Thermal control of the bead portion of a glass ribbon

A technology of glass ribbon and curling, which is applied in glass forming, glass forming, glass manufacturing equipment, etc., and can solve problems such as defective displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

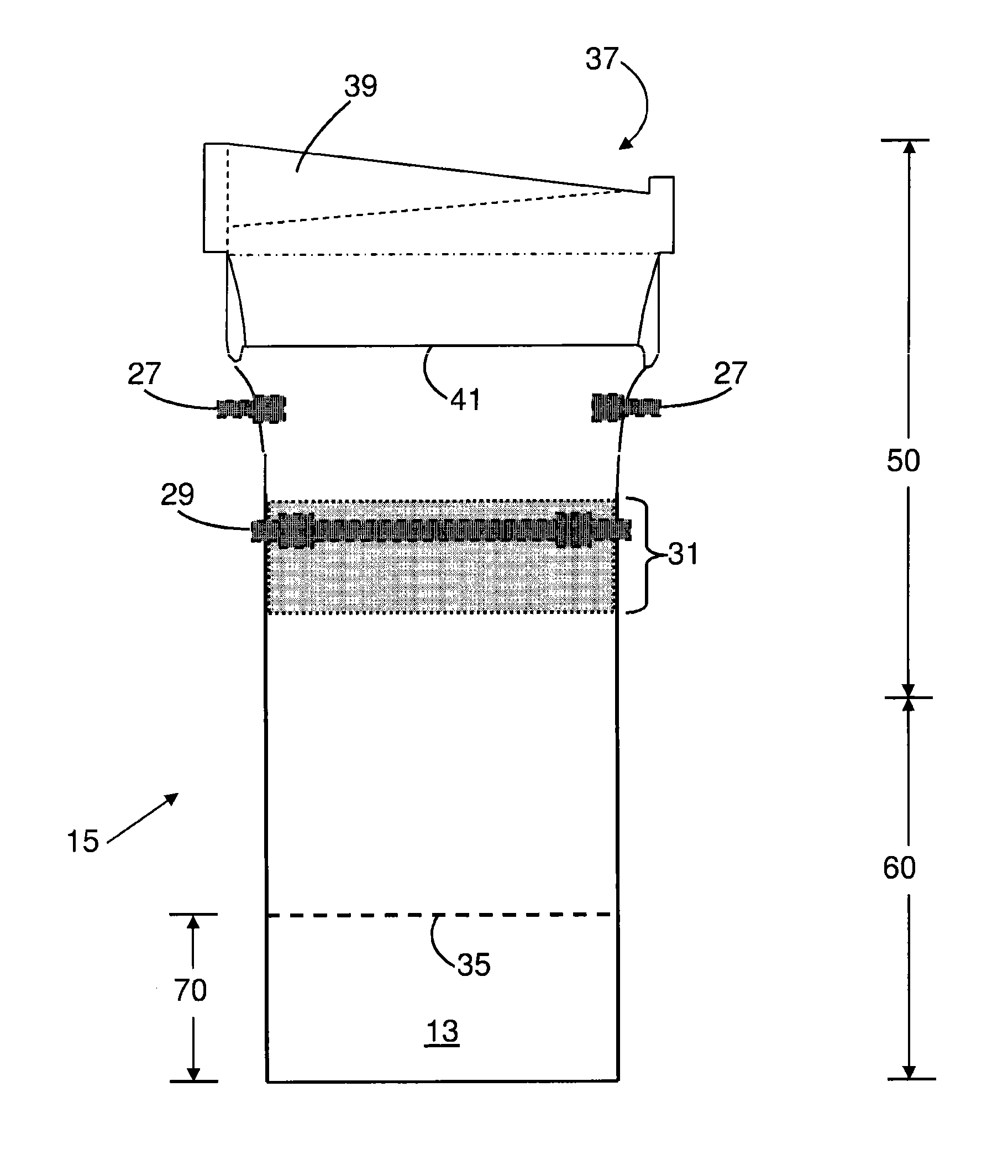

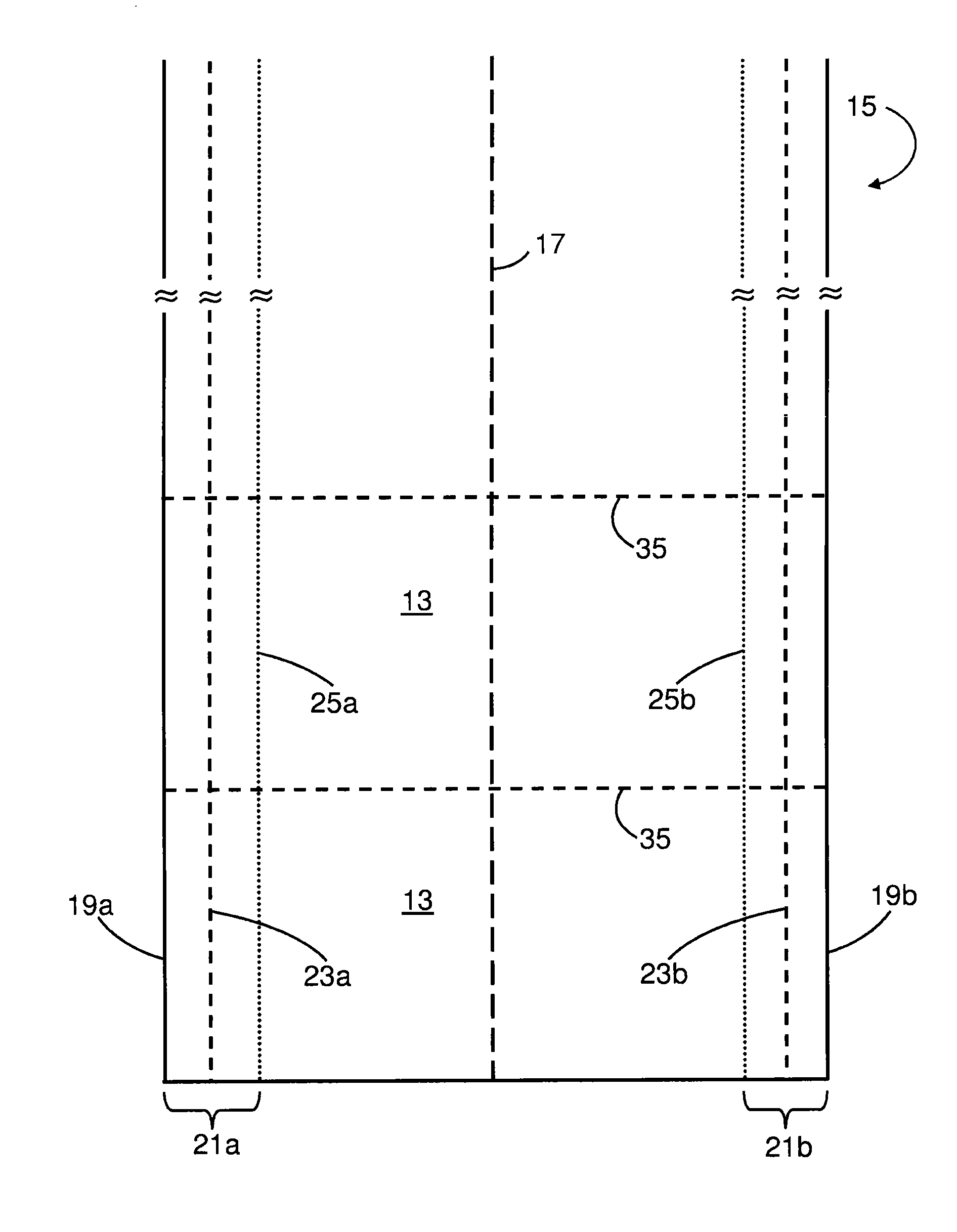

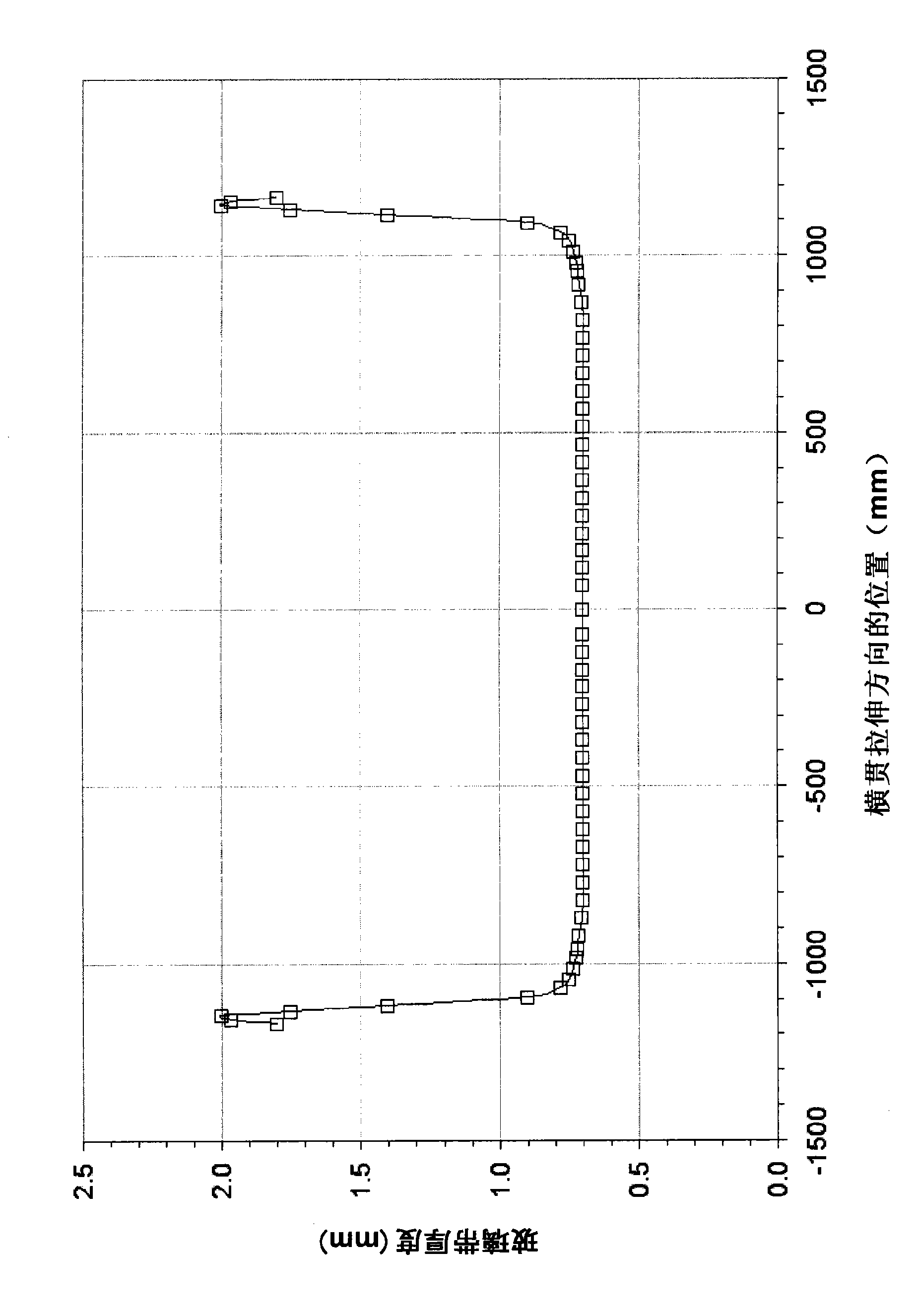

[0120] This example shows a uniform drop in temperature of the high hem during stretching to closely match the temperature nearby. (In this example and Examples 2-4, ρ·C p The v product is assumed to be 160kW / °K m 2 . ) Figure 10 The temperature distribution across the stretching direction without seam cooling (○ data points) and with seam cooling (□ data points) are compared. (In this and similar figures, the zero point corresponds to the centerline of the glass ribbon.) As can be seen from these two curves, the cooling provides a significantly flatter temperature distribution across the stretching direction.

