Solid-solution powder, method to prepare the solid-solution powder, ceramic using the solid-solution powder, method to prepare the ceramic, cermet powder including the solid-solution powder, method to

A solid solution, cermet technology, applied in the direction of metal processing equipment, non-metallic elements, nitrogen and non-metallic compounds, etc., can solve problems such as failure to provide solid solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] As an example, using 99+% pure anatase-TiO 2 , NiO with a purity of 99% (average particle size is 45μm) and WO with a purity of 99+% 3 (The average particle size is 20 μm).

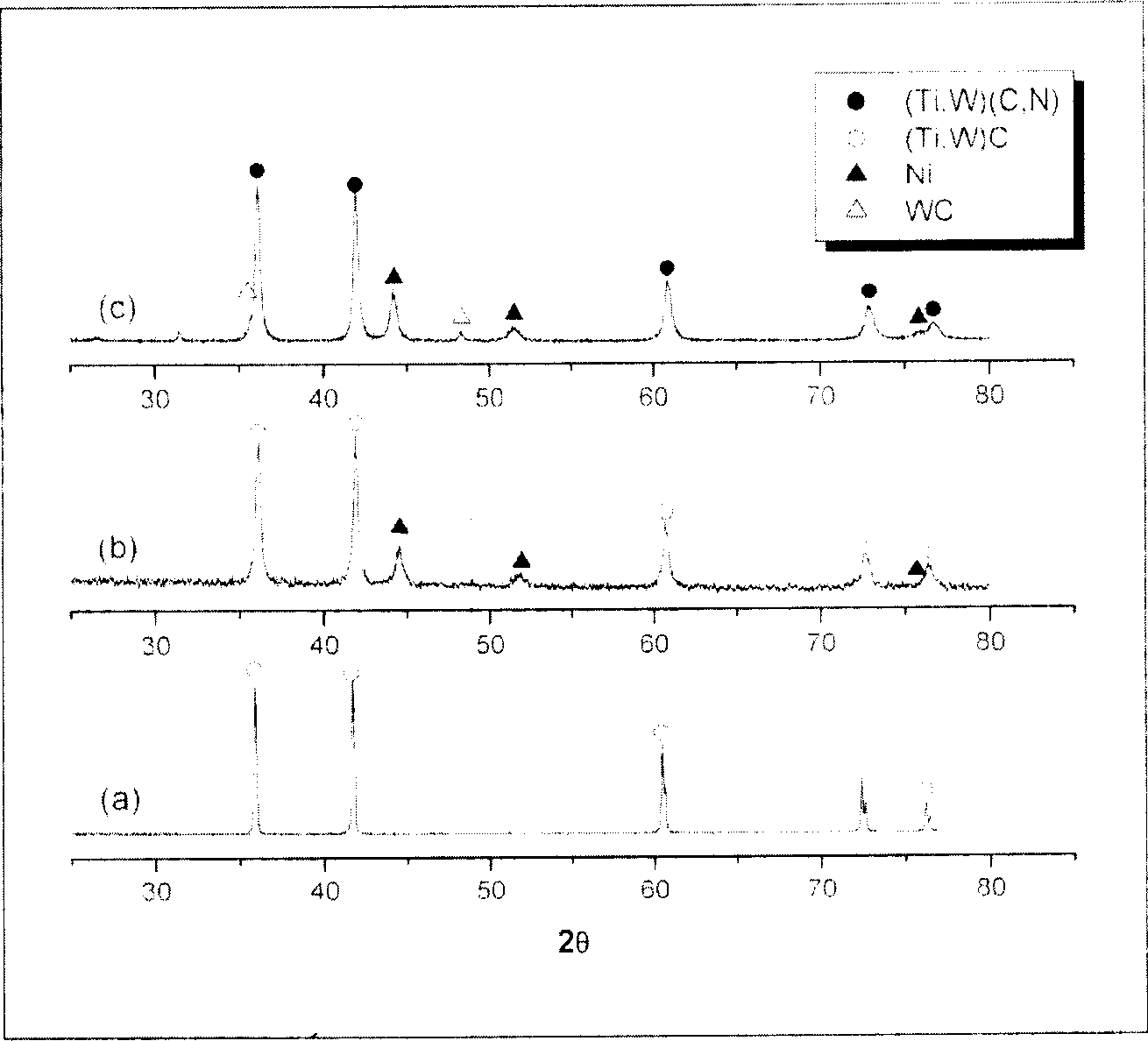

[0118] The above components were mixed with carbon powder to obtain the following 5 target compositions: (i) (Ti, W) C-Ni (containing 15% by weight WC), (ii) (Ti, W) C-Ni (containing 30% by weight WC), (iii) (Ti, W) (C, N)-Ni (containing 15% by weight WC, C / N=2:1), (iv) (Ti, W) (C, N) -Ni (with 30 wt% WC, C / N=3:1) and (v) (Ti,W)C (with 15 wt% WC), (vi)(Ti,W)C (with varying WC content).

[0119] The above mixture was milled, ie, milled with high-energy balls using a planetary mill (Fritsch Pulverisette 7). Tungsten carbide (WC) balls with a diameter of 5 mm were used as milling media and mixed with the powder at a ball: powder weight ratio of 20:1.

