Gray melting poly-fluid bed powder coal gasification method

A technology for gathering and pulverizing coal, which is applied in the field of pulverized coal gasification of ash-melting and agglomerating fluidized beds, and can solve the problems of low production capacity and high compression energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

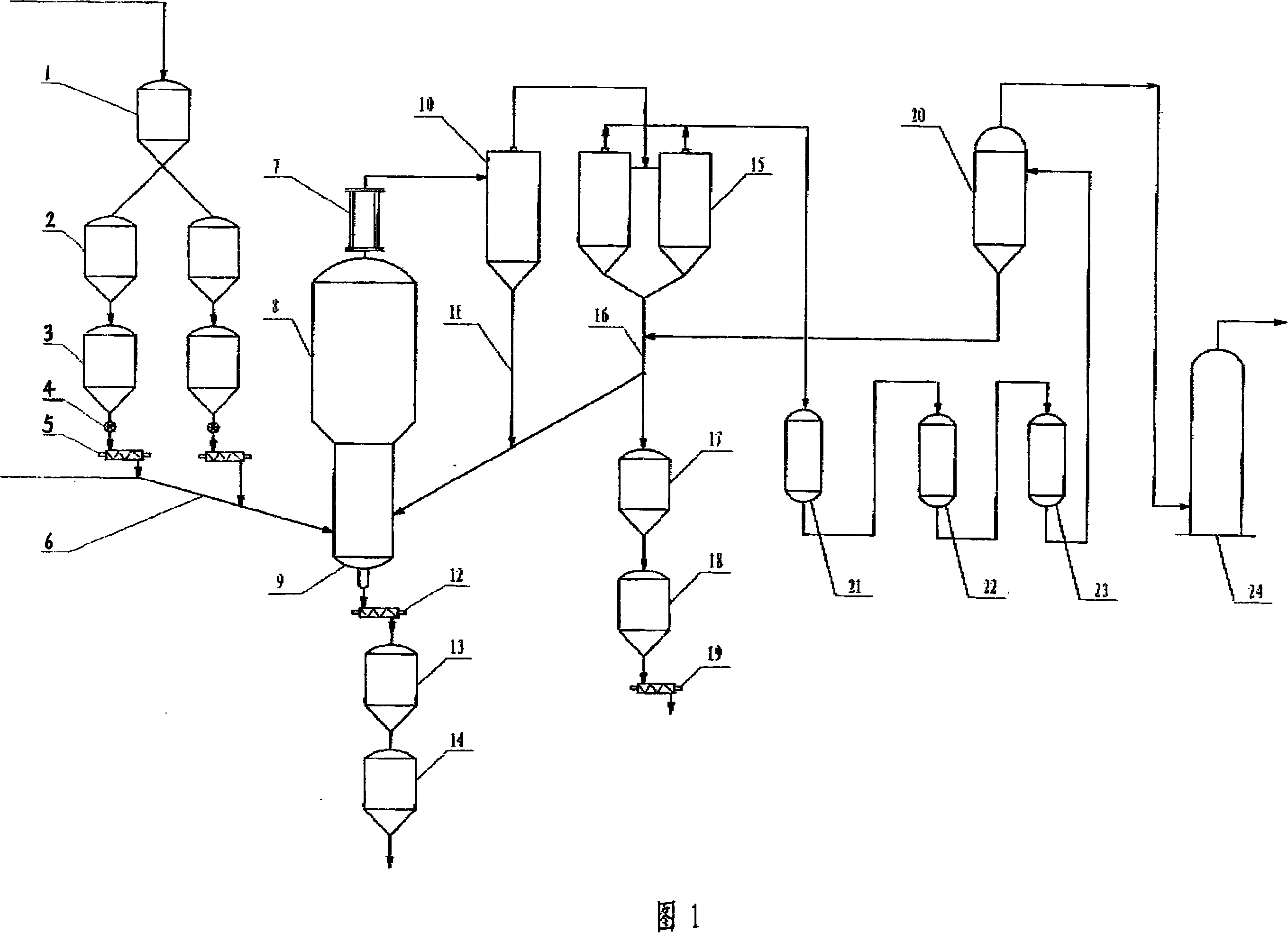

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0014] Referring to Fig. 1, the present invention is composed of a coal feeding system, a fluidized bed gasification system, a slag discharge system, an ash discharge system, a waste heat recovery system, a dust removal system and a gas washing and cooling system;

