Manganese cobalt germanium-based alloy room temperature magnetic refrigeration material and preparation method thereof

A technology of magnetic refrigeration materials and base alloys, which is applied in the directions of magnetic materials, inorganic materials, magnetic objects, etc., to achieve the effects of easy realization, simple preparation method and excellent magnetic refrigeration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Manganese sheet, zirconium sheet, cobalt block, germanium block according to Mn 0.96 Zr 0.04 The molar ratio of each element in the CoGe alloy is weighed and melted into an alloy ingot in a vacuum induction melting furnace.

[0026] (2) Put the smelted alloy ingot in a vacuum environment (vacuum degree ≤ 10 -2 Pa), annealed for 100 hours, and the annealing temperature was 1123K. After the annealing was completed, it was quenched with tap water to prepare the sample.

Embodiment 2

[0028] (1) Manganese sheet, zirconium sheet, cobalt block, germanium block according to Mn 0.95 Zr 0.05 The molar ratio of each element in the CoGe alloy is weighed and melted into an alloy ingot in a vacuum induction melting furnace.

[0029] (2) Put the smelted alloy ingot in a vacuum environment (vacuum degree ≤ 10 -2 Pa), annealed for 75 hours at an annealing temperature of 1273K, and quenched with tap water after annealing to prepare samples.

Embodiment 3

[0031] (1) Manganese sheet, zirconium sheet, cobalt block, germanium block according to Mn 0.94 Zr 0.06 The molar ratio of each element in the CoGe alloy is weighed and melted into an alloy ingot in a vacuum induction melting furnace.

[0032] (2) Put the smelted alloy ingot in a vacuum environment (vacuum degree ≤ 10 -2 Pa), annealed for 85 hours, the annealing temperature is 1173K, quenched with tap water after the annealing is completed, and the sample is prepared.

