Magnetorheological damper composite work mode high output method and damper

A magneto-rheological damper and working mode technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of a single effective damping channel length in the working mode, to increase the effective damping channel length, The effect of reducing manufacturing cost and large damping output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

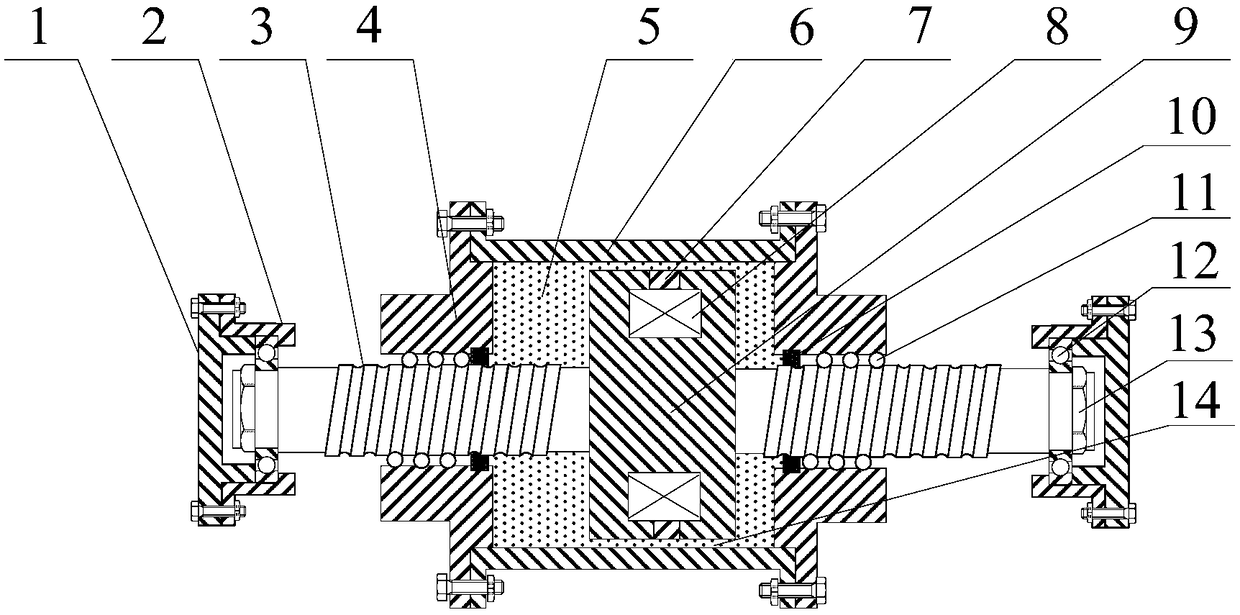

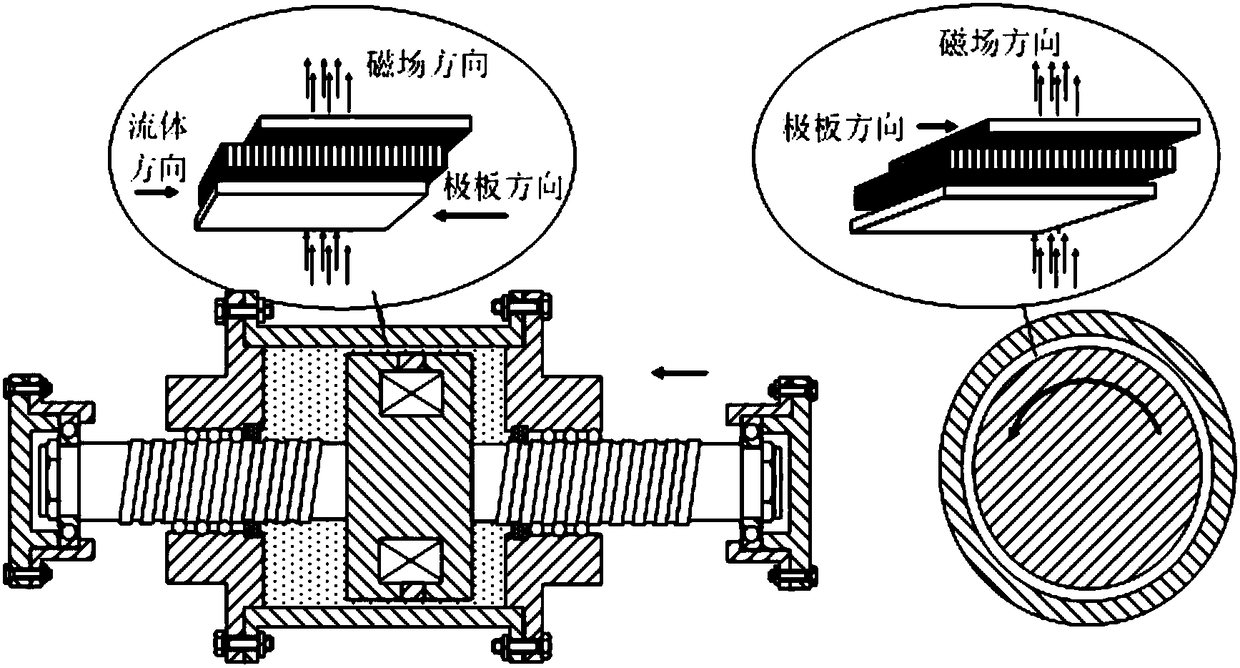

[0020] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the present invention includes connector end cap 1, connector body 2, lead screw piston rod 3, end cap 4, magnetorheological fluid 5, cylinder wall 6, hysteresis ring 7, induction coil 8, piston 9, seal ring 10, ball nut pair 11, bearing 12, fixed nut 13 and effective damping channel 14; the cylinder body is filled with magnetorheological fluid 5, and the two ends of the piston rod 5 protrude from the cylinder body; the screw rod piston rod 3 is provided with a piston 9 , sliding in the cylinder, the piston 9 is provided with an annular groove, the induction coil 8 is wound in the groove, and the induction coil 8 is connected with a wire. In order to avoid the influence brought by the rotation of the screw piston rod 3, the two ends of the damper are provided with a connection device consisting of a connector end cover 1, a connector body 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com