Patents

Literature

124results about "Oxy/sulfo carbides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

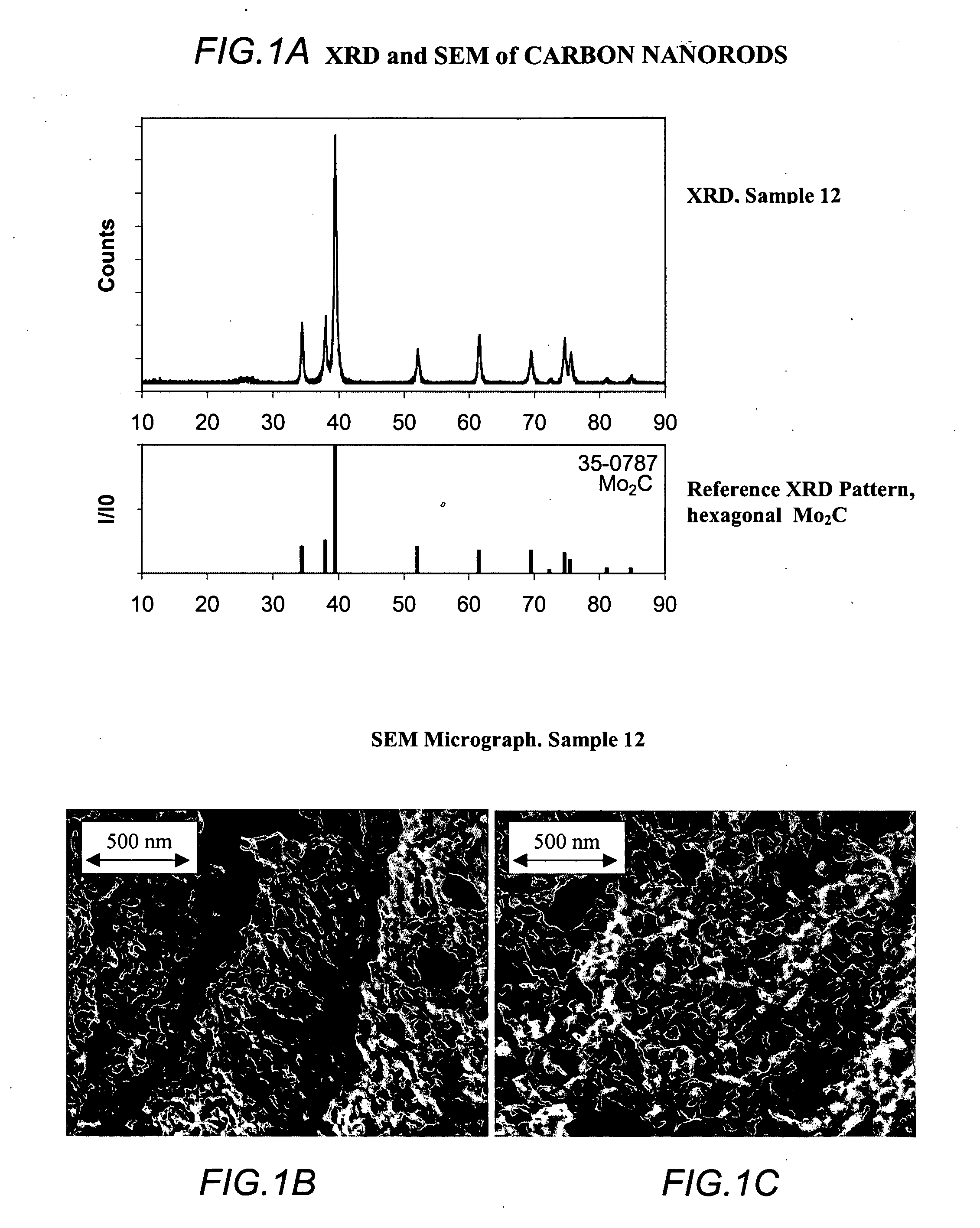

Method of using carbide and/or oxycarbide containing compositions

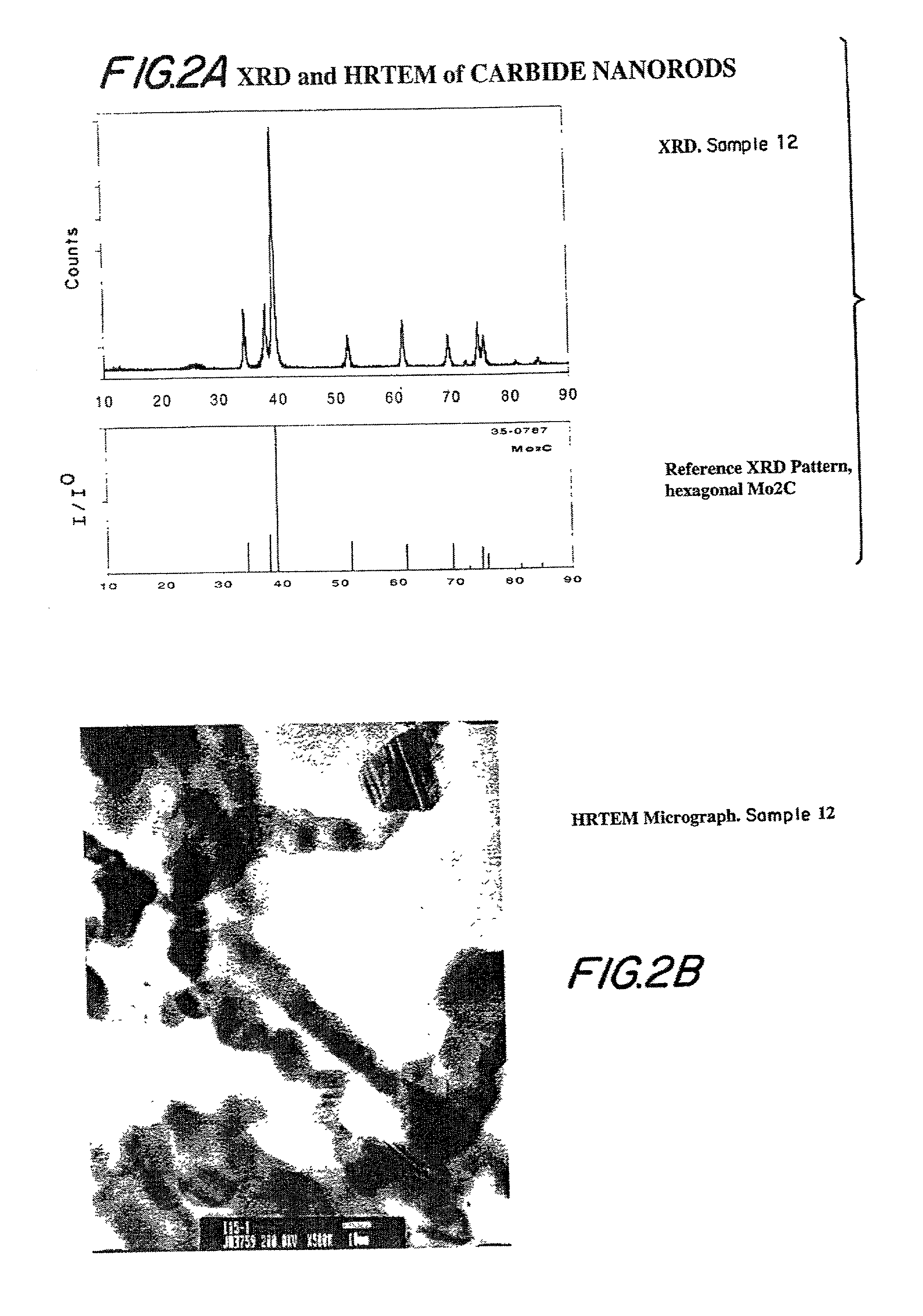

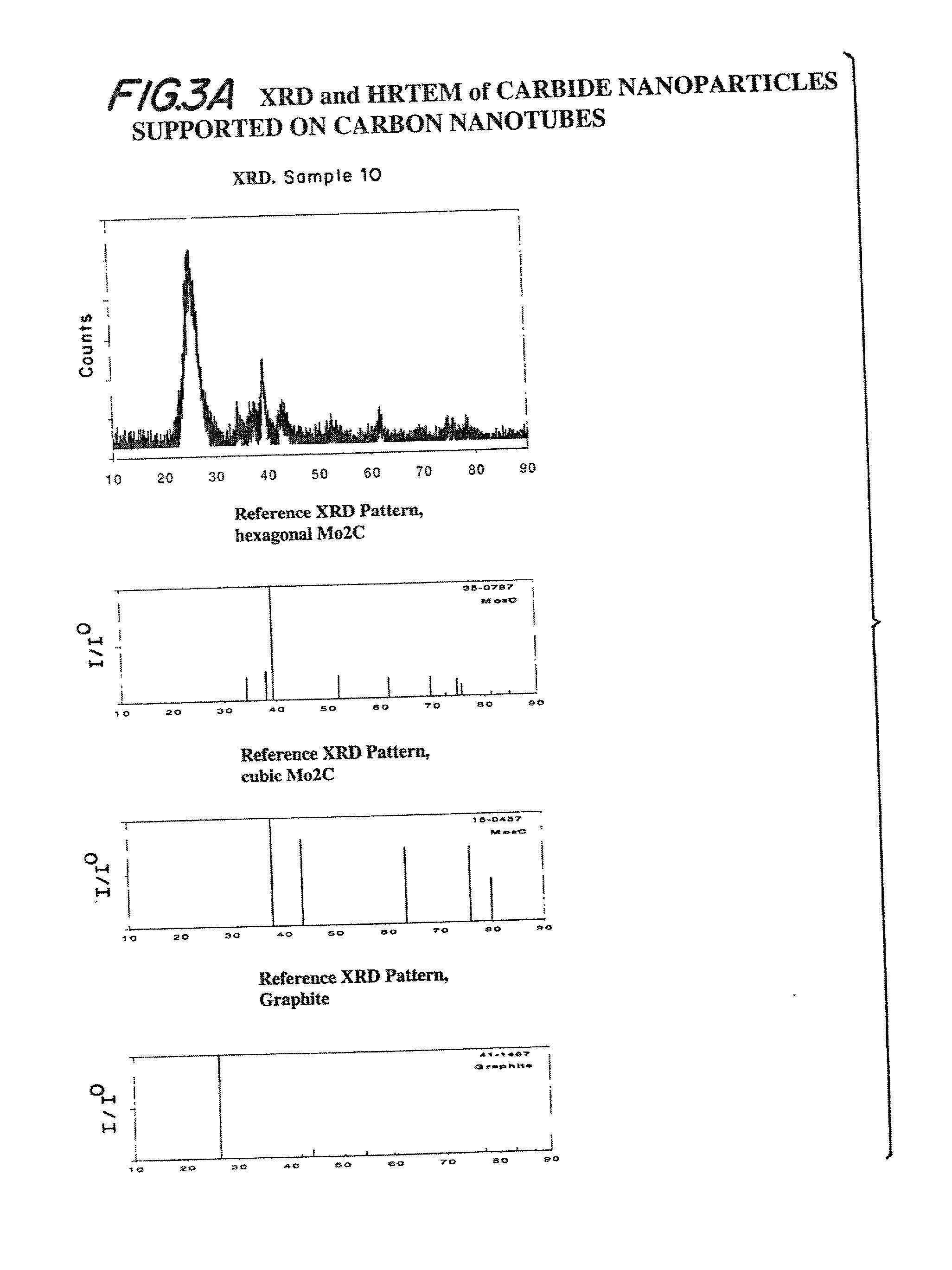

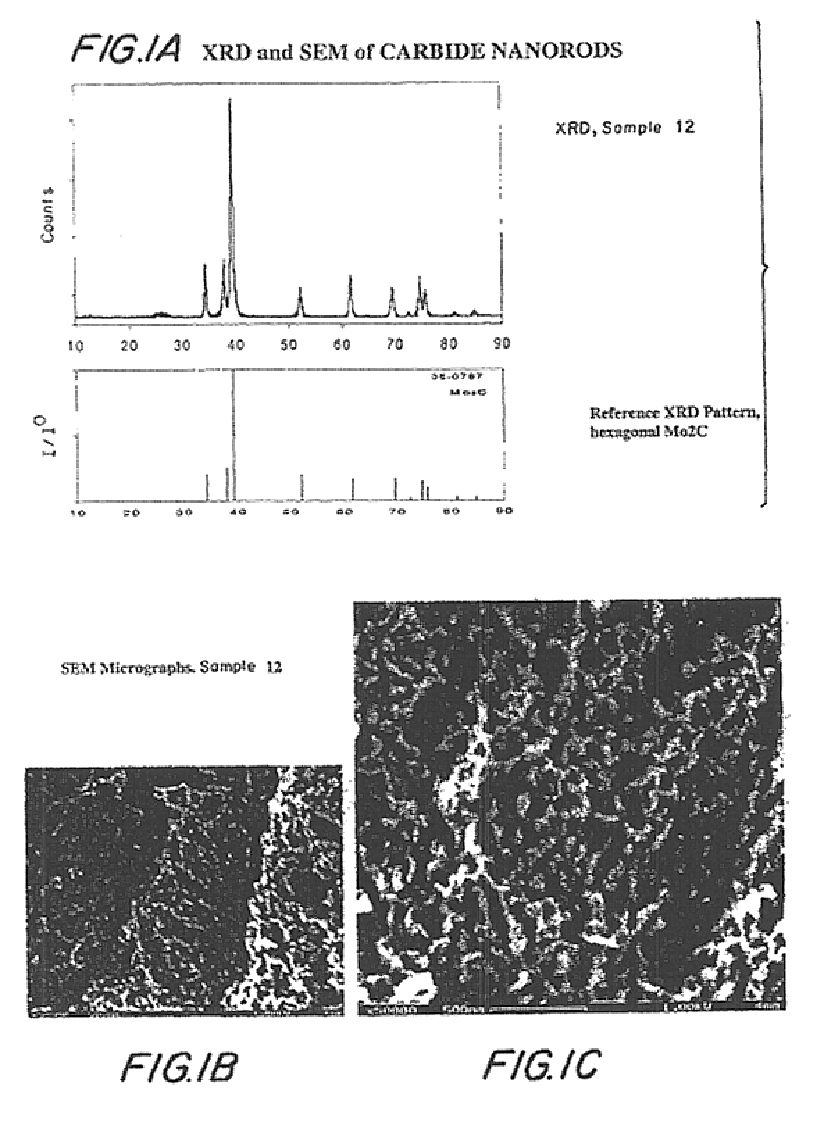

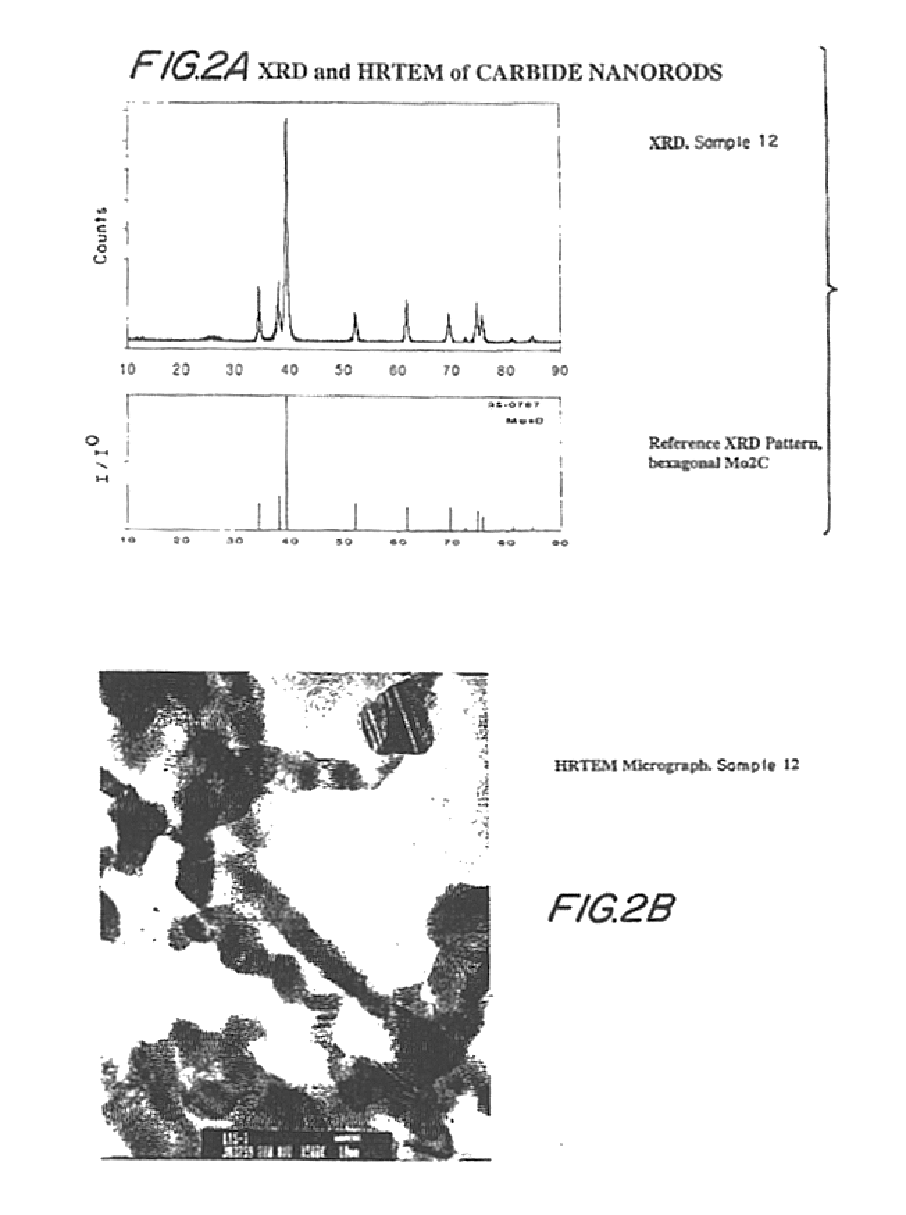

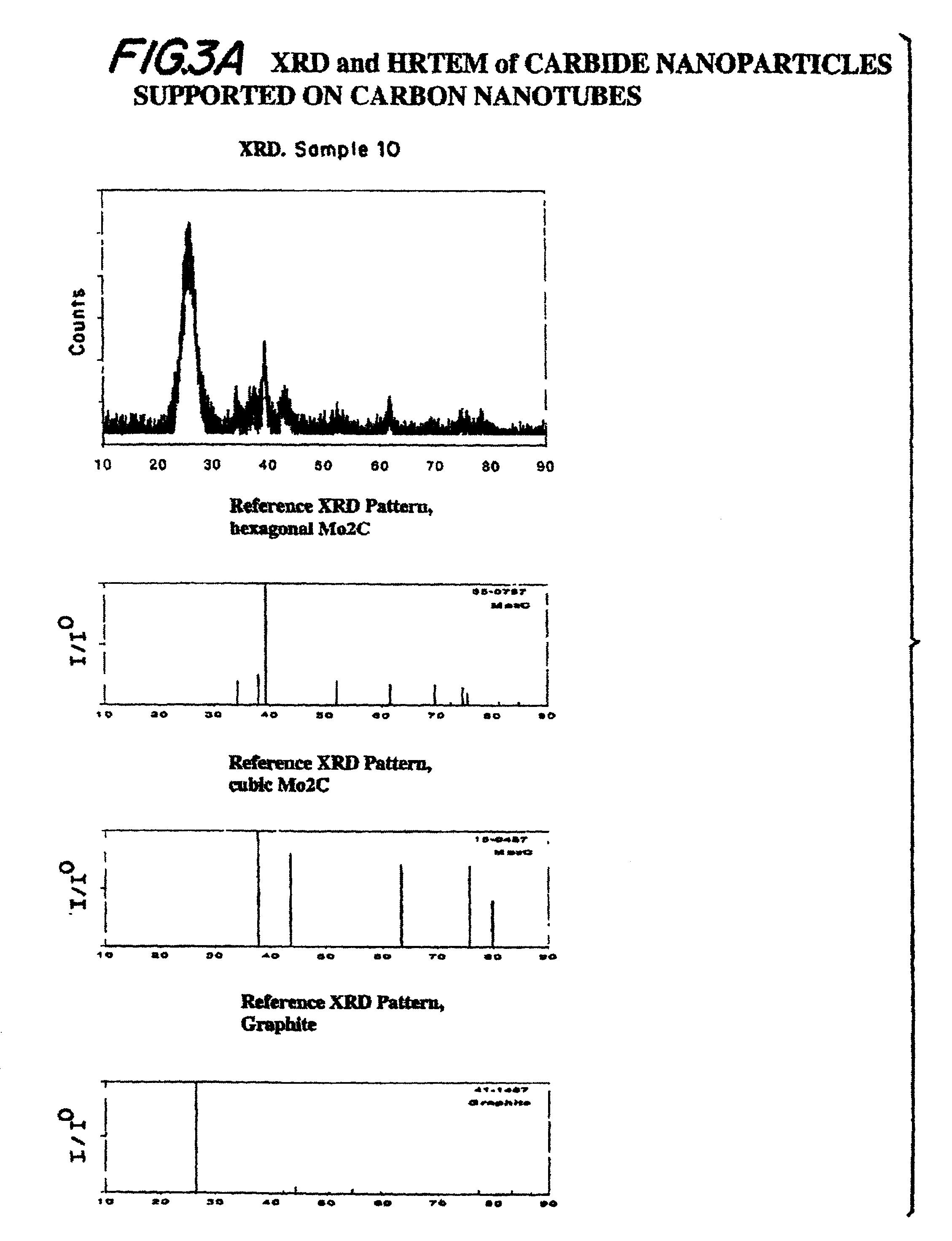

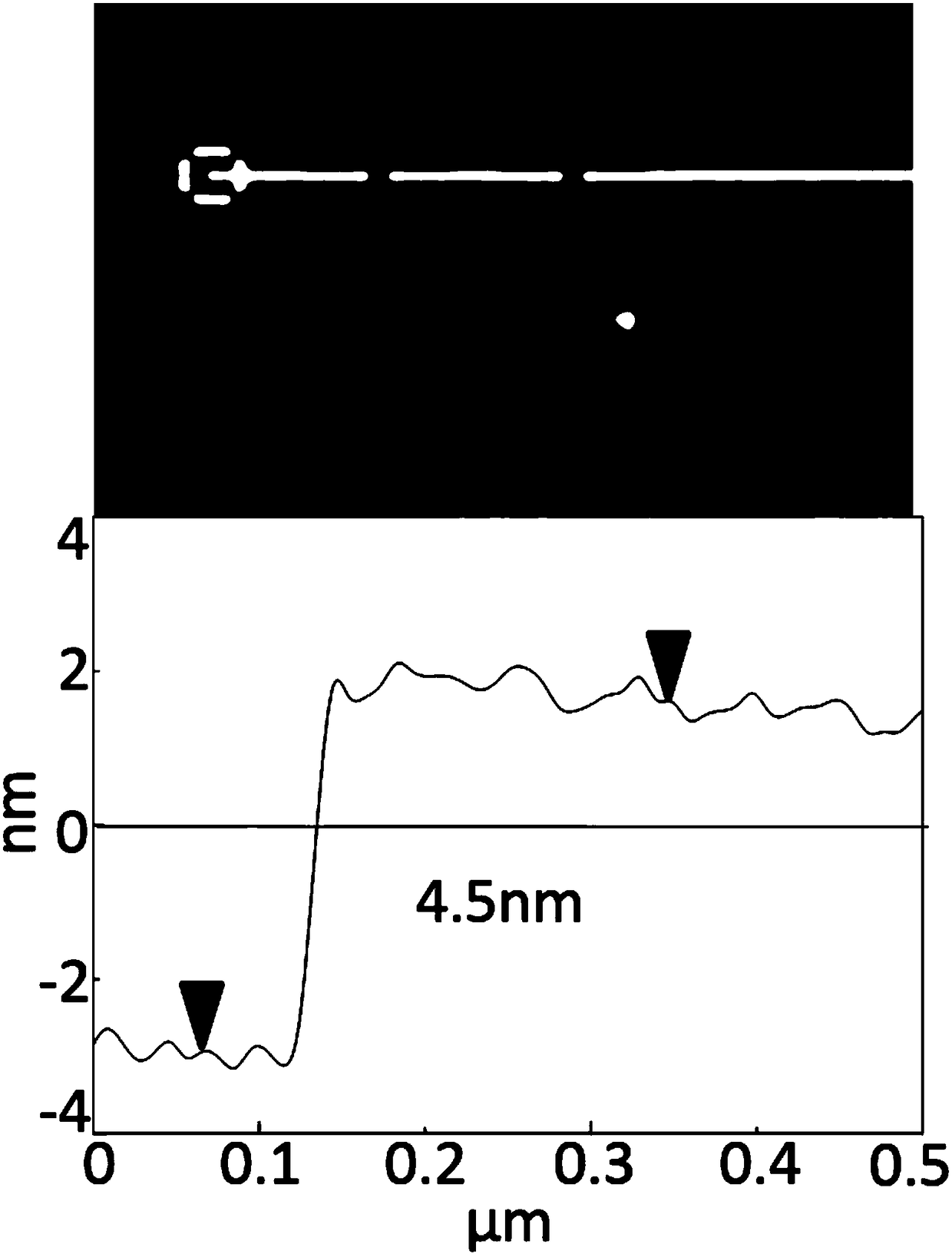

InactiveUS20020121460A1Facilitated DiffusionHigh porosityMaterial nanotechnologyHydrocarbon by isomerisationFluid phaseChemical reaction

