Patents

Literature

961 results about "Coal particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processes for Preparing a Catalyzed Coal Particulate

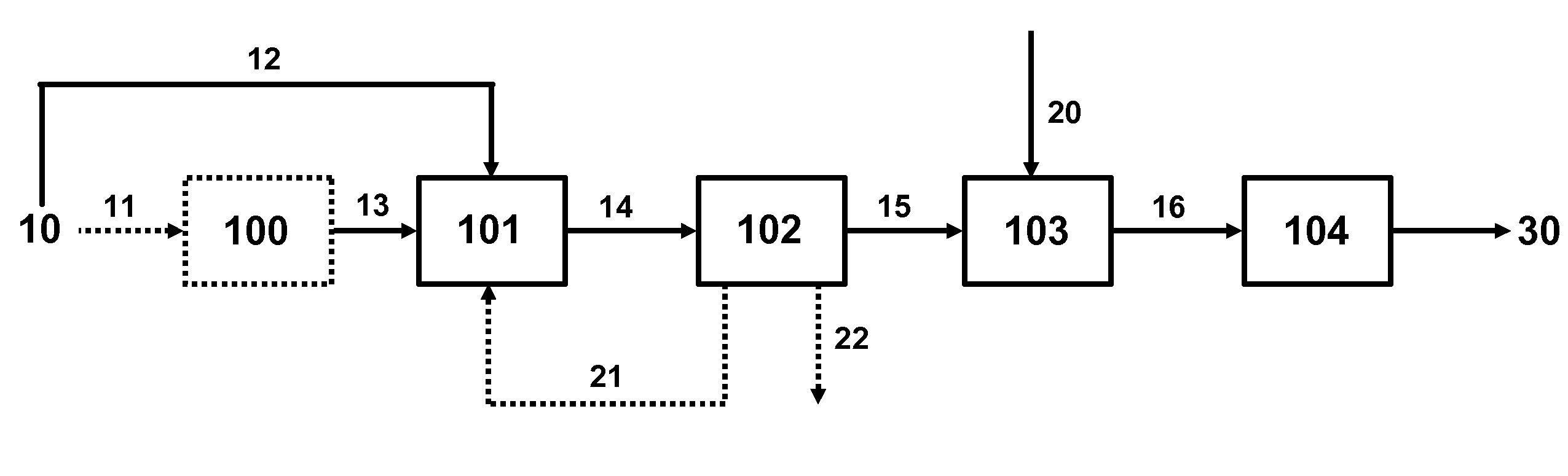

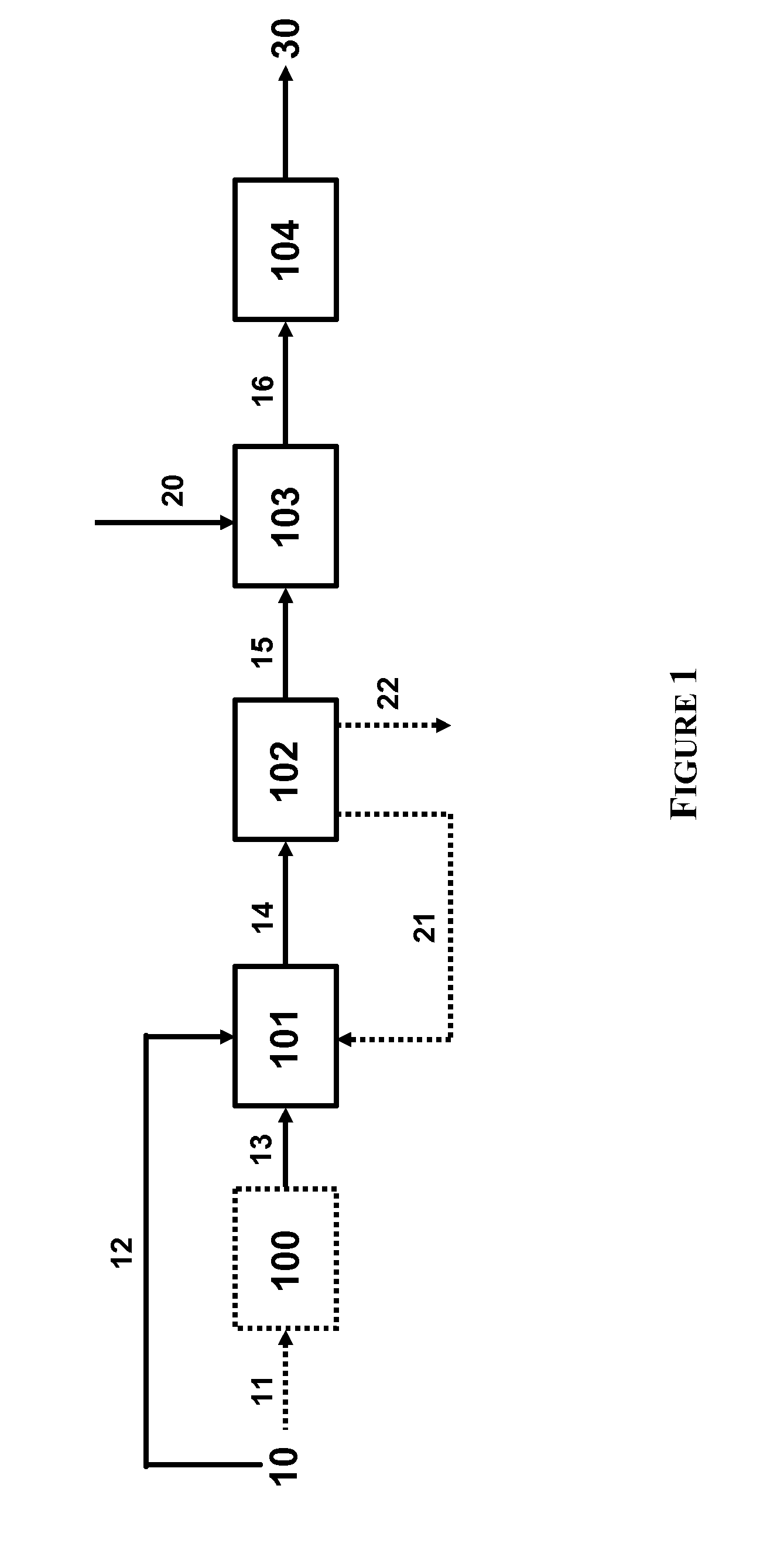

Processes are provided for preparing a substantially free-flowing alkali metal gasification catalyst-loaded coal particulate suitable for use as a feedstock for the production of gaseous products, and in particular methane, via the catalytic gasification of the catalyst-loaded coal particulate in the presence of steam.

Owner:SURE CHAMPION INVESTMENT LTD

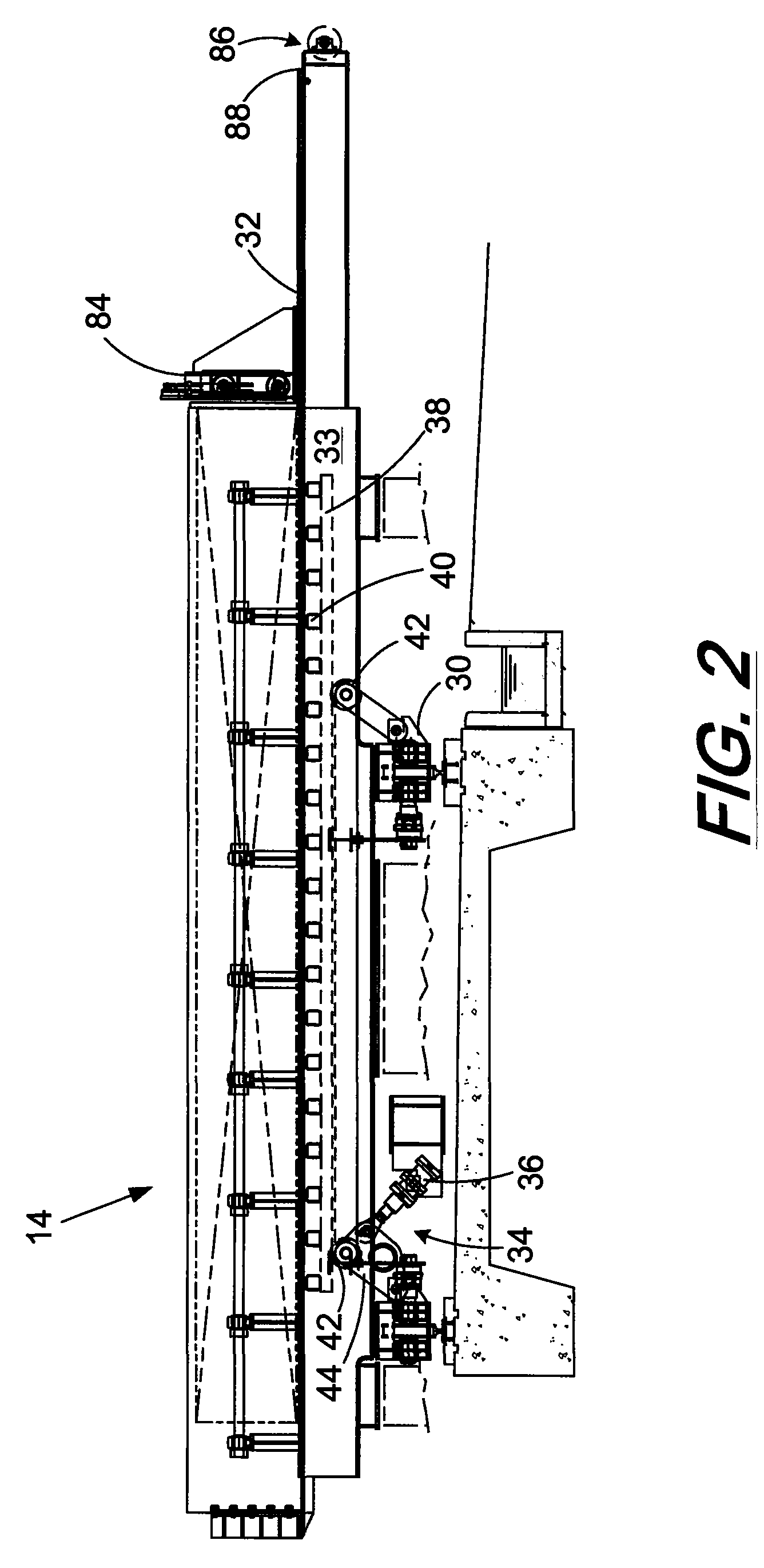

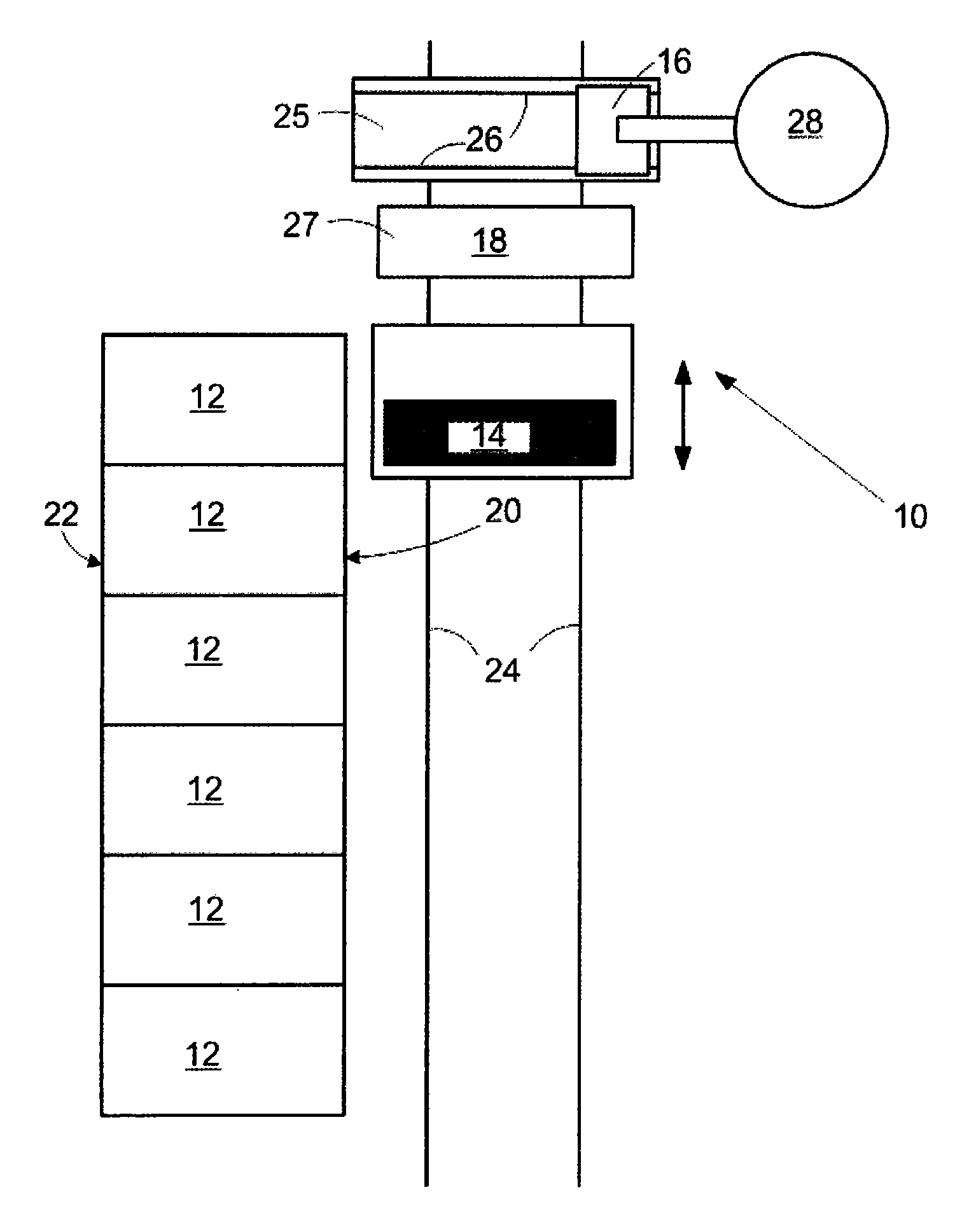

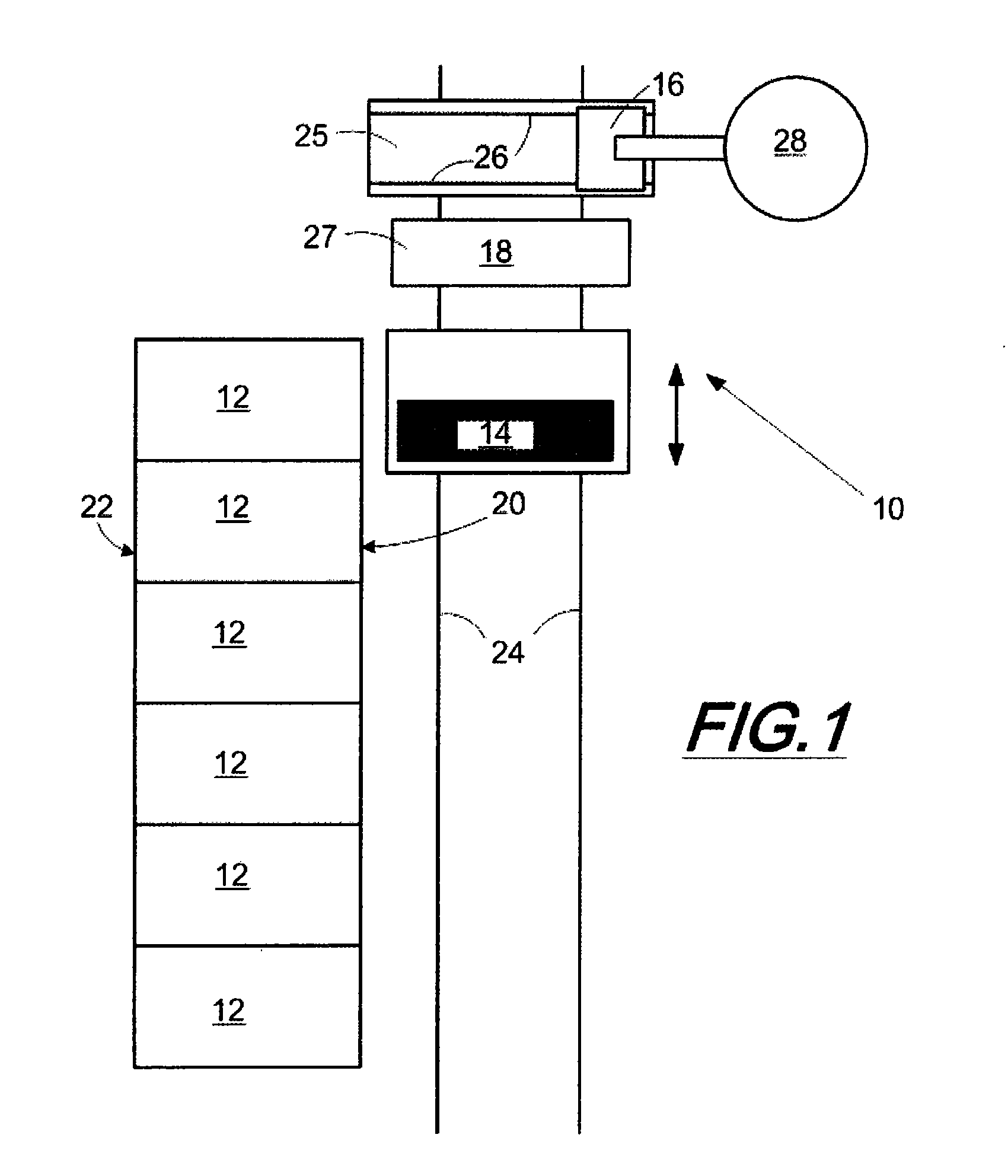

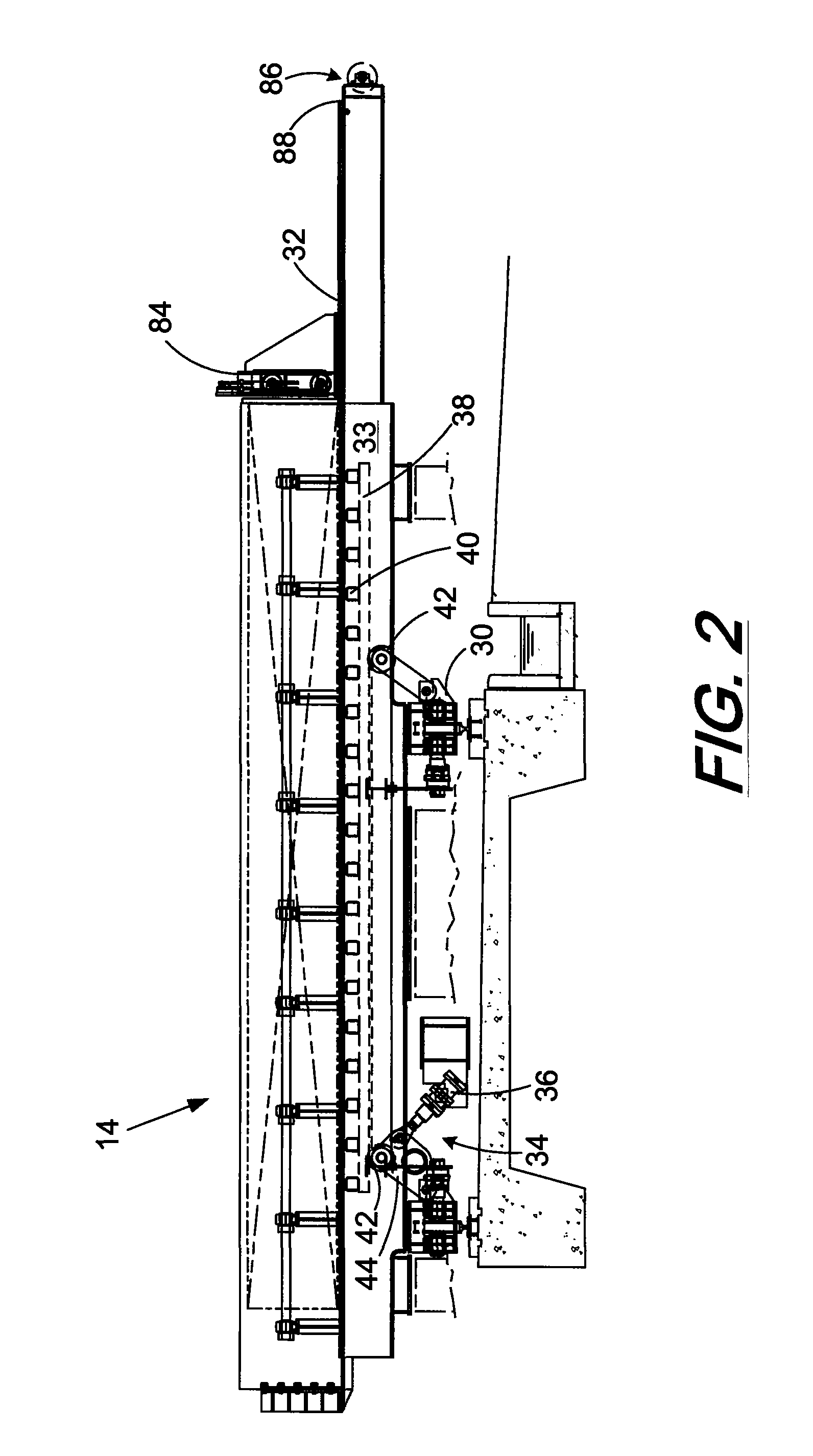

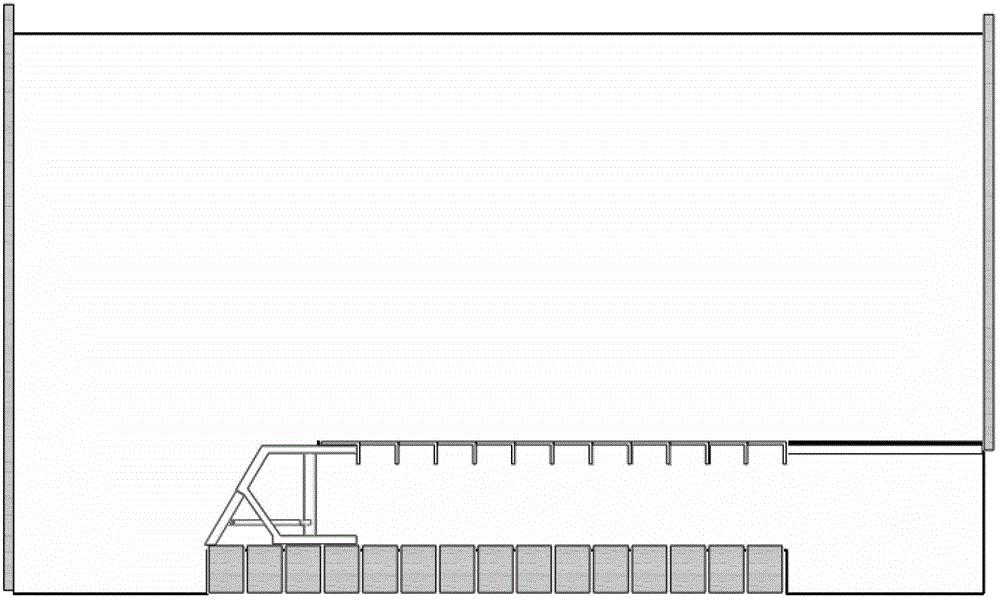

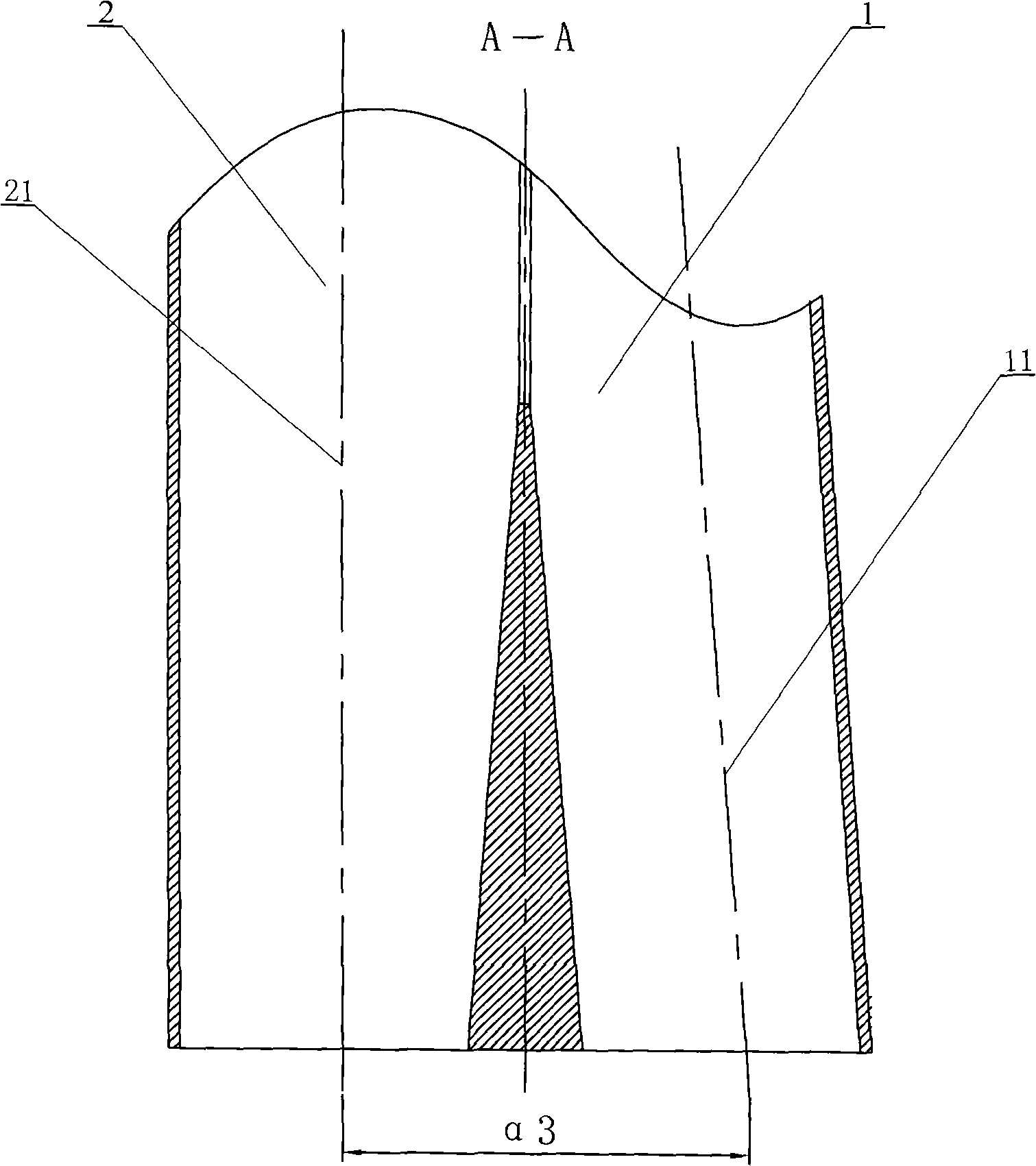

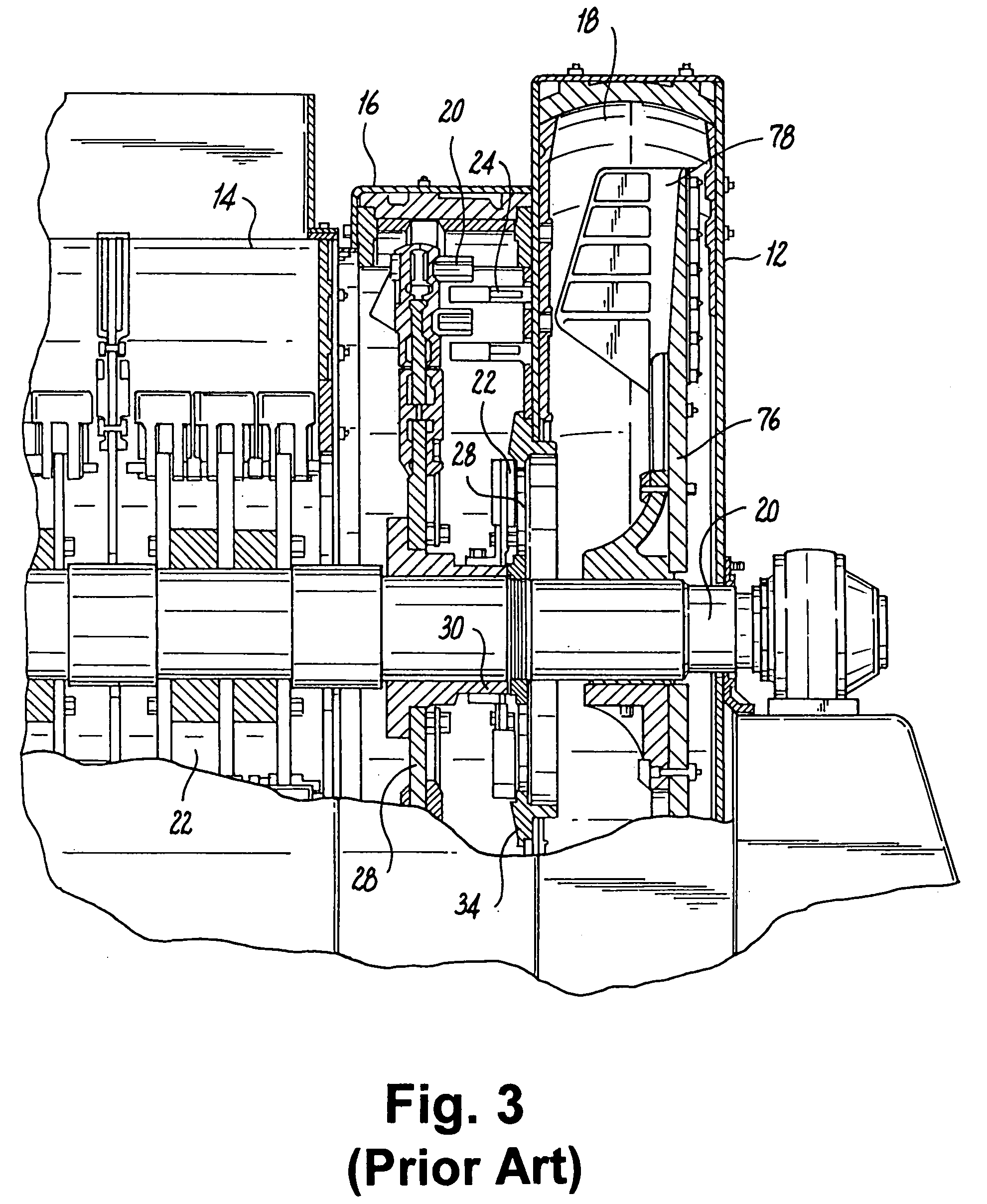

Method and apparatus for compacting coal for a coal coking process

InactiveUS7497930B2Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsEngineeringCoke oven

