Patents

Literature

73 results about "Additive color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive color, or "additive mixing", is a property of a color model that predicts the appearance of colors made by coincident component lights with distinct colors, i.e. the perceived color can be predicted by summing the numeric representations of the component colors. Modern formulations of Grassmann's laws describe the additivity in the color perception of light mixtures in terms of algebraic equations. It is important to note that additive color predicts perception and not any sort of change in the photons of light themselves. These predictions are only applicable in the limited scope of color matching experiments where viewers match small patches of uniform color isolated against a grey or black background.

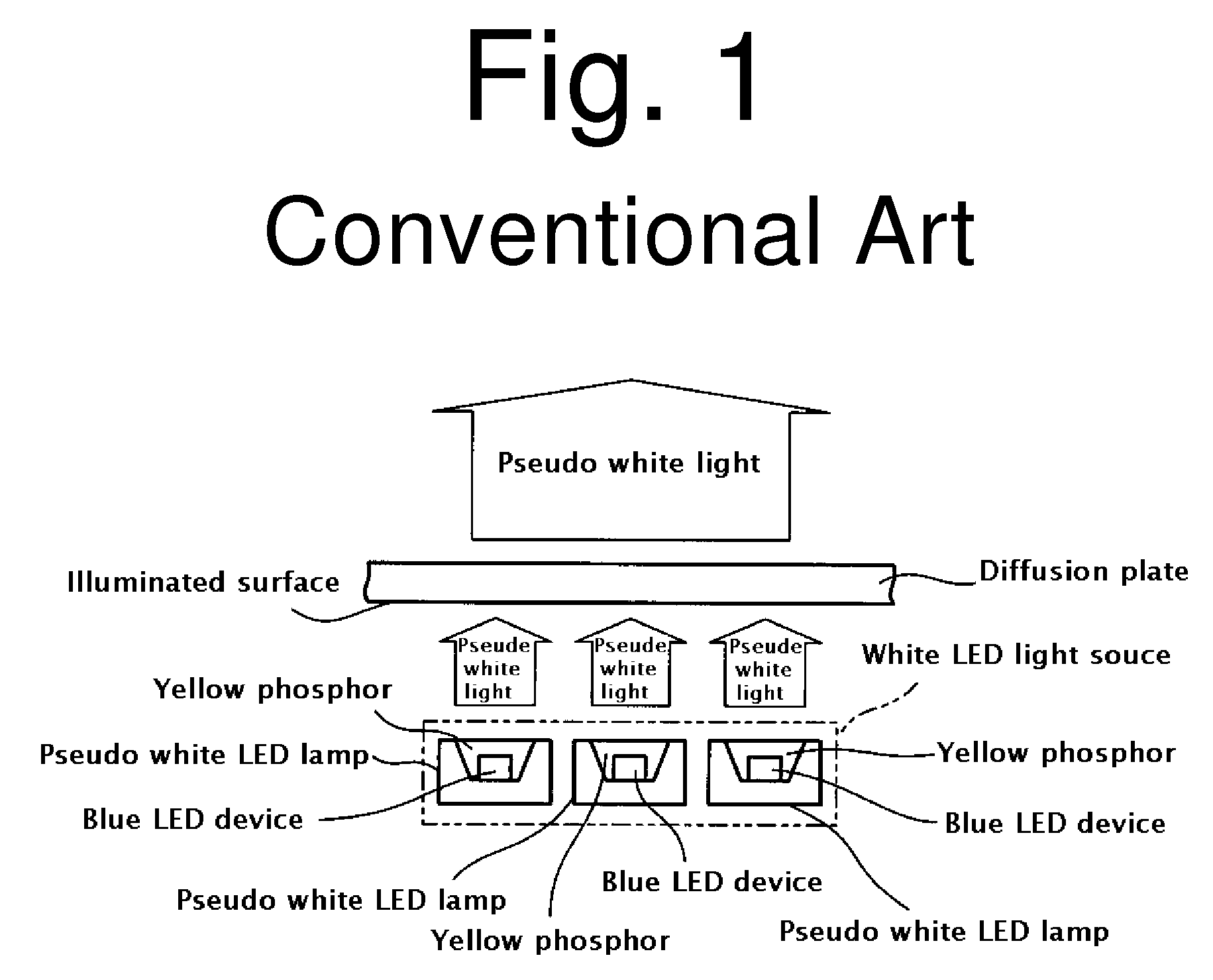

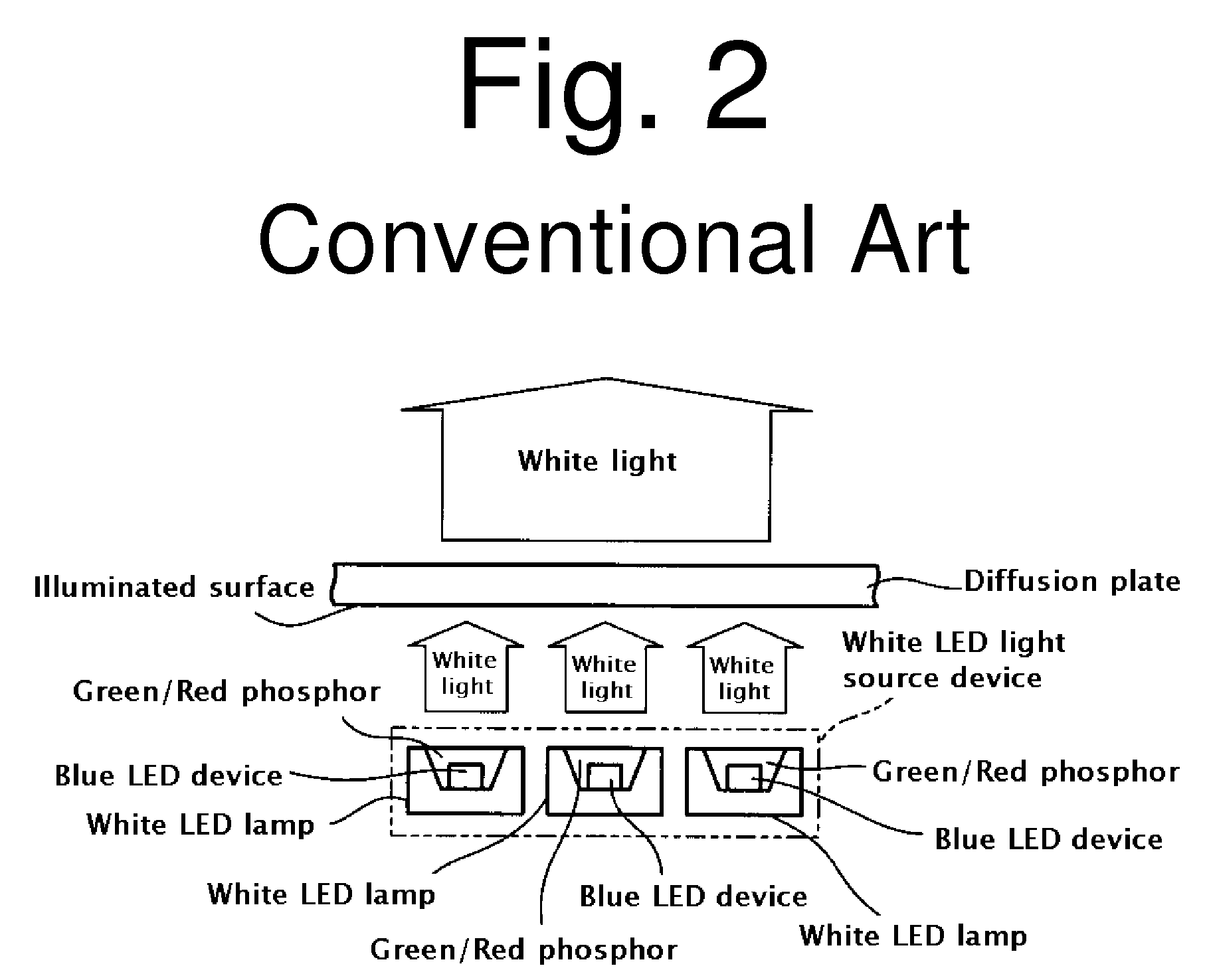

Method, apparatus and computer program for embedding barcode in color image

InactiveUS20080023546A1Reduce laborShorten the timeCharacter and pattern recognitionVisual presentationColor imageBarcode reader

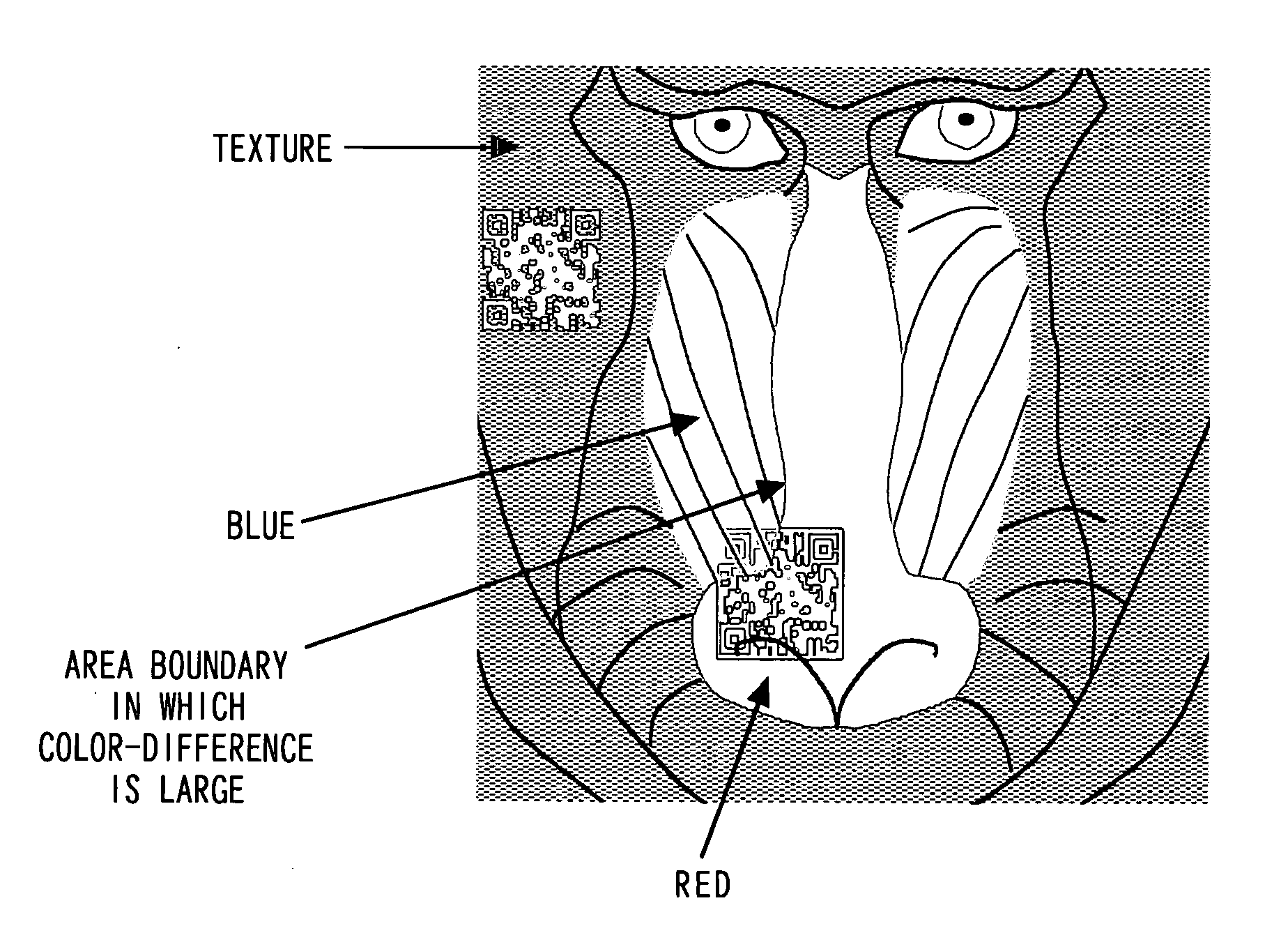

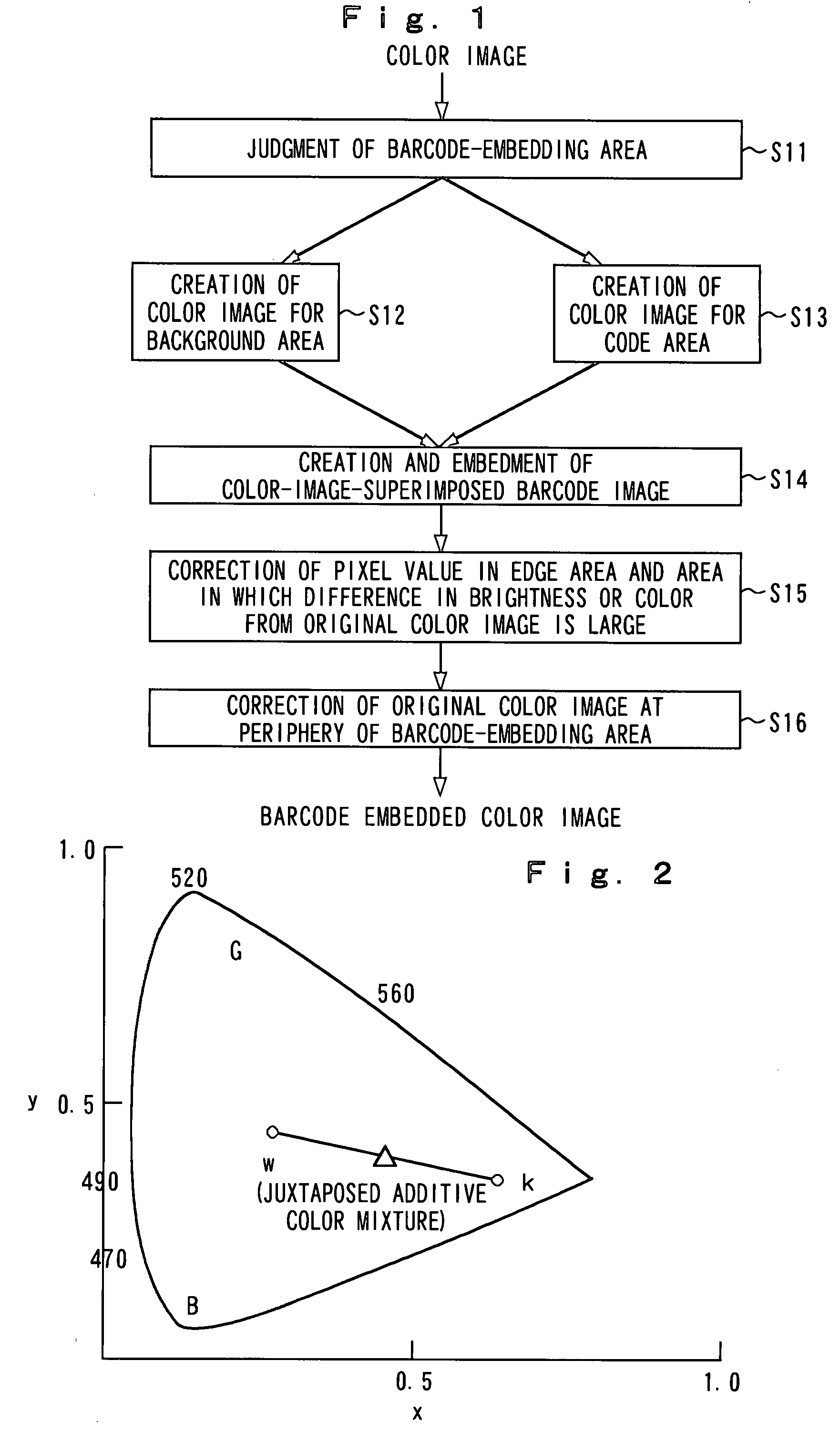

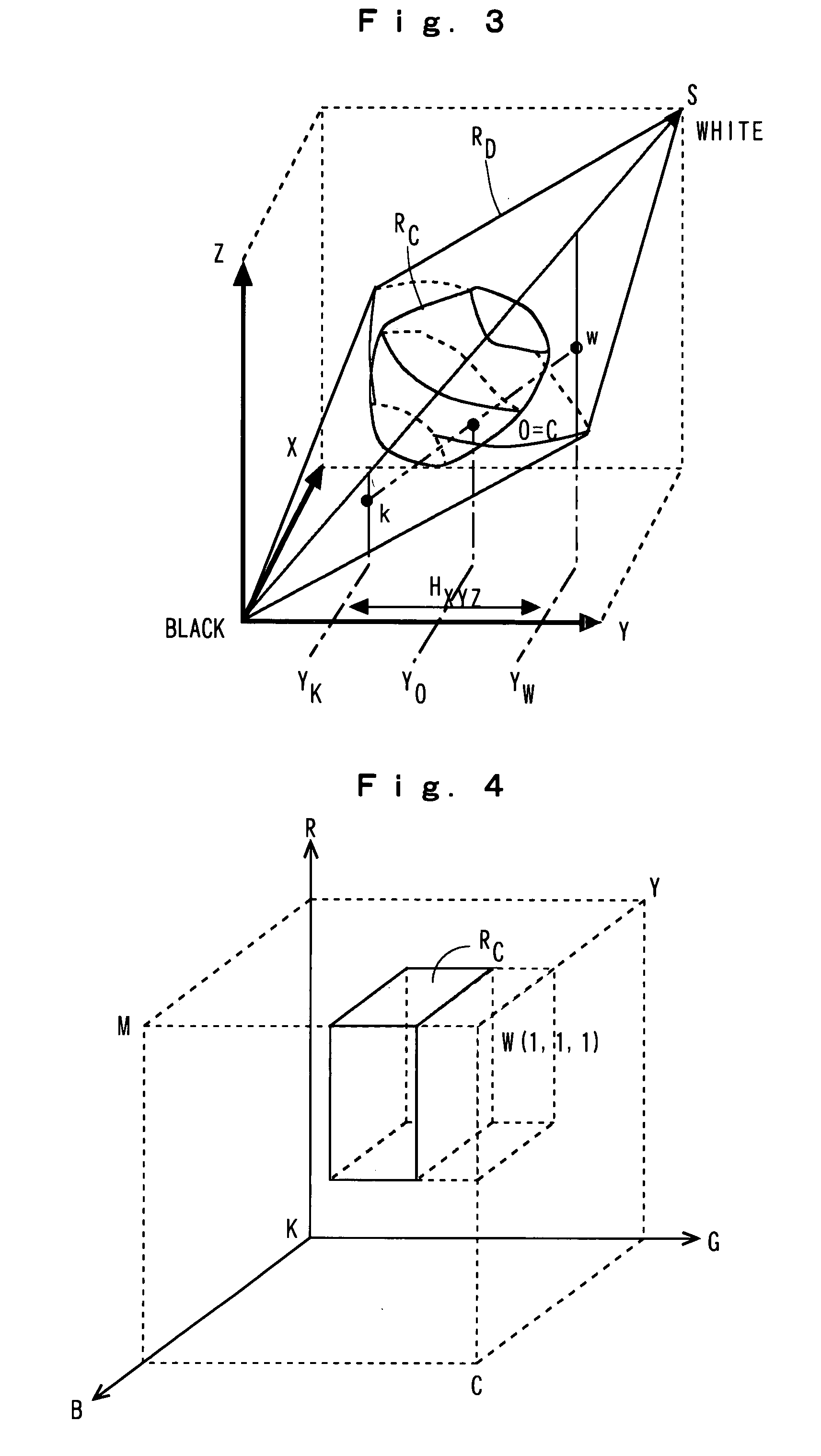

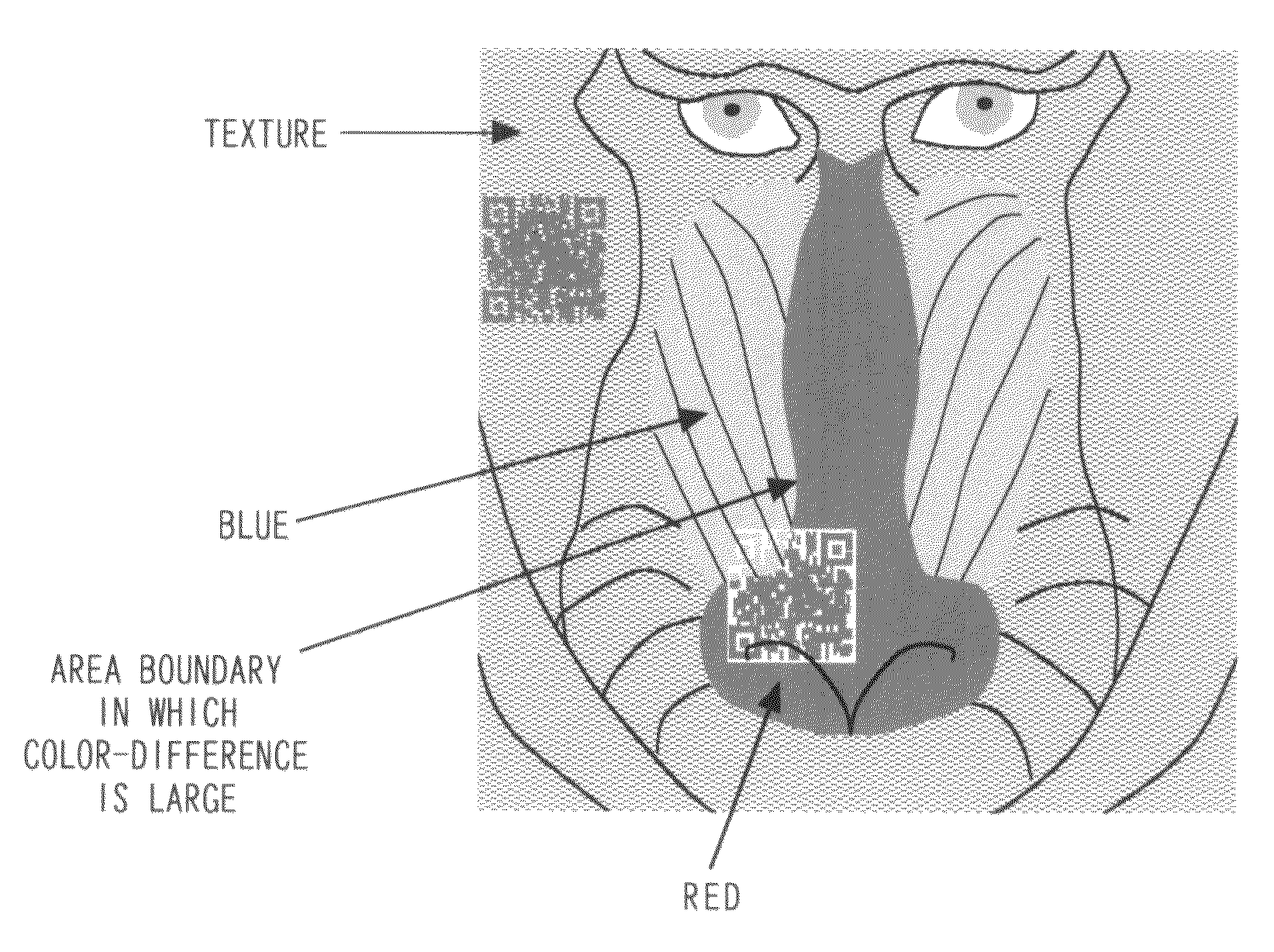

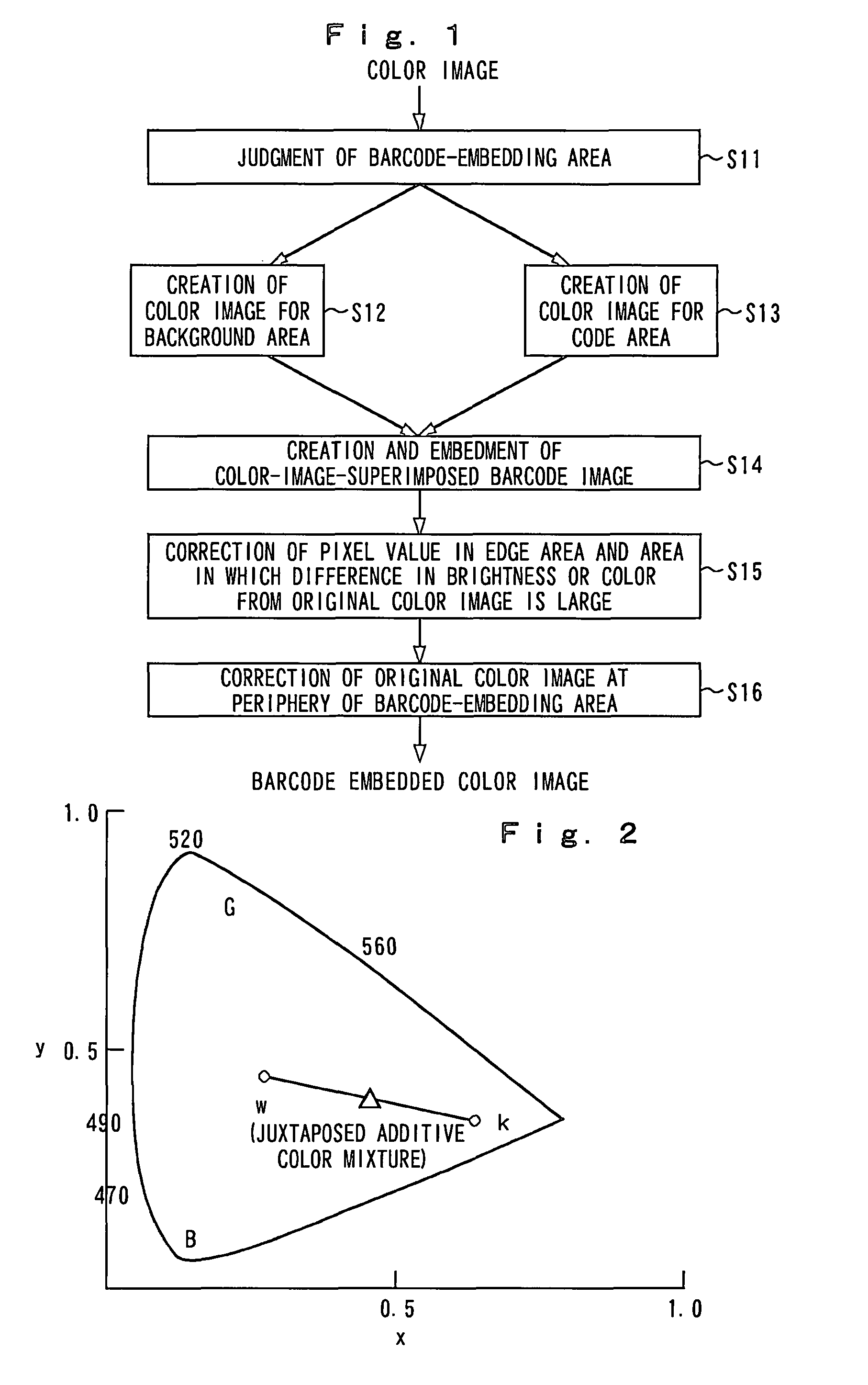

A barcode-embedding area is obtained in a color image based on expression possibility by the juxtaposed additive color mixture and possibility of reading of pixels separately by a barcode reader (S11), a color image in the barcode-embedding area is expressed by the juxtaposed additive color mixture, and color images for the code area and the background area, which are readable by the barcode reader, are created (S12, S13), a color-image-superimposed barcode image is created by using the color images for the code area and the background area, and the same color-image-superimposed barcode image is embedded in the barcode-embedding area (S14), and the color-image-superimposed barcode image and the original color image are corrected if necessary (S15, S16).

Owner:KDDI CORP

Light emitting device for generating specific colored light, including white light

InactiveUS6850002B2Improve efficiencyDischarge tube luminescnet screensElectric discharge tubesCeriumMetallic sulfide