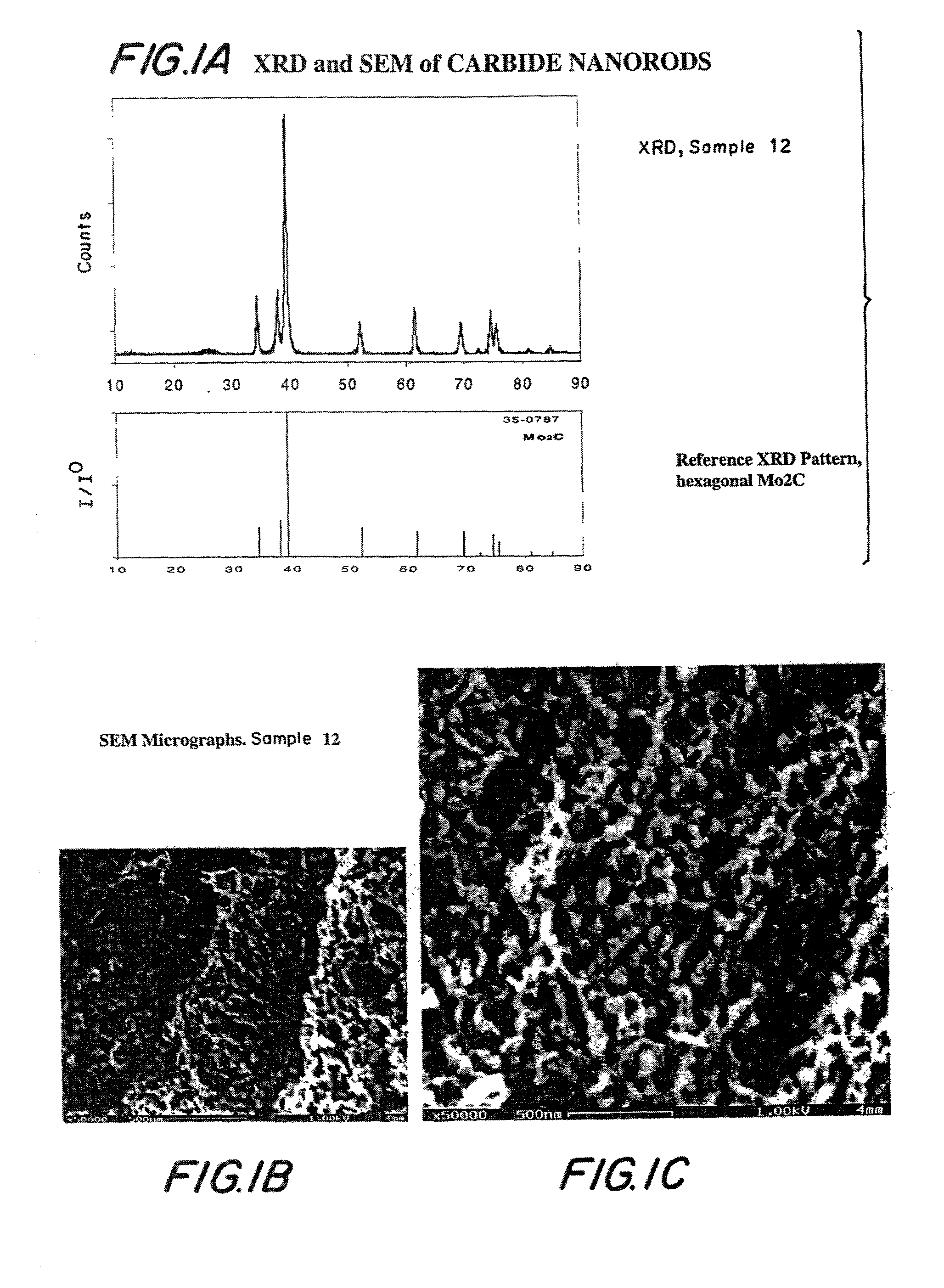

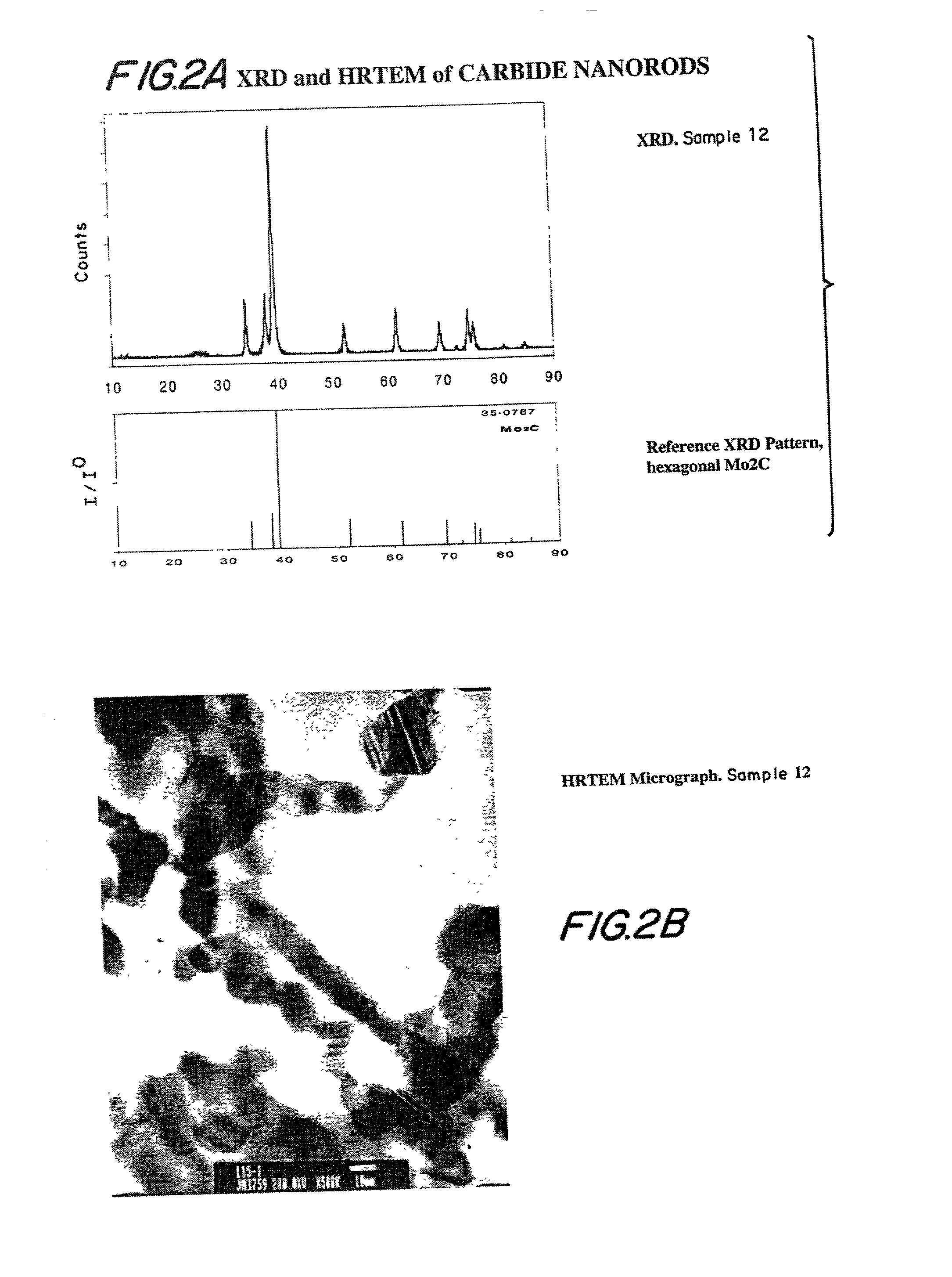

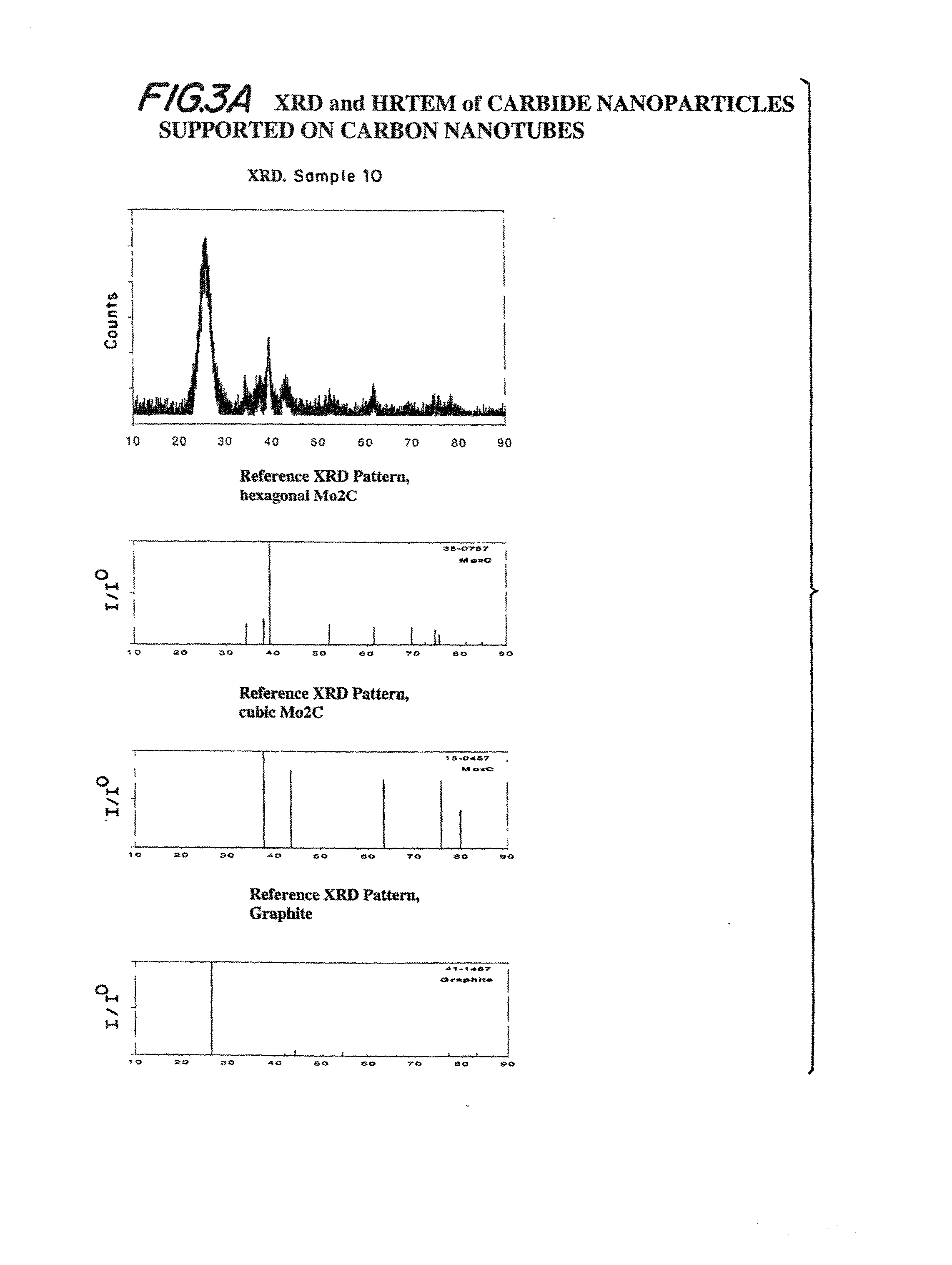

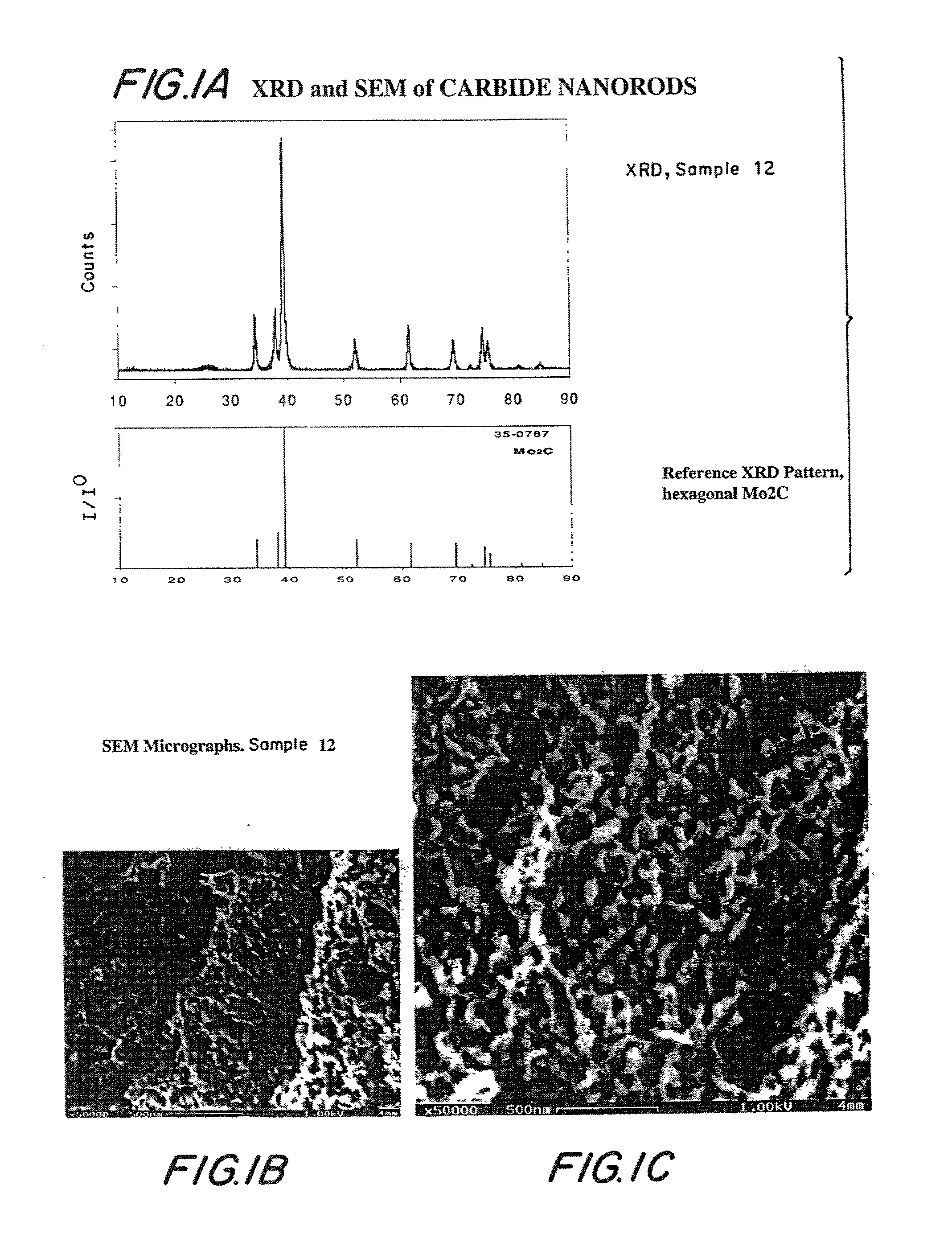

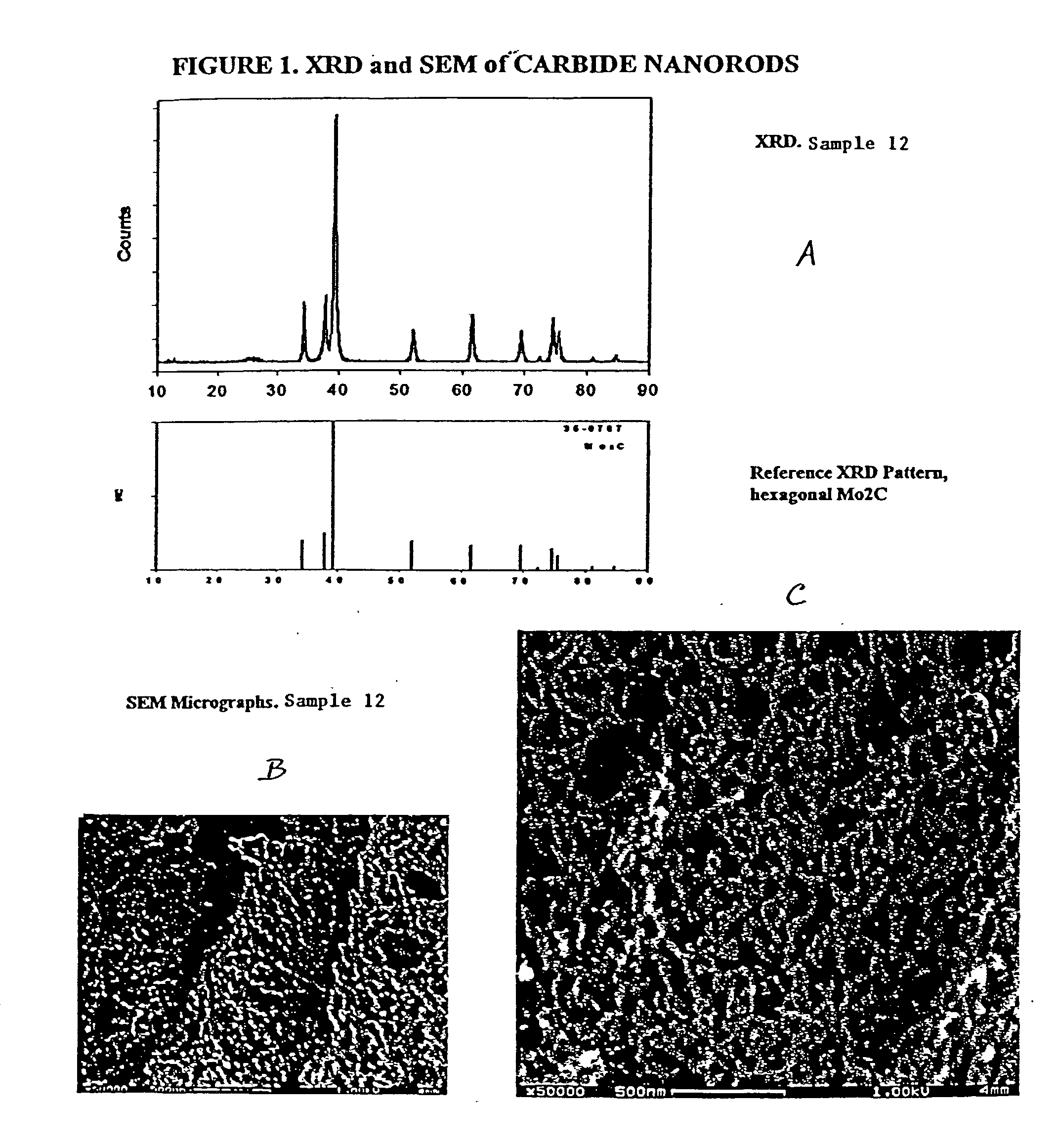

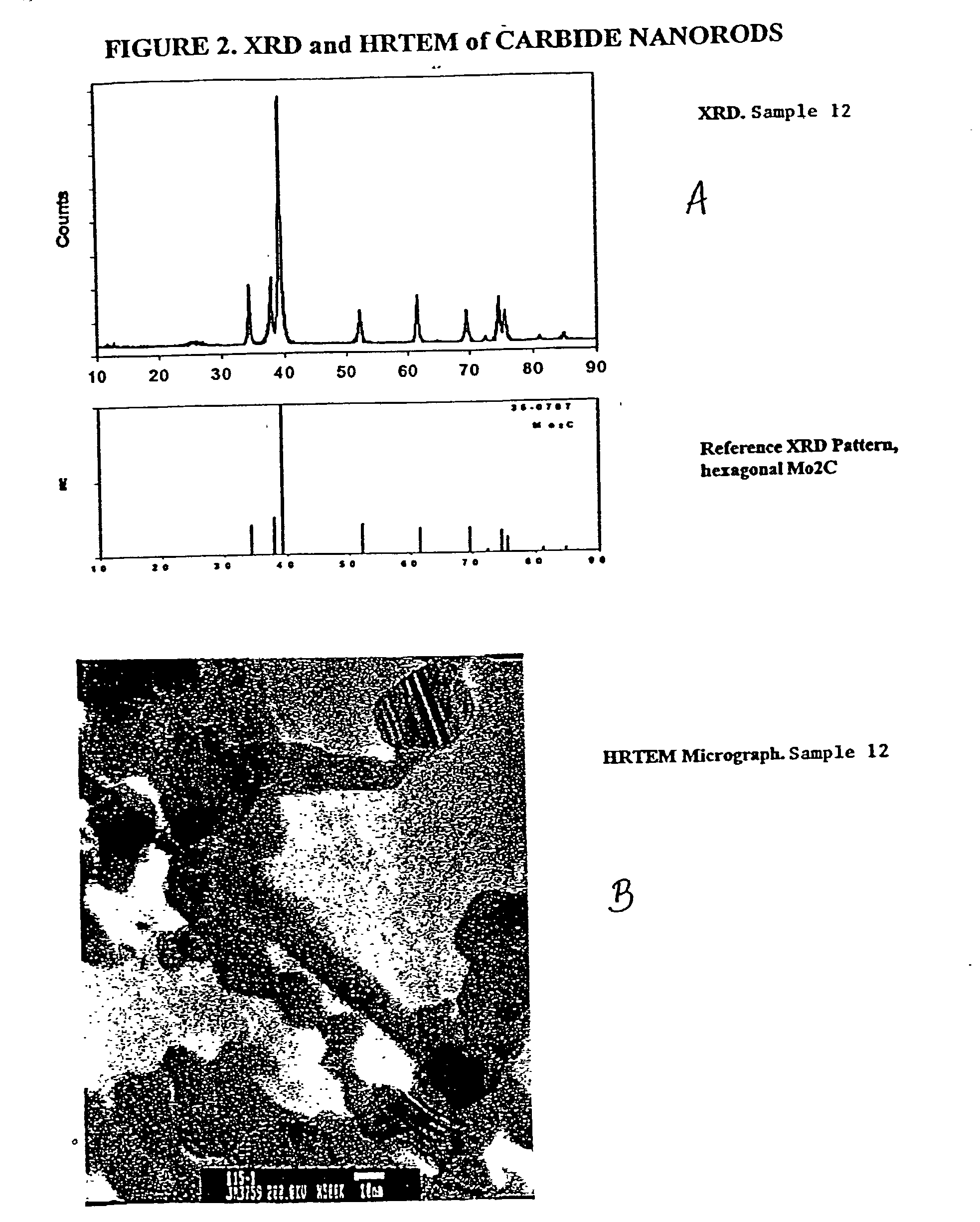

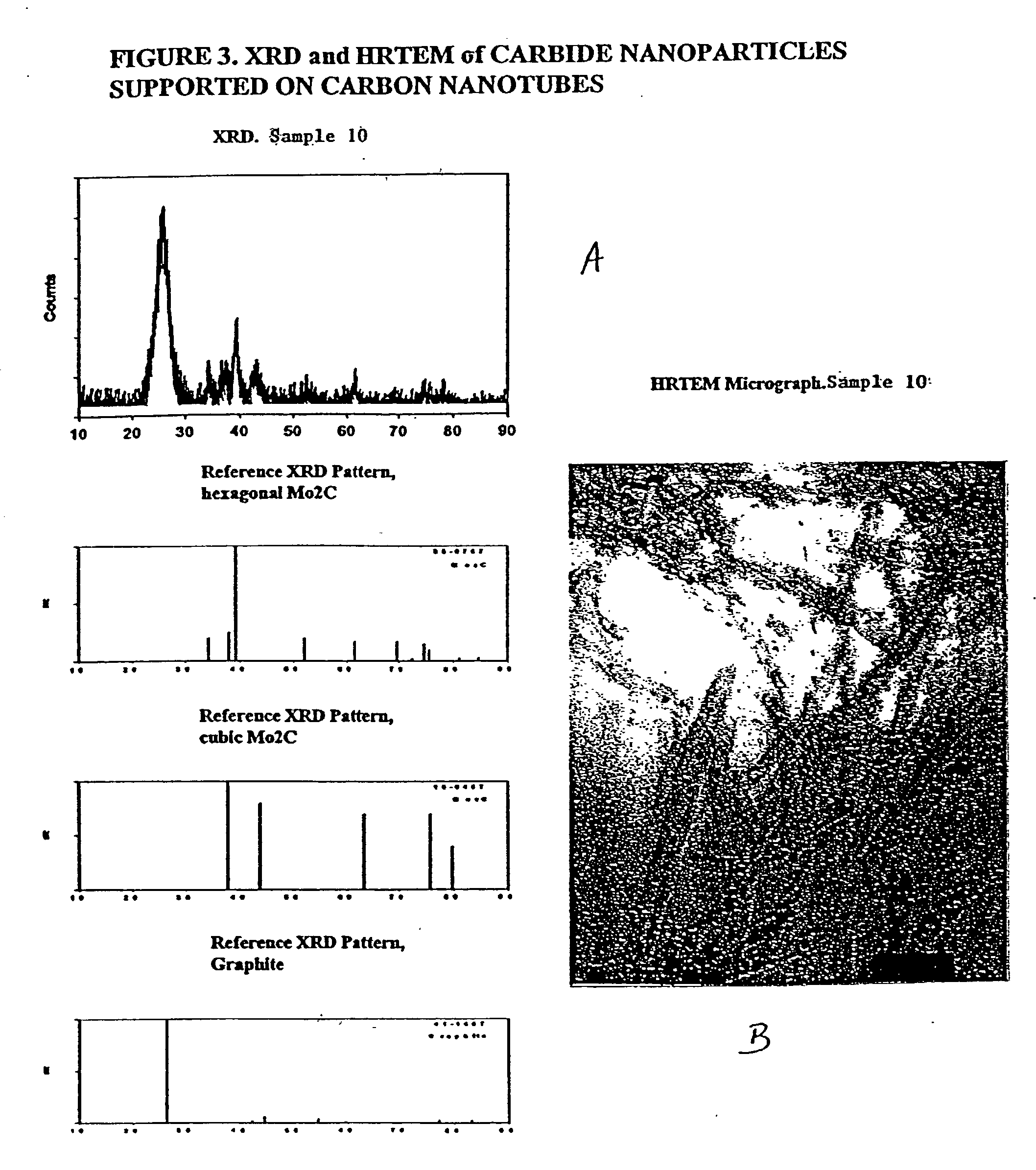

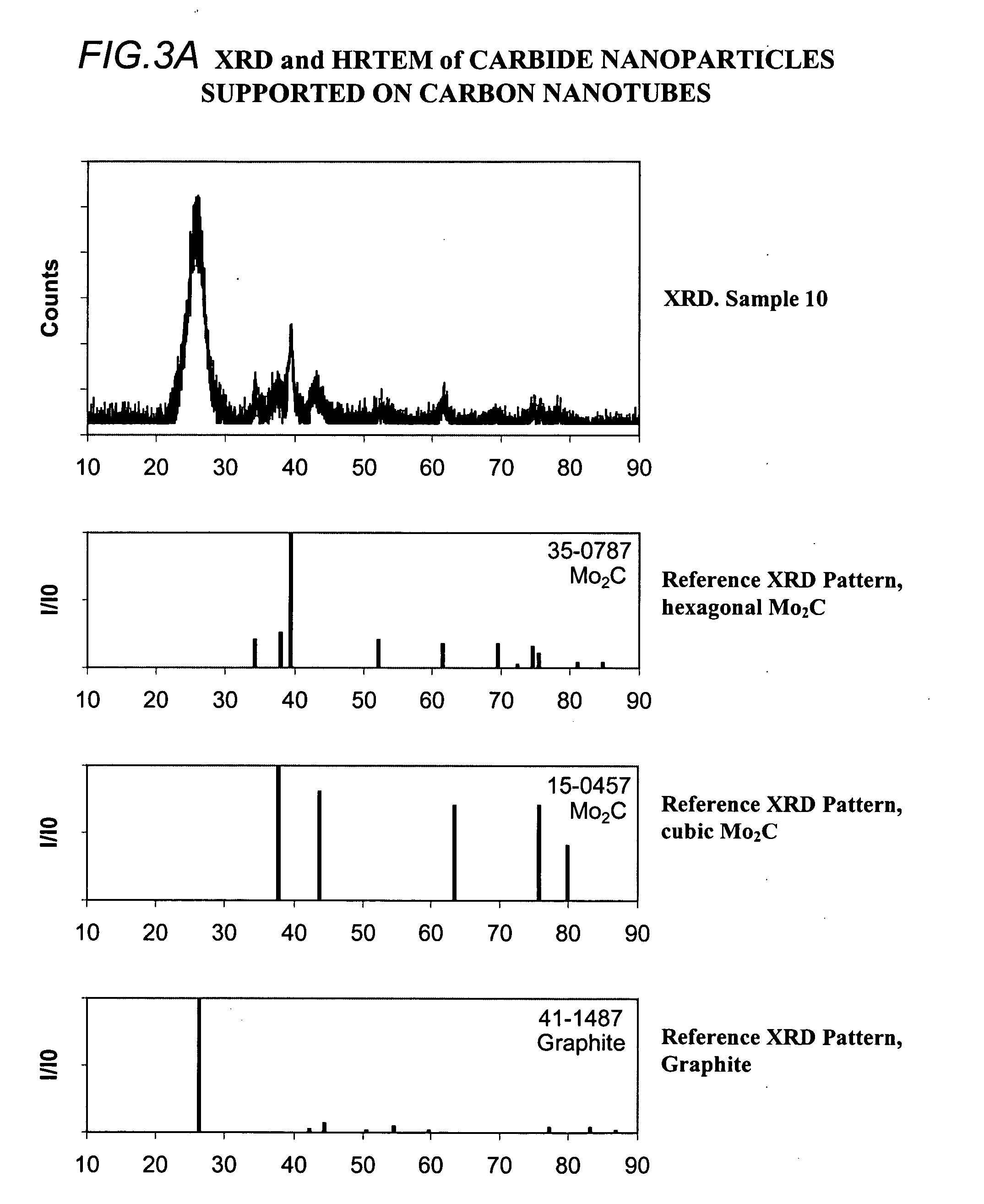

Compositions including carbide-containing nanorods and / or oxycarbide-containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including oxycarbide-containing nanorods and / or carbide containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