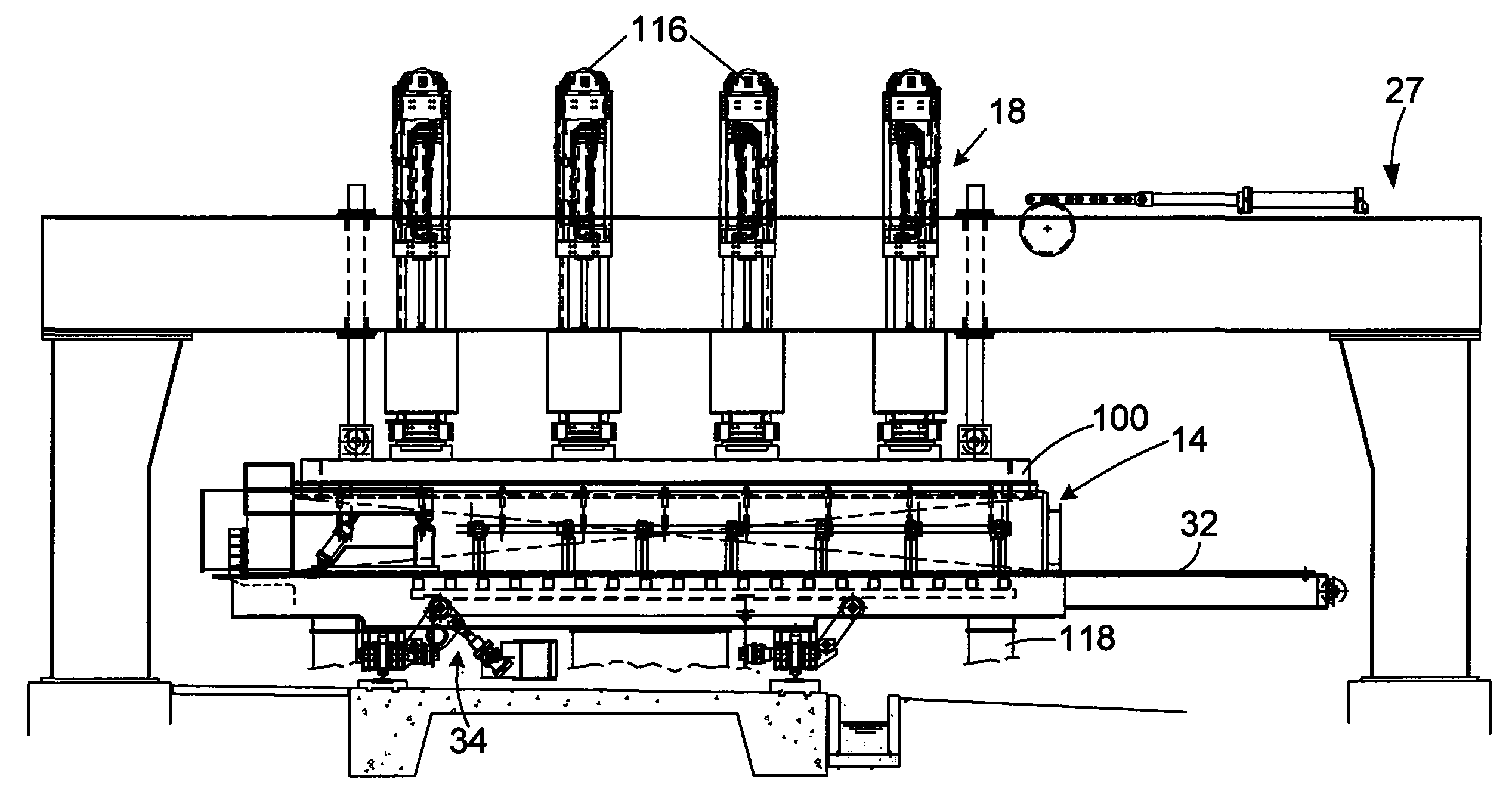

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

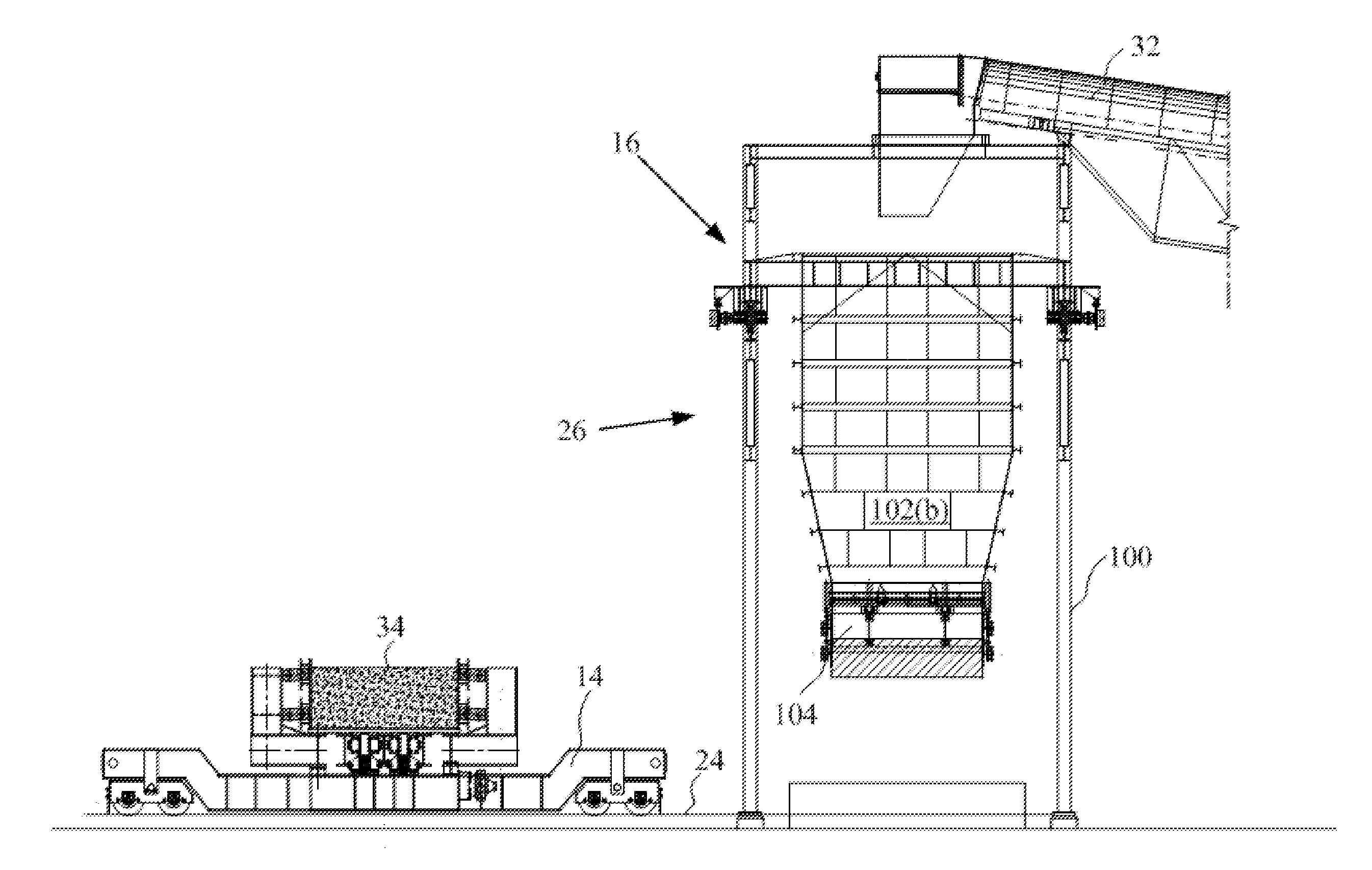

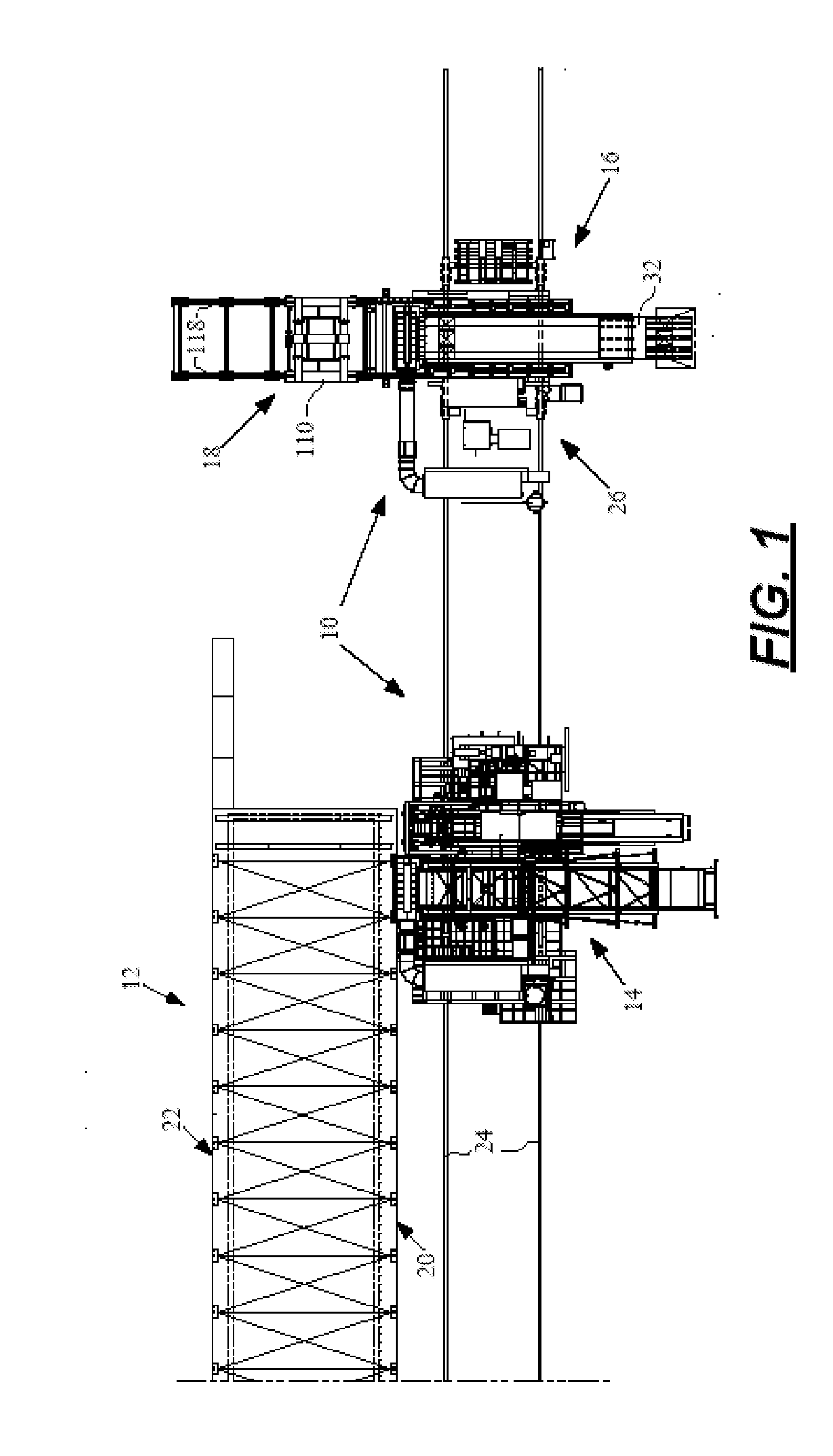

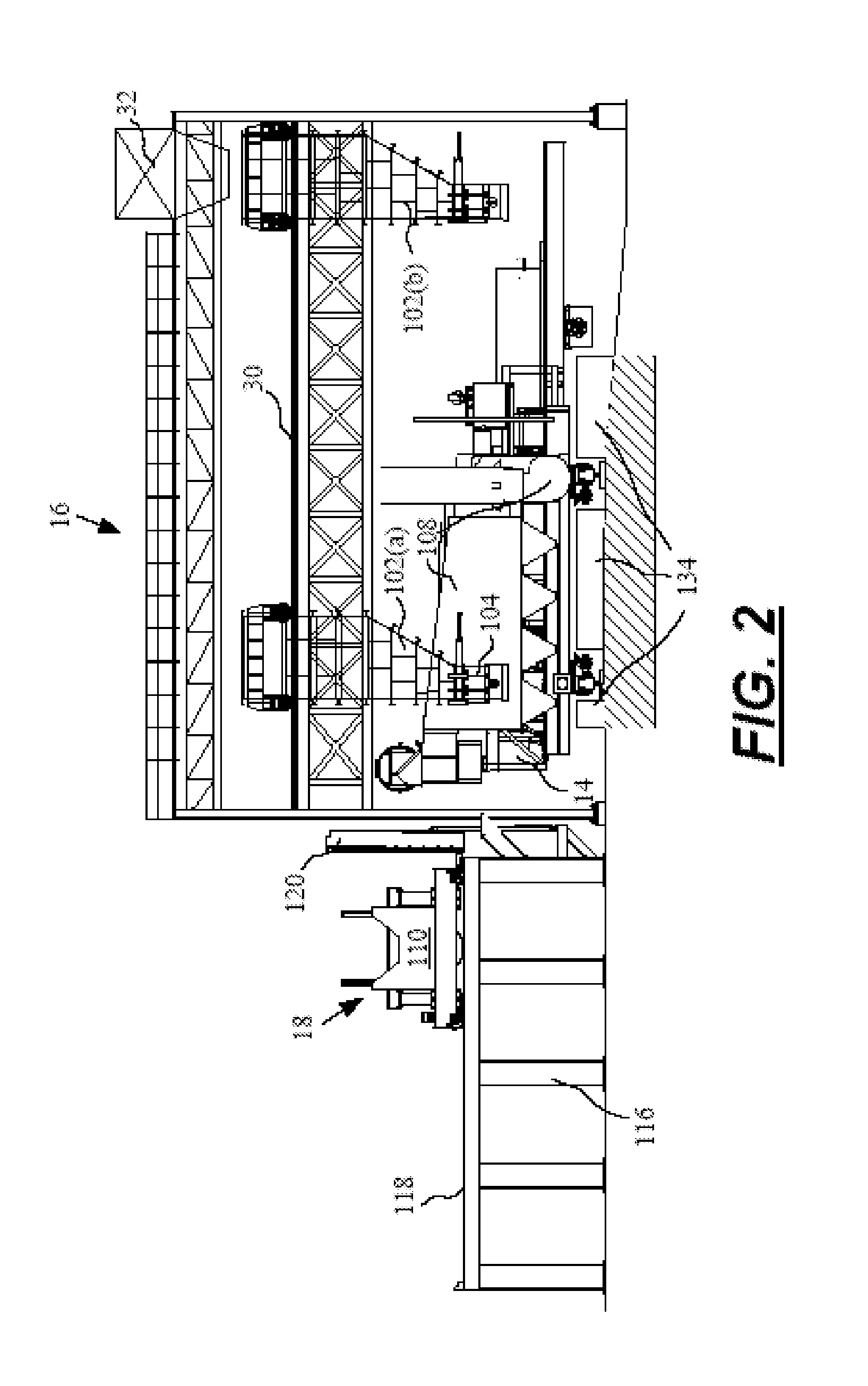

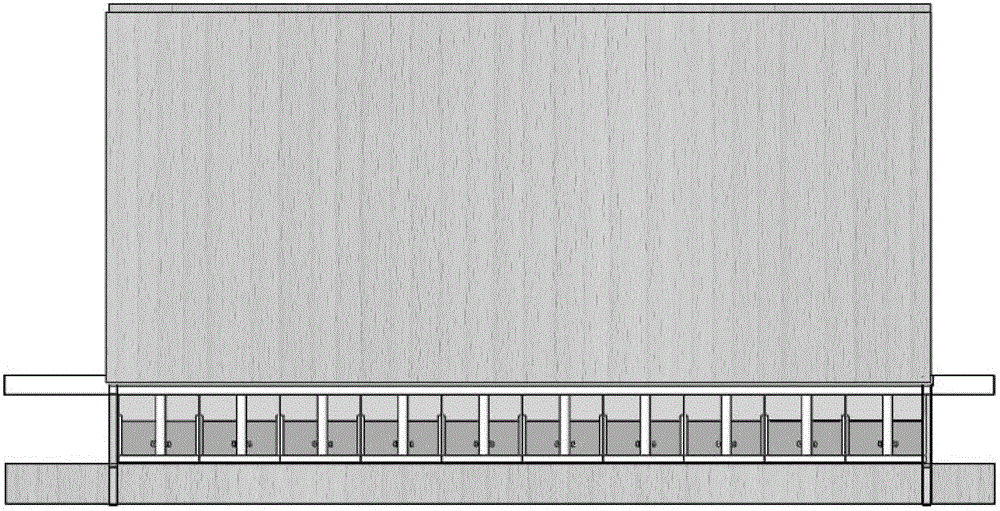

Method and apparatus for compacting coal for a coal coking process

ActiveUS20120030998A1High bulk densityShort timeCharging-discharging device combinationsSolid fuelsDiameter ratioEngineering

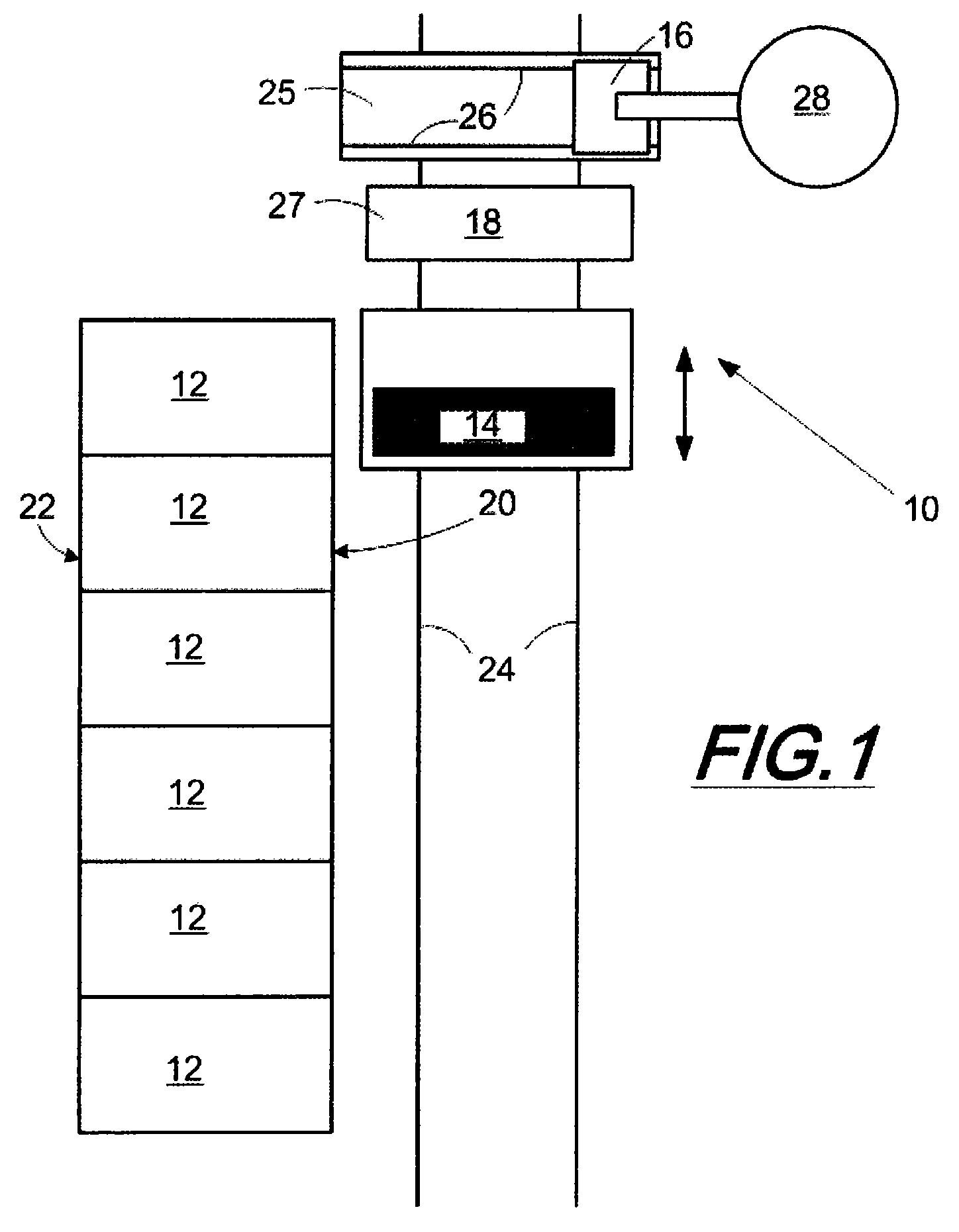

Relatively high speed methods for increasing the bulk density of coal particles without impacting the coal particles and an apparatus for compacting coal for making metallurgical coke. The method includes depositing coal particles onto a charging plate external to a coking oven. The charging plate has side walls, and at least one movable end wall to provide an elongate bed of dry, uncompacted coal having an upper surface on the charging plate. The uncompacted coal is compacted by passing a vibratory cylindrical compactor along a length of the uncompacted coal for a number of passes sufficient to decrease a thickness of the bed of coal to less than about 80 percent of an original thickness of the uncompacted coal. The vibratory cylindrical compactor has a length to diameter ratio ranging from about 1.4:1 to about 2:1.

Owner:SUNCOKE TECH & DEV LLC

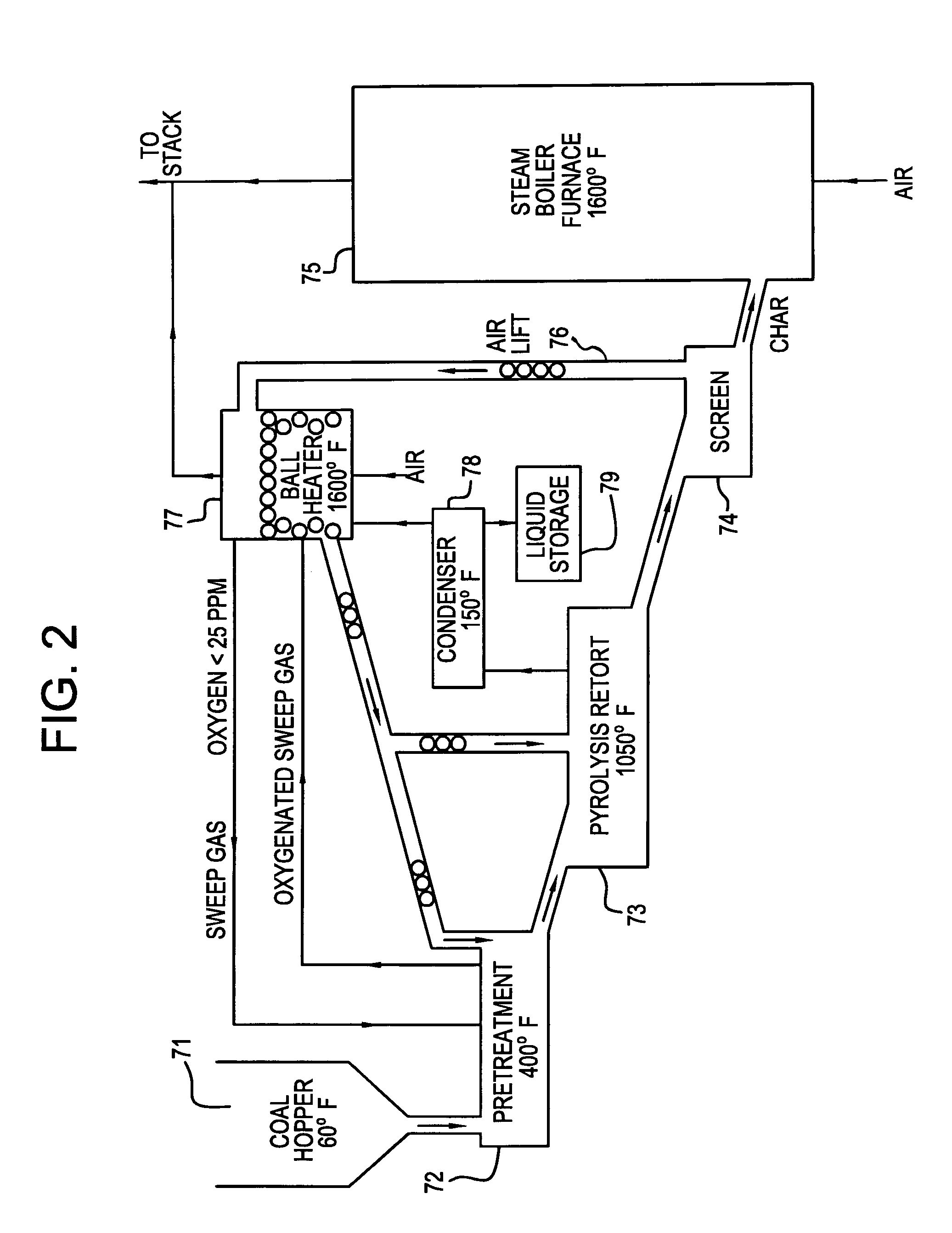

Process for treating agglomerating coal by removing volatile components

InactiveUS20110011720A1Gain weightSolid waste disposalDirect heating destructive distillationOxygen contentCoal particle