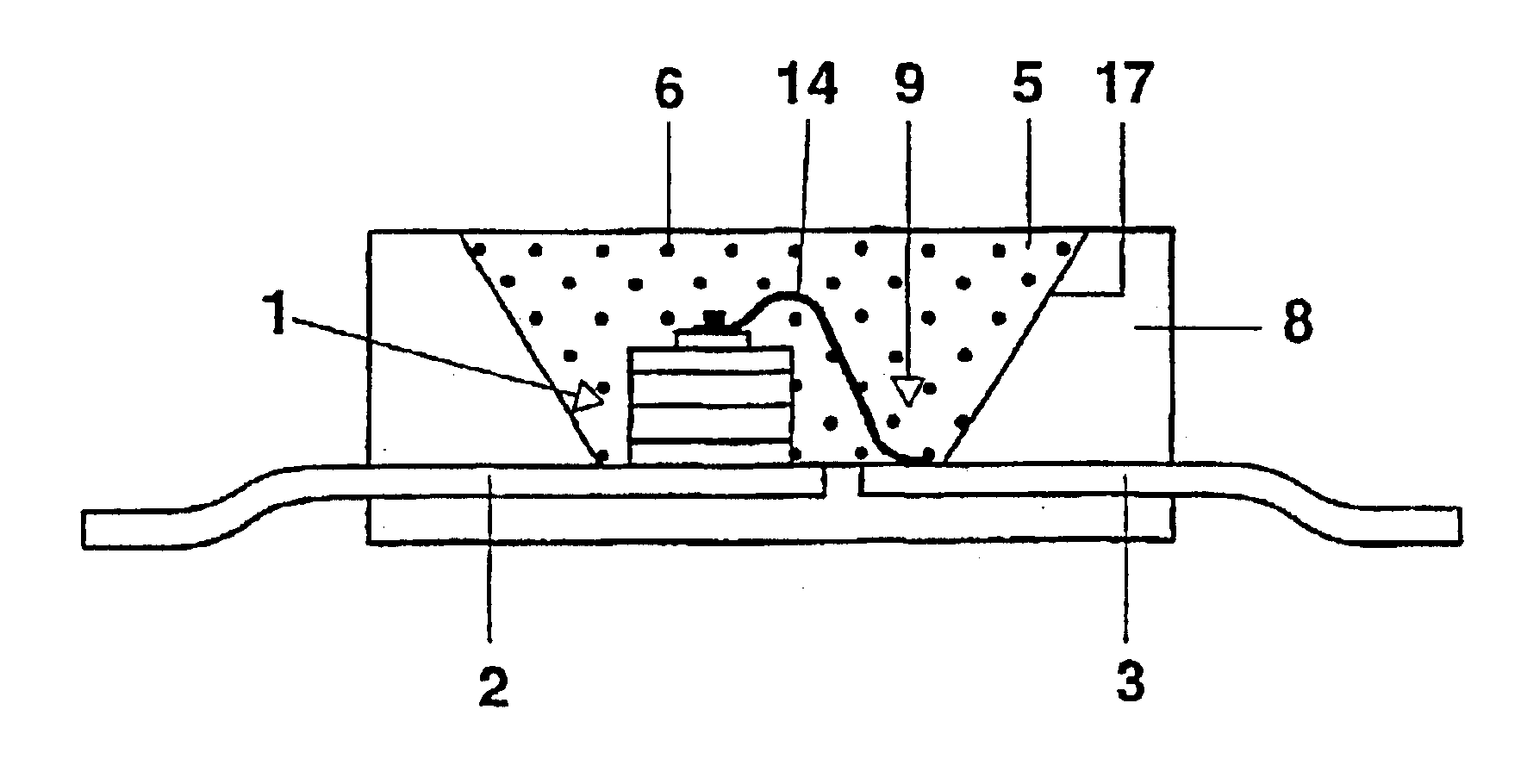

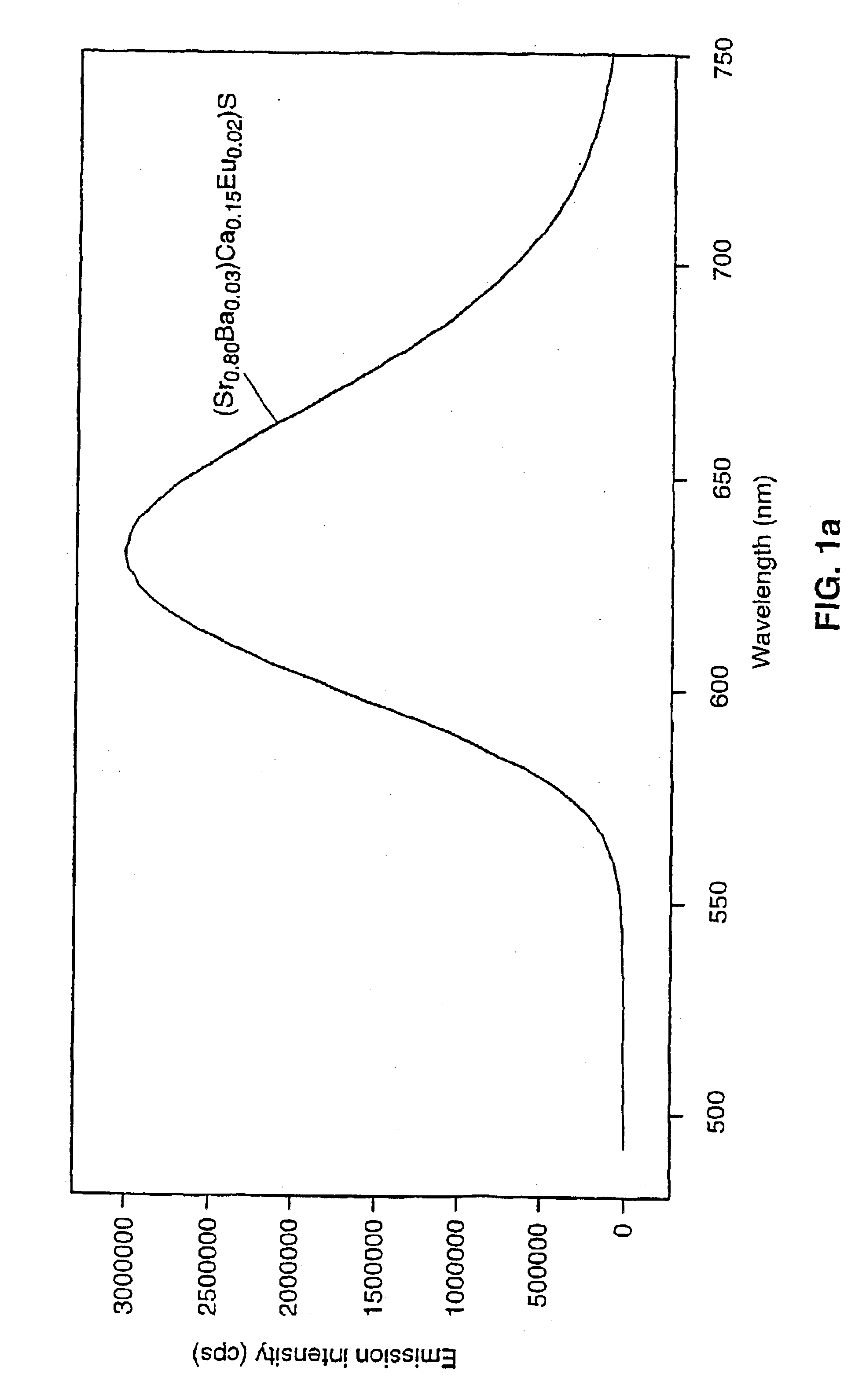

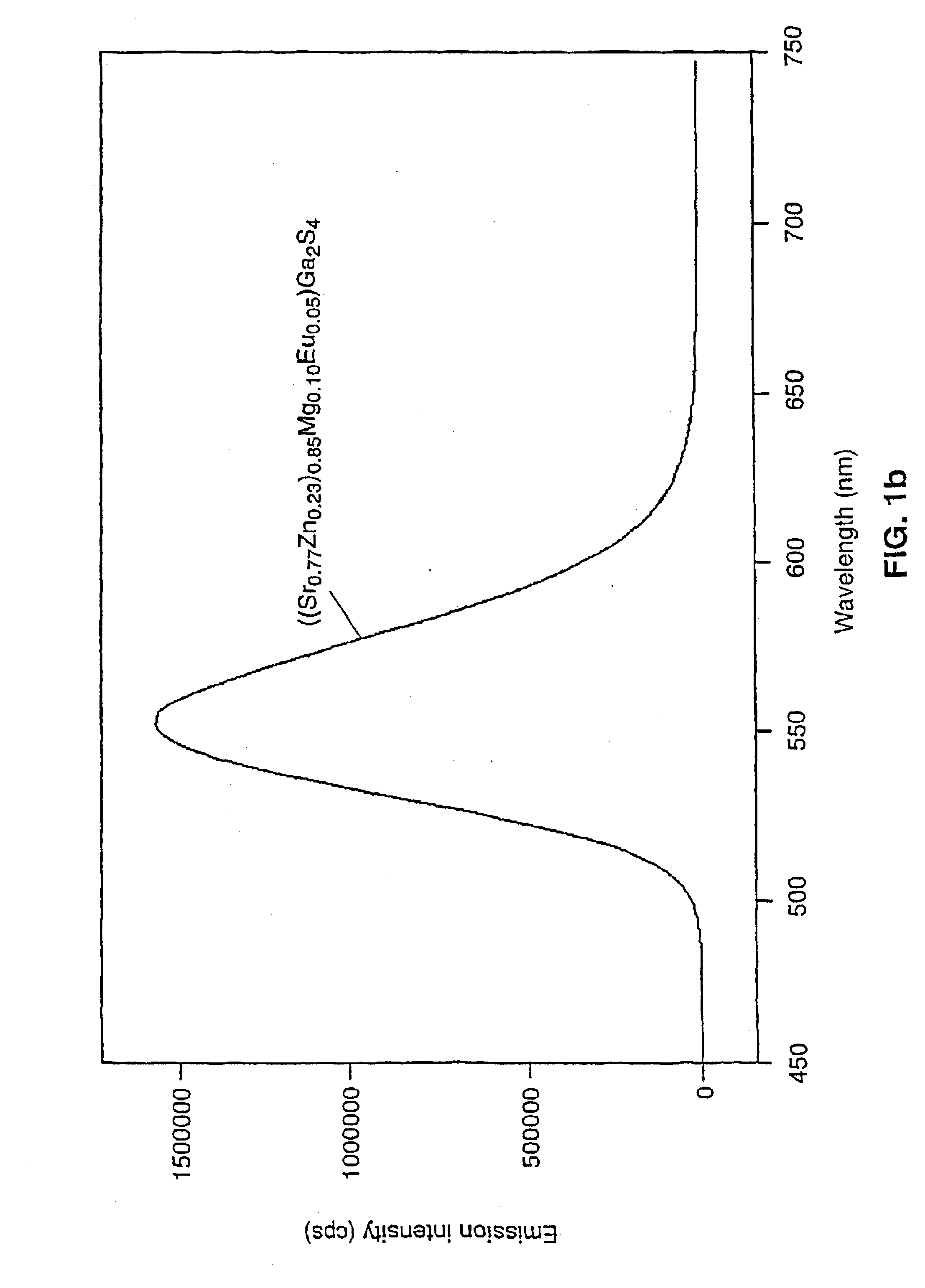

A device for the generation of specific colored light including white light by luminescent down conversion and additive color mixing based on a light-emitting diode (LED) comprising a semiconductor light-emitting layer emitting near UV light about 370-420 nm or blue light about 420-480 nm and phosphors which absorb completely or partly the light emitted by the light-emitting component and emit light of wavelengths longer than that of the absorbed primary light, wherein the light emitting layer of the light emitting component is preferably a Ga(In)N-based semiconductor; and at least one of the phosphors contains a metal sulfide fluorescent material activated with europium containing at least one element selected from the group consisting of Ba, Sr, Ca, Mg and Zn; and / or at least another phosphor which contains a complex thiometalate fluorescent material activated with either europium, cerium or both europium and cerium containing 1) at least one element selected from the group consisting of Ba, Sr, Ca, Mg and Zn and 2) at least one element selected from the group consisting of Al, Ga, In, Y, La and Gd.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH +1

Method, apparatus and computer program for embedding barcode in color image

InactiveUS8550366B2Reduce laborShorten the timeCharacter and pattern recognitionVisual presentationColor imageBarcode reader

A barcode-embedding area is obtained in a color image based on expression possibility by the juxtaposed additive color mixture and possibility of reading of pixels separately by a barcode reader (S11), a color image in the barcode-embedding area is expressed by the juxtaposed additive color mixture, and color images for the code area and the background area, which are readable by the barcode reader, are created (S12, S13), a color-image-superimposed barcode image is created by using the color images for the code area and the background area, and the same color-image-superimposed barcode image is embedded in the barcode-embedding area (S14), and the color-image-superimposed barcode image and the original color image are corrected if necessary (S15, S16).

Owner:KDDI CORP

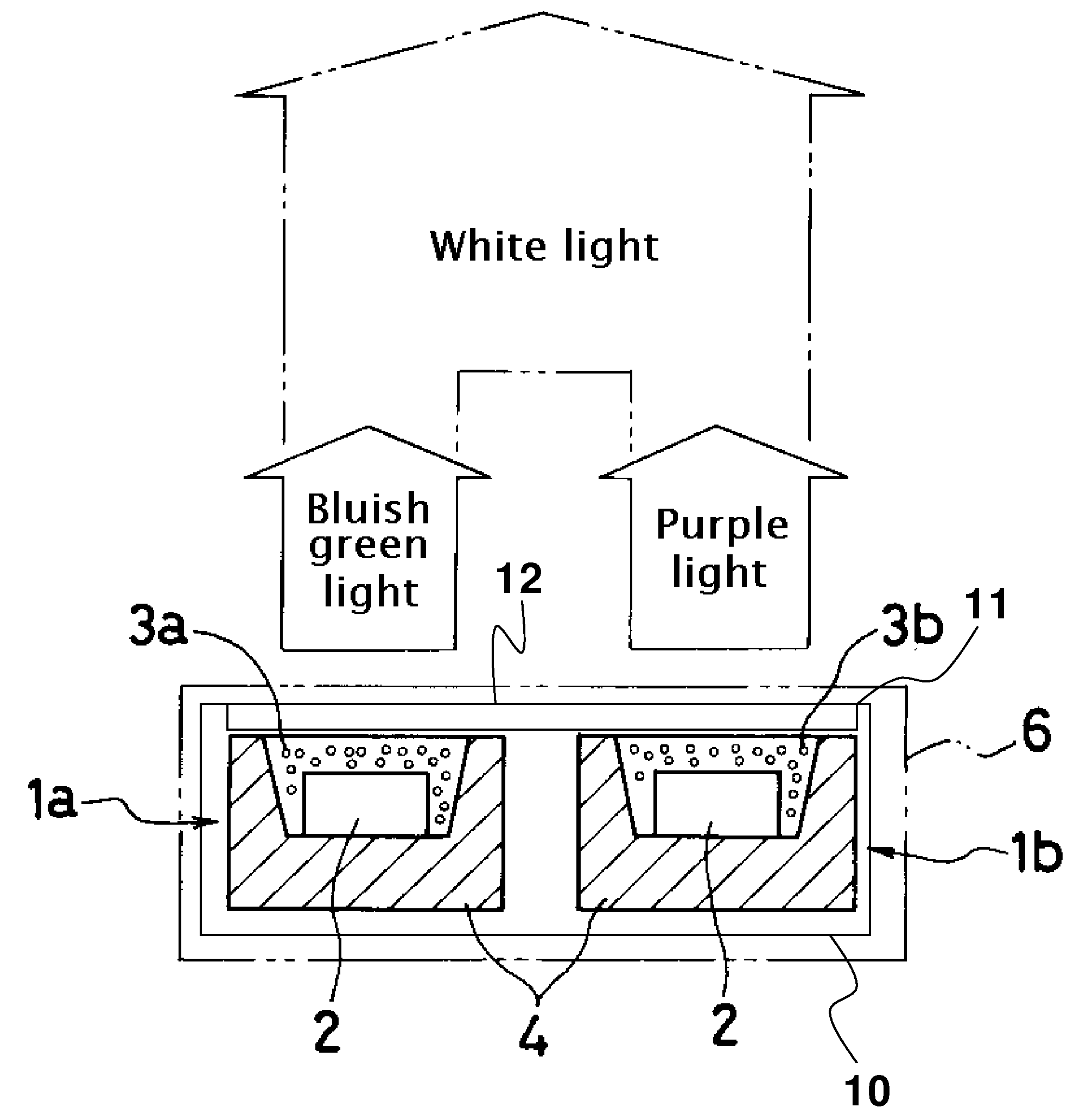

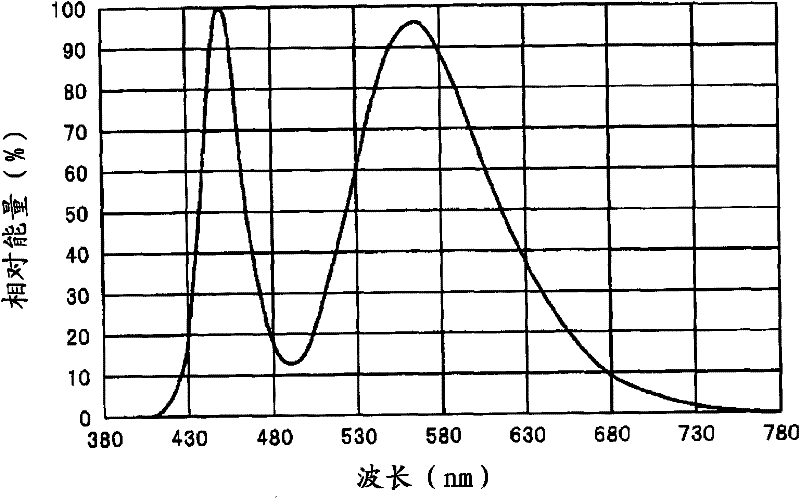

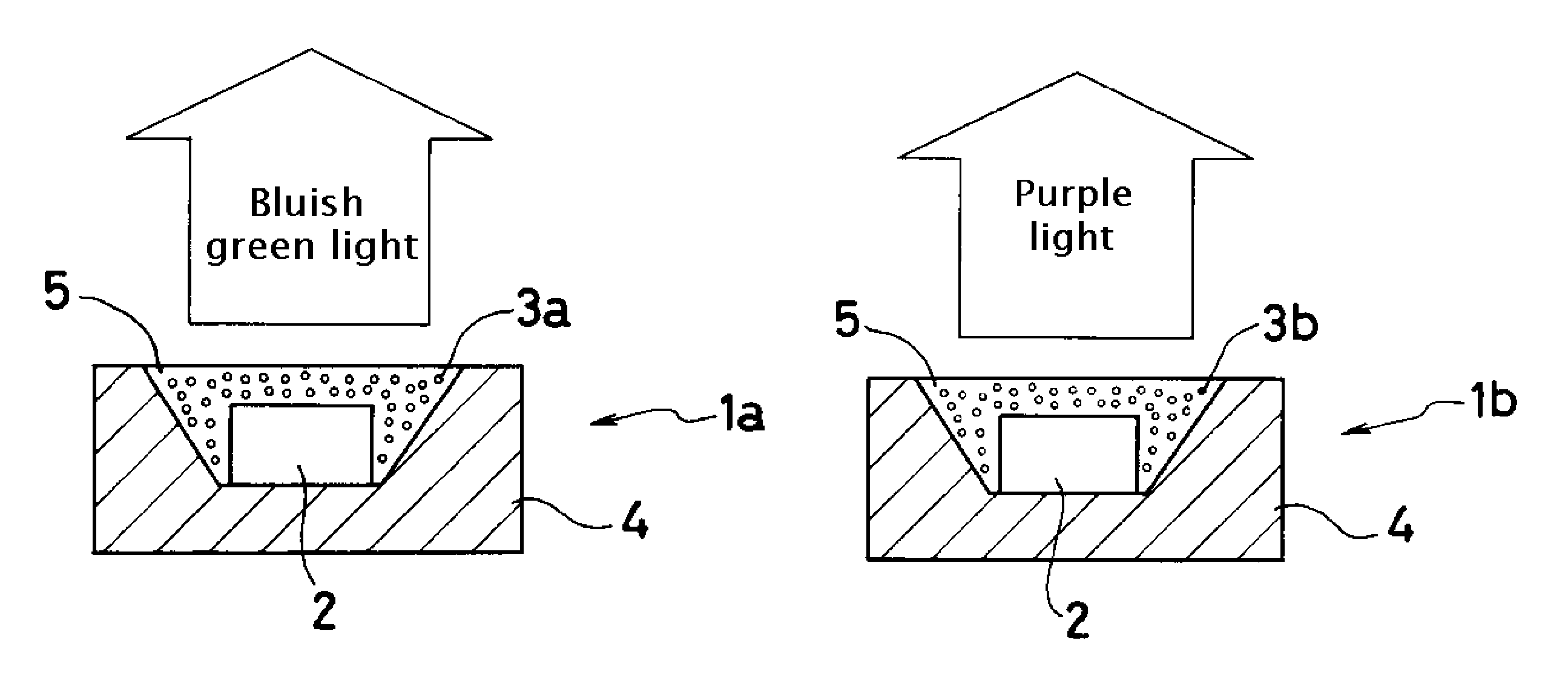

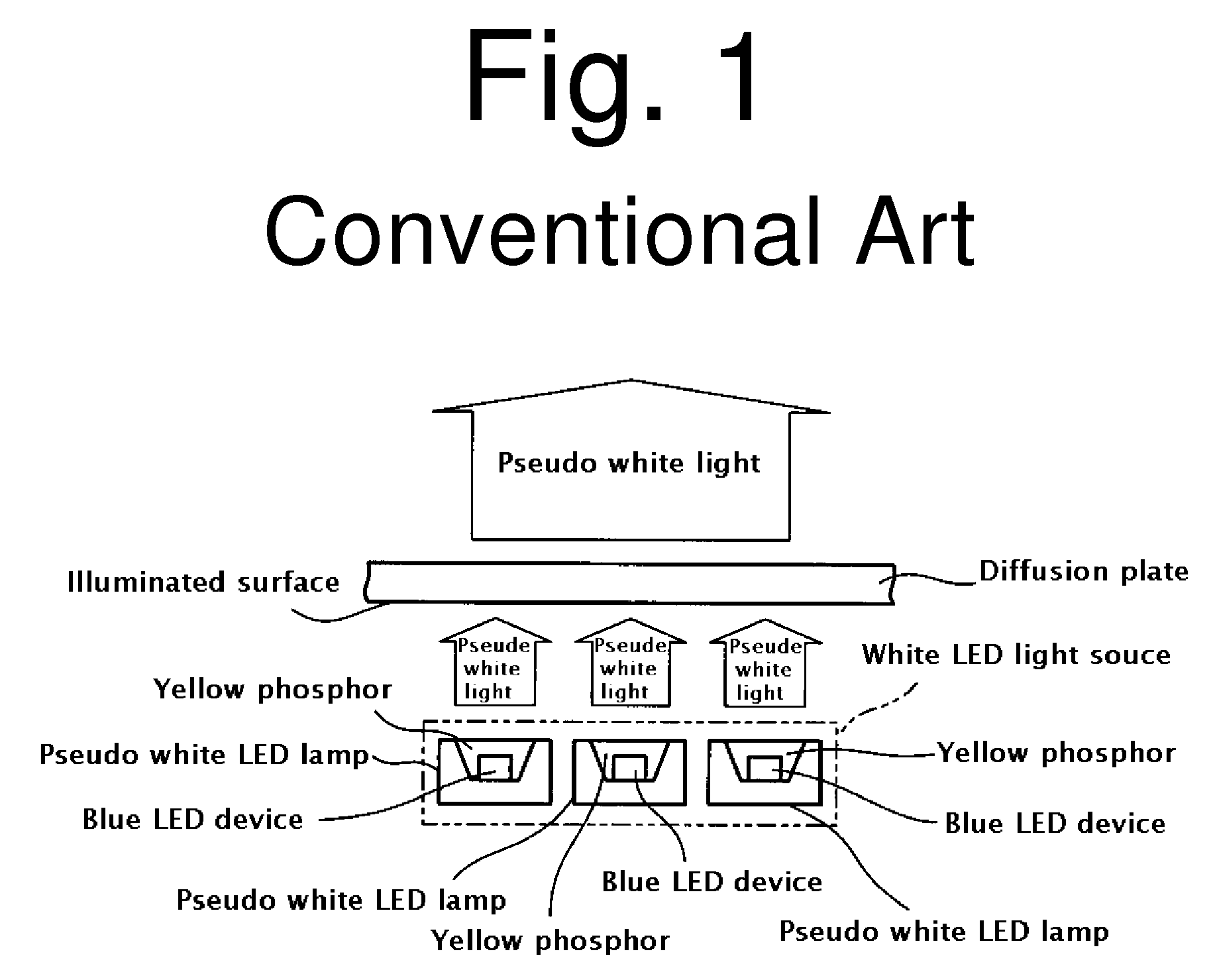

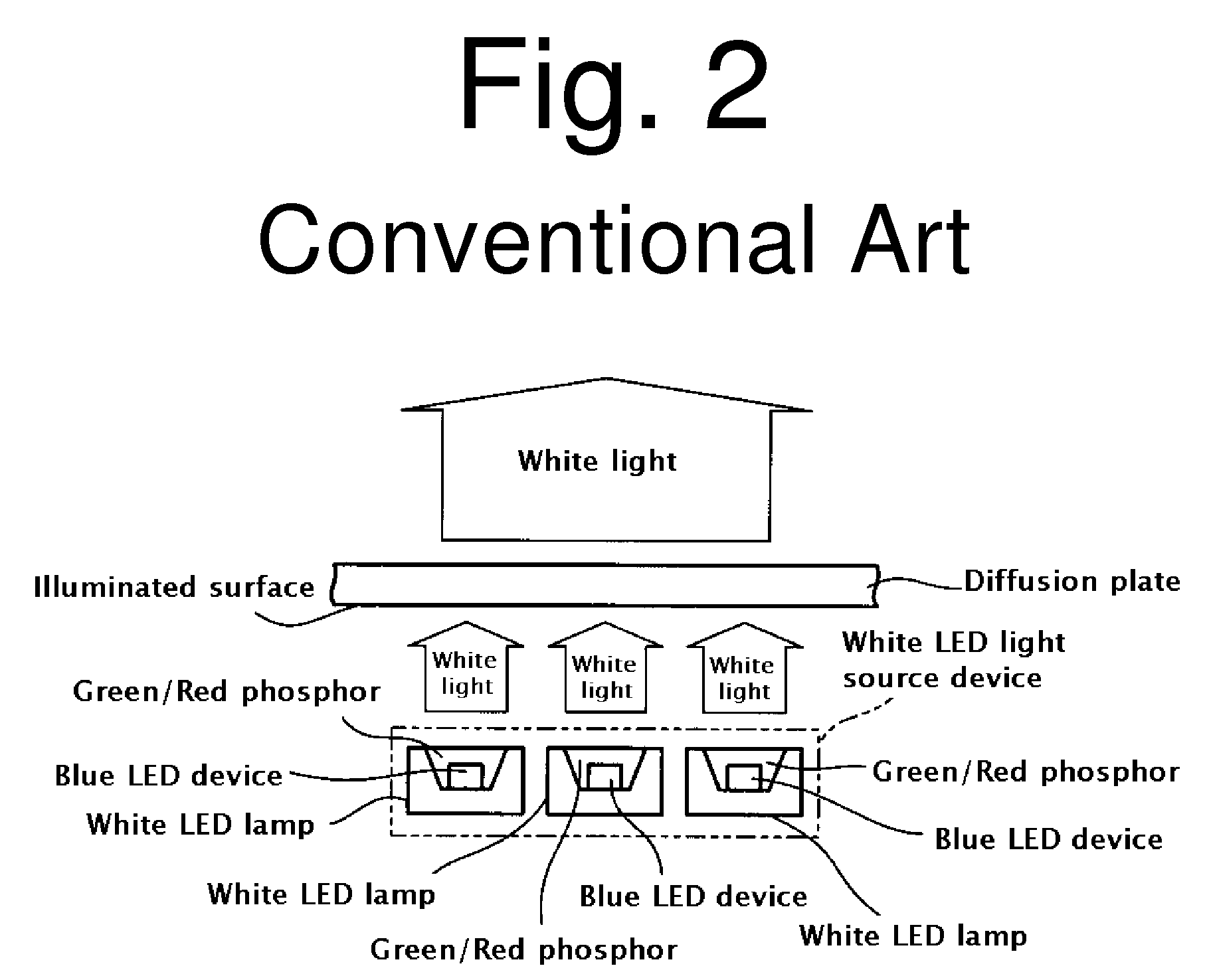

White LED Light Source Device and LED Backlight Using the Same

InactiveUS20080151527A1Improve utilization efficiencyWide range of colorsPoint-like light sourceGas discharge lamp usageLuminous intensityGreen-light

A white LED light source device and an LED backlight using the white LED light source can produce, among other features, white light with sufficient luminous intensity, uniform color tone, and high luminous utilization efficiency. A light path for producing white light with favorable color mixture can be shortened. The white LED light source device can be configured to include a bluish green LED lamp which can emit bluish green light by the combination of a blue LED device and a green phosphor material and a purple LED lamp which can emit purple light by the combination of a blue LED device and a red phosphor material. The bluish green light from the bluish green LED lamp and the purple light from the purple LED lamp are subjected to additive color mixture to produce white light with a spectrum containing three primary color wavelength components.