[0120] Tungsten carbide bowls were used and all grinding was performed in air at 250 RPM for 20 hours.

[0121] Here, the milled nanopowders were ...

Embodiment 2

[0158] As an example, a simple target composition is first selected, for which TiO with a crystal size of 100 nm is prepared according to the respective contents 2 、WO 3 , NiO nano oxide.

[0159] As the target composition, the following two compositions were selected: (i) (Ti, W)C-Ni (containing 15 wt% WC), (ii) (Ti, W)C-Ni (containing 30 wt% WC).

[0160] Mix and grind the carbon powder and the prepared above-mentioned nano-oxide, and put the ground nano-powder under vacuum or hydrogen, CH 4 、CO / CO 2 Annealed at 1300°C for 2 hours in atmosphere to reduce and carbonize it.

[0161] During sintering of the prepared cermet powder, nitrogen gas of 1-100 Torr is introduced into the furnace at the sintering temperature, and the pressure (1-100 Torr) is formed and maintained until the cooling process.

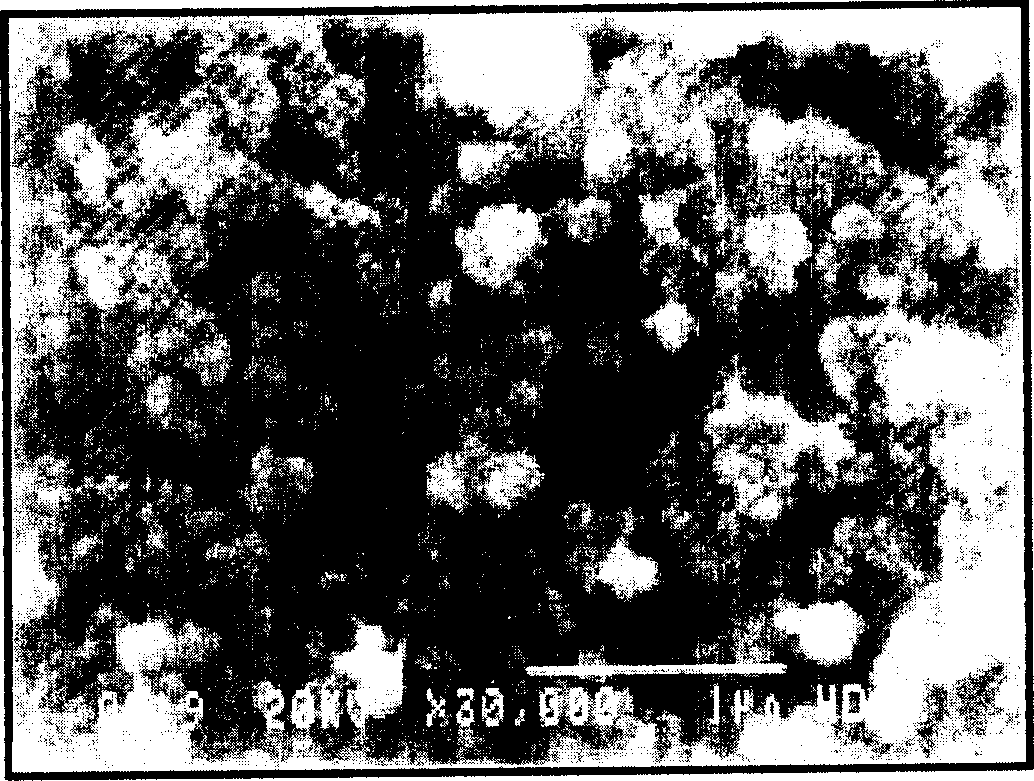

[0162] Figure 4a To show the FE-SEM image of a sintered sample (1510° C., 1 hour) of (Ti, W)C—Ni cermet powder (containing 15 wt. % WC) prepared in a nitrogen atmosphere accor...