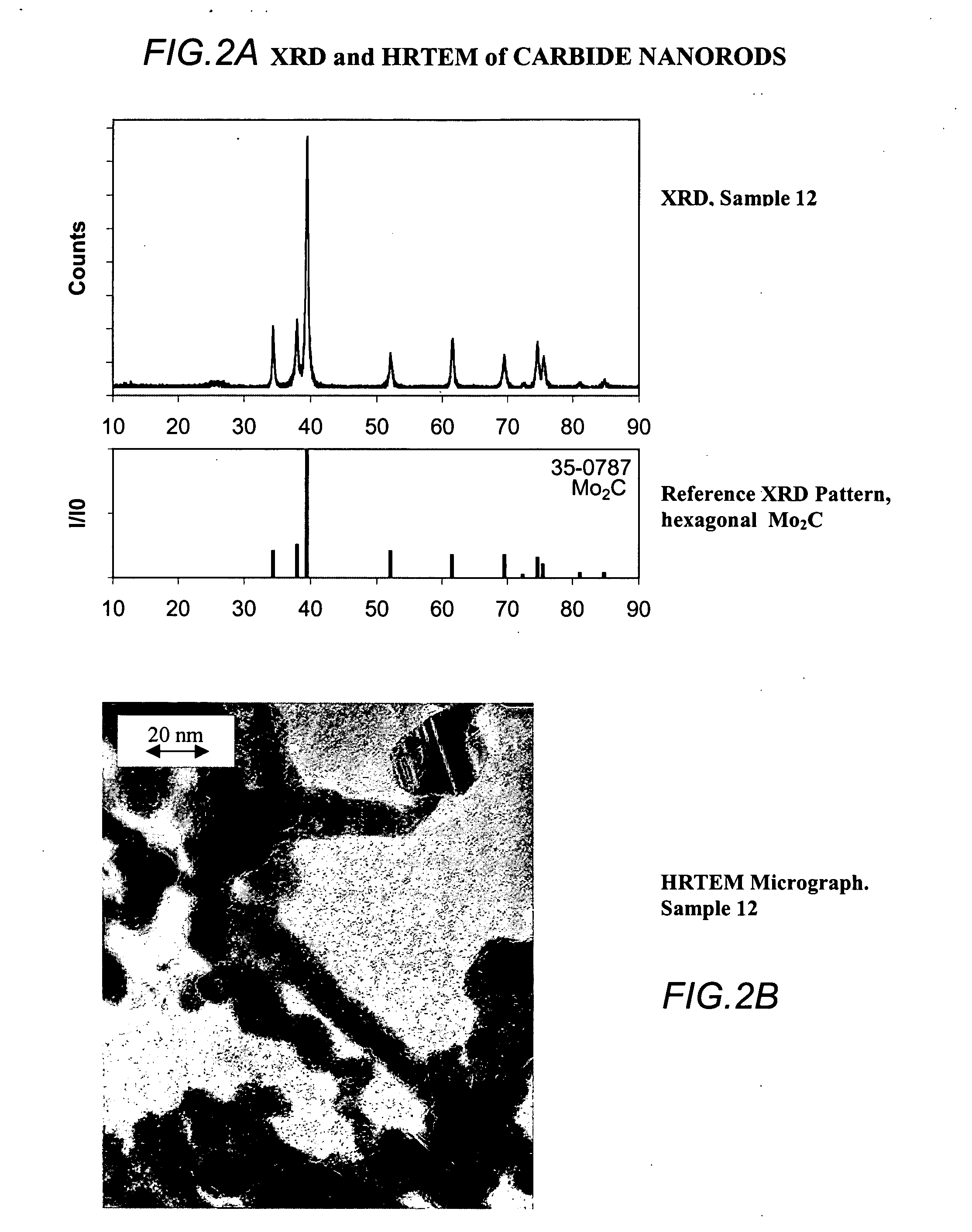

Modified carbide and oxycarbide containing catalysts and methods of making and using thereof

InactiveUS20030008772A1Improve propertiesHigh selectivityMaterial nanotechnologyHydrocarbon by isomerisationChemical reactionFluid phase

Compositions including modified carbide-containing nanorods and / or modified oxycarbide-containing nanorods and / or modified carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including modified oxycarbide-containing nanorods and / or modified carbide containing nanorods and / or modified carbon nanotubes bearing modified carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

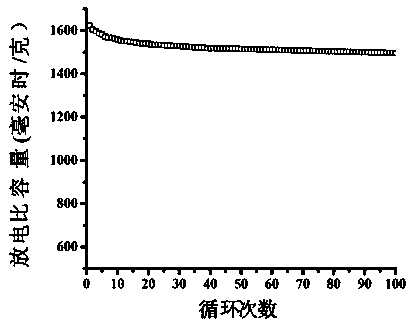

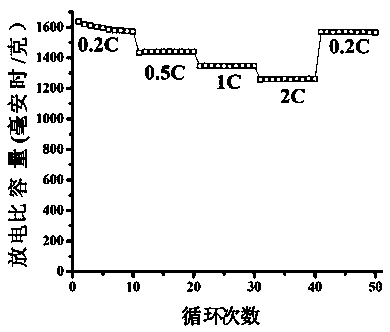

Sulfur-nitrogen doped carbon nanofiber-MXene composite material for lithium-sulfur battery and preparation method thereof

ActiveCN109449404ASmall apertureHigh porosityCell electrodesOxy/sulfo carbidesElectrospinningVolume expansion

The invention relates to a sulfur-nitrogen doped carbon nanofiber-MXene composite material for a lithium-sulfur battery and a preparation method thereof. Mxene doped polyacrylonitrile nanofiber is prepared by an electrospinning technology, a nitrogen-doped carbon nanofiber-MXene composite material is obtained by high-temperature carbonization, and the sulfur-nitrogen doped carbon nanofiber-MXene composite material is prepared through sulfur doping by a ball-milling and hot melting method. When the composite material obtained by preparation is used as the positive electrode material applied toa lithium-sulfur battery, lithium polysulfide can be effectively absorbed, and the beneficial effects of suppressing a shuttle effect and reducing volume expansion during the charge-discharge processare achieved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Method for producing higher silanes

Owner:EVONIK OPERATIONS GMBH

Process to prepare mixed molded precursor material to obtain carbides, nitrites, and sulfides

InactiveUS20070286781A1Unnecessary additionImprove mechanical propertiesNickel compoundsRefining by selective hydrogenationHybrid compoundSorbent

A process to prepare multi-metal materials based on transition metals, using co-precipitation of mixed compound from solutions containing the metals, more specifically a process to prepare multi-metal materials based on transition metals, using co-precipitation, preferably seeking a condition of formation of a gel, from the mixture of precursor solutions containing the metals. The parameters of the process are set in such a way that the material is able to be molded by extrusion, obtaining extruded material with superior physico chemical properties, which may be used as an adsorbent, a catalyst or catalyst support, or even as filler in the reactor or column.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Carbide and oxycarbide based compositions, rigid porous structures including the same, methods of making and using the same

InactiveUS20030035769A1High purityIncrease resistanceMaterial nanotechnologyHydrocarbon by isomerisationPtru catalystIsomerization

Owner:HYPERION CATALYSIS INT

Method of using carbide and/or oxycarbide containing compositions

InactiveUS6809229B2Improve economyHigh purityMaterial nanotechnologyHydrocarbon by isomerisationFluid phaseChemical reaction

Compositions including carbide-containing nanorods and / or oxycarbide-containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including oxycarbide-containing nanorods and / or carbide containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

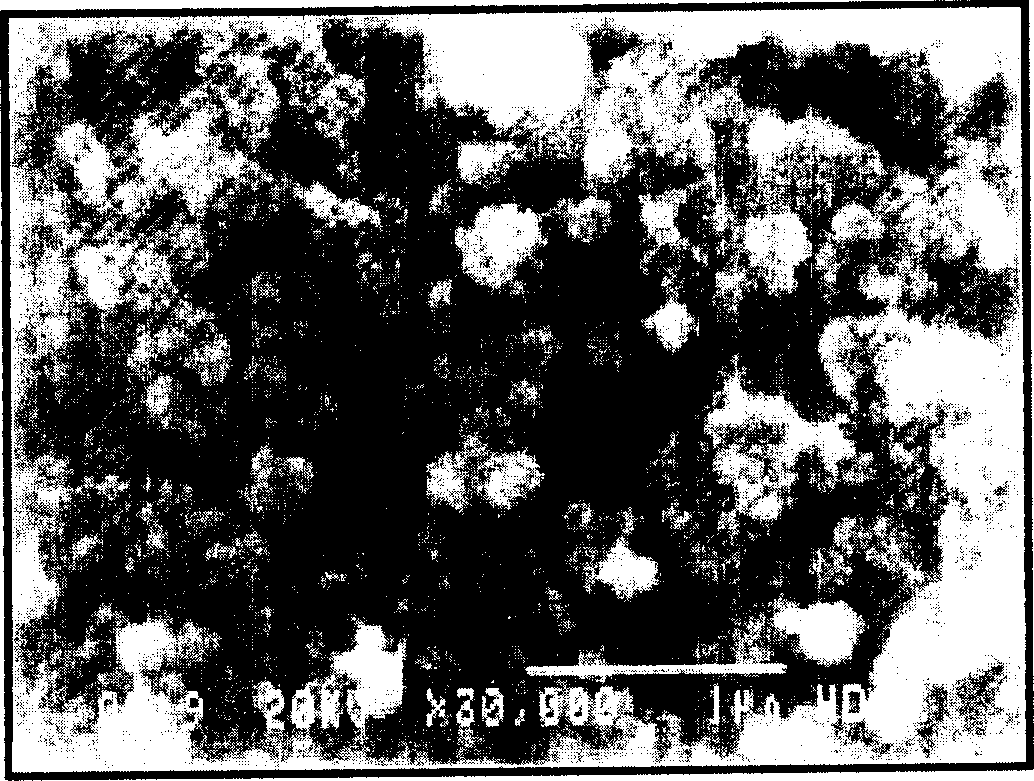

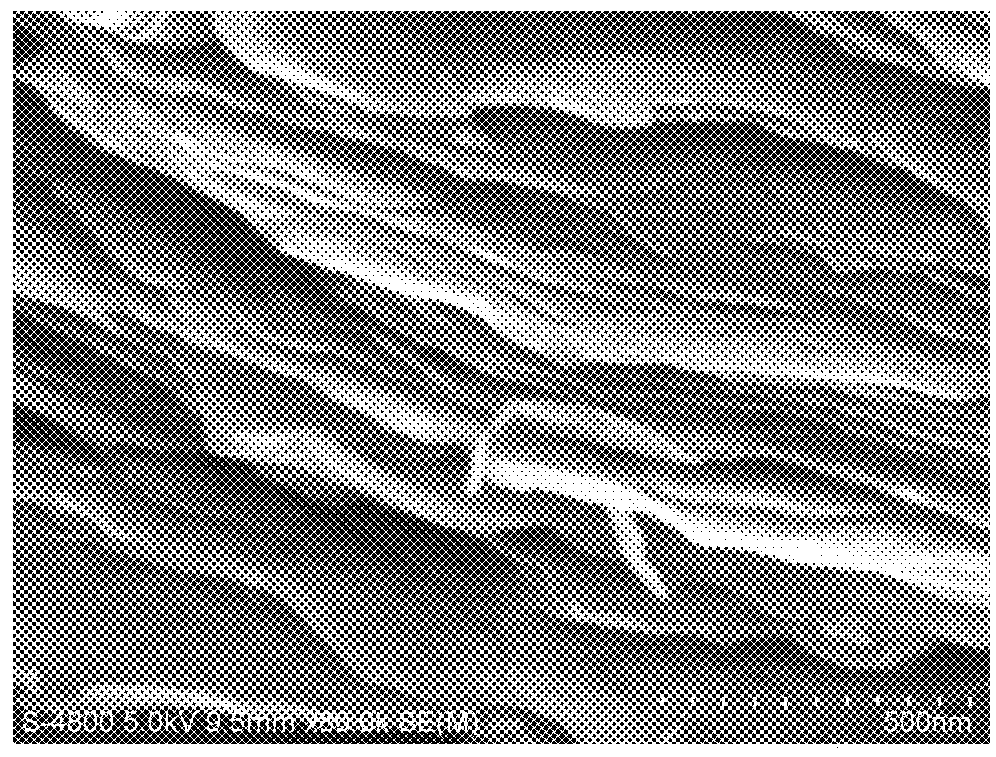

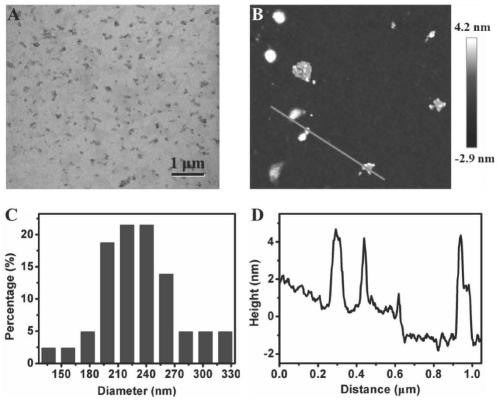

Metal-based composite material as well as preparation method and application thereof

ActiveCN108275683ACoated evenlyUniform covering thicknessElectrolytic coatingsNitrogen-metal/silicon/boron binary compoundsMetal matrix compositeStructural formula

The invention relates to a metal-based composite material which comprises a metal substrate and an MXene material membrane layer, wherein the MXene material membrane layer is arranged on the bottom surface of the metal substrate in a wrapping layer and is of a structural formula Mn+1Xn(Ts); an MXene material is prepared by removing A from a compound of a structural formula Mn+1AXn; in the formula,M, A and X are respectively three different elements; n is a positive integer; Ts is an end sealing group on the surface of the MXene material. The surface of the metal-based composite material provided by the invention is uniformly wrapped with the MXene material membrane layer, the number of sheet layers of the MXene material is only 1-15, the wrapping thickness is smaller than 250 nm, the thickness is uniform, the wrapped surface is smooth and flat, surface defects can be avoided, and the corrosion velocity of the obtained metal-based composite material is very low, that is, is only about0.06% of that of a conventional metal substrate; the invention further discloses a novel method for preparing the metal-based composite material, and by adopting the method, no complex instrument equipment is needed, and the metal-based composite material can be conveniently and rapidly prepared.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

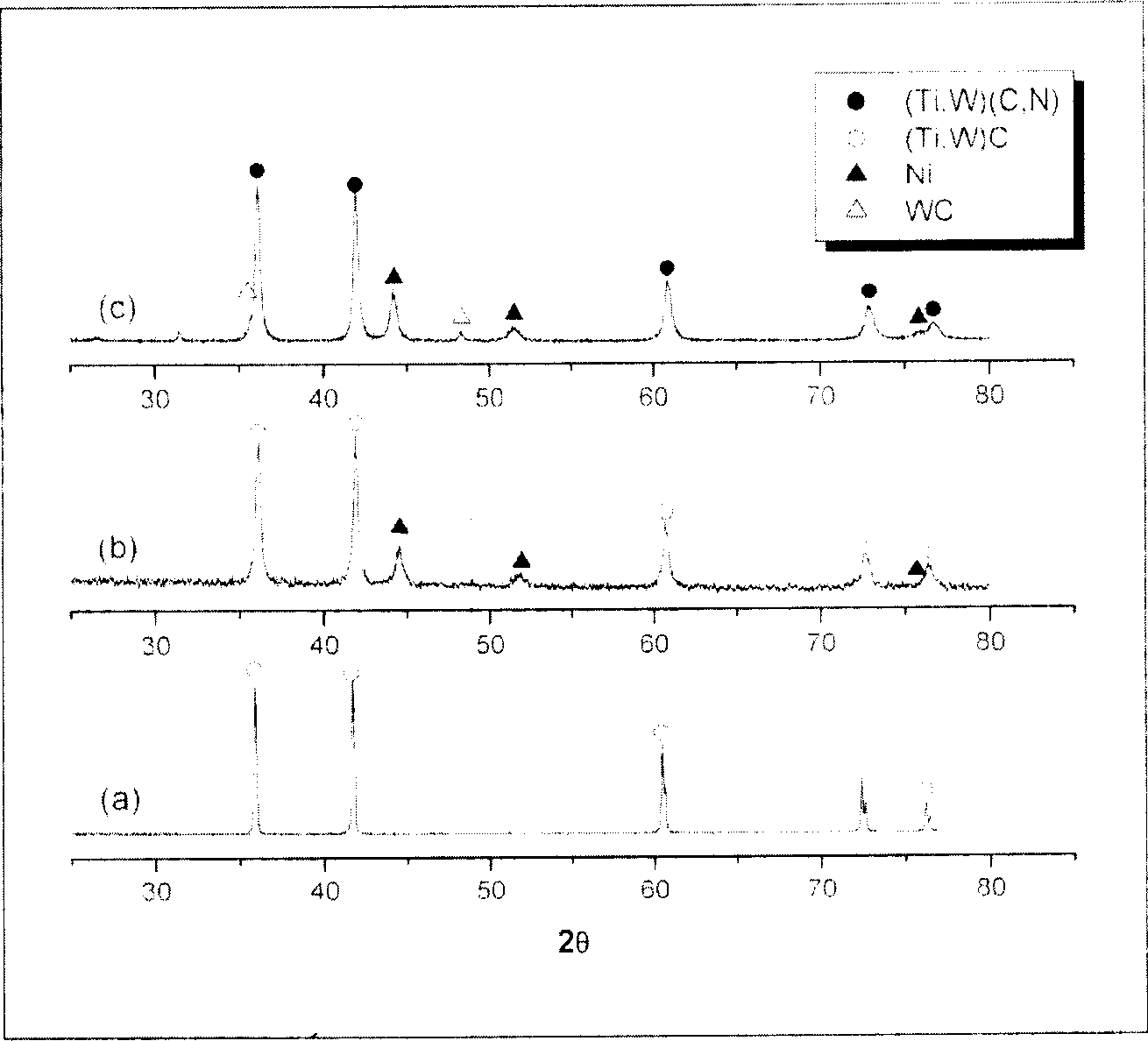

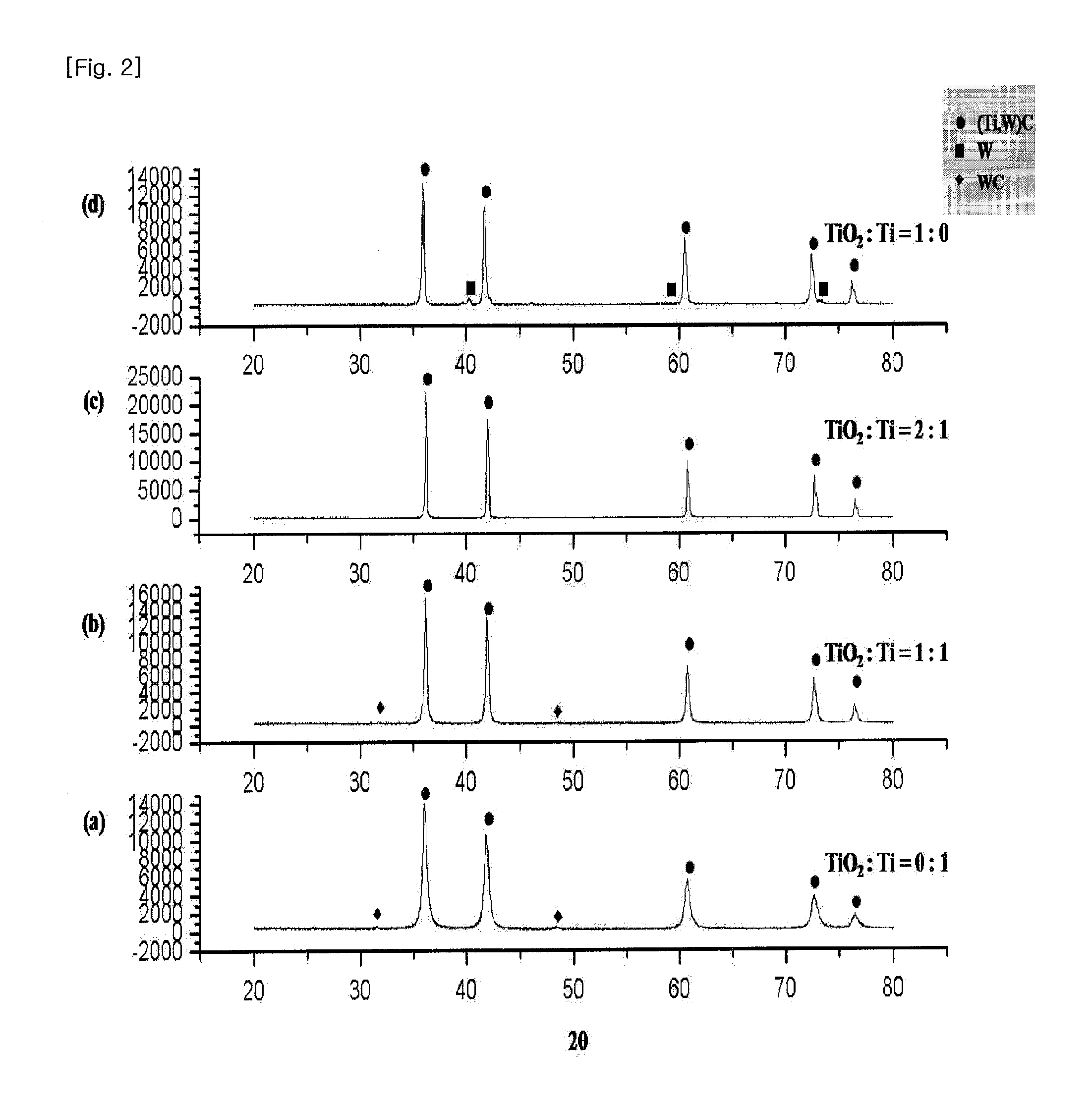

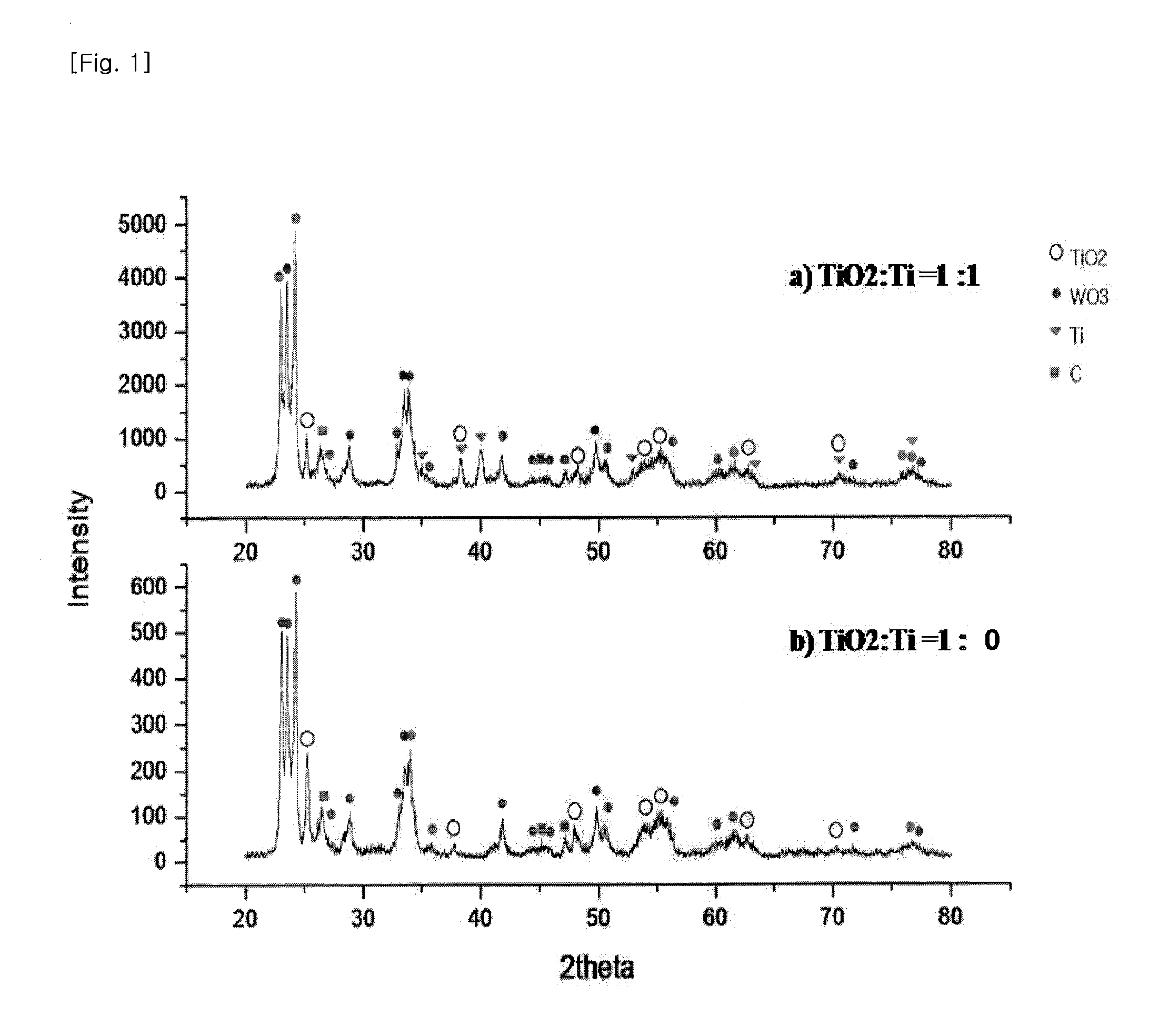

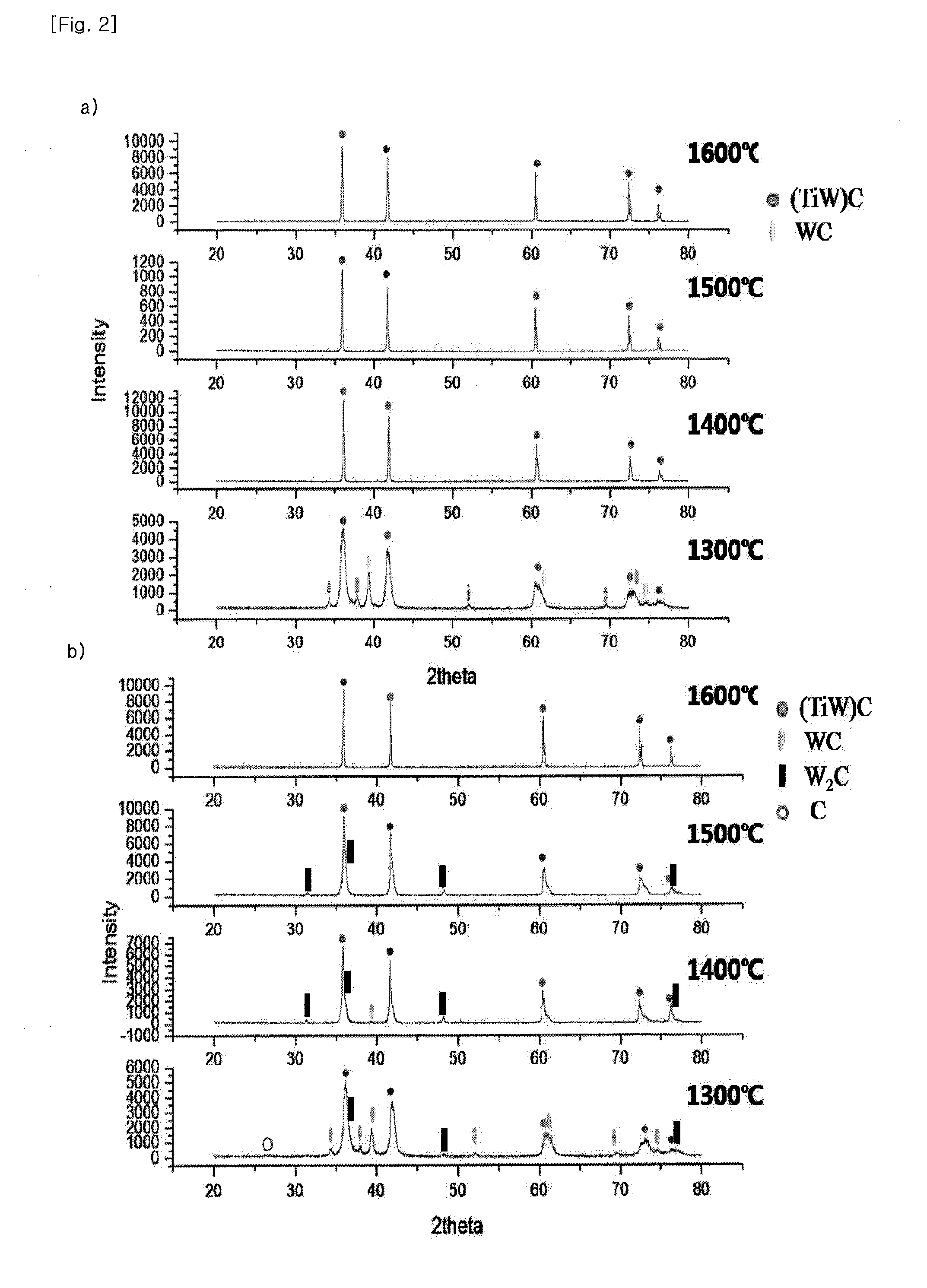

Solid-solution powder, method to prepare the solid-solution powder, ceramic using the solid-solution powder, method to prepare the ceramic, cermet powder including the solid-solution powder, method to

Disclosed are a solid-solution powder, a method for preparing the solid-solution powder, a ceramic using the solid-solution powder, a method for preparing the ceramic, a cermet powder including the solid-solution powder, a method for preparing the cermet powder, a cermet using the cermet powder and a method for preparing the cermet. According to the present invention, the problem of low toughness due to high hardness that conventional cermets (especially TiC or Ti(CN) based cermet) have is resolved because a complete solid-solution phase without core / rim structure can be obtained as a microstructure, and wherein further increased the hardness as well as the toughness, thereby substantially and considerably increasing general mechanical properties of materials using the ceramic or the cermet and thus substituting WC-Co hard material and allowing manufacturing of cutting tools with high hardness and toughness, and wherein the complete solid-solution phase without core / rim structure can be obtained even in the reducing and carburizing condition of low temperature of 1300 DEG C or less and relatively short time, thereby increasing an efficiency of the overall process.

