Patents

Literature

405 results about "Magnetic hysteresis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic hysteresis occurs when an external magnetic field is applied to a ferromagnet such as iron and the atomic dipoles align themselves with it. Even when the field is removed, part of the alignment will be retained: the material has become magnetized. Once magnetized, the magnet will stay magnetized indefinitely. To demagnetize it requires heat or a magnetic field in the opposite direction. This is the effect that provides the element of memory in a hard disk drive.

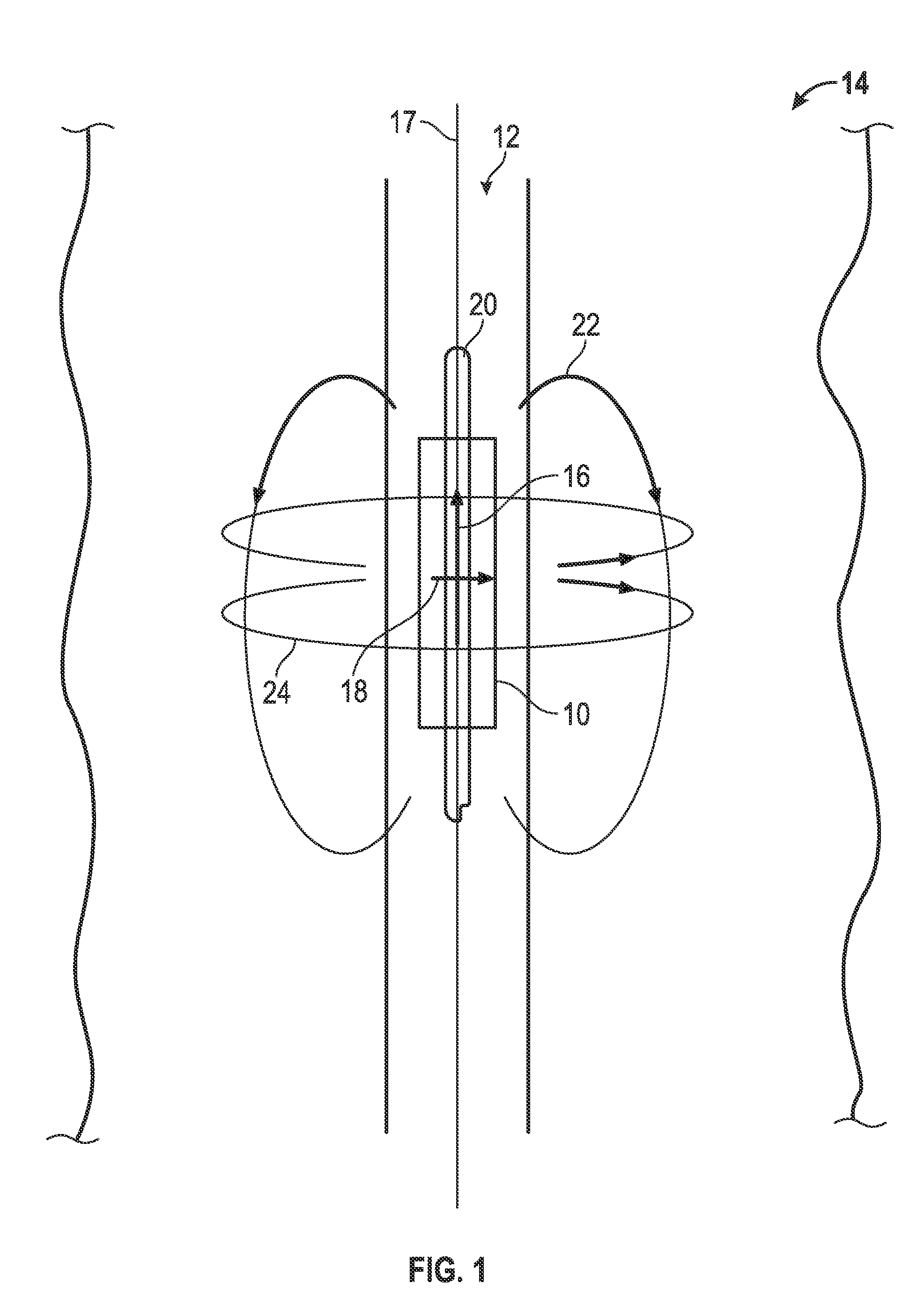

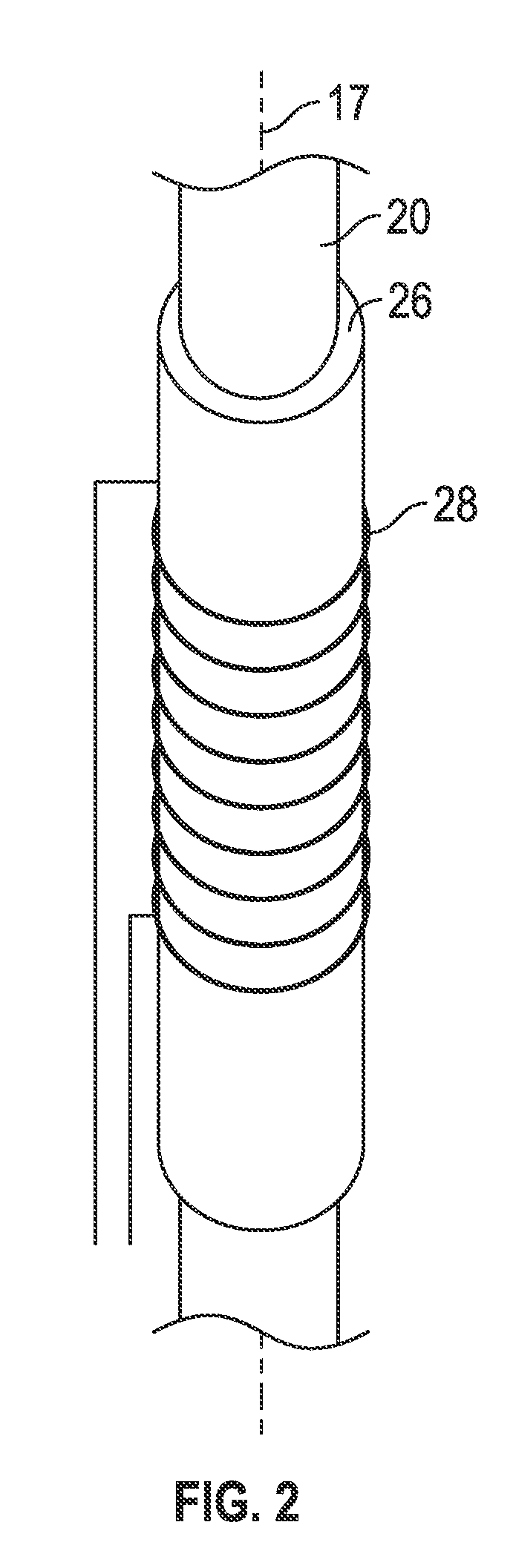

Method and apparatus of using magnetic material with residual magnetization in transient electromagnetic measurement

ActiveUS20050189945A1Facilitates highly effective generationQuick switchElectric/magnetic detection for well-loggingAcoustic wave reradiationWell loggingTransmitter antenna

Owner:BAKER HUGHES INC

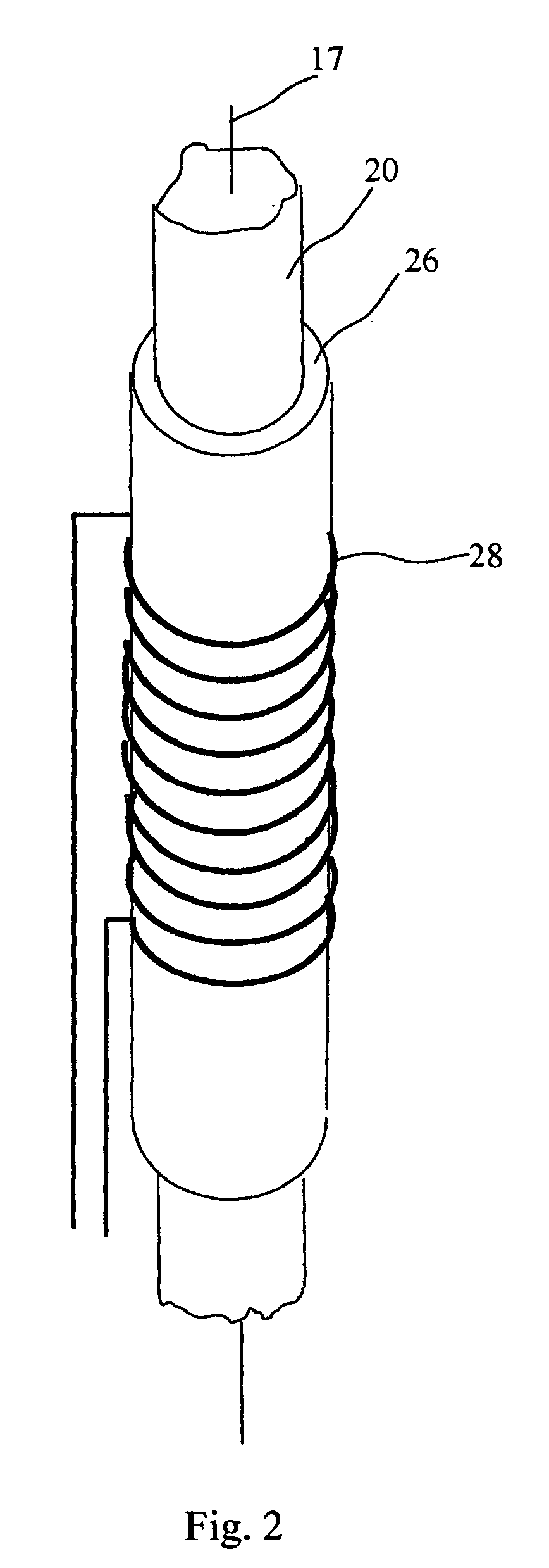

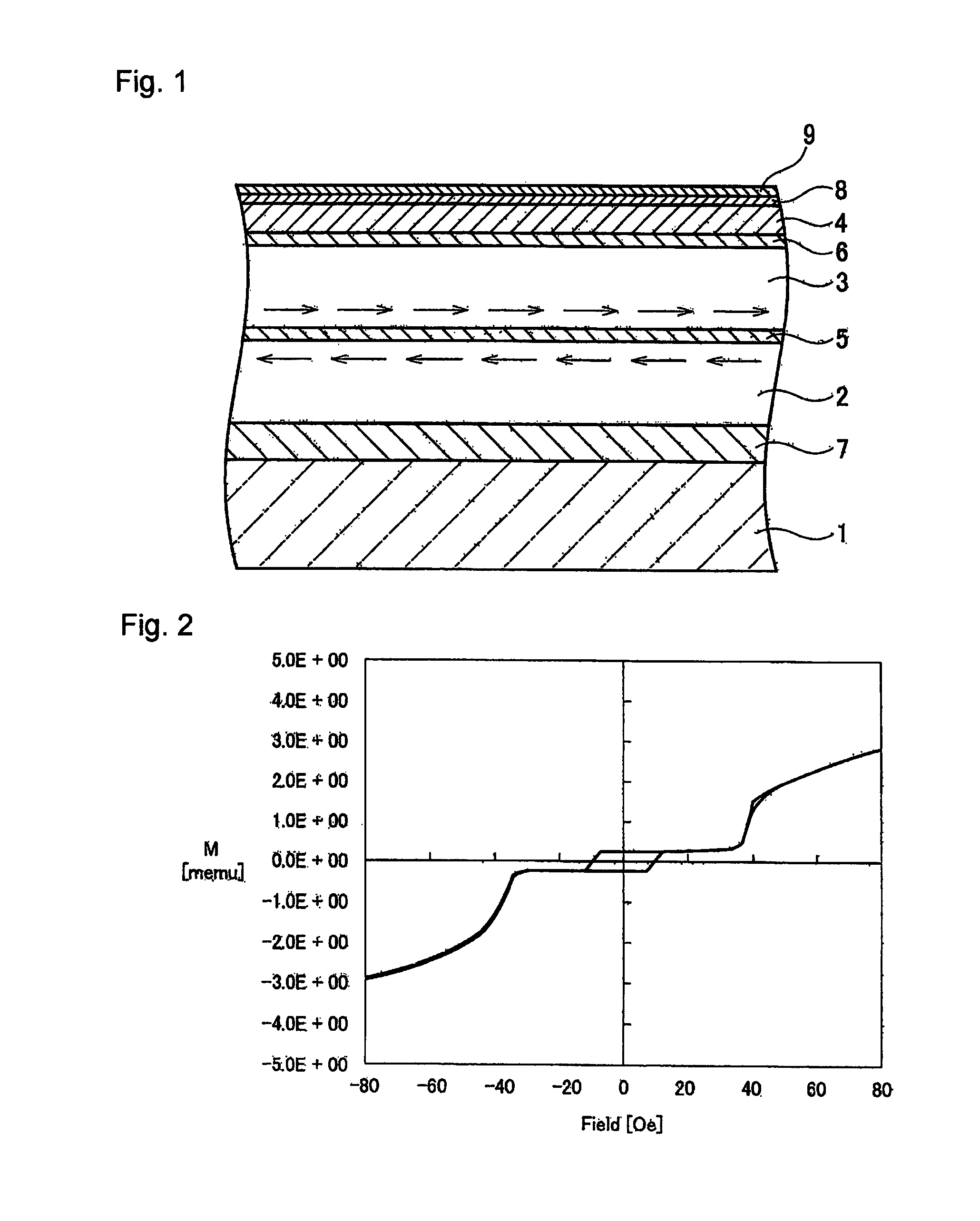

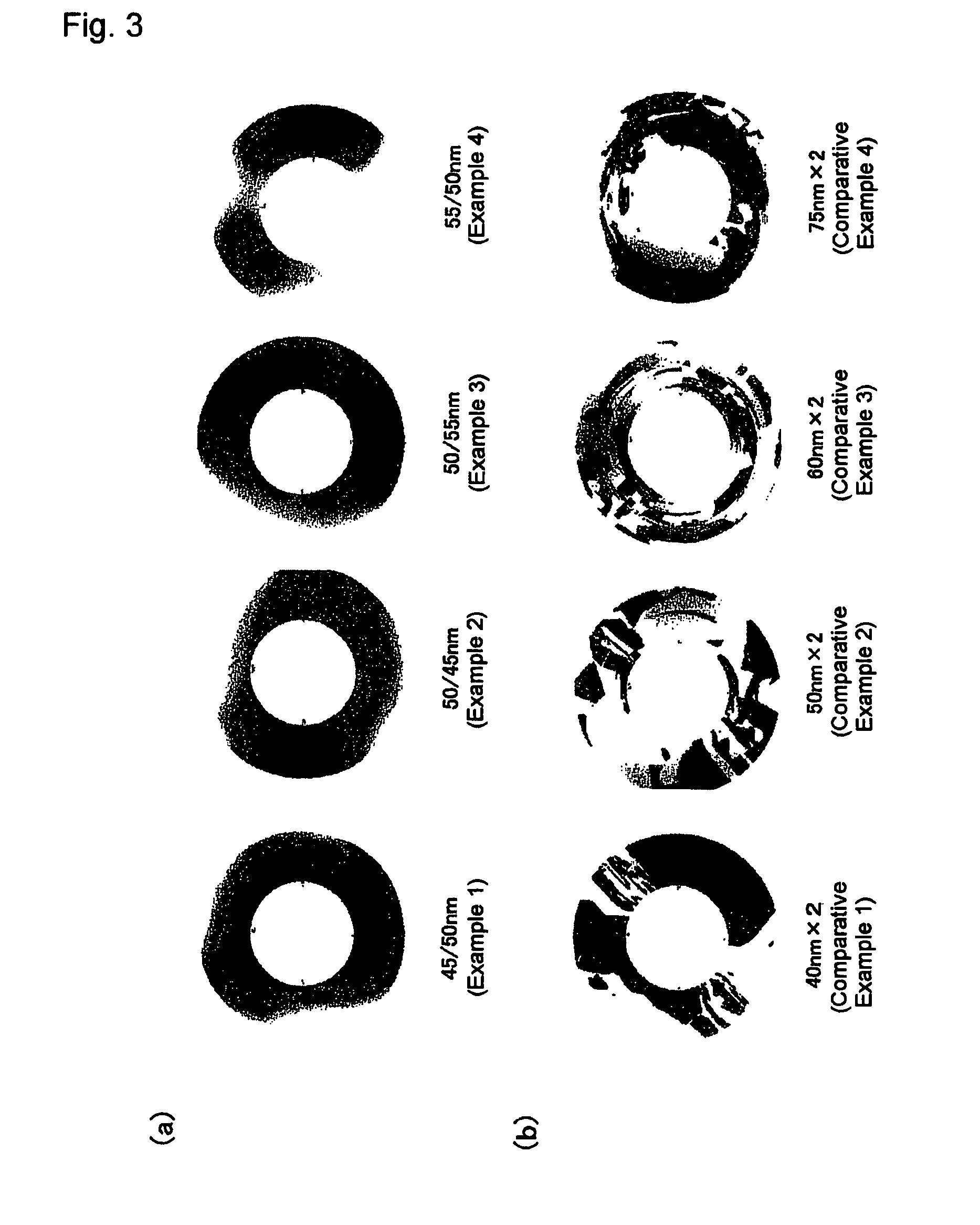

Magnetic recording medium substrate and perpendicular magnetic recording medium

InactiveUS7955723B2Inhibition formationSuppress generation of medium noiseLayered productsRecord information storageNon magneticMagnetic characteristic

A perpendicular magnetic recording medium comprising a pair of soft magnetic layers that are laminated via a non-magnetic layer and antiparallel-coupled to each other and that are provided between a non-magnetic substrate and a magnetic recording layer, wherein spike noise and medium noise can be positively suppressed when information recording and reproduction are carried out at high recording surface density. At least one pair of soft magnetic layers are laid and formed via a non-magnetic layer on a substrate of a non-magnetic material so that magnetic characteristics obtained by integrating the pair of soft magnetic layers have a magnetic hysteresis to thereby prevent the formation of a magnetic domain wall.

Owner:WESTERN DIGITAL TECH INC

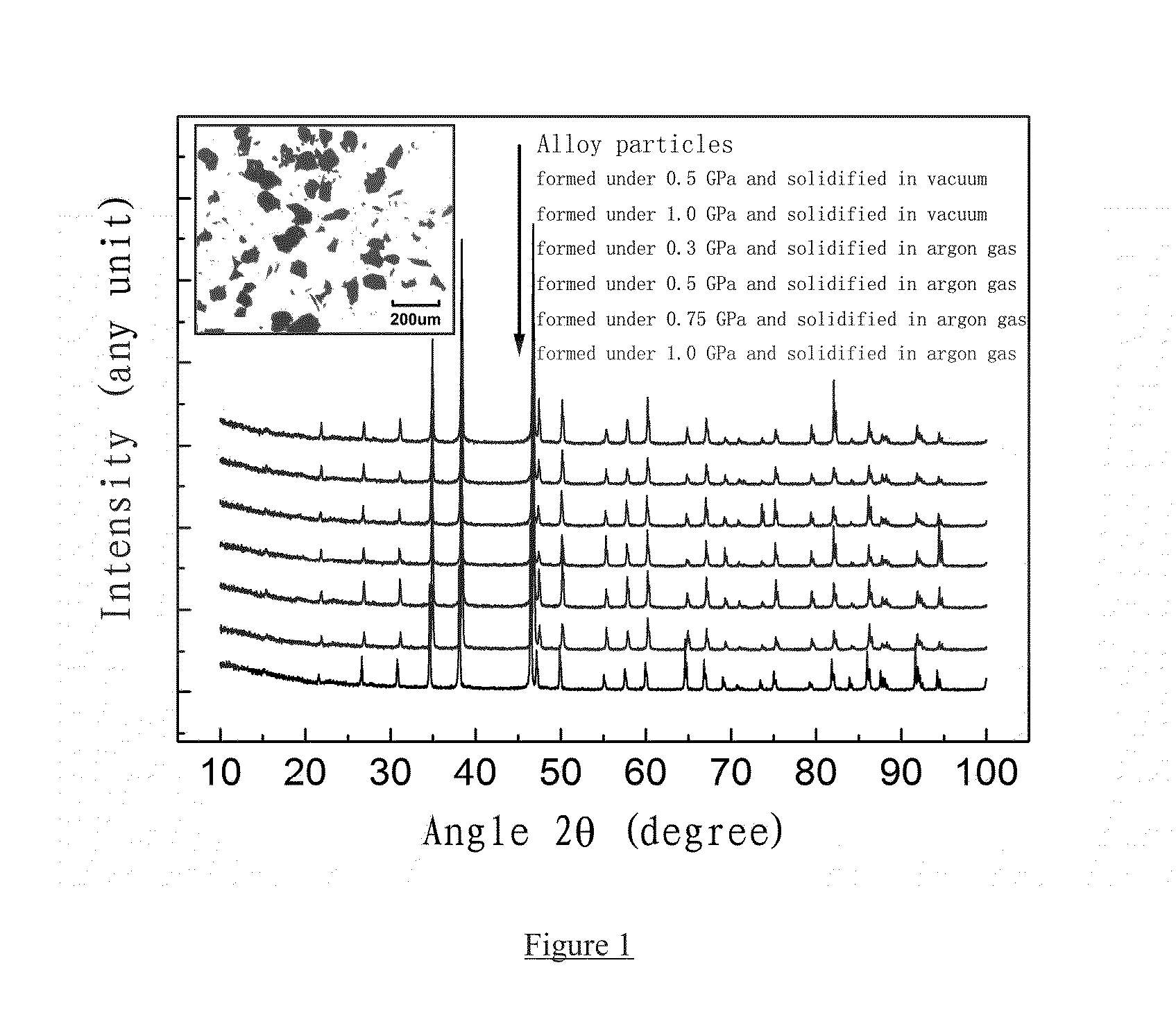

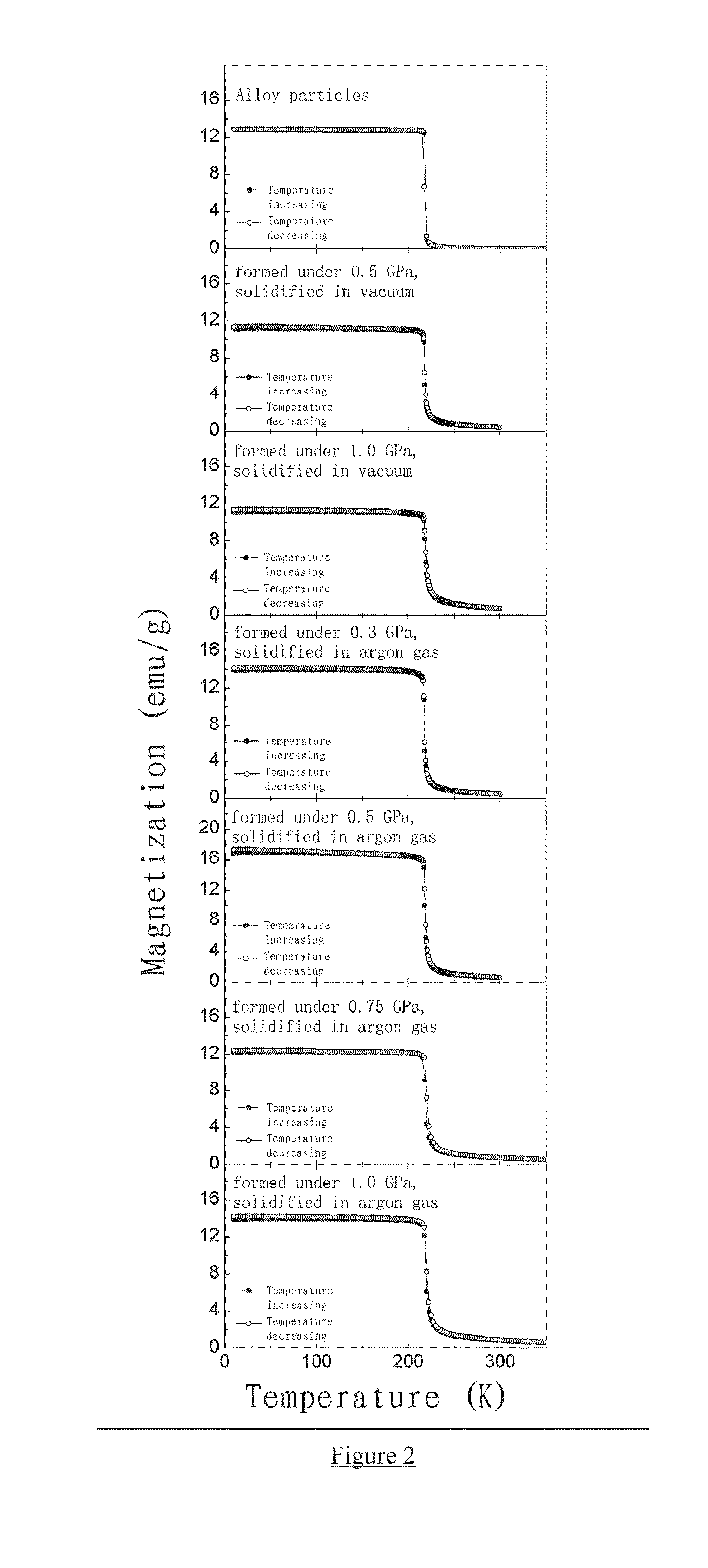

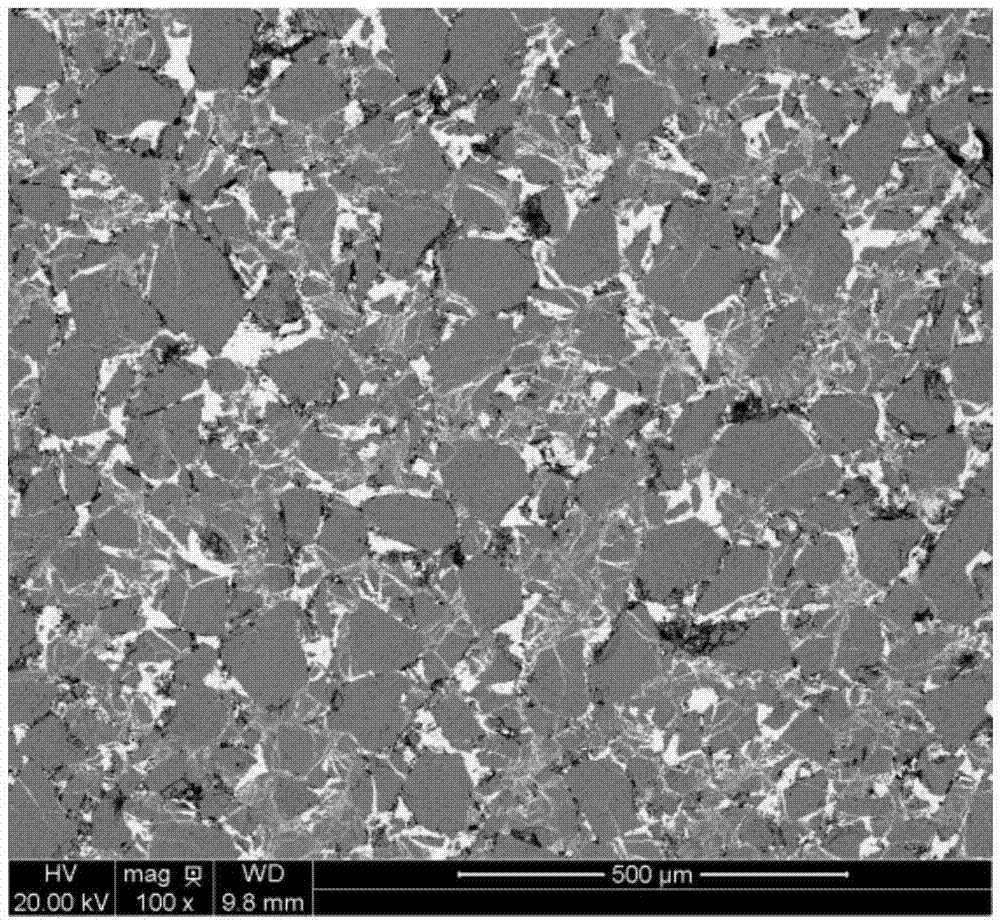

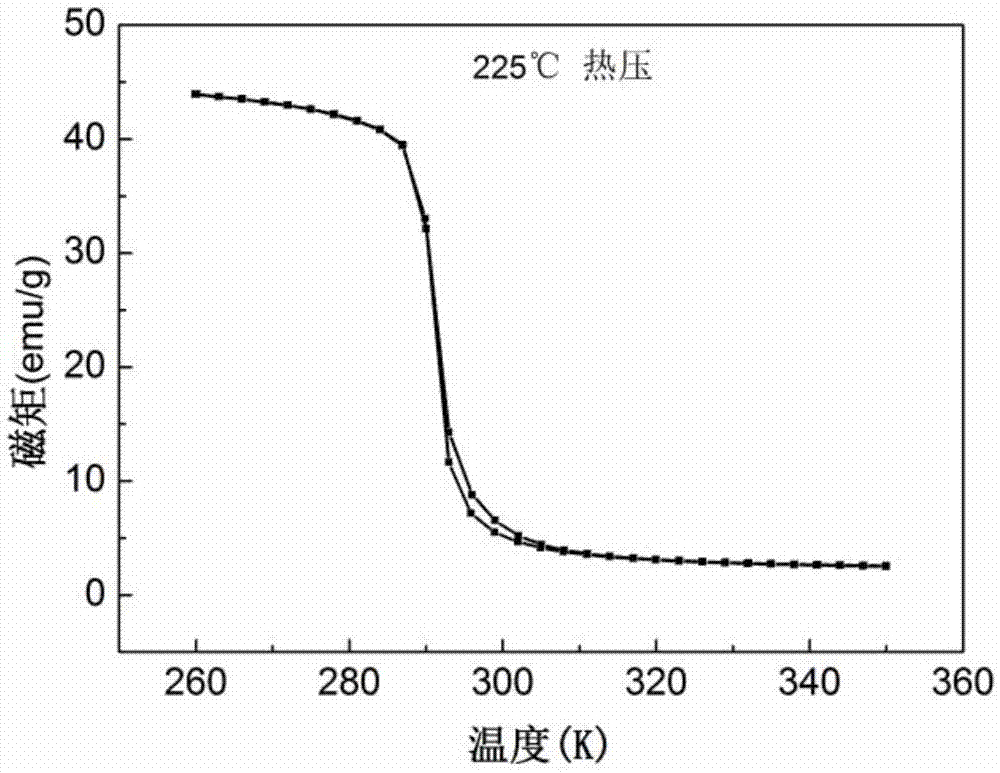

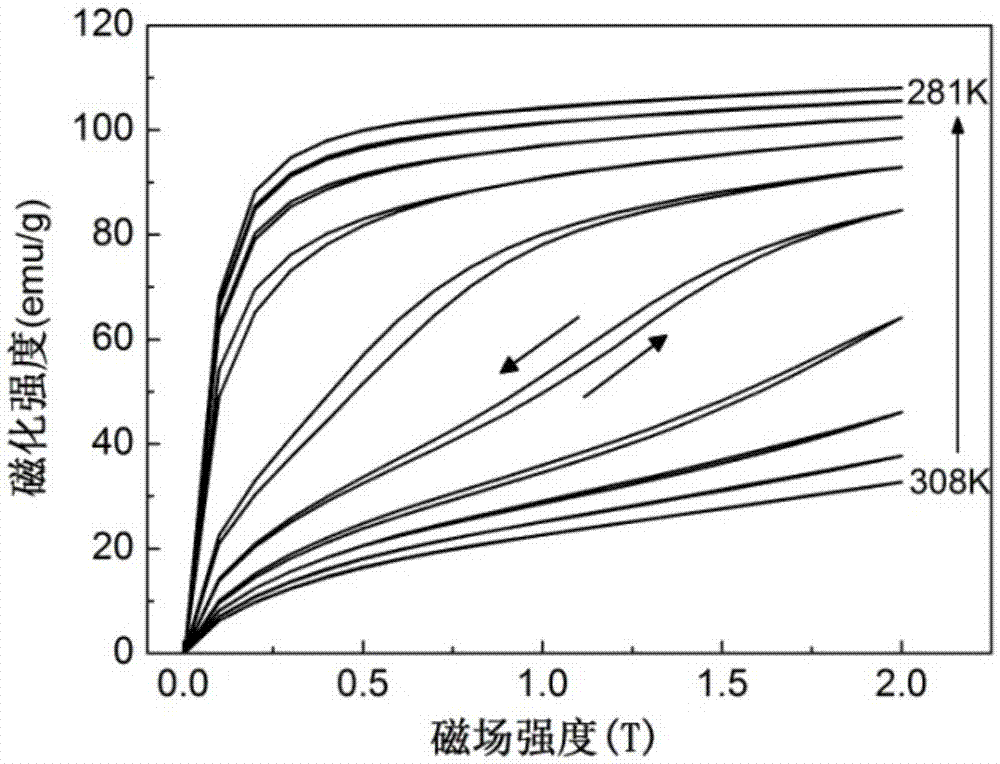

BONDED La(Fe,Si)13-BASED MAGNETOCALORIC MATERIAL AND PREPARATION AND USE THEREOF

InactiveUS20150047371A1Low priceEasy to operateInorganic material magnetismMachines using electric/magnetic effectsCeriumCobalt

