Patents

Literature

167 results about "Machine industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The machine industry or machinery industry is a subsector of the industry, that produces and maintains machines for consumers, the industry, and most other companies in the economy. This machine industry traditionally belongs to the heavy industry. Nowadays, many smaller companies in this branch are considered part of the light industry. Most manufacturers in the machinery industry are called machine factories.

Phenolic resin/phosphate hybrid adhesive and preparation method thereof

InactiveCN101875830AEasy to prepareImprove thermal stabilityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPhosphateWorking temperature

The invention provides a phenolic resin / phosphate hybrid adhesive and a preparation method thereof, relating to an adhesive and a preparation method thereof. The invention solves the problems of low working temperature, rigorous curing process and low adhesion strength of the conventional high-temperature resisting phenolic resin adhesive. The adhesive is prepared from phenolic resin, heat-resistant reinforced resin, a coupling agent, a toughening agent, phosphate, a curing agent, a framework material, fillers and a dispersing agent. The preparation method comprises the following steps of: mixing the phenolic resin, the heat-resistant reinforced resin, the coupling agent and the toughening agent and then evenly stirring to obtain a phenolic resin component; then mixing the phosphate, the curing agent, the framework material and the fillers and then evenly stirring to obtain a phosphate component; and then adding the phosphate component and the dispersing agent into the phenolic resin component and evenly stirring. The adhesive can be applied in aerospace, military and machining industries with the working temperature above 800 DEG C.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

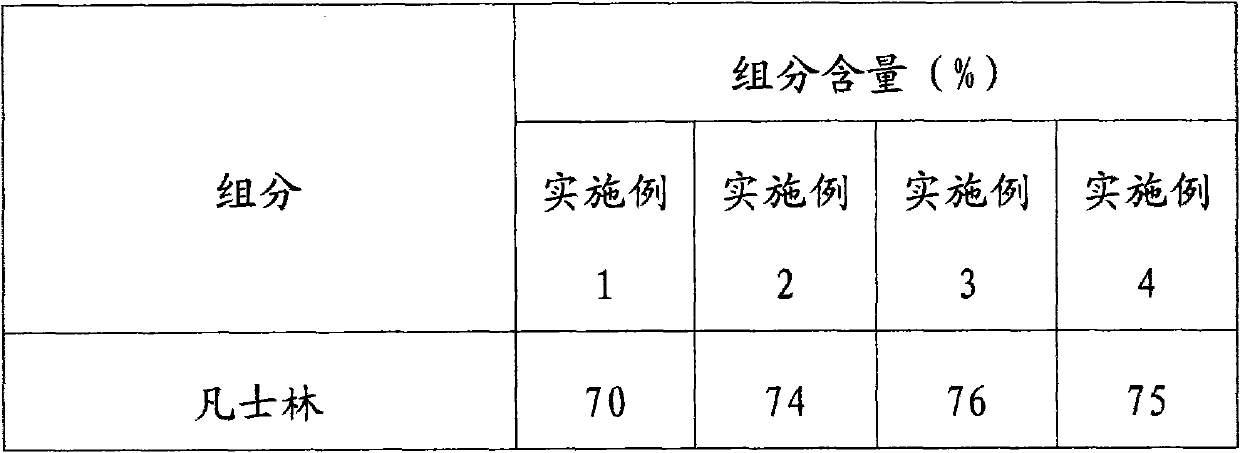

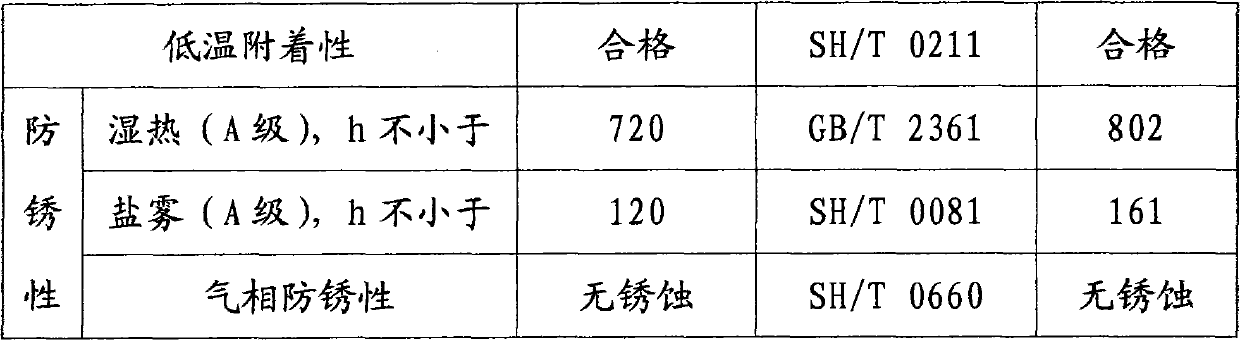

Lipid type antirust oil with gaseous phase antirust function

The invention discloses a lipid type antirust oil with gaseous phase antirust function; the composition of the lipid type antirust oil in weight percent is as follows: 70-90% of base lipid, 4-15% of antirust agent, 1-5% of gaseous phase antirust agent and 5-10% of oil film modifying agent; the inventive antirust oil has long protection period, sun and rain exposure resistance, non-leakage at hightemperature, non-cracking at low temperature, transparent and soft oil film, good paintability, and easy removal, and is mainly applied for antirusting for various metalwares, precise instruments, mechanical equipments, metal rotation sequence of workshops in machining industry, etc.