Owner:财团法人SEOUL大学校产学协力财团

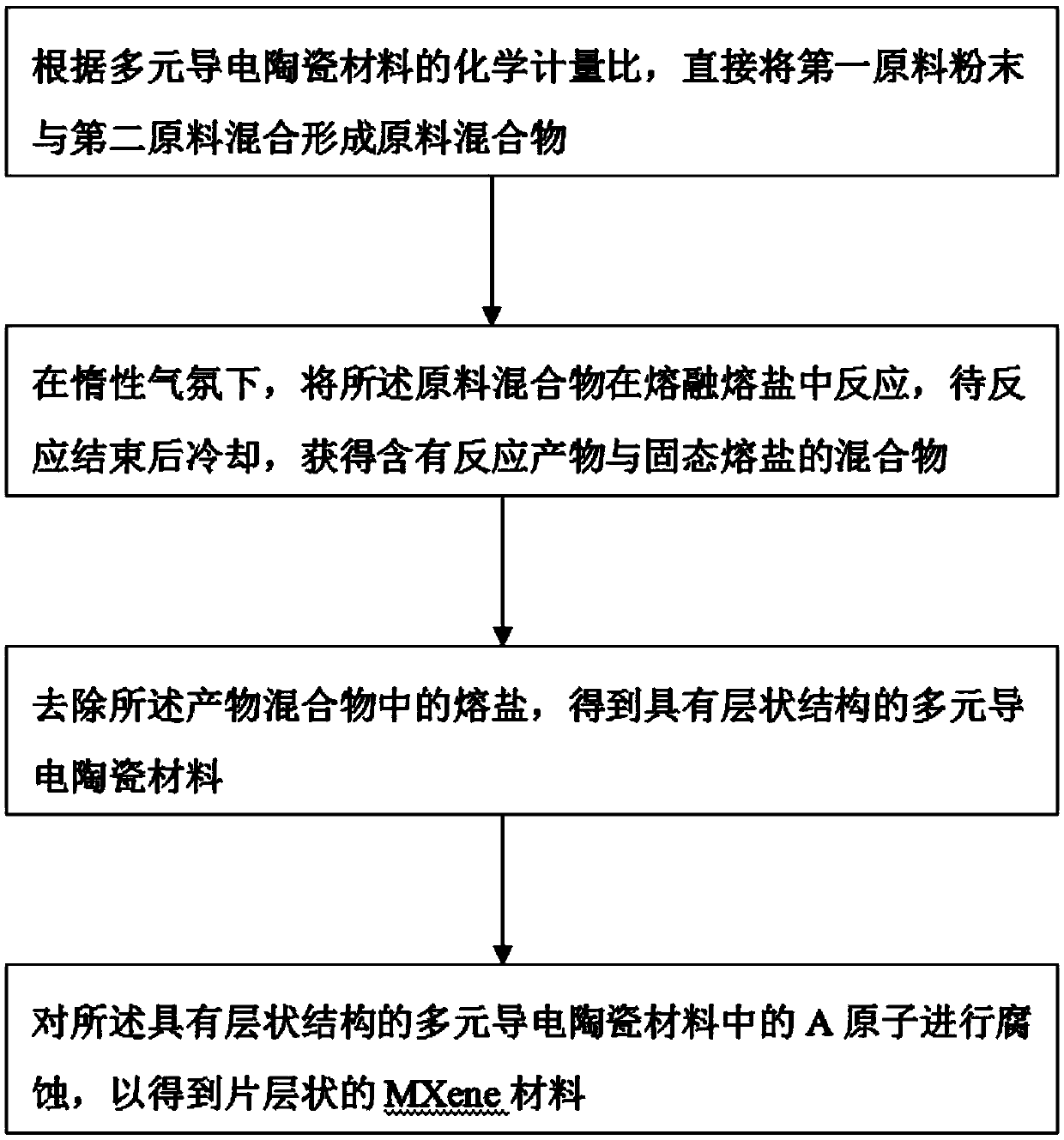

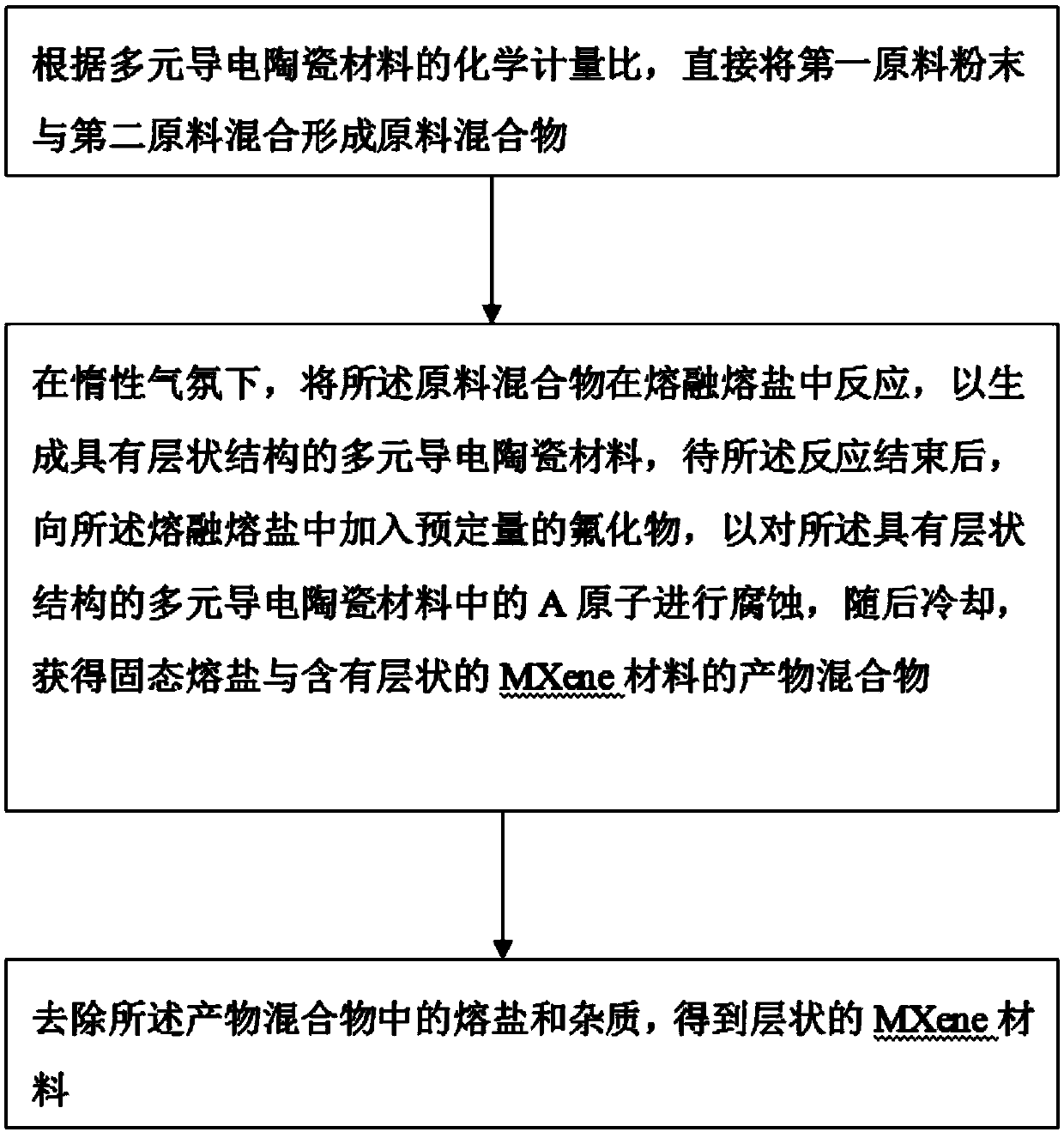

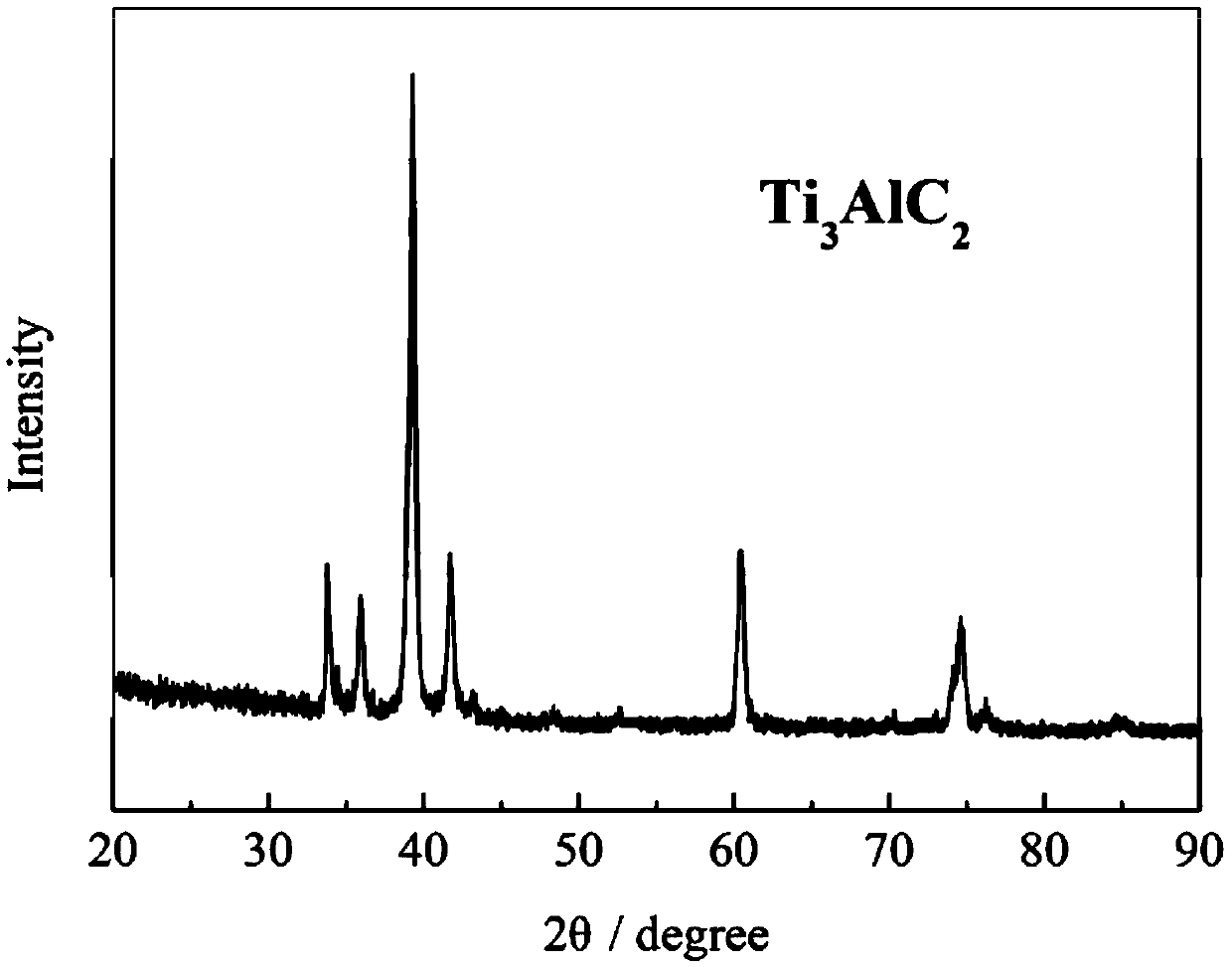

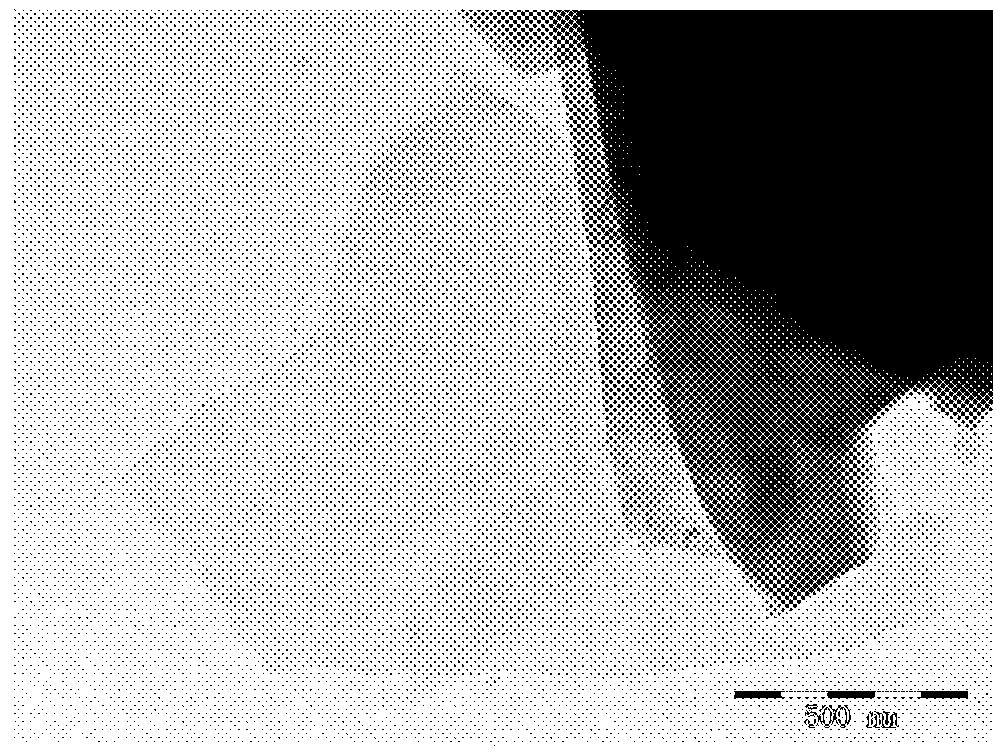

Lamellar MXene material and preparation method thereof and energy storage material

PendingCN110304632ALow costLow process costMaterial nanotechnologyCell electrodesMaterials preparationMolten salt

The invention provides a lamellar MXene material preparation method and a battery material thereof. The method includes: directly forming a raw material mixture according to a stoichiometric ratio, wherein a structural formula of a multi-element conductive ceramic material is (M1-xYx)n+1ACn, n is equal to 1, 2 or 3, x is greater than or equal to 0 and less than or equal to 1, M and Y are transition metal elements, A refers to an IIIA or IVA element with an atomic number greater than 13, and C refers to carbon; in an inert atmosphere, subjecting the raw material mixture to reaction in molten salt, and cooling after reaction is finished; removing the molten salt from a product mixture to obtain the multi-element conductive ceramic material; subjecting A atoms in the conductive ceramic material to corrosion to obtain a lamellar MXene material. At least one of problems including high synthesis temperature, complexity in preparation process and equipment, high cost and the like of an existing MXene material can be solved, and the method has advantages of quickness, high efficiency, energy saving, environmental friendliness, low cost, easiness in implementation of large-scale productionand the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

