Patents

Literature

362 results about "Solution phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A solution may exist in any phase. A solution consists of a solute and a solvent. The solute is the substance that is dissolved in the solvent. The amount of solute that can be dissolved in solvent is called its solubility.

Pharmaceutical co-crystal compositions

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphonic acid, phosphinic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, sp2 amine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, s-heterocyclic ring, thiophene, n-heterocyclic ring, pyrrole, o-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES +2

Hydrophobic membrane materials for filter venting applications

The present invention relates to filtration media having both hydrophobic (water-repellent) properties. The filtration media are produced using a fluorothermoplastic material, such as a terpolymer of tetrafluoroethylene, vinylidene fluoride, and hexafluoropropylene. The invention also relates to methods of preparing such filtration media using casting solution phase inversion.

Owner:PALL CORP

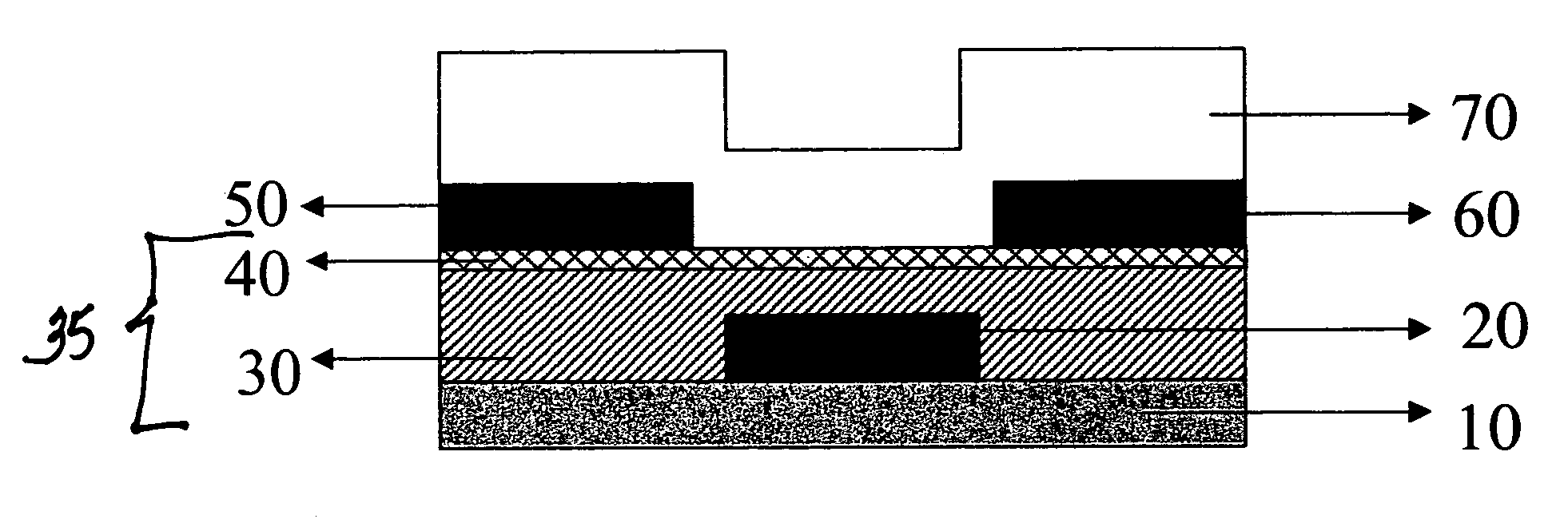

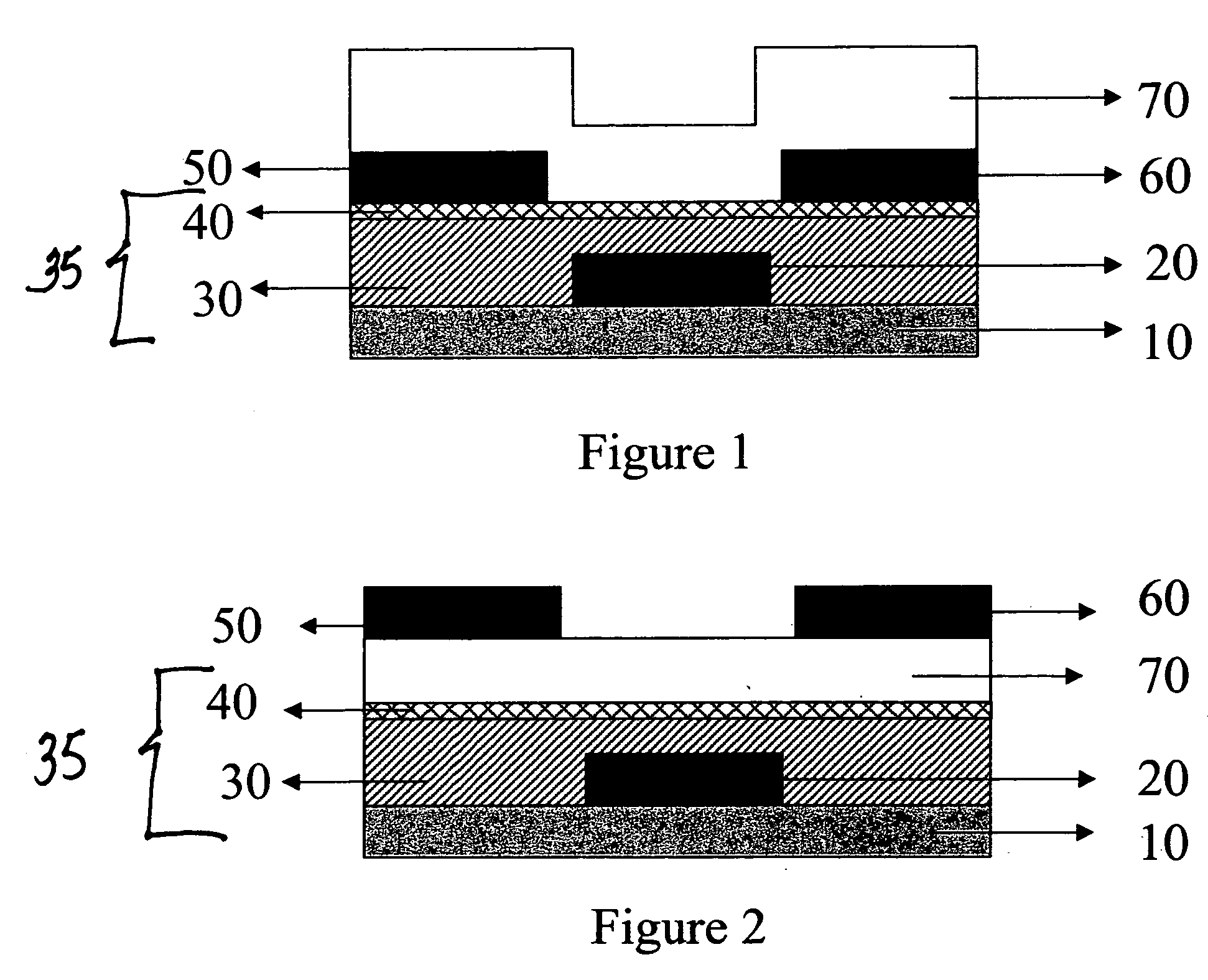

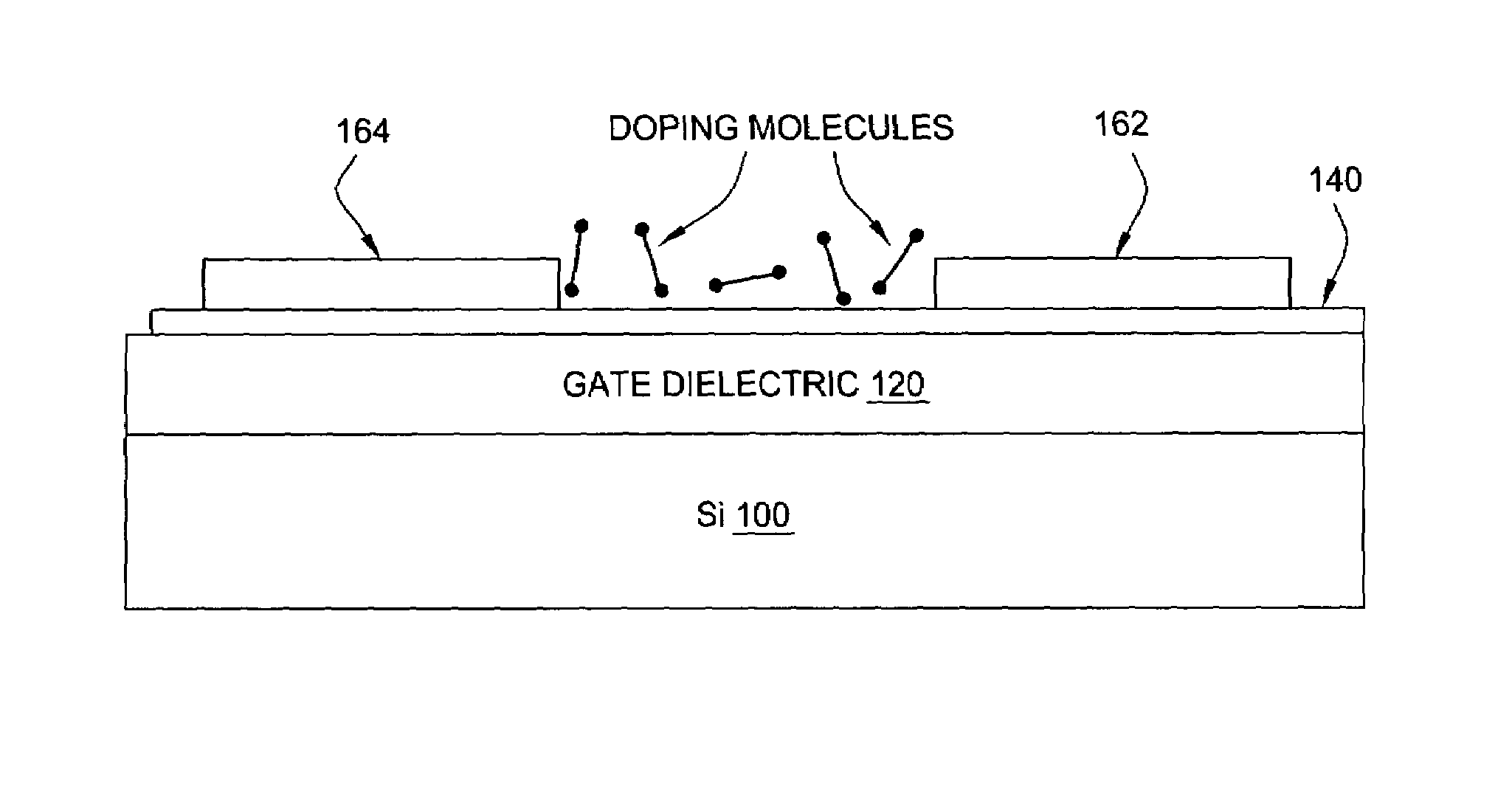

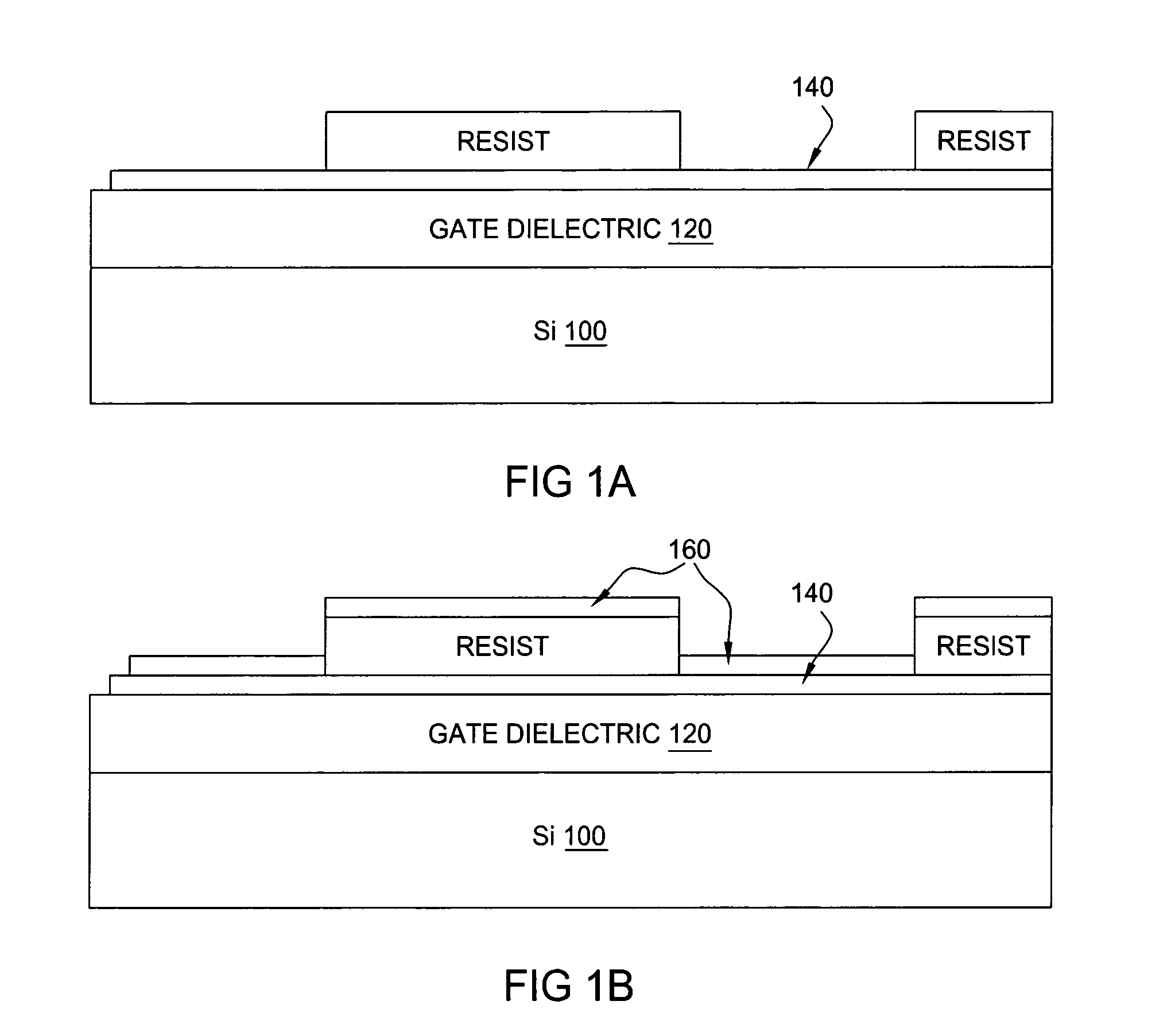

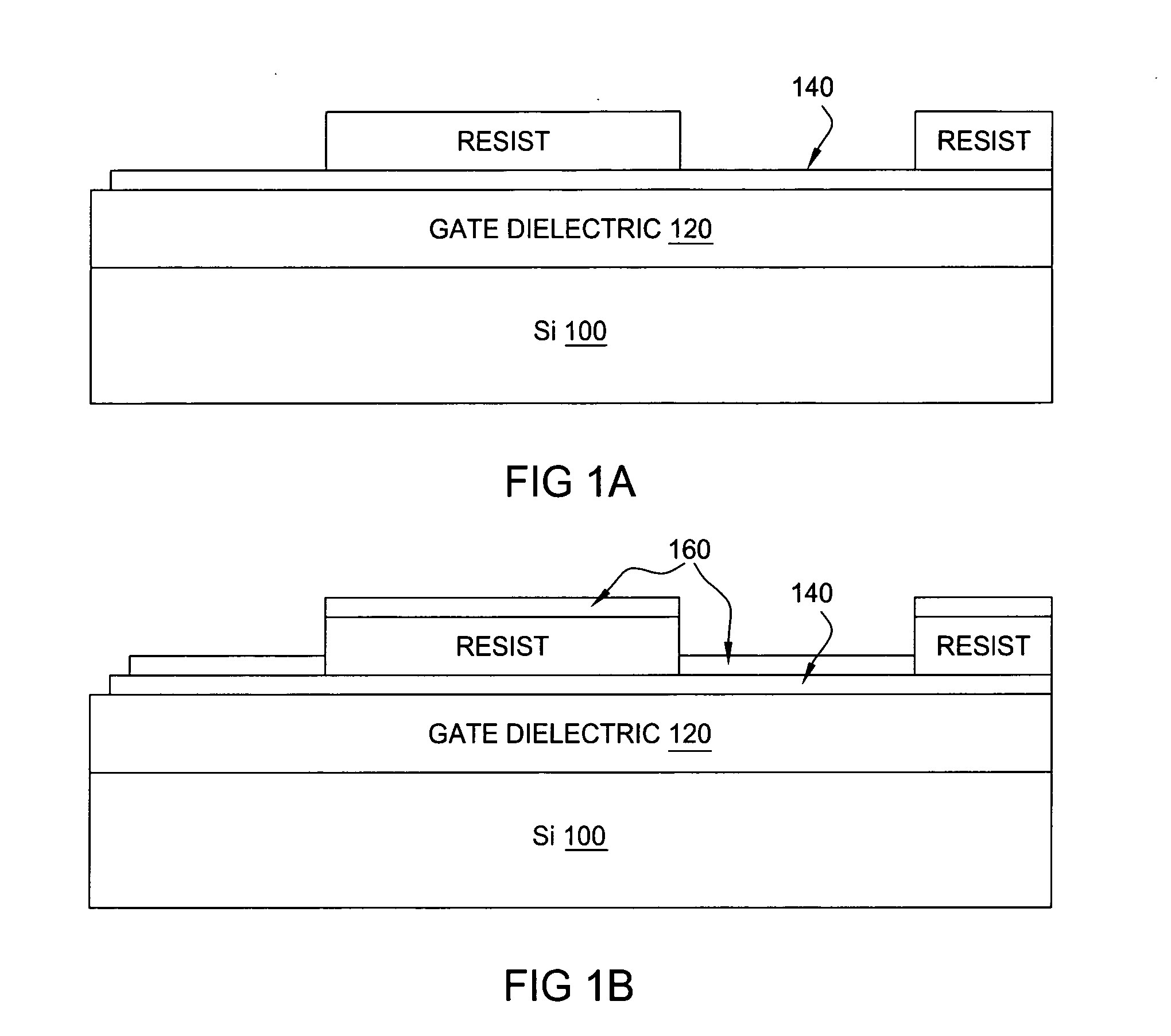

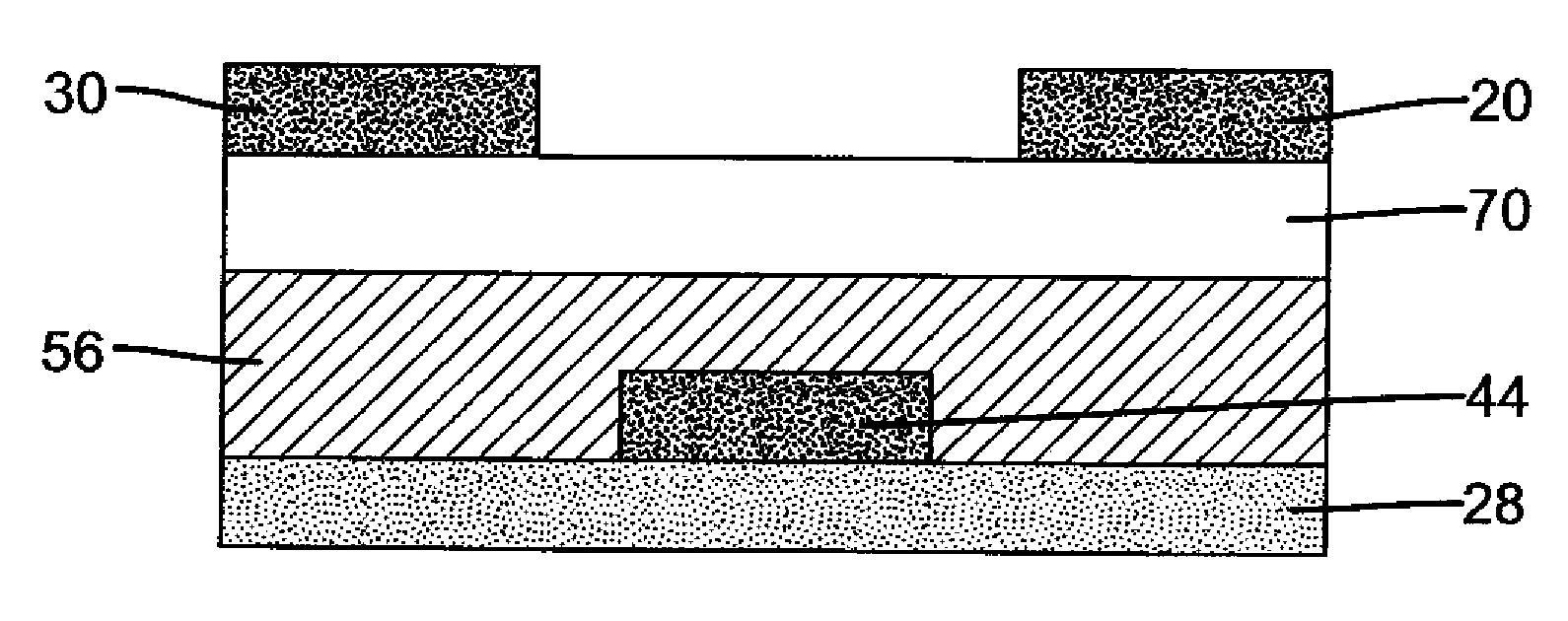

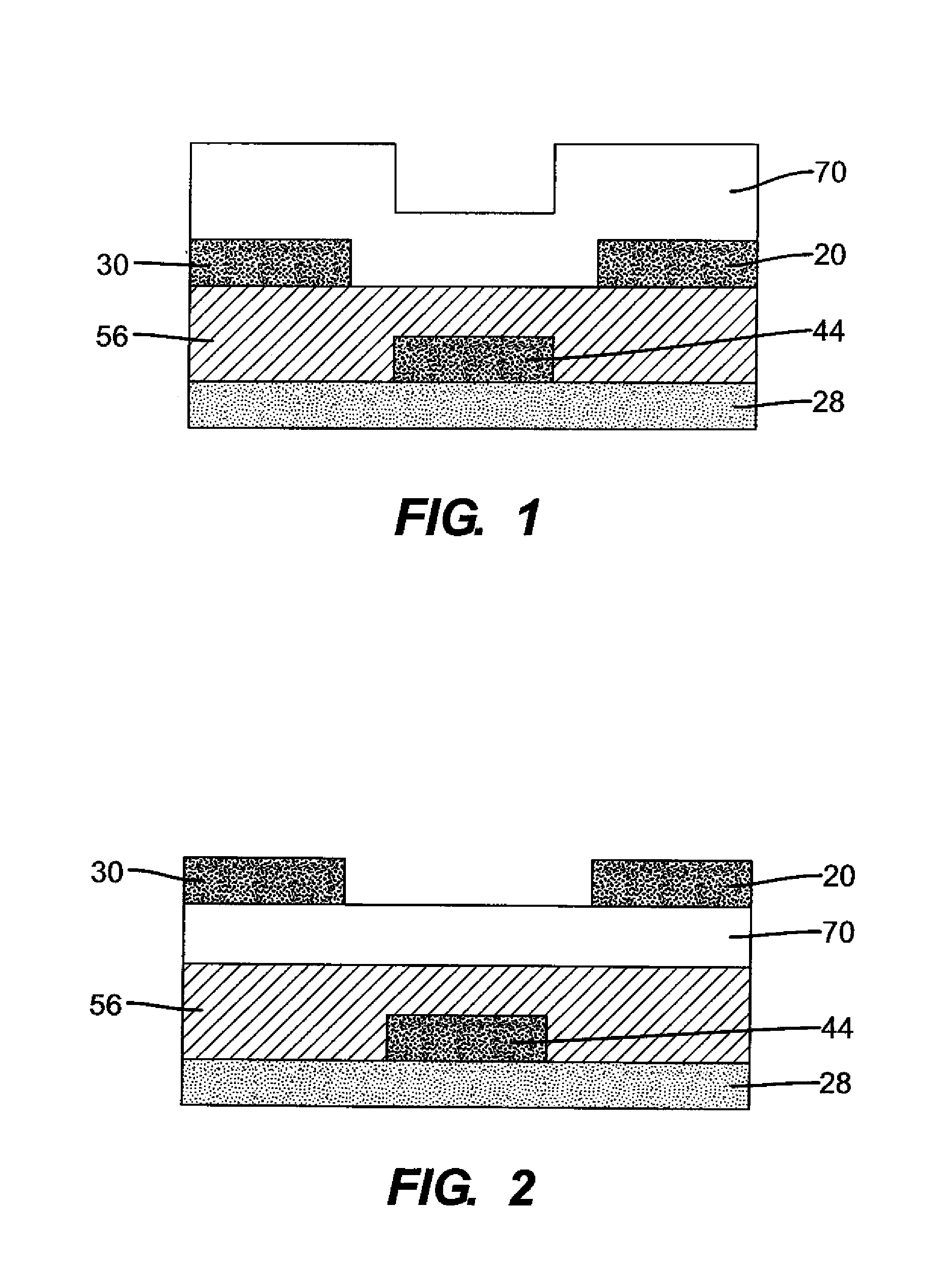

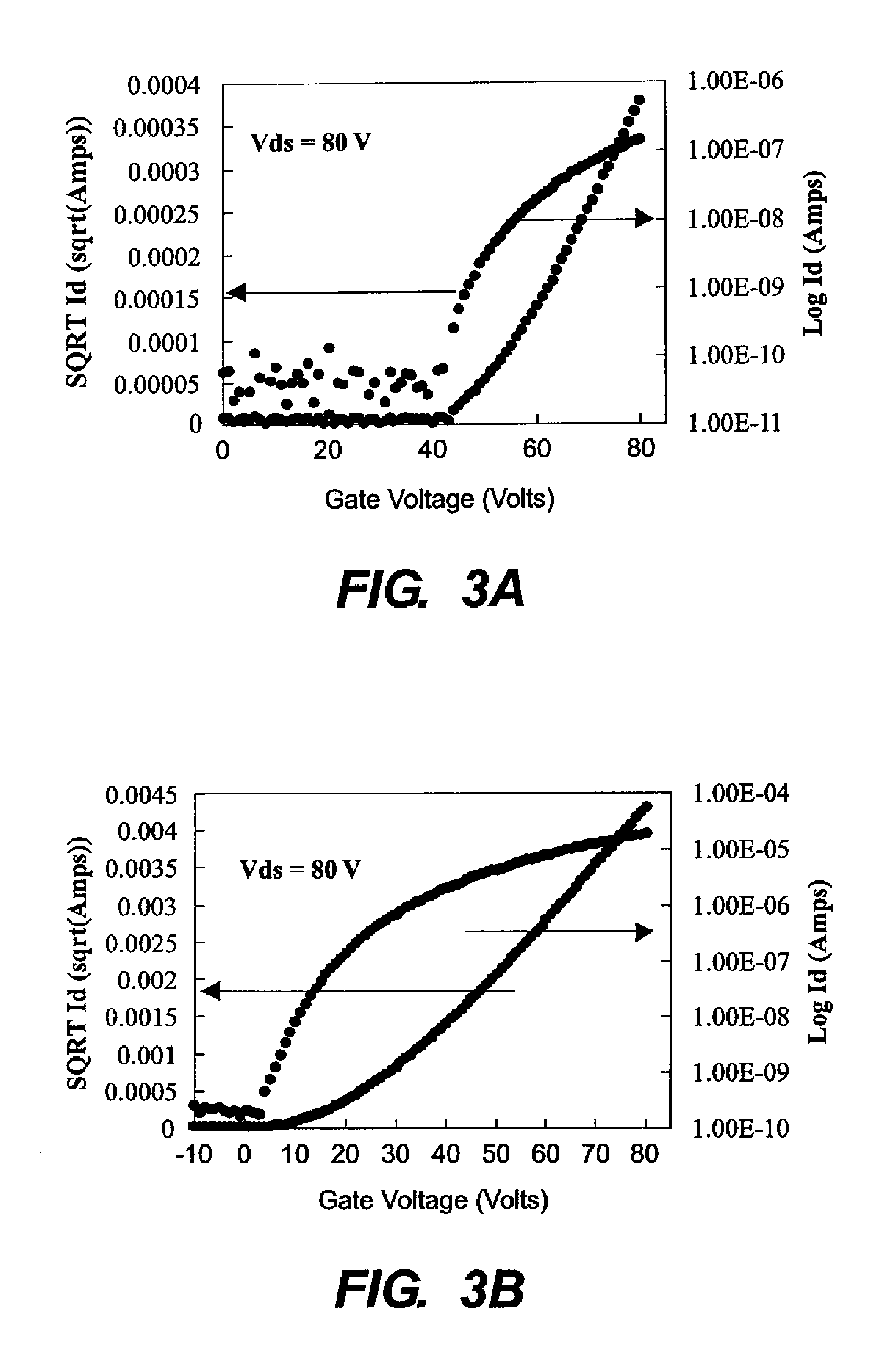

Polymeric gate dielectrics for organic thin film transistors and methods of making the same

