Patents

Literature

104 results about "Carbon nanotube fet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

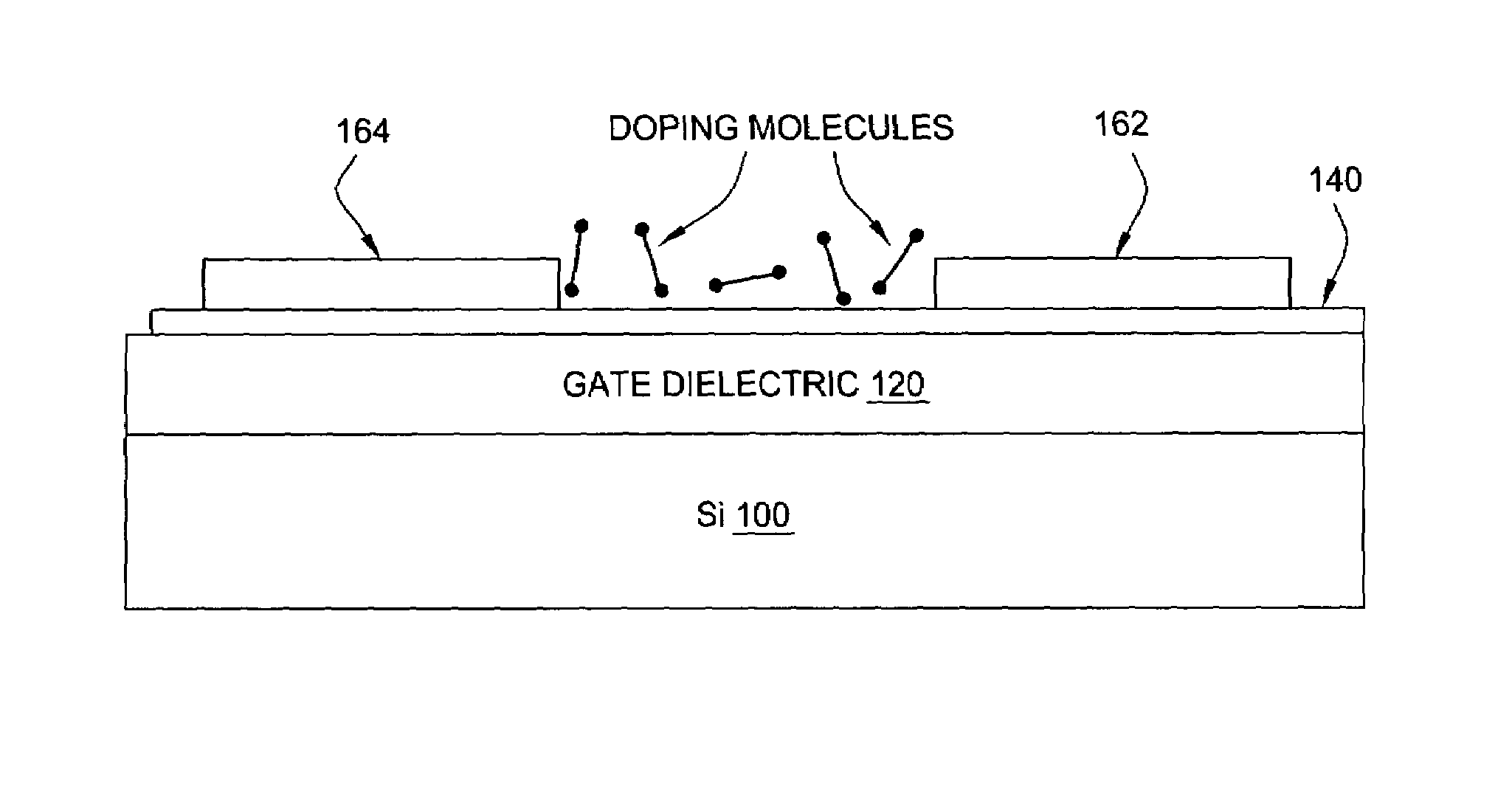

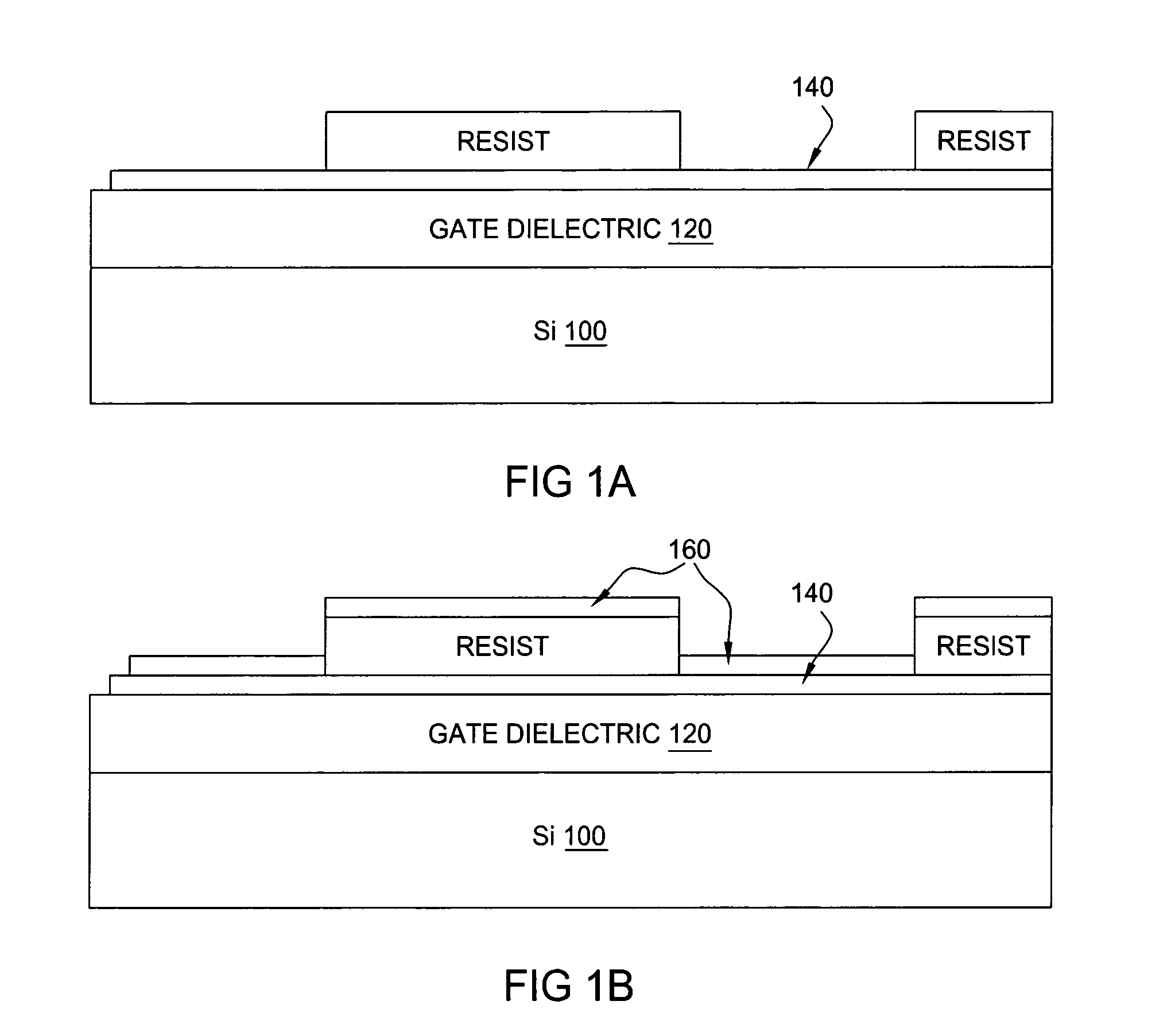

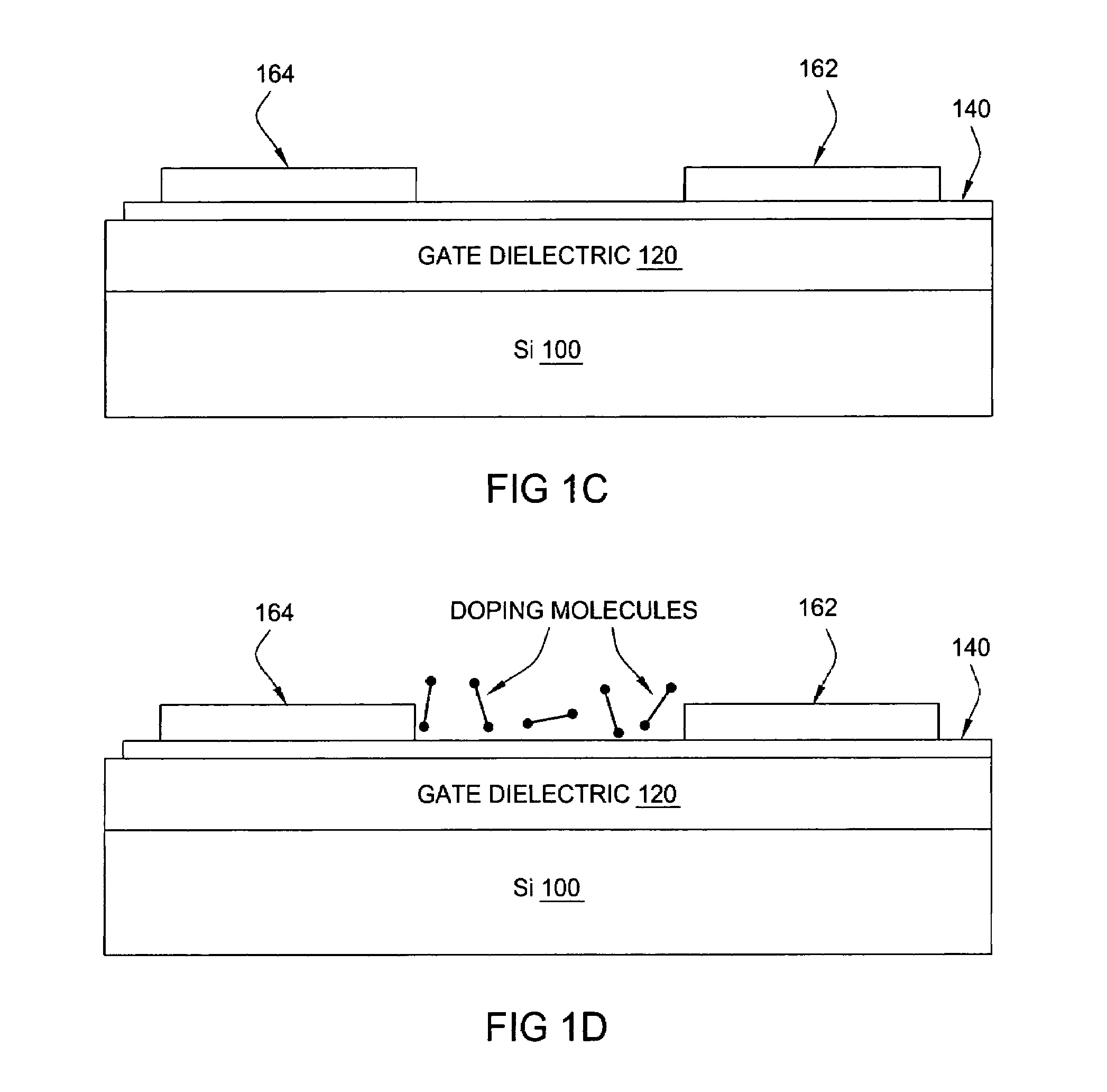

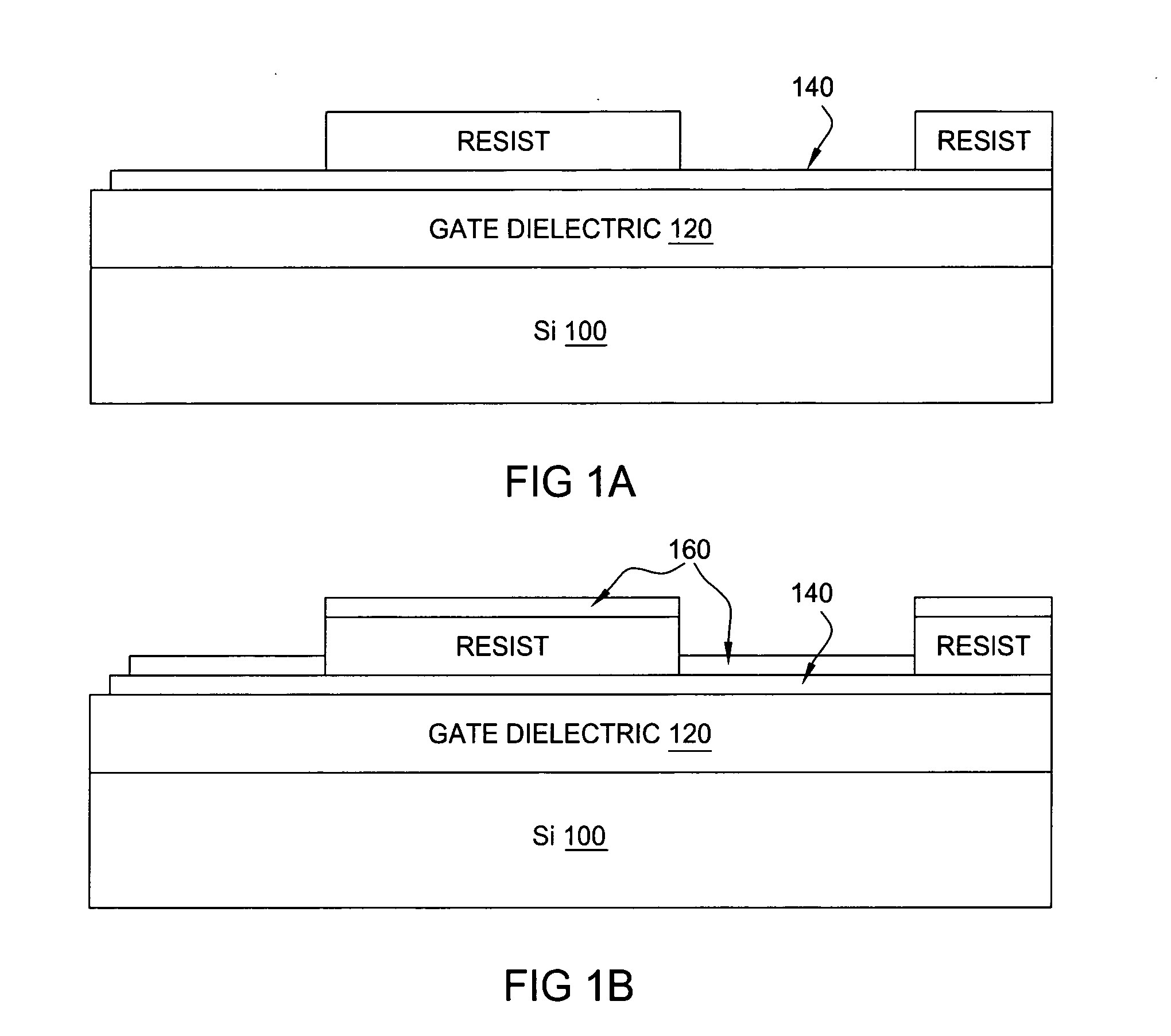

Method and apparatus for solution processed doping of carbon nanotube

A method is provided for doping a carbon nanotube. The method comprises exposing the nanotube to a one-electron oxidant in a solution phase. A method is also provided for forming a carbon nanotube FET device.

Owner:GLOBALFOUNDRIES U S INC

Method of manufacturing a light filament from carbon nanotubes

InactiveUS6957993B2Large specific surface areaIncreased durabilityMaterial nanotechnologyNanoinformaticsCarbon nanotube yarnCarbon nanotube fet

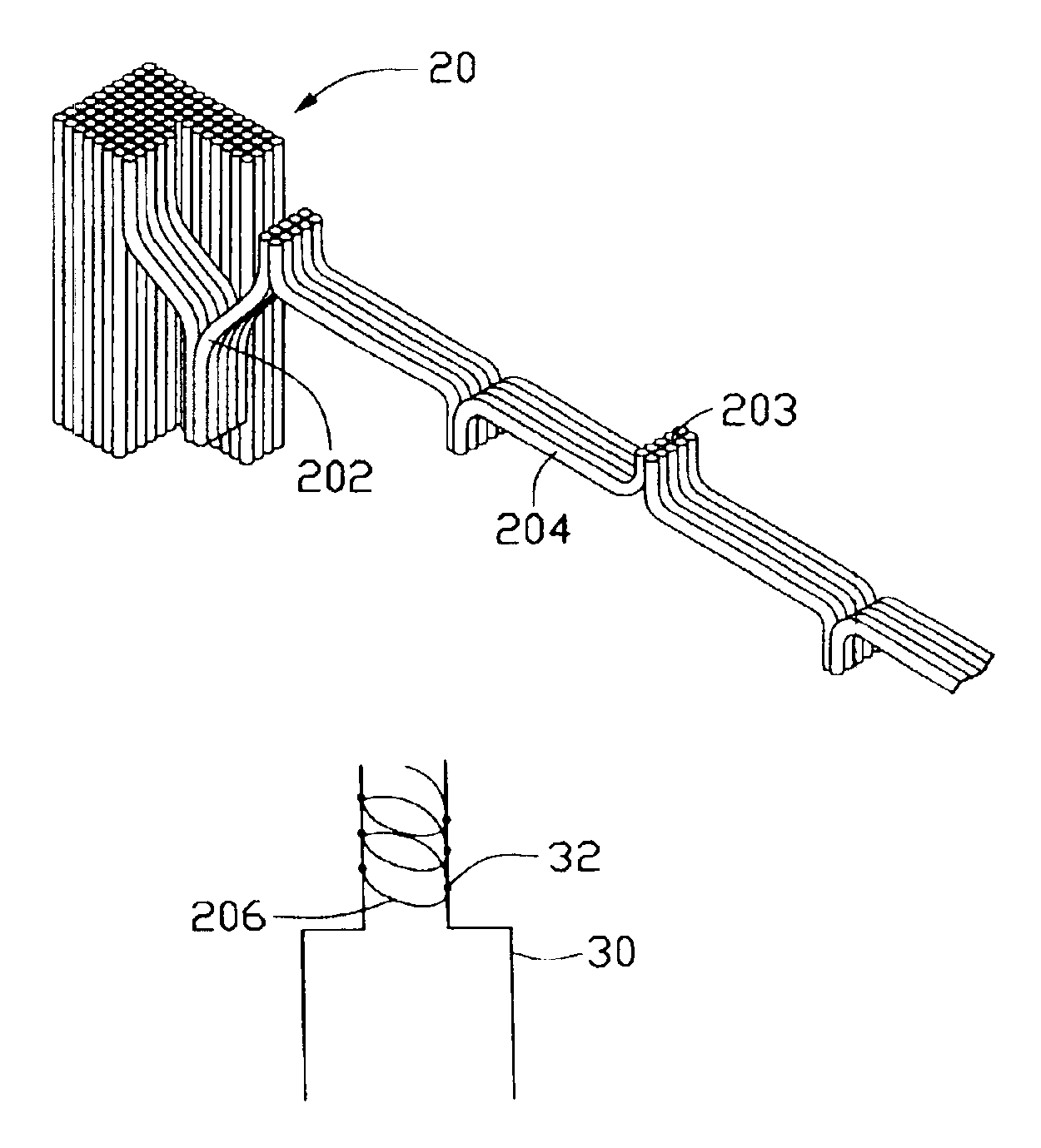

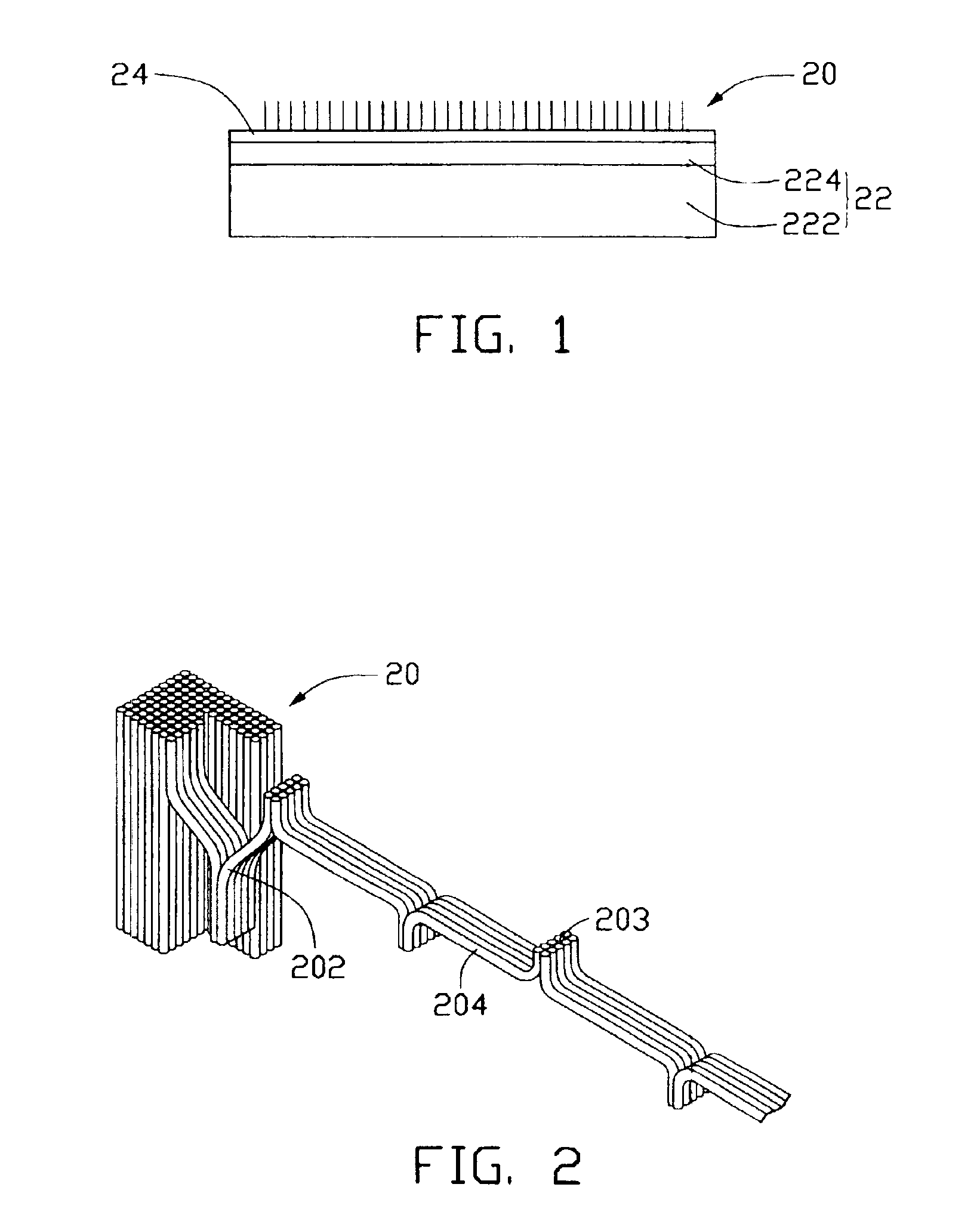

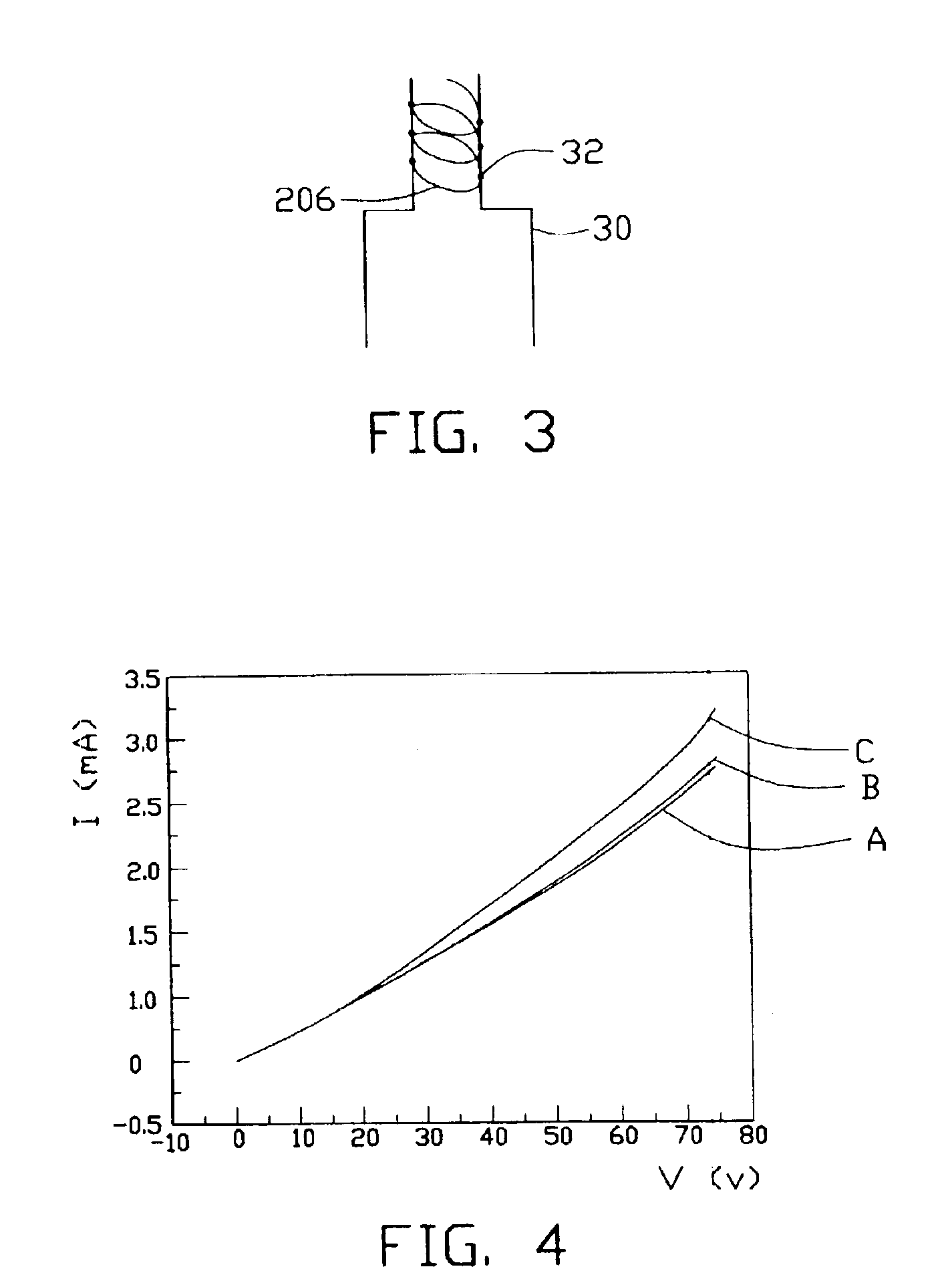

A light filament (206) formed from carbon nanotubes is characterized by high mechanical strength and durability at elevated temperatures, a high surface area to volume ratio, and high emissivity. Additionally, electrical resistance of the light filament does not increase with increasing temperature as much as electrical resistance of metallic light filaments. Accordingly, power consumption of the light filament is low at incandescent operating temperatures. A method for making a light filament made of carbon nanotubes includes the steps of: forming an array of carbon nanotubes (20); pulling out carbon nanotube yarn (204) from the carbon nanotube array; and winding the yarn between two leads (30) functioning as electrodes to form the light filament.

Owner:HON HAI PRECISION IND CO LTD +1

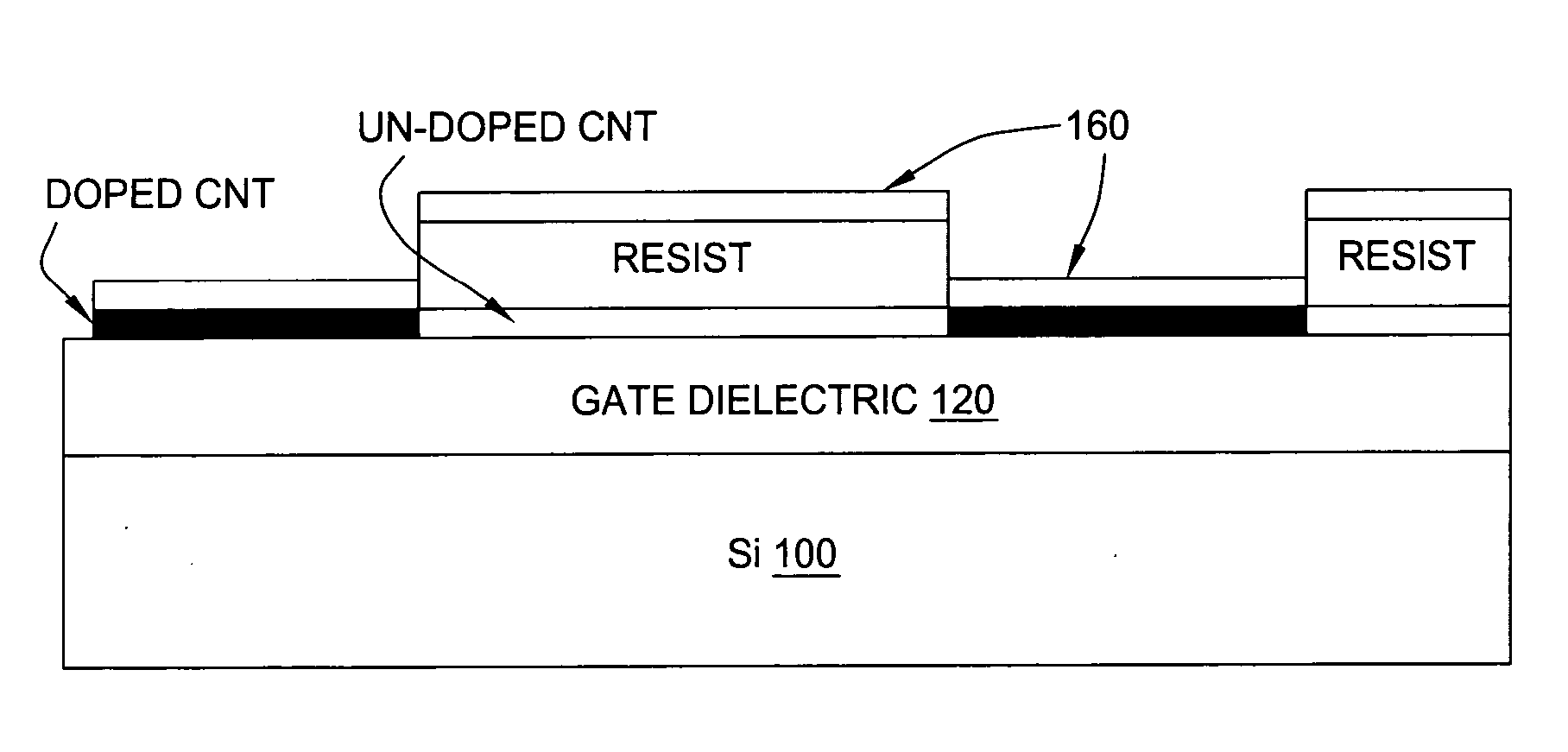

Method and apparatus for solution processed doping of carbon nanotube

A method is provided for doping a carbon nanotube. The method comprises exposing the nanotube to a one-electron oxidant in a solution phase. A method is also provided for forming a carbon nanotube FET device.