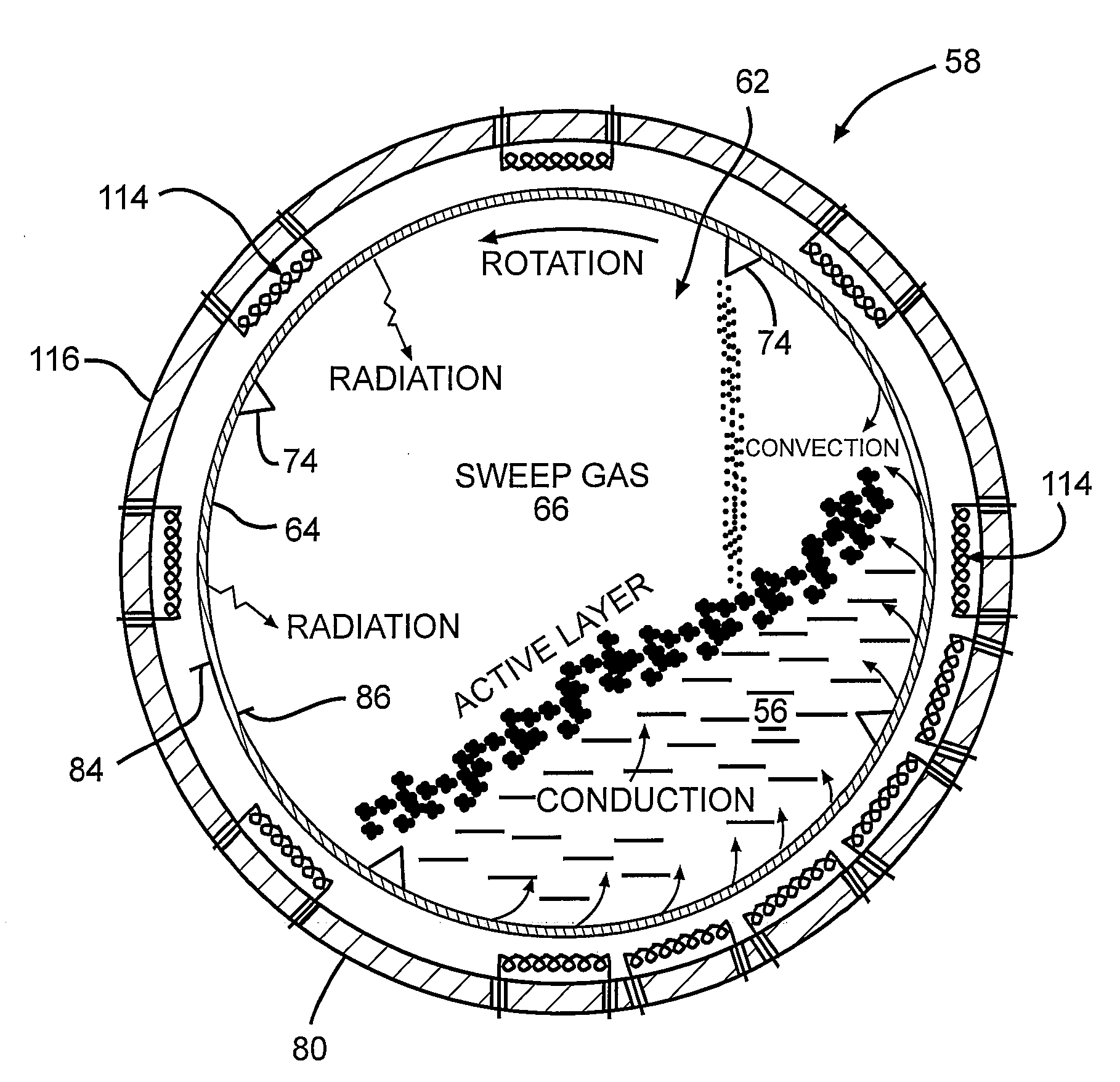

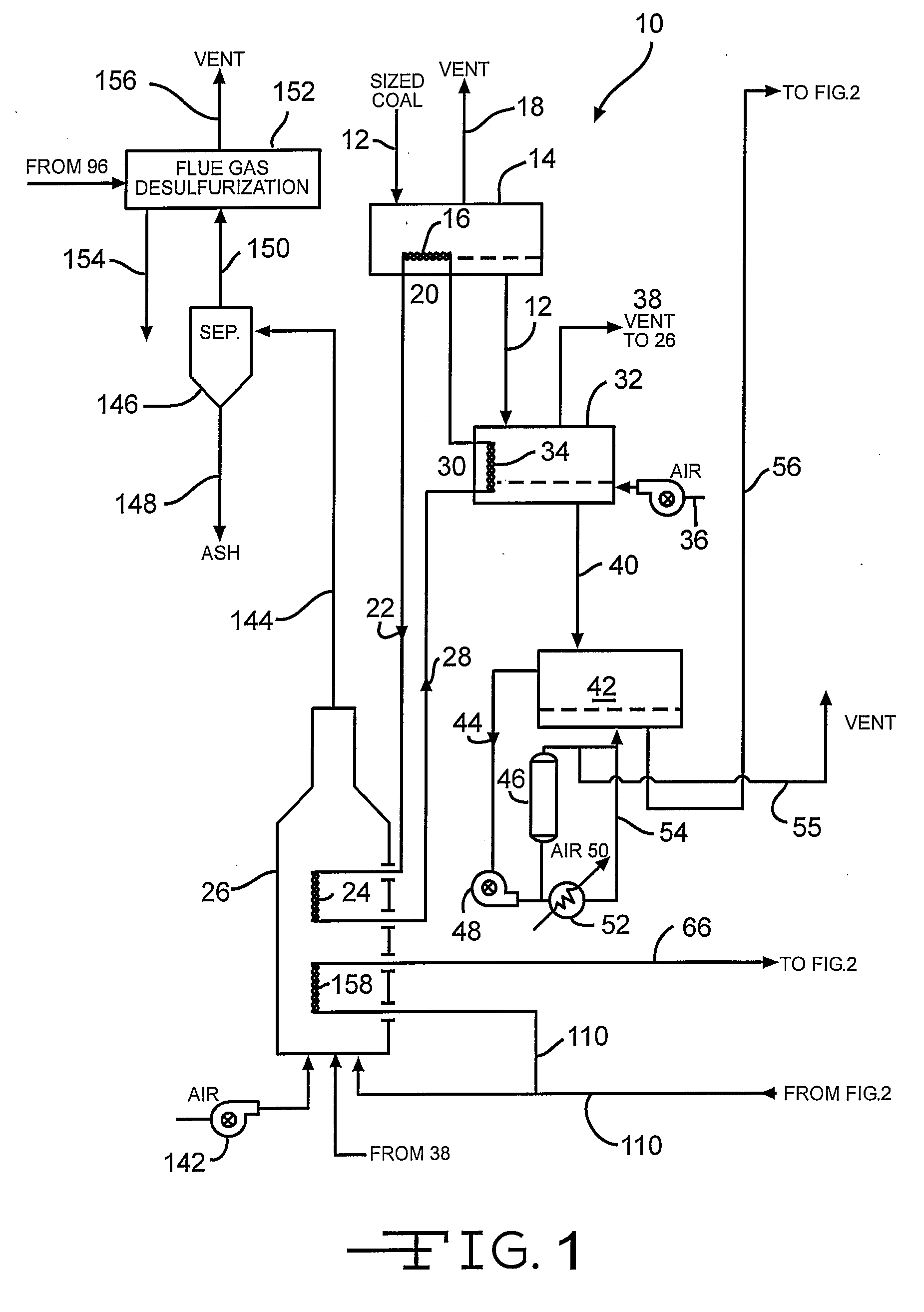

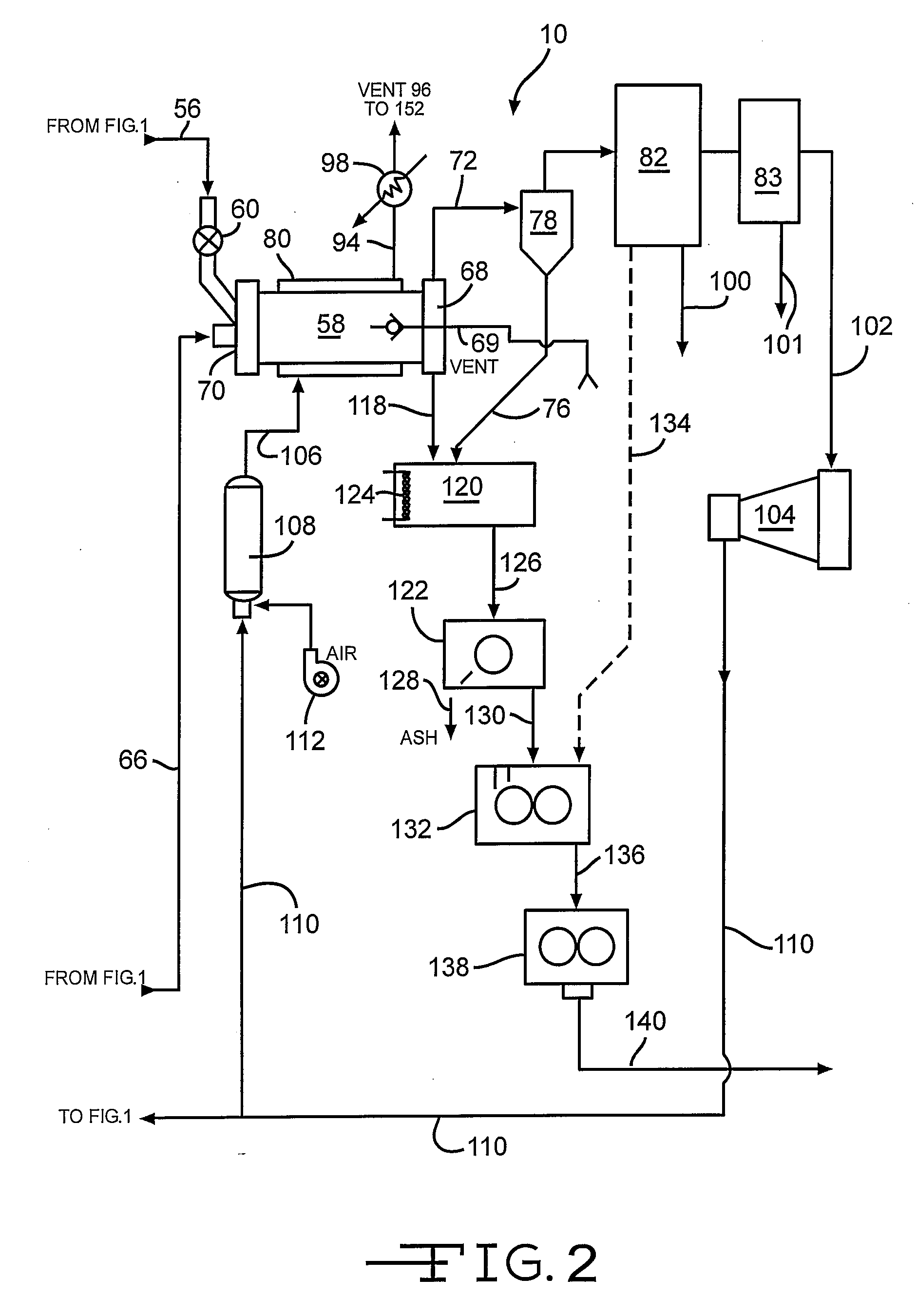

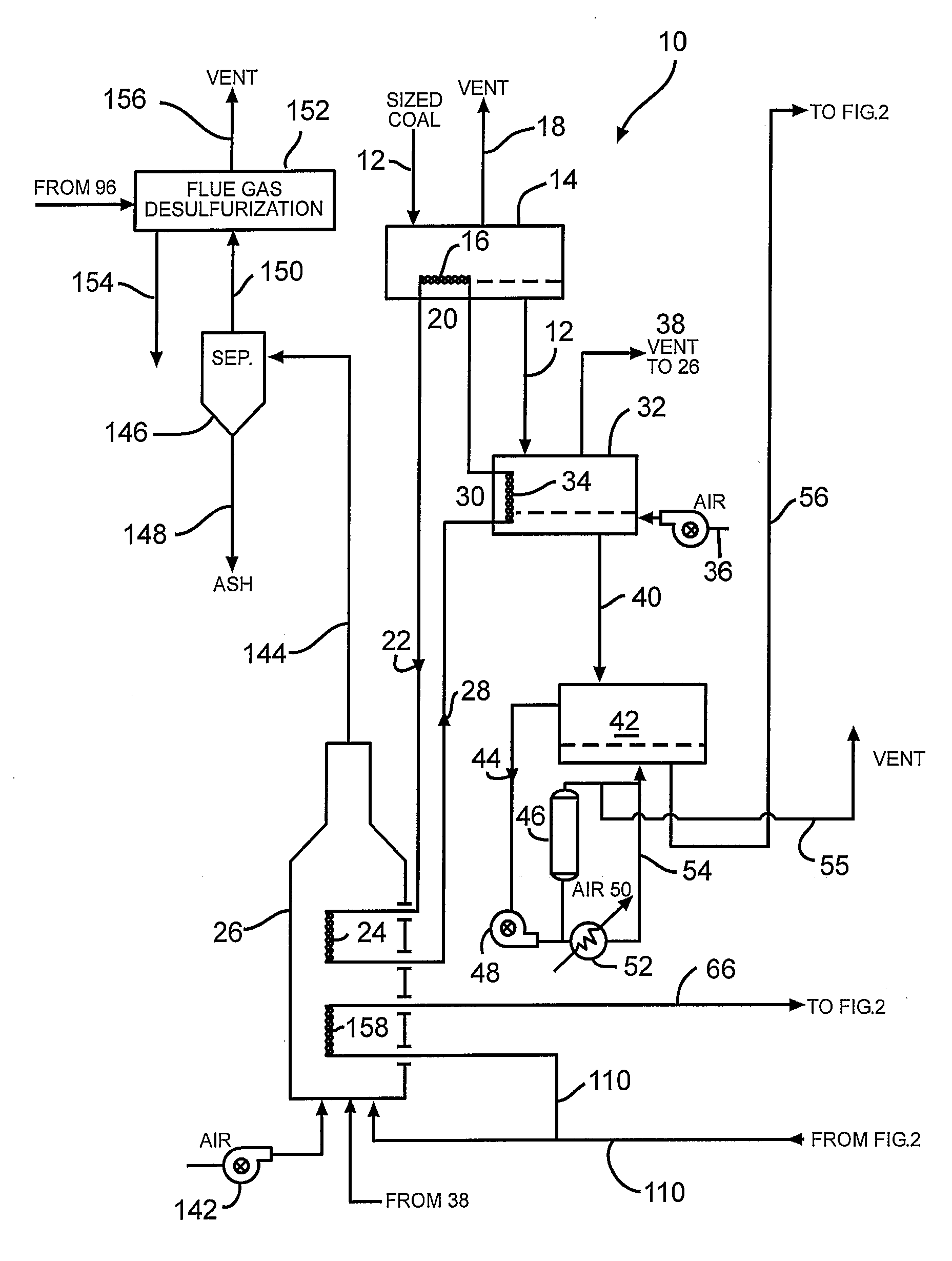

A process for treating agglomerating coal includes providing dried, pulverized, agglomerating coal, and treating the coal in a vessel with a gas stream having an oxygen content sufficient to form at least some oxides on surface of coal particles, wherein the oxides are sufficient to convert coal into substantially non-agglomerating coal. The treated coal is transferred into a pyrolyzing chamber and passed into contact with an oxygen deficient sweep gas, the sweep gas being at a higher temperature than the temperature of the coal so that heat is supplied to the coal. The process further includes providing additional heat to coal indirectly by heating the chamber, wherein the heating of coal by the sweep gas and by the indirect heating from the chamber causes condensable volatile components to be released into the sweep gas. The sweep gas is removed from the chamber and treated to remove condensable components of coal.

Owner:C2O TECH

Process for treating bituminous coal by removing volatile components

InactiveUS20110011719A1Reduce ashReduce total sulfurCombustible gas coke oven heatingDirect heating destructive distillationSulfurProcess engineering

A process for treating bituminous coal includes providing dried, pulverized coal, and treating the pulverized coal in a vessel with a gas stream having an oxygen content sufficient to form oxides on surface of coal particles. The treated coal is transferred into a pyrolyzing chamber and passed into contact with an oxygen deficient sweep gas, the sweep gas being at a higher temperature than the temperature of the coal so that heat is supplied to the coal. The process further includes providing additional heat to the coal indirectly by heating the chamber, wherein the heating of coal by the sweep gas and by the indirect heating from the chamber causes condensable volatile components to be released into the sweep gas. Some of the oxides are converted into paramagnetic mineral components, which are removed from coal to form a coal char having reduced ash and sulfur.

Owner:C2O TECH

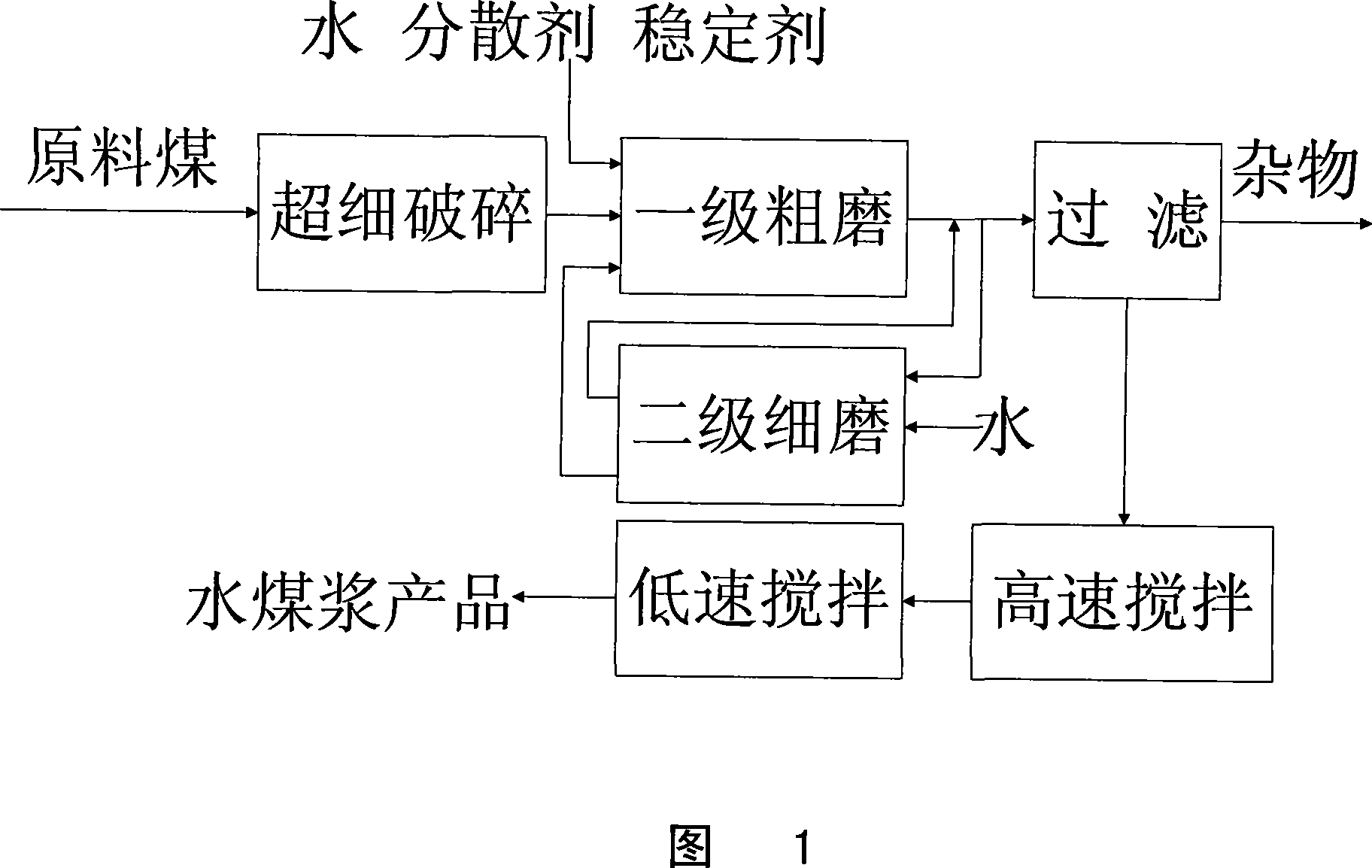

Method for preparing high concentration water-coal-slurry by low-rank coal

ActiveCN101173765AImprove particle size distributionReduce preparation energy consumptionLump/pulverulent fuel preparationHigh concentrationCoal water

The invention relates to a method for preparing high-concentration coal-water slurry by using low-rank coal. The steps include: 1) ultrafine crushing of low-rank coal; 2; 3) wet coarse grinding of the mixture; 4) ① mix 10% to 30% of the total amount of coal slurry after coarse grinding with water in a mass ratio of 5:1 to 2, and then carry out Wet fine grinding; ②The coal slurry after wet coarse grinding other than wet fine grinding is directly sent to the filter device; 5) The coal slurry after step 4) ① fine grinding is processed in the following way: ①Return all the coal slurry to step 3 ) for circulating coarse grinding; or ② return part of the coal slurry to step 3) for circulating coarse grinding, and send another part of finely ground coal slurry directly into the filter device; or ③ directly send all the coal slurry into the filter device; 6) The coal slurry sent to the filter device is filtered through a 18-20 mesh filter, and then stirred at a high speed in the stirring device, left standing, or stirred at a low speed to obtain a high-concentration coal-water slurry product.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Method and apparatus for compacting coal for a coal coking process

InactiveUS20070289861A1Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsCoke ovenEngineering

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

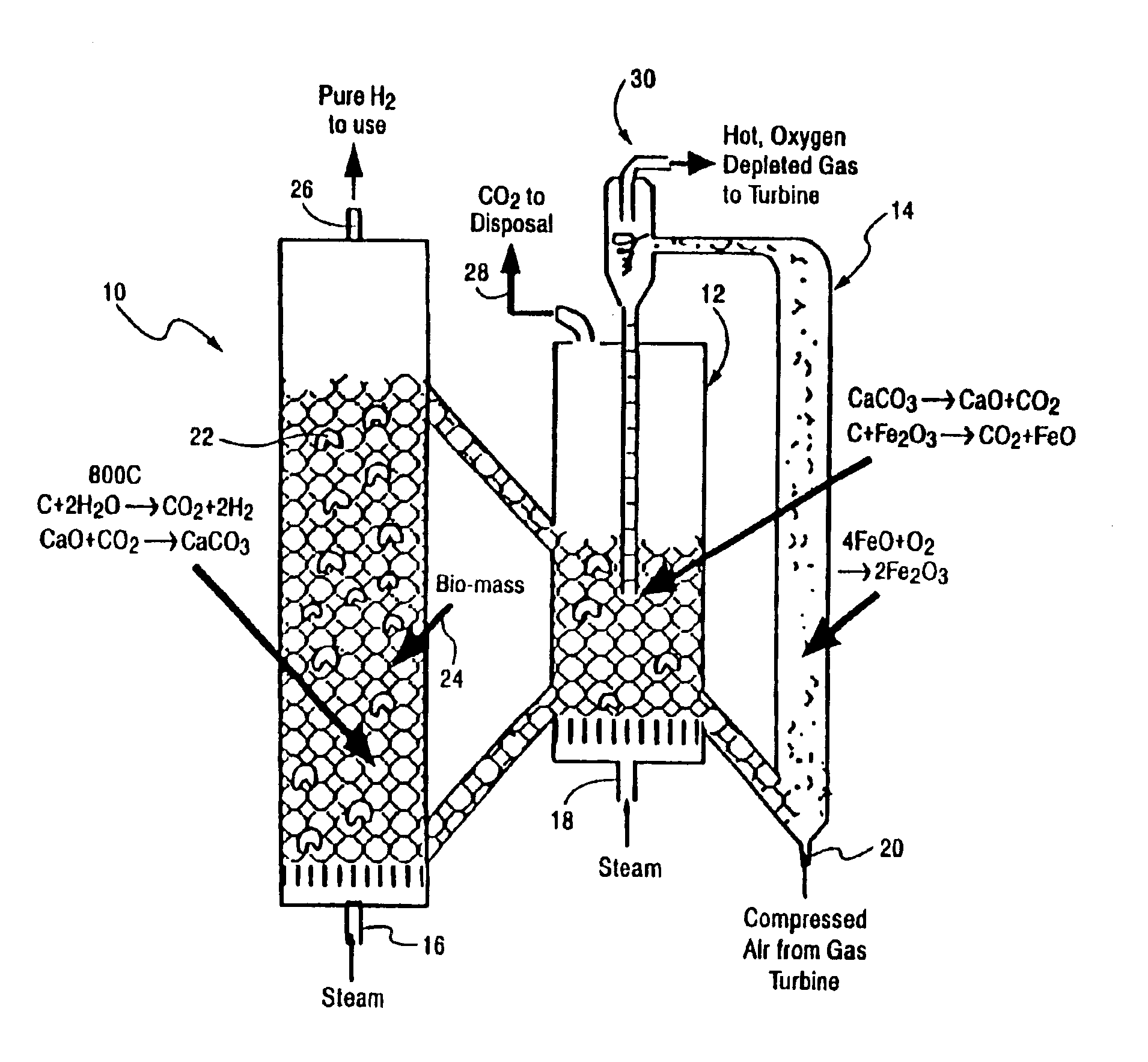

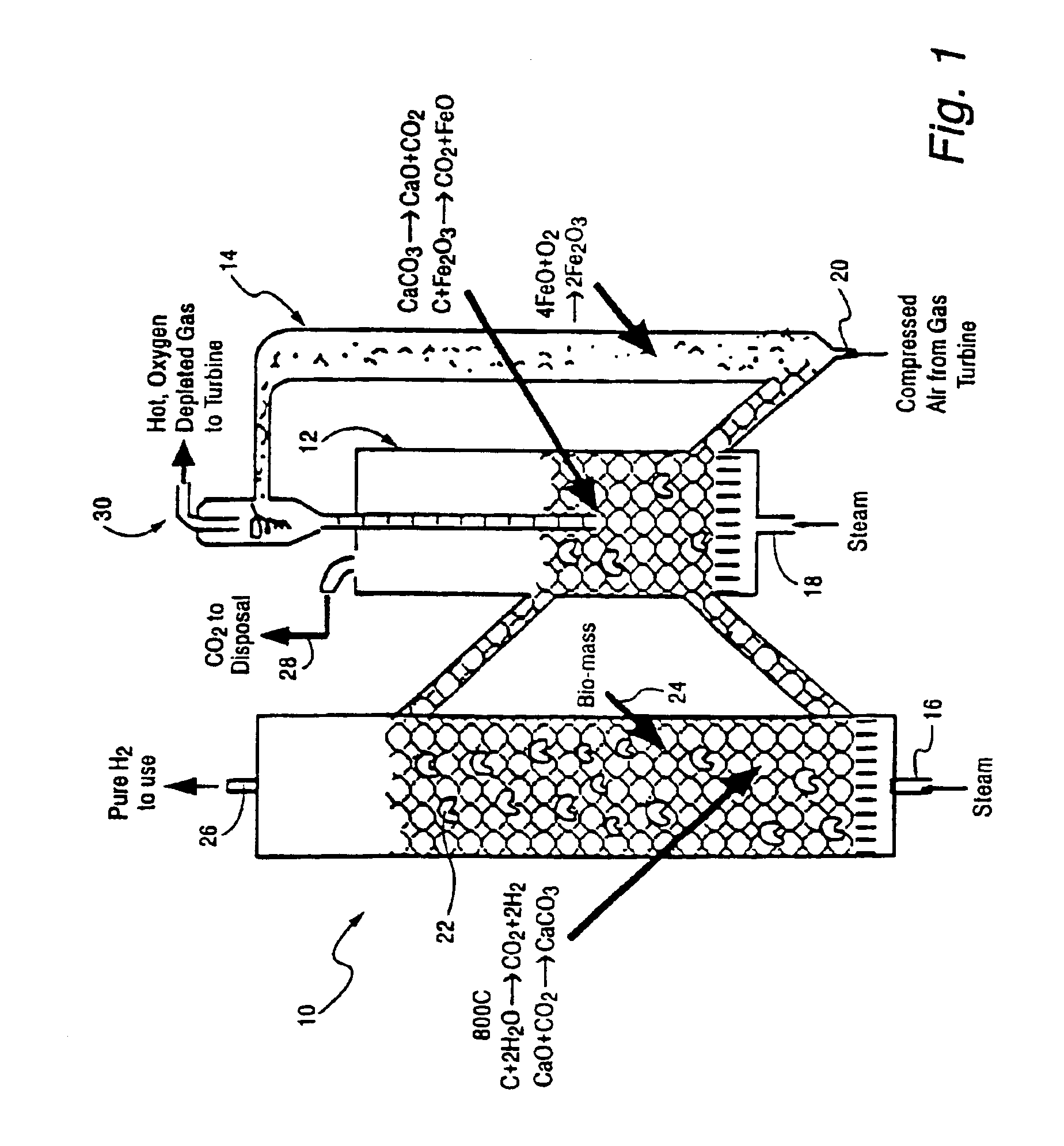

Apparatus for converting coal into fuel cell quality hydrogen and sequestration-ready carbon dioxide

An apparatus for burning coal to produce substantially pure hydrogen for use in fuel cells, together with “sequestration ready” carbon dioxide and a stream of oxygen depleted air for powering gas turbines. The apparatus includes two fluidized bed reactors and a third transfer line reactor. The first reactor is supplied with coal particles or “char” and fluidized with high temperature steam. The second reactor is fluidized with high temperature steam and the third reactor is fluidized by compressed air. Solids circulated among these three reactors include a mixture of materials containing coal, calcium compounds (present as CaO, CaCO3 and mixtures thereof) and iron compounds (present as FeO, Fe2O3 and mixtures thereof).

Owner:GENERAL ELECTRIC CO

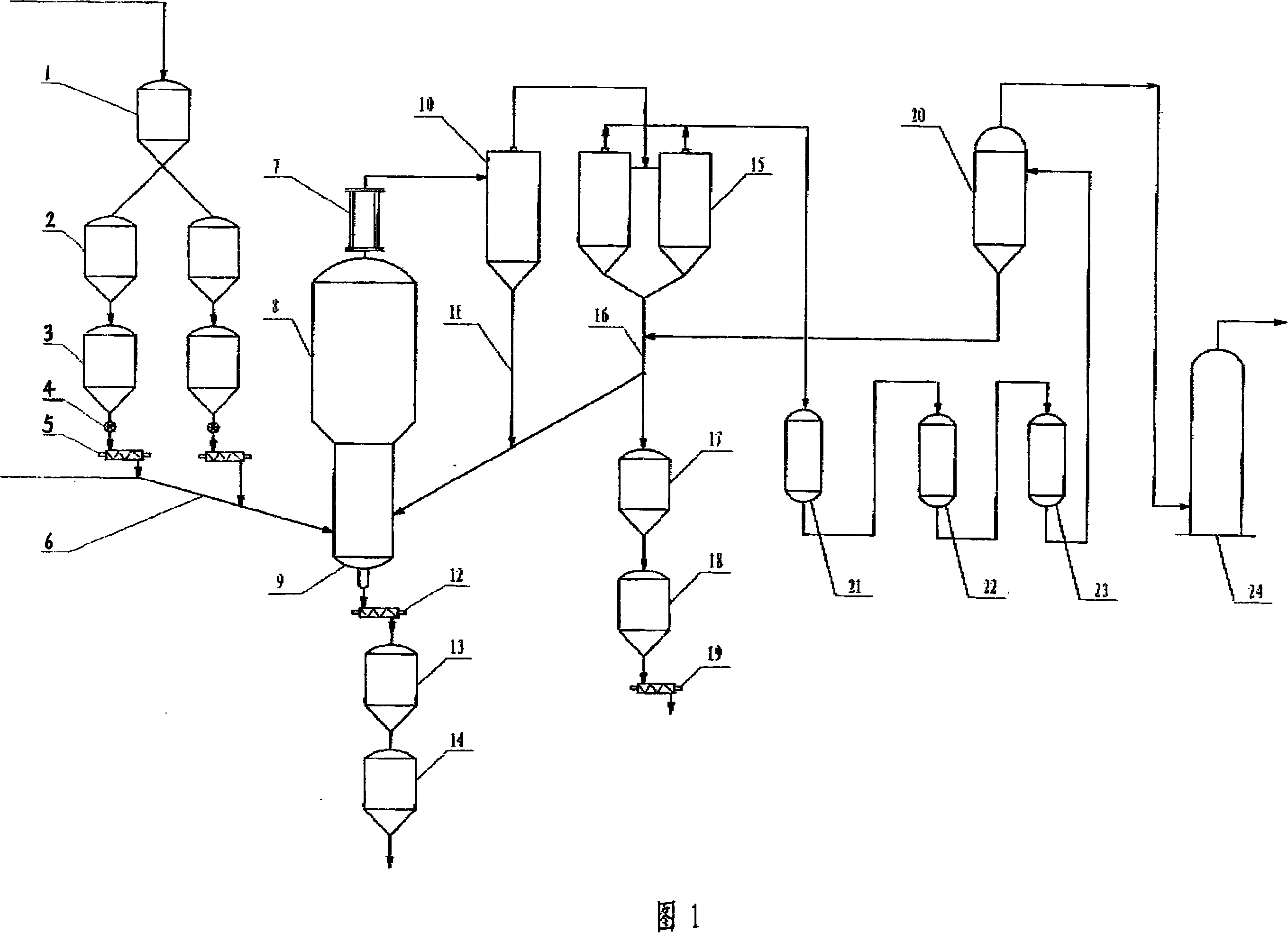

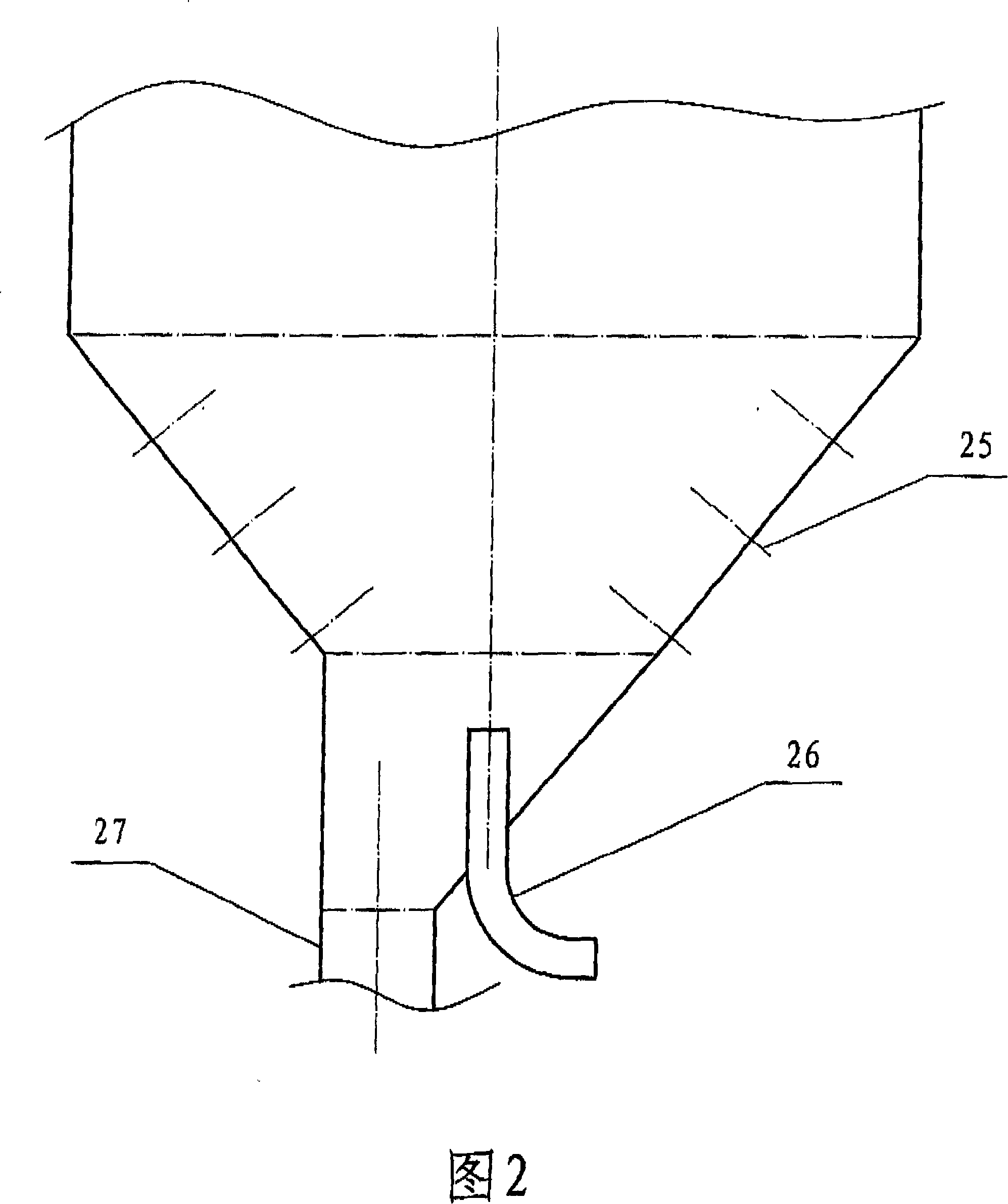

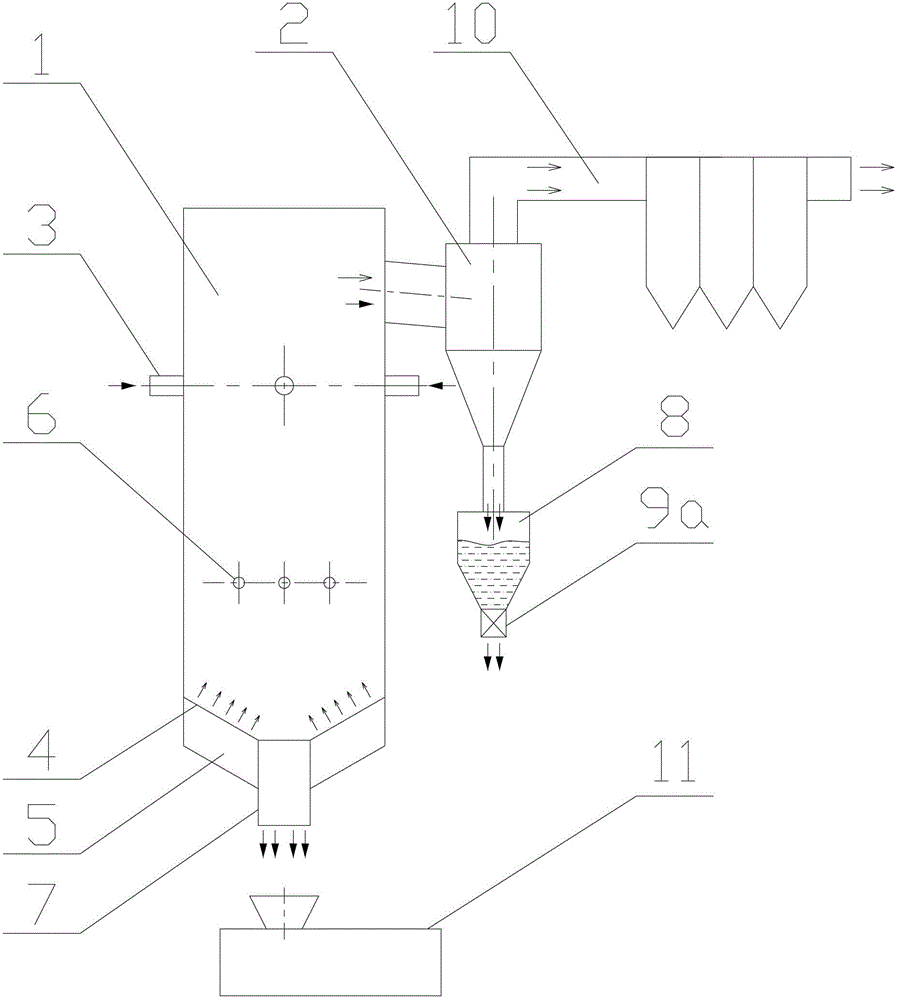

Gray melting poly-fluid bed powder coal gasification method

ActiveCN101108986AAdaptableEasy to operateCombined combustion mitigationGranular/pulverulent flues gasificationCycloneCooling tower

