Patents

Literature

199 results about "Periclase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Periclase is a magnesium mineral that occurs naturally in contact metamorphic rocks and is a major component of most basic refractory bricks. It is a cubic form of magnesium oxide (MgO). In nature it usually forms a solid solution with wüstite (FeO) and is then referred to as ferropericlase or magnesiowüstite.

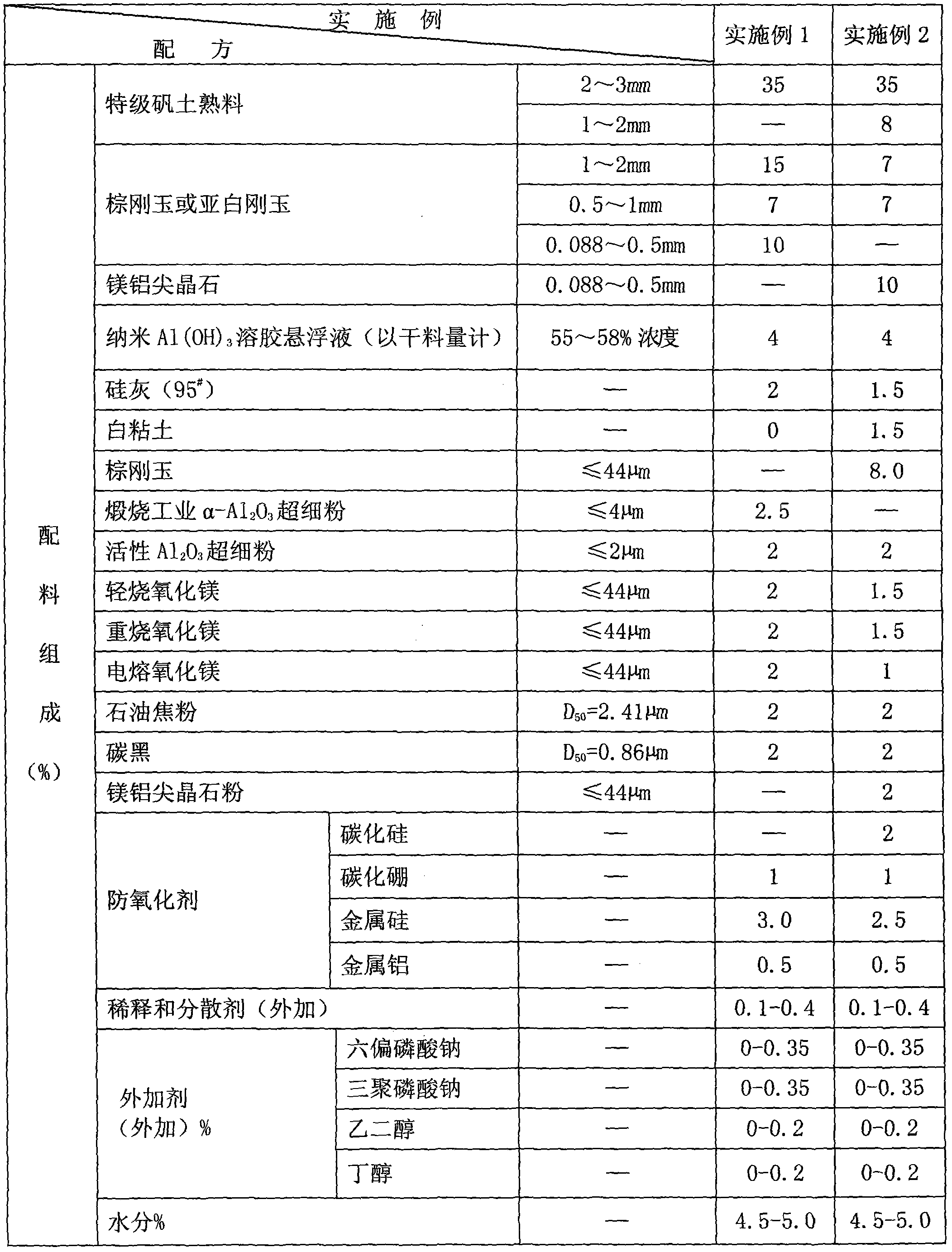

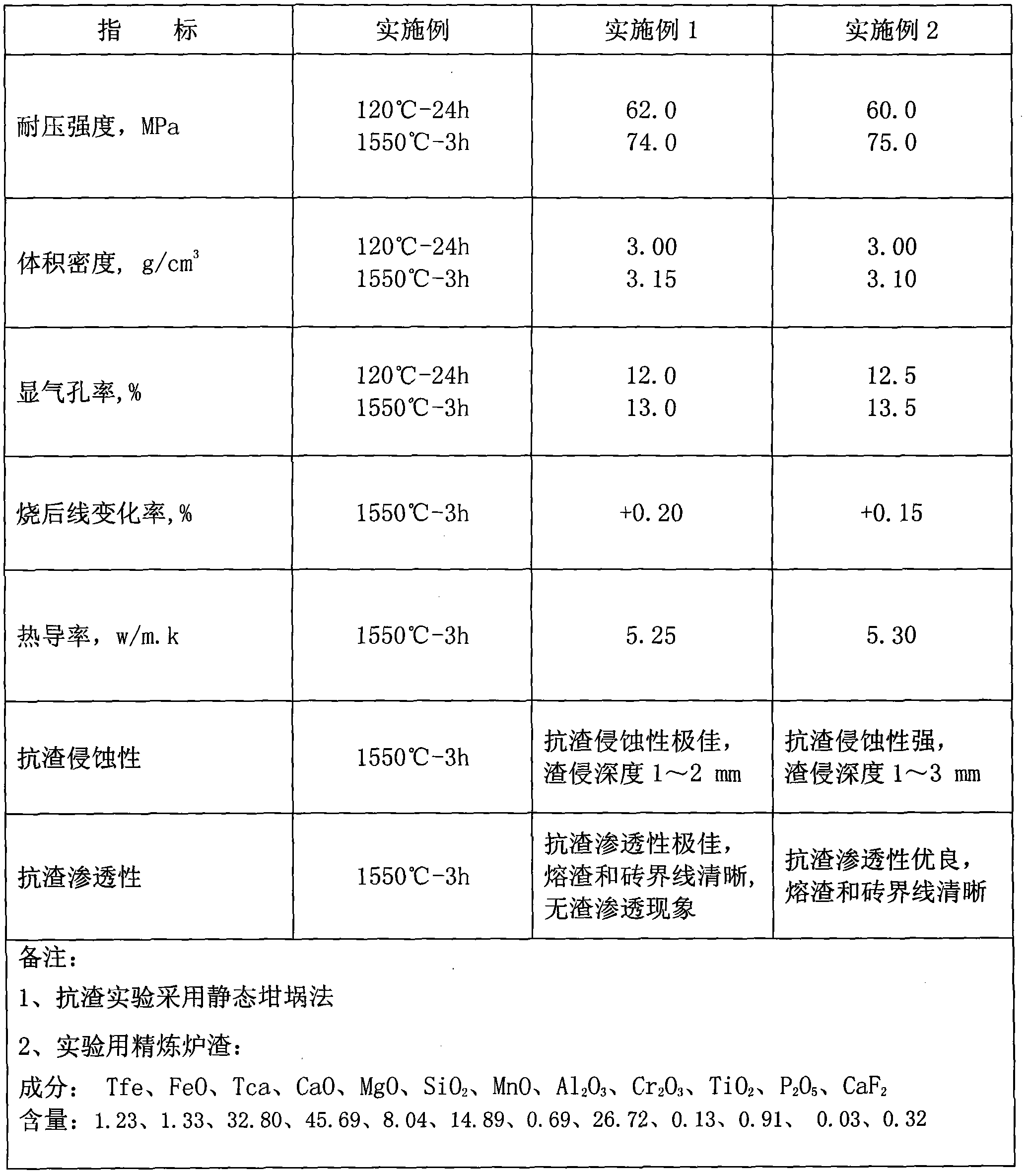

Periclase-magnesium aluminate spinel composite refractory brick and technique for producing the same

