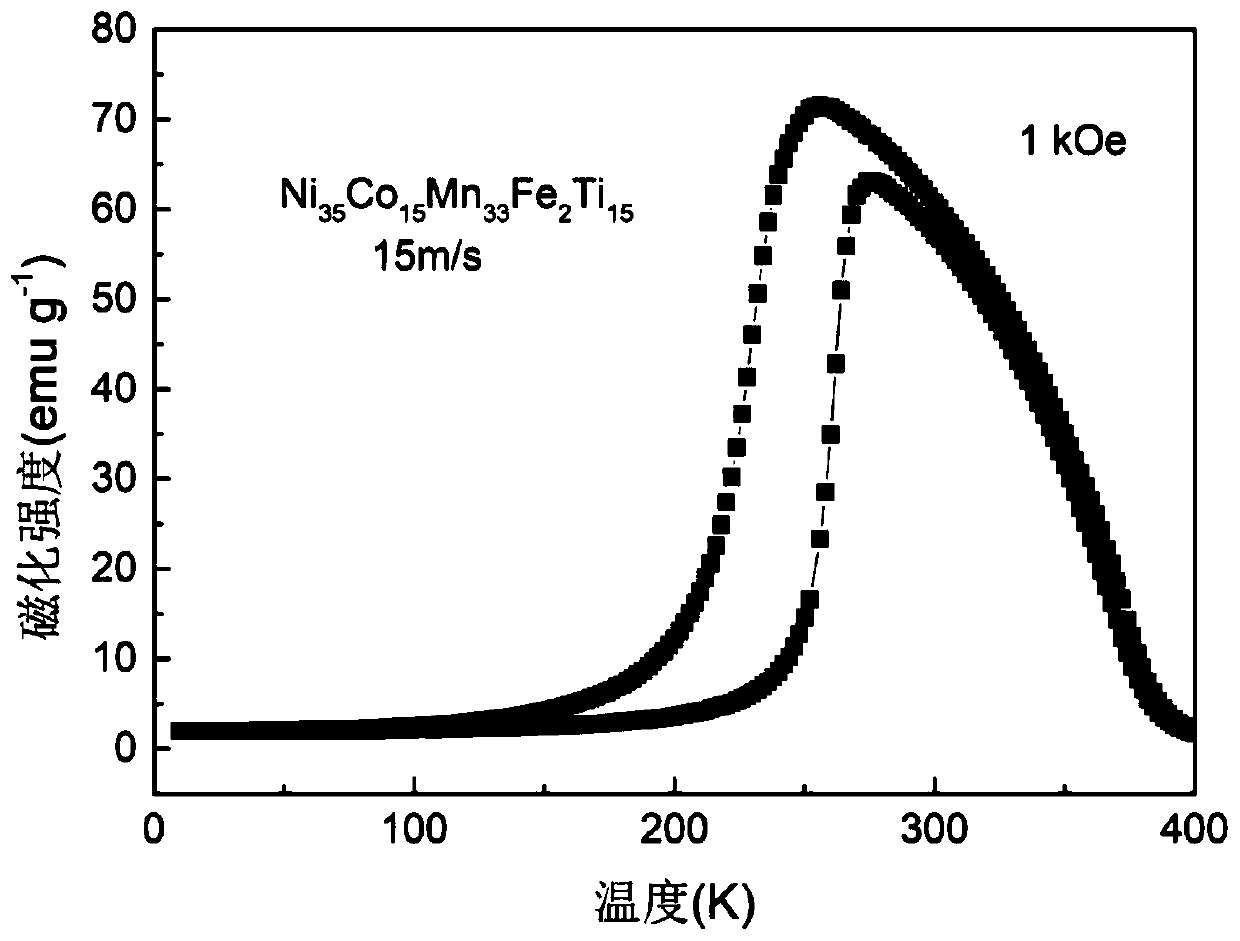

ActiveCN111210959AGood magnetocaloric effectStrong torsional controllabilityInorganic material magnetismInductances/transformers/magnets manufactureQuenchingMagnetic refrigeration

The invention belongs to the field of magnetic materials and relates to a material capable of regulating and controlling magnetism and related magnetic effects through bending or twisting, a preparation method of the material and application of the material. The chemical formula of the material is Ni50-aCoaMn35-bFebXc, wherein a is larger than or equal to 12 and smaller than or equal to 17, b is larger than or equal to 0 and smaller than or equal to 10, c is larger than or equal to 5 and smaller than or equal to 20, and X comprises Sn, Ga, In, Si, Ge, Ti, Zr, Hf, V, Nb and Ta. The preparationmethod of the material comprises the following steps of: carrying out electric arc melting on high-purity raw materials to obtain a NiMi-based alloy block; and carrying out melt rapid quenching on theblock under vacuum to obtain a phase-change thin strip material. According to a method for regulating and controlling magnetism by applying isostatic pressure in the prior, the effect of the method is single, the controllability of the method is poor, the pressure applying mode of the method is complex, and the application of the method is limited. With the preparation method of the invention adopted, the above problems in the prior art can be solved; the obtained phase-change alloy thin strip can show large magnetic regulation and control and large magnetocaloric effects near the room temperature, can be effectively applied to a magnetic refrigeration process, and can achieve strain output through bending or twisting; and therefore, the magnetism and related magnetic effects of the phase-change alloy thin strip are regulated and controlled, and the application prospect of the phase-change alloy thin strip is effectively expanded.

Owner:HANGZHOU DIANZI UNIV

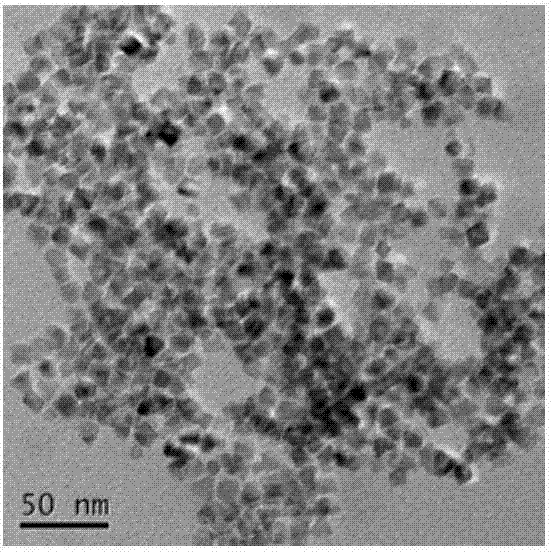

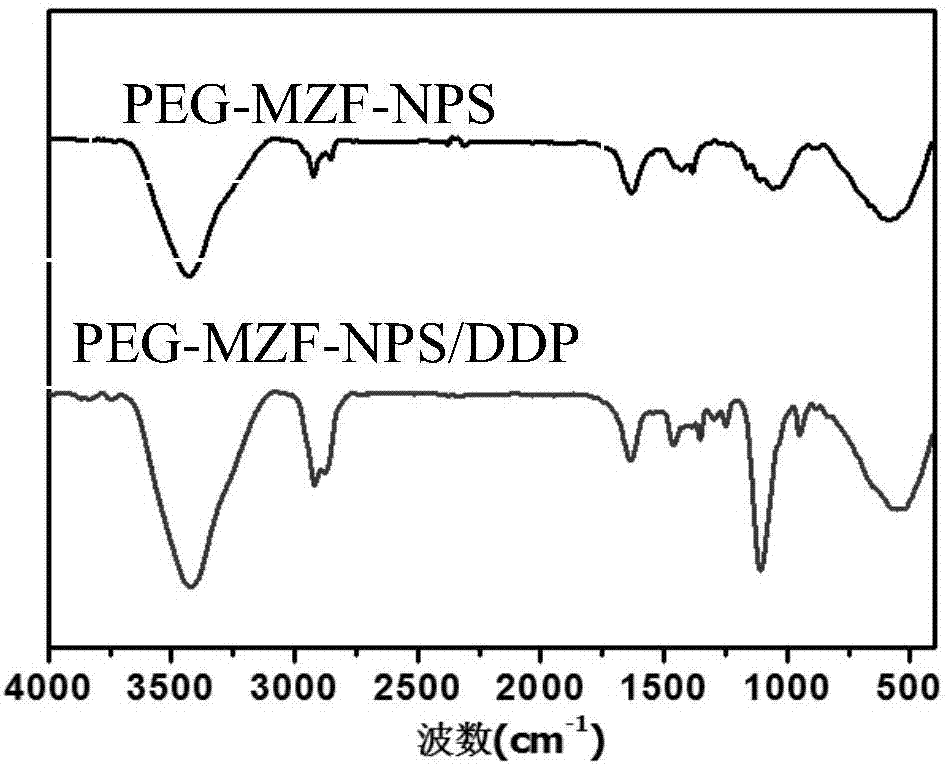

CD44-shRNA/PEG-MZF-NPs/DDP nano-liposome and preparation method thereof

InactiveCN107158409AGood dispersionGood magnetic responseHeavy metal active ingredientsEnergy modified materialsVascular proliferationCD44

