Patents

Literature

972 results about "Glass manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

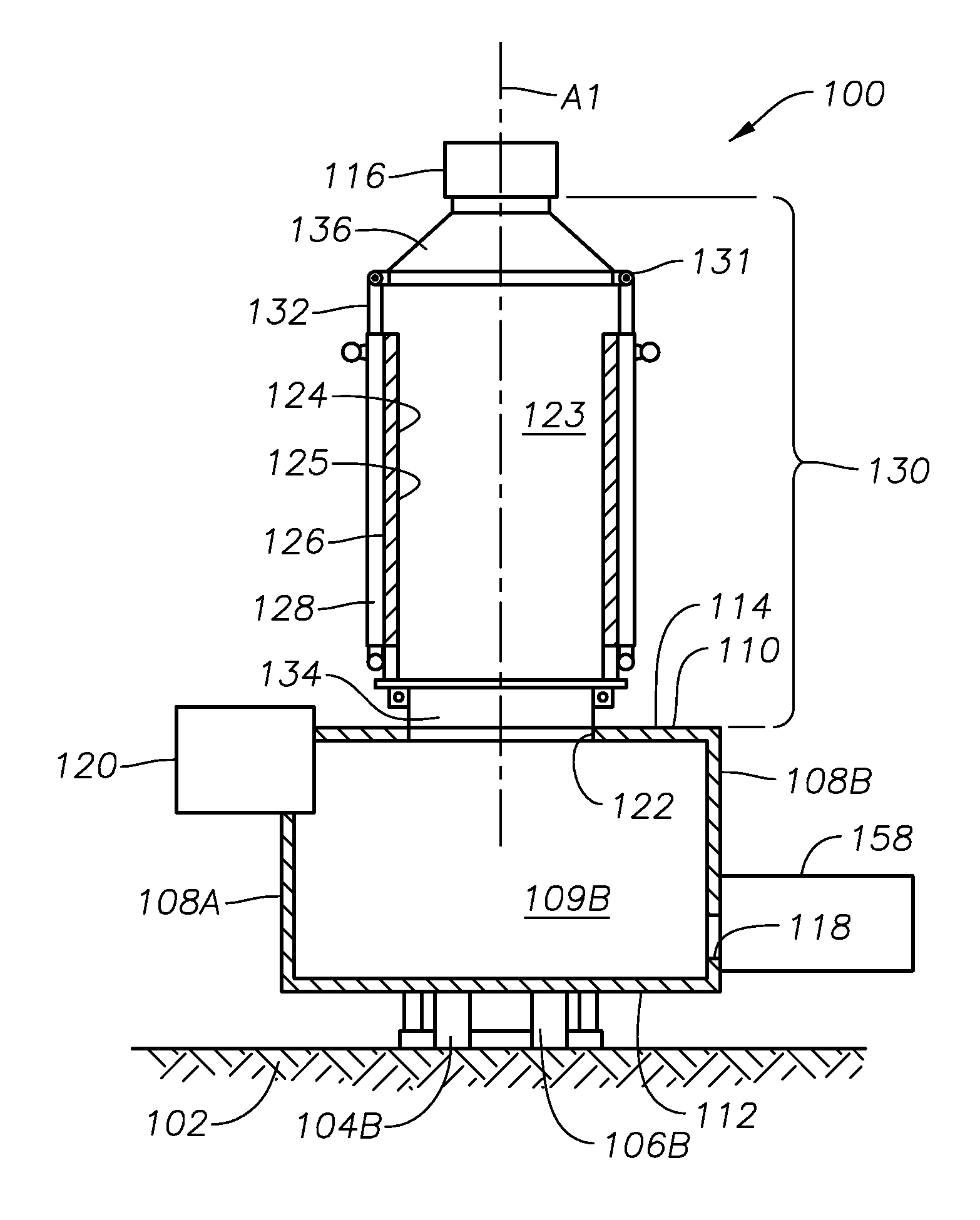

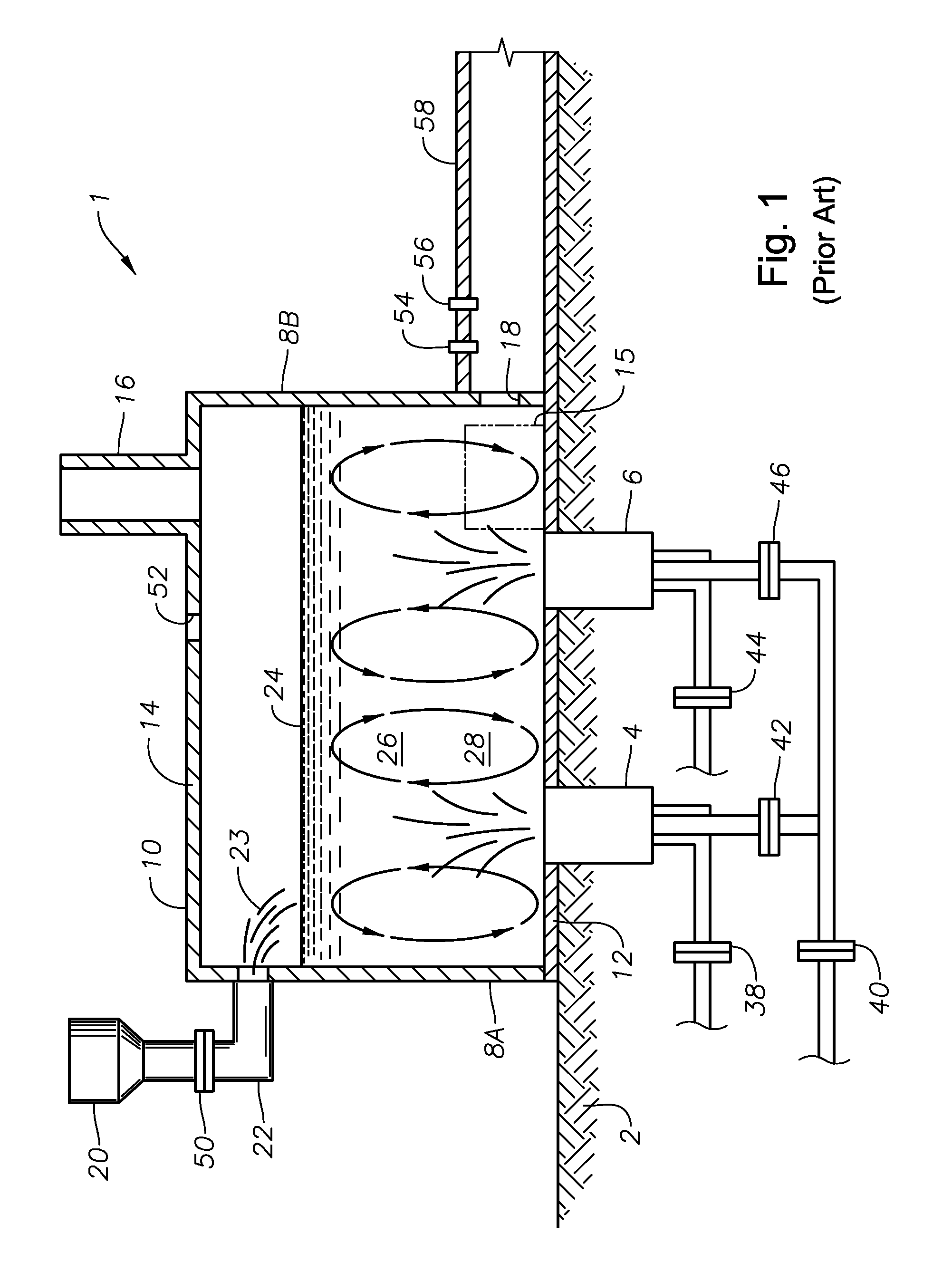

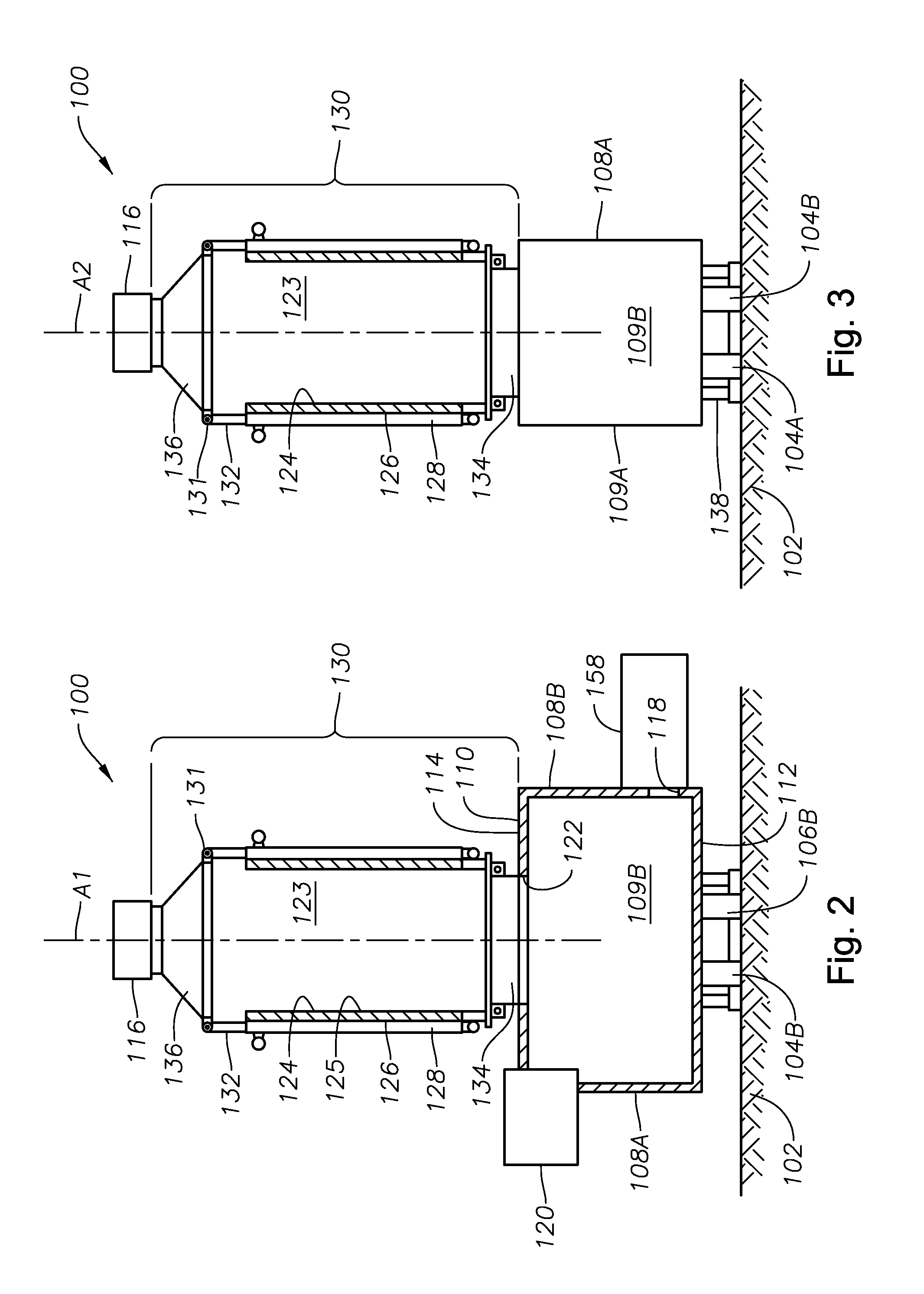

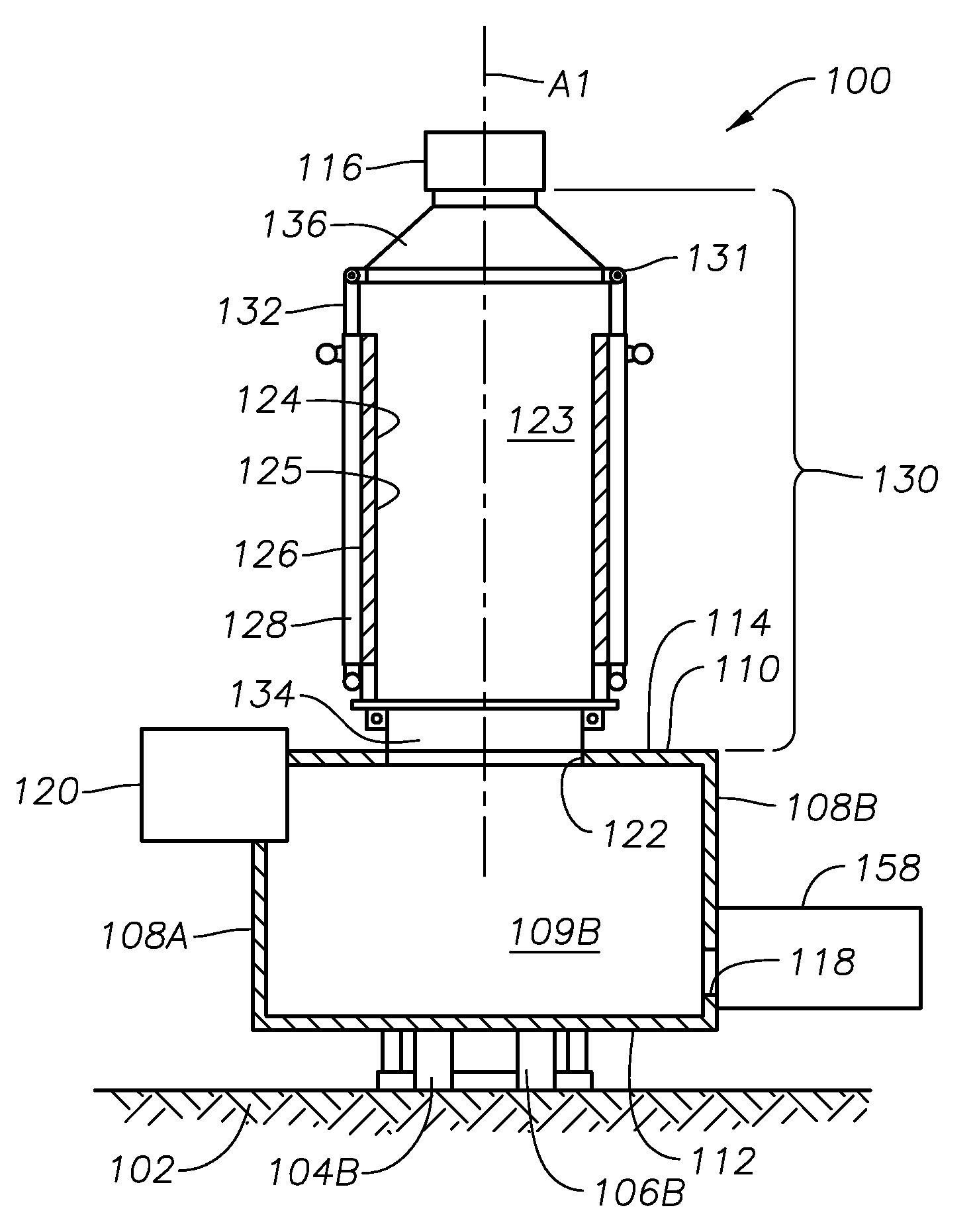

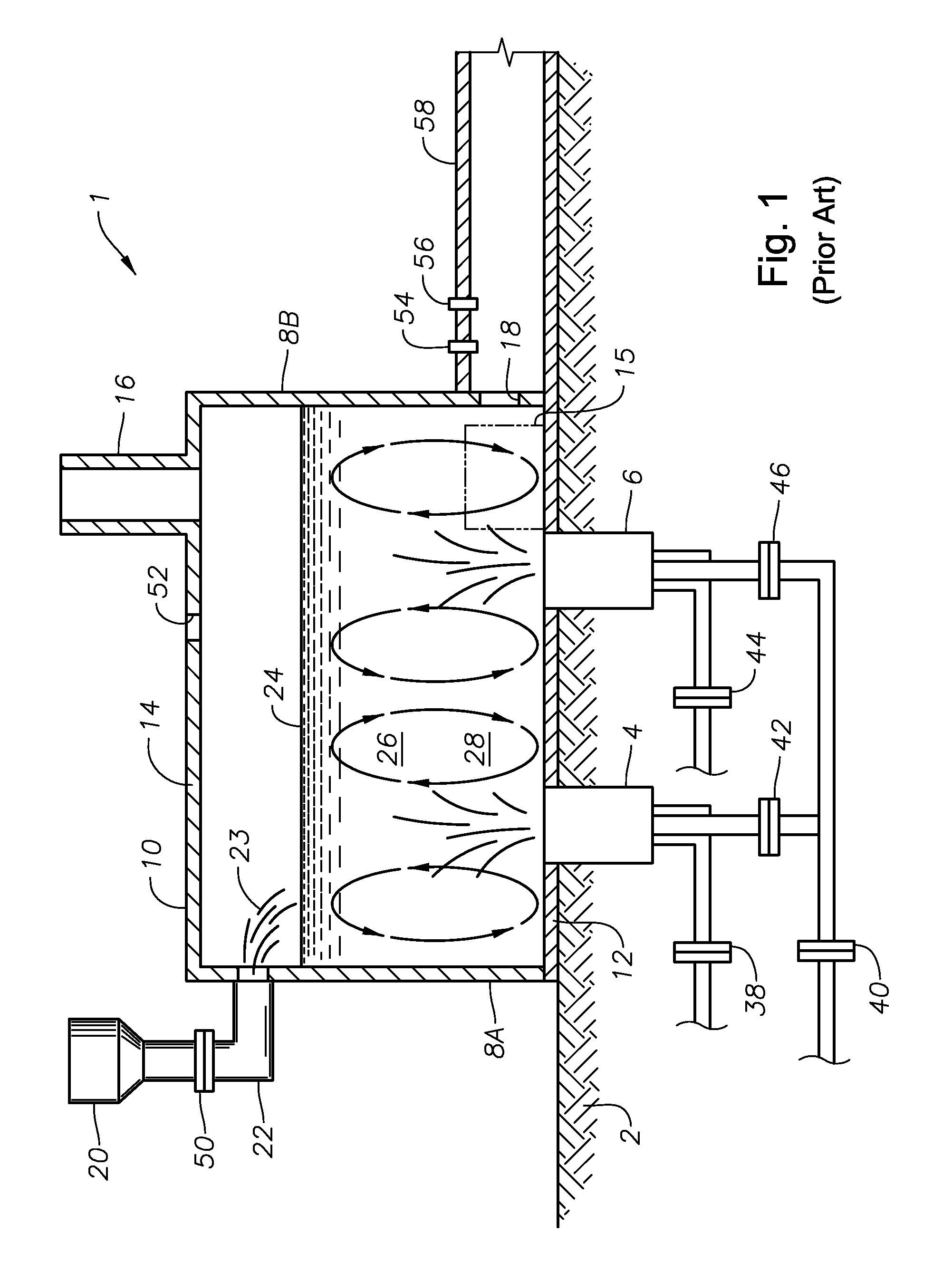

Submerged combustion glass manufacturing systems and methods

ActiveUS20130086950A1Reduction of melter pressure fluctuationReduce carryoverGlass furnace apparatusGlass melting apparatusGlass manufacturingTemperature and pressure

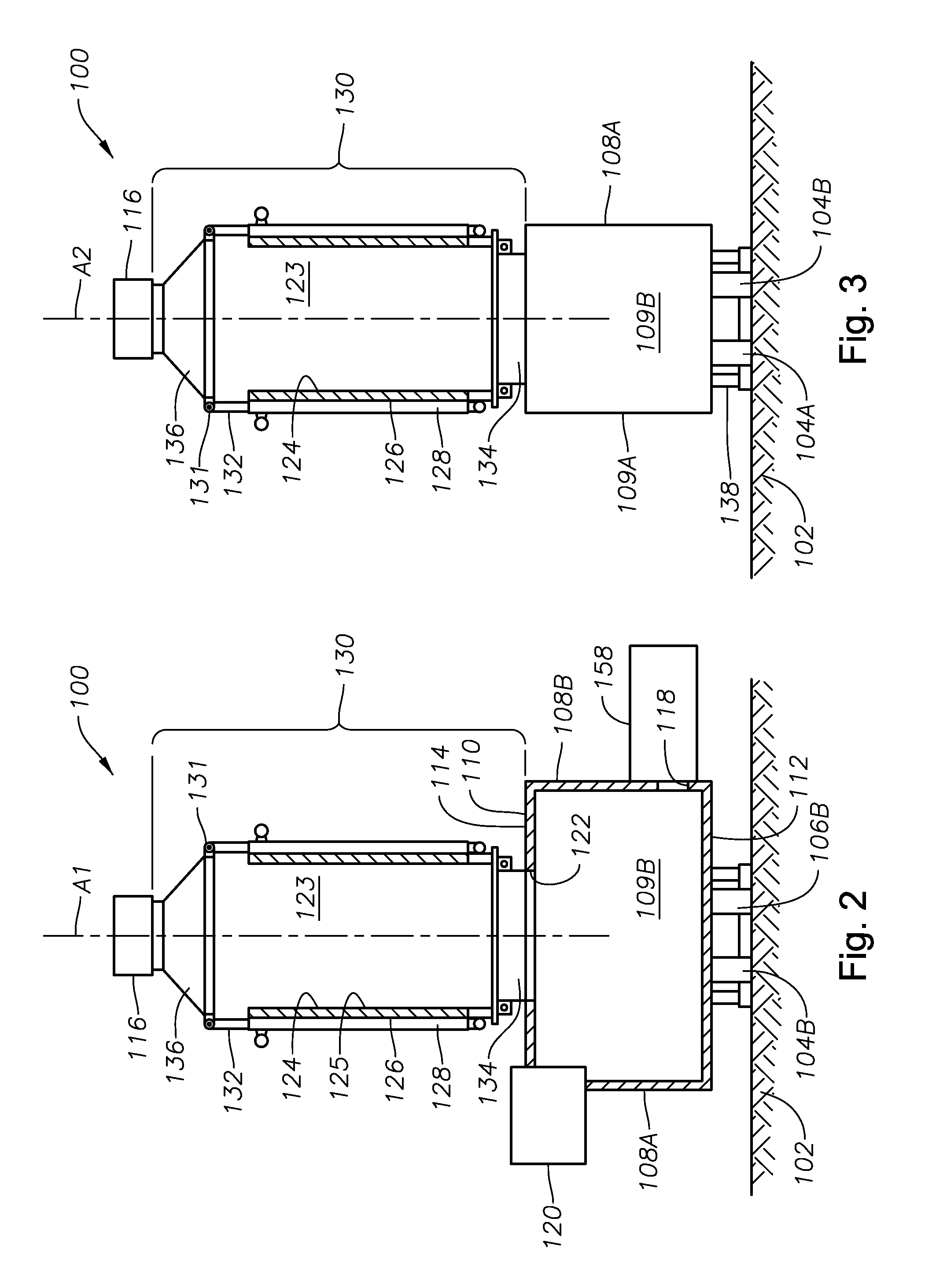

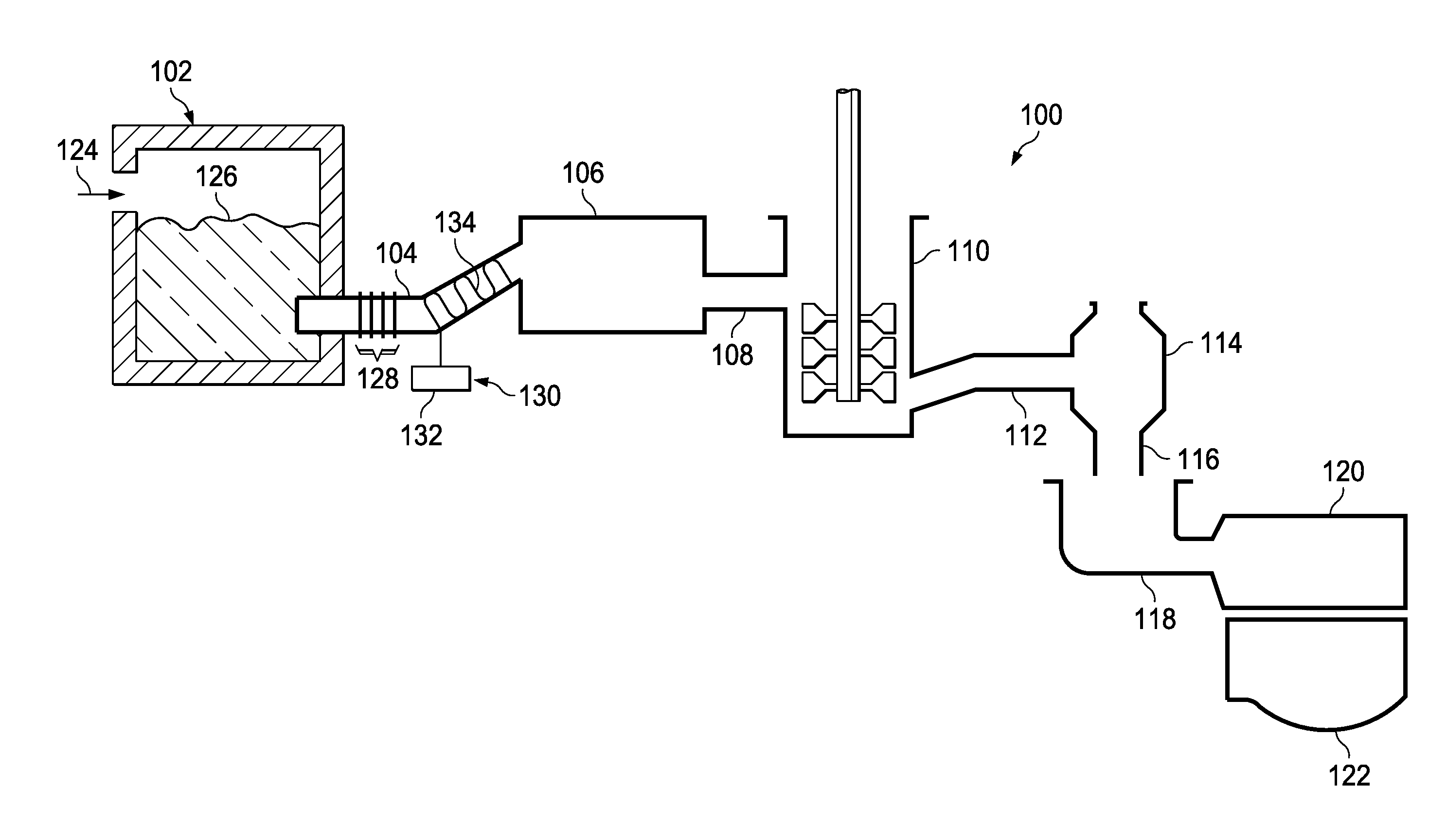

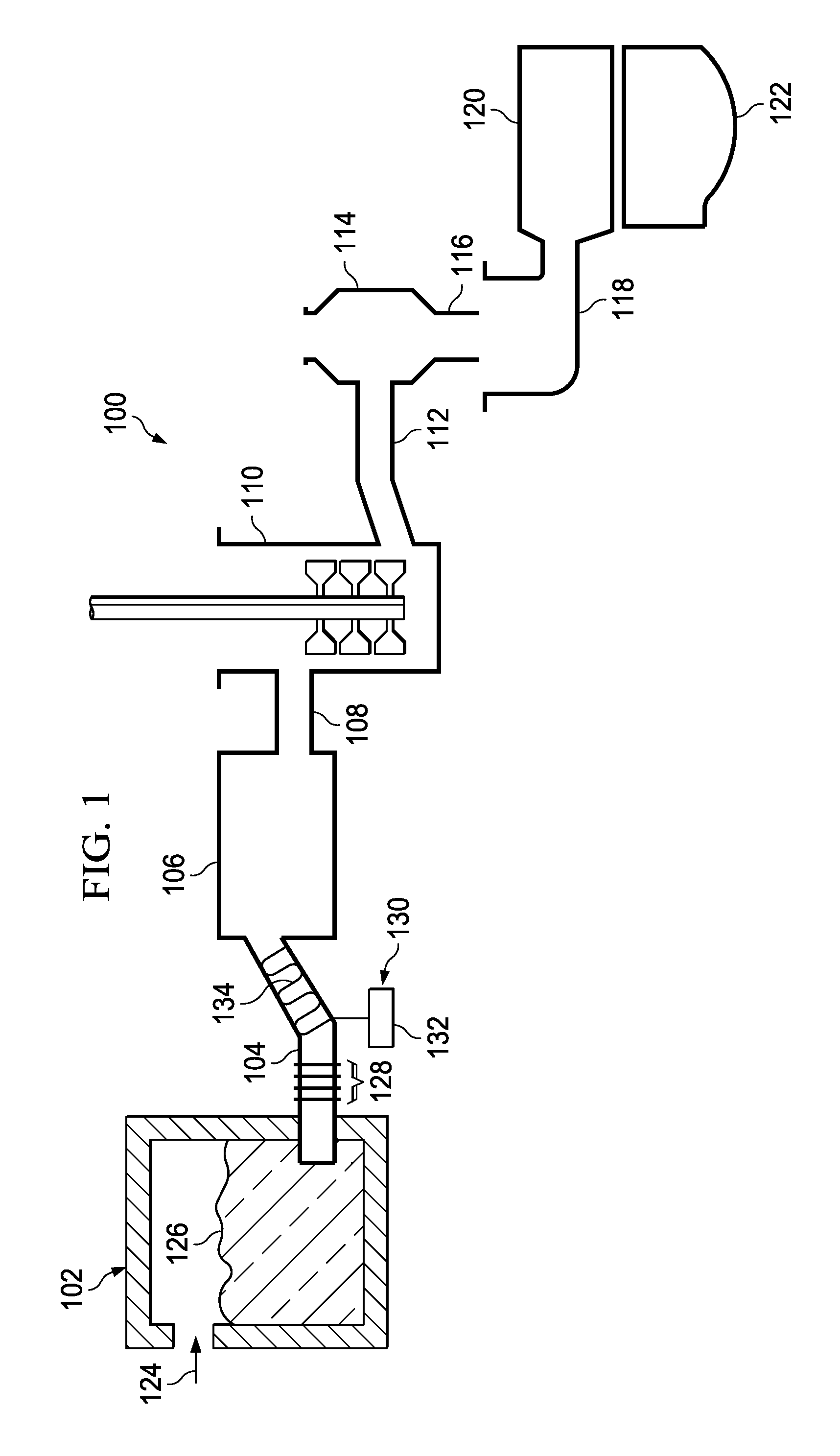

Submerged combustion glass manufacturing systems include a melter having a floor, a roof, a wall structure connecting the floor and roof, and an exhaust passage through the roof. One or more submerged combustion burners are mounted in the floor and / or wall structure discharging combustion products under a level of material being melted in the melter and create turbulent conditions in the material. The melter exhausts through an exhaust structure connecting the exhaust passage with an exhaust stack. The exhaust structure includes a barrier defining an exhaust chamber having an interior surface, the exhaust chamber having a cross-sectional area greater than that of the exhaust stack but less than the melter. The barrier maintains temperature and pressure in the exhaust structure at values sufficient to substantially prevent condensation of exhaust material on the interior surface.

