Patents

Literature

46results about How to "Play a role in self-healing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing coating with metal surface corrosion inhibition and self-repair functions

InactiveCN101613543AShape is not limitedUnlimited sizeAnti-corrosive paintsTectorial membraneLayer by layer self assembly

The invention belongs to the field of anticorrosion materials, and relates to a green and environment-friendly method for protecting metal from corroding, which can particularly control metal corrosion for long time effectively, and play a role in self-repairing the metal surface to a certain extent. The method is characterized in that an inhibitor molecule and polyelectrolyte are alternately deposited on the surface of a silicon dioxide nano-particle through green environment-friendly type metal inhibitor micromolecules and polyelectrolyte by adopting layer-by-layer self-assembly technology and utilizing the penetrating controllability of a polyelectrolyte self-assembly membrane so as to prepare a functional nano-particle with the inhibitor and the polyelectrolyte self-assembly composite membrane which are coated on the surface; and the prepared functional nano-particle is mixed with sol-gel to prepare the functional sol-gel membrane coated on the metal surface to be protected. The coating has the function of metal surface self-repairing, and ensures that the inhibitor molecules released by the functional membrane are adsorbed on the metal surface to reform a protecting membrane in a coating damaged microsection to play a certain role in self repairing. The method is applicable to corrosion protection of various metals.

Owner:UNIV OF SCI & TECH BEIJING

Molybdate doped polypyrrole/epoxy resin self-healing coating, preparation method thereof and application thereof

InactiveCN105001759AExcellent self-healing performanceAvoid corrosionEpoxy resin coatingsEpoxyPolypyrrole

The invention relates to a molybdate doped polypyrrole / epoxy resin self-healing coating, a preparation method thereof and an application thereof, and belongs to the field of metal anti-corrosion coatings. The coating is composed of two parts, namely a polypyrrole / epoxy resin system mother liquor, and a polyamide curing agent. The polypyrrole / epoxy resin system mother liquor comprises molybdate doped polypyrrole, epoxy resin, an anti-settling agent, an anti-foaming agent, a levelling agent and an organic solvent. The molybdate doped polypyrrole is added in the organic solvent and then the mixture is uniformly dispersed in an ultrasonic dispersion instrument. After that, the anti-settling agent, the antifoaming agent and the levelling agent are added respectively, and are stirred on a magnetic stirring apparatus. Then the epoxy resin is added to form the uniformly dispersed polypyrrole / epoxy resin system mother liquor. The polyamide curing agent is added in the prepared mother liquor, and is stirred to be uniformly dispersed. In this way, a molybdate doped polypyrrole / epoxy resin self-healing coating can be obtained. The coating is sprayed or brushed onto the 2024 type aluminum alloy after being subjected to oil-removing treatment. After the drying and curing process of the coating at the room temperature, a molybdate doped polypyrrole / epoxy resin self-healing coating can be formed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

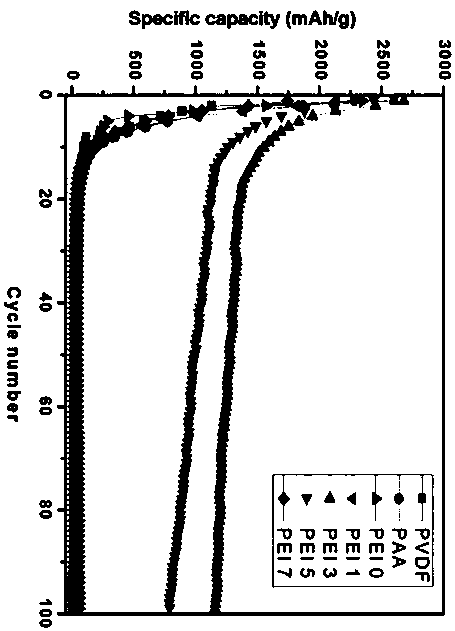

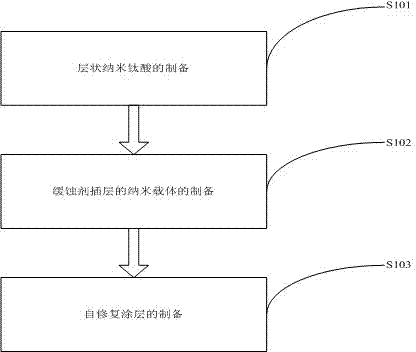

Method for preparing lithium ion battery negative electrode binder, and method for preparing lithium ion battery negative electrode material

ActiveCN108933254AImprove rheologyRich functional groupSecondary cellsElectrode collector coatingSolubilityVolume expansion

The invention provides a method for preparing a lithium ion battery negative electrode binder, and a method for preparing a lithium ion battery negative electrode material. The crosslinked PEI binderprepared in the invention has the advantages of high solubility in water, low toxicity, non-flammability, greenness, environmental protection, and realization of industrial production; the prepared crosslinked PEI binder has a hyperbranched network structure, and the structure can form a multidimensional strong hydrogen bond together with silicon in order to firmly wrap silicon nano-particles, andthe flexible hyperbranched PEI molecular chain can effectively buffer the stress generated by the volume expansion of silicon, and flows to the damaged surface when the volume of the silicon shrinksto afresh form a hydrogen bond in order to achieve an effective self-repairing effect; and the network structure can effectively limit the movement of silicon, improve the deformation resistance of electrodes and ensure the integrity of a negative electrode, and can effectively solve the volume effect of the silicon negative electrode, so the cycle stability of the silicon negative electrode is greatly improved, thereby the demand of electric vehicles and other large energy storage devices for high specific capacity batteries is met, and the development prospect is broad.

Owner:JIAXING UNIV

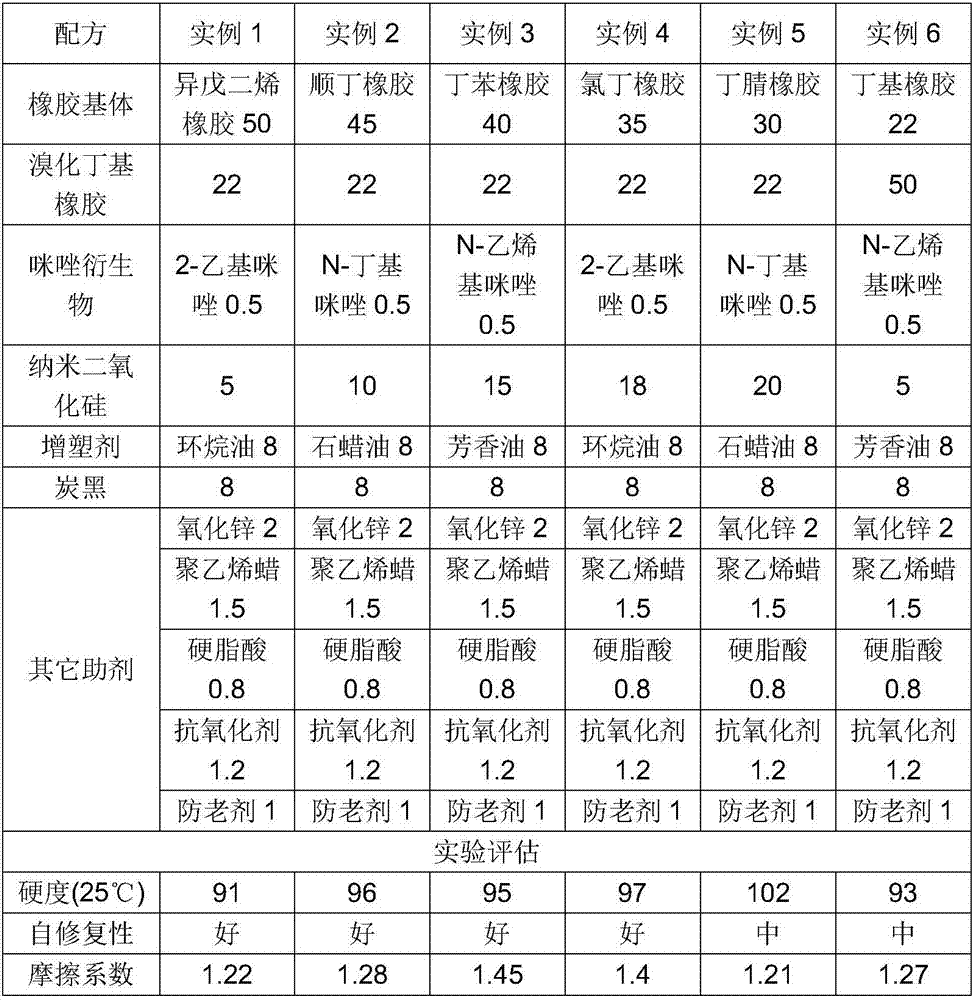

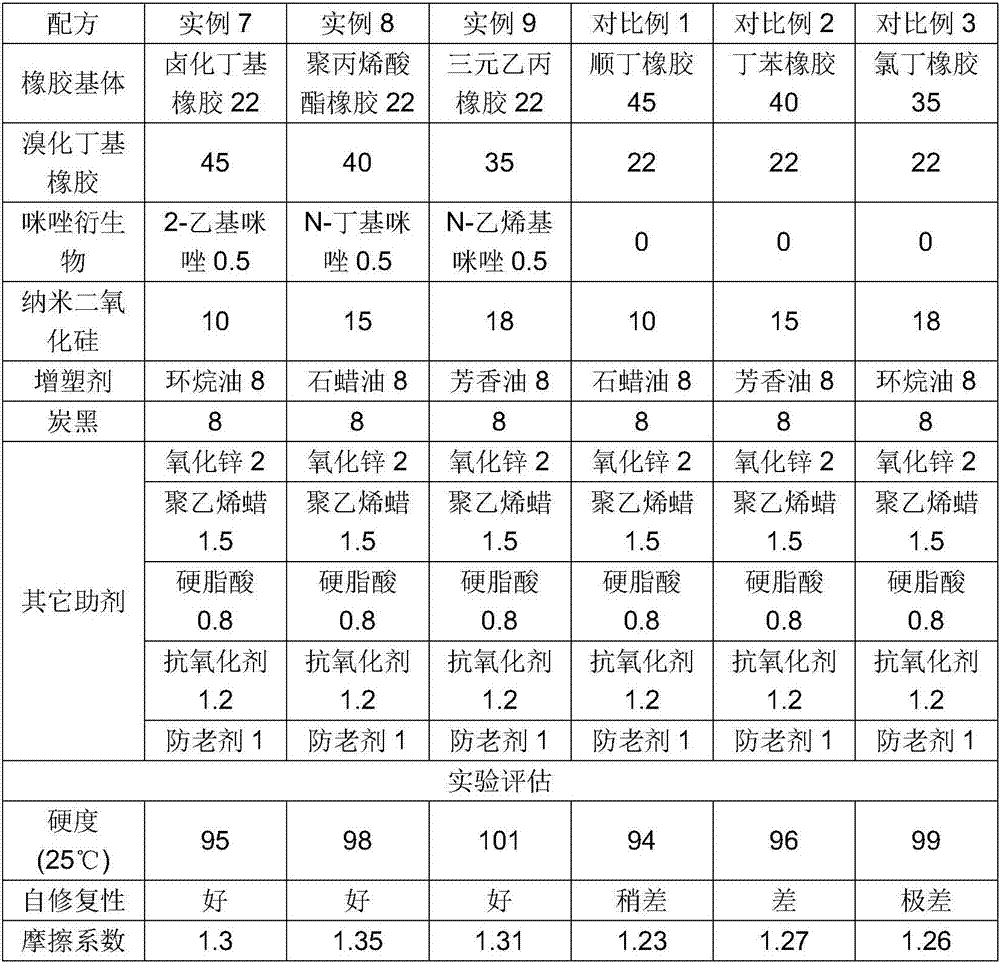

Self-healing antiskid unvulcanizedrubber material and preparation method thereof

The invention discloses a self-healing antiskid unvulcanized rubber material comprising the following components in percentage by weight: 20-50wt% of a rubber matrix, 1-50wt% of brominated butyl rubber, 0.1-0.5wt% of an imidazole derivative, 5-25wt% of nano silicon dioxide, 5-20wt% of a plasticizer, 5-10wt% of carbon black, and 1-5wt% of an auxiliary agent. The invention also discloses a preparation method. The self-healing antiskid unvulcanized rubber material disclosed by the invention has excellent weathering resistance, water tightness and air tightness, has good resistance to chemicals, oils, solvents and the like, can be used for manufacturing a sole material, automobile tires, and antiskid wear-resistant materials in various aspects of processing and manufacturing, and can also be used as a sealing ring and a waterproof material.