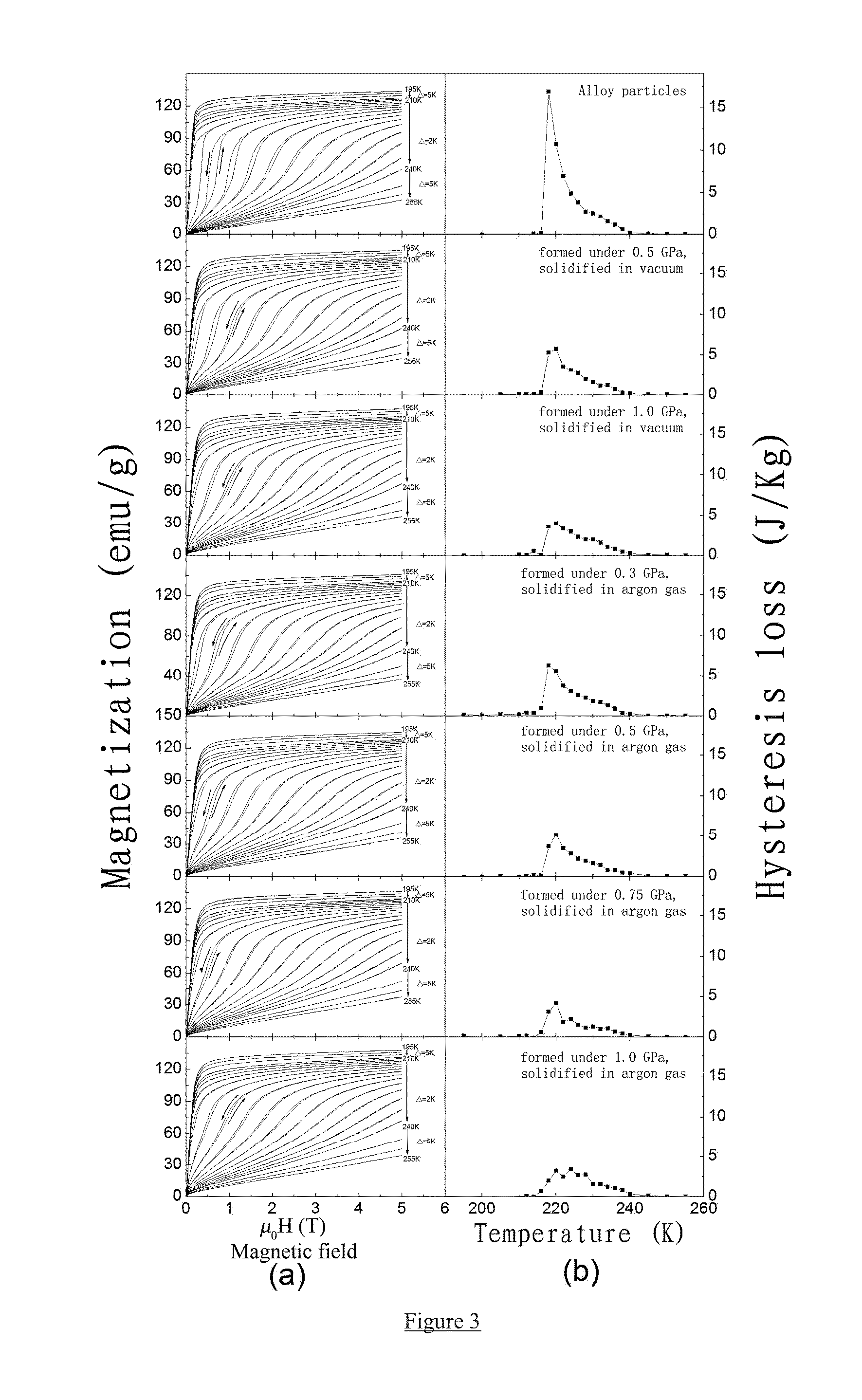

Provided is a high-strength, bonded La(Fe, Si)13-based magnetocaloric material, as well as a preparation method and use thereof. The magnetocaloric material comprises magnetocaloric alloy particles and an adhesive agent, wherein the particle size of the magnetocaloric alloy particles is less than or equal to 800 μm and are bonded into a massive material by the adhesive agent; the magnetocaloric alloy particle has a NaZn13-type structure and is represented by a chemical formula of La1-xRx(Fe1-p-qCopMnq)13-ySiyAα, wherein R is one or more selected from elements cerium (Ce), praseodymium (Pr) and neodymium (Nd), A is one or more selected from elements C, H and B, x is in the range of 0≦x≦0.5, y is in the range of 0.8≦y≦2, p is in the range of 0≦p≦0.2, q is in the range of 0≦q≦0.2, α is in the range of 0≦α≦3.0. Using a bonding and thermosetting method, and by means of adjusting the forming pressure, thermosetting temperature, and thermosetting atmosphere, etc., a high-strength, bonded La(Fe, Si)13-based magnetocaloric material can be obtained, which overcomes the frangibility, the intrinsic property, of the magnetocaloric material. At the same time, the magnetic entropy change remains substantially the same, as compared with that before the bonding. The magnetic hysteresis loss declines as the forming pressure increases. And the effective refrigerating capacity, after the maximum loss being deducted, remains unchanged or increases.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

Optimization design method for high-efficiency synchronous motor of new energy automobile

InactiveCN104319969AElectronic commutation motor controlVector control systemsSynchronous motorNew energy

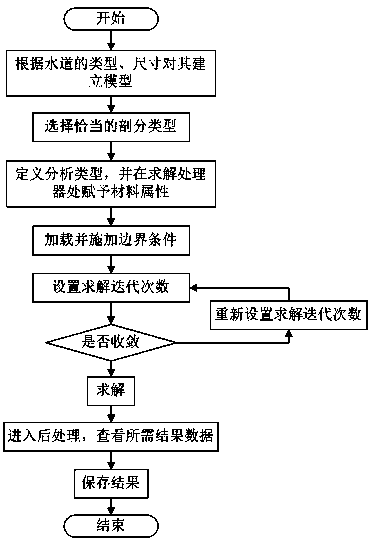

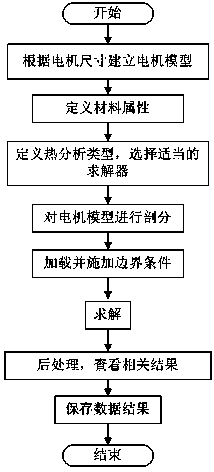

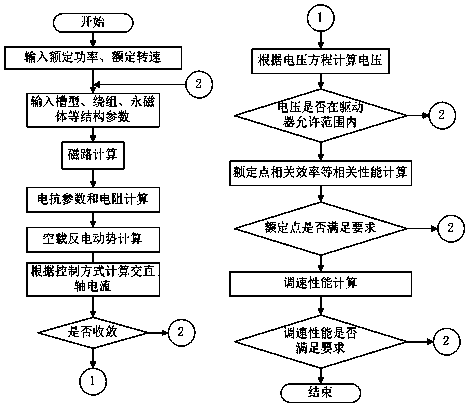

The invention relates to an optimization design method for a high-efficiency synchronous motor of a new energy automobile. The method includes the steps that an iron loss computation model is established for the permanent magnet synchronous motor, and magnetic density changes are researched, so that magnetic hysteresis losses and no-load iron losses corresponding to different sub-harmonic magnetic fields are obtained; theoretical analysis and finite element solving are performed on load stray losses of the permanent magnet synchronous motor of the automobile in the aspects of a stator, a rotor and a permanent magnet, and permanent magnet eddy-current losses are restrained; a water cooling system of the motor is analyzed, influences on the high-efficiency range and weak magnetic performance by parameter matching are analyzed, the rotor structure form, polar trough matching and no-load counter electromotive force of the motor sample are designed, and the motor sample is tested. Through analyzing the magnetic field features, the magnetic hysteresis losses and eddy-current losses, the degree and distribution of rotor losses and the permanent magnetic eddy-current losses are accurately computed under matching between different rotor structures and polar troughs, and therefore effective measures for restraining the rotor losses and permanent magnetic eddy-current losses are found.

Owner:芜湖杰诺瑞汽车电器系统有限公司

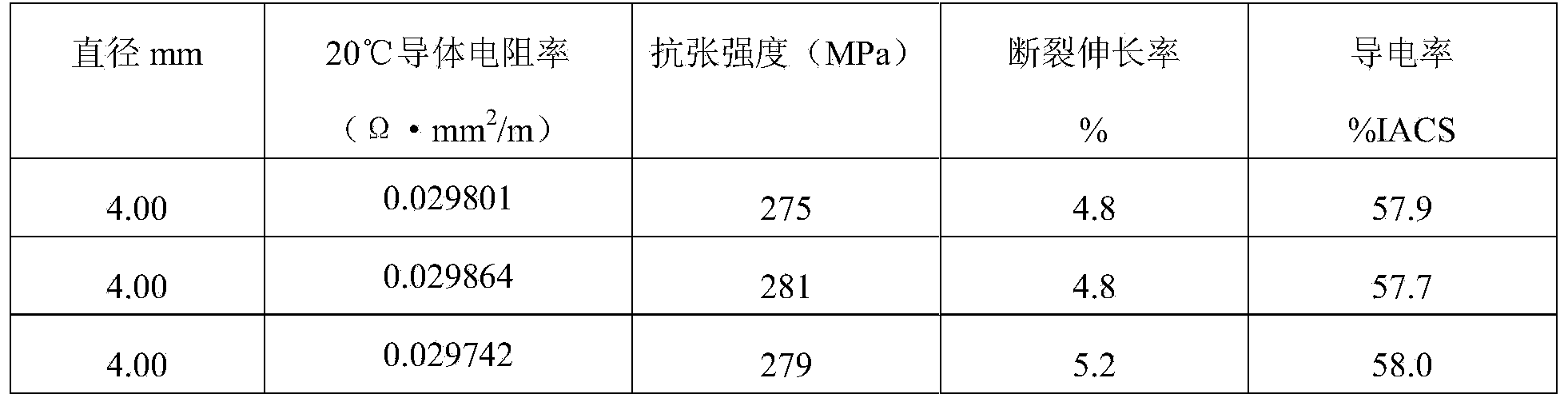

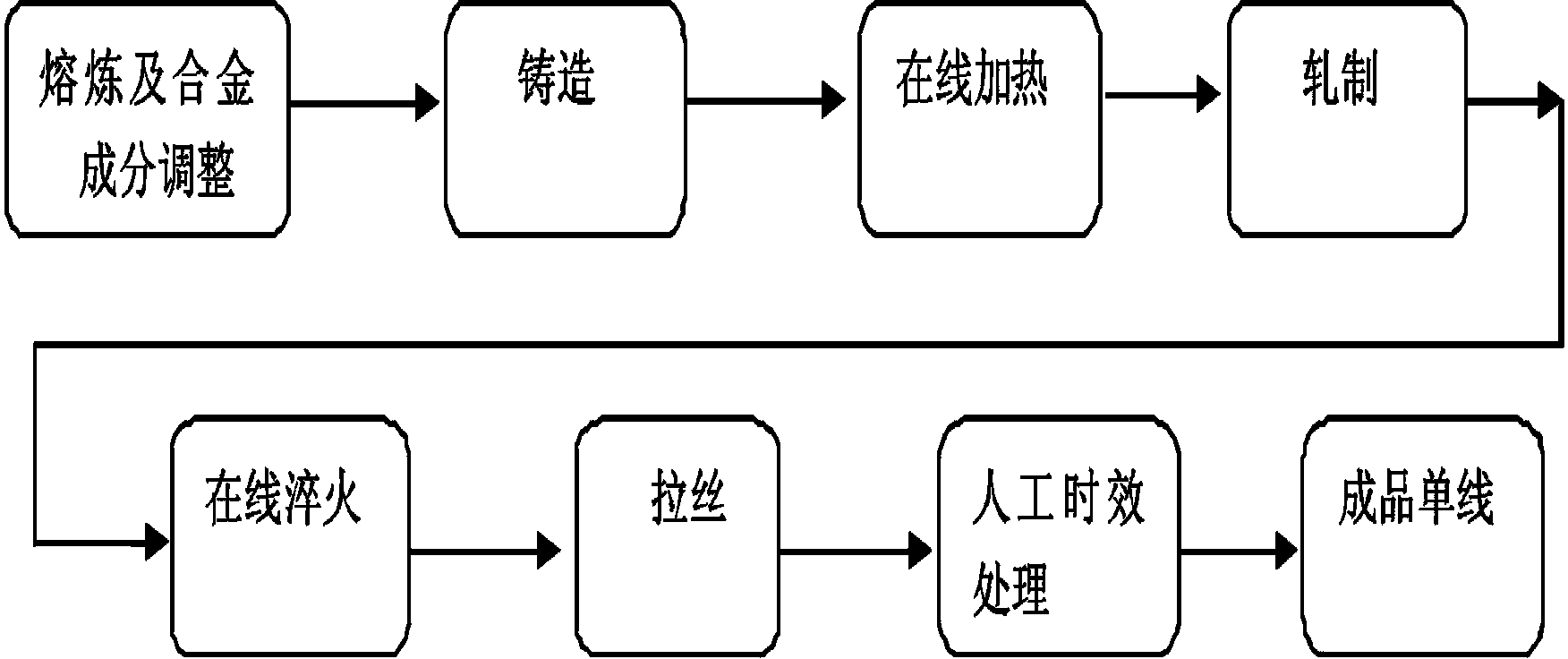

Intermediate-strength aluminum alloy wire and process for manufacturing same

ActiveCN104028961APurify gas impuritiesHigh strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsEddy currentSolid solution

The invention belongs to the field of overhead power transmission technologies, and discloses an intermediate-strength aluminum alloy wire and a process for manufacturing the same. The intermediate-strength aluminum alloy wire is used for an overhead conducting wire. The process includes adjusting components of alloy to a certain extent, and controlling an online deaeration purification system, rolling and an online solid-solution quenching system; performing wire drawing and ageing processing to ultimately obtain the single intermediate-strength aluminum alloy wire. The tensile strength of the single intermediate-strength aluminum alloy wire ranges from 260MPa to 300MPa, the elongation of the single intermediate-strength aluminum alloy wire is higher than or equal to 3.5%, and the single-wire conductivity of the single intermediate-strength aluminum alloy wire is higher than or equal to 57.5% IACS. The intermediate-strength aluminum alloy wire and the process have the advantages that the intermediate-strength aluminum alloy wire manufactured by the aid of the process is high in strength and elongation and good in conductivity, and an intermediate-strength aluminum alloy stranded wire which is formed after a plurality of intermediate-strength aluminum alloy wires are stranded with one another can be used for an overhead power transmission line and is high in tensile weight ratio, so that the running safety of the line can be improved; magnetic hysteresis loss and eddy current loss due to conventional steel-cored aluminum stranded wires can be prevented by the stranded wire which is completely formed after the intermediate-strength aluminum alloy wires are stranded with one another, and electric energy loss of the line can be greatly reduced.

Owner:FAR EAST CABLE +2

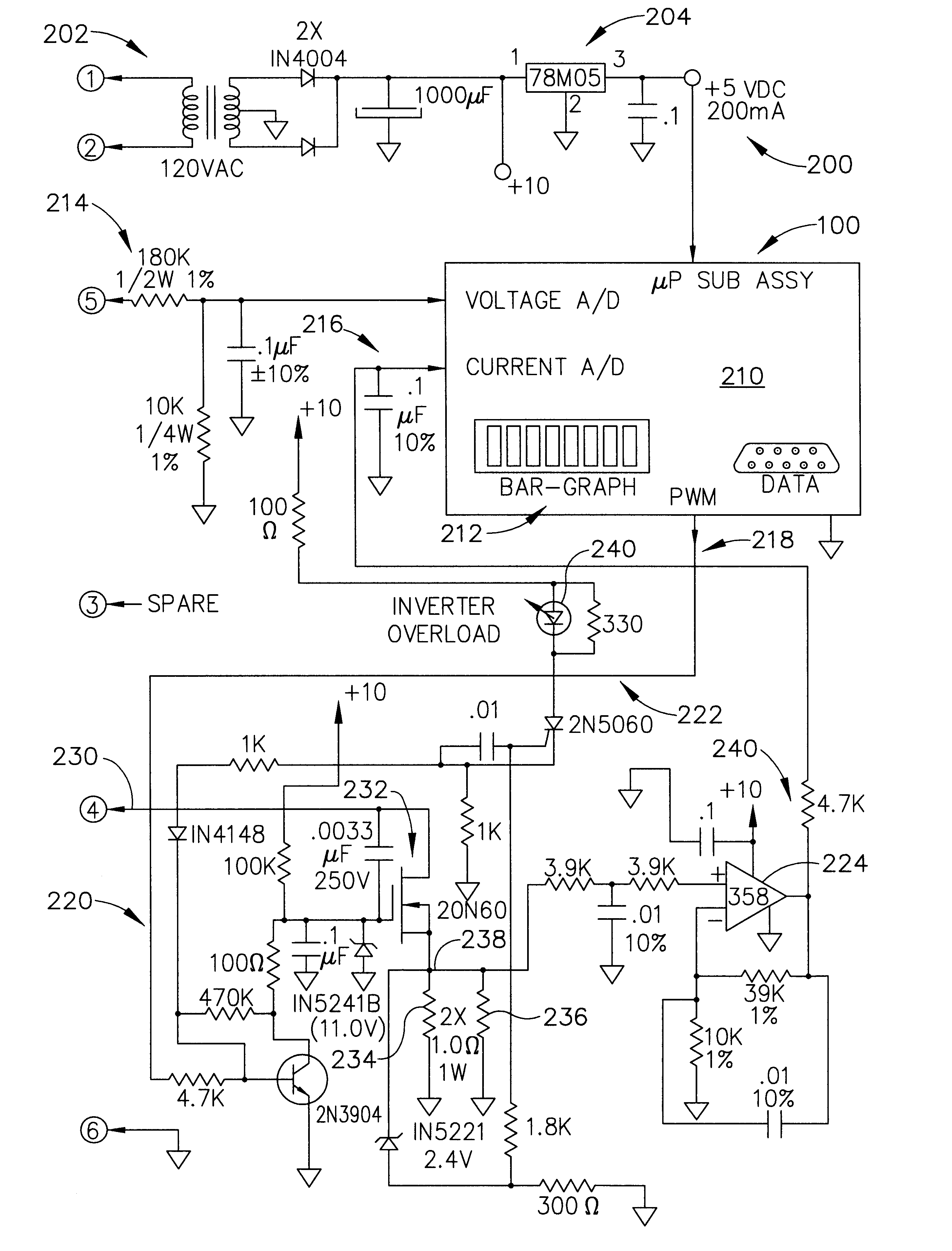

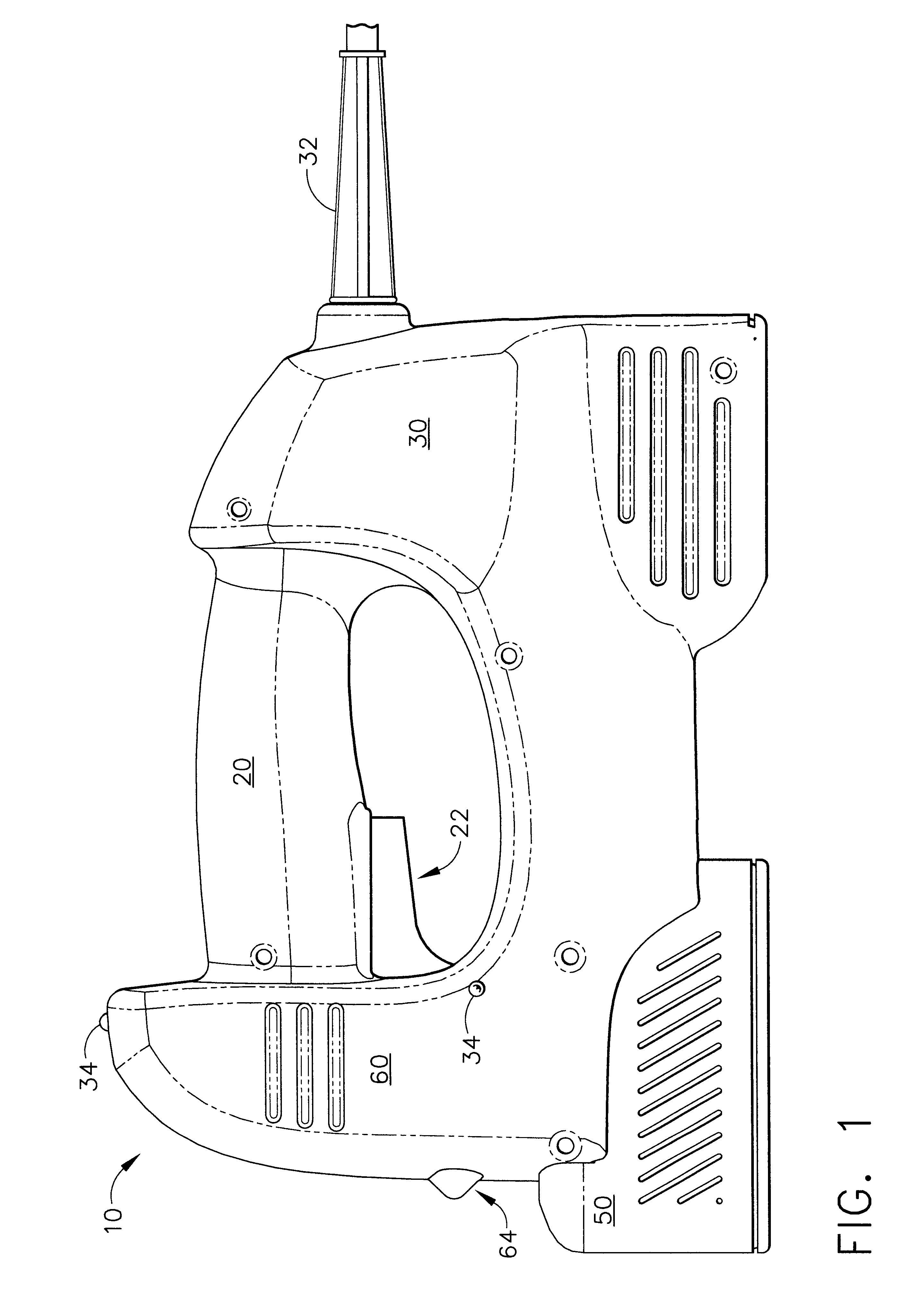

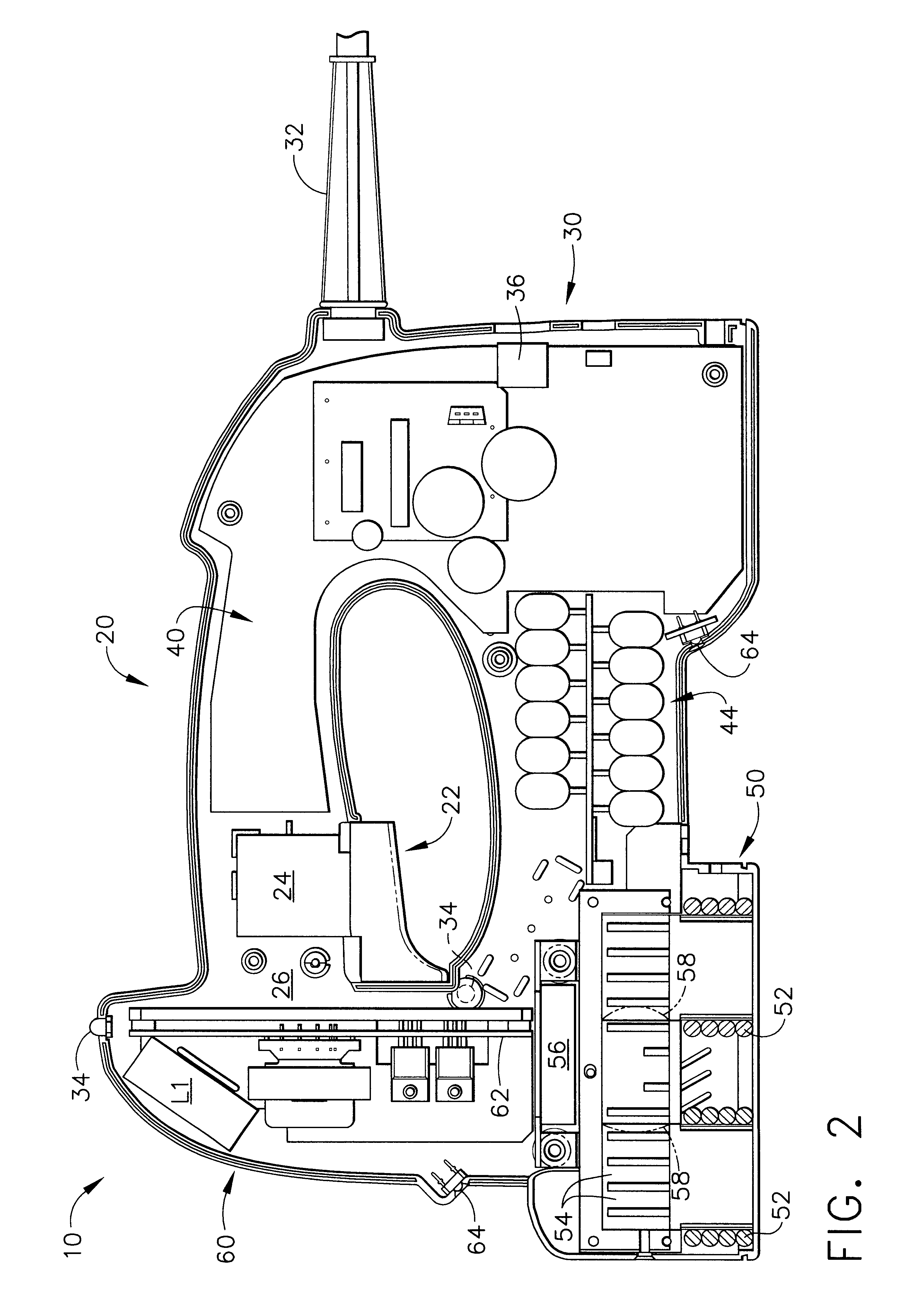

Hand held induction tool with energy delivery scheme

An apparatus and system for using magnetic fields to heat magnetically susceptible materials within and / or adjacent to adhesives, resins, or composites so as to reversibly or irreversibly bond, bind, or fasten opaque or non-opaque solid materials to one another. The system makes use of the effect that alternating magnetic fields induce eddy currents and generate heat within susceptors, and the effect that alternating magnetic fields additionally induce magnetic hysteresis that occurs in magnetic materials and thereby generate heat. An induction heating tool is used to emit the magnetic field at its work coil, and an electronic controller measures the energy being used by a power converter that generates the alternating current driving the work coil which creates the magnetic field. The distance between the susceptor and work coil is repeatedly analyzed based upon the power converter's input energy, and the work coil is driven at a repeatedly corrected power level during the heating cycle. Once a sufficient accumulated energy has been delivered to the susceptor, the magnetic field is turned off automatically by the tool, thus preventing overheating of the susceptor.

