Patents

Literature

71results about How to "Intensity has no effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

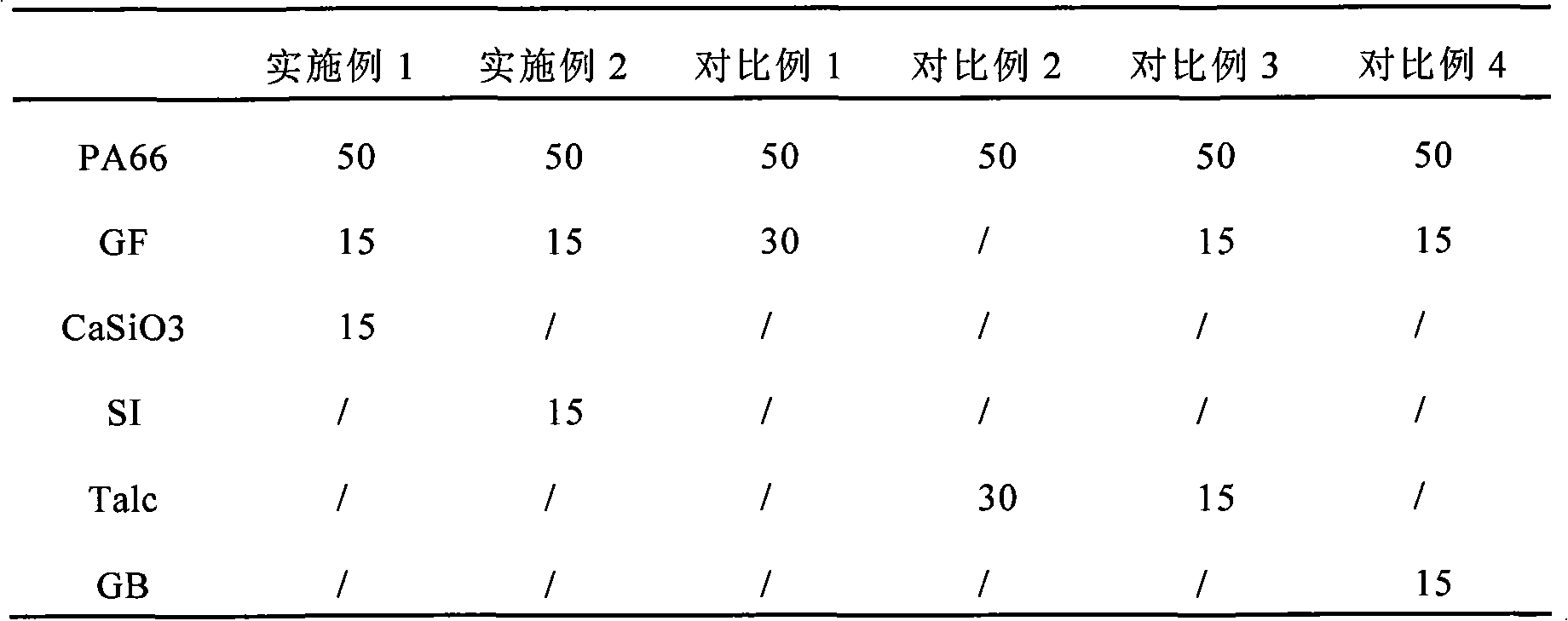

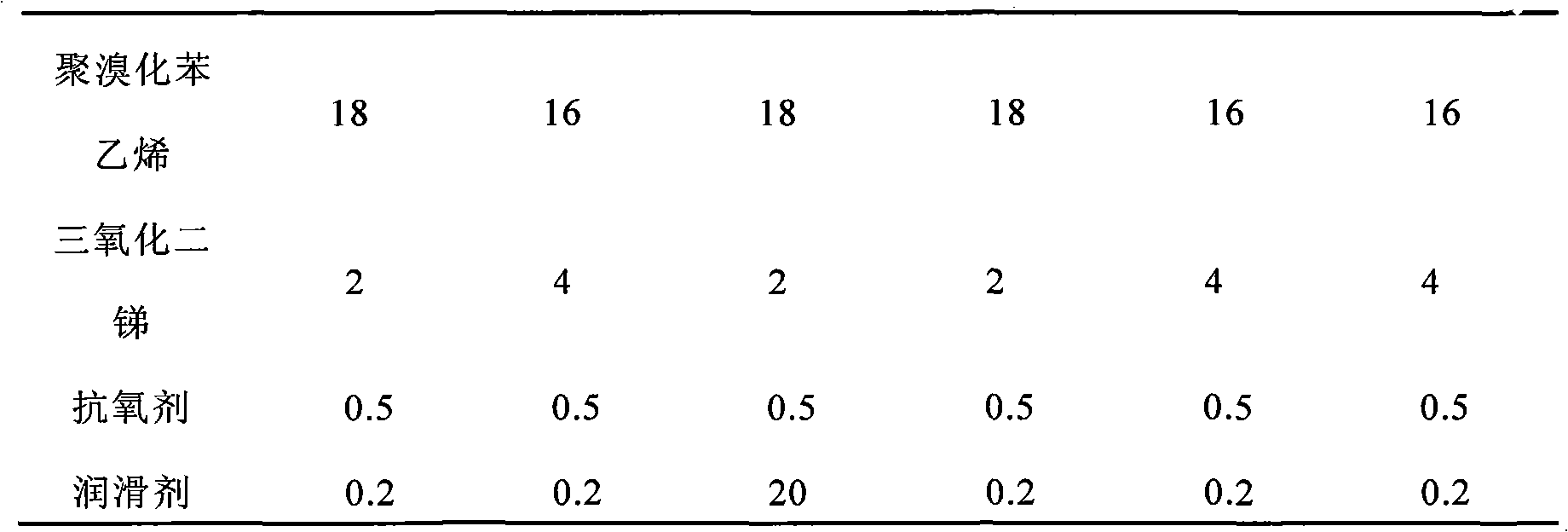

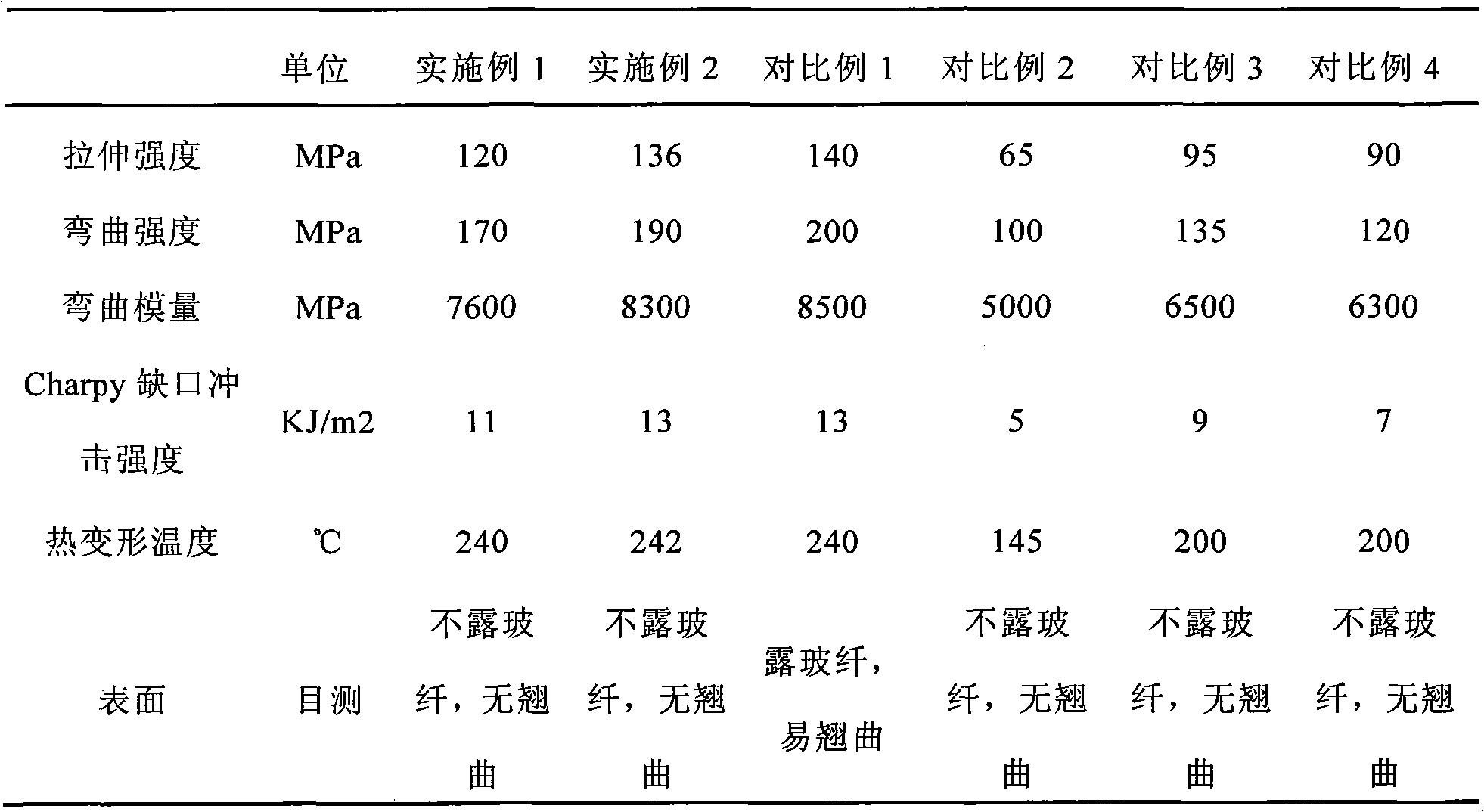

Plastic case material for breaker and preparation method thereof

ActiveCN102108204ASolve the problem of exposureHigh strengthProtective switch detailsBreaking strengthGlass fiber

The invention relates to a plastic case material for a breaker and a preparation method thereof. The material comprises the following components in parts by weight: 22-80 parts of nylon, 5-25 parts of glass fiber, 5-25 parts of needle-like filling material, 8-20 parts of fire retardant, 2-6 parts of auxiliary fire retardant and 0.1-2 parts of other auxiliaries. The preparation method comprises the following steps: evenly mixing the raw materials with a high-speed mixer at a high speed; and then bracing and pelleting the mixed materials with a screw extruder at the temperature of 220 DEG C-290DEG C to obtain the plastic case material. Compared with the prior art, the plastic case material has high breaking strength and elastic modulus, the strength of a compound material is barely influenced by a proper addition of the raw materials, and the obtained product has the advantages of no glass fiber rich surface, no buckling deformation, high strength and good heat resistance.

Owner:HEFEI GENIUS NEW MATERIALS

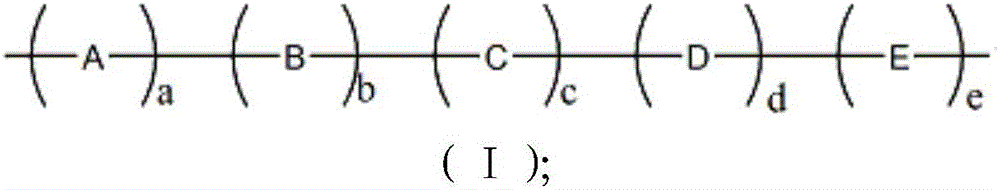

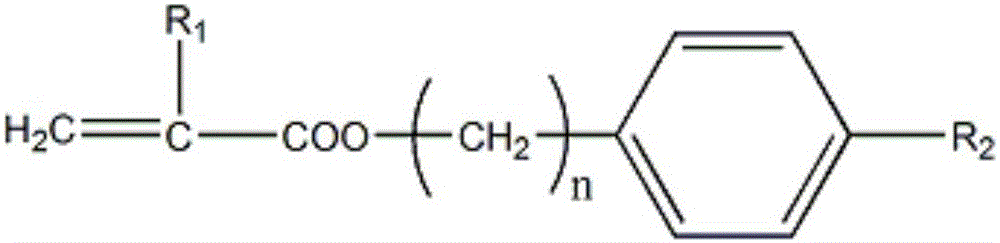

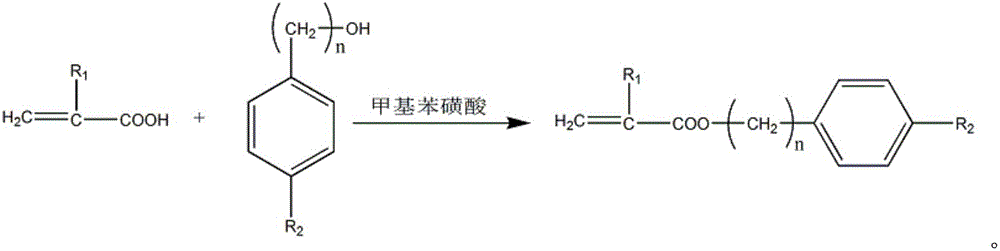

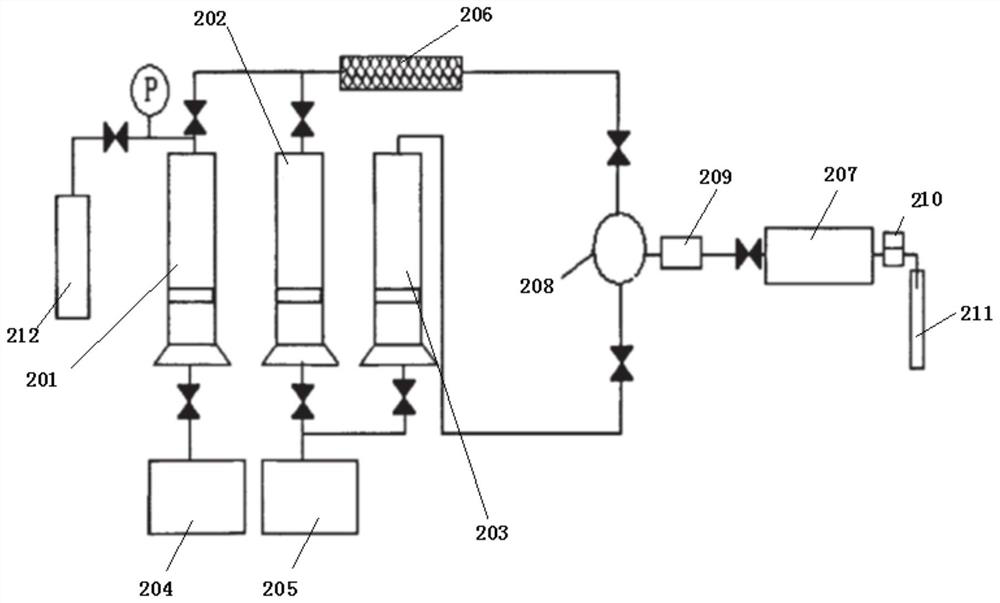

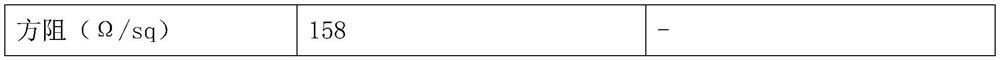

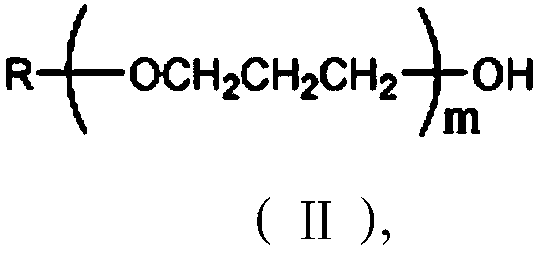

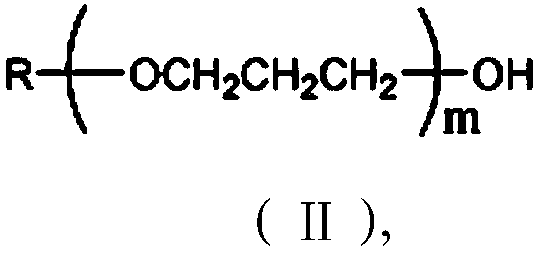

Surface tension adjustment reduction type polycarboxylate superplasticizer and preparation method thereof

The present invention provides a preparation method of a surface tension adjustment reduction type polycarboxylate superplasticizer. The method is simple and high in cost performance, wherein raw materials are easily available and low in cost. The invention also provides a surface tension adjustment reduction type polycarboxylate superplasticizer prepared by the above method. The surface tension adjustment reduction type polycarboxylate superplasticizer can significantly reduce the surface tension of the aqueous solution. The result of the reduction test on the concrete shows that, the surface tension adjustment reduction type polycarboxylate superplasticizer is good in reduction effect. Compared with a conventional ether type polycarboxylate superplasticizer produced by the company of the invention, the shrinkage ratio of the concrete is reduced by 71%. When the polycarboxylate superplasticizer is applied to the concrete, the workability and the strength of the concrete are not affected at all. Therefore, the cost performance is high.

