Solar photovoltaic interlining curtain wall glass manufacturing process

A solar photovoltaic and manufacturing process technology, applied in sustainable manufacturing/processing, wall, final product manufacturing, etc., can solve the problem of not found solar photovoltaic interlayer curtain wall glass process, etc., to achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

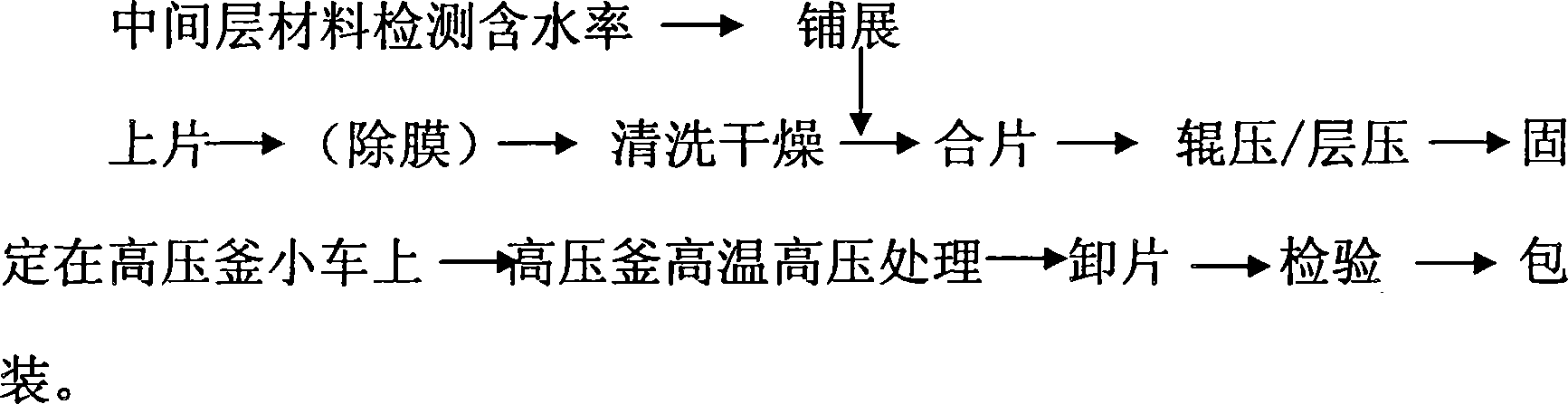

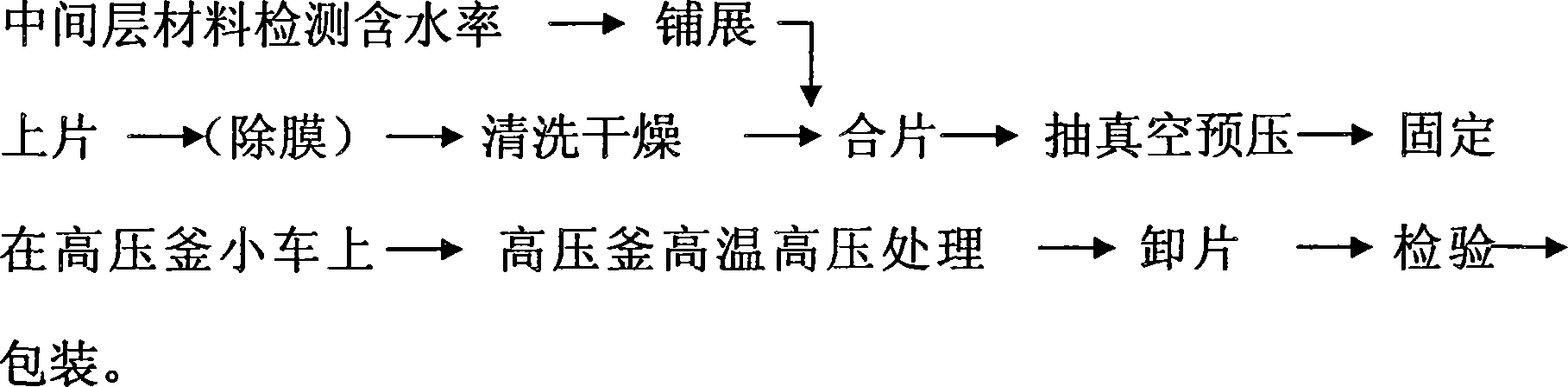

[0026] The production process of solar photovoltaic laminated curtain wall glass includes two parts: one is the screening and series connection of solar cells, and the other is the production of solar photovoltaic laminated glass.

[0027] The screening of solar cells refers to visually inspecting the integrity of crystalline silicon solar cells and whether there are obvious defects on the surface, such as obvious defects such as uneven color, peeling, scratches, etc., and rejecting cells with cracks and obvious defects. For crystalline silicon solar cells, visually inspect and measure the bending of the cells, and remove cells whose curvature exceeds 3% of the corresponding side; in the next step, use two fingers for each crystalline silicon solar cell Hold the part more than one-third away from the edge of the cell, and fan it slowly to remove the solar cells that may have cracks.

[0028] The series connection of the solar cells refers to welding lines and bus bars on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com