Owner:STANLEY ELECTRIC CO LTD

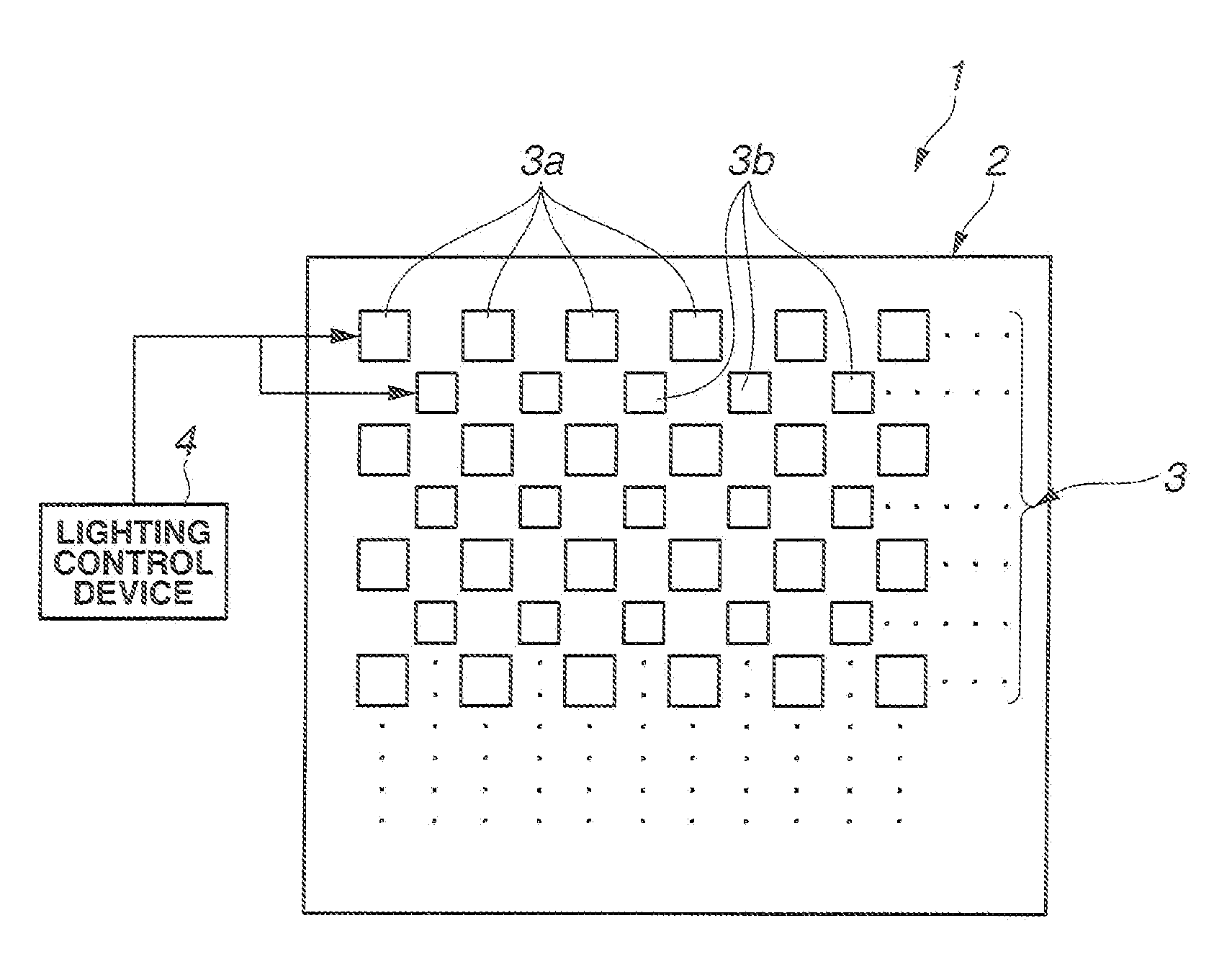

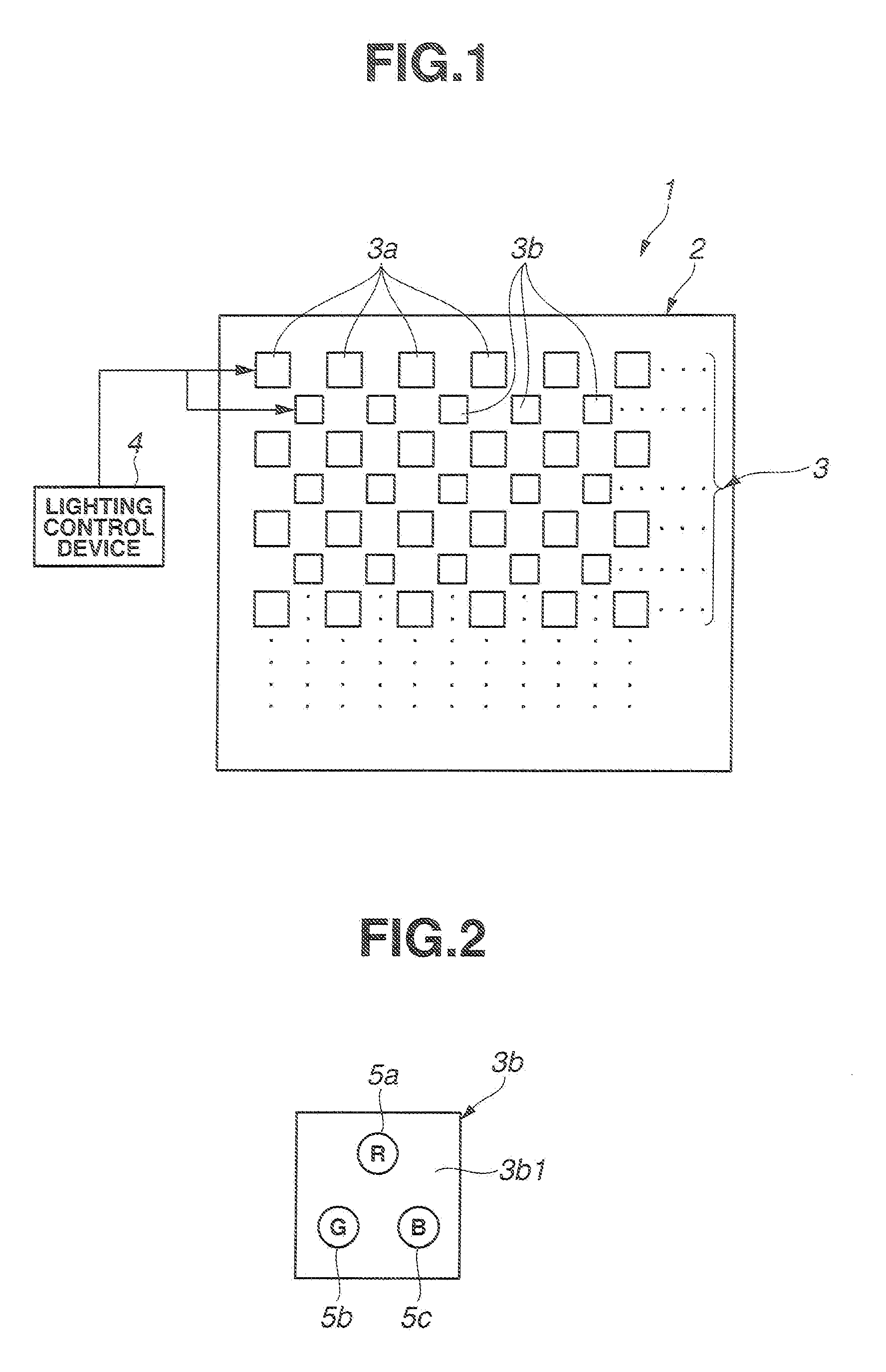

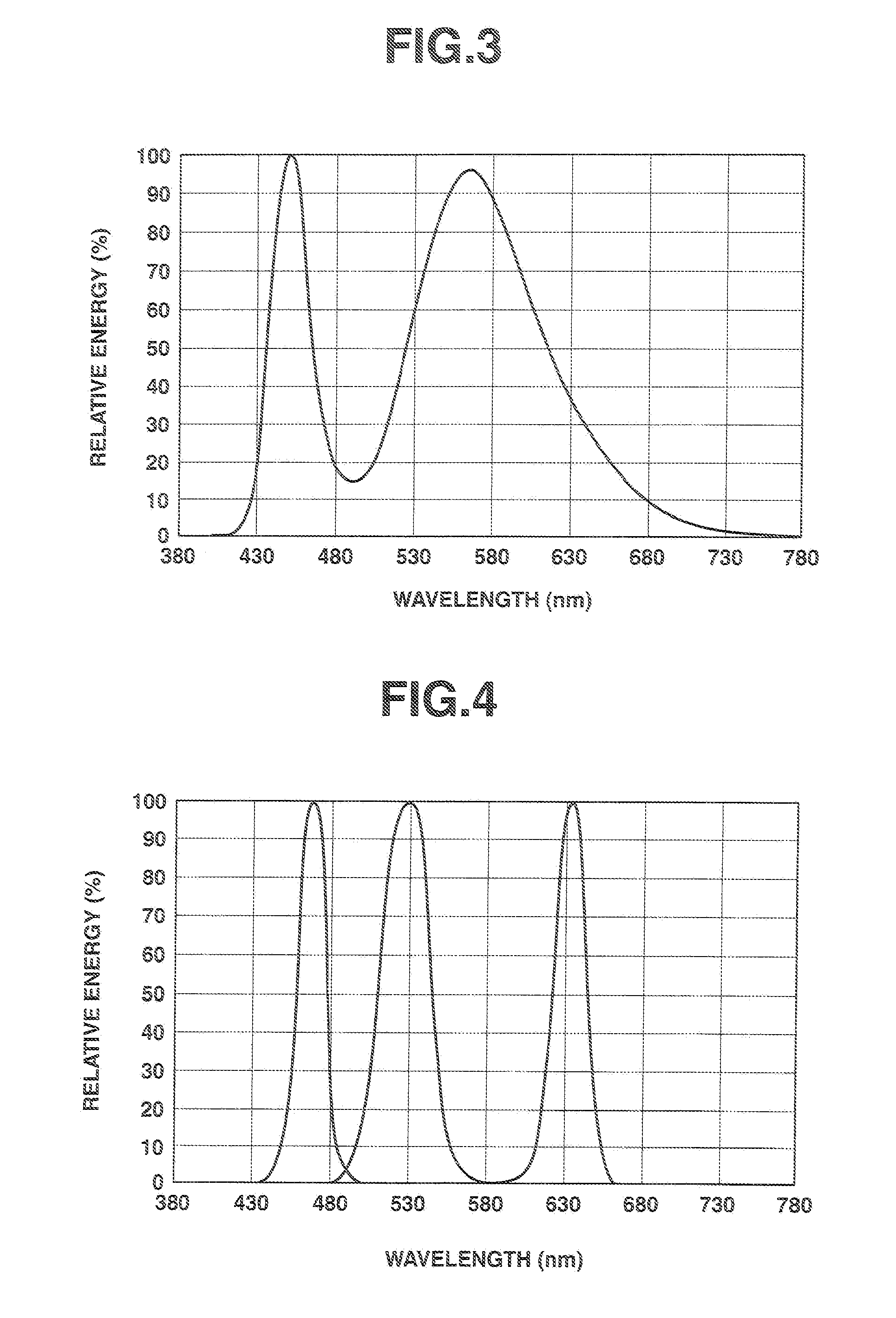

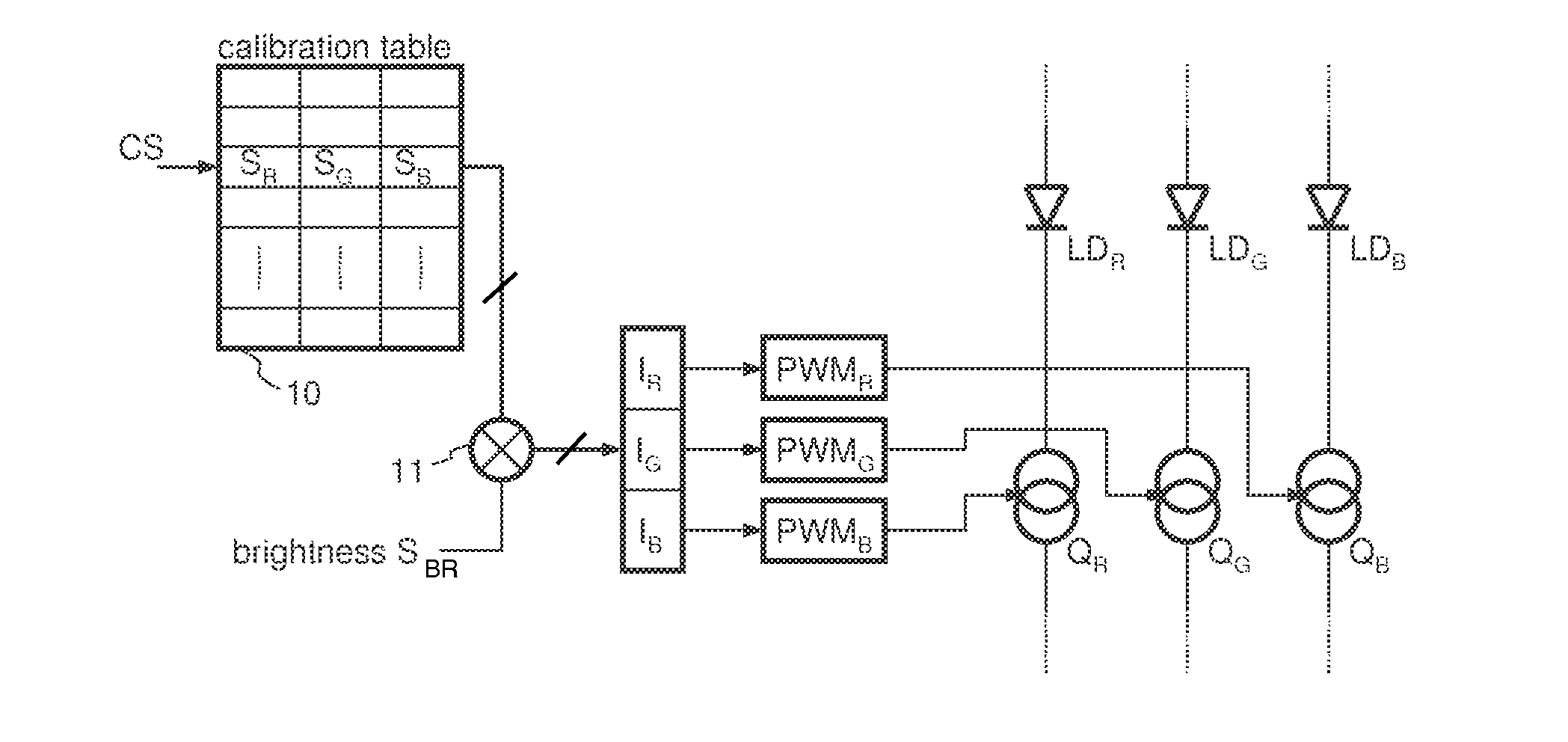

Lighting apparatus

Owner:TOSHIBA LIGHTING & TECH CORP +1

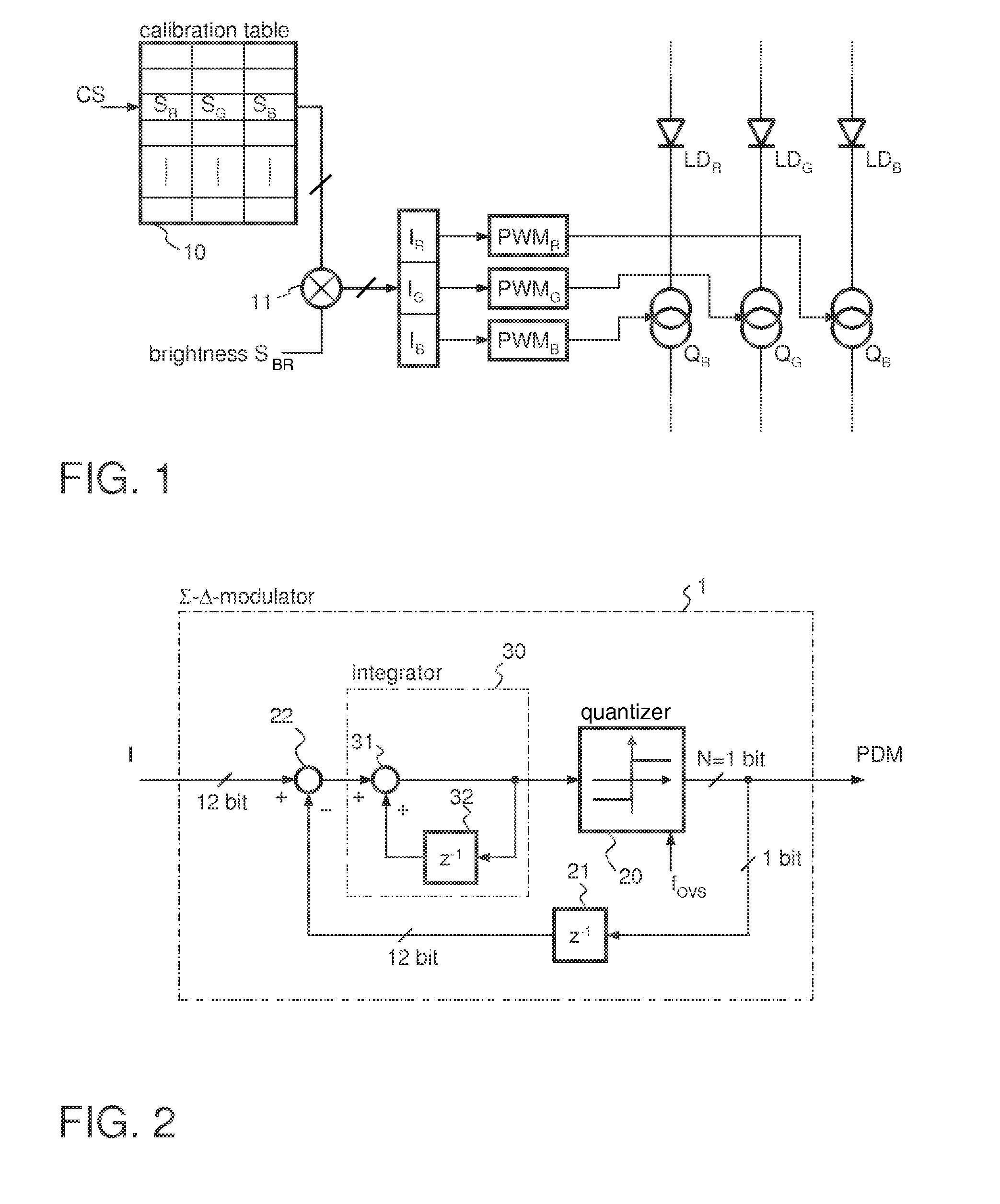

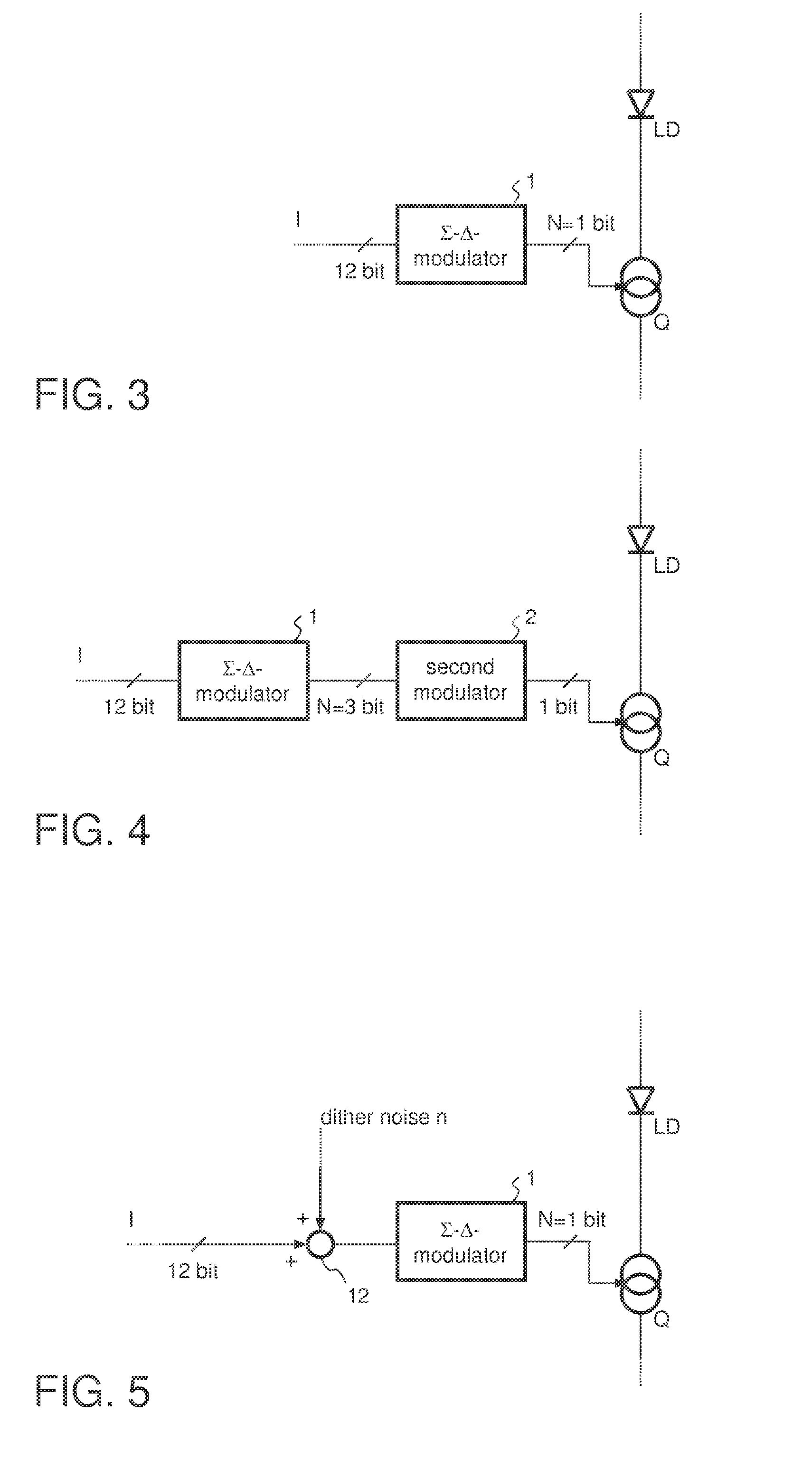

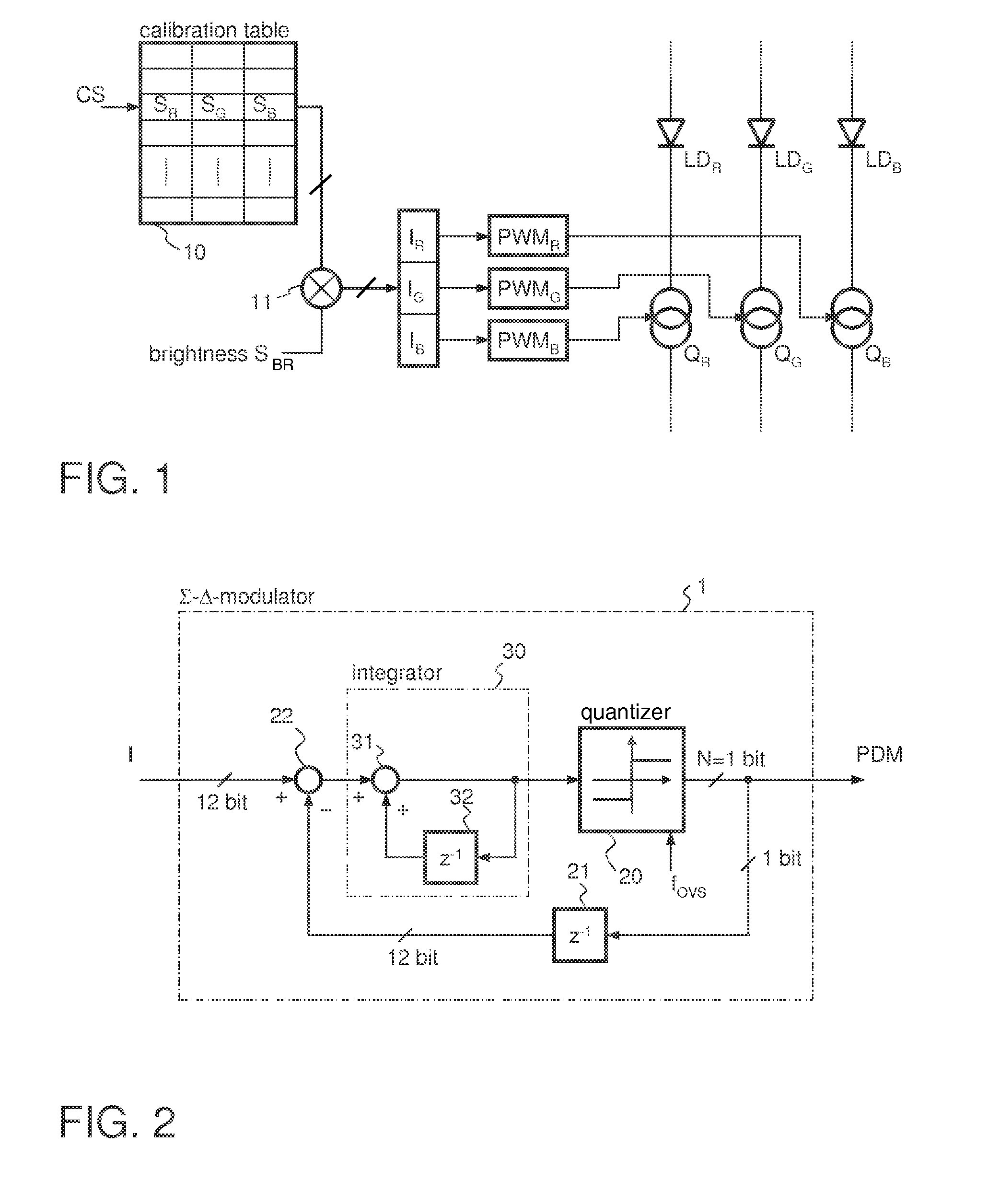

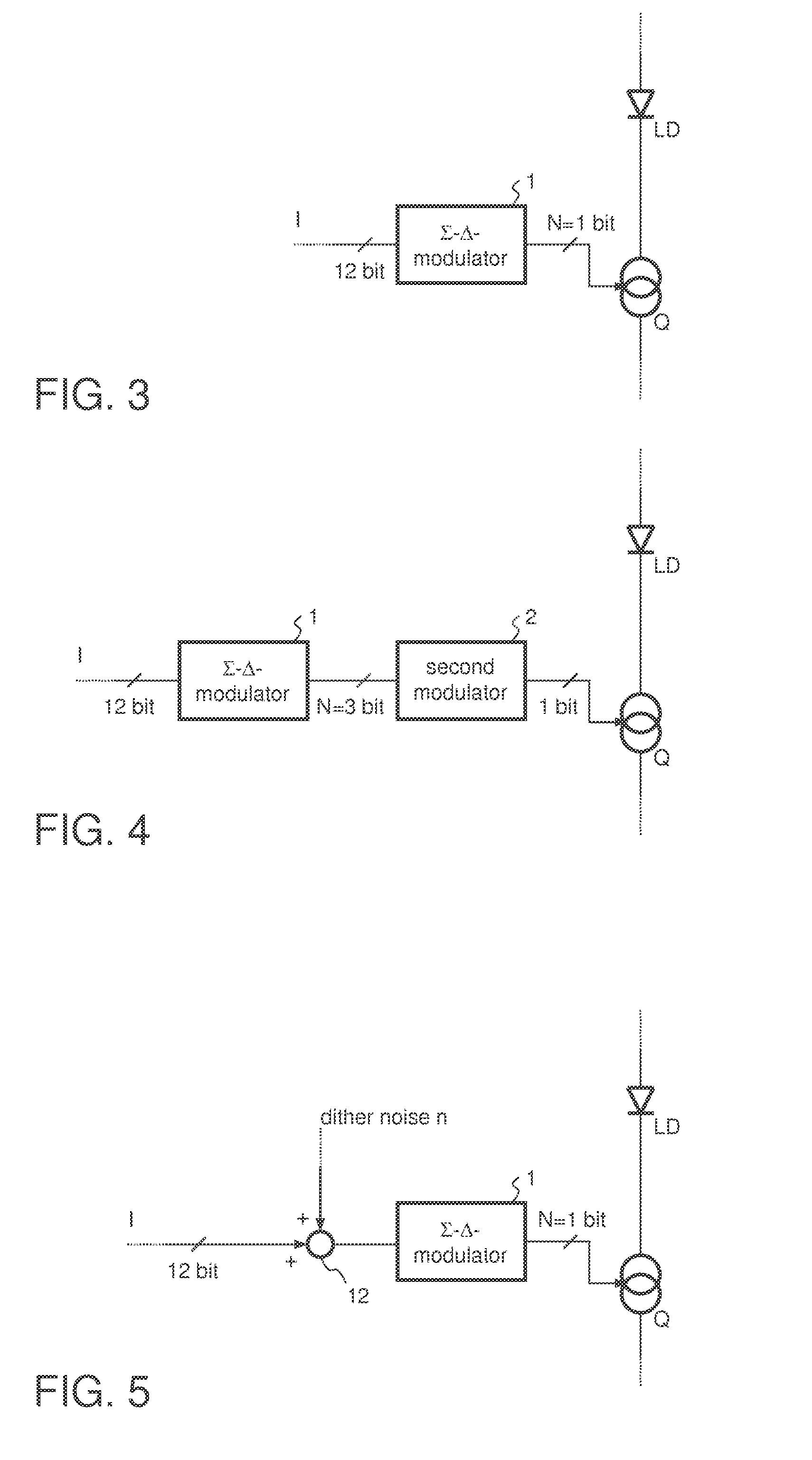

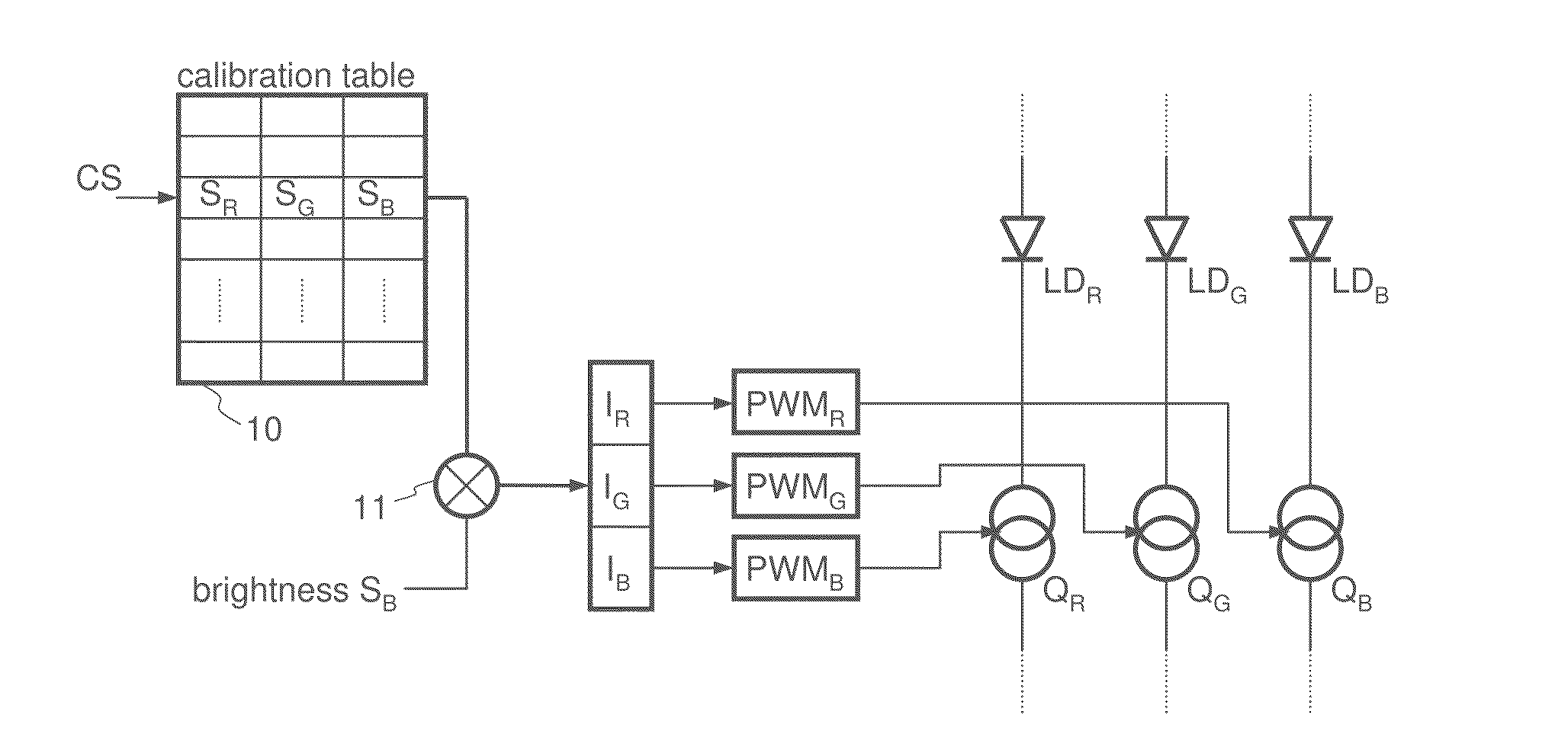

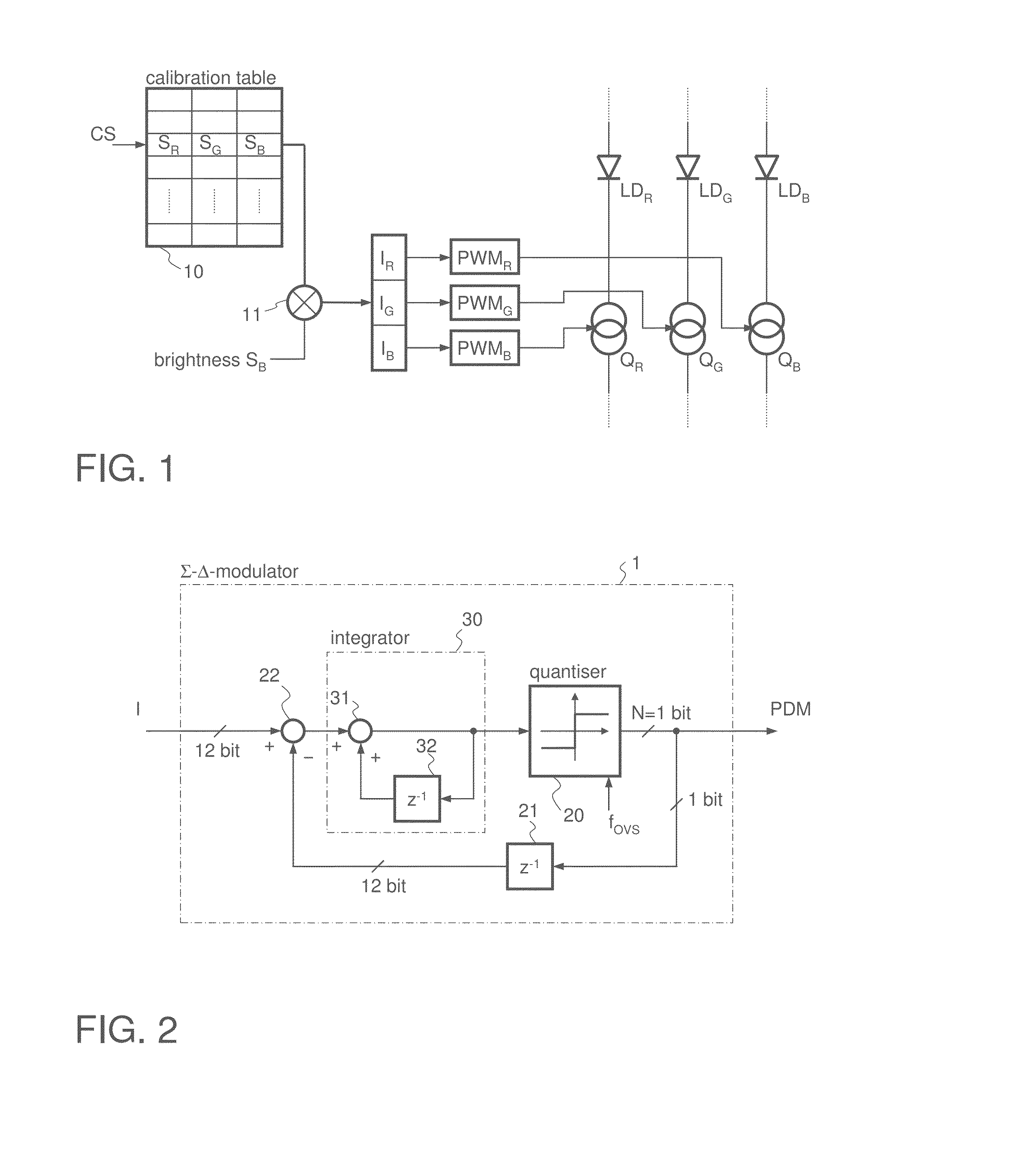

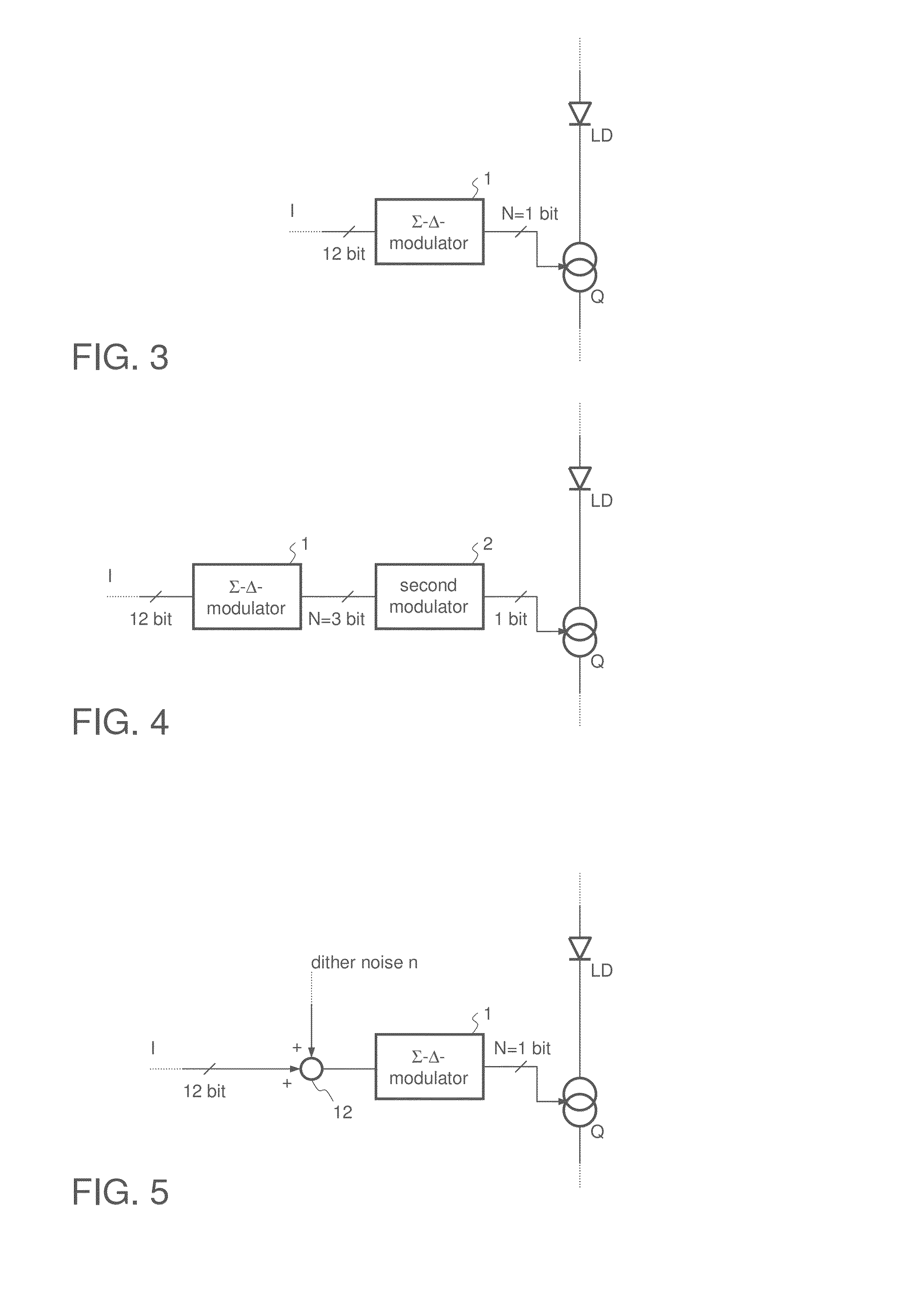

Sigma delta current source and LED driver

A circuit arrangement includes a first light emitting diode and a second light emitting diode emitting light of different colors arranged adjacent to each other for additive color mixing. A first and second controllable current sources are connected to the first and second light emitting diode, respectively, such that the load currents of the light emitting diodes depend on respective control signals received by the current sources. First and second sigma-delta modulators are connected to the first and second light emitting diodes, respectively, and provide bit-streams as control signals to the current sources. The mean value of each bit-stream corresponds to the value of an input signal of the respective sigma-delta modulator.