Owner:EASTMAN KODAK CO

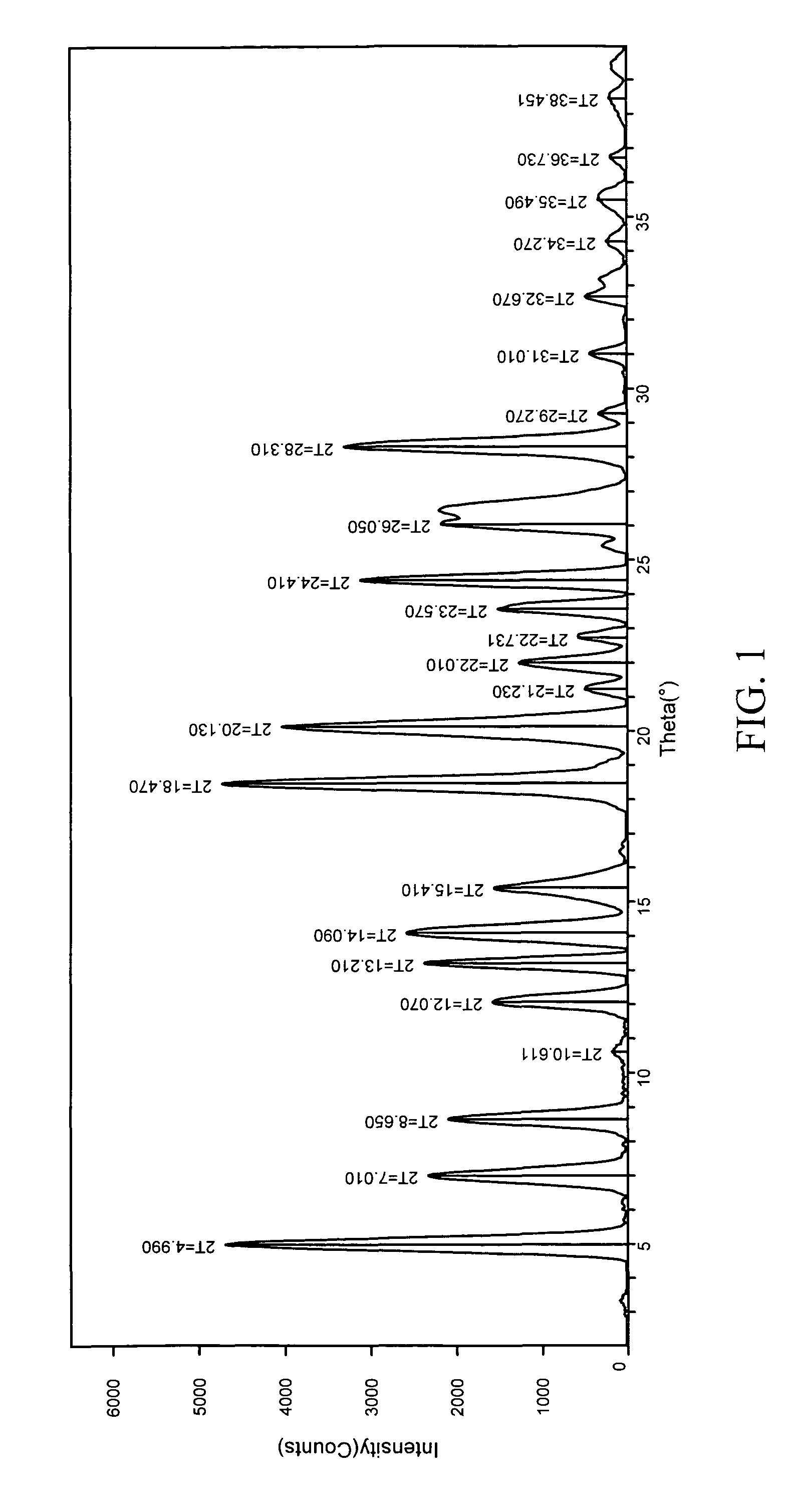

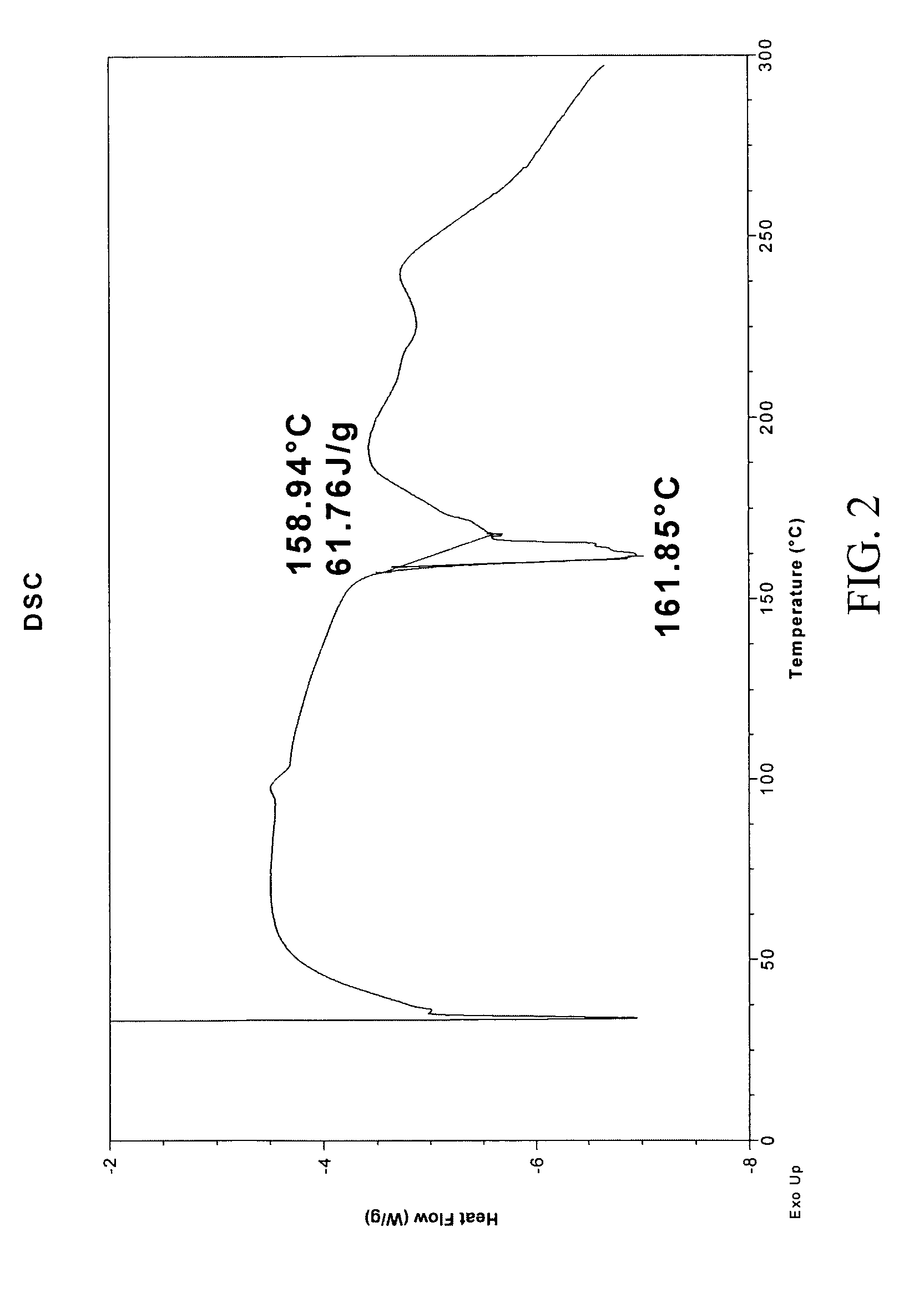

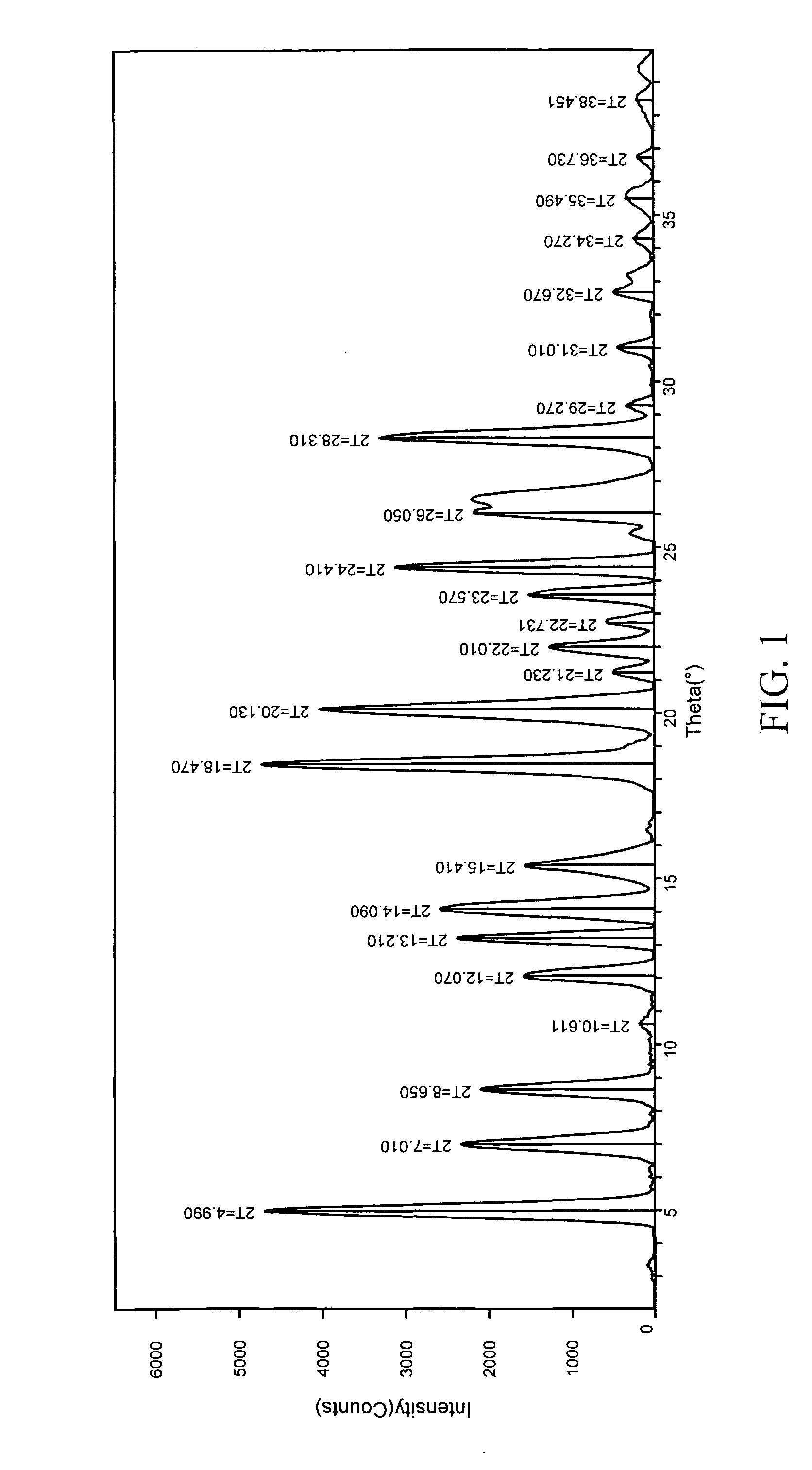

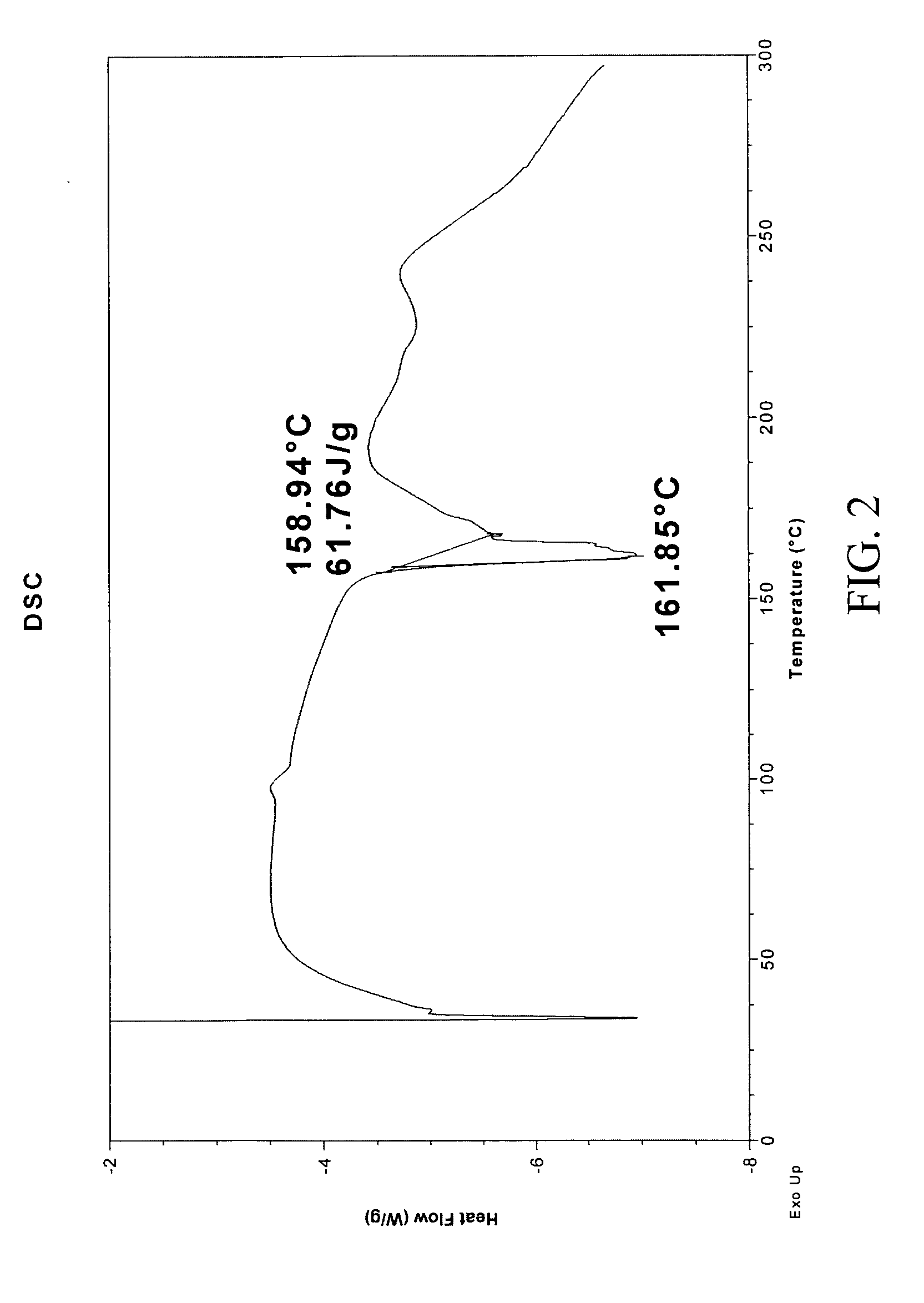

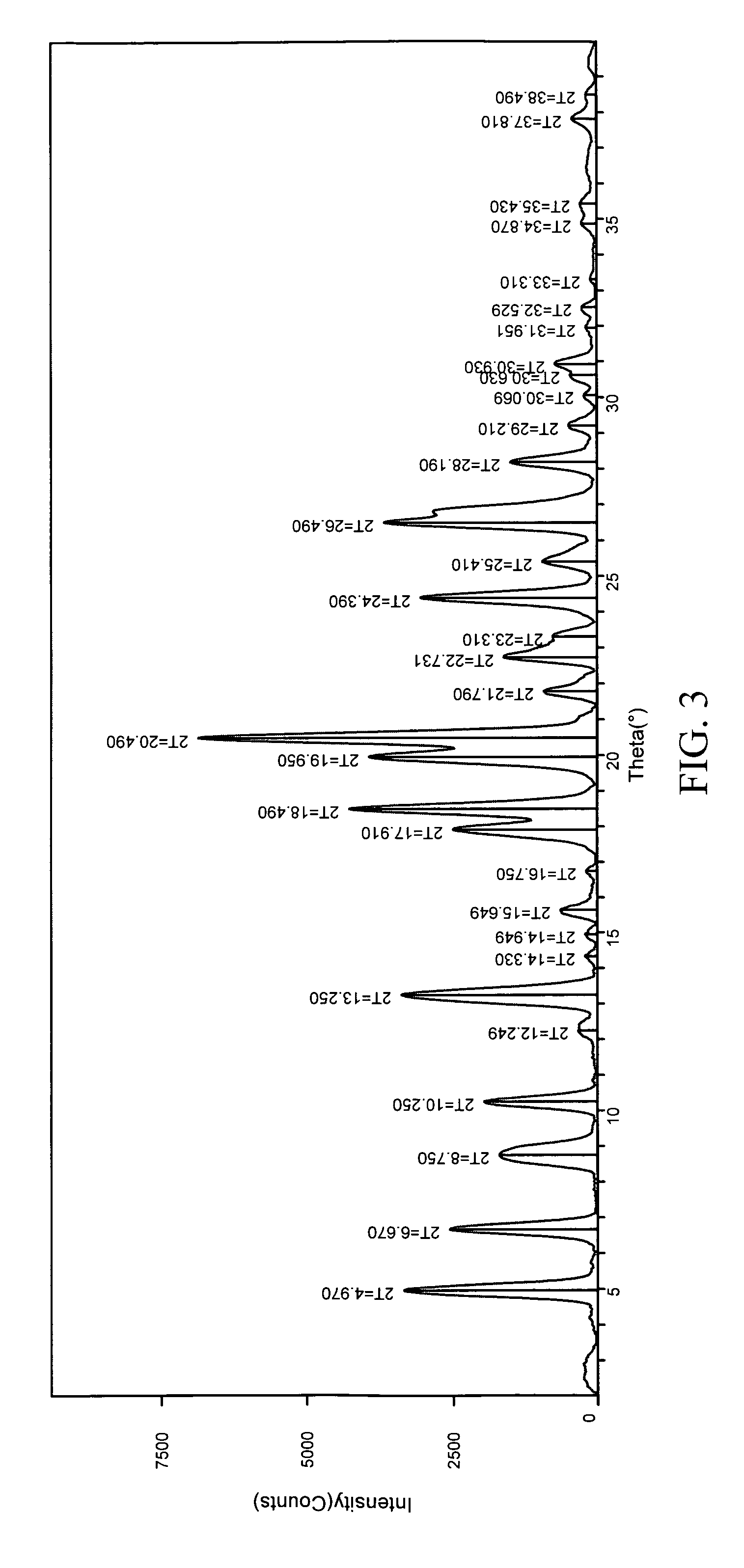

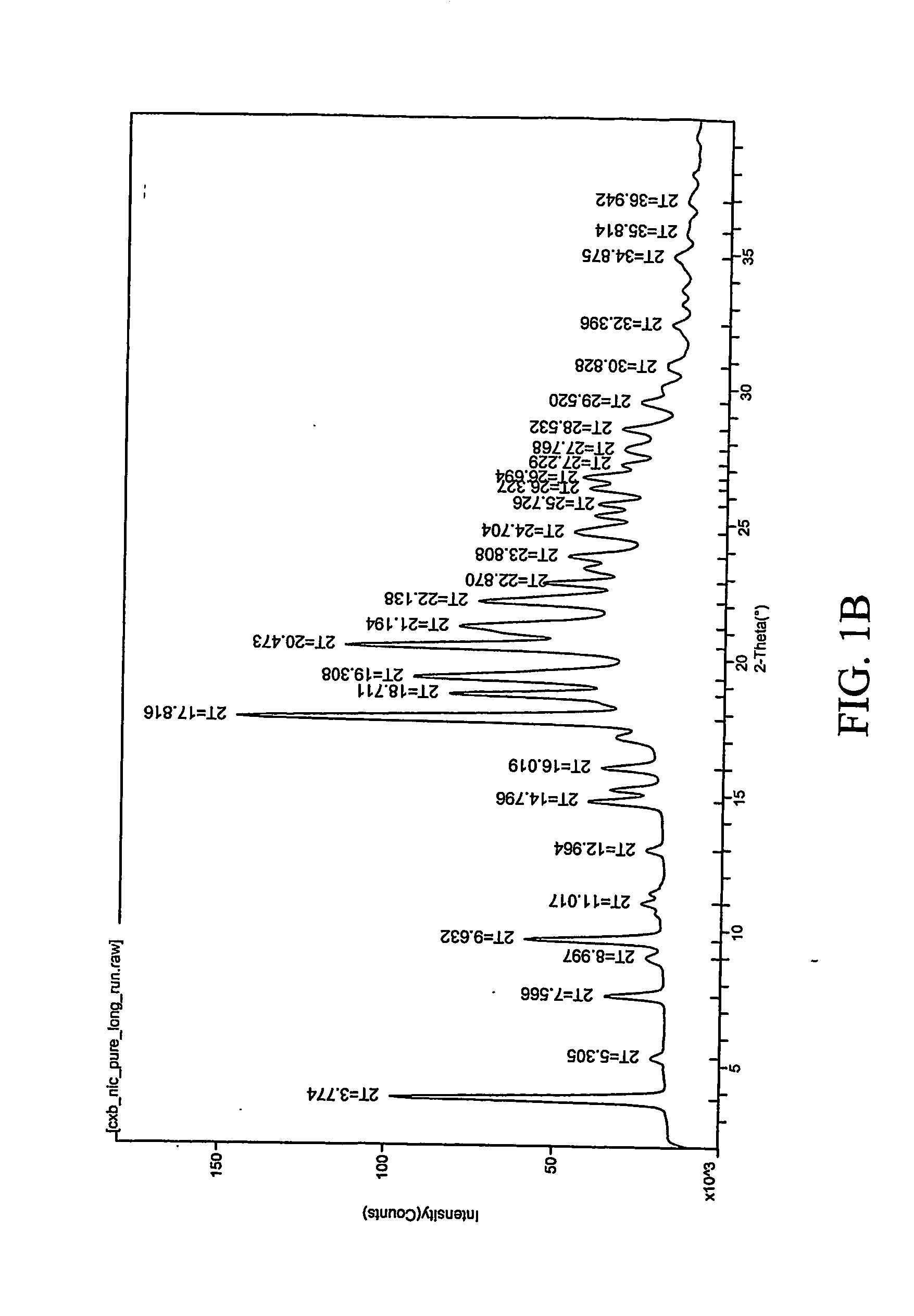

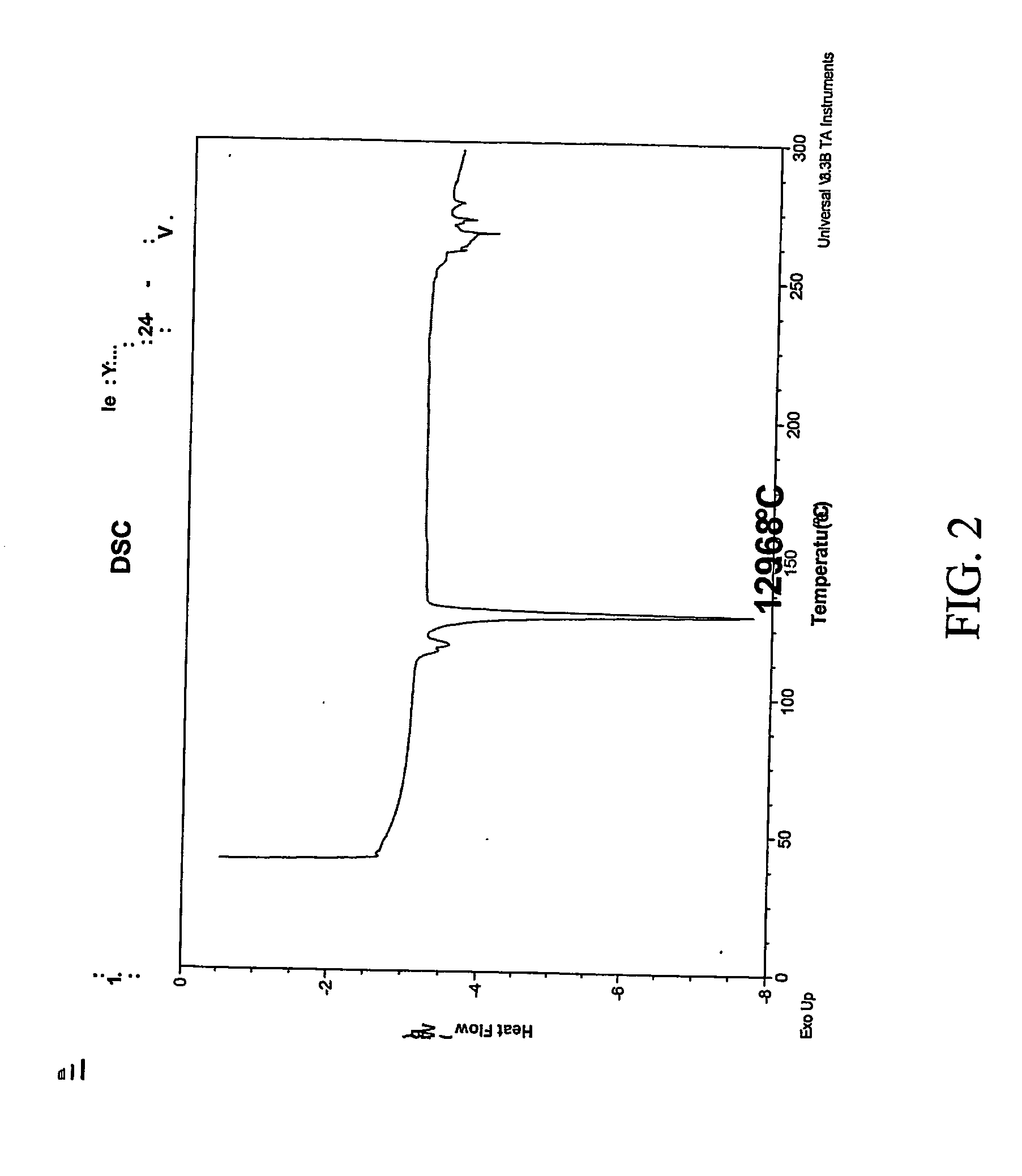

Pharmaceutical co-crystal compositions

InactiveUS20070026078A1Improve solubilityLow hygroscopicityBiocidePowder deliveryThioketoneHydroxamic acid