Owner:OMG INC

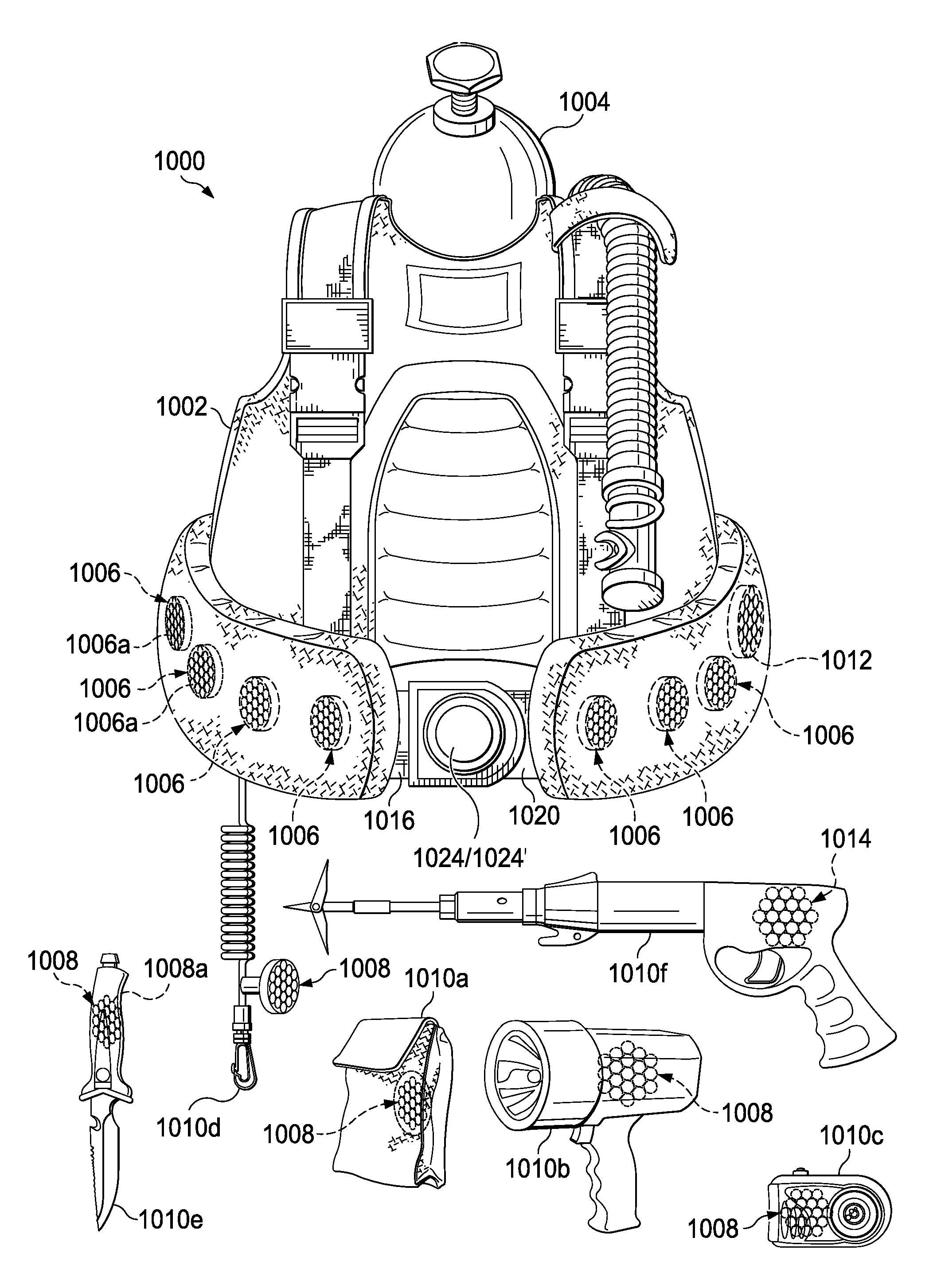

Correlated magnetic harness and method for using the correlated magnetic harness

A harness is described herein that uses correlated magnets to enable objects to be secured thereto and removed therefrom. Some examples of such a harness include a construction work harness, a soldier harness, an astronaut harness, and a scuba harness (e.g., buoyancy compensator). For instance, the scuba harness can have different types of objects secured thereto and removed therefrom such as a weight pouch, a utility pocket, a dive light (flash light), a camera, a scuba lanyard, a navigation board, a depth gauge, a spear gun, or any type of military equipment.

Owner:CORRELATED MAGNETICS RES LLC

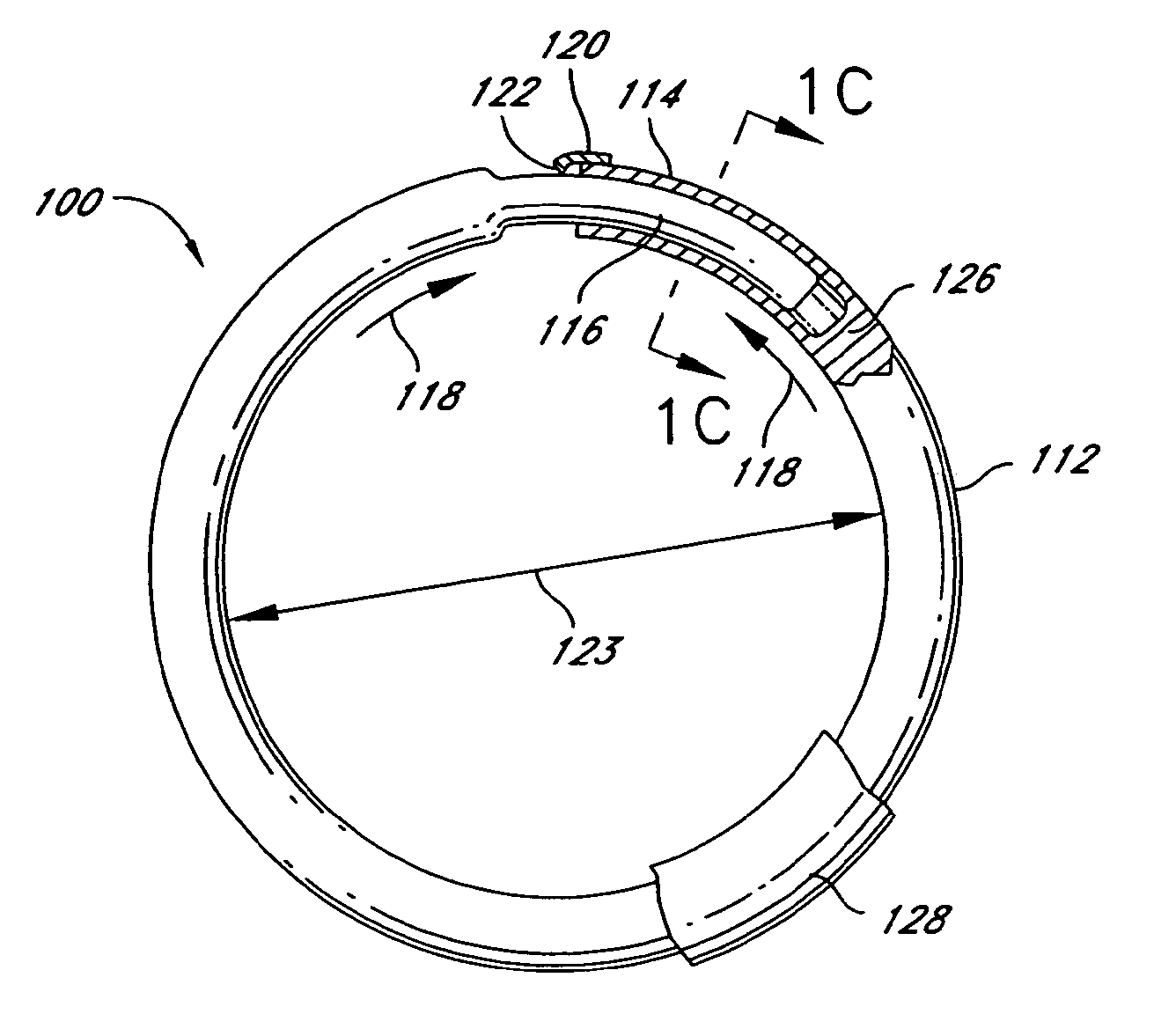

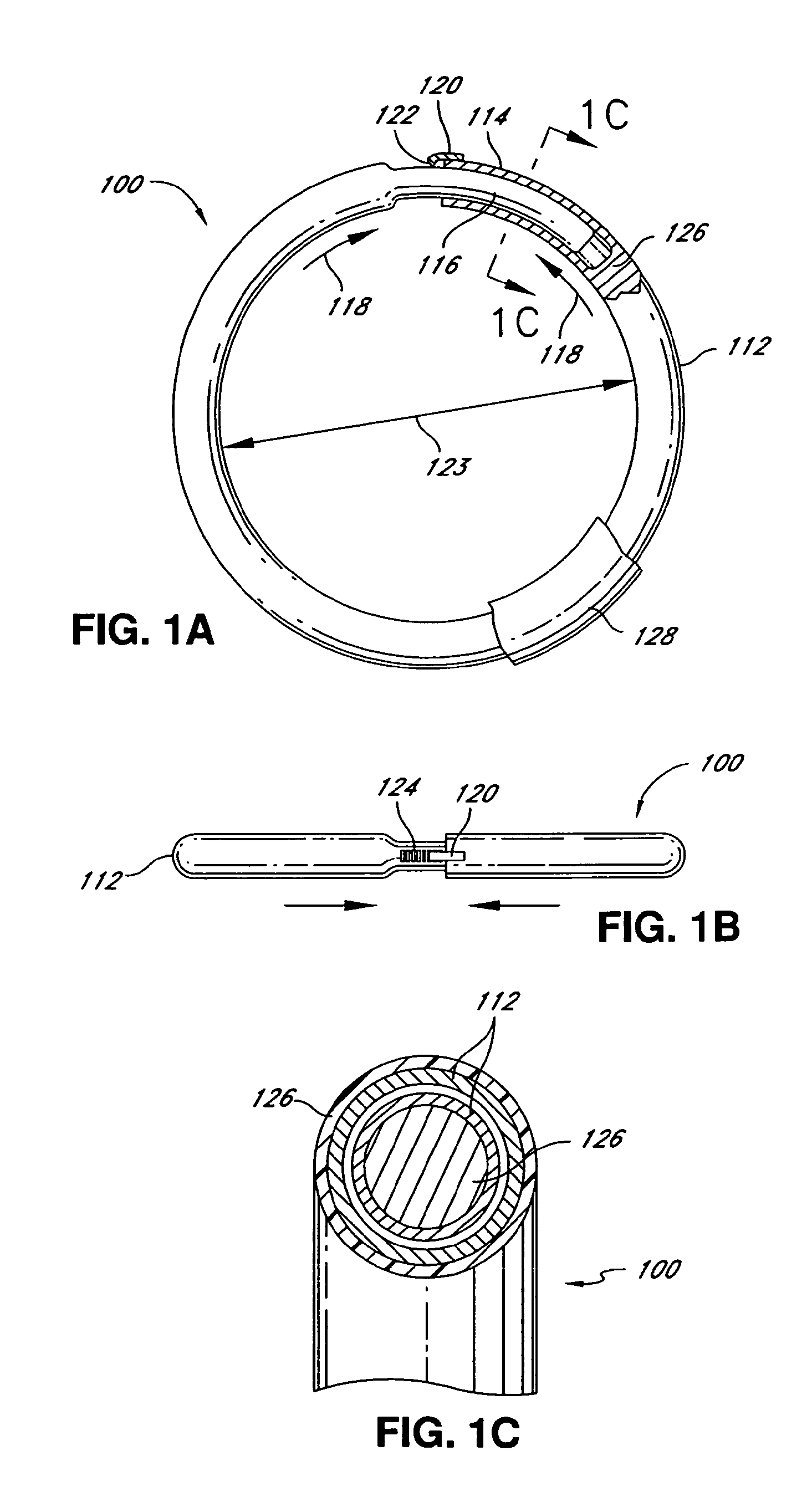

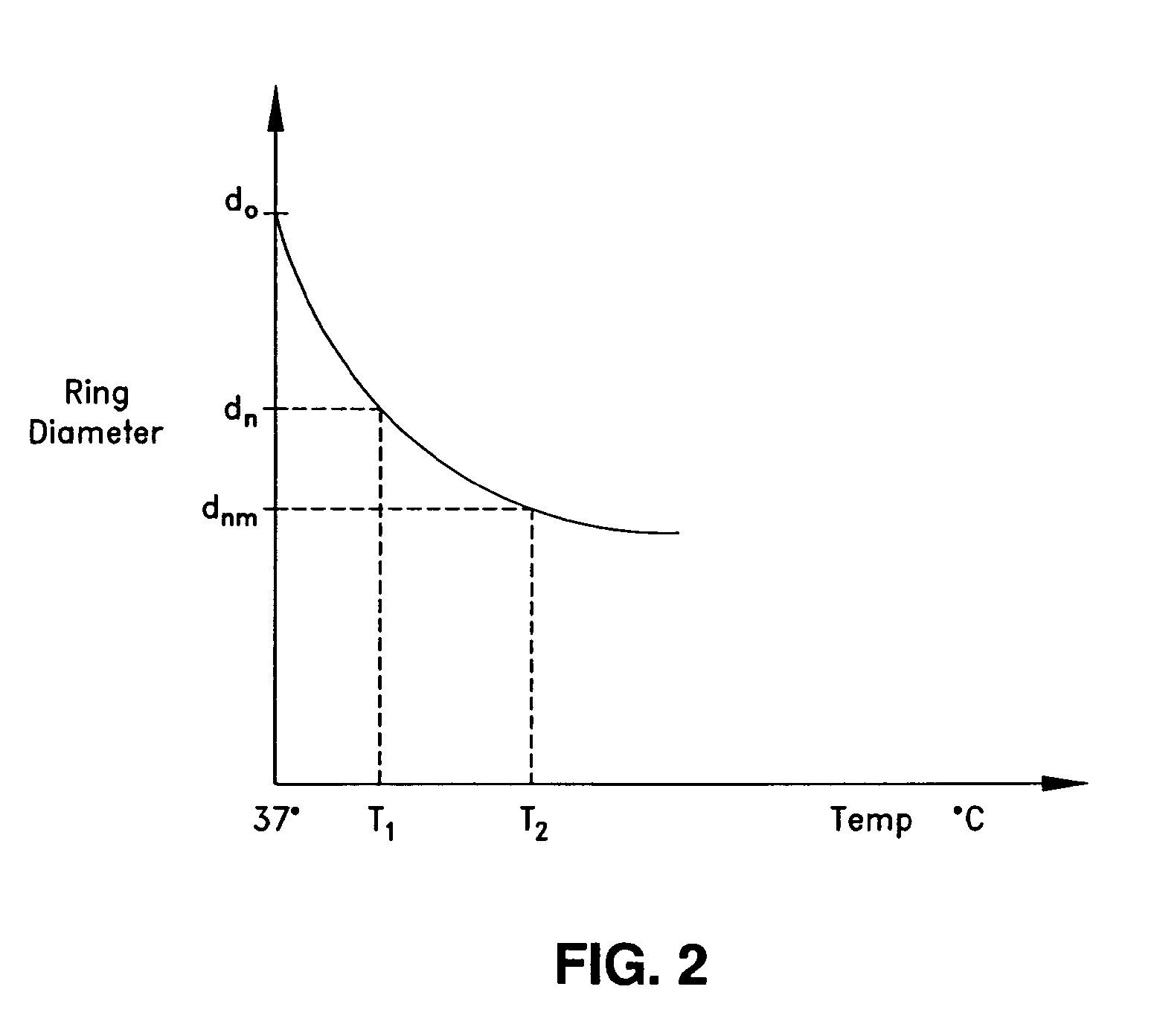

Adjustable annuloplasty ring activation system

InactiveUS20120221101A1Annuloplasty ringsTubular organ implantsActivation energyBiological activation

An adjustable annuloplasty device is described. The device includes a body member comprising a shape memory material, the body member configured to be placed at or near a base of a valve of a heart. The device further includes a hysteretic material configured to undergo magnetic hysteresis in response to a first activation energy, the hysteretic material being in thermal communication with the shape memory material. The body member may have a first size of a body member dimension in a first configuration and a second size of the body member dimension in a second configuration. When the body member is in position in the heart, a change from the first configuration to the second configuration changes a size of a dimension of the annulus of the valve.

Owner:MICARDIA CORP

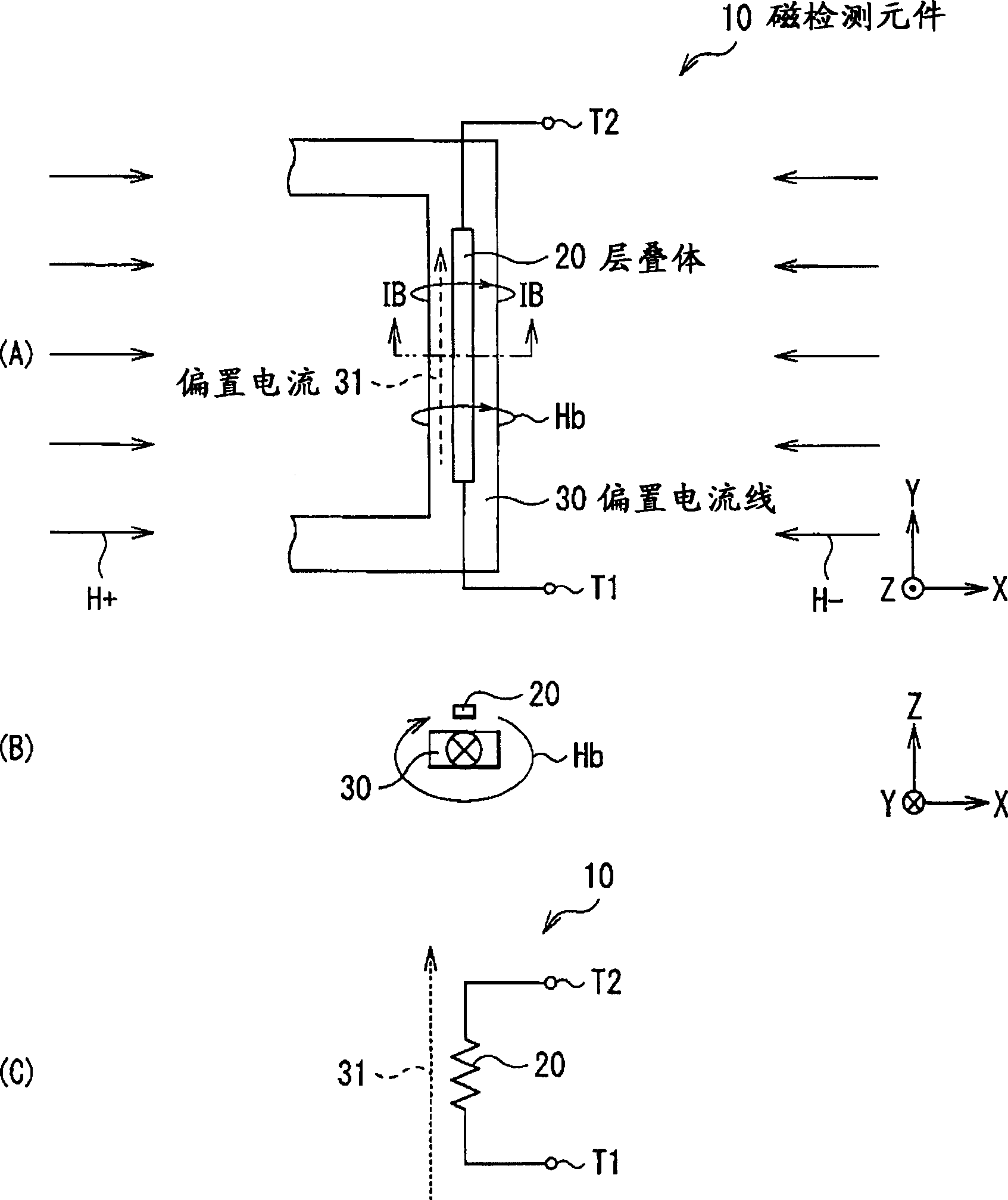

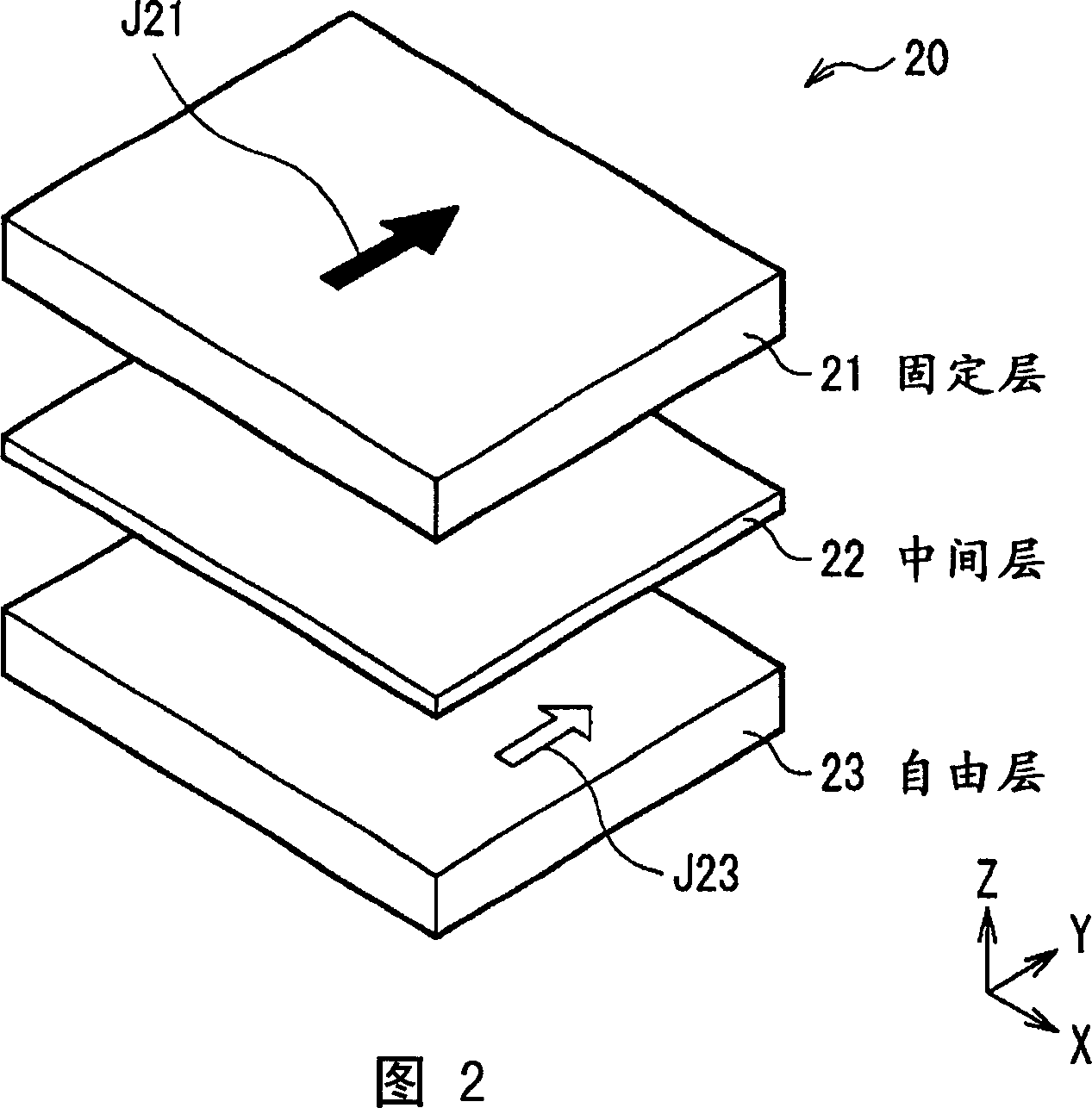

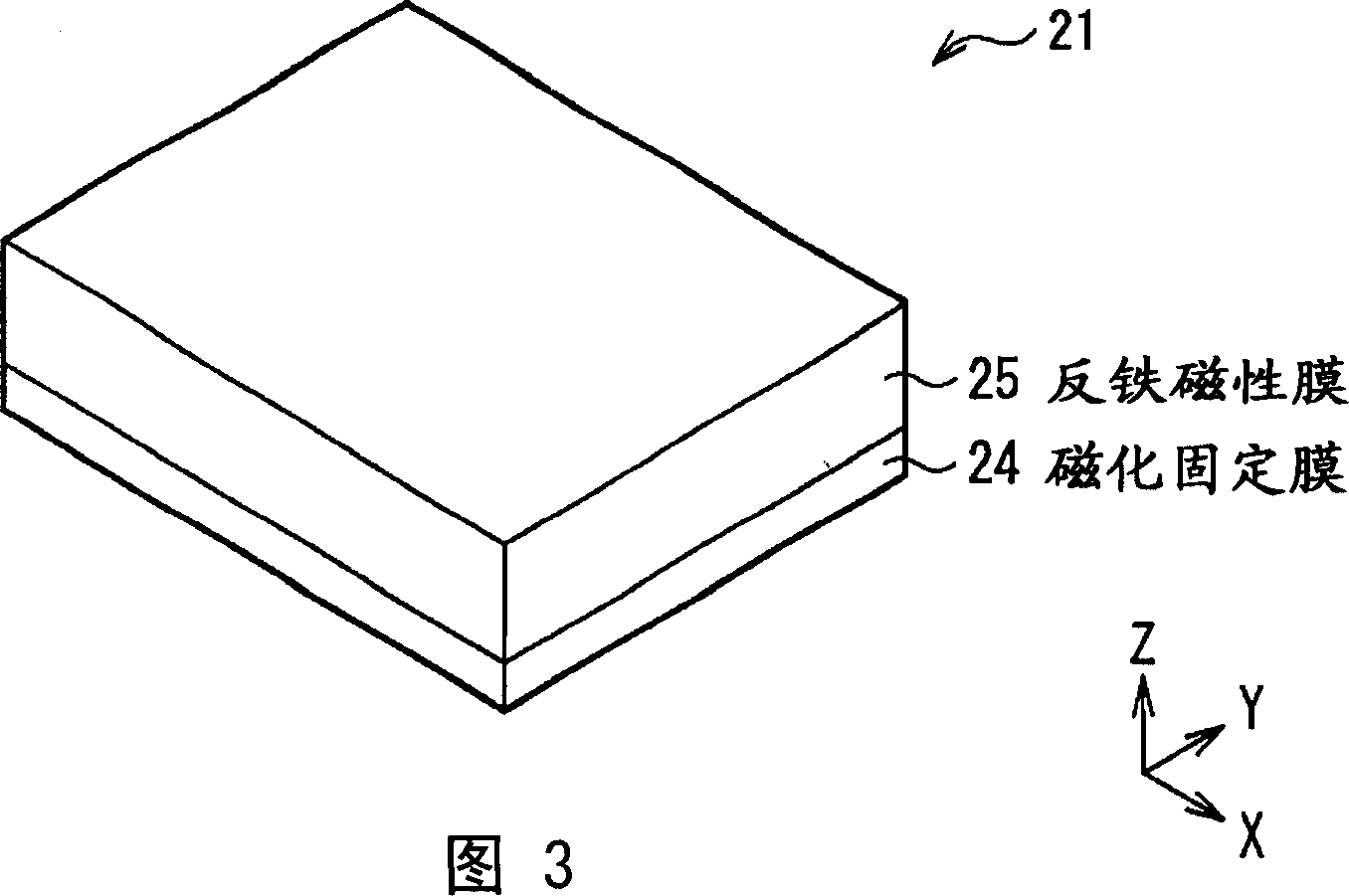

Magnetic sensing device, method of forming the same, magnetic sensor, and ammeter

ActiveCN1657967ASuppression hysteresisReduce offsetNanostructure applicationNanomagnetismHysteresisElectrical resistance and conductance