The invention relates to an alkaline composite refractory brick, which consists of a periclase-magnesium aluminate spinel flame retardant coating and a periclase-forsterite thermal-protective coating. The proportion of the alkaline composite refractory brick is as follows: 1) the proportion of the flame retardant coating is as follows: 29 to 48 percent of magnesite of between 5 and 1 millimeter, 7 to 16 percent of the magnesium aluminate spinel of between 3 and 1 millimeter, 6 to 20 percent of the magnesite of between 1 and 0.088 millimeter, 0 to 4 percent of desilicated zirconia granules of between 0.4 and 0.088 millimeter, 16 to 25 percent of the magnesite of less than 0.088 millimeter, 0 to 10 percent of magnesite micropowder of less than 0.020 millimeter, 0 to 5 percent of desilicated zirconia micropowder of less than 0.020 millimeter, 0 to 3 percent of calcium carbonate micropowder less than 0.020 millimeter, 0 to 6 percent of lanthanum oxide of less than 0.020 millimeter, and 0 to 0.3 percent of additional water reducing agent (sulfonated naphthaldehyde polymer, sulfonated melamine polymer and polycarboxylic acid or sodium salt thereof); and 2) the proportion of the thermal-protective coating is as follows: 0 to 20 percent of the magnesite of between 3.2 and 1.0 millimeter, 35 to 45 percent of the forsterite of between 3.2 and 1.0 meter, 5 to 15 percent of the magnesite of between 1.0 and 0.088 millimeter, 5 to 15 percent of the forsterite of between 1.0 and 0.088 millimeter, and 30 to 40 percent of grinding powder of the magnesite and the forsterite of less than 0.088 millimeter. The material has the advantages that the material improves the erosion resistance of the flame retardant coating by micropowder technology, and allows the sintering temperature of the flame retardant coating to be matched with that of the thermal-protective coating, thereby producing the periclase-magnesium aluminate spinel alkaline composite refractory brick which has excellent.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

