Patents

Literature

65 results about "Structural phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for evaluating stress concentration and fatigue damage based on feature permeability detection

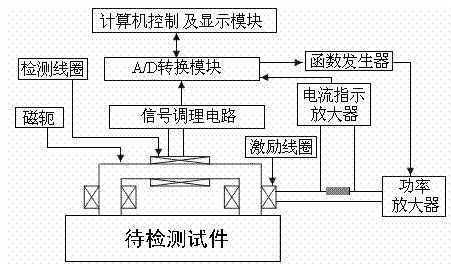

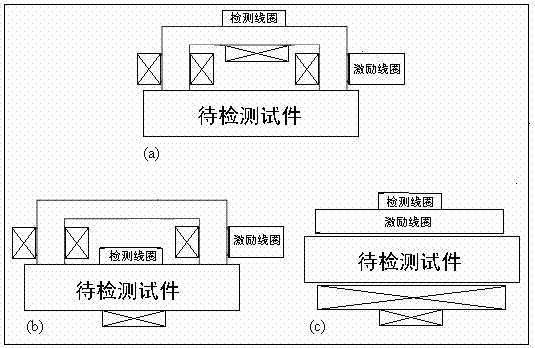

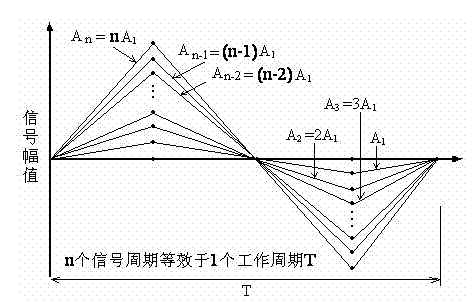

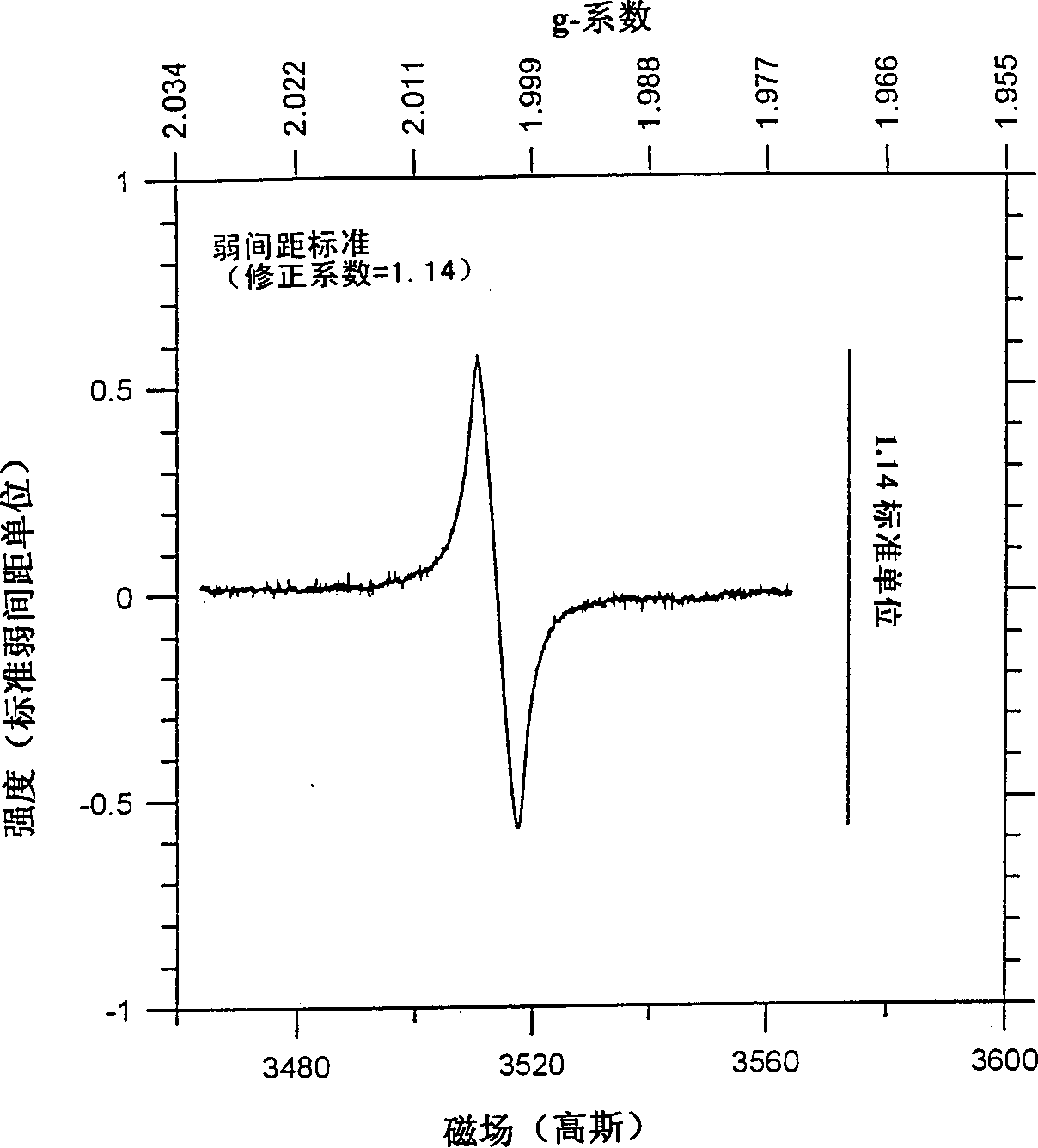

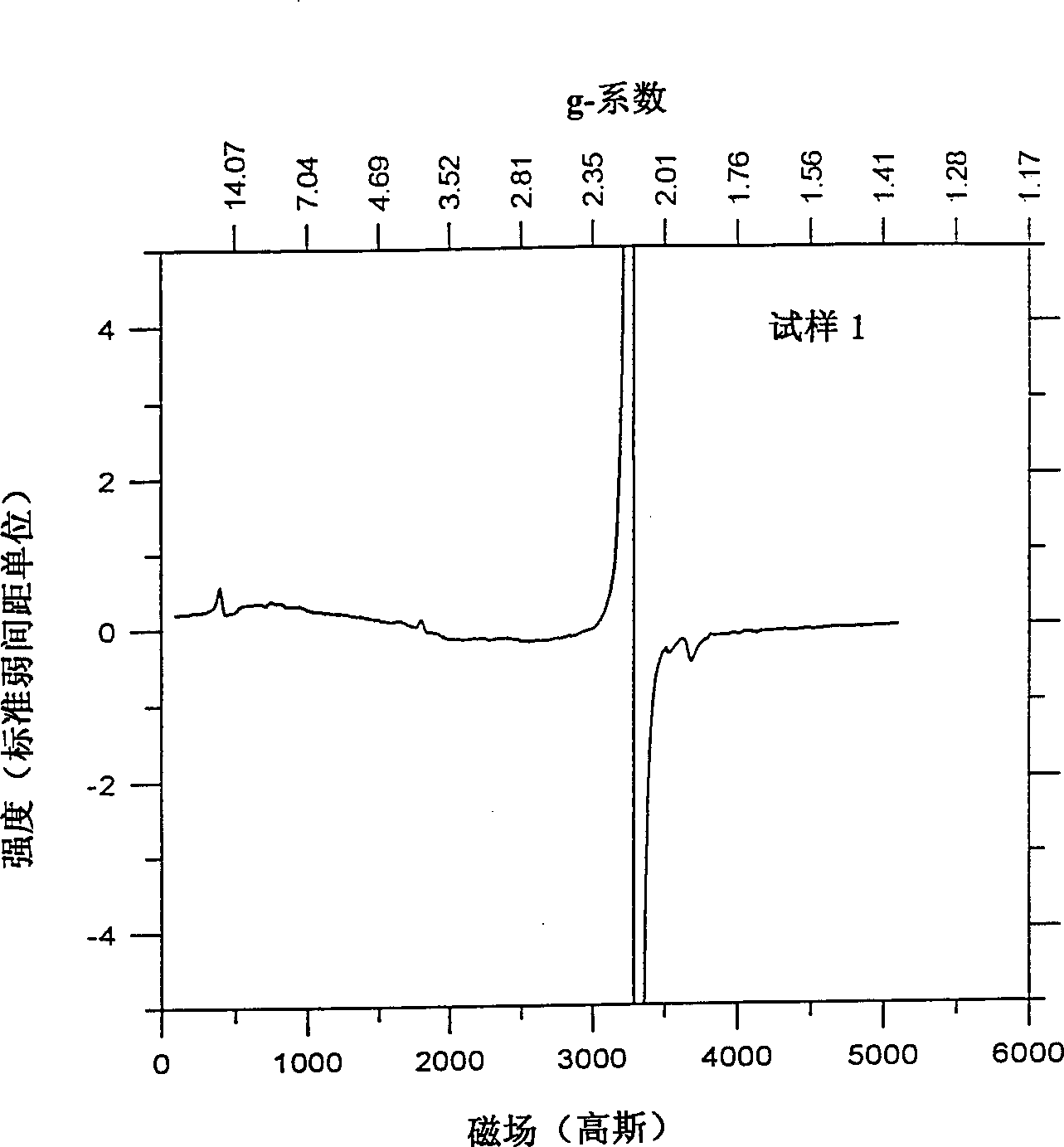

The invention relates to a new method for evaluating stress concentration and fatigue damage based on feature permeability detection. The microstructure feature of material is closely related with a technical magnetizing process, so that the magnetizing process can be changed by formation and change of the stress concentration, enhancement of the fatigue damage, change of the defect dislocation density, crack formation and structural phase change. The feature permeability represented by the invention is a differential permeability, which is related with the magnetizing process and the maximal magnetic field intensity. In a differential permeability matrix, a differential permeability matrix element with the maximal change rate along the microstructure variable of the material is the feature permeability corresponding to the microstructure variable. Different microstructure feature variables are corresponding to different permeability matrix elements and have different feature permeability. The feature permeability is related with specific material and microstructure change property of the specific material, and different microstructure feature changes are corresponding to different feature permeability. A circuit structure for the feature permeability detection mainly comprises an excitation coil, a detection coil, a power supply module, an A / D (Analogue / Digital) conversion module, a computer control module, a signal conditioning circuit, and the like. A specific data evaluation model is mainly dependent on the data of a low field magnetic hysteresis loop system. An excitation signal is mainly in a triangular waveform and waveform change feature in a working cycle is controlled by software programming.

Owner:NANCHANG HANGKONG UNIVERSITY

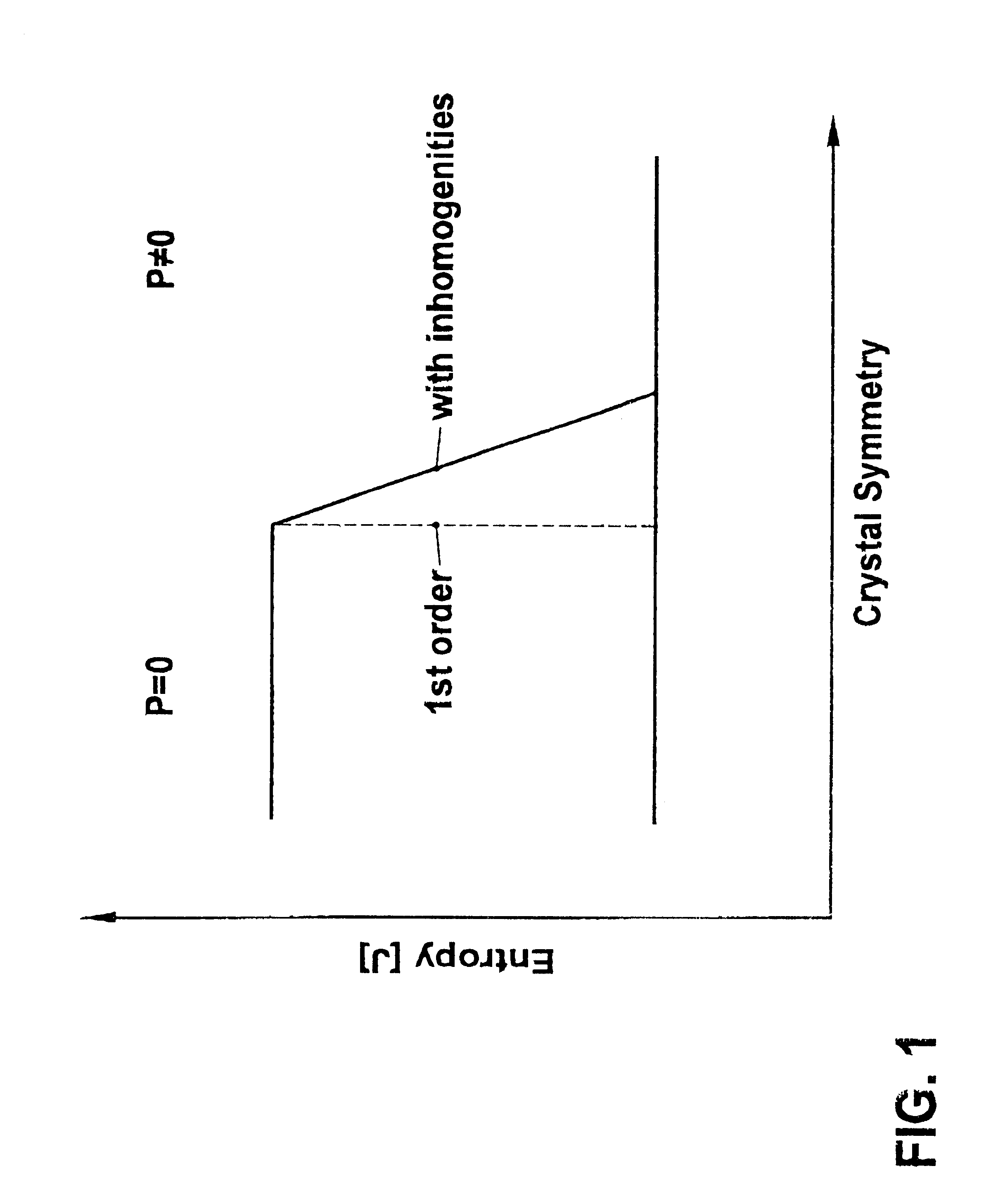

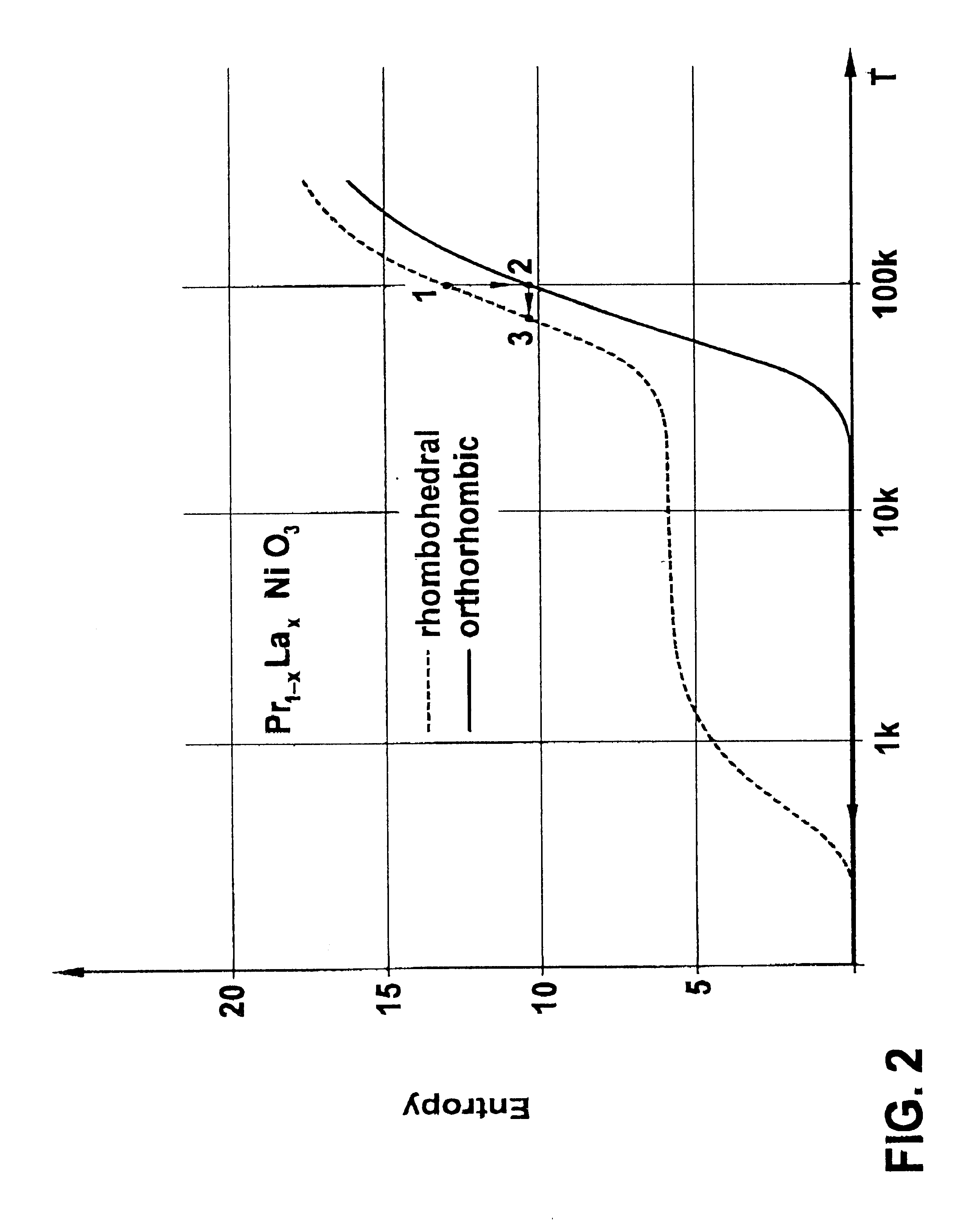

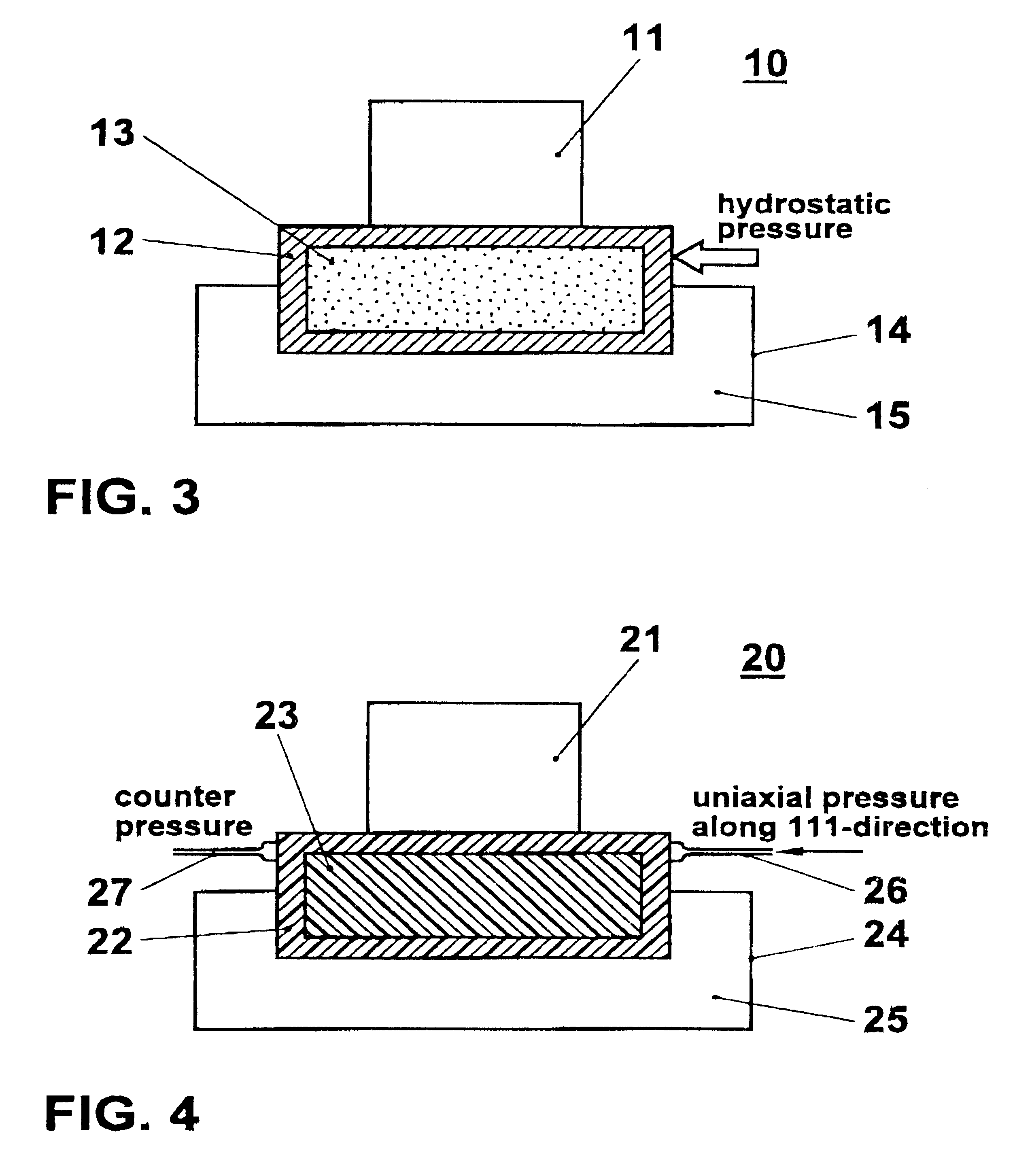

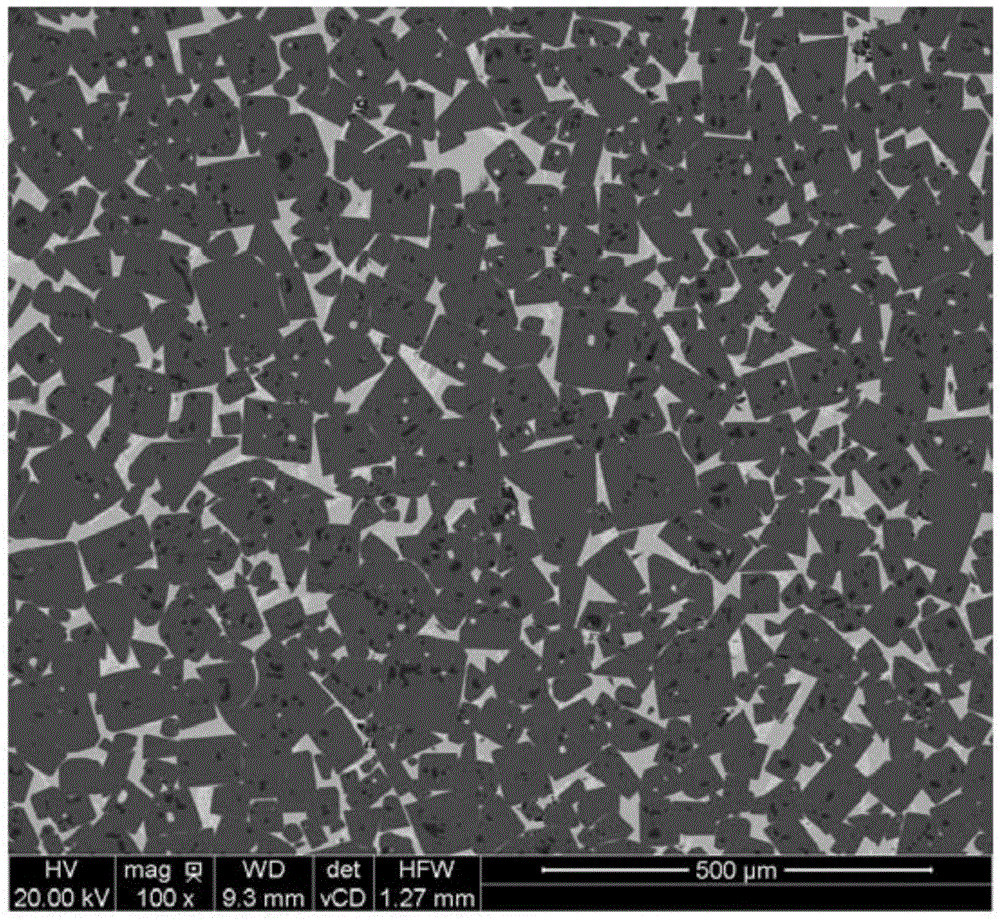

Method for cooling by altering crystal field interaction

InactiveUS6558434B1X-ray/infra-red processesCrystallization separationStructural phaseMaterials science

A method for cooling is provided which makes use of materials which undergo a pressure induced structural phase transition such that the material's crystal field interaction changes, and which colds down during this phase transition. This effect is used for cooling objects which are thermally coupled to the material.

Owner:FURRER ALBERT +2

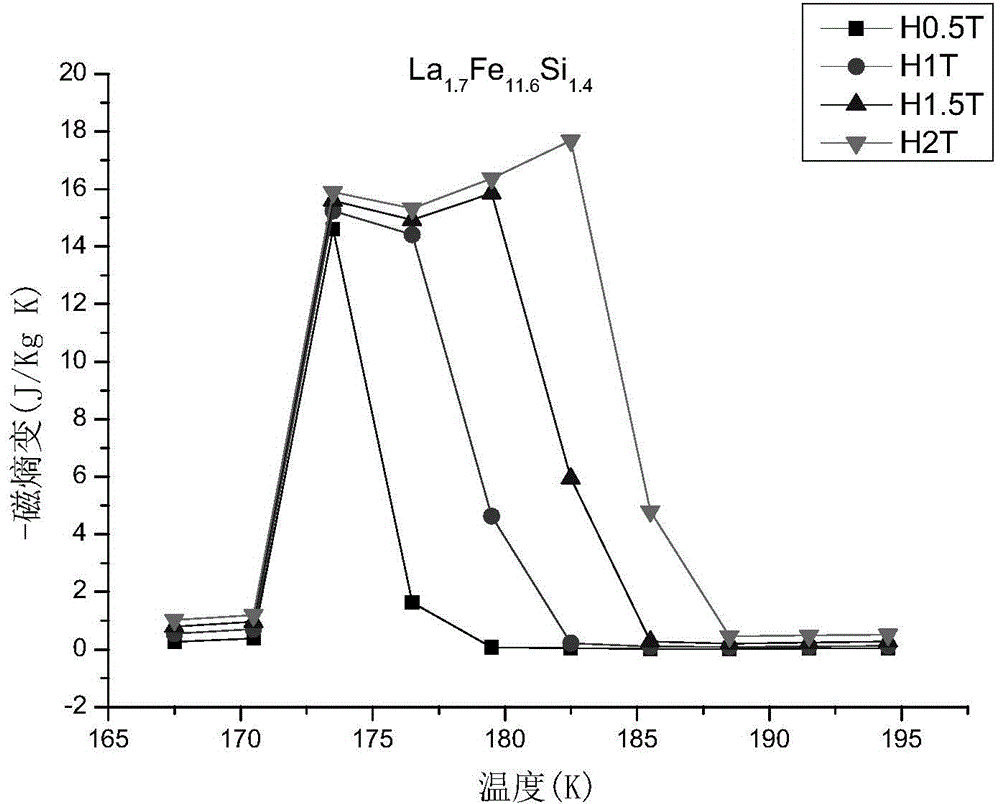

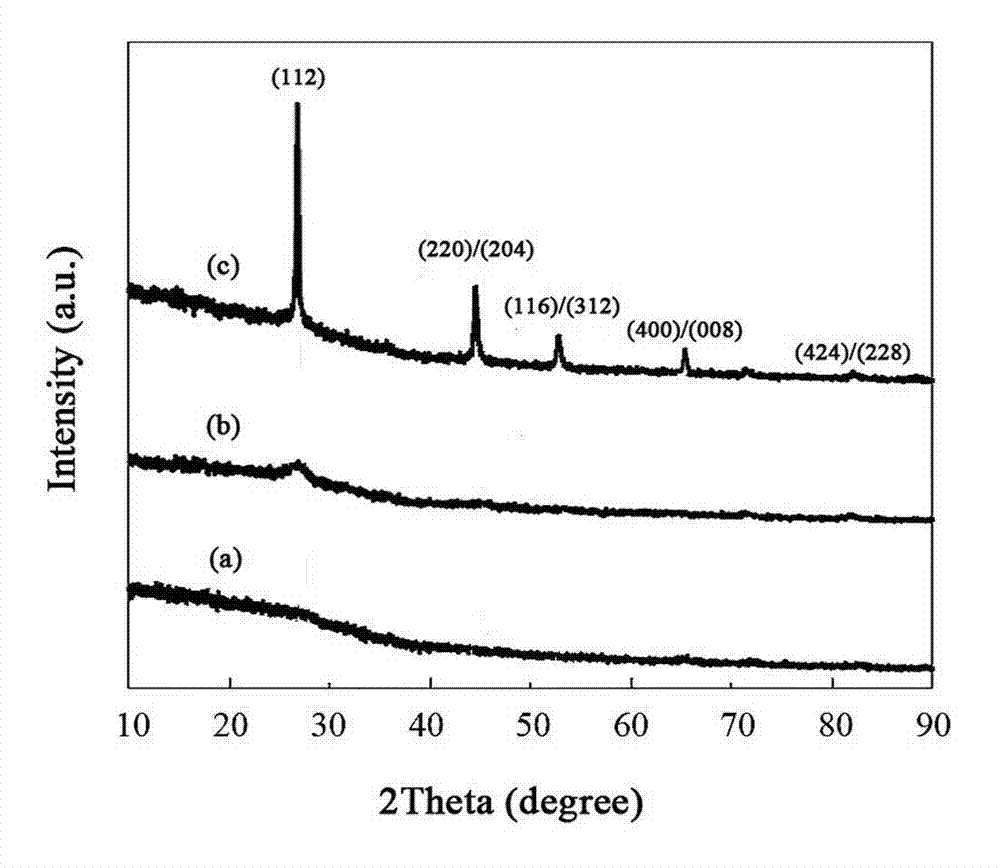

LaFeSi-based magnetic refrigeration material as well as preparation method and application thereof

ActiveCN104694813AGrain intactMagnetic entropy change does not decreaseHeat-exchange elementsHysteresisStructural phase

The invention discloses a LaFeSi-based magnetic refrigeration material as well as a preparation method and application thereof. The chemical formula of the refrigeration material is La1+aFe13-b-cCobSicHd and the refrigeration material comprises a NaZn13 structural phase, wherein a is greater than 0 but less than or equal to 1, b is greater than or equal to 0 but less than or equal to 1.2, c is greater than or equal to 1.0 but less than or equal to 1.8 and d is greater than or equal to 0 but less than or equal to 3. The preparation method comprises the following steps: preparing raw materials according to the chemical formula and smelting in the presence of high-purity inert gas to obtain an alloy ingot with uniform components; annealing the alloy ingot in the presence of high-purity inert gas and then quickly quenching to obtain the La(Fe, Co, Si)13-based block magnetic refrigeration material containing the NaZn13 structural phase; and furthermore, introducing hydrogen into the block magnetic refrigeration material. According to the block magnetic refrigeration material, the forming period of a magnetic thermal phase is obviously shortened. The material before hydrogenation needs not to be mechanically crushed to small particles, and the block can be fully hydrogenated to be saturated. The material has a huge magnetocaloric effect and low hysteresis, so that the material is an ideal near room-temperature magnetic refrigeration working material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

