Patents

Literature

268results about How to "Good surface effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic nano particle and polymer composite modified emulsified asphalt

InactiveCN101143967AGood resistance to UV agingImprove heat aging performanceBuilding insulationsPolymer scienceButadiene-styrene rubber

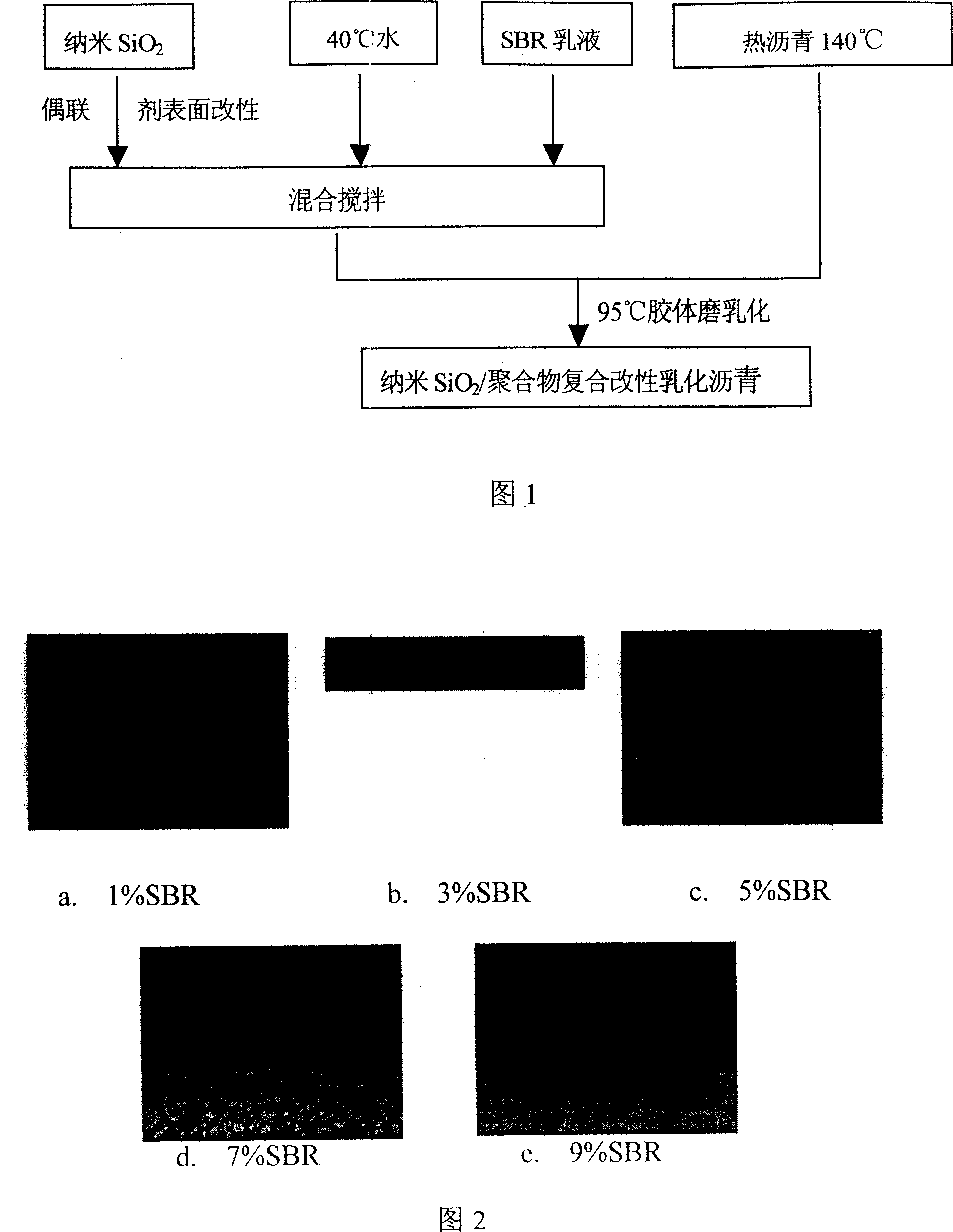

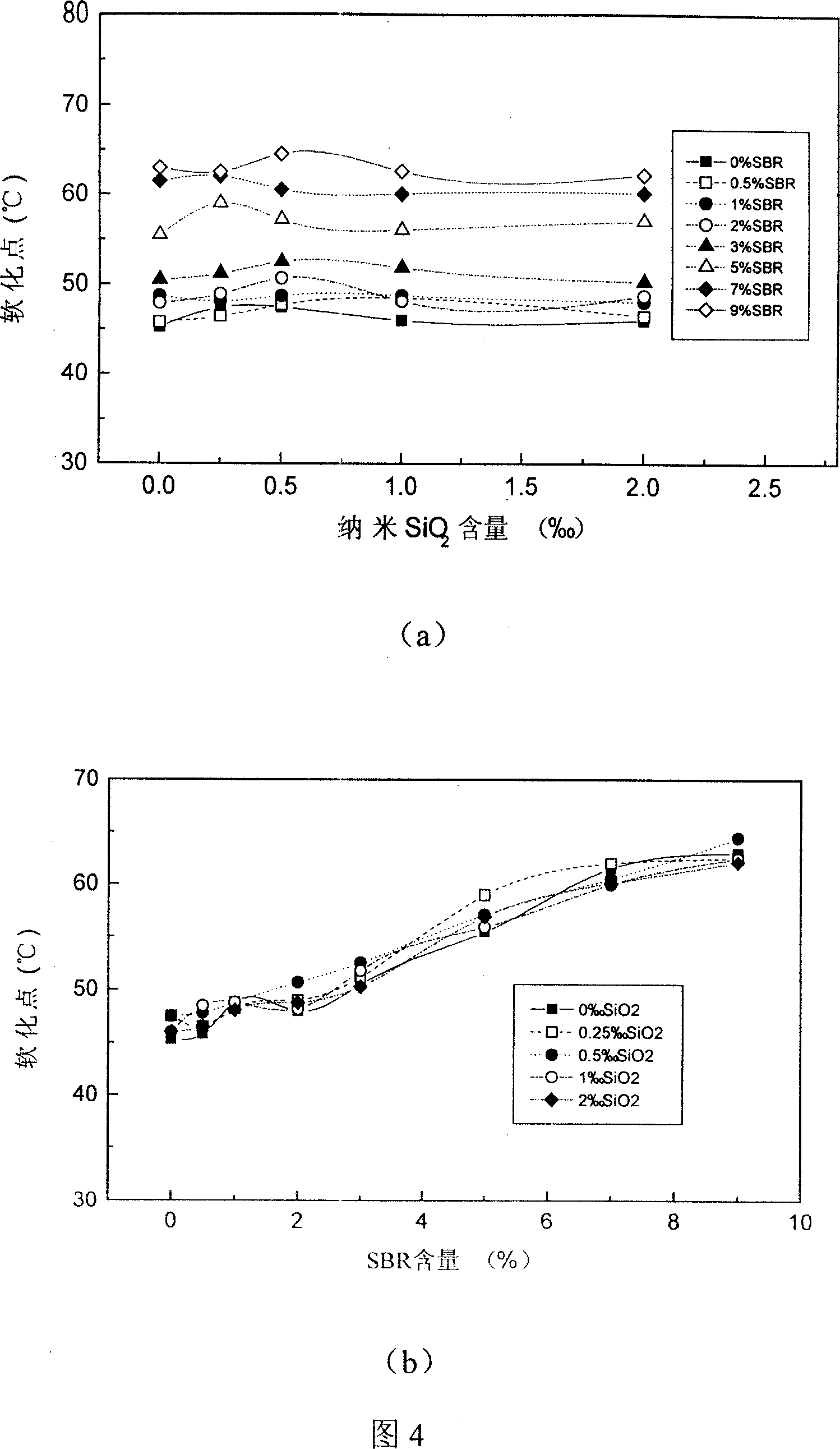

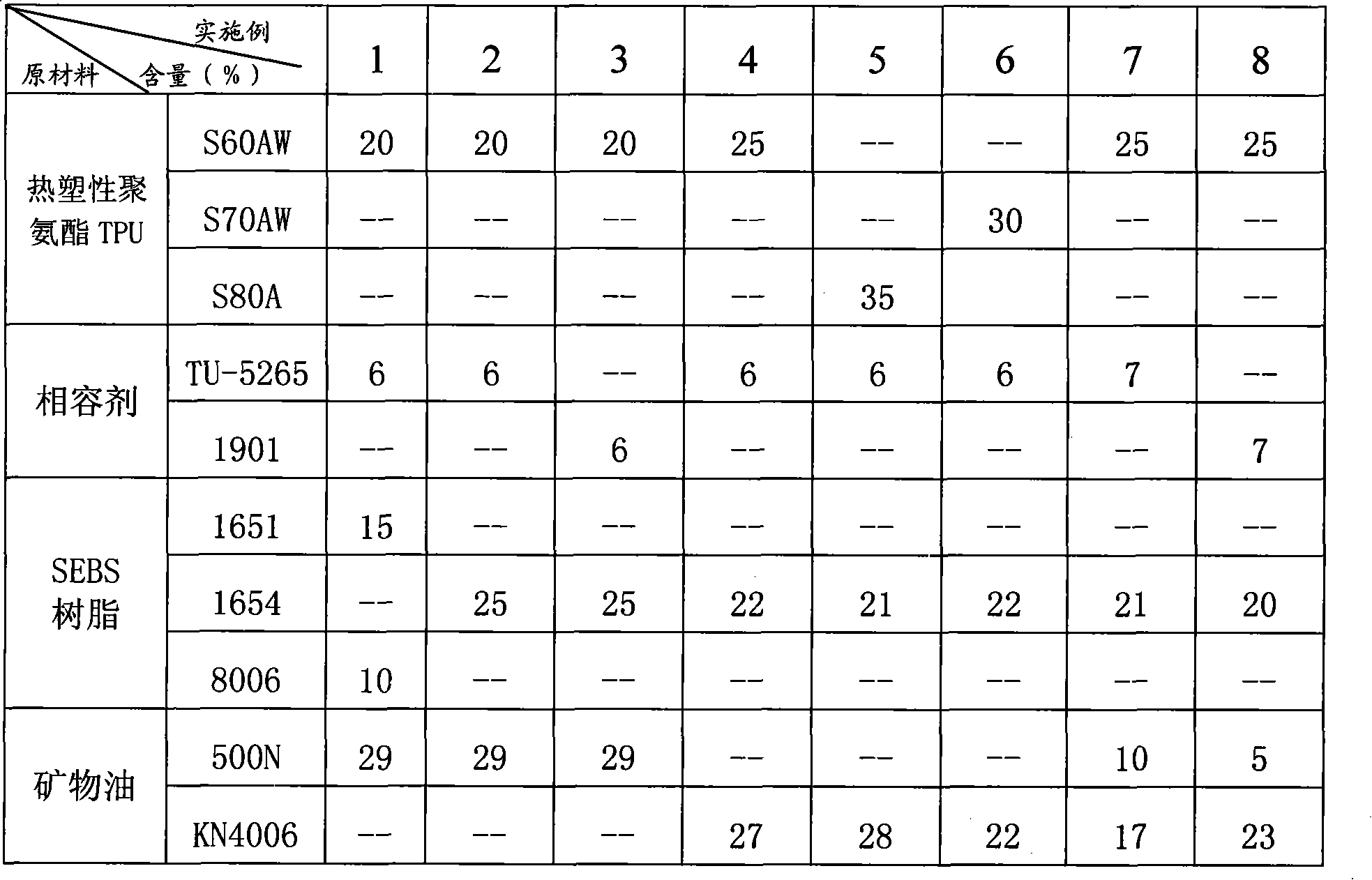

A modified emulsion asphalt compounded by inorganic nano-particles and polymer contains 200-700 parts by weight of asphalt, 2-80 parts by weight of modified inorganic nano-particles, 5-50 parts by weight of styrene-butadiene rubber latex, and 170-793 parts by weight of water, wherein the modified inorganic nano-particles is prepared by mixing 95-98 parts by weight of inorganic nano-particles with 2-5 parts by weight of coupling agent, and each components are mixed, followed by normal emulsion treatment to get the emulsion asphalt. The invention utilizes unique surface effect, small size effect and macroscopic quantum tunneling effect etc. of the inorganic nano-particles to give the product comprehensive properties, such as good wear resistance, intensity sum, anti-aging property and fine waterproof effect etc. Using the invention can increase the road maintenance cycle and decrease the cost. Furthermore, the water-proof cost of construction industry is greatly decreased.

Owner:HUNAN UNIV

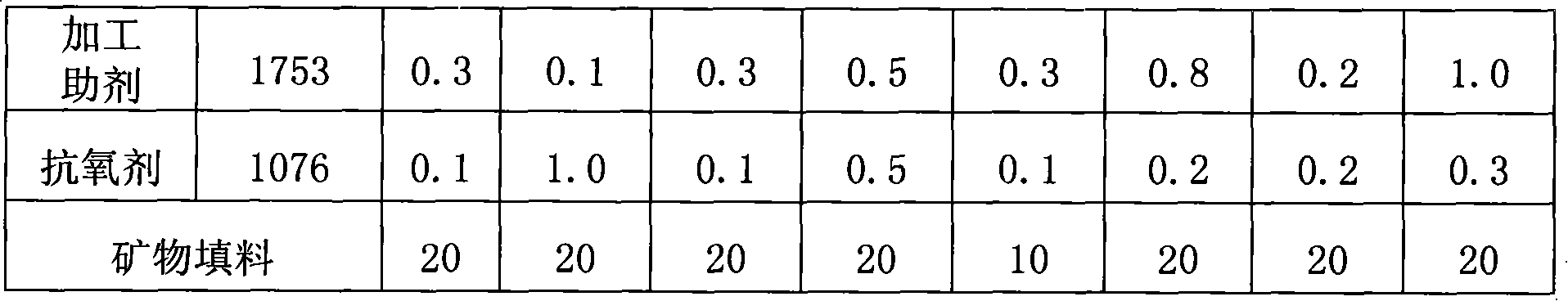

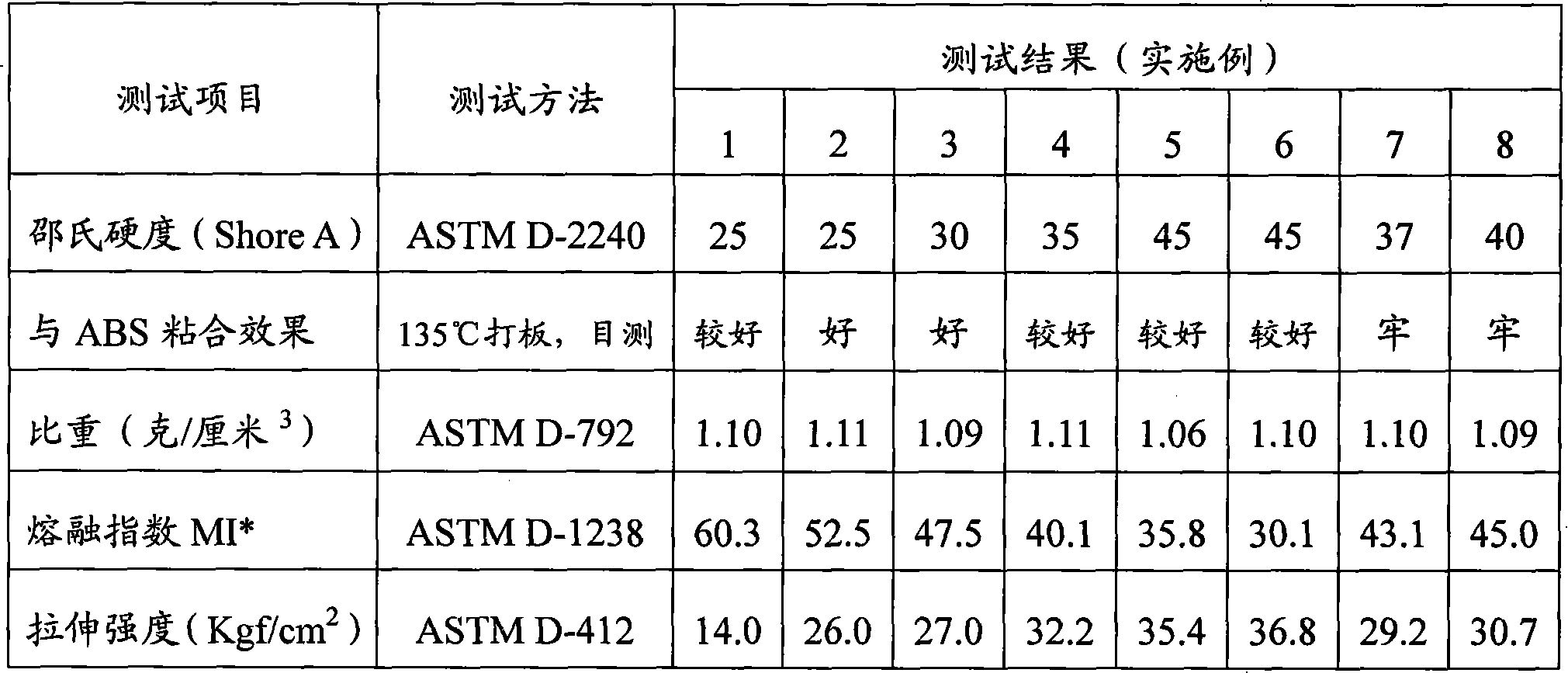

Thermoplastic elastic body for jetting and adhibiting with ABS at low-temperature

The invention relates to a thermoplastic elastomer used for projecting and clinging with ABS at low temperature, and components of the raw material are: thermoplastic polyurethane: 20 to 35 portions; compatilizer: 6 to 7 portions; SEBS resin: 20 to 25 portions; mineral oil: 22 to 29 portions; mineral filling: 10 to 20 portions and antioxidant: 0.1 to 1 portion, and 0.1 to 1 portion of processing aid can be added selectively. The thermoplastic elastomer used for projecting and clinging with ABS at temperature is low in hardness, good in surface effect at the injection temperature of 135 DEG C, good in the property of projecting and clinging with the ABS resin at low temperature.

