Carbon nanotube-styrene block copolymers (CNT-SBS) modified asphalt

A CNT-SBS, 1. CNT-SBS technology, applied in the field of modified asphalt, can solve the problems of inaccurate composition ratio and insignificant effect, and achieve the effect of reducing the amount of CNT, good environmental conditions, and improving the modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

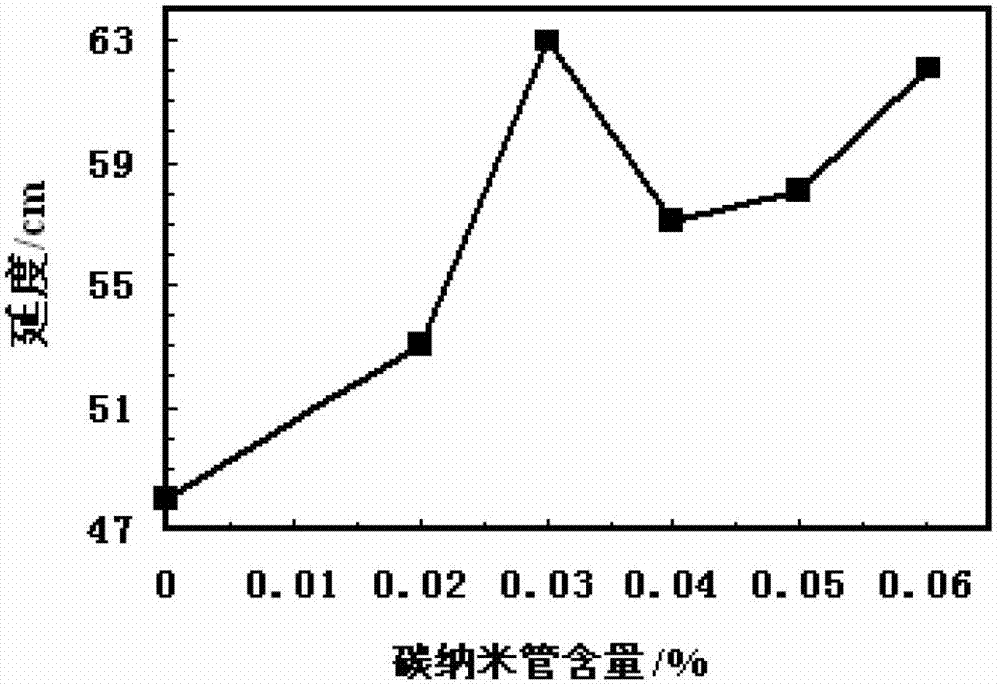

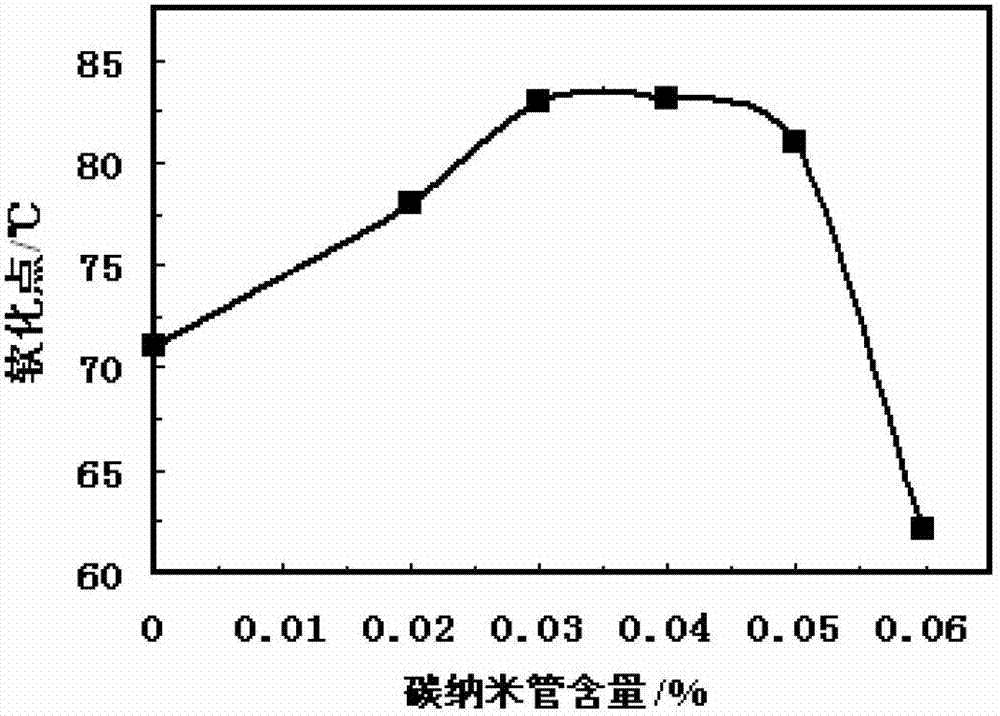

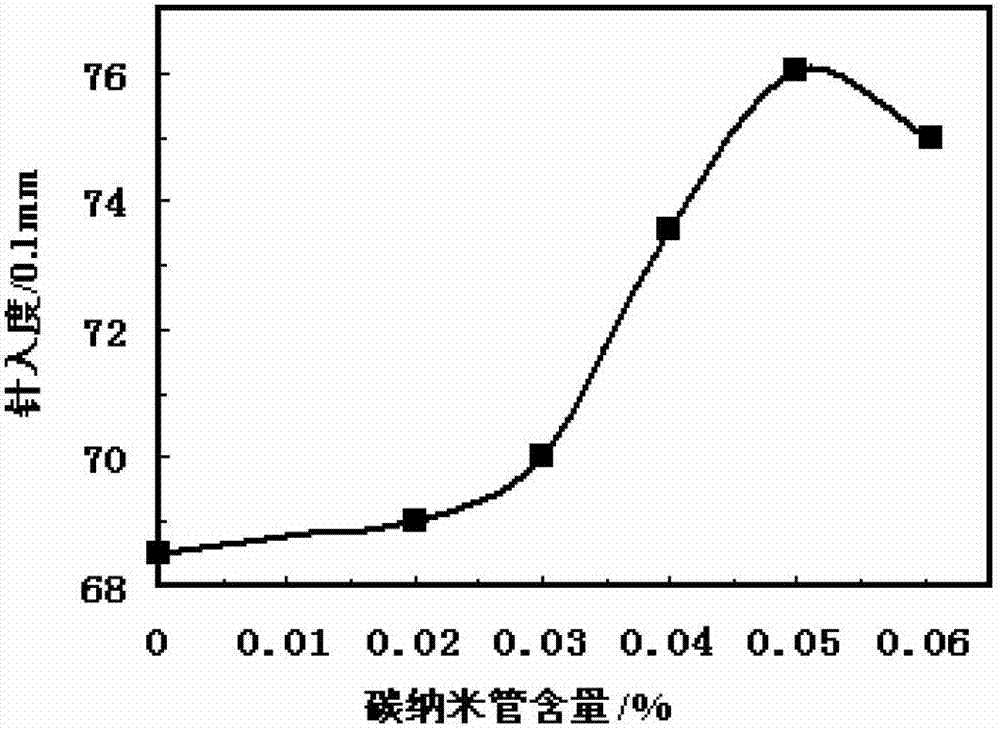

[0013] Embodiment 1: The CNT-SBS modified asphalt of this embodiment is characterized in that the CNT-SBS modified asphalt is composed of 95.97% base asphalt and 4% linear styrene-butadiene-styrene block by mass percentage The copolymer powder and 0.03% carbon nanotube are made; wherein, the base asphalt is No. 110 petroleum asphalt; the fineness of the linear styrene-butadiene-styrene block copolymer powder is 60-100 mesh.

[0014] The preparation method of CNT-SBS modified asphalt is achieved through the following steps: 1. First, use a pulverizer to crush the linear styrene-butadiene-styrene block copolymer particles to a powder with a fineness of 60-100 mesh shape to obtain linear SBS powder; 2. uniformly mix the linear SBS powder obtained in step 1 with carbon nanotubes at a mass ratio of 400:3 to obtain a CNT-SBS composite modifier; 3. mix the matrix in an oven Heat the asphalt to 110-130°C, then add the CNT-SBS composite modifier accounting for 4.2% by mass of the base ...

specific Embodiment approach 2

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in the step 3 of the preparation method of CNT-SBS modified asphalt, cut 5min with the rotating speed of 4000r / min with asphalt shearer, then use mixer to The rotating speed of 800r / min was stirred for 3min, and other steps and parameters were the same as in Embodiment 1.

[0016] Prove the beneficial effect of the present invention by following test:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com