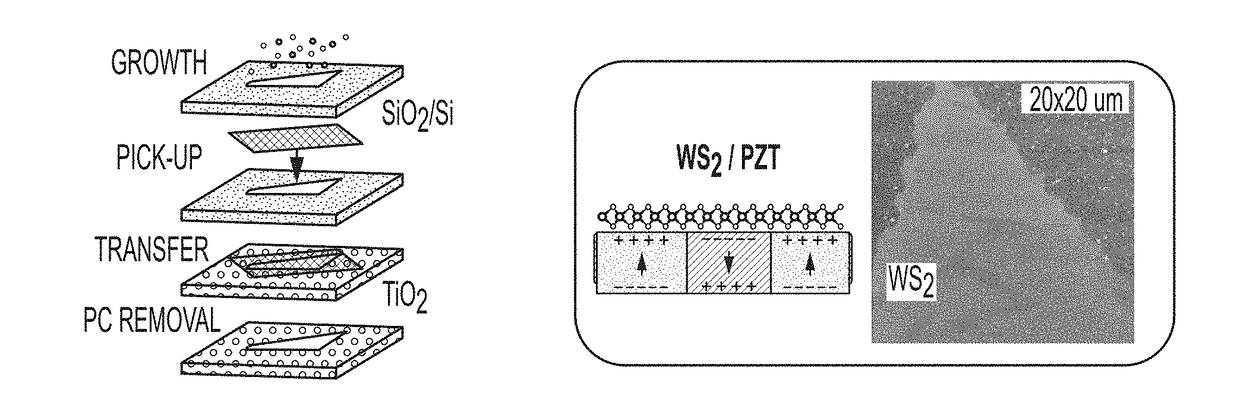

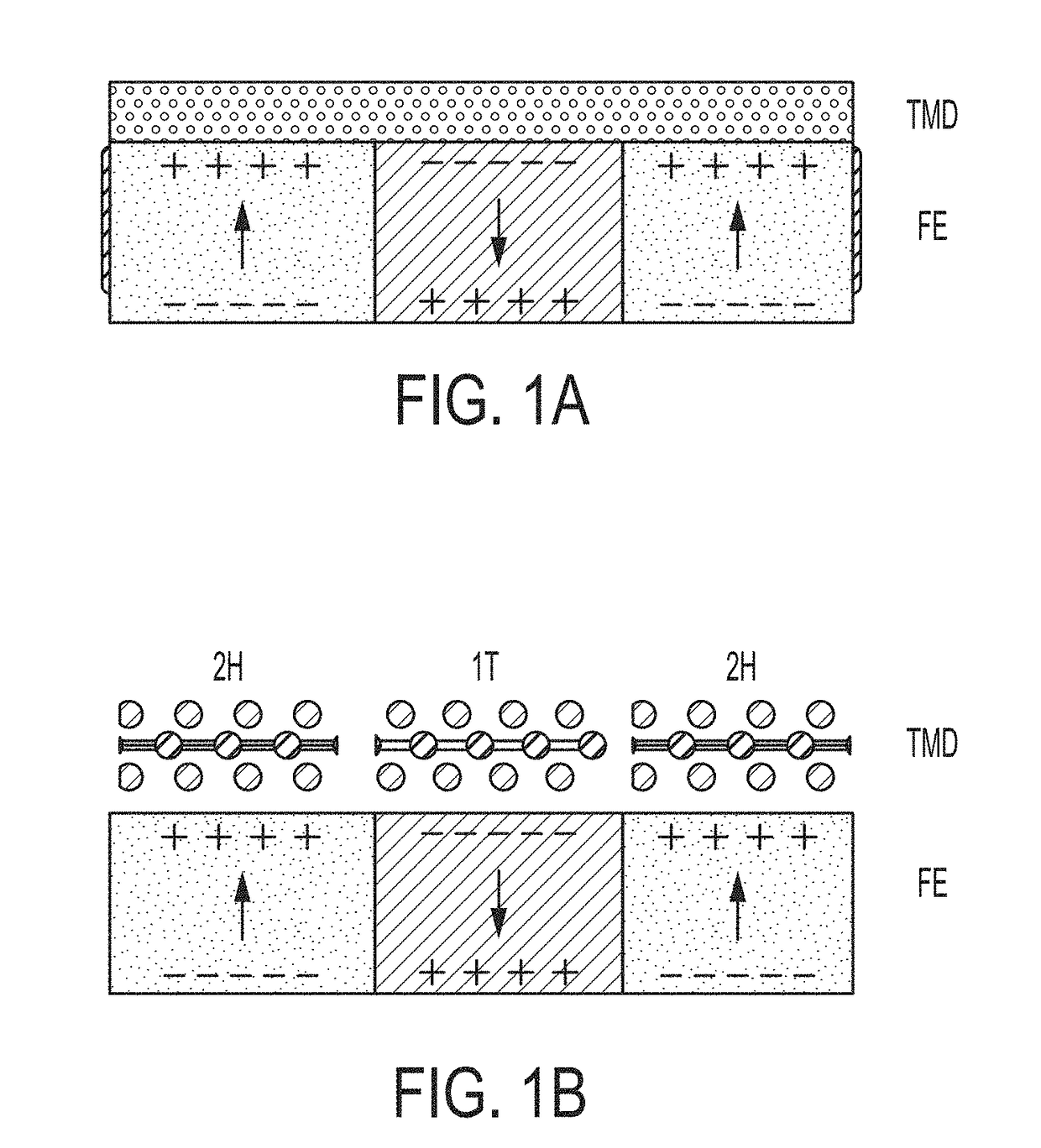

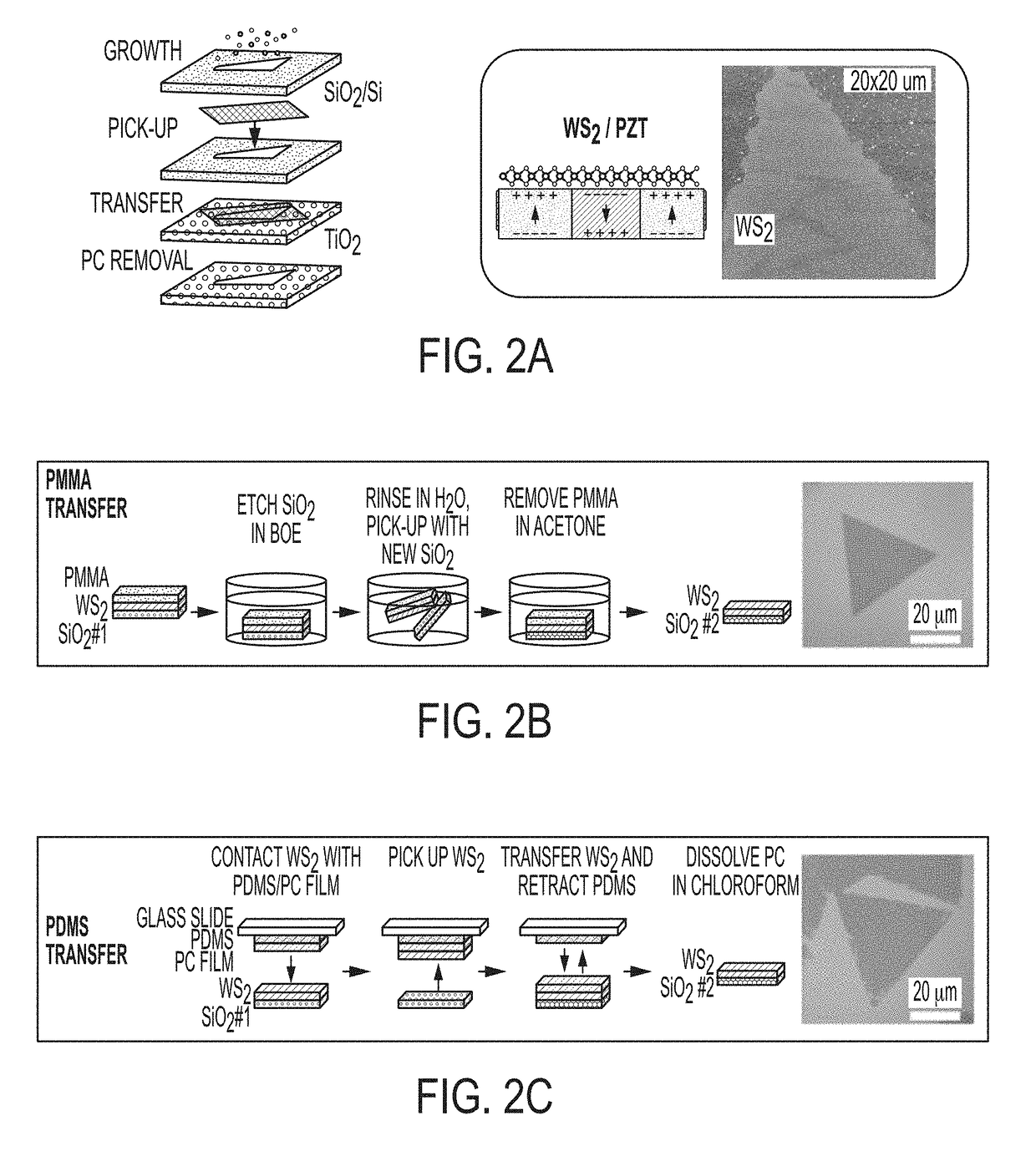

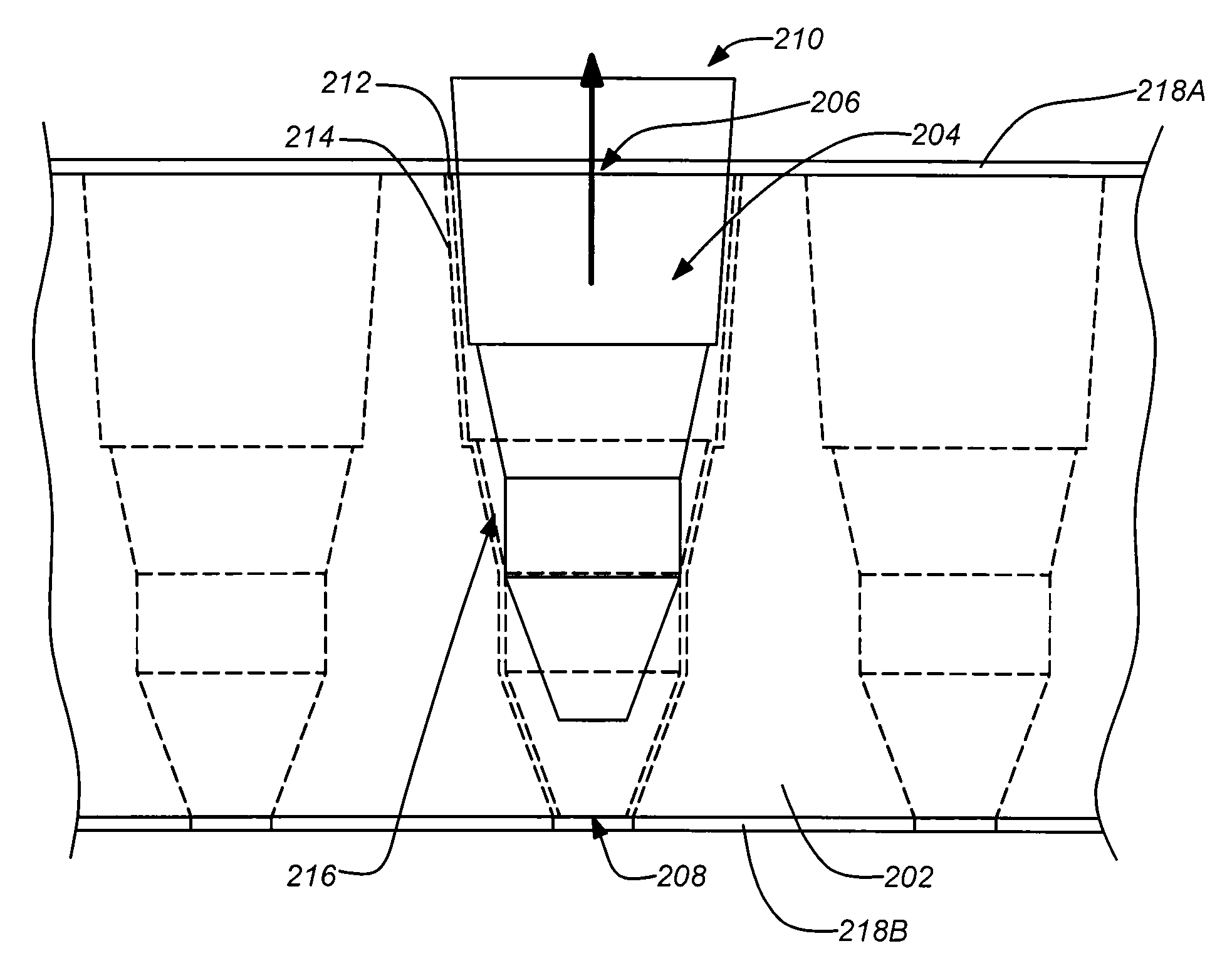

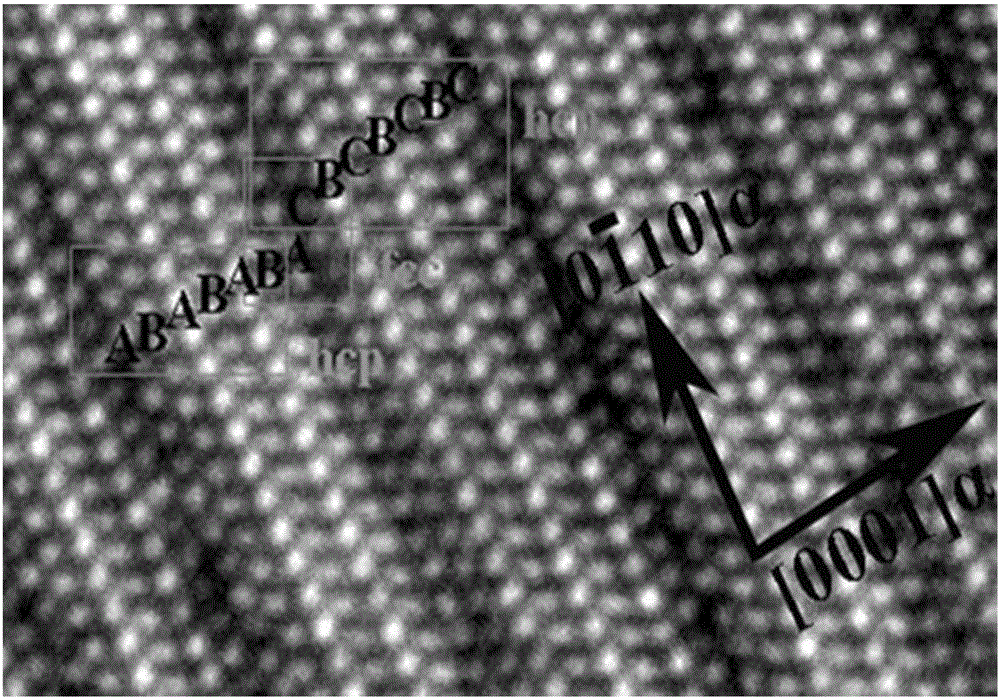

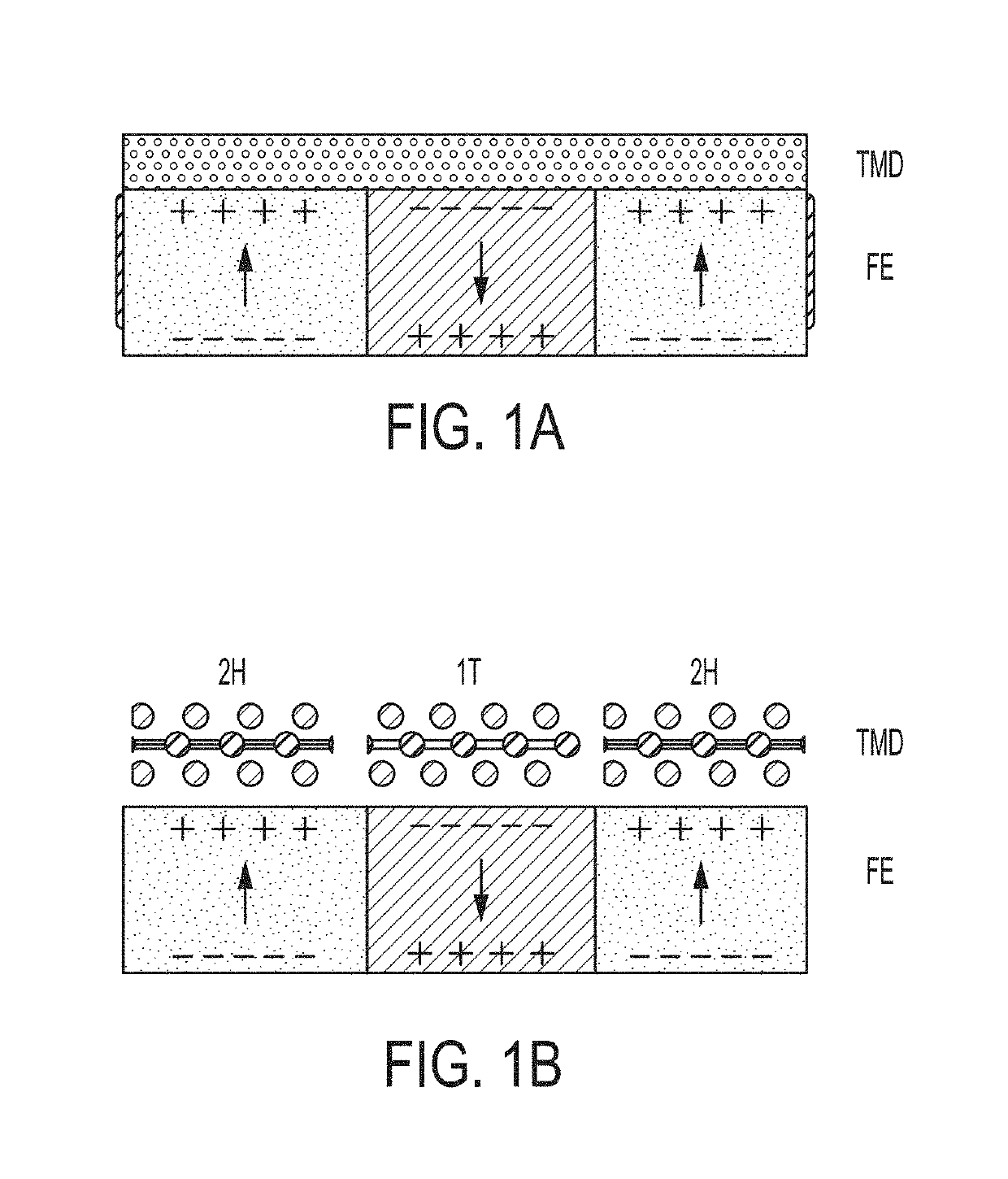

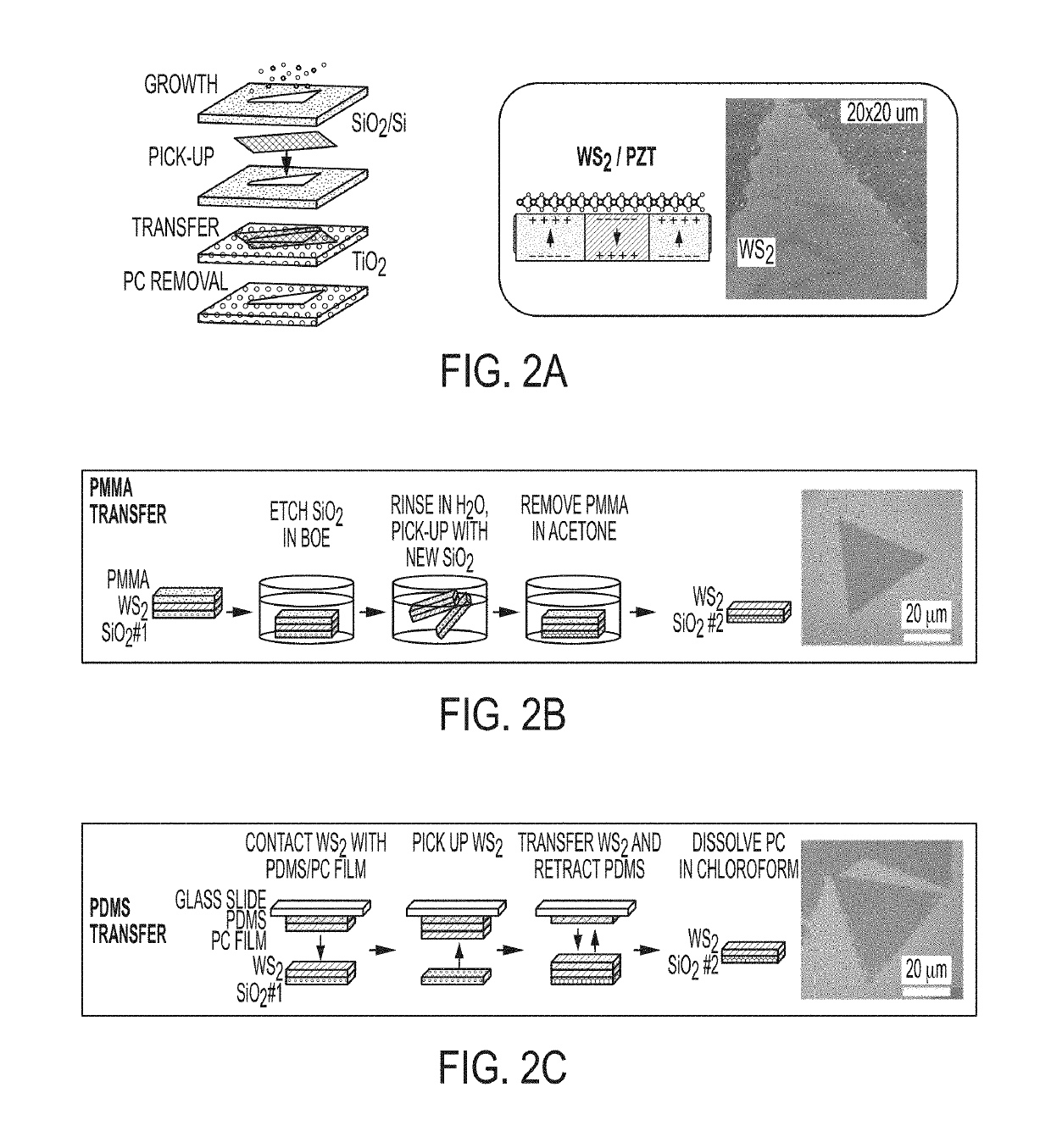

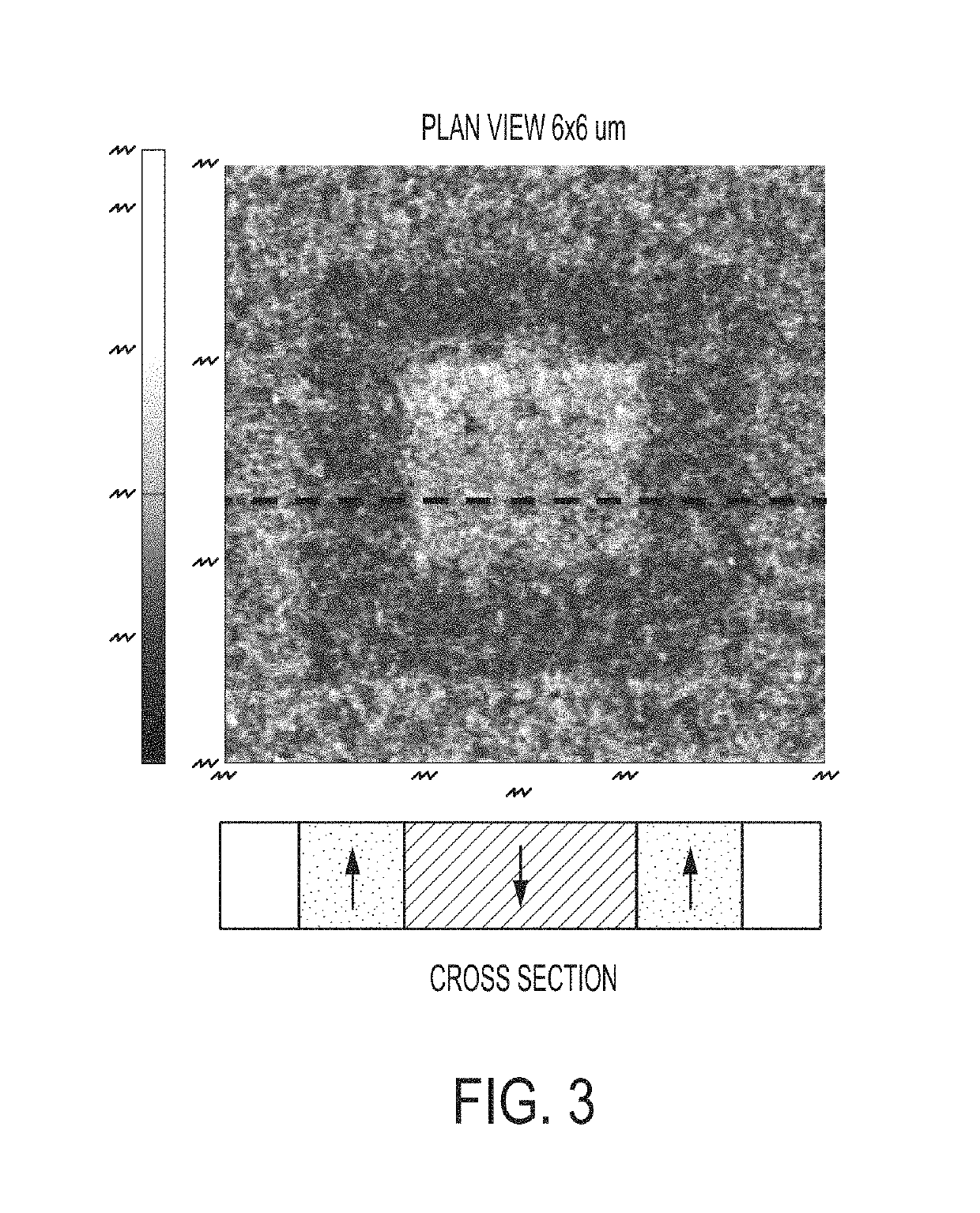

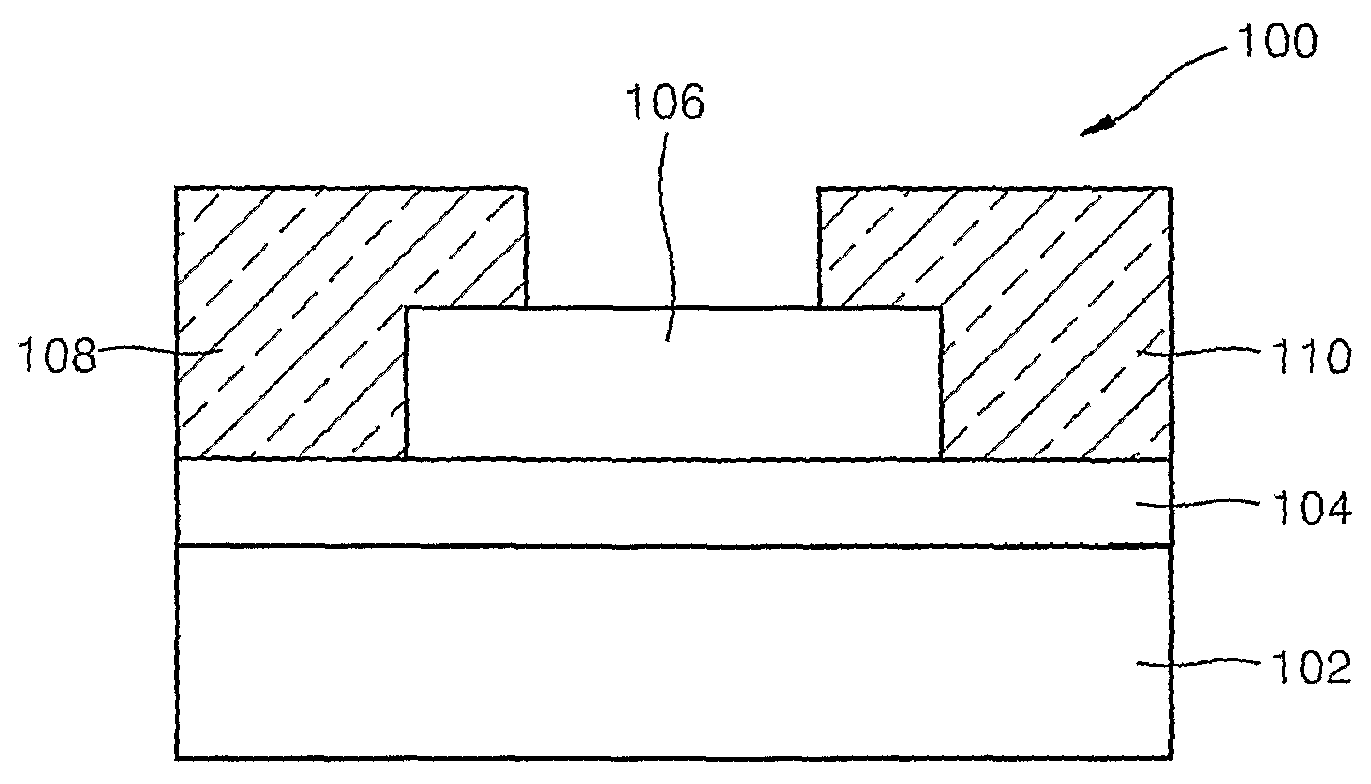

Controlling structural phase transitions and properties of two-dimensional materials by integrating with multiferroic layers

ActiveUS20180158955A1Magnetic measurementsMaterial analysis by electric/magnetic meansStructural phaseNon magnetic

The invention relates to heterostructures including a layer of a two-dimensional material placed on a multiferroic layer. An ordered array of differing polarization domains and surface charges in the multiferroic layer produces corresponding domains having differing properties in the two-dimensional material. When the multiferroic layer is ferroelectric, the ferroelectric polarization domains in the layer produce local electric fields that penetrate the two-dimensional material. The local electric fields and surface charges can control the structural phase of the two-dimensional material, which in turn determines whether the two-dimensional material layer is insulating or metallic, has a band gap or no band gap, and whether it is magnetic or non-magnetic. Methods for producing the heterostructures are provided. Devices incorporating the heterostructures are also provided.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