Owner:东莞市国丰塑业有限公司

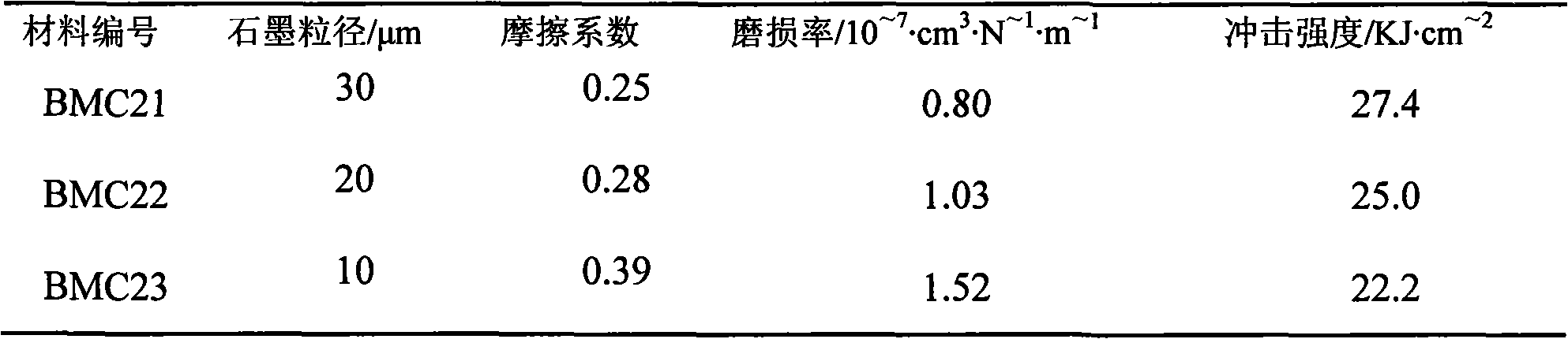

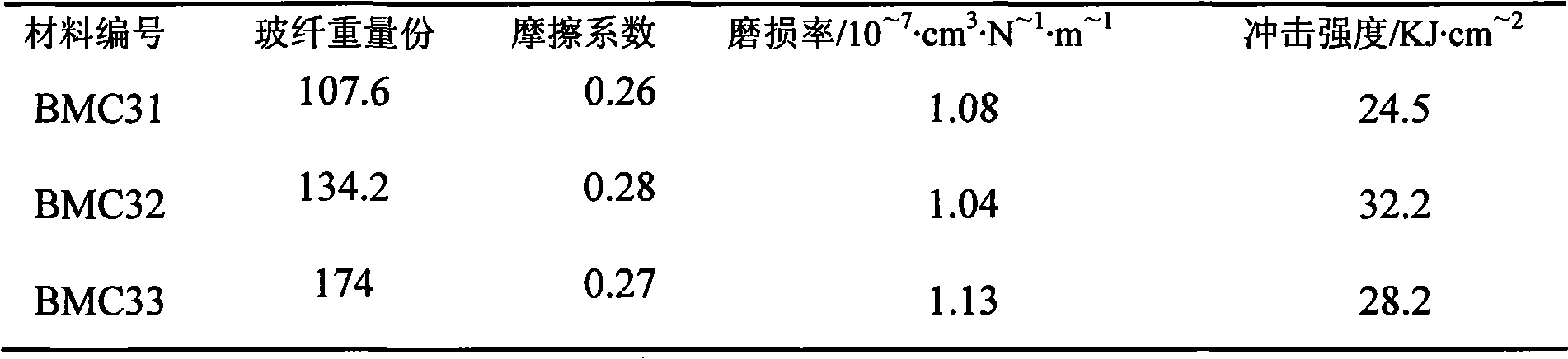

Self-lubricating wear-resisting agglomerate moulding material

The invention relates to a self-lubricated abrasion-proof lumpy molding compound. The premix of the molding compound contains an unsaturated polyester resin in an amount of 60 to 80 parts by mass; a low shrink additive in an amount of 20 to 40 parts by mass; an internal molding lubricant in an amount of 3 to 5 parts by mass; an inorganic filler in an amount of 140 parts to 170 parts by mass; an initiator in an amount of 0.5 to 2 parts by mass; a thickening agent in an amount of 0.5 to 1.5 parts by mass; a lubricant in an amount of 10 to 40 parts by mass; a reinforcing material in an amount of 83.5 to 188 parts by mass. The total number of the parts of the unsaturated polyester resin and the low shrink additive is 100. The self-lubricated abrasion-proof lumpy molding compound has excellent mechanical property and acid and alkali corrosion resistance, and is light in weight so as to save fuel and discharge little pollution. The invention is designed freely; the components are integral; the dimensional stability is excellent; the surface is smooth; the components can be self-lubricated without needing other lubricants for reducing friction; the molding compound can be used for molding once; and molded products have accurate sizes and good surfaces, thus avoiding machining, heat treatment and surface modification of metal abraded parts; in addition, the production cycle is short.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

Polyester type ultra-low density polyurethane resin for shoes

The present invention is the recipe of three component polyurethane resin for insole. The polyurethane resin includes one component A of active hydrogen-containing mixture comprising long chain polyol polymer, chain expanding agent, cross-linking agent, surfactant, foaming agent and other assistants; one component B comprising polyester or polyether modified MDI pre-polymer; and one component C or catalyst component of glycol solution of triethylidene diamine. The polyurethane resin has density as low as 0.25-0.30 g / cu cm, capacity of making the product firm and good in appearance, and other advantages.

Owner:无锡双象新材料有限公司

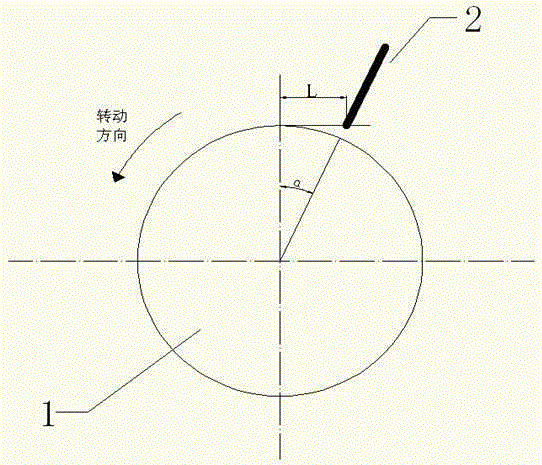

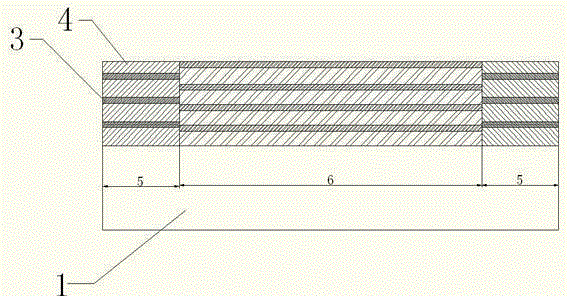

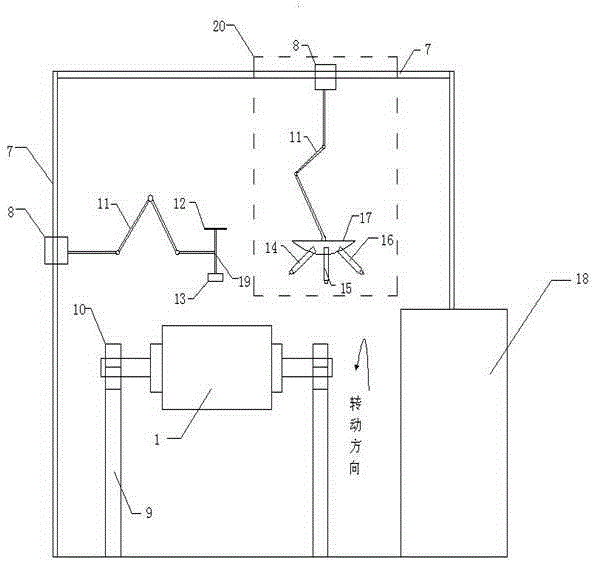

Surfacing welding method for abraded large roll shaft

ActiveCN105382378AReduce defectsImprove forming qualityArc welding apparatusWelding/cutting media/materialsFatigue damageSlag

The invention discloses a surfacing welding method for an abraded large roll shaft. The surfacing welding method is characterized by comprising the following steps that 1, preweld material analysis is carried out, preweld cleaning is carried out on the roll shaft, and preweld preparation is carried out; 2, after preweld preparation is finished, preweld preheating is carried out; 3, after preweld preheating is finished, automatic submerged arc welding is adopted for surfacing welding; 4, after surfacing welding is finished, welding slag is broken down, and postweld heat treatment is carried out; and 5, after heat treatment is finished, finally machining is carried out according to requirements. After the surfacing welding method is adopted, surfacing welding layer defects at the surfacing welding position are few, and the forming quality of a welding channel is good; the hardness of the surfacing welding position is distributed in a ladder manner from low to high from inside to outside, and the hardness of the outermost layer even ranges from 55 HRC to 60 HRC; the impact toughness and strength of the surfacing welding position are equal to those of the roll shaft and even exceed those of a base material by 1-2 times; the capacity for resisting spalling fatigue damage is high, the surfacing welding effect is remarkable, and the welding quality requirement can be completely met; and the whole surfacing welding process is easy to master and control, and good economical efficiency is achieved.

Owner:JIANGSU JINHANG MACHINERY MFG CO LTD

High-content fiberglass-reinforced halogen-free flame-retardant PC (polycarbonate) composite and preparation method thereof

The invention discloses high-content fiberglass-reinforced halogen-free flame-retardant PC (polycarbonate) composite and a preparation method thereof, comprising the following components according to percent by weight: 50-60% of polycarbonate, 34-45% of fiberglass, 2-5% of a toughener, 8-20% of a flame retardant, 1-3% of a flame-retardant synergist, 0.1-1% of a lubricant, and 0.1-1% of an antioxidant; the polycarbonate is a mixture of common polycarbonate and siloxane copolymer. The polymer is formed of PC (polycarbonate) and siloxane, PC is amorphous resin with good performance, and the siloxane copolymer has the advantages of low temperature resistance, chemical corrosion resistance, good dielectric property and the like; the siloxane-PC copolymer has the advantages of both the siloxane copolymer and PC and has reduced stress cracking performance and gap sensitivity, improved low temperature impact performance, and improved weathering resistance.

Owner:DONGGUAN HONOUR E P

Chitosan fluid dressing film

The invention relates to a medical article, and mainly relates to a chitosan fluid dressing film for accelerating wound healing for skin burn, trauma, and body surface ulcers, and infection treatment. The chitosan fluid dressing film is prepared by using chitosan as a main raw material; the chitosan is dissolved with acids, and mixed with gelatin fully swelled in water; then glycerin and a silver salt solution are added; under the action of ultrasonic wave, simple substance silver exists in the fluid in a form of nanometer colloidal silver so as to obtain nanometer silver sol. The dressing film of the invention adopts chitosan as a main raw material, has wide-spectrum antibacterial properties, and can be used as dressing for skin modification and skin wound. A lot of -NH2 and -OH are contained in the molecules, which can form cage-shaped molecules with a structure like a net with metal ions through hydrogen bonds, and thus stable coordination is provided for silver ions. Chitosan adsorbed with silver ions has more effective bactericidal effect.

Owner:HANGZHOU CROR BIOTECH

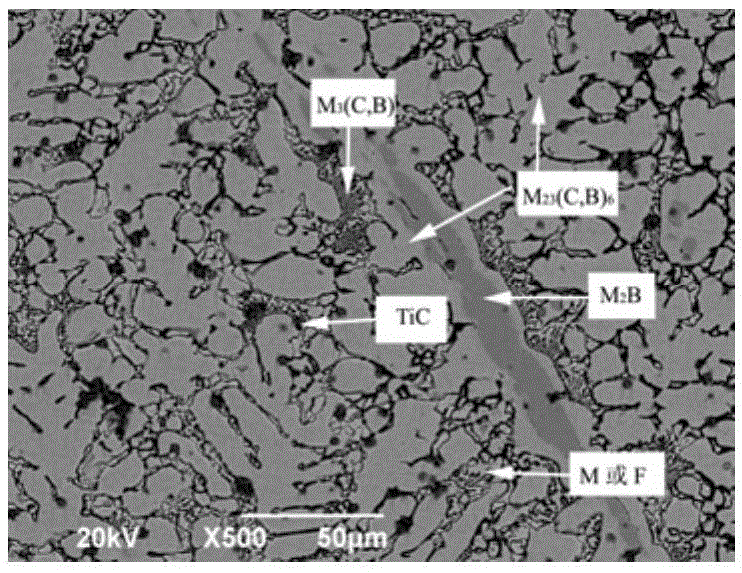

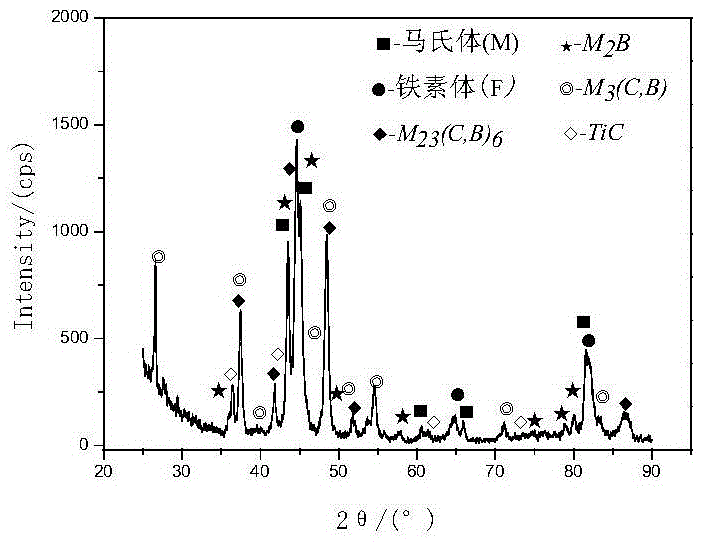

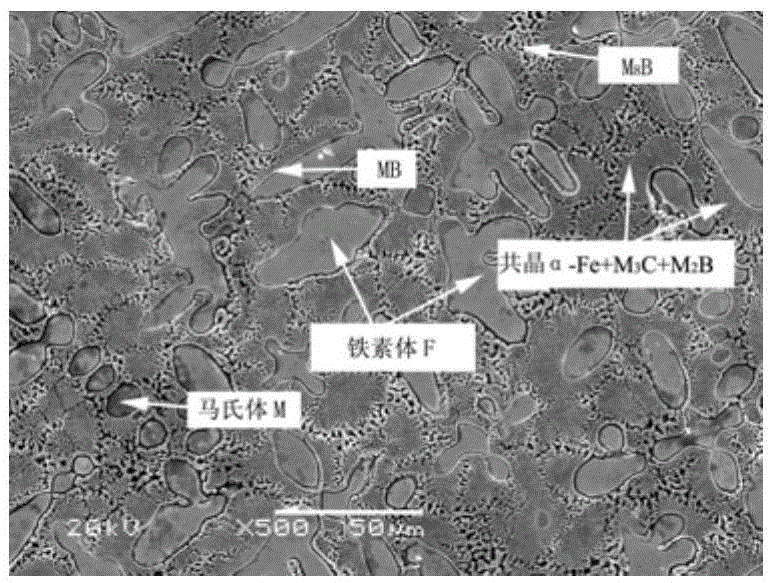

Carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire

InactiveCN105537797ARealize carbon control and tougheningReduce carbon contentWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention discloses a carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire. According to the technical scheme, a low-carbon-steel H08A cold-rolled thin steel strip is adopted as an outer sheath, and an alloy, graphite and other metal powder are mixed in the sheath to form a powder core, wherein the surfacing alloy is alloy powder obtained by adding high-content ferro-boron, high-carbon ferrochrome and ferrotitanium with different melting properties into the flux-cored wire; by virtue of open-arc surfacing current control, a high-boron surfacing melt with the alloy component in an incompletely-molten and unevenly-mixed state is formed, so that an alloy element phase structure is selectively optimized and configured; the powder core mainly consists of the following components: ferro-boron, high-carbon ferrochrome, ferrotitanium, graphite, medium-carbon ferromanganese, ferrosilicon and reduced iron powder. The carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire overcomes the defect that a current high-boron surfacing alloy is great in brittleness due to microstructure characteristics of the high-boron surfacing alloy, can be widely applied to surfacing manufacturing or repairing of parts with abrasive wear resistance, for example, a concrete cement conveying tube, and is especially suitable for surfacing manufacturing or paring of the parts with low-stress abrasive wear resistance.