Owner:成都微熵科技有限公司

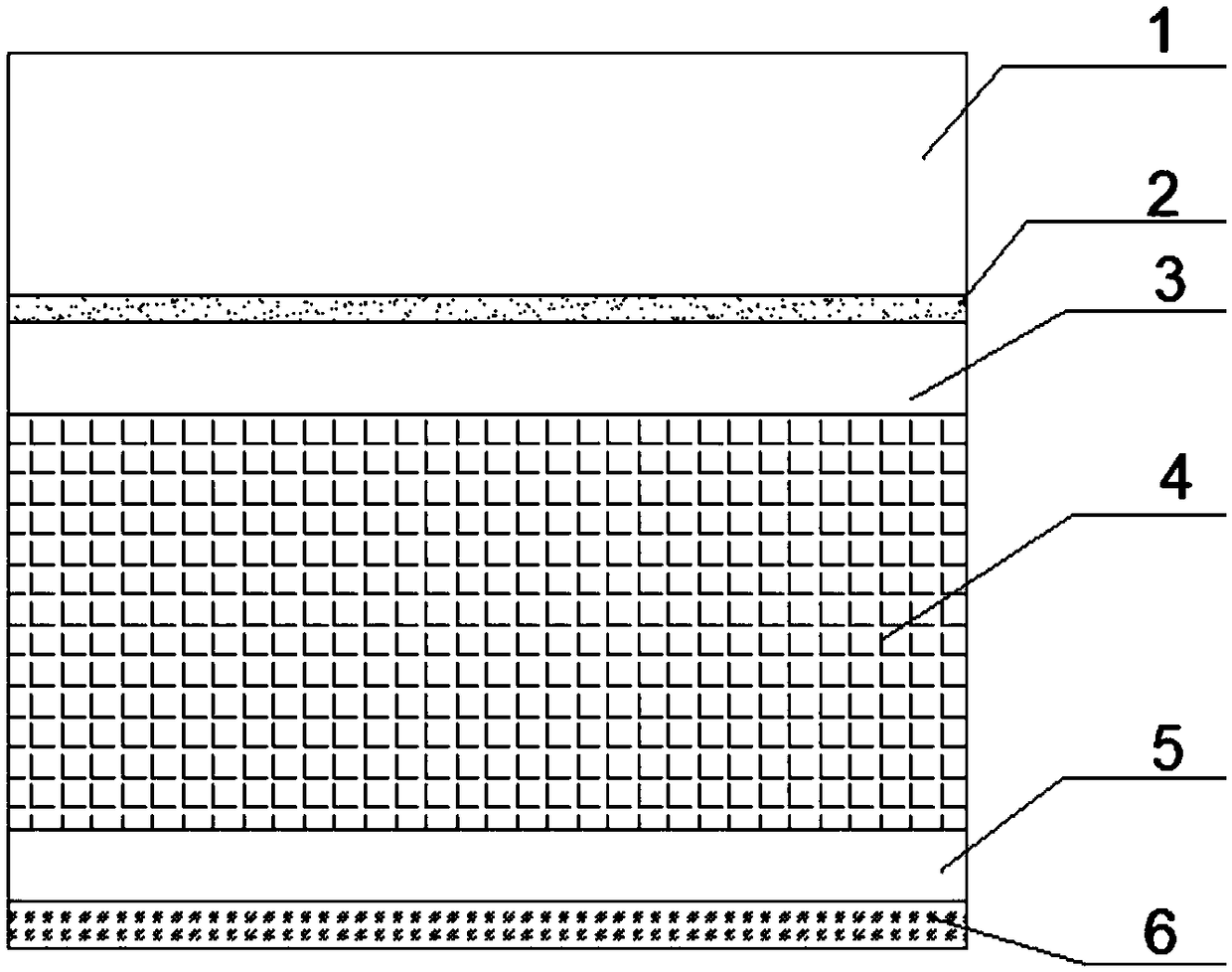

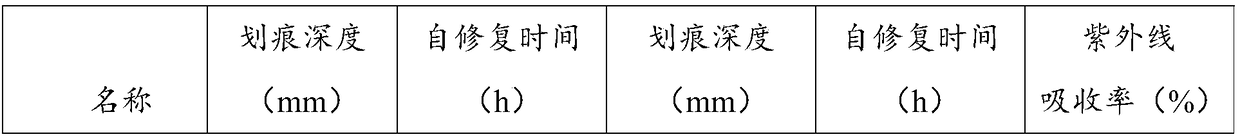

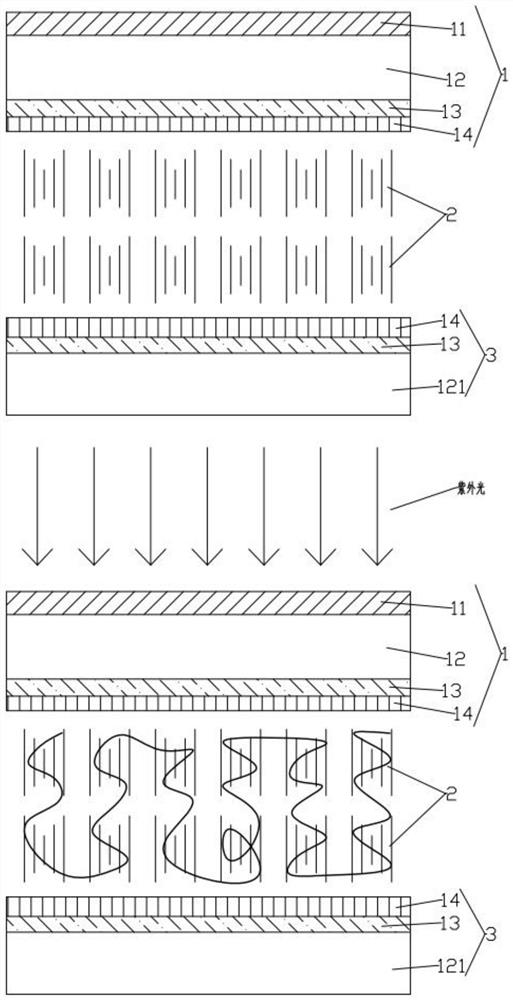

Ultraviolet-proof invisible car cover film with self-repairing function and preparation method of ultraviolet-proof invisible car cover film

InactiveCN108728007AExtend your lifeAchieve absorptionAntifouling/underwater paintsPaints with biocidesUltravioletEngineering

The invention discloses an ultraviolet-proof invisible car cover film with a self-repairing function and a preparation method of the invisible car cover film. The ultraviolet-proof invisible car coverfilm comprises a TPU base material layer, a self-repairing layer, a protecting silica layer, a PET layer, a pressure sensitive adhesive layer and a release layer, wherein the self-repairing layer, the protecting silica layer and the PET layer are sequentially arranged on the upper surface of the TPU base material layer from bottom to top; the pressure sensitive adhesive layer and the release layer are sequentially arranged from top to bottom. By coating the upper surface of the TPU base material layer with a special self-repairing layer, the TPU layer has excellent functions of preventing doodling and fouling and self preparing; an ultraviolet absorbent is added in the self-repairing layer and the pressure sensitive adhesive layer and realizes mass absorption of ultraviolet rays, so thatthe damage of the ultraviolet rays to car paint.

Owner:LONGCHANG YUXI NEW MATERIAL TECH

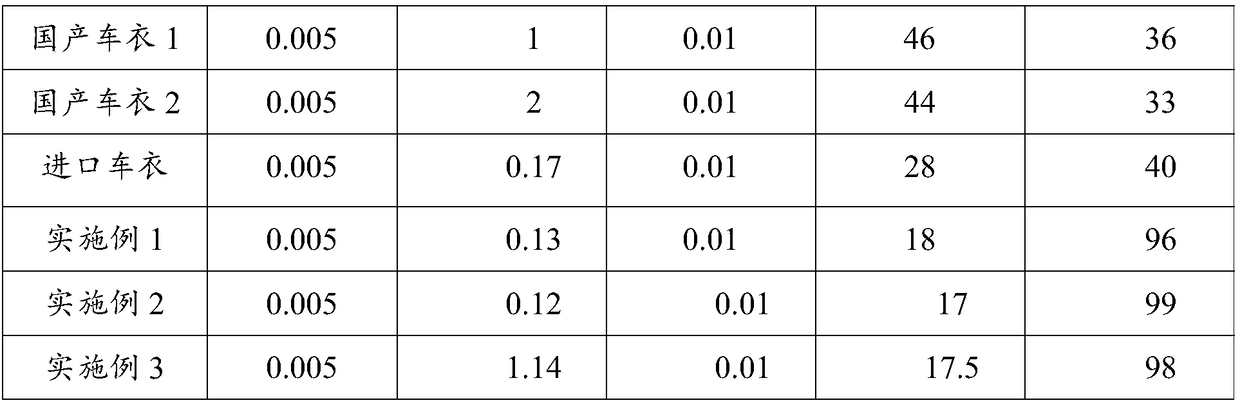

Preparation method of self-repair coating based on corrosion inhibitor intercalated nano-titanate carrier

InactiveCN103483897APlay self-healing functionIntrinsic structure restorationAnti-corrosive paintsThioureaDysprosium titanate

The invention relates to a preparation method of a self-repair coating based on a corrosion inhibitor intercalated nano-titanate carrier. The preparation method comprises the following steps: preparation of layered nano-titanate, preparation of the corrosion inhibitor intercalated nano-carrier and preparation of the self-repair coating, wherein the preparation of the layered nano-titanate comprises the step of grinding K2CO3 and TiO2 solids according to a certain molar ratio; the preparation of the corrosion inhibitor intercalated nano-carrier comprises the steps of taking organic amines, imidazoles, allyl thiourea and other nitrogen-containing organic matters as objects, taking the layered nano-titanate as a subject, and preparing the collision inhibitor intercalated nano-carrier through intercalation reaction in an ethanol solvent under microwave conditions; the preparation of the self-repair coating comprises the step of finally mixing prepared functional particles with sol-gel to prepare a functional sol-gel film to coat on the surface of a metal to be protected. The preparation method disclosed by the invention has the advantages of simplicity in preparation, large loading capacity and corrosion inhibition release-response function, expands the types of loaded corrosion inhibitors, enables an inherent structure of the titanate to tend to be restored, and plays a self-repair role.

Owner:YANCHENG INST OF TECH

Preparation method of lithium ion battery negative electrode adhesive and method for preparing lithium ion battery negative electrode material

ActiveCN108899548AImproved rheological propertiesImprove charge and discharge cycle stabilityCell electrodesSecondary cellsCross-linkPolyetherimide

The invention provides a preparation method of a lithium ion battery negative electrode adhesive and a method for preparing the lithium ion battery negative electrode material. A cross-linked PEI (Polyetherimide) adhesive prepared according to the invention is water-soluble, low in toxicity, nonflammable, green, environment-friendly and capable of realizing industrial production, the prepared cross-linked PEI adhesive has a hyperbranched network structure, and the structure can form multi-dimensional strong hydrogen bonds with silicon, so that silica nanoparticles are firmly coated. The flexible hyperbranched PEI molecular chain is capable of effectively buffering stress generated by silicon volume expansion, and flows to the damage surface while shrinking the silicon volume to form hydrogen bonds again, and the self-repairing effect is effectively achieved; movement of the silicon can be effectively limited by the network structure, deformation resistance of the electrode is improved,the integrity of the electrode is ensured, and the volume effect problem of the silicon negative electrode can be effectively solved, so that the cycling stability of the silicon negative electrode is greatly improved, the requirements of electric vehicles and other large energy storage devices on high-specific capacity cells are further met, and the development prospects are wide.

