Multi-ferric composite material based on giant magneto-caloric La-Fe-Co-Si, and preparation method and application thereof

A technology of la-fe-co-si and composite materials, applied in the direction of magnetic materials, inductor/transformer/magnet manufacturing, inorganic material magnetism, etc., can solve the problems of long annealing time, high annealing temperature, etc., and achieve the goal of shortening the annealing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

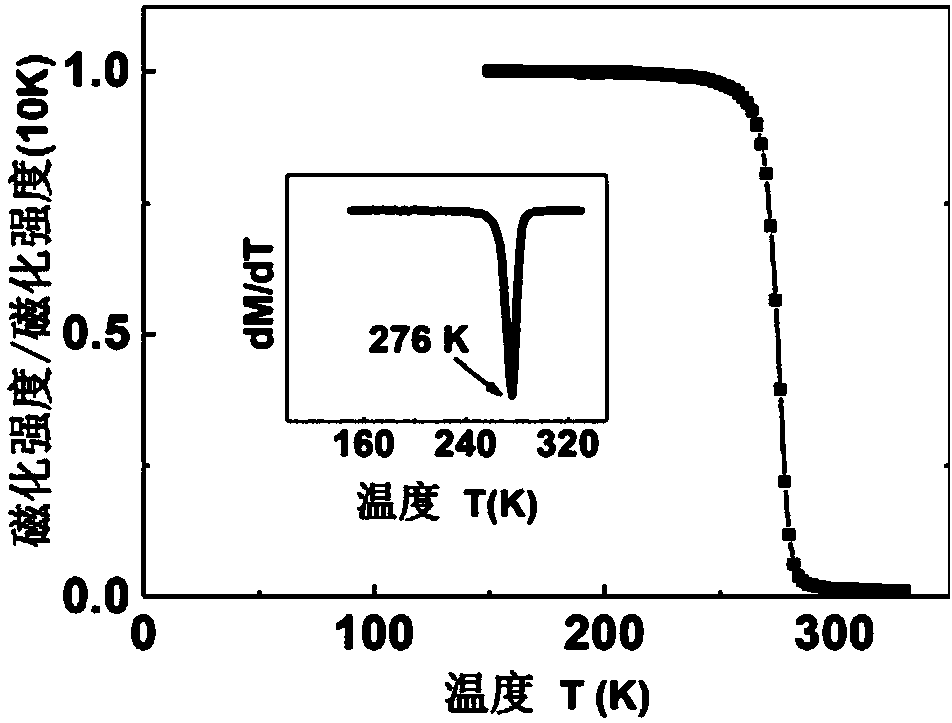

[0053] The structure of the multiferroic composite material of the present embodiment is: La-Fe-Co-Si / Au / PMN-PT(011) / Au, and La-Fe-Co-Si is composed of: La(Fe 1-x co x ) 13-y Si y , where x=0.06, y=1.2, the flakes are obtained by thinning, with a thickness of 100 μm; annealed at 1100°C for 1 month, and quenched with liquid nitrogen; the top electrode is Au, the thickness is 200nm; the bottom electrode is Au, the thickness is 200nm.

