Glass composition, glass low in impurity content and preparation method and application of glass

A low-inclusion and composition technology, which is applied in glass manufacturing equipment, glass molding, glass furnace equipment, etc., can solve the problems of difficult removal of inclusions and low content of inclusions, and achieve increased volume and reduced N2 gas content. The effect of pressure and content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] According to a preferred embodiment of the present invention, the composition contains 56-63wt% SiO 2 , 17-22wt% Al 2 o 3 , 0-5.2wt% of B 2 o 3 +P 2 o 5 , 1-5wt% MgO, 2-8wt% CaO, 0-8wt% SrO, 1-12wt% BaO, 0.3-4wt% ZnO, 0.2-3wt% TiO 2 , 0.1-4wt% Y 2 o 3 +La 2 o 3 +Nd2O 3 , 2 O, where R 2 O is for Li 2 O, Na 2 O, K 2 The sum of the O content.

[0044] Preferably, the composition contains B 2 o 3 0-5wt%, P 2 o 5 It is 0-7wt%, preferably 0-5wt%. e.g. B 2 o 3 0-4.7wt% and / or P 2 o 5 It is 0-1.5wt%.

[0045] Preferably, the composition contains Y 2 o 3 0-2wt%, La 2 o 3 0-3wt%, Nd 2 o 3 It is 0-3wt%. e.g. Y 2 o 3 0-1wt%, La 2 o 3 0-1.7wt% and / or Nd 2 o 3 0-2wt%.

[0046] Preferably, the composition contains Li 2 O is 0.01wt% or less, Na 2 O is 0.01wt% or less, K 2 O is 0.01 wt% or less.

[0047] According to the present invention, the composition for glass of the present invention may further contain a chemical clarifier as necessary. ...

