Fatigue testing machine capable of adjusting coaxiality and loading chain centering adjustment method

A fatigue testing machine and centering adjustment technology, applied in the field of testing machines, can solve the problems of inability to adjust in real time, uncontrollable accuracy of manual assembly adjustment, etc., and achieve the effect of high reliability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

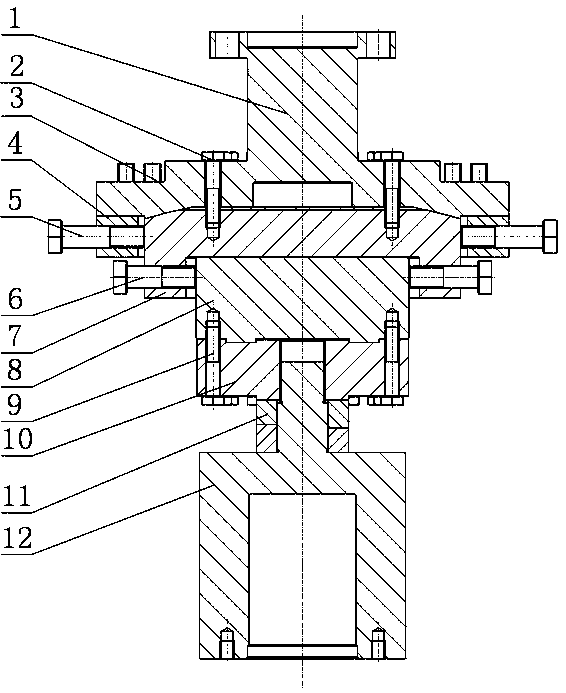

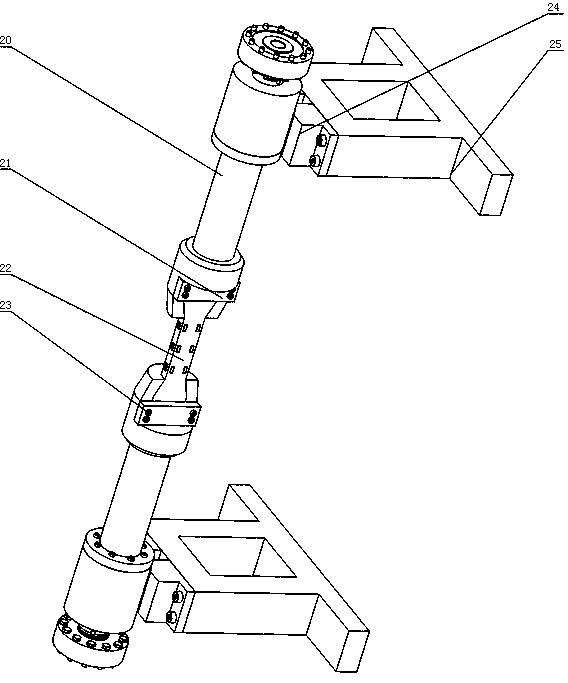

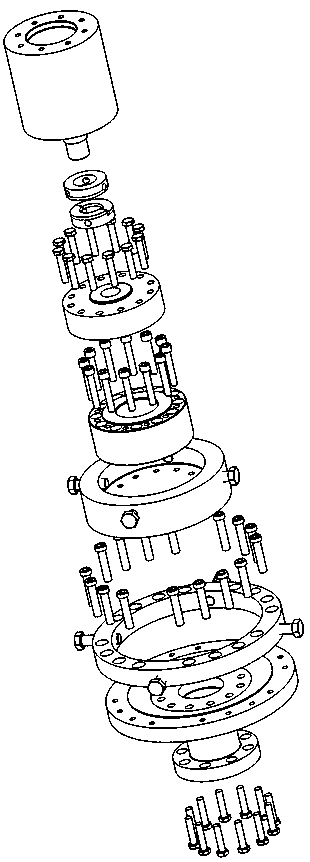

[0063] The detailed content and specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0064] See Figure 1 to Figure 12 As shown, the fatigue testing machine with adjustable coaxiality and the load chain centering adjustment method of the present invention solves the problem that the coaxiality of the load chain of the existing testing machine needs to be disassembled and the load chain cannot be adjusted in real time, and it fills in to a certain extent The blank of the prior art; the adjustment amount reaches 0.01mm / div, the adjustment range is ±1mm, ±0.35°; the centering device can be adjusted with five degrees of freedom, which can realize the adjustment of any angle and direction on the loading chain; adjustment device The internal wearing parts and parts with high positioning accuracy requirements are all standardized designs; the centering device and the loading chain of the whole machine are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com