Patents

Literature

101results about How to "Large load capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

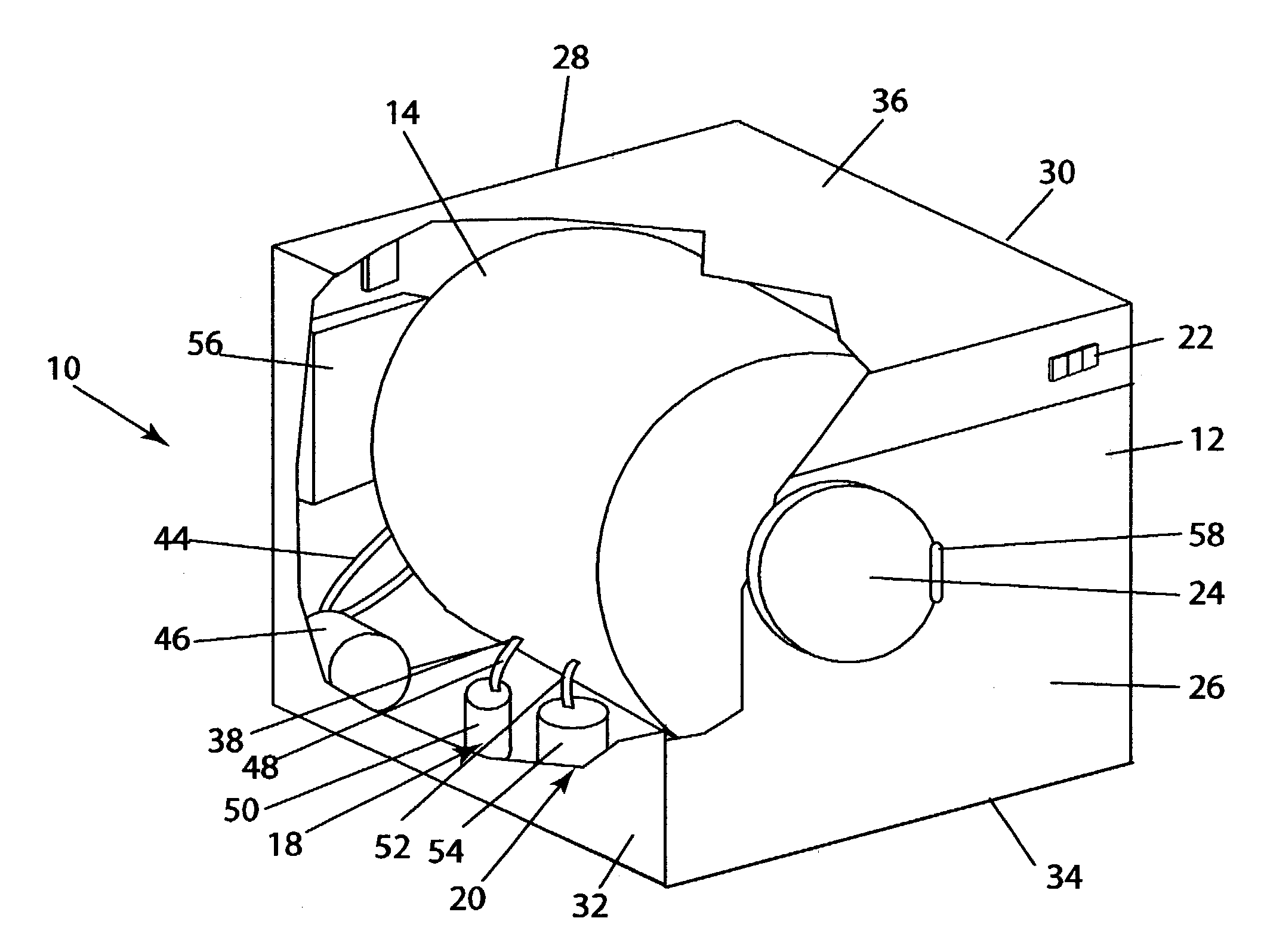

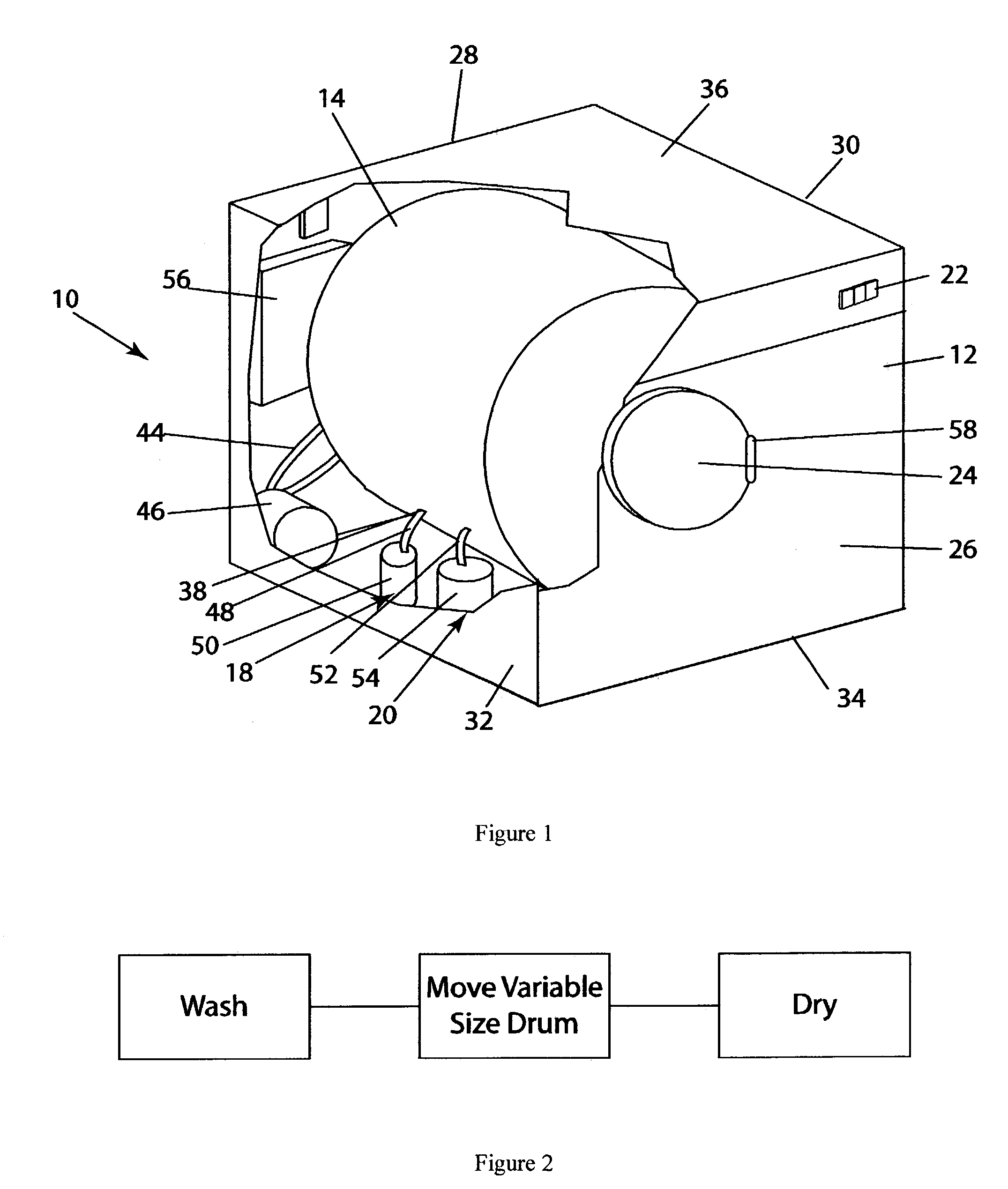

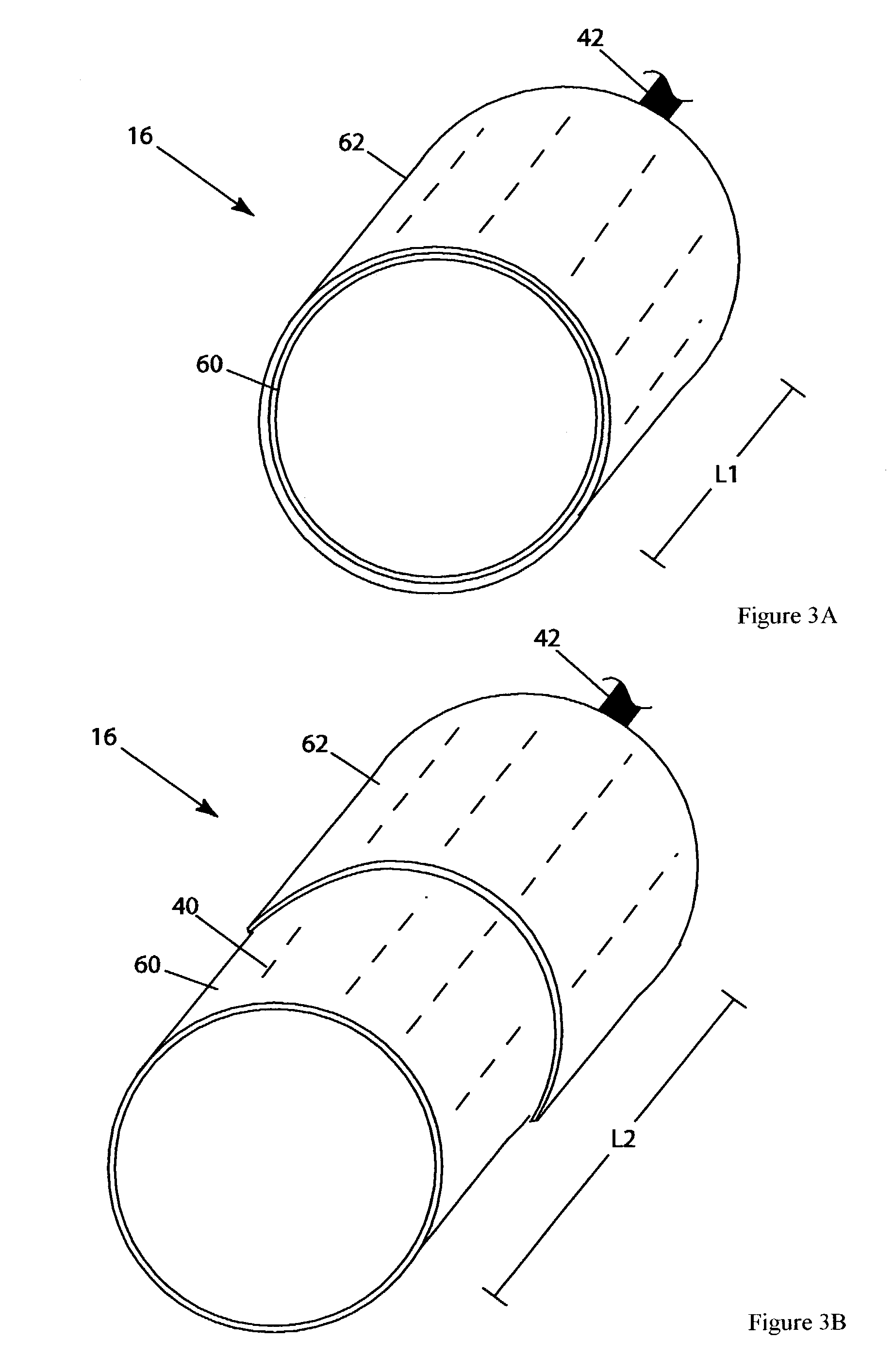

Combined washer dryer

InactiveUS7380423B1Large load capacityDry ability be improveOther washing machinesControl devices for washing apparatusAerospace engineeringWater treatment system

A combined washer dryer is provided. The combined washer dryer comprises an outer drum; a rotatable cylindrical variable size inner drum arranged coaxially within the outer drum and movable from a first position to a second position; a water handling system adapted to intake water into the inner drum and to remove water from the outer drum; an air handling system adapted to intake air into the inner drum and to remove air from the outer drum; and a control system adapted to control the movement of the variable size inner drum.

Owner:MUSONE JOHN P

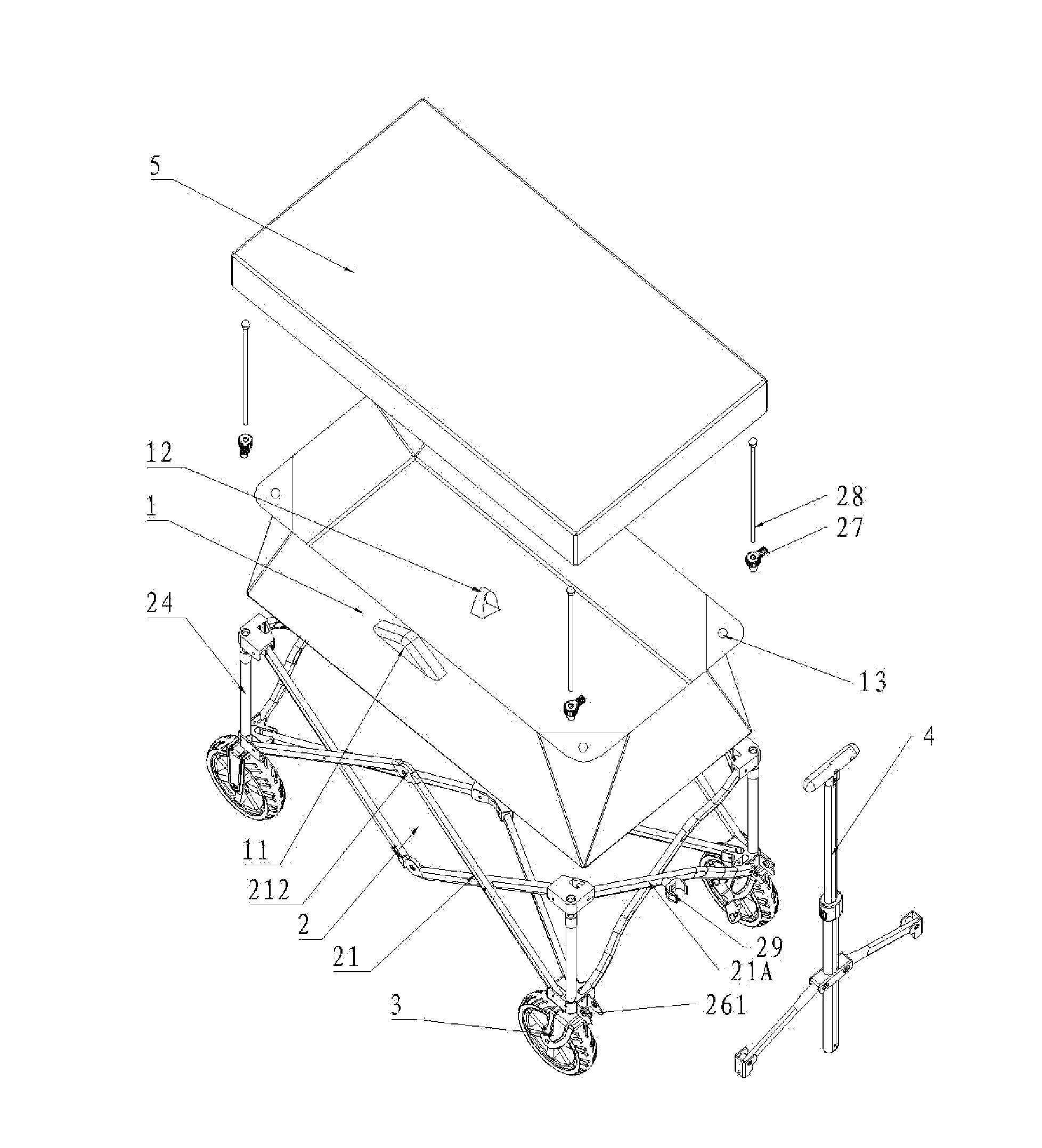

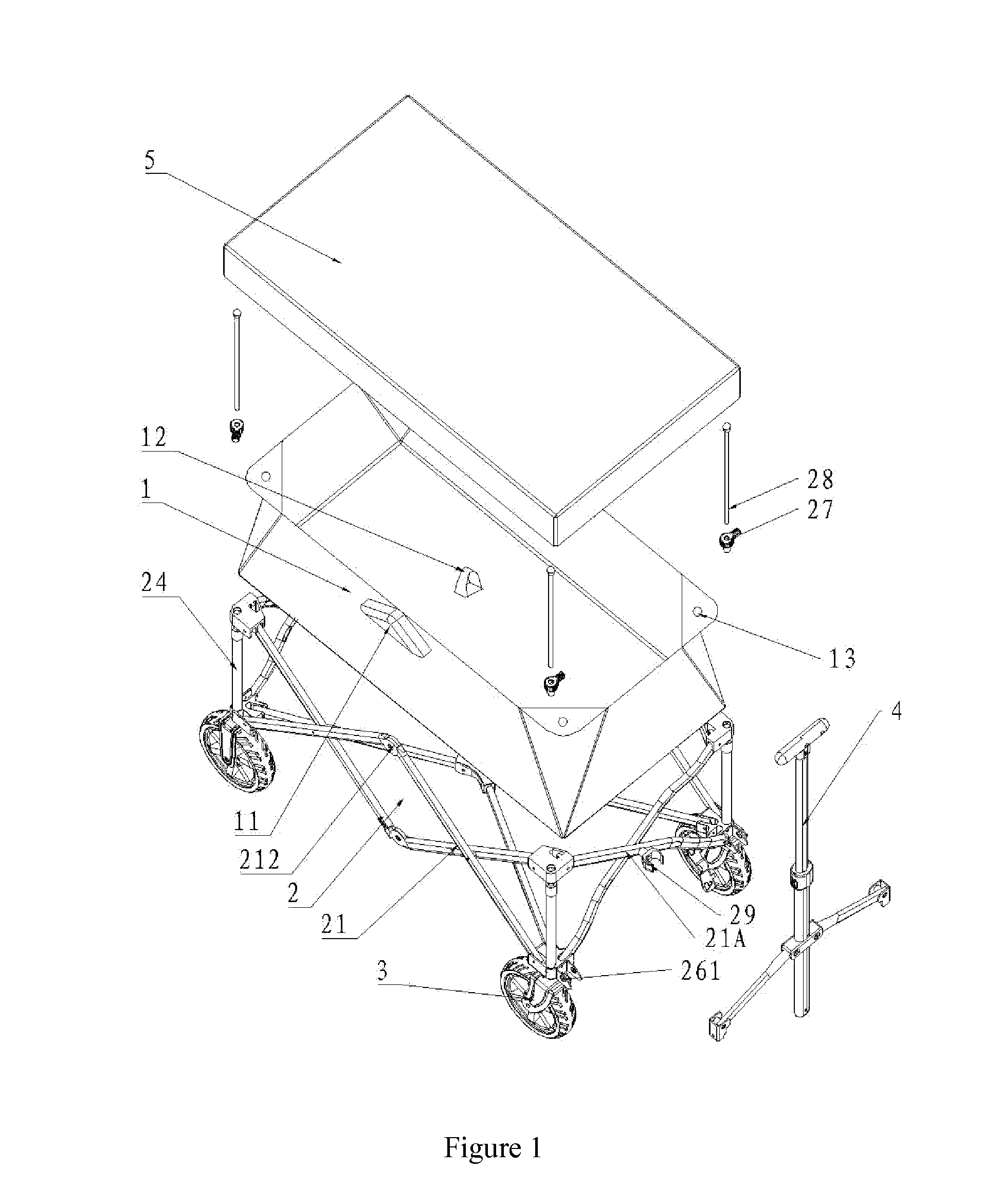

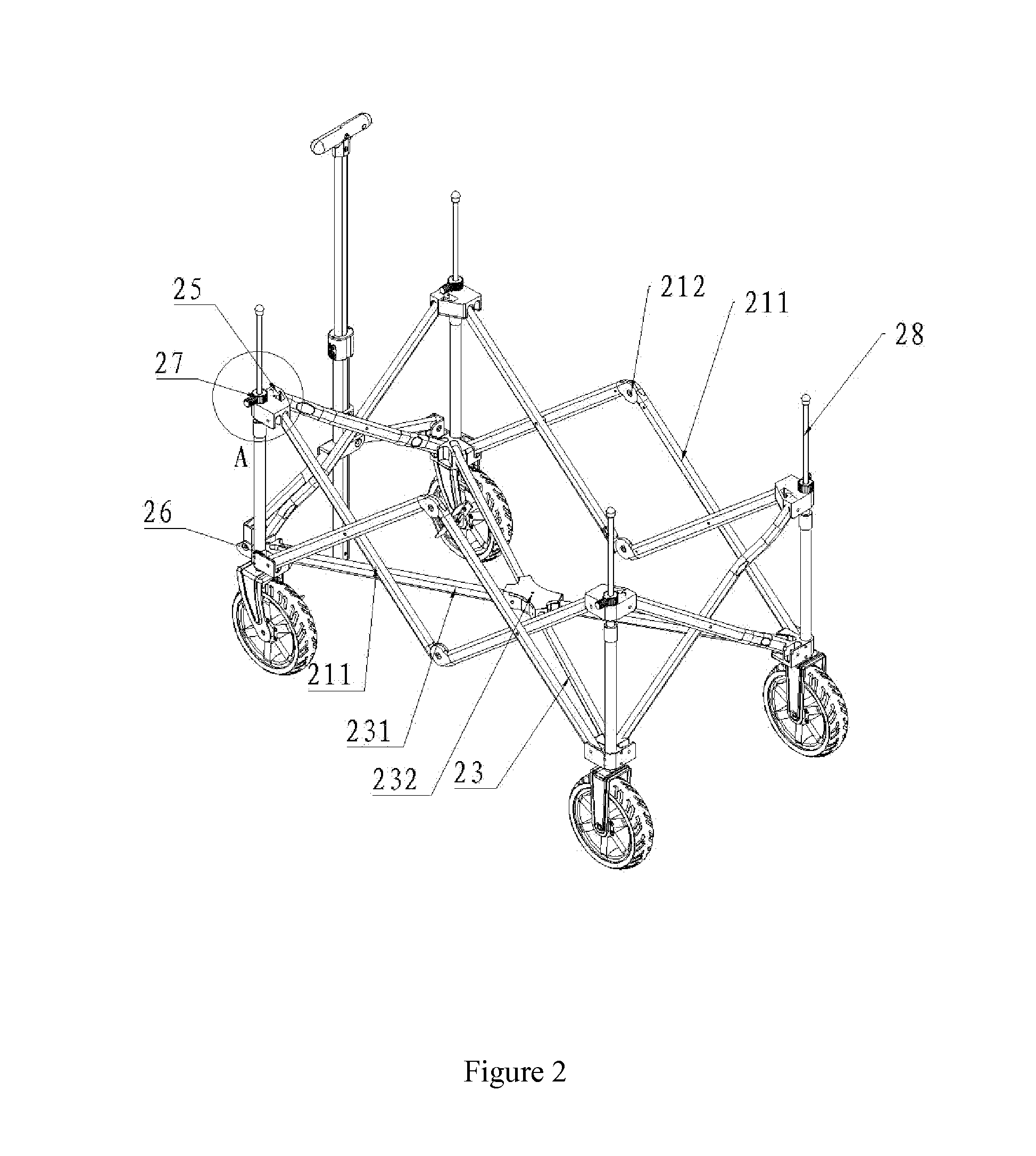

Folding trolley

InactiveUS20150151771A1Increase edge strengthLarge load capacityCarriage/perambulator accessoriesHand carts with one axisEngineeringFuselage

A folding trolley includes a folding trolley frame and a storage pocket. Said trolley frame includes side brackets and a bottom support bracket; said side bracket comprises two cross connecting rods hinged at the central point; said bottom support bracket includes bottom support rods and a central hinged seat. the side bracket is a multi-stage connecting rod structure, including at least two pairs of corresponding hinged connecting rods; the ends of the connecting rods are hinged to form pocket support ends; said storage pocket is provide with downward openings; a pulling member corresponding to the location of said central hinged seat and used for folding the trolley body is provided at the interior bottom of said storage pocket. The trolley can realize convenient fold of the whole body, increase edge strength of the storage pocket, and ease using operation for different users, and has stable structure and larger loading capacity.

Owner:JIN XUGANG

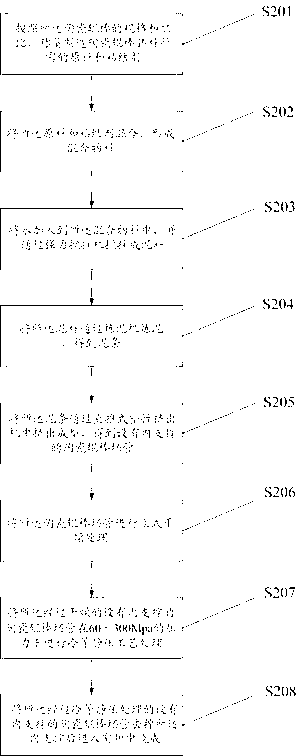

Self-repairing paint and preparation method thereof

InactiveCN107201140AGood dispersionGood compatibilityAnti-corrosive paintsEpoxy resin coatingsMicrosphereFirming agent

The invention relates to self-repairing paint and a preparation method thereof, and belongs to the technical field of metal protection. The preparation method comprises the following steps: adding self-made mesoporous silicon dioxide nanoparticles into a benzotriazole ethanol solution, and stirring to obtain mesoporous silicon dioxide nanoparticles loading a corrosion inhibitor; adding the mesoporous silicon dioxide nanoparticles loading the corrosion inhibitor into a zirconium n-propoxide alcohol solution and stirring; adding a nitric acid solution and stirring; filtering to obtain filter residues; adding the filter residues into a chitosan solution; after carrying out ultrasonic dispersion, centrifugally separating to obtain sediment; adding the sediment into a sodium alginate solution; after carrying out the ultrasonic dispersion, centrifugally separating to obtain a layer-by-layer packaged corrosion inhibitor; finally, uniformly stirring epoxy resin, a diluting agent, a curing agent, the layer-by-layer packaged corrosion inhibitor and a dispersant, and carrying out the ultrasonic dispersion to obtain the self-repairing paint. The self-repairing paint has the advantages of simplicity in preparation, large load capacity and corrosion inhibitor release-response function, and has a good repairing capability on coating corrosion damages caused by the natural environment.