Embodiment 2

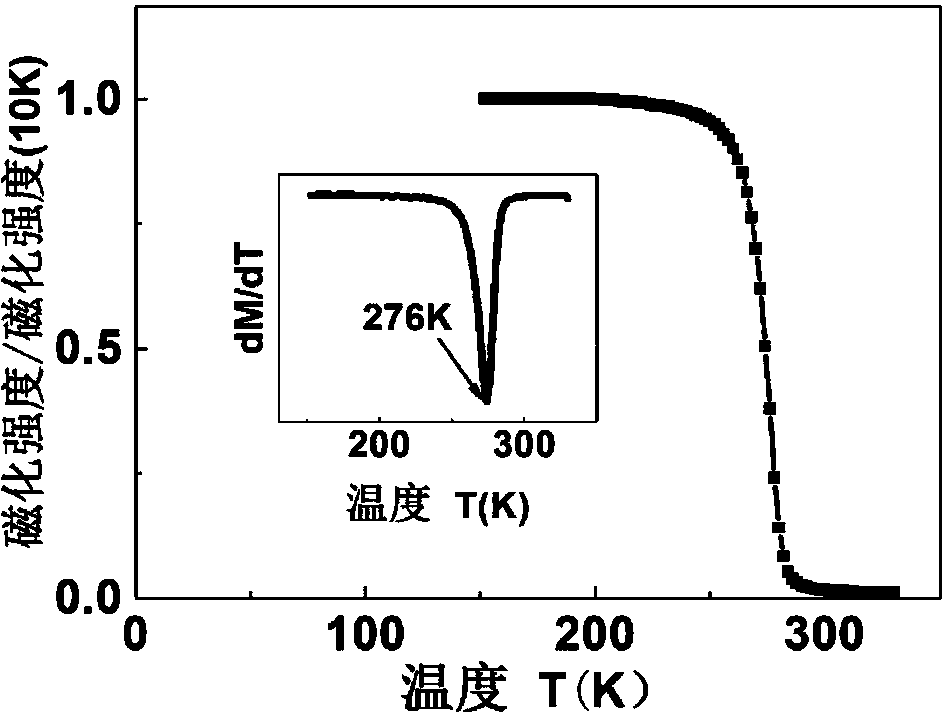

[0055] This example is carried out in the same manner as Example 1, except that the thickness of the La-Fe-Co-Si flake is 50 μm, the thickness of the top electrode is 100 nm, and the thickness of the bottom electrode is 500 nm.

Embodiment 3

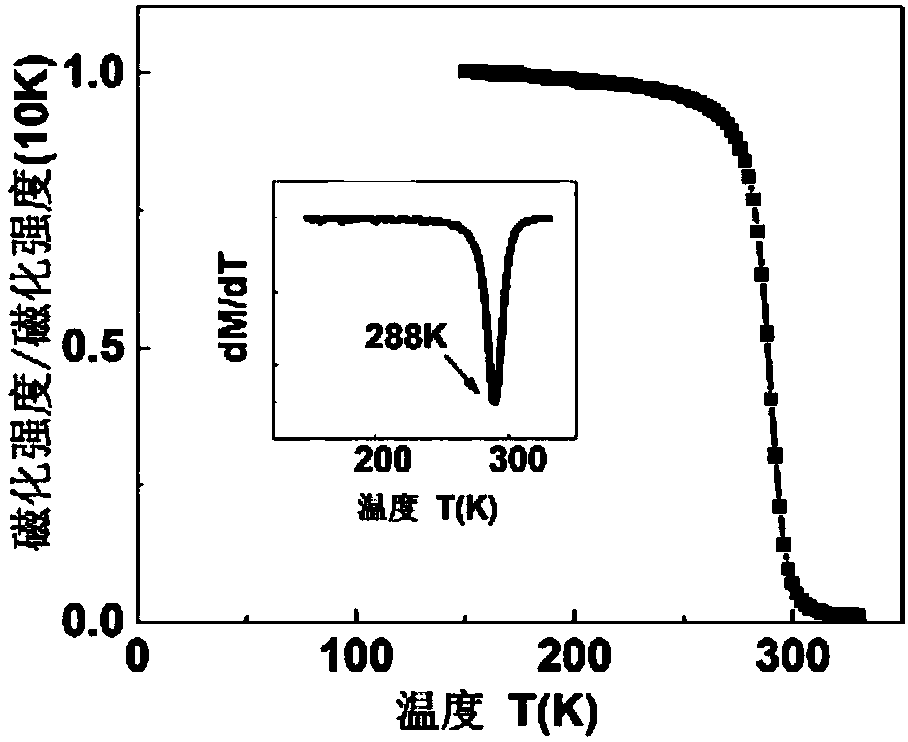

[0057] This example is carried out in the same manner as Example 1, except that the thickness of the La-Fe-Co-Si sheet is 22 μm, the thickness of the top electrode is 20 nm, and the thickness of the bottom electrode is 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com