An ash agglomerating fluidized bed gasification method is provided. First, the coal powder is added in a gasification furnace; the gasification agent enters the bottom of the gasification furnace through a nozzle of a gas distributor, a central tube and a ring canal to make the coal powder gasified to produce gas under the fluidization state; the gas enters a first dust collector cyclone and a secondary dust collector cyclone after entering a first steam generator from the top of the gasification furnace, and enters a secondary steam generator to produce the saturated steam and enters a steam superheater and a boiler feed water preheater to continuously recycle the after heat of the gas, and then enters a final washing and cooling tower of the gas to further remove dust and reduce temperature and send to a follow-up system after dust removal via a deduster. The invention adopts the theory of fluidization to add the powder coal of the raw materials continuously in the dense phase of the gasification furnace. The gasification agent is blown in from the bottom of the gasification furnace to make the coal particle boiled and fluidized. The gas phase and solid phase are fully mixed and contact under the high temperature caused by combustion to carry out the thermolysis and the viscosity of the coal and the oxidation-reduction reaction of the carbon to realize the complete gasification of the coal finally.

Owner:陕西华祥能源科技集团有限公司

Process for preparing coal-based agglomerated activated carbon

The invention discloses a process for preparing coal-based agglomerated activated carbon. The process has the following beneficial effects: the non-caking coal produced in the wide ditches is taken as a main raw material; the special caking coal type, namely gas-fat coal, is blended in the coal blending procedure; furthermore, the oxidation procedure is added in the process; the process parameters such as pulverized coal particle distribution, forming pressure, coal activation temperature and time and the like in the general production process are adjusted; at the same time, the slow carbonization technology is used instead of the traditional rapid carbonization procedure; and oxygen-enriched air is fed into activation equipment. The coal-based activated carbon prepared by the process can ensure the product strength and bulk density on the basis of satisfying the iodine adsorption of the activated carbon and is better in industrial application value.

Owner:SHENHUA XINJIANG ENERGY

Fully mechanized caving top coal caving three-dimensional simulation experiment platform and experiment method

InactiveCN102749432ARemove the influence of recovery statisticsSolve the roof fall problemFuel testingThree dimensional simulationEngineering

The invention discloses a fully mechanized caving top coal caving three-dimensional simulation experiment platform and an experiment method. The platform and the method are used for researching the influences of elements in coal mine fully mechanized caving working face, such as mining-caving ratio, caving manner, caving technology, bracket tail beam inclination angle, coal caving port size, and broken top coal particle sizes, upon fully mechanized caving working face top coal recovery rate, and for verifying the influence of the spatial arrangement of an onsite top coal tracker upon onsite actual measurement precision of top coal recovery rate. According to the experiment platform provided by the invention, a mobile immediate roof is arranged, such that the influence of roof caving during an experiment process upon the recovery rate can be avoided. Coal pillars are preserved on the boundary, and only central-area recovery rate is counted, such that the influence of experiment method boundary conditions upon recovery rate statistics can be basically eliminated. Experimental-area residual coal amount can be obtained by using sheet metal inserts, such that top coal recovery rates under different conditions can be obtained. Therefore, guidance can be made for actual engineering, and an optimal fully mechanized caving scheme can be selected.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

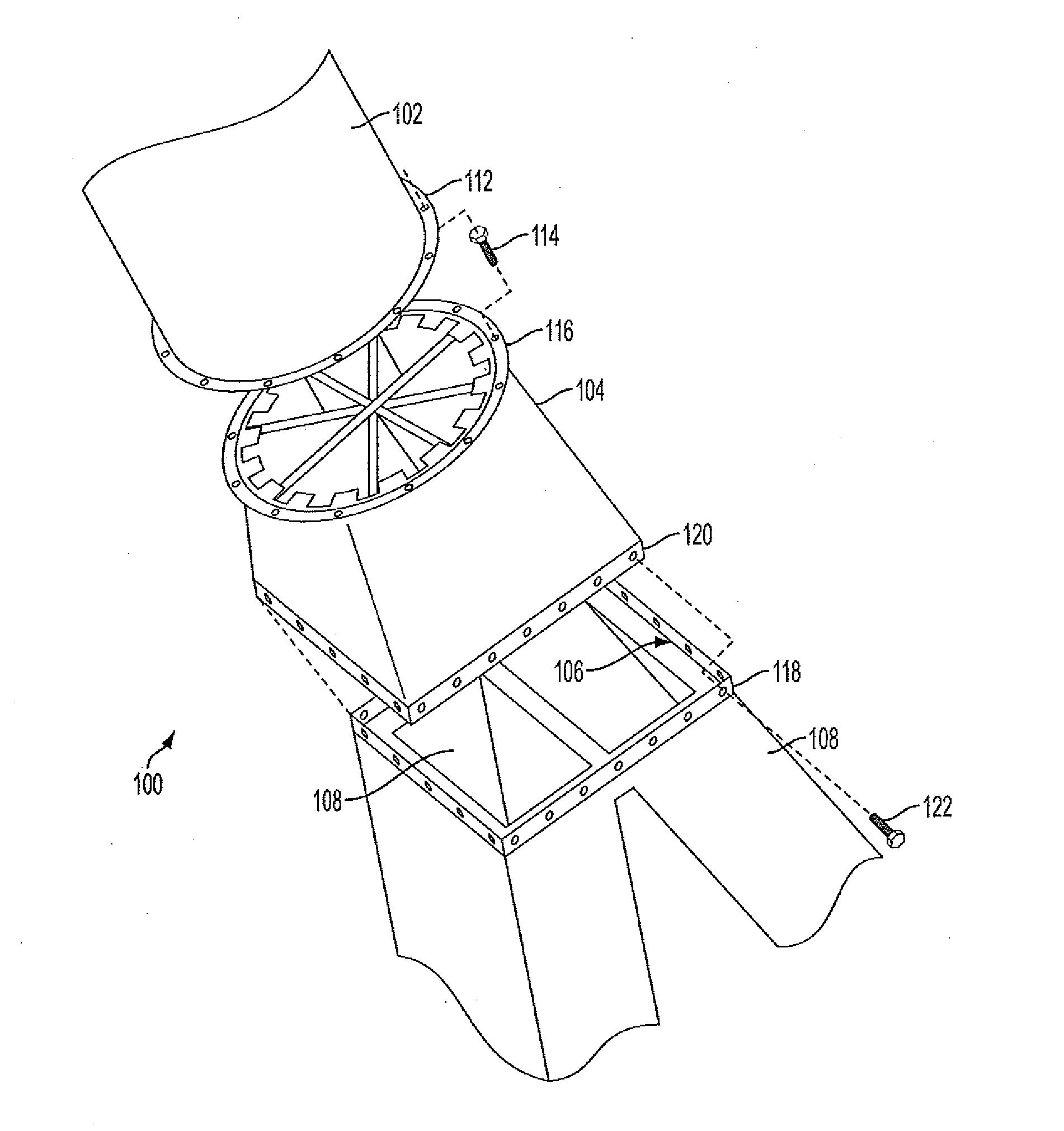

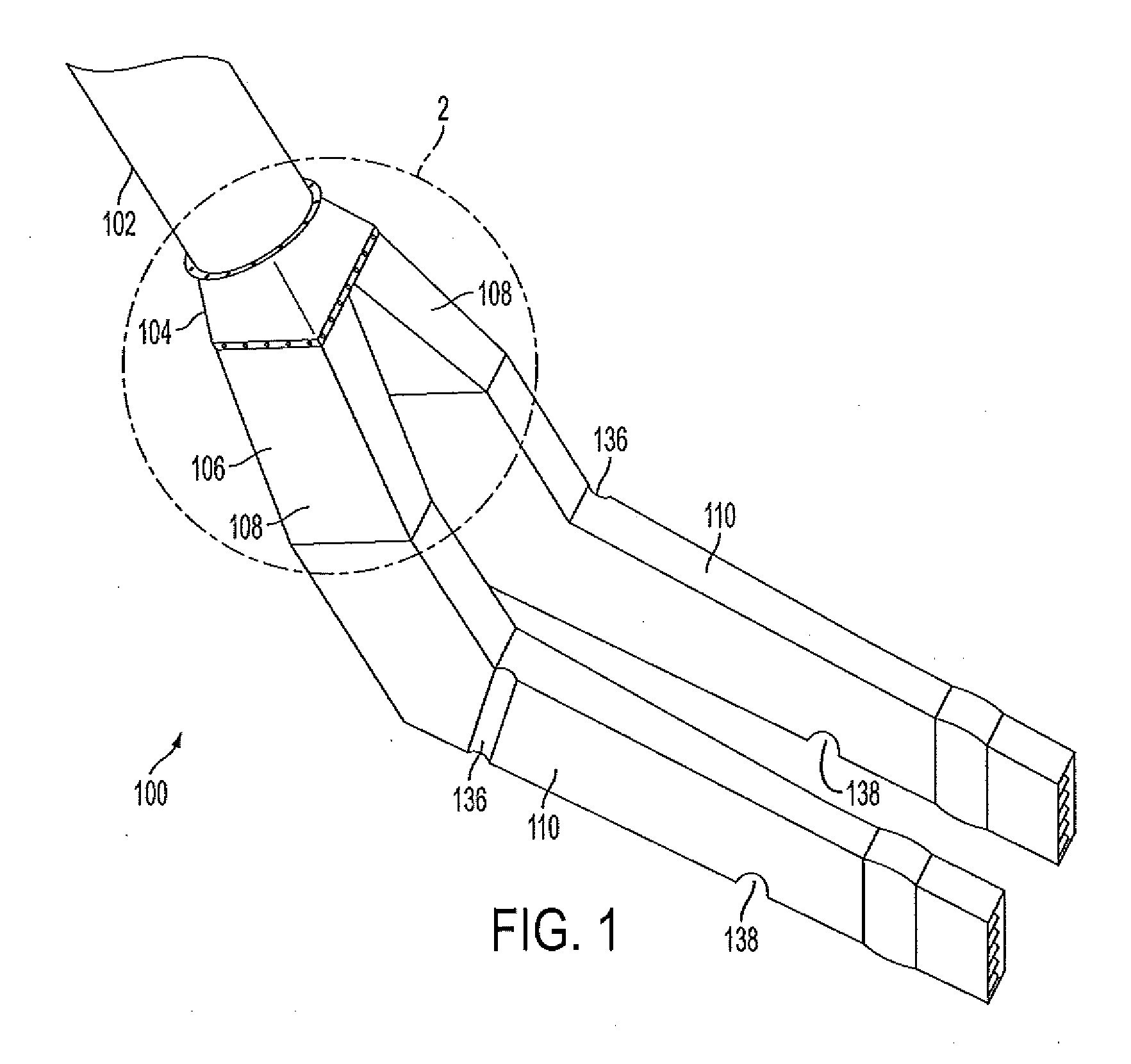

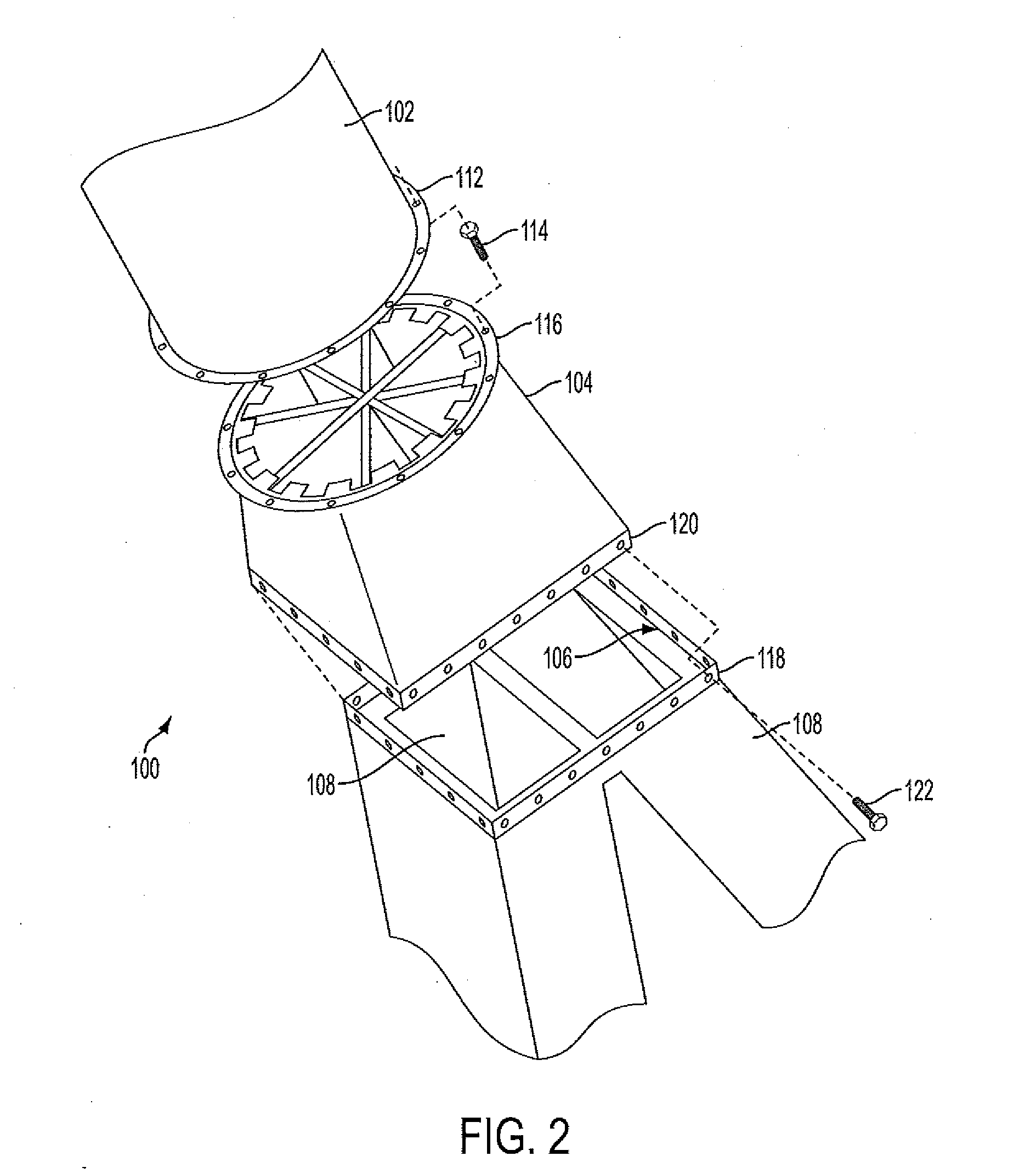

Coal flow balancing devices

InactiveUS20120186501A1Reduce unevennessImprove uniformityFuel feeding arrangementsBulk conveyorsParticle flowSolid particle

A flow splitter distributes solid particles flowing in a fluid, such as coal particles flowing in air, through a piping system. The flow splitter includes a divider housing having an inlet configured to connect to an upstream pipe and having an outlet configured to connect to a plurality of downstream pipes, e.g., by way of a divider head. A divider body is mounted within the divider housing. A plurality of divider vanes is included, each extending from the divider body to the divider housing. The divider housing, divider body, and divider vanes are configured and adapted to reduce non-uniformity in particle concentration from the inlet and to supply a substantially equal particle flow from the outlet to each of the downstream pipes.

Owner:BABCOCK POWER SERVICES

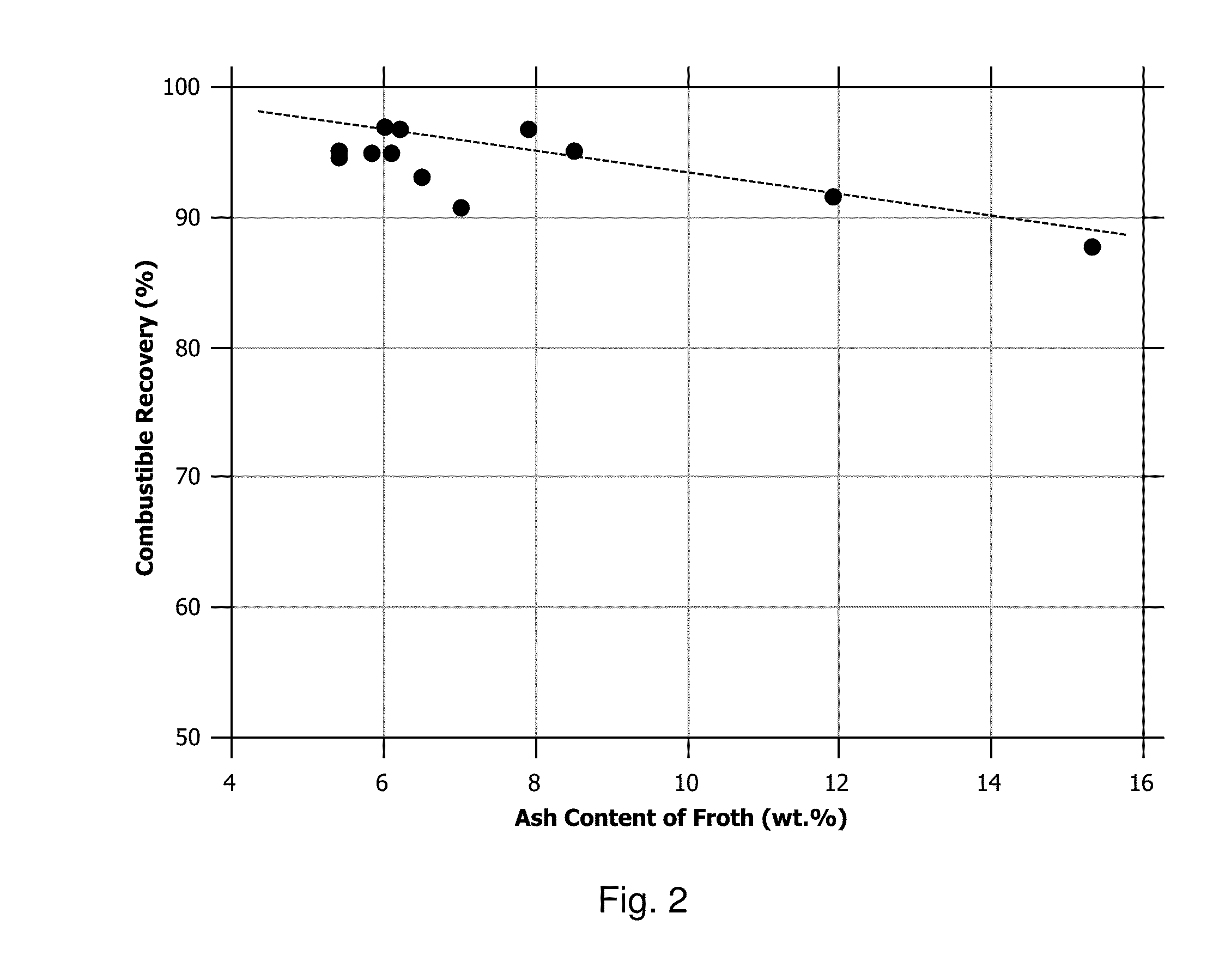

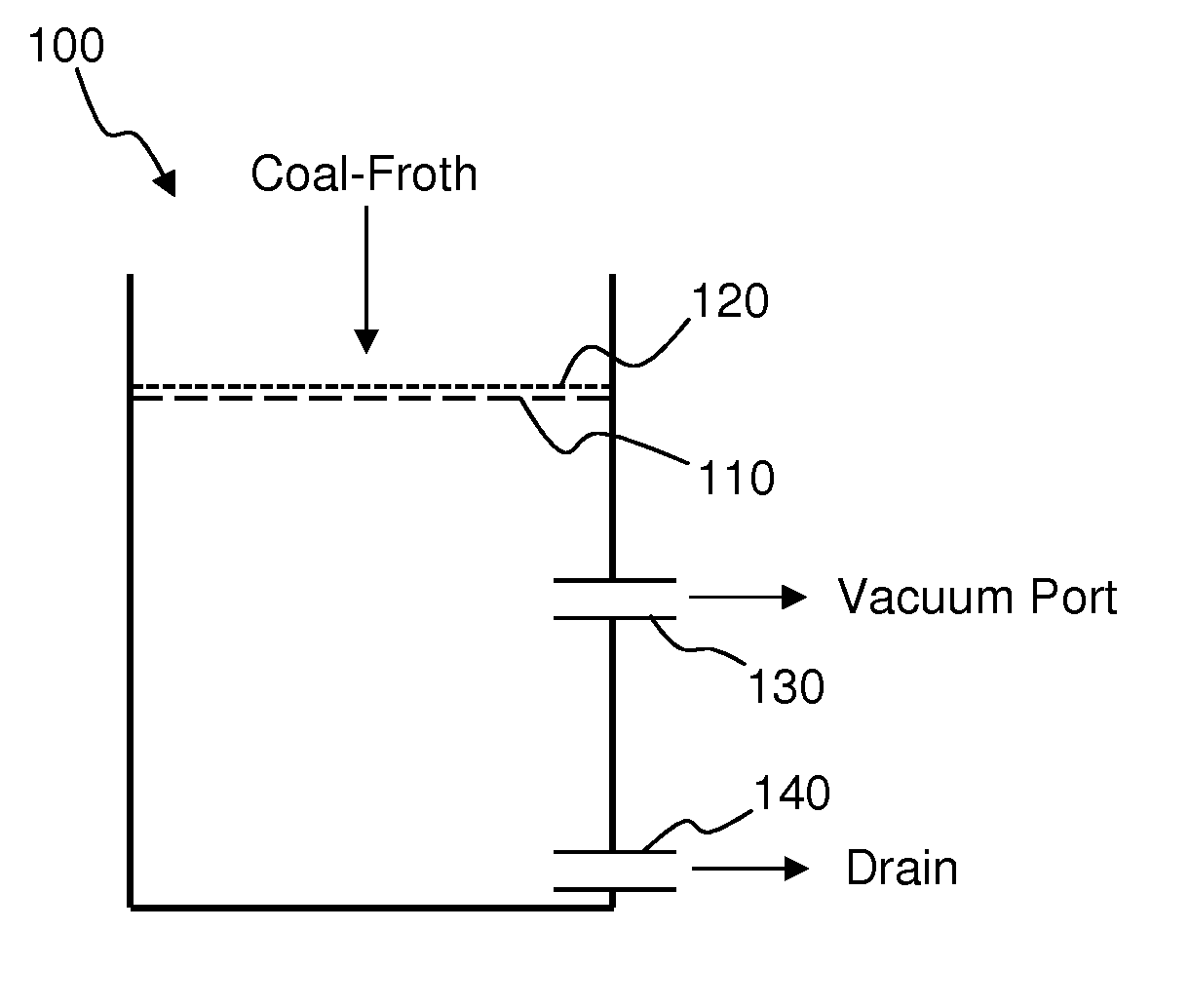

Flotation separation of fine coal particles from ash-forming particles

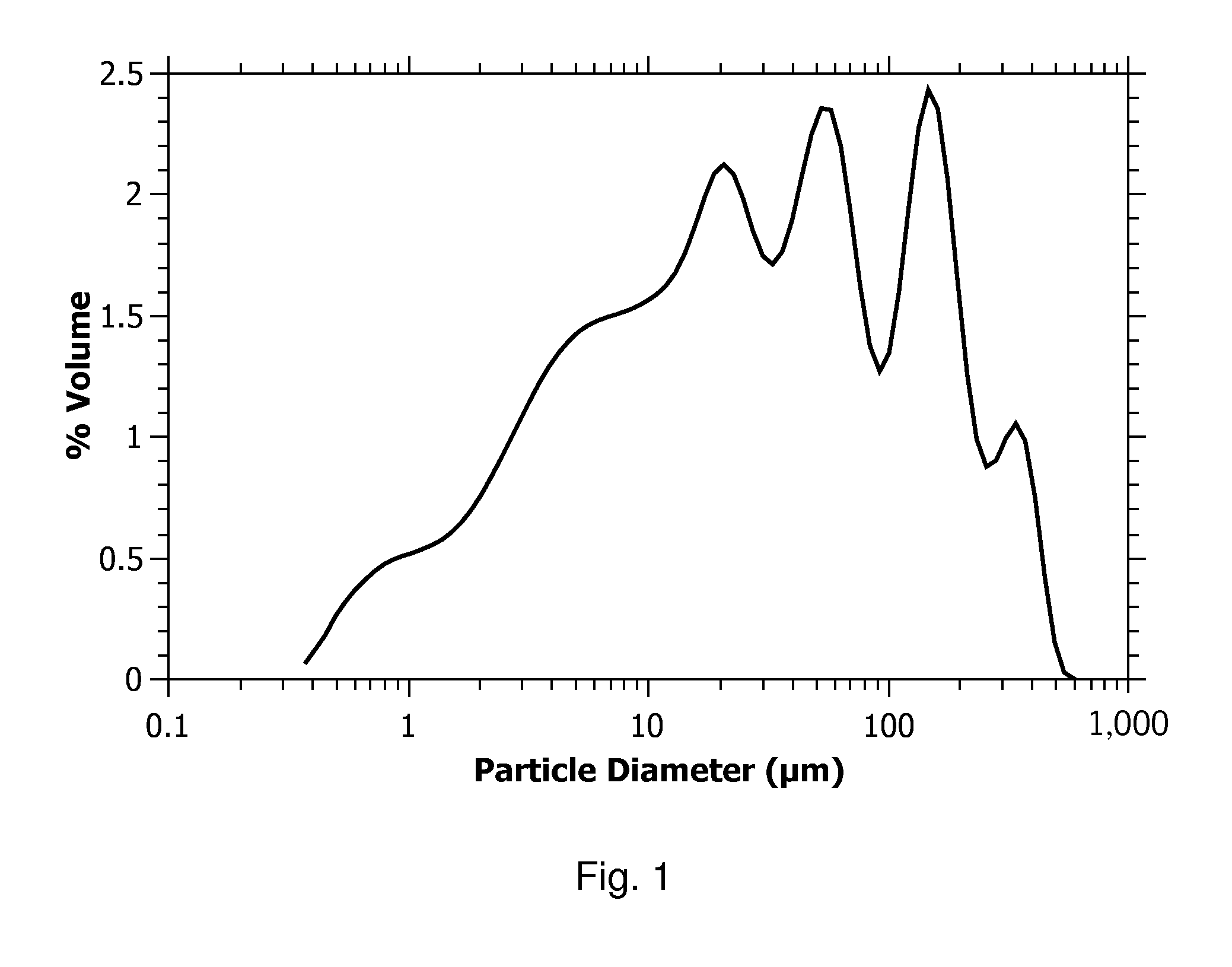

InactiveUS20160082446A1Provide froth-building capacityEasy to separateSolid fuelsLiquid carbonaceous fuelsPrillSlurry

Coal fines are processed by flotation separation to separate coal particles from ash-forming component particles. Coal fines are mixed water under high shear mixing conditions to form an aqueous slurry of coal fines containing between 15 wt. % and 55 wt. % coal fines. The aqueous slurry is introduced into a coal flotation cell to separate coal particles from ash-forming component particles by flotation separation, wherein the coal fines have a particle size less than 500 μm, and more preferably less than 300 μm. Bubbles are generated in the coal flotation cell having a bubble size and bubble quantity selected to float the coal particles and to form a coal-froth containing at least 15 wt. % solid particles. The solid particles include coal particles and ash-forming component particles. The coal-froth is collected for further processing.