Owner:天津蓝星清洗有限公司

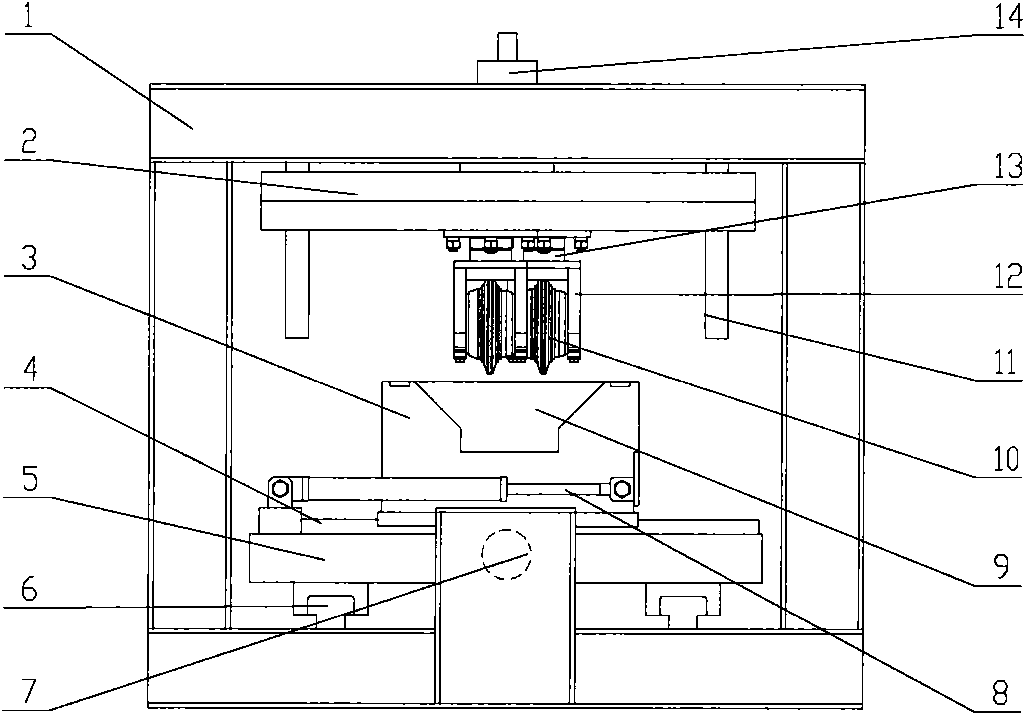

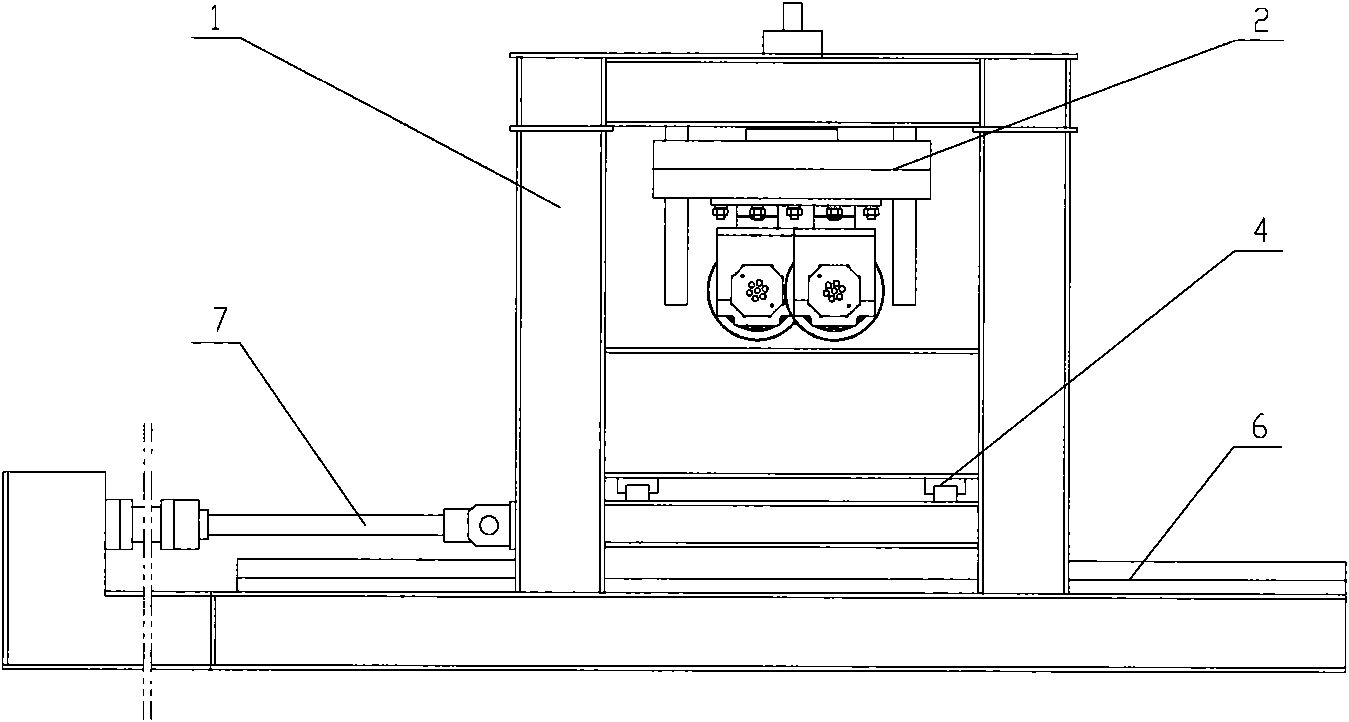

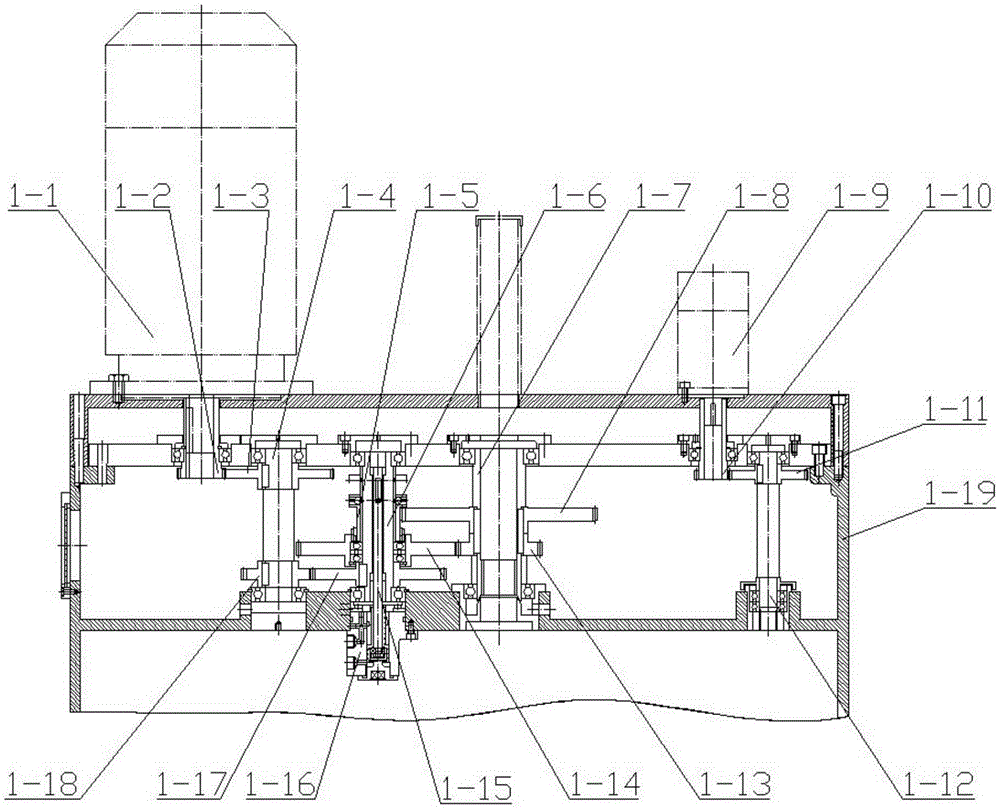

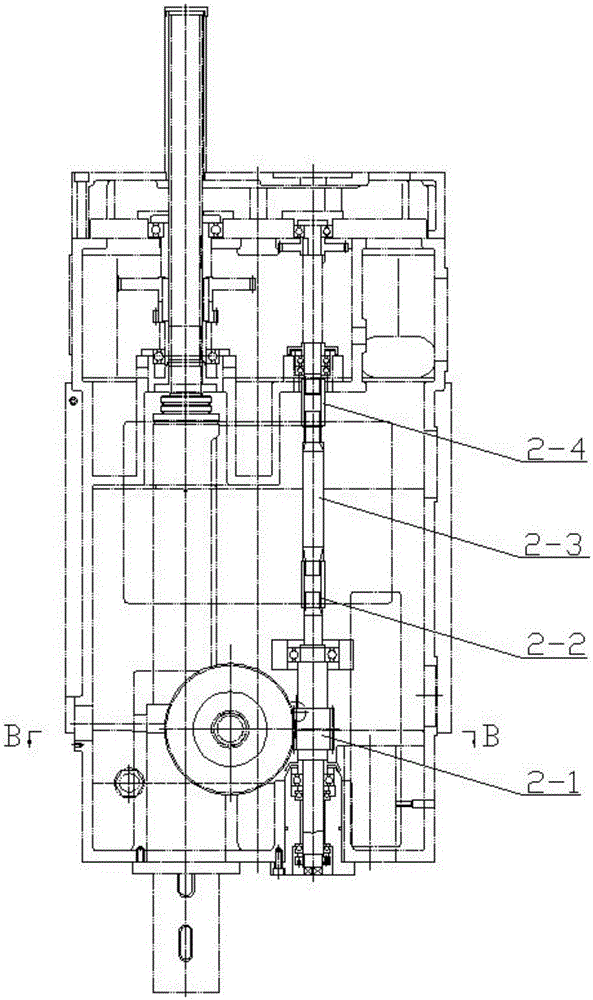

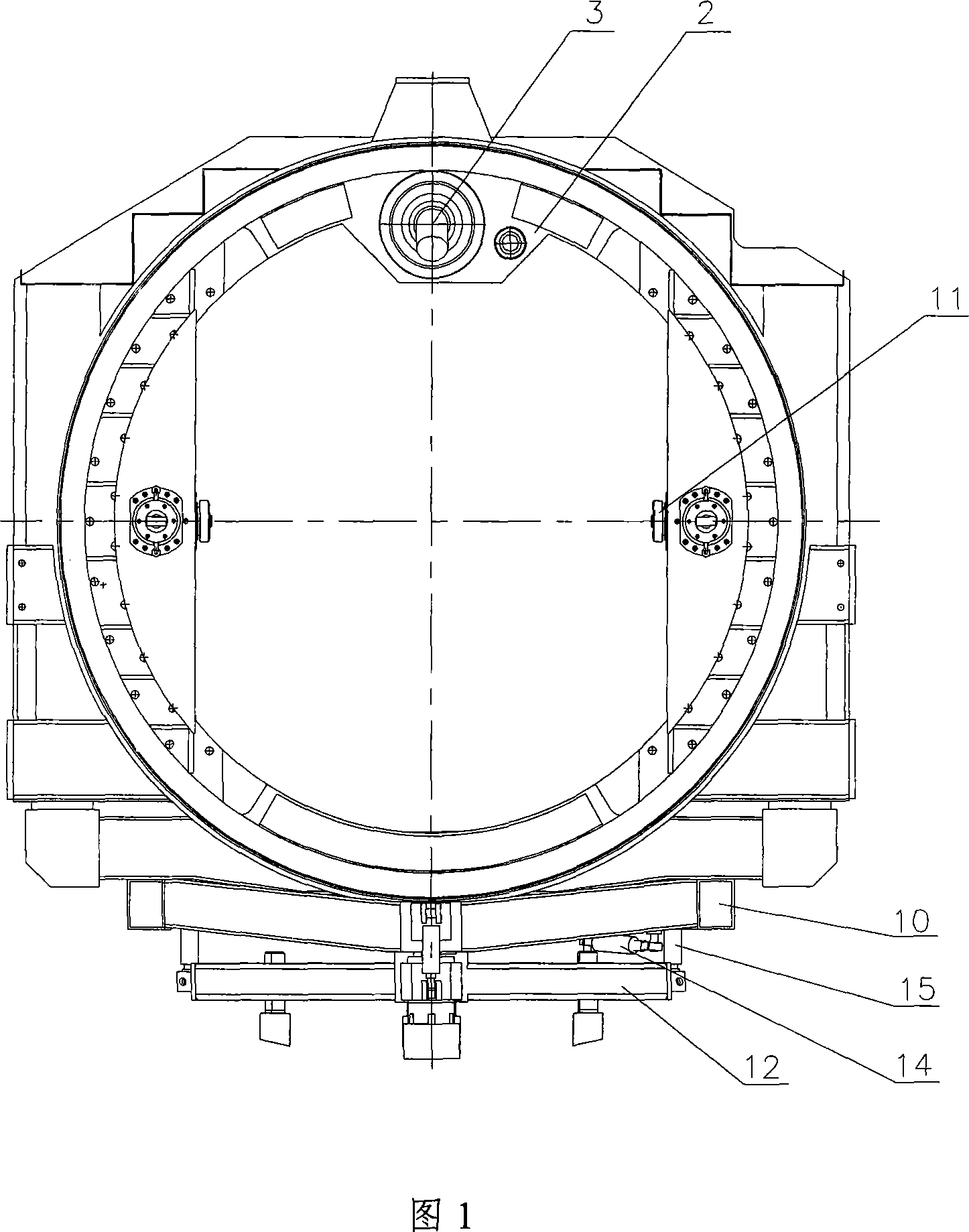

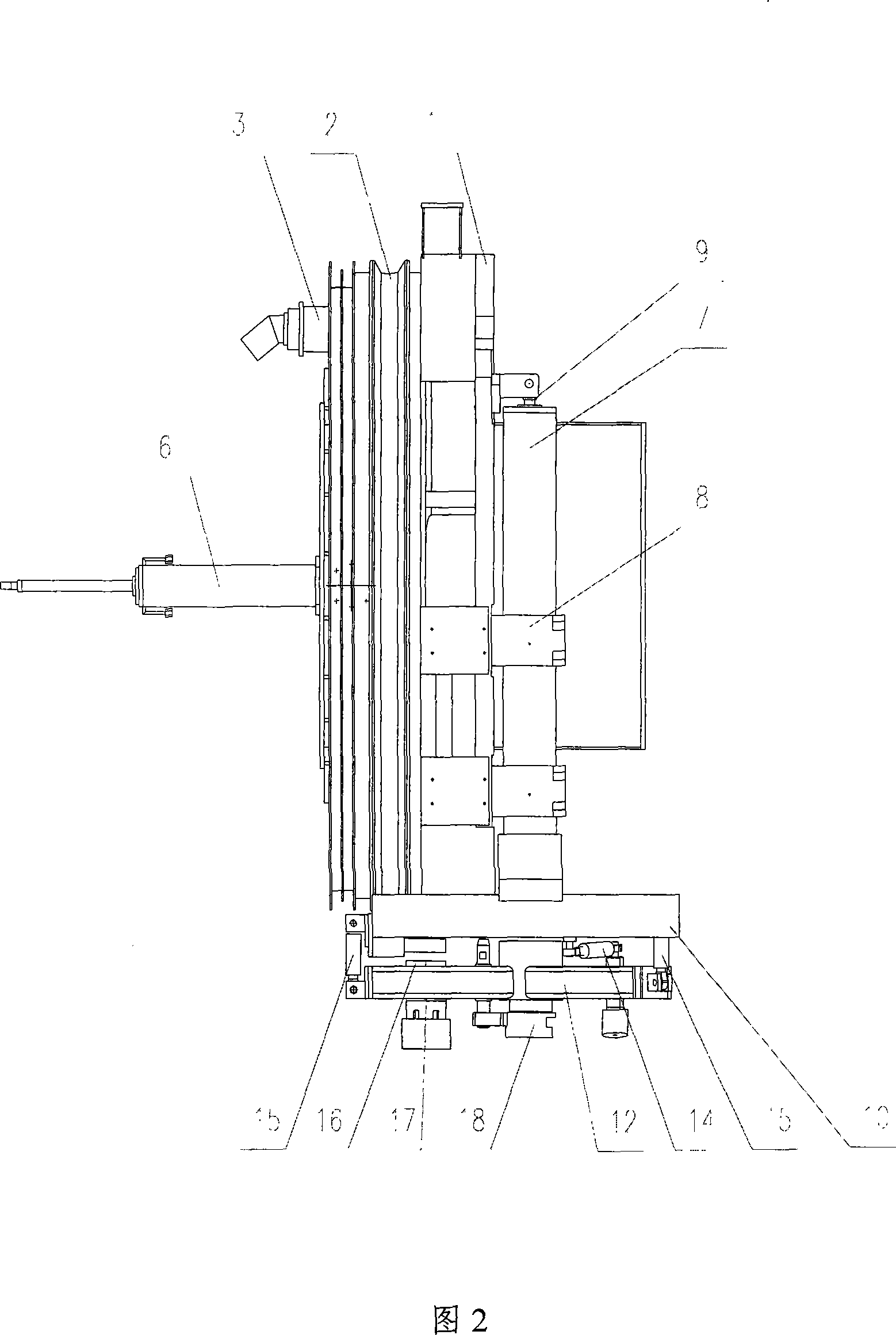

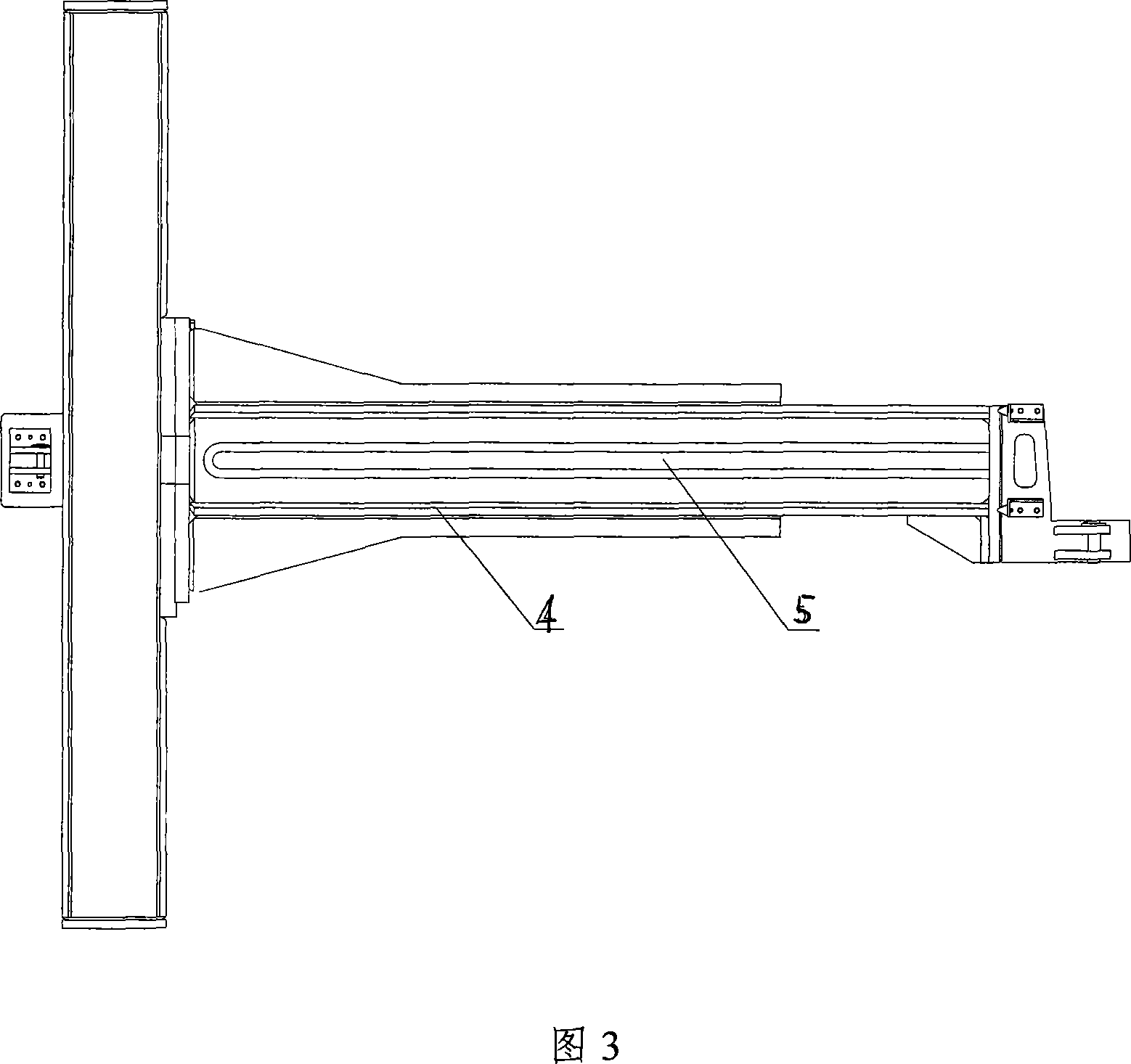

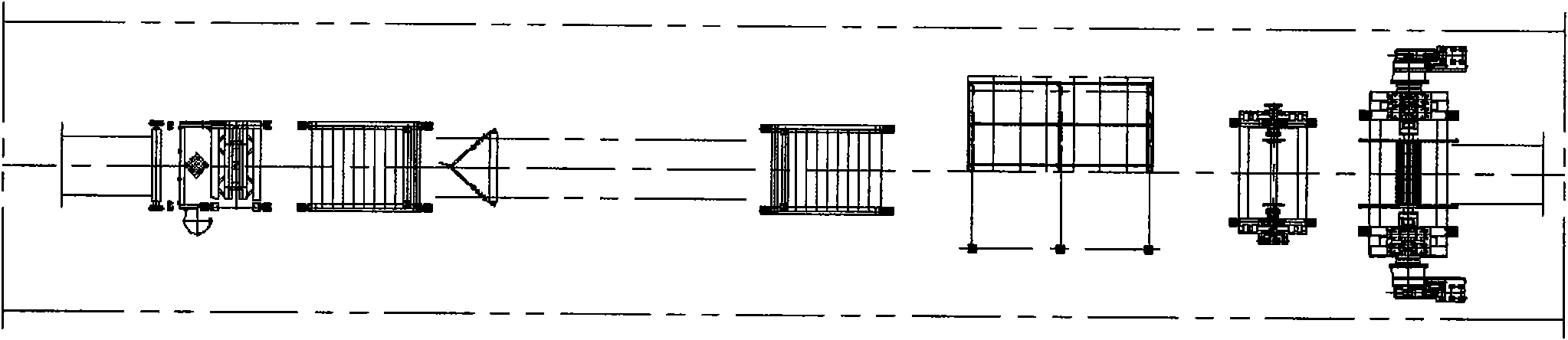

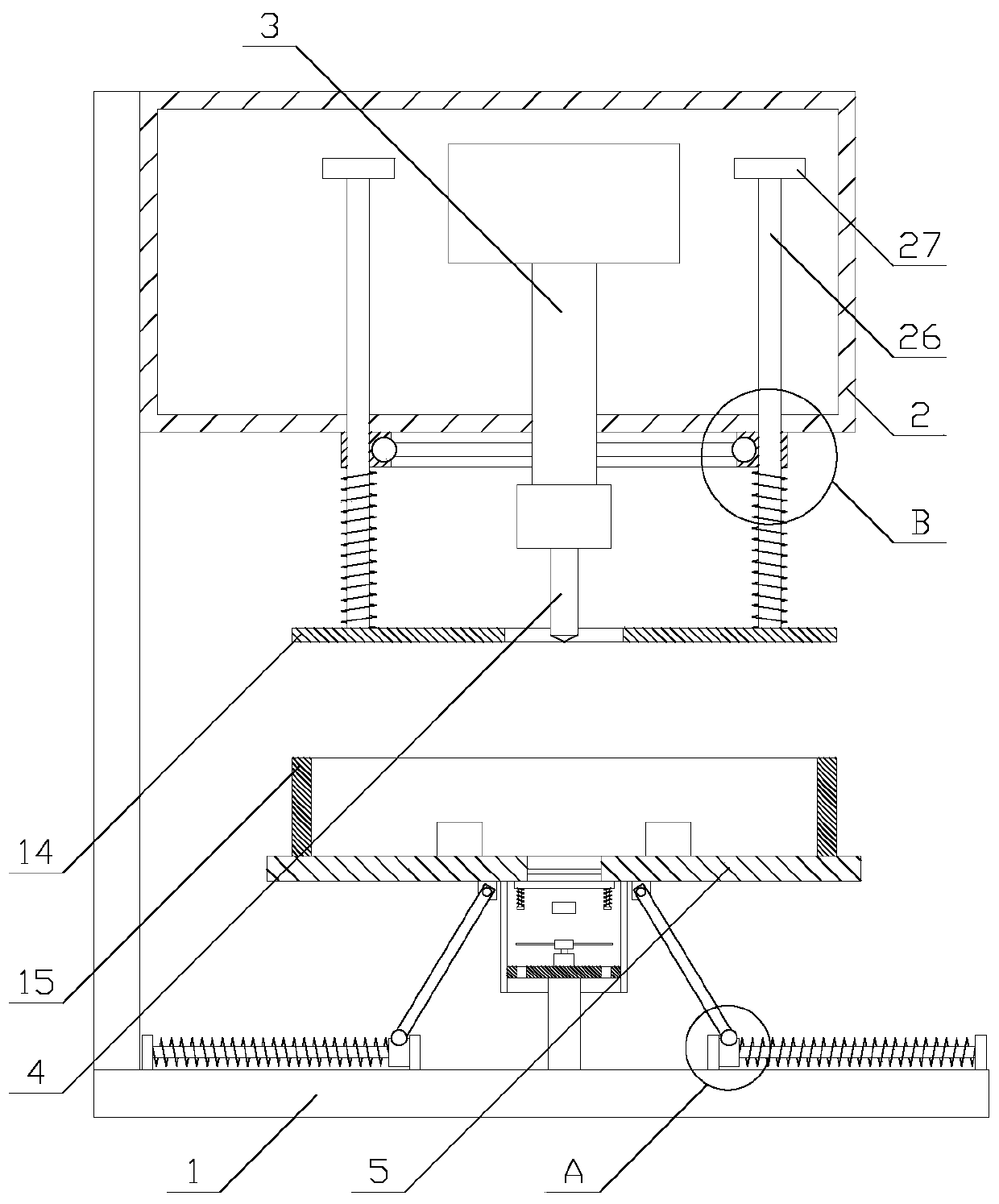

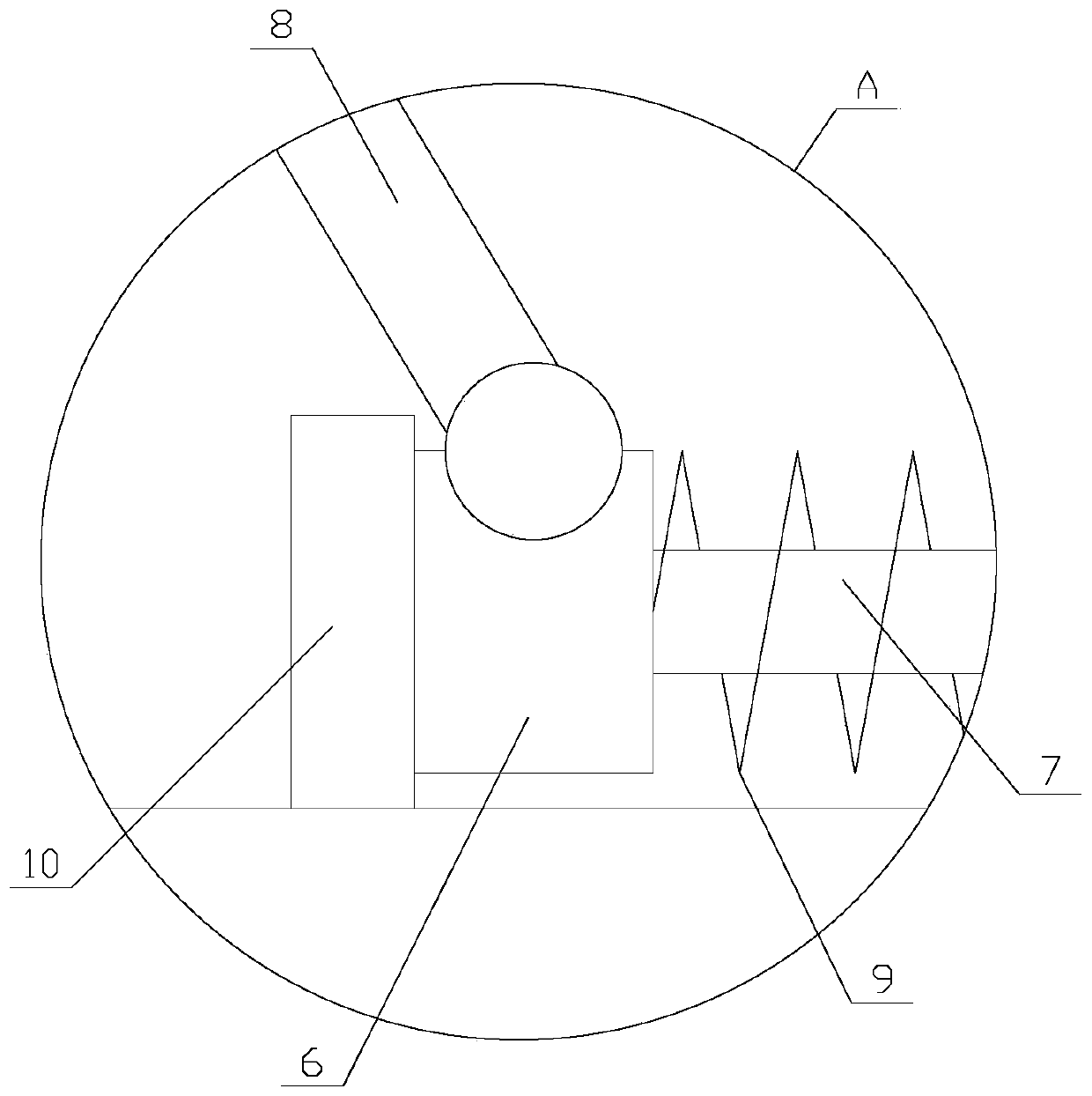

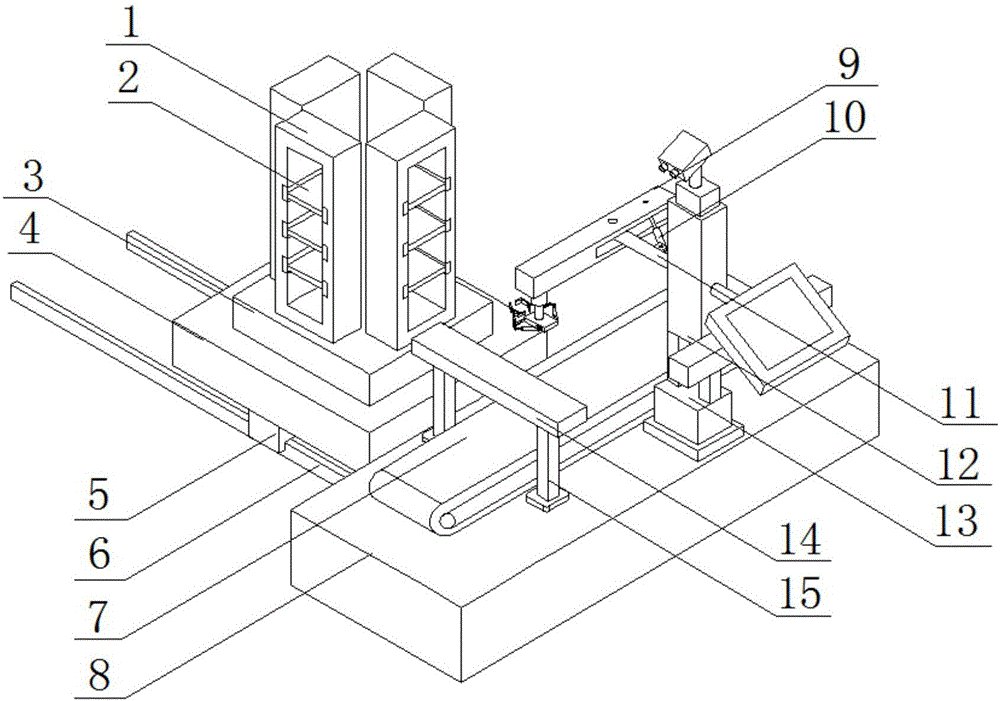

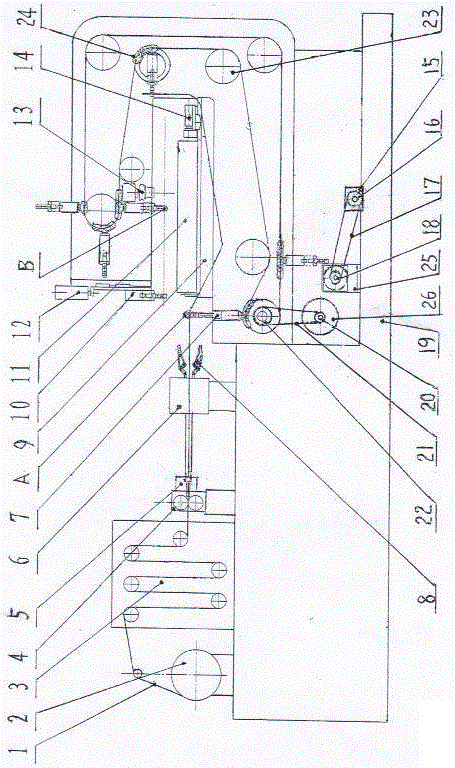

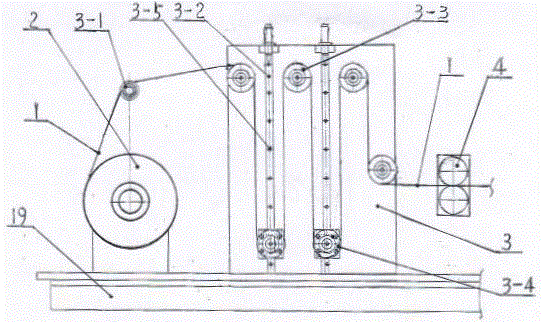

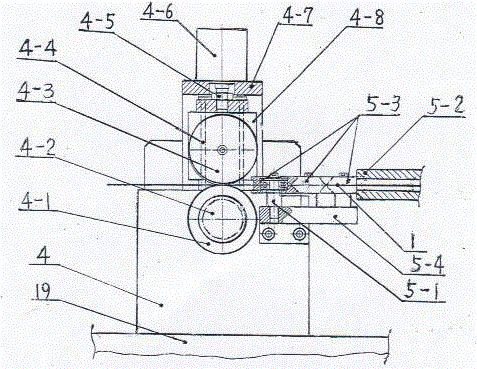

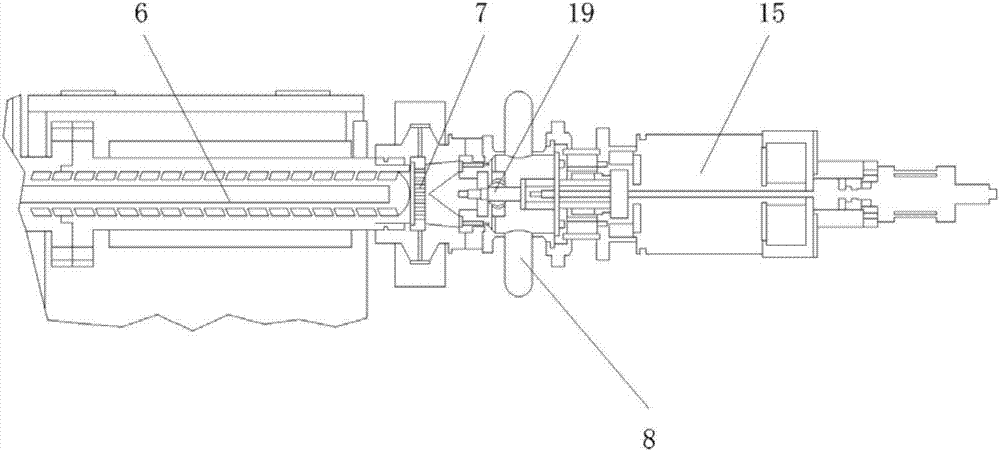

Synchronous detection test device for multi-item parameters of linear TBM hobs

InactiveCN101592533ARock breaking test data is accurateShorten the development and design cycleForce measurementMechanical clearance measurementsHydraulic cylinderPhase difference

The invention provides a synchronous detection test device for multi-item parameters of linear TBM hobs applied in the full-section hard-rock tunneling machine industry. The whole device consists of a self-counterforce frame, a regulate tool rest, an X-direction moving worktable, an X-direction linear guide rail, a Y-direction moving worktable, a Y-direction linear guide rail, an X-direction hydraulic cylinder, a rock sample, a hob, a four-rod guide mechanism, three-direction pressure sensors, a Z-direction hydraulic cylinder and the like, wherein the lateral movement direction of the rock sample is set as an X axis; the axial direction of the hob is set as a Y axis; the direction perpendicular to the surface of the rock sample is set as a Z axis; the rock sample is fixed on a trolley; the regulate tool rest is arranged on the four-rod guide mechanism; the X-direction moving worktable and the Y-direction moving worktable are arranged on a horizontal linear guide rail; the hob is arranged in a hob seat and is connected with the regulate tool rest through the three-direction pressure sensors; the rock sample is arranged and clamped on the X-direction moving worktable; and the three direction hydraulic cylinders are fixed with the fixed self-counterforce frame respectively. The device has the advantage of more precise function of simulating the process of breaking rocks through the hob, and is used for the synchronous detection of three-direction force, tool interval, penetration degree, wear degree, phase difference and other parameters of the hob in the states of linear paths and high-speed rotation of a plurality of hobs.

Owner:SHENYANG HEAVY MACHINERY GROUP

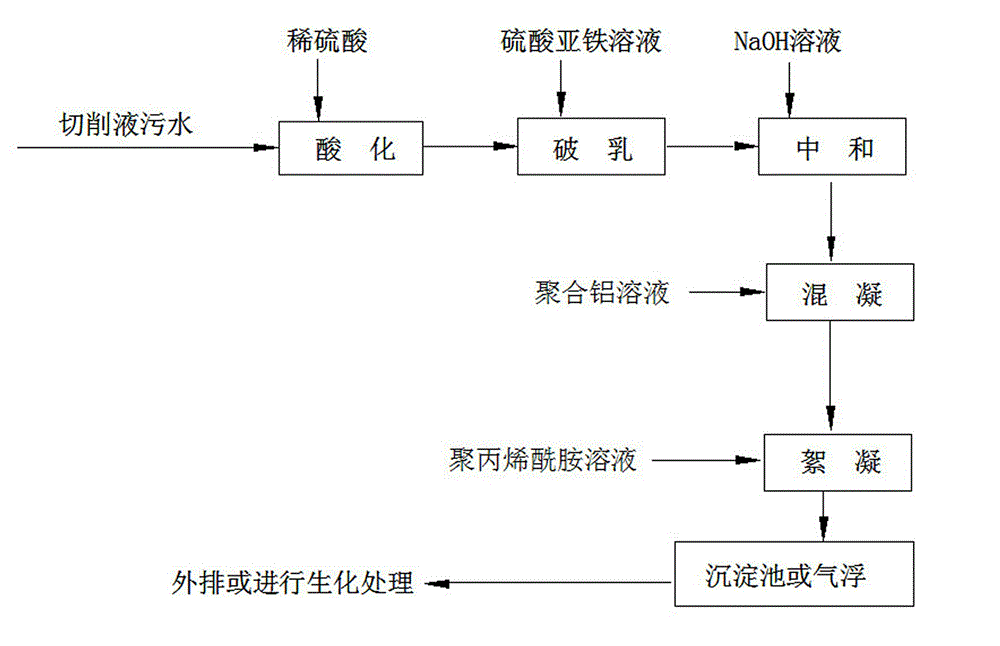

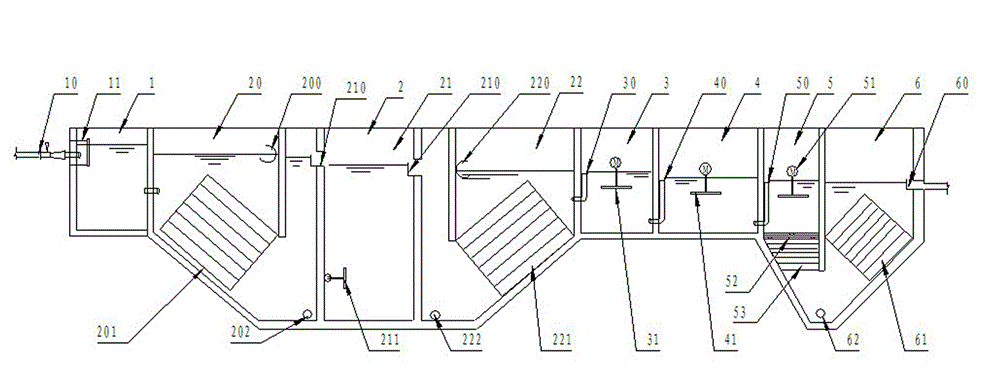

Demulsifying and flocculating treatment method of machining cutting fluid sewage water

InactiveCN102910765ALower surface potentialReduce repulsionMultistage water/sewage treatmentPollutionPolyacrylamide

The invention discloses a demulsifying and flocculating treatment method of machining cutting fluid sewage water, comprising the following steps: conveying cutting fluid sewage water in an acidification pool and adding diluted sulfuric acid for acidification; adjusting the pH to be 3.5-5.5; then conveying in a demulsifying device and adding ferrous sulfate solution for demulsification and precipitation; then conveying in a neutralization pond and adding NaOH solution for neutralization; conveying in a coagulating basin after neutralization and adding a coagulating agent for coagulation; then adding polyacrylamide to a flocculation tank; flowing down by a sieve body through the square rectifying plate of the flocculation tank after flocculating; depositing through the sloped tube stuffing body of a flocculation precipitation pool; discharging out supernatant fluid from a water collection weir; and removing precipitated sludge floccule. The method has the characteristics of integrating oil removal, demulsifying and flocculating, and being thorough for pollution control, good in application effect and economic and efficient; the effluent COD (Chemical Oxygen Demand) of cutting fluid sewage water treated through the method can be decreased to below 500mg / L; and the method can be widely applied to sewage water treatment in machining industry.

