A giant magneto-squeezing magneto-rheological damper self-adaption method and damper

A magnetorheological damper, extrusion technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., to achieve the effect of reasonable structure space utilization, low cost and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

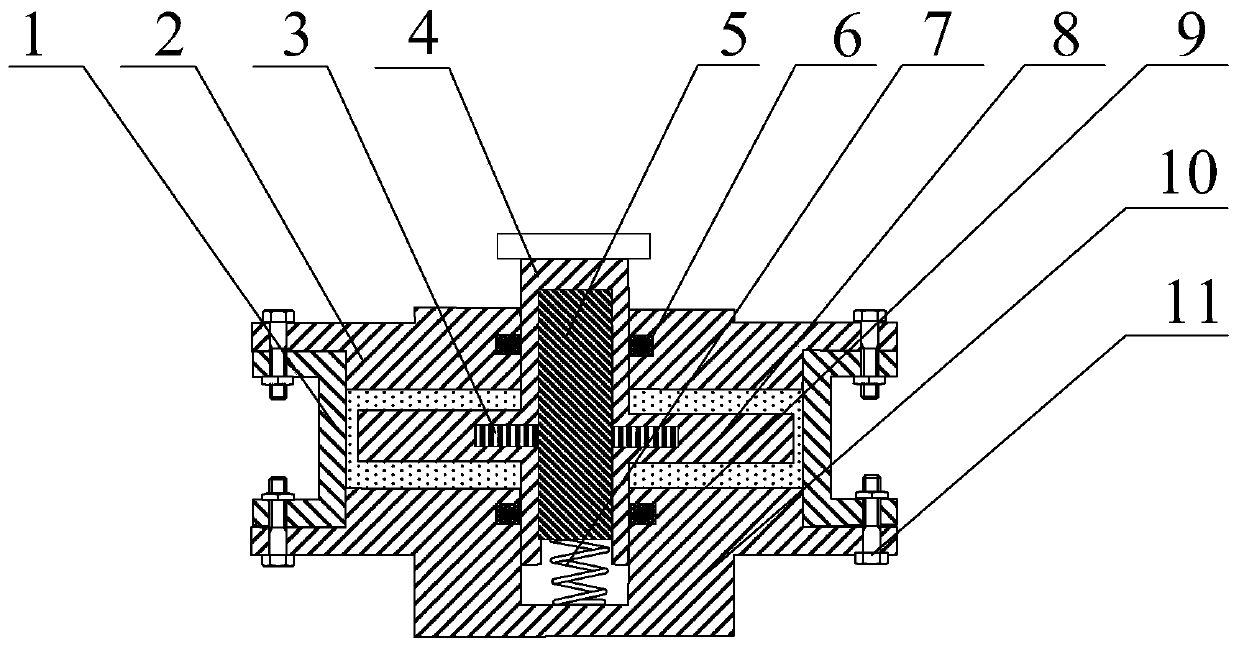

[0021] The present invention will be further described below in conjunction with the accompanying drawings. like figure 1 As shown, the present invention includes a cylinder 1, an upper end cover 2, a permanent magnet 3, a piston rod 4, a giant magnetostrictive rod 5, a sealing ring 6, an elastic element 7, an extrusion disc 8, a magnetorheological fluid 9, and a lower end cover 10 and connecting bolts 11; the cylinder body is filled with magnetorheological fluid 5, and one end of the piston rod 4 extends out of the cylinder body. A permanent magnet 3 is arranged in the extrusion disc 8 , a giant magnetostrictive rod 5 is located in the hollow piston rod 4 , and an elastic element 7 connects the giant magnetostrictive rod 5 with the lower end cover 10 .

[0022] Working principle of the present invention:

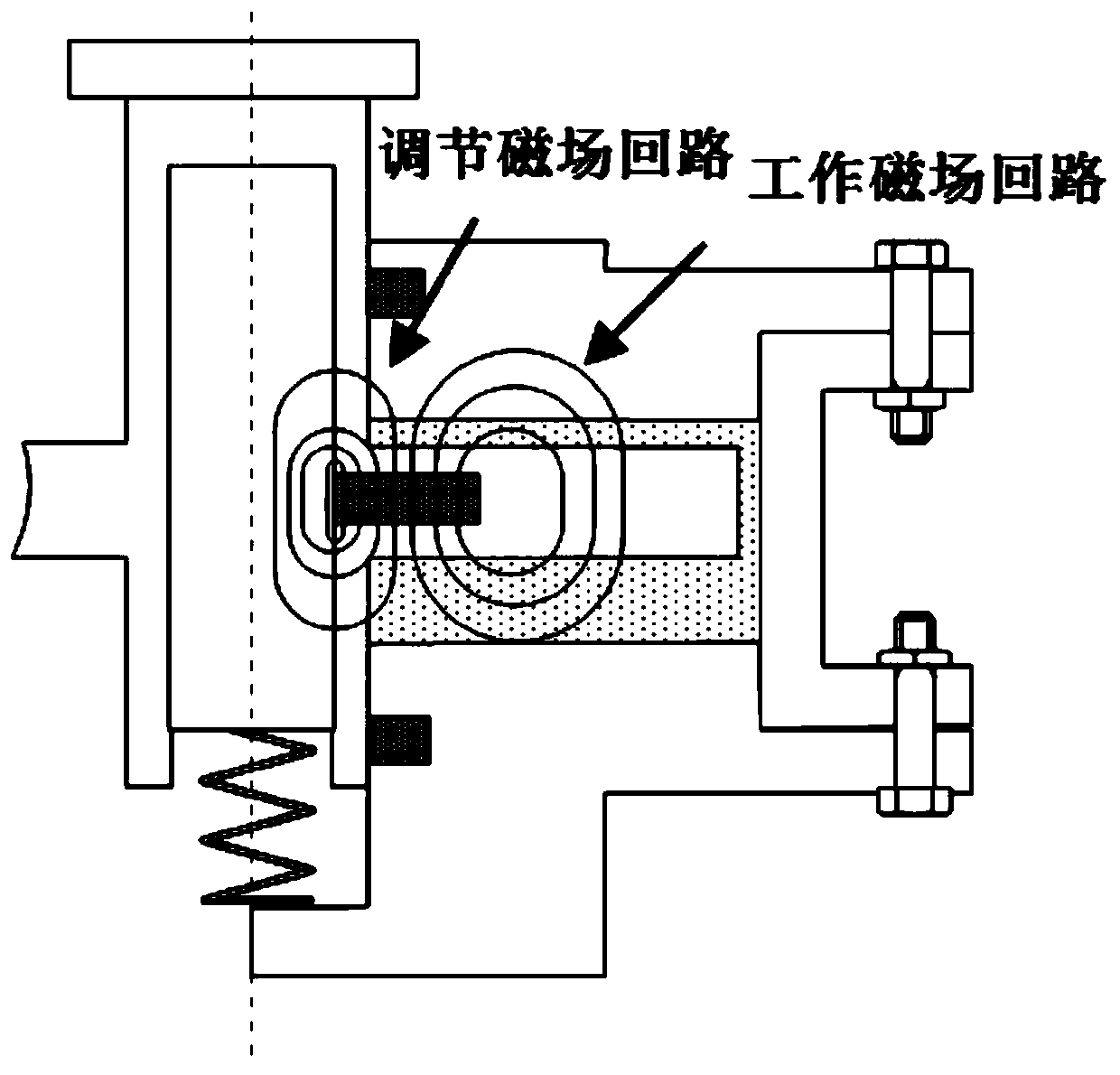

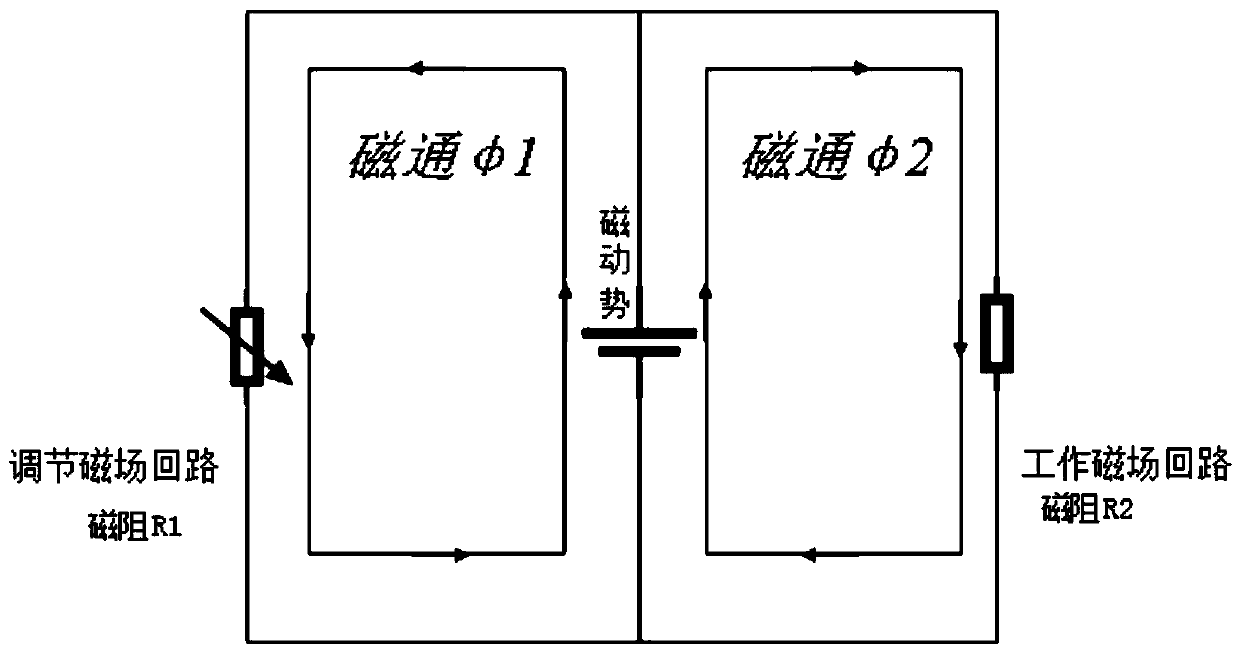

[0023] like figure 2 As shown, the magneto-rheological damper is equipped with a ring-shaped permanent magnet inside the extrusion disk, which respectively generates tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com