Owner:GLOBALFOUNDRIES US INC

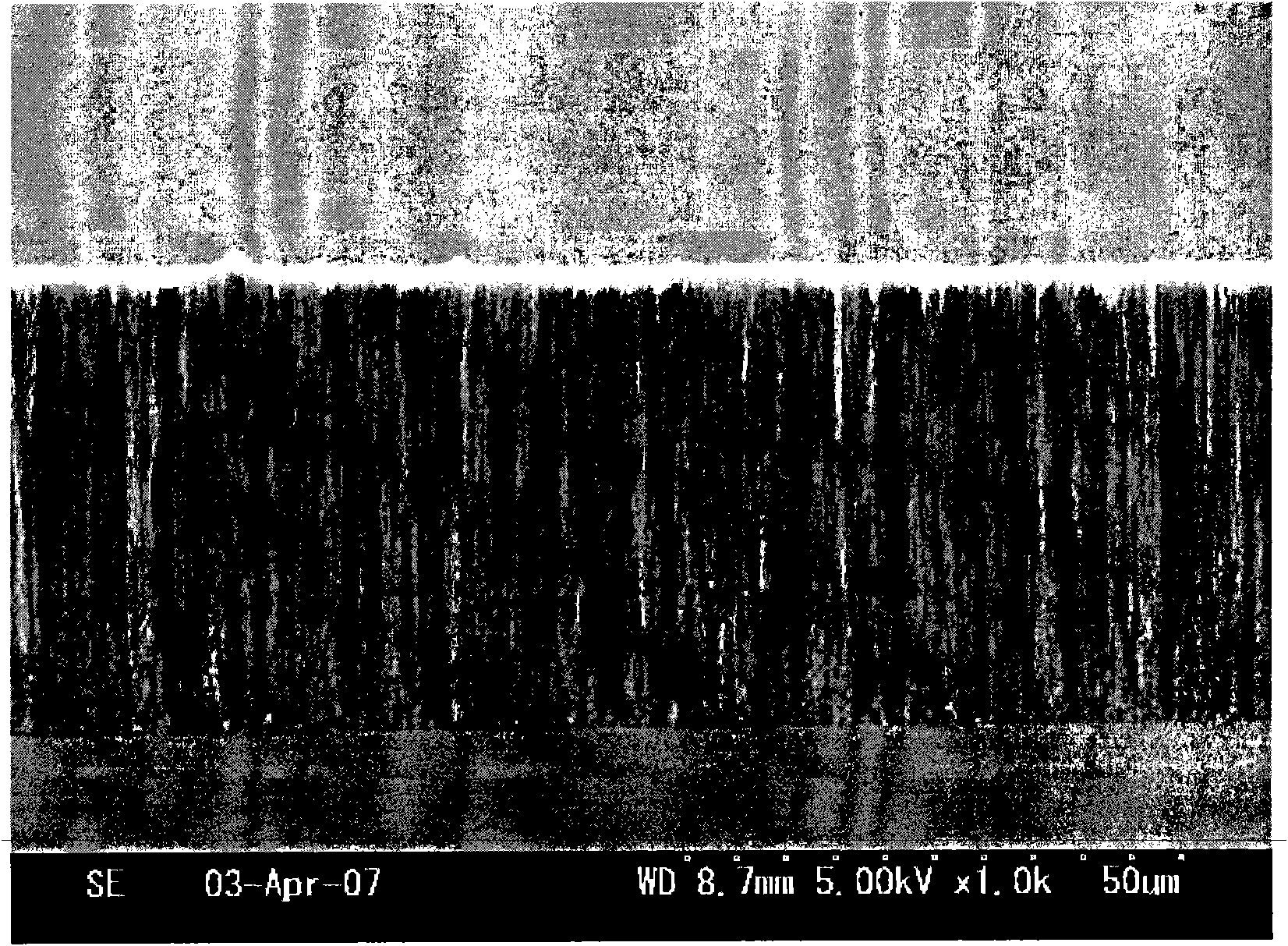

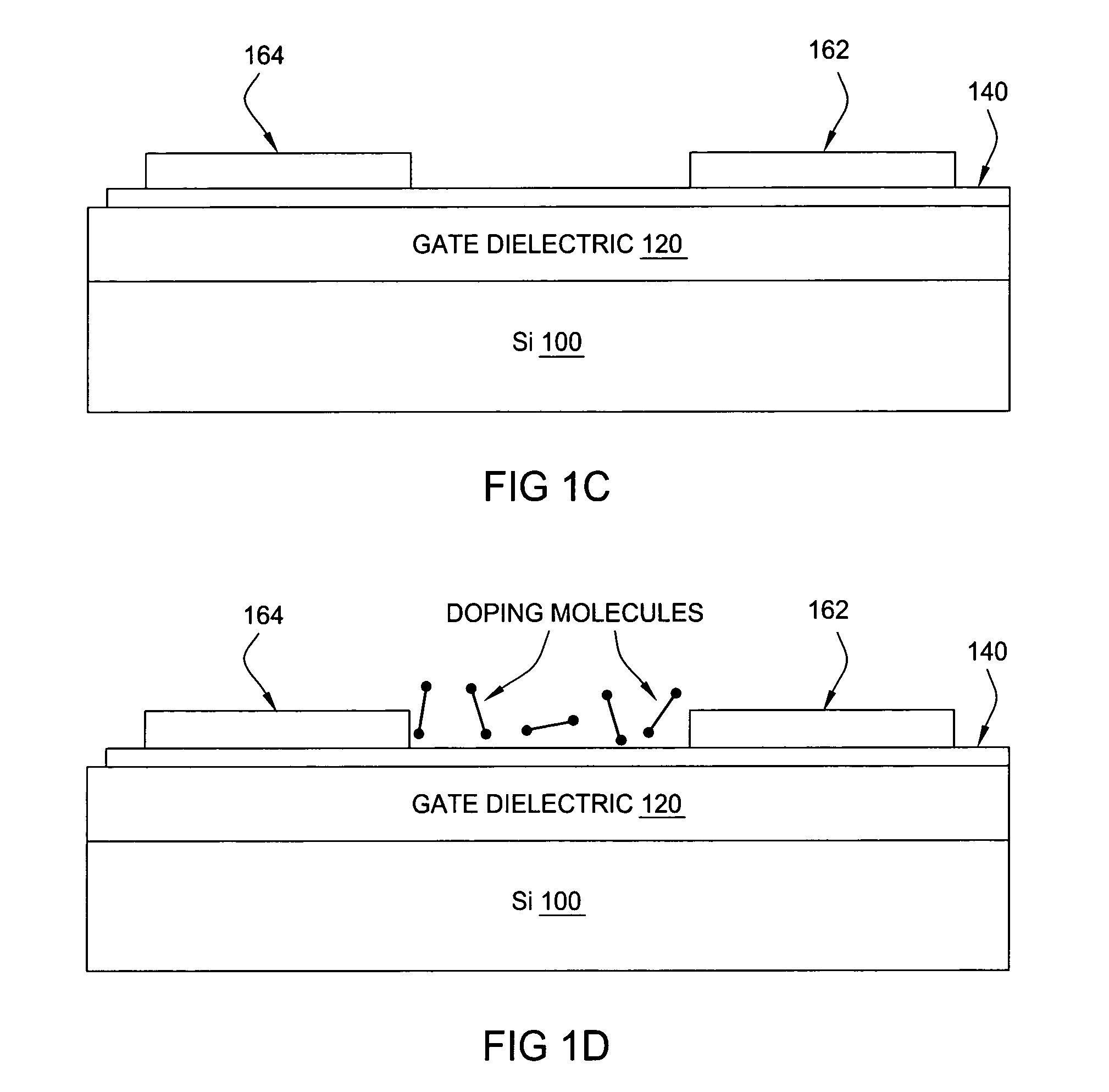

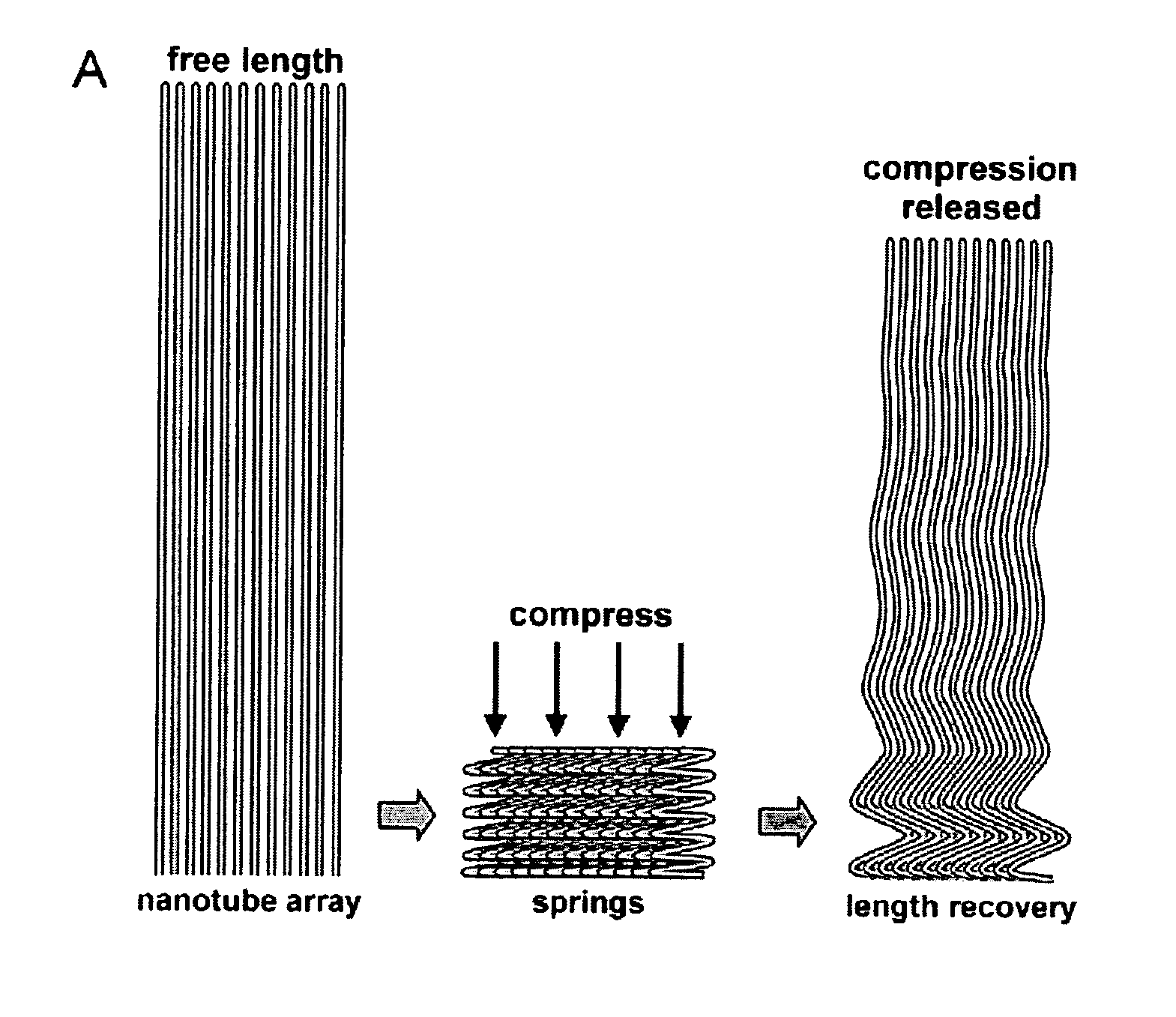

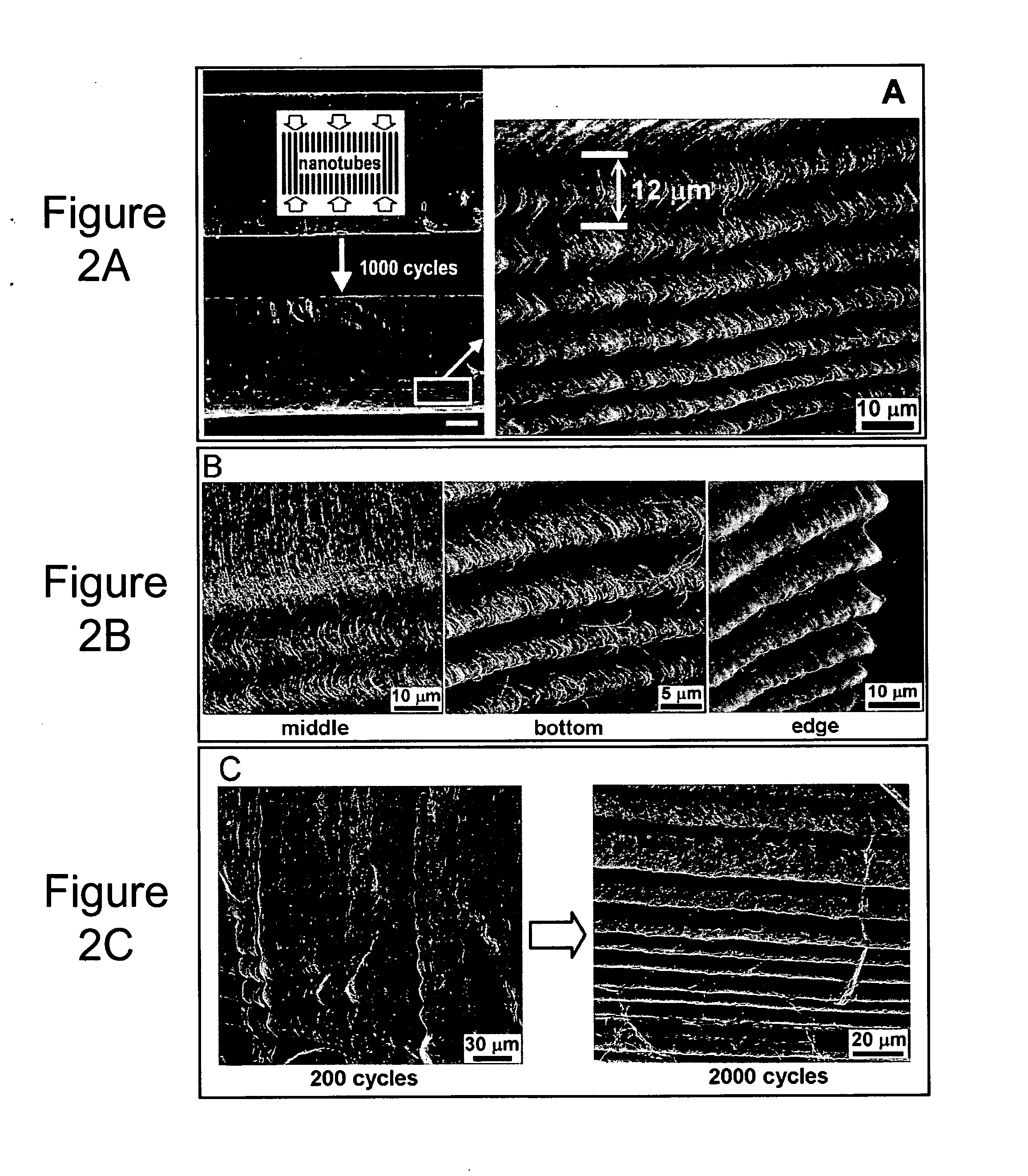

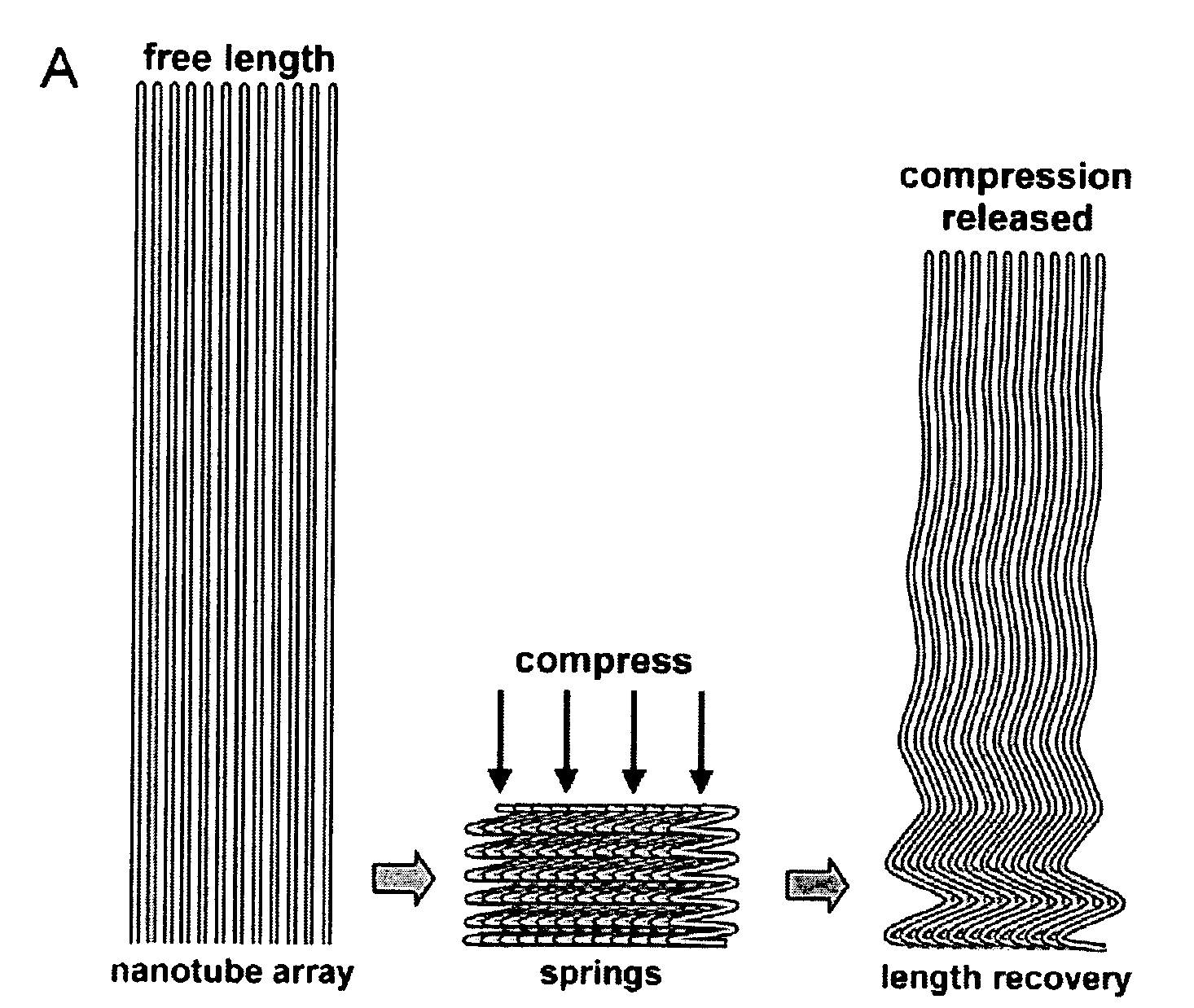

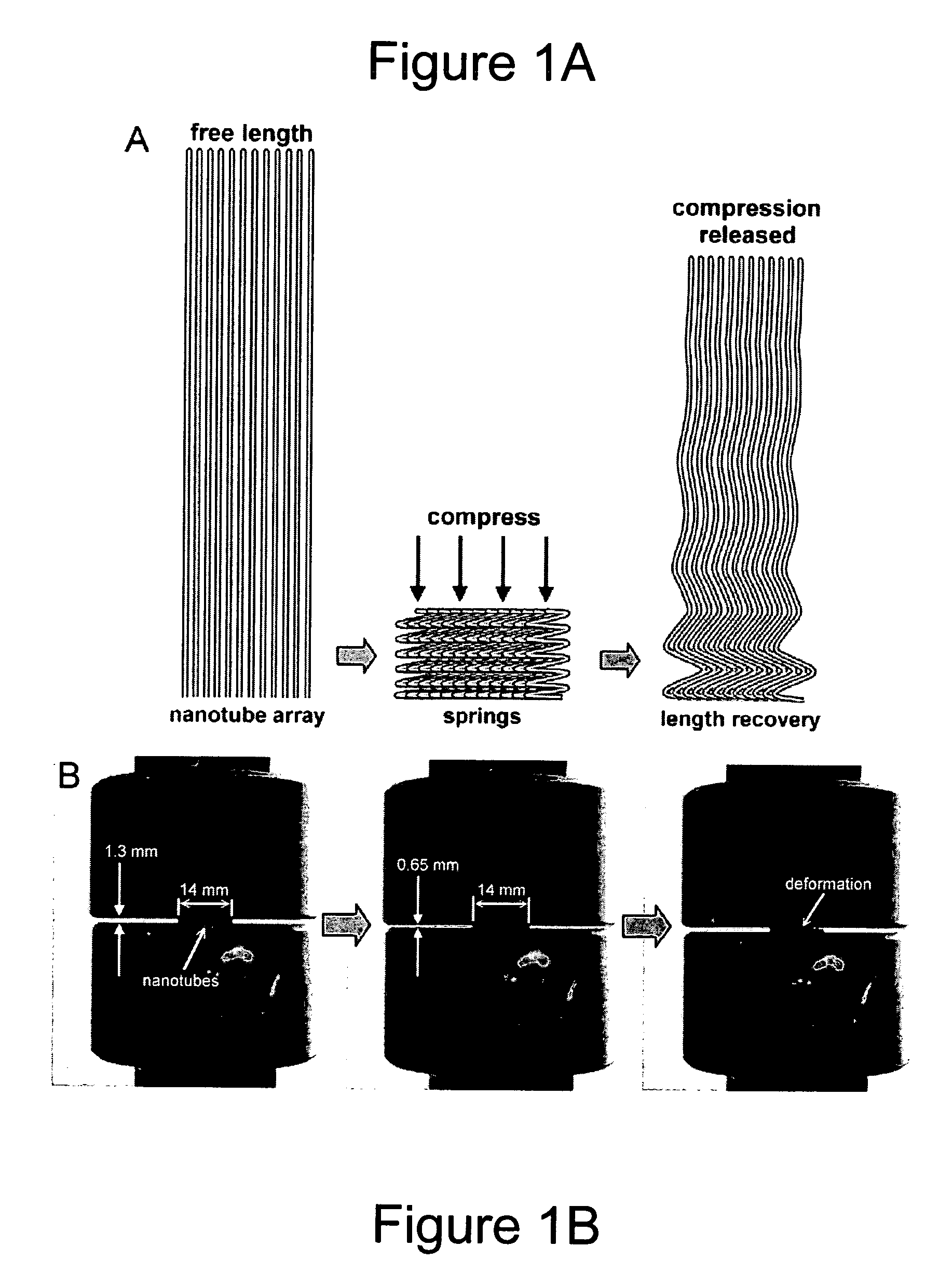

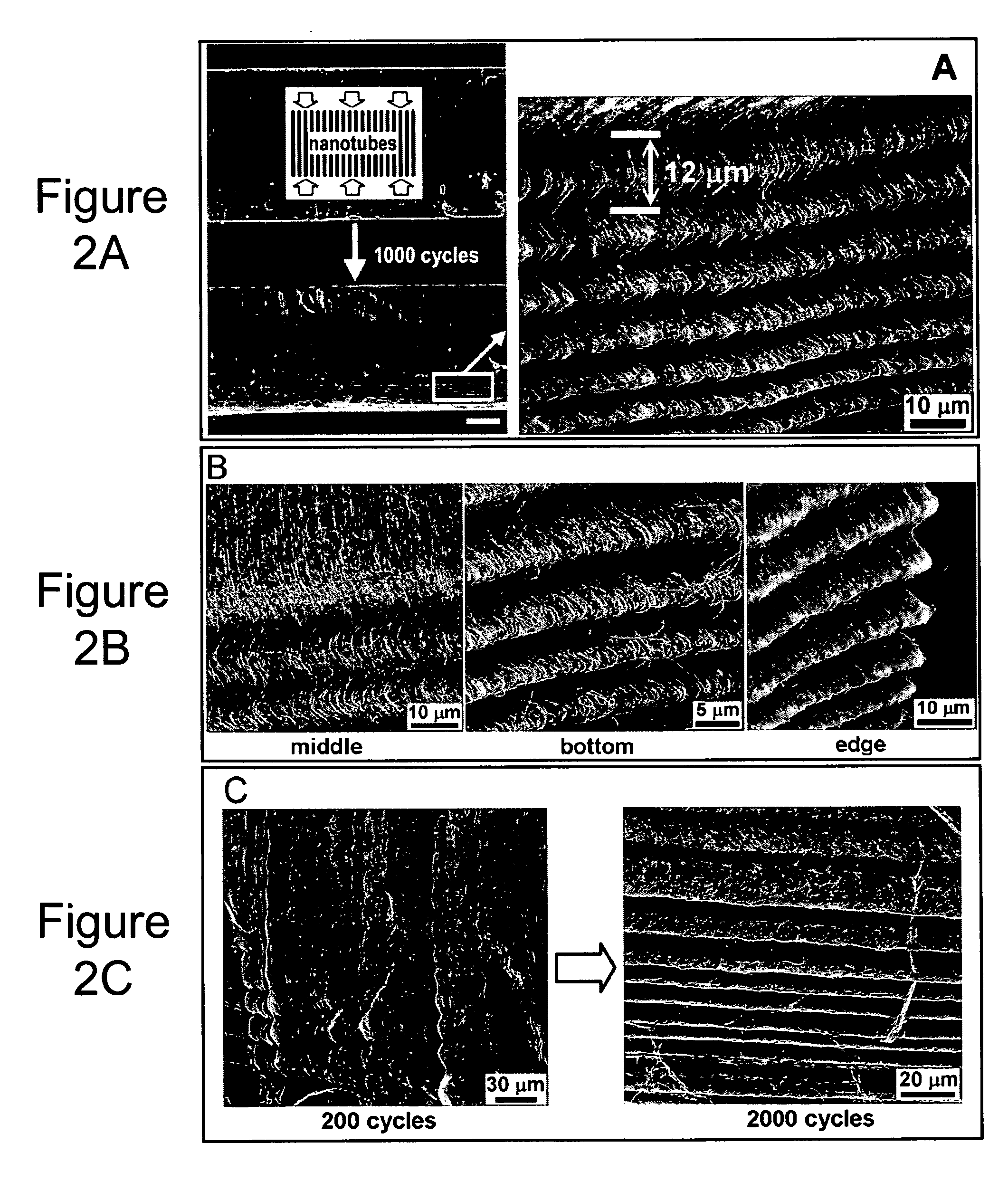

Super-compressible carbon nanotube films and micro-bundles

An open-cell carbon nanotube foam is made of a plurality of separated carbon nanotubes. The foam exhibits a Poisson's ratio substantially equal to zero, a compressibility of at least 85%, a recovery rate of at least 120 mm / min, a compressive strength of at least 12 MPa, a sag factor of at least 4, a fatigue resistance to no more than 15% permanent deformation when subjected to at least 1,000 compressive cycles at a strain of 85%, and / or a resilience of between 25% and 30%. The carbon nanotubes may be multiwalled carbon nanotubes that are aligned parallel to a thickness of a film comprising the foam.

Owner:RENESSELAER POLYTECHNIC INST

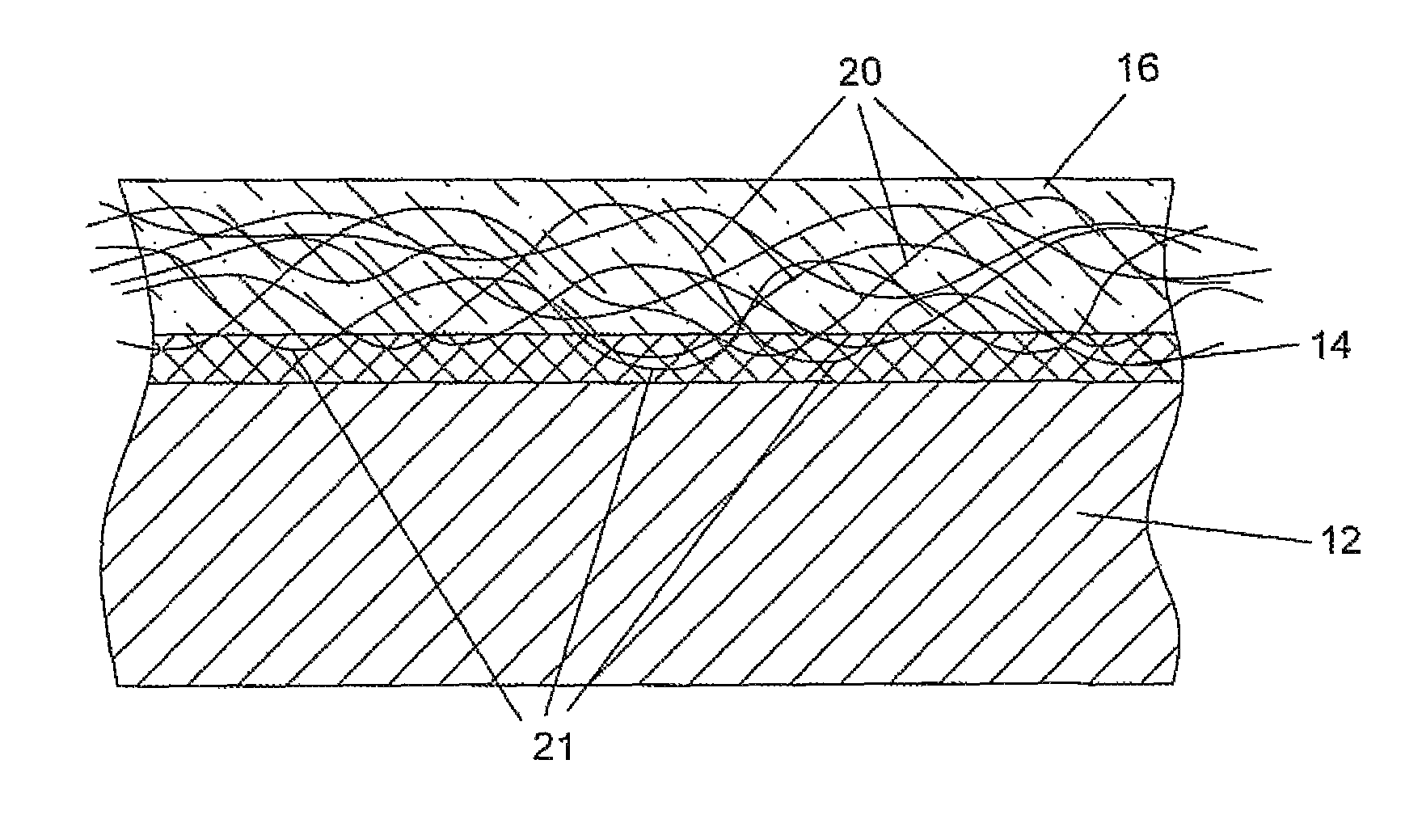

TBC with fibrous reinforcement

A substrate exposed to high temperatures, the substrate having a TBC layer that includes fibers of reinforcing material to add strength to the layer of TBC. The fibers are made from carbon nanotubes to withstand the high temperatures, and have a diameter of about 0.1 mm or less in order that a thin layer of TBC can completely cover and embed the fibers within the layer. A bond coat is applied to the substrate and the fibers are attached to the bond coat to limit the fibers from being pulled away from the substrate. The carbon nanotubes also provide for improved heat transfer through the TBC to improve the cooling capability of the TBC.

