Patents

Literature

231results about How to "Increase partial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

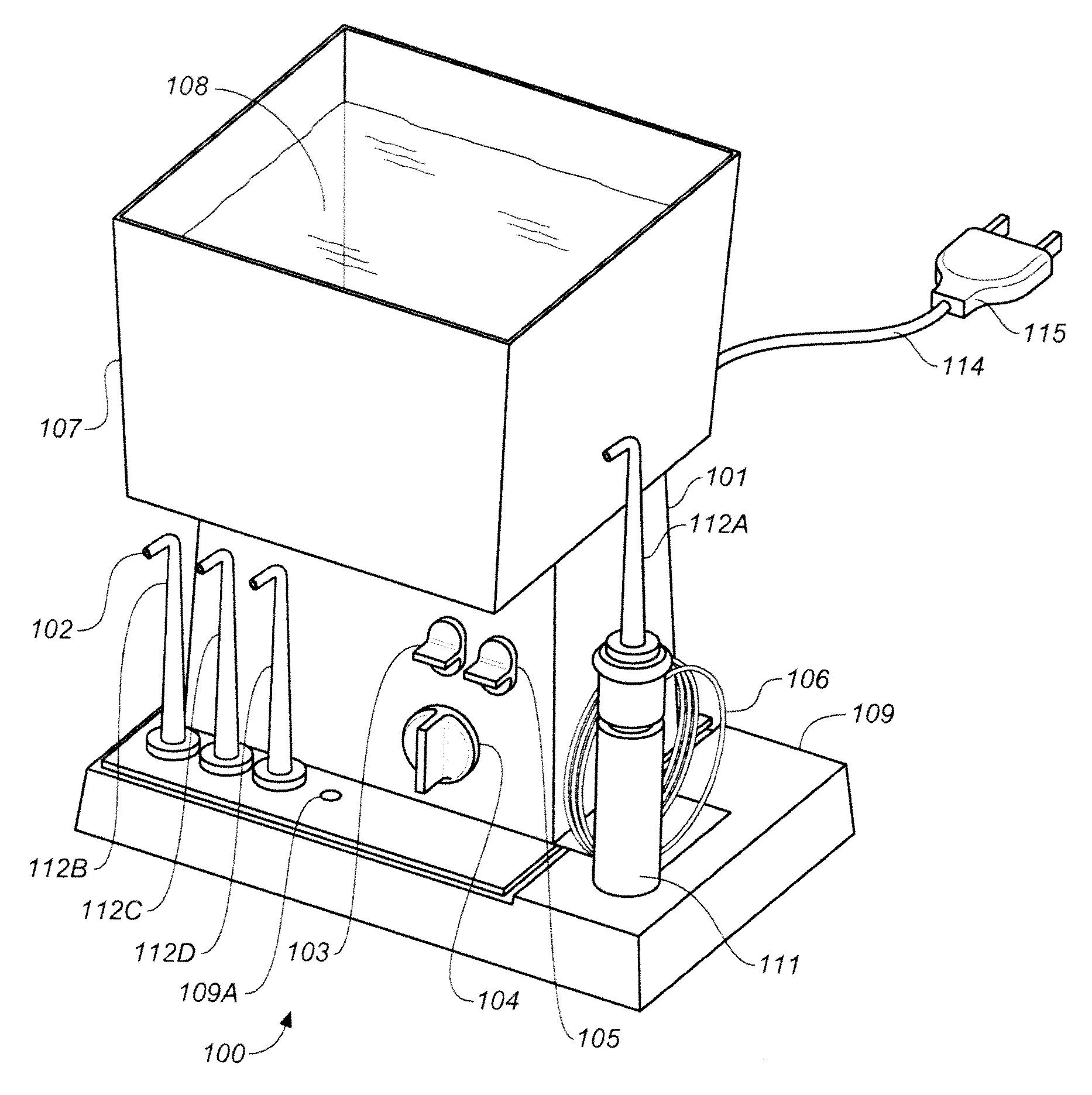

Sensitizer Solutions, Systems, and Methods of Use

InactiveUS20080255498A1Reduce riskIncreased oxygen levelsElectrotherapyPhotodynamic therapySolventChemistry

A kit cleaning system and method is disclosed. One embodiment of the present invention has a photosensitizer solution supplied by a pressurized nozzle to the target site. Specific application of the solution is to an oral or skin surface target site. The photosensitizer solution is illuminated with sensitizing light creating reactive chemical species. Pressure and a solvent having an elevated concentration of oxygen or oxygen species improve the efficiency of the killing of pathogens. Methods of using the system within an oral cavity are also disclosed.

Owner:OROSCI

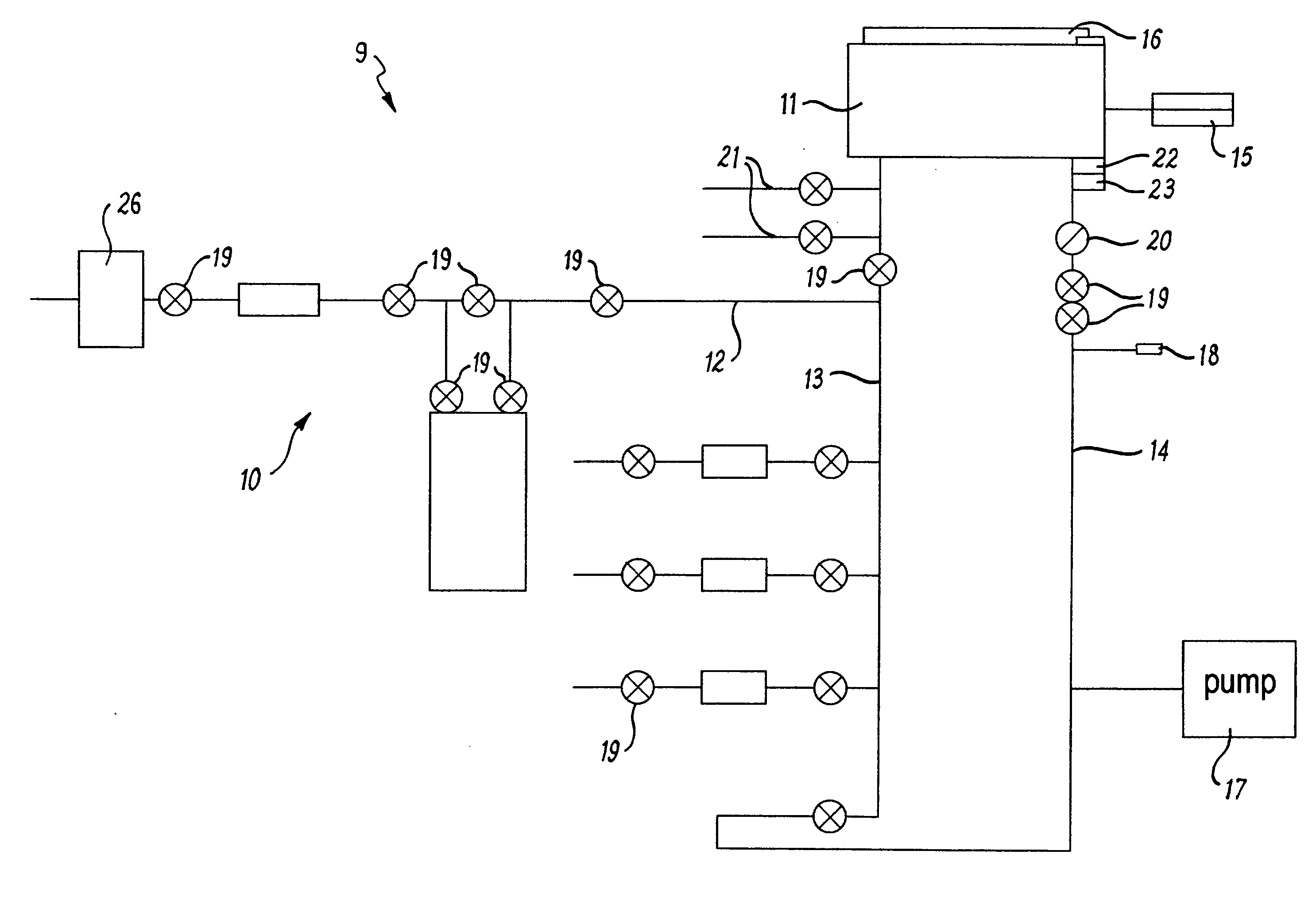

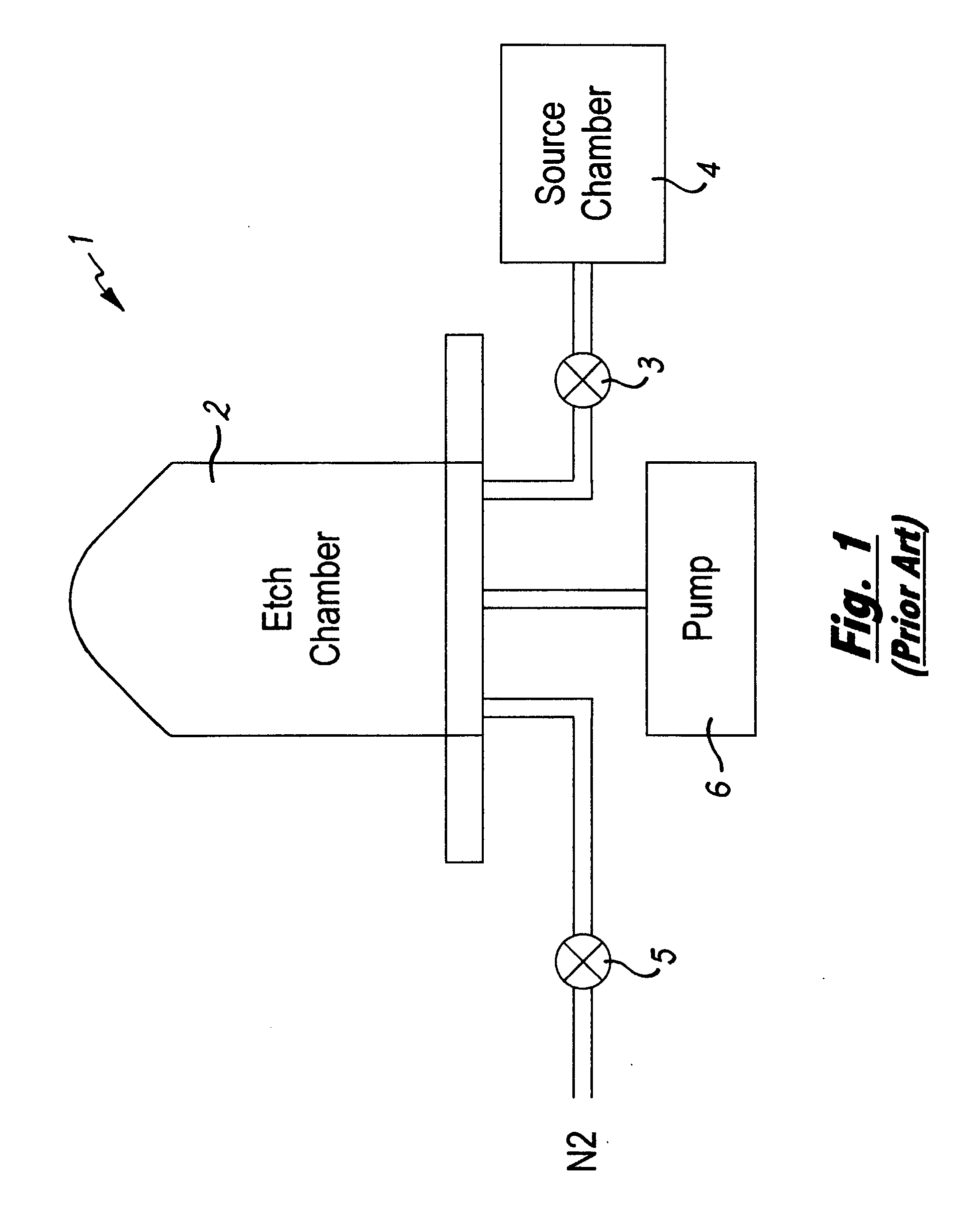

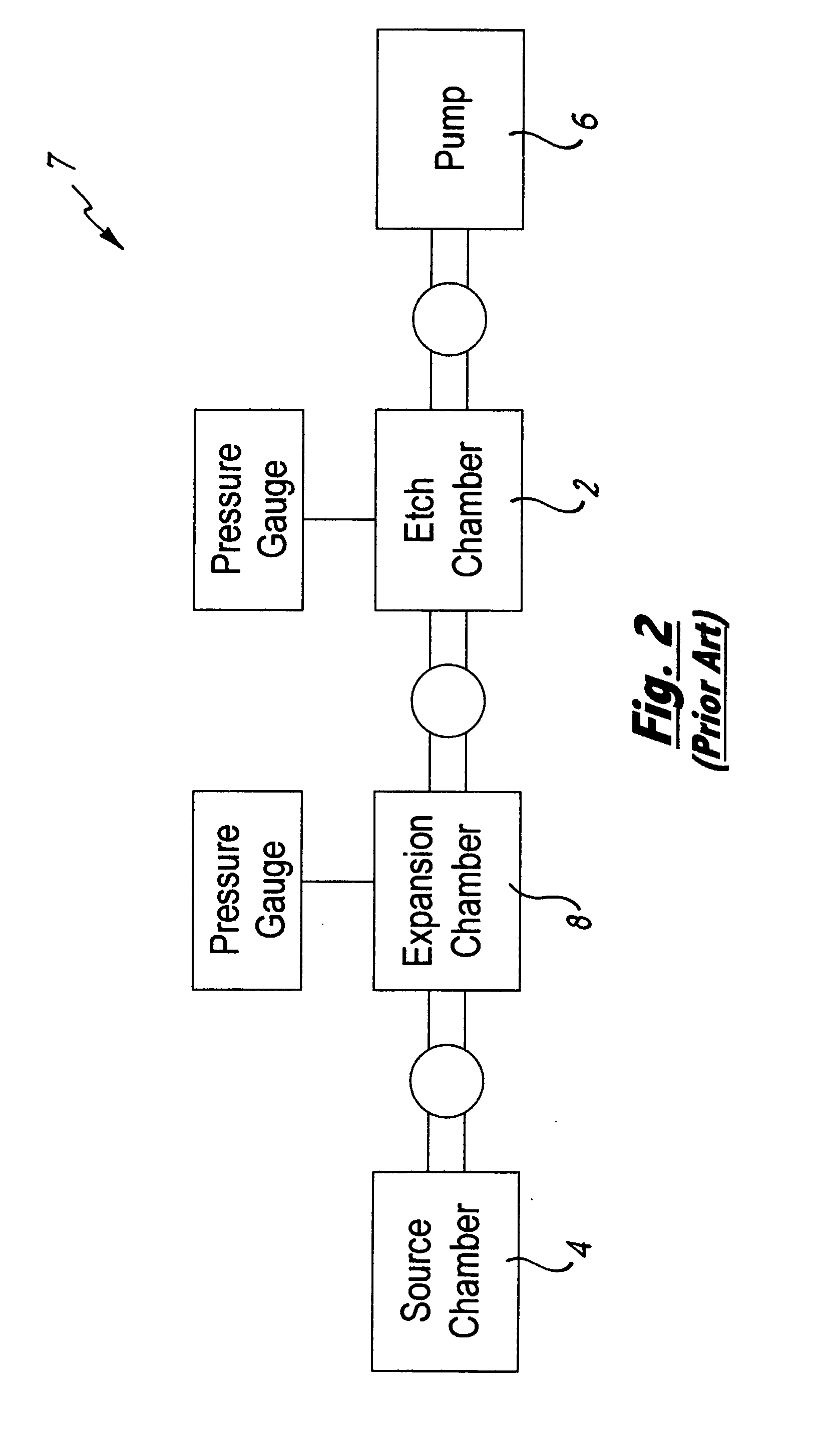

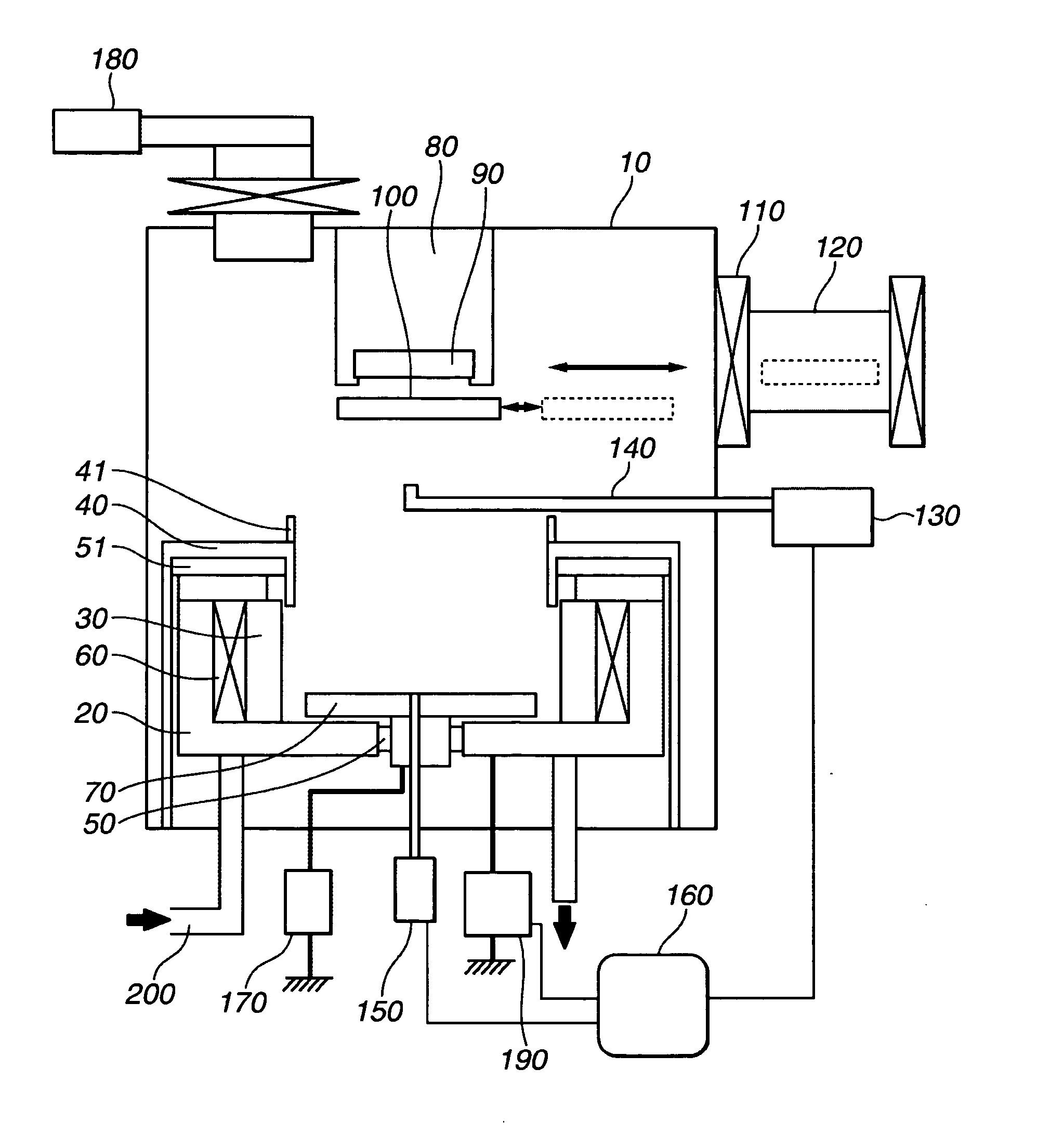

Method and Apparatus for the Etching of Microstructures

InactiveUS20080035607A1Increase partial pressureIncrease ratingsElectric discharge tubesDecorative surface effectsEtchingContinuous flow

An apparatus and method for providing an etching gas source for etching one or more microstructures located within a process chamber. the apparatus has a gas source supply line attached to a gas source and one or more chambers for containing an etching material. In use, the etching material is transformed into an etching material vapor within one or more of the chamber and the gas supply line provides a supply of carrier gas to the etching material vapor and also supplies the etching material vapor transported by the carrier gas to the process chamber. Advantageously, the apparatus of the invention does not require the incorporation of any expansion chambers or other complicated mechanical features in order to achieve a continuous flow of etching gas.

Owner:MEMSSTAR

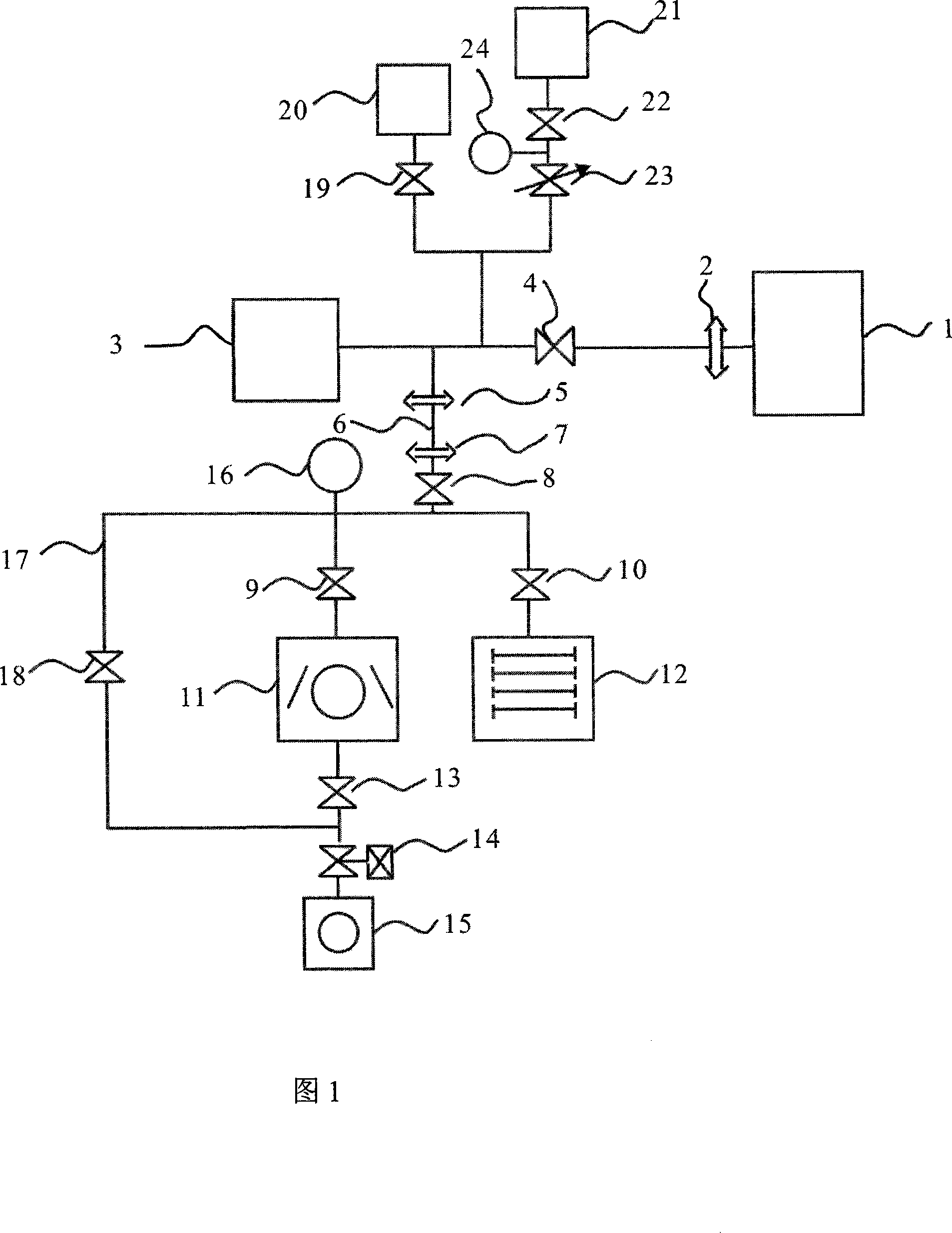

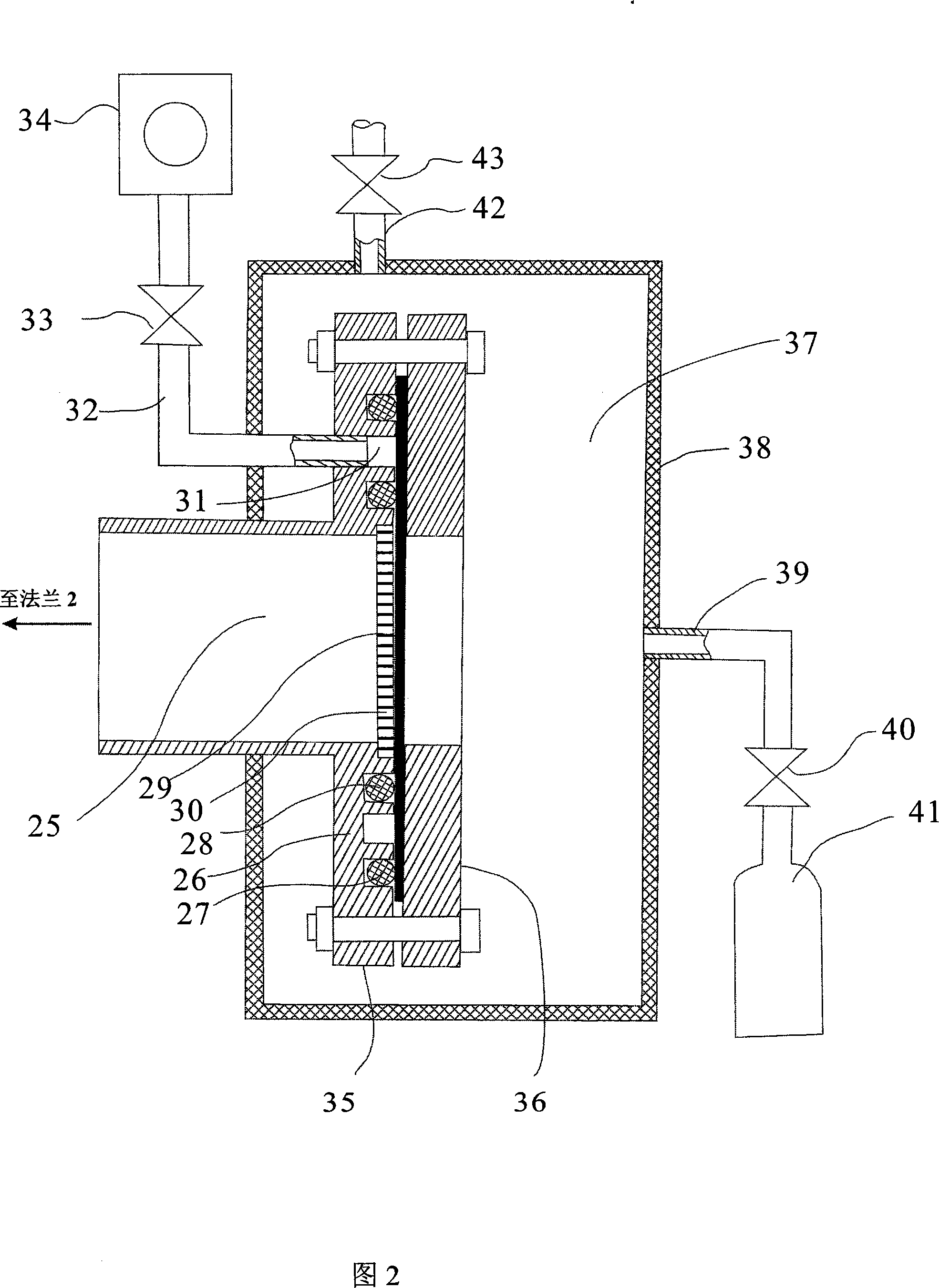

Device and method for measuring air permeability of isolation material

InactiveCN101246095AReduced leak rate into vacuum chamberReduce the pressure valueWithdrawing sample devicesMaterial analysis by electric/magnetic meansMeasurement deviceCurrent limiting

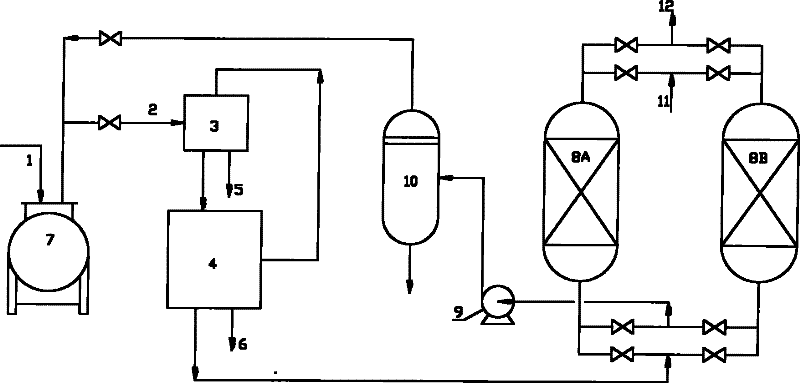

The present invention discloses an isolating material air permeability measuring device which comprises a double vacuum sealing structure permeating gas sampling device and an isolation material air permeability measuring device of the current limiting air extraction pipeline, the device comprises a permeation gas sampling device with double vacuum sealing structure, an ultrahigh vacuum system, a mass spectrograph and a calibrating device, wherein the permeation gas sampling device is connected to the mass spectrograph 3, the current limiting air extraction pipeline 6 and the calibrating device 19-24 through the flange 2 and the vacuum valve 4. The device can overcome the defects of low signal-to-noise ratio when the mass spectrum signal of the permeation air is measured and difficulty for measuring the isolation material with low air permeability existing in the existing technique, and has the characters of quick measuring speed, being able to measure the permeability rate of all gases to the isolation material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

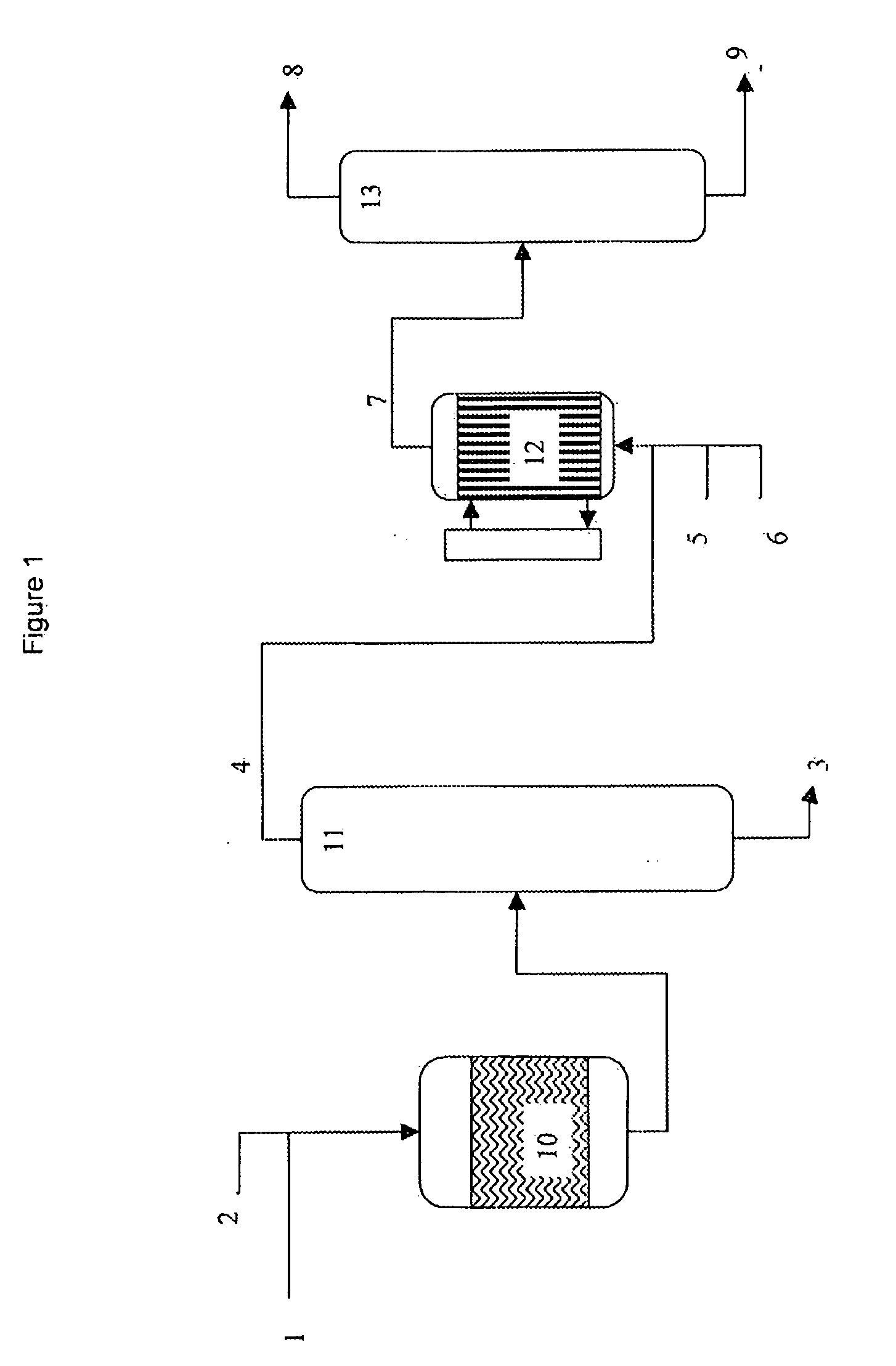

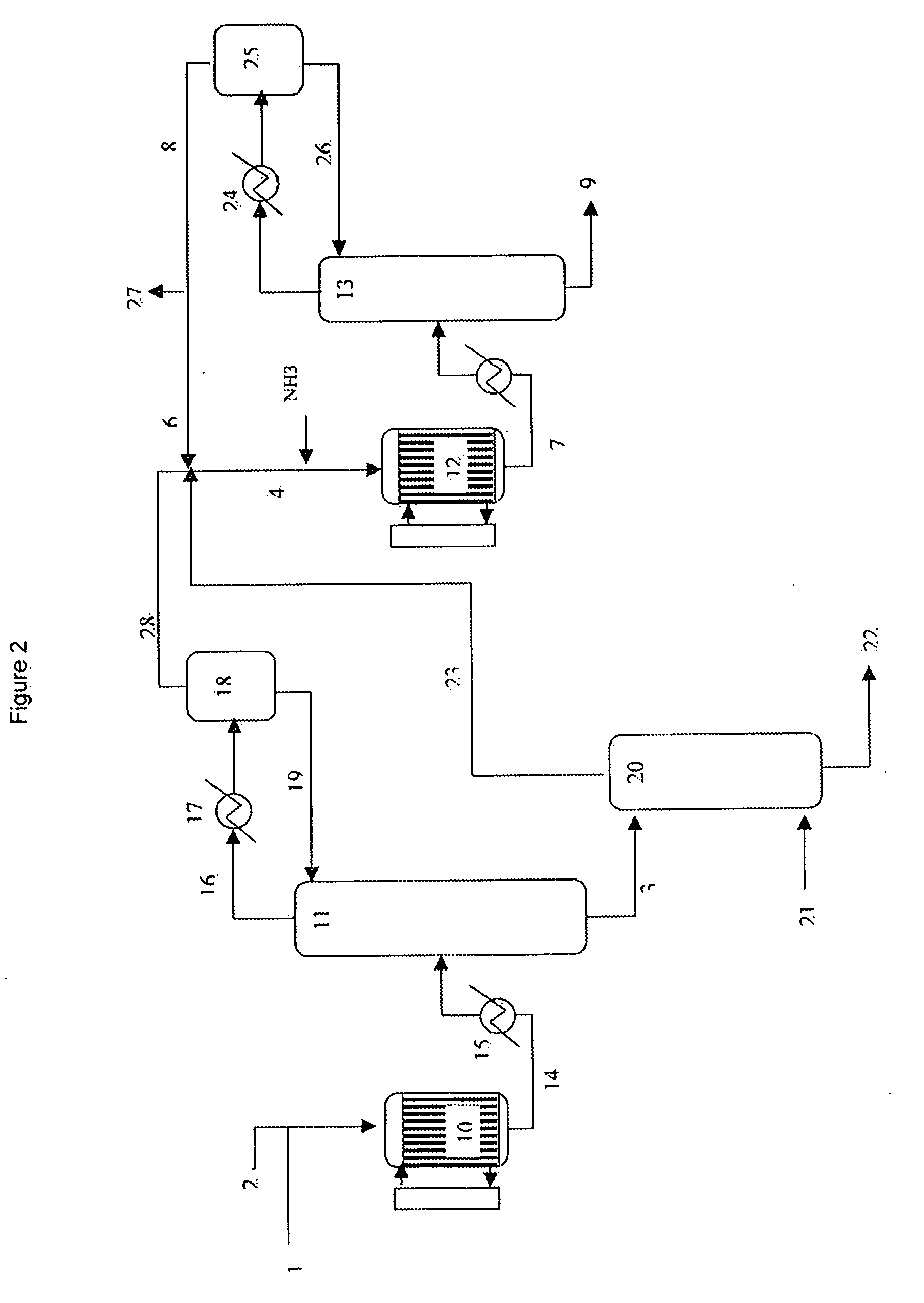

Method for the synthesis of acrylonitrile from glycerol

InactiveUS20100048850A1Less heat releaseIncrease partial pressureOrganic compound preparationPreparation by hydrocarbon ammoxidationGas phaseGlycerol

The invention relates to a novel way to synthesize acrylonitrile from a renewable raw material and more particularly relates to a method for producing acrylonitrile by the ammoxidation of glycerol in gaseous phase. The method can be implemented in a single step, or the glycerol can be previously submitted to a dehydration step. The acrylonitrile thus obtained meets the requirements of green chemistry.

