Patents

Literature

325 results about "Zirconium hydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium hydride describes an alloy made by combining zirconium and hydrogen. Hydrogen acts as a hardening agent, preventing dislocations in the zirconium atom crystal lattice from sliding past one another. Varying the amount of hydrogen and the form of its presence in the zirconium hydride (precipitated phase) controls qualities such as the hardness, ductility, and tensile strength of the resulting zirconium hydride. Zirconium hydride with increased hydrogen content can be made harder and stronger than zirconium, but such zirconium hydride is also less ductile than zirconium.

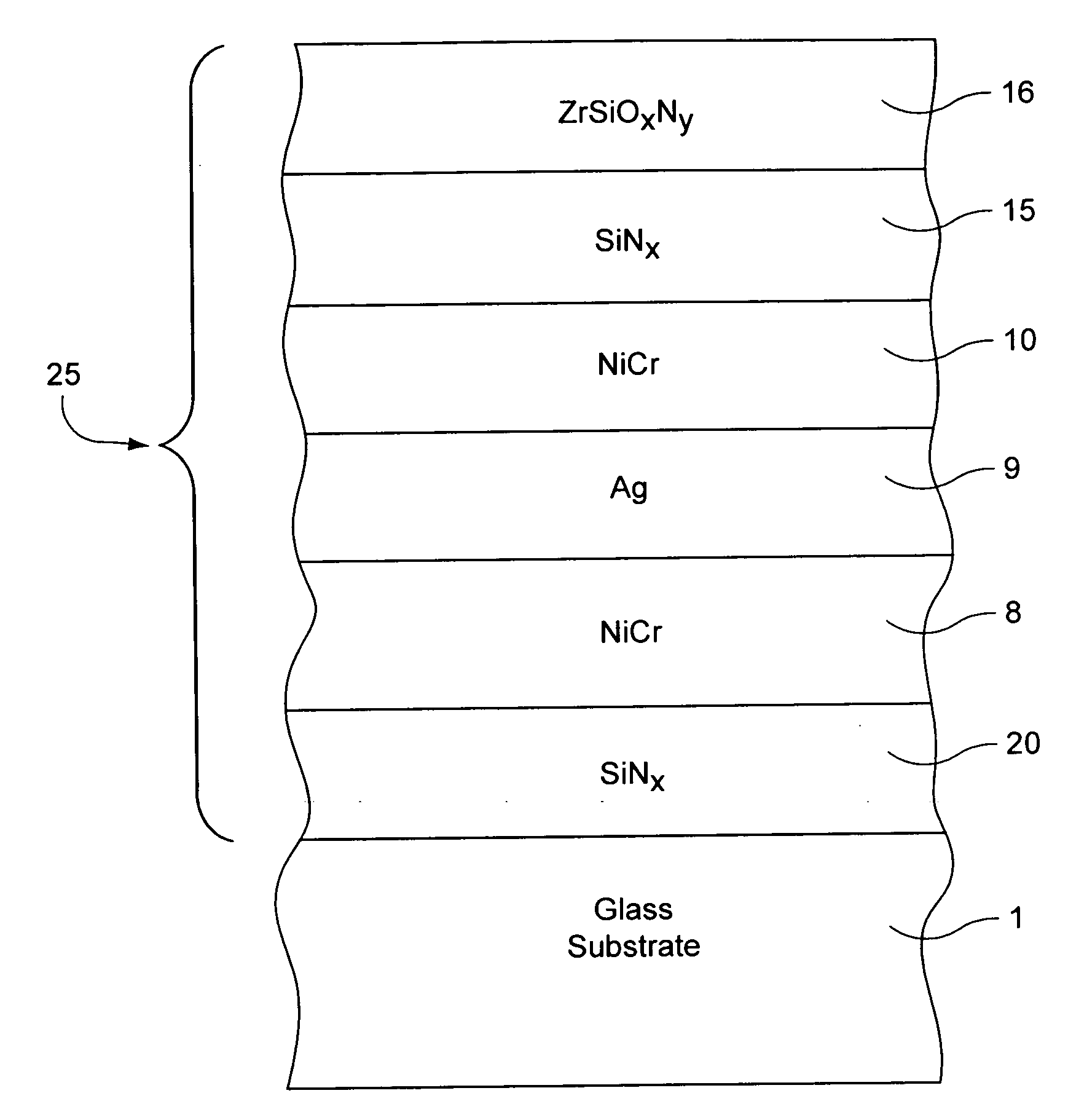

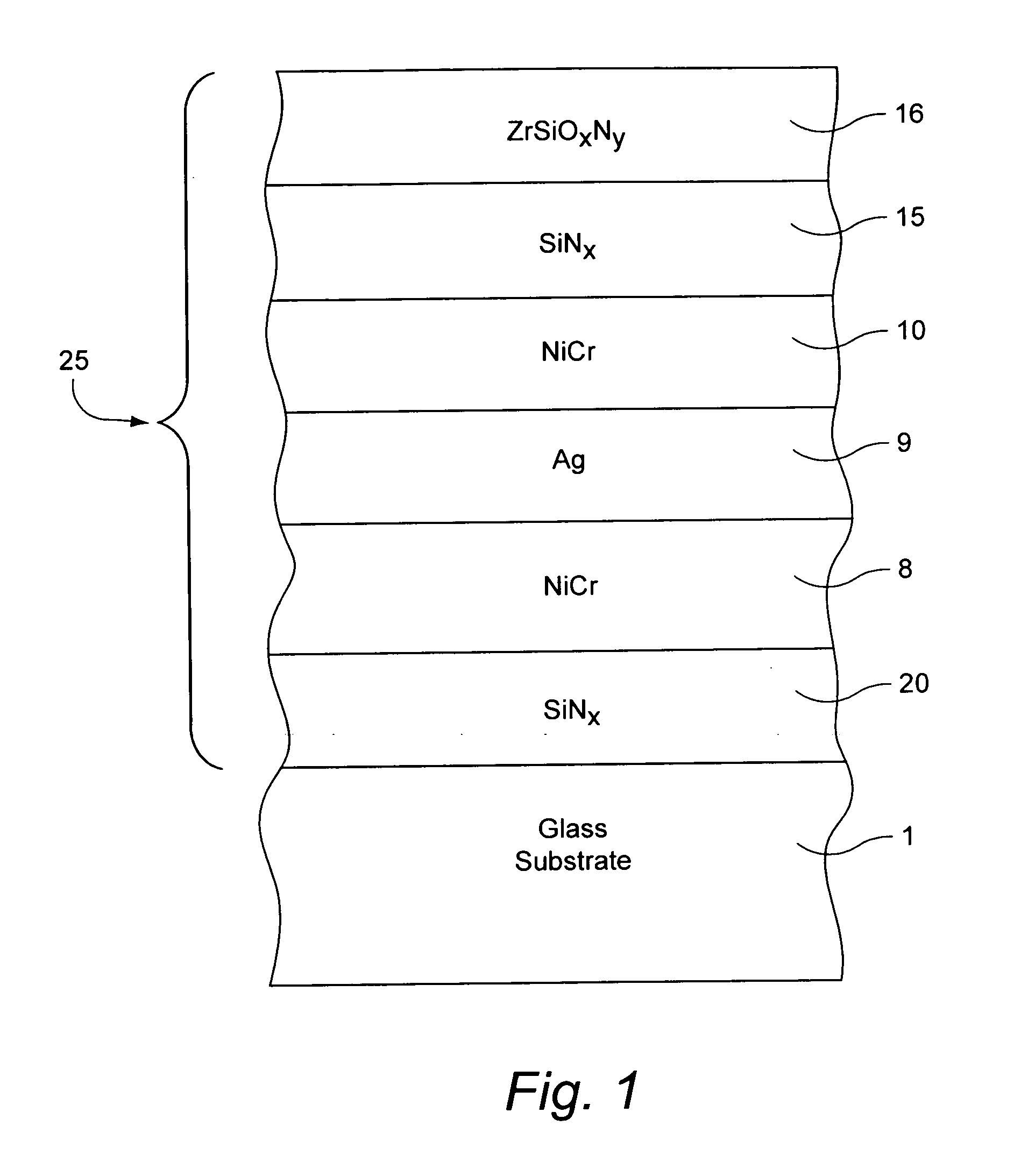

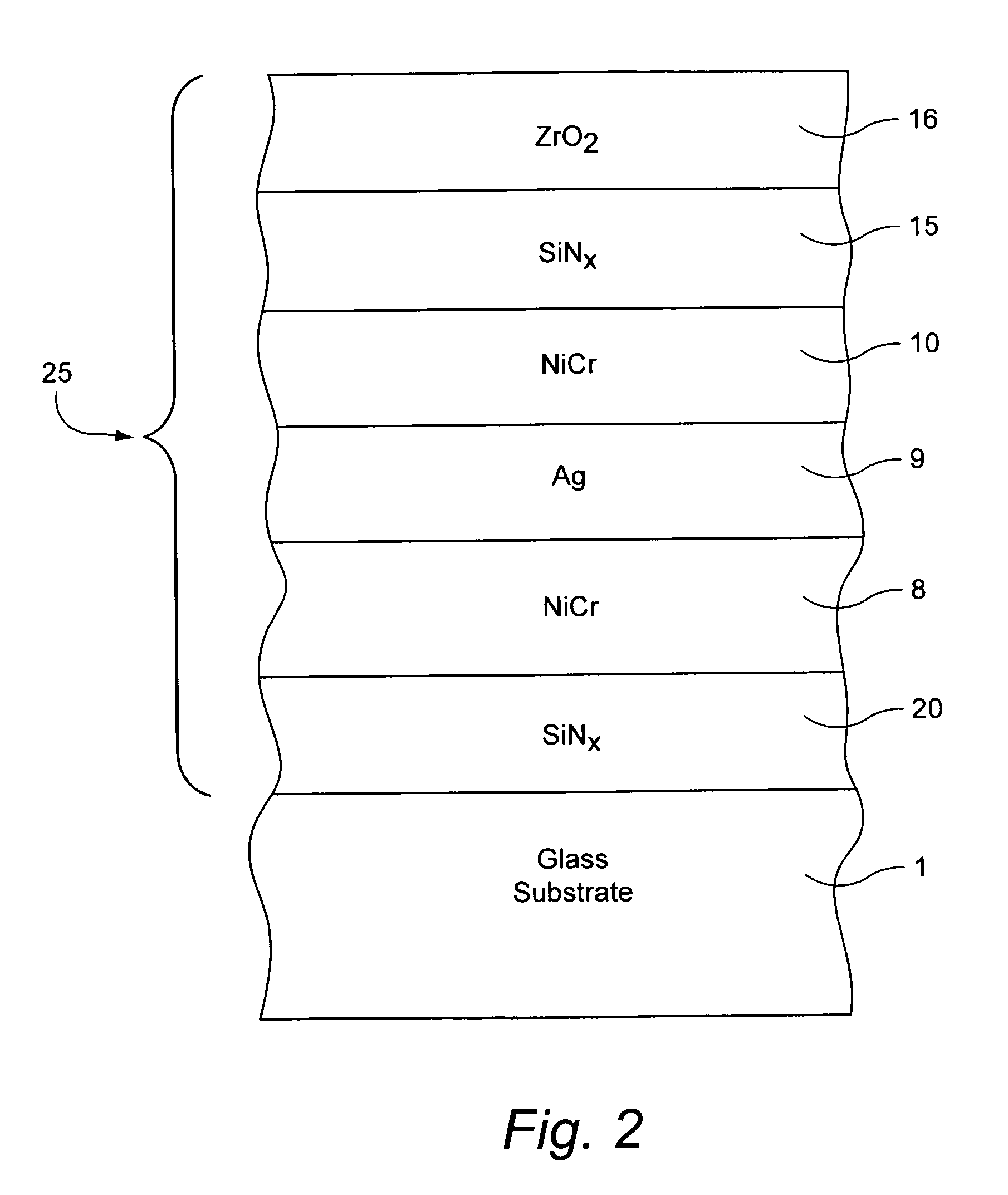

Coated article with low-E coating including zirconium oxide and/or zirconium silicon oxynitride and methods of making same

InactiveUS20090324967A1Reduce sheet resistanceImprove transmittanceGlass/slag layered productsCoatingsZirconium hydrideHeat stability

This application relates to a coated article including at least one infrared (IR) reflecting layer of a material such as silver or the like in a low-E coating. In certain embodiments, at least one layer of the coating is of or includes zirconium oxide (e.g., ZrO2) or zirconium silicon oxynitride (e.g., ZrSiOxNy). When a layer comprising zirconium oxide or zirconium silicon oxynitride is provided as the uppermost or overcoat layer of the coated article (e.g., over a silicon nitride based layer), this results in improved chemical and heat stability in certain example embodiments. Coated articles herein may be used in the context of insulating glass (IG) window units, vehicle windows, or in other suitable applications such as monolithic window applications, laminated windows, and / or the like.

Owner:GUARDIAN GLASS LLC

Exhaust gas catalyst

InactiveUS6180075B1Favorable degree of conversionExceptional heat and aging resistanceNitrogen compoundsInternal combustion piston enginesZirconium hydrideCerium(IV) oxide

A single-layered three-way catalytic converter containing palladium as the only catalytically active noble metal, with high activity and heat resistance. The catalyst contains, in addition to finely divided, stabilized aluminum oxide, at least one finely divided cerium / zirconium mixed oxide and optionally finely divided nickel oxide as well as highly dispersed amounts of cerium oxide, zirconium oxide and barium oxide. The palladium is distributed largely uniformly throughout the entire catalyst.