The invention belongs to the technical fields of medicines and genetic engineering and particularly relates to a CD44-shRNA / PEG-MZF-NPs / DDP nano-liposome as well as a preparation method and application thereof. According to the nano-liposome, a PEG-MZF-NPs nano-magnetic-particle is taken as a carrier and is loaded with DDP and a plasmid CD44-shRNA. The preparation method comprises the steps of firstly preparing a PEG-MZF-NPS / DDP compound, and mixing the PEG-MZF-NPS / DDP compound with the plasmid CD44-shRNA, so as to obtain the nano-liposome. The invention further discloses application of the nano-liposome in the preparation of drugs for treating ovarian cancer. The nano-liposome has relatively good proliferation inhibition and apoptosis induction effects to ovarian cancer cells under the action of an external alternating magnetic field, the effects are obviously superior to any single treatment, and the mechanism may be that the protein expression of CD44, Survivin, VEGF and Bcl-2 is reduced so as to inhibit cell proliferation, induce cell apoptosis, inhibit vascular proliferation or directly induce cell death.

Owner:JIANGSU TAIZHOU PEOPLES HOSPITAL

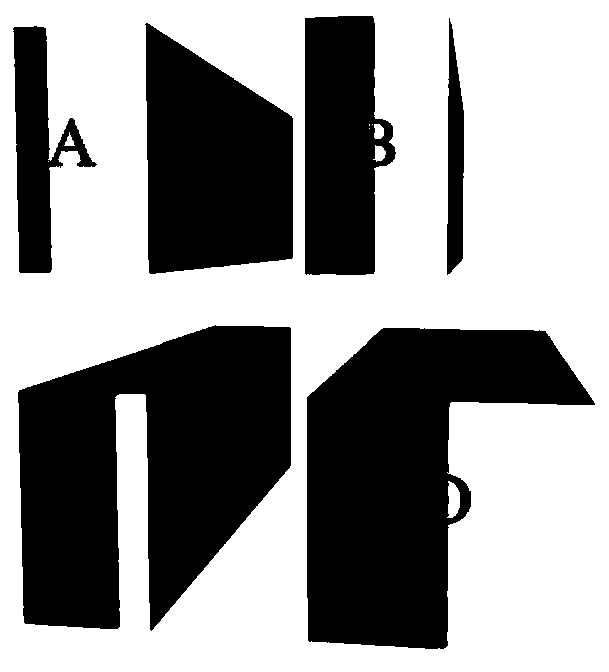

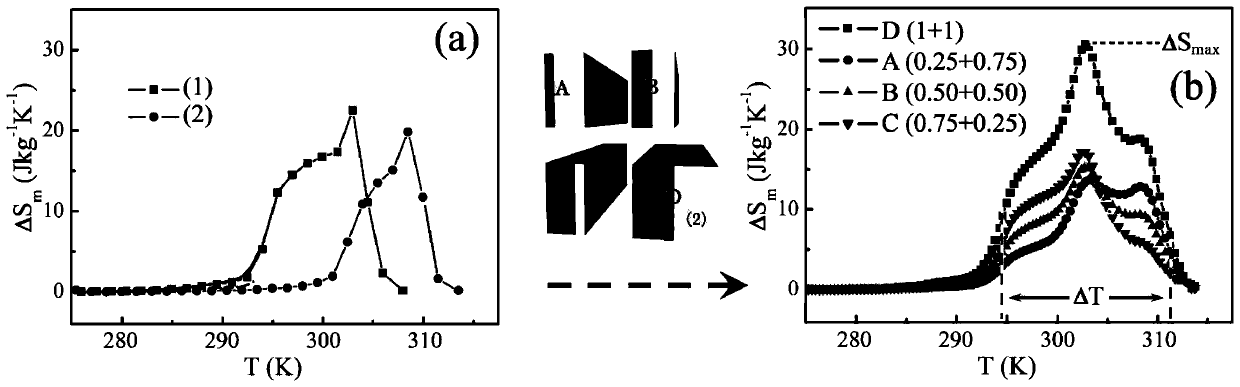

Temperature-graded magnetic heating material and preparation method thereof

ActiveCN109913816AImprove the magnetocaloric effectLarge magnetocaloric effectVacuum evaporation coatingSputtering coatingMagnetic heatingWorking temperature

The invention belongs to the field of magnetic refrigeration, and particularly relates to a temperature-graded magnetic heating material and a preparation method thereof. The temperature-graded magnetic heating material comprises a Ni50Mn37Sn13 alloy film layer and a Ni50Mn35In15 alloy film layer. The phase change temperature of the Ni50Mn37Sn13 alloy film layer ranges from 295 K to 305 K. The phase change temperature of the Ni50Mn35In15 alloy film layer ranges from 301 K to 310 K. The thickness ratio of the Ni50Mn37Sn13 alloy film layer to the Ni50Mn35In15 alloy film layer is 1:3 to 3:1. According to the temperature-graded magnetic heating material and the preparation method thereof, by carrying out gradient design and preparation on the magnetic heating material, the work temperature zone of an existing magnetic heating material can be expanded, and the magnetic heating effect of the material can be improved; and a design rule and a regulating and control mechanism of the magnetic heating material are set up, and the gradient magnetic heating temperature material is pushed to develop towards application.