Owner:TDK CORPARATION

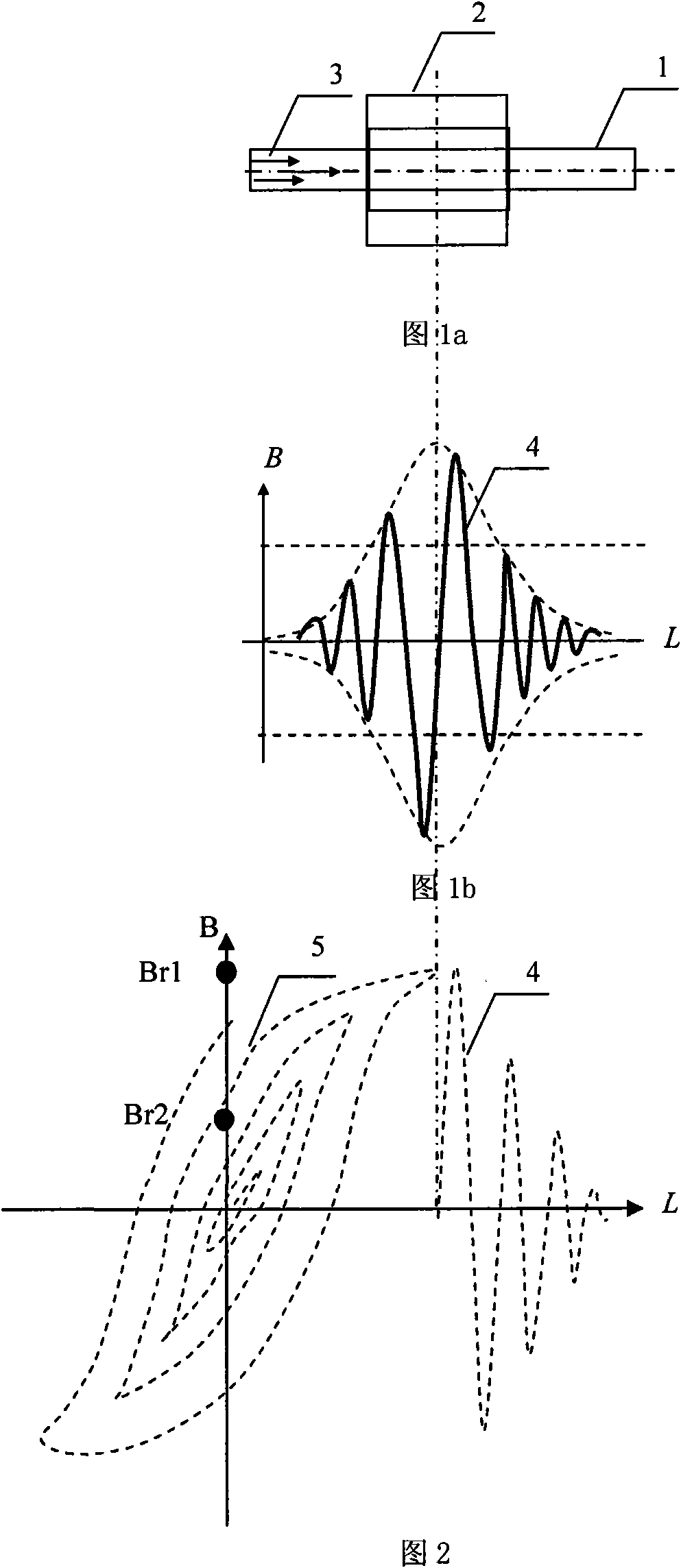

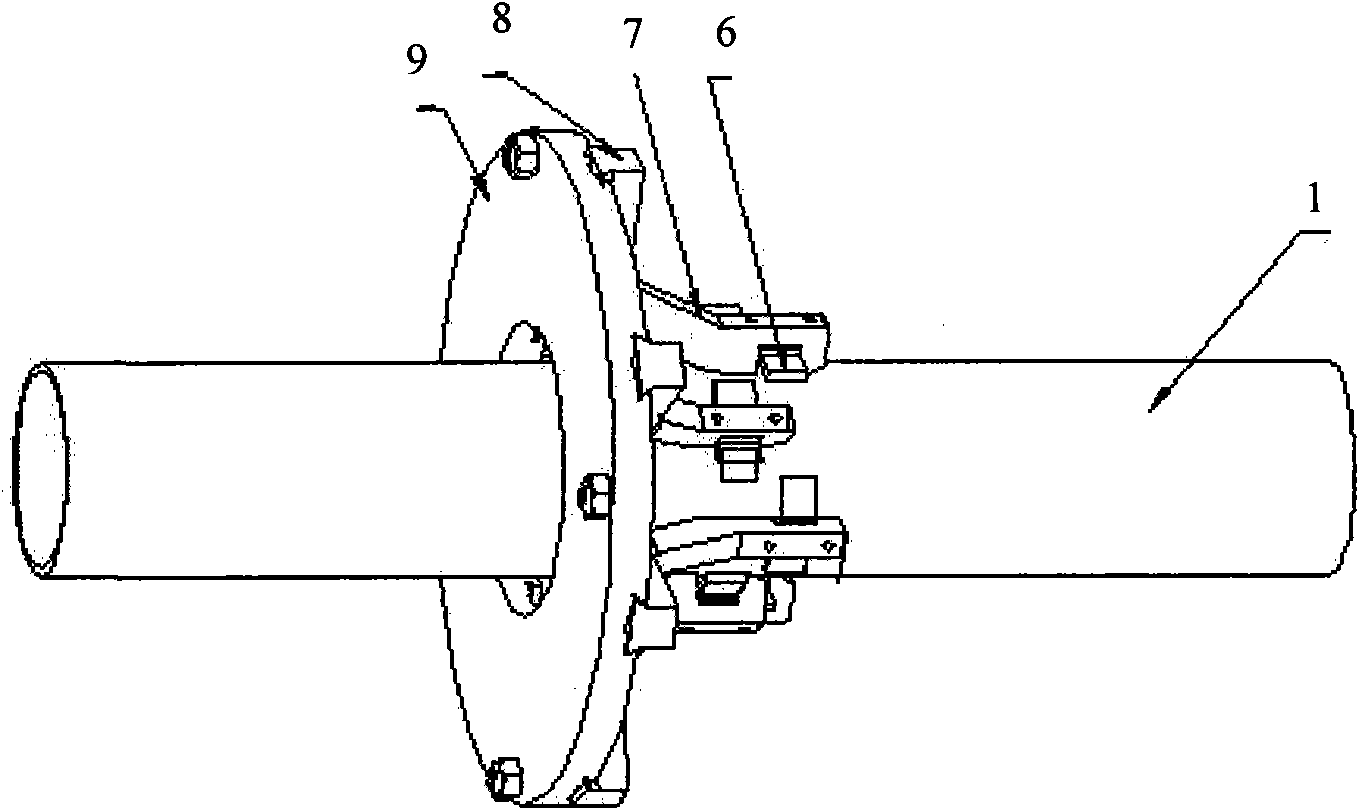

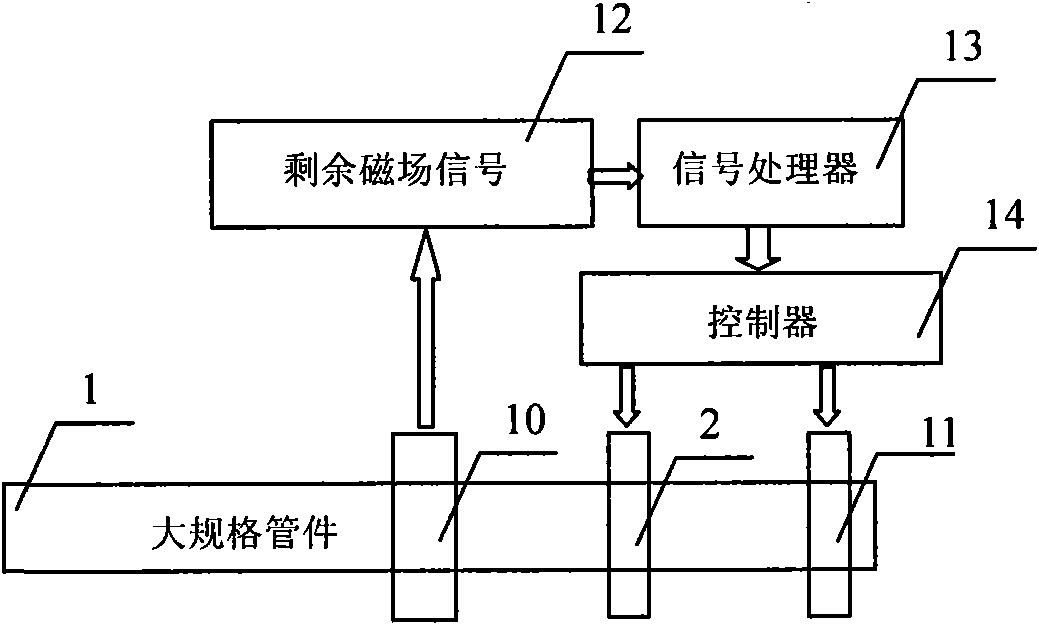

Demagnetization method of large-scale ferromagnetic pipe fitting and magnetic-sensitive sensor

InactiveCN101651006AOvercome the problem of not being able to cover the residual magnetism of pipe fittingsTargeted for degaussingMagnetic bodiesMagnitude/direction of magnetic fieldsPipe fittingResidual magnetic field

The invention relates to a demagnetization method of a large-scale ferromagnetic pipe fitting and a magnetic-sensitive sensor. The invention is characterized in that: for a remnant magnetic field formed at the end of the large-scale ferromagnetic pipe fitting under the action of an axial DC magnetic field, the pipe fitting is demagnetized by the DC magnetic field, wherein the direction of the DC magnetic field is opposite to that of the remnant magnetic field, the strength of the DC magnetic field is consistent with that of the detected remnant magnetic field, and then the pipe fitting is demagnetized by an alternating magnetic field with the strength gradually damped to zero; for an alternating remnant magnetic field formed in the axial direction of the large-scale ferromagnetic pipe fitting under the action of an axial alternating magnetic field with variable directions, pitches and strength, a section of pipe fitting in each pitch is demagnetized by the DC magnetic field, wherein the direction of the DC magnetic field is opposite to that of the remnant magnetic field, the strength of the DC magnetic field is consistent with that of the detected remnant magnetic field, and the pipe fitting is demagnetized by the alternating magnetic field with the strength gradually damped to zero. By adopting a complex demagnetization method, the invention solves the problem that magnetic hysteresis loops can not cover the remnant magnetic field of the pipe fitting sometimes in the conventional damped AC demagnetization method.

Owner:HEFEI ZHONGDA INSPECTION TECH

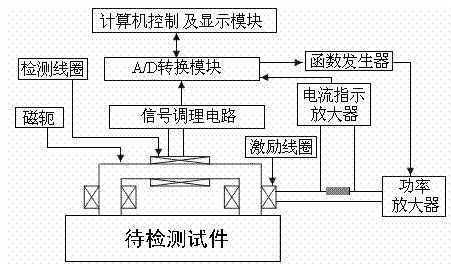

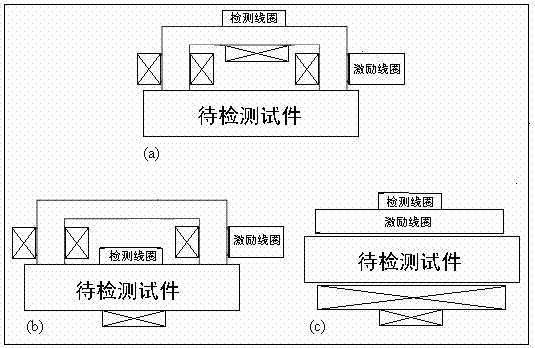

Method for evaluating stress concentration and fatigue damage based on feature permeability detection

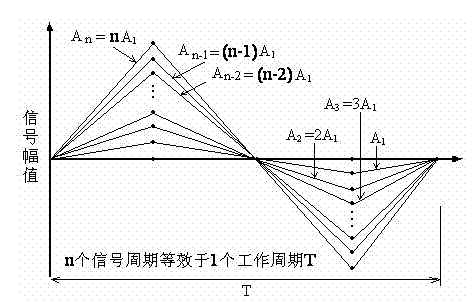

The invention relates to a new method for evaluating stress concentration and fatigue damage based on feature permeability detection. The microstructure feature of material is closely related with a technical magnetizing process, so that the magnetizing process can be changed by formation and change of the stress concentration, enhancement of the fatigue damage, change of the defect dislocation density, crack formation and structural phase change. The feature permeability represented by the invention is a differential permeability, which is related with the magnetizing process and the maximal magnetic field intensity. In a differential permeability matrix, a differential permeability matrix element with the maximal change rate along the microstructure variable of the material is the feature permeability corresponding to the microstructure variable. Different microstructure feature variables are corresponding to different permeability matrix elements and have different feature permeability. The feature permeability is related with specific material and microstructure change property of the specific material, and different microstructure feature changes are corresponding to different feature permeability. A circuit structure for the feature permeability detection mainly comprises an excitation coil, a detection coil, a power supply module, an A / D (Analogue / Digital) conversion module, a computer control module, a signal conditioning circuit, and the like. A specific data evaluation model is mainly dependent on the data of a low field magnetic hysteresis loop system. An excitation signal is mainly in a triangular waveform and waveform change feature in a working cycle is controlled by software programming.

Owner:NANCHANG HANGKONG UNIVERSITY

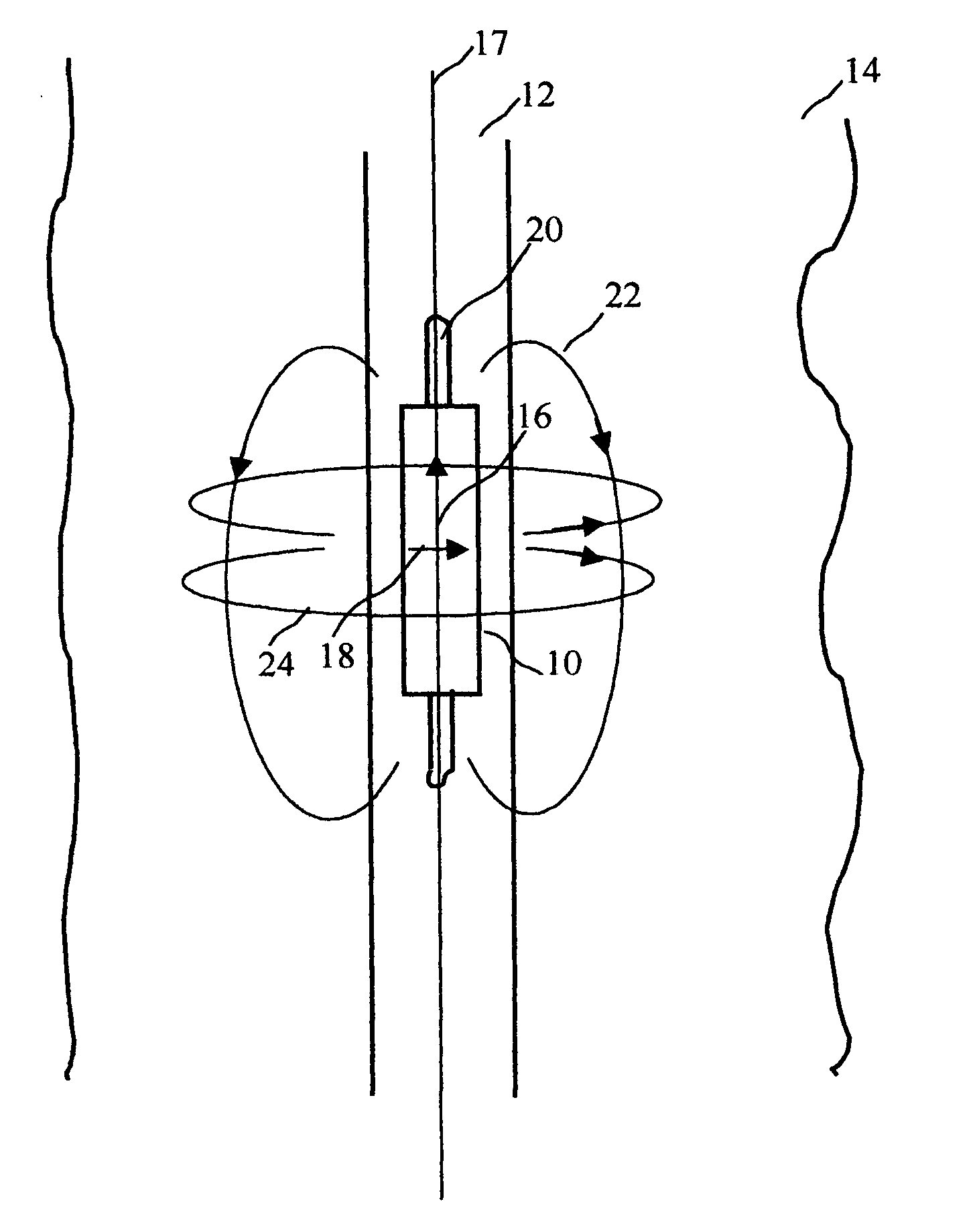

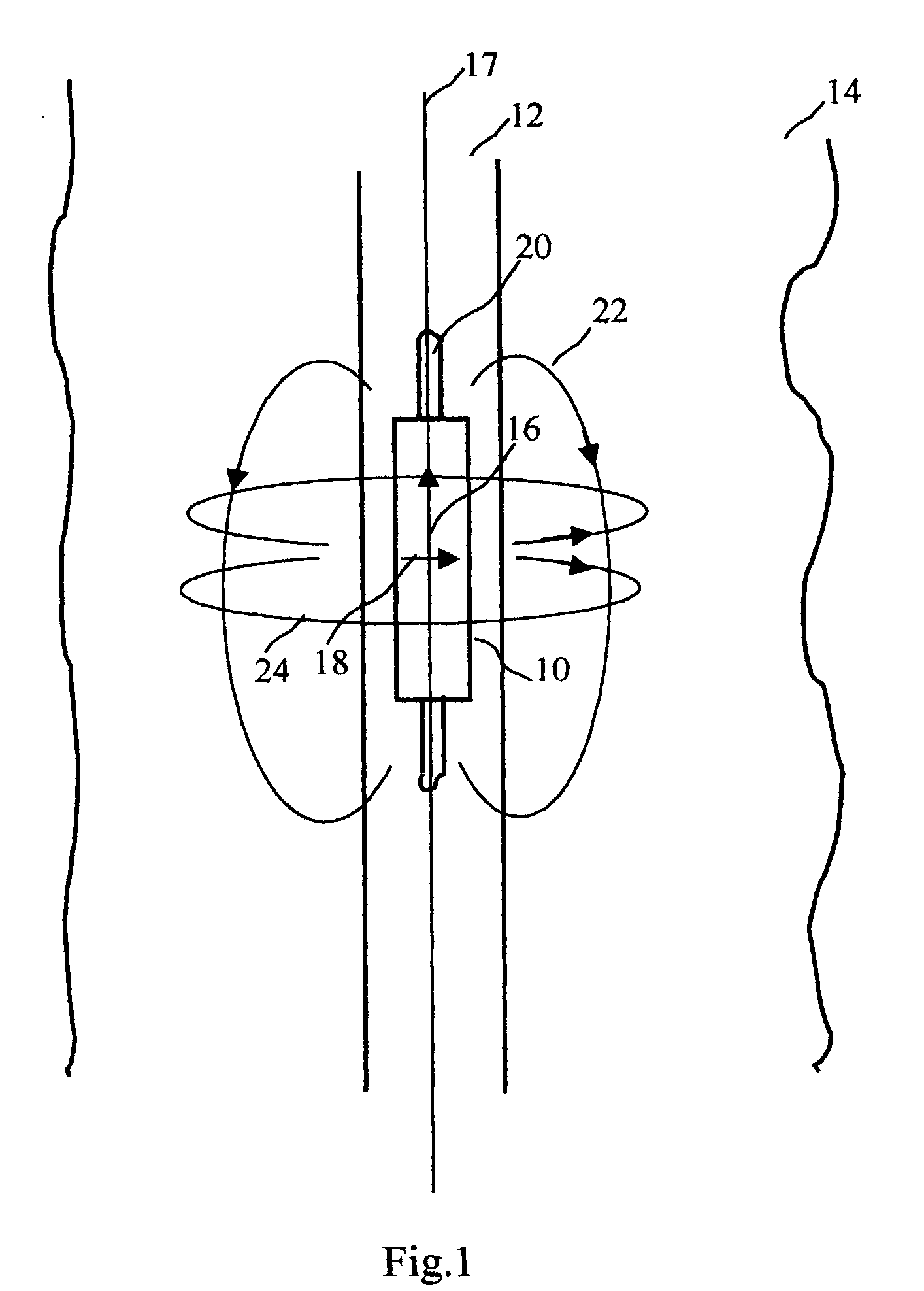

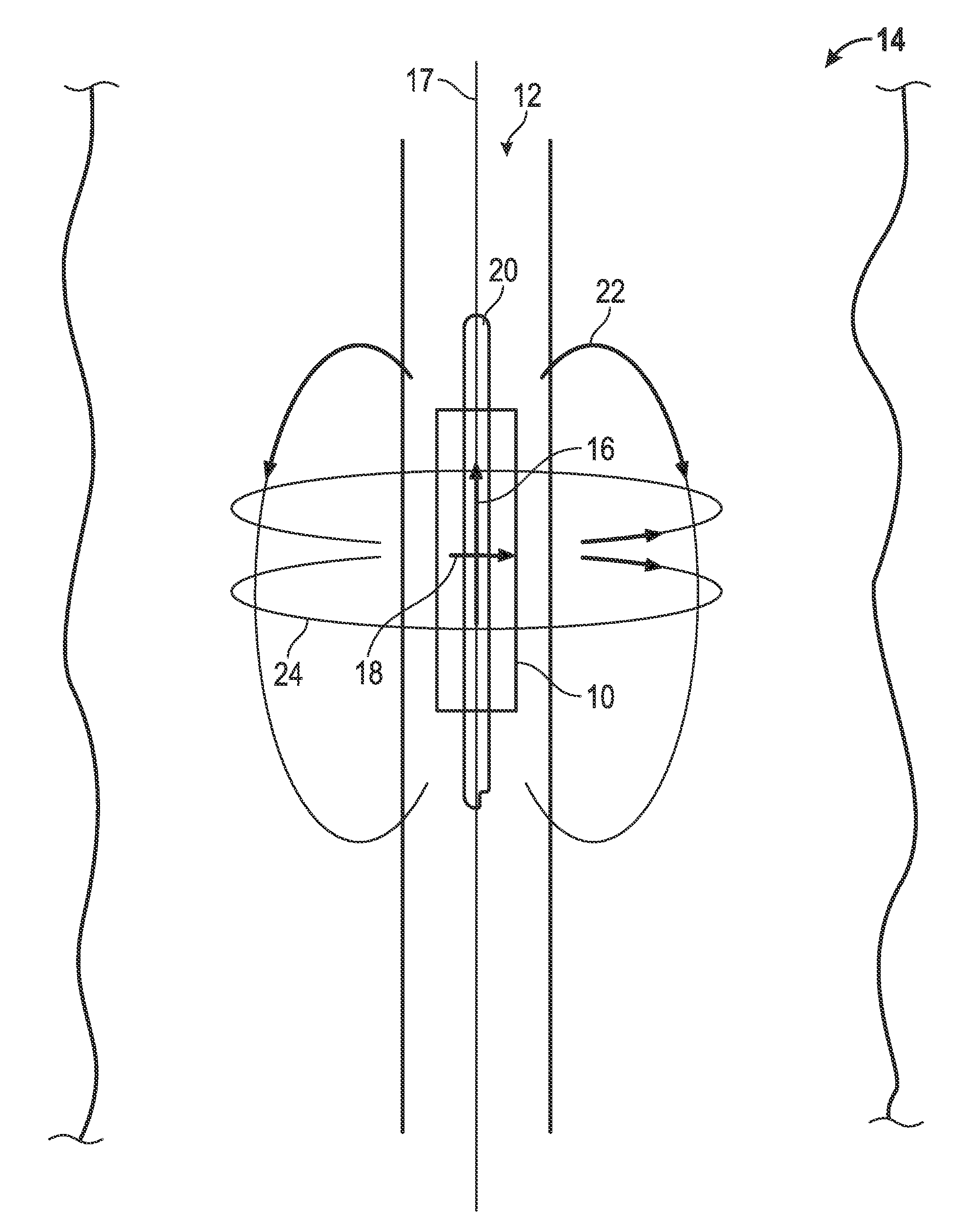

Method and apparatus of using magnetic material with residual magnetization in transient electromagnetic measurement

ActiveUS8432167B2Facilitates highly effective generationQuick switchElectric/magnetic detection for well-loggingAcoustic wave reradiationWell loggingTransmitter antenna

A transmitter antenna assembly for transient electromagnetic well logging instrument comprises an antenna coil coupled with a current source and a magnetic core having residual magnetization. Switching current in the antenna coil results in magnetization reversal in the magnetic core and change in magnetic dipole moment of the antenna. After the magnetization reversal is complete the current is removed and the new vector of magnetic dipole of the antenna maintains constant (steady-state phase of the antenna dipole) due to magnetic hysteresis of magnetic material employed for the magnetic core. No power expenditure during the steady-state phase of the magnetic dipole facilitates highly effective generation and fast switching of a large magnetic dipole. The magnetic core also serves as a shield between the antenna coil and any conductive part of the antenna assembly. Embodiments suitable for measurement-while-drilling or measurements through casing make use of residual magnetization of magnetic drill collar or magnetic casing respectively.

Owner:BAKER HUGHES INC

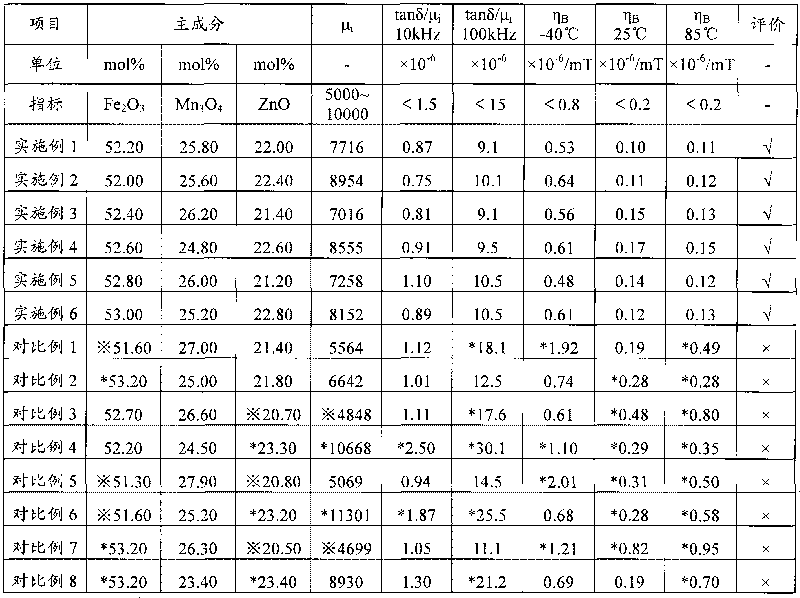

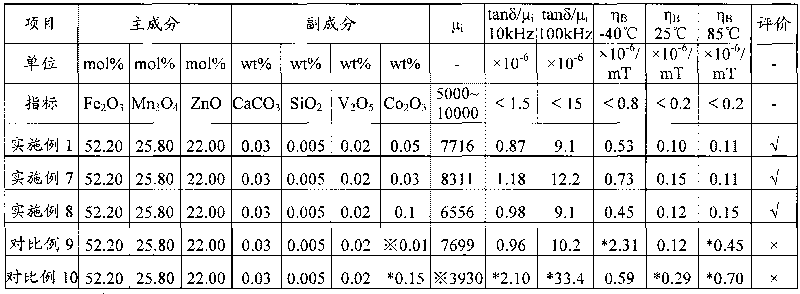

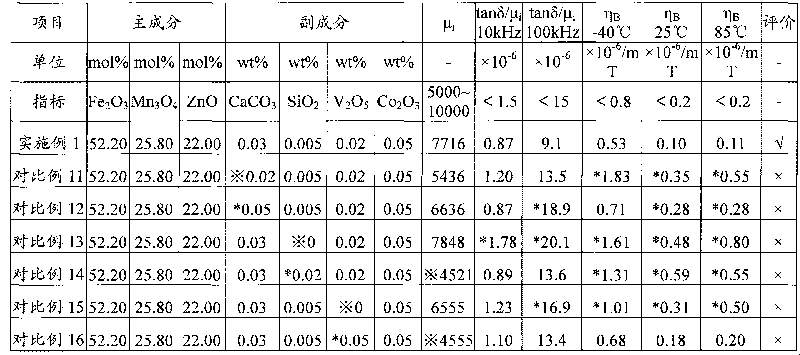

Wide-temperature low-distortion mangan zinc ferrite and preparation method thereof

ActiveCN101728048AReduce production energy consumptionBurn-in lowInorganic material magnetismLow distortionTransformer

The invention relates to a wide-temperature low-distortion mangan zinc ferrite applicable to a broadband network transformer and a preparation method thereof. The mangan zinc ferrite mainly comprises the following components: 52.0 to 53.0 mol percent of iron oxide computed by Fe2O3, 21.0 to 23.0 mol percent of zinc oxide computed by ZnO, and the balance of trimanganese tetroxide, and also comprises the following auxiliary components in percentage by weight (wt %) computed by respective standard substance CaCO3, SiO2, V2O5 and Co2O3: 0.03 to 0.04 of CaCO3, 0.005 to 0.01 of SiO2, 0.01 to 0.03 of V2O5 and 0.03 to 0.1 of Co2O3. The mangan zinc ferrite is prepared by an oxide method and sintered under the condition of bell-type furnace densification. A product has higher initial magnetic permeability mu i, low relative loss factor tan delta / mu i, and wide-temperature low-magnetic hysteresis coefficient eta B (-40 to 85 DEG C), is capable of reducing waveform distortion, reducing transmission errors and prolonging transmission distance in the process of transmitting signals, and meets the requirement of the application in outdoor severe environment.