Owner:JOHNS MANVILLE CORP

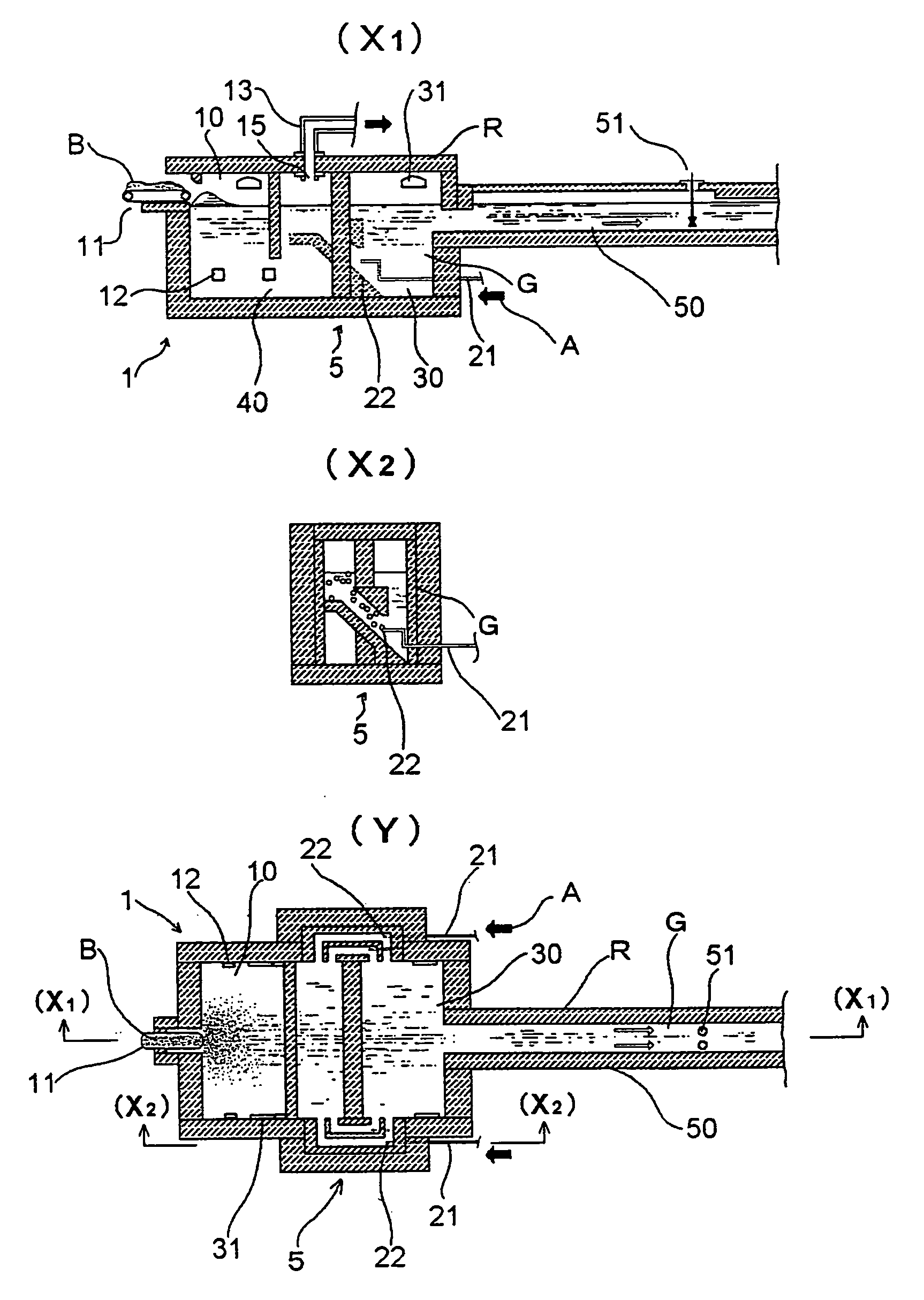

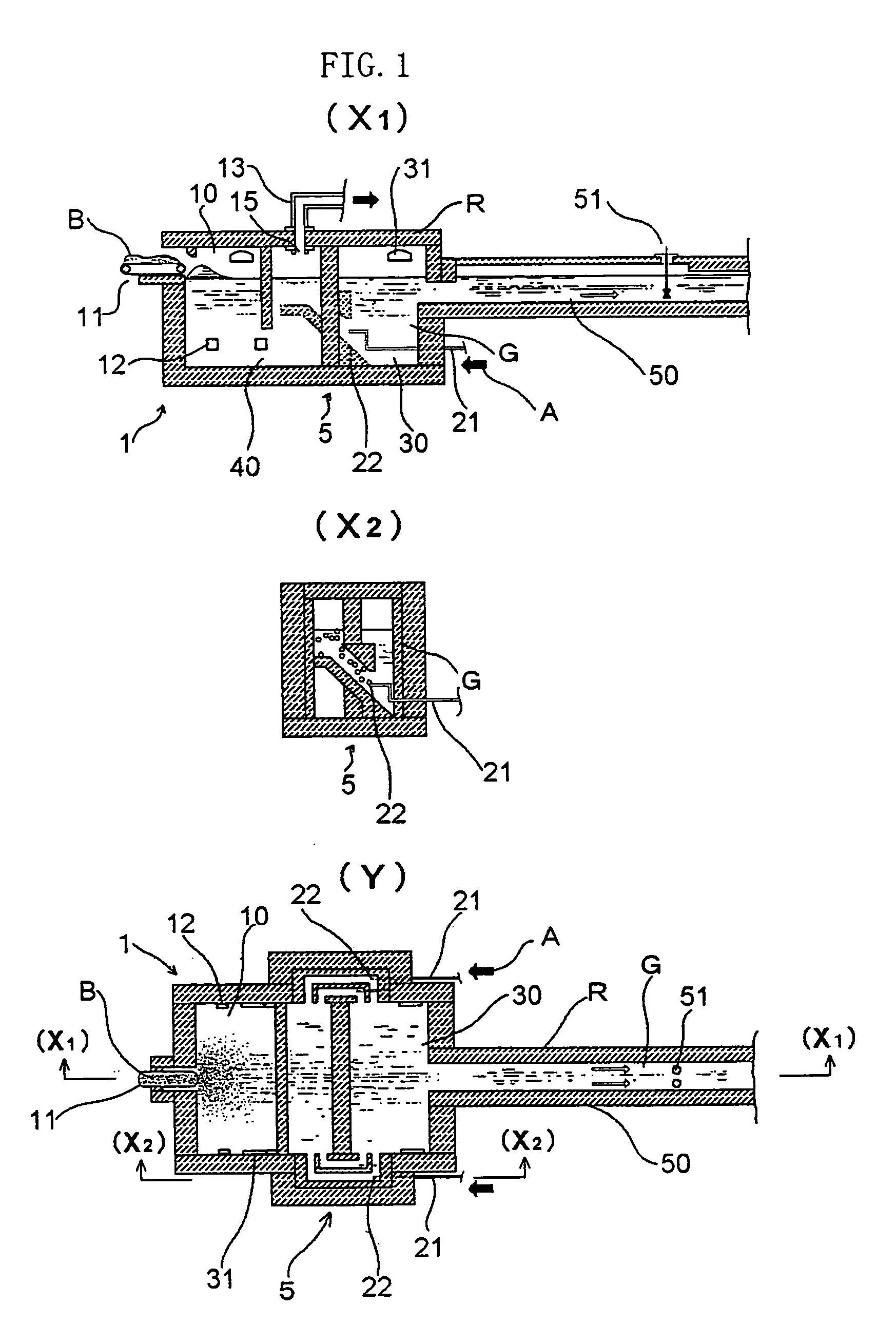

Glass melting gurnace and method for producing glass

InactiveUS20060101859A1Precise maintenanceReduce the environmentGlass furnace apparatusGlass pressing apparatusMelting tankNoble gas

A charged glass raw material B is melted in a melting tank 10 by heating with a burner 31 and by heating with electrodes 12, to form molten glass G. Then, the molten glass G flows into a tank additionally provided as a noble gas dissolving tank 20 through a throat 40. The noble gas dissolving tank 20 is provided with a noble gas dissolving device 53, and the noble gas dissolving device 53 is provided with sixteen noble gas inlets 22 for introducing a helium or neon gas supplied to a hearth through heat resistant gas introduction tubes 21 into the noble gas dissolving tank 20. Bubbles of a helium gas A having a purity of 99% are blown out from the noble gas inlets 22 in volumes such that the bubbles have an average diameter of 80 mm or less in the molten glass G.

Owner:NIPPON ELECTRIC GLASS CO LTD

Submerged combustion glass manufacturing systems and methods

ActiveUS8707740B2Suppress pressure fluctuationsAvoid condensationGlass furnace apparatusGlass melting apparatusGlass manufacturingTemperature and pressure

Submerged combustion glass manufacturing systems include a melter having a floor, a roof, a wall structure connecting the floor and roof, and an exhaust passage through the roof. One or more submerged combustion burners are mounted in the floor and / or wall structure discharging combustion products under a level of material being melted in the melter and create turbulent conditions in the material. The melter exhausts through an exhaust structure connecting the exhaust passage with an exhaust stack. The exhaust structure includes a barrier defining an exhaust chamber having an interior surface, the exhaust chamber having a cross-sectional area greater than that of the exhaust stack but less than the melter. The barrier maintains temperature and pressure in the exhaust structure at values sufficient to substantially prevent condensation of exhaust material on the interior surface.

Owner:JOHNS MANVILLE CORP

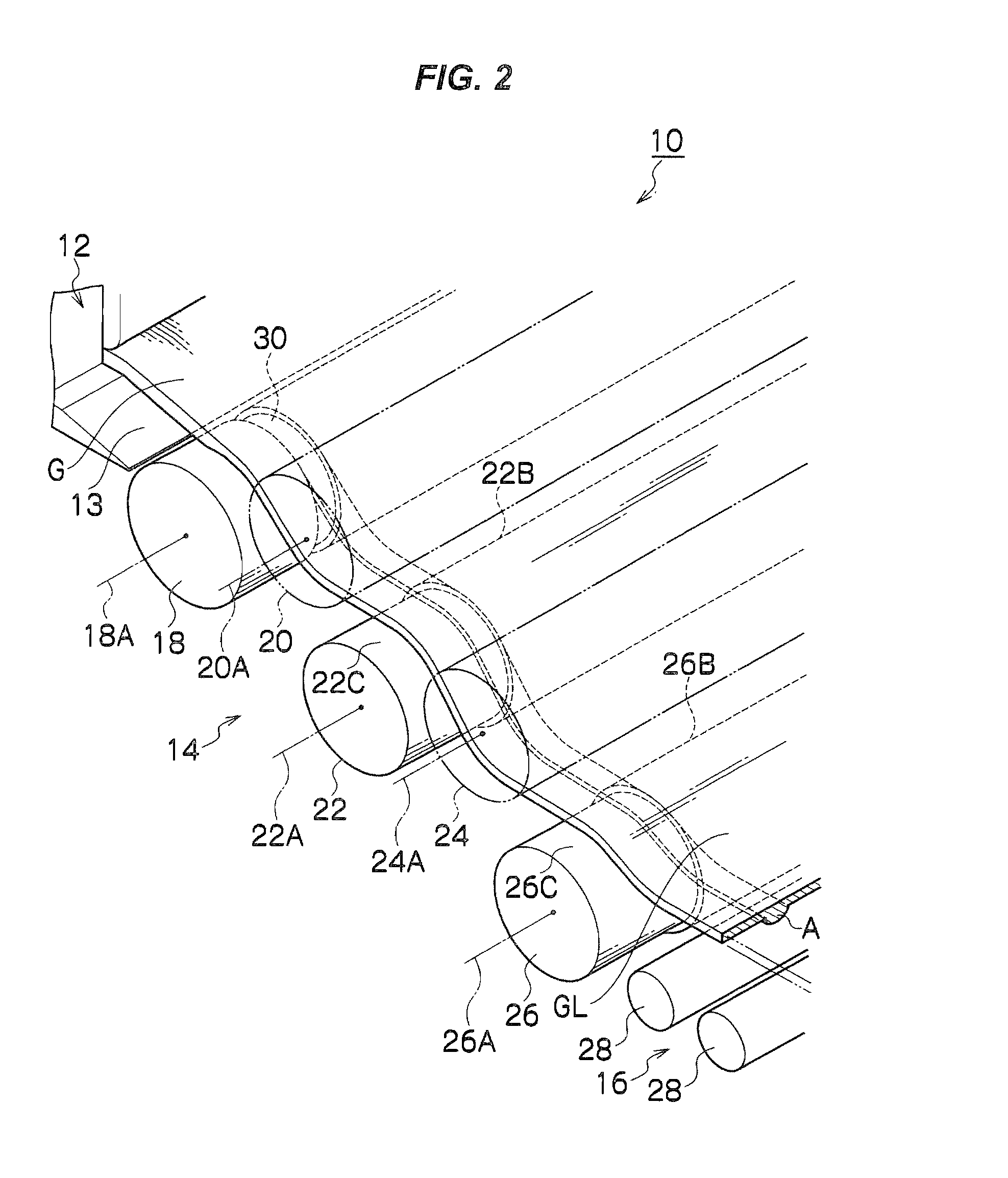

Systems and methods for glass manufacturing

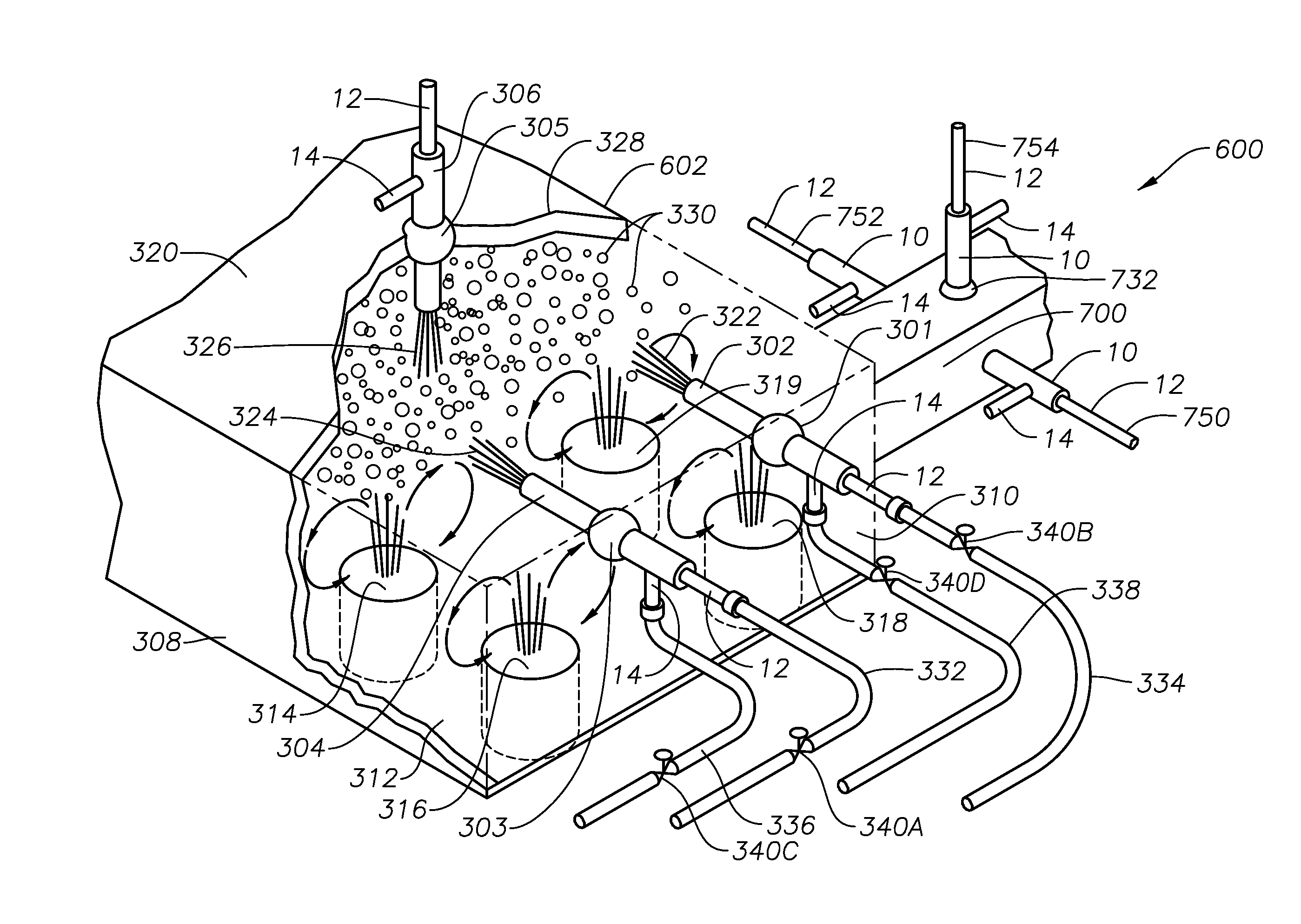

Submerged combustion systems and methods of use to produce glass. One system includes a submerged combustion melter having a roof, a floor, a wall structure connecting the roof and floor, and an outlet, the melter producing an initial foamy molten glass. One or more non-submerged auxiliary burners are positioned in the roof and / or wall structure and configured to deliver combustion products to impact at least a portion of the bubbles with sufficient force and / or heat to burst at least some of the bubbles and form a reduced foam molten glass.

Owner:JOHNS MANVILLE CORP

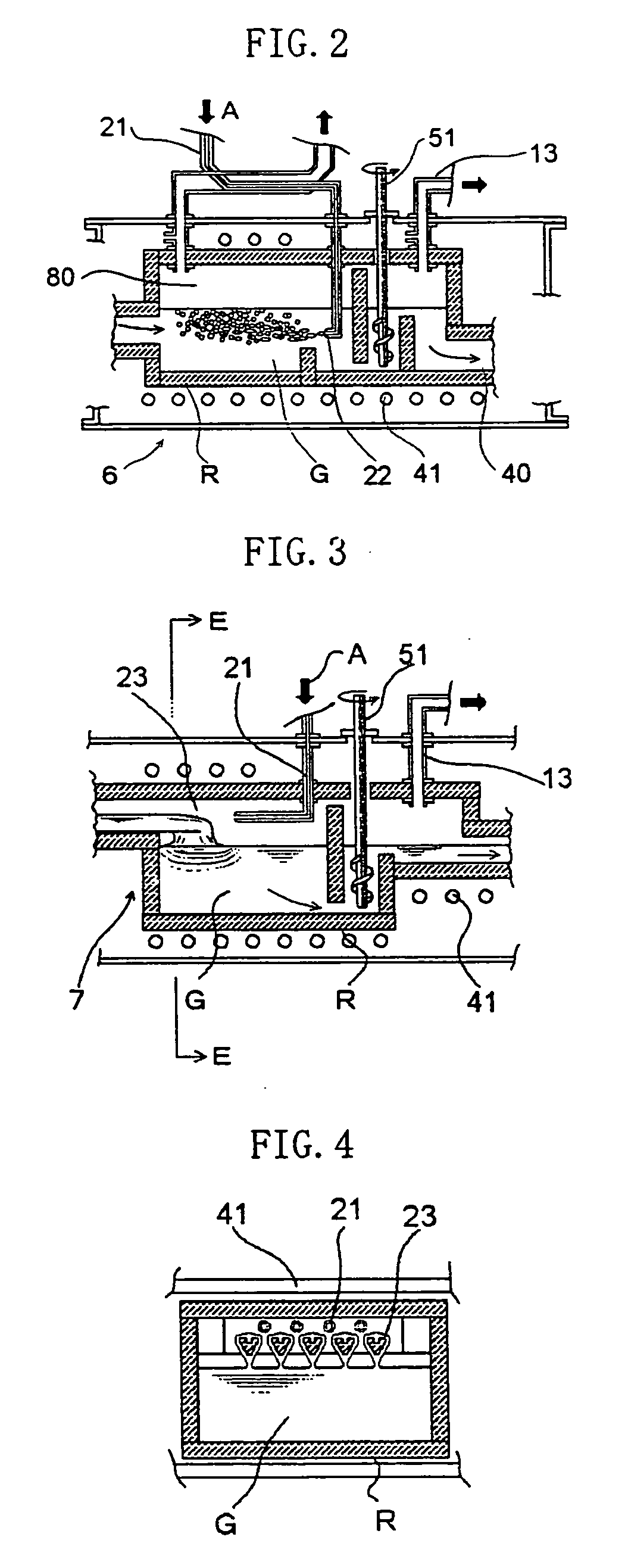

Apparatus and method for reducing gaseous inclusions in a glass

InactiveUS20100199721A1Lower the volumeForehearthsGlass furnace apparatusFlat panel displayGlass manufacturing

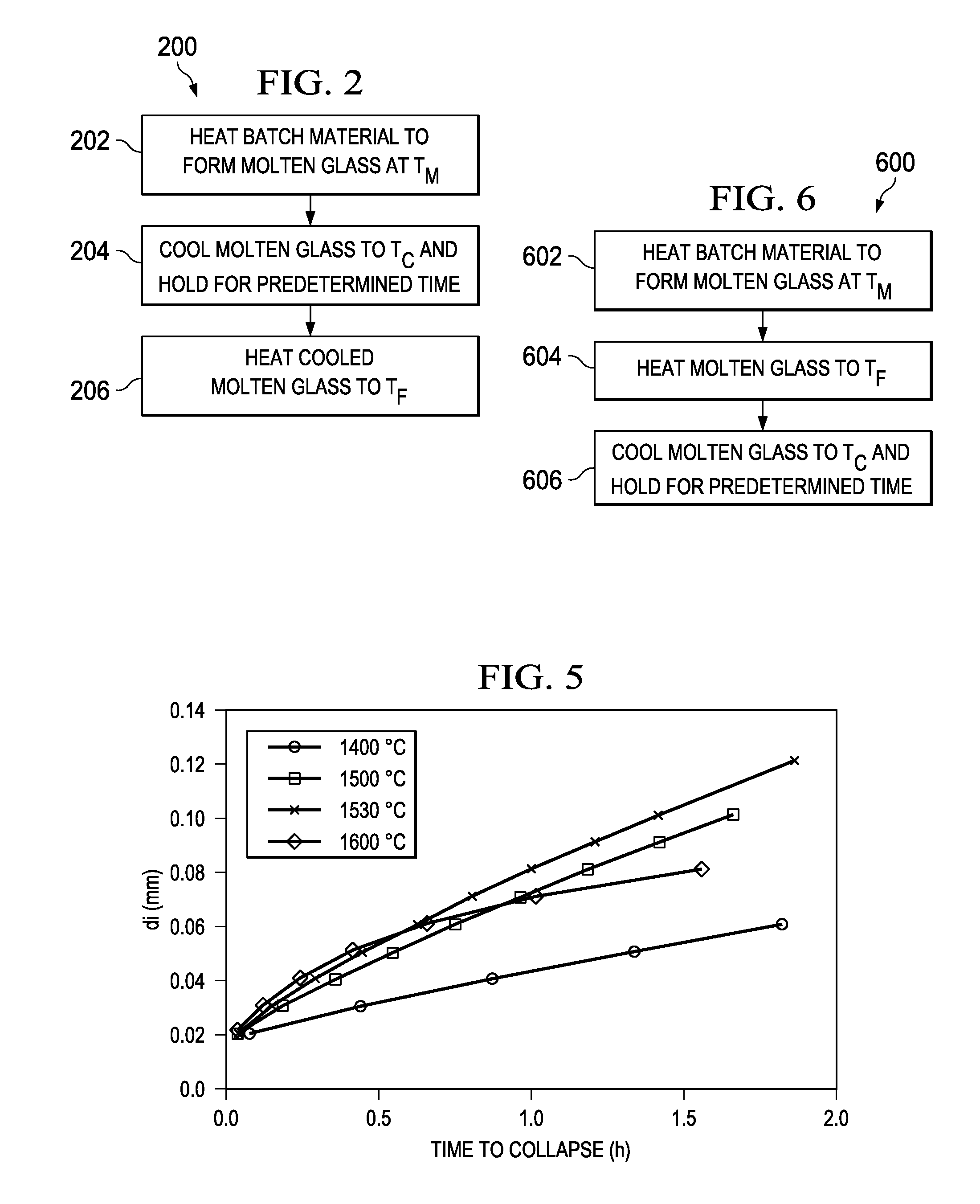

A glass manufacturing system and a method are described herein for reducing gaseous inclusions in high melting temperature or high strain point glasses, such as those that are used as glass substrates in flat panel display devices. In one embodiment, the method including the steps of: (a) heating a batch material within a melting vessel to form molten glass at a melting temperature TM, the molten glass comprising a multivalent oxide material; (b) heating the molten glass within a fining vessel to a fining temperature TF≧TM; and (c) cooling the molten glass within a refractory tube after the first heating step or after the second heating step to a cooling temperature TC less than TM, where the molten glass remains within the refractory tube for a predetermined resident time to reduce a volume of the gaseous inclusions in the molten glass and cause gas species to migrate out of the gaseous inclusions into the molten glass such that at least a portion of the gaseous inclusions collapse into the molten glass.

Owner:CORNING INC

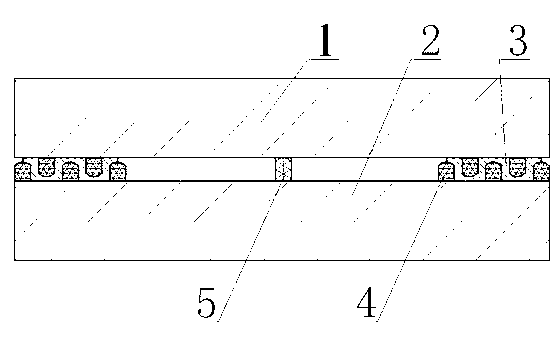

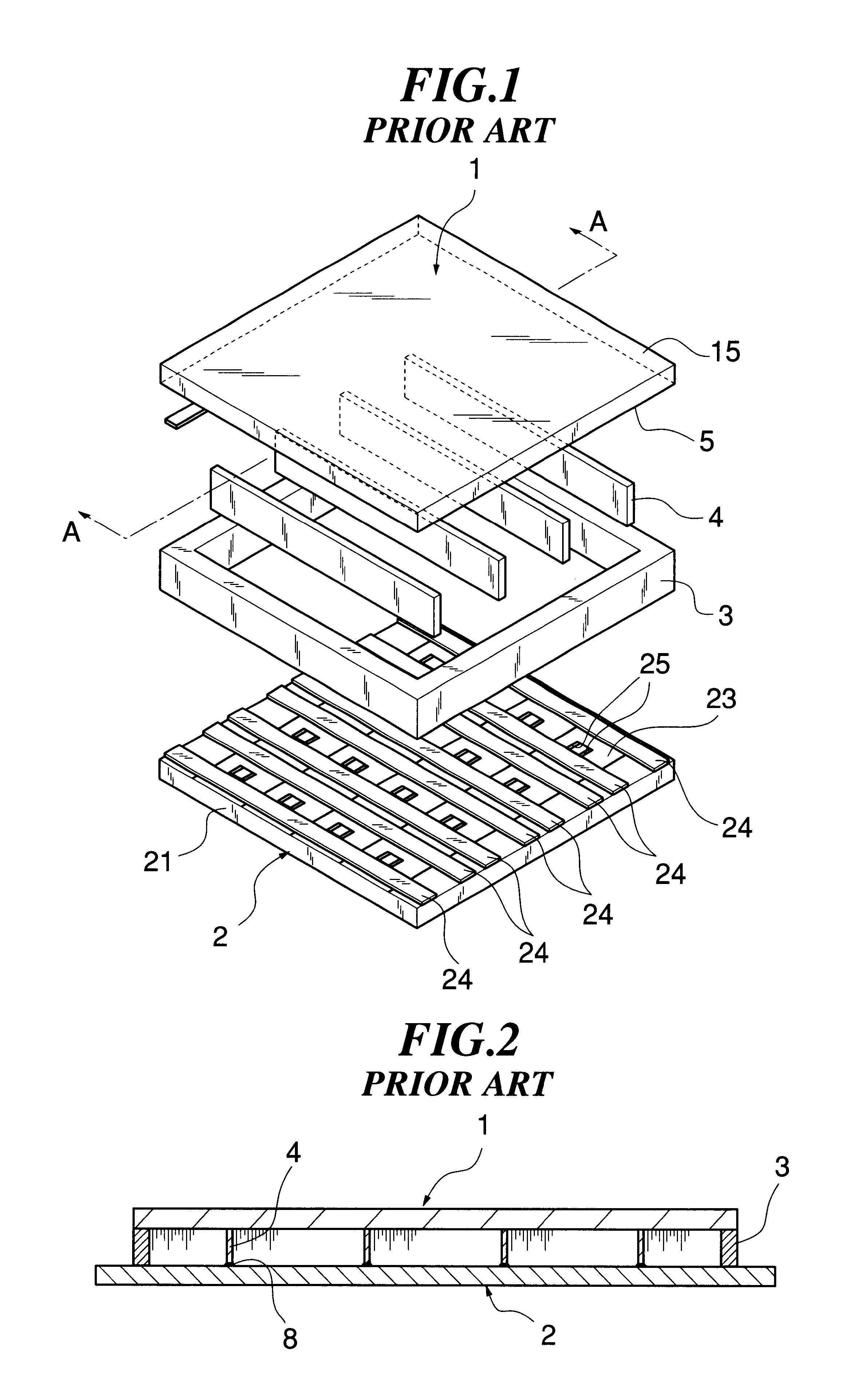

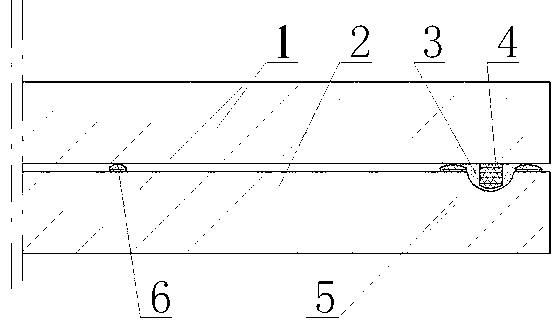

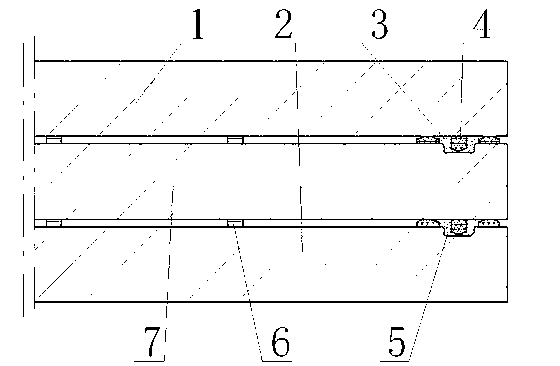

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

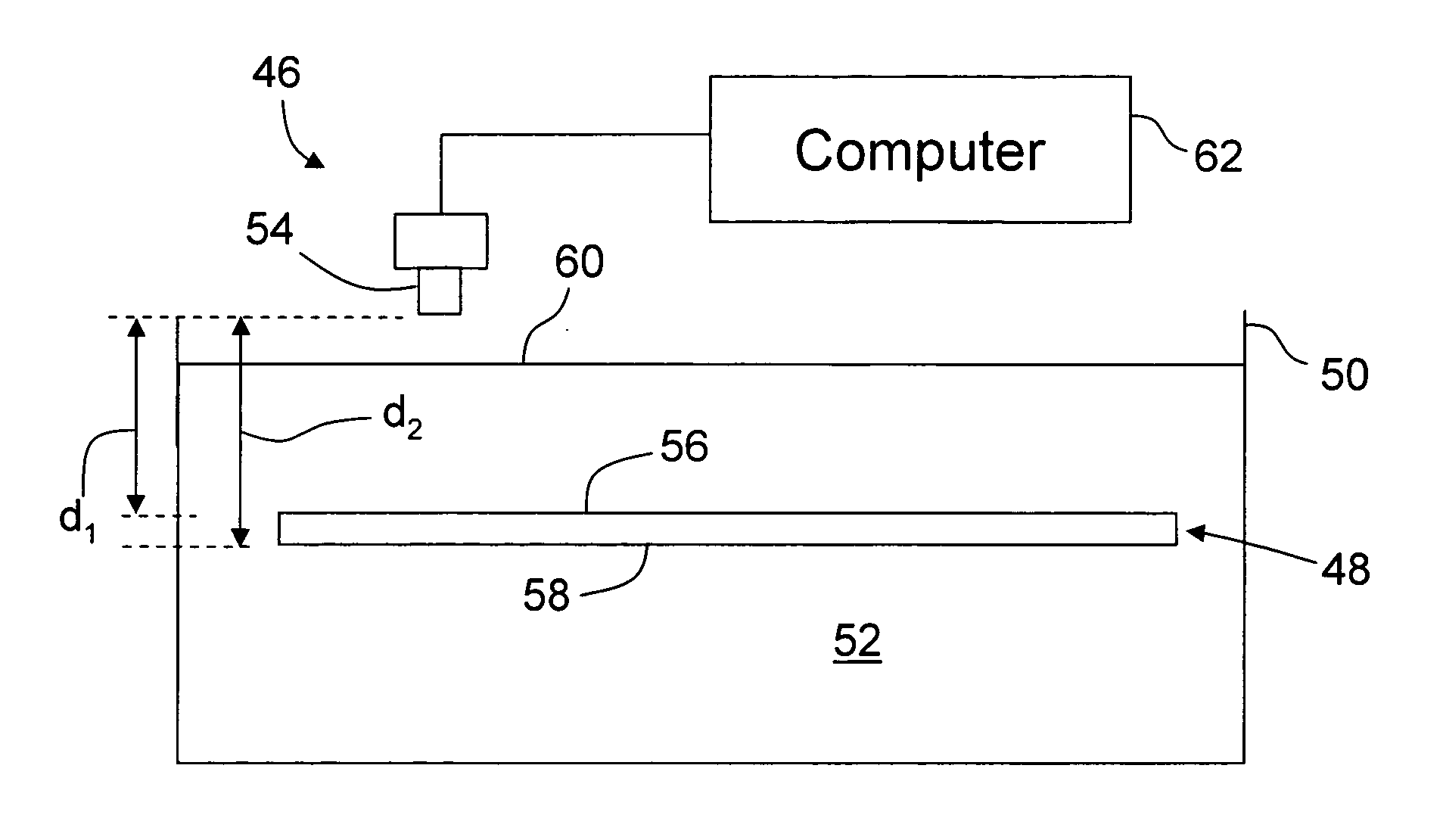

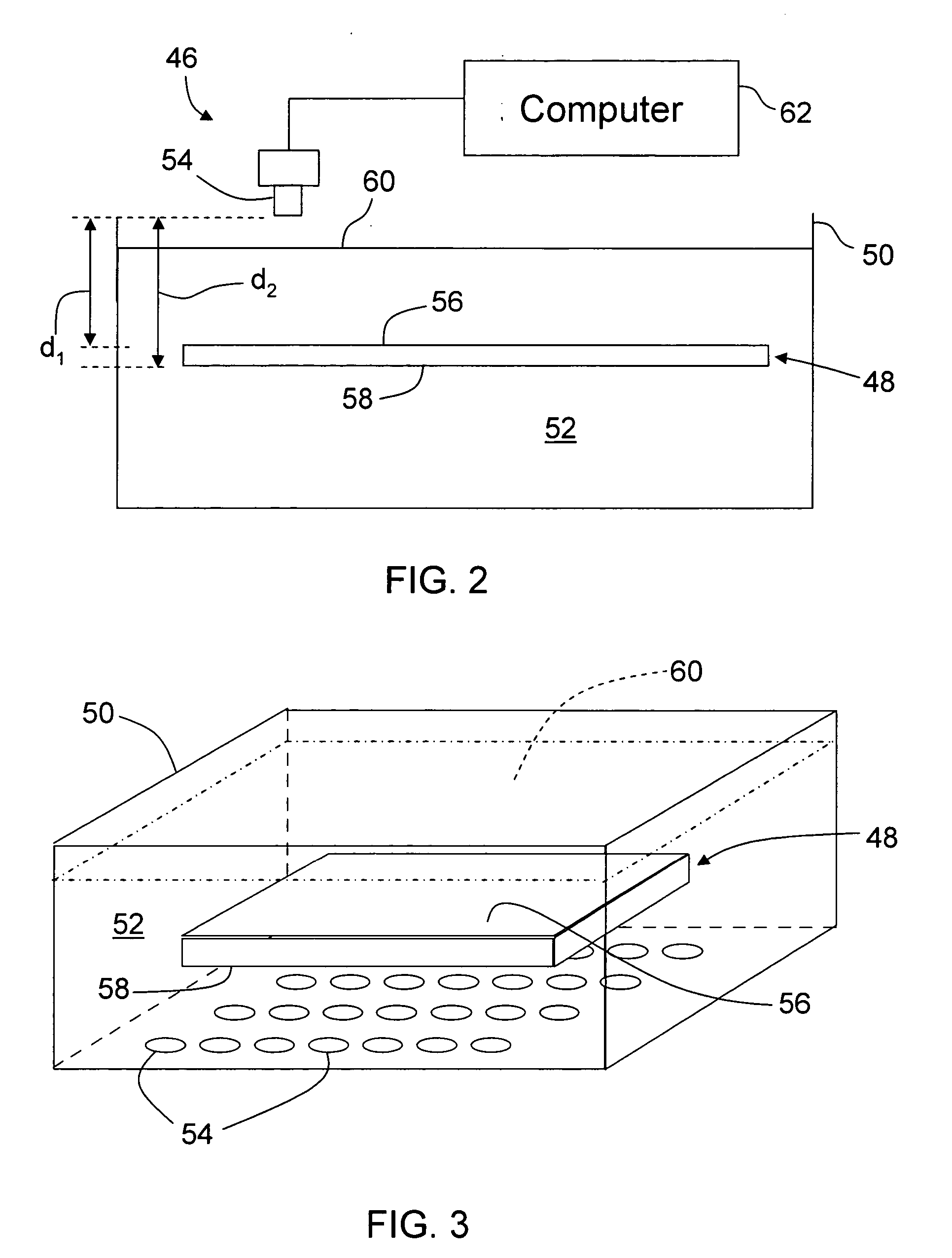

Process and apparatus for measuring the shape of an article

InactiveUS20070028681A1Easy to understandUsing subsonic/sonic/ultrasonic vibration meansGlass pressing apparatusEngineeringGlass sheet