Owner:王建东

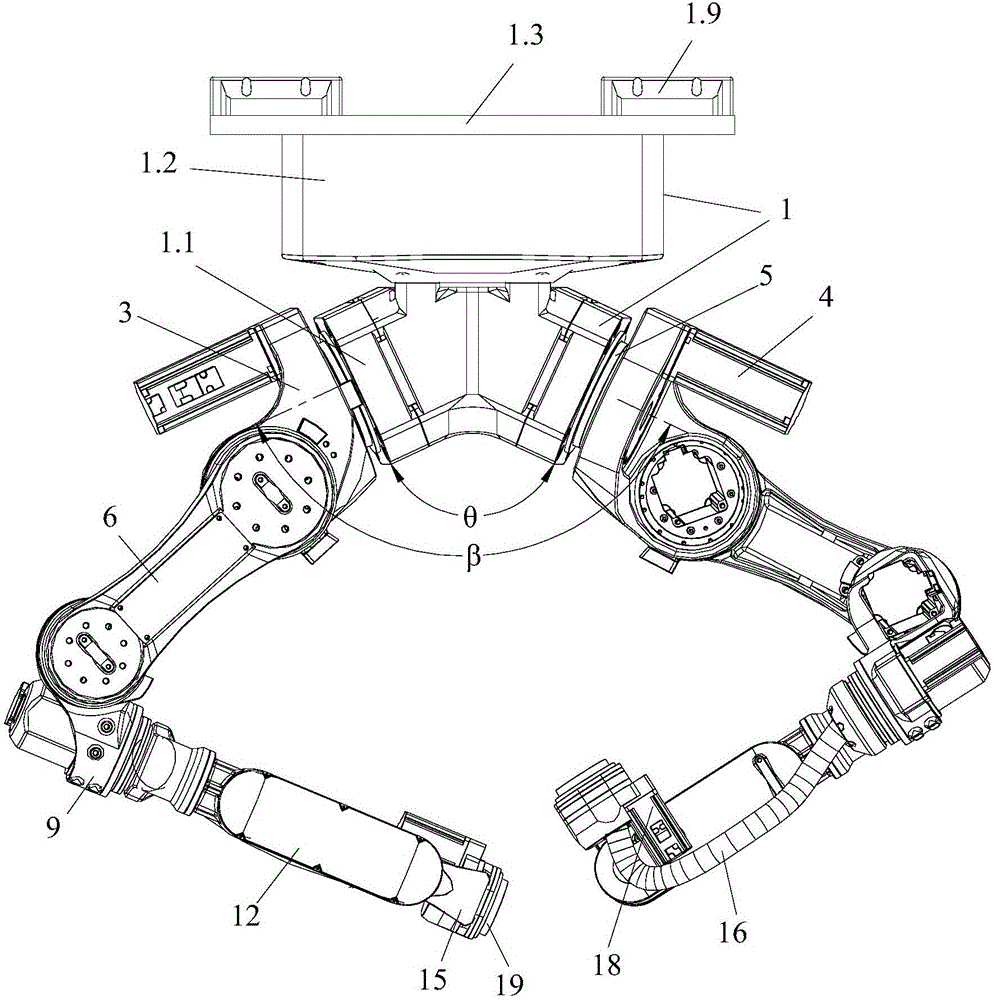

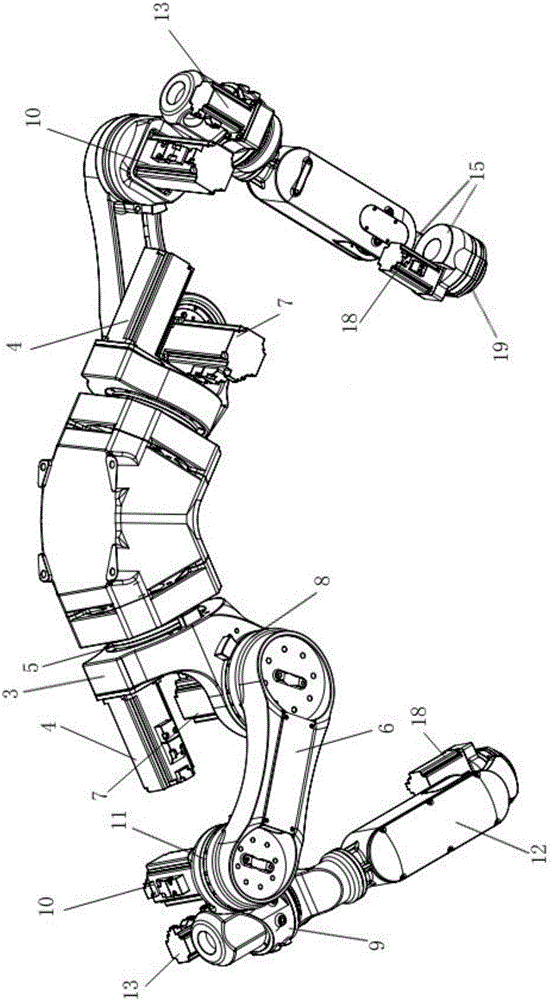

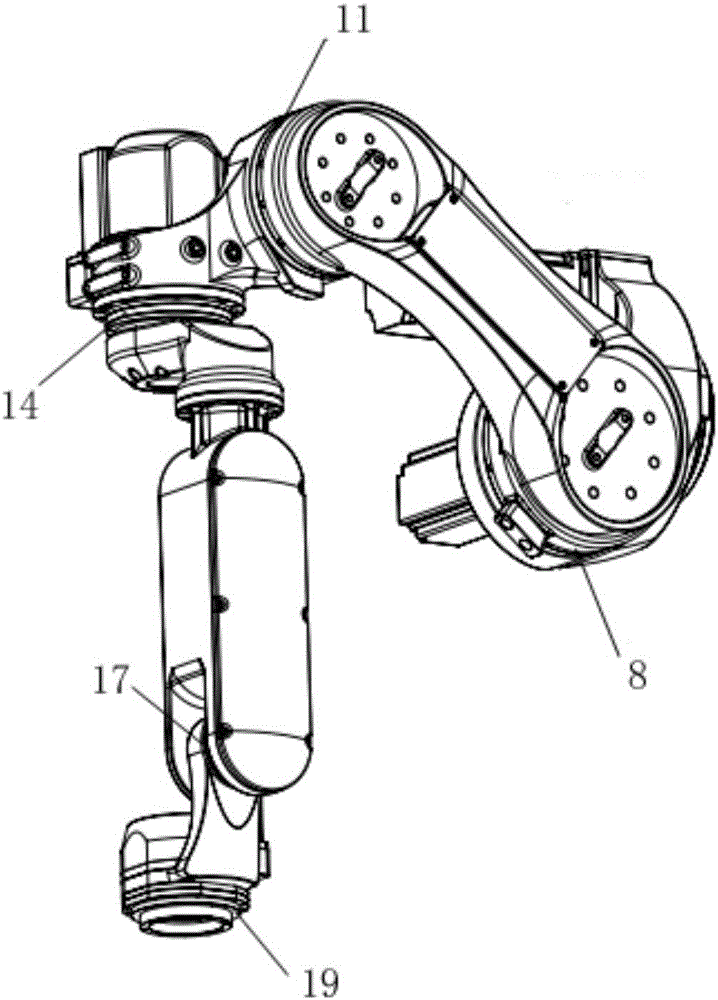

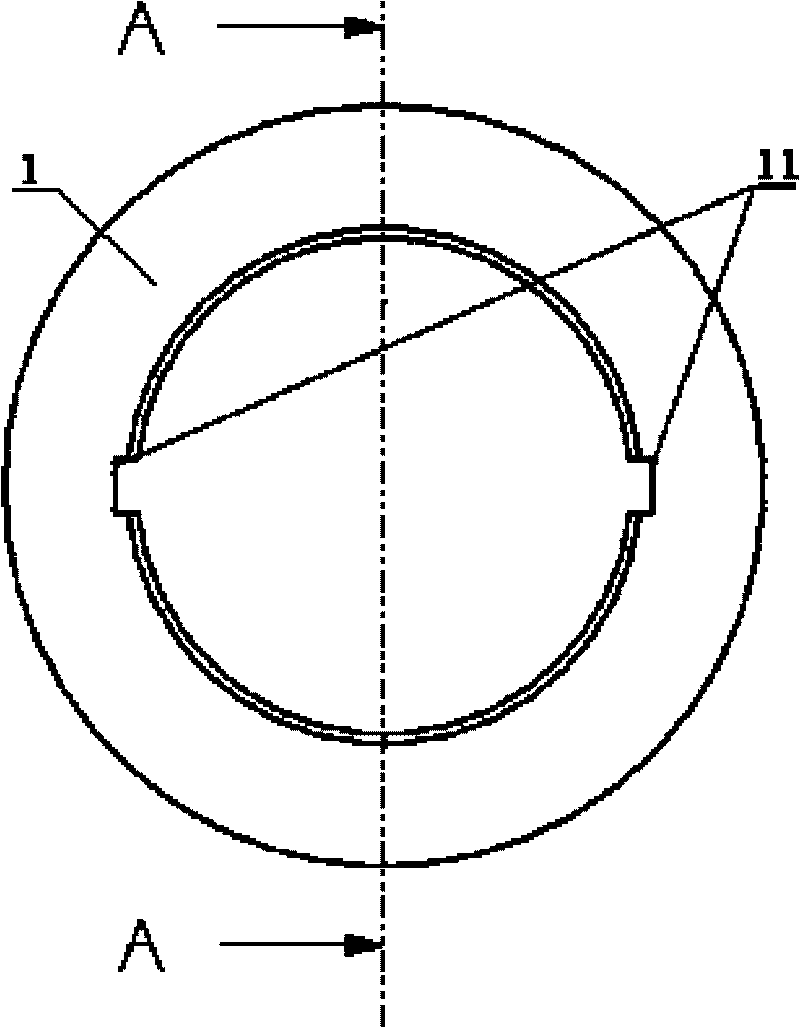

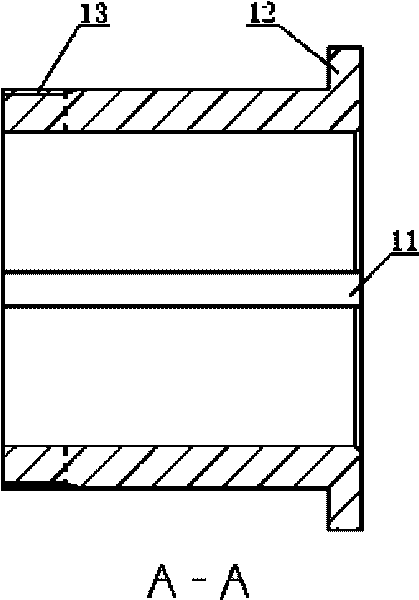

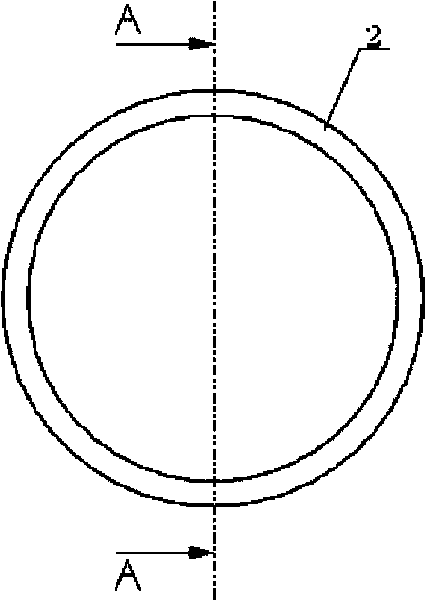

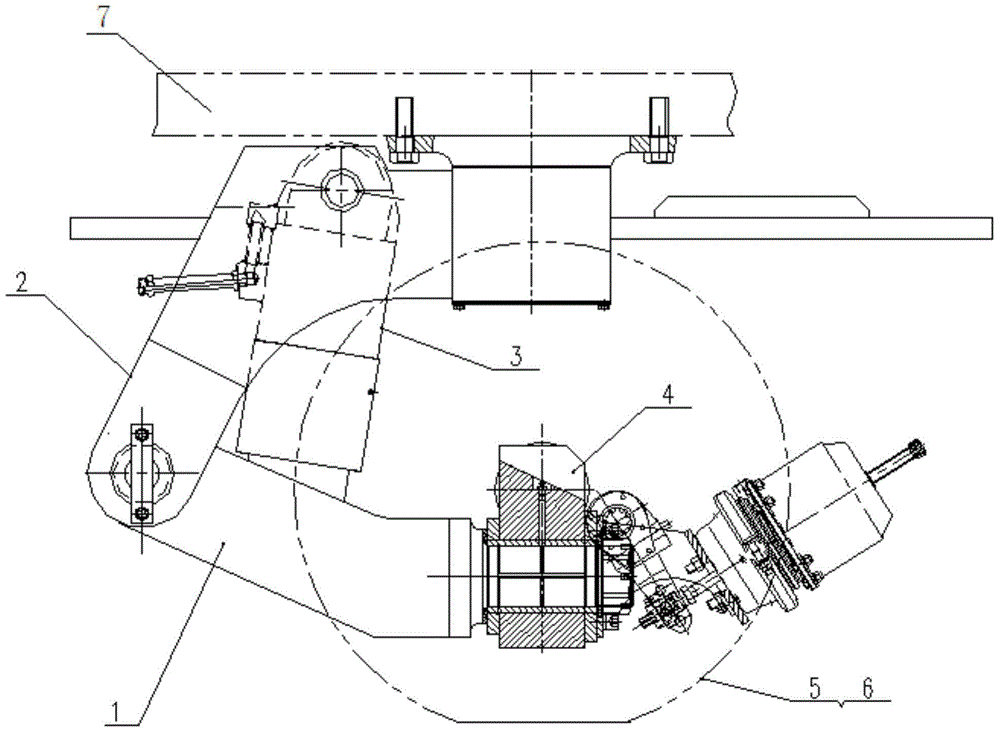

Intelligent cooperation dual-arm robot

ActiveCN106041897AGood mechanical structure rigidityReduce sizeProgramme-controlled manipulatorJointsEngineeringStructural rigidity

The invention provides an intelligent cooperation dual-arm robot. The robot comprises a mounting base and two arms, the two arms are arranged on the two sides of the mounting base in a mirror symmetry manner, and each arm comprises a shoulder arm assembly, a rear end arm assembly, a toggle arm assembly, a front end arm assembly and a wrist arm assembly connected with a tail end execution component, all of which are sequentially connected; one end of each shoulder arm assembly is connected with the mounting base, each shoulder arm assembly can rotate around the mounting base, one end of each rear end arm assembly is rotatably connected with the side wall of the other end of the corresponding shoulder arm assembly, the side face of one end of each toggle arm assembly is rotatably connected with the other end of the corresponding rear end arm assembly, one end of each front end arm assembly is connected with the other end of the corresponding toggle arm assembly, and each front end arm assembly can rotate around the axial direction; and one end of each wrist arm assembly is connected with the other end of the corresponding front end arm assembly, each wrist arm assembly can swing in the length direction of the corresponding front end arm assembly, and the other end of each wrist arm assembly is connected with the corresponding tail end execution component. The robot is compact in structure and reasonable in design, and the intelligent cooperation dual-arm robot is good in mechanical structural rigidity, small in size and small in weight.

Owner:广东省智行机器人科技有限公司

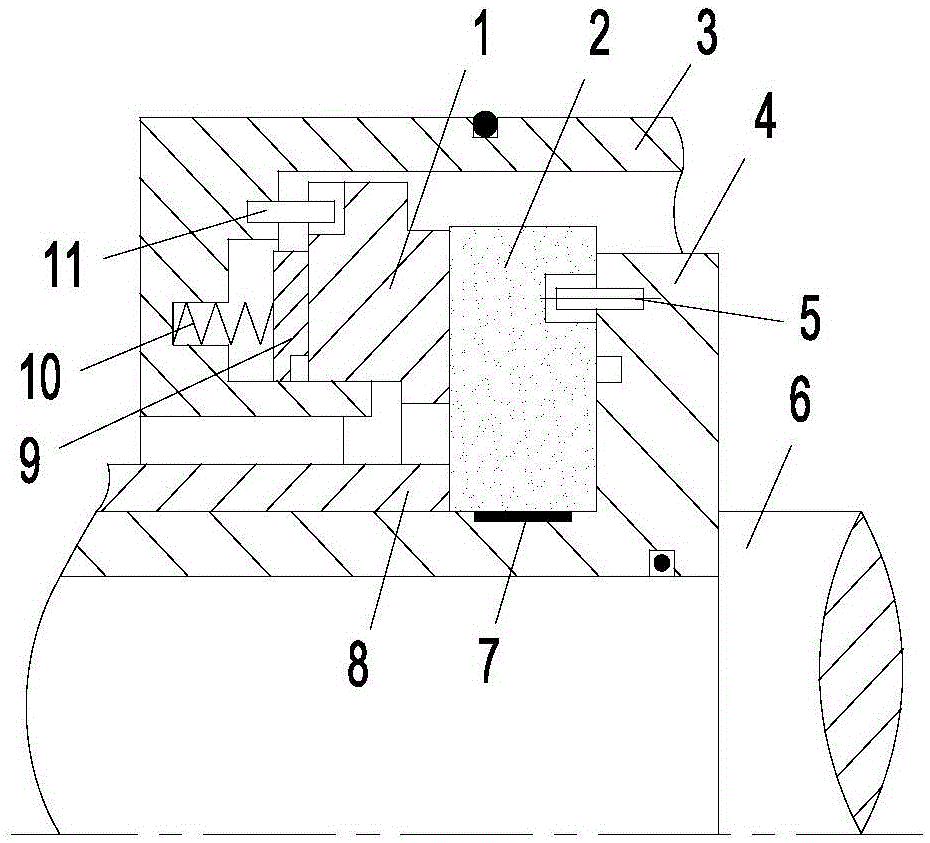

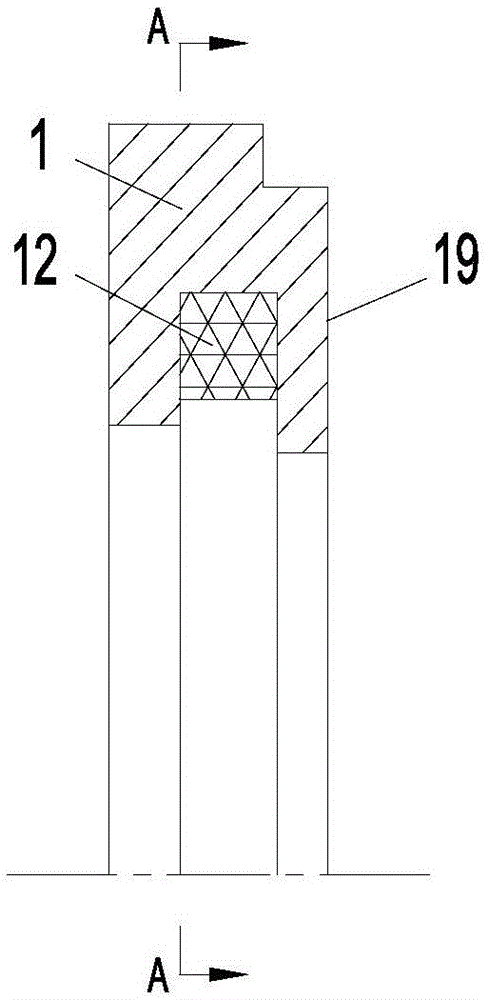

Dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid

ActiveCN101718297AImprove wear resistanceAccelerated corrosionBearing componentsSliding contact bearingsWater basedCarrying capacity

The invention discloses a dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid, which comprises a bearing sleeve, wherein a flange is arranged at one end of the bearing sleeve, and external threads are arranged at the other end of the bearing sleeve; a ceramic shaft sleeve is assembled at the outer layer of the bearing sleeve; a ceramic shaft bushing which comprises a special liquid cavity and a liquid hole structure is arranged outside the ceramic shaft sleeve; a shaft bushing sleeve with the special liquid cavity and the liquid hole structure is assembled at the outer layer of the ceramic shaft bushing; and the bearing of the invention also comprises a bearing end cover, wherein a ceramic ring is assembled at the inner end of the bearing end cover, and internal threads matched with the external threads of the bearing sleeve are arranged on the inner ring of the bearing end cover. The bearing of the invention can improve the wear resistance and the corrosion resistance, can operate in the poor water condition where sandy solid particles are contained, can be lubricated by the water-based lubricating liquid formed by adding other additives into water or water-based liquid; at the same time, the bearing has larger carrying capacity and rigidity, and can ensure a safe and stable operating state, thereby greatly prolonging the operation life.