Owner:XIANGTAN UNIV

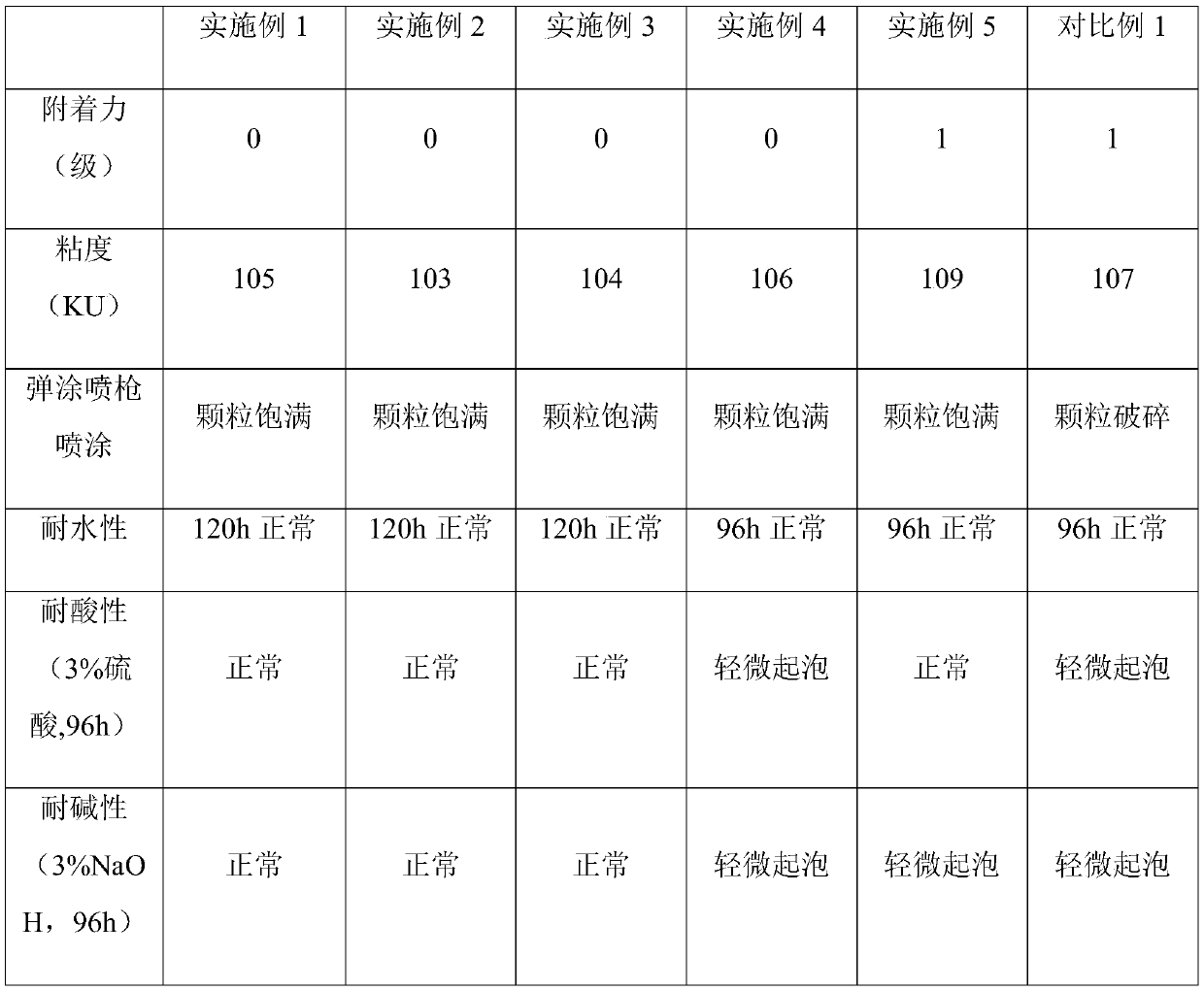

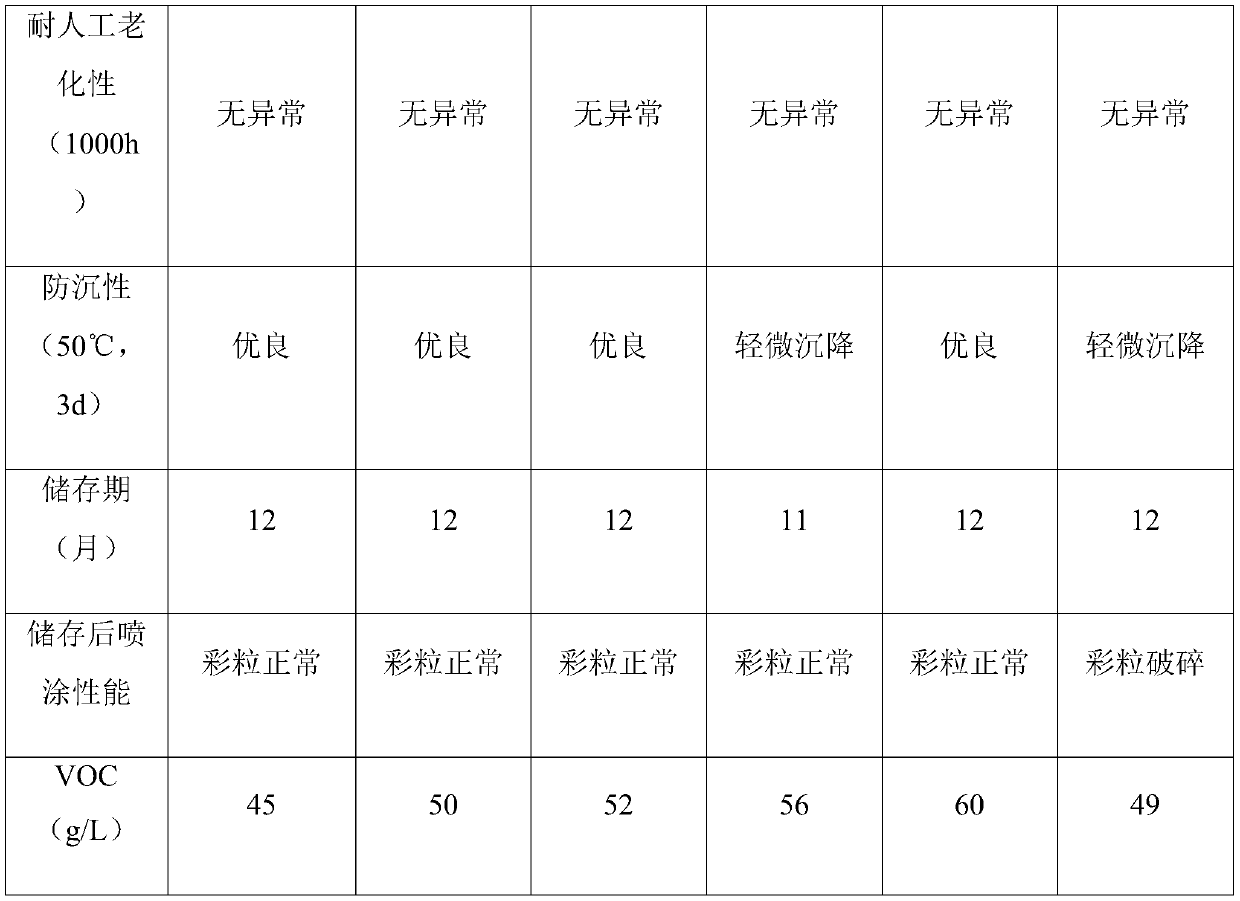

Water-coated sand coating and preparation method thereof

ActiveCN110372265AImprove pressure resistanceIncrease spaceSolid waste managementRough surfaceCellulose

The invention discloses a water-coated sand coating and preparation method. The water-coated sand coating is prepared from 20-25 parts of a protective adhesive solution, 20-25 parts of a color-adjusted basis coating, 10-15 parts of continuous phase emulsion and 30-40 parts of color sand. According to the water-coated sand coating, raw materials and the raw material ratio in the protective adhesivesolution are adjusted, and thus the prepared protective adhesive solution has high steric hindrance and viscosity stability; in the color-adjusted basis coating, associated cellulose is selected, thus the cellulose is associated with the emulsion to form a mesh structure, the strength of the basis coating is improved, and thus the coating can adapt to higher spray pressure; an anionic wetting agent with the high performance is selected to enhance the wettability between color particles and other aggregates and the emulsion, thus the color particles and the other aggregates adhere to the meshstructure in a wrapped mode, and the situation that color points are destroyed in the high pressure spraying environment is prevented; and according to the water-coated sand coating, a coating close to the texture of rough surface stone can be obtained through one step spraying.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Method for glazing specular gloss on paper surfaces

InactiveCN103334338ASimple processReliable technologyNon-fibrous pulp additionCoatings with pigmentsAdhesivePlastic film

The invention relates to a method for glazing specular gloss on paper surfaces and glazing specular gloss on paper print surfaces, and in particular relates to a method for glazing specular gloss on paper surfaces. The existing vacuum aluminum plating transfer method comprises the following steps of: coating a mold release on the surface of a plastic film, drying, rolling, carrying out vacuum aluminum plating, attaching a complex adhesive on the paper surface, baking, coiling, laying aside, and peeling to obtain a finished product. The existing vacuum aluminum plating transfer method has the disadvantages of expensive equipment, complicated process, long cycle and high cost. The invention aims at researching and developing the method for glazing specular gloss on paper surfaces. The method comprises the following steps of: a. preparing complex oleoresin; b. compounding paper pieces; and c. separating paper from the film. The method has the characteristics that a layer of prepared complex oleoresin coating is coated on the surface of the plastic film in the step of compounding paper pieces, and the complex oleoresin coating is immediately compounded with amplitude-like paper material under a stressed condition by a wet method to obtain complex curing paper. The method for glazing specular gloss on the produced paper surfaces has the effects of simplicity, good product quality, low production cost and environmental protection.

Owner:李玉龙

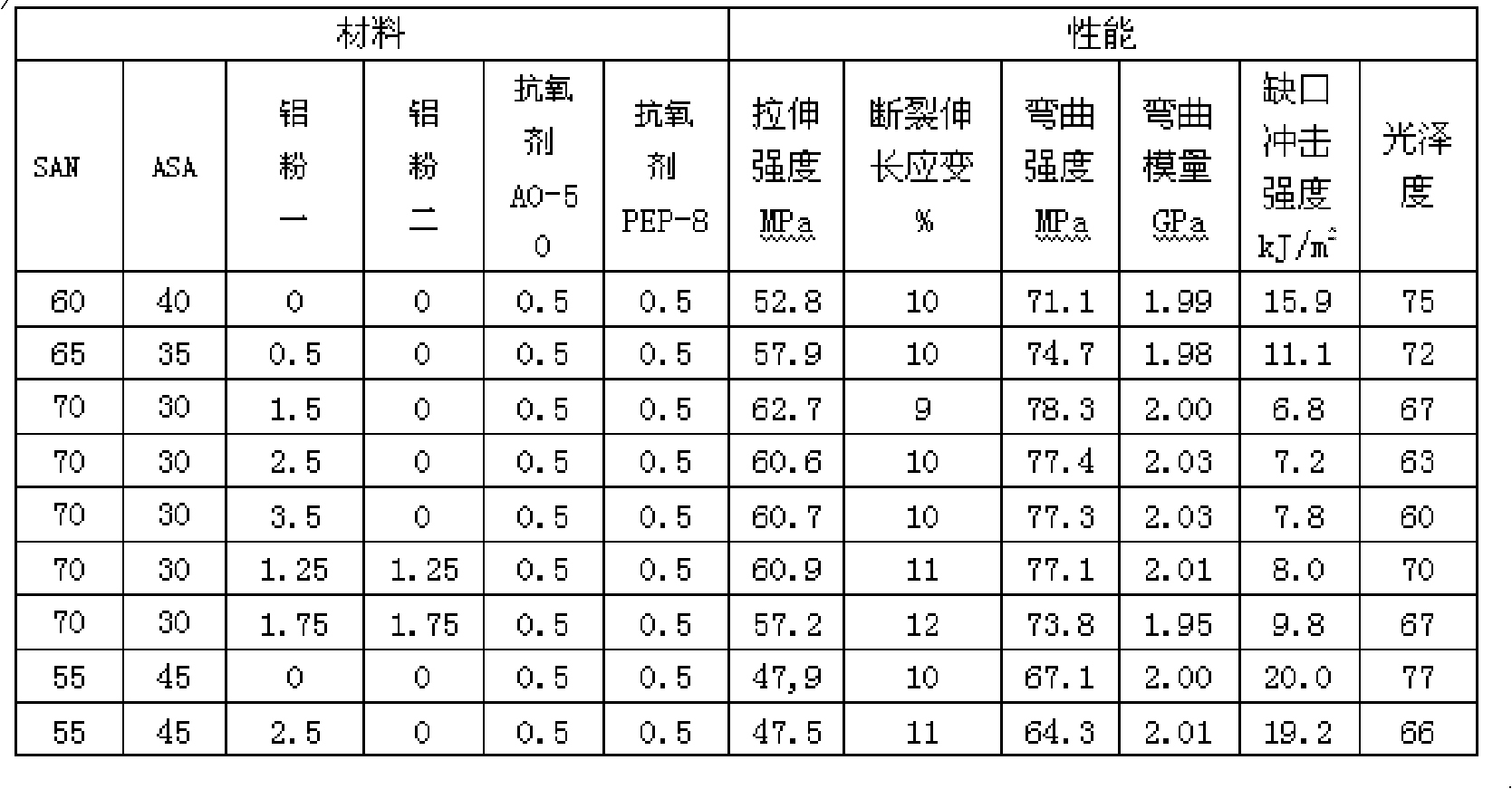

Formula of plastic material with metallic luster and preparation method thereof

The invention discloses a formula of a plastic material with metallic luster and a preparation method thereof. The formula comprises 55 to 70 parts of SAN resin, 30 to 45 parts of ASA resin, 0.5 to 3.5 parts of aluminium powders and 1 part of antioxidant. A product prepared by the method has good metallic luster, high durability, and particularly high lightfast aging performance; the metallic luster cannot fall off or fade; even if the surface of the product is scraped and abraded, the inside of the product still has the metallic luster, and a surface treatment process of spraying metallic flashing paint or metallic surface plating layer on the surface is not needed; therefore, the plastic material is suitable to serve as an automotive workpiece and can also replace the metallic workpiece. The method is simple and easy to implement, can substantially reduce production cost, and has good use effect.

Owner:国家复合改性聚合物材料工程技术研究中心

Ultrahigh heat-resistant polyester alloy for vehicle lamp and preparation method thereof

InactiveCN101724229AEasy to processImprove low temperature resistancePolyesterPolytetramethylene terephthalate

The invention provides an ultrahigh heat-resistant polyester alloy for a vehicle lamp, which comprises the following components in part by weight: 30 to 40 parts of PET nucleating agent blend, 30 to 50 parts of PBT, 0.5 to 0.8 parts of antioxidant, 0.6 to 1.2 parts of chain extender, 1 to 1.5 parts of dispersing aid, 10 to 20 parts of montmorillonoid, 0.5 to 0.9 part of silicone powder, 10 to 15 parts of talcpowder treated by coupling agent, 0.8 to 2 parts of antimonite and 0.8 to 2 parts of sodium dihydrogen phosphate. The polyester alloy of the invention keeps good workability, low temperature resistance, weather resistance and chemical resistance of thermoplastic polyester, improves the crystallinity and shaping workability of PET, has excellent heat resistance (the thermal deformation temperature under 0.46MPa reaches 222 DEG C) and good size stability, can replace the traditional BMC manufactured reflection component, and realizes integration of a reflector of a head lamp and a lamp body.

