Part-filling assembling lapping buckling-proof support

An anti-buckling bracing, local technology, applied in the direction of earthquake resistance, building components, etc., can solve the problems of many production and processing procedures, difficult construction positioning, large welding residual stress, etc., to improve material utilization, high material utilization efficiency, reduce The effect of repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

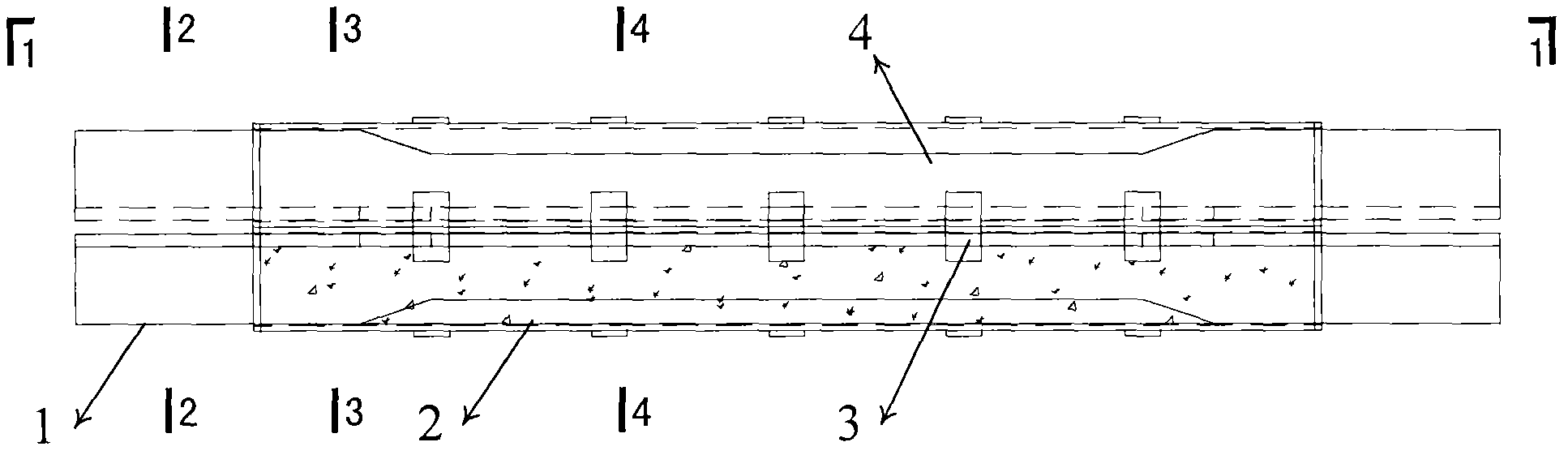

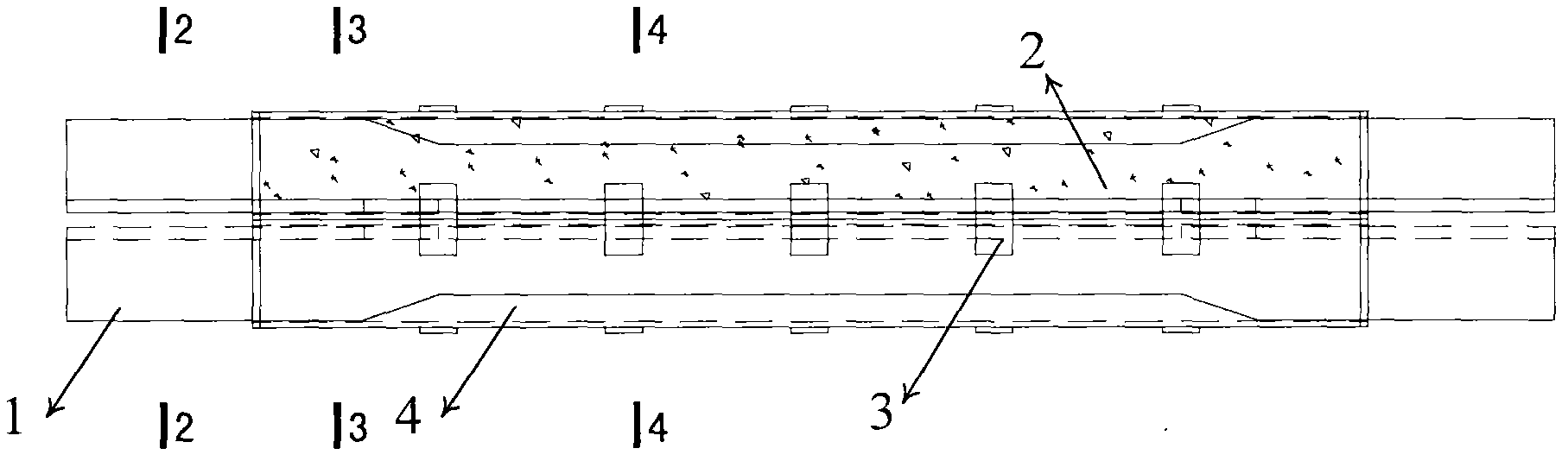

[0024] refer to Figure 1 to Figure 7 , we can know the appearance and structural requirements of the device of the present invention.

[0025] The present invention is implemented according to the following steps:

[0026] (1) Determine the installation location and quantity of this device, and arrange it as far as possible in the weakest part of the structure for earthquake resistance.

[0027] (2) According to the structural analysis and design, determine the parameters of the device such as yield bearing capacity, stiffness and joint connection force.

[0028] (3) Carry out the design and processing of the device of the present invention in combination with the specific construction measures of the device according to the design parameters.

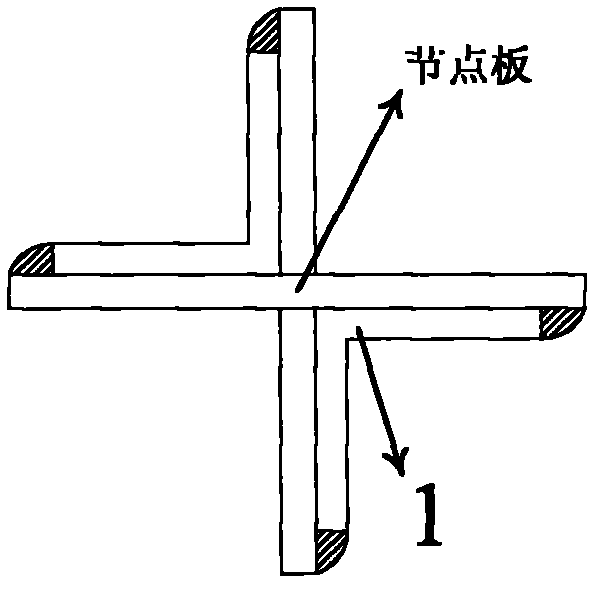

[0029] (4) The device of the present invention is connected to the cross-shaped gusset plate with the main body of the building structure by overlapping fillet welds, specific examples are as follows image 3 and Figure 7 shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com