Owner:TDG HLDG CO LTD

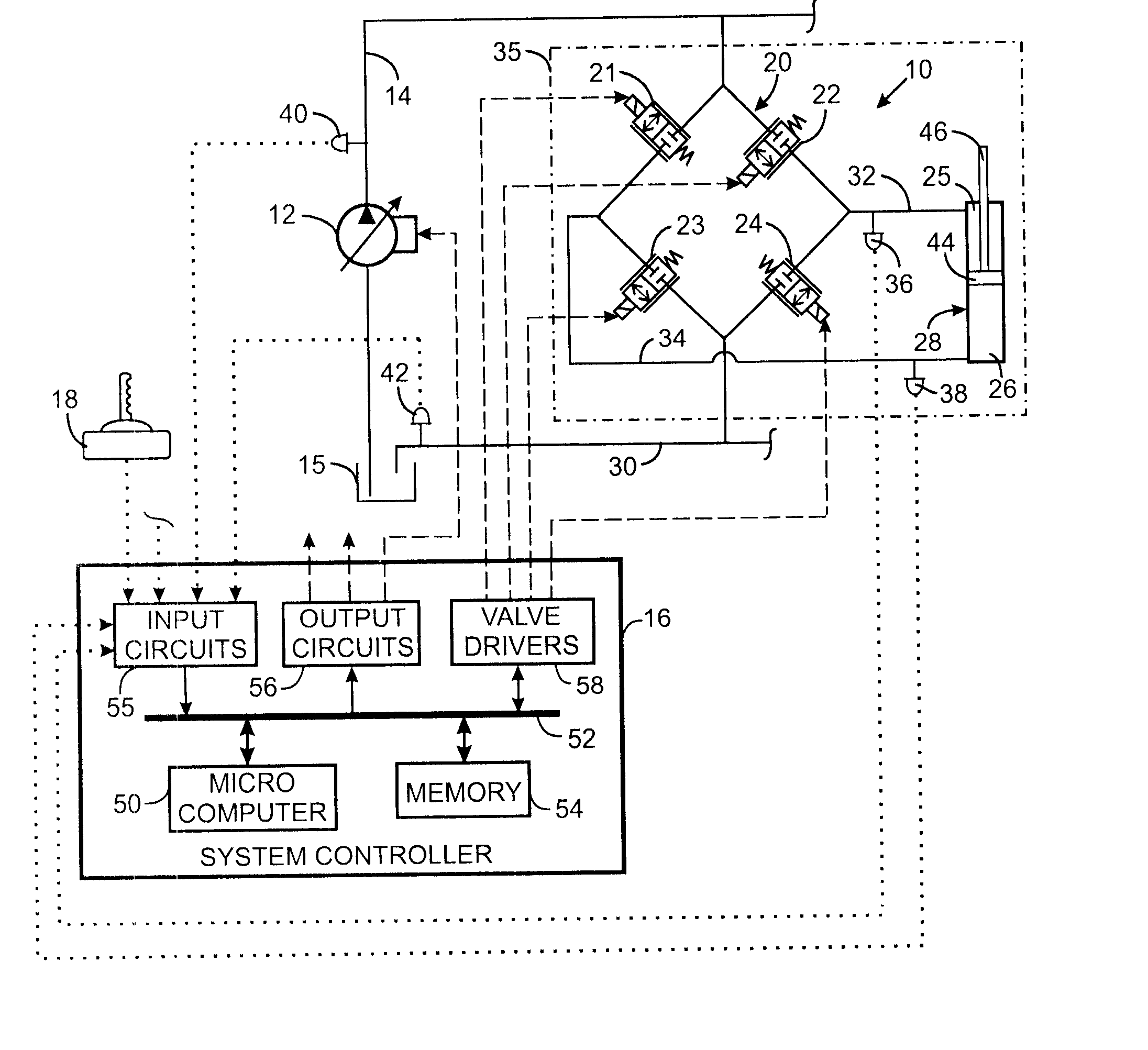

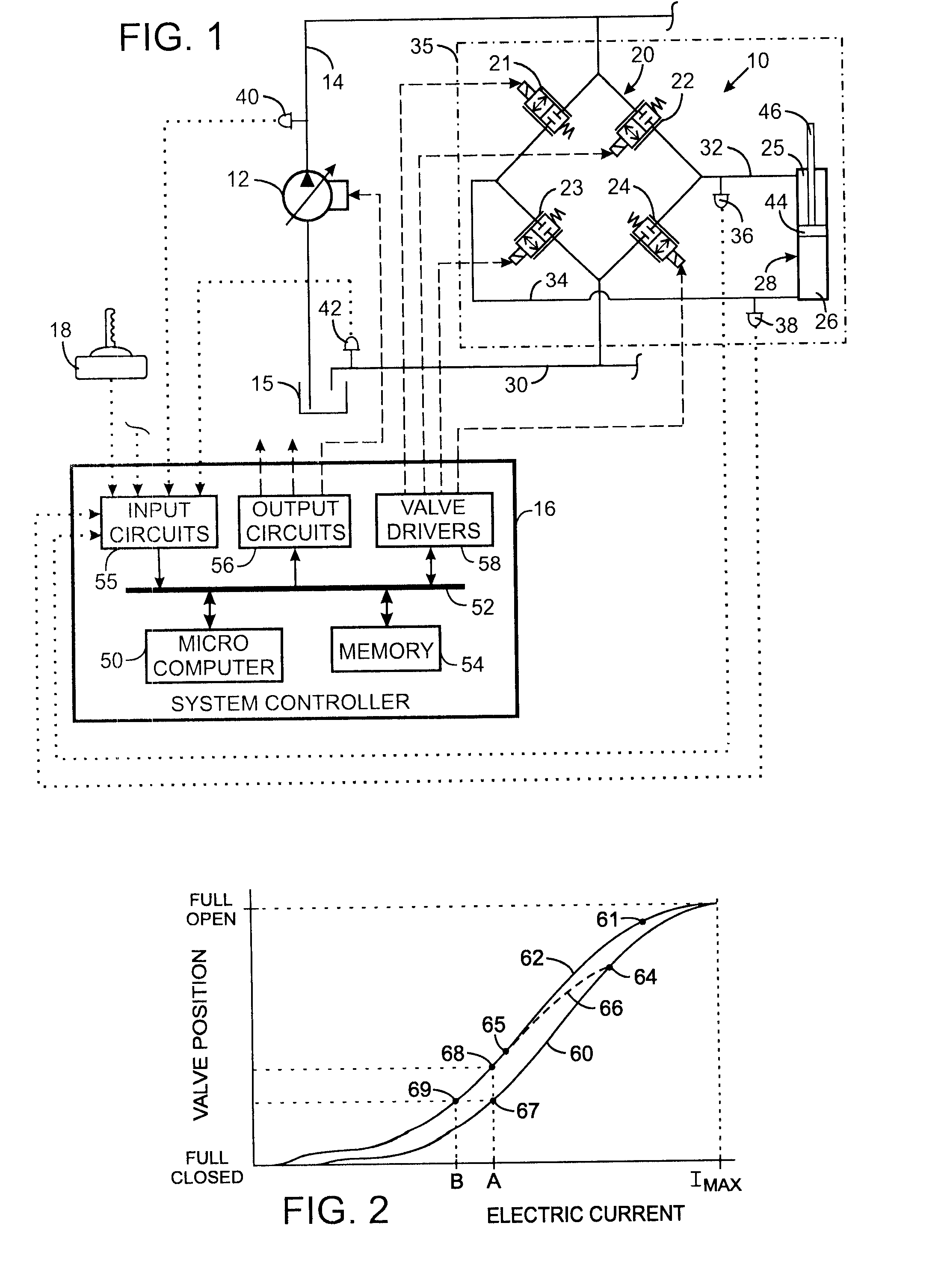

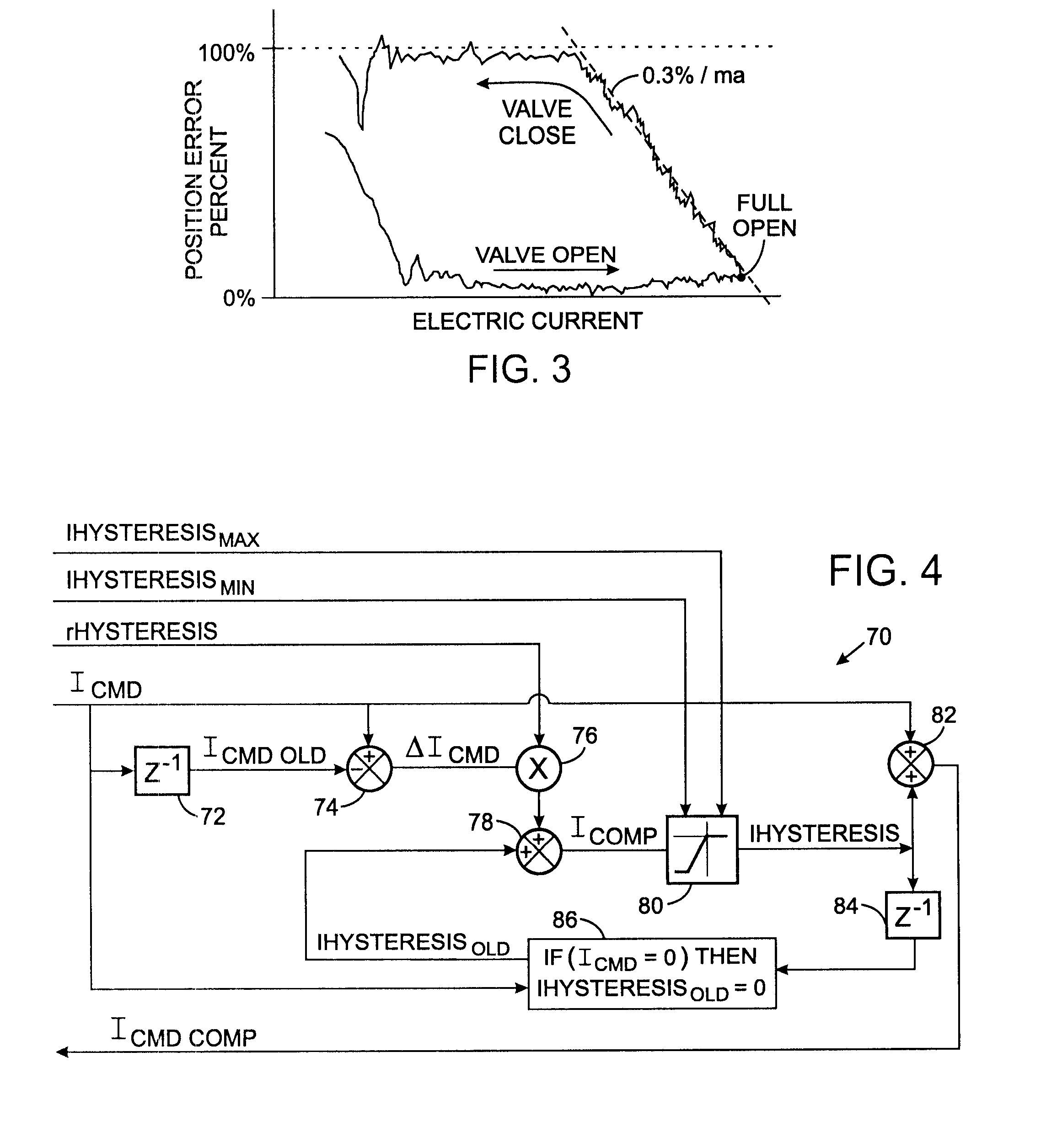

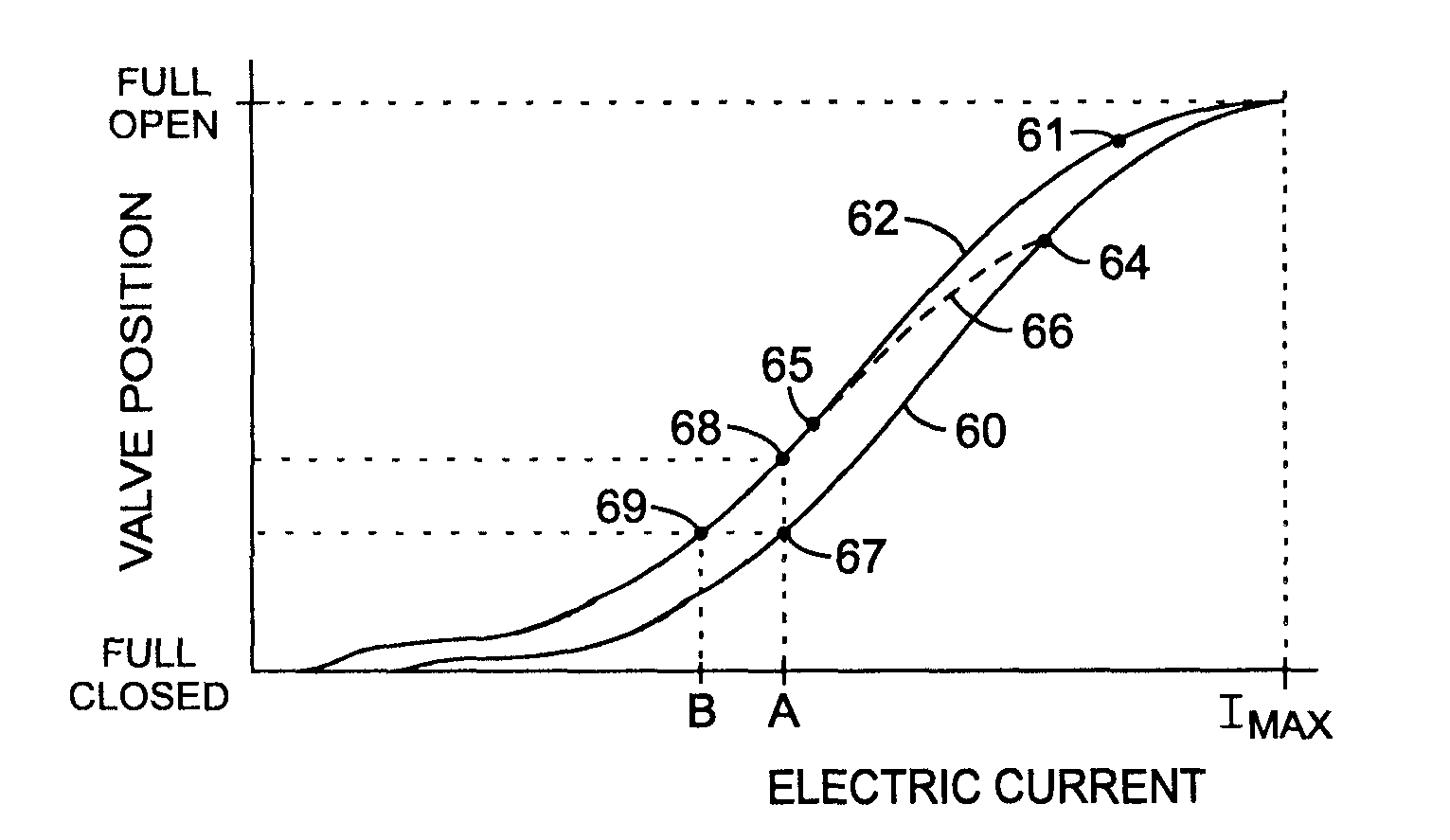

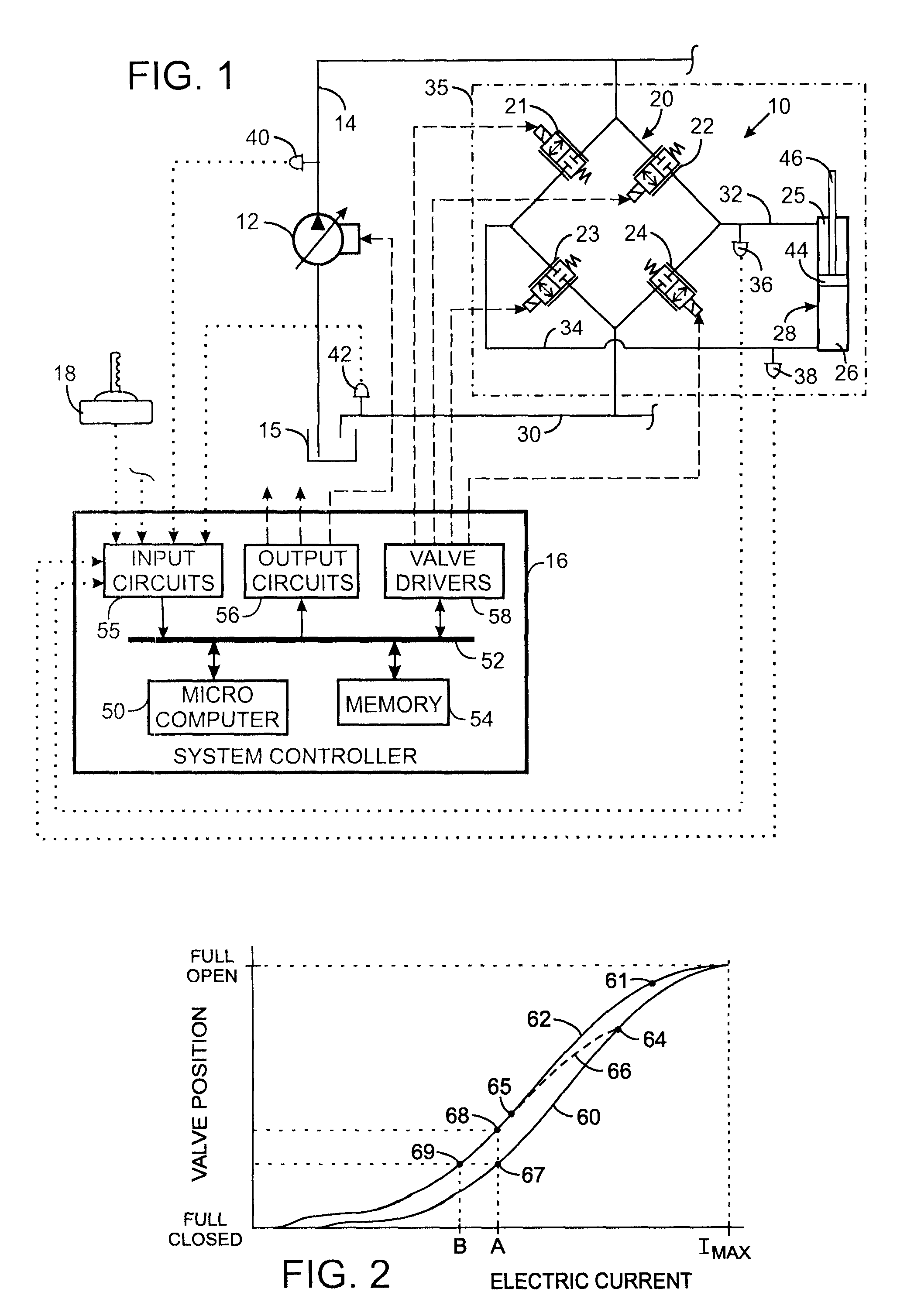

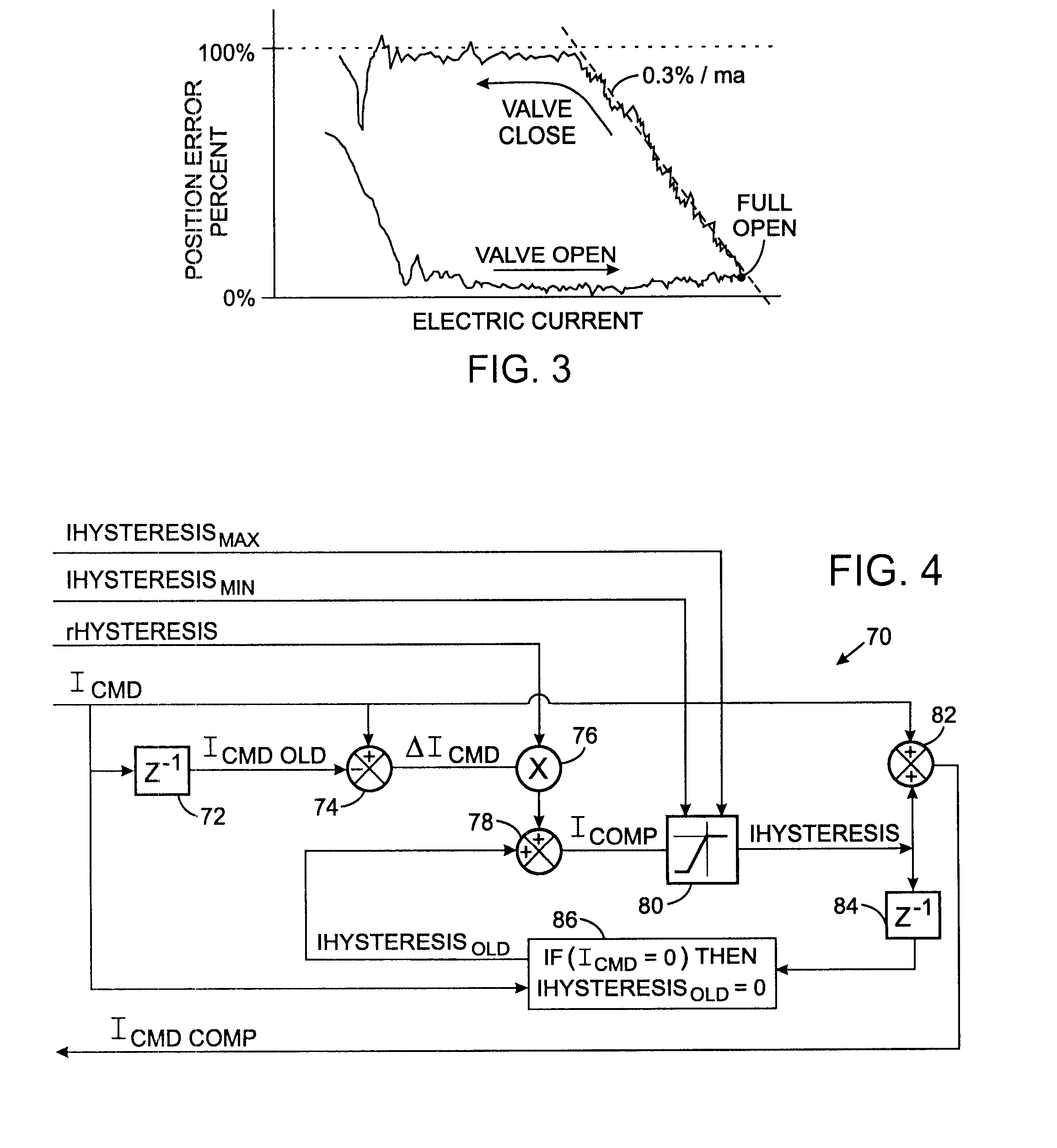

Electrohydraulic Valve Control Circuit With Magnetic Hysteresis Compensation

ActiveUS20080042087A1Compensation effectOperating means/releasing devices for valvesServomotorsEngineeringControl circuit

A method for operating an electrohydraulic valve initially derives a characterization value that denotes how magnetic hysteresis affects valve operation. Upon receiving a command that designates a desired magnitude of electric current to be applied to the electrohydraulic valve, that command is modified based on the characterization value to compensate for the magnetic hysteresis. The modified command then is employed to apply electric current to the electrohydraulic valve.

Owner:HUSCO INT INC

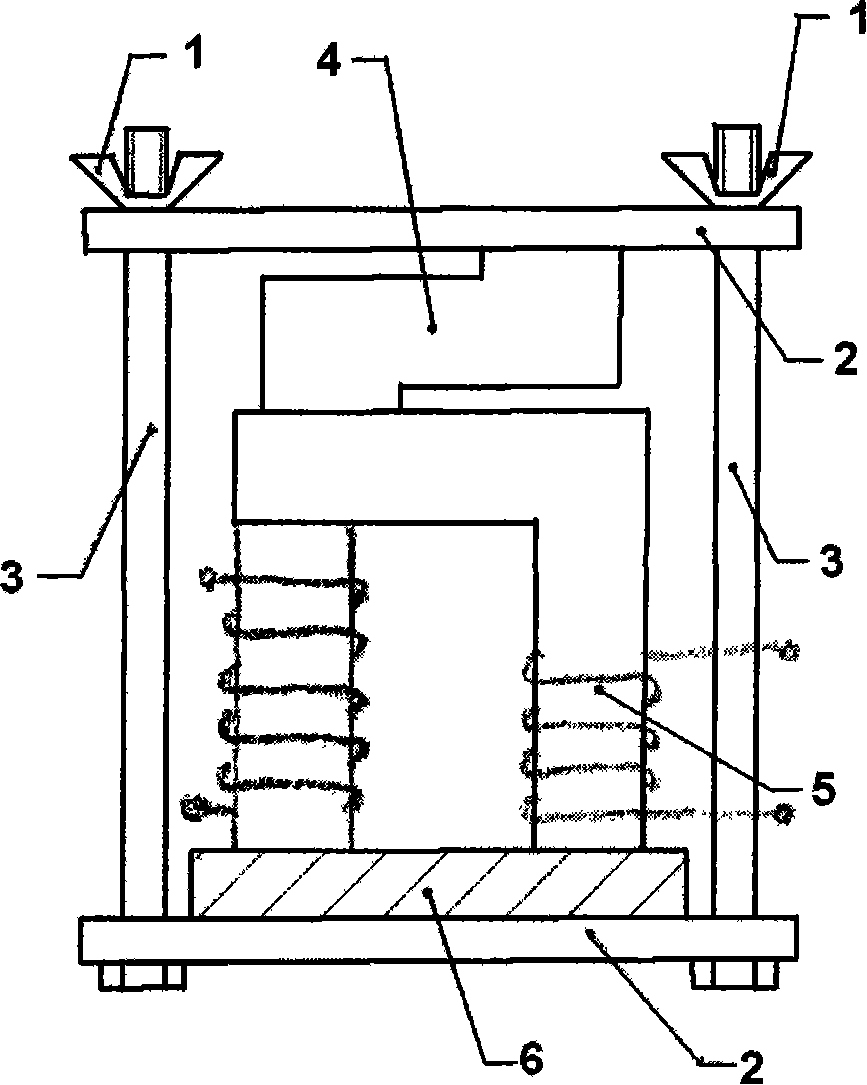

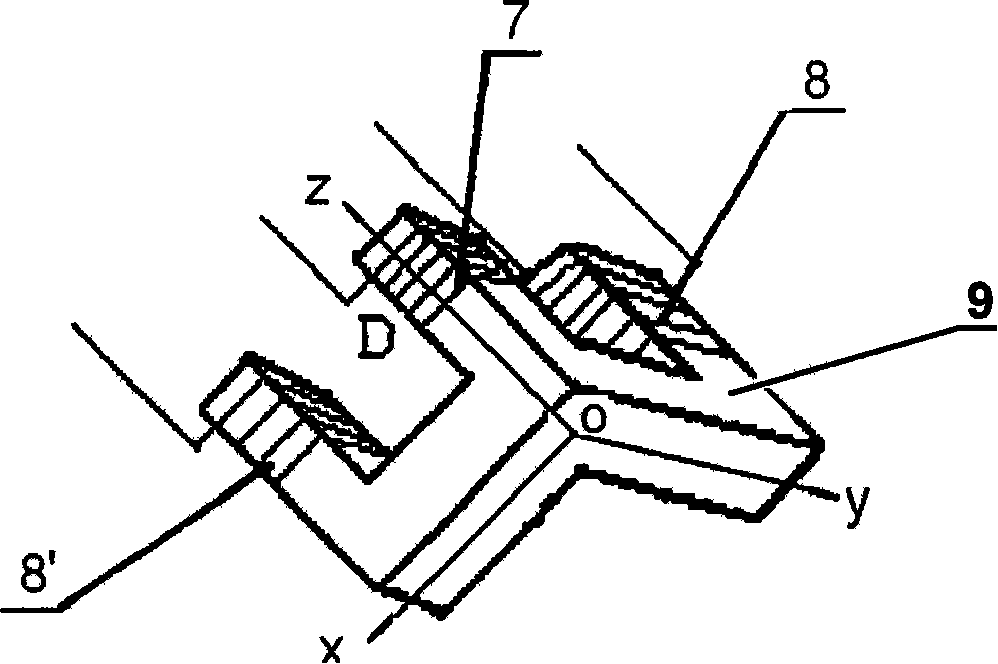

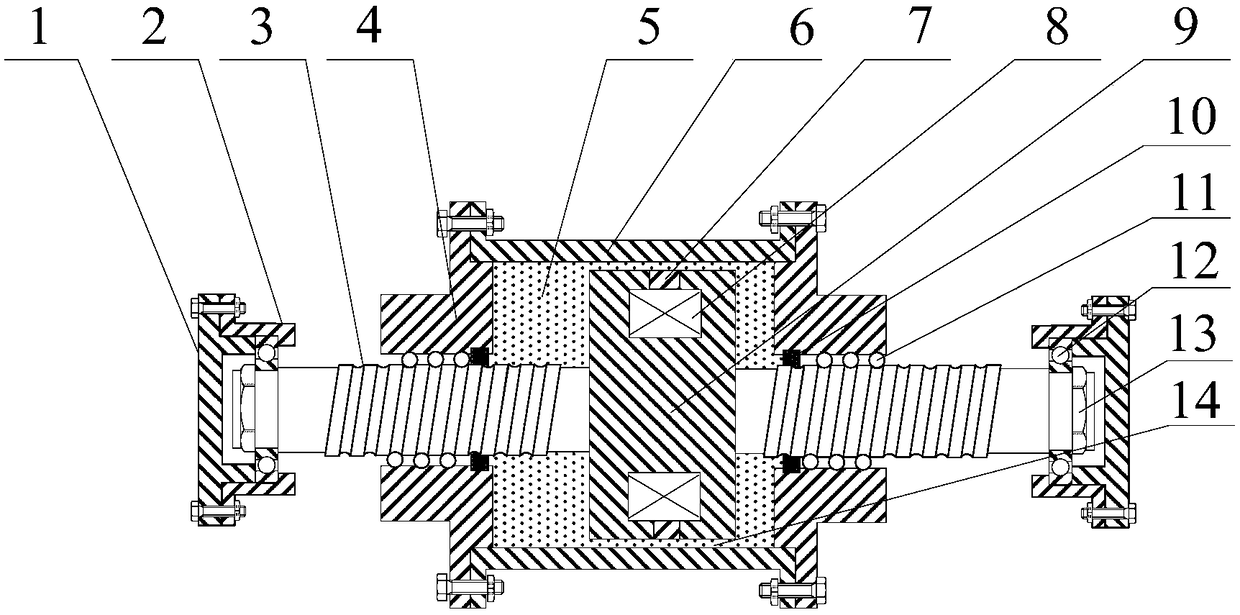

Device for measuring ferromagnetic material internal stress by impulse electromagnetic field

The invention relates to a device for measuring internal stress of ferromagnetic material by pulse electromagnetic field. It is composed of detector, pulse electromagnetic field circuit and data acquisition and processing device, the detector part is composed of drive coil (7), heel piece (9) with one fieldpole and two measure poles and two groups of induction coil (8, 8'), weighing cell (4) is placed above the detector (5), the detector (5) is placed above the tested workpiece (6), which are clamped by jig; the pulse electromagnetic field circuit provides 1-3 Tesla strong incentive pulsed electromagnetic field for drive coil (7), the current signal in drive coil (7), the voltage signals of the two groups of drive coils (8, 8') are processed by data acquisition and processing device, then the magnetization curve and magnetic hysteresis loop of the tested workpiece (6) are obtained, after various kinds of magnetic parameters of the tested workpiece are determined, the rating curve between the internal stress and various kinds of magnetic parameters are established.