Owner:上海红京印实业有限公司

Method for surface laser-etching of ceramic product

ActiveCN103302400AGood surface effectStrong ornamentalDecorative surface effectsLaser beam welding apparatusLaser etchingComputer programming

The invention discloses a method for surface laser-etching of a ceramic product. The method comprises the steps as follows: firstly, the ceramic product is preprocessed, the chromaticity, the glossiness and the roughness of the surface of the ceramic product are guaranteed to meet the design requirements; then laser etching is performed on the surface of the ceramic product, and patterns on the surface of the ceramic product are designed through computer programming; then laser carving is performed on the surface of the ceramic product by using a laser system; the patterns are controlled by a computer, so that three-dimensional concave-convex patterns are formed on the surface of the ceramic product. According to the method, the surface of the ceramic product is etched and processed with laser, high-temperature heat produced by laser beams instantly gasifies the surface of the ceramic product; the patterns are controlled by the computer, so that the concave-convex patterns having a three-dimensional effect are formed on the surface of the ceramic product. At the same time, the invention further provides the ceramic product subjected to surface laser etching processing with the method.

Owner:CHAOZHOU THREE CIRCLE GRP

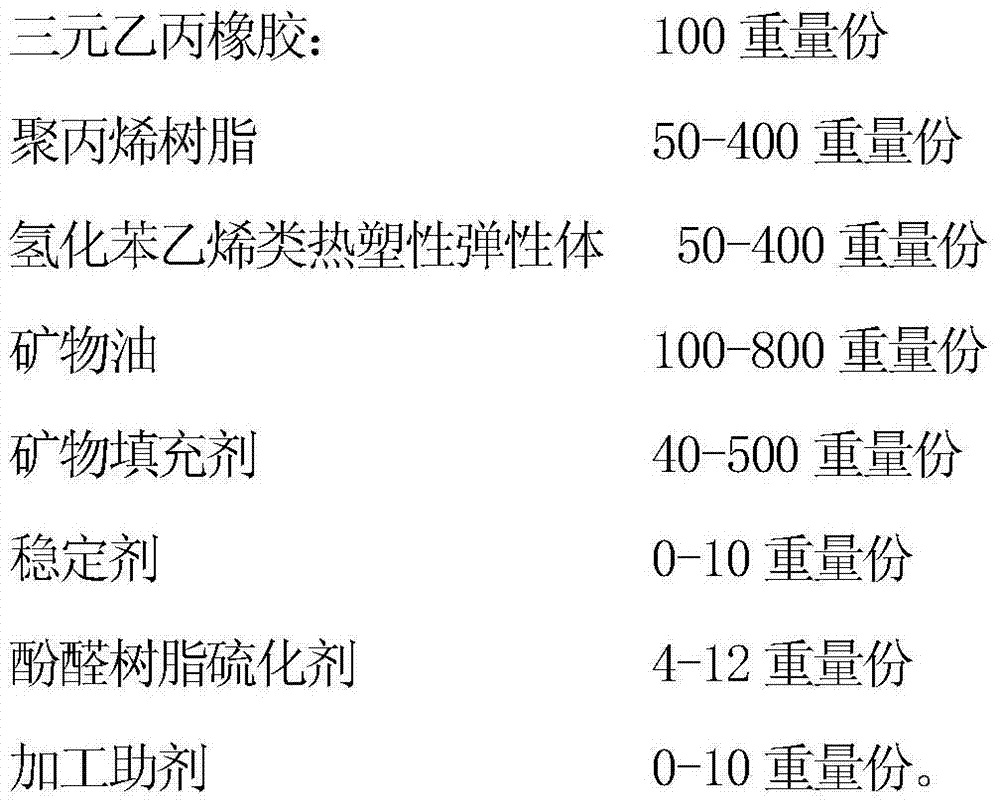

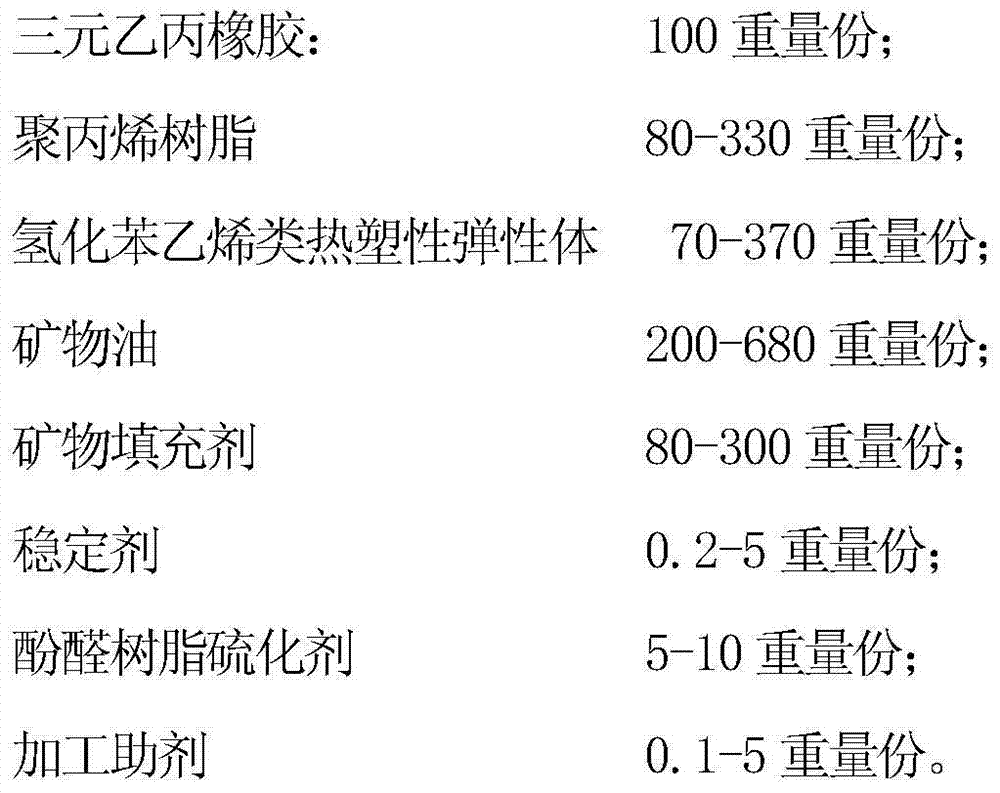

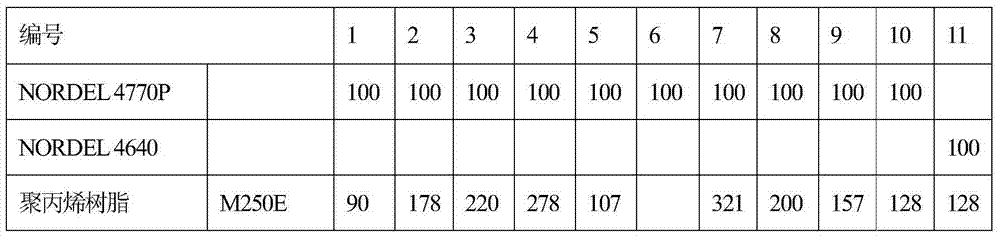

Thermoplastic vulcanizate elastomer composition and preparation method thereof

The invention discloses a thermoplastic vulcanizate elastomer composition and a preparation method thereof. The composition comprises the following components in parts by weight: 100 parts of ethylene-propylene-diene monomer rubber, 50-400 parts of polypropylene resin, 50-400 parts of a hydrogenated styrenic thermoplastic elastomer, 100-800 parts of mineral oil, 40-500 parts of a mineral filling agent, 0-10 parts of a stabilizer, 4-12 parts of a phenolic resin vulcanizing agent and 0-10 parts of processing aids. Compared with traditional TPV, the thermoplastic vulcanizate elastomer composition remains the characteristic of low compression set and is improved in term of fluidity and therefore the appearance of an injection molded surface is improved. The thermoplastic vulcanizate elastomer composition has hardness which is adjustable between 30A-55D, has soft and smooth handfeel, has damping and denoising effects and can meet the requirements of fields such as machinery, autos and electronics and electric products.

Owner:SINOTEX INVESTMENT & DEV CO LTD

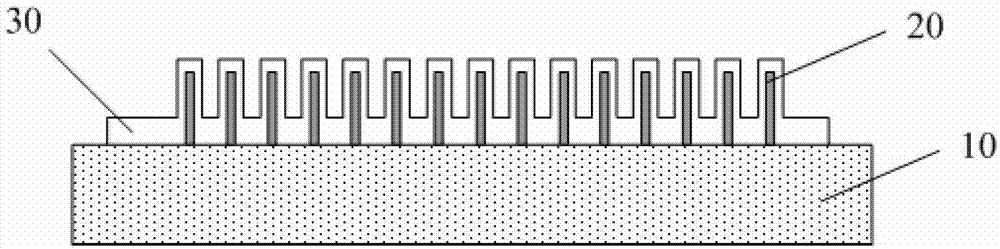

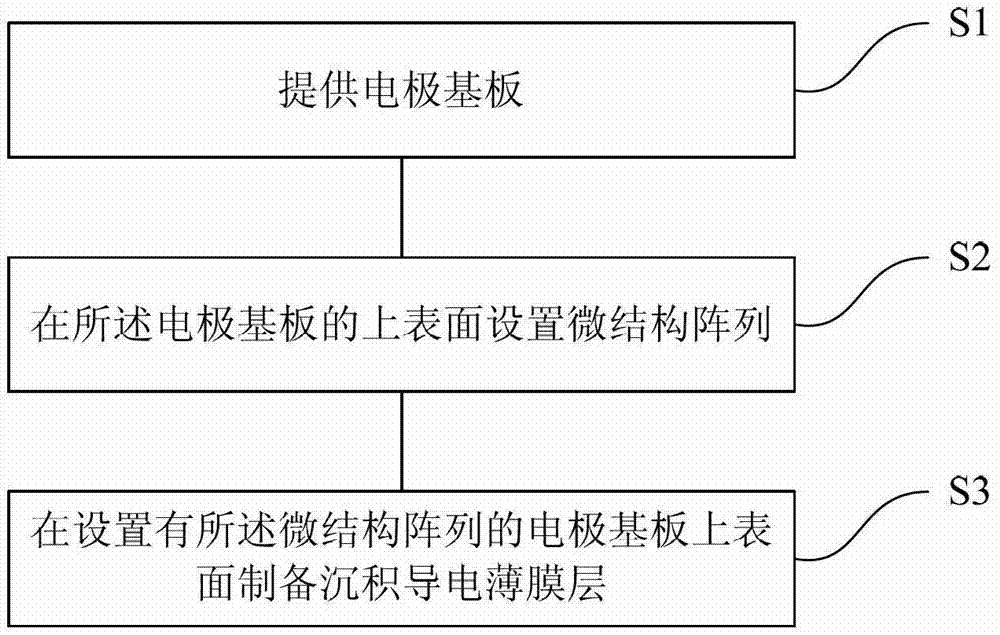

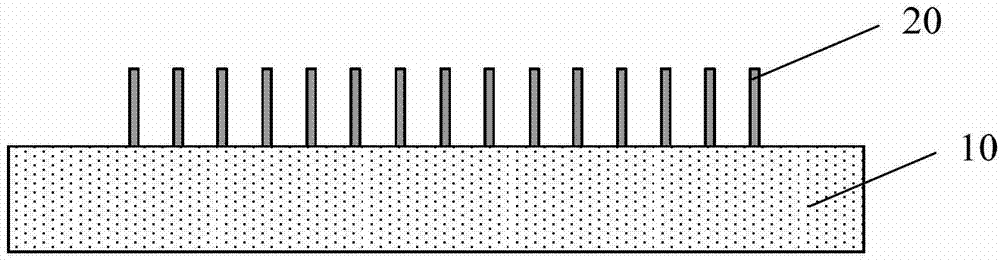

Composite electrode and preparation method thereof

InactiveCN103779400AIncrease surface areaHigh surface energySemiconductor/solid-state device manufacturingSemiconductor devicesMicro structureComposite electrode

The invention provides a composite electrode, which comprises an electrode substrate, a micro structure array and a conductive film layer, wherein the micro structure array is arranged on the upper surface of the electrode substrate; and the conductive film is deposited on the surface of the electrode substrate provided with the micro structure array. Correspondingly, the invention further provides a preparation method for the composite electrode. According to the invention, a surface modification layer provided with the micro structure layer is prepared on the surface of the electrode substrate, thereby enabling the electrode surface to have the micro structure array, and being capable of effectively increasing the mutual contact area when the composite electrode and other materials are contacted or friction is generated therebetween.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