[0015] The coal feeding system is composed of a coal hopper 1, a coal lock 2, a feed hopper 3, a star feeder 4, a spiral coal feeder 5 and a coal feed gravity pipe 6 connected in sequence;

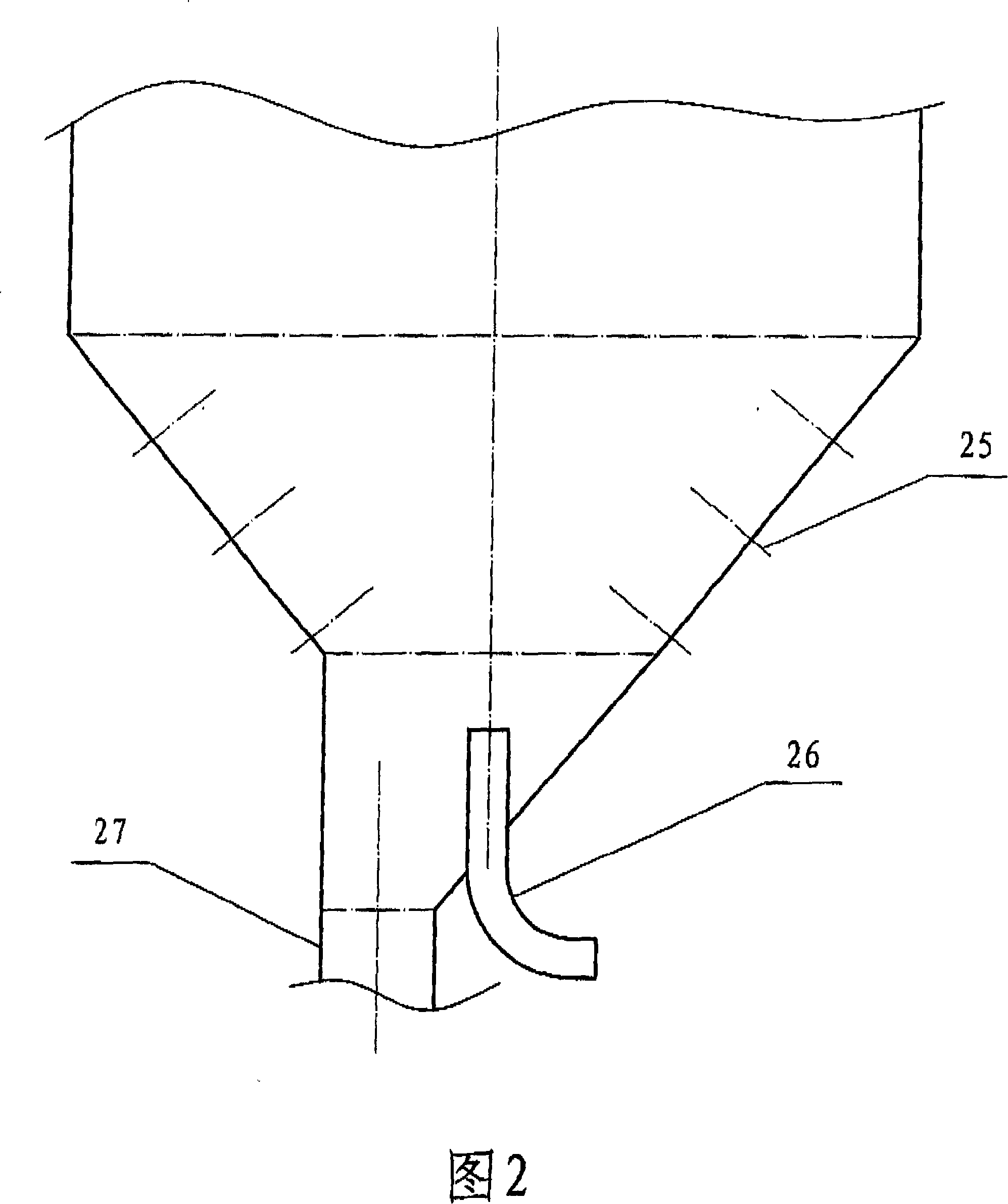

[0016] The fluidized bed gasification system is composed of a gasification furnace 8 and a gas distributor 9, wherein the gasification furnace is connected with the coal feeding gravity pipe 6;

[0017] The slag removal system is composed of a spiral slag cooler 12 connected to the gasifier 8, a slag receiver 13, and a slag lock 14;

[0018] The waste heat recovery system is composed of a first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com