Owner:上海利鑫生物科技有限公司

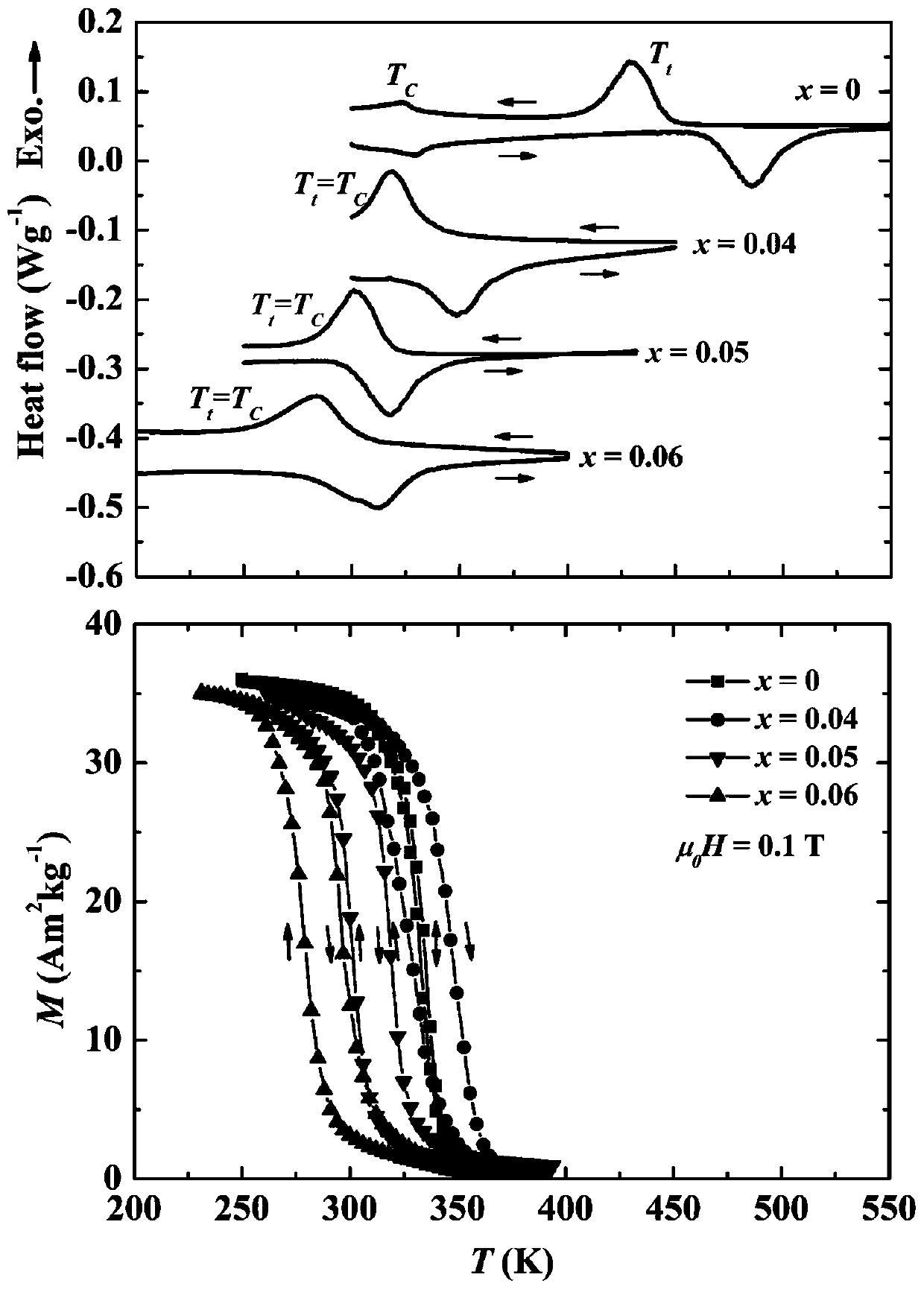

Near-room-temperature magnetic refrigeration manganese-germanium-based refrigeration material and preparation method thereof

ActiveCN112226659ALow Curie temperatureReduce hysteresis lossInorganic material magnetismSustainable buildingsPhysical chemistryManganese

The invention relates to a near-room-temperature magnetic refrigeration manganese-germanium-based refrigeration material and a preparation method thereof. The preparation method specifically comprisesthe steps that (1) manganese powder, germanium powder and titanium powder are weighed according to the stoichiometric ratio of Mn5Ge<3-x>Ti<x> (wherein x is 0.5 to 1) and heated, melted and mixed under the protection of inert gas, and a homogenized sample is obtained; and (2) the homogenized sample is taken out, cooled and annealed to obtain the target product. Compared with the prior art, the near-room-temperature magnetic refrigeration manganese-germanium-based refrigeration material and the preparation method thereof have the advantages that the manganese-germanium-based refrigeration material prepared by the preparation method disclosed by the invention has extremely small hysteresis loss, relatively large magnetocaloric effect and adjustable temperature width, meanwhile, the phase change property is secondary and is continuously adjustable at a near room temperature (265K-290K), so that the requirements of a near room temperature magnetic refrigeration technology are met.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Rare earth-based bulk metallic glass with adjustable rear earth ingredient content

InactiveCN103290340AImprove the magnetocaloric effectExcellent magneto-optic effectMetallurgyPhysical chemistry

The invention relates to rare earth-based bulk metallic glass with adjustable rear earth ingredient content, belonging to the preparation field of bulk metallic glass. The rare earth-based bulk metallic glass with adjustable rear earth ingredient content provided by the invention is composed of Re65Co25Al10, wherein Re refers to CexLayPrzSmsGdt, x is not smaller than 13% while not larger than 30%, y is not smaller than 13% while not larger than 22%, z is not smaller than 4% while not larger than 13%, s is not smaller than 6% while not larger than 13%, t is not smaller than 4% while not larger than 13%, and the sum of x, y, z, s, t is 65%. The bulk metallic glass can be prepared only if proportions of the rear earth elements are randomly adjusted within the range provided by the invention; therefore, the problem that an amorphous state cannot be formed in the preparation process due to slight change of content of one rear earth element is eliminated, thereby reducing the preparation difficulty. More La and Ce with cheap price can be added when preparing the rare earth-based bulk metallic glass so as to effectively reduce the preparation cost of alloy.