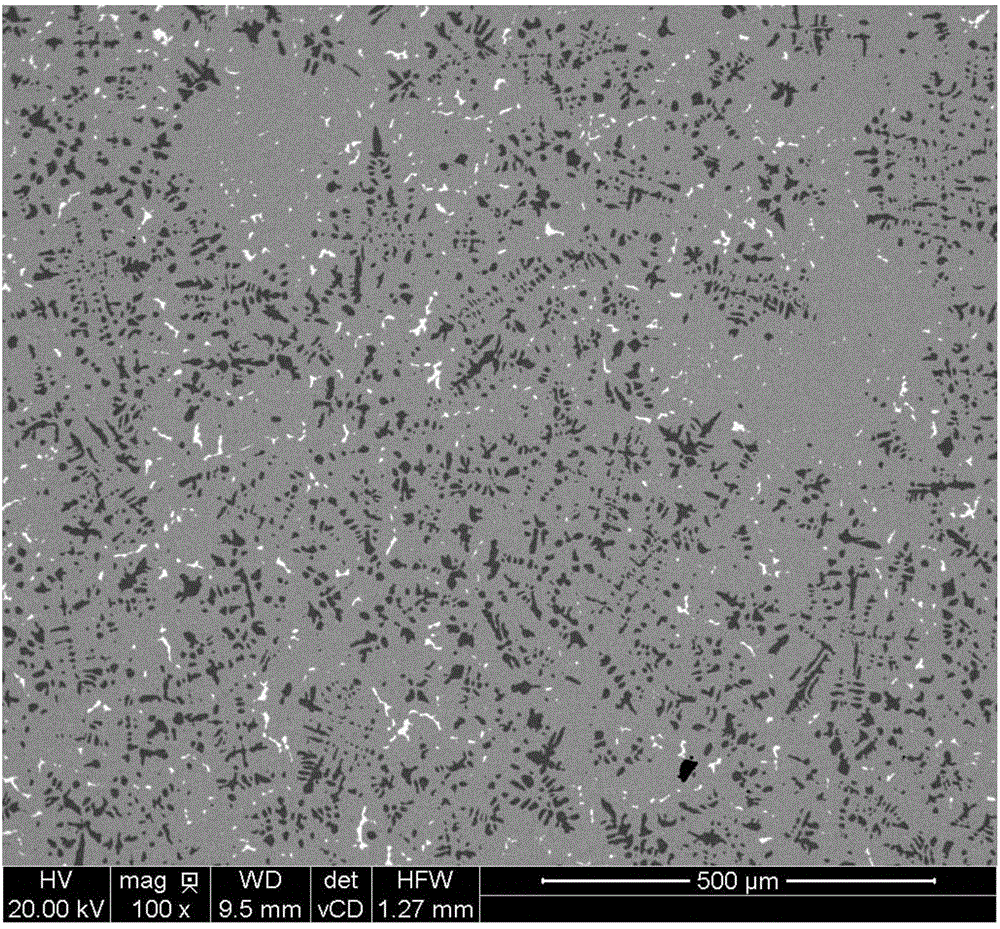

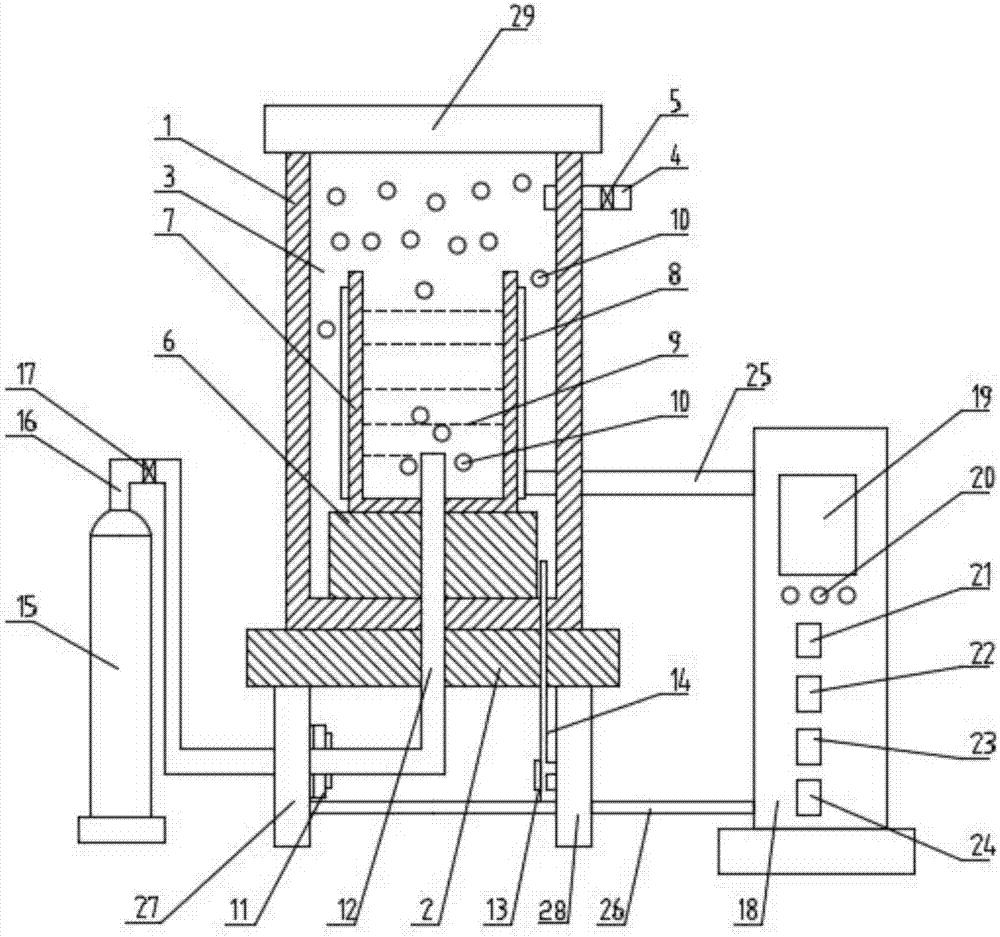

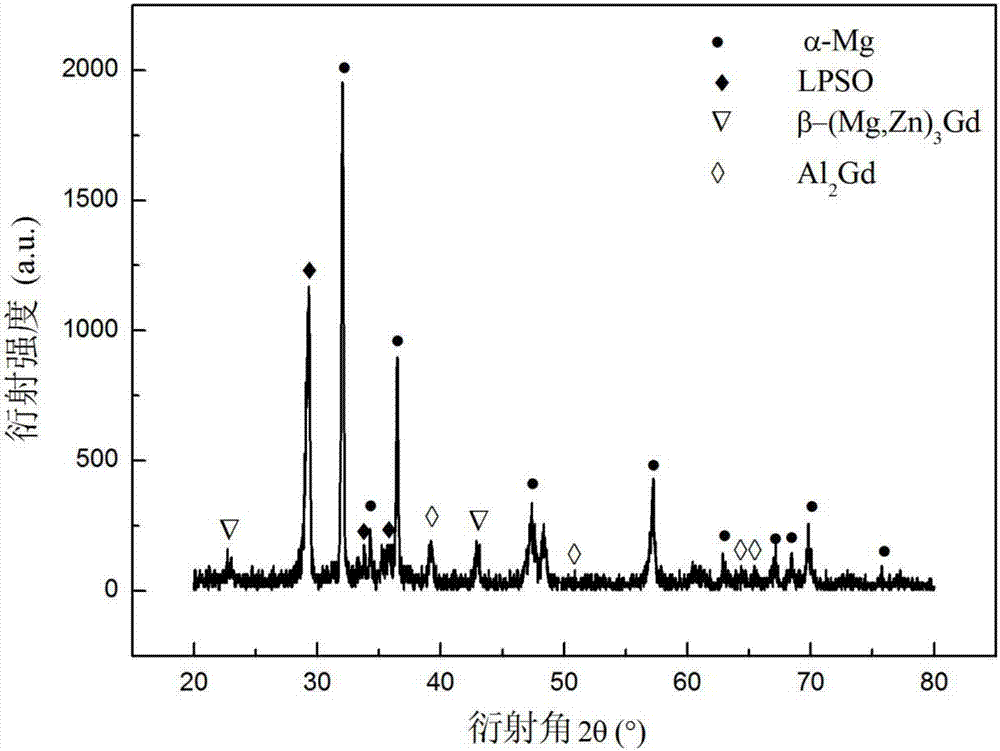

High-intensity high-toughness Mg-Zn-Y-Gd-Zr alloy and preparation method thereof

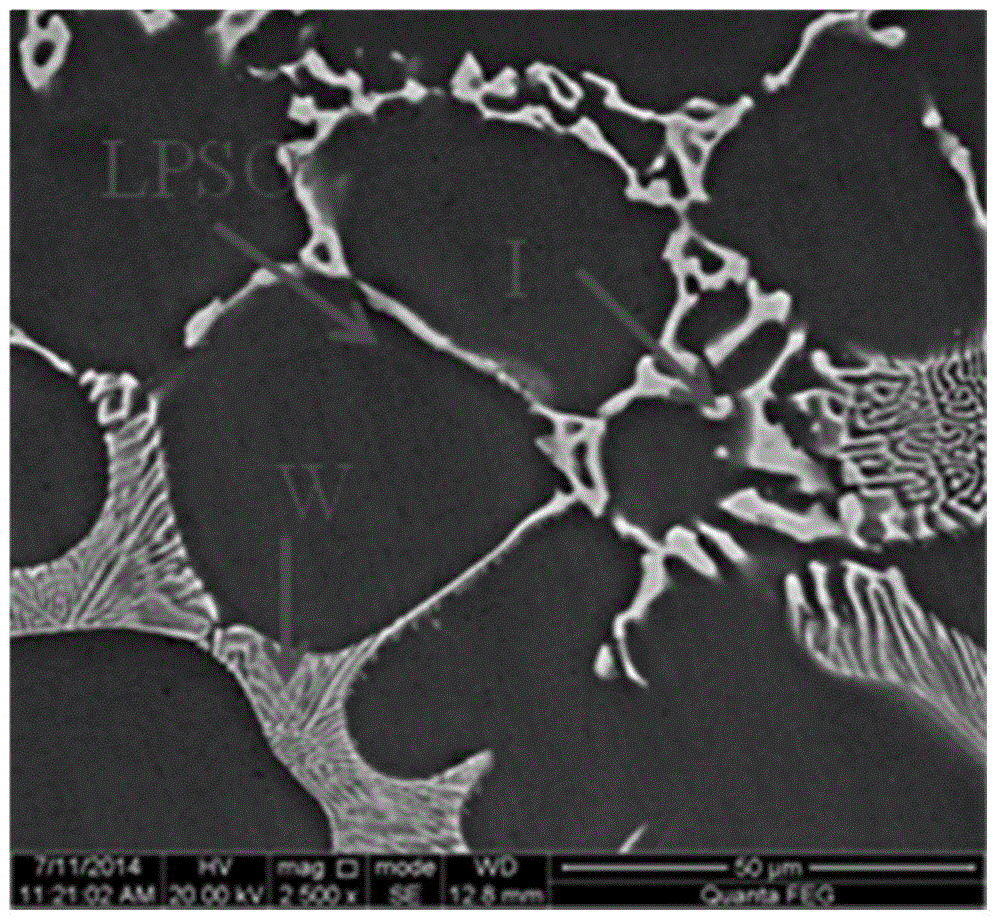

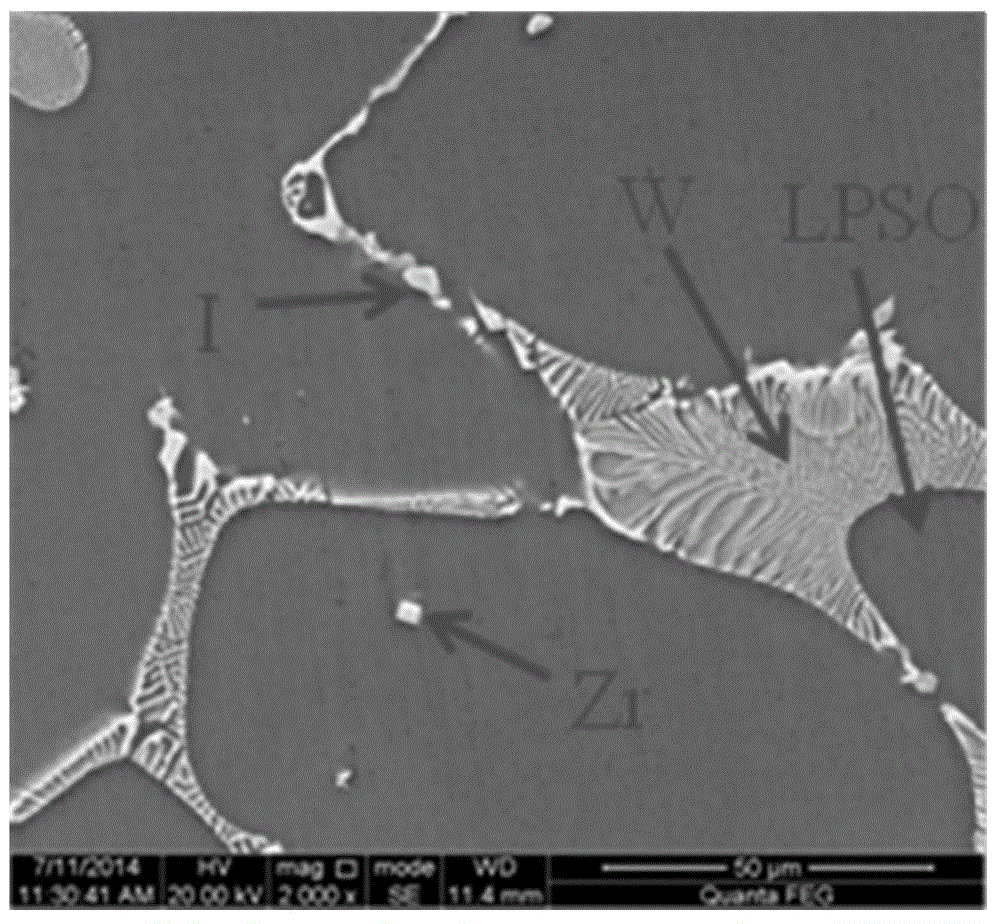

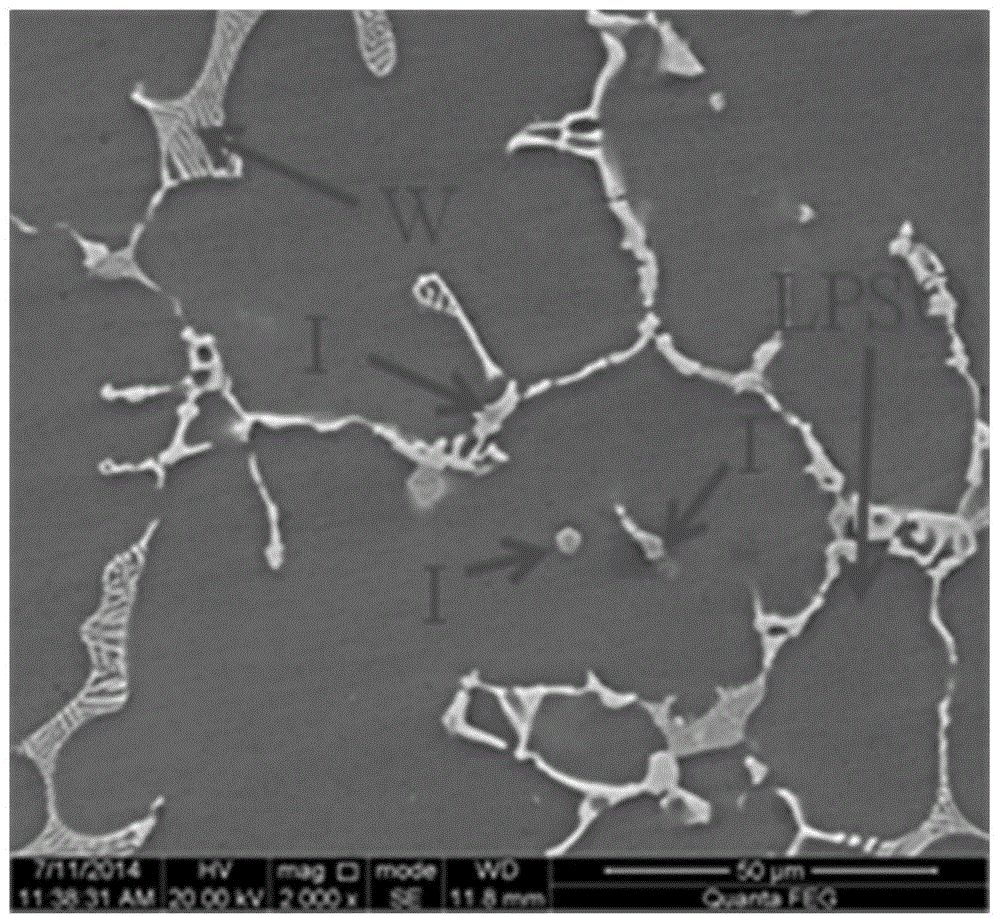

The invention discloses a high-intensity high-toughness Mg-Zn-Y-Gd-Zr alloy and a preparation method thereof and relates to an alloy and a preparation method thereof. The invention aims to solve the technical problem of high rare earth content in an alloy prepared by an existing method. The alloy disclosed by the invention consists of Zn, Y, Gd, Zr and Mg. The preparation method comprises the following steps: weighing raw materials, adding pure magnesium into a crucible, heating the crucible and then filling mixed gas of CO2 and SF6 into the crucible to carry out protection; after the pure magnesium is completely molten, sequentially adding other raw materials; preparing a cast ingot; homogenizing and extruding the cast ingot, carrying out heat preservation at an aging temperature and cooling to obtain the high-intensity high-toughness Mg-Zn-Y-Gd-Zr alloy. The total rare earth content of the high-intensity high-toughness Mg-Zn-Y-Gd-Zr alloy is lower than 6 weight percent; by improving zinc content and a Zn / RE atomic ratio, a stable quasicrystalline phase and a long-period ordered structural phase (LPSO) are obtained; tensile intensity of the alloy disclosed by the invention is higher than 500MPa; elongation of the alloy disclosed by the invention is greater than 5 percent. The invention belongs to the field of preparation of alloys.

Owner:HARBIN INST OF TECH

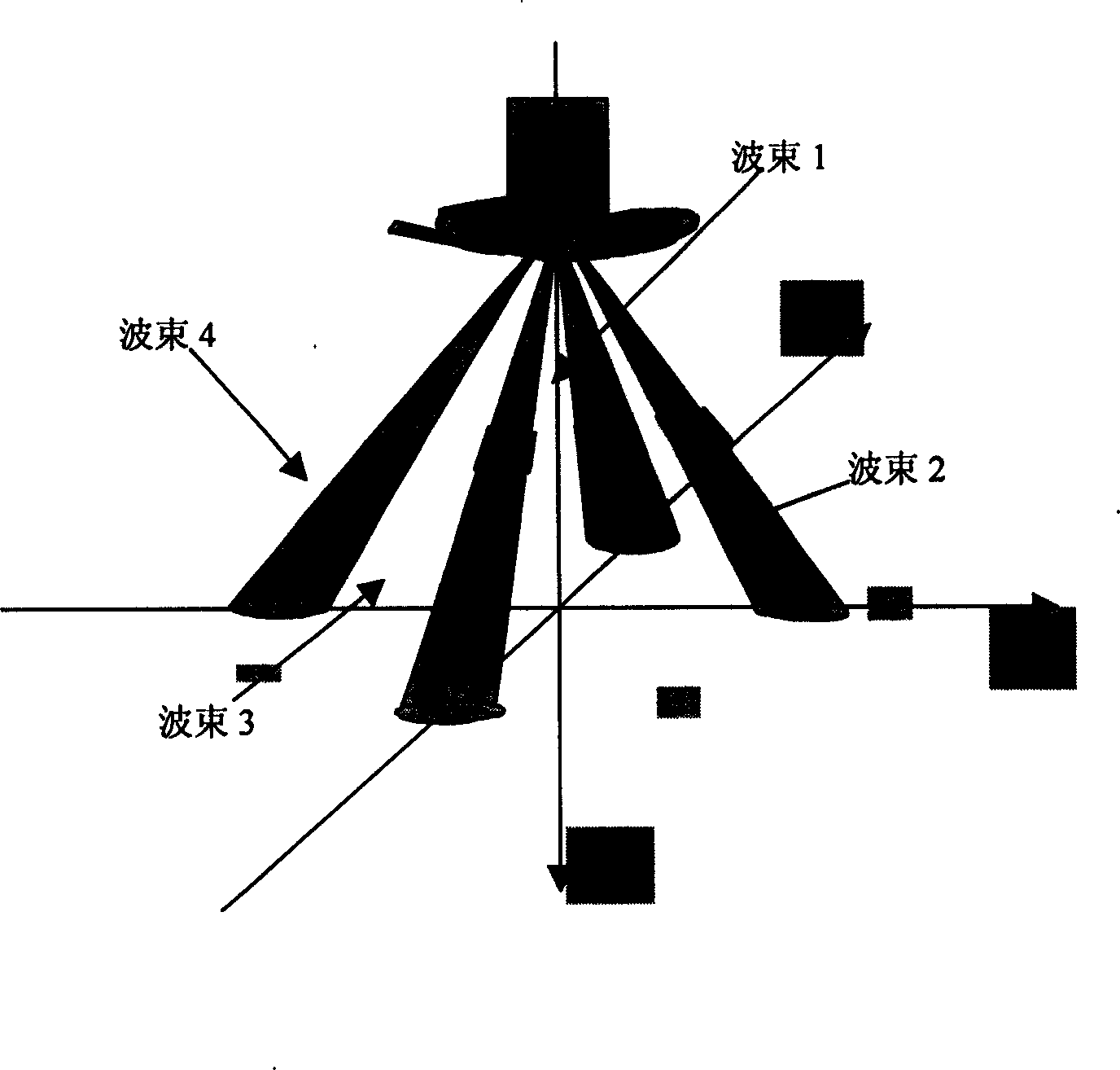

Phase control transducer array and phase control method for acoustic Doppler ocean current profile instrument

ActiveCN1588120AReduce physical sizeReduce weightAcoustic wave reradiationRelative energyStructural phase

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP +1

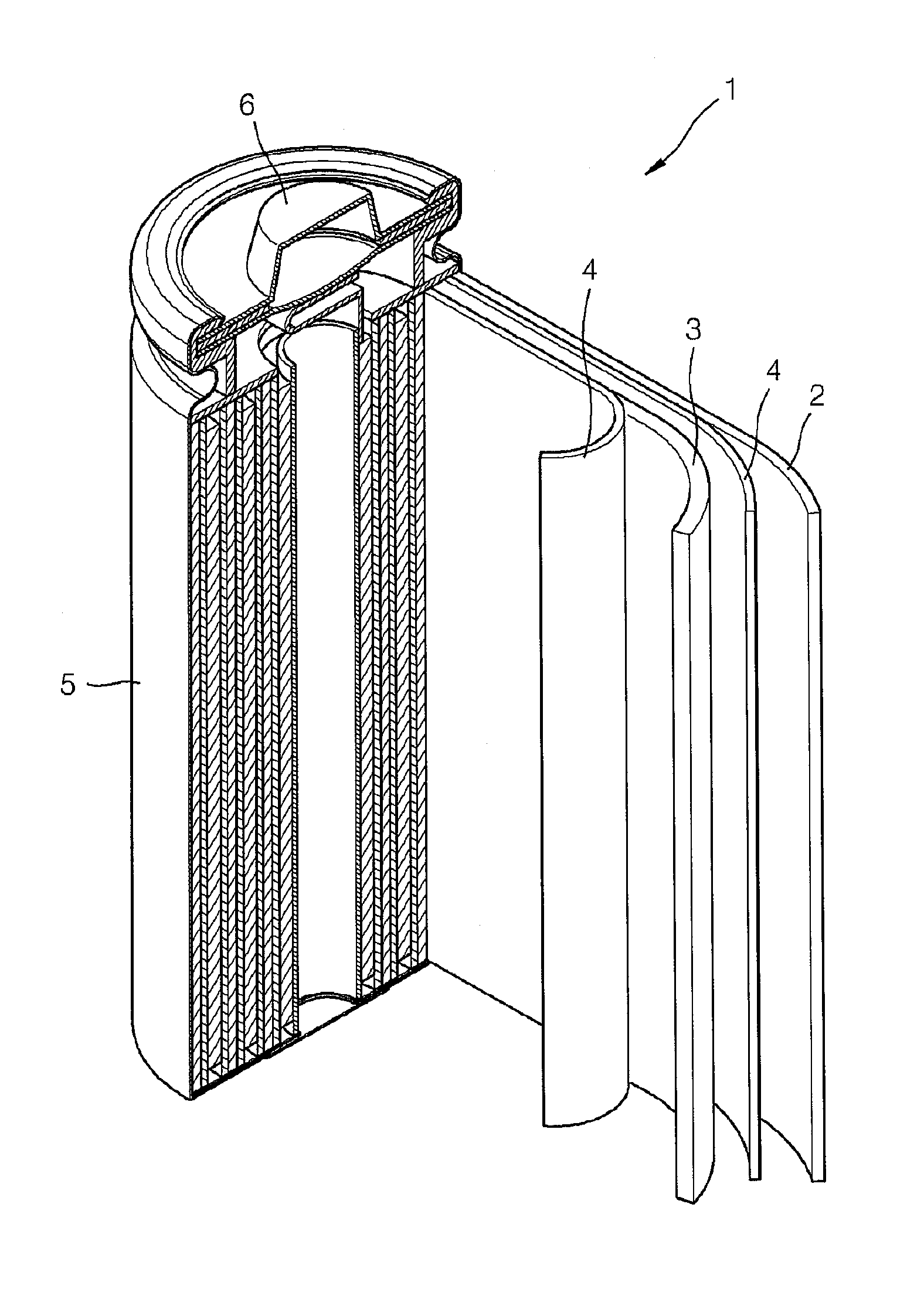

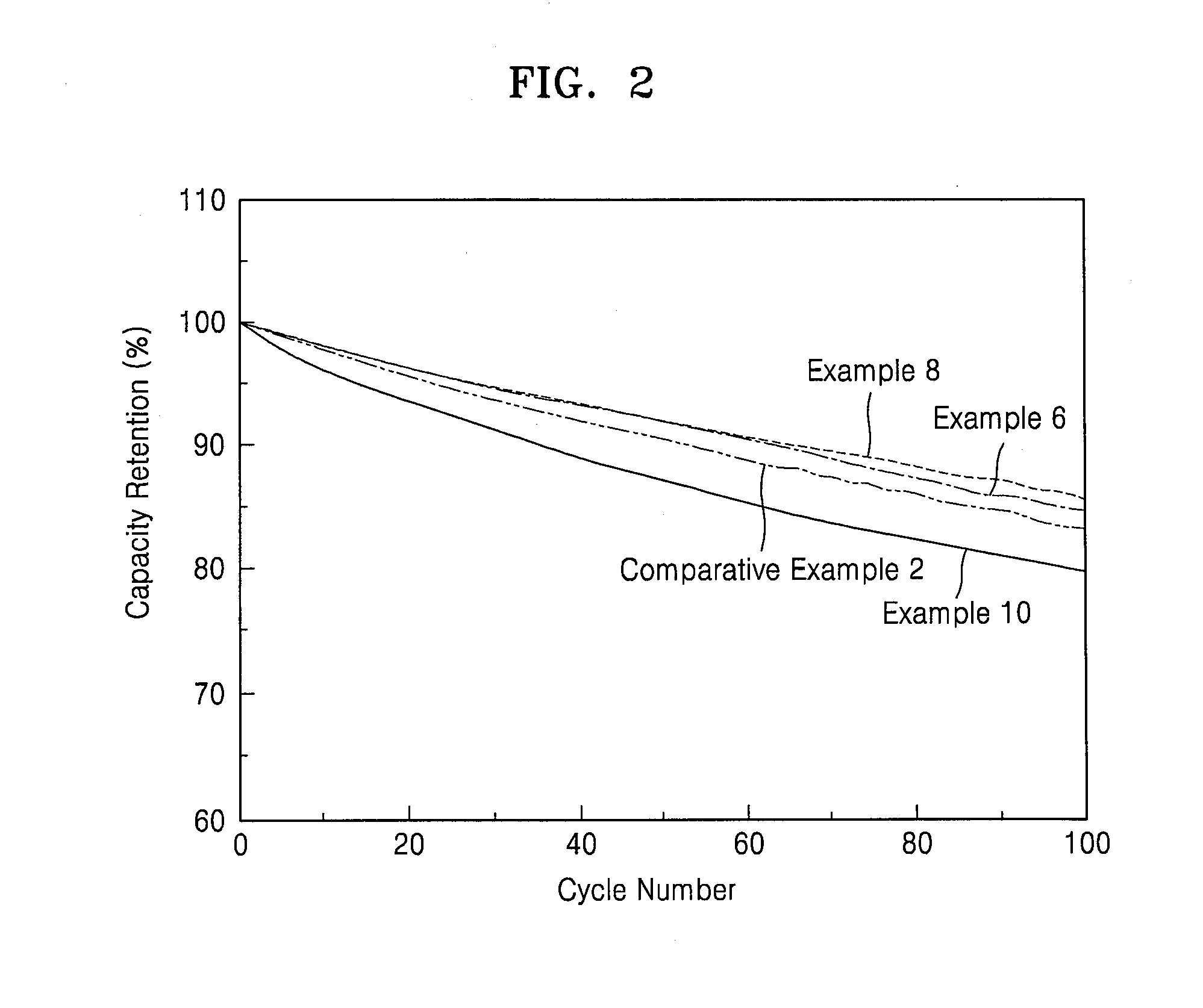

Composite cathode active material, cathode and lithium battery including the material, and method of preparing the material

A composite cathode active material including a lithium transition metal oxide, wherein the lithium transition metal oxide includes a layered structural phase and a spinel structural phase, and an amount of residual lithium is about 0.30 wt % or less; a cathode and a lithium battery including the composite cathode active material; and a method of preparing the composite cathode active material.

Owner:SAMSUNG SDI CO LTD

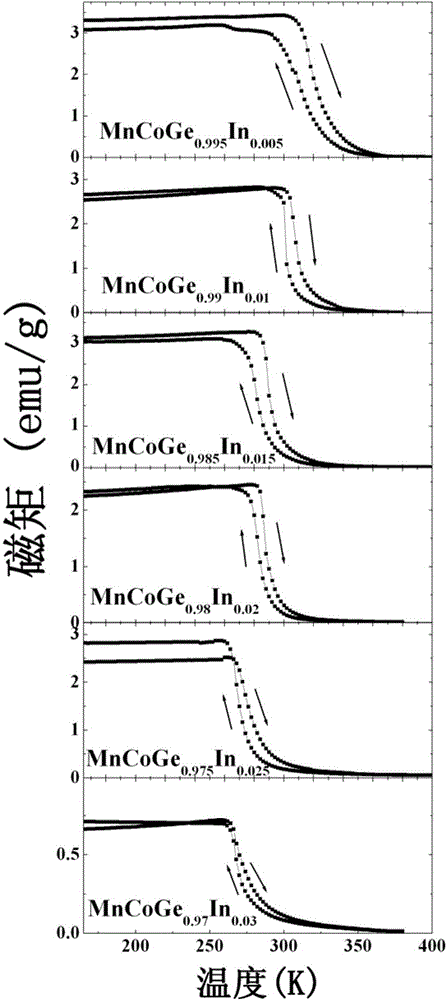

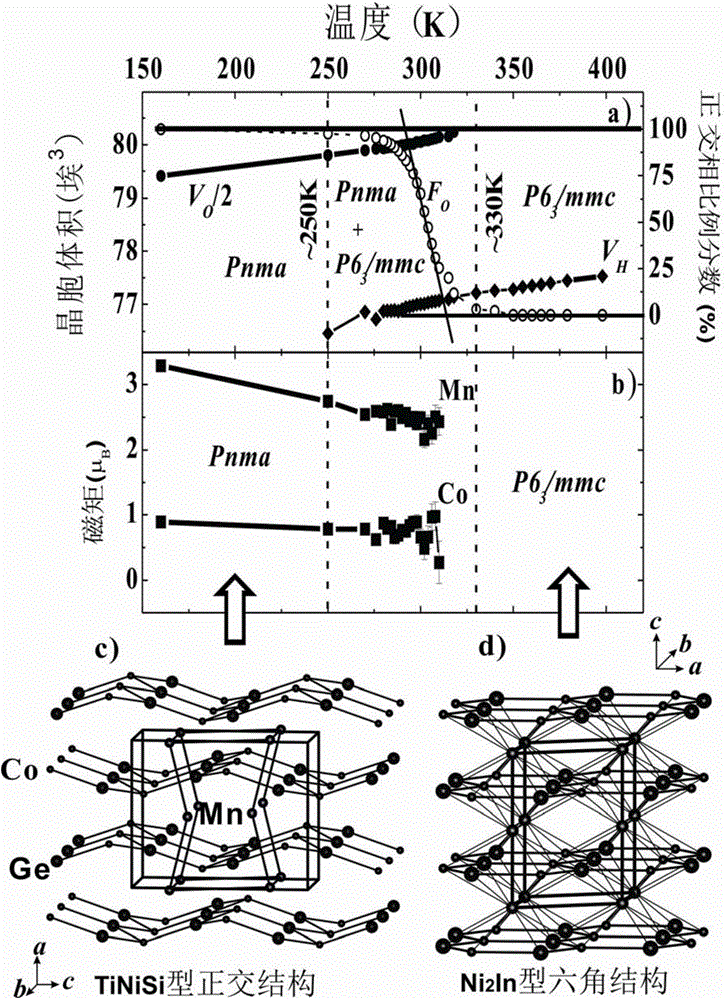

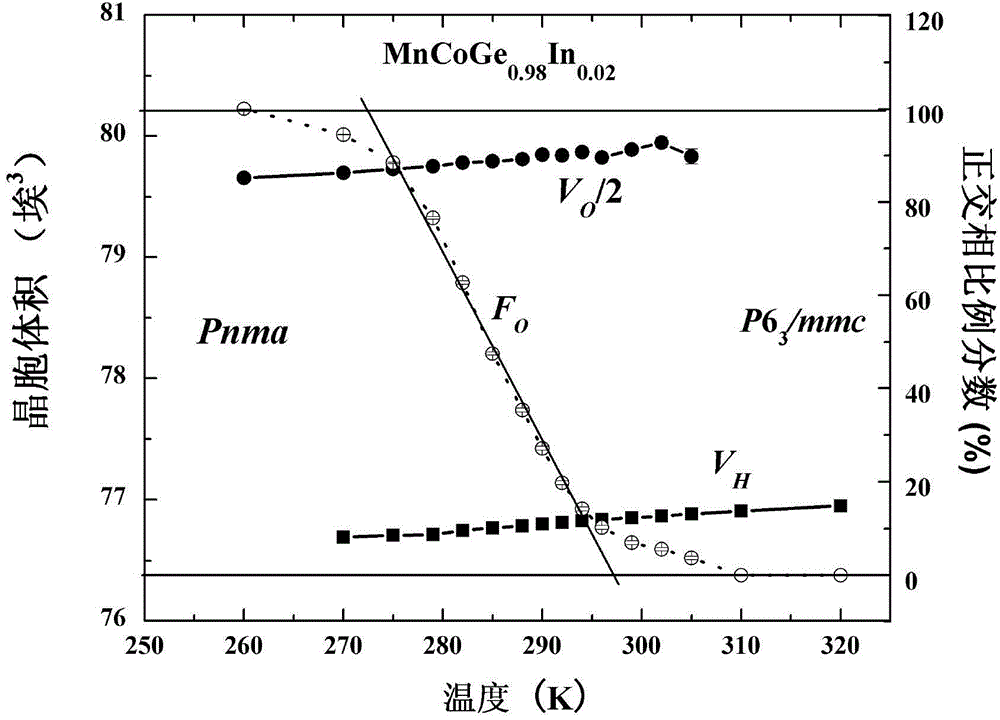

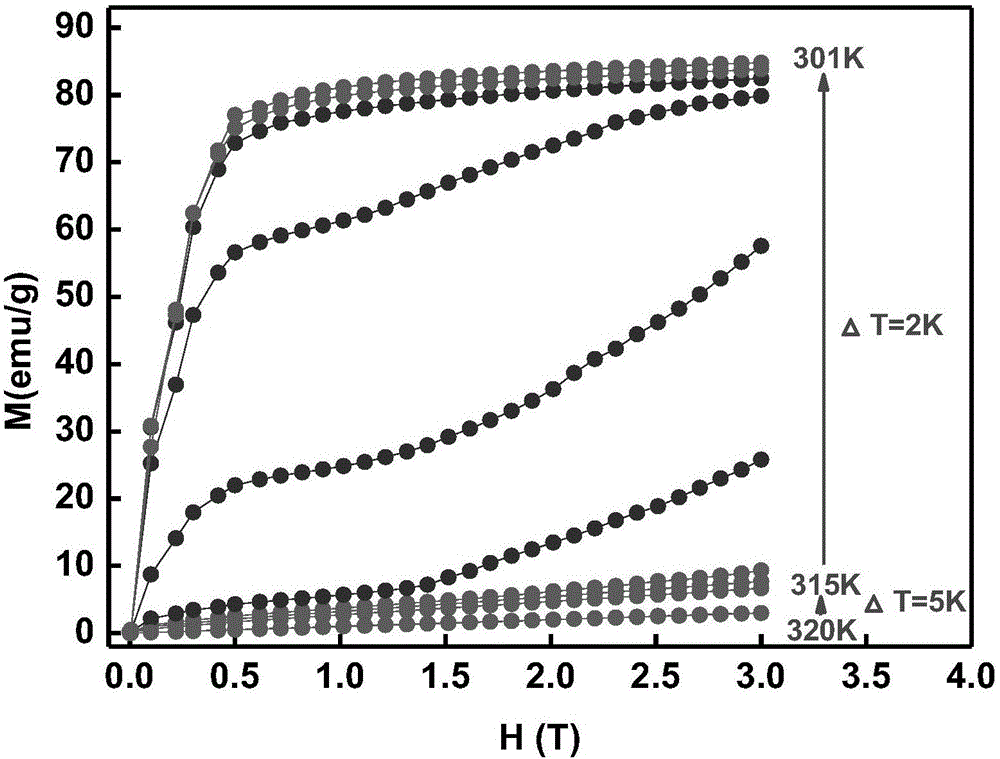

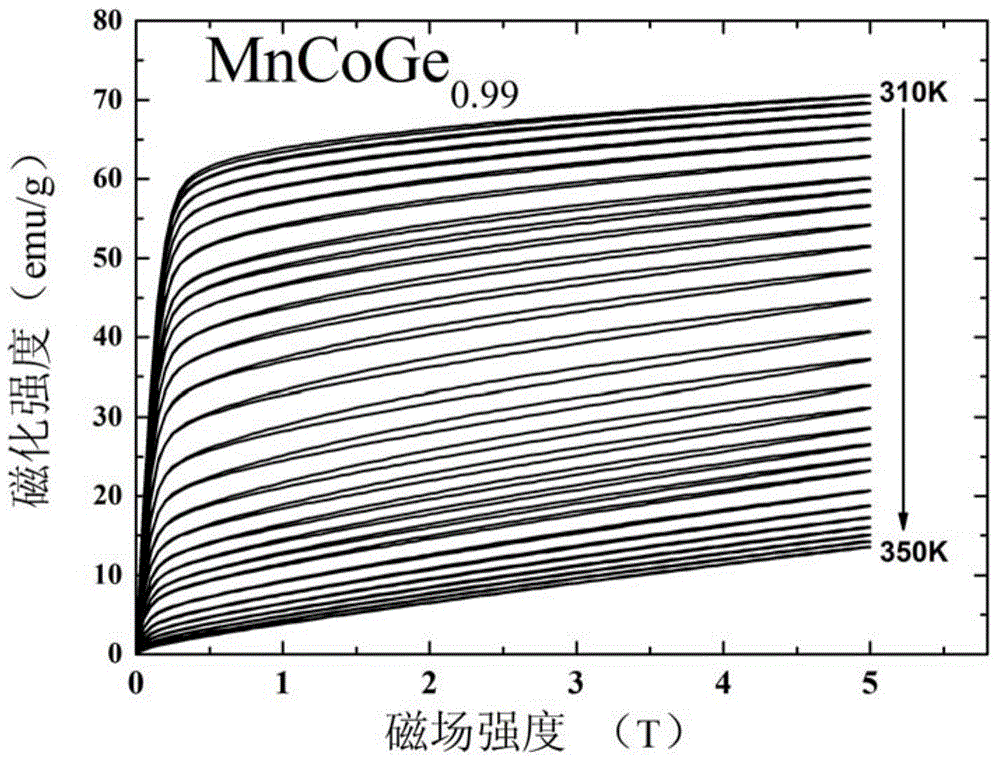

MnCoGe-based magnetic material with giant piezocaloric effect as well as preparation method and application thereof

ActiveCN104946954AReduce manufacturing costReduce dependenceMagnetic materialsThermoelectric devicesStructural phaseCoupling

The invention provides a MnCoGe-based magnetic material with a giant piezocaloric effect as well as a preparation method and application thereof. A chemical general formula of the MnCoGe-based magnetic material is MnCoGe1-xInx, wherein x is more than 0 and less than or equal to 0.03, and the MnCoGe-based magnetic material has a Ni2In type hexagonal structure. The MnCoGe-based magnetic material has the characteristic that martensitic structural phase transition and magnetic phase transition are coupled, and coupling is carried out at the temperature close to room temperature. The MnCoGe-based magnetic material shows an adverse piezocaloric effect under the action of pressure, the amplitude of entropy change under the action of pressure of 3kbar and at the temperature close to room temperature is at least 50J / (Kg.K). Along with change of In content, the magnetic structure coupling temperature Tmstru of the material is adjustable at a wide temperature region close to room temperature, so that the giant piezocaloric effect appears in the wide temperature region close to room temperature. The MnCoGe-based magnetic material has the advantages of simple preparation method, green and environmental-friendly raw materials, high efficiency and energy conservation.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