Owner:DMC2 DEGUSSA METALS +1

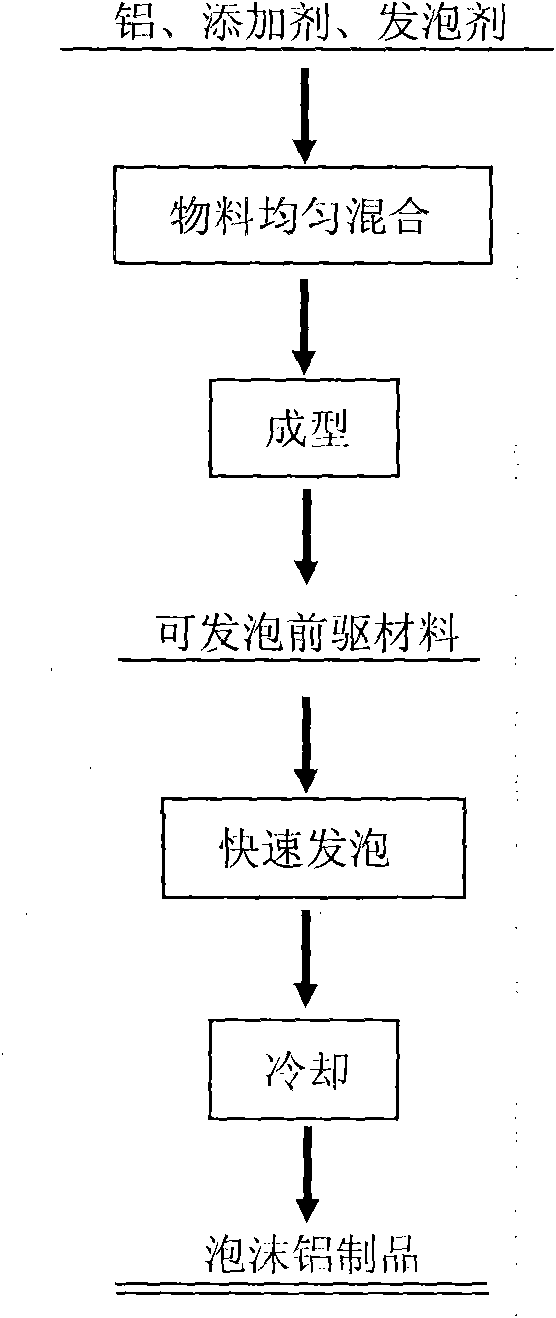

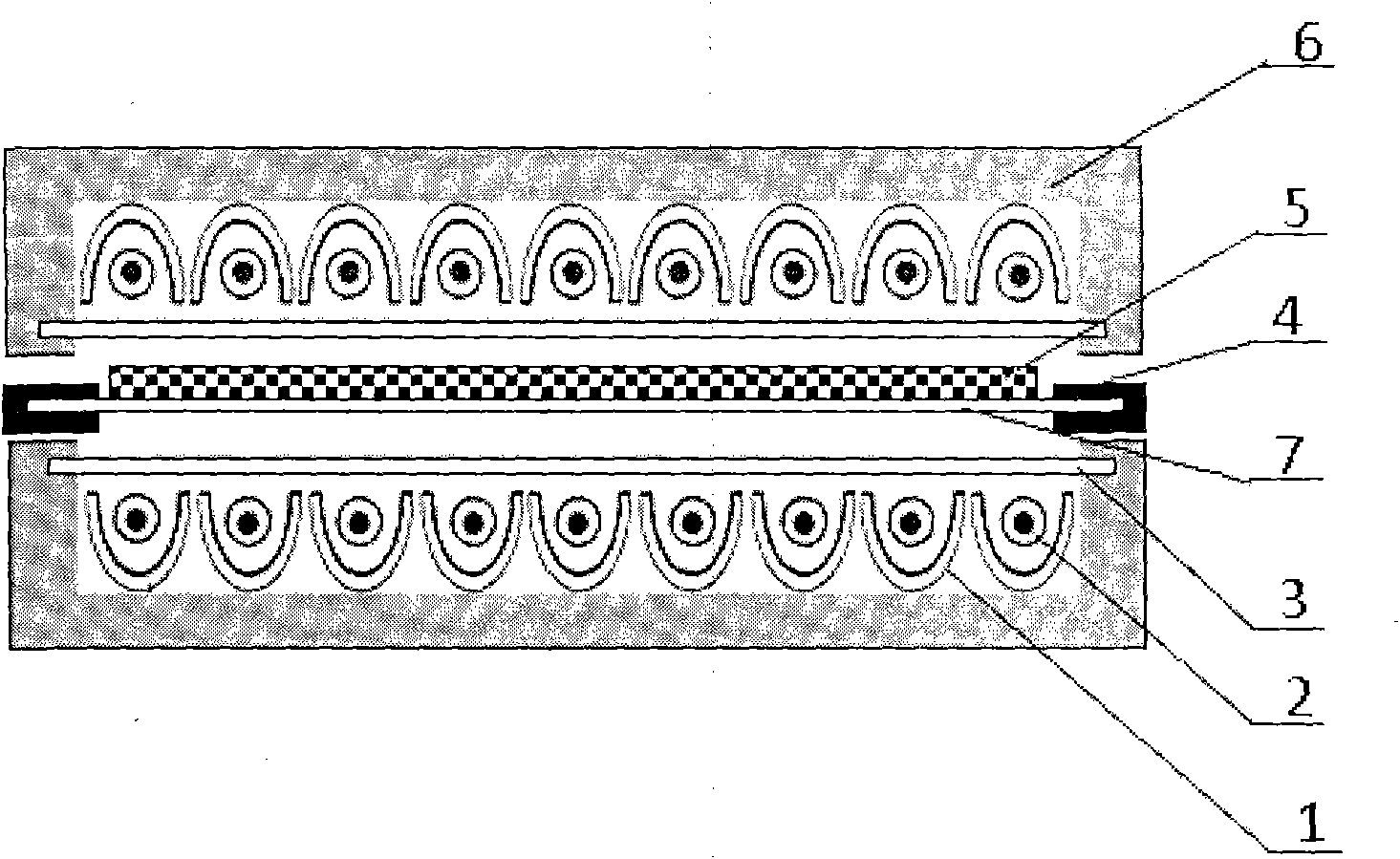

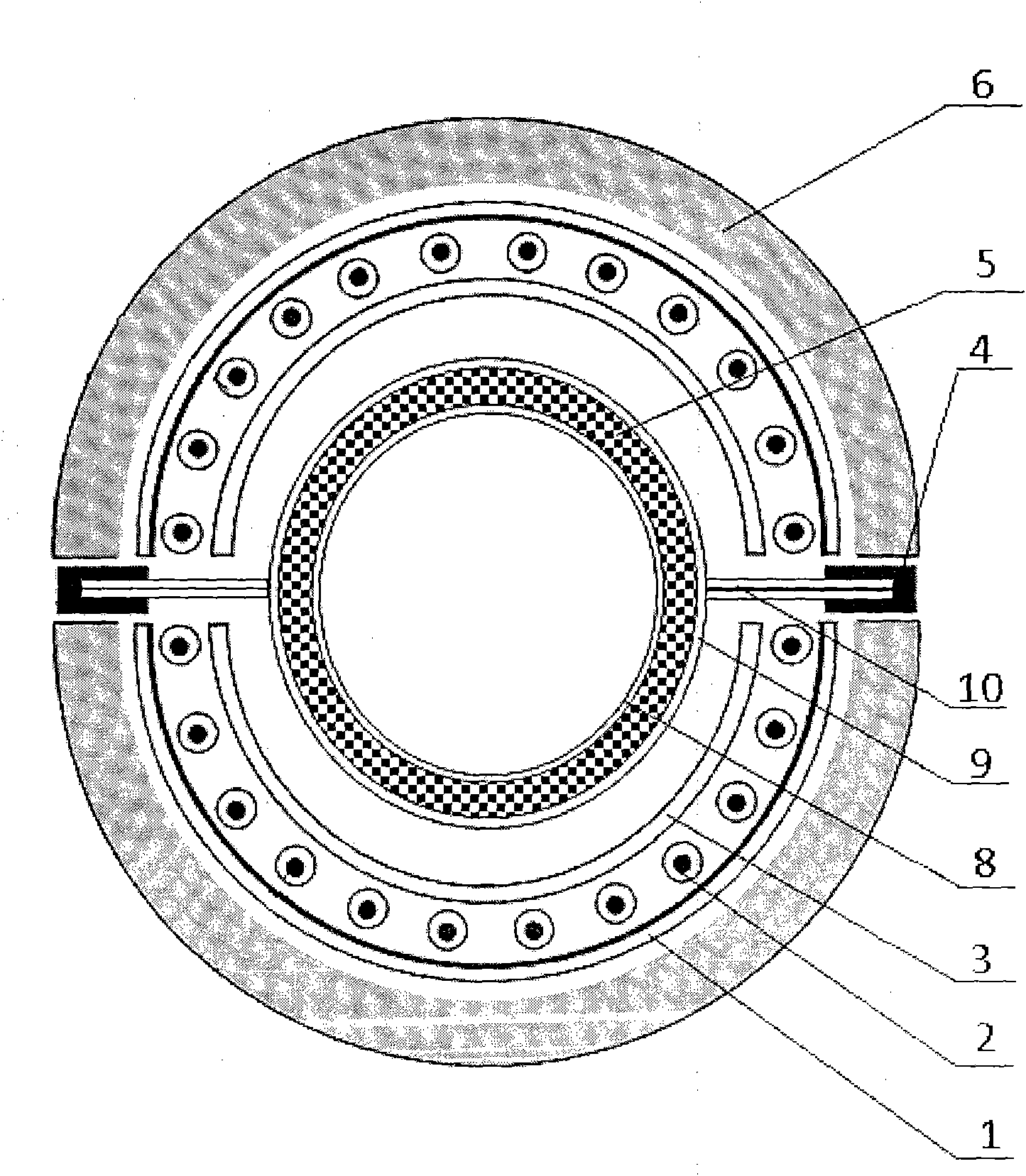

Preparation method and device of metal foam material

The invention discloses a preparation method and a device of a metal foam material. The preparation method comprises the following steps: mixing 93-99 wt% of aluminium matrix, 0.5-5 wt% of additive and 0.5-2 wt% of foaming agent uniformly to form a shaped foamable precursor material, putting the foamable precursor material in a foaming furnace with infrared heating to foam the foamable precursor material fast under infrared radiation, then taking the foam material out from the foaming furnace and cooling, wherein, the aluminium matrix is pure aluminium, aluminium powder or aluminium alloy, the foaming agent is titanium hydride, zirconium hydride, or calcium carbonate, and the additive is calcium, carborundum powder, or alumina powder. The device is a foaming furnace with infrared heating,has the advantages of fast foaming the precursor material, eliminating the hole gradient, easily controlling the foaming and cooling process, making the product have reproducibility and maneuverability, and improving cellular uniformity. According to the invention, metal foam sandwich panels can be prepared directly, and the mechanical properties of the aluminium-based foam material are improved.

Owner:NORTHEASTERN UNIV

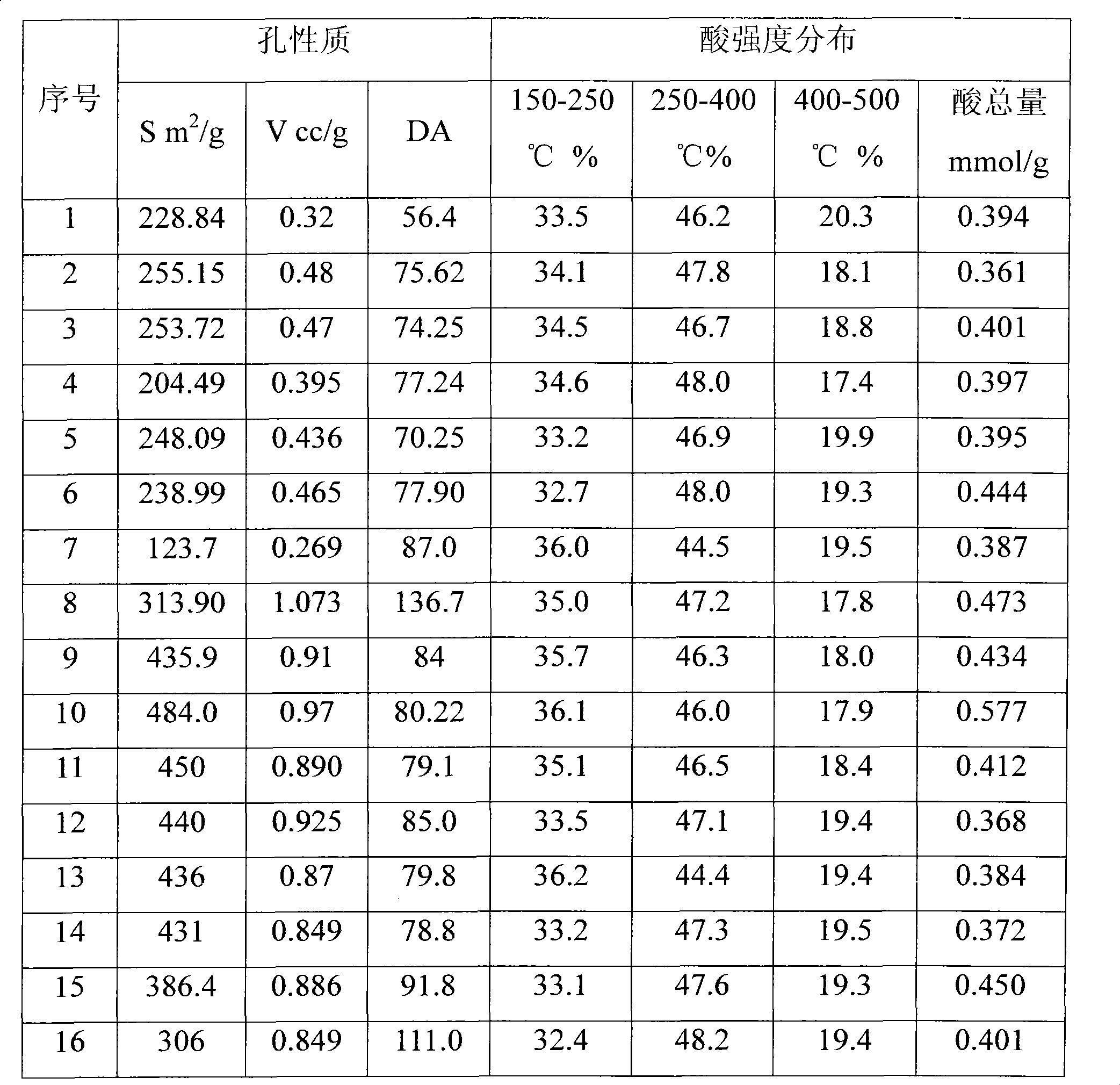

Composite oxide carrier and preparation method thereof

ActiveCN101433863ALarge hole volumeLarge specific surface areaCatalyst carriersZirconium hydrideSilicon dioxide

The invention relates to a compound oxide carrier and a preparation method, and belongs to the filed of catalyst preparation, wherein the compound oxide carrier is prepared by compounding gamma-aluminum oxide, silicon dioxide and zirconium dioxide. The method comprises the following steps: co-precipitating precursors of the aluminum oxide, the silicon dioxide and the zirconium dioxide with alkali solution, adding surfactant into the mixture to improve the pore structure and acidity and alkaline, then washing, filtering and roasting the obtained sediment at high temperature to obtain compound oxide powder, and finally extruding and molding the compound oxide powder to obtain the carrier. The pore structure and the acidity and the alkaline of the obtained carrier have wide adjustable ranges, the specific surface of the carrier is 200 to 500 m<2> per gram, the pore volume thereof is 0.4 to 1.2 milliliters per gram, and the total acid amount of NH3-TPD is 0.2 to 0.8mmol / g. The carrier prepared by the method is suitable for preparing hydrogenation catalysts of petroleum fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

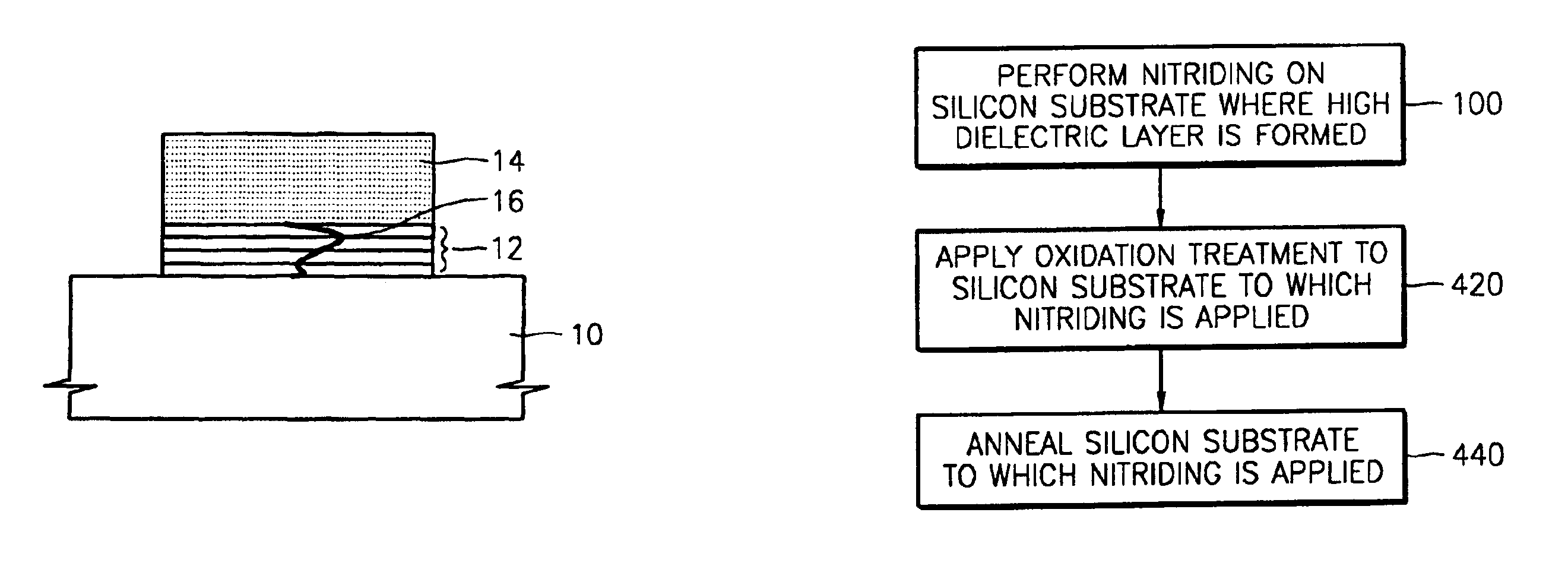

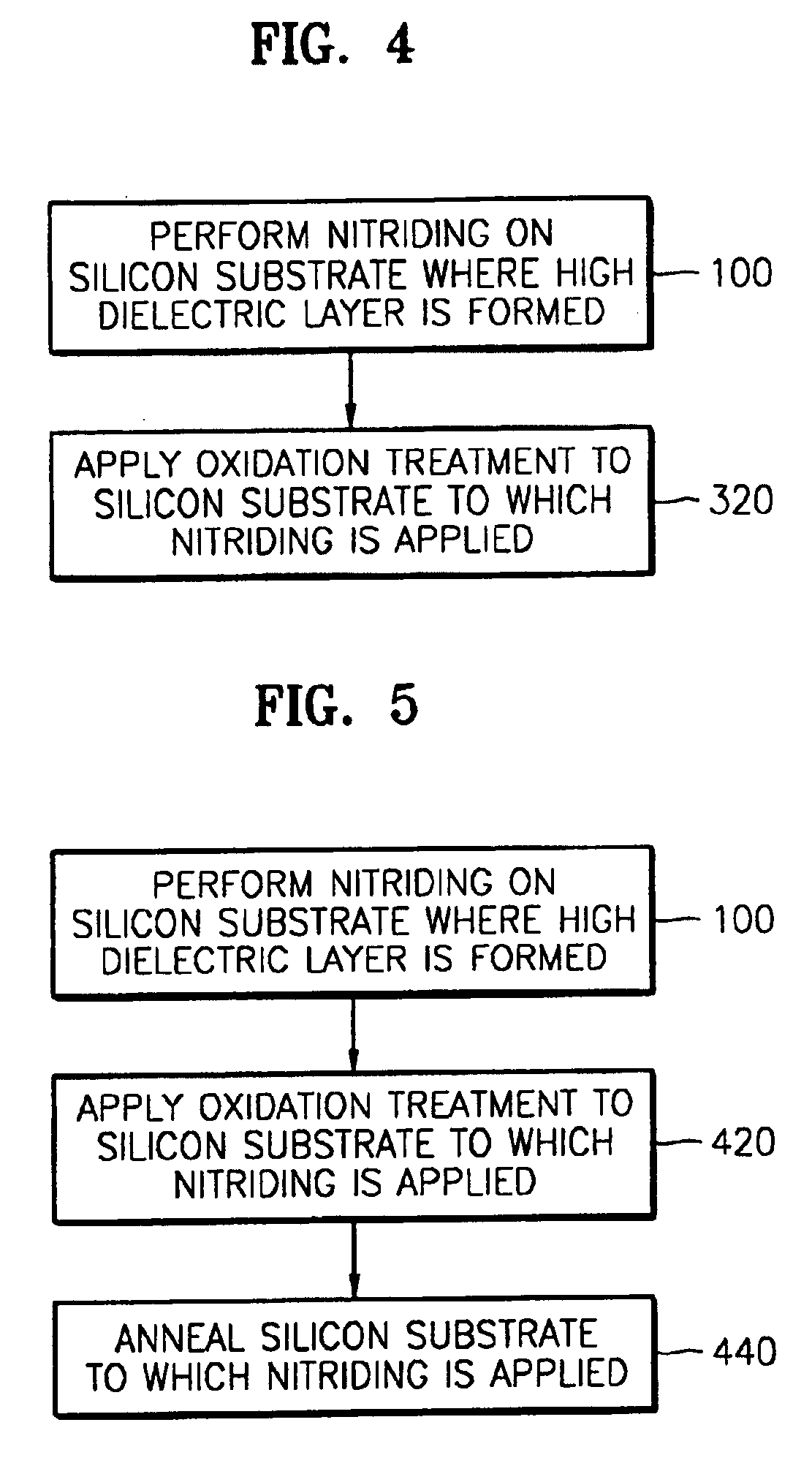

Post thermal treatment methods of forming high dielectric layers in integrated circuit devices

InactiveUS6875678B2Semiconductor/solid-state device manufacturingNanotechnologyZirconium hydrideThermal treatment

High dielectric layers formed from layers of hafnium oxide, zirconium oxide, aluminum oxide, yttrium oxide, and / or other metal oxides and silicates disposed on silicon substrates may be nitrided and post thermally treated by oxidation, annealing, or a combination of oxidation and annealing to form high dielectric layers having superior mobility and interfacial characteristics.

Owner:SAMSUNG ELECTRONICS CO LTD

Gradient transparent zirconium oxide dental ceramic and preparation method thereof

The invention discloses a gradient transparent zirconium oxide dental ceramic and a preparation method thereof, which belongs to the technical field of preparation of dental ceramics. The raw material is formed by mixing 2 to 5 kinds of zirconium oxide ceramic powder with different sintering transparences. The transparence of the sintered zirconium oxide ceramic from the bottom to the top is gradually increased, and the ceramic comprises 5 to 11 types of ceramic layers with different transparences. The preparation method comprises five steps, namely preparation of mixed powder, dry pressing, cold isostatic pressing, pre-sintering and blank restoration. The preparation method is simple and feasible, the transparence distribution characteristic of the prepared dental zirconium oxide full-ceramic material is similar to that of natural teeth, and the attractiveness of the zirconium oxide full-ceramic restoration is improved.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

Method for recycling zirconium oxide and yttrium oxide from yttrium oxide steady zirconium oxide solid fused mass waste matter

ActiveCN101244843ASignificant progressTo achieve the effect of resource utilizationRare earth metal compoundsZirconium oxidesZirconium hydrideYttria-stabilized zirconia

The invention relates to a method for recovering zirconia and yttria from the yttria-stabilized zirconia solid solution waste, which comprises the following steps: mixing the solid solution waste powder, sulfate and salt; acidizing and calcining at 200 to 320 DEG C; leaching the acidizing water and / or mother liquor under self-heating conditions; concentrating the leaching solution to leach zirconium sulfate; dissolving the zirconium sulfate in the water and purifying; neutralizing the zirconium hydroxide with alkali and precipitating; calcining the zirconium hydroxide to obtain zirconia; precipitating zirconium mother liquor to produce by-product of ammonium sulfate; neutralizing yttrium rich mother liquor and precipitating to obtain yttrium; dissolving yttrium rich residue with acid and purifying; precipitating oxalate to obtain yttrium oxalate; calcining to obtain the yttria. The method has the advantages of effectively separating the yttria from the zirconia in stable zirconia solid solution waste with optional yttrium ion under low temperature condition, changing the zirconia solid solution waste into valuables and utilizing the resources.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