Owner:JILIN UNIV

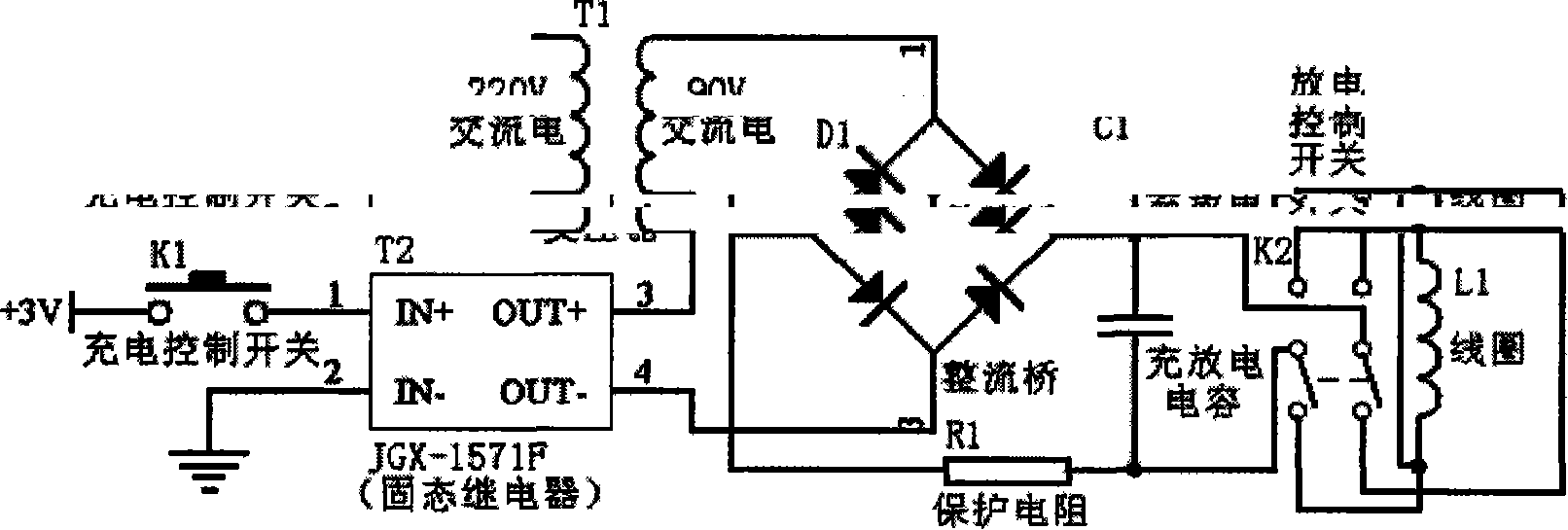

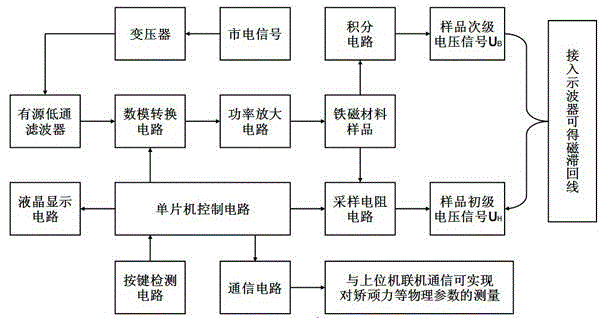

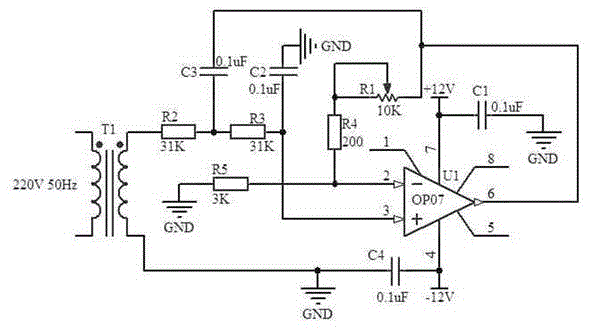

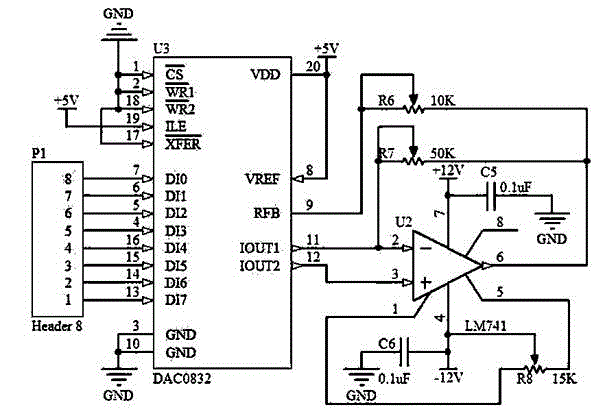

Measuring device for hysteresis loop made of ferromagnetic material and application method of measuring device

InactiveCN102721939ASolve the problem of easy contactSolve the shortcomings such as easy loose gearsHysteresis curve measurementsHysteresisMicrocontroller

The invention discloses a measuring device for a hysteresis loop made of a ferromagnetic material and an application method of the measuring device. The measuring device for the hysteresis loop made of the ferromagnetic material comprises an excitation circuit, a control circuit, an integrating circuit, a sampling resistor circuit, a liquid crystal display circuit, a key detecting circuit and an oscilloscope. According to the method, step values of excitation voltage and excitation resistance are set through programming a singlechip; the oscilloscope displays the hysteresis loop to be measured; and an upper computer measures and analyzes the coercivity, the remanence induction strength, the maximum field, the maximum magnetic induction strength and the magnetic hysteresis loss of the ferromagnetic material according to the hysteresis loop. The original mechanical switch and manual knob type switch control mode is replaced by a program control mode, and shortcomings that contacts of a knob switch are in a poor contact state easily, gears are easy to loosen, and the like are overcome. By an experimental instrument developed in the invention, the reliability of experimental equipment can be increased, and the service life of the experimental equipment can be prolonged. Owing to the program control mode, the step values of the excitation voltage are low, gears of the excitation voltage are sufficient, measurement precision is high, and practicality and accuracy are good.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Intermediate strength aluminum alloy wire for overhead conductor

ActiveCN103451498AHigh elongationEffective solution treatmentSingle bars/rods/wires/strips conductorsConductive materialElectrical resistance and conductanceSolution treatment

The invention belongs to the technical field of overhead conductors of electric transmission lines, and particularly relates to an intermediate strength aluminum alloy wire for an overhead conductor. According to the intermediate strength aluminum alloy wire provided by the invention, solution treatment is effectively carried out on an aluminum alloy rod and subsequent aging treatment realizes a better effect through certain alloy composition adjustment, rolling and control of online quenching, so that the intermediate strength aluminum alloy wire with the elongation which is not less than 3.5%, the electric conductivity which is not less than 58.5%IACS (International Annealed Copper Standard) and the tensile strength which is not less than 245MPa is finally obtained. The elongation of the intermediate strength aluminum alloy wire provided by the invention is remarkably superior to that of aluminum alloy wires in the prior art. The intermediate strength aluminum alloy wire has the advantages that the wire is great in pulling weight ratio, good in sag characteristic, good in high temperature characteristic and damage- resistant in the surface. As no steel cores are available, magnetic hysteresis loss and eddy loss are avoided. In operation, the alternating current resistance of the wire is lower than that of aluminum cable steel reinforced, so that the electric energy loss is reduced. The intermediate strength aluminum alloy wire provided by the invention is used more and more in electric transmission lines and has a wider range of application.

Owner:STATE GRID CORP OF CHINA +1

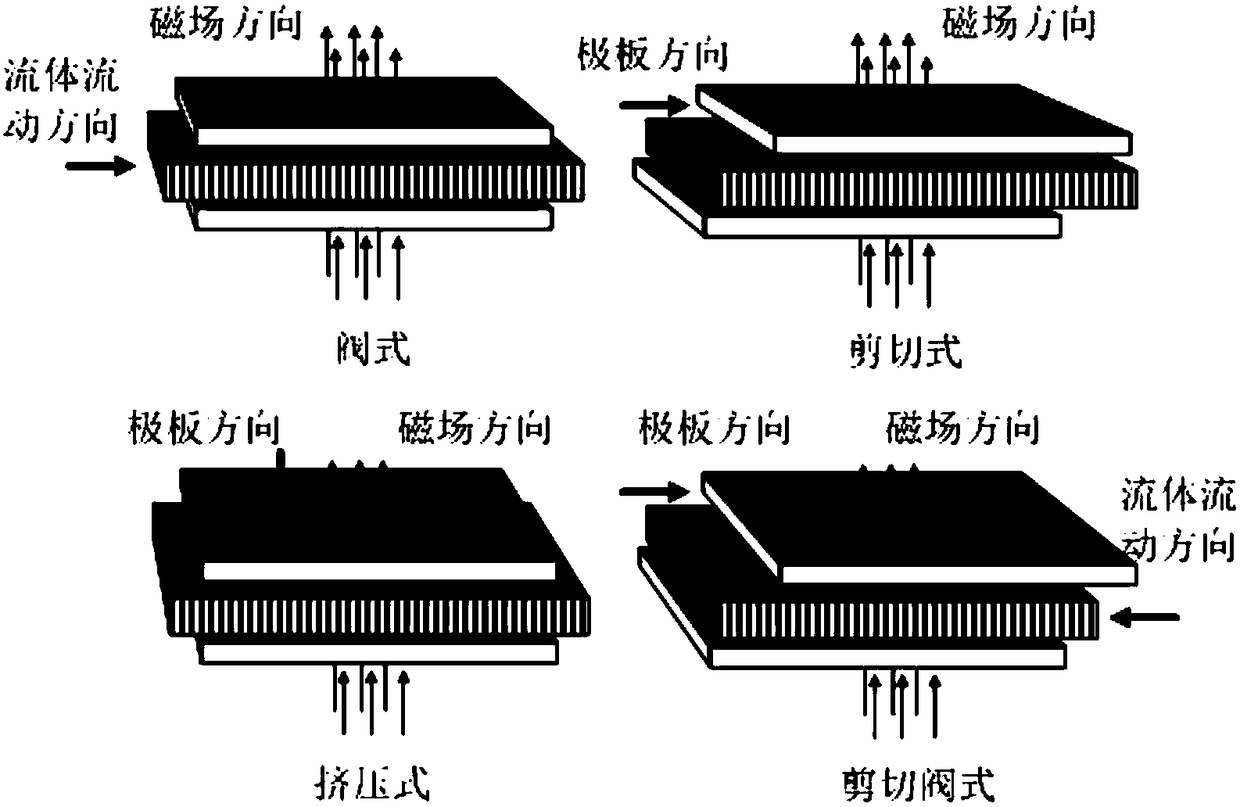

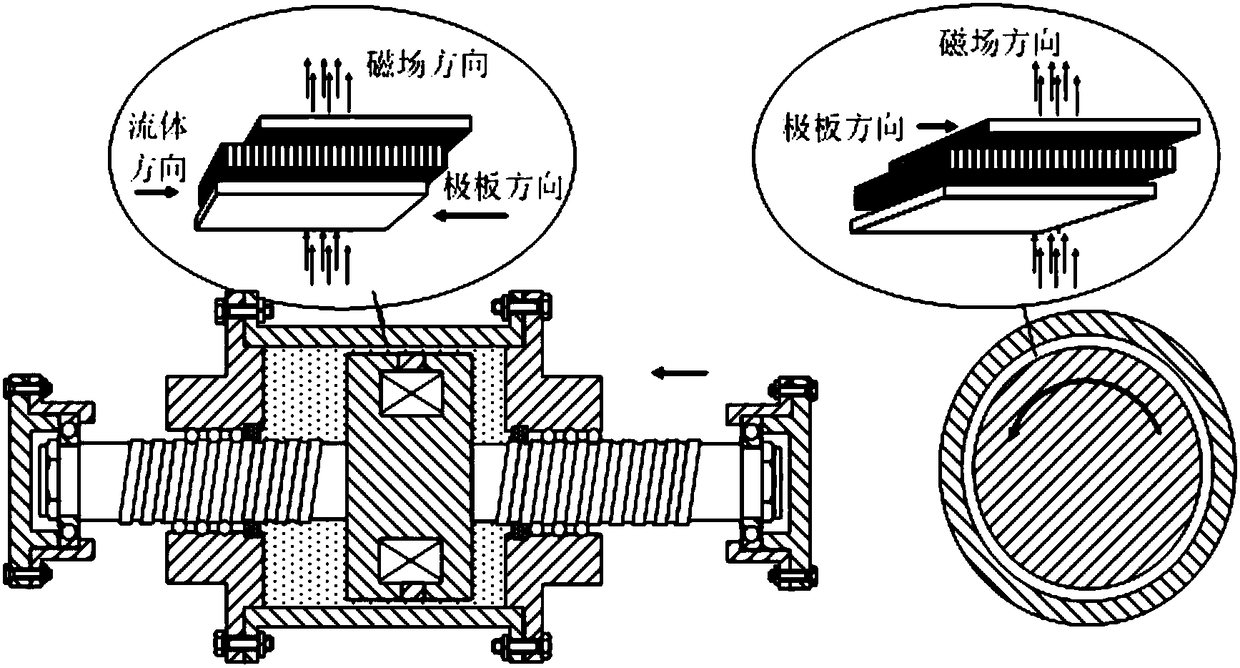

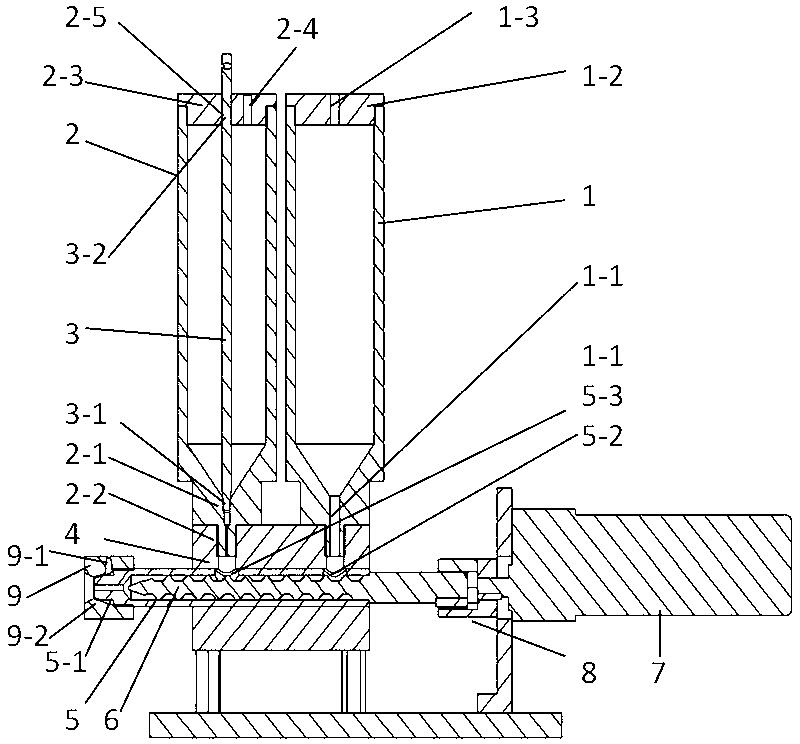

Magnetorheological damper composite work mode high output method and damper

ActiveCN108278320ARealize shear valve working modeLarge damping outputSpringsNon-rotating vibration suppressionBall screwSnubber

The invention discloses a magnetorheological damper composite work mode high output method and a damper. A piston rod is provided with a lead screw thread matched with a ball nut pair on a cylinder. When the piston rod does the linear movement relative to the cylinder under the action of outer loads, the piston rod can rotate around the axis of the piston rod through a ball screw motion pair, meanwhile, a piston is driven to linearly move relative to the cylinder and rotate around the axis of the piston, the piston needs to overcome dual damping in the axial direction and the circumferential direction, and two typical work modes of two magnetorheological dampers are combined. A magnetic hysteresis ring is arranged on the peripheral surface of the piston, distribution of magnetic inductionlines is more reasonable, the effective work length of a damping channel is increased, and efficient damping force output can be achieved from the two above aspects. The magnetorheological damper composite work mode high output method and the damper have the beneficial effects that firstly, the two work modes are integrated; secondly, the magnetic path optimization potential is large; and thirdly,the structure is simple and feasible.

Owner:NORTHEASTERN UNIV

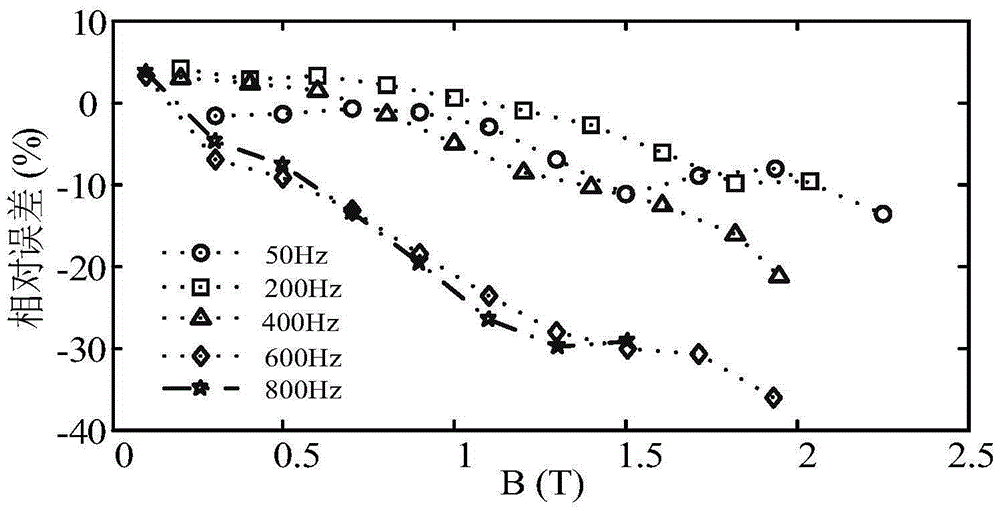

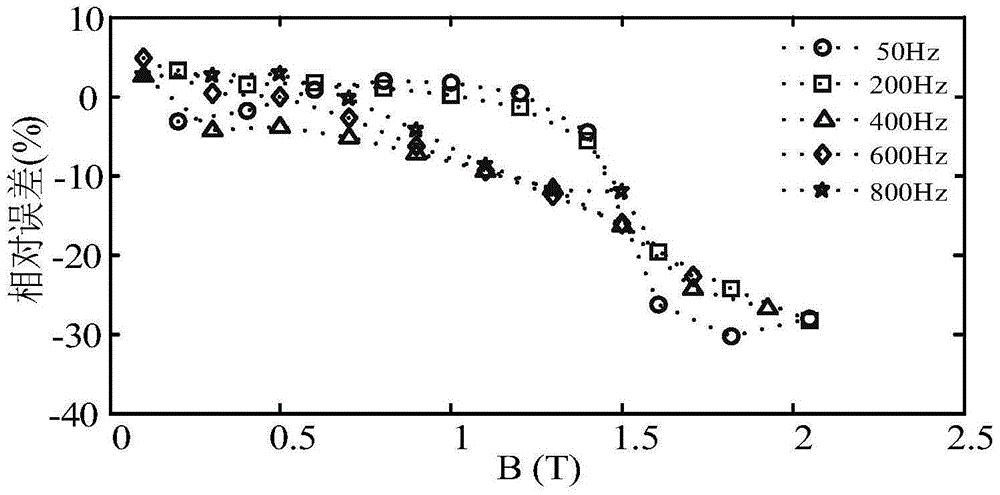

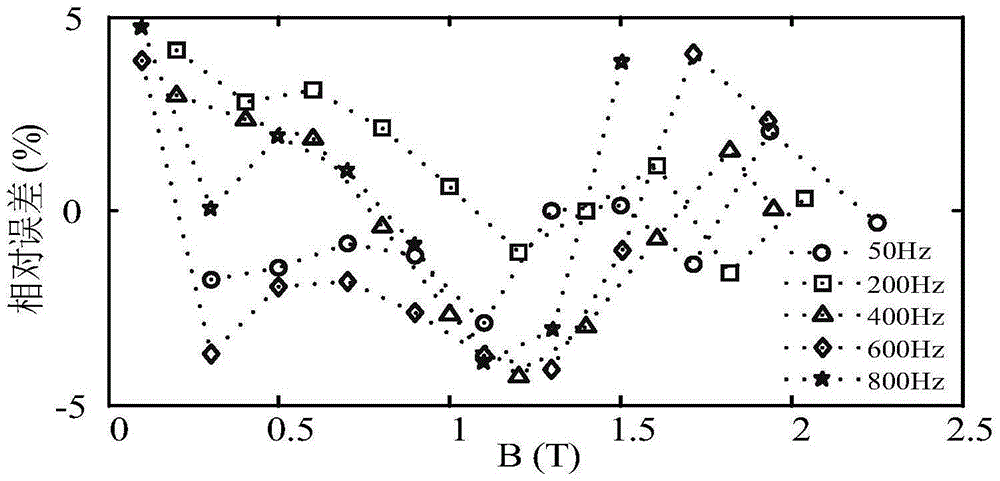

Segmented variable-coefficient iron loss model for fine analysis of loss of alternating-current motor

ActiveCN105205234AGuaranteed suitabilityAccurate separationSpecial data processing applicationsHarmonicEddy current

The invention discloses segmented variable-coefficient iron loss model for fine analysis of loss of an alternating-current motor and belongs to the technical field of loss calculation and analysis of the alternating-current motor. The model is shown in the specification. According to the model, loss data of silicon steel sheets are measured actually at a series of frequencies and in magnetic density and analyzed in combination of a classical binomial model, eddy-current loss increase caused by magnetic circuit saturation and magnetic hysteresis loss increase caused by harmonic magnetic fields are considered, four additional loss coefficients changing with the magnetic density and the frequencies in a segmented manner are introduced in an eddy-current item and a magnetic hysteresis loss item, and accordingly, the model is established. The main coefficients in the model change with magnetic density amplitudes and frequencies, besides, magnetic hysteresis loss and eddy-current loss caused by fundamental waves and harmonic magnetic fields can be accurately separated by means of the model, and the fine analysis of the iron loss can be realized.

Owner:SIEMENS STANDARD MOTORS LTD

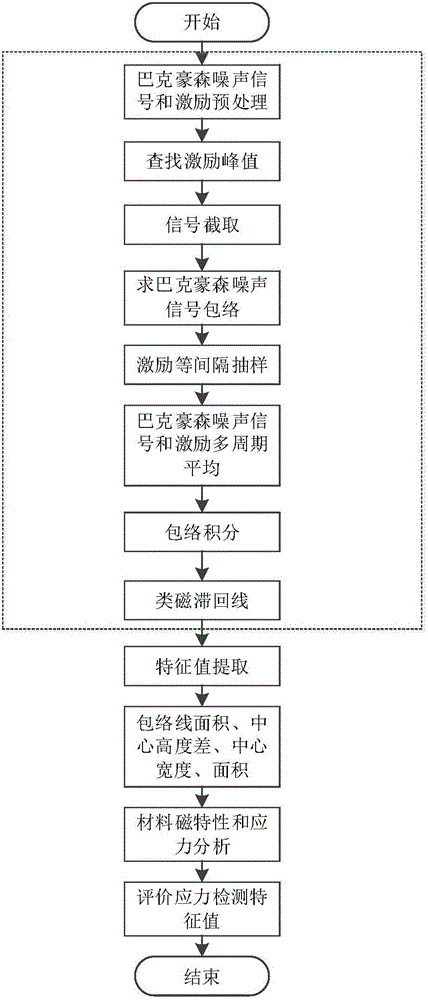

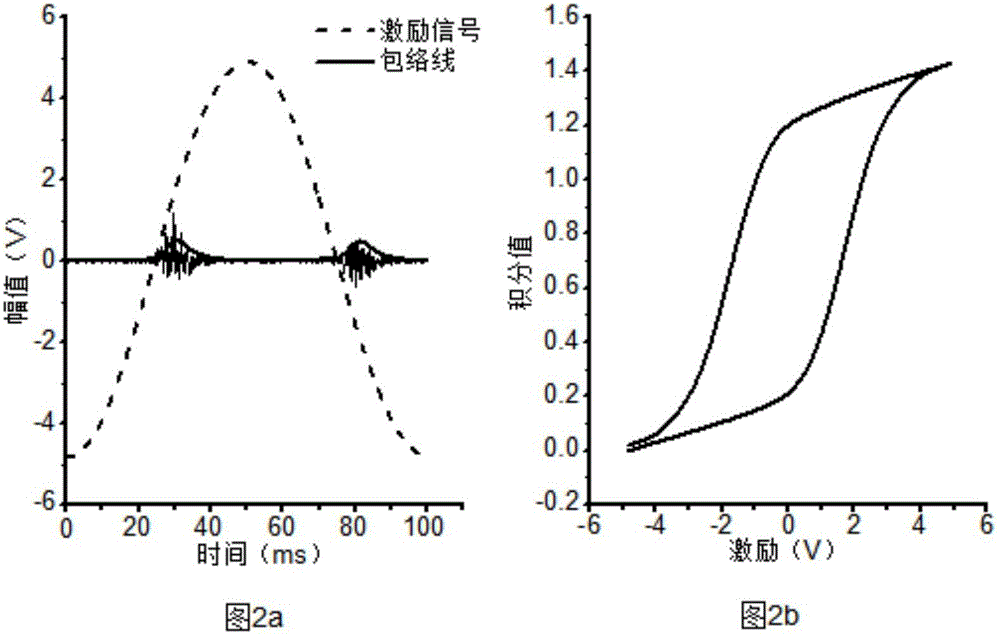

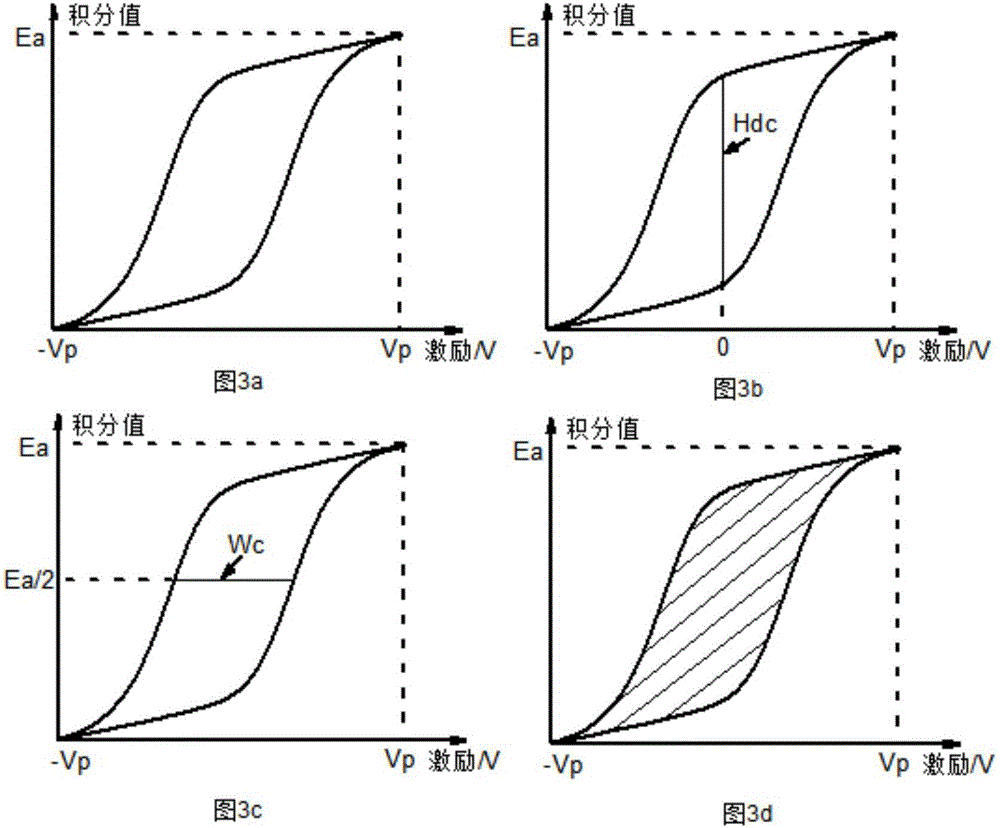

Method for detecting material magnetic properties and stress based on Barkhausen principle

InactiveCN106248781ASimple detection systemRemove restrictionsForce measurement by measuring magnetic property varationHysteresis curve measurementsHeight differenceMagnetic characteristic