Owner:JIAXING UNIV

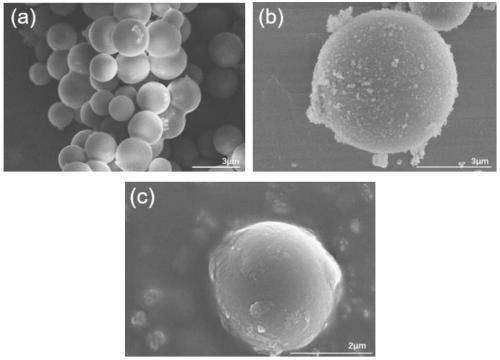

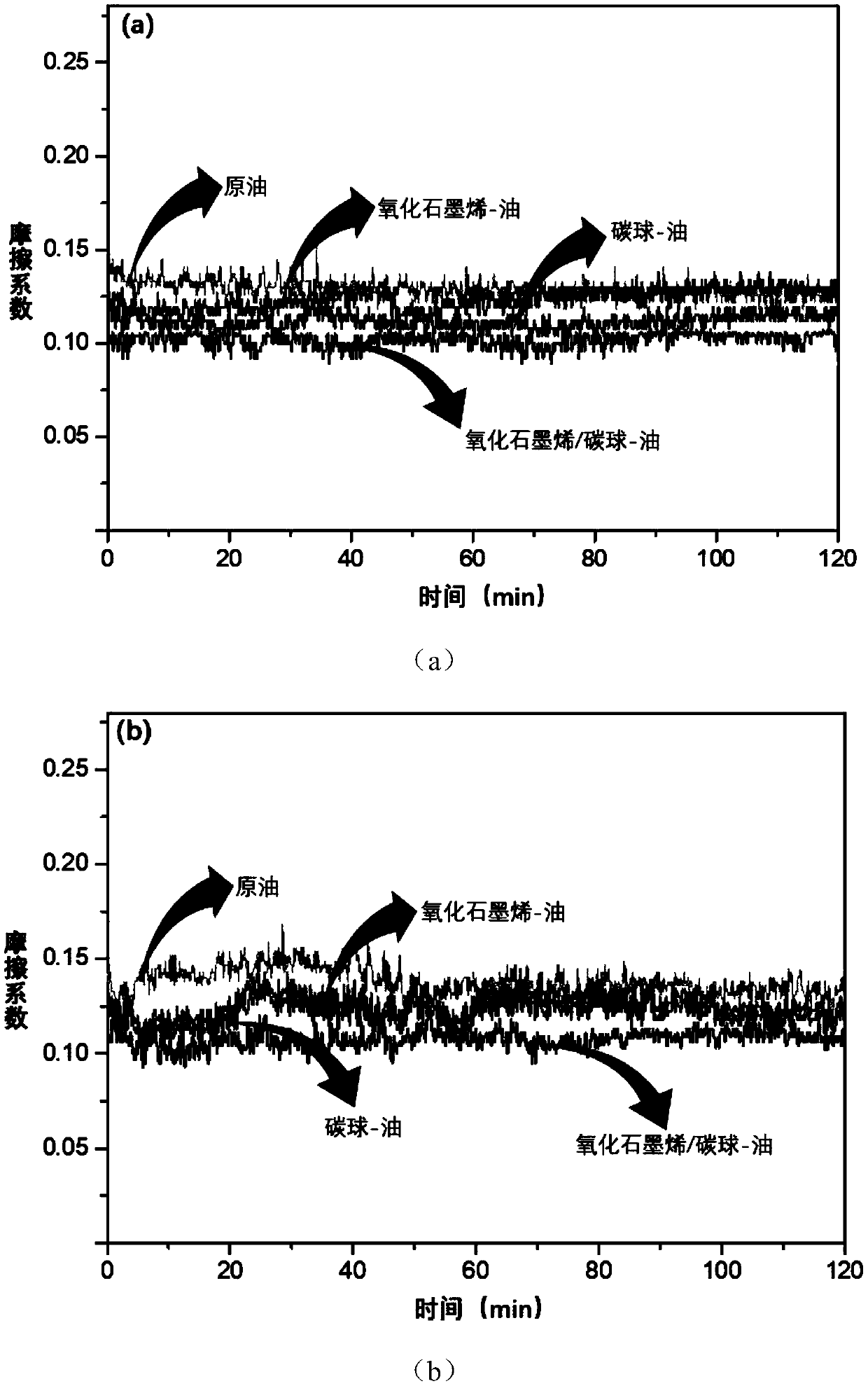

Preparation method of graphene oxide coated carbon microsphere composite material

The invention discloses a preparation method of a graphene oxide coated carbon microsphere composite material. The method comprises the following steps: preparing a dextrose solution as a carbon source; performing hydrothermal reaction under an acidic condition; washing the obtained product in a plurality of times; performing suction filtering; drying to obtain carbon microspheres; dissolving thecarbon microspheres in a mixed solution consisting of water and absolute ethyl alcohol; then adding a mixed solution of a silane coupling agent and the absolute ethyl alcohol; performing condensing and reflowing under a room temperature or a heating condition; washing the obtained product in a plurality of times; performing suction filtering; drying to obtain modified carbon microspheres; adding graphene oxide to DMF; then adding an activating agent; ultrasonically treating to obtain a graphene oxide solution; adding the modified carbon microspheres to the graphene oxide solution; ultrasonically processing to obtain an uniform mixed solution A; adding a catalyst to the mixed solution A; performing condensing and reflowing under a heating condition; washing the obtained product in a plurality of times; and performing suction filtering and drying to obtain the graphene oxide coated carbon microsphere composite material.

Owner:SHAANXI UNIV OF SCI & TECH

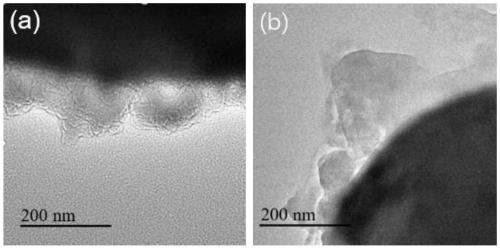

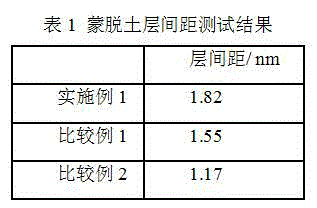

Inhibitor-loaded montmorillonite/epoxy self-healing coating

ActiveCN104098984AImprove corrosion resistanceIncrease spacingAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention provides an inhibitor-loaded montmorillonite / epoxy self-healing coating. The coating is prepared by the following steps: (1) dissolving montmorillonite with deionized water, and adding a blender subjected to acidizing treatment under fiercely stirring to obtain a modified montmorillonite; (2) dissolving the montmorillonite obtained in step (1) into a mixed solution of acetone and water, adding an inhibitor according to a certain rate to obtain an inhibitor-loaded montmorillonite; (3) adding the montmorillonite obtained in step (2) into epoxy resin, a mixed solvent, a dispersing agent, a flatting agent and the like to obtain an inhibitor-loaded montmorillonite / epoxy component I, then mixing the inhibitor-loaded montmorillonite / epoxy component I with an inhibitor-loaded montmorillonite / epoxy component II according to a certain rate to obtain the inhibitor-loaded montmorillonite coating. According to the invention, after the montmorillonite is subjected to loading, the distance between the two layers is increased, and the property of hydrophilicity of the montmorillonite is changed into lipophilicity, so that the compatibility of the montmorillonite with an organic phase is facilitated; the inhibitor-loaded montmorillonite / epoxy self-healing coating provided by the invention has excellent corrosion resistance.

Owner:STATE GRID CORP OF CHINA +2

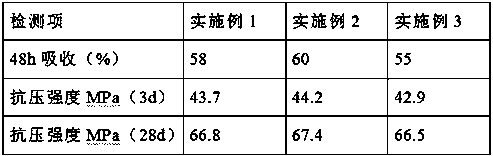

Porous concrete waterproofing agent and preparation method thereof

The invention discloses a porous concrete waterproofing agent and a preparation method thereof. The waterproofing agent is prepared from, by weight, 25-40 parts of modified gel, 4-6 parts of an oxidizing agent, 5-9 parts of a cross-linking agent and 3-5 parts of a photoinitiator; the modified gel is prepared from, by weight, 30-40 parts of pretreated microspheres, 25-30 parts of 3,4-dihydroxyphenylacetic acid, 15-20 parts of N-hydroxysuccinimide, 15-20 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 18-25 parts of sodium alginate and 10-14 parts of propyne. According to the porous concrete waterproofing agent and he preparation method thereof, process design is simple, and component proportion is reasonable; chitosan and sodium alginate are modified, and a Michael addition reaction and a chemical click reaction are used for forming a compact double-gel network, so the waterproof and seepage-proof performance of concrete can be effectively improved in use, meanwhile, the waterproofing agent can be self-repaired, and the waterproofing agent can be widely applied to concrete construction and has high practicability.