Owner:UNIV OF JINAN

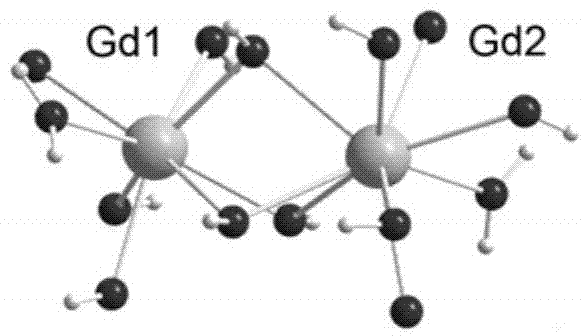

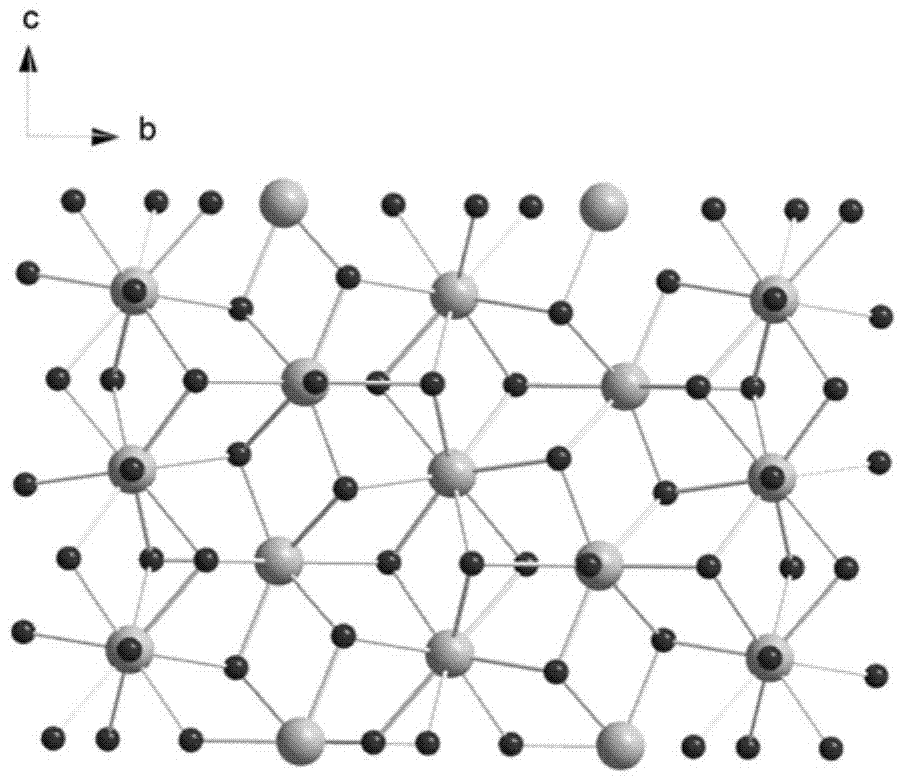

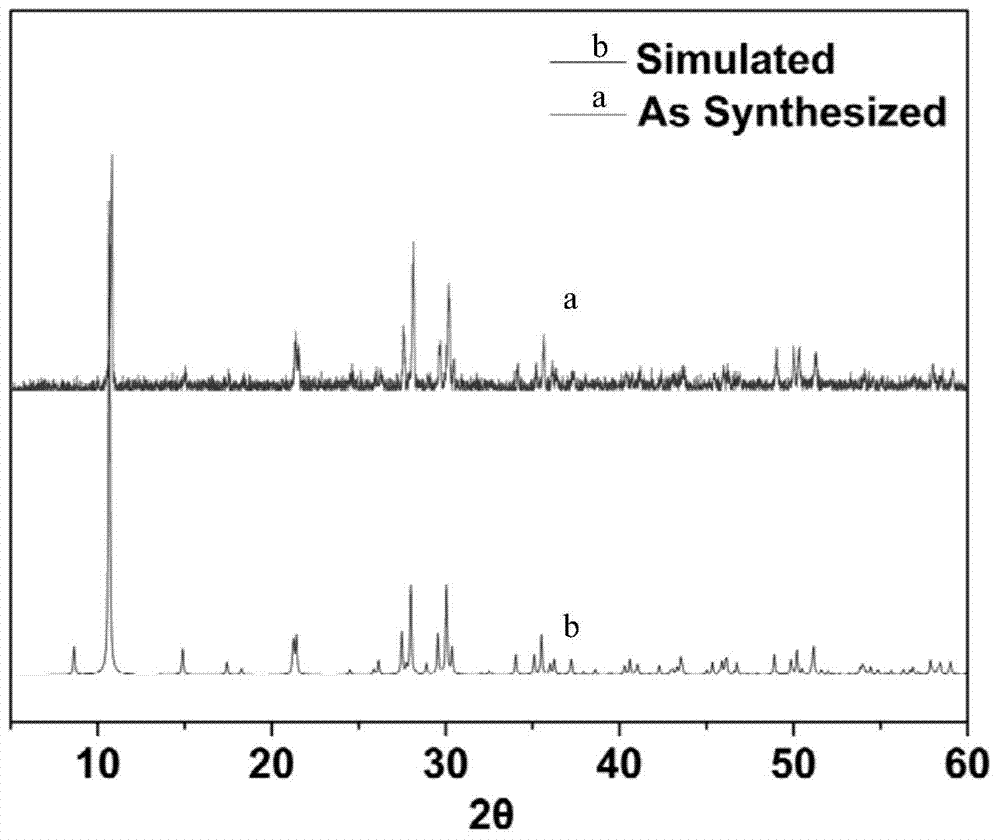

Tetrahydroxy gadolinium oxide dihydrate and preparation and applications thereof

ActiveCN104499056ASynthesis device is simpleFast preparation methodPolycrystalline material growthFrom normal temperature solutionsGadolinium oxideRare earth

The invention discloses tetrahydroxy gadolinium oxide dihydrate and preparation and applications thereof and relates to hydroxyl coordinate rare earth gadolinium materials. The tetrahydroxy gadolinium oxide dihydrate belongs to an orthorhombic system and a space group Cmcm and the molecular formula is Gd2O(OH)4(H2O)2. Cell parameters a is equal to 16.5835, b is equal to 12.9747, c is equal to 7.3106 and V is equal to 1573.05. During preparation, gadolinium nitrate hexahydrate, sodium formate and glycine are dissolved in water, the above is transferred to a reaction still after the pH (Potential Of Hydrogen) is adjusted through ammonium hydroxide, the temperature is risen to 160 degrees and the temperature keeps consistent, then the temperature is reduced to the room temperature, and the tetrahydroxy gadolinium oxide dihydrate which is colorless acicular crystal is obtained after filtering and washing. The tetrahydroxy gadolinium oxide dihydrate can be applied to preparation of magnetic refrigeration materials.

Owner:XIAMEN UNIV

Multi-ferric composite material based on giant magneto-caloric La-Fe-Co-Si, and preparation method and application thereof

ActiveCN108511142AImprove the magnetocaloric effectHigh densityVacuum evaporation coatingSputtering coatingAdhesiveMagnetic memory

The invention provides a multi-ferric composite material having both magnetic refrigeration effect, electrically-controlled magnetic effect and magnetic memory effect nearby the room temperature, anda preparation method and application thereof. The multi-ferric composite material comprises a ferroelectric PMN-PT monocrystalline substrate, and a La-Fe-Co-Si ferromagnetic alloy layer with giant magneto-caloric effect, wherein metal electrodes are evaporated on two surfaces of the PMN-PT monocrystalline substrate, and two surfaces are adhered with the La-Fe-Co-Si ferromagnetic alloy layer through adhesive so as to form the multi-ferric composite material. The advantage of the multi-ferric composite material is that the considerable electrically controlled magnetic effect is provided nearby the room temperature, and the magnetic memory effect induced by the pulse voltage is represented. And meanwhile, since the ferromagnetic layer of the structure has giant magneto-caloric effect, a new model for overcoming the heating of the storage unit by using the magnetic refrigeration is provided. The multi-ferric composite material provided by the invention has important and actual significancefor developing a novel multifunctional composite device having both the magnetic refrigeration effect and the magnetic memory effect.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