Owner:INFINEON TECH AUSTRIA AG

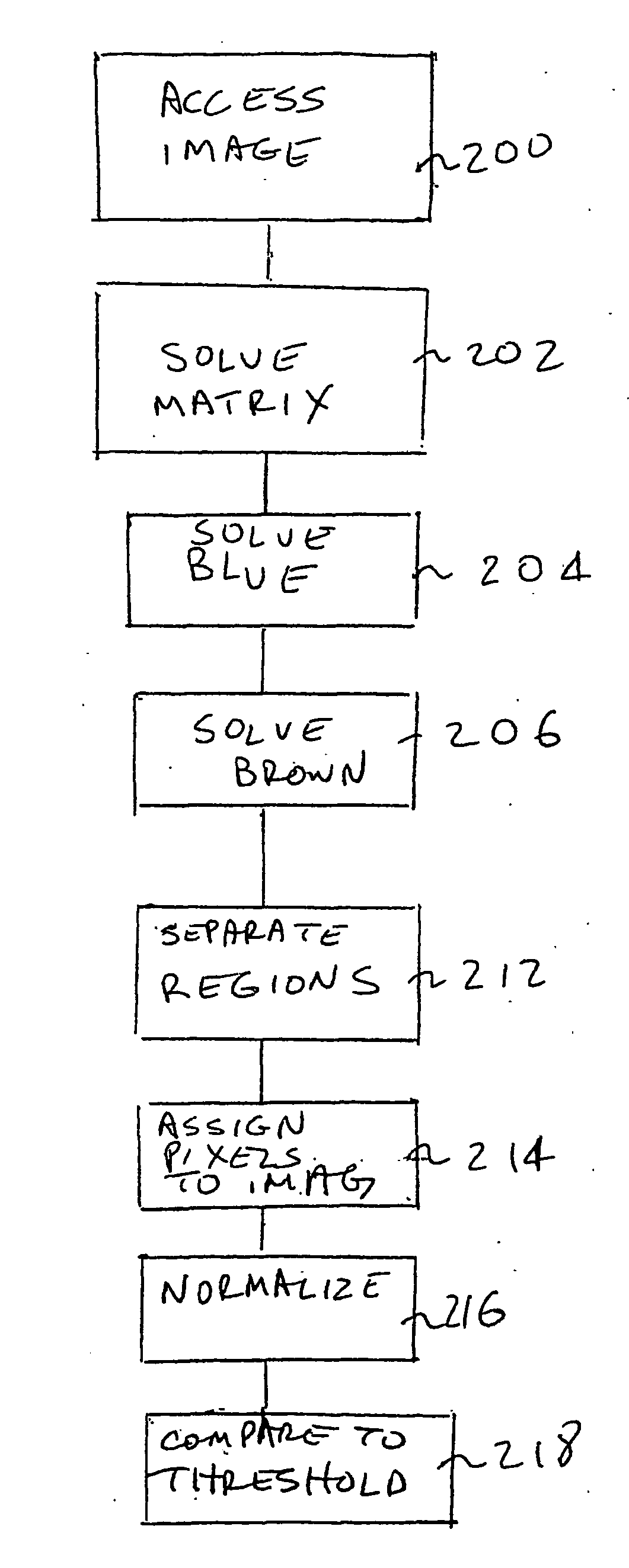

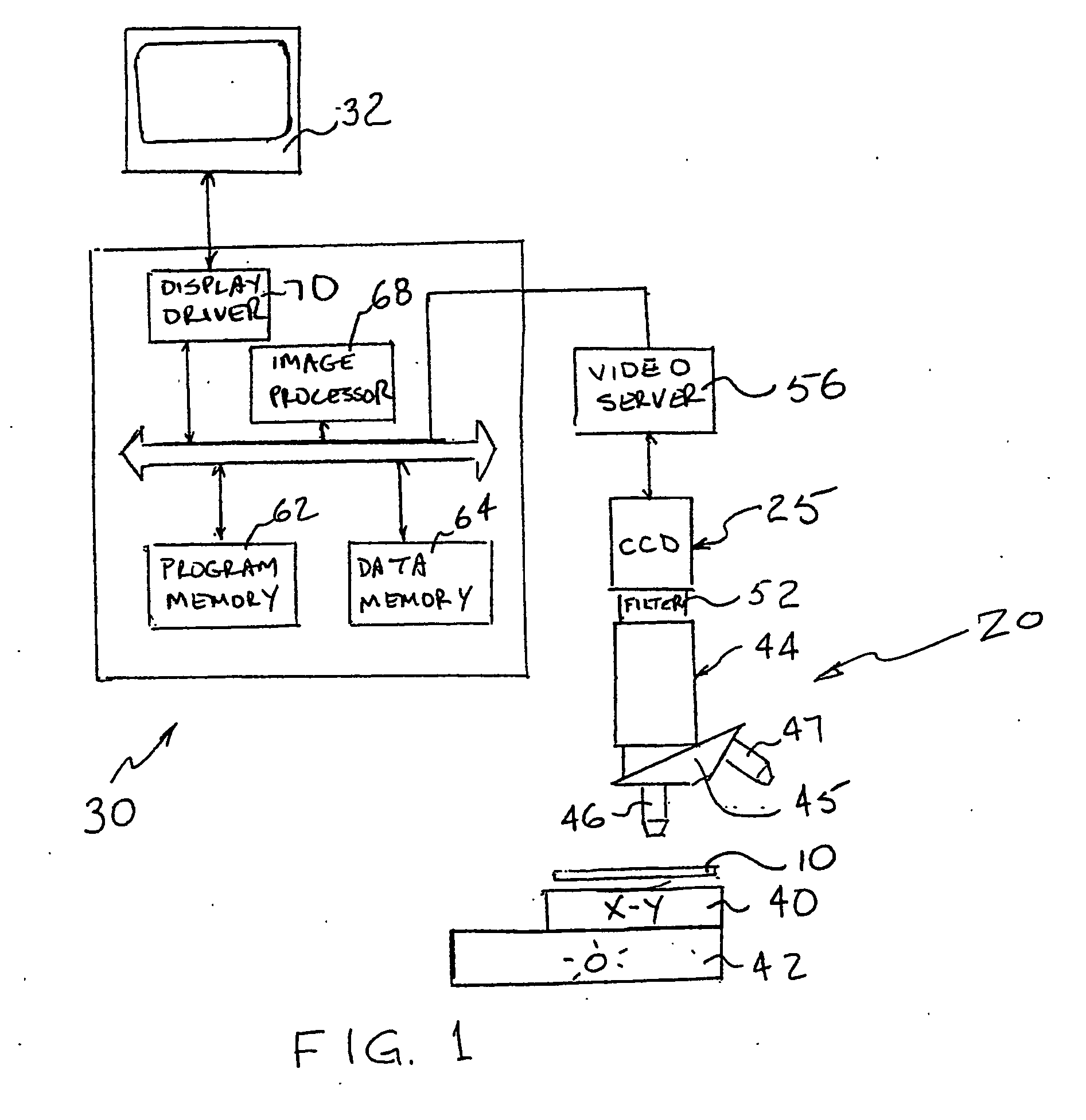

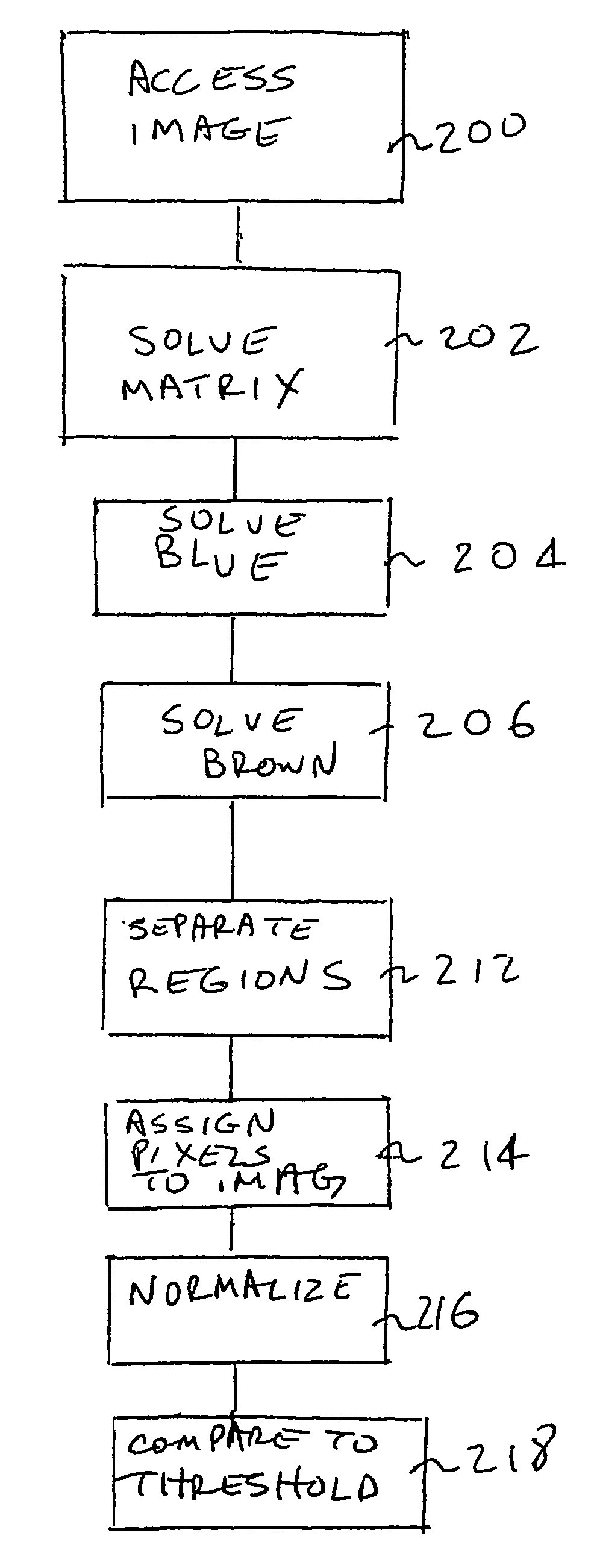

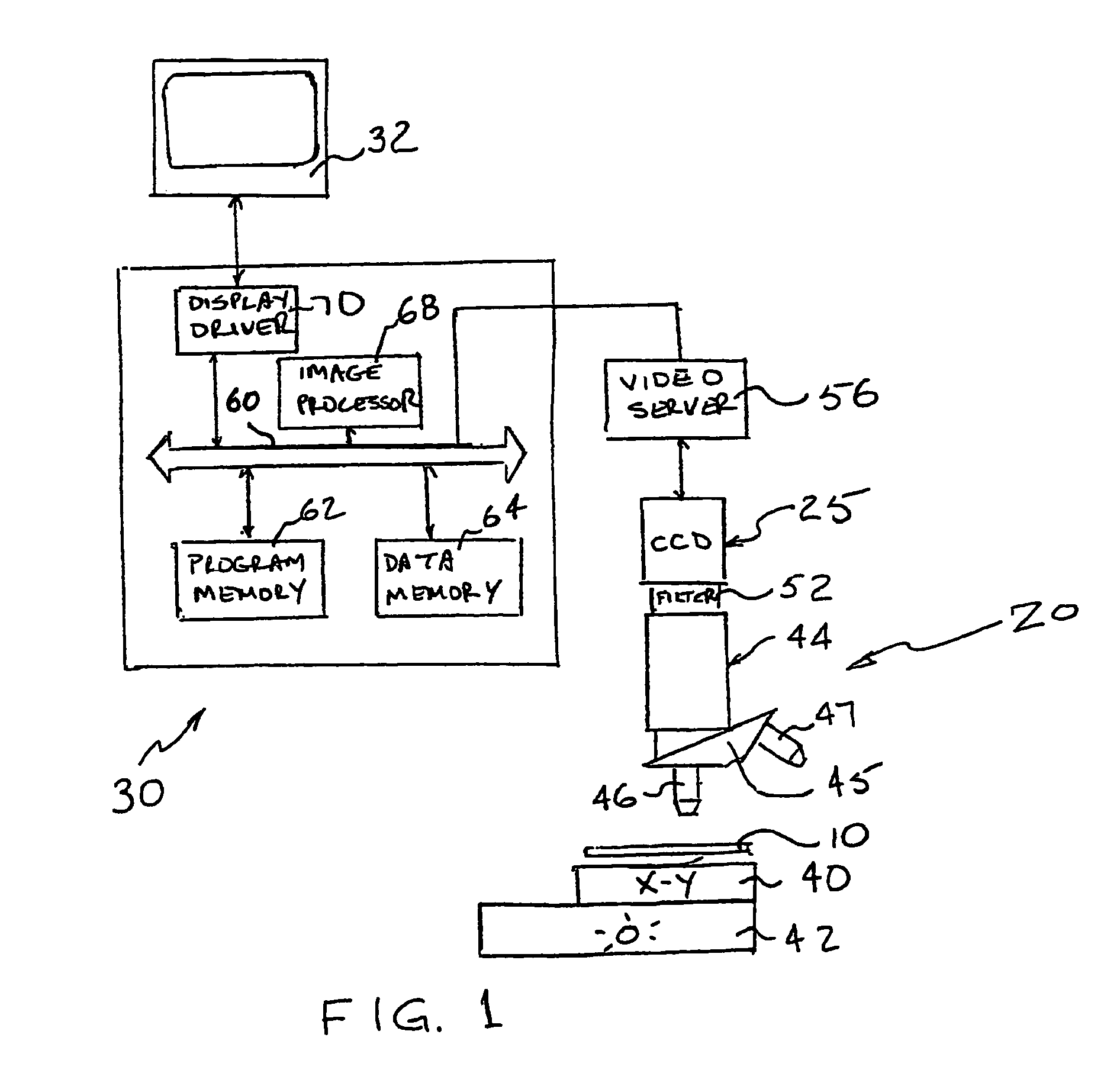

Color unmixing and region of interest detection in tissue samples

InactiveUS20070053573A1Acquiring/recognising microscopic objectsImage data processingMatrix decompositionTissue sample

In a method and system and machine-readable medium, colors in an image (200) are unmixed (202) using a matrix X=AS, where A is a ns×nd matrix of spectral definitions, where s is the number of spectral components and d is the number of dyes into which the image is decomposed, and where S is a ns×l matrix of amounts of each dye at every pixel, where l is the number of pixels; the matrix X is constrained for solution by an unsupervised matrix decomposition method having constraints consistent with properties of an additive color model; and nd is determined. A texture is determined to identify areas of interest. Further processing may automatically measure cell dye concentration in the determined regions of interest.

Owner:RABINOVICH ANDREW M

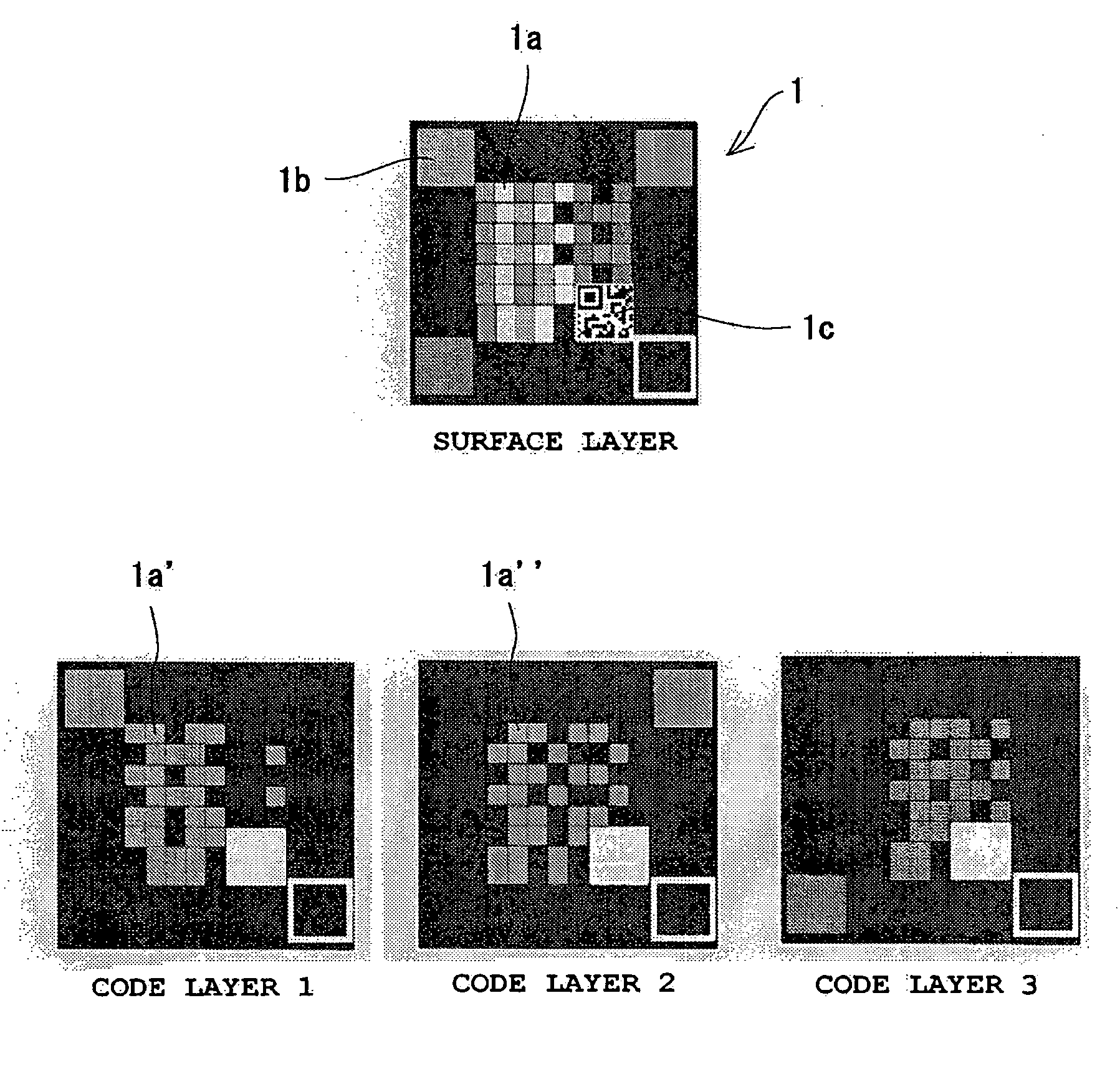

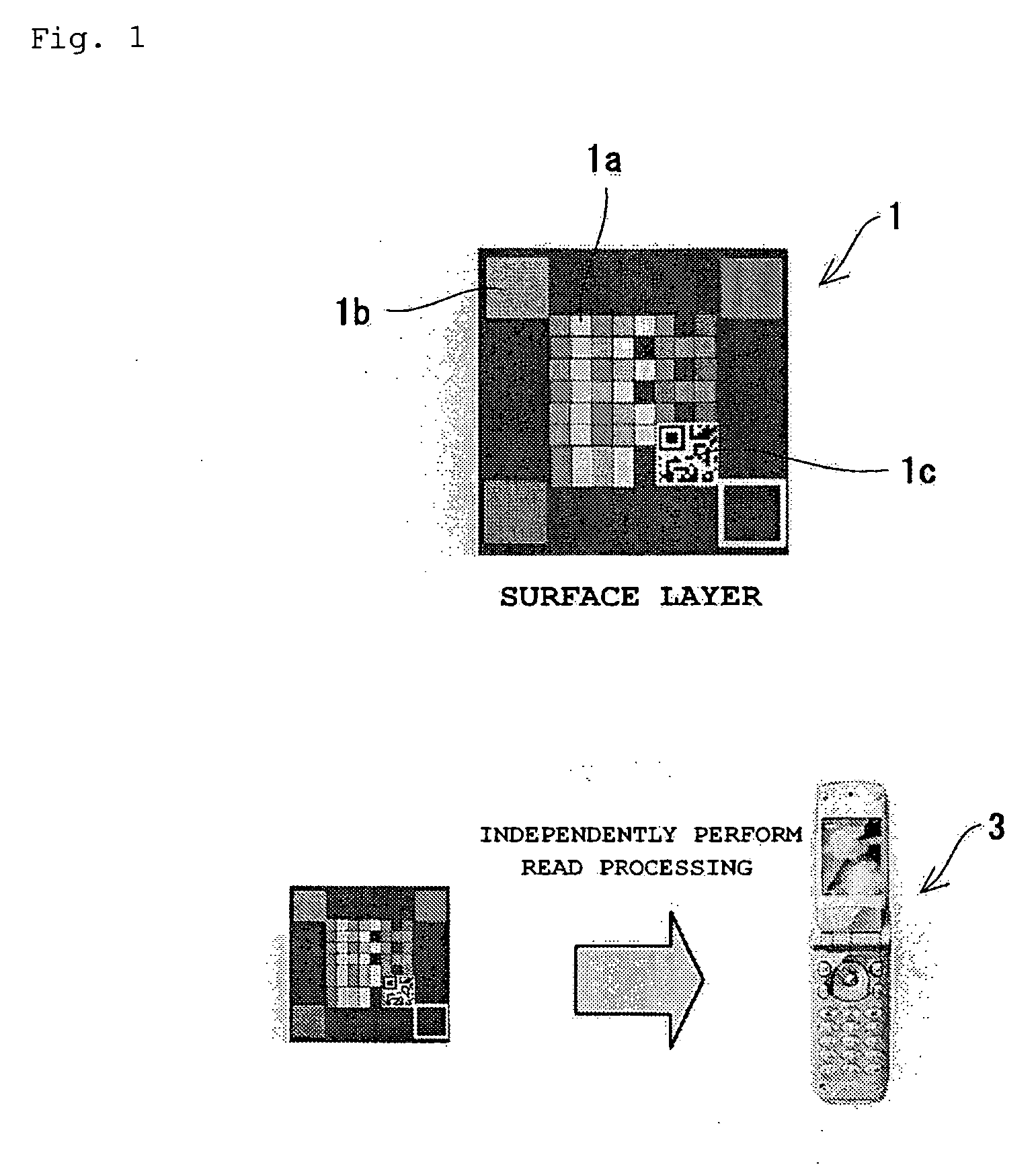

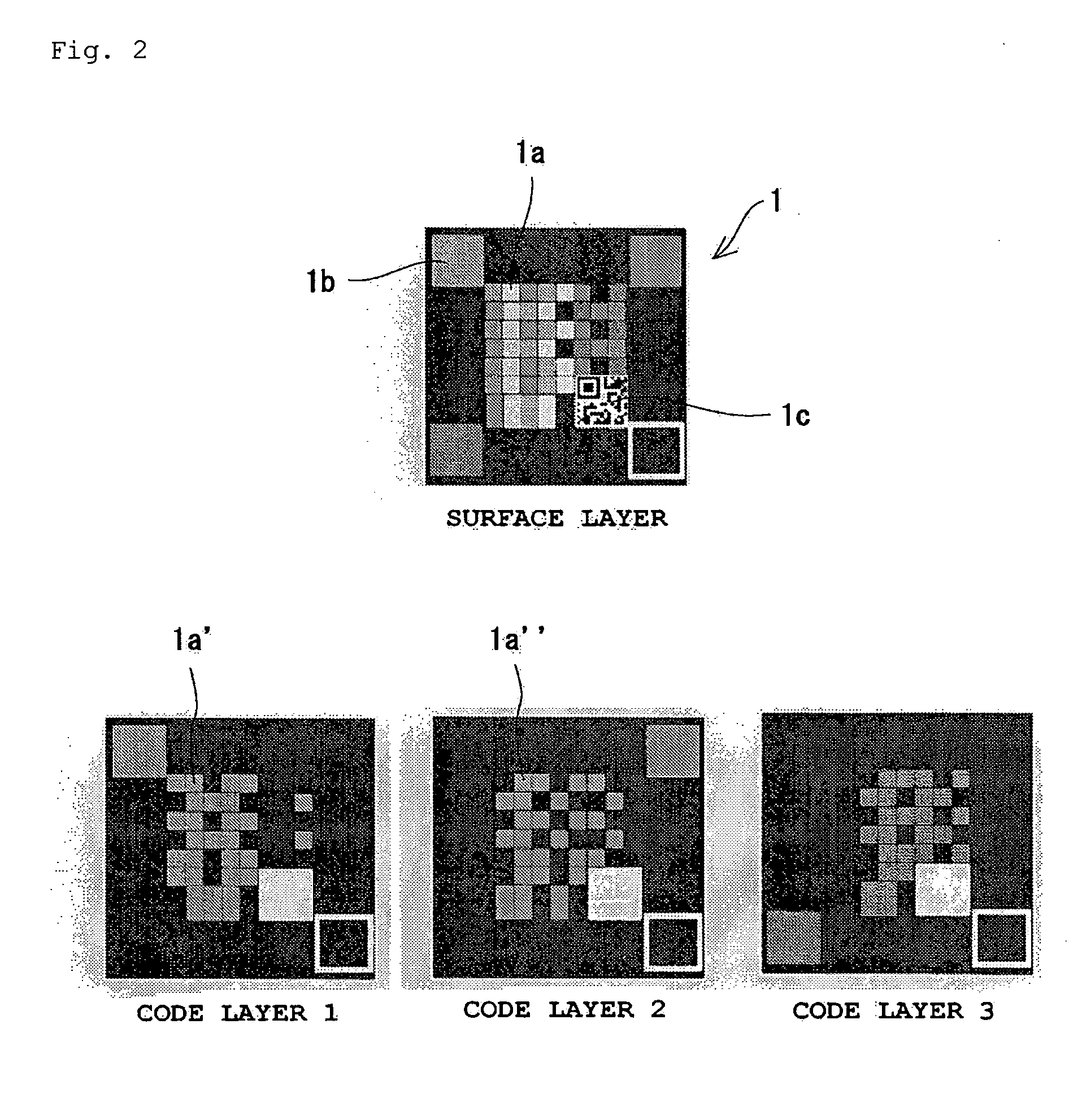

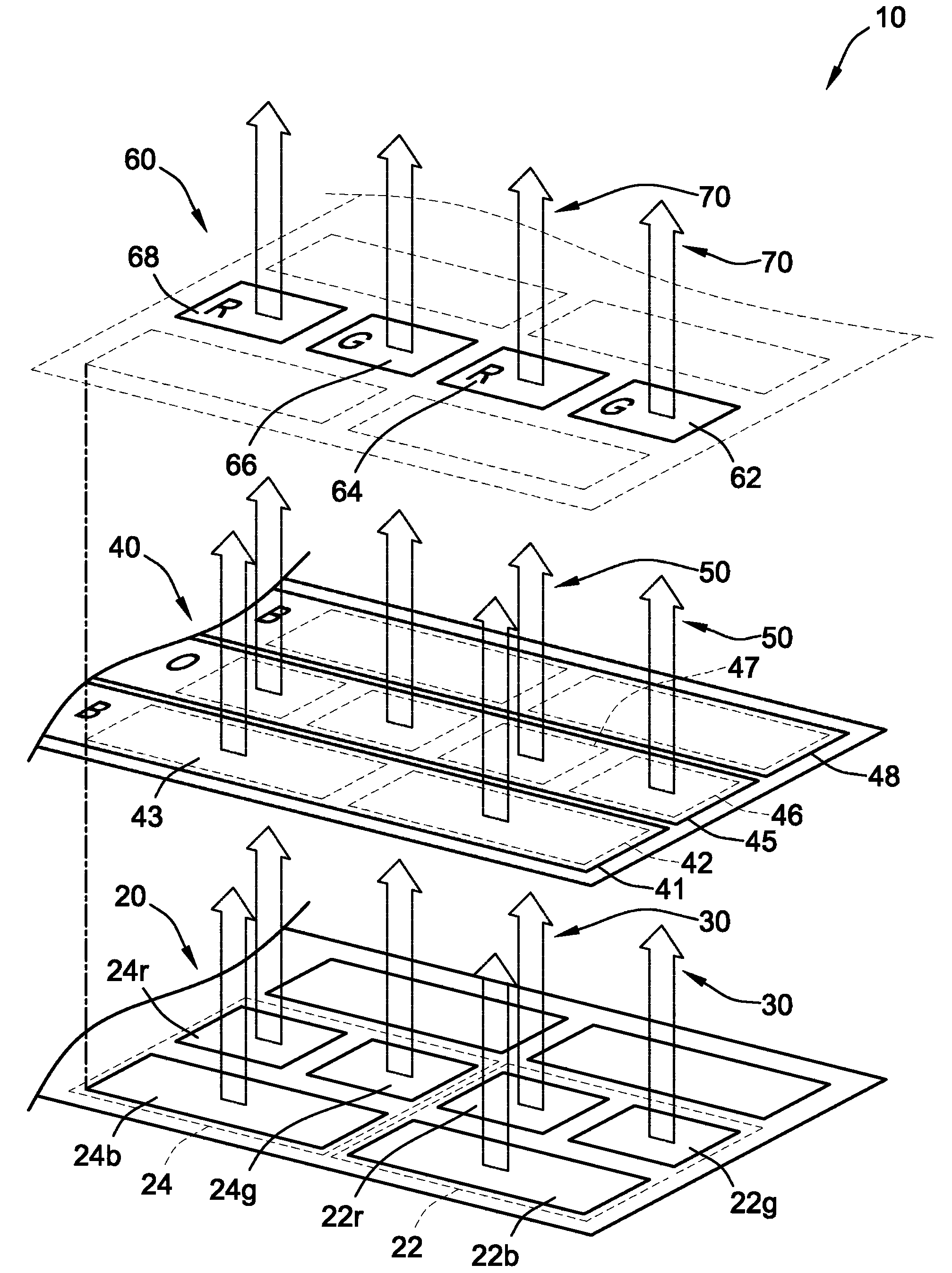

Layered two-dimensional code, creation method thereof, and read method

ActiveUS20090166418A1Increase data capacityIncrease the areaLaminationLamination apparatusData capacityComputer architecture

The present invention provides a layered two-dimensional code which can be considerably improved in the data capacity thereof without increasing the area thereof by integrating a plurality of two-dimensional codes by a predetermined correlation and expressing it as one two-dimensional code, a method of creating the layered two-dimensional code, and a method of reading the layered two-dimensional code. The layered two-dimensional code is formed as a surface layer by layering a plurality of code layers (for example, code layers 1, 2, and 3) each having information cells (1a′, 1a″, and the like) arranged in a two-dimensional matrix and by integrating the plurality of code layers. An index information code 1c essentially including the information of an RGB value of each code layer is included at one part of the surface layer. When the information cells (1a′ and 1a″) of the code layers 1 and 2 are superposed one upon the other at a position thereof corresponding to the surface-layer information cell 1a, the color of the surface-layer information cell la is obtained by executing an additive color mixture of the color of the code layer 1 and that of the code layer 2.

