Patents

Literature

359results about How to "Temperature resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

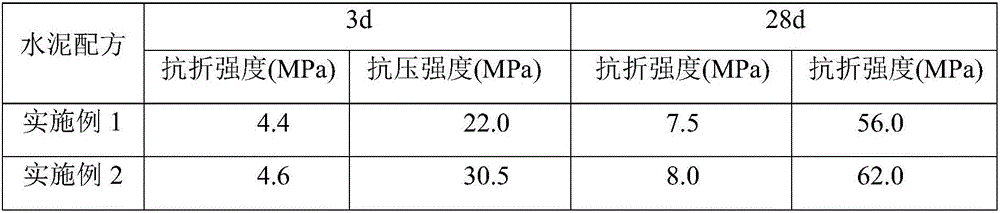

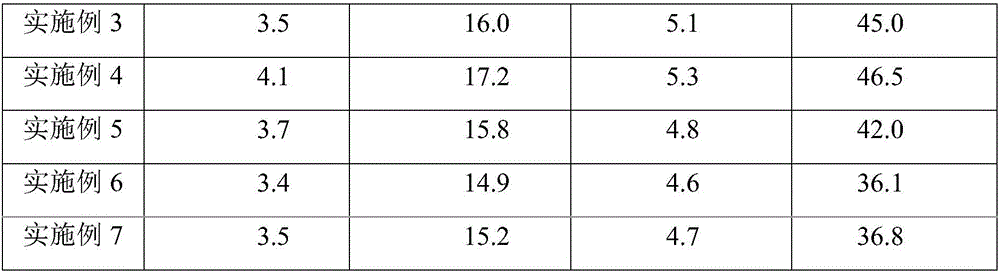

Modified magnesium oxy-sulfur cement

InactiveCN102924038AImprove mechanical propertiesImprove water resistanceAqueous solutionMaterials science

The invention relates to modified magnesium oxy-sulfur cement. The cement consists of the following raw materials in parts by weight: 100 parts of magnesium oxide, 0.05-10 parts of additive, 50-200 parts of 10%-30% magnesium sulfate aqueous solution and 0-300 parts of filler. The modified magnesium oxy-sulfur cement has excellent mechanical property and water resistance, is temperature-resistant, does not crack, can be used for substituting for a magnesium oxy-chloride cement and can be used for producing materials of mortar, concrete, slabs, crafts and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

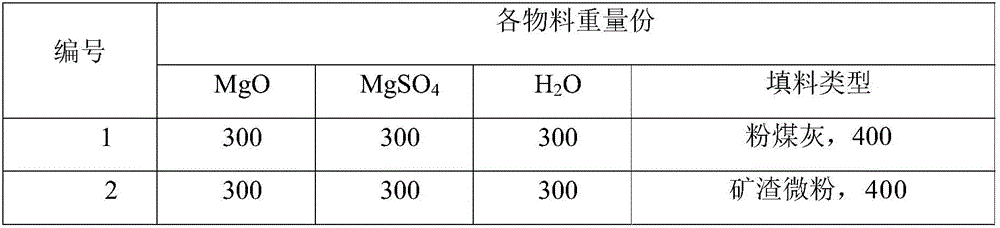

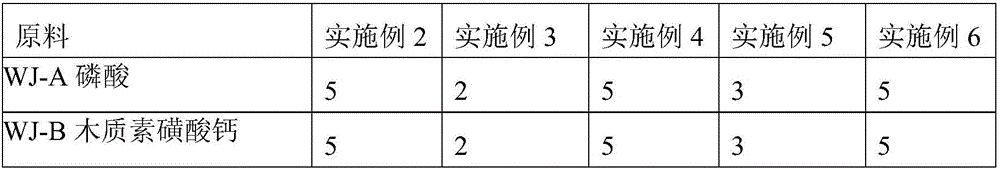

Modified magnesium oxysulfate cement for foaming and foam material thereof

InactiveCN105859166ASuppress generationPromote generationCeramicwareMagnesium sulphate heptahydrateCement

The invention relates to the field of cement and particularly relates to modified magnesium oxysulfate cement and a foam material prepared by adopting the magnesium oxysulfate cement. The modified magnesium oxysulfate cement is prepared from the raw materials in parts by weight: 100 parts of magnesium sulfate, 50-200 parts of magnesia, 0-500 parts of filler and 30-350 parts of water, wherein an admixture may be added. The invention also relates to the foam material prepared by adopting the magnesium oxysulfate cement. According to the modified magnesium oxysulfate cement and the foam material thereof, by adding the admixture, the generation of magnesium hydroxide in the cement is inhibited, so that the mechanical properties and water resistance of the magnesium oxysulfate cement are effectively improved; and meanwhile, the magnesium oxysulfate cement has the characteristics of heat resistance and no cracking.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Cellulose acetate nanofiltration membrane and preparing method thereof

The invention discloses a cellulose acetate nanofiltration membrane and a preparing method thereof. The preparing method of the cellulose acetate nanofiltration membrane includes the steps that cellulose acetate serves as a raw material, an organic metal framework compound and a small molecule pore-forming agent serve as a mixed additive, the raw material and the mixed additive are dissolved through a solvent to prepare a cellulose acetate membrane casting solution, a dry and clean glass plate with a supporting layer is coated with the prepared membrane casting solution to form a plate nascent-state membrane or the prepared membrane casting solution and a medium with an inner fiber cavity are extruded through a spinneret plate to obtain a hollow fiber nascent-state membrane, the hollow fiber nascent-state membrane is solidified and subjected to heat treatment, and the cellulose acetate nanofiltration membrane is prepared. As the cellulose acetate nanofiltration membrane is prepared through the organic metal framework compound, the porosity factor of the cellulose acetate nanofiltration membrane is increased, and the water flux is improved; the amine-modified organic metal framework compound is introduced into the formula of the membrane casting solution of the cellulose acetate, the nanofiltration membrane can show charged positive electricity after cross-linking, separation of amino acid with positive charges and protein with positive charges can be promoted, and the reject rate of the nanofiltration membrane is increased.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-efficiency ferment for fermenting bean pulp and bean pulp fermentation technology using the ferment

The invention relates to a high-efficiency ferment for fermenting bean pulp, belonging to the biologic enzymolysis fermentation technical field. The high-efficiency ferment is formed by mixing bacillus subtilis, bacillus licheniformis, lactobacillus acidophilus, lactobacillus casei, saccharomyces cerevisiae and candida utilis. The fermentation technology comprises the following steps: crushing the bean pulp and corn; activating the strains; uniformly mixing the bean pulp and the fermentation liquor using a mixer; packing the mixed bean pulp in fermentation bag; fermenting the packaged bean pulp and processing fermented bean pulp: drying-crushing-detecting-packaging-finished product. The technology is simple and the product quality is stable and the content of the anti-nutrient factor in the bean pulp is eliminated and obviously reduced, therefore the bean pulp is a safe plant protein feeder for infant animal with balanced nutrient, good quality and low price and help for health growth of the infant animal, in replace of animal protein feeder of bone powder, fish powder or the like.

Owner:MINXIONG BIOTECH CO LTD LONGYAN FUJIAN

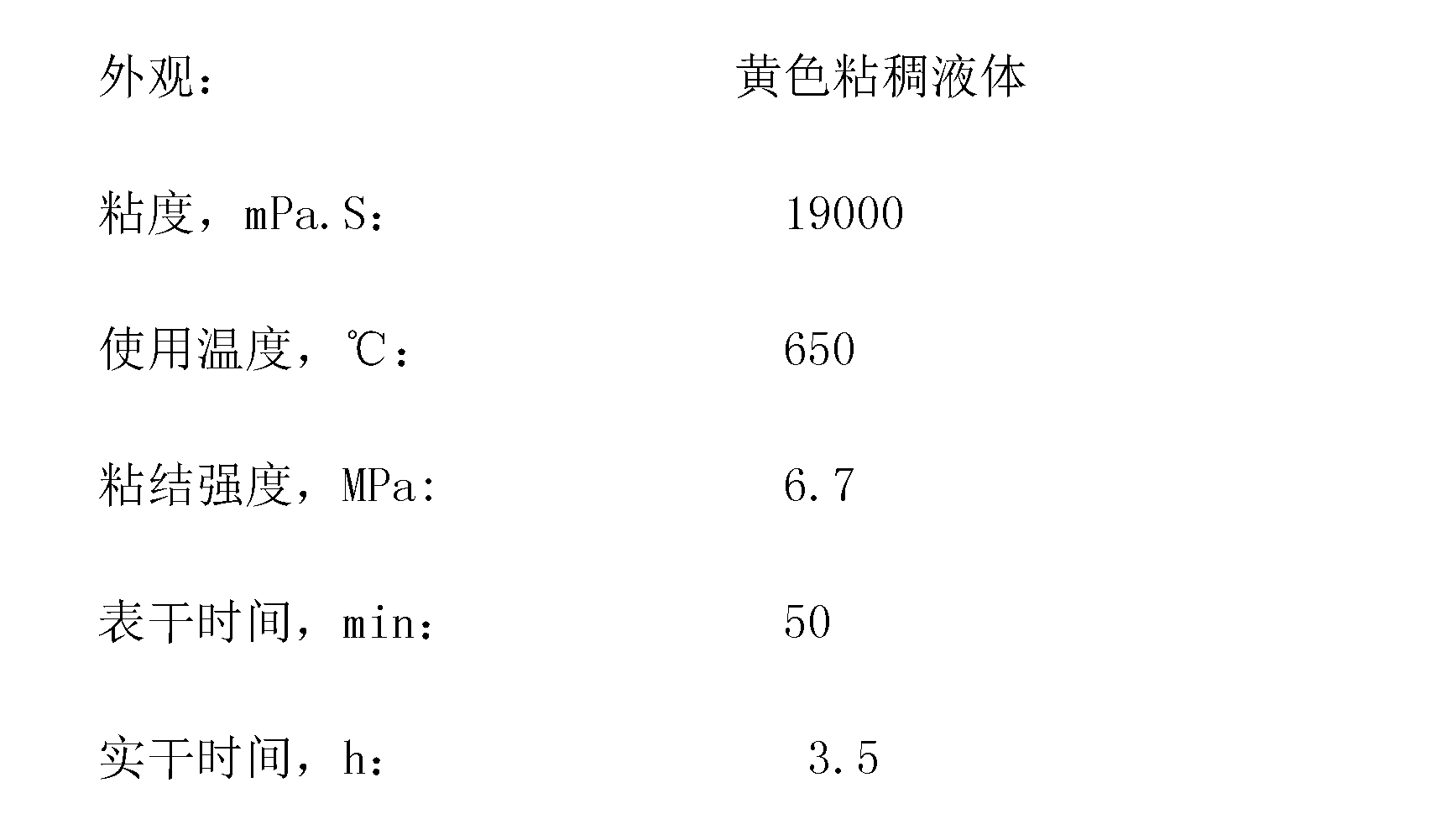

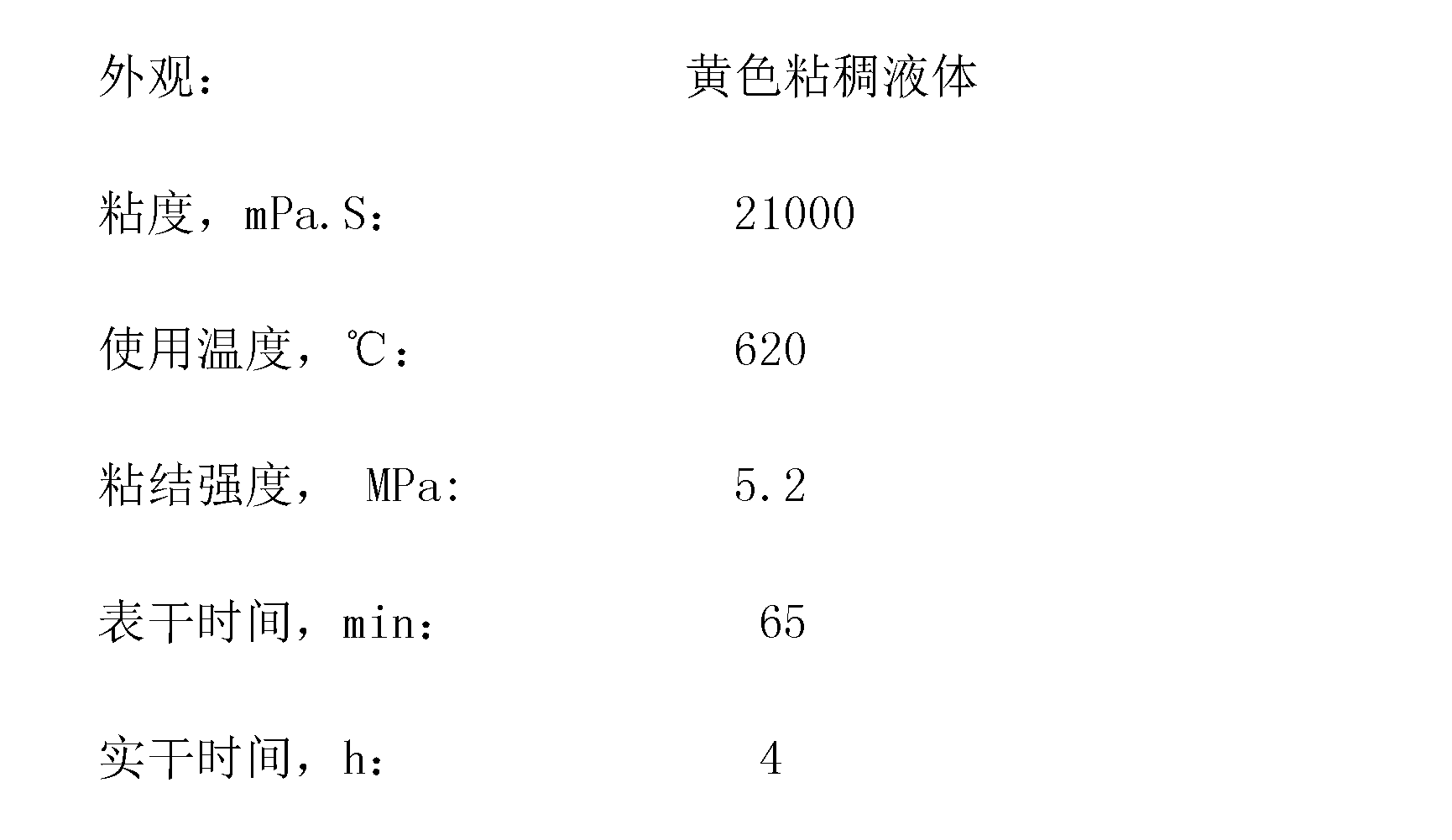

Borosiloxane and preparation method thereof

The invention relates to borosiloxane and a preparation method thereof. According to the method, a hydrolysis solvent and a boron compound are mixed proportionally and added to a reactor, the temperature keeps from 10 DEG C to 35 DEG C, and a mixed monomer is slowly dropwise added under the stirring condition for a hydrolysis reaction; the dropwise-adding time is controlled in 3-6 hours, the reactor is slowly heated to the temperature ranging from 55 DEG C to 65 DEG C after the dropwise-adding is finished, a stirring reaction is performed for 1 hour, and still standing is performed; acid water on the lower layer is separated and neutralized to be neutral, a saturated NaCl solution is used for washing, and an oil phase material is obtained; reduced pressure distillation is performed to remove the solvent, a catalyst I is added, the mixture is heated to 110-130 DEG C, and the rearrangement reaction is performed for 3-5 hours; the mixture is heated to 150-160 DEG C, the splitting cyclization reaction is performed for 2-5 hours, the reaction is finished, the mixture is cooled, and a polyborosiloxane prepolymer is obtained; an end-capping reagent and a catalyst II are added to a system and heated to 110-130 DEG C, and react for 2-4 hours; and pressure is reduced to remove a low-boiling-point substance, and a polyborosiloxane resin is obtained. The borosiloxane and the preparation method have the advantages of good temperature resistance, ageing resistance, impact resistance, toughness and low-temperature flexibility, high adhesion and the like.