Owner:GUANGDONG REDWALL NEW MATERIALS +1

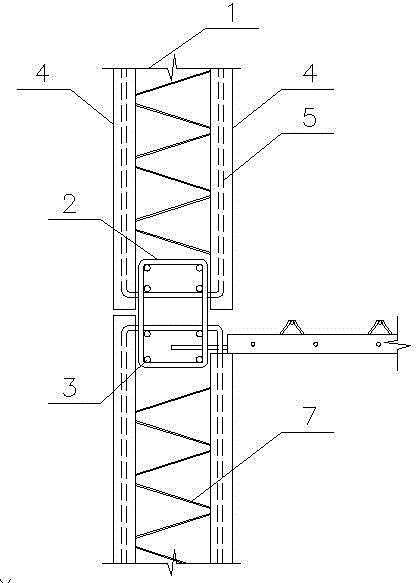

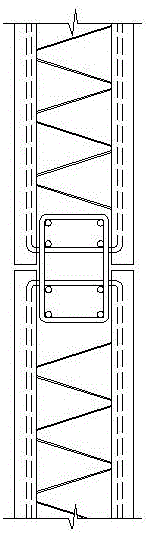

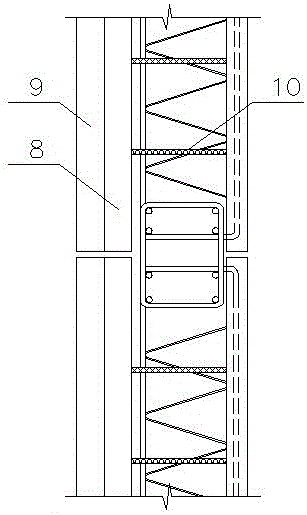

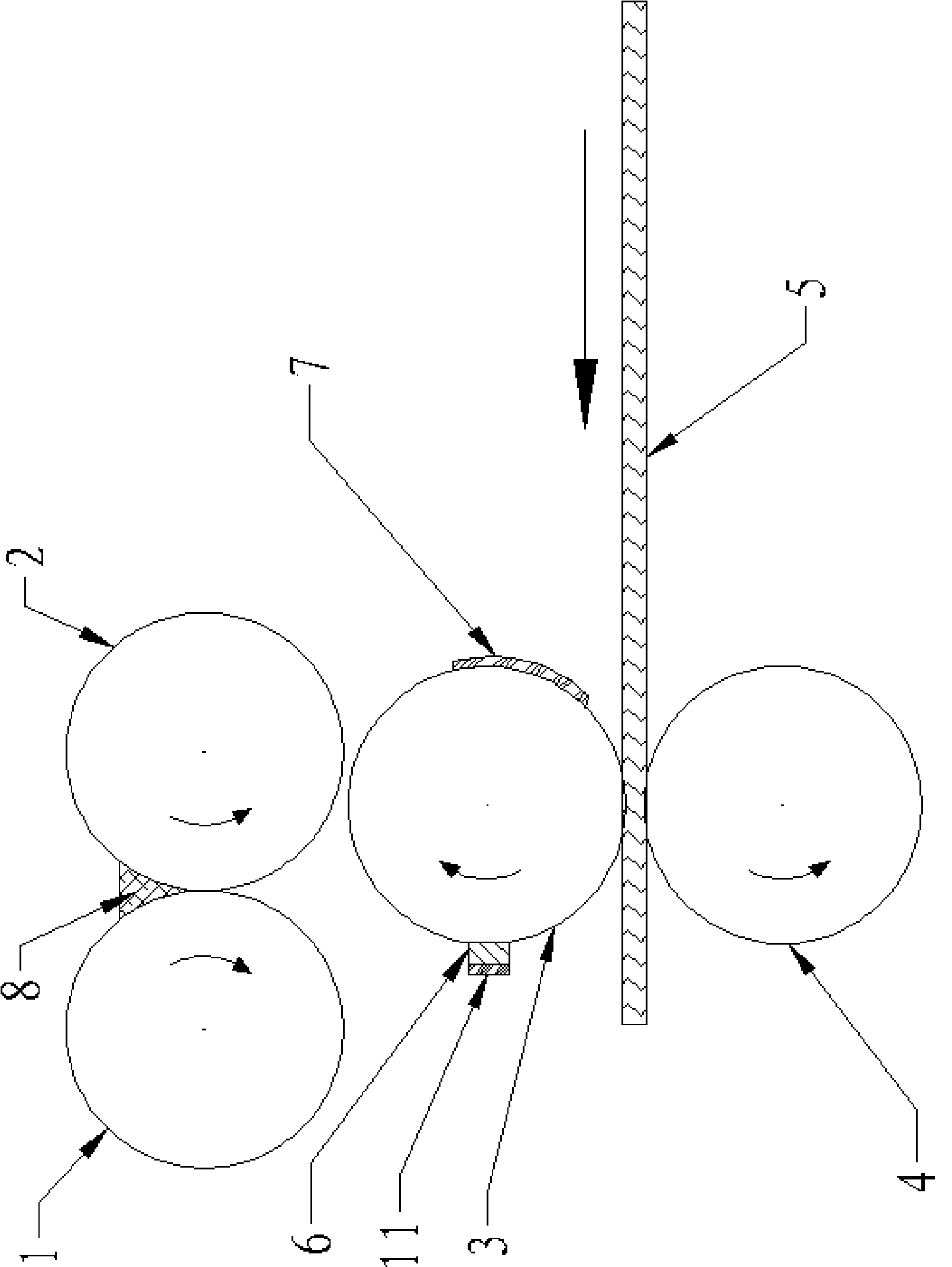

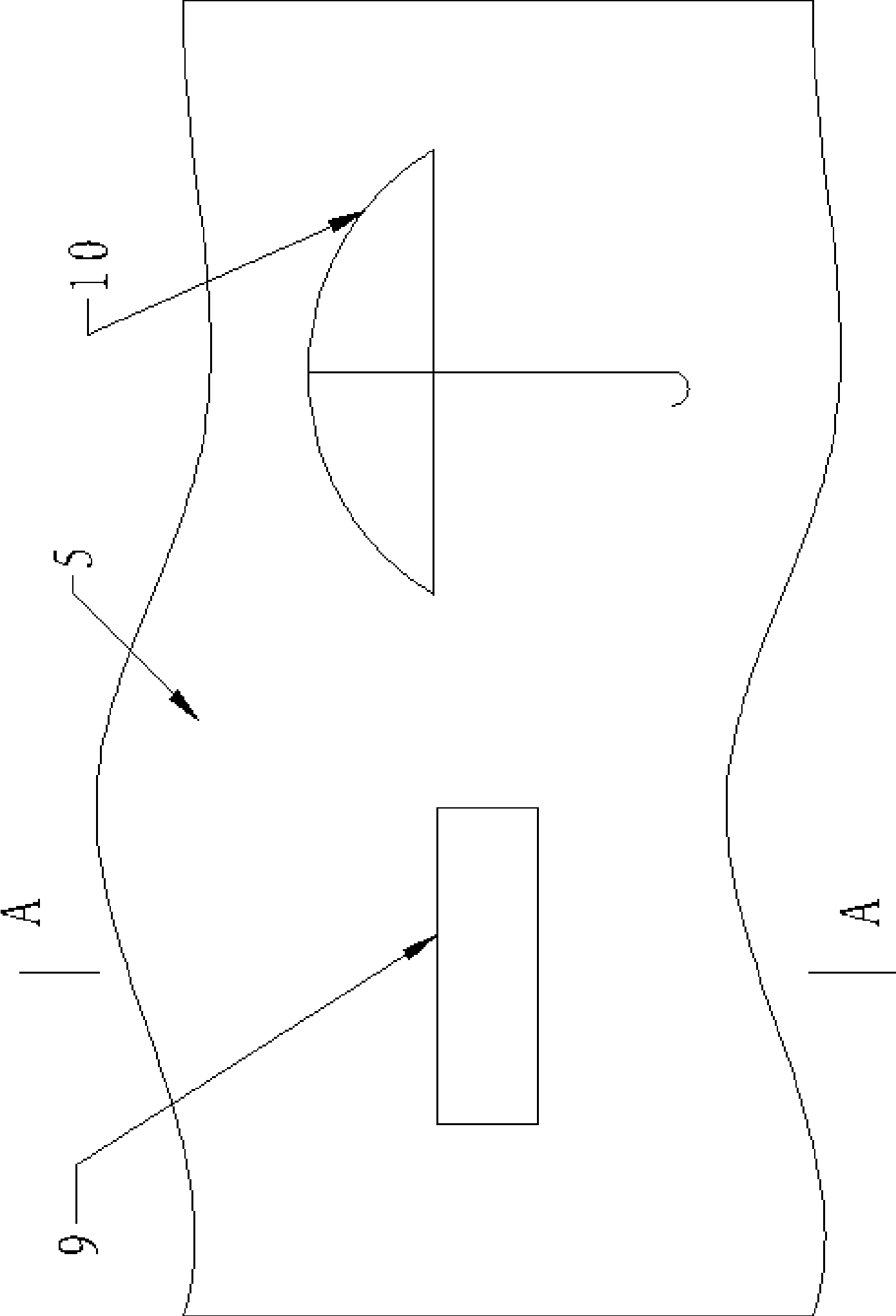

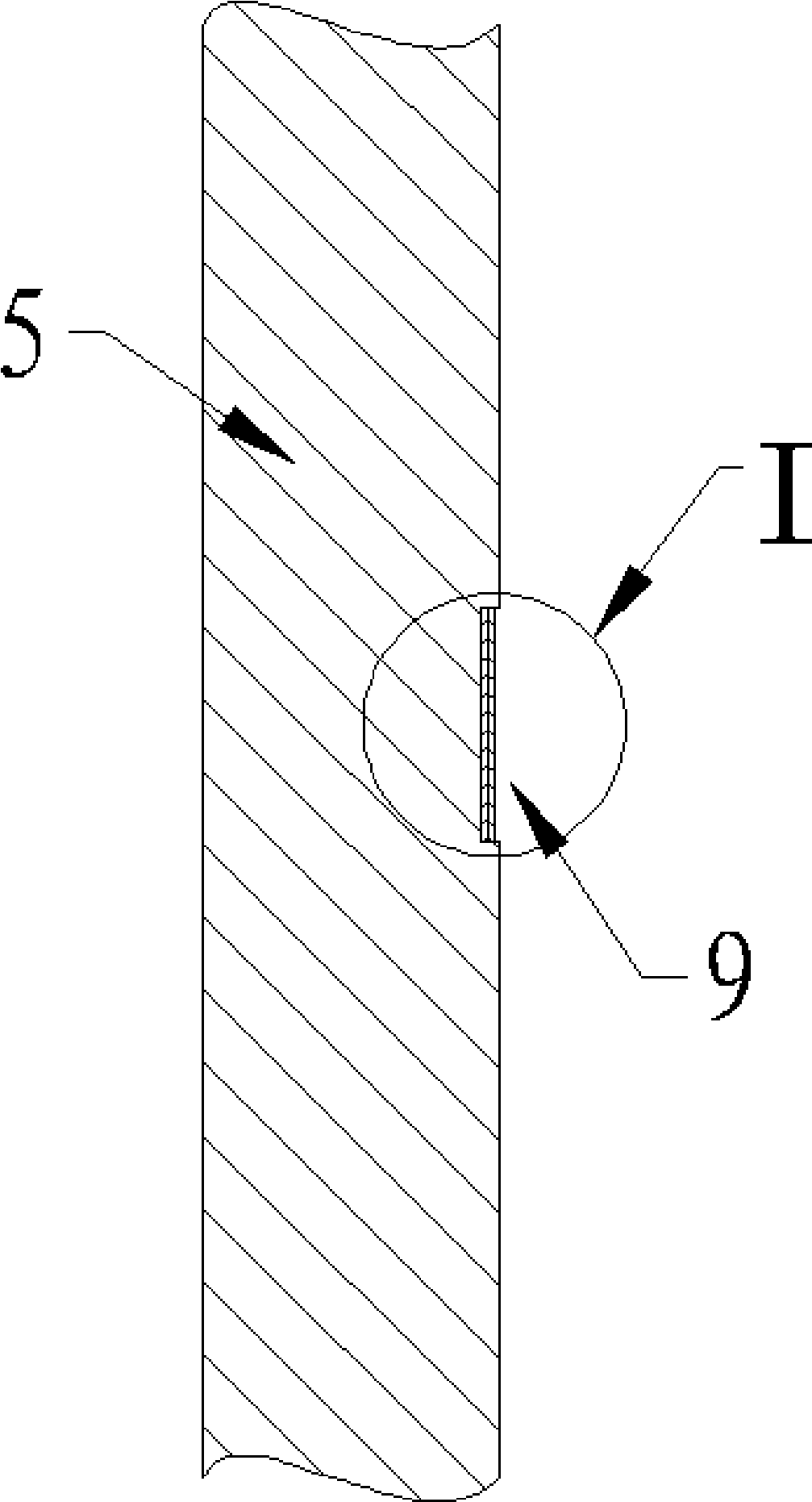

Longitudinal connection structure for superimposed slab concrete shear walls and connection method

The invention provides a longitudinal connection structure for superimposed slab concrete shear walls and a connection method, and solves the problems of a traditional longitudinal connection method for prefabricated part walls that the prefabricated part production process is complicated, field hole aligning is difficult, the loss of a grouting material during field mixing is huge, the grouting material is quick in setting and hardening, and the mixing qualities are much different during mixing. The longitudinal connection structure comprises a closed ring-shaped connecting stirrup (2), the connecting stirrup extends into an upper superimposed slab concrete shear wall (1) and a lower superimposed slab concrete shear wall (1) which are mutually connected to form a transition space together with ring-shaped longitudinal bars (5) of the upper superimposed slab concrete shear wall and the lower superimposed slab concrete shear wall, pin joint longitudinal bars (3) penetrate into the transition space in a manner of being perpendicular to the plane where the connecting stirrup is positioned, and the ring-shaped longitudinal bars of the upper superimposed slab concrete shear wall and the lower superimposed slab concrete shear wall are integrated with the pin joint longitudinal bars. The connection method is applied to the longitudinal connection structure for the superimposed slab concrete shear walls.

Owner:HUBEI YUHUI NEW BUILDING MATERIAL

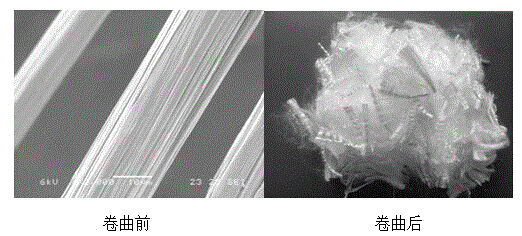

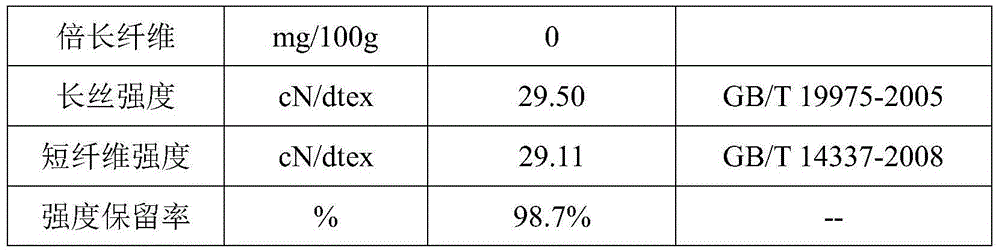

Ultrahigh molecular weight polyethylene short fiber and preparation method thereof

InactiveCN106283246AMeet the requirements of different styles of spinning processEasy to combSevering to form staple fibresArtificial filament heat treatmentFiberPolymer science

The invention discloses ultrahigh molecular weight polyethylene short fiber and a preparation method thereof. The preparation method includes: preparing protofilament of the ultrahigh molecular weight polyethylene short fiber, subjecting the protofilament to assembly winding and bundling, and cleaning oil on the protofilament; applying anionic high-strength polyethylene short fiber oil, performing cold crimping, and loosening and setting the crimped fiber at 80-120 DEG C, wherein drying time is 5-30min, and drying thermosetting temperature is 90-100 DEG C; adjusting tension, and cutting to obtain ultrahigh molecular weight polyethylene short fiber of 3-10 / 25mm in crimp number, wherein cutting length is 3-102mm. The section of the ultrahigh molecular weight polyethylene short fiber is special-shaped, the short fiber has certain natural crimping characteristic and is easy to comb and glue, and cohesion, spinnability and blending performance of the short fiber are improved; fiber number of the short fiber is 0.5-2.5dtex, cutting length is 3-102mm, and strength is 10-40cN / dtex, so that requirements on different styles of subsequent spinning processes can be met.

Owner:SINOPEC YIZHENG CHEM FIBER +1

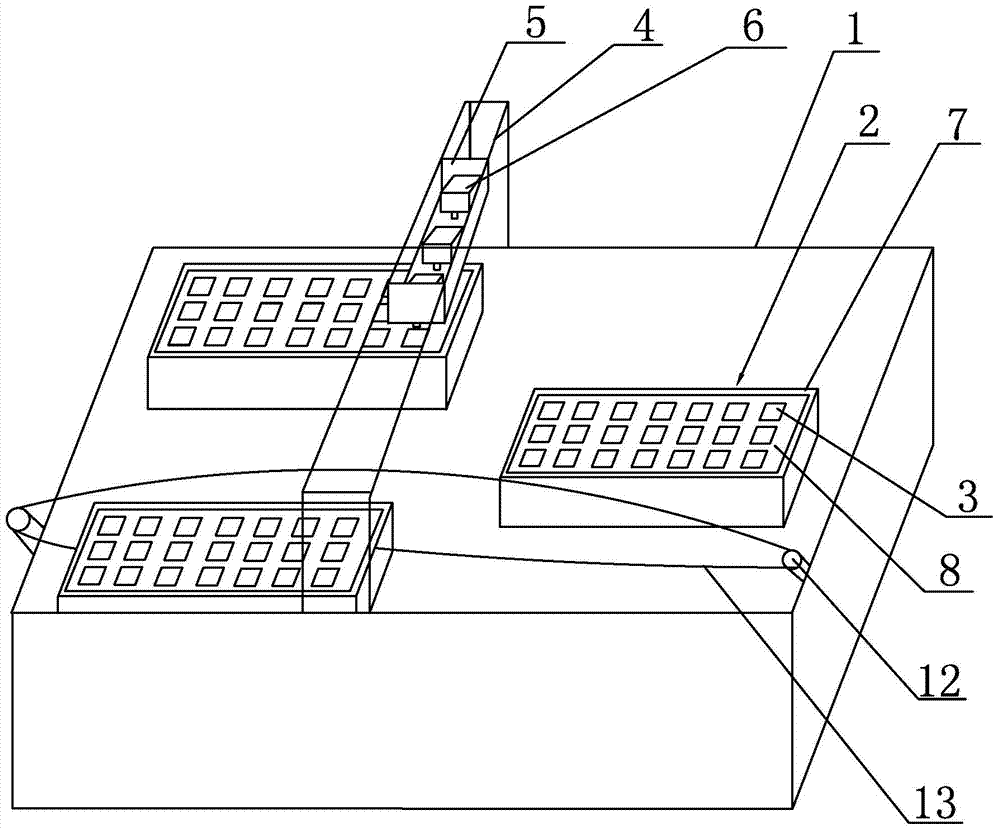

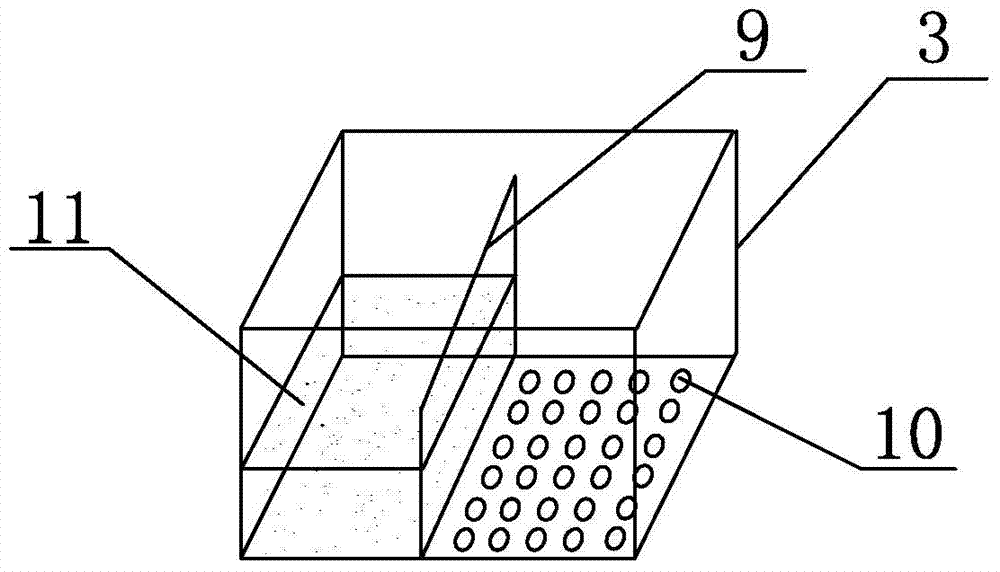

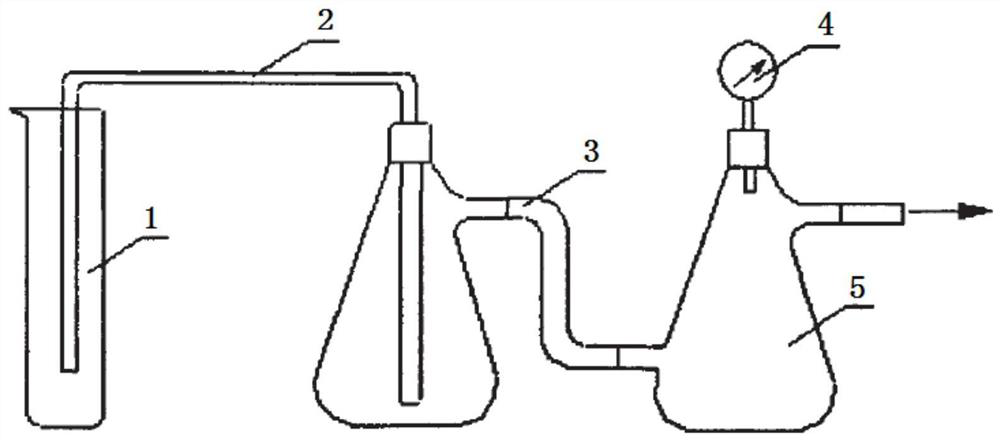

Fodder feeding system for culturing aquatic organisms in baskets on water surface

