Low-energy-consumption lignite drying process for recovering lignite moisture and drying equipment

A technology of drying equipment and drying process, which is applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc. It can solve the problems of ineffective recovery of water, ineffective use of secondary steam, and low energy utilization efficiency in the drying process. Achieve the effect of high usable value, reduce the consumption of steam for external use, and improve the efficiency of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

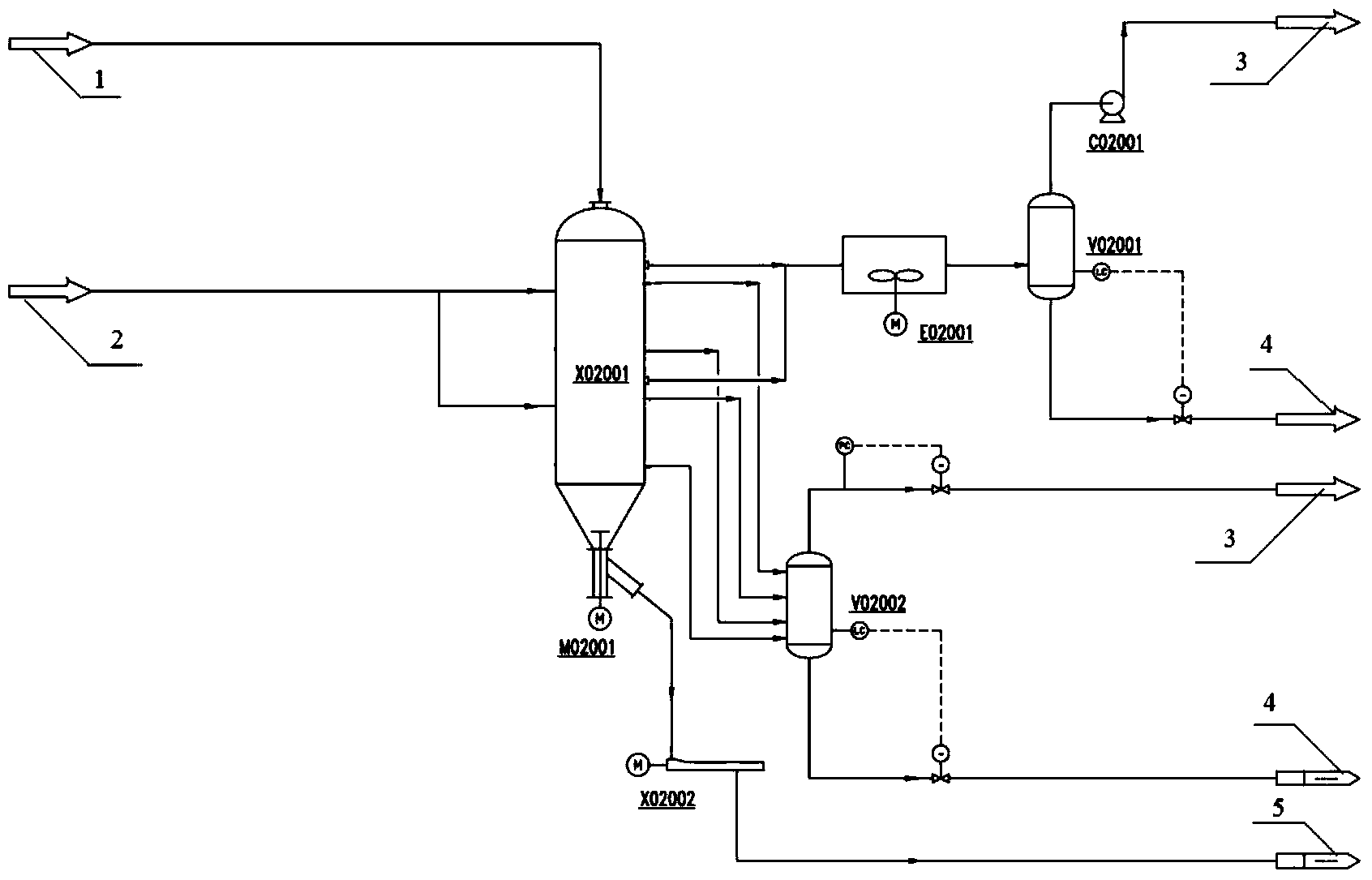

[0037] This embodiment is a lignite pre-drying process for recovering lignite drying moisture. The lignite processing capacity is 5 million tons / year, and its technological process is shown in figure 1 .

[0038] The lignite pre-drying process for recovering dry moisture mainly includes: lignite pretreatment, lignite moving bed pre-drying, secondary steam condensate recovery, and heating steam condensate recovery.

[0039] 1. Lignite pretreatment system: the lignite with rich water content of 15wt% ~ 55wt% and coal particle size ≤ 300mm from the boundary area enters the raw coal silo, and is sent to the double-roller crushing through the unloading belt conveyor and the feeding belt conveyor Machine, the double-roll crusher with high-alloy material crushes the material to the size of the gap between the two rolls. The crushed coal particles are less than or equal to 30mm, and the crusher is sent to the silo through the feeding belt conveyor, and the coal particles from the si...