Owner:上海爱世博有机硅材料有限公司

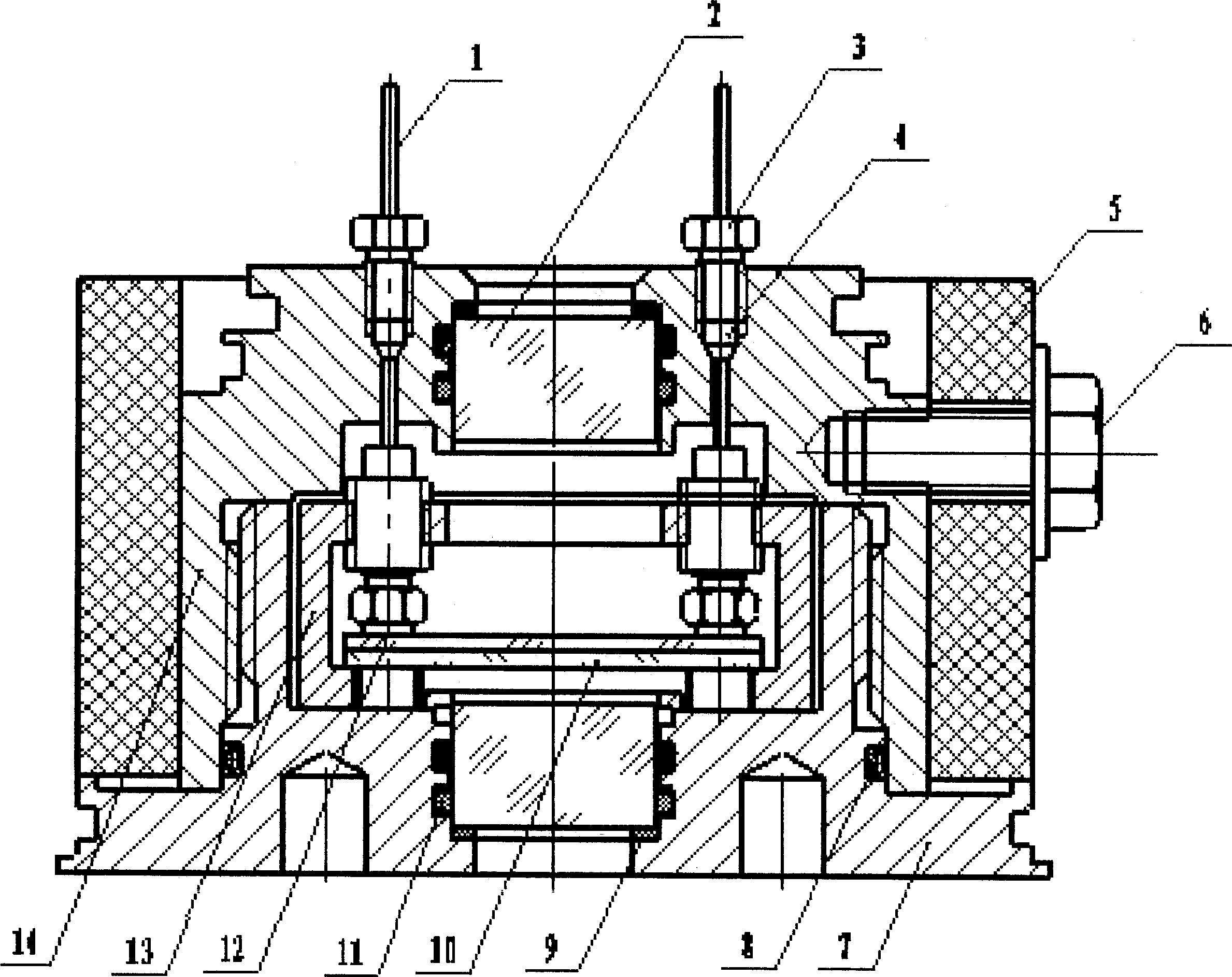

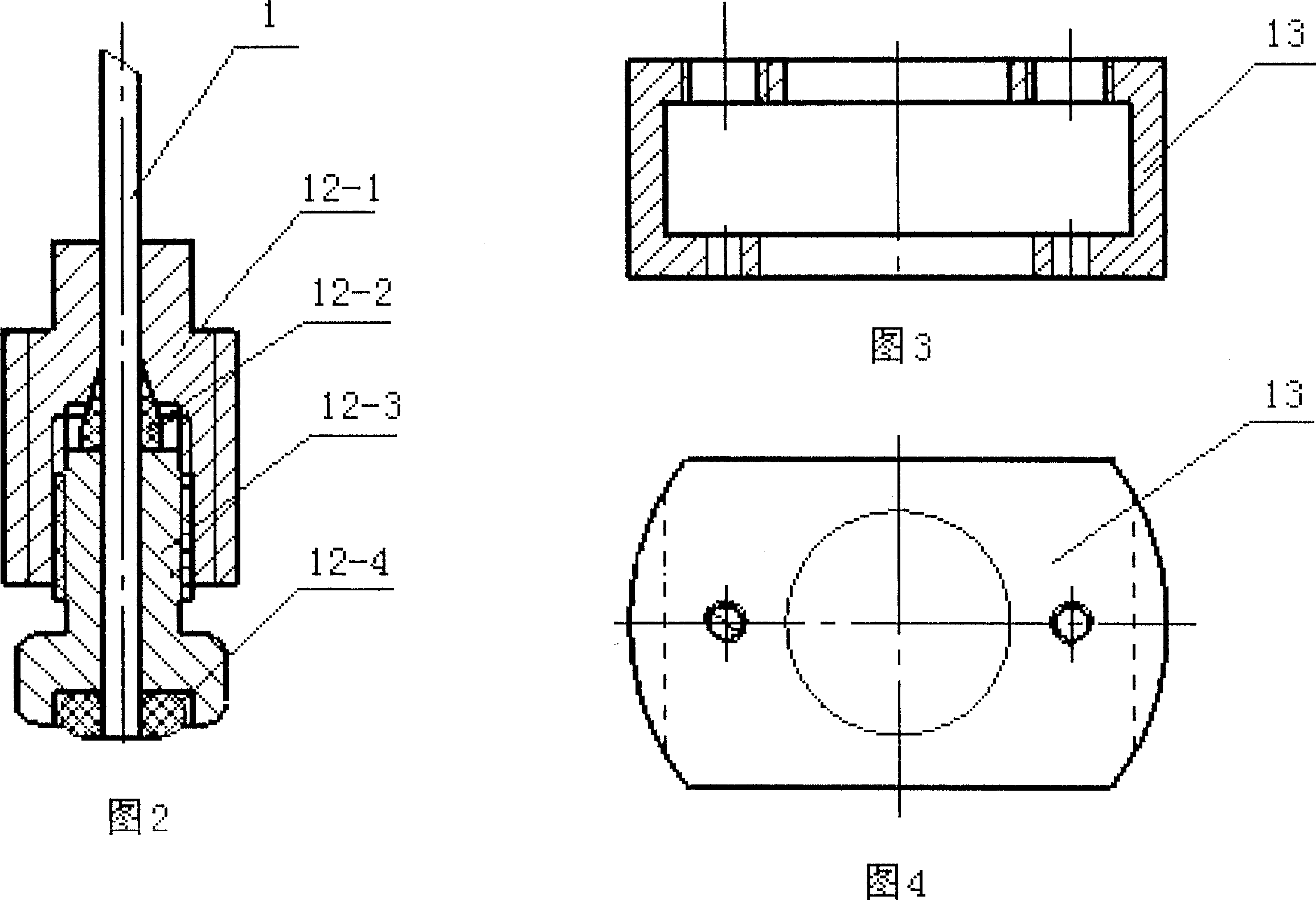

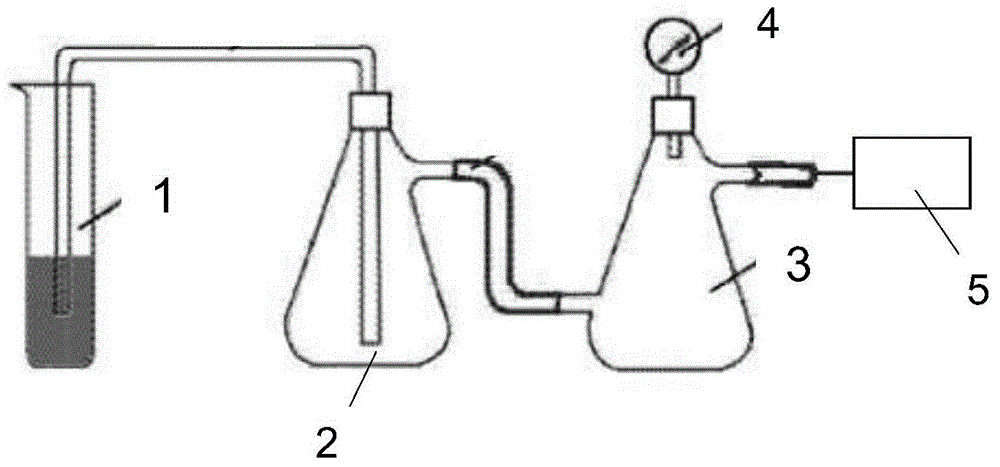

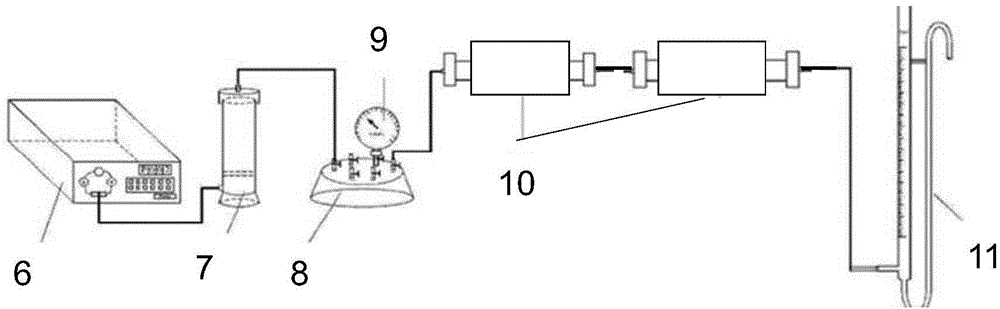

Holder for high-temperature high-pressure glass microscopic model

ActiveCN1963146AHigh result reference valueImprove completenessSurveyFluid removalPorosityEngineering

The clamper is used for high temperature and high pressure glass miniature modules that is meant to judge the water drive oil effects and review in oil and gas exploration. On the base of the module and the center of the module cap, there are holes with steps and glass viewing window inside. Among the glass viewing window, module base and the inner wall of the central hole of the module's top cap, there is an O type sealing gasket. Between the module base and the top cap of the module, a high pressure confined chamber is formed. A high pressure pipe is fixed on the duct that is the head of the top cap of the module. Inside the high pressure confined chamber, there is a module bracket. A miniature transparent simulation porous module is pressed tightly against the module bracket. The invention can finish the simulative study of miniature transparent simulative porous module under the high temperature and high pressure of the strata, observing the module porosity and the liquid within the clamper clearly under the microscope. The experiment data surpass the current result in constant temperature and pressure.

Owner:PETROCHINA CO LTD

Method for applying metal wire-imitated coating film on surface of engineering plastics

ActiveCN102166565AAnti-corrosionWear-resistantCoatingsSpecial surfacesWater savingEngineering plastic

The invention provides a method for applying a metal wire-imitated coating film on the surface of engineering plastics, and relates to a surface treatment method of the engineering plastics. The method for applying the metal wire-imitated coating film on the surface of engineering plastics can improve the function and the quality of a plastic metalized product, can simplify the technology, can reduce the production cost, and is water-saving and environment-friendly without needing any water liquid in the whole technological process. The method comprises the steps of adding dye into plastic master batch, and coloring; cleaning and activating a plastic blank in a drying way; spraying a color coat onto the plastic blank; performing the wire drawing to a work piece so as to obtain the surface with wire drawing veins; cleaning and activating the work piece in a drying way; and spraying finishing paint to the work piece with the wire drawing veins so as to apply the metal wire-imitated coating film on the surface of the engineering plastics.