The invention discloses a method for detecting material magnetic properties and stress based on a Barkhausen noise principle, wherein the method includes the steps: (1) through an envelope line of a Barkhausen noise signal, reckoning a ferromagnetic material magnetic hysteresis loop: (2) extracting stress detection characteristic values on the ferromagnetic material magnetic hysteresis loop: envelope area, center height difference, center width and integral curve area; (3) carrying out magnetic property and stress analysis of a ferromagnetic material by using the stress detection characteristic values, to obtain detection values of the material magnetic properties and stress; and (4) evaluating the stress detection characteristic values, and verifying the accuracy of the material magnetic property and stress detection values obtained by the magnetic property and stress analysis. The Barkhausen noise signal and the magnetic hysteresis loop are correlated in detection, the magnetic properties of the material are directly reflected and determined by the new characteristic values and the stress is detected by the new characteristic values, and the accuracy of stress detection is further improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

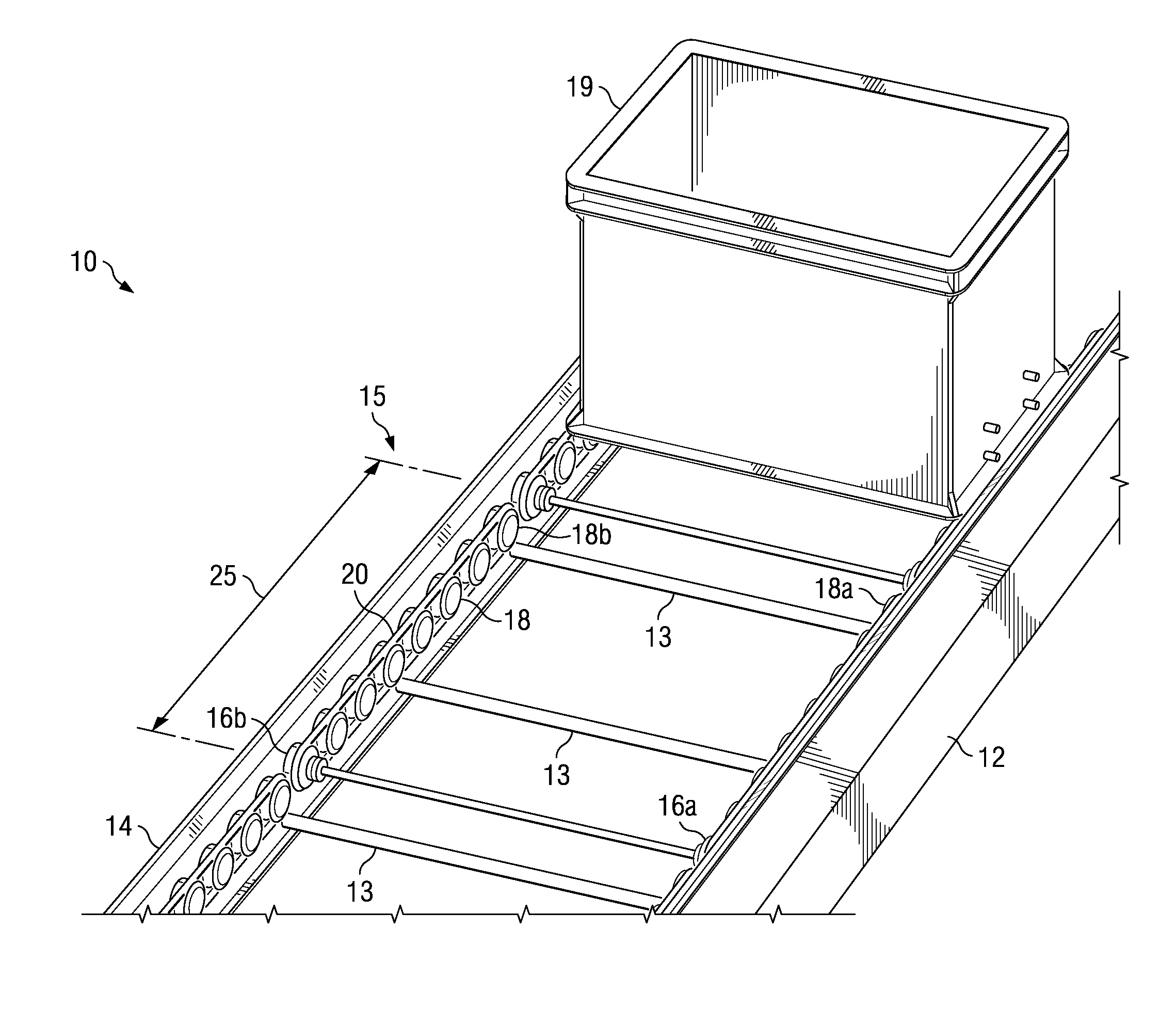

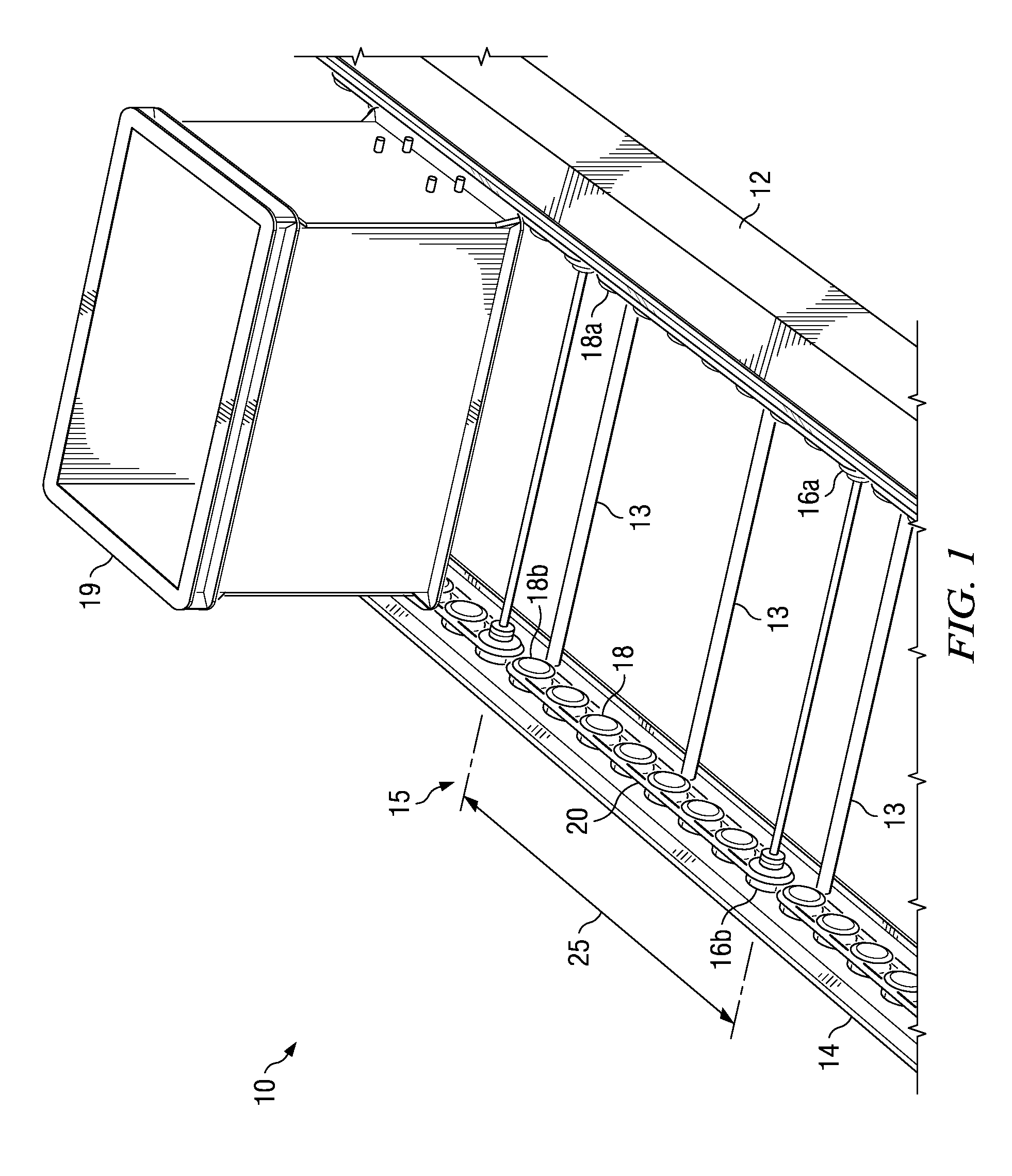

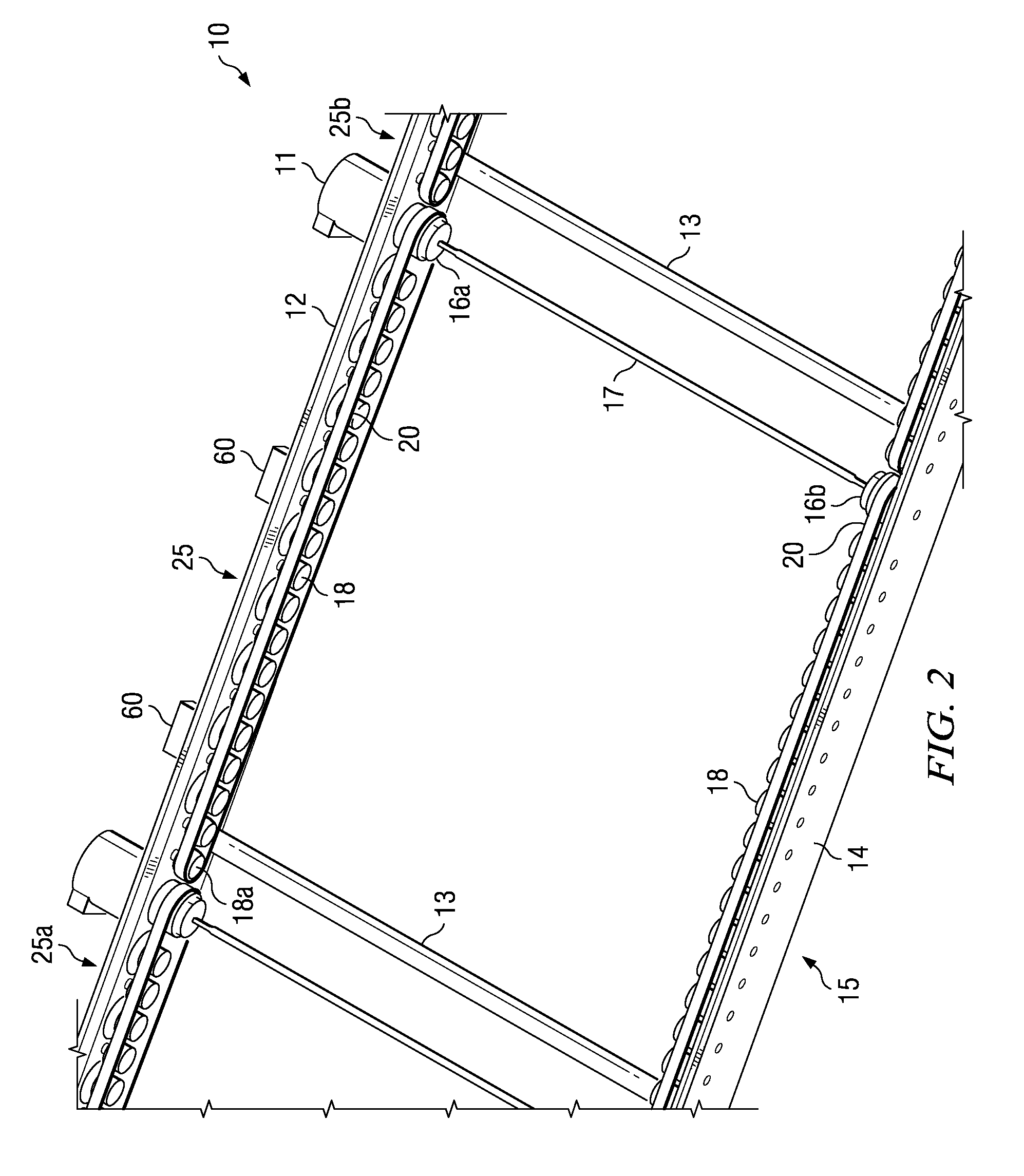

Clean, high density, soft-accumulating conveyor

InactiveUS20090266678A1Reduce speed differenceMaintain levelDigital data processing detailsConveyor partsDrive wheelHigh density

A conveyor for clean manufacturing applications. The conveyor comprises interconnected conveyor modules, each of which includes a conveyor belt segment (s). Each conveyor belt segment includes a pair of side rails that are in parallel or substantially in parallel to each other; a pair of autonomous, belt-drives for transporting work pieces or objects carrying work pieces from a proximal end of the belt segment to a distal end of the belt segment; a pair of driving wheels for turning the belt-drives, and a motor for directly or indirectly driving each of the pair of driving wheels. One of the driving wheels is mechanically or magnetically coupled to a magnetic hysteresis clutch that allows the driving wheels to disengage from the drive shaft of the motor if the inertia of the work piece does not permit synchronization of work piece with the drive speed of the motor during acceleration or deceleration.

Owner:MIDDLESEX GEN INDS MESNE

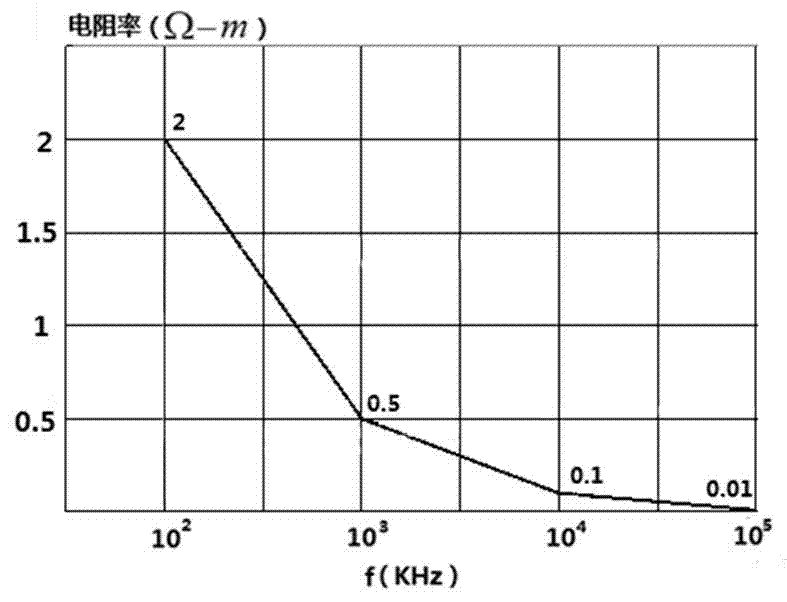

Magnetic core loss separation calculating method

The invention discloses a magnetic core loss separation calculating method. The method includes the following steps: under the condition of the given magnetic flux density variable quantity, , forming a magnet loss construction separation equation set to separate magnetic hysteresis loss from vortex loss by using loss data of any two working points with different frequency under sinusoidal excitation, simulating corresponding relation of resistance rate of magnetic core materials and frequency of the magnetic core materials through a linear interpolation method, and gathering the additional vortex loss of the rest loss to a classical conduction vortex loss. The magnetic core loss separation calculating method has the advantages of being clear in physical concepts, simple in separation calculation process, capable of effectively separating loss components of the magnetic core without dependence on a special instrument, and being widely applied to simulation software to simulate size of loss of the magnetic core materials in power electronic application under different frequency and magnetic induction intensity.

Owner:NANJING UNIV OF POSTS & TELECOMM

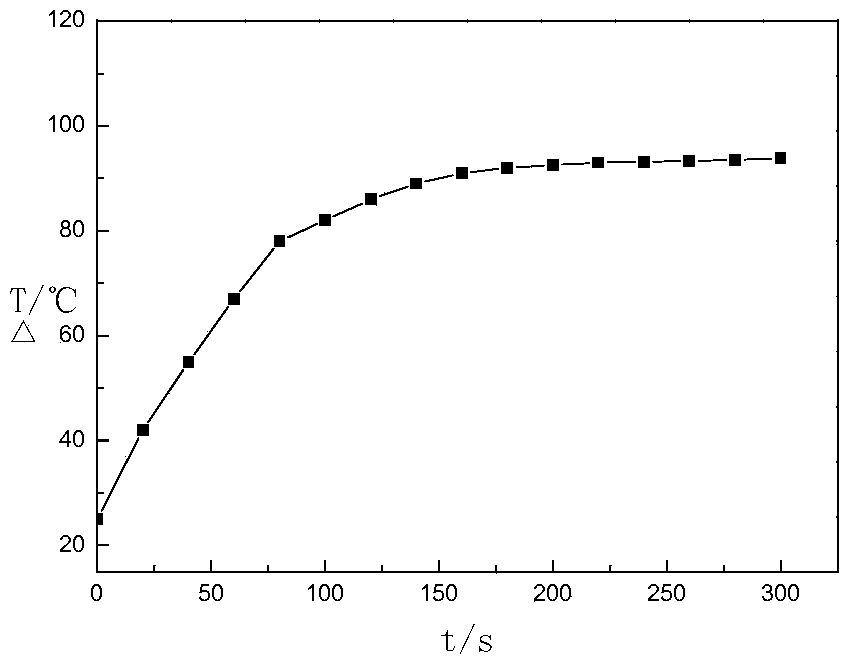

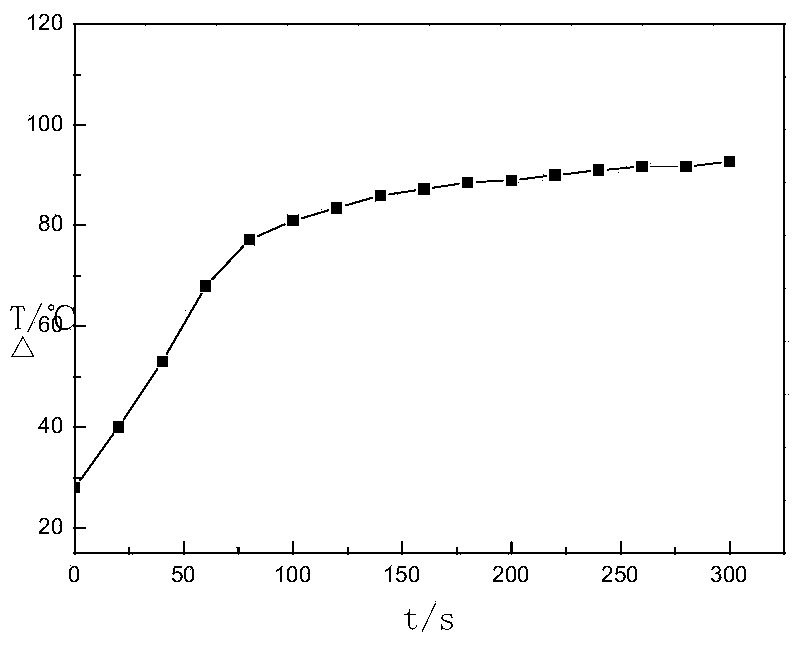

Magneto-calorific curing method for thermosetting resin adhesive

The invention relates to a magneto-calorific curing method for a thermosetting resin adhesive, and the magneto-calorific curing method for the thermosetting resin adhesive is a novel curing method and has the advantages of low temperature, low cost, quickness, high intensity and high toughness. The magneto-calorific curing method is based on magnetic particles and has the characteristic of magnetothermal effect, nanometer magnetic ferrite is evenly dispersed into the thermosetting resin adhesive, during the use, an alternating magnetic field is exerted onto the adhesive, during the magnetic pulsing process of the magnetic ferrite, the energy of the magnetic field is absorbed extensively through magnetic hysteresis loss, eddy loss, residual loss and the like, the magnetic energy is converted into heat energy, and heat produced by nanometer ferrite particles quickly extend to the periphery in a radiating way, therefore, resin adjacent molecules are prompted to be in quick and even curing reaction.

Owner:SHENYANG LIGONG UNIV

LaFeSi based magnetic refrigeration composite material and preparation method and application thereof

ActiveCN106906408ARaw materials are cheap and easy to getHigh thermal conductivityHeat-exchange elementsAlloyThermal hysteresis

The invention discloses a LaFeSi based magnetic refrigeration composite material and a preparation method and application thereof. The LaFeSi based magnetic refrigeration composite material comprises functional body components such as LaFeSi based alloy particles and matrix components such as low-melting-point metal or alloy, and the LaFeSi based alloy particles are bonded and coated by the matrix components to form a bulk material; and the LaFeSi based alloy particles are of a NaZn13 type structure. According to the LaFeSi based magnetic refrigeration composite material and the preparation method and application thereof, composite hot pressing is conducted between the cheap and easily-obtained low-melting-point metal or alloy and the LaFeSi based alloy particles, the appropriate low-melting-point components are selected, the pressing pressure, the hot pressing temperature, the pressure maintaining time and the like are adjusted, and thus the high-thermal-conductivity LaFeSi based magnetic refrigeration composite material can be obtained; the magnetic entropy change of the LaFeSi based magnetic refrigeration composite material is less reduced compared with that before hot pressing, the magnetic hysteresis loss is low, and thermal hysteresis is avoided; and in addition, the process is simple and easy to operate, the process conditions are relatively mild, energy consumption is little, the cost is low, the repeatability is good, and the preparation method can be widely used in preparation of magnetic refrigeration materials.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

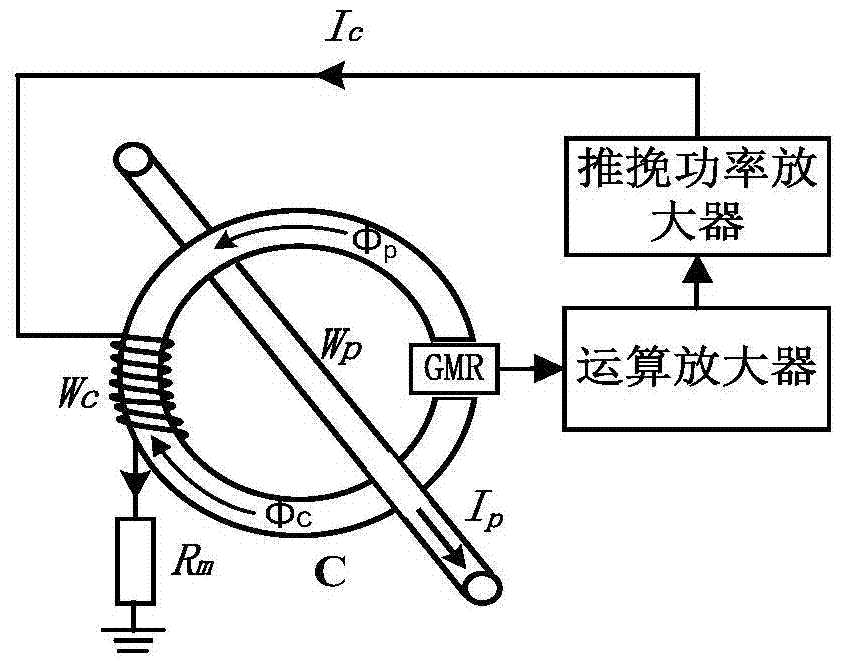

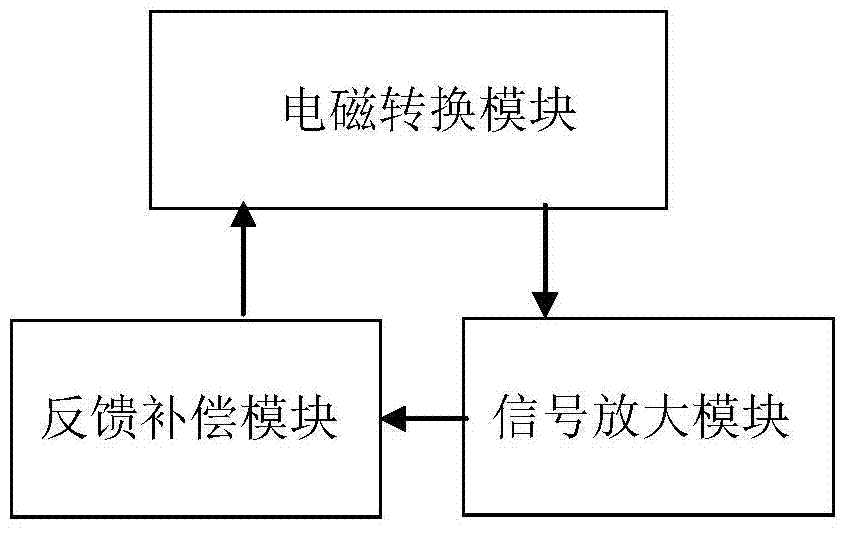

Giant magnetoresistance current sensor

InactiveCN103616550AHighlight substantive featuresAccurately measure the current valueCurrent/voltage measurementClosed loopPush pull

The invention relates to a giant magnetoresistance current sensor and relates to a device for measuring currents. The giant magnetoresistance current sensor is composed of an electromagnetic conversion module, a signal amplification module and a feedback compensation module, wherein the electromagnetic conversion module comprises a magnetic core of a magnetism accumulation ring, a primary winding and a giant magnetoresistance chip, the signal amplification module comprises an operational amplifier and a push-pull power amplifier, and the feedback compensation module is a feedback winding. The whole measurement circuit forms a closed loop system, and the giant magnetoresistance chip and the magnetic core of the magnetism accumulation ring form a closed structure. The giant magnetoresistance current sensor overcomes the defects that a giant magnetoresistance current sensor in the prior art is very prone to interference of an external stray magnetic field, temperature drift and zero drift cannot be eliminated completely, and the measurement accuracy is affected by intrinsic magnetic hysteresis existing in a magnetic device.

Owner:HEBEI UNIV OF TECH

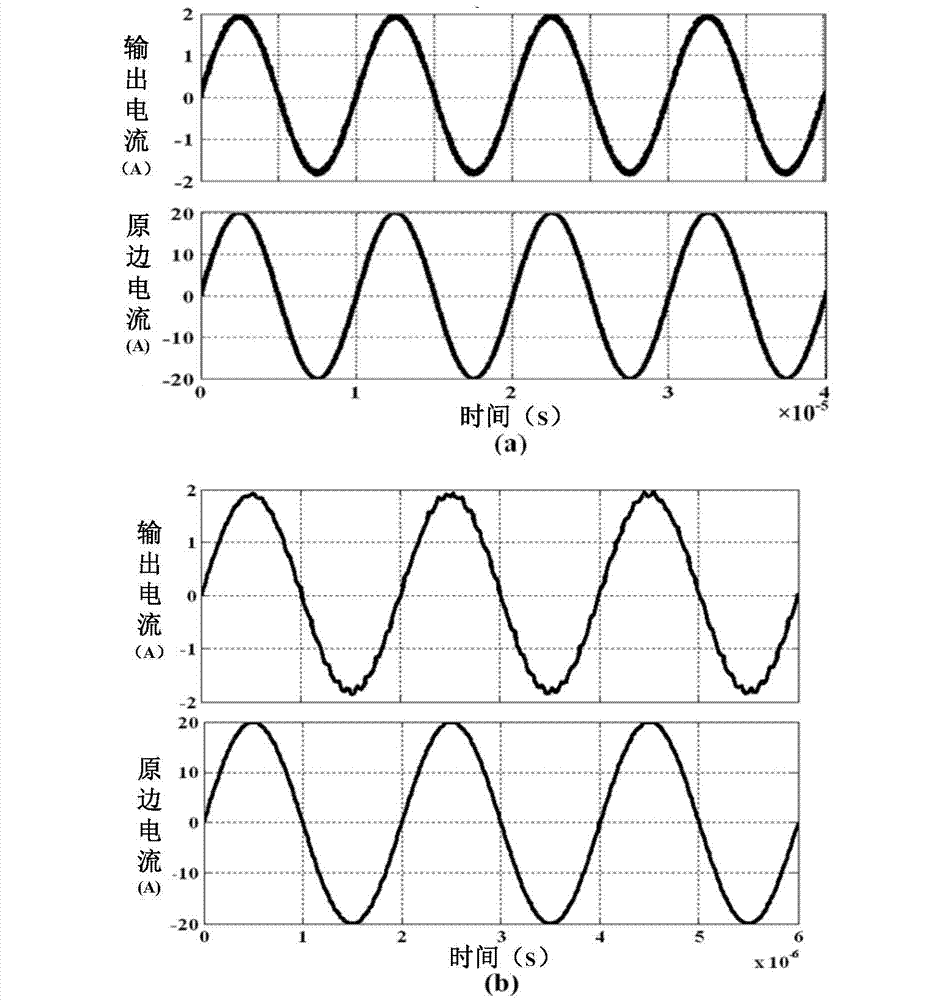

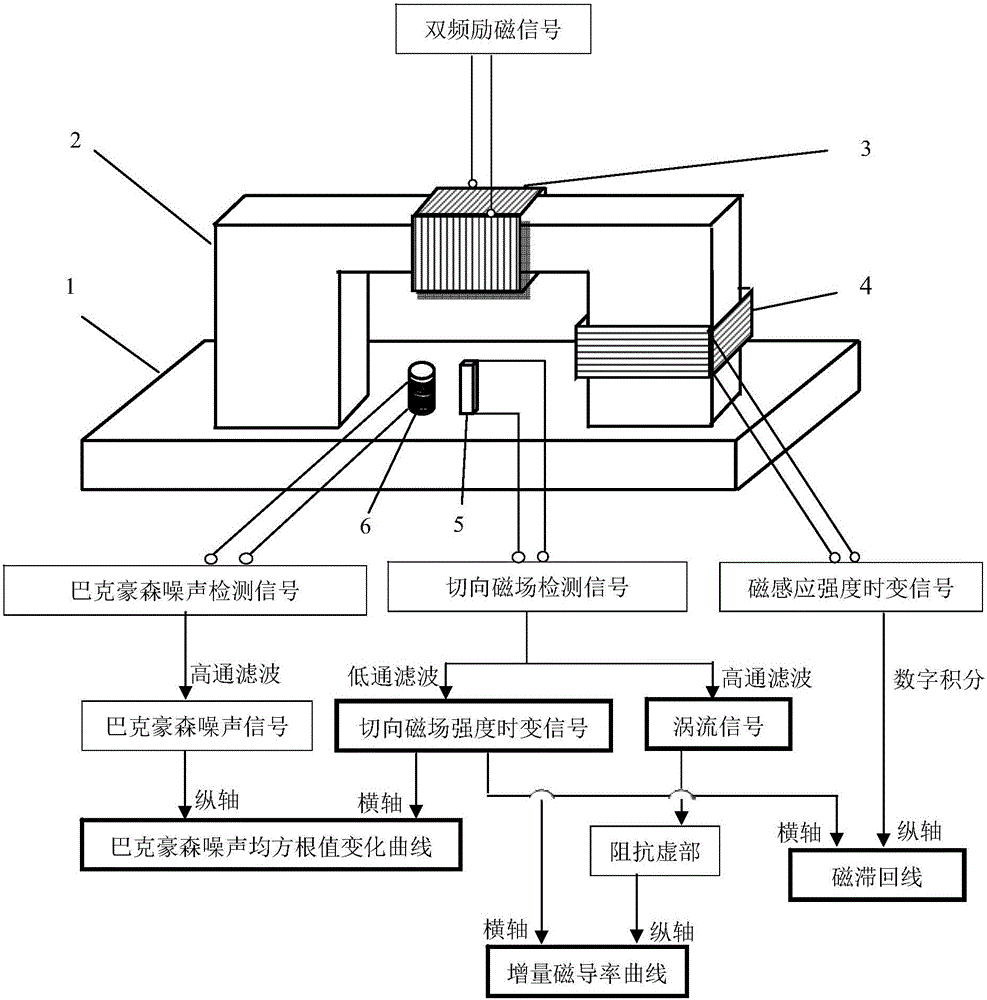

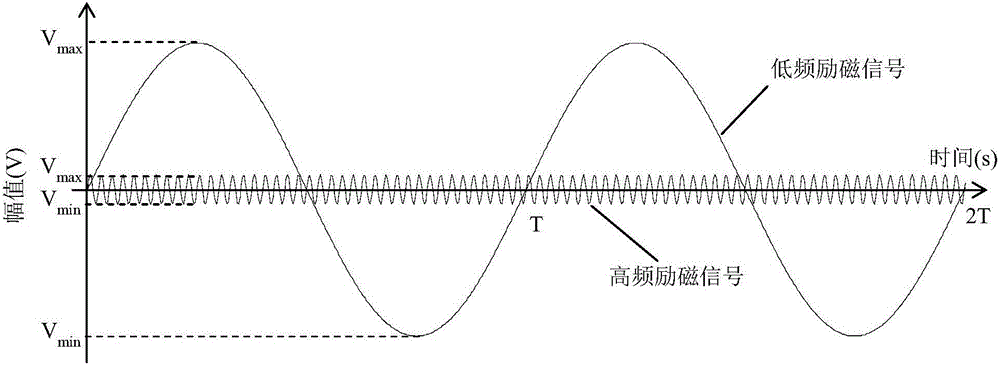

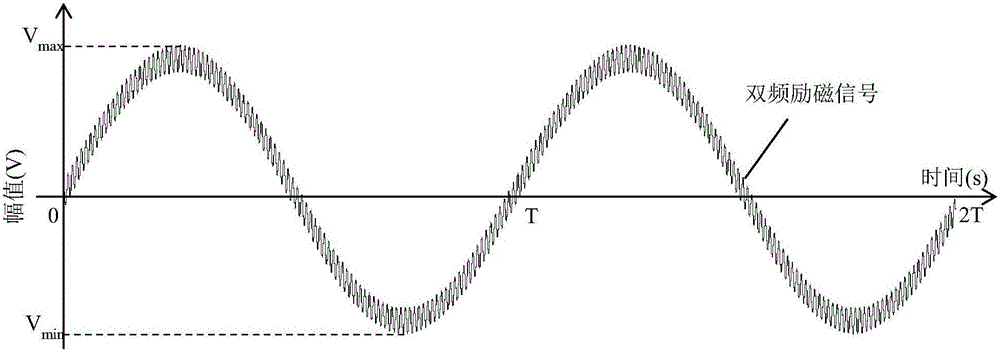

Common source double-frequency excitation type multifunctional micro-magnetic signal synchronous detection method