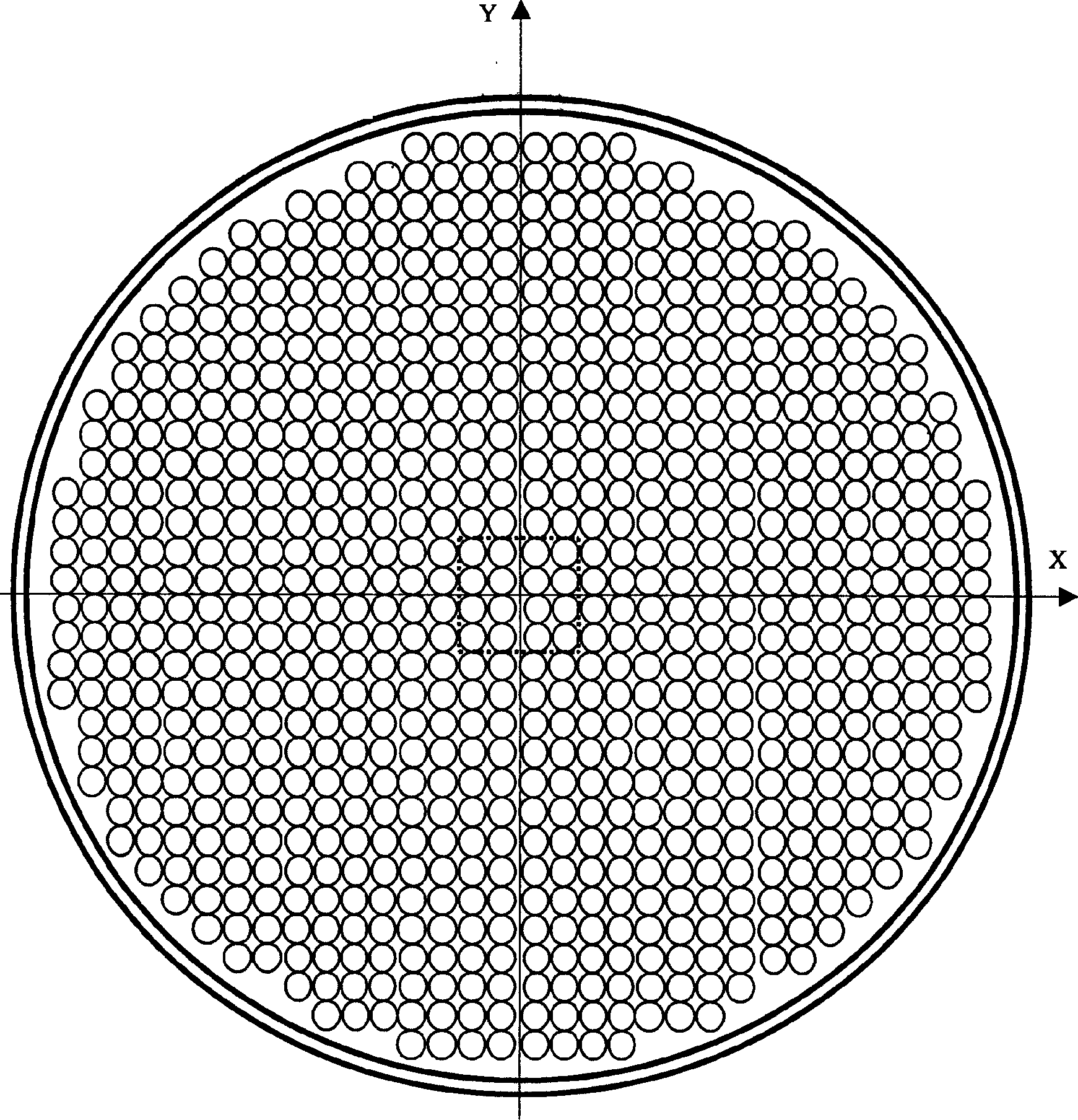

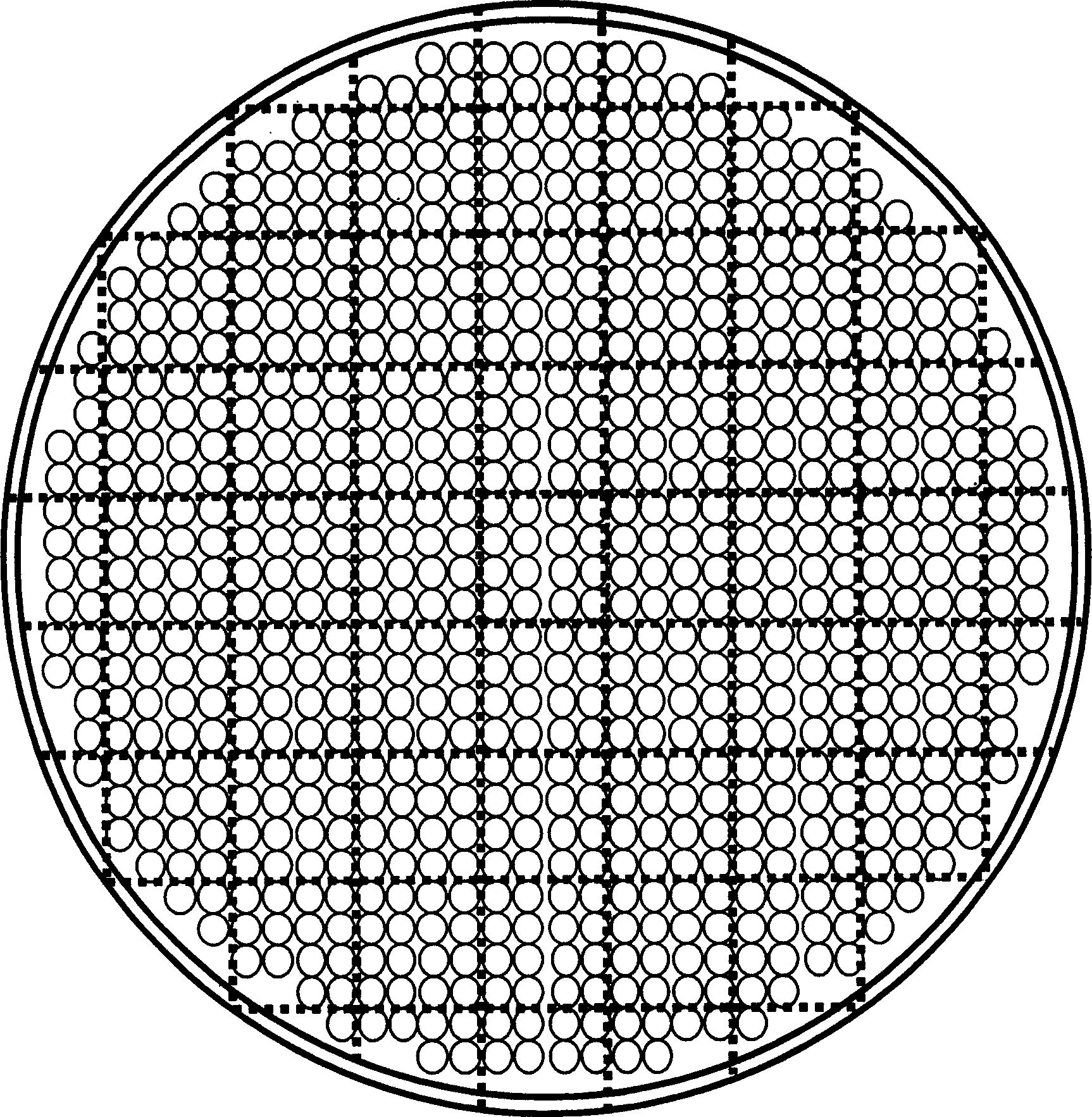

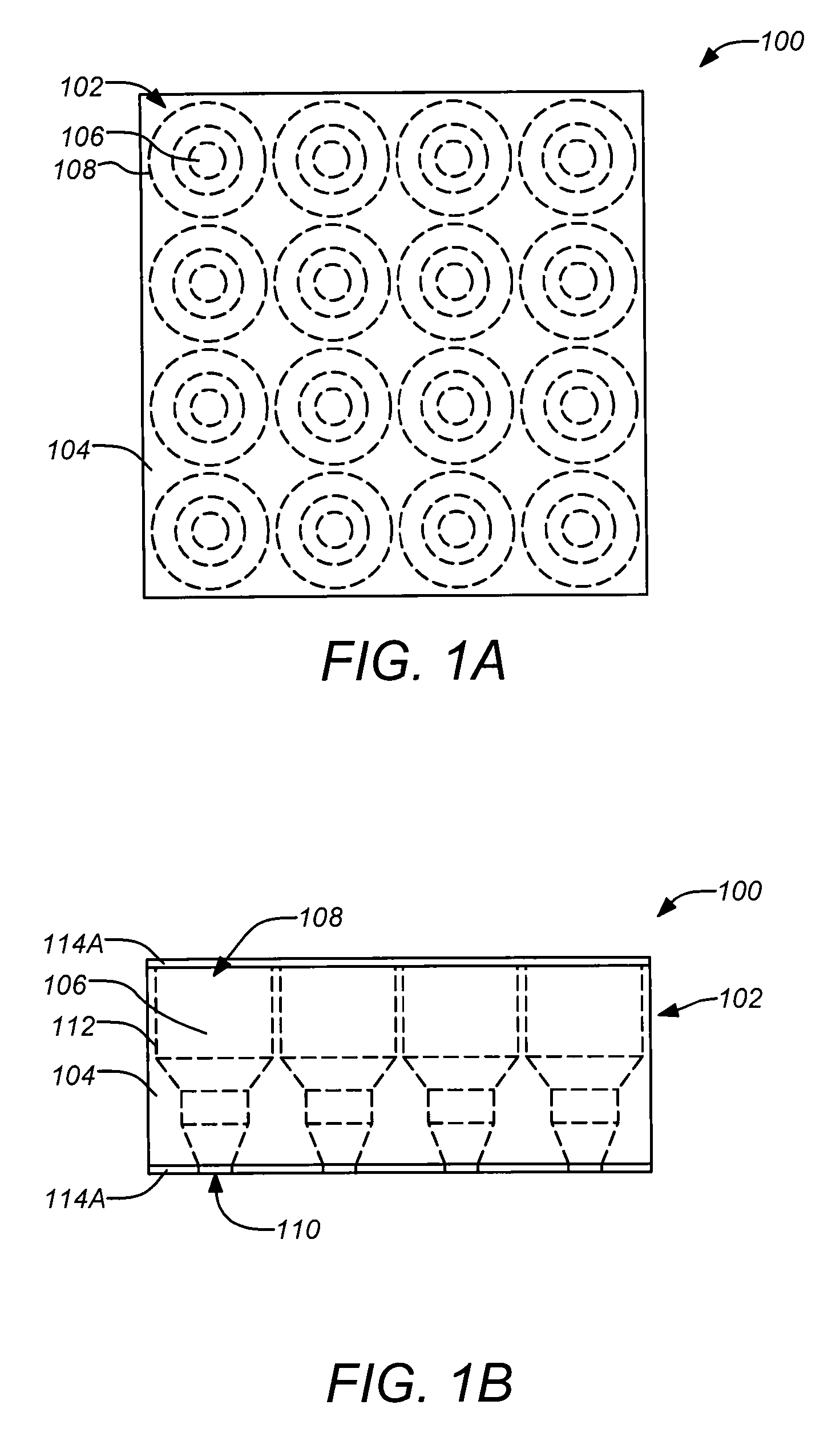

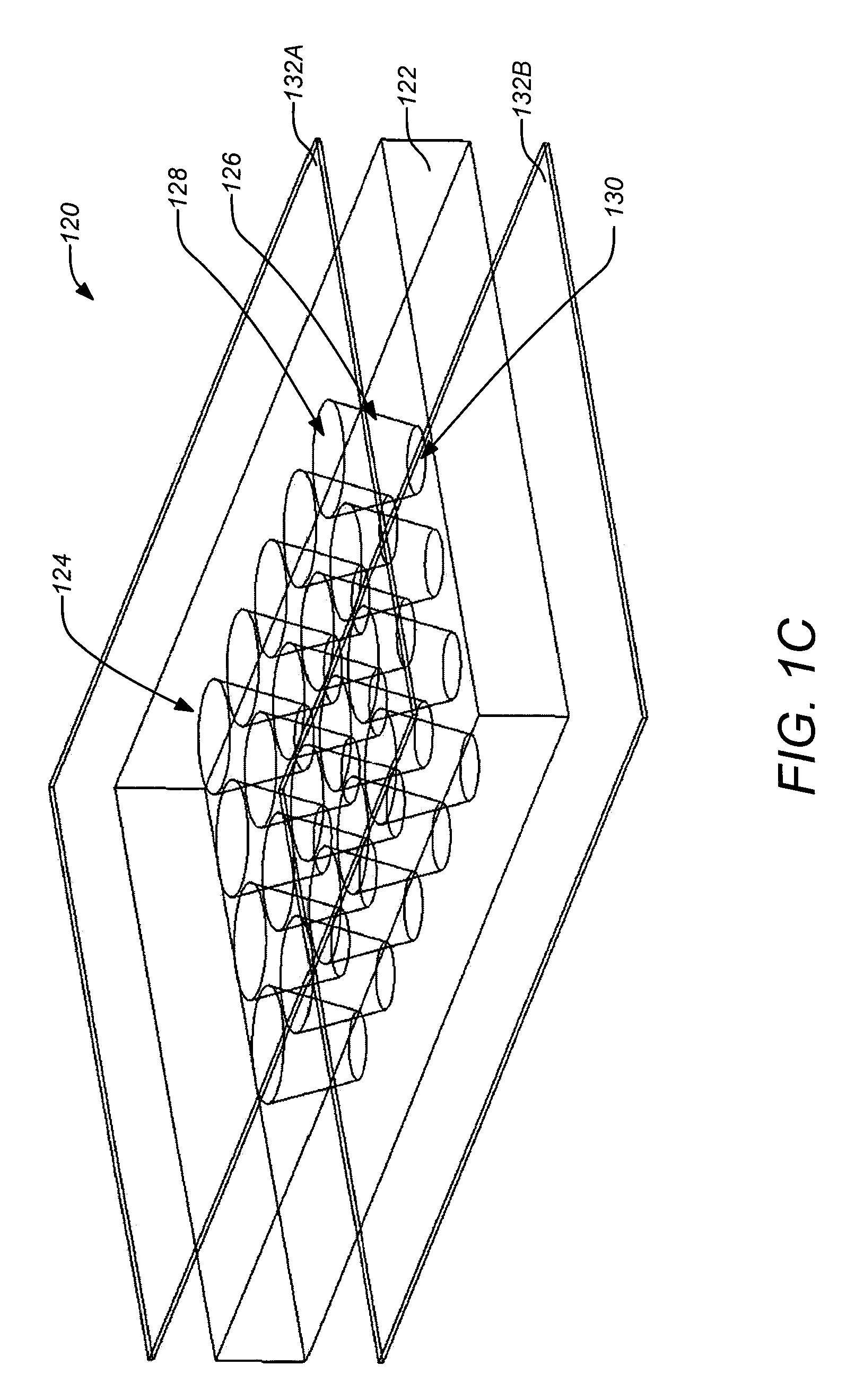

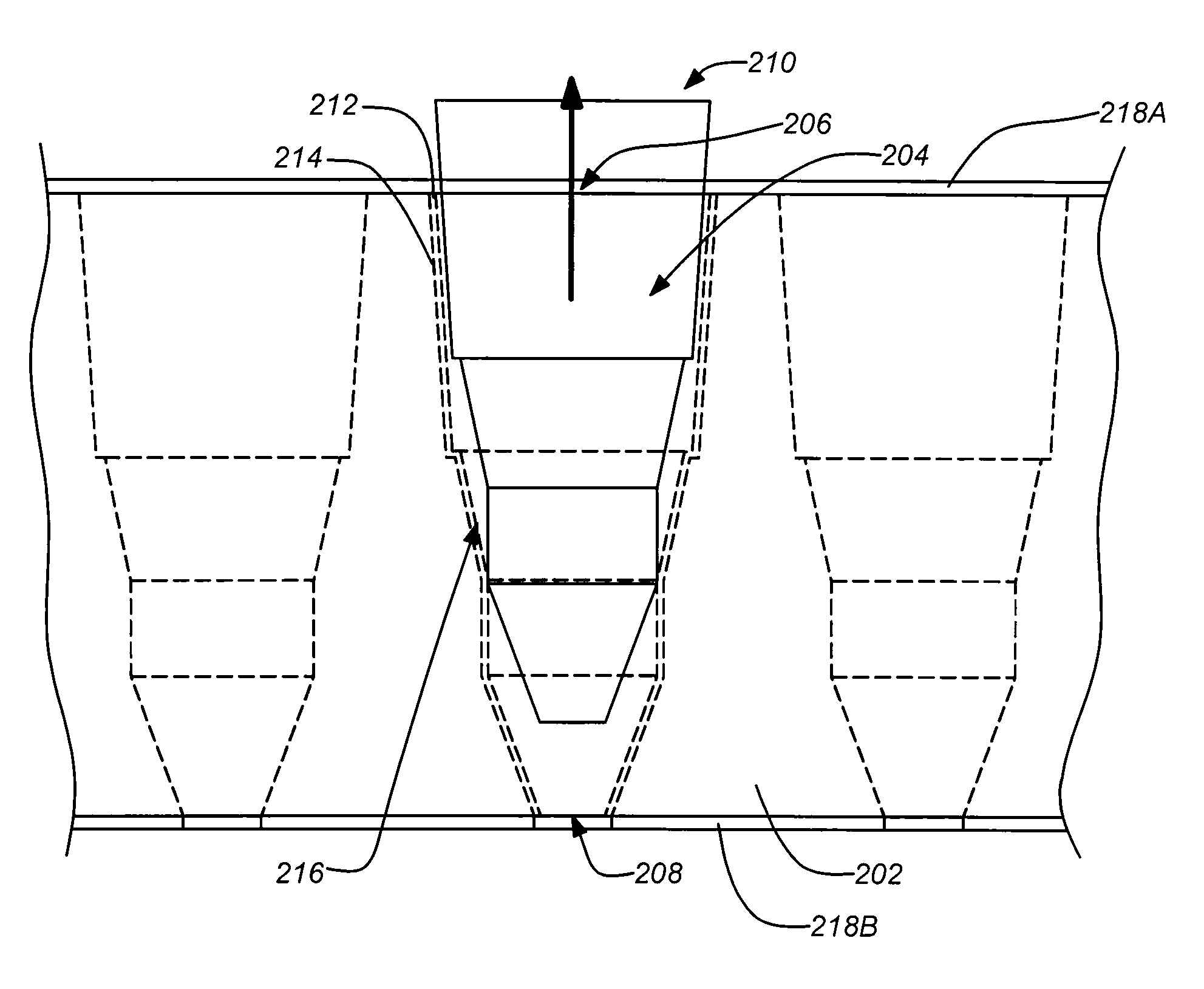

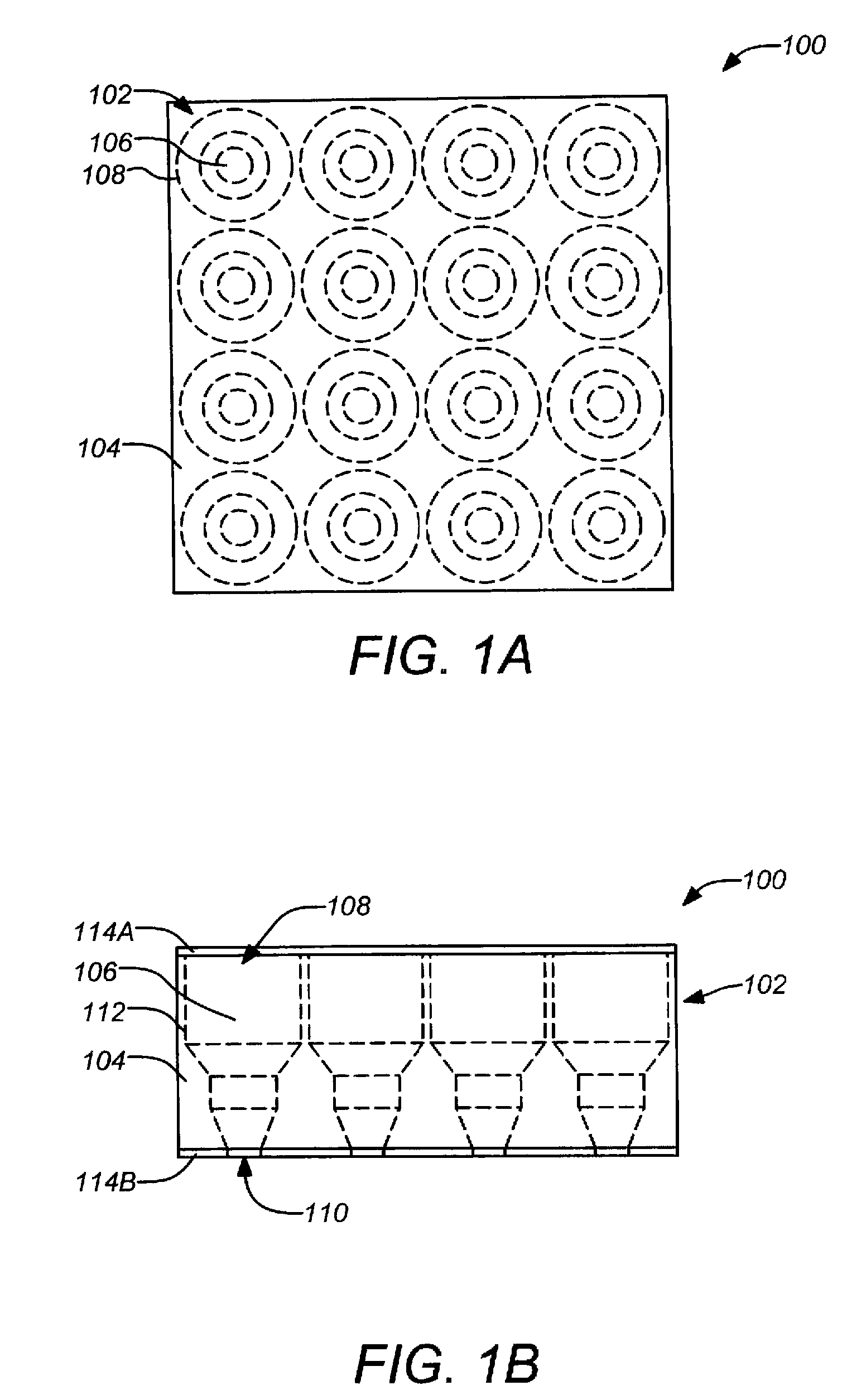

Structural feed aperture for space based phased array antennas

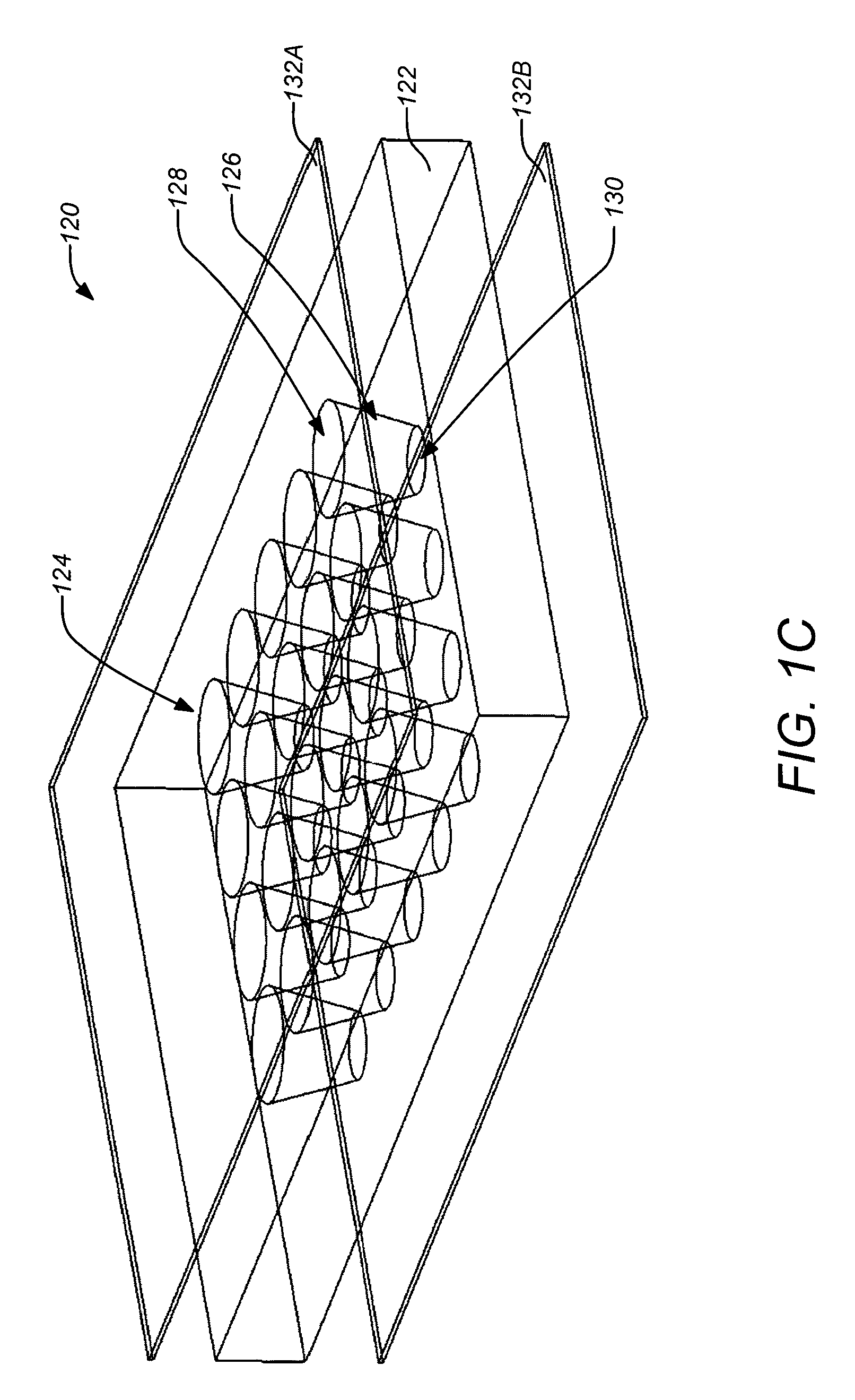

InactiveUS20090184881A1Low costReduce volumeAntenna arraysAntenna adaptation in movable bodiesStructural phaseEngineering

A structural phased array antenna and method for manufacturing are disclosed. An integrated structural antenna aperture can be used to reduce net weight, cost, and volume where an array of antenna elements are incorporated into a structural member, e.g. in a spacecraft. A structural material layer, such as a structural foam, may be used with the array of individual antenna element cavities machined into the layer. The antenna element cavities are lined with a conductive material, such as plated aluminum. Facesheets may be bonded to the front and / or backside of the structural material layer in order to increase strength and / or stiffness using an RF transparent material. The array of antenna elements may be coupled to filters at the back side of structural material layer.