Owner:XIAMEN RUNNER IND CORP

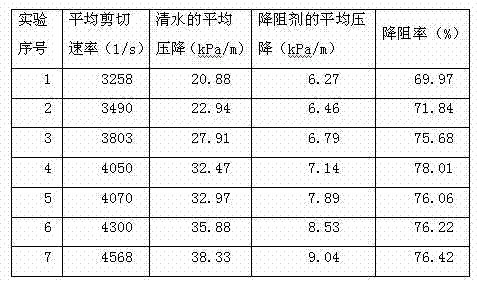

Resistance reducing agent for fracturing quick water of shale gas and preparation method thereof

ActiveCN103755868AHigh temperature resistantReduce frictionDrilling compositionEmulsion polymerizationOil phase

The invention relates to a resistance reducing agent for fracturing quick water of a shale gas and a preparation method thereof. The resistance reducing agent for fracturing quick water of the shale gas is formed by reverse emulsion polymerization by means of combination of a water phase and an oil phase, wherein the weight part ratios of monomers to water in the water phase are sequentially as follows: the ratio of acrylamide: 2-acrylamide-2-methyl propanesulfonic acid: water is (0.7-1.3):(0.7-1.5):1; the weight ratio of monomers to oil in the oil phase is sequentially as follows: the ratio of tween 80:OP-10: white oil is (0.1-0.35):(0.1-0.35):1; and the weight ratio of the water phase to the oil phase is 1:(0.35-0.85). The preparation method comprises the following steps: (1) selecting acrylamide and 2-acrylamide-2-methyl propanesulfonic acid, and dissolving acrylamide and 2-acrylamide-2-methyl propanesulfonic acid in proportion in deionized water to prepare the water phase; (2) selecting tween 80 and white oil and mixing the tween 80 and white oil in a certain proportion to form the oil phase; (3) proportioning the water phase and the oil phase in a certain proportion, and fully mixing to form a stable water-in-oil inverse emulsion base fluid; and (4) catalyzing and initiating by an initiator to synthesize the resistance reducing agent.

Owner:郑州三山石油技术有限公司

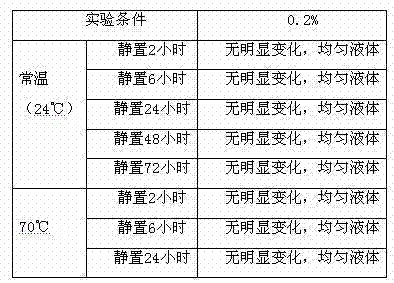

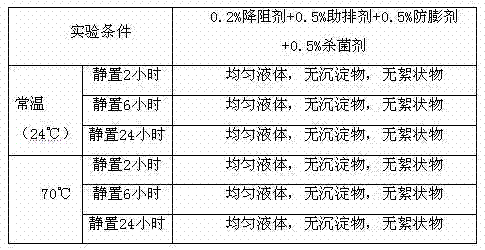

Profile modifying/water plugging agent and preparation method and application thereof

The invention relates to the technical field of oil field development, and in particular relates to a profile modifying / water plugging agent for oil well water plugging and profile modification. The water plugging agent is prepared from the following components in mass percent: 1-15% of polysaccharide, optimally 2-10% of the polysaccharide; 0.5-10% of a suspension stabilizer, optimally 1-6% of the suspension stabilizer; 0.5-20% of a gel strength accelerating agent, optimally 2-10% of the gel strength accelerating agent; and the balance of preparation fluid. The invention also provides a method for preparing the water plugging agent and application thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

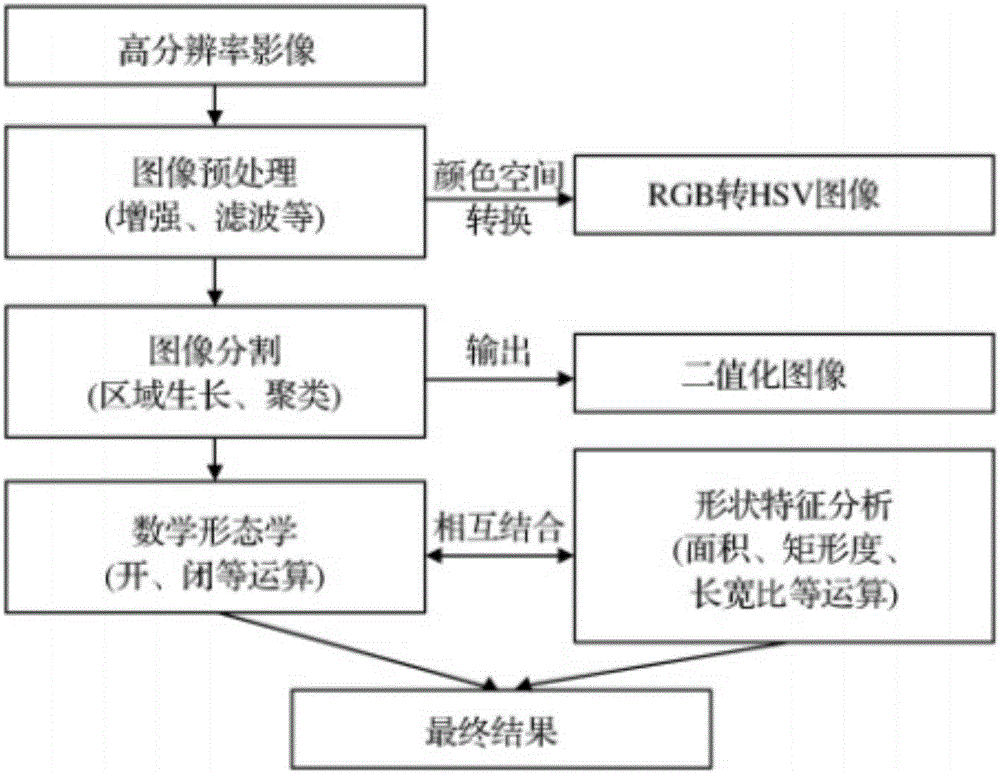

High-resolution remote sensing image road information extraction method

InactiveCN106295562AImprove adhesionWith tenacityCharacter and pattern recognitionRgb imageImage segmentation

The present invention discloses a high-resolution remote sensing image road information extraction method. The method comprises the following steps: image preprocessing: employing an enhanced and filtering method to realize the purpose of the difference of a road image and a background image; a road image segment method: improving the traditional area growth algorithm and adding a secondary cluster method after growth to remove the complex small plates distributed in the image as much as possible so as to allow the ground object connected with the road to be separated from each other as far as possible; image analysis and identification: and employing a mathematical morphology method and structural elements with a certain shape to measure and extract the corresponding shaped in the image to reach the purpose of the analysis and identification of the image, convert the RGB image to an HSV image in the image processing process and improve the area growth algorithm to adapt for the extraction road so as to greatly improve the quality of the road segment, have high precision of the extraction of the city road, and especially adapt for the extraction of the city main road.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI

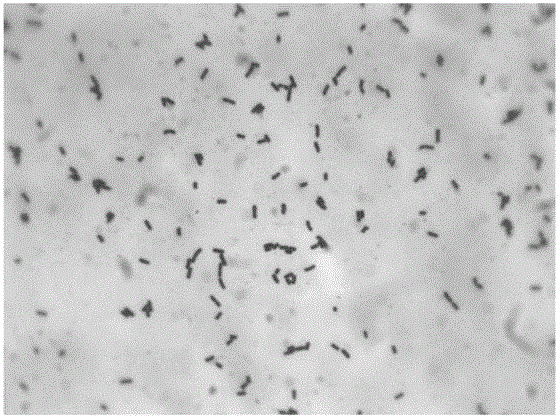

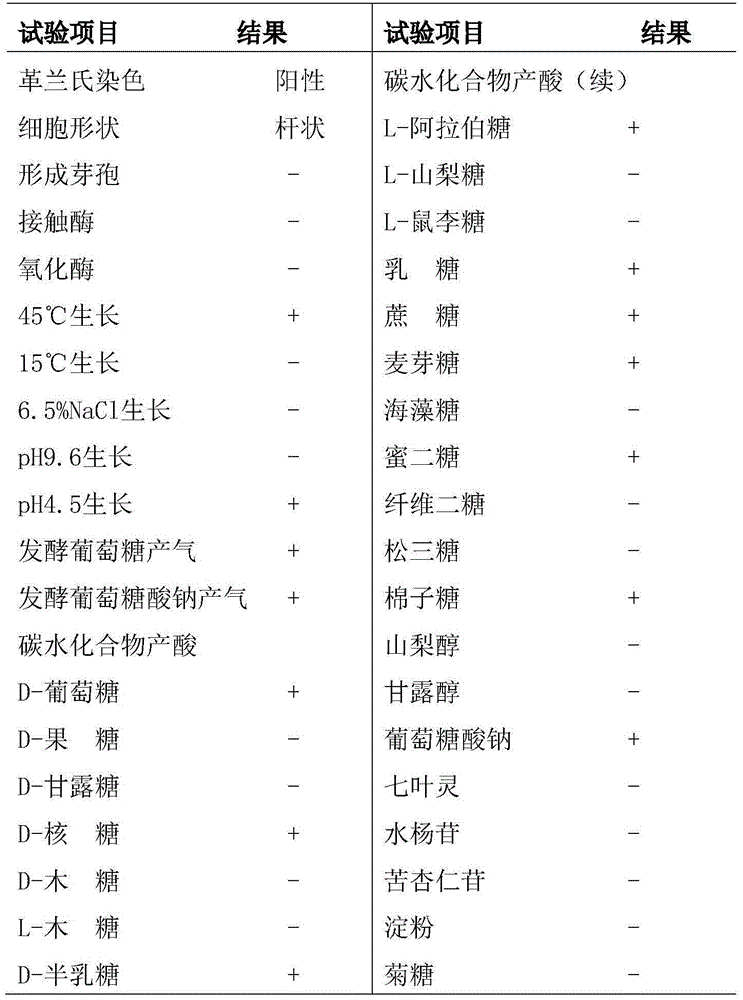

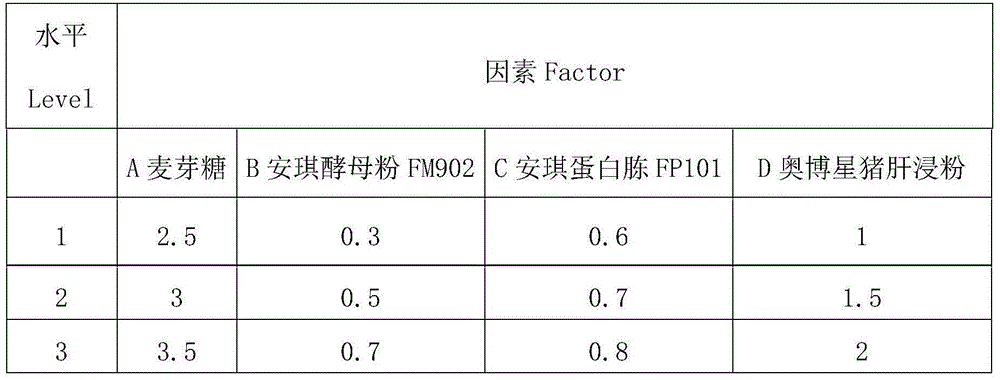

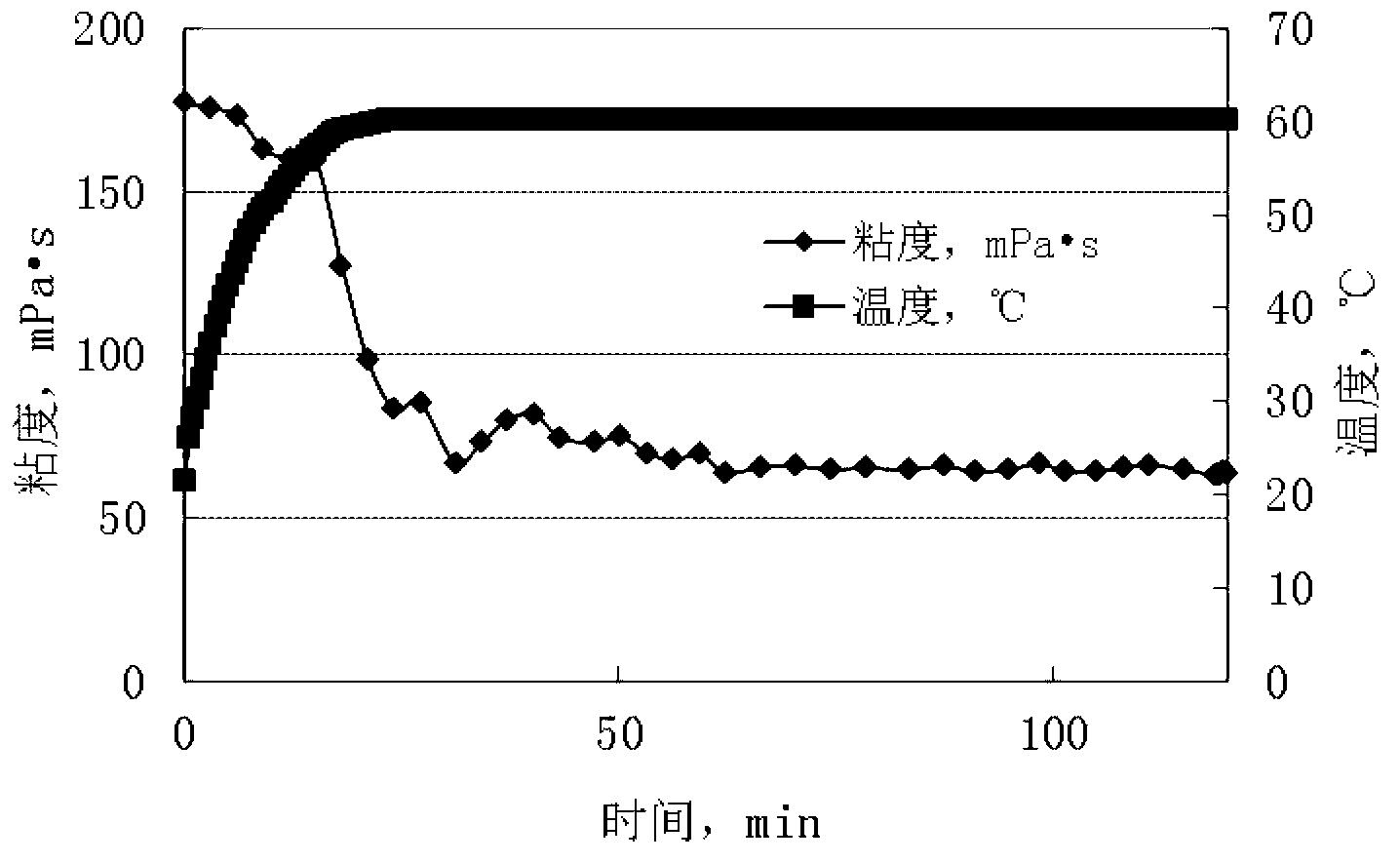

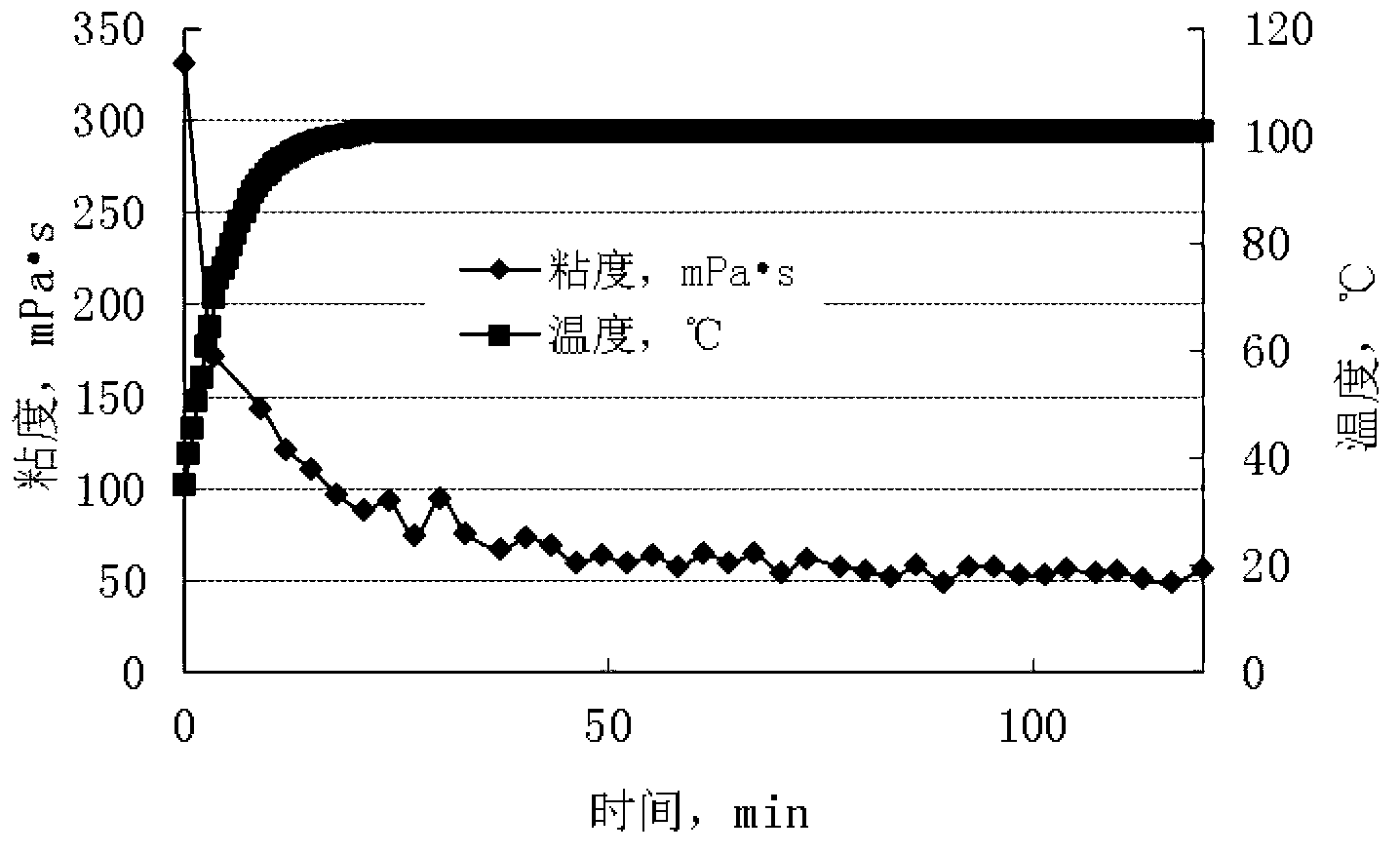

Lactobacillus reuteri and application thereof

PendingCN105062933AConducive to survivalTemperature resistantBacteriaAnimal feeding stuffEscherichia coliHigh survival rate

The invention relates to lactobacillus reuteri and application thereof. Lactobacillus reuteri is lactobacillus reuteri LZ262 which is preserved in the Common Microorganism Center of the China Committee for Culture Collection of Microorganisms on 13 August, 2015 with the preservation number of CGMCCNo.11240. Lactobacillus reuteri LZ262 is from the intestinal tract of a healthy pig, can be colonized in a human body and an animal body, and has higher tolerance to gastric acid and bile salt; in addition, lactobacillus reuteri LZ262 has a better suppression effect on Escherichia coli, and has a higher survival rate after spray-drying, and higher fermentation density is achieved by improving a fermentation formula; the strain has a better effect of synergistic growth with other types of lactic acid bacteria, can be used for food and animal feed additives, and can also be widely applied to other food and biological products.

Owner:BEIJING BOJINYUAN BIOTECH

Fracturing fluid prepared by recovery waste water of crude oil and preparation method of fracturing fluid

ActiveCN103074049AAlleviate needsSolve processing problemsDrilling compositionCross-linkFracturing fluid

The invention discloses an association polymer fracturing fluid prepared by recovery waste water of crude oil. The fracturing fluid comprises the following components: 0.2-1.4wt% of thickening agent, 0.01-0.1wt% of thickening assistant, 0.05-0.1% of metal ion stabilizing agent, 0.02-0.05wt% of water block preventive, 0.05-0.2wt% of high-temperature stabilizing agent, 1-2wt% of clay stabilizing agent and the balance of the recovery waste water of the crude oil. Compared with the prior art, the fracturing fluid has the benefits that the fracturing fluid system adopts an association polymer as a primary thickening agent, no cross-linking agent is used, structural viscosity is formed by the synergetic effect of the association polymer and an ampholytic surfactant, and the fracturing fluid has the characteristics of temperature resistance, good salt tolerance, shear resistance, bacterial corrosion resistance and low friction, and has a good solid carrying behavior when the viscosity is greater than 20mPa*s.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

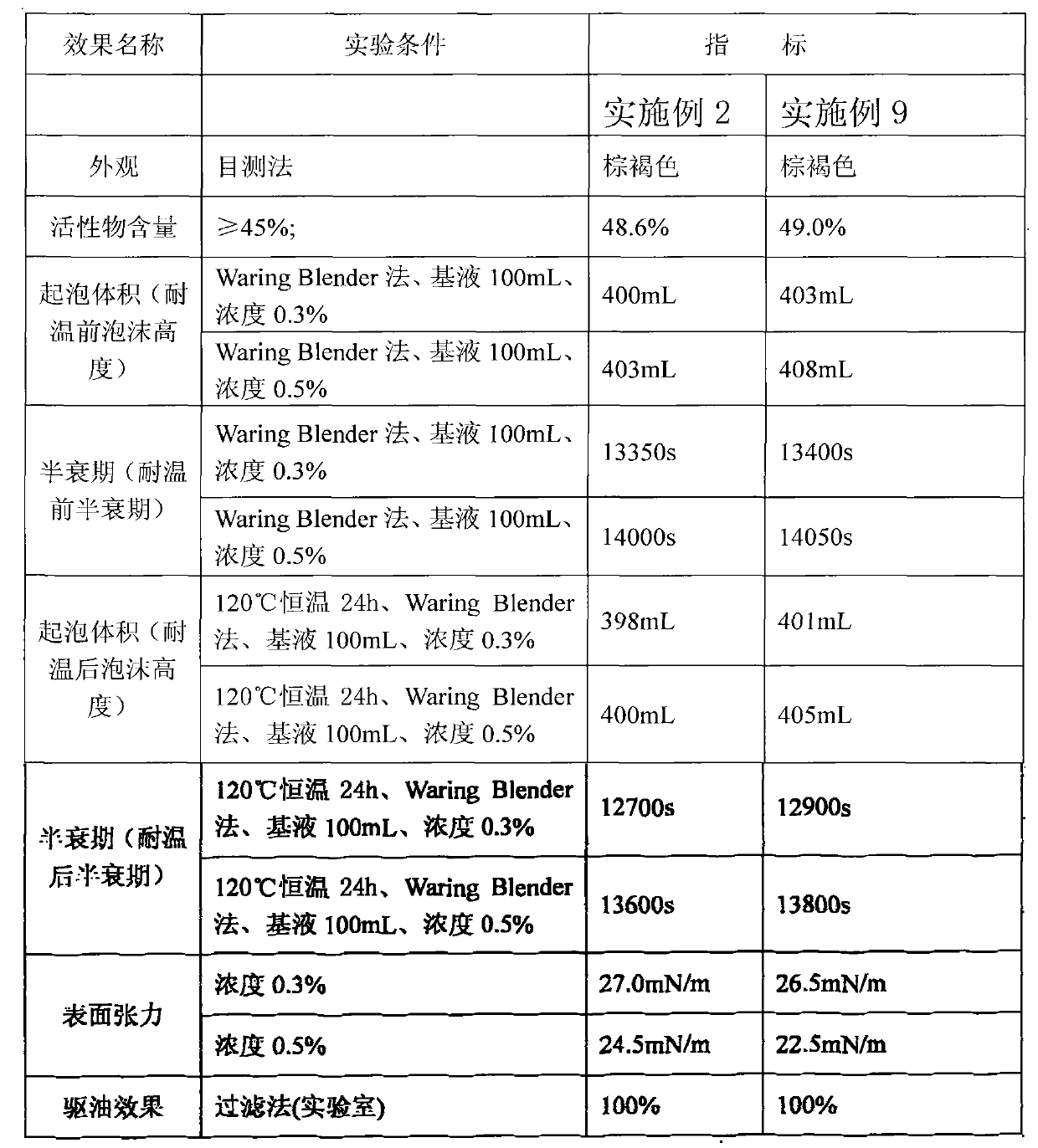

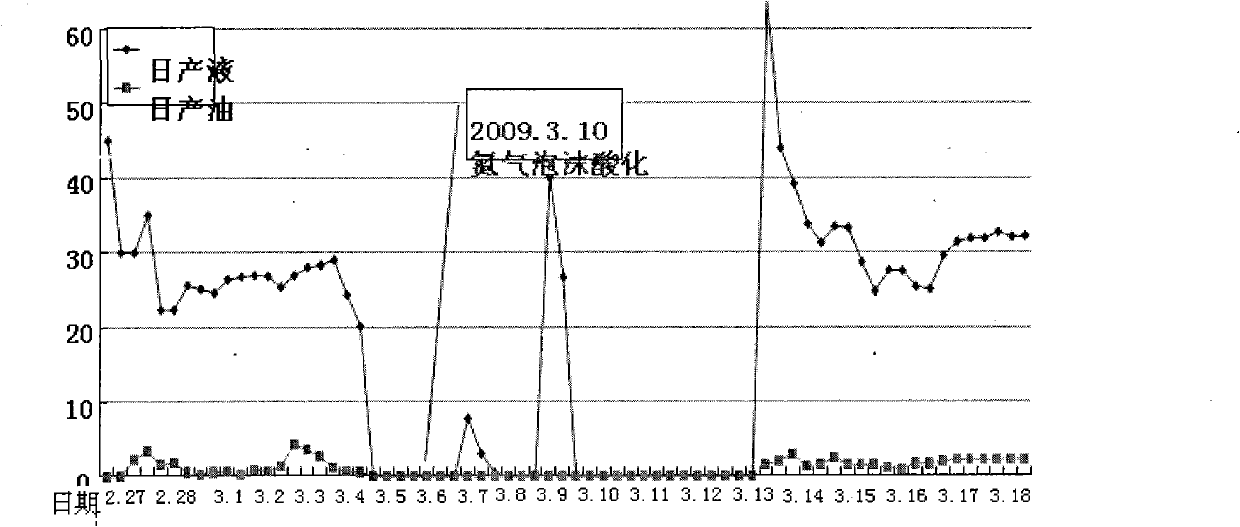

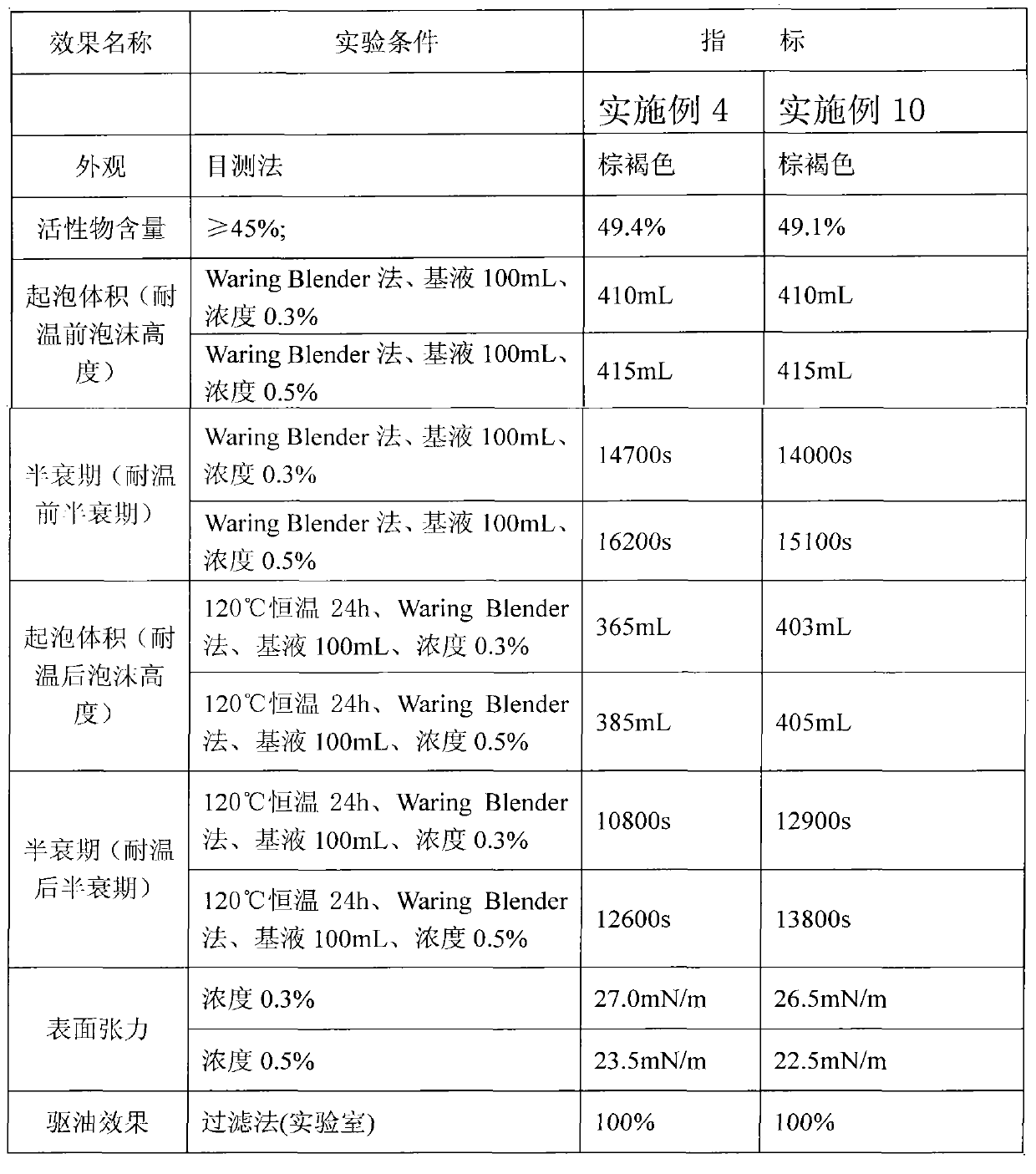

Camellia saponin type oilfield foaming agent and preparation method and application thereof

ActiveCN101906296AHigh foaming ratioLong bubble timeDrilling compositionChemical recyclingChemistryChemical synthesis

The invention relates to a camellia saponin type oilfield foaming agent and a preparation method and application thereof. The oilfield foaming agent comprises the following components in part by mass: 100 parts of camellia saponin based on the solid content, 1 to 10 parts of cocoanut oil diethanol amide, 1 to 10 parts of amine ether alkyl glucoside, 1 to 10 parts of dodecyl betaine, and 0.5 to 2 parts of lauryl dimethy amine oxide, wherein the camellia saponin is natural plant source camellia saponin or structure-modified camellia saponin. The camellia saponin type oilfield foaming agent is used as an oilfield foaming agent in oil recovery, has the characteristics of acid, alkali and salt resistance, temperature resistance, high foam expansion ratio, long stable foam time and the like, can meet oil extraction requirements under different geological and weather conditions, cannot pollute an oilfield soil layer employing the foaming agent, can prevent a chemically synthesized foaming agent from harming the oilfield stratum, and has remarkable environmental protection characteristic.