ActiveCN105911489ARealize synchronized measurementsImprove detection efficiencyPermeability measurementsHysteresis curve measurementsMagnetic field magnitudeMagnetic signal

A common source double-frequency excitation type multifunctional micro-magnetic signal synchronous detection method is disclosed and belongs to the technical field of micro-magnetic nondestructive testing. Via use of the common source double-frequency excitation type multifunctional micro-magnetic signal synchronous detection method, five types of typical micro-magnetic detection parameters can be obtained synchronously, and detecting efficiency can be greatly improved. A standard micro-magnetic probe comprises an excitation magnetic circuit consisting of a magnetic core and an excitation wire coil, an induction wire coil wounded around the magnetic core, a Hall element used for detecting surface tangential magnetic field change of a ferromagnetic component being detected, and a Barkhausen noise detection wire coil. Sine wave superposed signals having a low frequency less than 100 Hz and a high frequency greater than 1k Hz that matche with an amplitude ration are used as excitation signals, and the excitation signals are sent into the excitation wire coil of the standard micro-magnetic probe so as to magnetize the ferromagnetic component being detected. The induction wire coil, the Hall element and the Barkhausen noise detection wire coil are respectively used for synchronously picking characteristic signals such as magnetic induction intensity time-varying signals, tangential magnetic field detection signals and Barkhausen noise detection signals; magnetic hysteresis loops, tangential magnetic field intensity time-varying signals, Barkhausen noise, eddy current impedance and incremental magnetic permeability can be quickly detected.

Owner:BEIJING UNIV OF TECH

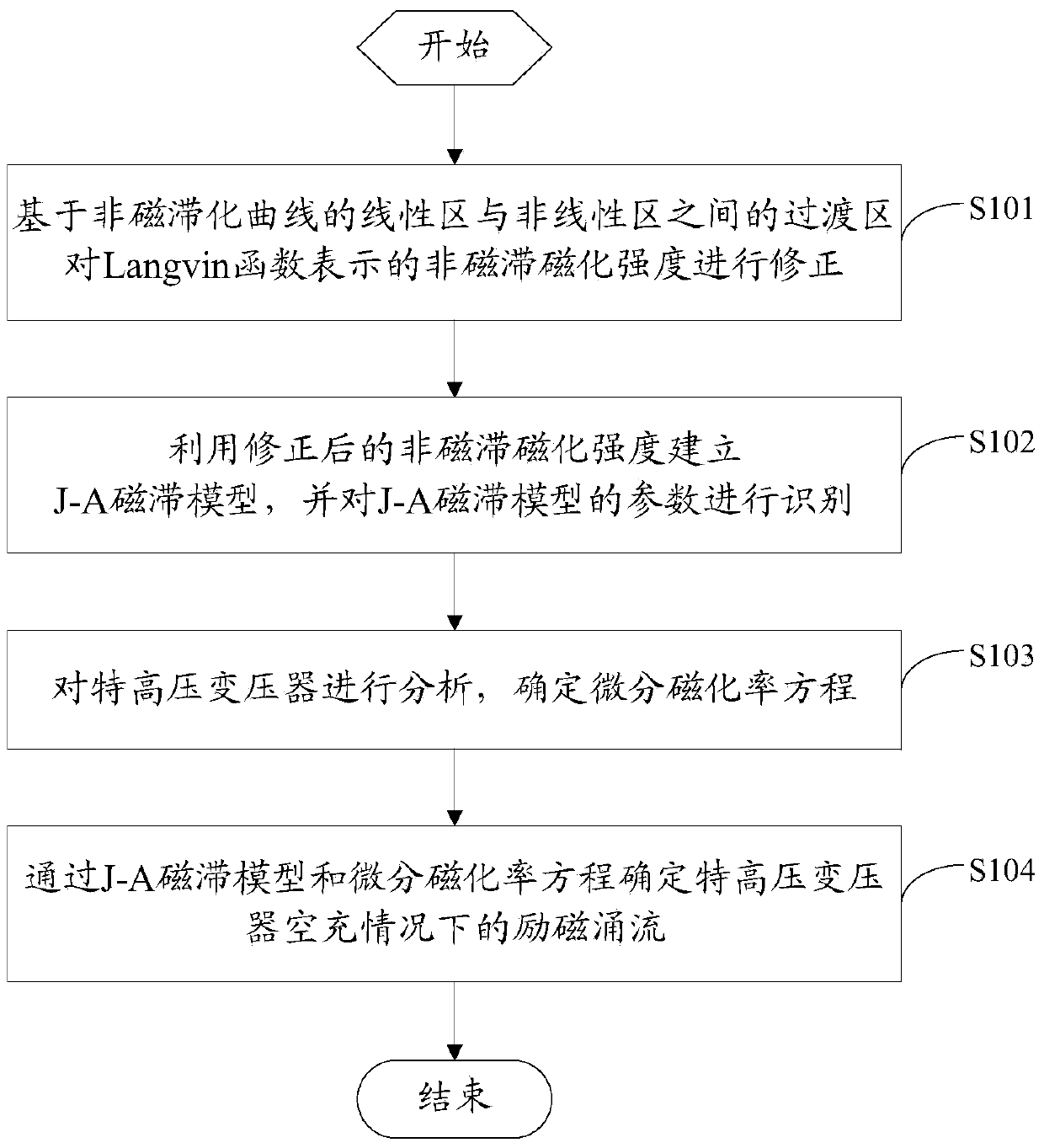

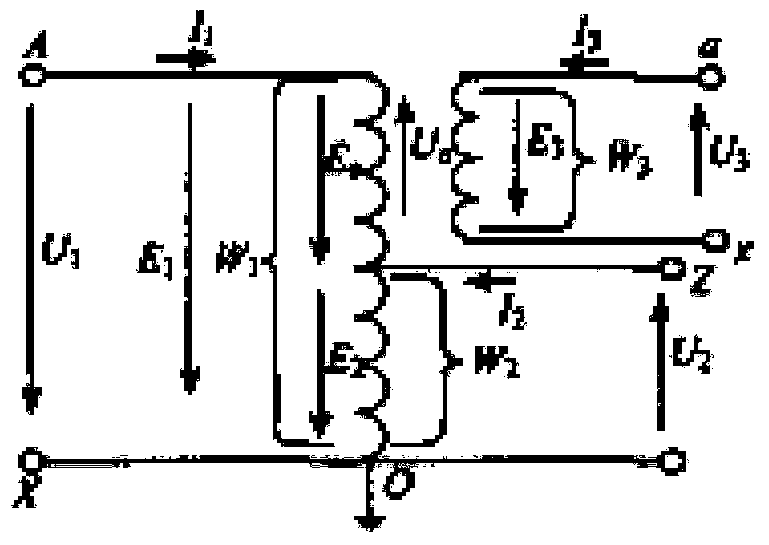

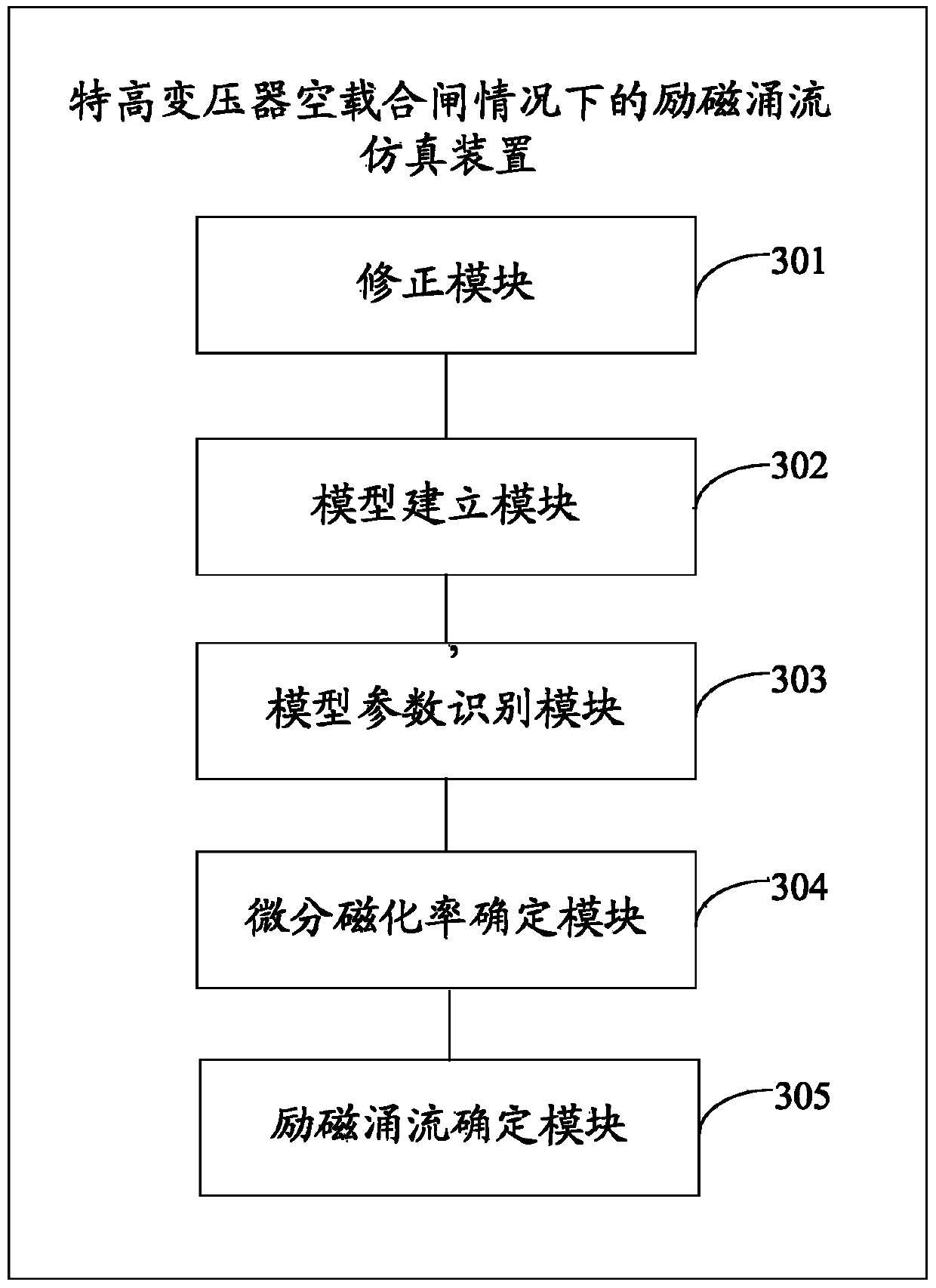

Excitation inrush current simulation method and device for ultra-high voltage transformer under condition of no-load closing

ActiveCN104200055ACorrected anhysteretic magnetizationEnable accurate simulationSpecial data processing applicationsHysteresisMagnetic susceptibility

The invention provides an excitation inrush current simulation method and device for an ultra-high voltage transformer under a condition of no-load closing. The excitation inrush current simulation method comprises the following steps: on the basis of the transitional area between the linear area and the non-linear area of the non-hysteresis curve, non-hysteresis magnetization intensity indicated by Langvin function is corrected; the corrected non-hysteresis magnetization intensity is utilized to establish a J-A magnetic hysteresis model; the parameters of the J-A magnetic hysteresis model are recognized; an analysis is conducted on the ultra-high voltage transformer and the differential magnetic susceptibility equation is determined; through the J-A magnetic hysteresis model and the differential magnetic susceptibility equation, the excitation inrush current of the ultra-high voltage transformer under the empty charging condition is determined. The excitation inrush current simulation method and device for the ultra-high voltage transformer under the condition of non-load losing correct the non-hysteresis magnetization intensity, enable the transitional area between the linear area and saturation area of the non-hysteresis curve to be closer to a true value and accurately simulate the magnetization characteristics of the transformer; moreover, the special construction of the ultra-high voltage transformer is considered and the excitation inrush current of the ultra-high voltage transformer under the condition of empty charging is simulated. Errors in the simulation are reduced.

Owner:STATE GRID CORP OF CHINA +3

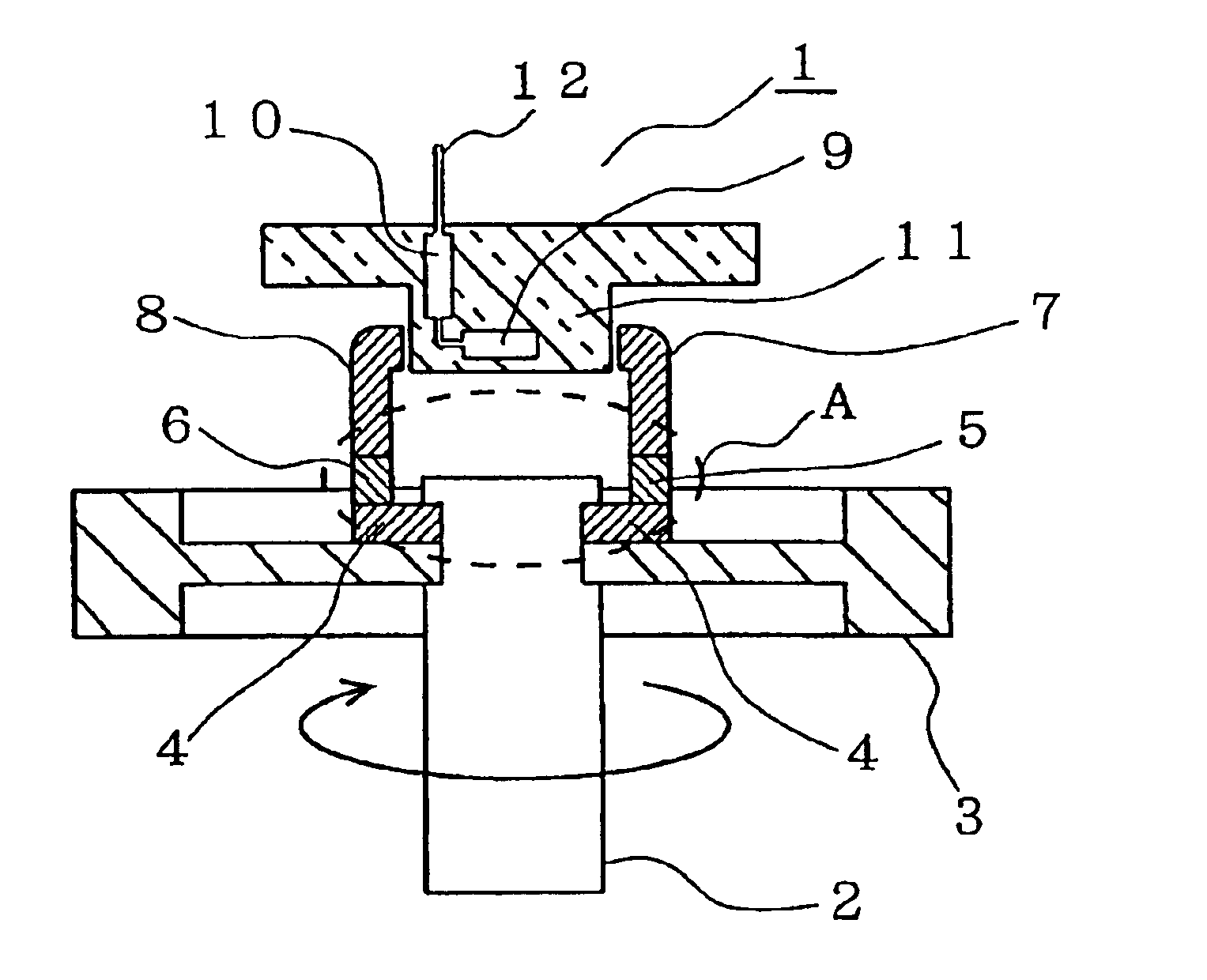

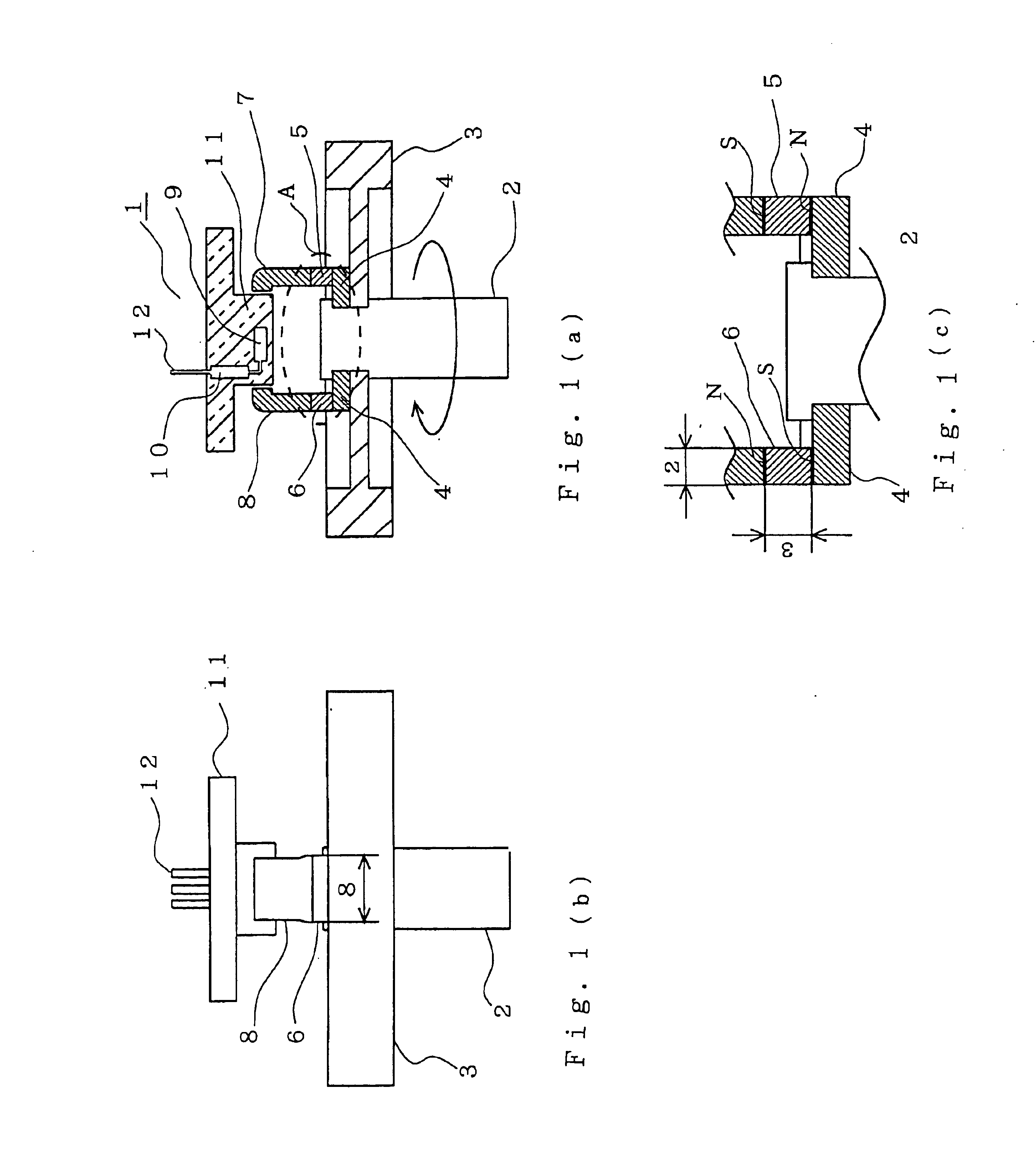

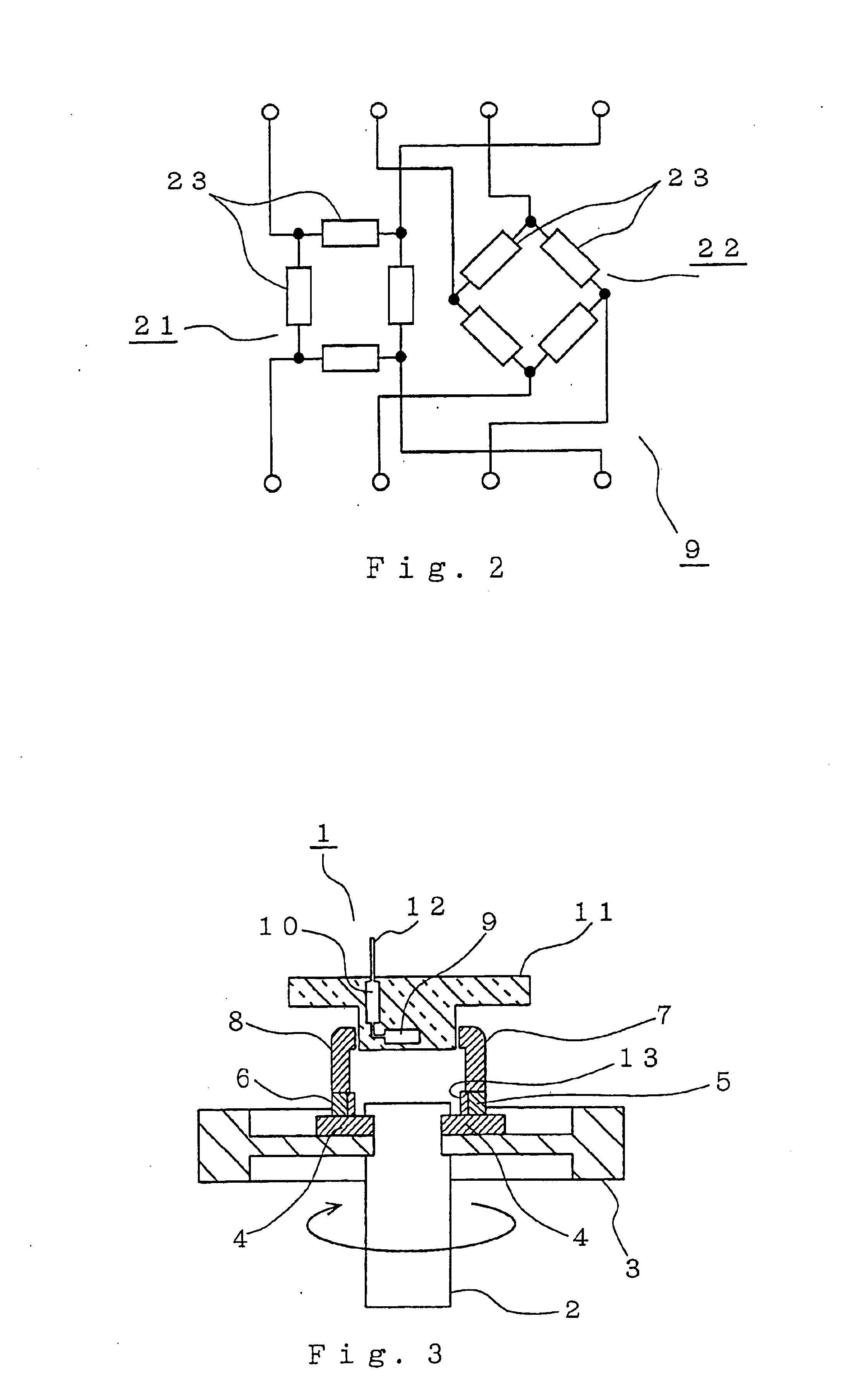

Non-contact type rotation-angle sensing device

InactiveUS6867584B1Low costRemoving magnetic hysteresis of the sensor outputUsing electrical meansConverting sensor output electrically/magneticallyMagnetic reluctanceContact type

In a non-contact type rotation-angle sensing device, a rotation angle sensor (9) having magnetoresistance elements detects a rotation angle of an object to be measured. The object is rotatable round a rotary shaft (2) with respect to the rotation angle sensor (9) and includes a permanent magnet (5, 6). The permanent magnet (5, 6) is disposed symmetrically about said rotary shaft (2) of said object, and a magnetic element (7, 8) is disposed on said object between said permanent magnet (5, 6) and the magnetoresistance elements. In the non-contact type rotation-angle sensing device of above constitution according to the invention, linearity is secured by reducing magnetic hysteresis of the sensor output with respect to the rotation angle, thus a small-sized permanent magnet and reduction in cost being achieved.

Owner:MITSUBISHI ELECTRIC CORP

Soft magnetic iron powder core manufactured by aluminum coated oxidation method

InactiveCN102890993AReduce eddy current lossReduce hysteresis lossInorganic material magnetismIron powderAlloy

The invention discloses a soft magnetic iron powder core manufactured by an aluminum coated oxidation method. The soft magnetic iron powder core is characterized in that a pure aluminum layer or an aluminum iron alloy coated layer containing a small amount of iron is coated on iron-based soft magnetic powder quickly; the layer is formed into a good-quality oxidation film through the oxidation method, thereby reducing the eddy loss; after the product is formed by pressing, a heat treatment is carried out on the oxidation film at a relatively high temperature to finish an alloying treatment and an annealing treatment, thereby reducing the magnetic hysteresis loss; and a main process of the soft magnetic iron powder core comprises the following five steps: the first step: producing the iron-based soft magnetic powder; the second step: coating the aluminum on the iron-based soft magnetic powder quickly; the third step: forming the aluminum oxidation film; the fourth step: forming by pressing; and the fifth step: performing the alloying treatment and the annealing treatment.

Owner:TIANJIN CHANGING POWER TECH

Electrohydraulic valve control circuit with magnetic hysteresis compensation

ActiveUS7857281B2Compensation effectOperating means/releasing devices for valvesServomotorsEngineeringControl circuit

A method for operating an electrohydraulic valve initially derives a characterization value that denotes how magnetic hysteresis affects valve operation. Upon receiving a command that designates a desired magnitude of electric current to be applied to the electrohydraulic valve, that command is modified based on the characterization value to compensate for the magnetic hysteresis. The modified command then is employed to apply electric current to the electrohydraulic valve.

Owner:HUSCO INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com