Owner:安徽新天安全环境科技有限公司

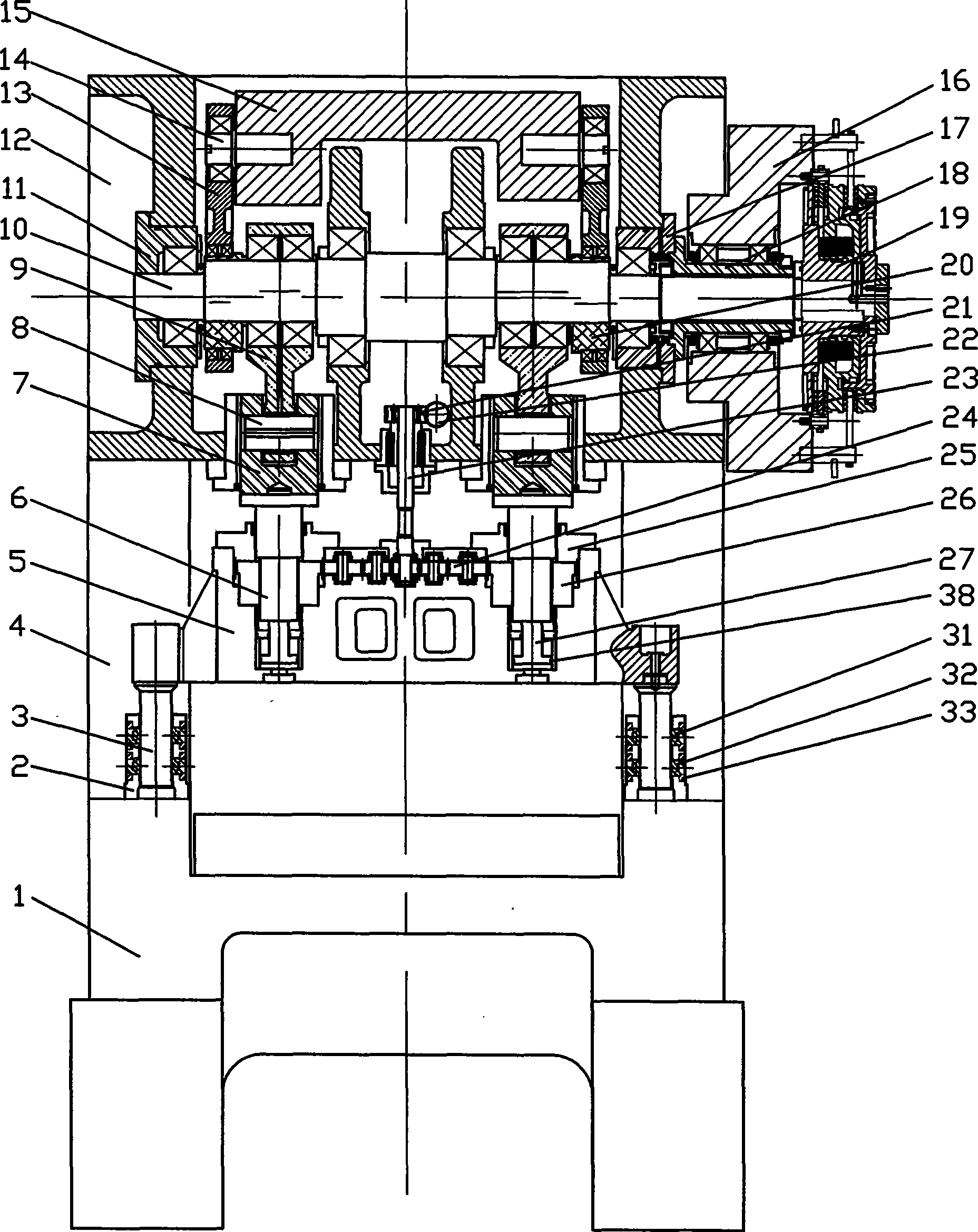

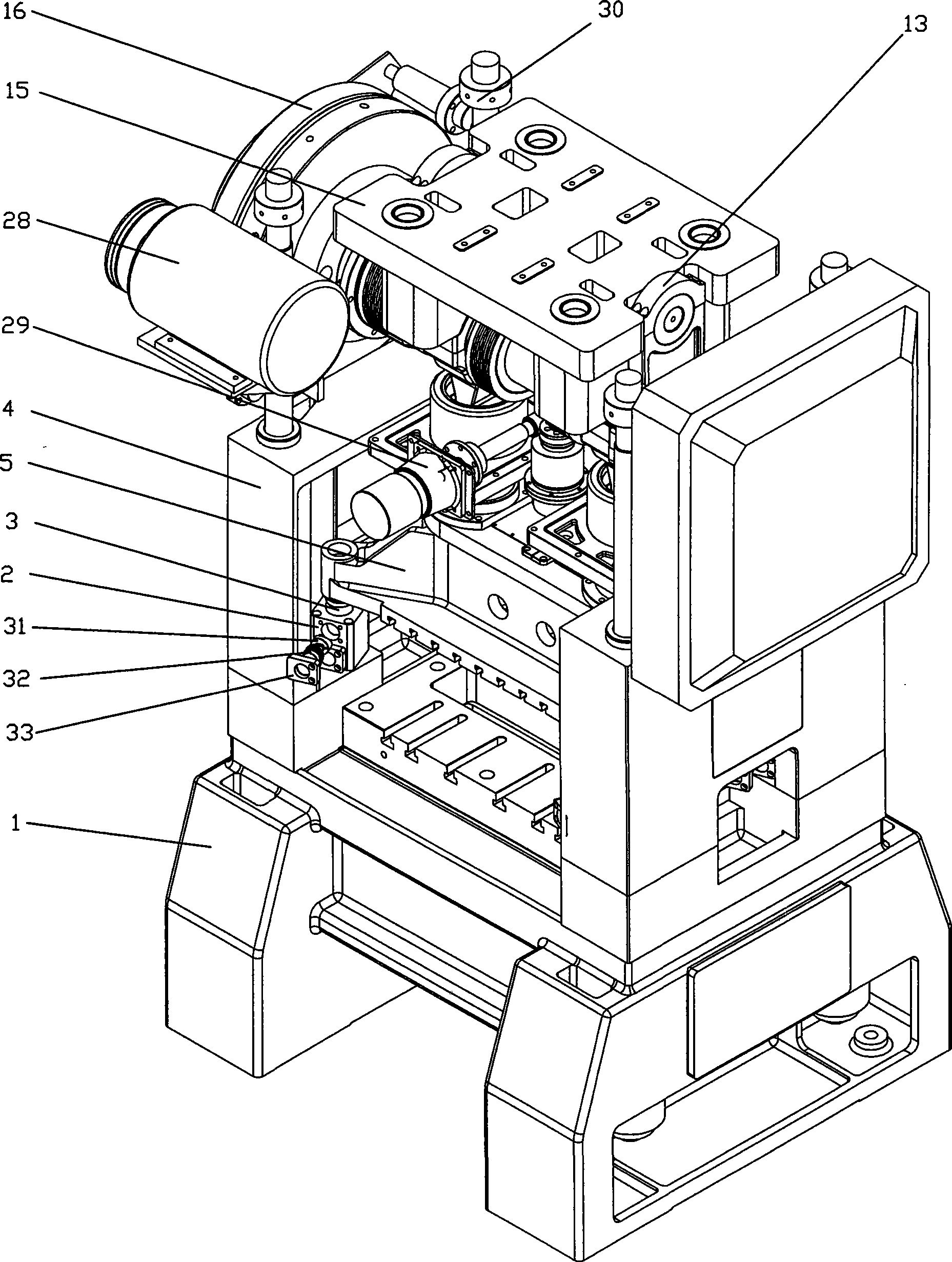

High-speed precision punching machine

The invention relates to a dieing machine, which comprises a pedestal and an abutment body. A crankshaft transmission part is provided with a fly wheel, a clutch brake assembly, a dynamic balance piece, and one end of a connecting rod; the other end of the connecting rod is fixed on a slide block, the slide block is connected with a block adjusting and guiding device; a dynamic balance piece is provided with eccentric lantern rings which are arranged at two ends of a crankshaft; and a double connecting rob, a bearing and a pin which are connected with the eccentric lantern rings are connected with the dynamic balance piece to form the eccentric lantern rings, so that eccentric force generated by the motion of the crankshaft is offset, and left and right swing and deformation are prevented simultaneously. When processing different products, the dieing machine needs to change moulds and adjust the height of the slide block; and after the height of the slide is adjusted, a locking oil cylinder locks the slide lock so as to ensure that the position of the arranged mould does not change and the machining accuracy does not change. The slide block adopts a guide ring guiding structure so as to break a four guide pillar structure which is used for multiple years in punching machine industry. The over-positioning of the prior four guide pillar is replaced by the freely-jointed positioning of a guide sleeve, so that the assembling error can be solved through free displacement.

Owner:宁波米斯克精密机械工程技术有限公司

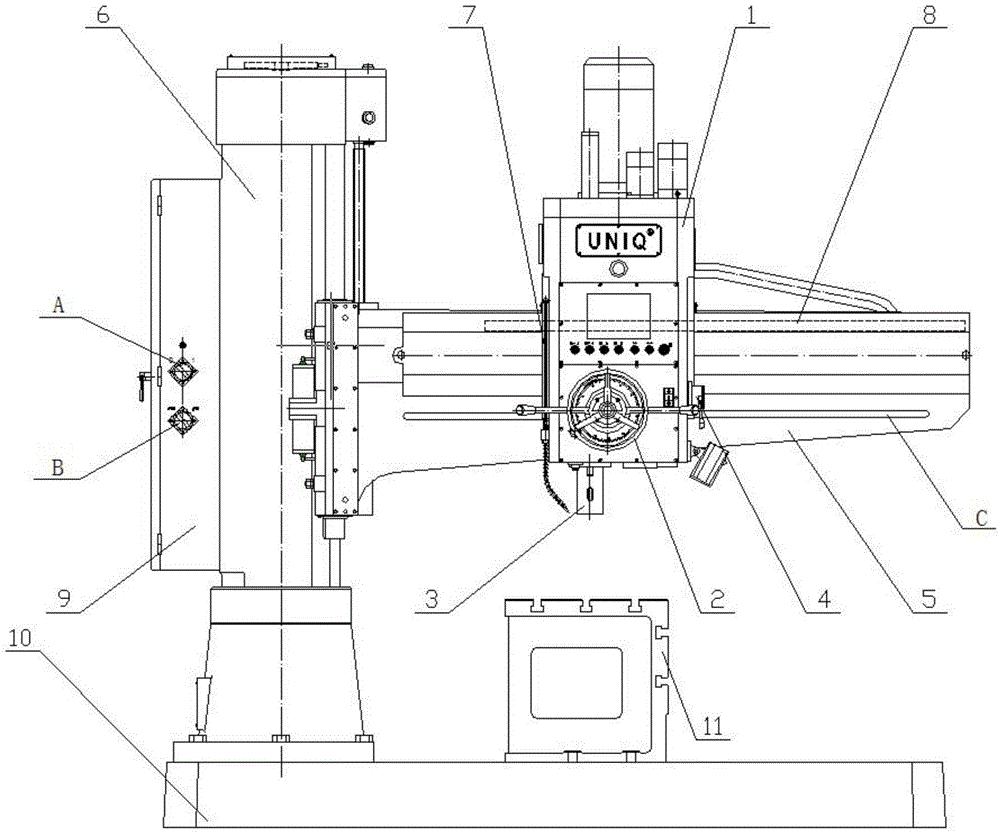

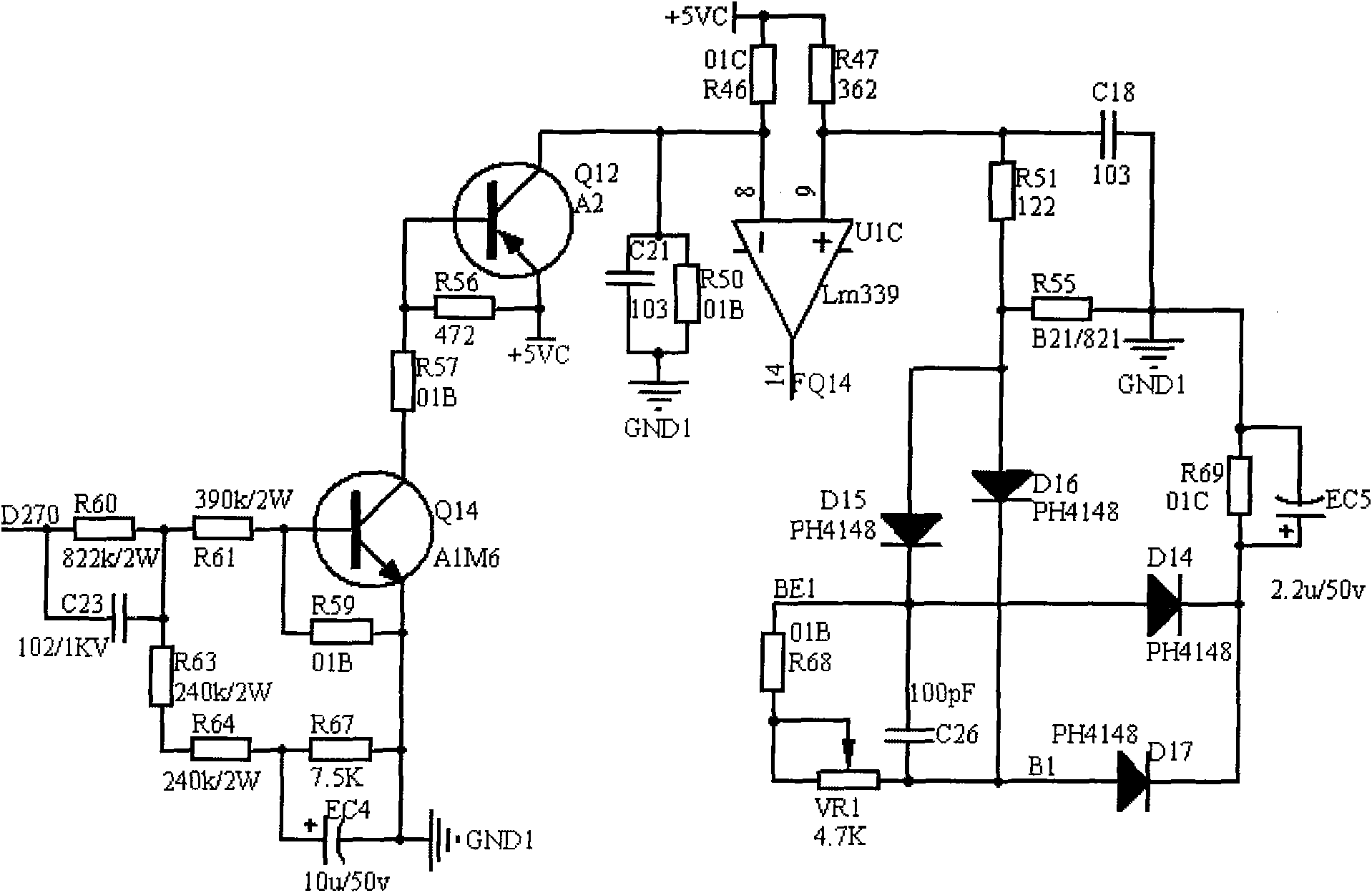

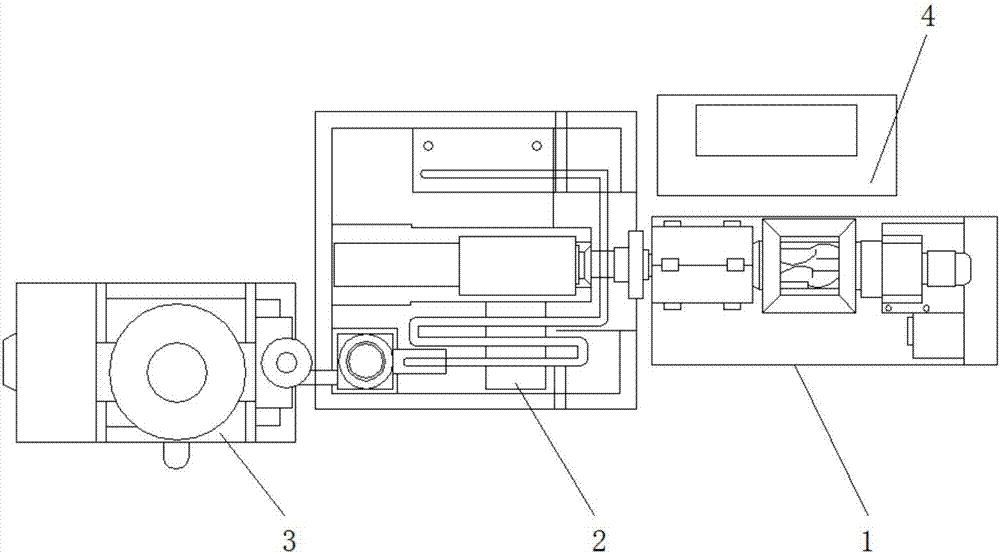

Numerical display type radial drilling machine

ActiveCN105252035AHigh guiding precisionEasy to fixMeasurement/indication equipmentsFeeding apparatusGraphicsBalancing machine

The invention provides a numerical display type radial drilling machine, comprising a spindle speed regulating and spindle feeding speed regulating system, a spindle feeding mechanism, a spindle and balance mechanism, a spindle positive / negative rotation and variable-speed control mechanism, a rocker arm and clamping mechanism, an upright and rocker arm lifting mechanism, a hydraulic and cooling system, a testing system, a numerical display control system and the like; the upright and rocker arm lifting mechanism is mounted on a base; the rocker arm and clamping mechanism is mounted on the upright and rocker arm lifting mechanism; the numerical display control system is mounted on the upright and rocker arm lifting mechanism; the spindle speed regulating and spindle feeding speed regulating system is mounted on the rocker arm and clamping mechanism; the spindle feeding mechanism, the spindle and balance mechanism, the spindle positive / negative rotation and variable-speed control mechanism, and the hydraulic and cooling system are mounted on the spindle speed regulating and spindle feeding speed regulating system. According to the numerical display type radial drilling machine, stepless speed changing of a spindle can be realized without shutdown; graphic and numerical display can be realized at working positions; a die wall clamping device of a guide rail and a spindle limiting structure are sensitive and reliable; in short, the numerical display type radial drilling machine is applicable to machining industries.