Owner:青田中野天然植物科技有限公司

Fireproof door core board and a preparation method thereof

InactiveCN105837247AImprove flexural strengthImprove water absorptionSolid waste managementFireproof doorsBuilding productFoaming agent

The invention relates to the field of building products, and in particular to a fireproof door core board and a preparation method thereof. The fire door core board is prepared from sulfur magnesium oxychloride foam cement, which contains by weight 100 parts of magnesium sulfate, 50-200 parts of magnesium oxide, 0 -500 parts of a filler, 30-350 parts of water, and 8-50 parts of a foaming agent; and the sulfur magnesium oxychloride foam cement also contains an admixture accounting for 0.1-5 wt% of the sulfur magnesium oxychloride foam cement. The fireproof door core board is prepared by using the sulfur magnesium oxychloride cement as the material, and the prepared fireproof door core board has excellent comprehensive performances, such as fire prevention, thermal conductivity, density, compressive strength, bending strength, water absorption, shrinkage, and light weight.

Owner:天津中晶建筑材料有限公司

Inorganic silver-impregnated zeolite antibiotic papers and method of producing the same

InactiveCN101182689AIncreased durabilityHigh safety to human bodyCoatings with pigmentsPaper/cardboardIon exchangeTemperature resistance

The invention discloses an inorganic silver-loaded zeolite antibacterial paper and a preparation method thereof. In the method, the zeolite is first mixed with a sodium nitrate solution with a mass concentration of 20-30% in a solid-liquid ratio of 1 g / ml, and the reaction is carried out at 70-95 DEG C for 1 ~2 hours, centrifugation and washing to prepare Na-type zeolite; load high content of silver ions by ion exchange method to prepare inorganic silver-carrying antibacterial zeolite for papermaking. The antimicrobial agent is then added to the wet-end sheet or mixed with a coating for surface coating. Calculated by mass percentage content, the silver content of the inorganic silver-carrying zeolite antibacterial paper is 0.05-0.40%. The antibacterial paper prepared by the invention has better antibacterial performance, safety, temperature resistance and durability, simple preparation process and convenient application, and can better meet the antibacterial requirements of household paper and food packaging paper.

Owner:SOUTH CHINA UNIV OF TECH

Compound filter material, method and application thereof

InactiveCN101596384AExtended service lifeHigh acid and alkali resistanceFiltration separationFolding enduranceAntistatic agent

The invention discloses a compound filter material, a method and application thereof, and relates to a filter material. The invention provides a compound filter material which has good folding endurance, corrosion resistance and wear resistance and can be used as a high-temperature environment filter material, a method and application thereof. The compound filter material comprises the following components in percentage by mass: 1 to 99 percent of basalt fiber and 1 to 99 percent of polytetrafluoroethylene fiber. The preparation method comprises the following steps of: mixing the basalt fiber and the polytetrafluoroethylene fiber to obtain a mixed fiber; and adding an antistatic agent to the mixed fiber for mixing to obtain the compound filter material. According to the mass percentage, the adding amount of the antistatic agent is 0.1 to 20 percent of the mixed fiber. The compound filter material can be used for directly preparing composite filter cloth with single-layer structure or multi-layer structure, and the prepared composite filter cloth with single-layer structure or multi-layer structure can be used for producing a filter device.

Owner:厦门美达斯环保工业有限公司

Tissue culture and rapid propagation method for Acer rubrum 'Brandywine'

InactiveCN104663450ADrought tolerantTemperature resistantPlant tissue cultureHorticulture methodsAceraceaePlantlet

The invention discloses a tissue culture and rapid propagation method for Acer rubrum 'Brandywine'. The Acer rubrum 'Brandywine' is an Aceraceae Acer tall deciduous tree, has the characteristics of high adaptability, drought resistance, temperature resistance, growth fastness and the like and is a fine tree species for landscaping. At present, the Acer rubrum 'Brandywine' mainly propagates seedlings with a seed sowing propagation method, but the seed fruiting rate is lower, so that supply of a large number of seedlings of the Acer rubrum 'Brandywine' is limited. According to the method, stems with buds are used as explants, tissue-cultured regenerated plants of the Acer rubrum 'Brandywine' are successfully obtained through steps of induction, multiplication, rooting, acclimatization, transplantation and the like, a systematic tissue-cultured plant regeneration system for the Acer rubrum 'Brandywine' is established, and a reference is provided for mass factory culture of the seedlings of the Acer rubrum 'Brandywine'.

Owner:罗焕荣

Modified ultra-high molecular weight polyethylene resin

The invention discloses a production formula and a manufacturing method of a modified ultra-high molecular weight polyethylene resin. The modified ultra-high molecular weight polyethylene resin comprises an ultra-high molecular weight polyethylene resin, molybdenum disulfide, nano graphite, superfine talcum powder, ethylene bis stearamide, polytetrafluoroethylene and benzoyl peroxide. The modified ultra-high molecular weight polyethylene resin has ultra high wear resistance and favorable temperature tolerance and self-lubricating property. Compared with the resin before the modification, the modified resin has the advantages that the heat distortion temperature is increased by 38 DEG C, the Shore hardness is improved by 20 degrees, the friction factor is decreased by 40%, and the expansion factor is decreased by 30%. The modified resin is widely used for producing products such as gears, valves, artificial joints, skis, oil field transfer pipelines and the like.

Owner:王崇高

Water-blocking filling paste for optical cable

InactiveCN101645329ATemperature resistantSalt water resistantOther chemical processesInsulated cablesAntioxidantOil separation

The invention relates to a water-blocking filling paste for an optical cable, which mainly comprises the following components: base oil, an oil separation inhibitor, a thickening agent, a super absorbent, a water blocking agent, a dispersant, an antioxidant and a pour depressant, and has the characteristics of temperature resistance, salt water resistance, and ultra strong water absorption power.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

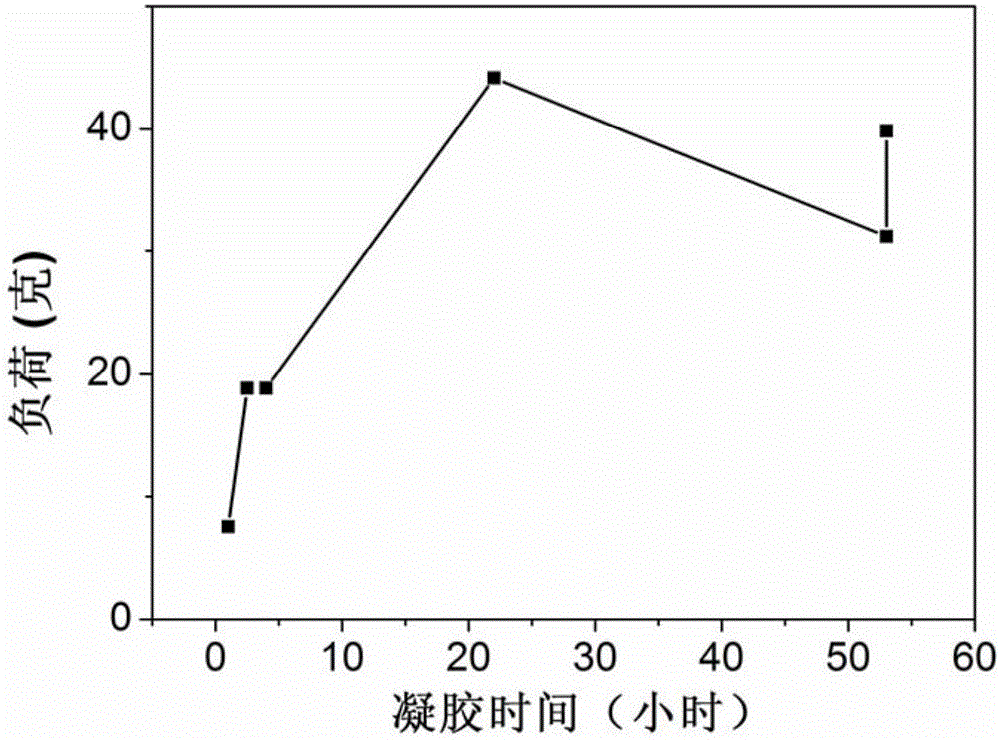

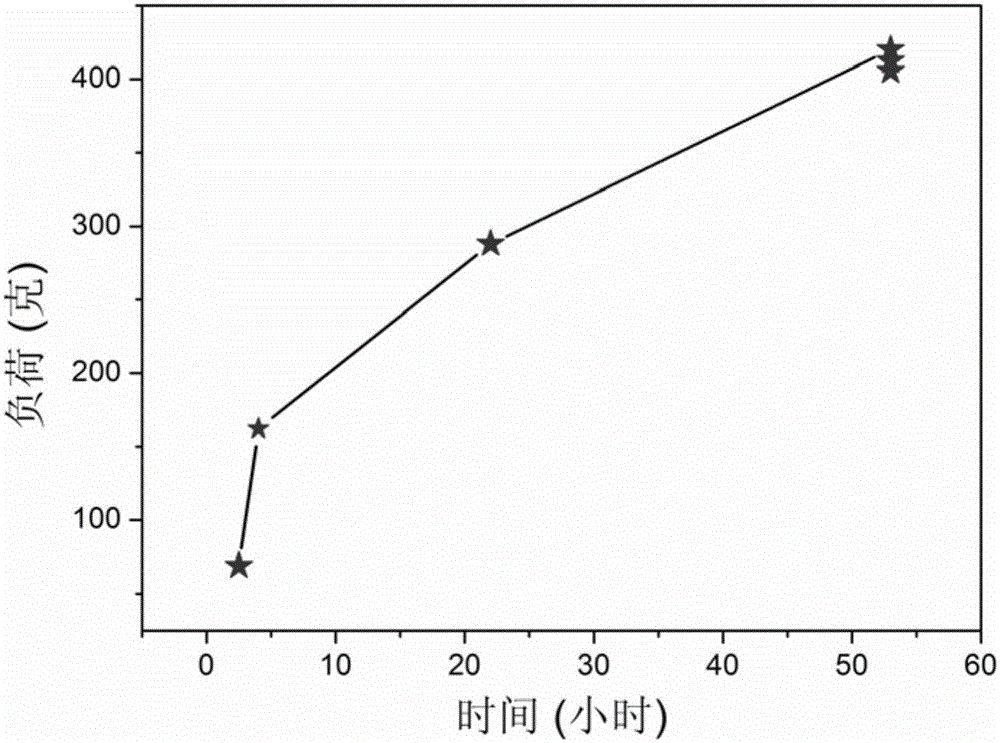

Underground gel-forming blocking agent suitable for medium-high temperature high-salt low-permeability reservoirs and preparation method therefor

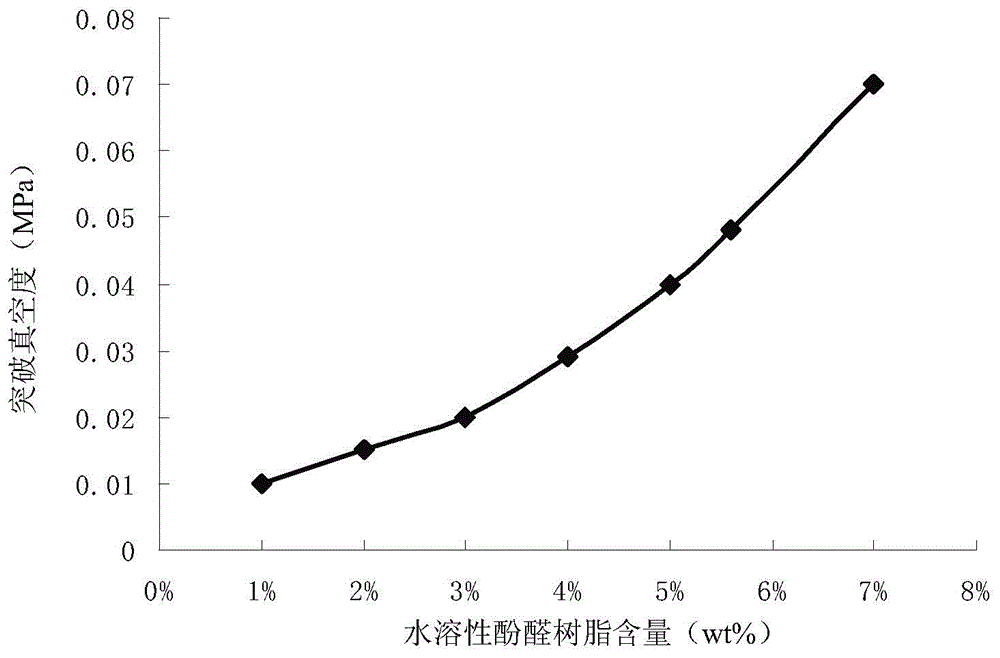

ActiveCN104974724AStrong ability to delay polycondensation and solidificationEffective blockingDrilling compositionChromatographic separationConcentration ratio

The invention provides an underground gel-forming blocking agent suitable for medium-high temperature high-salt low-permeability reservoirs and a preparation method therefor. By taking the total weight of the blocking agent as reference, the blocking agent comprises the following raw materials: 1% to 4% of water-soluble phenol-formaldehyde resin, 0.5% to 2% of stabilizer, 0 to 10% of flexibilizer and the balance of water. The preparation method of the blocking agent comprises the following steps: selecting the raw materials in proportion, and uniformly mixing so as to obtain the underground gel-forming blocking agent suitable for the medium-high temperature high-salt low-permeability reservoirs. The blocking agent provided by the invention is a homogeneous-phase, transparent and low-viscosity water solution before gel forming; the blocking agent can be selectively injected in a deep stratum water flow preferential migration passage, the shearing, adsorption and chromatographic separation of a stratum for the blocking agent can be ignored, and deep placement does not influence the concentration ratio of the blocking agent; and the polycondensation is delayed at the high temperature in the deep stratum, so that the formed gel has the advantages of high blocking rate, high blocking strength, water flow impact resistance, high temperature resistance and high hydrolysis resistance.