Owner:FLORIDA TURBINE TECH

TiAl-base composite material enhanced by three-dimensional network Ti2AlC and manufacturing method thereof

The invention relates to the making of TiAl based composite material with reinforced three dimensional net structure Ti2AlC. It solves the poor indoor plasticization and low strength issue of existing material. The newly invented material is made in the following combination based on atomic percentage: Ti powder 45-50at.%, Al powder 40-49at.%, 1-15at.% of one or more of Nb,Cr,Mn,V, Ni,W,Ta,Mo,Zr,Si,B powders, and carbon nanometer tube with the total weight of Ti, Al and element powder 0.05-20%, with two or more of Nb,Cr,Mn,V,Ni,W, Ta,Mo,Zr,Si,B, with all the element powders in random atomic percentages. It is made through ball grinding, mixing powder after feeding carbon nanometer tube, plasma sintering to get the final product.

Owner:HARBIN INST OF TECH

Super-compressible carbon nanotube films and micro-bundles

An open-cell carbon nanotube foam is made of a plurality of separated carbon nanotubes. The foam exhibits a Poisson's ratio substantially equal to zero, a compressibility of at least 85%, a recovery rate of at least 120 mm / min, a compressive strength of at least 12 MPa, a sag factor of at least 4, a fatigue resistance to no more than 15% permanent deformation when subjected to at least 1,000 compressive cycles at a strain of 85%, and / or a resilience of between 25% and 30%. The carbon nanotubes may be multiwalled carbon nanotubes that are aligned parallel to a thickness of a film comprising the foam.