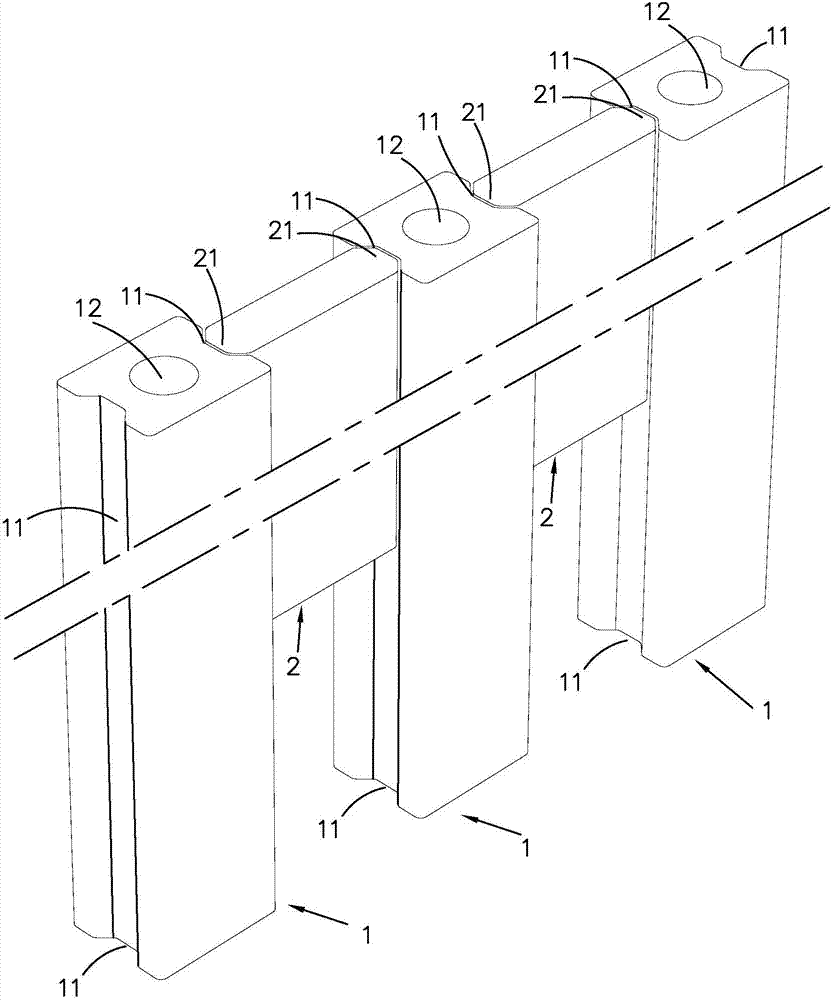

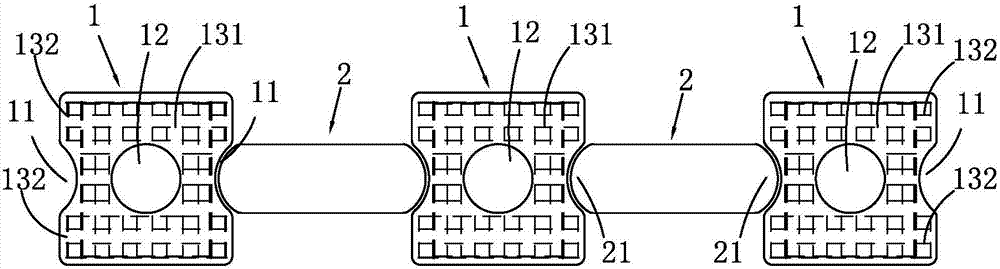

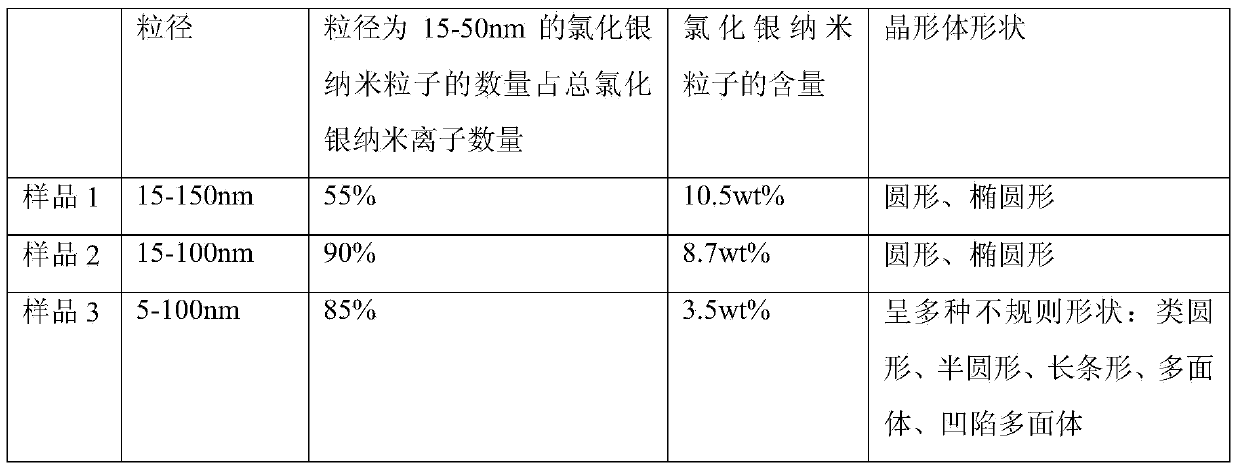

Ecological landscape combination revetment

An ecological landscape combination revetment comprises stress piles and inserting sheet piles, wherein, the inserting sheet piles are used for being in fit connection with the stress piles and used for blocking soil and stopping water, the left and right sides of one of the stress piles and the inserting sheet piles are correspondingly provided with inserting slots extending in the longitudinal direction, and the left and right sides of the other one of the stress piles and the inserting sheet piles are correspondingly provided with inserting parts which extend in the longitudinal direction and are matched with the corresponding inserting slots in a mutual abutting mode. A new technical scheme of the ecological landscape combination revetment is provided, the ecological landscape combination revetment is mainly composed of the stress piles and the inserting sheet piles, every two stress piles are connected through one inserting sheet pile for blocking soil and stopping water, the stress piles and the inserting sheet piles adopt two specifications, and the requirements for revetment and supporting stress can be met; and the skipped piling construction method is adopted during construction, thus the soil-squeezing effect is weakened, the positioning accuracy is high, and the effect of the formed surface is good.

Owner:建华建材科技(江苏)有限公司 +1

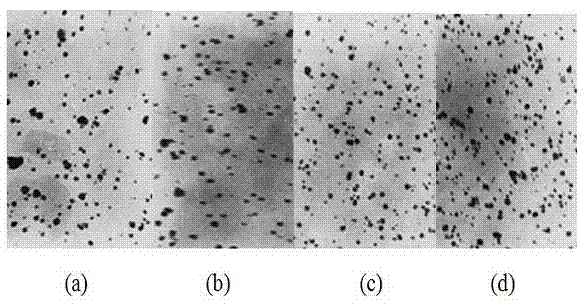

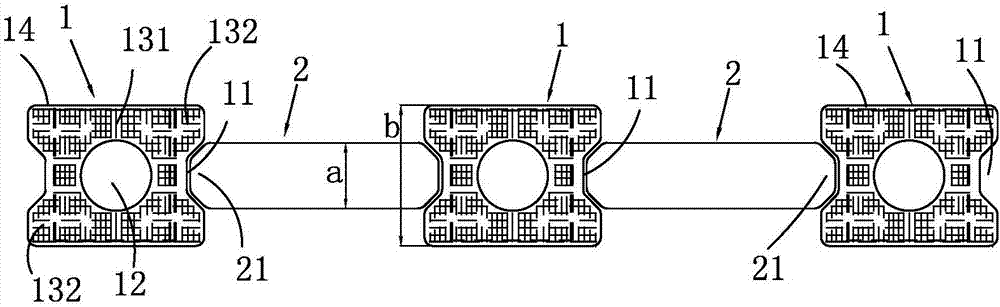

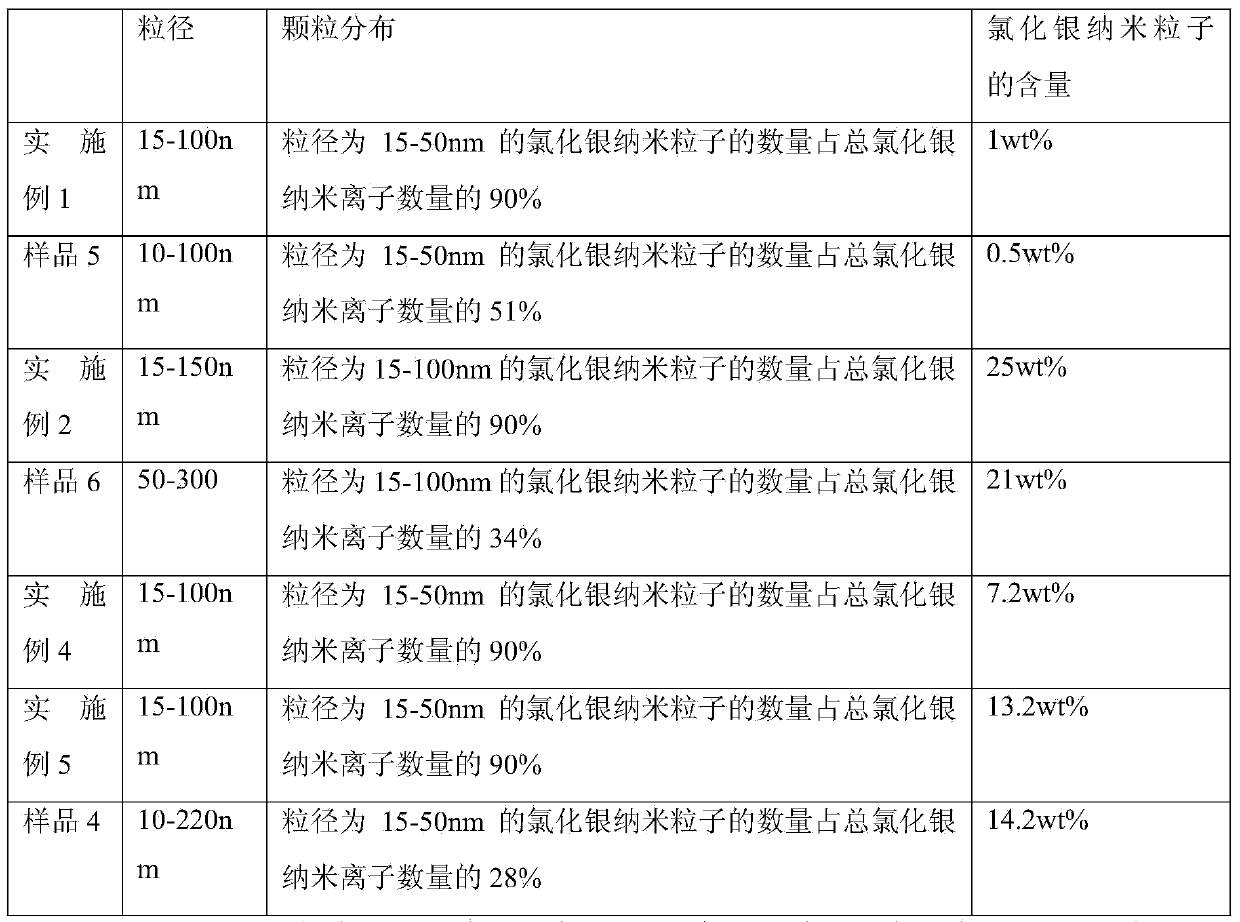

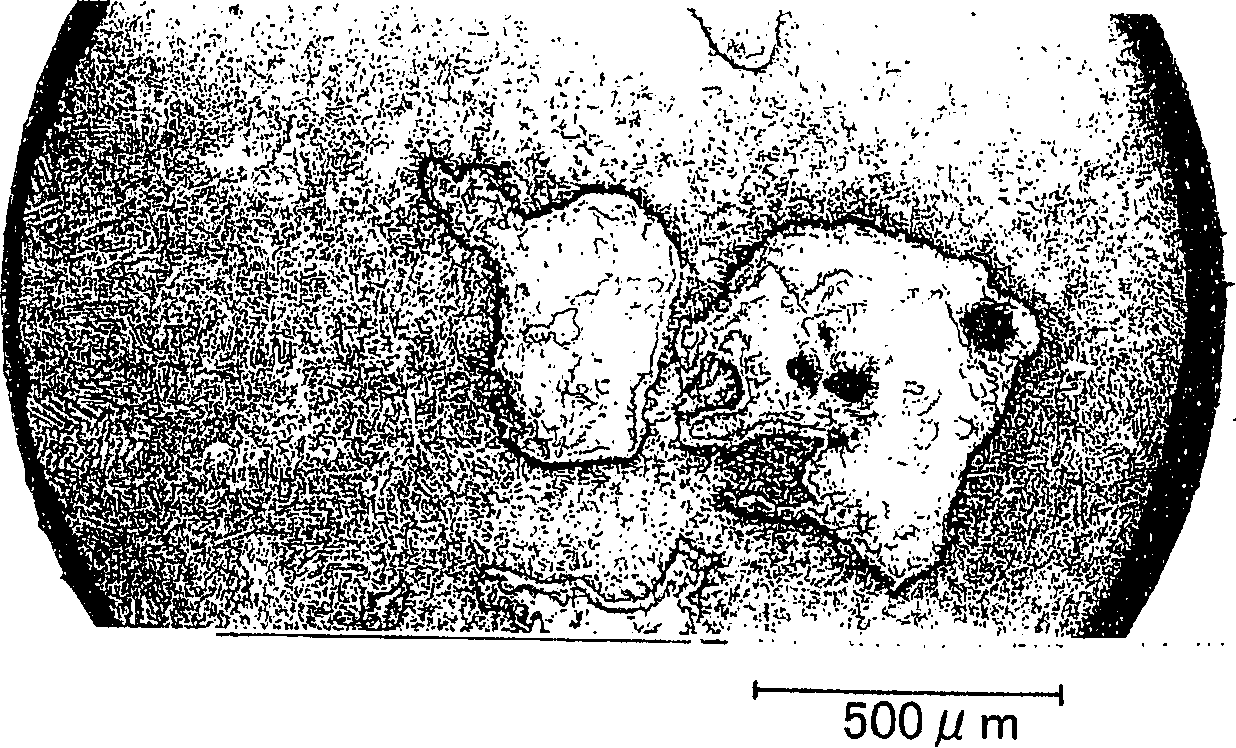

Bacterial cellulose fiber containing nano-silver chloride particles and preparation method of fiber

ActiveCN103469542ANarrow particle size distributionExcellent Surface EffectMonocomponent cellulose artificial filamentWet spinning methodsAnti bacterialBacterial cellulose

The invention belongs to the field of preparation of cellulose fiber and specifically relates to bacterial cellulose fiber containing nanoscale silver chloride particles. The diameter of the bacterial cellulose fiber is 10-50 microns, the silver chloride nano-particles are attached to the surface of the micro-fiber, the particle size of the silver chloride nano-particles is 15-150nm, the silver chloride nano-particles with the particle size of 15-100nm account for above 90% of total silver chloride nano-ions, and the content of the silver chloride nano-particles is 1-25 wt%. The invention further provides a preparation method of the bacterial cellulose fiber containing the nanoscale silver chloride particles. The particle size distribution of the silver chloride particles loaded on the bacterial cellulose fiber is narrow, the silver chloride particles have small and uniform particle size, the purity of the silver chloride particles is very high, and an antibacterial effect is very excellent.

Owner:CHINESE TEXTILE ACAD

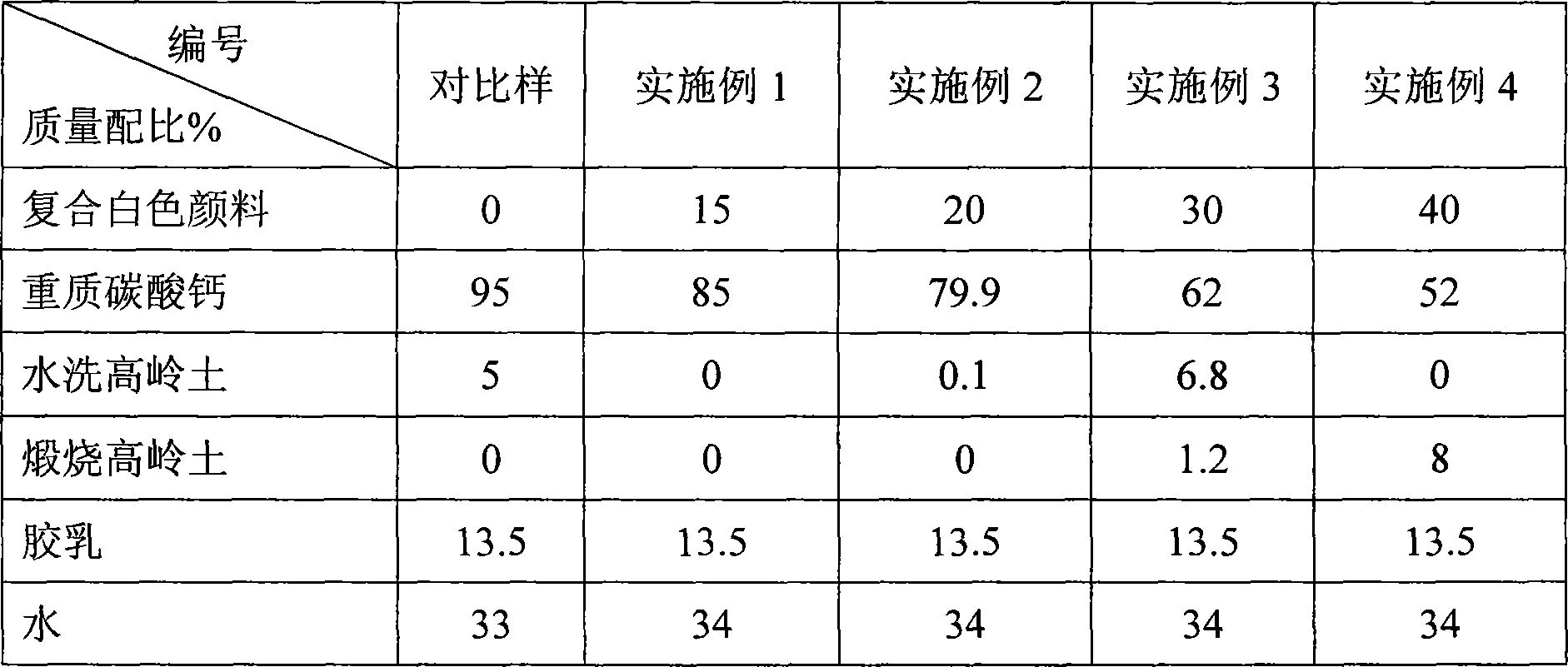

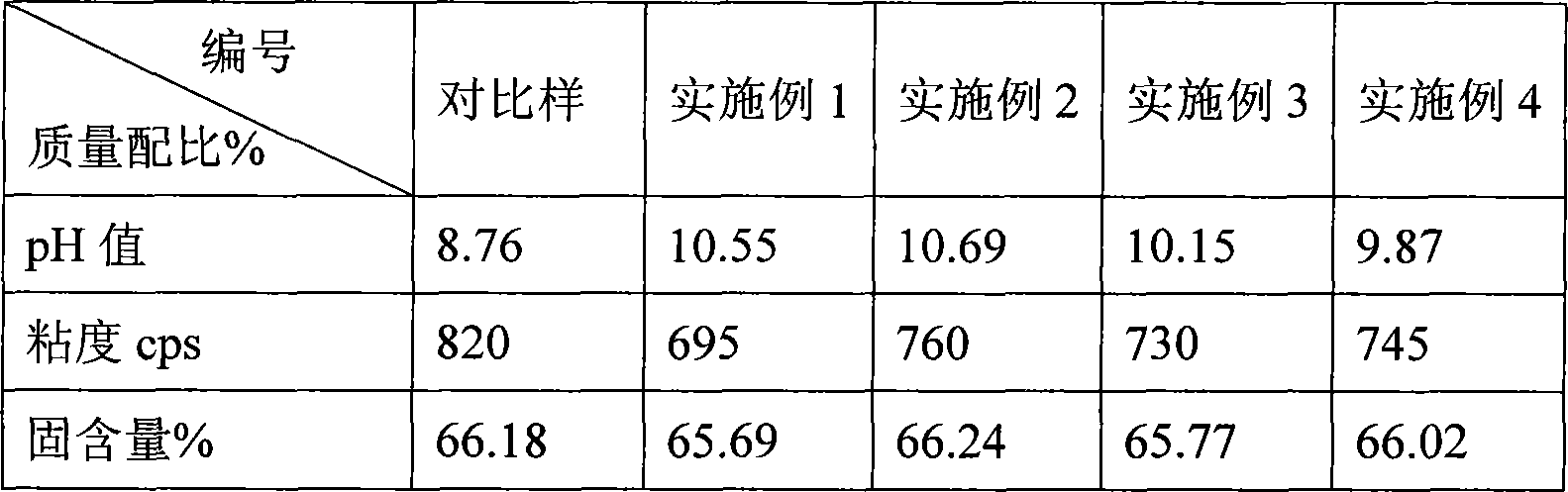

Dope used as back coat of white bottom coated white board paper and its preparing method and application