Embodiment 2

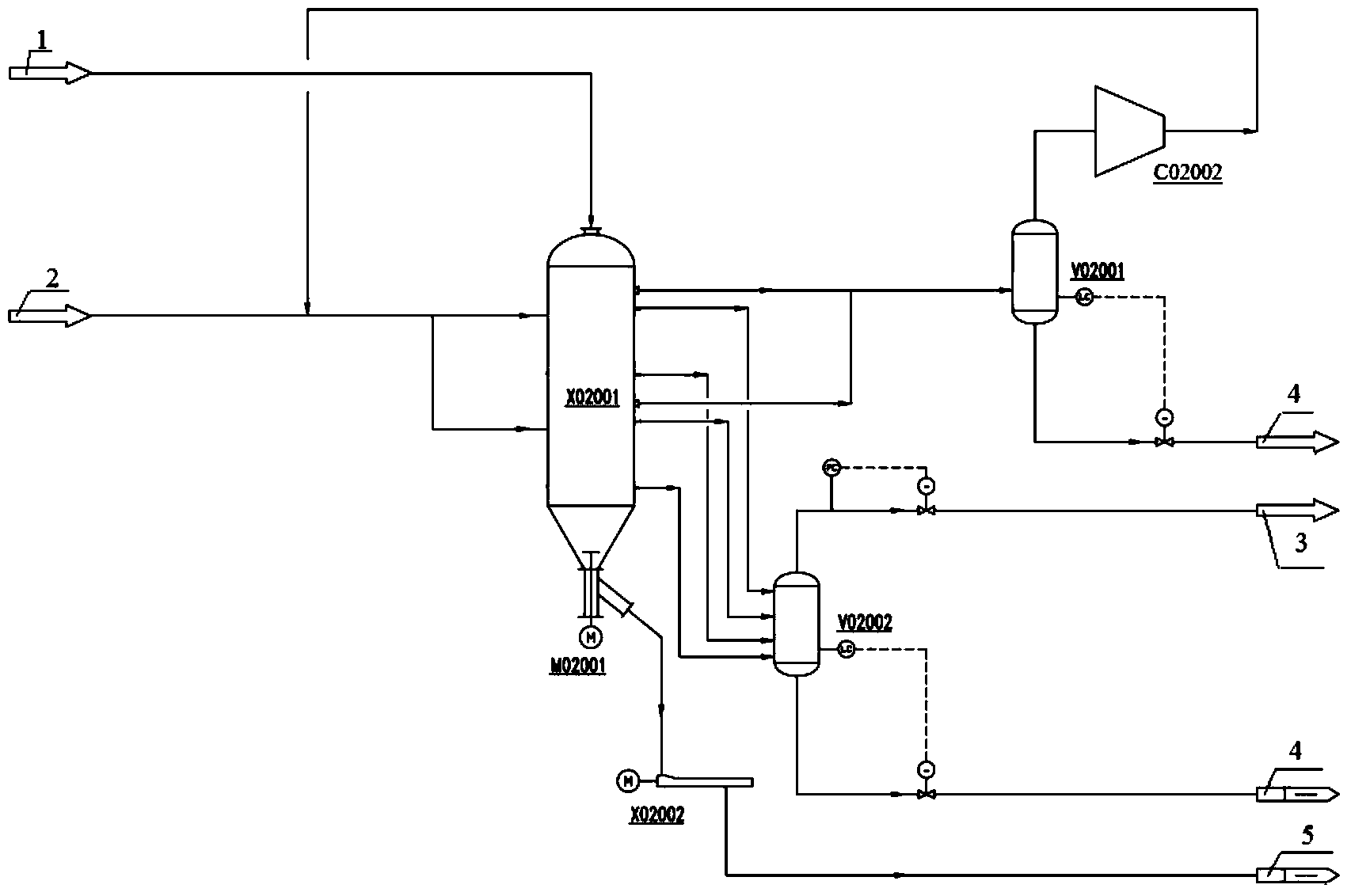

[0053] This embodiment is a lignite pre-drying process using secondary steam boosting as a drying heat source. The lignite processing capacity is 5 million tons / year, and its technological process is shown in figure 2 .

[0054] The lignite pre-drying process with secondary steam boosting as the drying heat source mainly includes: lignite pretreatment, moving bed drying system pre-drying, secondary steam boosting and reuse as heating steam, and recovery of heating steam condensate.

[0055] 1. Lignite pretreatment system: the lignite with rich water content of 15wt% ~ 55wt% and coal particle size ≤ 300mm from the boundary area enters the raw coal silo, and is sent to the double-roller crushing through the unloading belt conveyor and the feeding belt conveyor Machine, the double-roll crusher with high-alloy material crushes the material to the size of the gap between the two rolls. The crushed coal particles are less than or equal to 30mm, and the crusher is sent to the silo...