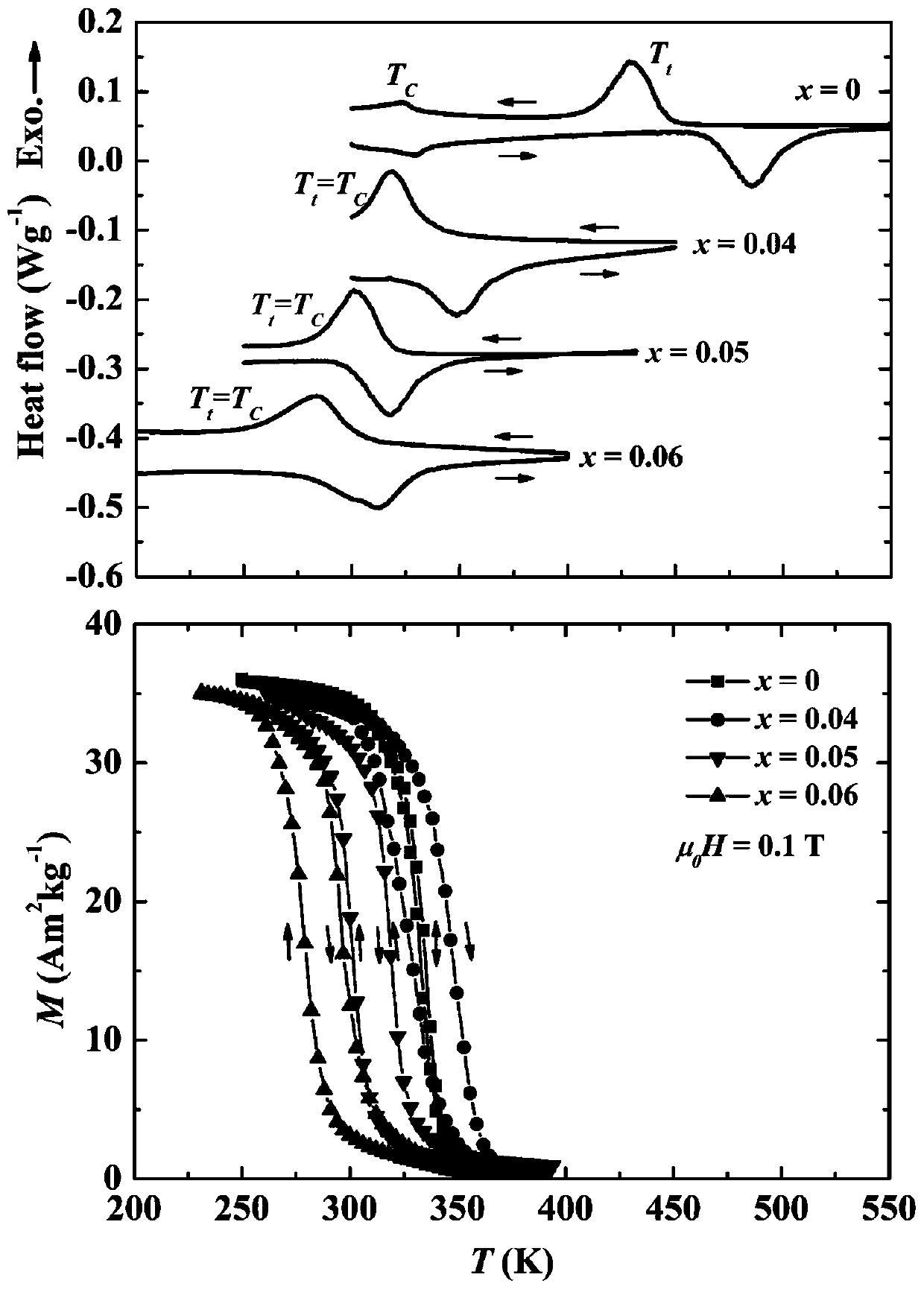

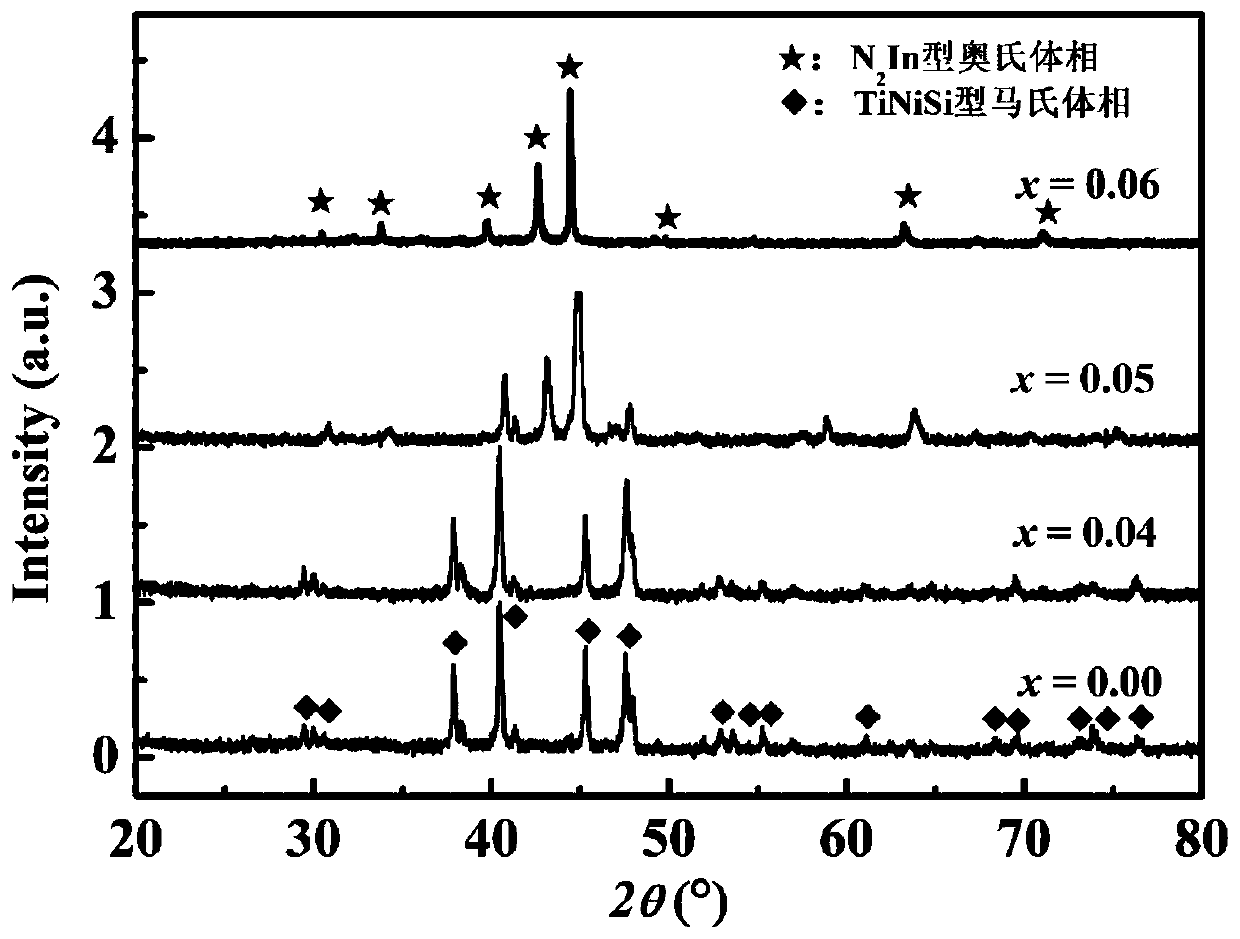

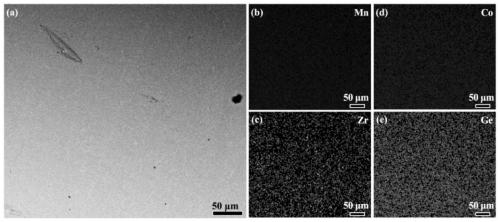

[0033] To the Mn that above-mentioned embodiment 1-3 makes 1-x Zr x CoGe ( x =0.04, 0.05, 0.06) alloys were analyzed by X-ray diffractometer (XRD), differential scanning calorimeter (DSC), scanning electron microscope (SEM), X-ray energy spectrometer (EDS) and comprehensive physical property measurement system (PPMS) The crystal structure, phase transition thermodynamics, microscopic morphology, element distribution and magnetic properties were analyzed respectively.

[0034] figure 1 For the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com