Owner:EARTH TECH USA

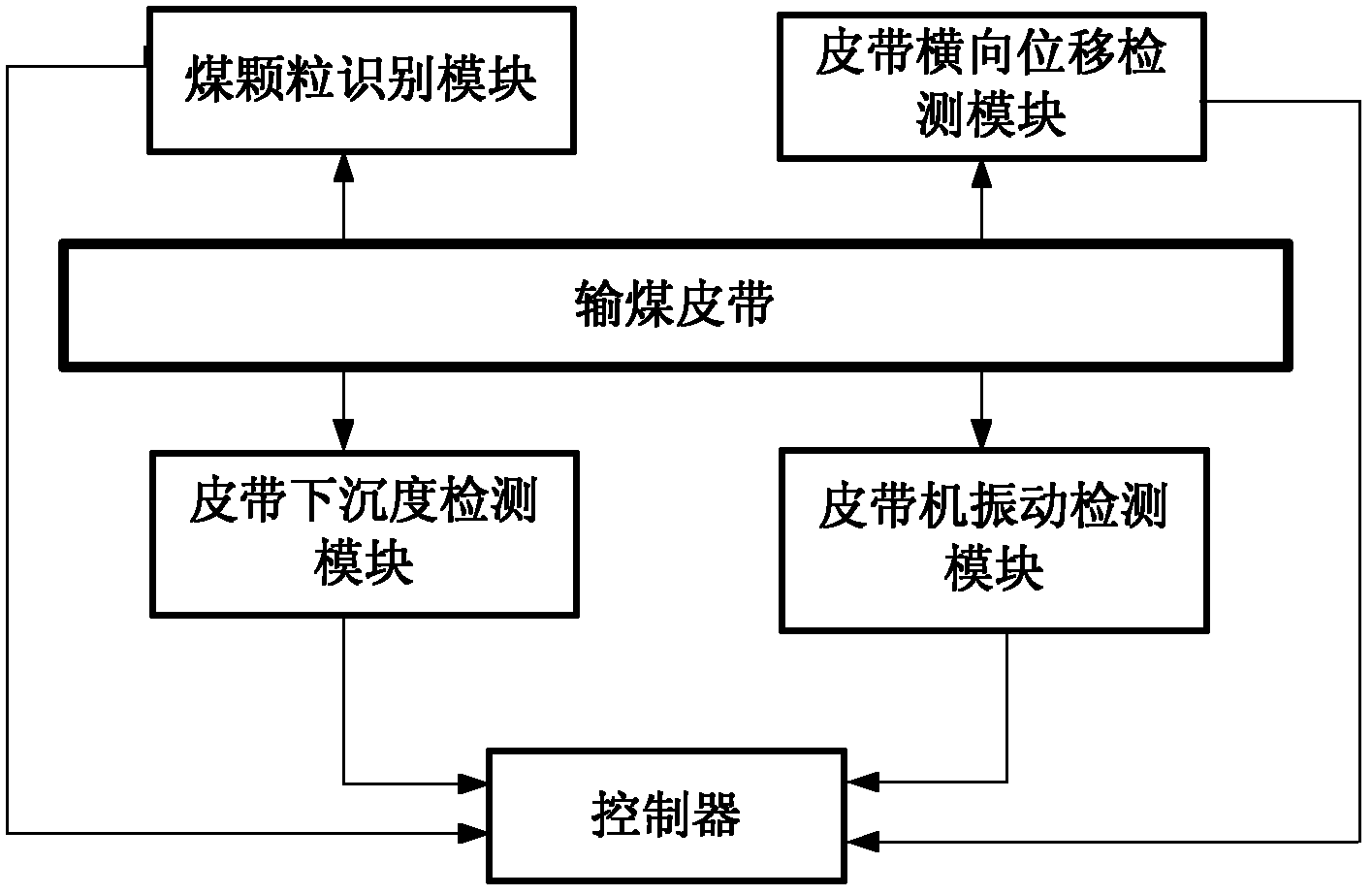

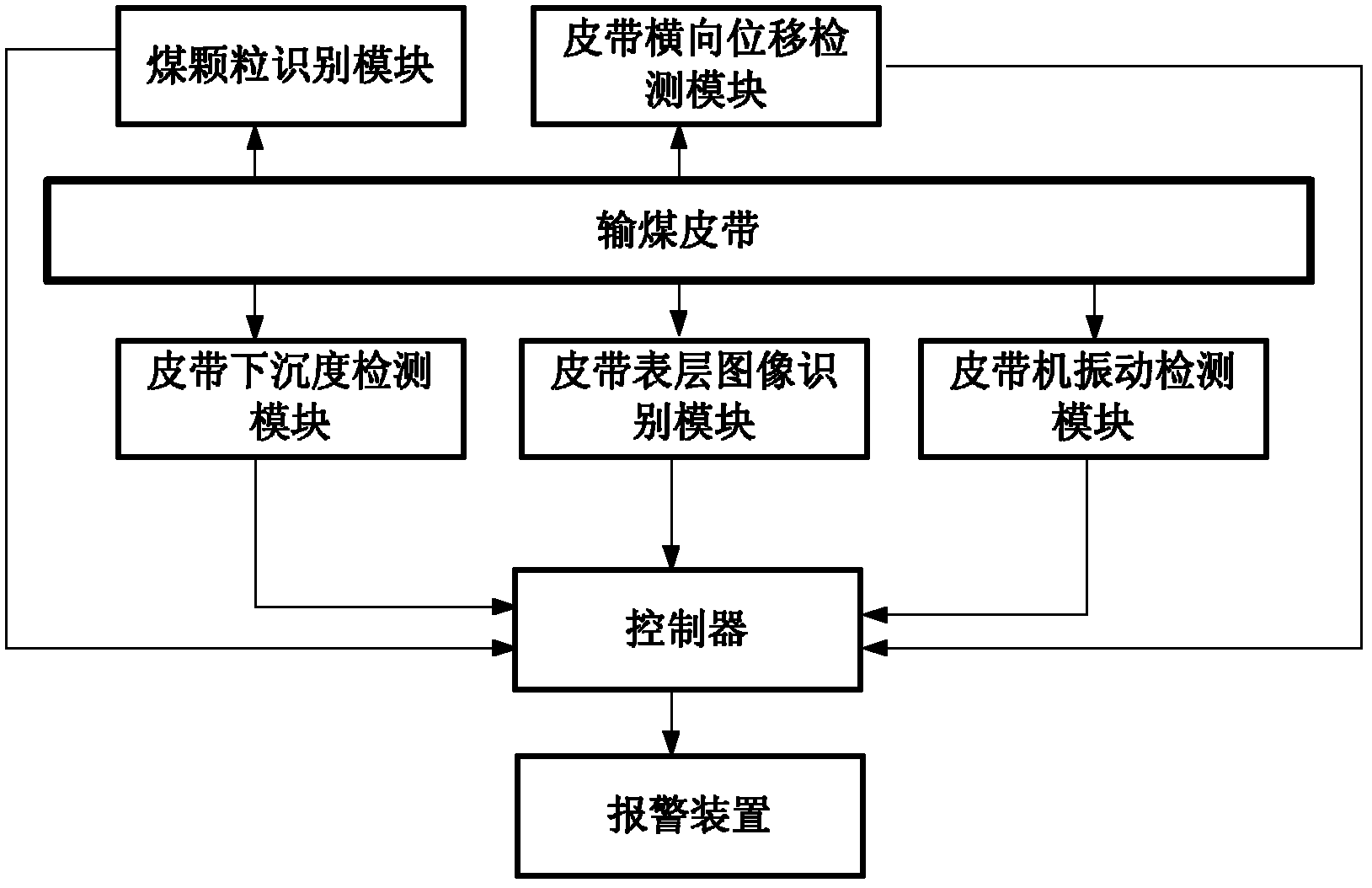

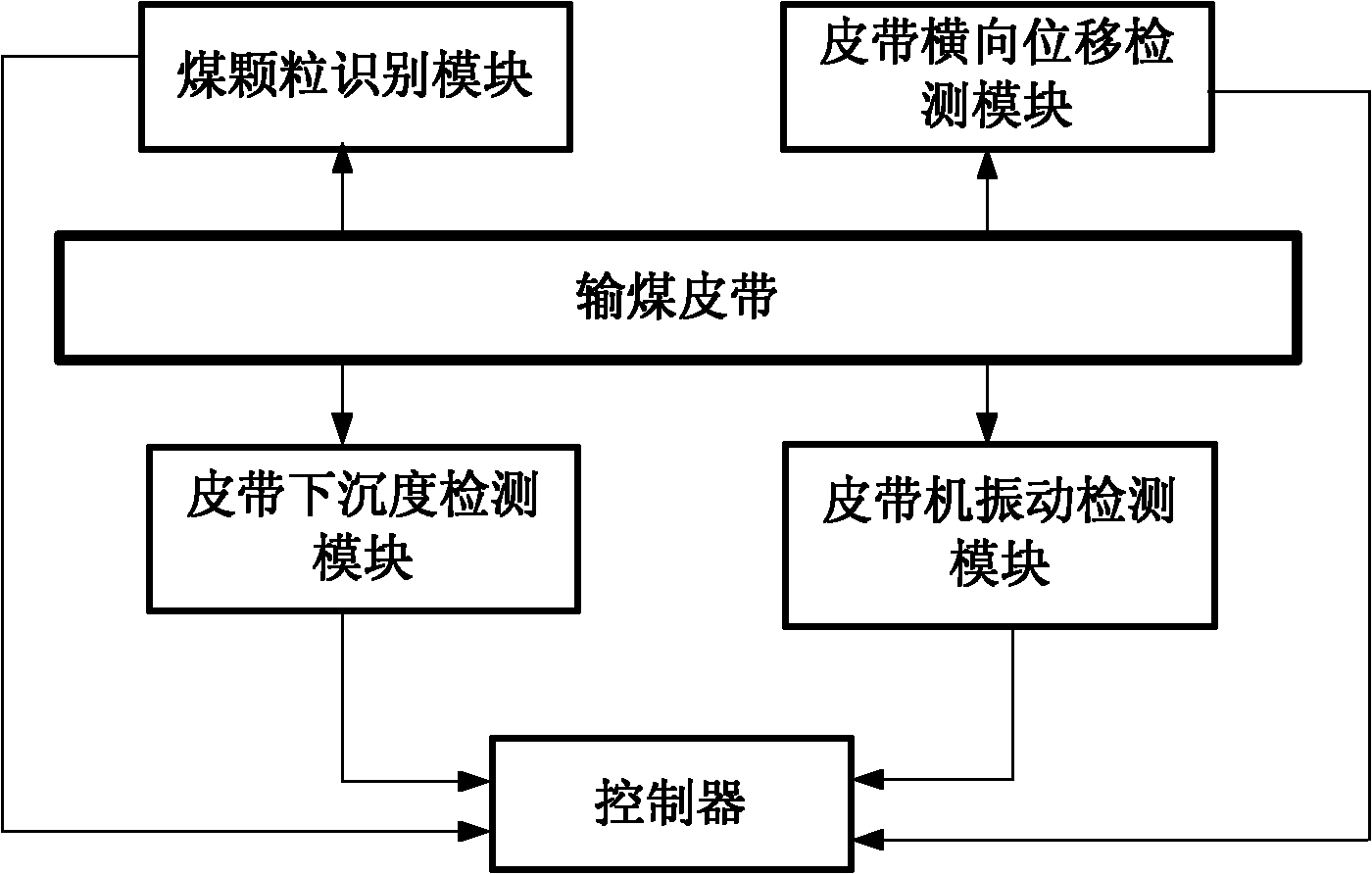

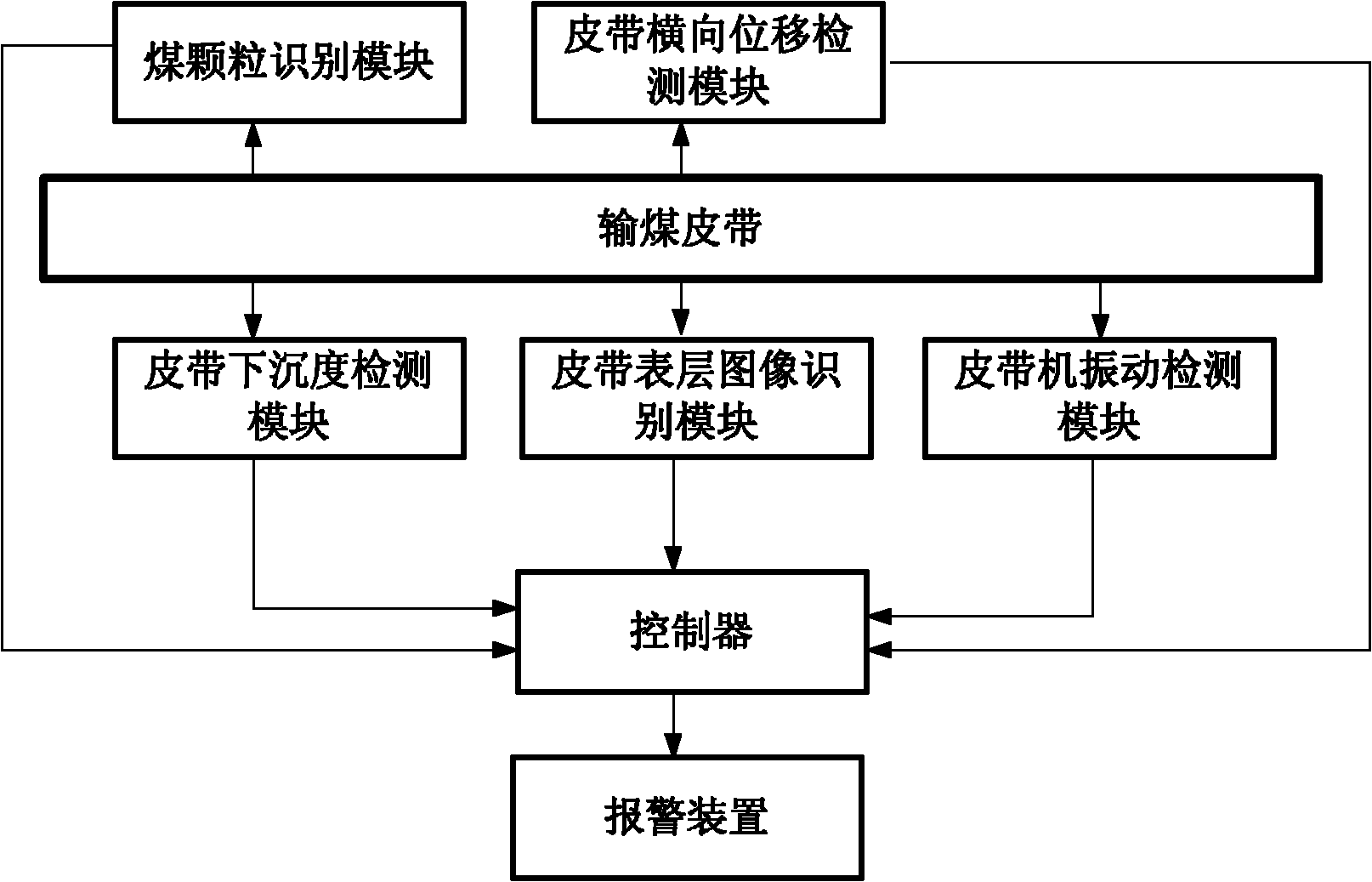

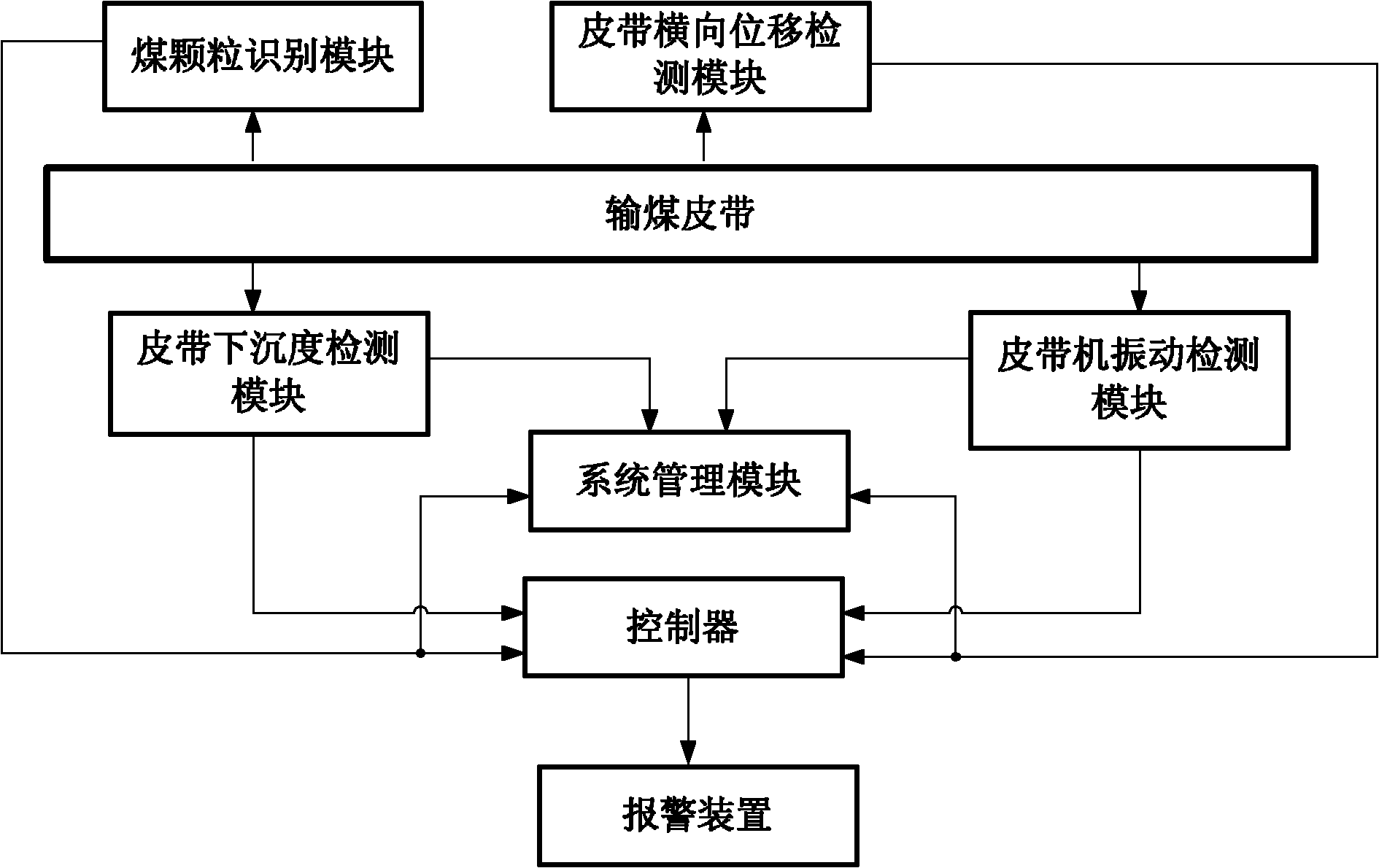

Intelligent monitoring system for monitoring coal conveying belt for of coal conveying system

InactiveCN102320457AReduce the risk of being tornExtend your lifeControl devices for conveyorsMonitoring systemEngineering

The invention relates to an intelligent monitoring system for monitoring a coal conveying belt of a coal conveying system, comprising a coal particle identification module, a belt sinkage detecting module, a horizontal belt displacement detecting module, a belt conveyor vibration detecting module and a controller, wherein the controller is connected with all the modules in a wired or wireless manner; the coal particle identification module is used for monitoring whether large coal blocks exist on the coal conveying belt by firstly detecting whether coal cutoff occurs and then utilizing a particle image identification technology; the belt sinkage detecting module is used for monitoring whether large coal blocks exist on the coal conveying belt by judging the sinking degree of the belt; the horizontal belt displacement detecting module is used for monitoring whether the coal conveying belt deviates or is torn; the belt conveyor vibration detecting module is used for monitoring whether the coal conveying belt is impacted by the large coal blocks or generates friction with the large coal blocks by detecting the vibrating frequency of a belt conveyor; and the controller sends a braking instruction after receiving an instruction needing to brake the belt conveyor so as to brake the belt conveyor.

Owner:北京纵横兴业科技发展有限公司 +3

Pneumatic particle size classifying device for solid particles

InactiveCN102716857AAffect balanceAffect normal working conditionsGas current separationSolid particleEngineering

A pneumatic particle size classifying device for solid particles comprises a fluidized bed main body, a cyclone separator, material inlets, an air distributing system, a secondary air port, a coarse material outlet and a fine material collecting and discharging system. The material inlets are positioned on the middle upper portion of the fluidized bed main body and are distributed on four walls in a multi-point manner, the hopper-shaped air distributing system consists of an inclined air distributing plate, the coarse material outlet is arranged in the center of the inclined air distributing plate, the fine material collecting and discharging system consists of a fine material collecting chamber and an intermittent discharging valve and is directly connected with a lower particle outlet of the cyclone separator, or the fine material collecting and discharging system can consist of a fine material collecting chamber and a fine material discharge port and is connected with a particle outlet of a feedback valve. The pneumatic particle size classifying device is simple in structure, effective pneumatic particle size classification for selective coking coal particles is carried out by fluidization technology, retaining time of the particles in the bed body can be effectively prolonged, the pneumatic particle size classifying device is stable in running and fine in separation effect, and energy and coking coal resources are greatly saved.