A method of measuring the shape of a glass sheet is provided. The method includes positioning the glass sheet in contact with a fluid and measuring the distance between a sensor and a surface of the glass sheet at a plurality of locations on the surface thereof. The method may further include deconvolving the shape of the glass sheet into at least one simple shape element, such as cylindrical or spherical, and may further include varying the temperature profile of an array of heaters in a glass manufacturing process based on the at least one shape element.

Owner:CORNING INC

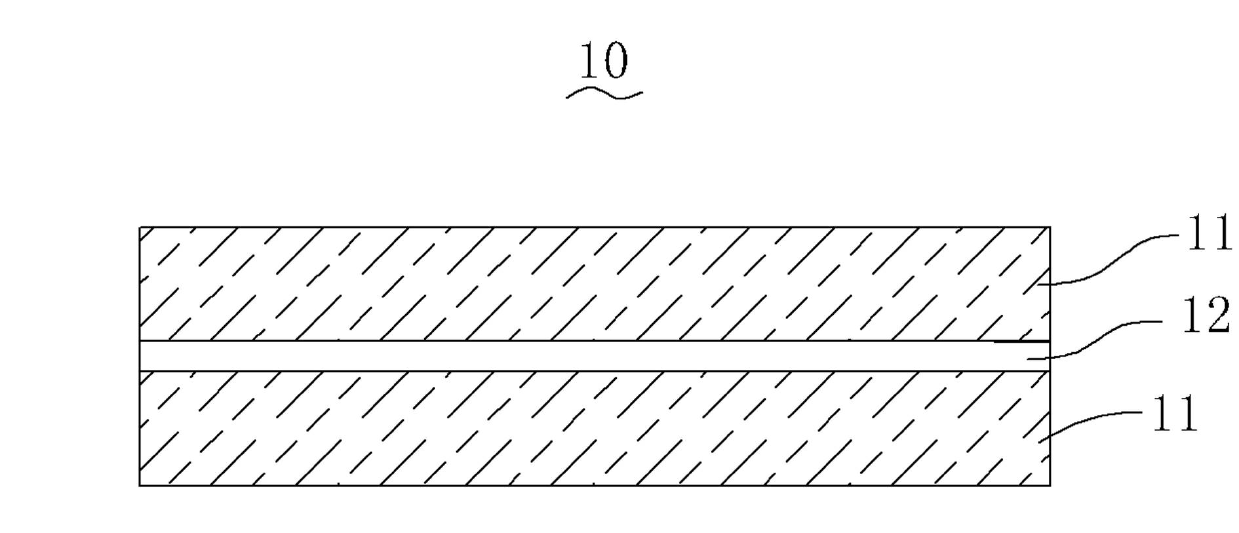

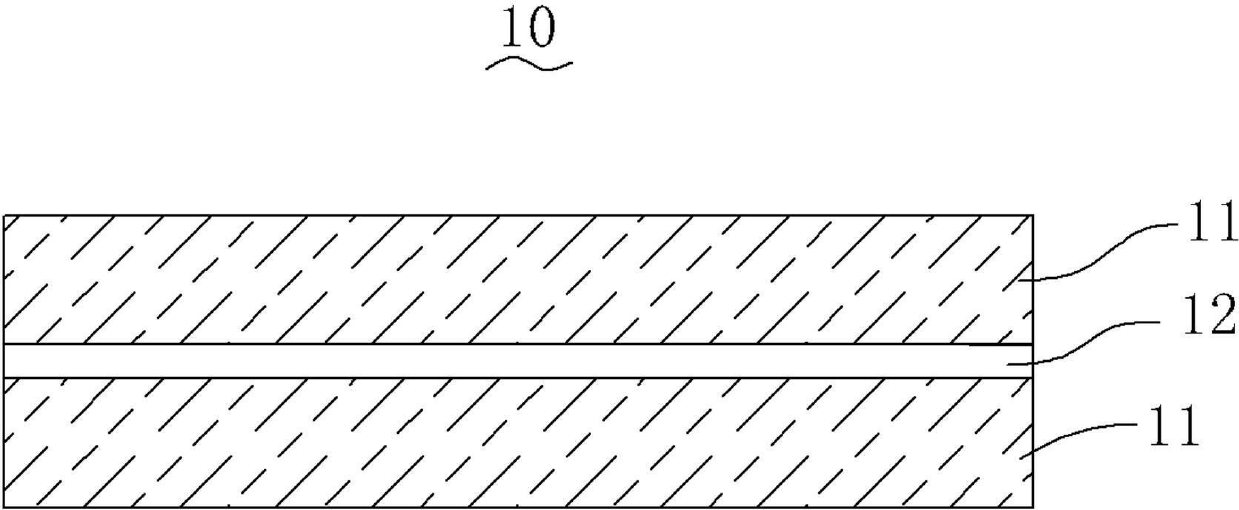

Thermochromic laminated glass and manufacturing method thereof

InactiveCN102674713AWithout changing the basic structureReduce investmentArchitectural glassVanadium dioxide

The invention relates to a thermochromic laminated glass. The thermochromic laminated glass comprises two pieces of glass and a thermochromic film which is clamped between the two pieces of glass, wherein the thermochromic film comprises a polyvinyl butyral base film and tungsten oxide-doped vanadium dioxide powder which is dispersed in the polyvinyl butyral base film. The invention also relates to a manufacturing method for the thermochromic laminated glass. The thermochromic laminated glass adopts the tungsten oxide-doped vanadium dioxide powder which is dispersed in the polyvinyl butyral base film to form the thermochromic film, the basic structure of the conventional laminated glass is not changed, the investment is low, and a high-efficient color change effect is achieved. Due to the adoption of metal oxides, the thermochromic laminated glass is non-toxic, green, environment-friendly and non-flammable, has high safety and meets the current requirements of energy saving and emission reduction. In addition, the thermochromic laminated glass does not basically change the conventional preparation process when manufactured, is simple in preparation process and low in cost, and is suitable for the fields of building glass, automobile sunroof glass, side window glass and the like.

Owner:信义超薄玻璃(东莞)有限公司

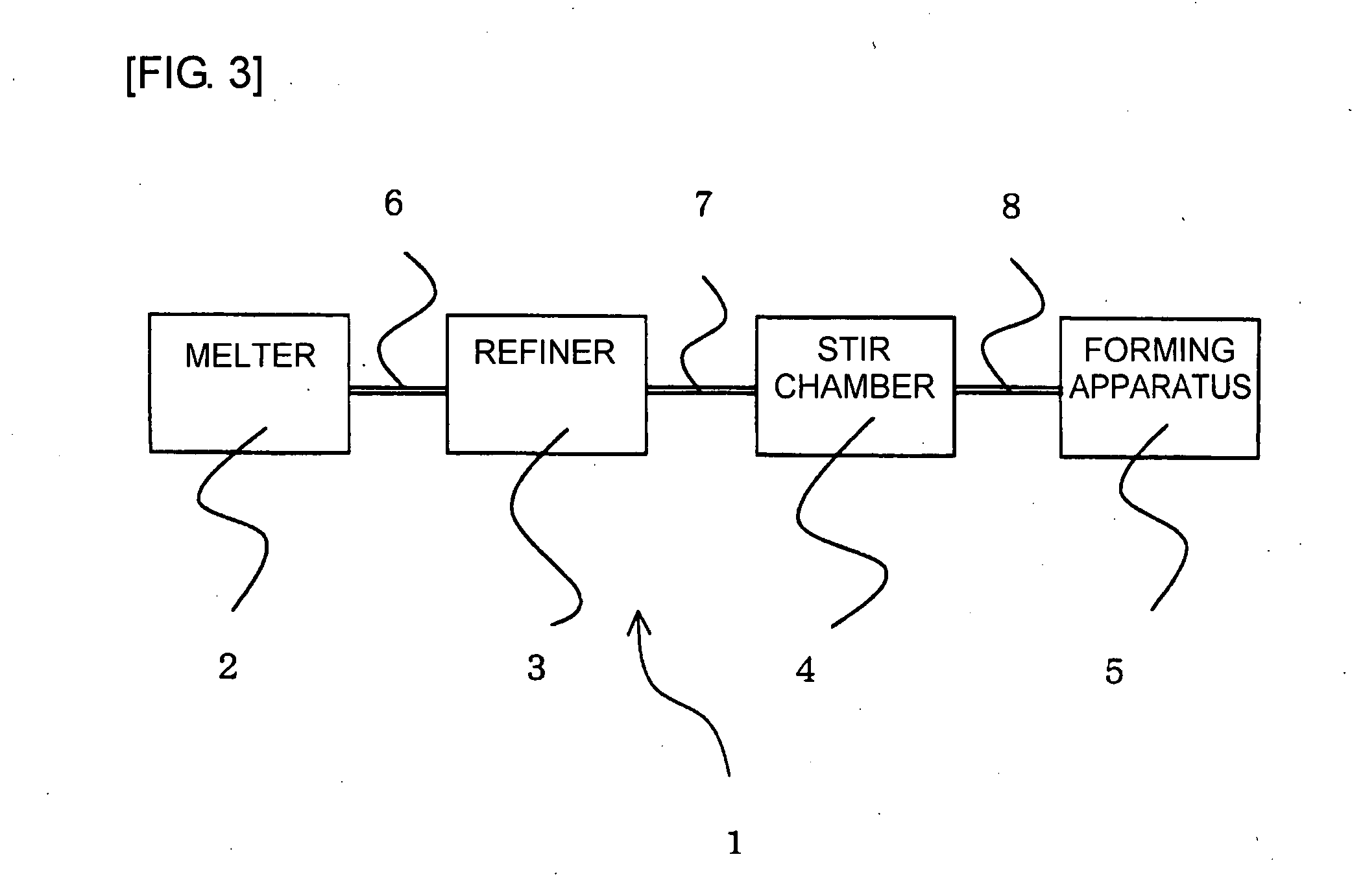

Glass manufacturing equipment used for reducing impurity in glass and its method

InactiveCN1903755AReduce oxidationReduce corrosionGlass furnace apparatusGlass productionMetallurgyProduct gas

The present invention relates to glass-making equipment capable of reducing impurity content in the glass in the glass-making process. Said equipment includes the following several portions: melting bath, clarifier, cooling device, glass melt supply device and glass product forming device. Said invention also provides the concrete structure of every above-mentioned portion and connection mode of all the above-mentioned portions.

Owner:HENAN ANCAI HI-TECH +1

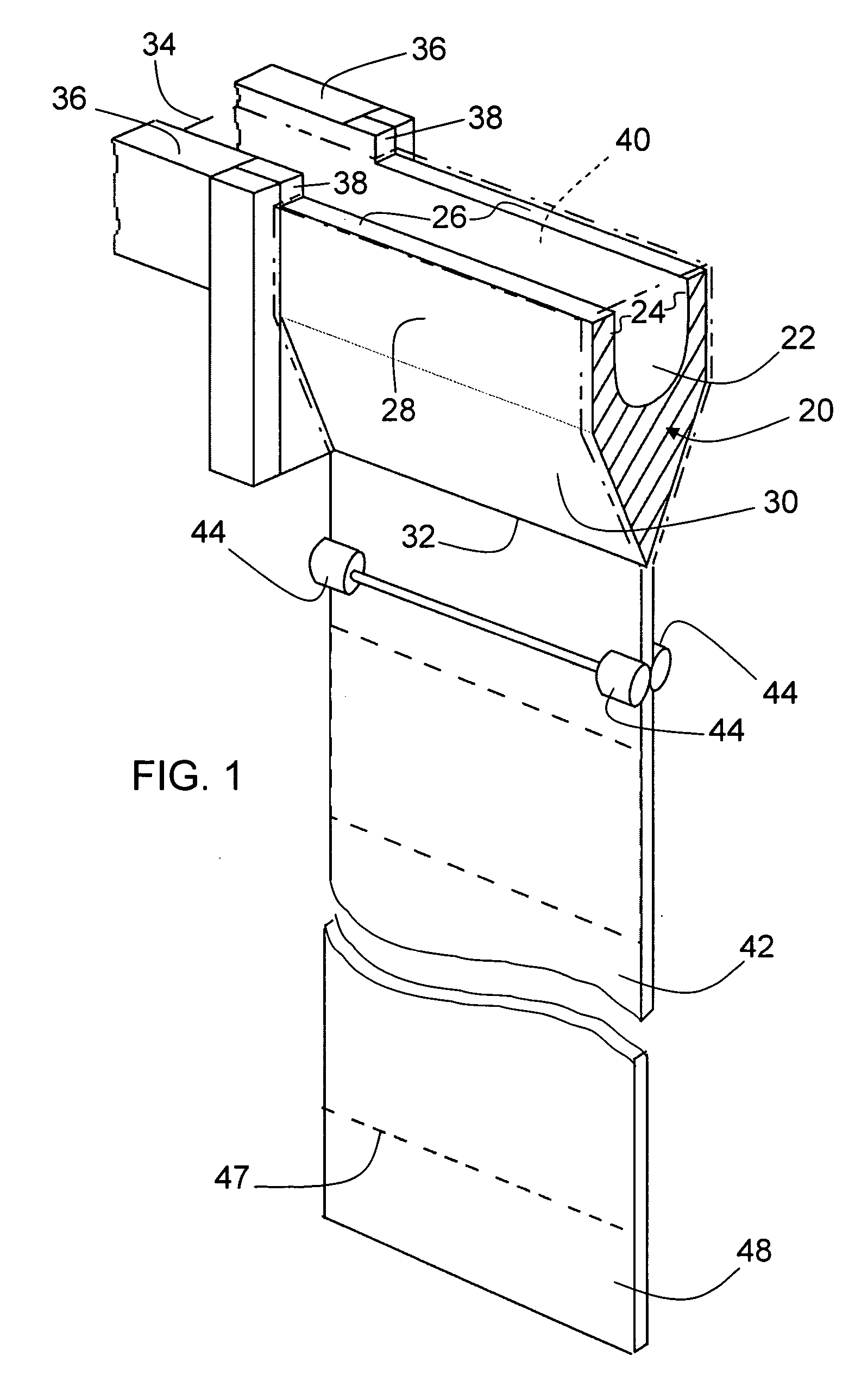

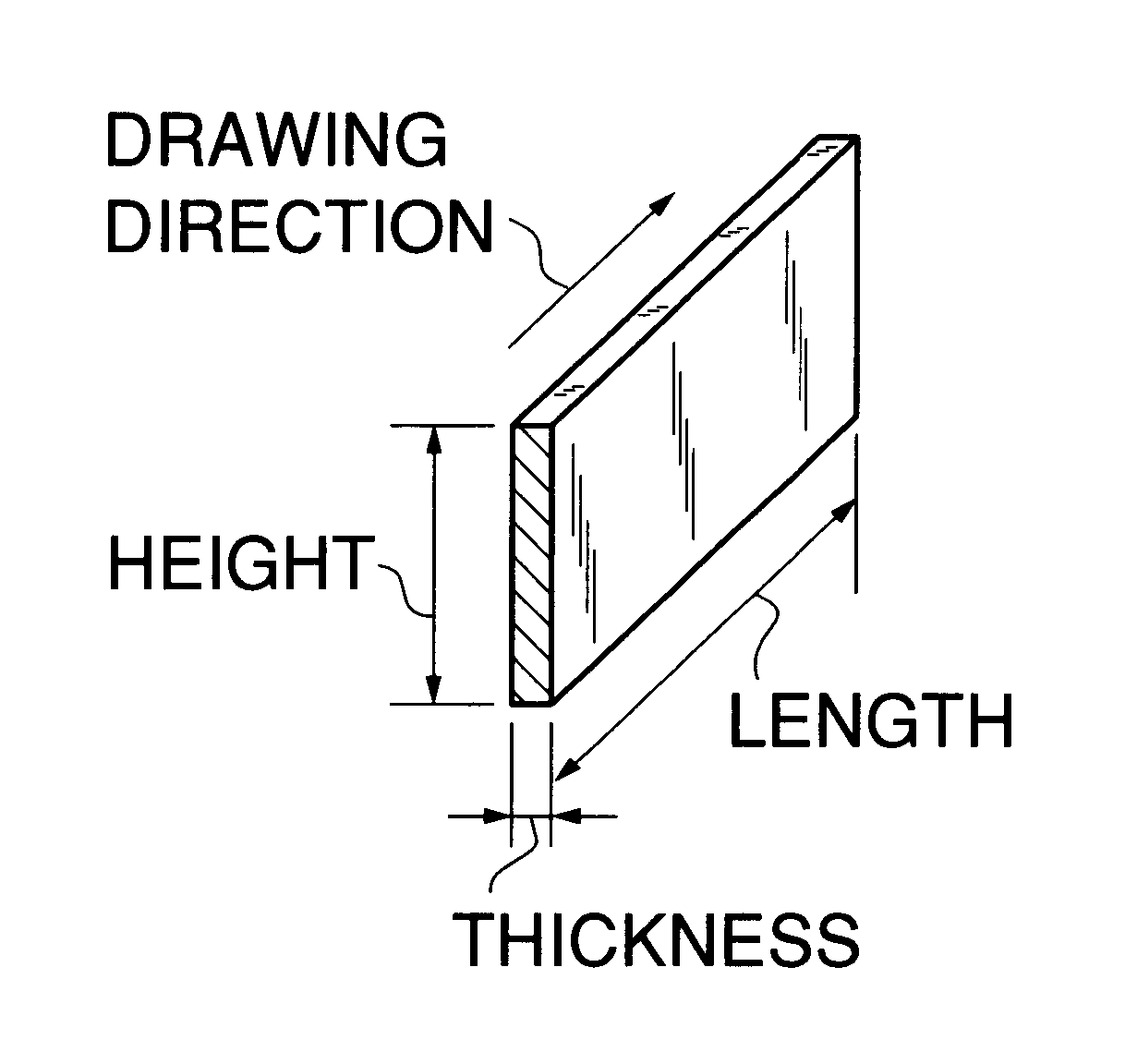

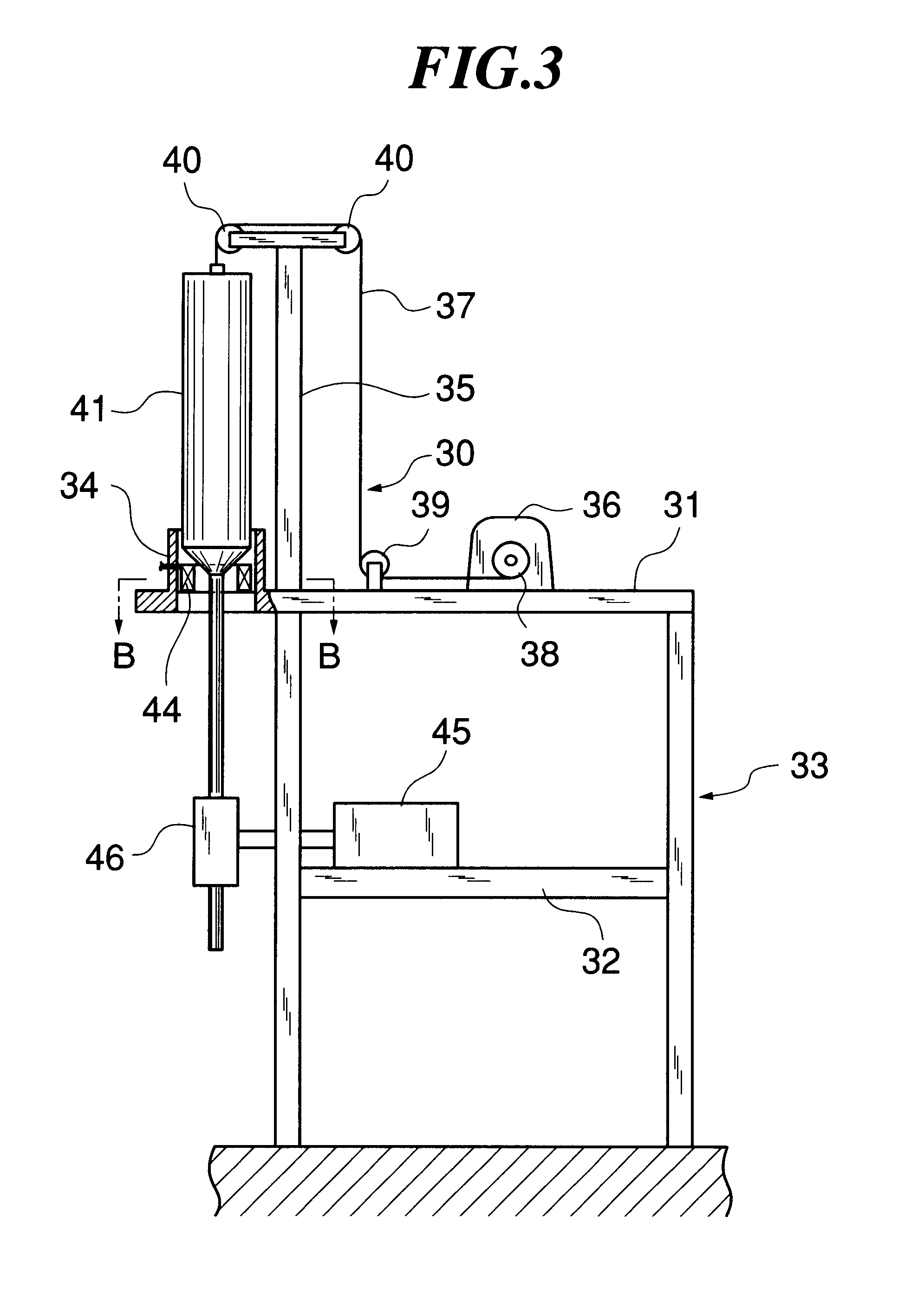

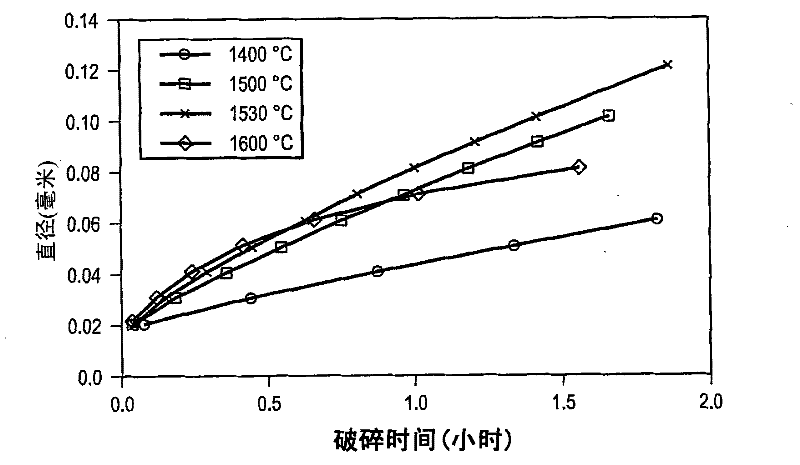

Method of manufacturing glass spacers

InactiveUS6385998B1Cathode-ray/electron-beam tube vessels/containersImage/pattern display tubesMetallurgyPoise

A method of manufacturing glass spacers is provided which can enhance the degree of similarity in cross section between the mother glass and the drawn glass when manufacturing glass spacers by hot drawing the mother glass. A mother glass having a similar cross section to a desired cross section of the glass spacers is prepared. The mother glass is drawn while it is heated to a viscosity of 105 to 109 poise.