[0121] Figure 11 and 12 are the temperature and heat flux distributions down the stretching direction for this example, where in each case ○ data points are for thickness equal to t b and without seam cooling across the stretch direction, □data points are for the same cross-draw position with seam cooling, ◇data points are for thickness equal to t q And for th...

example 2

[0125] This example shows insufficient non-uniform cooling of the high hem temperature during stretching. As in example 1, Figure 13 The temperature distribution across the stretching direction without seam cooling (○ data points) and with seam cooling (□ data points) are compared. It can be seen from these two curves that the cooling provides a significantly flatter temperature distribution across the stretching direction, but not as flat as in Example 1. In particular, the temperature at the thickest point of the bead is already substantially equal to the temperature in the adjacent good (or near good) region, but the temperature on either side of the thickest point is higher than the adjacent temperature . Figure 14 and 15 The temperature distribution down the stretching direction and the Q" distribution for this case are shown.

example 3

[0127] This example shows non-uniform supercooling of the high hem temperature during stretching. As in examples 1 and 2, Figure 16 The temperature distribution across the stretching direction without seam cooling (○ data points) and with seam cooling (□ data points) are compared. It can be seen from these two curves that in this case, without substantially flattening the temperature distribution across the direction of stretching, the distribution with cooling exhibits a temperature change of a magnitude similar to that without cooling The situation is similar, but with opposite signs. This distribution is useful when it is desired to introduce a shape or stress distribution in the glass ribbon opposite to that which would occur without cooling.

[0128] Figure 17 and 18 The temperature profile and Q" profile for the draw down for this case are shown. Since the added cooling is stronger in this case, when the crimp cooling is applied t q The temperature distribution at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com