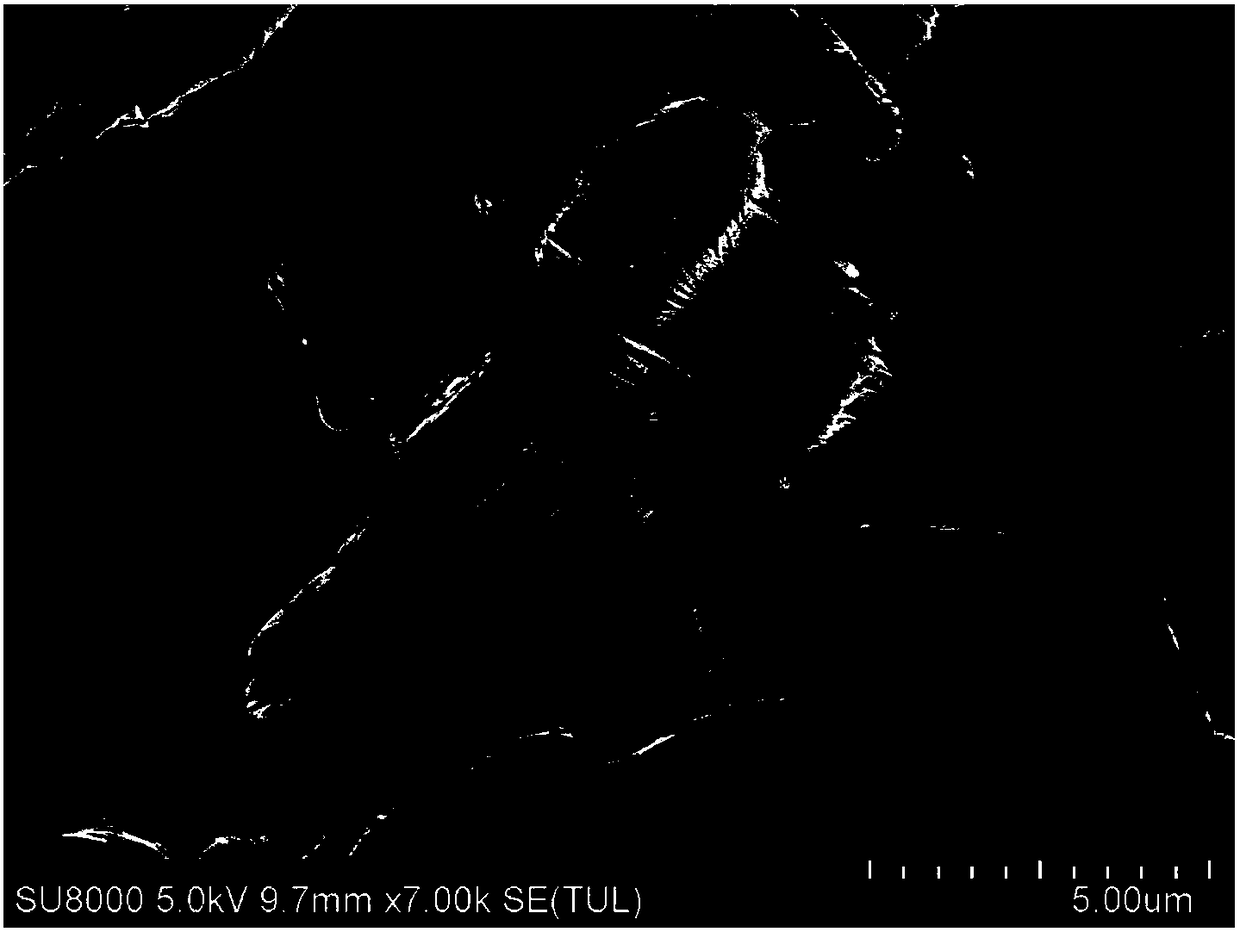

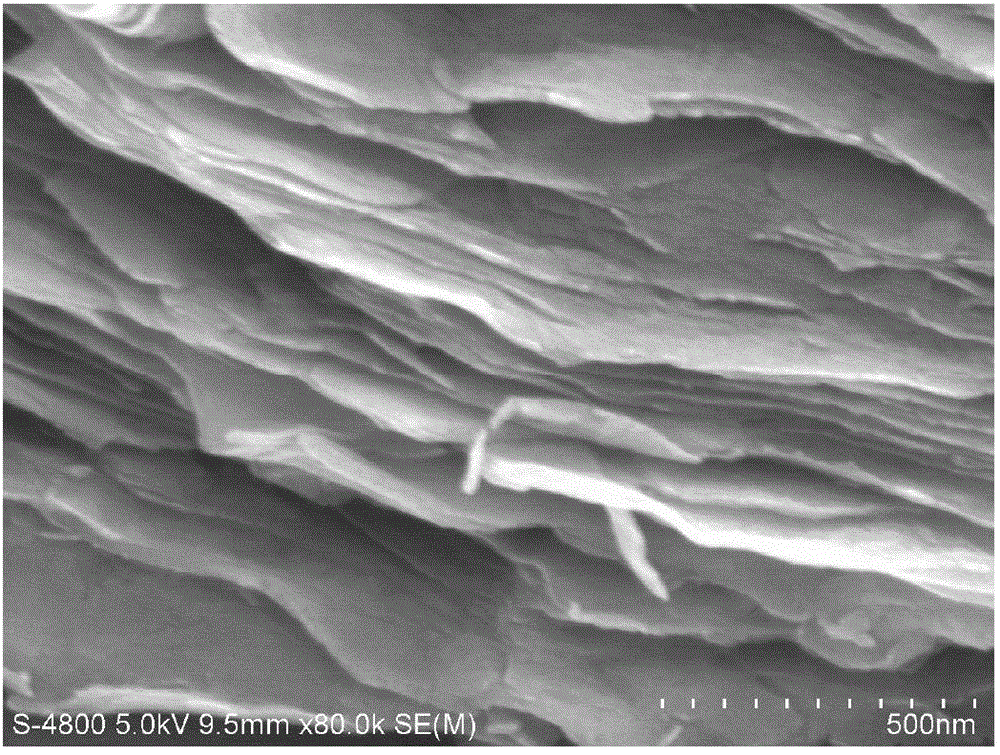

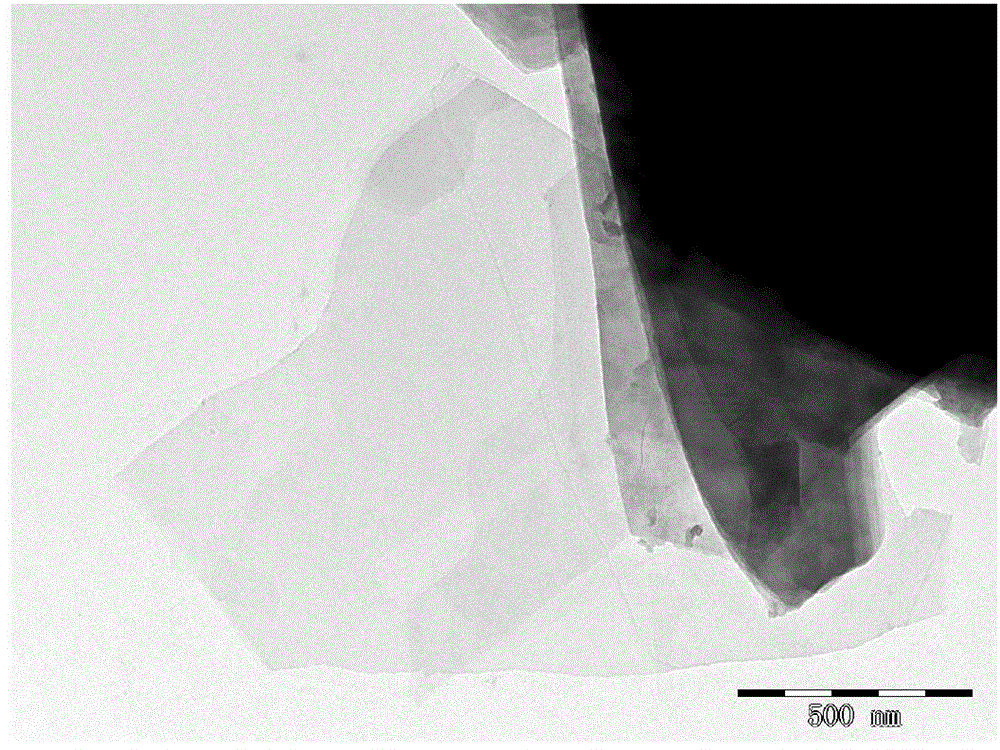

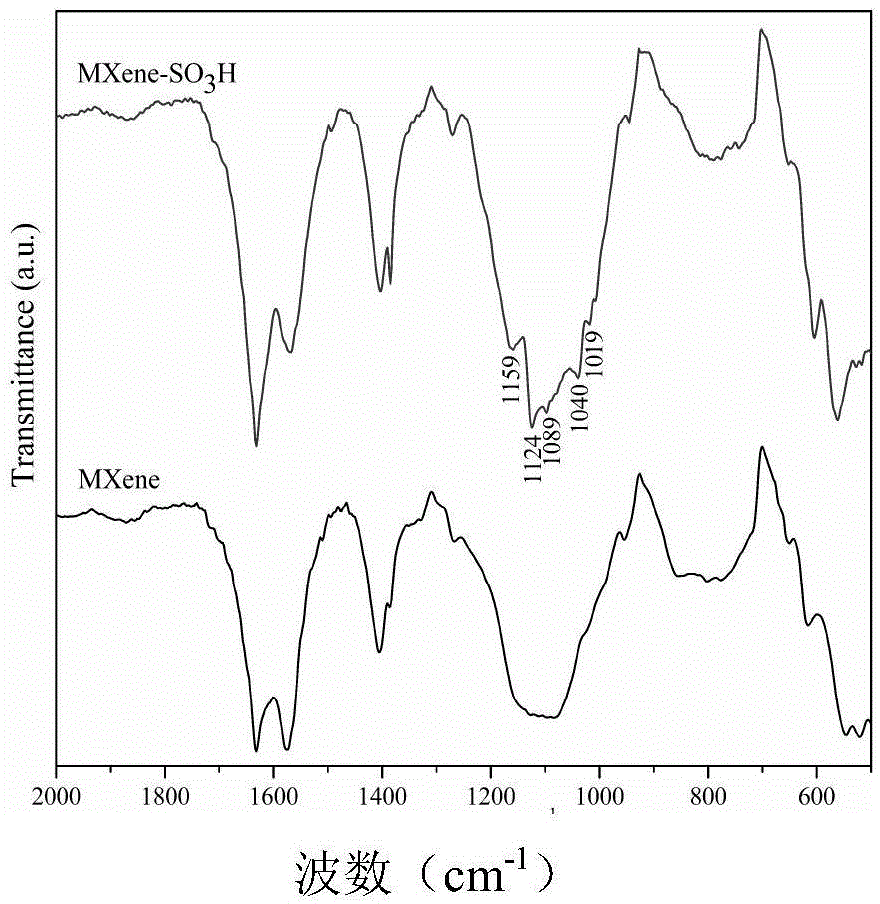

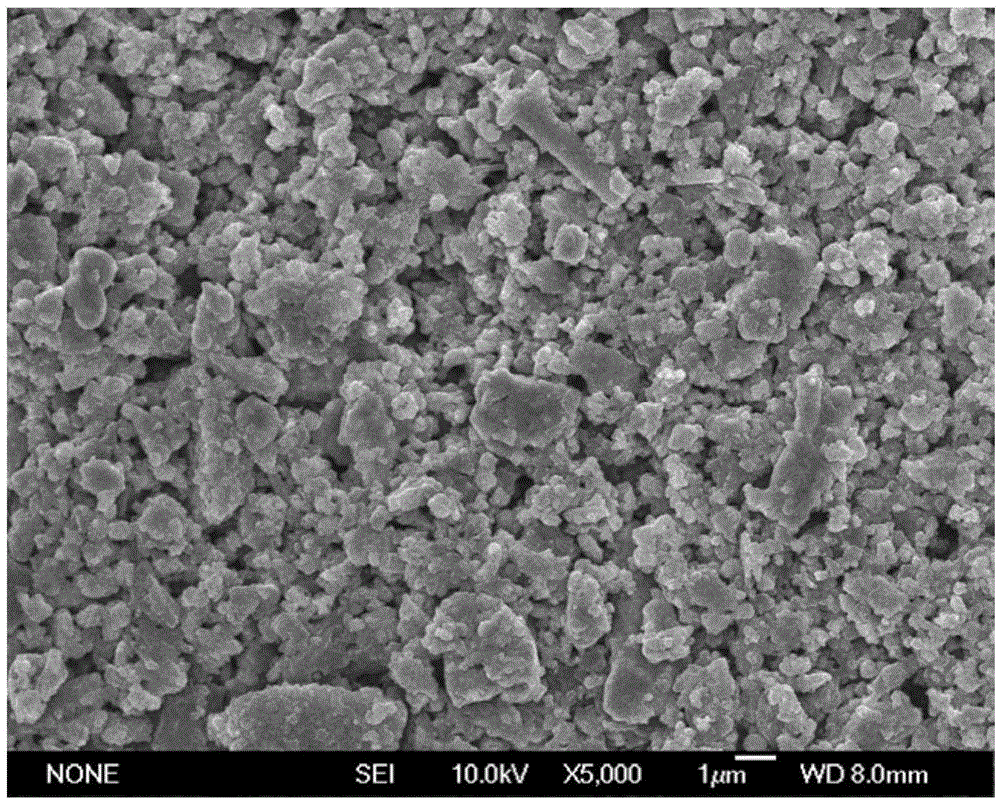

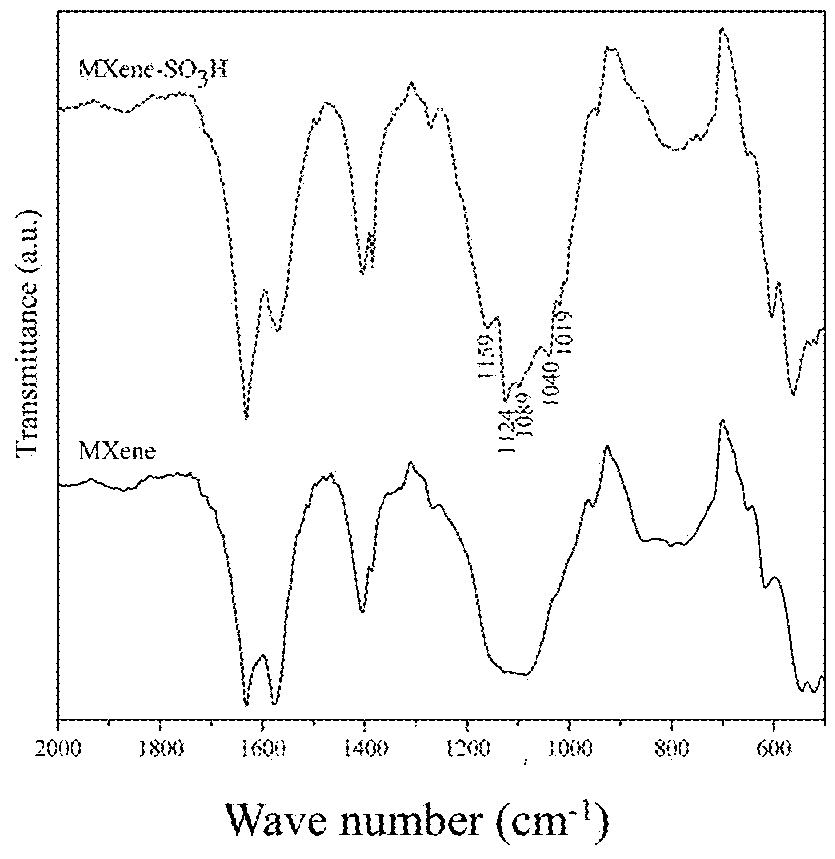

Preparation method of sulfonated two-dimensional titanium carbide nanosheet

InactiveCN104961131AGood dispersionQuality improvementMaterial nanotechnologyTitanium carbideHydrofluoric acidOrganic solvent

The invention discloses a preparation method of a sulfonated two-dimensional titanium carbide nanosheet. The preparation method comprises the following steps of preparing two-dimensional titanium carbide by utilizing aluminum atomic layers in hydrofluoric acid chemical stripping layer-shaped titanium aluminum carbide; preparing aminobenzenesulfonic acid diazonium salt; performing sulfonation reaction of the two-dimensional titanium carbide and the aminobenzenesulfonic acid diazonium salt, so as to prepare the sulfonated two-dimensional titanium carbide nanosheet. The sulfonated two-dimensional titanium carbide nano material prepared by adopting the preparation method has good dispersibility in water and common organic solvents, and the single-layer or few-layer sulfonated two-dimensional titanium carbide nanosheet with large size and high quality can be obtained after ultrasonic treatment is performed on dispersion liquid. The preparation method has the characteristics of low production cost, easiness in obtaining raw materials, simplicity and controllability in a preparation process and the like.

Owner:HOHAI UNIV

(Ti,M)C nano solid solution powder and preparation method thereof

ActiveCN107758666AHigh reactivityWell mixedMaterial nanotechnologyOxy/sulfo carbidesCrucibleHigh energy

The invention discloses (Ti,M)C nano solid solution powder and a preparation method thereof. The (Ti,M)C nano solid solution powder is prepared from the following components in percentage by weight: 35 to 79.9 percent of Ti, 0.1 to 35 percent of M and the balance of C, wherein the M is at least one of W, Mo, Cr, Ta, V and Nb. The preparation method comprises the following steps of mixing Ti powder, carbon black powder and a powdery raw material of the component M, carrying out high-energy ball milling, drying a mixture obtained after the ball milling, then putting the dried mixture into a crucible, adding a halogenating agent, afterwards, in the protection condition of an Ar gas, carrying out heat preservation for 2h to 4h at 900 to 1,000 DEG C, so as to obtain halogenating agent mixed (Ti,M)C nano solid solution powder, finally, dissolving the halogenating agent by using distilled water, centrifuging and drying, so that the (Ti,M)C nano solid solution powder is subsequently obtained.The method provided by the invention can be used for completing the carbonization and solid-solution reactions of (Ti,M)C at 900 to 1,000 DEG C; the prepared (Ti,M)C solid solution powder has the characteristic of a single-phase component and has the average particle size which is less than 100nm; the powder is high in purity and the content of the C is easy to precisely regulate and control.

Owner:自贡市泰昶硬质材料有限责任公司

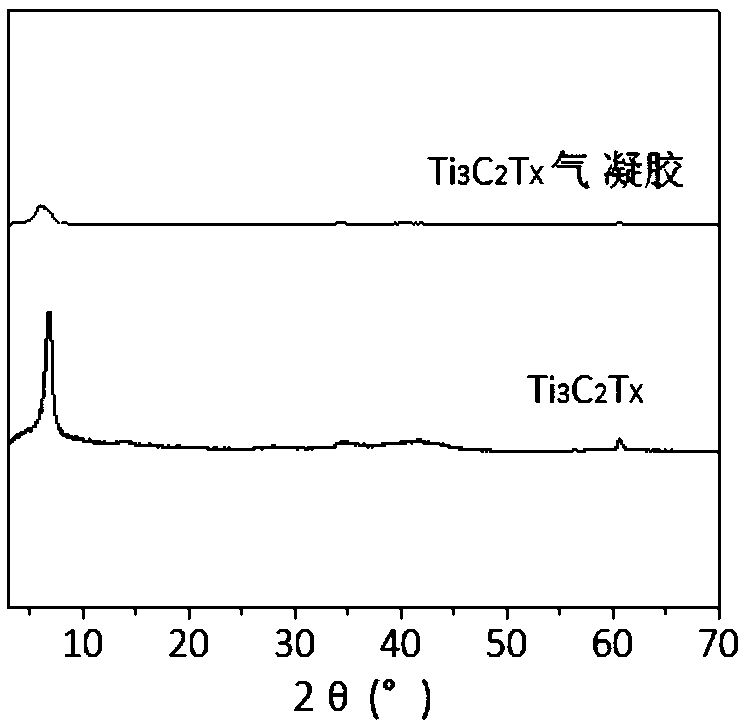

Two-dimensional transition metal carbide (nitride) aerogel as well as preparation method and application thereof

ActiveCN109437202APromote full accessEasy to operateOther chemical processesWater contaminantsTransition metal carbidesFreeze-drying

The invention discloses a two-dimensional transition metal carbide (nitride) aerogel as well as a preparation method thereof and application thereof. A HCl (Hydrochloric acid)+LiF (LithiumFluoride) solution is adopted to corrode a ternary layered carbide (nitride) MAX powder, and stable colloidal-state suspension liquid of two-dimensional transition metal carbide (nitride) nano sheets is obtainedby washing and stripping. A hydrochloric acid solution is added to break electrostatic equilibrium between the two-dimensional transitionp metal carbide (nitride) nano sheets, and the two-dimensionaltransition metal carbide (nitride) nano sheets are guided to be self-assembled to form hydrogel, and finally, vacuum freeze-drying is performed to obtain the two-dimensional transition metal carbide (nitride) aerogel. The prepared aerogel has a high specific surface area and developed holes, has adsorption capacity of 246 mg / g to lead ions, has adsorption capacity of 17 g / g to methylbenzene, and is an ideal adsorption material. The preparation method disclosed by the invention is simple and safe, is easy to control, and is suitable for large-scale industrial production; and the prepared two-dimensional transition metal carbide (nitride) aerogel has a good application prospect in the field of adsorption.

Owner:NANJING UNIV OF TECH

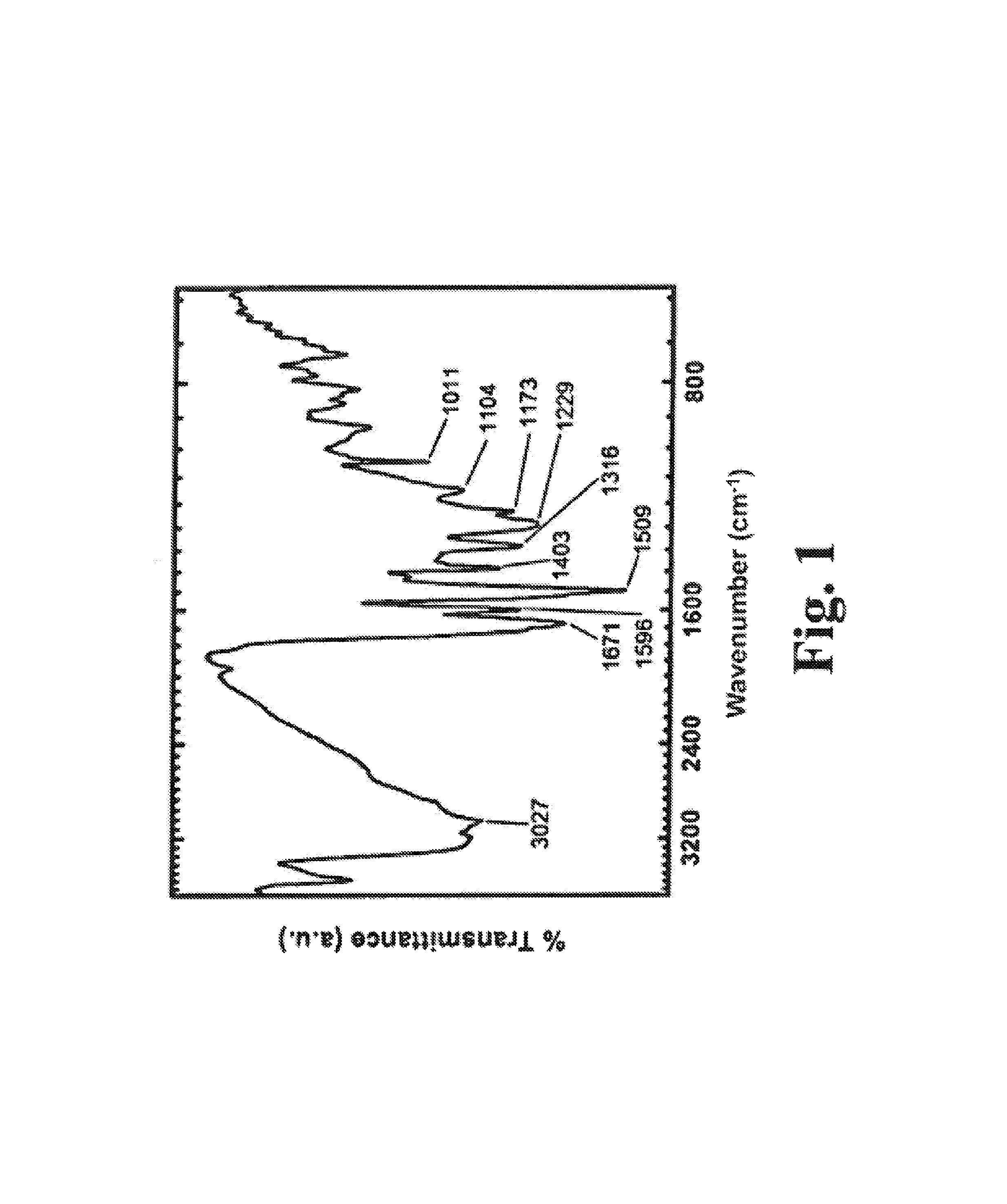

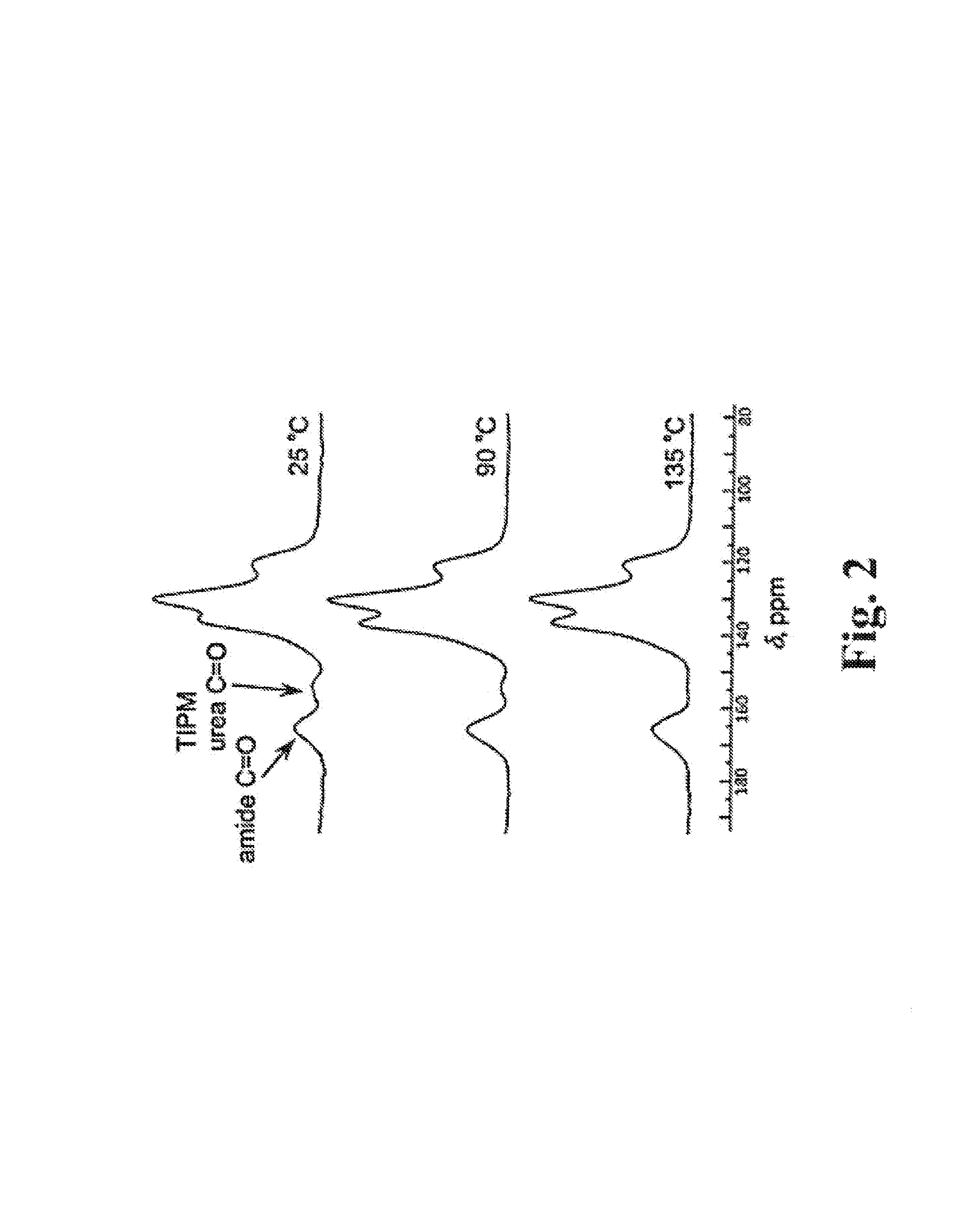

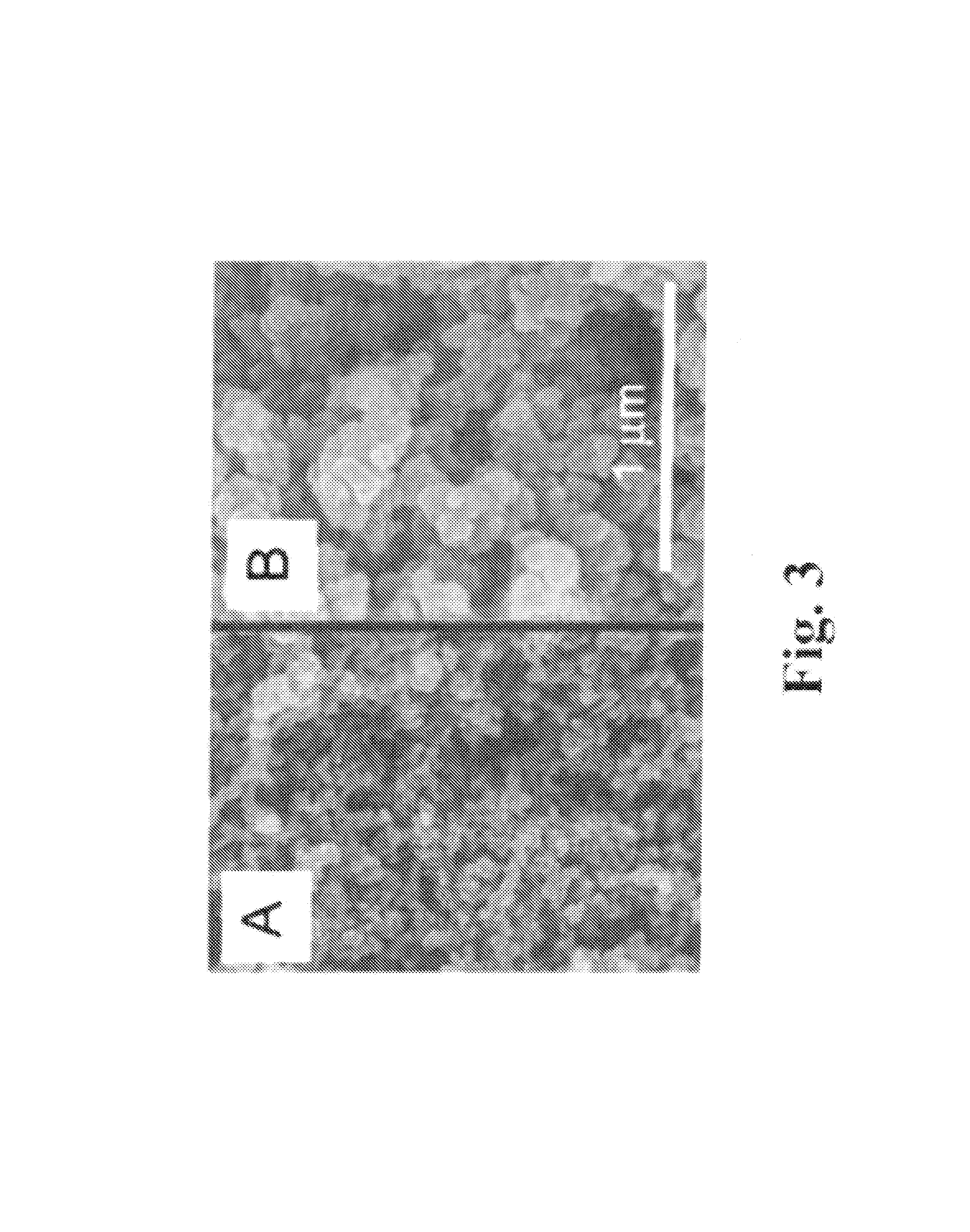

Multifunctional porous aramids (aerogels) and fabrication thereof

ActiveUS9260581B2Easy to optimizePhysical/chemical process catalystsOrganic compound preparationPorosityFerrocene

The present disclosure provides a series of new and improved porous polyamide aerogels derived from multifunctional aromatics that combine the high mechanical strength of aramids with the pore structure of aerogels. The polyamide aerogels have a hyperbranched structure, relatively low density, high porosity and may be derived from functionalized monomers having more aromatic groups than functional groups. The present disclosure also provides a new method for producing the porous polyamide aerogels by polymerizing an aromatic multifunctional carboxylic acid or a ferrocene multifunctional carboxylic acid with a polyfunctional aromatic isocyanate at moderate reaction conditions followed by drying with liquid CO2. Also disclosed are various methods of use of these polyamide aerogels in a variety of applications.

Owner:UNIVERSITY OF MISSOURI

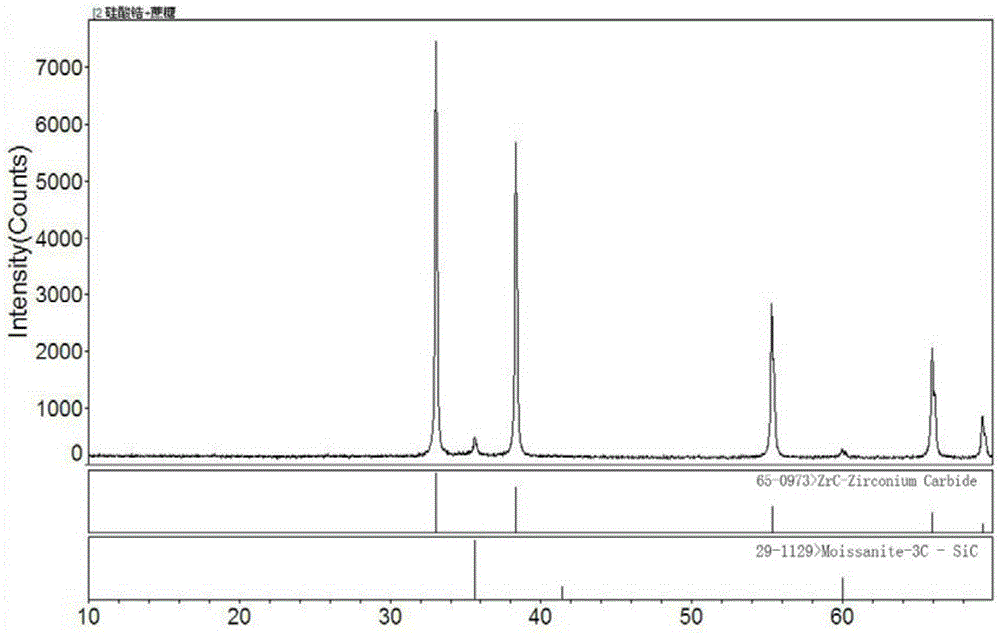

Synthetic method of high-purity ultrafine ZrC-SiC composite powders

The present invention belongs to the field of inorganic nonmetallic materials, and relates to a synthetic method of high-purity ultrafine ZrC-SiC composite powders. The synthetic method comprises the following steps: taking only zirconium silicate or zirconium silicate added with one or both of zirconium oxide or colloidal silica as a zirconium source and a silicon source material, taking sucrose or glucose as a carbon source material, and taking acrylamide monomer and a methylene-bisacrylamide cross-linking agent as a gel material to prepare the high purity ultrafine ZrC-SiC composite powders. The ZrC-SiC composite powders synthesized by the synthetic method provided by the present invention are mixed very uniformly and are quite high in purity, and the purity is greater than or equal to 99%, and the particle size d is less than or equal to 50 [mu]m. An aqueous pulp containing acrylamide monomer and the methylene bisacrylamide cross-linking agent is subjected to in-situ gel curing, C can closely coat the surfaces of solid phase powder particles very uniformly, so that segregation of raw materials in dehydration and reaction processes is avoided, and carbothermal reduction synthesis reaction can be carried out fully.

Owner:SHANDONG ULSTREETCARING FINE CERAMICS

Preparation method of sulfonated two-dimensional titanium carbide nanosheet

ActiveUS20180179070A1Low production costSimple controllabilityMaterial nanotechnologyTitanium carbideDispersityHydrofluoric acid

The present invention discloses a preparation method of a sulfonated two-dimensional titanium carbide nanosheet, which comprises the following steps of preparing two-dimensional titanium carbide by using aluminum atomic layers in hydrofluoric acid chemical stripping layer-shaped titanium aluminum carbide; preparing sulfanilic acid diazosalt; conducting a sulfonation reaction between the two-dimensional titanium carbide and the sulfanilic acid diazosalt to prepare the sulfonated two-dimensional titanium carbide nanosheet. The sulfonated two-dimensional titanium carbide nano material prepared through the present invention has good dispersity in water and common organic solvents, and a single-layer or few-layer sulfonated two-dimensional titanium carbide nanosheet with large size and high quality can be obtained after ultrasonic treatment is performed on a dispersion liquid. The preparation method has the characteristics of low production cost, easiness in obtaining raw materials, and simplicity and controllability during preparation.