Owner:NIPPON SHEET GLASS CO LTD

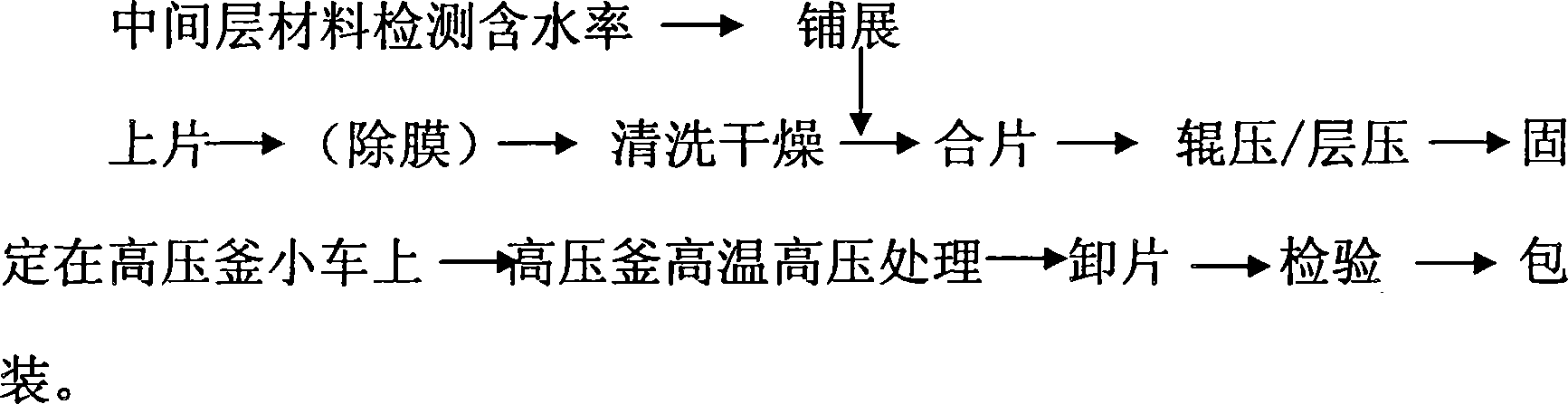

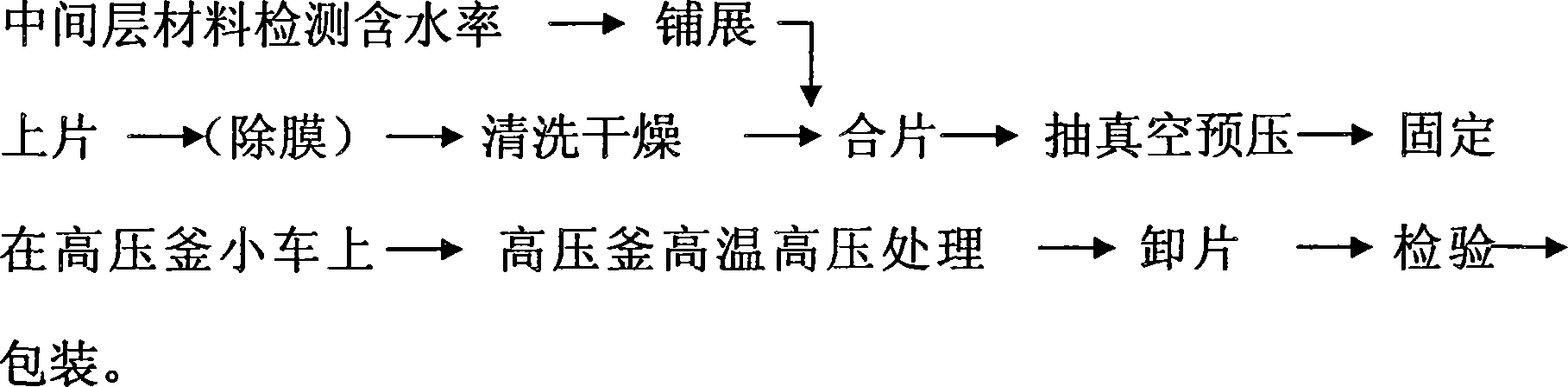

Solar photovoltaic interlining curtain wall glass manufacturing process

The invention provides a process for sandwich curtain wall glass inside provided with a solar cell slice capable of generating electricity. The film layer structure of the solar sandwich curtain wall glass comprises a glass sheet, a bonding layer, a solar cell, a tack coat and a glass sheet in turn. The process is of the cleanness of dry glass sheet; the closure of the slice; roll-in or lamination or vacuumizing; the fixation on a high-pressure autoclave wheelbarrow; and the treatment of high-pressure autoclave high temperature and high pressure; the solar cell can be a crystal silicon solar cell slice or the combination of a plurality of crystal silicon solar cells; the glass collects glass and solar cell into a whole and is capable of generating electricity. Therefore, the glass can be independently taken as curtain wall glass or can be compounded with other glass to form hollow glass and taken as curtain wall glass.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP

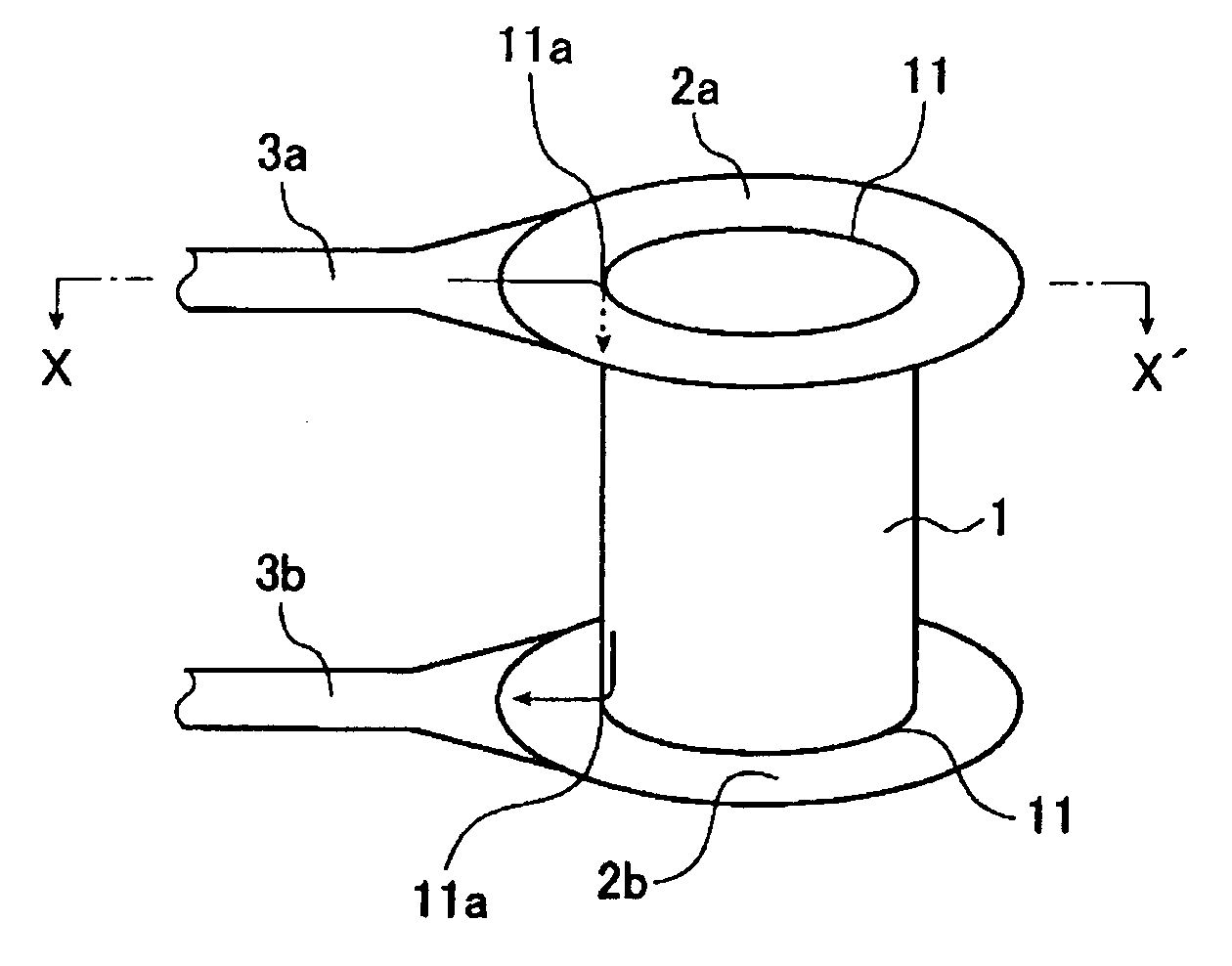

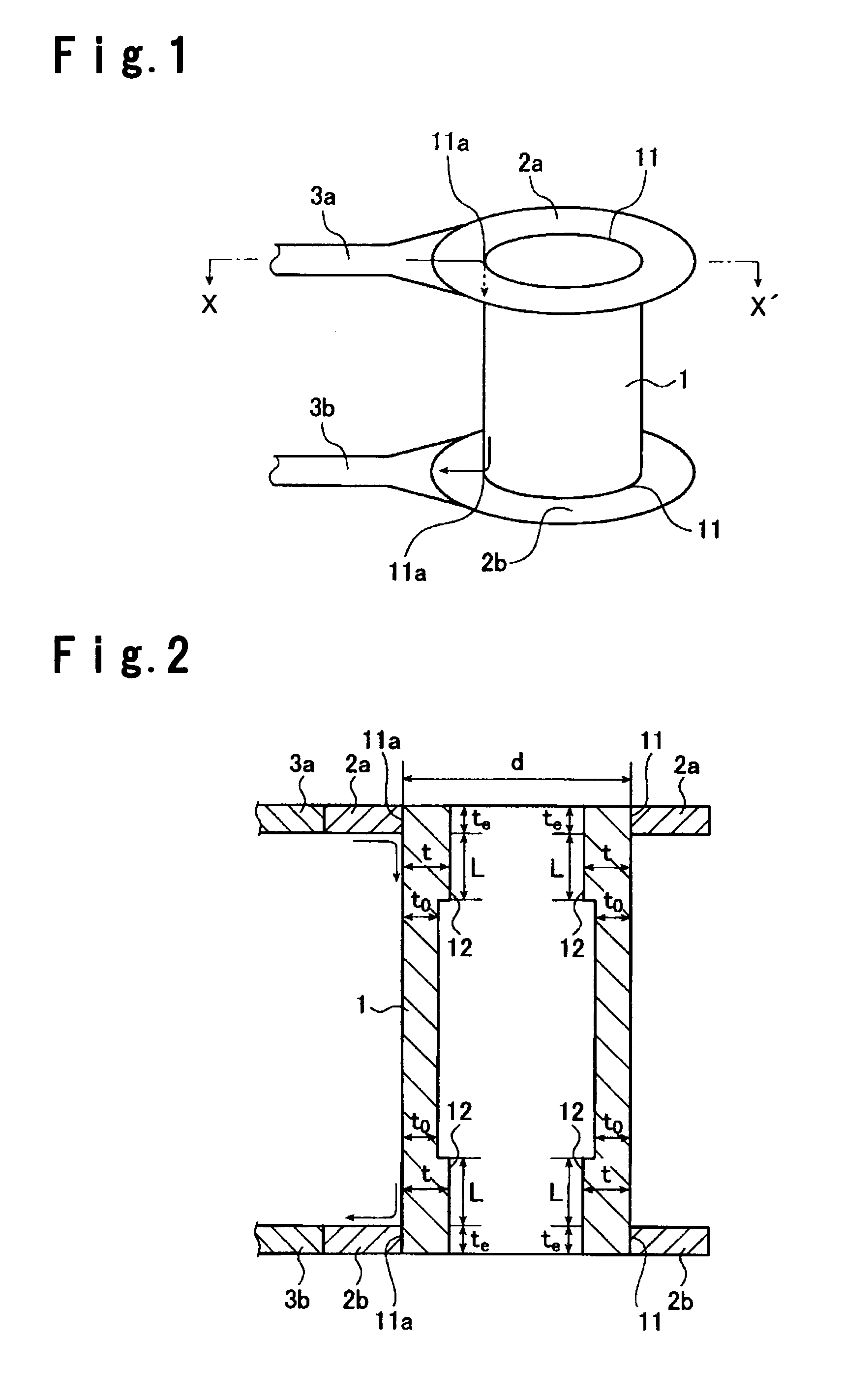

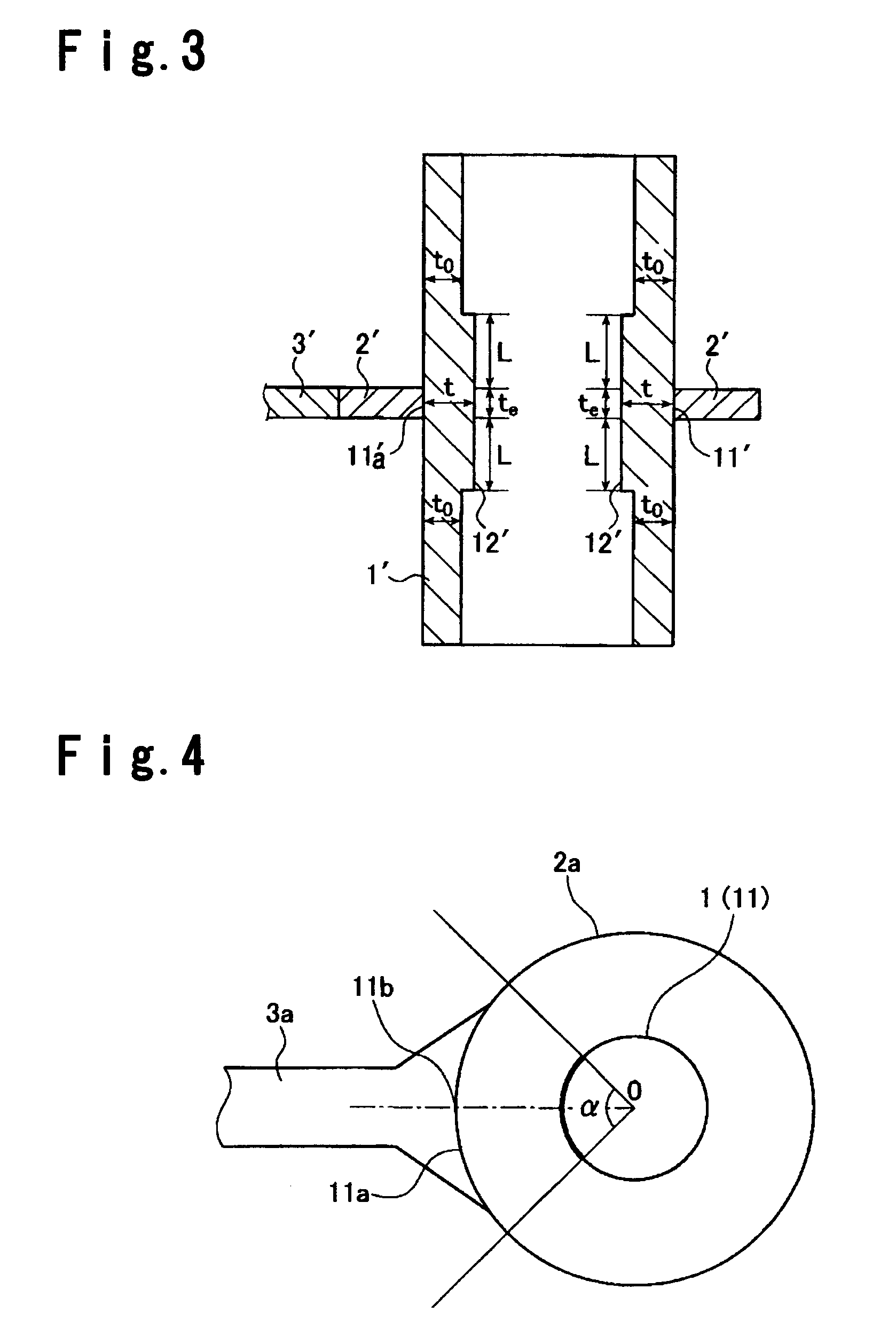

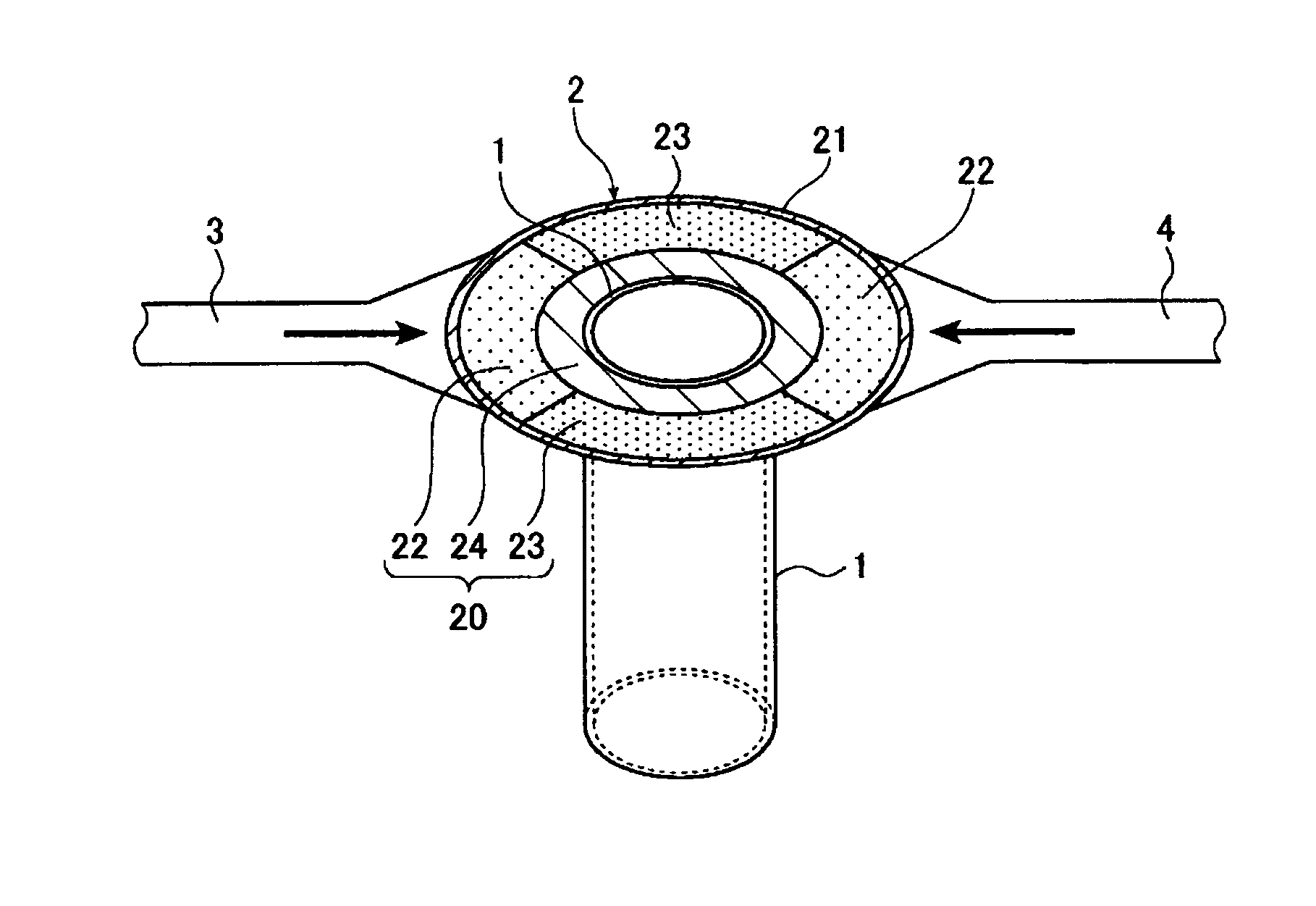

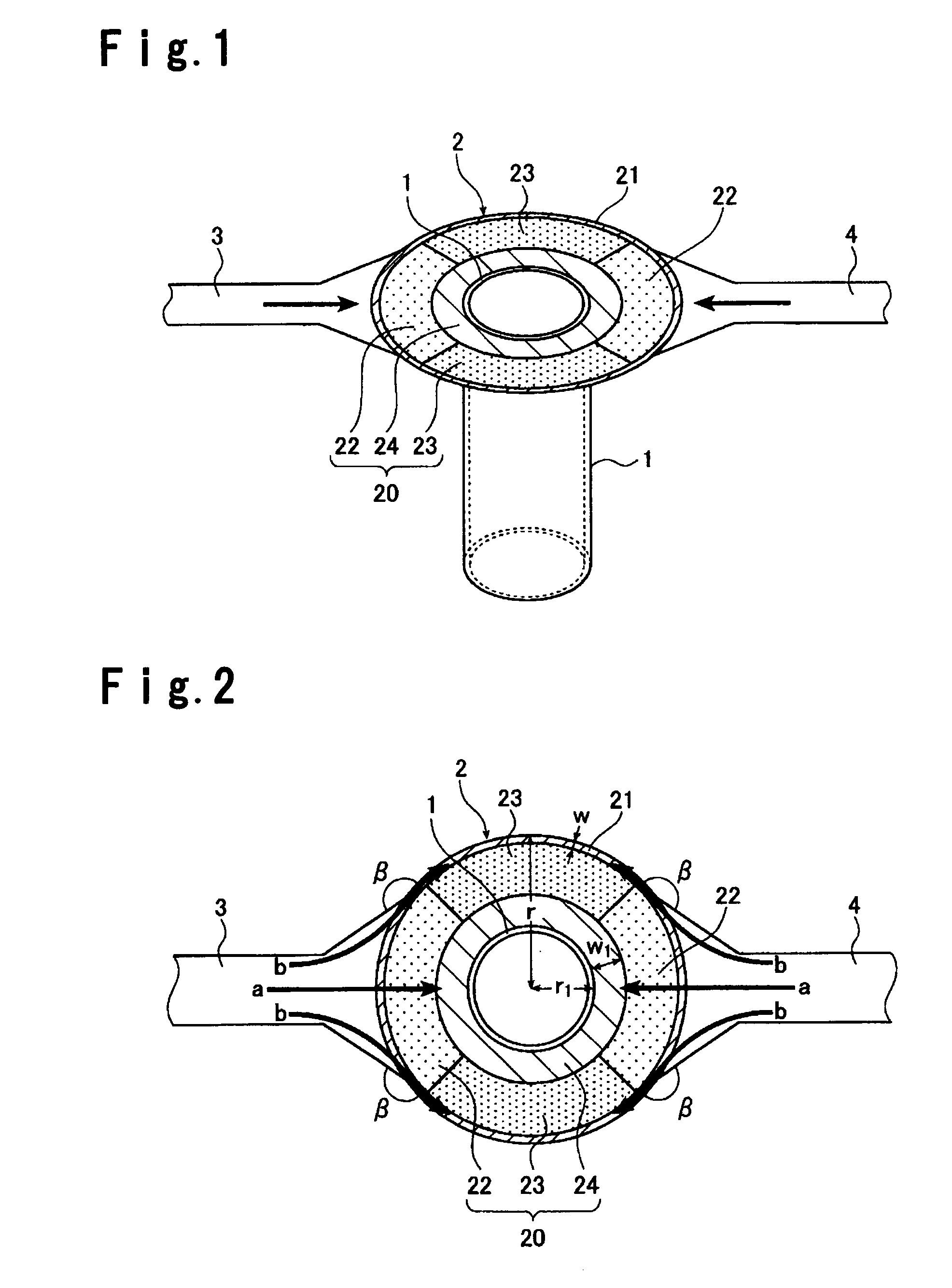

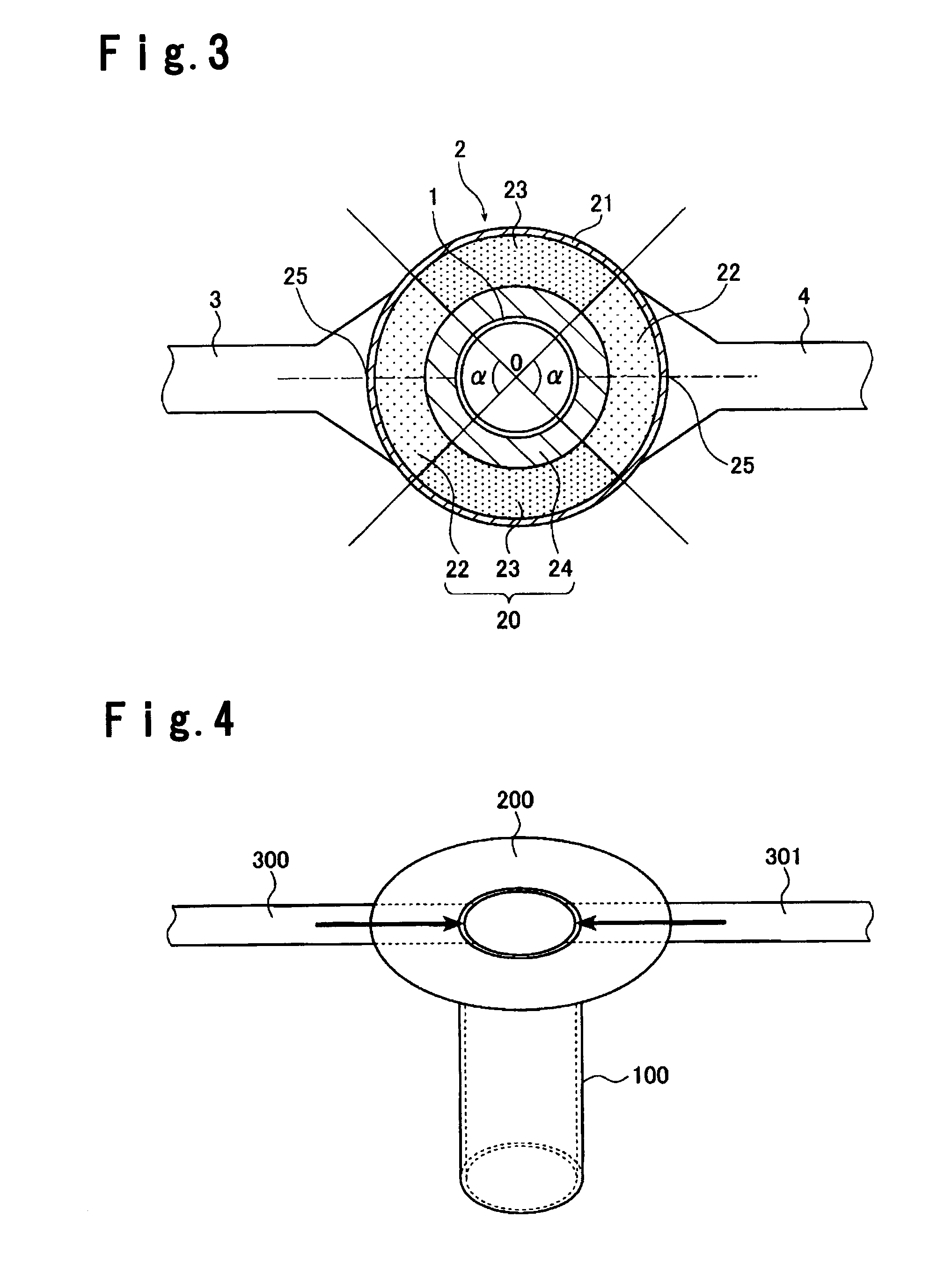

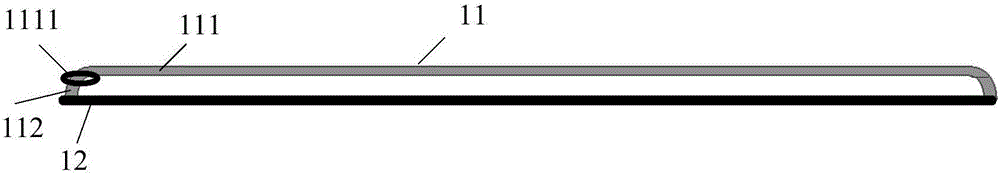

Glass manufacturing apparatus, a structural member thereof and method for heating the structural member by conduction heating

A hollow tubular body for molten glass in which local-overheating is reduced at the time of conduction heating. The hollow tubular body has a platinum or platinum alloy hollow tube, used for conduction heating, wherein a platinum or platinum alloy ring electrode is joined to the outer circumference of the hollow tube, a lead-out electrode is joined to an outer edge of the ring electrode, and a thick portion is provided in at least the joint portion closest to the lead-out electrode, of the ring electrode and in the vicinity thereof.

Owner:ASAHI GLASS CO LTD

Glass manufacturing apparatus and a structural member thereof

ActiveUS20080087046A1Avoid conductionGlass drawing apparatusGlass transportation apparatusPlatinumMetallic materials

A hollow tubular body for molten glass by which local-overheating in the electrode for conduction heating is prevented. A hollow tubular body having a platinum or platinum alloy hollow tube, used for conduction heating is characterized in that a ring electrode is joined to the outer circumference of the hollow tube, at least one lead-out electrode is joined to an outer edge of the ring electrode, and the ring electrode comprises a core portion of electrode of platinum or platinum alloy and a thick portion of platinum or platinum alloy or of a metallic material other than platinum or platinum alloy, provided at an outer side of the core portion of electrode.

Owner:ASAHI GLASS CO LTD

Compound clarifying agent for high-aluminum alkali-free borosilicate glass

The invention discloses a compound clarifying agent for high-aluminum alkali-free borosilicate glass and belongs to the field of glass manufacturing. The compound clarifying agent comprises the following components by weight percent: 80-89% of thinning agents, 3-6% of sulfates, 4-6% of chlorine alkaline earth salts and 4-10% of stannous oxides. The invention provides a better clarifying agent for a fusing process of the high-aluminum alkali-free borosilicate glass, so as to facilitate the discharging of air bubbles during the glass fusing process and increase the yield.

Owner:成都中光电科技有限公司 +1

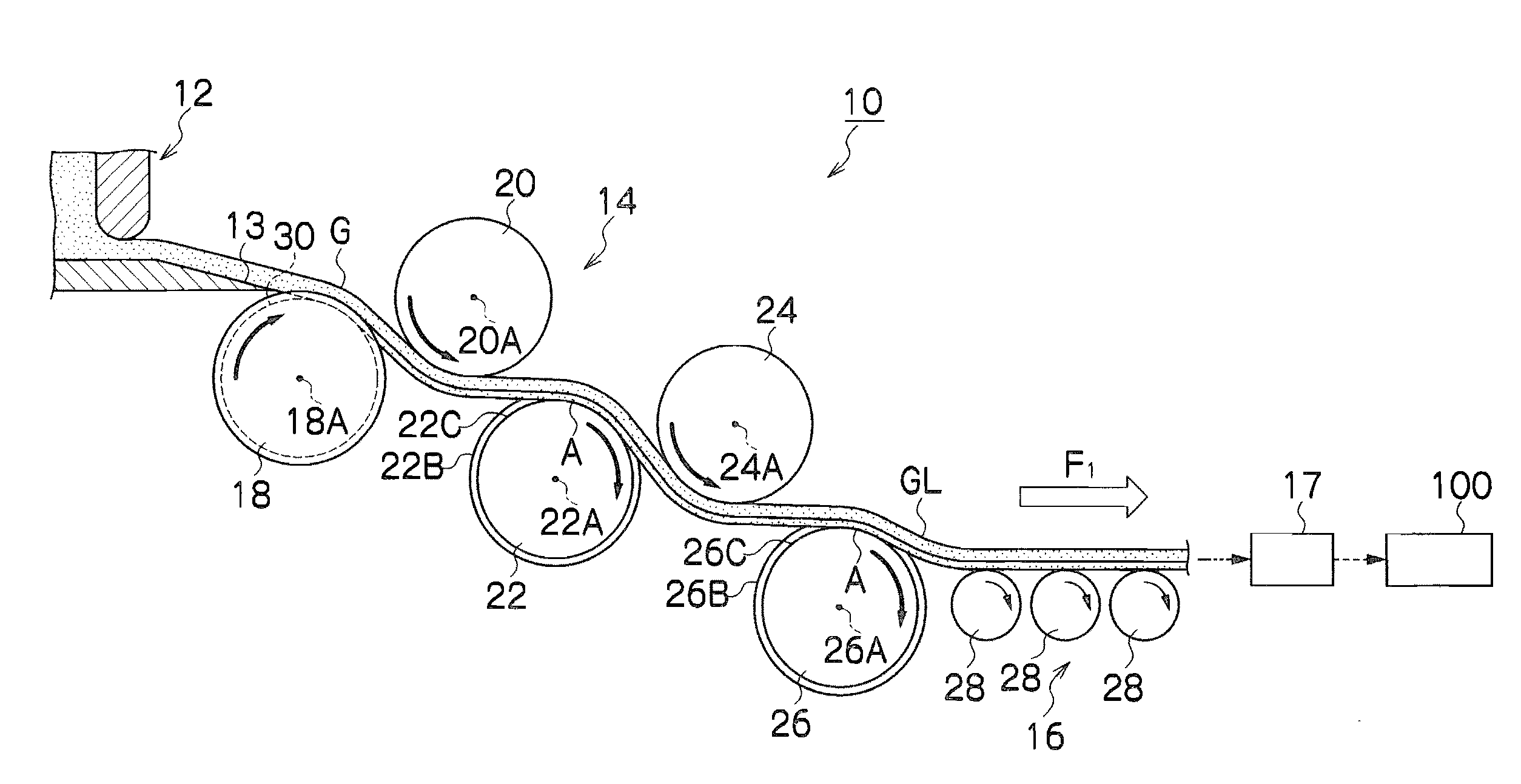

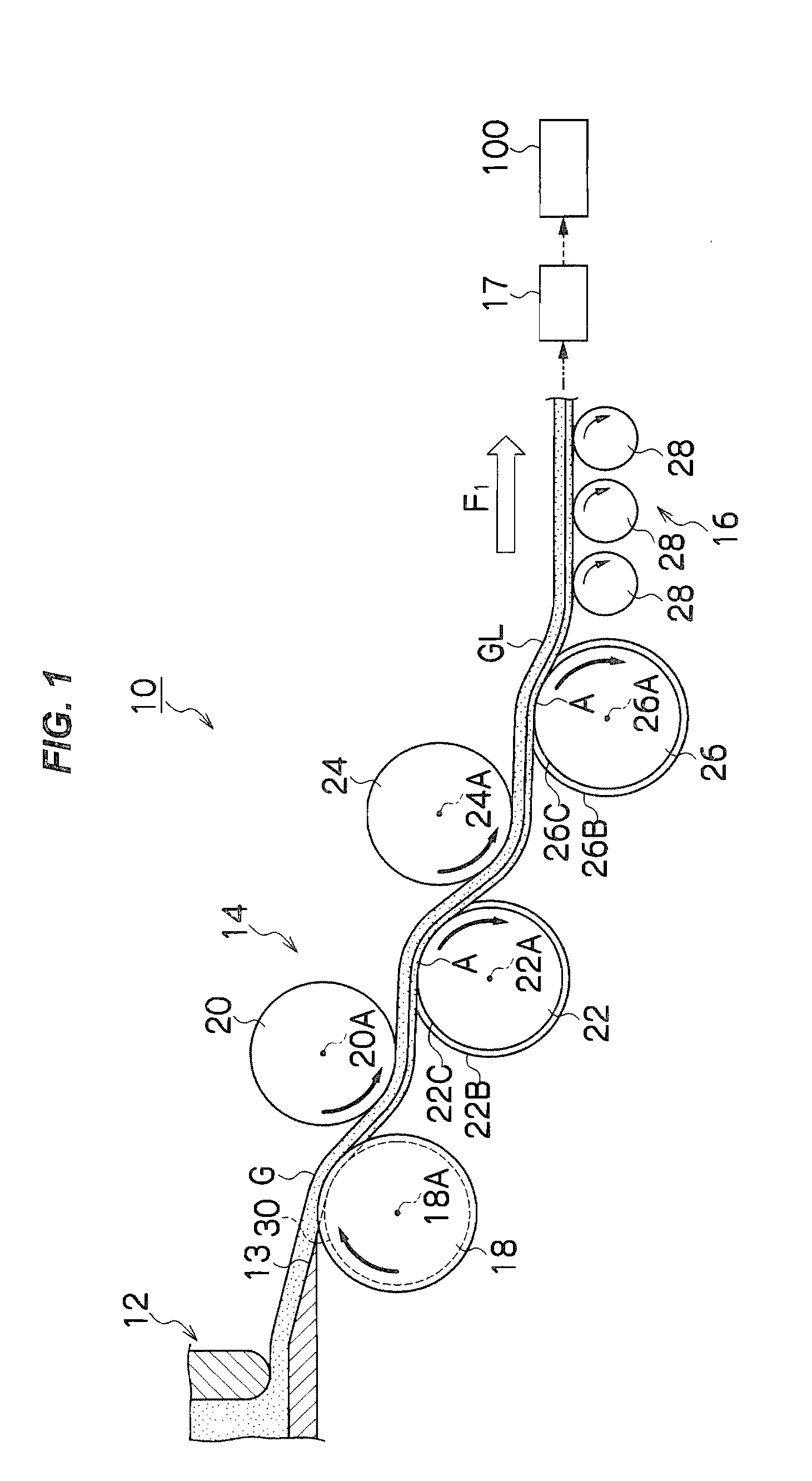

Plate glass manufacturing device and plate glass manufacturing method

InactiveUS20120159989A1Quality improvementGlass transportation apparatusGlass forming apparatusFlat glassContinuous flow

A flat glass production apparatus includes a molten glass ribbon supply part supplying a continuous flow of molten glass to a forming part as a glass ribbon of a formable temperature; the forming part including a plurality of tension rollers for forming the glass ribbon of the formable temperature supplied from the molten glass ribbon supply part into a glass ribbon of an unformable temperature; and a carriage part carrying out the glass ribbon of the unformable temperature on a downstream side of the forming part.