Owner:TSINGHUA UNIV

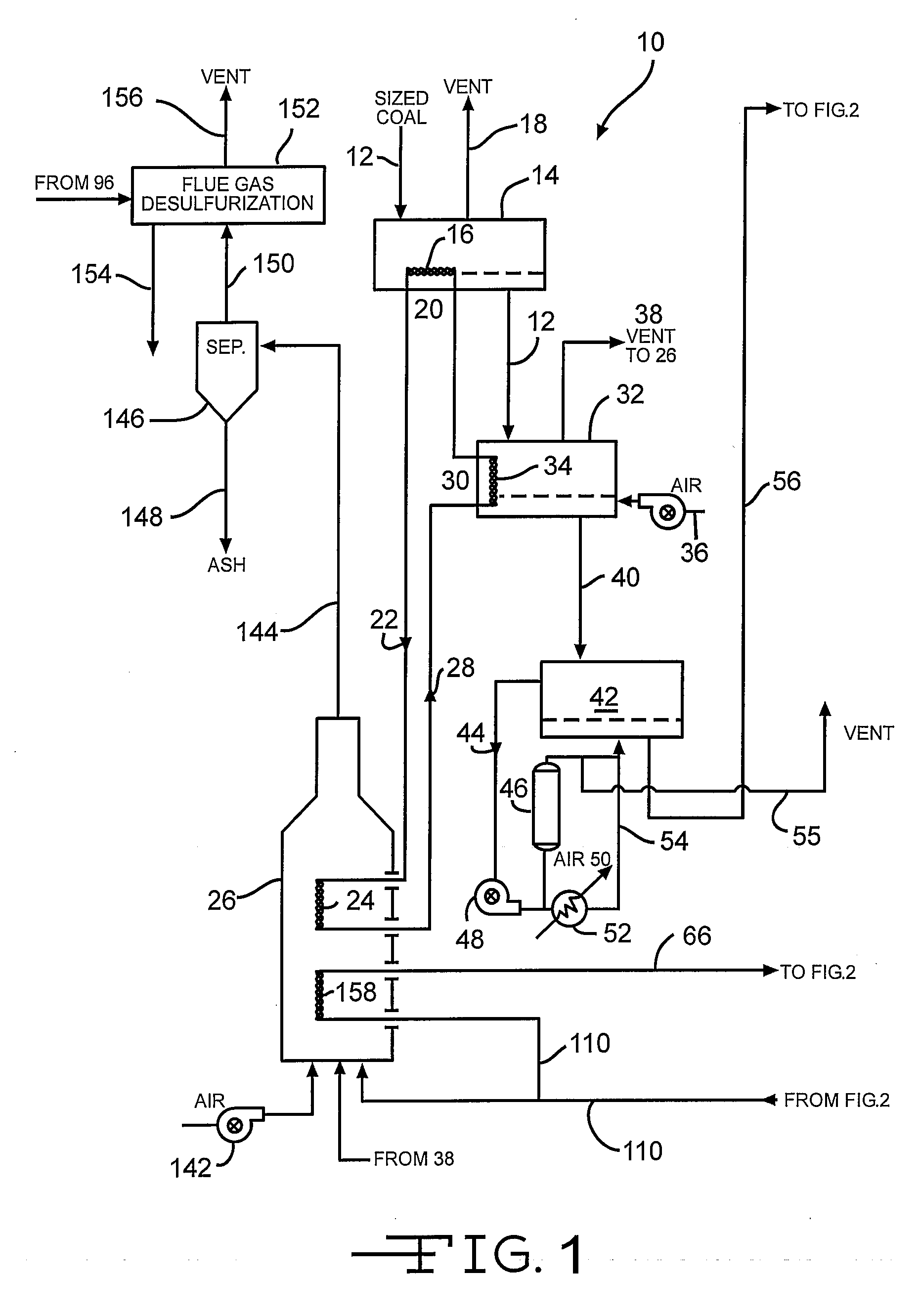

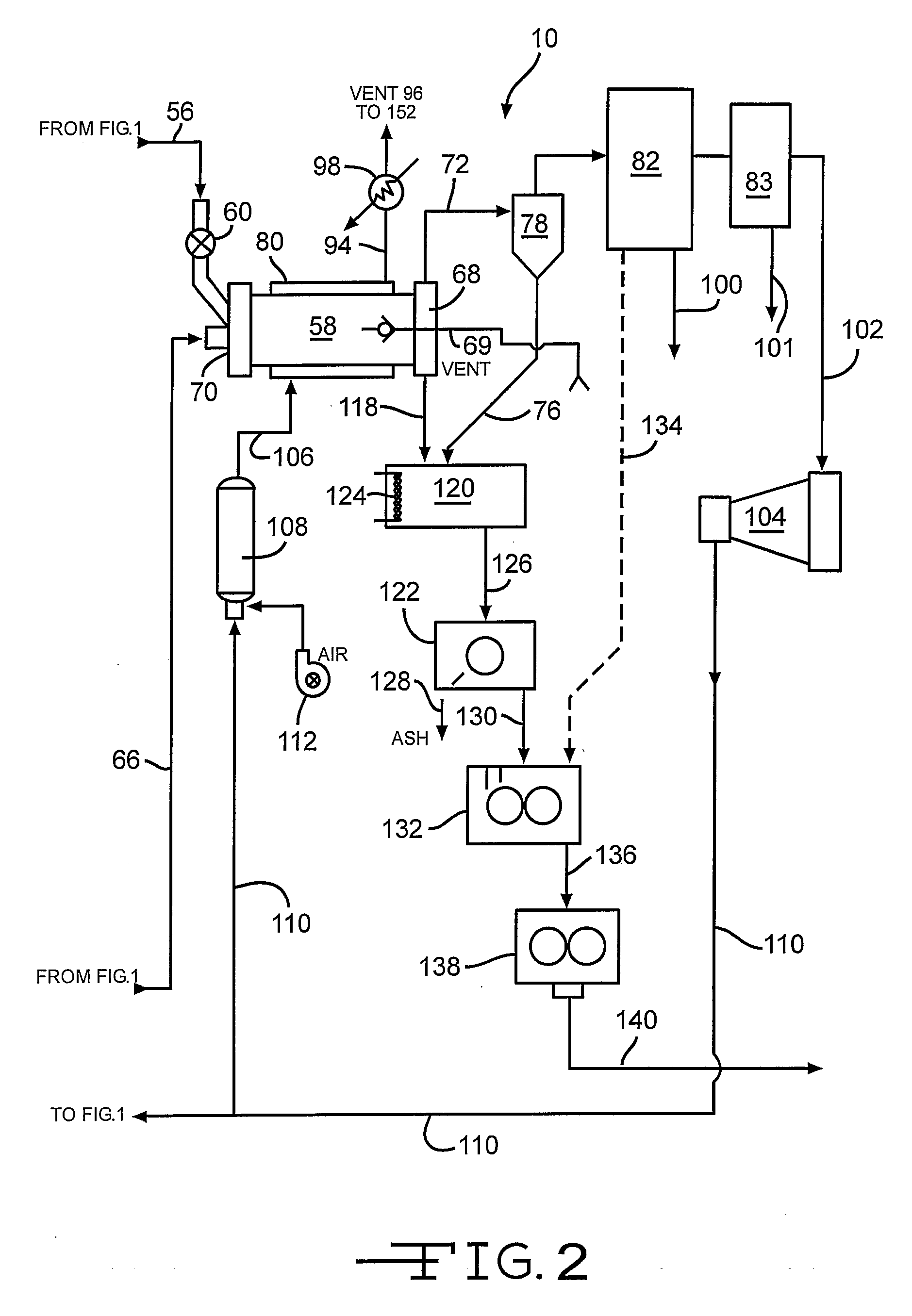

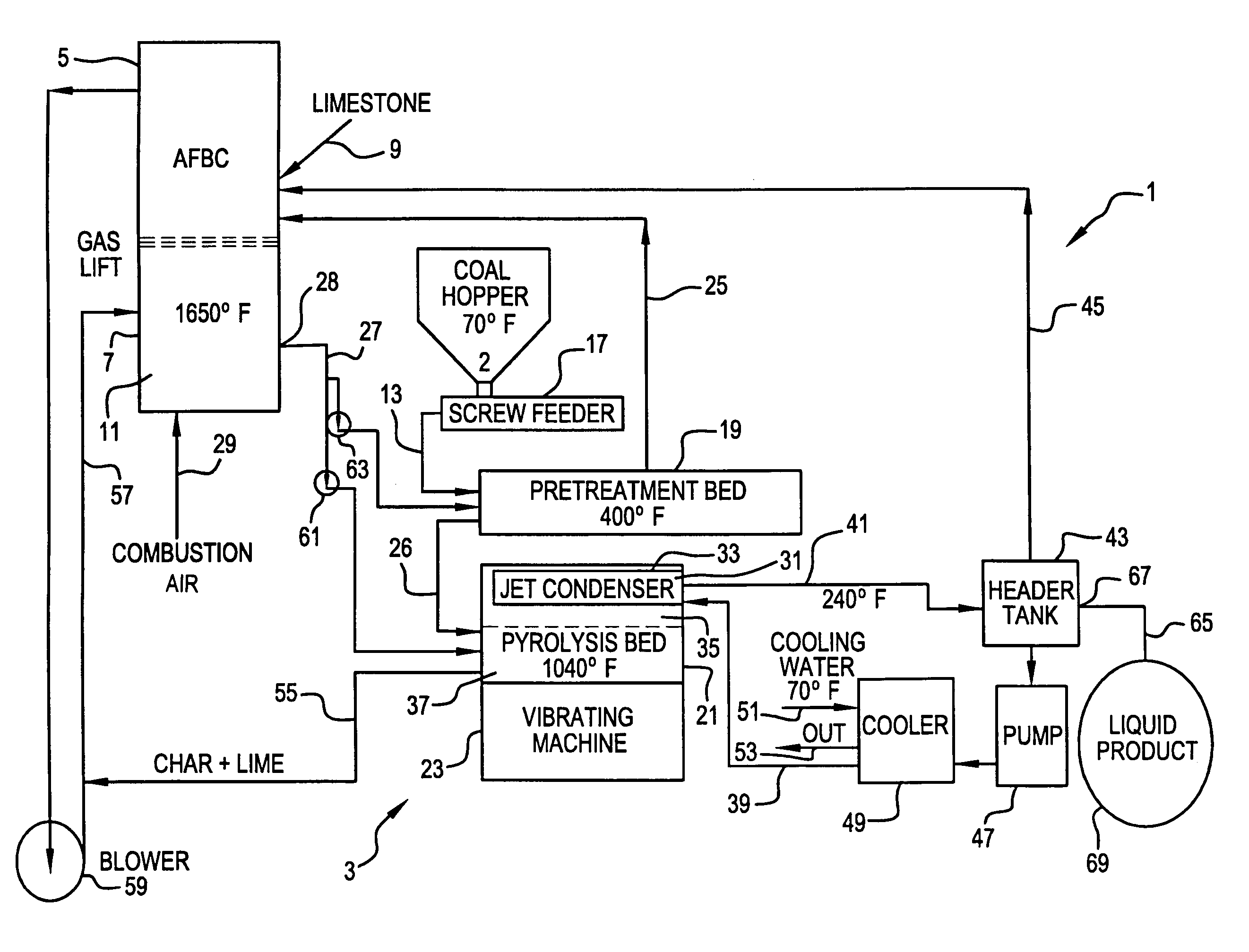

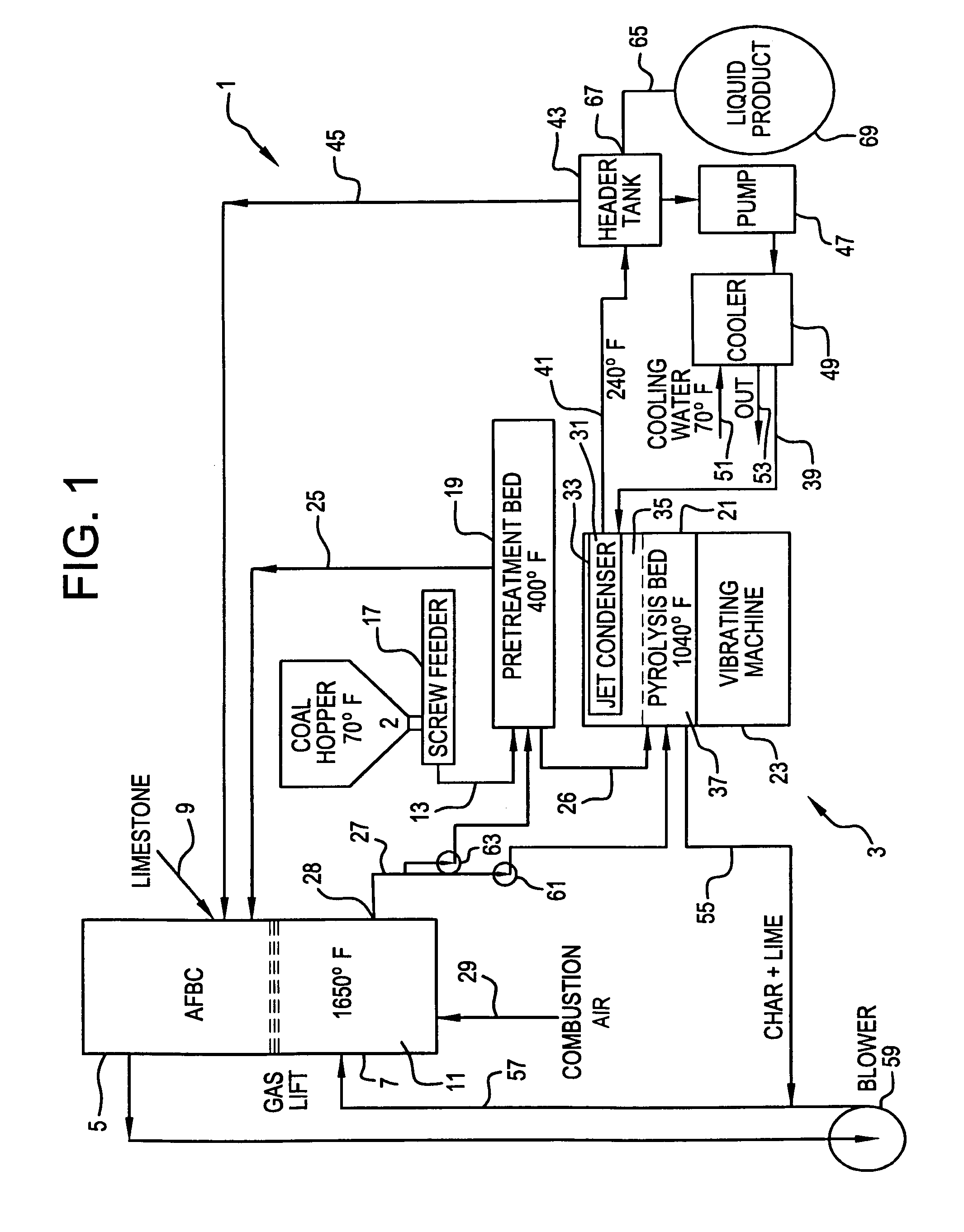

Pretreatment process to remove oxygen from coal en route to a coal pyolysis process as a means of improving the quality of the hydrocarbon liquid product

InactiveUS7008459B1Heat loss minimizationOxygen in-leakage can be kept extremely lowMechanical conveying coke ovensDirect heating destructive distillationLiquid productFlue gas

A process and apparatus for coal pyrolysis pretreatment. The apparatus is made up of a pretreatment vessel for holding a bed of coal particles, a preheater for heating the bed of coal particles to a temperature below the coal pyrolysis temperature range and an oxygen remover for removing oxygen released from the heated coal particles. The apparatus can also have a flue gas source as an oxygen removal sweep gas to the bed of coal, a collector for collecting non-condensable combustible gases, and the preheater having a furnace holding ceramic balls which are circulated from the furnace to the bed of coal particles. The process involves heating the bed of coal particles to a temperature below the coal pyrolysis temperature range and preventing air from contacting the bed of coal particles in addition to collecting non-condensable combustible gases or the preheating step accomplished by having a furnace holding ceramic balls which are circulated from the furnace to the bed of coal particles.

Owner:MACLEAN JOHN DR

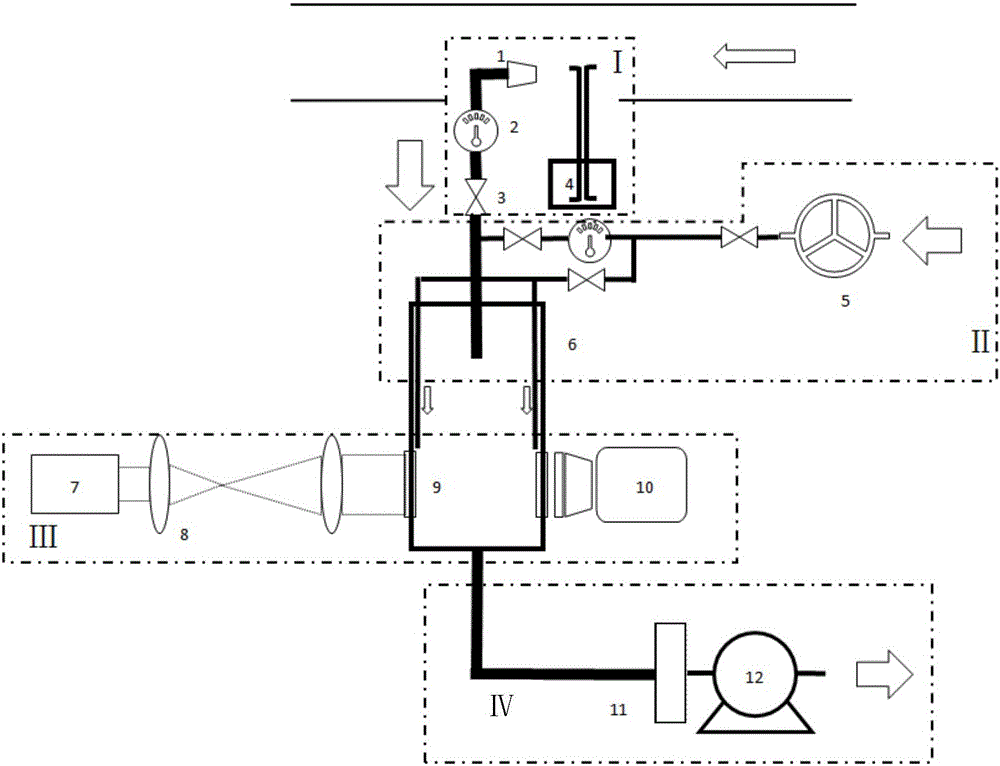

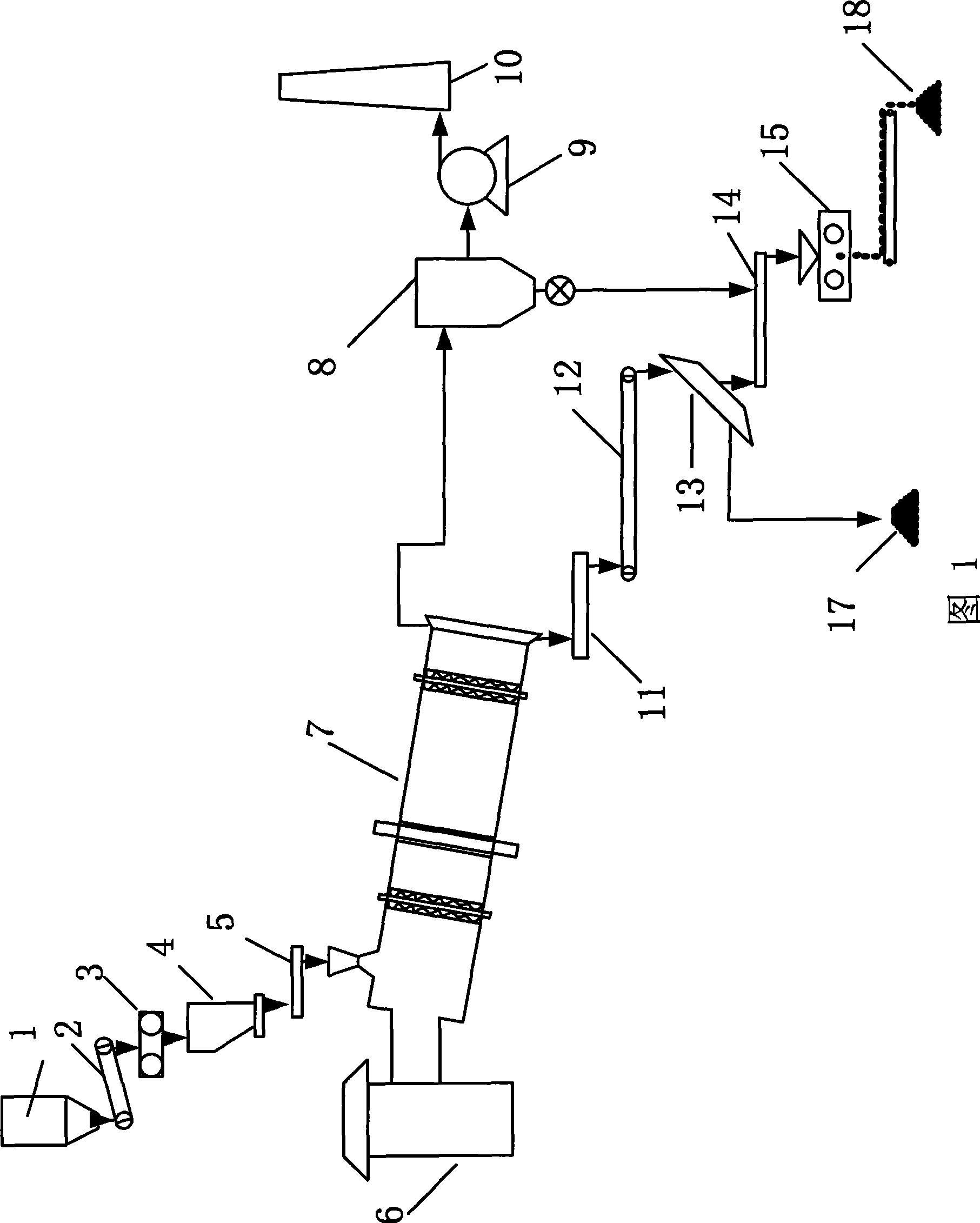

Pipeline powdered coal particle size measuring device and measuring method

ActiveCN106323825ARealize online quantitative measurementEasy to operateParticle size analysisParticle suspension analysisMeasurement deviceMaterial resources

The invention relates to a digital holographic technique, and aims to provide a pipeline powdered coal particle size measuring device and a measuring method. The method comprises the following steps: sampling a gas in a powdered coal conveying pipeline by a sampling nozzle, mixing clean air with the sampled gas to form a mixed gas, and taking the mixed gas as a sample to be delivered into a diluting chamber; combining a laser with a spatial filter to generate collimated laser, and projecting the collimated laser to a CCD camera by virtue of a laser channel of the diluting chamber; and processing a holographic image acquired by the CCD camera to obtain concentration and particle size distribution information of the measured sample, and then obtaining concentration and particle size distribution data of the powdered coal in the sampled gas according to a dilution ratio of the measured sample. By use of the device and the method provided by the invention, online quantitative measurement on the particle size and the concentration of the powdered coal in a pipeline can be achieved at the same time. The device is easy to operate and has a relatively high automation degree, and the measurement process does not need artificial interference; and by virtue of computer calculation, a measurement result close to reality can be given, manpower and material resources are saved, and daily running monitoring and maintenance work of coal-fired boiler equipment are facilitated.

Owner:ZHEJIANG UNIV

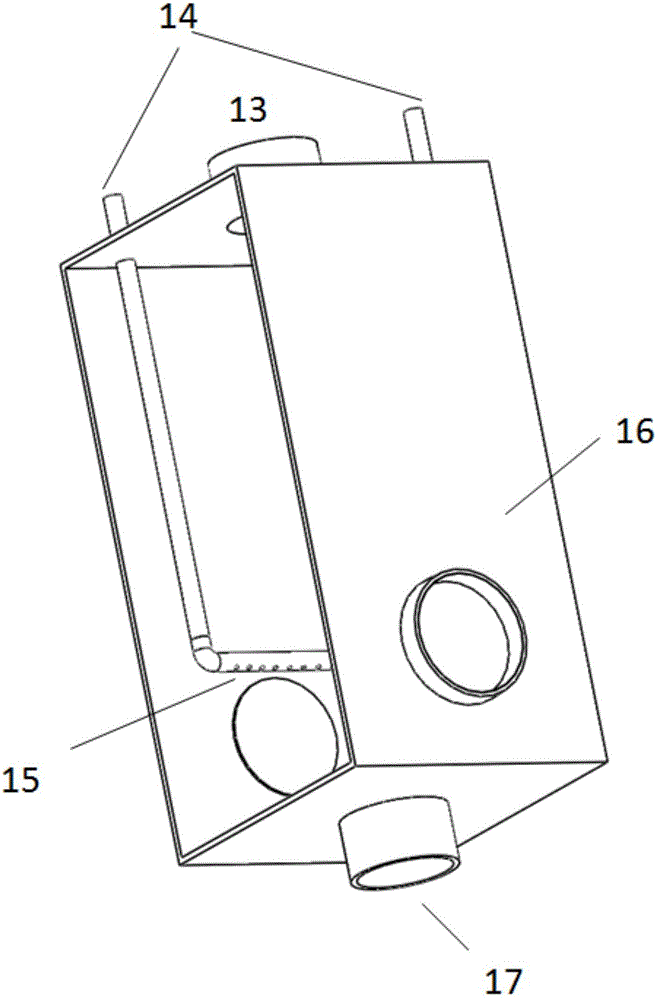

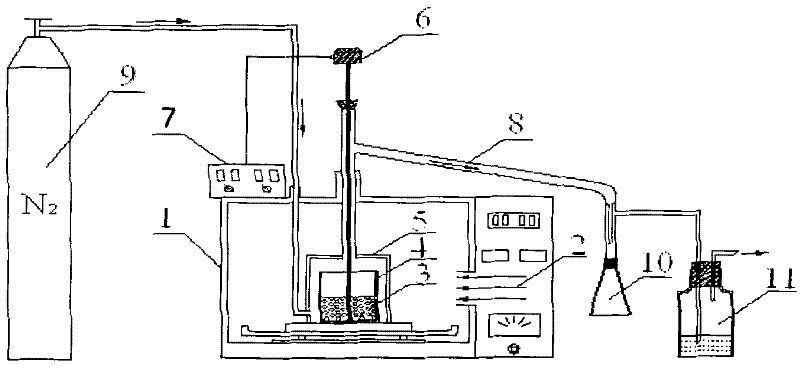

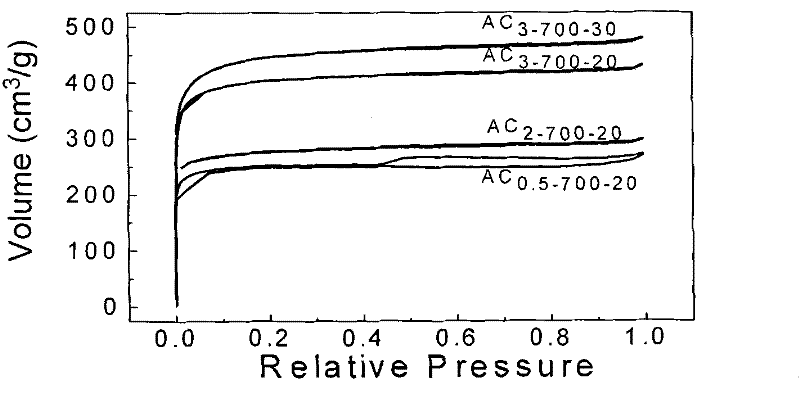

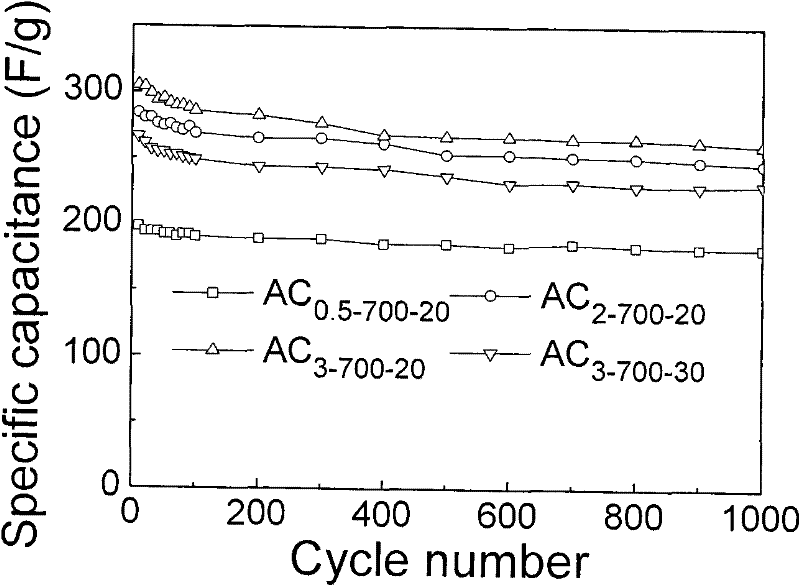

Device and method for preparing activated carbon material for electrochemical capacitor

InactiveCN102205962AFacilitate the activation of pore formationAvoid temperature gradientsElectrolytic capacitorsPotassium hydroxideBiological activation

The invention provides a device and method for preparing an activated carbon material for an electrochemical capacitor, belonging to the technical fields of coal chemical industry and microwave chemistry. The method comprises the following preparation processes of: deashing coal particles serving as raw materials by using hydrochloric acid and hydrofluoric acid, modifying the deashed coal by using nitric acid in an auxiliary way, mixing the modified coal serving as a carbon source with potassium hydroxide and deionized water, stirring to obtain a mixture, stirring and evaporating the mixture to obtain a solid mixture, and then performing microwave-assisted activating, washing, drying and grinding on the solid mixture to obtain the activated carbon. The invention has the advantages that the activation time is only 20-30 minutes, the mass ratio of potassium hydroxide to coal is (0.5-3):1, the preparation process is simple, the microwave-assisted heating is uniform, efficient and energy-saving, the consumption of the potassium hydroxide is reduced, and the activation process has the advantages of uniformity and high efficiency. The prepared activated carbon is used as an electrode material of the electrochemical capacitor and has better stability and excellent comprehensive property.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Chemical deashing method for coal

ActiveCN102041128AGood deashing effectImproved deashing efficiencyCalcium/strontium/barium fluoridesDispersed particle separationHydrofluoric acidReaction temperature

The invention discloses a chemical deashing method for coal, belonging to the technical field of clean coal. A novel deashing acid solution is adopted for deashing coal and is a mixed acid of hydrofluoric acid and at least one other inorganic acid, wherein the mass percentage content of the hydrofluoric acid is 5-30%, the mass percentage content of other inorganic acids is 10-40%, and total acid concentration is 10-40%; during acid leaching, the mass ratio of the deashing acid solution to the raw material coal is (1-6):1, reaction temperature is 10-80DEG C, and the process of acid leaching lasts for 4-24 hours; and meanwhile, after exhaust gas and scouring water, generated in a defluorination processing, are graded and reused and a waste mixed acid solution is repeatedly reused, a lime solution is adopted for absorption. The method provided by the invention is suitable for deashing larger coal particles of which the diameter is 1-5mm, and can achieve a better deashing effect. A moderate reaction condition is adopted to ensure that the deashing mixed acid containing hydrofluoric acid is difficult to volatilize, so that energy consumption and cost are lowered and environmental pollution is lightened at the same time.

Owner:YIBIN TIANYUAN GRP CO LTD

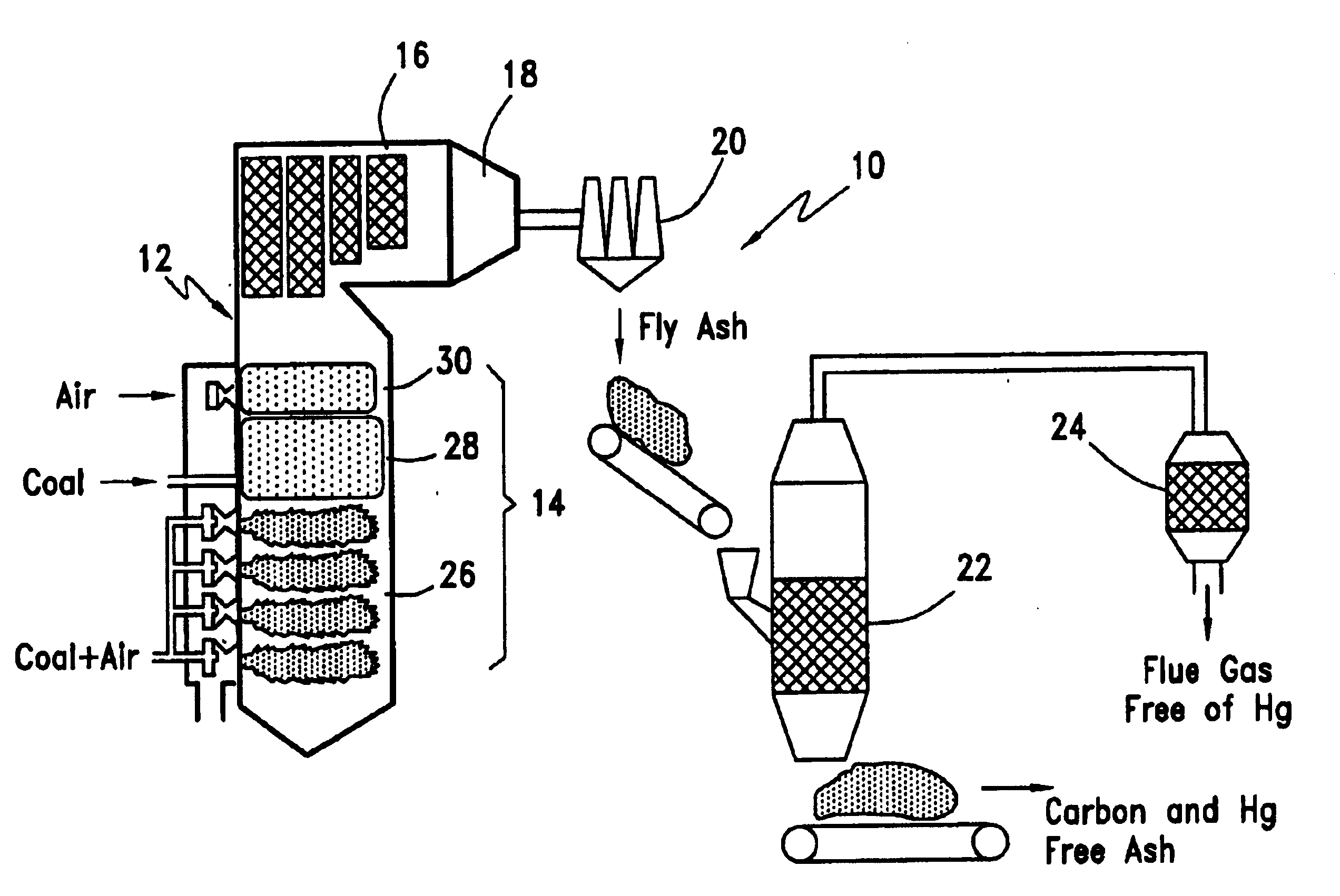

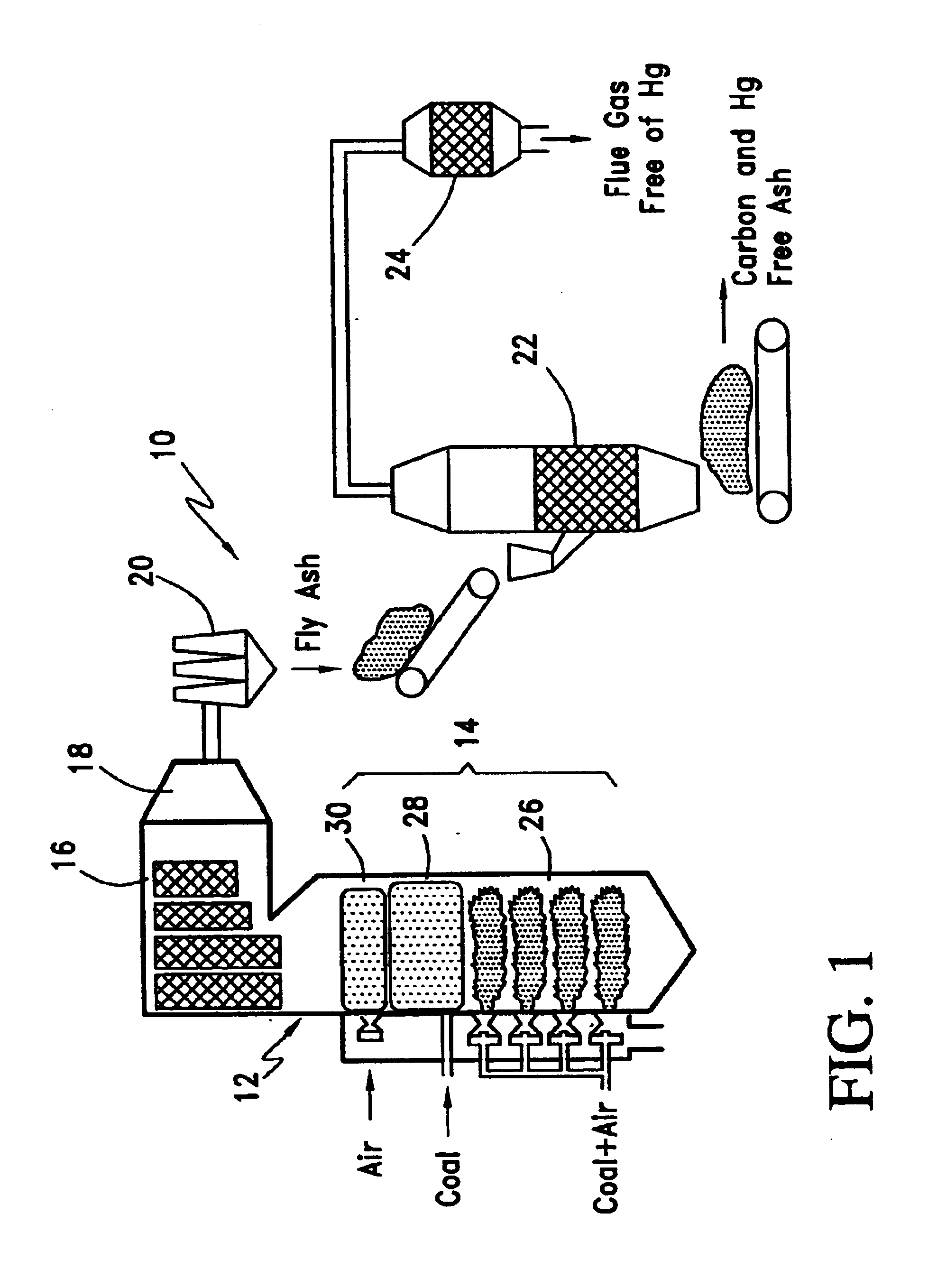

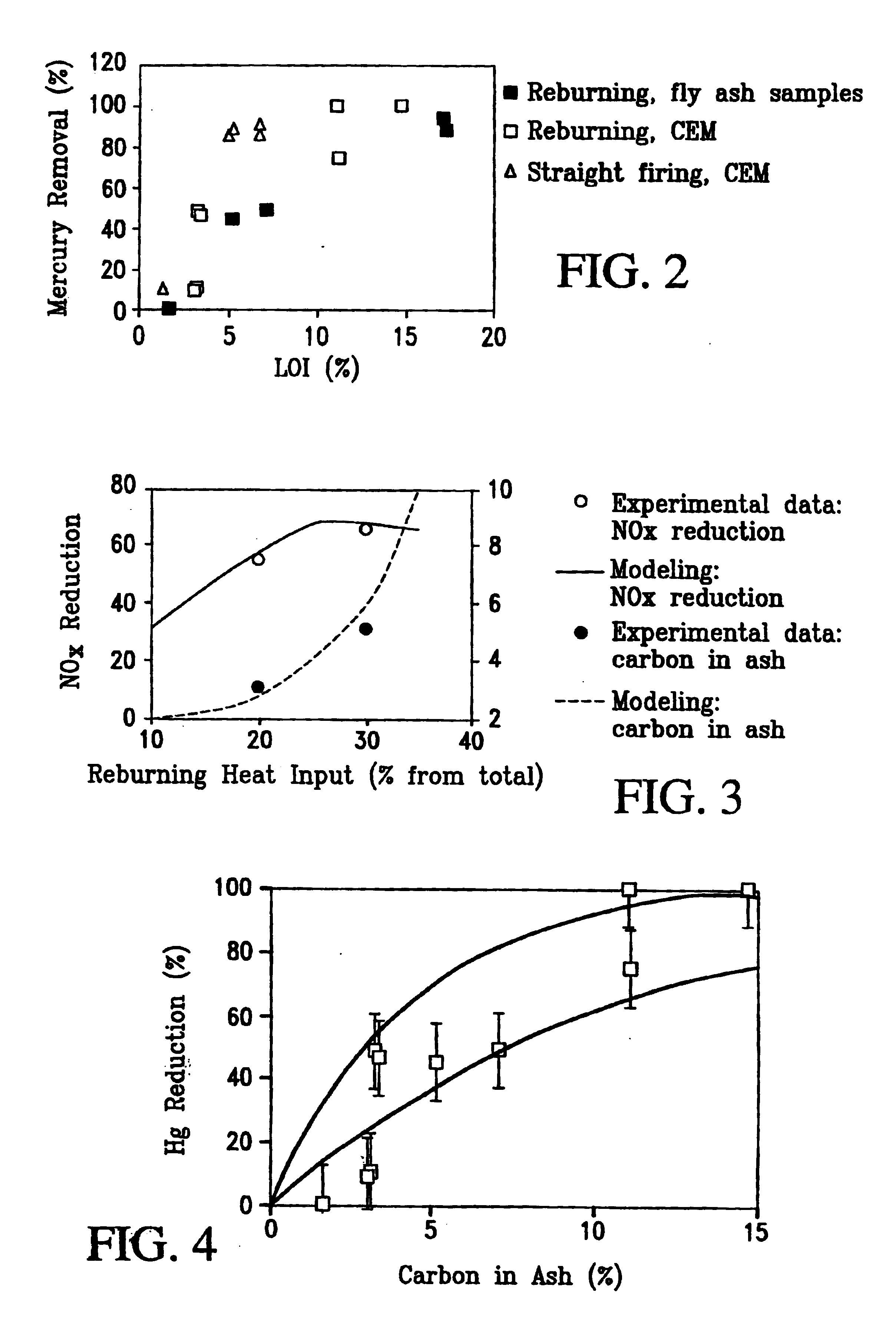

Process to reduce mercury emission

InactiveUS6863005B2Emission reductionEnhanced unburned carbonUsing liquid separation agentChemical/physical processesFlue gasProcess engineering

In a method to decrease emission of mercury, a factor is selected to control a combustion process to generate a flue gas comprising fly ash with enhanced unburned carbon; the combustion process is controlled according to a factor selected from reburning fuel, flue gas temperature, OFA injection, coal particle size, LNB flow, LNB design, combustion zone air, stoichiometric ratio of fuel, fuel / air mixing in a primary combustion zone and fuel / air mixing in a secondary combustion zone to produce the flue gas comprising fly ash with enhanced unburned carbon and to vaporize mercury; and the flue gas is allowed to cool to collect fly ash with enhanced unburned carbon with absorbed mercury. A system to decrease emission of mercury; comprises a combustion zone that is controlled to generate a flue gas comprising fly ash with enhanced unburned carbon and that produces vaporized mercury; and a post combustion zone to cool the flue gas to collect fly ash with enhanced unburned carbon with absorbed mercury.