Owner:PETROCHINA CO LTD

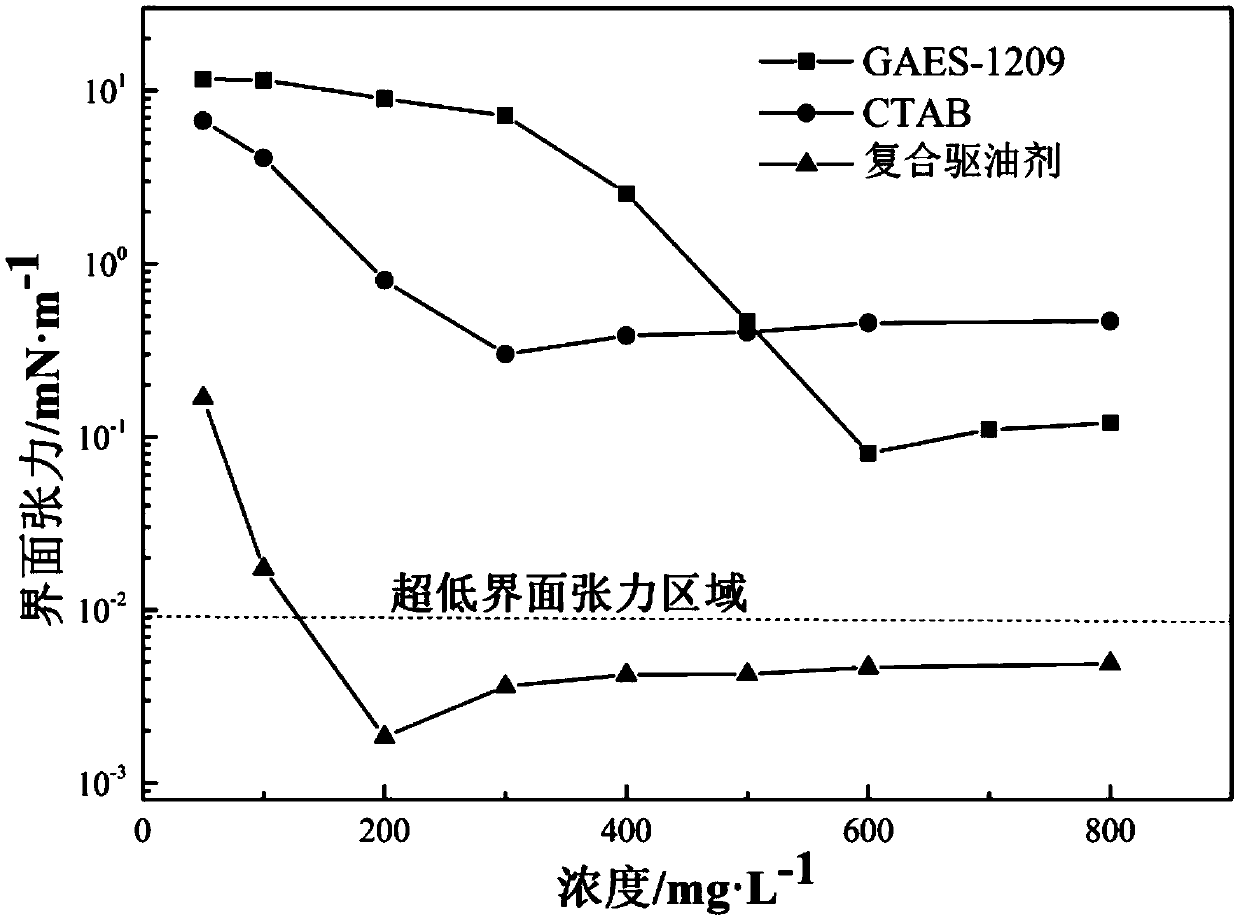

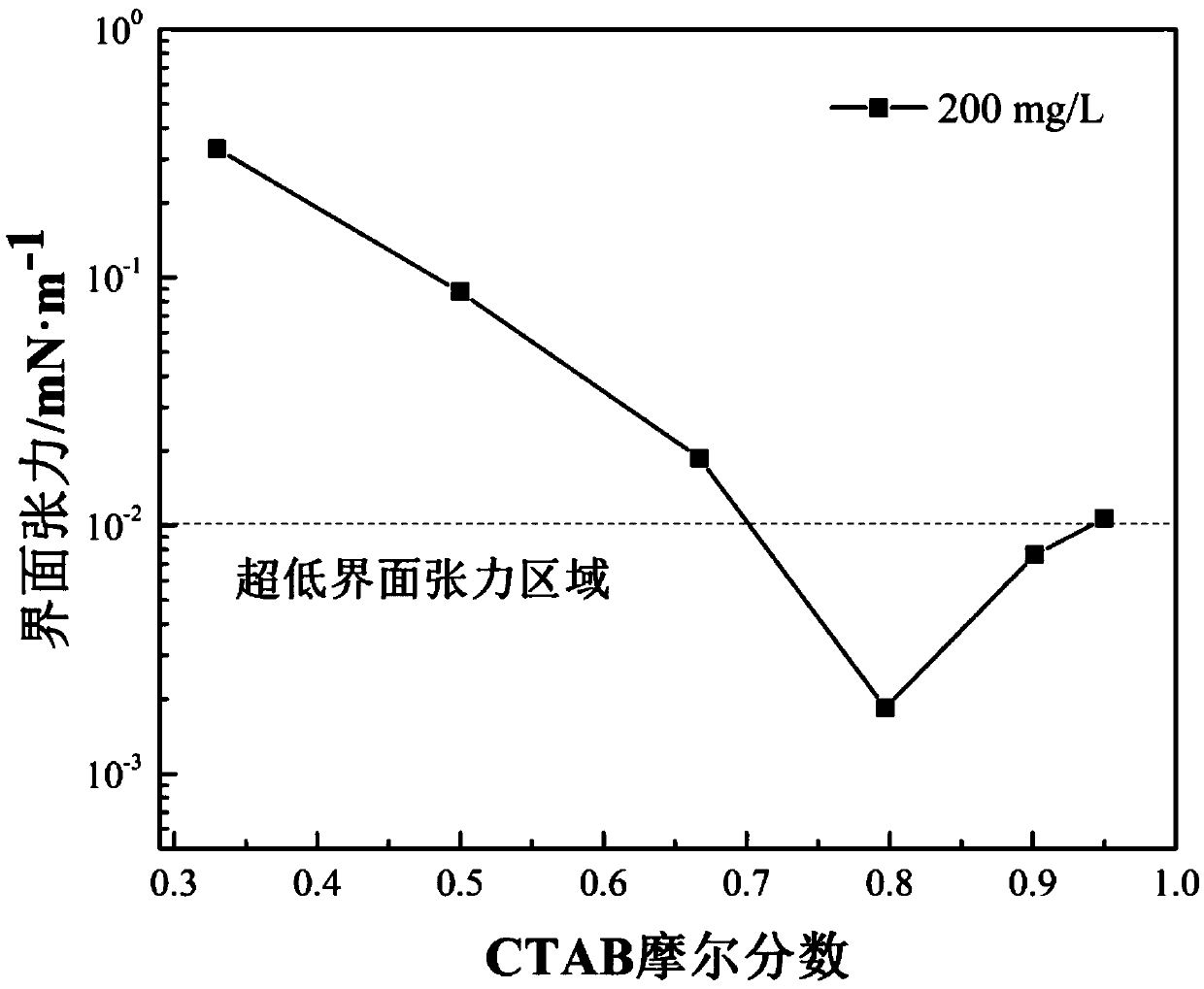

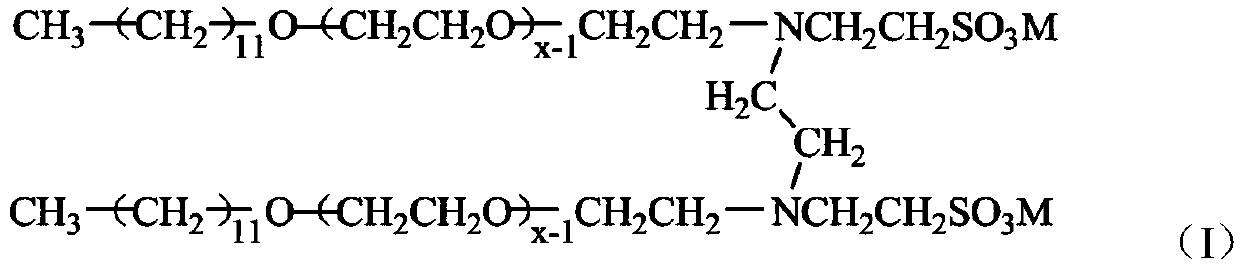

Composite oil displacement agent and preparation method and application thereof

ActiveCN109652048AStrong surface/interface activityReduce tensionFluid removalDrilling compositionChemistryLow permeability

The invention provides a composite oil displacement agent and a preparation method and an application thereof. The composite oil displacement agent includes a symmetrical alkyl alcohol polyoxyethyleneether sulfonate anionic-non-gemini surfactant and a cationic surfactant, with the balance being water. The mol ratio of the symmetrical alkyl alcohol polyoxyethylene ether sulfonate anionic-non-gemini surfactant to the cationic surfactant is 1:2-1:4. The composite oil displacement agent can significantly reduce the oil-water interfacial tension, especially can produce ultra-low interfacial tension for low-permeability reservoirs, has excellent interfacial activity, and has significance for efficient development of the low-permeability reservoirs and the improvement of crude oil recovery efficiency.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

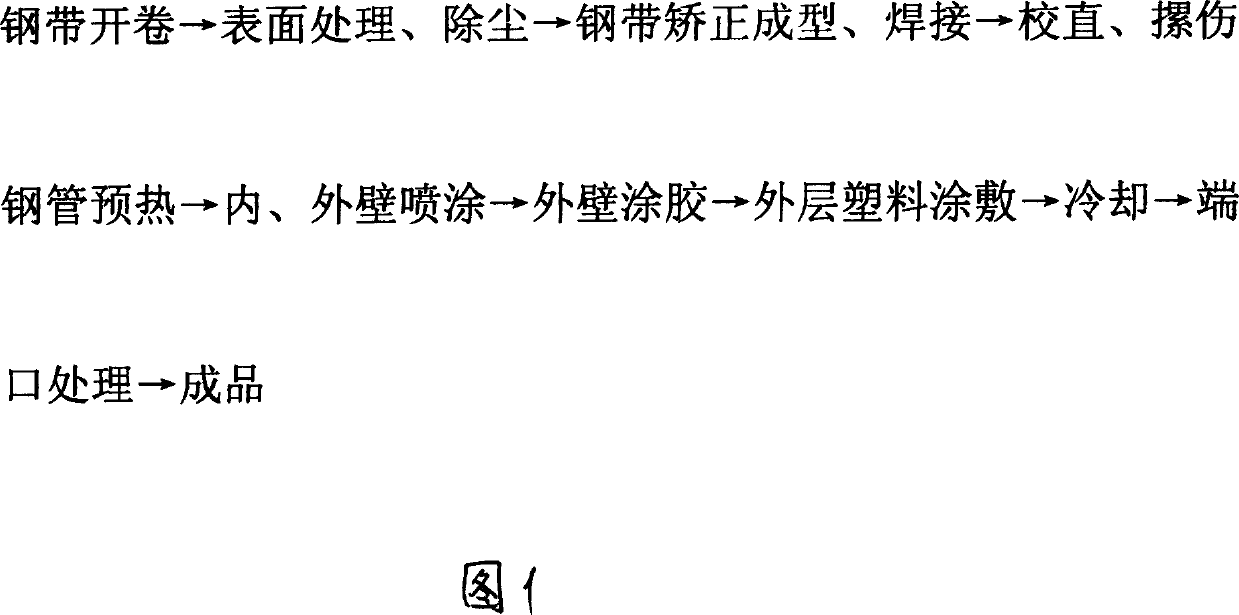

Production process of composite plastic-steel pipe with anti-corrosive coating

InactiveCN1417507ACorrosion resistanceTemperature resistantRigid pipesUltimate tensile strengthSteel belt

The production process of composite plastic-steel pipe with anticorrosion coating includes the steps of: unwinding steel belt, surface treatment, straightening, welding to form, straightening and fault finding, preheating, spraying in the outer and inner walls, painting glue to outer wall, coating outer plastic layer, cooling and end treatment. It is low in power consumption, produces no waste pollution, and the produced composite plastic-steel pipe with anticorrosive coating in its outer and inner surface is anticorrosive, heat resistant, long in life, non-toxic, high in strength, and has many other merits.