Owner:ASAHI GLASS CO LTD

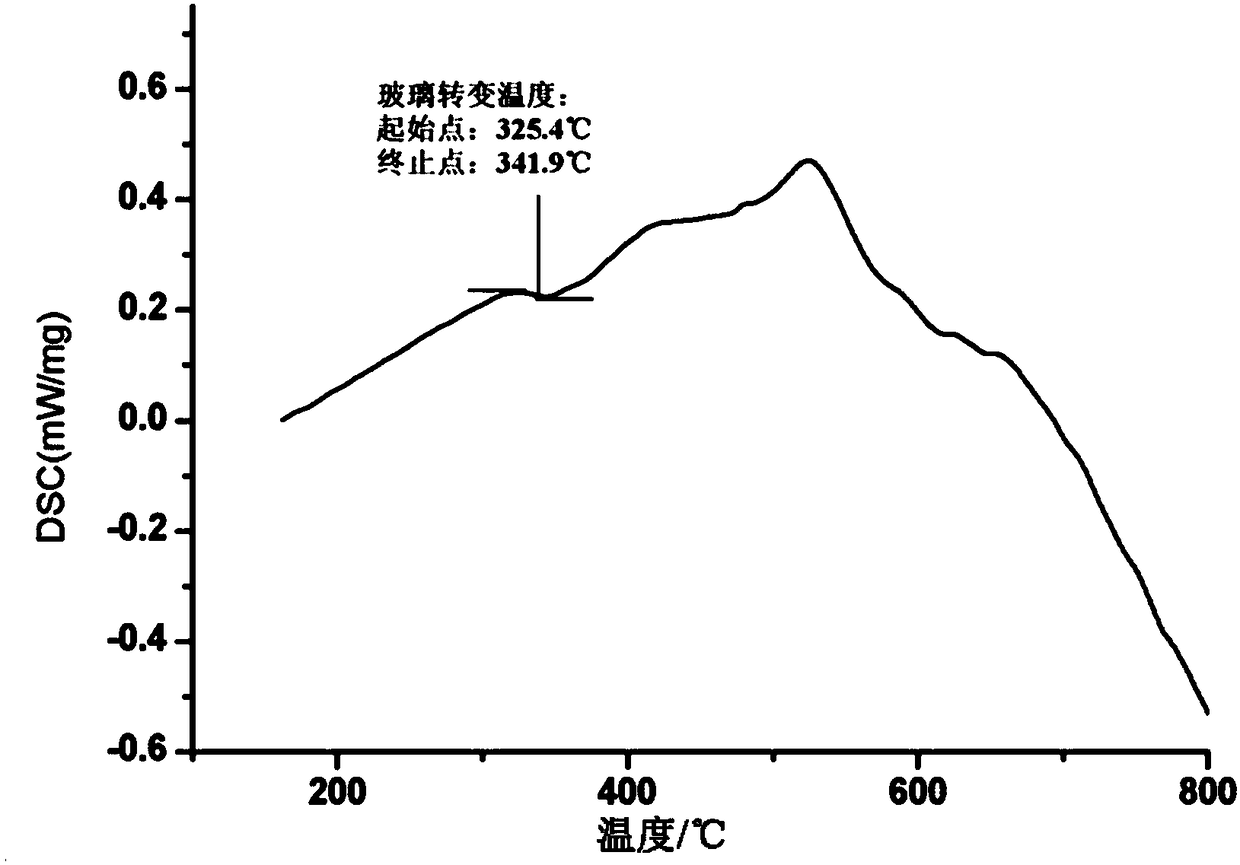

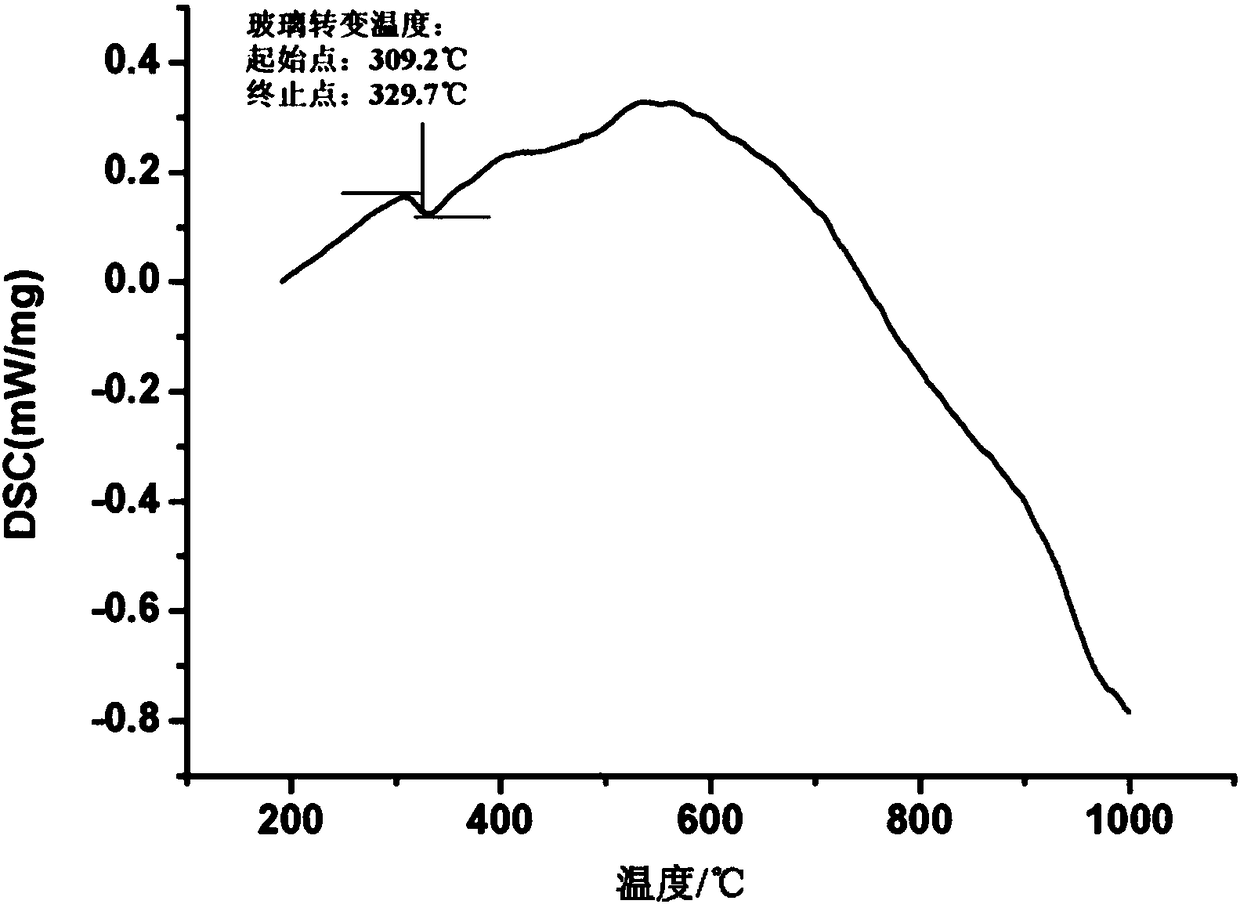

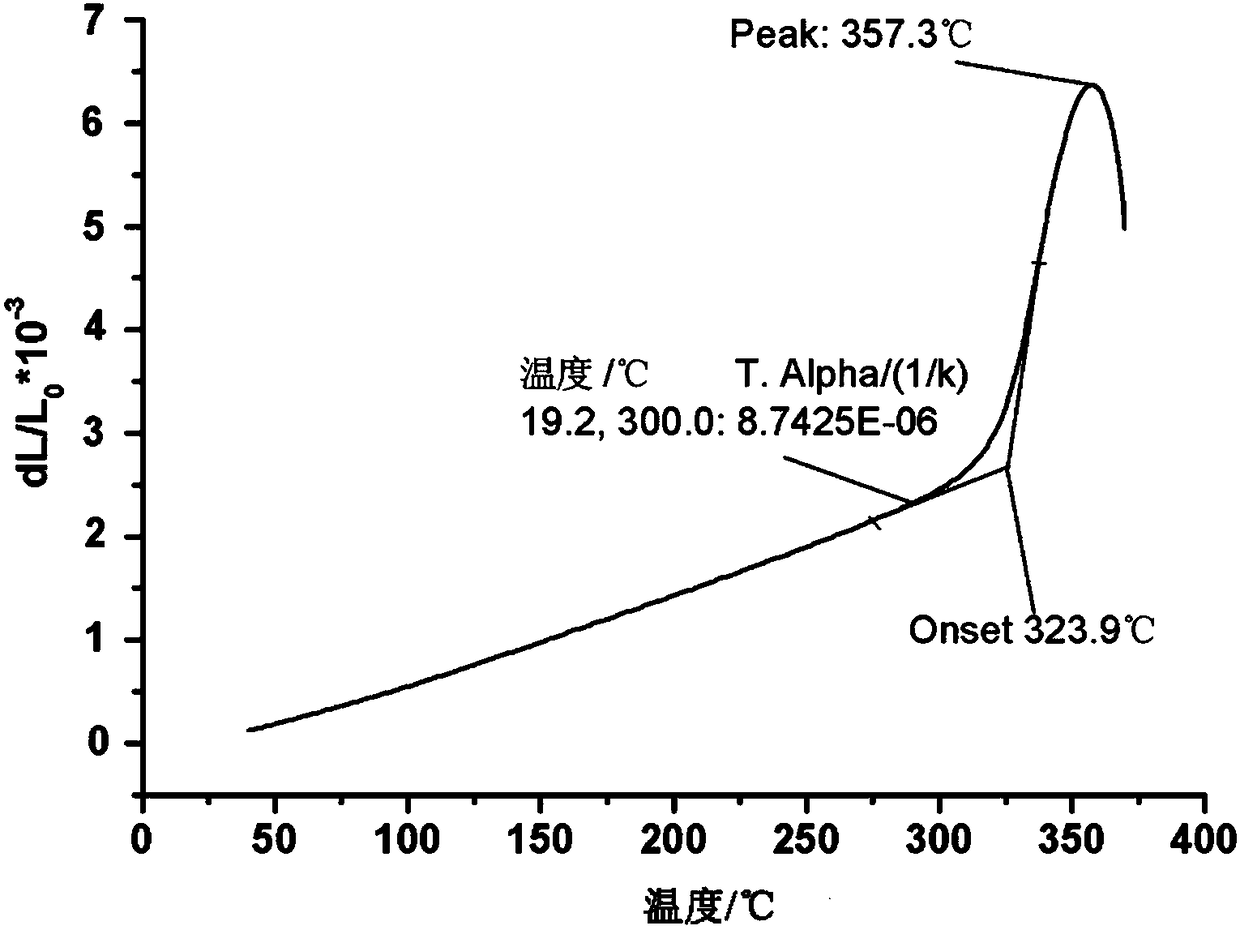

Vacuum glass sealing low-melting-point glass powder and anodic bonding enhanced packaging method

ActiveCN108298822ALower working temperatureThe range of thermal expansion coefficient is adjustableThermal expansionUltimate tensile strength

The invention relates to the technical field of vacuum glass manufacturing, in particular to a vacuum glass sealing material and an anodic bonding enhanced sealing method thereof. An adopted edge sealing material is lead-free low-melting-point glass powder, and the glass powder is characterized by being low in sealing temperature and adjustable in thermal expansion coefficient, the requirements for low temperature sealing can be met, and the anodic bonding is used to enhance the vacuum glass sealing to achieve a low temperature sealing process. The lead-free low-melting-point glass powder is fully melted and does not crack during the sintering process at 300-450 DEG C, and forms a good infiltration with substrate; and at the same time, an anodic bonding sealing technology is used to further lower the sealing temperature and improve the sealing strength and quality. A new technical scheme is provided for vacuum glass edge sealing, a vacuum glass sealing process is improved, and a new solution is provided for preparing the vacuum glass excellent in performance.

Owner:WUHAN UNIV OF TECH

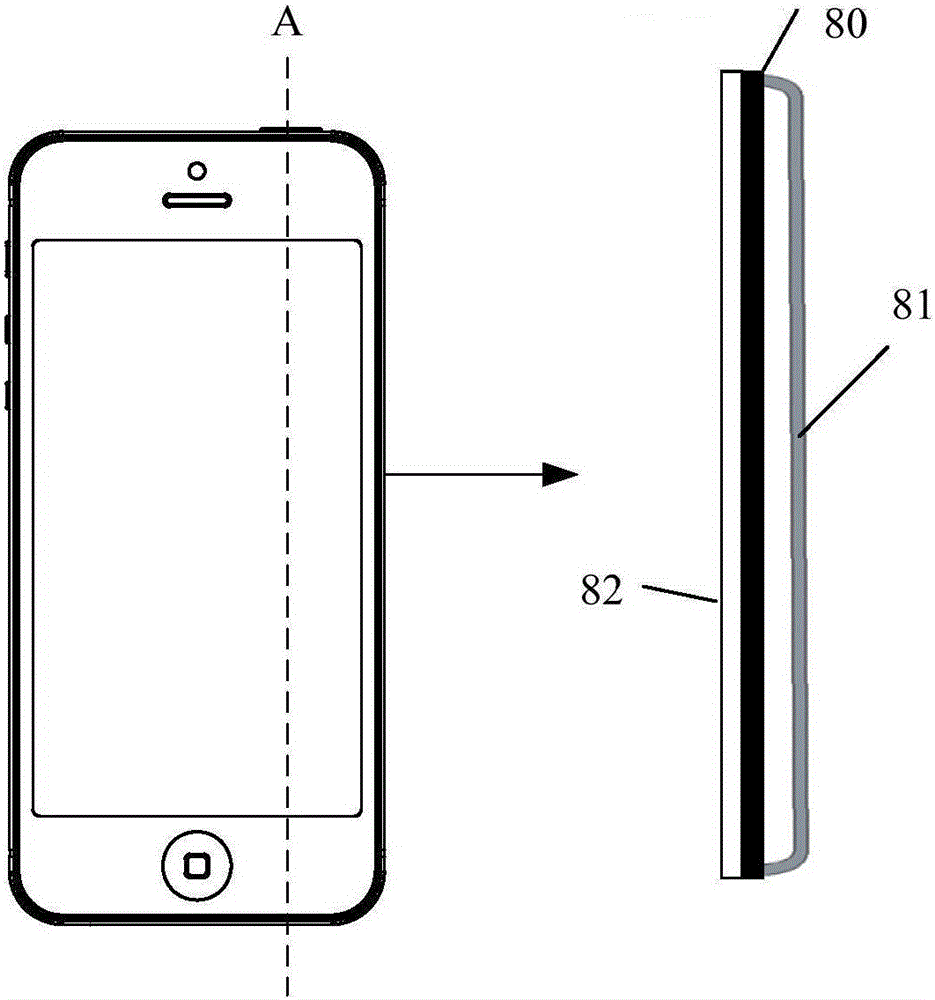

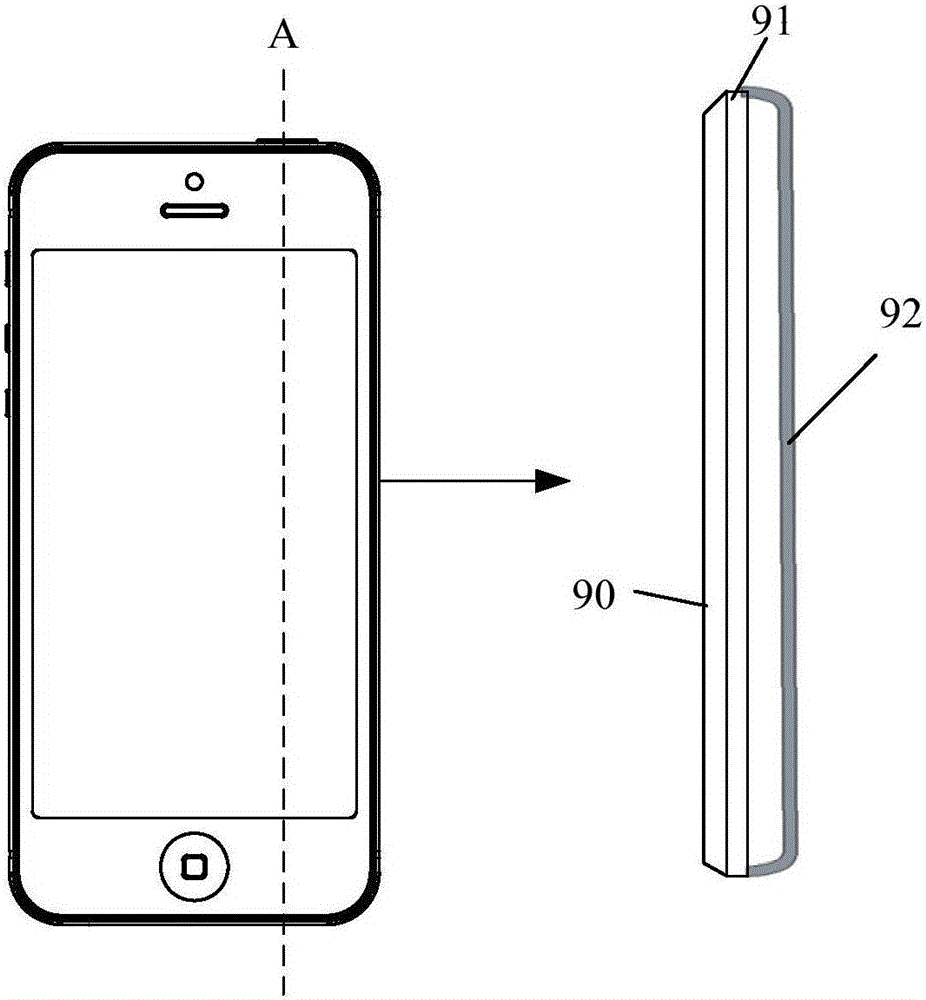

Electronic equipment and curved glass manufacturing method

ActiveCN105976712AImprove yieldThree-dimensional effectEdge grinding machinesGlass reforming apparatusOptoelectronicsGlass sheet

The invention discloses electronic equipment and a curved glass manufacturing method. The electronic equipment comprises a glass panel, wherein the glass panel is fixedly connected with a frame body of the electronic equipment, and at least part of the glass panel is a curved surface; the glass panel comprises a first glass substrate and a second glass substrate; the first glass substrate is located above the second glass substrate, and the first glass substrate and the second glass substrate are tightly attached; a first part of the first glass substrate is a curved surface to form the curved surface of the glass panel.

Owner:LENOVO (BEIJING) LTD

Coating Material For Platinum Material, Platinum Material Coated With Such Coating Material, And Glass Manufacturing Apparatus

InactiveUS20080090087A1Inhibits bubble formationBubble formation can be suppressedGlass furnace apparatusPretreated surfacesPlatinumRefractory

Owner:TANAKA PRECIOUS METAL IND +1

Method for manufacturing vacuum glass

A manufacture method of vacuum glass belongs to the glass manufacturing technology field, including steps as follows: a piece of sheet glass and a piece of convex glass are cut according to requirement, and edging process is implemented according to requirement; a lined adhesive glass film is adopted to overlap the surrounding edges of the sheet glass and the convex glass and then is put on a glass fixture into a vacuum lined adhesive furnace, which is pumped to be vacuum. The furnace is heated for 1-3h at 140-160 degree Celsius to fuse the glass and the film; the glass is taken out of the furnace after being cooled naturally, and protective sealant is used to seal and reinforce the vacuum glass. The production process of the invention is easy to be operated and is constructed through connecting the convex glass and the sheet glass directly, which leads to the more stable support in the hollow region of the two-layer glass. The lined adhesive glass film adopted for the sealing of the surrounding edges has the advantages of strong heat resistance and cold resistance and high mechanical strength and can keep various physical performance indexes within the range of 40 degree Celsius subzero to 120 degree Celsius above aero stable. Vacuum glass can be pumped sealed in batches to realize the highly efficient production.

Owner:刘华俊

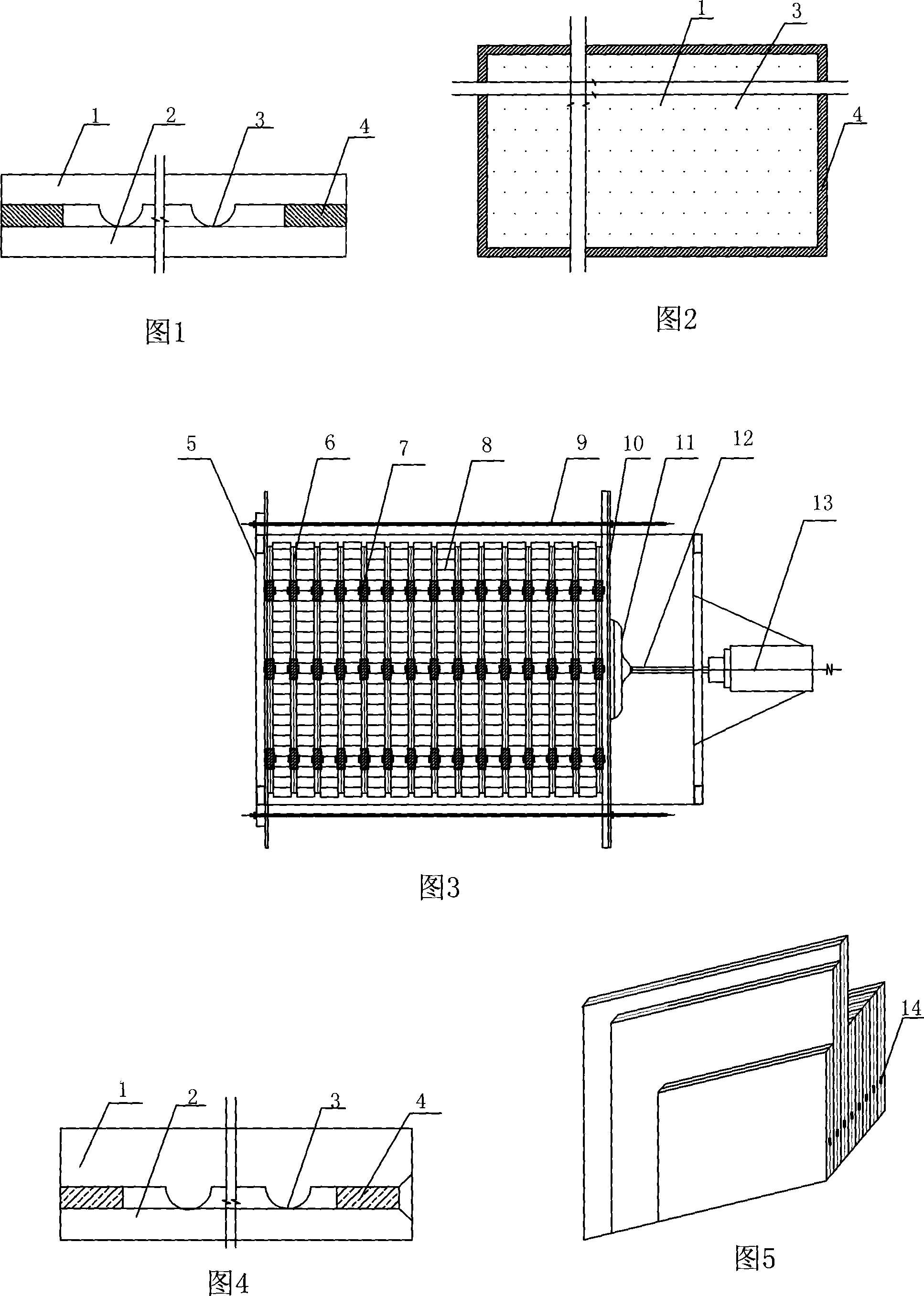

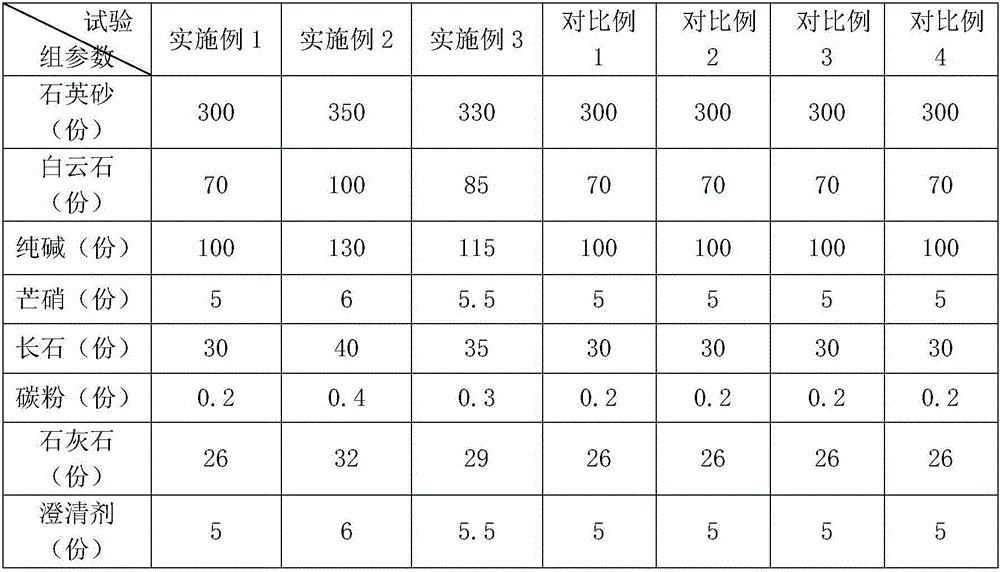

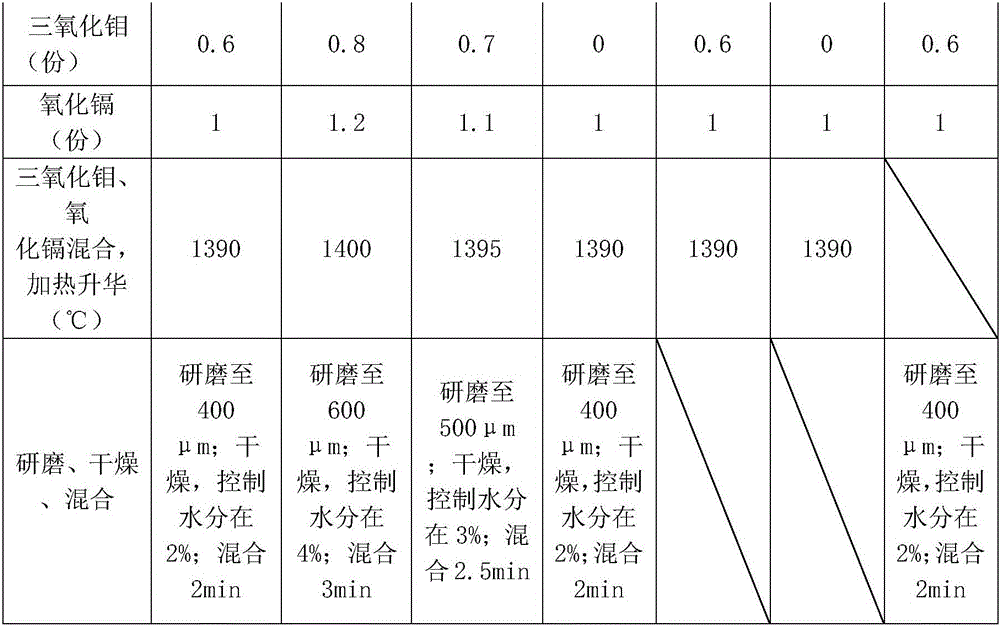

Tempered glass manufacturing technique

ActiveCN106587606AHigh transparencyAvoid poor resultsGlass tempering apparatusGlass productionDolomiteToughened glass

The application of the invention belongs to the field of glass manufacturing techniques, and particularly discloses a tempered glass manufacturing technique which comprises the following processing steps: (1) burdening: in parts by weight, taking 300-350 parts of quartz sand, 26-32 parts of limestone, 70-100 parts of dolomite, 100-130 parts of sodium carbonate, 5-6 parts of mirabilite, 30-40 parts of feldspar, 0.2-0.4 parts of carbon powder, 5-6 parts of a clarifying agent, 0.6-0.8 parts of molybdenum trioxide, and 1.0-1.2 parts of cadmium oxide; (2) grinding, drying and mixing: grinding raw materials in step (1) to 400-600 mu m, drying powder after grinding, and controlling the water content at 2-4%; put dried raw materials into a mixer and mixing the materials for 1.5-2 min; (3) melting; (4) molding; (5) preheating; (6) preheating; (7) rapid heating; (8) cooling; (9) cooling again; (10) homogeneous processing. Tempered glass manufactured by adopting the tempered glass manufacturing technique has excellent quality, the spontaneous explosion rate of the tempered glass is effectively reduced, and the safety is good.