The invention discloses a fodder feeding system for culturing aquatic organisms in baskets on a water surface. The fodder feeding system comprises a rectangular aquaculture pond, and is characterized in that a plurality of rectangular aquaculture unit blocks capable of floating in water are arranged in the aquaculture pond, a plurality of aquaculture baskets are longitudinally and transversely uniformly arranged in each aquaculture unit block, overhead rails which are higher than the water surface are arranged in the middle of the aquaculture pond along the width direction of the aquaculture pond, a rectangular support capable of moving along the overhead rails back and forth is arranged on the overhead rails, a plurality of feeding machines are arranged in the rectangular support, the quantity of the feeding machines is identical to the quantity of rows of the aquaculture baskets in each aquaculture unit block, and shifting mechanisms for shifting the integral aquaculture unit blocks along the length direction of the aquaculture pond back and forth are arranged on two sides of the aquaculture pond, and can drag the aquaculture unit blocks to be slowly shifted while the feeding machines feed fodder into the aquaculture baskets column by column. The fodder feeding system has the advantage that the fodder feeding system is suitable for accurately, quickly, efficiently and conveniently feeding the fodder into the aquaculture baskets on the large-area water surface.

Owner:NINGBO UNIV

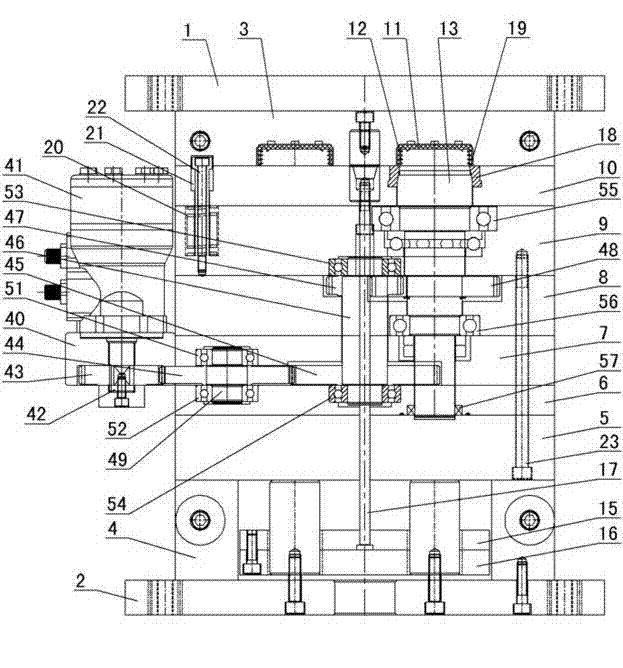

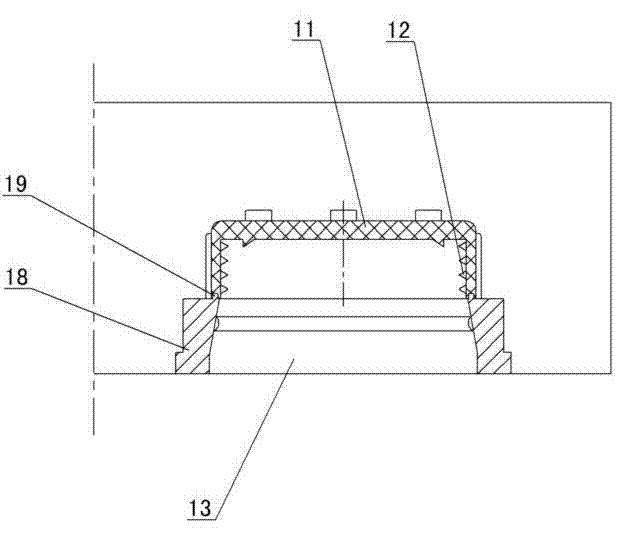

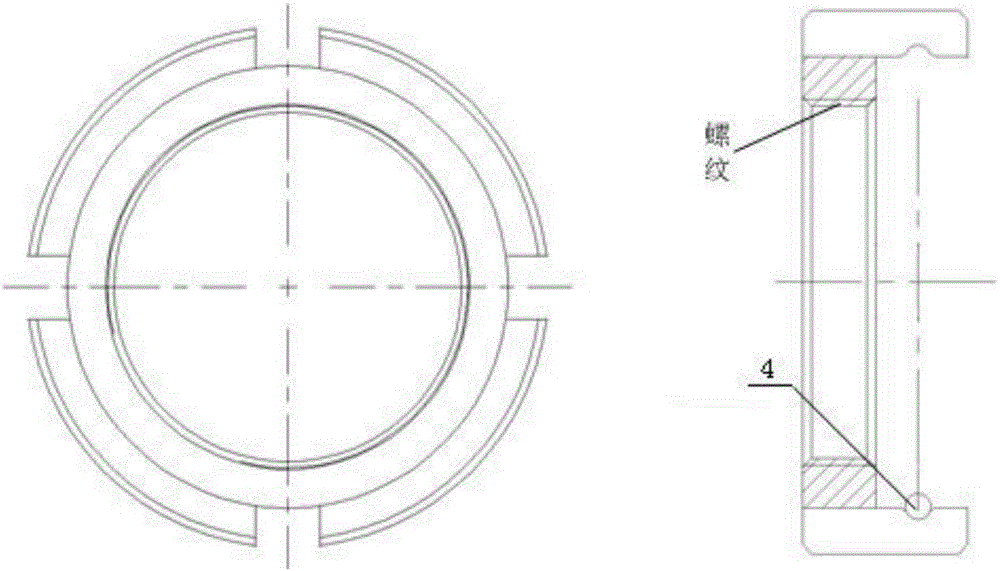

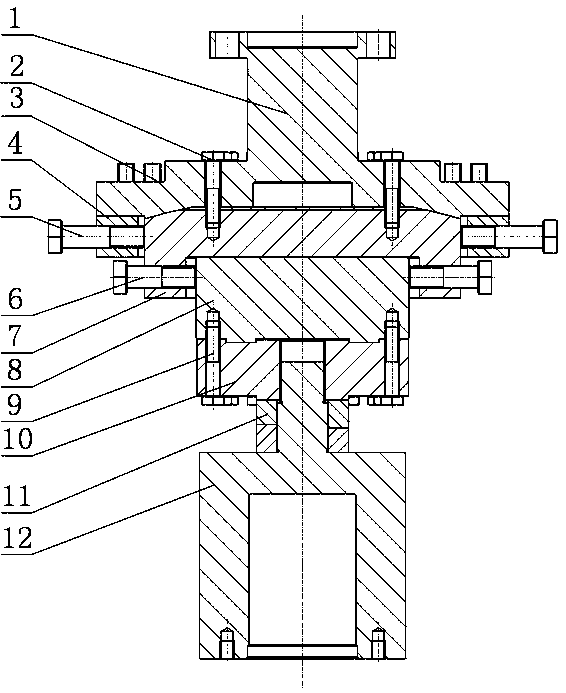

Plastic mold internal screw thread floating stopping demolding mechanism

Provided is a plastic mold internal screw thread floating stopping demolding mechanism. The mechanism comprises an upper doubling plate and a lower doubling plate. A fixed mold plate is arranged under the upper doubling plate. Support blocks are arranged on the lower doubling plate. A movable mold bottom plate, a lower gear fixing plate, an upper gear fixing plate, a transition gear fixing plate and a movable mold clamping plate are arranged on the support blocks. A movable platen is arranged on the movable mold clamping plate. There is a mold cavity between the movable platen and a fixed mold plate. A product is arranged in the mold cavity. Internal screw threads are arranged in the inner wall of the product. A screw thread core is arranged on the movable mold bottom plate. The head of the screw thread core is matched with the internal screw threads. The screw thread core is driven to rotate by power through a gear drive assembly. An upper top plate, a lower top plated and an ejector pin are arranged between the support blocks. The head of the ejector pin contacts a material handle after injection molding. A stopping insert block is arranged on the outer wall of the screw thread core. A stopping pin is arranged on the stopping insert block. The stopping insert block is embedded into the bottom of the wall body of the product. A floating spring is arranged on the movable mold clamping plate. A stop slot is arranged in the movable mold plate. A stop screw is arranged in the stop slot. The stop screw goes through the floating spring and is connected with the movable mold clamping plate.

Owner:TAIZHOU HUANGYAN WEIDA PLASTIC MACHINERY

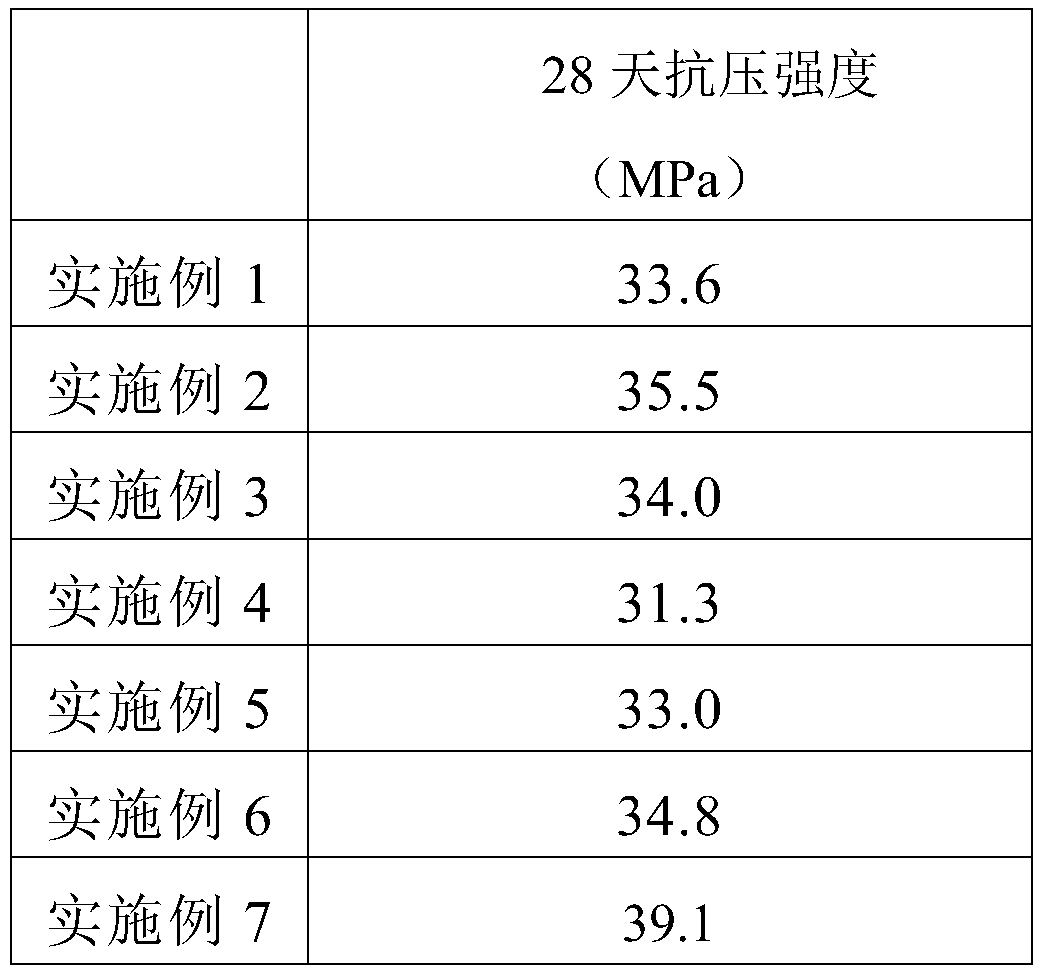

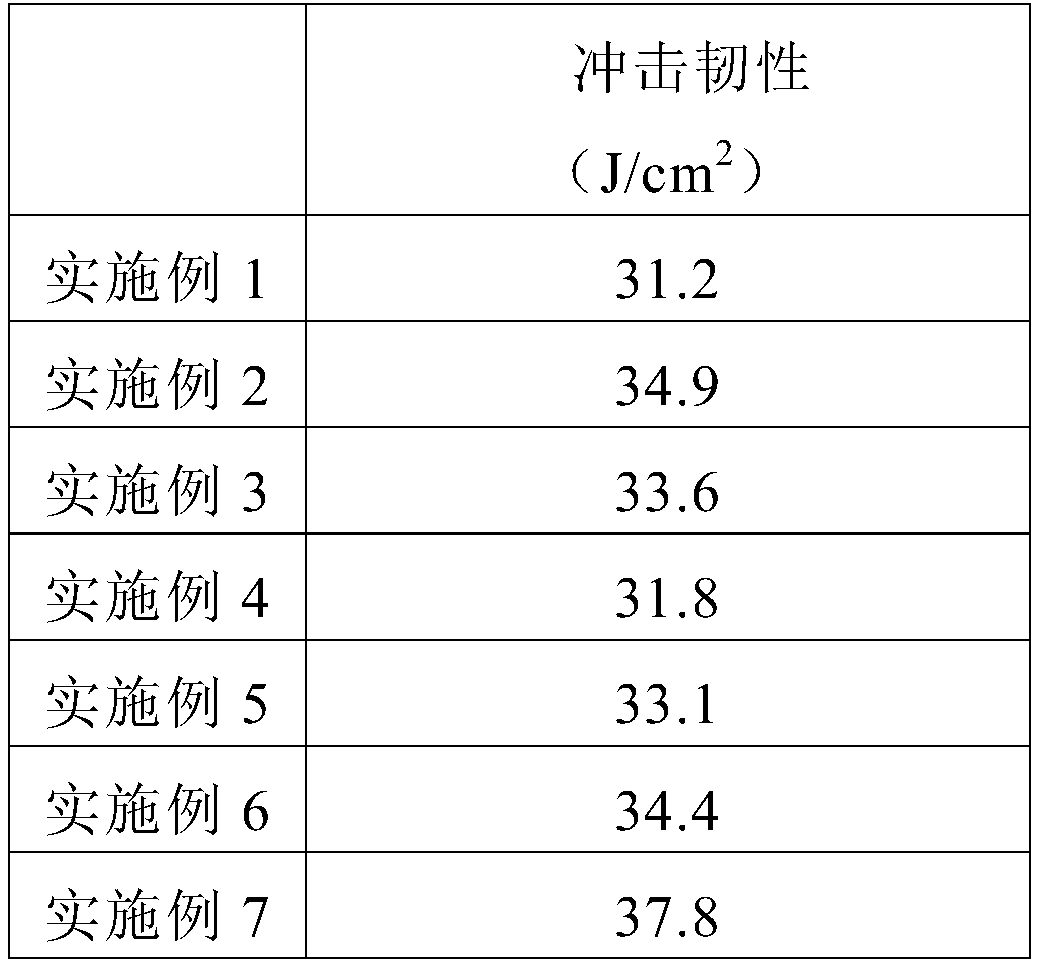

Sludge concrete and preparation method thereof

The invention discloses sludge concrete and a preparation method thereof. The sludge concrete comprises the following raw materials in parts by weight: 200-296 parts of cement, 172-180 parts of water, 1,030-1,066 parts of stone, 56-75 parts of fly ash, 40-78 parts of mineral powder, 530-680 parts of sand and 4.1-6.5 parts of an admixture as well as 150-180 parts of sludge, wherein the sludge is pumped from natural inland rivers, filtered and stacked, the fineness of the sludge is 0.4-0.6, the fly ash is at II grade, and the admixture is a high-performance intensifier. The sludge concrete adopts the sludge as fine aggregate instead of partial sand, as a result, the compactness and permeability of the concrete are enhanced, the durability of the concrete is improved, the production cost is lowered, and the sludge concrete has higher market popularization value and application prospects.