Owner:佛山市志必合材料有限公司

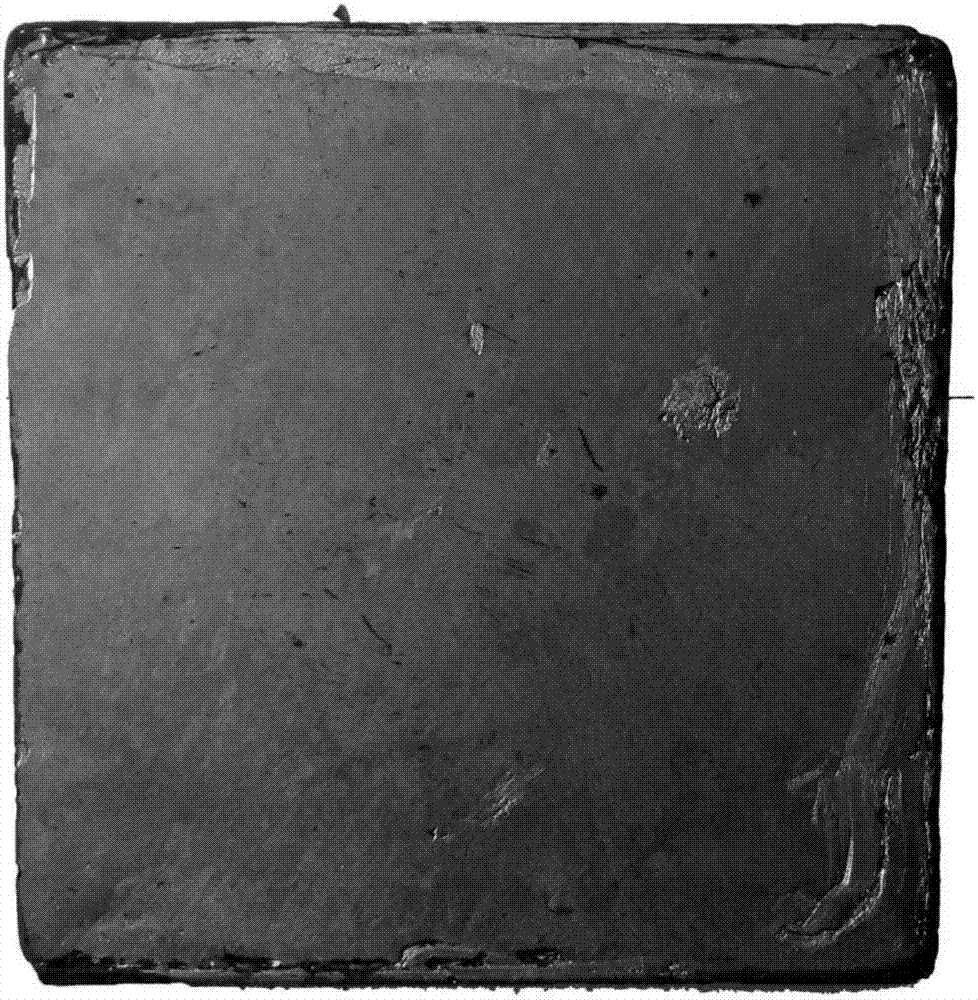

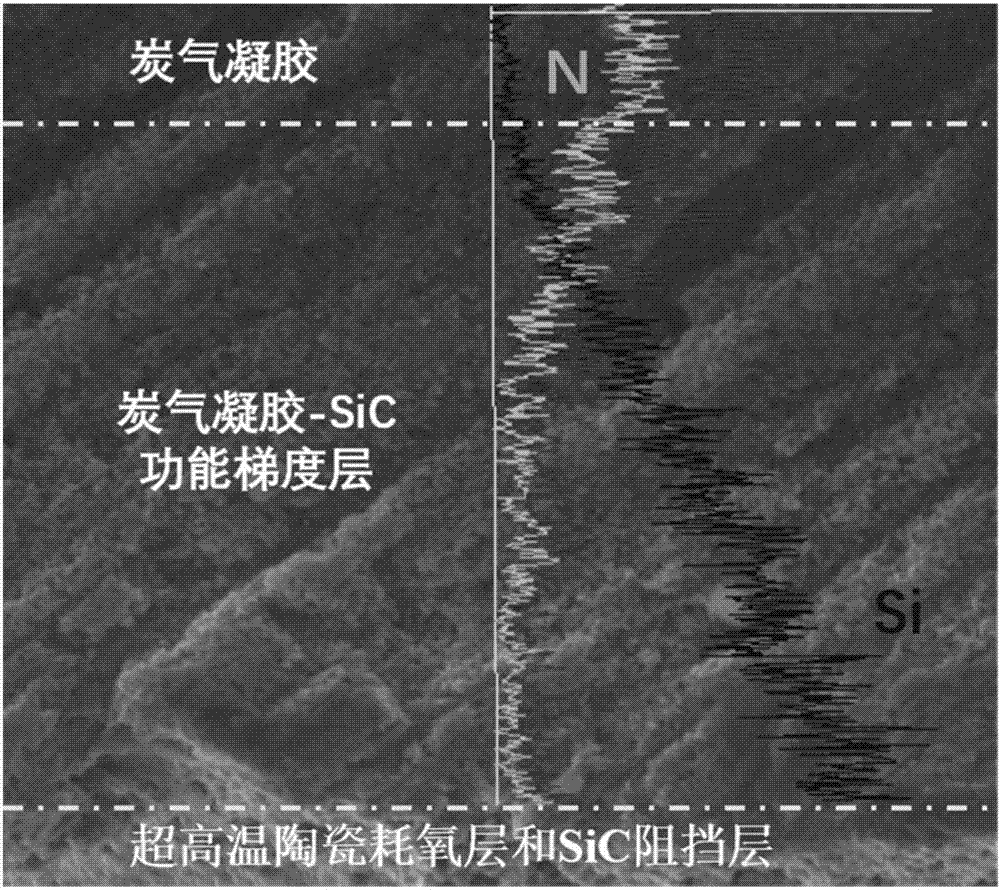

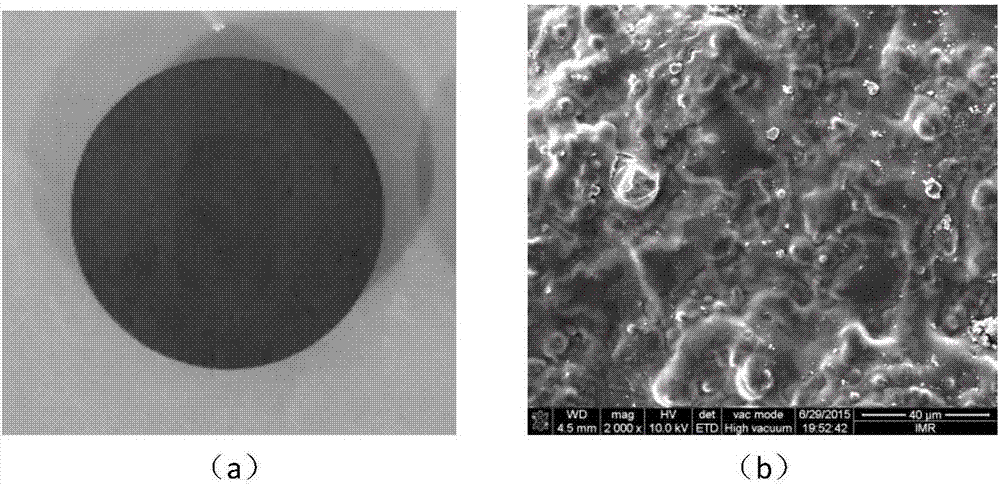

Heat-insulation-and-bearing-integrated carbon aerogel and ceramic layered composite material and preparation method and application thereof

ActiveCN107473761AGood anti-ablation propertiesHigh bonding strengthCeramicwareCeramic compositeGas phase

The invention discloses a heat-insulation-and-bearing-integrated carbon aerogel and ceramic layered composite material and a preparation method and application thereof, and belongs to the technical field of a carbon aerogel and ceramic composite material. The composite material comprises a high-strength carbon aerogel body layer, a function gradient SiC and carbon aerogel transition layer, and a superhigh-temperature ceramic and SiC antioxidant composite coating. The high-strength carbon aerogel body layer is made through five steps of solution preparation, sol-gel, solvent replacement, normal-pressure drying and high-temperature carbonization through normal-pressure drying technology. The function gradient SiC and carbon aerogel transition layer is made by deep deposition of SiC on a carbon aerogel surface through a chemical vapor infiltration process. The superhigh-temperature ceramic and SiC antioxidant composite coating is made through compound technology of spraying and chemical vapor deposition. The composite material is good in ablation and oxidation resistance, low in thermal conductivity and density, and high in strength, can resist high temperature as high as 1800 DEG C, and is suitable for heat-insulation materials of aircrafts.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Micro-nano mineral grain lubricating additive with self-repairing function, lubricating oil and production method

InactiveCN101787321AImprove anti-friction and anti-wear effectExcellent self-healing functionAdditivesMicro nanoChemical reaction

The invention discloses a micro-nano mineral grain lubricating additive with self-repairing function, lubricating oil and a production method. The method comprises the following steps: preparing nano MgO grains by adopting a sol-gel method respectively; modifying the grains by adopting oleic acid as surface modification agent; and mixing the grains and the base lubricating oil according to a certain proportion to form a lubricating agent which contains the micro-nano mineral grain lubricating additive and has the self-repairing function. When a mechanical metal part rubbing pair works, the additive material in the lubricating agent and the iron-based metal on the rubbing surface undergo physical and chemical reactions so as to continually generate compact iron-based silicate metal ceramic layers, partially or totally recover the size of the abraded part and finish self-repairing of the abraded part in the running dynamic process of the parts. Compared with the base lubricating oil, the lubricating agent can remarkably prolong the service life of the parts, improve the rubbing surface hardness and finishment, and greatly reduce the friction coefficient.

Owner:DALIAN MARITIME UNIVERSITY

Silane coupler-coated self-repairing agent as well as preparation and application thereof

InactiveCN103468231AImplement automatic repairImprove toughness and crack resistanceDrilling compositionSealing/packingHydration reactionSilanes

The invention relates to a silane coupler-coated self-restoration agent which is prepared from the following components in parts by weight: 100 to 130 parts of active mineral and 0.2 to 7.0 parts of silane coupler, wherein the active mineral is of mineral residues, coal ash, cement or coal gangue; and the KH560 silane coupler and the KH570 silane coupler are adopted. The invention further provides a preparation method and an application of the silane coupler-coated self-repairing agent. The active mineral is coated by the silane couplers, so that a waterproof protective film is formed on the surface of the active mineral. Thus, the activity of the active mineral is changed into the potential activity. Therefore, the active mineral cannot participate in a hydration reaction in a cement slurry system for well cementation, and can perform the hydration reaction only when the surface film of the active mineral is damaged due to the damage of a cement ring for the well cementation, so that a hydration product is formed so as to automatically repair the damaged position of the cement ring. As a result, the silane coupler-coated self-restoration agent has a great significance for guaranteeing the service life and the mining safety of oil and gas wells.

Owner:XI'AN PETROLEUM UNIVERSITY +1

Epoxy resin modified starch film-forming agent

The invention belongs to the technical field of glass fiber processing and specifically relates to an epoxy resin modified starch film-forming agent. The method comprises the following steps: utilizing yeast to consume citric acid; slowly releasing cupric ions combined with citric acid and reducing cupric ions by using L-ascorbic acid; adsorbing the reduced copper nanoparticle by poly (styrene-acrylic acid), thereby acquiring the dry bottom precipitate; heating and pasting the corn starch; utilizing a potassium hydroxide solution to disperse the amylose in the corn starch and then dissolving in a sodium chloride solution; centrifugally separating and then mixing and refining the supernatant containing the amylose and n-butyl alcohol; by using sodium hydroxide as a catalyst, reacting the refined corn starch with 3,4-epoxy cyclohexyl methyl 3,4-epoxy cyclohexyl formate, thereby acquiring epoxy resin modified refined corn starch; and ball-milling and mixing the epoxy resin modified refined corn starch with the dry bottom precipitate, thereby acquiring the epoxy resin modified starch film-forming agent. The epoxy resin modified starch film-forming agent provided by the invention has excellent film-forming property, low use viscosity and high storage stability.