Owner:PMCODE CO LTD

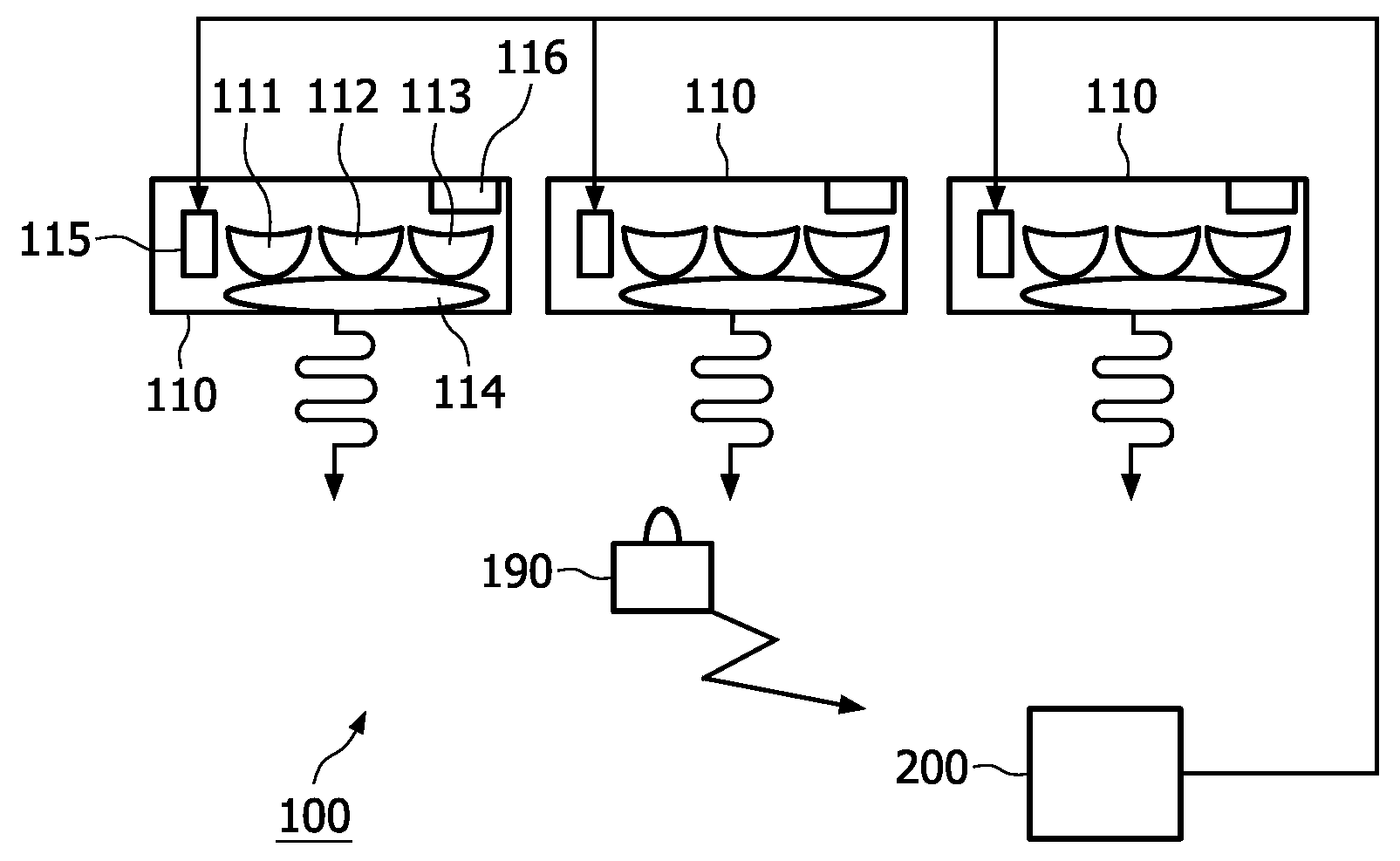

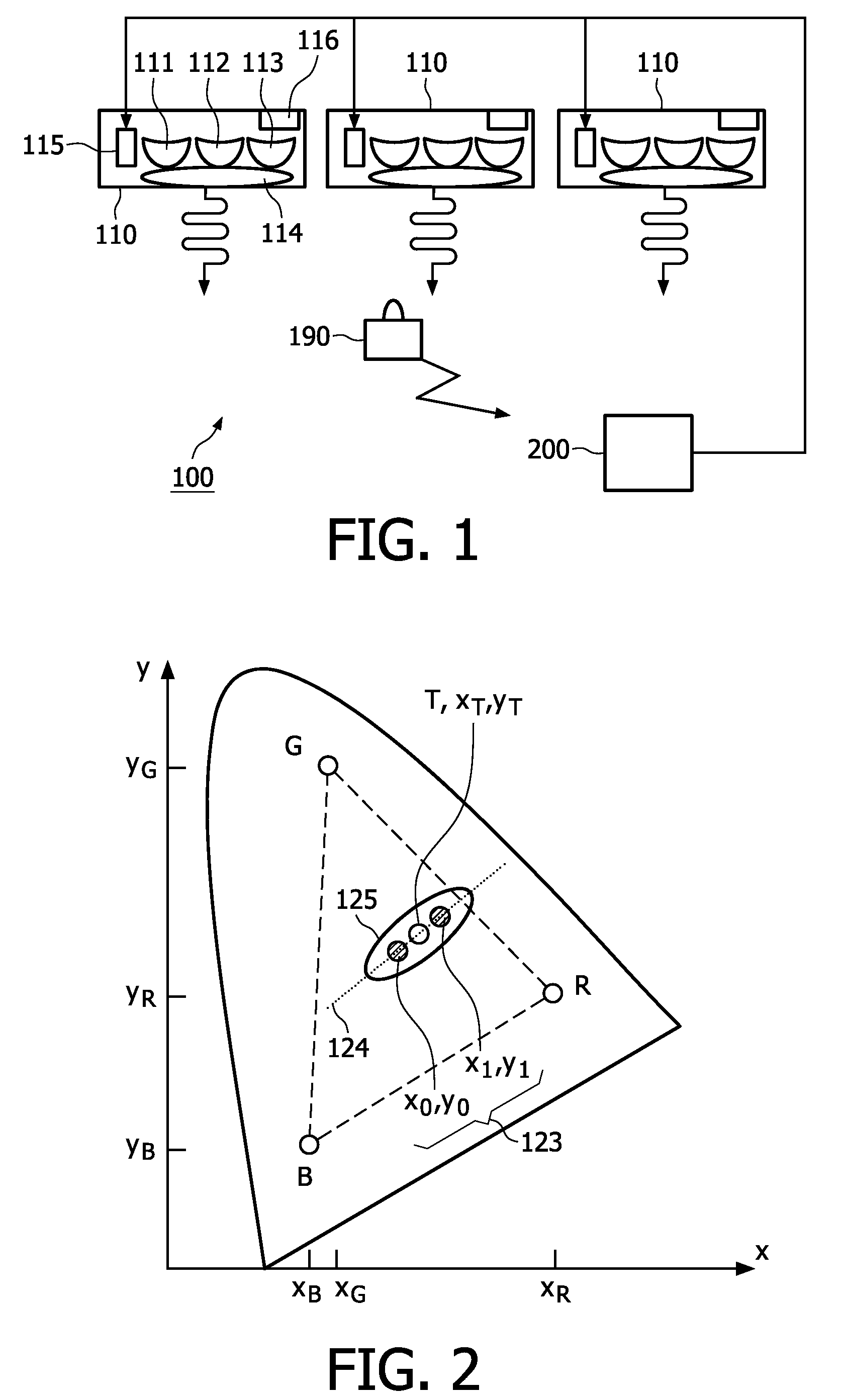

Light module, illumination system and method incorporating data in light emitted

ActiveUS20110044701A1Minimize visibilityMaximize detectabilityElectric light circuit arrangementClose-range type systemsUltimate tensile strengthVisual perception

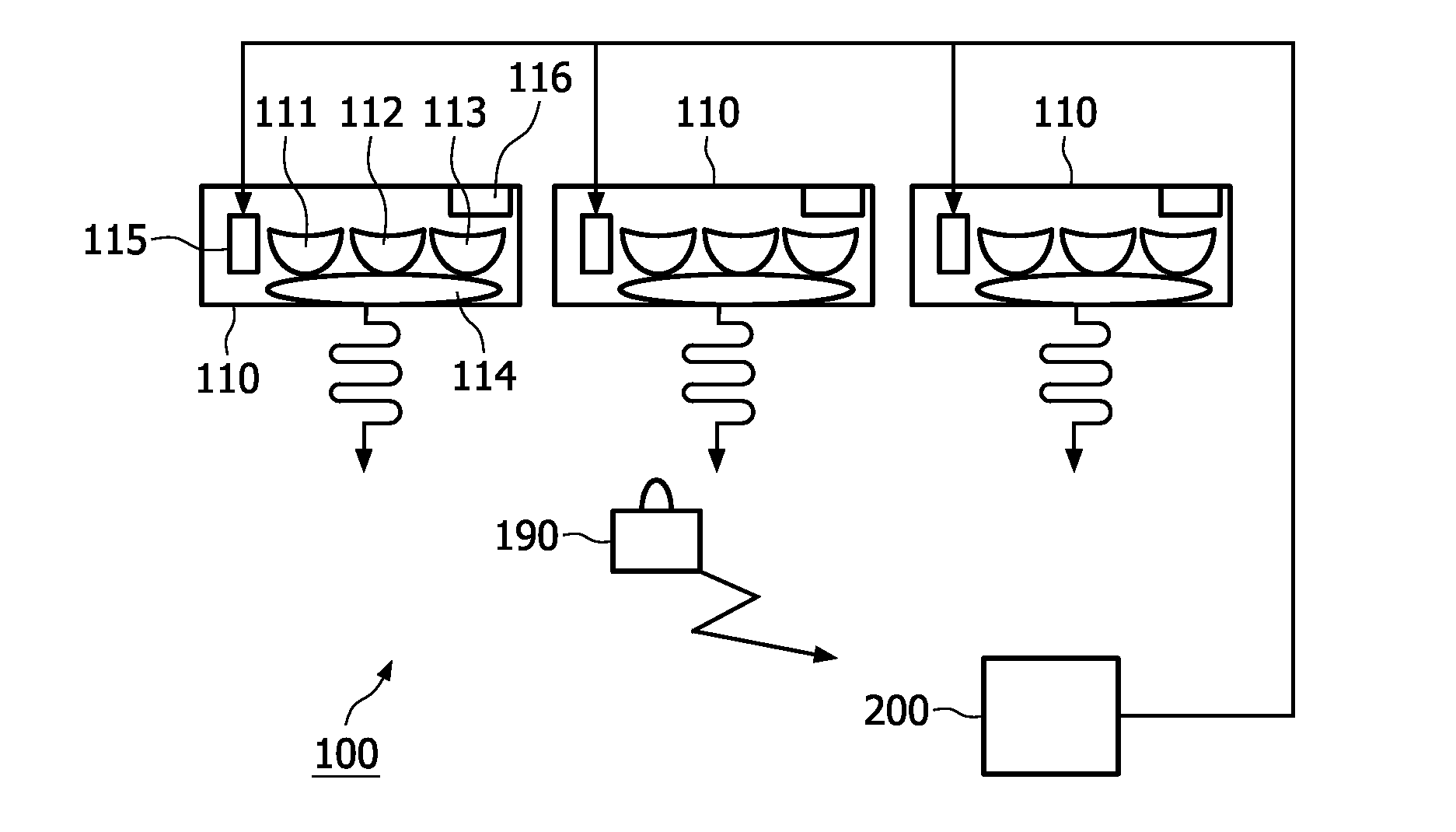

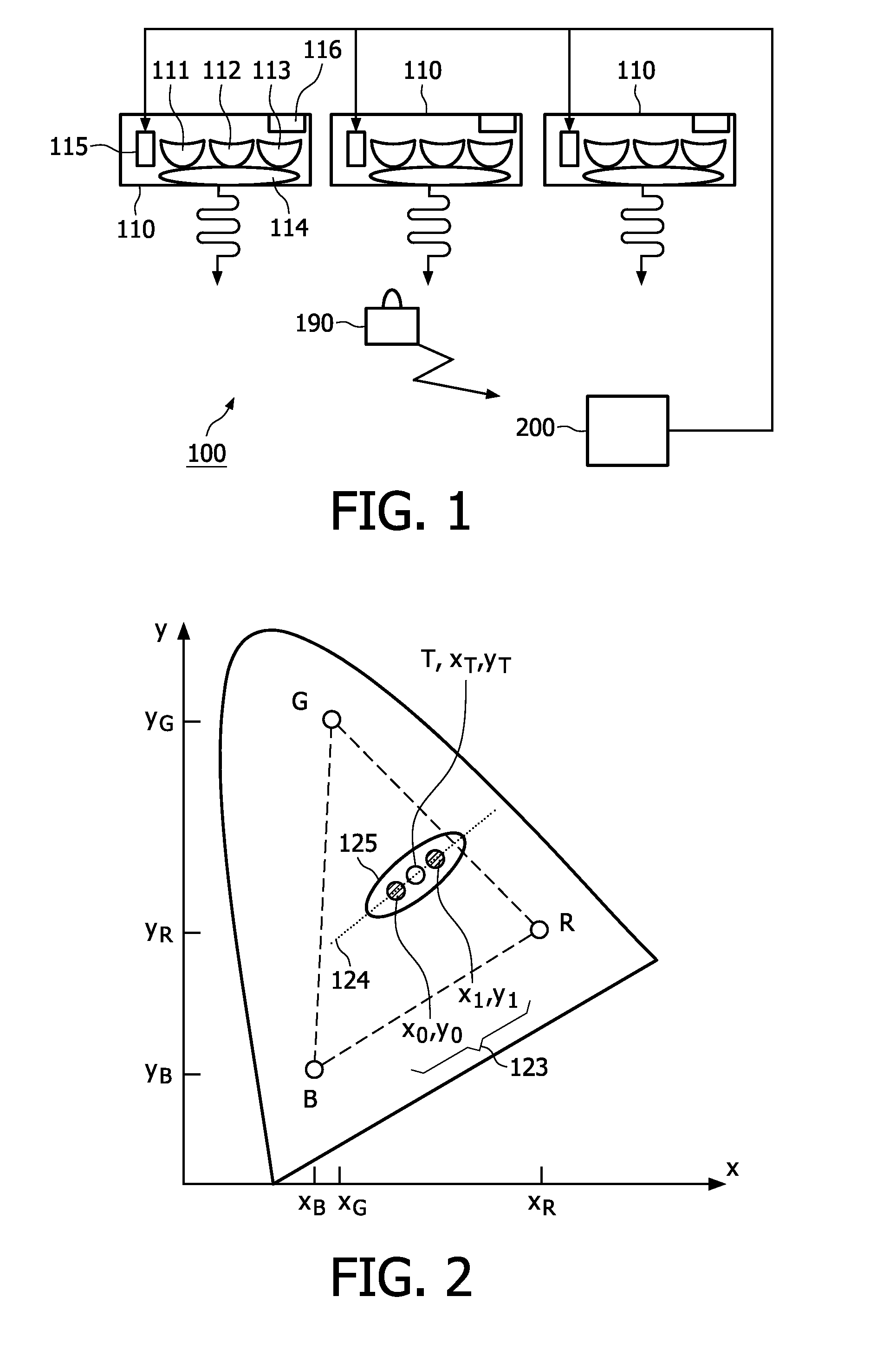

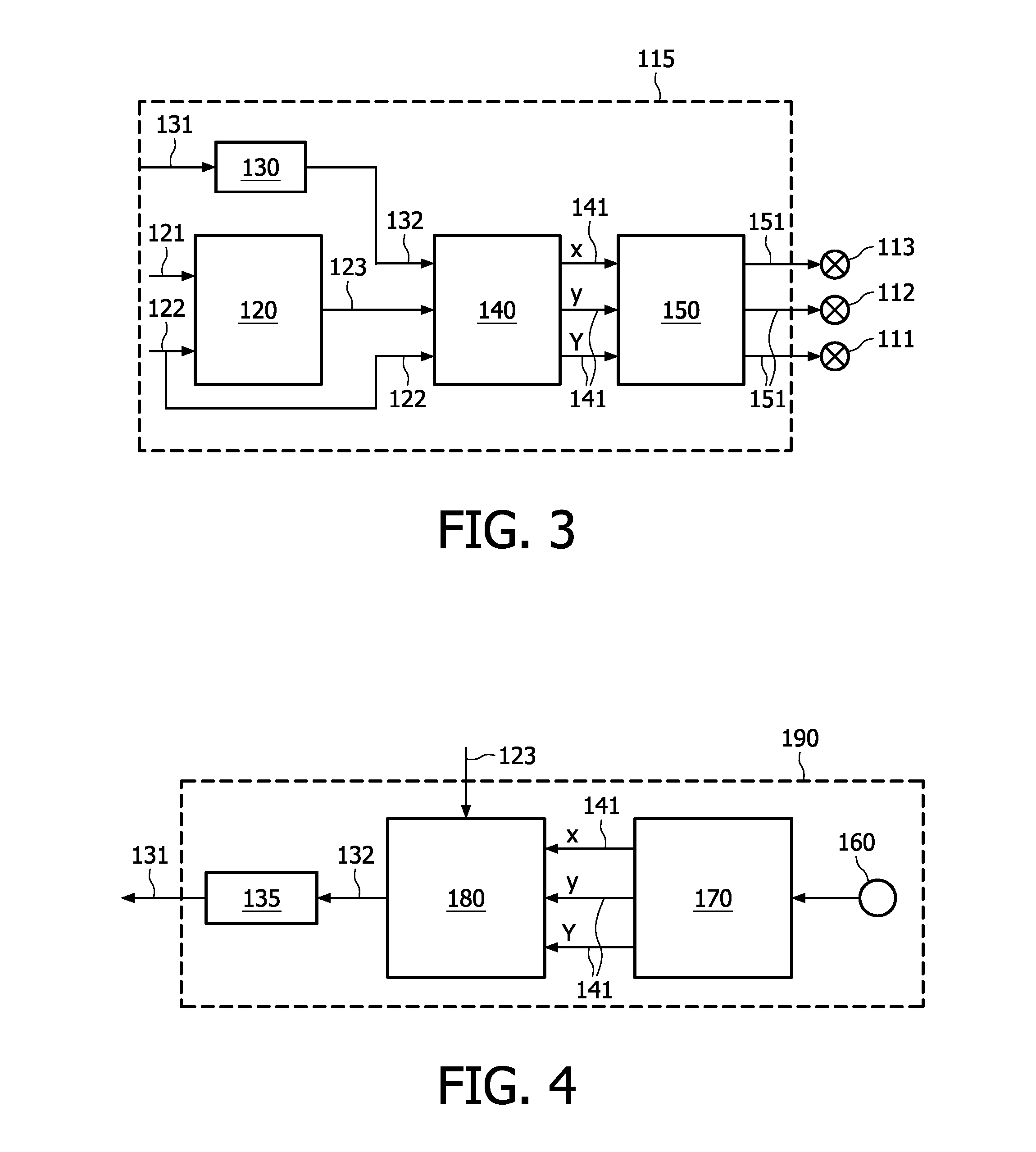

Proposed is a light module (110) comprising at least two primary light sources (111,112,113) capable of emitting a primary color light. This allows the light module to emit light having intensity (Y) and color coordinates (x,y) through additive color mixing of the constituent primary colors. The light module further comprises an modulator (115) capable of modulating the primary light sources enabling embedment of data in the light emitted. The modulator (115) is arranged to modulate the color coordinates of the light emitted for embedding the data. This is especially advantageous as the sensitivity of the human eye to changes in color is lower than to changes in intensity. The invention thus advantageously allows embedding the data into the light emitted from the light modules (110) of an illumination system (100) without reducing the performance of its primary function as an aid to human vision.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Sigma Delta Current Source and LED Driver

A circuit arrangement includes a first light emitting diode and a second light emitting diode emitting light of different colors arranged adjacent to each other for additive color mixing. A first and second controllable current sources are connected to the first and second light emitting diode, respectively, such that the load currents of the light emitting diodes depend on respective control signals received by the current sources. First and second sigma-delta modulators are connected to the first and second light emitting diodes, respectively, and provide bit-streams as control signals to the current sources. The mean value of each bit-stream corresponds to the value of an input signal of the respective sigma-delta modulator.

Owner:INFINEON TECH AUSTRIA AG

Color unmixing and region of interest detection in tissue samples

InactiveUS7689023B2Acquiring/recognising microscopic objectsImage data processingPattern recognitionMatrix decomposition

In a method and system and machine-readable medium, colors in an image (200) are unmixed (202) using a matrix X=AS, where A is a ns. ×nd matrix of spectral definitions, where ns is the number of spectral components and nd is the number of dyes into which the image is decomposed, and where S is a nd×l matrix of amounts of each dye at every pixel, where l is the number of pixels; the matrix X is constrained for solution by an unsupervised matrix decomposition method having constraints consistent with properties of an additive color model; and nd is determined. A texture is determined to identify areas of interest. Further processing may automatically measure cell dye concentration in the determined regions of interest.

Owner:RABINOVICH ANDREW M

Light module, illumination system and method incorporating data in light emitted

ActiveUS8594510B2Reduce sensitivityImprove performanceElectric light circuit arrangementClose-range type systemsLighting systemHuman eye

Proposed is a light module (110) comprising at least two primary light sources (111,112,113) capable of emitting a primary color light. This allows the light module to emit light having intensity (Y) and color coordinates (x,y) through additive color mixing of the constituent primary colors. The light module further comprises an modulator (115) capable of modulating the primary light sources enabling embedment of data in the light emitted. The modulator (115) is arranged to modulate the color coordinates of the light emitted for embedding the data. This is especially advantageous as the sensitivity of the human eye to changes in color is lower than to changes in intensity. The invention thus advantageously allows embedding the data into the light emitted from the light modules (110) of an illumination system (100) without reducing the performance of its primary function as an aid to human vision.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

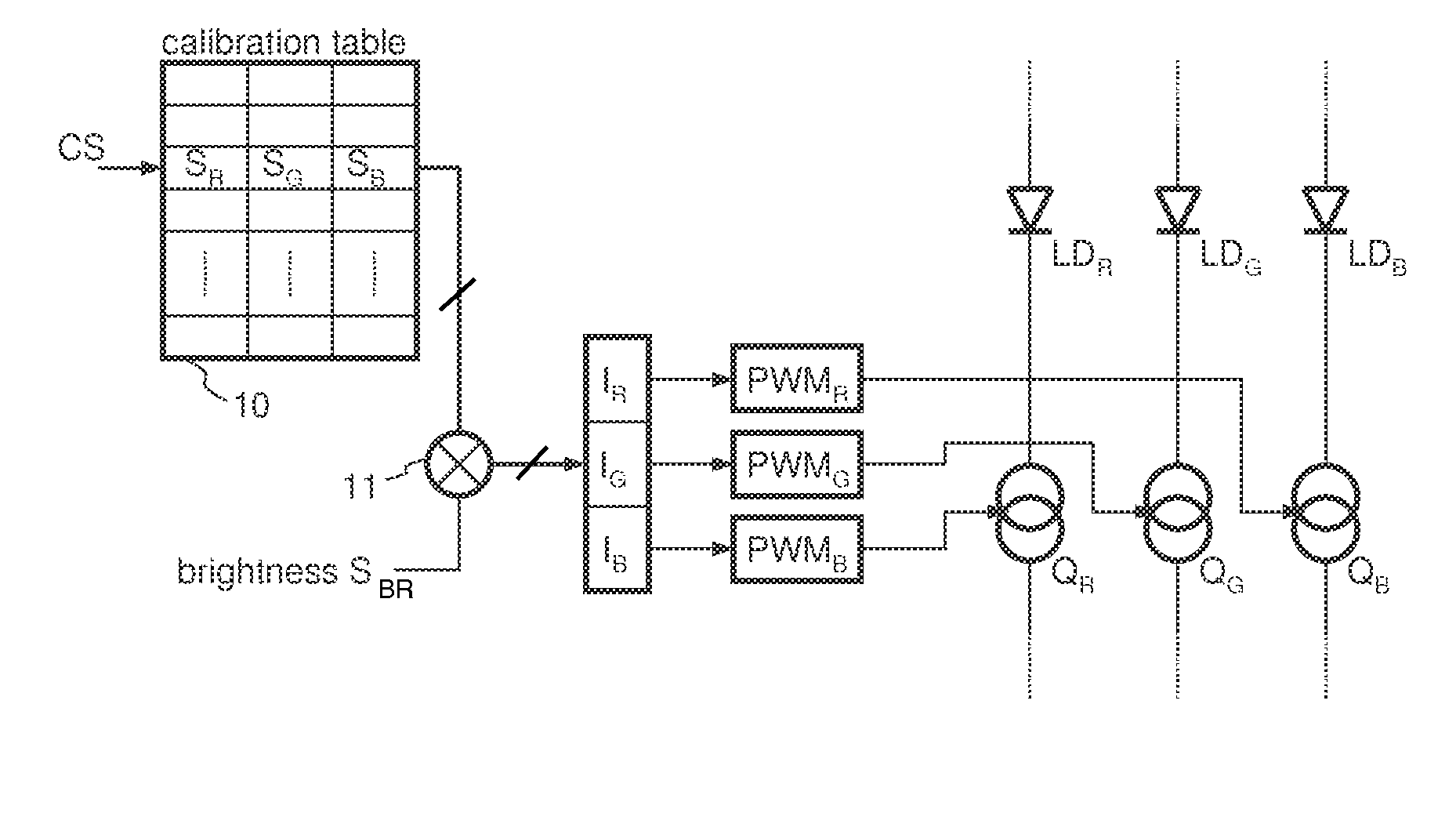

LED Driver With Compensation of Thermally Induced Color Drift

A circuit arrangement includes a number of light emitting diodes emitting light of different colors arranged adjacent to each other for additive color mixing to provide a desired color. A temperature sensing circuit is configured to provide a temperature signal representing temperature(s) of the light emitting diodes. Current sources are configured to provide the light emitting diodes with respective load currents in accordance with corresponding control signals received by the current sources. First and second modulator units are configured to generate the control signals which are modulated such that a time average value of each control signal corresponds to the value of a corresponding input signal of the respective sigma-delta modulator. A calibration circuit is configured to provide the input signals dependent on a color signal defining the desired color and dependent on the temperature signal.

Owner:INFINEON TECH AG

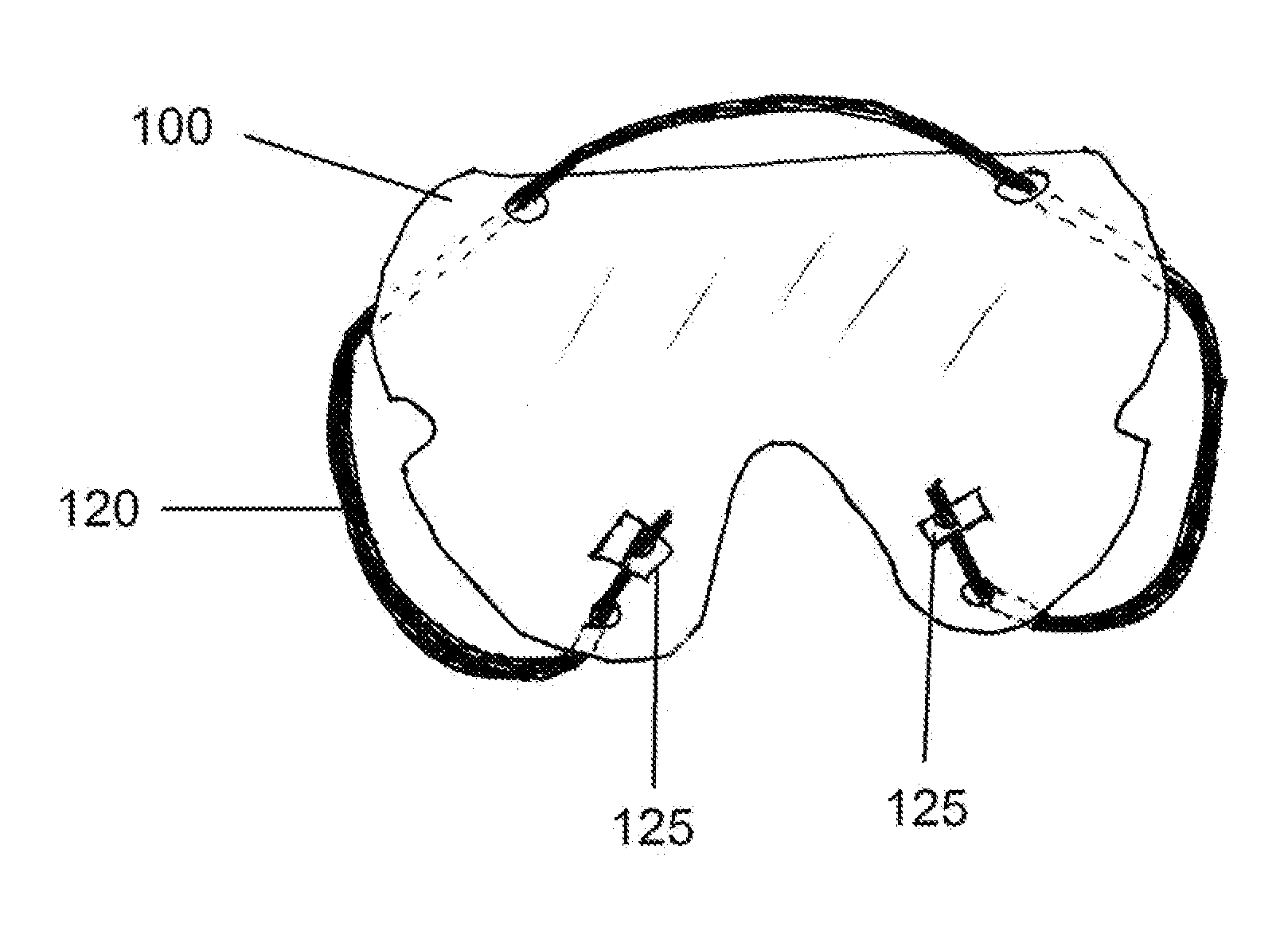

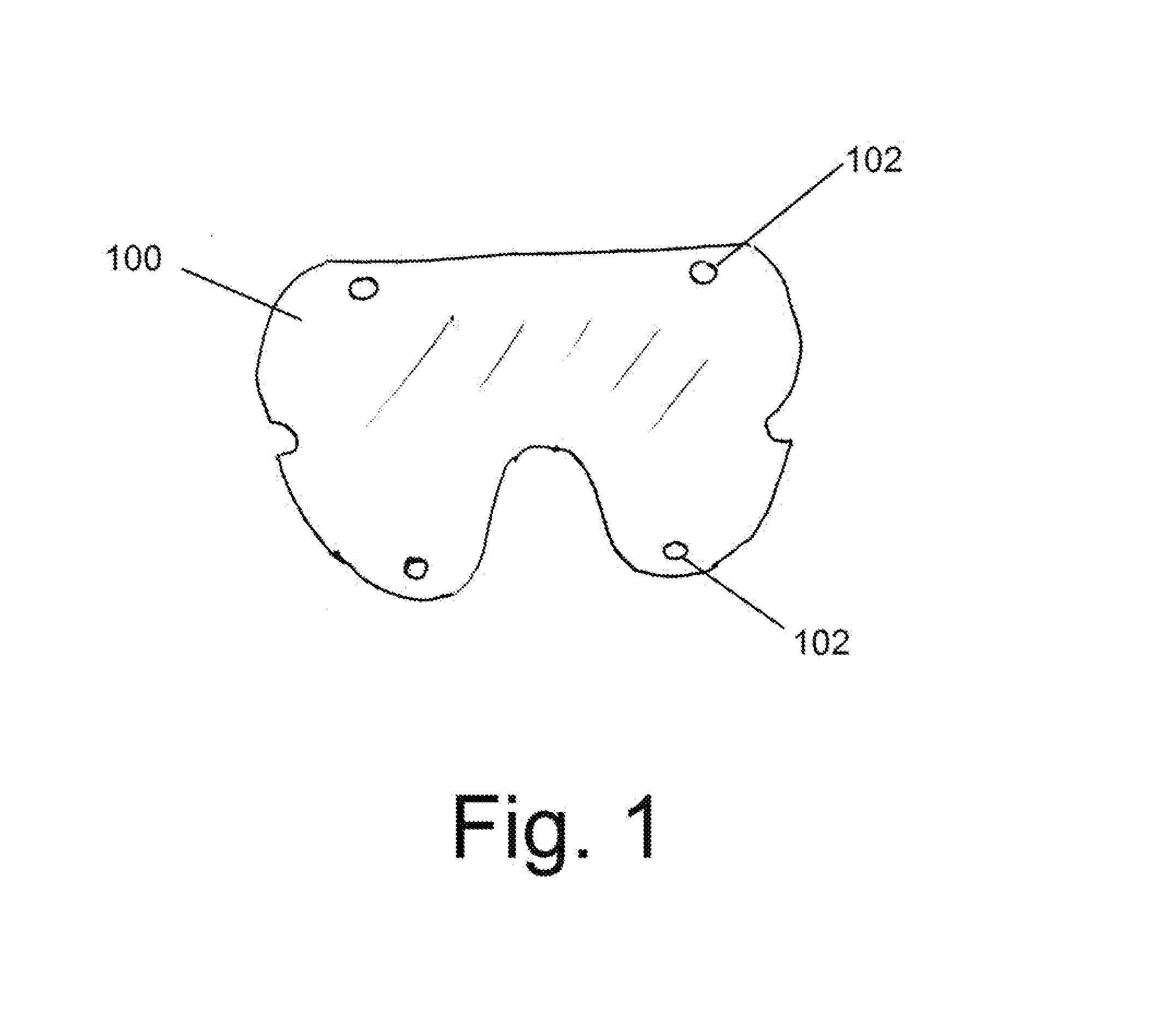

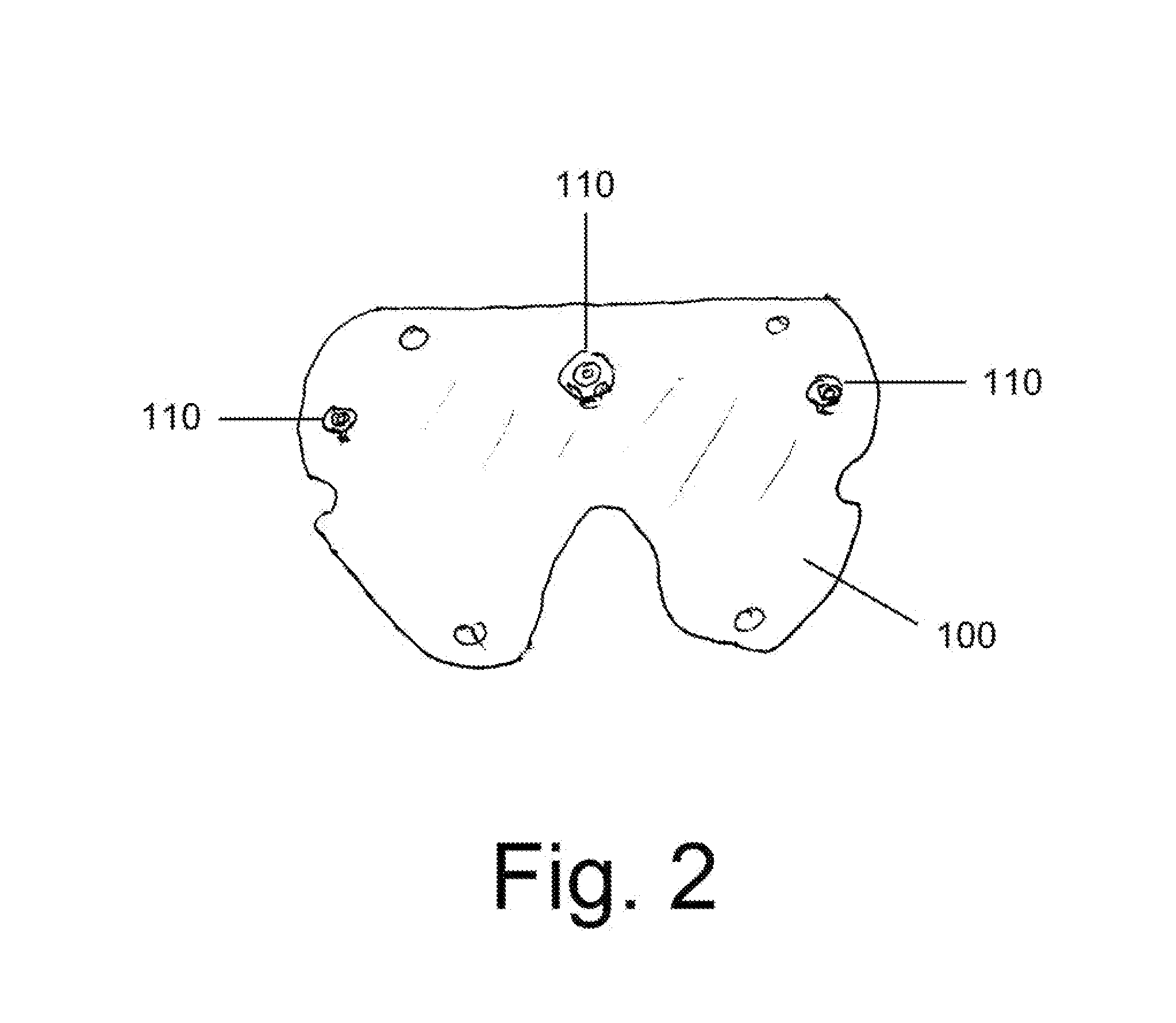

Replaceable Light Filter for Diving Mask and Method for Replacement

InactiveUS20160062149A1Improve viewing effectAuxillary optical partsOptical partsLength waveLight filter

The invention is a device for adjusting underwater viewing. The device comprises a shaped lens consisting of a thin, transparent, tinted material. The shaped lens is an additive color filter configured to add missing wavelengths to light propagating through the shaped lens, the missing wavelengths being within a range of 577 nm to 750 nm. The shaped lens is configured to be removably secured to the visor of a diving mask. The device may further comprise one or more suction cups, one or more clips, or a strap disposed through openings in the lens. The device may further comprise a means for attaching the lens to the visor of a diving mask.

