Photocureable magnetic-conductive and light-conductive pressure-sensitive adhesive, adhesive tape and preparation method of adhesive tape

A technology of light-curing and pressure-sensitive adhesives, applied in the direction of pressure-sensitive films/sheets, adhesives, non-polymer organic compound adhesives, etc., which can solve the problem of affecting the continued use of components, difficult to clean magnetically conductive adhesives, and damage to the surface of materials, etc. Problems, to achieve excellent light and magnetic conductivity, easy processing, low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A preparation method of light-curing, magnetic-conducting and light-conducting pressure-sensitive adhesive tape, coating the above-mentioned light-curing, magnetic-conducting and light-conducting pressure-sensitive adhesive on a release film, drying at 120°C for 10 minutes, and then placing it under a UV lamp at a distance of 15cm Radiation cross-linking, that is, light-curing, magnetic-conducting and photo-conductive pressure-sensitive adhesive tape, which can be used for pasting on the surface of materials, which is equivalent to the usage of double-sided adhesive tape. The UV light source is preferably a light source produced by carbon arc lamps, ultra-high pressure mercury lamps, metal halide lamps, fluorescent lamps, and xenon lamps. The light source intensity, emission stability, and uniformity of spectral energy distribution are relatively good.

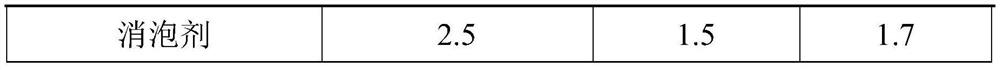

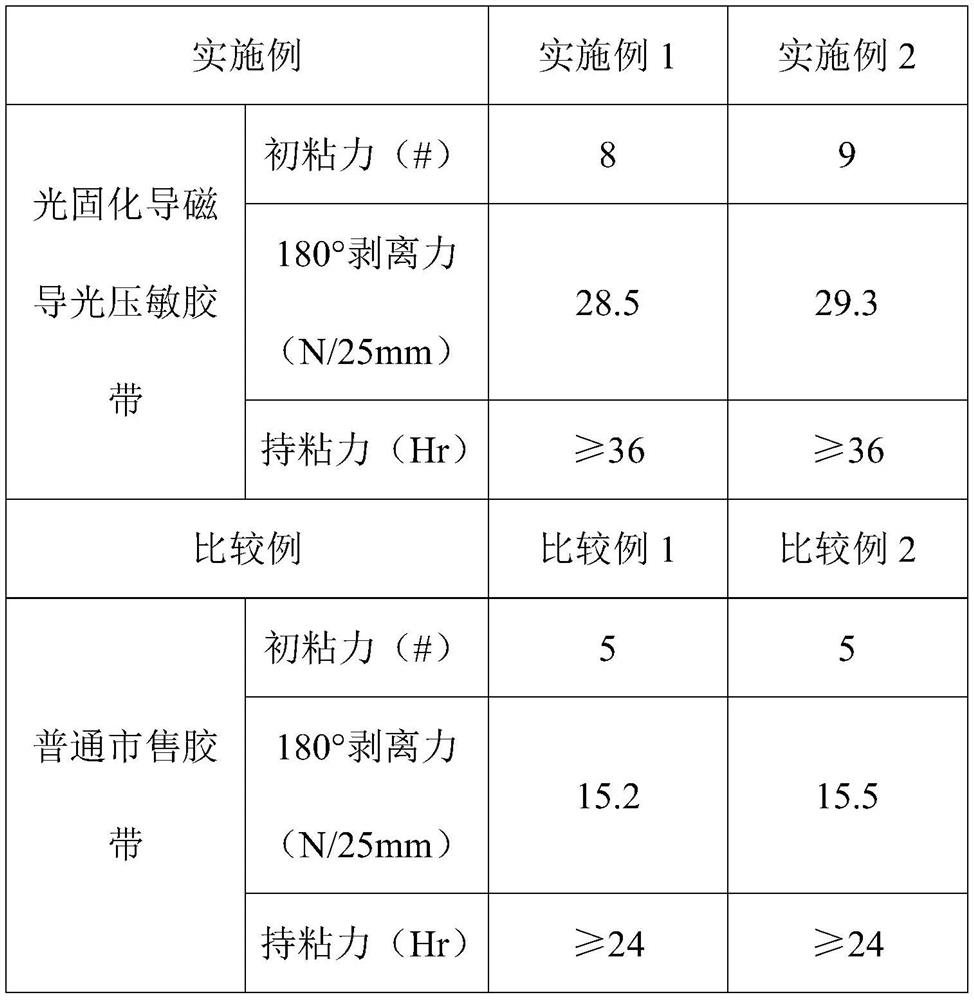

[0054] The proportioning of each component of Examples 1-3 is shown in Table 1.

[0055] The component formula of tab...

Embodiment 1

[0059] The functional monomer is N-methacrylamide, the tackifying resin is terpene resin, the diluent is ethanol, the photoinitiator is 2-hydroxy-2-methyl-1-phenyl-1-acetone, and the light-conducting filler is Nano titanium dioxide, magnetic filler is nano iron powder, leveling agent is polybutyl acrylate, dispersant is sodium hydroxypropyl acrylate, coupling agent is propenyl butanone dichlorosiloxane, defoaming agent is benzoic acid Epoxypentanol esters.

Embodiment 2

[0061]The functional monomer is N-hydroxyethylacrylamide, the tackifying resin is petroleum resin, the diluent is ethanol + HDDA, and the photoinitiator is 2,2'-bis(2-chlorophenyl)-4,4',5 ,5'-Tetraphenyl-1,2'-biimidazole, the optical filler is nano-zinc oxide, the magnetic conductive filler is nano-carbonyl iron powder, the leveling agent is polyethylacrylate, and the dispersant is sodium carboxyethyl benzoate , the coupling agent is isobutyl vinyl dimethyl siloxane, and the defoamer is nitroheptyl laurate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com