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphonic acid, phosphinic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, sp2 amine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, s-heterocyclic ring, thiophene, n-heterocyclic ring, pyrrole, o-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES +2

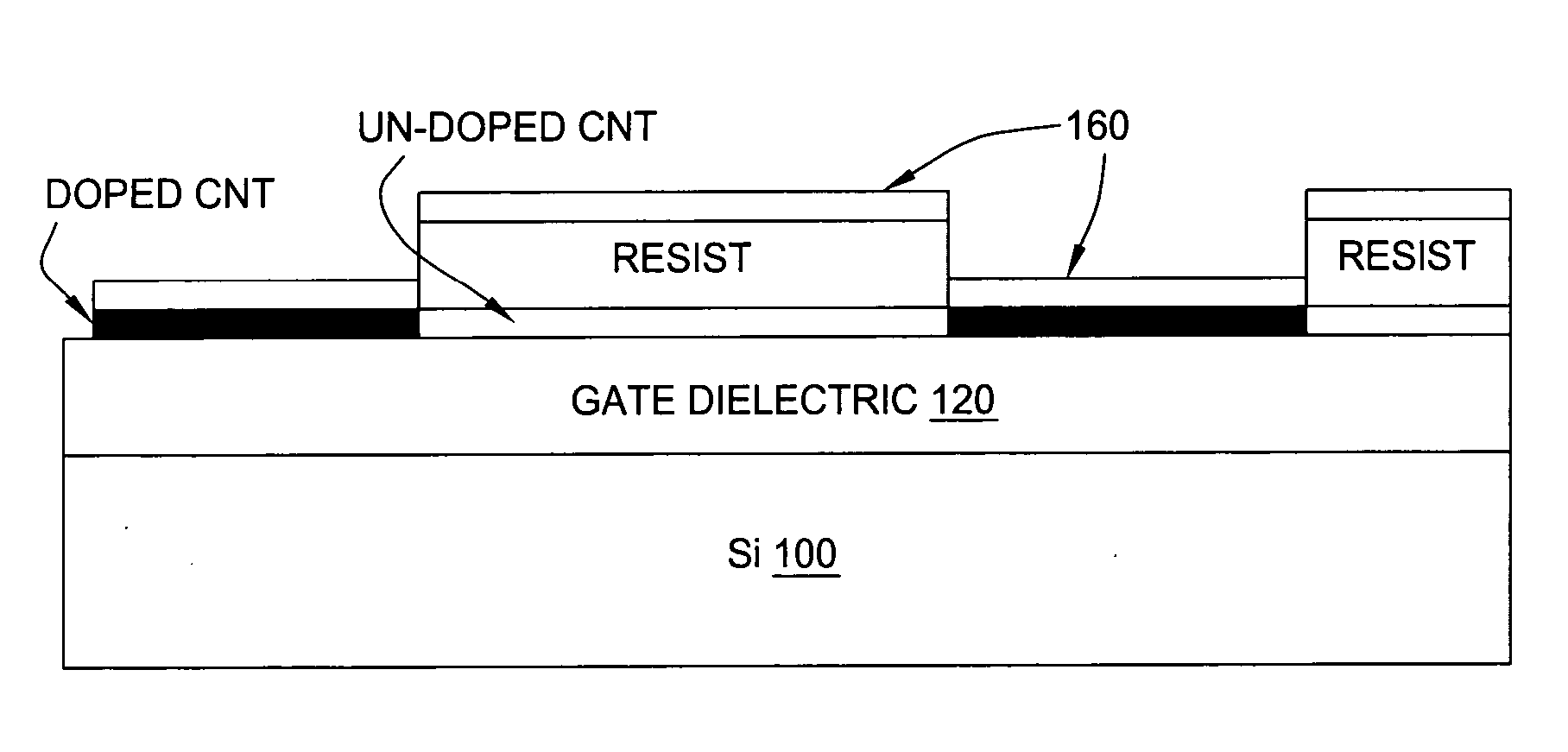

Method and apparatus for solution processed doping of carbon nanotube

A method is provided for doping a carbon nanotube. The method comprises exposing the nanotube to a one-electron oxidant in a solution phase. A method is also provided for forming a carbon nanotube FET device.

Owner:GLOBALFOUNDRIES U S INC

Methods of nonspecific target capture of nucleic acids

ActiveUS20080286775A1Sugar derivativesMicrobiological testing/measurementTarget captureSolution phase

Methods for capturing a target nucleic acid from a sample by using a capture probe that binds nonspecifically to the target nucleic acid and binds specifically to an immobilized probe via a specific binding pair that has one member on the capture probe and one member on the immobilized probe are disclosed. Compositions that include a capture probe that binds nonspecifically to a target nucleic acid and specifically to an immobilized probe via binding of members of a specific binding pair in a solution phase of a reaction mixture are disclosed.

Owner:GEN PROBE INC

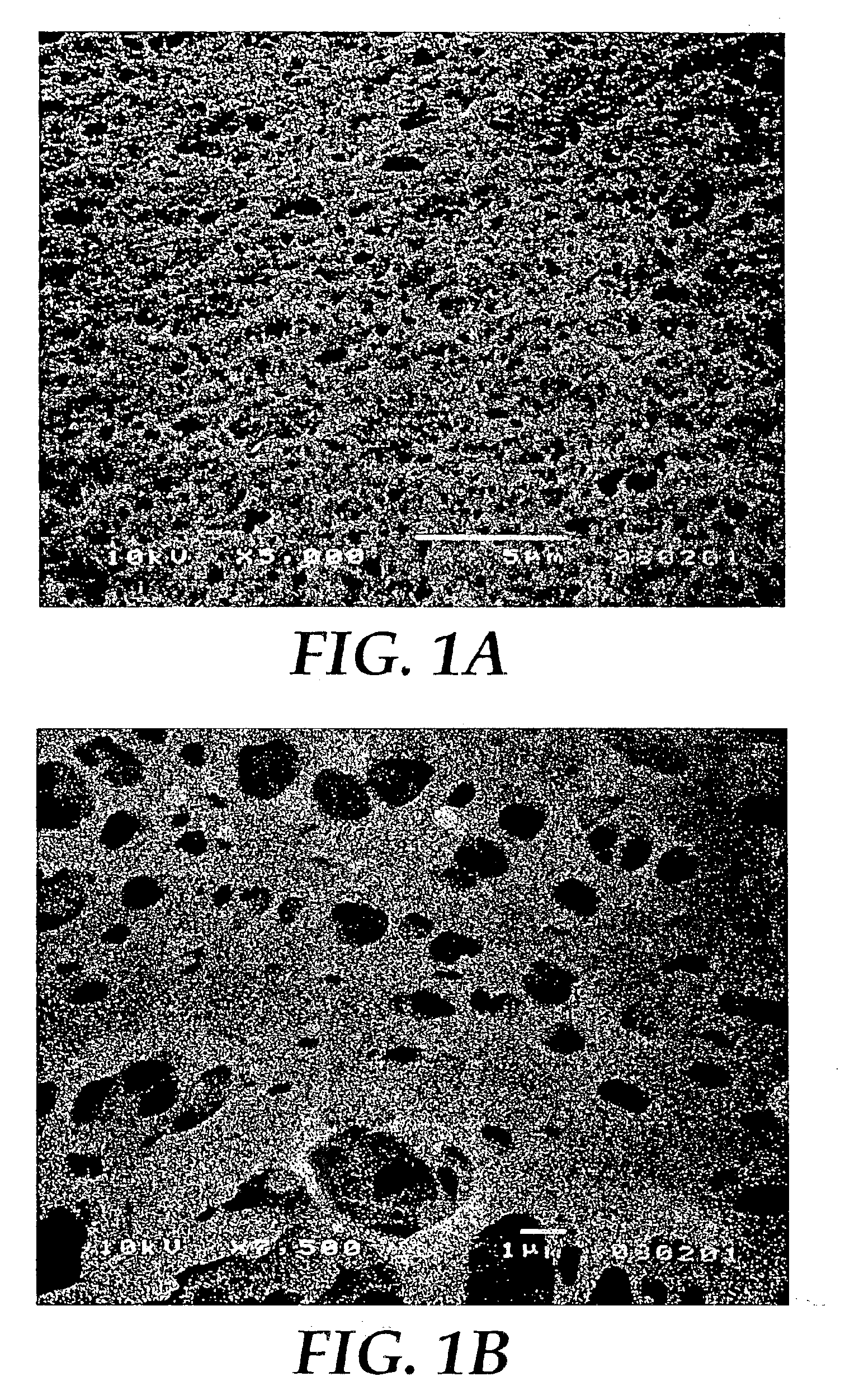

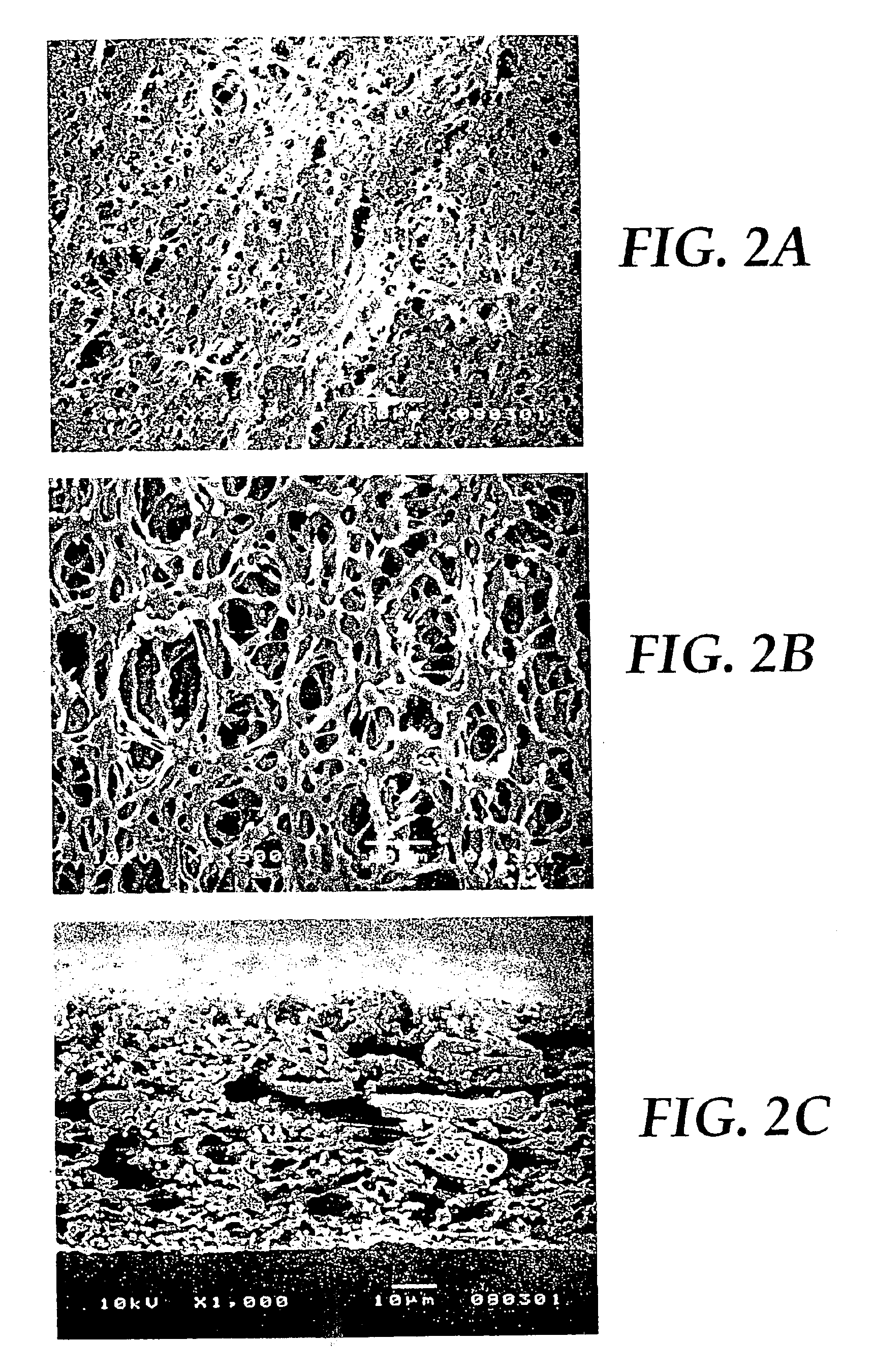

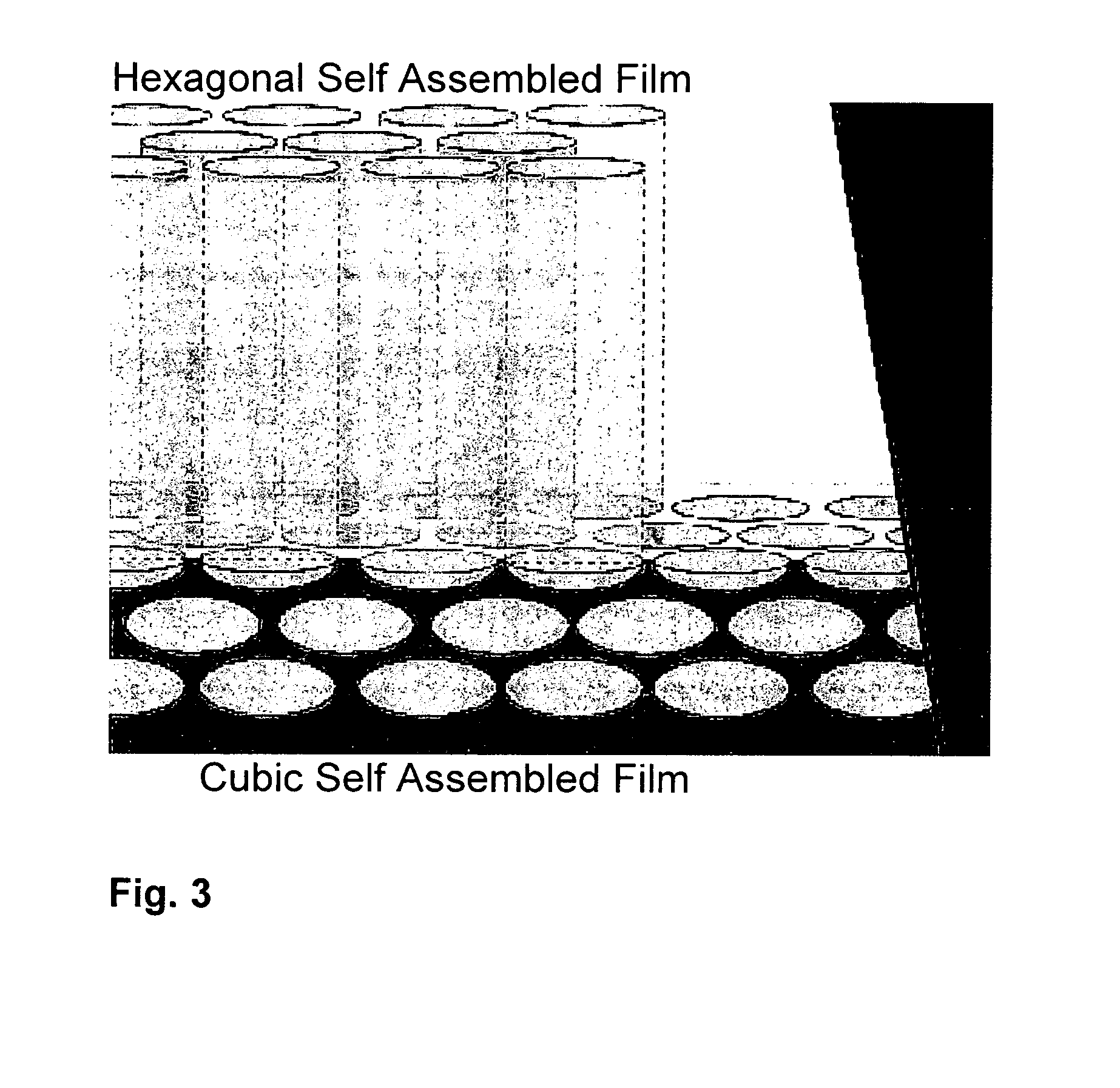

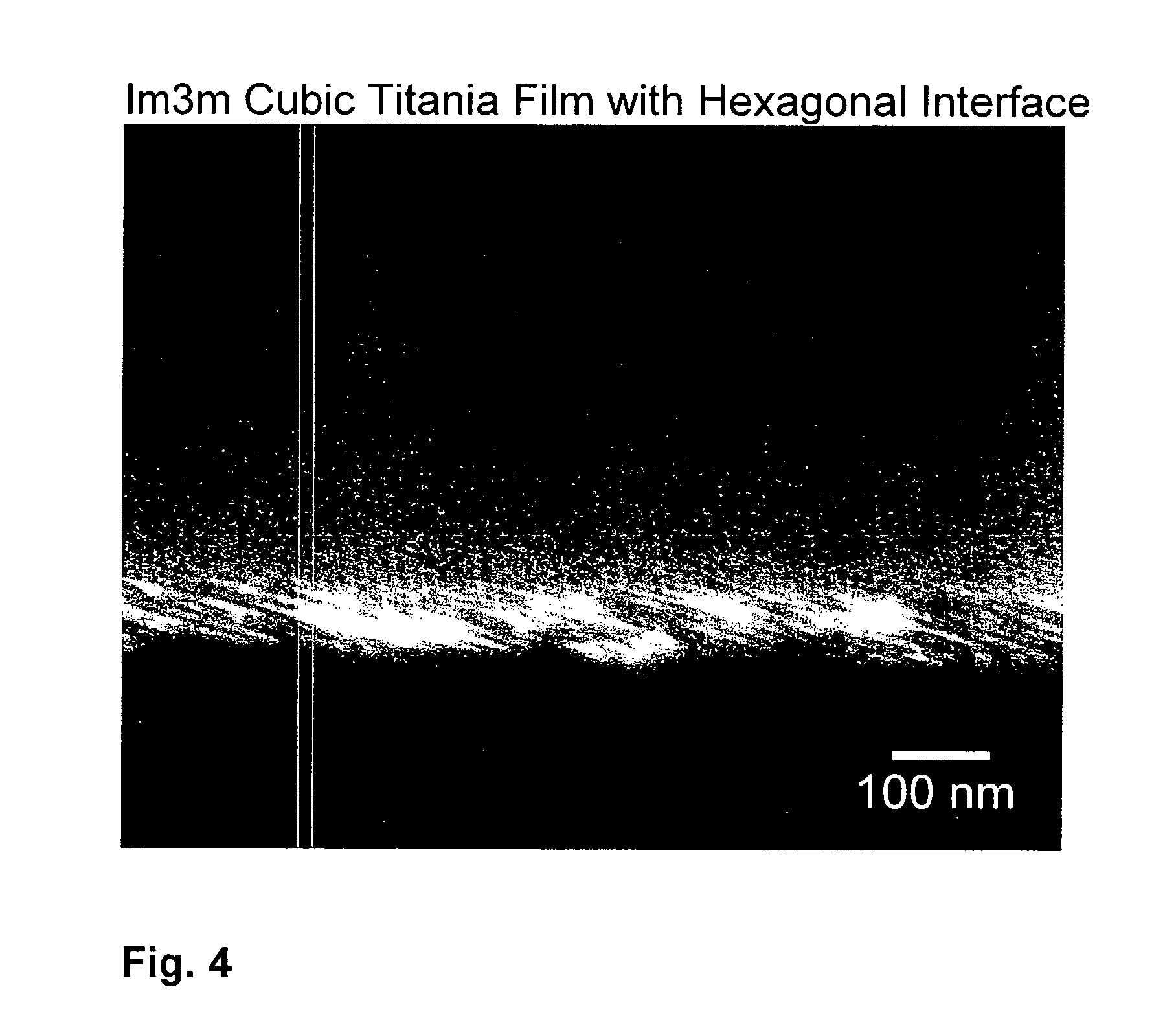

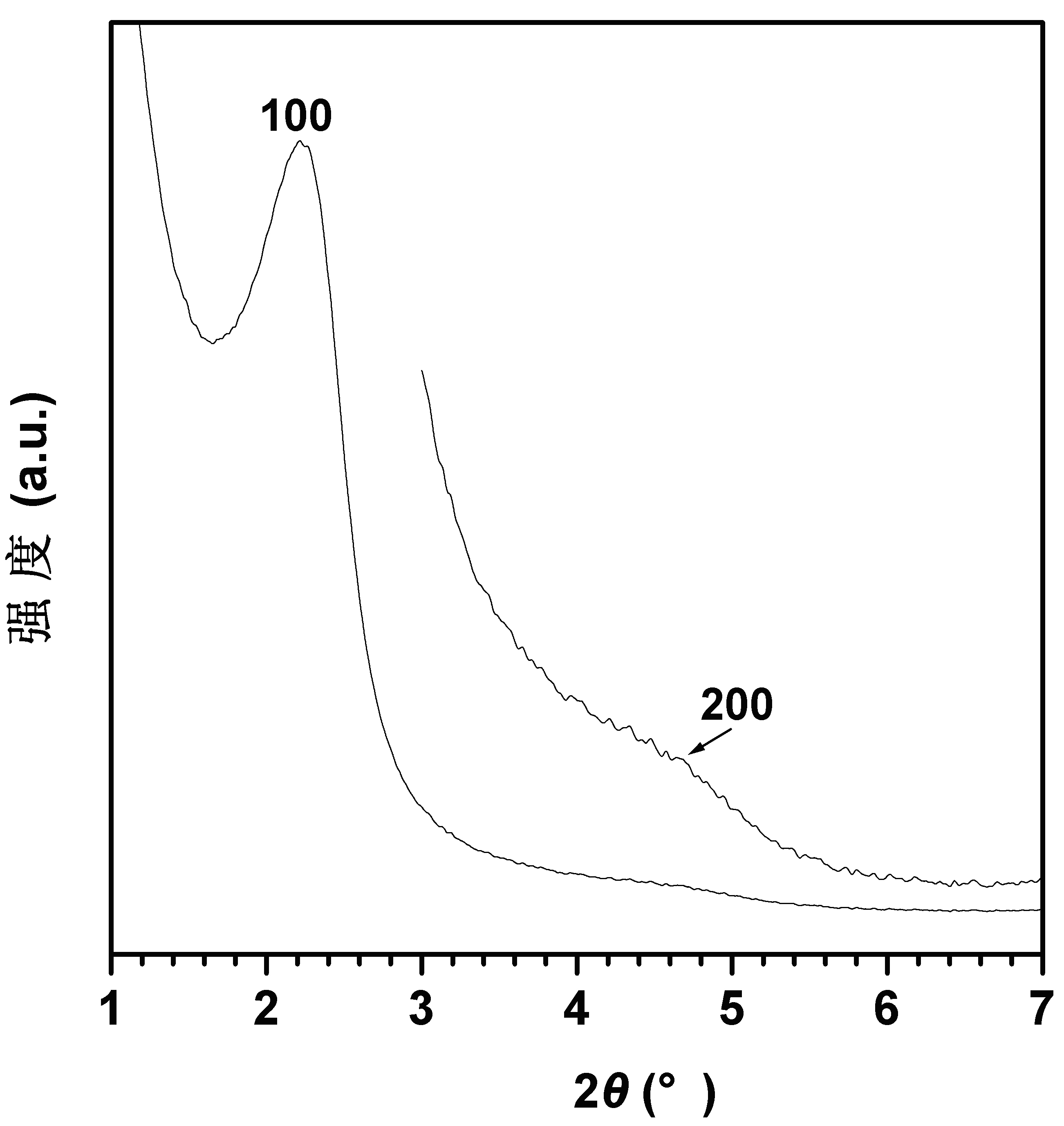

Ordered vertically oriented porous inorganic films produced through solution processing

InactiveUS20060278158A1Easy to produceFrom gel statePhotosensitive materialsPatterned substrateSelf-assembly

Porous films with straight pores oriented normal to the plane of the films are produced through solution processing techniques. The production takes advantage of inorganic-surfactant or inorganic-polymer co-assembly and a patterned substrate. The patterned substrate, which is also produced via solution phase self-assembly, forces vertical orientation in a hexagonal cylinder system with no practical limits in substrate size or type. This provides a route to vertically oriented inorganic pores with a pitch ranging from 3 nm to over 15 nm and pore sizes ranging from 2 nm to over 12 nm. The size is tuned by choice the choice of organic templating agents and the deposition conditions. The pores can be produced with or without a capping layer which can be used to seal the nanopores.