Owner:常州市海若纺织品有限公司

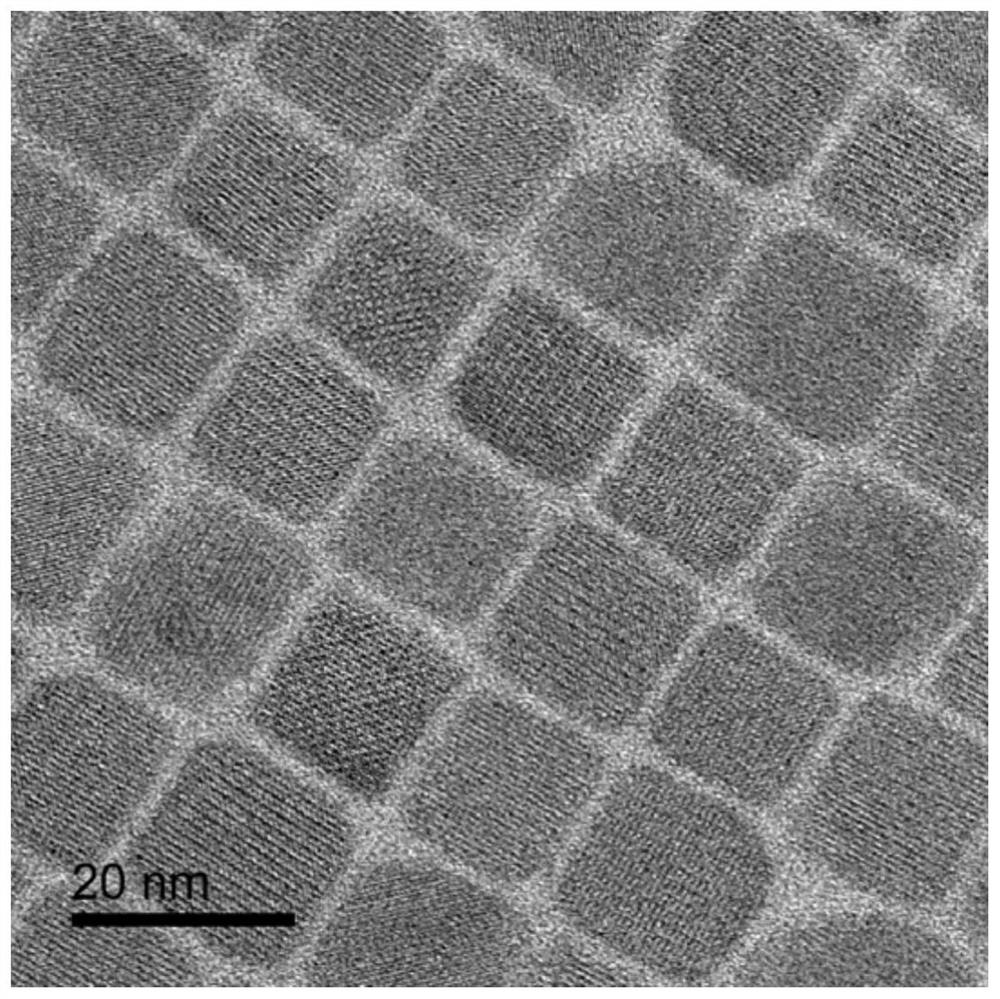

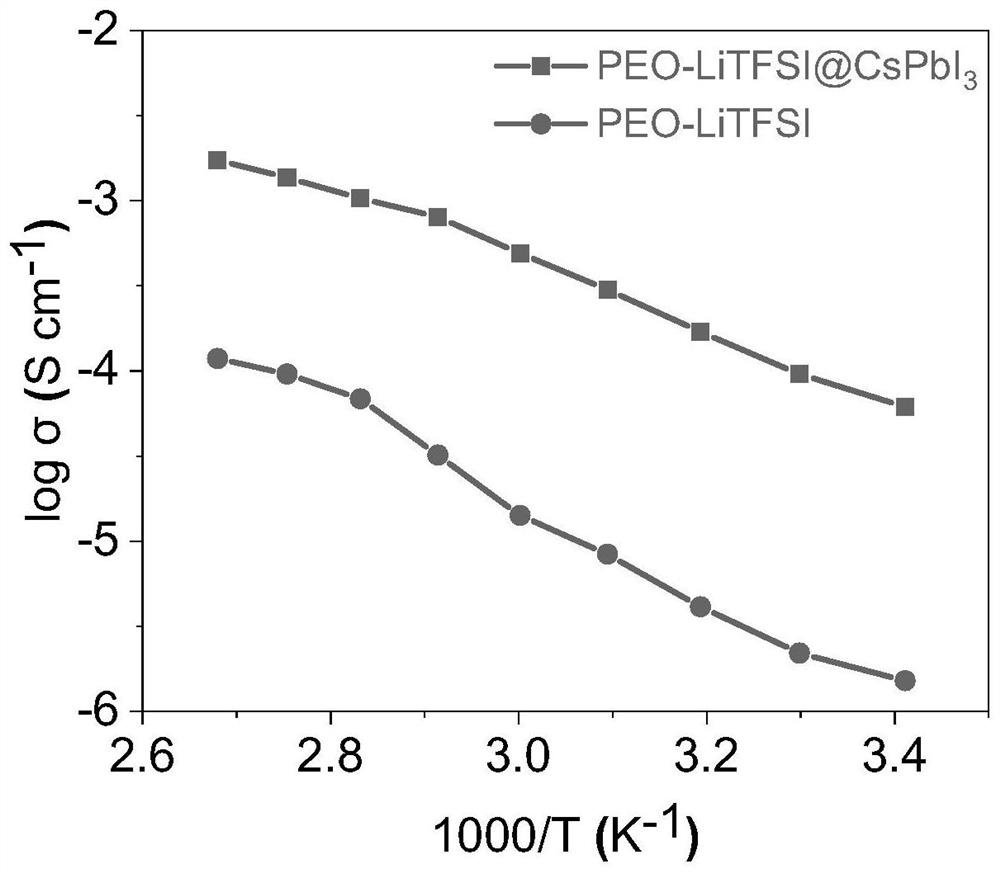

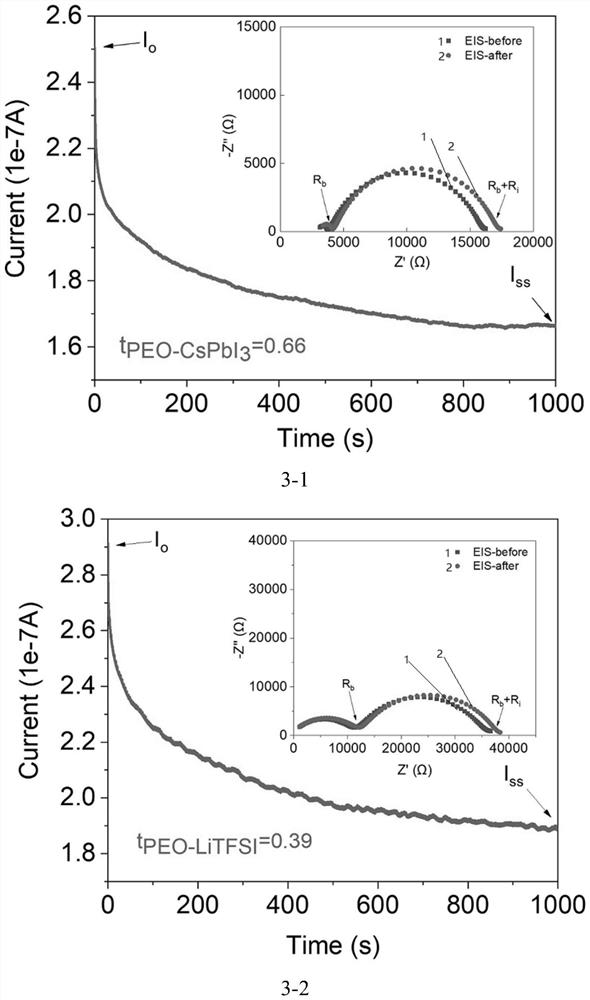

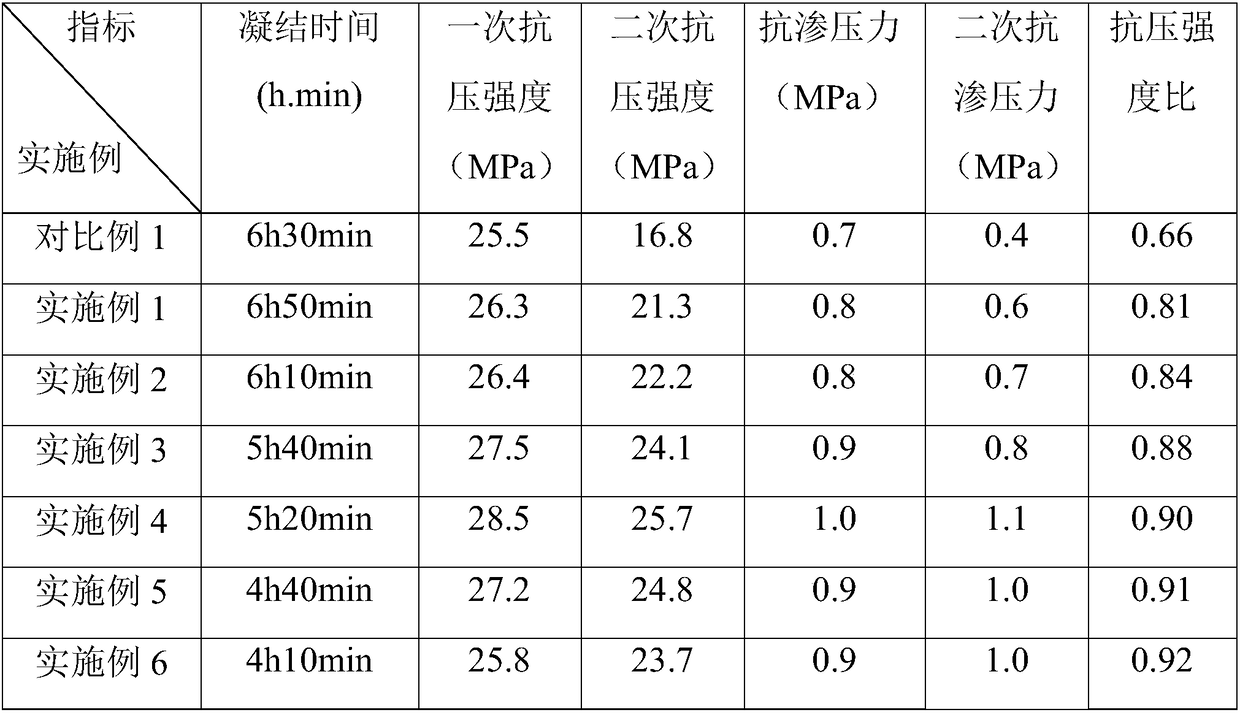

High-conductivity polymer solid electrolyte and preparation method thereof

ActiveCN113394464APrevent crystallizationDestroy orderFinal product manufactureElectrolytesPolyethylene oxideConductive polymer

The invention discloses a high-conductivity polymer solid electrolyte and a preparation method thereof. The preparation method comprises the following steps: adding PEO powder into a solution containing lithium salt, then adding perovskite quantum dots, heating and stirring at 50-70 DEG C for 20-28 hours to obtain uniform slurry, putting the slurry into a mold to form a membrane, removing a solvent, and finally performing vacuum drying to prepare a high-conductivity polymer solid electrolyte membrane. A PEO-based polymer solid electrolyte is mainly modified, the room-temperature ionic conductivity, the lithium ion transference number and the compatibility to a lithium metal negative electrode can be greatly improved through the modified polymer solid electrolyte, and finally the PEO-based polymer solid electrolyte with the high conductivity characteristic is obtained.

Owner:SOUTHWEST JIAOTONG UNIV

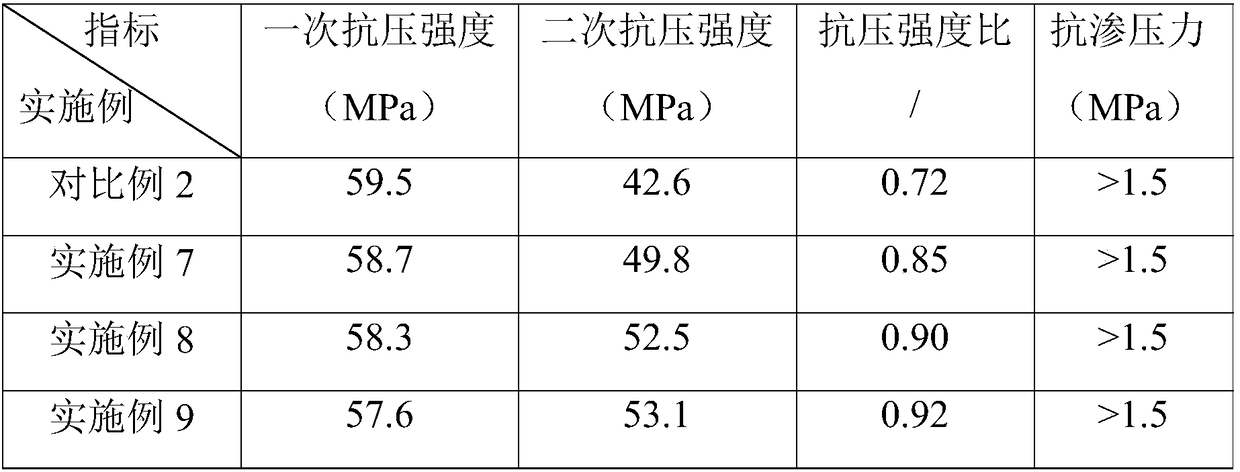

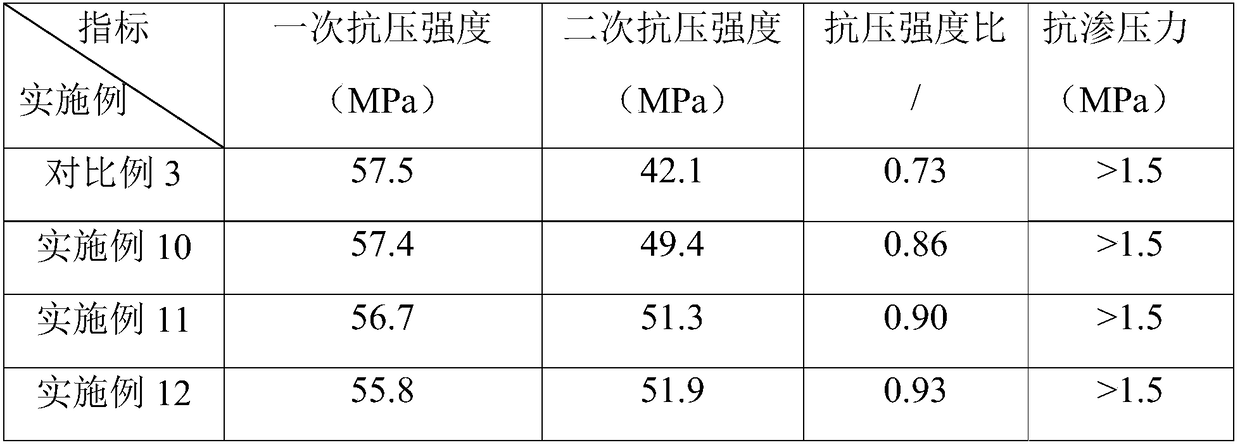

Composite additive for enhancing self-repairing property of cement-based material and preparation method thereof

The invention provides a composite additive for enhancing the self-repairing property of a cement-based material. The composite additive is prepared from the following components in percent by weight:5%-10% of free calcium-oxide powder, 10%-20% of calcium stearate, 40%-74% of calcium-oxide powder, 10%-20% of fumaric acid and 1%-10% of lithium silicate powder. The composite additive for enhancingthe self-repairing property of the cement-based material has the advantage that the self-repairing property of the cement-based material can be improved and enhanced.

Owner:TIANJIN BUILDING MATERIALS SCI RES INST +1

Preparation method of self-healing conversion film coated with rare earth elements on the surface of magnesium-aluminum alloy

ActiveCN105442006BImprove corrosion resistanceExtend service timeAnodisationRare-earth elementRare earth ions

The invention provides a preparation method for a micro-capsule-coated rare earth element self-repairing conversion coating on the surface of magnesium-aluminum alloy and belongs to the field of preparation methods of self-repairing conversion coatings. The self-repairing conversion coating aims to solve the technical problems that according to a conversion coating obtained through an existing method, local corrosion occurs in a corrosive environment, and micropores are formed in the coating due to high-content rare earth. The preparation method comprises the following steps that an Arabic gum aqueous solution is added into a gelatin aqueous solution, a rare earth ion solution is added, and a micro-capsule solution of coating slow-release preparations is obtained; the micro-capsule solution of the coating slow-release preparations is added into a conversion coating solution, a micro-capsule-coated rare earth conversion coating solution is obtained, magnesium alloy after being pretreated serves as a matrix, voltage as large as 12 V is applied between the matrix and a positive electrode, brushing plating is conducted at a constant speed in one direction for ten minutes, and the self-repairing conversion coating is obtained. By means of the preparation method, the content of corrosion inhibitors in the conversion coating can be increased, and micropores, caused by excessively high content of rare earth ions, of the coating can be prevented.