Owner:YANCHENG GUOTAI CONCRETE

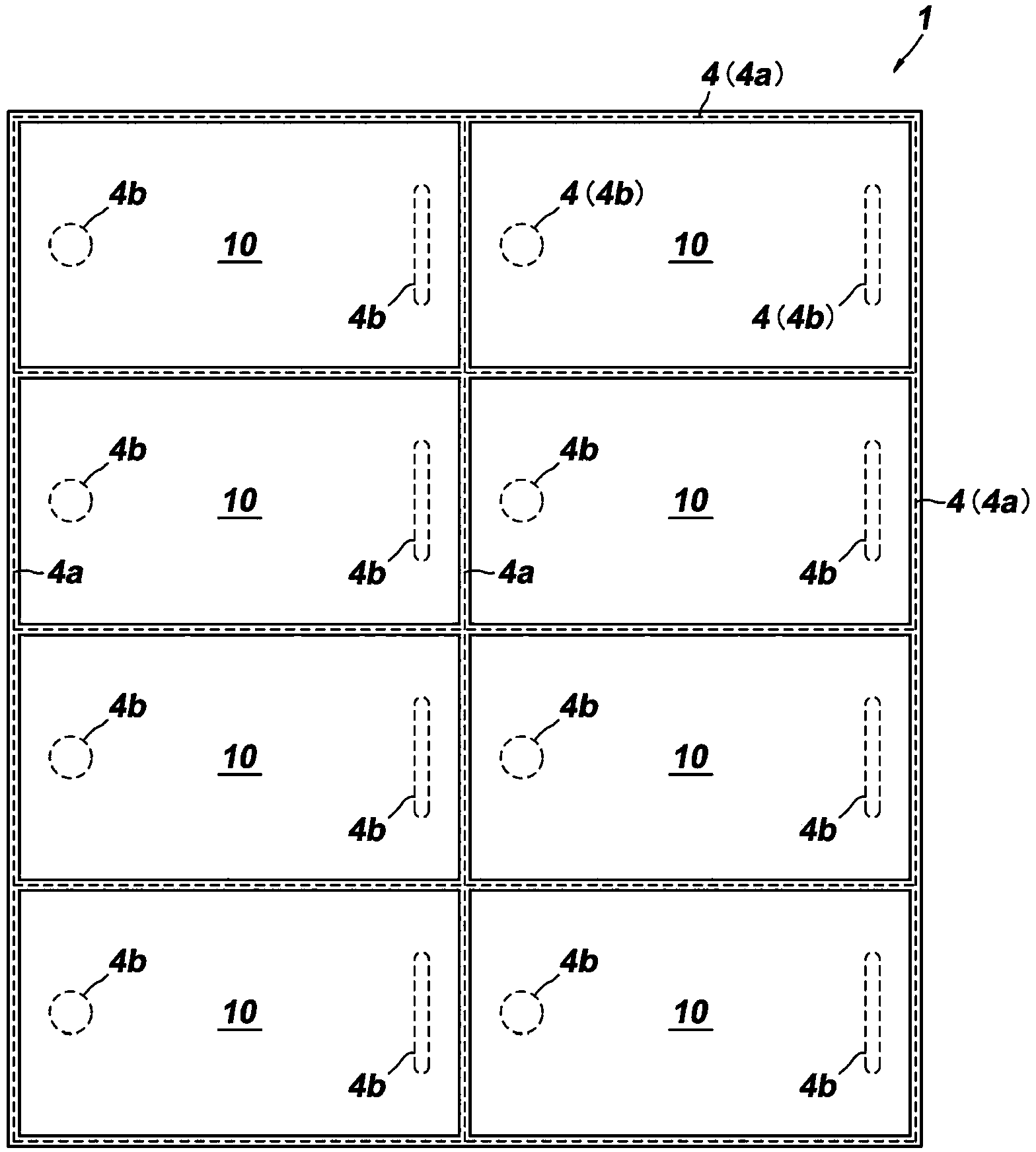

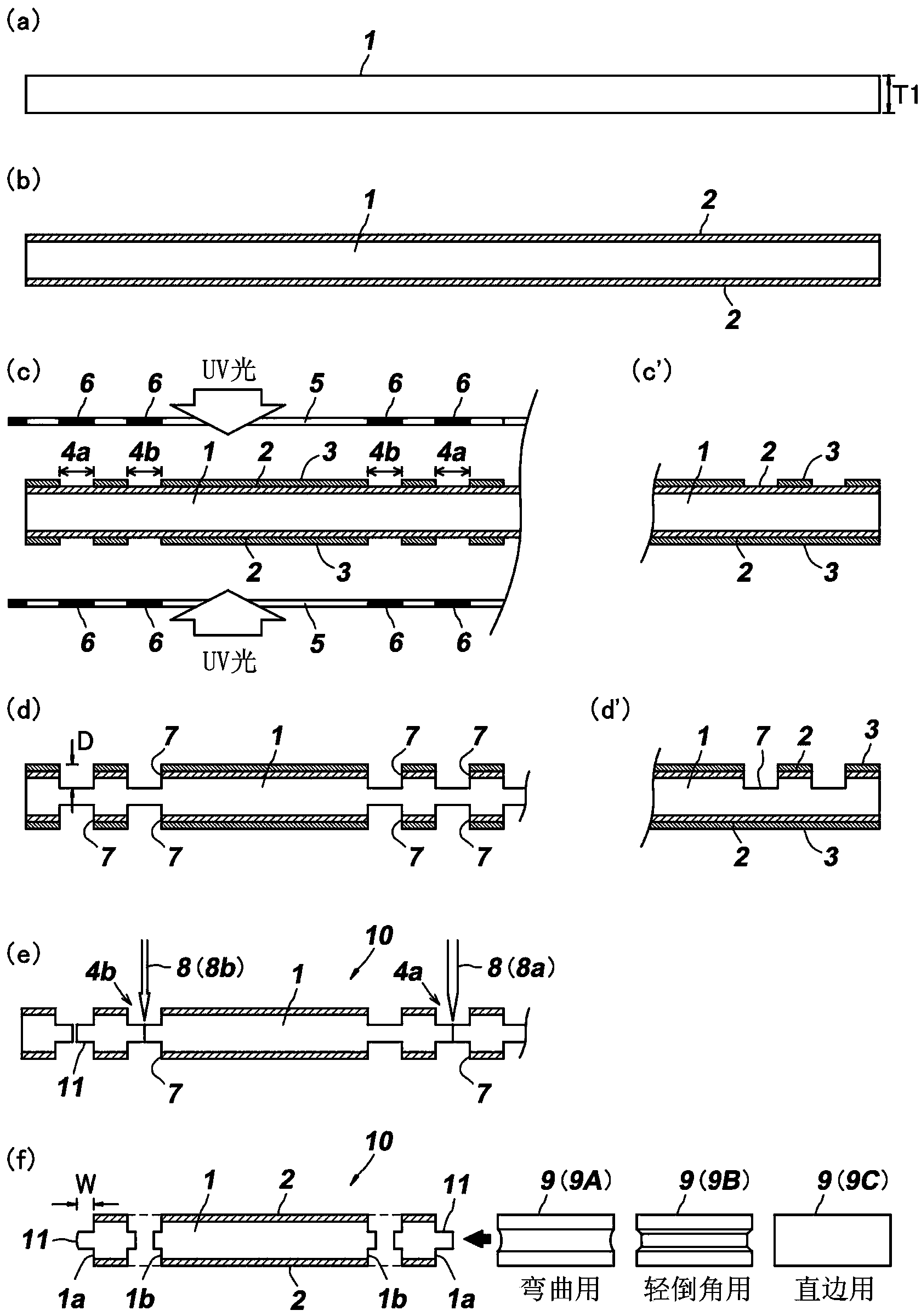

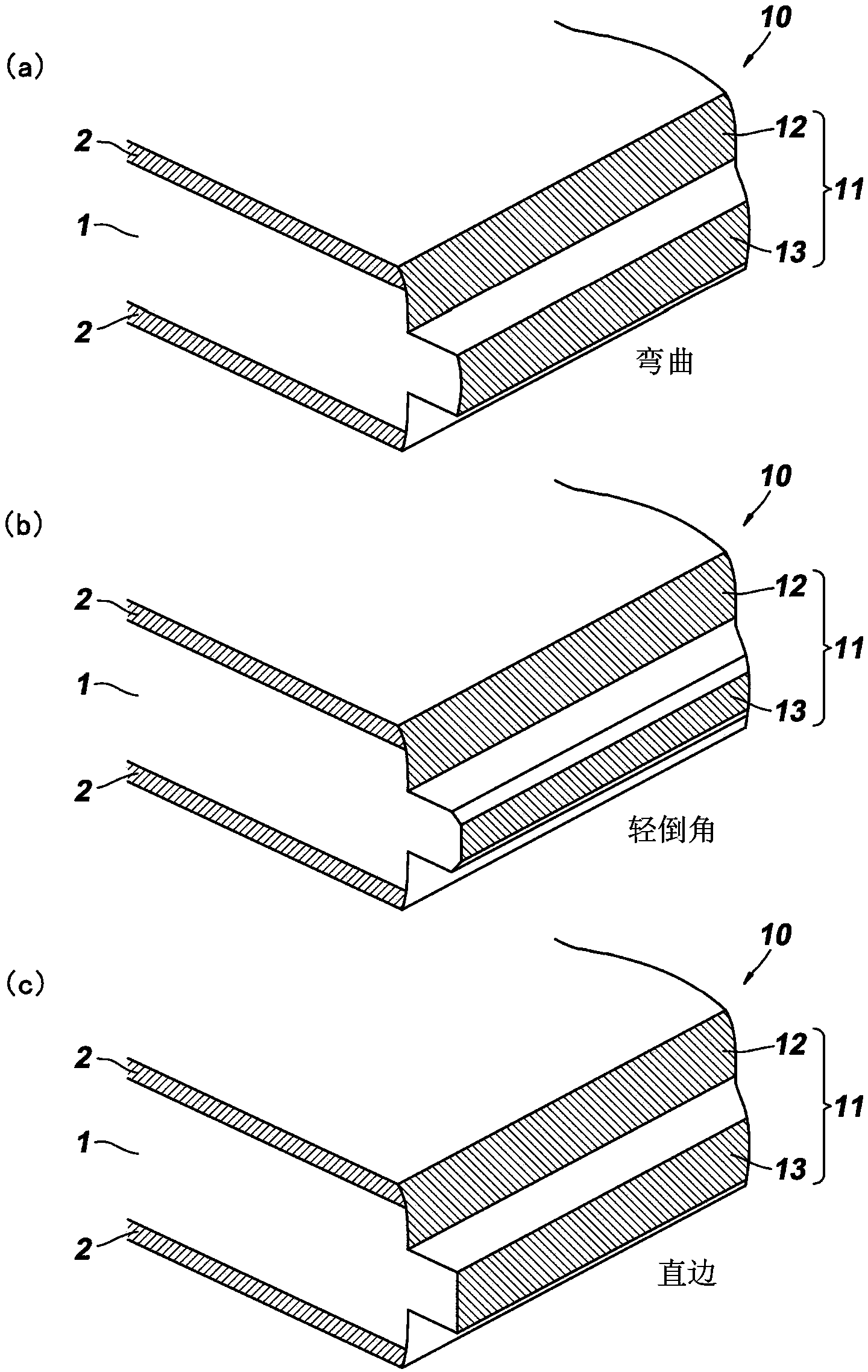

High-strength glass, touch panel, and method for manufacturing high-strength glass

InactiveCN103987668AIntensity has no effectAvoid breakingGlass severing apparatusCoatingsTectorial membraneHigh intensity

The present invention provides a high-strength glass in which damage such as cracking due to microcracking or the like can be prevented, the time required for treatment for maintaining strength can be shortened, production efficiency can be improved, and the end surfaces can be formed to a desired shape. A reinforcement layer (2) is formed on both surfaces of a glass plate (1), and a protective film (3) is formed on regions excluding cut sections (4). Next, recesses (7) obtained by corrosion through an etching treatment are formed on the cut sections (4) of the glass plate (1) not covered by the protective film (3). Then, a hole is formed using a cutting machine (8b) at the opening sections (4b), and peripheral edge sections (4a) are cut using a cutting machine (8a) to obtain diced high-strength glass (10). A stepped section (11) having a convex cross section and comprising an inner side surface (12) obtained by corrosion through an etching treatment and an outer side surface (13) cut by mechanical machining is formed at the peripheral edge end surface (1a) and opening end surface (1b) of the glass plate (1). Since the end surface of the stepped section (11) is mechanically machined, the end surface can be machined to a desired shape.

Owner:MICRO TECH CO LTD

Anticorrosion anti-sulfur wear-resistant oil pipe laser cladding coating preparation process

InactiveCN105586588AIntensity has no effectGuaranteed StrengthMetallic material coating processesMelting tankHeat-affected zone

The present invention discloses an anticorrosion anti-sulfur wear-resistant oil pipe laser cladding coating preparation process. According to the preparation process, a 5000 W cross-flow CO2 laser is used, and the work platform is a digital control laser processing machine; nickel-based alloy powder is automatically conveyed into a laser cladding pool by using a coaxial or paraxial powder conveying device, and a uniform and compact anticorrosion anti-sulfur wear-resistant laser cladding coating with a thickness of 3-6 mm is formed on the processed surface; and a laser surface cladding process is used, the heat-affected zone is small and the strength of the oil pipe is not affected during the cladding process, and the nickel-based alloy with characteristics of good corrosion resistance and high strength is used, such that the oil pipe achieves excellent corrosion resistance and excellent wear resistance while the strength of the oil pipe is ensured. According to the present invention, corrosion resistance, sulfur resistance and wear resistance of the oil pipe are reinforced, the service life of the oil pipe is prolonged, and the long-term problem in the application fields of the oil pipes and the oil pipe corrosion in the petroleum exploration, the oil, gas and water well production operation and construction, and maintenance is solved.

Owner:HUBEI XINCHEN AUTOMATION EQUIP

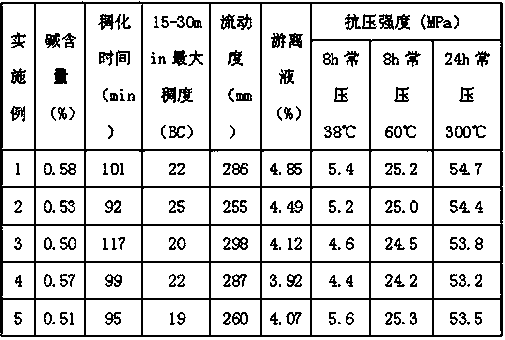

High-intensity and high-temperature-resistant anti-erosion oil well cement and preparation method thereof

The invention discloses high-intensity and high-temperature-resistant anti-erosion oil well cement and a preparation method thereof. The high-intensity and high-temperature-resistant anti-erosion oilwell cement is mainly prepared from the following ingredients in percentage by mass through mixing: 50 to 60 percent of grade G high-resistant oil well clinker, 10 to 15 percent of aluminophosphate cement clinker, 20 to 30 percent of unbonded silica sand, 4.0 to 6.0 percent of phosphogypsum, 3.5 to 5.5 percent of silicon powder, 0.05 to 0.2 percent of fluid loss agents and 0.3 to 0.5 percent of retarders. Through the reasonable formula, on the basis of improving the cement intensity (under the conditions of 24h normal pressure and 300 DEG C, the intensity can reach a value being 53.0MPa or more), the thickening time (such as 90 to 120 min) can be effectively controlled; in addition, no special retarder and the like is added, so that the high-temperature-resistant performance of the cementis obvious; the use temperature can reach 300 DEG C; at 300 DEG C, the intensity is not influenced; a test body is complete and not damaged.

Owner:葛洲坝石门特种水泥有限公司

Laser-cladding coating preparation process of corrosion-resistant, sulfur-resistant and wear-resistant tubing coupling

ActiveCN104032301AIntensity has no effectGuaranteed StrengthMetallic material coating processesMelting tankNumerical control

The invention discloses a laser-cladding coating preparation process of a corrosion-resistant, sulfur-resistant and wear-resistant tubing coupling. A 5000 W cross-flow CO2 laser is used; a working platform is a numerical control laser machine; a coaxial or paraxial powder feeding device is used for automatically feeding nickel-based alloy powder into a laser molten pool; and a corrosion-resistant, sulfur-resistant and wear-resistant laser-cladding coating with uniformity and compactness is formed on a processing surface, and is 3-6 mm thick. A laser surface cladding process is adopted; in the cladding process, a heat-affected zone is small, and no influence is generated on the strength of the coupling; and nickel-based alloy with good corrosion resistance and high strength is adopted, so that the coupling obtains excellent corrosion resistance and wear resistance while the strength of the coupling is guaranteed. The preparation process intensifies the corrosion resistance, sulfur resistance and wear resistance of the tubing coupling, prolongs the service life of the tubing coupling, and solves a difficulty unsolved for a long time in the corrosion-resistant application field of an oil tube and the tubing coupling in the oil exploitation and the production operation and maintenance of oil, gas and water wells in our country.

Owner:江苏点金激光科技有限公司

Mud-containing concrete and preparation method thereof

The invention discloses a mud-containing concrete and a preparation method thereof. The preparation method comprises the following steps: a, weighing all raw materials; and b, adding a water reducingagent to water, performing stirring for uniform mixing to obtain a mixed solution, adding cement, mud, fly ash, crushed basalt stones, river sands, polypropylene fibers and a nano-reinforcing agent into a concrete mixer, performing stirring for uniform mixing, adding the mixed solution, and continuing stirring for uniform mixing in order to obtain the mud-containing concrete. A certain proportionof the mud is added to the formula of the concrete, and the proportioning ratio and the preparation method of the concrete are reasonably optimized by test, so the strength of the concrete is not affected, the concrete is easy to construct, the production cost is greatly reduced, and the concrete is successfully applied to roads; the mud is used as a raw material, so the use amount of the cement is reduced, and many solid wastes are used and the prepared concrete has the advantages of good workability and construction performances, environmental friendliness, great market promotion values andgreat application prospect.