Owner:RGT UNIV OF CALIFORNIA

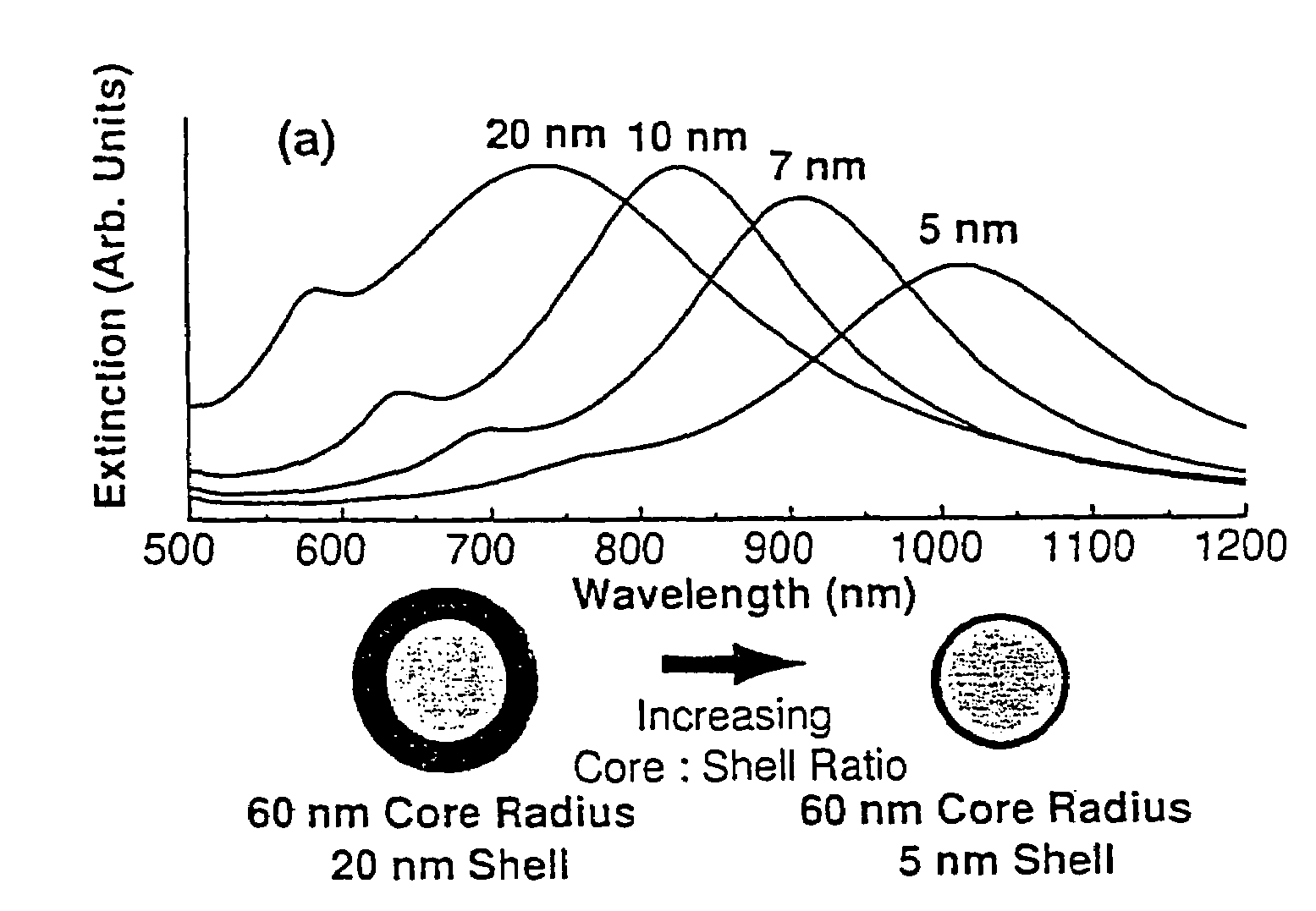

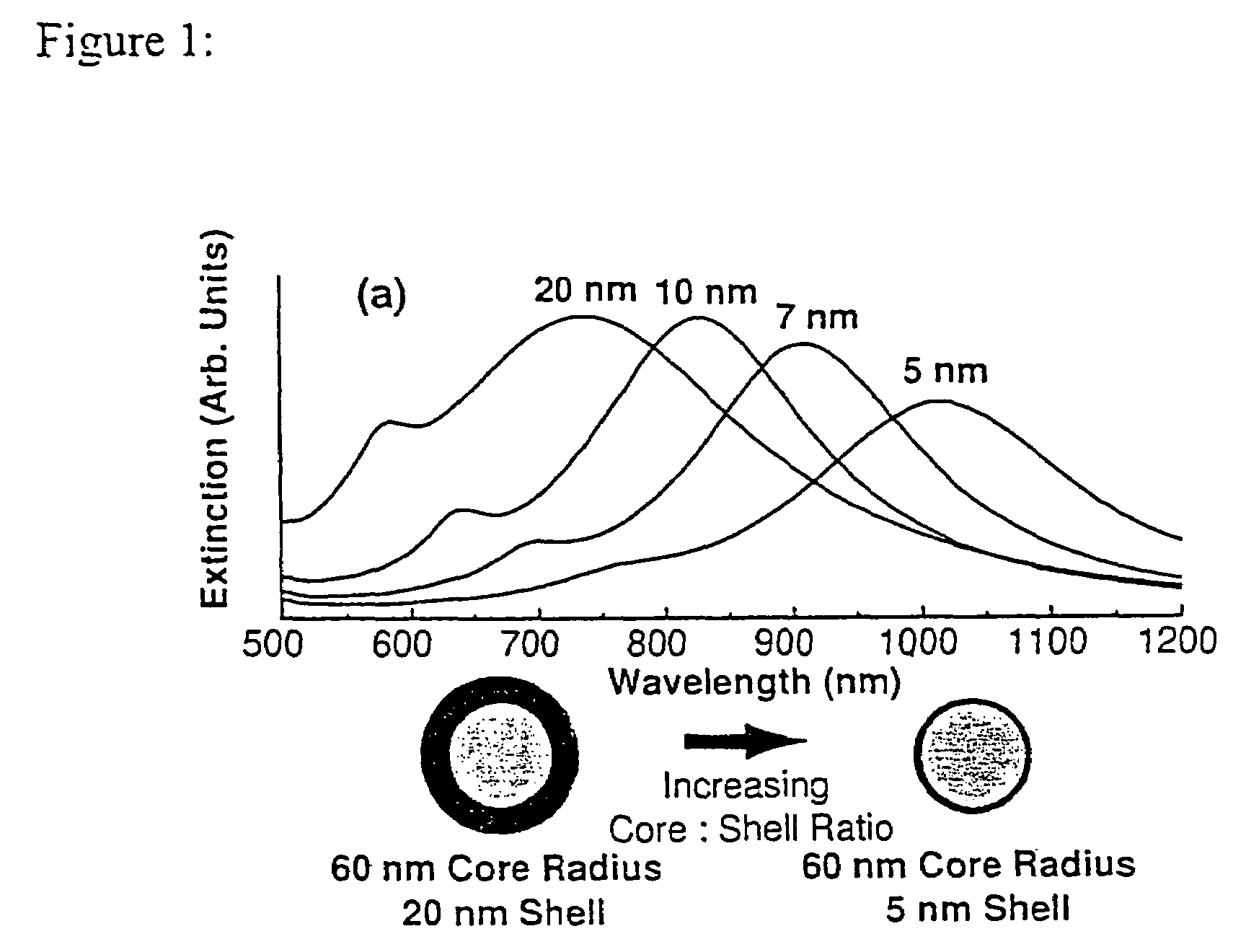

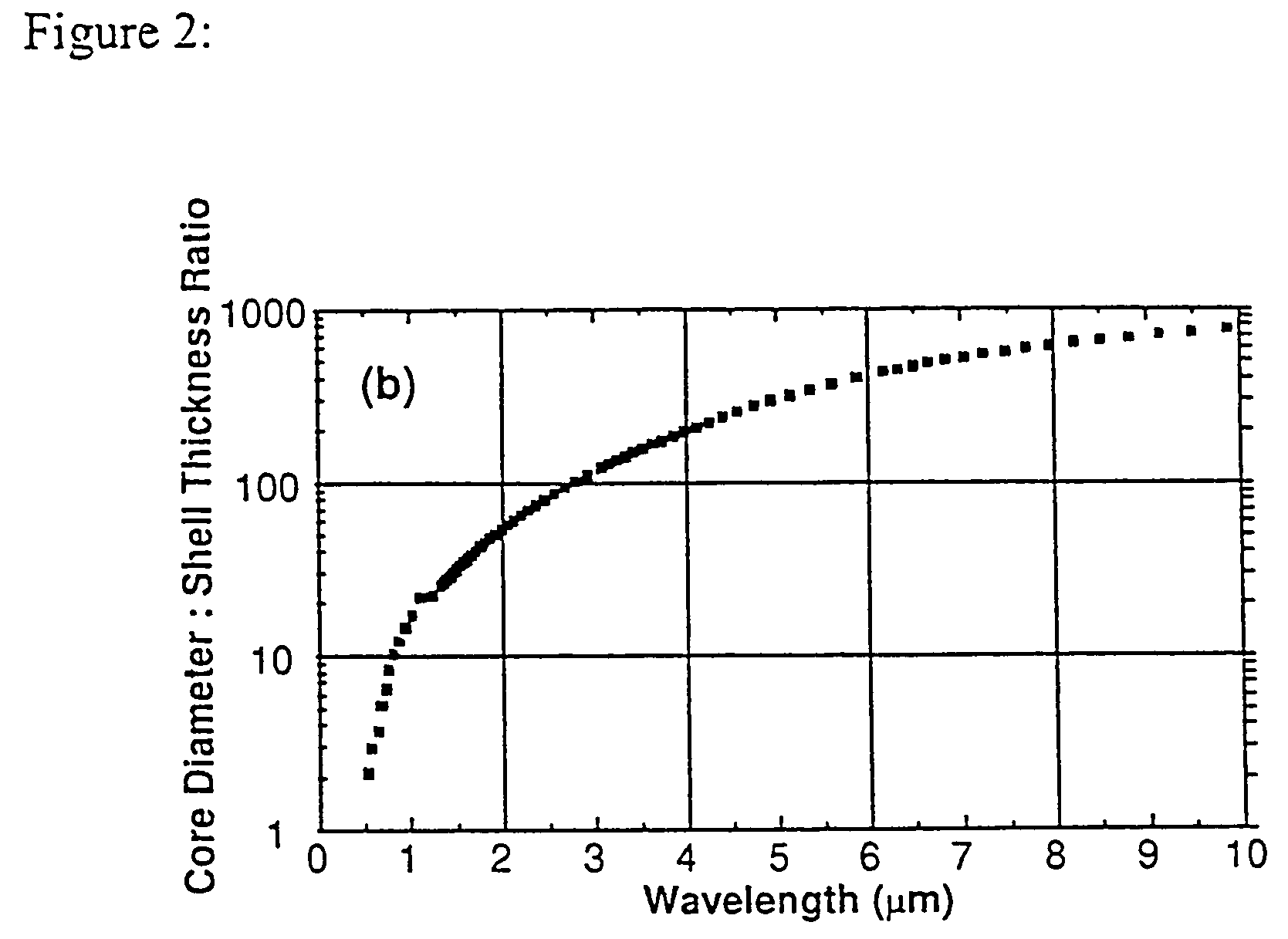

Nanoparticle comprising nanoshell of thickness less than the bulk electron mean free path of the shell material

InactiveUS7371457B2Increase polarizabilityGood optical performancePigmenting treatmentMaterial nanotechnologyParticulatesConductive materials

The present invention is for particulate compositions and methods for producing them that can absorb or scatter electromagnetic radiation. The particles are homogeneous in size and are comprised of a nonconducting inner layer that is surrounded by an electrically conducting material. The ratio of the thickness of the nonconducting layer to the thickness of the outer conducting shell is determinative of the wavelength of maximum absorbance or scattering of the particle. Unique solution phase methods for synthesizing the particles involve linking clusters of the conducting atoms, ions, or molecules to the nonconducting inner layer by linear molecules. This step can be followed by growth of the metal onto the clusters to form a coherent conducting shell that encapsulates the core.

Owner:RICE UNIV

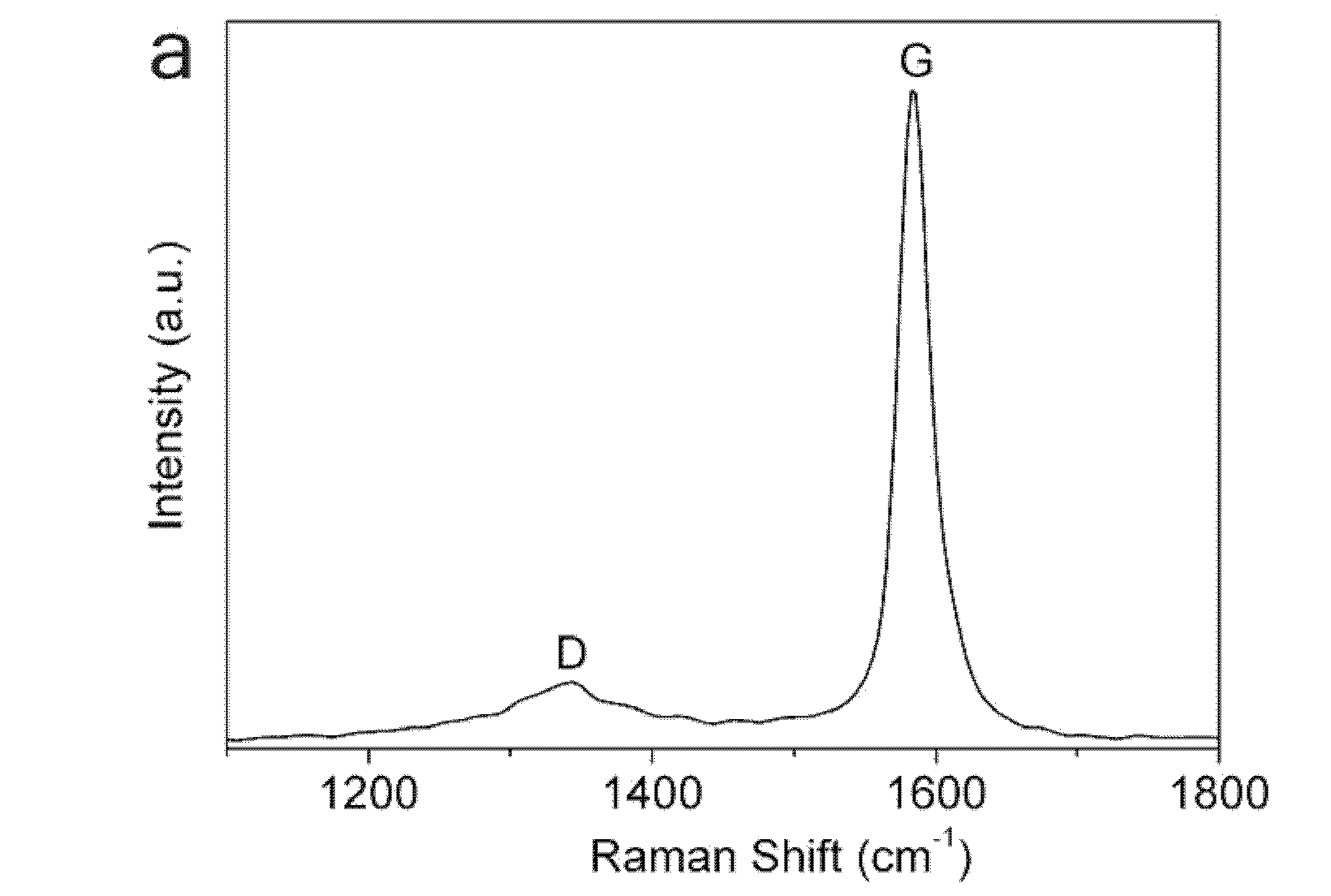

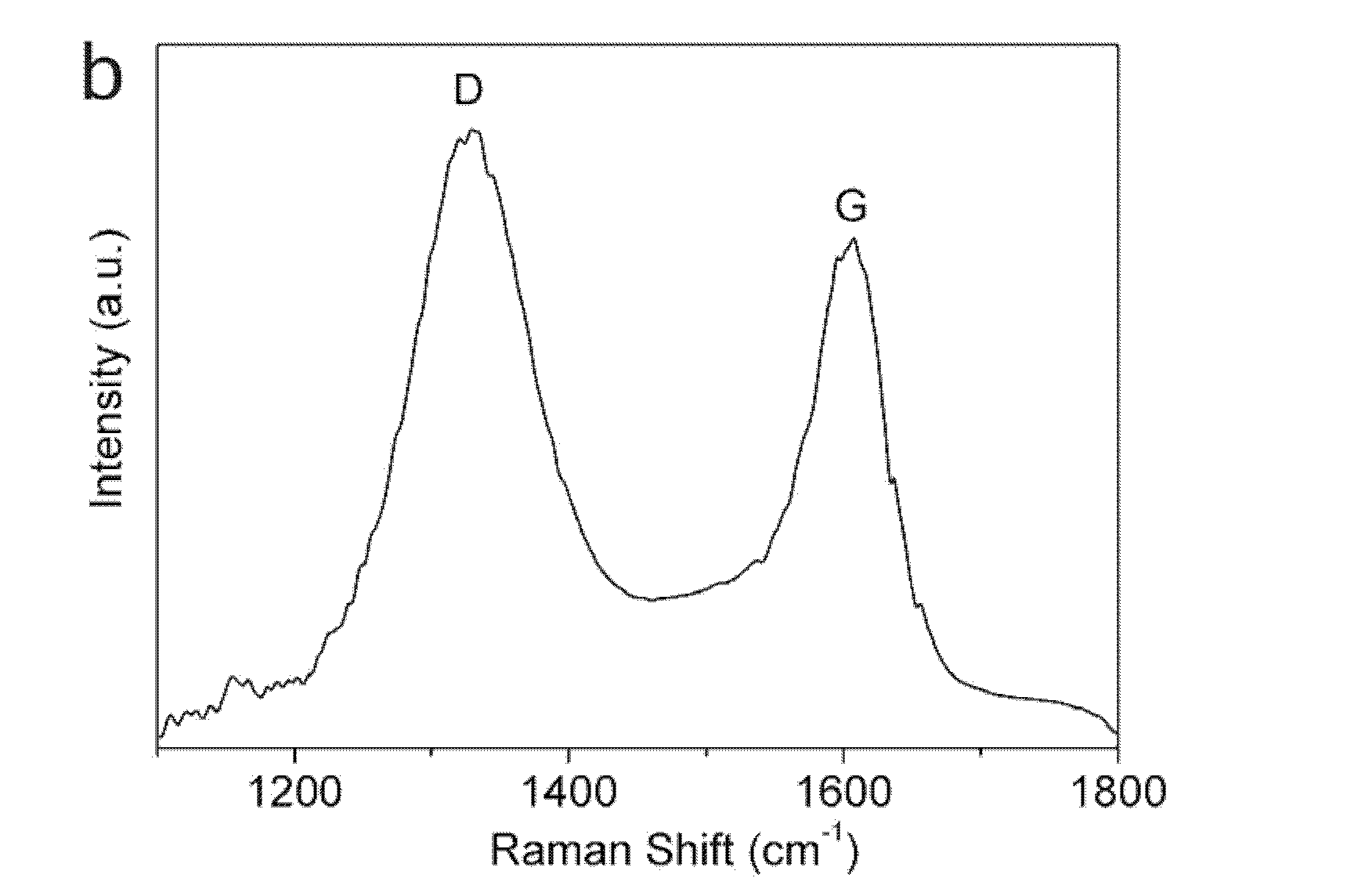

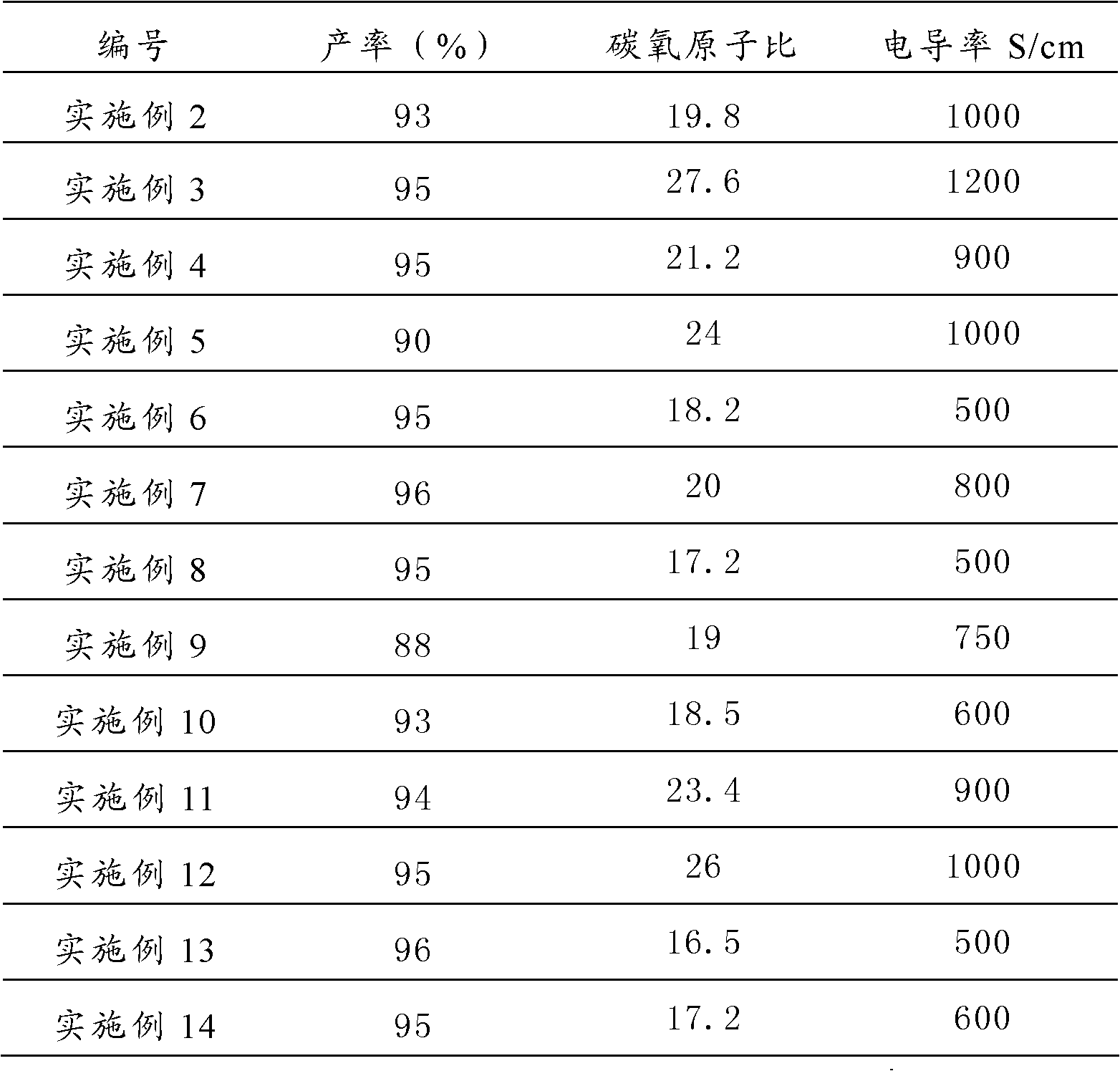

Preparation method of graphene solution phase

The invention relates to a preparation method of graphene solution phase. The method is characterized by comprising the following steps: (1) oxidizing graphite, (2) stripping mother liquid of the oxidized graphite, (3) reducing graphene oxide, wherein, polymer surface-active agent added into colloidal solution of graphene oxide is used as stabilizing agent and hydrazine hydrate is used as reducing agent. Compared with the prior art, the invention has the advantages that the obtained graphene has large area which can reach thousands or more square microns; the effective control of the sizes of graphene product can be realized only by selecting the size of the raw material of graphite, and the size of graphene can be effectively controlled between 20-200 microns; the concentration of the obtained graphene soliquid is high, which can be up to 5-10g / l, the stability of the graphene soliquid is good, and the graphene soliquid can not be subsided when being stewed for months; the method has the advantages of simple whole process, strong controllability and low price of adopted polymer surface active agent, thus being applicable to low-cost and large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

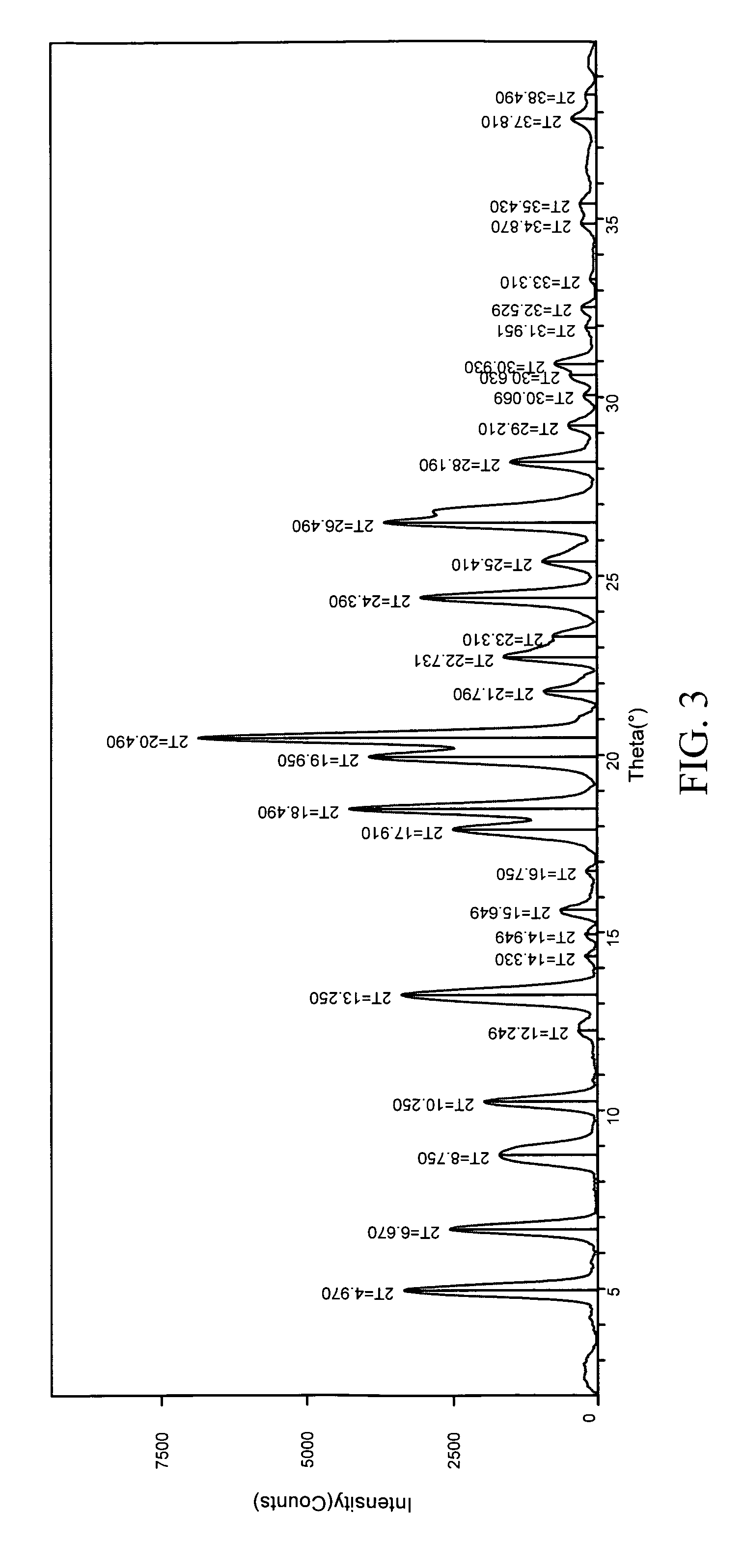

Pharmaceutical co-crystal compositions of drugs such as carbamazepine, celecoxib, olanzapine, itraconazole, topiramate, modafinil, 5-fluorouracil, hydrochlorothiazide, acetaminophen, aspirin, flurbiprofen, phenytoin and ibuprofen