Owner:RENESSELAER POLYTECHNIC INST

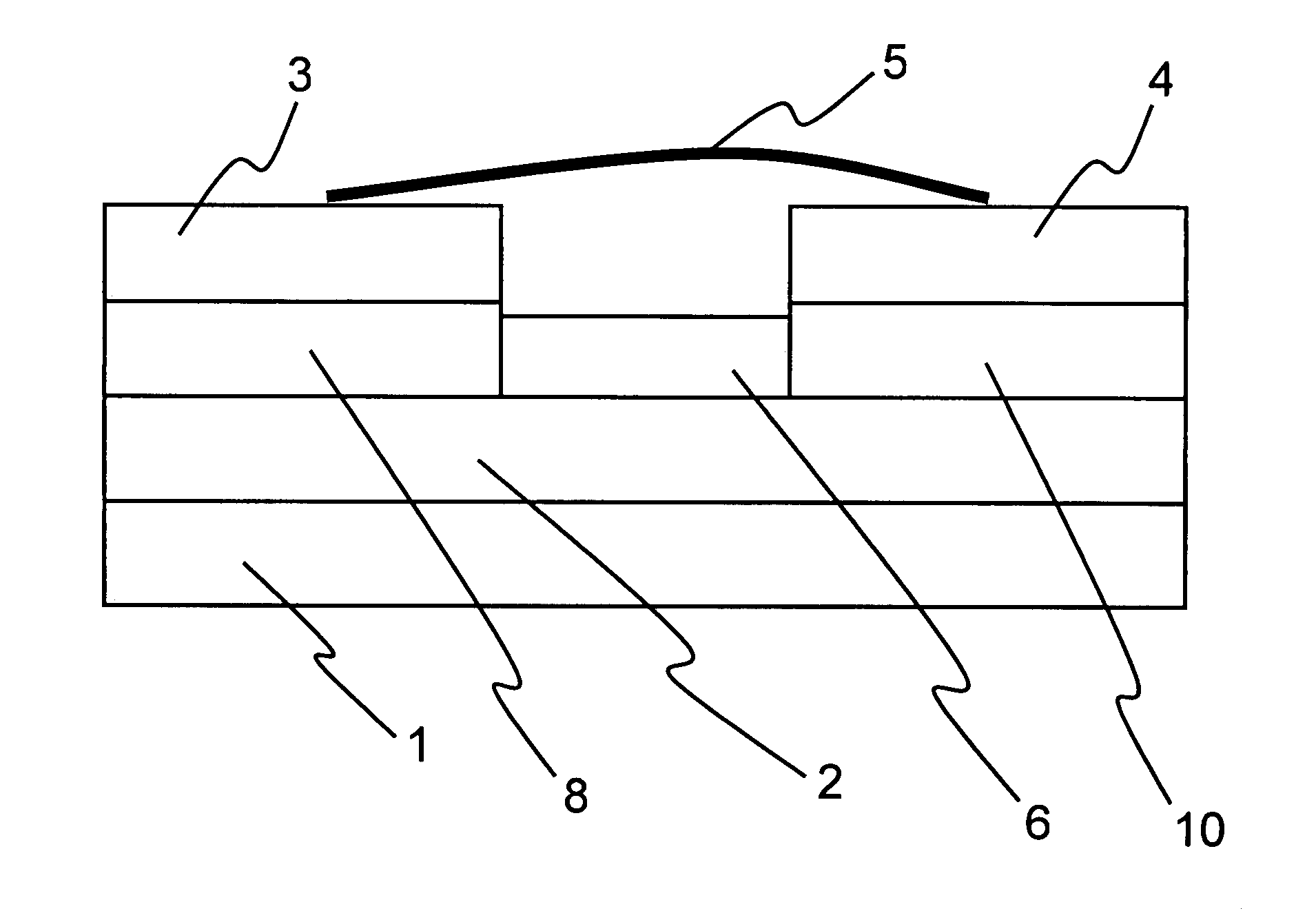

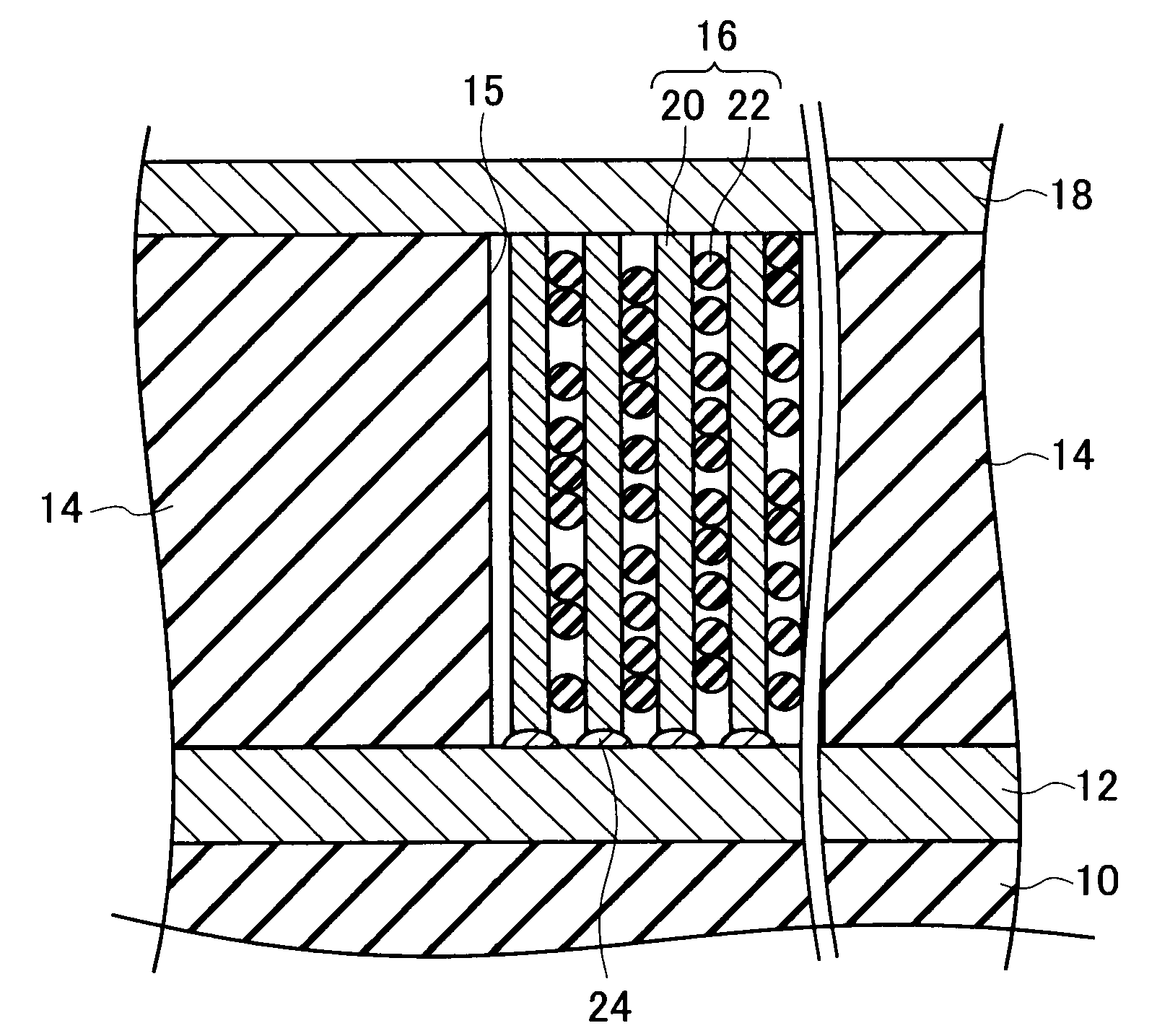

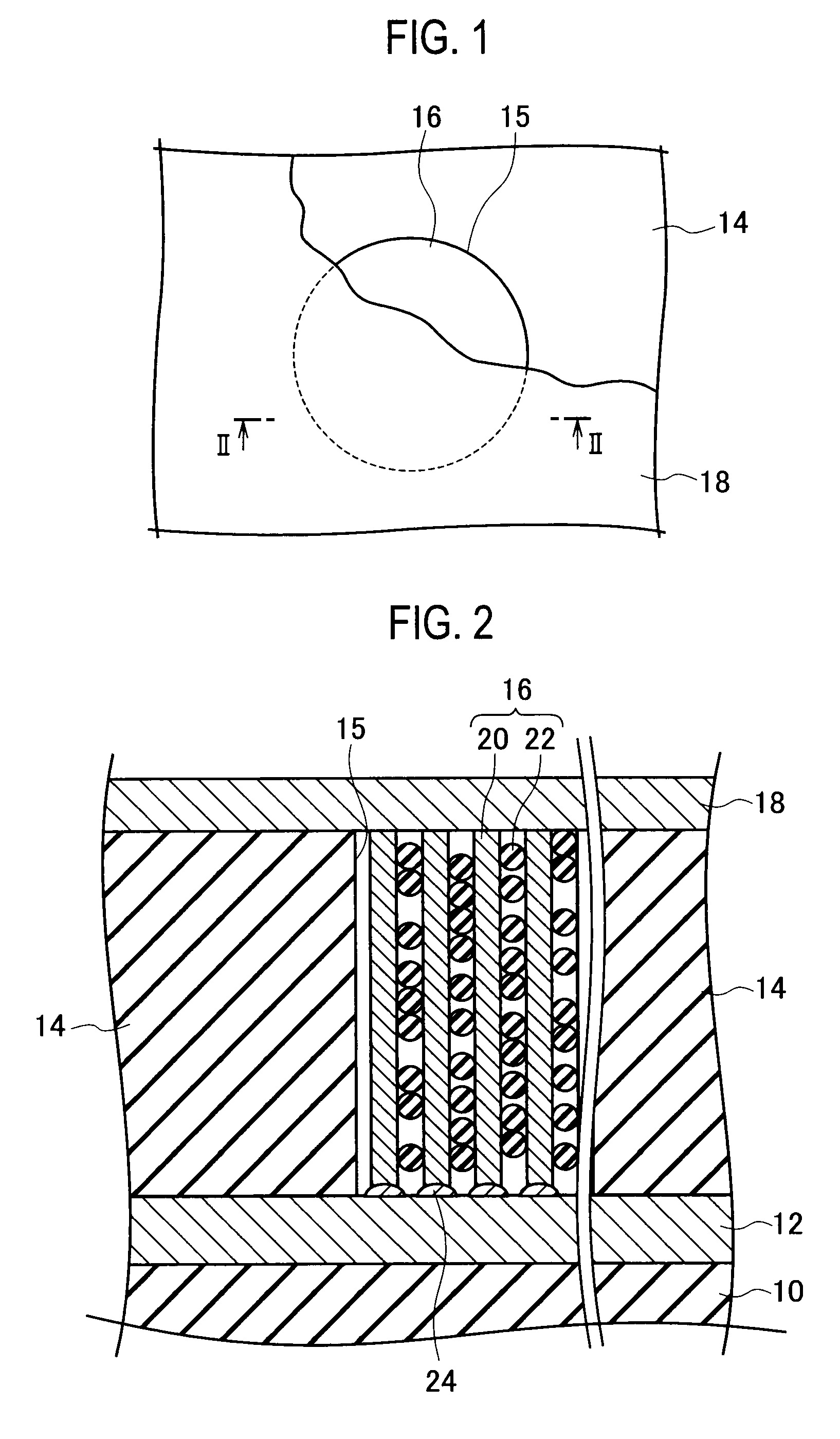

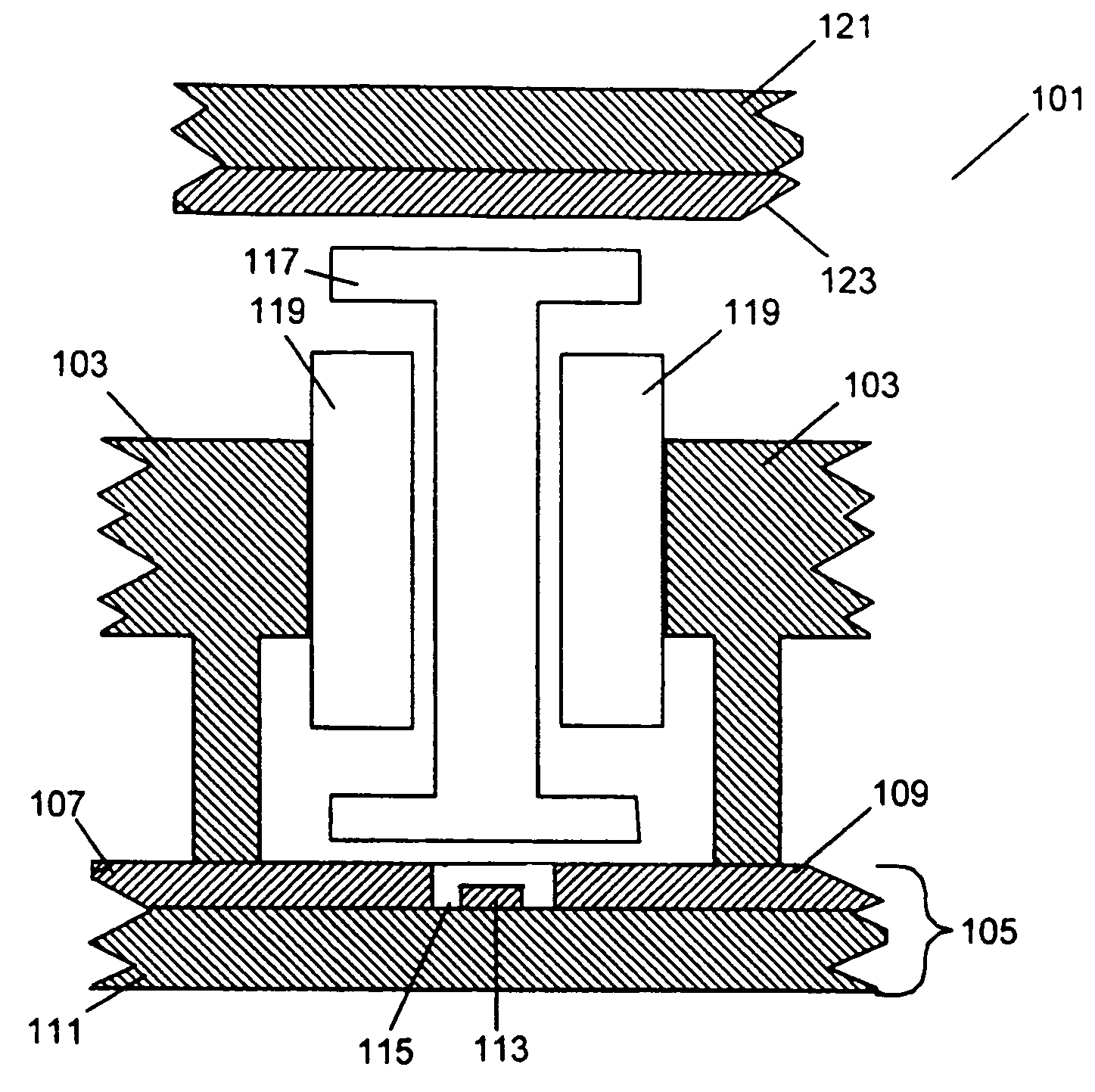

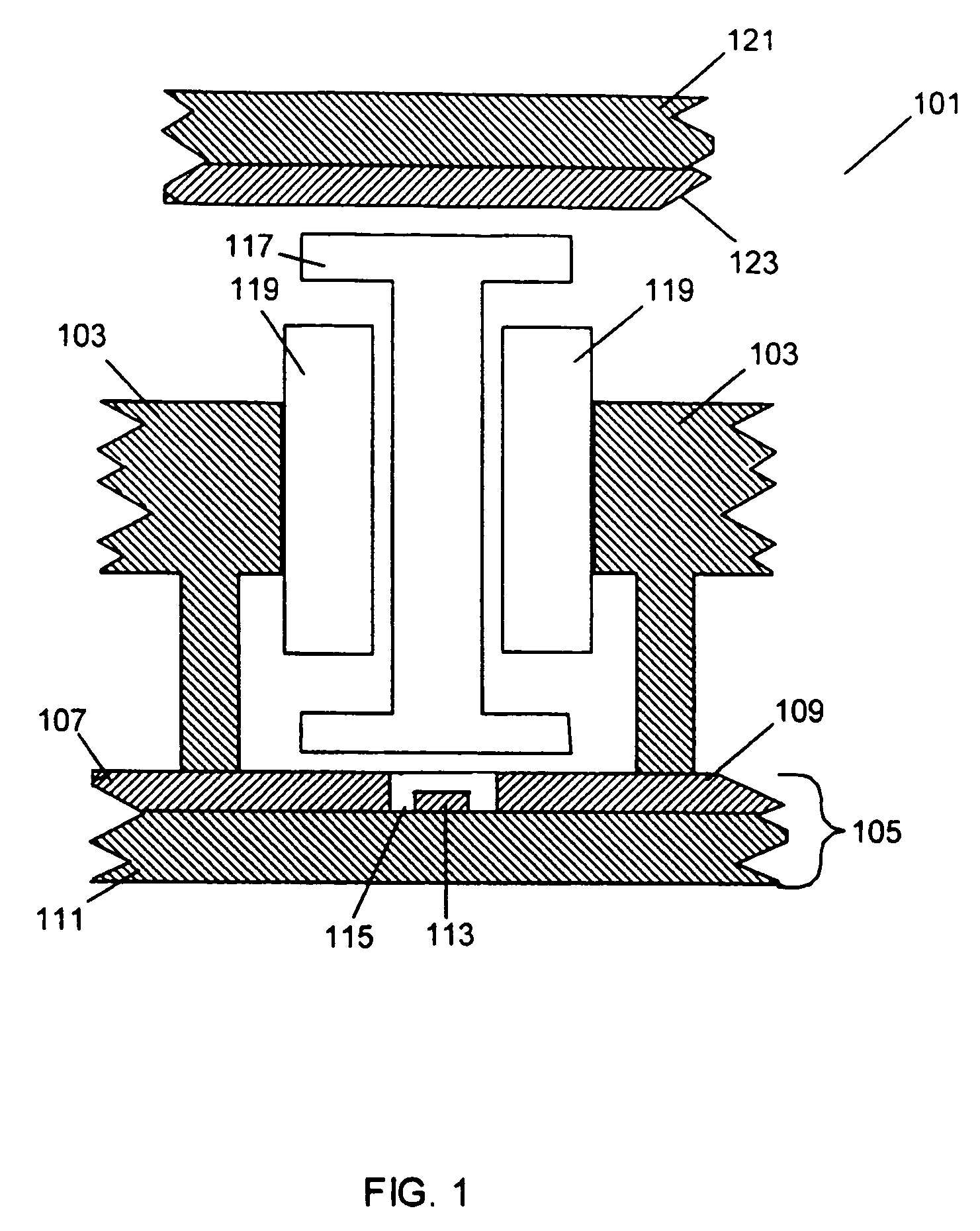

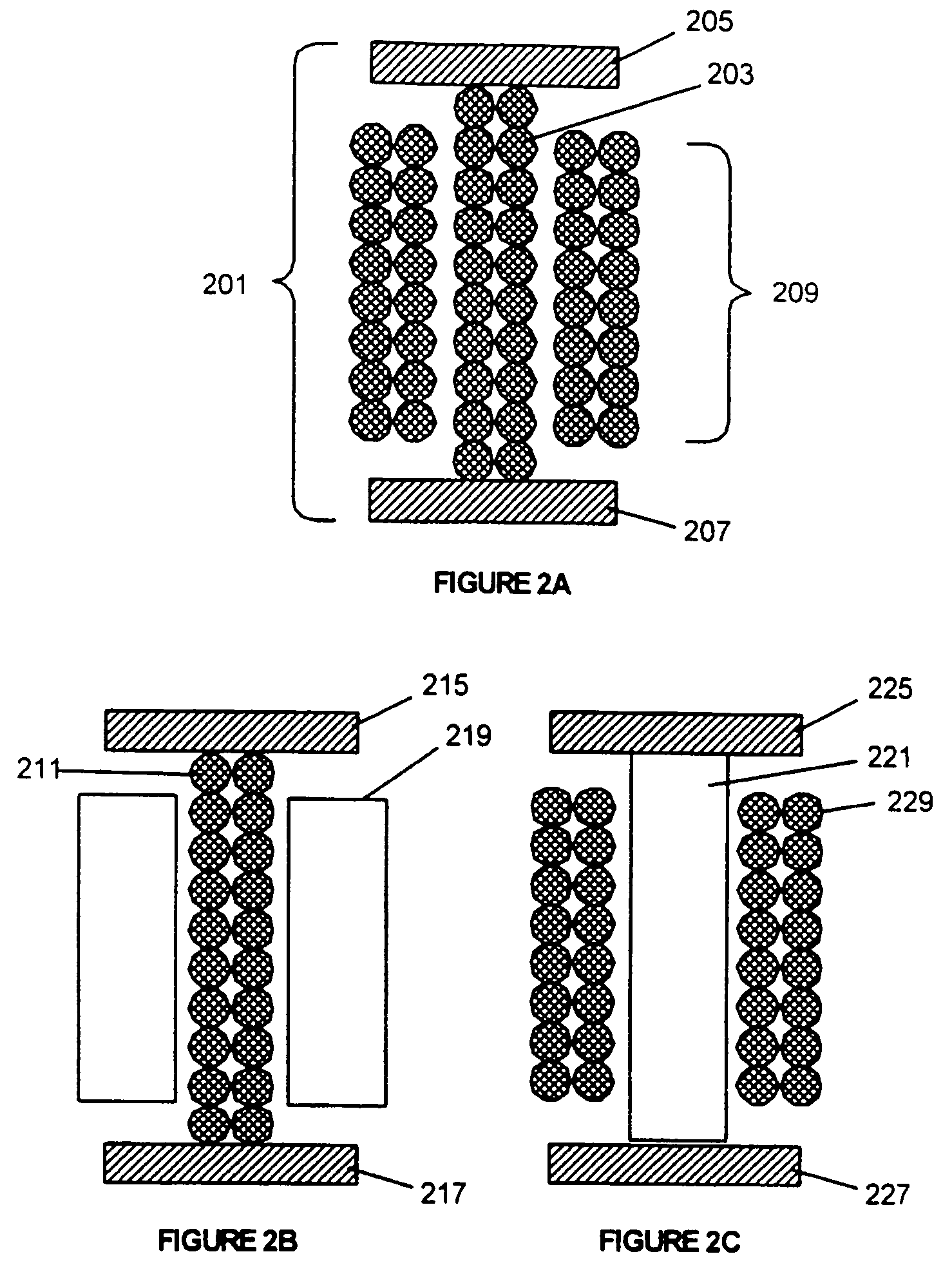

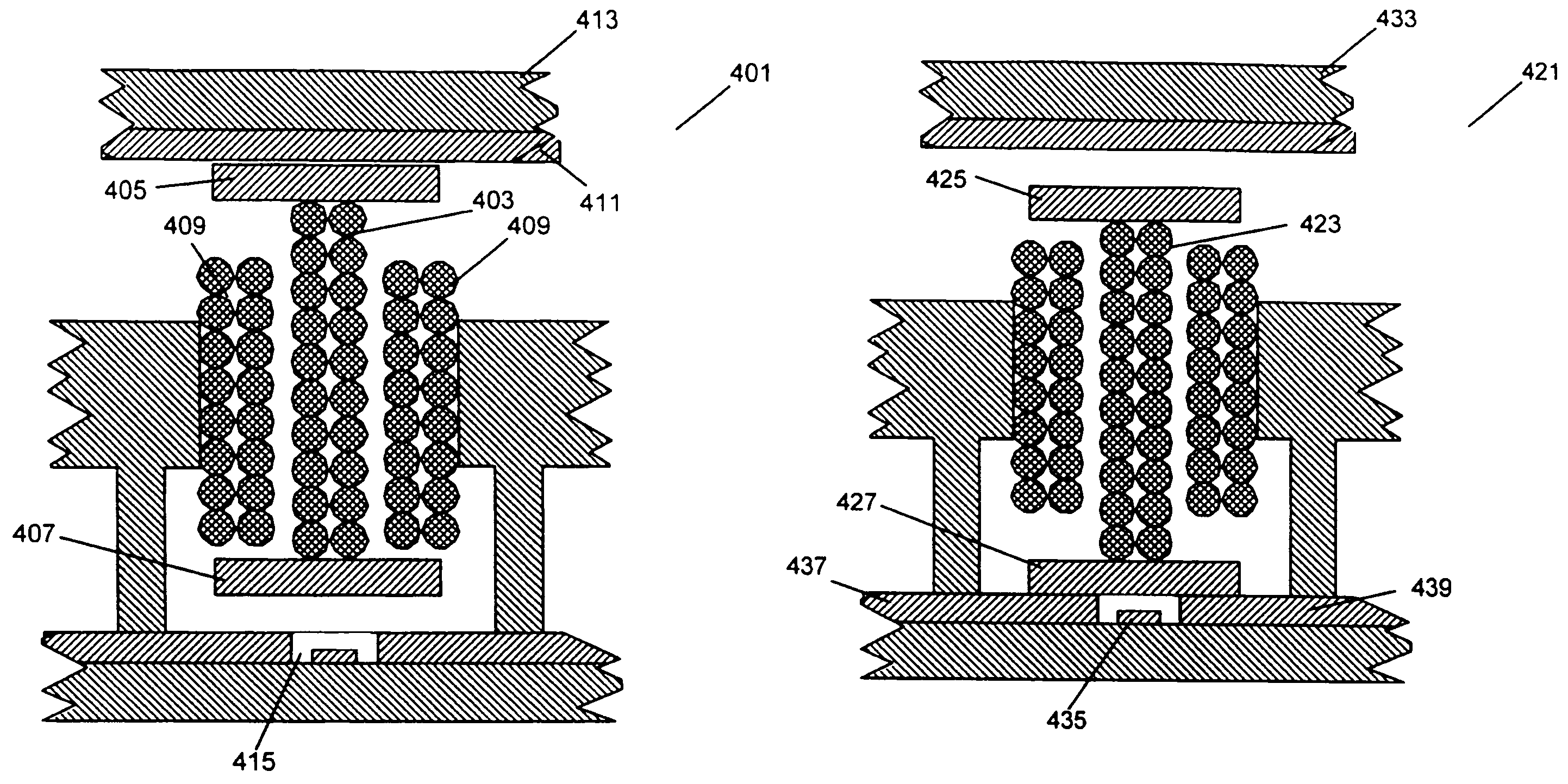

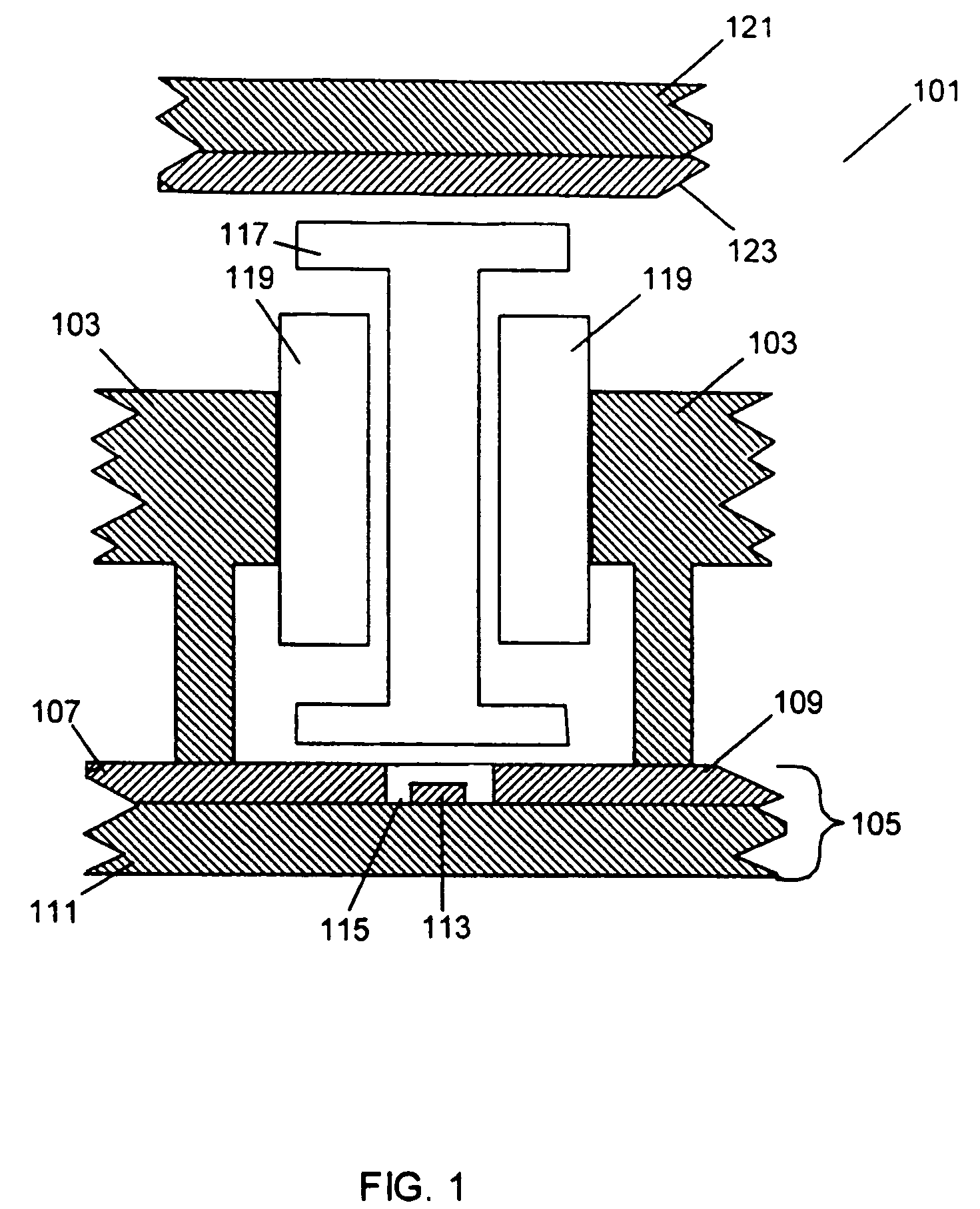

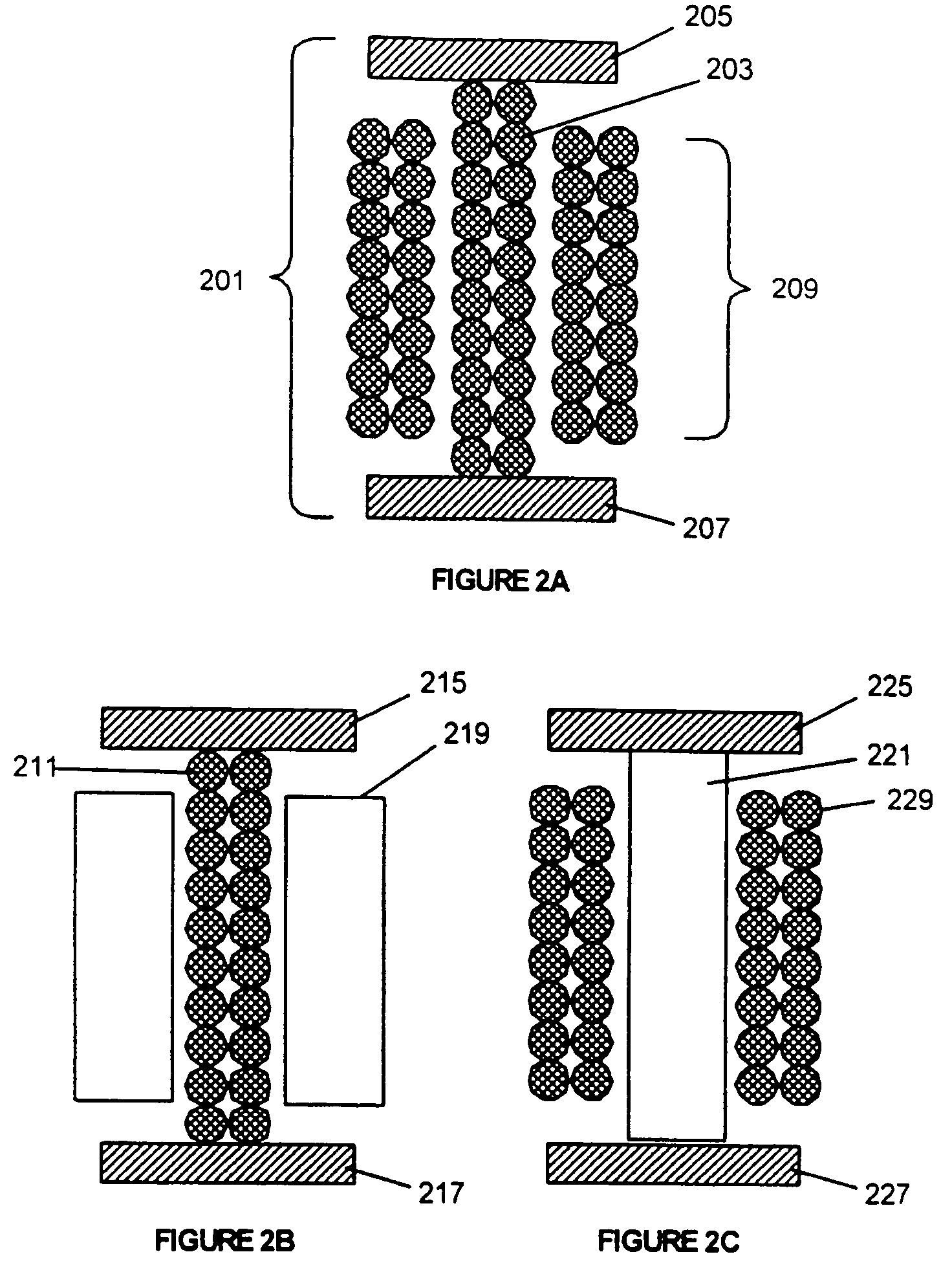

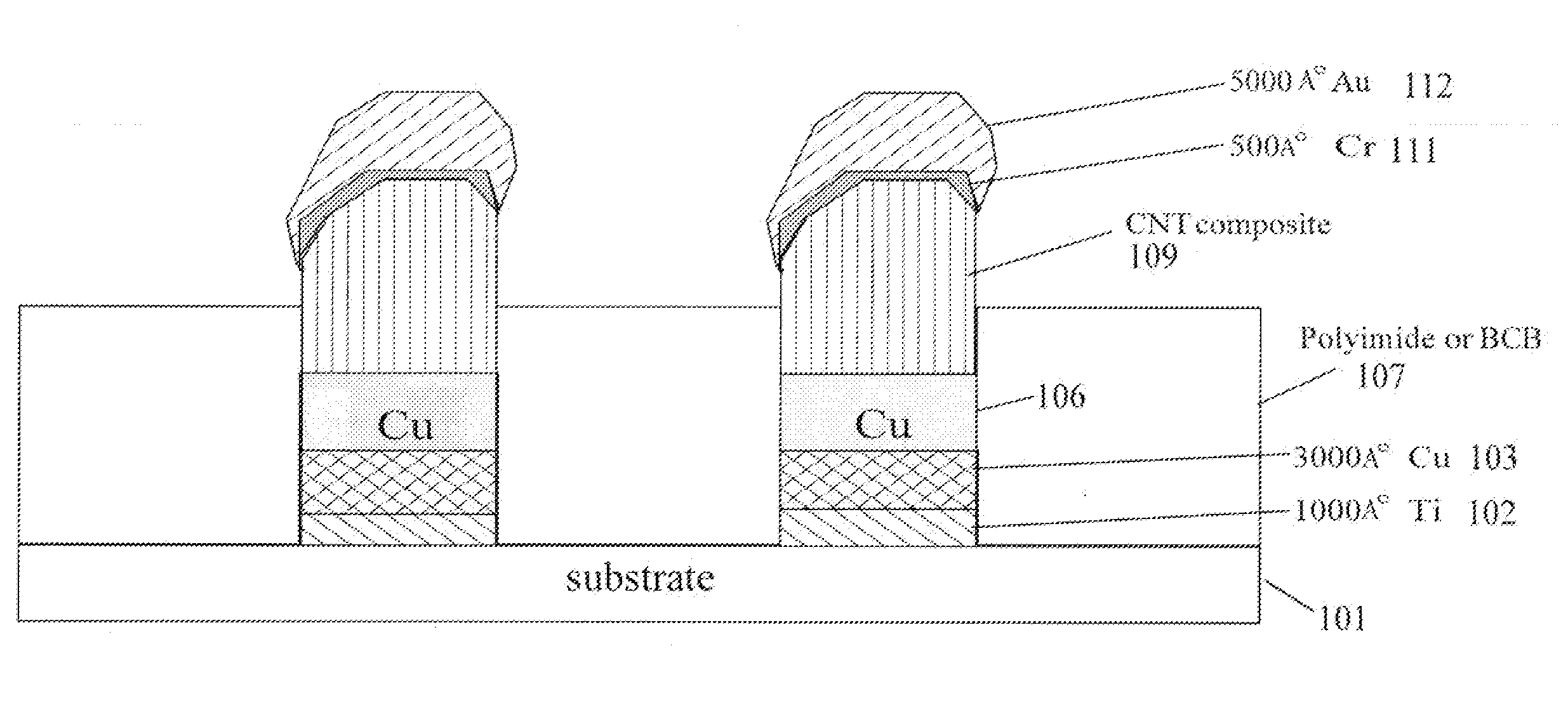

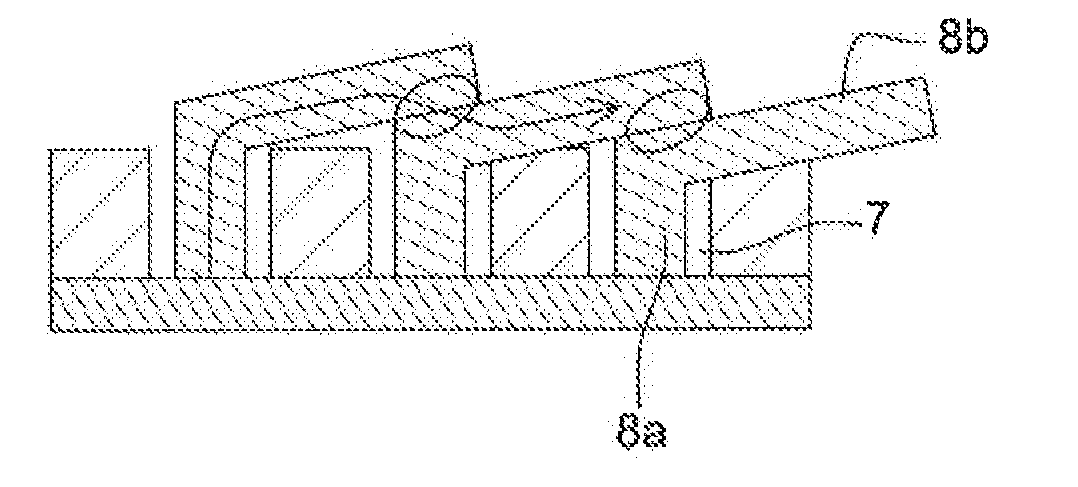

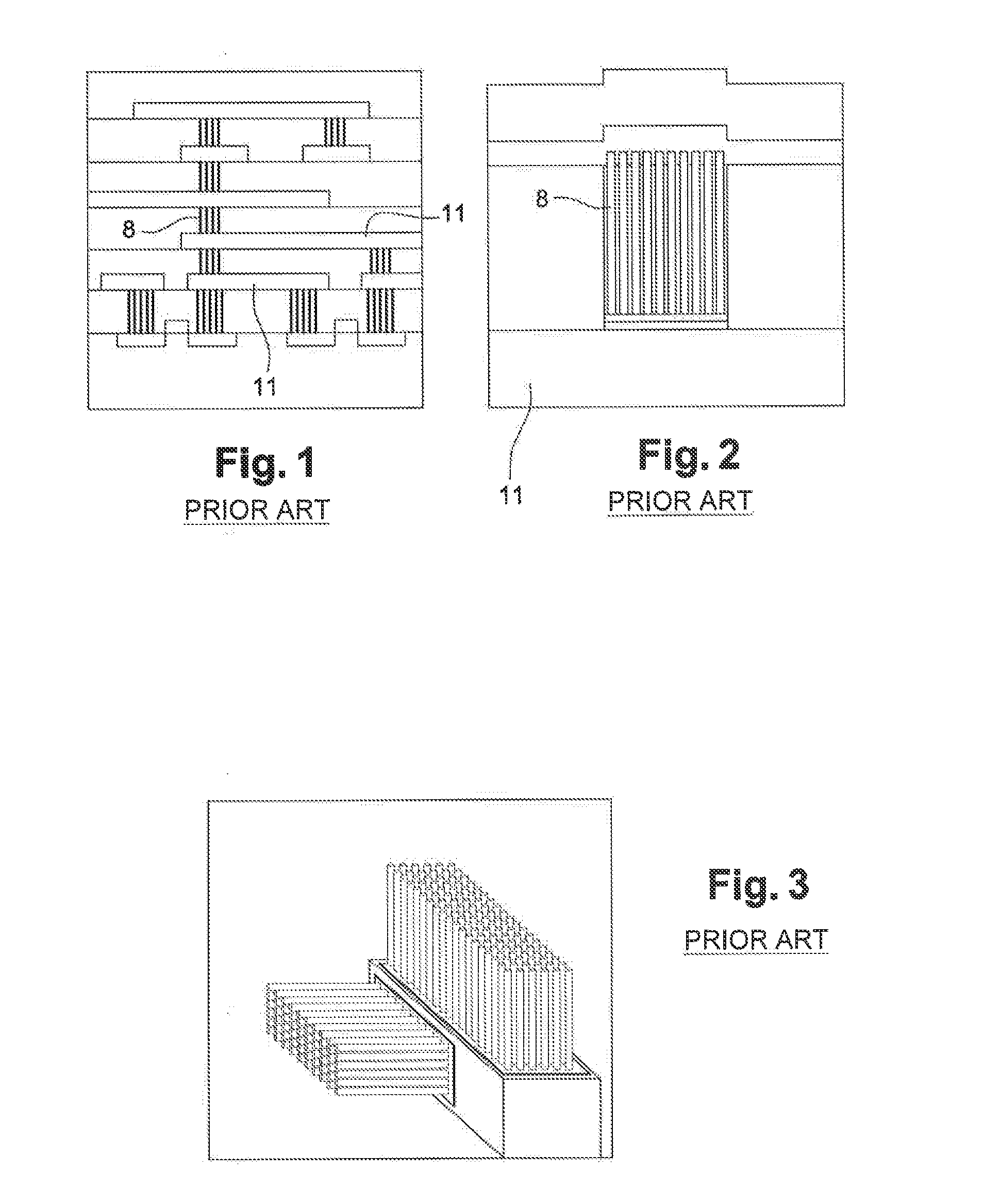

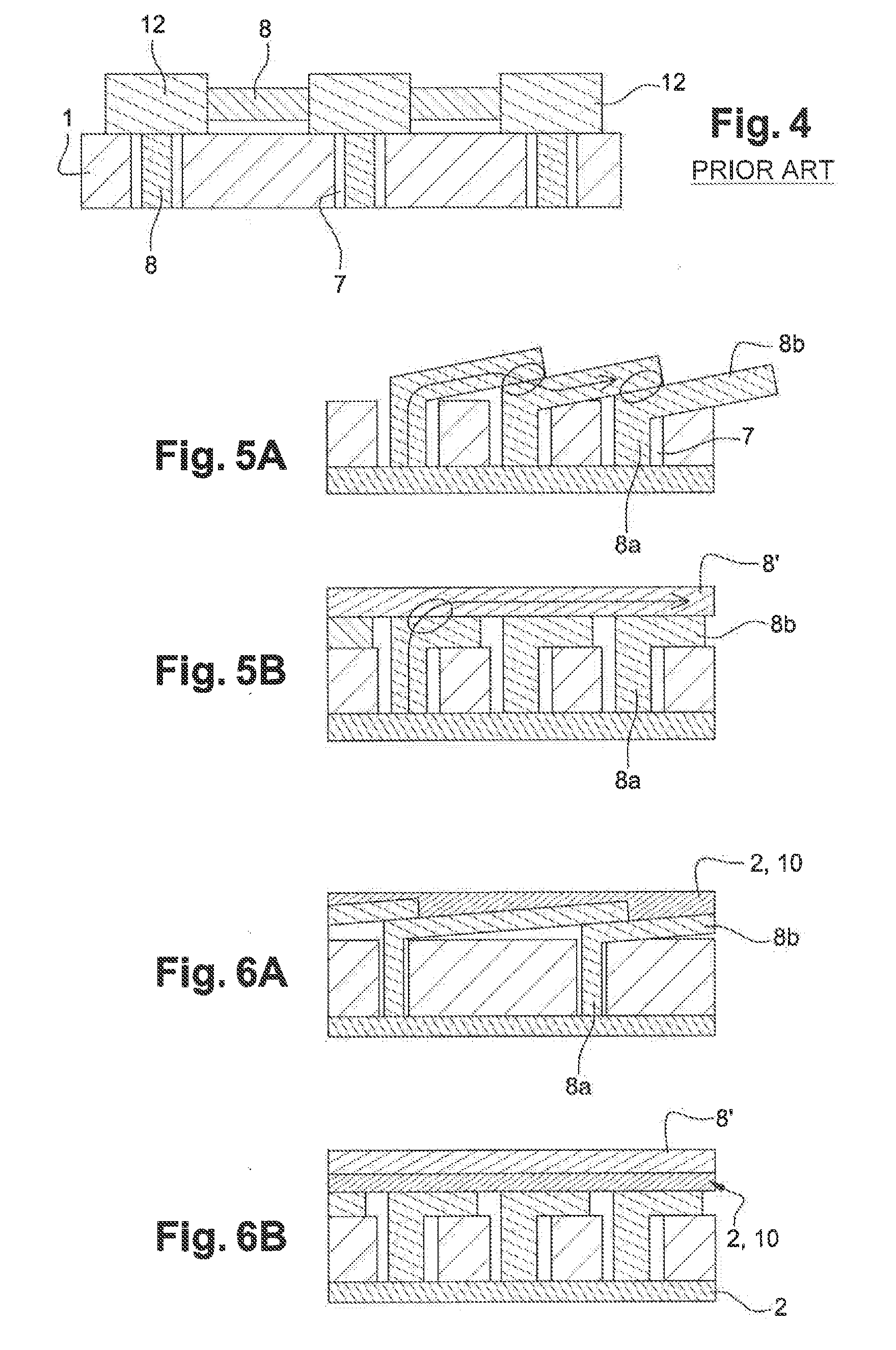

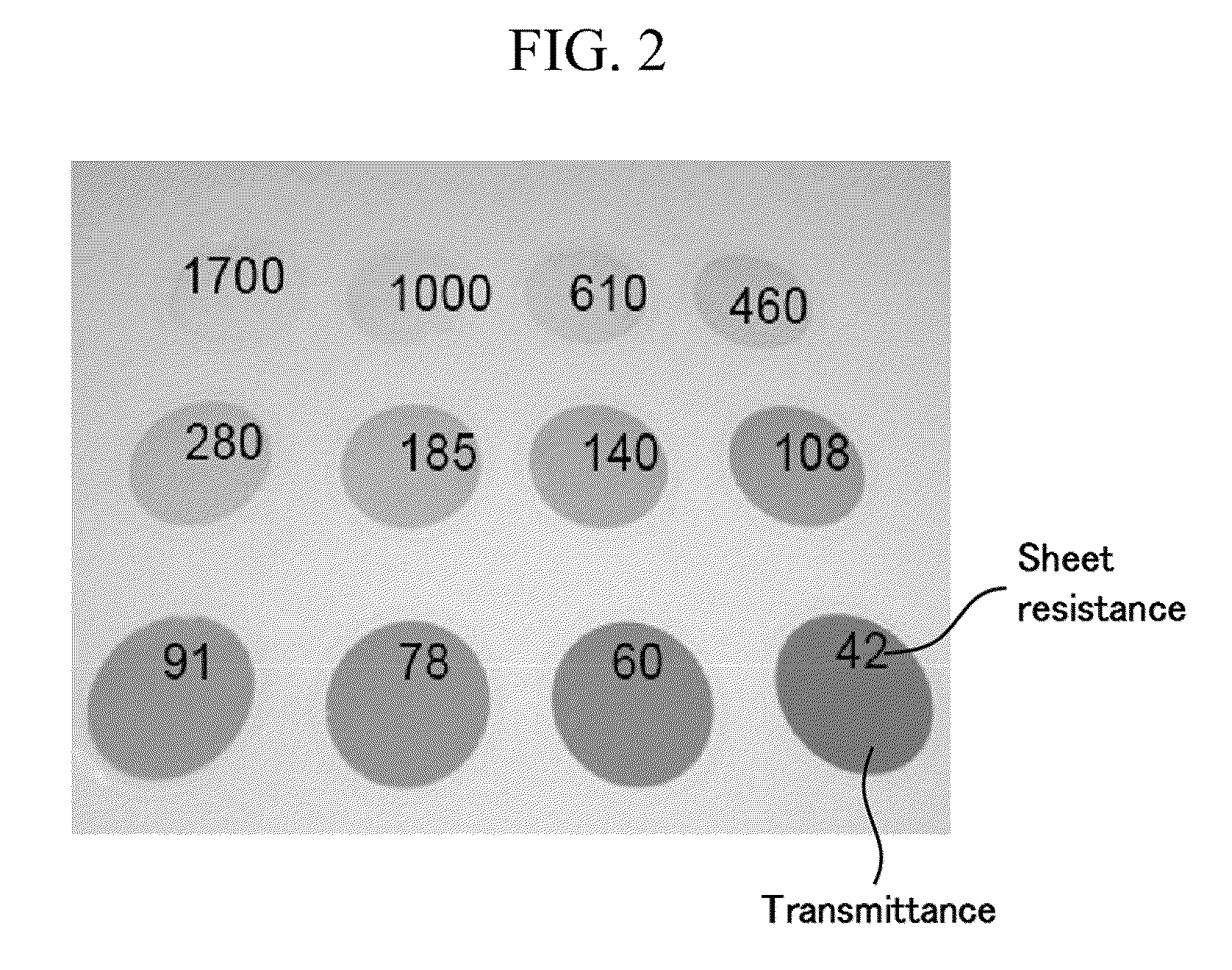

Hybrid carbon [nanotude] nanotube FET(CNFET)-FET static RAM (SRAM) and method of making same

Hybrid carbon nanotube FET (CNFET), static ram (SRAM) and method of making same. A static ram memory cell has two cross-coupled semiconductor-type field effect transistors (FETs) and two nanotube FETs (NTFETs), each having a channel region made of at least one semiconductive nanotube, a first NTFET connected to the drain or source of the first semiconductor-type FET and the second NTFET connected to the drain or source of the second semiconductor-type FET.

Owner:NANTERO

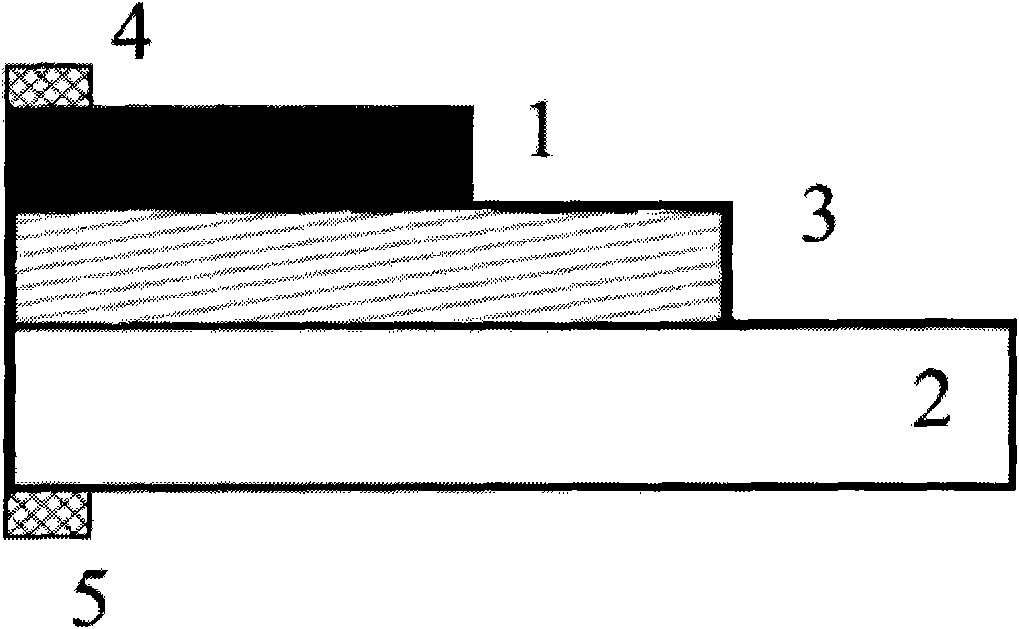

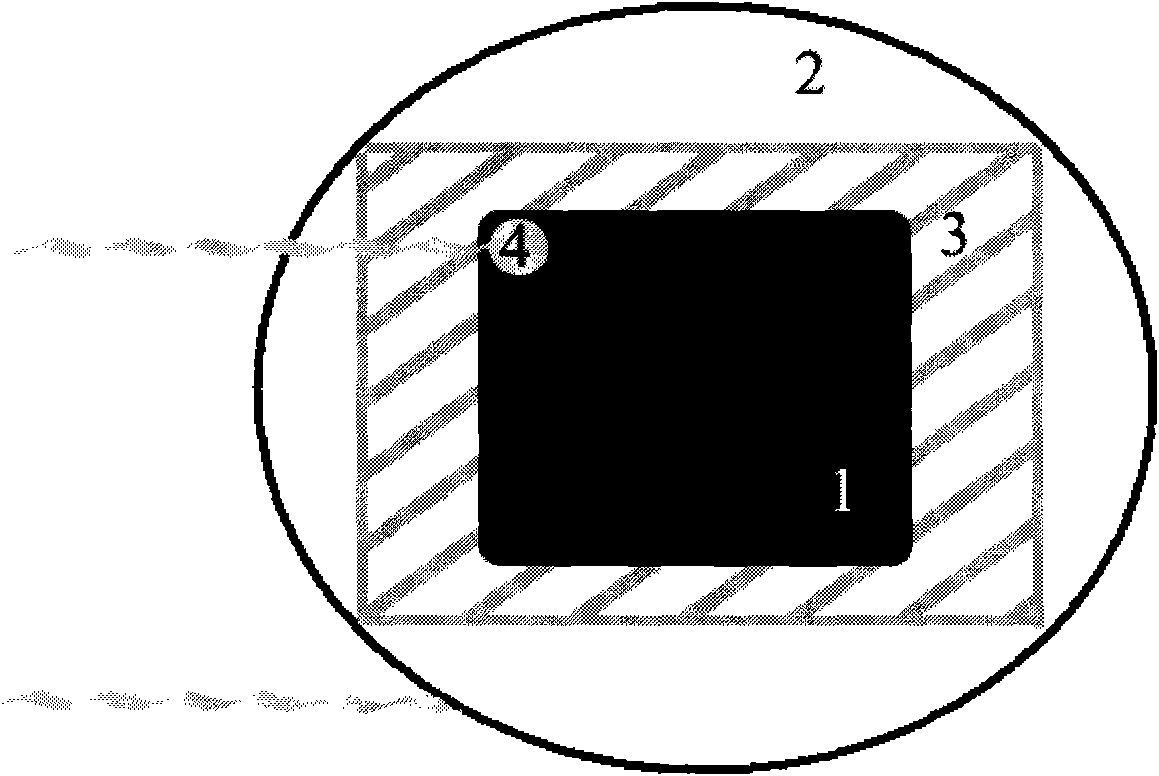

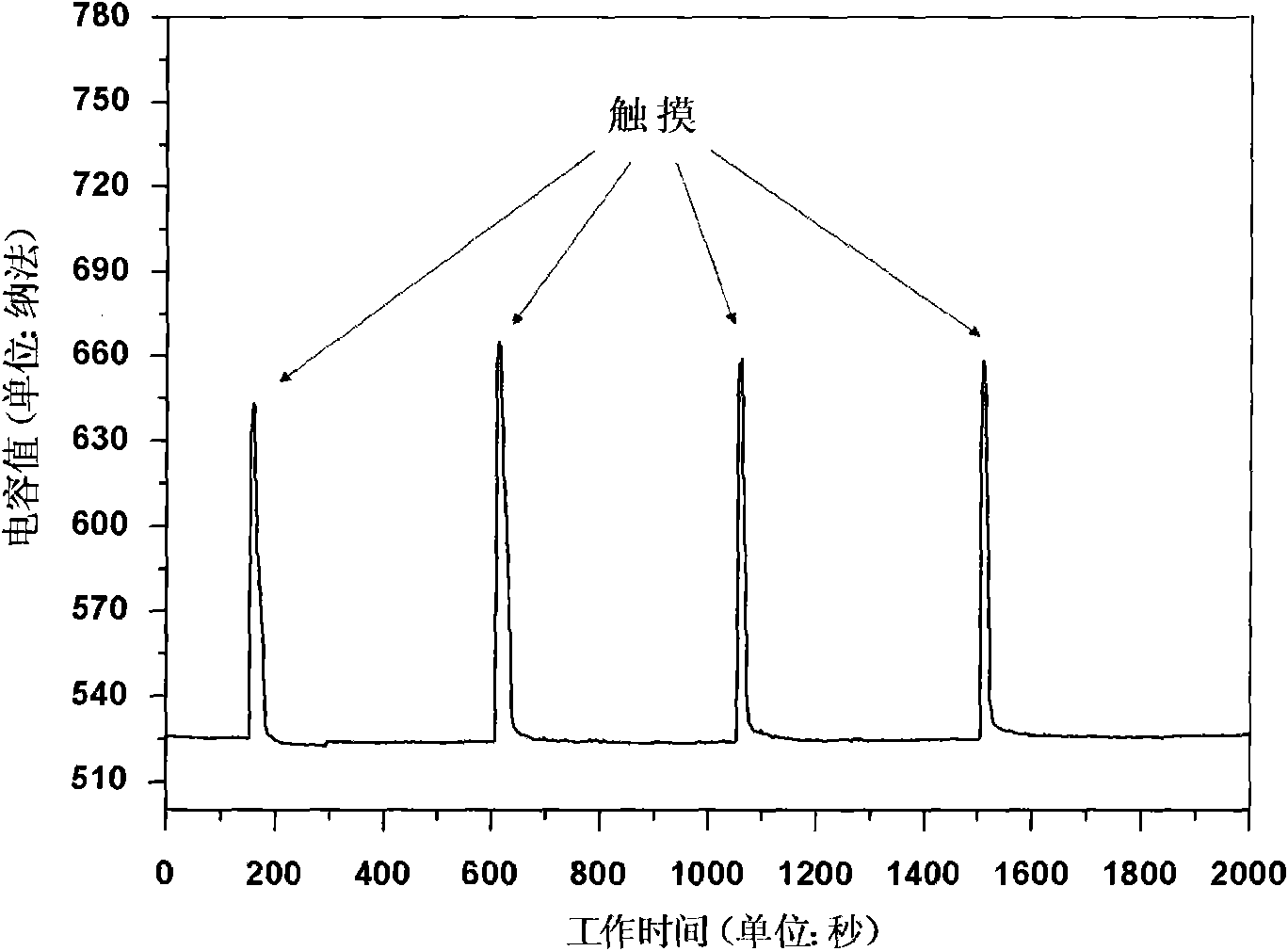

Capacitor touch pad based on carbon nanotube film

ActiveCN102129336AIncrease capacitanceHigh sensitivityInput/output processes for data processingAnti jammingDouble wall