Owner:ARKEMA FRANCE SA

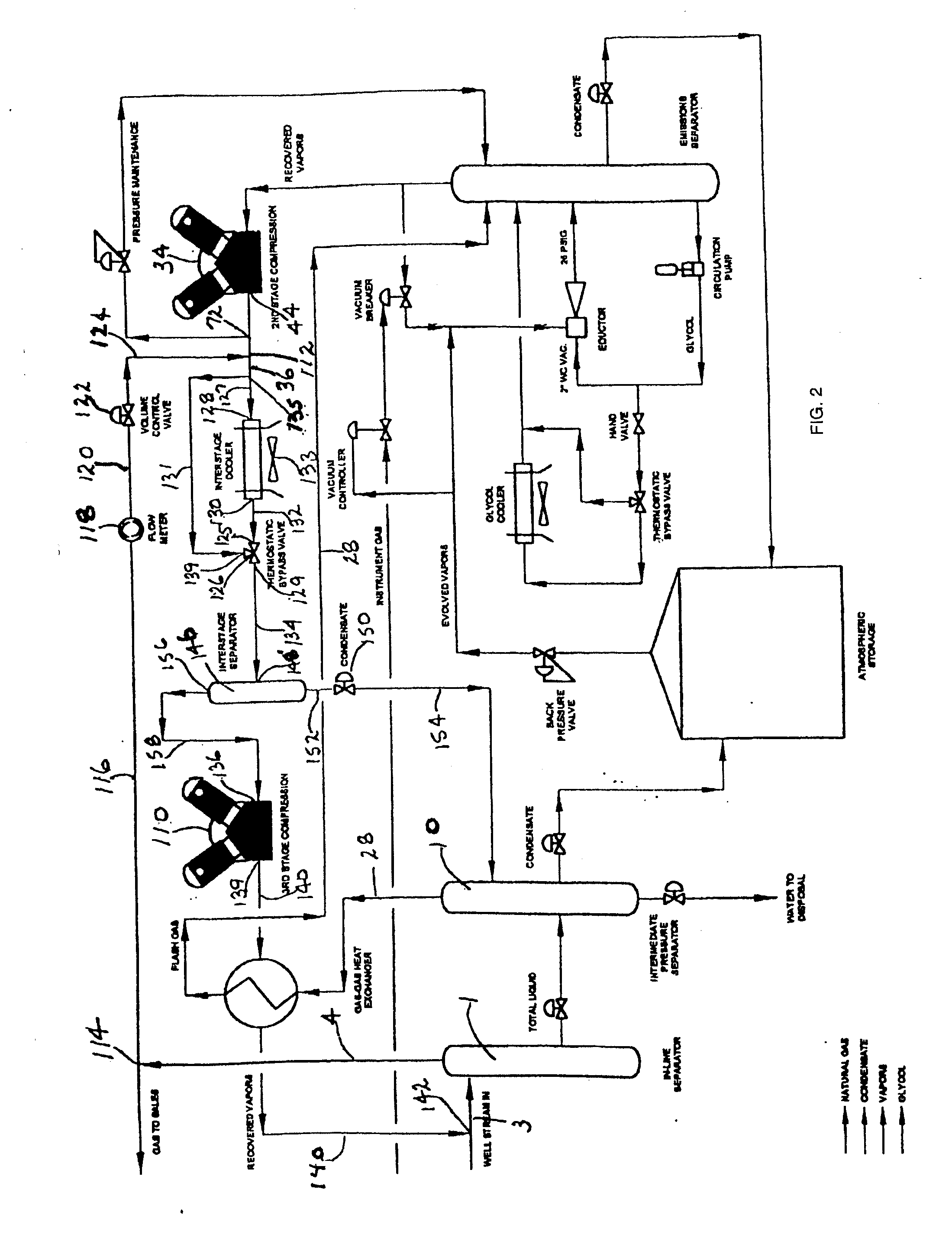

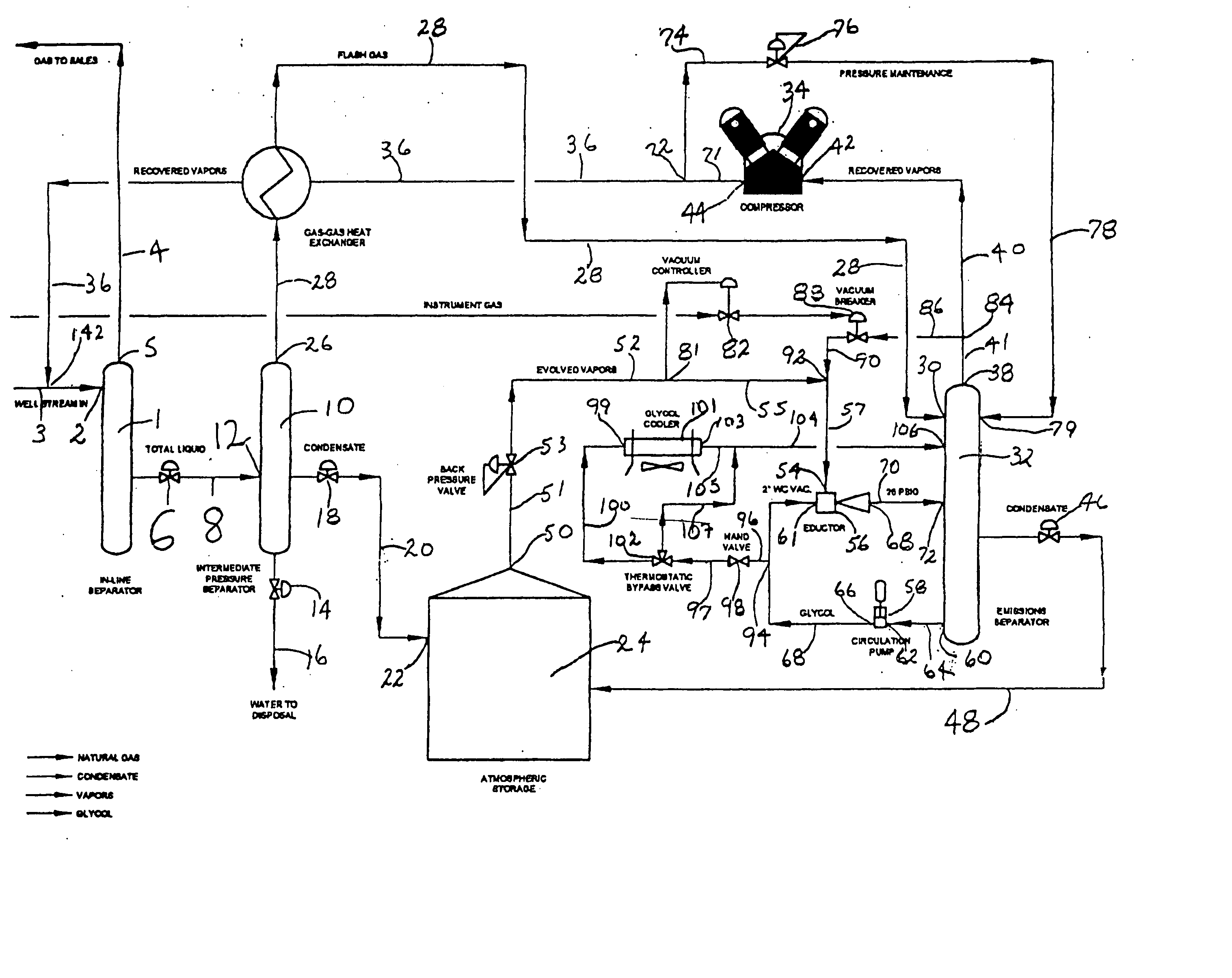

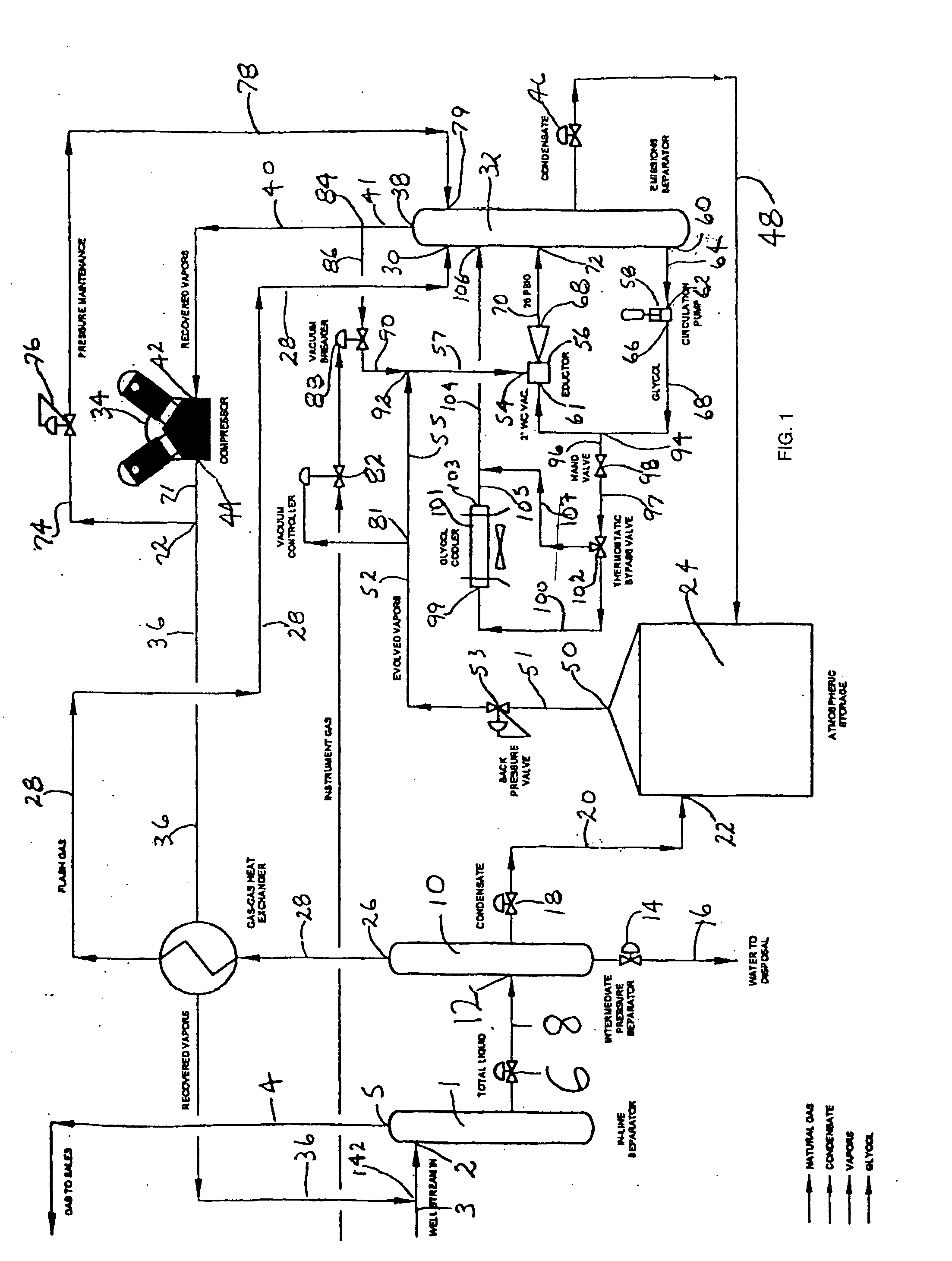

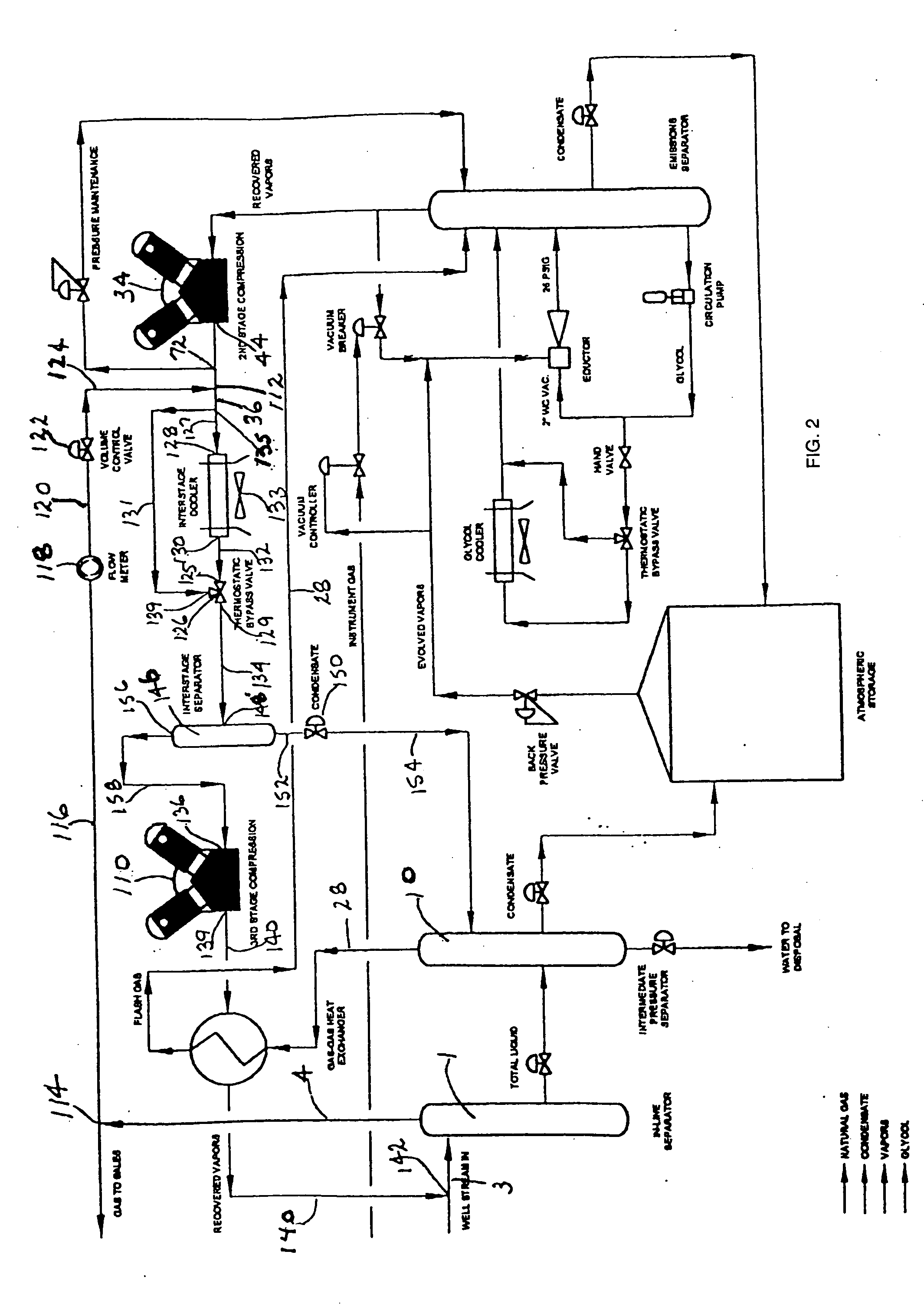

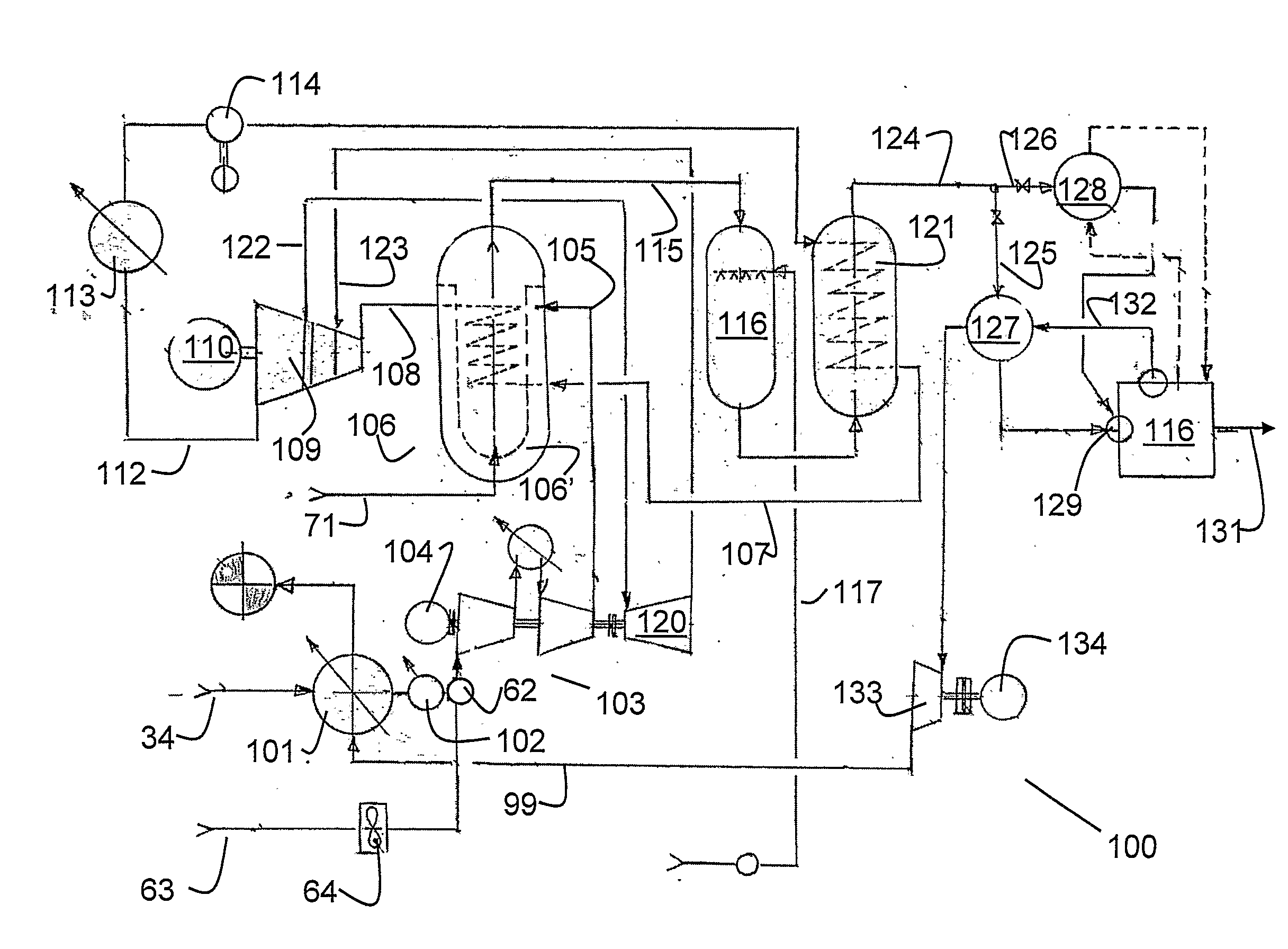

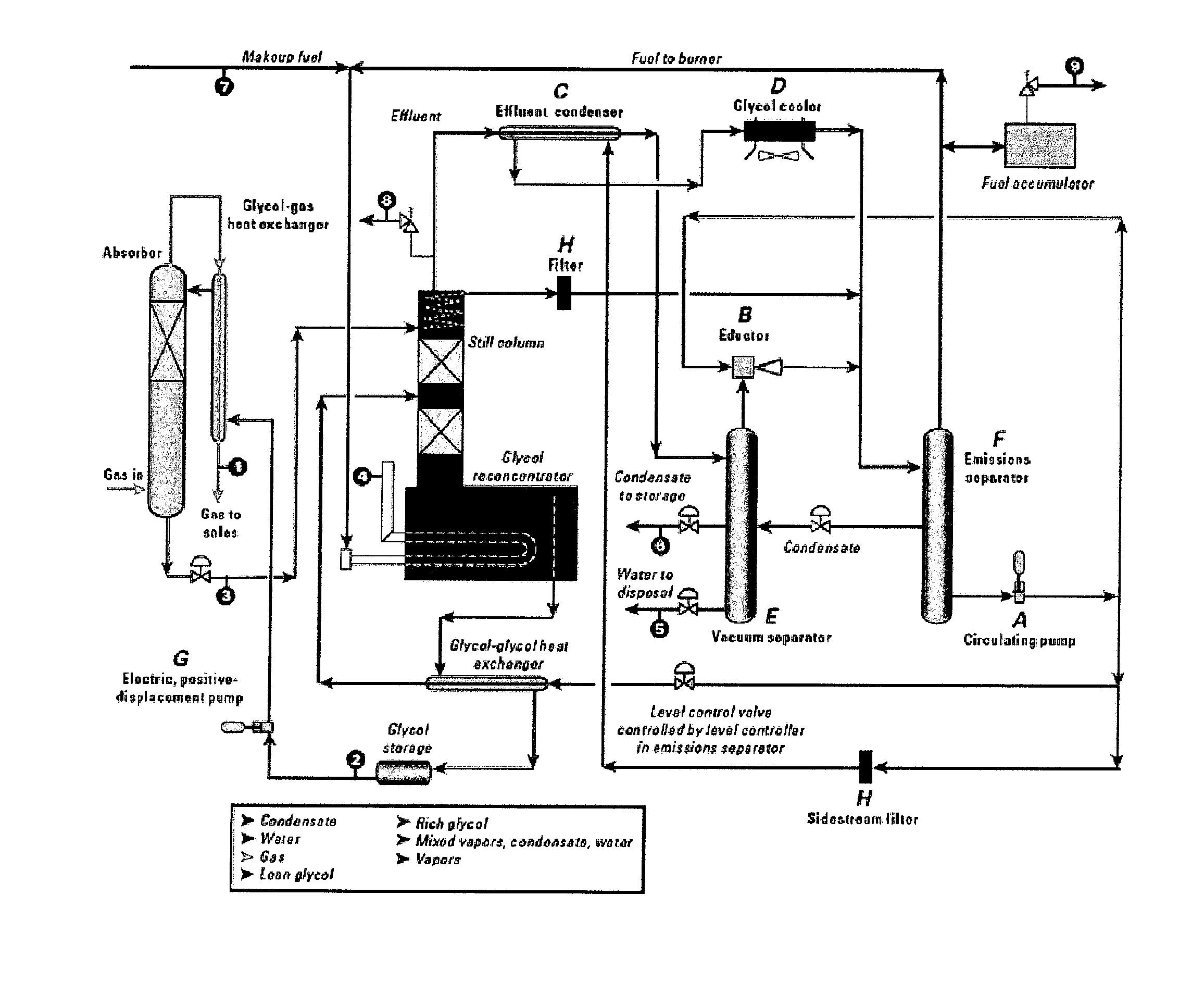

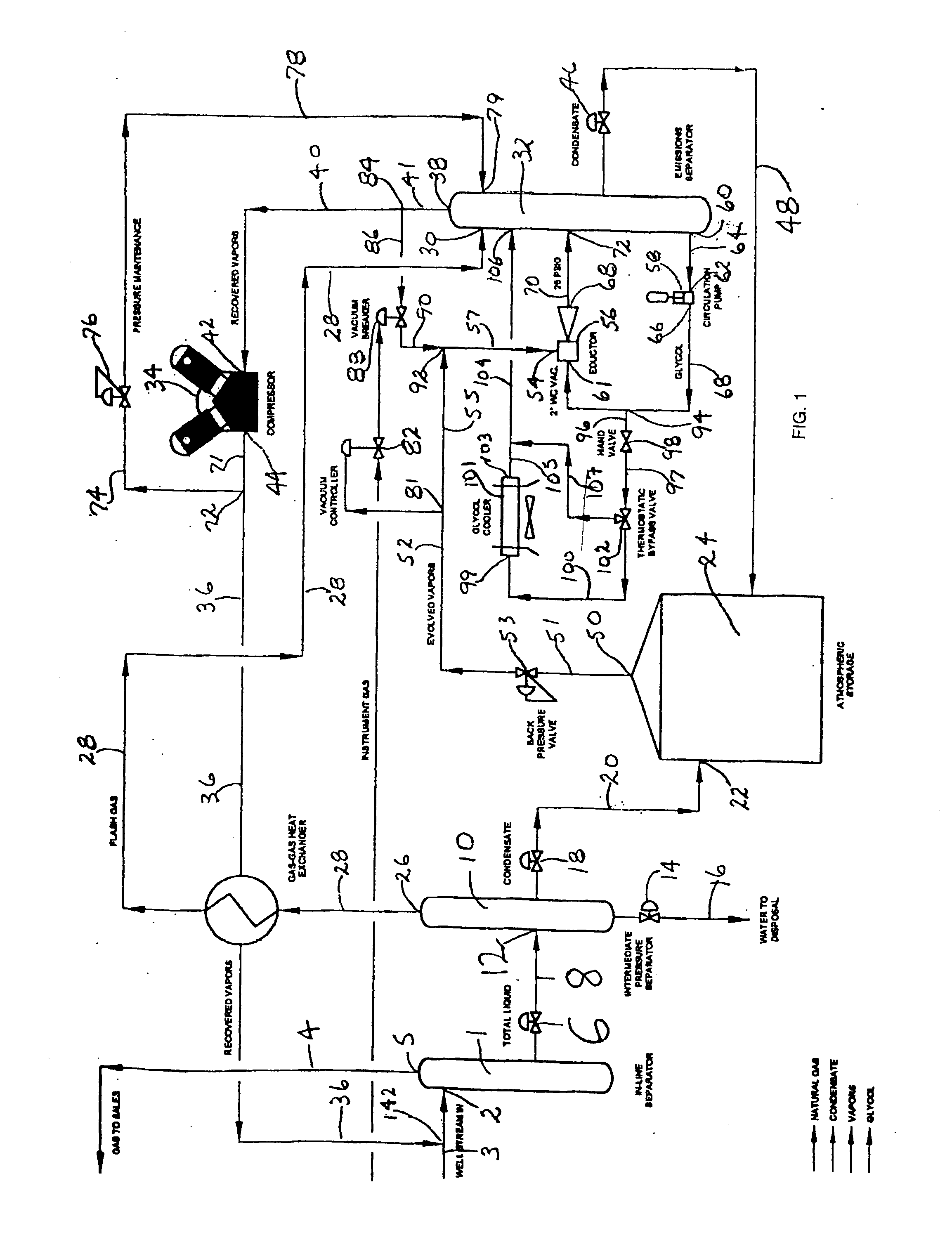

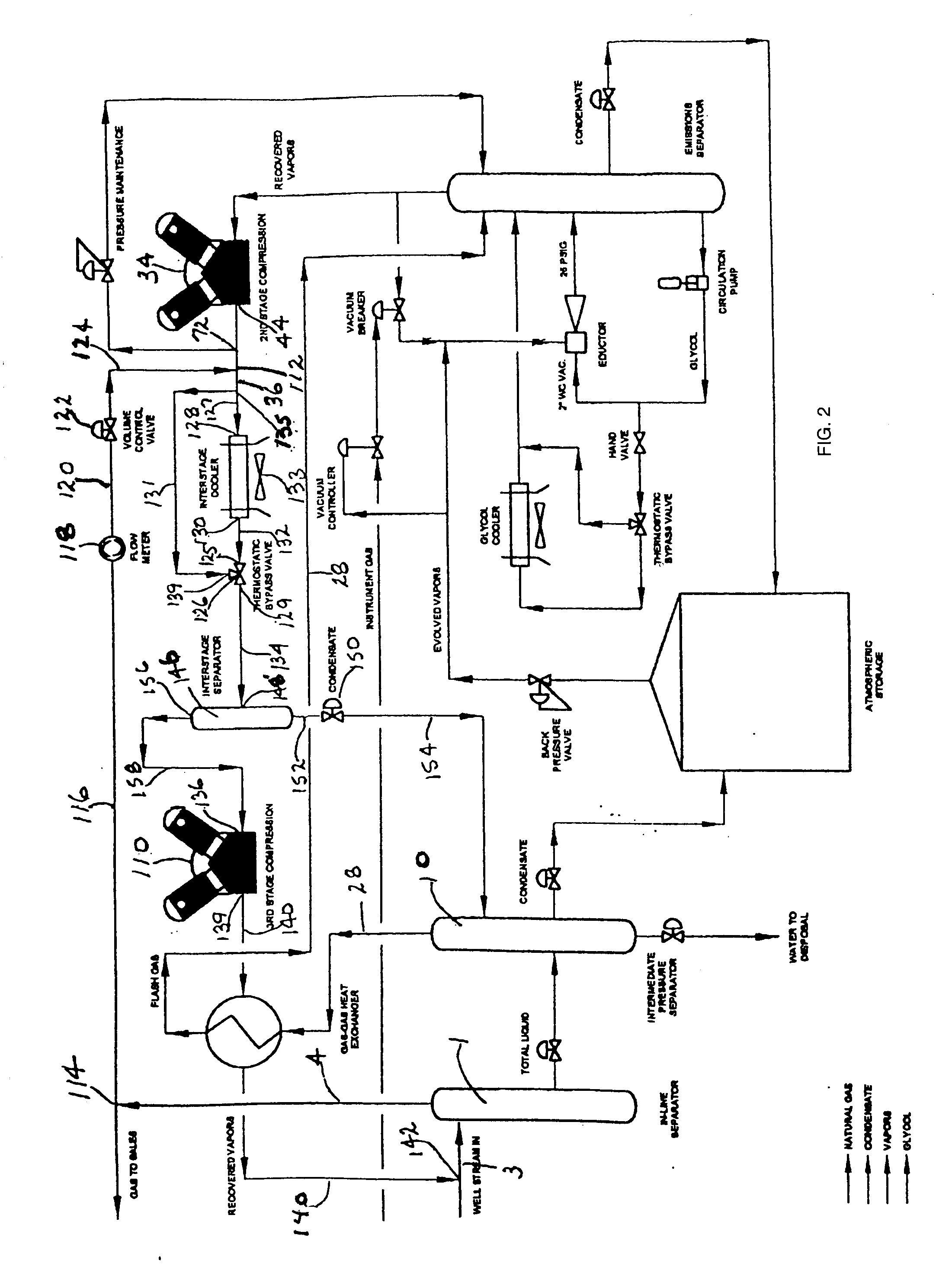

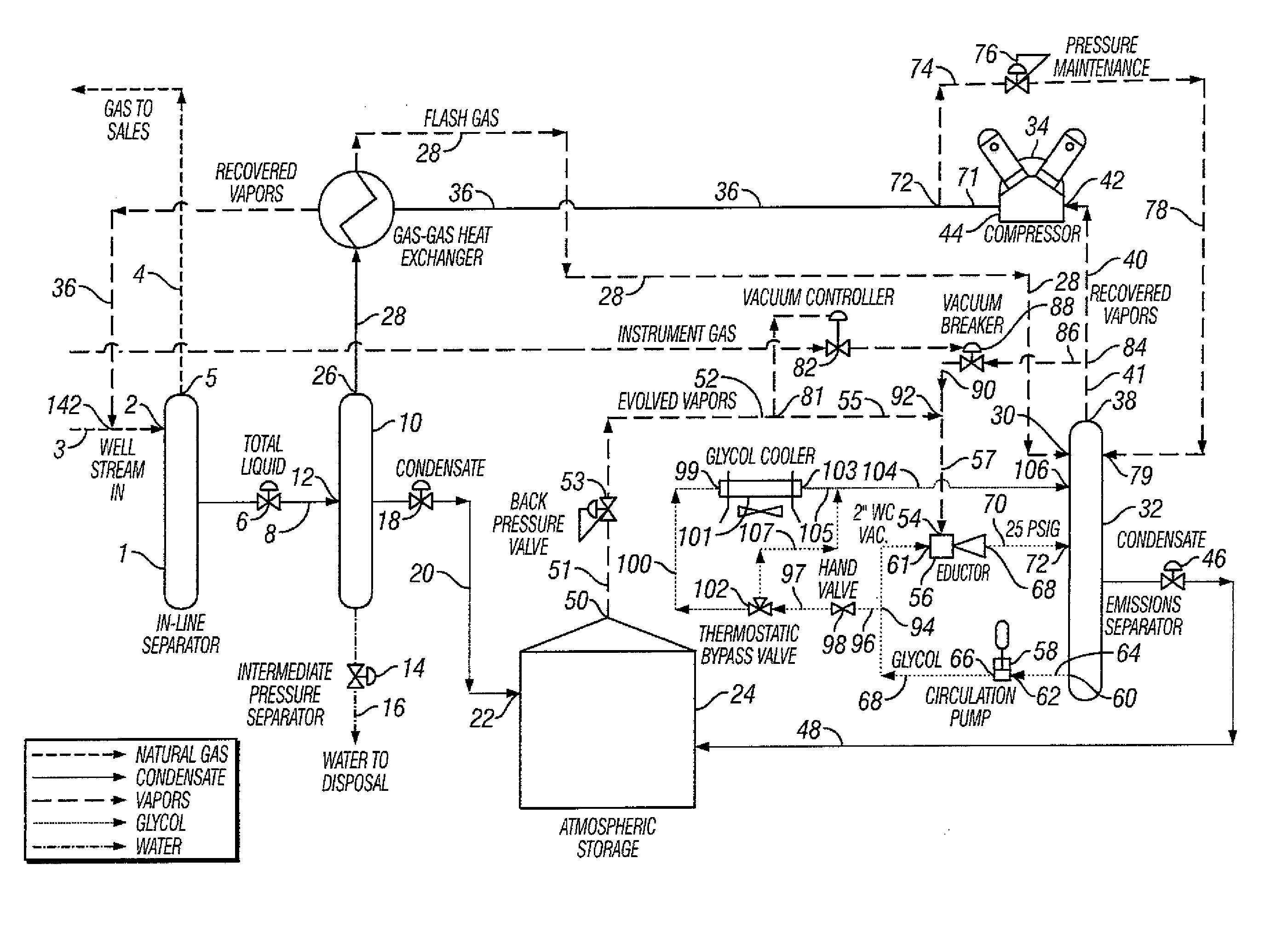

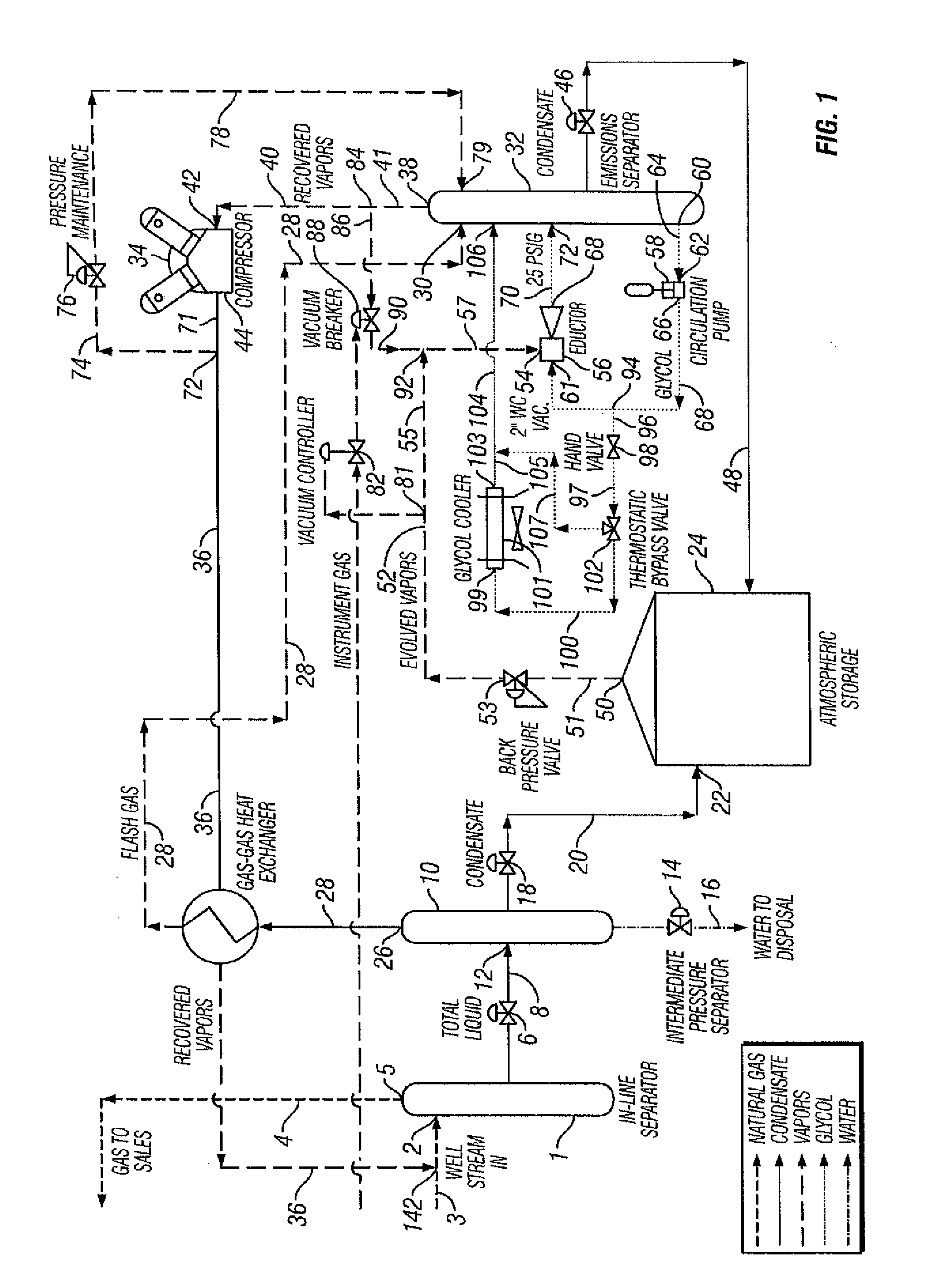

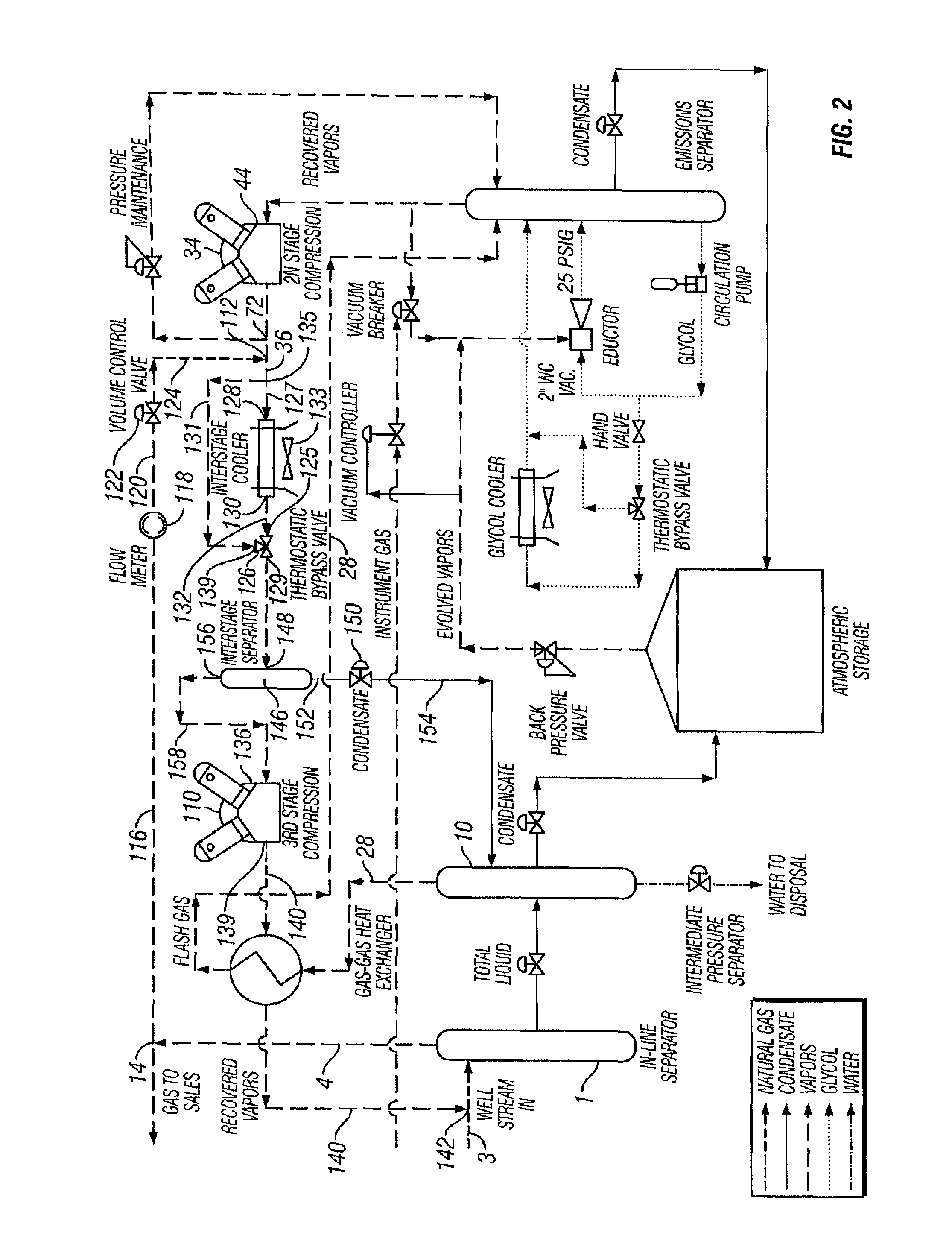

Natural Gas Vapor Recovery Process System

InactiveUS20070186770A1Reduce BTU and partial pressureIncrease partial pressureLiquid degasificationDispersed particle separationProcess systemsLiquid state

The present invention provides for a natural gas well vapor recovery processing system and method comprising recovering gaseous hydrocarbons to prevent their release into the atmosphere including providing a method for preventing the gaseous hydrocarbons from returning to a liquid state.

Owner:HEATH RODNEY T +2

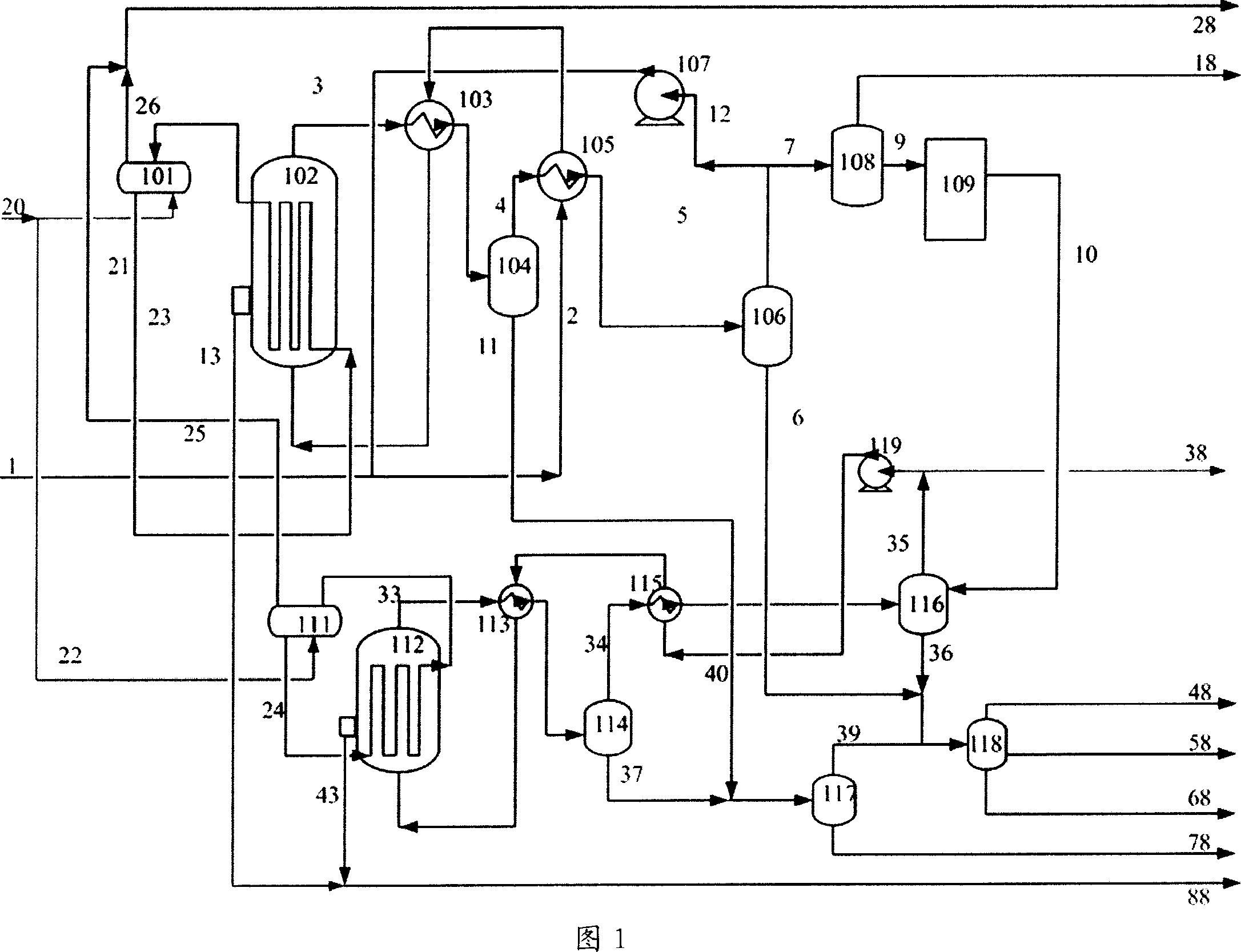

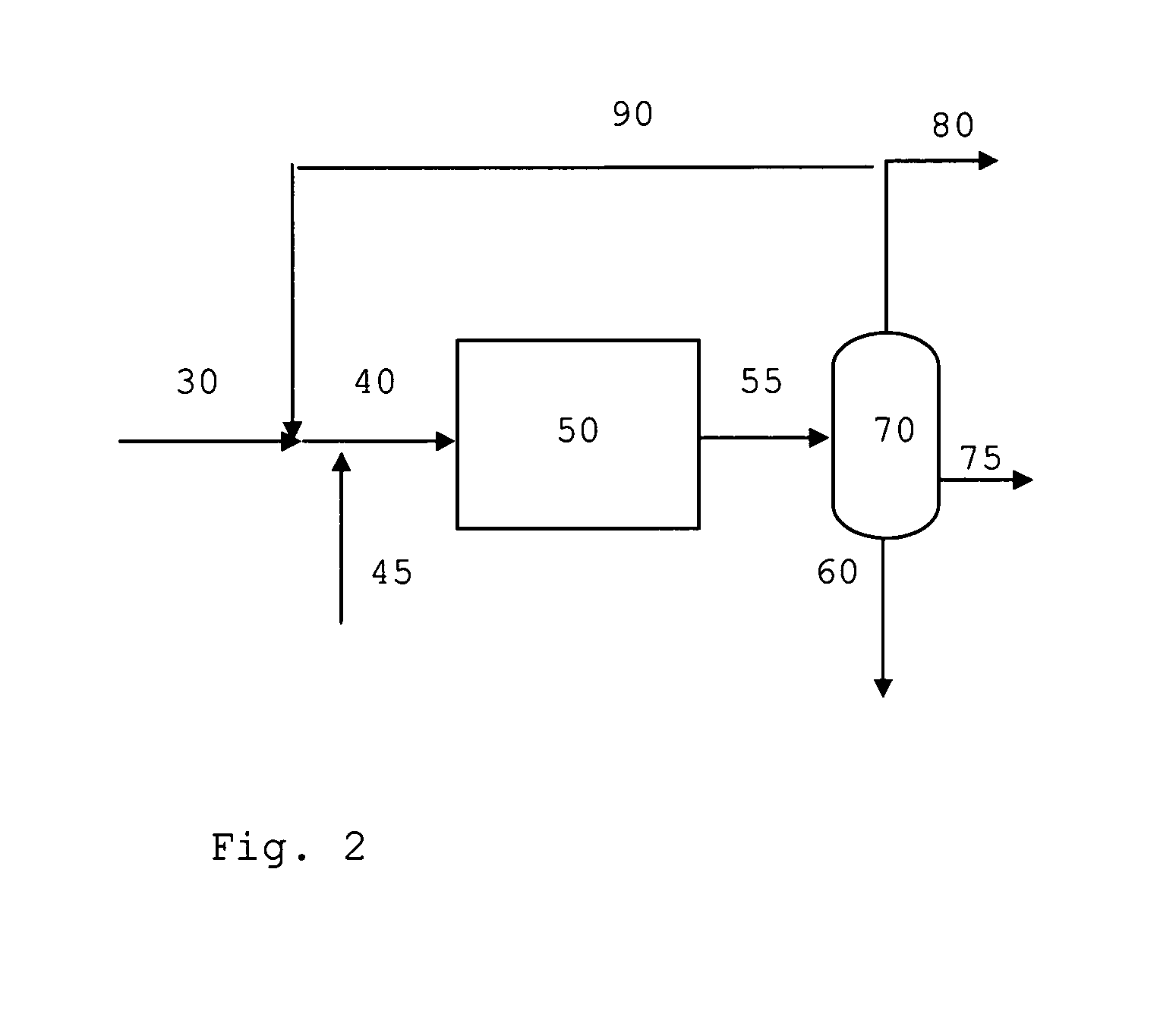

Two stage Fischer-Tropsch synthesis method

ActiveCN1948438AHigh yieldSeverity GuaranteeLiquid hydrocarbon mixture recoveryAlkaneSynthesis methods

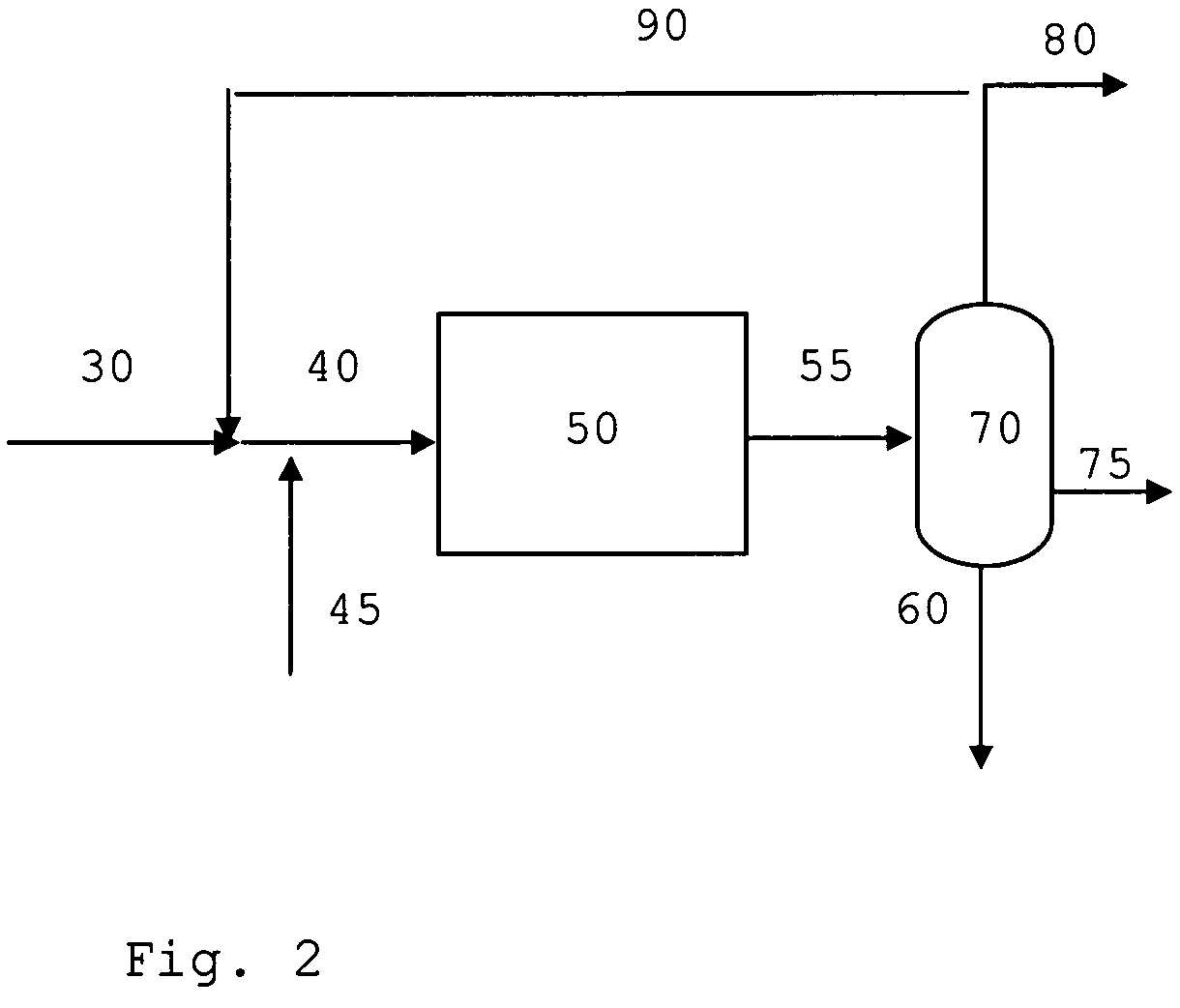

This invention relates to a synthesis method of fischer-tropsch. Its preparation includes (a) Synthesis gas material enters into the first fischer-tropsch synthesis reactor to conduct fischer-tropsch synthesis reaction under the action of accelerant, (b) Segregating the first grade reaction product and letting parts of end gas return to the first fischer-tropsch reactor for recycling, and then letting C1-C4 alkanes containing in other surplus end gas to transform into synthetic gas.(c) Mixing the end gas transformed at step (b) and the second fischer-tropsch synthesis reaction circulation gas, and then entering the second fischer-tropsch synthesis reactor to conduct fischer-tropsch synthesis reaction under accelerant. (d) Segregating the second fischer-tropsch synthesis reaction product, and most of the gas returning to the second fischer-tropsch synthesis reactor for circulating reaction, and then evacuating other end gas. The transformation efficiency of CO+H2 is higher than 96% and the yield of methyl hydride is lower than 3%, and the yield of unit space-time of accelerant reaches 185 g / kg*h.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