Owner:GERTON JEFF

Illuminating device

InactiveCN102341925APoint-like light sourceElectroluminescent light sourcesColored whiteFluorescence

A lighting apparatus includes a red LED; a green LED; a blue LED; and a white LED made up of a blue light-emitting element and a yellow phosphor, wherein the red LED, the green LED, the blue LED, and the white LED generate 26 to 38%, 35 to 50%, 0 to 2%, and 12 to 33% of light, respectively, and white light obtained by additive color mixing of light from the red, green, blue, and white LEDs has a correlated color temperature of 2800 K or more to less than 3500 K, a deviation of 0.02 or below in absolute value, and a color gamut area ratio of 120% or more to 140% or less. Consequently, the lighting apparatus can radiate an illuminating light which makes colors look vivid.

Owner:TOSHIBA LIGHTING & TECH CORP +1

Environment-friendly coating method for implementing blackening bronze wire drawing element on metal piece

ActiveCN102218961AAnti-corrosionWear-resistantNatural patternsDecorative surface effectsTemperature resistanceAdditive color

The invention provides an environment-friendly coating method for implementing a blackening bronze wire drawing element on a metal piece, relating to a surface processing method of a metal piece. The method comprises the steps of dry cleaning and activating metal blanks; performing metallic black dyeing on the activated metal blanks; carrying out wire drawing on the black dyed metal blanks to draw out required patterns; dry cleaning and activating the wire-drawn metal blanks; painting additive color finishing varnish on the metal blanks that have wire-drawing patterns, and finishing implementing environment-friendly coating on the blackening bronze wire drawing element on the metal piece. On the basis of tests, the coating metal product has the advantages of corrosion resistance, wear resistance, weathering resistance, temperature resistance, colorful performance and the like, and is comparative to the quality of the traditional water (wet) plating metal product. Meanwhile, the methodhas the advantages of simple procedure, less consumption of metals used in the process and less waste gas and waste water, therefore being an economic and environment-friendly novel coating technology.

Owner:NINGBO RUNNER INDAL CORP

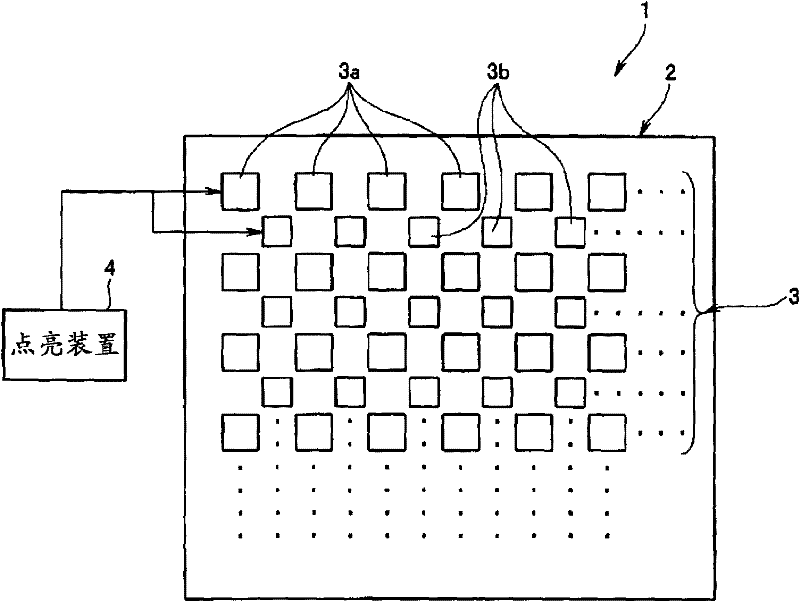

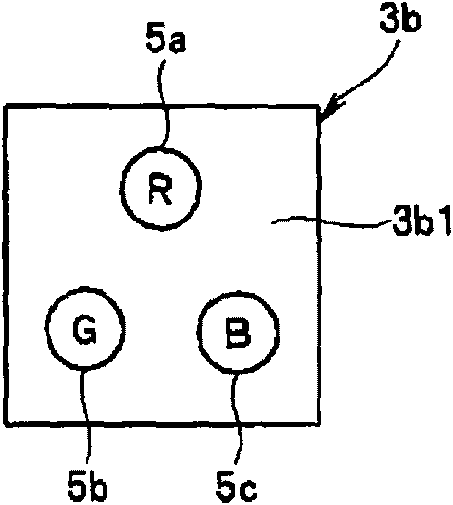

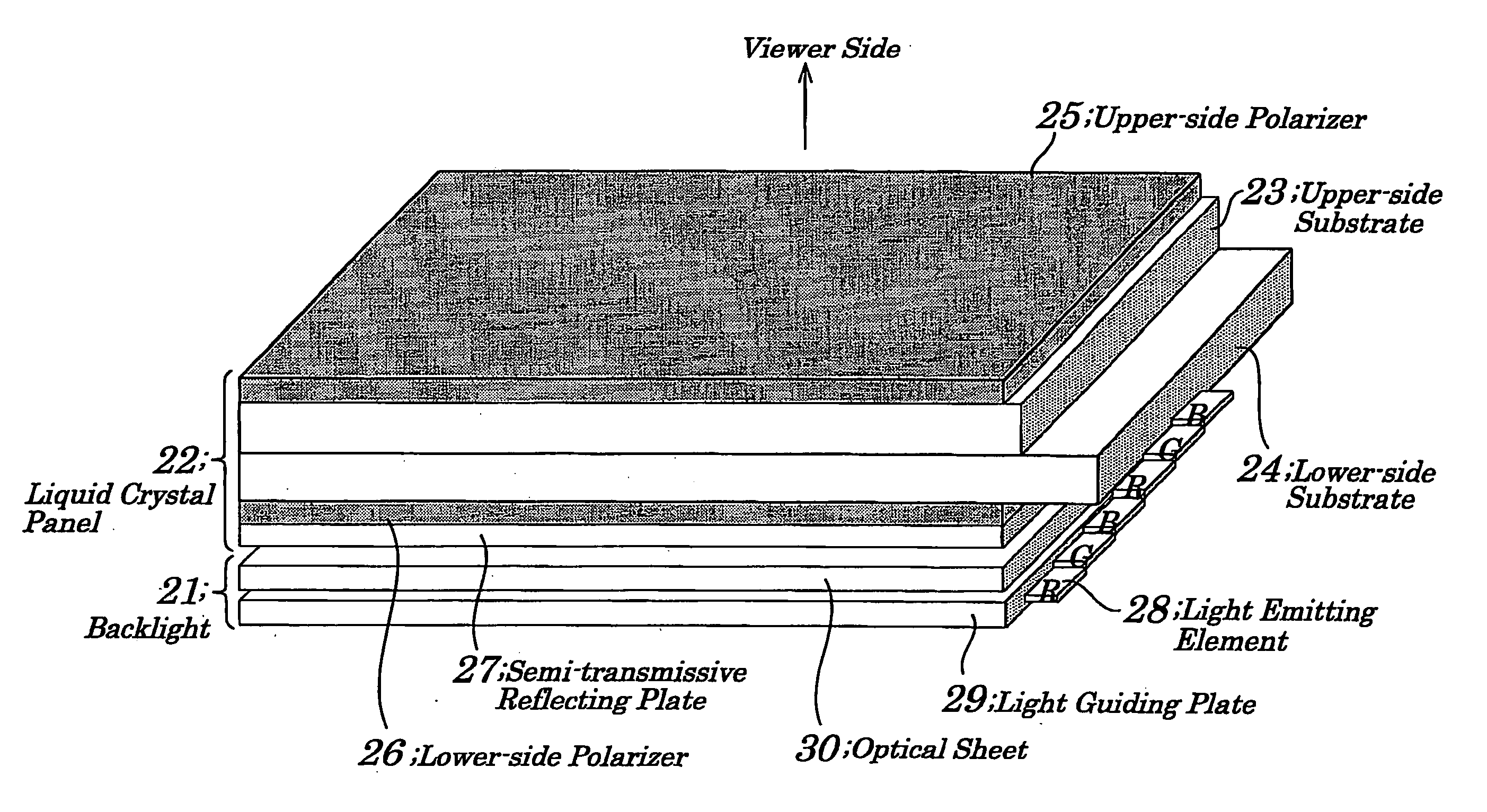

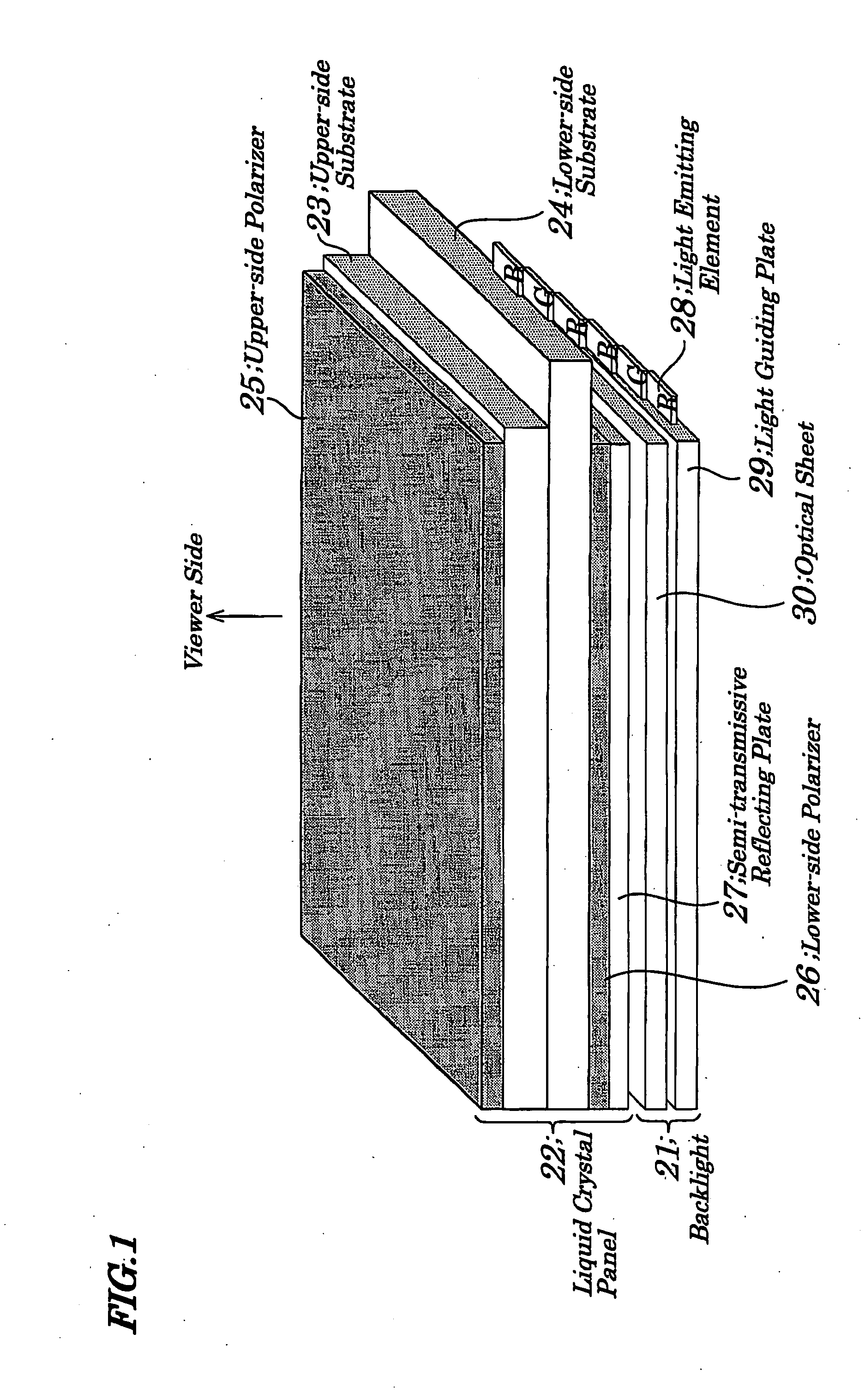

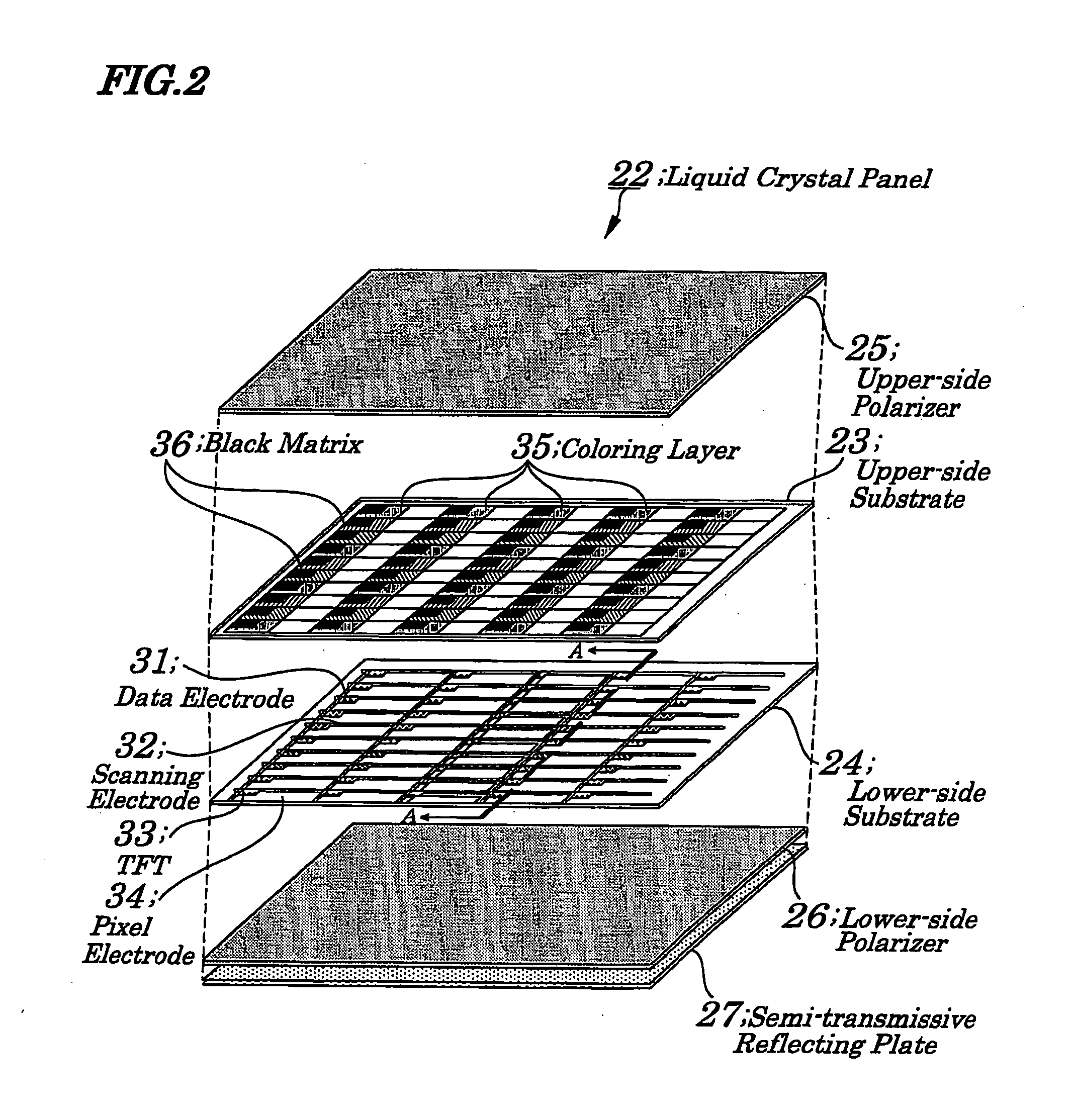

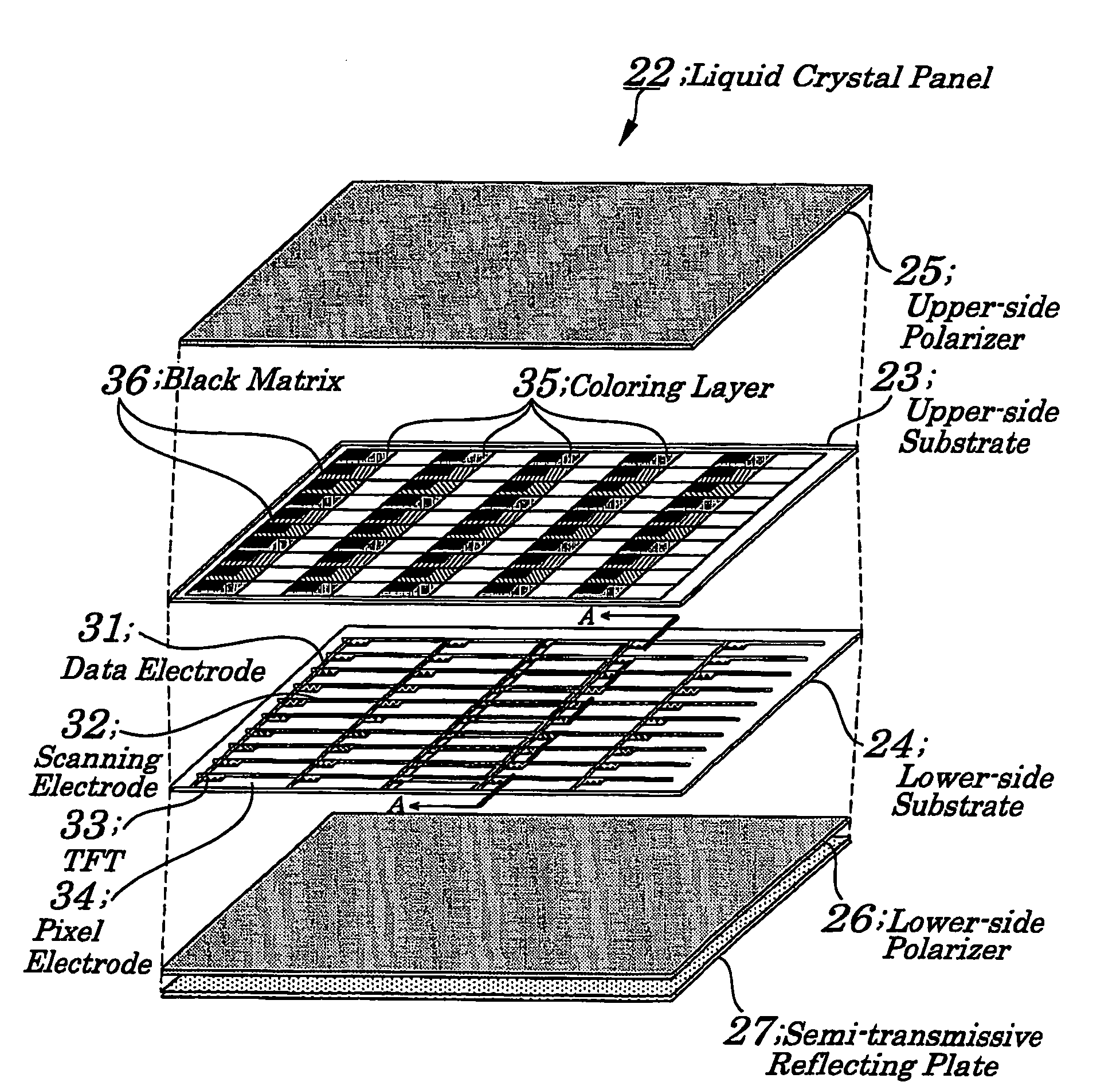

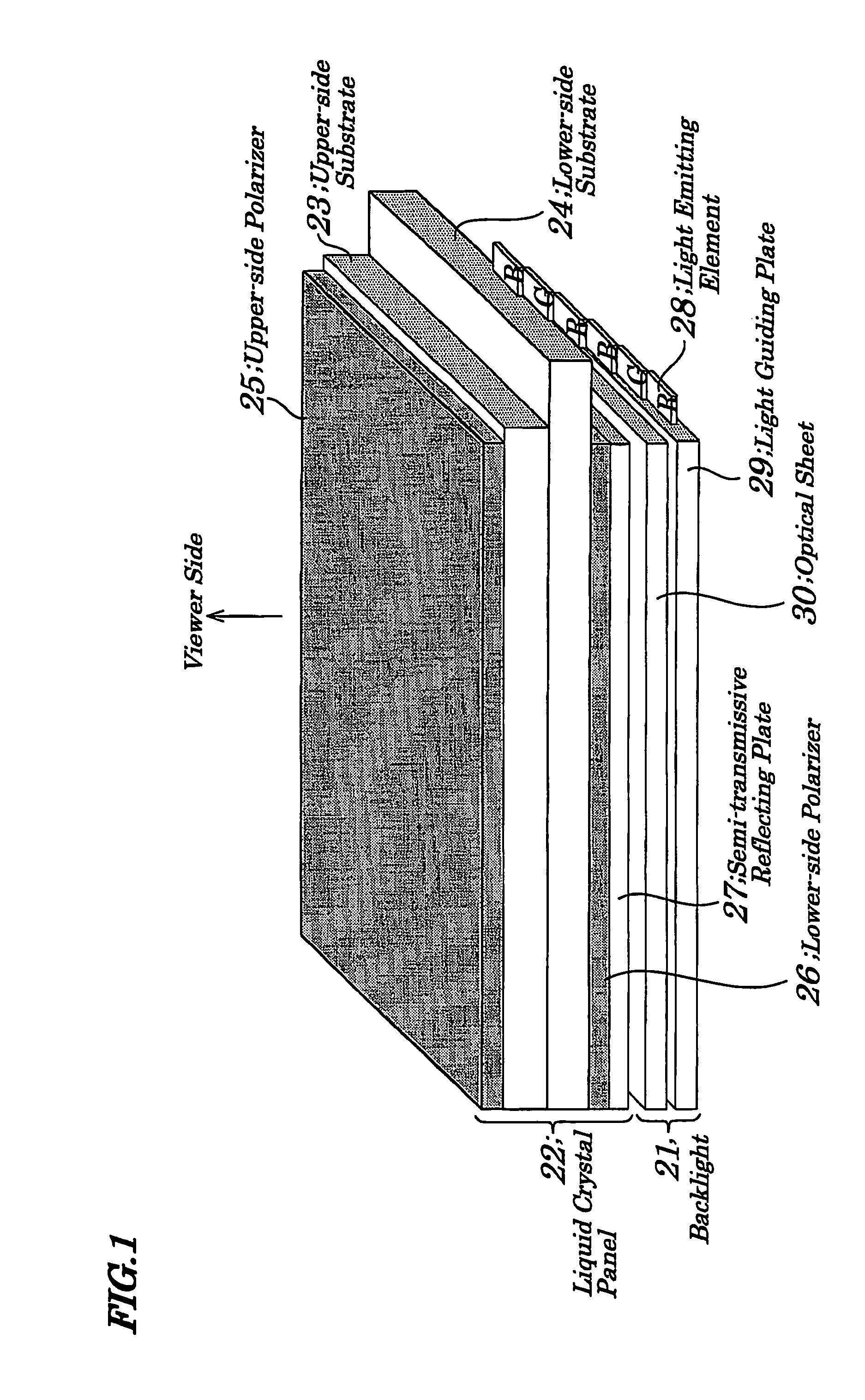

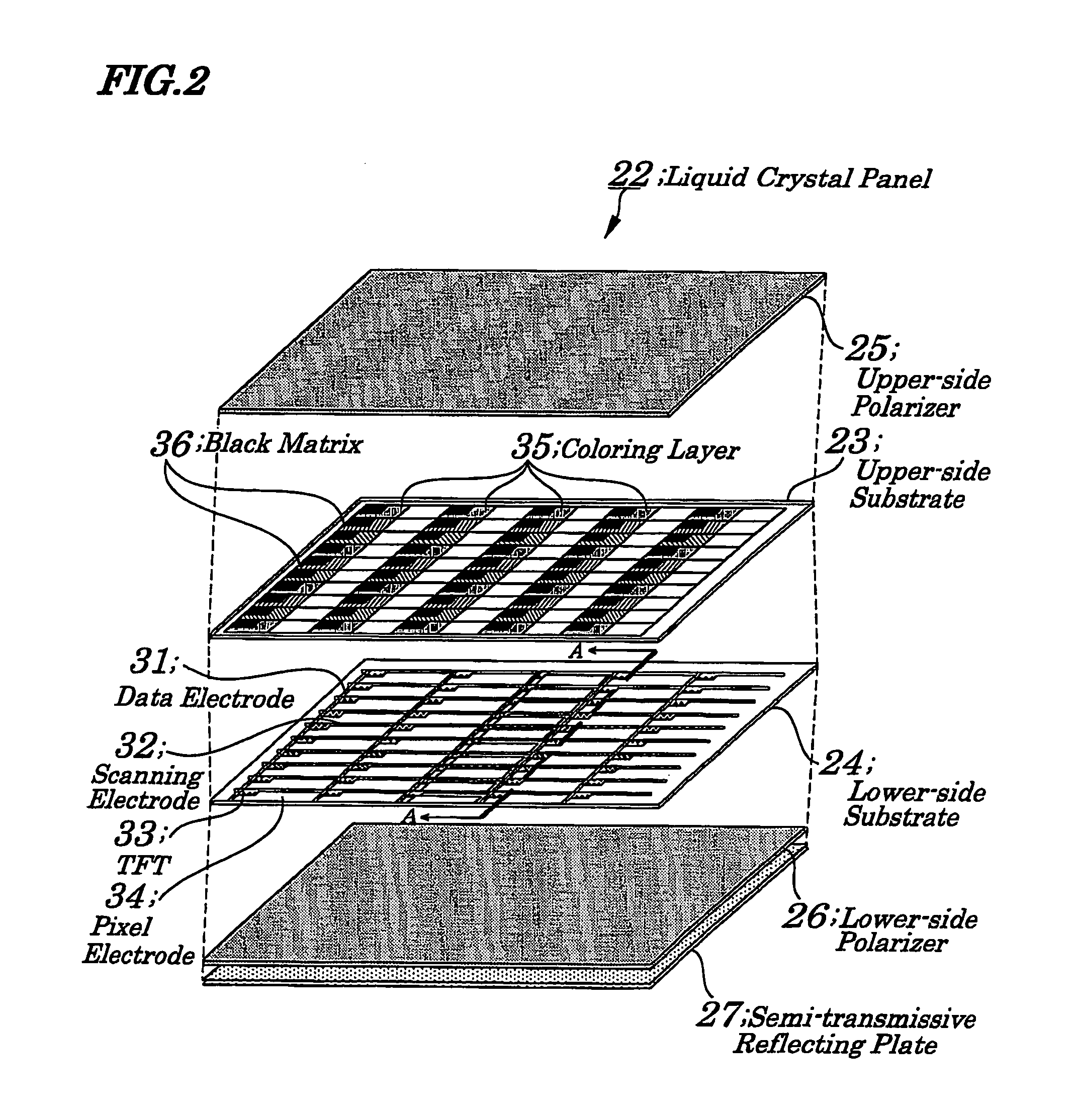

Liquid crystal display device and driving method used in same

InactiveUS20060187183A1Broad color reproducibilityDisplay brightCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayData signal

A liquid crystal display device is provided which is capable of reducing a number of components and fabricating processes and of realizing a bright display even at time of a transmissive display and of simplifying configurations of a data signal. Transistors are controlled ON / OFF based on selecting signals input to selecting signal lines and a one kind of data signal input from data lines distributed and supplied, as a sub-pixel data, to a data electrode selected based on selecting signals corresponding to a successive additive color mixture or juxtapositional additive color mixture process. At time of the transmissive display operation, data electrodes corresponding to three sub-pixels making up each pixel are simultaneously selected and, at time of the reflective display operation, data electrodes selected based on selecting signal corresponding to the juxtapositional additive color mixture.

Owner:NEC LCD TECH CORP

White LED light source device and LED backlight using the same

InactiveUS7810947B2Improve efficiencyFavorable color mixturePoint-like light sourceGas discharge lamp usageLuminous intensityPhosphor

A white LED light source device and an LED backlight using the white LED light source can produce, among other features, white light with sufficient luminous intensity, uniform color tone, and high luminous utilization efficiency. A light path for producing white light with favorable color mixture can be shortened. The white LED light source device can be configured to include a bluish green LED lamp which can emit bluish green light by the combination of a blue LED device and a green phosphor material and a purple LED lamp which can emit purple light by the combination of a blue LED device and a red phosphor material. The bluish green light from the bluish green LED lamp and the purple light from the purple LED lamp are subjected to additive color mixture to produce white light with a spectrum containing three primary color wavelength components.