Owner:刘群

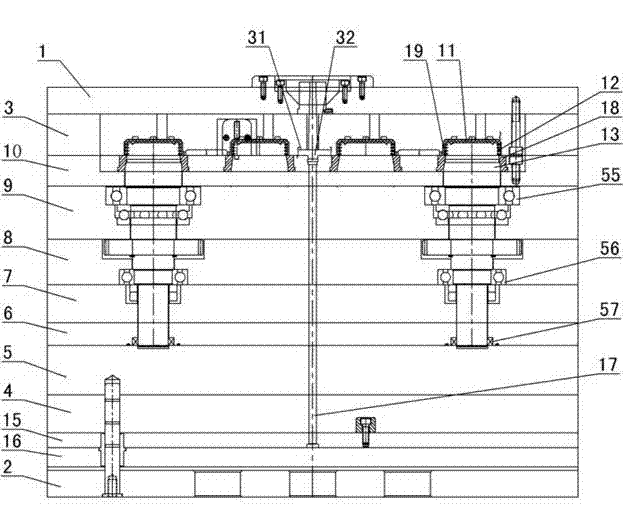

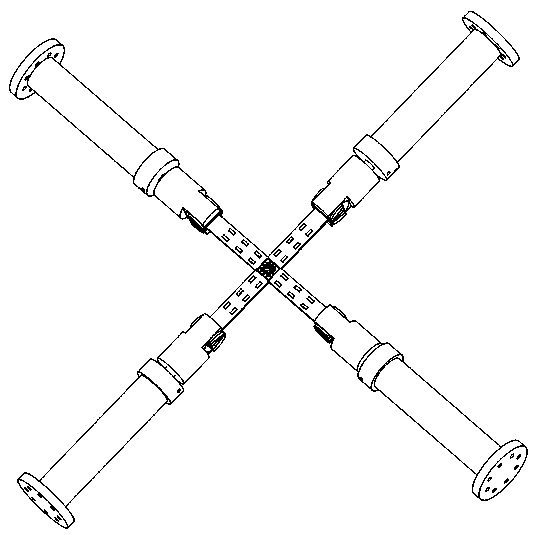

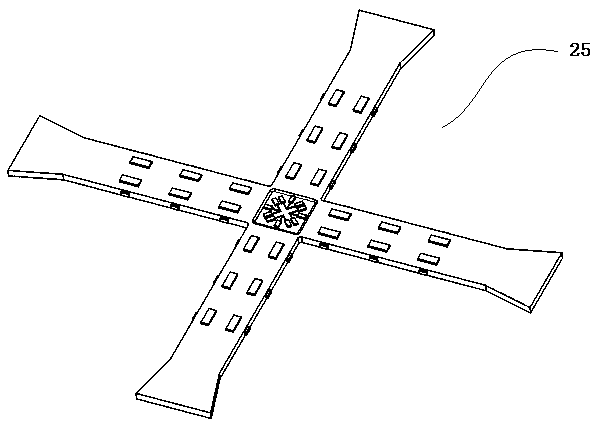

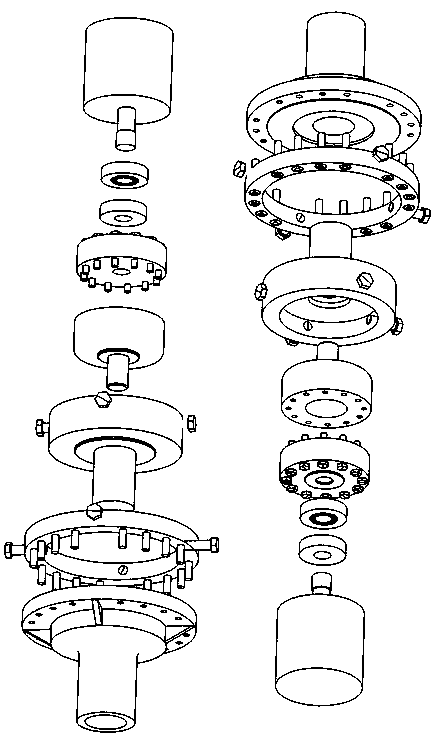

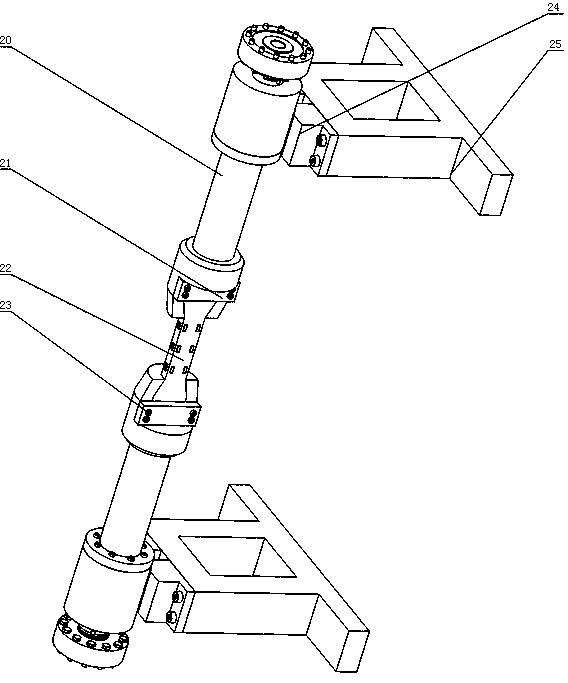

Four-axis centering adjustment system and method for biaxial tensile testing machine

ActiveCN110726636ASolve problems that cannot be adjusted in real timeSolve the uncontrollable accuracy of manual assembly adjustmentMechanical measuring arrangementsStrength propertiesControl engineeringMachine

The invention relates to a four-axis centering adjustment system and method for a biaxial tensile testing machine and belongs to the field of testing machine technologies. The system comprises a spindle loading chain, a centering adjustment device, a centering sensor, a feedback device and a rack, wherein the centering adjustment device is installed on the spindle loading chain, the spindle loading chain is installed on the rack, and a detection and feedback mechanism is installed on the rack and is used for detecting and controlling the adjustment amount. The system has the advantages that adjustment at five degrees of freedom can be realized, and precision is correspondingly matched with a detection device; the system is connected with a complete machine loading chain, the strength of the whole device is improved, and damage to a loading shaft is reduced; and the system is high in adaptability, can match loading chains in different forms and multiple types of fixtures, occupies a small space, is easy to operate and high in repeated adjustment precision, improves experimental precision and makes measured data more precise.

Owner:JILIN UNIV

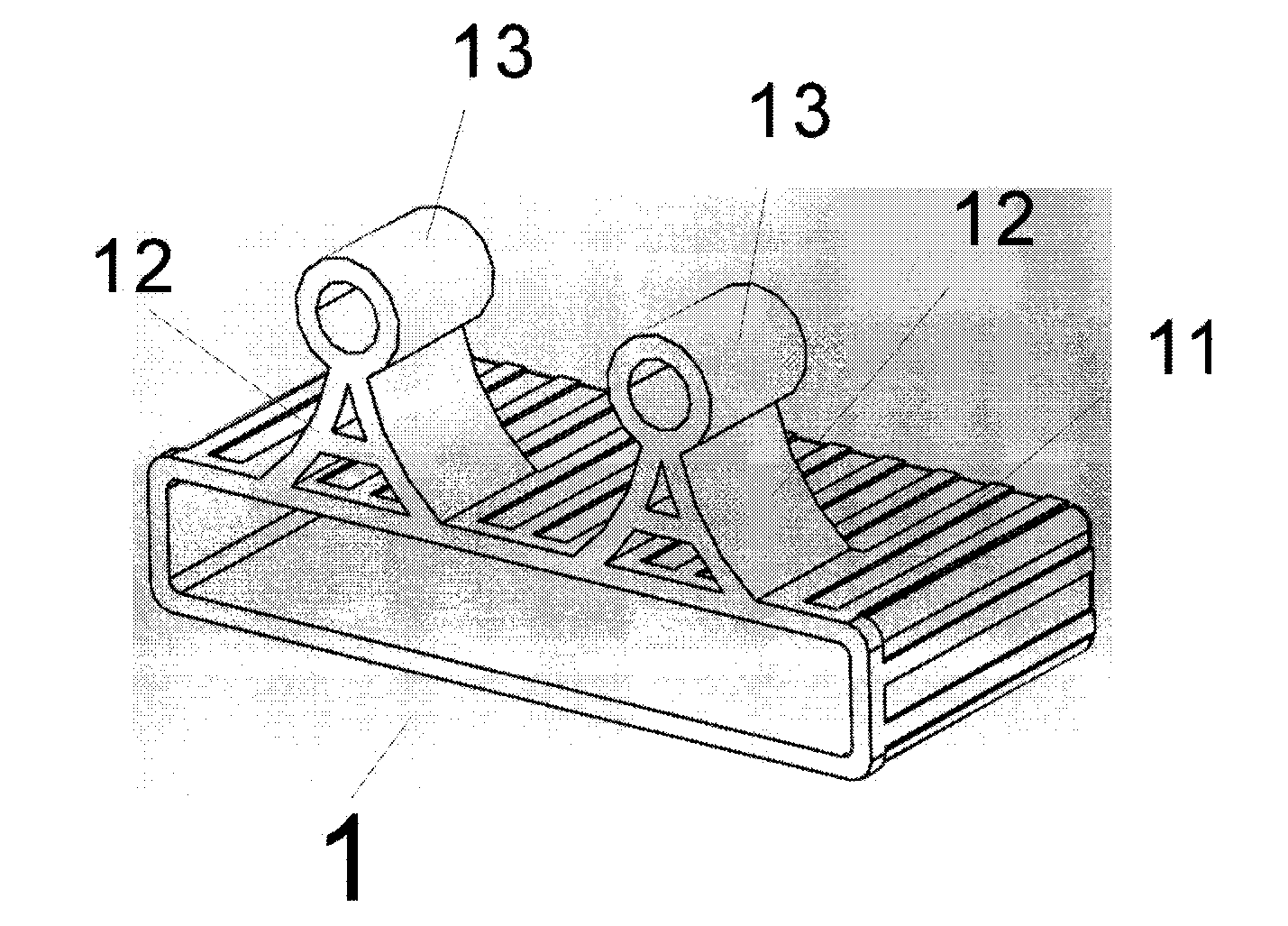

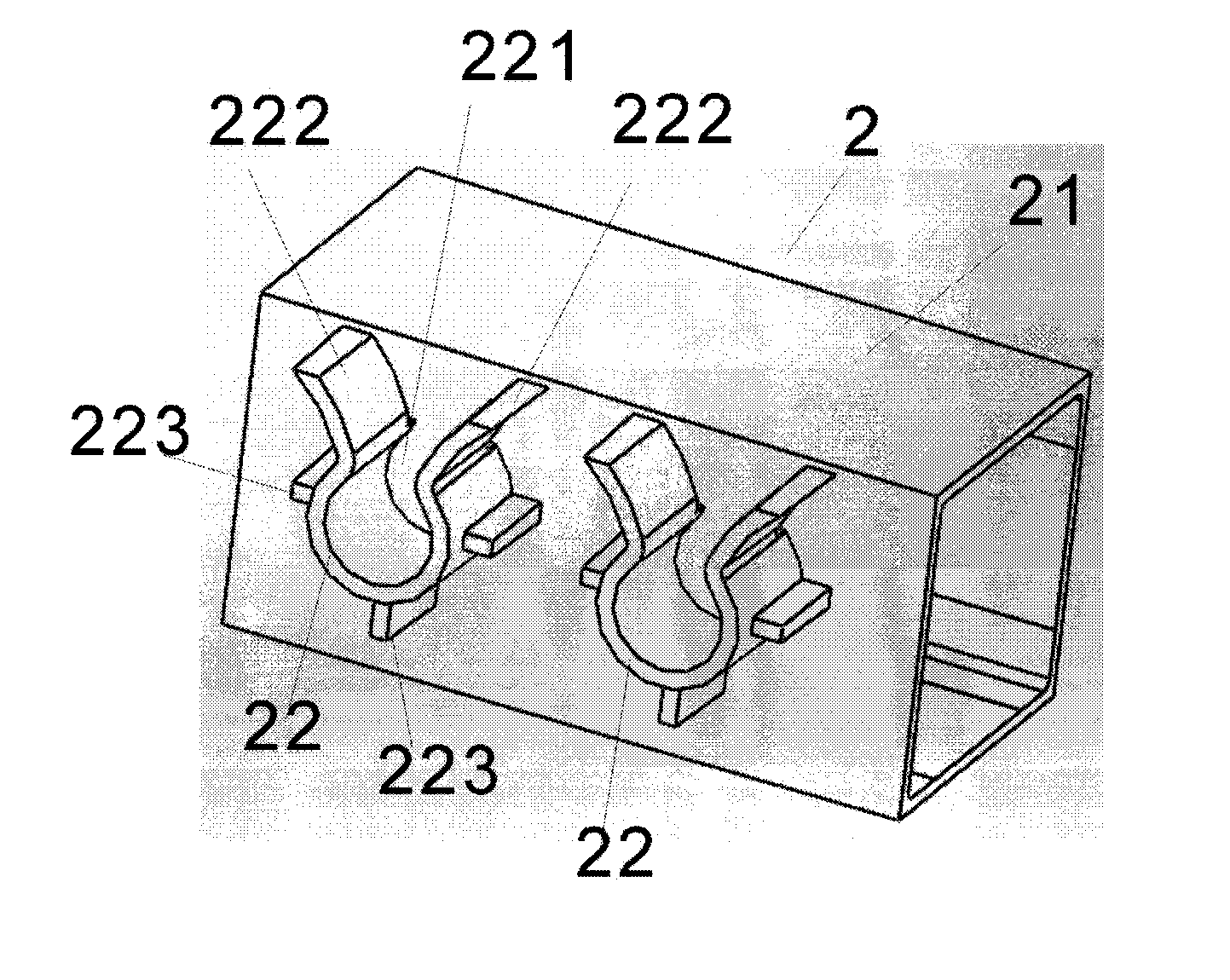

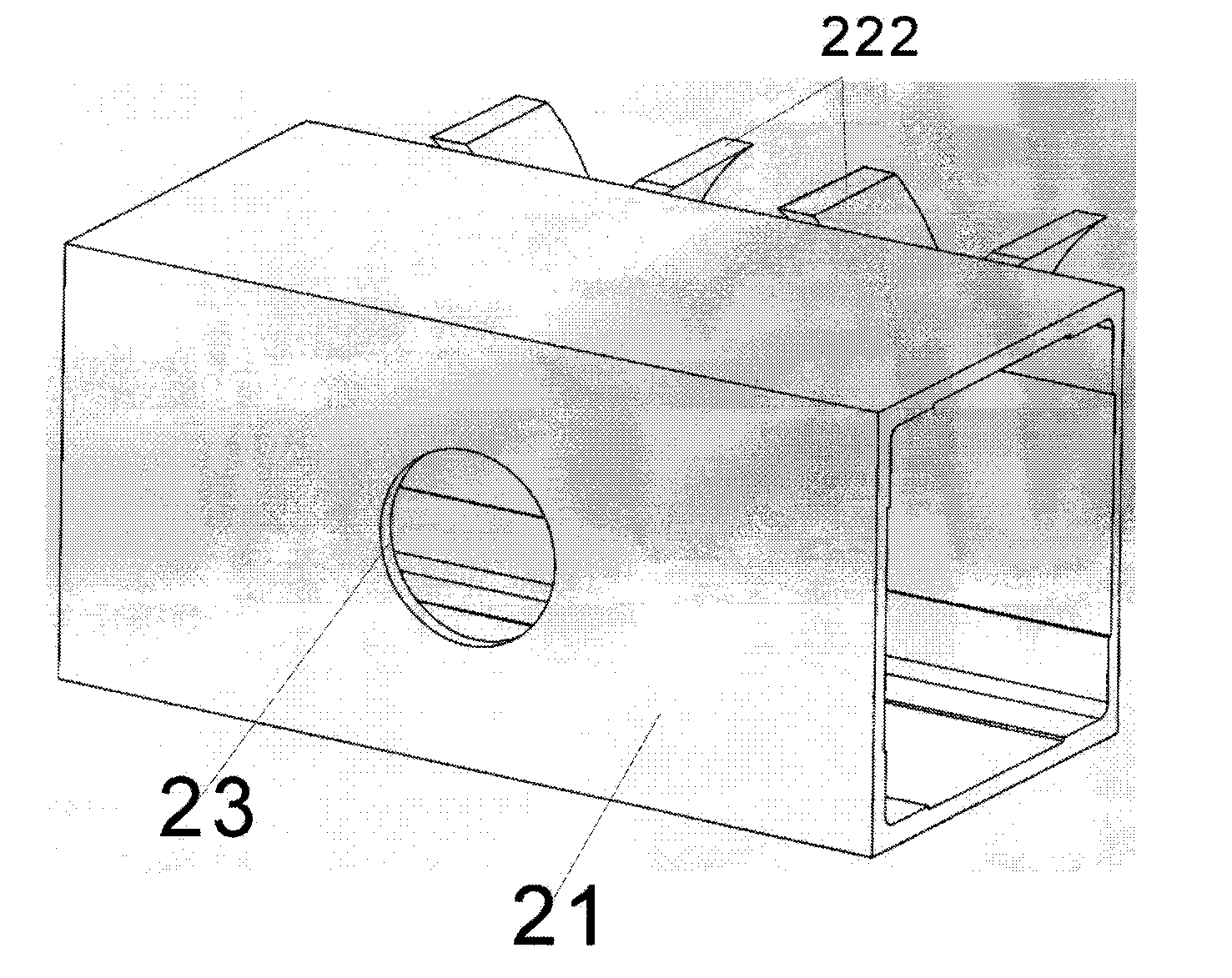

Male sleeve and female sleeve for bed frame

The invention discloses a male sleeve and a female sleeve for a bed frame. The female sleeve comprises a rectangular sleeve and two open hollow cylindrical concave buckles, wherein the two ends of the female sleeve are open, the two open hollow cylindrical concave buckles are arranged outside the rectangular sleeve, the inner diameter of the opening of each concave buckle is smaller than the inner diameter of the concave buckle, the openings of the concave buckles are connected with horn-shaped concave buckle leading-in protective wings, reinforcing ribs are arranged on the peripheries of the concave buckles, and a fixing hole is formed in the rectangular sleeve. The male sleeve comprises a bed sleeve, horn-shaped positioning legs and cylindrical convex buckles, wherein the two horn-shaped positioning legs are arranged outside the bed sleeve, the cylindrical convex buckles are arranged on the bottoms of the positioning legs, and the inner diameter of each convex buckle is larger than that of the opening of each convex buckle and is smaller than that of each concave buckle. The rectangular sleeve is arranged in the bed frame in a sleeved mode, the convex buckles, at the two ends of a bed rib, of the male sleeve are inserted into the concave buckles of the female sleeve, and then the bed rib can be installed on and connected and fixed to borders of the bed frame. By the adoption of the male sleeve and the female sleeve for the bed frame, holes do not need to be punched or drilled in the boarders of the bed frame, production cost is reduced, productivity is increased, both disassembly and assembly are convenient, and the bed frame is more durable. The male sleeve and the female sleeve for the bed frame are mainly applied to the field of supporting of berths, sofas, storage racks and the like.