The invention relates to a capacitor touch pad based on carbon nanotube film, which comprises a conducting layer arranged on the surface of a conducting substrate and more than two electrodes; the two electrodes are respectively and electrically connected with the conducting layer and the conducting substrate; the conducting layer comprises at least one carbon nanotube film layer; the carbon nanltube film mainly consists of a network interwoven by any one or two of a market single-wall carbon nanotube, a double-wall carbon nanotube and a multi-wall carbon nanotube, wherein the dosage of the carbon nanotube is 0.01-0.7 mg / sq.cm, the light transmittance of the carbon nanotube film is 50-97%, the conductivity is 30-500 omega / cm, and the tensile strength is between 200 MPa and 2000 MPa. Carbon nanotube film made of market carbon nanotube is taken as the conducting layer; therefore, the capacitor touch pad has high capacitance, high sensitivity, strong anti-jamming capability, fast responding speed, low power consumption and simple preparation technique, and is capable of realizing large batch and large area preparation, easy source, low cost and no pollution to the environment.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

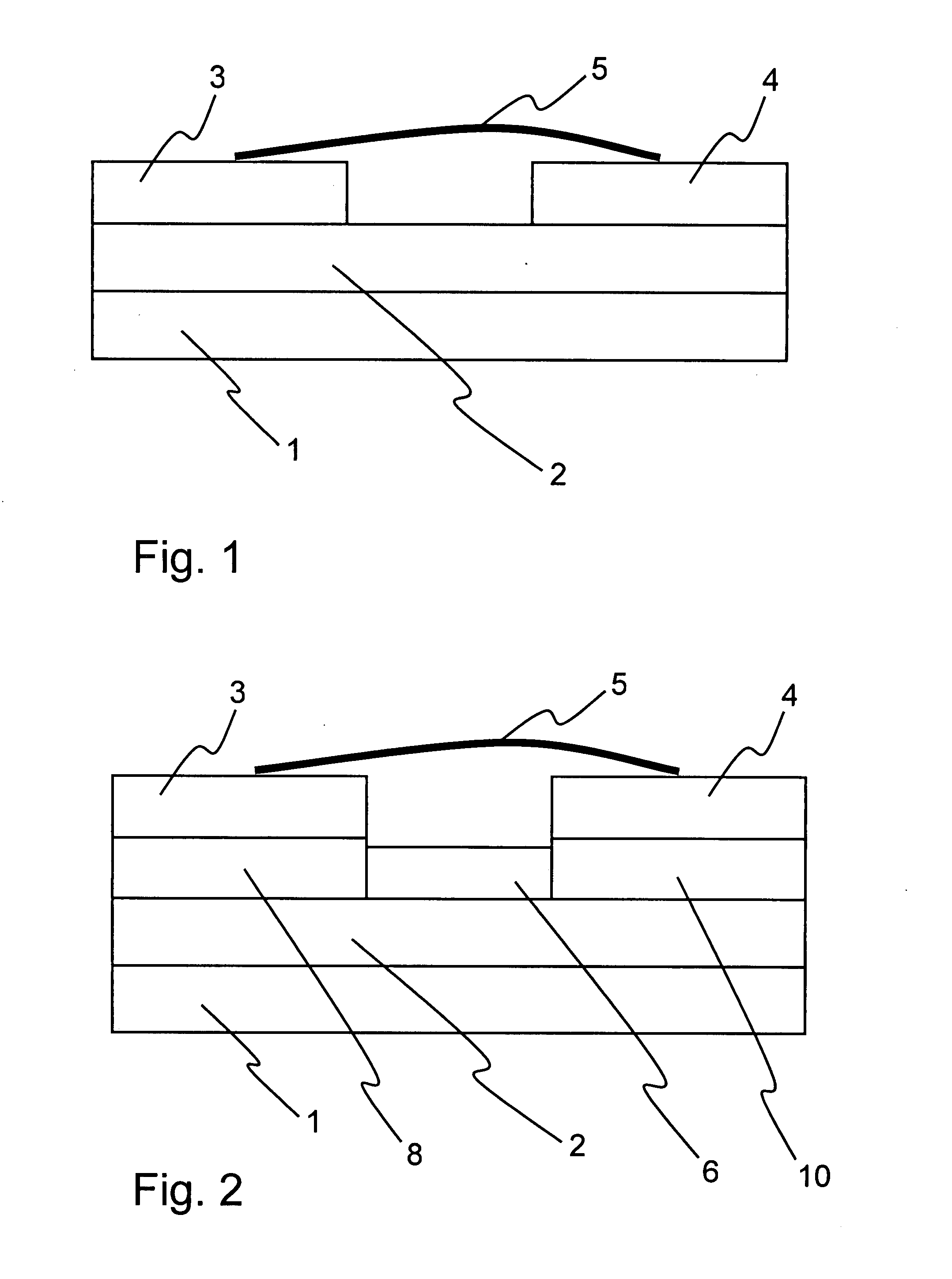

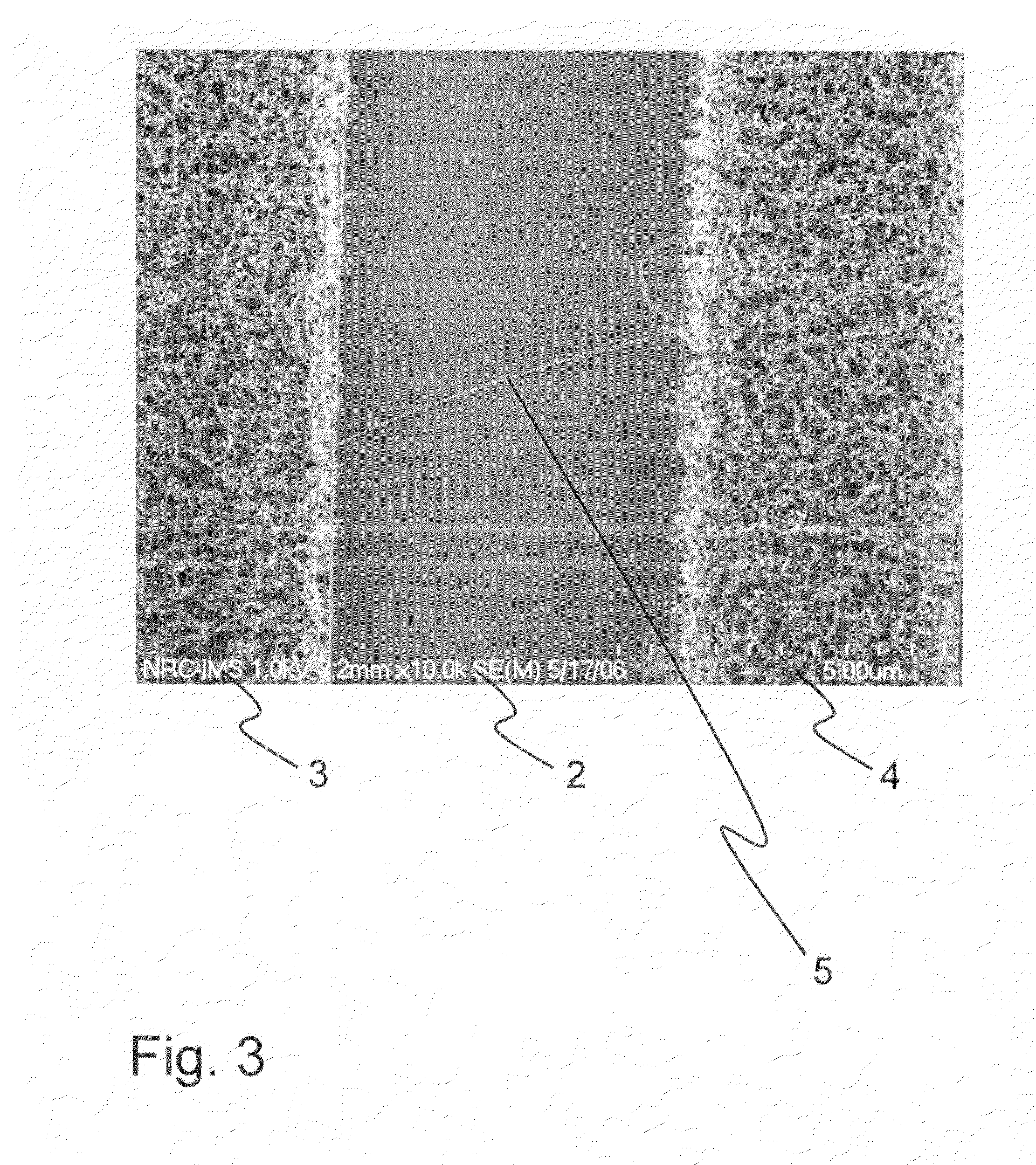

Carbon nanotube field effect transistor and method of making thereof

InactiveUS20080135892A1Simplified method of fabricatingNanoinformaticsSolid-state devicesCarbon nanotubeEngineering

This invention relates to field effect transistors having carbon nanotube contacts and to a method of making these field effect transistors. The field effect transistors have better contacts as the source and drains as well as the bridge are made of carbon nanotubes. The fabrication of the proposed embodiment becomes possible by using a fabrication process which involves exposing the structure to two different temperatures.

Owner:FINNIE PAUL

Interconnection, electronic device and method for manufacturing an electronic device

ActiveUS20080245553A1Improve reliabilitySuppressing performance deteriorationNon-insulated conductorsSemiconductor/solid-state device detailsCarbon nanotubeCrystal structure

An interconnection includes a bundle of conductive members, each of the conductive members being made of carbon nanotube having an end connected to a first conductive film, and another end connected to a second conductive film separated from the first conductive film; and carbon particles each having a diamond crystal structure, dispersed between the conductive members.

Owner:KK TOSHIBA

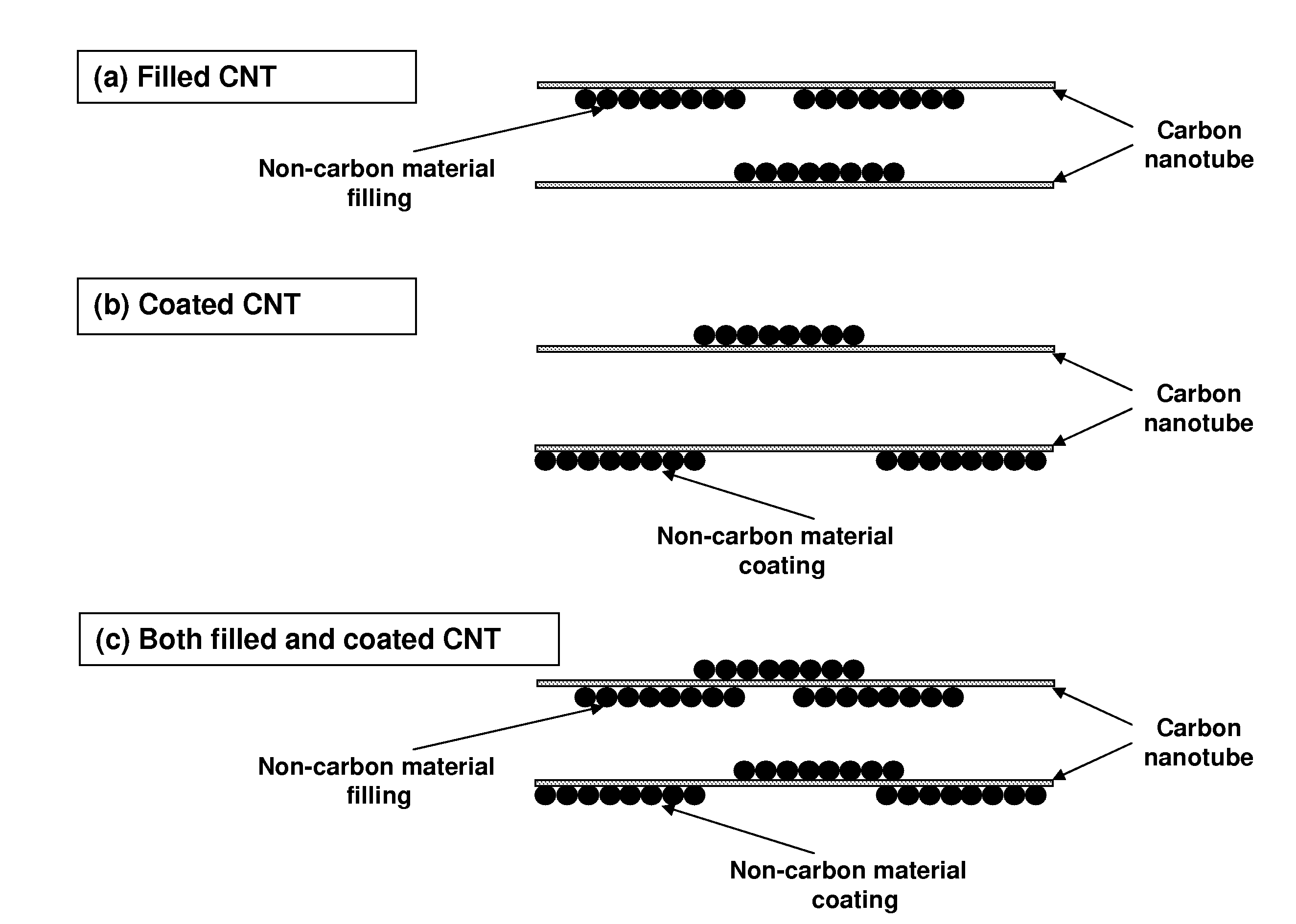

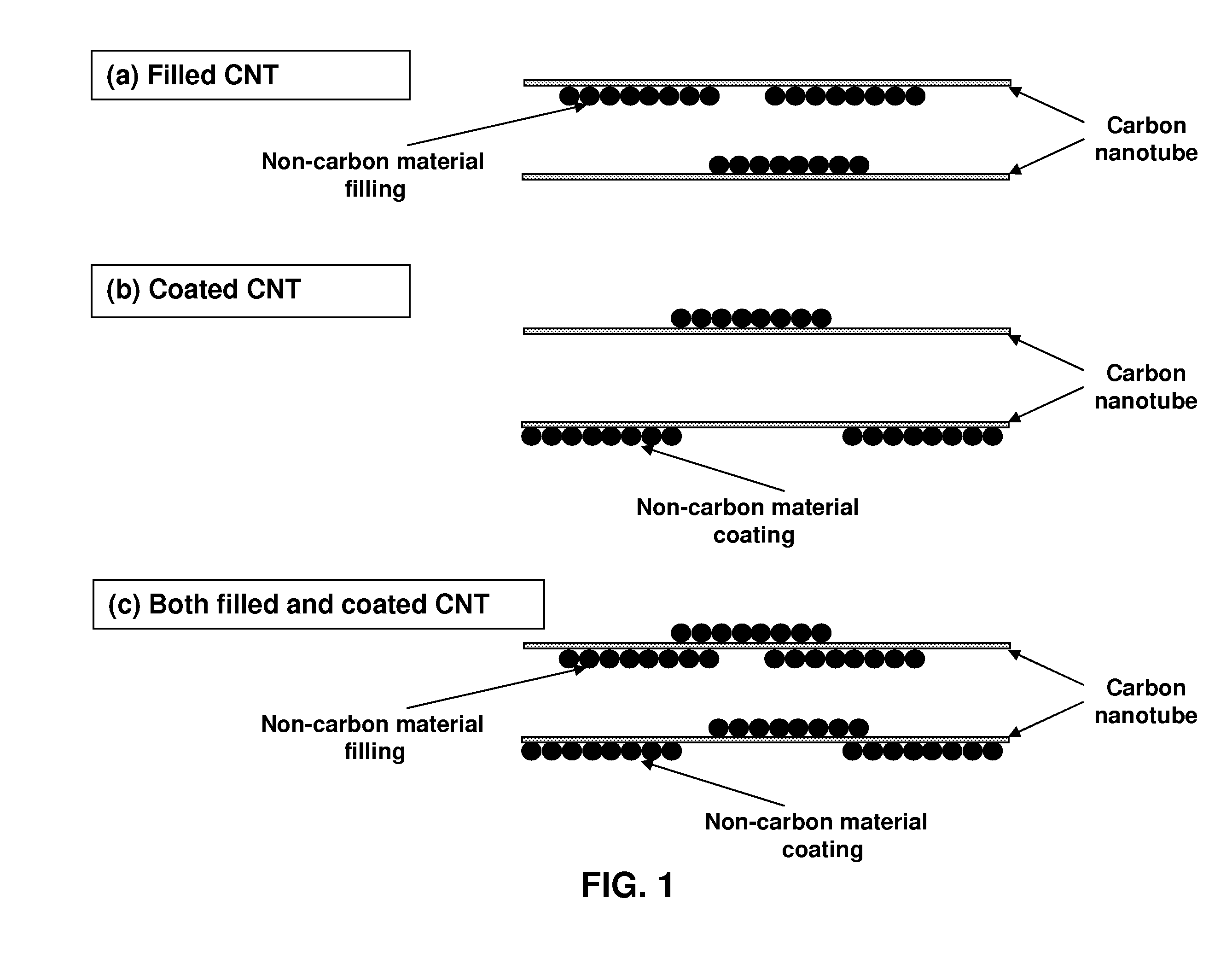

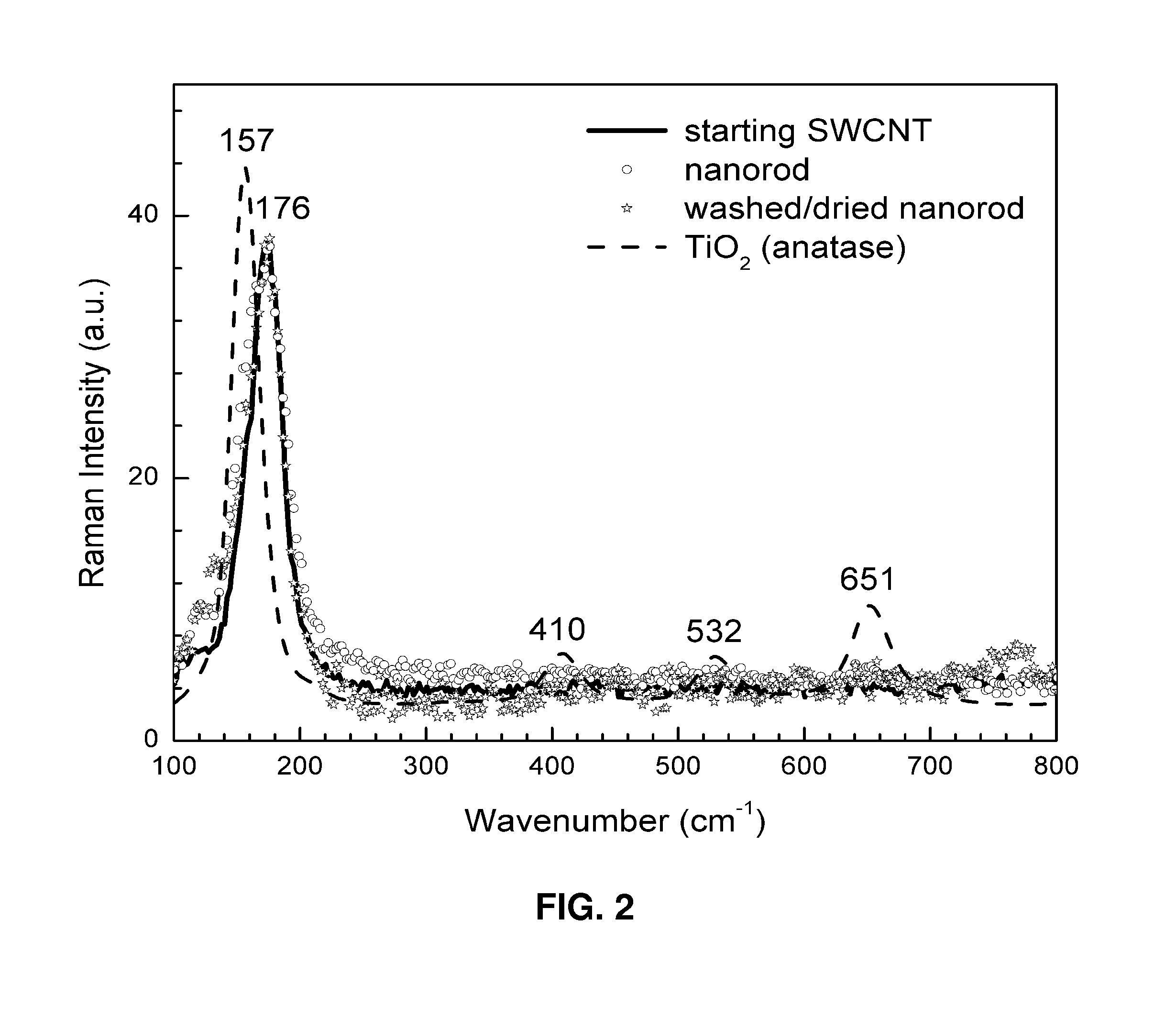

Organized carbon and non-carbon assembly and methods of making

InactiveUS7938987B2Material nanotechnologyElectric discharge heatingCarbon nanotubeCarbon nanotube fet

This invention relates generally to organized assemblies of carbon and non-carbon compounds and methods of making such organized structures. In preferred embodiments, the organized structures of the instant invention take the form of nanorods or their aggregate forms. More preferably, a nanorod is made up of a carbon nanotube filled, coated, or both filled and coated by a non-carbon material. This invention is further drawn to the separation of single-wall carbon nanotubes. In particular, it relates to the separation of semiconducting single-wall carbon nanotubes from conducting (or metallic) single-wall carbon nanotubes. It also relates to the separation of single-wall carbon nanotubes according to their chirality and / or diameter.

Owner:YAZAKI CORP

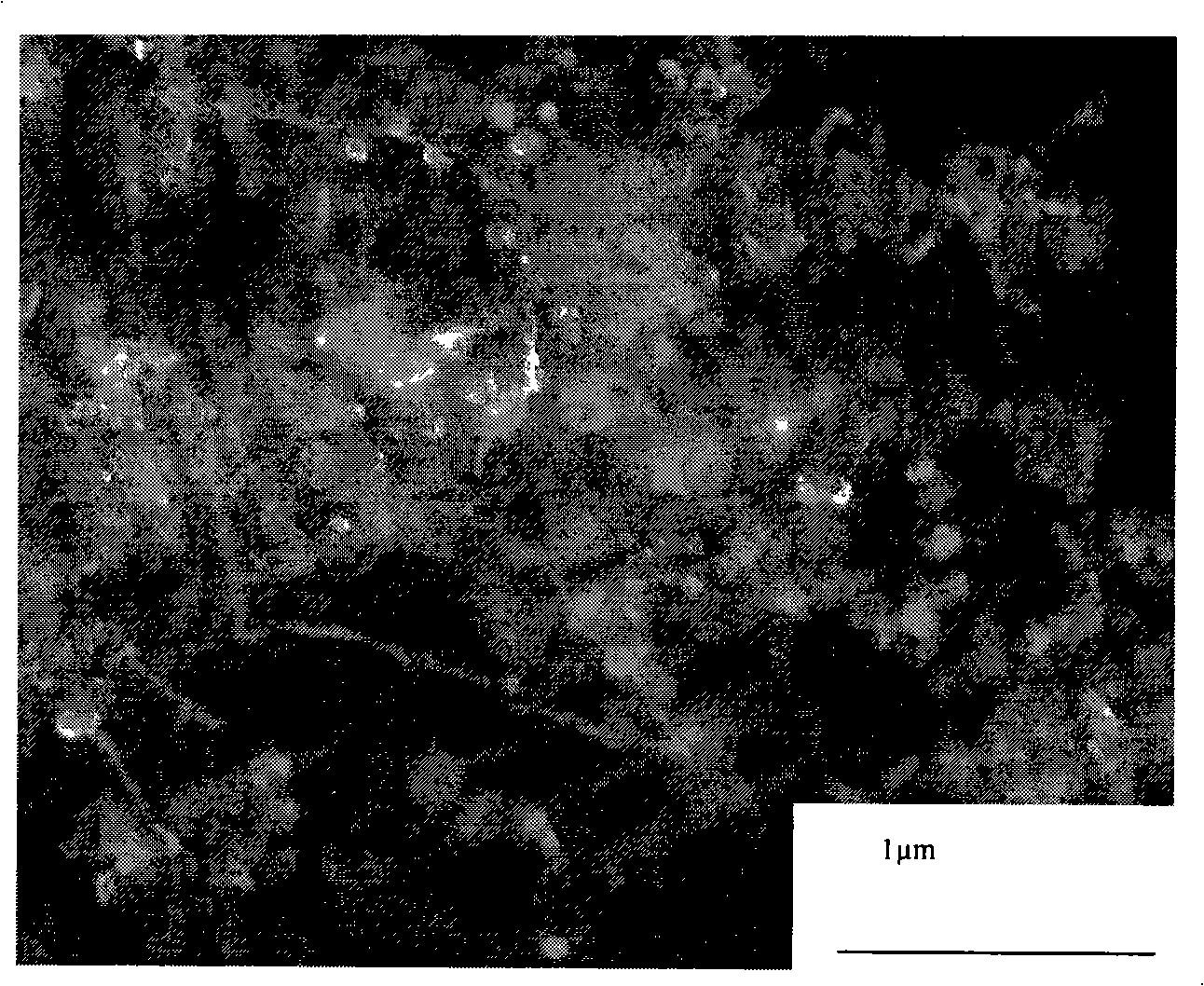

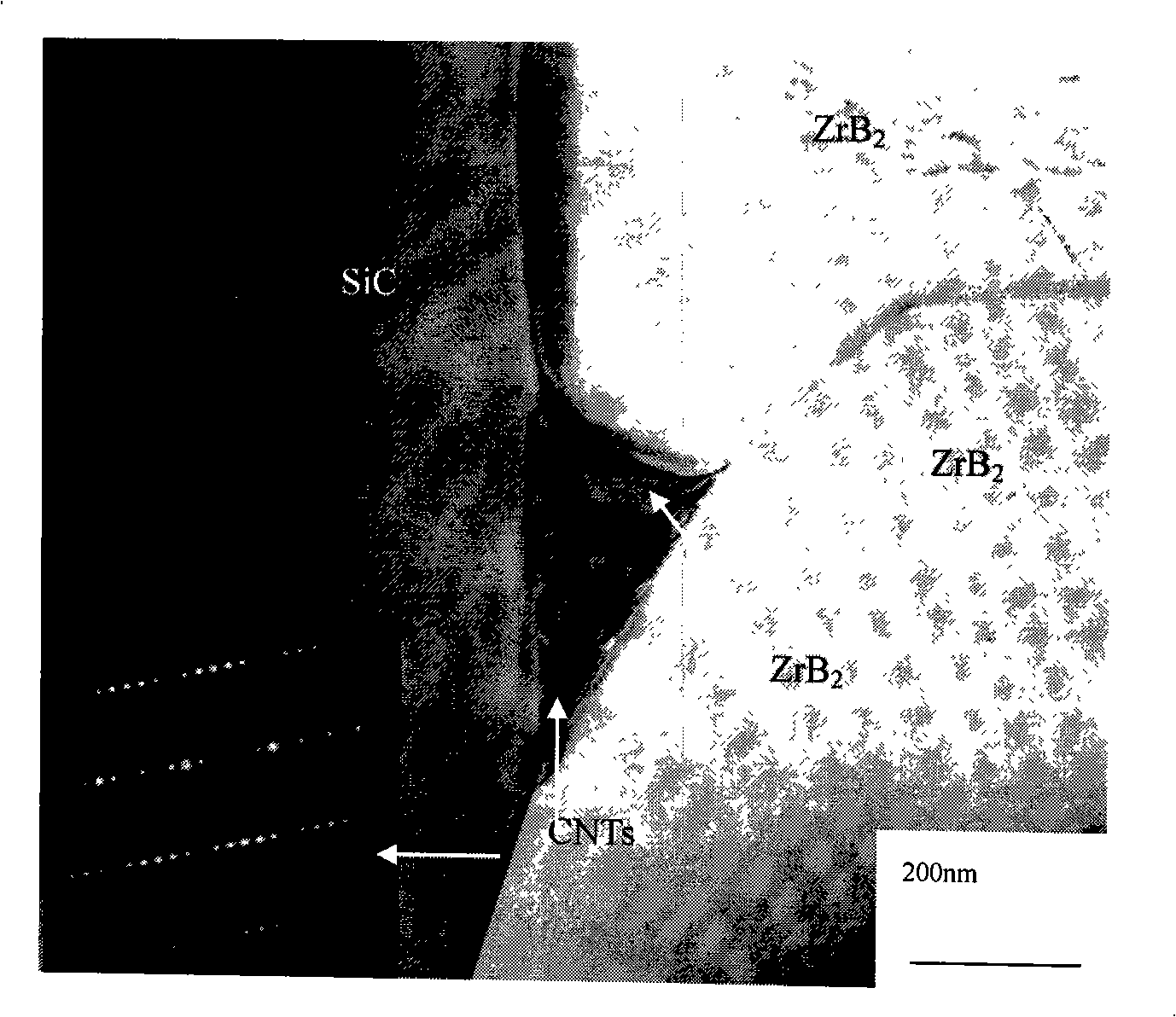

Carbon nano-tube zirconium boride-carborundum based material and preparation method thereof

A carbon nano-tube zirconium boride-silicon carbide composite and a method for the products thereof relate to a zirconium boride-silicon carbide composite and a method for the products thereof. The invention solves the problem that the prior zirconium boride - silicon carbide composite is fragile, low-intensity and poor in sintering performance. The inventive product is mainly prepared by zirconium boride, silicon carbide and carbon nano-tube. The preparation method of the invention includes: dispersing carbon nano-tubes ultrasonically in dispersing agents; adding zirconium boride and silicon carbide; then ball milling and dispersing, drying, grinding; putting the mixed powder into a graphite die coated with release agent for hot pressing. The inventive composite material has a relative density of 98.1%-99.8%, a fracture toughness increased by 19%-44% than that of zirconium boride - silicon carbide base, a bending strength increased by 13 per cent-85 per cent than that of zirconium diboride - silicon carbide base and a sintering temperature reduced to 1800 DEG C.