Owner:HARBIN ENG UNIV

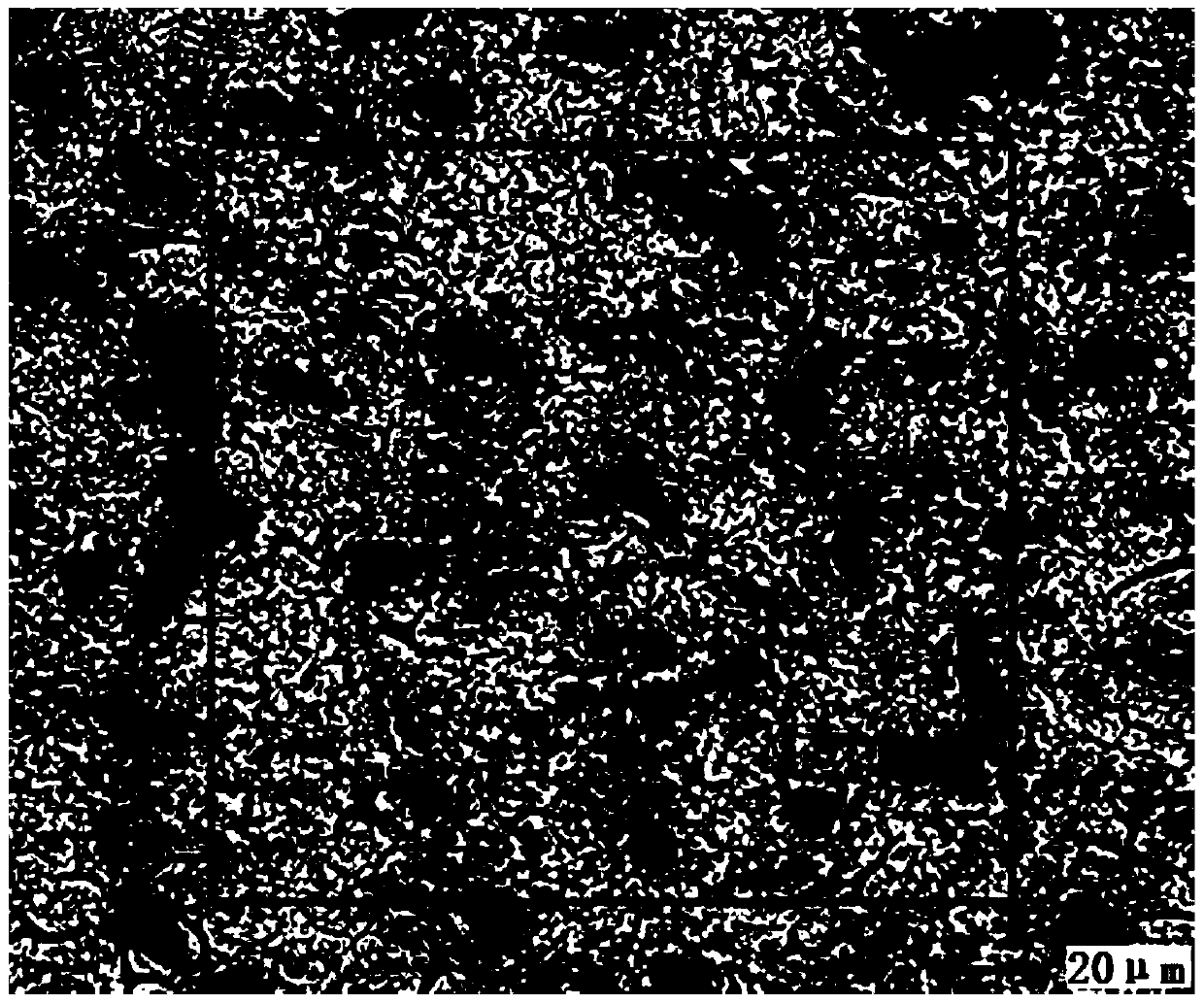

Self-repairing cement for thermal damage tunnel

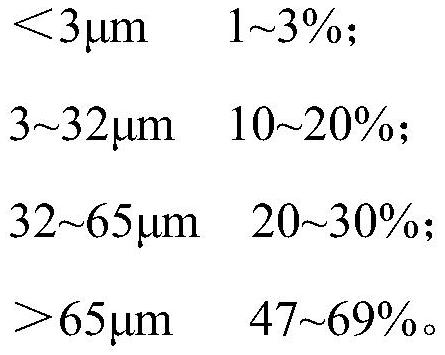

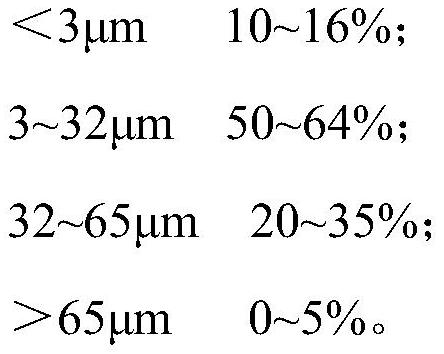

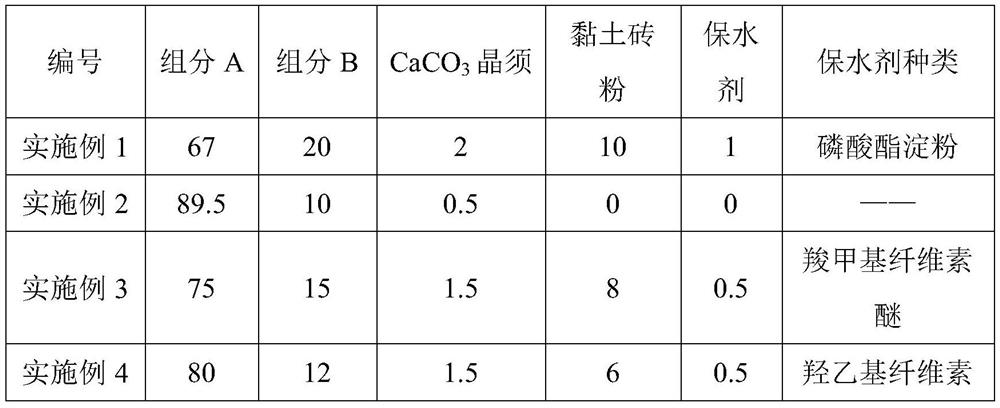

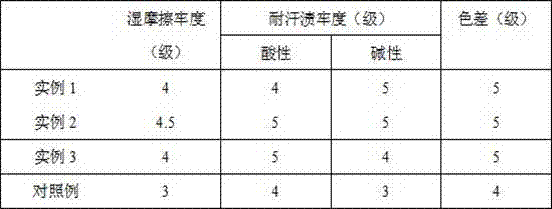

The invention relates to the technical field of building materials, in particular to self-repairing cement for a thermal damage tunnel, the self-repairing cement is prepared from the following raw materials in percentage by mass: 67-89.5% of component A, 10-20% of component B, 0-10% of clay brick powder, 0.5-2% of CaCO3 whisker and 0-1% of water-retaining agent; each of the component A and the component B comprises 90-95% of self-repairing cement clinker and 5-10% of dihydrate gypsum; the self-repairing cement clinker is prepared from 20-30% of C3S, 35-55% of C2S, 1-3% of C3A, 17-26% of C4AF and 4-8% of MgO; the size of periclase in the self-repairing cement clinker of the component A is less than 1 [mu] m; the size of periclase in the self-repairing cement clinker of the component B is 35 [mu] m, and the particle size of 47-69% of the component B is greater than 65 [mu] m. Through the self-repairing cement, the problems of early structural damage, wide later cracks and poor durability of lining concrete can be effectively prevented.

Owner:JIAHUA SPECIAL CEMENT +1

Wet rubbing fastness improver for dyed fabrics

InactiveCN107268307AIncrease the number ofGood compatibilityDyeing processPotassium persulfateIron powder

The invention relates to a wet rubbing fastness improver for dyed fabrics, belonging to the technical field of preparation of textile aids. Firstly, citric acid is utilized for complexing and adsorbing ferrous ions in a solution and is gradually consumed by saccharomycetes during reaction, and ferrous ions are released and are reduced into superfine iron powder through reducibility of L-ascorbic acid and is simultaneously is adsorbed with polyaspartic acid, so that the agglomeration of the iron powder is avoided; and the superfine iron powder is taken as a core and is matched with L-ascorbic acid and the like to form a reducing agent, copper ions are reduced by virtue of the reducing agent so as to generate superfine copper powder, the superfine copper powder is subjected to centrifugal drying to generate composite superfine powder, and the composite superfine powder is subjected to ultrasonic dispersion and reacts with potassium persulfate as an initiator, so as to generate wet rubbing fastness improver for the dyed fabrics. The prepared wet rubbing fastness improver for the dyed fabrics has a good fastness improvement effect and has wide application prospects.

Owner:方建波

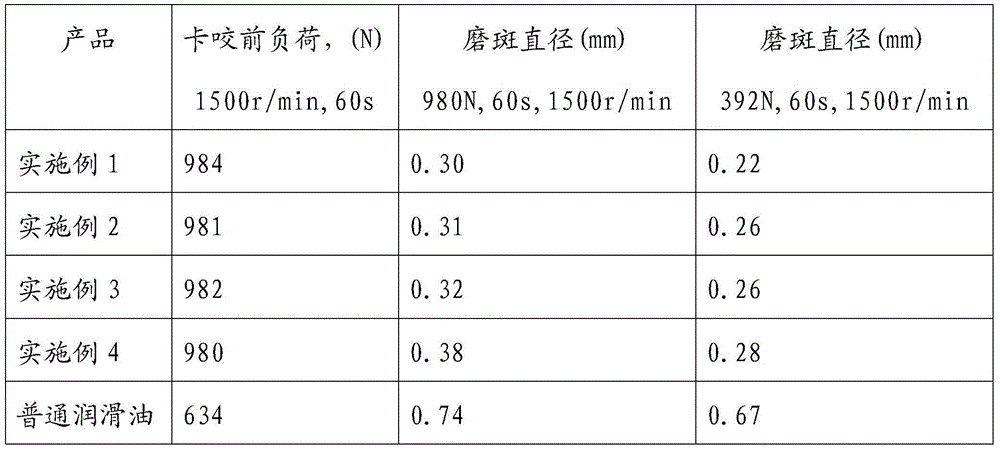

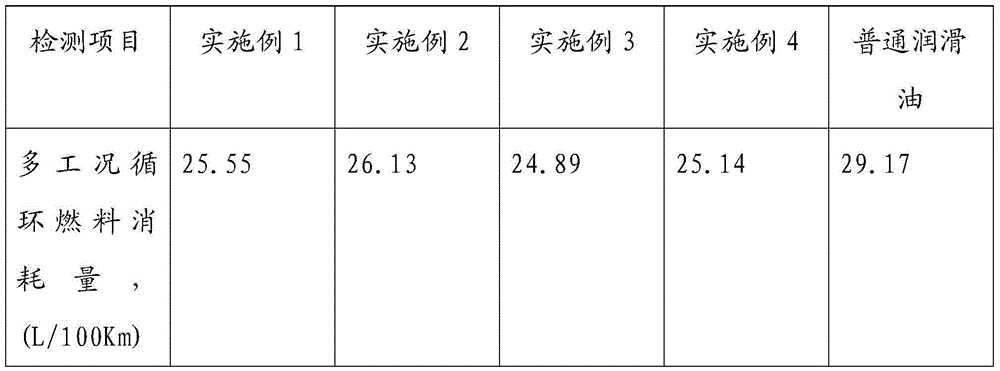

Polyester lubricating oil and process

The invention discloses polyester lubricating oil and a blending process thereof. The polyester lubricating oil comprises the following components in percentage by mass: 18-25 percent of PAO4 base oil, 38-44 percent of PAO6 base oil, 12-16 percent of polyol ester base oil, 10-12 percent of a tackifier, 0.2-0.5 percent of a pour point reducer, 0.7-1.2 percent of a friction modifier and 11.30001-12.70003 percent of a complexing agent, wherein the complexing agent comprises 8.0-8.5 mass percent of high-alkali number petroleum calcium sulfonate, 2.0-2.5 mass percent of zinc butyl octyl dithiophosphate, 1.3-1.7 mass percent of zinc dialkyl dithiophosphate and 0.0001-0.0003 percent of methyl silicone oil ester. The polyester lubricating oil disclosed by the invention can meet the performance of the traditional lubricating oil, is high in stability, can achieve the effects of reducing pollution emission and energy consumption and automatically repairing abrasion equipment and has an environment-friendly effect.

Owner:ZHUHAI SINOCU LUBRICATING TECH CO LTD

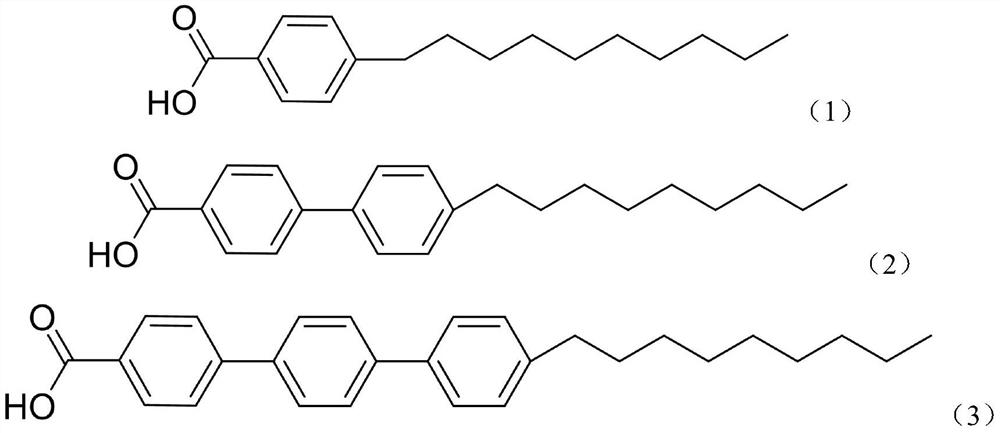

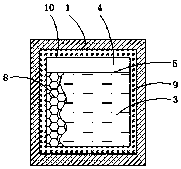

Composite liquid crystal film capable of being quickly self-repaired and preparation method thereof

ActiveCN112677596AImprove stabilityExtended service lifeSynthetic resin layered productsPolyurea/polyurethane coatingsPolymer networkThin membrane

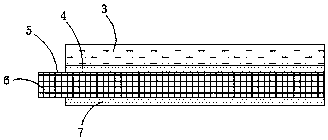

The invention discloses a composite liquid crystal film capable of being rapidly self-repaired and a preparation method thereof. The composite liquid crystal film capable of being rapidly self-repaired comprises an anti-ultraviolet PET transparent conductive film with one side plated with ITO, a polymer self-repairing material liquid crystal composite system thin layer and a PET transparent conductive thin film with one side plated with ITO, and the three layers are connected from top to bottom. According to the composite liquid crystal film capable of being rapidly self-repaired, the wear resistance and the service life of the film are improved; meanwhile, the ultraviolet aging resistance of the film is greatly enhanced; and the contrast ratio and the response time of a writing board are greatly improved, and favorable conditions are created for self-repairing of a polymer network. In addition, the polymer network in the film can be self-repaired after being damaged. The composite liquid crystal film capable of being rapidly self-repaired has excellent stability and long service life, the production process is simple, the manufacturing cost is low, and industrial production is facilitated.