Owner:HOHAI UNIV

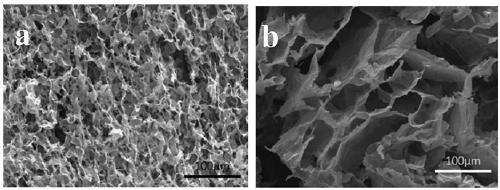

Preparation method of three-dimensional MXene

InactiveCN108328616AEasy to operateMild preparation conditionsTitanium carbideOxy/sulfo carbidesSolventUltrasonic dispersion

The invention discloses a preparation method of three-dimensional MXene and belongs to the technical field of functional materials. The preparation method comprises the following steps: dispersing two-dimensional MXene into a solvent according to the mass / volume ratio (g to mL) of (0.2 to 1) to 100 under the protection of inert gas; carrying out ultrasonic dispersion for 30 to 90min to form a two-dimensional MXene dispersion solution; then freezing; after freezing, drying in a freezing dryer to obtain three-dimensional MXene. The method disclosed by the invention has the advantages of simplicity in operation, moderate preparation conditions, greenness and no pollution and low cost; laminar stacking problems in two-dimensional laminar MXene preparation and application processes can be solved; the prepared three-dimensional MXene has a three-dimensional porous net-shaped structure and a high specific surface area.

Owner:KUNMING UNIV OF SCI & TECH

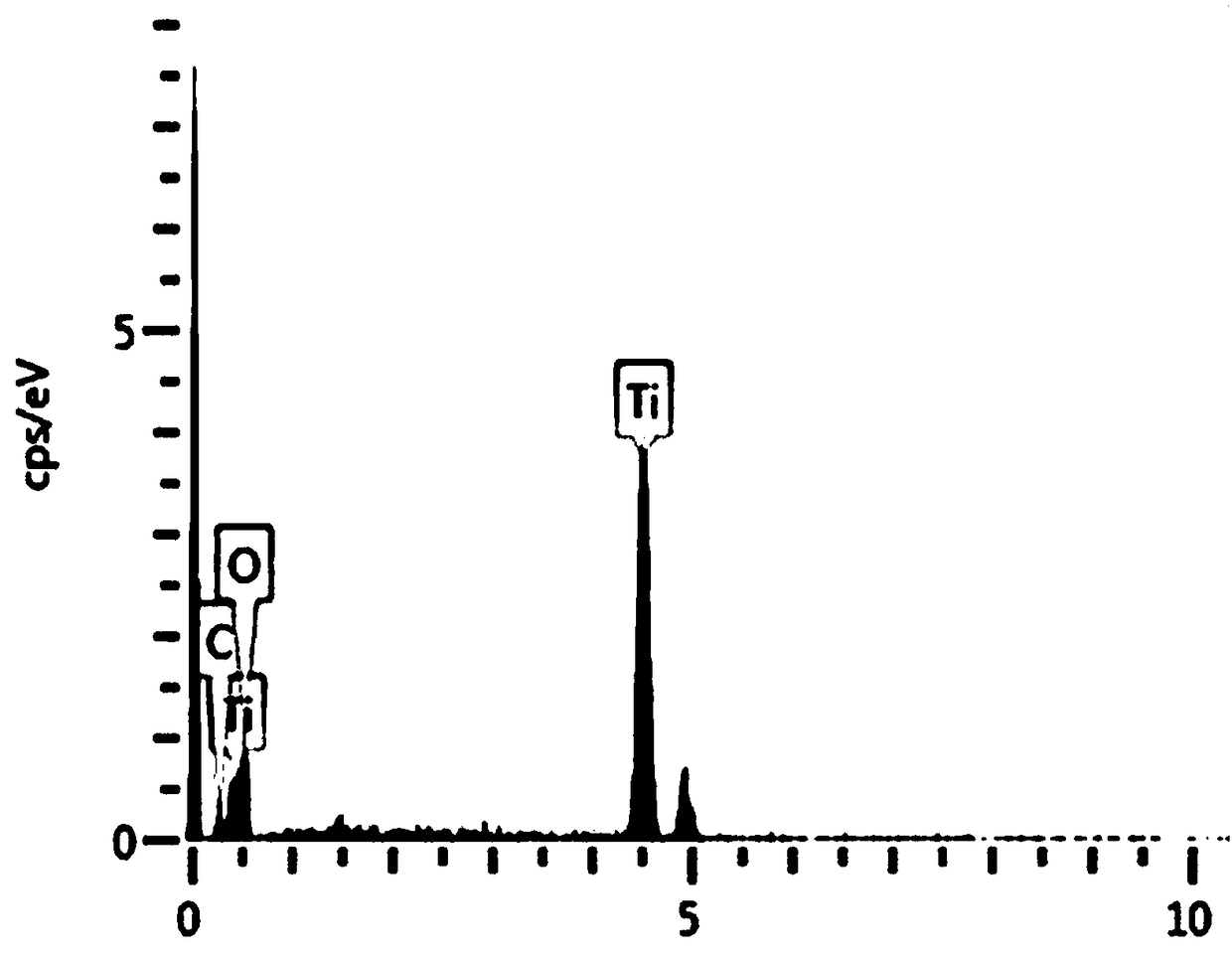

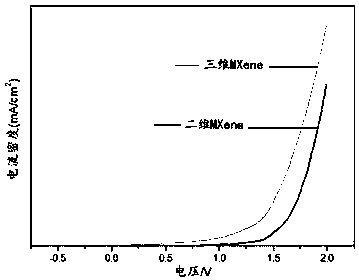

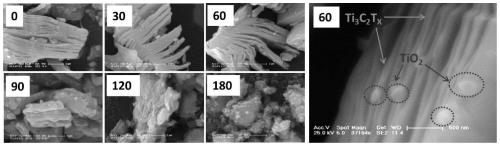

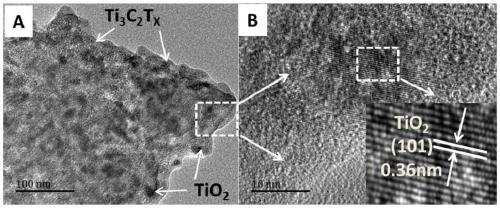

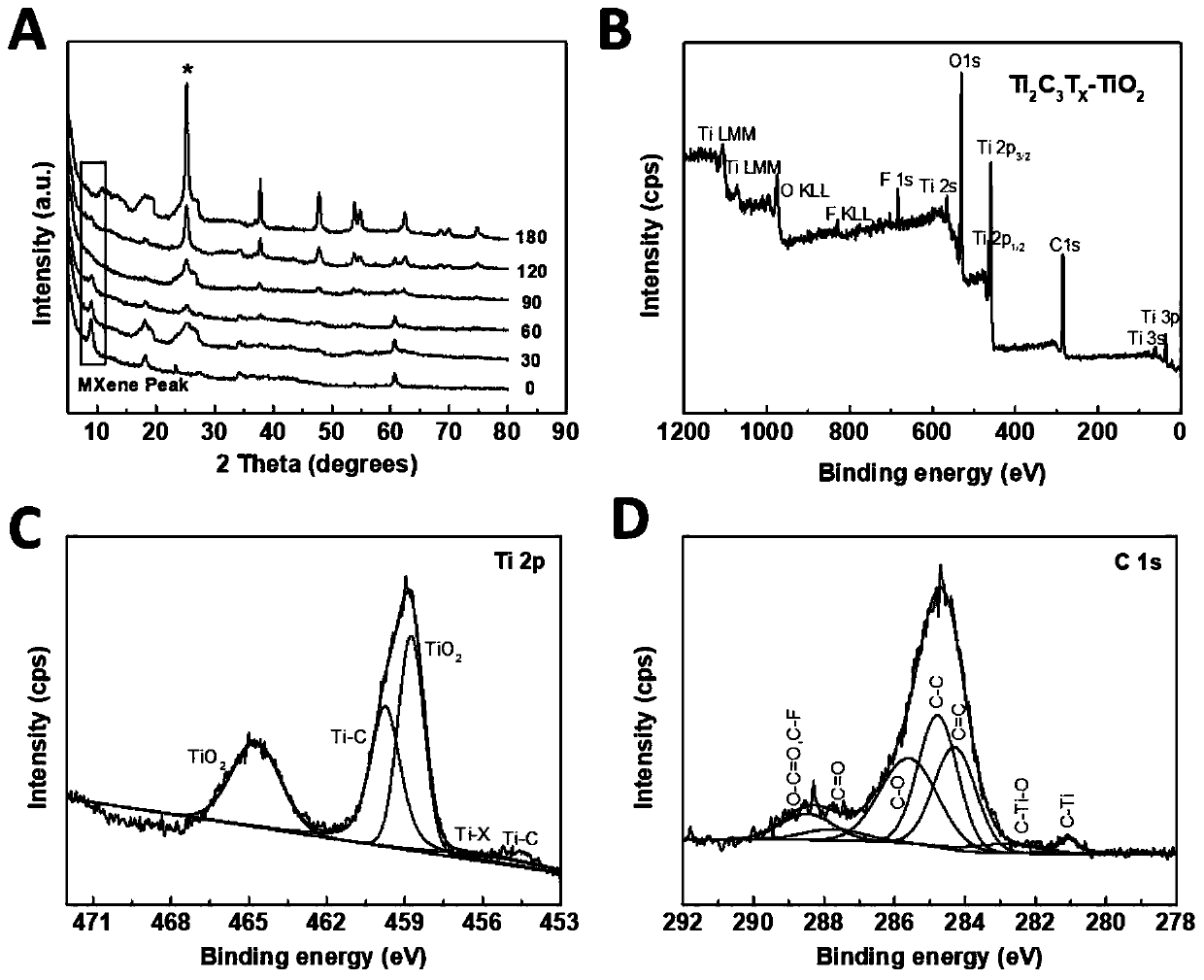

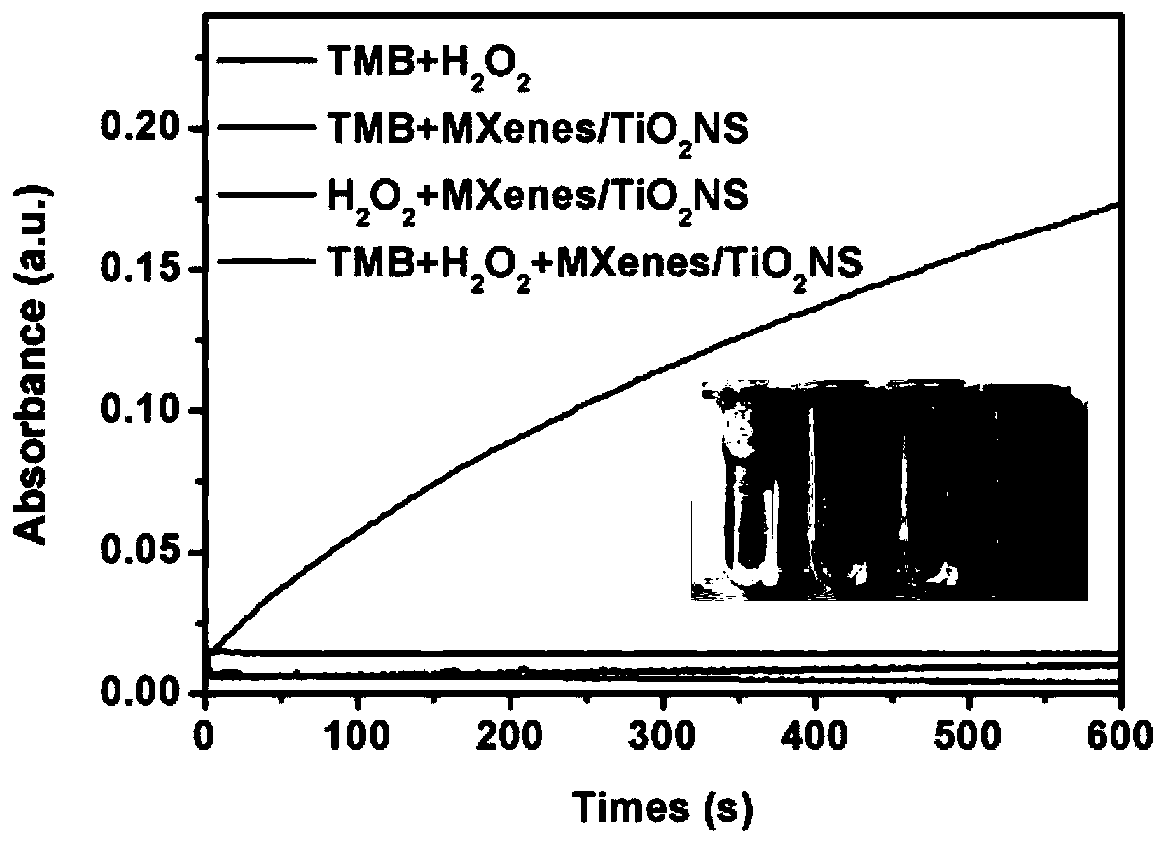

Ti3C2Tx-TiO2 composite material as well as preparation method and application thereof

InactiveCN111482188AImprove photoelectric responseGood photocurrent responsePhysical/chemical process catalystsOxy/sulfo carbidesPhotocurrentPhotoelectric sensor

The invention belongs to the field of photoelectric materials, and discloses a Ti3C2Tx-TiO2 composite material and a preparation method and application thereof. The preparation method comprises the following steps: dispersing layered Ti3C2Tx Mxene powder into water and stirring, then adding a hydrogen peroxide solution, and carrying out a stirring reaction for 1-3 h at the temperature of 80-120 DEG C; and then carrying out ultrasonic treatment on the mixed solution after the reaction, washing and drying to obtain the Ti3C2Tx-TiO2 composite material. The mass volume ratio of the layered Ti3C2TxMxene powder to H2O2 is 1:(0.3-0.9) g / mL. According to the invention, the composite material with high photoelectric response is obtained by controlling the oxidation degree of Ti3C2Tx. The compositematerial has good photocurrent response and excellent stability and photocorrosion resistance, and can be used for preparing detection chips or sensors. The photoelectric sensor prepared by the method has excellent stability and repeatability.

Owner:GUANGZHOU UNIVERSITY

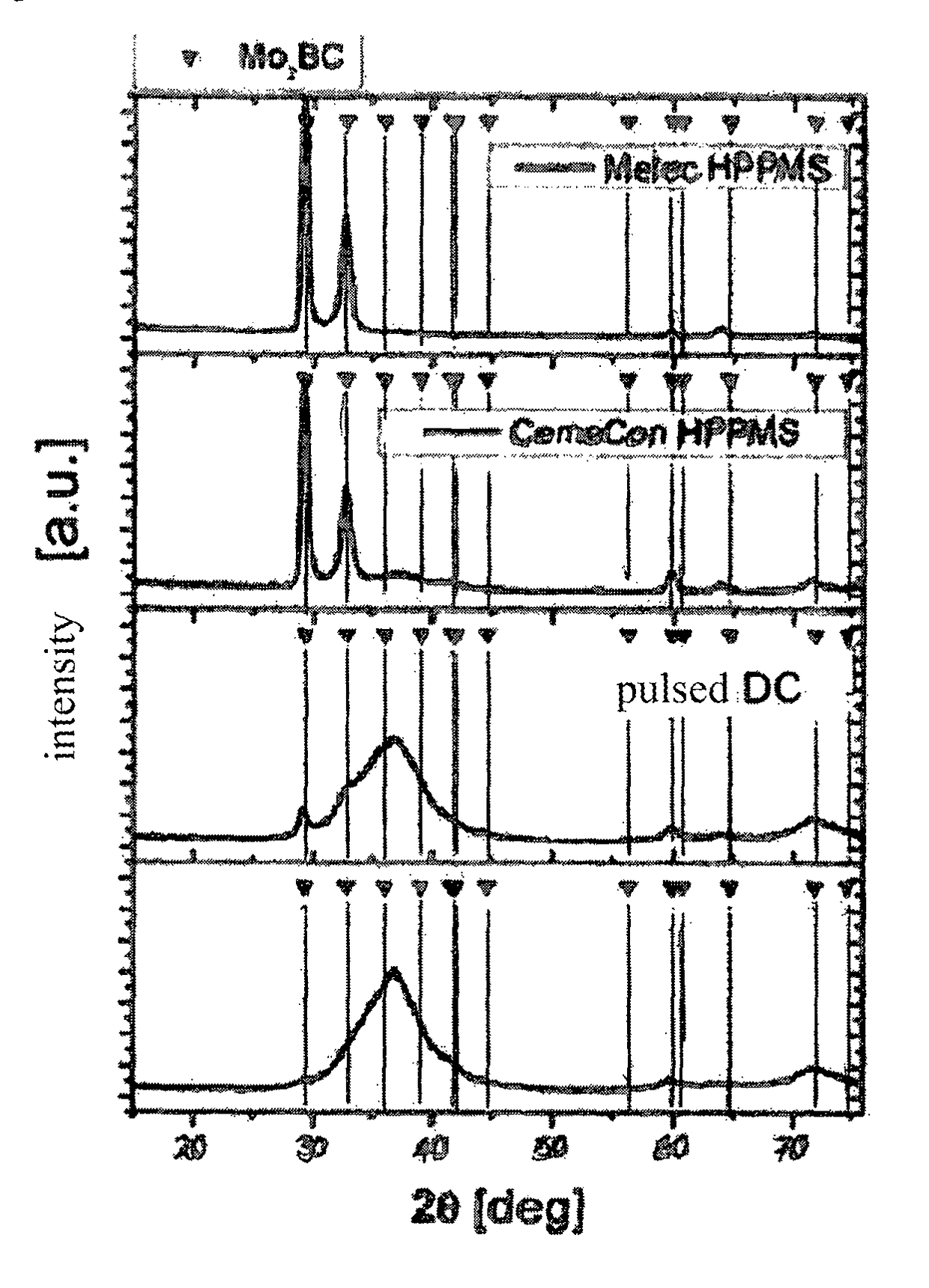

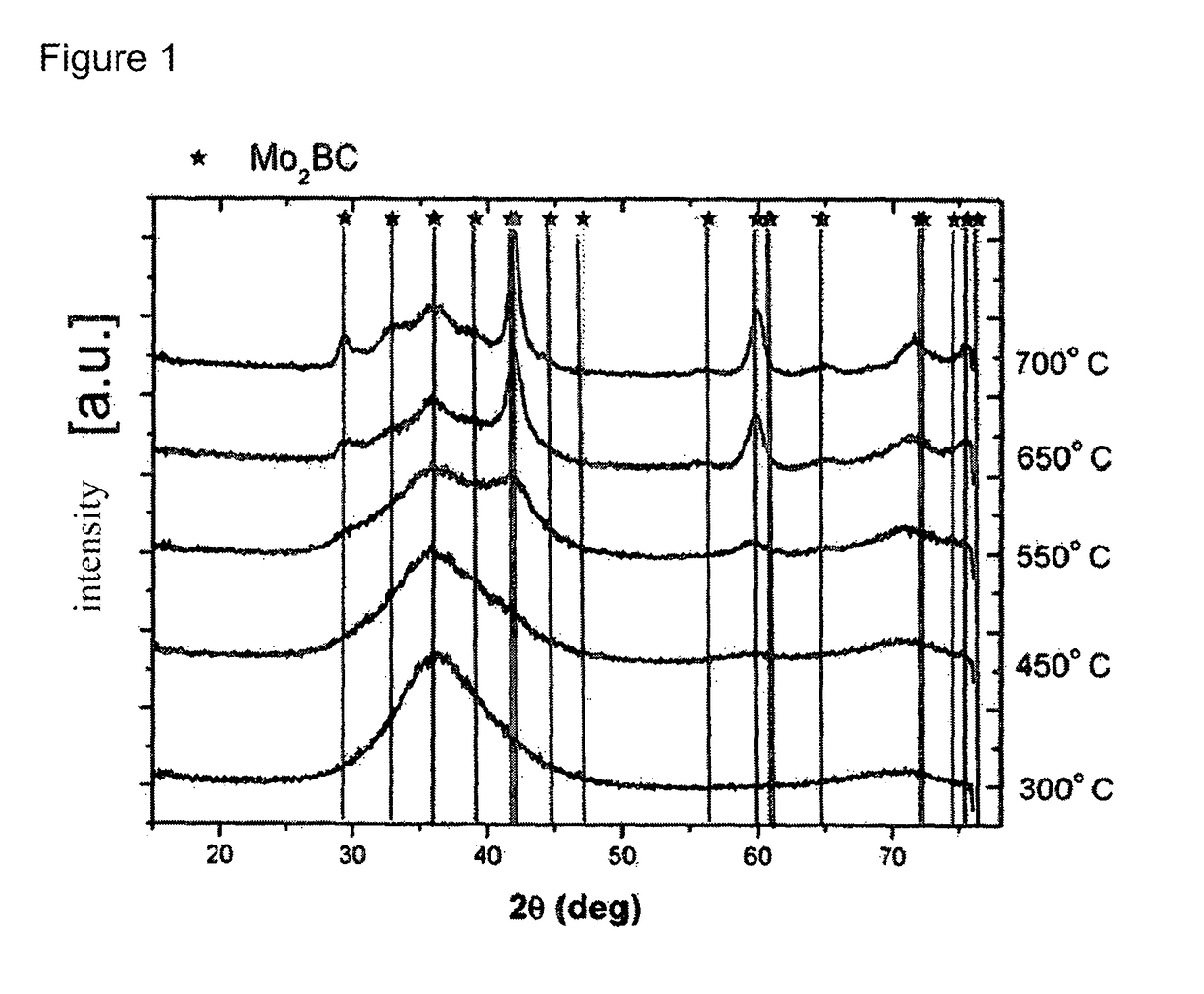

Method for manufacturing a metal-borocarbide layer on a substrate

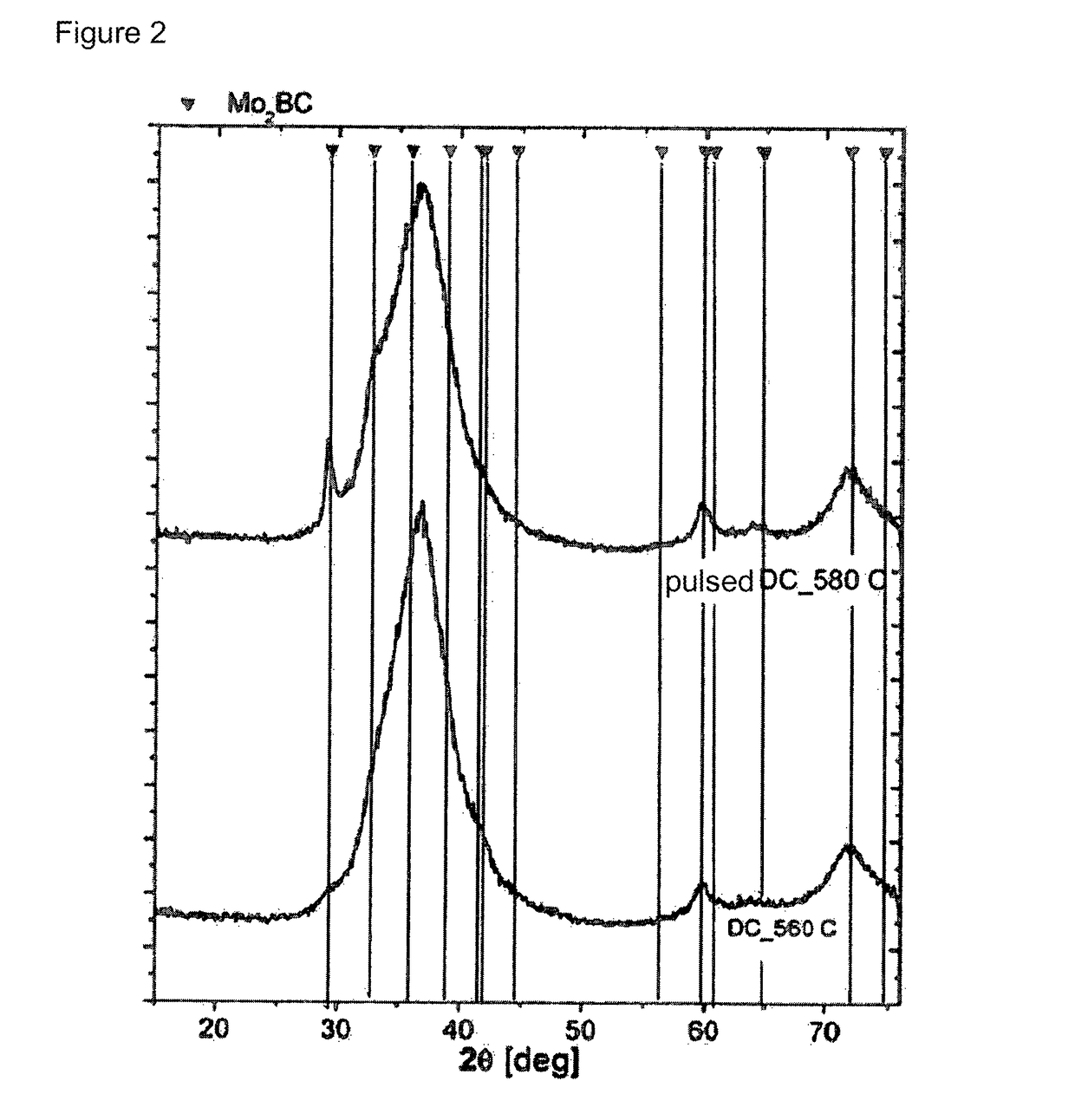

ActiveUS9624571B2Improve processing stabilityReduces formation of dropletElectric discharge tubesVacuum evaporation coatingX ray spectraBoron

The invention relates to a PVD process for coating a substrate with a layer containing at least one microcrystalline metallic borocarbide phase. During the PVD process, the source output is pulsed such that the at least one peak of which the half intensity width allows conclusions to be drawn about the presence of a microcrystalline phase of the metallic borocarbide layer can be identified in the x-ray spectrum of a layer produced in this way at a substrate temperature below 600° C.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Method of producing a metal-containing single-phase composition

A method of producing a single-phase composition Mn+1AzXn, primarily the production of the single-phase material Ti3SiC2, where n lies within a range of 0.8-3.2, where z lies within a range of 0.8-1.2, where M is at least one metal taken from the group of metals Ti (titanium), Sc (scandium), V (vanadium), Cr (chromium), Zr (zirconium), Nb (niobium) and Ta (tantalum), where X is at least one of the non-metals C (carbon) and N nitrogen), and where A is at least one of the chemical elements Si (silicon), Al (aluminum) and Sn (tin) or a compound of those elements, such that the final, desired compound will include the components Mn+1AzXn. A powder mixture of the components is formed and is ignited under an inert atmosphere to prevent promotion of dissociation and to cause the components to react.

Owner:DREXEL UNIV +1

Preparation method of M-site doped vanadium MXene

ActiveCN111634914AImprove liquid phase stripping abilityHigh purityOxy/sulfo carbidesAluminium powderMolten salt

The invention discloses a preparation method of M-site doped vanadium MXene. The preparation method comprises the following steps: mixing metal powder, aluminum powder, carbon powder and fused salt according to a certain proportion to prepare powder; then putting the powder into a mortar, adding a grinding fluid, and grinding for 3-8 minutes under an air condition so that the powder is primarily mixed; transferring into a ball milling tank and carrying out ball milling for 3-6 hours to obtain powder; then putting the powder into a magnetic boat for high-temperature atmosphere sintering to obtain M-site doped MAX-phase powder; and mixing the M-site doped MAX-phase powder with an etching agent according to a certain ratio, then magnetically stirring at 20-35 DEG C for 12-36 hours, cleaning,centrifugally separating and drying to obtain M-site doped V2CTxMXene. The MXene powder material prepared by the method has the characteristics of high purity, multiple hybrid sites and the like, canbe subjected to structure fine adjustment according to working condition requirements, and has a wide application prospect in the field of electrochemistry.