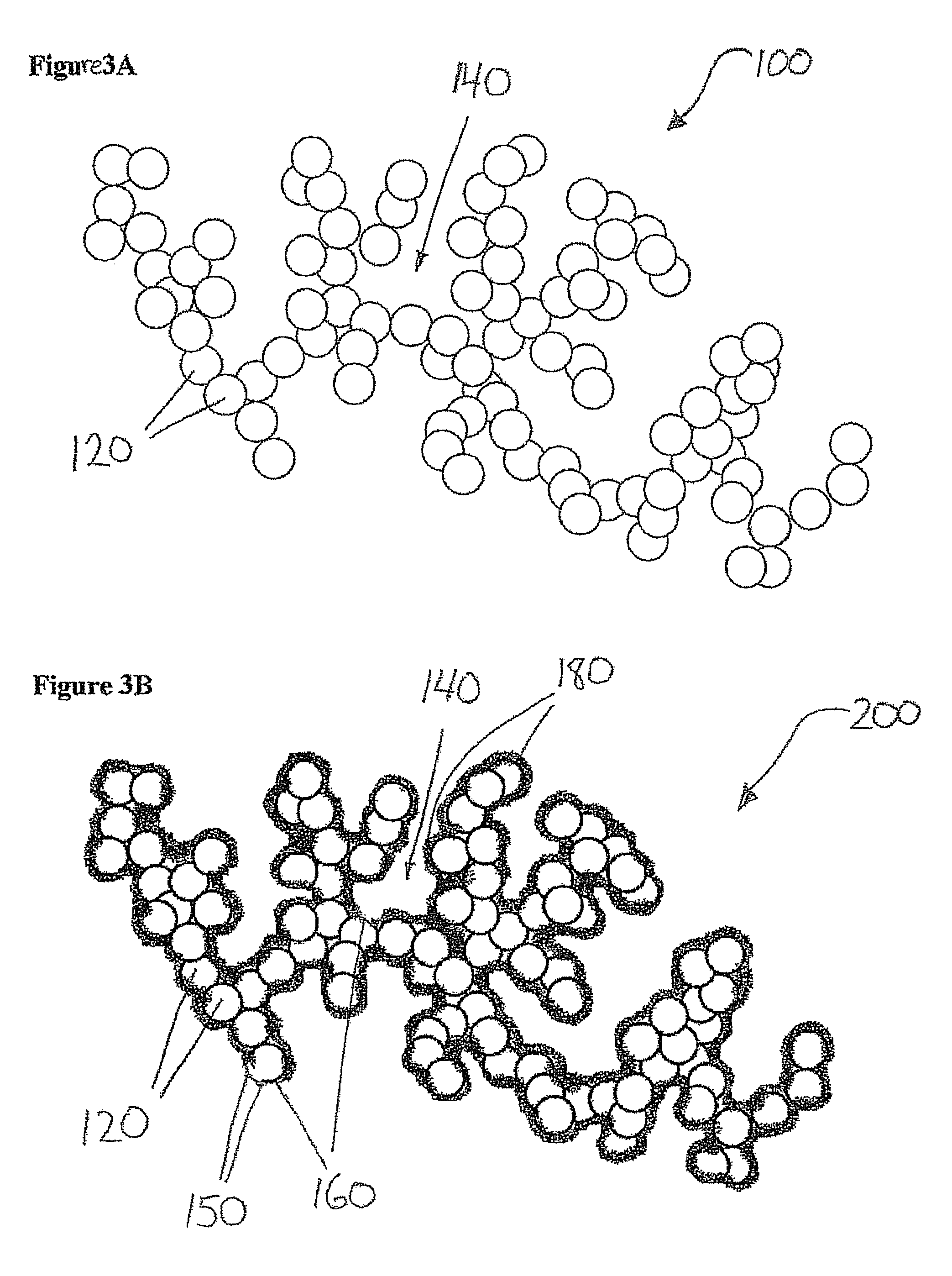

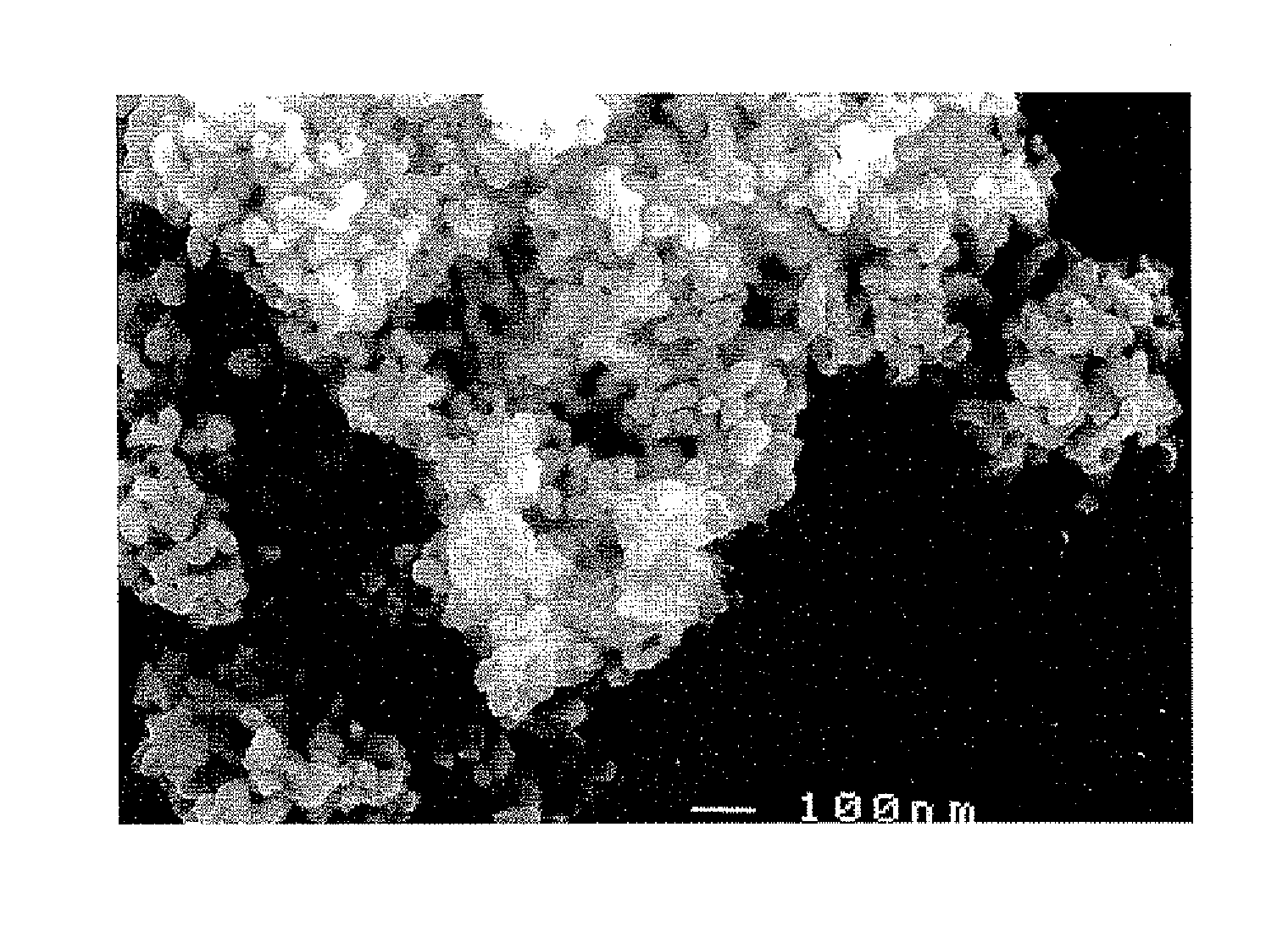

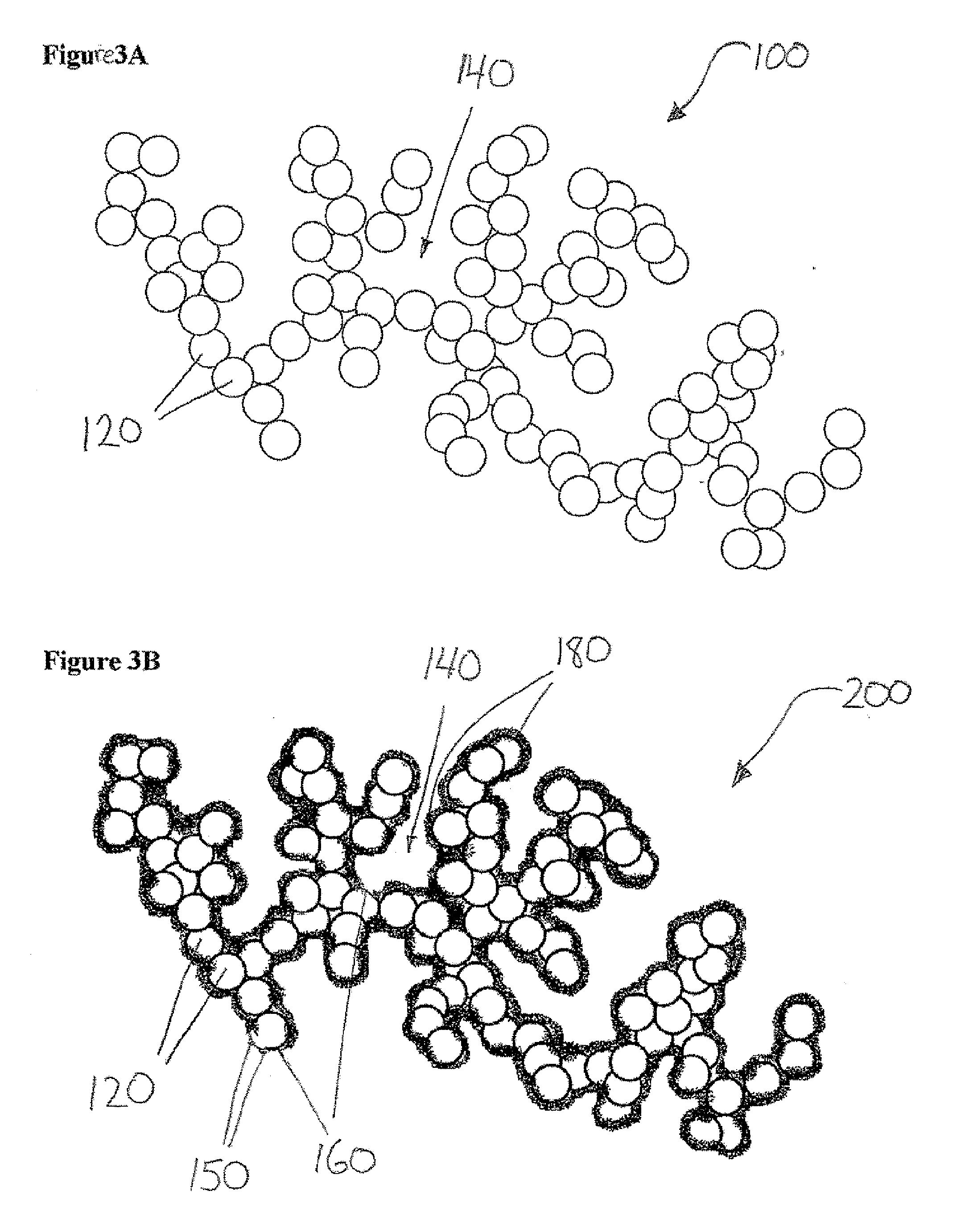

Porous clusters of silver powder promoted by zirconium oxide for use as a catalyst in gas diffusion electrodes, and method for the production thereof

ActiveUS8142938B2Long lastingRobust structureCellsFuel and primary cellsZirconium hydrideSilver particles

A catalyst including: a plurality of porous clusters of silver particles, each cluster including: (a) a plurality of primary particles of silver, and (b) crystalline particles of zirconium oxide (ZrO2), wherein at least a portion of the crystalline particles of ZrO2 is located in pores formed by a surface of the plurality of primary particles of silver.

Owner:BAR ILAN UNIV REASERCH & DEV

Zirconium oxide thermal barrier coating for turbine buckets of gas turbine and preparation method thereof

ActiveCN102094170AProcess parameters are easy to controlComposition controllableBlade accessoriesVacuum evaporation coatingZirconium hydrideThermal barrier coating

The invention relates to a zirconium oxide thermal barrier coating for turbine buckets of a gas turbine and a preparation method thereof. The zirconium oxide thermal barrier coating for the turbine buckets of the gas turbine is characterized in that adhesive layer materials and ceramic layer materials are plated on a metal surface; the adhesive layer materials include the following materials in percentage by weight: 15-30% of Co, 20-30% of Cr, 6-16% of Al, 0.2-1.0% of Y, and the balance of Ni; and the ceramic layer materials are zirconium oxide (ZrO2 / (5-8%)Y2O3) with stable yttrium oxide. The prepared zirconium oxide thermal barrier coating has compactness, good combining capacity with a base body and good thermal cycle resisting capacity and high temperature corrosion resisting capacity.