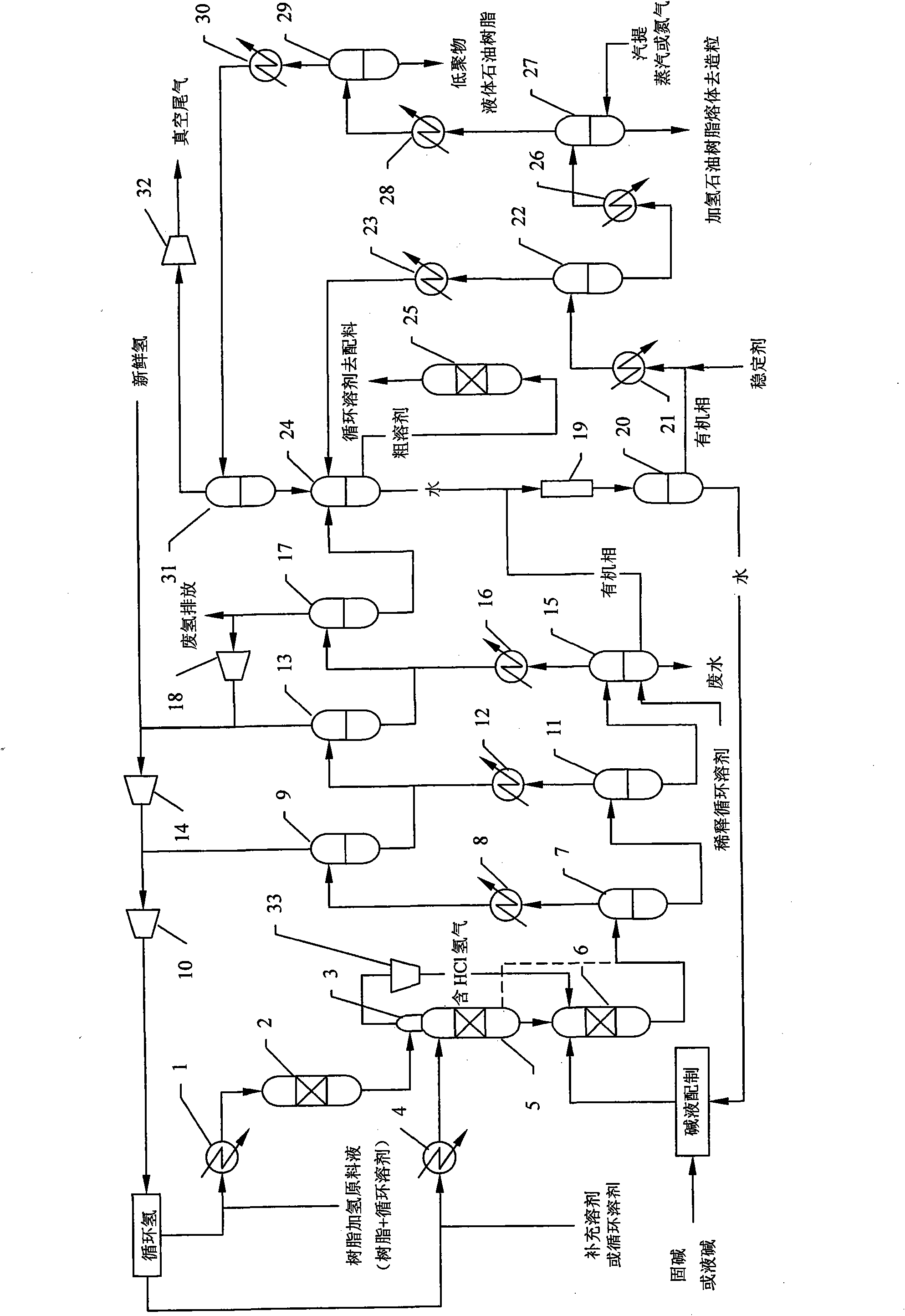

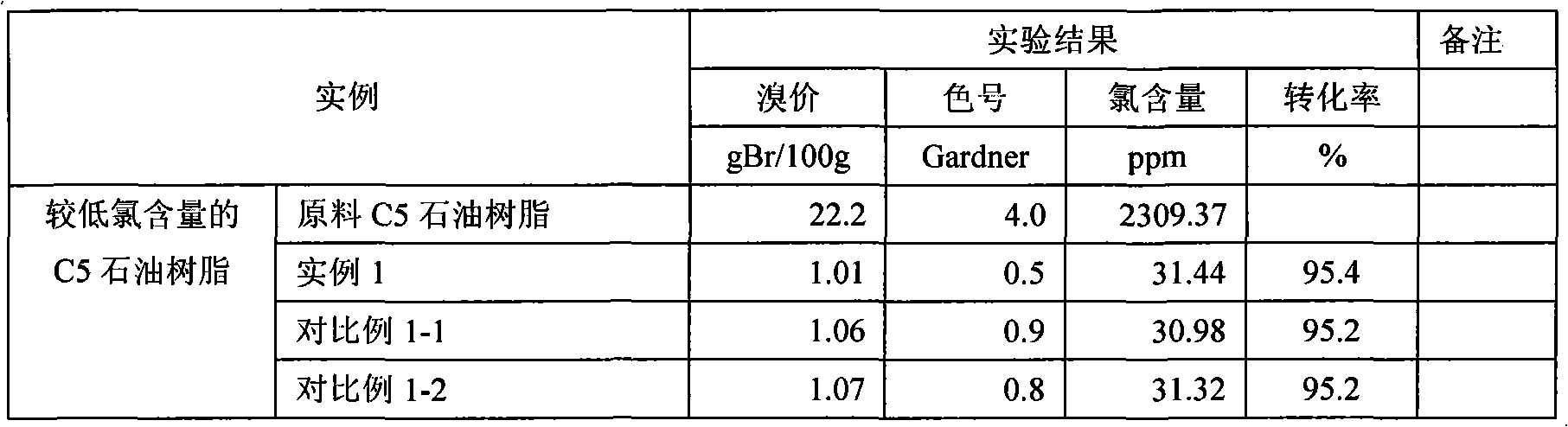

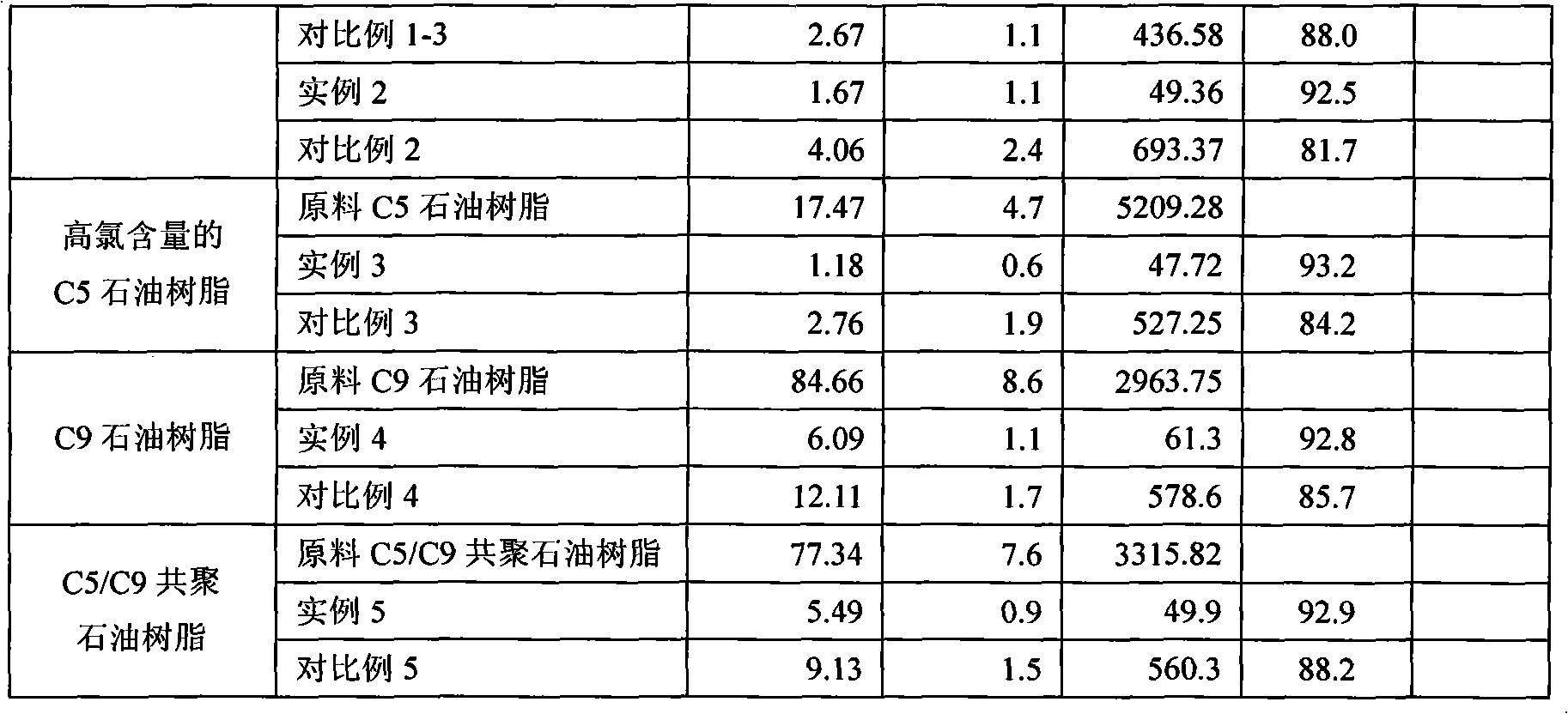

Industrial manufacture method for hydrogenated petroleum resin

ActiveCN102382259ASimplify the caustic cleaning processReduce corrosionPetroleum resinHydrogenation reaction

The invention relates to an industrial manufacture method for hydrogenated petroleum resin, which comprises the following steps of: generating hydrogenation reaction on petroleum resin which is obtained by polymerizing cracking C5 and C9 fractions under the proper condition of the existence of hydrogenation catalyst and solvents by adopting the processes of two-section hydrogenation and combination alkaline cleaning neutralization; hydrogenating the unsaturated component in the petroleum resin to reduce double-bond content; hydrogenating a non-ferrous perssad to fade; hydrogenating to remove chlorine retained in the polymerization process; and carrying out alkaline cleaning, water cleaning, stabilizer injection and solvent removal to obtain light or colourless hydrogenated petroleum resin. The method further simplifies the process through the organic combination of unit operation, and the industrial manufacture method for the hydrogenated petroleum resin, which has the advantages of wide adaptability on hydrogenated raw materials, less corrosion on system equipment, high product quality and high production capability is formed.

Owner:CHINA PETROLEUM & CHEM CORP

Vapor process system

ActiveUS20060144080A1Inhibition releaseReduce BTU and partial pressureSolidificationLiquefactionProcess systemsLiquid state

The present invention provides for a natural gas well vapor processing system and method comprising recovering gaseous hydrocarbons to prevent their release into the atmosphere including providing a method for preventing the gaseous hydrocarbons from returning to a liquid state.