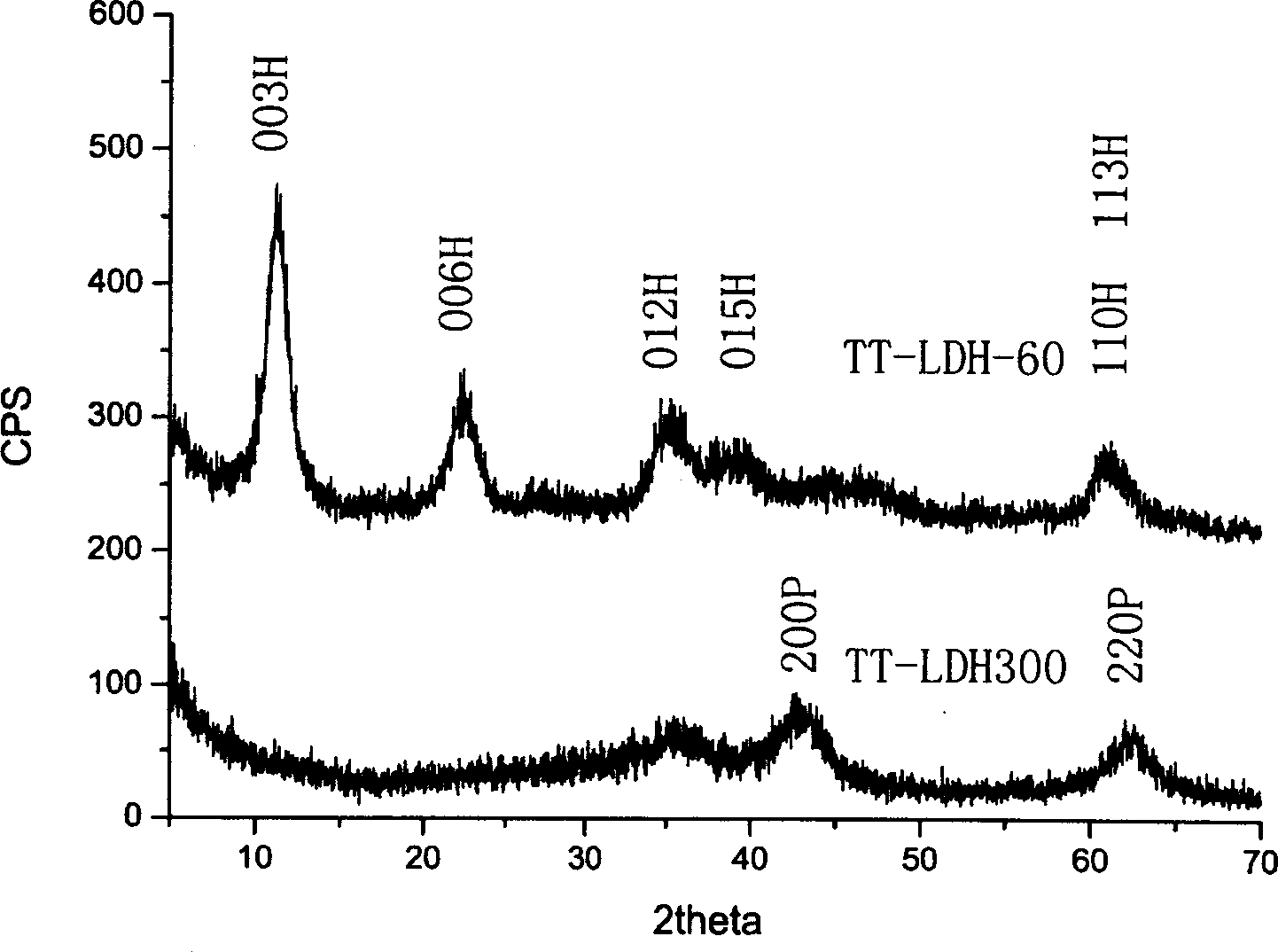

Prepn of laminated dihydrogen oxide and its derivative quasi-periclase

InactiveCN1506315ALow pricePracticalPhysical/chemical process catalystsWater/sewage treatment by ion-exchangeLiquid wasteChemical reaction

The present invention features that by using industrial acid waste water and inorganic salt in waste liquid as material and through inorganic chemical reaction, laminated dihydroxide (LDH) is synthesized; and through high temperature calcination, the derivative quasi-periclase is produced. The present invention is one new waste water processing technology and new LDH synthesizing technology for processing waste water and preparing LDH simultaneously. The prepared LDH or derivative quasi-periclase may be used as water purifying agent for processing waste water and drinking water. The present invention realizes the comprehensive waste treatment and resource utilization.