Owner:李志雄

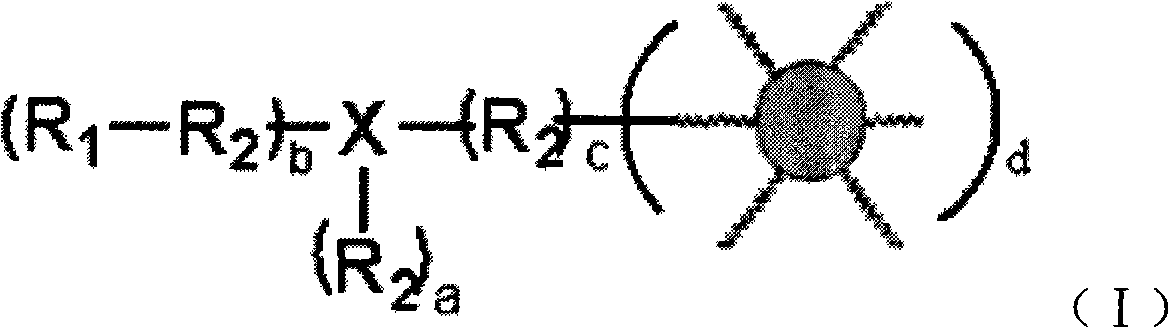

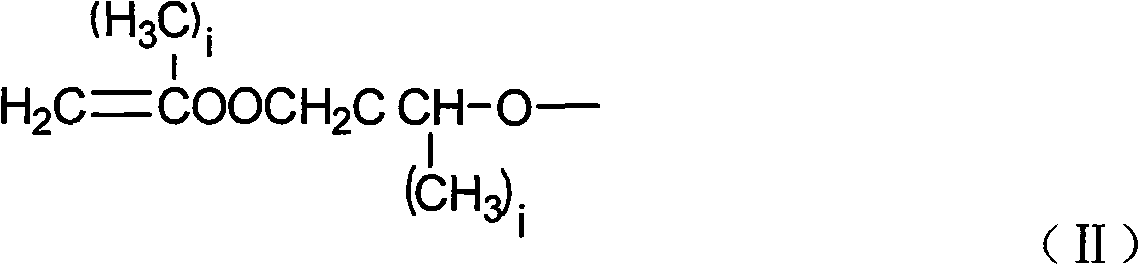

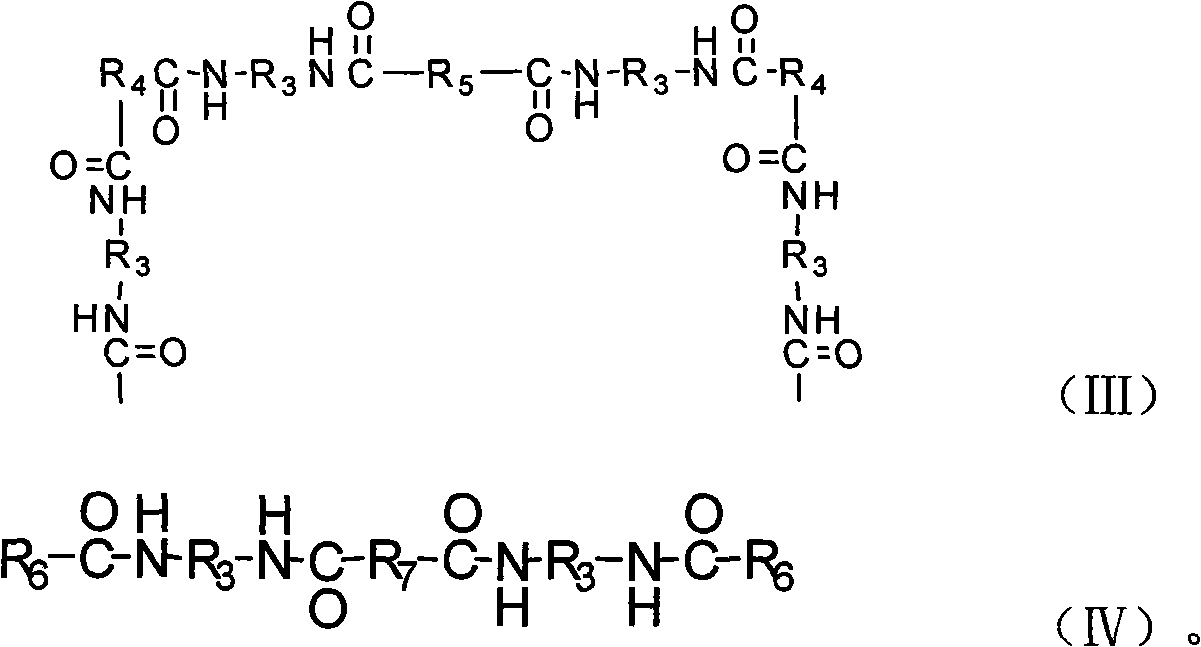

Multiple curable aqueous hyperbranched polyurethane inorganic nanomaterial hybrid coating agent and preparation method thereof

InactiveCN101597461AHigh strengthImprove rigidityPolyurea/polyurethane coatingsLeather surface finishingStructural formulaTemperature resistance

The invention relates to a multiple curable aqueous hyperbranched polyurethane inorganic nanomaterial hybrid coating agent and a preparation method thereof. The coating agent comprises the following compositions in percentage by mass: 20 to 45 percent of polyurethane shown in a structural formula below, and 55 to 80 percent of deionized water. A film coated by the coating agent has the characteristics of flatness, smoothness, temperature resistance, oil resistance and the like, and has excellent low-temperature toughness performance. Leather coated by the coating agent has the characteristics of high gloss, good hand touch, abrasion resistance, difficult cracking, good elasticity, excellent water resistance and deflection resistance, and the like.

Owner:ZHEJIANG DONGHUA IND

Instant guar gum and preparation method thereof

The invention belongs to instant guar gum and a preparation method thereof. The instant guar gum is prepared from the following raw materials in parts by weight: 20-80 parts of guar gum raw powder, 10-25 parts of propylene oxide, 4-10 parts of chloroacetic acid, 5-10 parts of hydrochloric acid with mass concentration of 20 percent, 150-200 parts of solvent alcohol, 8-20 parts of alkali liquor with concentration of 10 percent, 150-200 parts of water, 20-50 parts of hydrophobic modification material and 1000 parts of washing medium, wherein the solvent alcohol is any one of methanol, ethanol, ethylene glycol or isopropyl alcohol; the hydrophobic modification material is any one of bromododecane, bromohexadecane or bromooctadecane; the washing medium is any one of isopropyl alcohol, methanol or ethanol. According to the instant guar gum and the preparation method thereof, a step of taking hydroxypropyl guar gum out in oil field fracturing construction is not needed, a reaction process is saved, and pollution and waste caused by post-treatment of the reaction process are reduced.

Owner:张春雨

Thermoplastic elastomer material and plastic plug made of same

InactiveCN102086287AInjection moldableIncrease elasticityPharmaceutical containersMedical packagingMarket competitionPolypropylene

The invention discloses a thermoplastic elastomer material and a plastic plug made of same. The thermoplastic elastomer material consists of the following components in percentage by weight: 40 to 60 percent of main material, 8 to 27 percent of main filler, 25 to 35 percent of toughening agent and 0 to 6.5 percent of auxiliary filler, wherein the main material is ethylene propylene rubber; the main filler contains polypropylene; and the toughening agent contains styrene, ethane, butane and styrene block copolymer (SEBS). The thermoplastic elastomer material has high elasticity, strength and resilience of rubber, and has the characteristic of capacity of being subjected to injection molding; compared with the traditional process, the method has the advantages of greatly shortening working time; and the thermoplastic elastomer material has the advantages of environmental friendliness, nontoxicity, safety, wide hardness range, good dyeing property, soft touch, weather resistance, fatigue resistance, temperature tolerance, and excellent processability, is not needed to be sulfurized, and can be recycled, so that the cost is reduced and the market competition is improved.

Owner:JIANGSU RUNDE MEDICAL MATERIALS

Moisture-curing polyurethane epoxy coal-tar bitumastic

InactiveCN101760135AUniform thicknessNo effect on cure speedAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyCyclohexanone

The invention relates to a moisture-curing polyurethane epoxy coal-tar bitumastic. The invention adopts a technical scheme that: the bitumastic is formed by a component A and a component B in a weight ratio of 1:1-1:2; and the preparation method comprises the following steps of: placing 37 to 40 parts of polymethylene polyphenyl isocyanate, 11 to 13 parts of polyether 330 or 3,030, 2 to 3 parts of polyether 635 or 450, 8 to 9 parts of DOP or DBP, 3 to 4 parts of epoxy resin, 0.002 to 0.003 part of phosphoric acid and 33 to 37 parts of solvent No.S10,000 or industrial xylene in a reaction kettle at the temperature of between 81 and 86 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component A; and placing 62 to 66 parts of coal-tar, 9 to 10 parts of cyclohexanone, 10 to 11.5 parts of toluene, and 7 to 8 parts of solvent No.S1,000or industrial xylene in the reaction kettle at the temperature of between 115 and 120 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component B. The coating applied by the bitumastic is waterproof and long in life time and can further protect equipment and pipes.

Owner:孙锡宁

Environment-friendly coating method for implementing blackening bronze wire drawing element on metal piece

ActiveCN102218961AAnti-corrosionWear-resistantNatural patternsDecorative surface effectsTemperature resistanceAdditive color

The invention provides an environment-friendly coating method for implementing a blackening bronze wire drawing element on a metal piece, relating to a surface processing method of a metal piece. The method comprises the steps of dry cleaning and activating metal blanks; performing metallic black dyeing on the activated metal blanks; carrying out wire drawing on the black dyed metal blanks to draw out required patterns; dry cleaning and activating the wire-drawn metal blanks; painting additive color finishing varnish on the metal blanks that have wire-drawing patterns, and finishing implementing environment-friendly coating on the blackening bronze wire drawing element on the metal piece. On the basis of tests, the coating metal product has the advantages of corrosion resistance, wear resistance, weathering resistance, temperature resistance, colorful performance and the like, and is comparative to the quality of the traditional water (wet) plating metal product. Meanwhile, the methodhas the advantages of simple procedure, less consumption of metals used in the process and less waste gas and waste water, therefore being an economic and environment-friendly novel coating technology.

Owner:NINGBO RUNNER INDAL CORP

Self-lubricating antiseiznig materials and preparing method thereof

InactiveCN1583904AImprove coating application performanceOvercoming the disadvantages of electrostatic sprayingCoatingsFritAtmospheric temperature

This invention adopts the ceramic material and Fluorine resin with moist slippery characteristic to mix altogether, it is wear-resisting to make one, it is warm to be able to bear, corrosion-resistant, do not glue the wear-resisting sizing of pottery of the function. It is become membrane material, ceramic packing, a piece of coating of one pair of groups made up of the solvent and solidification pharmaceutical, succeed the membrane material and include the cellulosic nitric acid ester, gather the acrylic acid. the mixture of three kinds of resin of the polytetrafluoroethylene (PTFE), low-temperature glass dust, the ceramic pcking makes up. Will become membrane material and solvent first while preparing, the solidification pharmaceutical will be mixed evenly, and then put into the ceramic packing, then adopts the disperse the equipment, after mixing evenly, processes in grinding the equipment, sieve, pack. It becomes membrane under normal atmospheric temperature, improve coating coating construction performance, adopt and brush and roll scribbling and spraying, overcome coating must adopt static shortcoming of spraying at present, become low temperature products after the membrane, the high temperature frits again, any little member does not remain materials, has guaranteed this application in the tableware and wear-resisting trade of coating.