Owner:HEATH RODNEY T +2

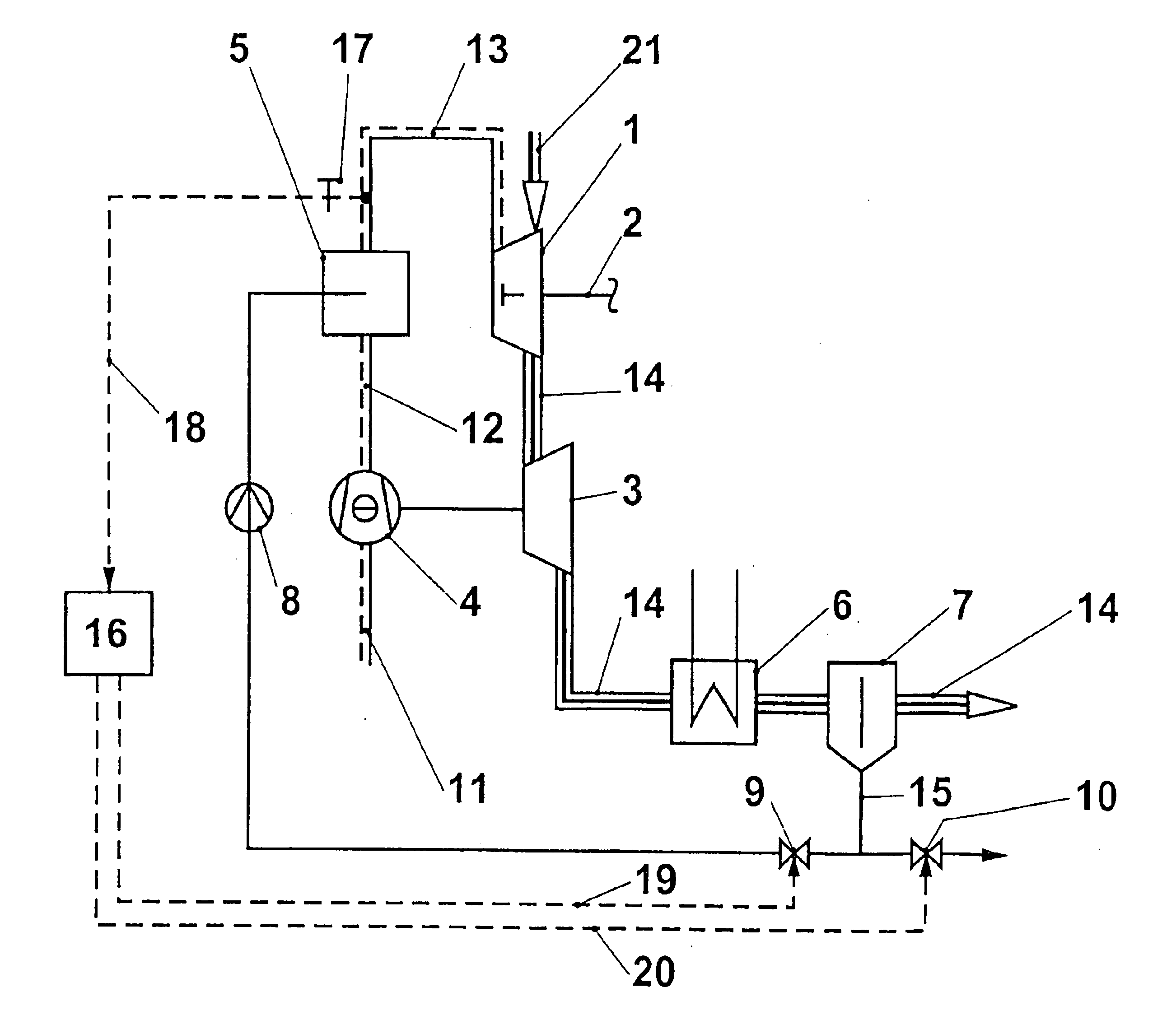

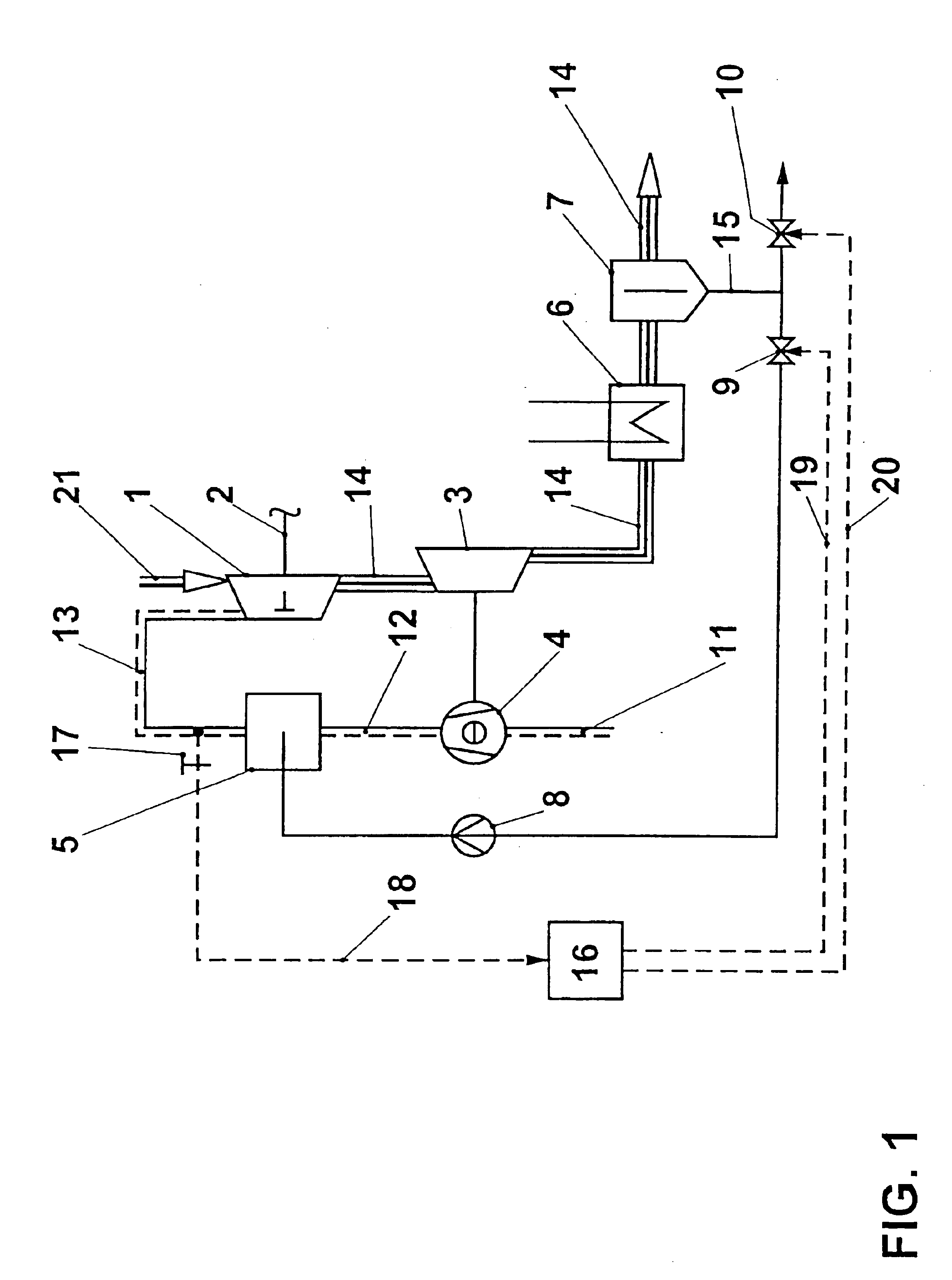

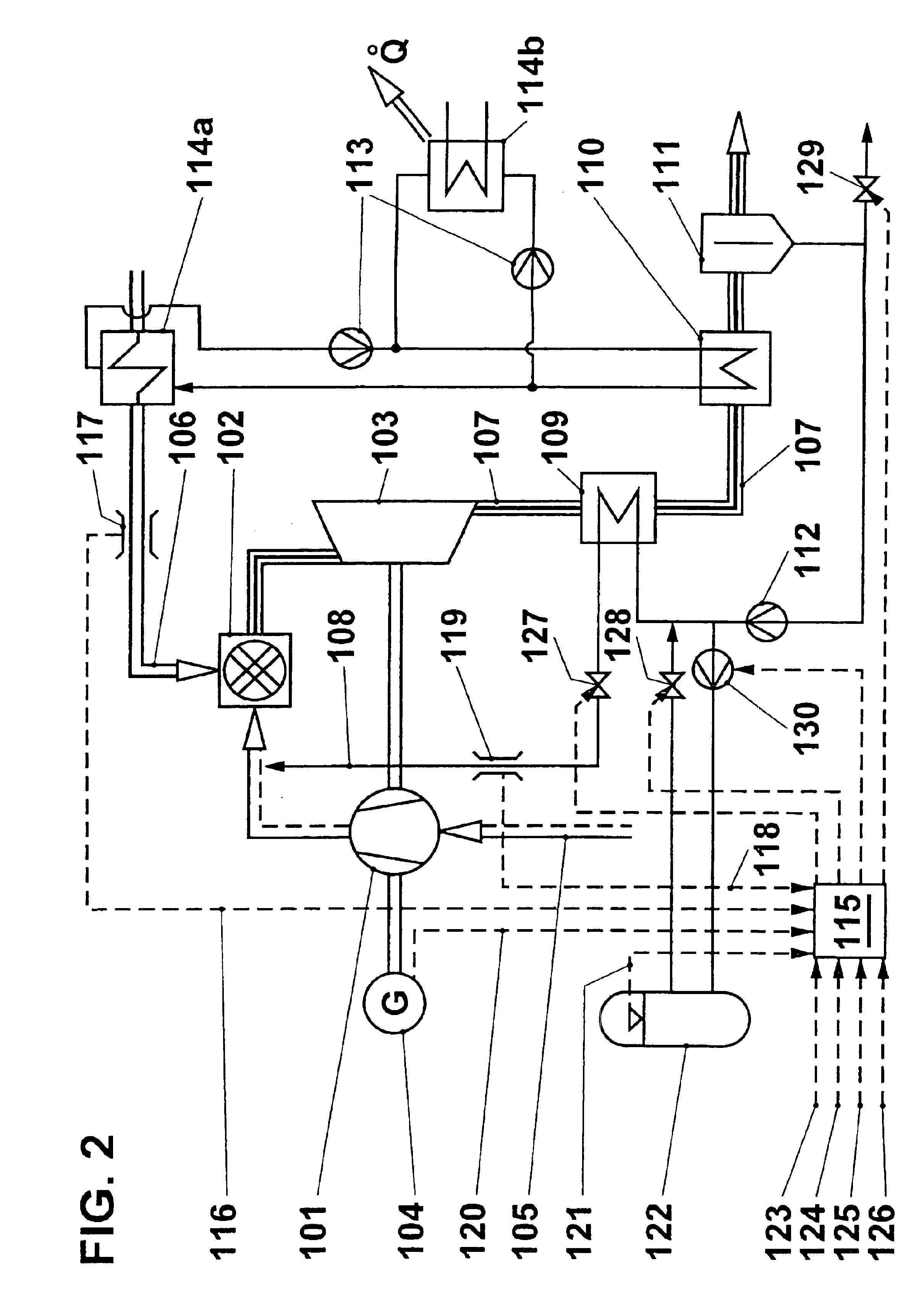

Method for operating an internal combustion engine

InactiveUS6845738B2Keep for a long timeLow loading rateInternal combustion piston enginesNon-fuel substance addition to fuelExhaust gasIntercooler

In a turbocharged diesel engine, the charge air is cooled in a charge air cooler designed as an injection intercooler. The water which has been introduced into the working medium of the diesel engine in the charge air cooler, after the working medium has been expanded, is condensed out of the exhaust gas by means of a condenser and a separator and is returned to the charge air cooler. According to the invention, the engine is started without injection of externally supplied water into the charge air cooler. Water which forms during the combustion in the diesel engine is condensed out of the exhaust-gas stream and returned to the charge air cooler. Additional water vapor formed continuously during operation through combustion of diesel fuel is likewise condensed out and introduced into the charge air cooler. In this way, the working medium is laden with moisture until the water mass flow that can be separated out of the exhaust gas is sufficient for the set cooling power of the charge air cooler. Further combustion water that is formed can be used for other purposes. In this way, engines with internal combustion in which water is introduced into the working medium can be operated without an external supply of water.

Owner:ALSTOM TECH LTD

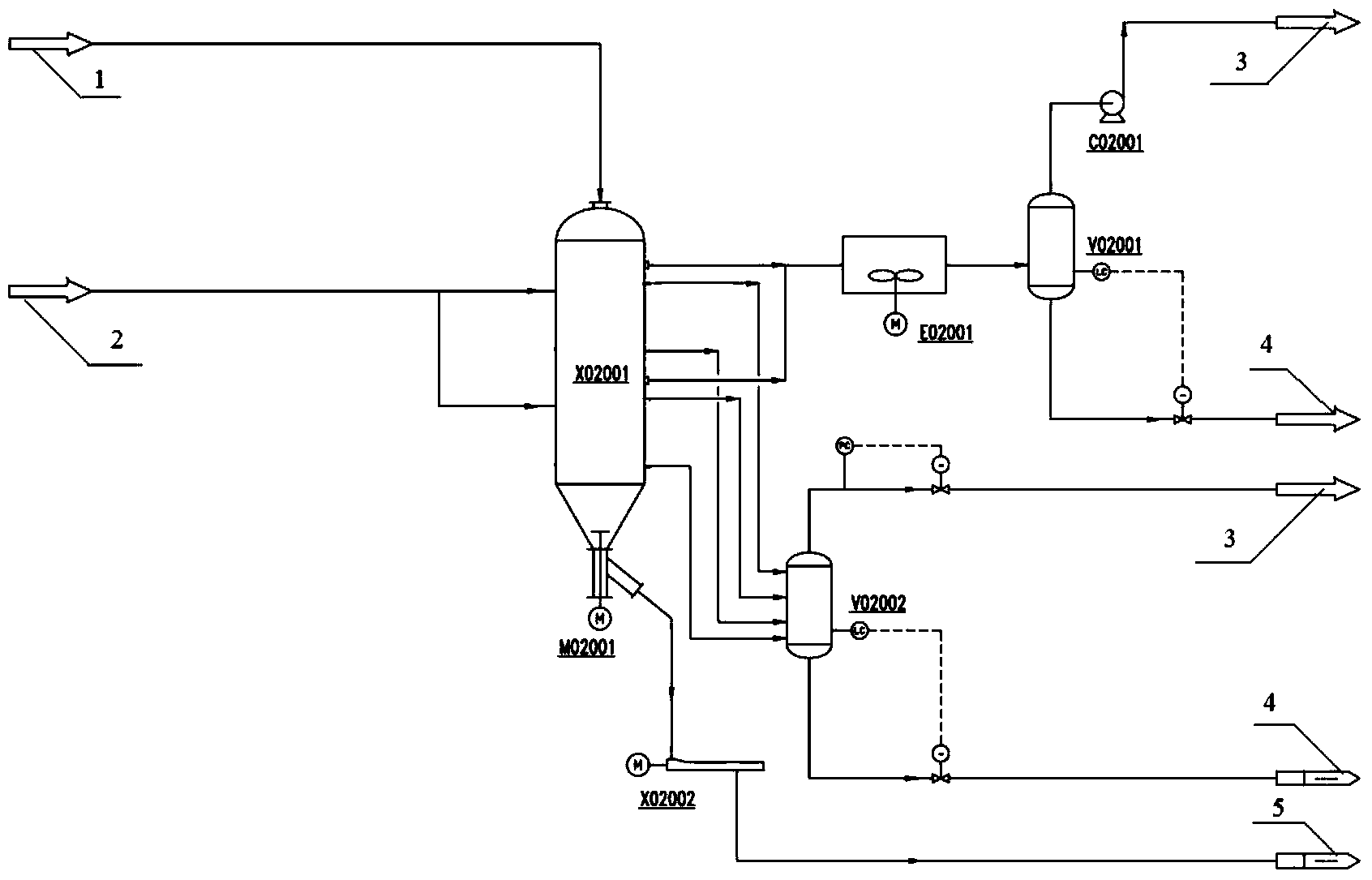

Method for recovering oil gas and device

InactiveCN102441310AExtended service lifeReduce the temperatureDispersed particle separationVapor condensationRecovery methodGas phase

The invention relates to a method for recovering oil gas and a device. Oil gas exhausted from an oil product storage device is firstly condensed; condensate is recovered; uncondensed gas phase enters an adsorption device for adsorption; after being in adsorption saturation, the adsorption device is regenerated by adopting a vacuum regeneration manner; and concentrated oil generated by vacuum regeneration is recycled to the oil product storage device. According to the method and the device, provided by the invention, the oil gas is recovered by combining the mode of returning the oil gas to the oil product storage device and an oil gas recovery technology, desorbed oil gas is returned to the gas-liquid balanced system of the oil product storage device, the partial pressure of the oil gas is increased, and the loss of an oil product, caused by evaporating, is fundamentally reduced. The method and the device, provided by the invention, have the characteristics of large operating flexibility, low energy consumption, small investment, no potential safety hazard, reachability in tail gas emission standards, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon Conversion to Ethylene

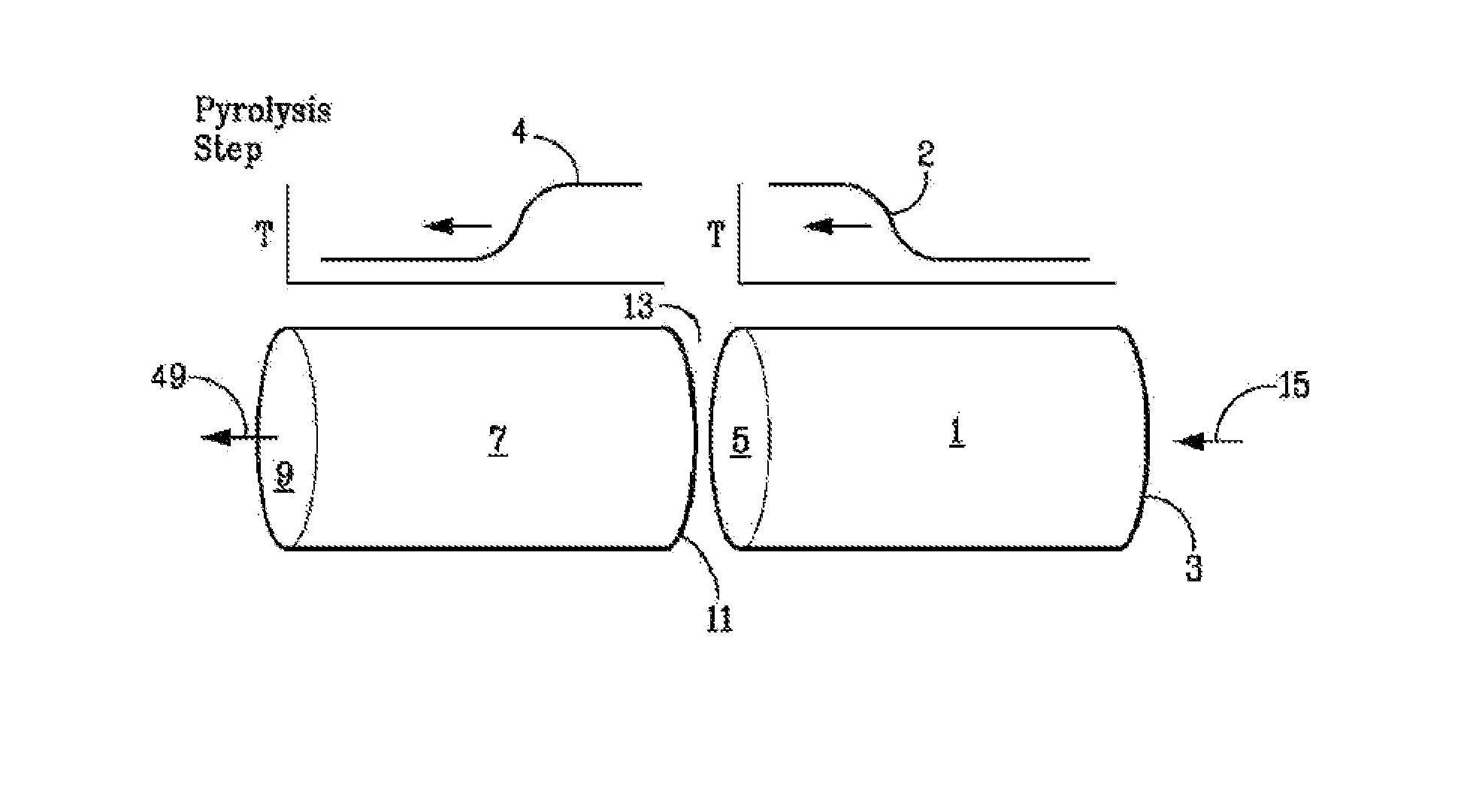

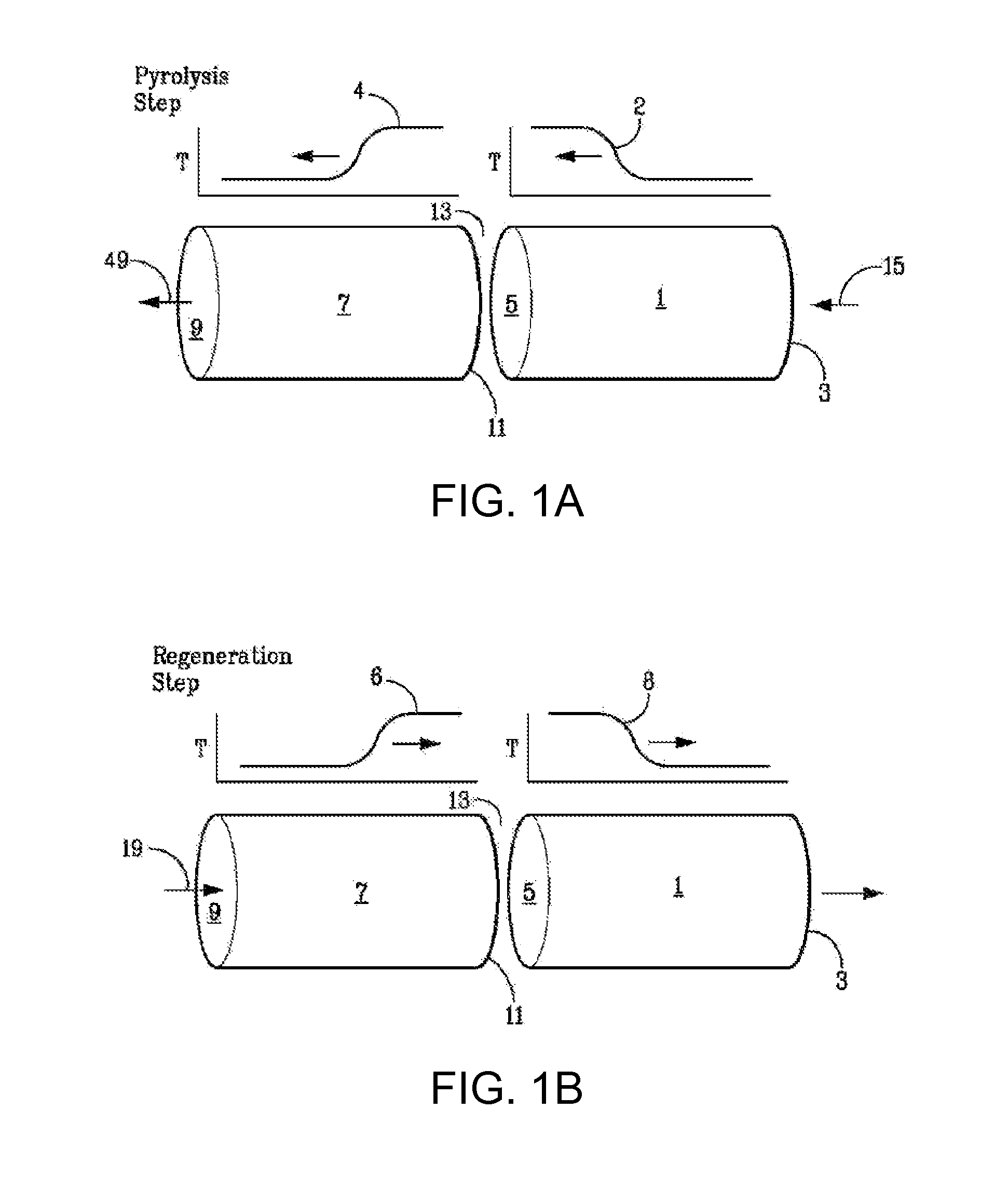

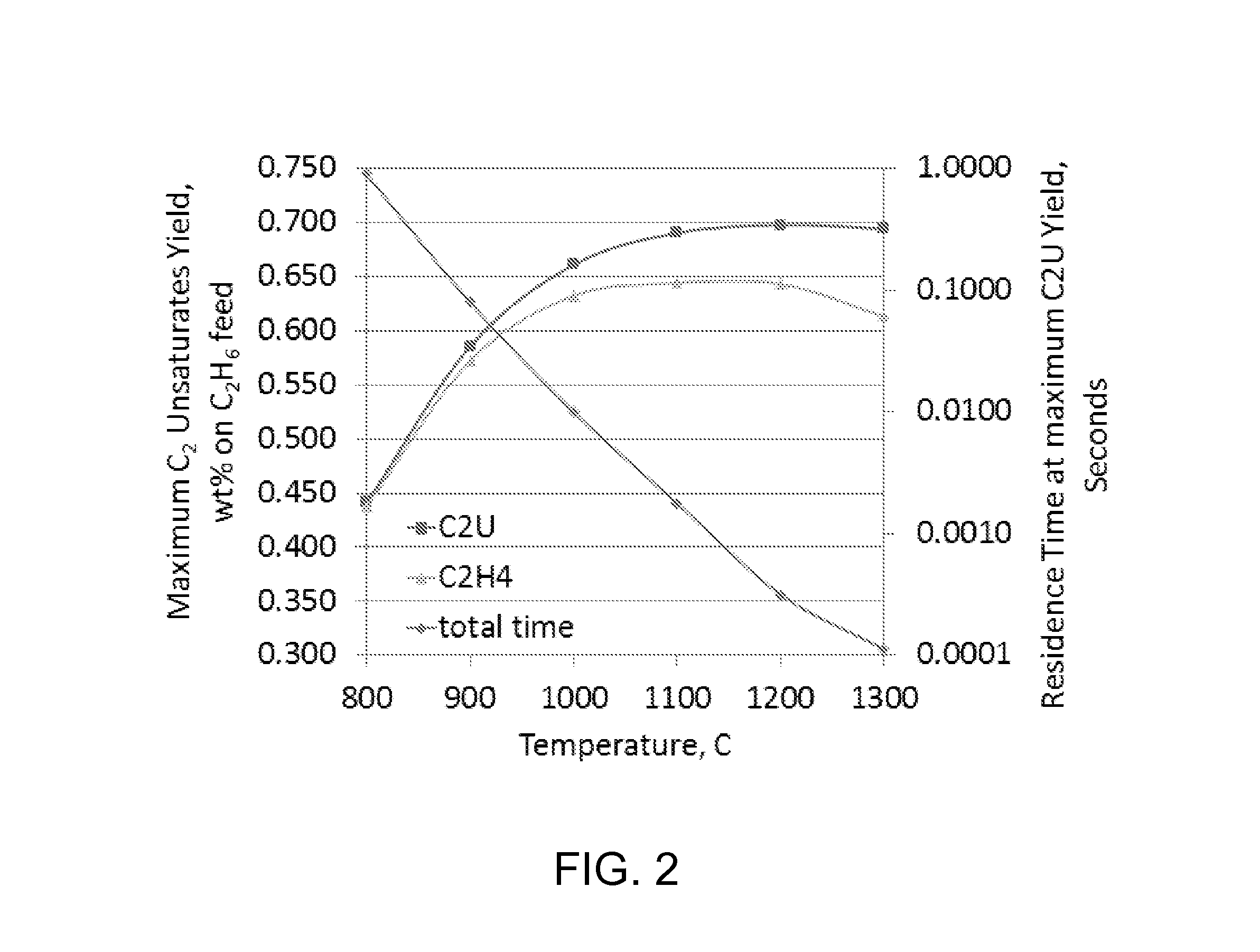

ActiveUS20160176781A1Increases overall equilibrium production of ethyleneReduce energy consumptionThermal non-catalytic crackingHydrocarbon by dehydrogenationReaction zoneEthylene

The invention relates to a hydrocarbon conversion process and a reactor configured to carry out the hydrocarbon conversion process. The hydrocarbon conversion process is directed to increasing the overall equilibrium production of ethylene from typical pyrolysis reactions. The hydrocarbon conversion process can be carried out by exposing a hydrocarbon feed to a peak pyrolysis gas temperature in a reaction zone in the range of from 850° C. to 1200° C.

Owner:EXXONMOBIL CHEM PAT INC

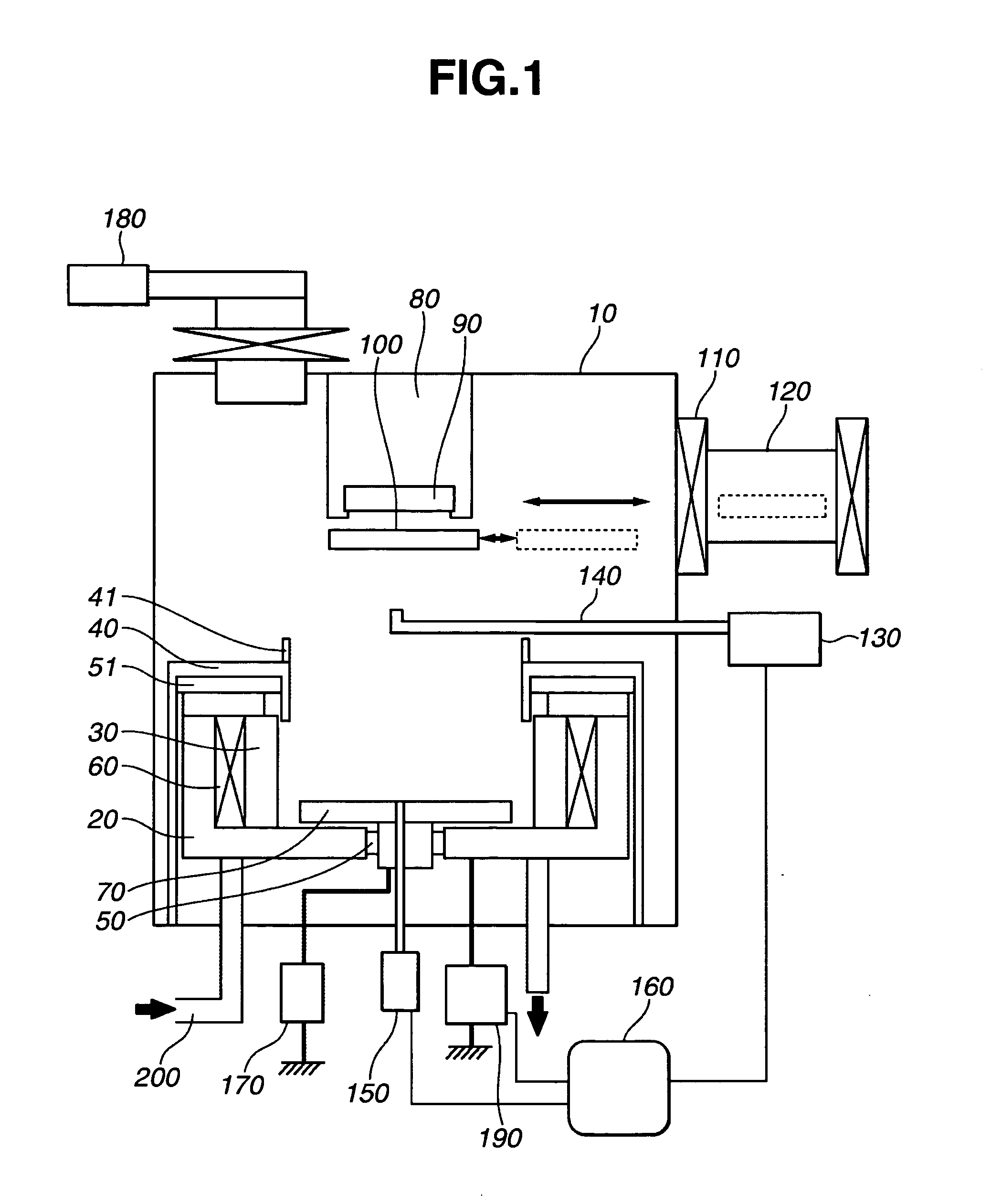

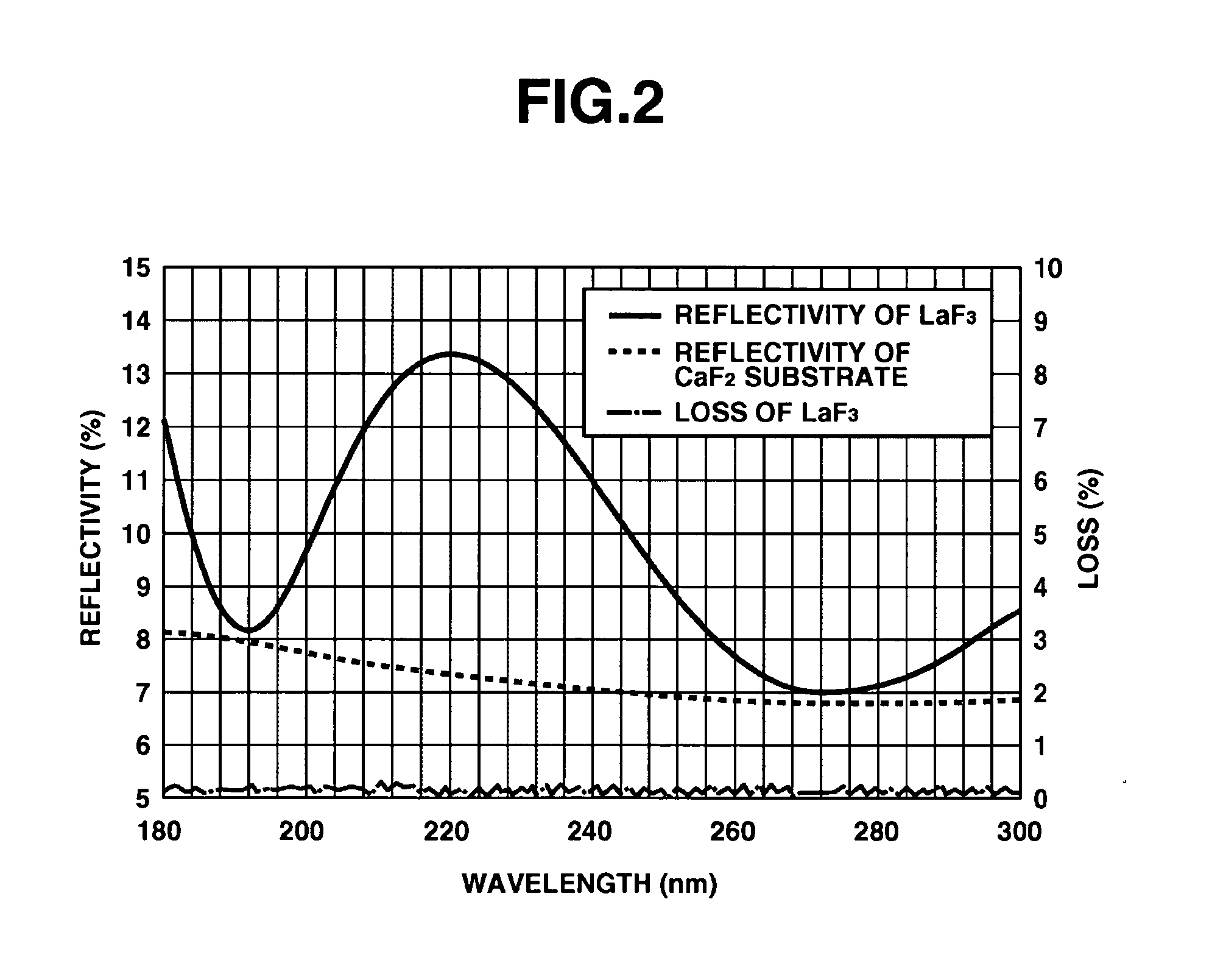

Reactive sputtering method

InactiveUS20050023130A1Prevent surfaceLarge sputtering rateCellsElectrical controlReactive gasOptical thin film

In a reactive sputtering apparatus, an inert-gas supplying hole is provided in a movable target unit whose one end is open and whose conductance is controlled, and a reactive gas containing at least fluorine or oxygen can be supplied to a space between the target and a substrate. The apparatus is constructed so as to emit the reactive gas toward the substrate. A reactive-gas emitting location is in the space between the target and the substrate such that a concentration of the reactive gas on the substrate surface can be maintained at a higher level. When the target is moved, a reactive-gas emitting port is moved or the reactive-gas emitting location is changed. The concentration of the reactive gas on the substrate surface can be effectively kept constant, and a high-quality optical thin film can be formed.