Owner:沈阳天贺新材料开发有限公司

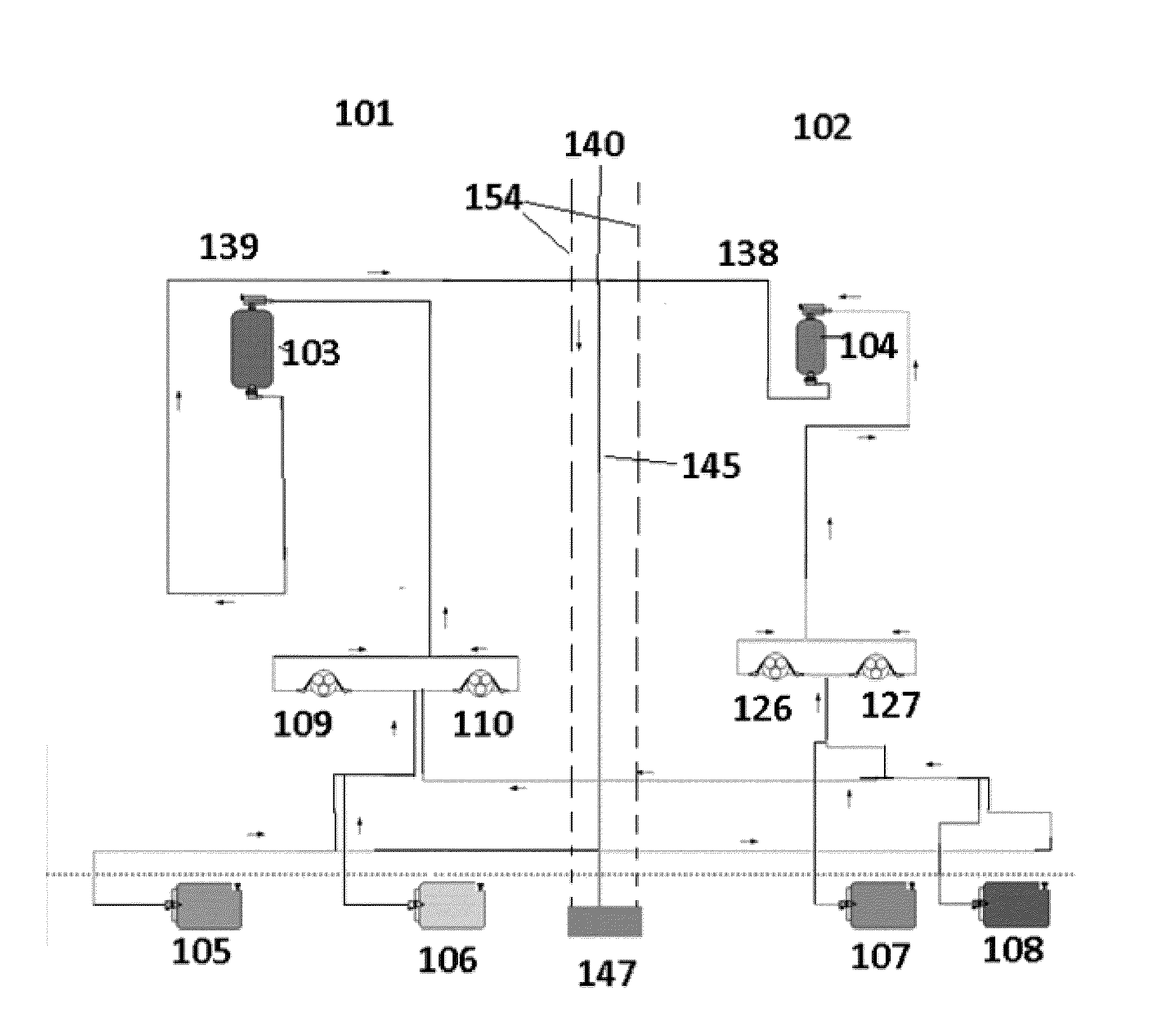

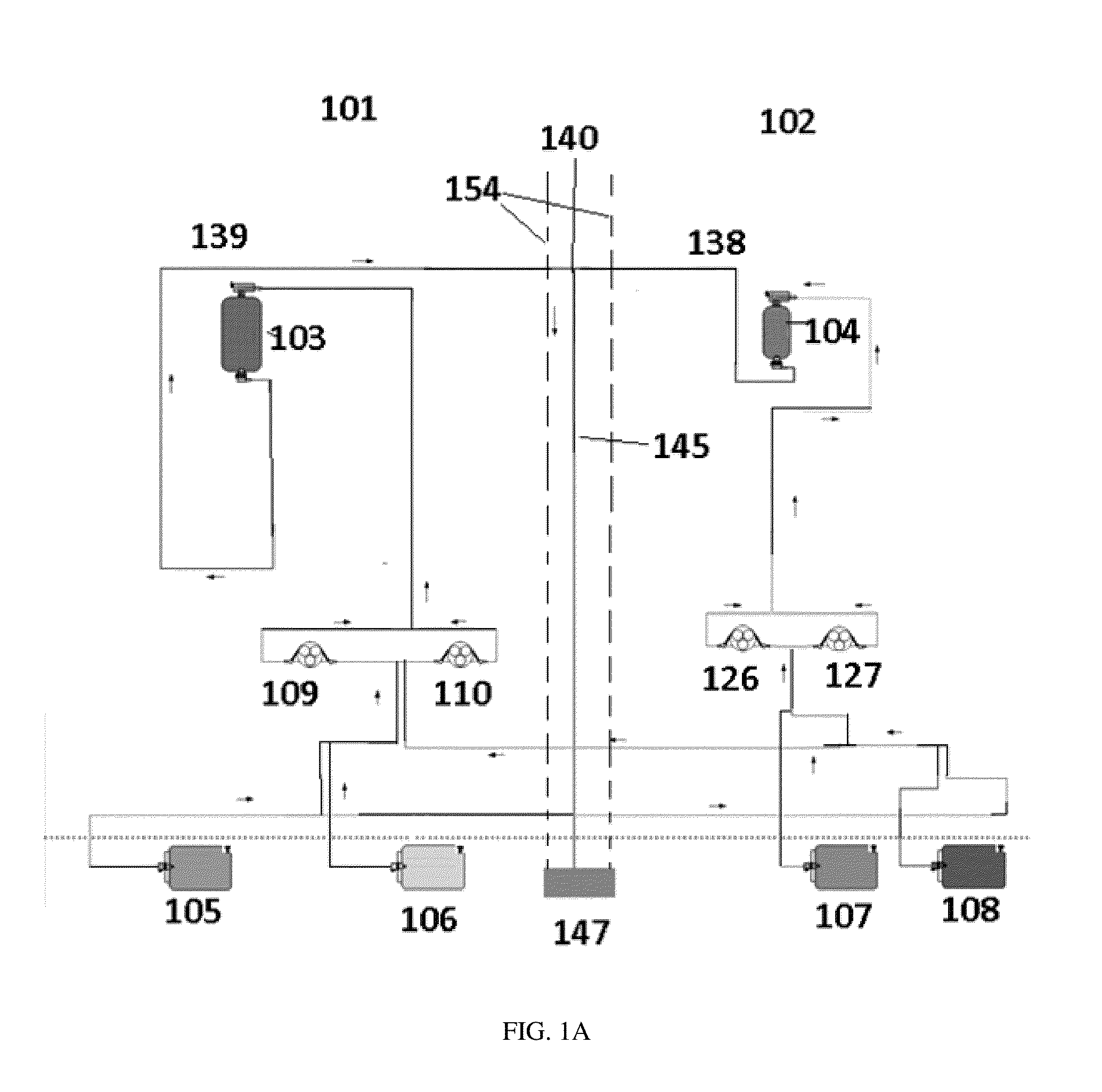

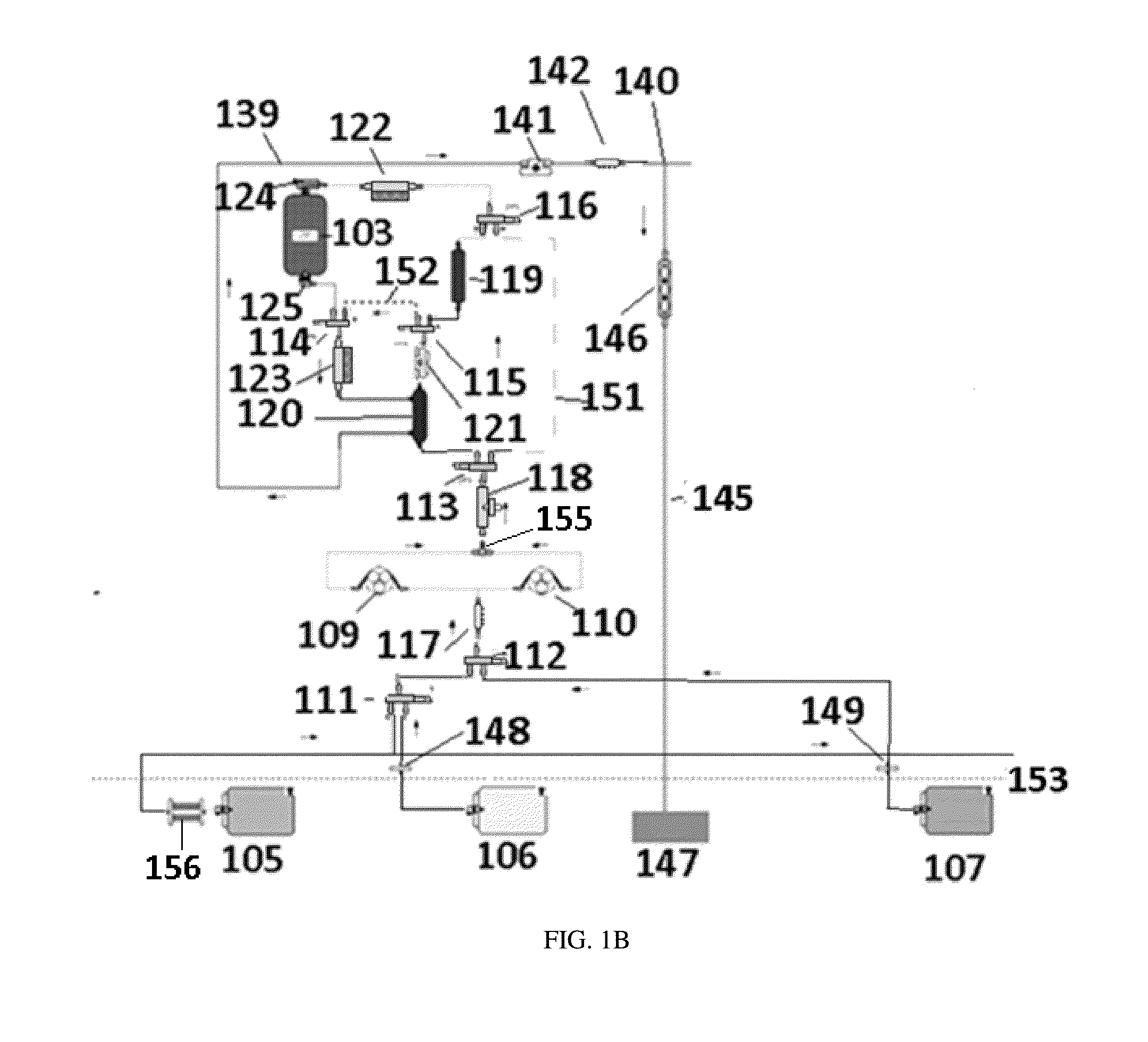

Zirconium phosphate and zirconium oxide recharging flow paths

Systems and methods for recharging zirconium phosphate and zirconium oxide are provided. The systems and methods provide for recharging of the zirconium phosphate and zirconium oxide in reusable sorbent modules. The systems and methods include recharging flow paths for recharging zirconium phosphate independently or concurrently.

Owner:MOZARC MEDICAL US LLC

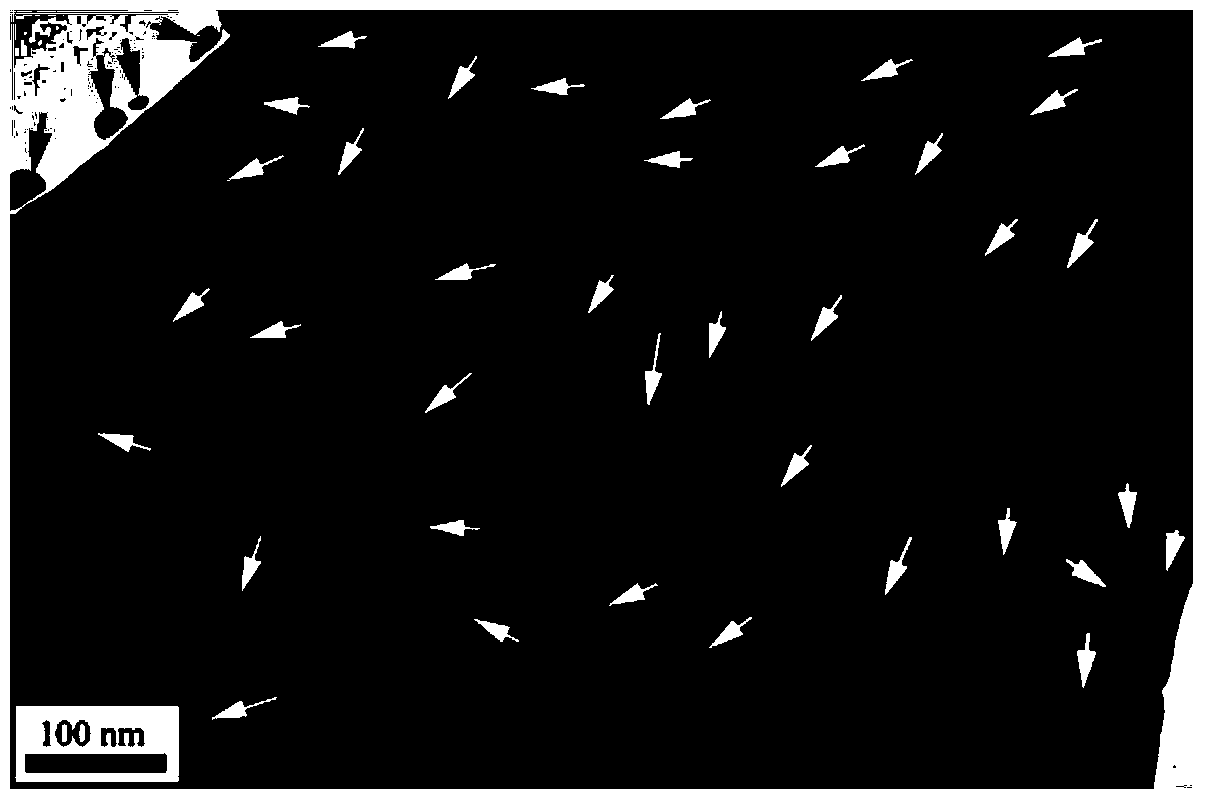

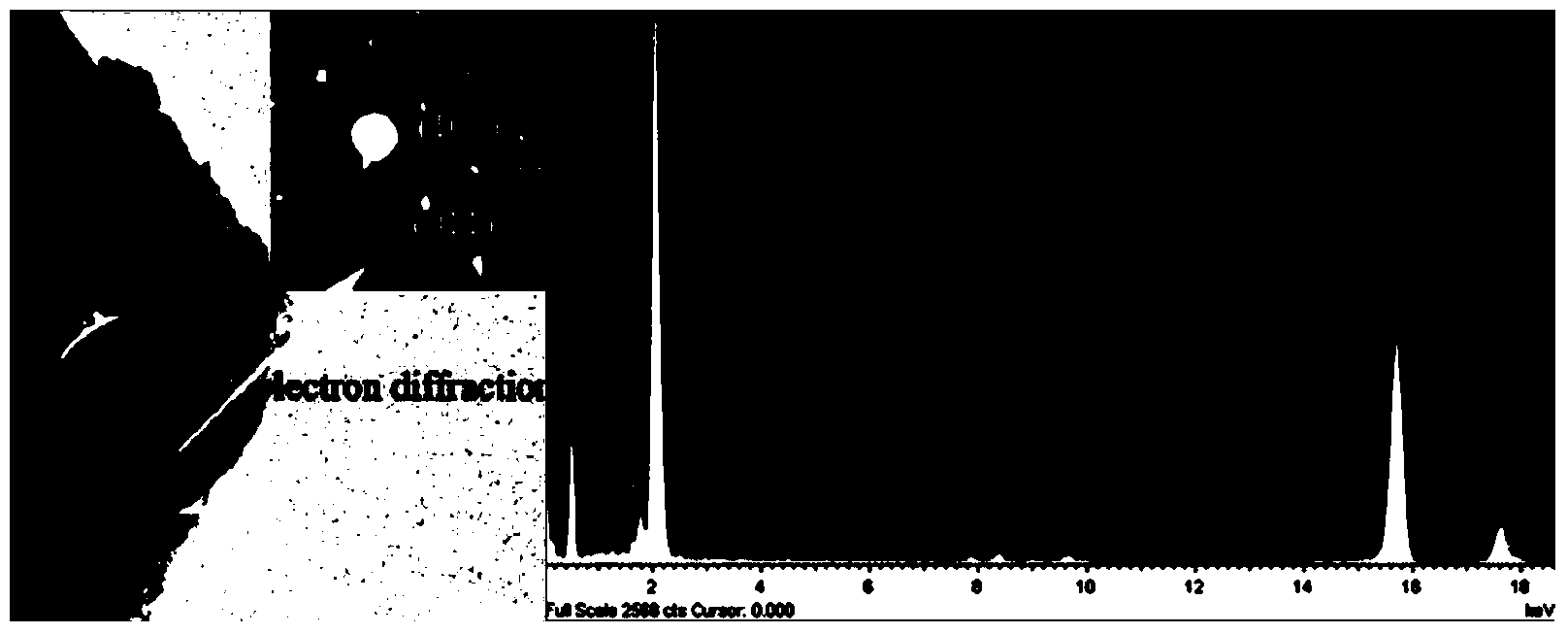

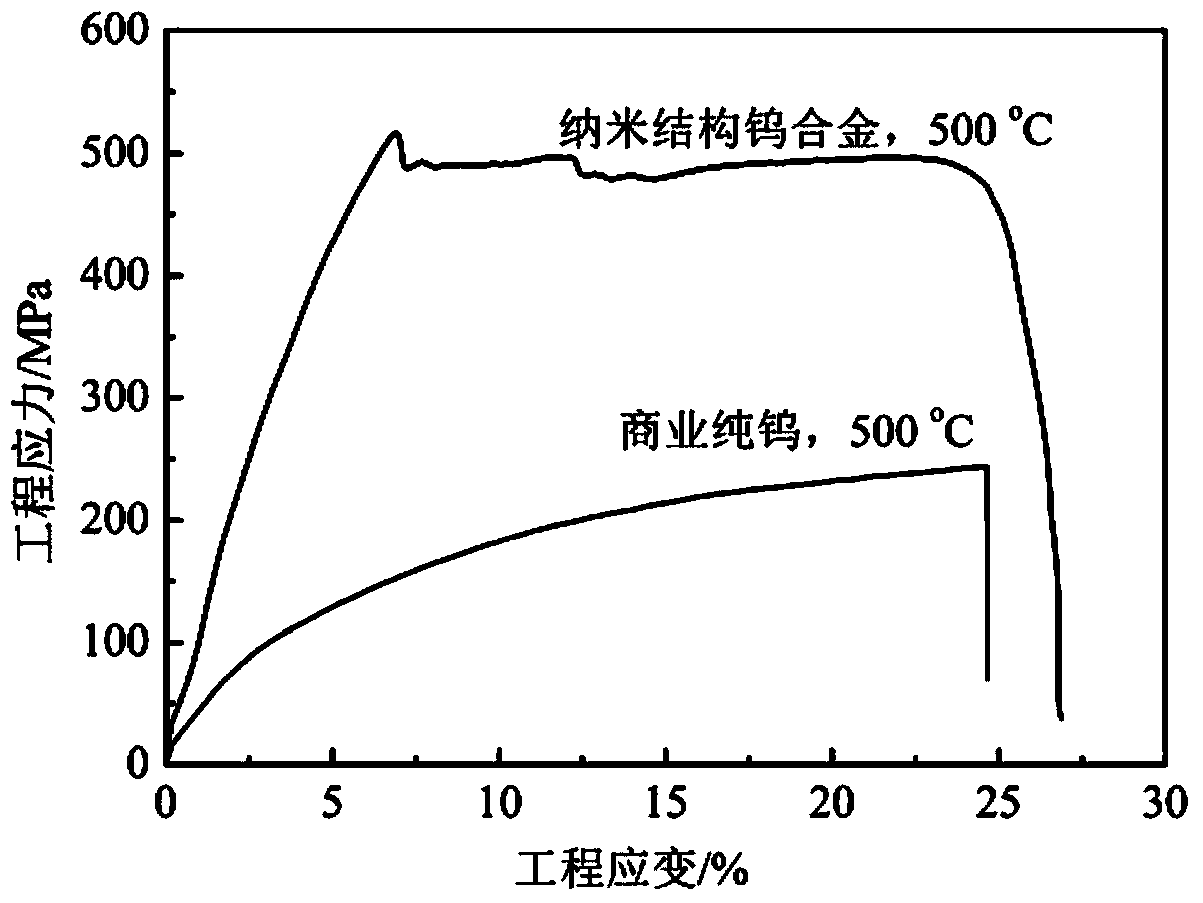

Nanostructure tungsten alloy and preparation method thereof

The invention discloses nanostructure tungsten alloy and a preparation method thereof. The alloy mainly comprises tungsten, and also comprises 0.05 to 1.0wt percent of zirconium and 0.2 to 2.0wt percent of rare-earth metal oxide particles, wherein the rare-earth metal oxide particle adopts yttrium oxide particles, lanthanum oxide particles or cerium oxide particles distributed in tungsten crystal particle. The method comprises the steps of firstly preparing ammonium paratungstate, rare-earth metal nitrate, citric acid and deionized water into transparent mixed liquor, stirring the transparent mixed liquor, obtaining gel after reaction, heating and drying the gel, then calcining the gel, so as to obtain a mixed powder of tungsten oxide and rare-earth metal oxide, putting the mixed powder into hydrogen atmosphere, so as to obtaining a mixed powder of tungsten and rare-earth metal oxide after reduction reaction, mixing the mixed powder with zirconium and zirconium hydride powder, so as to obtain a mixed powder of tungsten, zirconium, or zirconium hydride, and rare-earth metal oxide, and finally performing compaction and sintering to the mixed powder, so as to obtain the nanostructure tungsten alloy. The nanostructure tungsten alloy can be applied to fields of lighting, high-temperature components, aerospace devices, high temperature resistance containers and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

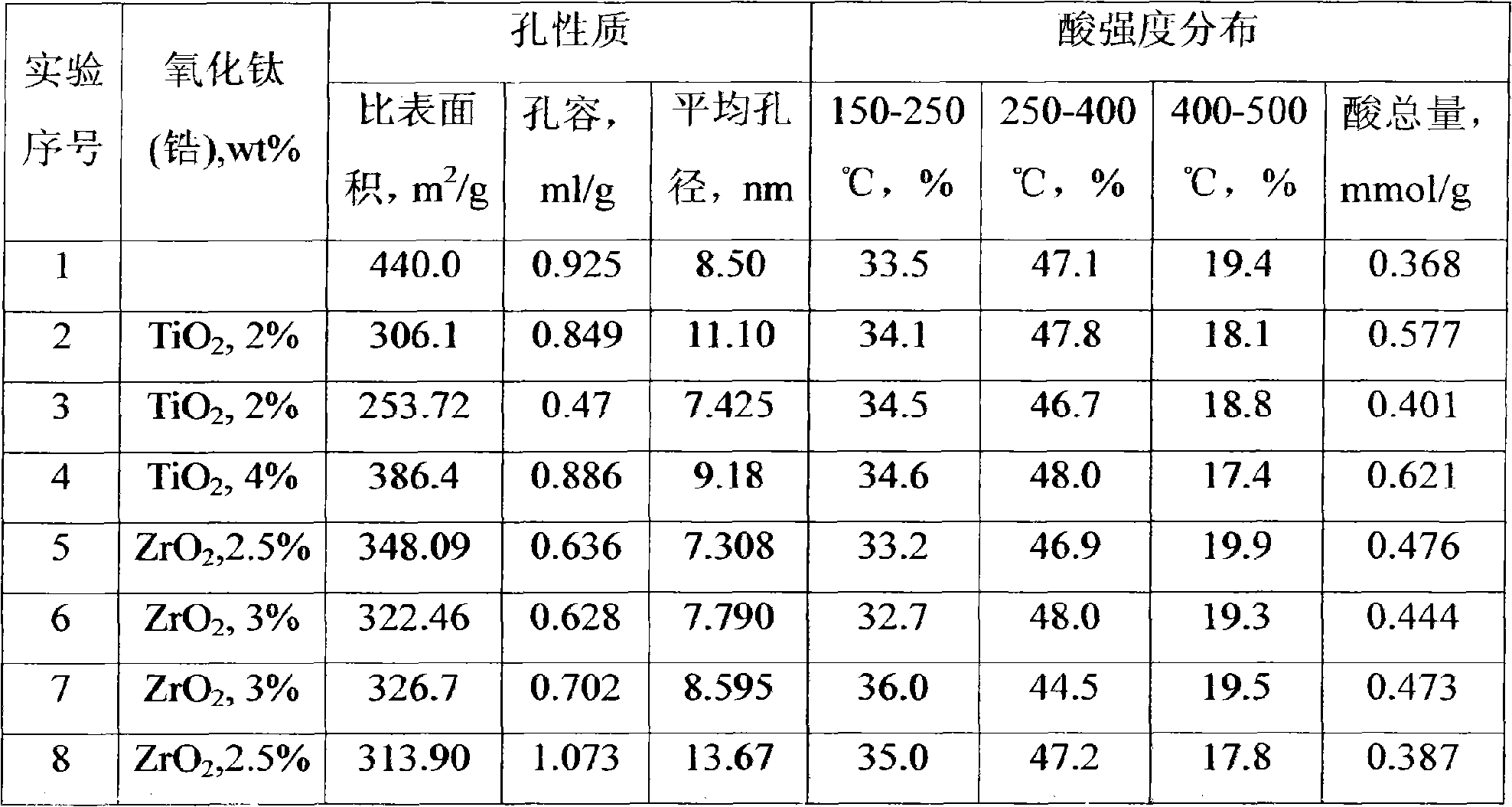

Catalyst carrier and preparation method thereof

ActiveCN101491775AGood dispersionAccelerated vulcanizationCatalyst carriersZirconium hydrideDip-coating

The invention relates to a method for preparing a catalyst carrier. The method comprises: molding alumina dry glue powder and drying the molded alumina dry glue powder to obtain an alumina carrier; loading a solution, sol or suspension containing titanium oxide or / and a zirconium oxide precursor onto the alumina carrier by a dip coating method; and obtaining the catalyst carrier after drying and baking. The preparation method adopts dip coating to disperse titanium oxide or zirconium oxide on the surface of the carrier to modify the surface of alumina, adjust the acid content of the surface of the carrier, reduce acting force between metallic component and the carrier and finally increase the hydrogenation activity of catalyst. The catalyst carrier obtained by the preparation method has a zirconium oxide or titanium oxide content of 1 to 15 weight percent of, a specific surface area of 250 to 500m / g, a pore volume of 0.6 to 1.0ml / g and a NH3-TPD total acid content of 0.3 to 0.8 mmol / g. Moreover, the catalyst carrier is suitable to be used in the preparation of petroleum fractions hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing molybdenum alloy TZM by powder metallurgy

InactiveCN1962911AImprove performanceImprove uniformityRoll mill control devicesMetal rolling arrangementsZirconium hydrideFragility

The invention discloses a preparing method of difficult dissolving alloy through powder metallurgical technique, which is characterized by the following: selecting titanium hydride and zirconium hydride particle of Fisher grain at 5-10um with maximum particle not more than 10um; preparing TZM modybdenum alloy; dispersing evenly in the sintering course due to little second phase grain size; improving high-temperature property and normal-temperature fragility.