Owner:TIANJIN UNIV

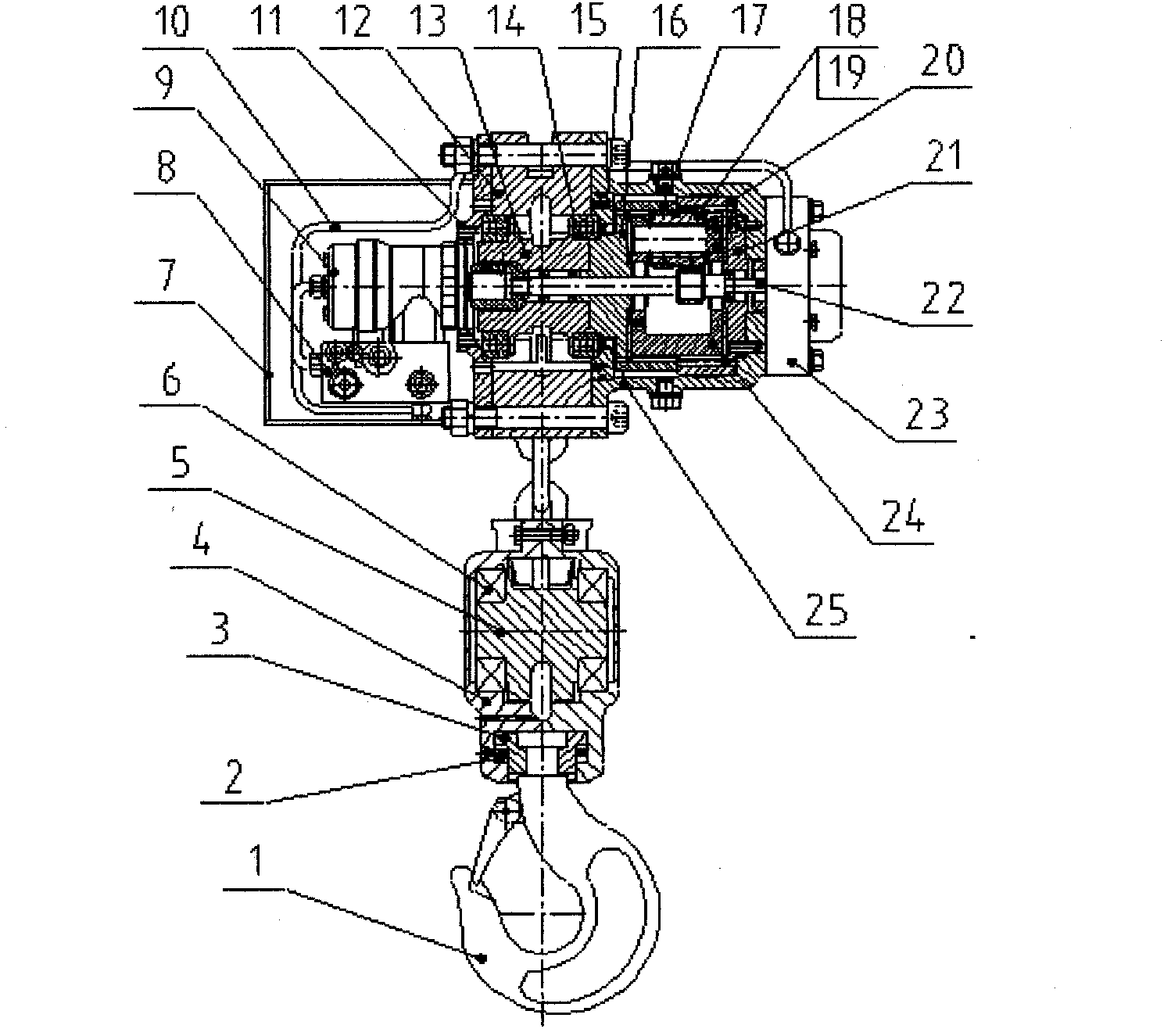

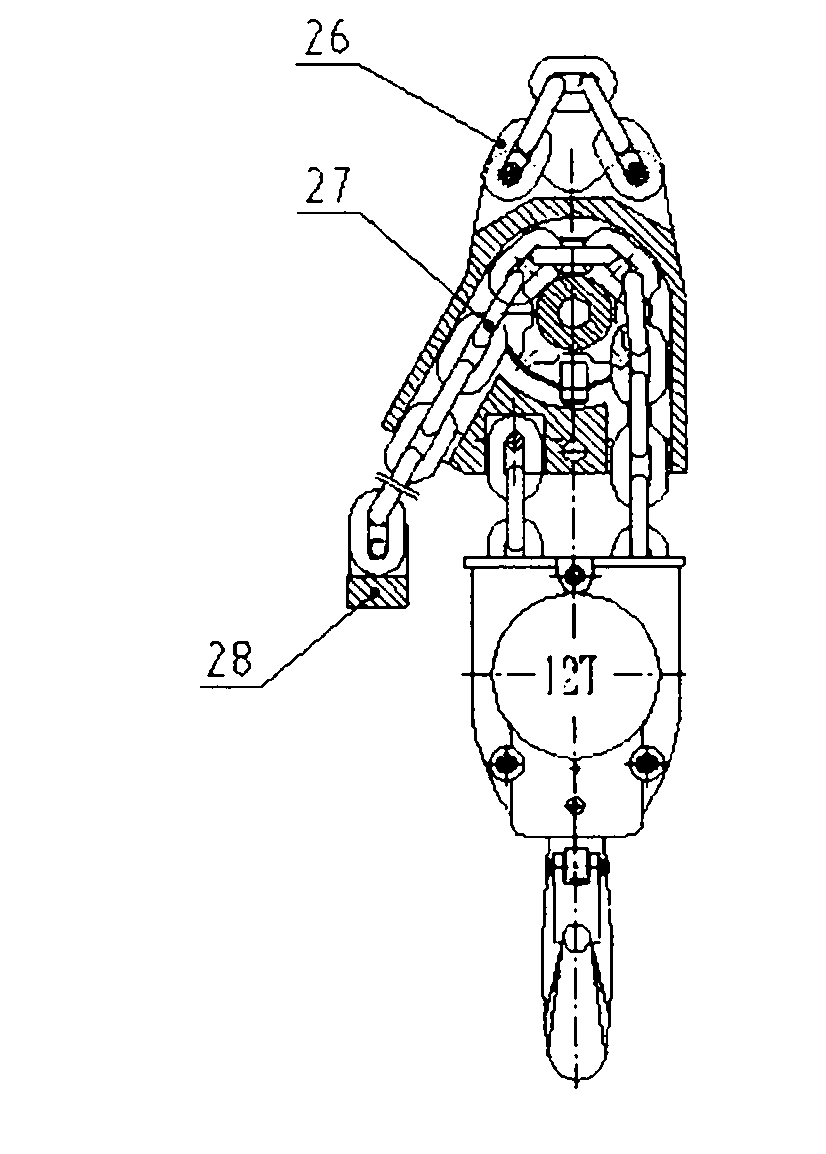

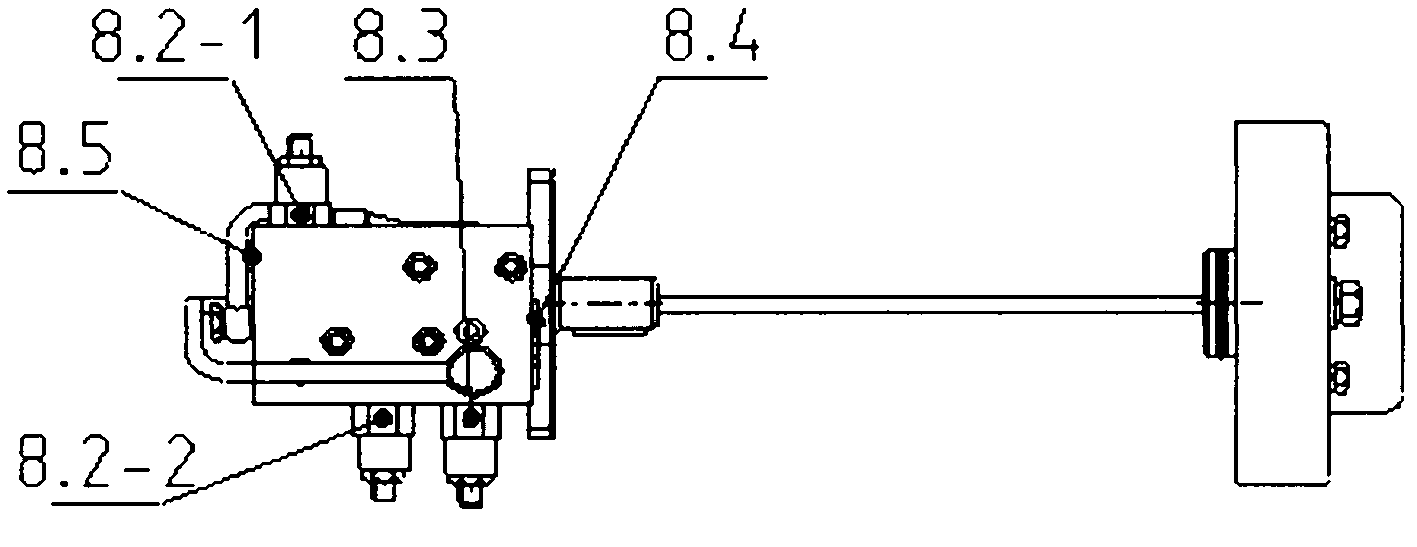

Chain-type hydraulic hoist for lifting

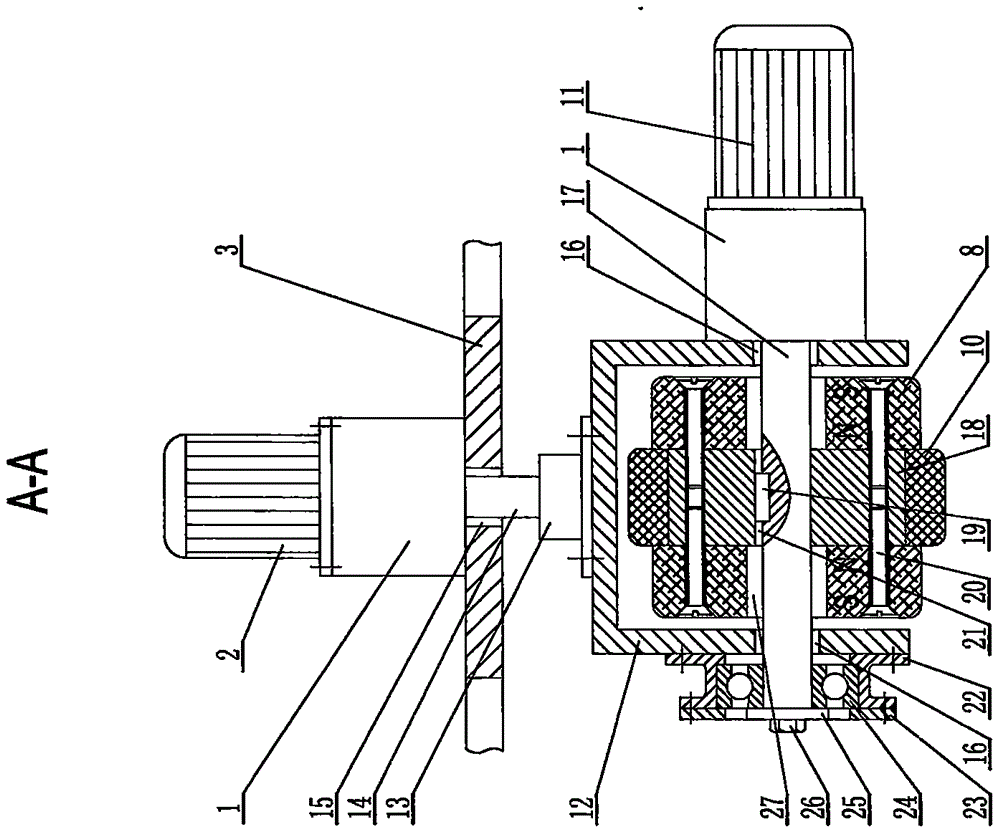

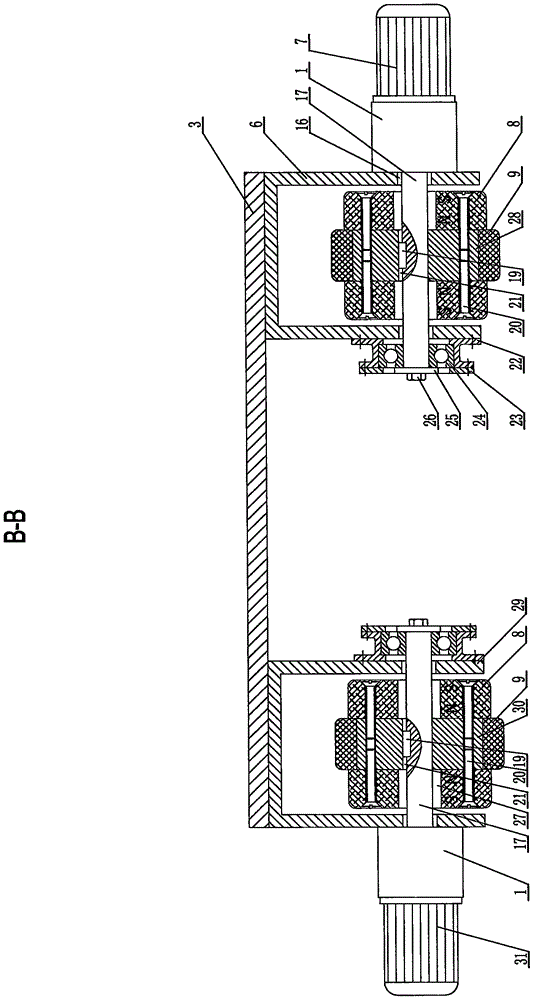

ActiveCN102838049ACompact structureReduce volumePortable liftingToothed gearingsHydraulic motorControl engineering

The invention discloses a chain-type hydraulic hoist for lifting, which comprises a lifting hook, a hydraulic drive control part, a lifting part, a planetary reducer and a high-strength lifting chain; the hydraulic drive control part comprises a valve block, a hydraulic motor, a non-brake oil tube and a hydraulic brake; the lifting part comprises an end cover, a housing, a driving chain wheel, a locating bearing and a primary drive gear; the planetary reducer comprises a sun wheel shaft, a planetary gear, a planetary gear shaft, a planetary gear rack, a primary gear ring, a fixed gear, a secondary gear ring and a planetary reducer shell; the hydraulic hoist provides a control oil tube by a matched hydraulic system on mining machinery, and drives the planetary reducer by the hydraulic motor; the planetary reducer outputs a torque to drive a lifting driving chain wheel, and drives an annular lifting chain and a lifting hook device to lift and put down heavy objects, and also can be used for horizontally dragging the heavy objects (namely used as a hydraulic winch). The chain-type hydraulic hoist is suitable for downhole operation of coal mine, and has the advantages of being reasonable in structure, large in lifting ratio in equal volume, simple and convenient to operate, high in work efficiency, safe and reliable.

Owner:BEIJING JINXUANYE TECH

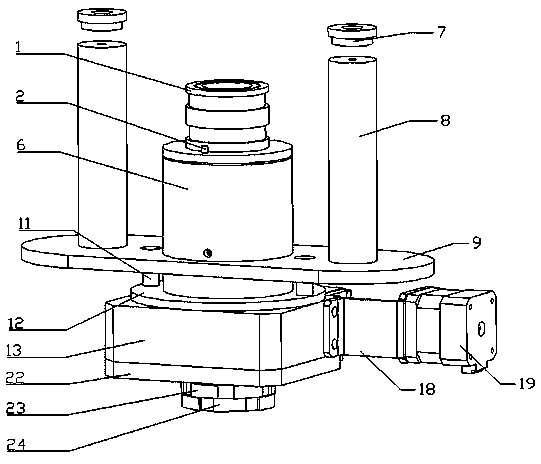

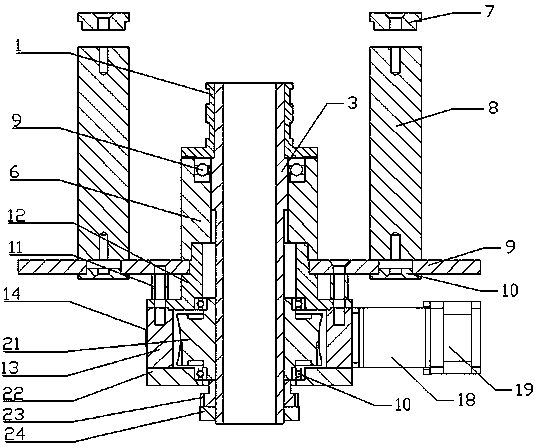

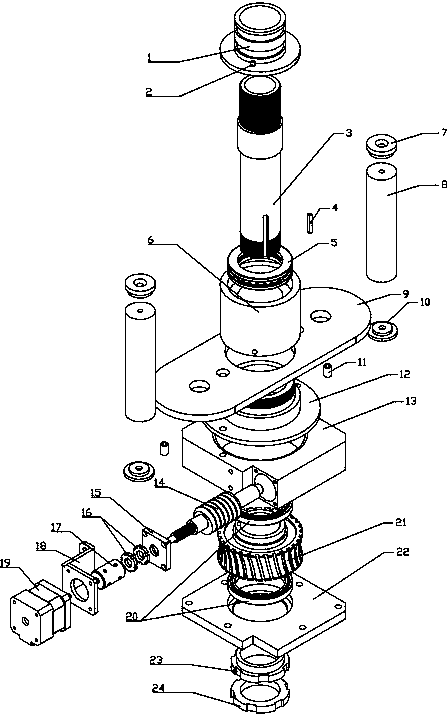

Novel rotary manipulator

InactiveCN102528800ASave construction spaceLarge load capacityProgramme-controlled manipulatorGripping headsSpatial structureAgricultural engineering

The invention discloses a mechanical device and relates to a novel rotary manipulator. The novel rotary manipulator comprises a servo motor, a stepping motor, a speed reducer, a synchronous belt pulley, a vertical adapter plate, a horizontal adapter plate, a linear guide rail, a thin type cylinder, a ball guide shaft sleeve, a rotating shaft, a synchronous belt, a bearing, a sucker device, a sucker device adapter plate and a horizontal panel. The linear guide rail comprises an X-axis linear guide rail and a Z-axis linear guide rail, the ball guide shaft sleeve comprises a spline shaft and a screw cap, wherein the screw cap is fixed in the rotating shaft, the bearing is fixed on the horizontal adapter plate, the vertical adapter plate is arranged above the horizontal adapter plate, the rotating shaft is fixed in the horizontal panel by the bearing, the synchronous belt pulley is arranged on the rotating shaft, and the sucker device is arranged on the sucker device adapter plate. The novel rotary manipulator disclosed by the invention saves structural space, is large in loading capability, and long in movement service life, and also has the advantages of vacuum adsorbing function, good sealing effect, attractive spatial structure and the like.

Owner:苏州光宝康电子有限公司

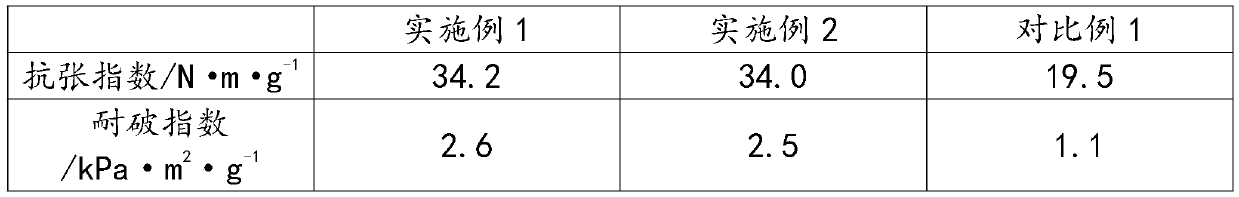

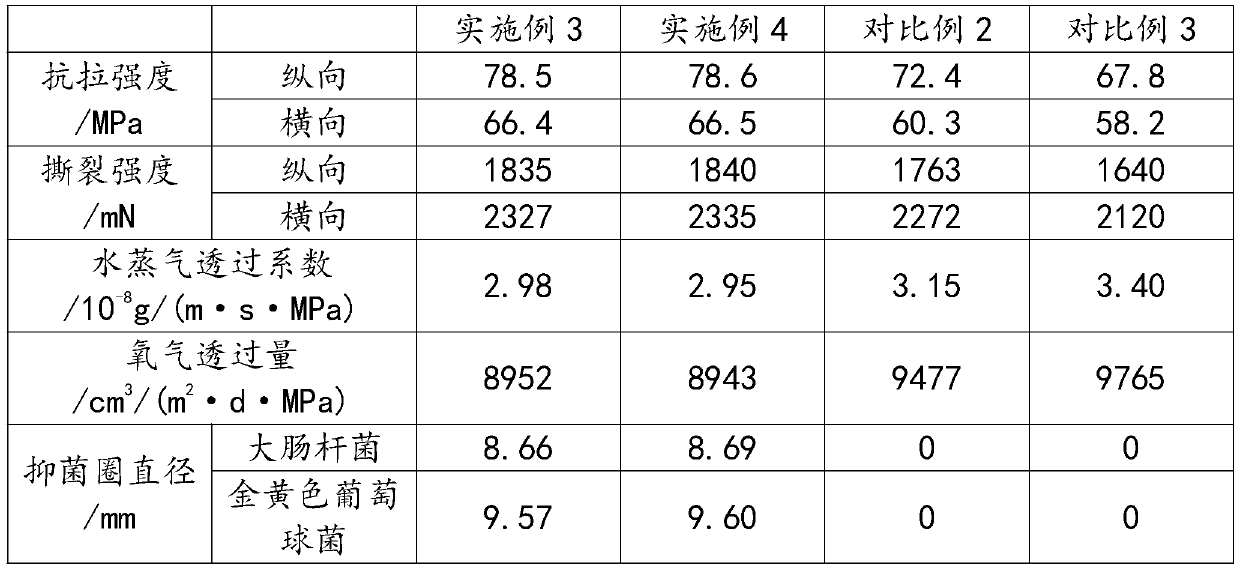

Environment-friendly high-barrier packaging paper and preparation method thereof

PendingCN110284371AImprove physical strengthHigh strengthFlexible coversWrappersFiberPulp and paper industry

The invention discloses environment-friendly high-barrier packaging paper and a preparation method thereof. The packaging paper comprises a base paper body and a coating applied on the surface of the base paper body; coating liquid is uniformly applied on the surface of the base paper body and single-sided coating is adopted; after coating is completed, the coated paper is immediately put into a drying box for drying; finally, the dried coated paper is placed in a constant-temperature and constant-humidity box for rewetting treatment, and the packaging paper is obtained. The base paper body prepared by mixing plant fiber and mucor fiber not only has high physical strength and good hydrophobic performance, but also is free of toxics, environmentally friendly and easy to degrade. By coating the surface of the base paper body with the coating liquid, the coating liquid fills paper fiber gaps, a dense film is formed on the surface of the paper, and the physical strength and barrier performance of the packaging paper are improved. An antibacterial agent in the coating liquid can make the packaging paper endowed with good antibacterial performance, and the packaging paper which is easy to degrade, free of toxics, environmentally friendly, good in antibacterial performance and high in barrier performance is prepared.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

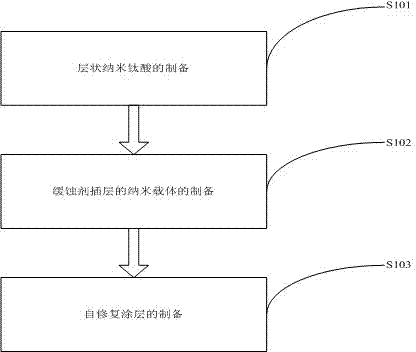

Preparation method of self-repair coating based on corrosion inhibitor intercalated nano-titanate carrier

InactiveCN103483897APlay self-healing functionIntrinsic structure restorationAnti-corrosive paintsThioureaDysprosium titanate

The invention relates to a preparation method of a self-repair coating based on a corrosion inhibitor intercalated nano-titanate carrier. The preparation method comprises the following steps: preparation of layered nano-titanate, preparation of the corrosion inhibitor intercalated nano-carrier and preparation of the self-repair coating, wherein the preparation of the layered nano-titanate comprises the step of grinding K2CO3 and TiO2 solids according to a certain molar ratio; the preparation of the corrosion inhibitor intercalated nano-carrier comprises the steps of taking organic amines, imidazoles, allyl thiourea and other nitrogen-containing organic matters as objects, taking the layered nano-titanate as a subject, and preparing the collision inhibitor intercalated nano-carrier through intercalation reaction in an ethanol solvent under microwave conditions; the preparation of the self-repair coating comprises the step of finally mixing prepared functional particles with sol-gel to prepare a functional sol-gel film to coat on the surface of a metal to be protected. The preparation method disclosed by the invention has the advantages of simplicity in preparation, large loading capacity and corrosion inhibition release-response function, expands the types of loaded corrosion inhibitors, enables an inherent structure of the titanate to tend to be restored, and plays a self-repair role.

Owner:YANCHENG INST OF TECH

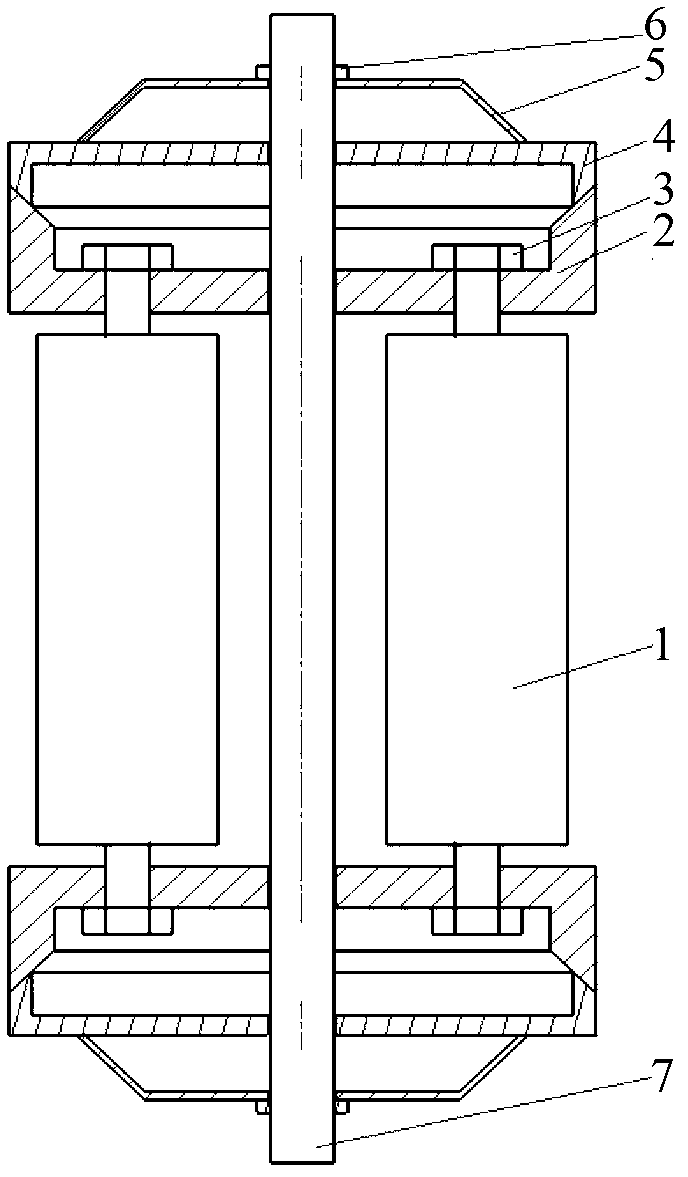

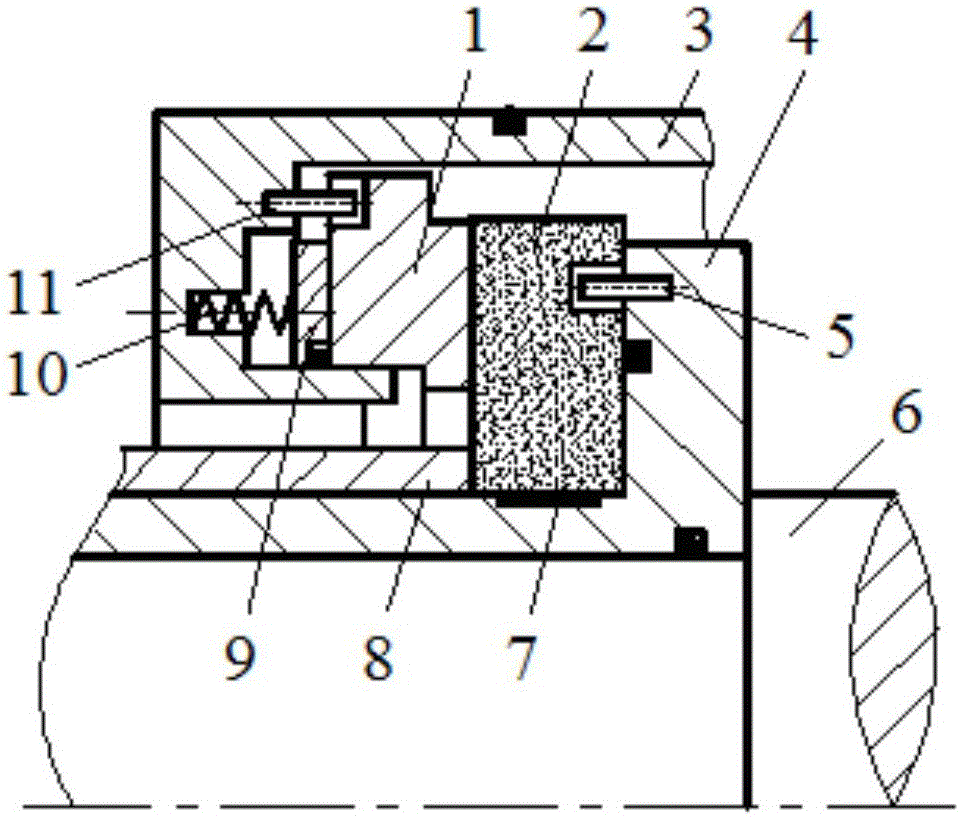

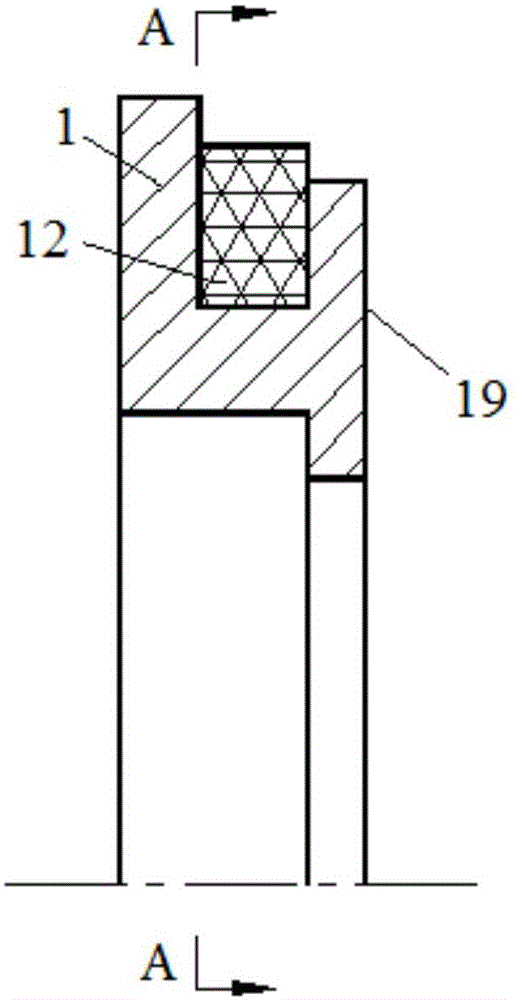

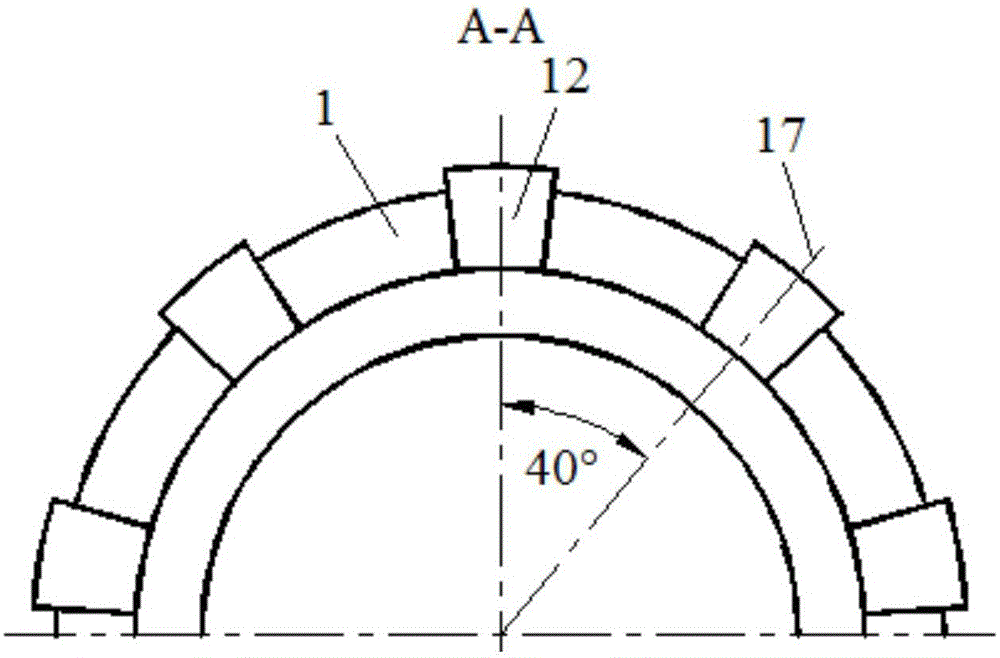

Electric rotating machine based on super magnetostriction material

InactiveCN102983778AHigh precisionImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesElectric machineMagnetostriction