Owner:CANON KK

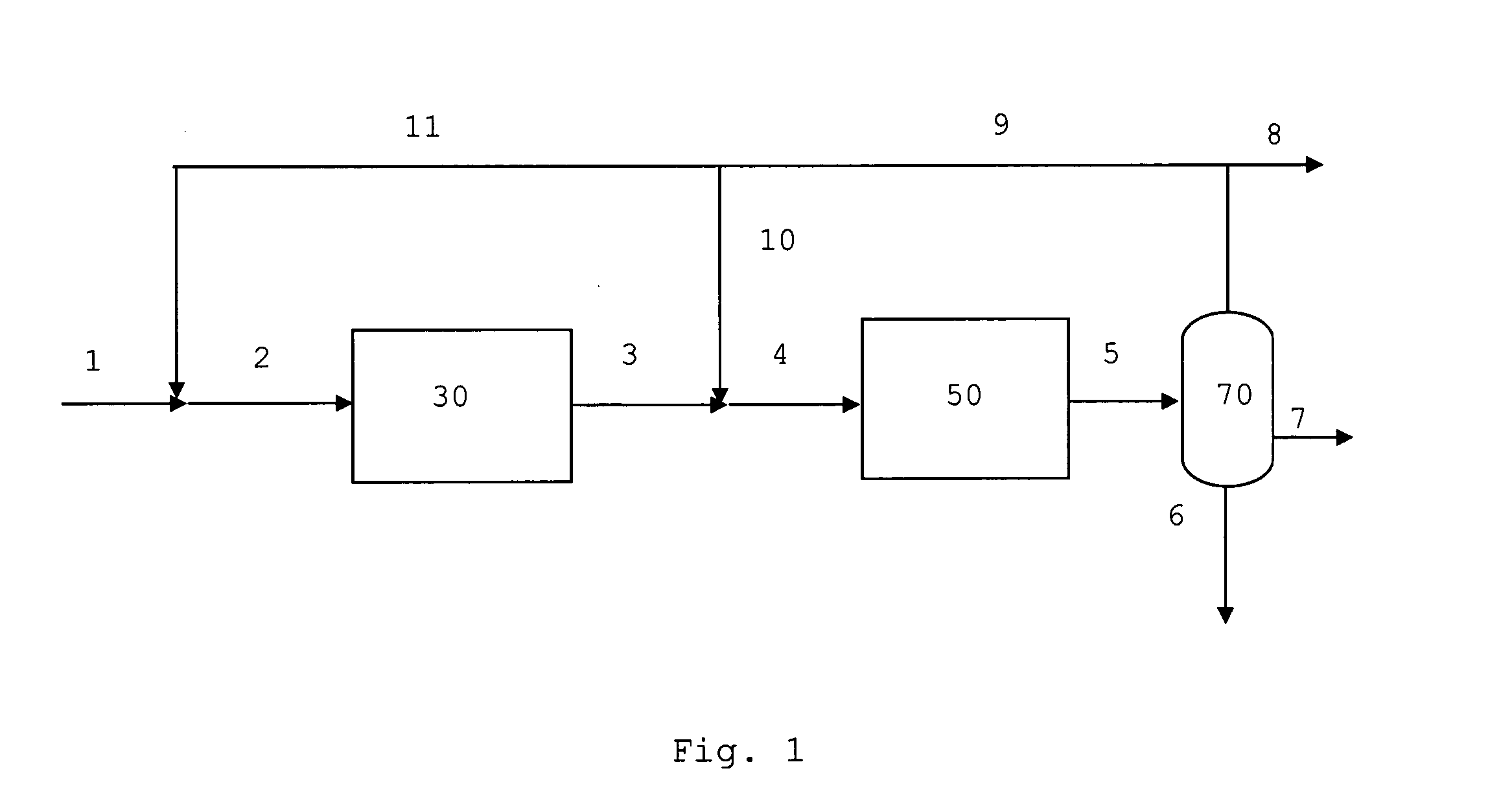

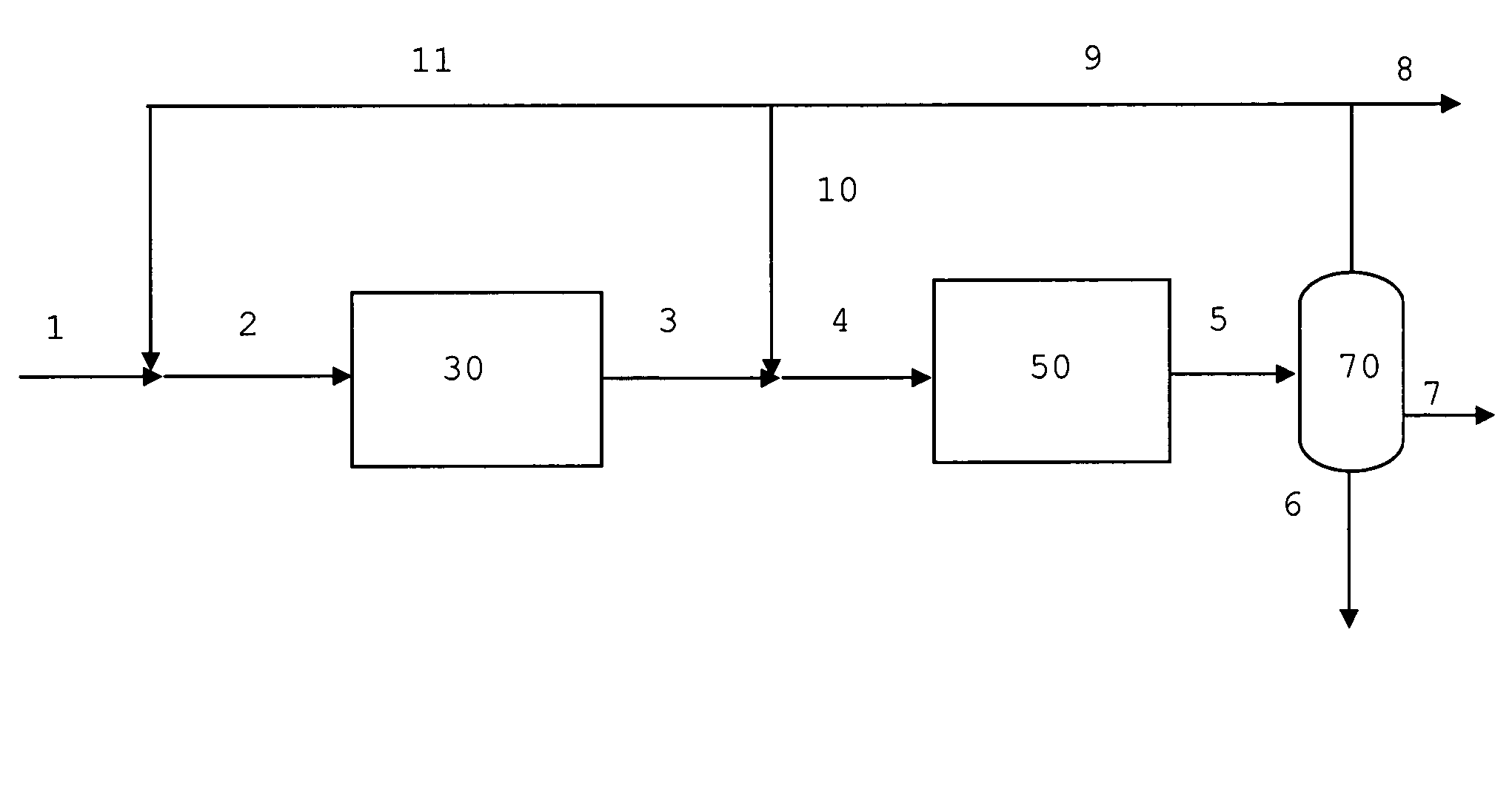

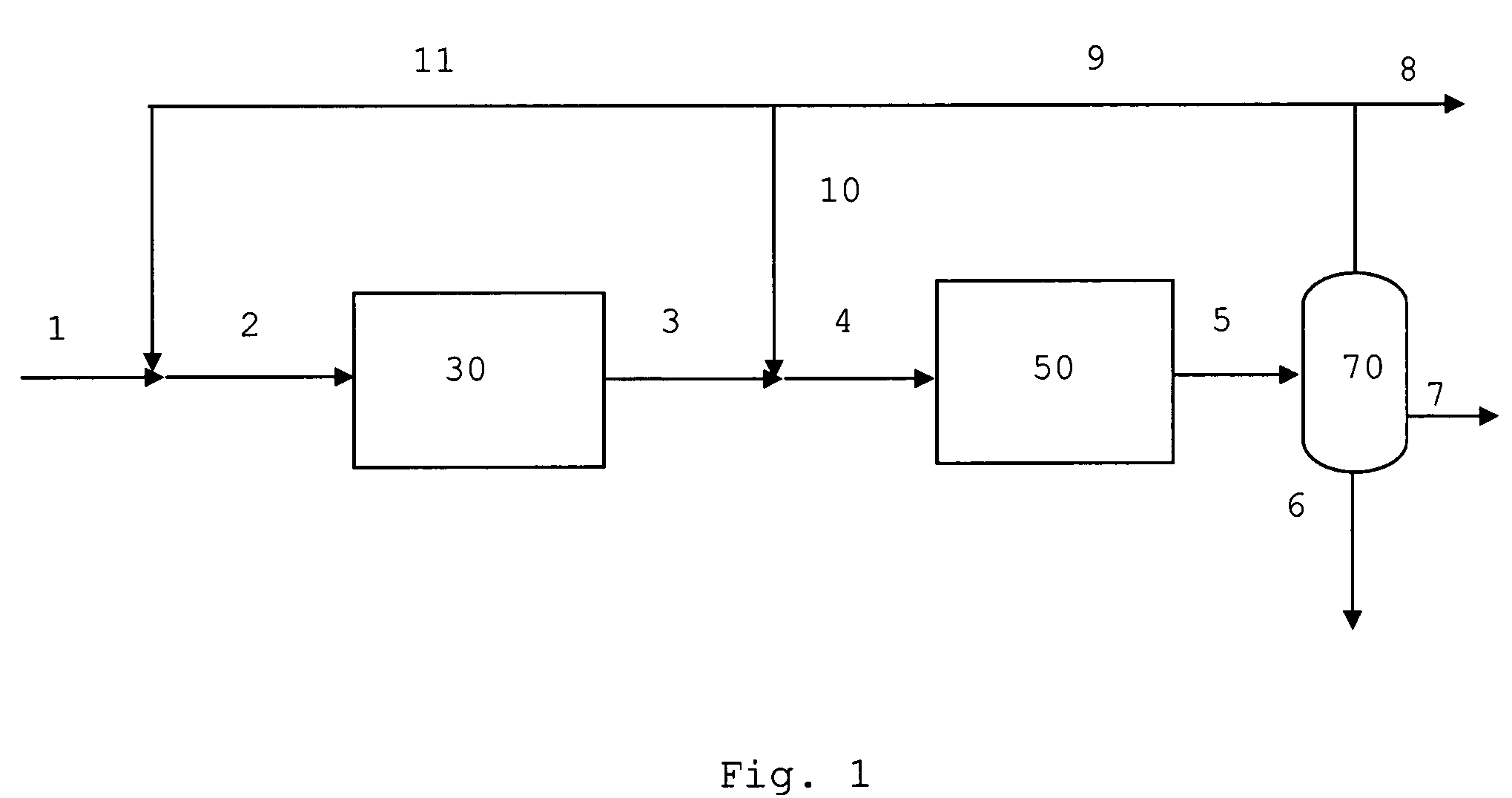

Process For Converting Difficultly Convertible Oxygenates to Gasoline

InactiveUS20080228021A1Few propensityLong cycle timeOrganic compound preparationHydroxy compound preparationSyngasOxygenate

Process for converting oxygenate compounds to hydrocarbons comprising the steps: (a) introducing a feed stream of synthesis gas to a synthesis section for the production of easily convertible oxygenates, (b) passing the effluent stream from said synthesis section containing easily convertible oxygenates to a gasoline synthesis section, (c) passing the effluent of said gasoline synthesis section to a separator and withdrawing from said separator hydrocarbons boiling in the gasoline boiling range, (d) admixing a recycle stream from the separator containing unconverted synthesis gas volatile hydrocarbons with the feed stream of synthesis gas of step (a), (e) introducing a feed containing difficulty convertible oxygenates to the synthesis section of step (a).

Owner:HALDOR TOPSOE AS

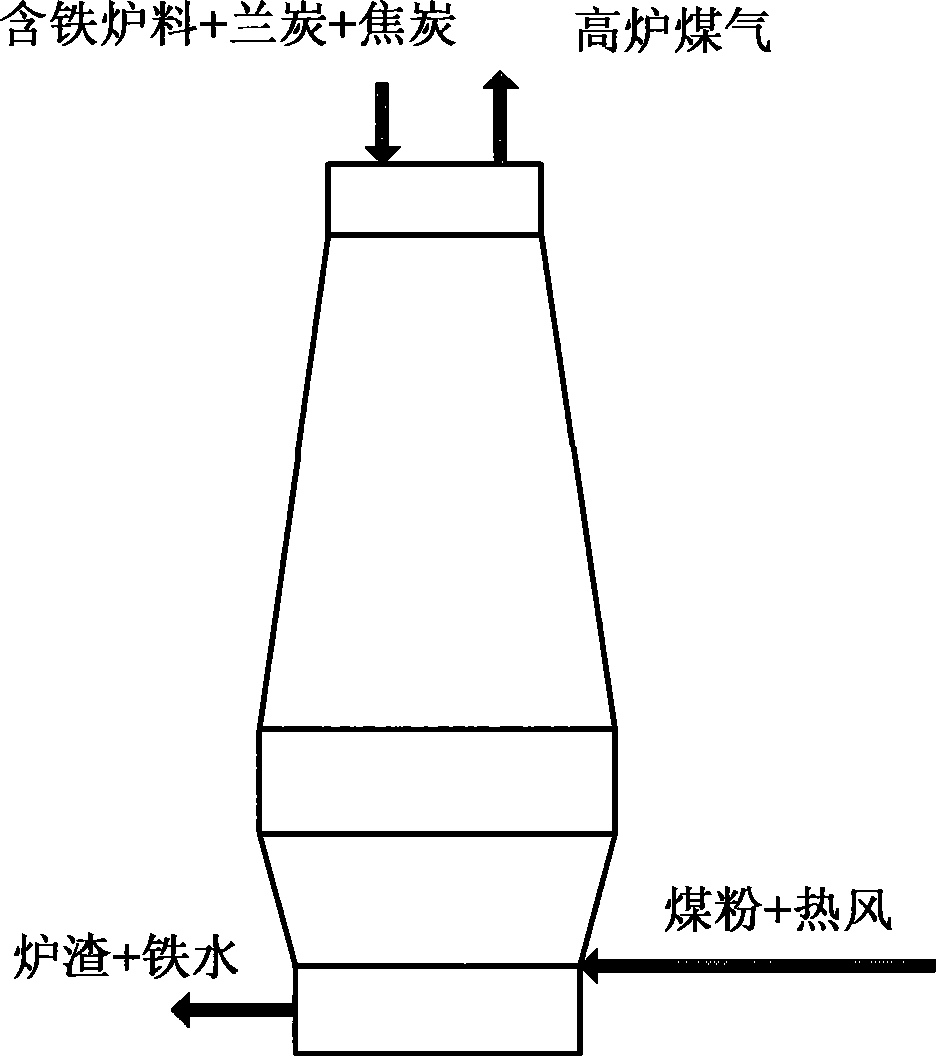

Blast furnace iron manufacturing process

InactiveCN101476002APromote reductionImprove economyBlast furnace detailsSmelting processBlast furnace

The present invention provides a blast furnace iron-smelting method, including: a first step, loading coke, semi-coke and other iron-contained charging stock into the blast furnace, wherein, the semi-coke has a scheduled weight ratio in the coke and semi-coke; and a second step, performing conventional iron-smelting operations after the loading. The method can use semi-coke to replace part of coke, thus can reduce the amount of coke in the blast furnace iron-smelting process.

Owner:BEIJING ZHONGDIAN HUAFANG TECH +1

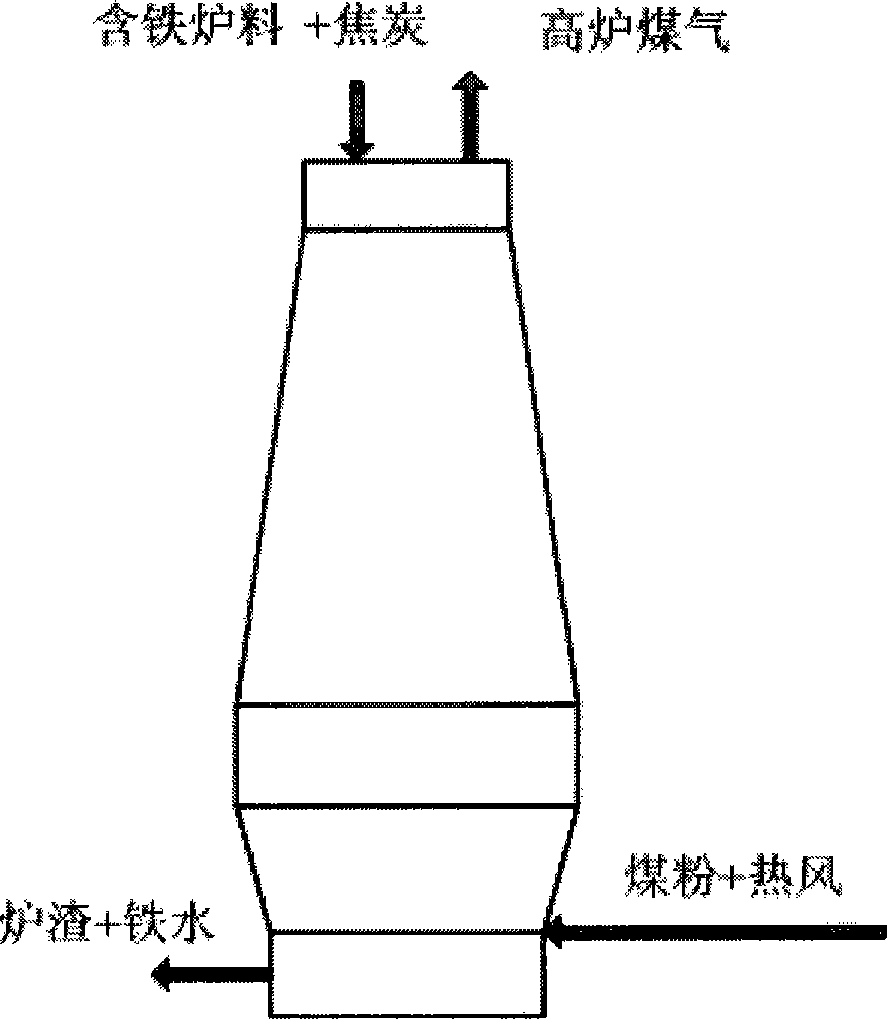

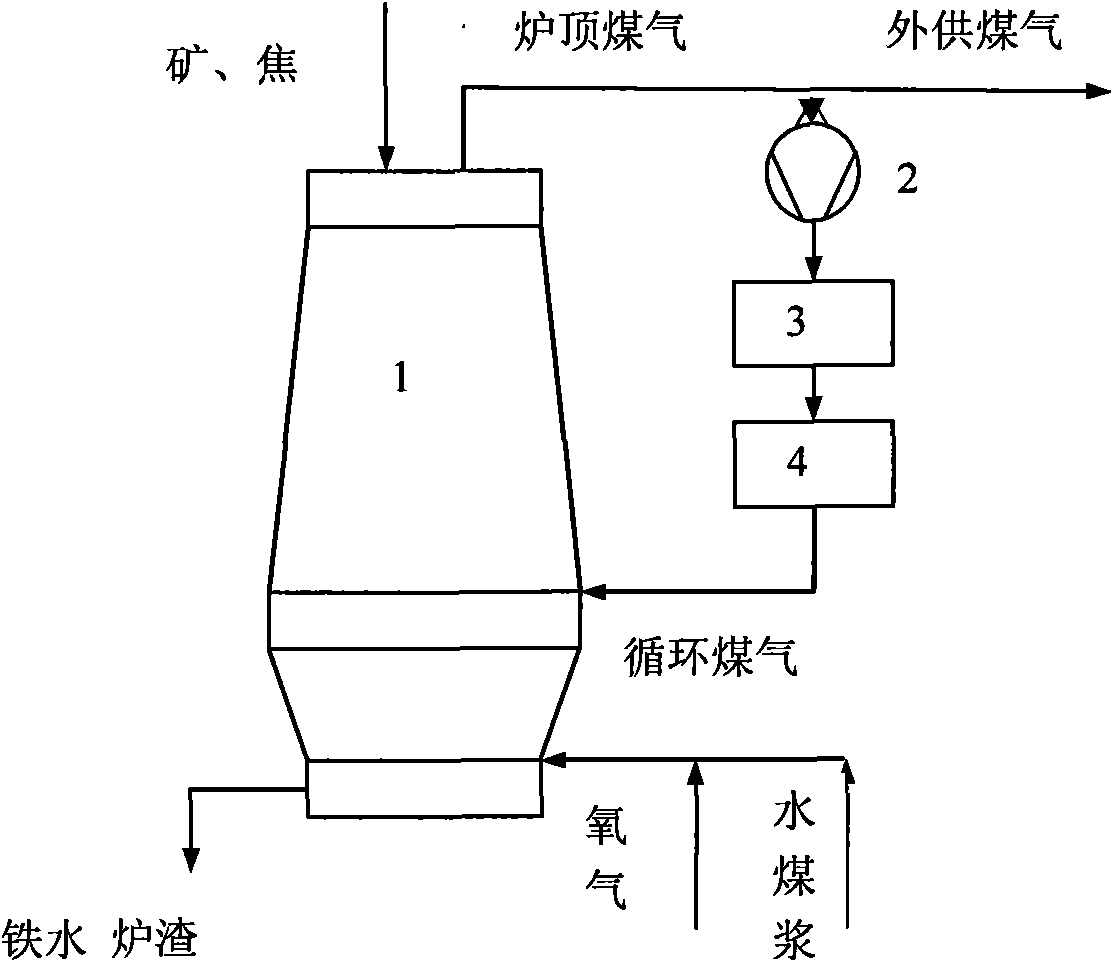

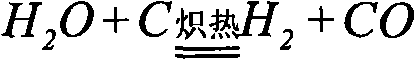

Oxygen blast furnace iron-making process adopting water-coal-slurry as fuel

InactiveCN101555533AImprove productivityReduce adverse effectsBlast furnace detailsDecompositionCoal dust

The invention belongs to the field of ferrous metallurgy and relates to a blast furnace iron-making process using water-coal-slurry as fuel and reducer for iron-making. The process using water-coal-slurry is simple and safe, and the injecting process of water-coal-slurry provides convenience for accurate control and precise measurement. A water-coal-slurry oxygen blast furnace utilizes normal-temperature oxygen and water-coal-slurry as fuel which is injected into the blast furnace so as to partially displace coke and coal dust; the injected amount of oxygen is 200 to 500 Nmt HM, the injected amount of water-coal-slurry is 200 to 400 Nm / t HM, the required weight ratio between coal and water in the water-coal-slurry is 7:3, and the required thermal value of the water-coal-slurry is larger than 20 MJ / kg. The water-coal-slurry is decomposed and burnt to generate water-gas reaction in a circulation zone of a blast-furnace tuyere, the absorbed heat can be adopted to solve the problem of 'lower hot' caused by smelting with prior oxygen blast furnaces, and a large amount of gas generated by the decomposition and burning of the water-coal-slurry raises and can relieve the problem of 'upper cold' caused by the full-oxygen injection of the blast furnace; and the water-coal-slurry oxygen blast furnace contains rich H2 so as to enhance the penetrating power and reduction performance of blast-furnace coal gas, raise the indirect reduction degree of the blast furnace and reduce the emission amount of CO2 by 200 to 500 Nm / t HM. The process reduces both manufacturing cost and pollution to environment.

Owner:UNIV OF SCI & TECH BEIJING

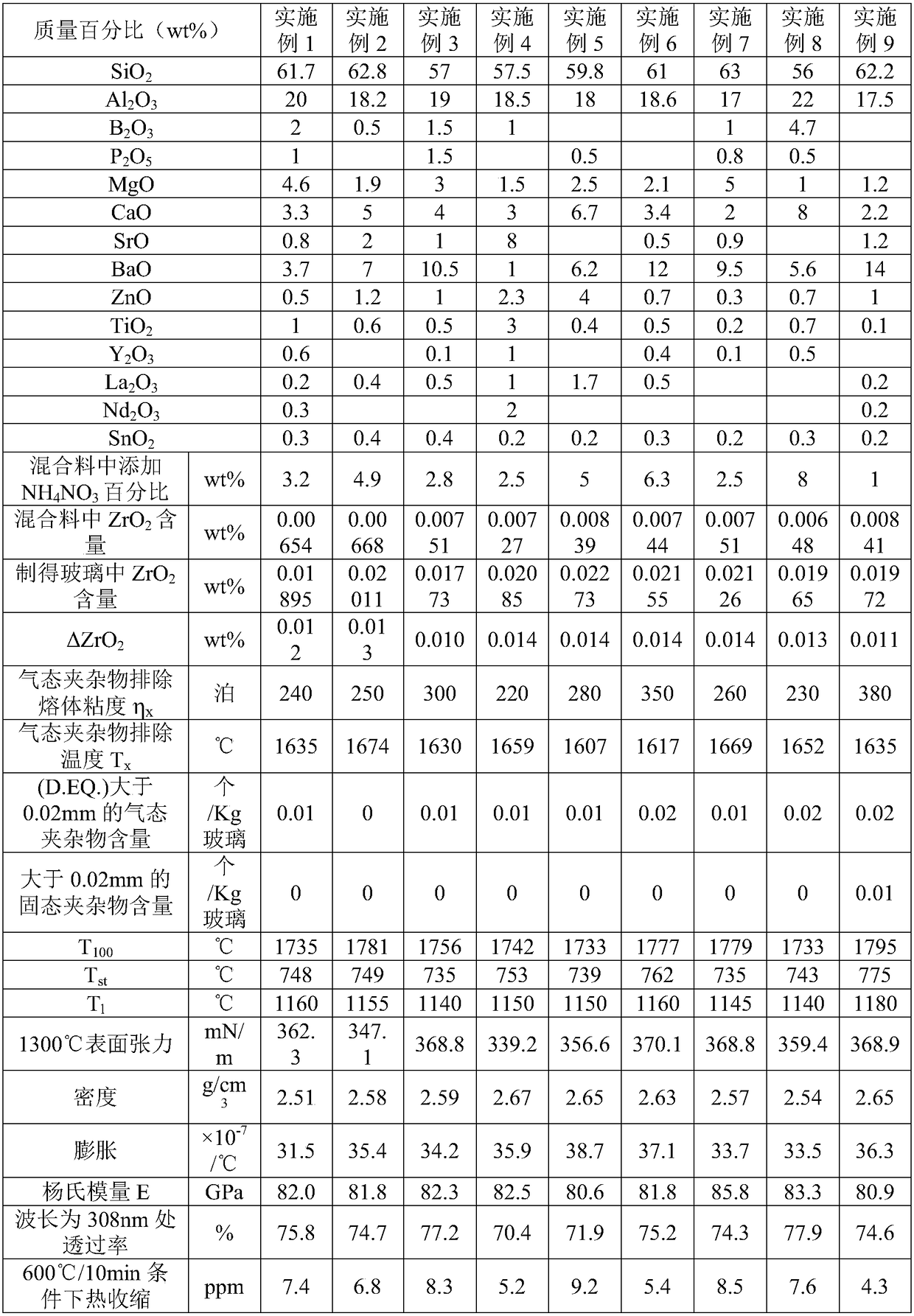

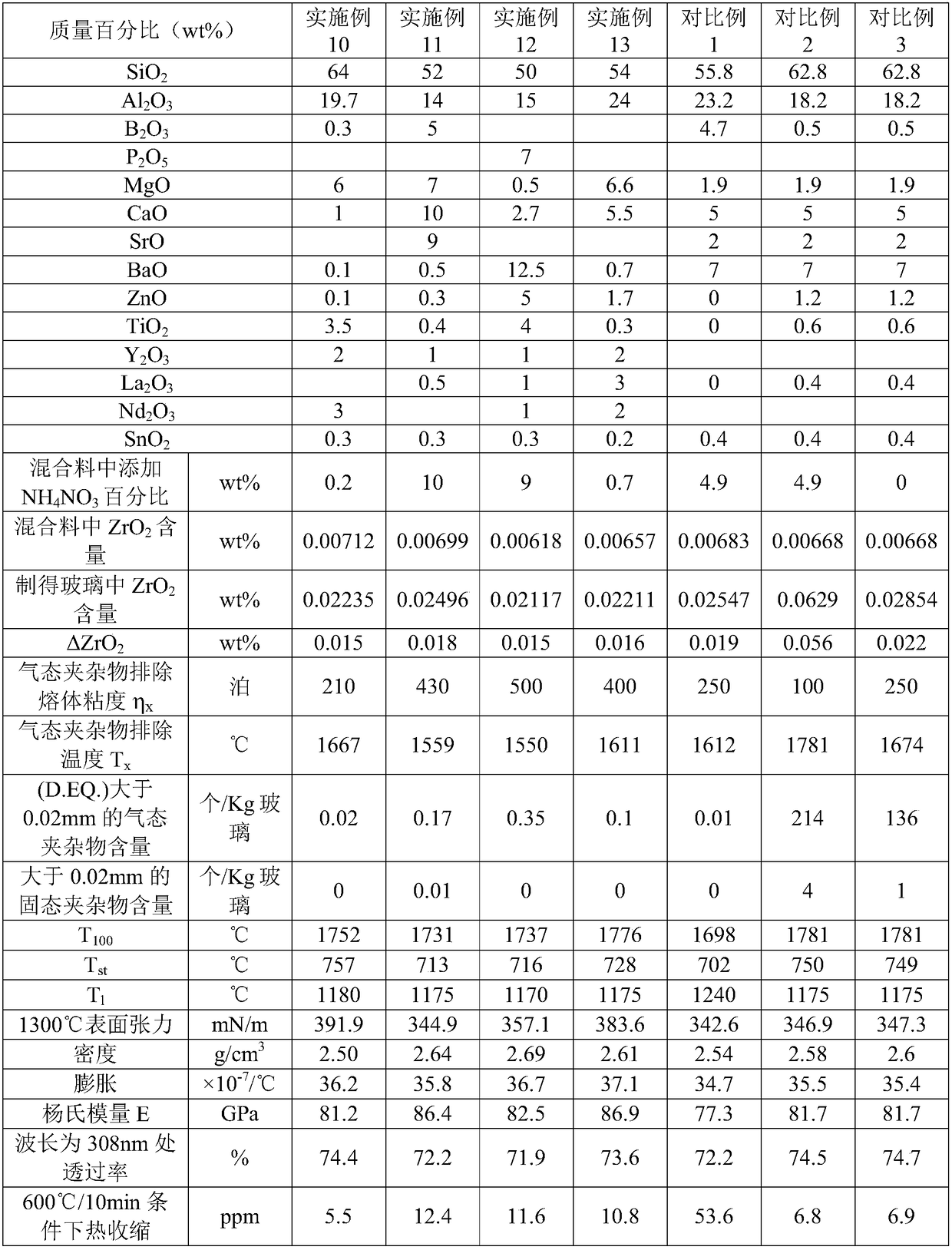

Glass composition, glass low in impurity content and preparation method and application of glass

ActiveCN108341595AIncrease partial pressureIncrease in sizeGlass furnace apparatusGlass reforming apparatusGlass manufacturingViscosity

The invention relates to the field of glass manufacturing, and discloses a glass composition, glass low in impurity content and a preparation method and application of the glass. The composition comprises, by weight, 50-64% of SiO2, 14-24% of Al2O3, 0-7% of B2O3 and P2O5, 0.5-7% of MgO, 1-10% of CaO, 0-9% of SrO, 0.1-14% of BaO, 0.1-5% of ZnO, 0.1-4% of TiO2, 0.1-7% of BaO, 0.1-5% of ZnO, 0.1-4% of TiO2, 0.1-7% of Y2O3, La2O3 and Nd2O3 and 0.05% of R2O, wherein R2O is the total content of Li2O, Na2O and K2O. The composition satisfies the following conditions that the temperature T100 corresponding to the viscosity of 100 P is 1730 DEG C or above; the surface tension is smaller than 420 mN / m at the temperature of 1300 DEG C. The glass prepared through the glass composition and the preparation method of the glass low in impurity content has the advantages of being low in impurity content, simple in preparation process, low in cost and the like.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