Owner:HARBIN INST OF TECH

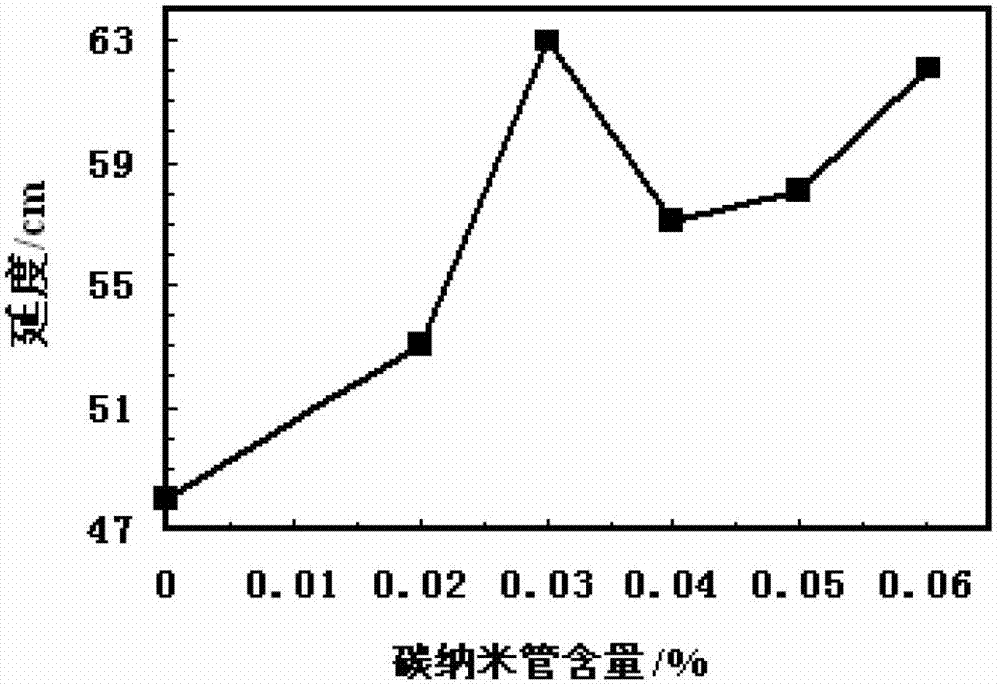

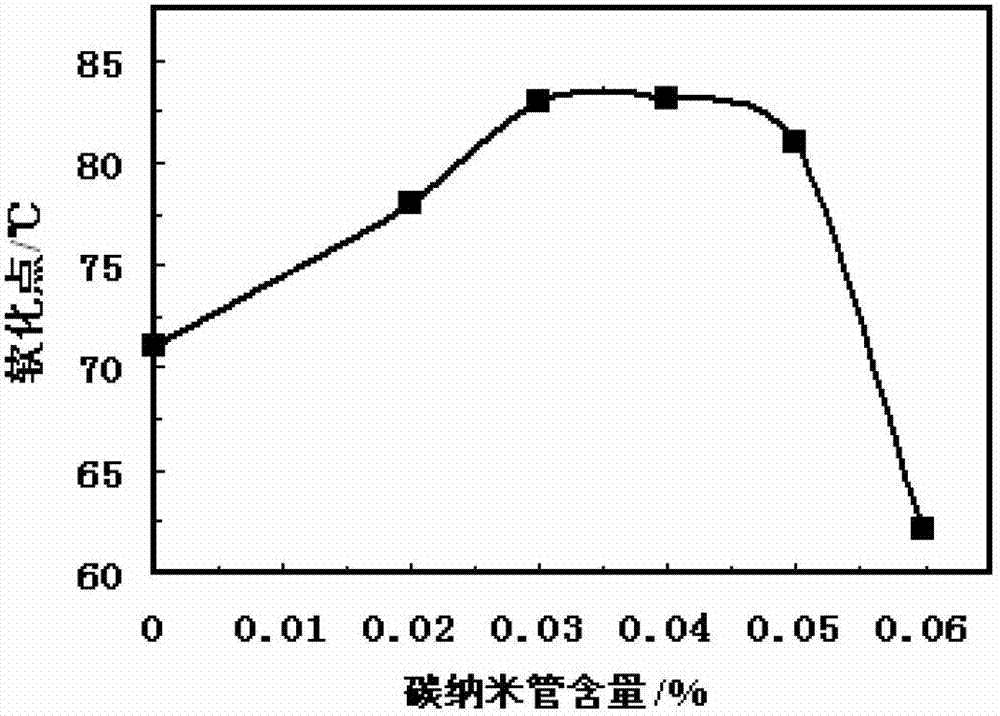

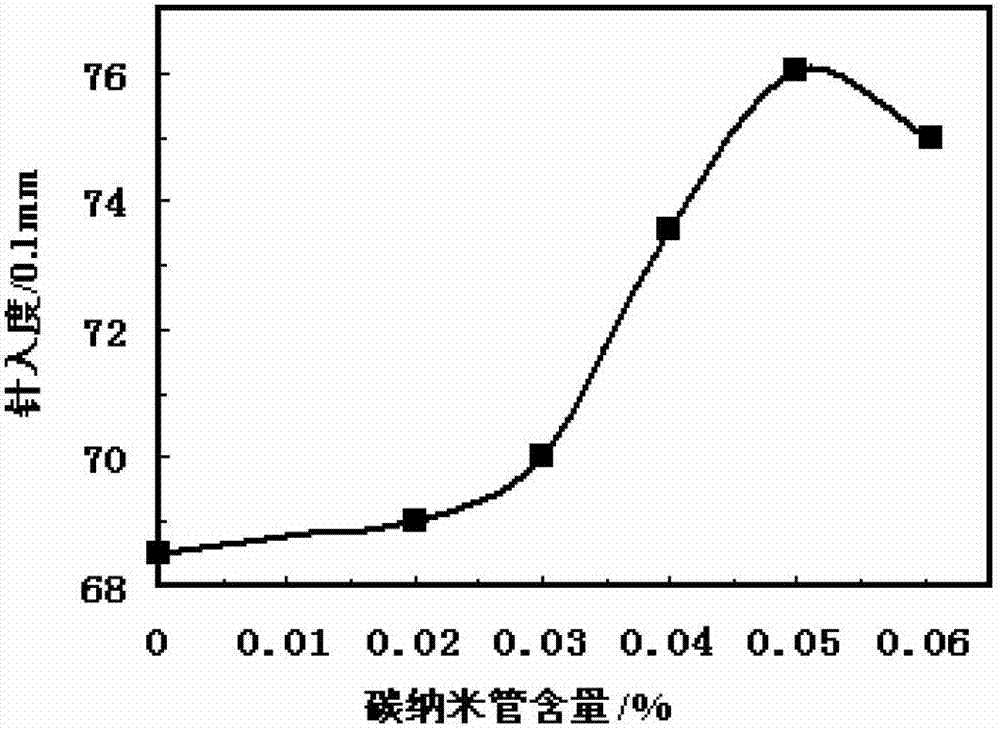

Carbon nanotube-styrene block copolymers (CNT-SBS) modified asphalt

InactiveCN102766339AReduce dosagePrecisely optimize the ratioBuilding insulationsCrack resistanceWorking temperature

The invention discloses a carbon nanotube-styrene block copolymers (CNT-SBS) modified asphalt, relates to a modified asphalt, and solves the problems that prior CNT-SBS modified asphalts are unobvious in effects of improving ductility and softening point temperature and inaccurate in component proportion compared with SBS modified asphalts. The CNT-SBS modified asphalt is prepared by materials of, by mass, 95.97% of matrix asphalts, 4% of linear styrene-butadiene- styrene block copolymer powders and 0.03% of carbon nanotubes. Compared with the SBS modified asphalts, the CNT-SBS modified asphalt has the advantages that the ductility is increased by 31.3%, the softening point is increased by 16.9%, compression resistance, crack resistance are high, plasticity is good and temperature sensibility is low, the CNT-SBS modified asphalt can preferably adapt to environmental condition of areas with large temperature difference, working temperature and area ranges are widened, high temperature compression resistance of the asphalt is improved, and the CNT-SBS modified asphalt is suitable for industrial production of the modified asphalt.

Owner:HEILONGJIANG INST OF TECH

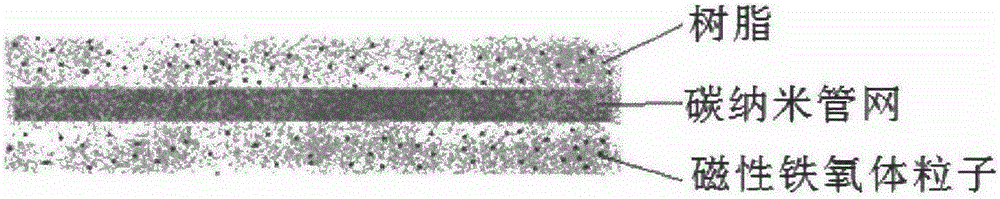

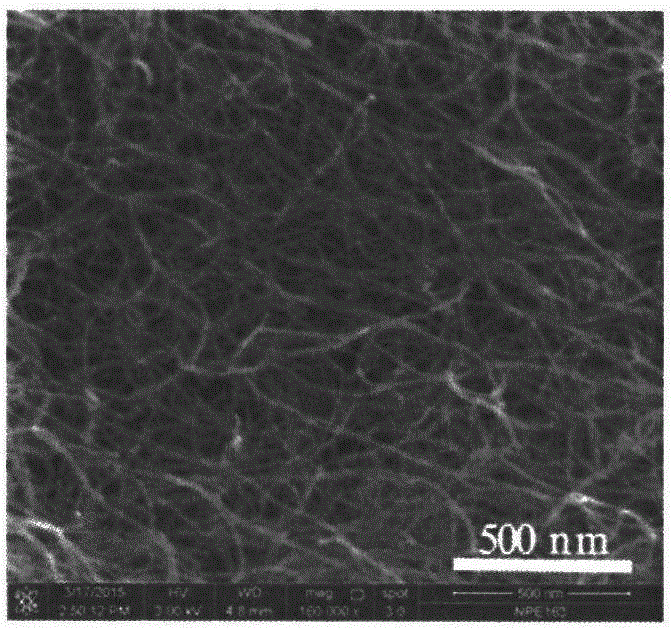

Stratified electromagnetic shielding material containing carbon nanotube network resin base, and preparation method thereof

The invention discloses a stratified electromagnetic shielding material containing a carbon nanotube network resin base. The stratified electromagnetic shielding material comprises at least one electrical conductive layer; the electrical conductive layer is a carbon nanotube network prepared from carbon nanotubes; each of the two side surfaces of the electrical conductive layer is provided with a binder layer respectively; a resin containing magnetic ferrite particles is taken as a binder of the binder layers; the resin comprises a thermosetting resin and a thermoplastic resin; the thermosetting resin comprises epoxy resin, phenolic resin, and unsaturated polyester resin; and the thermoplastic resin comprises polyethylene, polypropylene, nylon, polyester, and ABS resin. The invention also provides a preparation method of the stratified electromagnetic shielding material; the stratified electromagnetic shielding material is reasonable in structure, and excellent in electromagnetic shielding performance.

Owner:常熟华尚新材料科技有限公司

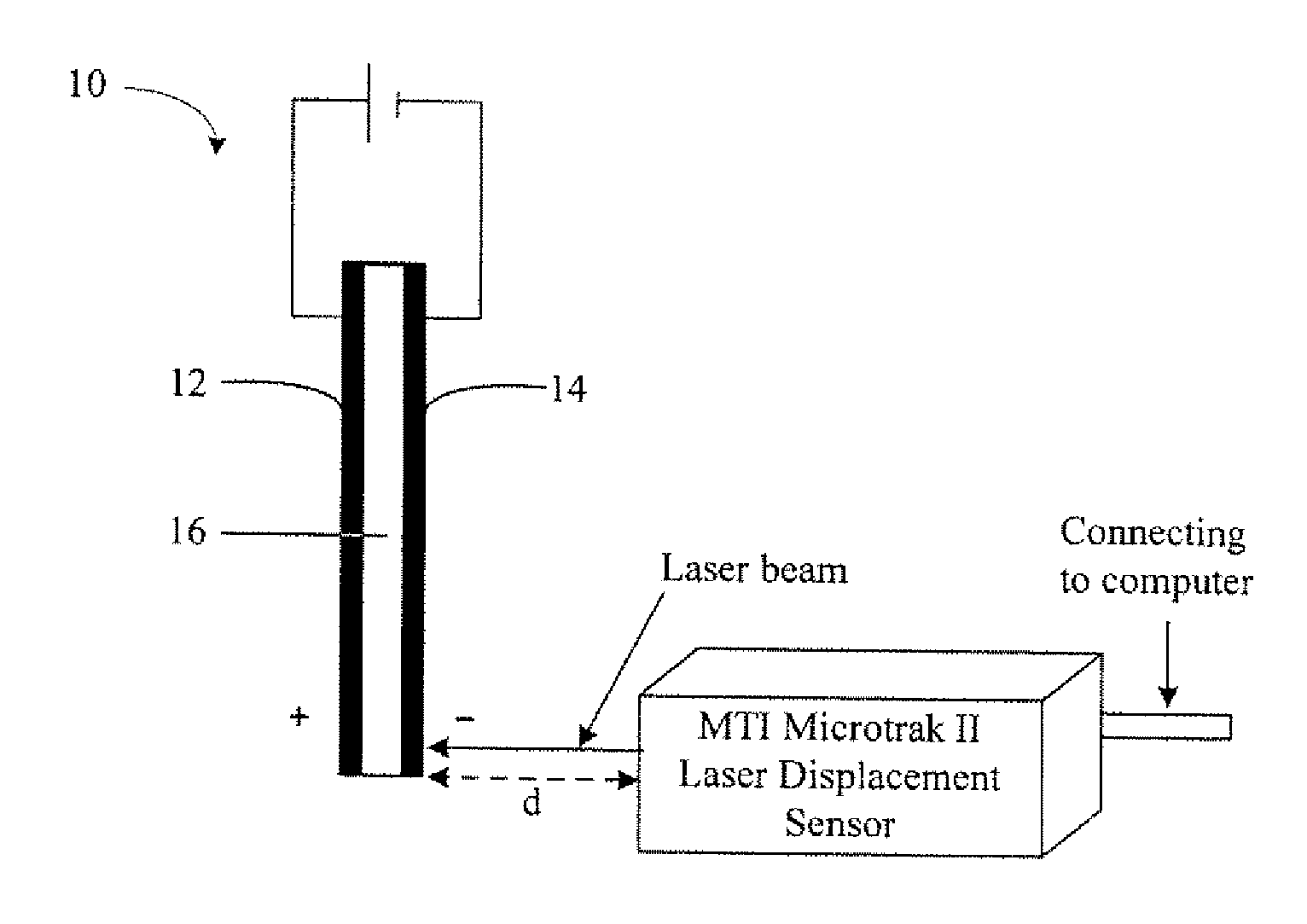

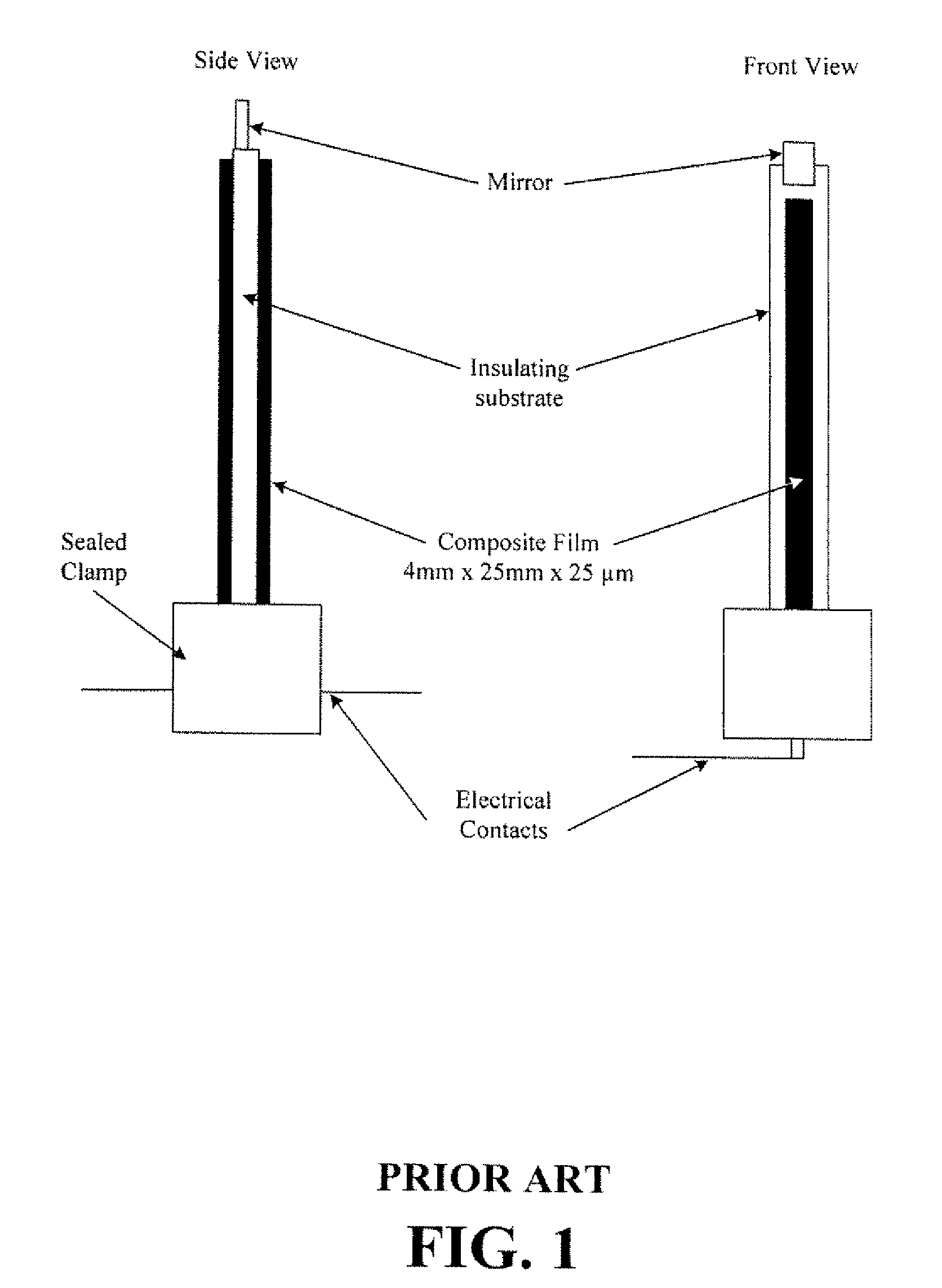

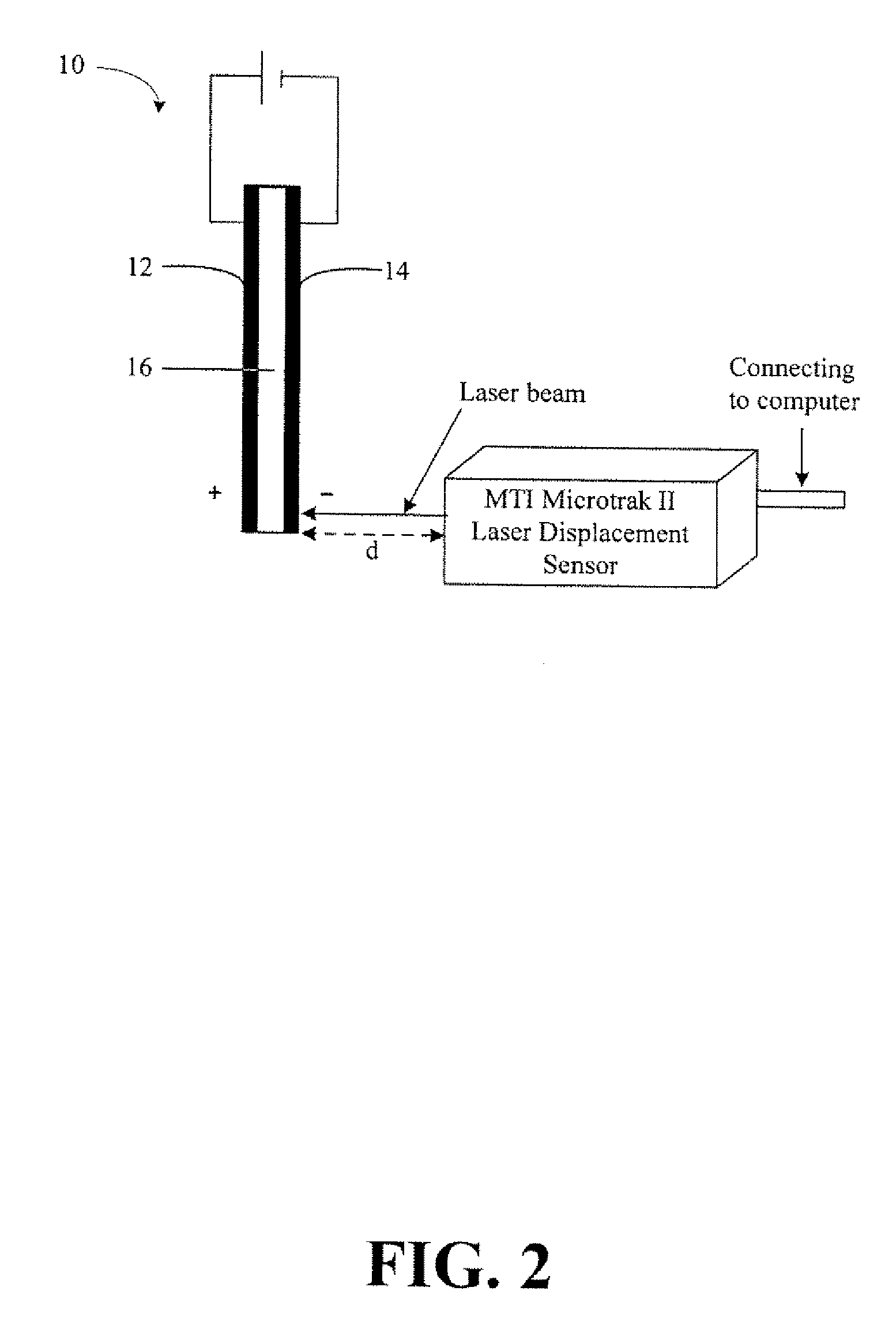

Actuator Device Including Nanoscale Fiber Films

ActiveUS20100080975A1Piezoelectric/electrostrictive device manufacture/assemblyCovering/liningsFiberPolymer electrolytes

A method for making an actuator capable of dry actuation is provided. The method includes providing a first nanoscale fiber film, providing a second nanoscale fiber film, positioning a solid polymer electrolyte at least partially between and adjacent to the first nanoscale fiber film and the second nanoscale fiber film, and then affixing the solid polymer electrolyte to the first nanoscale fiber film and the second nanoscale fiber film. The nanoscale fiber films may be buckypapers, made of carbon nanotubes. The actuator is capable of dry actuation.

Owner:FLORIDA STATE UNIV RES FOUND INC

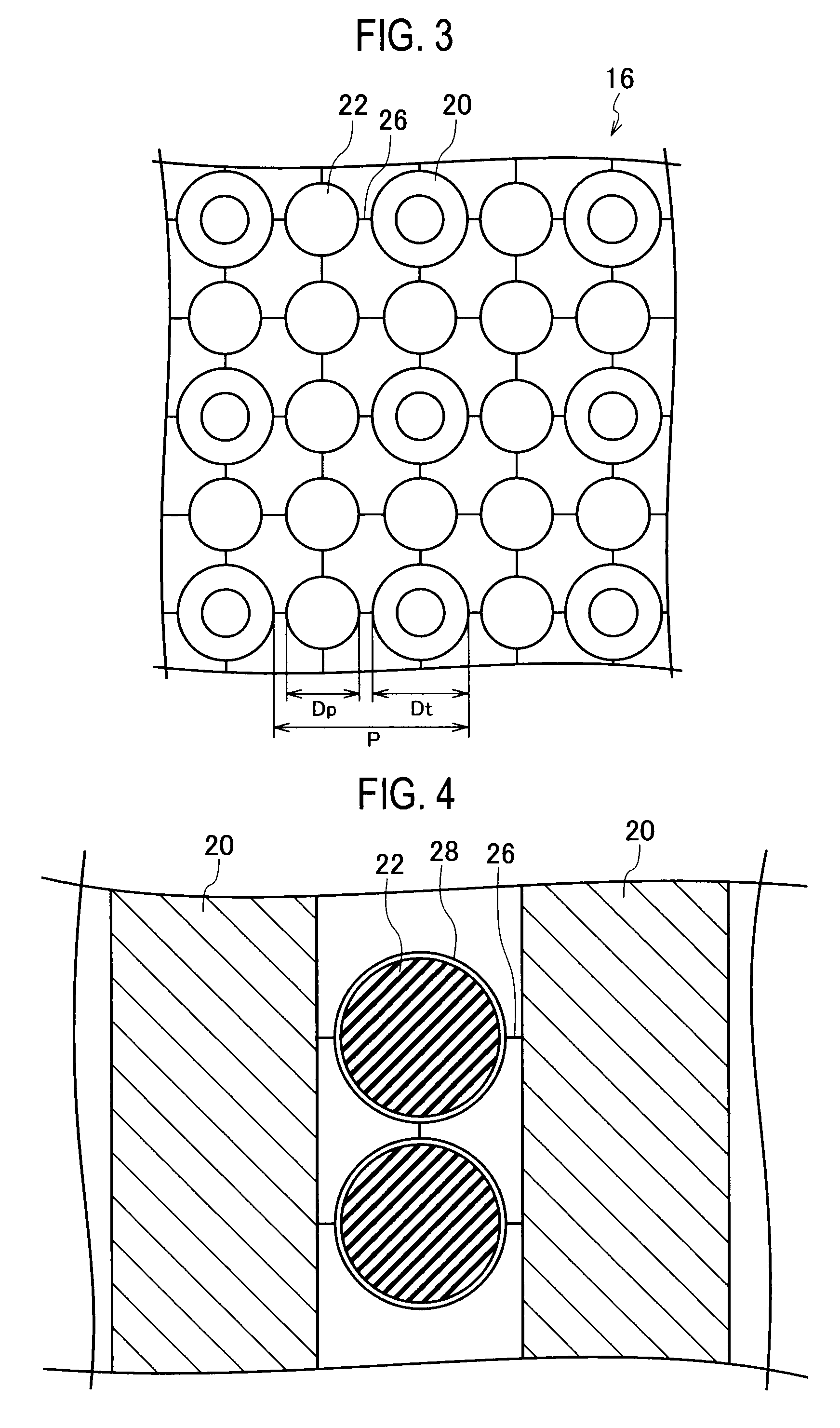

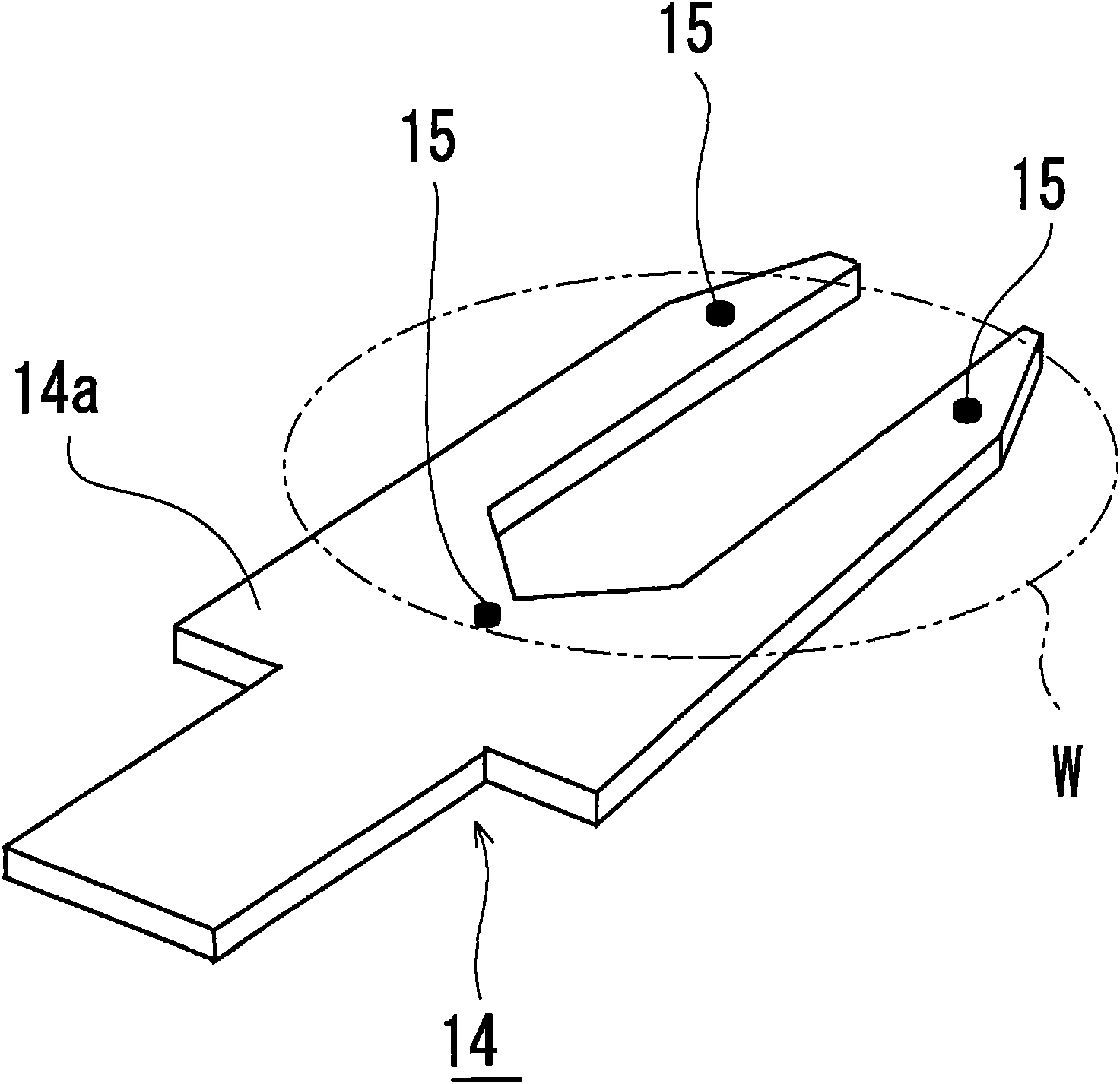

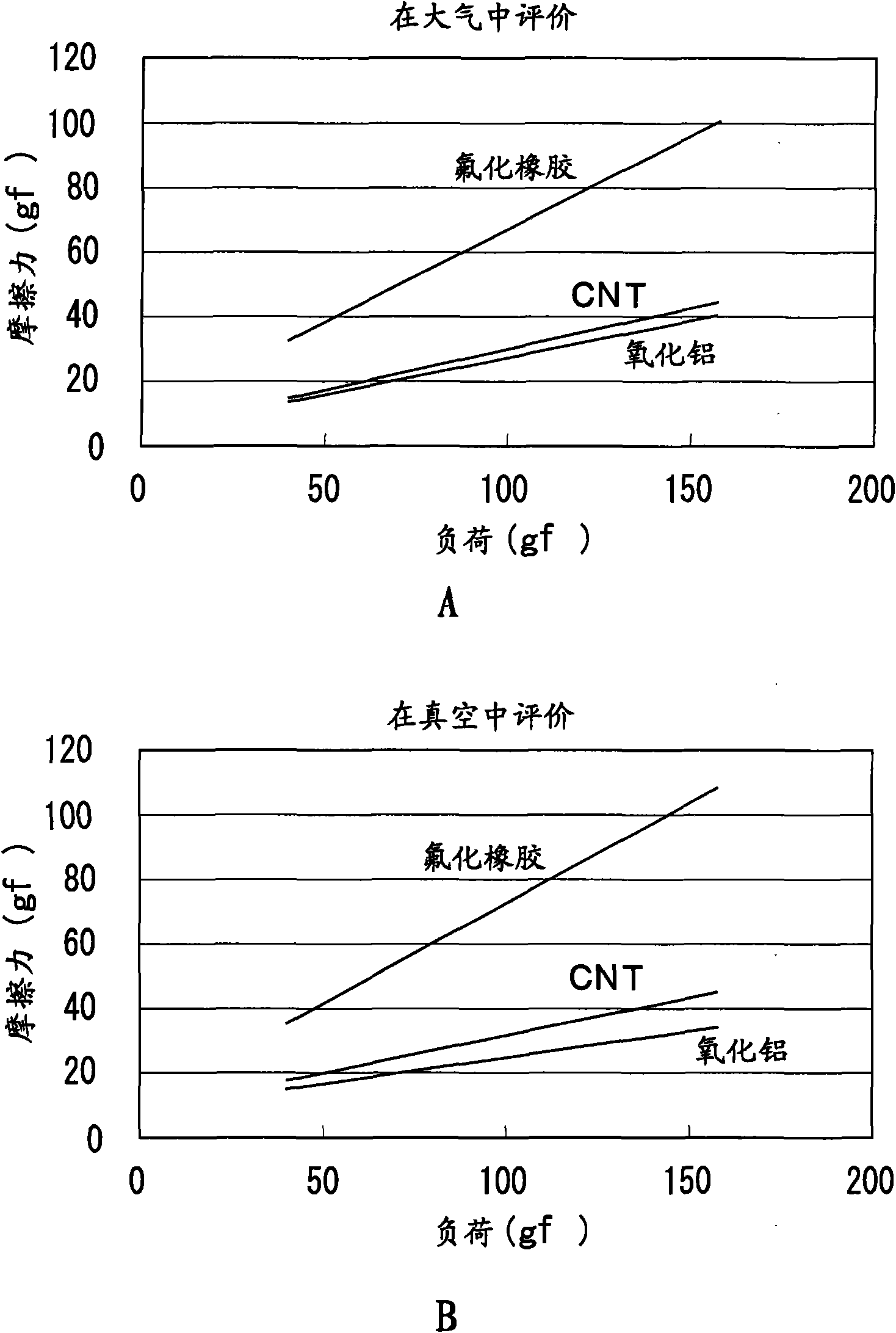

Substrate supporting mechanism

InactiveCN101678970AAchieve high speedCorrect handlingGripping headsSemiconductor/solid-state device manufacturingSuction forceAtmospheric air

The invention provides a substrate supporting mechanism which can achieve high speed conveyance of a substrate while ensuring proper conveyance operation. In the substrate supporting mechanism,a holding portion (15) made of carbon nano tubes is installed on the supporting surface (14a) of an end effector (14), and a substrate (W) is supported by the distal ends of the carbon nano tubes. An intermolecular force is generated between the substrate and the carbon nano tube and the substrate is supported with a fixed suction force to the supporting surface. The suction force is generated both in the atmosphere and in the vacuum and a bigger force is obtained for a larger number of carbon nano tubes perunit area. With such an arrangement, slip of a conveyance article on the supporting surface can be suppressed effectively and high speed conveyance of a substrate can be attained. Since the carbon nano tube is excellent in heat resistance, poor conveyance due to deterioration or sticking of the holding portion by heat is prevented during use under high temperature environment and proper conveyance operation of substrate can be ensured.

