Single-axis actuator

An actuator, single-axis technology, used in the direction of shafts, bearings, shafts and bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ]

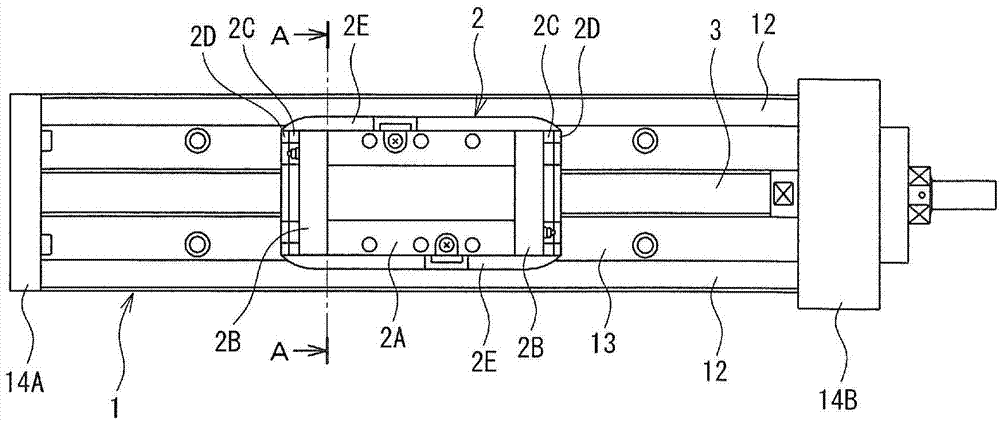

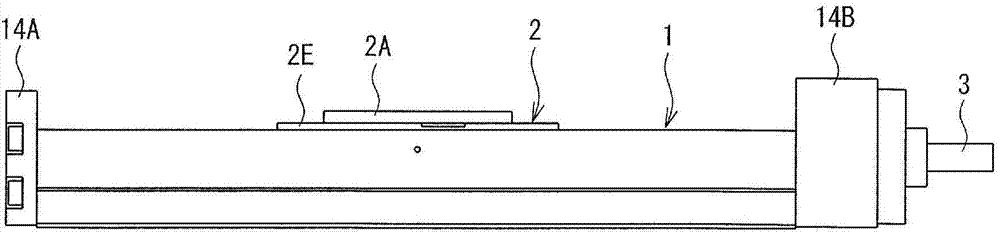

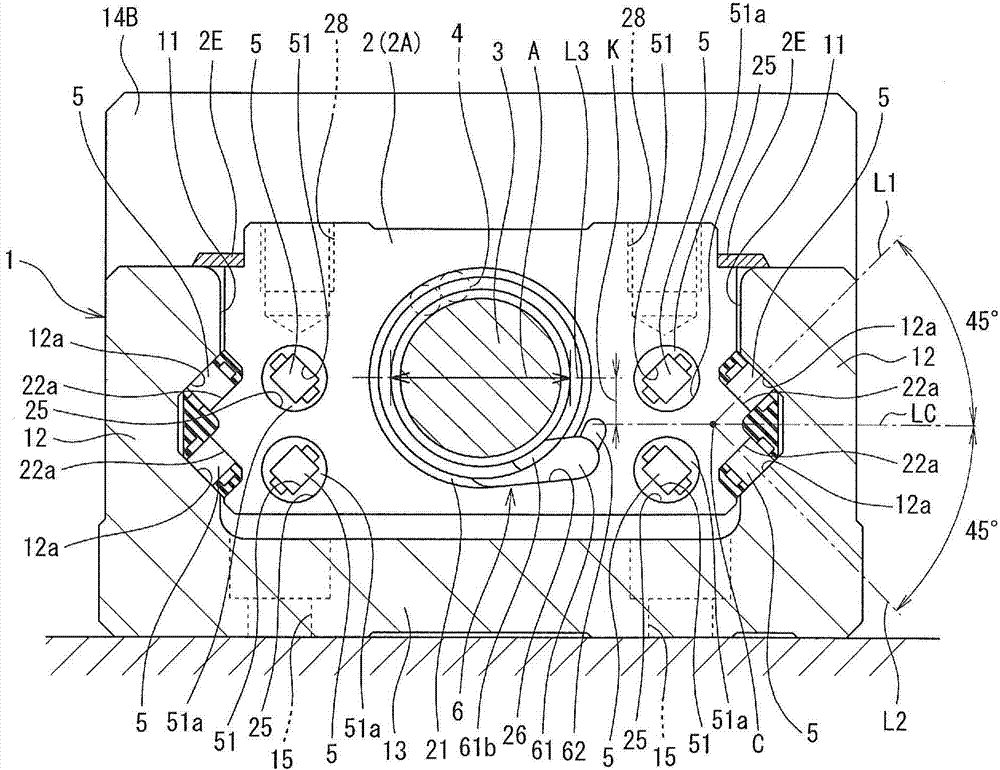

[0067] Figure 1~3 It is a plan view, a side view, and a cross-sectional view (along figure 1 A cross-sectional view of line A-A in).

[0068] Such as Figure 1~3 As shown, the uniaxial actuator includes: a guide rail 1 , a sliding body 2 , a screw shaft 3 , a ball 4 , a roller 5 , and an end reverser 6 .

[0069] The cross section of the guide rail 1 perpendicular to the longitudinal direction is U-shaped, and the slider 2 is housed in the U-shaped concave portion 11 . The guide rail 1 is composed of a bottom portion 13 , end members 14A, 14B, and a pair of side portions 12 , and the inner surfaces of the side portions 12 face the respective side surfaces of the slider 2 . On the inner surface of each side portion 12, a rolling surface 12a constituting a rolling passage of the roller 5 is formed. Through-holes 15 for inserting mounting bolts are formed in the bottom portion 13 of the guide rail 1 . The through hole 15 is formed at a position bordering each side part 12 o...

no. 2 Embodiment approach ]

[0089] exist Figure 7 The uniaxial actuator of the second embodiment shown is the same as the uniaxial actuator of the first embodiment except that the rolling elements of the linear guide mechanism are different.

