Strain-gauge-based coaxiality adjusting system and coaxiality dimension reduction adjusting method

A technology for adjusting the system and coaxiality. It is applied in the directions of strength characteristics, instruments, measuring devices, etc. It can solve the problems of disassembly and cannot be adjusted in real time, and achieve the effect of improving strength, strong adaptability and easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

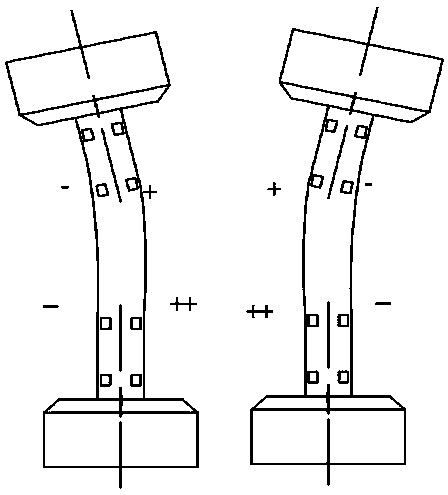

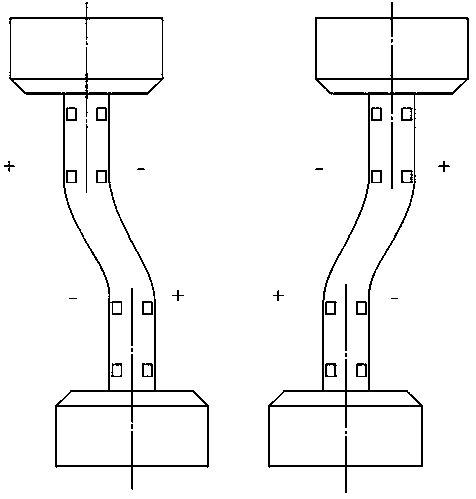

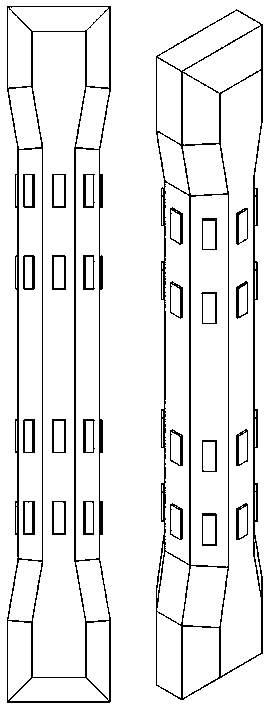

[0057] see Figure 1 to Figure 17 As shown, the coaxiality adjustment system and coaxiality dimension reduction adjustment method based on strain gauges of the present invention solve the problem that the loading chain coaxiality of the existing testing machine needs to be disassembled and cannot be adjusted in real time, and to a certain extent It fills in the gaps in the prior art; the centering device of the present invention can realize the adjustment of five degrees of freedom, and at the same time index the adjustment bolt, so that the adjustment amount reaches 0.01mm, the adjustment range is large (±0.5mm), and the adjustment angle (±0.5°); the dimension reduction adjustment method of the present invention uses different types of centering sensors to learn from each other’s strengths, and can also only use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com