Owner:SHAANXI UNIV OF SCI & TECH

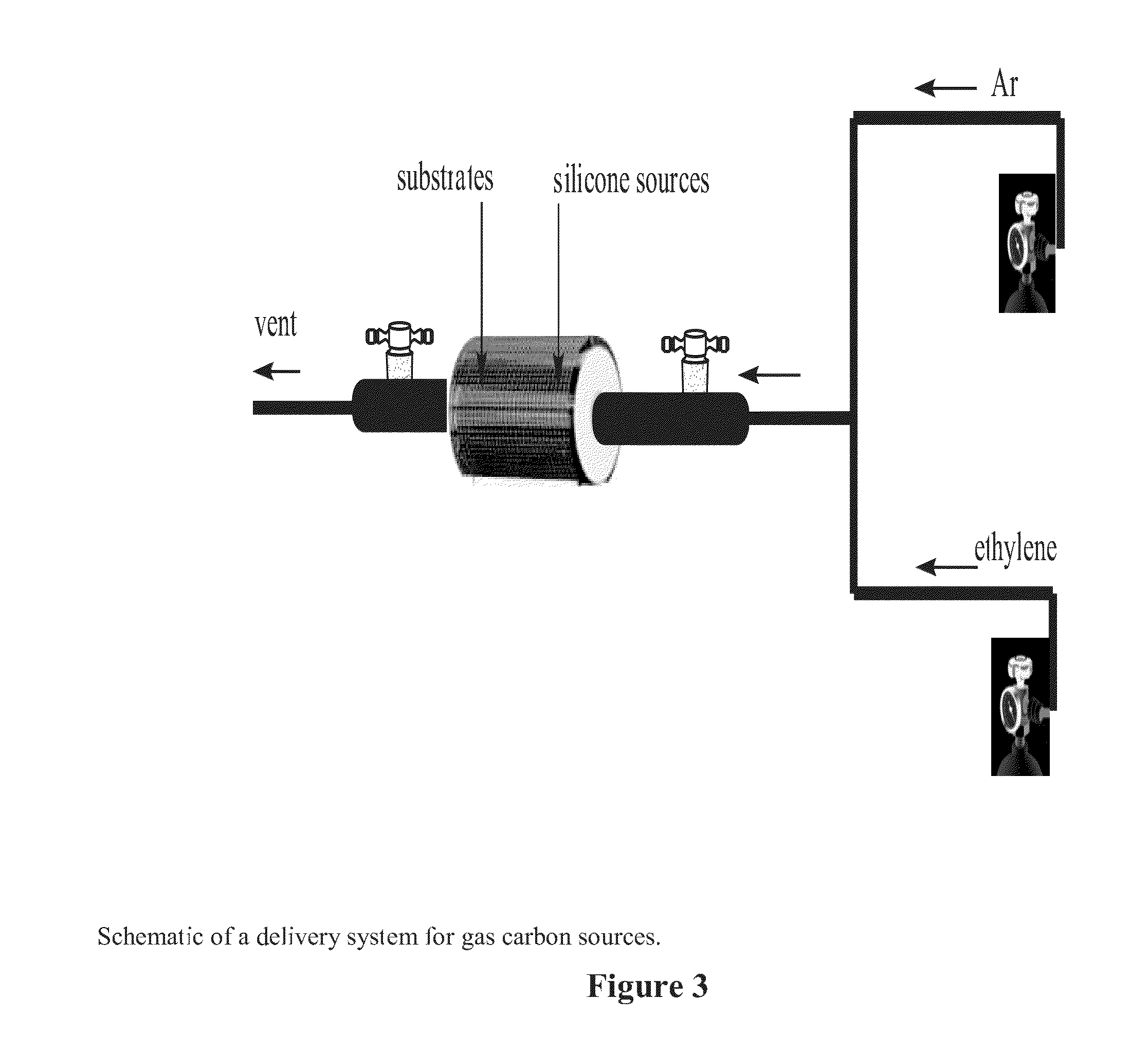

Graphene-like nanosheet structure network on a substrate and the method for forming the same

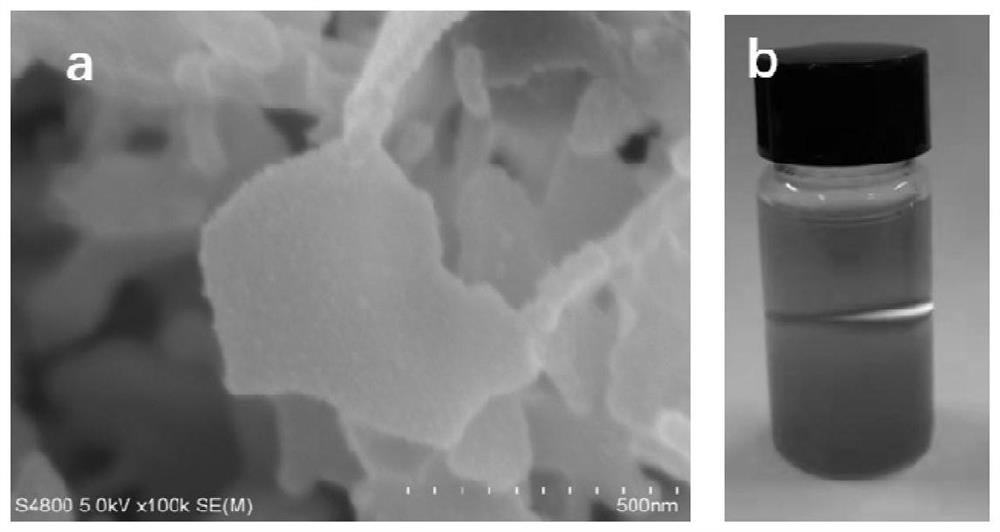

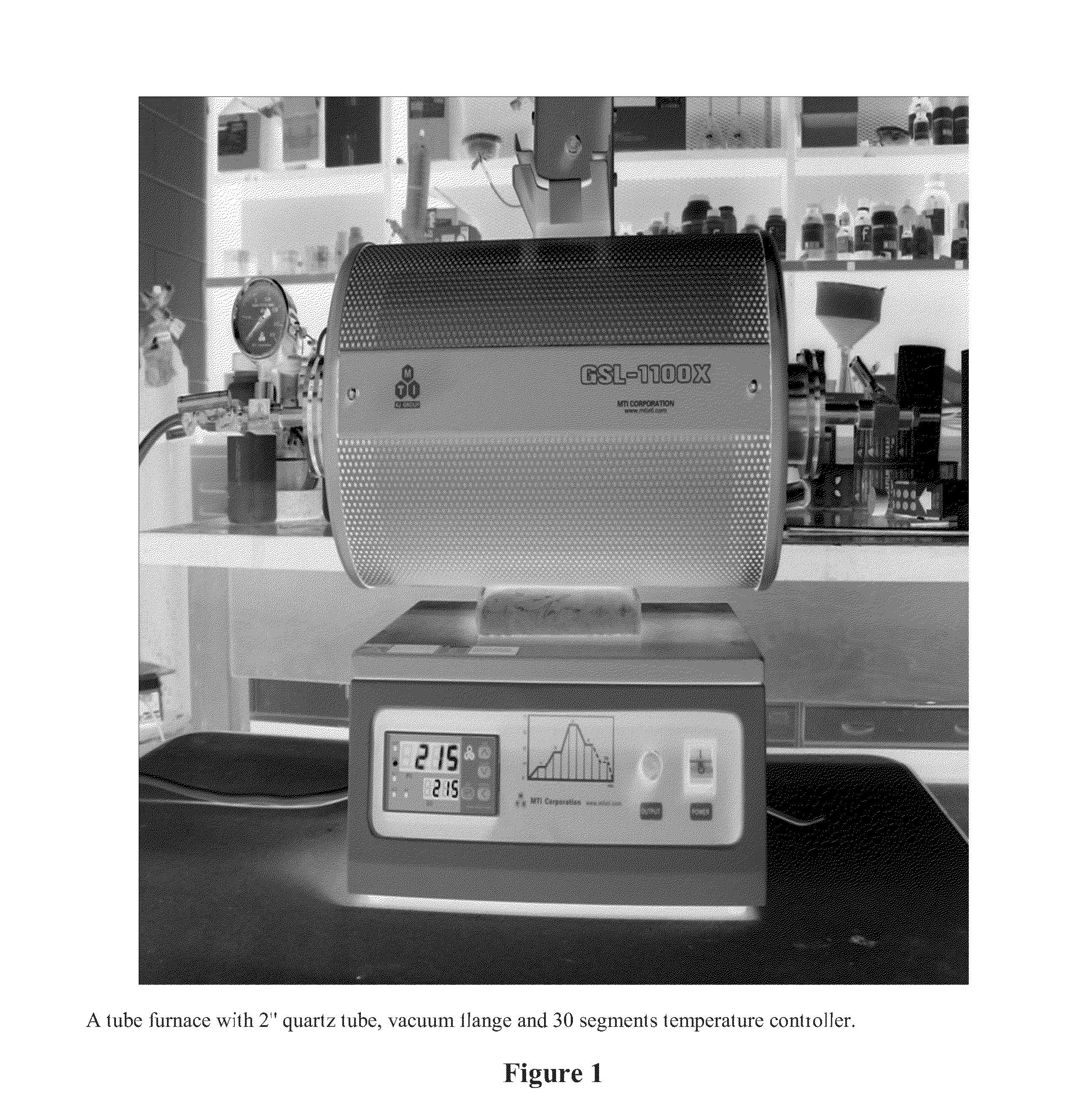

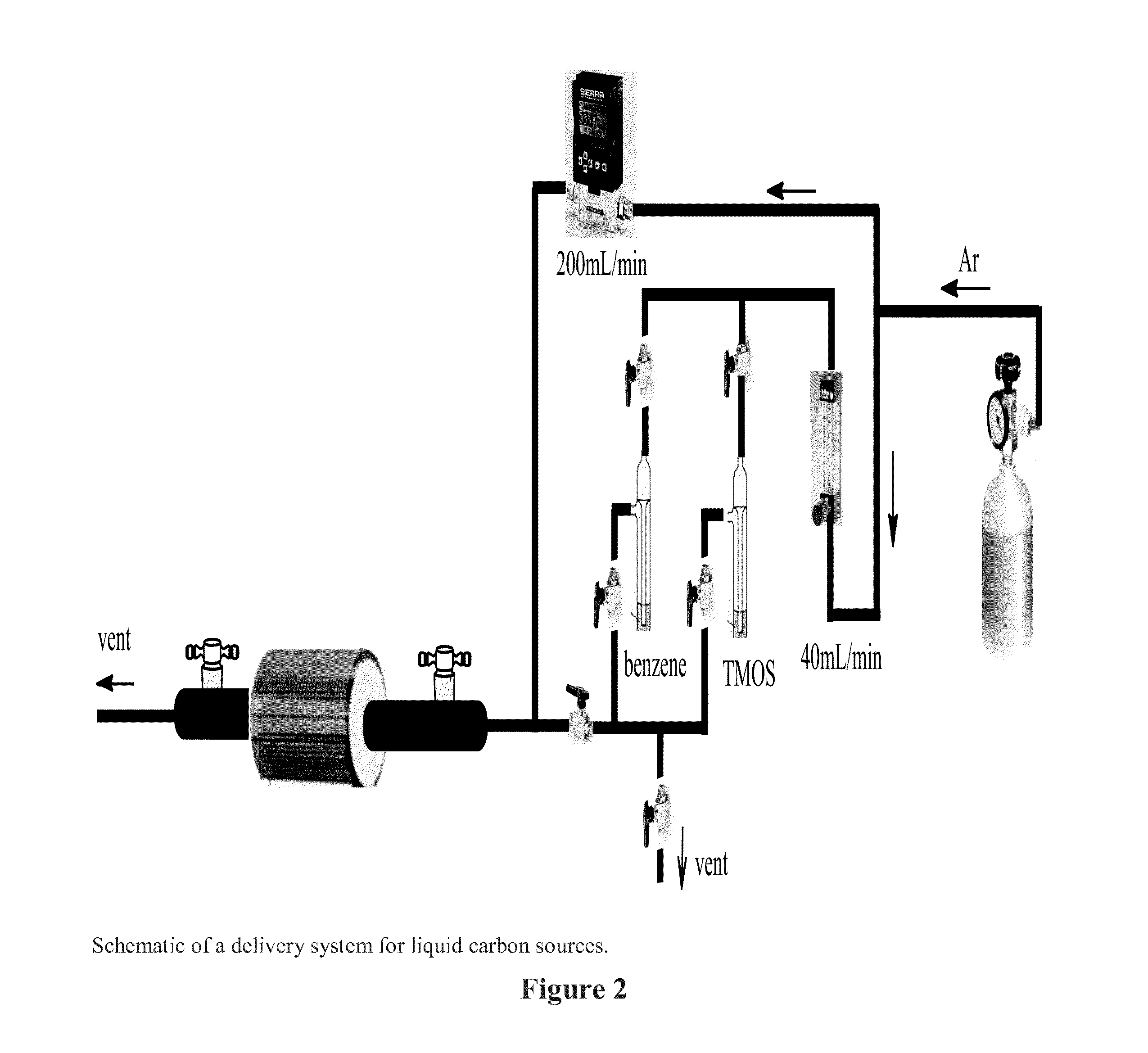

ActiveUS20150023860A1Increase pressureUnique propertyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOxy/sulfo carbidesCarbideNetwork on

A facile method to produce covalently bonded graphene-like network coated on various solid substrates is disclosed in the present invention. According to one embodiment, a combination of chemical vapor deposition (CVD) of carbon sources and a silicon compound with or without a metal containing compound under an inert gas flow is processed at high temperatures to produce covalent carbide bonding among graphene-like structures and between graphene-like structures and substrate surface.

Owner:NANOMATERIAL INNOVATION

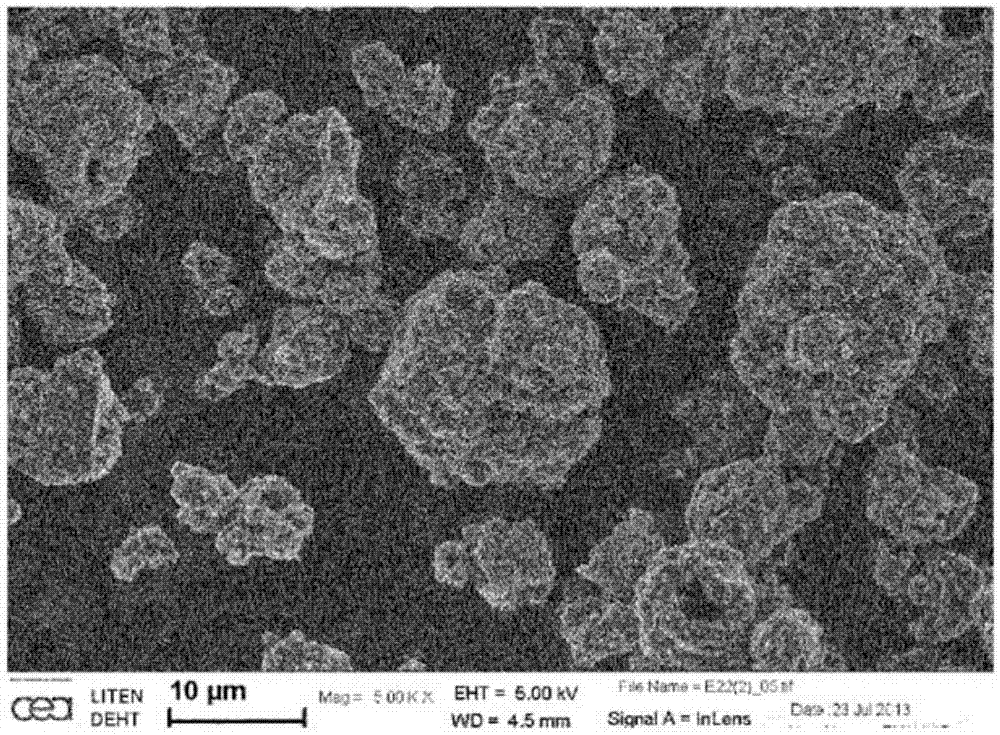

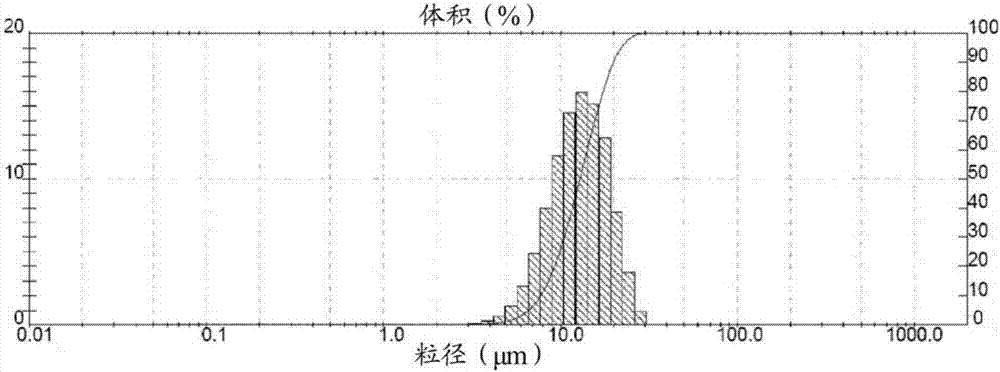

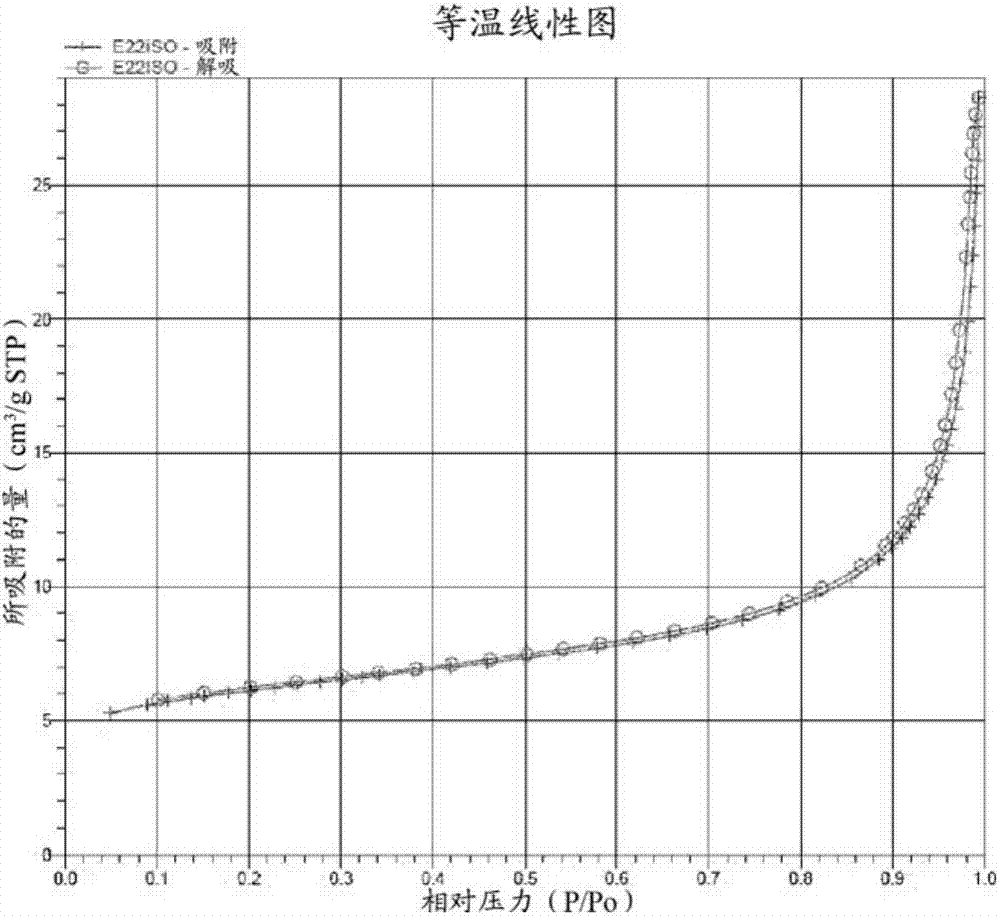

Sioc composite electrode material

The invention discloses a SiOC composite electrode material. The present invention relates to a SiOC composite material in microparticulate form, characterized in that the microparticles are formed, in whole or in part, of an amorphous SiOC matrix with Si ranging from 20 wt% to 60 wt%, O from 20 wt% to 40 wt% and C from 10 wt% to 50 wt%, based on the total weight of the SiOC matrix, wherein amorphous or crystallized silicon particles are embedded within said SiOC matrix and wherein the microparticles are of core / coating structure with a core formed of said amorphous SiOC matrix and coated with at least one amorphous carbon layer; and to a method for producing such SiOC composite material. It also relates to an electrode active material, an electrode and a battery, especially a lithium-ion battery, including the aforementioned SiOC composite material.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

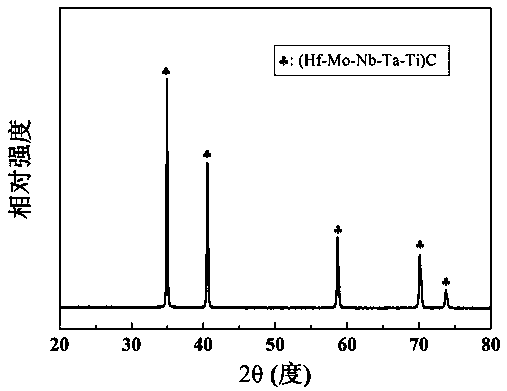

High-purity superfine high-entropy ceramic powder and preparation method thereof

The invention discloses a preparation method of high-purity superfine high-entropy ceramic powder. The method includes: putting HfO2, MoO3, Nb2O5, Ta2O5, TiO2 and sucrose into a ball mill according tocertain ratio, adding distilled water, performing mixing, then conducting drying and sieving treatment to obtain mixed powder with a particle size of 0.15-5microm; then putting the mixed powder intoa graphite mold, and putting the graphite mold into a spark plasma sintering furnace for sintering; and at the end of sintering, performing furnace cooling to room temperature, thus obtaining the high-entropy ceramic powder. The high-entropy ceramic powder prepared by the method provided by the invention has high purity and small particle size, is beneficial to lowering the sintering temperature of the ceramic material, is easier for densification, and is particularly suitable for preparation of ceramic blocks which have stable properties when serving under an ultrahigh-temperature working condition. In addition, by adjusting the formula and technological parameters, regulation and control of the performance of the high-entropy ceramic powder material can be achieved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Solid-solution carbide/carbonitride powder and method for preparing thereof

InactiveUS20100273638A1Improve performanceEasy procedureNitrogen compoundsOxy/sulfo carbidesCarbideSolid solution

The present invention relates to a complete solid solution powder used for preparing a cermet composite sintered body, and method for preparing thereof. Particularly, the present invention is directed to a complete solid solution powder which can improve, to a great extent, toughness of a cermet sintered body which is used for high-speed cutting tool materials and die materials in the field of metal working, such as various machine industries and automobile industry, and method for preparing thereof.

Owner:SEOUL NAT UNIV R&DB FOUND

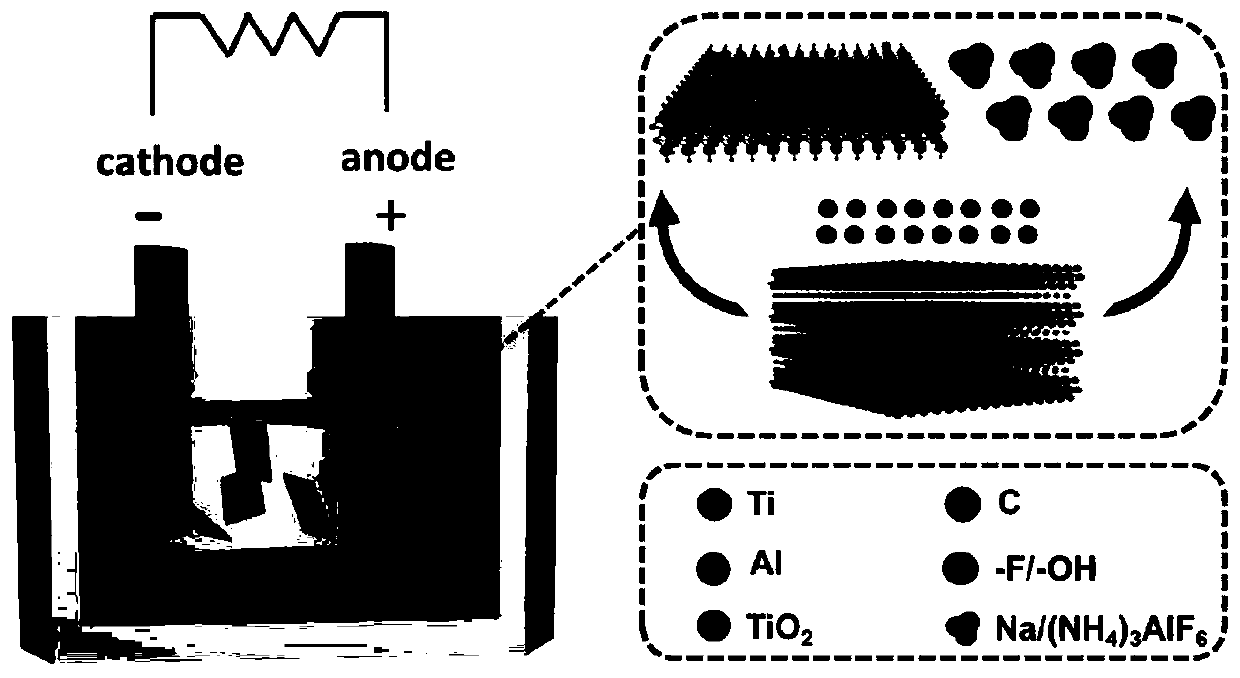

Method for preparing MXenes and derivative nanosheets by electrochemical process

ActiveCN109694074AGet quicklyHarm reductionMaterial nanotechnologyElectrolysis componentsElectrolysisNon toxicity

The invention belongs to the technical field of preparation of MXenes and derivative nanosheets thereof, and relates to a method for preparing MXenes and derivative nanosheets by an electrochemical process. The method comprises the following steps: weighing 1.43 g of ammonium bifluoride powder, 0.93 g of ammonium fluoride powder and 1.55 g of sodium bifluoride powder, respectively placing above powders in a 50 mL beaker, taking and adding 50 mL of deionized water into the beaker containing the powders, placing the beaker on a magnetic stirrer, and completely dissolving the ammonium bifluoridepowder; fixing a large block of Ti3AlC2MAX to a clip electrode to form as an anode, using a Pt sheet electrode (with an area of above 1.0 cm<2>) as a cathode, applying a direct current constant voltage of 3 V, and performing a reaction for 6-24 h; and performing centrifugation to obtain the product. Compared with the prior art, the method has the advantages of avoiding of a mixture of fluoride andhigh-concentration hydrofluoric acid or hydrochloric acid by using low-concentration ammonium bifluoride in the preparation process, non-toxicity, low hazards, elimination of potential hazardous processes, greenness and environmental protection; and electrolysis of the large block of MAX using the through electrochemical process shortens the reaction time and improves the peeling property.