Owner:HEFEI UNIV OF TECH

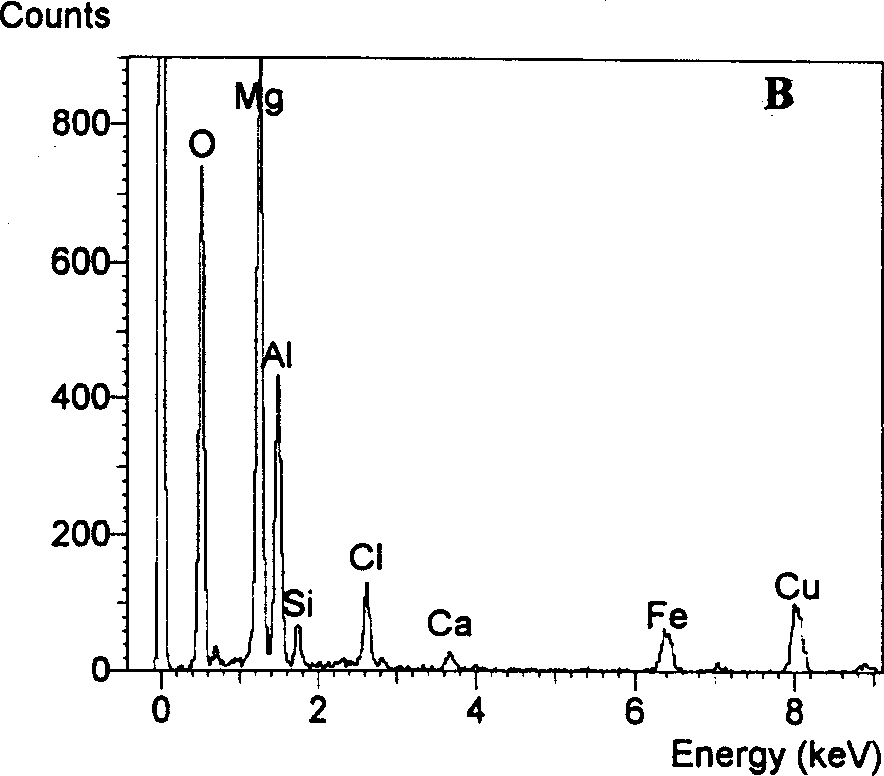

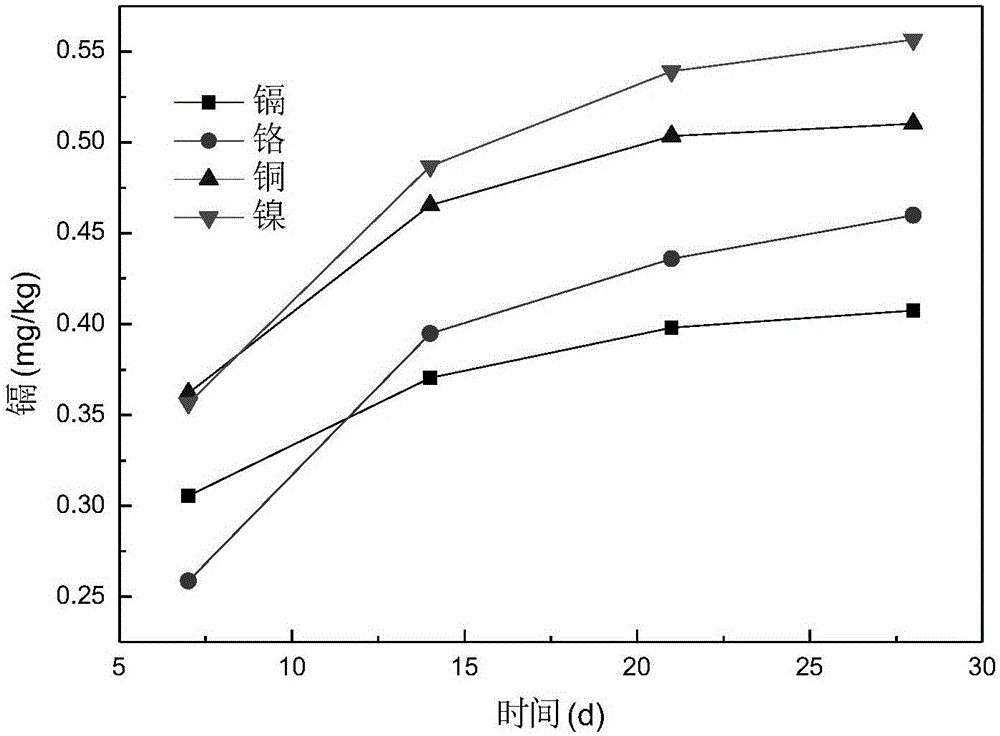

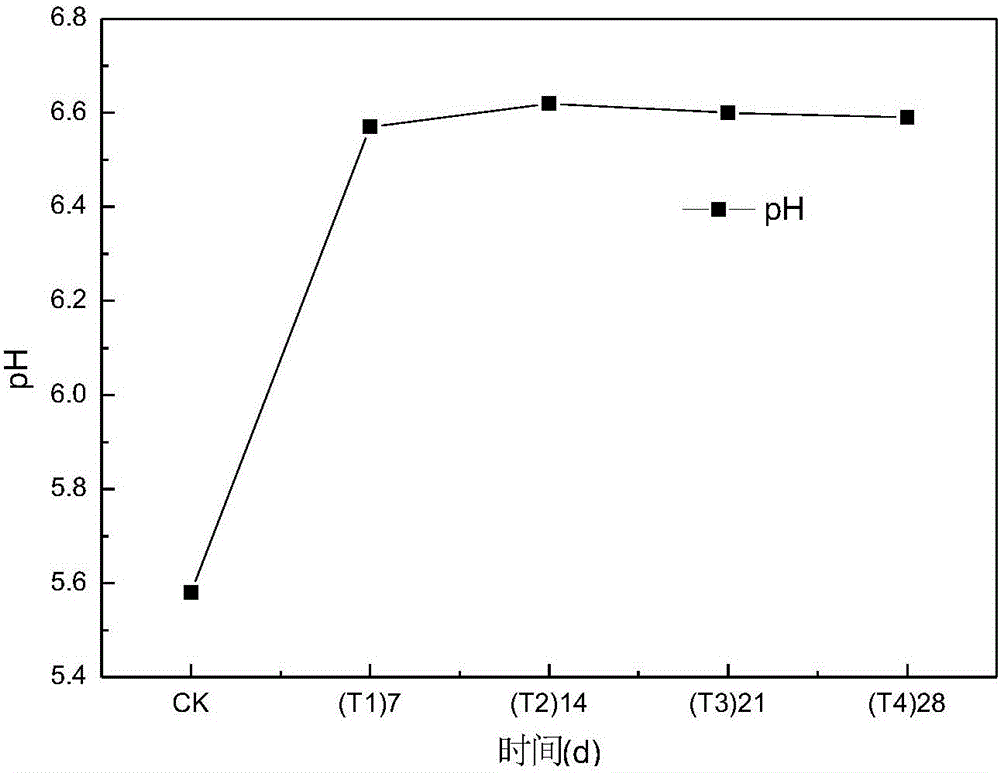

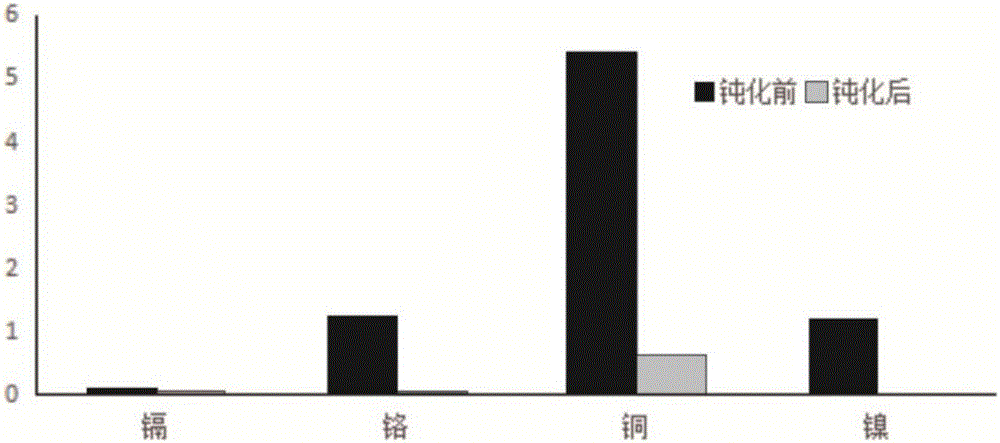

Passivator for remediation of farmland soil subjected to combined pollution of heavy metals, and preparation method and use method of passivator

InactiveCN106800933AImprove adsorption capacityImprove water retentionAgriculture tools and machinesMagnesium fertilisersIon exchangeBinding state

The invention relates to a passivator for remediation of farmland soil subjected to combined pollution of heavy metals such as cadmium, chromium, copper and nickel, and a preparation method and a use method of the passivator. The passivator is prepared from a passivator A and a passivator B, wherein the passivator A is prepared from montmorillonite, kieselguhr, sepiolite, illite and ferrous sulfate; the passivator B is prepared from periclase, calcite, calcium magnesium phosphate fertilizer, plant ash and calcium hydroxide; the passivator is suitable for the farmland soil subjected to the combined pollution of the cadmium, the chromium, the copper and the nickel, and is prepared from the multiple different porous absorption materials with specific contents and a passivation material; the components of the passivator have complementary advantages, and the principles such as absorption and stabilization are combined; the combination forms of the heavy metals are effectively enhanced by ion exchange, complexing, chelating and adsorption methods, and the combination forms are converted into more stable strong organic binding states and residue states, so that the effective state contents of the heavy metals in the farmland soil are effectively reduced, and the passivation effect is long-acting and stable; therefore, the passivator has a great repair effect for the farmland soil subjected to combined pollution of the cadmium, the chromium, the copper and the nickel.

