Self-repairing cement for thermal damage tunnel

A self-repairing and tunneling technology, applied in the field of building materials, can solve the problems of lining concrete structure damage, narrowing crack width, poor durability of concrete, etc., and achieve the effects of reducing water loss, reducing plastic shrinkage, and being easy to grind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

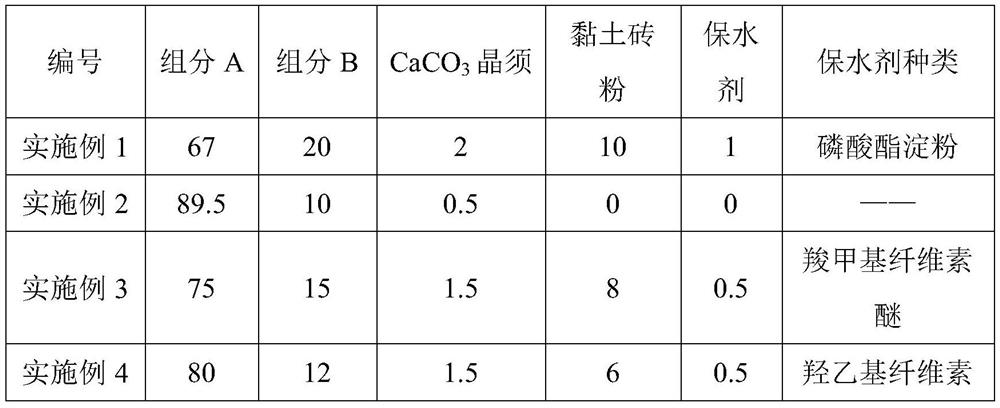

Embodiment 1

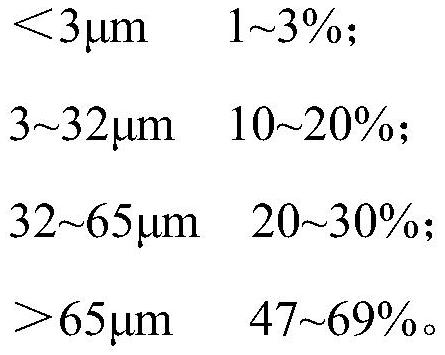

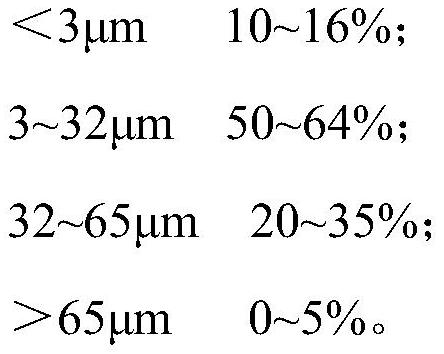

[0049] The particle distribution of component A is implemented as follows: 65 μm particles account for 0%. γ-C in the clinker of this component 2 The S content is 1%, the periclase (MgO crystal) content is about 4%, and the size of the periclase is less than 1 μm.

[0050] The particle distribution of component B is as follows: 65 μm particles account for 47%. The cement clinker in component B cools slowly, making part C 2 S transforms from β-type to γ-type, and γ-C in the clinker of this component 2 The S content is 5%; the periclase content in the clinker is about 2%, and the size is 3 μm.

[0051] Clay brick powder Al 2 o 3 The content is 40%, and the particle distribution is as follows: 150 μm particles account for 0%.

[0052] CaCO 3 The whiskers have a diameter of 0.5 μm, a length of 20 μm, and an aspect ratio of 40.

Embodiment 2

[0054] The particle distribution of component A is implemented as follows: 65 μm particles account for 5%. γ-C in the clinker of this component 2 The S content is 1.5%, the periclase (MgO crystal) content is about 3.5%, and the size of the periclase is less than 1 μm.

[0055] The particle distribution of component B is as follows: 65 μm particles account for 69%. The cement clinker in component B cools slowly, making part C 2 S transforms from β-type to γ-type, and γ-C in the clinker of this component 2 The S content is 15%; the periclase content in the clinker is about 3%, and the size is 5 μm.

Embodiment 3

[0057] The particle distribution of component A is implemented as follows: 65 μm particles account for 3%. γ-C in the clinker of this component 2 The S content is 1%, the periclase (MgO crystal) content is about 4%, and the size of the periclase is less than 1 μm.

[0058] The particle distribution of component B is as follows: 65 μm particles account for 58%. The cement clinker in component B cools slowly, making part C 2 S transforms from β-type to γ-type, and γ-C in the clinker of this component 2 The S content is 10%; the periclase content in the clinker is about 4%, and the size is 3.5 μm.

[0059] Clay brick powder Al 2 o 3 The content is 46%, and the particle distribution is as follows: 150 μm particles account for 5%.

[0060] CaCO 3 The whiskers have a diameter of 0.5 μm, a length of 10 μm, and an aspect ratio of 20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Whisker diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com