Method for evaluating stress concentration and fatigue damage based on feature permeability detection

A technique for fatigue damage and stress concentration, applied in the direction of material magnetic variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

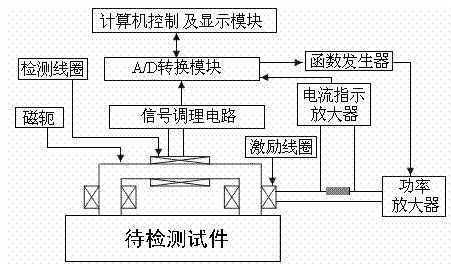

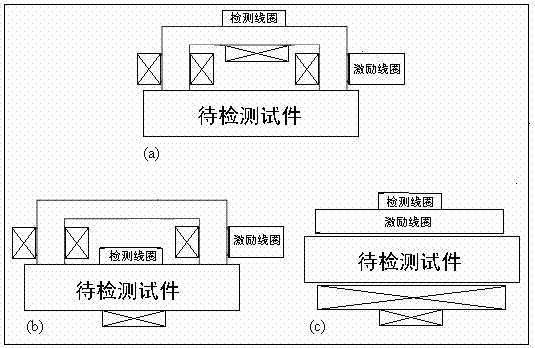

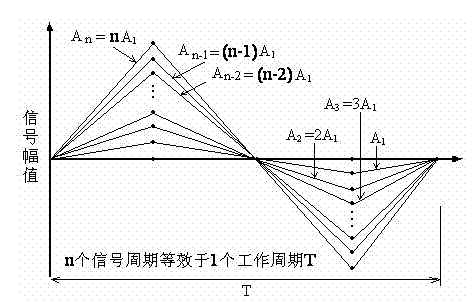

[0017] The invention is a new detection method of stress concentration and fatigue damage, which is called metal characteristic magnetic permeability detection method here. The detection method is characterized in that the maximum differential permeability is used to detect the change of the microstructure characteristic value corresponding to the ferromagnetic test piece. The metal characteristic magnetic permeability detection method can detect the stress concentration area and fatigue damage degree of metal components; it can detect the transition status of mechanical toughness and mechanical brittleness of components; it can detect ferromagnetic materials austenite and martensite, ferrite and pearlite The phase transition process of the body; it can detect the defects and dislocation density of ferromagnetic materials; it can detect the changes of grains and grain boundaries. The detection method of the invention is characterized in that the maximum differential permeabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com