Owner:STANLEY ELECTRIC CO LTD

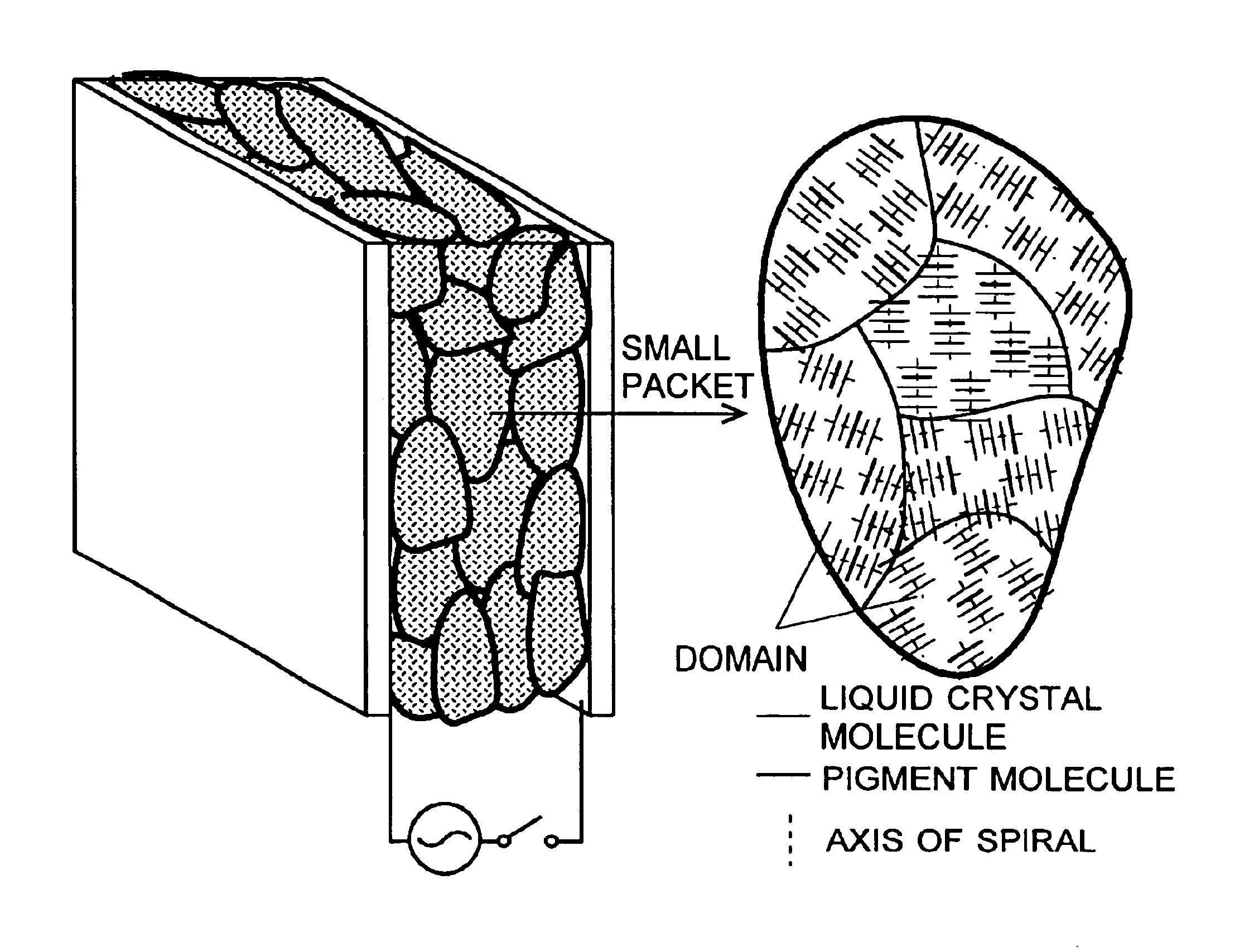

Liquid crystal display device and its production method

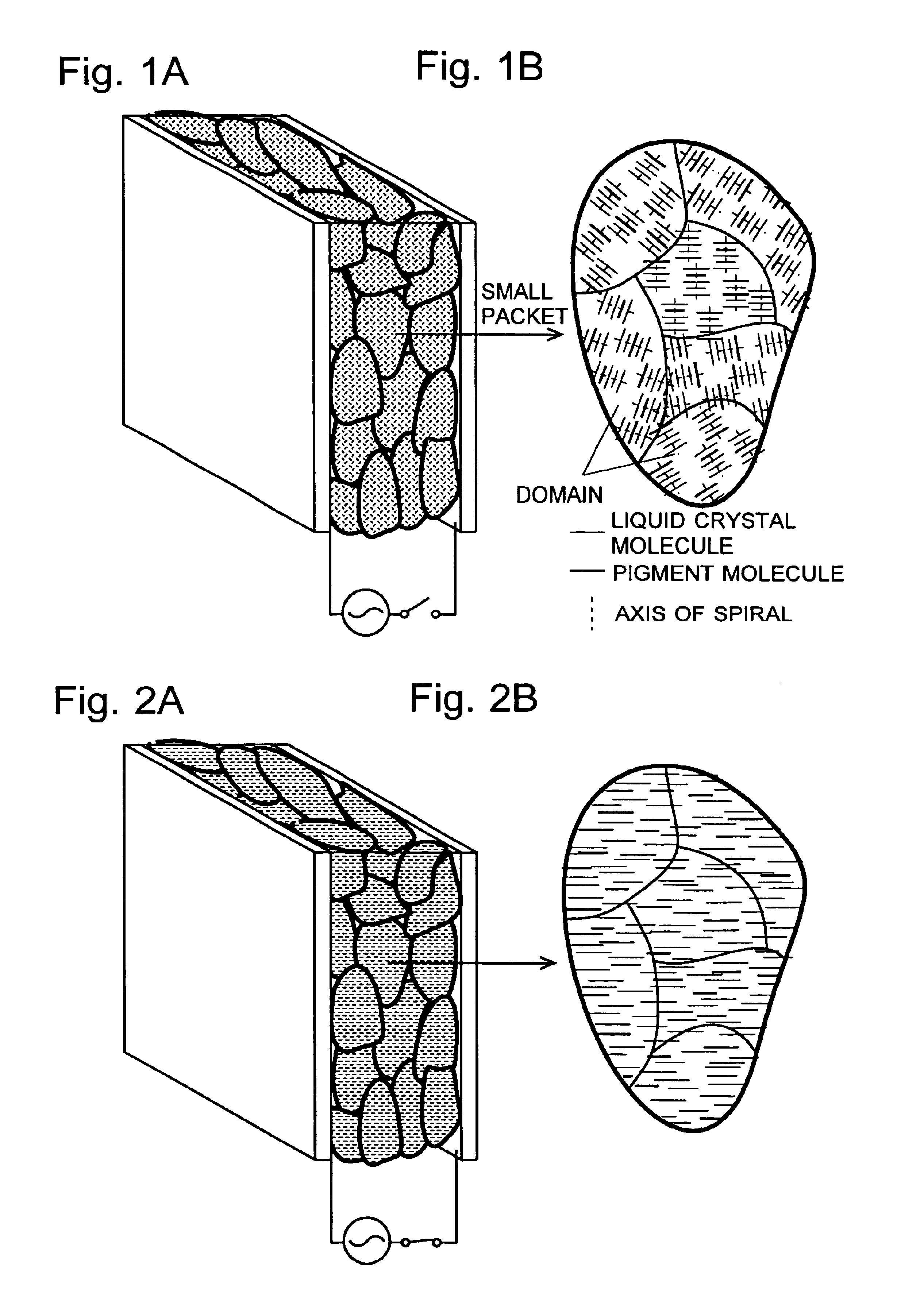

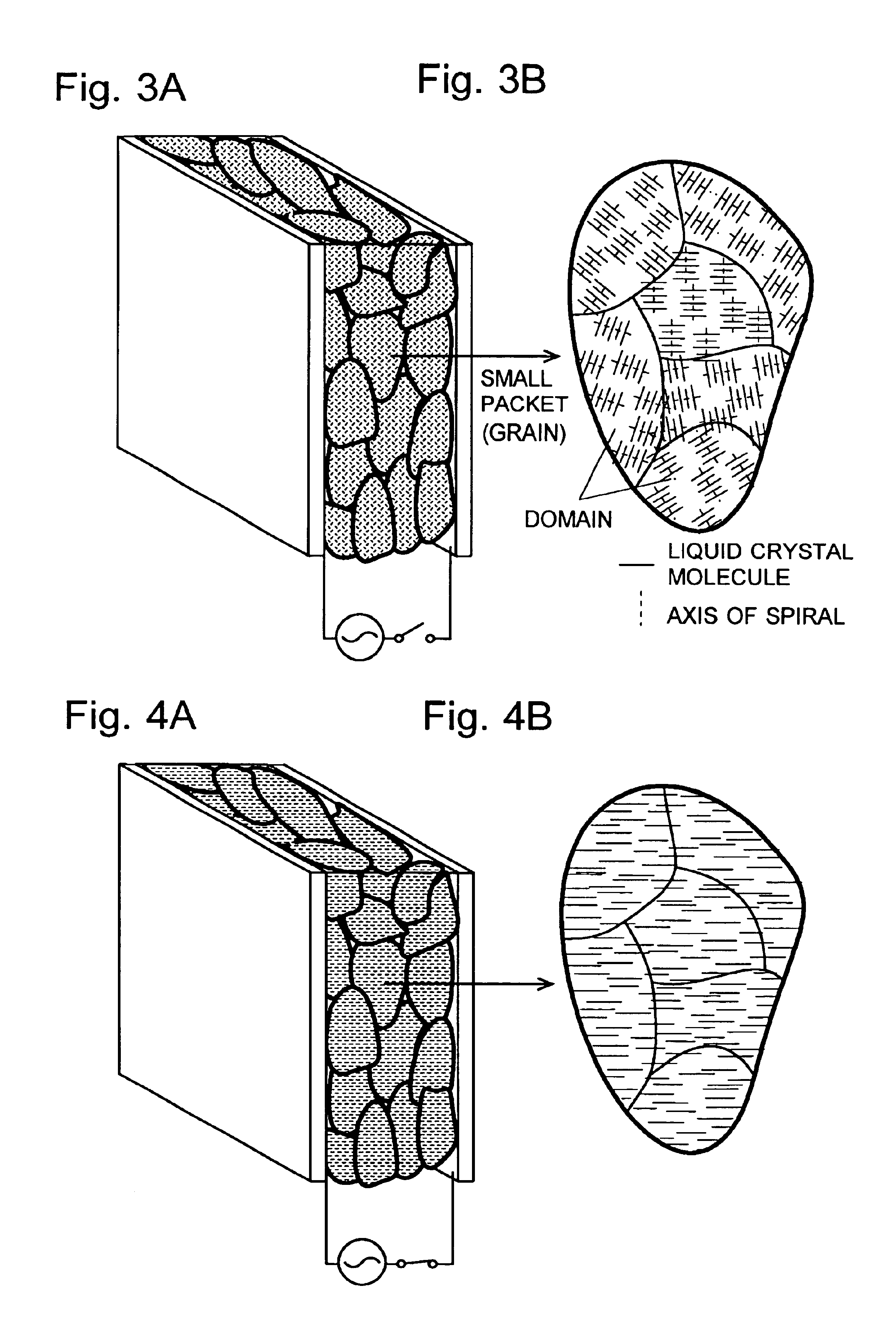

InactiveUS6924873B2Quick responseLiquid crystal compositionsNon-linear opticsPolymerCholesteric liquid crystal

The objective of the present invention is to provide a liquid crystal display device for displaying colors by transmission and reflection modes and a method for producing such devices, whereby the additive color mixing can be used, the structure is simplified, the driving-voltage is lower, the contrast is higher, the response speed is higher, and the screen can be larger. This objective can be achieved by a method including the following steps: mixing 0.001 to 20 wt % of dichromatic melanotic pigment into chiral nematic liquid crystal mixed with chiral dopant; preparing a mixture of the liquid crystal and prepolymer to be polymerized into transparent polymeric solid; inserting the mixture into the space between two conductive substrates, wherein at least one of which is transparent; and irradiating ultra-violet light or neighboring short-wavelength light onto the mixture. This process creates an accumulation of small packets composed of the liquid crystal packed with a thin film of the transparent polymeric solid within a light-controlling layer between the two conductive substrates. When no voltage is applied, the pigment molecules absorb light because they are distributed within the space with their longitudinal axis randomly directed. When a voltage is applied, elongated liquid crystal molecules are oriented perpendicular to the substrates, and the pigment molecules are also oriented in a similar manner. In this state, the black color of the pigment molecules does not appear, so that light is allowed to pass therethrough.

Owner:ASADA TADAHIRO

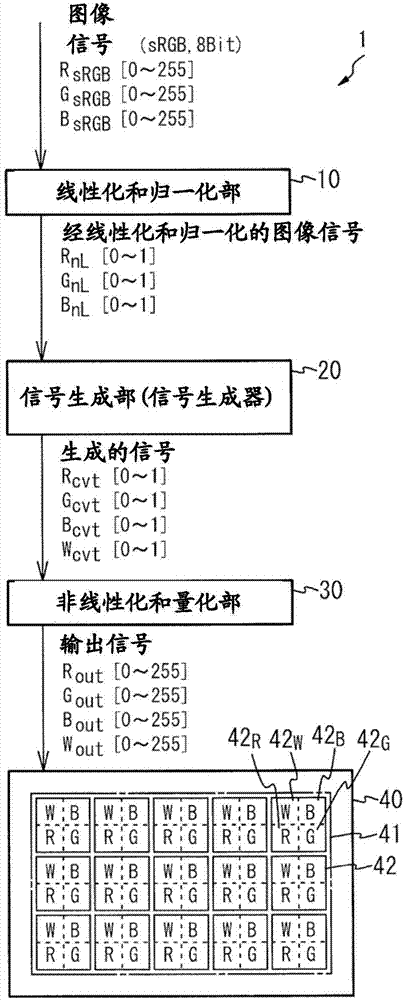

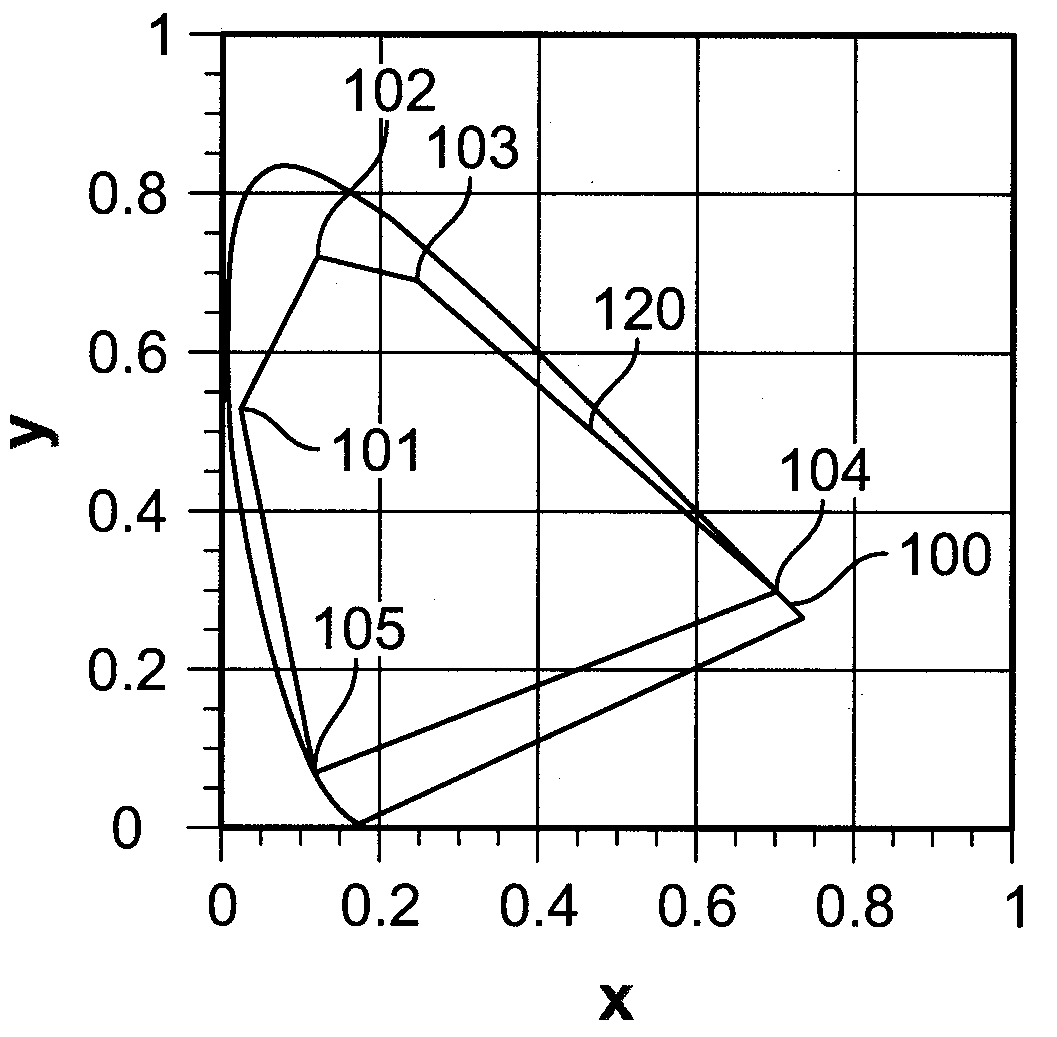

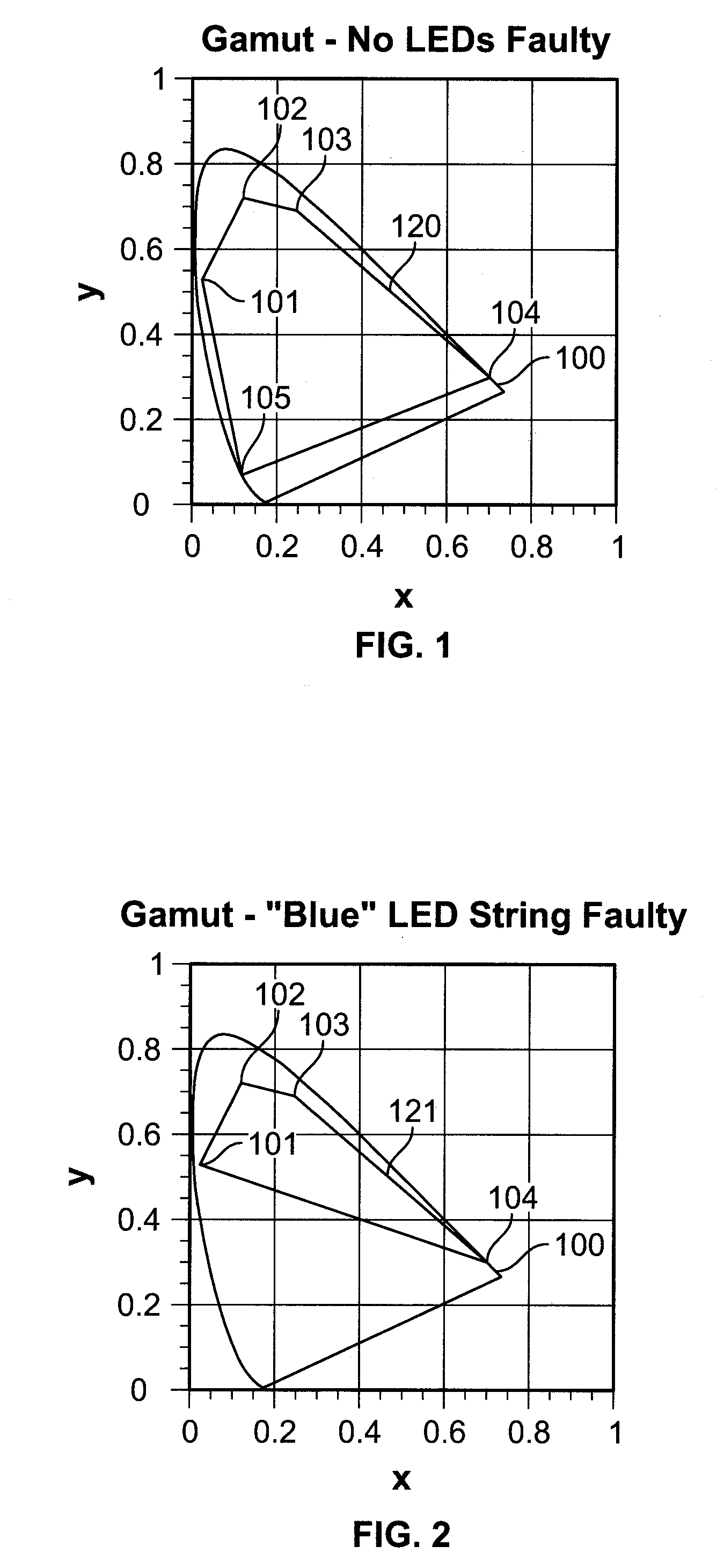

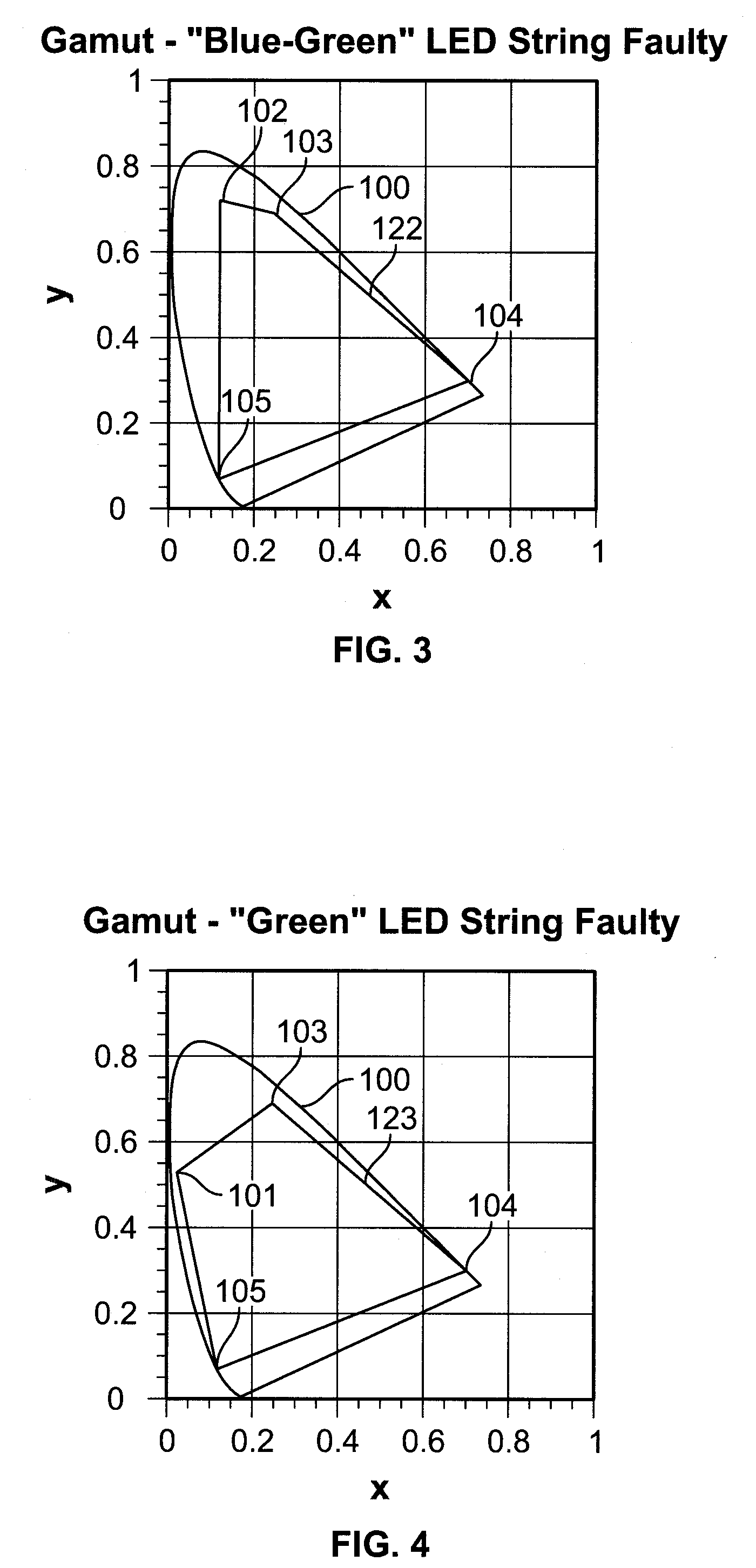

Image display unit, method of driving image display unit, signal generator, signal generation program, and signal generation method

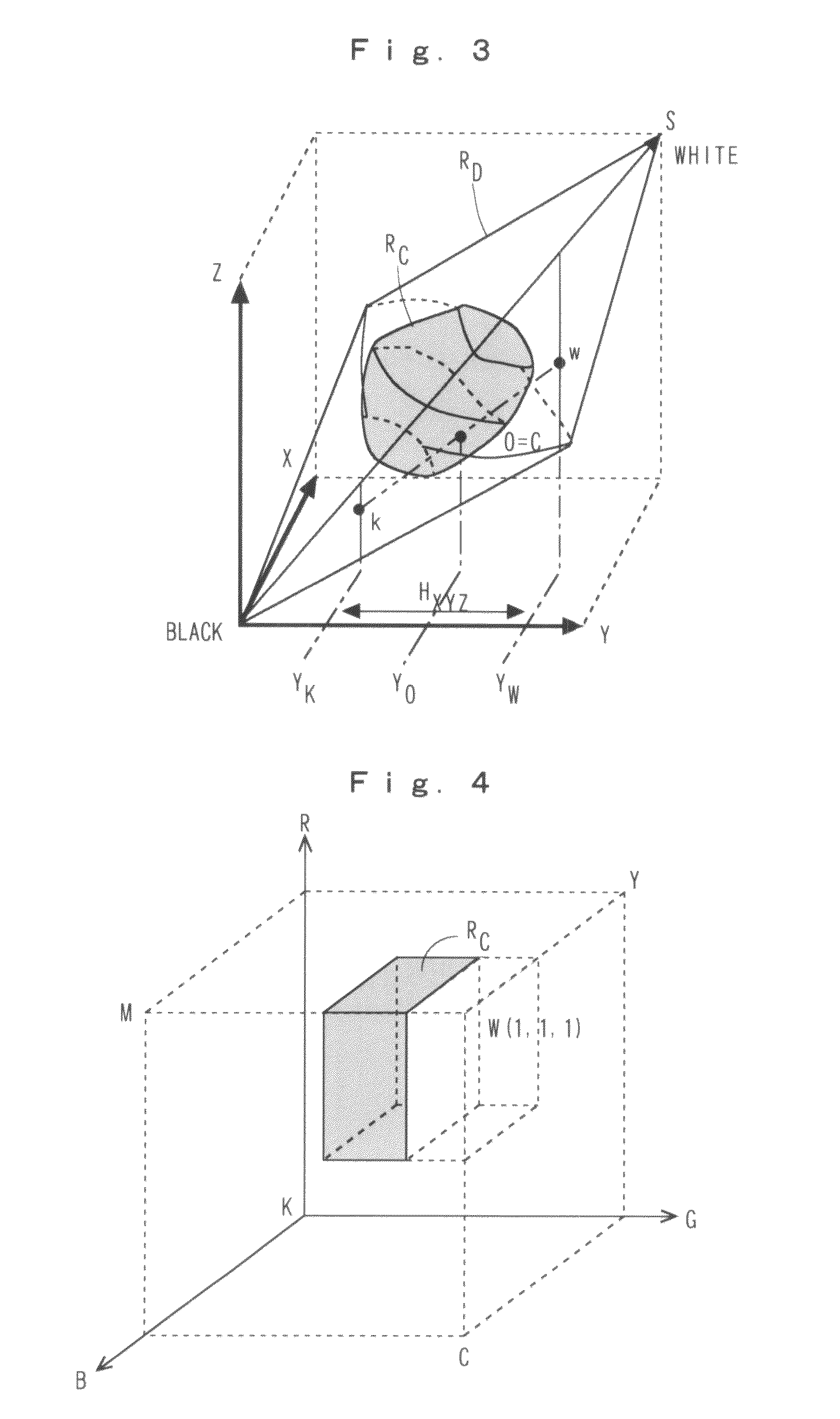

The present disclosure relates to an image display unit and to a method of driving an image display unit, as well as to a signal generator, to a signal generation program, and to a signal generation method. A signal for a red sub-pixel signal, a signal for a green sub-pixel signal, a signal for a blue sub-pixel signal, and a signal for a white sub-pixel signal are generated based on an image signal for red display, an image signal for green display, and an image signal for blue display that are provided in accordance with an image to be displayed. Values of the red sub-pixel signal Rcvt, the green sub-pixel signal Gcvt, and the blue sub-pixel signal Bcvt are determined based on a first matrix and a second matrix, with use of a coefficient 'Purity', an additive-color-mixture matrix, and a purity coefficient '[Psi]', and a value of the white sub-pixel signal Wcvt is configured to be employed as a value of min (RnL, GnL, BnL). According to the invention, the luminance can be raised assuredly even in the case where display is performed by reflecting external light, etc.

Owner:SONY CORP

Real wood grain generation technique ecologic floor production technique

The invention discloses a production process of ecological floors produced with an especially natural wood production technology, adopts high density fiber boards as the substrate material and includes the following steps of: 10 days of curing; cutting the material into small pieces to form floor blanks and 7 days of curing; groove opening and 7 days of curing; spraying waterproof paint at a naked part of the groove; coating an oily adhesive agent, two shaded priming paints, two ink printing patterns and finally a top coating on the back; 24 days of curing; coating an oily adhesive agent and a transparent putty on the front face; making 240 meshes of sanding, and varnishing two shaded priming paints, two ink printing patterns and a wear resistant priming paint on the front face; varnishing a sanding priming paint , making 320 meshes of sanding and varnishing a wear resistant priming paint on the front face; varnishing a sanding priming paint, making 320 meshes of sanding, varnishing an additive color priming paint, rolling a top coating, spraying a top coating and finally rolling and coating a scratching resistant top coating on the front face; packaging after all paints are dried and 7 days of curing. The production process protects the environment, saves materials with real and beautiful surface effects; and the floors can not easily deform and each performance is excellent.

Owner:ZHEJIANG CHANX WOOD

Method for compensating for a chromaticity shift due to ambient light in an electronic signboard

ActiveUS20090040205A1Improve functionalityImprove reliabilityCathode-ray tube indicatorsInput/output processes for data processingVisual perceptionMaterials science

A method for use with an electronic signboard (e.g., an LED signboard) compensates psychovisual chromaticity shift due to ambient light. The method first measures a color of light reflected from the signboard. Based on the measurement a set of calorimetric equations defining the desired light to be perceived as being displayed by each pixel of the signboard are solved. The calorimetric equations are the additive color mixture of the ambient light and the light to be actually displayed by the pixel in the absence of ambient light. The calorimetric equations may be expressed in units of uniform color space. The solutions of the colorimetric equations are then used to control the light actually displayed by the pixel.

Owner:LANDMARK SCREENS

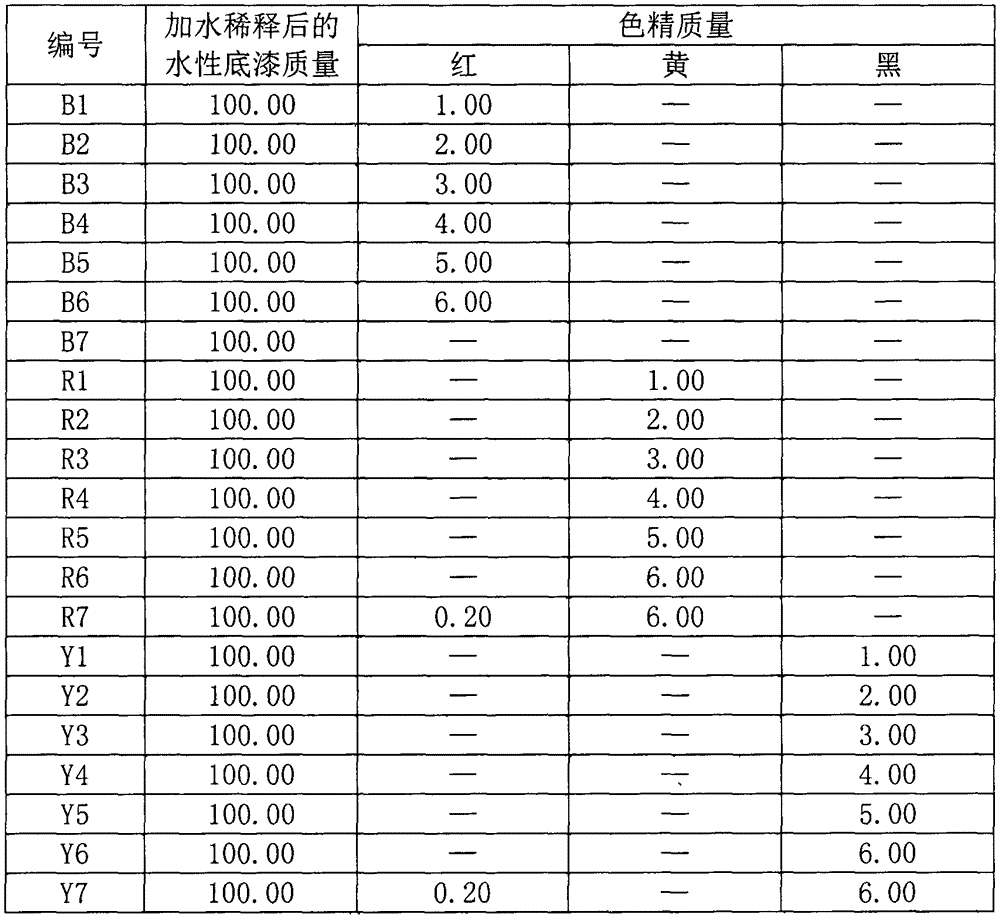

Method for mixing colors of solid wood floor paint

InactiveCN104699897AImprove accuracyImprove efficiencySpecial data processing applicationsWater basedPaperboard

The invention relates to a method for mixing colors of solid wood floor paint. The method comprises the following steps: according to six ratios being 1 percent, 2 percent, 3 percent, 4 percent, 5 percent and 6 percent of three color concentrates of red, yellow and black relative to the quality of water-based primer, mixing to prepare an additive color primer sample; coating the black and white paperboard with the additive color primer sample through a coating rod, and thus obtaining a paint film sample; by means of a color measuring and matching system composed of a spectral color measurement instrument and Colibri color matching software, detecting the color data of the paint film sample, and saving the color data in the color matching system; inputting the quality data of the water-based primer used for manufacturing the paint film sample and the three color concentrates of red, yellow and black into the color matching system, computing and processing the quality data with the Colibri color matching software, and thus building a color concentrate database; before the colors of the paint is mixed, detecting the color of a plain floor board as a bottom color and the color of a painted finished product floor as a target color; by means of the color concentrate database, automatically computing the application proportion of the three color concentrates of red, yellow and black of paint films with various thicknesses through the color matching system. The accuracy and efficiency of color mixing of paint are high.

