Preparation method of self-repair coating based on corrosion inhibitor intercalated nano-titanate carrier

A nano-carrier and corrosion inhibitor technology, applied in the field of preparation of self-healing coatings, can solve the problems of being easily eroded by the natural environment, weakening the protective performance of the coating, complex preparation methods, etc., and achieves easy promotion, good protective performance, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

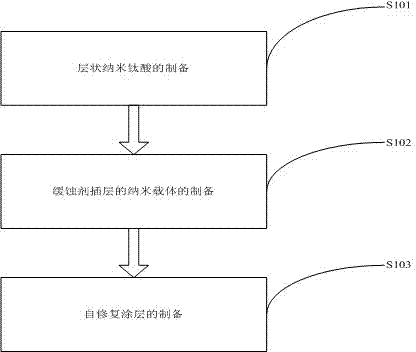

[0023] Preparation of layered nano-titanic acid The nano-layered titanic acid in step S101 has excellent organic pillar support properties, and the nitrogen-containing organic corrosion inhibitor can be easily inserted into the titanic acid layer to obtain a nano-titanic acid carrier intercalated with a corrosion inhibitor , the intercalation behavior of organic matter changes the inherent lattice structure of titanic acid, so it is not thermodynamically stable. When there is a lack of intercalation organic matter in the external environment and there are species that can interact with intercalation organic matter (such as H + ), the intercalant will inevitably come out of the interlayer, so that the inherent structure of titanic acid tends to recover, so as to realize the response-release function of the corrosion inhibitor-intercalated nano titanic acid carrier during the corrosion process.

[0024] In the preparation of nano-carrier intercalated with corrosion inhibitors, in...

example 1

[0033] Example 1 is implemented like this:

[0034] (1) Step S101 for the preparation of layered nano titanic acid

[0035] Will K 2 CO 3 and TiO 2 The solids are fully mixed according to a certain molar ratio (1:2~1:4.5), and sintered at a certain temperature (400°C~800°C) for 40h, and taken out every 10h and fully ground once to obtain K 2 Ti 4 o 9 . Take 5g K 2 Ti 4 o 9 In 100 ml 1 mol L -1In the hydrochloric acid solution, continuously stirred at 70°C for 3 days, the hydrochloric acid solution was changed once a day, after repeated washing with pure water to neutrality, after vacuum drying, the layered nano-titanic acid H was obtained. 2 Ti 4 o 9 .

[0036] (2) Preparation of nano-carrier intercalated with corrosion inhibitor in step 2 S102

[0037] H 2 Ti 4 o 9 The samples were mixed with 50 ml ethanol solution of 50% organic amine (n-octylamine, n-dodecylamine or n-hexadecylamine) and placed in a microwave reactor at a certain power (100W-1000W ) Microw...

example 2

[0042] Example 2 is implemented like this:

[0043] (1) Step S101 for the preparation of layered nano titanic acid

[0044] Will K 2 CO 3 and TiO 2 The solids are fully mixed according to a certain molar ratio (1:2~1:4.5), and sintered at a certain temperature (400°C~800°C) for 40h, and taken out every 10h and fully ground once to obtain K 2 Ti 4 o 9 . Take 5g K 2 Ti4O 9 In 100 ml 1 mol L -1 In the hydrochloric acid solution, continuously stirred at 70°C for 3 days, the hydrochloric acid solution was changed once a day, after repeated washing with pure water to neutrality, after vacuum drying, the layered nano-titanic acid H was obtained. 2 Ti 4 o 9 .

[0045] (2) Preparation of nano-carrier intercalated with corrosion inhibitor in step 2 S102

[0046] H 2 Ti 4 o 9 The samples were mixed with 50 ml ethanol solution with a volume fraction of 50% benzotriazole, and placed in a microwave reactor for microwave reaction at a certain power (100W-1000W) for 3h. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com