The invention provides an electric rotating machine based on super magnetostriction material. The electric rotating machine based on the super magnetostriction material comprises a precompression system, a stator and two rotors, wherein the precompression system comprises an output shaft, two springs and two spring fixing pieces, the two rotors are respectively connected with two ends of the stator, the output shaft penetrates the center of the stator and the centers of the rotors and is connected with the stator and the rotors in a sleeved mode, the springs are respectively sleeved on two ends of the output shaft and press the rotors tightly, and the spring fixing pieces are connected with the output shaft and press the springs tightly. The stator comprises two stator driving ends, a plurality of super magnetostriction units and a plurality of fixing pieces, wherein the super magnetostriction units are evenly arranged between the two stator driving ends, two ends of each super magnetostriction unit are respectively connected with the stator driving ends through the fixing pieces, and the stator drives the rotors to rotate by friction. The electric rotating machine based on the super magnetostriction material has the advantages of being high in accuracy, free of noise, fast in response, big in bearing capacity, big in working bandwidth, good in stability, high in reliability, free of fatigue, free of overheating failure and the like.

Owner:SHANGHAI JIAO TONG UNIV

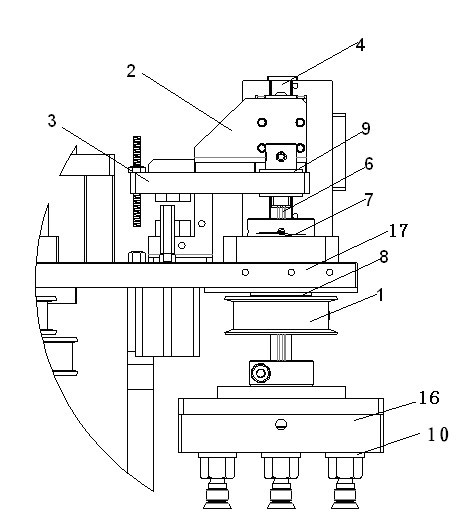

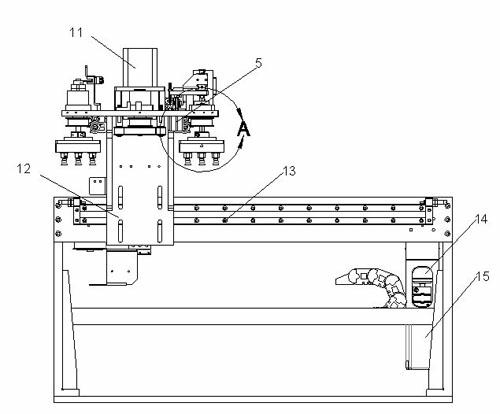

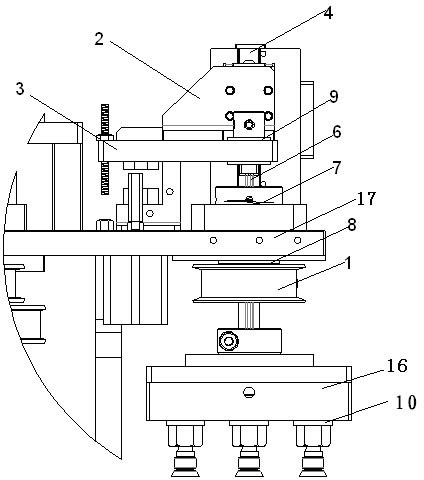

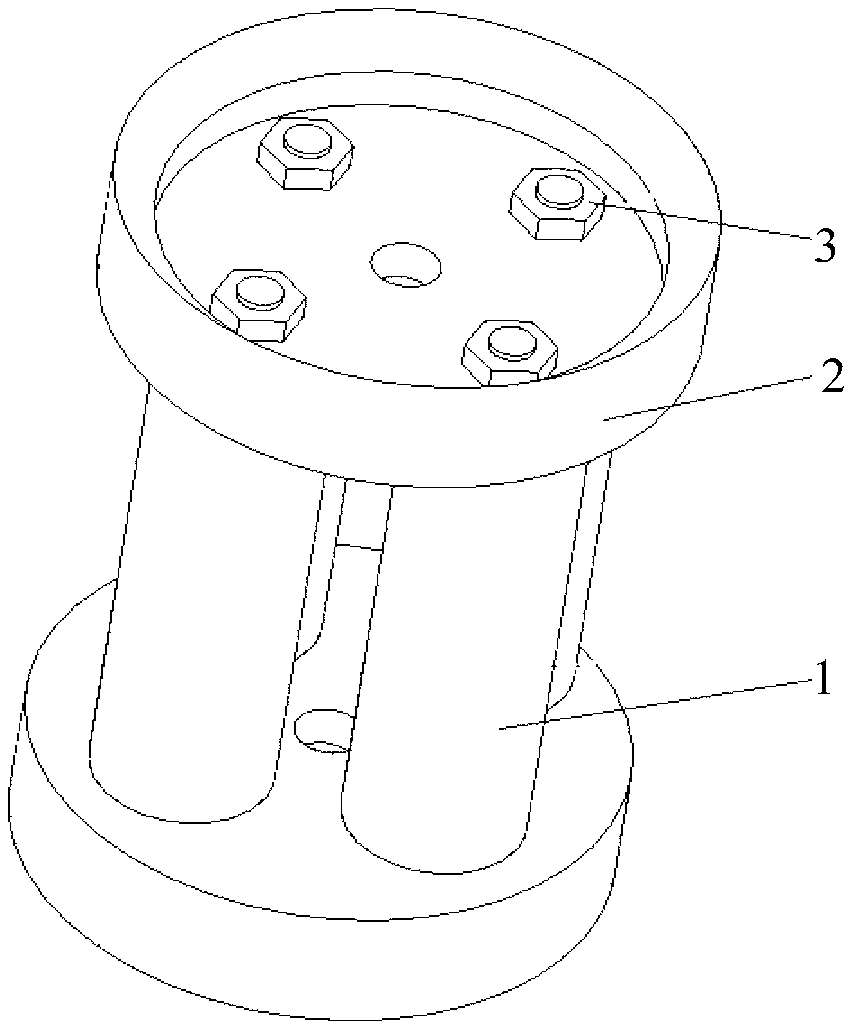

Automation device for testing wind sensor

ActiveCN104330591AHigh precisionReduce volumeTesting/calibration of speed/acceleration/shock measurement devicesWind sensorLiquid crystal

The invention relates to an automation device for testing a wind sensor. The body of the automation device comprises a wind sensor mounting seat, a locating pin, a wind hole locating block, a support arm, a transverse plate, a body fastening block, a transverse plate fixing sleeve, a rotating shaft, a flat key, a planar thrust bearing, a rotating shaft sleeve, a reduction gearbox connecting sleeve, a main bearing pre-tightening ring, an auxiliary bearing pre-tightening ring, a reduction gearbox, a deep groove bearing, a worm wheel, a reduction gearbox bottom plate, a worm, a worm seal cover, a worm pre-tightening ring, a coupling, a step motor mounting seat and a step motor; the control part comprises a device controller, a liquid crystal screen, keys, a step motor driver and the wind sensor. Compared with the prior art, the automation device realizes to automatically test the wind speed and wind direction of the wind sensor; the automation device replaces the previous manual operation mode of operators, reduces the influence of manual factors on the data precision in the testing stage and greatly improves the wind direction and wind speed testing precision.

Owner:ZHONGHUAN TIG TIANJIN METEOROLOGICAL INSTR

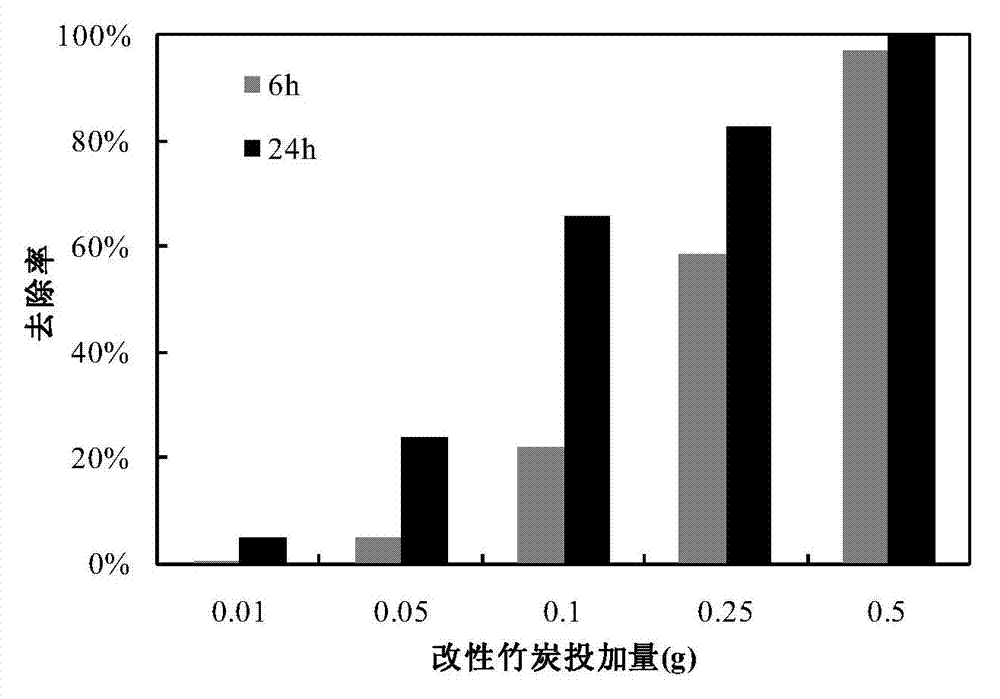

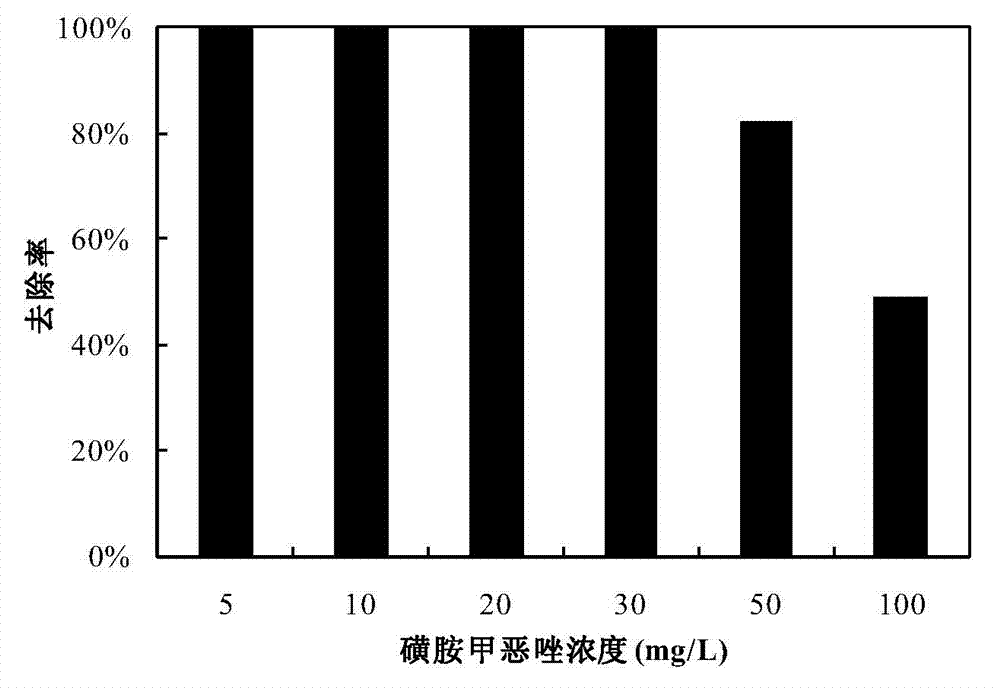

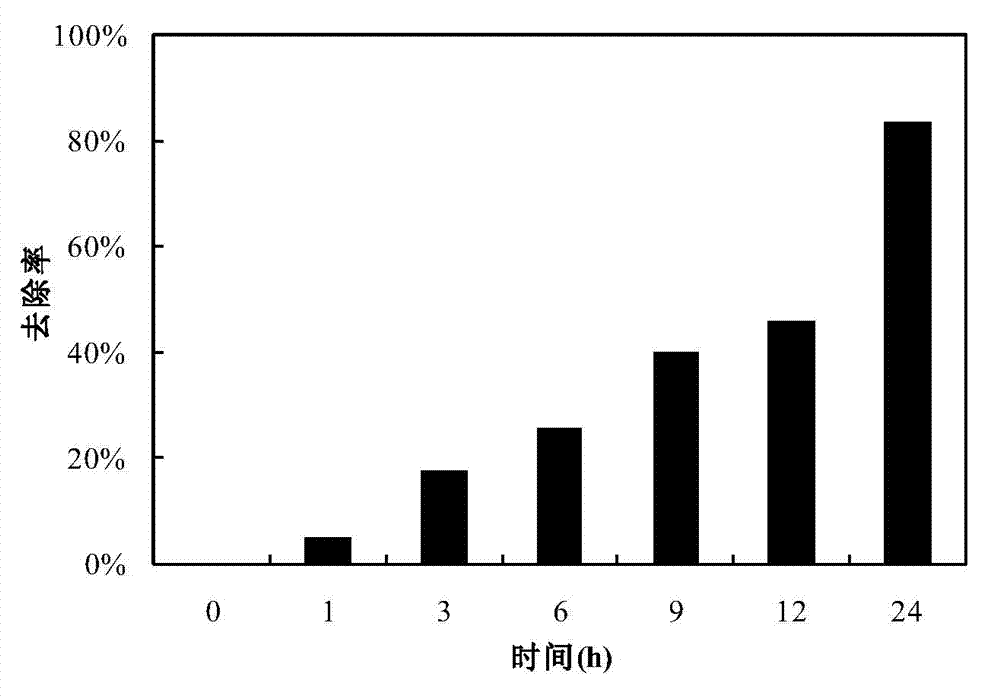

Method for removing sulfamethoxazole in water body by using modified bamboo charcoal

InactiveCN104261504AHigh porosityLow priceOther chemical processesWater contaminantsState of artSorbent

The invention belongs to the technical field of water treatment, and relates to a method for removing sulfamethoxazole in a water body by using modified bamboo charcoal, which comprises the following steps: sequentially carrying out pulverization, ultrasonic treatment, impregnation-process iron oxide loading and freeze-drying on bamboo charcoal to obtain modified bamboo charcoal, and adsorbing and removing sulfamethoxazole in the water body by using the modified bamboo charcoal as a filler or adsorbent. Compared with the prior art, the ultrasonic / impregnation-process iron oxide loading greatly enhances the antibiotic removal capacity of the bamboo charcoal. The adsorbent is high in adsorbability and easy to prepare; and the method is convenient to operate and low in price. The method is applicable to a sulfamethoxazole wastewater treatment technique, and has favorable economic and environmental benefits.

Owner:TONGJI UNIV

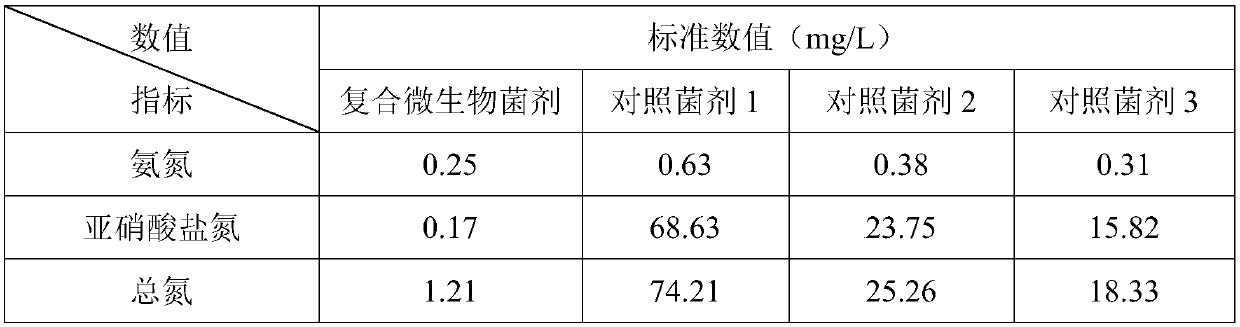

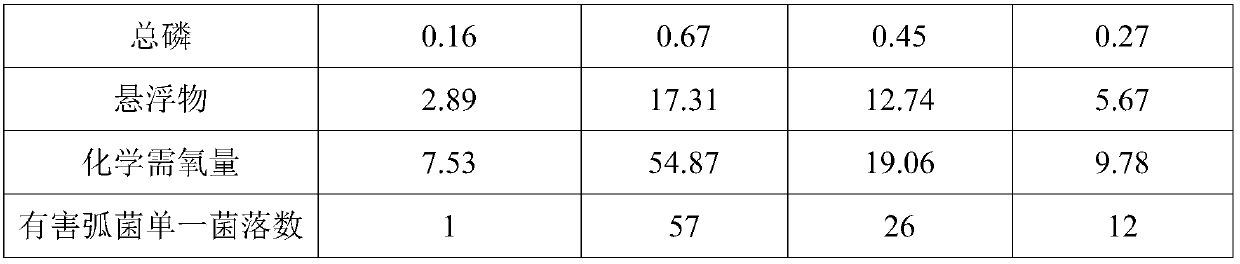

Compound microbial inoculant for purifying mariculture wastewater

InactiveCN109516570ABig spaceIncrease the areaSeawater treatmentWater contaminantsBiocompatibility TestingFlora

The invention discloses a compound microbial inoculant for purifying mariculture wastewater. The compound microbial inoculant comprises a compound microbial flora, an adsorption vector and an effervescent auxiliary material, wherein the compound microbial flora is primarily composed of pseudomonas SC221-M and bacillus subtilis. The adsorption vector comprises nano titanium dioxide, nano silicon dioxide, medical stone flour and bamboo carbon powder. The effervescent auxiliary material is preferably carbonate and an organic acid. The invention also discloses a preparation method of the compoundmicrobial inoculant for purifying mariculture wastewater. The invention has the beneficial effects that the compound microbial inoculant is prepared by mixing the compound microbial flora, the adsorption vector and the effervescent auxiliary material, wherein the specific surface area, adsorptivity, biocompatibility and good microorganism fixing property of the adsorption vector is coordinated with gas buoyancy generated by the effervescent auxiliary material to increase the contact area of the compound microbial inoculant and the mariculture wastewater, enhance the degrading ability to pollutants and remove wastewater pollutants effectively, so as to achieve the purpose of purifying the mariculture wastewater.