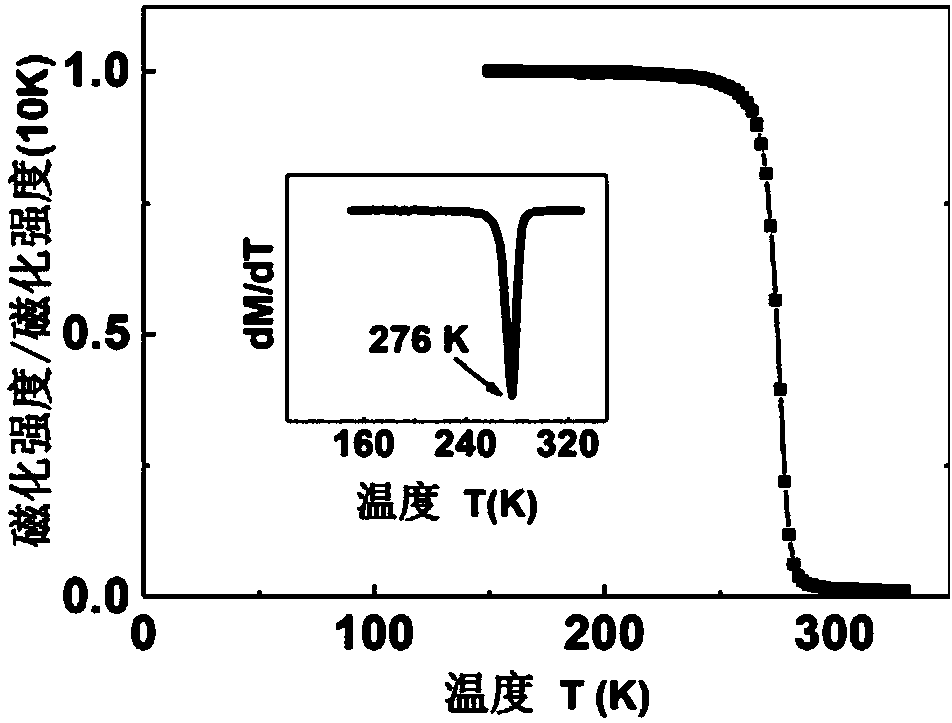

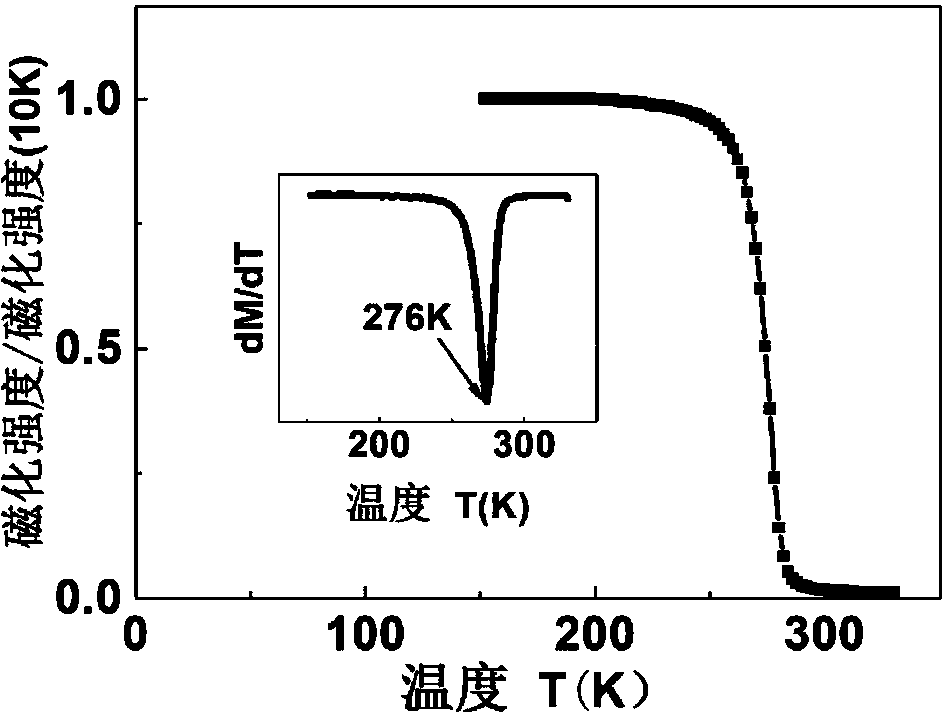

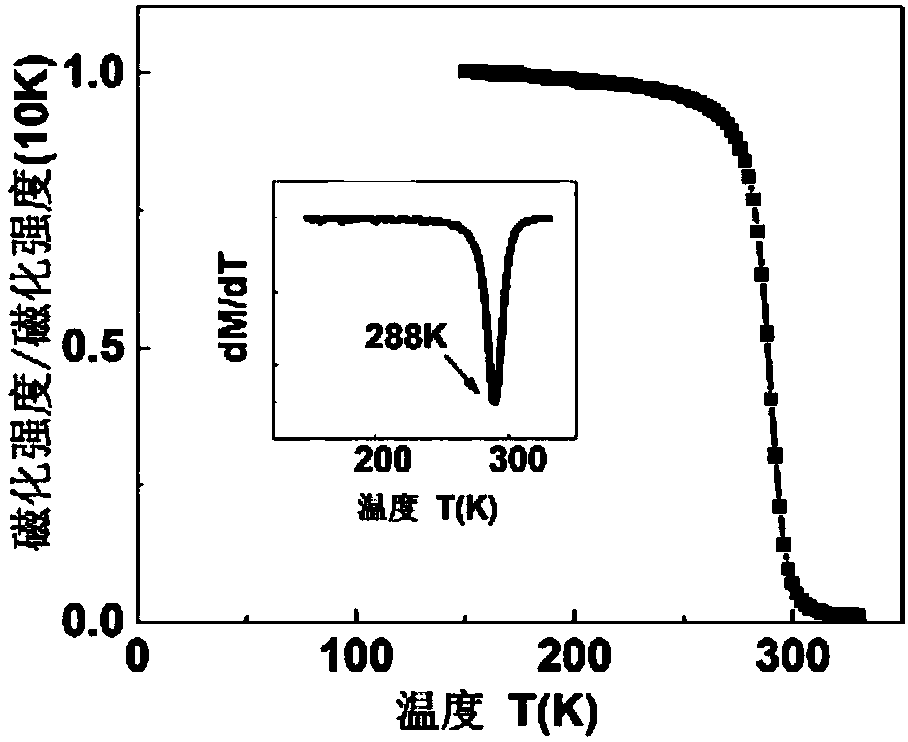

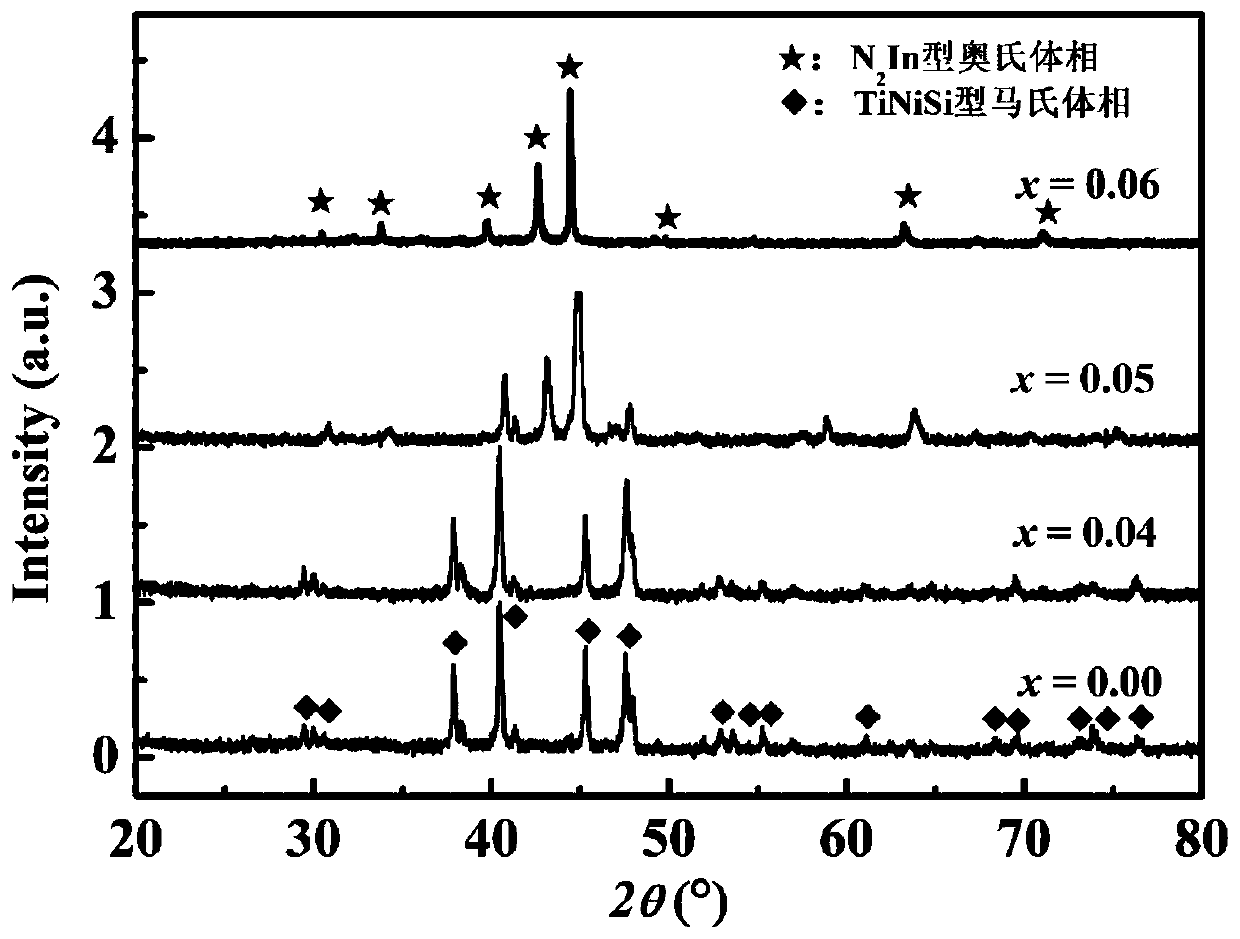

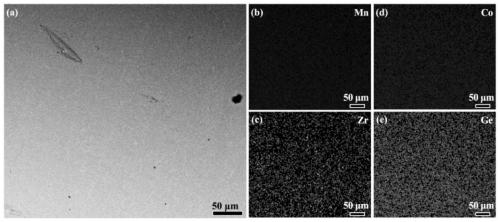

Manganese cobalt germanium-based alloy room temperature magnetic refrigeration material and preparation method thereof