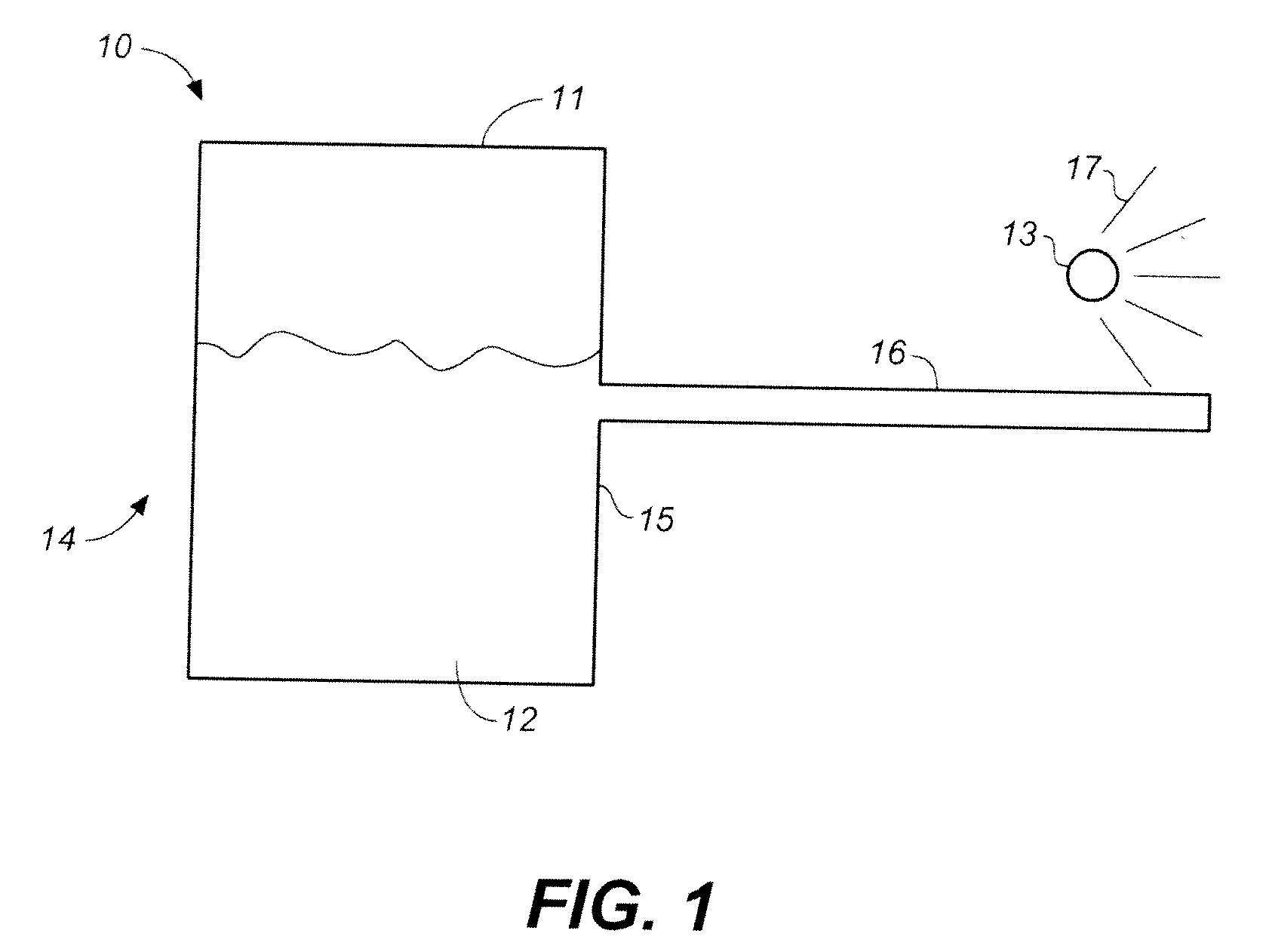

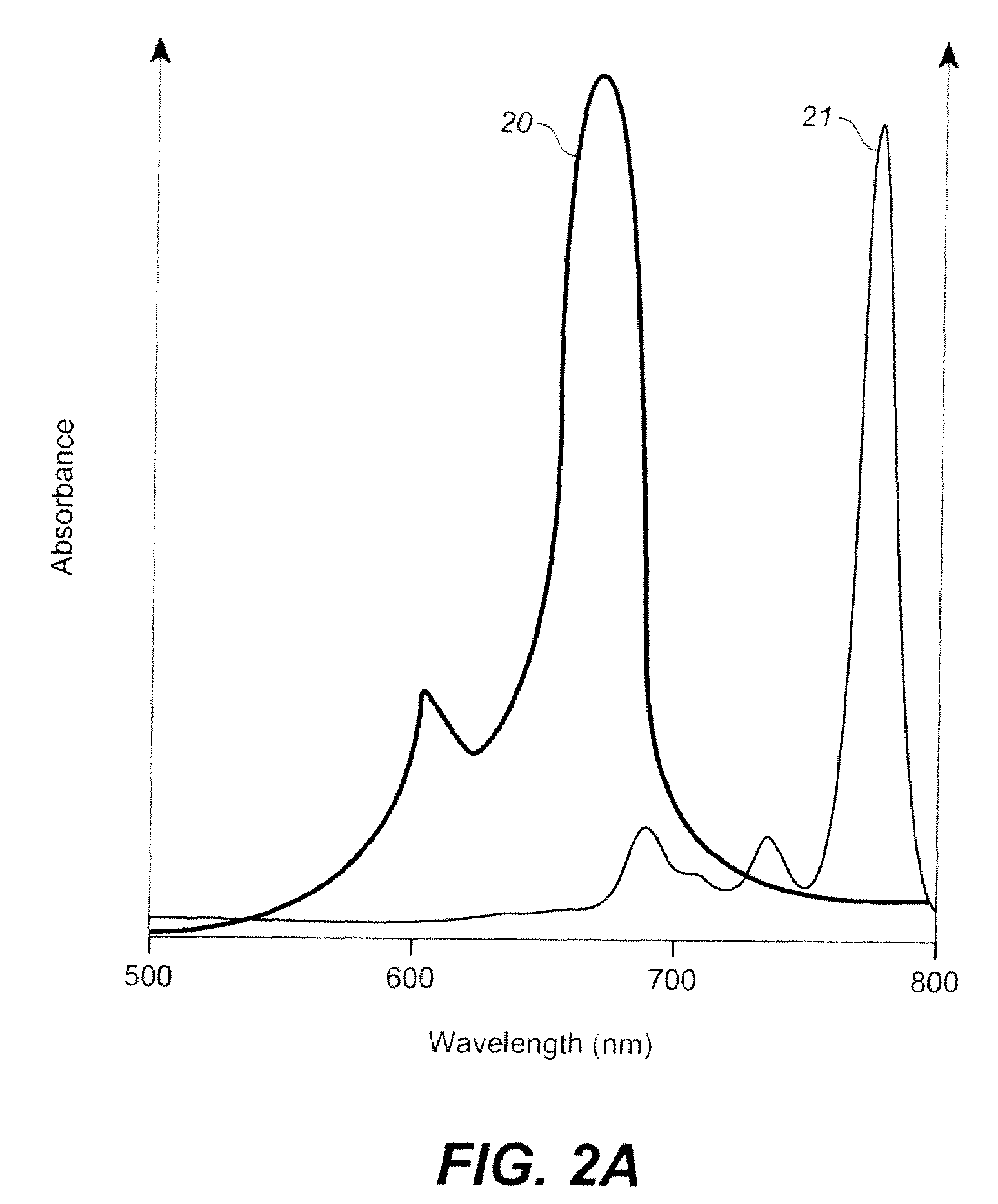

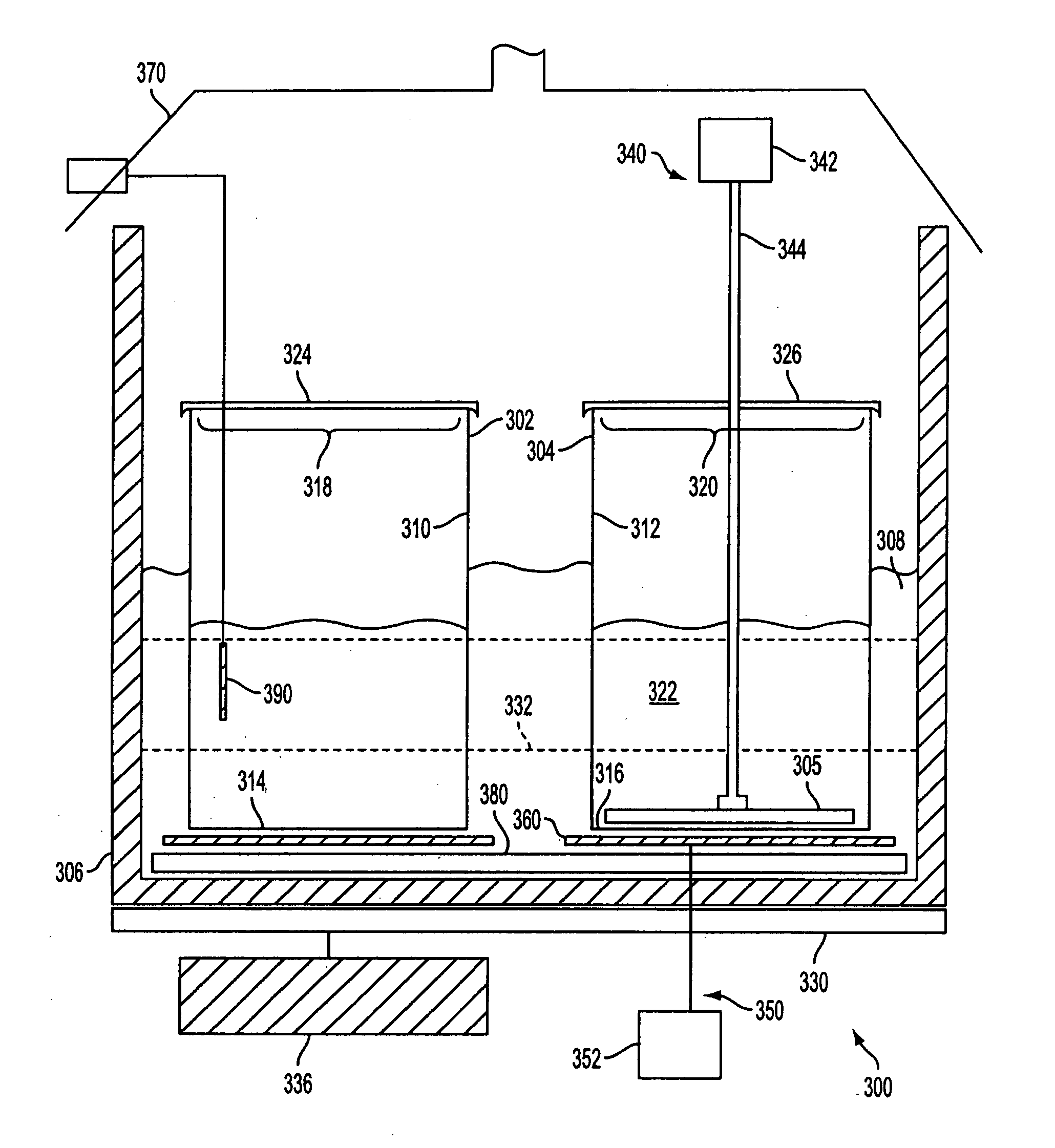

Ultrasonic assisted etch using corrosive liquids

ActiveUS20050016959A1Increase partial pressureDecorative surface effectsSemiconductor/solid-state device manufacturingUltrasonic assistedAqueous solution

An ultrasonic etching apparatus for chemically-etching a workpiece is disclosed. The apparatus includes an outer tank at least partially filled with an aqueous solution, an inner tank at least partially disposed within the outer tank and in contact with aqueous solution, the inner tank at least partially filled with an etching solution, a lid engaged with the mouth of said inner tank; and an ultrasonic transducer coupled to the outer tank to impart ultrasonic energy to the etching solution in said inner tank. Also disclosed are methods of using the apparatus to etch workpieces.

Owner:QUANTUM GLOBAL TECH

Method and plant for co2 enrichment

InactiveUS20100037771A1Efficient and less-expensiveLower the volumeGas treatmentAuxillary pretreatmentCycloneProduct gas

The present invention relates to a method and a plant for CO2 enrichment of a CO2 containing gas, such as an exhaust gas from an industrial plant or a thermal power plant, by means of serially connected centrifuges of cyclones. Enrichment of CO2 reduces the volume of the exhaust gas, increases the partial pressure of CO2 therein and makes a less expensive and more effective capture of CO2 possible. The invention also relates to plants for carrying out the method.

Owner:SARGAS

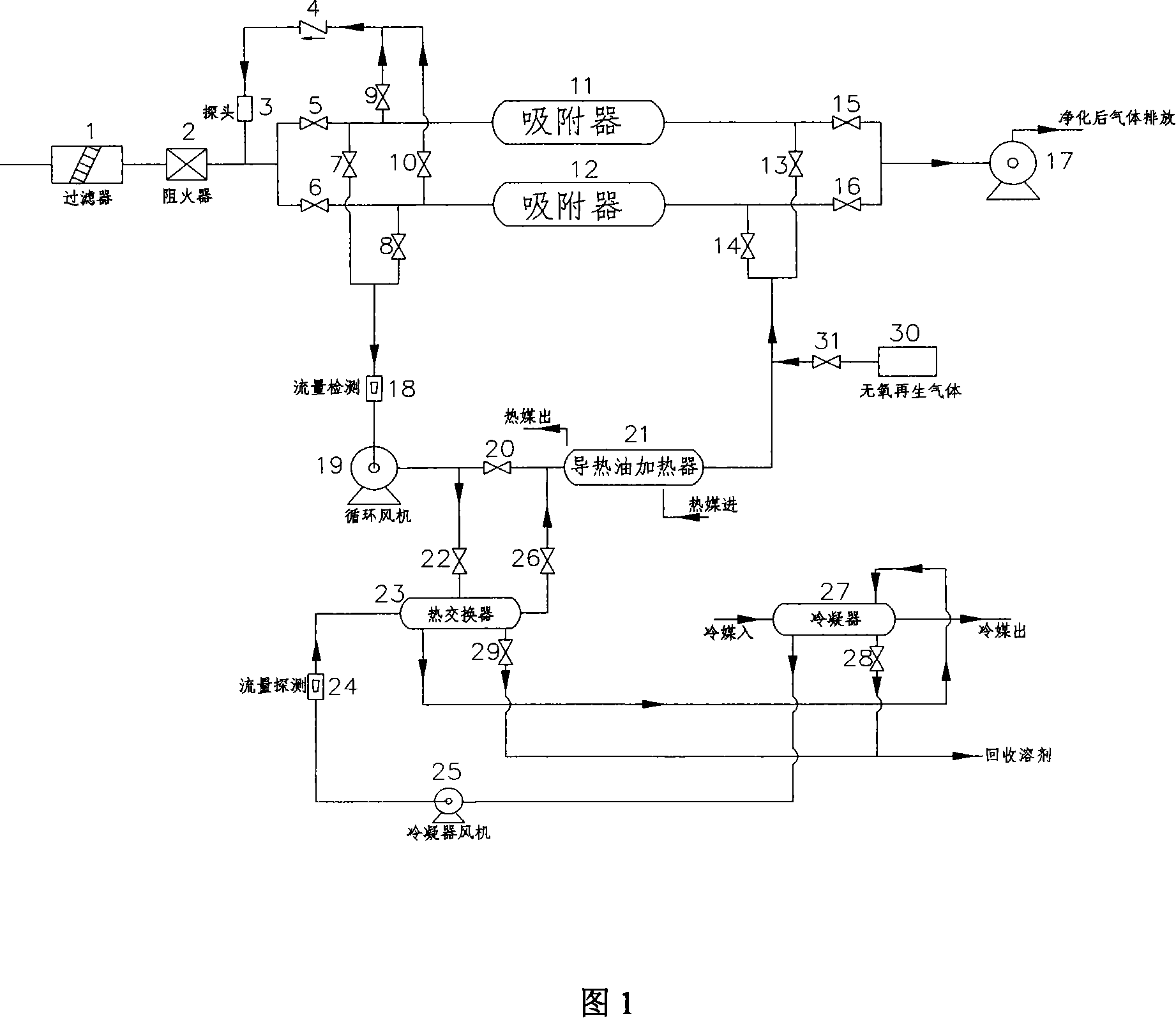

Adsorbent bed circulating desorption distributary recovery regeneration process and device thereof

InactiveCN101081361AIncrease partial pressureControl total oxygenOther chemical processesDispersed particle separationOrganic solventDesorption

The present invention belongs to the field of chemical separating and environment protecting technology, and is especially circular desorbing, shunting, recovering and regenerating process in an adsorbing bed and the apparatus. The technological process includes circular desorbing on hot gas in an adsorbing bed, and by-pass heat exchange and condensing recovery of partial desorbed gas flow. The present invention has the advantages low power consumption, low cost and high purity of the recovered organic matter, and is especially suitable for use in chemical adsorbing and separating process, contaminated gas purifying, organic solvent recovery, etc.

Owner:TONGJI UNIV

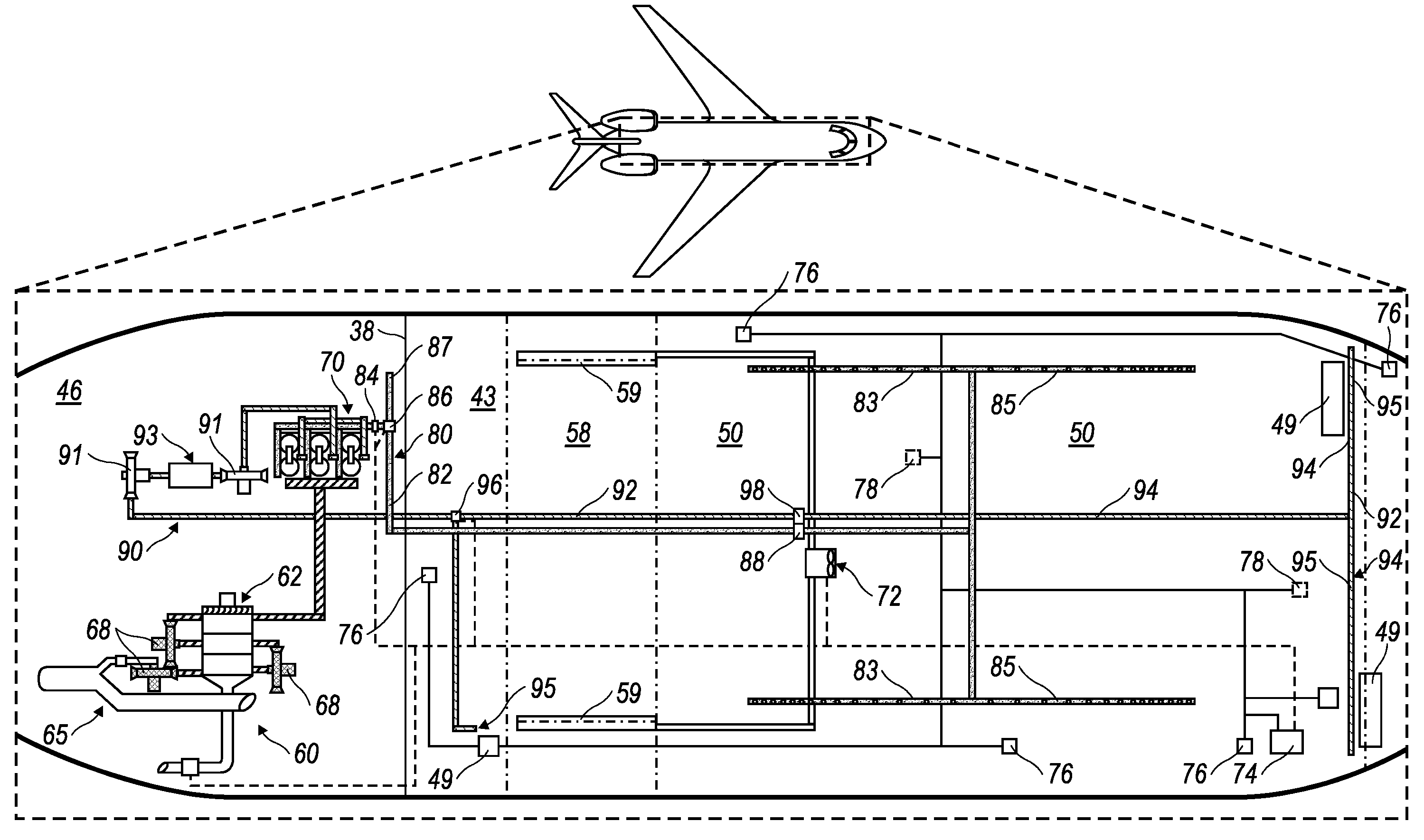

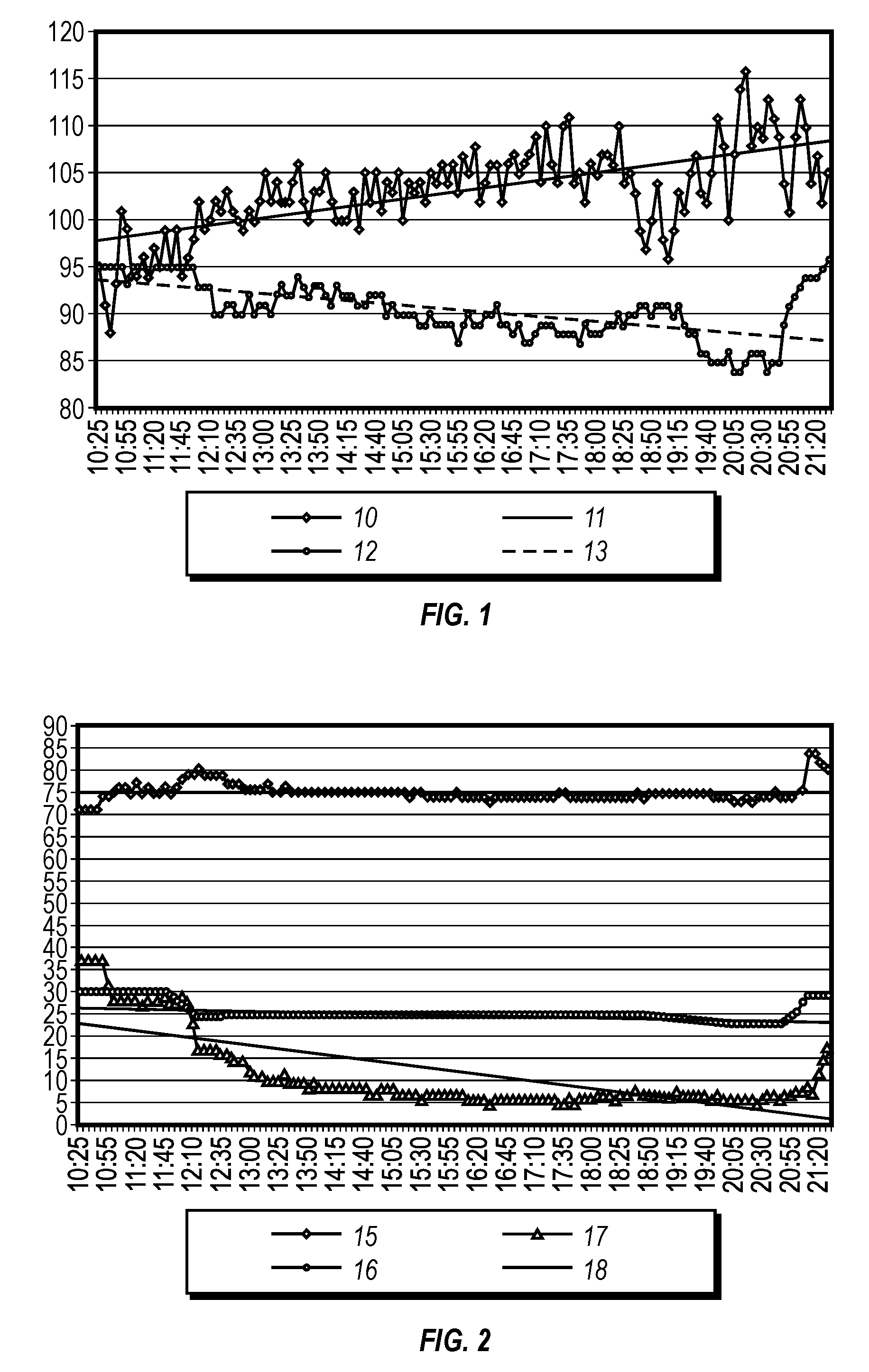

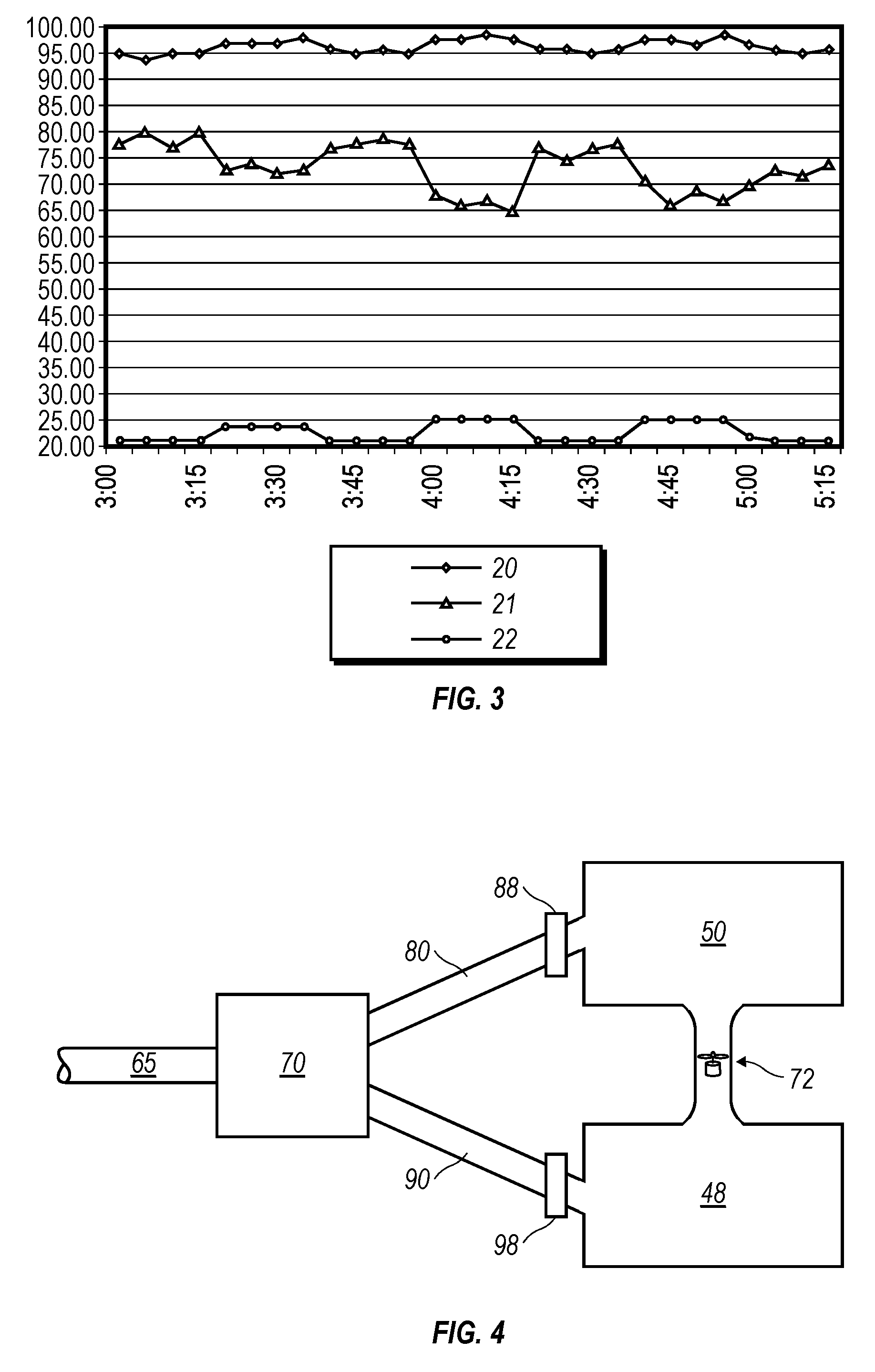

System and method for aircraft cabin atmospheric composition control

InactiveUS20050115565A1Early detectionEarly extinguishmentLiquefactionCosmonautic vehiclesHigh concentrationCombustion

Method and arrangement for adjusting nitrogen and oxygen concentrations within regions of an aircraft. The method includes separating nitrogen from ambient air onboard an aircraft thereby establishing a high-concentration nitrogen supply and then dispensing high-concentration nitrogen from the supply to a fire-susceptible, non-habitable region of the aircraft where the high-concentration nitrogen is reservoired thereby decreasing the capability for the atmosphere therein to support combustion. Oxygen is also separated from the ambient air thereby establishing a high-concentration oxygen supply that is dispensed to an occupant cabin of the aircraft thereby increasing the level of oxygen concentration within the cabin to a level greater than the naturally occurring concentration of oxygen at the experienced internal cabin pressure. When it is determined that reduced oxygen concentration is required in the occupant cabin, the reservoired high-concentration nitrogen is moved into the passenger cabin diluting the oxygen-elevated environment.

Owner:GULFSTREAM AEROSPACE CORP

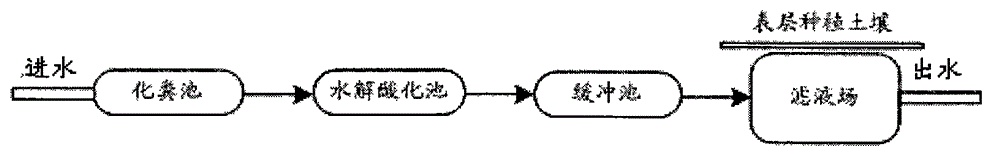

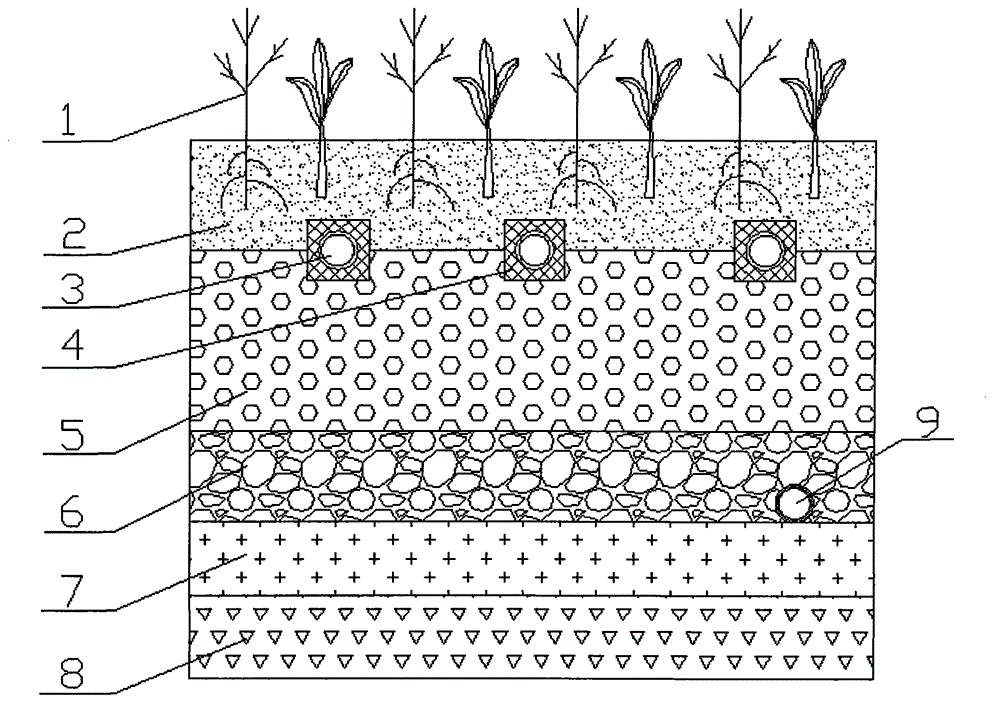

Soil percolation system applicable to sewage ecological processing

InactiveCN104528940AImprove breathabilityImprove water retentionTreatment with anaerobic digestion processesMultistage water/sewage treatmentSlagWater collection

A disclosed soil percolation system applicable to sewage ecological processing is composed of a plant layer, a plantation soil layer, an artificial soil layer, a supporting layer, a sand filtering layer and an impervious layer from top to bottom; the plant layer is formed by combining plants with relatively developed roots; the plantation soil layer is composed of fertile cultivation soil and is embedded with crushed straws, and earthworm is introduced into the plantation soil layer; the artificial soil layer is formed by mixing 80% of sand clay and 20% of furnace slag; the plantation soil layer and the artificial soil layer are both provided with water distribution trenches in which water inlet pipes are spread; the supporting layer is composed of gravels with the diameter of 30 mm and is inside provided with a water collection pipe; the sand filtering layer is backfilled with grits; and the impervious layer is constructed by employing C25 plain concrete. The system employs a composite purification technology for processing domestic sewage by comprehensively utilizing the combined action of soil, straws, microbes and plants, especially earthworm is utilized for processing straws, and the purposes of changing waste into valuables and purifying environment are realized.