[0090] In the second embodiment, since the balls 7 are provided as rolling elements, the rolling grooves (rolling surfaces) 12b of the balls 7 are formed on the inner surface of the side portion 12 of the guide rail 1, and the rolling grooves (rolling surfaces) are formed on the slider main body 2A. 22b. Further, a through-hole 29 extending in the longitudinal direction of the screw shaft is formed in the slider main body 2A as a return path for the ball 7 .

[0091] Thus, the linear guide mechanism of the uniaxial actuator is constituted by the rolling groove 12b of the guide rail 1, the rolling groove 22b of the slider body 2A, the ball 7, the return passage 29 of the slider body 2A, and the direction switching passage of the end cover 2B. . In addition to th...

no. 3 Embodiment approach ]

[0094] The uniaxial actuator of the third embodiment is the same as the uniaxial actuator of the first embodiment except that the structure of the slider is different.

[0095] Figure 8 A front view showing the slider main body constituting the uniaxial actuator of this embodiment is shown in Figure 9 Rear view is shown in . which is, Figure 8 is a diagram showing one end surface of the slider main body in the longitudinal direction of the screw shaft, Figure 9 It is a diagram showing the other end surface in the longitudinal direction of the screw shaft. Figure 10 is a diagram showing a cross-section of one end of the slider body in the longitudinal direction of the screw shaft, and corresponds to the Figure 8 A cross-sectional view of line A-A in. Figure 11 is a diagram showing the cross-section of the other end of the slider body in the longitudinal direction of the screw shaft, which corresponds to the Figure 9 A cross-sectional view of line A-A in.

[0096]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com