ActiveCN111593249ALower phase transition temperatureImprove the magnetocaloric effectInorganic material magnetismMagnetic refrigerationTa element

The invention relates to a manganese cobalt germanium-based alloy room temperature magnetic refrigeration material and a preparation method thereof. The general chemical formula of the room temperature magnetic refrigeration material is Mn1-xZrxCoGe, wherein x is larger than or equal to 0.04 and is less than or equal to 0.06. The preparation method comprises the following steps of weighing manganese pieces, cobalt pieces and germanium blocks according to the molar ratio of each element in the general chemical formula, and smelting into alloy ingots; and annealing the smelted alloy ingots undervacuum condition (the vacuum degree is less than or equal to 10-2Pa) at the annealing temperature of 1123-1273K, preserving heat for 75-100 hours, and quenching to room temperature after heat preservation. The Mn atoms in MnCoGe mother alloy is replaced by Zr atoms, so that ferromagnetic phase transition and martensitic structure phase transition which are originally separated are coupled near room temperature, and the room temperature magnetic refrigeration material obtains an excellent magnetic thermal performance and is expected to be applied in the field of room temperature magnetic refrigeration.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

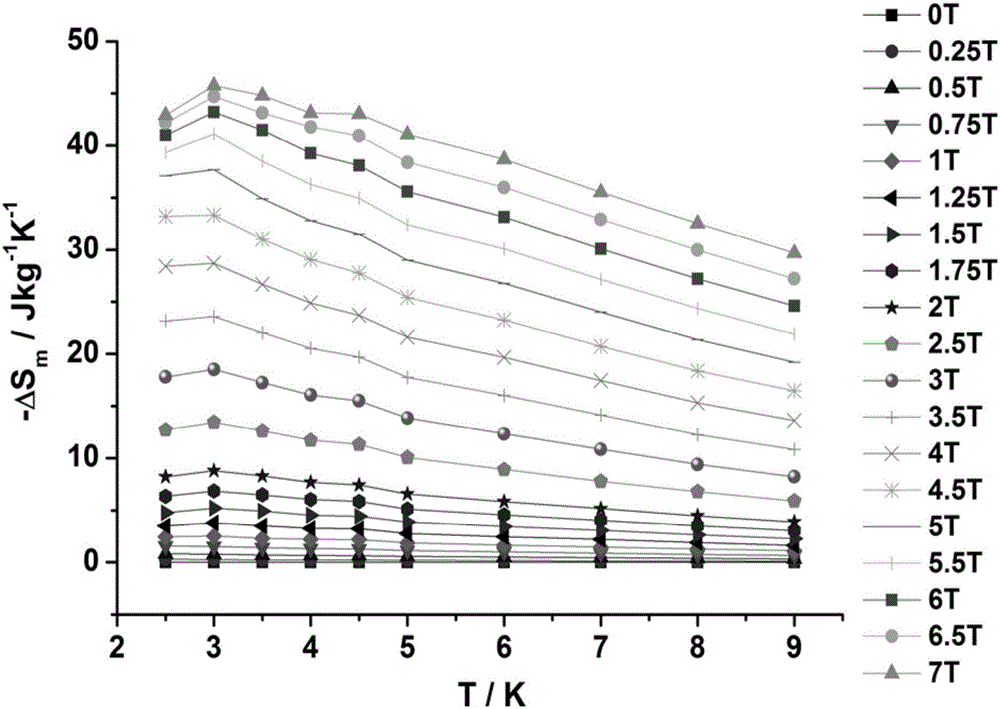

Fluorinated gadolinium carbonate as well as preparation method and application thereof

ActiveCN113277545AThe preparation method is convenientEasy to operateInorganic material magnetismRare earth metal compounds preparation/treatmentMagnetic anisotropySodium tetrafluoroborate

The invention discloses fluorinated gadolinium carbonate as well as a preparation method and application thereof and belongs to rare earth gadolinium materials. The fluorinated gadolinium carbonate is a novel fluorine and carbonate coordinated rare earth gadolinium material, and the structural composition formula of the fluorinated gadolinium carbonate is [GdCO3F] n (1), the maximum magnetic entropy change value of the material is 69.9 J kg <-1 > K <-1 > at 2K and 7T. The preparation method comprises the following steps of: adding hydrated gadolinium carbonate as a raw material into water; adding sodium tetrafluoroborate; fully stirring an obtained mixed solution, and transferring the solution into a hydrothermal kettle for hydrothermal reaction; and performing washing and drying to obtain a target product. A synthesis device of the fluorinated gadolinium carbonate is simple, preparation is convenient and fast, operation is easy, and the fluorinated gadolinium carbonate can be applied to preparation of magnetic refrigeration materials. Rare earth Gd < 3 + > with a high spinning ground state and small magnetic anisotropy is selected as cations, CO3 < 2-> with small molecular weight is selected as a ligand, the mass ratio of the rare earth to the ligand is increased to improve the magnetic density, and meanwhile, a fluorine ligand is doped into the material, so that the magnetic refrigeration effect of the material is greatly improved.