Owner:GENERAL ELECTRIC CO

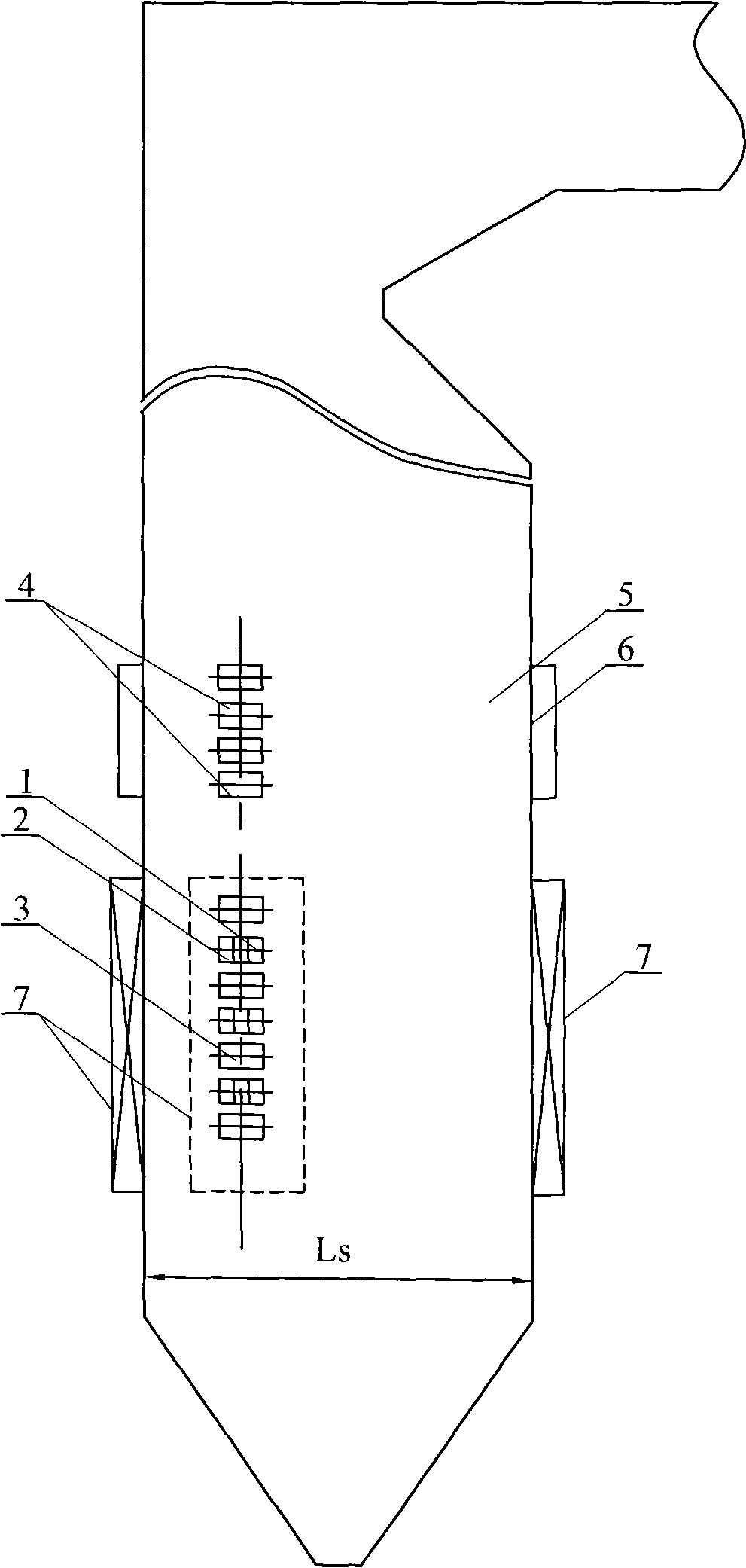

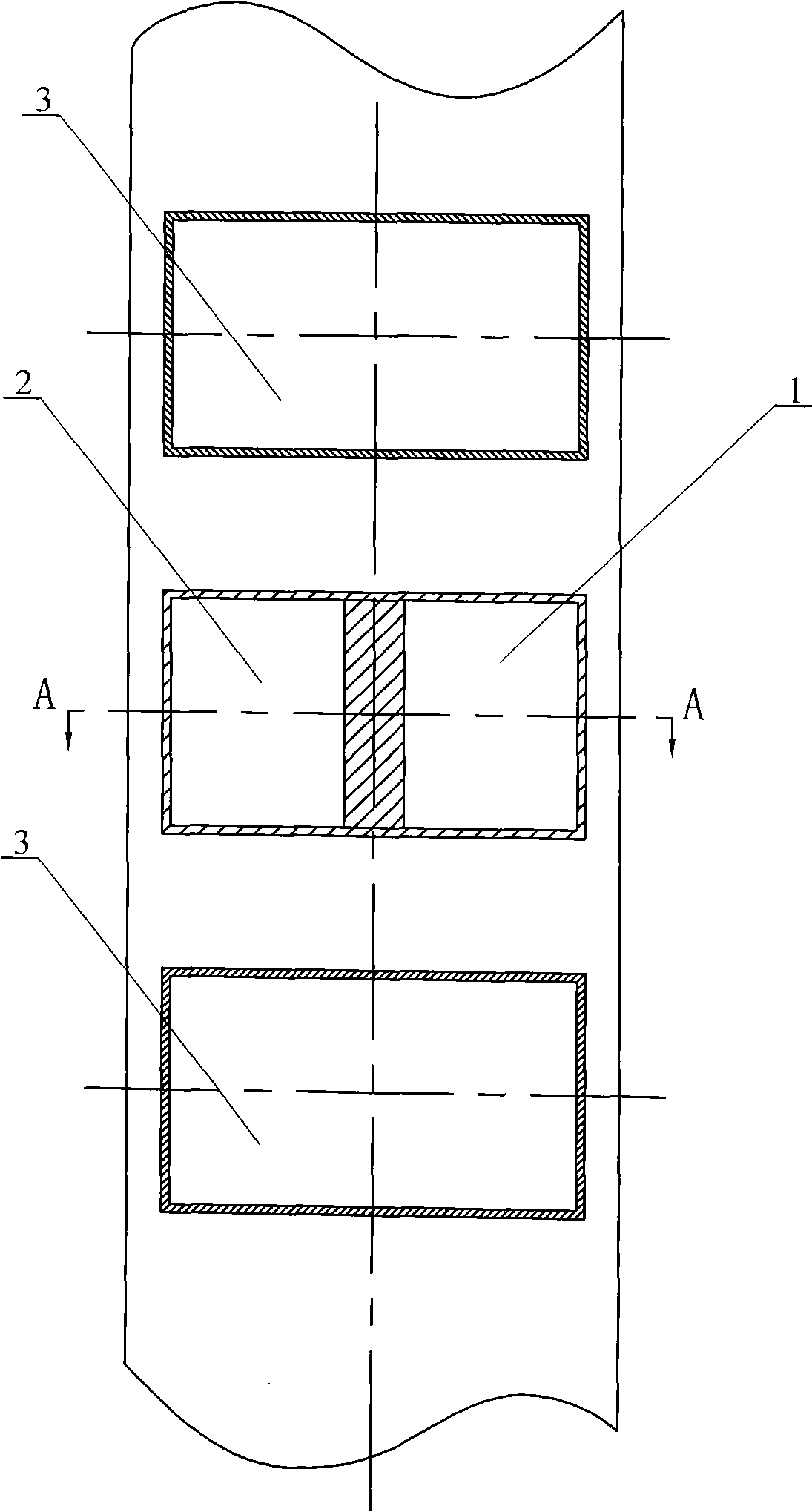

Wall type arranged horizontal rich-lean direct current combustion device

ActiveCN101315184AReduce skewReduce smoke temperature deviationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorSlag

A wall-mount horizontal bias direct-flow combustion device relates to a horizontal bias direct-flow combustion device. The invention solves the problems of the prior direct-flow combustor, such as four-corner tangential arrangement, different air supply conditions of coal flows on two sides, high risk of slag deposition due to declination and corrosion at high temperature. First dense / dilute air jet ports and a second air jet port (3) are formed on the water-cooled wall (6) of a furnace cavity (5) and combined to form a group of combustors (7). The central line (31) of the second air jet port and the central line (21) of the first dilute air jet port (2) are positioned in the fire-facing side direction, and have the included angles of alpha 1 and alpha 2 with relative to the water-cooled wall (6), on which the jet ports are positioned. The included angle between the central line (11) of the first dense air jet port and the central line (21) of the first dilute air jet port (2) is alpha 3. After-burn air jet ports (4) are arranged on the water-cooled wall (6) or at each corner of the furnace cavity (5). The After-burn air jet ports (4) are positioned above the combustors (7). The wall-mount horizontal bias direct-flow combustion device realizes reasonable combination of coal particles and air, prevents the deflection of coal flow, and ensures stable combustion, low load and low NOx discharge of boilers.

Owner:HARBIN INST OF TECH

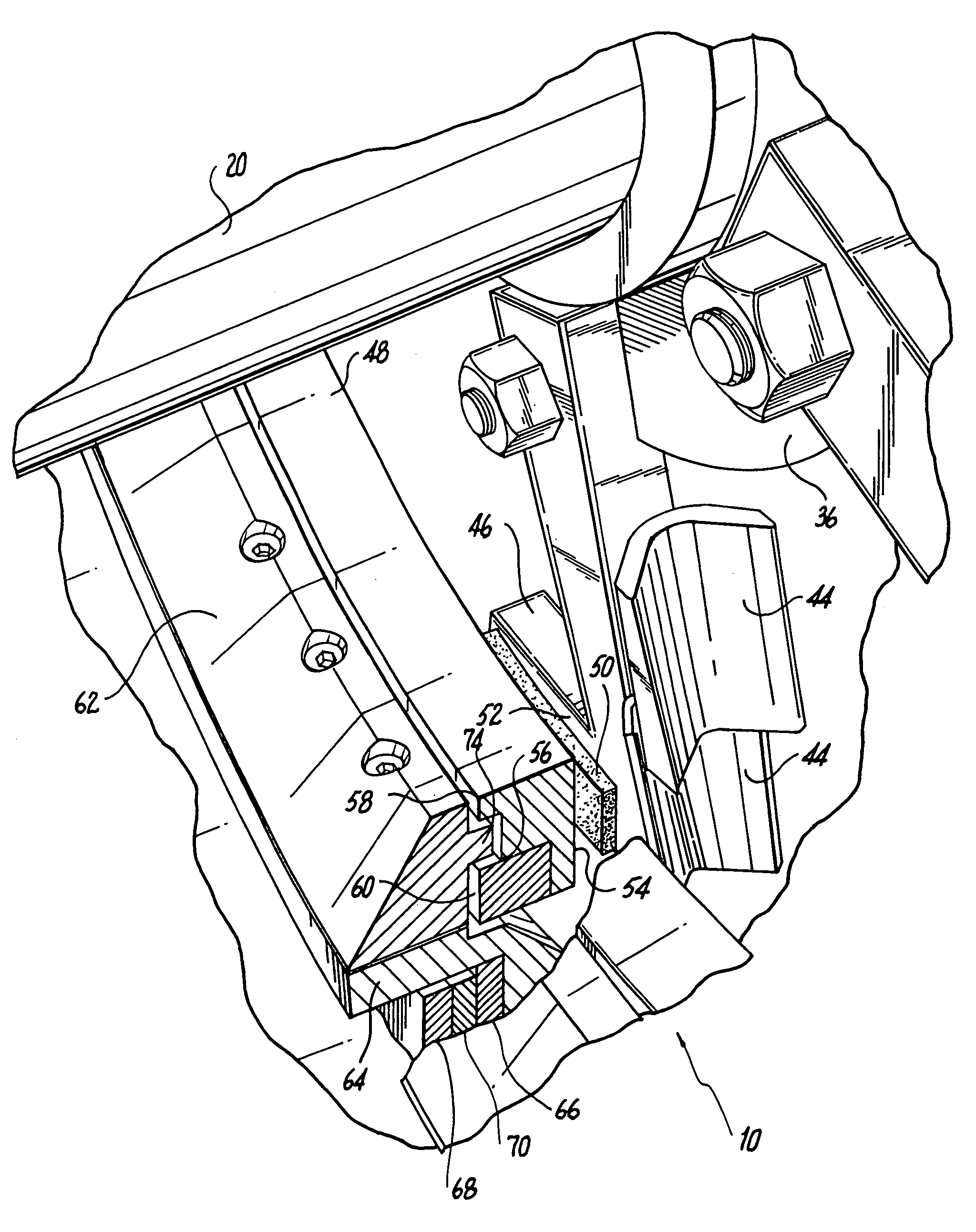

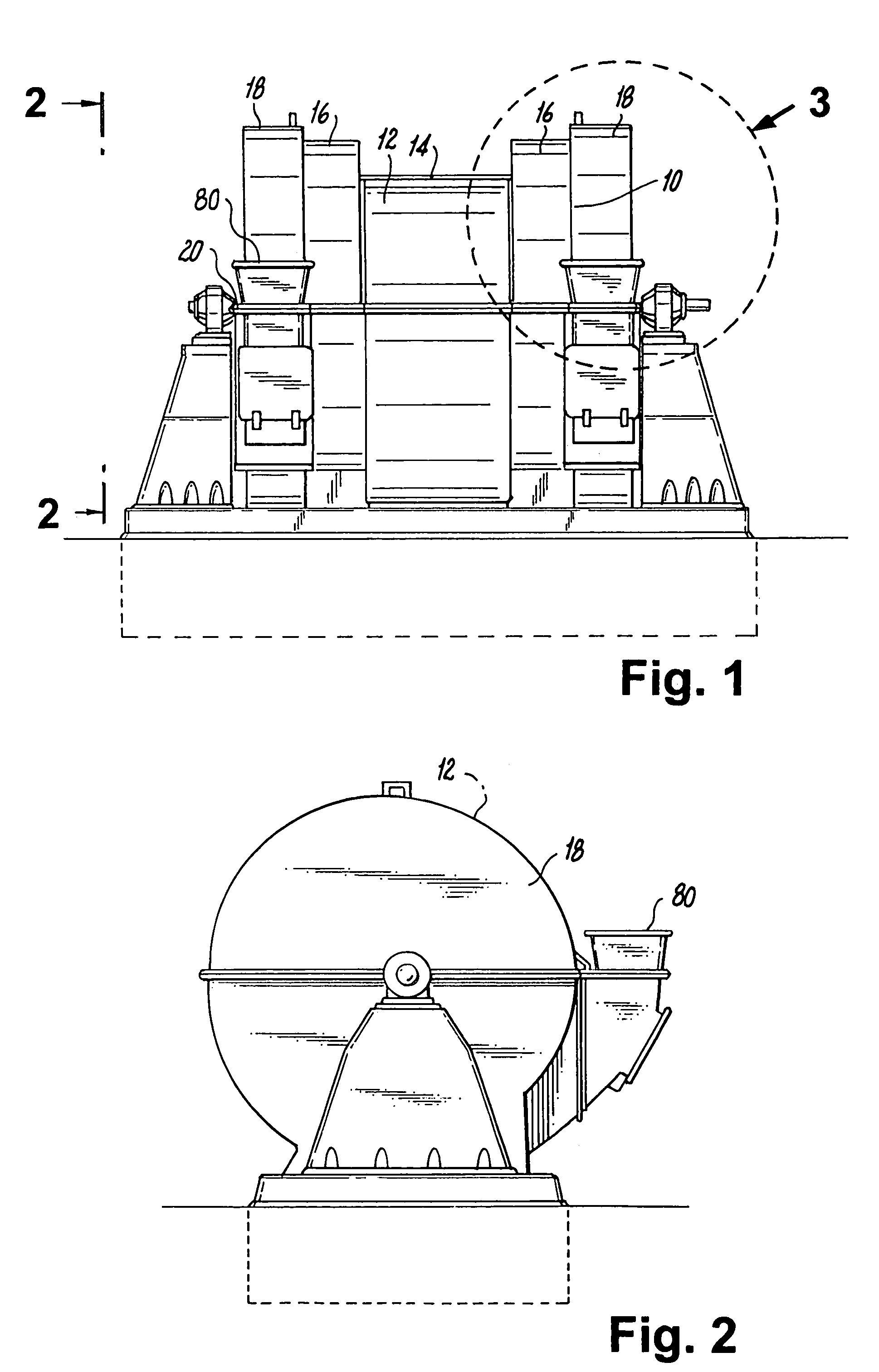

Dynamic ring classifier for a coal pulverizer

The present invention is directed to, among other things, a classifier assembly for mounting on the center shaft of a rotary coal pulverizer which includes a labyrinthian sealing arrangement operatively associated with the shaft for limiting the egress of unacceptably large coal particles from the pulverizer.

Owner:RILEY STOKER

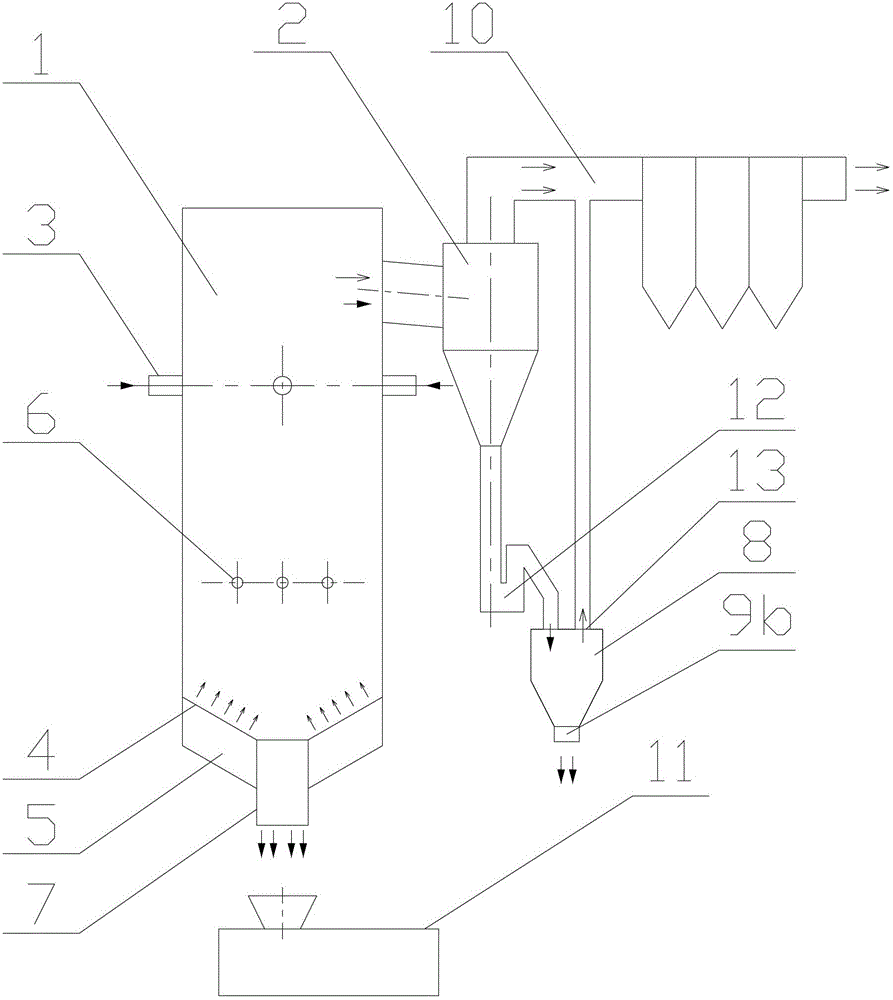

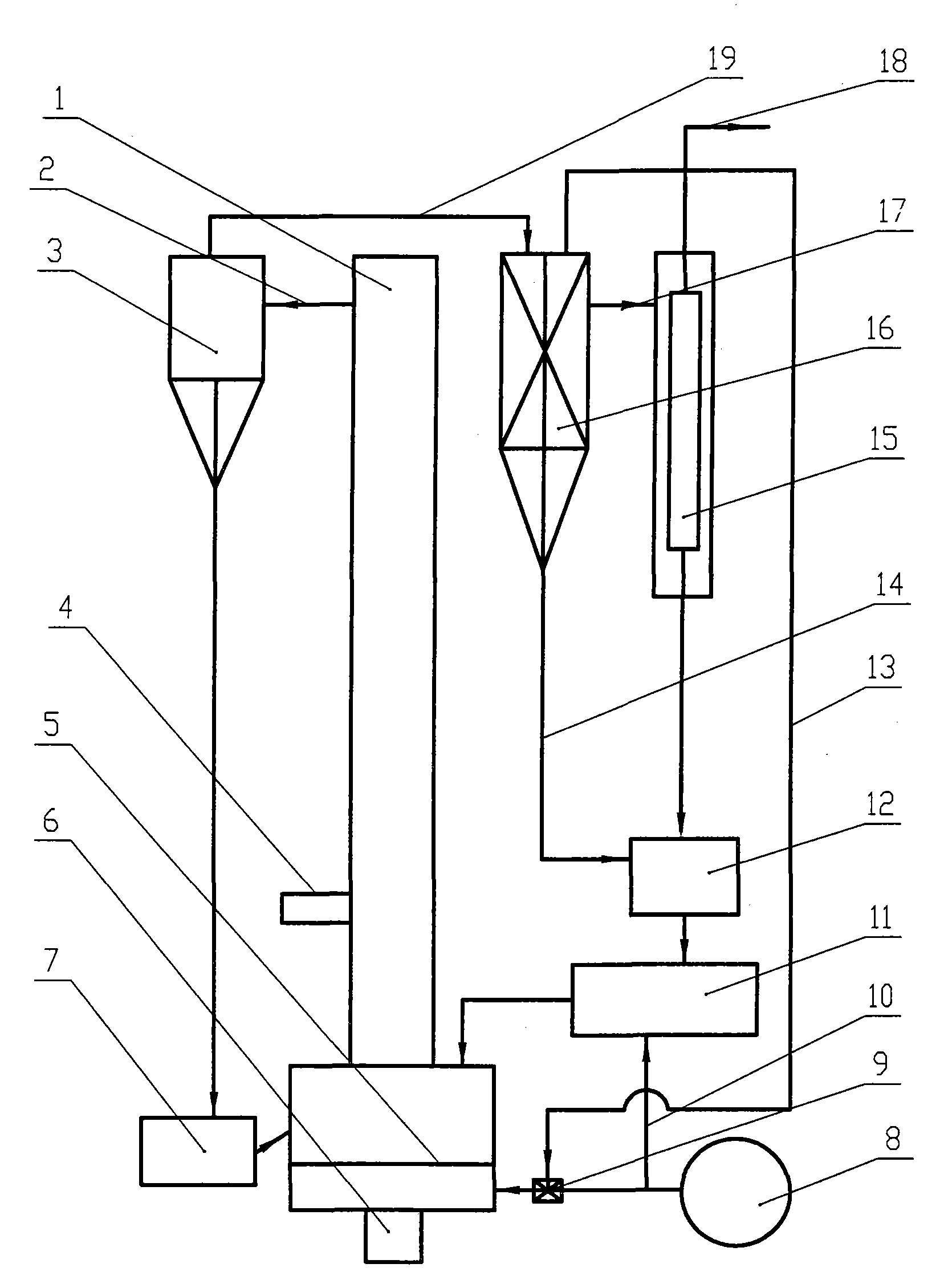

Method for producing coal gas by staged gasification of pulverized coal

InactiveCN102277200AAchieve desulfurizationAdaptableGranular/pulverulent flues gasificationCycloneSuperheated steam

The invention relates to a method for producing coal gas by staged gasification of pulverized coal. The steps are as follows: the pulverized coal fed into the furnace is mixed with rapidly fluidized high-temperature particles and gasification gas in a fluidized bed, and the pulverized coal of small and medium particles flows upwards. Pyrolysis at a high temperature of 900-1000°C, enter the cyclone separator through the gas-solid mixing pipeline for separation, the medium particles return to the lower part of the main body of the circulating fluidized bed through the first-stage feeder, and the gas carries small particles out of the upper port of the cyclone separator, and passes through the high temperature The gas pipeline enters the superheated steam heat exchanger for heat exchange and separation, and then enters the circulation separator, and the gas is discharged from the gas outlet for users. The invention has the characteristics of integrated circulating fluidized bed and entrained flow bed, high gasification intensity, flexible adjustment of production load, stable and reliable operation, high operation rate, reduced gas production cost, and no phenolic water pollution.

Owner:舒克孝

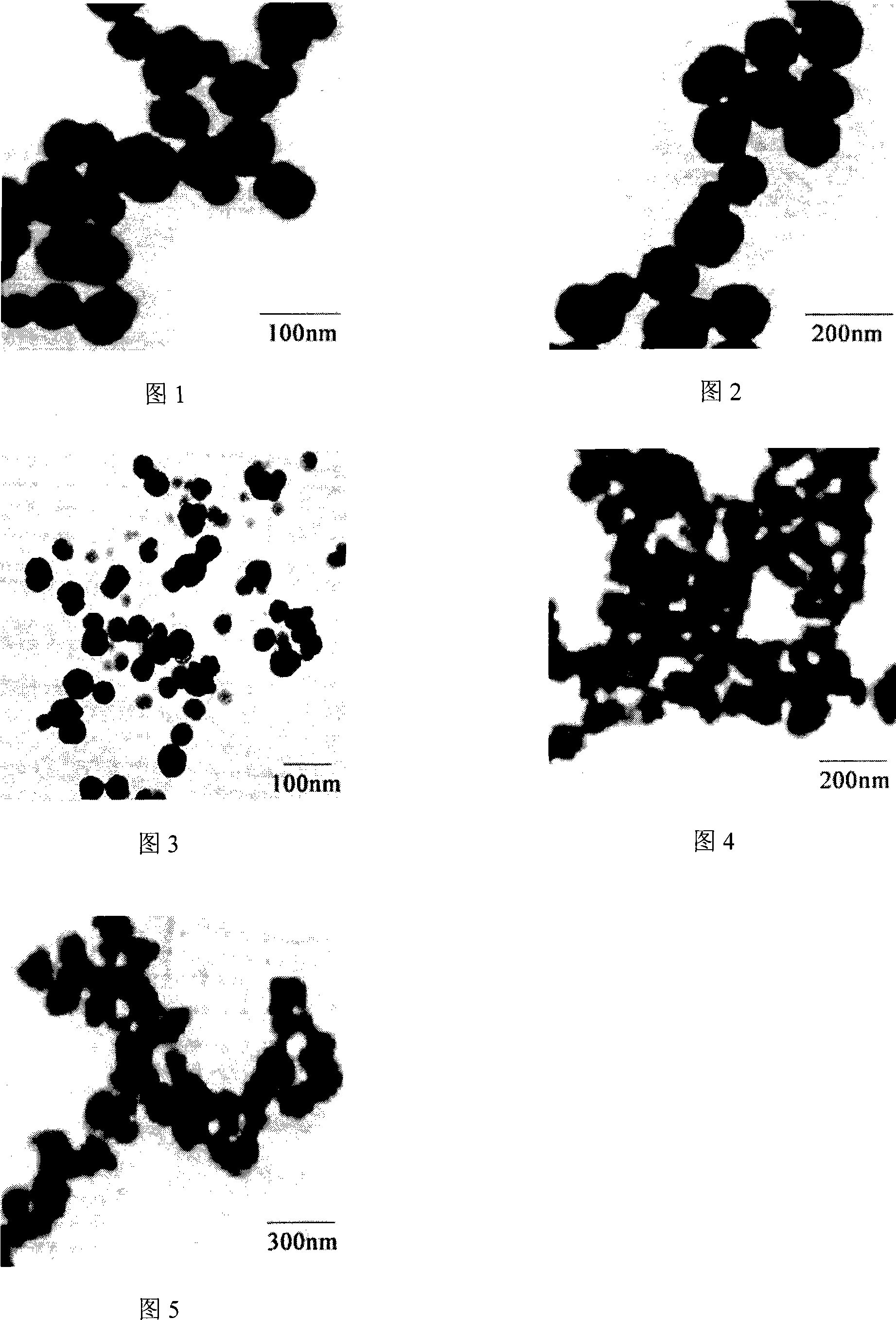

Stable ash-free method for preparing nano coal slurry

The invention discloses a preparation method of stable ashless nano coal slurry. The method includes: (1) preparing ultra-fine organic coal slurry by ball milling after the coal is swollen in an organic solvent; (2) removing the ash in the coal by organic solvent extraction; (3) removing the ash-free coal from the The organic solution is separated, and the structure control agent is used to control the growth process of coal molecules to form nano-coal particles with adjustable particle size. Finally, a stable ashless nano-coal slurry is prepared by adding a dispersion stabilizer. The dispersion medium can be water, alcohol , oil or a mixture of solvents. This method uses solvent extraction-precipitation method to prepare coal-based liquid fuel. Compared with traditional coal direct liquefaction and indirect liquefaction, it has the advantages of simple process, high energy utilization rate and low cost. The prepared coal slurry can be directly used in diesel engines, Gas turbines, central air-conditioning, oil-fired boilers, etc. are used to replace fuel oil and vaporize to prepare oxygen.