Owner:THE BOEING CO

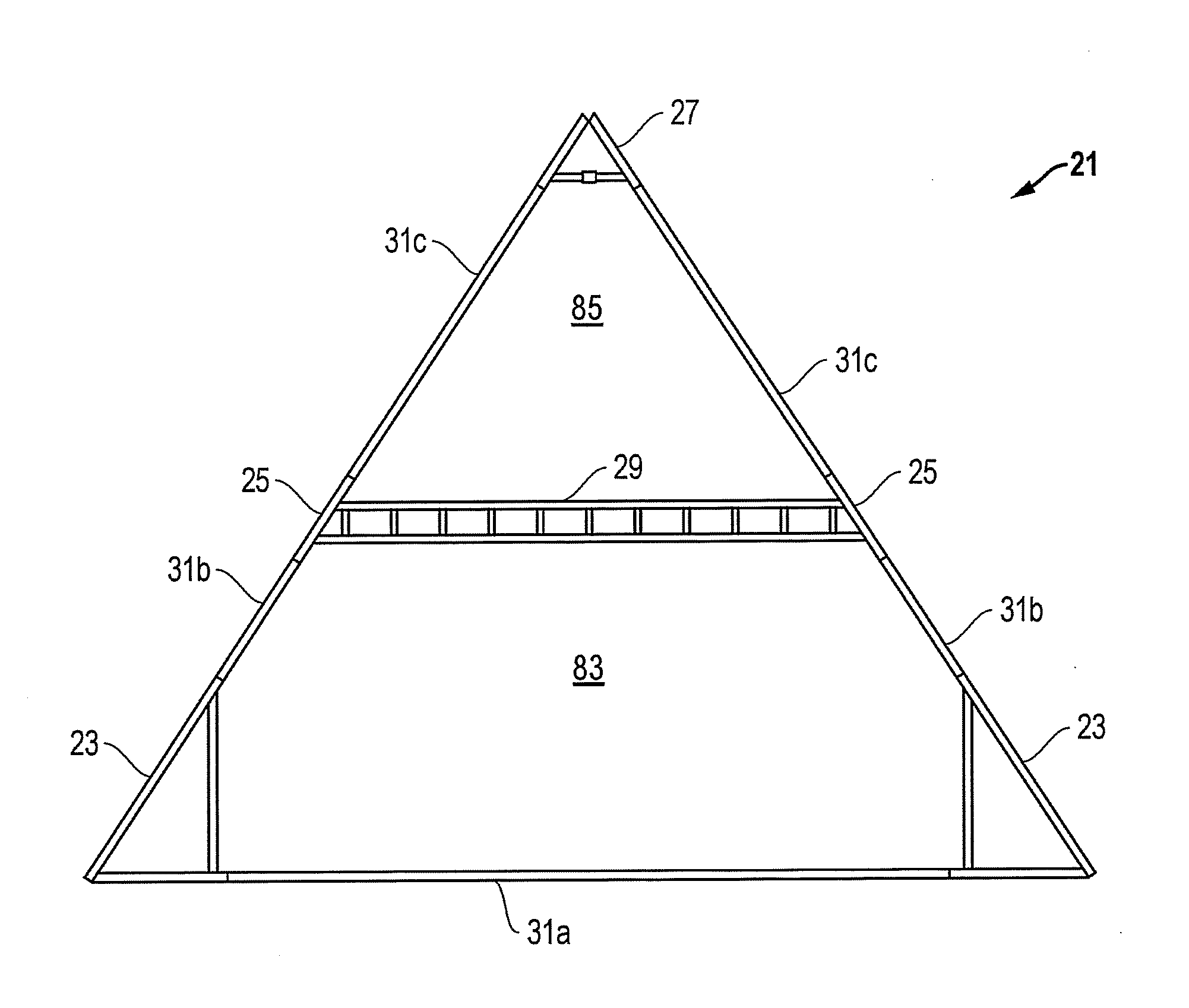

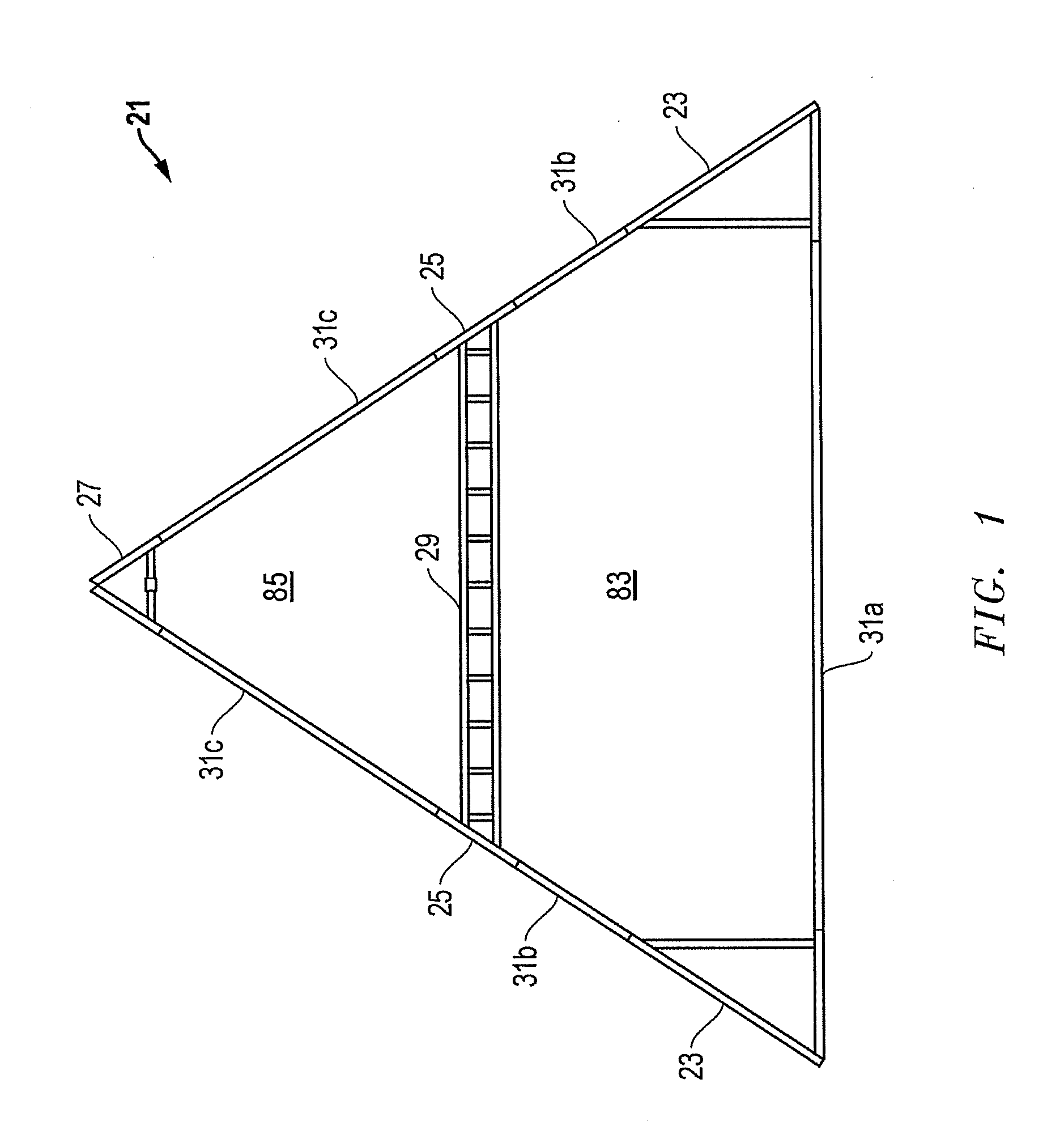

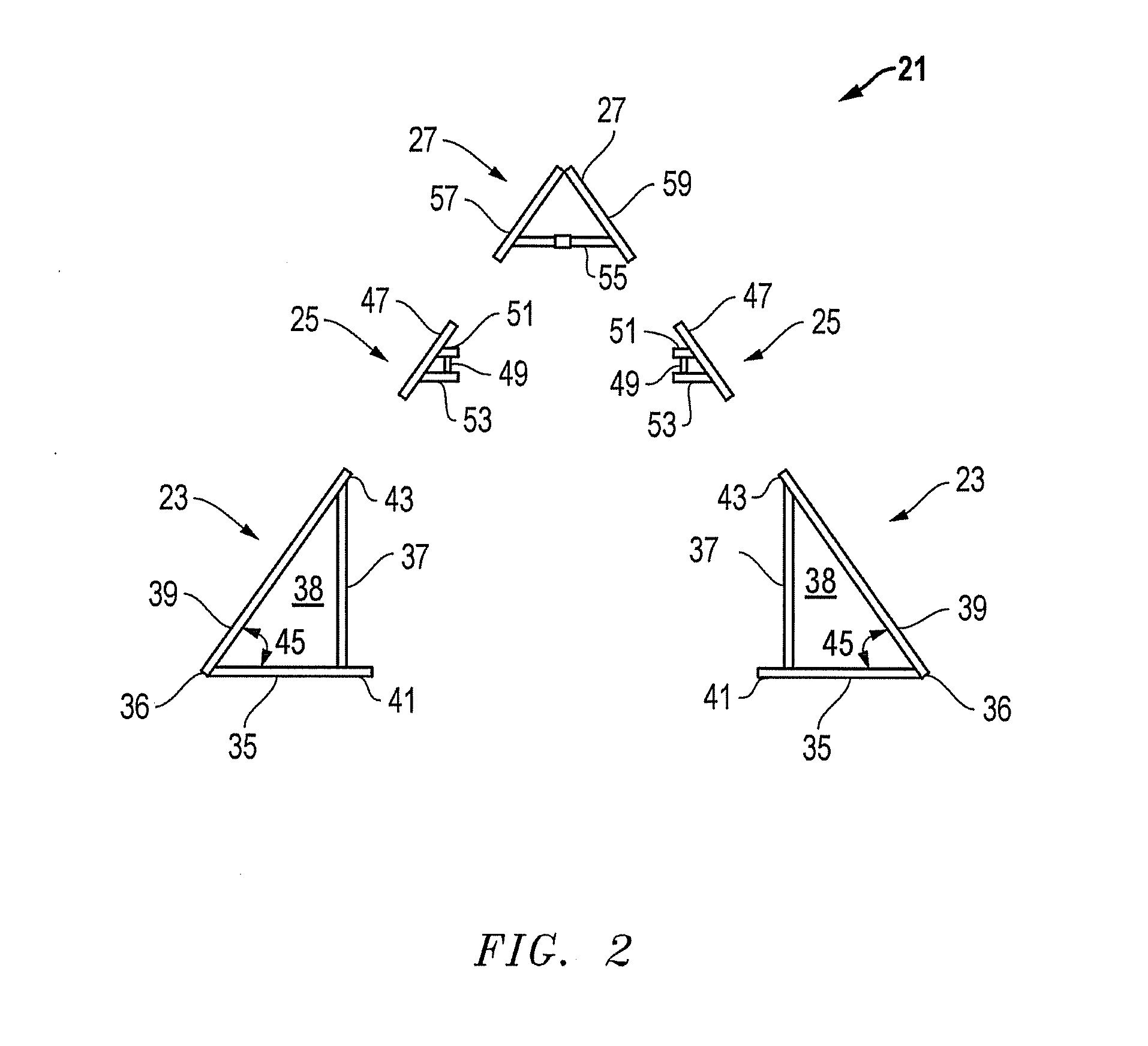

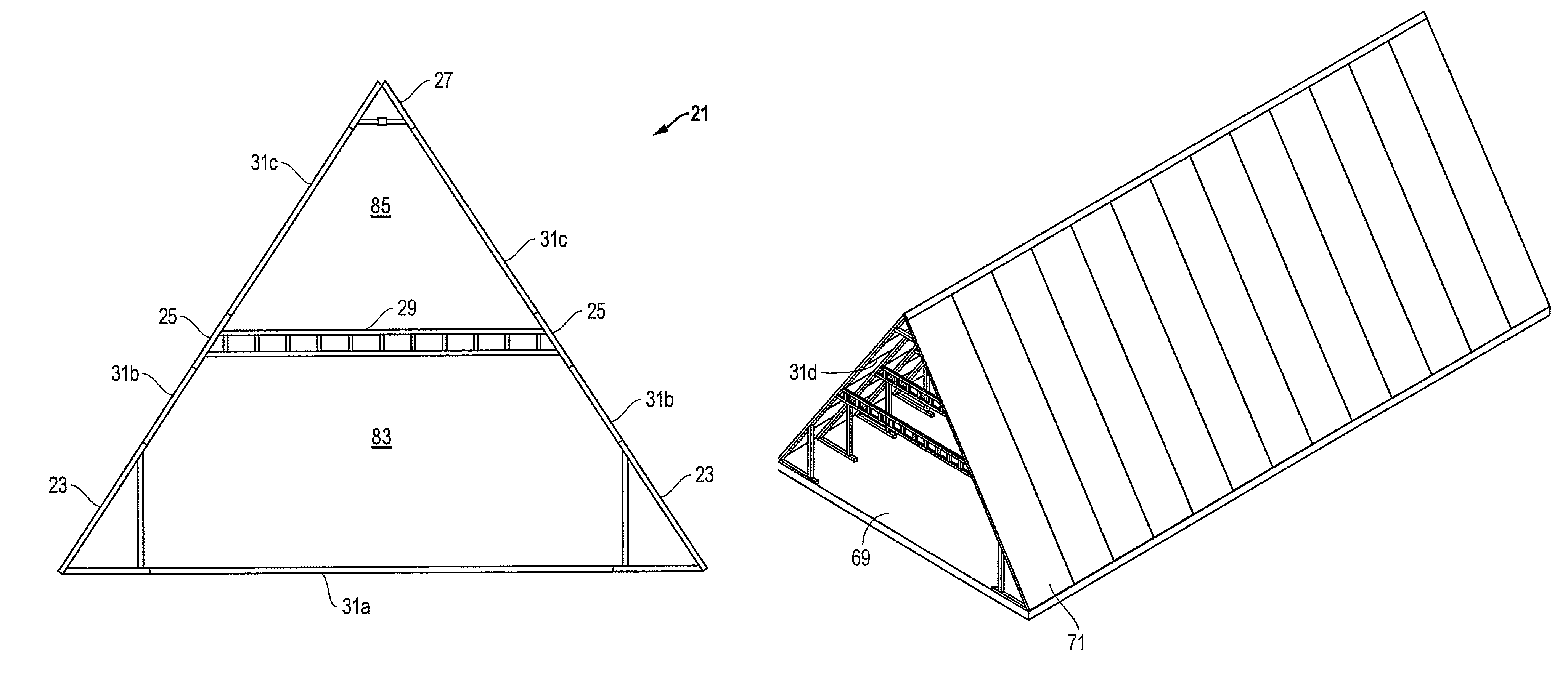

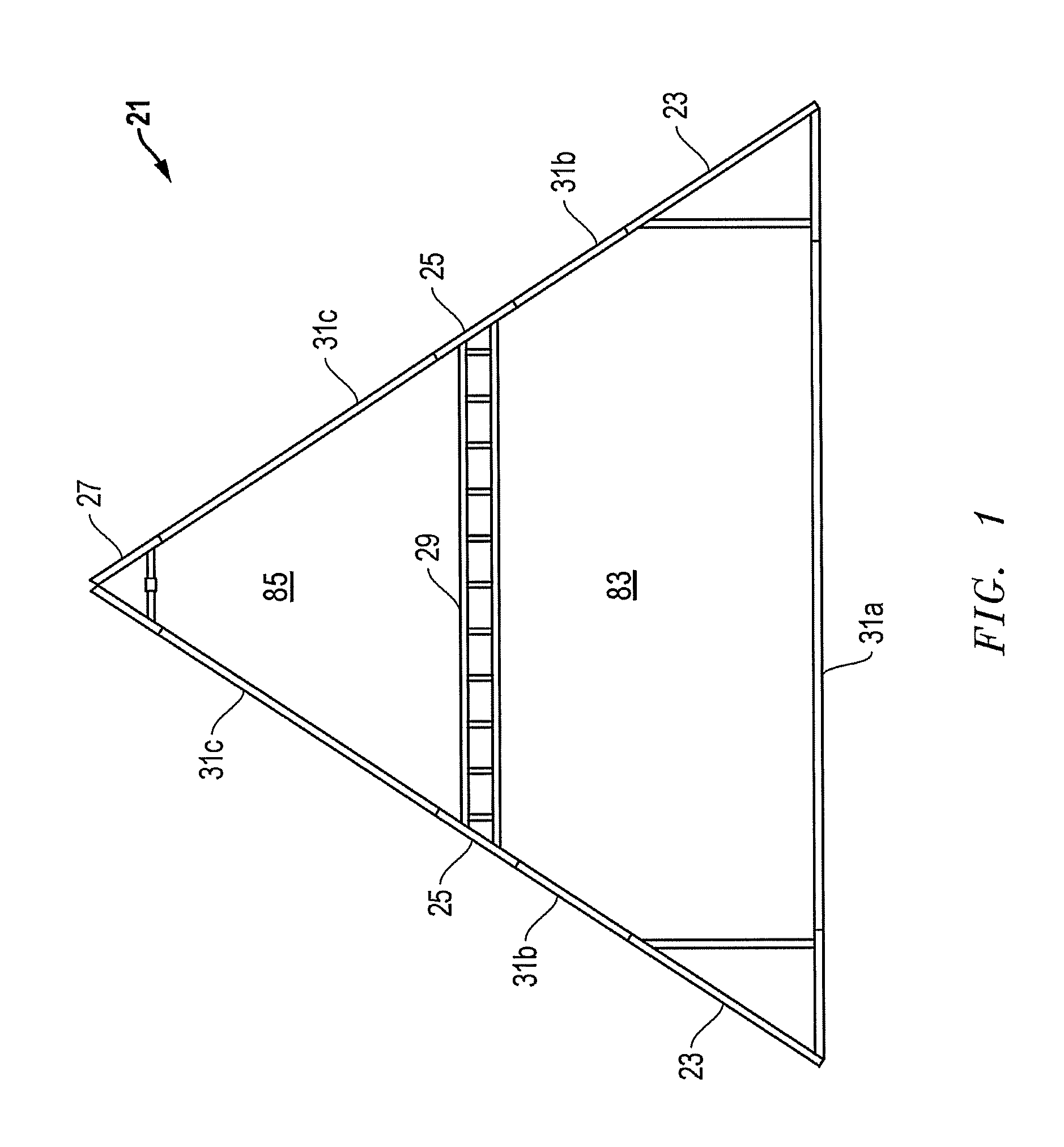

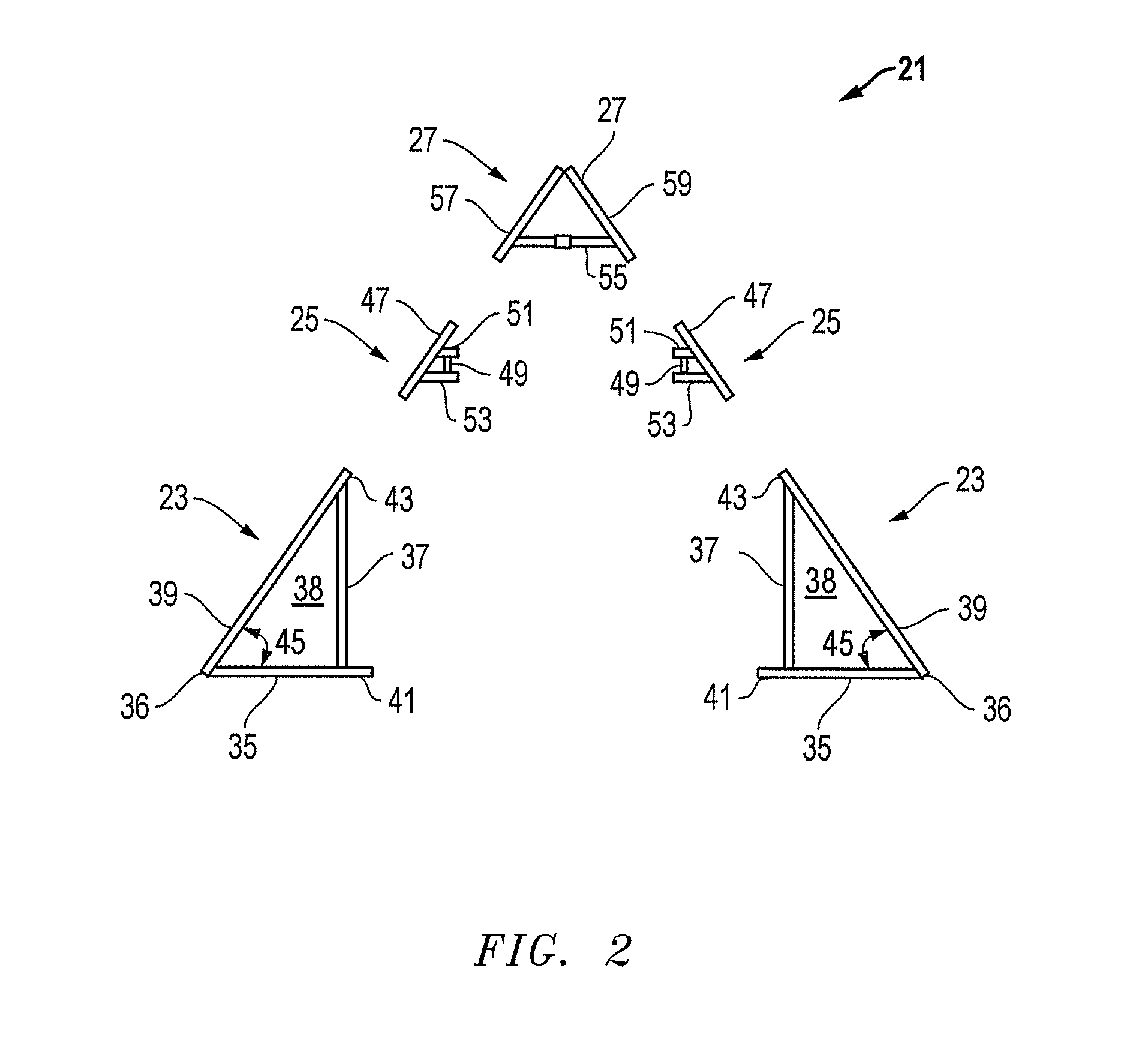

System, method, and apparatus for frame assembly and building

An A-frame assembly for constructing a building comprises only five major components that are formed from square, galvanized steel hollow tubing. These components include corner braces, side braces, a top brace, beams, and straight tubing. The straight tubing interconnects the other components to form a triangular frame assembly. The corner braces are secured with concrete footings or a complete foundation. A number of the frame assemblies are arrayed to form the basis of a structure. The frame assemblies are spaced apart from each other, joined with additional square tubing, and include an attic space and service spaces between the corner braces. A roofing structure is secured to the joined frame assemblies to complete the structural phase of the assembly.

Owner:BOATWRIGHT GARRY

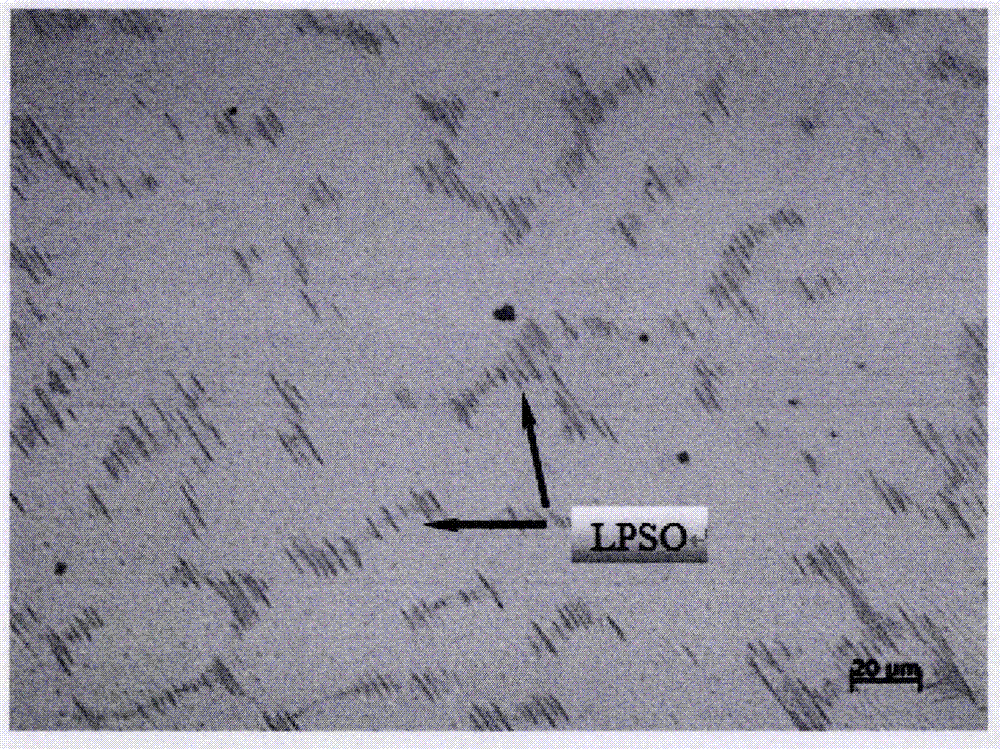

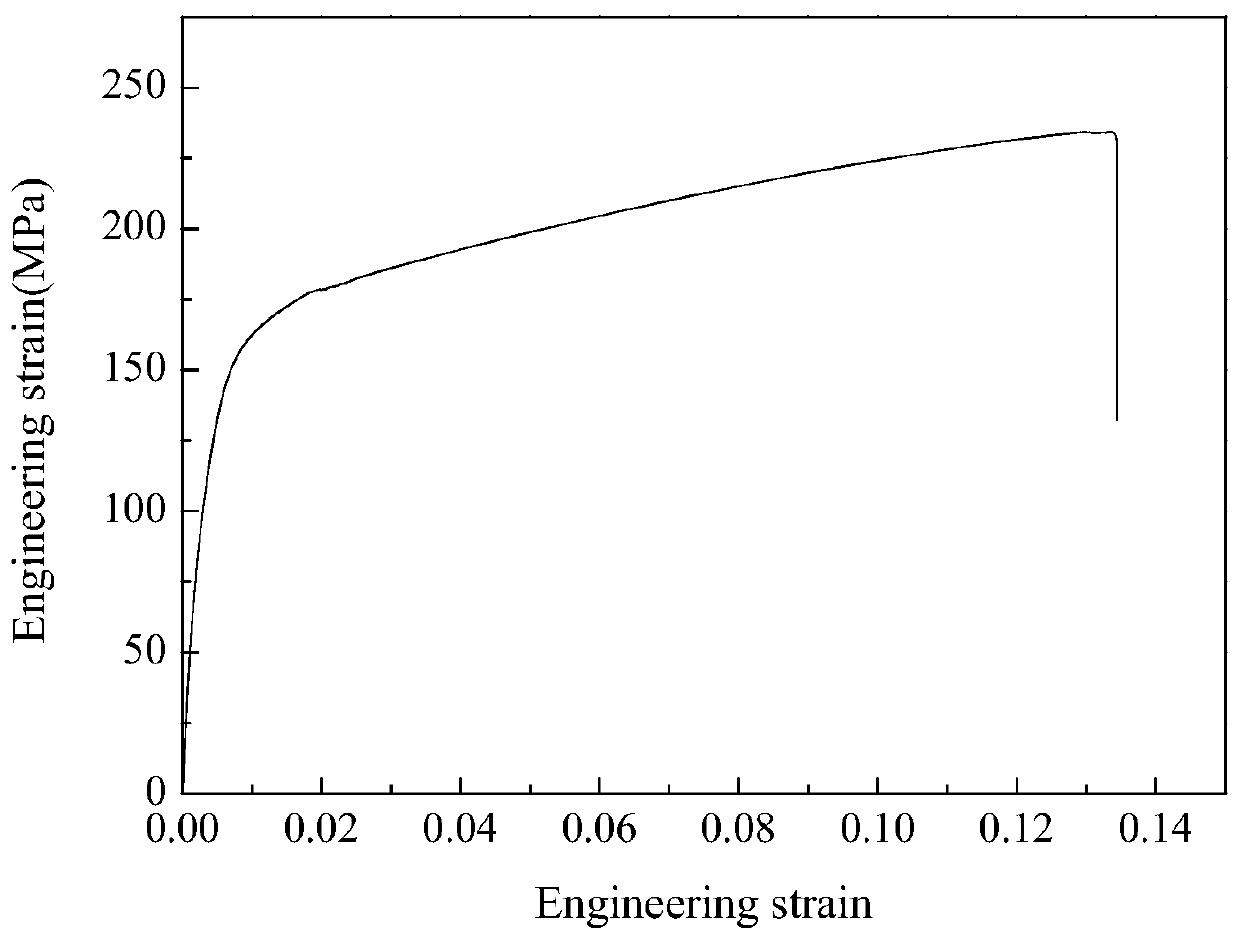

Method for improving room-temperature ductility of LPSO structural phase-containing Mg-RE-Zn system alloy

The invention discloses a method for improving the room-temperature ductility of an LPSO structural phase-containing Mg-RE-Zn system alloy, and belongs to the field of thermal treatment of metal and phase change. The method comprises the following steps: carrying out two-stage homogenizing treatment on the cast-state Mg-RE-Zn system alloy for 24 hours under a condition of 480 + / - 10 DEG C and for 32 hours under a condition of 500 + / - 5 DEG C, then cooling the alloy to 460 to 480 DEG C in a furnace, and preserving the heat for 2 hours and 10 minutes, thus obtaining the needle type LPSO structural phase-containing Mg-RE-Zn system alloy. According to the Mg-RE-Zn system alloy prepared through the method disclosed by the invention, under a condition of small change amplitude of the mechanical strength of a material, the percentage elongation of fracture of the material is obviously improved, namely the room-temperature ductility is obviously improved.

Owner:BAOJI TITANIUM IND +1

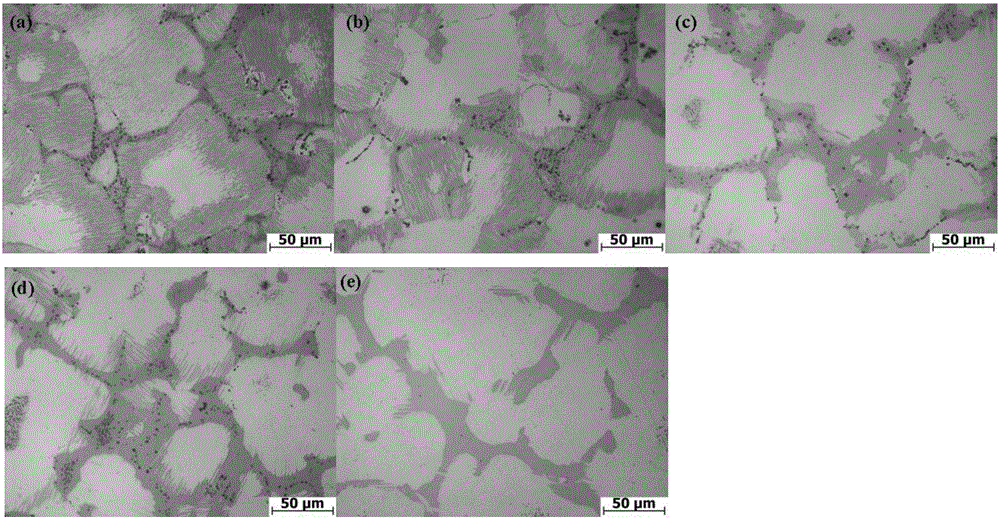

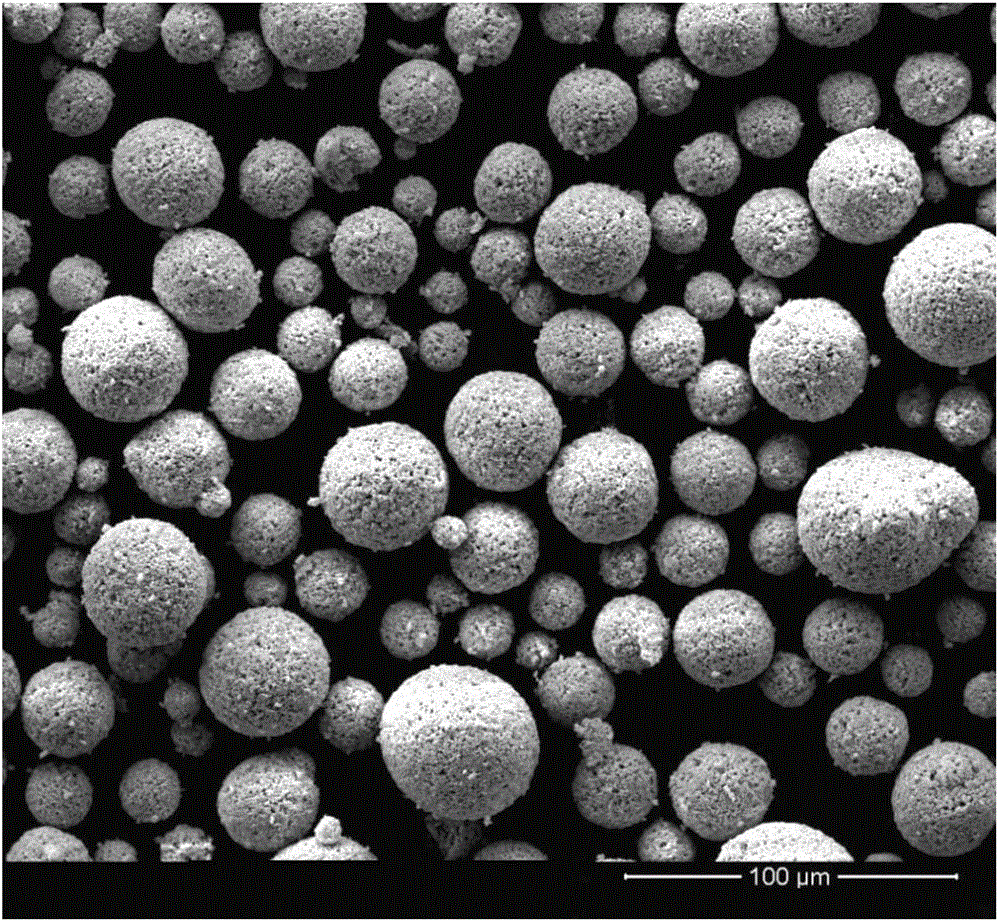

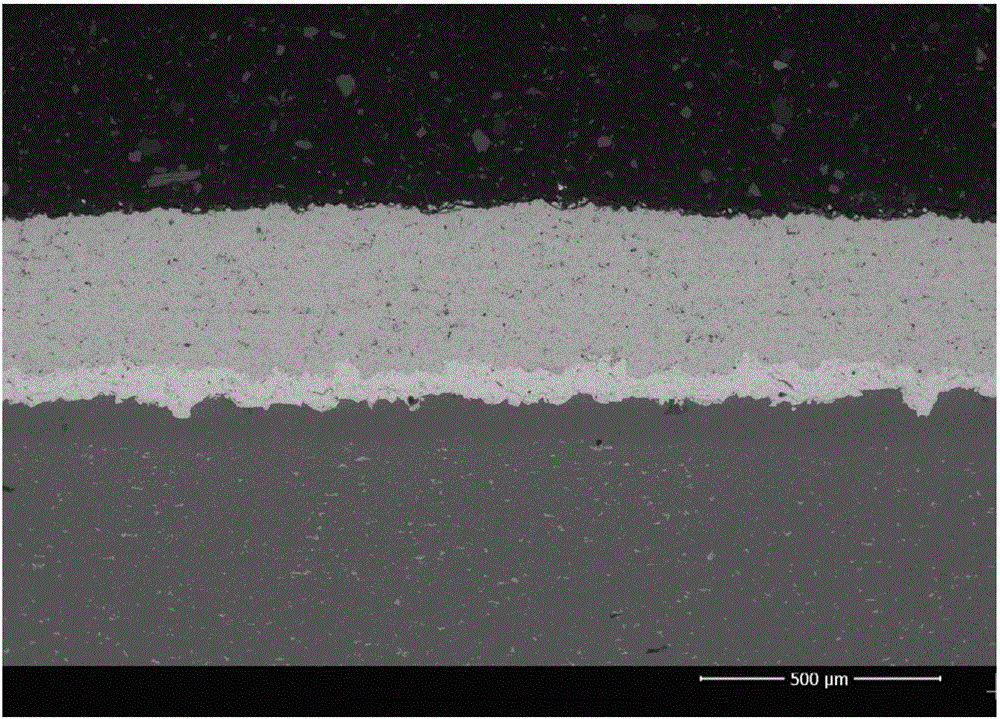

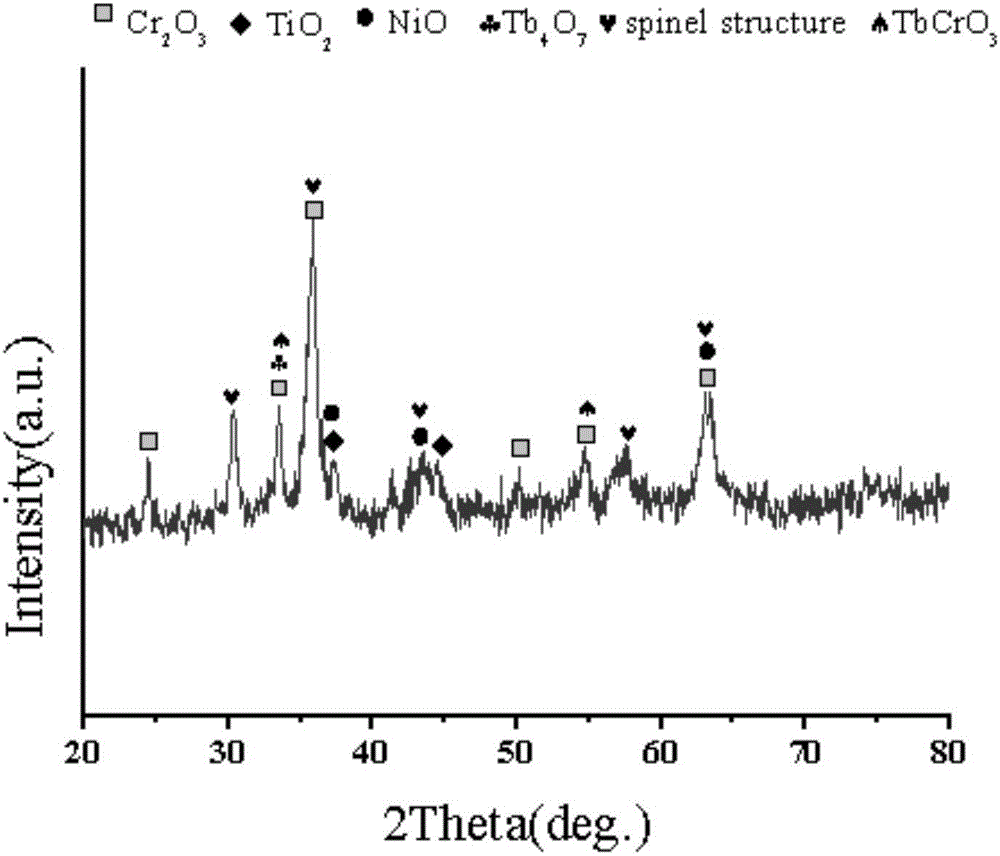

Chromic oxide-titanium oxide based high-temperature and high-emissivity coating and preparation method thereof

InactiveCN105861972AGood sphericityMeet the requirements of plasma sprayingMolten spray coatingThermal sprayingStructural phase

The invention discloses a preparation method of a chromic oxide-titanium oxide based high-temperature and high-emissivity coating and belongs to the technical field of thermal spraying. According to the preparation method, compound powder which is subjected to doping modification with rare earth oxide and contains multiple uniformly distributed oxides is prepared through agglomerating granulation; the compound powder is put in a muffle furnace and subjected to high-temperature sintering densification, dense organic-solvent-free powder with a spinel structural phase is obtained, and the advantageous feature of oxygen cavity defect filling of the rare earth oxide is played. The chromic oxide-titanium oxide based high-temperature and high-emissivity coating is prepared through plasma spraying, the generation of the spinel structural phase in the powder is promoted, and the stability of the coating keeping higher emissivity at the high temperature is improved. The compound powder has better degree of sphericity, the flowing property is 30-60 s / 50 g, and the apparent density is 1.0-3.0 g / cm<3>; the bonding strength of the prepared chromic oxide-titanium oxide based high-temperature and high-emissivity coating is higher than or equal to 20 MPa, and the emissivity at the temperature of 400-600 DEG C is higher than or equal to 0.88.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

