Preparation method of ultra-high molecular weight polyethylene fiber conductive weftless cloth

A technology of ultra-high molecular weight, polyethylene fibers, applied in the direction of single-component polyolefin rayon, ultrasonic/sonic fiber treatment, fiber type, etc., which can solve the adverse effects of strength and modulus, loss of coating, and adverse effects of performance and other issues to achieve low cost, simple operation, and strong universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

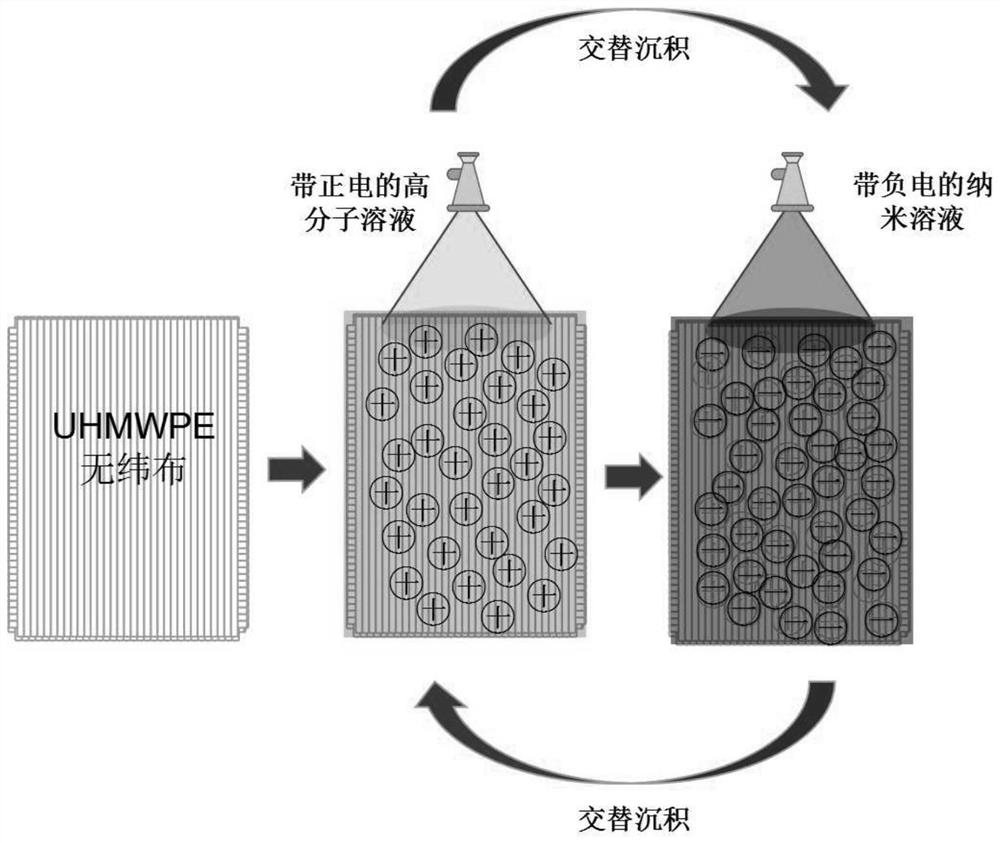

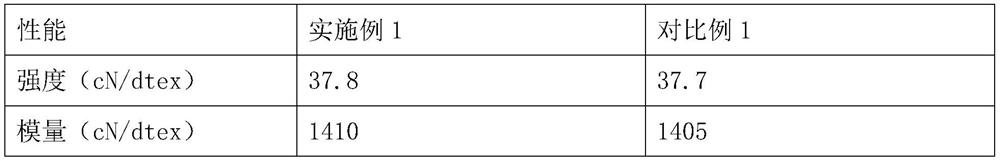

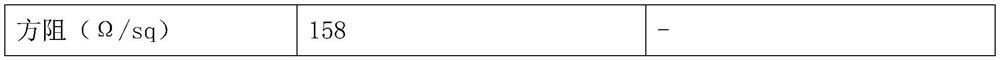

[0023] A preparation method of ultra-high molecular weight polyethylene fiber conductive non-weft cloth, comprising the following steps,

[0024] 1) mixing ultra-high molecular weight polyethylene and paraffin oil, swelling, spinning, stretching, drawing, to obtain ultra-high molecular weight polyethylene fibers;

[0025] 2) impregnating ultra-high molecular weight polyethylene fibers, curing and forming, and continuously cross-compositing the cured and formed ultra-high molecular weight polyethylene fibers to obtain ultra-high molecular weight polyethylene fiber non-weft fabrics;

[0026] 3) Place the ultra-high molecular weight polyethylene fiber non-weft cloth in acetone, ethanol, and deionized aqueous solution in sequence for 15 minutes to remove stains on the surface of the fabric and dry it;

[0027] 4) Etching the dried ultra-high molecular weight polyethylene fiber non-weft cloth with a plasma etching machine (power 200W), so that the surface of the ultra-high molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com