Owner:WESTERN METAL MATERIAL

Exhaust gas purifying catalyst

InactiveUS6602479B2Excels in heat resistant property and durabilityNitrogen compoundsInternal combustion piston enginesZirconium hydrideCerium

An exhaust gas purifying catalyst having a refractory three-dimensional structure coated with a catalytically active component comprising at least one kind of noble metals, a refractory inorganic oxide, and a zirconium oxide containing cerium and lanthanum, the crystal structure of the zirconium oxide containing cerium and lanthanum being a tetragonal structure of zirconium oxide.

Owner:UMICORE SHOKUBAI JAPAN CO LTD +1

Cerium oxide-zirconium oxide based composite rare-earth oxide with high specific surface area and high oxygen storage capacity and preparation method thereof

ActiveCN103191711ATotal pore volumeFresh specific surface area is highDispersed particle separationCatalyst activation/preparationZirconium hydrideSlurry

The invention discloses a method for preparing a cerium oxide-zirconium oxide based composite rare-earth oxide. The method comprises the following steps of: (1) heating a zirconium salt solution at room temperature, slowly adding sulfate ions, controlling the temperature rise rate so that the temperature is increased in the range of 90-95 DEG C when the sulfate ions are added completely, and then preserving heat for 20-100 minutes, thereby forming a zirconium basic sulfate composite salt precursor; (2) adding a cerium salt and a rare-earth metal salt to the precursor solution and stirring evenly, thereby obtaining a slurry; (3) settling the slurry by using basic carbonate and / or a basic oxalate solution, thereby obtaining a precipitate; and (4) filtering and washing the precipitate obtained in the step (3), removing purities, and calcining the washed precipitate. The cerium oxide-zirconium oxide based composite rare-earth oxide prepared by the method by controlling raw materials and process conditions has the characteristics of being high in total fine pore volume, high in fresh specific surface area, high in oxygen storage capacity and the like.

Owner:CHAOZHOU THREE CIRCLE GRP

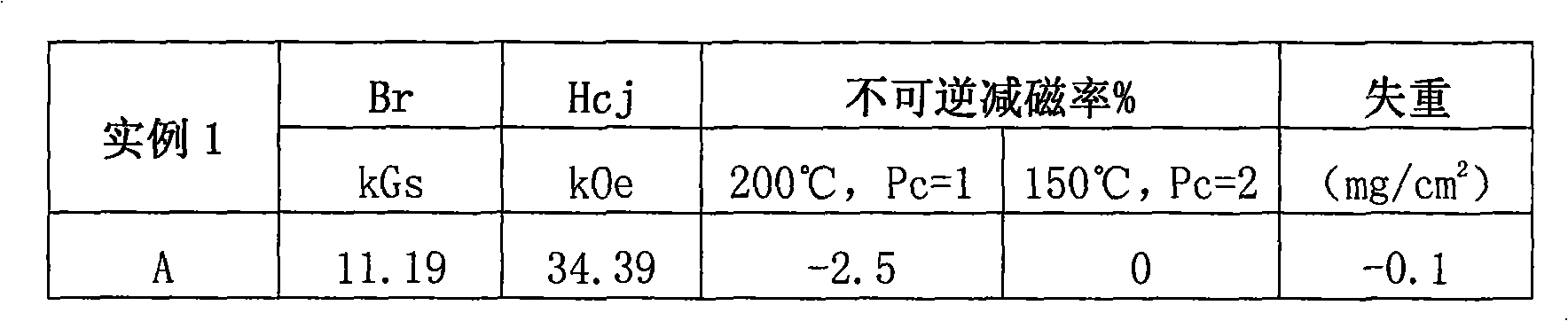

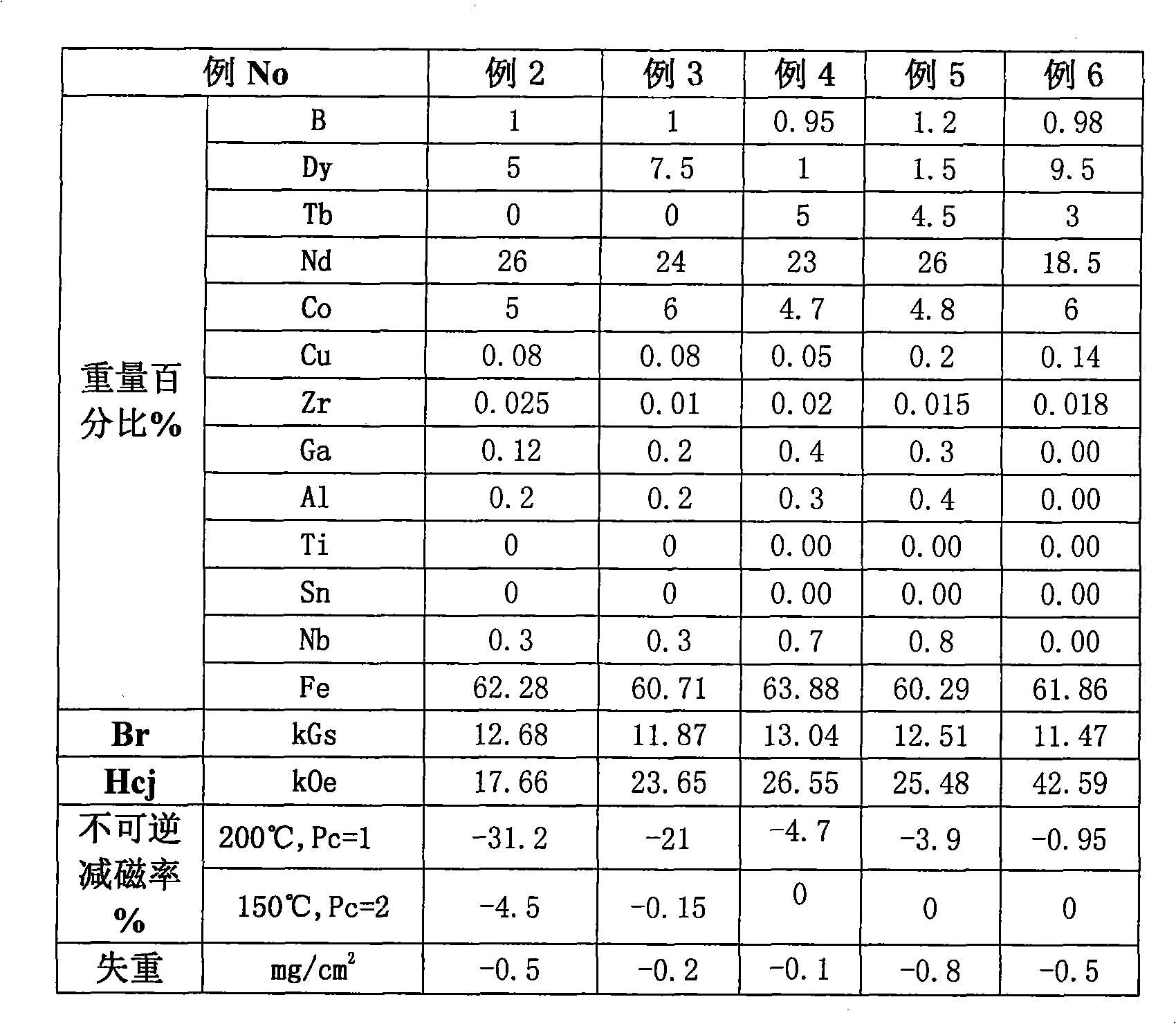

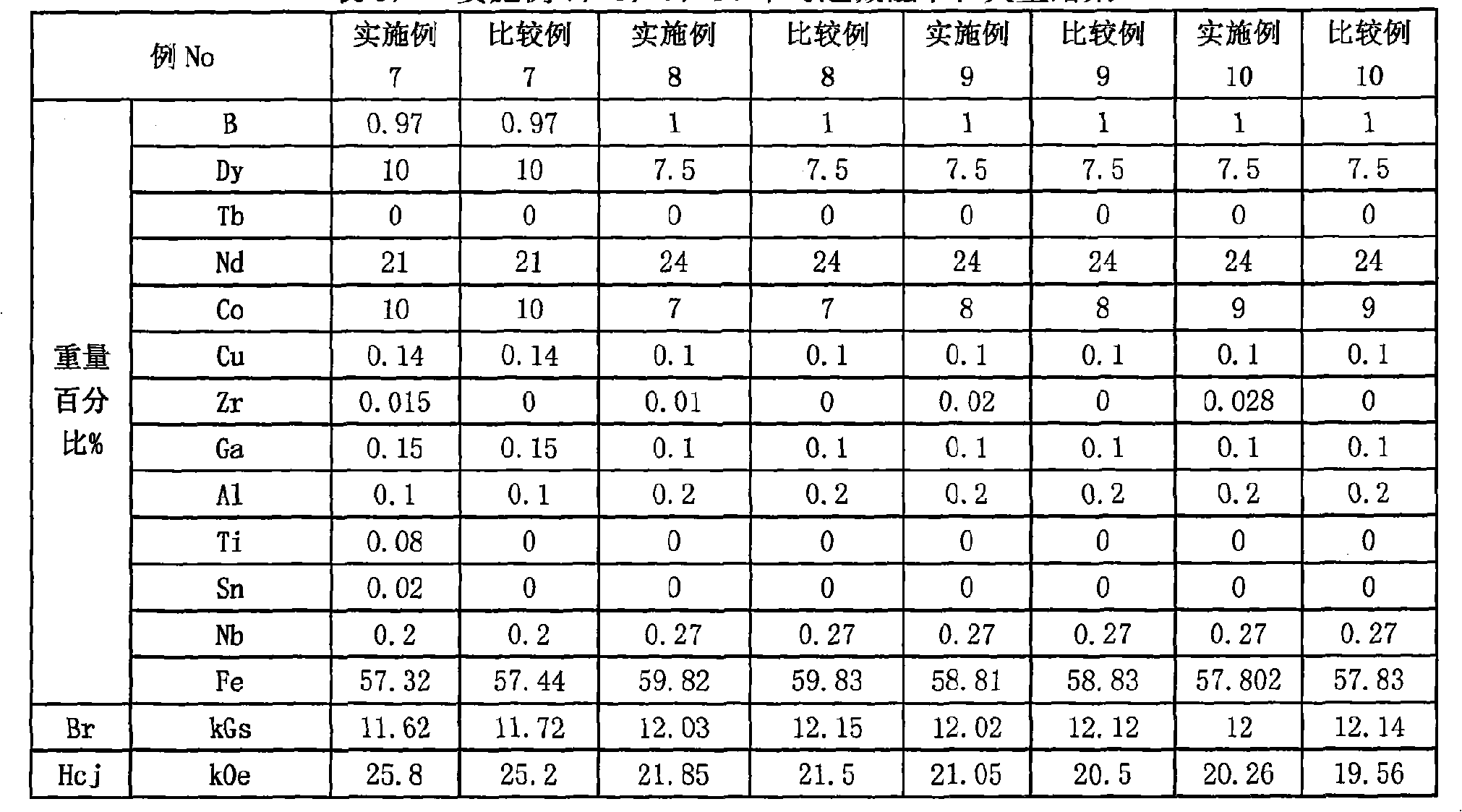

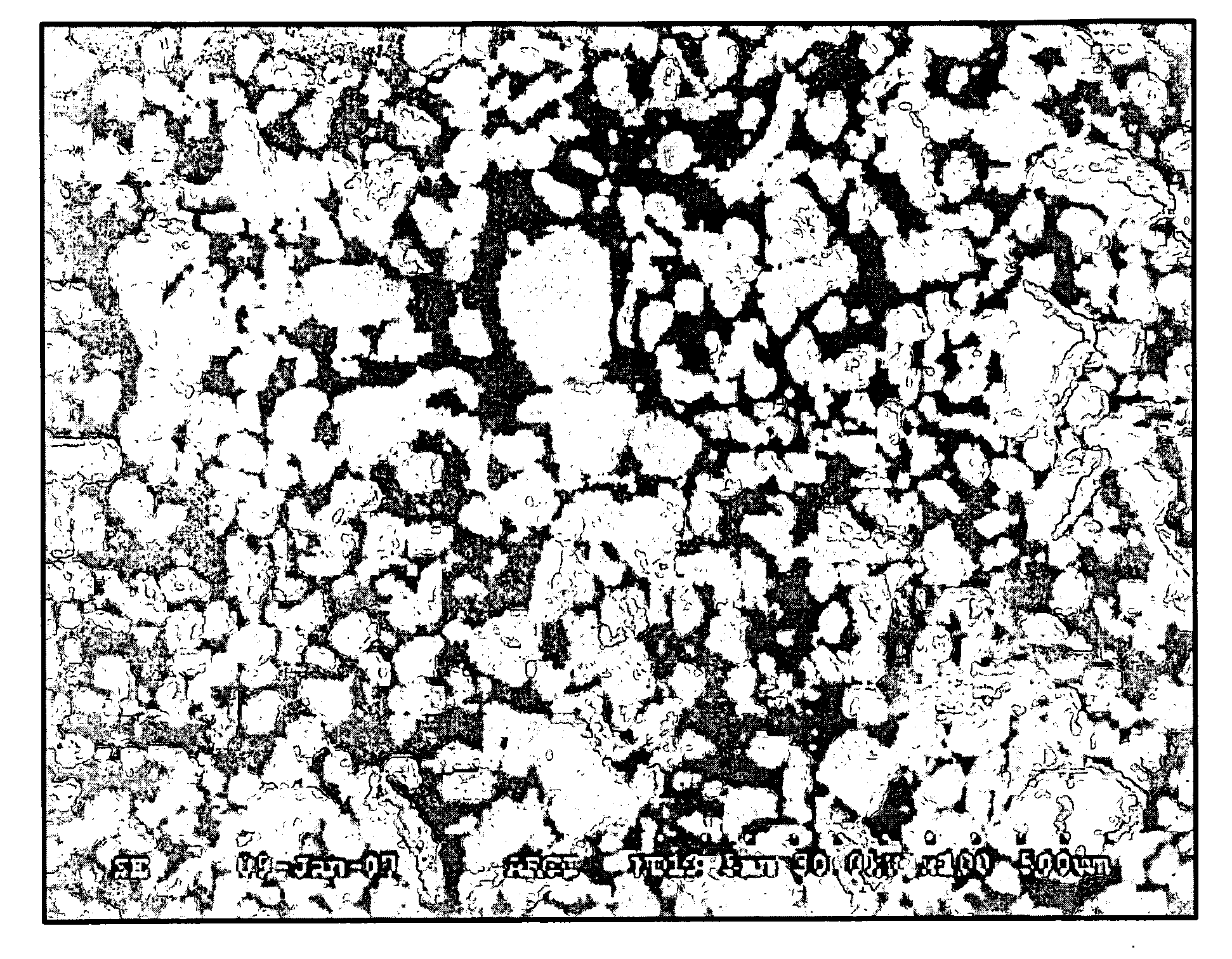

Fire resistant permanent magnet alloy and manufacturing method thereof

ActiveCN101315825AImprove matchImprove the disadvantages of poor temperature resistanceMagnetic materialsZirconium hydrideAdditive ingredient

The invention relates to a permanent magnet alloy with excellent heat resistance and a preparation method thereof, and the alloy consists of components according to the following formula: R29-32Al0-0.4Nb0-0.8(Ti+Sn)0-0.1Zr0.01-0.029Ga0-0.4B0.95-1.2Co4.5-10Cu0.05-0.2Fe remaining, wherein, R at least selects from one of Ce, Pr, Nd, Dy or Tb, Fe remaining is Fe and inevitable impurities. In the preparation method, Zr is added by a 10-30 nanometer zirconium oxide powder form when mixing fine powder; as the zirconium oxide disperses in crystal boundary phase of an NdFeB magnet and is of square crystal structure, oxygen content distribution of the magnet and microstructure are effectively improved. The permanent magnet alloy with excellent heat resistance optimizes the matching of elements, improves the shortcoming of bad heat resistance of sintered NdFeB material, expands the application range of the sinterable NdFeB, improves the performance of the sintered NdFeB in two aspects of ingredient and technique, and can make up the shortcoming of low use temperature of the sintered NdFeB.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Cerium oxide and zirconium oxide based composite rare earth oxide with favorable ageing resistance and high reduction activity and preparation method of cerium oxide and zirconium oxide based composite rare earth oxide

ActiveCN103191712AHigh reactivityTotal pore volumeCatalyst activation/preparationRare earth metal compoundsReduction ActivityZirconium hydride

The invention discloses a preparation method of a cerium oxide and zirconium oxide based composite rare earth oxide. The method comprises the following steps of: (1) weighting zircon salt with a certain mass and preparing a zircon salt solution; (2) mixing urea and sulfuric acid or sulfate to prepare an activating agent solution; (3) heating the zircon salt solution under the room temperature, meanwhile, slowly and dropwise adding the activating agent solution, controlling the temperature rise speed to ensure that the temperature is raised to 60 DEG C after the addition of the activating agent solution is finished, continuing to raising the temperature to 90-95 DEG C, and keeping the temperature for 20-100min to form a basic zirconium sulfate composite salt precursor solution; (4) preparing soluble cerate and rare earth metal salt, adding the soluble cerate and the rare earth metal salt into the basic zirconium sulfate composite salt precursor solution, and settling by using a soluble hydroxide or an aqueous solution of ammonia; and (5) filtering and cleaning precipitates, and then, calcining the precipitates to obtain the cerium oxide and zirconium oxide based composite rare earth oxide. The cerium oxide and zirconium oxide based composite rare earth oxide prepared by using the method provided by the invention has favorable ageing resistance and high reduction activity.