Owner:SHENYANG JINGHONG NUMERICAL CONTROL EQUIP CO LTD

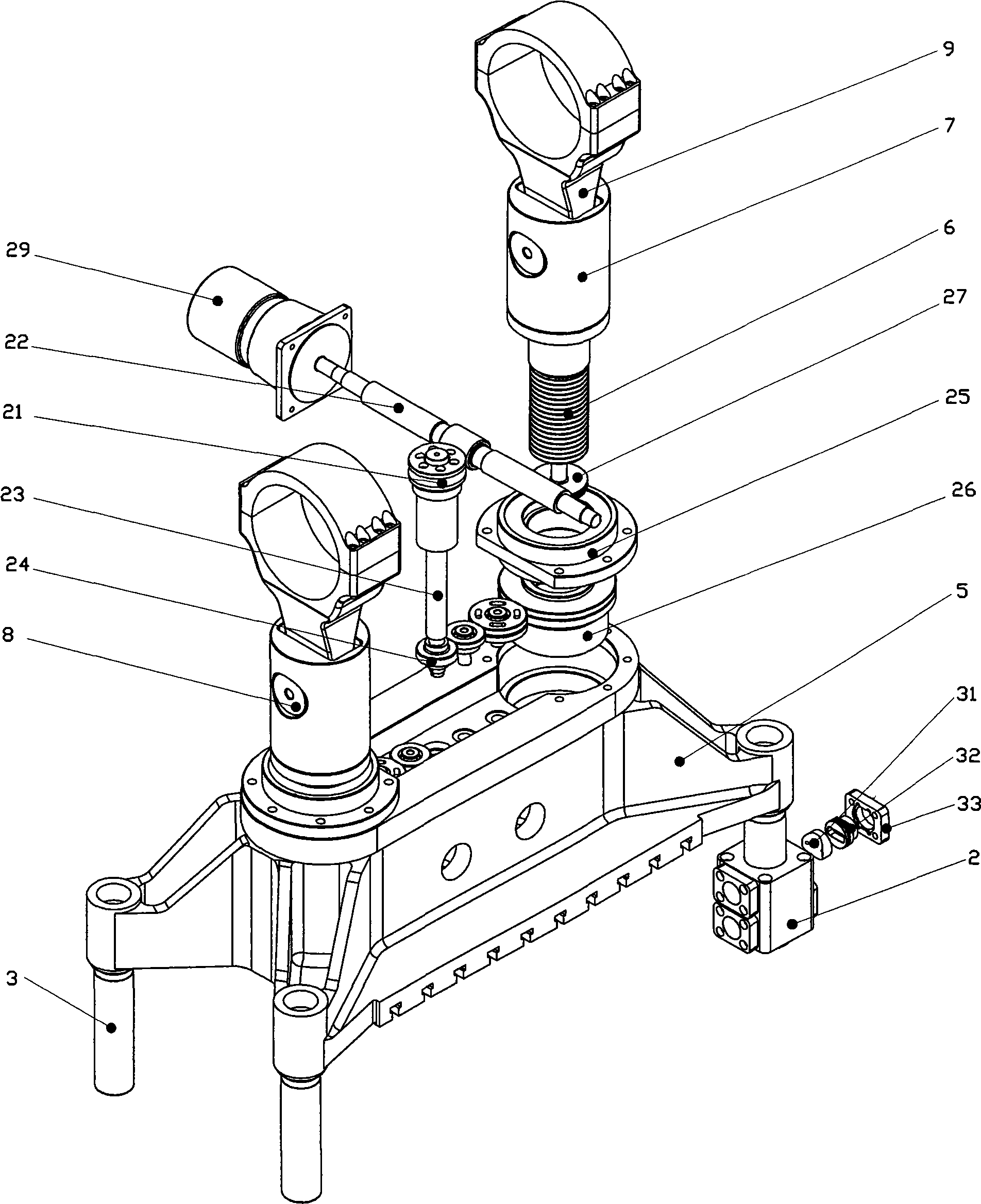

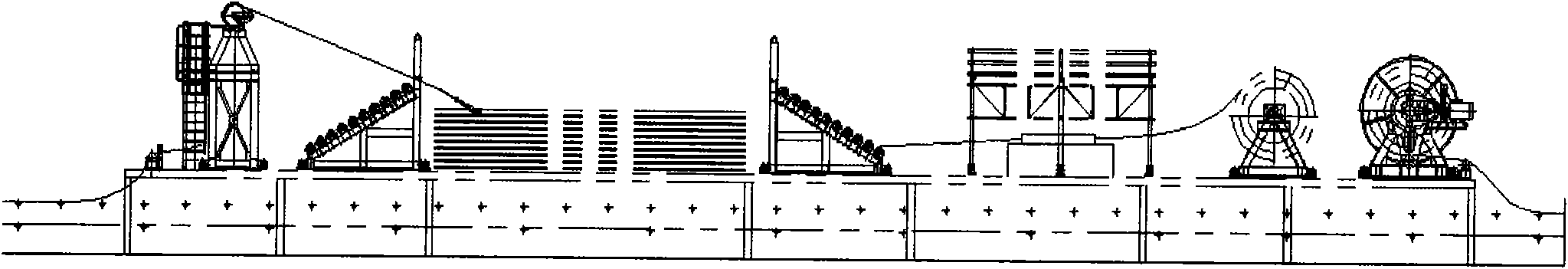

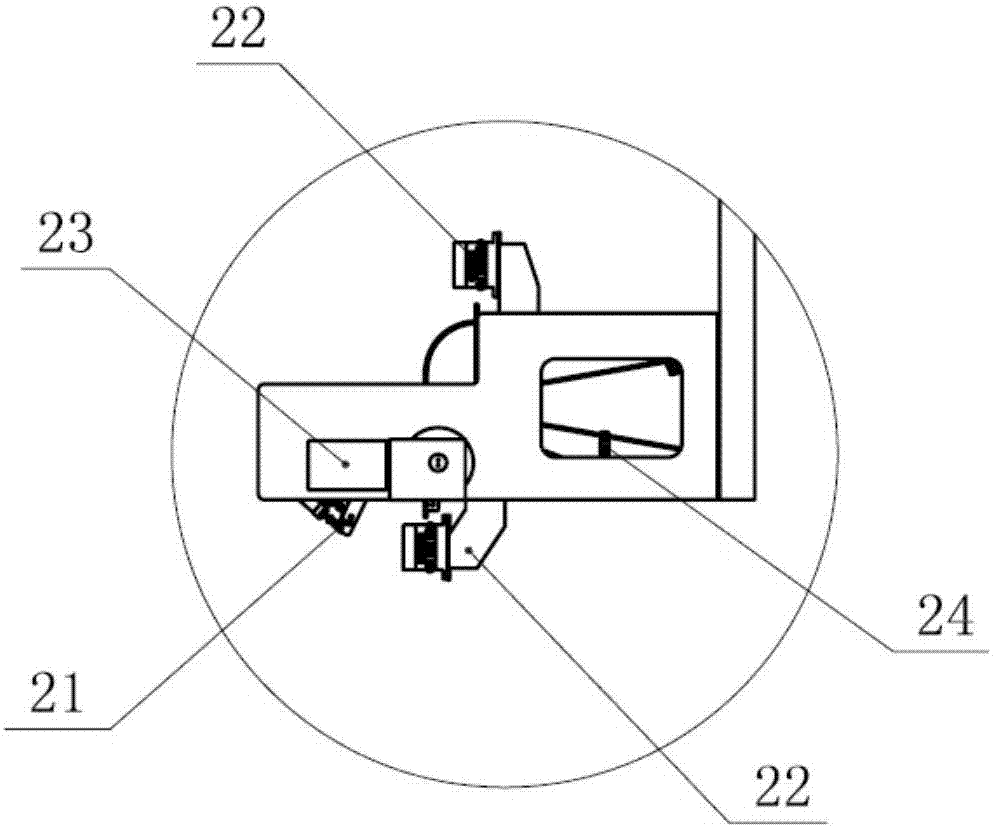

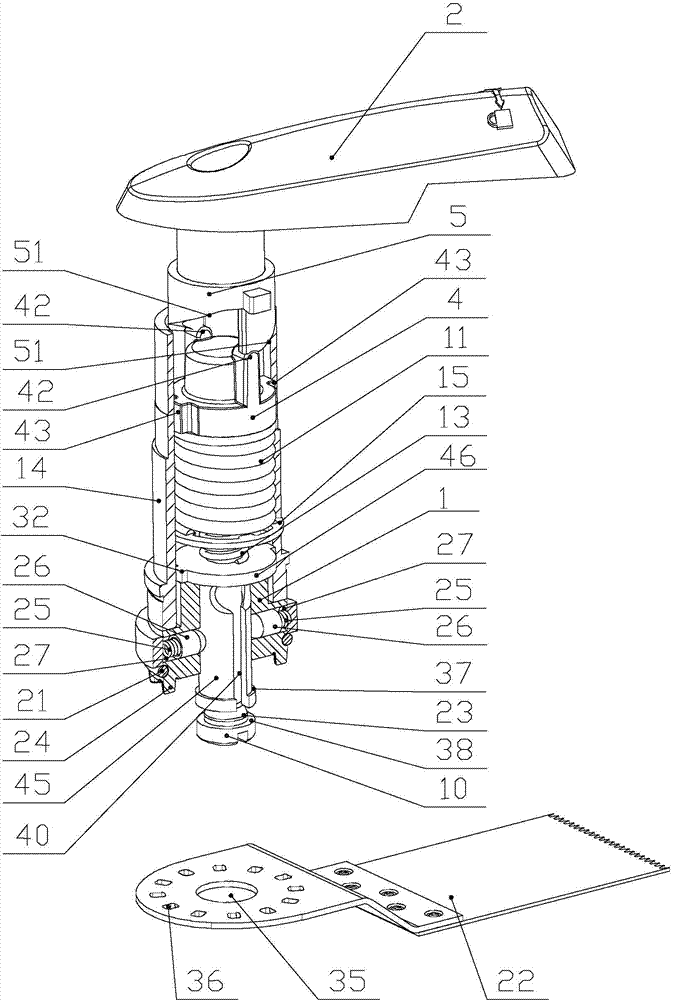

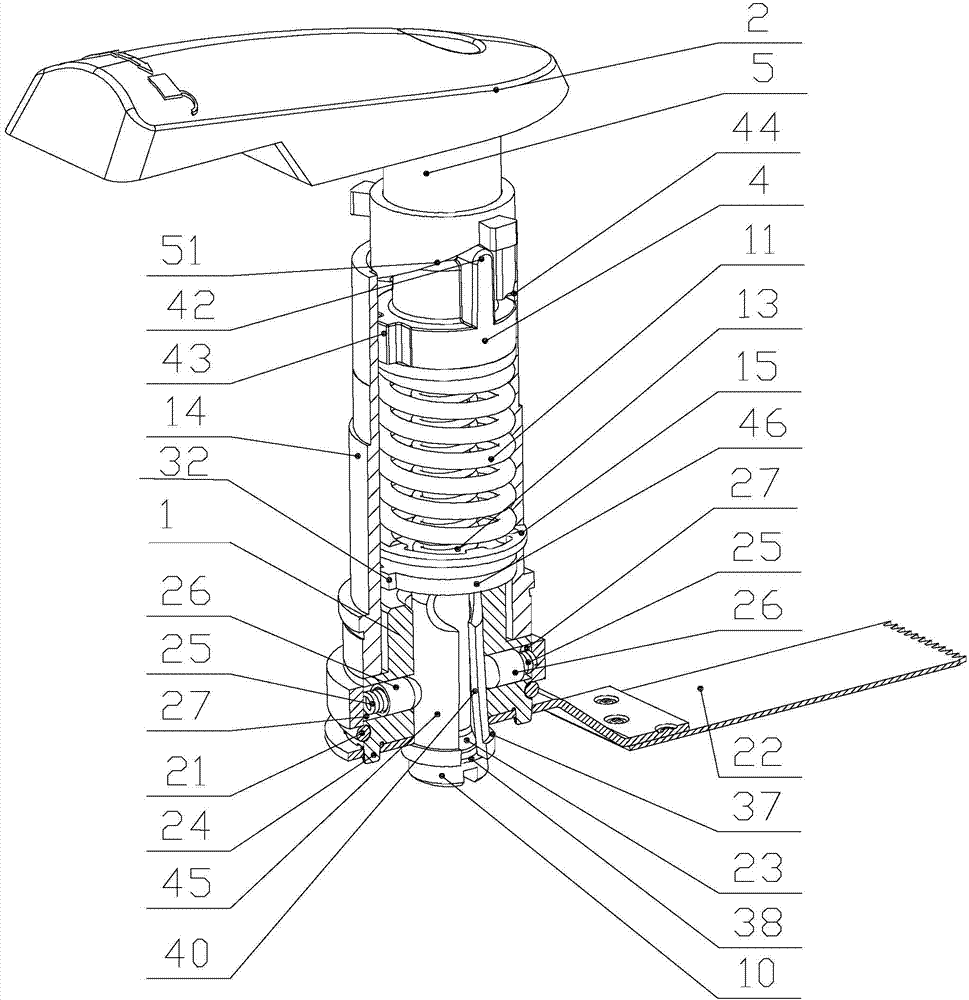

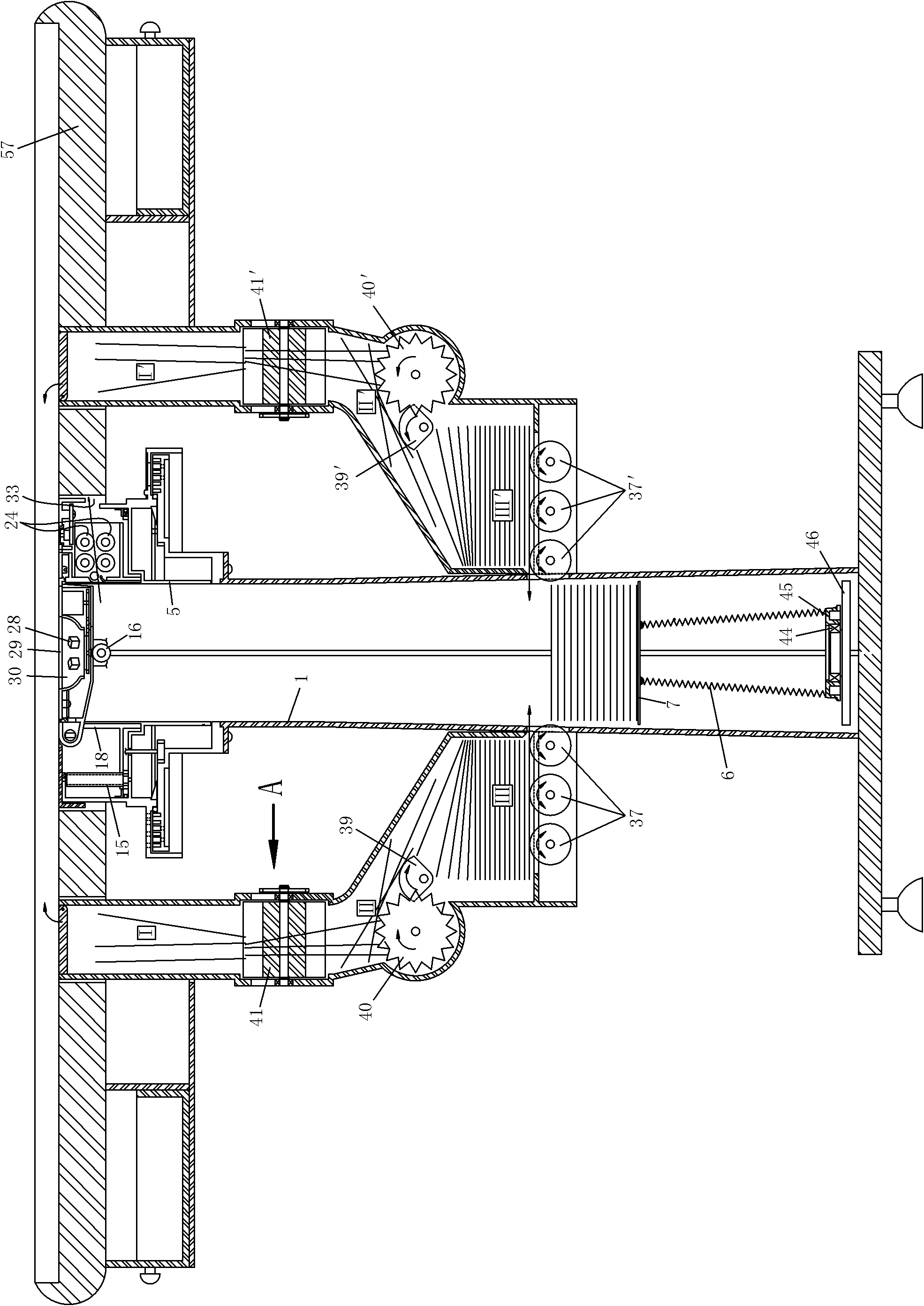

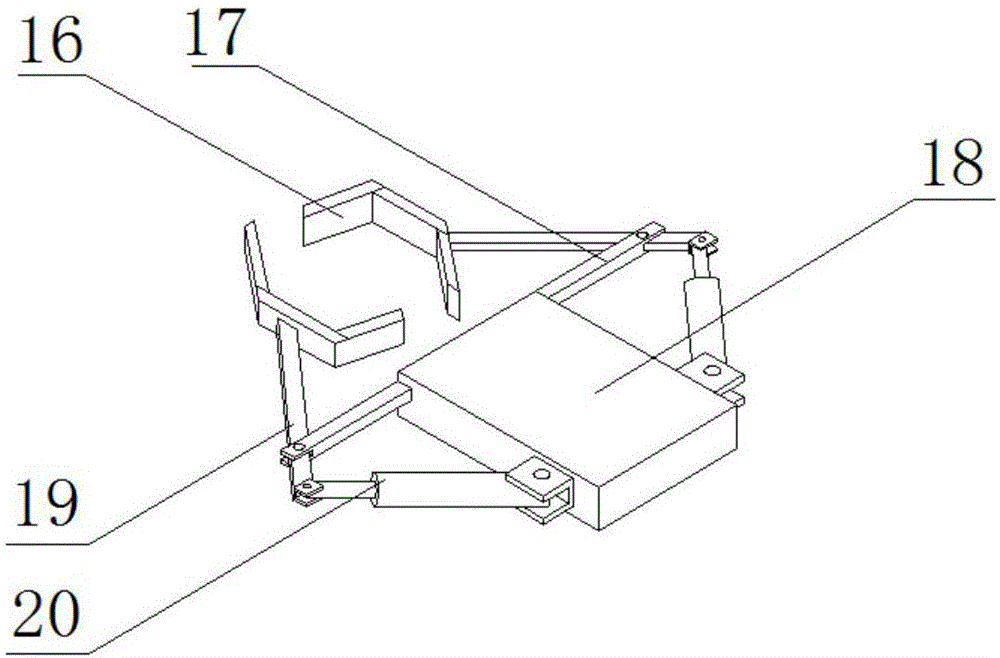

Manipulator of automatic positioning and rapid grasping pipe piece

InactiveCN101200063AImprove assembly efficiencyEasy to adjust postureUnderground chambersTunnel liningCantilevered beamHydraulic motor

Disclosed is a self-positioning manipulator for fast grasping segments used in tunnel engineering construction machine industry, which is composed of a rotating ring, a driving device, a cantilever beam, a lifting frame, four rolling wheels, a grasping platform, grasping oil cylinders and a grasping head. The axial direction of the tunnel is set as an X axis; the radial horizontal direction of the tunnel is set as a Y axis; the radial vertical direction of the tunnel is set as a Z axis. The axial lines of the rotating ring and a fixed ring coincide with the X axis; the driving device is fixed on the fixed ring; a hydraulic motor of the driving device drives a small gear through a reduction gear box so as to drive a big gear ring and the rotating ring connected with the big gear ring to rotate around the X axis, so that the lifting frame connected with the rotating ring is driven to move. The cantilever beam is fixed along and in parallel with the axial direction of a shield machine in the inner side of the shield machine; the outside of the shield machine are provided respectively with channel shaped railway for four rolling wheels rolling; the four rolling wheels are fixed respectively at the two sides of the inner wall of the fixed ring; the cylinder bodies of two translational oil cylinders are fixed on the cantilever beam; piston rods of the oil cylinders are fixed and hinged with the fixed ring. The device has the function to install the segments in omni direction, the segments can reach any preset installing position with more flexible grasping head and four movements, and the assembling efficiency of the segments is increased effectively.

Owner:SHENYANG HEAVY MACHINERY GROUP

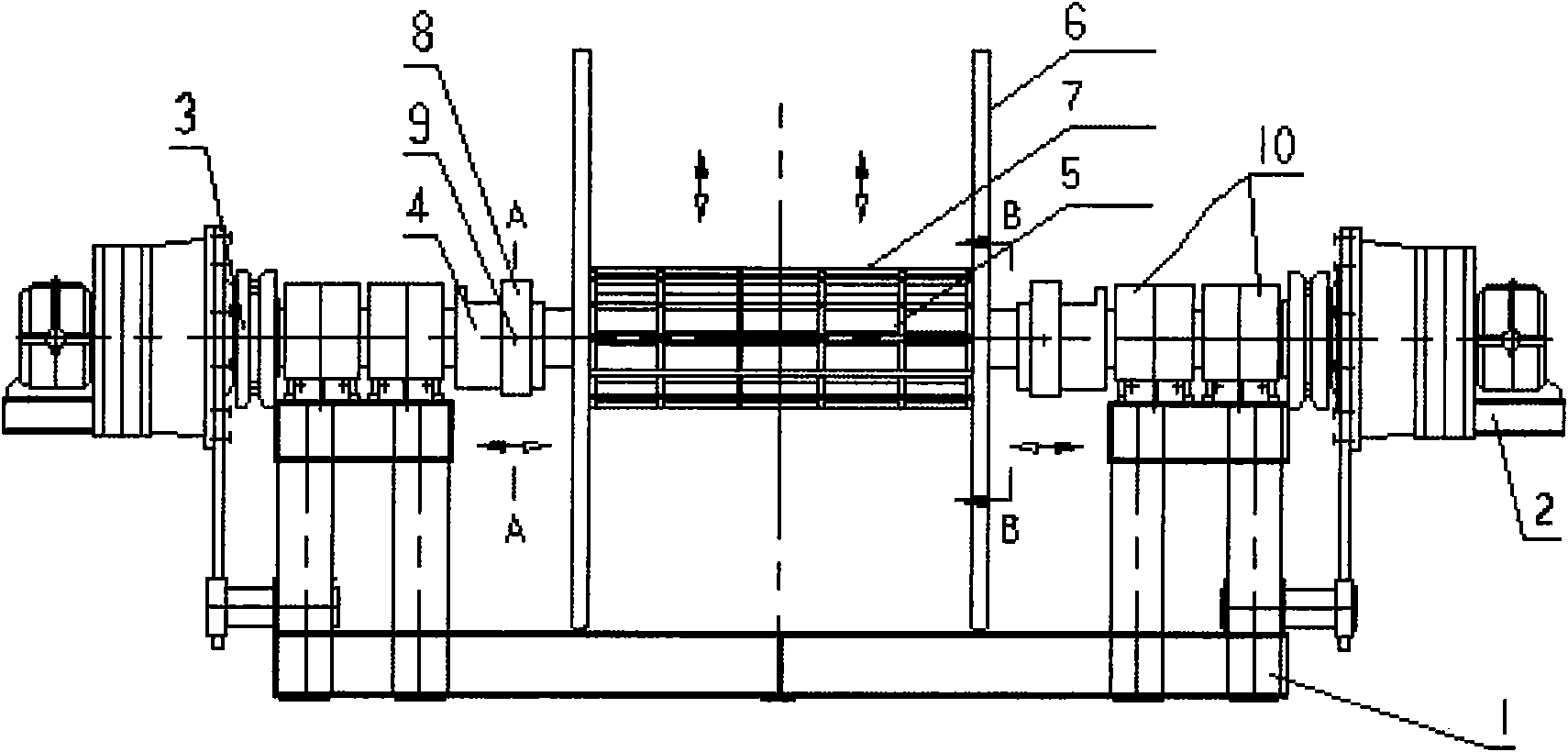

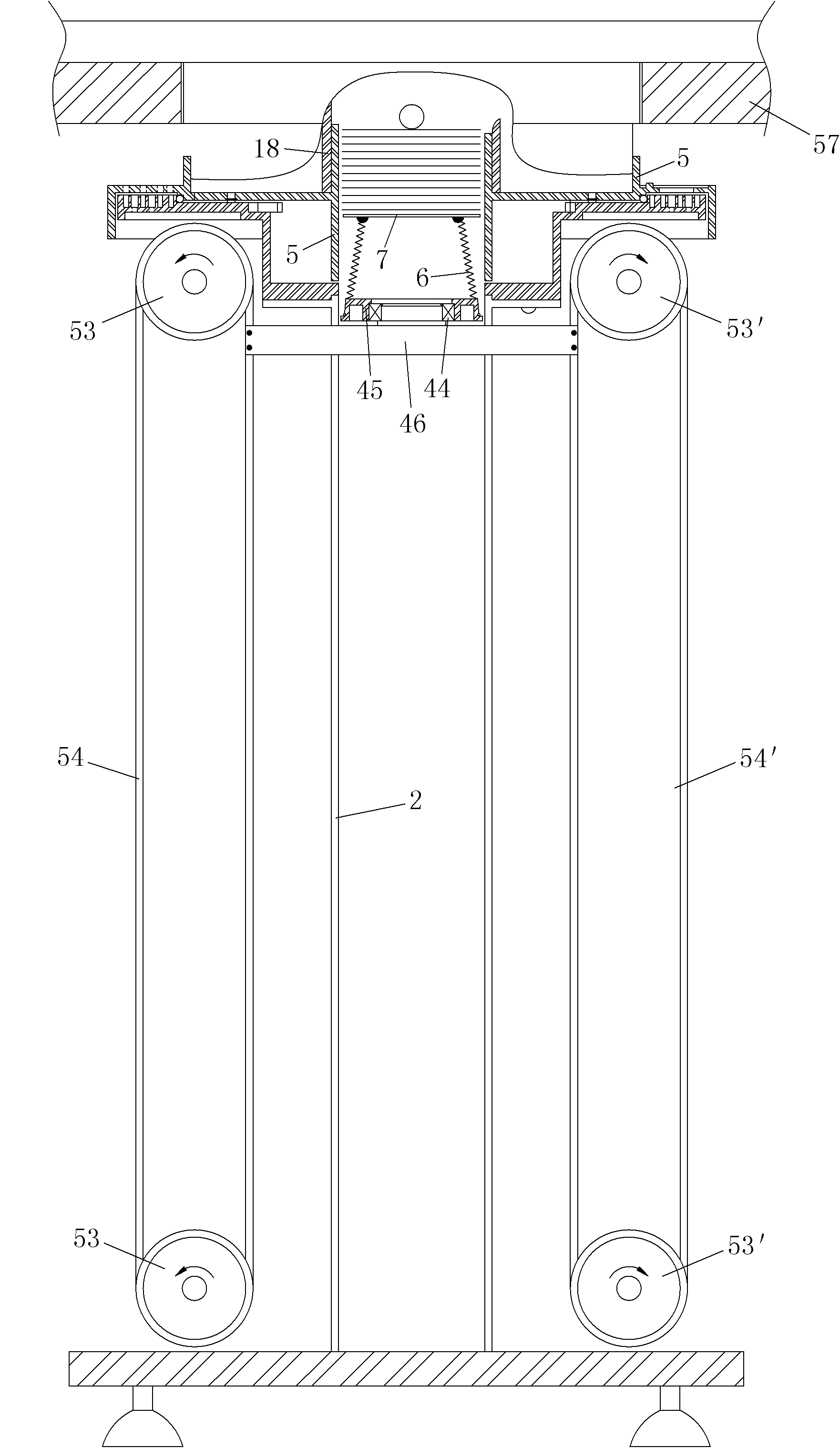

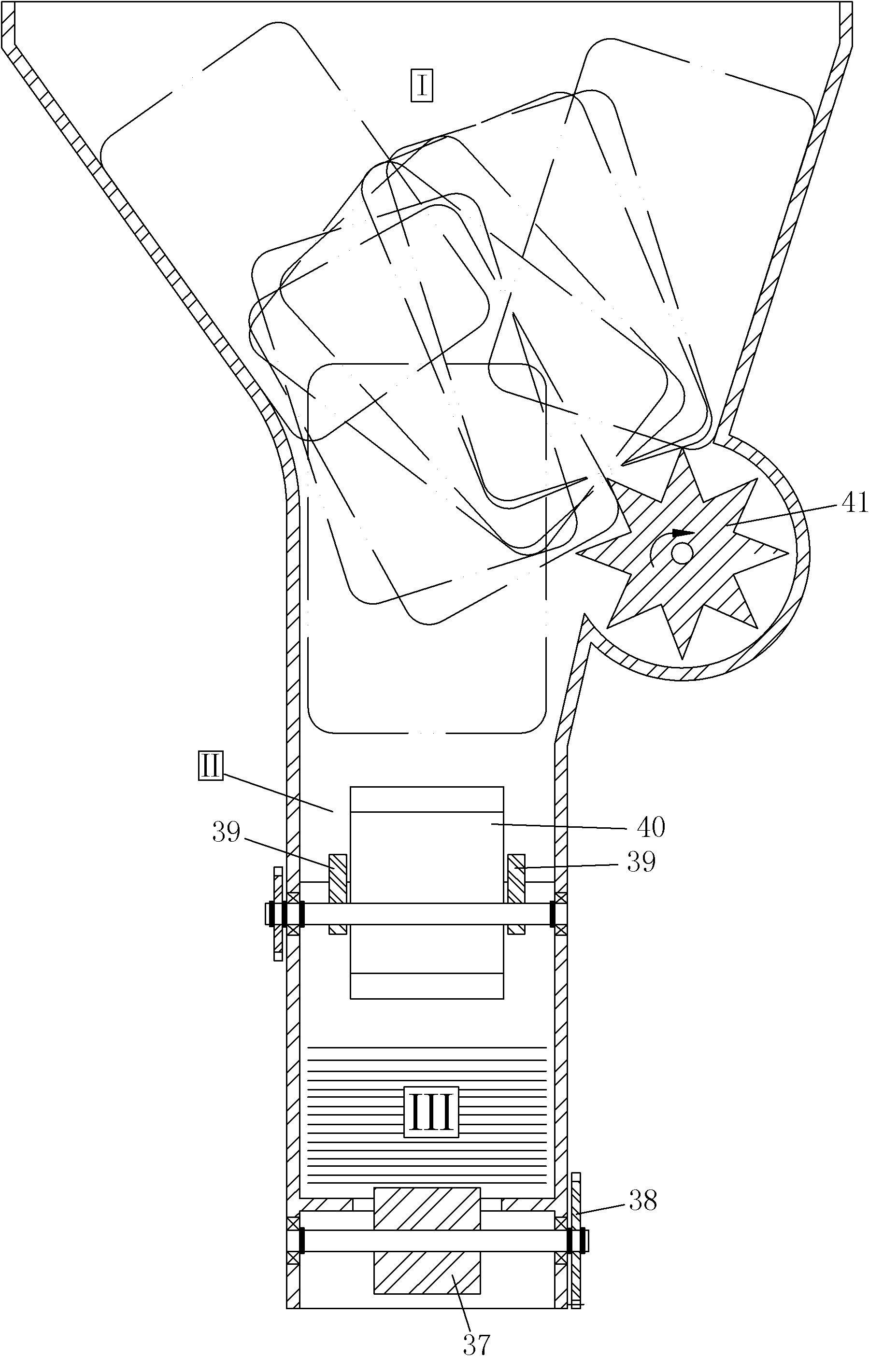

Tape replacing device of belt type conveyer

InactiveCN101973468AEasy to useReduce labor intensityConveyorsArticle deliveryAdhesive beltDrive shaft

The invention relates to a tape replacing device of a belt type conveyer, applied to an adhesive tape machine industry, comprising four parts, i.e. a tape winding device, a tape releasing device, a tape storing device and a traction device, wherein the tape winding device, the tape releasing device, the tape storing device and the traction device are sequentially arranged; a first bracket of the tape winding device adopts four trapezoidal structures; the output part of a driving device adopts a hollow shaft structure, and a transmission shaft adopts a solid shaft structure; one side end part of the transmission shaft is provided with a square groove; the hollow shaft of the driving device is connected and fixed with the transmission shaft through a locking disc; a first square shaft is a square solid shaft; a tape core is arranged between two guard rings; the first square shaft end is embedded into the square groove positioned on the transmission shaft end; a clamp ring is in an annular structure; the first square shaft is fixed with or separated from the square groove positioned on the transmission shaft end; a positioning pin is fixed with the clamp ring; and a double-bearing seat is in a mode of symmetrically arranging two independent bearing seats. The tape replacing device can be used for replacing a tape of the integral adhesive tape machine by fixing on one point; links are closely connected in the whole tape replacing process; and in addition, an optimal process is selected, and the installation position of the tape replacing device is freely selected, which is very beneficial the use for the adhesive tape machine; and the labor intensity of operators is greatly reduced through the innovation of the tape replacing device.