Owner:XIAMEN UNIV

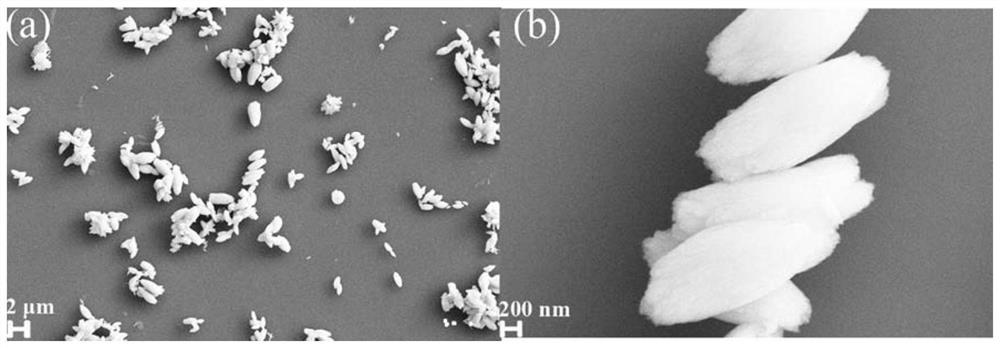

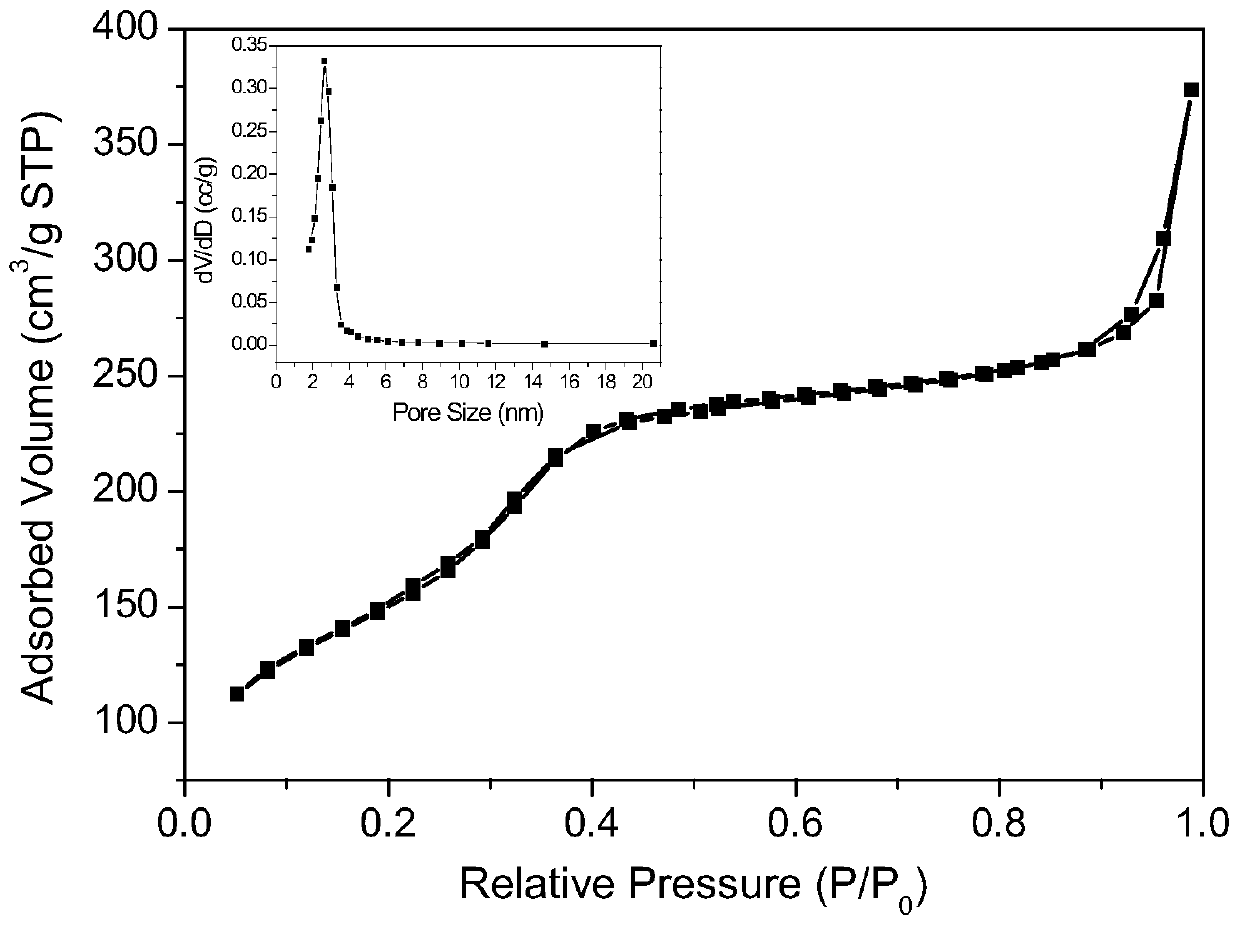

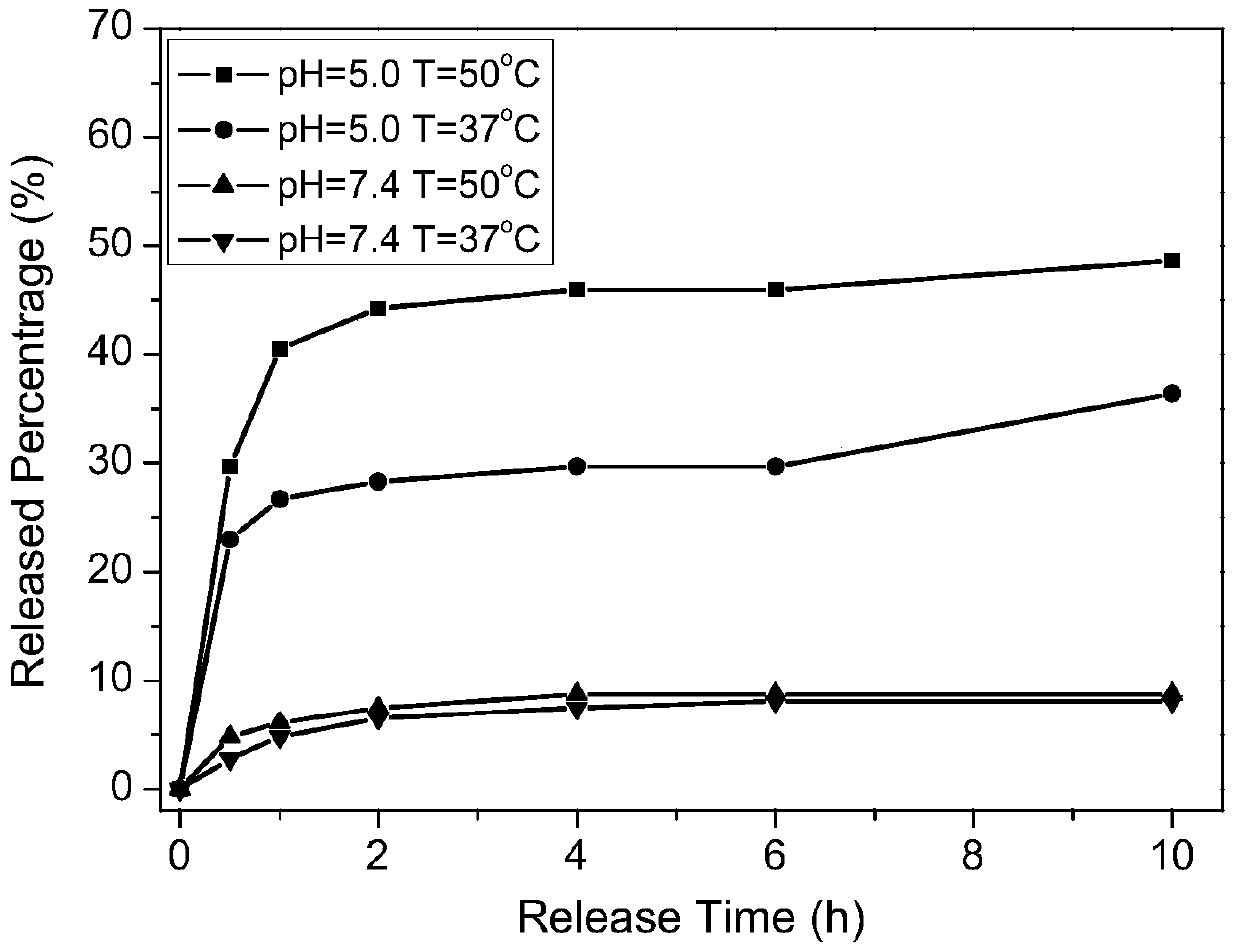

A kind of nano-medicine carrier with magnetocaloric and photothermal effect and preparation method thereof

ActiveCN105997944BFacilitated releaseSuitable for storageOrganic active ingredientsEnergy modified materialsSilicic acidMesoporous silica

The invention discloses a nano-drug carrier with the magnetothermal and photothermal effects. The particle size is 50 nanometers to 300 nanometers, and the nano-drug carrier is prepared from mesoporous silica particles, Fe3O4 nanoparticles embedded into the mesoporous silica particles and graphene oxide with which the surfaces of the mesoporous silica particles are coated. The invention further provides a preparation method of the nano-drug carrier. The superparamagnetic Fe3O4 nanoparticles are prepared through a solvothermal method, the Fe3O4 nanoparticles are composited by taking hexadecyl trimethyl ammonium bromide as a structure-directing agent and taking tetraethoxysilane as a silicon source through the sol-gel self-assembling process, and then magnetic mesoporous nanoparticles Fe3O4 / mSiO2 with the magnetic property adjustable and controllable are prepared; the surfaces of the Fe3O4 / mSiO2 mesoporous nanoparticles are coated with graphene through the ion interaction or electrostatic interaction or hydrogen-bond interaction, and then the nano-drug carrier which both can efficiently deliver anti-cancer drugs and has the magnetothermal and photothermal effects is obtained. Accordingly, cancer treatment in which medical chemotherapy cooperates with magnetothermal and photothermal treatment can be achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