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphinic acid, phosphonic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, imine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, S-heterocyclic ring, thiophene, N-heterocyclic ring, pyrrole, 0-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:UNIV OF SOUTH FLORIDA +3

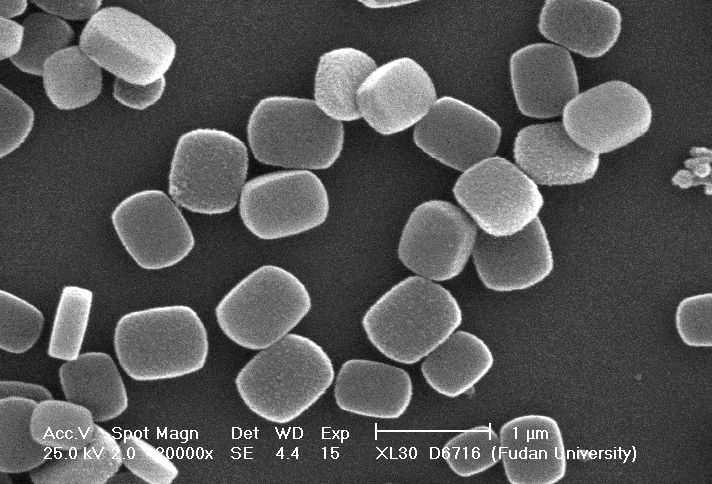

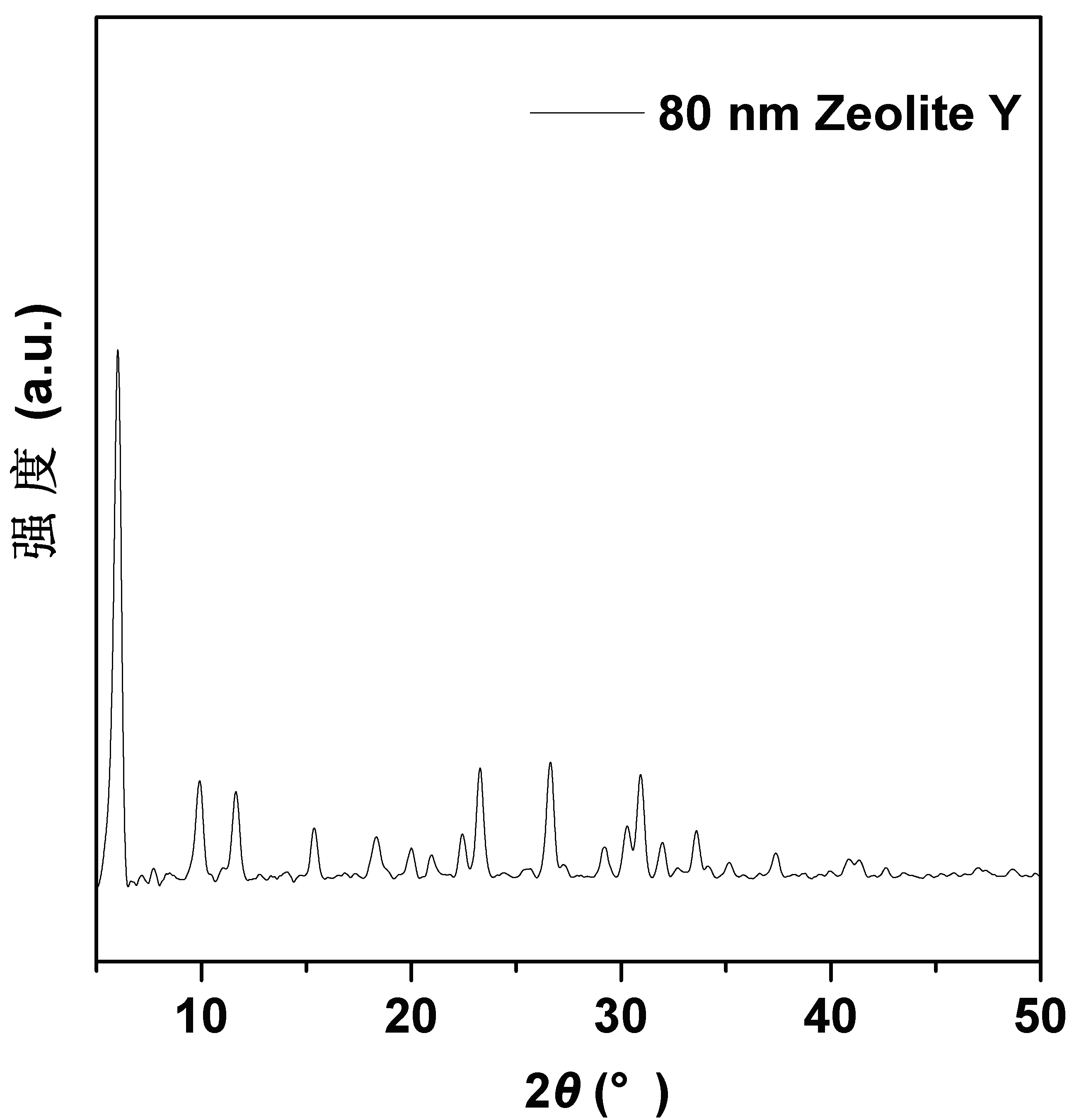

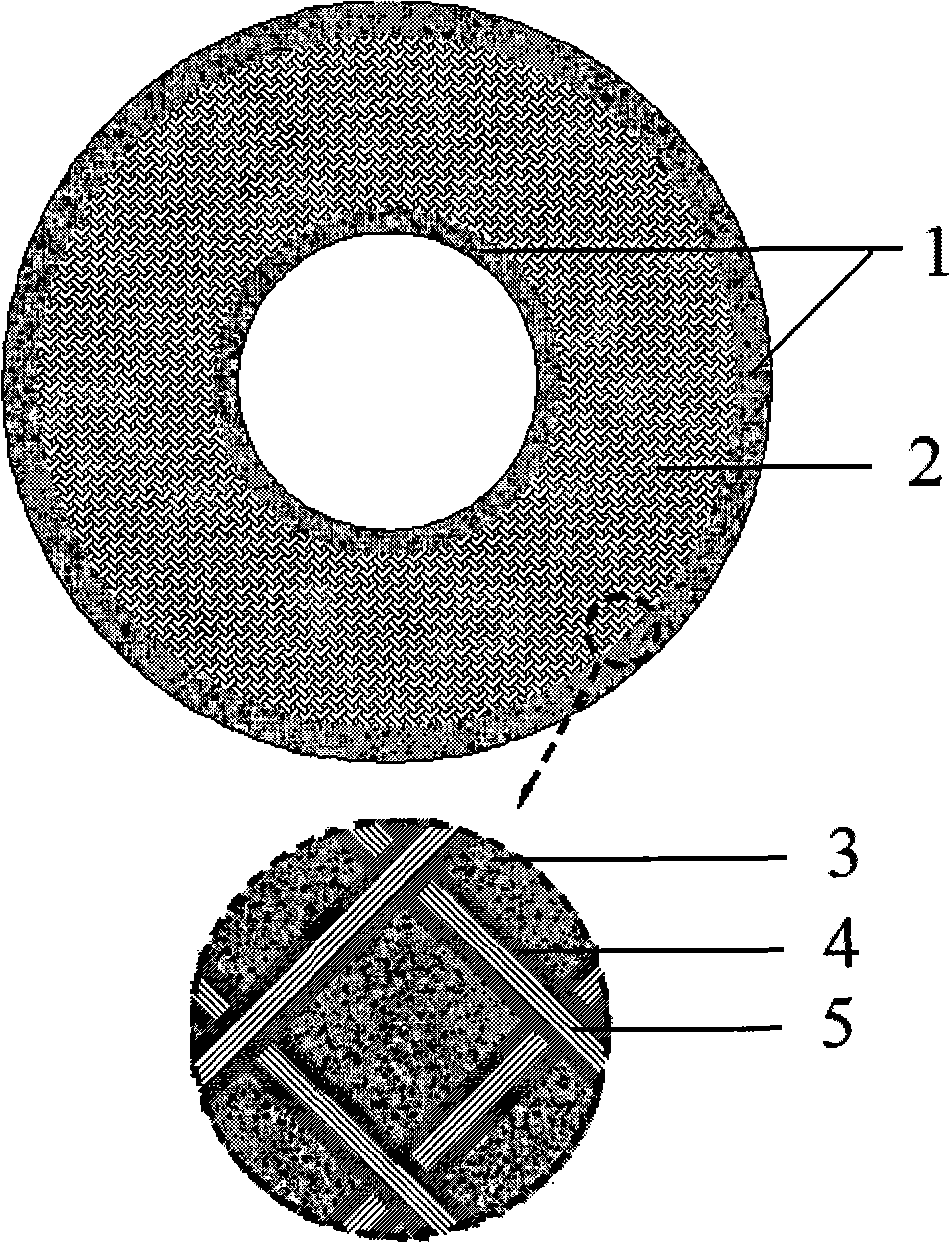

Preparation method for mesopore-micropore core-shell composite molecular sieve catalyst

ActiveCN101890363AMaintain microporosityHigh and adjustable microporosityMolecular sieve catalystsSilicon oxideSolution phase

The invention belongs to the technical field of material preparation and oil chemical engineering, and in particular discloses a preparation method for a mesopore-micropore core-shell composite molecular sieve catalyst. Zeolite particles are dispersed in organic solvent / water mixed solution which contains cationic surfactant and alkali under the action of ultrasound, and then silicon or silicon-aluminum species are introduced into the mixed solution to obtain a mesopore-micropore core-shell composite molecular sieve by solution phase self-assembly and a sol-gel process, wherein micropore zeolite serves as a core, and mesopore silicon oxide or aluminum-containing mesopore silicon oxide serves as a shell layer. The obtained composite molecular sieve has a retained zeolite micropore framework and an ordered two-dimensional hexagonal mesopore structure, a mesopore path is vertical with the surface of the zeolite particles, the path has high openness, the thickness of the mesopore shell layer is adjustable, and after the mesopore shell is packed, the mesopore-micropore can maintain high un-obstruction. The method has the advantages of simple operation, low raw material cost, low equipment requirement and the like.

Owner:上海介孔谷新材料发展有限公司

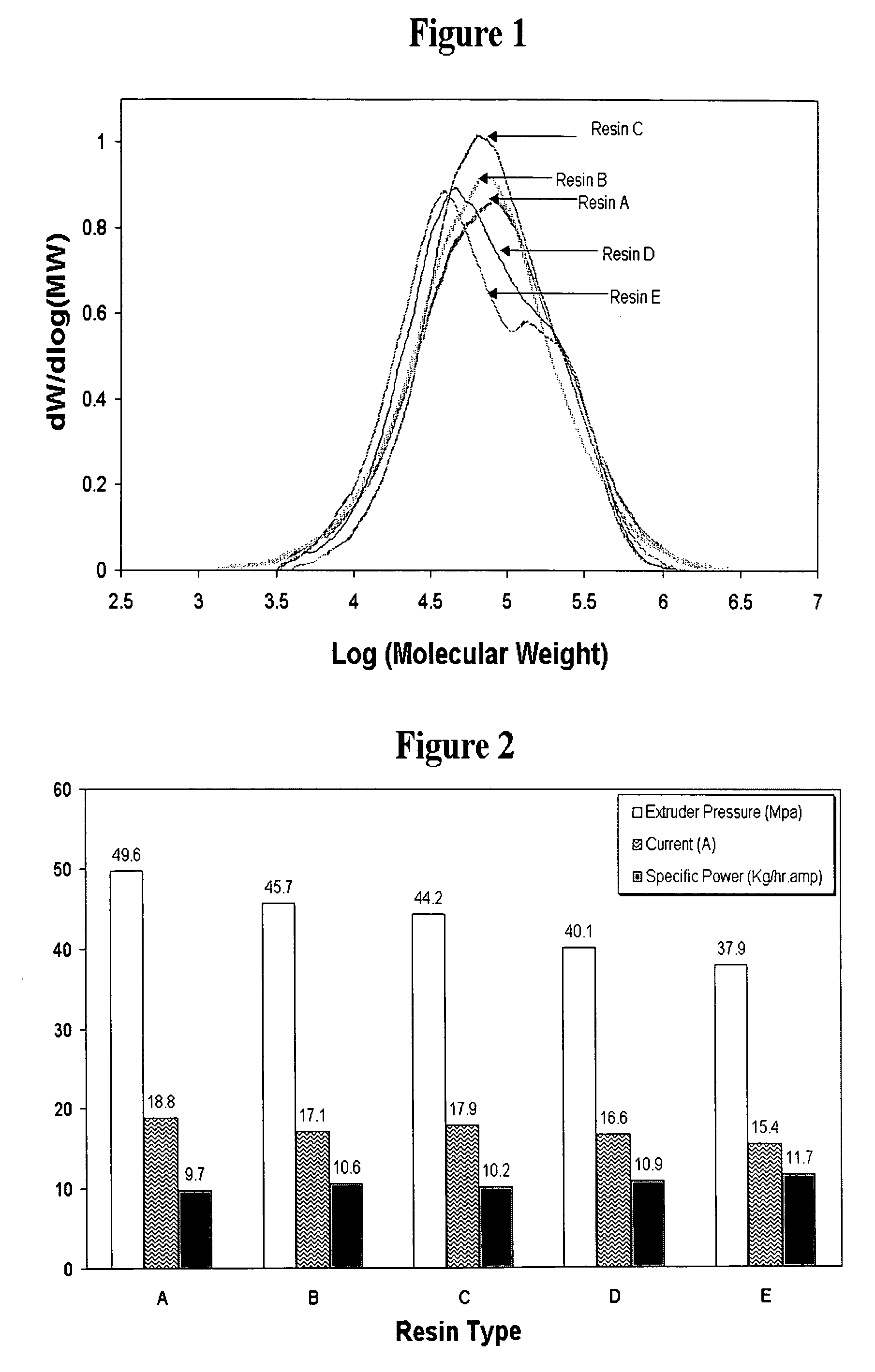

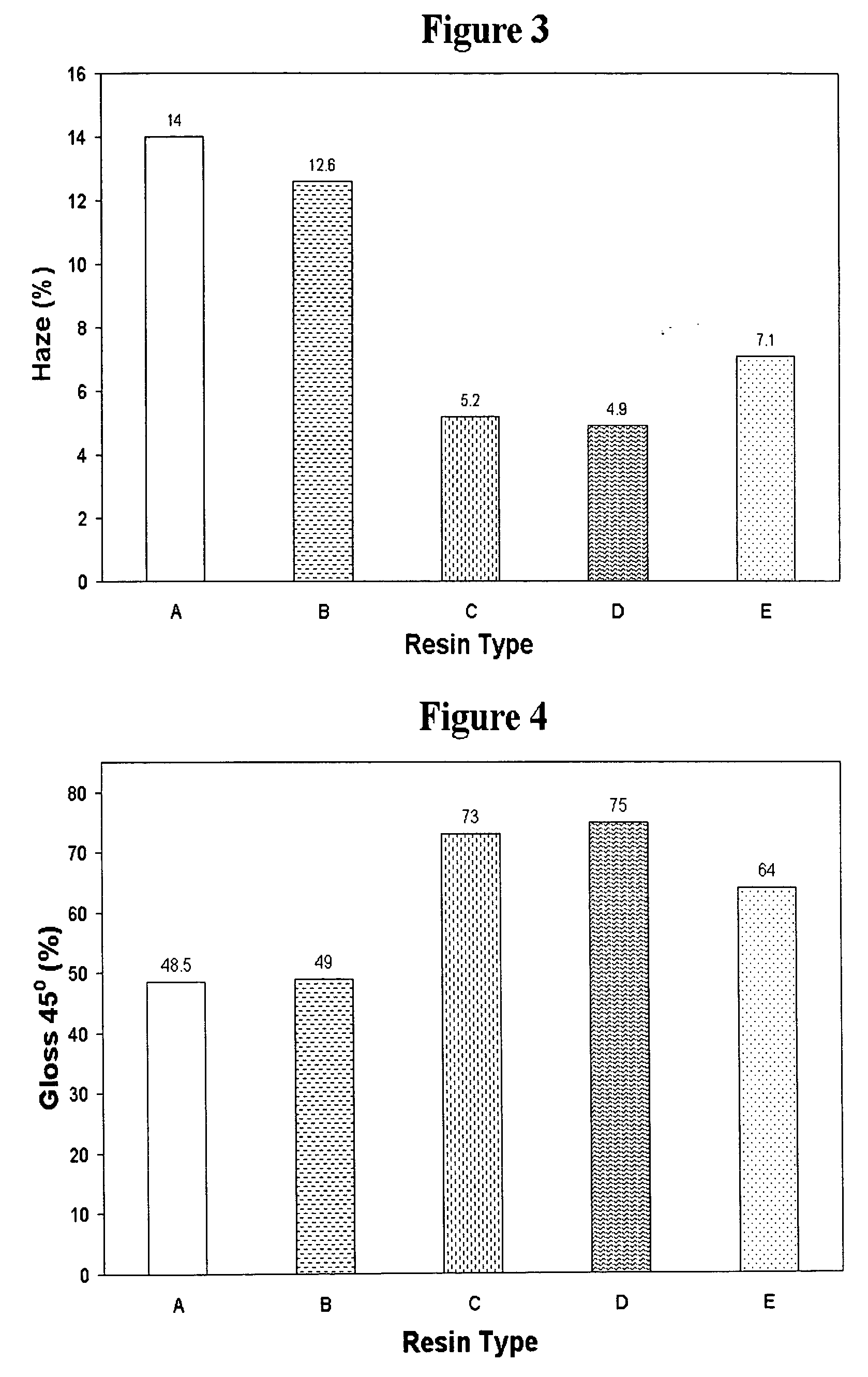

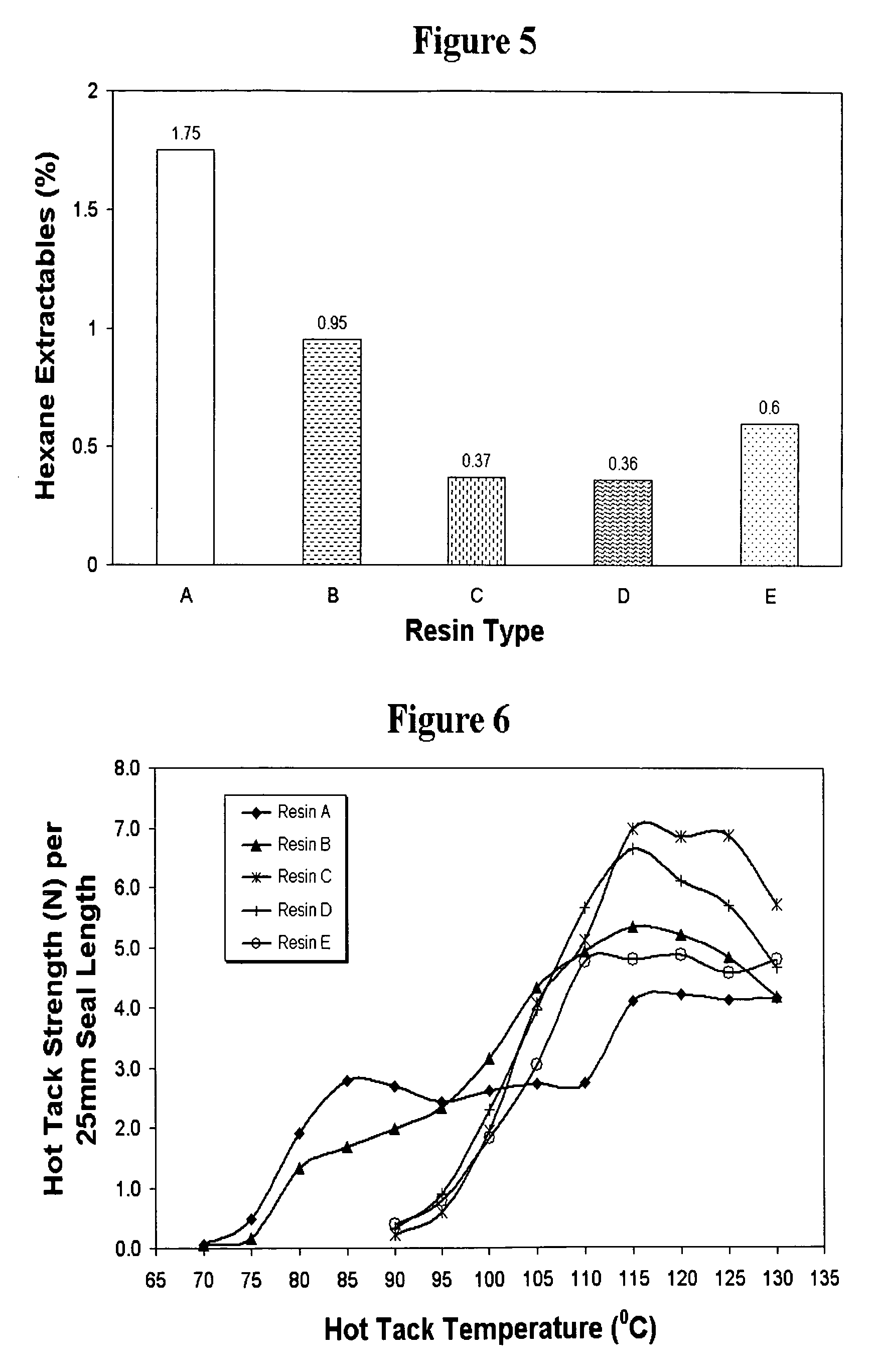

Dual reactor polyethylene resins for electronic packaging-films, tapes, bags and pouches

InactiveUS20060247373A1Good optical performanceHeat sealabilityLinear low-density polyethylenePolymer science