Owner:沈阳矿山机械有限公司

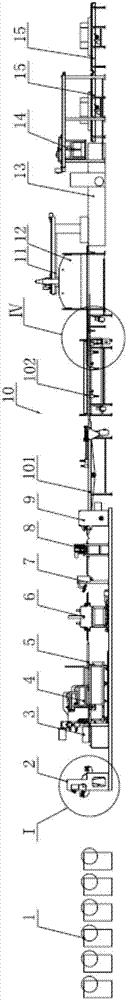

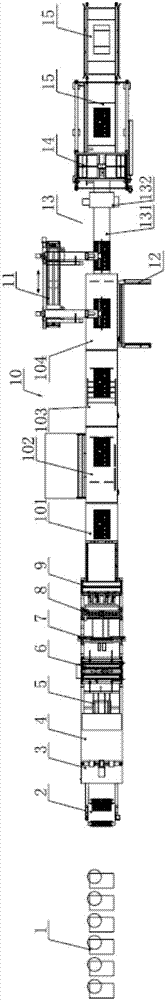

Integral-type mesh welding machine

ActiveCN107253053AMeet development needsIncrease productivityOther manufacturing equipments/toolsMetal working apparatusPunchingMesh reinforcement

The invention belongs to the field of steel bar mesh welding devices and discloses an integral-type mesh welding machine. The integral-type mesh welding machine is sequentially provided with a longitudinal bar conveying mechanism, a welding mechanism, a transverse bar blanking mechanism, a mesh pulling mechanism, a shearing mechanism, a conveying mechanism, a packaging machine, a stacking mechanism and a tray travelling mechanism according to the steel bar mesh machining sequence. A punching mechanism and / or a wire reversing mechanism and / or a mesh wiping mechanism capable of being selectively started are further arranged between the mesh pulling mechanism and the shearing mechanism. According to the integral-type mesh welding machine, through arrangement of all the mechanisms, welding, punching, wire welding and reversing, bending, stacking and packaging of a mesh piece can be automatically and integrally completed, and therefore a steel bar mesh with special requirements is machined; and the current development demands of machining industries are effectively met, and the production efficiency is improved.

Owner:TJK MACHINERY TIANJIN

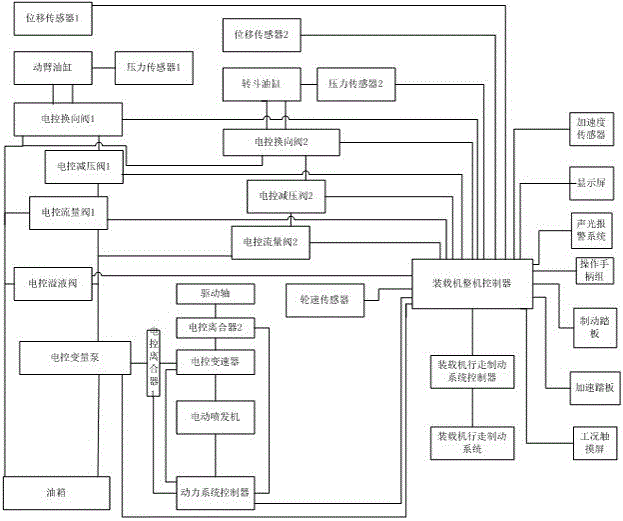

Intelligent control method of loading machine

ActiveCN106245706AReduce labor intensityImprove working conditionSoil-shifting machines/dredgersElectric controlPressure reduction

The invention provides an intelligent control method of a loading machine. An intelligent control system is provided, and the system comprises a whole machine controller and further comprises a storage device, a first displacement sensor, a first pressure sensor, a first electric control flow valve, a first electric control reversing valve, a second displacement sensor, a second pressure sensor, a second electric control flow valve, a second electric control reversing valve, a first electric control pressure reduction valve, a second electric control pressure reduction valve, an electric control variable pump, an electric control overflow valve capable of adjusting highest oil pressure of a work system, an electric control transmission, a first electric control clutch connected with the loading machine electric control variable pump and the electric control transmission, a second electric control clutch connected with a loading machine drive shaft and the electric control transmission and a power system controller, all of which are connected with the whole machine controller. Through control over the intelligent system, loading automation of a shovel bucket is achieved. According to the technical scheme, a driver can be replaced for automatic and intelligent material shoveling and containing, the labor strength of the driver is relieved, the machine work state is improved, and the more efficient and healthier development of the loading machine industry is promoted.

Owner:FUZHOU UNIV

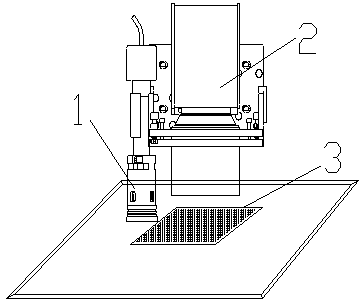

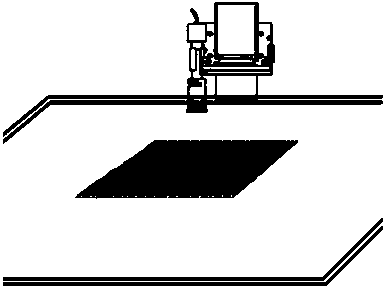

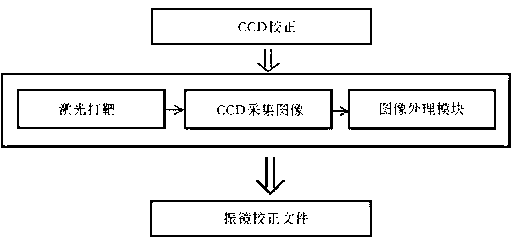

Quick correction method for galvanometer correction system

InactiveCN103212873AAchieve correctionShorten the timeLaser beam welding apparatusImaging processingGalvanometer

The invention relates to a quick correction method for a precise galvanometer correction system and mainly solves the problems that a galvanometer correction system in the prior art is time-consuming, labor-consuming and is high in cost. The invention adopts the quick correction method for the precise galvanometer correction system. The galvanometer correction system comprises a galvanometer correction plate, a CCD (charge coupled device) image acquisition device and an image processing module, wherein a galvanometer scanning module controls laser to form a matrix target on the galvanometer correction plate; the CCD image acquisition device is used for carrying out image acquisition to the matrix target on the galvanometer correction plate; and the image processing module is used for outputting a galvanometer compensation file to correct the galvanometer after processing the matrix target collected by the CCD image acquisition device. By adopting the technical scheme, the problems are well solved, and the quick correction method for the galvanometer correction system is applicable to laser machining industry.

Owner:KUNSHAN THETA MICRO

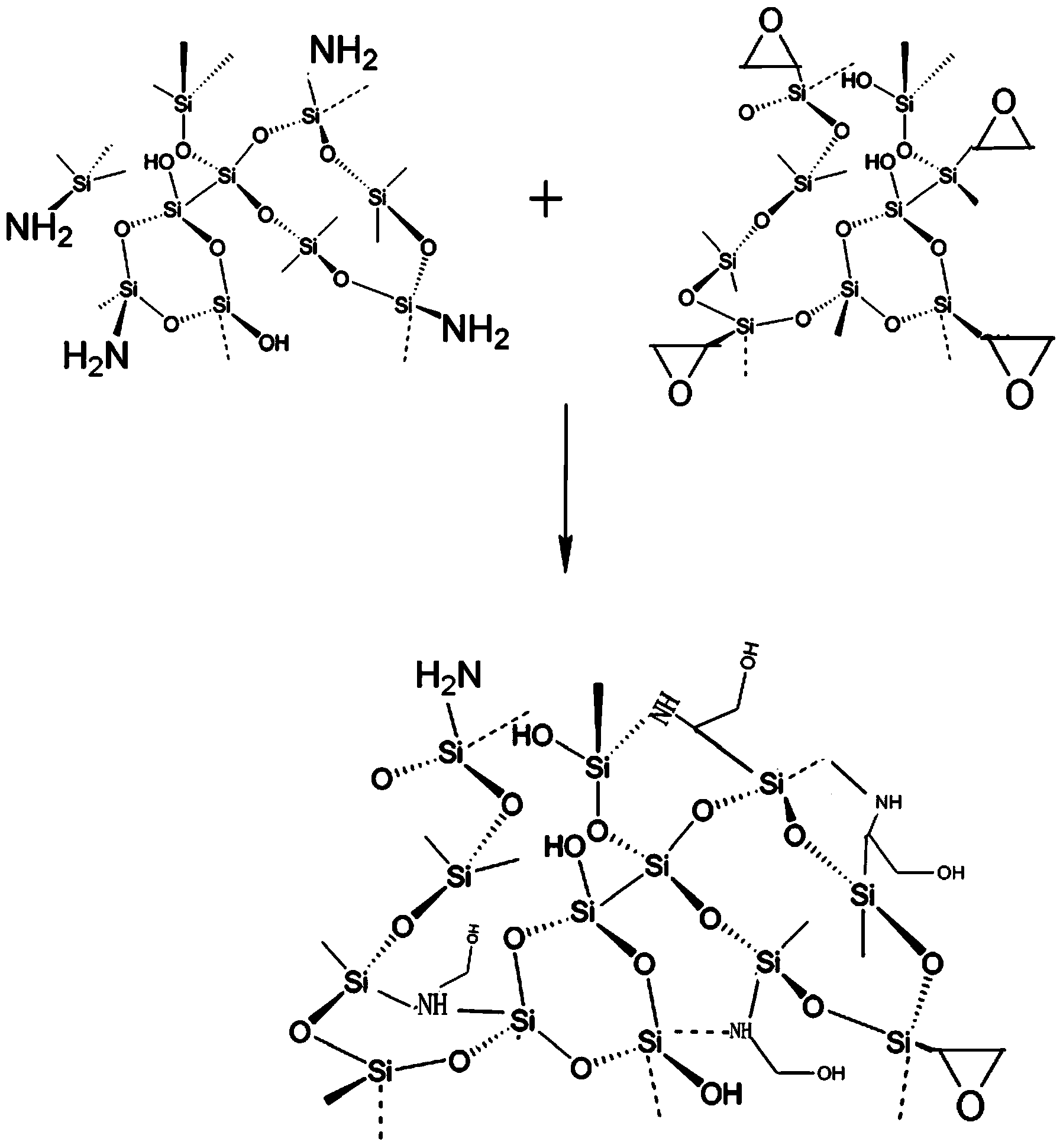

Ordinary temperature curing high-hardness organic-inorganic hybrid coating as well as preparation and use method thereof

The invention belongs to the technical field of hybrid coatings, and discloses an ordinary temperature curable high-hardness silicon dioxide-based organic-inorganic hybrid coating as well as a preparation and use method thereof. The coating comprises a component A and a component B, wherein the component A is amino modified organic-inorganic hybrid sol; the component B is epoxy modified organic-inorganic hybrid sol. On the basis of siloxy hydrolytic condensation reaction, epoxy groups and amino groups are reacted to prepare a reaction type double-component silicon dioxide-based organic-inorganic hybrid coating, and with the combination of inorganic hydrolytic condensation and organic chemical reaction, the ordinary temperature curing process of a coating system is accomplished, and the prepared coating overcomes the defects that an existing coating is easy to gel, the storage period is relatively short and the like; after being used, the coating is excellent in property, has various special functions of high hardness, high adhesion, wearing resistance, scrapping resistance, corrosion resistance and the like in a thickness as low as 1-50 mu m, and can be widely applied to various fields, such as buildings, the electric appliance and electronic industry, the machine industry and household articles.

Owner:西藏宣和新材料股份有限公司

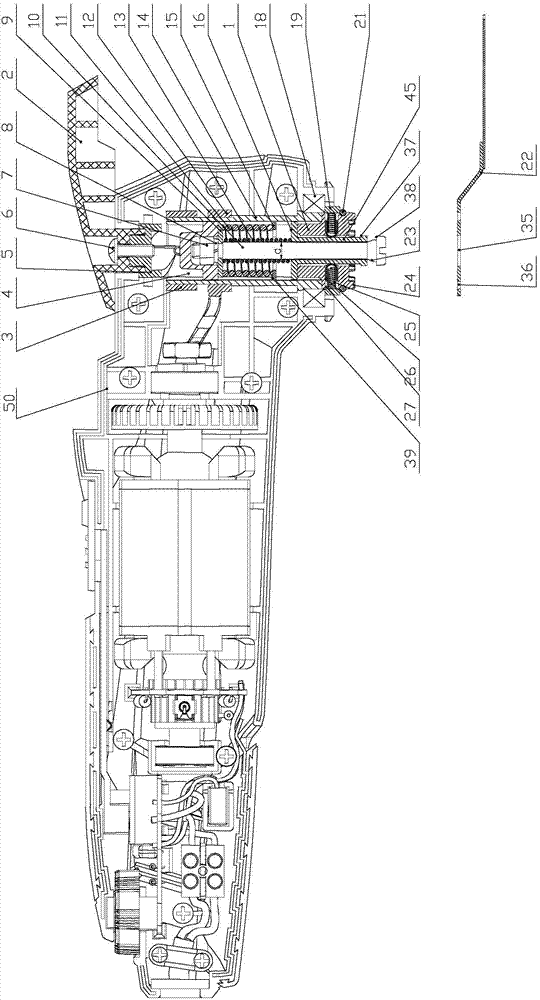

Multifunctional tool and rapid replacement structure thereof

ActiveCN104708606AEasy to installEasy to disassemblePortable power-driven toolsReplacement methodWrench

The invention belongs to the technical field of electric tools in the machine industry, and particularly relates to a multifunctional tool and a rapid replacement structure thereof. The multifunctional tool can perform cutting, sanding and the like. The rapid replacement structure comprises an output shaft assembly. An elastic chuck capable of moving axially is arranged in the output shaft assembly. A locking shaft is arranged in the elastic chuck and driven by an elastic assembly to move axially in the elastic chuck, and then expansion opening and closing of the elastic chuck are achieved. According to a traditional replacement method, screws on a saw web and a triangular sand tray are completely detached, the saw web or the triangular sand tray is arranged in a sleeving mode, then the screws are screwed up through a hexagon wrench, consequently, replacement efficiency is low, the hexagon wrench is prone to being lost, and replacement can not be performed once the hexagon wrench is lost. By means of the multifunctional tool, it is not needed to fix the saw web with one screw, axial sliding of the output shaft assembly and a locking shaft assembly is controlled by rotating a knob at the head of the multifunctional tool, then the saw web is controlled to be loosened or clamped, and therefore rapid replacement is achieved.

Owner:CHANGZHOU TONGYANG ELECTRICAL MFG

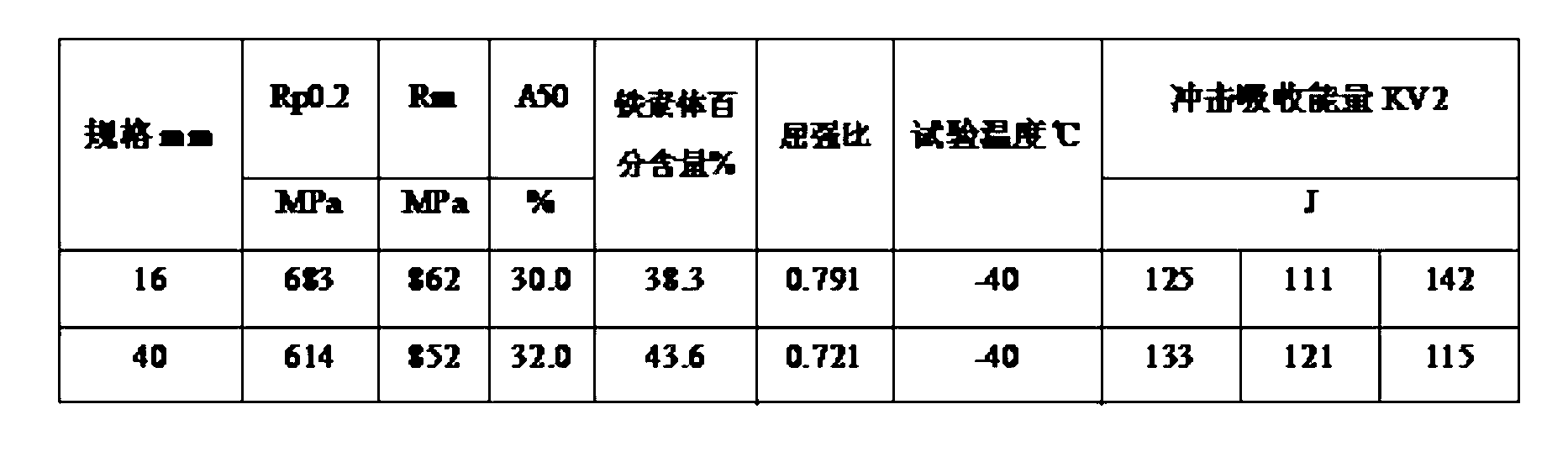

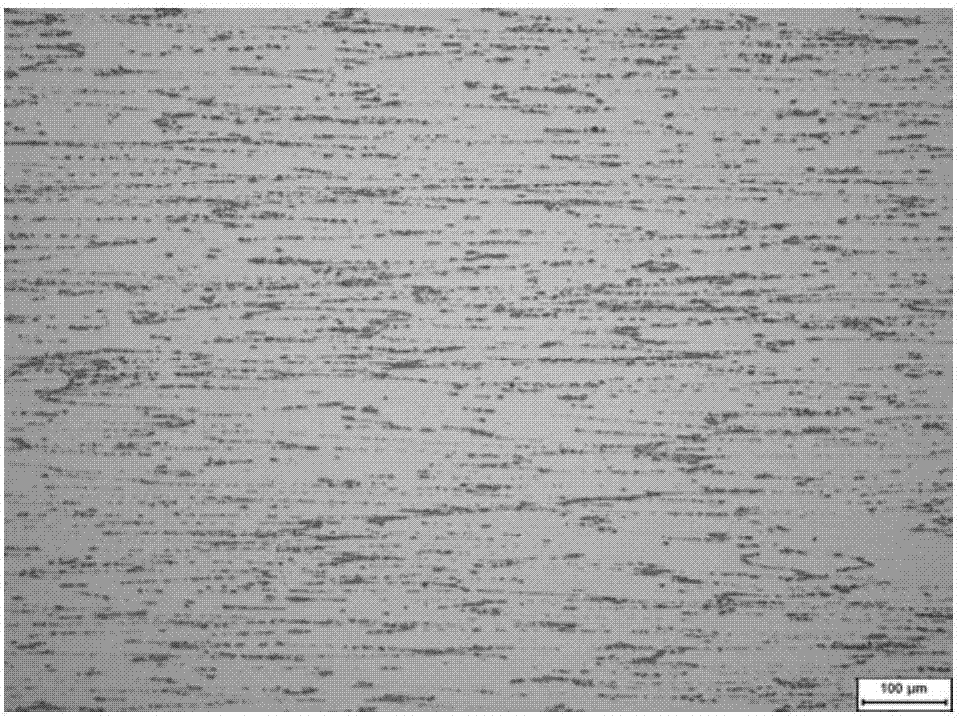

F+P+B type low-yield-ratio and high-strength medium steel plate and production method thereof

The invention discloses an F+P+B type low-yield-ratio high-strength medium steel plate and a production method thereof, and belongs to the technical field of high-strength medium steel plates. The steel plate comprises the following chemical compositions by weight percentage: 0.05-0.12% of C, 0.2-0.4% of Si, 1.7-2.0% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.02-0.05% of Al, 0.04-0.09% of Nb, 0.01-0.02% of Ti, 0.03-0.07% of V, 0.1-0.2% of Cr, 0.001-0.002% of B, and the balance of Fe and unavoidable impurities. The steel plate adopts a smelting, controlled rolling and mild ultra-fast cooling technology system, and has the advantages that precious metal elements such as Ni, Mo or Cu are not adopted, so that the alloy cost is low; thermal treatment techniques such as quenching or tempering are not adopted, so that the production cost is low; the production period is short; high-toughness, low-yield-ratio and high-strength steel can be produced stably; and the steel plate is applicable to fields of engineering machinery, coal machine industry and the like.