Owner:SOUTH CHINA UNIV OF TECH

Granule(powder) coal based fuel and preparation method thereof

InactiveCN101250455AExtended product chainImprove combustion efficiencySolid fuelsMass ratioGranularity

The invention discloses a grain(powder)-shaped coal-based fuel and the process for preparation, the coal-based fuel is prepared through adopting a wet fine grinding-dry rough grinding technique, namely the process for preparation comprises the following steps: mixing raw material coal and liquid whose mass ratio is (7-8):(2-3), and preparing into slurries with slurries through wet fine grinding, wherein the dosage of dispersing agent is 0.3-3% of the amount of dry coal in raw material coal, and the concentration of slurries is 70%-80%, coal particle content which is less than 74um in slurries is bigger than 90%, utilizing dry rough grinding to grind raw material coal and dispersing agent into dry coal powder, wherein dispersing agent is 0.3-3% of dry coal amount in raw material coal, coal particle content which is less than 74um in dry coal power is less than 50%, stirring the above slurries and the above dry coal powder according to 100:(30-80), controlling coal particles stacking efficiency in 60%-80%, shaping grain(powder)-shaped coal-based fuel, wherein maximum particle grain size is 300um, the content of coal particles which are less than 74um are bigger than 75%, and the content of coal is bigger 80%.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

Drying and moulding integrated process for low rank coal

InactiveCN101440323AKeep dryImprove product qualitySolid fuelsDrying machines with non-progressive movementsWater vaporCoal dust

The invention provides an integrated process for drying forming of low-rank coal. The process comprises the following steps: (1) crushing the low-rank coal to be dried so that the particle size of the crushed low-rank coal particles is less than 50 millimeters; (2) delivering the crushed low-rank coal into a roller dryer quantitatively; (3) rotating the roller dryer and introducing heating fluid to the roller dryer to heat the coal in a roller; (4) collecting the coal discharged from the roller dryer, and delivering the heating fluid, dust carried along with the heating fluid, and water vapor from the low-rank coal into a dust processing system; (5) classifying the low-rank coal collected from the roller dryer according to certain particle size, and delivering the low-rank coal with the particle size of larger than the certain particle size to a product warehouse as a first product; and (6) delivering the low-rank coal with the particle size of smaller than the certain particle size to an extrusion forming device through a sealed delivery device to be extruded and formed together with the coal dust collected from the dust processing system, and delivering the formed product to the product warehouse as a second product.

Owner:DATANG INT CHEM TECH RESINST +1

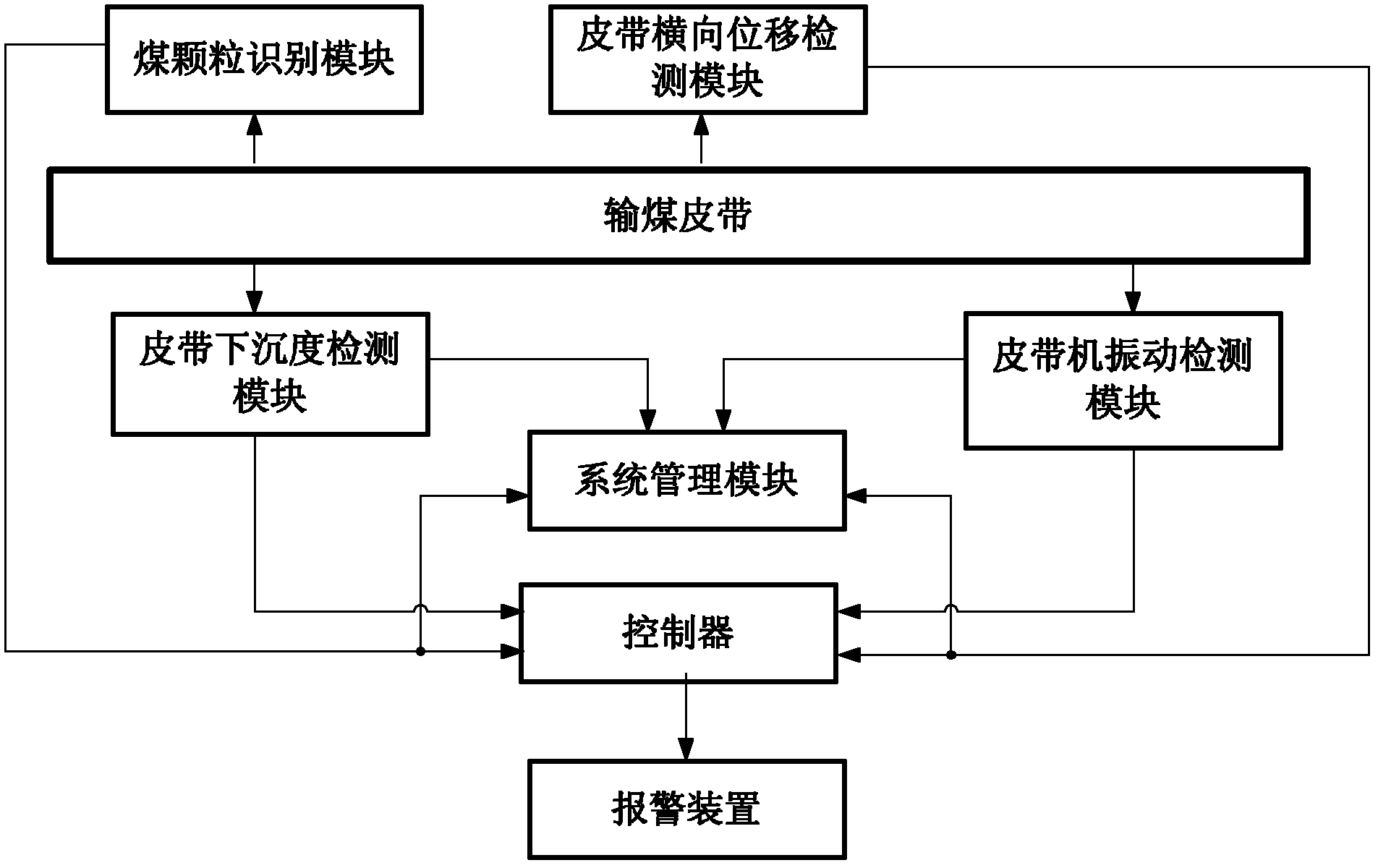

Method for monitoring coal conveying belt of coal conveying system by intelligent monitoring system

InactiveCN102424257AReduce the risk of being tornExtend your lifeControl devices for conveyorsMonitoring systemEngineering

The invention relates to a method for monitoring a coal conveying belt of a coal conveying system by an intelligent monitoring system. The intelligent monitoring system comprises a coal particles identifying module, a belt sinkage detecting module, a belt lateral displacement detecting module, a belt conveyor vibration detecting module and a controller, wherein the controller is connected with each module in a wired way or in a wireless way. The method comprises the following steps of: monitoring whether large-sized coal is existed on the coal conveying belt by the coal particles identifying module; monitoring whether the large-sized coal is existed on the coal conveying belt by the belt sinkage detecting module; monitoring the status of the coal conveying belt by the belt lateral displacement detecting module; monitoring the belt conveyor vibration condition of belt conveyor caused by the vibration of the coal conveying belt throughby the belt conveyor vibration detecting module; and braking athe belt conveyor by the controller, wherein the controller receives the instruction that the belt conveyor needs to be braked and sends out the braking instruction, so that the belt conveyor is braked.

Owner:北京纵横兴业科技发展有限公司 +3

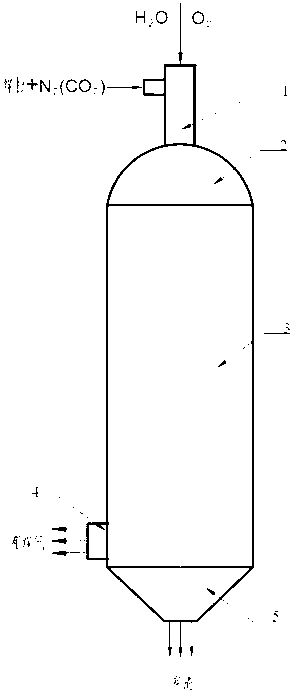

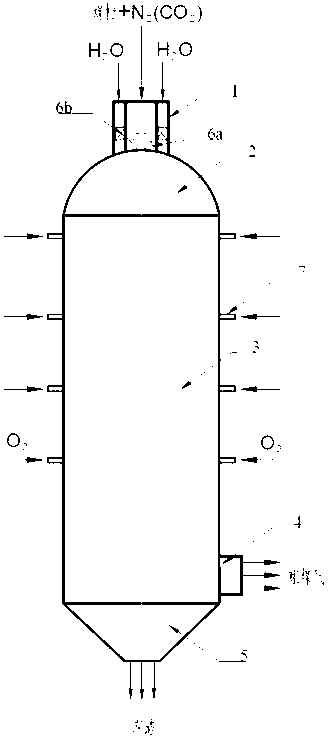

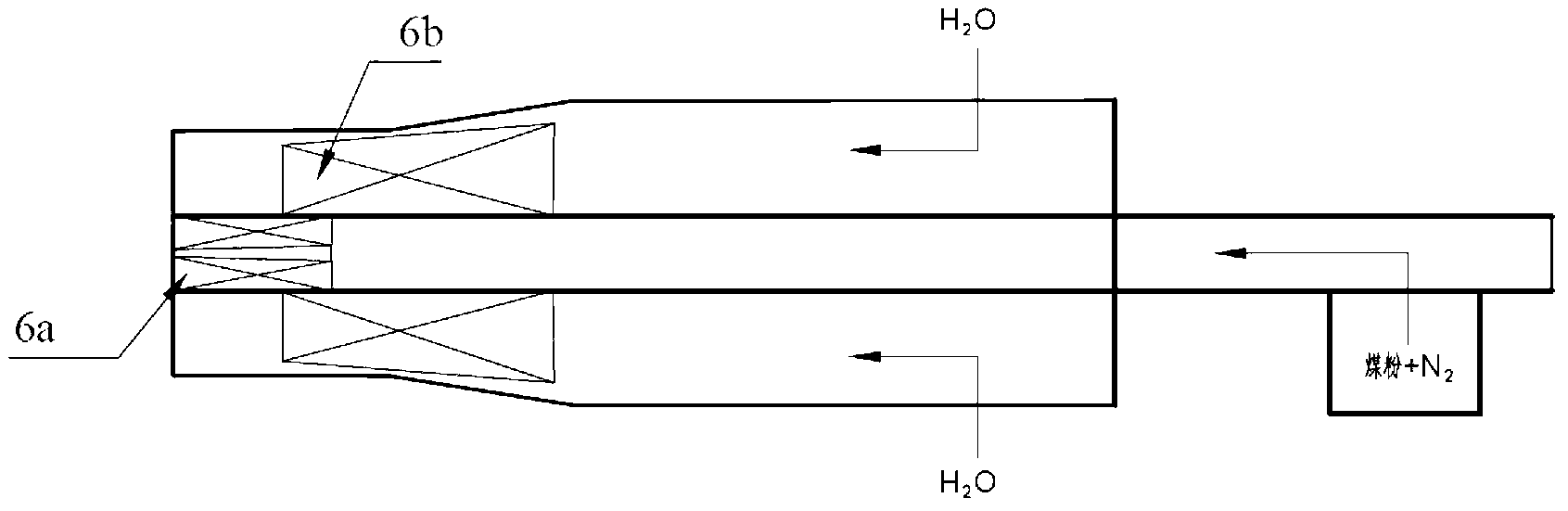

Dry pulverized coal cyclone entrained flow bed gasification furnace and gasification method thereof

InactiveCN102796566AImprove carbon conversionImprove conversion rateCombined combustion mitigationGranular/pulverulent flues gasificationCycloneWater vapor

The invention relates to a dry pulverized coal cyclone entrained flow bed gasification furnace and a gasification method thereof, which belong to the technical field of coal gasification device. The dry coal dust cyclone entrained flow bed gasification furnace comprises a top nozzle, a furnace roof, a gasification chamber, an exhaust port and a bottom slag discharge port. The top nozzle is an annular channel structure with inner, outer swirl vanes, at least one layer of a tangential O2 nozzle is arranged on the lateral wall of the gasification chamber. Pulverized coal gas flow and vapor are fed through a top nozzle in a whirling way, and the pulverized coal gas flow rotating downwards is formed in the near-wall area. The pulverized coal particles are subjected to film type gasification on a liquid slag film formed on the surface of the furnace wall under the centrifugal action of the high-speed rotation gas flow. The service life of the nozzle is effectively prolonged, the residing time of the pulverized coal in the furnace is increased, and the carbon conversion efficiency is increased; liquid slags reside on the wall surface, so as to effectively protect the wall surface; the multiple layers of the tangential O2 nozzles are arranged to effectively disperse heat load and the work reliability of the gasification furnace is increased.

Owner:TSINGHUA UNIV +1

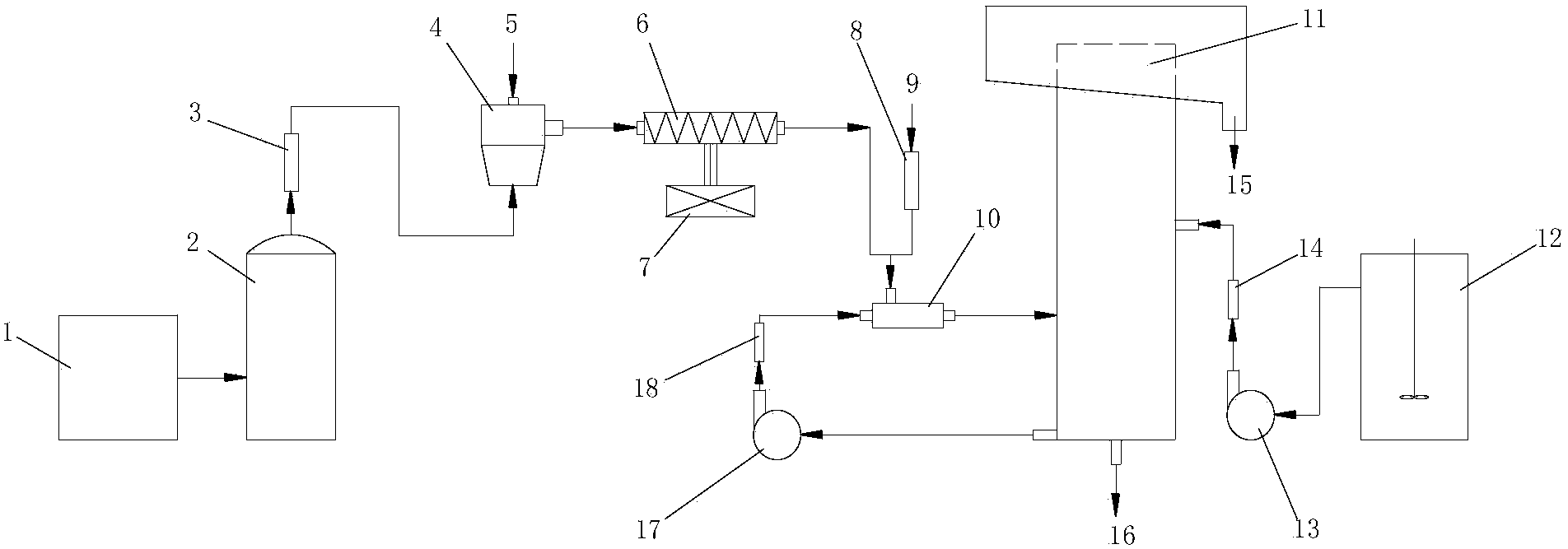

Method and device for reinforcing oil bubble column floatation process of low-order coal

The invention discloses a method and a device for reinforcing an oil bubble column floatation process of low-order coal, and belongs to floatation methods and floatation devices for the low-order coal. The method comprises the following steps: (1) adding a surfactant into a hydrocarbon oil collecting agent proportionally; (2) atomizing hydrocarbon oil mixed with the surfactant into oily mist beads in an atomizer by using air flow provided by an air compressor; (3) heating the air flow of the oily mist beads in a tubular temperature control evaporator until the temperature reaches hydrocarbon oil evaporation temperature to form oil evaporation gas; (4) mixing the heated oil evaporation gas with air, feeding the mixture into a bubble generator, and forming modified oil bubbles by wrapping bubbles with thin surfactant-modified hydrocarbon oil layers under the jet action of the bubble generator; (5) pre-wetting and uniformly mixing the low-order coal in a stirring barrel, and pumping the low-order coal into a floatation column; (6) in the floatation column, mineralizing the modified oil bubbles and low-order coal particles, carrying clean coal to float up by using the modified oil bubbles as carriers, and keeping tailings and high-ash fine silt which are not mineralized in the column to obtain the clean coal and the tailings. The method and the device have the advantages that the consumption of the hydrocarbon oil collecting agent is reduced; the floatation selectivity and the recovery rate of the low-order coal are improved.

Owner:CHINA UNIV OF MINING & TECH

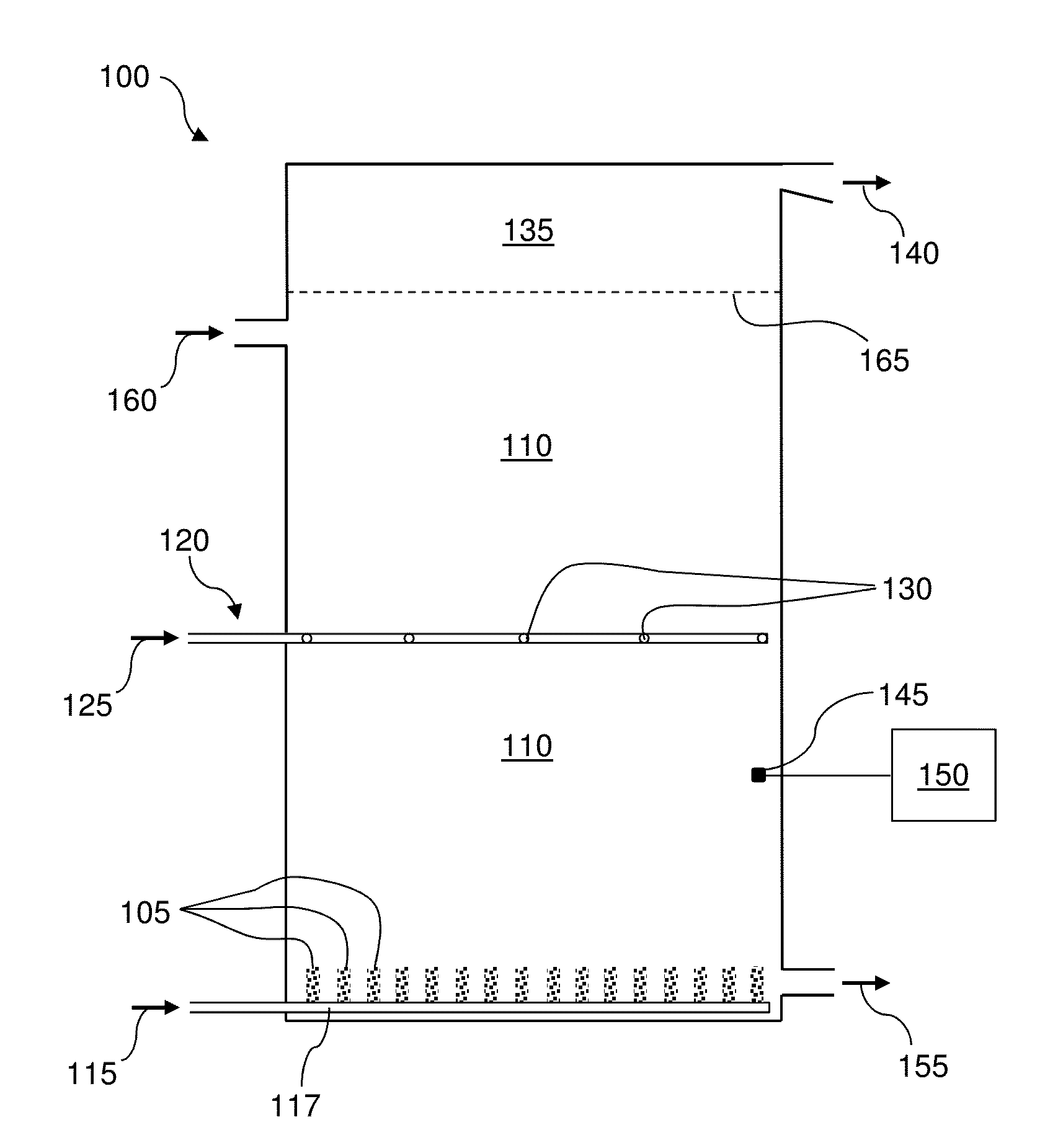

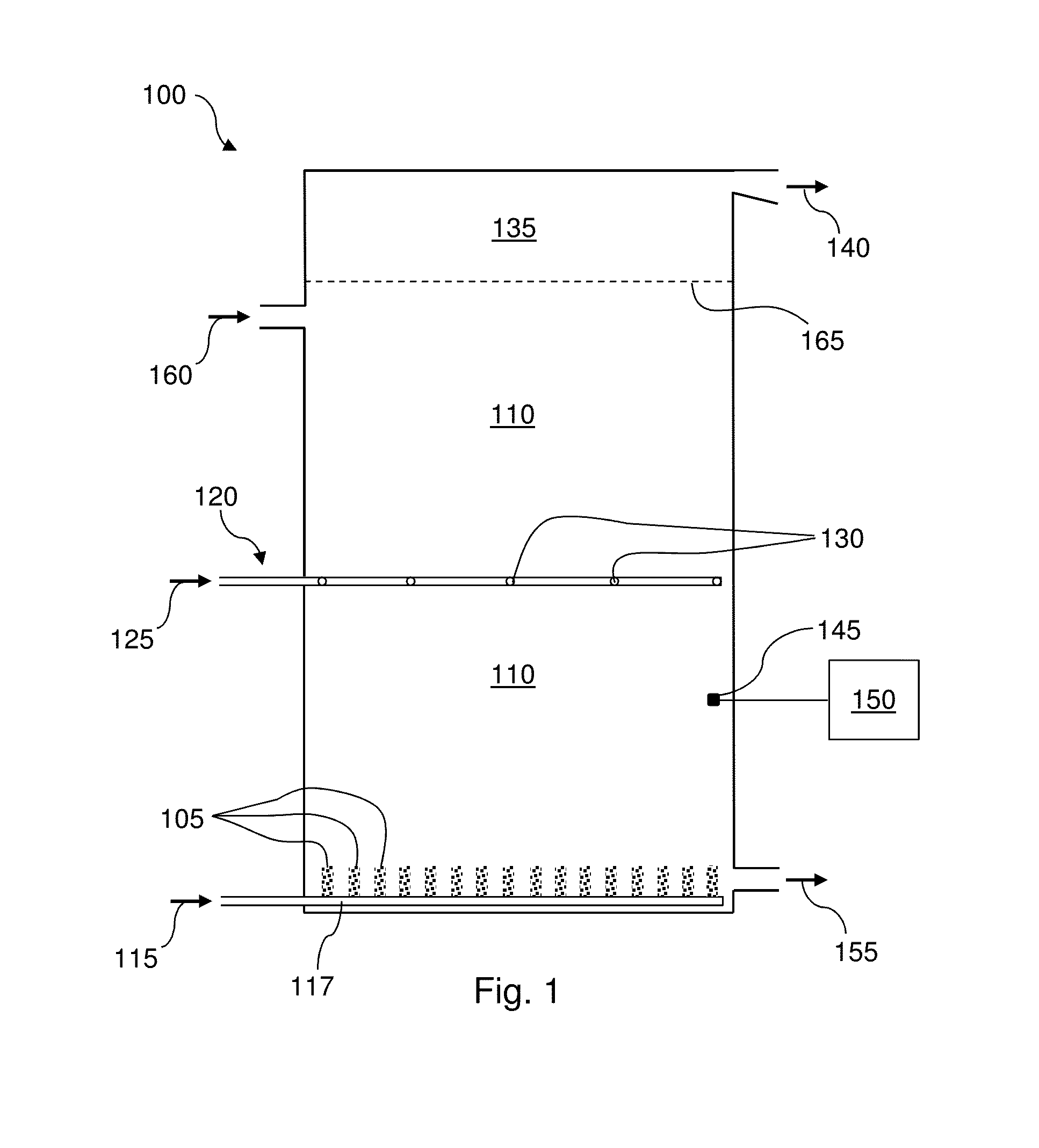

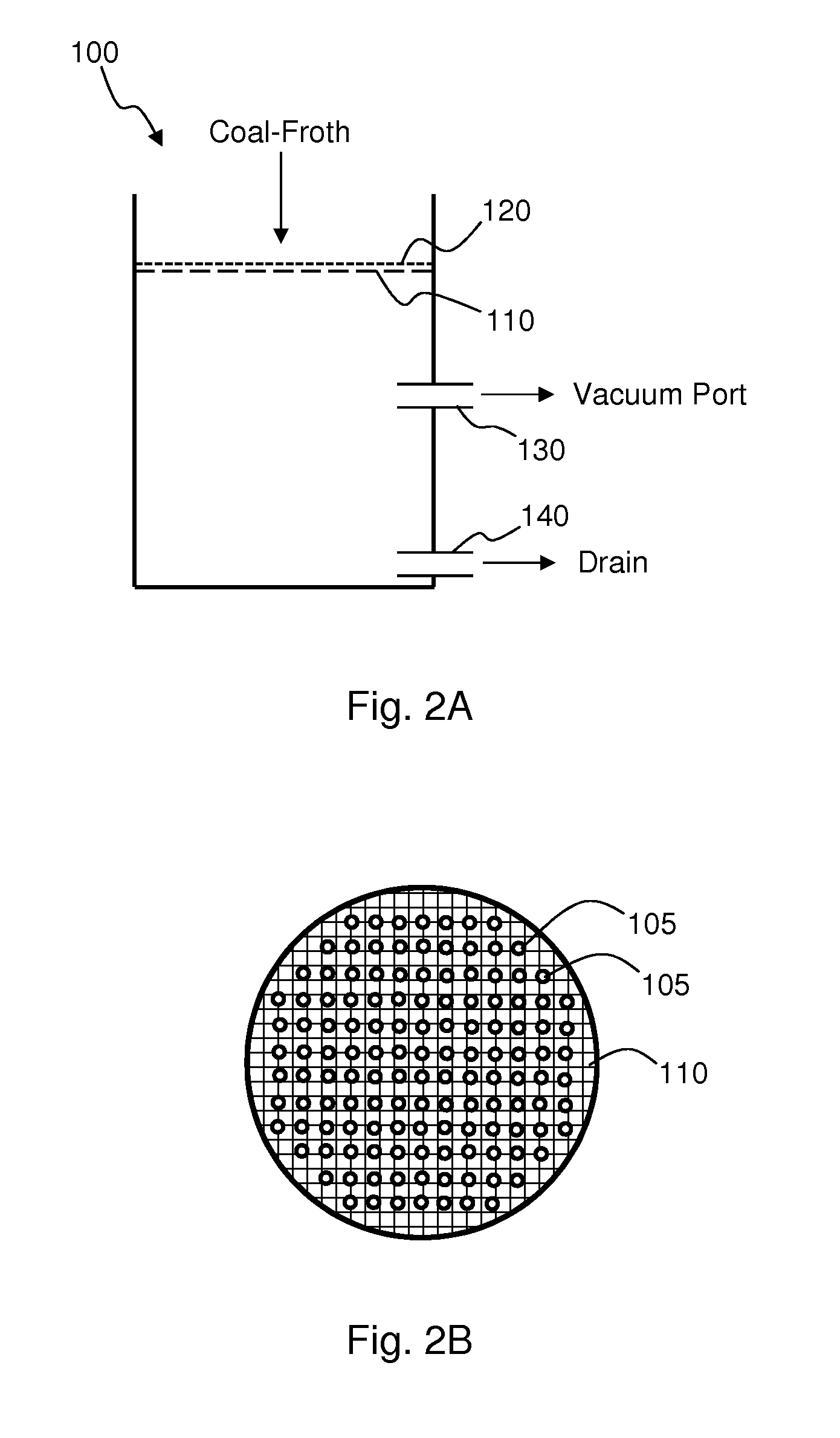

Vibration assisted vacuum dewatering of fine coal particles

Fine coal particles are dewatered by mechanically removing water from the coal particles by vibration assisted vacuum dewatering to form a coal particle filter cake. The filter cake typically has a water content less than 35% by weight, suitable for extrusion to form discrete, non-tacky pellets. The vibration assisted vacuum dewatering may operate at a vibration frequency in the range from about 1 Hz to about 500 Hz. The vibration frequency may be adjusted during the dewatering process. In some embodiments, the vibration frequency is increased as the moisture content of the coal particle filter cake is decreased. Washing the filter cake during dewatering removes soluble contaminants. Various vibration assisted vacuum dewatering devices may be used, including a vibration assisted rotary vacuum dewatering drum, a vibration assisted vacuum disk filter, and a vibration assisted vacuum conveyor system.

Owner:EARTH TECH USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com