Owner:NANJING FORESTRY UNIV

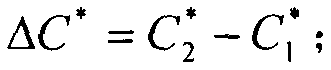

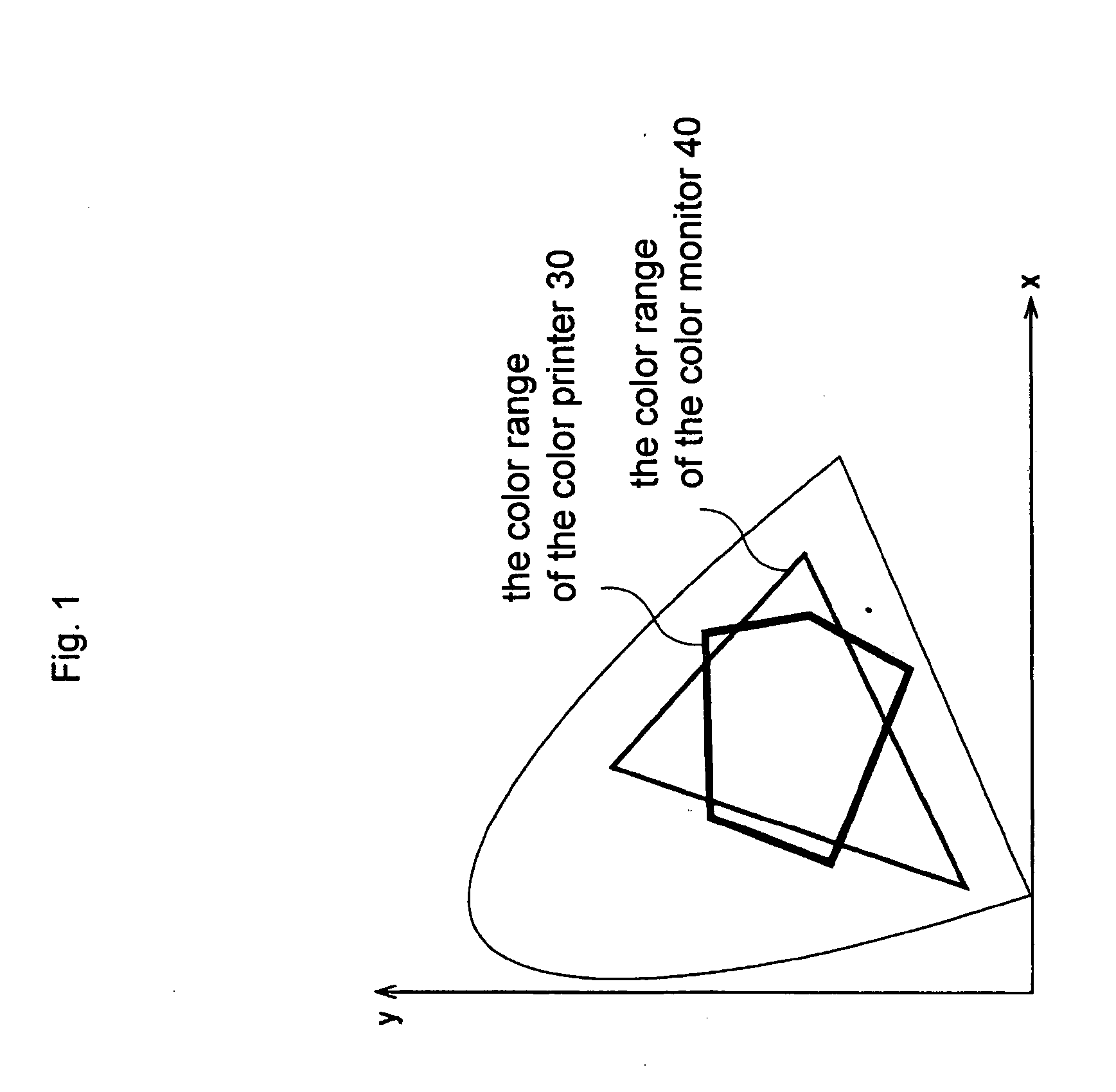

Generating a device independent interim connection space for spectral data

InactiveUS20090141322A1Wide applicabilityThe result is accurateTelevision system detailsDigitally marking record carriersComputer graphics (images)Orthogonal complement

Generation of an Interim Connection Space (ICS) of a full spectral space is provided. A space of illuminants is accessed, and the full spectral space is decomposed into a first subspace that is an orthogonal complement of a metameric black subspace for the space of illuminants. The Interim Connection Space is generated based on the first subspace. The generated ICS can be used, for example, for rendering an image on an additive color destination device. One image rendering workflow includes accessing color data of the image in an ICS, transforming the color data from the ICS into a device dependent color space of an additive color destination device, and rendering the transformed color data on the destination device.

Owner:CANON KK

Color chart

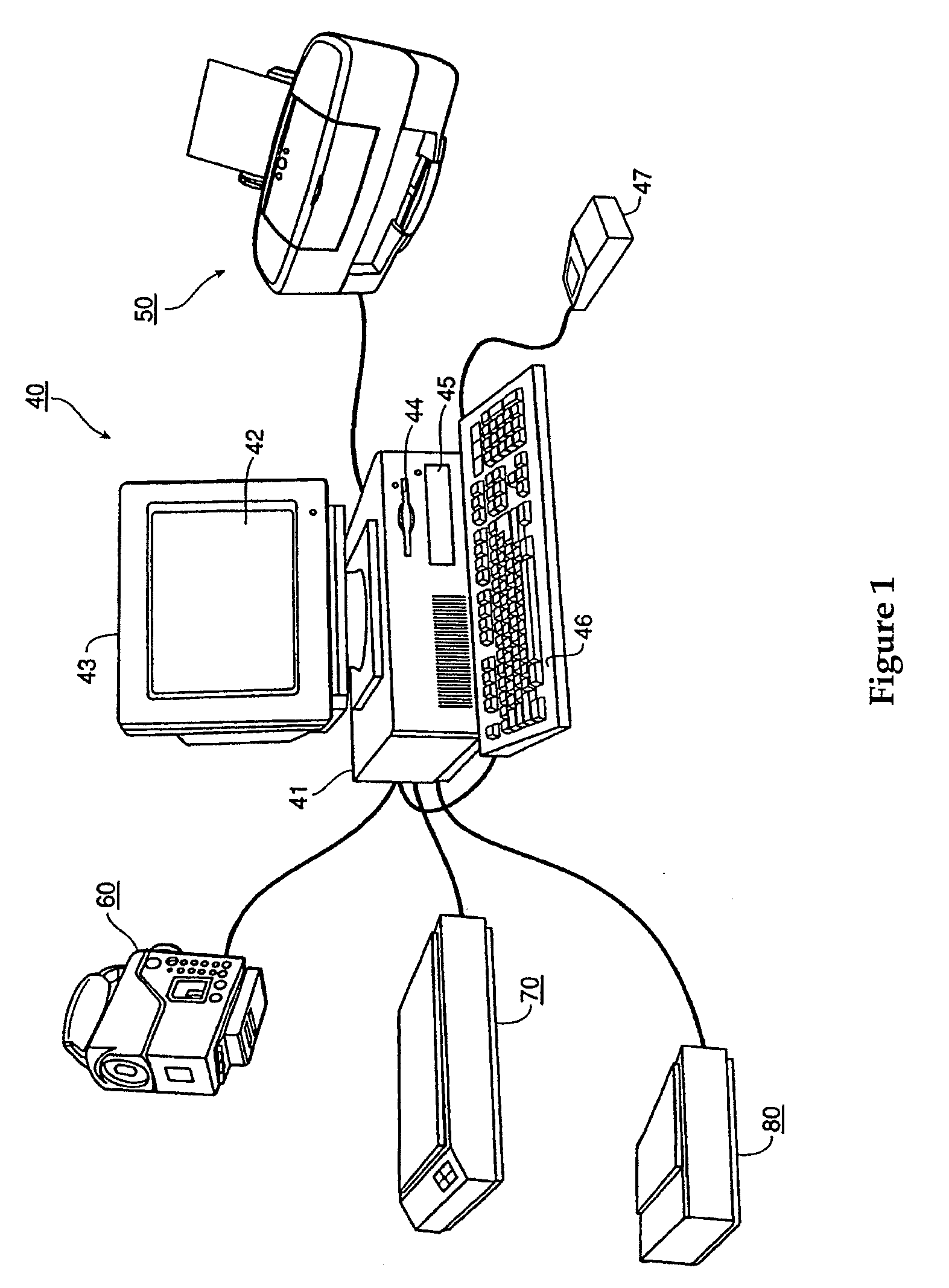

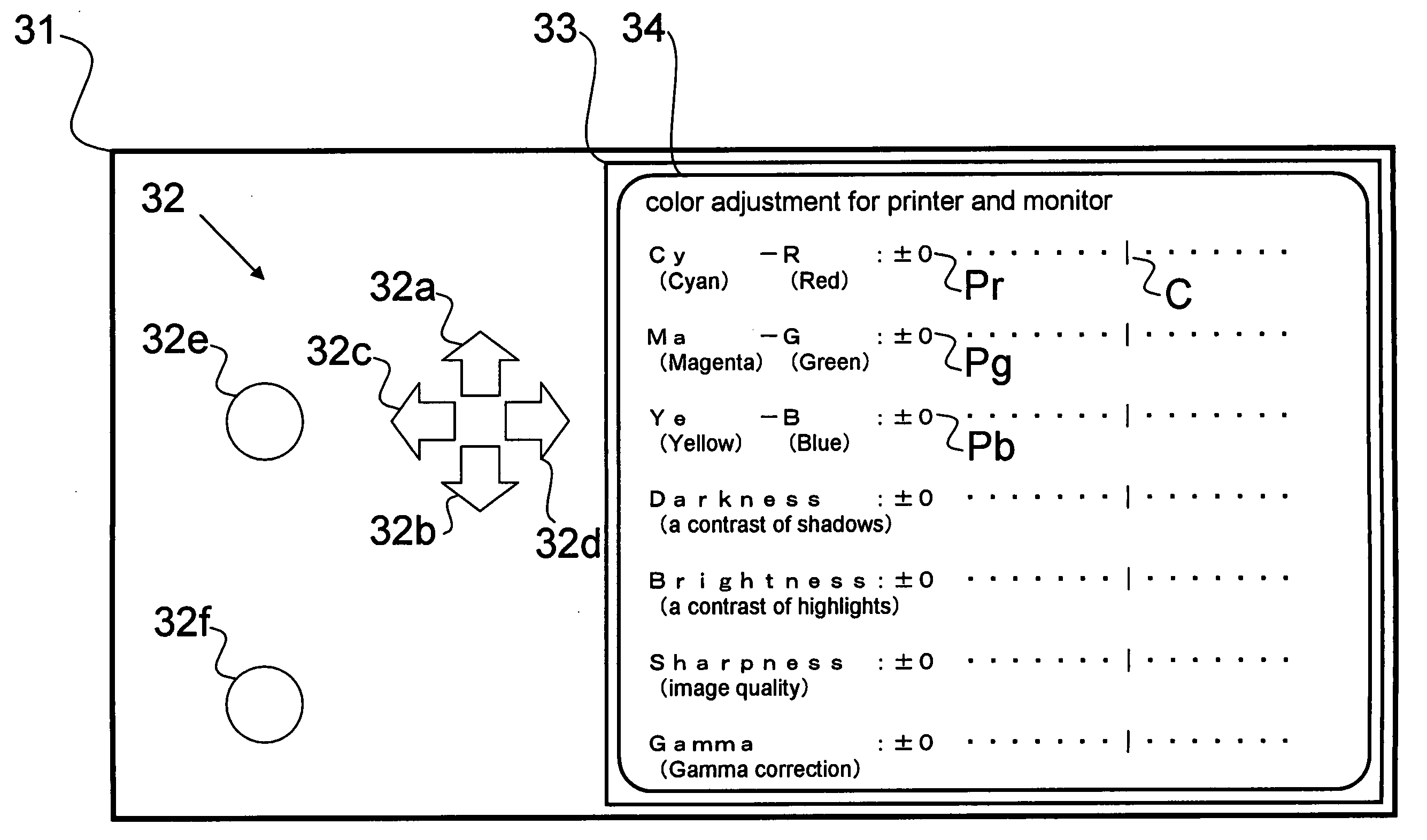

A color chart for a color adjustment of a color printer and a color monitor attached to an endoscope, has a predetermined number of color cells. The color cells have the same form, and are arranged in one of a grid state and a linear state. Each of the color cells is formed by blending two colors from a group of three colors comprising red, green, and blue, according to a predetermined ratio, in an additive color process. The color cells show a gradation of color such that a color tone of each of the color cells changes continuously in one direction.

Owner:HOYA CORP

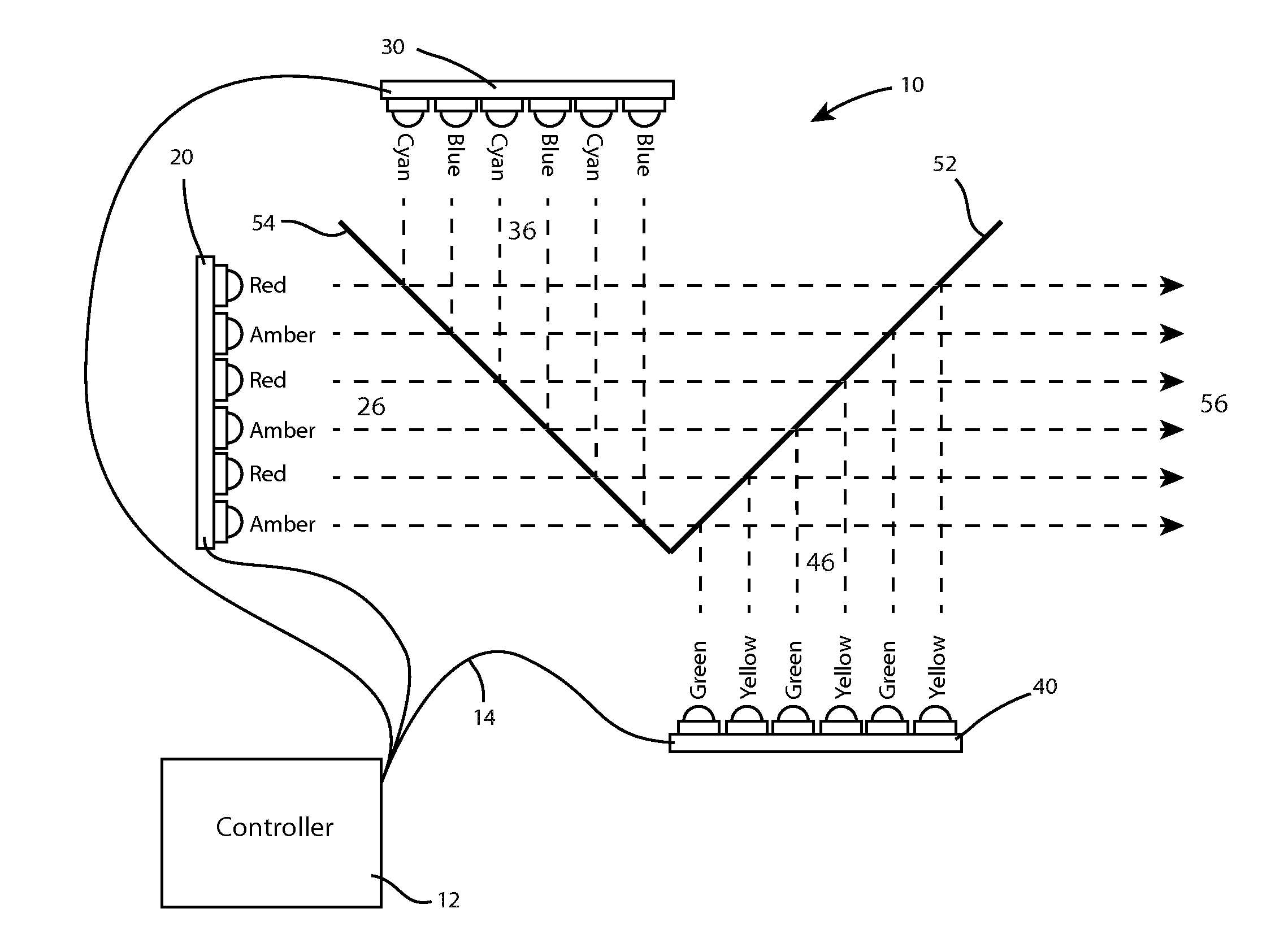

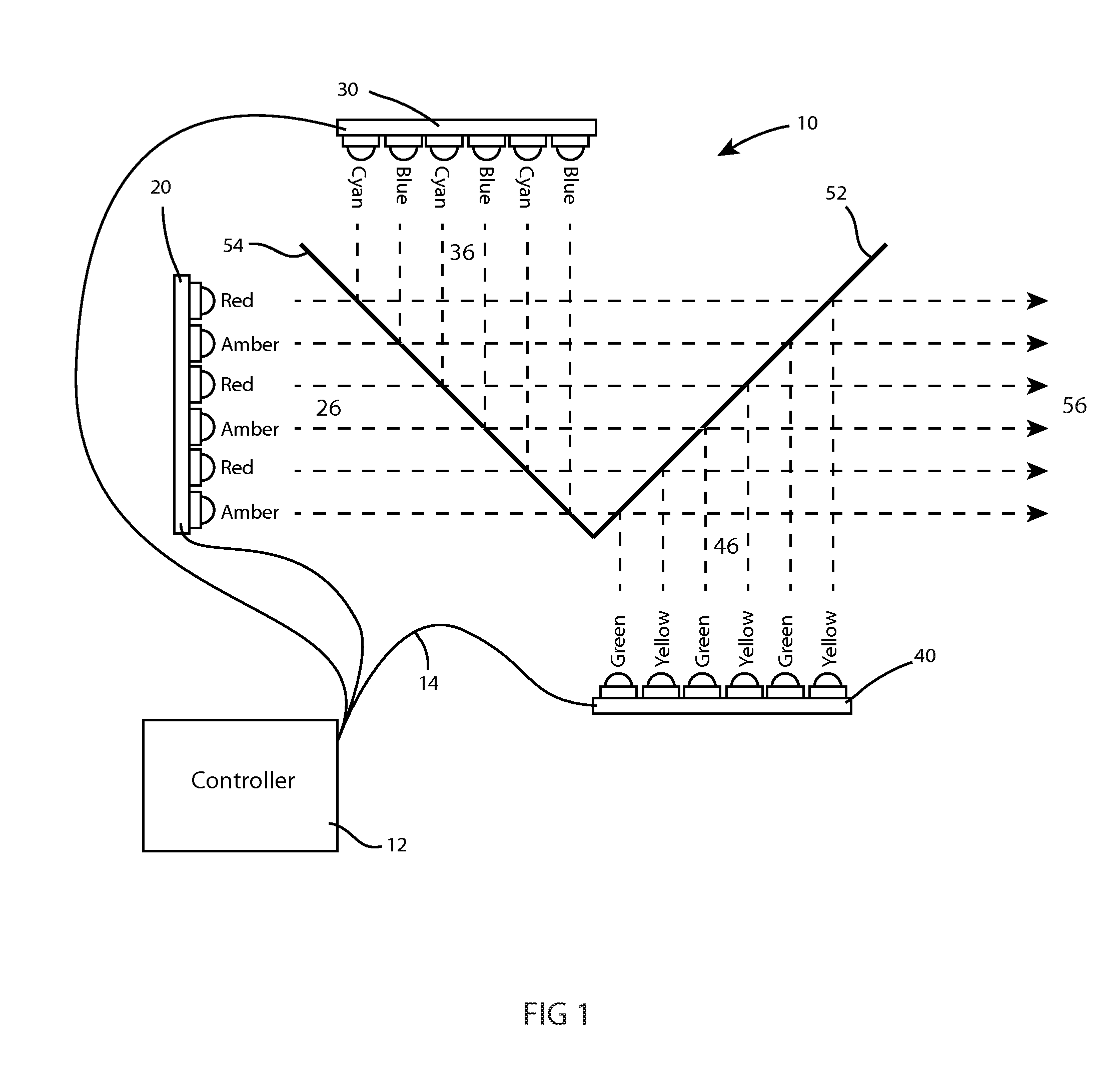

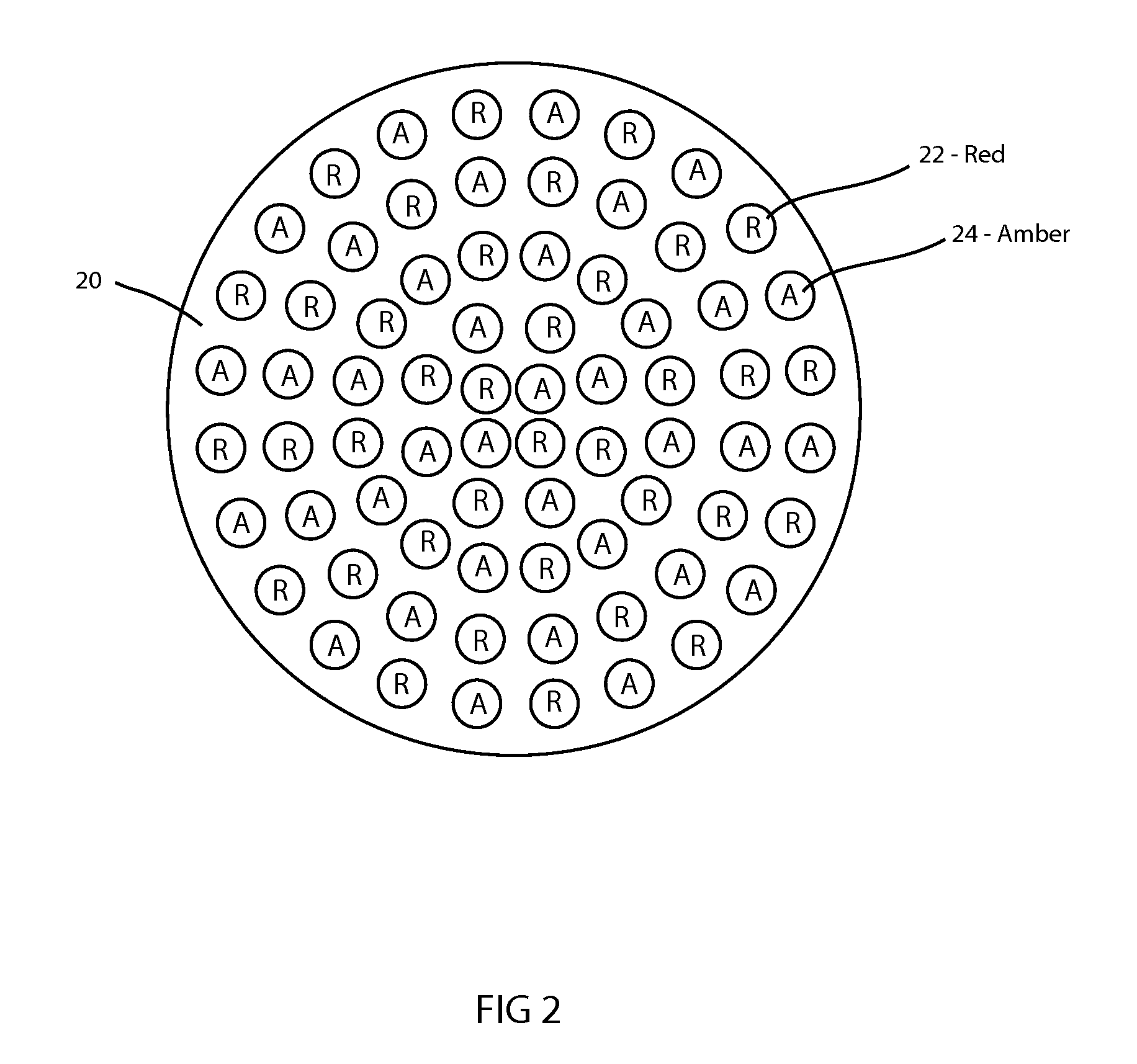

Homogenization system for an LED luminaire

A remotely directable luminaire with an improved color LED homogenization system for LED luminaires employing a plurality of LED arrays where an array employs a plurality of discrete peak LED groups and dichroic mirrors maximized for transmission / reflection of around the groups of LED's discrete peaks to generate a directional homogenized color light beam with additive color mixing.

Owner:ROBE LIGHTING

Anti-cracking ultraviolet-cured coating system for solid-wood sheet material

The invention belongs to the field of ultraviolet-cured new materials, and particularly relates to a coating system which is mainly applied to the protection and the decoration of solid-wood sheet materials of a solid-wood floor, a multilayer solid-wood floor, a bamboo-wood floor and other solid-wood floors. The invention provides a coating system which is used for solving the problem that a paint film cracks as a sheet material cracks when the solid-wood sheet material is used in an environment of which the diurnal temperature difference is relatively large. An anti-cracking ultraviolet-cured coating system for a solid-wood sheet material consists of aqueous additive color priming paint, UV (ultraviolet) flexible priming paint, UV hard priming paint and UV surface paint. The UV flexible priming paint forms a paint film which is high in binding force and high in flexibility by means of the coloring and the adhesive force of the aqueous additive color priming paint; then the UV hard priming paint and the UV surface paint are coated, and are cured by ultraviolet light to respectively form films under the action of a light initiator, so as to form a multilayer coating film structure which is high in binding force, good in flexibility and high in interlayer adhesive force, and the characteristics of anti-cracking, high hardness and high scratch resistance are realized.

Owner:HUNAN JINHAI SCI & TECH

Liquid crystal display device and driving method used in same

InactiveUS7755597B2Reduce in quantityDisplay brightCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayData signal

Owner:NEC LCD TECH CORP

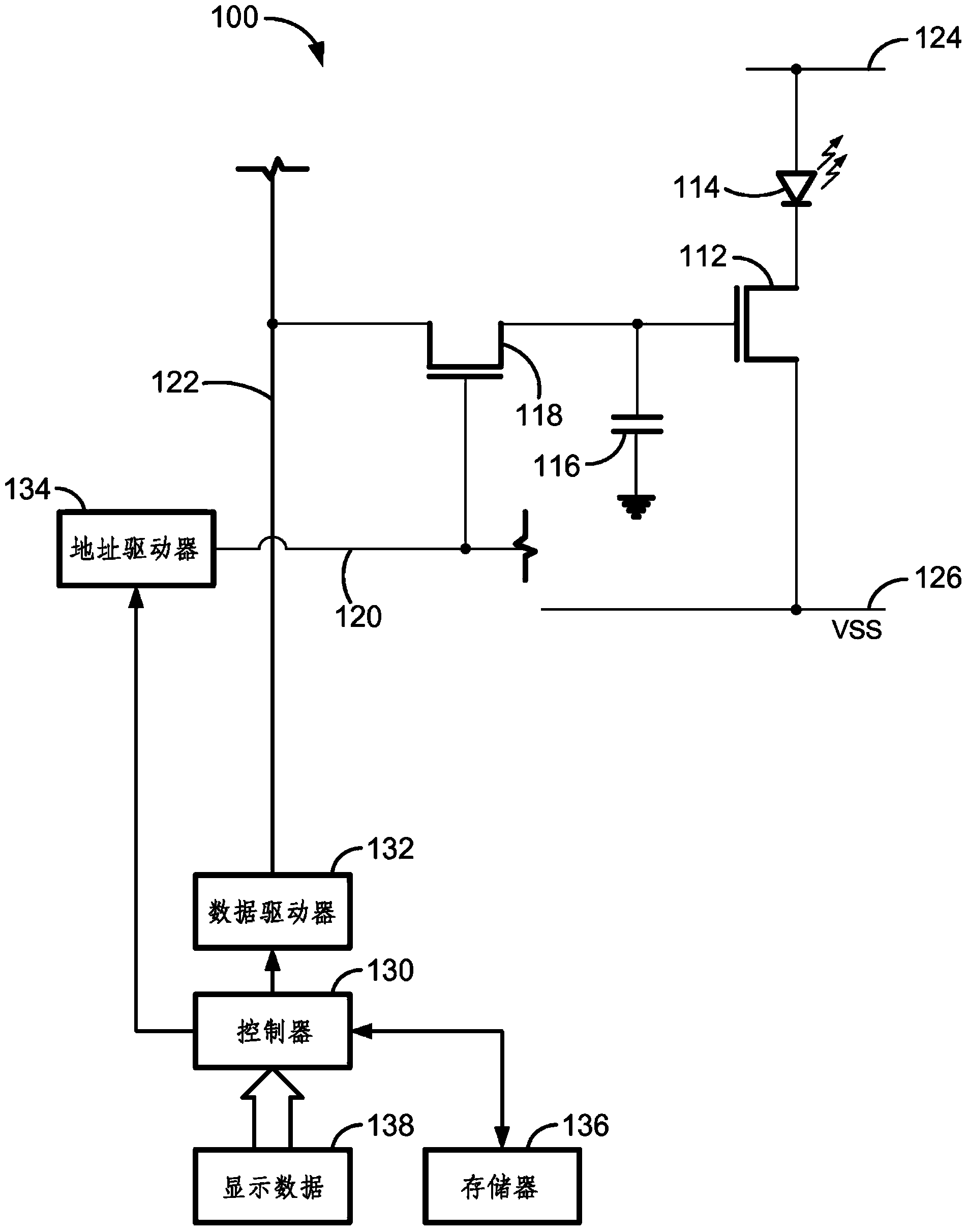

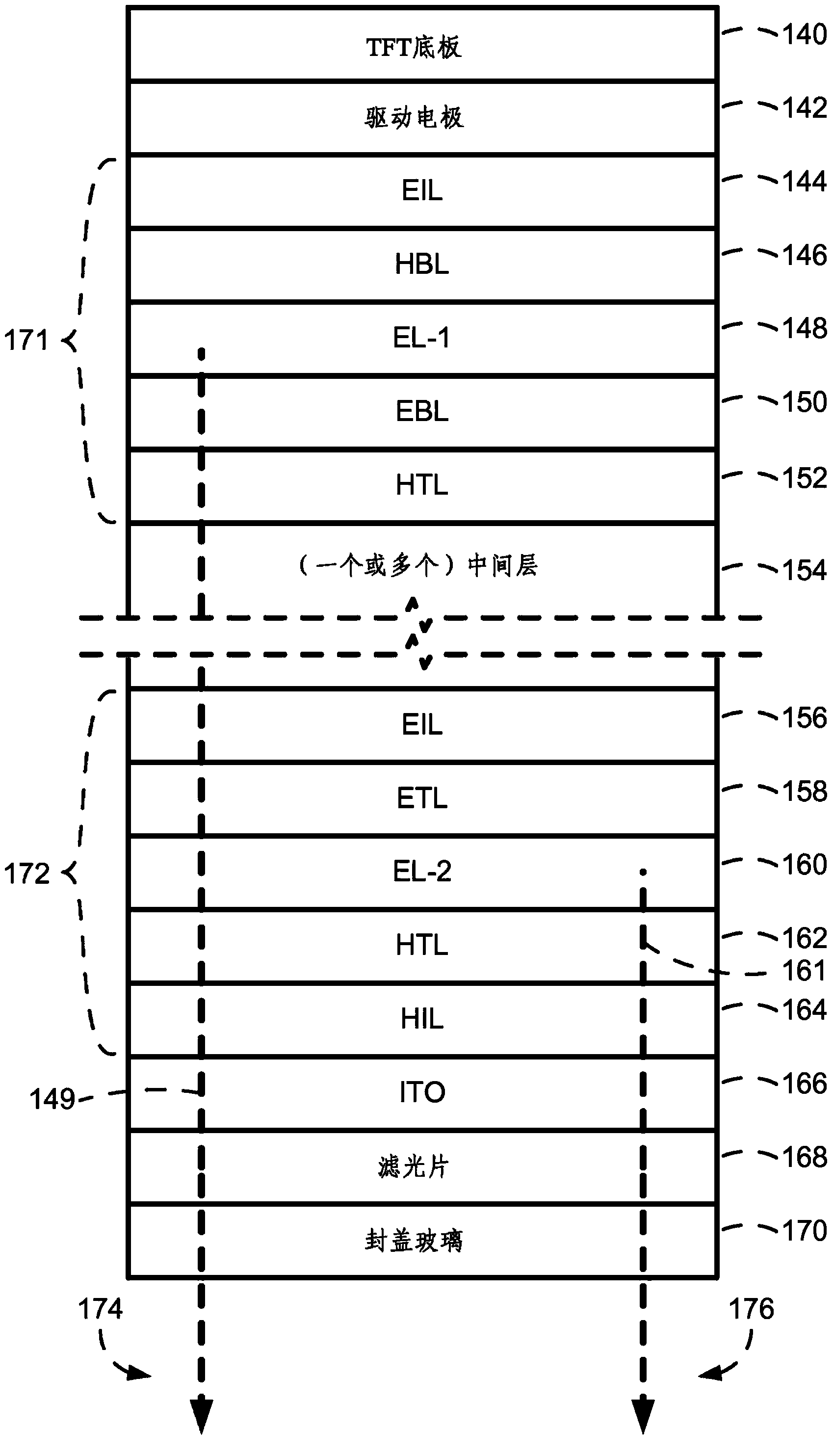

High resolution display architecture

ActiveCN104254915AStatic indicating devicesElectroluminescent light sourcesRegular patternActive matrix

An arrangement for a high resolution active matrix display includes organic emissive layers of distinct colors each deposited across continuous regions so as to include more than one pixel emissive region. Color filters are situated to partially block light from at least some of the emissive regions such that primary additive colors are transmitted from distinct subsets of pixels. The emissive layers may be deposited in alternating parallel stripes along rows or columns of the display, or may be oriented perpendicularly with respect to one another such that the emissive layers overlap in the emissive regions of at least some pixels. In some examples, red, green, and blue of pixels are arranged in regular patterns across the display and with the emissive regions for the blue pixels forming a relatively larger area of the display than either the red or green pixels.

Owner:IGNIS INNOVATION

Method for solving cold-batch pretreatment uneven dying

ActiveCN106012380ARemove completelyPromote moisture penetrationTwo or more solvent application treatmentDry-cleaning apparatus for textilesAcetic acidWater temperature

The invention discloses a method for solving cold-batch pretreatment uneven dying. Before the dyeing process, dyeing pretreatment is carried out on cloth and includes the steps of padding, batching and neutral washing. In the step of neutral washing, the batched cloth is put into a dye vat, water is fed, the batched cloth is operated for 10+ / -2 min in water at the temperature of 40-60 DEG C, and the water is drained; water is fed, the water temperature in the dye vat is made to be 88-98 DEG C, the cloth is operated for 10+ / -2 min and then cooled to 40-60 DEG C, and the water is drained; water is fed, the water temperature in the dye vat is made to be 40-60 DEG C, acetic acid is added, the cloth is operated for 5-10 min, then ferment is added, the cloth is operated for 5-10 min, and the water is drained. By adopting the method, the rate of additive color uneven dyeing can be reduced by 70%, and the ratio of uneven dying chromatic aberration is greatly reduced.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com