Owner:SHOUGANG CORPORATION

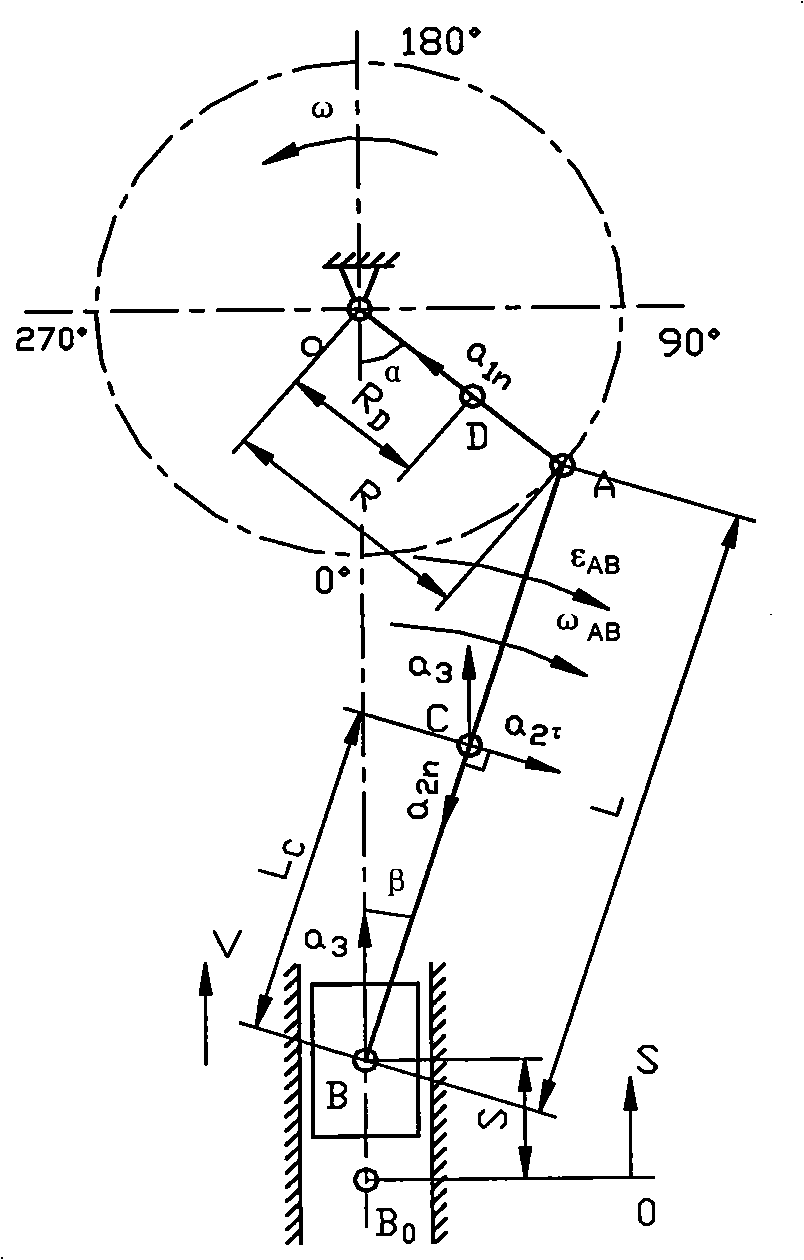

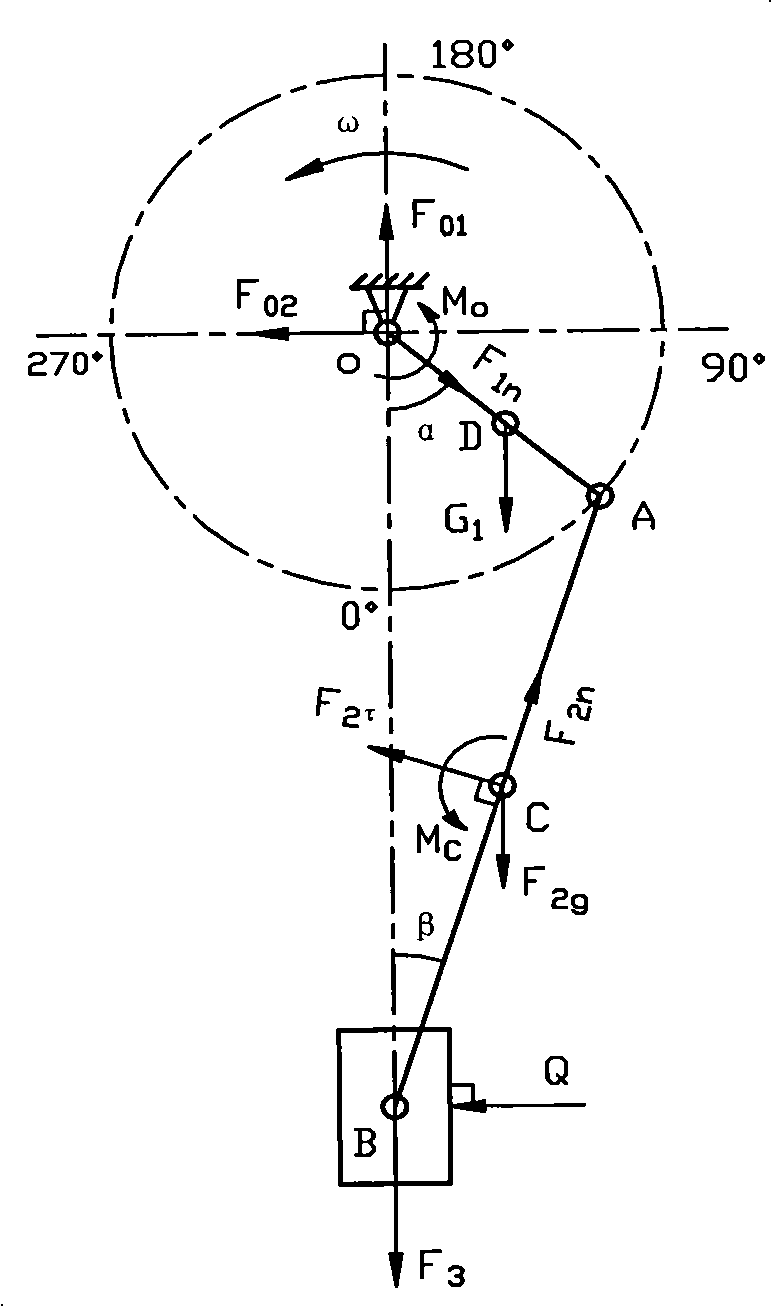

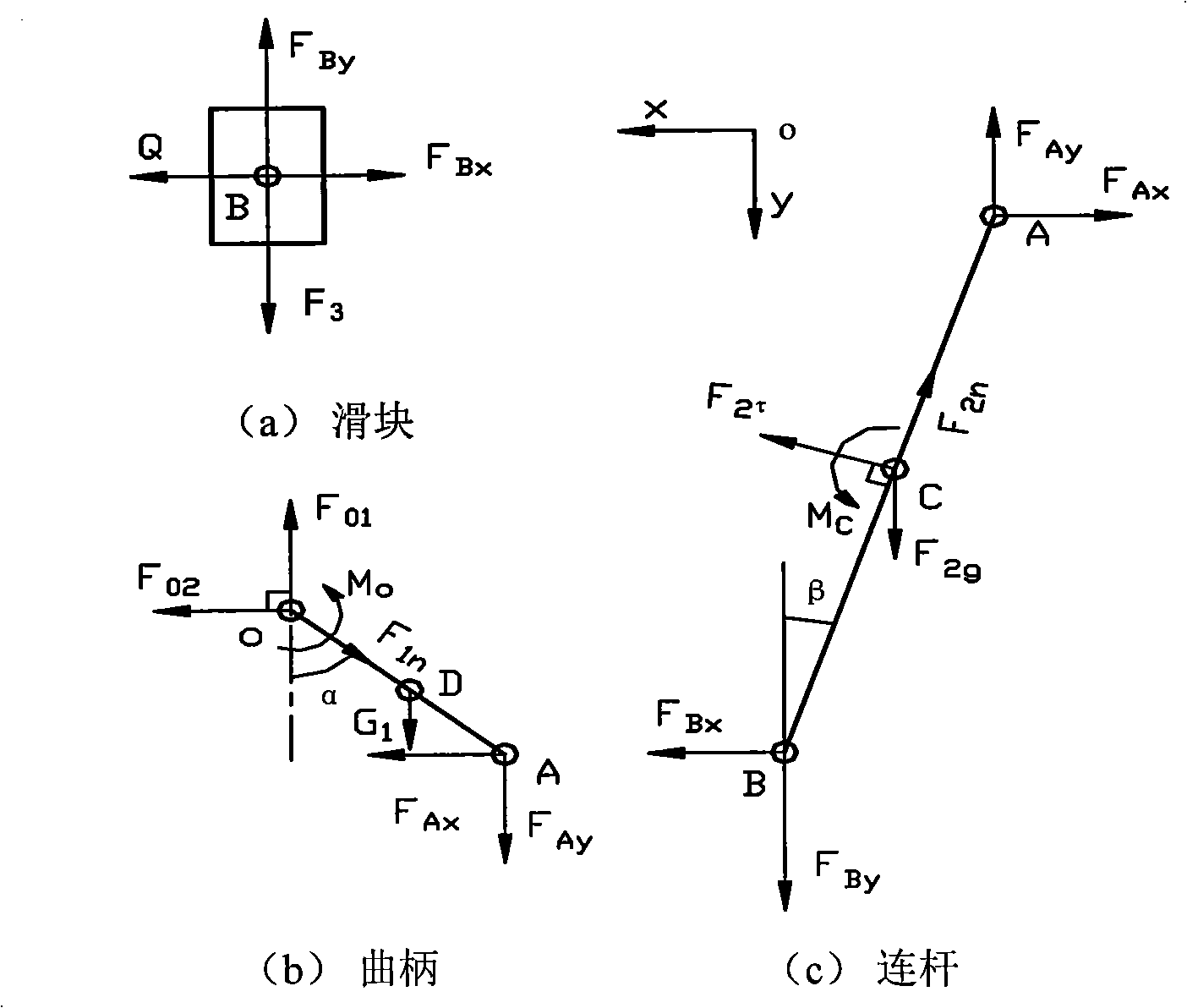

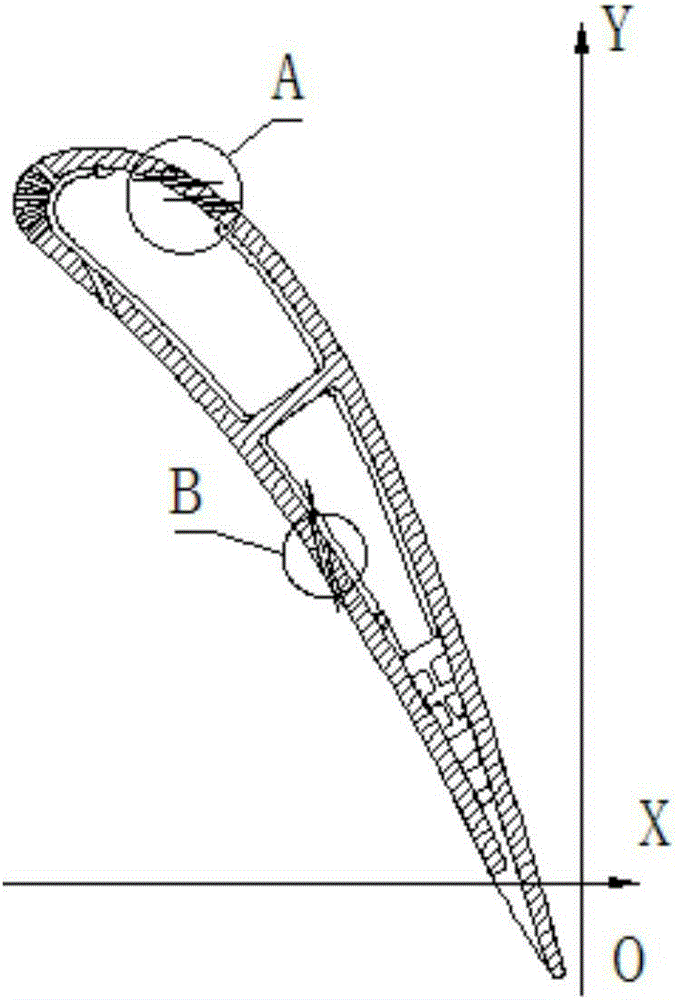

Inertia force balance method of high speed punching machine crank connecting rod sliding block mechanism

InactiveCN101303061AImprove balanceInertia force compensationSpecial data processing applicationsPunch pressDynamic balance

The invention discloses a method for balancing the inertial force of a crank lingage slider mechanism of a high speed punching machine, which is characterized in that: the mechanism that the crank lingage slider mechanism produces inertial force is disclosed, a correct calculating formula of the balancing mass of an eccentric block of a large gear on a crankshaft when the inertial force is in total balance is derived by taking the total balance of the inertial force as the design thought and the crank lingage slider mechanism with fully symmetric double-point or four-point double cranks as the basis, thus realizing the purpose of reaching the balance of the inertial force at a vertical direction by adjusting the mass of the eccentric block according to different mass of moulds, and obtaining good dynamic balance effect from the practical application in 1000kN high speed punching machine industry.

Owner:XI AN JIAOTONG UNIV

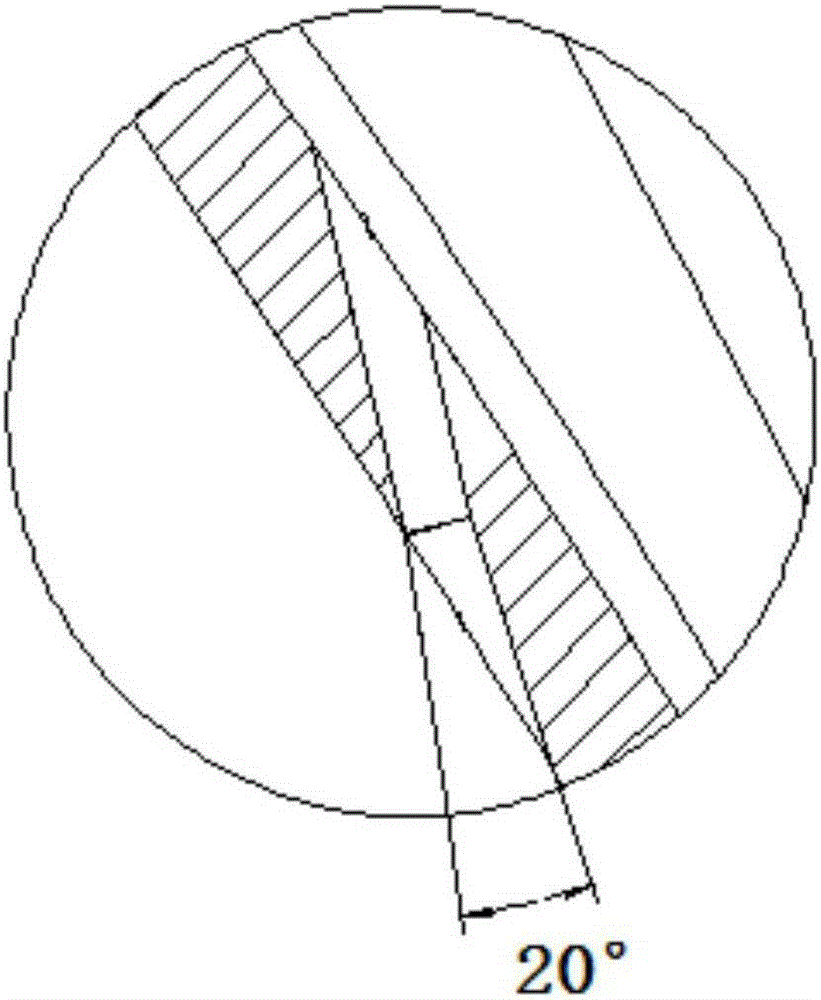

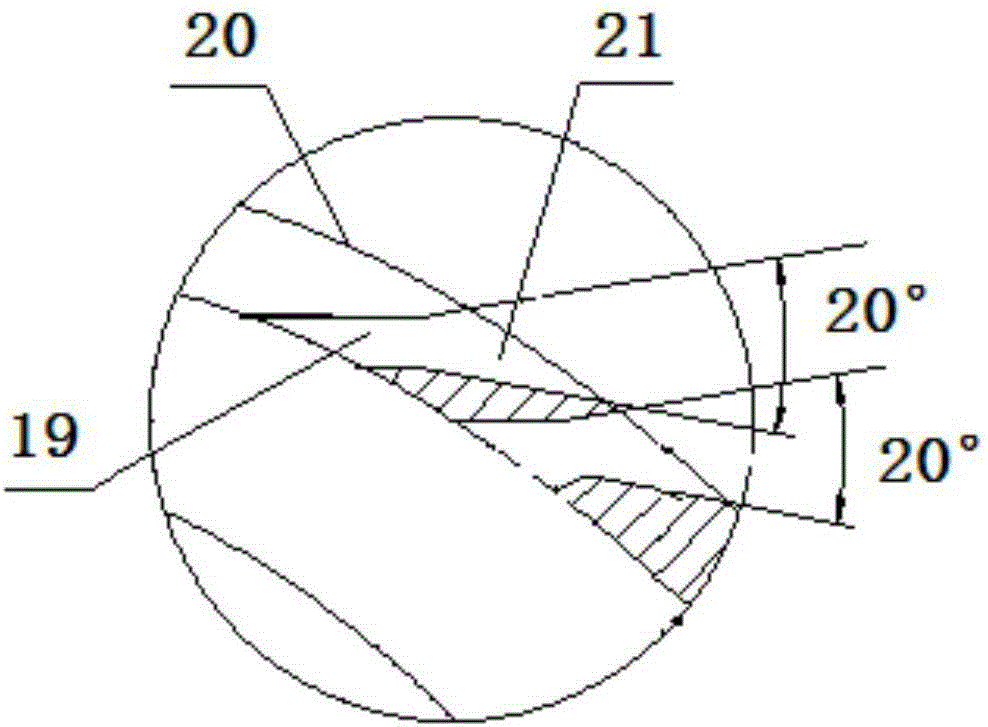

Technology for machining conical gas film holes of turbine guide blade

ActiveCN105171158AReduce processing difficultySolve processing technical problemsElectrical-based machining electrodesElectrical-based auxillary apparatusAviationTurbine blade

The invention provides a technology for machining conical gas film holes of a turbine guide blade. The technology mainly comprises the following steps that (1) a machining mode is selected; (2) a machining electrode is designed and manufactured; (3) a clamp is designed and manufactured; (4) cylindrical micro holes are machined; (5) parts are clamped; (6) the electrode is clamped and aligned; (7) the conical gas film holes are machined; and (8) the conical electrode is trimmed. By the adoption of the machining technology, the machining difficulty of the conical gas film holes is lowered, and thus the technical problem that the conical gas film holes are hard to machine in a blade body and a mounting plate of the high-pressure turbine guide blade is solved; machining and production operation of the blade is effectively guaranteed, production efficiency is greatly improved, it is guaranteed that products can be delivered on schedule, and meanwhile the percent of pass of the finished products is increased; the blank of the technology in the aviation turbine blade micro hole machining industry in China is filled.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Method for preparing fluorine hydride from acidic mixture of inorganic fluoride and sulphuric acid

InactiveCN101353156AMeet the requirements of large-scale productionFluorine/hydrogen-fluorideChemical industryDistillation

The invention discloses a method for preparing hydrogen fluoride with an acid mixture of inorganic fluoride and sulfuric acid and relates to a fluoride. The hydrogen fluoride gas is prepared by controlling operating conditions of the reaction volatilization, or distillation separation, or rectification separation process of the acid mixture of the inorganic fluoride and the sulfuric acid in a conventional equipment space, especially the pressure condition and the temperature condition, and carrying out a heat and mass transfer process to cause the water and sulfuric acid and sulfate in the acid mixture to be kept on a liquid phase. When the hydrogen fluoride is purified, a 40% hydrofluoric acid or anhydrous hydrogen fluoride is prepared. The method is suitable for recovering and preparing the hydrogen fluorine from the fluorine of the fluorine-containing intermediate materials or 'three industrial wastes' with the fluorine produced in the processes of chemical industry, electronics industry, glass machining industry, aluminum alloy machining industry and the like to make hydrogen. The method is especially suitable for enterprises to recover the materials with fluorine separated from the phosphoric acid, phosphate fertilizer and other phosphate chemical products produced by the wet process and make the hydrogen fluoride, or for the comprehensive utilization of the 'three industrial wastes' with fluorine.

Owner:GUIZHOU RES INST OF CHEM IND

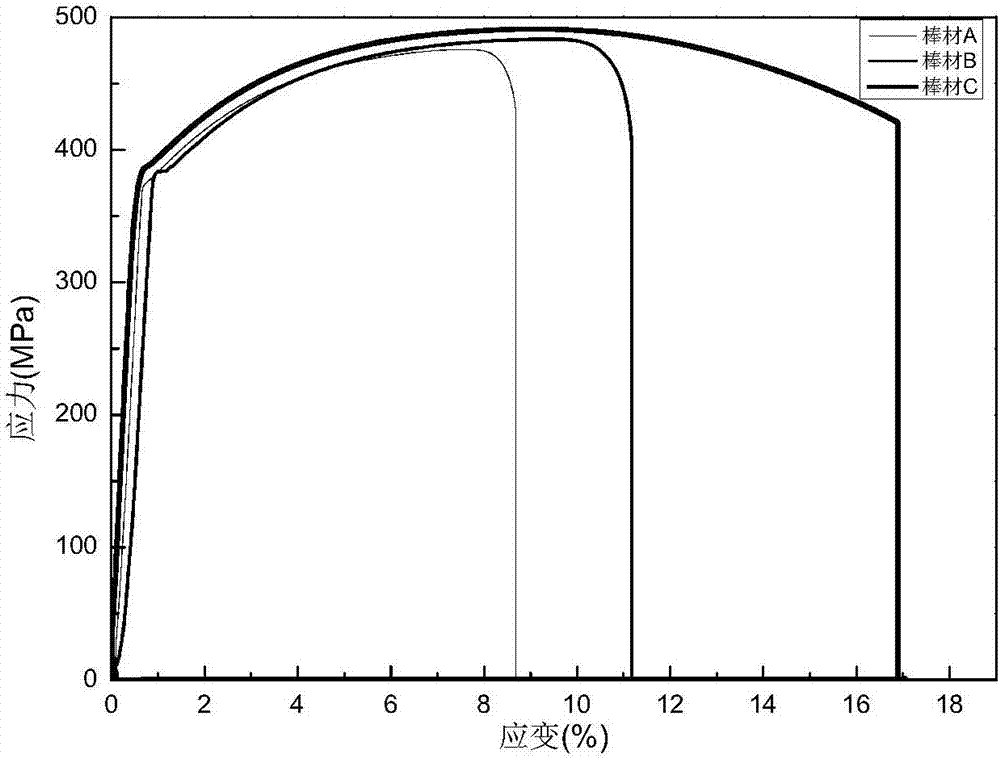

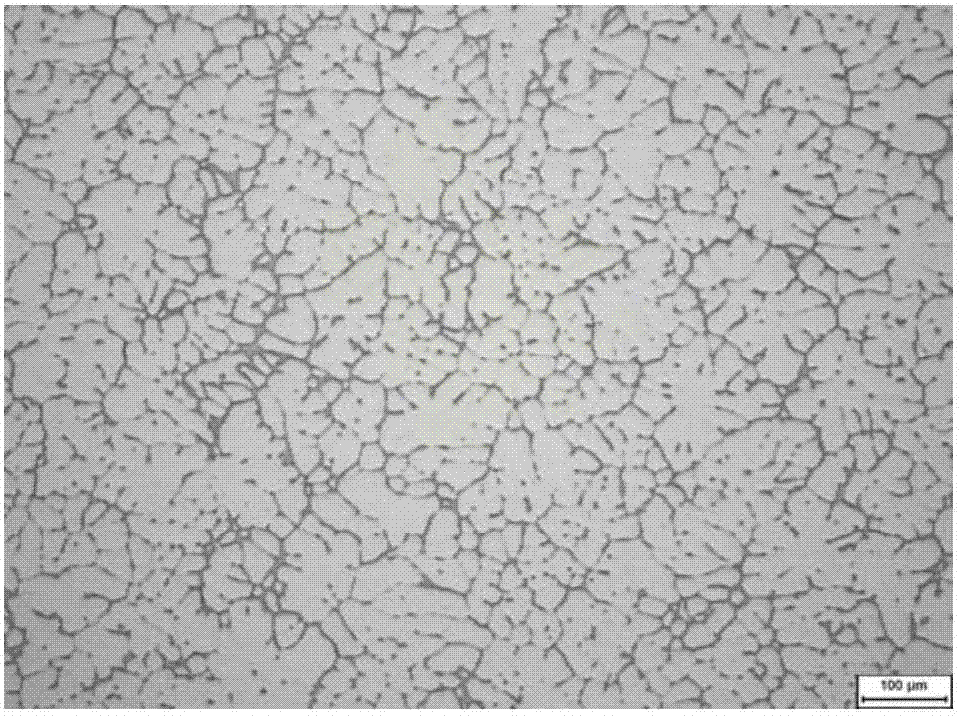

Method for simultaneously improving strength and percentage elongation of aluminum alloy

The invention belongs to the technical field of metal material plastic deformation and heat treatment, and relates to a method for simultaneously improving the strength and the percentage elongation of aluminum alloy, in particular to a thermomechanical treatment method for simultaneously improving the strength, the percentage elongation and other comprehensive properties of Al-Cu-Mg alloy. The method for simultaneously improving the strength and the percentage elongation of the aluminum alloy is characterized by comprising the steps that an Al-Cu-Mg series alloy ingot is subjected to primary extrusion and then subjected to homogenizing annealing treatment, secondary extrusion is conducted after homogenizing annealing treatment, and after a product with the required size and specification is manufactured, solution and aging treatment is conducted. According to the method, existing equipment in the aluminum machining industry is utilized, the tensile strength and the percentage elongation of the aluminum alloy are simultaneously improved by changing the thermomechanical treatment technology, and a high-quality aluminum extruded material is obtained.

Owner:NORTHEASTERN UNIV

Poker machine capable of fully automatically arranging, shuffling and dealing poker

InactiveCN101954186ASave the process of manual card managementAdd funCard gamesButt jointEngineering

The invention discloses a poker machine capable of fully automatically arranging, shuffling and dealing poker. A card base rotating a card dealing machine head is arranged in a card base lift cylinder, card arranging mechanisms are arranged at two sides of a left side plate and a right side plate of the card base lift cylinder, a card arranging cylinder of each card arranging mechanism consists of three parts of a card arranging bucket, a card stacking chamber and a card storing chamber, a card arranging roller is arranged at one side of the bottom of the card arranging bucket, a card stacking roller is arranged in the card stacking chamber, a card shuffling roller group is arranged at the bottom of the card storing chamber, and a card outlet of the card storing chamber is in butt-joint with a card inlet on a side plate of the card base lift cylinder. The invention improves a part of structure of the poker machine, increases the left and right card arranging mechanisms so as to make the poker machine have the function of fully automatically arranging, shuffling and dealing poker, saves the process of manually arranging card of users, can bring more funs for users, is very convenient to use, has simple whole structure and reasonable design, is an revolution of the poker machine industry, and must be a new favorite of the poker machine.