InactiveCN101210399AIncrease coverageIncrease brightnessCoatings with pigmentsCoatingsWhiteboardPaper sheet

The invention provides a coating material for back-coating white-bottom coated white paper board and a preparation method and an application thereof. The coating material comprises a composite white pigment 15 to 65 weight parts, heavy calcium carbonate 35 to 85 weight parts, latex 10 to 20 weight parts and water 25 to 45 weight parts. The composite white pigment is a composite material containing a titanium dioxide inner core and a calcium carbonate housing wrapping the inner core of the titanium dioxide particles. The coating material for back-coating white-bottom coated white paper board has the advantages of good covering performance, high brightness, uniform covering, uniform color and good surface effect, and can reduce the consumption of backside wood pulp by 20% to 50%.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Build-up wear-resistant copper alloy and valve seat

InactiveCN1806059AGood surface effectImprove solderabilityMachines/enginesMetallic material coating processesWear resistantImpurity

Owner:TOYOTA JIDOSHA KK

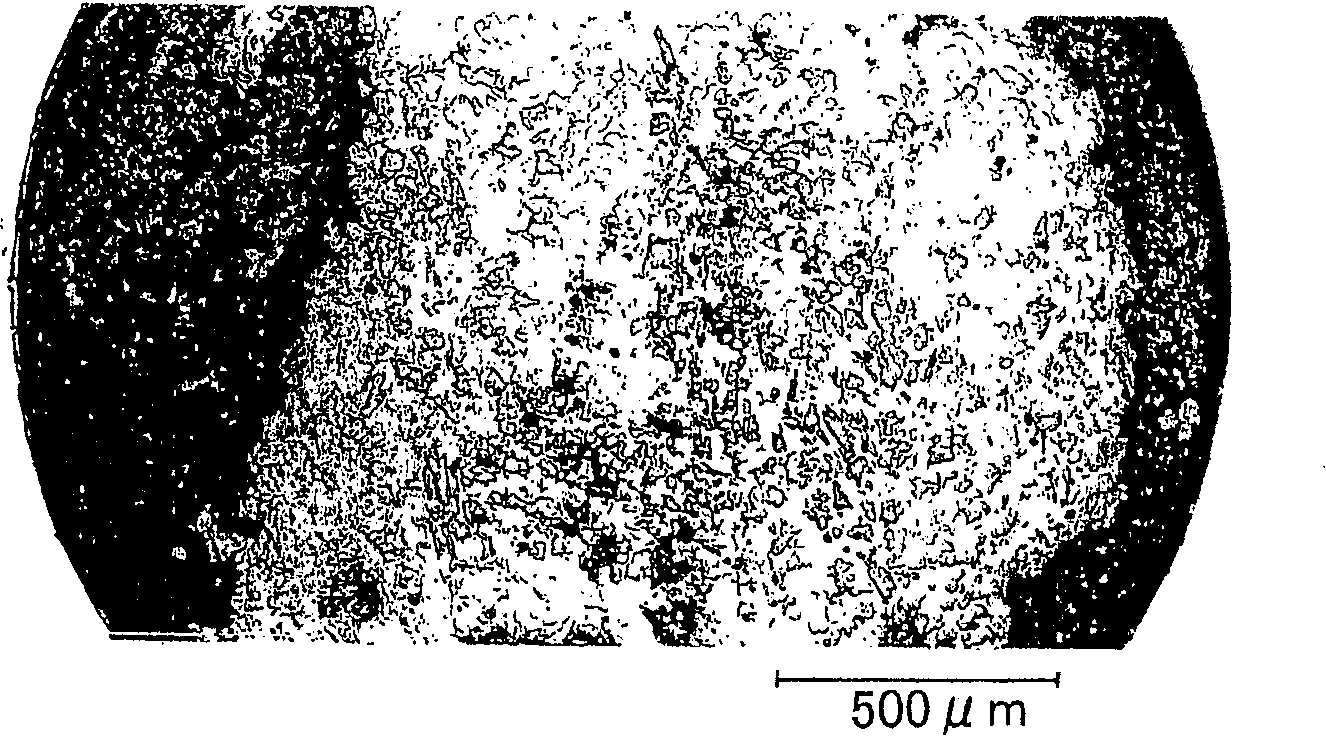

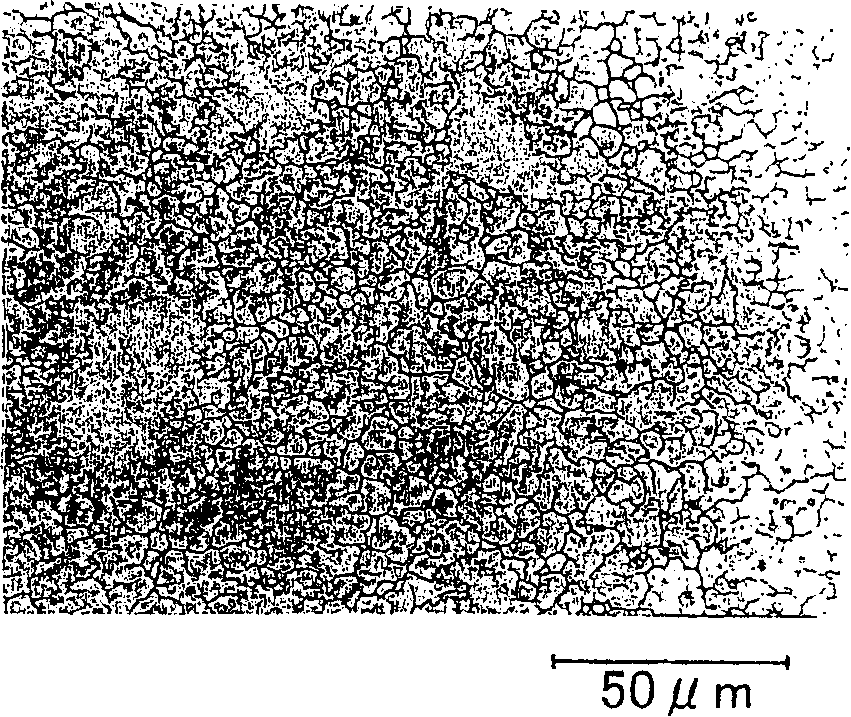

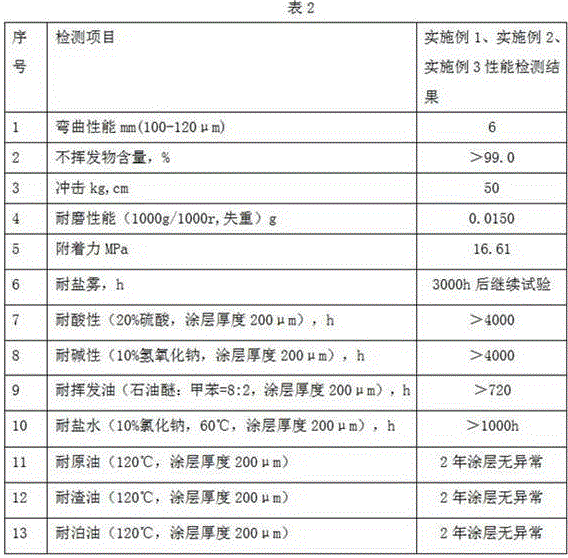

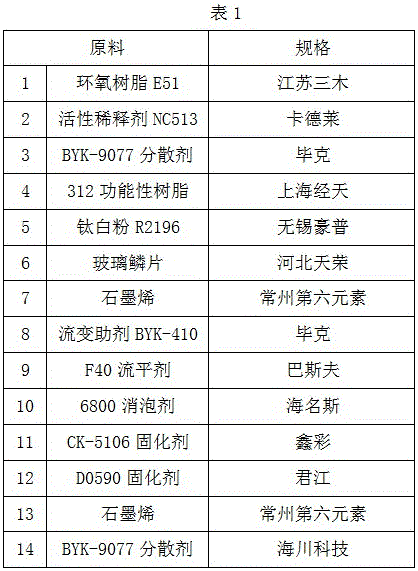

Low-viscosity solvent-free epoxy graphene glass-flake coating and preparation method thereof

ActiveCN106243922AEnsure structural dispersion stabilityGuaranteed flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention discloses a low-viscosity solvent-free epoxy graphene glass-flake coating and a preparation method thereof, and aims to solve the problems that the conventional solvent-free epoxy graphene glass-flake coating has a high requirement on a construction thickness, is not ideal in corrosion resistance, needs to apply heating spraying and has a large number of coating working procedures. The coating consists of two components specifically as follows: the component I is prepared from the following raw materials in percentage by mass: 37 to 40 percent of epoxy resin E51, 2 to 4 percent of an active diluents NC513, 0.2 to 0.6 percent of a dispersing agent BYK-9077, 15 to 23 percent of functional resin 312, 14 to 15 percent of titanium dioxide R2196, 20 to 25 percent of glass flakes, 0.2 to 0.3 percent of graphene, 0.2 to 0.5 percent of a rheological agent BYK-410, 0.2 to 0.4 percent of a leveling agent F40 and 0.2 to 0.6 percent of a defoaming agent 6800; the component II is prepared from the following raw materials in percentage by mass: 75 to 94 percent of a curing agent CK-5106, 5.6 to 24.2 percent of a curing agent D0590, 0.2 to 1.5 percent of graphene and 0.2 to 1.0 percent of the dispersing agent BYK-9077. The coating can be directly used for coating by a conventional construction process without being heated, and the construction is rapid, simple and convenient.

Owner:西北永新涂料有限公司

Overlaying welding flux-cored wire for S pipe valve, glass-like plate and wear ring of concrete pump

ActiveCN101602152AHigh hardnessImprove toughnessWelding/cutting media/materialsSoldering mediaNiobiumRare earth

The invention relates to an overlaying welding flux-cored wire for an S pipe valve, a glass-like plate and a wear ring of a concrete pump. The flux-cored wire comprises the following chemical compositions in percentage by weight: 3.0 to 4.0 percent of carbon, 2.5 to 3.5 percent of vanadium, 28 to 34 percent of chromium, 2.5 to 3.5 percent of niobium, 1.0 to 3.0 percent of manganese, 0.5 to 1.5 percent of boron, 0.5 to 2.0 percent of silicon, 2.5 to 3.0 percent of rare earth, 6.0 to 8.0 percent of tungsten, 2.5 to 3.5 percent of molybdenum, and the balance of iron. The sheath is made of a low carbon steel belt, and the core part is filled with alloy powder of the compositions and is drawn into the flux-cored wire. The overlaying welding flux-cored wire manufactured according to the chemical compositions has good overlaying welding performance, nice appearance, high strength, high hardness, excellent impact resistance, good wear resistance and long service life, has hardness reaching HRC of more than or equal to 65, and is the perfect overlaying welding flux-cored wire for manufacturing and repairing the S pipe valve, the glass-like plate and the wear ring of the concrete pump in the construction industry.

Owner:ZHUZHOU ZHENXIANG IND CO LTD

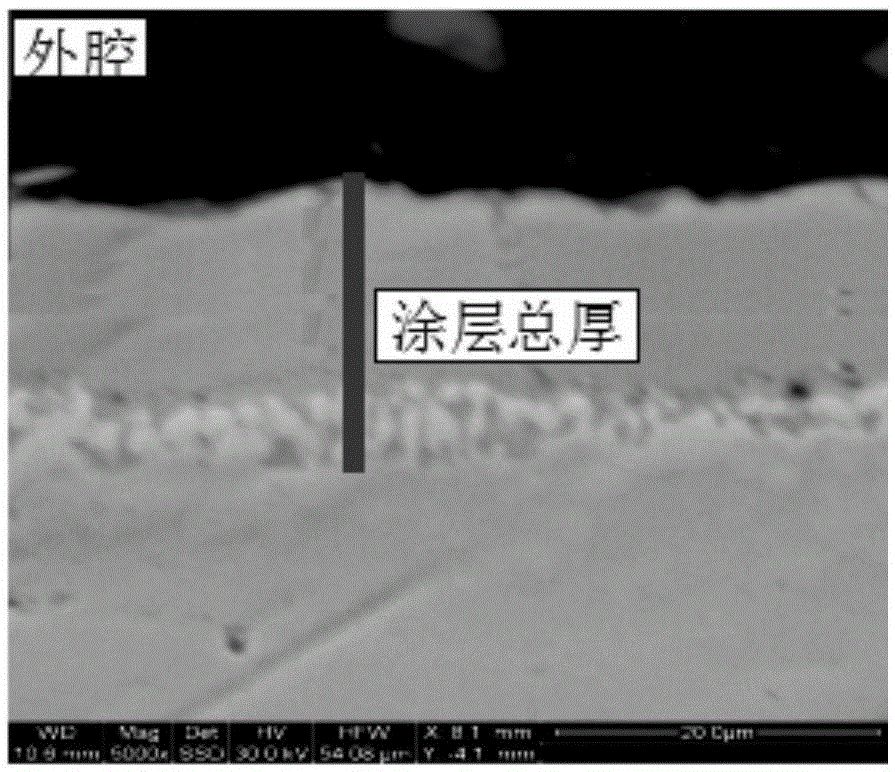

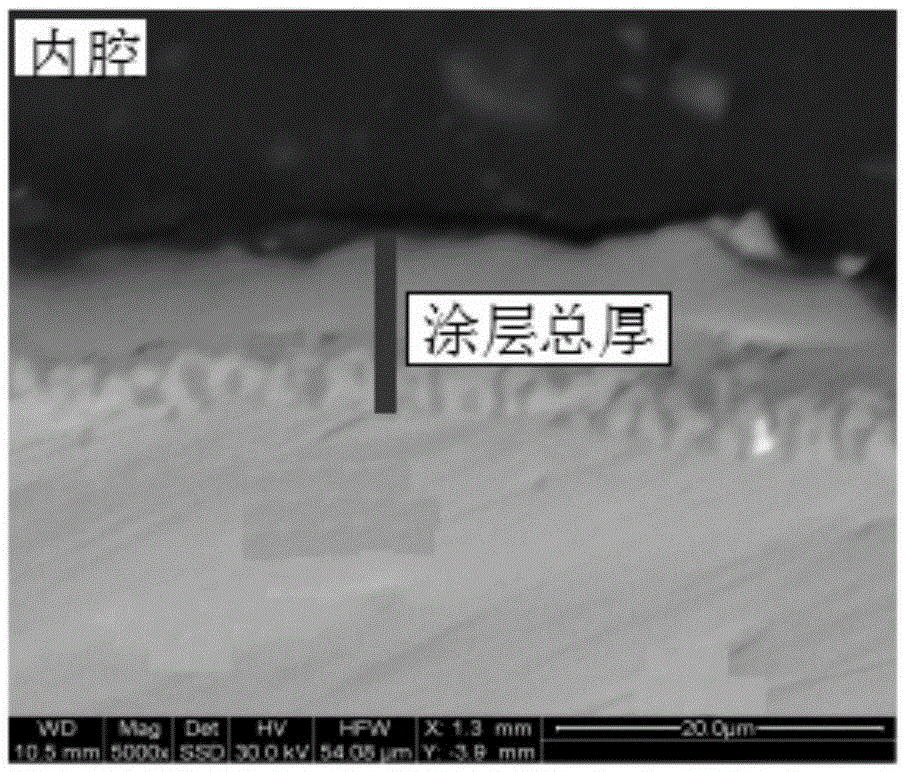

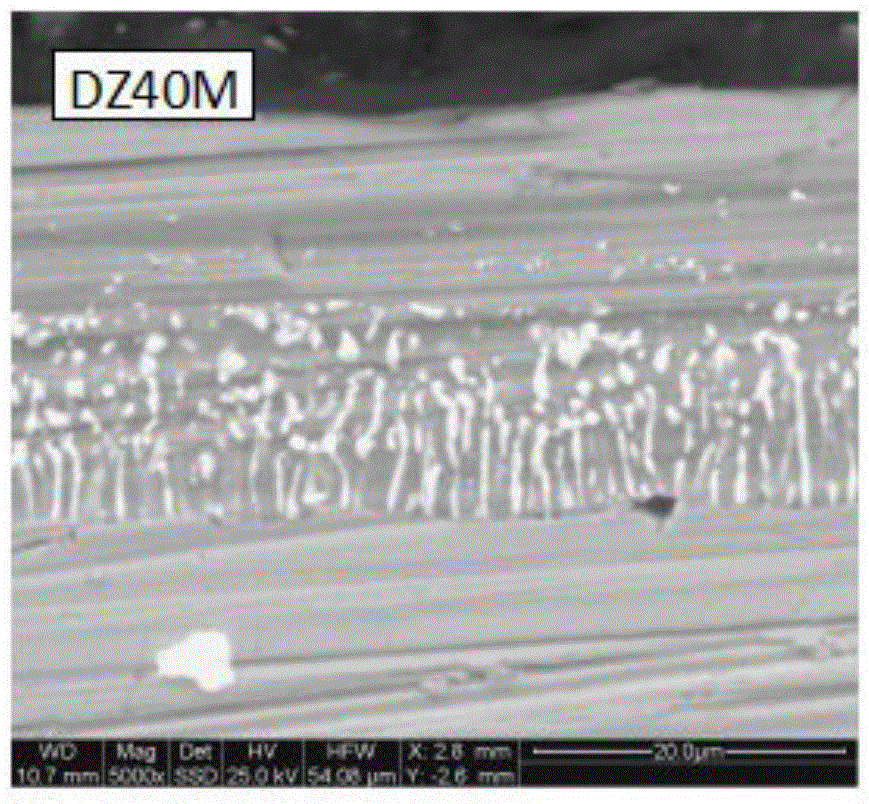

Aluminizing process method for inner cavity and outer surface of cobalt-base alloy blade