Owner:华东船舶工业学院

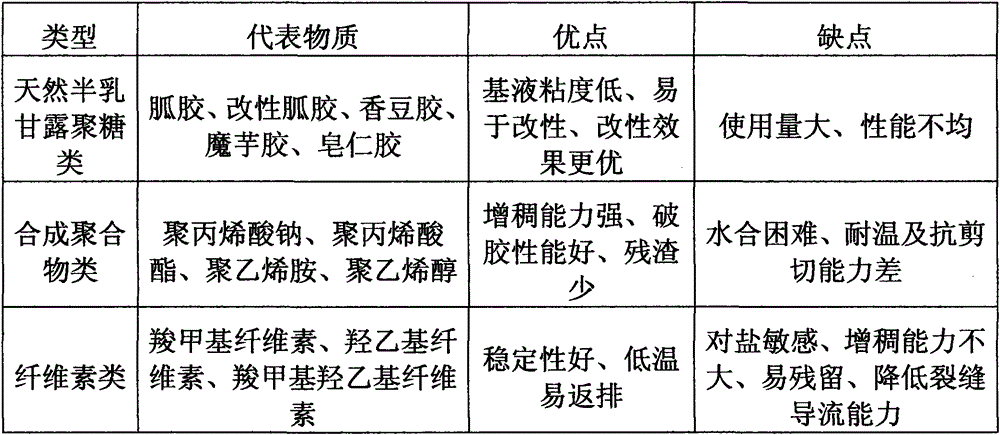

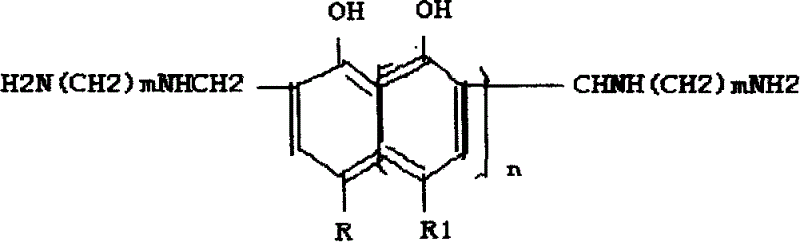

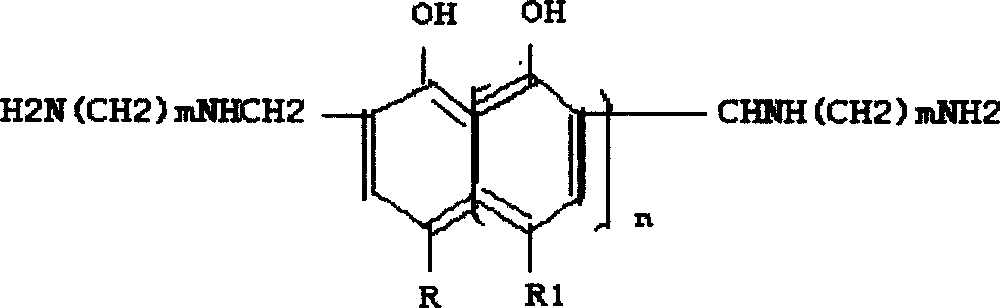

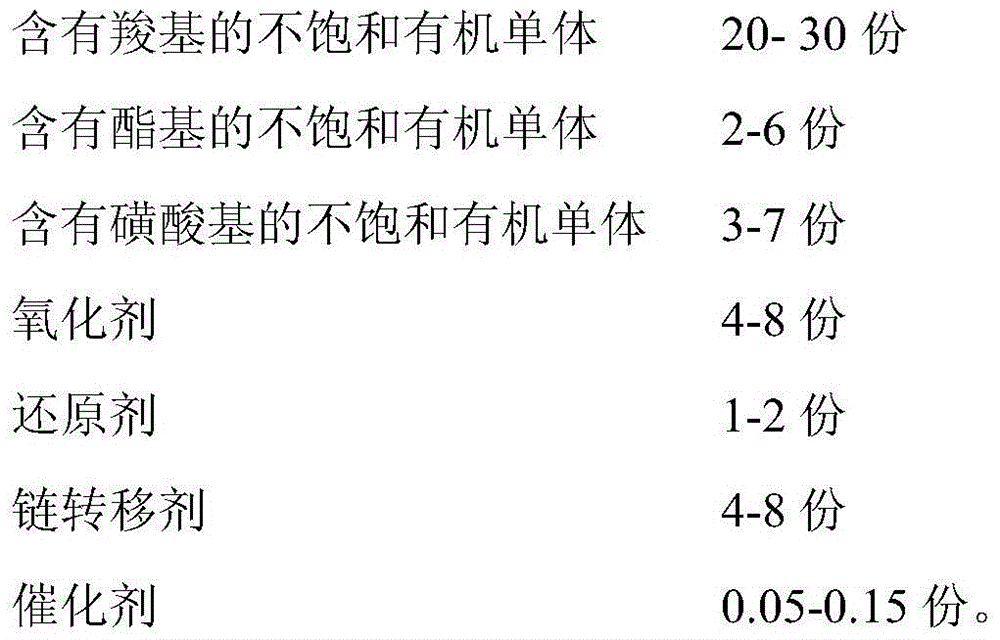

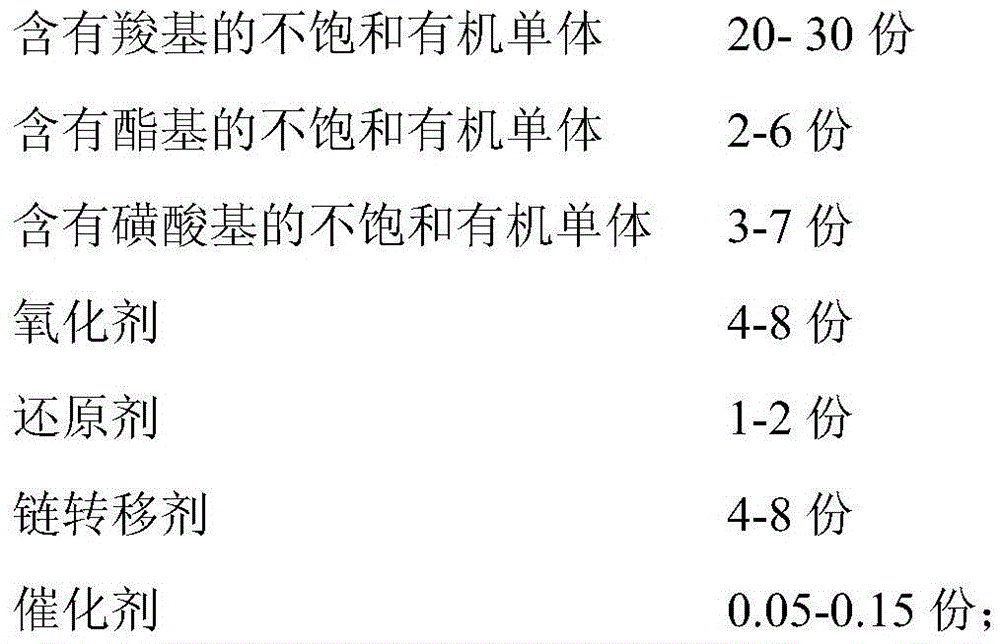

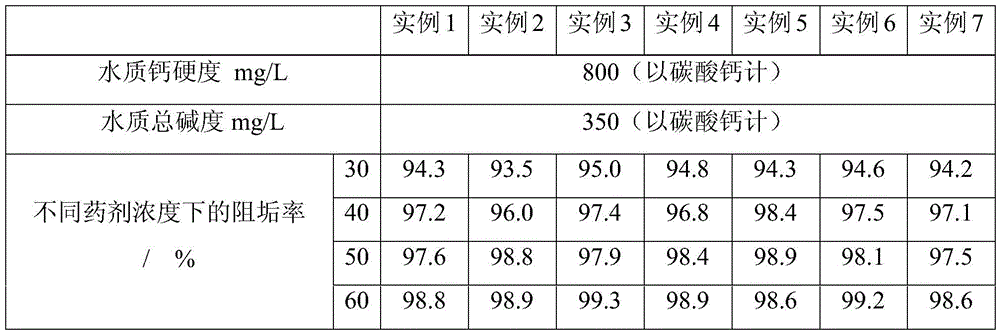

Multi-copolymer and preparation method and use thereof

ActiveCN105542055AWith anti-scalingWith dispersionWaste water treatment from quariesSeawater treatmentAcid groupCopolymer

The present invention belongs to the technical field of water treatment, relates to a multi-copolymer used for recycled water for industry and a preparation method and use thereof, particularly use as a scale and corrosion inhibitor, and especially as a low-phosphorus environmental-friendly scale and corrosion inhibitor. The multi-copolymer is obtained by copolymerization of a carboxyl-group-containing unsaturated organic monomer, an ester-group-containing unsaturated organic monomer and a sulfonic-acid group-containing unsaturated organic monomer, and the limiting viscosity number of the multi-copolymer is 0.035-0.055dL / g. The multi-copolymer has scale inhibition, dispersion, corrosion resistance, temperature resistance and other properties, can be used as a scale inhibition dispersant, especially as the low-phosphorus environmental-friendly scale and corrosion inhibitor, and can be used in circulating cooling water systems, oil field water injection systems, seawater desalination and other fields.

Owner:CHENGDU QIDA WATER TREATMENT ENG

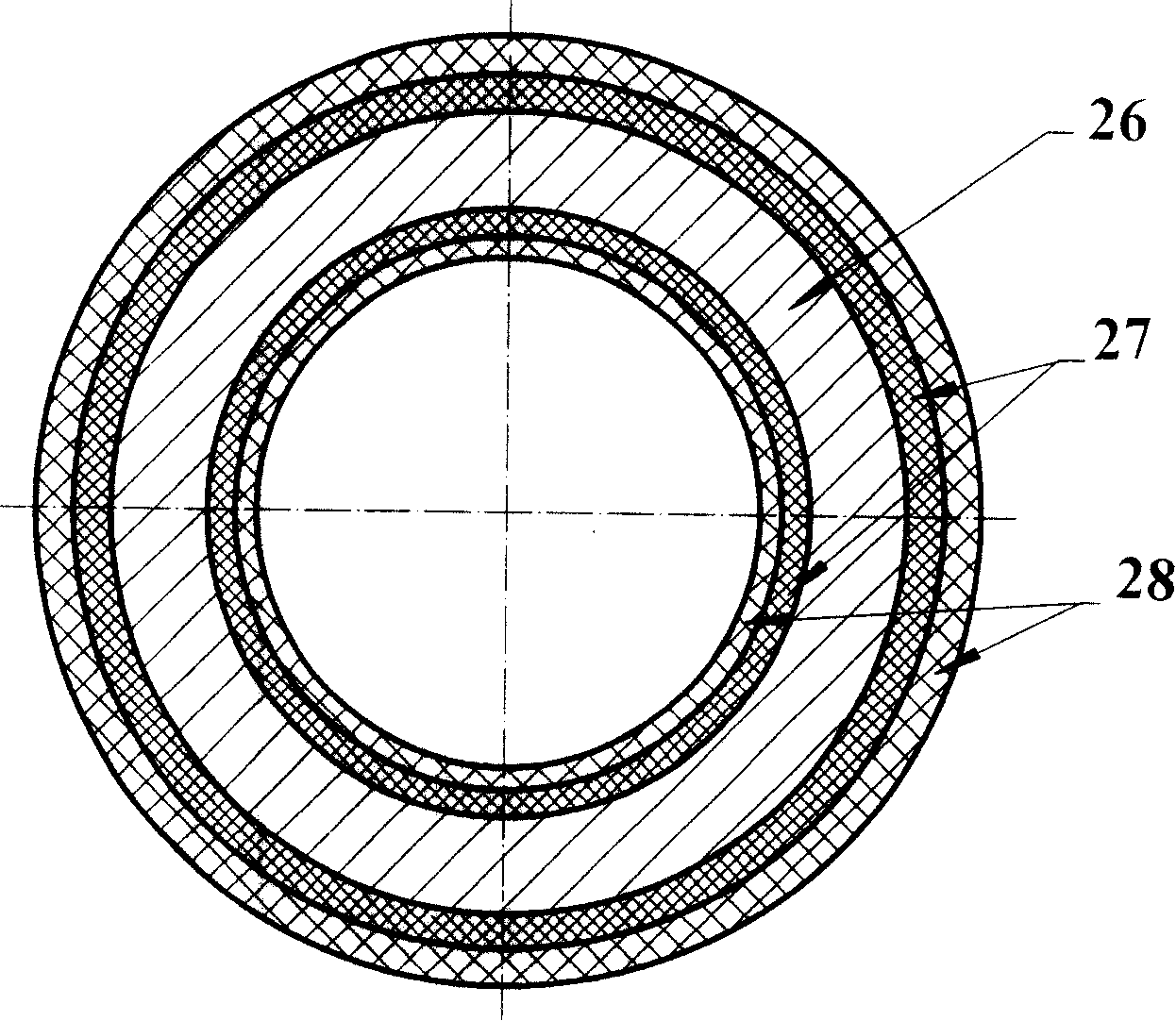

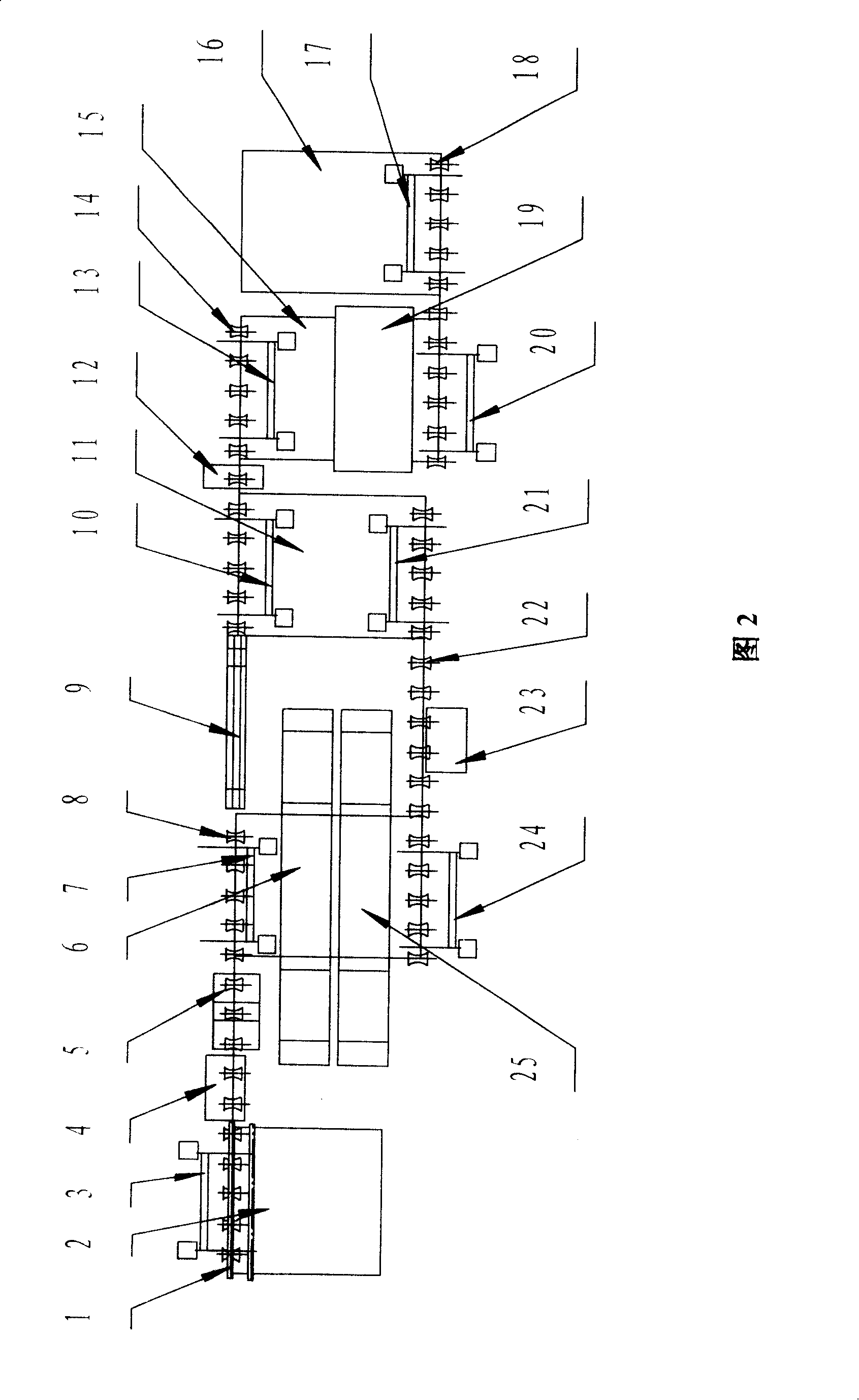

Nano coating protective pipe and its coating manufacture process

InactiveCN101169215ASmall volume shrinkageSmooth rotationCorrosion preventionPipe protection against corrosion/incrustationSteel tubeParaffin oils

The invention discloses a nanometer coating protective pipe prepared by nanometer squama coating and production technique of coating, wherein, the nanometer coating protective pipe consists of three parts of a pipe body, a basal layer and a function layer. The basal layer is the substrate of the nanometer coating and coated on the surface of the pipe body when contacts with a metal base body. The function layer is the facial layer of the nanometer coating and coated on the surface of the basal layer when the function layer contacts with corrosive medium. The nanometer coating the protective pipe disclosed in the invention changes the surface characteristic of the steel pipe products, and acquires a novel characteristic completely different from the original steel pipe products and enables the products to satisfy the need of people towards hi-tech development. The nanometer coating can provide oil pipe products with good performance in resisting corrosion, paraffin, scale and abrasion, so as to greatly prolong the maintenance period of the pipeline products in oil extracting wells, water injecting wells and conveying pipelines of oil fields.

Owner:白日忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com