Owner:CHAOZHOU THREE CIRCLE GRP

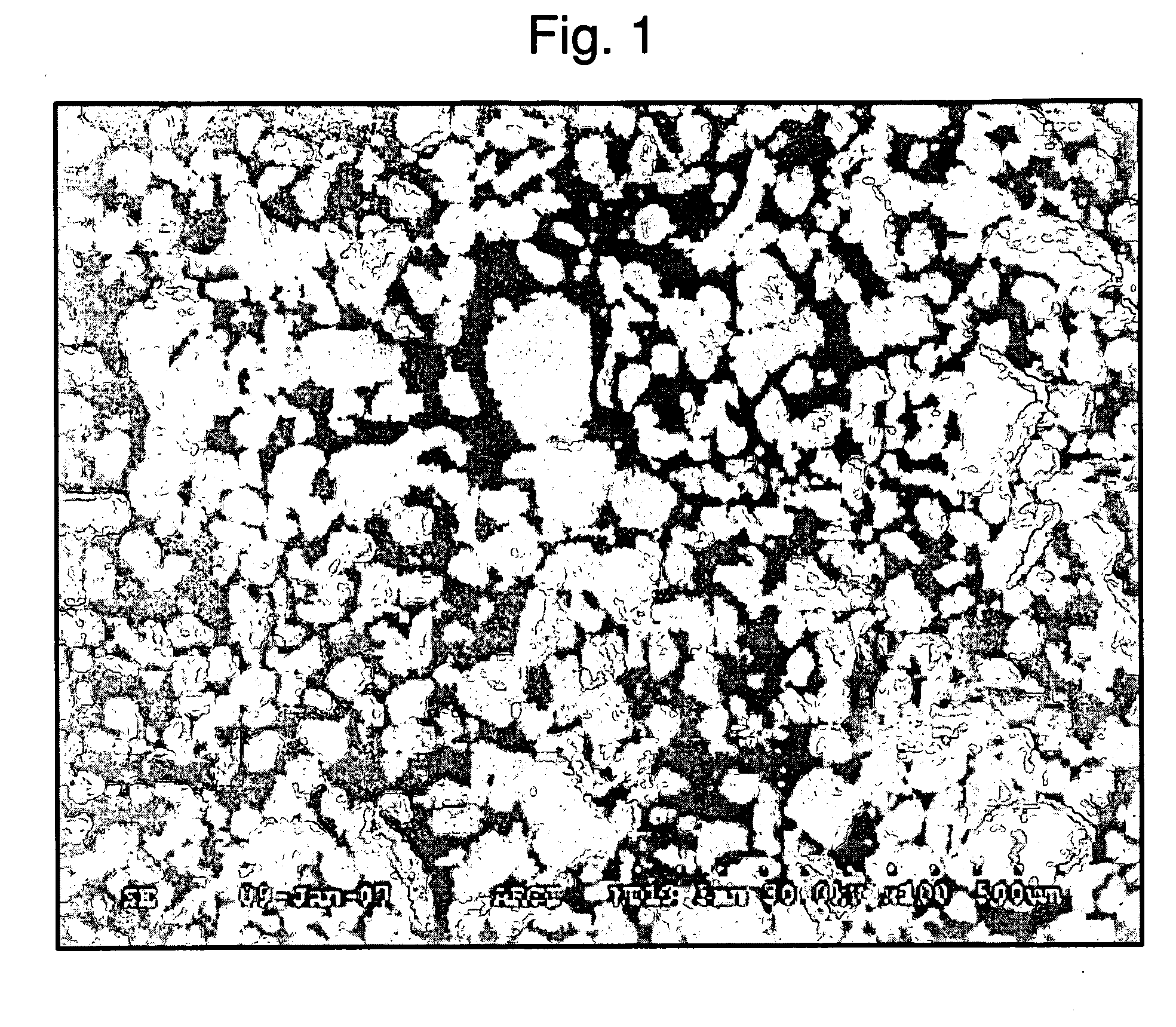

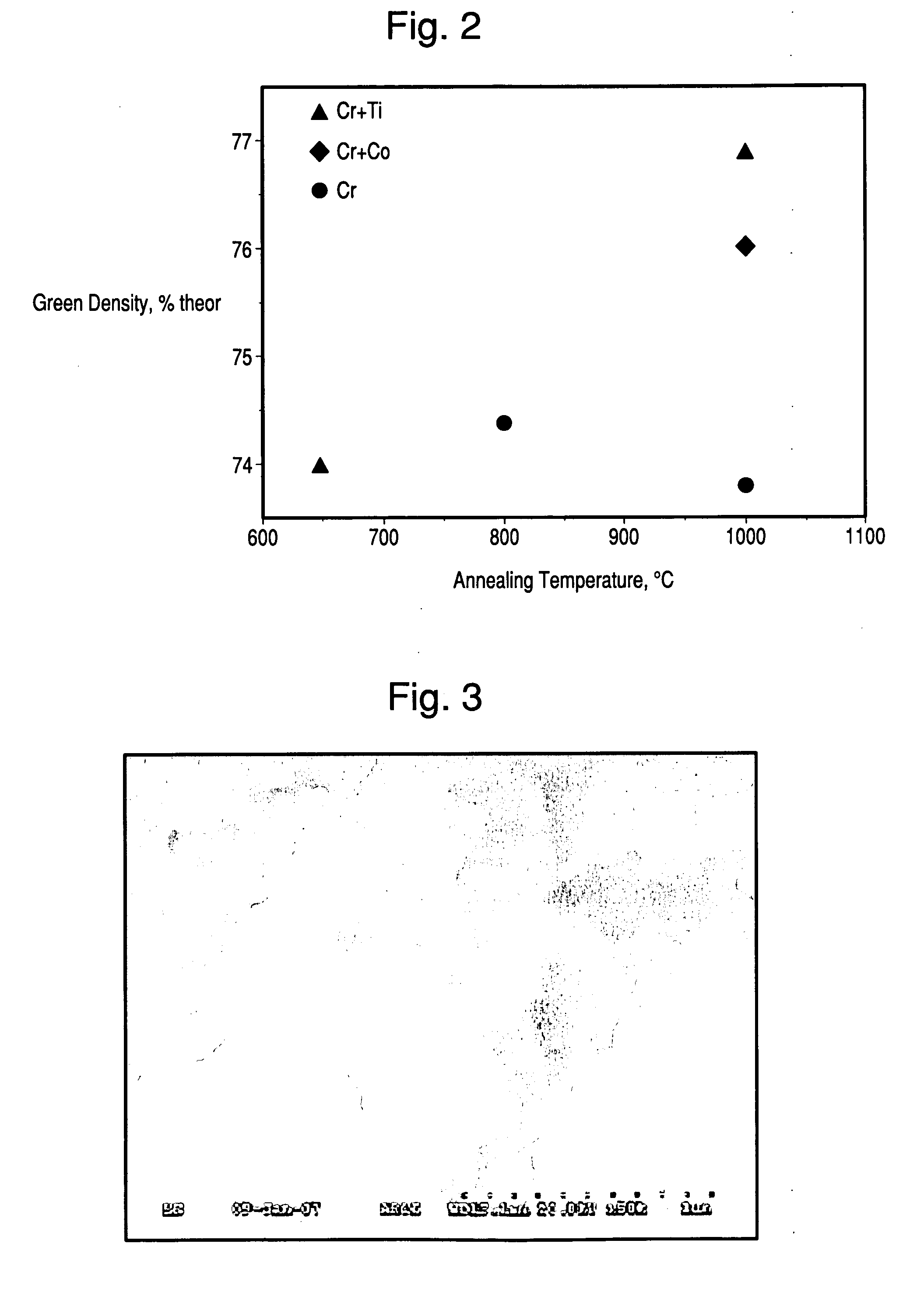

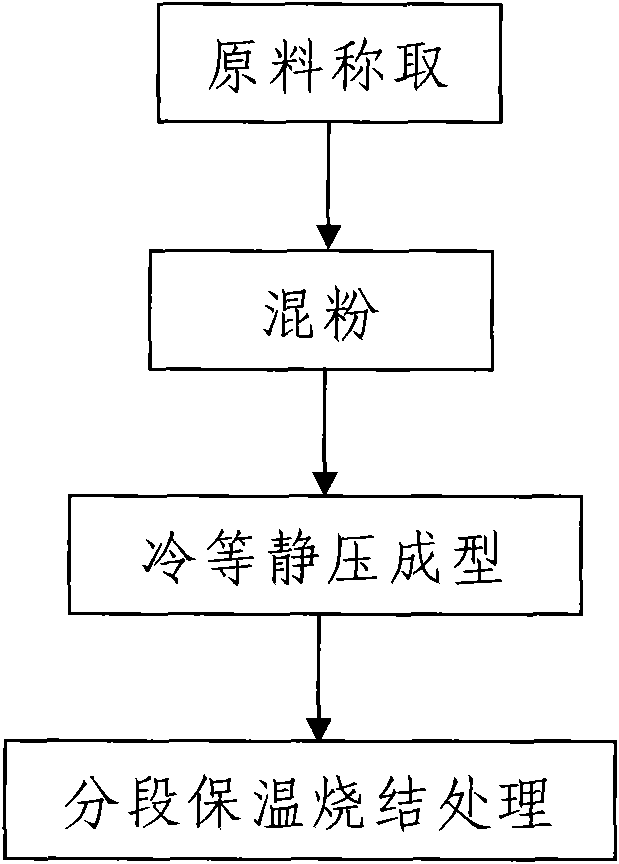

Processing of powders of a refractory metal based alloy for high densification

InactiveUS20090068055A1Transportation and packagingMetal-working apparatusZirconium hydrideFuel cells

A powder metallurgy method of making a chromium base alloy includes blending a first powder comprising a chromium powder and a second powder comprising at least one of titanium, titanium hydride, zirconium or zirconium hydride, annealing the first powder and the second powder in a reducing atmosphere after the step of mixing, compacting a blend of the first and the second powders, and sintering the compacted blend to form a chromium base alloy. The chromium alloy may be used as an interconnect for a solid oxide fuel cell, and includes least one of iron or nickel greater than zero and equal to or less than 7 weight percent, yttria greater than zero and equal to or less than 2 weight percent, at least one of titanium or zirconium greater than zero and equal to or less than 1 weight percent and at least 90 weight percent chromium.

Owner:BLOOM ENERGY CORP

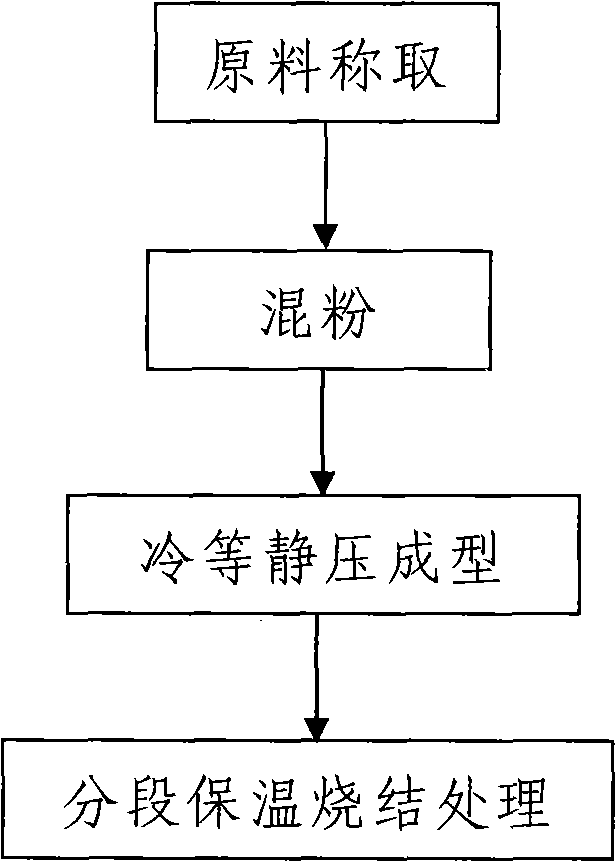

Method for preparing large powder metallurgy TZM blank with uniform carbon and oxygen distribution

The invention discloses a method for preparing a large powder metallurgy TZM blank with uniform carbon and oxygen distribution, which comprises the following steps of: 1, weighing raw materials; 2, mixing powder, namely mixing the weighed four raw materials twice under vacuum or the protection of inert gas, mixing titanium hydride powder, zirconium hydride powder and carbon black powder to prepare mixed powder, adding a volatile organic solvent into the mixed powder, uniformly stirring to prepare suspension, adding the weighed molybdenum powder into the suspension for uniform mixing, and adding residual molybdenum powder for uniform mixing; 3, performing cold isostatic pressing; and 4, sintering by keeping the temperature at stages, namely adopting a vacuum sintering furnace and sintering at three stages, wherein the process comprises the following steps of: raising the temperature at the first stage, raising the temperature at the second stage, and sintering at high temperature. The preparation method has the advantages of reasonable design, simple and convenient operation, and good using effect. The carbon content in the center and on the surface of the prepared larger-size TZM blank can be controlled to be approximately consistent, and the oxygen content in the center and on the surface of the TZM blank also can be reduced to a lower level.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

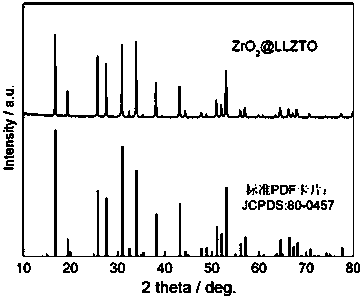

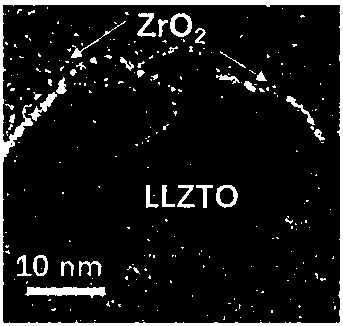

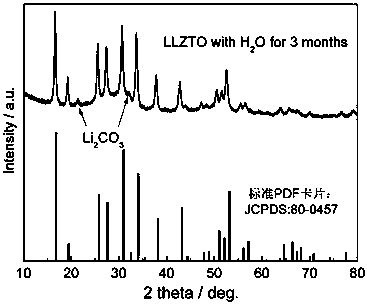

Lithium-lanthanum-zirconium oxide-based solid electrolyte material with stable surface, and preparation method and application thereof

ActiveCN110176628AGood chemical stabilityStop erosionFinal product manufactureElectrolytesZirconium hydrideLanthanum

The invention discloses a lithium-lanthanum-zirconium oxide-based solid electrolyte material with stable surface, and a preparation method and an application thereof. The solid electrolyte material comprises an inner core and a coating layer which coats the surface of the inner core; the inner core is a lithium-lanthanum-zirconium oxide-based solid electrolyte (LLZO); and a material of the coatinglayer is an oxide. The inner core part, namely, the LLZO is coated with the oxide coating layer; and the LLZO can maintain a stable three-dimensional phase structure with high ionic conductivity, sothat phase change or thermal decomposition does not occur. The material of the oxide coating layer can change the chemical composition and surface acid-base property of the surface of the LLZO, and can block the erosion of air and water to the LLZO, so that the chemical stability of the LLZO in the air and the water is greatly improved, the application range, the processing environment and the using condition of the LLZO are expanded, and the energy density and the cycling stability of a lithium-lanthanum-zirconium oxide-based battery are improved.

Owner:济宁克莱泰格新能源科技有限公司

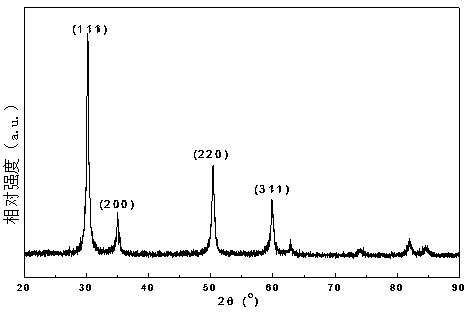

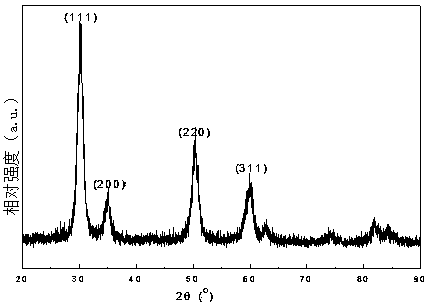

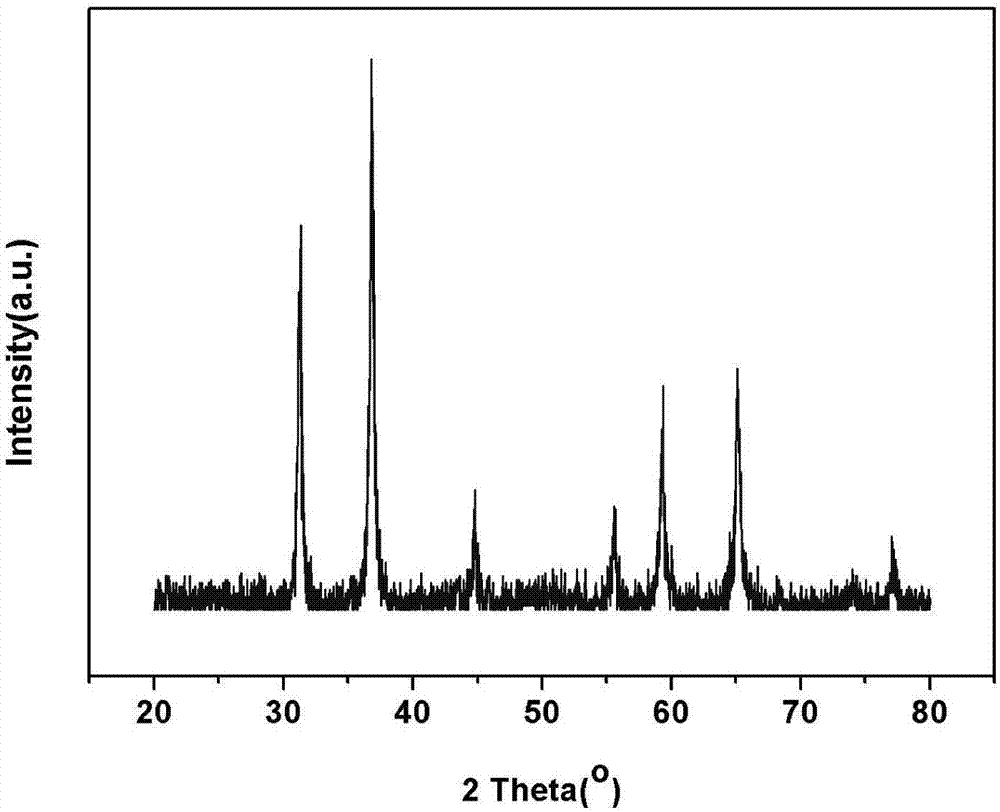

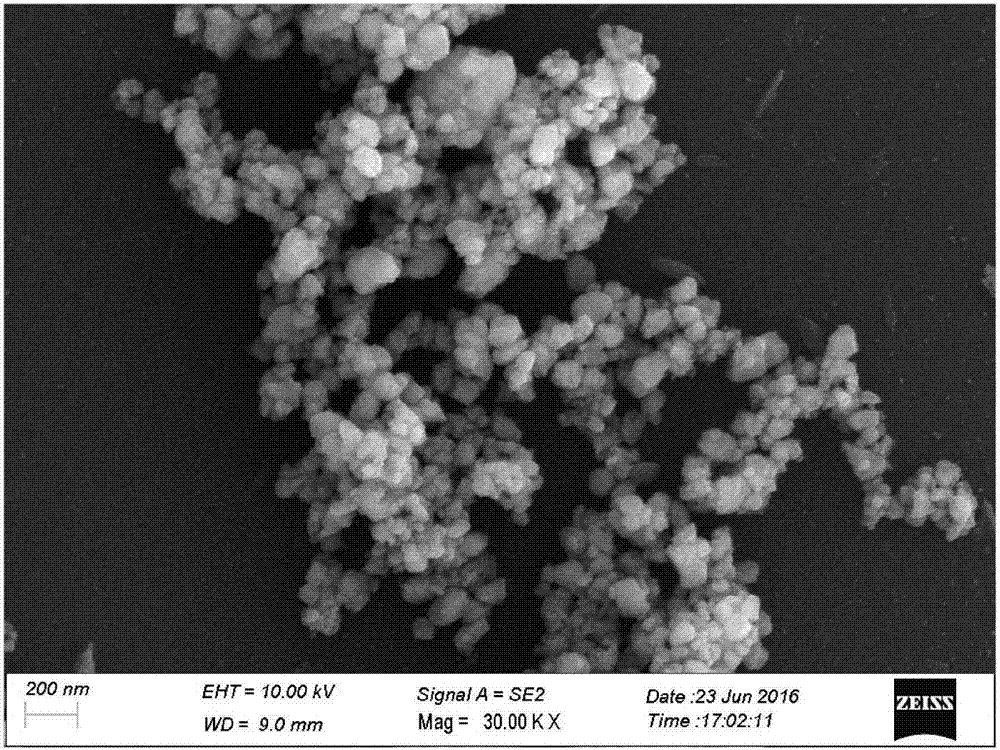

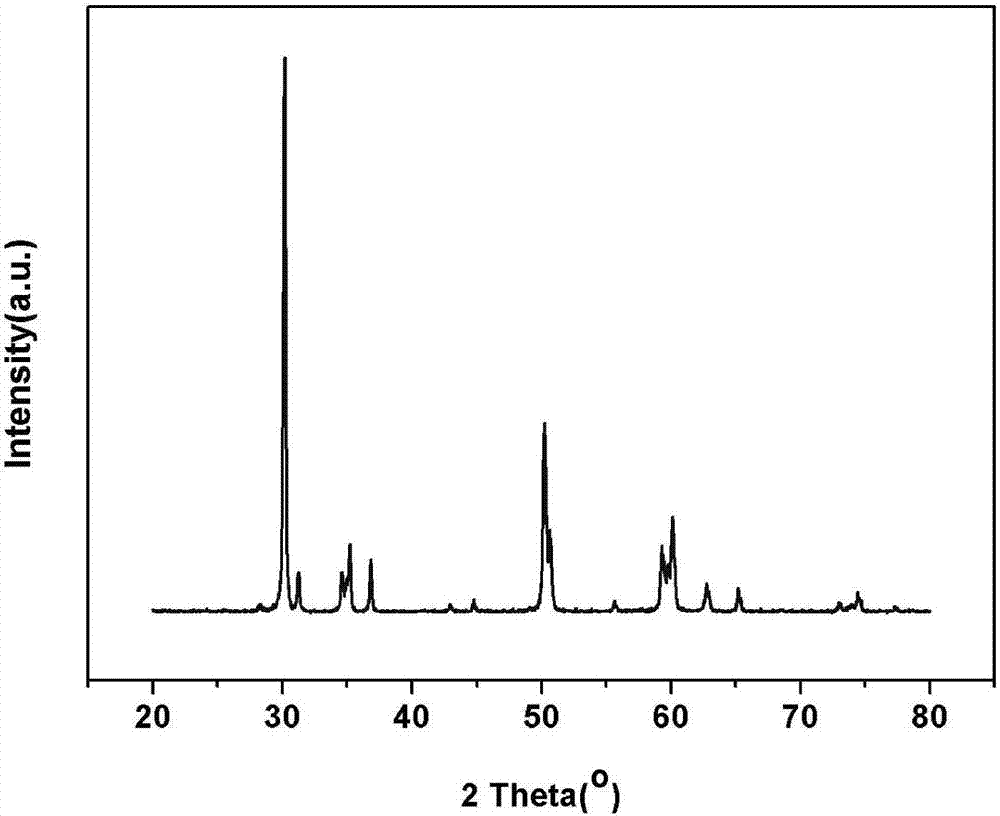

Preparation method of yttria-stabilized zirconia tetragonal nano powder with high specific surface area