Owner:赖新途

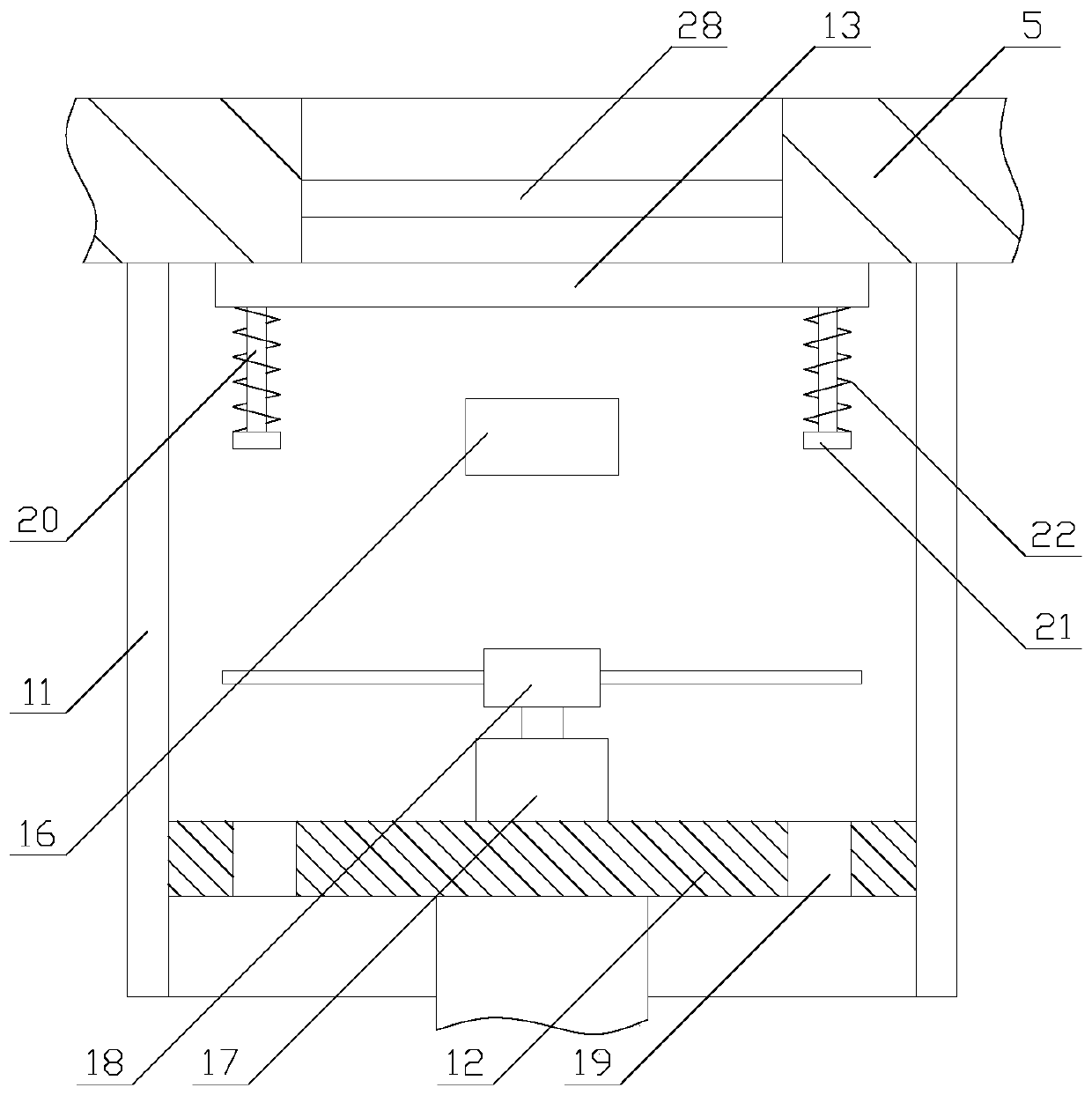

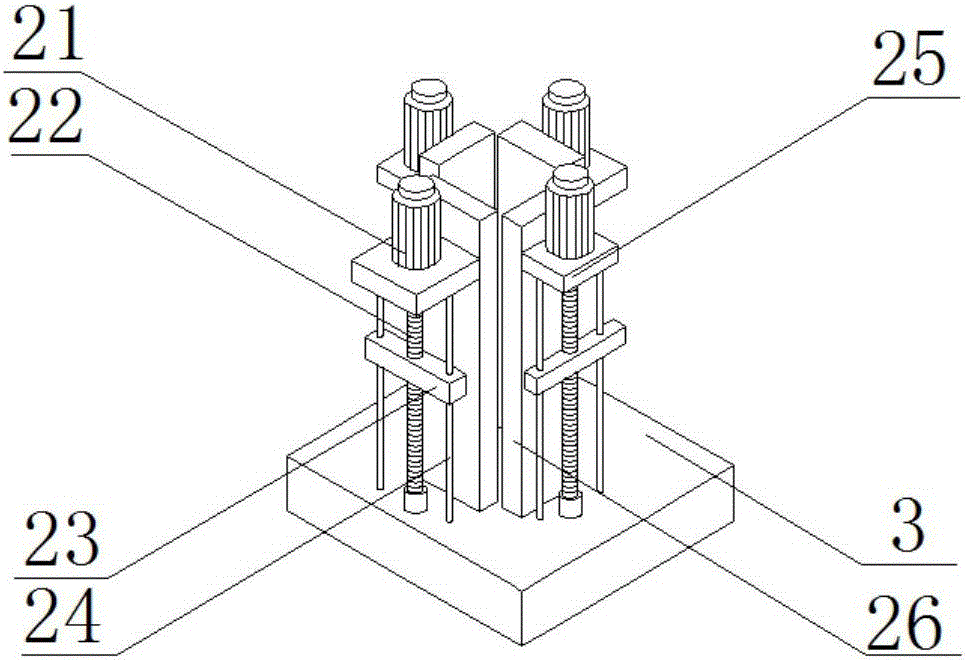

High-precision numerical control drilling equipment for machining industry

ActiveCN111001841AIngenious structurePracticalMaintainance and safety accessoriesBoring/drilling machinesNumerical controlDrive shaft

The invention relates to high-precision numerical control drilling equipment for the machining industry. The equipment comprises a bottom plate, a driving box, a transmission shaft and a drill rod; the driving box is arranged above the bottom plate and is fixedly connected with the bottom plate; the transmission shaft is perpendicular to the bottom plate; a mounting hole is formed in the bottom ofthe driving box; the transmission shaft penetrates through the mounting hole and is in sliding connection with the inner wall of the mounting hole; the drill rod is mounted at the bottom end of the transmission shaft; a numerical control operation system is arranged in the driving box; a buffering mechanism and a heat dissipation mechanism are arranged on the bottom plate; and the buffering mechanism comprises a supporting plate, a buffer assembly and two vibration assemblies. According to the high-precision numerical control drilling equipment for the machining industry, the buffering mechanism is adopted, and therefore, buffering and vibration reduction functions are achieved, and the situation that the drill rod is damaged due to long-term rigid impact is avoided; and in addition, a heat dissipation function is achieved through the heat dissipation mechanism.

Owner:ANHUI DOUBLE DRAGONS MACHINE TOOLS MFG

Method for producing precise linear guide slide seat for machining center

The invention relates to a method for producing a linear guide, in particular to a method for producing a precise linear guide slide seat on a machining center for processing workpieces in machining industries. The method comprises the steps of hot rolling, spheroidizing, head rolling, pickling, phosphate treatment, saponification treatment, cold drawing, process annealing, straightening, cuttingand the like. The method for producing the precise linear guide slide seat for the machining center has the advantages of high efficiency and low production cost.

Owner:WUXI NEWAY STEEL

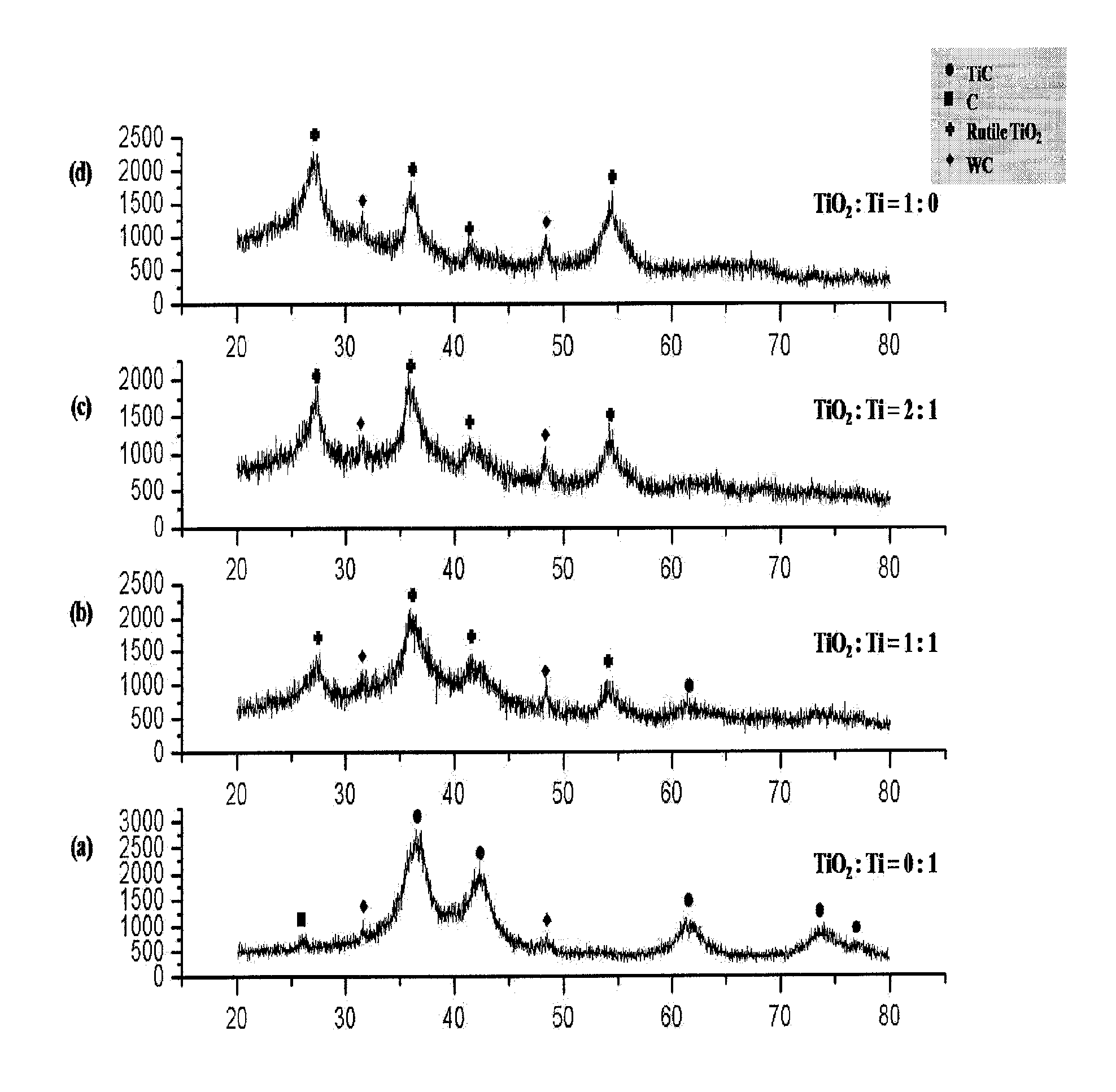

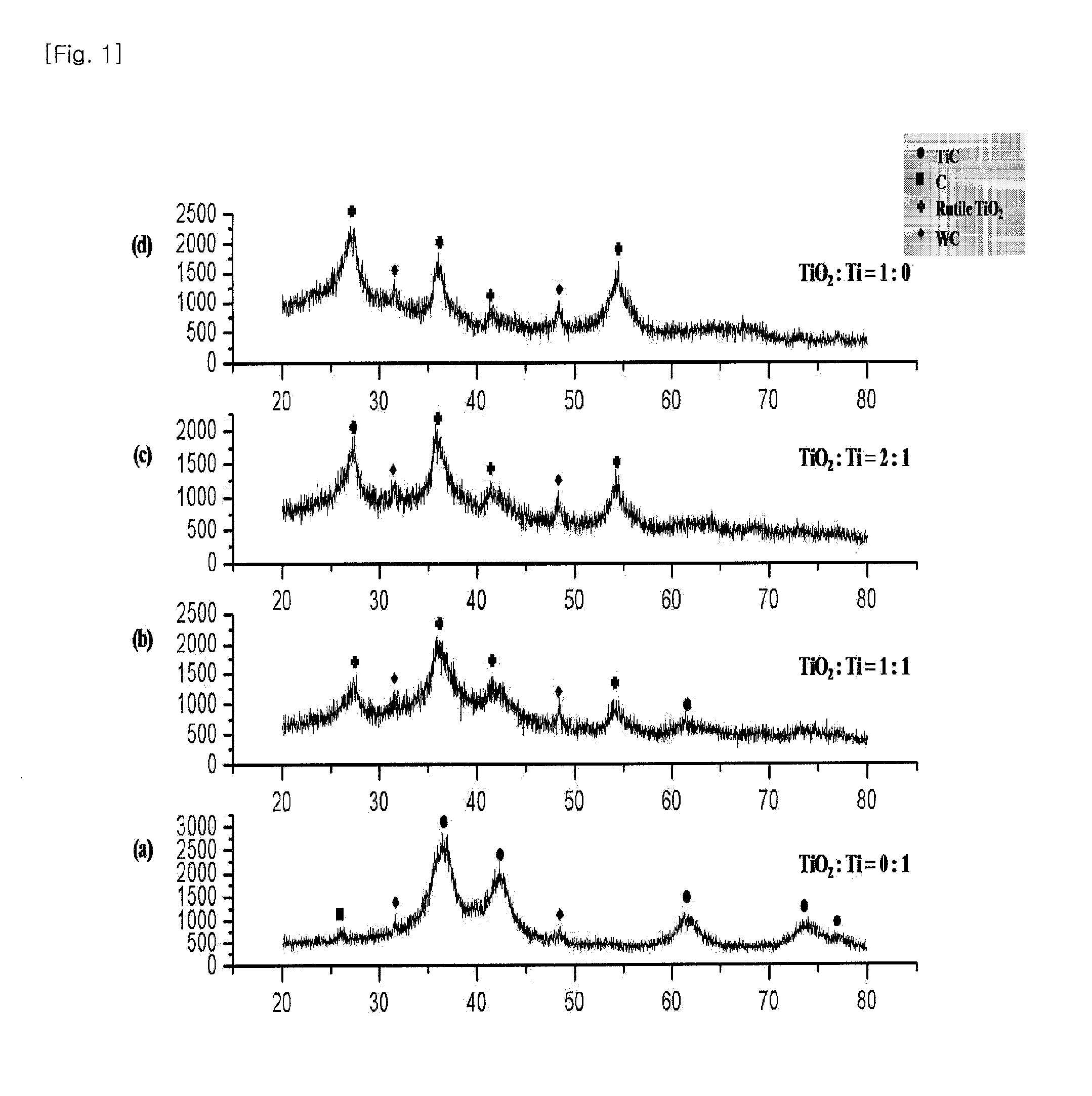

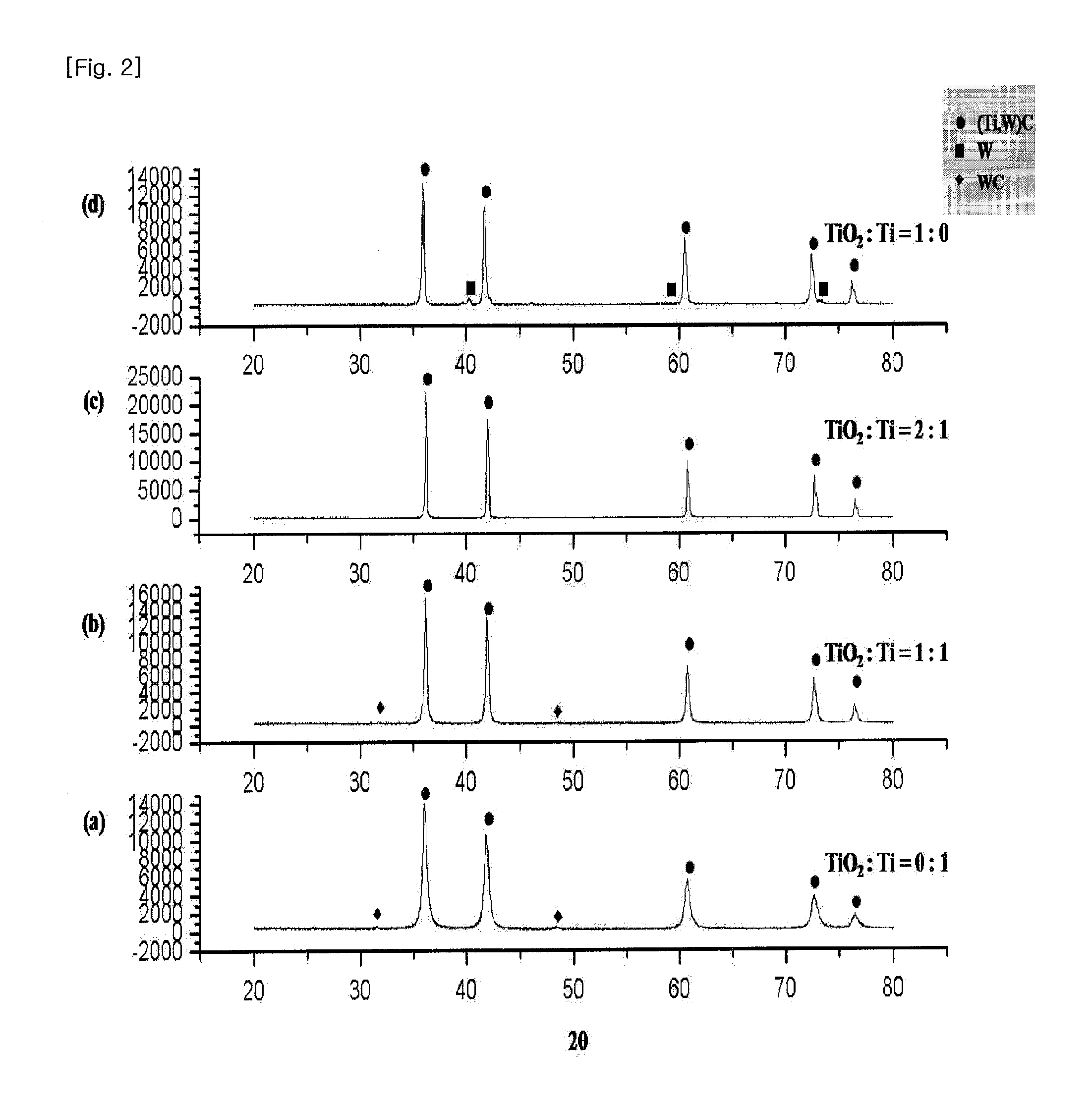

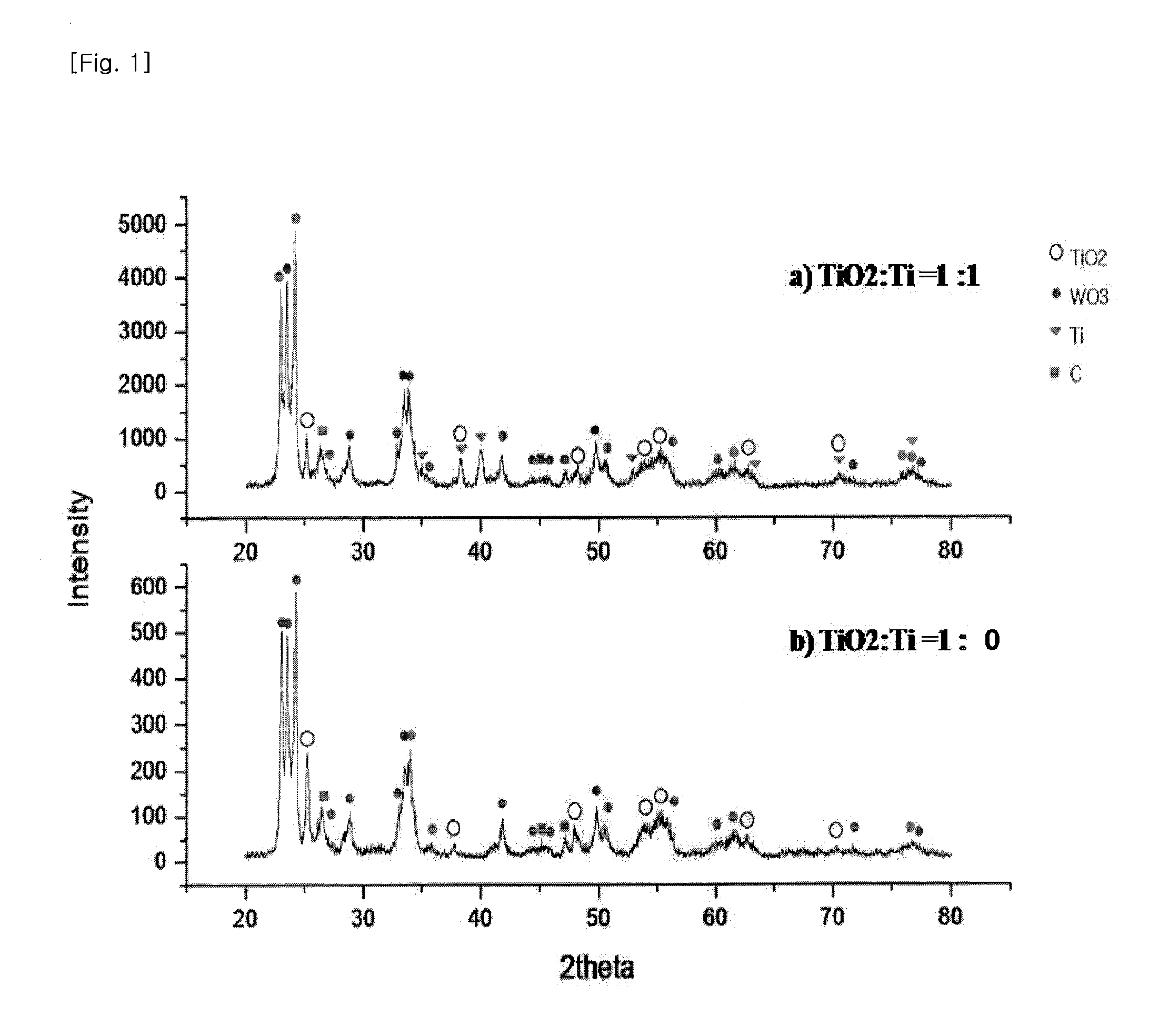

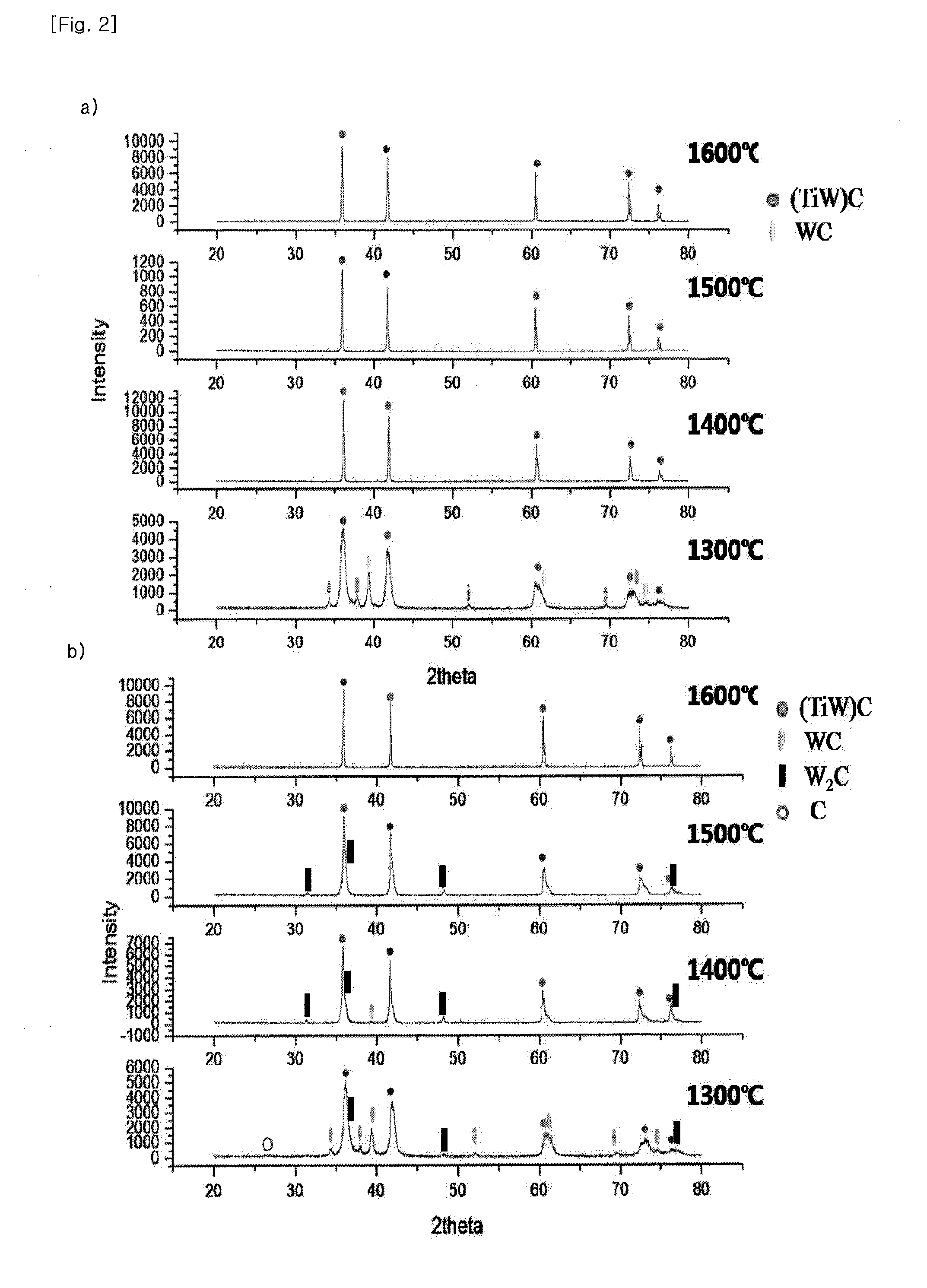

Solid-solution carbide/carbonitride powder and method for preparing thereof

InactiveUS20100273638A1Improve performanceEasy procedureNitrogen compoundsOxy/sulfo carbidesCarbideSolid solution

The present invention relates to a complete solid solution powder used for preparing a cermet composite sintered body, and method for preparing thereof. Particularly, the present invention is directed to a complete solid solution powder which can improve, to a great extent, toughness of a cermet sintered body which is used for high-speed cutting tool materials and die materials in the field of metal working, such as various machine industries and automobile industry, and method for preparing thereof.