Owner:安徽新天安全环境科技有限公司

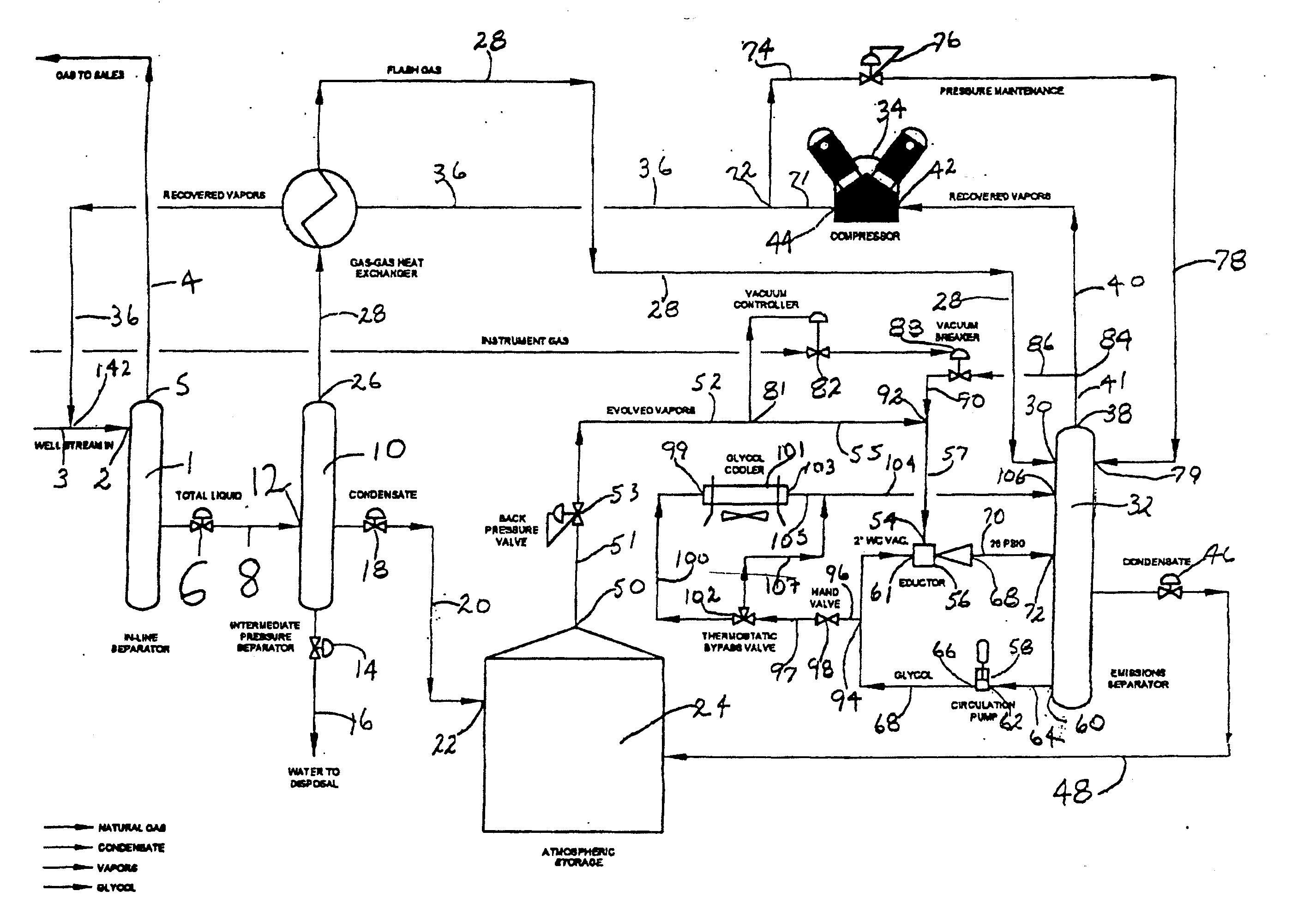

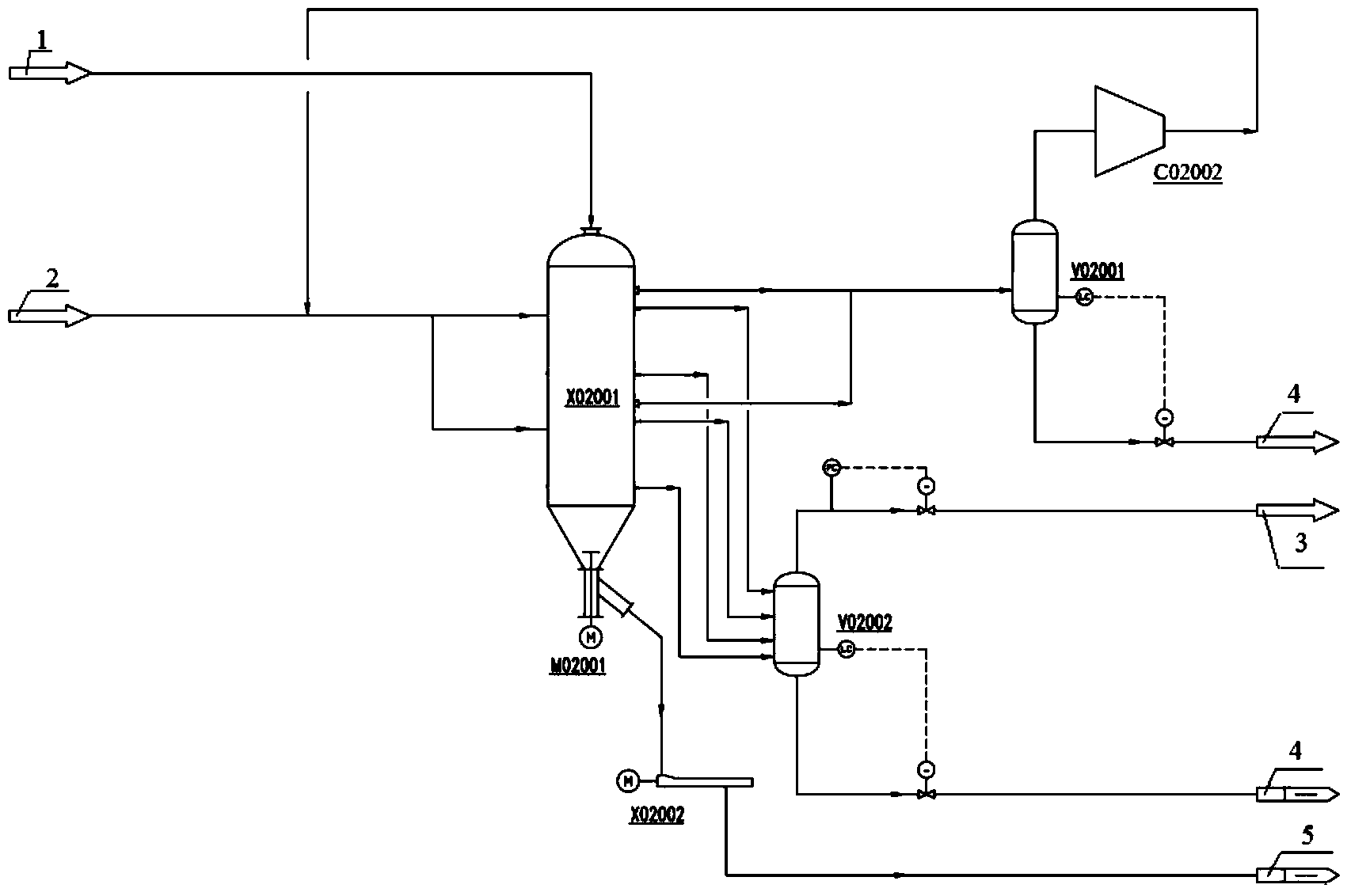

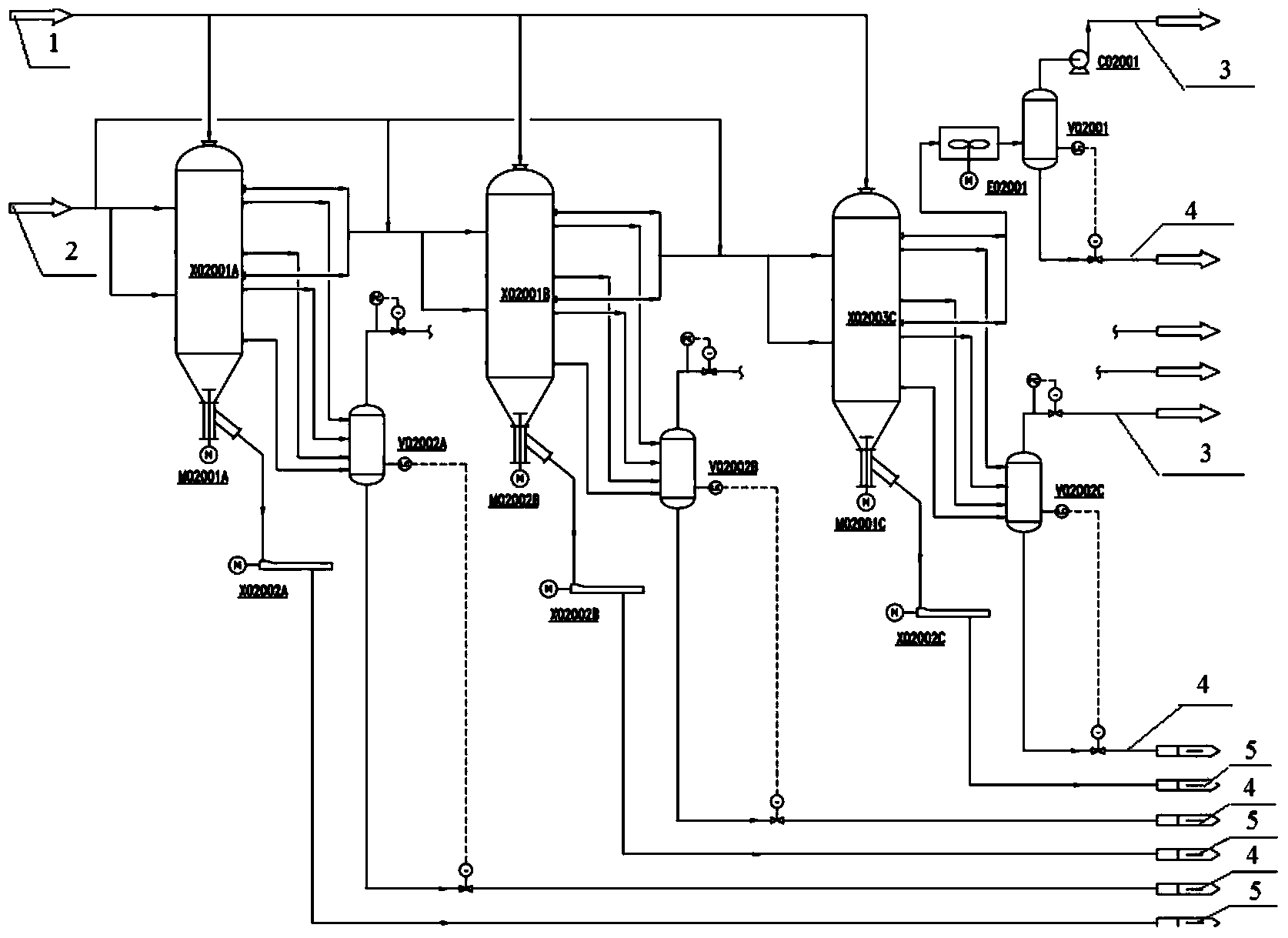

Vapor Recovery Process System

InactiveUS20070151292A1Reduce BTU and partial pressureIncrease partial pressureSolidificationLiquefactionProcess systemsLiquid state

The present invention provides for a natural gas well vapor recovery processing system and method comprising recovering gaseous hydrocarbons to prevent their release into the atmosphere including providing a method for preventing the gaseous hydrocarbons from returning to a liquid state.

Owner:HEATH RODNEY T +2

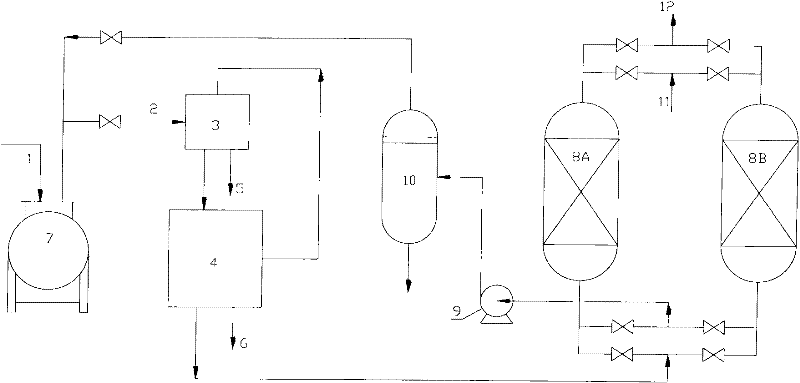

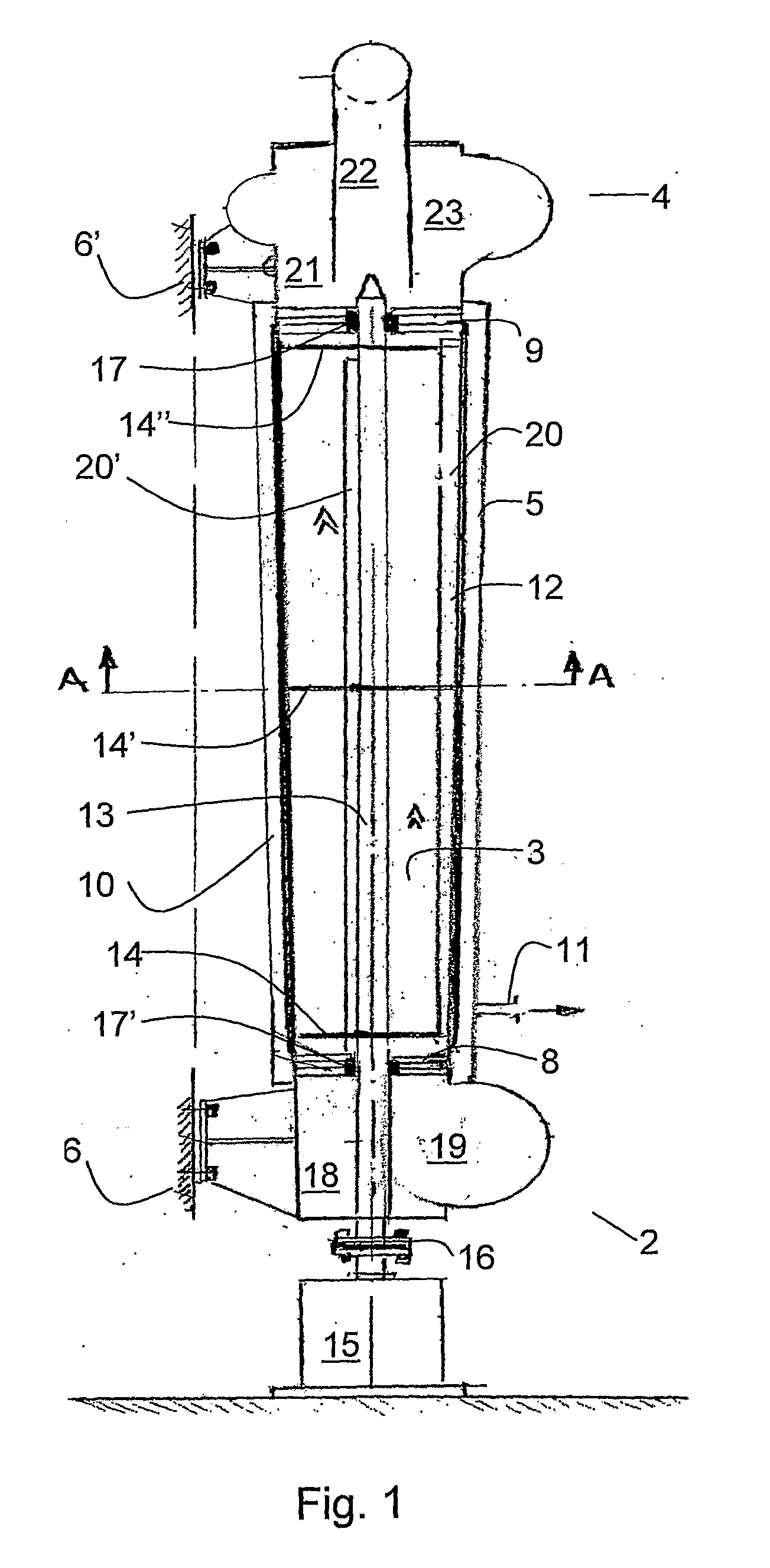

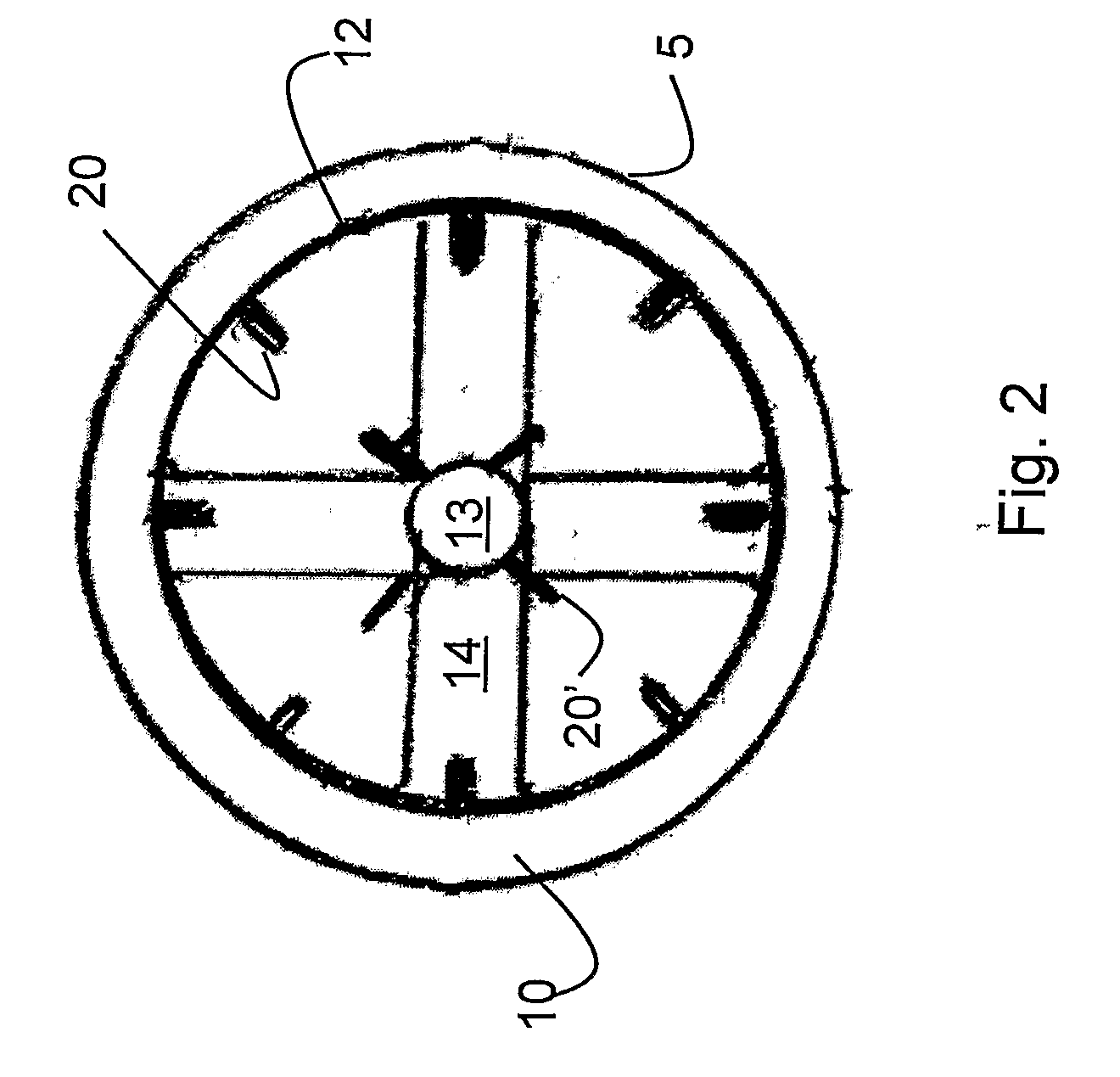

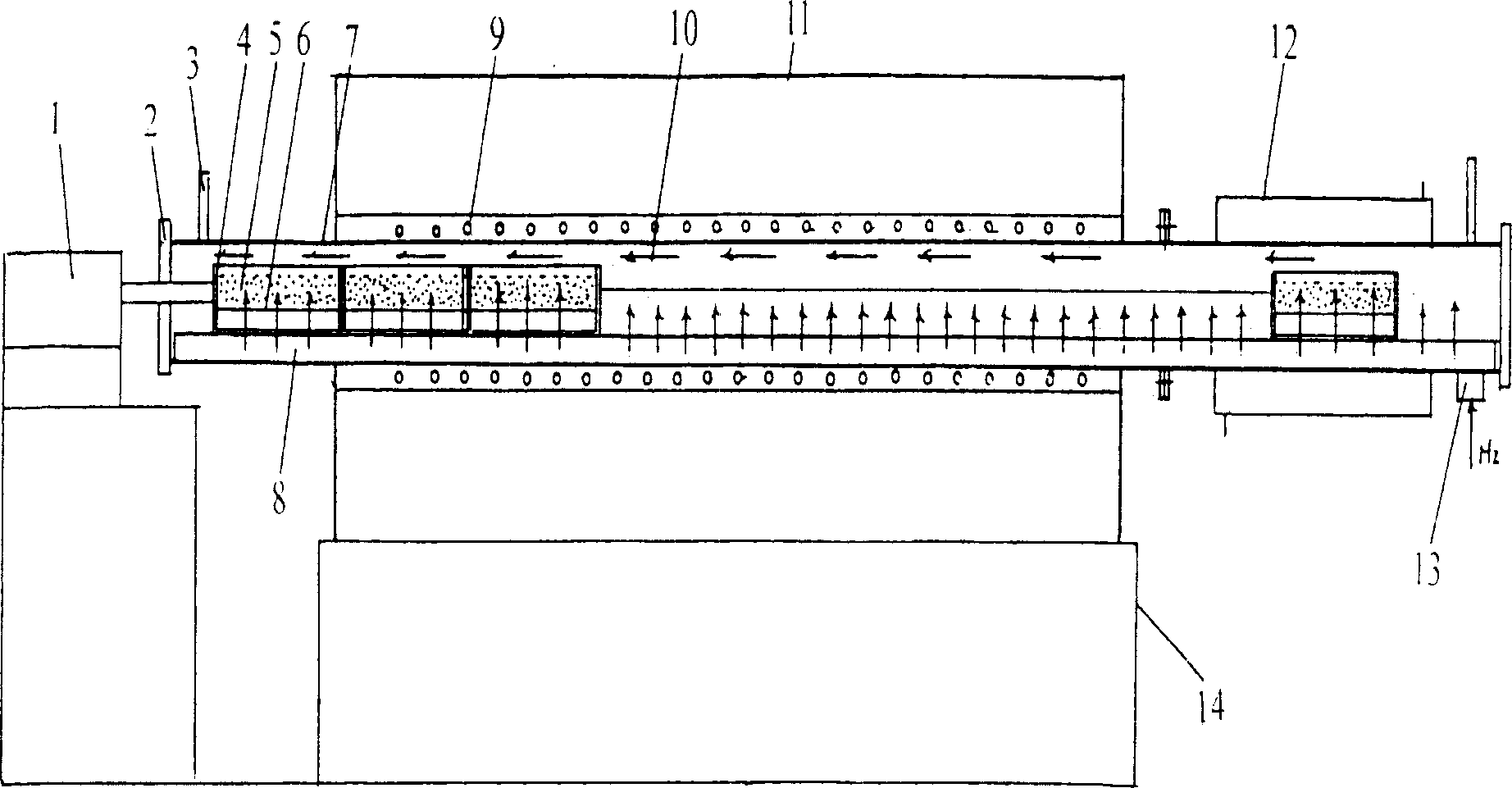

Ventilated forced drainage type nano tungsten powder reducing furnace for industrial use

InactiveCN1766510AEasy dischargeIncrease partial pressureCharge supportsMaintainance of heating chambersAirflowPositive pressure

The invention discloses a poromeric draining pipe type reducing furnace, which comprises the following parts: boating-pushing device (1), firedoor (2), exhaust ignition or recovery pipe (3), poromeric boat-container (4), nanometer tungsten oxide powder (5), boat-container poromeric floor (6), furnace tube (7), positive pressure H 2 supply porous air-cushion (8), heating plate (9), drainage air-flow channel (10), furnace case (11), cold water case (12), positive pressure air-supply system (13) and furnace rack (14), wherein the positive pressure H 2 supply porous air-cushion (8) is set on the bottom of furnace tube (7); the H 2 even pressure chamber is formed between the double-layer boat-container poromeric plate (6) and porous air-cushion (8), which pierces the boat-container poromeric floor (6) after buffering. The average grain size of nanometer tungsten powder is or less than 35.5 nm with the distribution breadth ranged from 45 to 50 nm.

Owner:UNIV OF SCI & TECH BEIJING

Low-energy-consumption lignite drying process for recovering lignite moisture and drying equipment

InactiveCN103453752APrevent leakageReduced inert gas contentDrying gas arrangementsDrying solid materialsResource utilizationDry heat

The invention relates to the technical field of lignite drying and comprehensive high-efficiency utilization of lignite, and discloses a low-energy-consumption lignite drying process for recovering lignite moisture and drying equipment. The drying equipment disclosed by the invention comprises a drier for realizing the indirect heating by steam. The lignite drying process comprises the steps that steam is used as heating media, and the steam enters the drier to carry out drying heat exchange with the lignite in the drier; and meanwhile, moisture removed from the lignite is heated to become secondary steam, and the secondary steam realizes the gas-solid separation through an outer sleeve made of porous gas-solid separation materials, and are discharged out of the drier to be recovered and utilized. The process and the equipment have the advantages that the moisture removed from the lignite can be recovered, and meanwhile, the energy consumption in the drying process can also be reduced, so the energy utilization efficiency, the resource utilization efficiency and the environmental protection benefit of the comprehensive utilization items of the lignite are improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

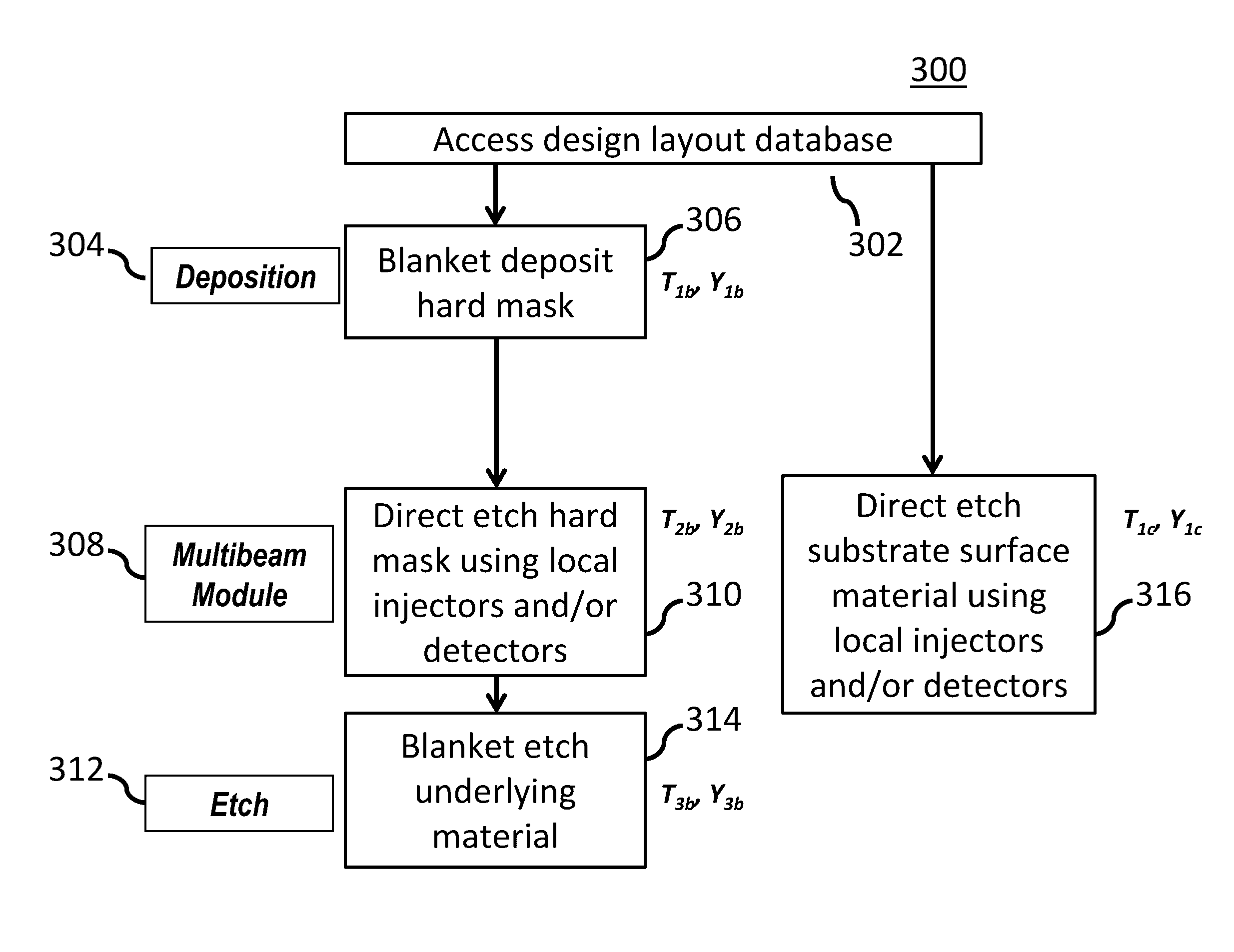

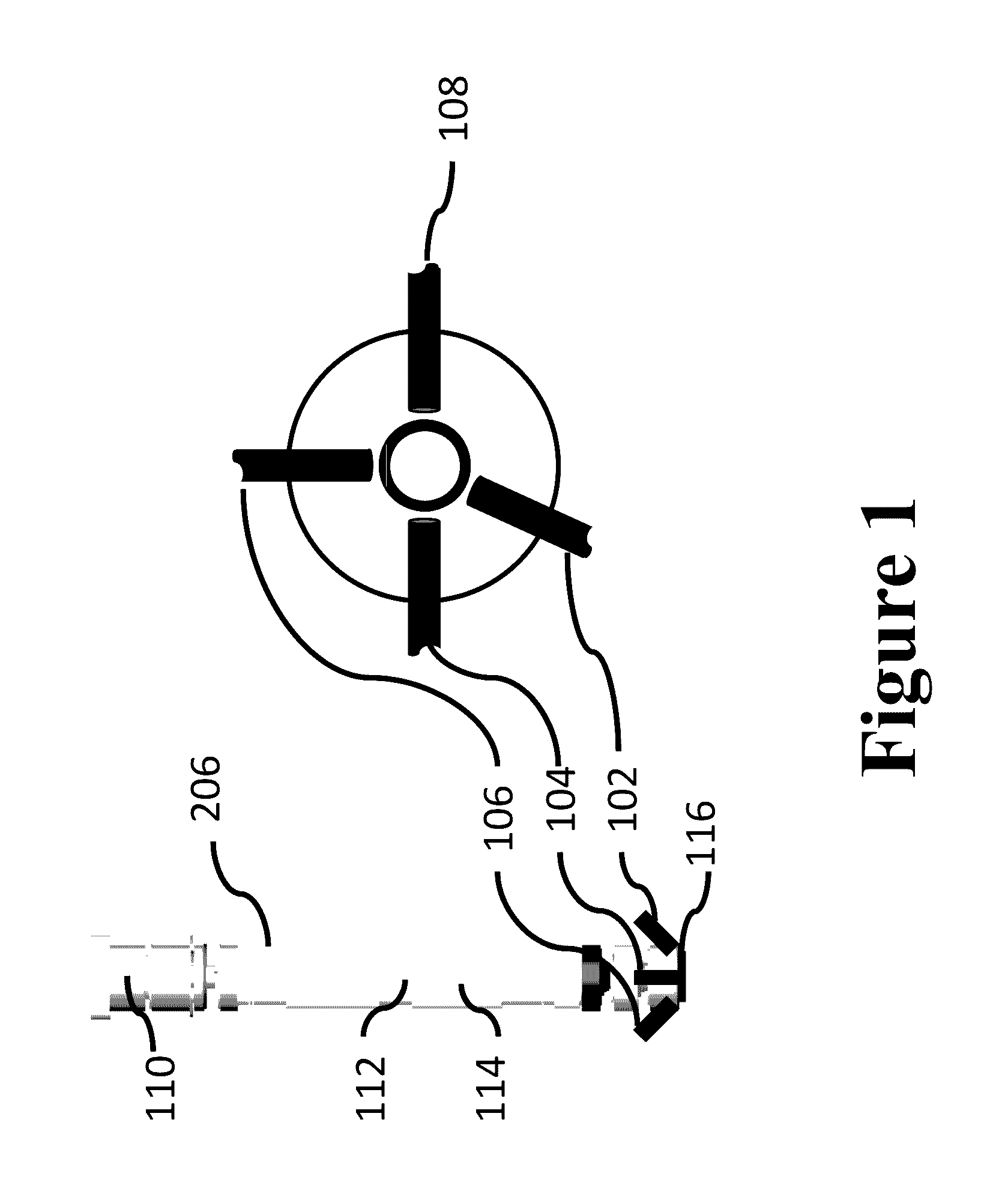

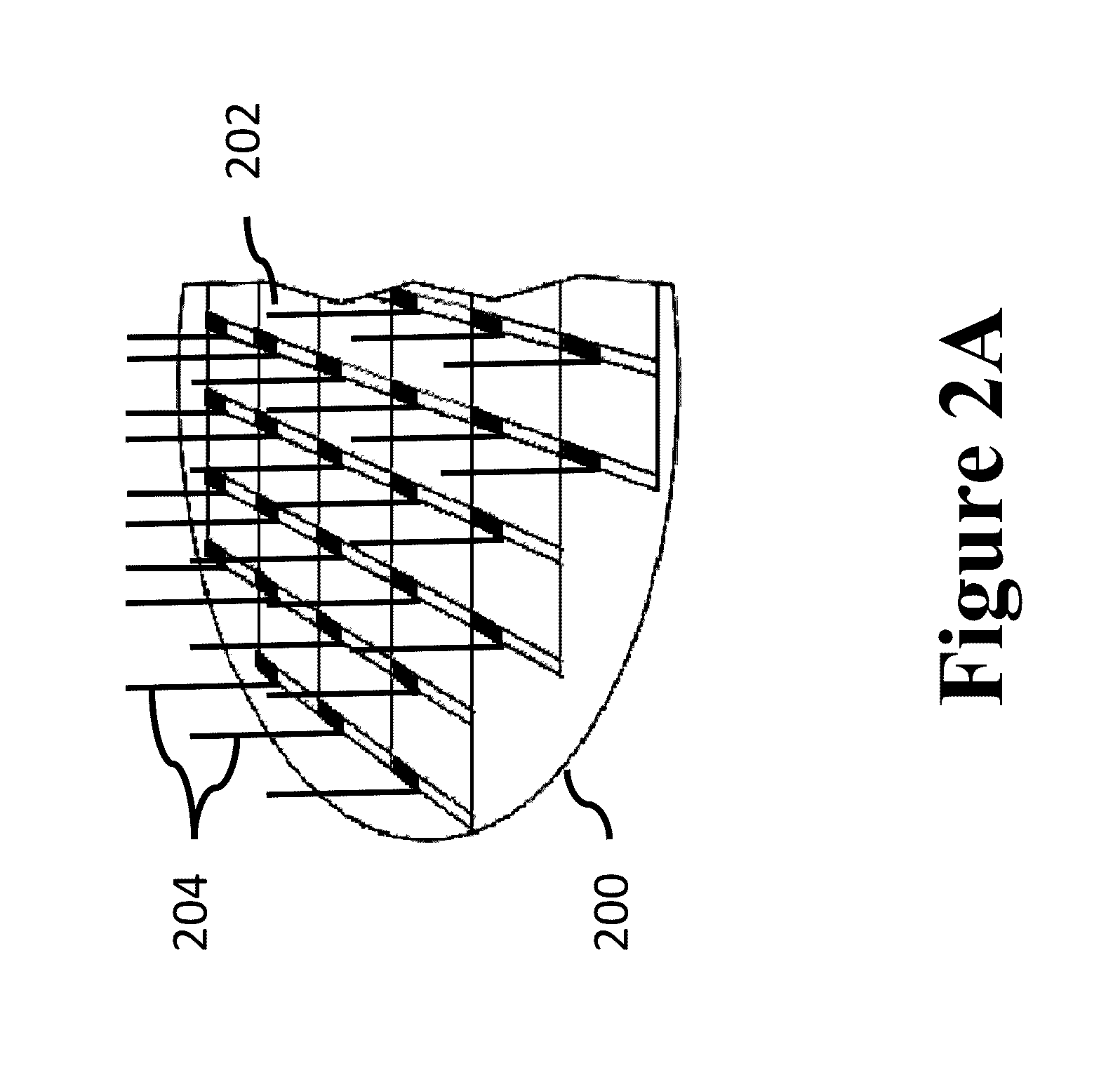

Precision substrate material removal using miniature-column charged particle beam arrays

ActiveUS9466464B1Reaction rate and efficiencyPrecise heatingSemiconductor/solid-state device testing/measurementElectric discharge tubesResistAs Directed

Methods, devices and systems for patterning of substrates using charged particle beams without photomasks and without a resist layer. Material can be removed from a substrate, as directed by a design layout database, localized to positions targeted by multiple, matched charged particle beams. Reducing the number of process steps, and eliminating lithography steps, in localized material removal has the dual benefit of reducing manufacturing cycle time and increasing yield by lowering the probability of defect introduction. Furthermore, highly localized, precision material removal allows for controlled variation of removal rate and enables creation of 3D structures or profiles. Local gas injectors and detectors, and local photon injectors and detectors, are local to corresponding ones of the columns, and can be used to facilitate rapid, accurate, targeted substrate processing.

Owner:MULTIBEAM CORP

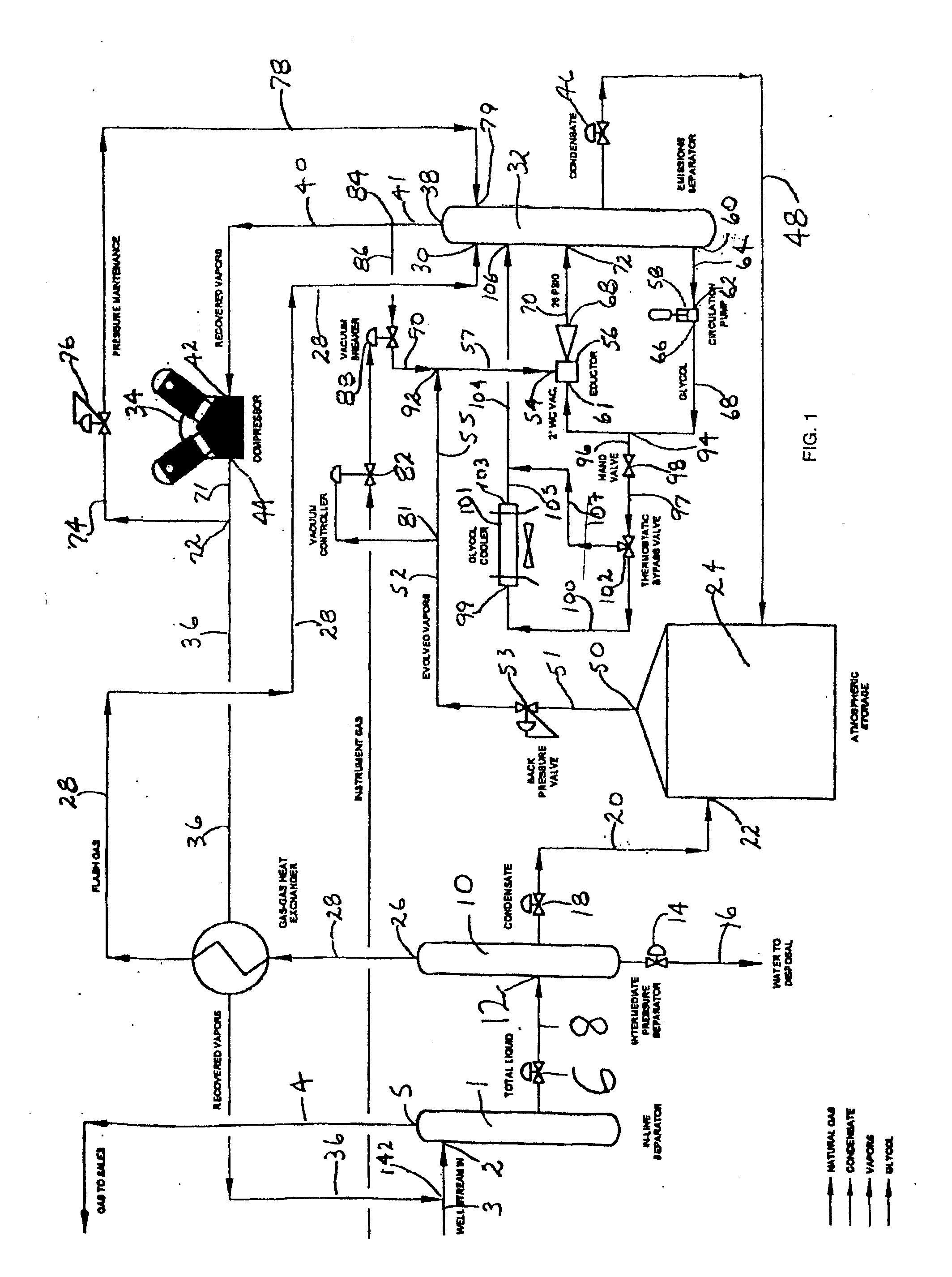

Vapor process system

ActiveUS9353315B2Reduce BTU and partial pressureIncrease partial pressureSolidificationLiquefactionProcess systemsLiquid state

The present invention provides for a natural gas well vapor processing system and method comprising recovering gaseous hydrocarbons to prevent their release into the atmosphere including providing a method for preventing the gaseous hydrocarbons from returning to a liquid state.