Owner:ZHEJIANG OCEAN UNIV

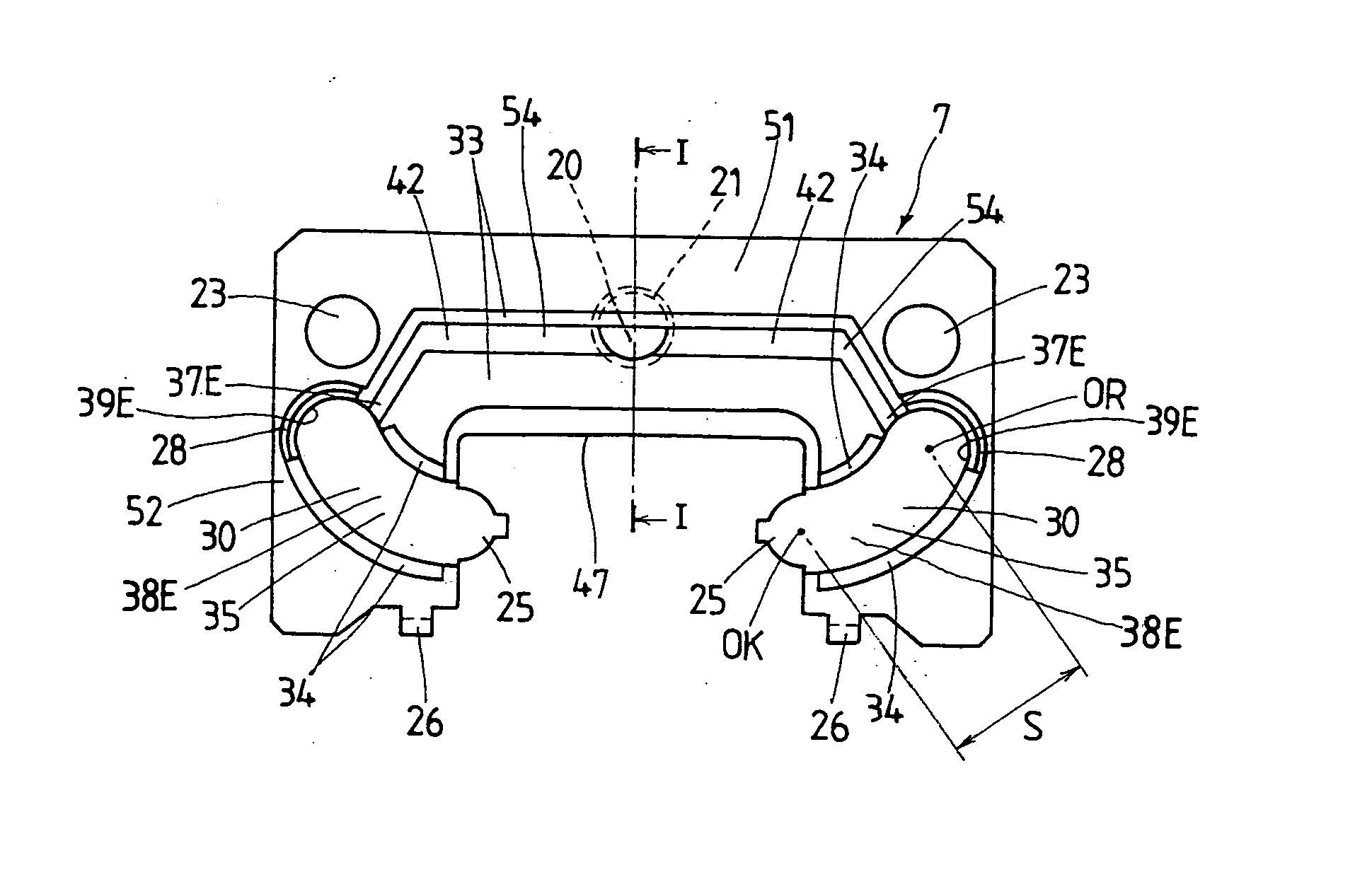

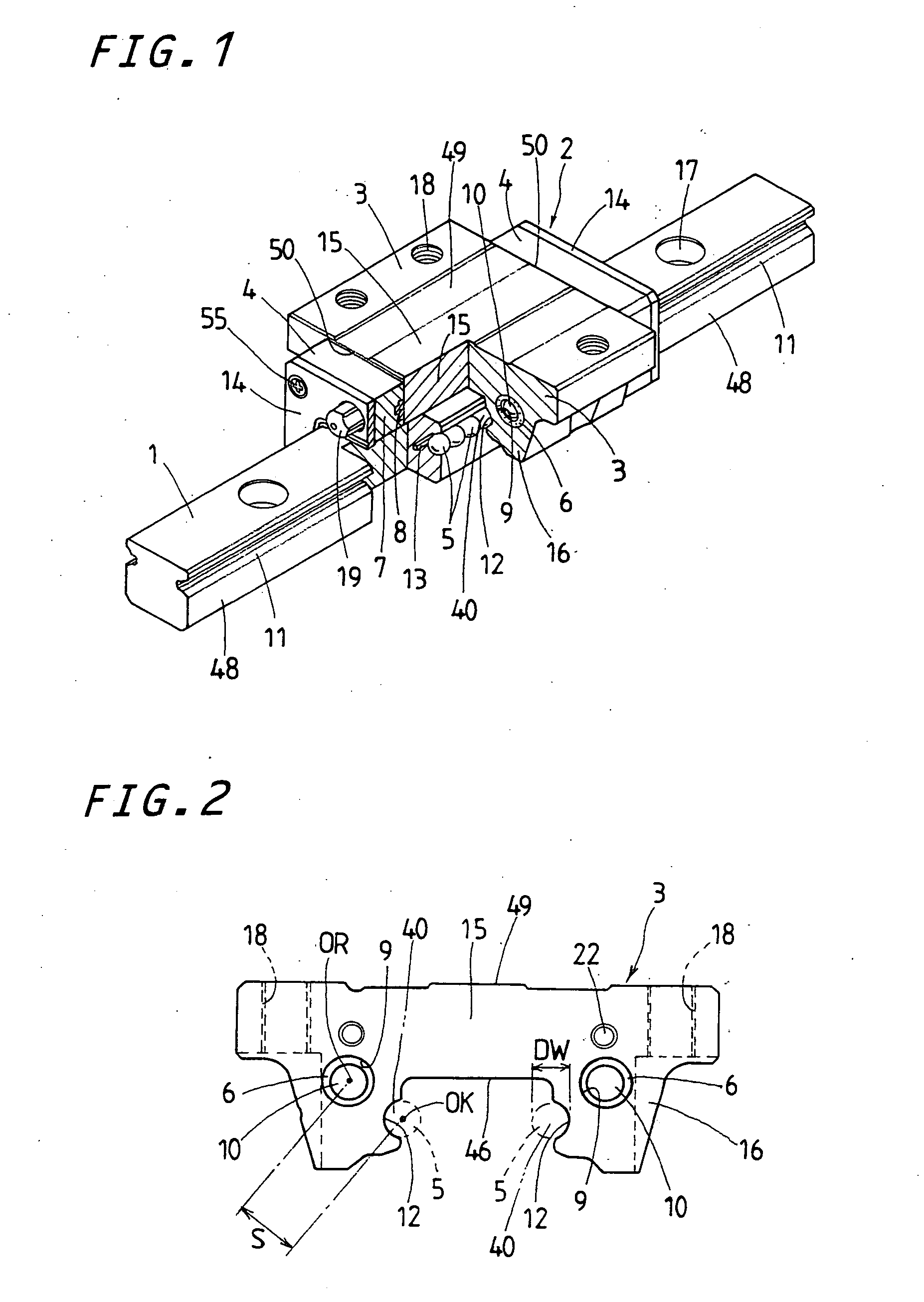

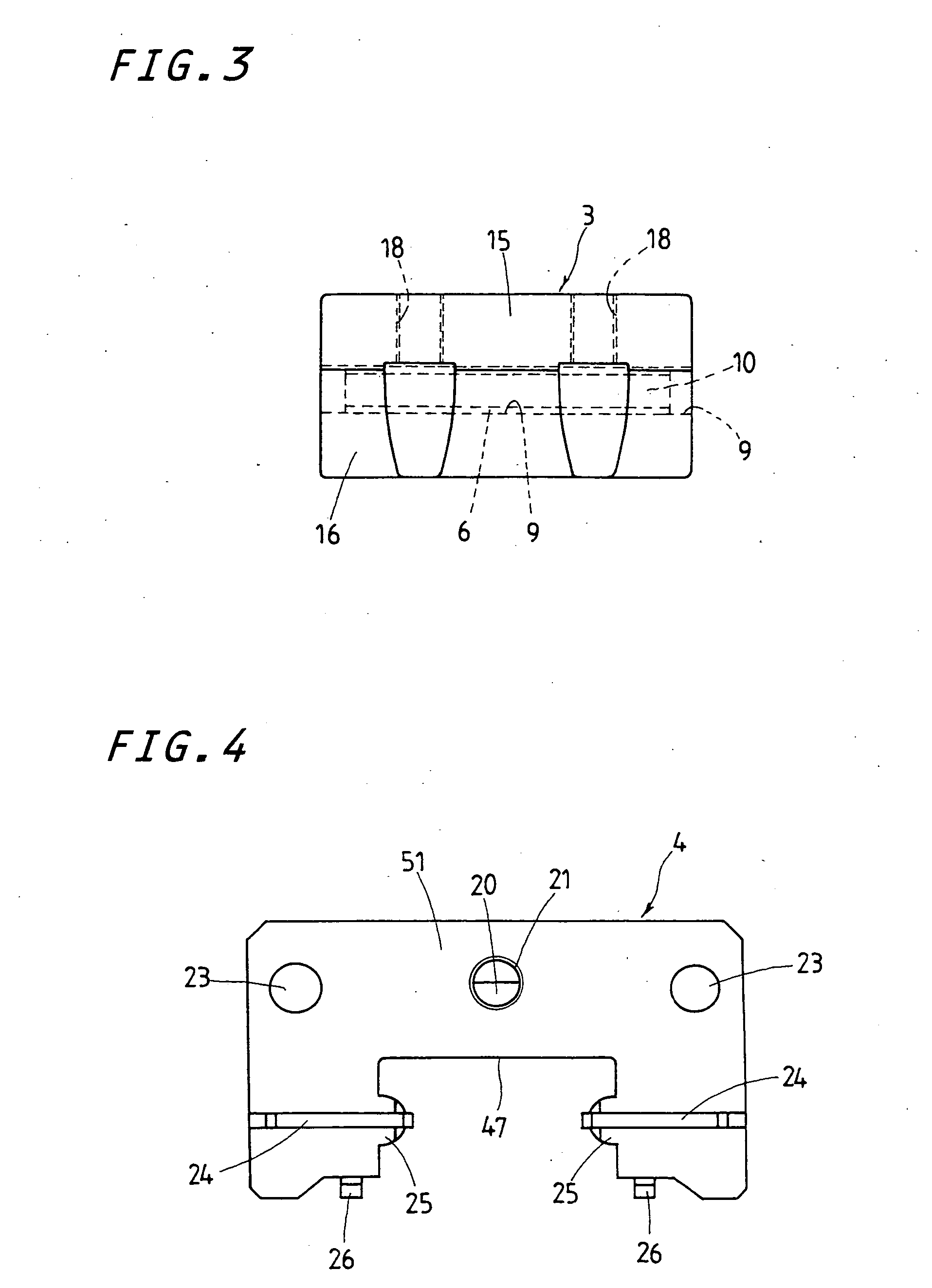

Linear motion guide unit

A linear motion guide unit permitted to operate for long service life with substantial maintenance-free for lubrication. The linear motion guide unit has heavy load capacity even with shrinking in construction. The linear motion guide unit is allowed to work with high-speed sliding operation and high tact. To this end, return passages are made inside a carriage of a slider in a geometry lying obliquely upwards of load-carrying races. The return passages are apart away from their associated load-carrying races by a distance less or equal to twice a diametral dimension of a rolling element. End caps are integrally made with spigots each of which is raised above a surface of the associated end cap facing on the carriage, thereby providing any one of forward and aft ends of the return passage. The spigots communicate with lubricant paths extending from lubricating ports made in the end caps.

Owner:NIPPON THOMPSON

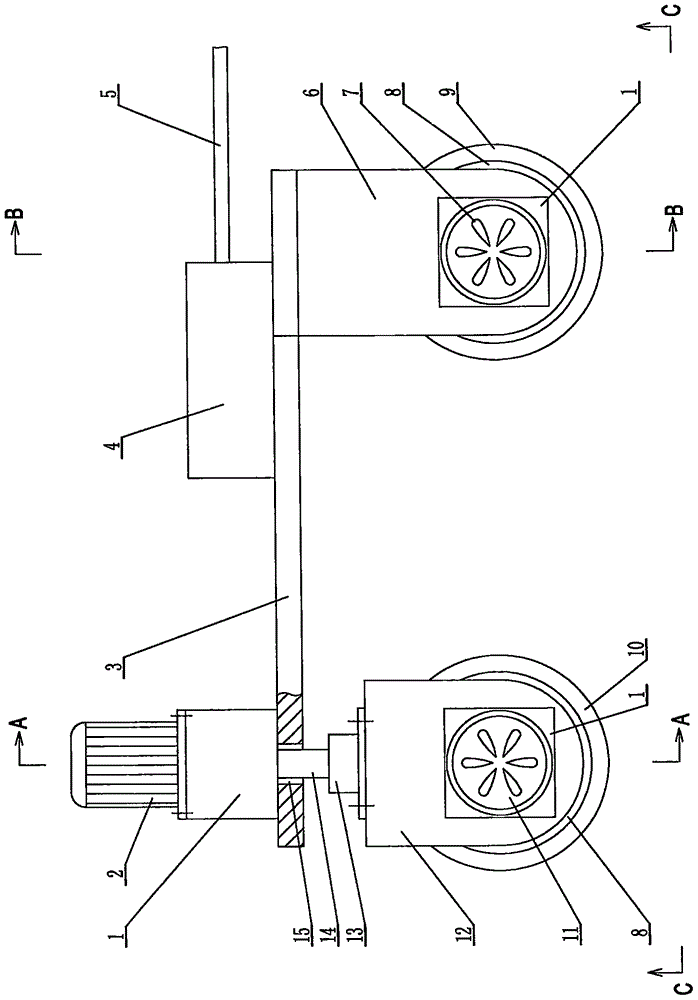

Three-magnetic-wheel giant steel pipe crawling type work platform

The invention discloses a three-magnetic-wheel giant steel pipe crawling type work platform. A left wheel support and a right wheel support are mounted on a triangular platform. A left hub and a right hub are mounted in the left wheel support and the right wheel support through drive shafts and bearings provided with bearing seats correspondingly, magnetic wheels are arranged on the two sides of the left hub and the two sides of the right hub correspondingly, and driving rubber wheels are fixed to the outer-diameter portion of the left hub and the outer-diameter portion of the right hub. One end of the left driving shaft is fixed into a speed reducer output hole provided with a left driving motor. One end of the right driving shaft is fixed into a speed reducer output hole provided with a right driving motor. Each steering wheel support is connected with a steering motor through a flange shaft sleeve, a steering shaft and a speed reducer. Steering hubs are mounted in the steering supports through driving shafts, magnetic wheels are arranged on the two sides of the steering hubs, and steering rubber wheels are fixed to the outer-diameter portions of the steering hubs. Steering driving motors are fixed to the right sides of the steering wheel supports through the speed reducers and connected with the driving shafts, and bearings are fixed to the left sides of the steering wheel supports and fixedly connected with the other ends of the driving shafts. A control unit provided with a cable is fixed to the triangular platform. The three-magnetic-wheel giant steel pipe crawling type work platform can be widely applied to various fields.

Owner:HARBIN GERUIDELAI ROBOT MFG CO LTD

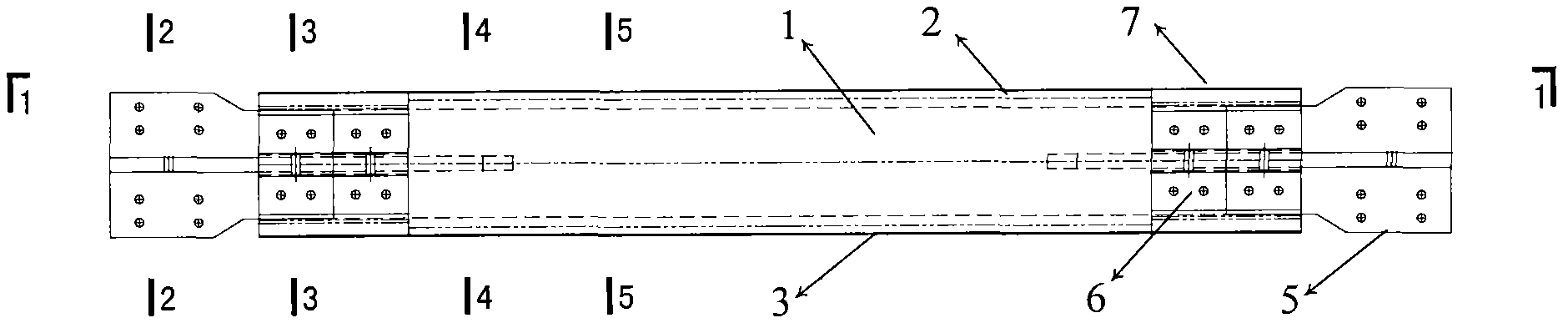

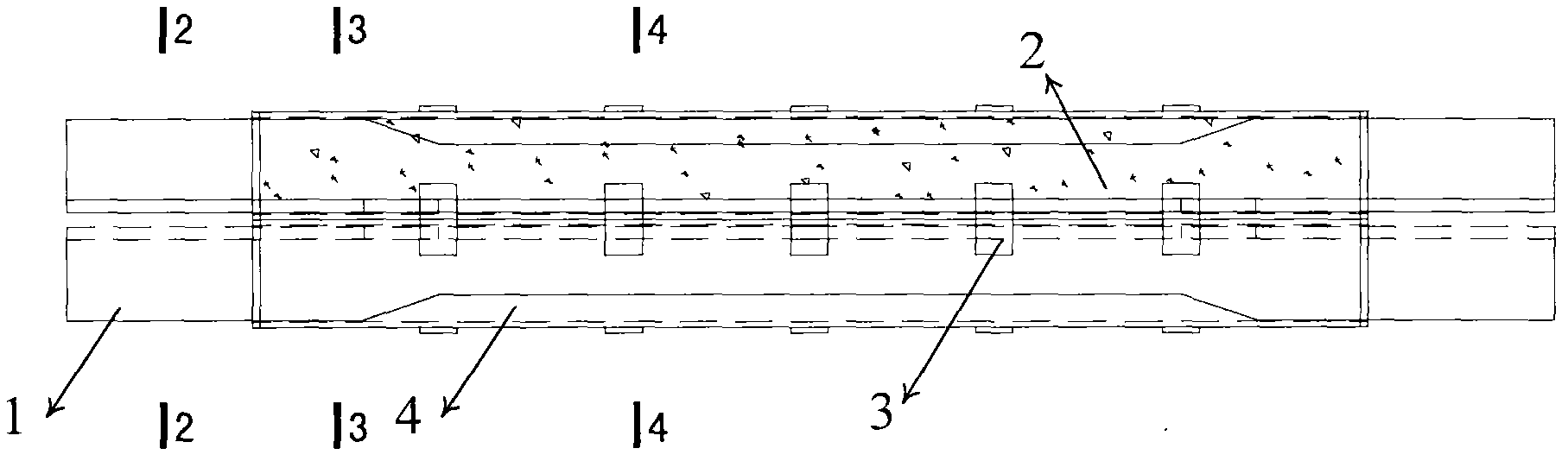

Core-replaceable partial filling type double-sleeve buckling-preventing support

InactiveCN103266683ARealize post-earthquake replacementImprove bending abilityShock proofingEconomic benefitsPartial filling

The invention provides a partial filling type double-sleeve buckling-preventing support. The core-replaceable partial filling type double-sleeve buckling-preventing support can consume a large amount of earthquake input energy, reduces the damage to the structure under rare occurrence earthquakes, connects energy consuming cores and a node elastic region through a detachable bolted connection method, can also achieve post-earthquake replacement of the energy consuming core, reuses a restraint unit, and lowers repairing and replacement cost. The core-replaceable partial filling type double-sleeve buckling-preventing support at least comprises (1) the linear type energy consuming cores, (2) an internal steel sleeve restraining the linear type energy consuming core from partially buckling, (3) an external steel sleeve guaranteeing the overall stability of the support, (4) concrete filler between the internal steel sleeve and the external steel sleeve, (5) supporting node stiffening plates, (6) bolt connecting plates and bolts between the energy consuming cores and the supporting node stiffening plates, and (7) steel channel stiffening ribs. The core-replaceable partial filling type double-sleeve buckling-preventing support is convenient to support and is designed flexibly, the internal steel sleeve mainly prevents the linear type energy consuming cores from partial buckling and damage, the outer steel sleeve and the concrete filler mainly prevent the entire support from buckling failure, and the function of the internal steel sleeve and the function of the external steel sleeve are relatively independent. The core-replaceable partial filling type double-sleeve buckling-preventing support has the advantages of being low in machining cost, light in self-weight, good in economic benefit, convenient to construct and the like.

Owner:BEIJING TINGFENGLU CULTURE DEV

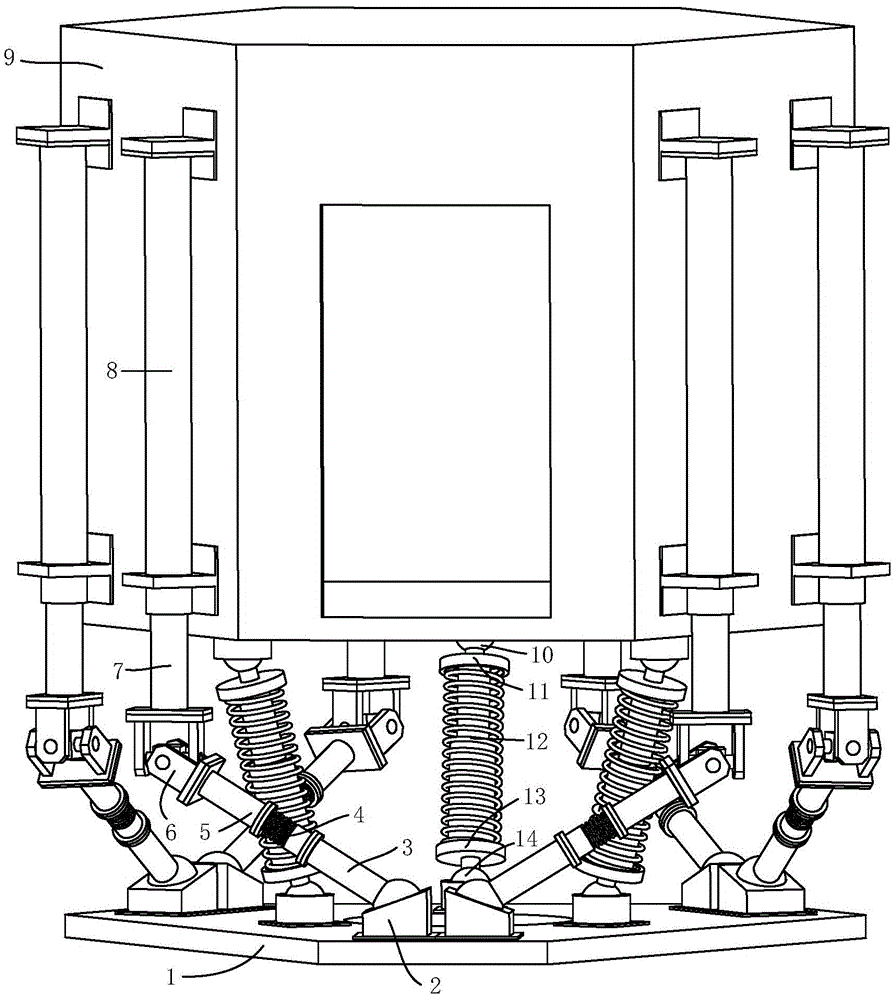

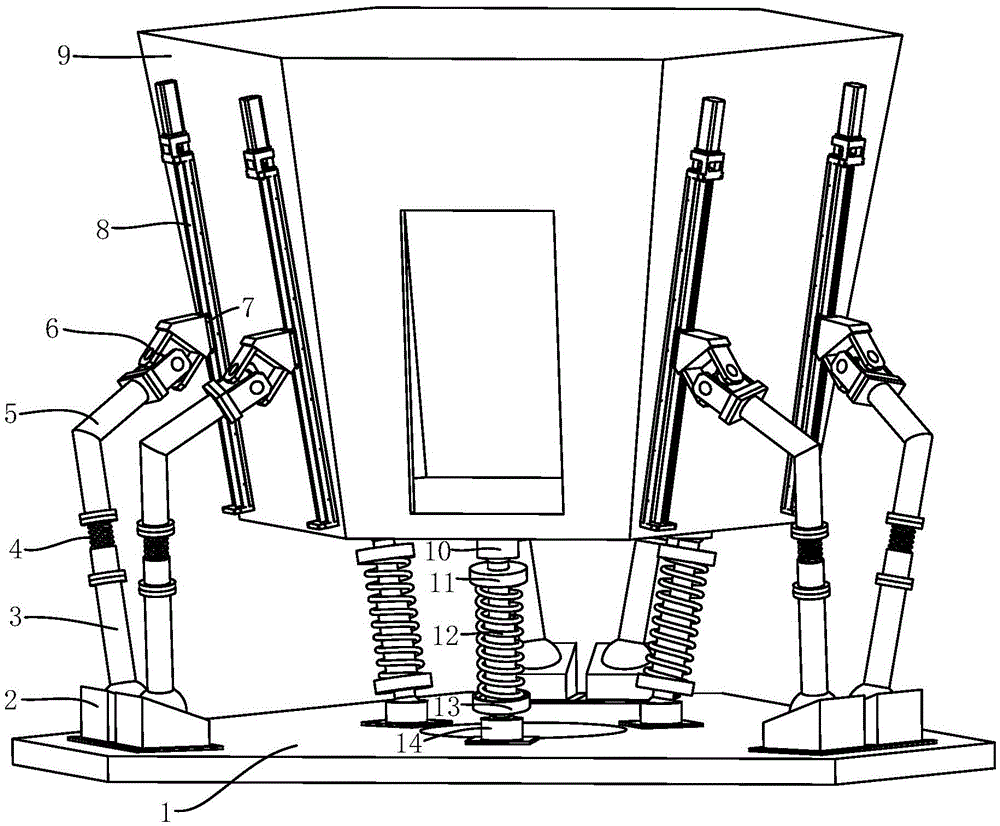

Six-degree-of-freedom parallel stabilizing and vibration-isolating cabin

ActiveCN105570378ALarge load capacityLarge space for activitiesNon-rotating vibration suppressionStands/trestlesDegrees of freedomEngineering

A six-degree-of-freedom parallel stabilizing and vibration-isolating cabin mainly comprises a base, six vibration-isolating branches, assisting bearing branches, a cabin body and six linear driving units fixedly connected onto the cabin body, wherein each of the six vibration-isolating branches comprises a spherical hinge, a first connecting rod, a vibration isolator, a second connecting rod and a universal hinge, one end of the first connecting rod is connected with the base by the aid of the spherical hinge, the other end of the connecting rod is connected with one end of the vibration isolator, the other end of the vibration isolator is connected with one end of the second connecting rod, and the other end of the second connecting rod is connected with one end of a moving rod of each of the six linear driving units by the aid of the universal hinge; the cabin body adopts a hexagonal prism structure, every two linear driving units form a group, driving directions are parallel, and the six linear driving units are uniformly and fixedly connected onto spaced side surfaces of the hexagonal prism; each of the assisting bearing branches comprises spherical hinges and an assisting part, and two ends of the branch are connected with the bottom of the cabin and the base by the aid of the spherical hinges. The six-degree-of-freedom parallel stabilizing and vibration-isolating cabin is low in overall height and high in bearing capacity and has very good stabilizing and vibration-isolating effects.

