Drying and moulding integrated process for low rank coal

A low-rank coal and process technology, applied in the direction of non-progressive dryers, material forming presses, drying, etc., can solve problems such as dust, and achieve the effects of avoiding dust pollution, simple process flow, and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

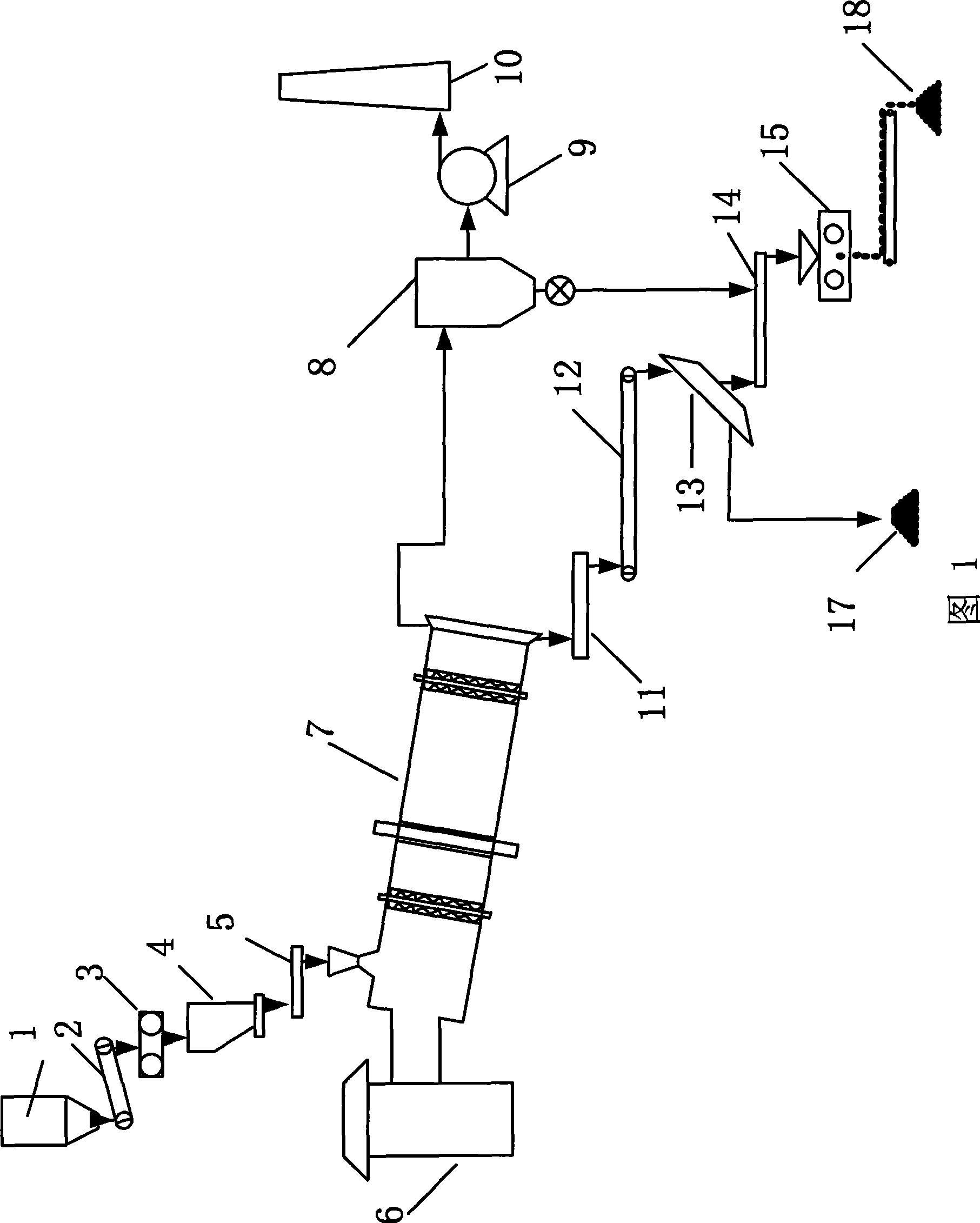

[0064] 1. Send the lignite that needs to be dried to the coal hopper 1. The moisture content of the lignite is about 33.4%. The lignite from the coal hopper 1 is sent to the crusher 3 through the belt conveyor 2 for crushing. The diameter is less than 25mm. The crushed lignite first passes through the quantitative feeder 4, and then continuously and stably feeds into the drum dryer 7 through the sealed scraper conveyor 5.

[0065] 2. The hot gas from the high-temperature heating device 6 is sent to the drum dryer 7, where the hot gas dries and dehydrates the lignite. The rotating speed of the drum dryer is set at 4r / min, the feeding speed is set at 16t / h, and the hot gas flow rate is 31000Nm 3 / h, the temperature is 700°C. The dried lignite is collected by a scraper conveyor 11, and the tail gas enters the bag filter 8 after drying.

[0066] 3. The air volume of the bag filter 8 in the dust treatment system is 30000-50000Nm 3 / h, the gas temperature at the inlet is 115-125...

example 2

[0071] 1. Send the lignite that needs to be dried to the coal hopper 1. The moisture content of the lignite is about 40%. The lignite from the coal hopper 1 is sent to the crusher 3 through the belt conveyor 2 for crushing. The diameter is less than 25mm. The crushed lignite first passes through the quantitative feeder 4, and then continuously and stably feeds into the drum dryer 7 through the sealed scraper conveyor 5.

[0072] 2. The hot gas from the high-temperature heating device 6 is sent to the drum dryer 7, where the hot gas dries and dehydrates the lignite. The rotating speed of the drum dryer is set at 4r / min, the feeding speed is set at 12t / h, and the hot gas flow rate is 31000Nm 3 / h, the temperature is 700°C. The dried lignite is collected by scraper conveyor 11, and the outlet gas enters bag filter 8.

[0073] 3. The air volume of the bag filter 8 in the dust treatment system is 30000-50000Nm 3 / h, the flue gas temperature at the inlet is 125-135°C; nitrogen i...

example 3

[0078] Other conditions are the same as example 1, just feed rate is increased to 25t / h, and molding pressure is increased to 10t / cm, and the moisture content of the unformed lignite particle after drying is not higher than 18% (mass ratio), and heat is no more than 18% (mass ratio). Less than 4500kcal / kg, the water content of the shaped coal is not higher than 9% (mass ratio) after inspection, and the heat is not lower than 5500kcal / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com