Owner:HEATH RODNEY T +2

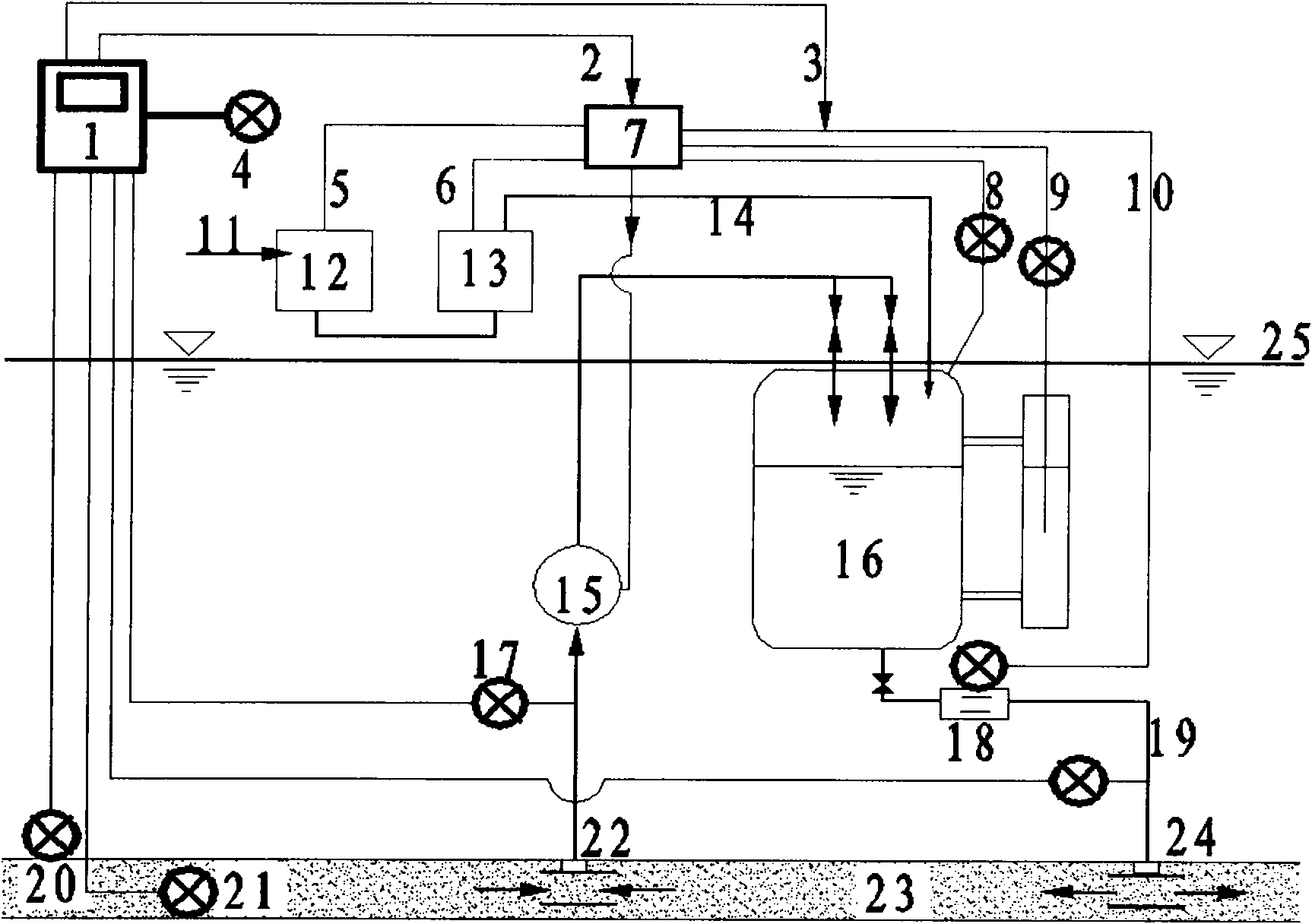

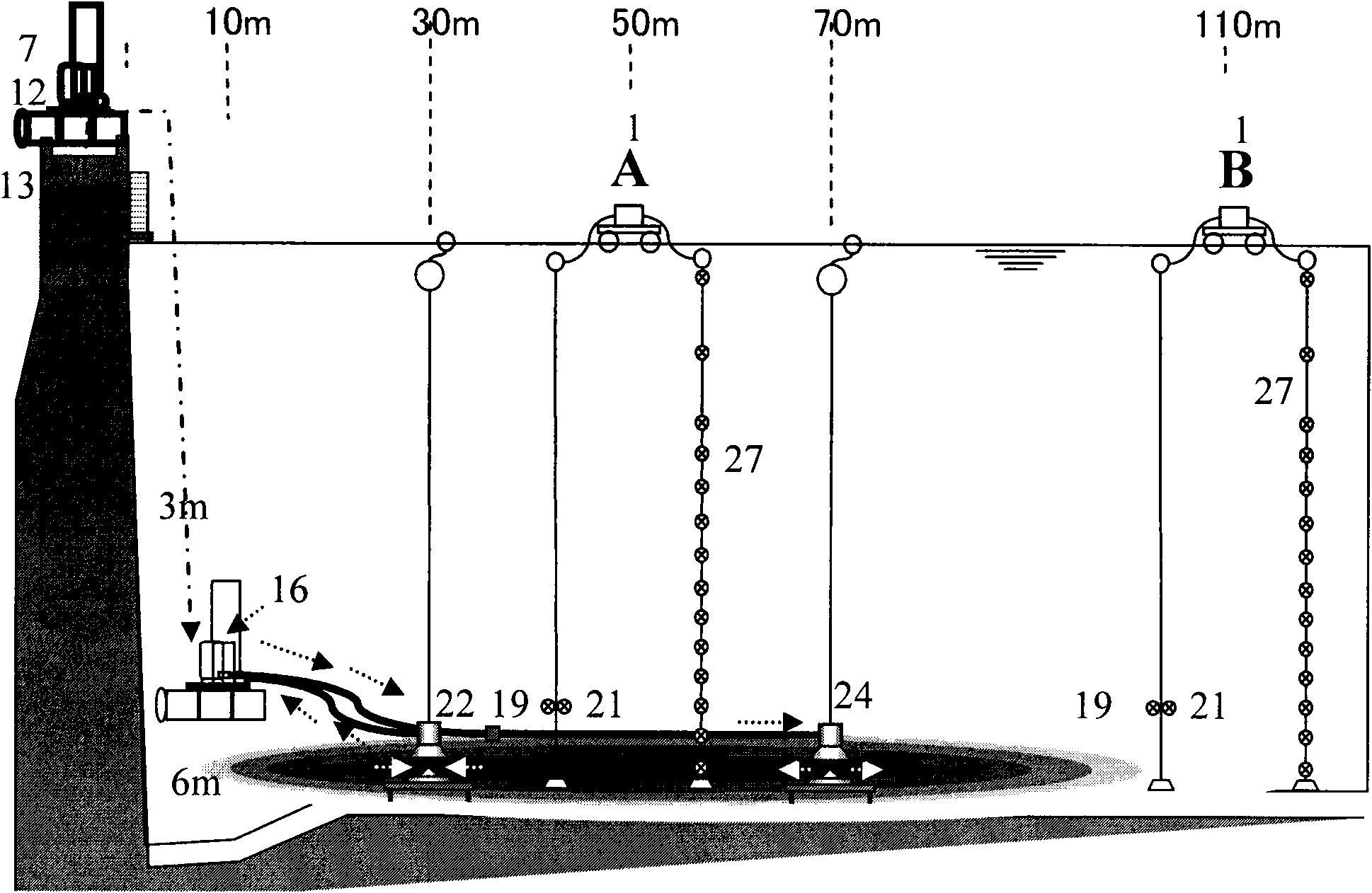

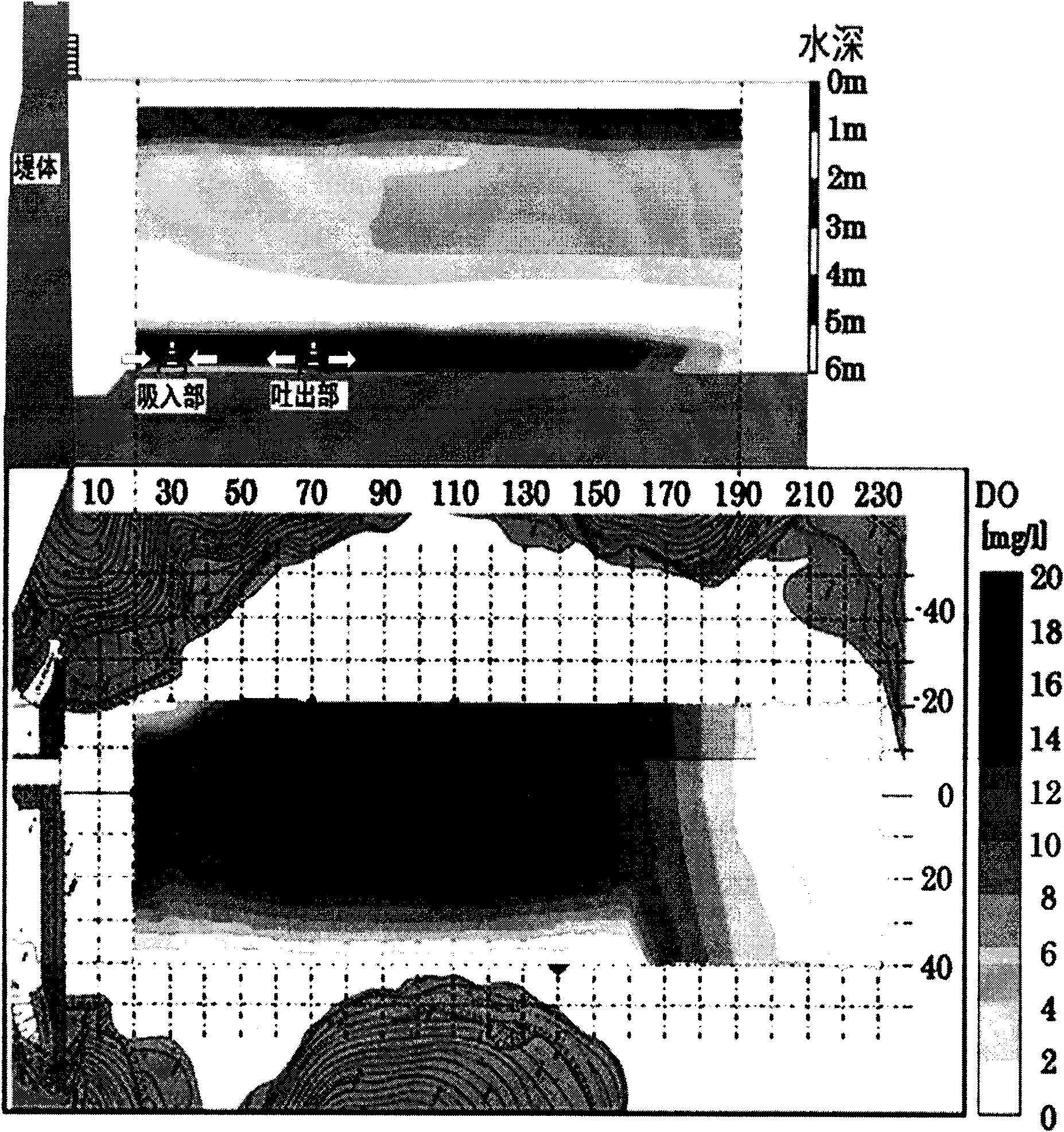

Submerged type bubble-free high-efficiency oxygenated water body restoration system

InactiveCN101602550AIncrease partial pressureAchieve fixWater aerationEnergy based wastewater treatmentHigh concentrationOxygen tank

The invention relates to a submerged type bubble-free high-efficiency oxygenated water body restoration system, comprising an oxygen supply system and a dissolved oxygen system; the oxygen supply system is used to inject oxygen in the water of the dissolved oxygen system and the dissolved oxygen system is used to release high-concentration oxygen in water body for dissolving oxygen in water. The oxygen supply system comprises an air compressor, an oxygen generator and dissolved oxygen tanks which are connected in sequence by pipelines and convey high-concentration oxygen to dissolved oxygen tanks of the dissolved oxygen system, and the high-concentration oxygen is generated by the oxygen generator and has purity of higher than 90%; the dissolved oxygen system also comprises a submerged pump which conveys water to the dissolved oxygen tanks, the oxygen tanks carries out bubble-free mutual dissolving with the oxygen so as to obtain high-concentration oxygenated water, and the high-concentration oxygen dissolved water is released into the water body through the dissolved oxygen tanks so as to realize bubble-free oxygenation. The system also can be provided with a control system so as to control self starting oxygenation, or is further provided with a monitoring system which adjusts and controls the starting and stopping and the flow rate of oxygenation in real time according to various indexes. The submerged type bubble-free high-efficiency oxygenated water restoration system has characteristics of low power consumption, high efficiency and the like, can effectively reduce the content of nitrogen and phosphorus in water sources and water bodies and can further restrict burst of water bloom.

Owner:TONGJI UNIV

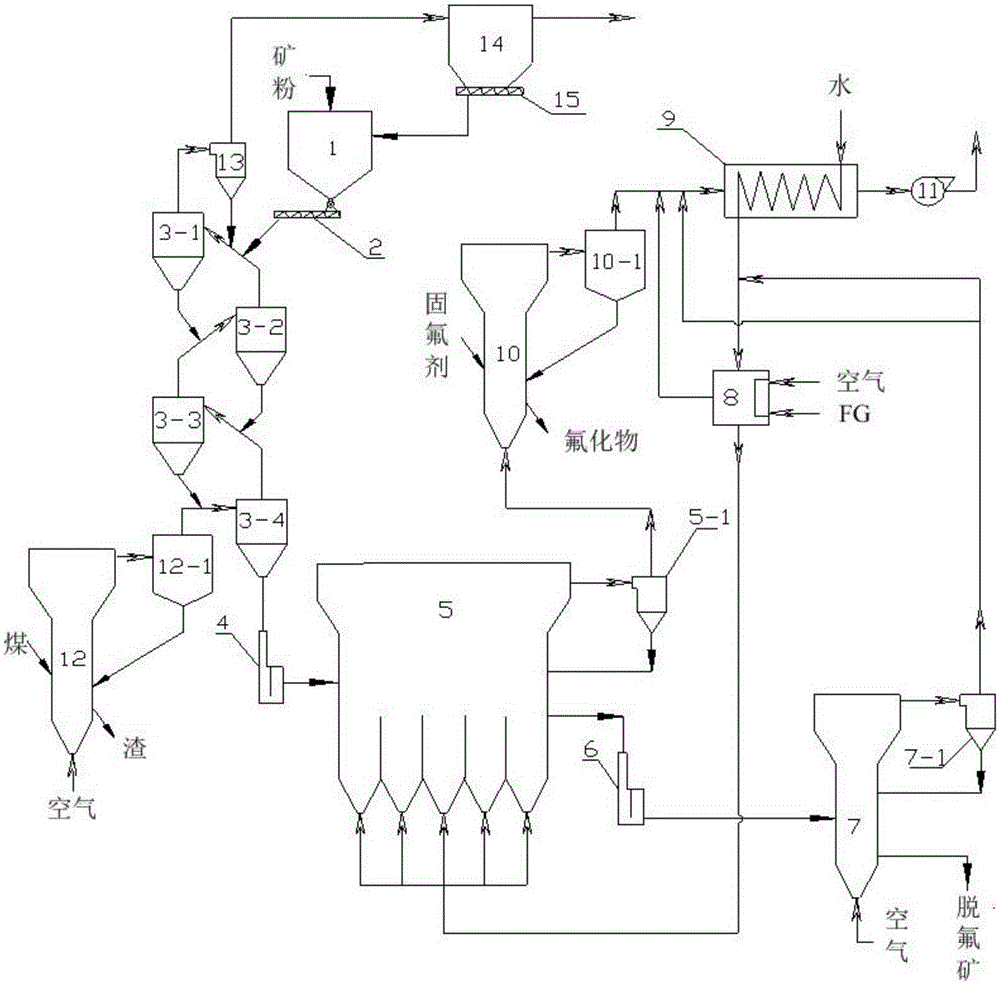

Roasting defluorination device and technology

The invention provides a roasting defluorination device and technology. The roasting defluorination device comprises a feeding system, a mineral powder preheating system, a fluidized-bed roasting system and a vapor preheating system. The fluidized-bed roasting system comprises a fluidized-bed roasting furnace. The feeding system is connected with the mineral powder preheating system. The mineral powder preheating system and the vapor preheating system are connected with the fluidized-bed roasting system. Optionally, the device further comprises a gas absorption system, a cooling system and an air guiding system, the gas absorbing system and the cooling system are connected with the fluidized-bed roasting system, and the air guiding system and the gas absorbing system are connected. The defluorination rate of the roasting defluorination device reaches more than 85%. A solid fluorine fixing agent is used for absorbing fluorine containing tail gas to recycle fluorine resources. Water of a vapor boiler is preheated by heat generated in the high-temperature defluorination tail gas and defluorination material cooling process to generate high-temperature vapor, the heat utilization rate is high, and vapor consumption is low. The roasting process is good in economical efficiency, and the roasting defluorination device and technology are suitable for large-scale continuous industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

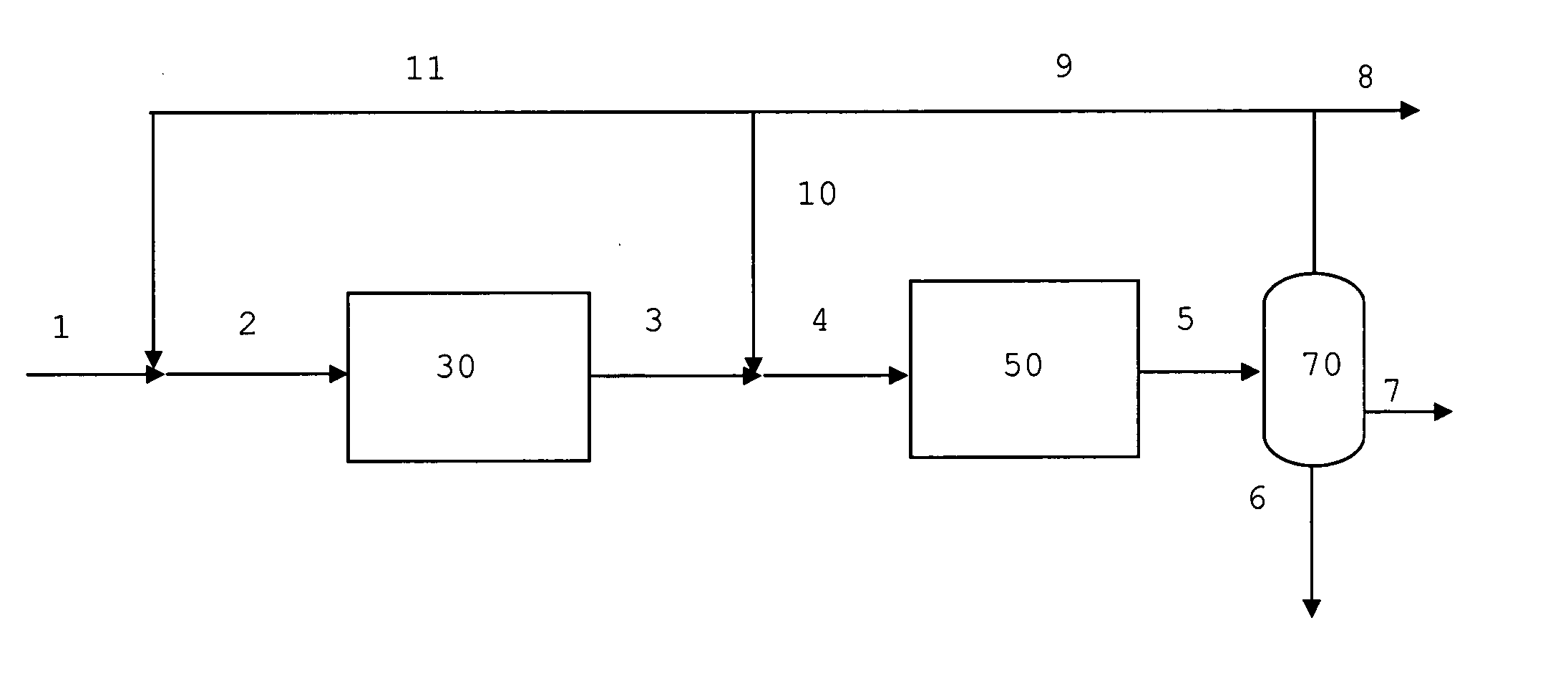

Process for converting difficulty convertible oxygenates to gasoline

InactiveUS7820867B2Few propensityLong cycle timeOrganic compound preparationOxygen compounds preparation by reductionSyngasOxygenate

Process for converting oxygenate compounds to hydrocarbons comprising the steps: (a) introducing a feed stream of synthesis gas to a synthesis section for the production of easily convertible oxygenates, (b) passing the effluent stream from said synthesis section containing easily convertible oxygenates to a gasoline synthesis section, (c) passing the effluent of said gasoline synthesis section to a separator and withdrawing from said separator hydrocarbons boiling in the gasoline boiling range, (d) admixing a recycle stream from the separator containing unconverted synthesis gas volatile hydrocarbons with the feed stream of synthesis gas of step (a), (e) introducing a feed containing difficulty convertible oxygenates to the synthesis section of step (a).

Owner:HALDOR TOPSOE AS

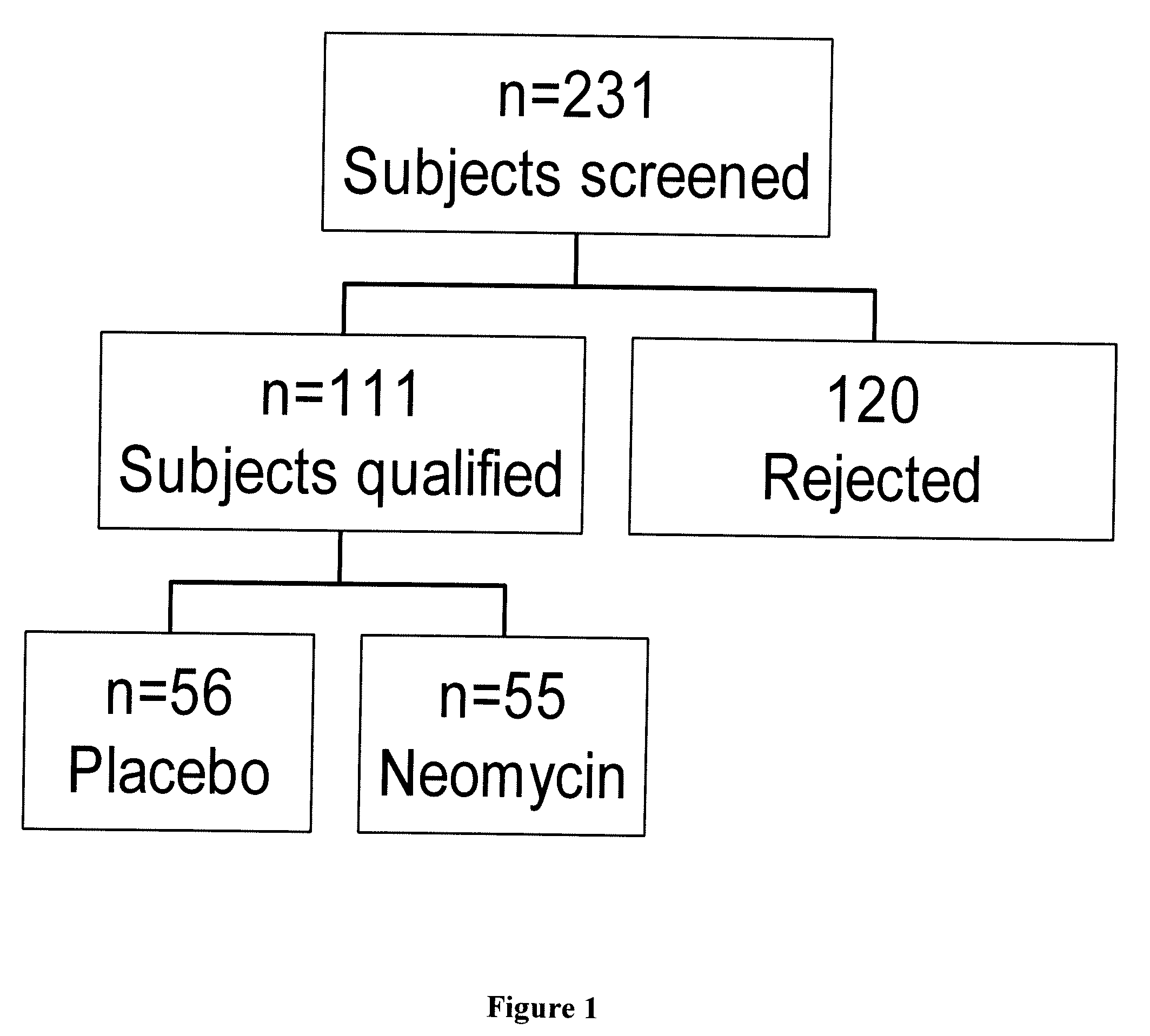

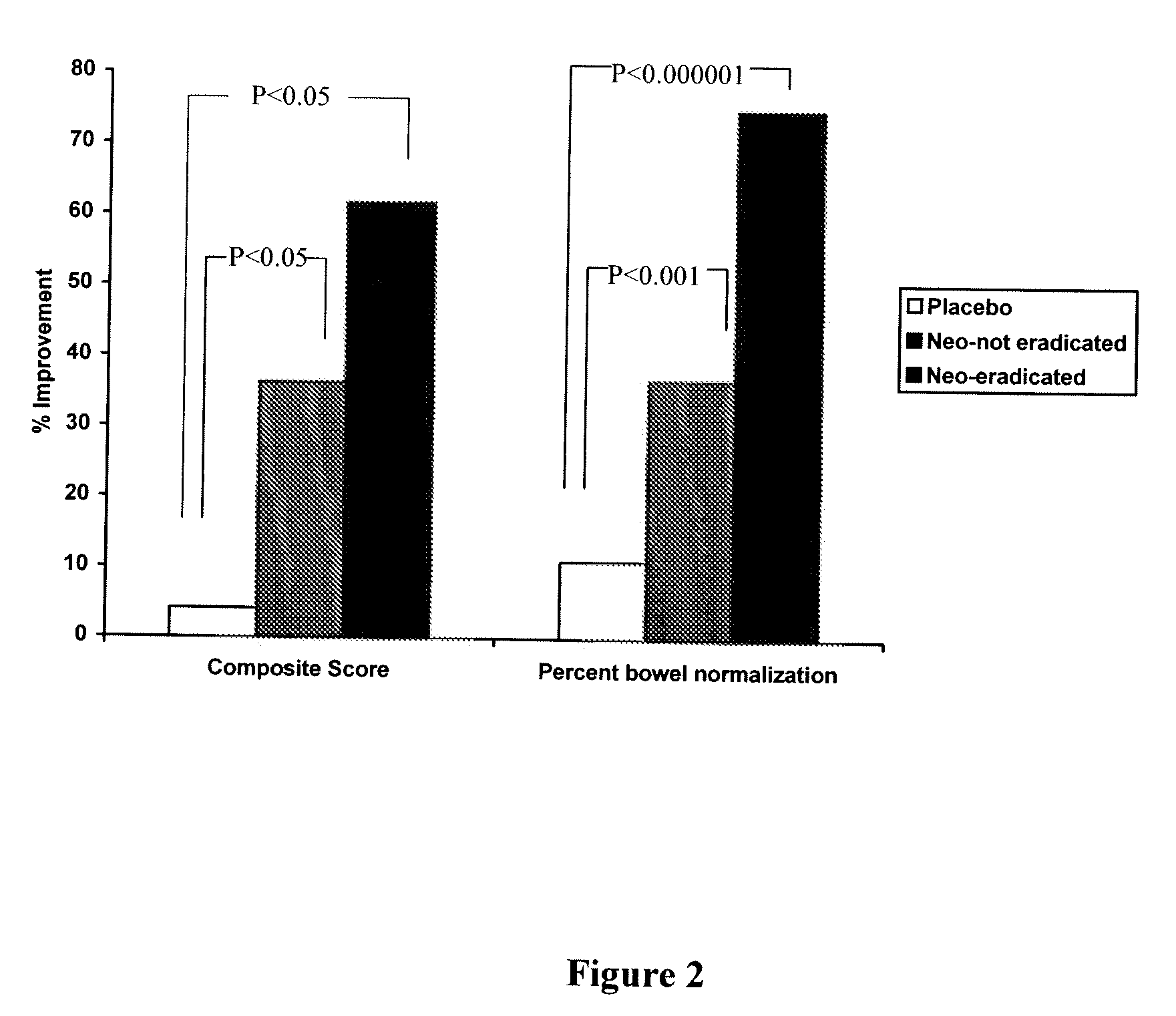

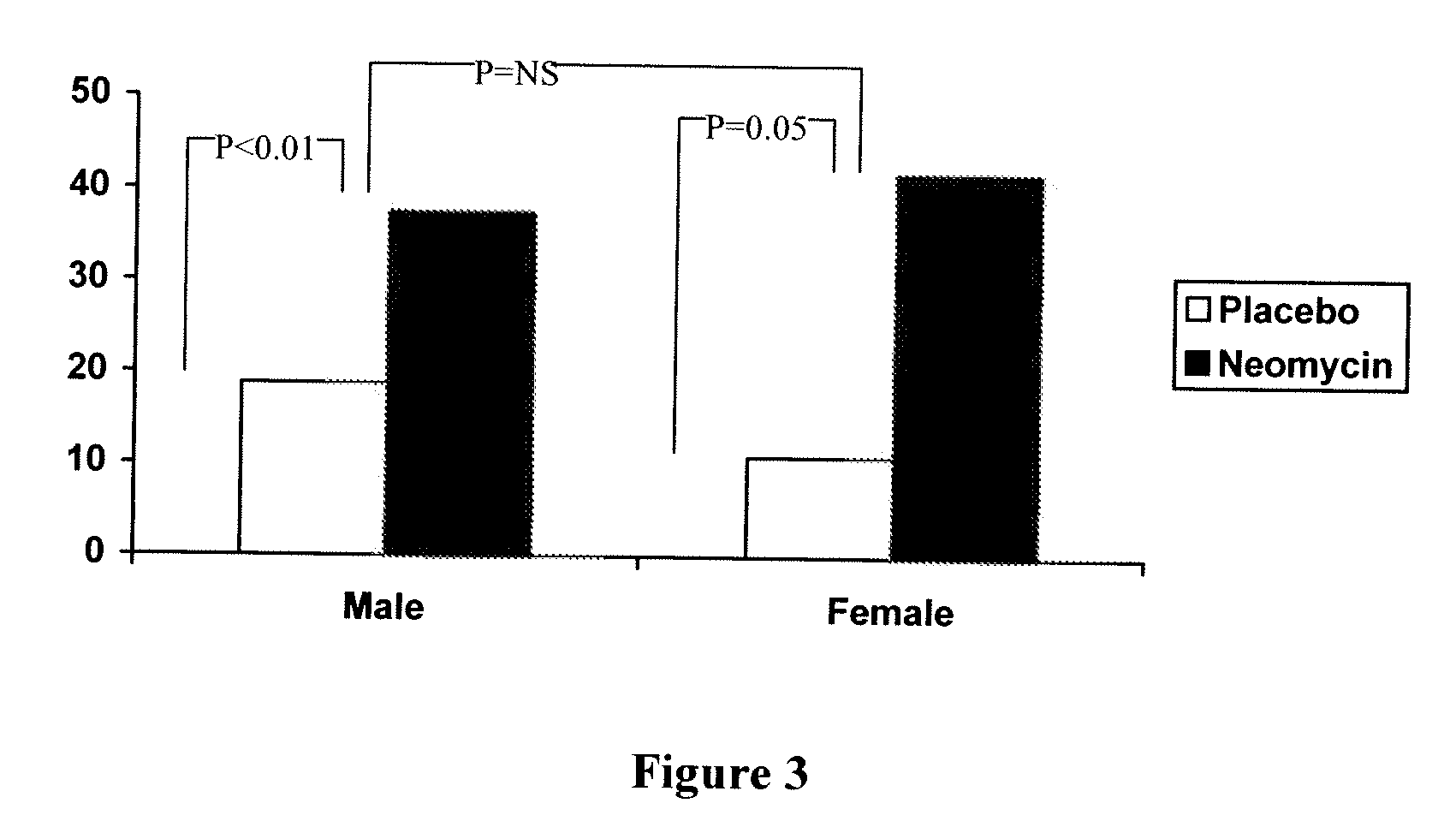

Method of using a probiotic agent for the treatment of diarrhea

ActiveUS20080138320A1Reduce probabilityIncreasing the rate of gastrointestinal transitBiocideHydrocarbon active ingredientsMethanogenesisGastrointestinal transit

Disclosed is a method of manipulating the rate of gastrointestinal transit in a mammalian subject. Also disclosed is the use, in the manufacture of a medicament for the treatment of constipation, of a selective inhibitor of methanogensis, a methanogen-displacing probiotic agent, or a prebiotic agent that inhibits the growth of methanogenic bacteria or promotes the growth of competing non-methanogenic intestinal flora. Alternatively, in accordance with the invention, is disclosed the use in the manufacture of a medicament for the treatment of diarrhea, of methane or a methane precursor, a methanogenic or other methane-enhancing probiotic agent, or a methanogenesis-enhancing prebiotic agent.

Owner:CEDARS SINAI MEDICAL CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com