Owner:ULVAC INC

Carbon nanotube-based electronic switch

InactiveUS20060273871A1Reduce switching powerImprove immunityNanotechNanoelectromechanical switchesCarbon nanotubeElectronic switch

An improved microelectromechanical switch assembly comprises a linearly movable switch rod constrained via a switch bearing, the switch rod being actuated by electrostatic deflection. Movement of the switch rod to one end of its travel puts the switch assembly in a closed state while movement of the switch rod to the other end of its travel puts the switch assembly in an open state. In an embodiment of the invention, one or both of the switch rod and the switch bearing are fabricated of a carbon nanotube. The improved microelectromechanical switch assembly provides low insertion loss and long lifetime in an embodiment of the invention.

Owner:CABOT MICROELECTRONICS CORP

Carbon nanotube-based electronic switch

InactiveUS7456482B2Reduce switching powerImprove immunityNanotechElectrostatic/electro-adhesion relaysCarbon nanotubeElectronic switch

An improved microelectromechanical switch assembly comprises a linearly movable switch rod constrained via a switch bearing, the switch rod being actuated by electrostatic deflection. Movement of the switch rod to one end of its travel puts the switch assembly in a closed state while movement of the switch rod to the other end of its travel puts the switch assembly in an open state. In an embodiment of the invention, one or both of the switch rod and the switch bearing are fabricated of a carbon nanotube. The improved microelectromechanical switch assembly provides low insertion loss and long lifetime in an embodiment of the invention.

Owner:CABOT MICROELECTRONICS CORP

Lithium ion battery cathode material

The invention relates to a lithium ion battery cathode material, which is prepared from coal coke, asphalt and a carbon nanotube in the weight ratio of (5-40):1:0.5. In the lithium ion battery cathode material, the particle size of the coal coke is 8-25 mum, and the specific surface area of the coal coke is less than or equal to 5m<2> / g; and the asphalt is coal asphalt or petroleum asphalt. A carbon modified material provided by the invention can be widely applied to a power lithium ion battery cathode material with a long cycle life. The material belongs to compound graphite, and has the advantages of high cycle performance, long battery service life, large gram volume, high compacted density, small specific surface area and excellent processing performance.

Owner:RIGHTFUL TECH

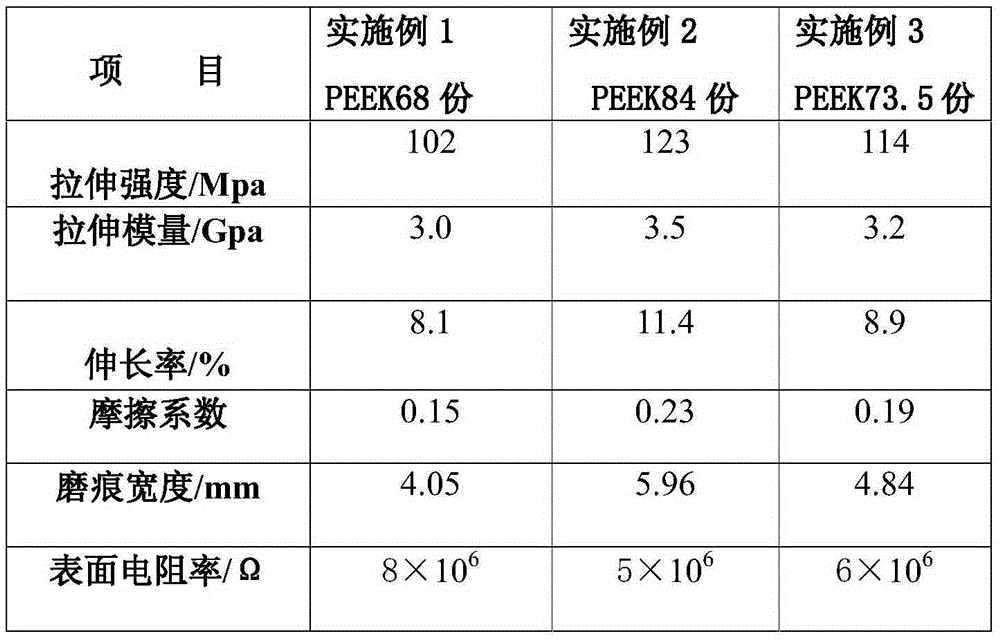

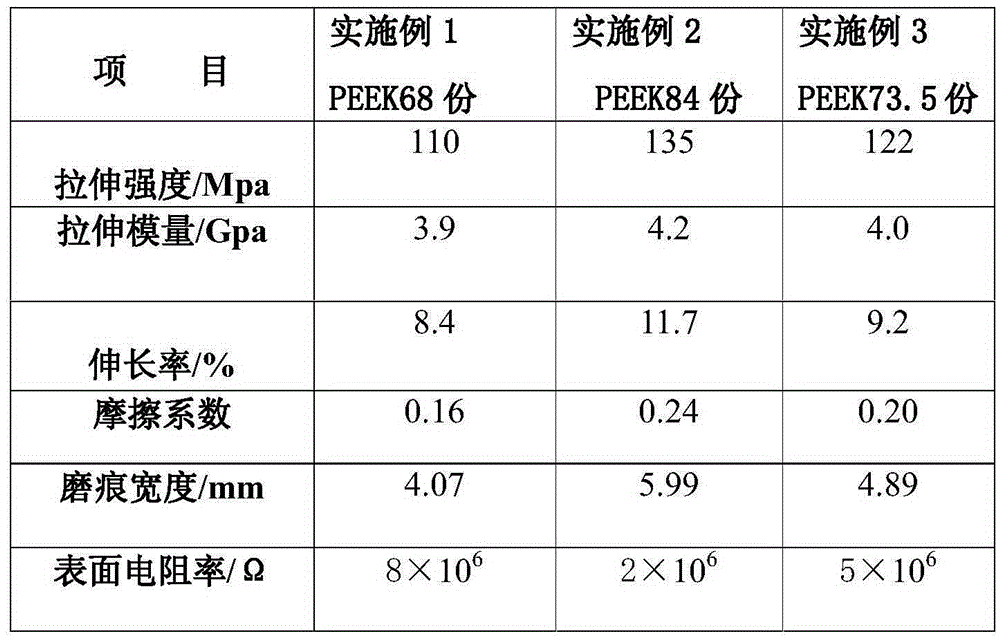

Antistatic PEEK composite material and preparation method thereof

The invention discloses an antistatic PEEK composite material. The antistatic PEEK composite material is prepared from 68-84 parts of PEEK, 15-30 parts of short carbon fibers and 1-2 parts of carbon nanotubes. The short carbon fibers and the carbon nanotubes are subjected to sulfonated PEEK surface treatment and a sulfonation degree of the sulfonated PEEK is 70-80. The invention also discloses a preparation method of the antistatic PEEK composite material. Through use of the short carbon fibers and the carbon nanotubes in PEEK, wear resistance, tensile strength and modulus of the PEEK material can be effectively improved, surface resistance is uniform and antistatic requirements are satisfied. The short carbon fibers and the carbon nanotubes are subjected to high sulfonated PEEK treatment so that surface activity is improved, dispersion in the PEEK base is promoted, agglomeration is reduced, carbon fibers, carbon nanotubes and PEEK in the composite material are bonded tightly, material toughness is improved and surface resistance is reduced.

Owner:NANJING COMPTECH COMPOSITES CORP +2

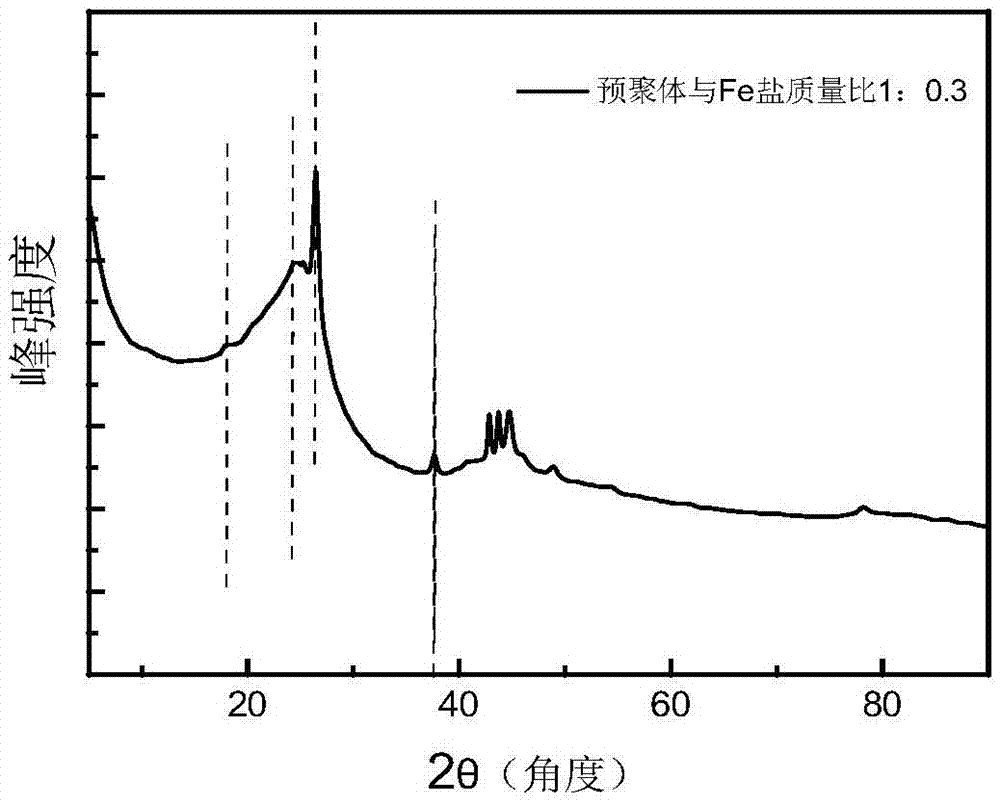

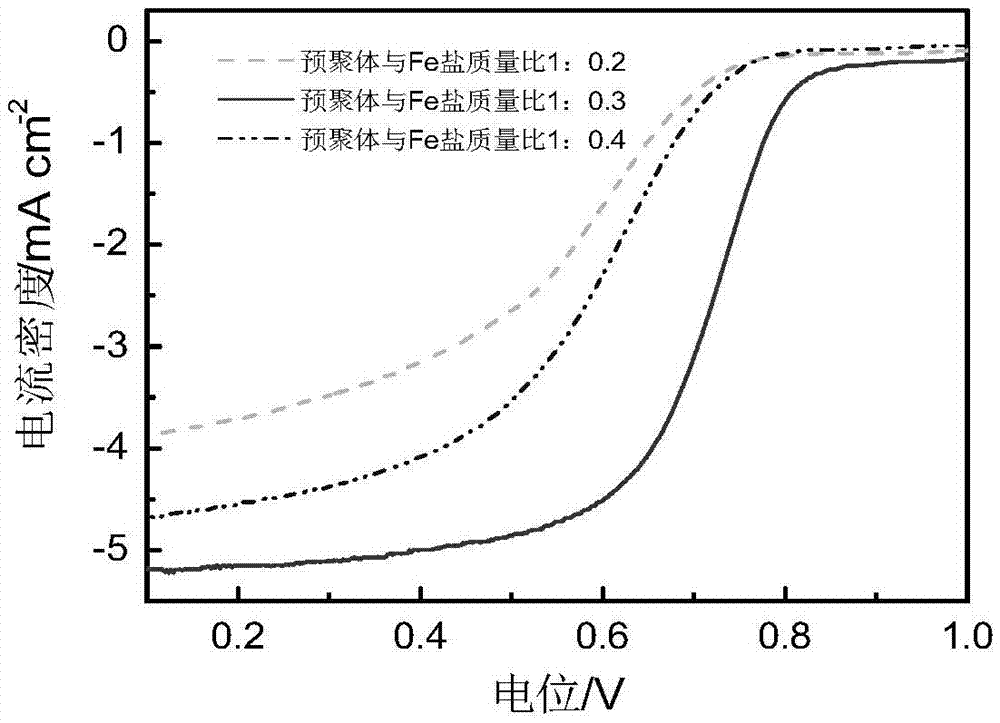

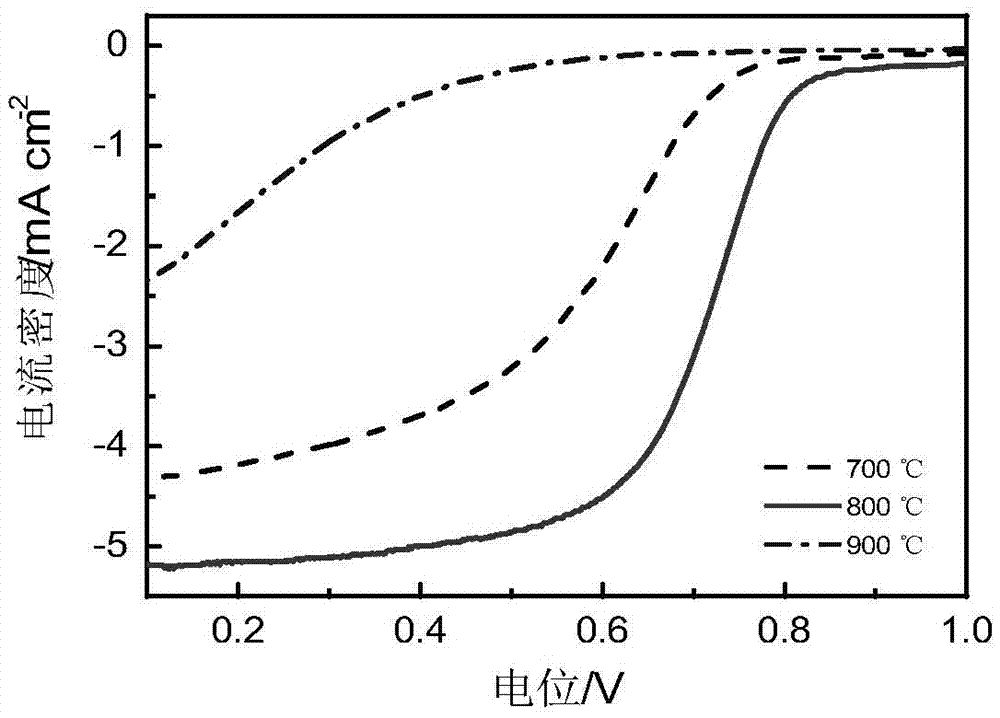

Catalyst prepared by in-situ growth of carbon nanotubes on ordered mesoporous carbon, and preparation method and application of catalyst

ActiveCN106876729AHigh active specific surfaceImprove conductivityCell electrodesCarbon nanotubeOxygen

The invention discloses a catalyst prepared by in-situ growth of carbon nanotubes on ordered mesoporous carbon, and a preparation method and an application of the catalyst. The composite catalyst is prepared by performing in-situ growth of carbon nanotubes on nitrogen-doped ordered mesoporous carbon; equivalently, a triblock copolymer is used as a soft template agent, and a soluble resin is used as a carbon source; transitional metal salt is added in the preparation process; a transitional metal element is introduced in an in-situ manner; and meanwhile, active points which facilitate growth of the carbon nanotubes are generated under mixed atmosphere of ammonia gas and hydrocarbons based on the transitional metal components introduced in a modifying process of the ordered mesoporous carbon material so as to realize nitridation and growth of carbon nanotubes in one step. The composite catalyst prepared by in-situ growth of carbon nanotubes on ordered mesoporous carbon has large activity specific surface and high conductivity performance, and shows excellent oxygen reduction catalytic performance and high electrochemical stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

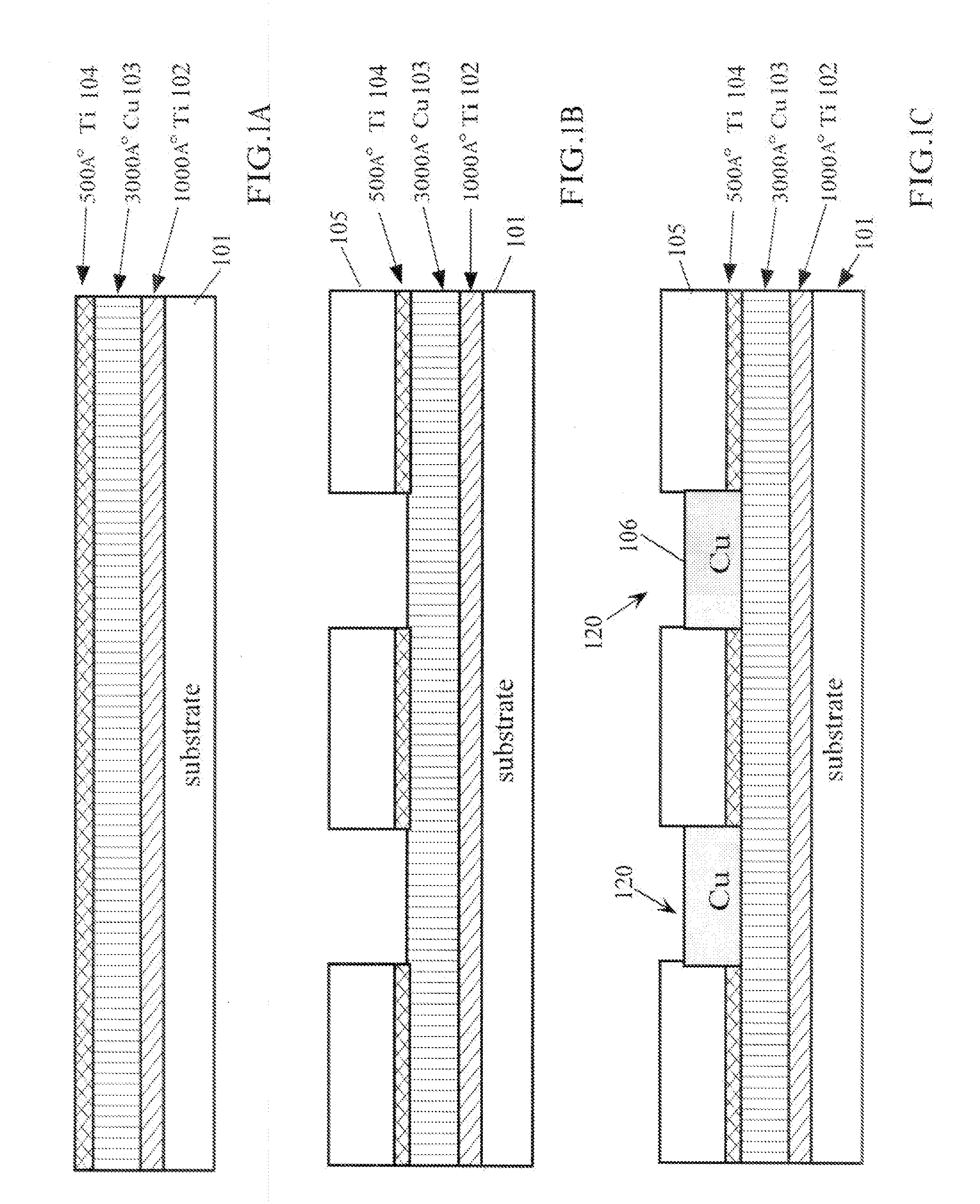

Compliant Bumps for Integrated Circuits Using Carbon Nanotubes

InactiveUS20080017981A1Semiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeInterconnection

Complaint bumps used for interconnections between integrated circuit chips are made with carbon nanotubes.

Owner:APPLIED NANOTECH HLDG

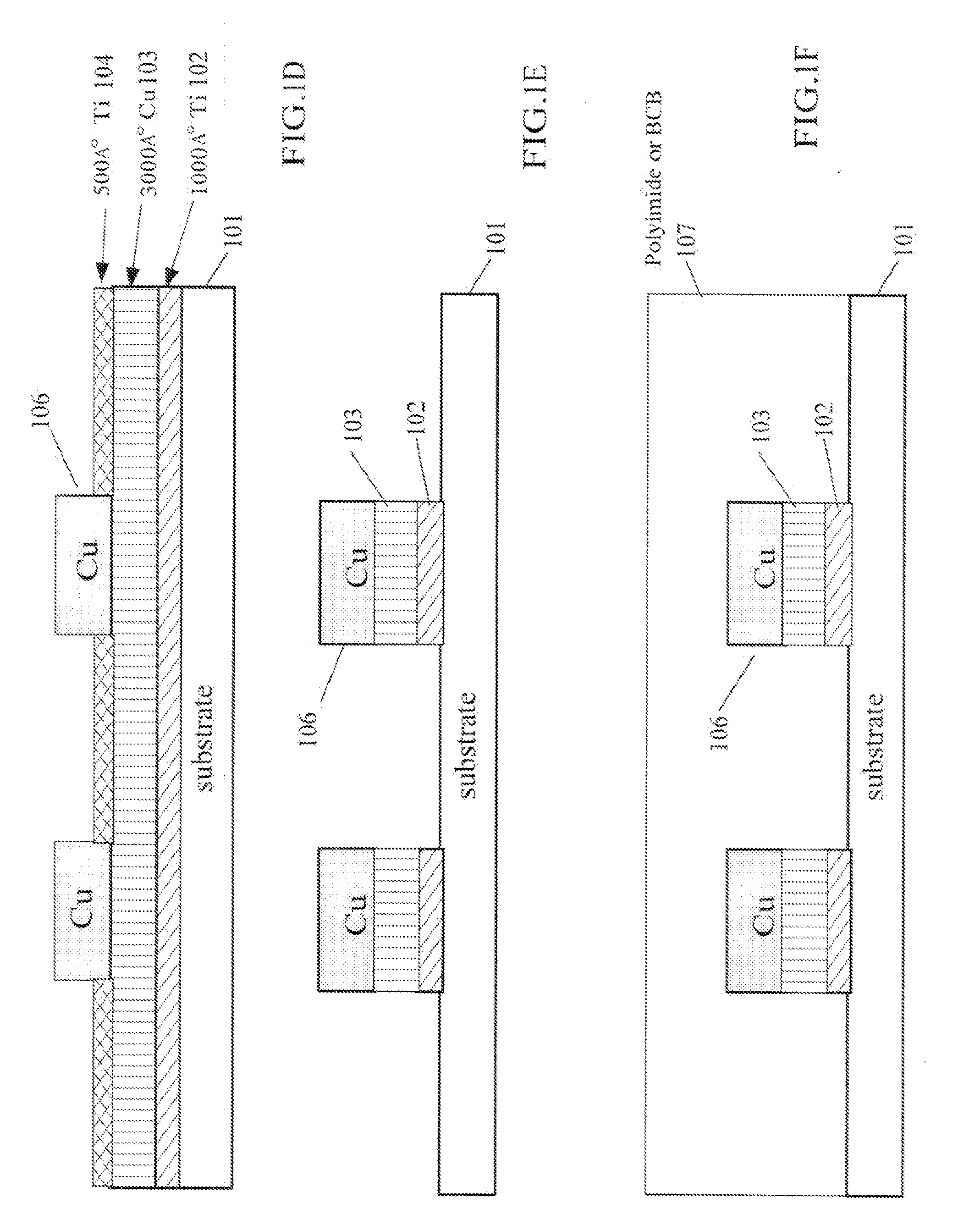

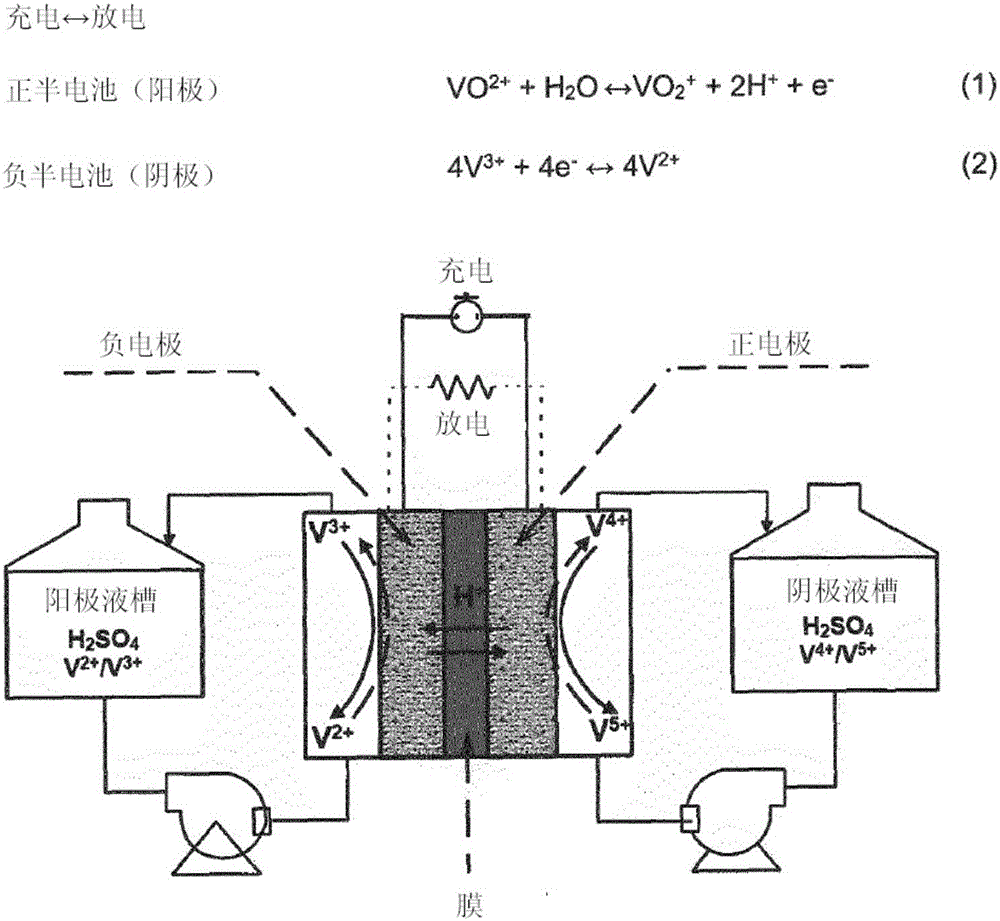

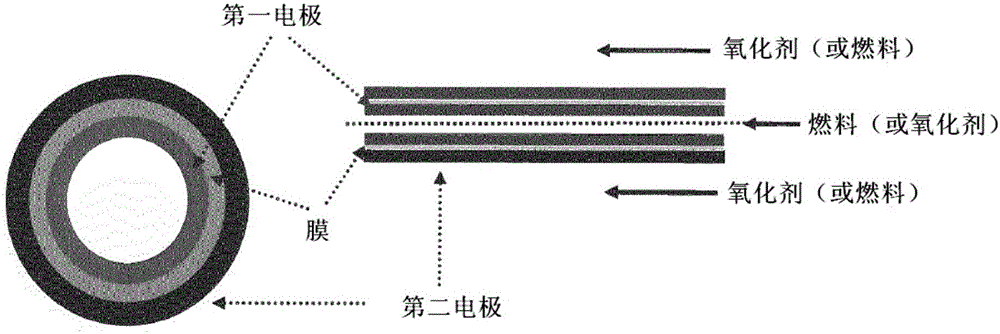

Microtubes made of carbon nanotubes

The present invention relates to microtubes made of carbon nanotubes or composites based on carbon nanotubes. The present invention also relates to the use of such microtubes made of carbon nanotubes or composites based of carbon nanotubes as stand alone electrodes electrodes or integrated with current collectors or as a part of membrane electrode assemblies applied in electrochemical systems such as primary and secondary batteries, redox flow batteries, fuel cells, electrochemical capacitors, capacitive deionization systems, electrochemical- and biosensors devices, or solar cells. Another use of the microtubes made of carbon nanotubes or composites based on carbon nanotubes relates to their application as supported or unsupported tubular membranes for water or wastewater filtration, in aqueous and organic solvent filtration, for blood filtration, for gas separation processes, in gas and liquid adsorption processes or in sensor applications.

Owner:迪威安德亚琛工业E.V.