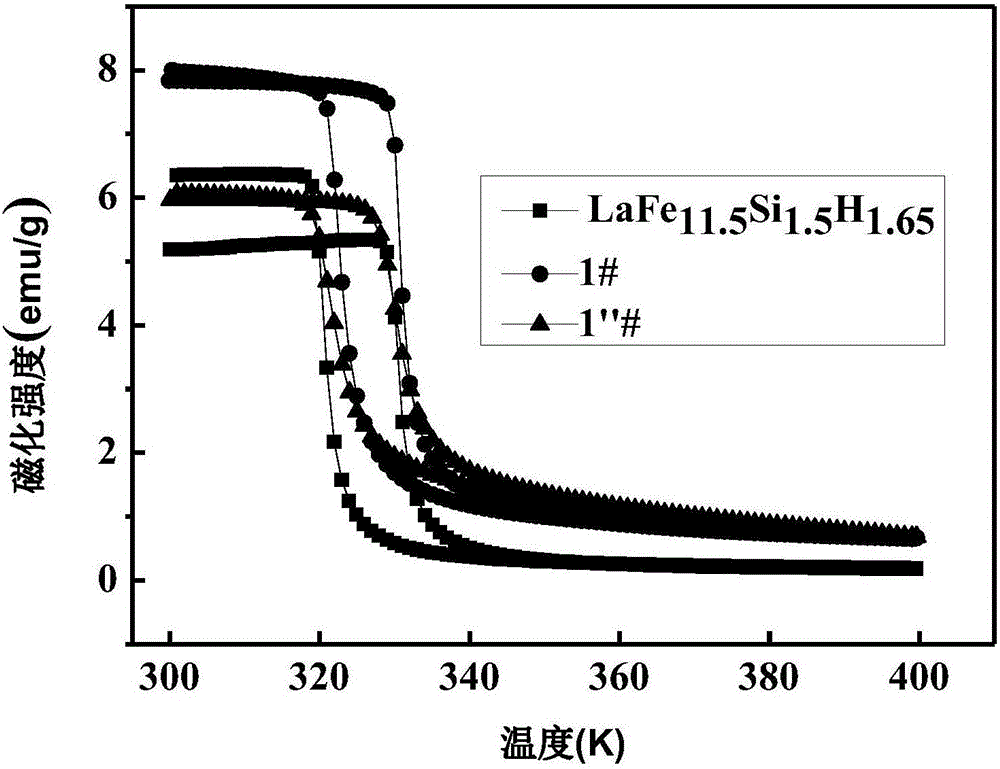

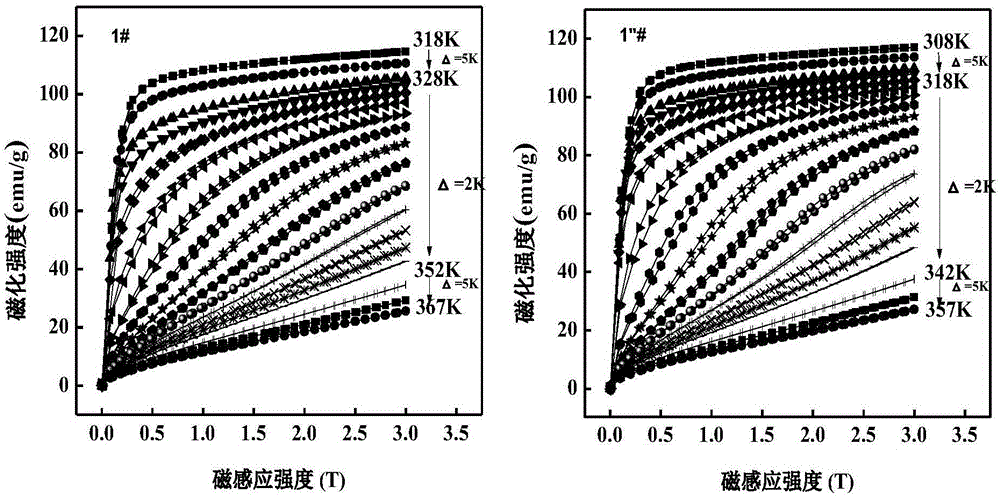

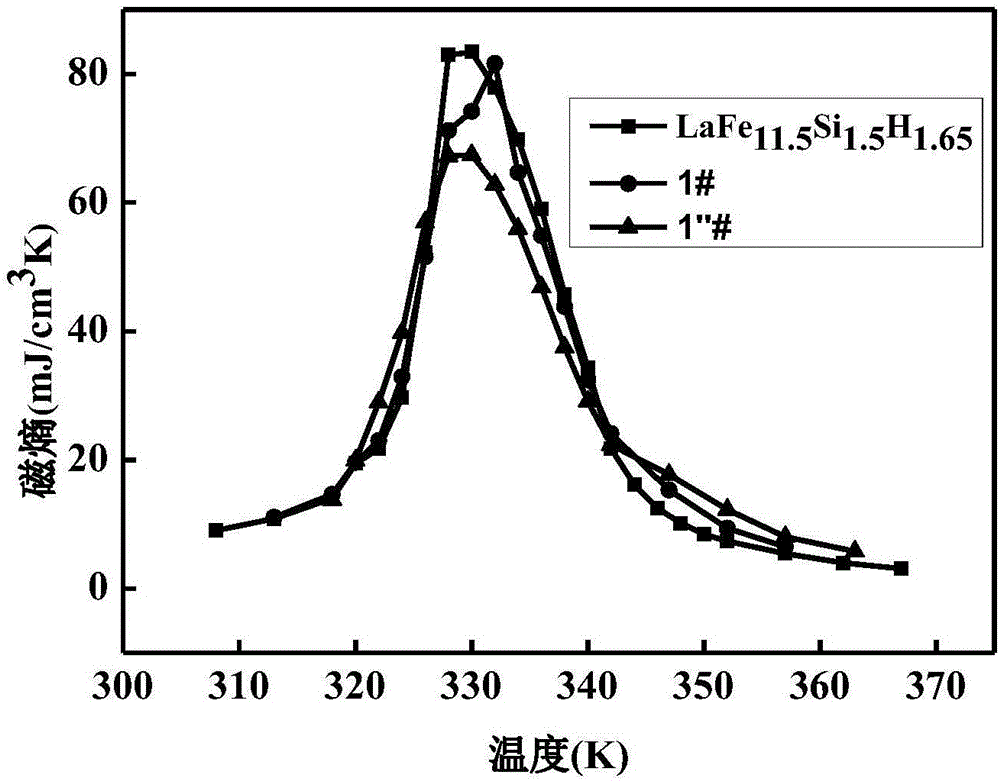

Adhesion La (Fe, Si)<13> bulk-shaped magnet with excellent heat-conducting property and preparation method therefor

ActiveCN106373691AImprove thermal conductivityHigh strengthTransportation and packagingMetal-working apparatusEpoxyHeat conducting

The invention discloses an adhesion La (Fe, Si)<13> bulk-shaped magnet with excellent heat-conducting property and a preparation method therefor, and belongs to the technical field of a functional material. A LaFe<11.5>Si<1.5>H<1.65> magnet is prepared by taking LaFe<11.5>Si<1.5>H<1.65> magnetic powder as a magnetic material, taking sodium silicate as a main binder, and taking high-temperature-resistant epoxy resin as an auxiliary binder. The strength of the obtained magnet is greatly improved while the prepared magnet has excellent heat-conducting property. By adoption of the adhesion La (Fe, Si)<13> bulk-shaped magnet with the excellent heat-conducting property and the preparation method therefor, the obtained magnet has high magnetothermal effect, relatively high strength, and simple equipment in an implementation process, simple and convenient operation, relatively low cost, easy realization of large-scale production, high economic value, and high application prospect in the magnetic cooling field.

Owner:宁波智合志远企业管理合伙企业(有限合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com