Owner:张心峰

Thermosetting foam profile control agent and application thereof

ActiveCN111826143APerformance is not affectedDoes not affect formationDrilling compositionSealing/packingPhenolformaldehyde foamPolymer science

The invention discloses a thermosetting foam profile control agent and application thereof. The thermosetting foam profile control agent comprises a foam fixing agent, a curing agent and a foaming agent, wherein the foam fixing agent is a resin prepolymer, and the curing agent is water-soluble temperature control decomposition type slow-release acid. According to the invention, by researching anddeveloping water-soluble temperature-controlled decomposition slow-release acid and a temperature-resistant foaming agent, an underground cross-linked thermosetting phenolic foam plastic (wet method)meeting a thick oil thermal recovery plugging control construction process is modified and researched; a low-molecular resin prepolymer and a curing agent stably exist in a foam liquid film, so that the foaming volume and the half-life period are not influenced; and a curing agent is decomposed to generate an acid at a high temperature, hydrophilic resin hydroxymethyl bonds are catalyzed to be subjected to condensation polymerization to form hydrophobic resin methylene bonds, free water bound by a space net structure and coated with a liquid film is formed, and the foam liquid film is converted into a thermosetting resin hard shell, so that the influence of high temperature, stratum pore size and injected water dilution scouring on foam plugging strength, heat stability and validity periodis avoided.

Owner:PETROCHINA CO LTD

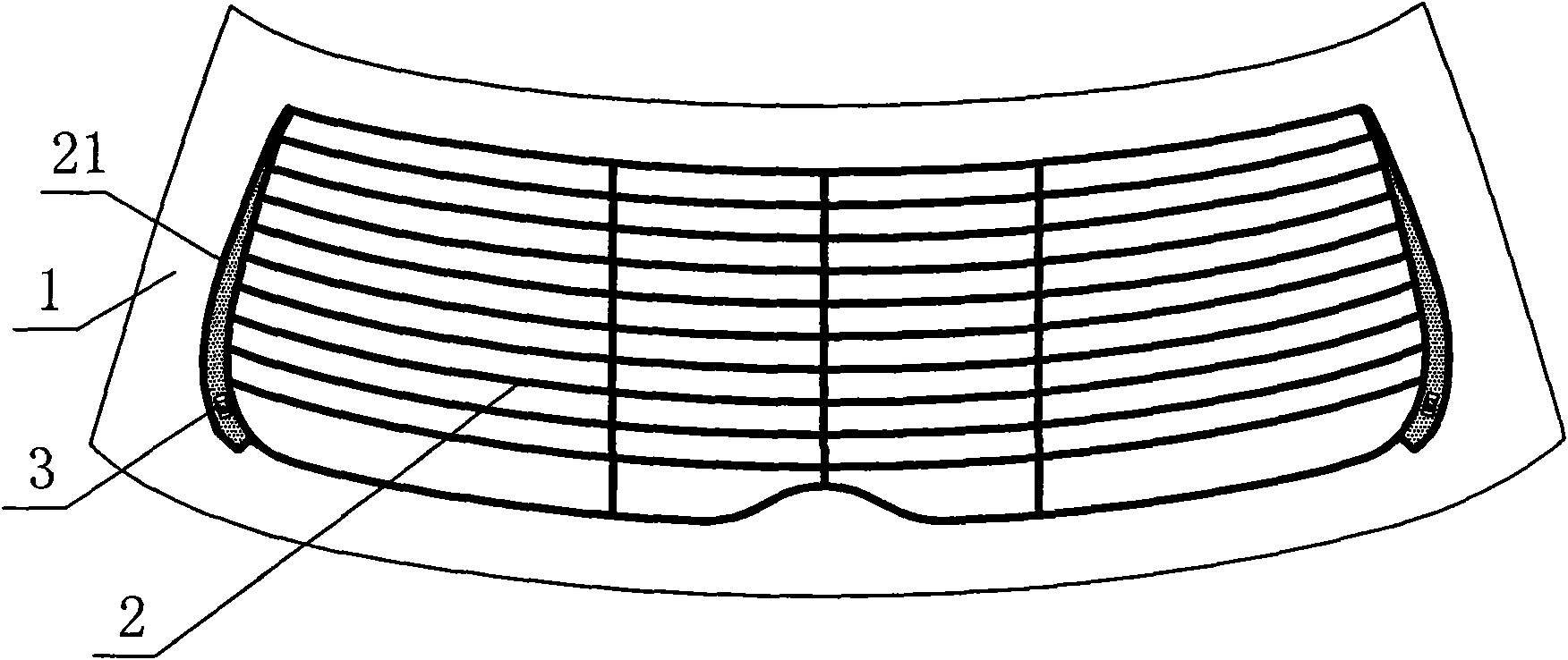

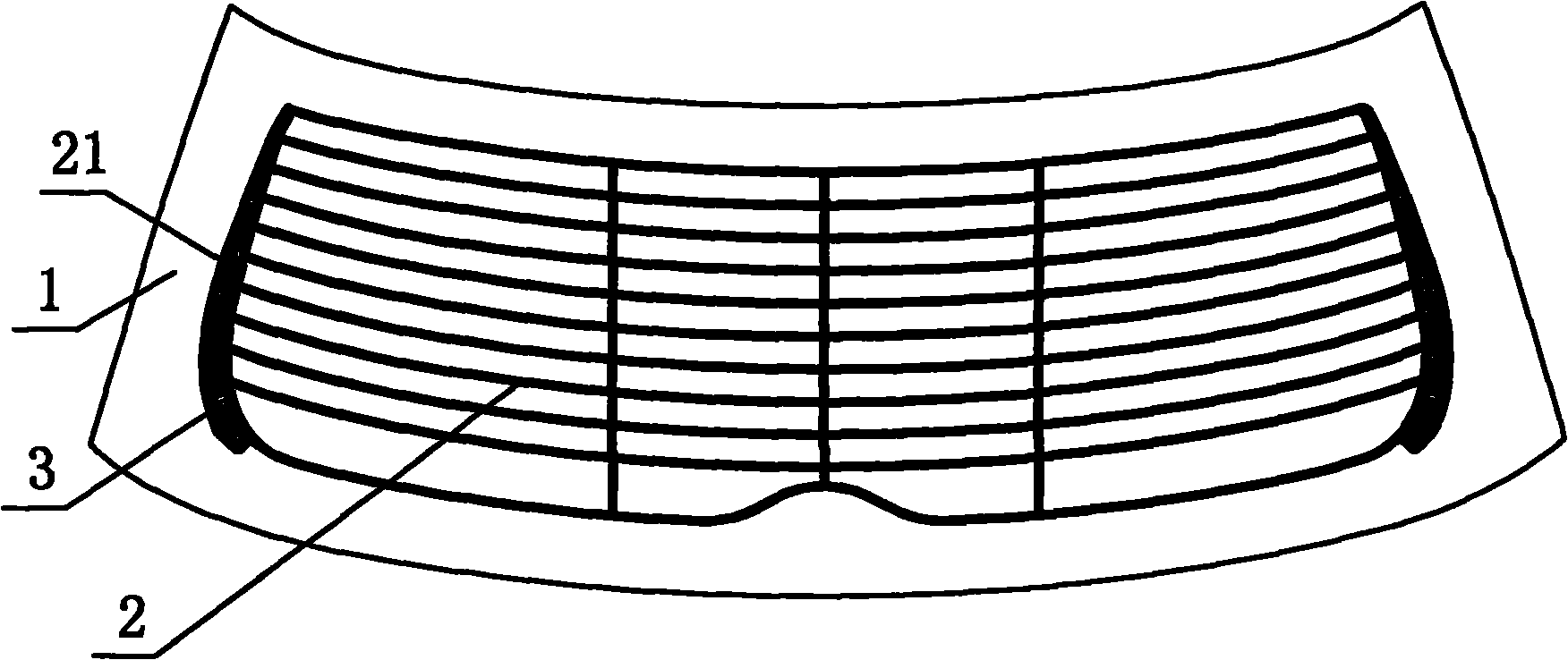

Method for welding tongue piece of automobile back windshield

InactiveCN101607333AAvoid localized heatAvoid defects caused by stress balance disruptionSoldering apparatusGlass fiberSilver paste

The invention discloses a method for welding a tongue piece of an automobile back windshield. The method not only requires low-cost equipments and has convenient application process but also overcomes the quality defects of the prior art. The method has following steps of: (1) making column-shaped soldering tin to be flat by adopting a knocking method or a pressing method, and cutting the flat soldering tin into soldering tin pieces matched with the size of the tongue piece for standby; (2) opening a self-air temperature-adjusting plastic welding gun for pre-heating and standby; (3) using a glass-fiber bar for wiping silver paste at the positions to be welded on the windshield surface so as to remove an oxide layer; (4) placing the soldering tin pieces on the welding position and putting the tongue piece on the position, and then rapidly adopting the welding gun to blow and heat the soldering tin pieces so as to complete the welding after melting the soldering tin; and (5) placing the windshield on a special frame for cooling after completing welding. The method is simple and practical and can be popularized easily.

Owner:珠海华尚汽车玻璃工业有限公司

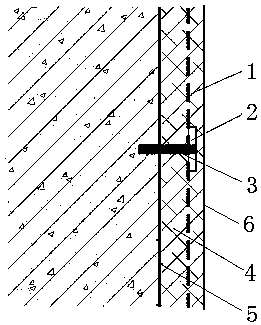

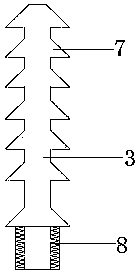

Heat insulation anchoring structure for water conservancy dam polyurea anti-seepage coatings and construction method

InactiveCN107435318AThe problem of customer service strippingRelieve crackingClimate change adaptationMarine site engineeringGlass fiberThermal insulation

The invention discloses a heat insulation anchoring structure for water conservancy dam polyurea anti-seepage coatings and a construction method. According to the heat insulation anchoring structure, a threaded rod with the length of 30-150mm is fixed into a screw hole reserved by a concrete casting template through an inner screw at the bottom of the threaded rod, a dam concrete substrate is coated with a polyurea layer, a rigid polyurethane foam with the thickness of 20-100mm is sprayed on the polyurea layer, a glass fiber rib with the diameter of 4-10mm is bound in an intersected manner on the surface of the foam by part of the exposed threaded rod, a tray rapidly covers a threaded rod body by the aid of a structure of the threaded rod body, the glass fiber rib presses on the surface of the rigid polyurethane foam, a rigid polyurethane foam with the thickness of 10-50mm is sprayed on the glass fiber rib and the tray and completely covers the threaded rod, the glass fiber rib and the tray, and an ice-resistant layer with the thickness of 2-6mm is constructed on the foam. The anchoring structure solves the problems of peeling of the polyurea anti-seepage coatings from the dam substrate and cracking, bulging and ice resisting of the heat insulation polyurethane foam.

Owner:STATE GRID CORP OF CHINA +3

Preparation method of autoclaving-free PHC (prestressed high strength concrete) pipe pile with reduction of usage amount of cementing material

InactiveCN104827563AReduce raw material costsImprove competitivenessCeramic shaping apparatusHigh strength concreteGrout

The invention discloses a preparation method of an autoclaving-free PHC (prestressed high strength concrete) pipe pile with reduction of usage amount of a cementing material. The preparation method comprises the following steps of (1) preparing and mixing concrete, wherein the total mass of the concrete per cubic meter is 2480kg to 2550kg, the mass of the cementing material is 450kg to 350kg, the mass ratio of water and the cementing material is 0.18 to 0.25:1, the usage amount of a water reducing agent is equal to 1.1% to 1.6% of the mass of the cementing material, the usage amount of an air entraining agent is equal to 0.005% to 0.10% of the mass of the cementing material, the balance is sand and stone, the mass ratio of the sand and the stone is 0.32 to 0.36:1, and the cementing material comprises cement and mineral mixtures; (2) feeding the mixed concrete into a feeding machine to distribute, closing a pipe pile mould, and tensioning; (3) centrifuging the pipe pile; (4) curing by steaming; (5) demoulding the pipe pile. The preparation method has the advantage that by mixing the air entraining agent, the usage amount of the cementing material of the autoclaving-free PHC pipe pile is reduced, the amount of remained grout is reduced, and the influence on strength and durability is avoided.

Owner:SOUTH CHINA UNIV OF TECH

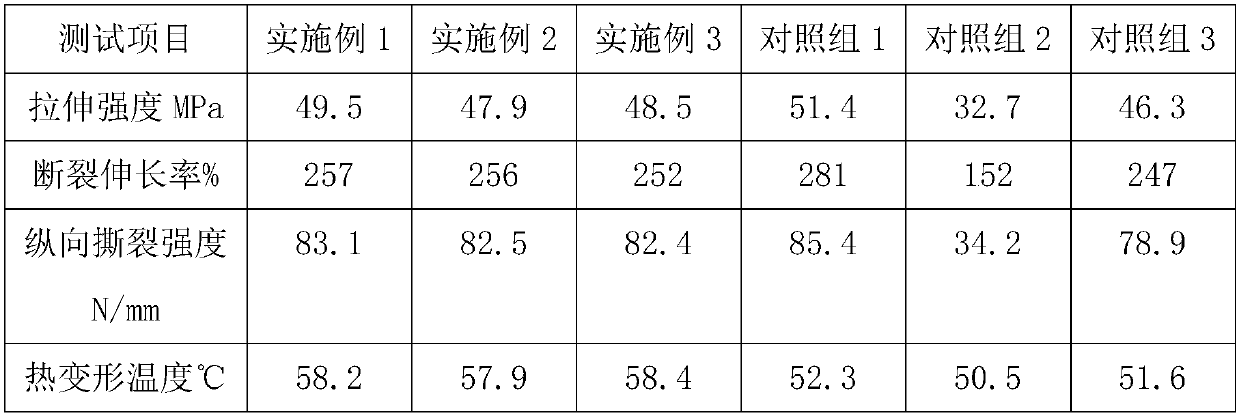

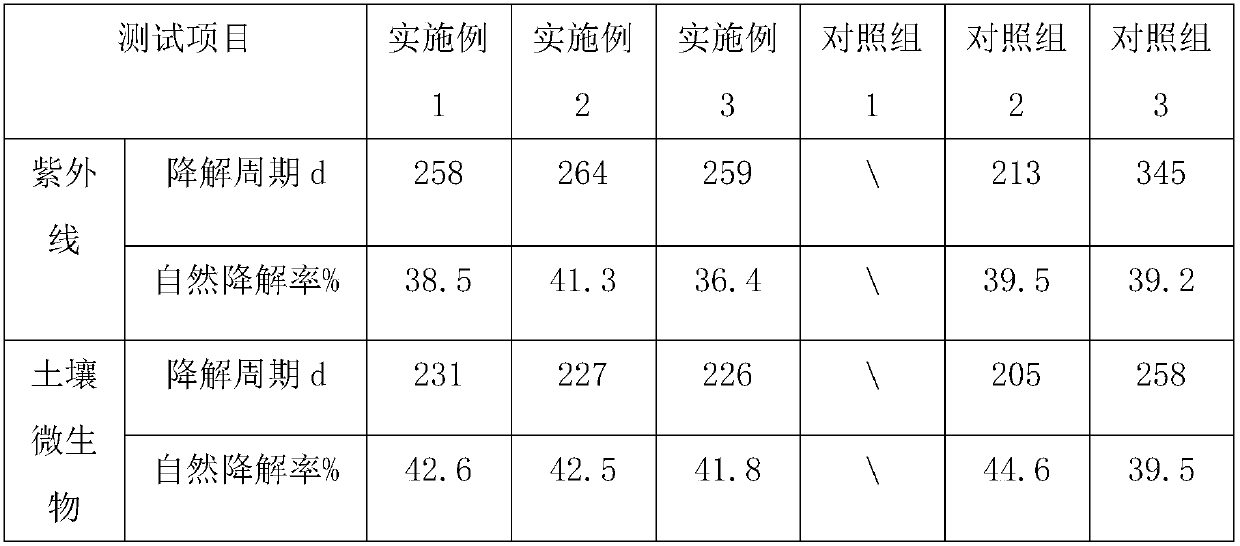

High-strength and easily-degradable composite material for garbage bag

The invention relates to the technical field of polymer materials, and in particular to a high-strength and easily-degradable composite material for a garbage bag. The composite material comprises thecomponents of polyvinyl chloride resin, polyamide resin, a TPVC (Thermoplastic Polyvinyl Chloride) elastomer, metamorphic starch, a compatibilizer, a plasticizer, a reinforcing agent, a degradation catalyst and a stabilizer, wherein the compatibilizer is maleic anhydride grafted polyethylene; the stabilizer is a calcium-zinc composite stabilizer; the reinforcing agent is carbon black; and the plasticizer is dibutyl phthalate, isosorbide diester or butyl triacetate; a photocatalyst is a compound formed by mixing nano zinc oxide, anatase titanium dioxide and polylactic acid in a mass ratio of 2:5:10. The composite material has high strength, good toughness and remarkable weather resistance and has the characteristics of high degradation rate and fast degradation speed.