ActiveCN103524128ASolve serious sintering and agglomerationSolution areaMaterial nanotechnologyZirconium hydrideSolution combustion

A preparation method of an yttria-stabilized zirconia tetragonal nano powder with high specific surface area. The method is characterized by comprising the following steps: (1) respectively weighing zirconium oxychloride octahydrate?and an yttrium raw material according to a stoichiometric ratio of zirconium and yttrium in (Y2O3)x(ZrO2) 1-2x (0.005<=x<=0.150), according to the amount of a target product, converting the yttrium raw material into an yttrium nitrate solution by dissolving, and then completely dissolving the zirconium oxychloride octahydrate; (2) respectively adding a soluble salt and organic fuel to the solution obtained in the step (1), heating for dissolving, continuing heating and concentrating to a sticky state, igniting in a heating furnace chamber at 400-1000 DEG C, and taking out the powder after complete combustion; and (3) washing, filtering and drying the powder obtained in the step (2). The invention effectively solves the problems of serious particle sintering agglomeration and small specific area in the process of solution combustion for synthesis of zirconium oxide; the powder has specific surface area as high as 378 m<2> / g and particle size about 2.8 nm; and the materials are more accessible and cheaper, so as to facilitate industrialized preparation.

Owner:赣州点金新材料科技有限公司

Low level noble metal-supporting three-way catalyst

ActiveUS8673809B2Improve efficiencyReduce the temperatureGas treatmentInternal combustion piston enginesZirconium hydridePt element

The invention provides a catalyst for catalytically removing three components, which are carbon monoxide, hydrocarbons and nitrogen oxides, from combustion exhaust gas generated by combusting fuel at around the stoichiometric air to fuel ratio. The catalyst includes:(A) a first catalyst component including at least rhodium, platinum, or palladium in a content of 0.01 to 0.5% by weight; and(B) a second catalyst component, which is the remainder, including a composite oxide or a mixed oxide including (a) at least zirconium oxide or titanium oxide, and (b) an oxide of at least praseodymium, yttrium, neodymium, tungsten, niobium, silicon, or aluminum, wherein the content of the oxide (a) in the composite oxide or the mixed oxide is in a range of 70 to 95% by weight. The invention further provides a two-layer catalyst that includes a surface catalyst layer containing the above-mentioned catalyst.

Owner:HONDA MOTOR CO LTD +1

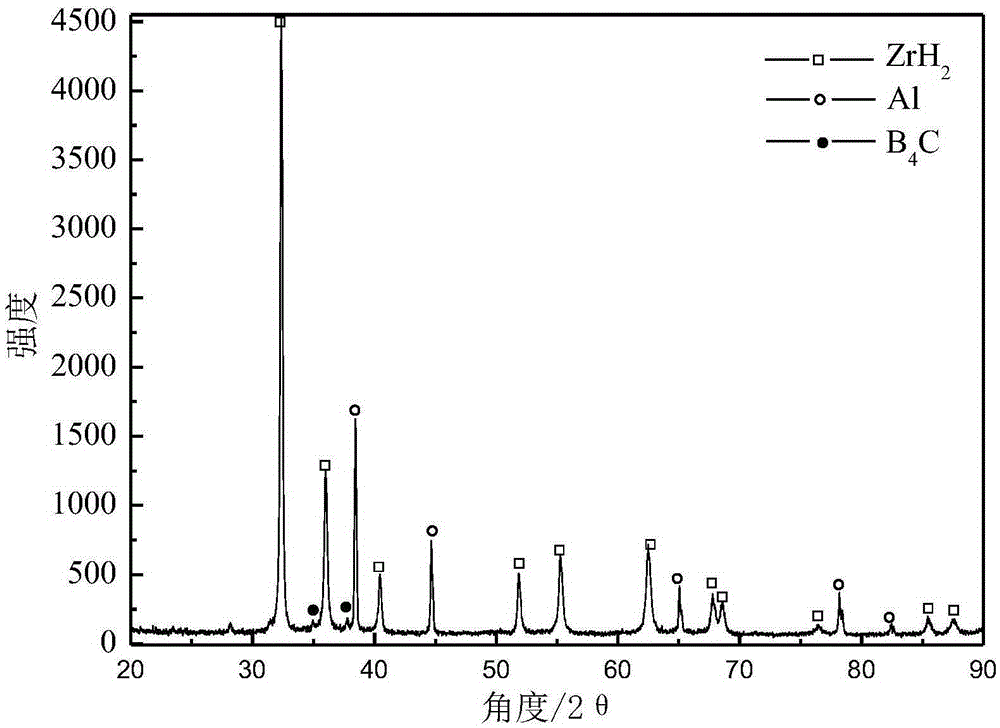

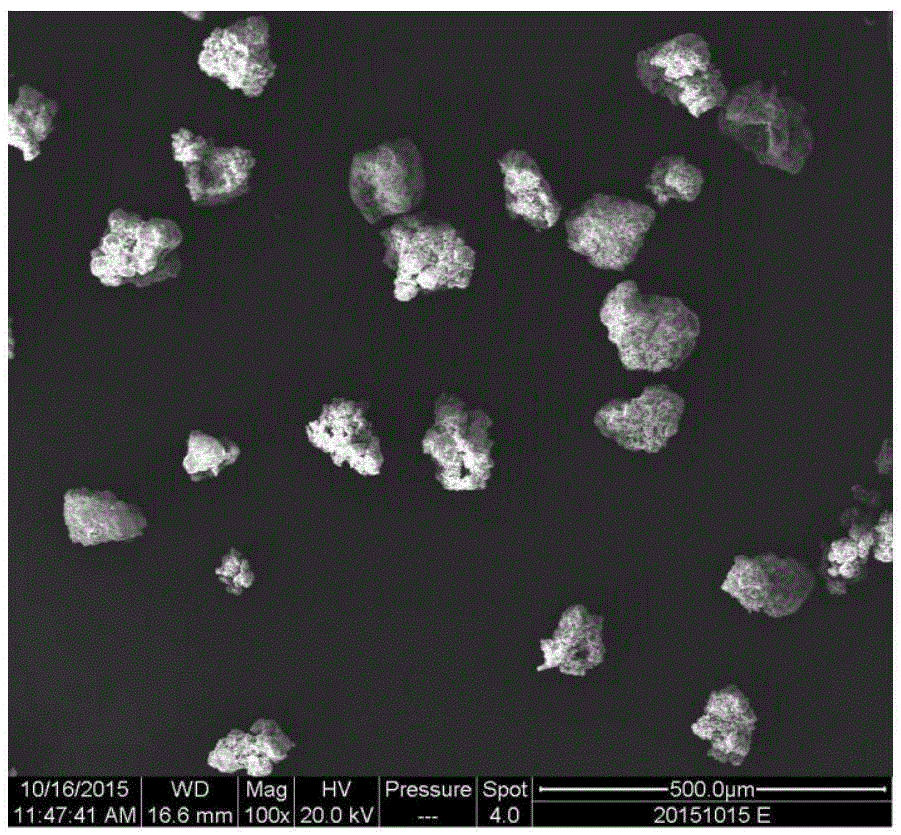

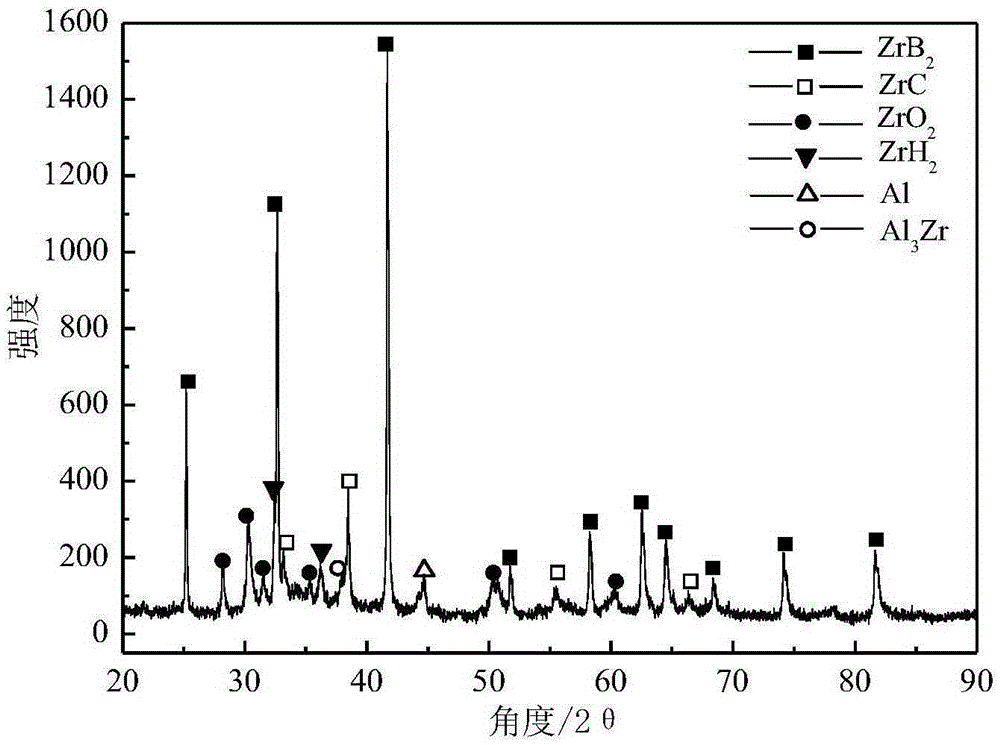

Spraying powder, hot-sprayed in-situ synthesized zirconium boride-zirconium carbide base ceramic coating and preparation method thereof

The invention provides spraying powder. The spraying powder comprises aluminum powder, zirconium hydride powder and boron carbide powder. Compared with the prior art, the spraying powder contains zirconium hydride, the zirconium hydride can replace metal zirconium so as to lower the spontaneous combustion risk of powder manufacturing and can be resolved to generate active zirconium and hydrogen gas in the spraying process, and the generated hydrogen gas can be ionized or combusted so as to further increase the temperature of a heat source and improve the reducing atmosphere; the spraying powder is good in liquidity and self-propagating reaction characteristic and can make a prepared ceramic base coating compact in structure and low in porosity. According to the invention, the compositions of the spraying powder are reasonably designed, the ceramic base coating mainly comprising zirconium boride and zirconium carbide can be synthesized in situ, and there is no need to spray zirconium boride powder and zirconium carbide powder independently for obtaining the ceramic base coating containing the zirconium boride and the zirconium carbide. The invention further provides the hot-sprayed in-situ synthesized zirconium boride-zirconium carbide base ceramic coating and a preparation method thereof.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Diffusion bonding method of zirconium diboride-silicon carbide composite material and metal alloy

The invention relates to a bonding method of a zirconium diboride-silicon carbide composite material and a metal alloy, particularly a diffusion bonding method of a zirconium diboride-silicon carbide composite material and a metal alloy. The invention aims to solve the problem of low strength of the active brazed joint of the existing zirconium diboride-silicon carbide composite material and metal alloy. The method comprises the following steps: 1. pretreating the zirconium diboride-silicon carbide composite material and the metal alloy; 2 pretreating a foam nickel middle layer; and 3. carrying out diffusion welding bonding. The method relieves the joint stress, and enhances the joint strength. The shear strength of the diffusion welding joint obtained by the method is 176.5-208.1MPa, andis enhanced by 76-197% as compared with the shear strength of the bonding joint by a brazing process. The invention can be used in the field of diffusion welding bonding.

Owner:HARBIN INST OF TECH

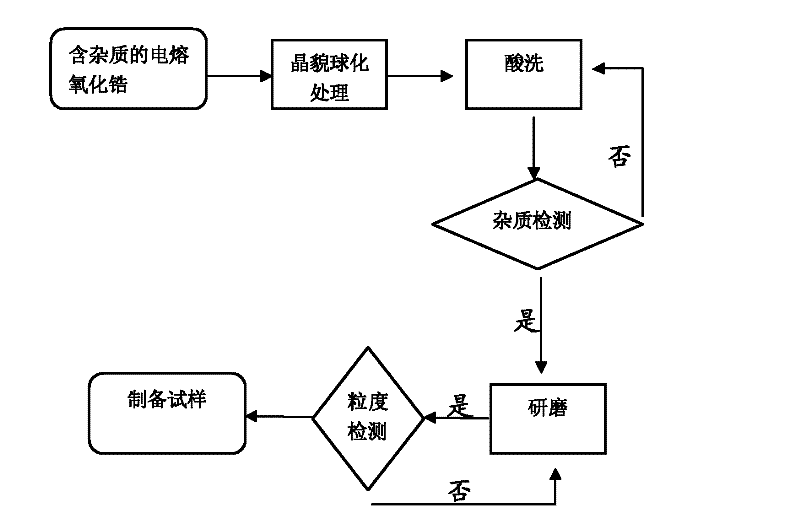

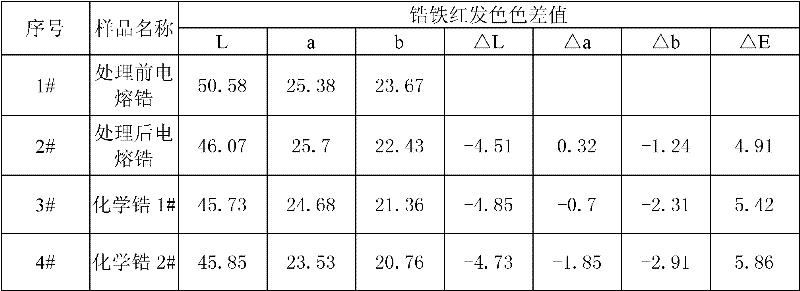

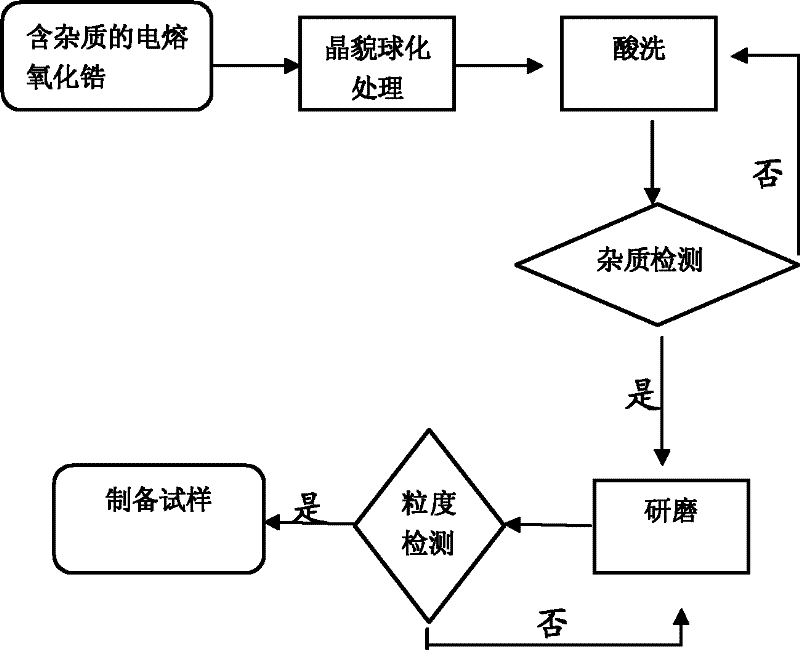

Method for preparing zirconium iron pink pigment from electrically-melted zirconium oxide

The invention discloses a method for preparing zirconium iron pink pigment from electrically-melted zirconium oxide. The method comprises the following steps of: 1) reshaping crystal appearance, namely performing zirconium oxide crystal appearance spheroidization on the common electrically-melted zirconium oxide powder by using a special device, so that the appearance of the electrically-melted zirconium oxide tends to be close to a spherical state; 2) removing impurities, namely washing the product obtained in the step 1) with diluted acid until the content of the impurities such as aluminium oxide (Al2O3), ferric oxide (Fe2O3), silicon oxide (SiO2), phosphorus pentoxide (P2O5) and the like is less than 0.1 percent, and then drying; 3) controlling granularity, namely grinding the electrically-melted zirconium oxide with impurities removed and controlling the granularity of the electrically-melted zirconium oxide to be 0 to 5 mu m; and 4) preparing samples, namely weighing the electrically-melted zirconium oxide obtained in the step 3), zirconium iron pink and other raw materials, mixing the materials completely and uniformly, grinding the mixture finely, heating the mixture to calcine for 5 hours, preserving heat for 1 hour when the temperature is 1,000 to 1,100 DEG C, cooling, and taking out the product. By the method, influence of reaction impurities is removed; reaction activity is improved; and the zirconium iron pink pigment is prepared from the electrically-melted zirconium oxide instead of zirconium, so the production cost of the zirconium iron pink pigment is reduced.

Owner:SANXIANG ADVANCED MATERIALS

Cerium oxide and zirconium oxide based sosoloid catalyst, preparation method and application thereof

InactiveCN101607195AImprove catalytic performanceImprove thermal stabilityDispersed particle separationCatalyst activation/preparationZirconium hydrideCerium(IV) oxide

The invention relates to a catalytic material for purifying tail gas of an automobile, in particular to a cerium oxide and zirconium oxide based sosoloid catalyst, a preparation method and application thereof. The cerium oxide and zirconium oxide based sosoloid catalyst comprises 50-79.5wt% of zirconium oxide, 20-49.5wt% of cerium oxide and 0.5-25wt% of oxides of other elements, wherein the zirconium oxide, the cerium oxide and the oxides of other elements is present in a sosoloid form, and the oxides of other elements are one or more oxides of lanthanons except cerium. The preparation method is as follows: continuous coprecipitation is carried out on zirconium oxychloride, saline solution of cerium and saline solution of lanthanons except cerium to obtain the cerium oxide and zirconium oxide based sosoloid catalyst. In the invention, by adding the zirconium oxide and the oxides of the lanthanons except cerium, the prepared cerium oxide and zirconium oxide based sosoloid catalyst has favorable catalytic performance and greatly improved thermal stability. The preparation method can prepare the cerium oxide and zirconium oxide based sosoloid catalyst under relatively lower temperature and normal pressure.