ActiveCN105296956AMeet design and manufacturing requirementsImprove antioxidant capacityChemical vapor deposition coatingGas phaseOxidation resistant

The invention belongs to the field of heat treatment and particularly relates to an aluminizing process method for an inner cavity and the outer surface of a cobalt-base alloy blade. The high-pressure engine turbine guide blade is manufactured from DZ40M cobalt-base casting alloy and is the important heat end component of an aero-engine. Under the harsh working environment, in order to improve the oxidation resistance and corrosion resistance of the inner surface and the outer surface of the blade, the high-temperature protection technology is adopted for the surface of an outer runner of the high-conductivity blade, in other words, aluminized layers are prepared on the inner cavity of and the surface of the outer runner of the high-conductivity blade at the same time, so that the reliability of the blade is improved, and the service life of the blade is prolonged. By means of the method, the design manufacturing requirement of the high-pressure engine turbine guide blade can be met, the depth of the aluminized layer of the surface of the outer runner of the high-conductivity blade ranges from 0.02 mm to 0.055 mm, and the depth of the aluminized layer of the inner cavity ranges from 0.01 mm to 0.035 mm; the effect that the surface of the blade is protected through chemical vapor deposition aluminizing is remarkable; and compared with a substrate, the oxidation resistance of the blade is improved by two times, corrosion resistance can be improved by two times, and the service life of the blade is prolonged.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

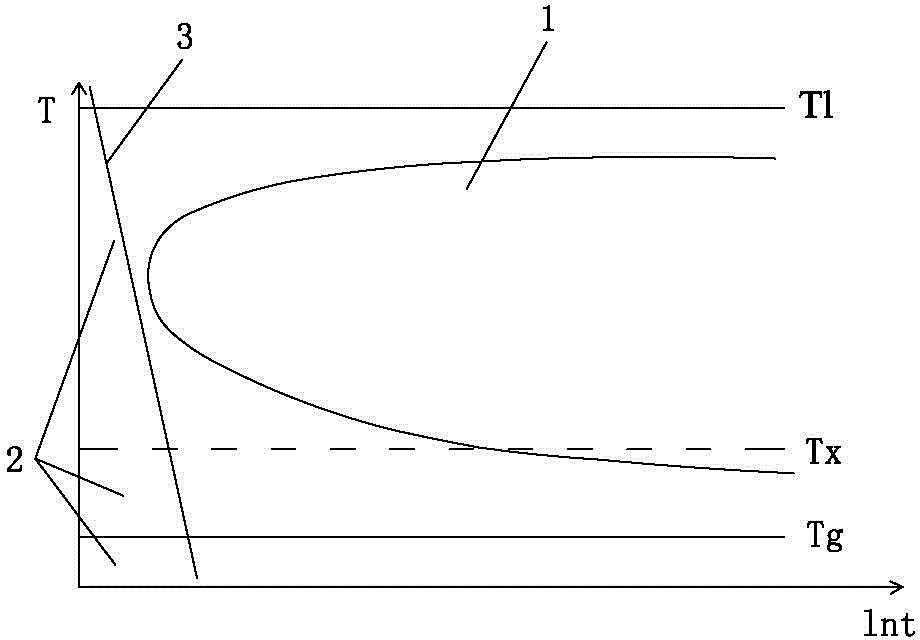

Amorphous alloy scalpel and manufacture method thereof

The invention relates to the technical field of amorphous alloy application and particularly relates to an amorphous alloy scalpel and a manufacture method thereof. The scalpel is an amorphous alloy scalpel manufactured by a zirconium-based amorphous alloy, a copper-based amorphous alloy, a titanium-based amorphous alloy, a nickel-based amorphous alloy, a palladium-based amorphous alloy or an iron-based amorphous alloy. The Vickers hardness of the scalpel is 400-600, the yield strength is 1000-3000 MPa, the elastic limit is 2-3%, and the nickel release amount is 0-0.015 mg / cm2 / week; the surface of the scalpel is not corroded after a salt spray test is done for 500-2000 hours. The manufacture method comprises the steps of preparing an integral outline shape of the scalpel through a die-cast formation method, and molding the knifepoint part through TPF or RDF to obtain the amorphous alloy scalpel. The amorphous alloy scalpel has the advantages of high precision, high strength, high elasticity, high hardness, scratch-resistance, corrosion-resistance, and sharp and long service life.

Owner:DONGGUAN PROMETAL TECH CO LTD

Flux-cored wire for additive manufacturing and preparation method of low-alloy high-strength steel

ActiveCN111360449AShorten the production cycleEasy to produceAdditive manufacturing apparatusArc welding apparatusRare-earth elementSheet steel

The invention discloses a flux-cored wire for additive manufacturing. The wire comprises a flux core and sheet steel. The flux core is composed of, by mass percent, 2.00%-3.83% of ferromanganese powder, 16.95%-20.85% of nickel powder, 8.35%-11.65% of chromium powder, 1.05%-3.00% of molybdenum powder, 0.90%-1.62% of ferrovanadium powder, 0.05%-0.10% of boron powder, 2.16%-10.82% of ferrotitanium powder, 0.5%-1.5% of ferrosilicon powder, 0.50%-1.00% of aluminum-magnesium powder, 0.80%-1.00% of rare earth elements and the balance being iron powder, wherein the sum of the mass percents of the components is 100%. The flux-cored wire is a wire used for arc additive manufacturing of low-alloy steel applied to a fan impeller. The invention further discloses a preparation method of low-alloy high-strength steel. The flux-cored wire has excellent comprehensive mechanical properties; and by the adoption of an additive manufacturing mode, the low-alloy high-strength steel can meet the requirementon the mechanical properties and is efficient and convenient to use.

Owner:XIAN UNIV OF TECH

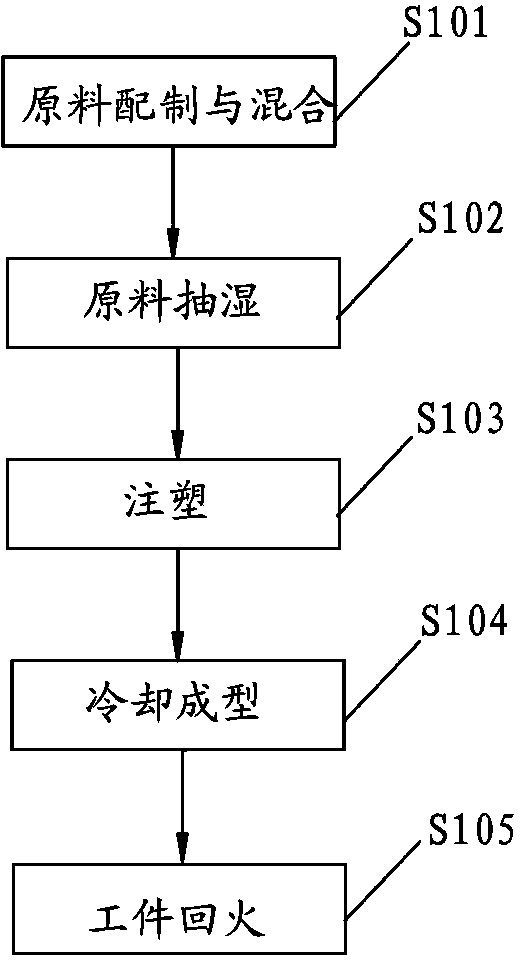

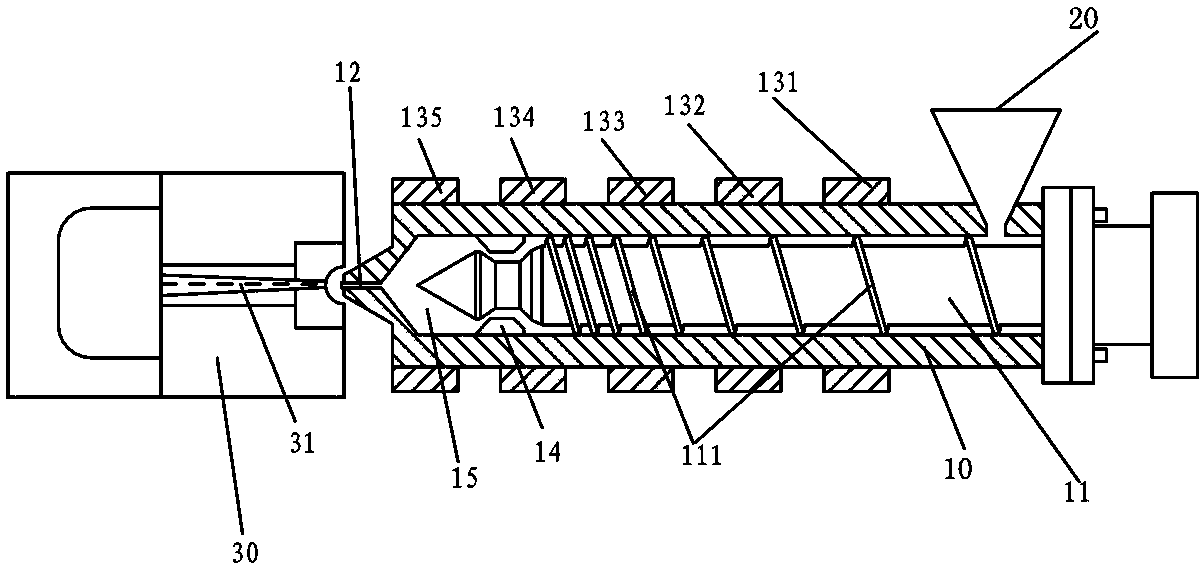

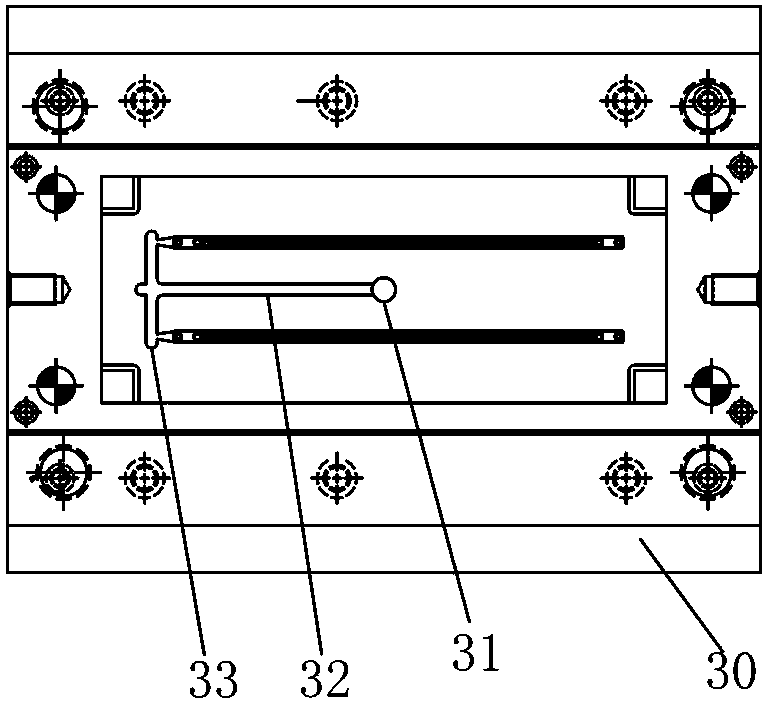

Injection moulding method of long glass fiber reinforced nylon 66 materials

An injection moulding method of long glass fiber reinforced nylon 66 materials comprises the steps of raw material preparing, mixing, raw material dehumidifying, injection moulding, cooling forming and workpiece tempering in sequence. In the step of injection moulding, mixed particle materials which are subjected to dehumidifying in the second step are placed to an injection moulding machine for melting, the portion between the tail end of the injection moulding machine to a jetting mouth is divided into five sections of temperature grades, temperature is controlled between 210-320 DEG C, so that the mixed particle materials are molten, then glue jetting is carried out slowly in a one-section or subsection mode through the injection moulding machine, the molten materials are added into a product mould in an injection-moulding mode, and the mould for injection moulding is kept under the constant temperature of 120 DEG C. According to the injection moulding method of the long glass fiber reinforced nylon 66 materials, under the situation that cost is not changed greatly, the fatigue resistance of a product is improved, and the service life of the product is prolonged. Meanwhile, according to the material formula used in the scheme, product tenacity can be effectively improved, and surface effect is good.

Owner:ZENGCHENG HUACHANG PLASTIC HARDWARE MOLD

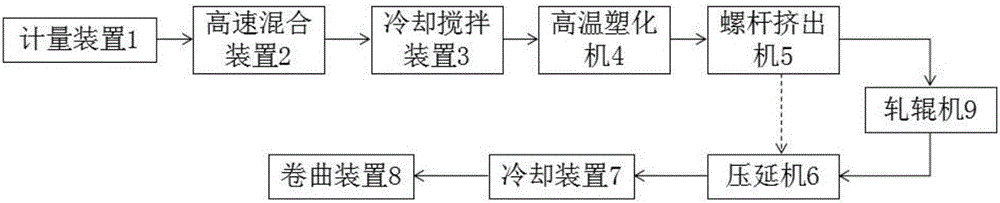

Multifunctional advertisement film preparation method

The invention discloses a multifunctional advertisement film preparation method and belongs to the field of film materials. The multifunctional advertisement film preparation method includes the steps of preparing raw materials including, by mass, 100 parts of PVC (polyvinyl chloride), 15-30 parts of plasticizers, 2-4 parts of barium-zinc composite stabilizers, 0-4 parts of nanometer fillers, 0.5-1.5 parts of uvioresistant materials UV531, 0.1-1 part of antioxidant CB, 1-2 parts of ACRs (accelerants) and 0.01-0.05 part of rutile titanium dioxide powder; metering the raw materials by a metering device, mixing and stirring by a high-speed mixing device, stirring by a cooling and stirring device, plastifying by a high-temperature plasticator, melting and extruding by a screw extruder, rolling, cooling and reeling to obtain the required film. The multifunctional advertisement film preparation method has the advantages that a polyester plasticizer is adopted, the molecular weight of the polyester plasticizer is controlled above 600, and due to the large molecular weight, the plasticizer of the formed rolled automobile film is less prone to transferring in a high-temperature environment, loss of the plasticizer is postponed, aging resisting performance of the film can be enhanced substantially, and falling of the film can be prevented.