Owner:CHONGQING SANXING JINGYI GLASS CO LTD

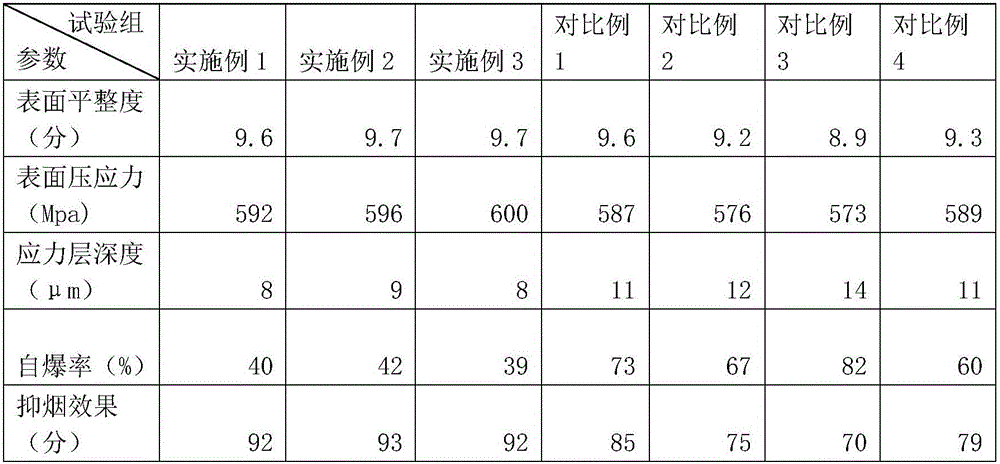

Flat vacuum glass welded by using glass welding material and provided with strip frame edge sealing and ditch groove edge sealing, and manufacturing method thereof

InactiveCN102976595AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionEngineeringGlass manufacturing

The invention relates to a vacuum glass, which comprises an upper glass and a lower glass, and is characterized in that the welding periphery of the upper glass is provided with an edge sealing strip frame, the welding periphery of the lower glass is provided with an edge sealing strip frame and an edge sealing ditch groove, and a glass welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the edge sealing strip frame and the edge sealing ditch groove. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

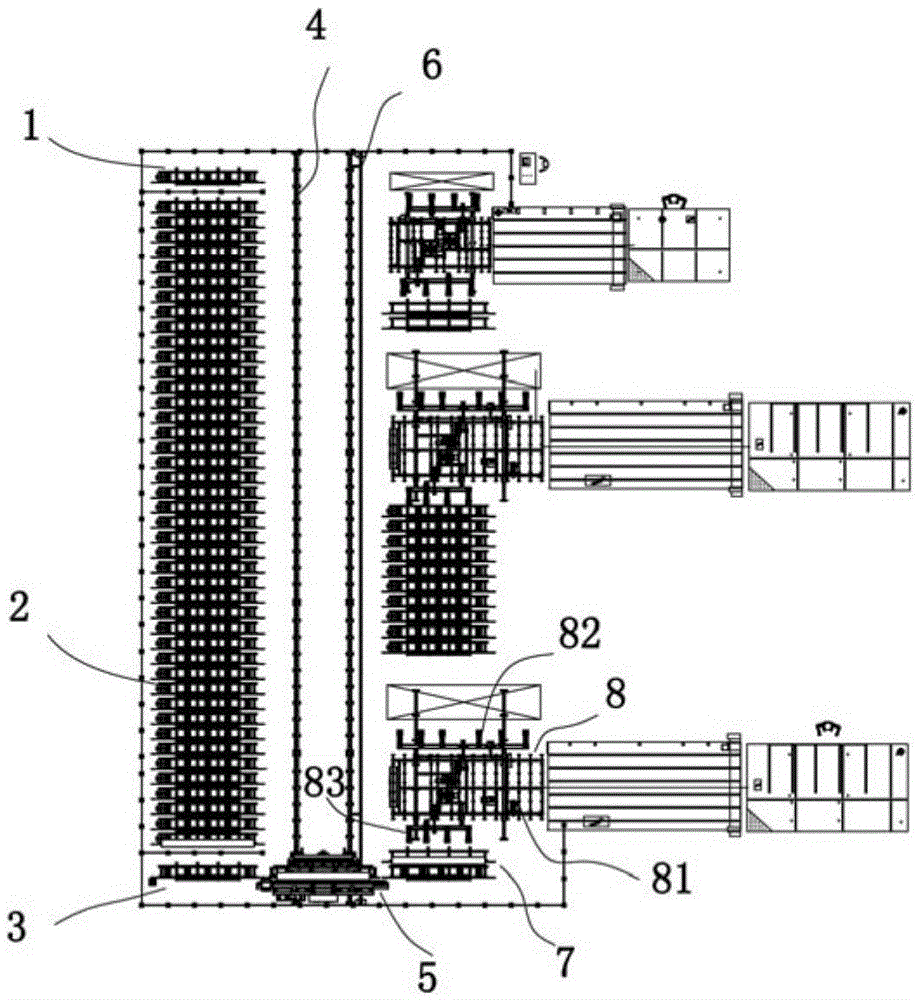

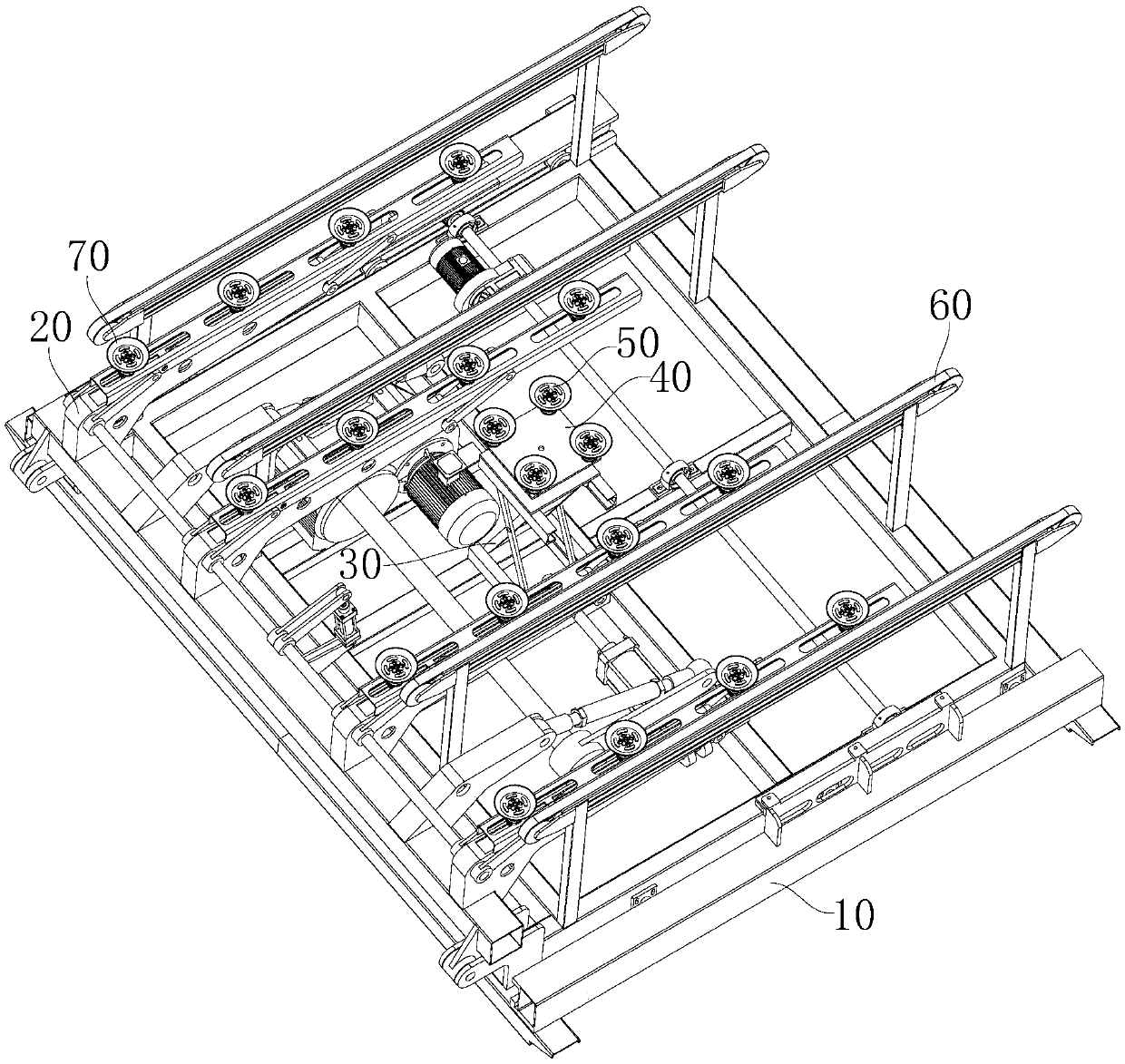

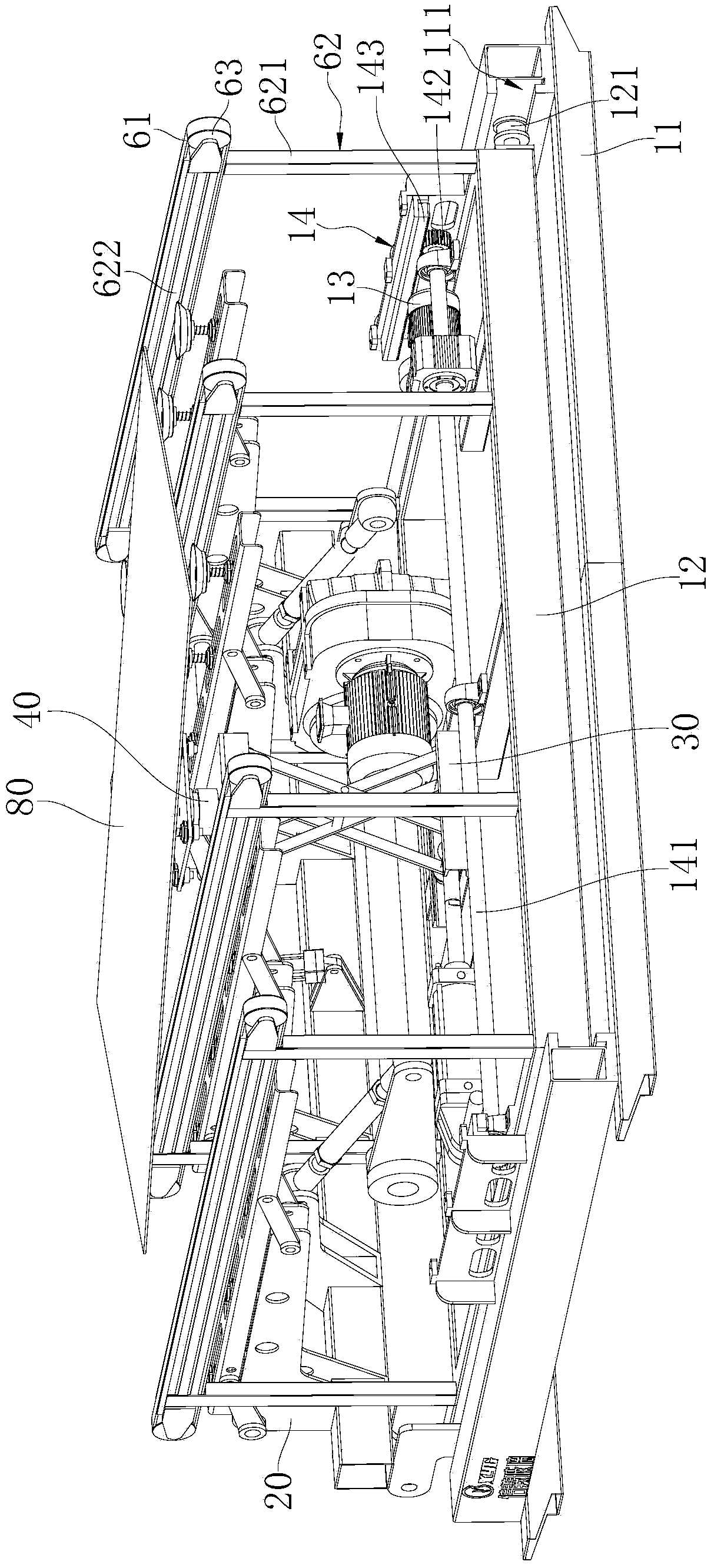

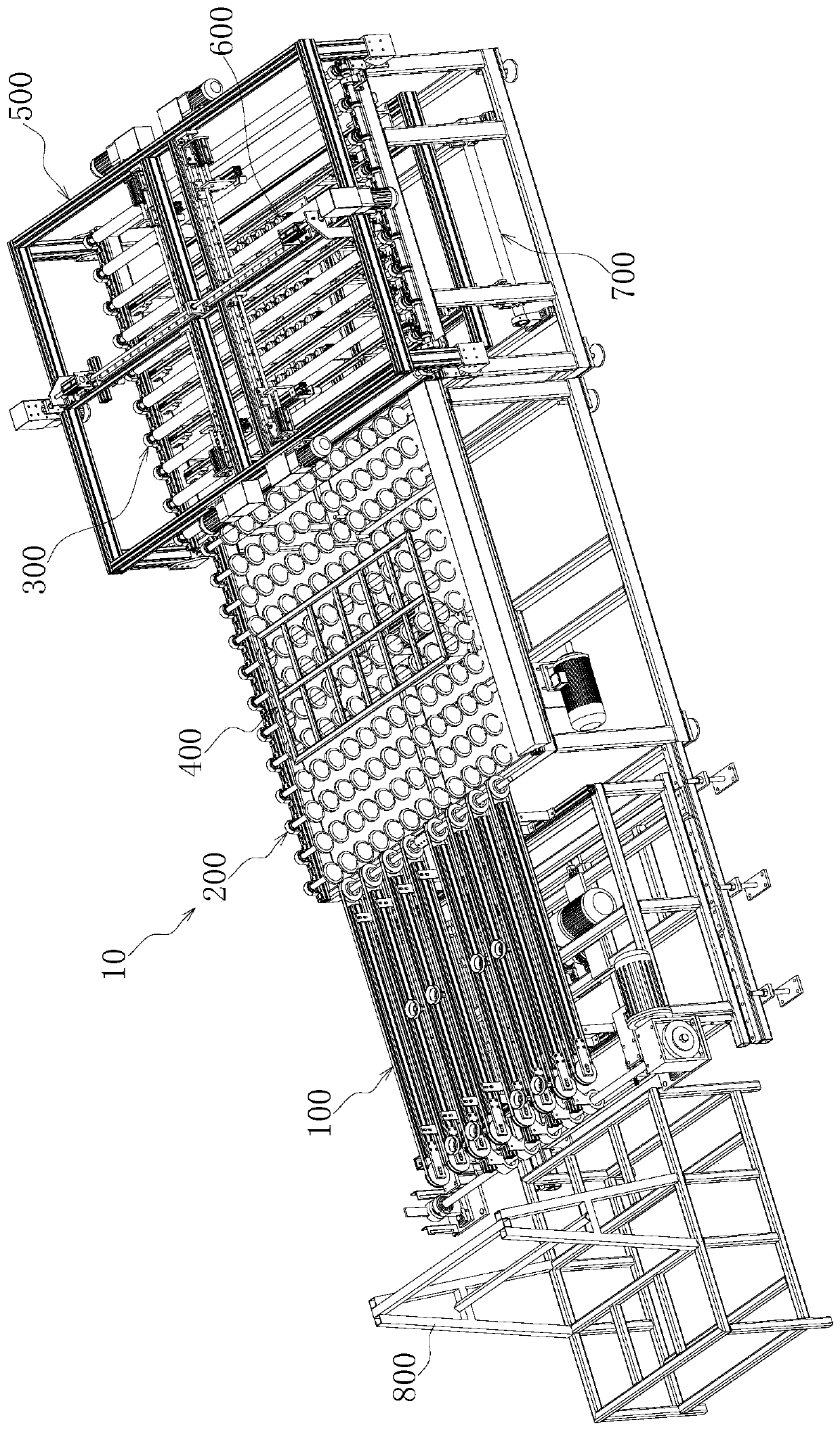

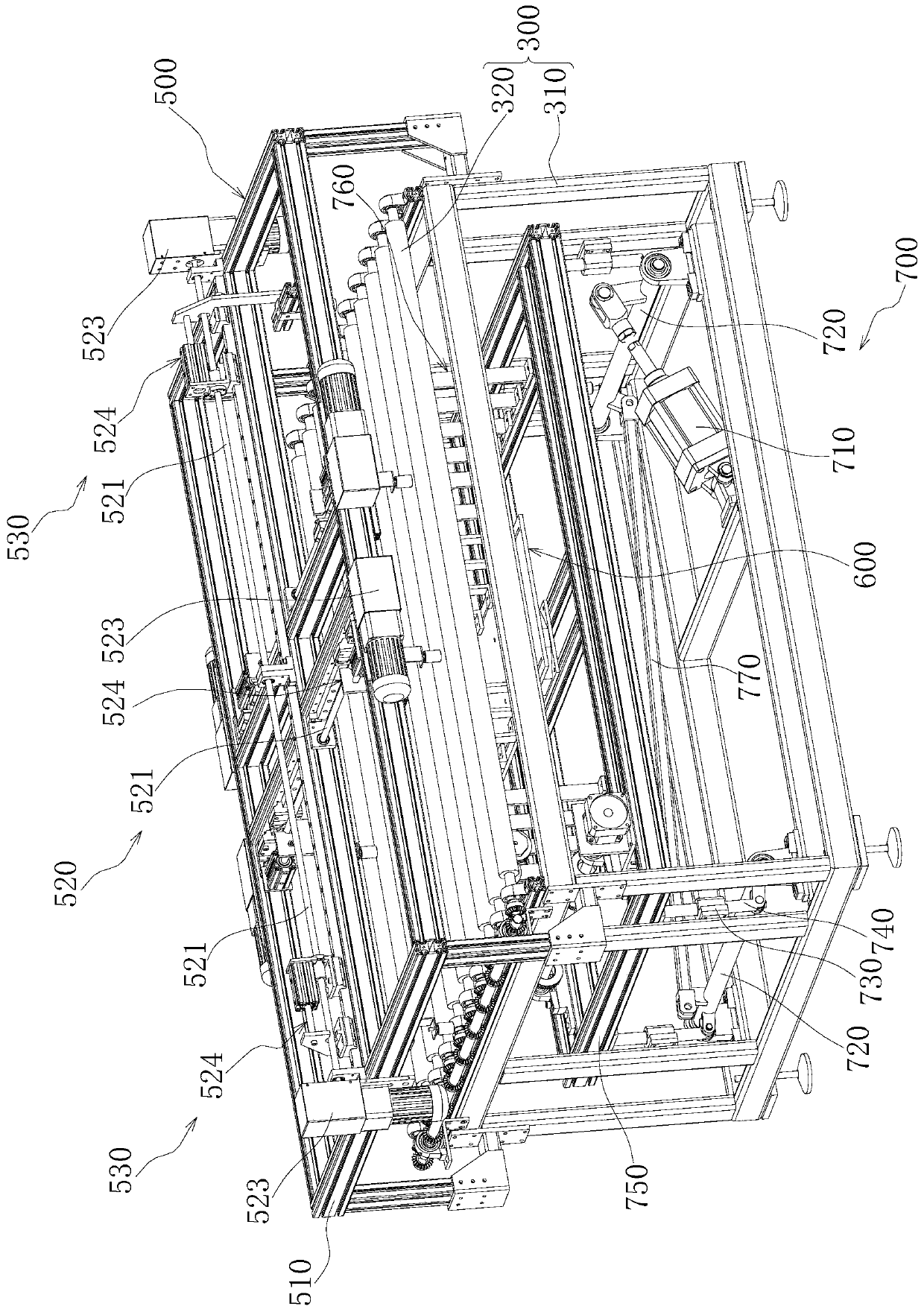

Full-automatic shuttling intelligent warehousing system

The invention discloses a full-automatic shuttling intelligent warehousing system. The full-automatic shuttling intelligent warehousing system comprises a first feeding station, a storage station, a second feeding station, a movable guide rail, a shuttling machine head, a power supply system, a material loading station and a piece loading station. The first feeding station and the second feeding station are arranged at the two ends of the storage station. The movable guide rail is arranged in the length direction of the storage station and is located on one side of the storage station. The shuttling machine head is installed on the movable guide rail. The power supply system is parallel to the movable guide rail and is electrically connected with the shuttling machine head. The material loading station and the piece loading station are arranged on one side of the shuttling machine head, and the shuttling machine head is located between the storage station and the material loading station. The full-automatic shuttling intelligent warehousing system can be combined with advanced management software such as ERP in a glass processing enterprise for automatically arranging production and has the advantages that the automation degree in the field of glass manufacturing can be easily improved, unmanned production is achieved, the storage amount is large, storage kinds are multiple, the operation speed is high, mechanical transmission is stable, the moving position is accurate, operation is easy, and maintaining cost is low.