Owner:QINGDAO UNIV

Solid-solution carbide/carbonitride powder and method for preparing thereof under high temperature

InactiveUS20100267542A1Improve performanceEasy procedureMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsCarbideSolid solution

The present invention relates to a complete solid solution powder used for preparing a cermet composite sintered body, and method for preparing thereof under high temperature. Particularly, the present invention is directed to a complete solid solution powder which can improve, to a great extent, toughness of a cermet sintered body which is used for high-speed cutting tool materials and die materials in the field of metal working, such as various machine industries and automobile industry, and method for preparing thereof under high temperature.

Owner:SEOUL NAT UNIV R&DB FOUND

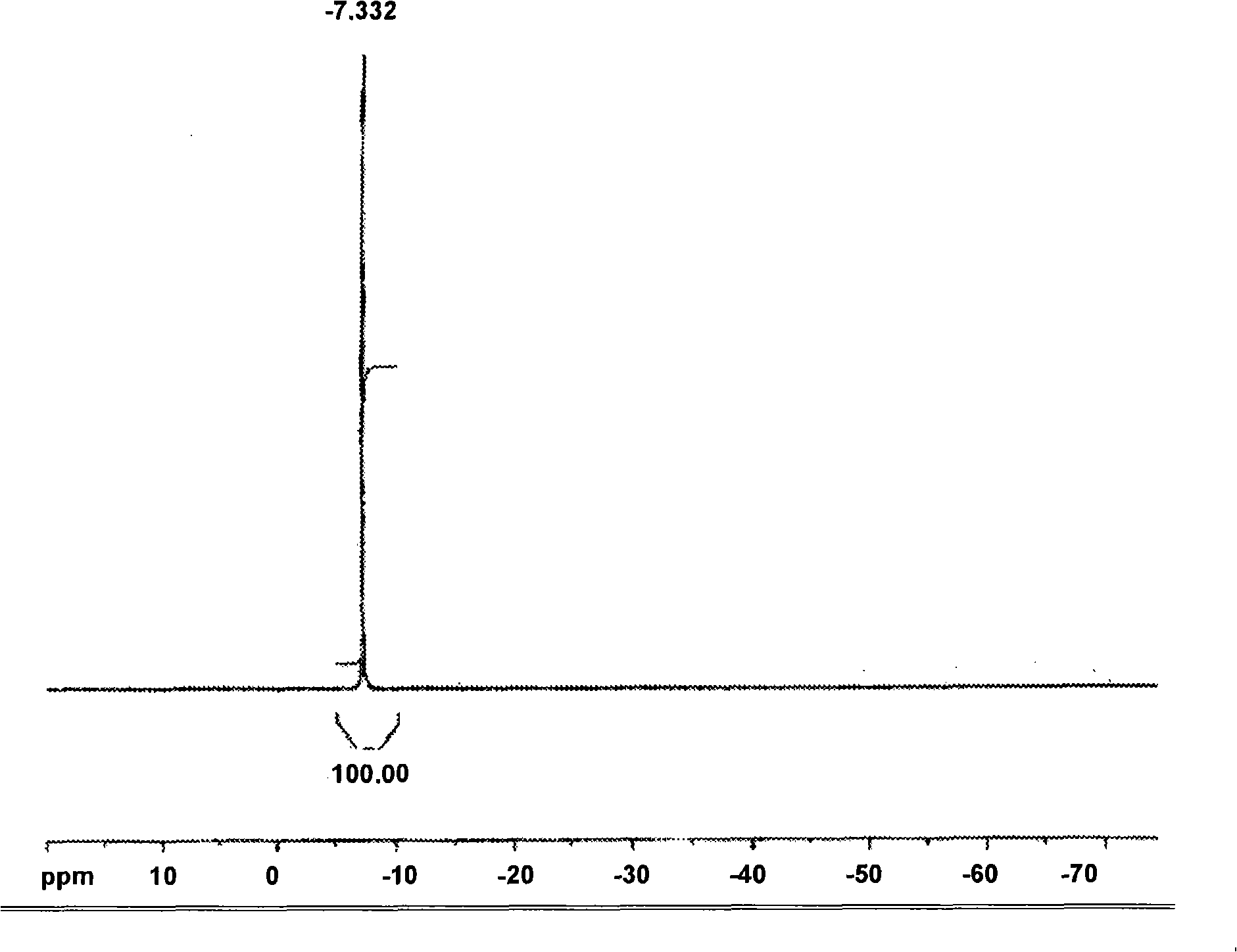

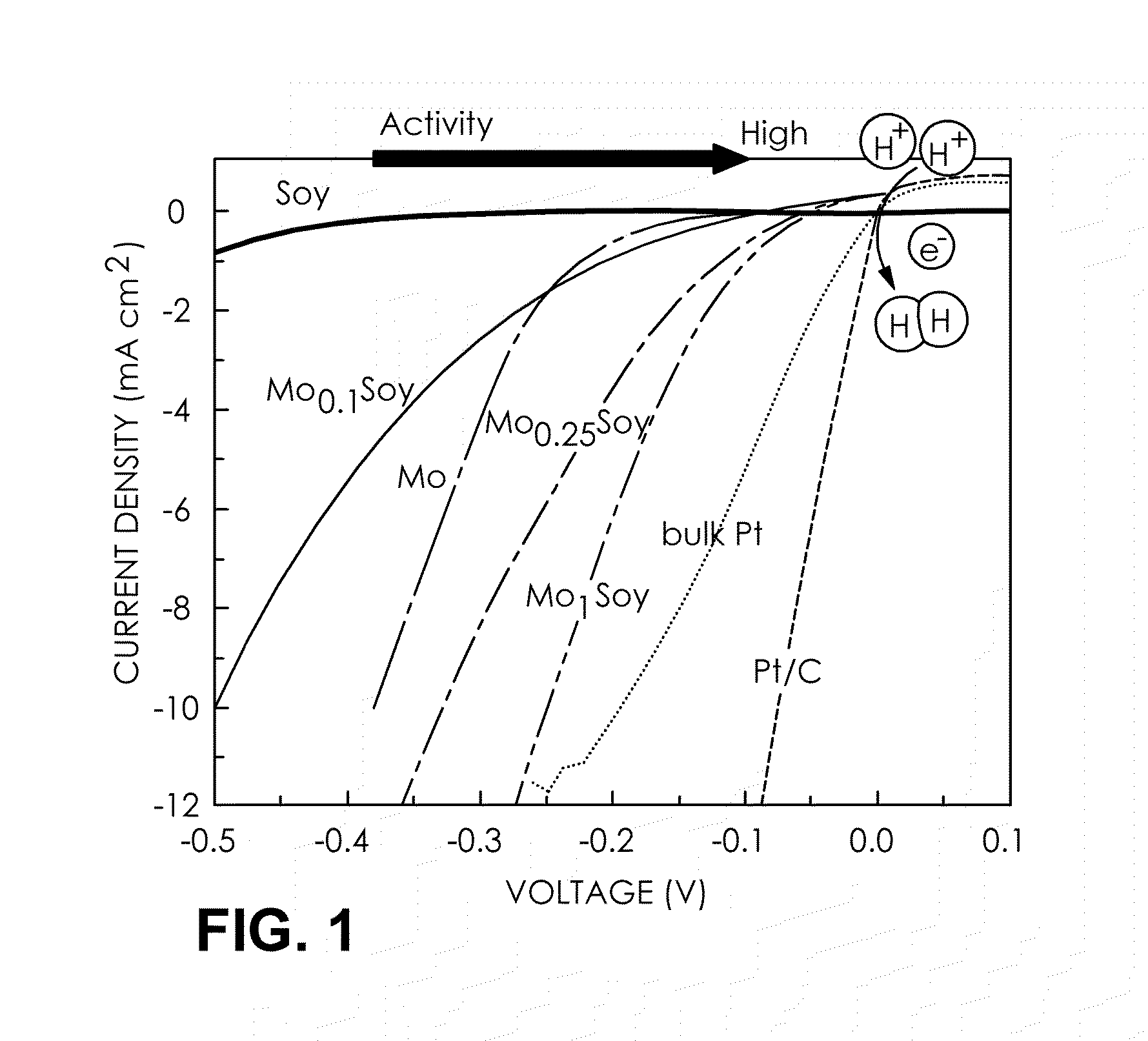

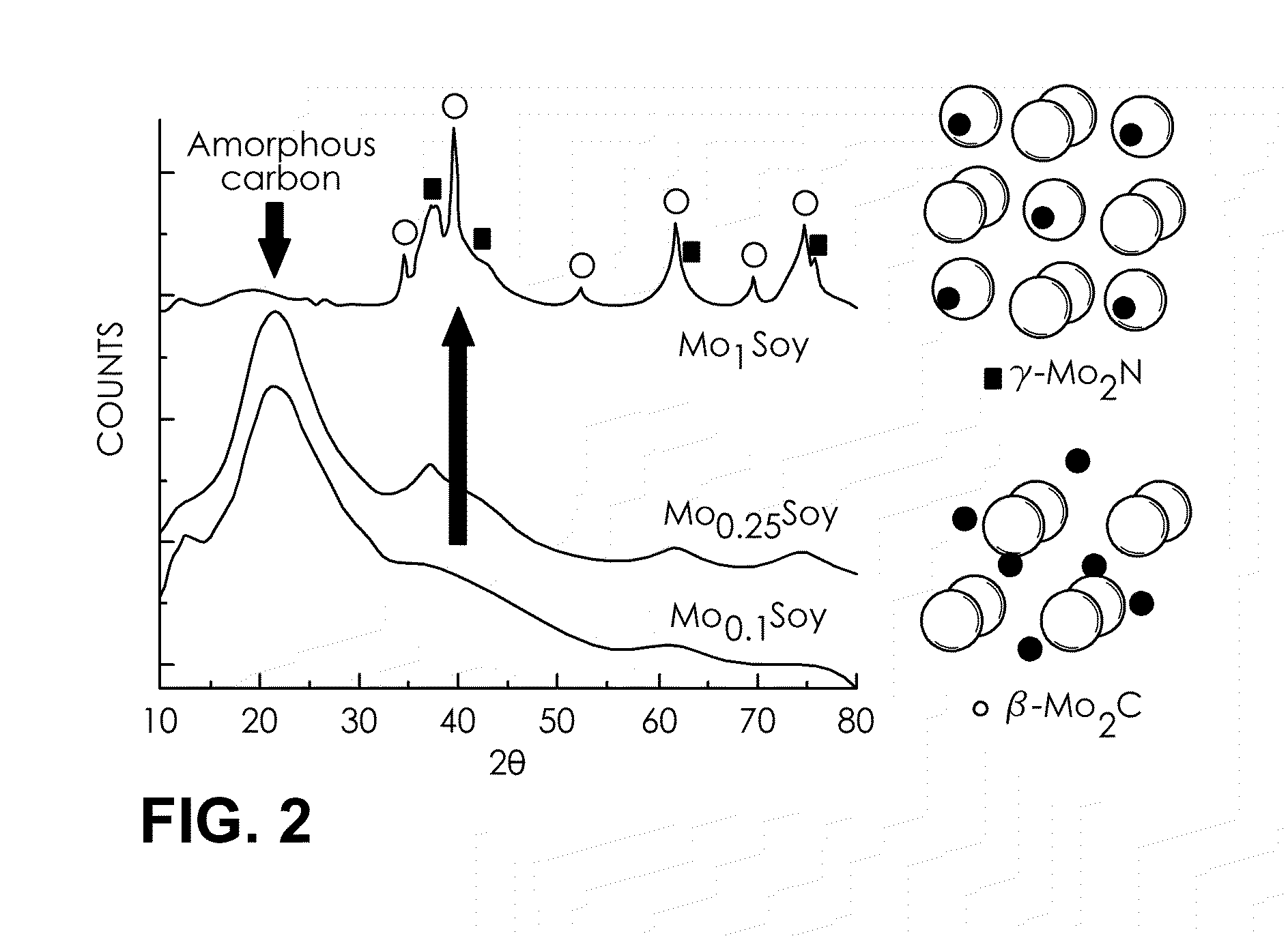

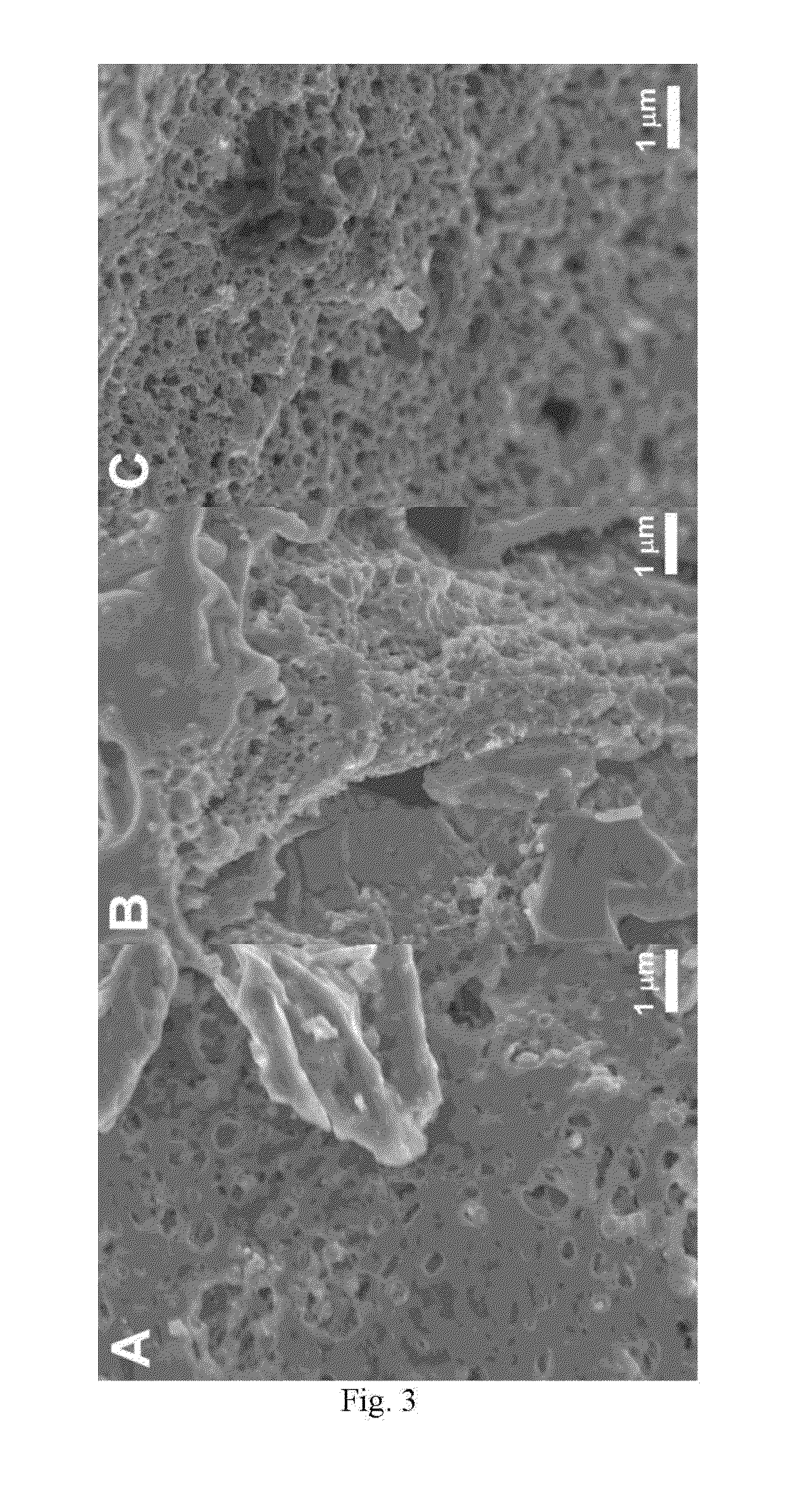

Biomass transition metal hydrogen-evolution electrocatalysts and electrodes

A catalytic composition from earth-abundant transition metal salts and biomass is disclosed. A calcined catalytic composition formed from soybean powder and ammonium molybdate is specifically exemplified herein. Methods for making the catalytic composition are disclosed as are electrodes for hydrogen evolution reactions comprising the catalytic composition.

Owner:BROOKHAVEN SCI ASSOCS

Modified carbide and oxycarbide containing catalysts and methods of making and using thereof

InactiveUS20050027153A1Improve propertiesHigh selectivityMaterial nanotechnologyHydrocarbon by isomerisationPtru catalystChemical reaction

Compositions including modified carbide-containing nanorods and / or modified oxycarbide-containing nanorods and / or modified carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including modified oxycarbide-containing nanorods and / or modified carbide containing nanorods and / or modified carbon nanotubes bearing modified carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

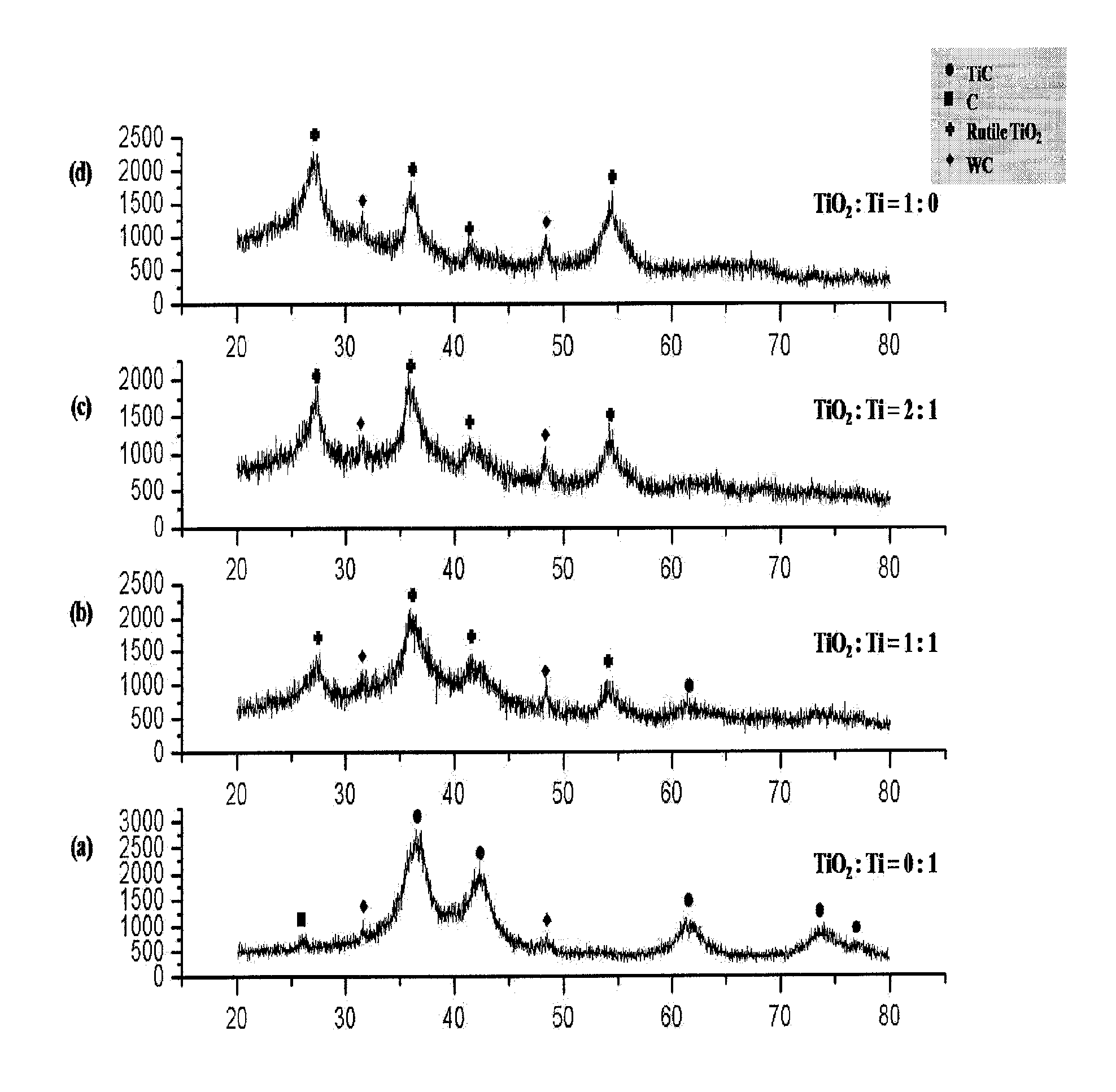

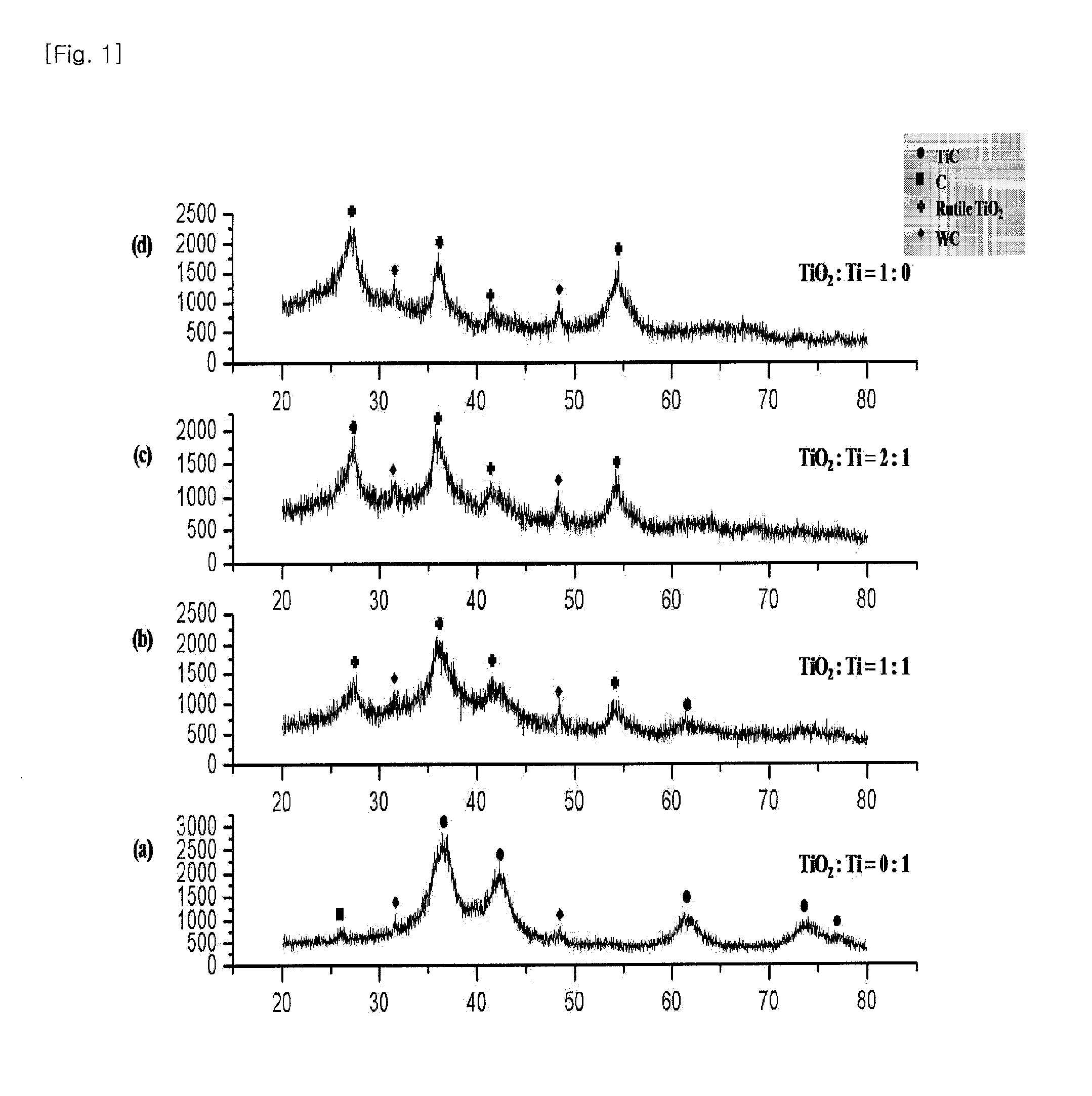

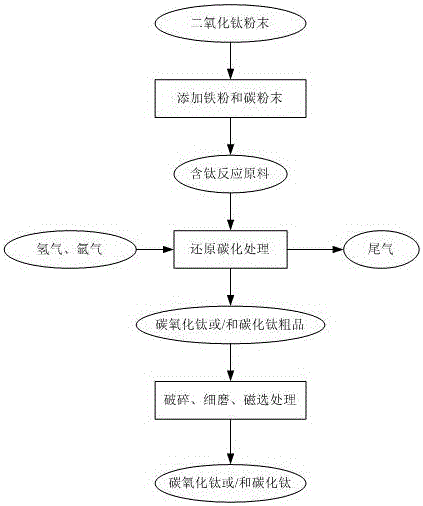

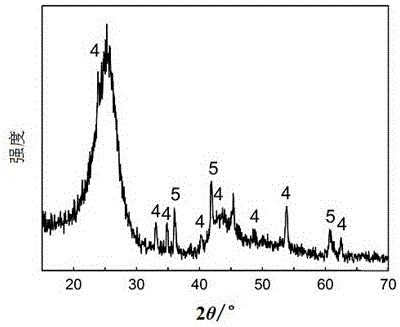

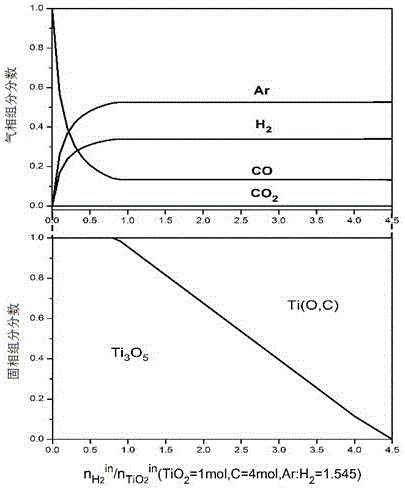

Method for preparing TiCxOy and/or TiC through carbon-added hydrogen reduction

ActiveCN106744960AEfficient productionQuick responseTitanium carbideOxy/sulfo carbidesHydrogenWater vapor

The invention provides a method for preparing TiCxOy and / or TiC through carbon-added hydrogen reduction. According to the method, pure titanium dioxide or rutile is used as an initial material, hydrogen and carbon powder are used as a reducing agent and a carburizing agent, the other role of the carbon powder is to reduce oxygen partial pressure, the preparation temperature is only required to be as low as 1,200-1,350 DEG C, hydrogen and a titanium-containing raw material are subjected to a gas-solid reduction reaction in a TiCxOy and / or TiC preparation process, the reduction efficiency is high, the reduction speed is high, the carbon powder fully and uniformly mixed with the raw material and vapor produced after hydrogen reduction are subjected to a water-gas reaction, the oxygen partial pressure in a material layer is reduced, a titanium oxide reduction is promoted, the uniformly mixed carbon powder greatly improves the carbonization efficiency, the carbonization rate is high, the reduction of TiC oxide at the lower temperature is realized, energy consumption cost is saved, and the problems of high preparation temperature, low production efficiency, high cost and the like in existing TiCxOy and TiC production technologies are well solved.

Owner:CHONGQING UNIV

Popular searches

Hydrocarbon by hydrogenation Catalytic naphtha reforming Carbon nanotubes Hydrocarbon from saturated and unsaturated hydrocarbon addition Artificial filament chemical after-treatment Hydrocarbon oils treatment Refining to eliminate hetero atoms Polycrystalline material growth Refining with metals Hydrocarbons

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com