Owner:NOVA CHEM (INT) SA

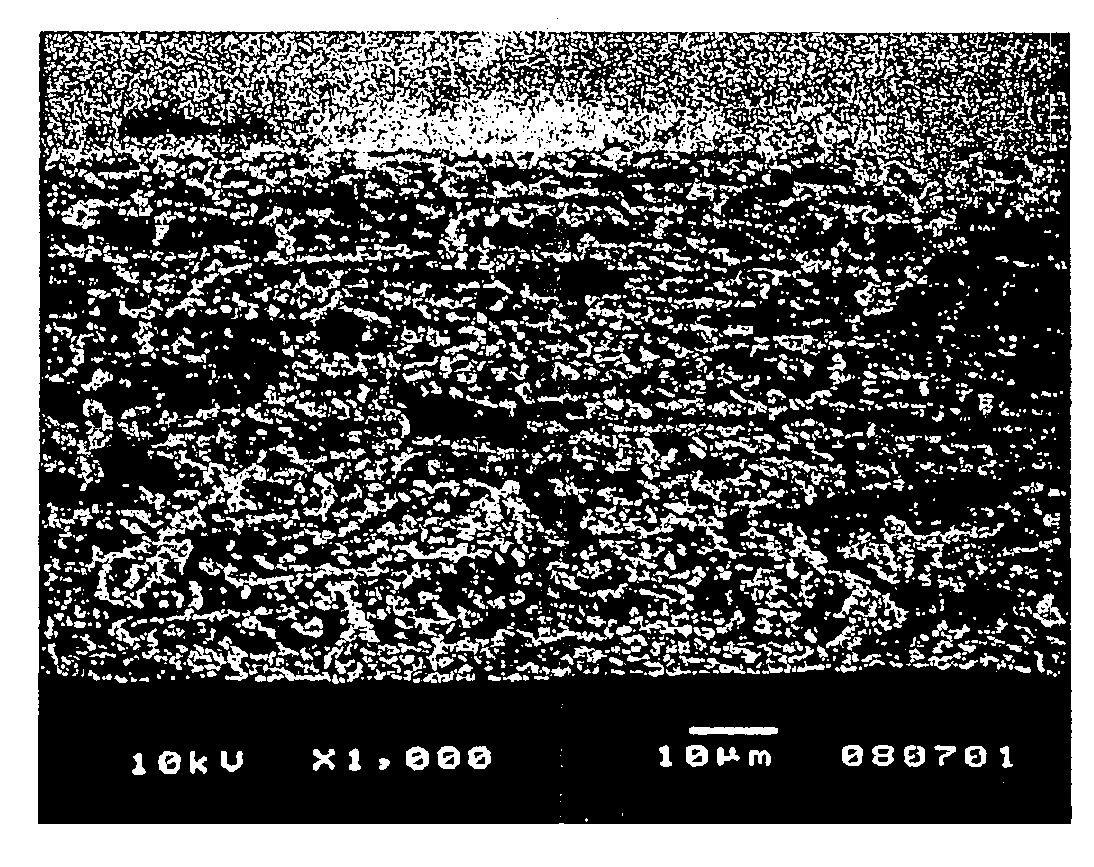

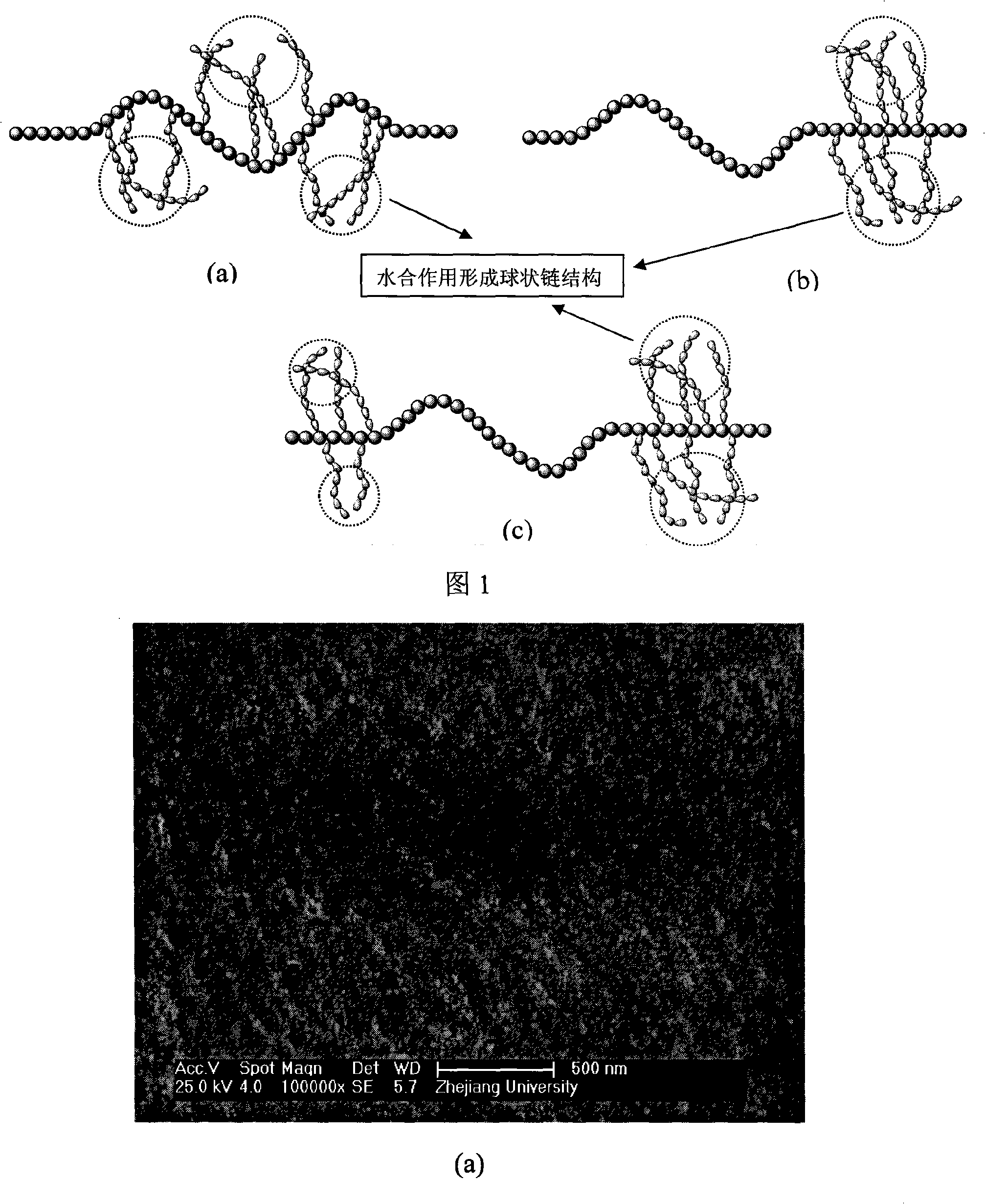

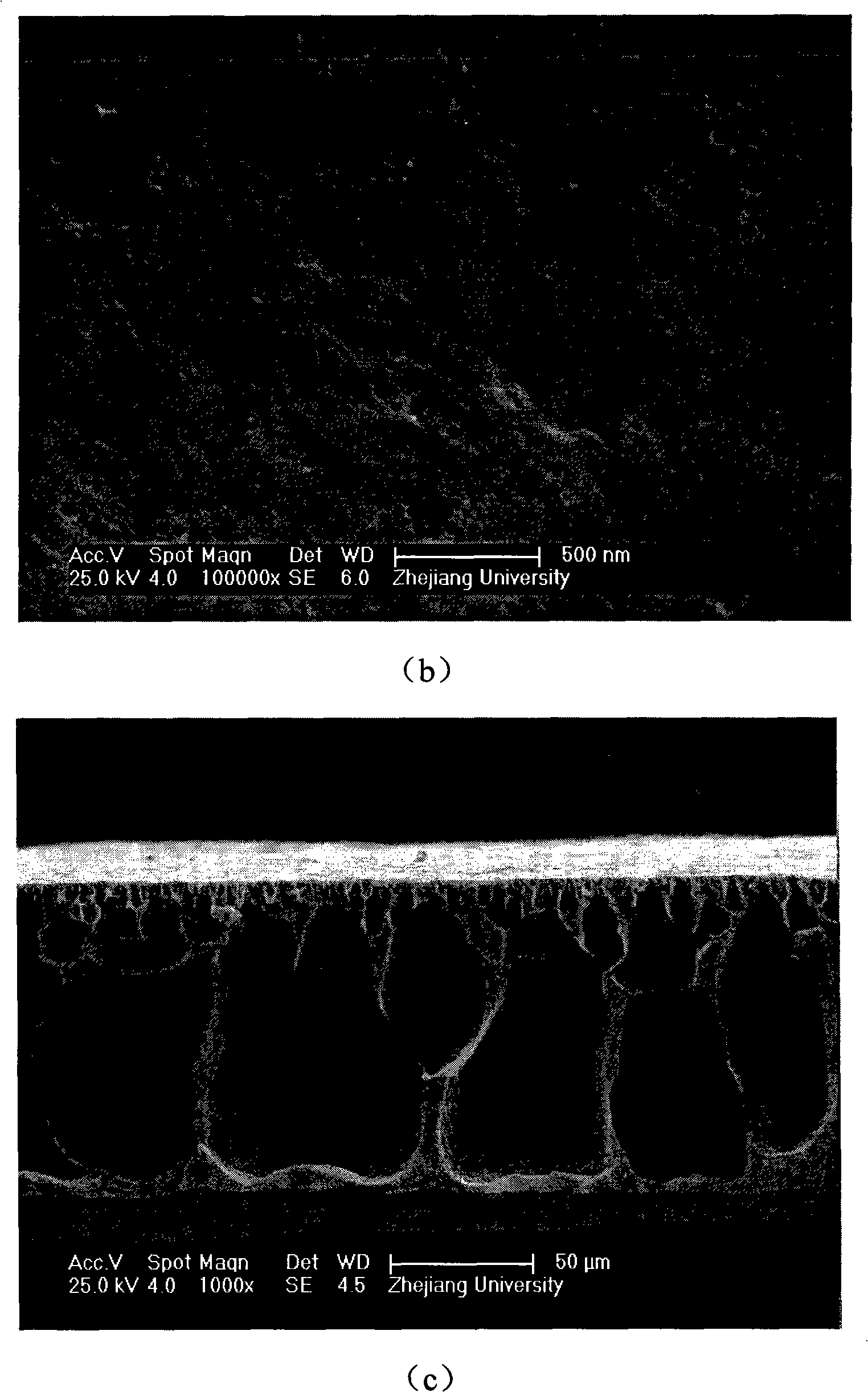

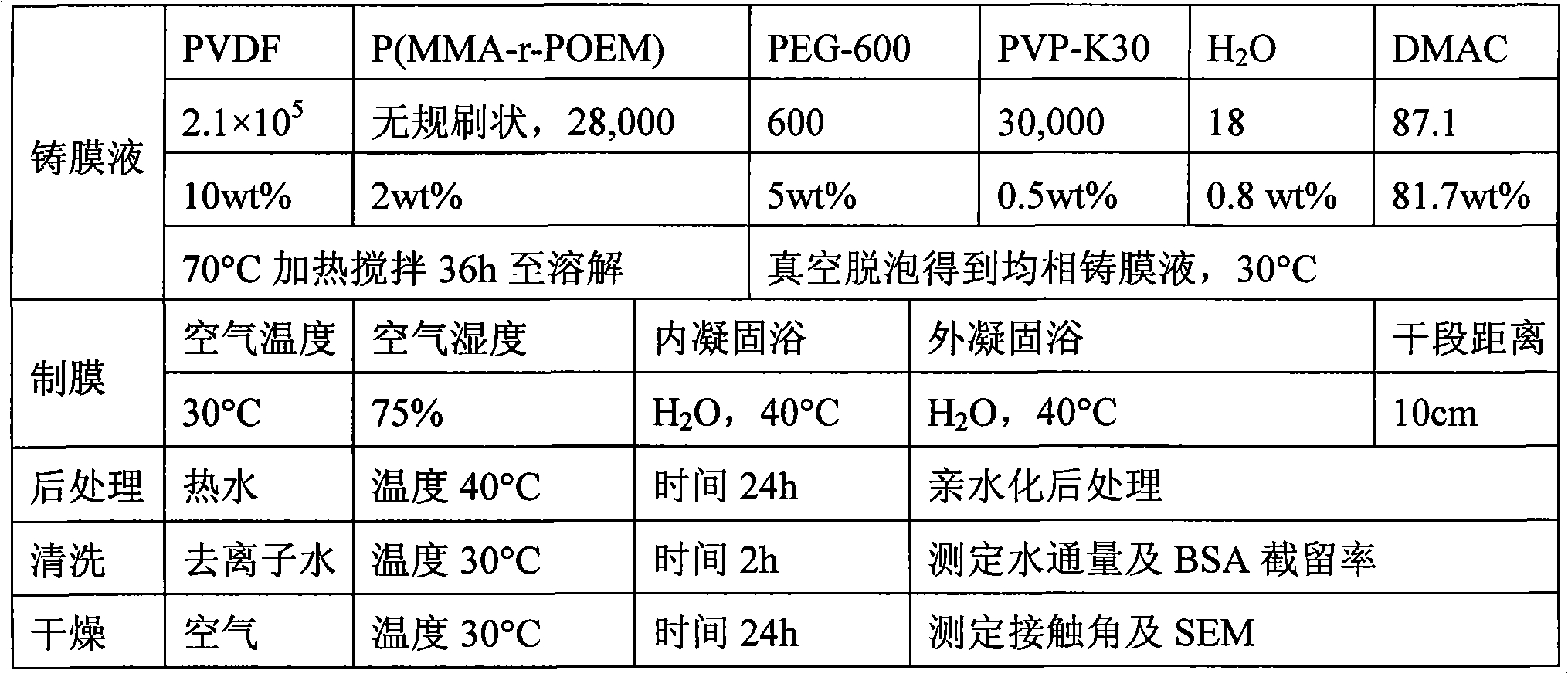

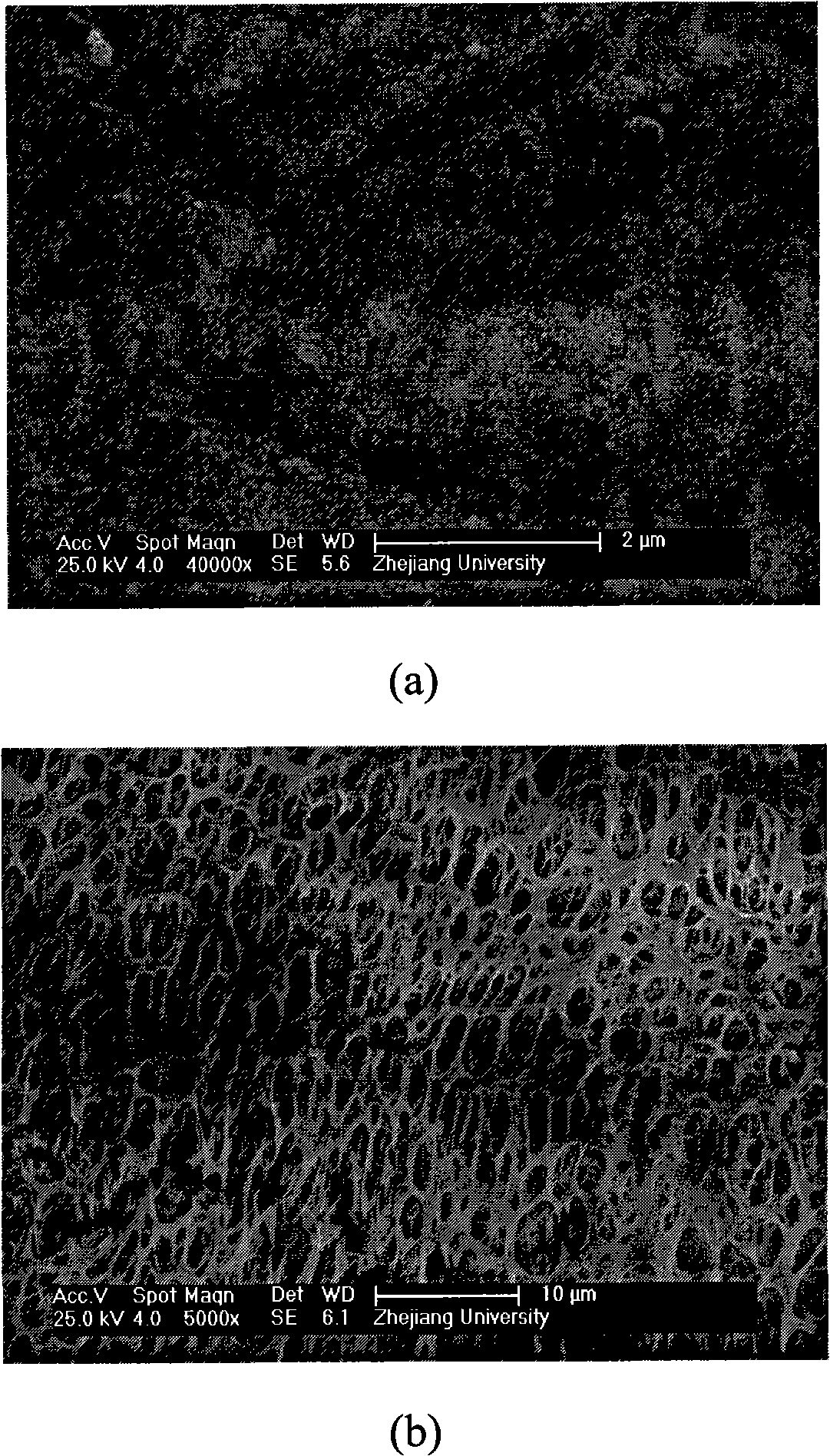

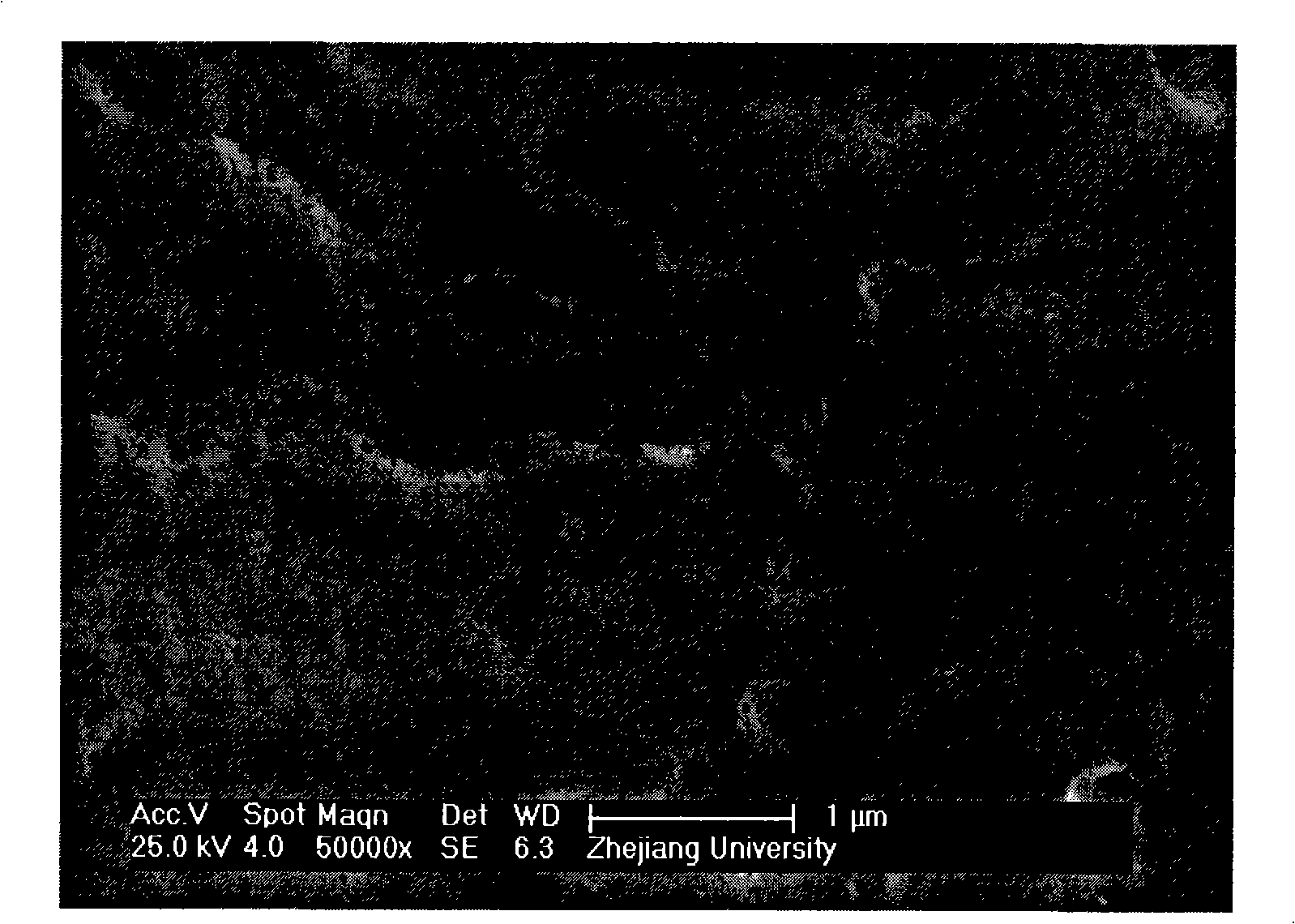

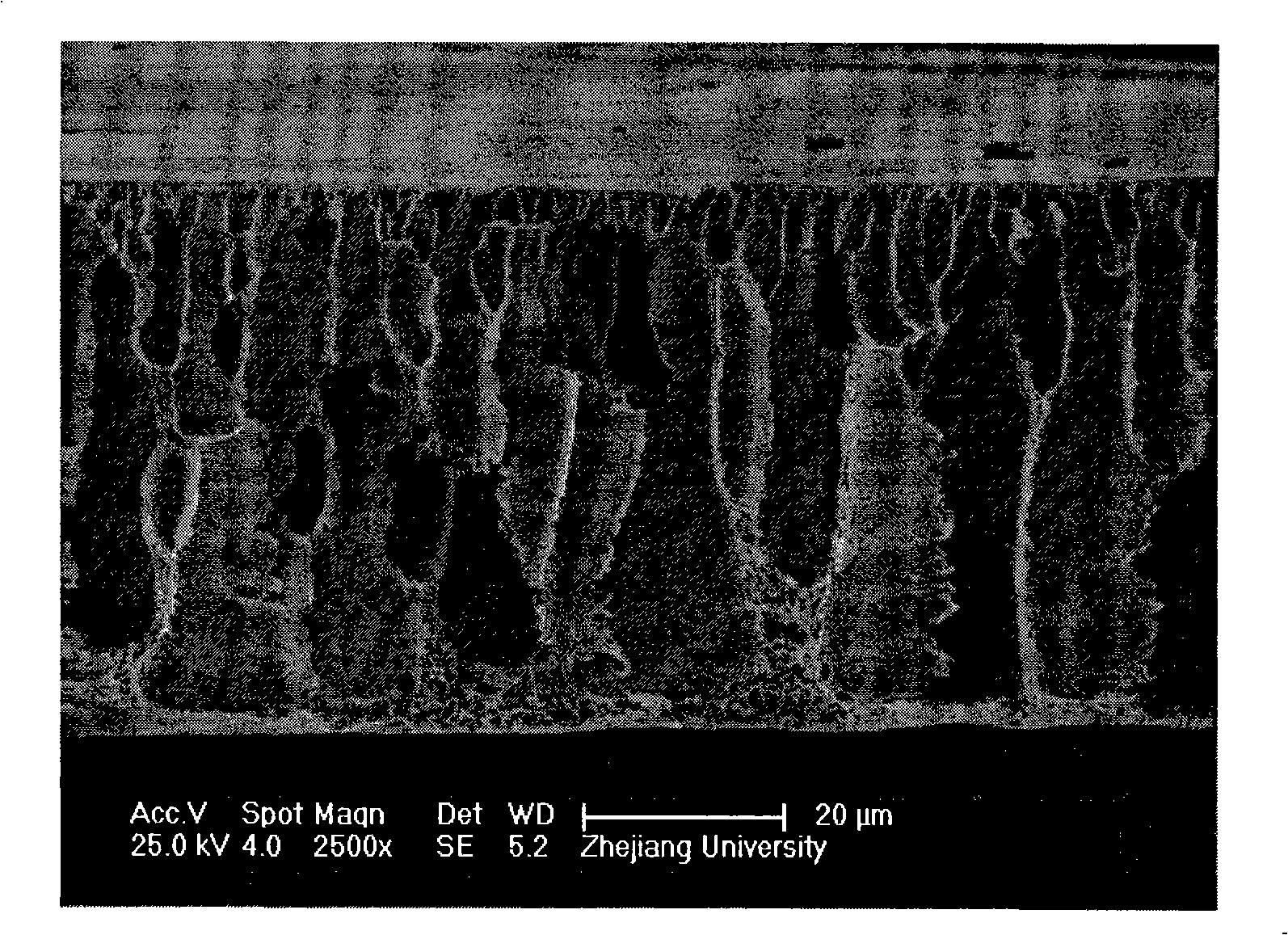

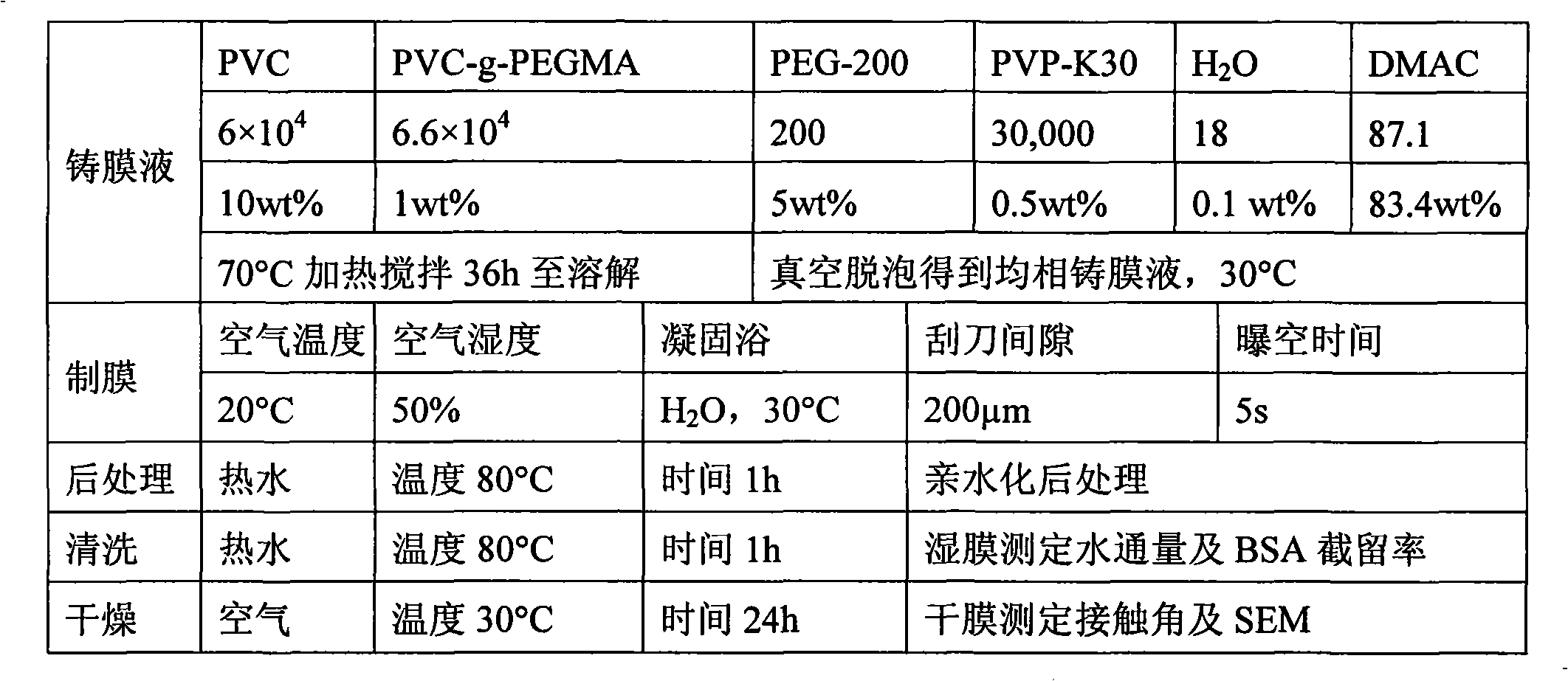

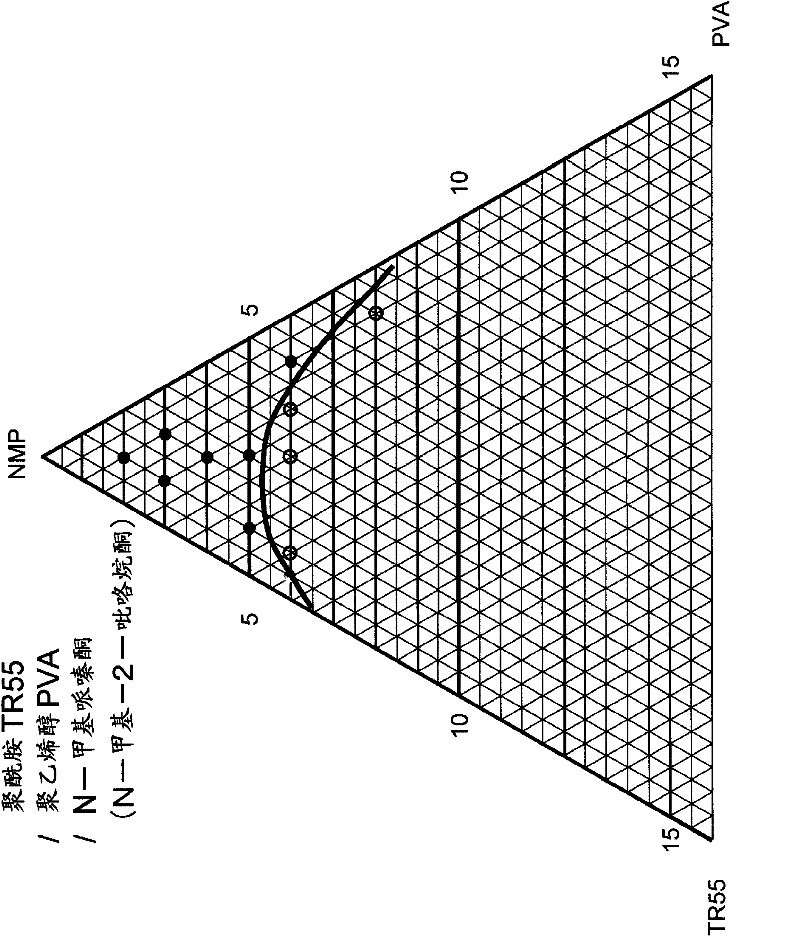

Method for modifying polyvinylidene fluoride ultrafiltration membrane by amphiphilic co-polymer

InactiveCN101264428AImprove hydrophilicityReduce energy consumptionSemi-permeable membranesUltrafiltrationDumbbell shaped

The invention discloses a method of producing the hyperfiltration membrane of amphiphilic copolymer modified polyvinylidene fluoride, comprising the following steps: 1) mixing polyvinylidene fluoride, poly (methyl methacrylate - monomethyl ether polyoxyethylene methyl methacrylate), additives, non-solvent and solvent to form the casting film solution; 2) making the casting film solution into the polyvinylidene fluoride membrane by using the film forming machine and then soaking in the coagulation bath; 3) conducting the posttreatment of hydrophilicity; 4)obtaining the hydrophilic polyvinylidene fluoride ultrafiltration membrane after cleaning and drying. The method is characterized in that the brush shape, chain ball shape or dumbbell shape amphiphilic copolymer are mixed with the polyvinylidene fluoride to produce the polyvinylidene fluoride hyperfiltration membrane with hydrophilicity, anti-pollution, large flux and high retention rate by adopting the solution phase conversion method. The method has the advantages that the obtained membrane is provided with dozens to hundreds nanometer of particular densified hydrogel surface layers, the contact angle of the membrane surface can be reduced below 60 degrees and can be lowered to 0 degree within tens of seconds, the water flux can reach 1000L / m<2> / h (0.1Mpa) or above, the retention rate of BSA can reach 90% or more and the recovery rate of water cleaning flux can reach 90% or higher.

