Injection moulding method of long glass fiber reinforced nylon 66 materials

An injection molding and long glass fiber technology, applied in the field of composite material manufacturing, can solve problems such as floating fibers, delamination, poor product surface quality, and poor melt fluidity, etc., to achieve good surface effect and good fatigue resistance Performance, effect of shear reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

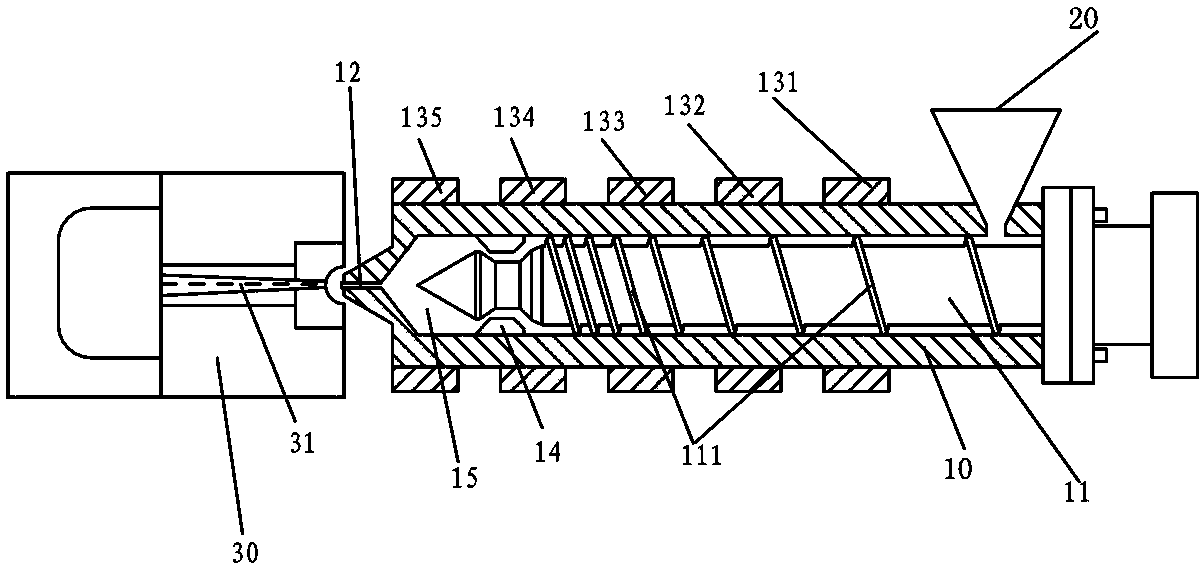

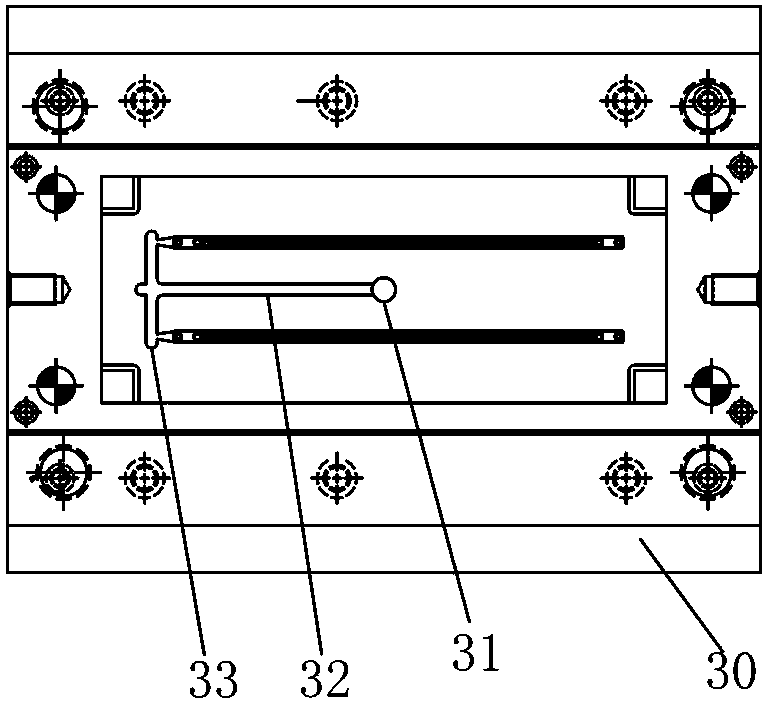

[0031] The features and advantages of the present invention will be further described in detail below with reference to the accompanying drawings and preferred embodiments. The following embodiments are only exemplary, and those skilled in the art can make obvious modifications on this basis, and these modifications are also included in the scope of the present invention.

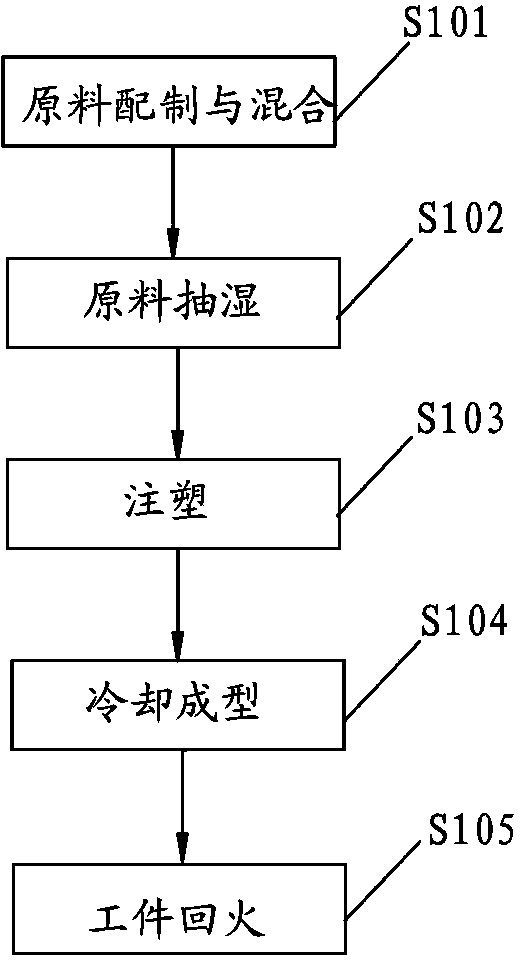

[0032] Such as figure 1 As shown, an injection molding method of long glass fiber reinforced nylon 66 material includes in sequence: preparation and mixing of raw materials, dehumidification of raw materials, injection molding, cooling molding and workpiece tempering. The following specifically introduces the detailed steps of the injection molding method of the long glass fiber reinforced nylon 6,6 material of the present embodiment:

[0033] Step 1 S101, preparation and mixing of raw materials: mechanically stir and mix A and B pellets at a weight ratio of 1:1; wherein, A pellets are composed of long gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com