Embodiment 3

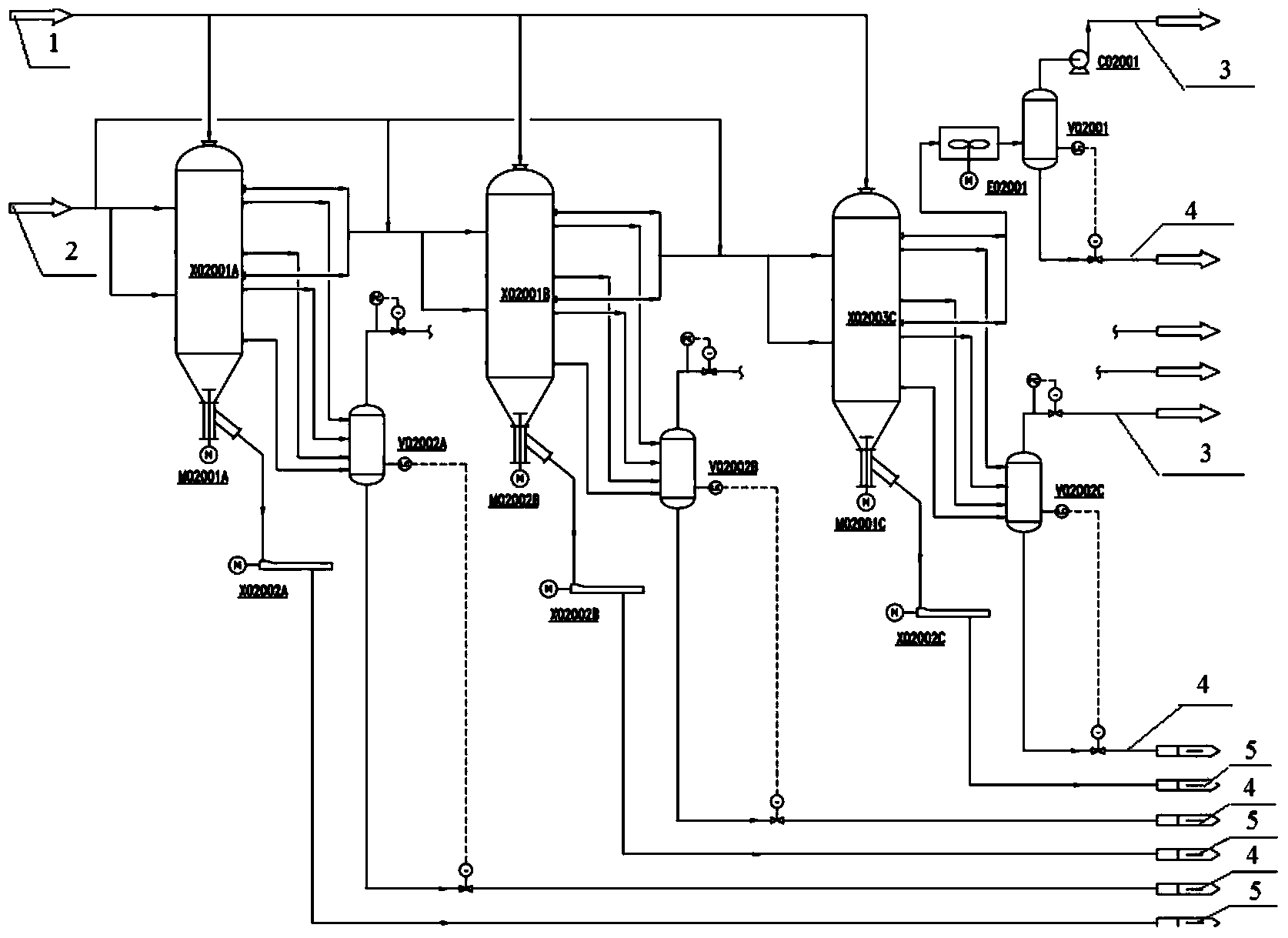

[0069] In this embodiment, a three-stage non-isobaric lignite pre-drying process is adopted. The lignite processing capacity is 5 million tons / year, and its technological process is shown in image 3 .

[0070] The lignite pre-drying process of the three-stage non-isobaric drying heat source mainly includes: lignite pretreatment, lignite moving bed pre-drying, and steam condensate recovery.

[0071] 1. Lignite pretreatment system: the lignite with rich water content of 15wt% ~ 55wt% and coal particle size ≤ 300mm from the boundary area enters the raw coal silo, and is sent to the double-roller crushing through the unloading belt conveyor and the feeding belt conveyor Machine, the double-roll crusher with high-alloy material crushes the material to the size of the gap between the two rolls. The crushed coal particles are less than or equal to 30mm, and the crusher is sent to the silo through the feeding belt conveyor, and the coal particles from the silo enter the relaxation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com