Owner:YANSHAN UNIV

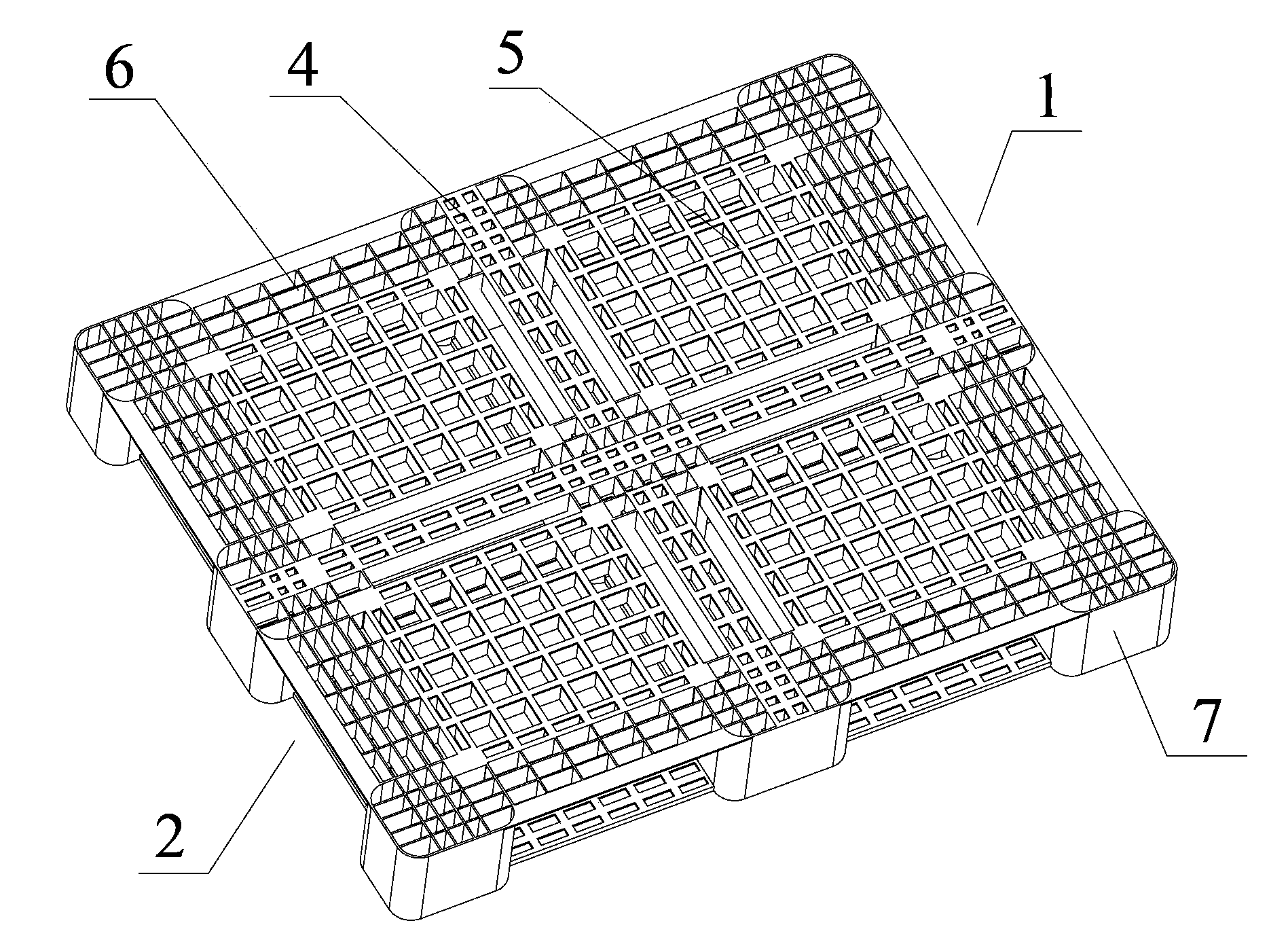

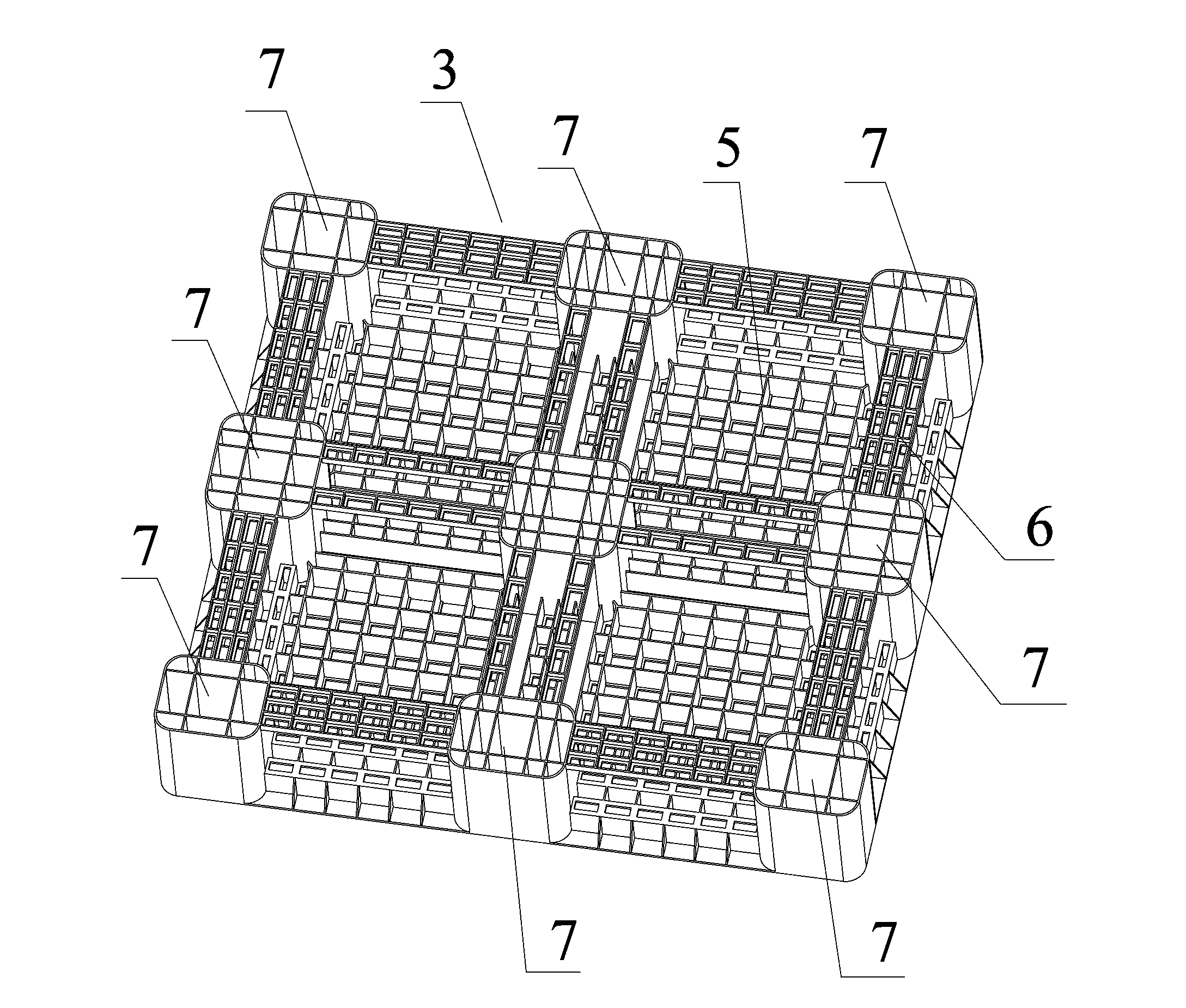

Strong-strength load bearing pallet

The invention relates to a strong-strength load bearing pallet. The pallet is formed by injection-molding a composite thermoplastic material, and consists of an upper surface, lateral surfaces and a lower surface, wherein the upper surface consists of four horizontal squared structures; hollow structures consisting of grating ribs are arranged between the squared structures; cross-shaped reinforcing ribs are arranged in the squared structures; the lateral surfaces are connected with the upper surface at 90 degrees, and rounded corners are adopted for transition at joints; positions for a forklift truck are arranged on the lateral surfaces; every two lateral surfaces are connected at 90 degrees, and rounded corners are adopted for transition at joints; and the lower surface is provided with nine footings, one footing is arranged at a central position, and the other eight footings are uniformly distributed on the periphery of the lower surface, and are connected through connecting ribs. Compared with the prior art, the invention has the advantages that the pallet has the advantages of light weight, high load bearing capacity and longer service life; and during logistics transfer and production transportation, the pallet has remarkable advantages, and the cost can be remarkably reduced.

Owner:HEFEI GENIUS NEW MATERIALS

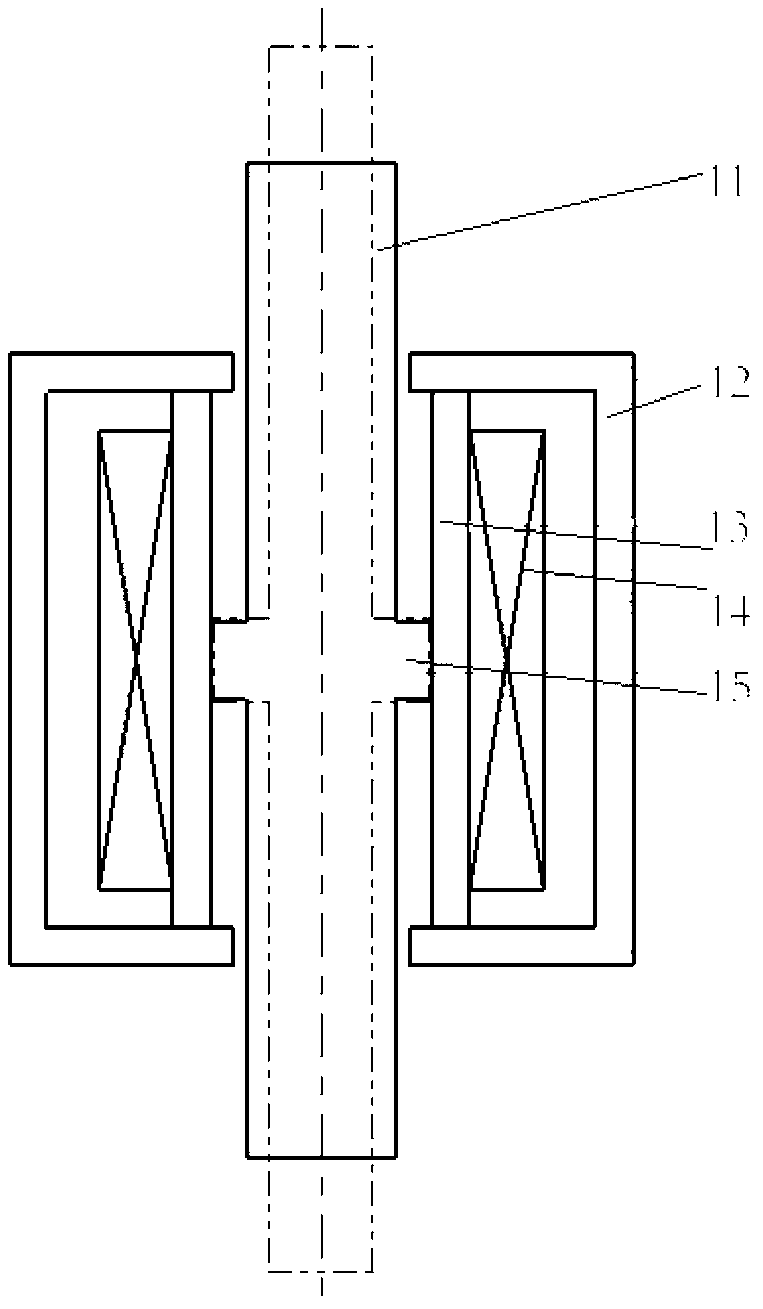

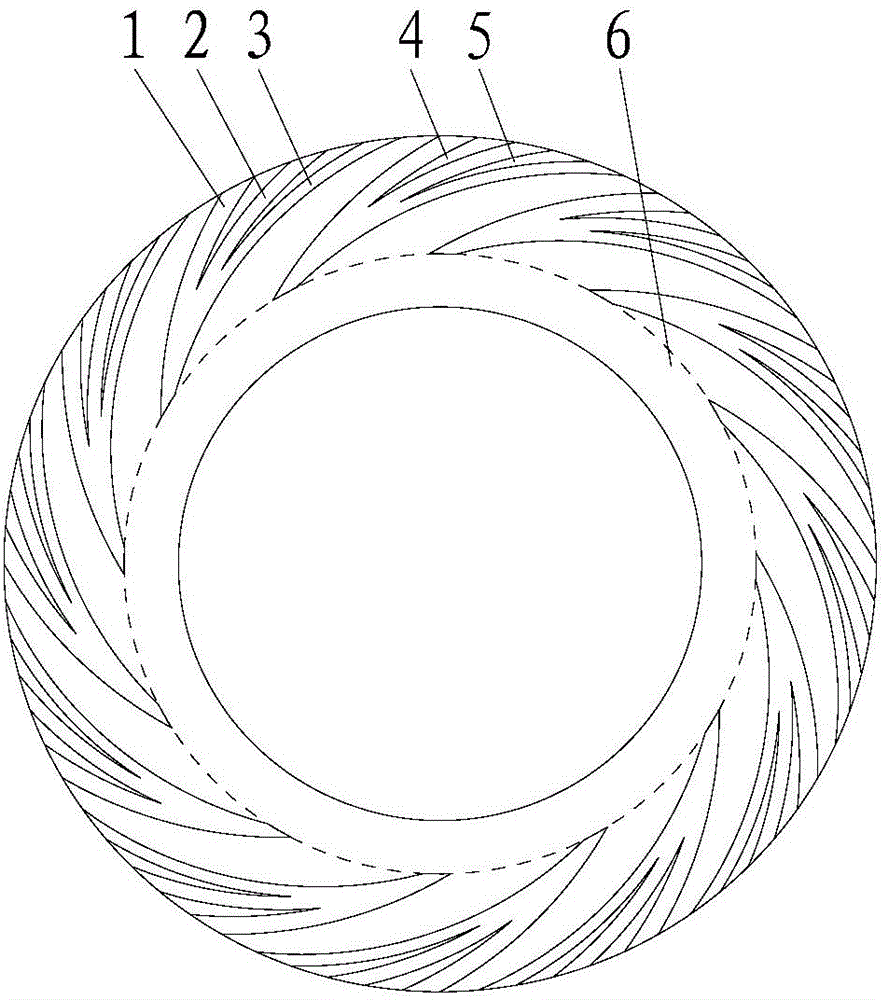

Mechanical seal device for end face seal ring with controllable bellows seal

ActiveCN105114626AImprove surface qualityEliminate or reduce the impactEngine sealsElectricityControl system

The invention relates to a mechanical seal device for an end face seal ring with controllable bellows seal. The mechanical seal device is provided with a moving ring and a non-rotating stationary ring, wherein the moving ring can synchronously rotate along with a rotating shaft, and the stationary ring is connected with a stationary ring base; the axial relative end faces of the moving ring and the stationary ring are the respective seal faces, and at least one seal face is in a plane structure. Electric heating structures keeping the distance with the seal faces are arranged in the circumferential direction of the stationary ring and / or the moving ring with the plane-structure seal surface at intervals, and the electric heating structures are connected with a control system. On the basis that the conventional end face bellows process is kept, the mechanical seal device can process the seal faces into high-precision planes and can obtain the high surface quality on the planes and the controllable bellows seal faces through heating control for the electric heating structures, therefore the influences on the seal effects caused by various factors can be effectively eliminated and avoided, the good hydrodynamic effect can be generated, and the ideal fluid film opening force and stiffness are obtained.

Owner:江苏光谷产业投资发展有限公司

Mechanical seal device with seal rings with controllable cone bevel seal end faces

The invention relates to a mechanical seal device with seal rings with controllable cone bevel seal end faces. The mechanical seal device is provided with a moving ring capable of synchronously rotating along with a rotary shaft and a non-rotating static ring connected with a static ring seat. Axially-opposite end faces between the moving ring and the static ring serve as respective seal faces. The seal face of at least one of the static ring and the moving ring is of a plane structure, and an annular electric heating structure concentric with the static ring and / or the moving ring is arranged at the position, spaced from the seal face, in the static ring and / or the moving ring and connected with a control system. On the basis of an existing end face processing technology, the seal faces can be processed into planes, the cone bevel structure seal faces with high surface quality and controllable cone angle sizes can be obtained on the planes through heating control over the annular electric heating structures, and therefore the influences of various factors on the seal effect can be effectively eliminated, a very good fluid hydrodynamic effect can be generated, and very ideal fluid film opening force and rigidity are obtained.

Owner:永嘉县环球机械密封件厂

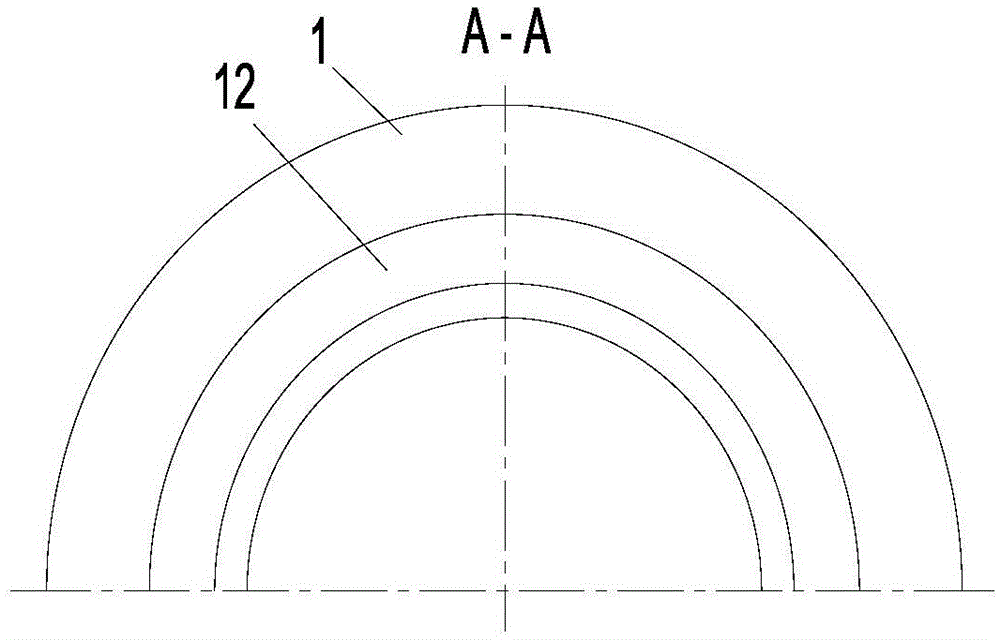

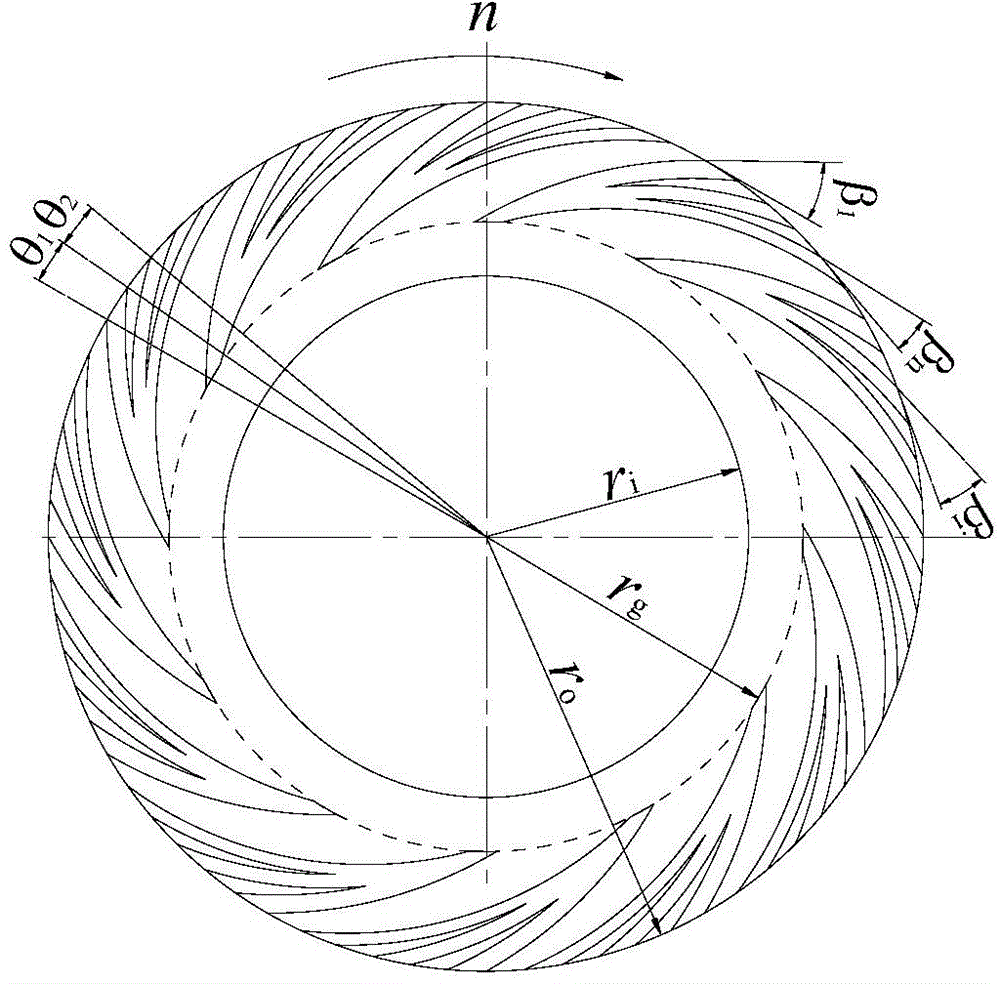

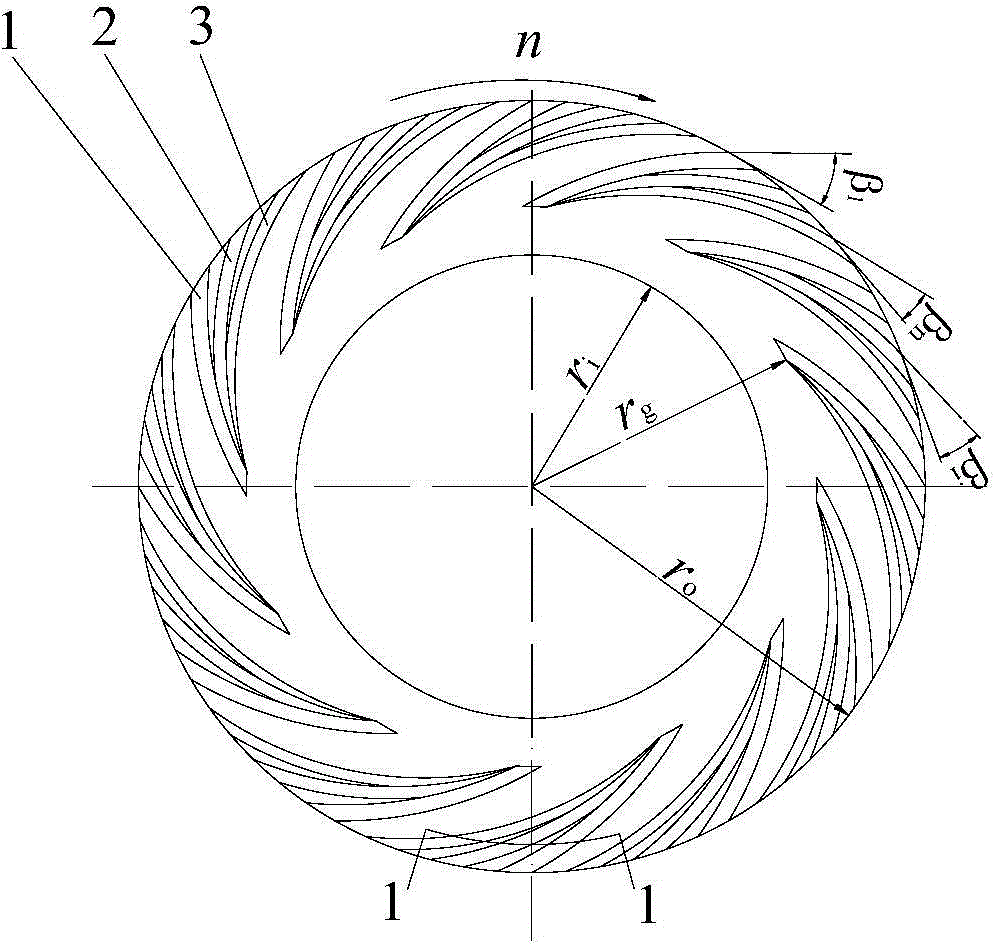

Gas lubrication cluster spiral groove end face mechanical sealing structure

InactiveCN104896099AStrong convergence propertiesImprove compression performanceEngine sealsLow speedGas lubrication

A gas lubrication cluster spiral groove end face mechanical sealing structure comprises a moving ring and a stationary ring of a mechanical seal. One side of the end face of the moving ring and one side of the end face of the stationary ring are high-pressure sides, namely, upper streams, and the other side of the end face of the moving ring and the other side of the end face of the stationary ring are low-pressure sides, namely, lower streams. A plurality of cluster spiral grooves symmetrically distributed along the circumference of the end face are formed in the end face of at least on sealing ring of the moving ring or the stationary ring, the cluster spiral grooves are formed by combining a plurality of micro spiral grooves with different spiral angles in the circumferential direction of the end face, the micro spiral grooves in the same cluster spiral groove are separated by a sealing weir free of grooves on the high-pressure side, the groove roots of the micro spiral grooves in the same cluster spiral groove are overlaid and communicated to a whole on the lower-pressure side, and sealing dams are arranged on the down streams of the cluster spiral grooves. Through the convergence configuration of bionic high-speed flyer wings and the alula structure of flyer wing front edges, the gas lubrication cluster spiral groove end face mechanical sealing structure has a high flow guide effect and compression function on fluid media, the low-speed start and stop characteristic, high-speed running stability and sealing performance of the seal can be improved, the high-speed disturbance rejection capacity of the seal is improved, and end face abrasion is avoided.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of composite algicide

InactiveCN107473345AIncrease layer spacingLarge load capacityBiocideAnimal repellantsChemical reactionCell membrane

The invention relates to the technical field of algicide preparation, in particular to a preparation method of a composite algicide. The preparation method comprises steps as follows: interlayer spacing of montmorillonite is widened firstly, the montmorillonite is soaked with citric acid, cobalt-iron ions are complexed with citric acid, magnetic cobalt ferrite is generated after calcination, hydroxyl free radicals, hydrogen peroxide and ozone produced through a photochemical reaction are promoted to effectively kill algae under the photomagnetic synergistic effect, then snailase rich in different enzymes is supported on a crude algicide product and adopted to damage slime outside the algae, the algae are enabled to be exposed from slime outside the algae, the exposed algae are contacted with copper ions, and the copper ions are adsorbed to algal cell walls, penetrate through the cell walls and remains on cell membranes to inhibit activity of enzymes in the cell membranes and result in algal death finally, so that the purpose of algae removal is achieved. The metal copper ions are chelated on the surface of a magnetic green body, the release speed is reduced, so that the long-time algae removal effect can be achieved, and the preparation method has broad application prospect.

