Magnetic refrigerating device based on repetitive pulsed magnetic field

A technology of repetitive pulse and magnetic refrigeration, which is applied in refrigerators, refrigeration and liquefaction, machines using electric/magnetic effects, etc., can solve the problems of large energy loss, high magnetic field strength, and low refrigeration power of magnetic refrigeration devices, and achieve improved Refrigeration power and efficiency, realization of control system, and enhanced heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

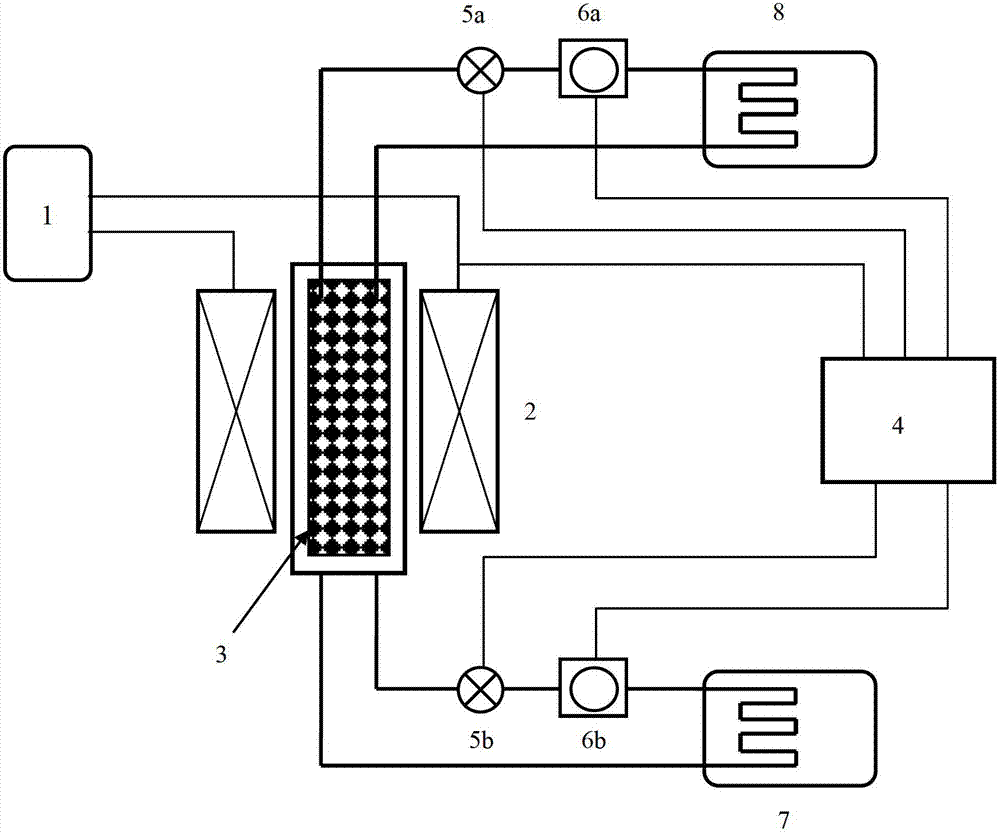

[0024] figure 1 An embodiment of the present invention is given, including repetitive pulse power supply 1 without freewheeling circuit, pulse magnet 2, magnetic refrigerant 3, control unit 4, control valves 5a and 5b, pumps 6a and 6b, cold end changer Heater 7 and hot end heat exchanger 8. The control unit 4, the control valve 5a, the pump 6a and the hot end heat exchanger 8 constitute the hot end heat exchange unit, and the control unit 4, the control valve 5b, the pump 6b and the cold end heat exchanger 7 constitute the cold end heat exchange unit. Wherein, the repetitive pulse power supply 1, the on-off time coordination of the control valves 5a and 5b, and the pumps 6a and 6b are controlled and realized by the control unit 4 .

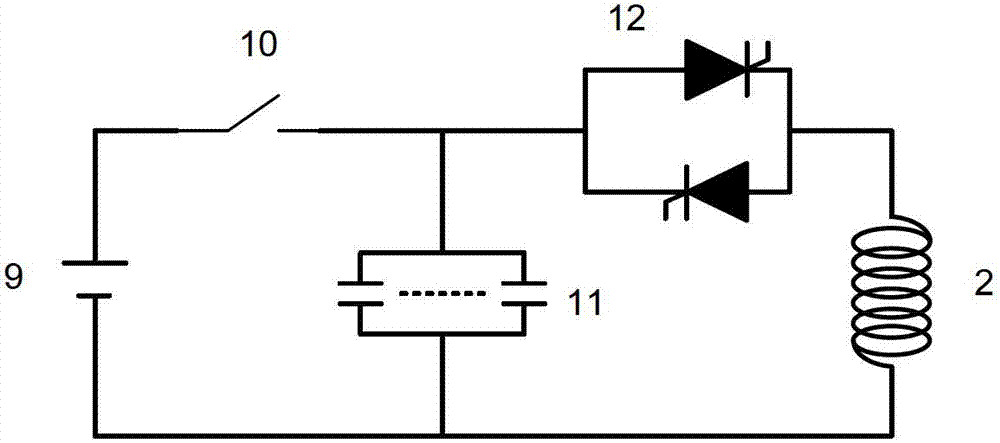

[0025] The repetitive pulse power supply in the existing pulse magnet technology generally includes a freewheeling circuit, so that the pulse width of the magnetic field will increase. However, such a large amount of electric energy will be consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com