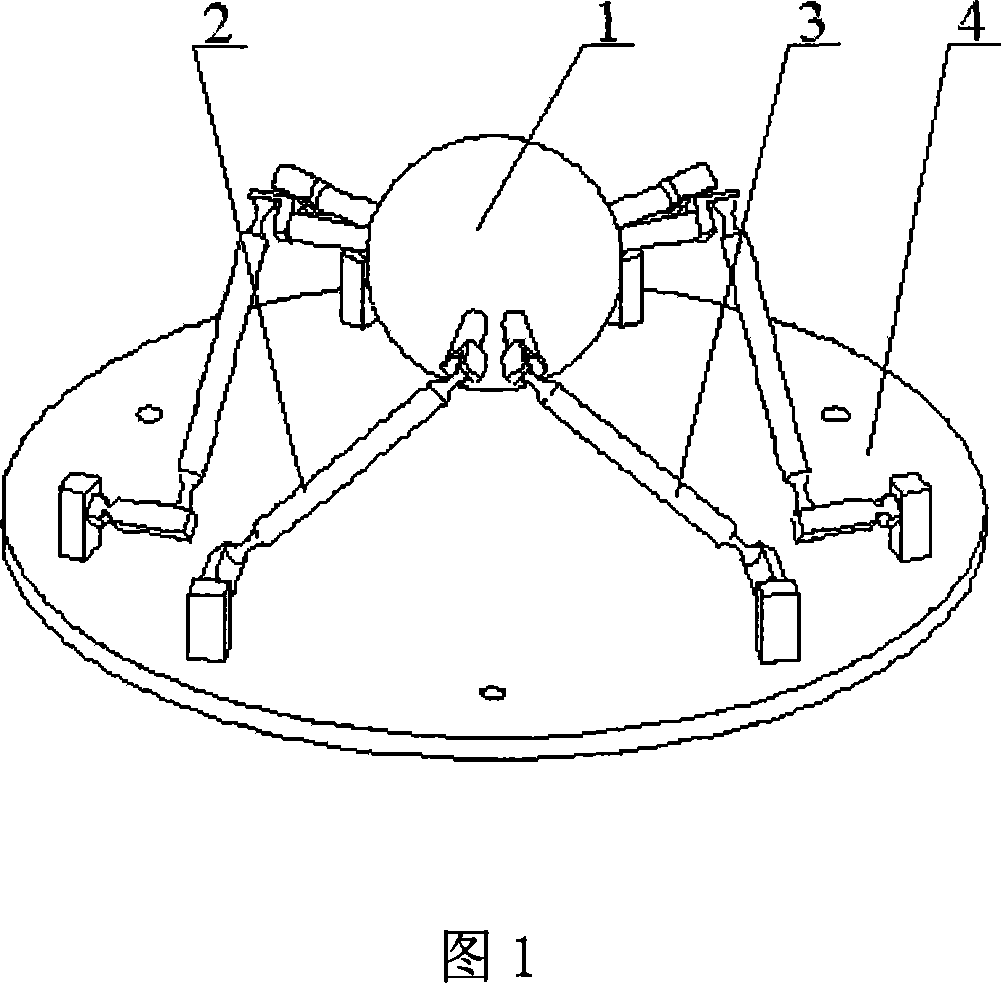

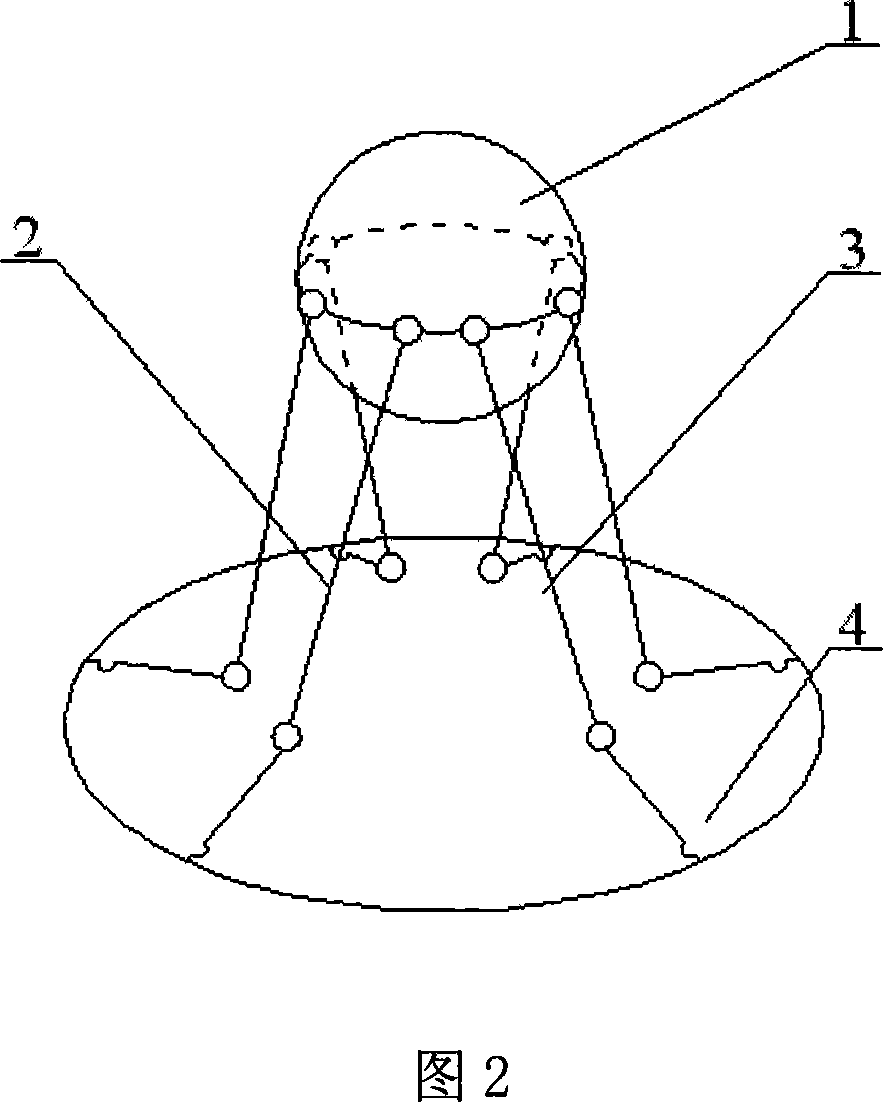

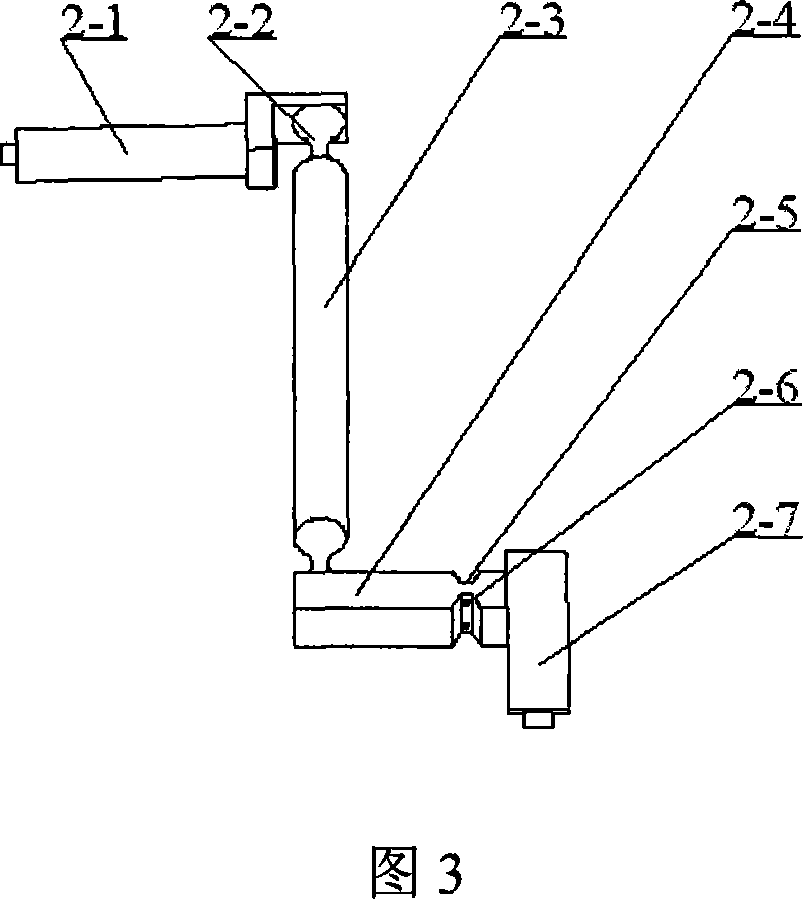

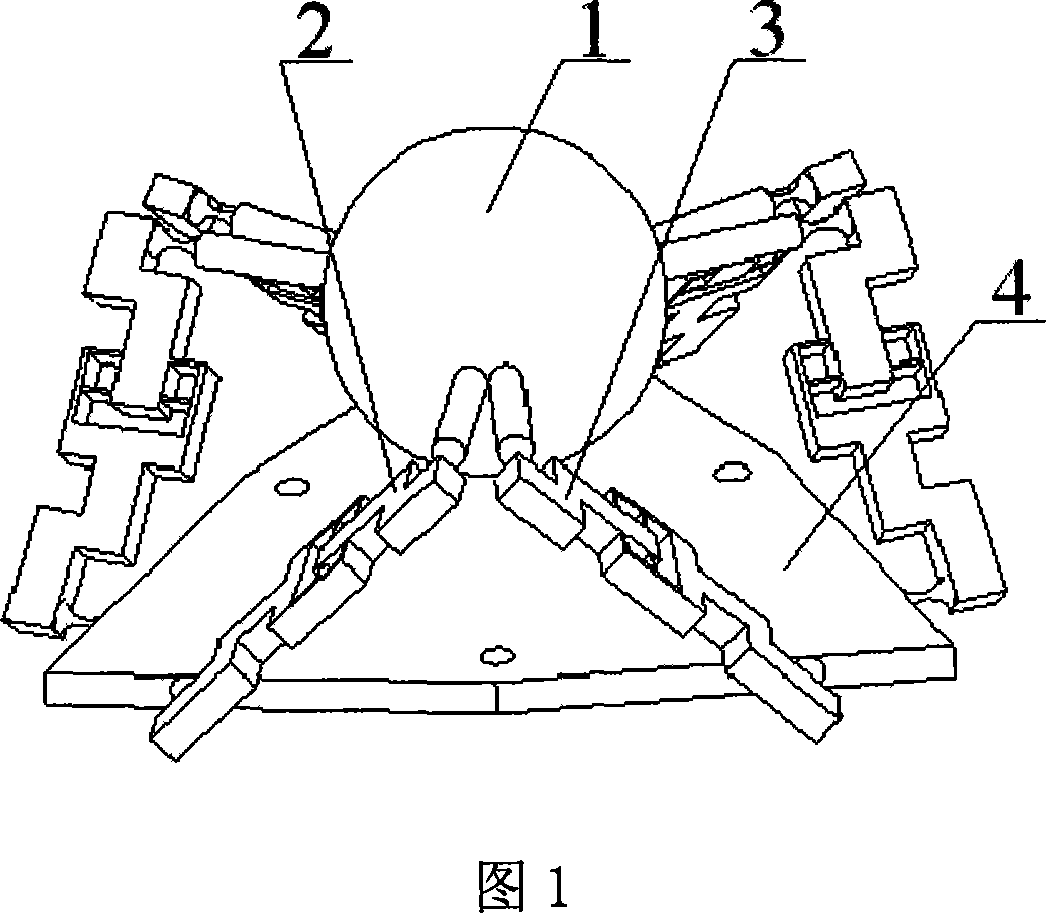

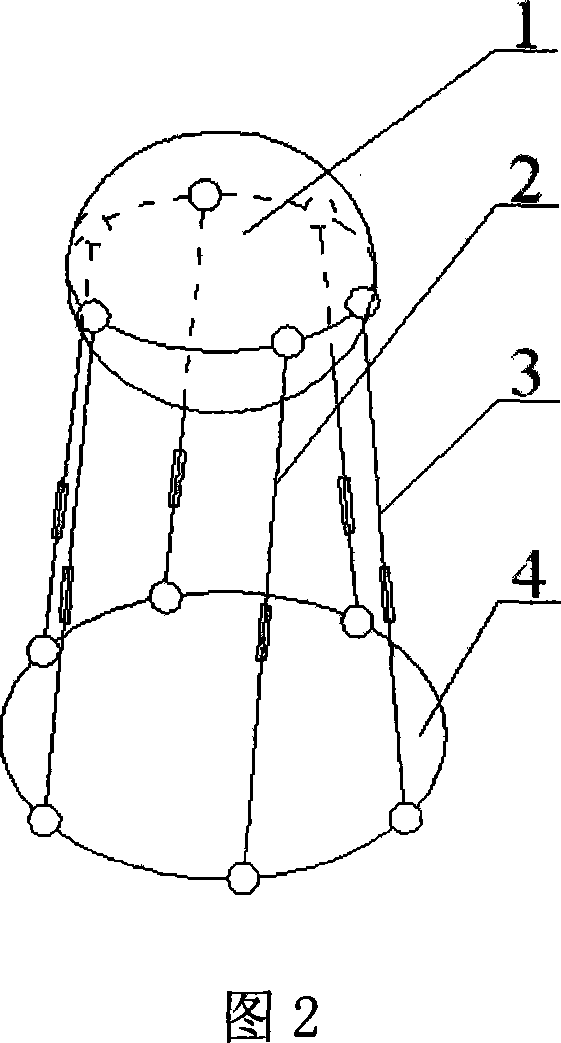

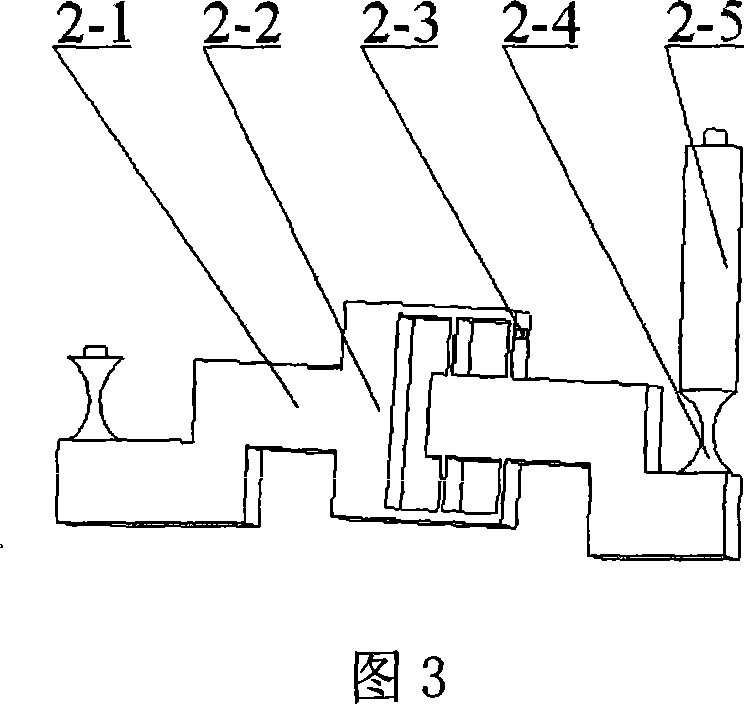

Six dimensional RSS acceleration transducer

InactiveCN101034096AThe theoretical design error is smallQuick responseAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsElastomerStructural phase

This invention disclose a 6 dof perpendicularity discoupling RSS acceleration transducer, the characteristic: inertial platform (1) join with fixed platform (3) by 3 groups branched chain, each group branched chain include Left Side branched chain ( 2) and right side branched chain ( 3) left and right branched chain have same structural phase but different gesture. Branched chain at fixed platform (4) submit circle symmetry disposal. Each strip branched chain (2) has two elasticity sphere deputy (2 - 2) and one elasticity turn deputy ( 2 - 5). on top of turn deputy perch (2-4), there has elasticity turn deputy ( 2-5) that cross section is rectangular. two surface of elasticity turn deputy (2 - 5) adhibit strain gauge ( 2 - 6). The elastomer in this invention quite right respond to corresponding parallel institution mechanical model, has normal and adult design philosophy, thus theoretical design error is smallness;owing to institution model possess favorable discoupling quality, the sendout synthesizing and decomposition algorithm are simplicity, response quickly; And has good isotropy.

Owner:YANSHAN UNIV

Layered lithium metal oxides free of localized cubic spinel-like structural phases and methods of making same

The present invention includes substantially single-phase lithium metal oxide compounds having hexagonal layered crystal structures that are substantially free of localized cubic spinel-like structural phases. The lithium metal oxides of the invention have the formula LialphaMbetaAgammaO2, wherein M is one or more transition metals, A is one or more dopants having an average oxidation state N such that +2.5<=N<=+3.5, 0.90<=alpha<=1.10, and beta+gamma=1. The present invention also includes dilithiated forms of these compounds, lithium and lithium-ion secondary batteries using these compounds as positive electrode materials, and methods of preparing these compounds.

Owner:UMCORE

Integrally-extruded honeycomb catalyst for selective catalytic reduction (SCR) smoke denitration and preparation process of catalyst

InactiveCN102886266AEasy to shapeHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsStructural phaseDesorption

The invention discloses an integrally-extruded honeycomb catalyst for selective catalytic reduction (SCR) smoke denitration. The catalyst consists of the following active ingredients: 65 to 80 percent of titanium dioxide, 5 to 15 percent of ferrous sulfate, 5 to 15 percent of tungsten trioxide, 1 to 4.5 percent of vanadium pentoxide and 0.05 to 0.5 percent of lanthanum nitrate. The catalyst has the advantages of high mechanical strength, wear resistance, long service life and low cost, and the catalyst is easy to form; particularly FeSO4 is added, so that a good catalyzing effect is achieved, and a synergistic effect of FeSO4 and Ti-V-W active ingredients is also achieved; because a La element is added, structural phase transition from an anatase to a rutile is greatly restrained, a phase transition temperature is obviously increased, the catalyst can be calcined at a temperature of 800 DEG C, and the catalyst of an anatase ontology is obtained; and moreover, the catalyst has a good denitration effect, is wide in applicable temperature range, and can help to achieve a desorption efficiency of 60 to 90 percent at the temperature of between 180 DEG C and 450 DEG C.

Owner:山东蓝天节能环保科技有限公司

Structural feed aperture for space based phased array antennas

InactiveUS7948443B2Low costReduce volumeAntenna arraysSimultaneous aerial operationsStructural phaseConductive materials

A structural phased array antenna and method for manufacturing are disclosed. An integrated structural antenna aperture can be used to reduce net weight, cost, and volume where an array of antenna elements are incorporated into a structural member, e.g. in a spacecraft. A structural material layer, such as a structural foam, may be used with the array of individual antenna element cavities machined into the layer. The antenna element cavities are lined with a conductive material, such as plated aluminum. Facesheets may be bonded to the front and / or backside of the structural material layer in order to increase strength and / or stiffness using an RF transparent material. The array of antenna elements may be coupled to filters at the back side of structural material layer.

Owner:THE BOEING CO

Six dimensional RSS acceleration transducer

InactiveCN101034097AThe theoretical design error is smallQuick responseAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsElastomerAutomatic control

This invention disclose a sort of 6 dof paralleling structure sps acceleration transducer, refer automatic control engineering region. The characteristic: inertial platform (1) join with fixed platform (4) by 3 groups branched chain, each group branched chain include Left Side branched chain ( 2) and right side branched chain ( 3) left and right branched chain have same structural phase but different gesture. Branched chain at fixed platform (4) submit circle symmetry disposal. Each strip branched chain has two elasticity sphere deputy (2 - 4) and one elasticity remove deputy (2 - 2). elasticity remove deputy ( 2 - 2) has a pair parallel plate, on the surface of parallel plate has pasted strain gauge ( 2 - 3). The elastomer in this invention quite right respond to corresponding parallel institution mechanical model; has normal and adult design philosophy; thus theoretical design error is smallness;owing to institution model possess favorable discoupling quality; the sendout synthesizing and decomposition algorithm are simplicity;response quickly; And has good isotropy.

Owner:YANSHAN UNIV

System, method, and apparatus for frame assembly and building

An A-frame assembly for constructing a building comprises only five major components that are formed from square, galvanized steel hollow tubing. These components include corner braces, side braces, a top brace, beams, and straight tubing. The straight tubing interconnects the other components to form a triangular frame assembly. The corner braces are secured with concrete footings or a complete foundation. A number of the frame assemblies are arrayed to form the basis of a structure. The frame assemblies are spaced apart from each other, joined with additional square tubing, and include an attic space and service spaces between the corner braces. A roofing structure is secured to the joined frame assemblies to complete the structural phase of the assembly.

Owner:BOATWRIGHT GARRY

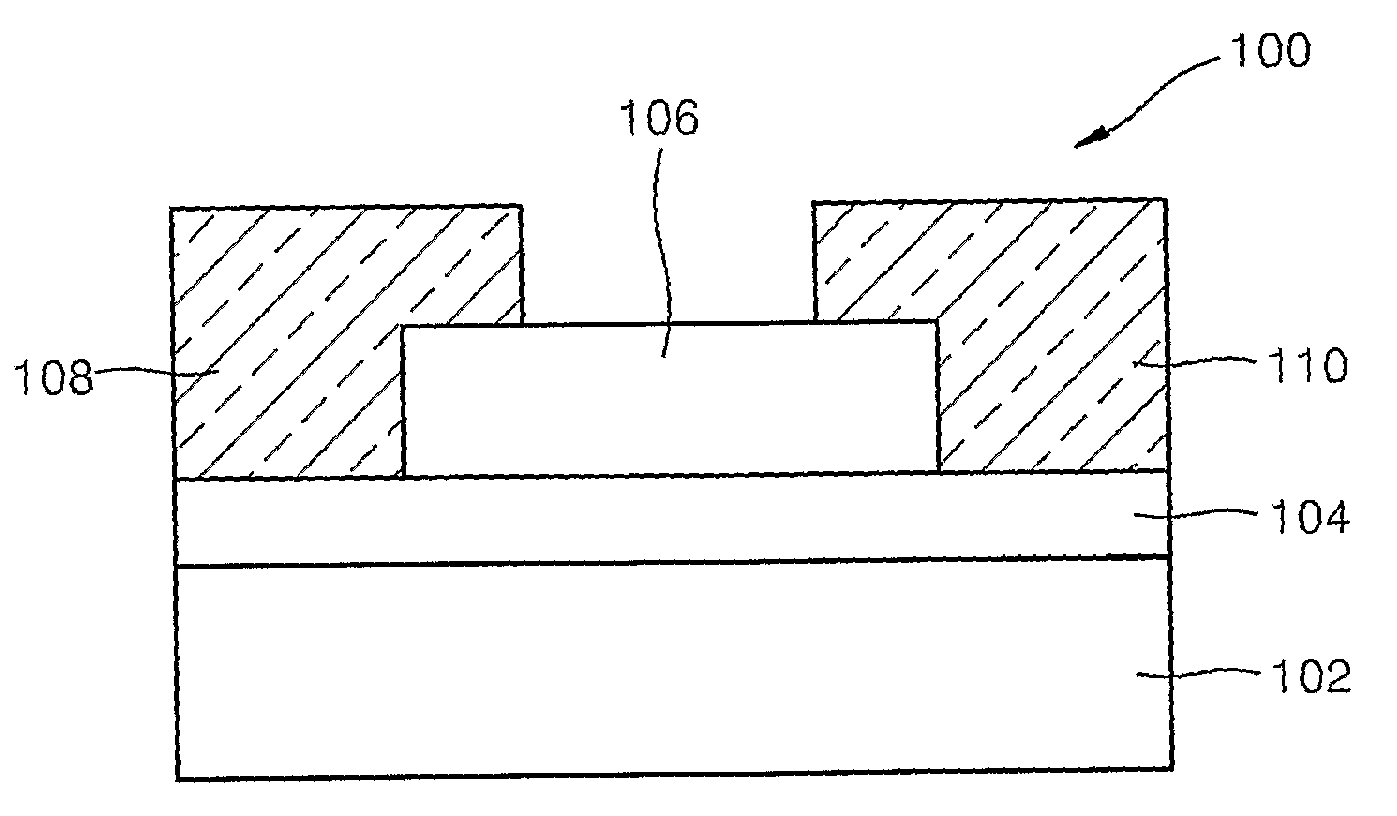

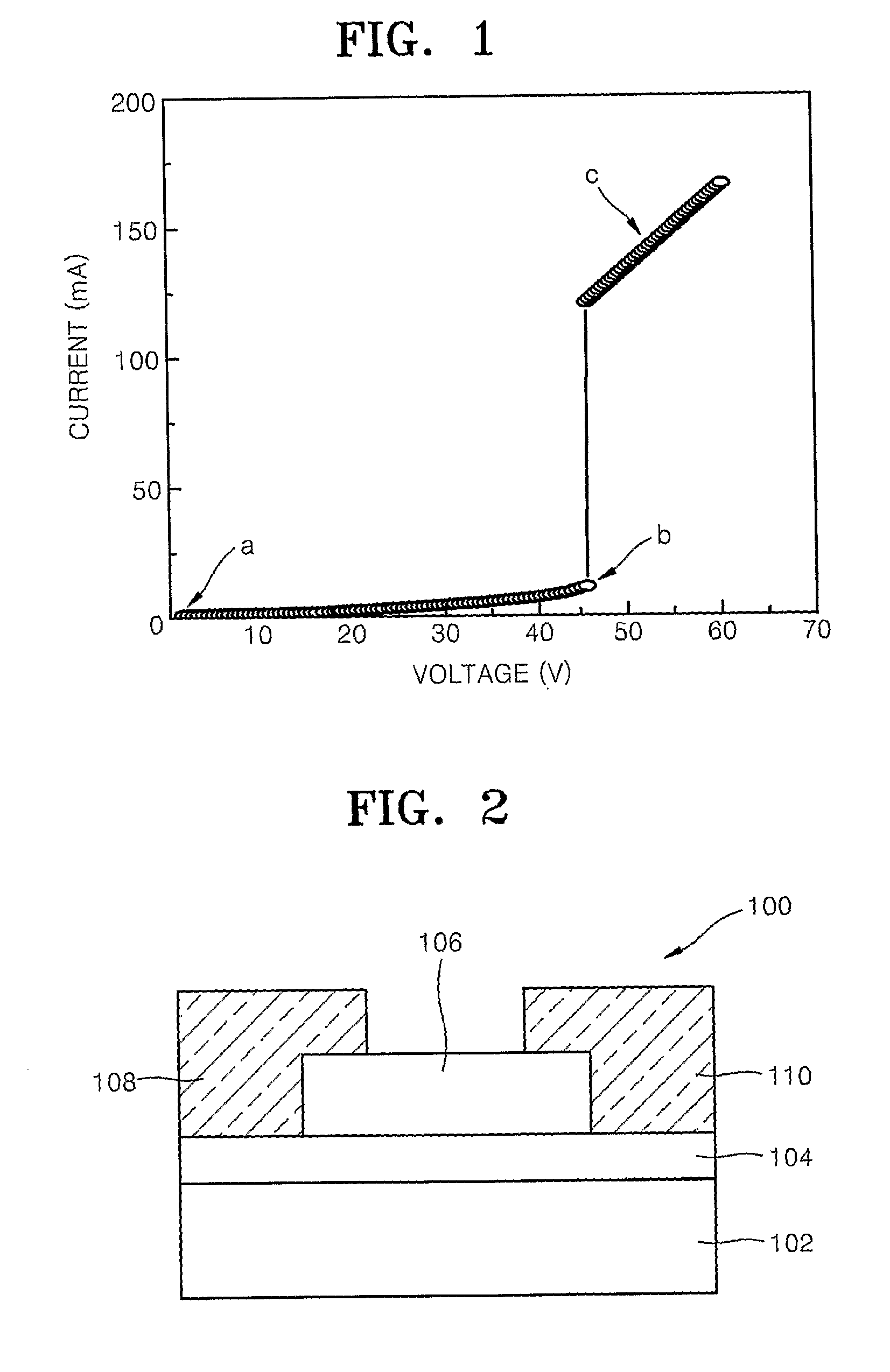

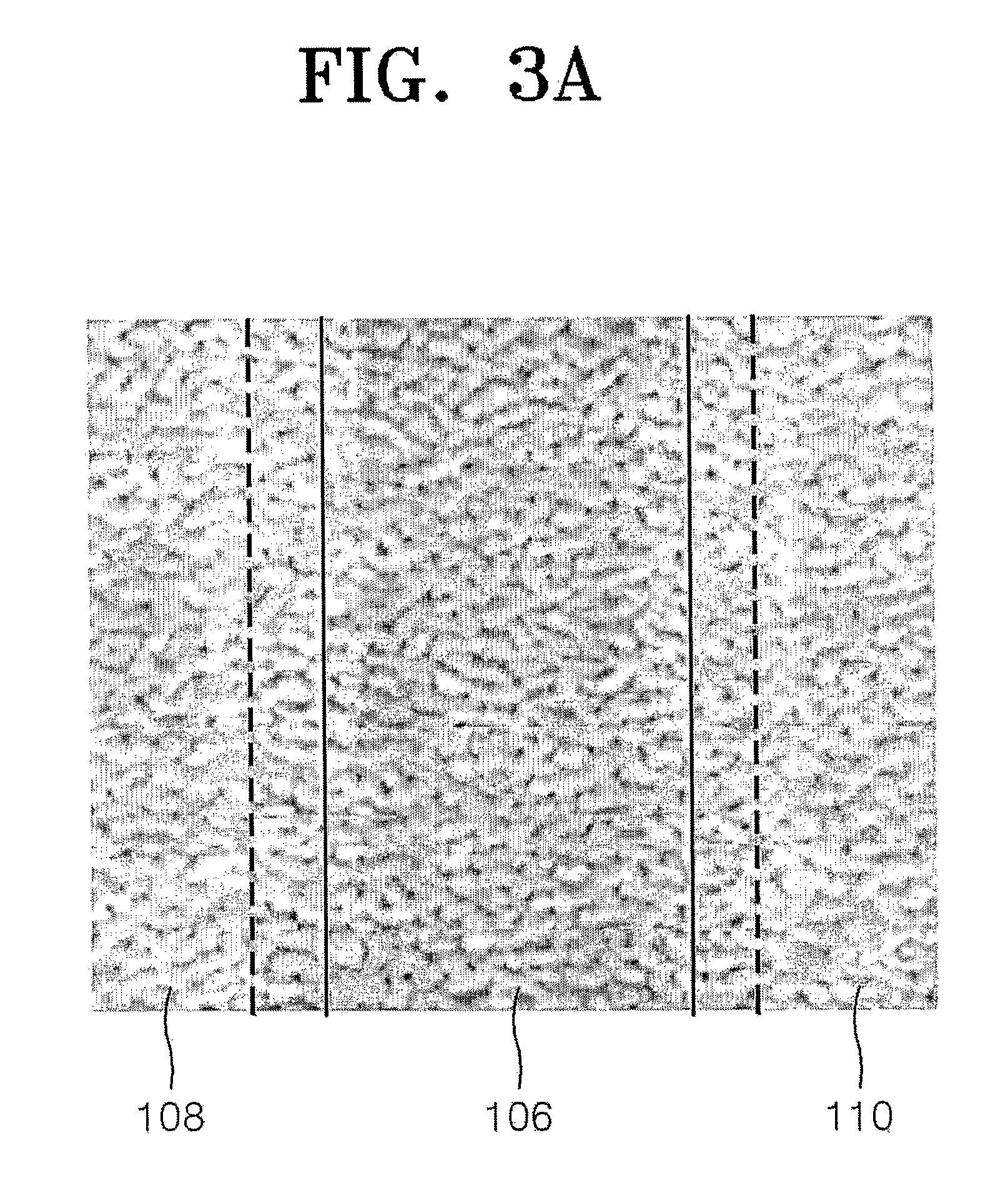

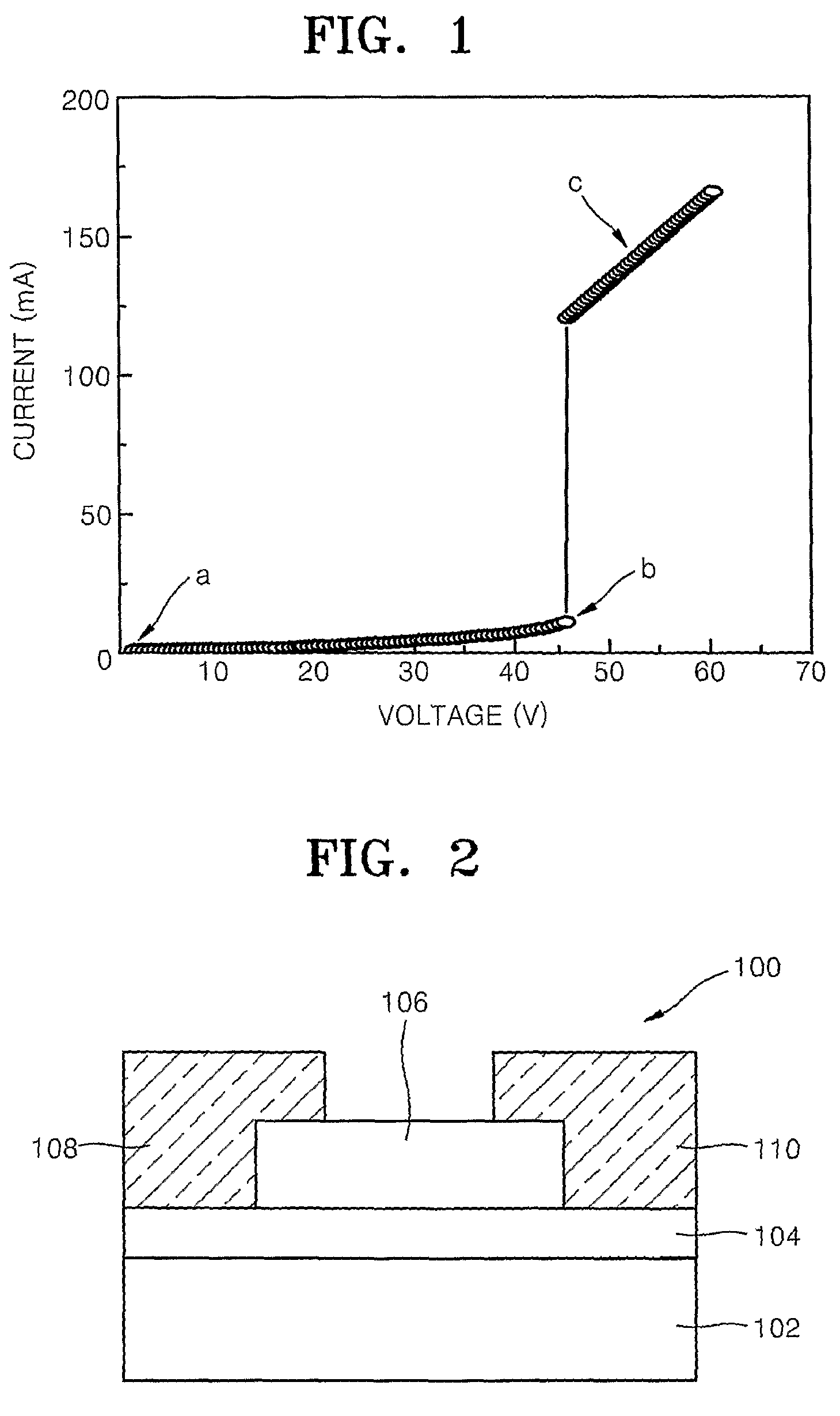

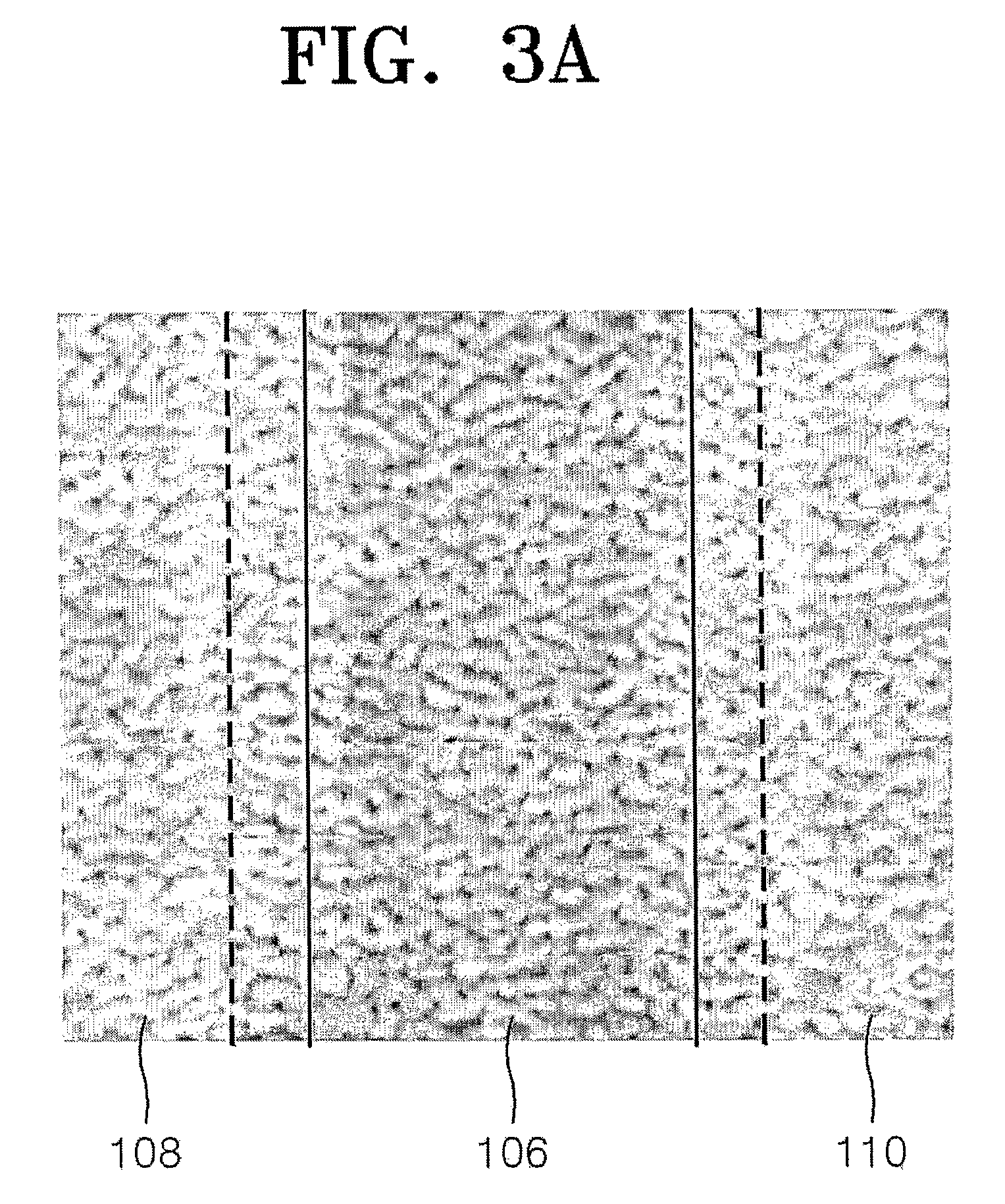

Memory device using abrupt metal-insulator transition and method of operating the same

InactiveUS20090114896A1High-speed switching operationMaintain consistencyNanoinformaticsSolid-state devicesEngineeringStructural phase

Provided are a memory device that undergoes no structural phase change, maintains a uniform thin film, and can perform a high-speed switching operation, and a method of operating the same. The memory device includes a substrate, an abrupt MIT material layer, and a plurality of electrodes. The abrupt MIT material layer is disposed on the substrate and undergoes an abrupt metal-insulator transition by an energy change between electrons. The plurality of electrodes are brought into contact with the abrupt MIT material layer and are melted by heat to form a conductive path on the abrupt MIT material layer.

Owner:ELECTRONICS & TELECOMM RES INST

Controlling structural phase transitions and properties of two-dimensional materials by integrating with multiferroic layers

ActiveUS10403753B2Magnetic measurementsMagnetic-field-controlled resistorsStructural phaseNon magnetic

The invention relates to heterostructures including a layer of a two-dimensional material placed on a multiferroic layer. An ordered array of differing polarization domains and surface charges in the multiferroic layer produces corresponding domains having differing properties in the two-dimensional material. When the multiferroic layer is ferroelectric, the ferroelectric polarization domains in the layer produce local electric fields that penetrate the two-dimensional material. The local electric fields and surface charges can control the structural phase of the two-dimensional material, which in turn determines whether the two-dimensional material layer is insulating or metallic, has a band gap or no band gap, and whether it is magnetic or non-magnetic. Methods for producing the heterostructures are provided. Devices incorporating the heterostructures are also provided.