Owner:顾冬萍

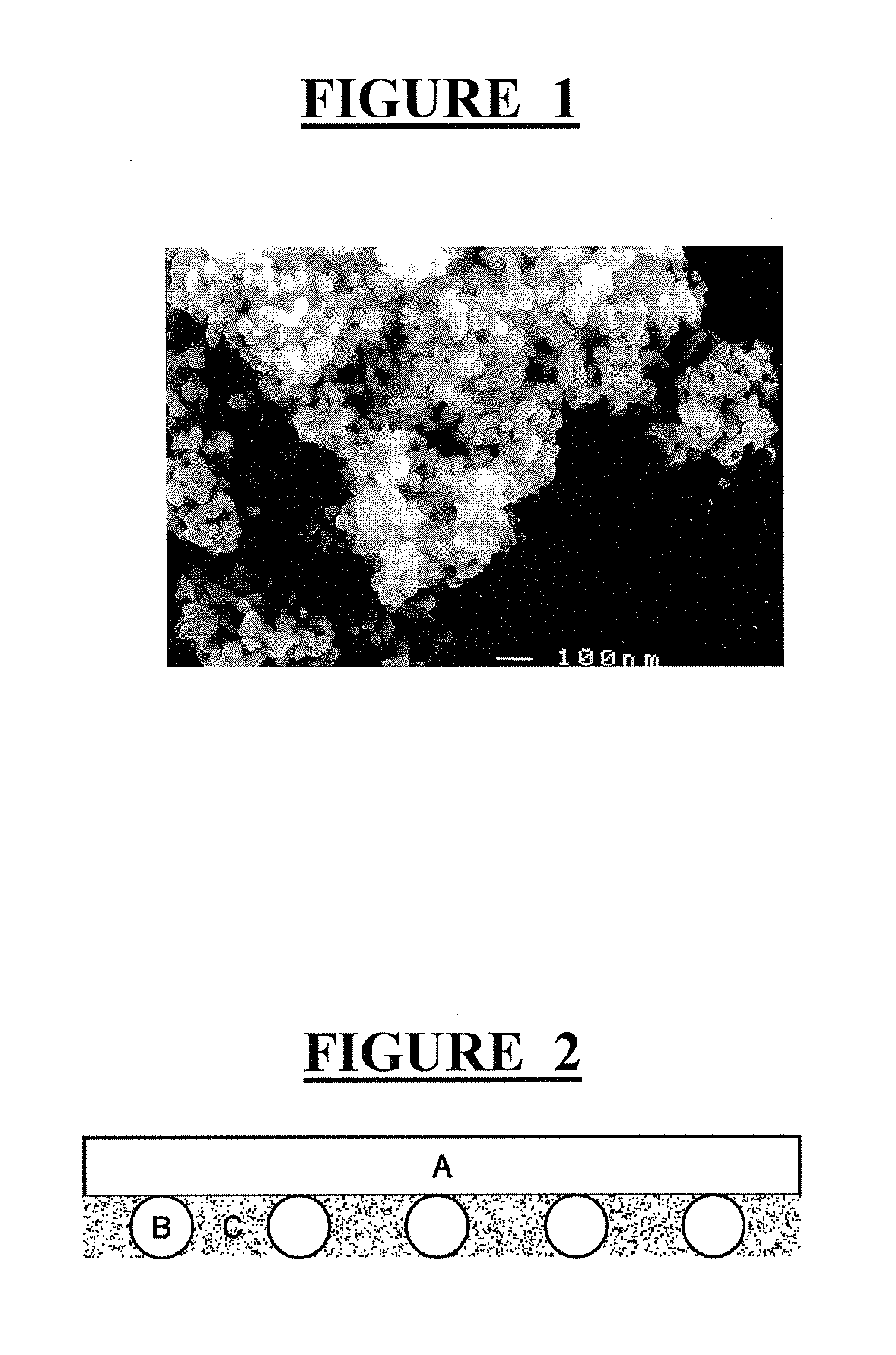

Medical prosthetic devices and implants having improved biocompatibility

InactiveUS20060155384A1Electrolytic inorganic material coatingBone implantZirconium hydrideEnzyme Inhibitor Drugs

A medical prosthetic device or medical implant containing a metal material (A) selected from the group consisting of titanium or an alloy thereof, zirconium or an alloy thereof, tantalum or an alloy thereof, hafnium or an alloy thereof, niobium or an alloy thereof and a chromium-vanadium alloy, wherein surface parts of the metal material (A) are coated with a layer of a corresponding hydride material (B) selected from titanium hydride, zirconium hydride, tantalum hydride, hafnium hydride, niobium hydride and chromium and / or vanadium hydride, respectively, said device or implant being characterised in that the layer of hydride material (B) comprises one or more biomolecule substances (C) associated therewith. The device or implant exhibits improved biocompatibility. The metal material (A) is preferably titanium. The biomolecule substance (C) may be selected from the following types of substances: Natural or recombinant bio-adhesives; natural or recombinant cell attachment factors; natural, recombinant or synthetic biopolymers; natural or recombinant blood proteins; natural or recombinant enzymes; natural or recombinant extracellular matrix proteins; natural or synthetic extracellular matrix biomolecules; natural or recombinant growth factors and hormones; natural, recombinant or synthetic peptide hormones; natural, recombinant or synthetic deoxyribonucleic acids; natural, recombinant or synthetic ribonucleic acids; natural or recombinant receptors; enzyme inhibitors; drugs; biologically active anions and cations; vitamins; adenosine monophosphate (AMP), adenosine diphosphate (ADP) or adenosine triphosphate (A TP); marker biomolecules; amino acids; fatty acids; nucleotides (RNA and DNA bases); and sugars.

Owner:NUMERICAL TECH INC

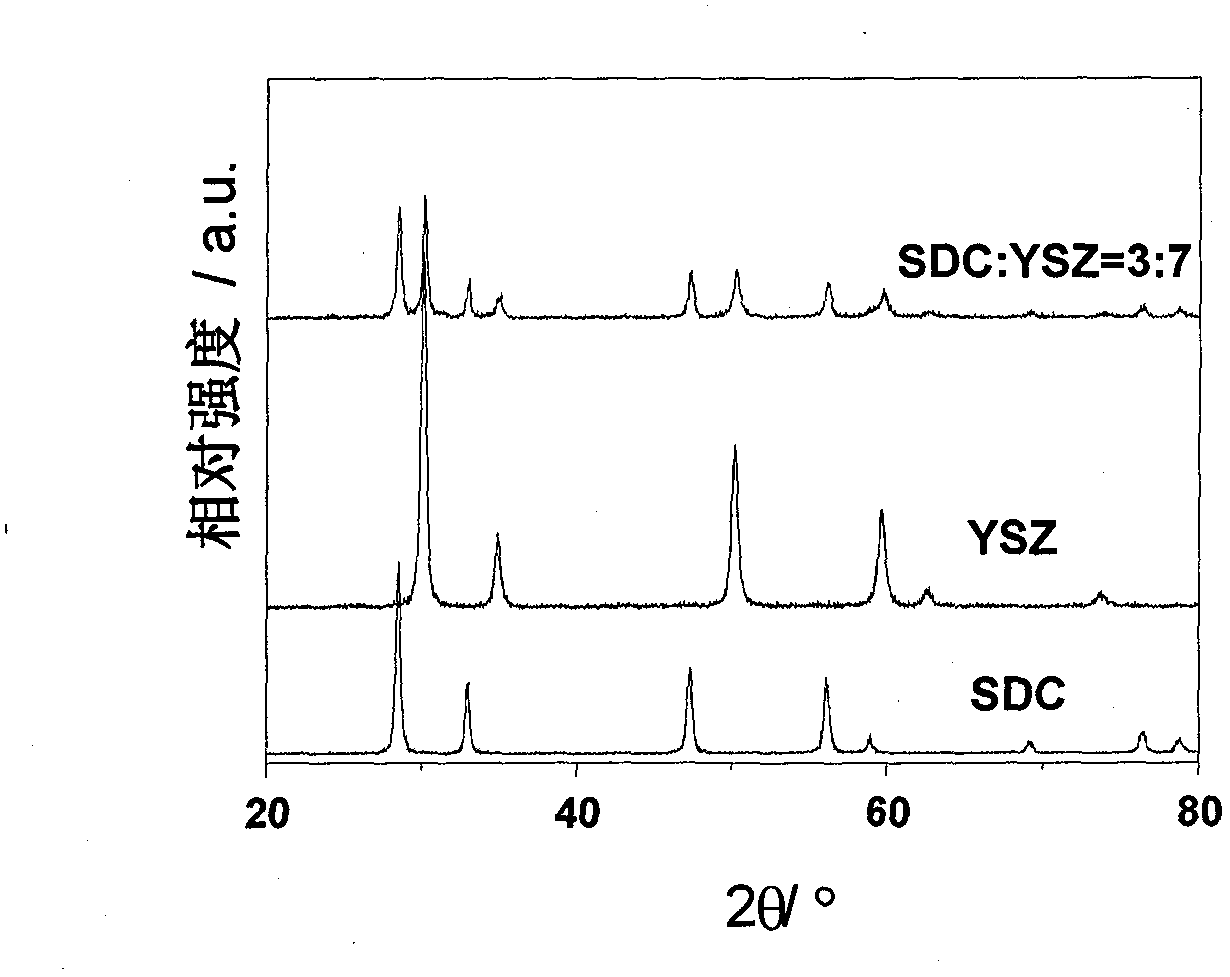

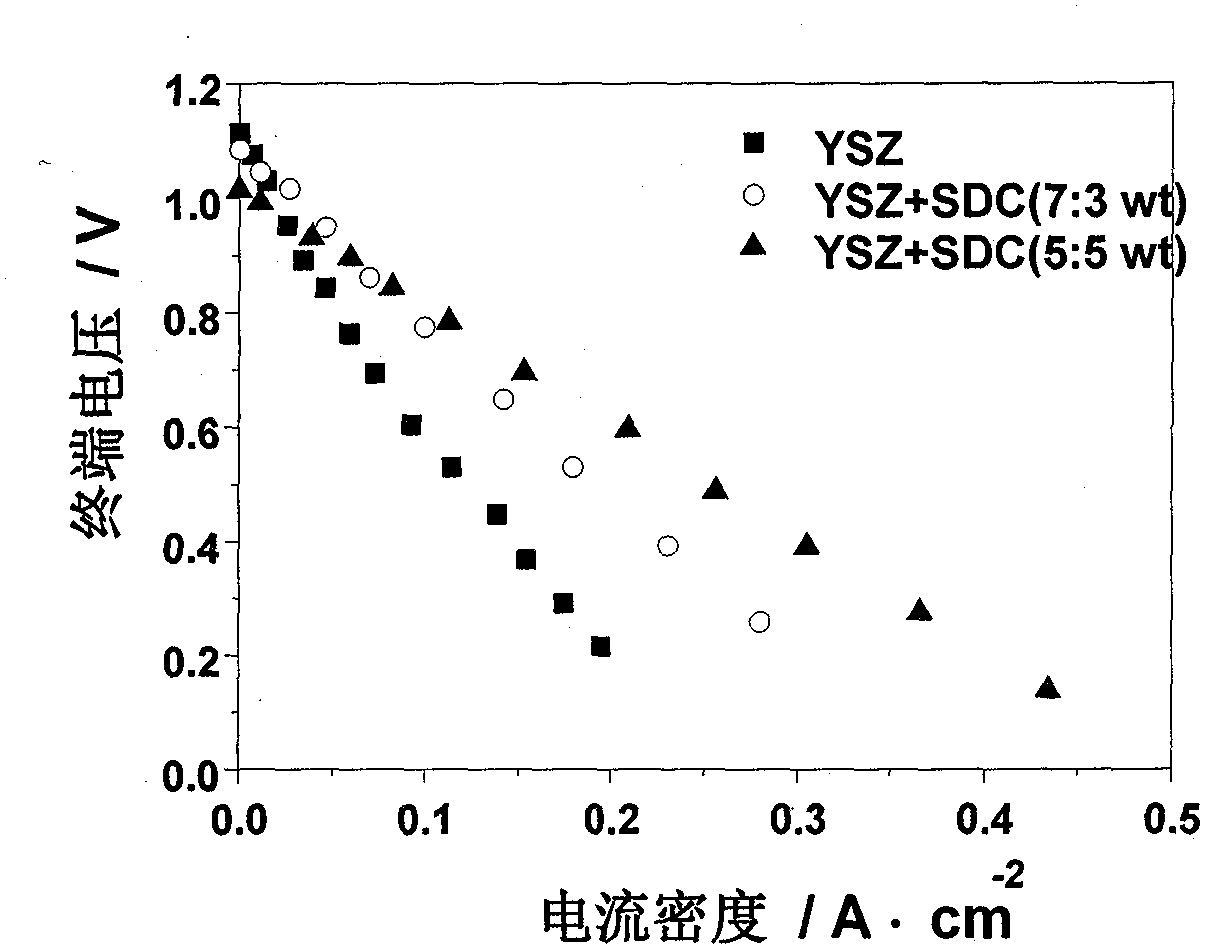

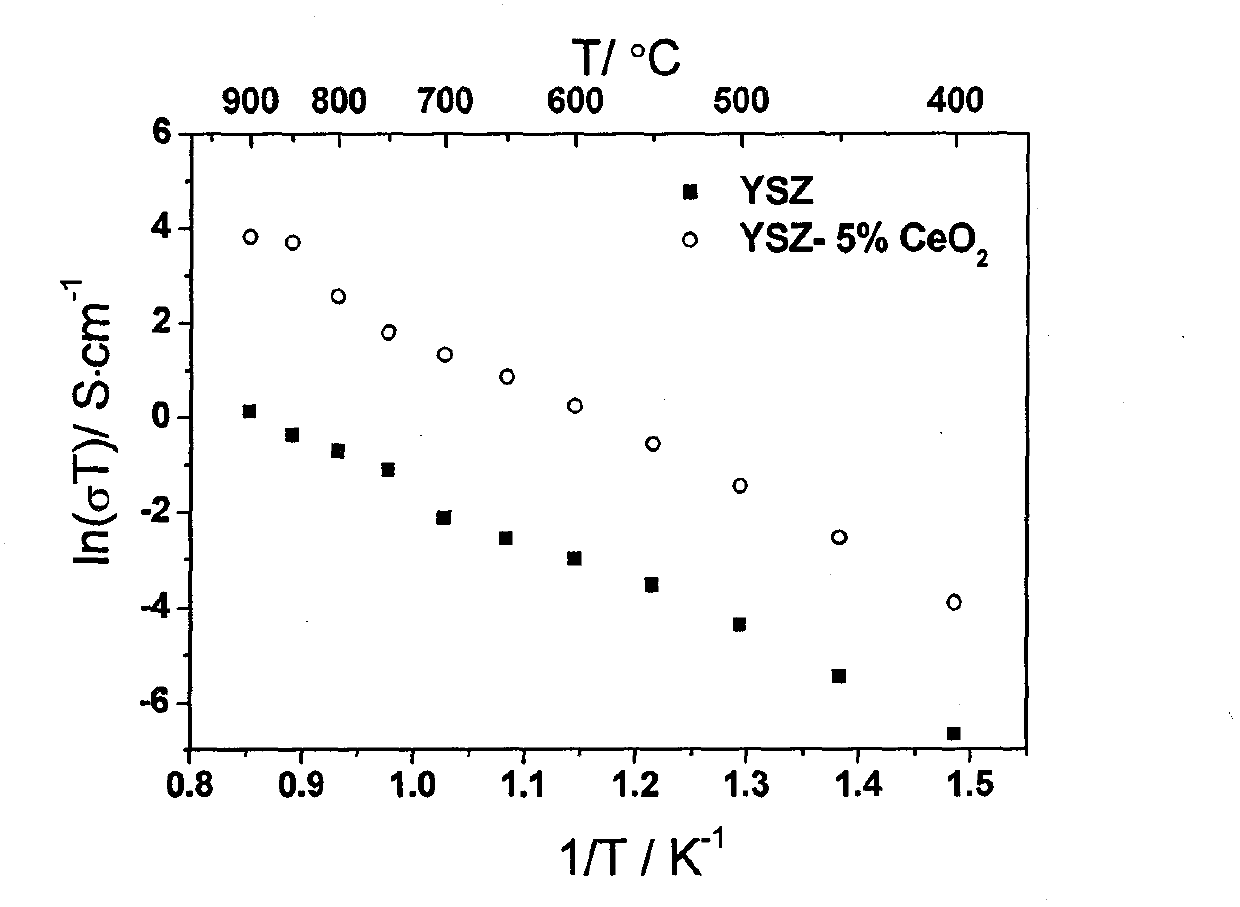

Composite electrolyte material based on zirconium oxide based oxide

InactiveCN103378364ALow costLow-cost commercializationFinal product manufactureSolid electrolyte fuel cellsZirconium hydrideComposite electrolyte

The invention relates to a composite electrolyte material based on a zirconium oxide based oxide for a solid oxide fuel battery. The composite electrolyte material is characterized by being prepared by steps of adequately grinding and sintering the zirconium oxide based oxide, inorganic slat, and / or other oxides or an oxide-doped mixture after thermal treatment. The composite electrolyte material provided by the invention has the advantages that the advantages of a zirconium oxide based electrolyte which is stable in property, compact in structure, high in voltage of an open circuit of a battery and the like are maintained, the conductive capacity of oxygen ions can be improved, the problem that the output voltage quickly attenuates along with increase of current density, and the output performance of the battery is improved. The composite electrolyte material is simple in preparation process and low in preparation cost.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH +1

Blue zirconium oxide ceramic and preparation method thereof

The invention provides blue zirconium oxide ceramic and a preparation method thereof. The preparation method comprises the following steps: mixing cobalt sesquioxide, aluminium oxide, silicon dioxide, a dispersing agent and water to obtain primary slurry; performing sanding treatment on the primary slurry to obtain first-level slurry; drying the first-level slurry and roasting to obtain a blue base material of a cobalt aluminum spinel structure; mixing the blue base material of the cobalt aluminum spinel structure, zirconium oxide, yttrium oxide, the dispersing agent and water to obtain second-level slurry; performing sanding treatment on the second-level slurry to obtain third-level slurry; mixing the third-level slurry and an adhesive, and pelleting, forming, discharging glue and roasting to obtain the blue zirconium oxide ceramic. The grain size of the materials obtained in each step can be fined to be below 80 nm by a sanding technology, the activity of powder materials is improved, the mass transfer distance between particles is shortened, and the cobalt aluminum spinel blue base material can be mixed uniformly, so that the color uniformly of the blue zirconium oxide ceramic is improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Porous clusters of silver powder promoted by zirconium oxide for use as a catalyst in gas diffusion electrodes, and method for the production thereof

ActiveUS20100143807A1Long lastingRobust structureMachining electrodesCellsZirconium hydrideSilver particles

A catalyst including: a plurality of porous clusters of silver particles, each cluster including: (a) a plurality of primary particles of silver, and (b) crystalline particles of zirconium oxide (ZrO2), wherein at least a portion of the crystalline particles of ZrO2 is located in pores formed by a surface of the plurality of primary particles of silver.

Owner:BAR ILAN UNIV REASERCH & DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com