Owner:JIANGSU DAHAI PLASTIC

Wall decoration board, UV transfer printing and coating technology thereof, and applications thereof

InactiveCN105298059AImprove protectionGood for healthCovering/liningsLayered productsWeather resistanceAdhesive

The invention discloses a wall decoration board, a UV transfer printing and coating technology thereof, and applications thereof. The wall decoration board is characterized in that the back surface of a substrate is coated with a UV back coating layer; the front surface of the substrate is sequentially coated with a UV penetration primer; the UV penetration primer is coated with UV filling putty; the UV filling putty is coated with a UV roller coat sanding primer; the UV roller coat sanding primer is coated with a UV rolling coat before-sprinkling roller; the UV rolling coat before-sprinkling roller is coated with a UV covering white primer; the UV covering white primer is coated with UV transfer printing glue; a transfer printing film is subjected to UV solidification and transfer printing on the UV transfer printing glue; the transfer printing film is coated with an adhesive; the adhesive is coated with a UV primer or a UV outdoor varnish layer; and the UV outdoor varnish layer is coated with a film covering layer. The wall decoration board is highly environment-friendly, is good in compound effect, water boiling resistance, water resistance, yellowing resistance and weather resistance, has multiple kinds of patterns, and is high in coating efficiency.

Owner:HUNAN BANFERT NEW MATERIALS TECH

Regenerating surface properties for composites

ActiveUS20110129646A1Reduce noiseReduce fluid resistanceMouldsFinal product manufacturePolyresinGelcoat

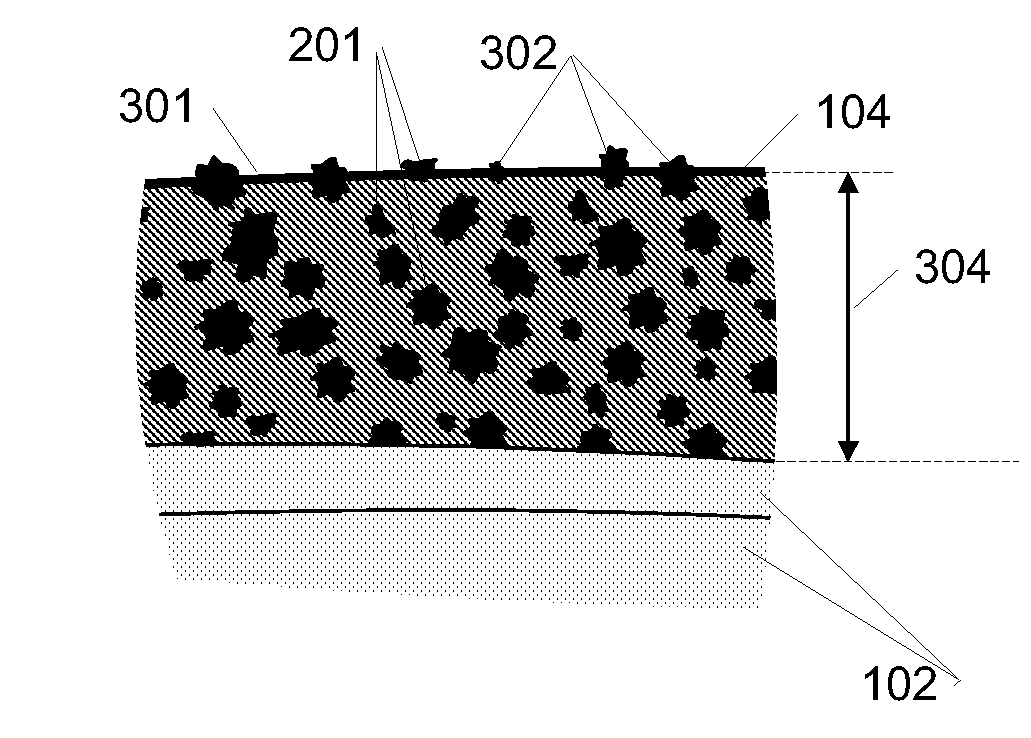

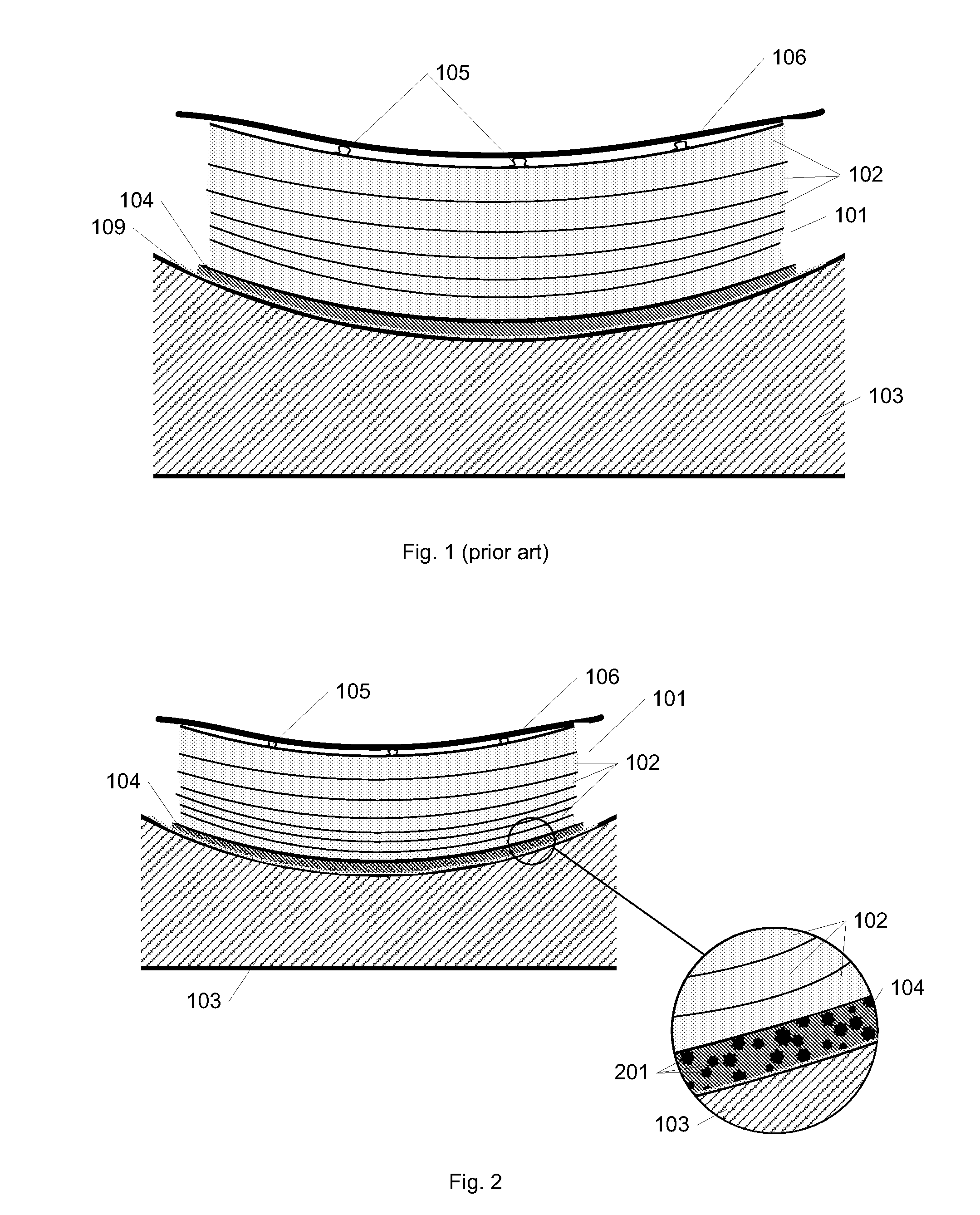

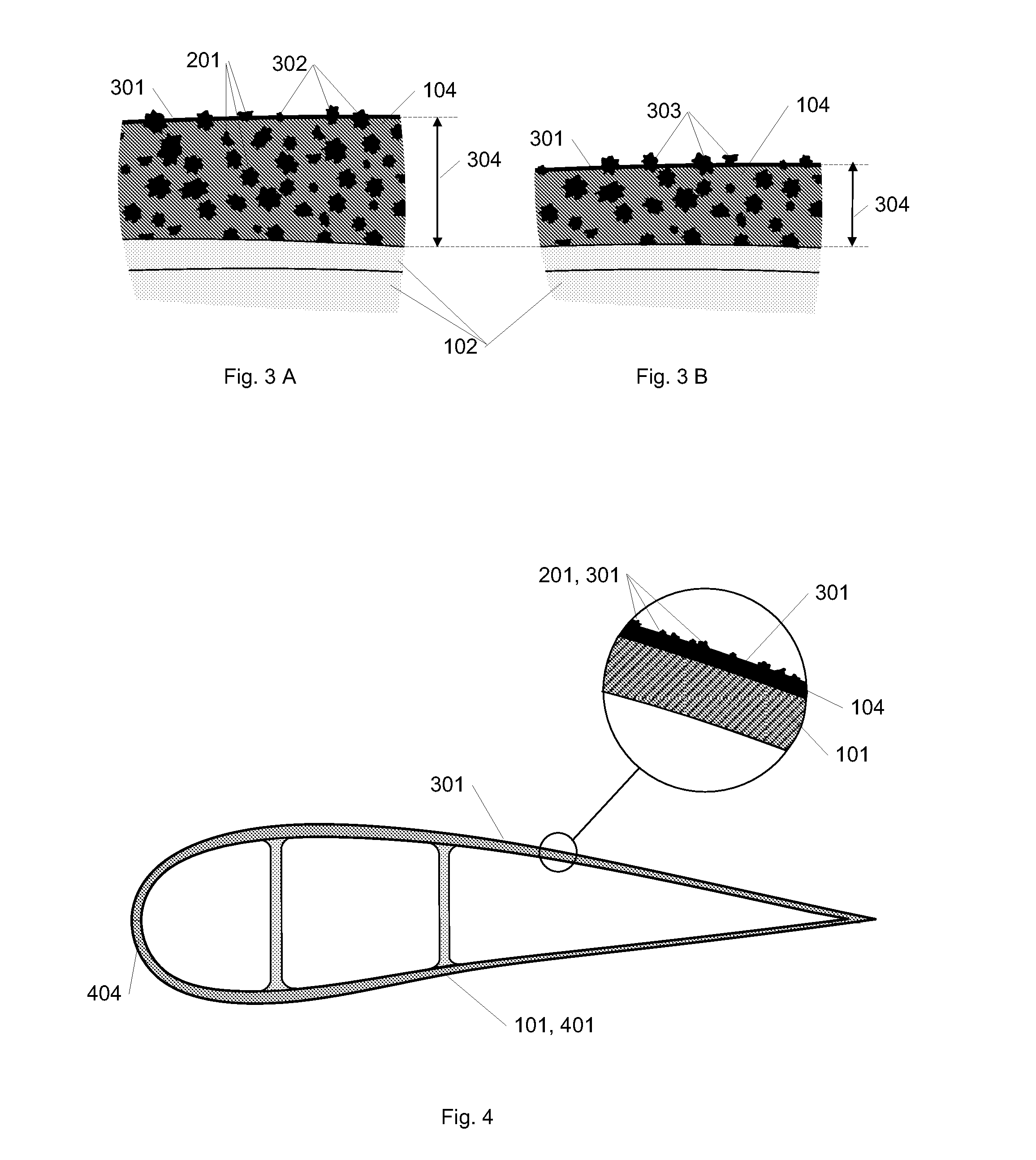

This invention relates to a method for manufacturing a composite member, where a number of different material layers including at least one layer of gelcoat are applied in a mould, and where resin is applied for joining of the layers. The method is new in that particles are added to the gelcoat, whereby the gelcoat comprising such particles forms an outermost layer on at least a part of the manufactured composite member. Hereby is obtained a composite with a hydrophobic and lotus-like surface yielding good self-cleaning properties and which is on the same time self-regenerating. The invention furthermore relates to composite members comprising such a gelcoat layer with particles and to the use of gelcoat comprising particles for giving regenerating self-cleaning properties.

Owner:LM GLASSFIBER

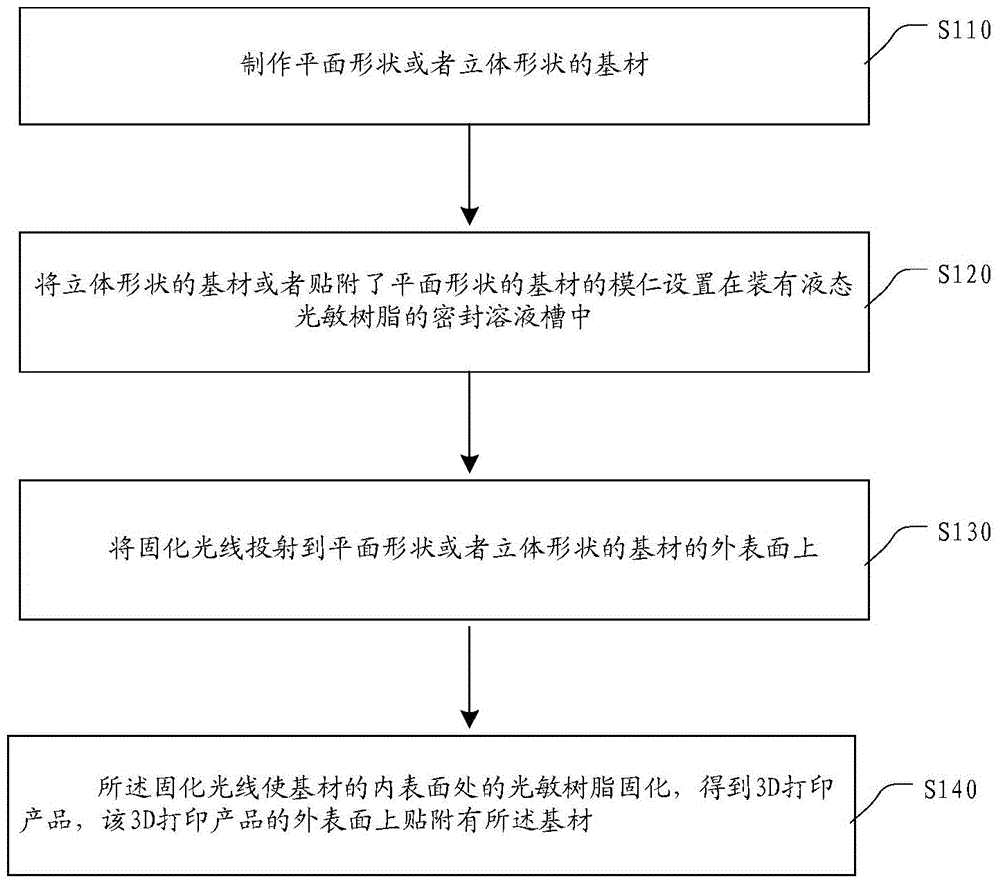

Stereo lithography apparatus (SLA)-based 3D printing implementation method and device

The invention provides a stereo lithography apparatus (SLA)-based 3D printing implementation method and device. The method mainly comprises the following steps of arranging a base in a sealed solution tank with liquid photosensitive resin, and carrying out curing ray casting on the outer surface of the base so that the photosensitive resin at the inner surface of the base is cured by the curing rays and a 3D printed product is obtained, wherein the base is attached to the outer surface of the 3D printed product. Through arrangement of a base with a three-dimensional shape or a mold core attached with the base with a flat shape into the sealed solution tank, the SLA-based 3D printed product is attached with the base with surface effects so that the surface of the SLA-based 3D printed product has various effects such as leather qualitative sense and effects, fashionable element patterns and effects, and the like, and diversity of surface effects of the 3D printed molded parts is improved.

Owner:AEROSPACE INFORMATION

Dual-component water-based bright colorized tile decorative crack-sealer

The invention discloses a dual-component water-based bright colorized tile decorative crack-sealer. The decorative crack-sealer is prepared from an ingredient A and an ingredient B by mixing according to a weight ratio of 1: 1-2. The ingredient A comprises, by weight, 70-90 parts of epoxy resin, 5-20 parts of an emulsifier, 0.5-2 parts of a rheology modifier, 3-20 parts of a flexible additive and 2-4 parts of a surfactant. The ingredient B comprises, by weight, 50-90 parts of a curing agent, 10-30 parts of pigments with different colors and fillers, 4-30 parts of deionized water, 4-10 parts of a brightening agent, 0.1-1.5 parts of a dispersant, 1-5 parts of a crack-resistant agent, 0.1-2 parts of a thickening agent, 0.1-1.5 parts of a dispersant, 0.25-2 parts of an antifoaming agent, 0.5-2 parts of a leveling agent, 1-5 parts of an anti-settling agent and 2-6 parts of an anti-sagging agent. The decorative crack-sealer has high brightness and high hardness, does not mildew, blacken, shrink, collapse, sag and fall, can resist water, oil stain, acid, alkali, etch, scrubbing and water immersion, has good adhesion and has excellent aesthetic feeling.

Owner:SHANGHAI YOUJIN COMPOSITE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com