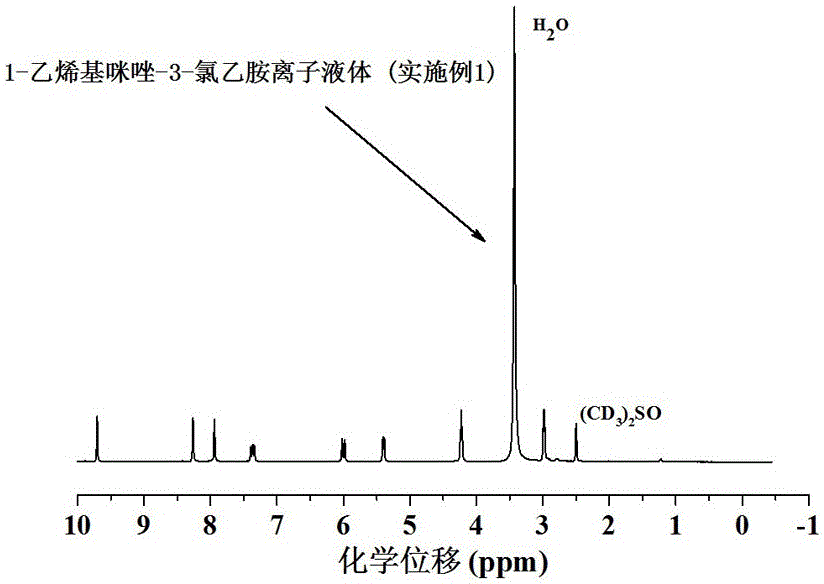

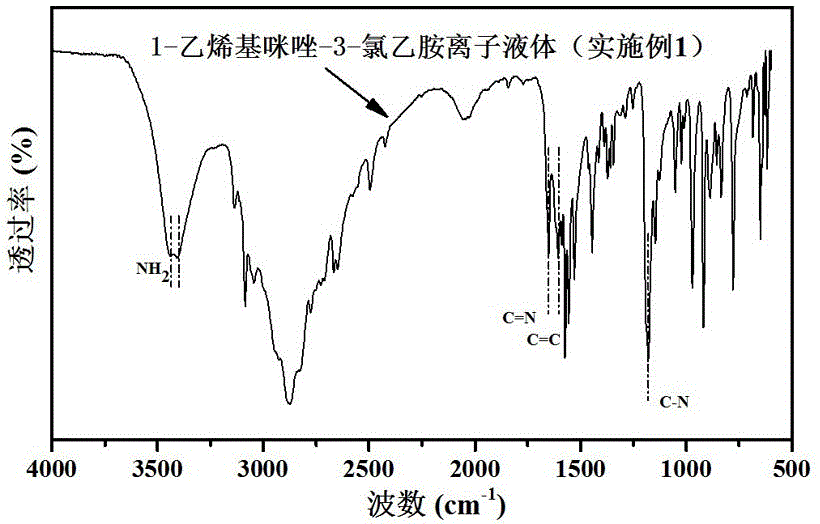

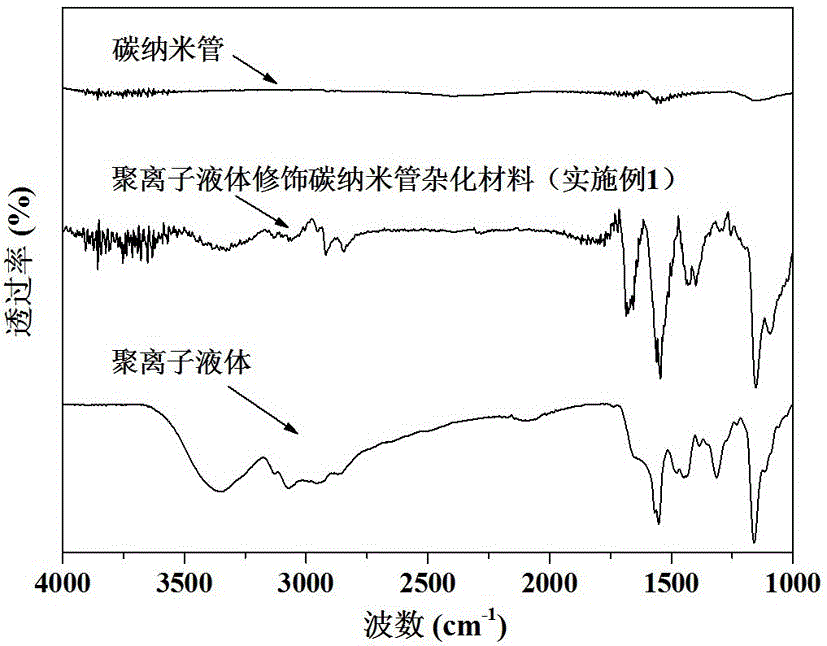

Polyion liquid-modified carbon nano-tube hybrid material and preparation method thereof

The invention discloses a polyion liquid-modified carbon nano-tube hybrid material and a preparation method thereof. The preparation method comprises the following steps: under the protection of nitrogen, mixing and heating vinyl N-heterocycle and 2-chloroethylamine hydrochloride; performing Menshutkin reaction to obtain an ionic liquid hydrochloride; neutralizing to obtain ion liquid monomers; reacting a certain ratio of monomers and a metal salt under a heating condition to obtain an ion liquid which contains an amino end group and a transition metal; dissolving obtained ion liquid in water, adding a fixed amount of carbon nano-tubes, performing ultrasonic dispersing, adding an initiator to perform surface-initiated polymerization, and filtering and drying a product to obtain the polyion liquid-modified carbon nano-tube hybrid material. According to the polyion liquid-modified carbon nano-tube hybrid material and the preparation method thereof, the hybrid material is prepared by coating the carbon nano-tubes with polyion liquid; the hybrid material has toughening and catalyzing functions; the preparation method has the characteristics of simple process and easiness in control.

Owner:SUZHOU UNIV

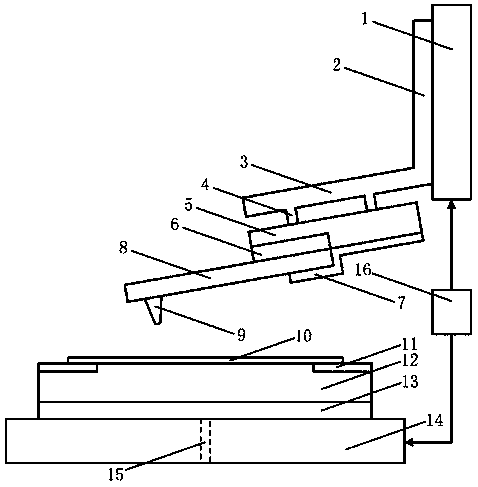

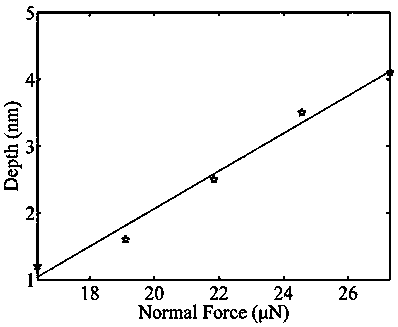

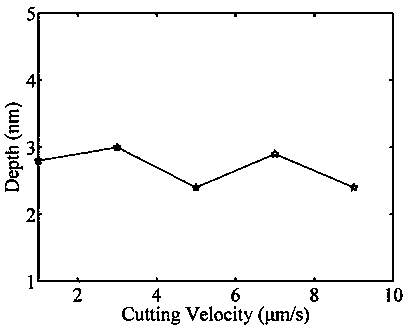

Method for processing graphene-carbon nanotube FET device

ActiveCN109052317AHigh sensitivityImprove performanceNanotechnologySemiconductor devicesMicro nanoCarbon nanotube

A method for processing graphene-carbon nanotube FET device comprises the following steps of: (1) assembling a graphene sheet on a cutting processing system; (2) setting cutting force, cutting speed and cutting path to the cutting processing system; (3) cutting the graphene sheet into graphene nanobelts; (4) processing a graphene nano-electrode; (5) establishing a stress model of a single-walled carbon nanotube in a non-uniform electric field; (6) titrating the single-walled carbon nanotube solution into the nano gap after the graphene nano-electrode is cut off. The processing method has the advantages of high precision, strong robustness, simple operation, flexibility and low cost. The processed graphene nano-electrode with the nano gap can be used as a probe for the nano point electricalproperty test and the detection of the biological molecules in a micro-environment, has higher sensitivity, and provides a new way for constructing micro-nano electronic equipment with smaller sizesand higher performances.

Owner:PINGDINGSHAN UNIVERSITY

Interconnection structure made of redirected carbon nanotubes

InactiveUS20120292103A1Reduce decreaseNanotechWave amplification devicesCarbon nanotubeInterconnection

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

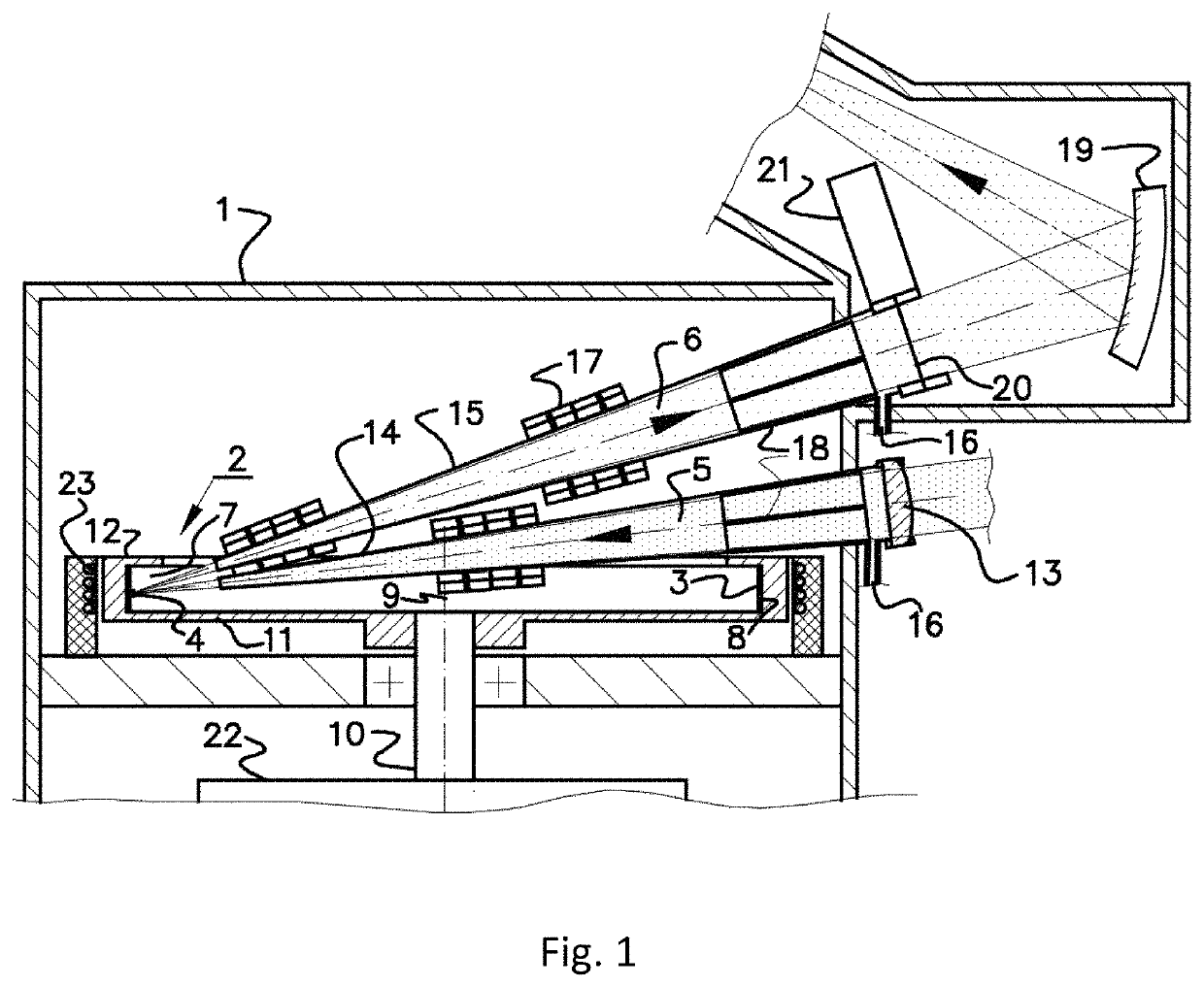

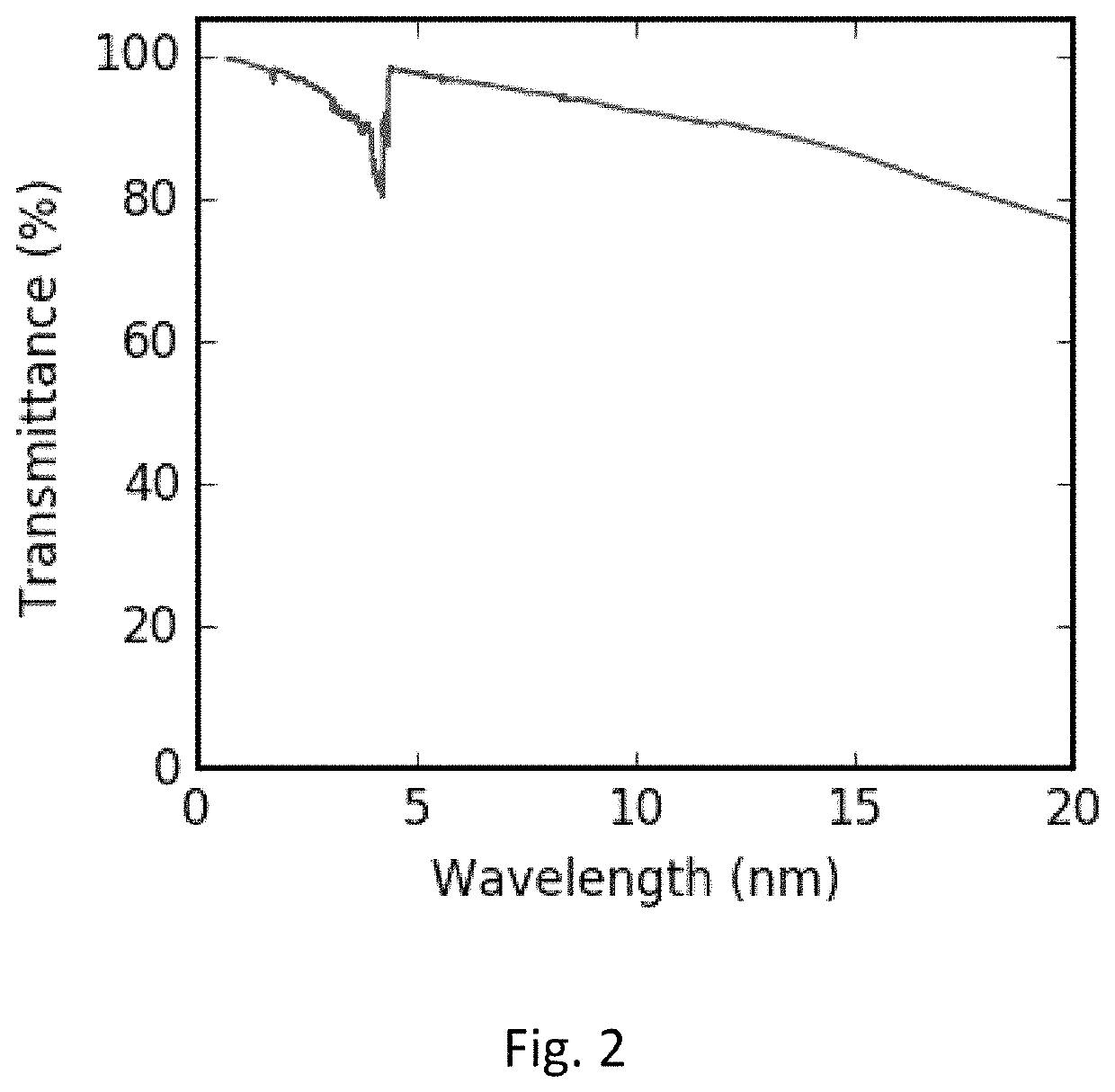

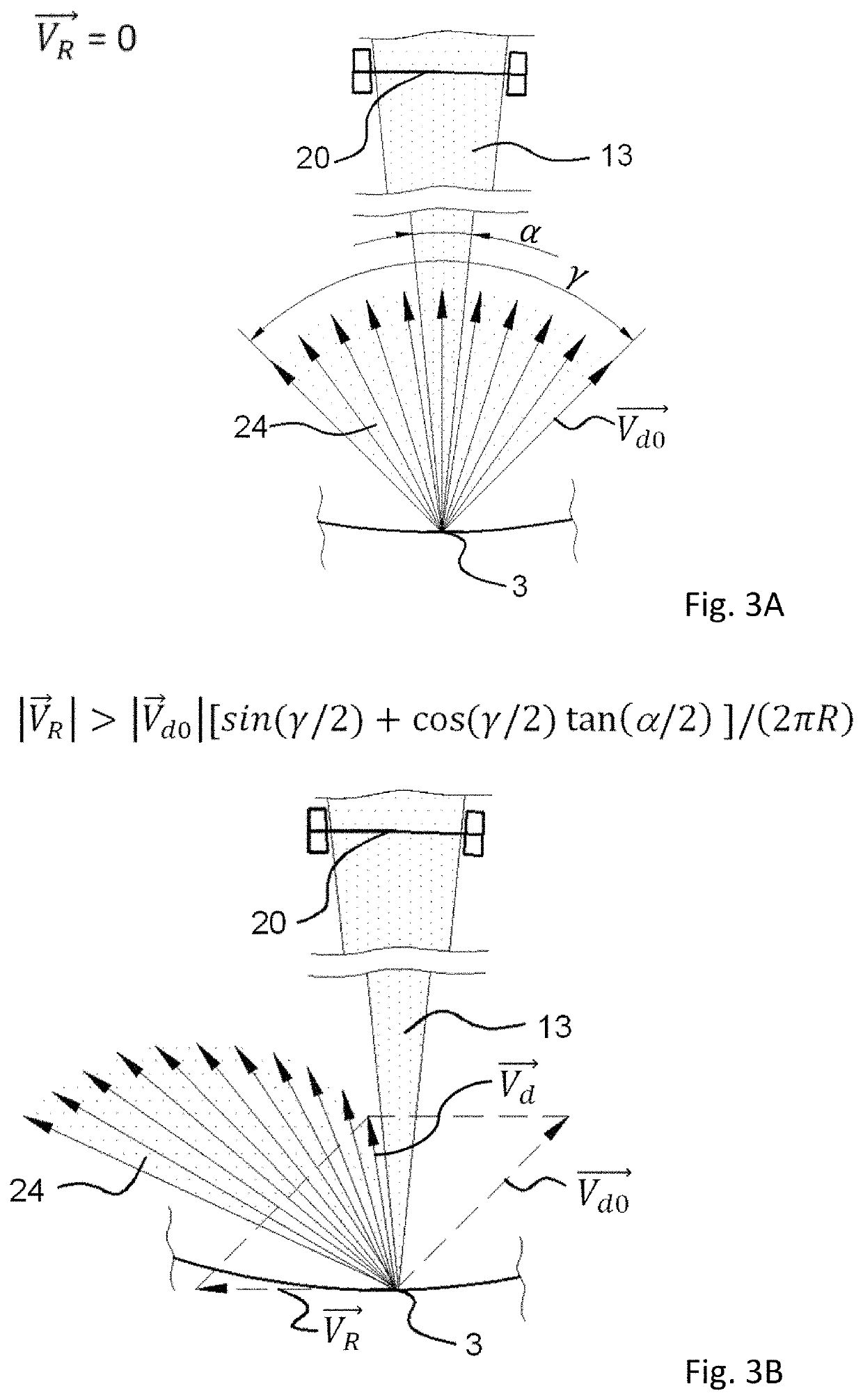

High brightness short-wavelength radiation source (variants)

ActiveUS10588210B1Inhibition releaseIncrease brightnessX-ray tube electrodesX-ray tube with very high currentCarbon nanotubeParticle physics

High-brightness short-wavelength radiation source contains a vacuum chamber with a rotating target assembly having an annular groove, an energy beam focused on the target, a useful short-wavelength radiation beam coming out of the interaction zone, wherein the target is a layer of molten metal formed by a centrifugal force on a surface of the annular groove facing a rotation axis. A replaceable membrane made of carbon nanotubes may be installed on a pathway of the short-wavelength radiation beam for debris mitigation. In the embodiments of the invention the energy beam is a pulsed laser beam. The pulsed laser beam may consist of pre-pulse and main-pulse, with parameters such as laser pulse repetition rate chosen in order to suppress debris. In other embodiments the energy beam is the electron beam produced by an electron gun and the rotating target assembly is a rotating anode.

Owner:ISTEQ BV +1

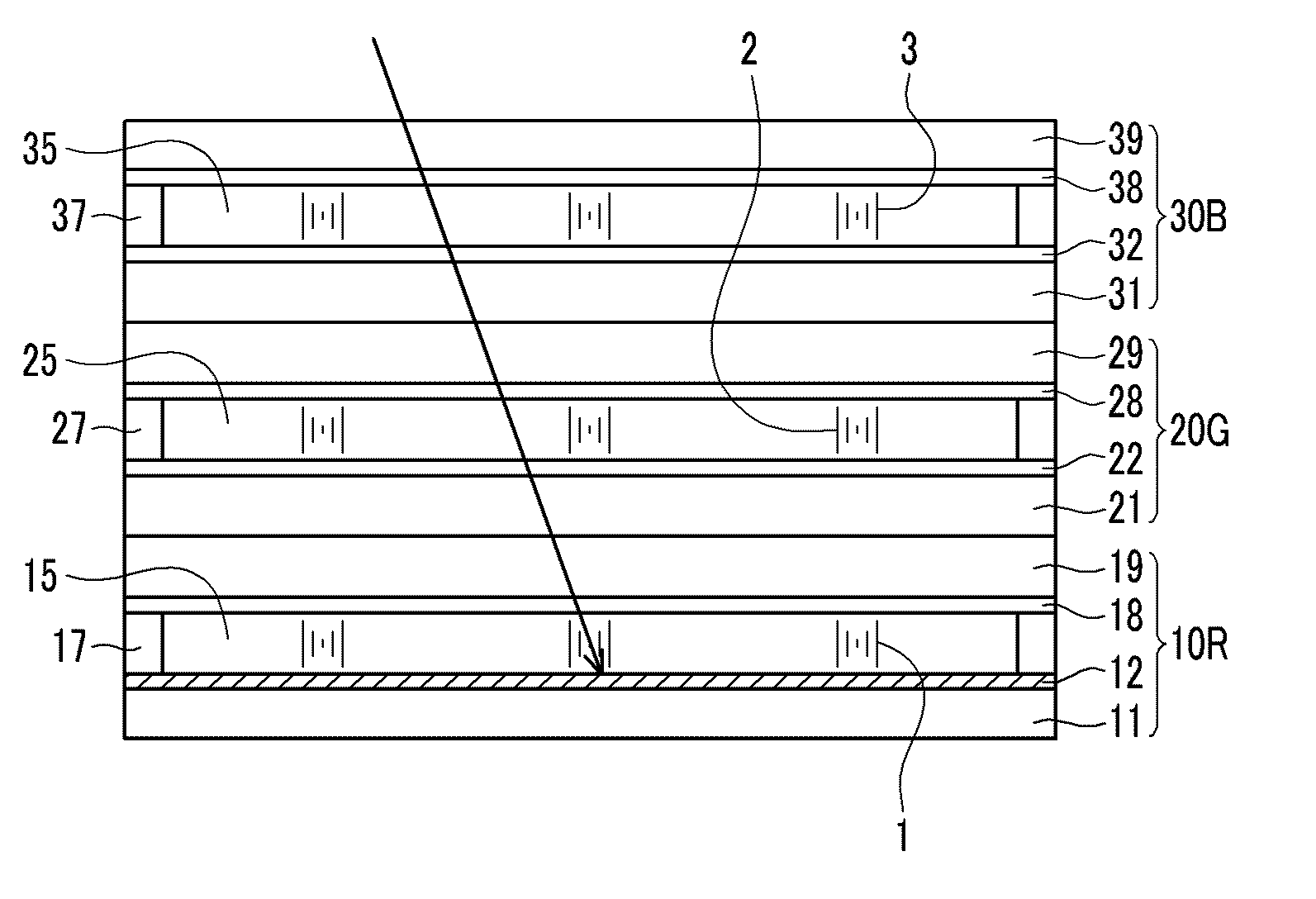

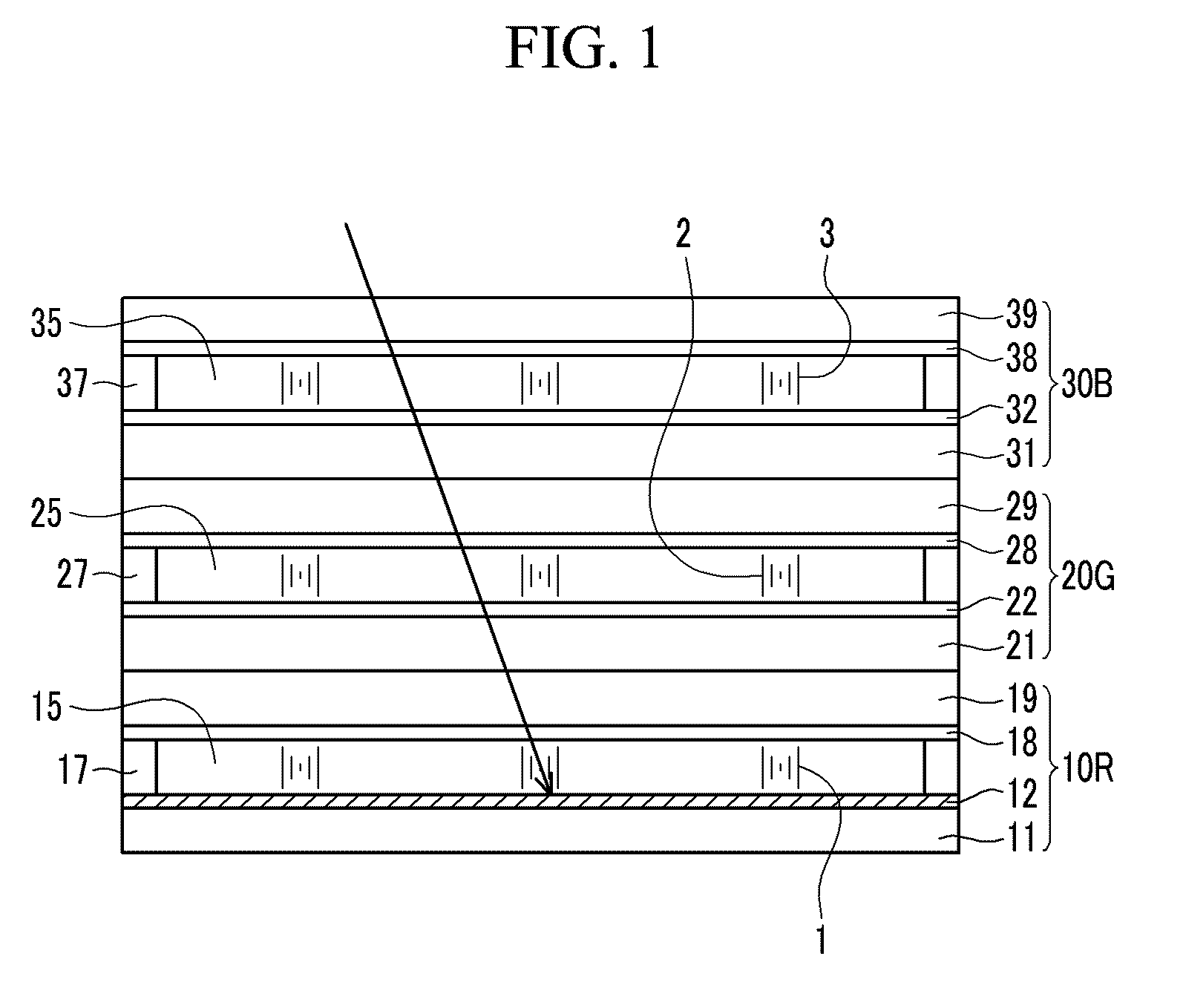

Liquid crystal display

ActiveUS20110069262A1Simple structureReduce manufacturing costNon-linear opticsLiquid-crystal displayCarbon nanotube

A liquid crystal display according to exemplary embodiments of the present invention includes a first panel including a first lower substrate, a first lower electrode formed on the first lower substrate, a first upper substrate facing the first lower substrate, a first upper electrode formed on the first upper substrate, and a first cholesteric liquid crystal injected between the first lower electrode and the first upper electrode, wherein the first lower electrode includes carbon nanotubes. The liquid crystal display including the first lower electrode made of the carbon nanotubes without a light absorption layer provides a simple structure capable of realizing a black state.

Owner:SAMSUNG DISPLAY CO LTD

Antistatic PEEK resin material and preparation method thereof

The invention discloses an antistatic PEEK resin material. The antistatic PEEK resin material is prepared from 68 to 84 parts of PEEK, 15 to 30 parts of short carbon fiber and 1 to 2 parts of carbon nanotubes, wherein the carbon nanotubes have undergone surface treatment by sulfonated PEEK, the sulfonation degree of sulfonated PEEK is 70 to 80, and the short carbon fiber has undergone surface oxidation treatment. According to the invention, the short carbon fiber and carbon nanotubes are added into PEEK, so wear resistance, tensile strength, modulus and other performance of a PEEK material can be effectively improved, and surface resistance is reduced; different methods are employed for surface modification of the short carbon fiber and carbon nanotubes, so dispersion of the short carbon fiber and carbon nanotubes in a PEEK matrix is more uniform and agglomeration is reduced compared with surface modification through a same method; and the carbon fiber, carbon nanotubes and PEEK in the resin material are more tightly bonded, which is beneficial for improving the mechanical performance of the material and reducing surface resistance.

Owner:NANJING COMPTECH COMPOSITES CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Hybrid carbon [nanotude] nanotube FET(CNFET)-FET static RAM (SRAM) and method of making same Hybrid carbon [nanotude] nanotube FET(CNFET)-FET static RAM (SRAM) and method of making same](https://images-eureka.patsnap.com/patent_img/186d61a6-7618-4e13-a066-cad324234b3f/US07598544-20091006-D00000.png)

![Hybrid carbon [nanotude] nanotube FET(CNFET)-FET static RAM (SRAM) and method of making same Hybrid carbon [nanotude] nanotube FET(CNFET)-FET static RAM (SRAM) and method of making same](https://images-eureka.patsnap.com/patent_img/186d61a6-7618-4e13-a066-cad324234b3f/US07598544-20091006-D00001.png)

![Hybrid carbon [nanotude] nanotube FET(CNFET)-FET static RAM (SRAM) and method of making same Hybrid carbon [nanotude] nanotube FET(CNFET)-FET static RAM (SRAM) and method of making same](https://images-eureka.patsnap.com/patent_img/186d61a6-7618-4e13-a066-cad324234b3f/US07598544-20091006-D00002.png)