Owner:UNITED STATES OF AMERICA

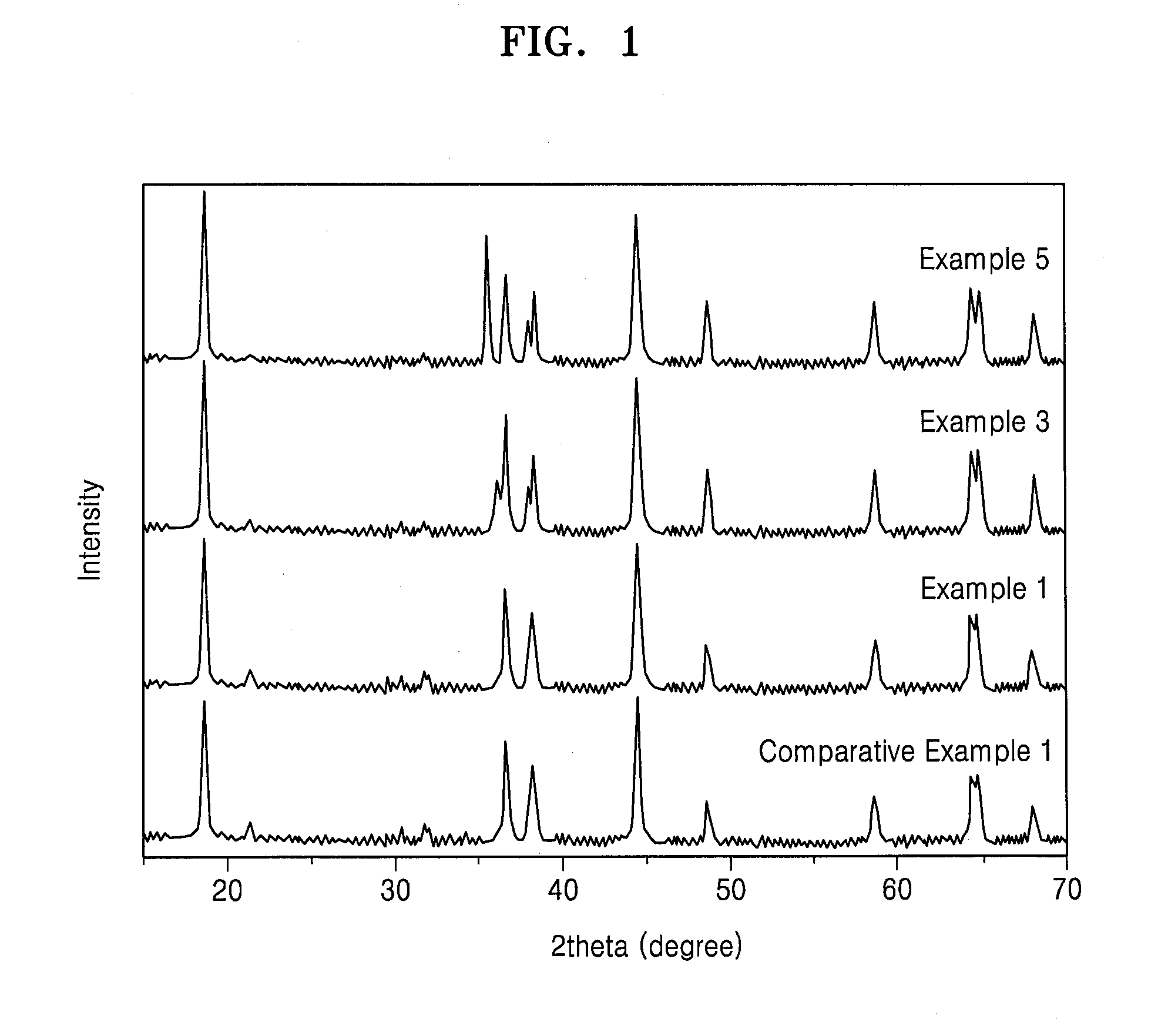

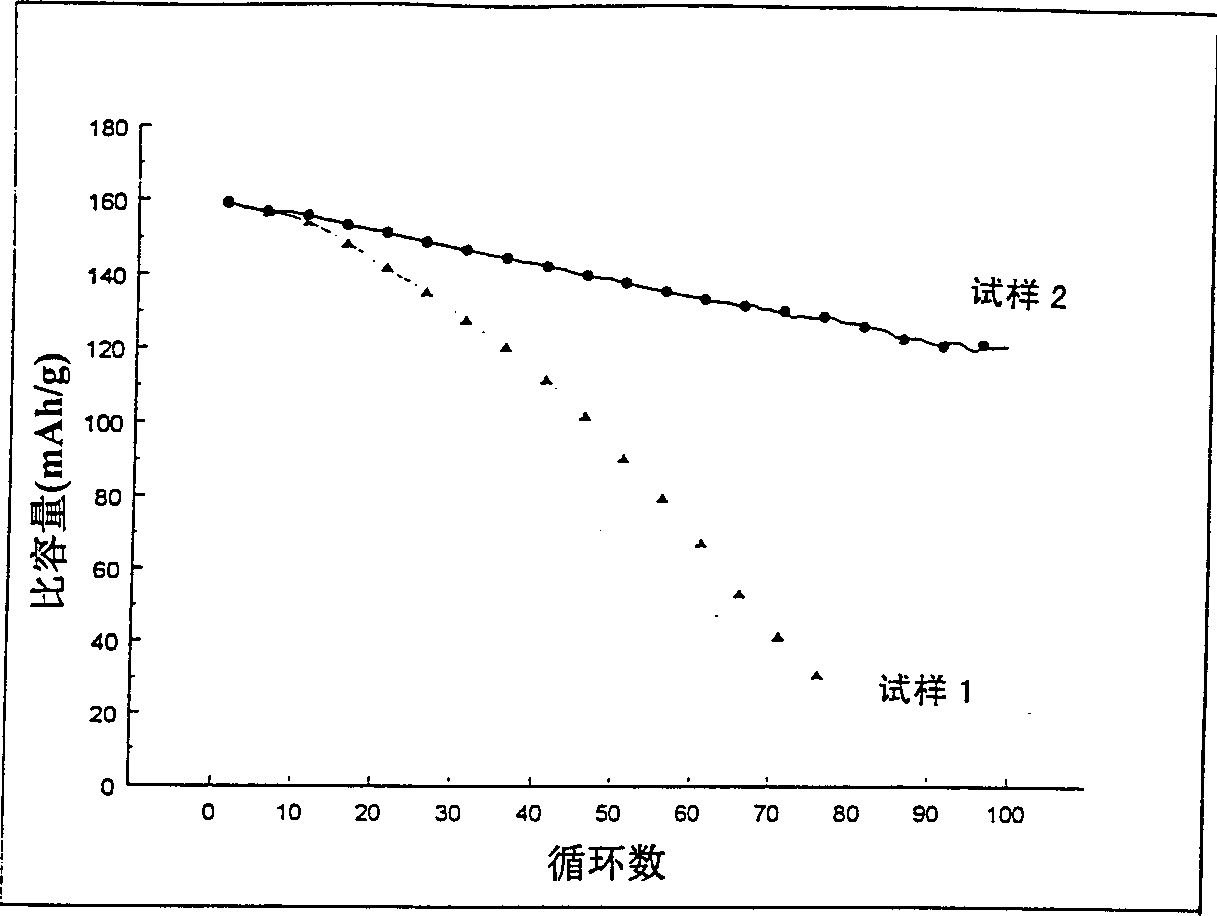

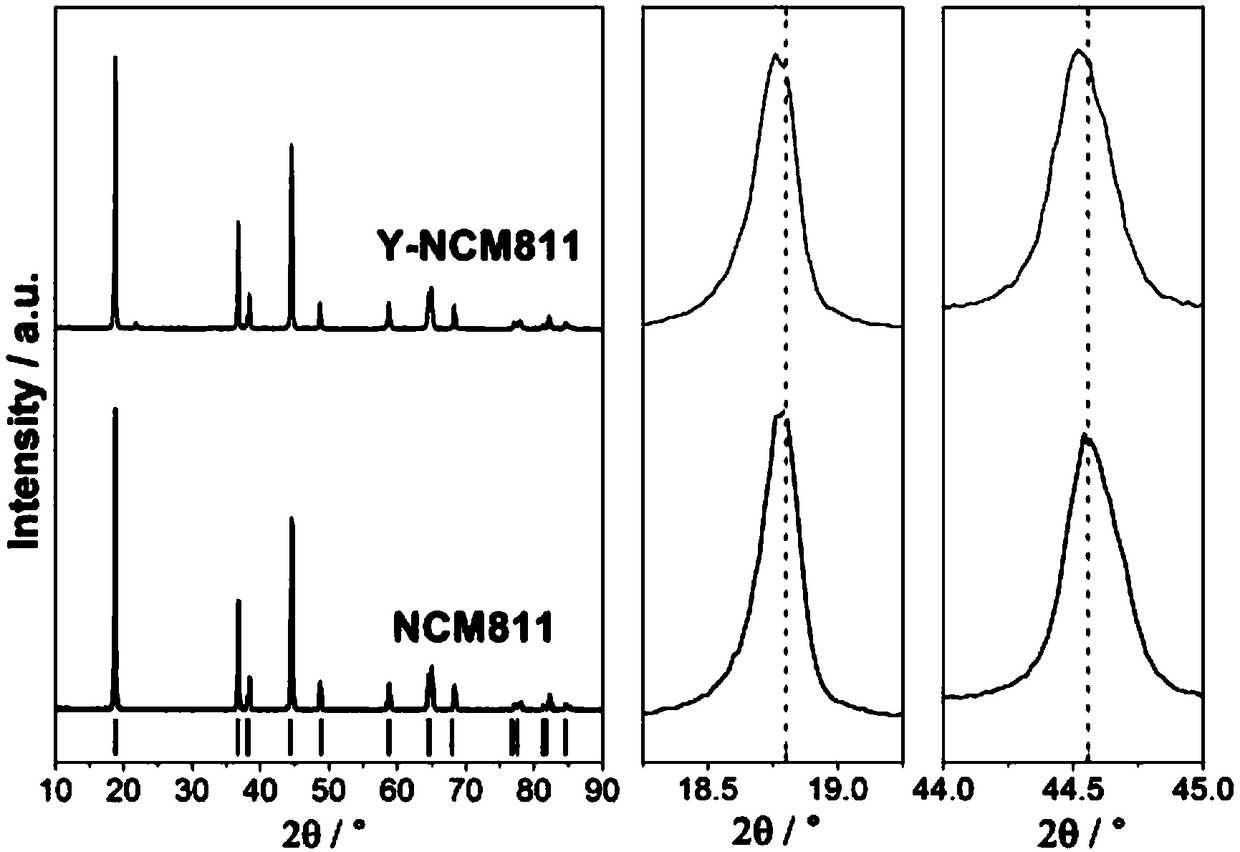

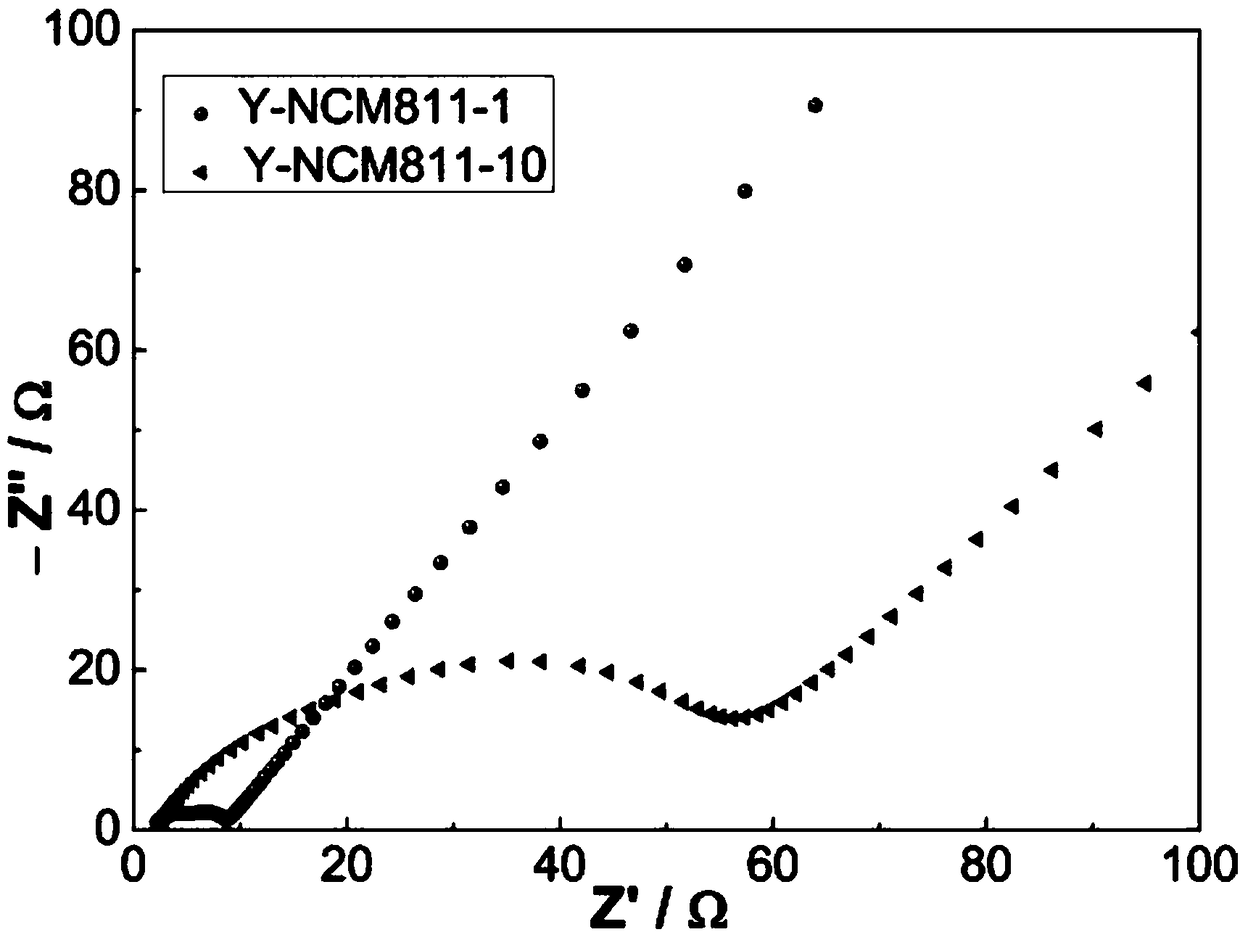

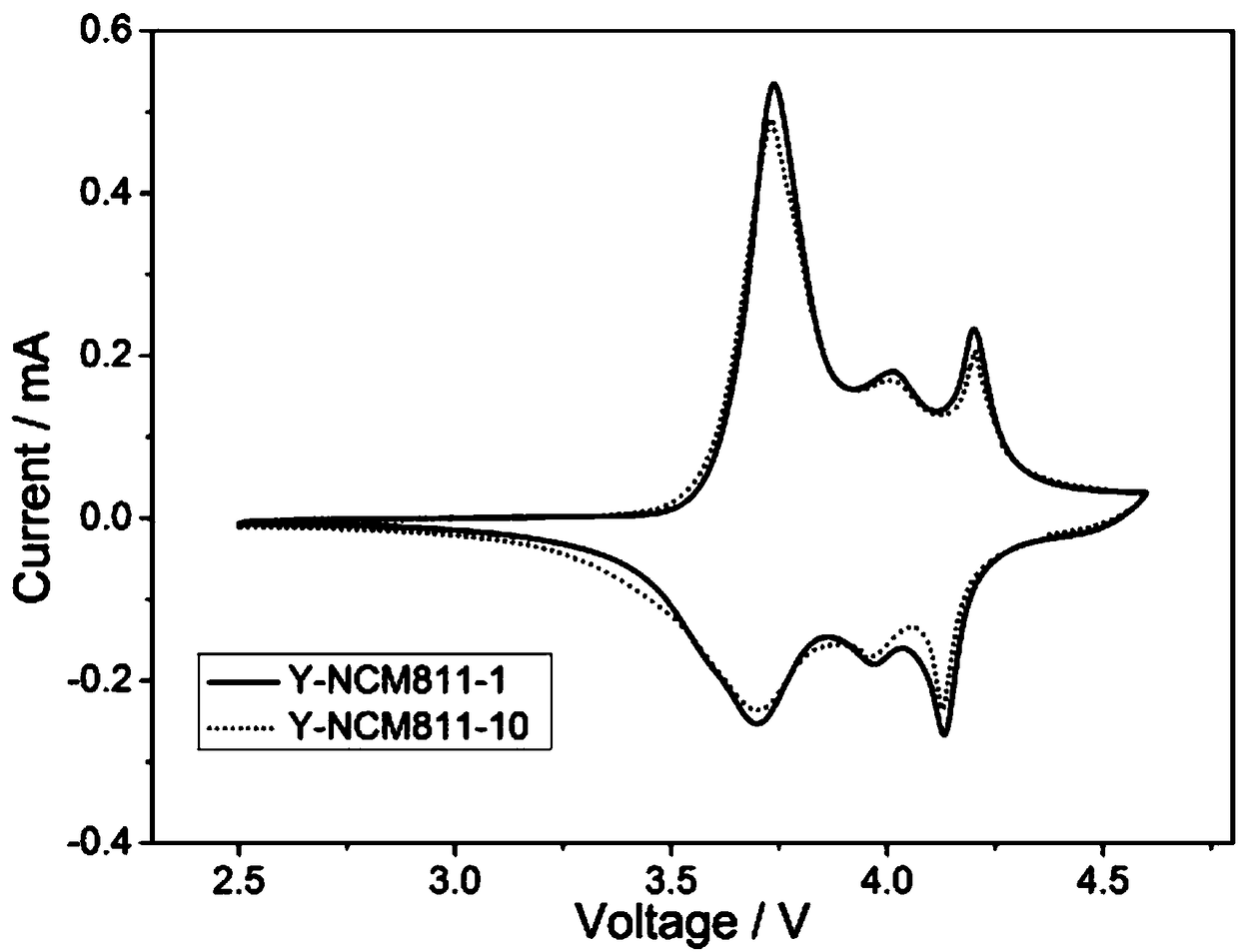

Preparation method of NCM ternary positive electrode material doped with Y<3+> on surface

InactiveCN108172820AInhibition of phase transitionImproved structural stability and reversible discharge capacityCell electrodesLi-accumulatorsHigh rateStructural phase

Belonging to the field of chemical energy storage batteries, the invention relates to a preparation method of an NCM ternary positive electrode material doped with Y<3+> on the surface. According to the method, Y<3+> doping is carried out in the mixing process of a nickel cobalt manganese hydroxide precursor and a lithium salt, the doped Y<3+> enters a transition metal layer on the surface, occupies the position of Ni<2+>, and can play the role of supporting the framework, inhibiting the surface structural phase transition and inhibiting Li<+> / Ni<2+> mixing. In addition, Y<3+> has a large ionradius, and after being doped into the transition metal layer, is conducive to broadening the insertion and deinsertion channel of Li<+> and improving the Li<+> transmission rate, and can significantly improve the electrochemical properties of the NCM ternary positive electrode material under high voltage and high rate (4.5V, greater than or equal to 1C).

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

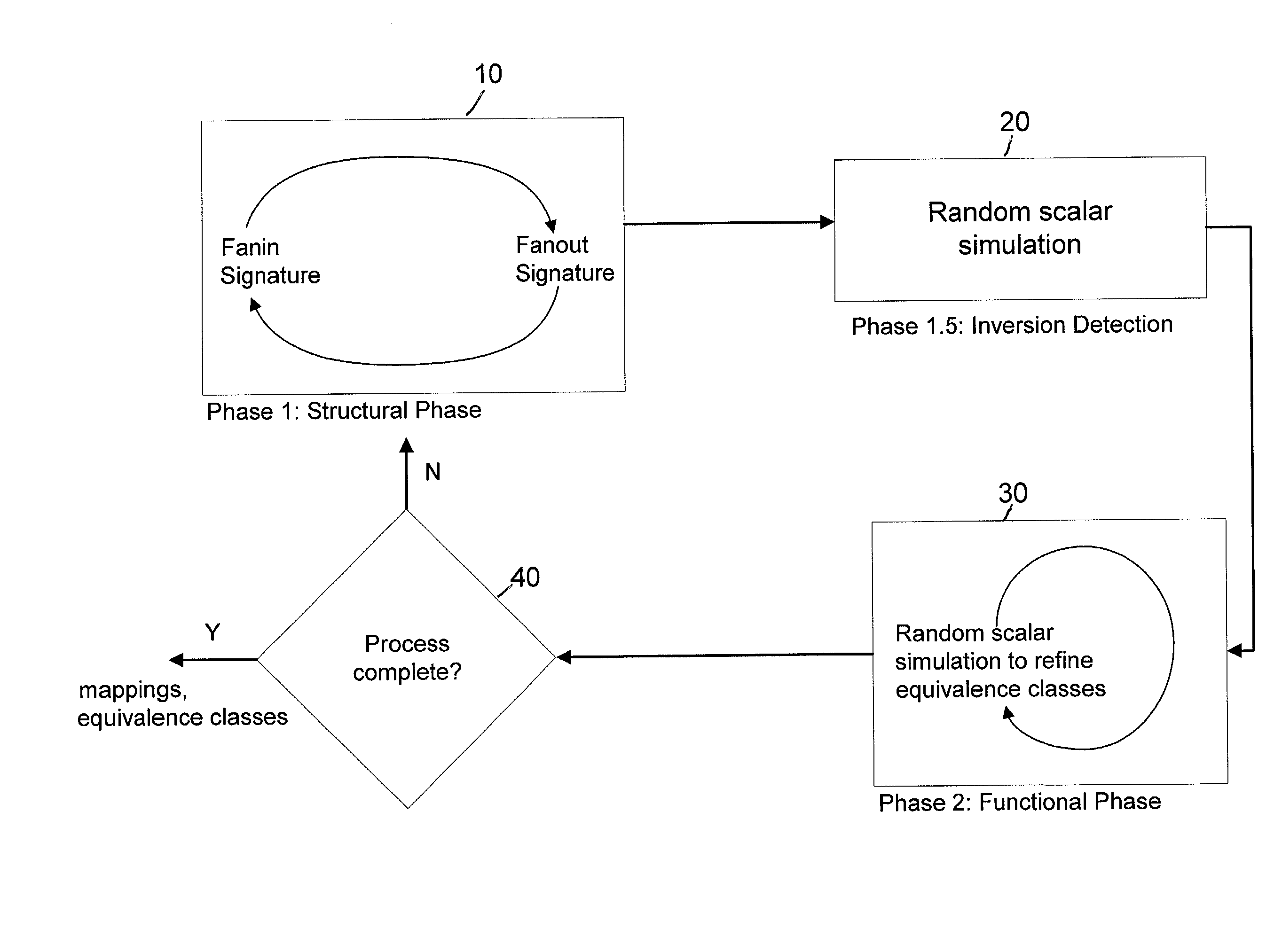

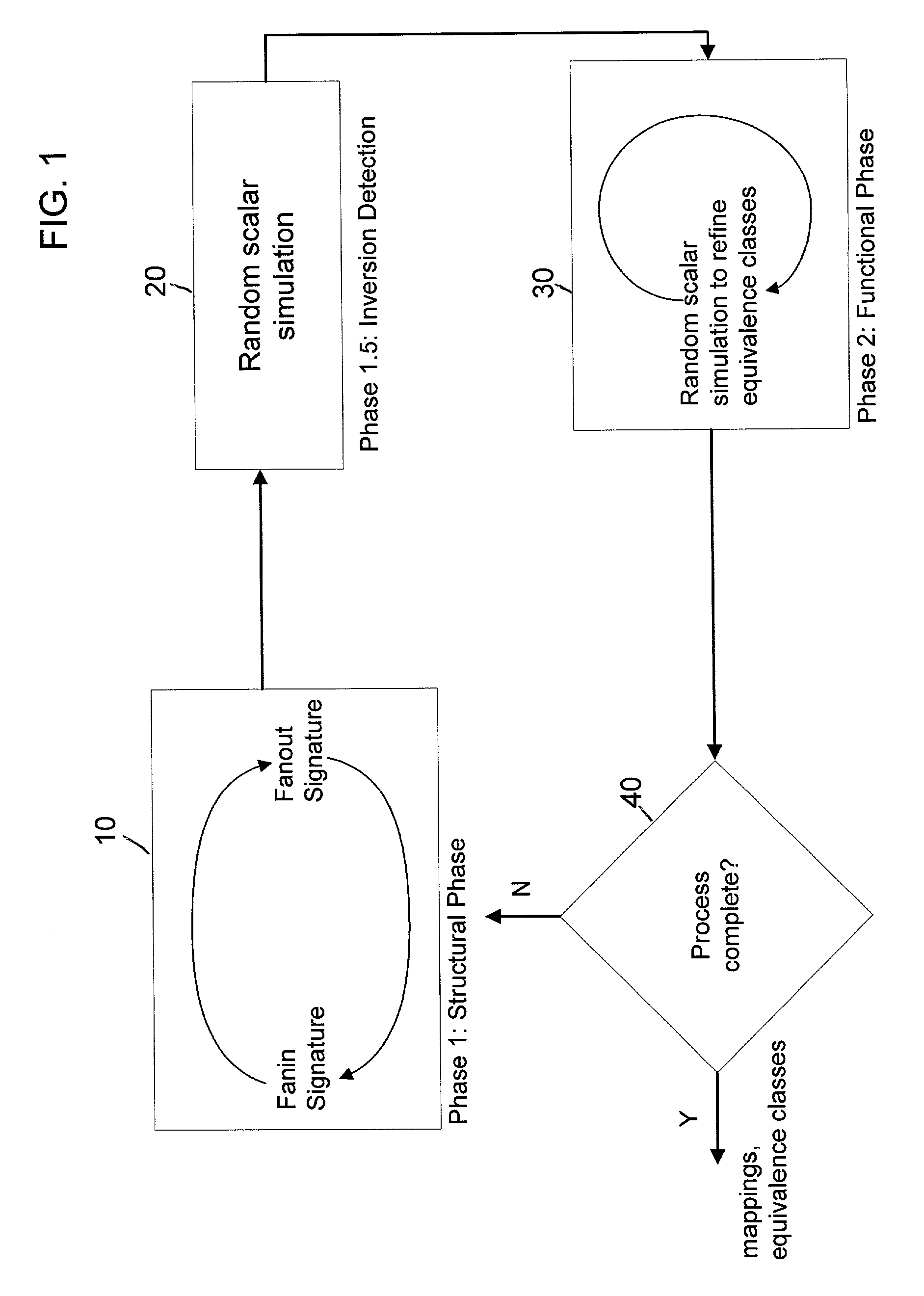

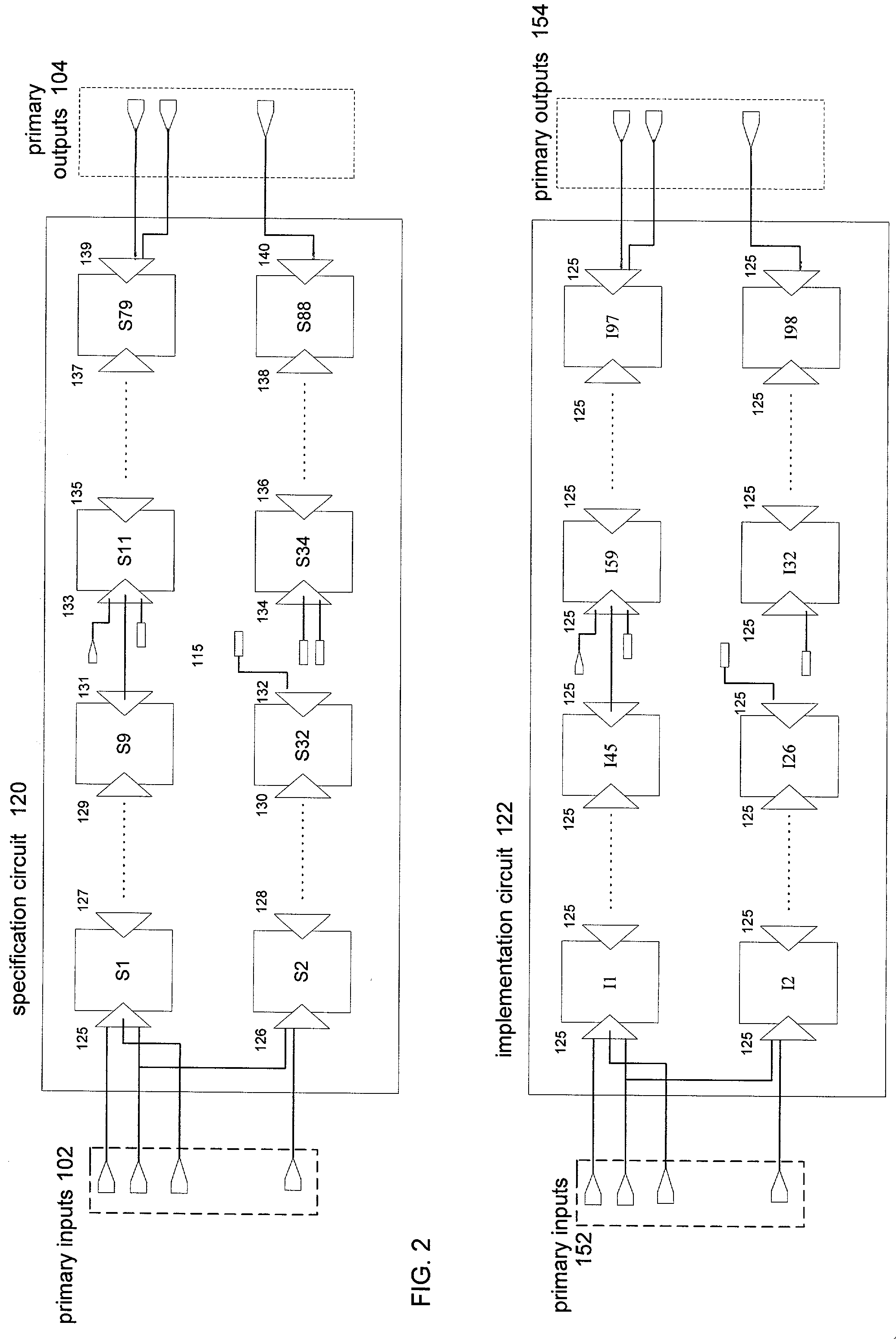

System and method for automatically mapping state elements for equivalence verification

InactiveUS7149675B2Analogue computers for electric apparatusAnalogue computers for chemical processesStructural phaseEngineering

A method for automatically mapping state elements between a first circuit and a second circuit is described. The method proceeds by comparing, in a structural phase, structural features of state elements in the first circuit to structural features of state elements in the second circuit for equivalence. Mappings between state elements of the first circuit and the second circuit are determined based on the comparison of structural features. “Don't care” input conditions are then accounted for prior to determination of functional features. During an inversion detection phase, the polarity of the mappings found in the prior structural phase are determined. A functional phase follows in which the functionality of state elements in the first circuit are compared to the functionality of state elements in the second circuit for equivalence using a three-valued random simulation and further mappings are determined based upon the functional comparison.

Owner:INTEL CORP

MnNiSi-based magnetic alloy capable of serving as magnetic refrigeration material

InactiveCN106636843ALarge magnetic entropy effectLarge magnetic differenceHeat-exchange elementsElectric arc furnaceIce water

The invention discloses a MnNiSi-base magnetic alloy capable of serving as a magnetic refrigeration material, and belongs to the technical field of magnetic materials. The chemical formula of the magnetic alloy is Mn(1-z)MzNi(1-y)M'ySi(1-x)Xx, wherein M and M' are transition metals, and comprise Fe and Co; X is a main group element, and comprises Ge and Ga; z is larger than or equal to 0.1 and less than or equal to 0.7; y is larger than or equal to 0 and less than or equal to 0.5; x is larger than or equal to 0 and less than or equal to 0.5. A preparation method of the MnNiSi-base magnetic alloy comprises the following steps: preparing raw materials in a molar ratio, placing the prepared raw materials into an electric arc smelting furnace or a suspended smelting furnace, performing vacuum pumping, and smelting under the protection of argon gas to obtain an alloy ingot; annealing the smelted alloy ingot under the protection pure inert gas, and directly quenching in ice water to obtain the magnetic alloy. The magnetic alloy can undergo structural phase change within a wide temperature range, has a great magnetocaloric effect, and can have high magnetic refrigeration efficiency and a wide-temperature-range working range as a magnetic refrigeration working medium.

