Process for preparing molybdenum alloy TZM by powder metallurgy

A technology of powder metallurgy and molybdenum alloy, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of reduced uniformity of material structure, influence of high temperature performance of materials, uneven sintering and diffusion, etc., to improve high temperature performance and room temperature brittleness, small particle size, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

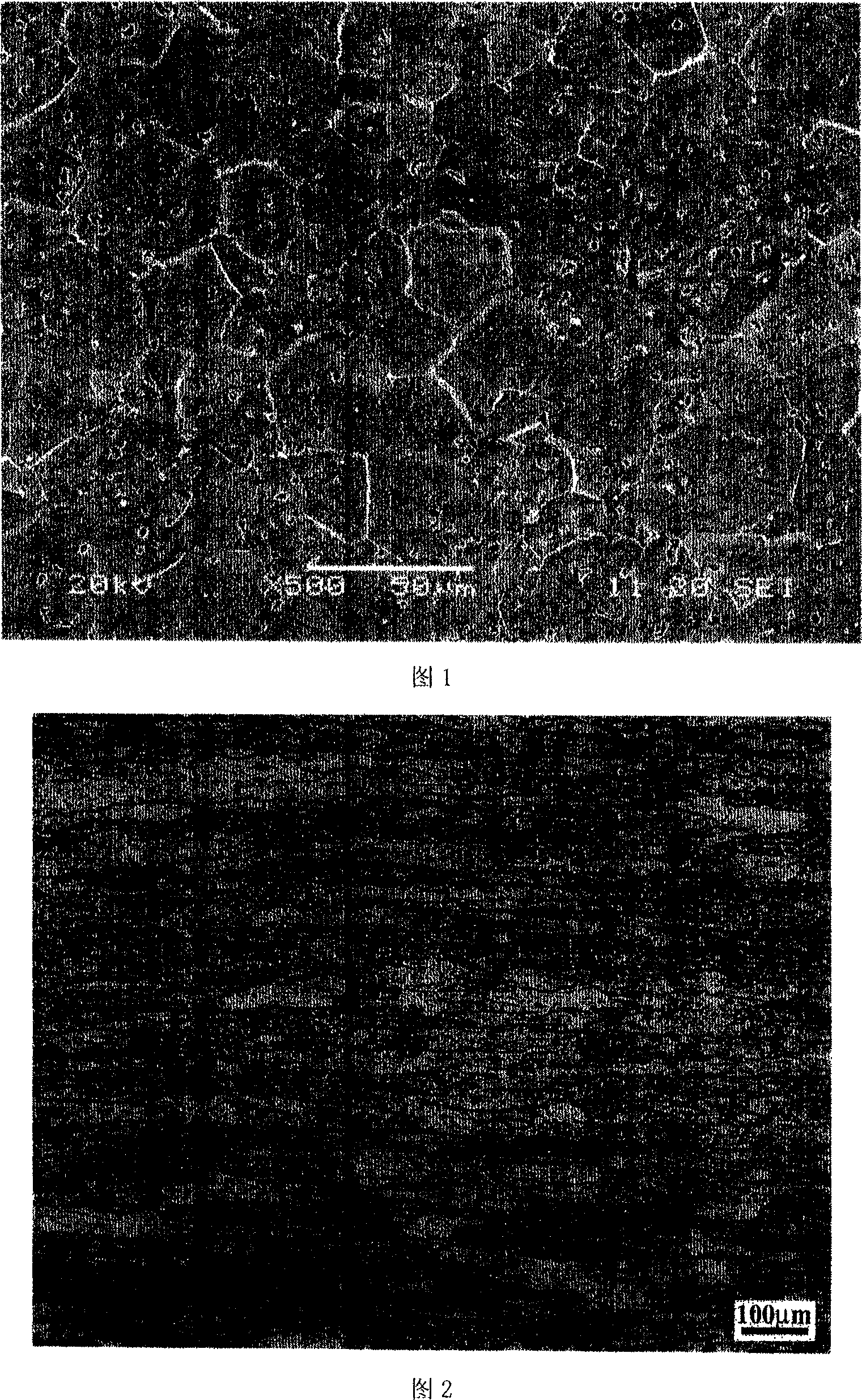

[0018] 10 kg of molybdenum powder, 50 grams of titanium hydride, 10 grams of zirconium hydride, and 6 grams of carbon black. Mix in a V-type mixer, the ball-to-material ratio is 0.2:1, and the mixing time is 24 hours. Choose a rubber sleeve with a diameter of 90mm, charge it, and press it isostatically with a pressure of 2.2t / cm 2 , holding time 2 minutes. Carry out sintering in a vacuum induction furnace, the sintering temperature is 1900°C, and the holding time is 4 hours. The density of the material after sintering is 9.5g / cm 3 , as shown in Figure 1. The carbon content of the sintered material is 0.01%, the oxygen content is 0.02%, the titanium content is 0.45%, and the zirconium content is 0.06%.

Embodiment 2

[0020] 10 kg of molybdenum powder, 50 grams of titanium hydride, 10 grams of zirconium hydride, and 6 grams of carbon black. Mix in a ball mill, the ratio of ball to material is 1:1, and the mixing time is 4 hours. Choose a rubber sleeve with a diameter of 90mm, charge it, and press it isostatically with a pressure of 2.2t / cm 2 , holding time 2 minutes. Carry out sintering in a vacuum induction furnace, the sintering temperature is 1900°C, and the holding time is 4 hours. The chemical composition of the sintered material conforms to the standard ASTM387-90, and the density is 9.5g / cm 3 . The bar is forged into a slab with a conventional process, and the thickness of the slab is about 25 mm. Rolling, annealing and corresponding alkali washing are adopted to treat the plate until the thickness of the plate is about 2.4mm. The test results show that the recrystallization temperature of the material is greater than 1550°C, and the scanning electron microscope photo after anne...

Embodiment 3

[0024] 80 kilograms of molybdenum powder, 400 grams of titanium hydride, 80 grams of zirconium hydride, and 48 grams of carbon black. Mix in a ball mill, the ratio of ball to material is 1:1, and the mixing time is 1 hour. Choose a rubber sleeve with a diameter of 220mm, charge it, and press it isostatically with a pressure of 2.2t / cm 2 , holding time 2 minutes. Sintering is carried out in a vacuum induction furnace, the sintering temperature is 1900°C, and the holding time is 6 hours. The chemical composition of the sintered material conforms to the standard ASTM387-90, and the density is 9.5g / cm 3 . The rods were forged to a diameter of 80 mm using conventional techniques. After annealing at 1150°C for 1 hour, the yield strength is 785MPa, the tensile strength is 852MPa, and the elongation is 28%. The corresponding metallographic photos are shown in Figure 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com