Owner:江阴金书简新材料科技有限公司

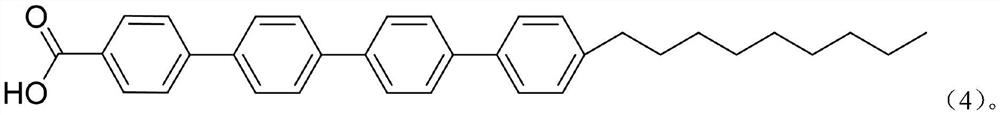

Preparation method of SiC aerogel/ceramic coating structure integrated heat prevention and insulation composite material

The invention belongs to the field of heat insulation materials, and discloses a preparation method of a SiC aerogel / ceramic coating structure integrated heat prevention and insulation composite material, the material is composed of four layers of structures, from a cold end face to a hot end face, the four layers of structures are high-strength SiC aerogel, a ZrB2 high-temperature oxygen consumption coating, a ZrO2 high-temperature heat insulation coating and an oxide high-radiation coating in sequence, therefore, the SiC aerogel / ceramic coating structure integrated heat prevention and insulation composite material is obtained. The material obtained by the technology has the advantages of excellent ablation resistance, excellent oxidation resistance, low density, high strength, low thermal conductivity, high temperature resistance of 1800 DEG C and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Nano graphite fluoride lubricant oil and preparation method therefor

The invention discloses nano graphite fluoride lubricant oil and a preparation method therefor. The nano graphite fluoride lubricant oil is prepared from the following ingredients in parts by weight:250-350 parts of base oil, 10-15 parts of detergent, 5-18 parts of dispersant, 3-10 parts of foam inhibitor, 5-15 parts of viscosity index improver, 15-30 parts of nano graphite fluoride, 1-2 parts ofemulsifier, 10-25 parts of extreme-pressure antiwear additive, 2-5 parts of pour point depressant and 3-9 parts of alcohols. According to the nano graphite fluoride lubricant oil prepared by the preparation method, a layered structure of the nano graphite fluoride is prone to sliding, the friction factor is small, and thus, the nano graphite fluoride lubricant oil has an excellent lubricating property. The graphite fluoride is highly stably dispersed in lubricant oil, is uniform in dispersion, is of a nanometer scale, is very small in particle size, easily enters a friction area and will deposit on a microscopic friction area of a worn-out surface under pressure to exert a self-repairing action, so that the nano graphite fluoride lubricant oil has excellent extreme-pressure and antiwear properties, can adapt to harsh environmental conditions such as high temperatures and extreme pressure and is environmentally friendly.

Owner:张家港希弗新能源科技有限公司

Permeable concrete and preparation process thereof

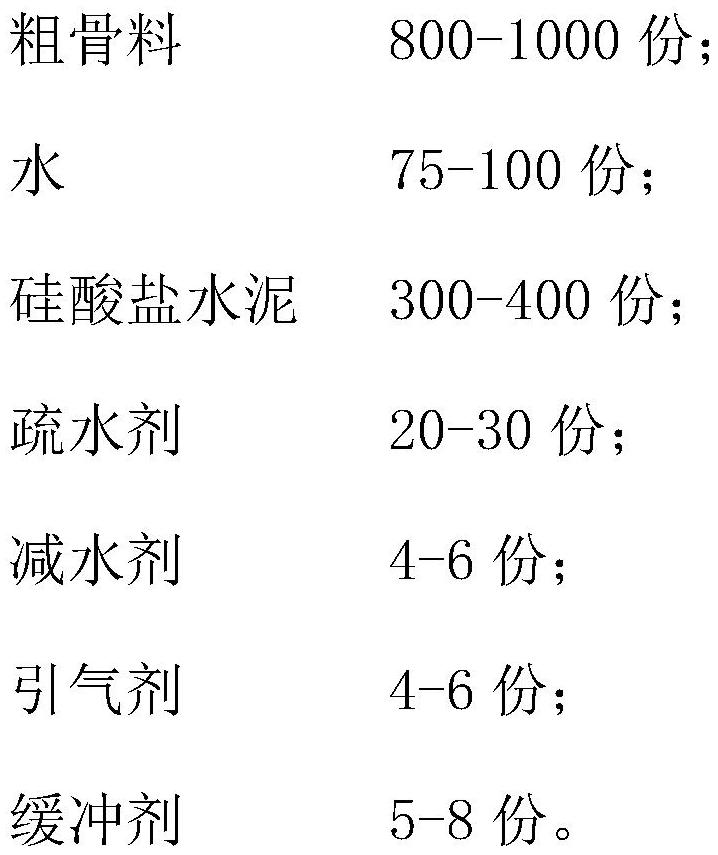

InactiveCN112239341AImprove hydrophobicityImprove frost resistanceCeramicwarePortland cementRepair material

The invention relates to the technical field of concrete, and particularly discloses a permeable concrete and a preparation process thereof. The permeable concrete comprises the following components in parts by weight: 800-1000 parts of coarse aggregate; 75-100 parts of water; 300-400 parts of Portland cement; 20-30 parts of a hydrophobic agent; 4-6 parts of a water reducing agent; 4-6 parts of anair entraining agent; and 5-8 parts of a buffer agent. The preparation process of the permeable concrete comprises the following steps: step 1, mixing and stirring the coarse aggregate and the Portland cement in proportion, then adding water and the water reducing agent in proportion, and stirring; step 2, adding the air entraining agent, the hydrophobic agent, the buffer agent and a self-repairing material into the mixture obtained in the step 1 in proportion, stirring, and controlling the stirring speed to be 100 r / min, so as to obtain a premix; and step 3, stirring the premix obtained in the step 2, controlling the stirring speed to be 100 r / min, paving the premix on a construction surface, and carrying out maintenance, compaction and molding to obtain the permeable concrete. The permeable concrete provided by the invention has the advantage of good frost resistance.

Owner:浙江欣成建设有限公司

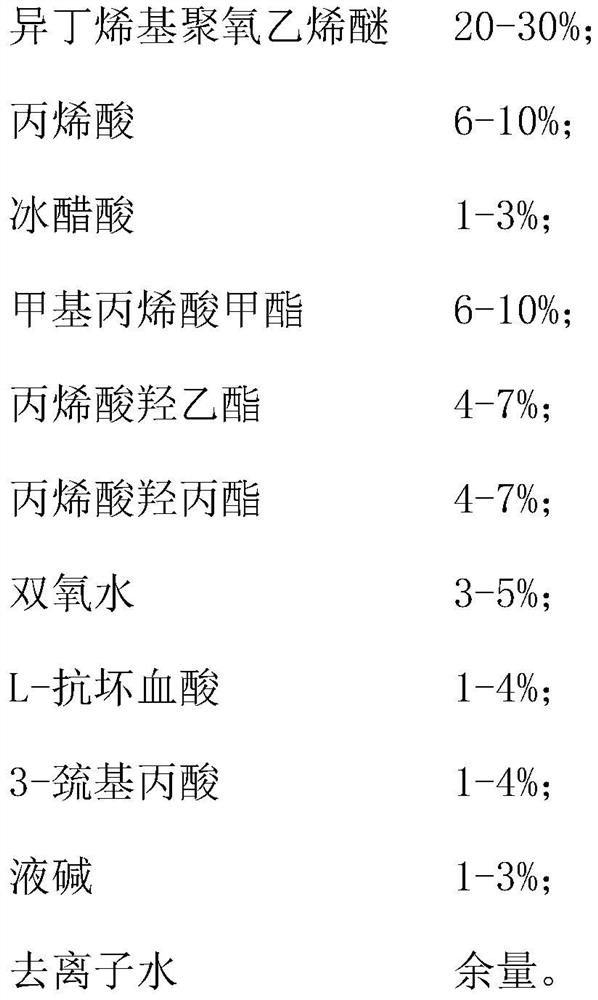

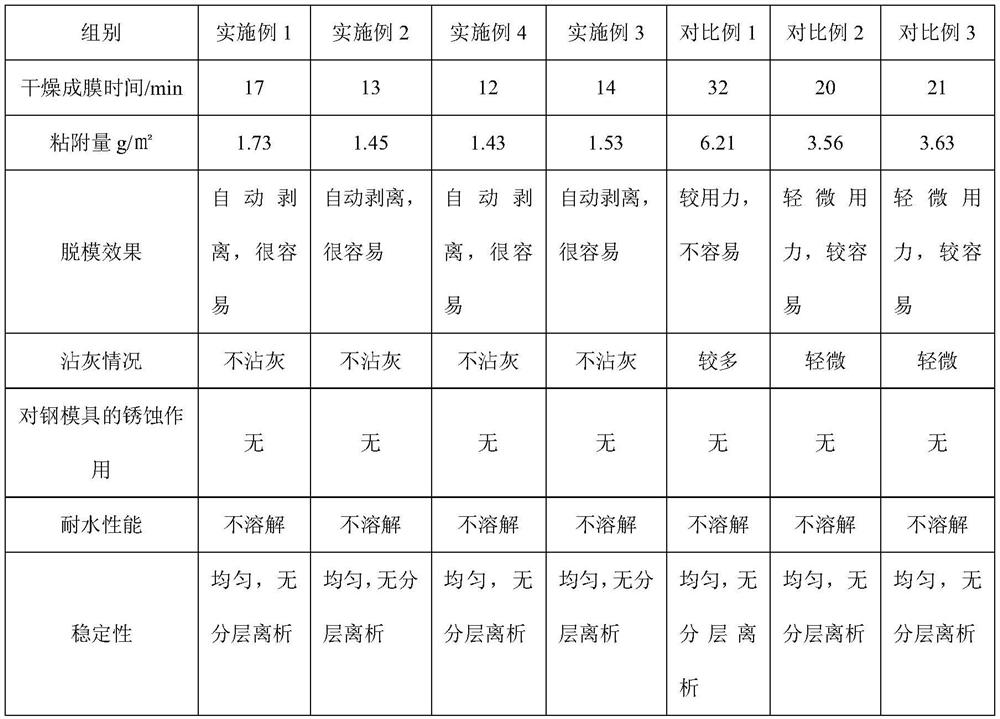

Environment-friendly release agent for autoclaved aerated concrete block and preparation method of environment-friendly release agent

InactiveCN112852533AGood release effectExcellent mold releaseCeramic shaping apparatusLubricant compositionVegetable oilPolyethylene glycol

The invention discloses an environment-friendly release agent for autoclaved aerated concrete blocks. The environment-friendly release agent is prepared from the following raw materials in parts by weight: vegetable oil, a POSS-phosphorylated vegetable oil polymer, polyethylene glycol, nano calcium carbonate, ammonium polycarboxylate, a compound emulsifier, C12 alcohol ester, emulsified silicone oil, xanthan gum and water. The invention also discloses a preparation method of the environment-friendly release agent for autoclaved aerated concrete blocks, which comprises the following steps: dispersing the POSS-phosphorylated vegetable oil polymer into the vegetable oil containing polyethylene glycol to obtain a dispersion liquid; dissolving a compound emulsifier, emulsified silicone oil and xanthan gum in hot water to obtain emulsified water; and adding nano calcium carbonate, ammonium polycarboxylate and emulsified water into the dispersion liquid, adding the C12 alcohol ester and adding water for dilution, and uniformly stirring all the components to obtain the modified vegetable oil environment-friendly release agent. The release agent disclosed by the invention has the advantages of high film forming speed, small adhesion amount, low cost, no toxicity, no pollution and good release effect.