Owner:ZHEJIANG UNIV

Method and apparatus for solution processed doping of carbon nanotube

A method is provided for doping a carbon nanotube. The method comprises exposing the nanotube to a one-electron oxidant in a solution phase. A method is also provided for forming a carbon nanotube FET device.

Owner:GLOBALFOUNDRIES US INC

Methods of nonspecific target capture of nucleic acids

InactiveUS20130209992A1Sugar derivativesMicrobiological testing/measurementTarget captureAnalytical chemistry

Methods for capturing a target nucleic acid from a sample by using a capture probe that binds nonspecifically to the target nucleic acid and binds specifically to an immobilized probe via a specific binding pair that has one member on the capture probe and one member on the immobilized probe are disclosed. Compositions that include a capture probe that binds nonspecifically to a target nucleic acid and specifically to an immobilized probe via binding of members of a specific binding pair in a solution phase of a reaction mixture are disclosed.

Owner:GEN PROBE INC

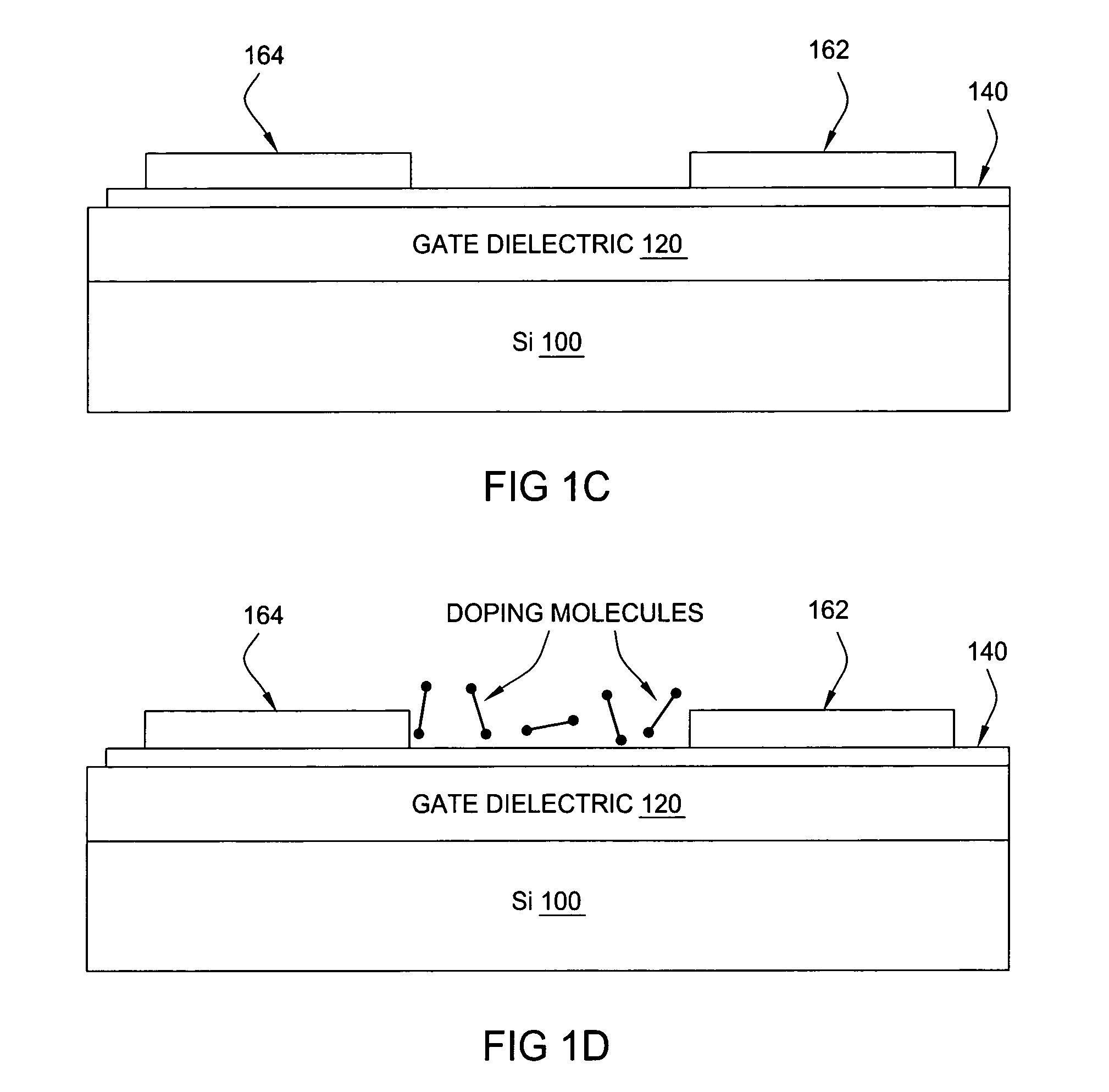

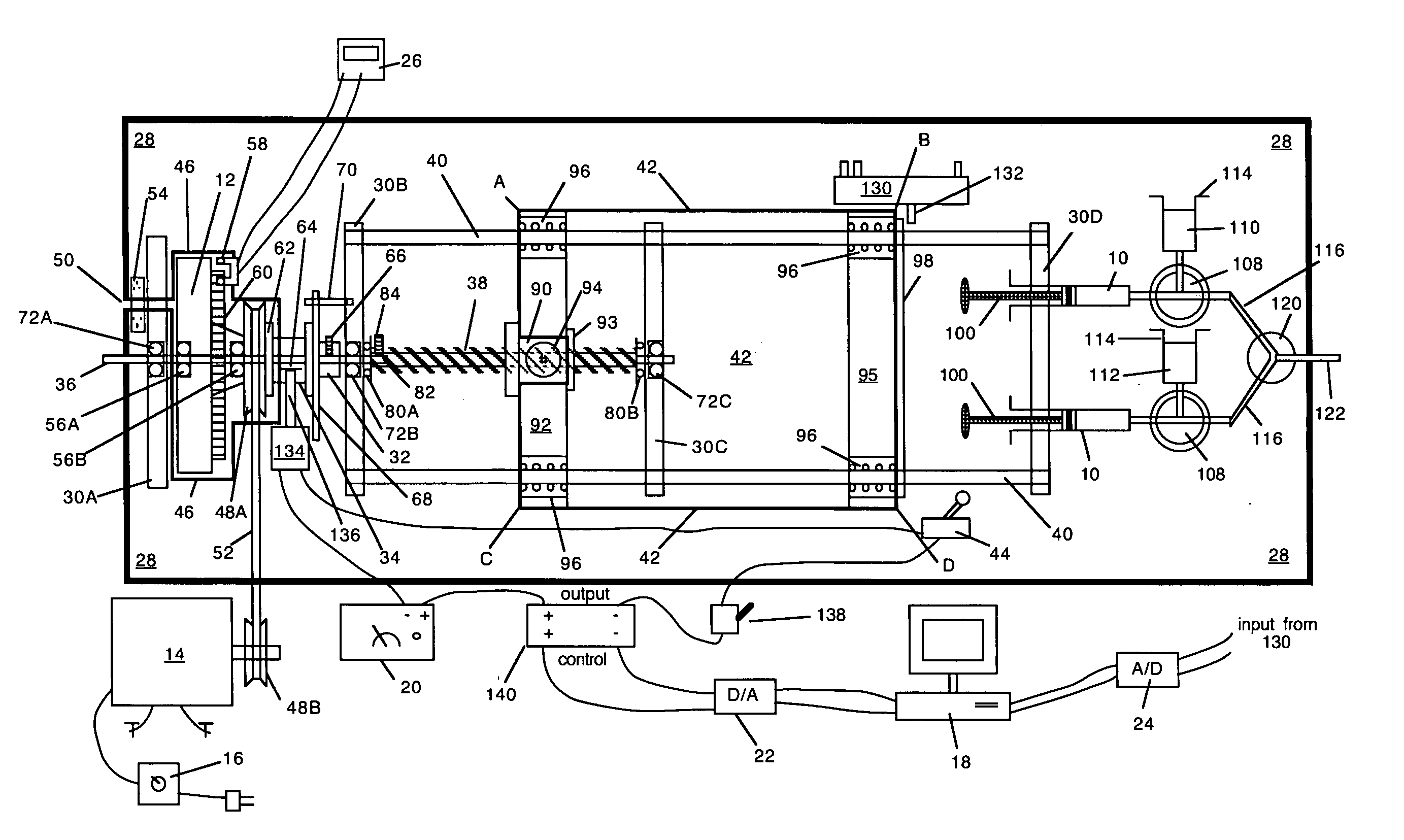

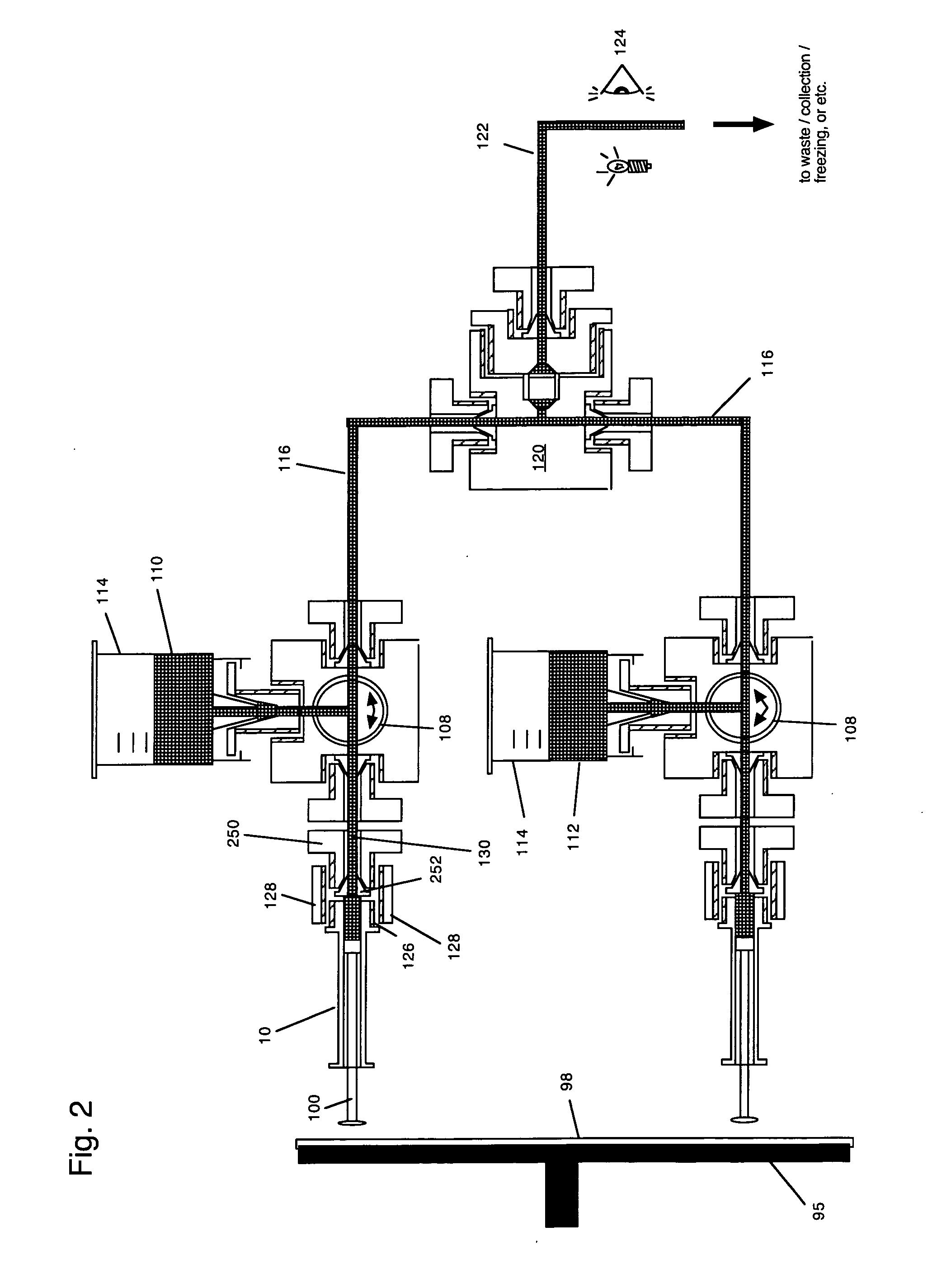

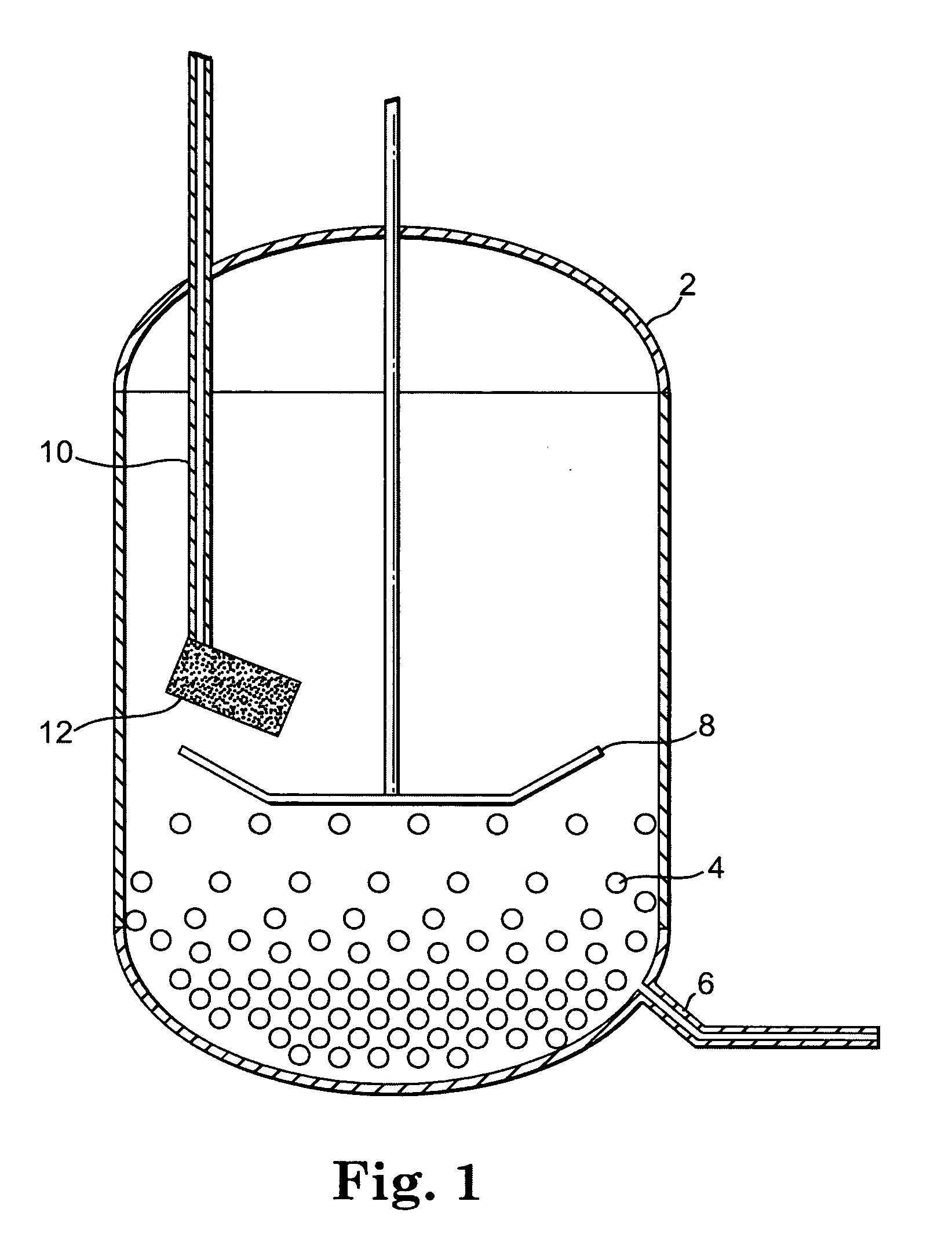

Wrap spring clutch syringe ram and frit mixer

A wrap spring clutch syringe ram pushes at least one syringe with virtually instantaneous starting and stopping, and with constant motion at a defined velocity during the intervening push. The wrap spring clutch syringe ram includes an electric motor, a computer, a flywheel, a wrap spring clutch, a precision lead screw, a slide platform, and syringe reservoirs, a mixing chamber, and a reaction incubation tube. The electric motor drives a flywheel and the wrap spring clutch couples the precision lead screw to the flywheel when a computer enables a solenoid of the wrap spring clutch. The precision lead screw drives a precision slide which causes syringes to supply a portion of solution into the mixing chamber and the incubation tube. The wrap spring clutch syringe ram is designed to enable the quantitative study of solution phase chemical and biochemical reactions, particularly those reactions that occur on the subsecond time scale.

Owner:SIMPSON FR B

Process for preparing composite hollow fiber membrane

A preparation of composite hollow fiber membrane adopts solution phase transfer hollow fiber spinning process, makes poly(ethylene terephthalate) or polysulfone, solvent and pore-forming agent into a base membrane spinning solution of composite hollow fiber membrane, makes polyvinylidene fluoride or other copolymers or mixture of same, solvent and pore-forming agent into composite layer spinning solution of composite hollow fiber membrane and simultaneously extrudes the said two spinning solution and core solution in the hole of the spinneret central pipe through the spinneret for outside condensation bath. The solvents and pore-forming agents in the two kinds of spinning solutions prepared in said step (1) and (2) enters condensation solution phase and the polymers, as the composite layer and the base membrane materials, precipitates into polymer hollow fiber membrane due to phase transfer, producing high-strength and high-flux hydrophilic composite hollow fiber membrane.

Owner:江苏美能膜材料科技有限公司

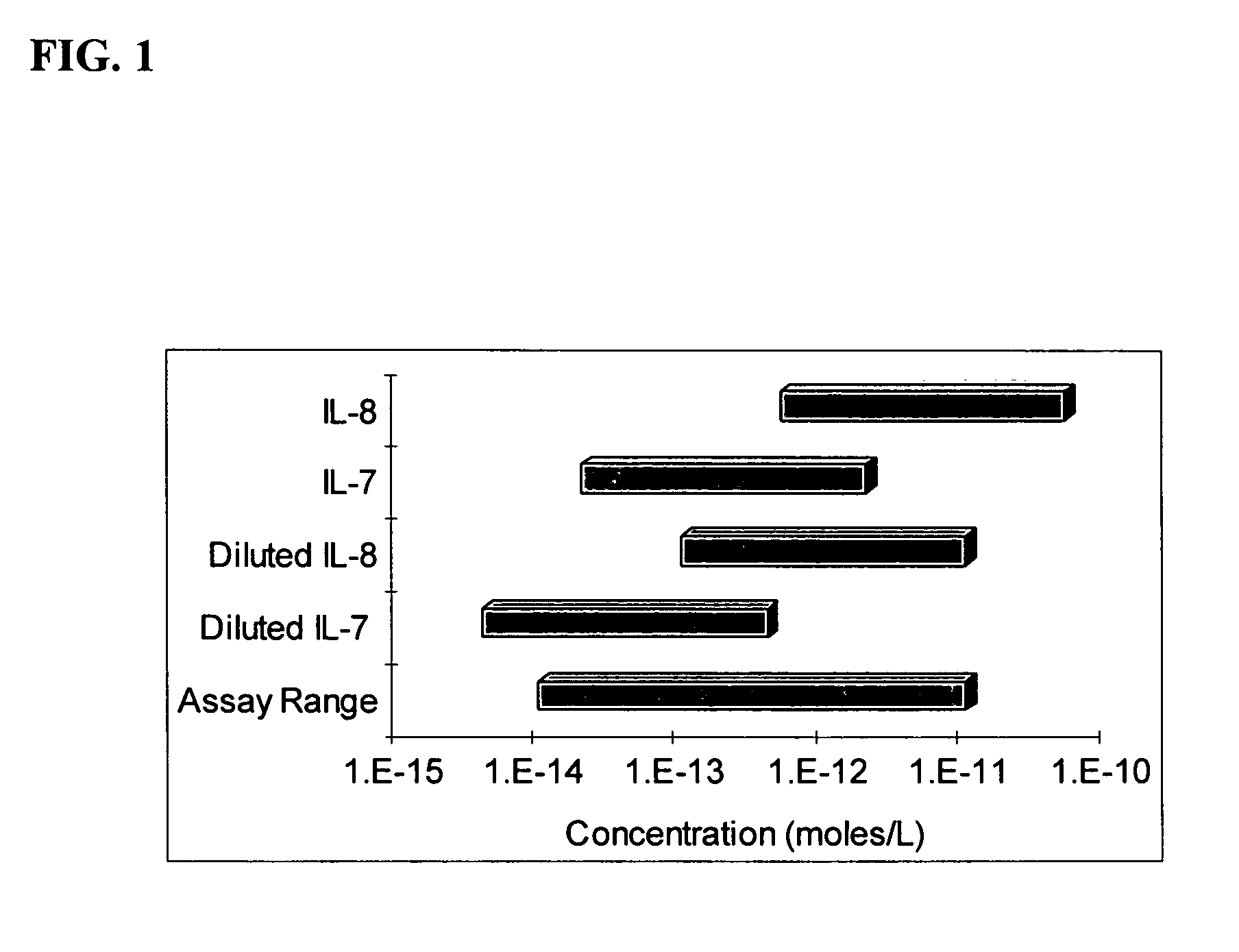

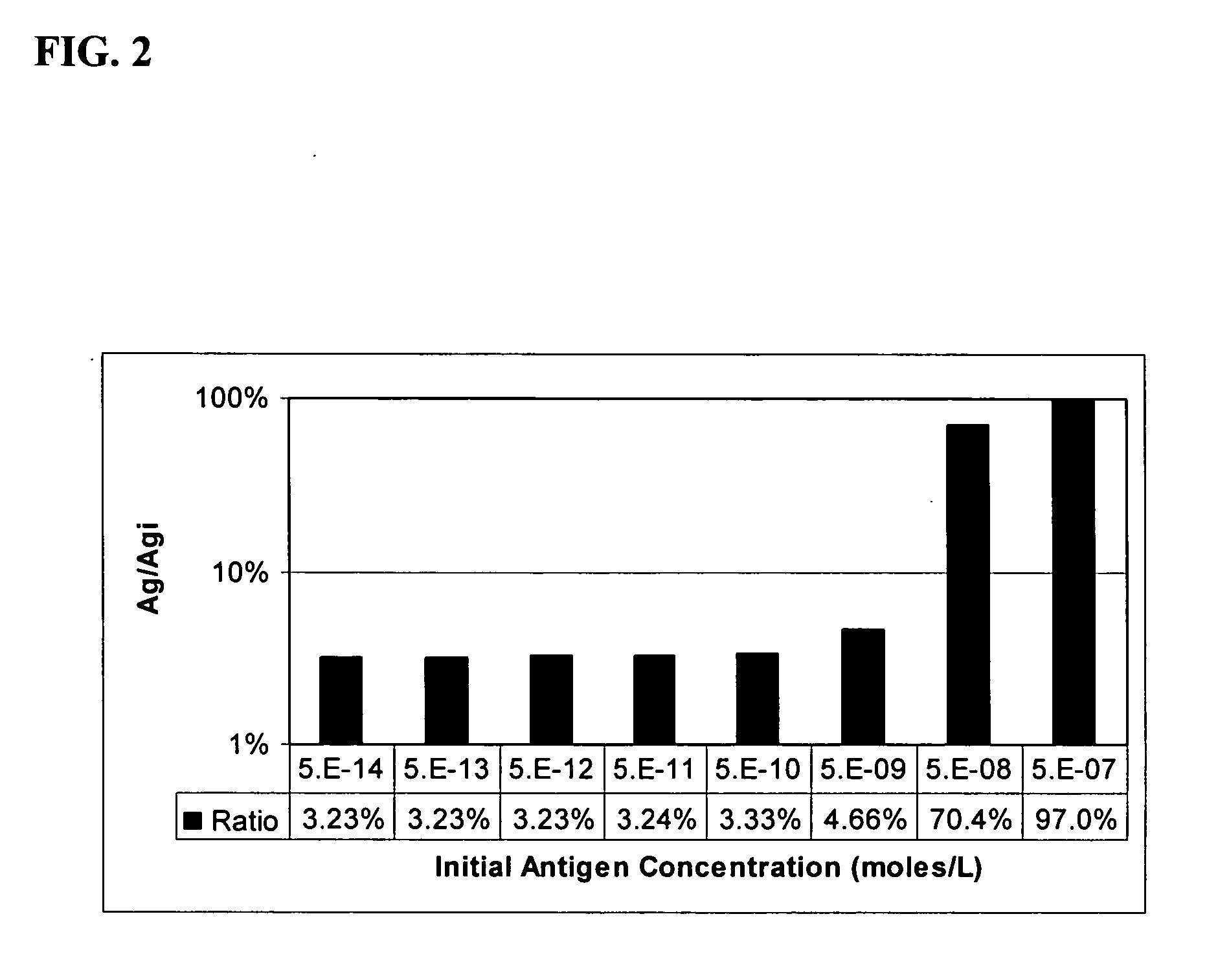

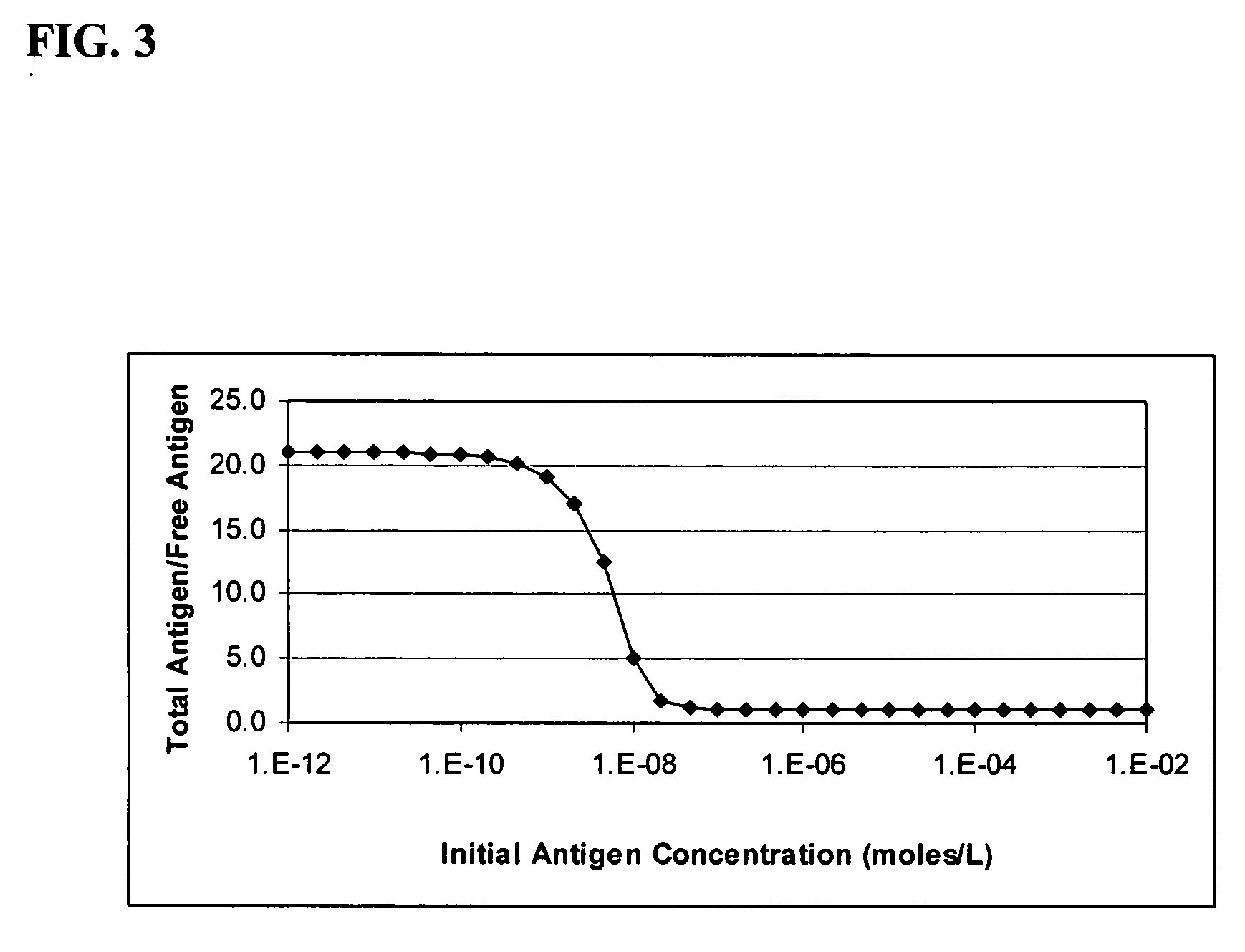

Method of adjusting the working range of a multi-analyte assay

InactiveUS20060177873A1Reduce available analyte concentrationHinder availabilityBiological testingSpecial data processing applicationsHigh concentrationMulti analyte

The invention features a method of adjusting the concentration of at least one but not all of a plurality of analytes in a fluid sample to match a known working range of detection of an analyte assay system, where each of the plurality of analytes may or may not be present within an expected initial concentration range having a high end and a low end, and at least one analyte has a high end expected concentration range that exceeds the high end of the working range of the assay system. The expected concentration of the high concentration analyte is adjusted by a proportional scaling constant, α, so that the high end of the adjusted expected concentration range is less than or equal to the high end of the working range, without adjusting the expected concentration range of at least one other of the plurality of analytes. Adjustment is preferably accomplished by adding to the solution phase of the assay one or more scaling agents, each scaling agent binding with specificity to an analyte and thereby preventing it from being detected by the assay system, e.g., by competing with binding to immobilized capture agent. This scaling method contrasts with prior methods, in which a concentration of available analyte is offset by a fixed amount to adjust the detectable threshold of the assay. Here, the amount of scaling agent is proportional to a scaling coefficient, and the scaling agent is present in the solution phase of the assay at high concentrations relative to analyte. Due to the equilibrium conditions established by the laws of mass transfer, the amount of free analyte remaining in solution in the presence of scaling agent is predictable and finite, and can be measured as a quantitative indicator of the initial concentration of the analyte in the sample.