Owner:BEIJING UNIV OF TECH

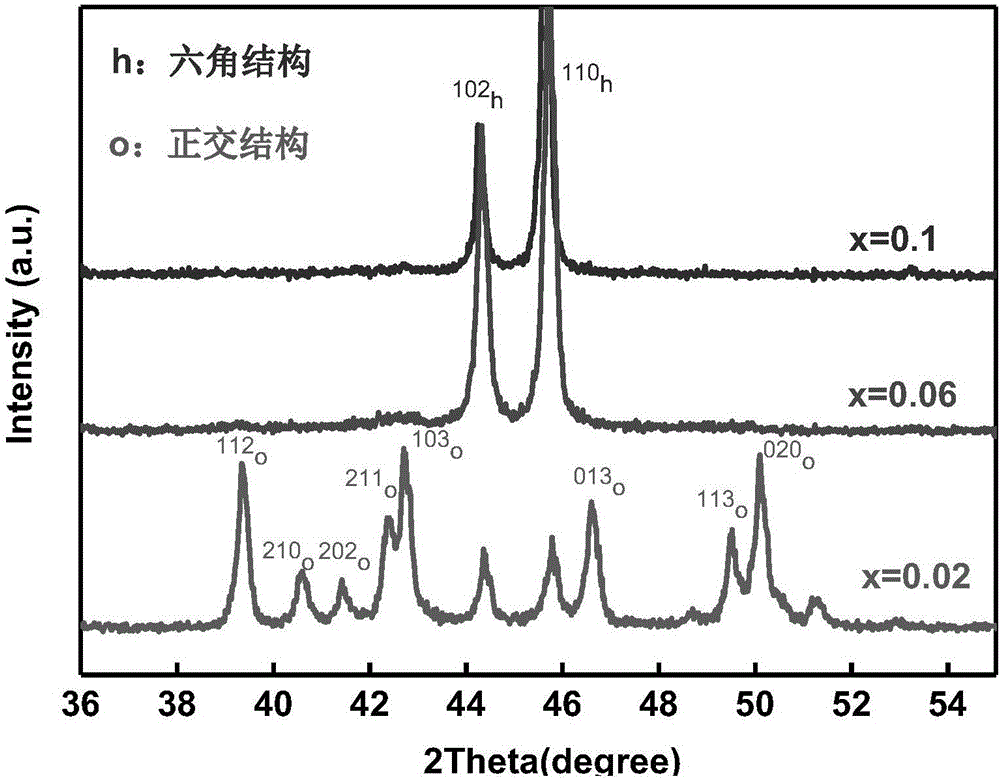

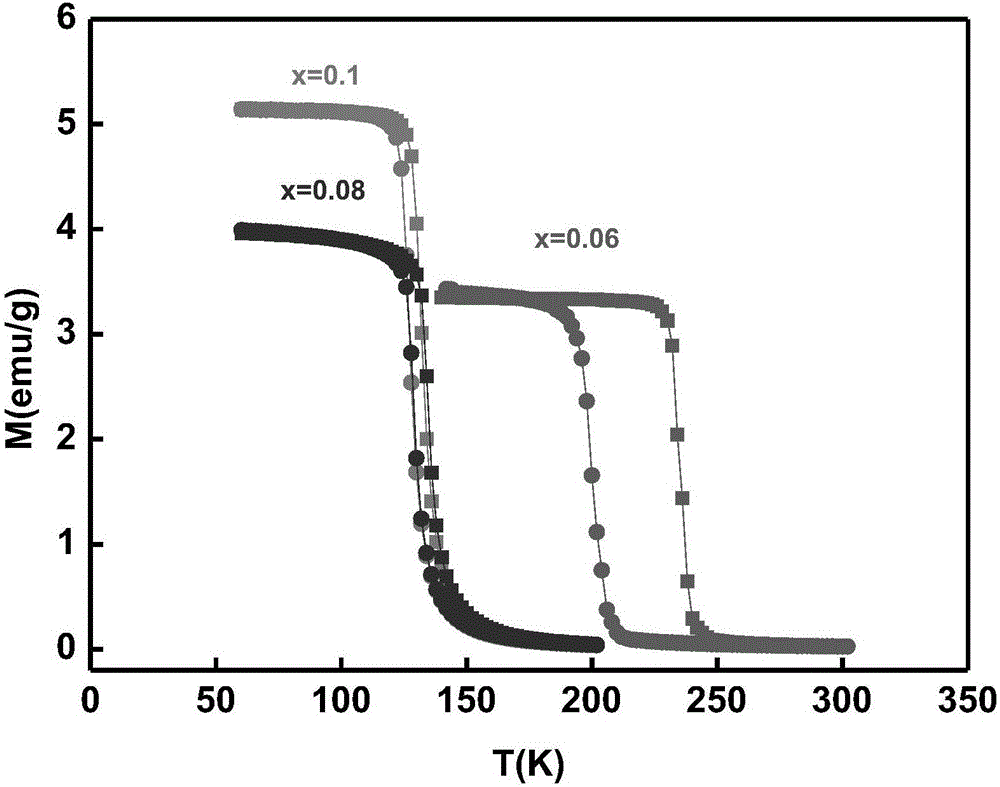

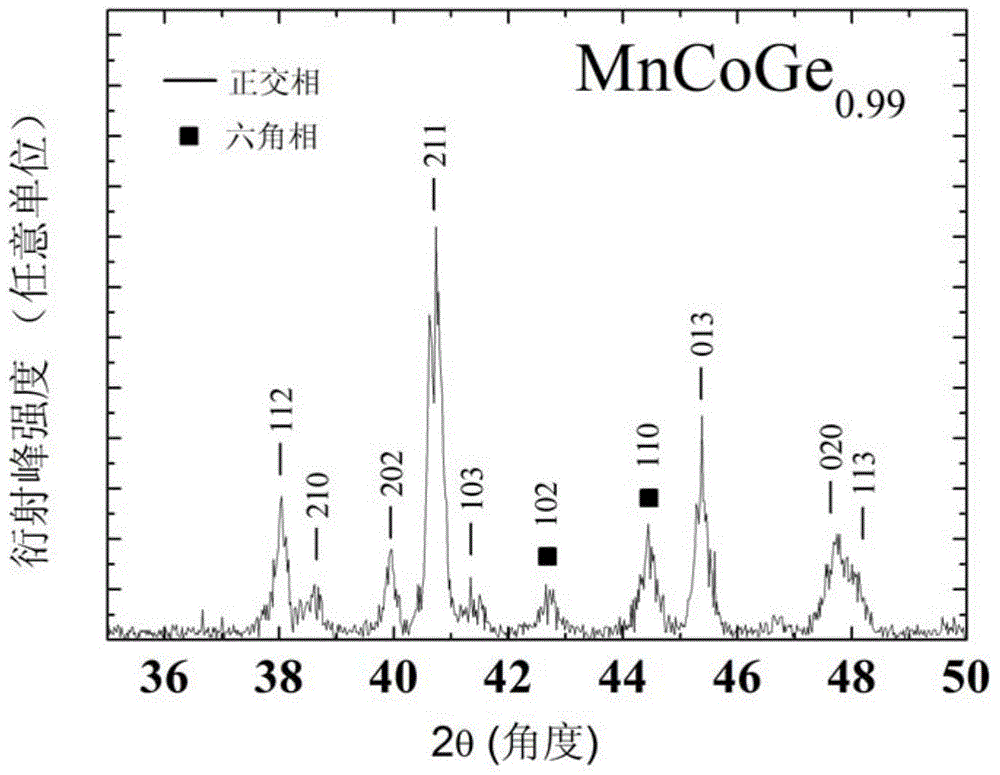

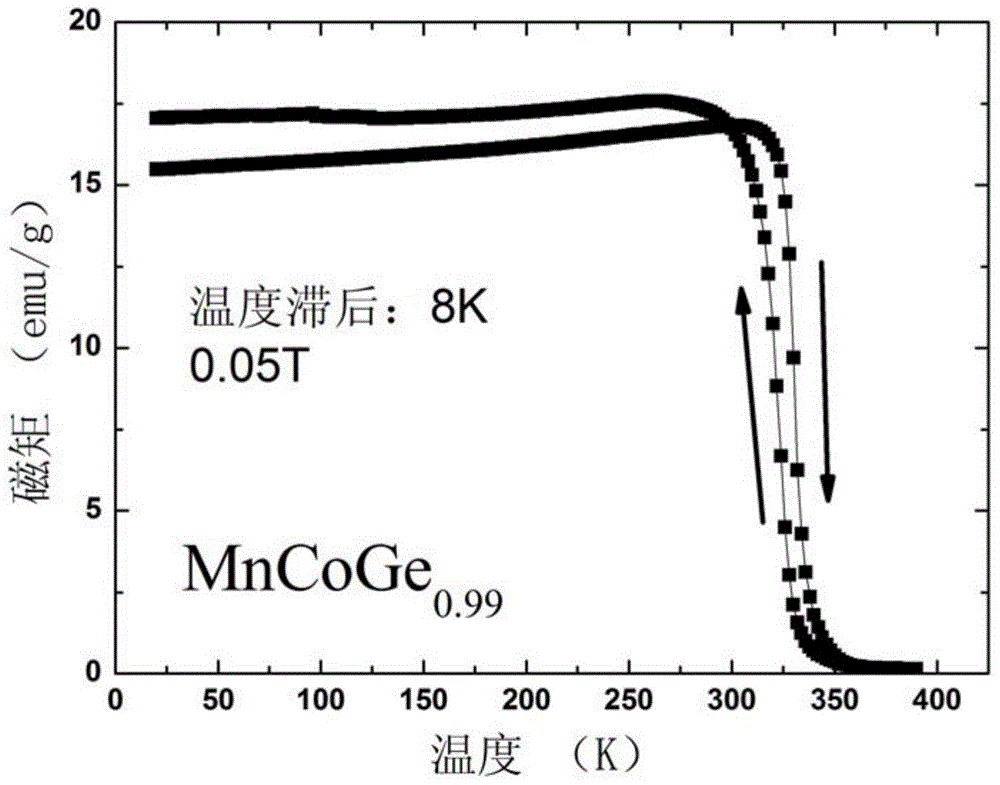

MnCoGe based ferromagnetic martensite phase-change material, preparation method and applications thereof

The invention provides a MnCoGe based ferromagnetic martensite phase-change material, a preparation method and applications thereof. The chemical formula of the phase-change material is MnCoGe<1-x>, 0<x<=0.05. The phase-change material has a martensite structure phase change, which is coupled with a magnetic phase change. As the temperature decreases, the phase change material changes from paramagnetic high-temperature austenite parent phase with a Ni2In hexagonal structure to ferromagnetic low-temperature martensite phase with a TiNiSi type orthorhombic structure, and the phase change property is one grade. The magnetic / structural phase-change coupling temperature of the provided phase-change material is continuously adjustable in a wide temperature range (310-340K), which is slightly higher than the room temperature, along with the change of the Ge vacancy concentration. The material system has the characteristics of abundant raw material reserves, simple technology, and suitability for industrial production.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

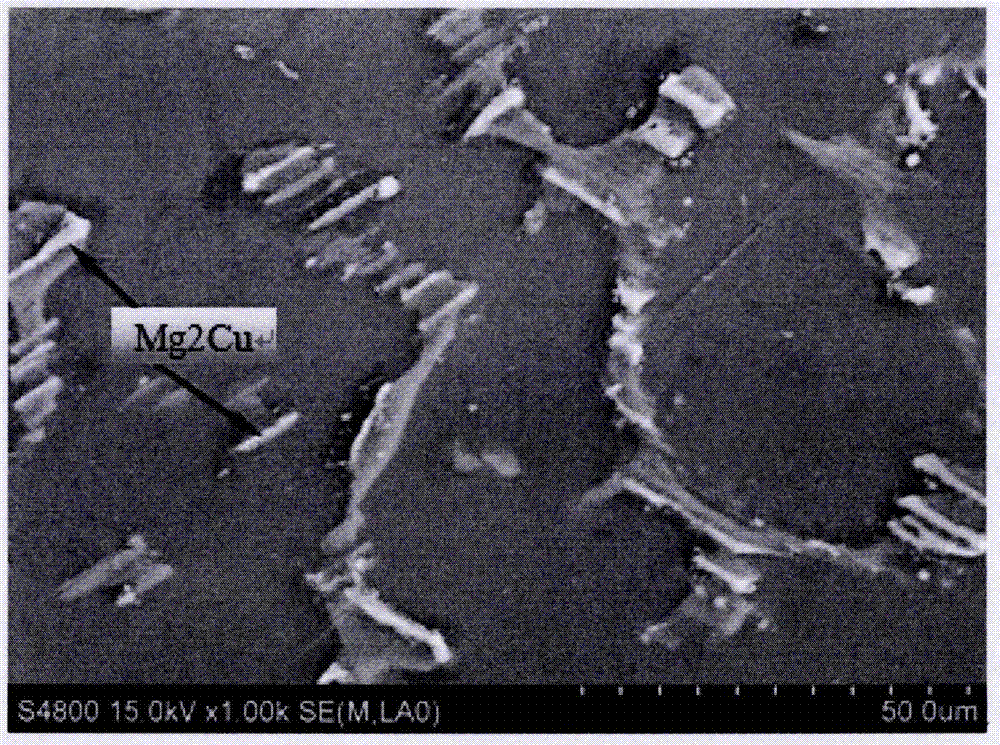

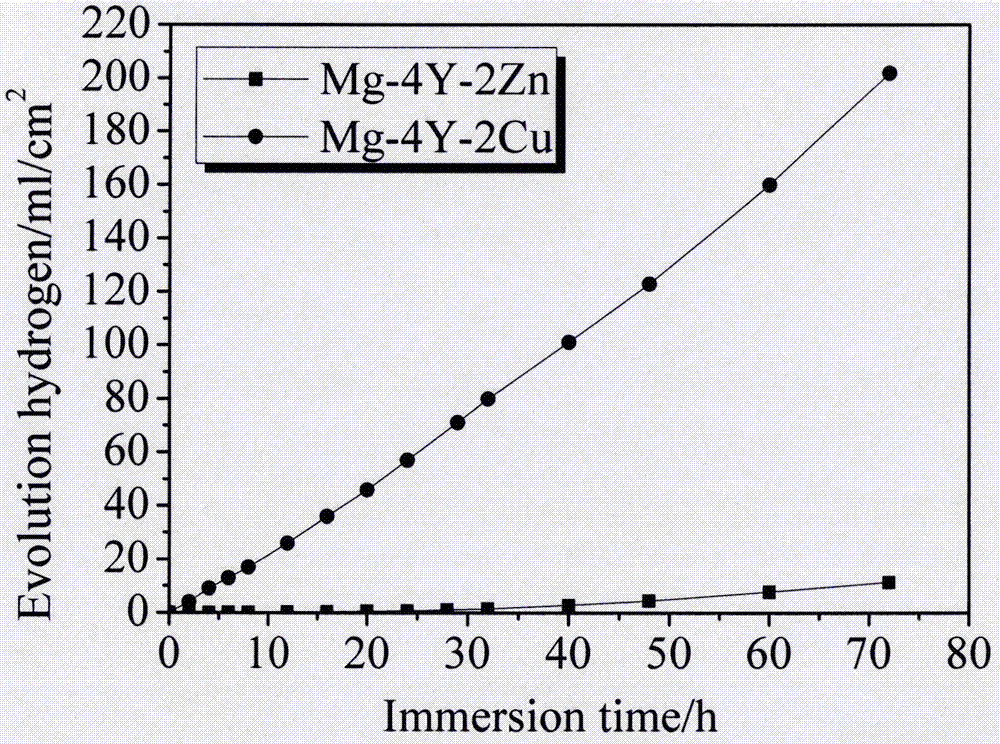

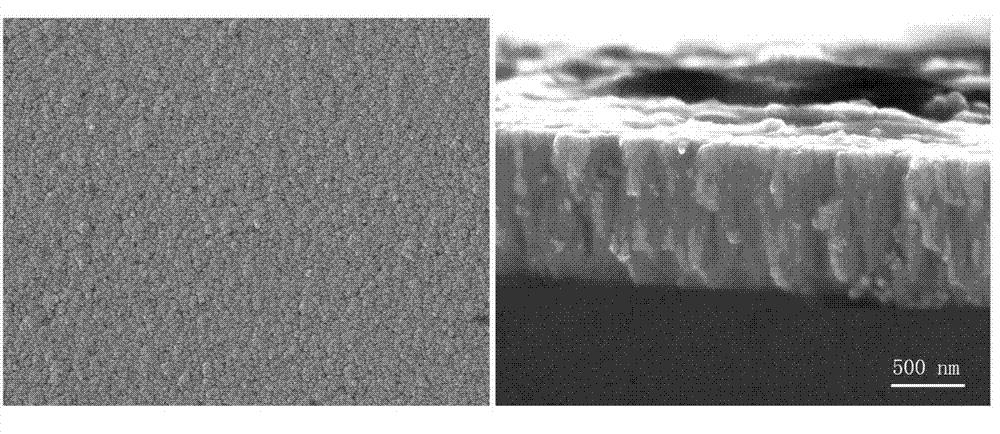

Preparation method of high-strength and high-toughness rapidly-degraded magnesium alloy

The invention discloses a preparation method of high-strength and high-toughness rapidly-degraded magnesium alloy. The preparation method comprises the following steps: preheating a crucible to be at a temperature of about 600 DEG C, spreading a small amount of molten salt covering agent on the wall and at the bottom of the crucible, adding a pure magnesium block and spreading a layer of molten salt covering agent on the surface of the magnesium block; heating the crucible, preserving heat when the temperature is raised to 720 DEG C, and adding Cu after magnesium is completely molten; raising the temperature of the crucible to 720-725 DEG C, adding Mg-Y intermediate alloy, and stirring while adding; continuing raising the temperature, raising the temperature of the crucible to740 DEG C, and adding a No. 5 magnesium alloy dedicated agent and a tranquilizer; cooling to 700 DEG C by standing, adding an intermediate phase into the alloy, and starting casting to obtain Mg-4Y-2Cu alloy. An LPSO structural phase capable of improving the strength, plasticity and toughness of the alloy as well as a Cu-containing precipitated phase Mg2Cu are formed in the alloy, and a part of Cu is solidified into an Mg matrix, so that the degradation rate of the high-strength and high-toughness rapidly-degraded magnesium alloy is significantly increased.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

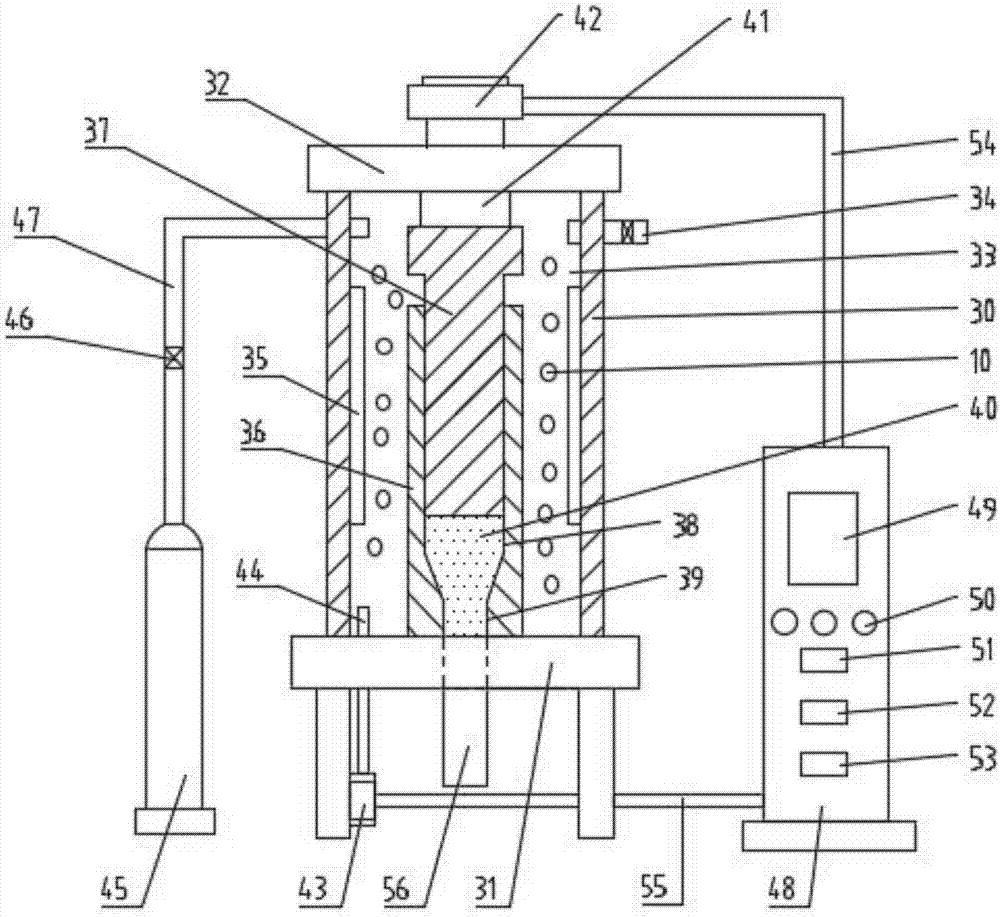

Preparation method of long-period stacking order (LPSO) structural phase enhanced magnesium gadolinium zinc calcium aluminium alloy plate

The invention relates to a preparation method of a long-period stacking order (LPSO) structural phase enhanced magnesium gadolinium zinc calcium aluminium alloy plate. The preparation method is aimed at the problem that an LPSO structural phase is hard to form in a cast magnesium gadolinium zinc alloy. The preparation method comprises the steps that calcium and aluminium elements are doped in the magnesium gadolinium zinc alloy, vacuum melting, argon bottom blowing protection and casting ingot forming are adopted, forming of the LPSO structural phase is induced, and a cast LPSO structural phase enhanced magnesium gadolinium zinc calcium aluminium alloy ingot is prepared; and an LPSO structural phase enhanced magnesium gadolinium zinc calcium aluminium alloy plate enhanced product is prepared through vacuum hot extrusion aging. The preparation method is advanced in technology, data is accurate and detailed, purity of the product is good and reaches 99.6%, strength reaches 417 MPa, elongation is 12%, corrosion voltage of the cast magnesium gadolinium zinc calcium aluminium alloy is minus 0.447 V, corrosion current density is 5.528 * 10<-6> A / cm<2>, corrosion voltage is improved by 3 times and corrosion rate is decreased by 500 times compared with those of the alloy in which Ca and Al are not added.

Owner:TAIYUAN UNIV OF TECH

Memory device using abrupt metal-insulator transition and method of operating the same

InactiveUS7791924B2High-speed switchingMaintain consistencyNanoinformaticsSolid-state devicesEnergy variationStructural phase

Provided are a memory device that undergoes no structural phase change, maintains a uniform thin film, and can perform a high-speed switching operation, and a method of operating the same. The memory device includes a substrate, an abrupt MIT material layer, and a plurality of electrodes. The abrupt MIT material layer is disposed on the substrate and undergoes an abrupt metal-insulator transition by an energy change between electrons. The plurality of electrodes are brought into contact with the abrupt MIT material layer and are melted by heat to form a conductive path on the abrupt MIT material layer.

Owner:ELECTRONICS & TELECOMM RES INST

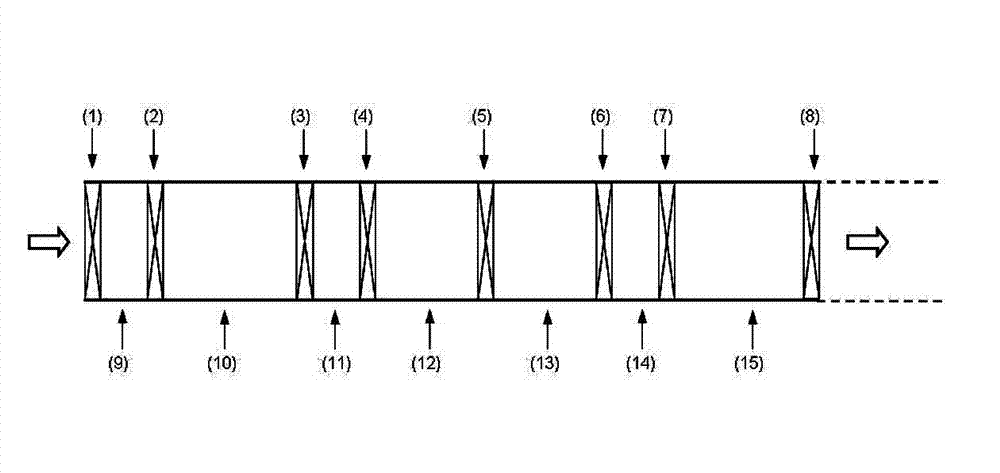

Preparation method of compound thin film for solar battery

ActiveCN102214737BRapid heat treatmentRapid coolingFinal product manufactureSemiconductor devicesIndiumStructural phase

The invention discloses a preparation method of a compound thin film for a solar battery. The method comprises the following steps of: firstly, sputtering a copper-indium-gallium-selenium (CIGS) quaternary compound target by using a direct-current pulse power supply, and depositing an amorphous or nano crystalline thin film material with uniform thickness, uniform components and ideal element proportions on a glass substrate at a low temperature; secondly, quickly and thermally treating the thin film in a heat field formed by a resistance heat source and a halogen tungsten lamp tube heat source to restrain the loss of an element Se so as to obtain a CIGS thin film with high crystallinity, large crystallite dimension, high compactness and good chalcopyrite structural phases, and feeding a proper amount of H2Se+Ar or H2S+Ar mixed gas into the heat field for compensation; thirdly, quickly transferring the thin film to an H2S+Ar atmosphere and suddenly cooling the thin film; and finally, performing low-temperature annealing on the CIGS thin film under the atmosphere of H2 and Ar mixed gas so as to eliminate the stress and an inner defect of the thin film and passivate a current carrier compound center.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Er-contained magnesium alloy and preparation method thereof

ActiveCN110616356AImprove mechanical properties at room temperatureHigh strengthStructural phaseSolid solution strengthening

The invention provides an Er-contained magnesium alloy and a preparation method thereof. The Er-contained magnesium alloy comprises the following components of, in percentage by atom, 0.2%-2.0% of Er,0.2%-2.0% of Y, 0.2%-2.0% of Zn and balance Mg and inevitable impurities. The method comprises the following steps of smelting, homogenizing treatment, deformation and aging treatment. According to the alloy and the method, the content the distribution in the magnesium alloy of a long-period ordered structural phase can be adjusted through the addition of the Er, and a precipitated phase can prevent a basal plane from dislocation glide, so that the strength of the alloy is improved; a LPSO phase and a magnesium matrix phase are in a coherency relationship, and the crack growth can be prevented, so that the plasticity of the alloy is improved; the Er and the magnesium have similar atomic radii, and a good solid solution strengthening effect is achieved by adding the Er in the Mg matrix; and W phases and the distribution of the W phases in the alloy can be effectively adjusted through addition of the Er, and the second phases all play dislocation glide prevention roles, so that the mechanical property of the alloy can be effectively adjusted and controlled through the addition of the Er.

Owner:HARBIN ENG UNIV

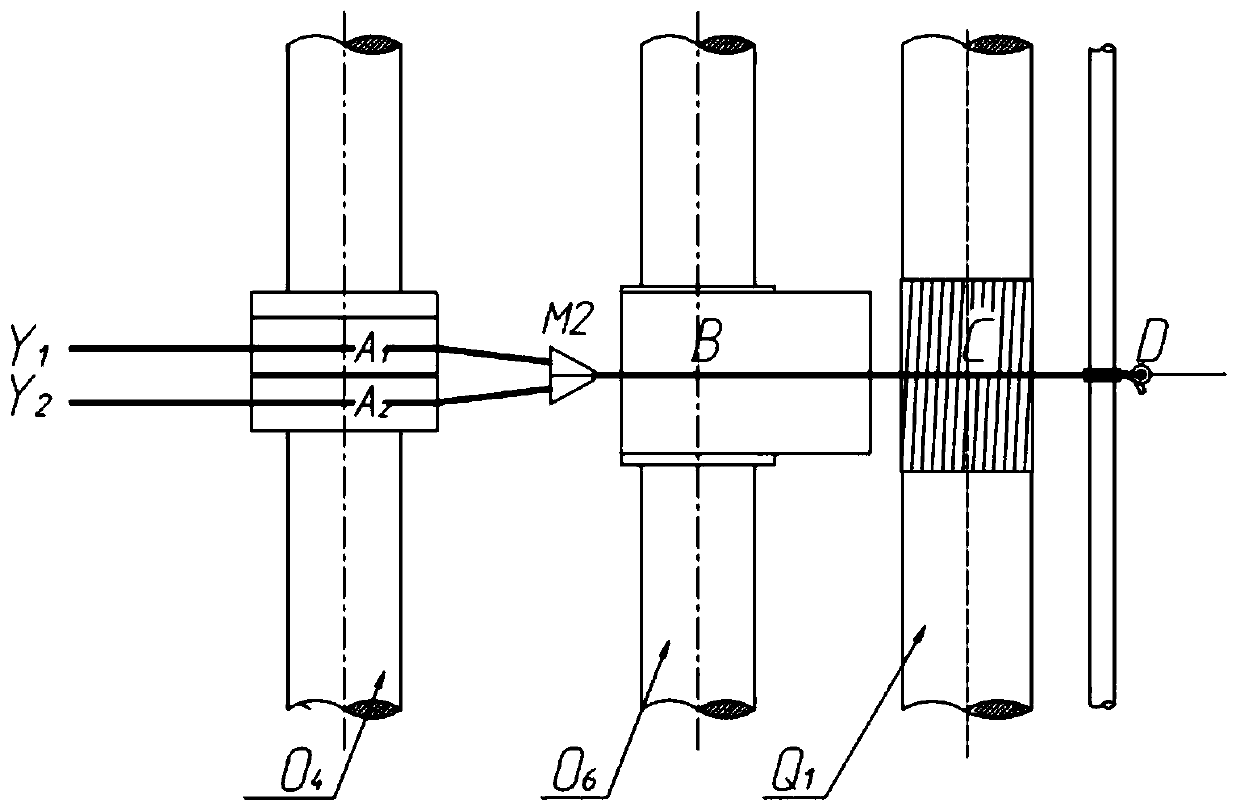

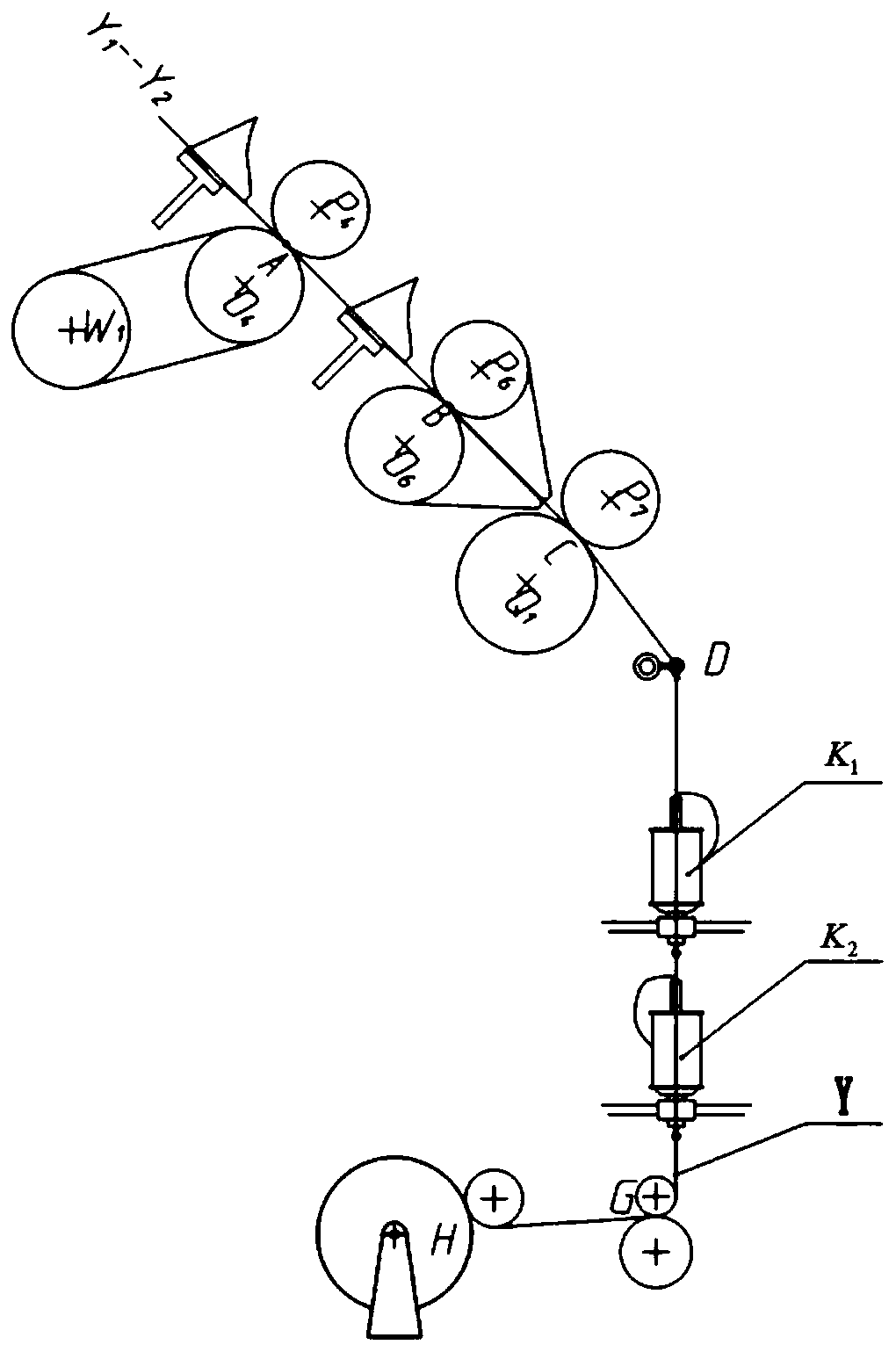

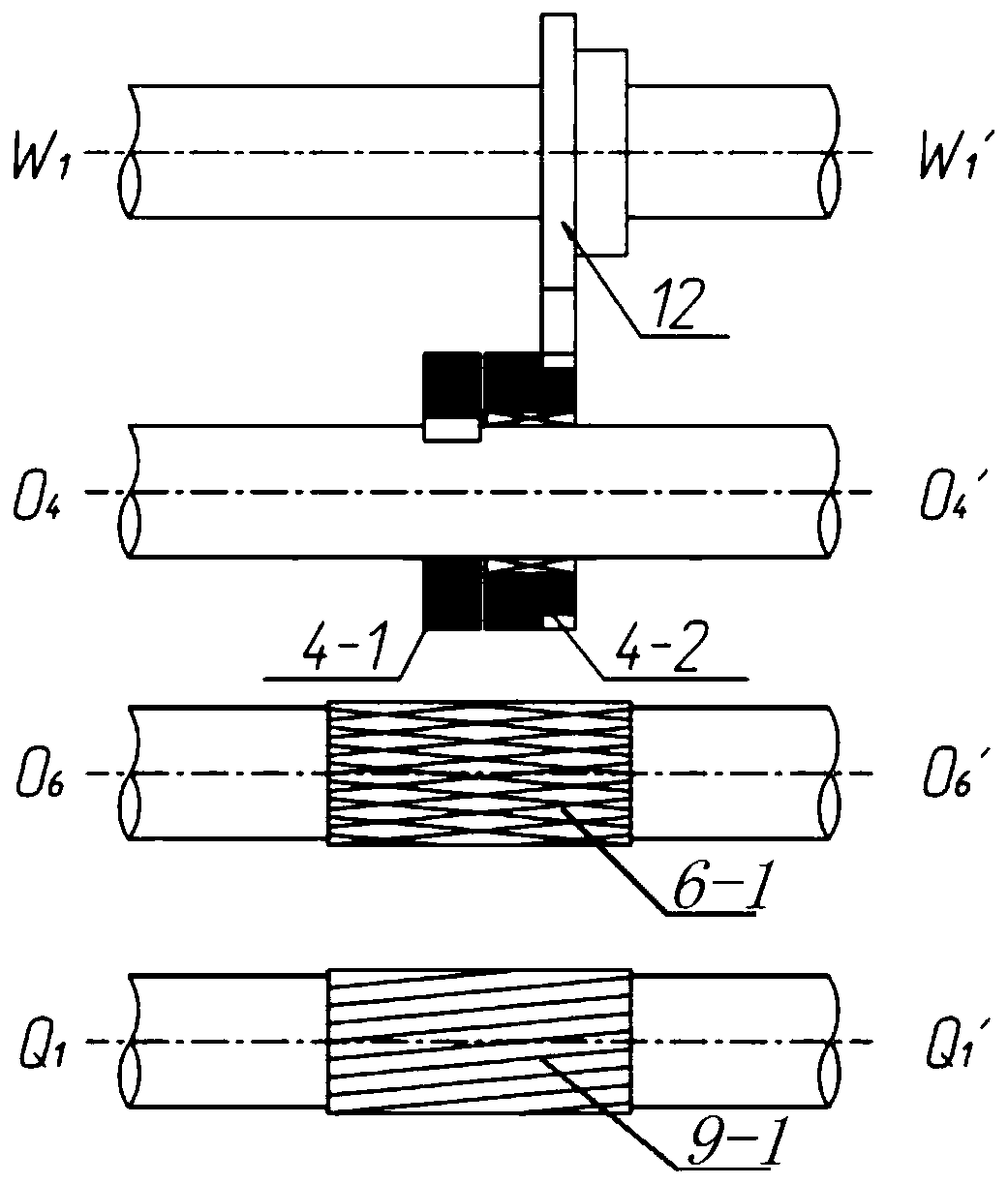

Composite yarn with reverse double-layer wrap structure and negative Poisson's ratio, four-passage hollow spindle spinning apparatus thereof, and control method of four-passage hollow spindle spinning apparatus

The invention relates to a composite yarn with reverse double-layer wrap structure and negative Poisson's ratio, a four-passage hollow spindle spinning apparatus thereof, and a control method of the four-passage hollow spindle spinning apparatus. A flexible fluffy staple-fiber strand is reversely wrapped with two high-modulus low-elongation filament fibers to form a composite yarn self-lock structure; upon low tension, the staple-fiber strand is nearly not restrained by the reversely-wrapped filament fibers and therefore is linear; upon high tension, the staple-fiber strand is bent into a spiral yarn under compression of the reversely-wrapped filament fibers; the structural phase can be changed quickly; particularly when high and low tensile stresses alternate frequently, the composite yarn with reversely-wrapped structure can better adapt to the reversible change of the structural phase, so that effectiveness of the negative Poisson's ratio effect of the composite yarn is guaranteed;in addition, linear density of a staple-fiber core is adjusted through an asynchronous drafting mechanism servo-driven by a PLC (programmable logic controller), the negative Poisson's ratio coefficient of the composite yarn is segmentally changed according to a preset law, and therefore, designability of the yarn structure and distribution controllability for the negative Poisson's ratio coefficient of the composite yarn can be achieved.

Owner:JIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com