Owner:薛向东

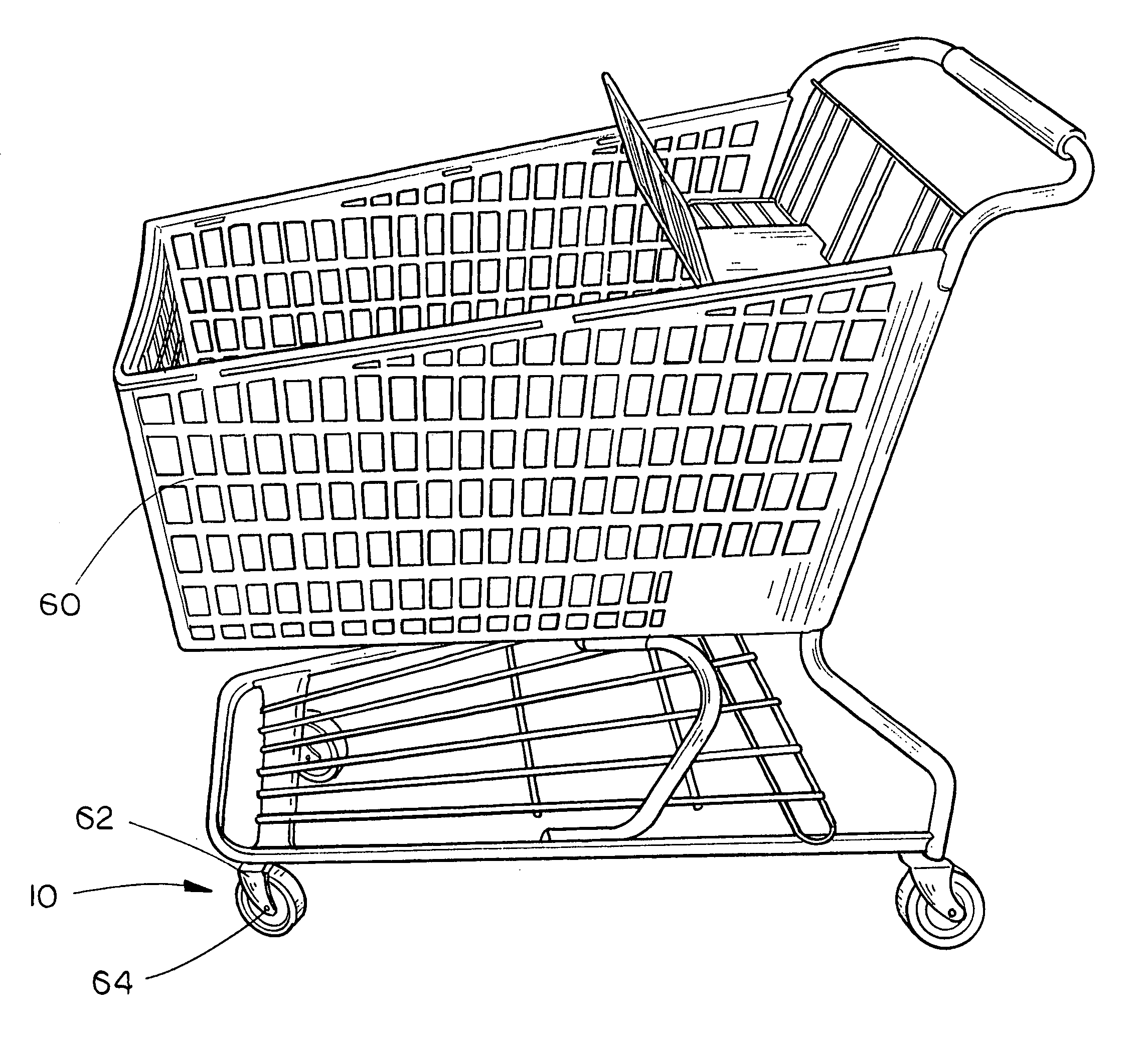

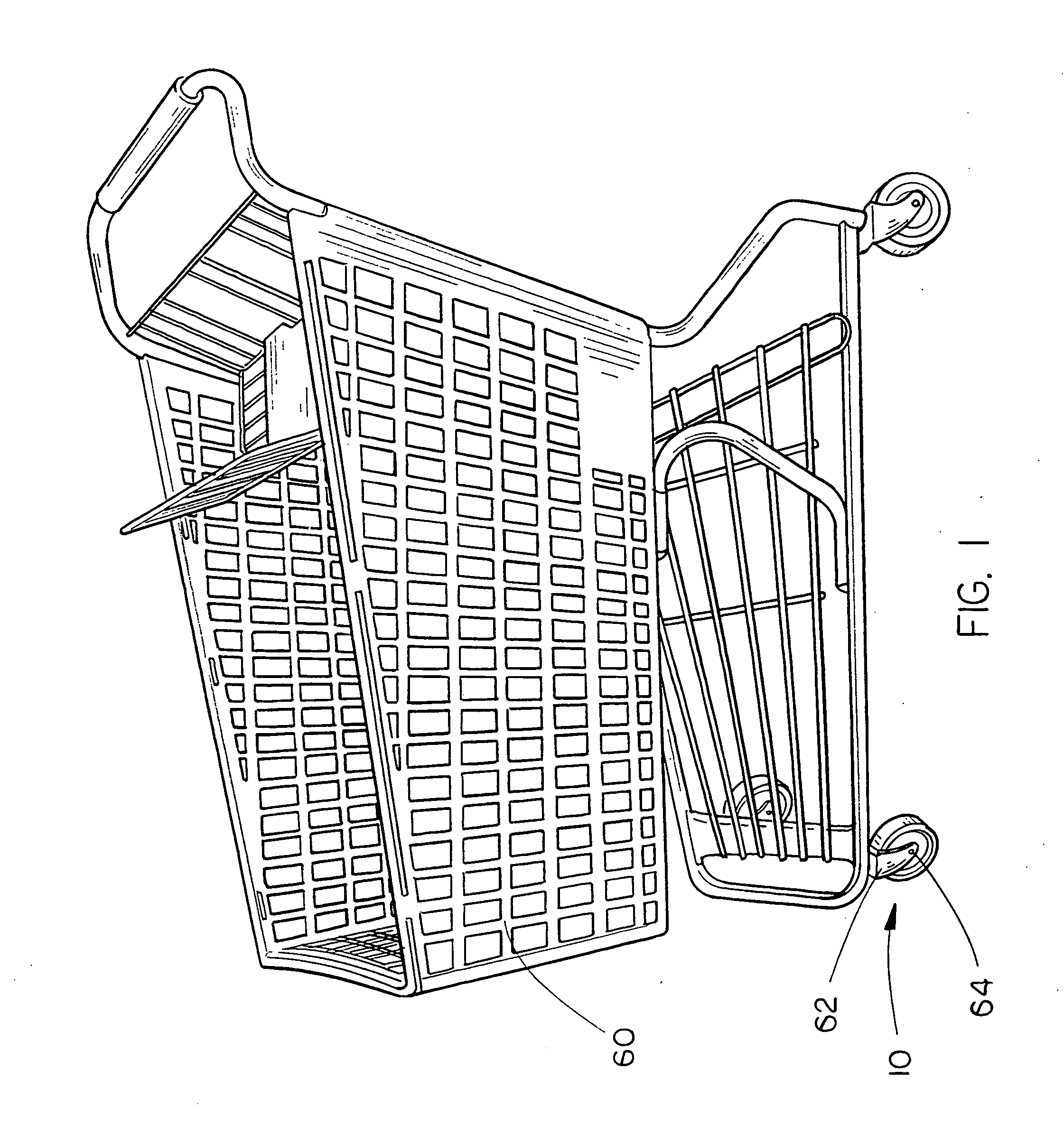

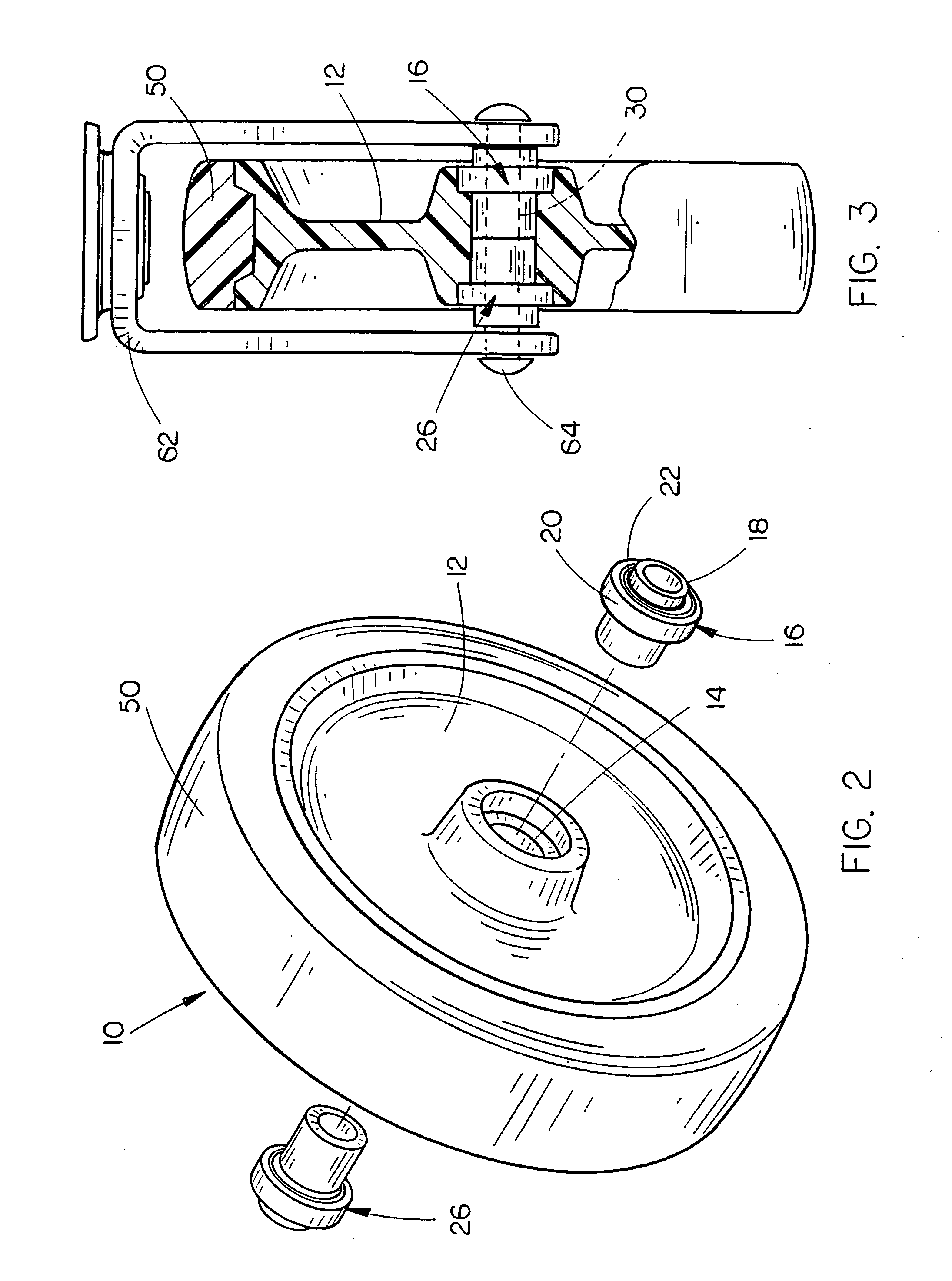

Shopping cart wheel

The present invention provides an improved shopping cart wheel which includes a wheel hub supporting a wheel thereon and having a central axial opening. Mounted within the central axial opening adjacent one end thereof is a first precision bearing unit having a rotating cylindrical central hub, an outer toroidal bearing jacket surrounding the central hub and a plurality of ball bearings rotatably mounted within the outer toroidal bearing jacket and rotatably supporting the rotating central hub therebetween, and mounted within the central axial opening adjacent the opposite end thereof is a second precision bearing unit which is substantially identical to the first precision bearing unit. The central hubs of the first and second precision bearing units generally contact one another in coaxial alignment within the central axial opening such that the improved shopping cart wheel will withstand greater side load forces and have increased weight-carrying capacity.

Owner:SWANSON TERRY +1

Hydraulic suspension structure of low platform carrier vehicle

InactiveCN104608575ALower the altitudeReasonable structureResilient suspensionsVehicle frameSuspension (vehicle)

The invention relates to a hydraulic suspension structure of a low platform carrier vehicle. The hydraulic suspension structure of the low platform carrier vehicle comprises a suspension frame, a suspension oil cylinder, a balance arm, an axle and a wheel component. The suspension frame is connected to the bottom of the vehicle frame of the platform carrier vehicle, the cylinder body of the suspension oil cylinder is connected with the suspension frame, the end portion of the balance arm is connected to the suspension frame, the axle is connected with the other end portion of the balance arm, the wheel component is connected with the axle, the a cylinder rod used for suspending the oil cylinder is connected with the balance arm, the distance from the connecting point of the cylinder body of the suspension oil cylinder and the suspension frame to the bottom of the vehicle frame is 70-80mm, and the distance between the connecting point of the cylinder rod of the suspension oil cylinder and the balance arm and the connecting point of the suspension frame and the balance arm is 205-215mm. The hydraulic suspension structure of the low platform carrier vehicle has the advantages that the structure is reasonable, the volume is small, the bearing capacity is large, under the condition that the bearing capacity is not changed, the height of the carrier vehicle is greatly lowered, so that the passing ability of the carrier vehicle with high goods in a driving process is guaranteed, the whole suspension structure is compact, the outline size is small, the volume is small, the weight is light, and the installation and the maintenance are convenient.

Owner:SUZHOU DAFANG SPECIAL VEHICLE

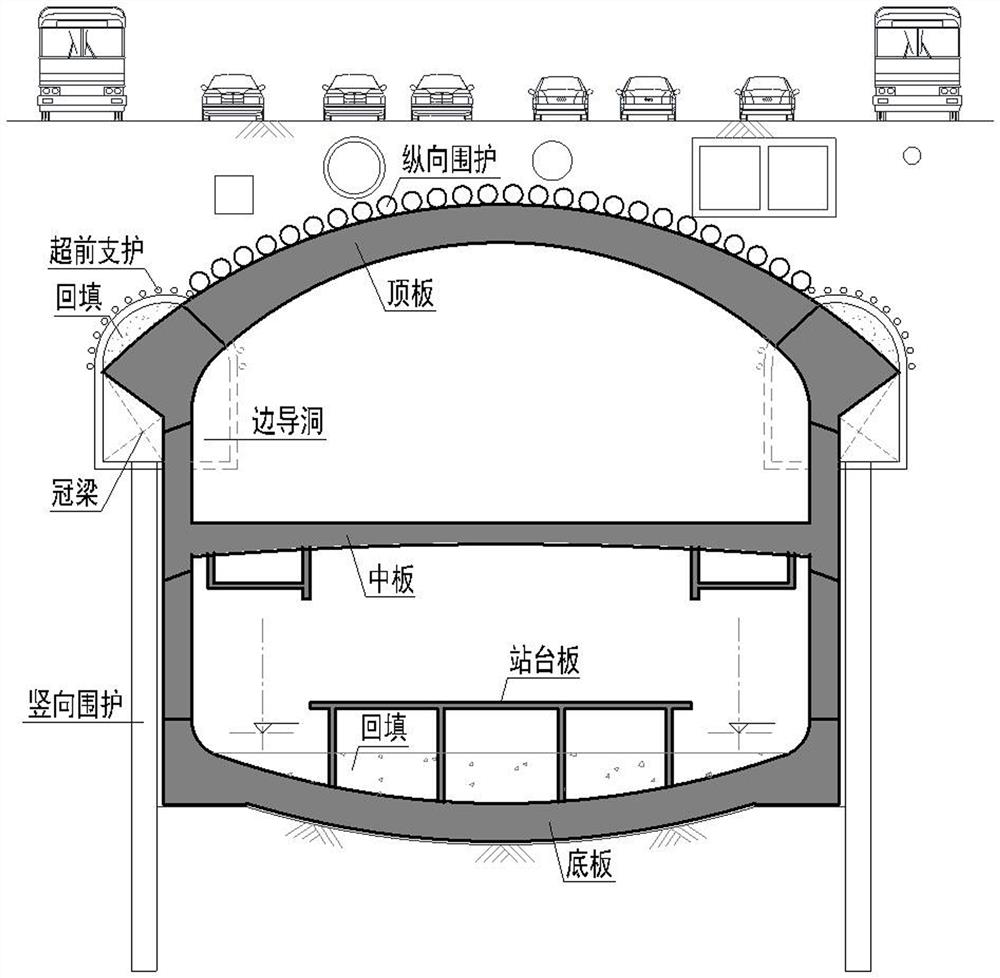

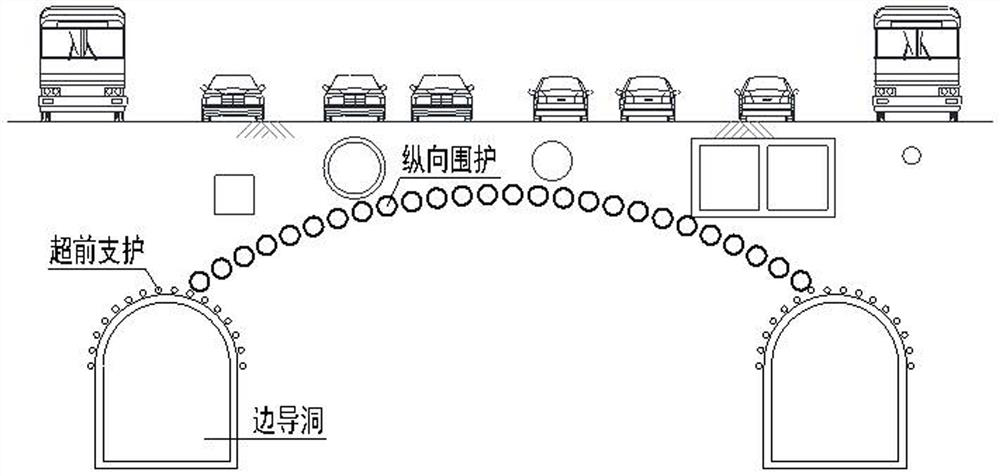

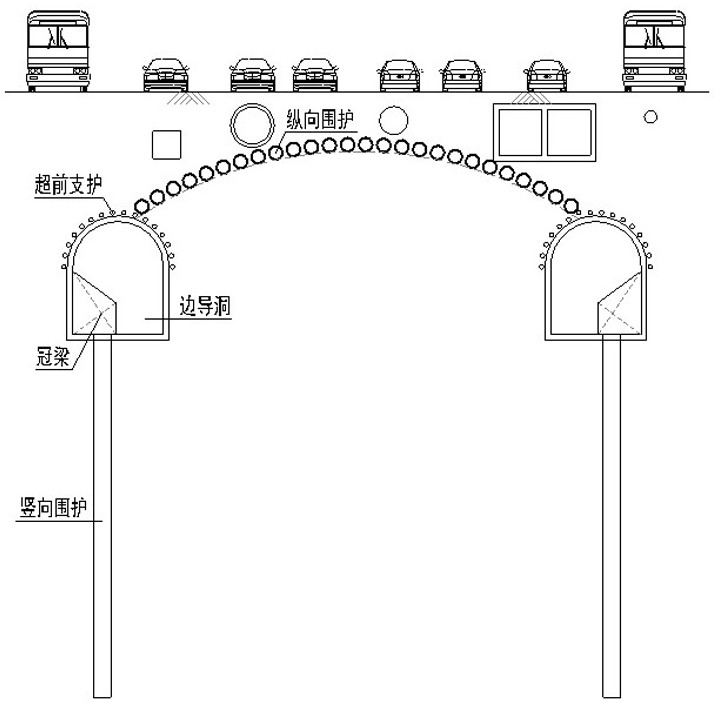

Underground excavation construction method for large-span column-free underground station

ActiveCN113847040AClear forceThe construction process is safe and reliableUnderground chambersTunnel liningStructural engineeringBoard structure

The invention discloses an underground excavation construction method for a large-span column-free underground station, and relates to the field of underground station underground excavation construction. The method comprises the steps that a longitudinal enclosure is constructed along the outer contour of an arched top plate of the underground station, and a left side pilot tunnel and a right side pilot tunnel are longitudinally constructed along the arch foot position of the top plate; a vertical enclosure is constructed in the supported side pilot tunnel, and a top beam is arranged at the top of the vertical enclosure; top plate arch feet and part of side wall structures are constructed in the side pilot tunnels, the arch feet and the top beam are anchored, and temporary cross braces are arranged between the side walls and the side pilot tunnels; advanced pre-grouting reinforcement is conducted on a soil body below the longitudinal enclosure, earthwork below the longitudinal enclosure is excavated section by section in the longitudinal direction, an arch top plate structure is constructed section by section, the arch top plate and arch feet are connected into a whole, and backfill grouting is conducted on the back of the top plate; after the arch crown structure is connected and reaches the design strength, a first underground layer soil body of the station is excavated, a side pilot tunnel primary support within the permanent structure range is broken, and a first underground layer middle plate and a side wall structure are constructed; and the remaining soil body is excavated layer by layer and the remaining station structure is constructed.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

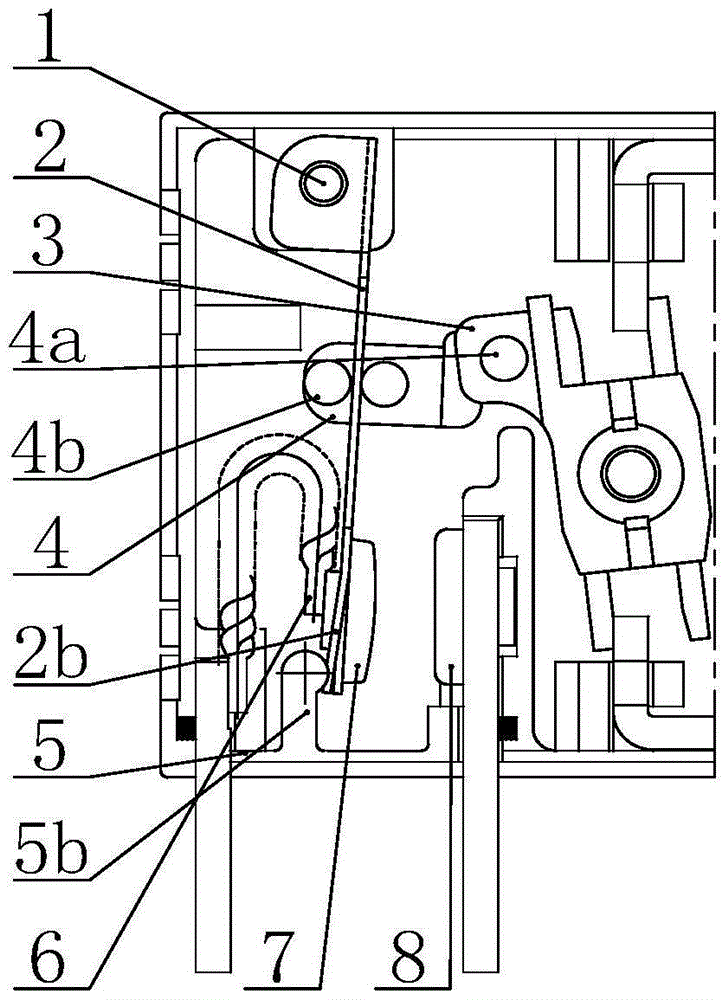

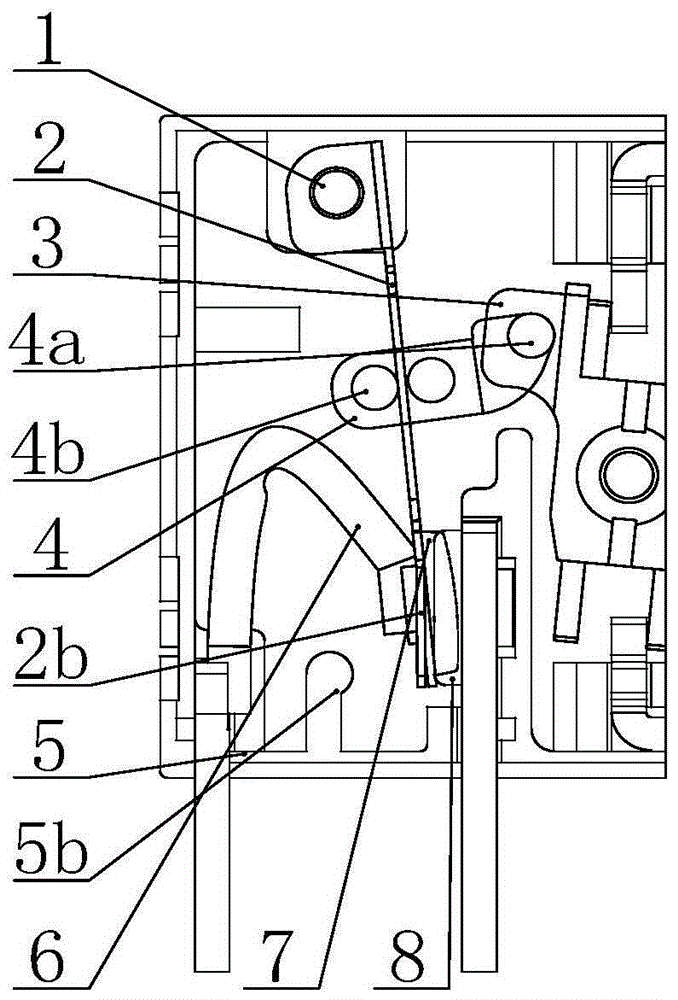

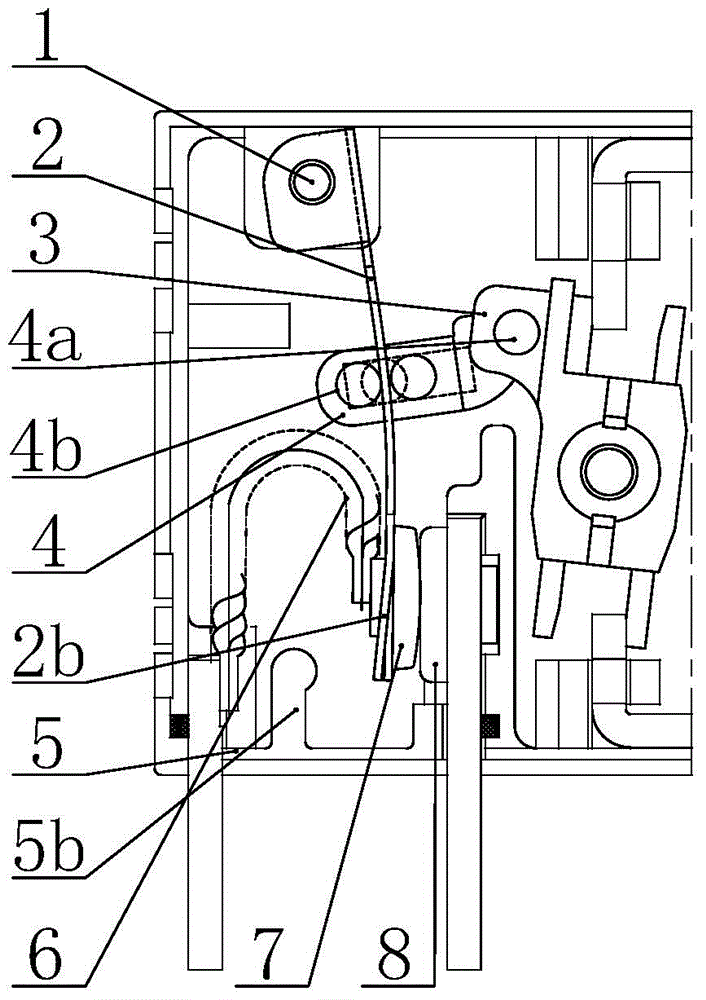

Moving contact push mechanism of magnetic latching relay

ActiveCN105244233AImprove electrical lifeLarge load capacityElectromagnetic relay detailsPower flowElastic component

The invention provides a moving contact push mechanism of a magnetic latching relay. The moving contact push mechanism comprises a contact system, an armature part and a push block, wherein the contact system comprises a moving contact and a static contact, the armature part drives the push block to move, and the push block moves to drive the moving contact to swing so as to achieve connection and disconnection of the moving contact and the static contact; a movable contact spring of the moving contact is an elastic component and is shaped as a rectangular sheet, a first end part of the moving contact is of a rotation structure, and a second end part of the moving contact is of a swinging structure; the push block is movably connected to the middle part of the movable contact spring, a structure having a guidance effect is arranged between the push block and a relay shell, and the push block and the armature part are directly or indirectly connected; and the moving contact and a movable leading-out pin are connected by a flexible connection wire. By the moving contact push mechanism, a transmission structure and a current direction are changed, the transmission loss is reduced, the contact opening distance is increased, and the high-current bearing ability is improved.