Owner:SEOUL NAT UNIV R&DB FOUND

Novel low-cost wear-resistant high-strength Q550D steel plate and production method thereof

InactiveCN103014522AGuaranteed mechanical propertiesGuaranteed Ultrasonic Flaw DetectionWear resistantSlow cooling

The invention discloses a novel low-cost wear-resistant high-strength Q550D steel plate and a production method thereof. The steel plate comprises the following elements: 0.04-0.10% of C, 0.15-0.40% of Si, 1.40-1.60% of Mn, not more than 0.020% of P, not more than 0.015% of S, 0.015-0.060% of Als, 0.005-0.060% of Ti, 0.30-0.70% of Cr, 0.02-0.07% of Nb and the balance of Fe and inevitable impurities. The production method comprises the steps of smelting in a converter, LF (ladle furnace) refining, VD (vacuum degassing) treatment (optional), continuous casting, casting blank slow cooling, heating, TMCP (thermomechanical control process) rolling and slow cooling. The steel plate and the production method have the beneficial effects that through the novel composite microalloying composition design idea and concise and effective process design, the indexes of the steel plate, such as mechanical properties, ultrasonic flow detection and the like are ensured; the wear resistance of the steel plate is improved; and the steel plate has uniform properties, excellent flaw detection quality and certain wear resistance, can be widely used in engineering machinery, coal machine industry, machinery manufacturing and the like, and has good promotion significance.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

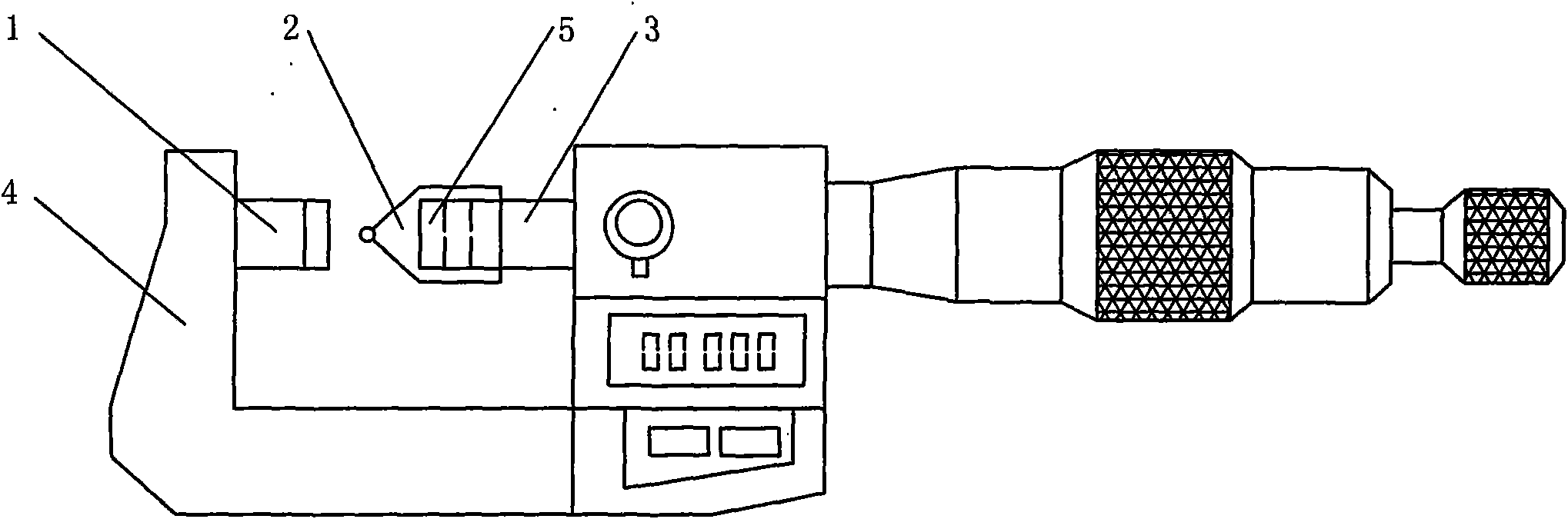

Multifunctional digital micrometer

InactiveCN101614512AFunction increaseLow costMicrometersMechanical diameter measurementsMicrometerReamer

The invention discloses a multifunctional digital micrometer, which is used for measuring the diameter dimension of a reamer with larger diameter and the thickness of a groove or an arc surface wall with a groove or an arc surface component in the machinery machining industry. The multifunctional digital micrometer comprises a digital micrometer, and is characterized in that a measuring anvil and / or a moving micrometric screw rod of the digital micrometer is provided with a measuring head, inner holes matched with the measuring anvil and the moving micrometric screw rod are made on one end of the measuring head, and magnetic sheets are mounted in the inner holes. The invention has advantages that the measuring head is designed aiming to measure the diameter dimension of the reamer with larger diameter and the thickness of the groove or the arc surface wall with the groove or the arc surface component, is installed on the measuring anvil and / or the moving micrometric screw rod to measure the reamer with the larger diameter, the groove or the arc surface and is matched according to a demand, thereby increasing functions of the digital micrometer; and the cost of matching the measuring head is less than that of matching a special digital micrometer.

Owner:SHENYANG AIRCRAFT CORP

Sorting robot applied to machining industry

InactiveCN106625587ARealize automatic grippingQuick sortingProgramme-controlled manipulatorSortingEngineeringHigh definition

The invention discloses a sorting robot applied to machining industry. The sorting robot comprises an operation platform, a visual identification device, a clamping device and a transferring and storage device, wherein the upper end of the operation platform is provided with a conveying belt for conveying parts, support rods are arranged at two ends of the conveying belt, a support plate is fixed at the upper ends of the two support rods, the visual identification device is arranged at the lower end of the support plate and comprises a high-definition camera and a flash lamp, a fixing block is arranged on one side of the conveying belt, a robot body is arranged at the upper end of the fixing block, a first fixing rod is arranged at the upper end of one side of the robot body, and a first support arm is arranged at the tail end of the first fixing rod. The sorting robot has the advantages that automatic clamping of appointed parts is achieved by using the visual identification device and the clamping device in a combined manner, automatic storage and transferring are achieved by the transferring and storage device, fast sorting is achieved, manpower cost is lowered, and the sorting robot is suitable for being popularized.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

Solid-solution carbide/carbonitride powder and method for preparing thereof under high temperature

InactiveUS20100267542A1Improve performanceEasy procedureMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsCarbideSolid solution

The present invention relates to a complete solid solution powder used for preparing a cermet composite sintered body, and method for preparing thereof under high temperature. Particularly, the present invention is directed to a complete solid solution powder which can improve, to a great extent, toughness of a cermet sintered body which is used for high-speed cutting tool materials and die materials in the field of metal working, such as various machine industries and automobile industry, and method for preparing thereof under high temperature.

Owner:SEOUL NAT UNIV R&DB FOUND

Automatic C-shaped track core bundle strapping machine

ActiveCN106143986AImprove work efficiencyImprove reliabilityFilament handlingBinding material applicationEngineeringC shaped

The invention belongs to the machine industry, and particularly relates to an automatic C-shaped track core bundle strapping machine. An uncoiling mechanism (2) is arranged above the left portion of a machine base (19). A temporary storage mechanism is arranged on the right side of the uncoiling mechanism (2). A wire feeding mechanism and a straightening mechanism are arranged on the part, on the right side of a buffering mechanism supporting plate (3), of the machine base (19). A movable workbench (9) and a bundle strapping mechanism are arranged on the right side of a wire conveying mechanism (6). A rack (19-1) is arranged on the right side of the machine base (19). The movable workbench (9) is arranged at the middle portion of the rack (19-1). The rack (19-1) is provided with a plurality of guiding wheels (23) according to the C-shaped walking track of a steel wire (1). Vertical pneumatic clamping fingers (10) are arranged on the guiding wheel (23) at the left upper corner in a symmetrically-vertical and left-horizontal manner and connected with the guiding wheels (23) through bilateral chains (24). A servo motor is adopted in the automatic C-shaped track core bundle strapping machine for finishing one-time wire feeding, the wire feeding time is shortened, and wire penetrating, wire feeding, core bundle strapping, a displacement mechanism, resetting and the like are all automatically controlled.

Owner:LIAONING DONGSHENG PRECISION MACHINERY CO LTD

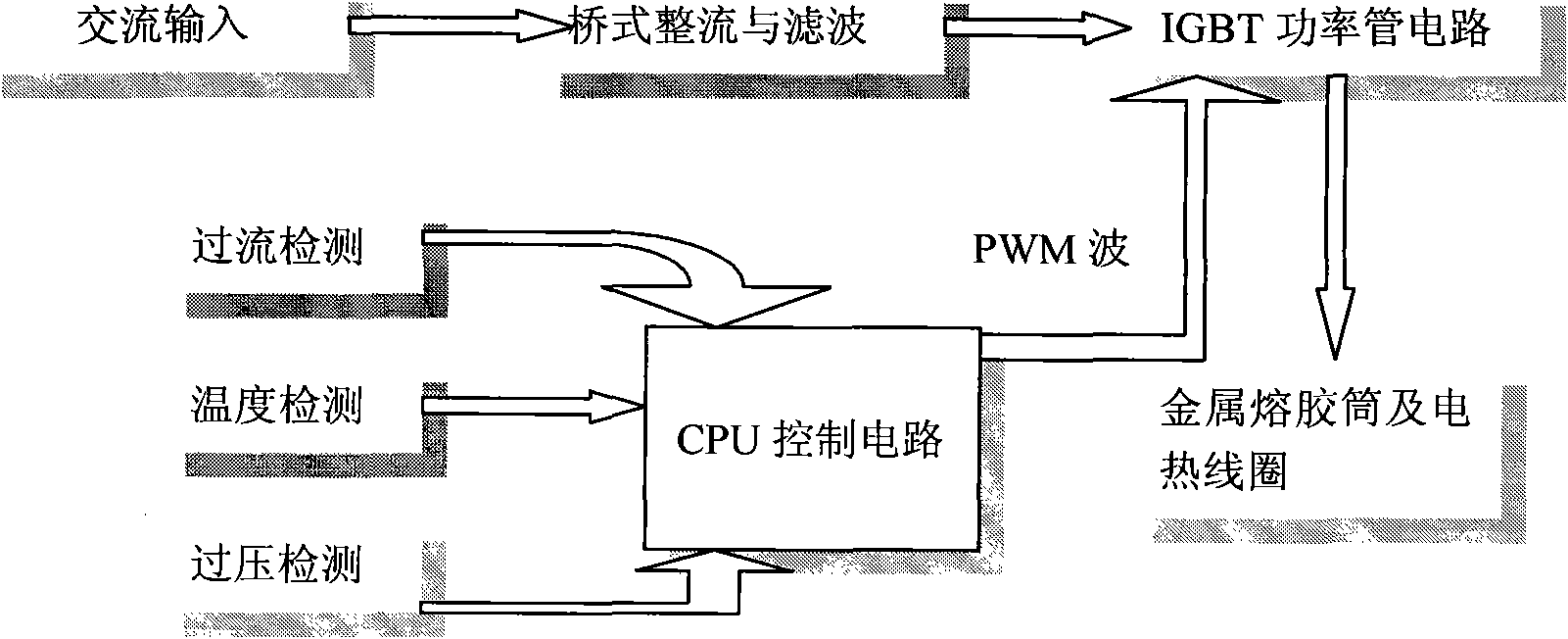

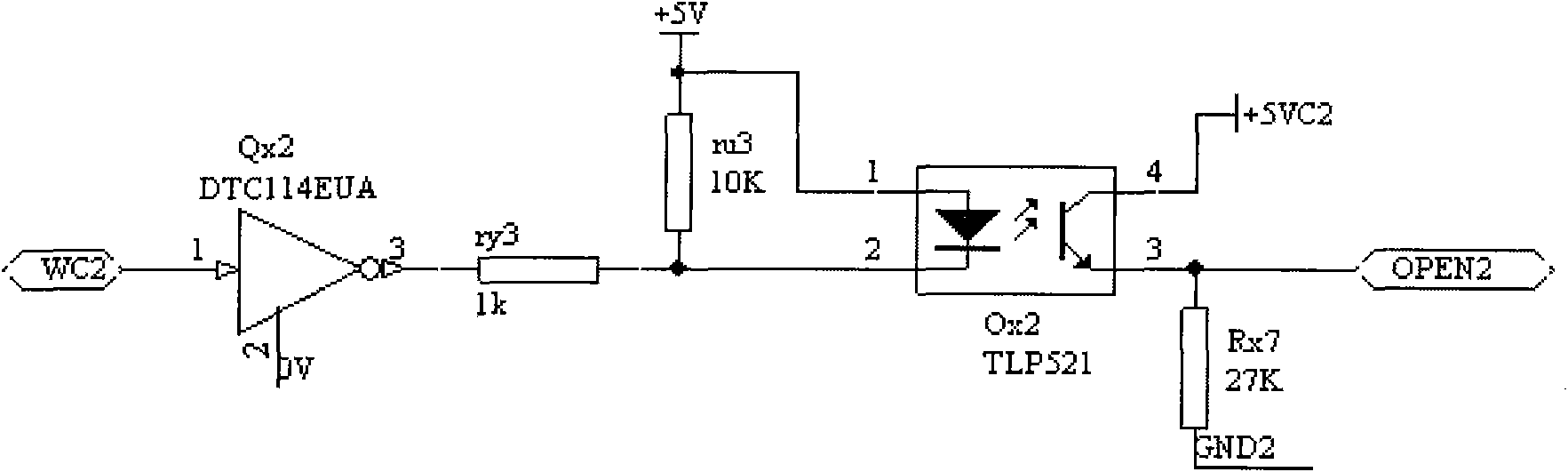

Electromagnetic heating system

InactiveCN101568205AControl leakageHigh precisionConversion with intermediate conversion to dcInduction current sourcesLow noiseInternational market

The invention relates to an electromagnetic heating system, comprising an alternating power supply, an over-current detection device, a temperature detection device, an over-voltage detection device and an electric heating coil; the alternating current power supply generates a direct current high voltage of more than 300V by a bridged rectifier and filter; the direct current voltage is connected with the electric heating coil of a metal glue-melting cylinder by an IGBT power tube; the over-current detection device, the temperature detection device, the over-voltage detection device are connected with a CPU control circuit (namely a microprocessor); the PWM wave generated by the microprocessor directly controls the G-pole control pin of the IGBT; the direct current voltage of 300V is inverted to the alternating current voltage; and the alternating current voltage generates a magnetic field in the electric heating coil. The electromagnetic heating system can achieve the technical characteristics of high precision, high efficiency, low energy dissipation, low noise, high automation, and the like, has wide prospect, can replace the traditional resistance-type heating injection machine, prompt the progress of the injection machine industry and improve the competitiveness capability to the international market.

Owner:NINGBO ZHIXIANG MOTOR DEVICE

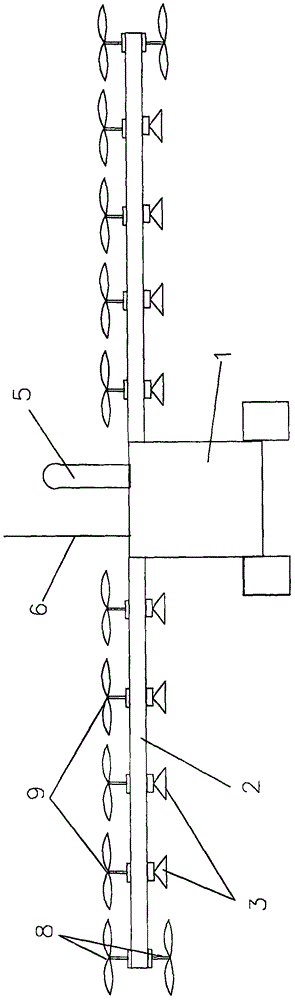

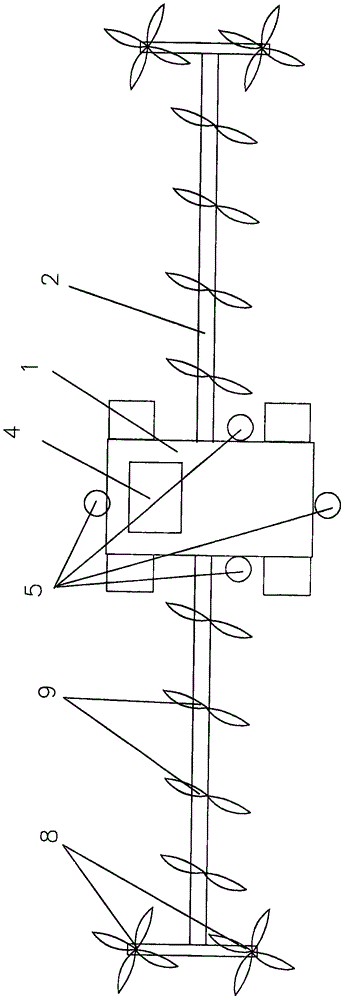

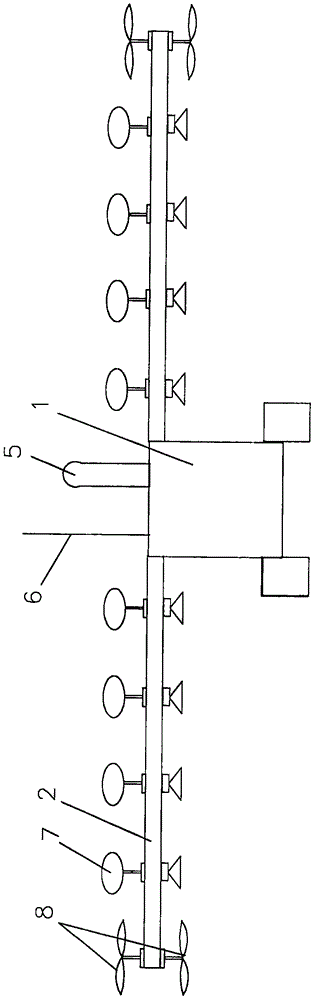

Plant protection machine and control system therefor

InactiveCN105831053AReduce Conservation FundingReduce pesticide poisoningInsect catchers and killersLiquid storage tankVolumetric Mass Density

The invention relates to a plant protection machine and a control system therefor. The plant protection machine comprises a remote-control electric vehicle body, wherein the remote-control electric vehicle body is provided with a horizontal supporting frame along the width direction of the vehicle body; a plant spraying device is arranged on the horizontal supporting frame; the plant spraying device comprises a liquid storage tank and spray nozzles; a power storage and supply device is arranged on the horizontal supporting frame; and video acquisition devices and a remote-control wireless data transmission device are arranged on the horizontal supporting frame. According to the plant protection machine and the control system therefor, disclosed by the invention, the plant protection machine and the control system therefor are used as wind power generation equipment in slack farming seasons; and in busy farming seasons, the plant protection machine and the control system therefor serve as plant protection equipment and are used for achieving precise and quantitative plant protection liquid spraying according to plant planting density, so that the plant protection machine is dual-purpose, vacancies for guarantee of safety of personnel and self-generation in the fields of products for agricultural plant protection at present are filled up, the efficiency of work is about 40 times that of the traditional manual work, and the innovation of the entire plant protection machine industry and development of clean energy resources are improved and can be accelerated and promoted.

Owner:王钧丰

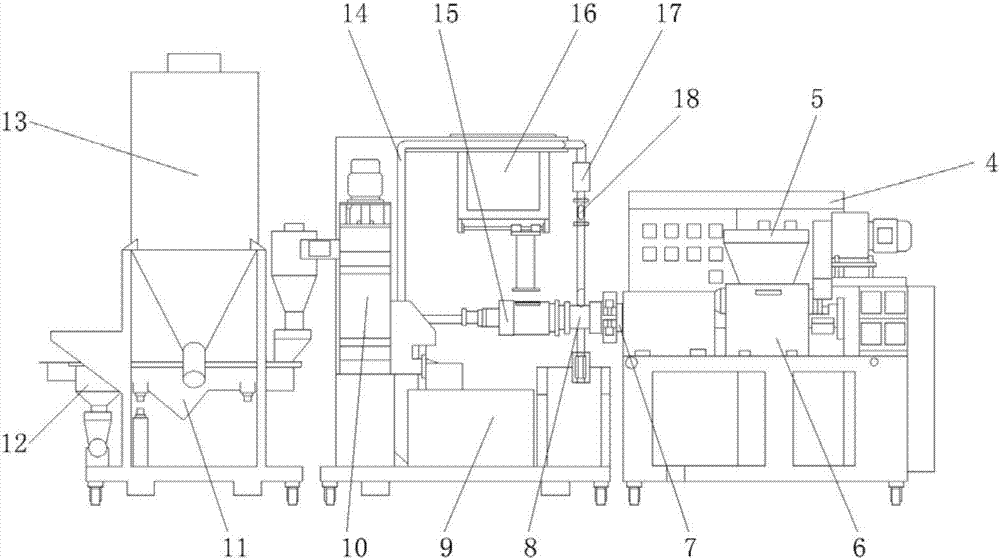

Full-automatic underwater pelletizing unit

PendingCN107283667AReasonable structureNo pollution in the processCoatingsAutomatic controlWater storage tank

The invention discloses a full-automatic underwater pelletizing unit. The full-automatic underwater pelletizing unit comprises an extrusion mechanism, a pelletizing template and a water removing machine. The left side of the extrusion mechanism is connected with a pelletizing water removing mechanism. The left side of the pelletizing water removing mechanism is provided with a drying storage mechanism. An electrical control cabinet is arranged behind the extrusion mechanism. A pelletizing motor is connected to the side face of a pelletizing chamber. The water removing machine is connected with a lower water storage tank. The left side of the water removing machine is connected with a vibration screen together. The side face of the vibration screen and a storage tank are fixedly installed together through a draught fan. According to the full-automatic underwater pelletizing unit, water cooling circulation usage is adopted, an impurity filtering system is arranged in the water tank, the whole machine does not discharge water outwards, and resources are saved. Meanwhile, viscosity of materials can be ignored during underwater pelletizing, the pelletizing speed is high, efficiency is high, and dust and smoke pollution is avoided; and meanwhile, through a PLC touch screen, full-automatic production control is achieved for the whole machine, pelletizing work can be better conducted, and development of the pelletizing machine industry is promoted.

Owner:JINJIANG LUGANG PLASTIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com