Owner:广西建工集团建筑产业投资有限公司

Novel high-Q-value capacitor

PendingCN109786109AMeet the urgent need for chargingHigh Q valueThin/thick film capacitorFixed capacitor electrodesCapacitanceCopper wire

The invention provides a novel high-Q-value capacitor, and relates to the field of capacitors. The novel high-Q-value capacitor comprises a capacitor core, a capacitor shell and tinned copper wires, wherein an insulating layer polypropylene film is arranged in the capacitor core. According to the novel high-Q-value capacitor, by changing a conventional method that the polypropylene film of the capacitor adopts traditional high-oil shielding and aluminum-zinc high-square-resistance evaporation, a small amount of special oil is added as a shielding layer in the evaporation process to prevent thepollution of a frequency band, and the phenomena of high-frequency loss and Q value reduction caused by the pollution of the frequency band due to large oil amount are avoided; meanwhile, a thin layer of aluminum is evaporated to serve as an electrode, so that the self-repair effect is achieved; the higher the Q value is, the lower the loss value of the capacitor is, the higher the efficiency is,so that double designs of low-oil shielding and pure-aluminum low-square resistance in the evaporation process are adopted to ensure a characteristic that the capacitor can realize high Q value and low loss; and the novel high-Q-value capacitor is easy to machine, relatively low in cost and relatively high in power factor, and meets the urgent needs of current wireless charging.

Owner:FOSHAN CITY XINYUAN ELECTRONICS CO LTD

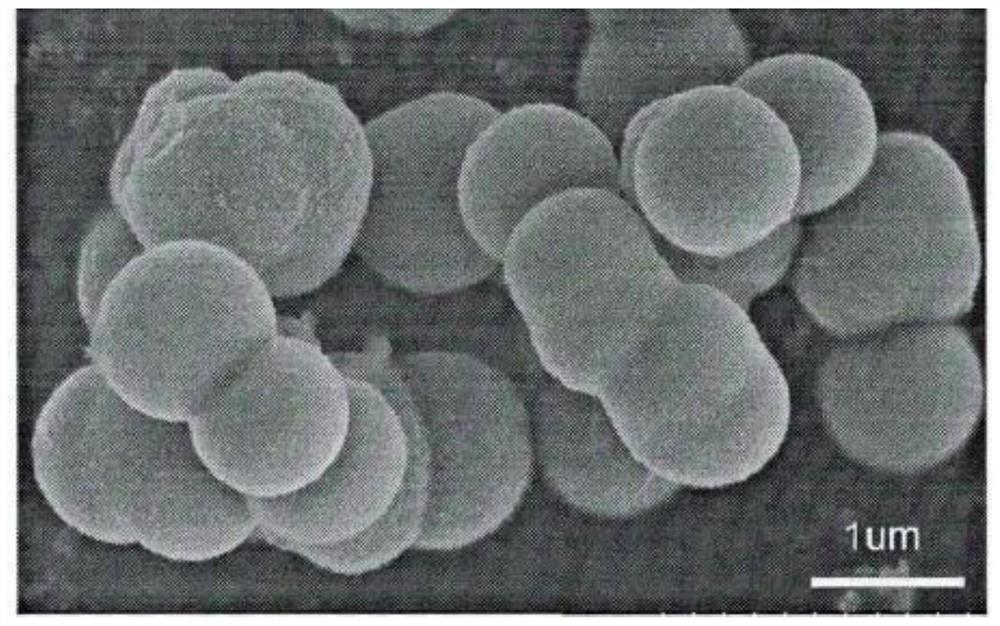

A preparation method of self-healing microcapsules and its application in superhydrophobic coatings

ActiveCN110449094BLarge specific surface areaImprove adsorption capacityCoatingsMicroballoon preparationSuperhydrophobeSuperhydrophobic coating

The invention relates to a preparation method of a self-repairing microcapsule and its application in a superhydrophobic coating. The self-repairing microcapsules provided by the present invention use porous nanoparticles wrapped with low surface energy as the capsule core. The nanoscale porous particle structure can make the nanoparticles fill the cracks when the microcapsules are damaged by acid and alkali, and play the role of self-repair. The structure can increase the specific surface area of the capsule core, increase the surface energy, and then the surface adsorption capacity is stronger, and can more easily adsorb low surface energy substances on the surface of the capsule core. When the pH of the microcapsule is 5‑9, it has better Self-healing effect; the wall of the microcapsule is made of a high molecular polymer, and through the synergistic effect of the core and the wall, when the structure of the wall is damaged, the surface of the core still has a relatively high roughness. The synergy with the capsule core can automatically repair the damaged super-hydrophobic surface.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

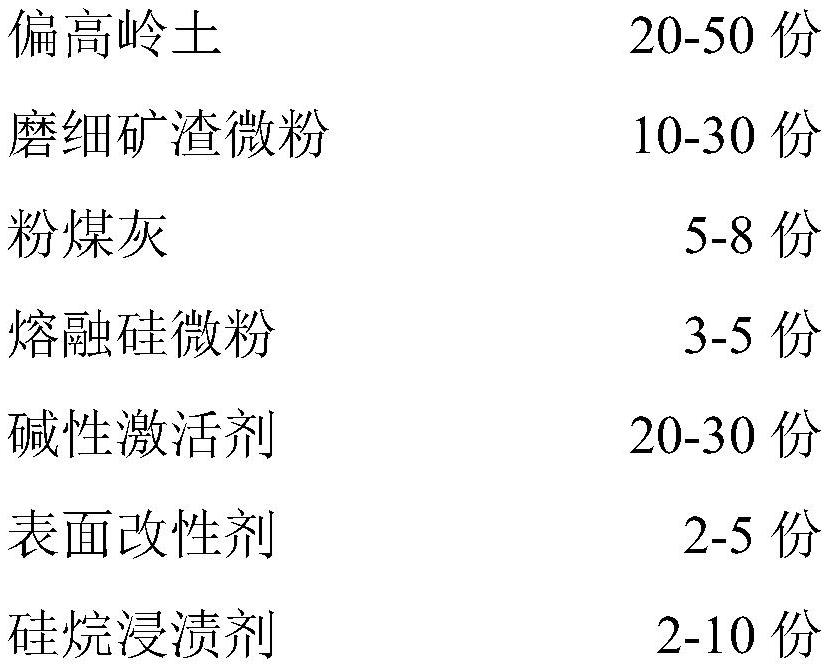

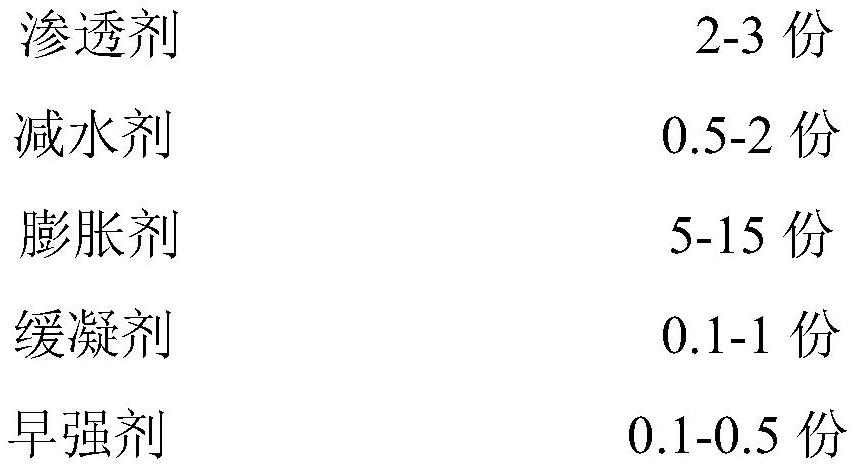

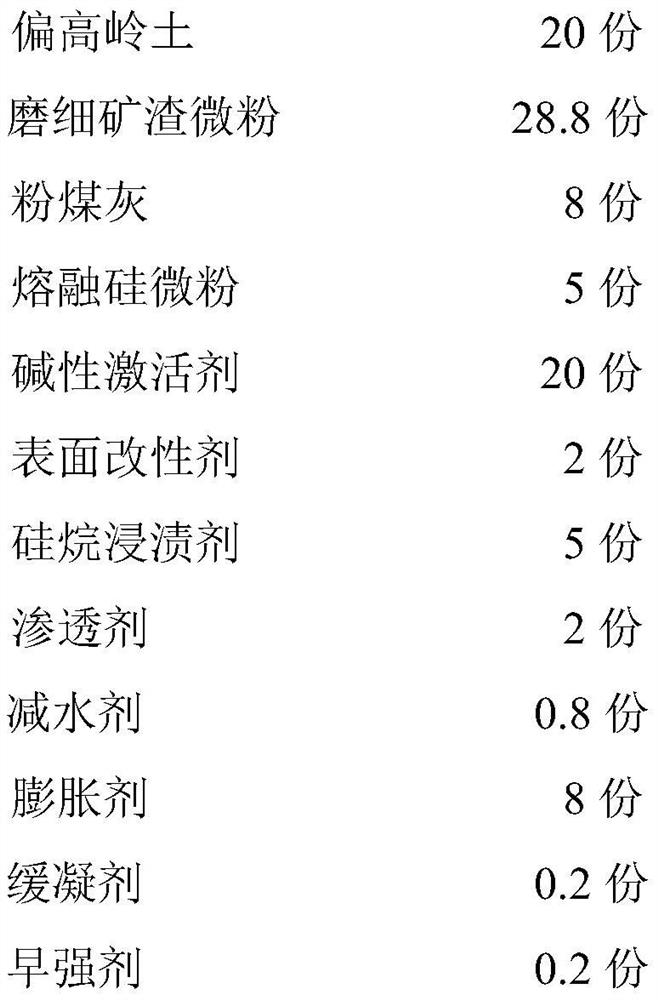

Self-repairing geopolymer-based permeable crystallization waterproof material and preparation method thereof

ActiveCN113979679AHigh compressive strengthGood toughness and durabilityCement productionMetakaolinMolten silicon

The invention discloses a self-repairing geopolymer-based permeable crystallization waterproof material and a preparation method thereof. The self-repairing geopolymer-based permeable crystallization waterproof material is prepared from the following components in parts by weight: 20 to 50 parts of metakaolin, 10 to 30 parts of ground superfine slag powder, 5 to 8 parts of fly ash, 3 to 5 parts of fused silica powder, 20 to 30 parts of an alkaline activator, 2 to 5 parts of a surface modifier, 2 to 10 parts of a silane impregnant, 2 to 3 parts of a penetrant, 0.5 to 2 parts of a water reducing agent, 5 to 15 parts of an expanding agent, 0.1 to 1 part of a retarder and 0.1 to 0.5 part of an early strength agent. The self-repairing geopolymer-based permeable crystallization waterproof material provided by the invention not only has relatively high compressive strength, but also has relatively good toughness, durability and good self-healing performance; and when a waterproof layer or a repaired crack is damaged, the alkali excitation reaction and the active substance are activated again when encountering water and are condensed into a compact crystal, so that a self-repairing effect is achieved.

Owner:SHANGHAI LIYANG ROAD REINFORCEMENT TECH

Anticorrosive material and production process thereof

PendingCN113930146AReduced risk of corrosionHigh densityAnti-corrosive paintsPolyurea/polyurethane coatingsPrepolymerIsocyanate

The invention relates to an anticorrosive material. The material is prepared from the following raw materials in parts by weight: 50 to 80 parts of an isocyanate-terminated polyurethane prepolymer, 2 to 5 parts of aminopropyltriethoxysilane, 3 to 5 parts of filler, 3 to 5 parts of fly ash, 15 to 28 parts of zinc powder, 3 to 5 parts of modified tin dioxide, 3 to 5 parts of a carbon nanotube material, 10 to 30 parts of water, 5 to 6 parts of anticorrosive microcapsules and 0.5 to 2 parts of amino trimethylene phosphonic acid. According to the invention, the anticorrosive microcapsules are added into the anticorrosive material, so that the anticorrosive material has certain self-repairing performance, when the anticorrosive material generates cracks under the action of external force, the microcapsules are broken and release linseed oil and tung oil in the microcapsules, and the linseed oil and tung oil have a repairing effect on the cracks, so that the self-repairing effect on an anticorrosive coating is achieved.

Owner:玉和建设有限公司

A kind of anti-cracking self-healing concrete and preparation method thereof

The invention discloses a crack-resistant self-repairing concrete and a preparation method thereof. The crack-resistant self-repairing concrete comprises 200-300 parts of cement, 100-180 parts of fly ash, 500-700 parts of gravel, 80-140 parts of water, 40 ‑60 parts of hemihydrate gypsum, 50‑100 parts of silicon powder, 20‑40 parts of polypropylene fiber, 10‑15 parts of silane coupling agent, 60‑80 parts of calcium oxide, 5‑10 parts of water reducer, 30‑50 parts Ammonium chloride, 10-20 parts of barium hydroxide octahydrate; its preparation method is mixing concrete slurry, mixing cement, fly ash, crushed stone, hemihydrate gypsum and silica fume, stirring for 30-40min, adding Water reducer and water, after stirring for 5-10min, add ammonium chloride and barium hydroxide octahydrate, stir for 40-60min, then add polypropylene fiber and silane coupling agent and stir for 20-30min to obtain concrete slurry; The calcium is sealed in the glass fiber tube, and then the glass fiber tube filled with calcium oxide is mixed in the concrete slurry to obtain the anti-crack self-repairing concrete. The invention has the advantages that the prepared concrete is anti-cracking, self-repairing cracks and has high strength after repairing.

Owner:北京天地建设砼制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com