Owner:SOOAR TIANJIN ELECTRICAL EQUIP CO LTD

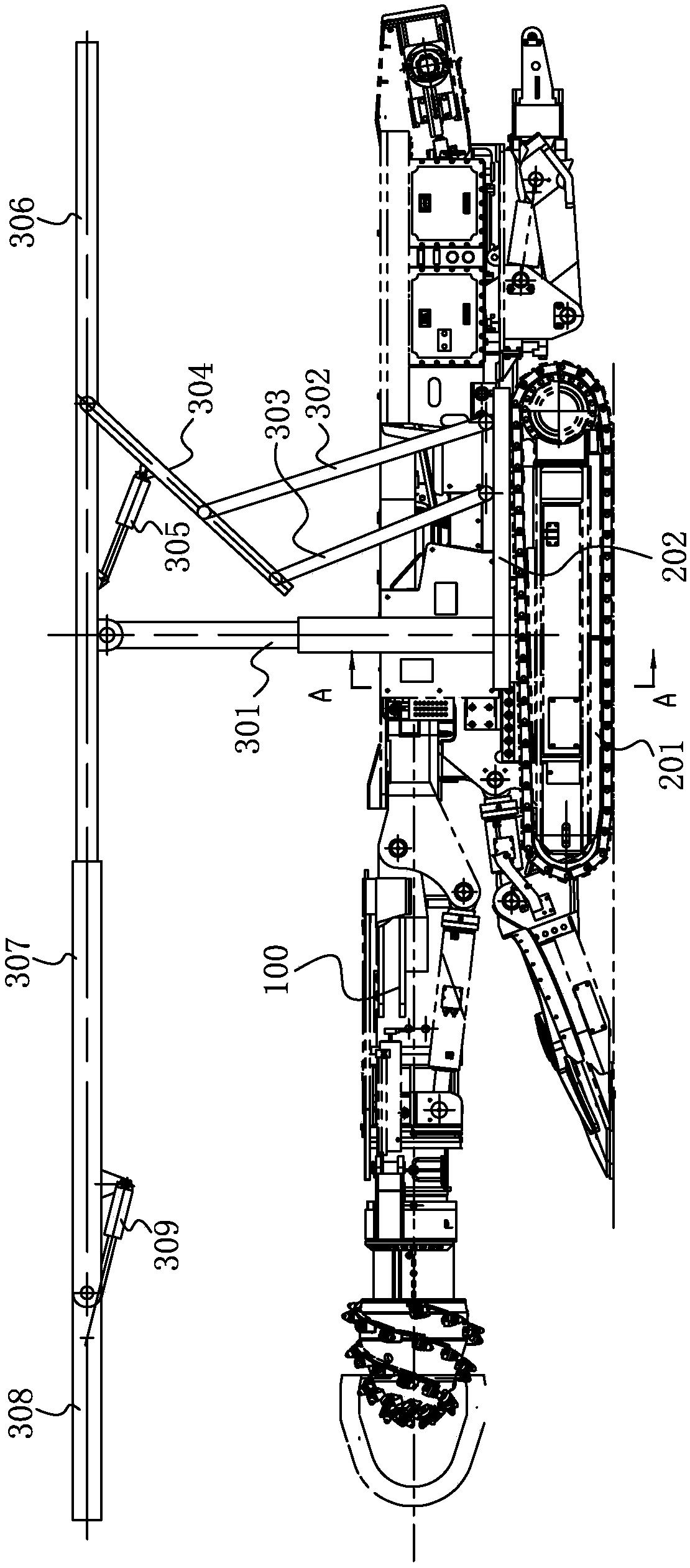

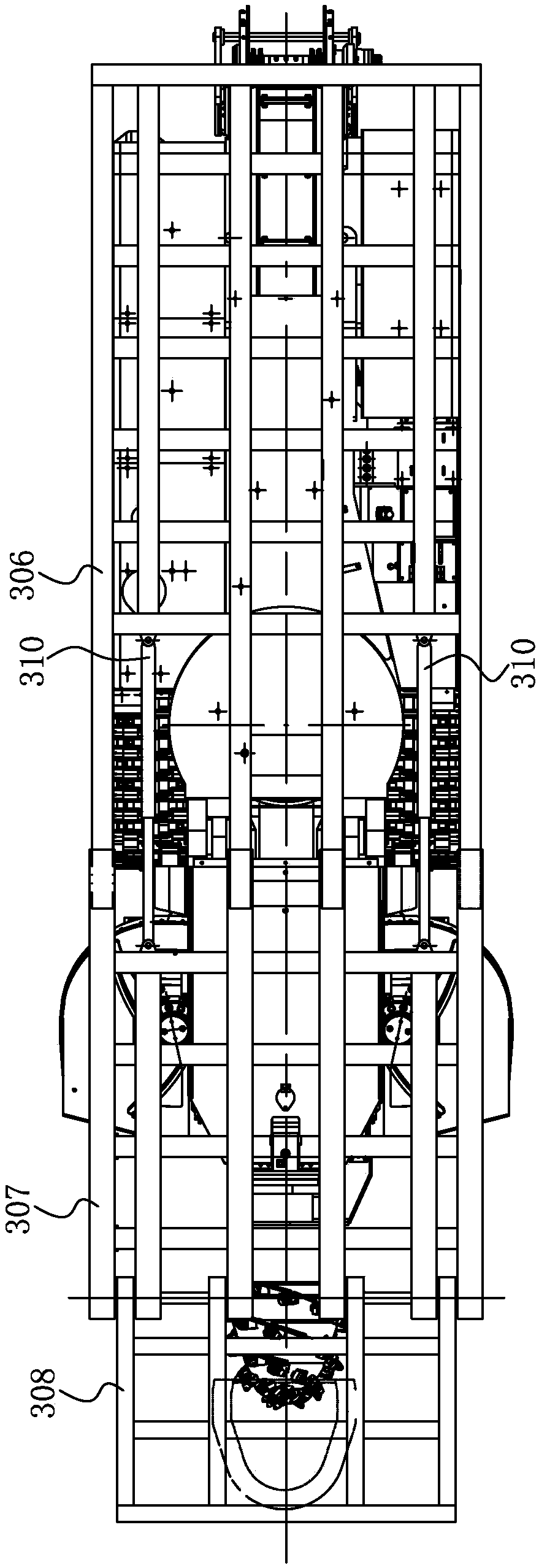

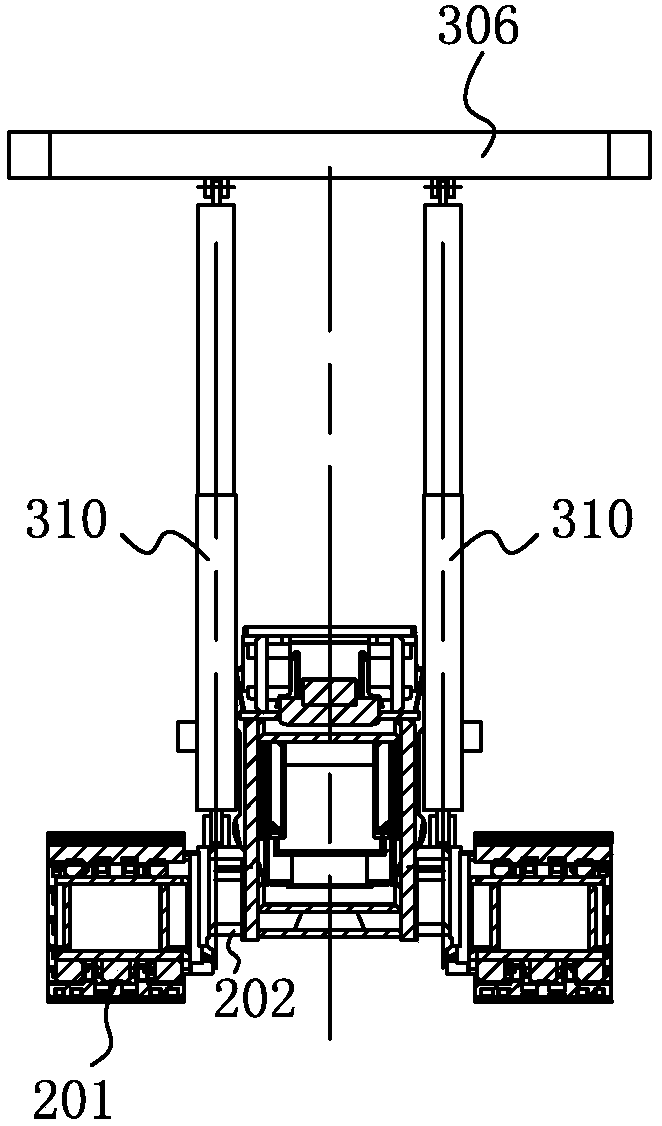

Cantilever type digging and protecting integrated machine

PendingCN108412514AIncrease the areaLarge load capacityTunnelsPropulsionHinge angleCarrying capacity

The invention discloses a cantilever type digging and protecting integrated machine. The machine comprises a chassis and a cantilever type cutting part; the base, wherein the base is arranged above the chassis through a bearing mechanism; a telescopic protective cover and / or a swinging shield, wherein the telescopic protective cover is in sliding connection with the base; a telescopic power devicethat is arranged between the base and the telescopic protective cover; the swinging shield is hinged with the telescopic protective cover through a transverse hinge shaft; and a swinging power devicethat is arranged between the swinging shield and the telescopic protective cover. For the ,cantilever type digging and protecting integrated machine, the load carried by the telescopic shield and / orthe rotary shroud is directly transmitted to the chassis via the base and the supporting mechanism, and is completely unaffected by the cantilever cutting portion. Therefore, the telescopic shroud and / or the revolving shroud can provide a wider range of protection for construction workers in front of the chassis of the roadheader. The temporary safety protection with greater carrying capacity ensures that the construction workers can be reliably and safely protected in the construction work ahead of the chassis of the roadheader.

Owner:日照市上普重型装备股份有限公司

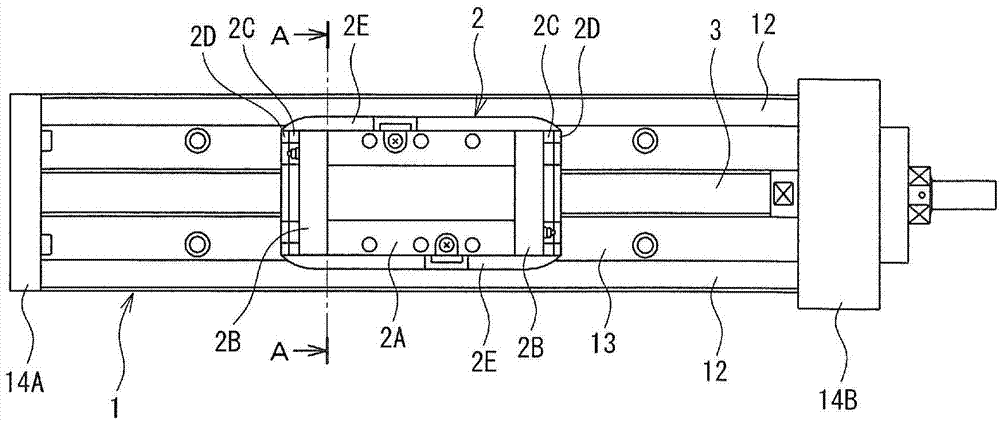

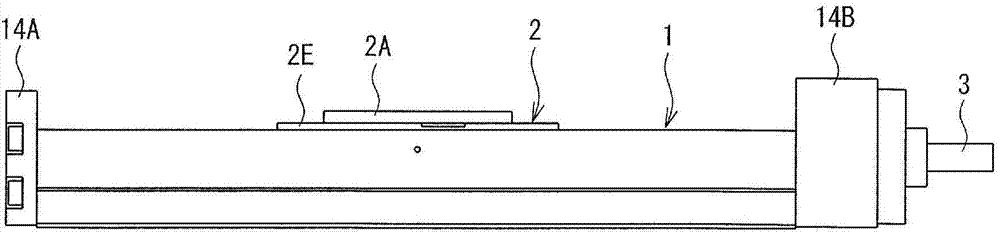

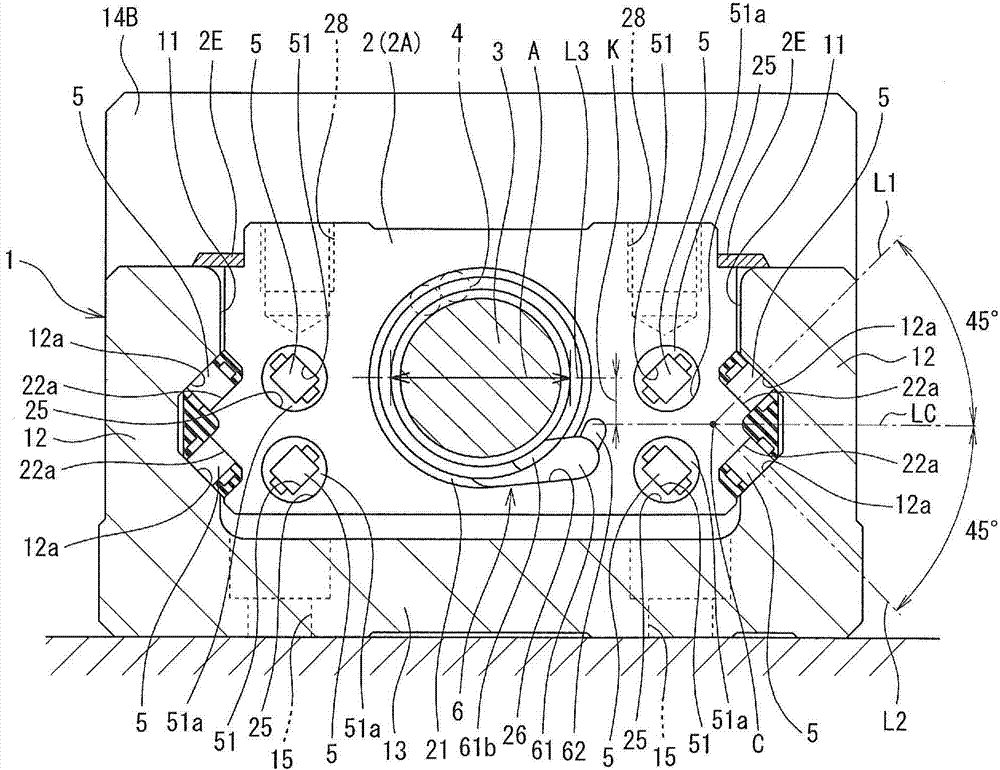

Single-axis actuator

The present invention addresses the problem of reducing the size of the cross-sectional shape perpendicular to the lengthwise direction of the threaded shaft of a slider when the diameter of the outer peripheral circle of a threaded shaft is the same as that of a single-axis actuator which uses a circulation tube to form the ball return path of the single-axis actuator, and of increasing the load capacity when the dimensions in the lengthwise direction of the threaded shaft of the slider are the same. With the present invention a ball return path, which returns the balls (4) of a ball screw mechanism from the terminal point to the starting point of a raceway, is formed by means of a through-hole (24) that penetrates in the lengthwise direction of a threaded shaft (3) of a slider (2), and by means of an end deflector (6). The end deflector (6) has a direction-switching path connecting with the through-hole (24). The main body (61) of the end deflector (6) is mated with notch parts (26) formed at both ends in the lengthwise direction of the threaded shaft (3) of the slider main body (2A).

Owner:NSK LTD

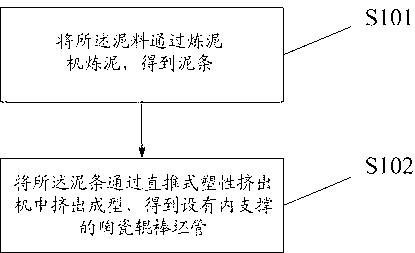

Ceramic roller molding process

The invention discloses a ceramic roller molding process. The molding process comprises the following steps carrying out pug milling on forearmed pug through a pugmill so as to obtain pug stripes; and carrying out extrusion molding on the pug stripes through a transductive plastic extruder so as to obtain a ceramic roller tube blank with an inner support. According to the invention, the molding process is rapid in molding speed, high in efficiency and low in loss; adopted equipment is simple in structure and convenient to maintain; and a manufactured ceramic roller is high in density, high in bending strength, large in load capacity and good in appearance regularity.

Owner:广东金刚新材料有限公司 +1

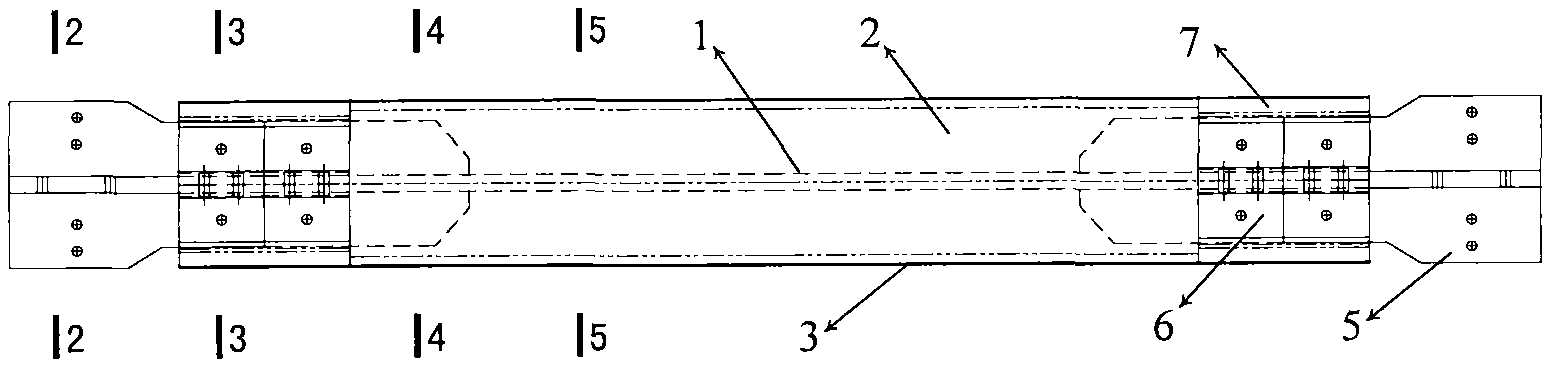

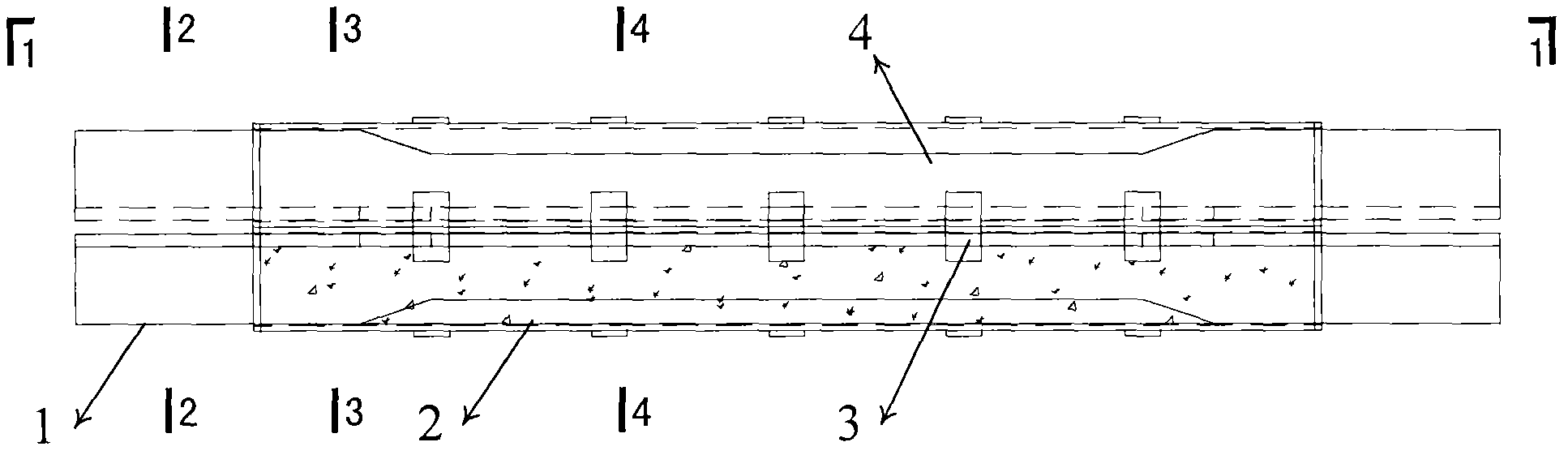

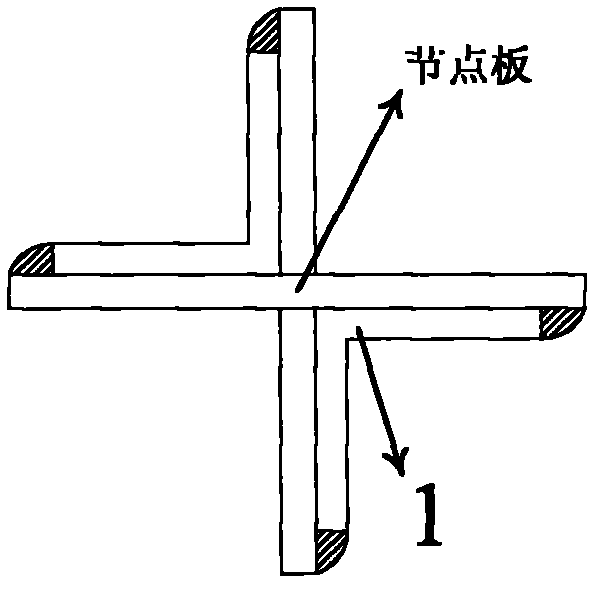

Part-filling assembling lapping buckling-proof support

InactiveCN103255852AImprove utilization efficiencyImprove performanceShock proofingFillet weldEconomic benefits

The invention provides a part-filling assembling lapping buckling-proof support. The part-filling assembling lapping buckling-proof support can greatly consume earthquake input energy, reduces damage on a structure by an earthquake, adopts a modularized installation mode, and reduces positioning difficulty of field installation. The support and pitch points are connected in a lap fillet weld mode, and connection ductility is improved. A plurality of connecting plates are used for connecting hollow steel tubes and concrete filled steel tubes to be a whole, wherein the hollow steel tubes provide whole flexural rigidity. Self-weight of the support is reduced, and material utilization ratio is improved. The hollow steel tubes can be recycled after the earthquake. The part-filling assembling lapping buckling-proof support has the advantages of being low in machining cost, light in self-weight, good in economic benefit, convenient to construct, and capable of partly recycled after the earthquake. The part-filling assembling lapping buckling-proof support at least comprises a pair of L-shaped energy dissipation steel cores, concrete filled steel tube units restraining the L-shaped energy dissipation steel cores respectively, a pair of hollow square steel tubes, a plurality of sleeve connecting plates and isolation materials between the energy dissipation steel cores and the restraining units.

Owner:BEIJING TINGFENGLU CULTURE DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com