Embodiment 3

[0171] As an example, a simple target composition is first selected, for which TiO with a crystal size of 100 nm is prepared according to the respective contents 2 、WO 3 , NiO nano oxide.

[0172] As the target composition, the following four compositions were selected: (i) (Ti, W) C-Ni (containing 15% by weight of WC), (ii) (Ti, W) C-Ni (containing 30% by weight of WC), (iii) (Ti,W)CN-Ni (containing 15 wt% WC) and (iv) (Ti,W)CN-Ni (containing 30 wt% WC).

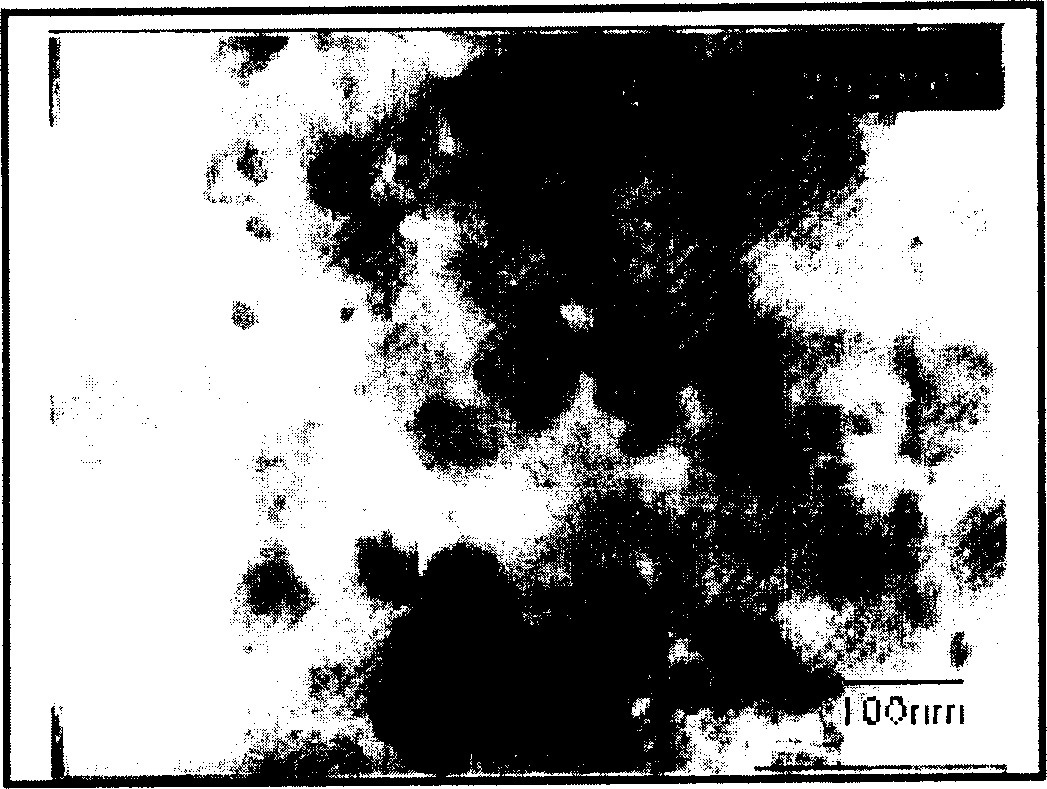

[0173] Mix and grind the carbon powder and the prepared above-mentioned nano-oxide, and put the ground nano-powder under vacuum or hydrogen, CH 4 P. CO / CO 2 Annealed at 1300°C for 2 hours in atmosphere to reduce and carbonize it. In the case of carbonitrides, nitrogen gas is injected into the vacuum furnace.

[0174] During sintering of the prepared cermet powder, a vacuum atmosphere (or argon, nitrogen) is used. In addition, a TiN coating was formed on the surface of the sintered cermet by PVD method. TiN coating ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com