Owner:HUMAN INTELLIGENT MACHINE

Thermal control of the bead portion of a glass ribbon

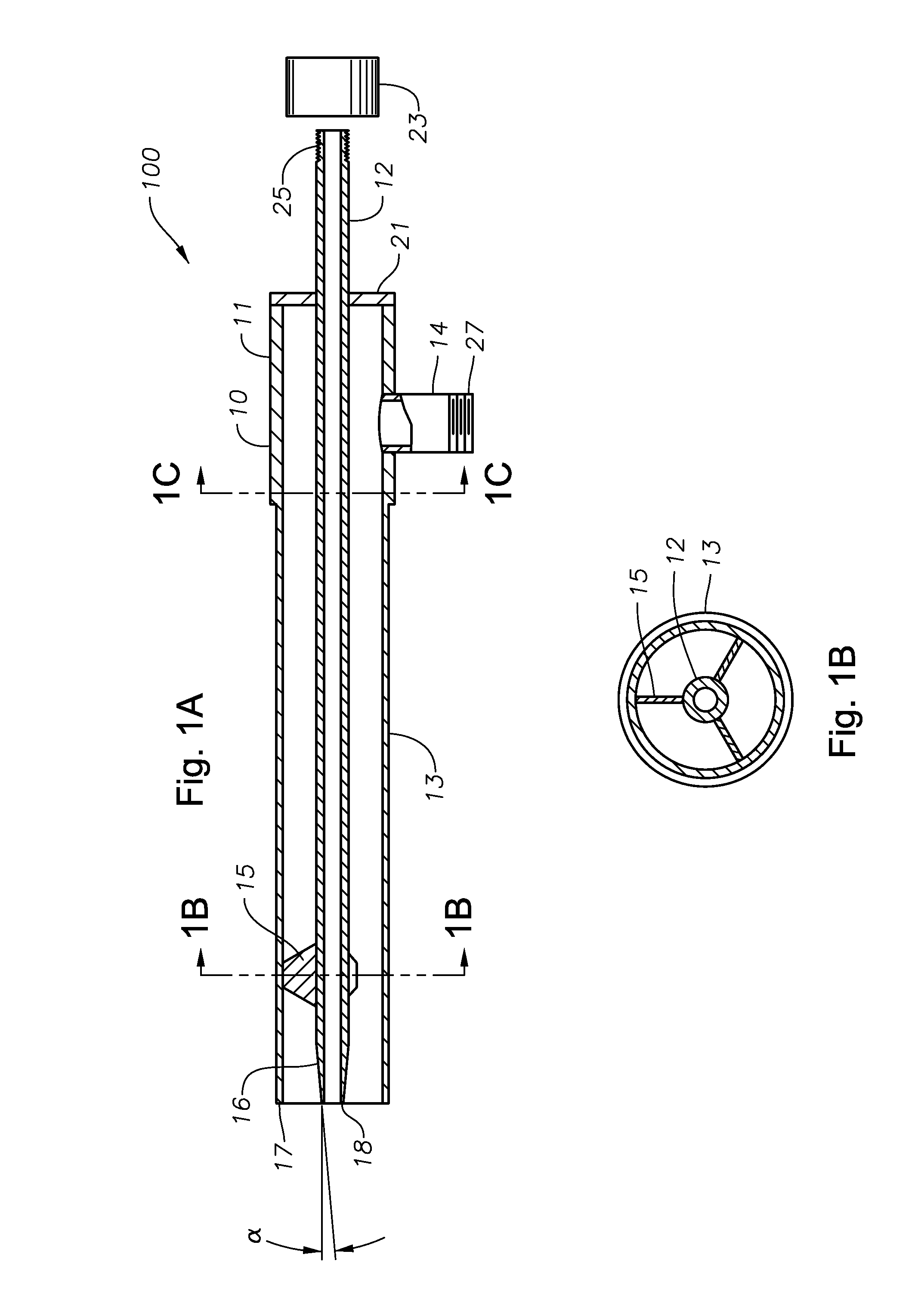

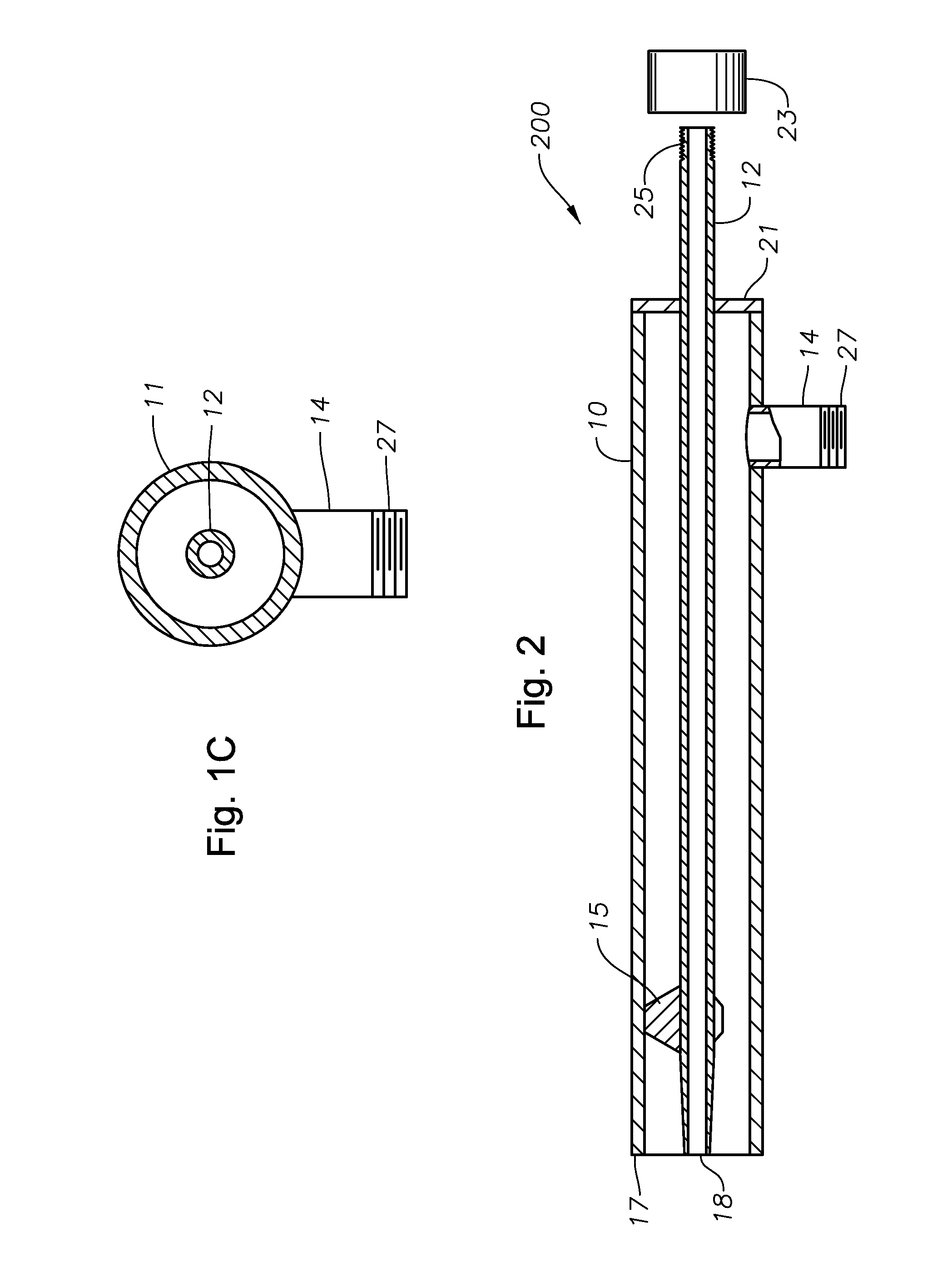

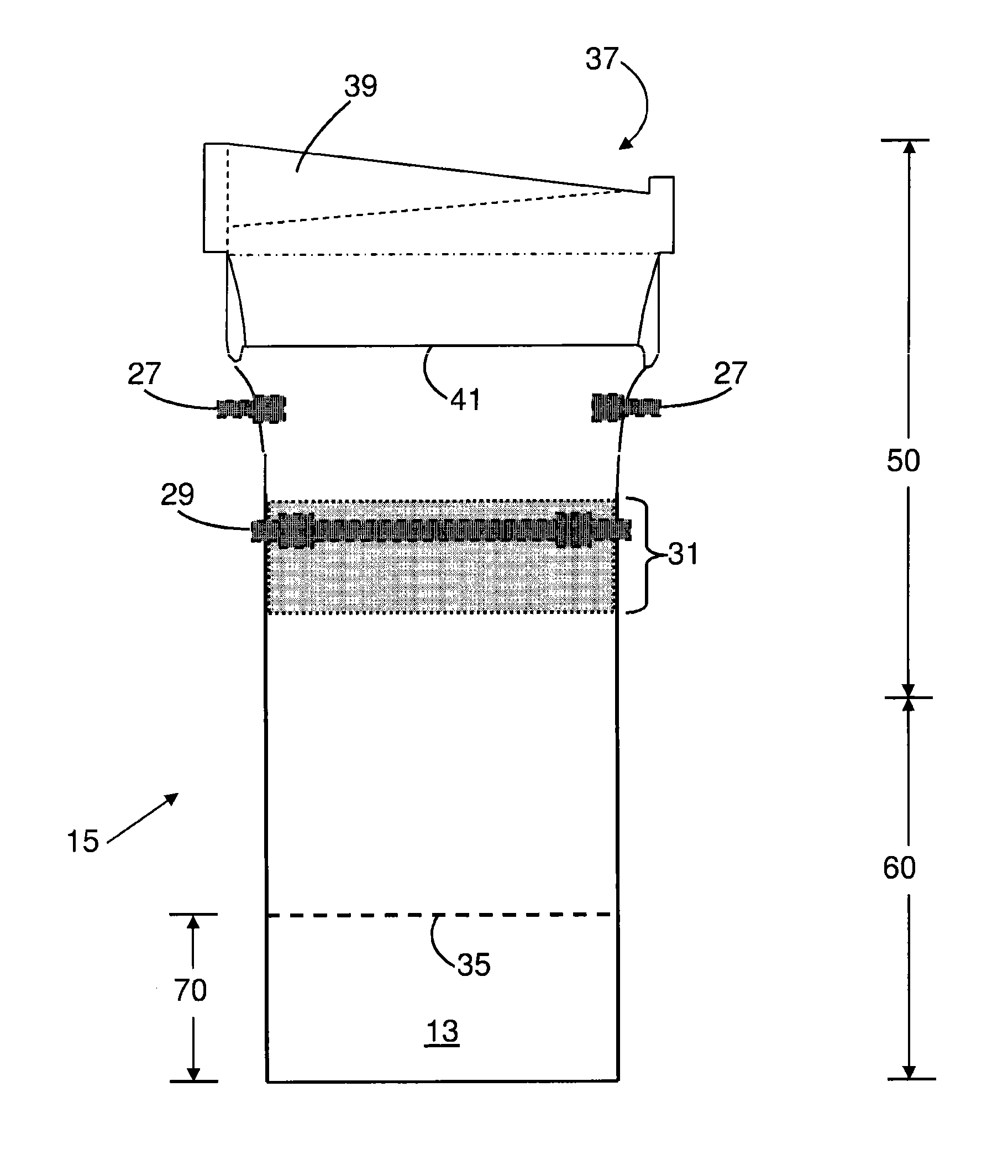

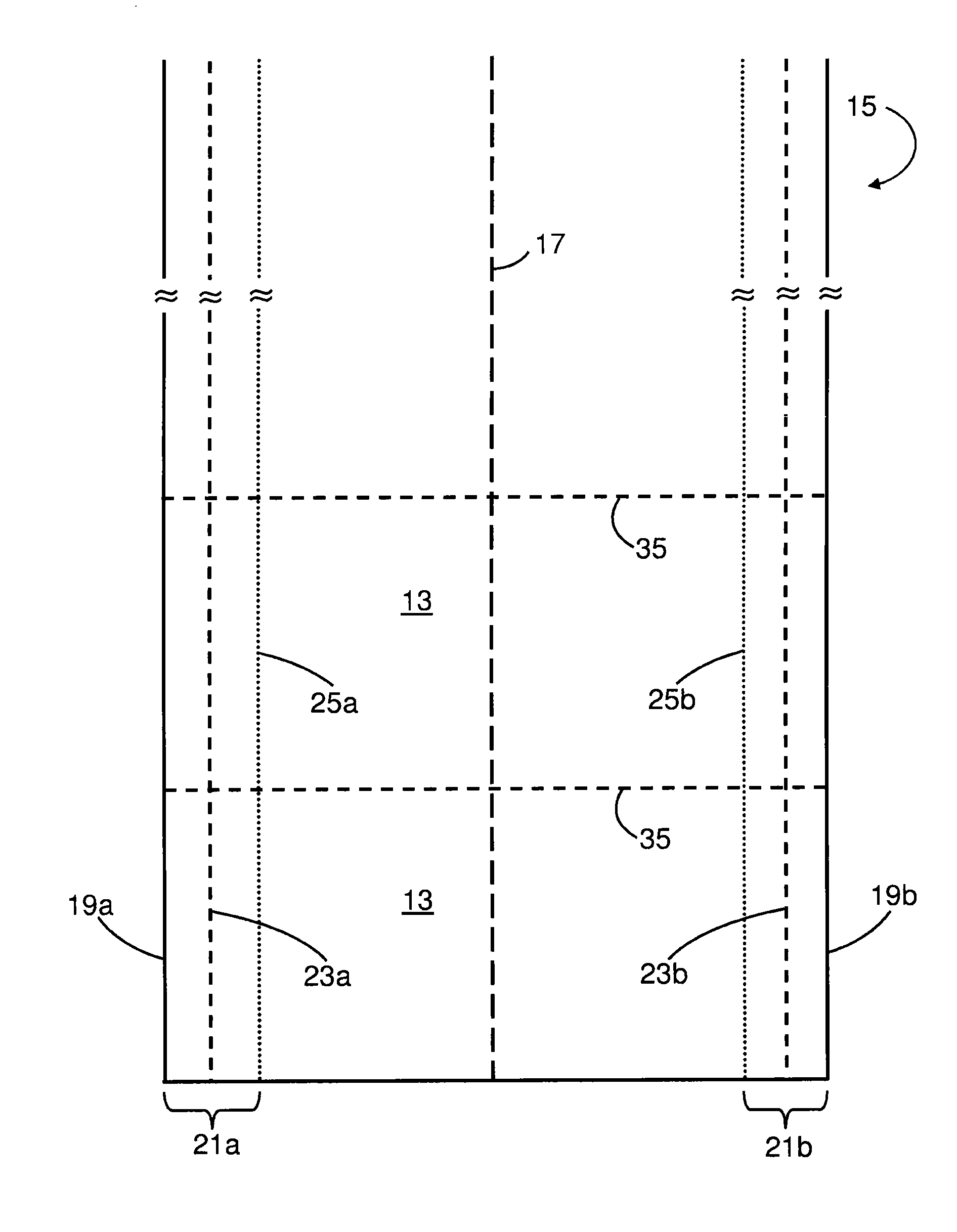

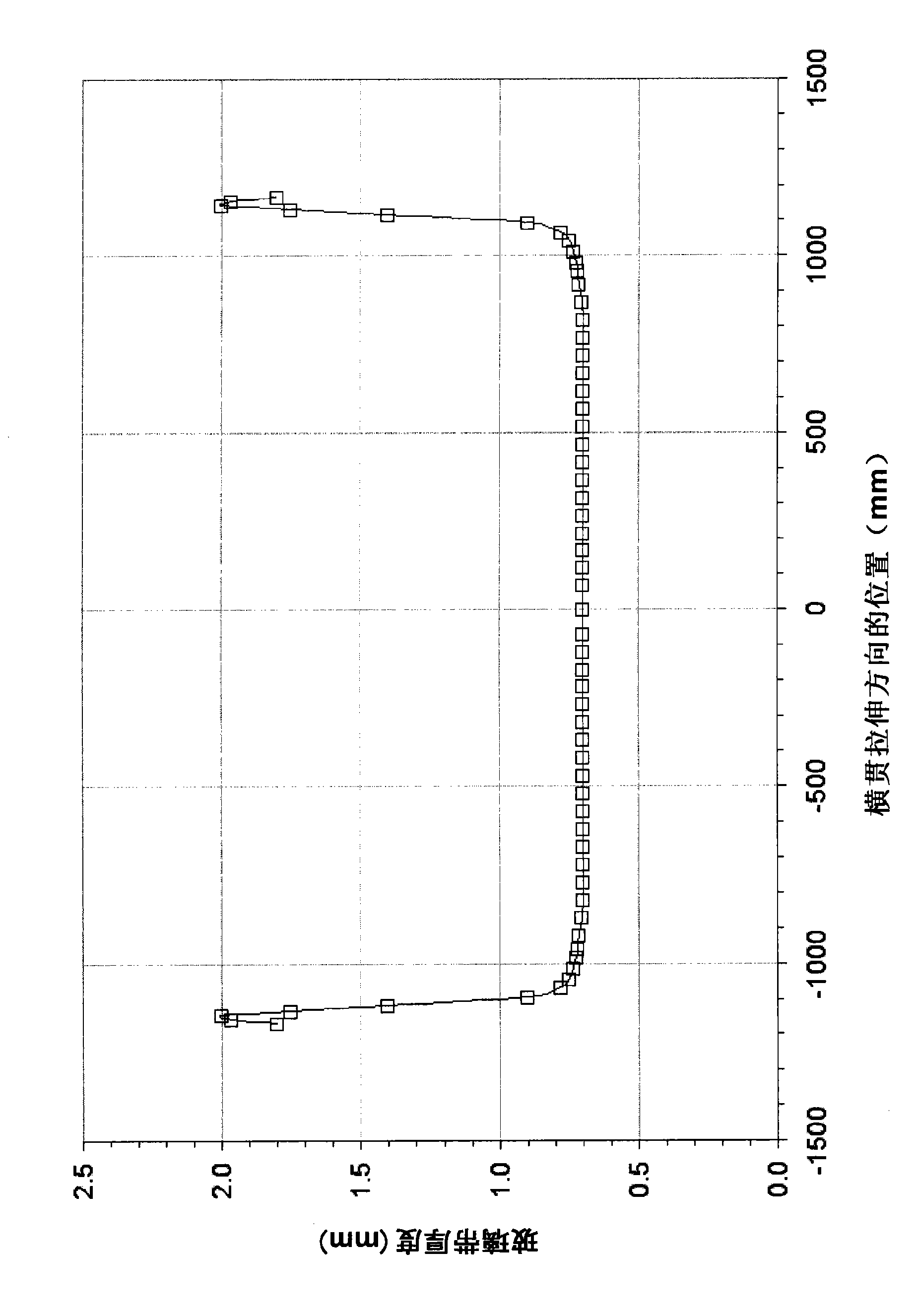

Methods and apparatus for controlling the stress in, and the shape of, the glass ribbon (15) formed in a downdraw glass manufacturing process (e.g., the fusion downdraw process) are provided. In certain embodiments, the control is achieved by cooling the bead portions (21a, 21b) of the ribbon (15) at a rate which provides a heat flux Q''b at the thickest part of the bead (23a, 23b) which is given by Q''b=Q''q+[Delta]Q'', where (i) Q''q is the heat flux at a transverse position adjacent to the bead portion (21a, 21b) at which the ribbon's thickness equals 1.05*tcenter, where tcenter is the final thickness at the ribbon's center line (17), and (ii) [Delta]Q''>=(tb / tq-1)Q''q+10 kilowatts / meter2, where tb is the thickness of the thickest part of the bead portion. The cooling can take place along the entire length of the ribbon (15) or at selected locations, e.g., in the portion (50) of the draw which includes the glass transition temperature region (31) or the portion (60) of the draw where individual glass sheets (13) are cut from the ribbon (15).

Owner:CORNING INC

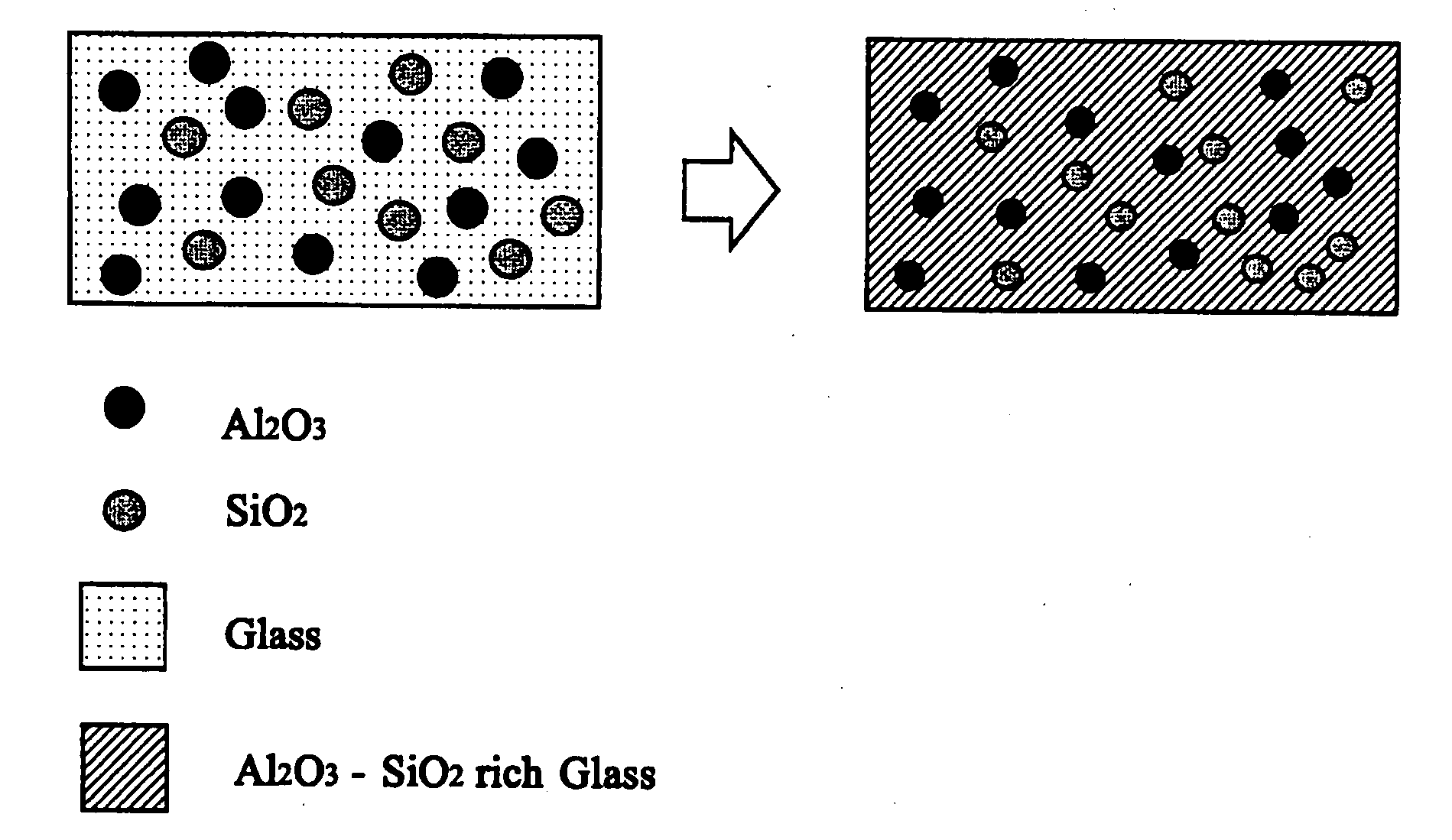

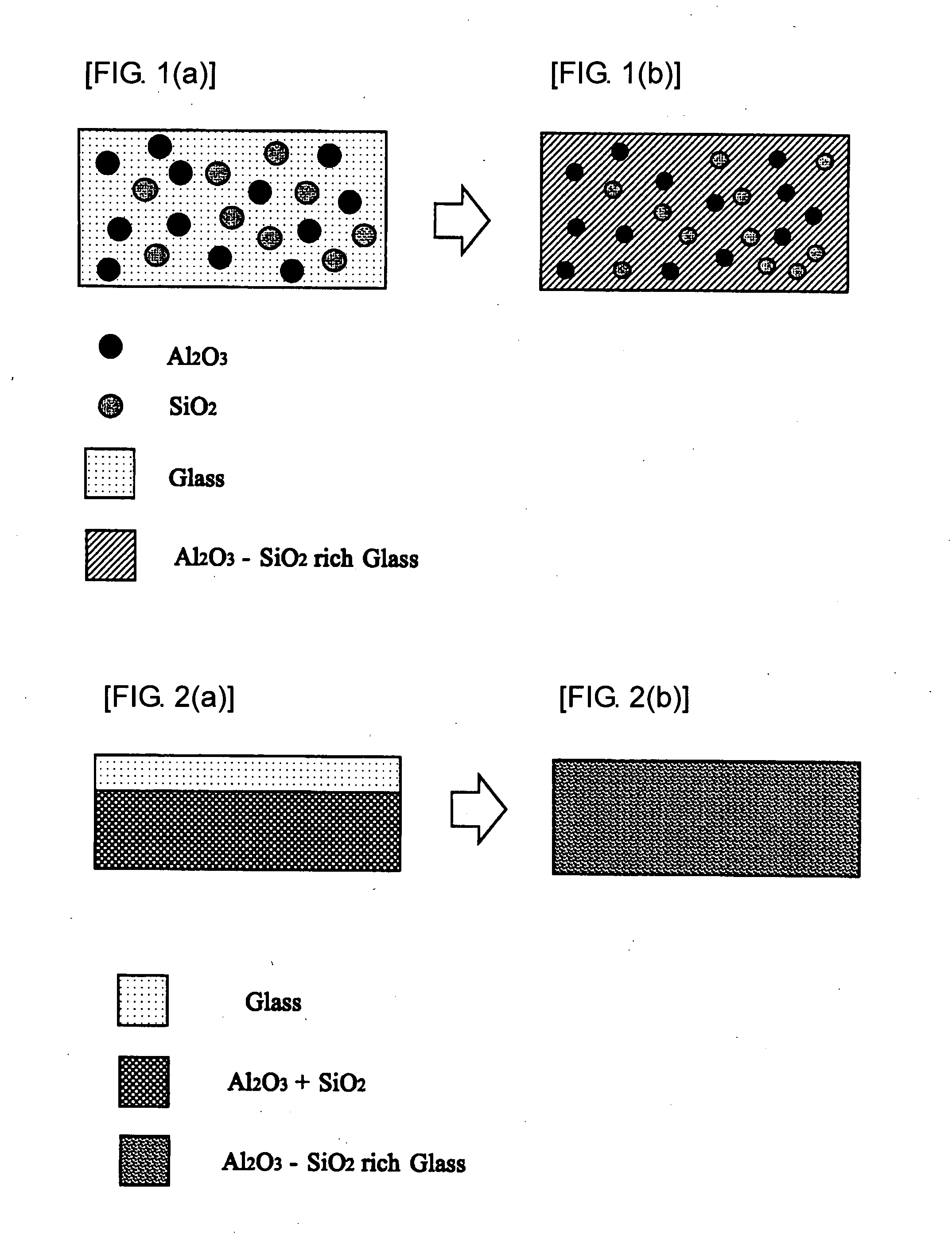

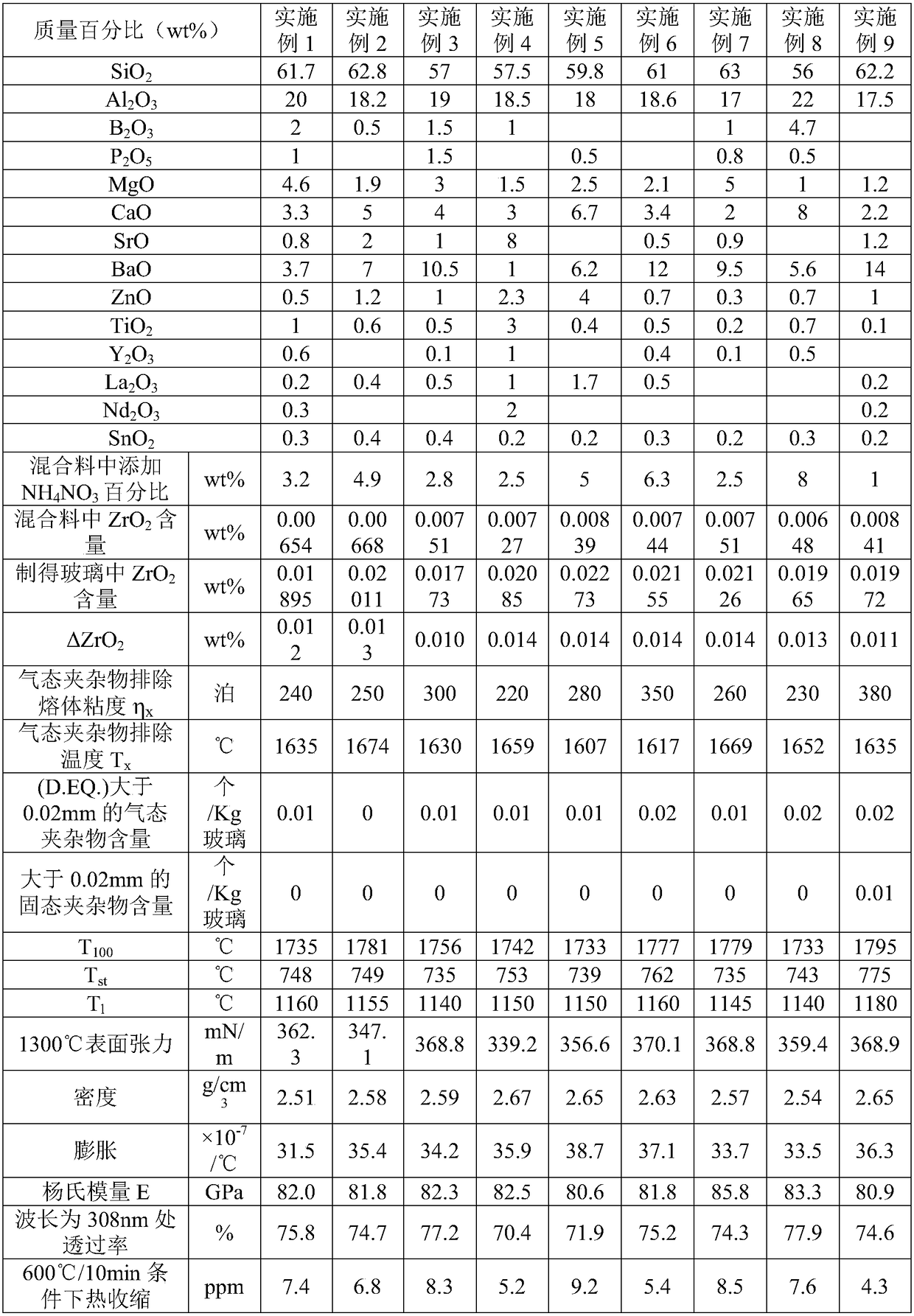

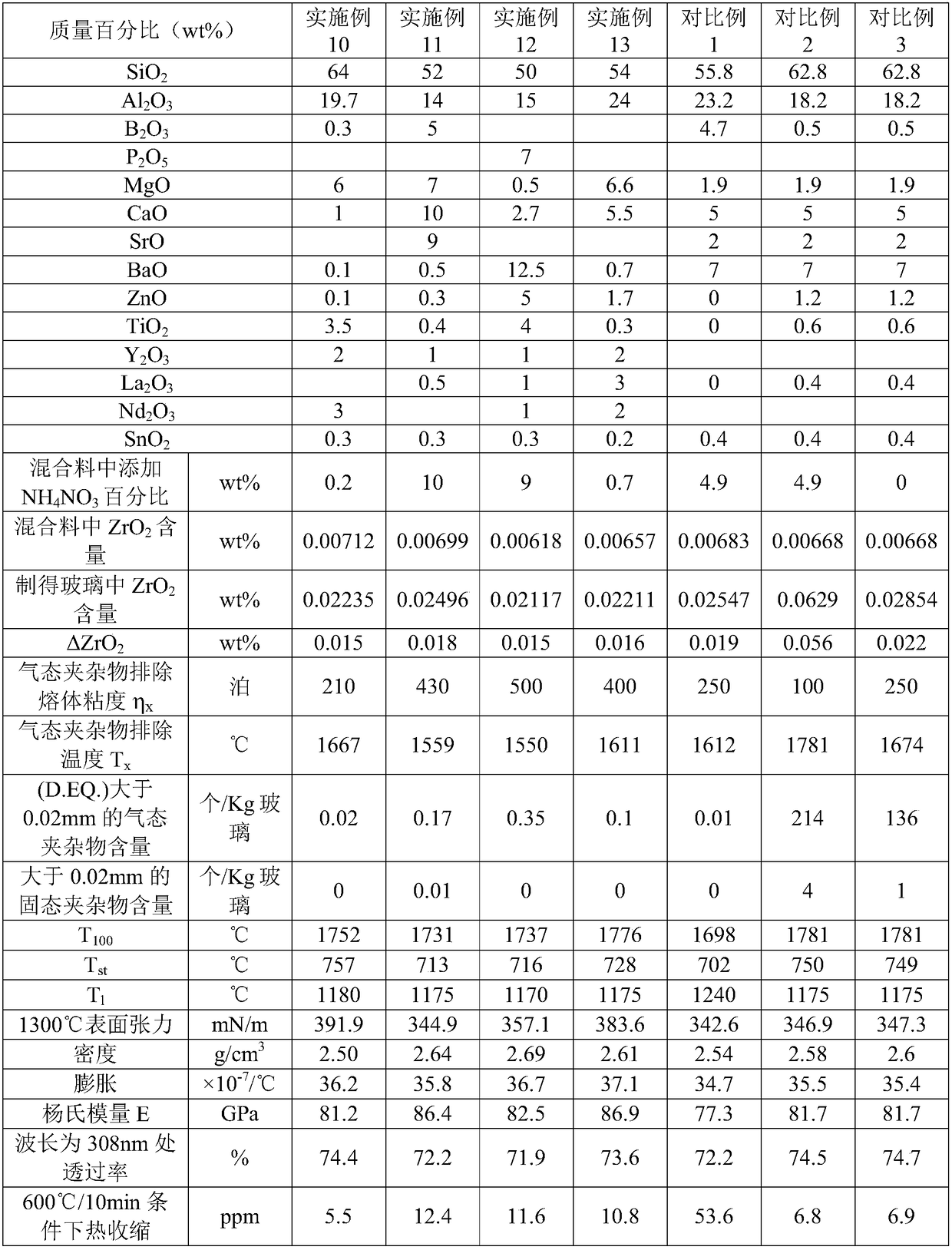

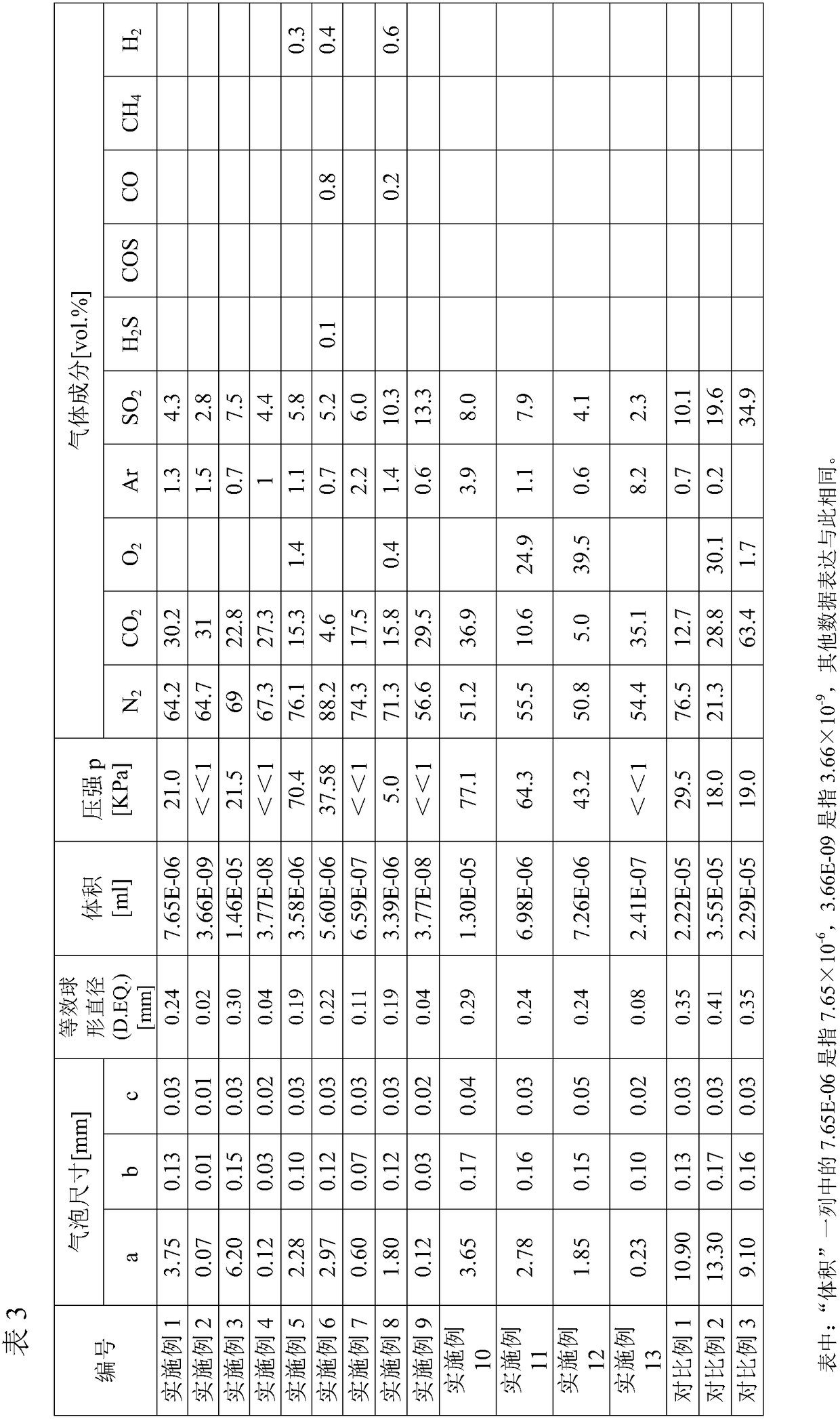

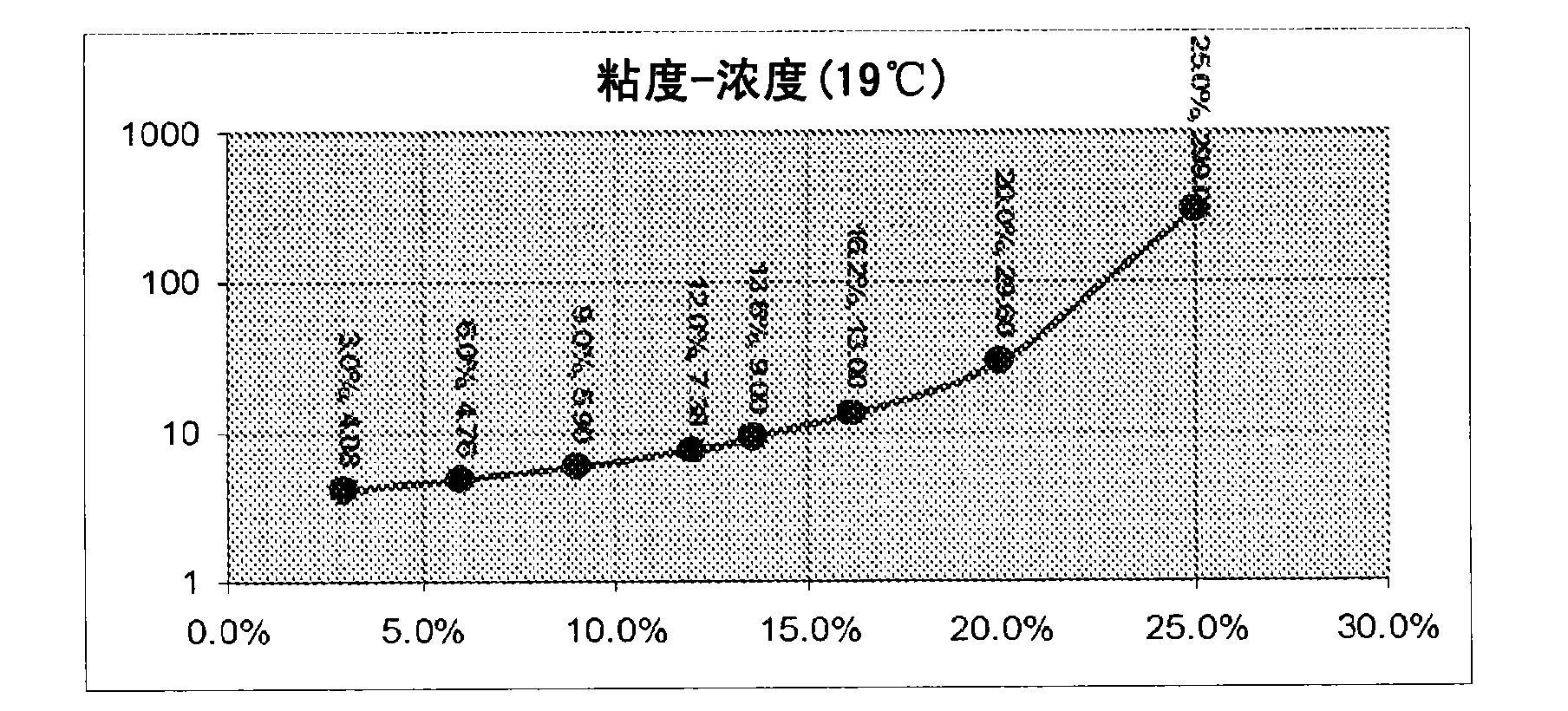

Glass composition, glass low in impurity content and preparation method and application of glass

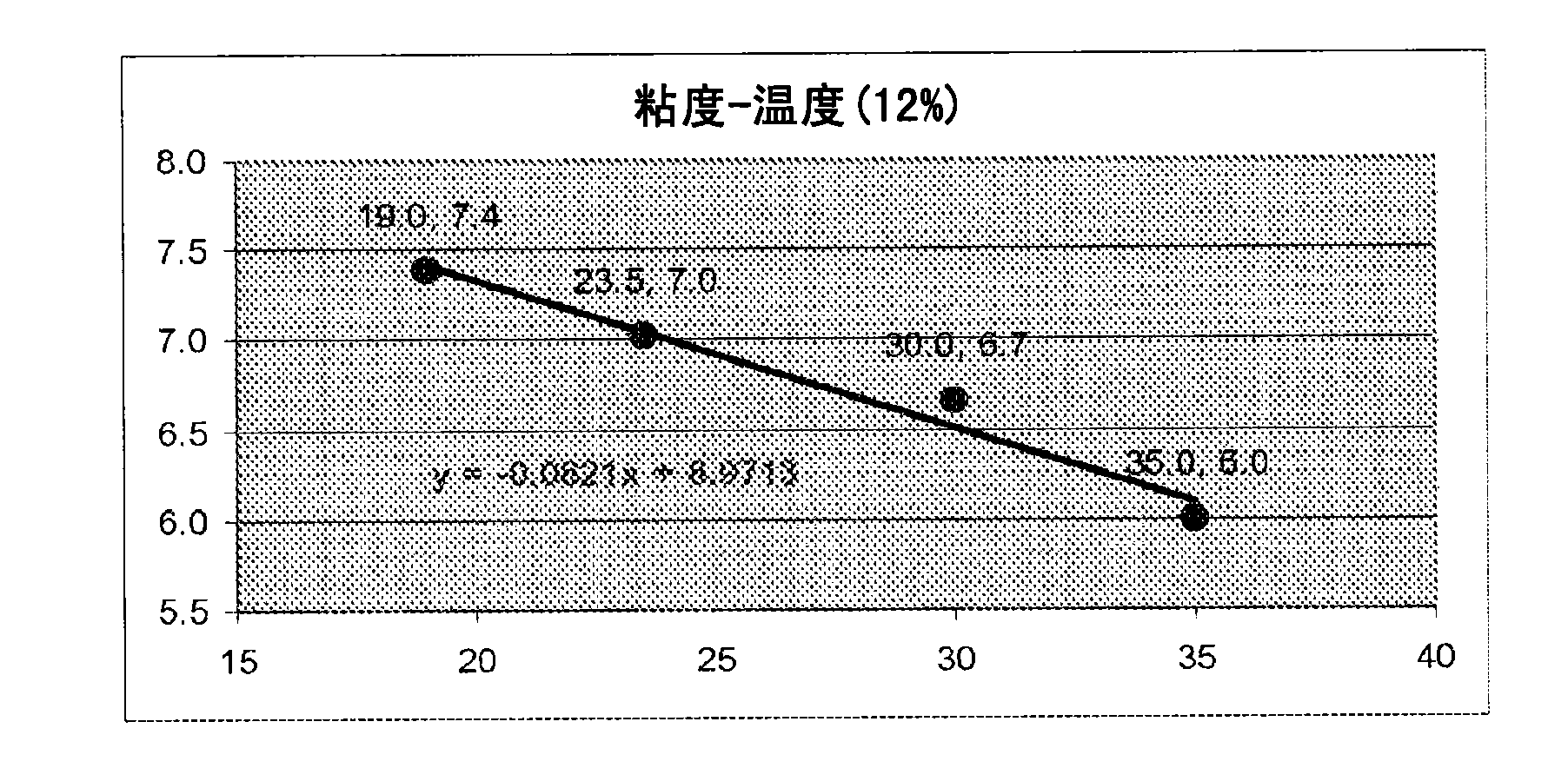

ActiveCN108341595AIncrease partial pressureIncrease in sizeGlass furnace apparatusGlass reforming apparatusGlass manufacturingViscosity

The invention relates to the field of glass manufacturing, and discloses a glass composition, glass low in impurity content and a preparation method and application of the glass. The composition comprises, by weight, 50-64% of SiO2, 14-24% of Al2O3, 0-7% of B2O3 and P2O5, 0.5-7% of MgO, 1-10% of CaO, 0-9% of SrO, 0.1-14% of BaO, 0.1-5% of ZnO, 0.1-4% of TiO2, 0.1-7% of BaO, 0.1-5% of ZnO, 0.1-4% of TiO2, 0.1-7% of Y2O3, La2O3 and Nd2O3 and 0.05% of R2O, wherein R2O is the total content of Li2O, Na2O and K2O. The composition satisfies the following conditions that the temperature T100 corresponding to the viscosity of 100 P is 1730 DEG C or above; the surface tension is smaller than 420 mN / m at the temperature of 1300 DEG C. The glass prepared through the glass composition and the preparation method of the glass low in impurity content has the advantages of being low in impurity content, simple in preparation process, low in cost and the like.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Protective coating for glass manufacturing and processing into articles

InactiveCN102123962ALow costReduce manufacturing costLaminationLamination apparatusAqueous solutionGlass manufacturing

The invention is directed to a method of protecting a glass surface during transportation and / or process using an aqueous solution of an acrylic material to protectively coat the surface of the glass sheet. The acrylic protective coating is applied by dipping, roller applying or spraying the coating on the glass using an aqueous solution of pH >= 9. The coating is then cured, dried or baked in an oven. Subsequently, the glass sheet is scored and separated into individual glass article blanks for further processing; for example, edge grinding to produce smooth edges and drilling / milling to produce openings such as holes in the surface of the glass. When processing of the glass article is completed, the protective coating can be removed or the article can be shipped to the end used who can remove the coating using an aqueous solution of pH > 12.