Embodiment 1-13、 comparative example 1-3

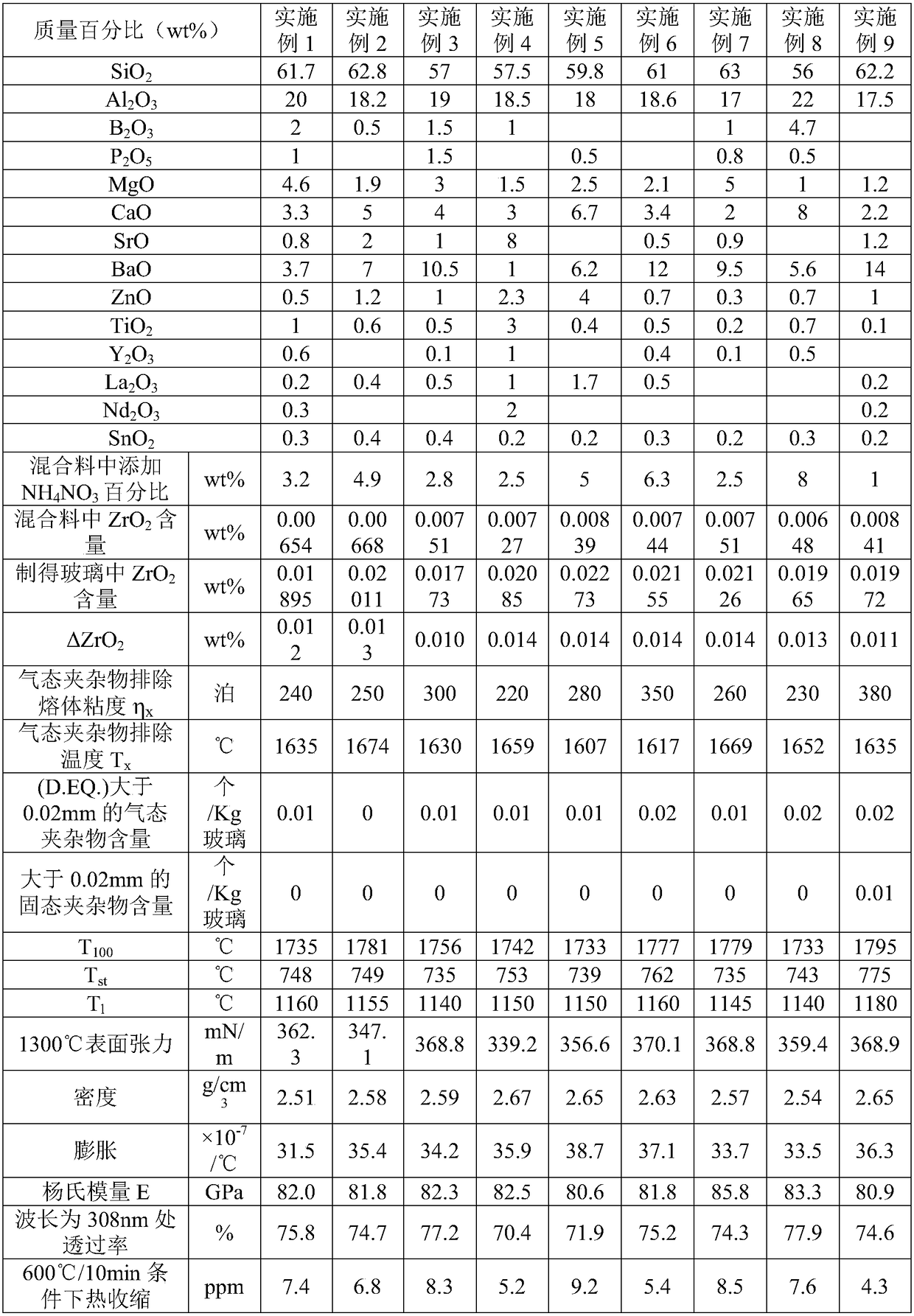

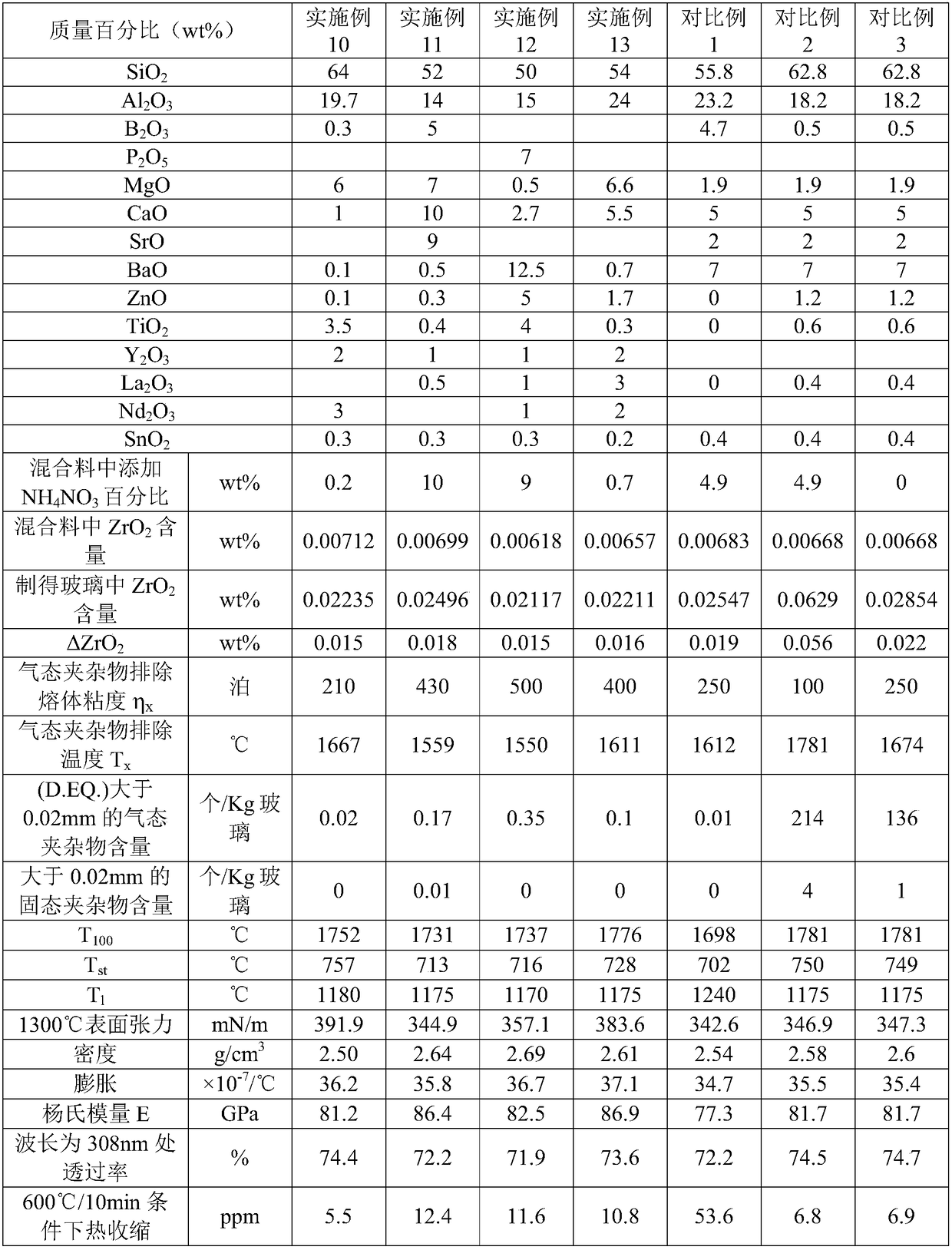

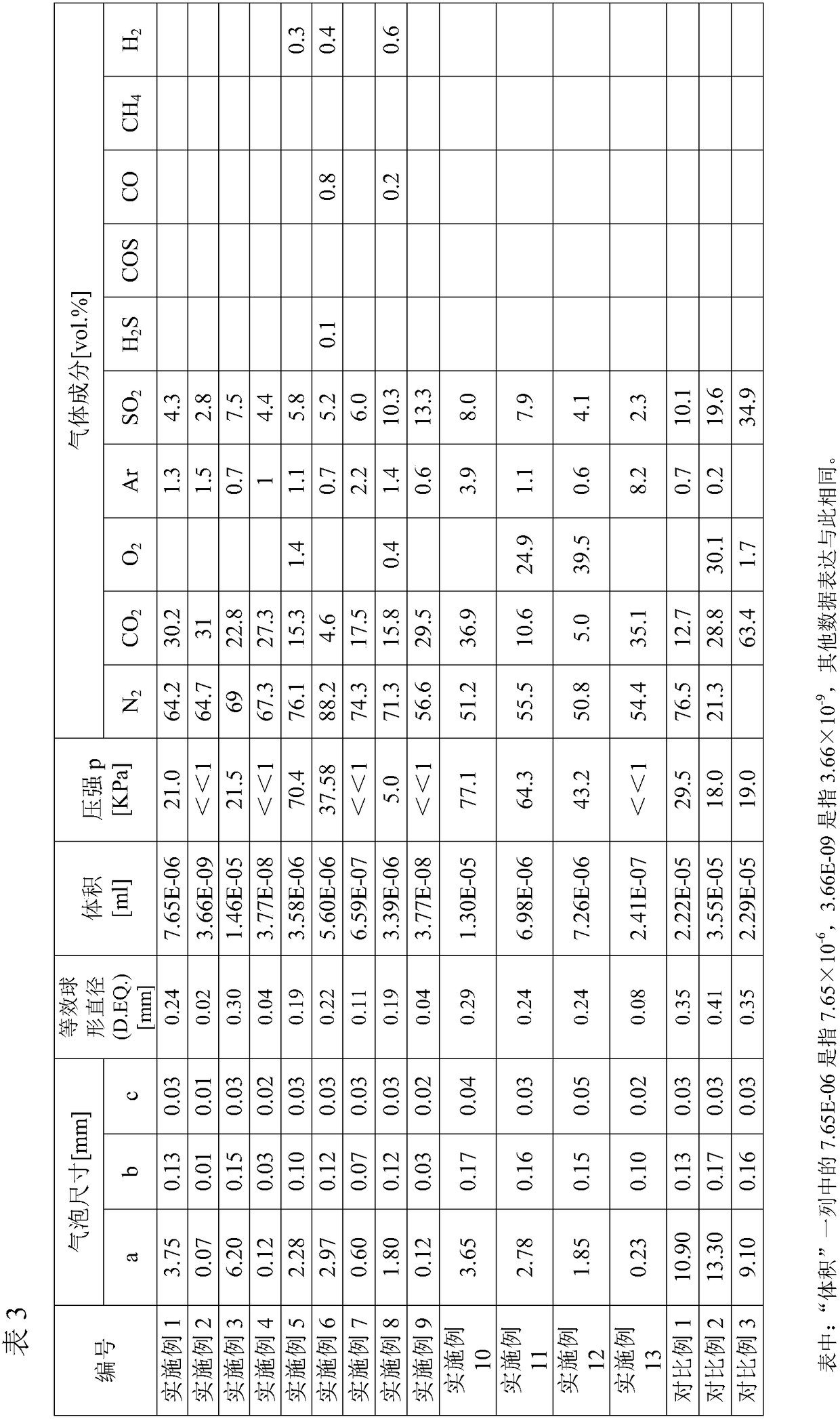

[0090] Weigh each raw material component according to the ratio shown in Table 1-2, mix well, and pour the mixture into a high zirconium brick crucible (ZrO 2 >85wt%), then in η x The temperature corresponding to Poise viscosity is T x Heated in a resistance furnace for 48 hours, and used high zirconium rods (ZrO 2 >85wt%) the stirrer stirs slowly at a constant speed. Quickly pour the molten glass into a stainless steel cast iron mold to form a specified block glass product, then anneal the glass product in an annealing furnace for 2 hours, turn off the power and cool down to 25°C with the furnace. The glass product is cut, ground and polished, then cleaned with deionized water and dried to obtain a finished glass product with a thickness of 0.5mm. Various properties of each glass product were measured respectively, and the results are shown in Table 1-2, and the composition of gaseous inclusions in the glass is shown in Table 3.

[0091] Table 1

[0092]

[0093] Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com