Owner:合肥易美特建材有限公司

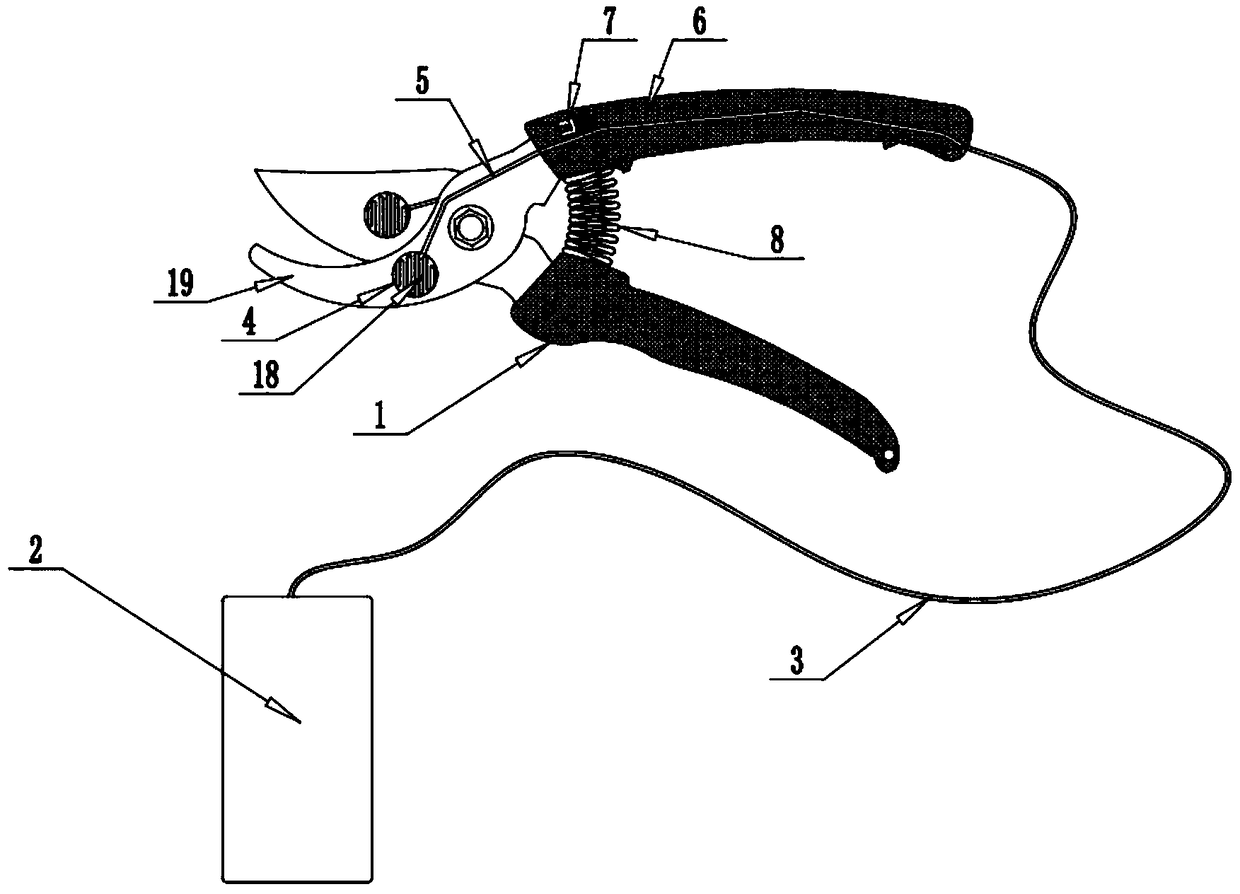

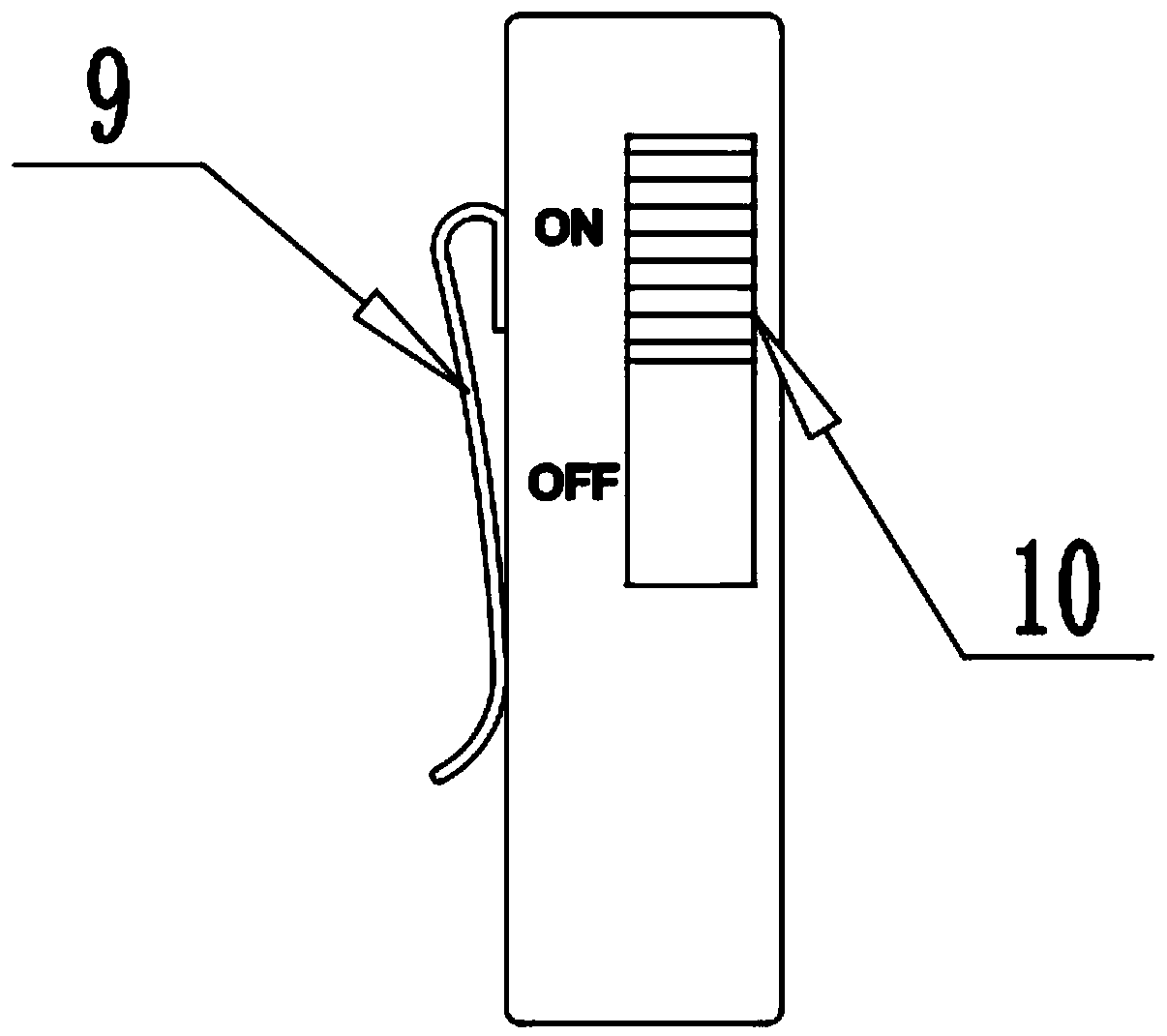

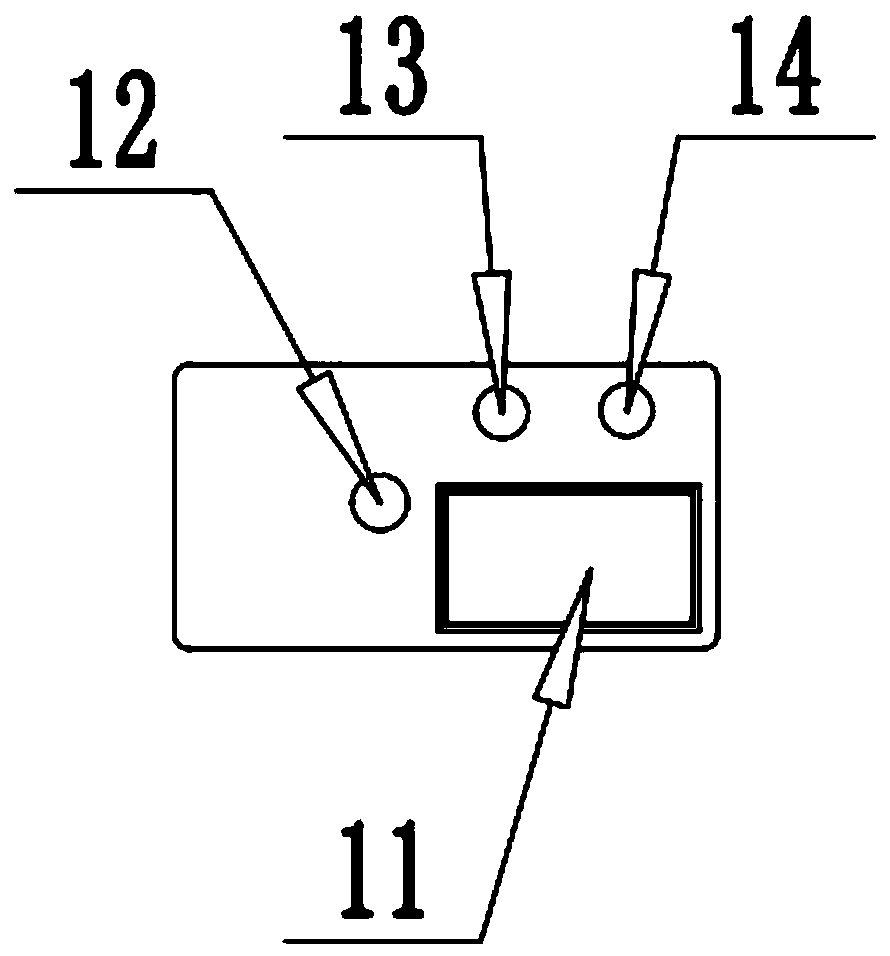

Electric-heating disinfected pruning shears

PendingCN109429761AIntensity has no effectImprove securitySecateursHorticulture methodsEngineeringPruning

An embodiment of the invention discloses electric-heating disinfected pruning shears and relates to the field of garden pruning tools. The pruning shears comprise a pruning shears body and an electricheating device; the pruning shears body is connected with the electric heating device through a conductor wire and comprises cutting edges and handles; the electric heating device comprises a power supply and heating pieces; at least one cutting edge is provided with the heating piece, and the power supply realizes heating of the heating pieces through the conductor wire. The electric-heating disinfected pruning shears overcome the defects in the prior art that it is incapable of preventing plant bacteria, fungi and virus transmission by disinfecting the cutting edges of the pruning shears and branch cuts.

Owner:刘伟芳

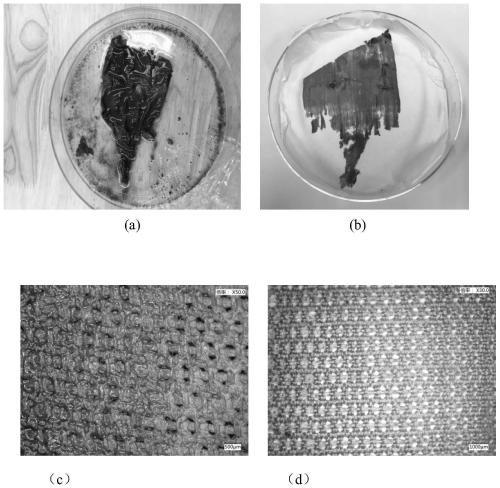

Water-based cleaning agent for textile relics and preparing and cleaning methods thereof

ActiveCN110305740AReduce surface tensionReduce the binding forceOrganic detergent compounding agentsNon-ionic surface-active compoundsWater basedCleaning methods

The invention provides a water-based cleaning agent for silk fabric relics and preparing and cleaning methods thereof. The water-based cleaning agent is characterized by comprising a cleaning solutionwhich is composed of, by mass, 5-10.0% of sophorolipid, 1.5-5% of N, N-dicarboxylmethyl aniline trisodium, 0.5-1.5% of tartaric acid, 0.5-3.5% of trypsae, 1-5% of alcohol and the balance of water. The water-based cleaning agent can remove dirt including mixed dirt of animal-plant protein degradation rotten residue, microorganisms and minerals on the silk fabric relics; the waste-based cleaning agent has no impact on strength of silk fabric; color and softness of the silk fabric relics after being treated are improved obviously; the water-based cleaning agent can be used for cleaning the silkfabric relics various in preservation condition including fragile and deteriorated unearthed silk fabric relics.

Owner:SHANGHAI MUSEUM

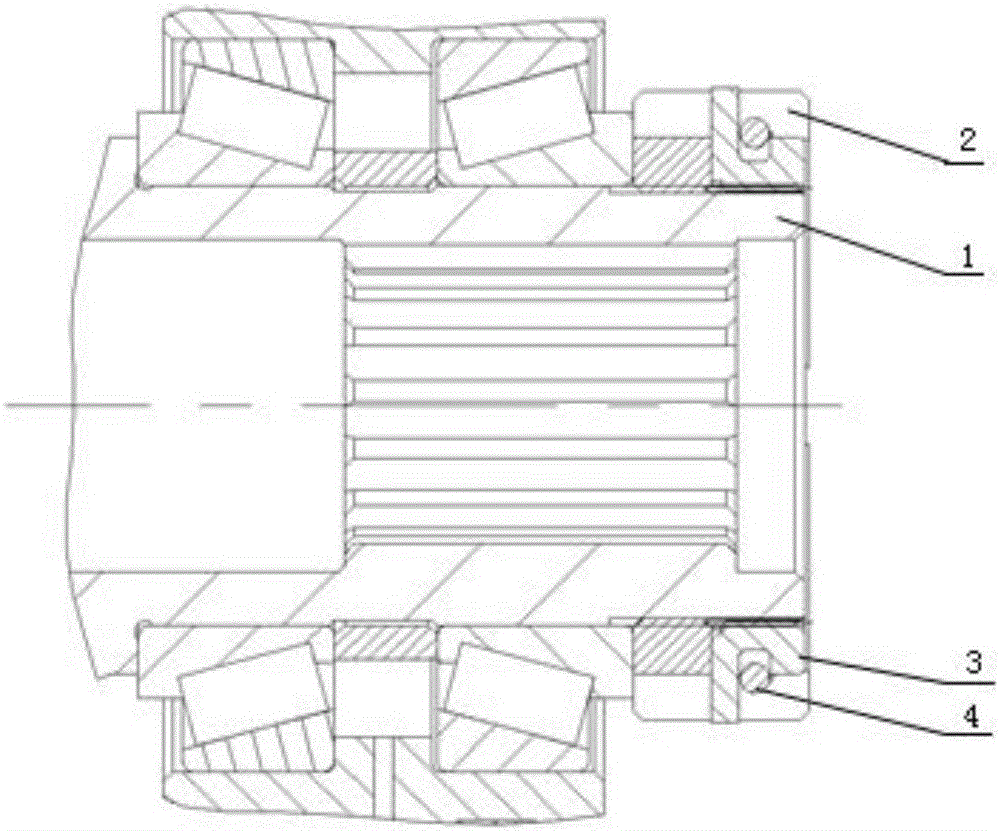

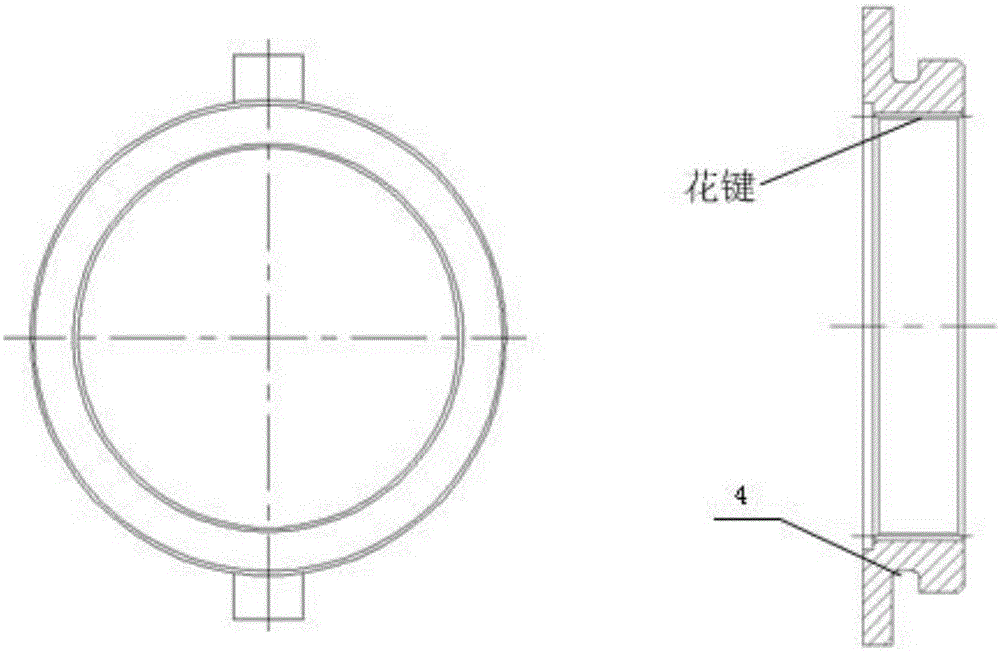

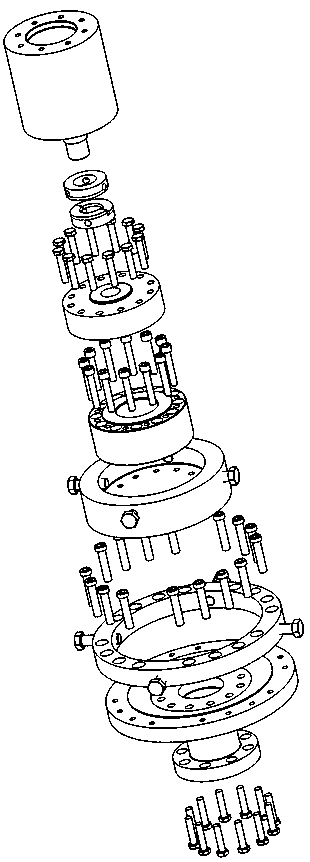

Shaft fastener

InactiveCN104989734AIntensity has no effectImprove the anti-loosening effectFastening meansBearing unit rigid supportBiochemical engineeringAxial force

The invention provides a shaft fastener which is characterized in that the fastener comprises a locating shaft (1), an axial fixing piece (2), a transverse fixing piece (3) and steel cable baffle rings (4), wherein the axial fixing piece (2) consists of two annular cylinders with the identical outer diameters and different inner diameters, and is arranged at the outer wall of the locating shaft (1) in a sleeving manner; the transverse fixing piece (3) is arranged between the other end of the axial fixing piece (2) and the locating shaft (1) in a sleeving manner; a baffle ring groove A is formed in the inner wall of the other end of the axial fixing piece (2); a baffle ring groove B is formed in the outer wall of the transverse fixing piece (3); and the steel cable baffle rings (4) are arranged in the baffle ring groove A and the baffle ring groove B. The fastener is reliable in anti-loosing effect, can be repeatedly dismounted, mounted and used, has no influence to the shaft strength, and can be used for axial locking and locating with a larger axial force.