Owner:COURTAGEN LIFE SCI

Preparation method of polyvinylidene fluoride hollow fiber composite microporous film with strong interface binding power

InactiveCN101357303AHigh mechanical strengthIncrease backwash pressureSemi-permeable membranesFiberInterfacial bonding

The invention discloses a preparation method of a polyvinylidene fluoride hollow fiber composite microporous membrane which has strong interfacial bonding force. The preparation method comprises the following steps: 1) neutral or amphiphilic substances which have good bonding force with braided fiber tubes and the polyvinylidene fluoride are prepared into dilute solution; 2) the dilute solution of the neutral or amphiphilic substances is coated once on the braided fiber tubes; 3) casting membrane liquid is used for secondary coating on the coated braided fiber tubes, and the polyvinylidene fluoride hollow fiber composite membrane is obtained by a solution phase transition method; 4) post-hydrophilization treatment is carried out; 5) the polyvinylidene fluoride hollow fiber composite membrane is cleaned and dried to obtain the hydrophilic polyvinylidene fluoride hollow fiber composite microporous membrane. The preparation method takes the braided fiber tubes as supporting tubes, uses an amphiphilic copolymer and the polyvinylidene fluoride to be blended, and prepares the polyvinylidene fluoride hollow fiber composite microporous membrane which has strong interfacial bonding force, hydrophilicity, pollution resistance, large flux, high interception rate and high mechanical strength by the solution phase transition method.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

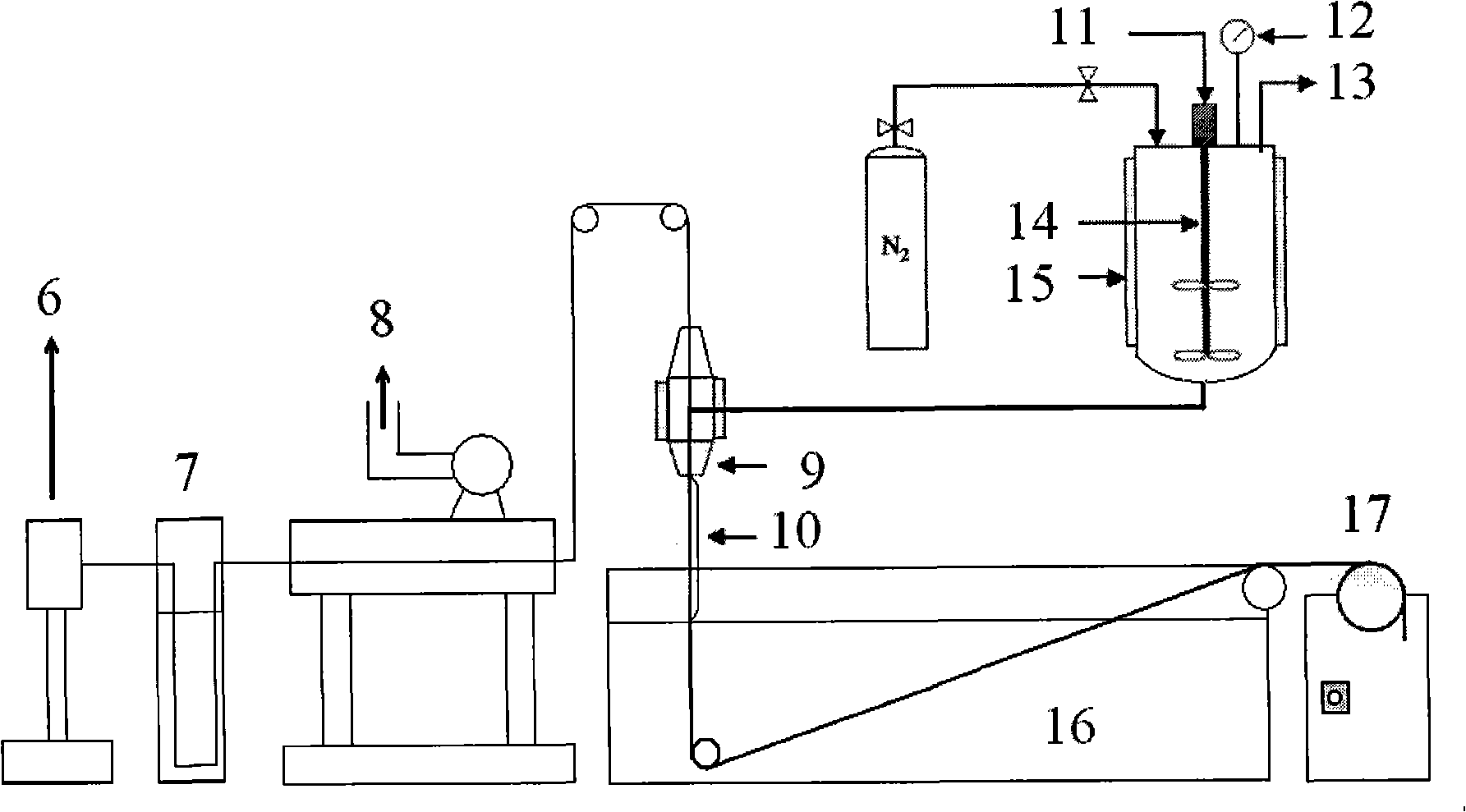

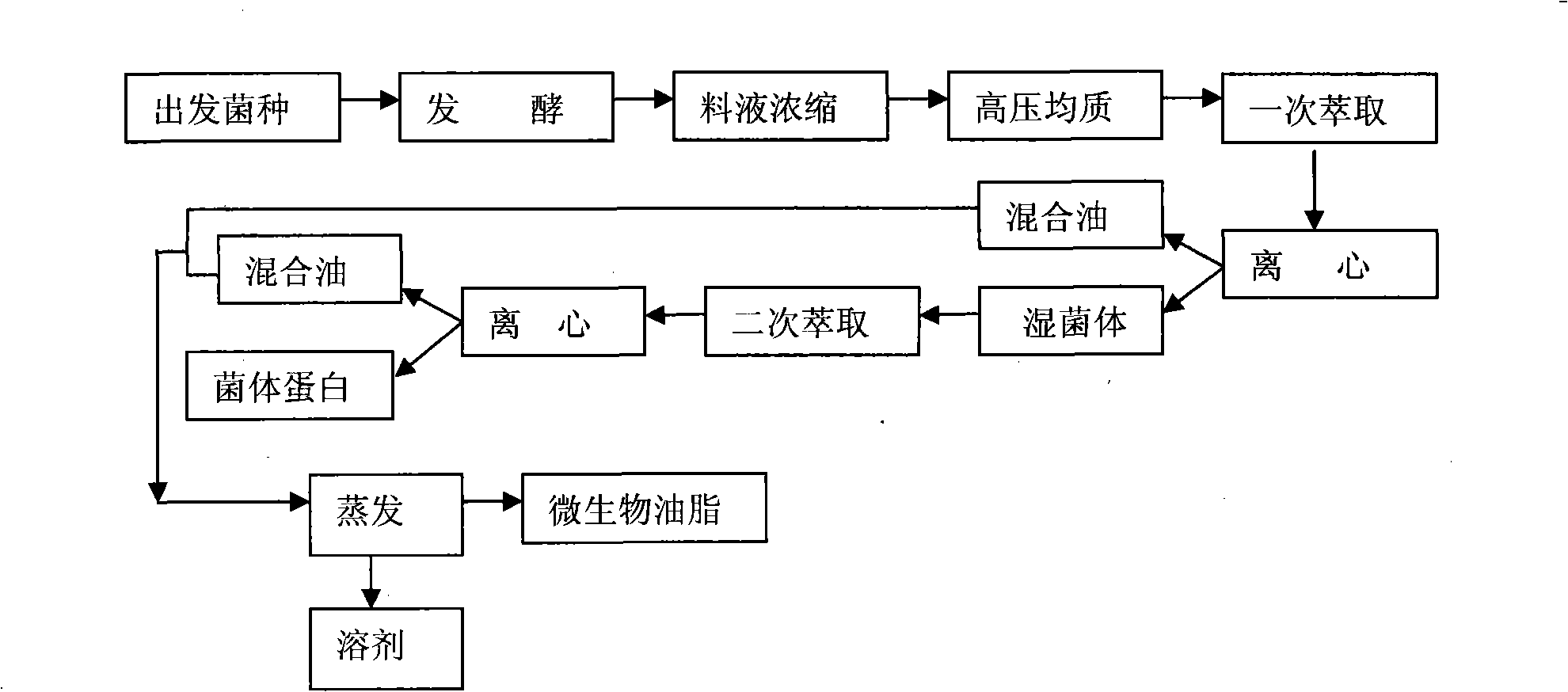

Separation and extraction method of microbial oil

InactiveCN101323865AHigh yieldSimple and fast operationMicroorganism based processesFermentationMicrobial oilOrganic solvent

A method for separating and extracting microbial oil comprises the following steps: (1) microbial strains are inoculated for fermentation; (2) the obtained fermentation liquor is concentrated to remove 45 percent to 55 percent of water in the fermentation liquor so as to obtain the concentrated fermentaton liquor; (3) the concentrated fermentation liquor is fed into a high pressure homogenizer with the pressure of 70 to 130MPa to carry out cell-crushing; (4) an extractive solvent is added, and after two times of extraction, the upper layer organic solution phase is separated and collected to obtain mixed oil; and (5) at last, the solvent in the mixed oil is vaporized and recycled to obtain the microbial oil. The method combines the fermented solution concentration with the high pressure homogenization technology to carry out cell crushing, and then adopts the two-time extraction to collect the contained oil and obtain bacterial protein accordingly. The process improves the original method which needs the steps, such as the separation of strains, drying, grinding and granulation, etc., thus greatly simplifying the technology, improving efficiency and reducing production cost. The method homogenizes the fermented solution under high pressure after concentration, which promotes the utilization rate of facilities, and reduces energy consumption.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

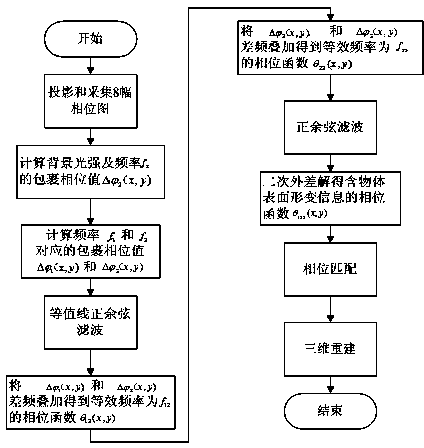

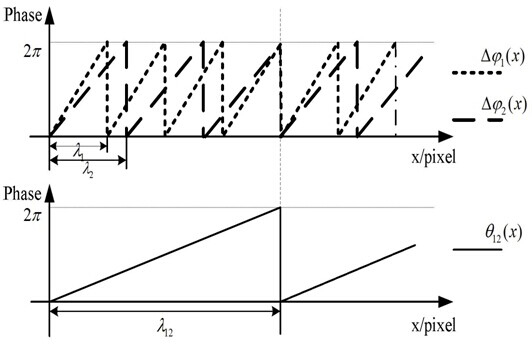

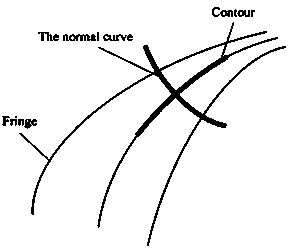

Heterodyne three-frequency unequal range phase displacement solution phase method

ActiveCN104330052AQuality improvementAccurate measurementImage analysisUsing optical meansGratingMiddle frequency

The invention relates to a heterodyne three-frequency unequal range phase displacement solution phase method, and the method is as follows: selecting three frequencies, firstly adopting four-step phase shift method to obtain the package phase and average light intensity of the middle frequency, adopting two-step phase shift method to obtain the package phase corresponding to the two frequencies under the condition with known light intensity, obtaining the true phase according to the heterodyne method, adopting the contour line sine and cosine filtering method in the optical grating projection three-dimensional measurement, using stripe direction information for filtering the package phase on isophasal line, the method uses less projection picture for exactly measuring and uses the stripe direction information for filtering the package phase picture for effectively removing the inconsistent points in the package phase picture, the heterodyne three-frequency unequal range phase displacement solution phase method is used in the phase method three-dimensional shape measurement for effectively raising the measuring efficiency and measuring accuracy.

Owner:TIANJIN POLYTECHNIC UNIV

Fluorine-containing N,N′-diaryl perylene-based tetracarboxylic diimide compounds as N-type semiconductor materials for thin film transistors

A thin film transistor comprises a layer of organic semiconductor material comprising a tetracarboxylic diimide 3,4,9,10-perylene-based compound having, attached to each of the imide nitrogen atoms a carbocyclic or heterocyclic aromatic ring system substituted with one or more fluorine-containing groups. Such transistors can further comprise spaced apart first and second contact means or electrodes in contact with said material. Further disclosed is a process for fabricating ac thin film transistor device, preferably by sublimation or solution-phase deposition onto a substrate, wherein the substrate temperature is no more than 100° C.

Owner:EASTMAN KODAK CO

Oil ammonia column shaping method of spherical aluminium oxide

InactiveCN1493524AAvoid pollutionEasy to manufactureCatalyst carriersAluminium hydroxide preparationOil phaseSurfactant free

A process for preparing spherical alumina by oil-ammonia column includes dripping the alumina sol in the oil-ammonia column composed of upper oil phase and lower electrolyte solution phase to generate spherical gel particles, ageing in electrolyte solution for 0.5-10 hr, drying and calcining. Its advantage is high purity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing graphene

ActiveCN102757038AQuality improvementIncrease productionGrapheneNanotechnologyGas phaseLithium-ion battery

The invention provides a method for preparing graphene. The method includes that graphite reacts in acid solution with an oxidant to obtain the graphene. Compared with the prior art, the method has the advantages that the graphene prepared by the method is good in quality, yield is greatly increased and productivity is greatly improved as compared with a mechanical exfoliation method, an epitaxial growth method and a chemical vapor deposition method; the quality of the graphene is greatly enhanced, structural defects of the graphene are greatly reduced, and electrical conductivity of the graphene is obviously improved as compared with a solution-phase oxidation reduction method; and the preparation process is simple, conditions are mild, cost is low, and large-scale production is realized easily. In addition, the graphene prepared by the method has an extremely broad prospect in fields of lithium ion batteries, super-capacitors, functional composites, transparent conductive thin films, microelectronic devices and the like.

Owner:NINGBO MORSH TECH

Method for preparing hydrophilic polyvinyl chloride alloy ultrafiltration membrane

InactiveCN101293183ASimple processImprove hydrophilicitySemi-permeable membranesUltrafiltrationAtom-transfer radical-polymerization

The present invention discloses a preparation method of hydrophilic PVC alloy ultrafiltration membrane. PVC amphiphilic graft copolymer is synthesized through an atom-transfer-free radical polymerization method, which is taken as a hydrophilic modifier and is blended with PVC to prepare the PVC alloy ultrafiltration membrane with controllable structure, hydrophilicity, pollution resistance, large flux and high rejection rate by a solution transformation method. The hydrophilic chain of the amphiphilic graft copolymer can self-assemble and transfer to the membrane surface for microphase separation in the process of solution phase inversion, thus forming a relatively thin hydrophilic surface layer (dozens to hundreds of nanometers). The membrane preparation and hydrophilic modification are carried out simultaneously and the hydrophilic modification of membrane and the interior of the membrane hole can be achieved. The surface contact angle of the ultrafiltration membrane is less than 60 degrees and can be reduced to 0 degree within dozens of seconds; the water flux reaches above 500L / m<2> h(0.1Mpa); the BSA rejection rate reaches above 90 percent; the recovery rate of water cleaning flux is above 90 percent.

Owner:ZHEJIANG UNIV

Peptide synthesis and deprotection using a cosolvent

InactiveUS20050165215A1Speed up the processMinimize impactPeptide/protein ingredientsVirus peptidesOrganic solventCombinatorial chemistry

The invention provides methods for synthesizing peptides, which include taking an organic solvent having non-resin bound protected peptide and performing a deprotection reaction on the non-resin bound protected peptide. In these methods it is not required that the peptide is dried immediately before providing to the deprotection reaction. Also provided are methods of synthesizing peptides, wherein a protected peptide is formed in a solution phase reaction, dissolved into an organic solvent, and then introduced into a deprotection reaction. Also provided are methods of synthesizing peptides, wherein a non-resin bound protected peptide is concentrated in an organic solvent prior to being subject to a deprotection reaction.

Owner:BIGELOW ROGER +2

Process of making polymer blends

In a process for producing a polymer blend, at least one first monomer is polymerized in a first slurry phase reaction zone in the presence of a supported first catalyst to produce a thermoplastic first polymer having a crystallinity of at least 30%. At least part of said first polymer is then contacted with at least one second monomer different from said first monomer in a second solution phase reaction zone in the presence of a second catalyst and in the absence of polyenes under conditions to produce a second polymer having a crystallinity of less than 20%.

Owner:EXXONMOBIL CHEM PAT INC

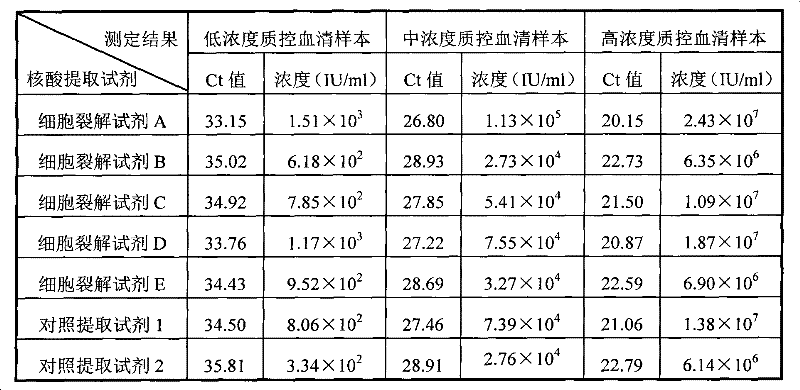

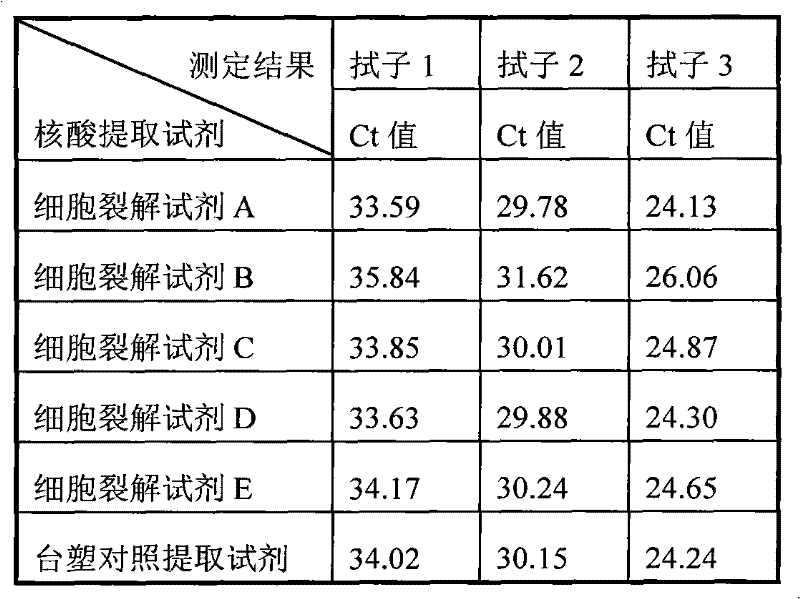

Cell lysis reagent for extracting and purifying nucleic acids in biological samples

The invention discloses a cell lysis reagent for extracting and purifying nucleic acids in biological samples. The solution of the reagent is alkaline and contains the following components: guanidinium, ammonium ions and a surface active agent, thereby, cells in the biological samples can be more fully cracked in an alkali solution-phase environment, and nucleic acids [deoxyribonucleic acid / ribonucleic acid (DNA / RNA)] released out of the cells can be promoted to be combined and absorbed with a solid material, and finally, is separated from the solid material through an elution step. The cell lysis reagent disclosed by the invention has the advantages of simplness and convenience in operation and high extraction yield of the nucleic acids, and can be used for extracting and purifying the nucleic acids in the biological samples with various types, such as whole blood, serum, blood plasma, saliva, urine, cerebrospinal fluid, cell and tissue culture solution or human nasopharynx and urogenital canal swabs and the like.

Owner:SHANGHAI XINGYAO MED TECH DEV CO LTD +1

Process of making polymer blends

In a process for producing a polymer blend, at least one first monomer is polymerized in a first slurry phase reaction zone in the presence of a supported first catalyst comprising a Ziegler-Natta component to produce a thermoplastic first polymer having a crystallinity of at least 30%. At least part of said first polymer is then contacted with at least one second monomer different from said first monomer and at least one polyene in a second solution phase reaction zone in the presence of a second catalyst under conditions to produce and at least partially cross-link said second polymer such that said second polymer comprises at least a fraction which is insoluble in xylene and has a crystallinity of less than 20%.

Owner:EXXONMOBIL CHEM PAT INC

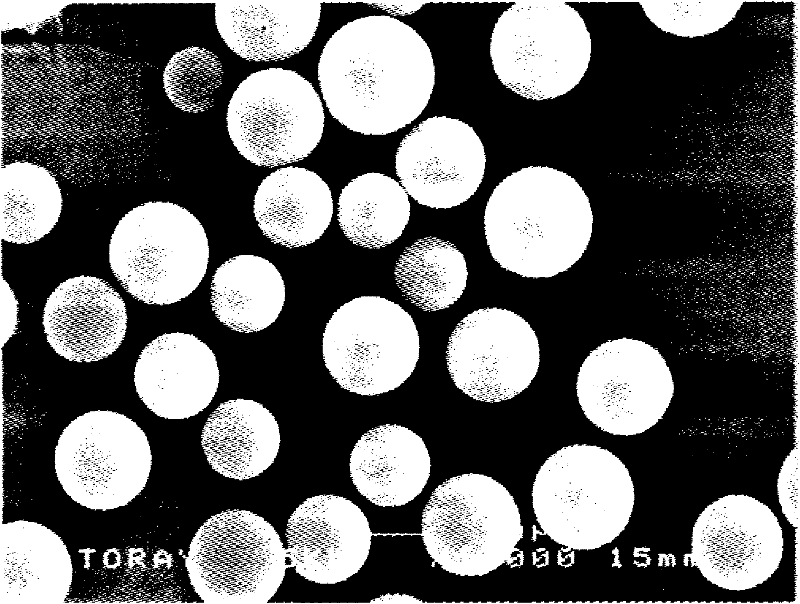

Method for producing polymer fine particle

Disclosed is a method for producing polymer fine particles, which is characterized in that after forming an emulsion in a system obtained by dissolving and mixing a polymer A, a polymer B and an organic solvent, and consisting of two separate phases, namely a solution phase mainly composed of the polymer A and a solution phase mainly composed of the polymer B, a poor solvent of the polymer A is brought into contact with the emulsion, thereby precipitating the polymer A. By this method, polymer fine particles having a narrow particle size distribution can be easily synthesized. Consequently, the method can be effectively applied to production of polymers having high heat resistance which have been difficult to produce.

Owner:TORAY IND INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com