Owner:CORNING INC

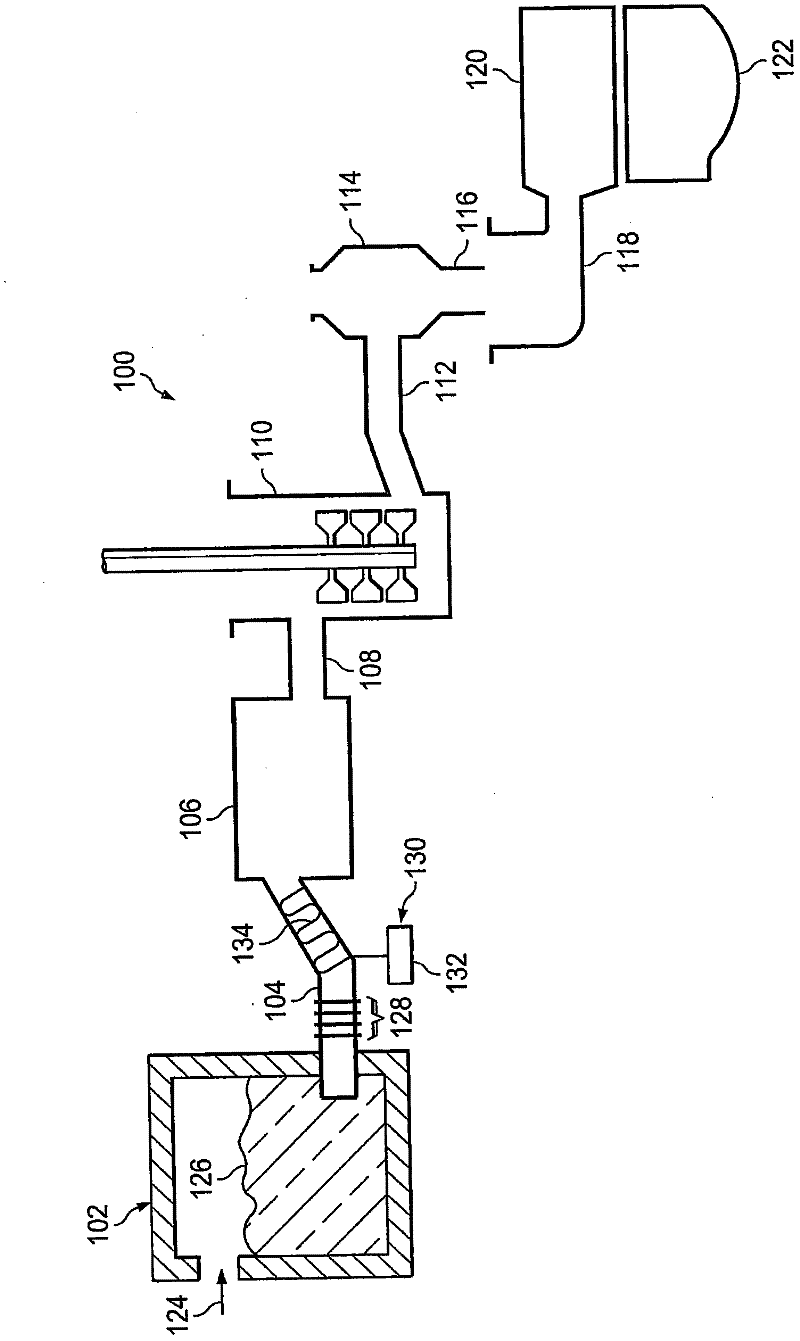

Apparatus and method for reducing gaseous inclusions in a glass

InactiveCN102307821AReduce gaseous inclusionsForehearthsGlass furnace apparatusDisplay deviceFlat panel display

A glass manufacturing system and a method are described herein for reducing gaseous inclusions in high melting temperature or high strain point glasses, such as those that are used as glass substrates in flat panel display devices. In one embodiment, the method including the steps of: (a) heating a batch material within a melting vessel to form molten glass at a melting temperature TM, the molten glass comprising a multivalent oxide material; (b) heating the molten glass within a fining vessel to a fining temperature TF = TM; and (c) cooling the molten glass within a refractory tube after the first heating step or after the second heating step to a cooling temperature TC less than TM, where the molten glass remains within the refractory tube for a predetermined resident time to reduce a volume of the gaseous inclusions in the molten glass and cause gas species to migrate out of the gaseous inclusions into the molten glass such that at least a portion of the gaseous inclusions collapse into the molten glass.

Owner:CORNING INC

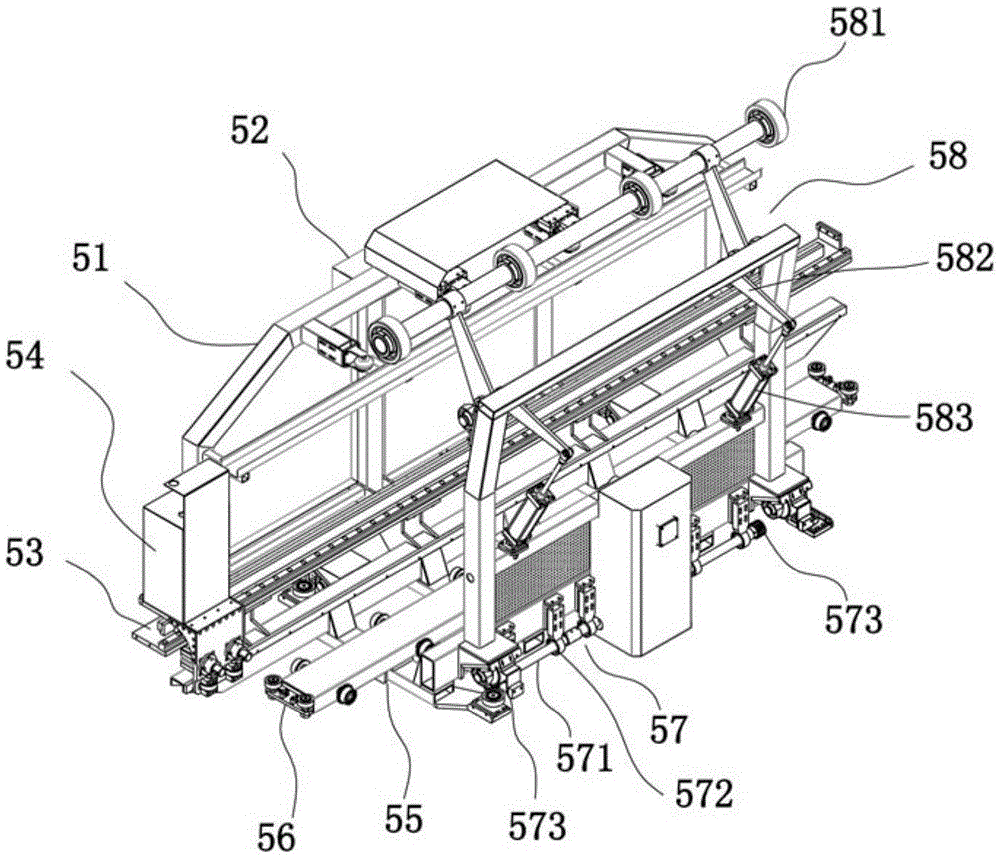

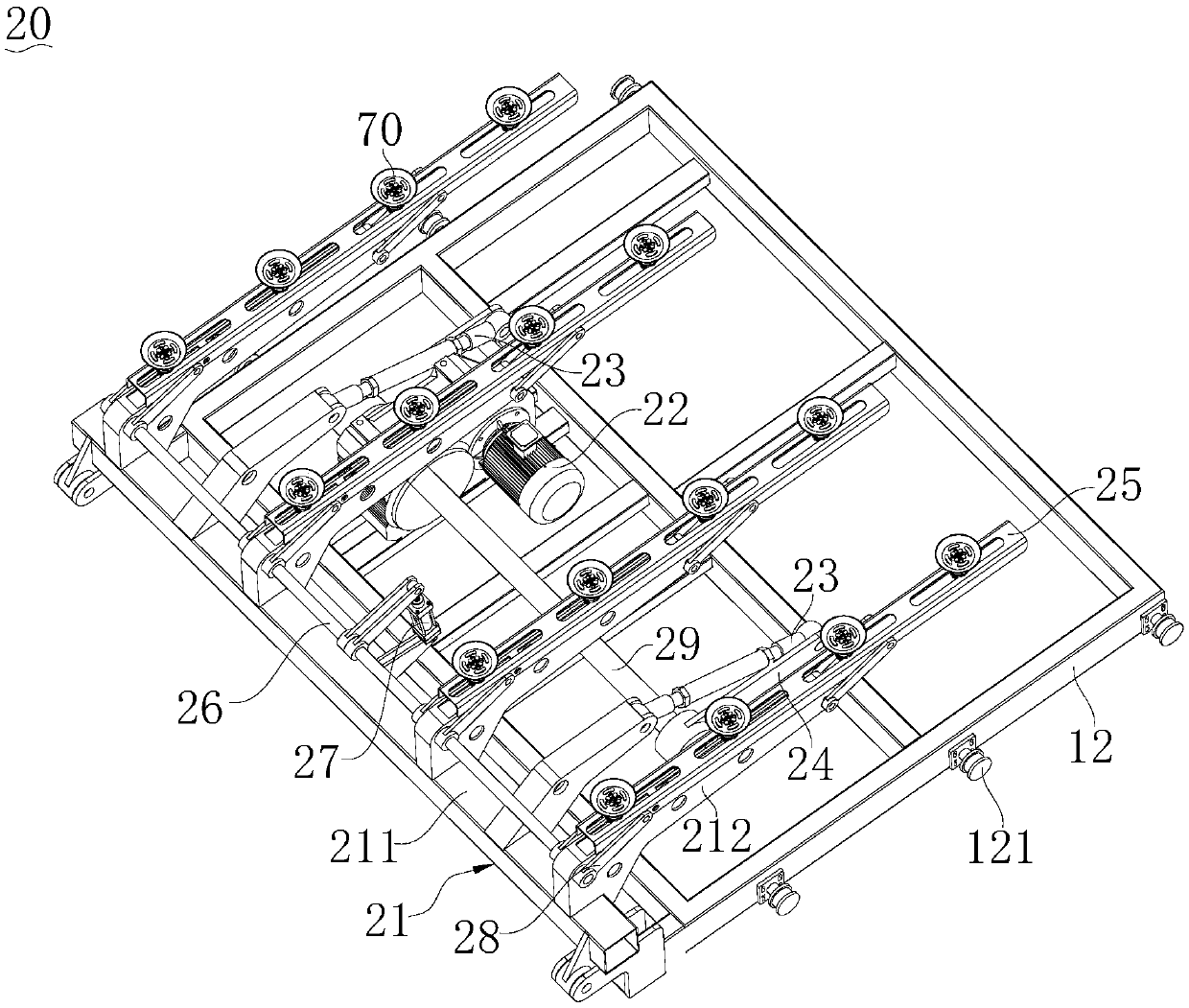

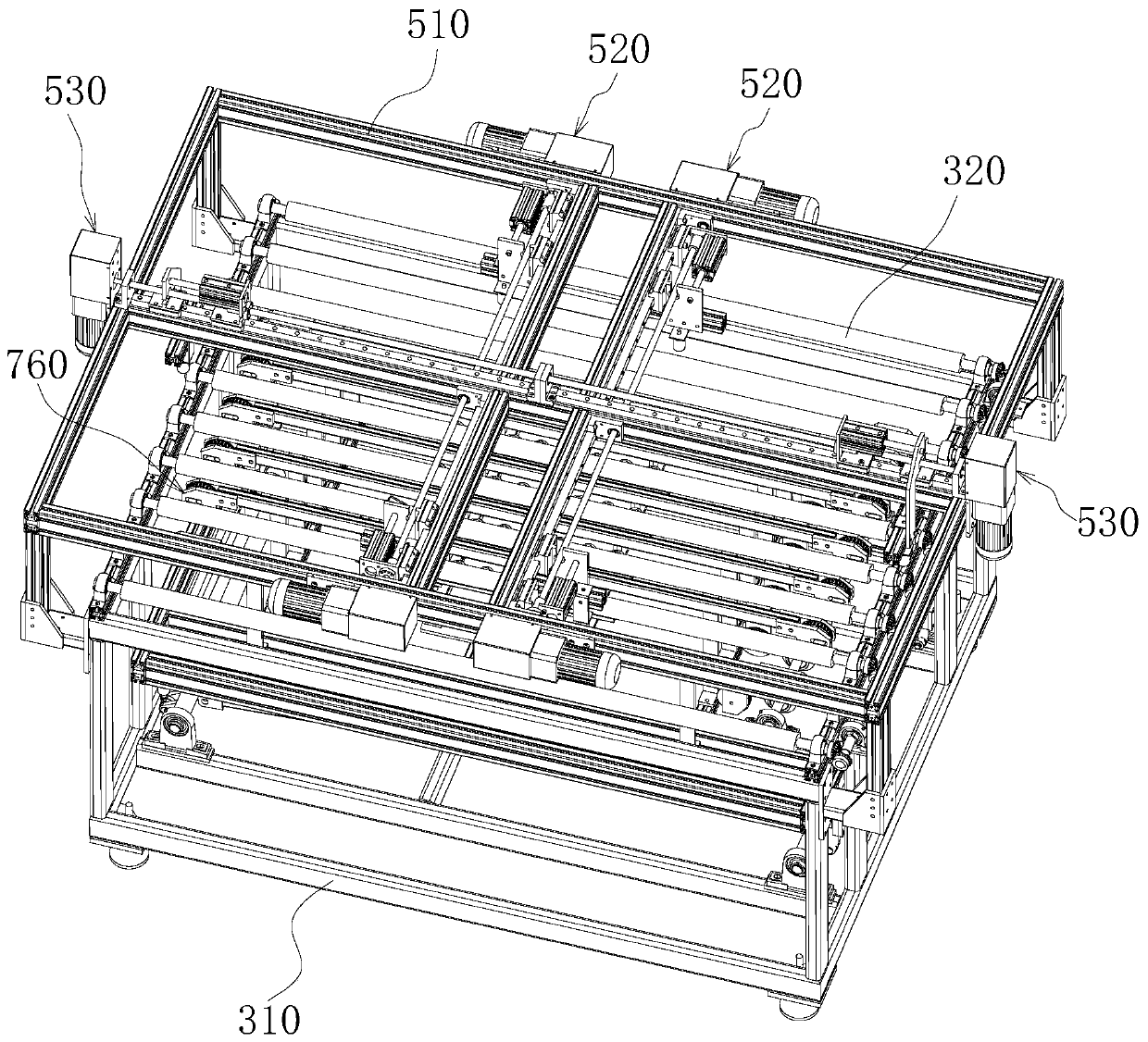

Glass sheet loading and unloading platform

PendingCN109533970ASatisfy diversified productionGuaranteed stabilityCharge manipulationConveyor partsEngineeringGlass sheet

The invention belongs to the technical field of glass manufacturing equipment and particularly relates to a glass sheet loading and unloading platform comprising a rack and a turnover mechanism. The turnover mechanism is installed on the rack and used for grabbing glass, and can be turned over relative to the rack. The glass sheet loading and unloading platform further comprises a rotating mechanism and a lifting mechanism. The rotating mechanism is provided with a suction assembly for sucking the glass. The lifting mechanism is installed on the rack and avoiding layout of the turnover mechanism. The lifting mechanism is connected with the rotating mechanism and used for driving the rotating mechanism to make lifting motion relative to the rack so that the suction assembly can suck the glass on the turnover mechanism or place the sucked glass to the overturn mechanism. The glass sheet loading and unloading platform can achieve loading, unloading and rotating of the glass through the lifting mechanism and the rotating mechanism, thereby meeting the diversified production requirements of the glass.

Owner:XINYI ENERGY SAVING GLASS SICHUAN CO LTD

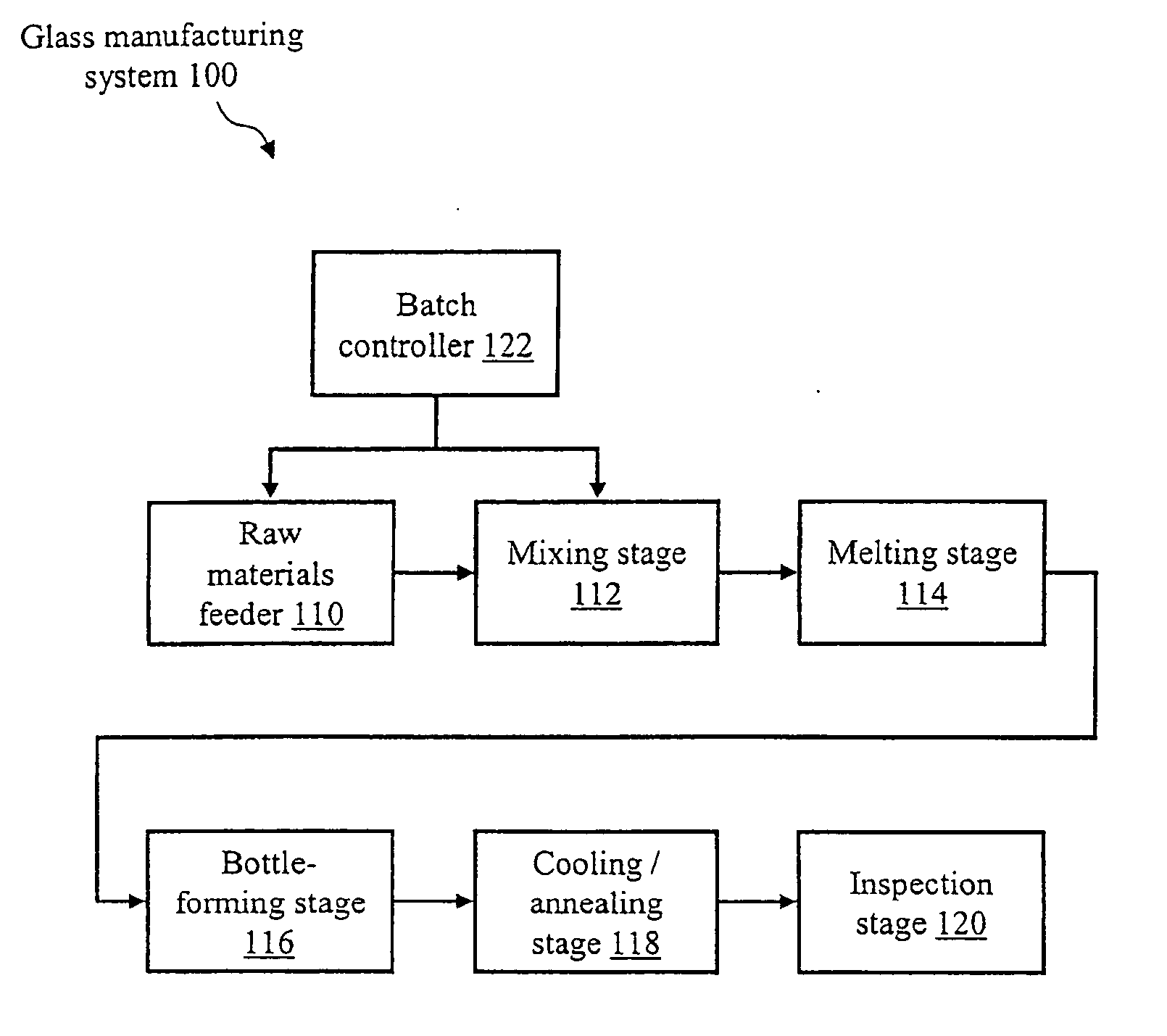

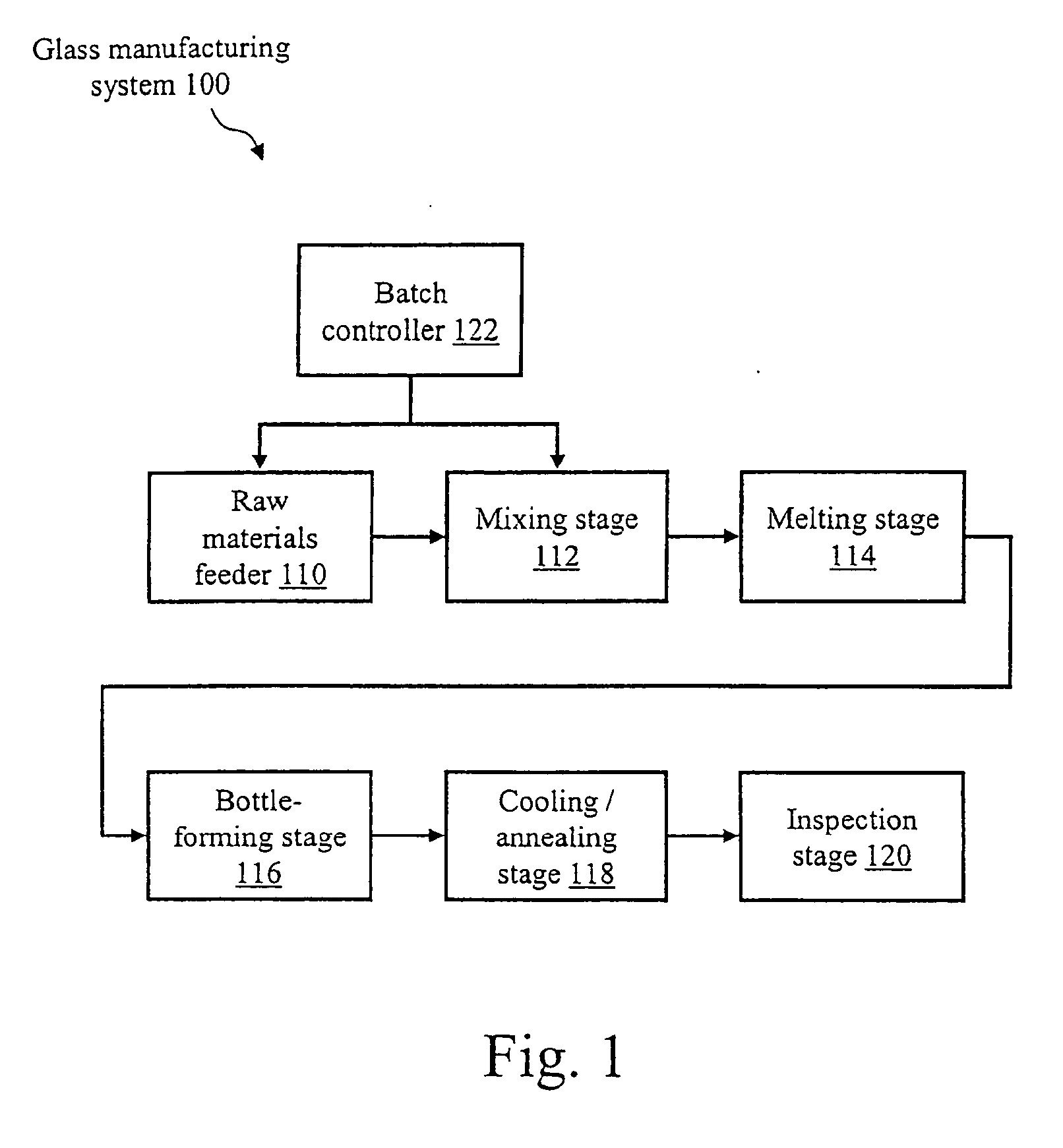

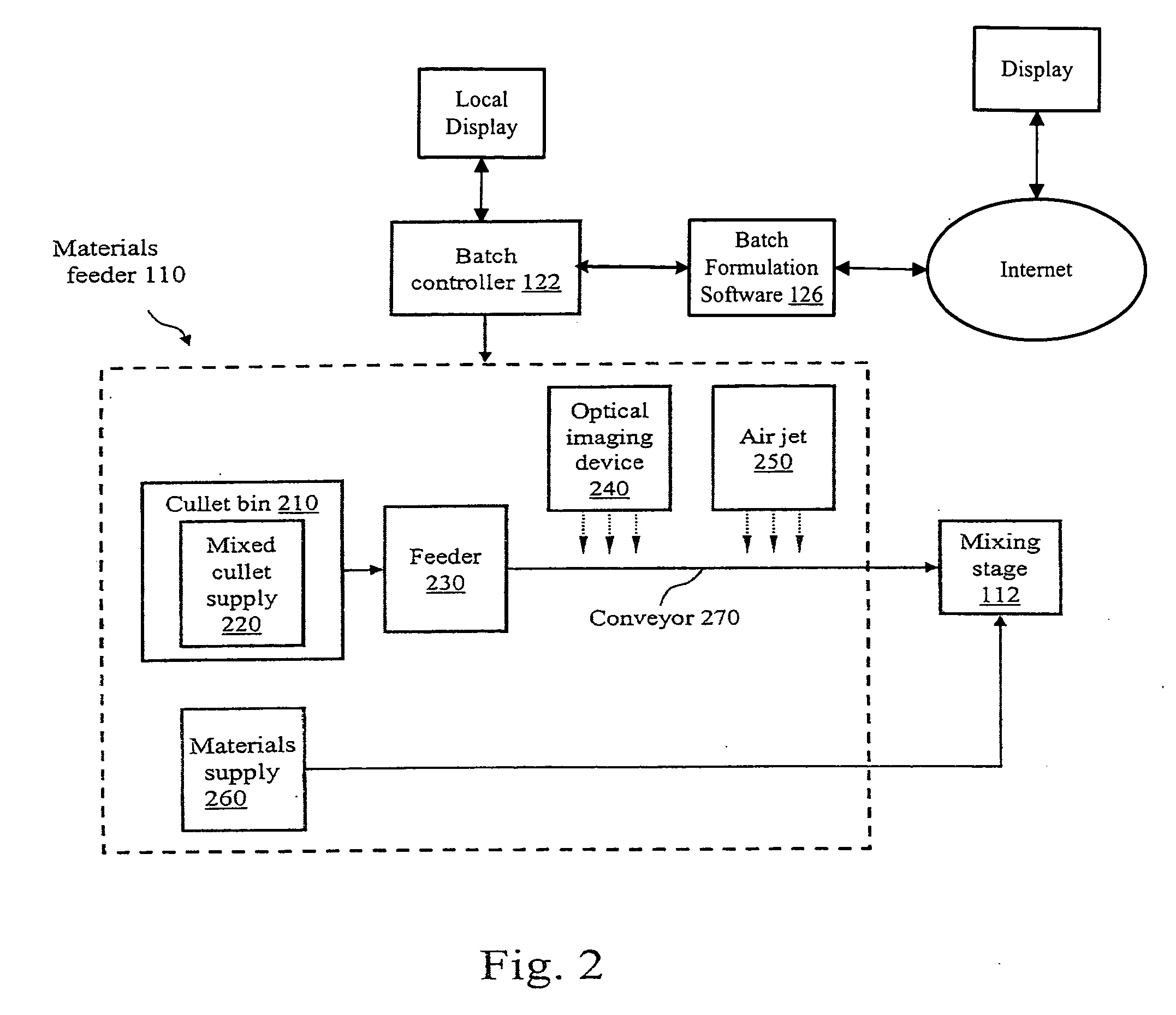

System for and method of batch analysis and optimization for glass manufacturing

InactiveUS20060230787A1Enhance culletEnhance end-productCharging furnaceBlowing machine gearingsAdditive ingredientProcess engineering

A system for and method of analyzing a cullet stream prior to batch formulation in glass manufacturing. Cullet is fed onto a conveyor where a real-time composition analysis is performed. Contaminants are optionally removed, and a determination is made as to whether the cullet batch color is consistent with a predetermined tolerance threshold. If necessary, the glass batch formulation is modified in view of the cullet analysis. Virgin raw materials requirements of the modified glass batch formulation may then be communicated to the batch controller before sending batch ingredients to the mixing stage and completing the overall glass manufacturing process.

Owner:CULCHROME LLC

Hurricane-proof glass manufacturing technique

InactiveCN1990402AAvoid ignoring other aspects of performanceAvoid destructionGlass tempering apparatusThin material handlingAcid etchingGlass manufacturing

The invention relates to a process of preparing anti-hurricane glass, comprising following steps: cutting and edging glass; heating glass in the tempering furnace to softening point; feeding the glass into cooling room at speed of 25-50 cm / s, the air pressure in cooling room should be controlled at 6.5-7.5 * 103 Pa to make the surface compressive stress reach to more than 150 MPa; putting glass into acid-etching slot for suitable acid etching; washing glass surface with clean water; coating the surface with organic silicon protecting membrane. The invention is characterized by low production cost and short producing time.

Owner:庄大建 +1

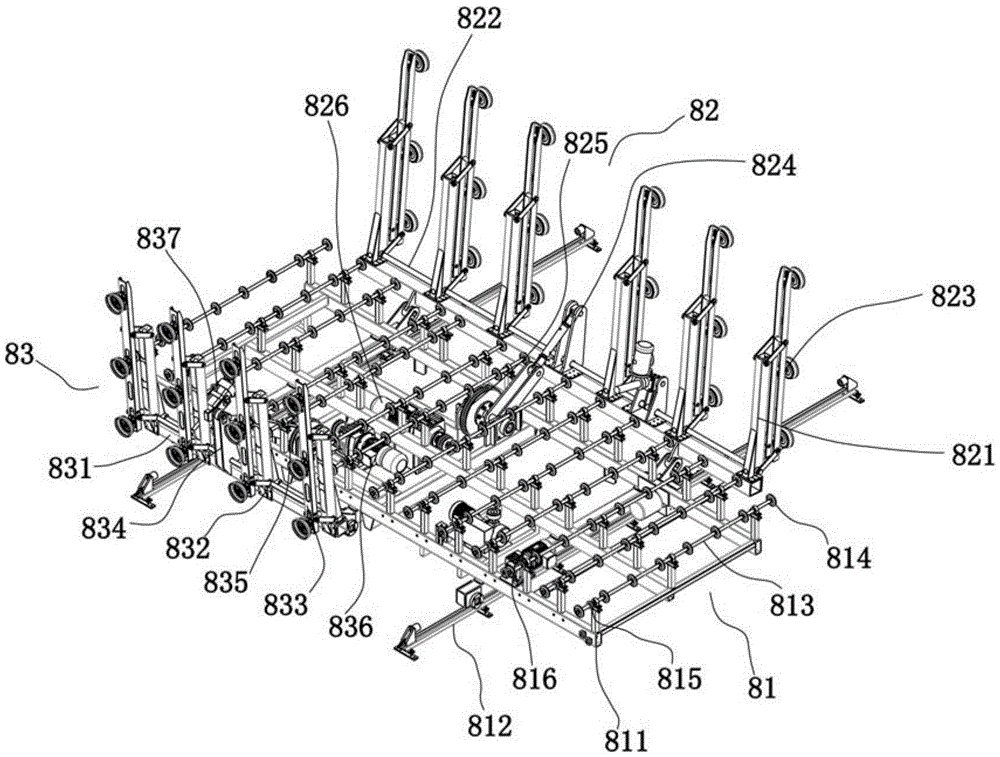

Glass piece loading device

PendingCN111591762ACorrect the movement distanceAccurate entryCharge manipulationConveyor partsEngineeringGlass manufacturing

The invention belongs to the technical field of glass manufacturing equipment, and particularly relates to a glass piece loading device. The glass piece loading device comprises a loading mechanism, apositioning mechanism and a conveying mechanism used for conveying glass, the loading mechanism is located on the loading position of the conveying mechanism and used for grabbing and conveying the glass to the conveying mechanism, the positioning mechanism is mounted on the conveying mechanism and located on the discharging position of the conveying mechanism, the positioning mechanism is used for adjusting the glass position to enable the glass to right face a bending die in a toughening furnace, according to the glass piece loading device, the automatic piece loading operation of the toughening furnace is achieved, the piece loading efficiency is greatly improved, in addition, in the piece loading process, the positioning mechanism carries out positioning adjusting on the glass position, the moving position of the glass on the conveying mechanism is corrected, the glass can accurately enter in the bending die in the toughening furnace, it is ensured that after subsequent glass bending, a good shape is achieved, the glass pass percent and the glass yield are improved, and the glass manufacturing cost is reduced.

Owner:SHENZHEN XINYI AUTOMOBILE GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com