Owner:CHINA NORTH VEHICLE RES INST

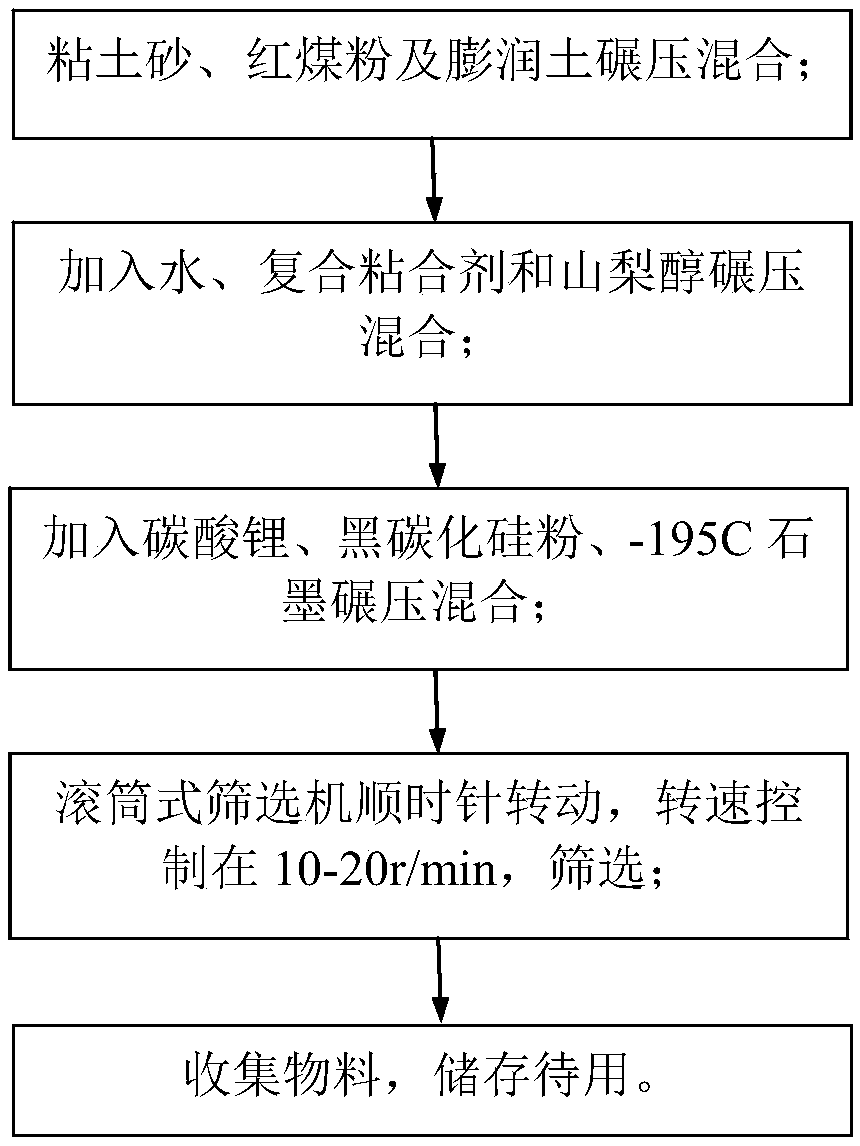

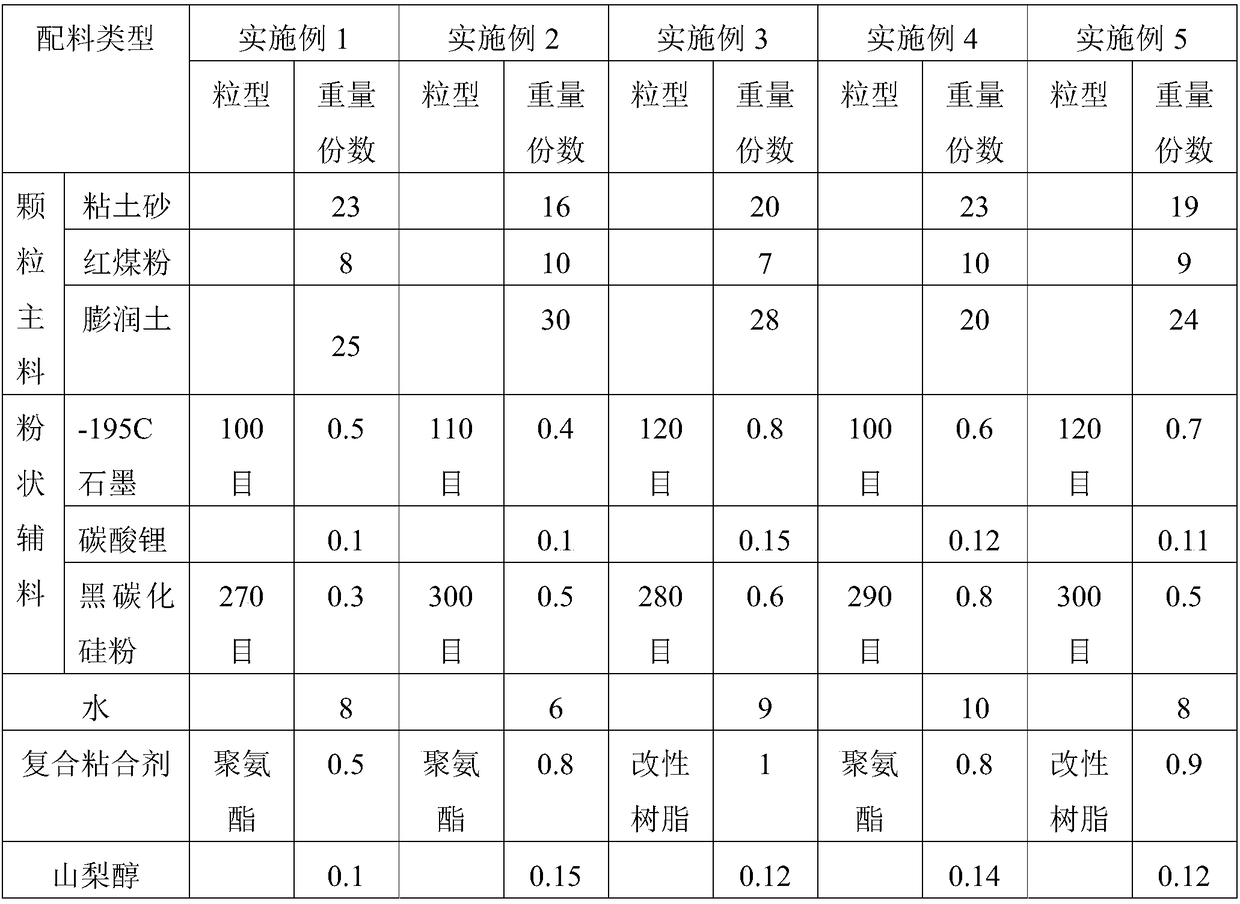

Formula and preparation process for sandbox molding sand

InactiveCN108772532AHigh strengthImprove thermal stabilityFoundry mouldsMould handling/dressing devicesSodium BentoniteAdhesive

The invention discloses a formula and preparation process for sandbox molding sand, belonging to the technical field of casting. The formula comprises a granular main material and a powdery accessorymaterial. The granular main material comprises, by weight, 16 to 23 parts of clay sand, 20 to 30 parts of bentonite and 6 to 10 parts of anthracite powder. The powdery accessory material comprises, byweight, 0.1-0. 15 part of lithium carbonate, 0.3-0.8 part of black silicon carbide powder, 0.3-0.8 part of -195C graphite, 6-10 parts of water, 0.5-1 part of a composite adhesive and 0.1 to 0.5 partof sorbitol. The sandbox molding sand prepared according to the formula has good dispersibility and strong cohesiveness, and is effectively improved in strength and enhanced in thermal stability, plasticity and air permeability; the sandbox molding sand is safe and reliable in use, and an inner wall is smooth and has low roughness, so the yield of castings is good; in addition, the sandbox moldingsand has good collapsibility, so castings are easy to demould, and working efficiency is improved.

Owner:MAANSHAN YIFENG INDAL GROUP

Method for welding tongue piece of automobile back windshield

InactiveCN101607333BAvoid localized heatAvoid defects caused by stress balance disruptionSoldering apparatusSilver pasteGlass fiber

The invention discloses a method for welding a tongue piece of an automobile back windshield. The method not only requires low-cost equipments and has convenient application process but also overcomes the quality defects of the prior art. The method has following steps of: (1) making column-shaped soldering tin to be flat by adopting a knocking method or a pressing method, and cutting the flat soldering tin into soldering tin pieces matched with the size of the tongue piece for standby; (2) opening a self-air temperature-adjusting plastic welding gun for pre-heating and standby; (3) using a glass-fiber bar for wiping silver paste at the positions to be welded on the windshield surface so as to remove an oxide layer; (4) placing the soldering tin pieces on the welding position and putting the tongue piece on the position, and then rapidly adopting the welding gun to blow and heat the soldering tin pieces so as to complete the welding after melting the soldering tin; and (5) placing thewindshield on a special frame for cooling after completing welding. The method is simple and practical and can be popularized easily.

Owner:珠海华尚汽车玻璃工业有限公司

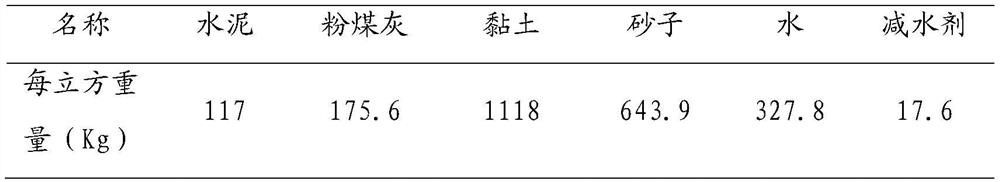

Low-strength low-permeability concrete and preparation method thereof

ActiveCN112062526ALow strength propertiesImprove low water permeabilitySolid waste managementExcavationsStructural engineeringUltimate tensile strength

The embodiment of the invention provides low-strength low-permeability concrete and a preparation method thereof. A concrete mixture of the low-strength low-permeability concrete comprises cement, flyash, clay, sand, water and a water reducing agent. Wherein the mass ratio of the cement to the fly ash to the clay to the sand to the water to the water reducing agent in each cubic meter of the concrete mixture is (82.9-117): (175.6-210.7): (1118-1235.2): (527-643.9): (320-330): (17-18), and the total mass of each cubic meter of the concrete mixture is 2300-2400 kg. The low-strength low-permeability concrete provided by the invention has good concrete workability, is convenient to construct, has good impermeability and is suitable for underground engineering; materials are convenient to obtain, and the economy is good.

Owner:中建四局建设发展有限公司 +1

A packaging box with bar-code protection groove and method and apparatus for producing the same

InactiveCN101531269AIntensity has no effectSolve technical problems that cannot be scannedContainer/bottle contructionRigid containersEngineeringMechanical engineering

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

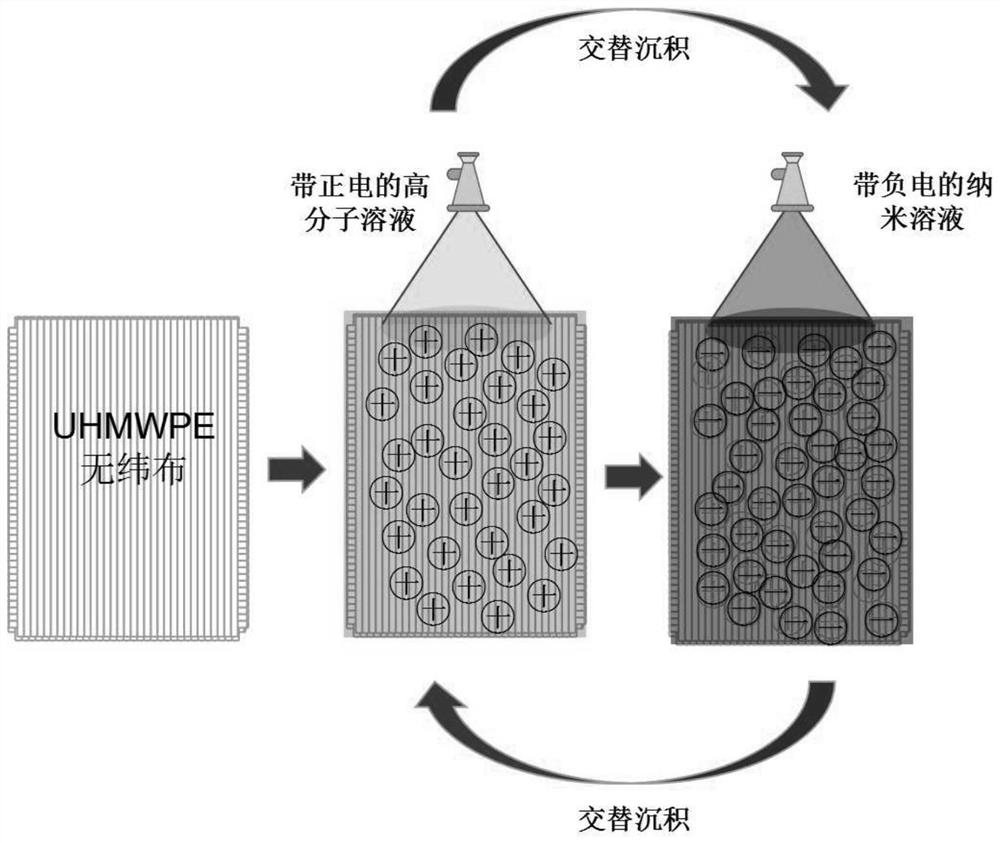

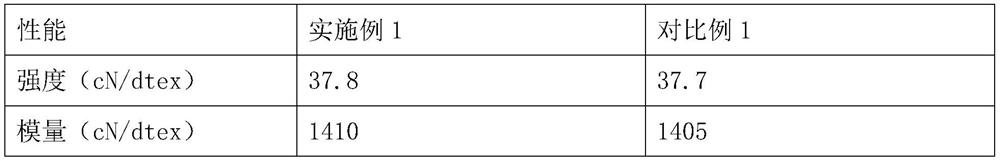

Preparation method of ultra-high molecular weight polyethylene fiber conductive weftless cloth

PendingCN112376263AIntensity has no effectModulus has no effectFibre typesUltrasonic/sonic fibre treatmentPolymer scienceSpinning

The invention relates to a preparation method of ultra-high molecular weight polyethylene fiber conductive weftless cloth. The preparation method comprises the following steps: mixing ultra-high molecular weight polyethylene resin and paraffin oil, swelling, spinning, stretching and drawing; dipping obtained ultra-high molecular weight polyethylene fibers into gum, curing to shape and carrying outcontinuous cross compounding to obtain the weftless cloth; placing obtained ultra-high molecular weight polyethylene fiber weftless fabric in acetone, ethyl alcohol and a deionized water solution insequence to be subjected to ultrasonic oscillation; etching the dried ultra-high molecular weight polyethylene fiber weftless cloth by using a plasma etching machine to ionize negative charges on thesurface of the ultra-high molecular weight polyethylene fiber weftless cloth; and alternately spraying a polymer solution with positive charges and an inorganic nano-material solution with the negative charges on the surface of the etched ultra-high molecular weight polyethylene fiber weftless fabric to obtain the ultra-high molecular weight polyethylene fiber conductive weftless fabric. Accordingto the preparation method, under the condition that the strength and modulus of the weftless cloth are not affected, the ultra-high molecular weight polyethylene fiber weftless cloth is endowed withconductivity.

Owner:HUNAN ZHONGTAI SPECIAL EQUIP

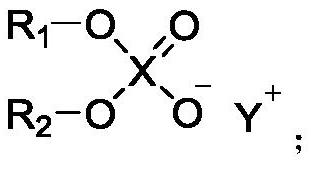

Application of water-retaining shrinkage-reducing polycarboxylate water-reducer in preparation of high-performance concrete

The invention provides an application of a water-retaining reduced polycarboxylic acid water reducer to preparation of high-performance concrete, and further provides the high-performance concrete containing the water-retaining reduced polycarboxylic acid water reducer. As polyhydroxy is introduced into molecular middle chains of the water-retaining reduced polycarboxylic acid water reducer, hydrogen bonds are formed between hydroxy and among the hydroxy and water molecules, a mico-crosslinking structure is formed, the viscosity of solution in cement paste capillary pores in the concrete is increased, the evaporation rate of the water molecules is delayed, and water-retaining property is remarkably improved, so that shrinkage of the high-performance concrete is reduced. High-performance concrete shrinkage test results indicate that the water-retaining reduced polycarboxylic acid water reducer has a good shrinkage effect, is high in cost performance has no influence on the workability and the strength of the high-performance concrete when being used for the high-performance concrete.

Owner:浙江红墙材料科技有限公司

Fireproof cable material and preparation method thereof

InactiveCN107216515AMaterials are readily availableEasy to prepareRubber insulatorsBulk chemical productionFiberPolyolefin

The invention relates to a fireproof cable material and a preparation method thereof. The fireproof cable material is prepared from the following raw material ingredients in parts by weight: 10 to 15 parts of activated high-purity magnesium oxide, 5 to 8 parts of magnesium chloride, 14 to 17 parts of plant fiber, 6 to 10 parts of lithopone, 4 to 9 parts of glass fiber, 8 to 12 parts of 4,4'-bis(alpha,alpha-dimethylbenzyl)diphenylamine, 5 to 10 parts of ceramic fiber, 8 to 10 parts of polyolefin, 5 to 12 parts of synthetic resin, 6 to 10 parts of silicon carbide, 6 to 9 parts of synthetic mica, 15 to 20 parts of HY-109 rubber adhesive, 3 to 12 parts of PVC, 50 to 60 parts of ethyl alcohol and 30 to 40 parts of helium. The materials of the fireproof cable material disclosed by the invention are easy to obtain; the fireproof cable material has the advantages of simple preparation method, low cost, large tensile strength, good self-lubricating effect, good electric insulating performance, good high temperature resistance, strong stability, oxidization resistance, good anti-ageing effect, small dielectric index, superstrong fireproof performance, small density, excellent heat-resistant effect and no crack in high temperature, low temperature and high pressure; service life of the fireproof cable material is prolonged.

Owner:方碧水

Fatigue testing machine capable of adjusting coaxiality and loading chain centering adjustment method

PendingCN110836830ASolve the problem that the loading chain needs to be disassembled and cannot be adjusted in real timeSolve problems that cannot be adjusted in real timeMechanical measuring arrangementsStrength propertiesMachineMechanical engineering

The invention relates to a fatigue testing machine capable of adjusting coaxiality and a loading chain centering adjustment method and belongs to the technical field of testing machines. The fatigue testing machine comprises a main shaft loading chain, a centering adjustment device, a centering sensor, a feedback device and a rack. The centering adjustment device is installed on the main shaft loading chain, the main shaft loading chain is installed on the rack, and a detection and feedback mechanism is installed on the rack and used for detecting and controlling an adjustment amount. The five-degree-of-freedom adjustment on the loading chain can be carried out. The strength of the device is improved, an adjusting module is mounted on a same parent body such that the rigidity of the deviceis improved, and the device is more stable and safer in a loading process. The adaptability is high, loading chains with different shaft diameters can be installed by adjusting the sizes of the parent body and other parts, and other types of testing machines can also be installed. The fatigue testing machine can be matched with various clamps and has the advantages of small occupation space, easyoperation, controllable adjustment precision, good stability and high repeated adjustment precision, the experiment precision can be improved, and the measurement data is more accurate.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com