Owner:SICHUAN YIKE ENVIRONMENTAL PROTECTION SCI ANDTECH

Tundish dry type vibration material taking waste magnesia carbon bricks as raw materials and preparation method thereof

The invention relates to a tundish dry type vibration material taking waste magnesia carbon bricks as raw materials and a preparation method thereof. The technical scheme is as follows: mixing 50-80wt% of the waste magnesia carbon bricks, 10-40wt% of fused magnesia or sintered magnesia fine powder, 3-8wt% of binding agent and 0.5-5wt% of additive, evenly stirring, carrying out vibration moulding, baking under the temperature of 200-400 DEG C, and demoulding to obtain the tundish dry type vibration material, wherein the MgO content in the waste magnesia carbon bricks are no less than 70wt%. The invention has the characteristics of simple process, low cost and energy conservation, is environmental friendly, and is convenient in construction. As for the tundish dry type vibration material, the main chemical components are MgO and C, the main crystalline phases are periclase and graphite, the continuous casting rate is high, the metallurgical effect is favorable, and the disassembly is easy after use. The tundish dry type vibration material is mainly applicable to continuous casting of tundish linings. The invention provides a new way for recycling the waste magnesia carbon bricks of a steel mill, and has important significances on energy conservation, consumption reduction and environment protection.

Owner:WUHAN UNIV OF SCI & TECH

Lightweight periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a lightweight periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. According to the scheme, the preparation method comprises the following steps of: uniformly dispersing 0.2 to 4wt% of magnesite micro powder and 0.2 to 4wt% of active alpha alumina micro powder into 5 to 8wt% of binding agent to obtain a modified binding agent; adding 50 to 70wt% of porous periclase-magnesium aluminate spinel ceramic particles to a vacuum agitating machine; vacuumizing to be below 2.5kPa; maintaining the constant pressure for 3 minutes; adding the modified biding agent to the vacuum agitating machine; agitating for 10 minutes; closing a vacuumizing system; then adding 10 to 25wt% of porous periclase-magnesium aluminate spinel ceramic fine powder, 4 to 20wt% of fine magnesia powder, and 1.5 to 4wt% of magnesium aluminate spinel fine powder to the vacuum agitating machine; uniformly agitating; mechanically pressing and modeling; drying; and maintaining the temperature of 1,500 to 1,650 DEG C for 2 to 10 hours. The lightweight periclase-magnesium aluminate spinel refractory material for the rotary cement kiln has the advantages of being low in heat conductivity, high in intensity, high in thermal shock resistance, high in kiln coating performance, and high in resistance to medium erosion.

Owner:WUHAN UNIV OF SCI & TECH

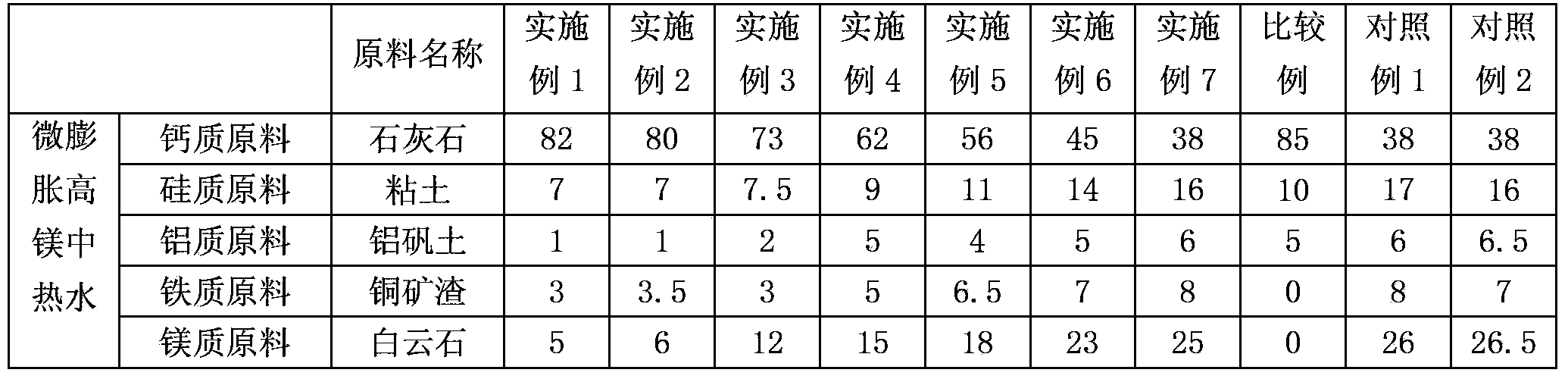

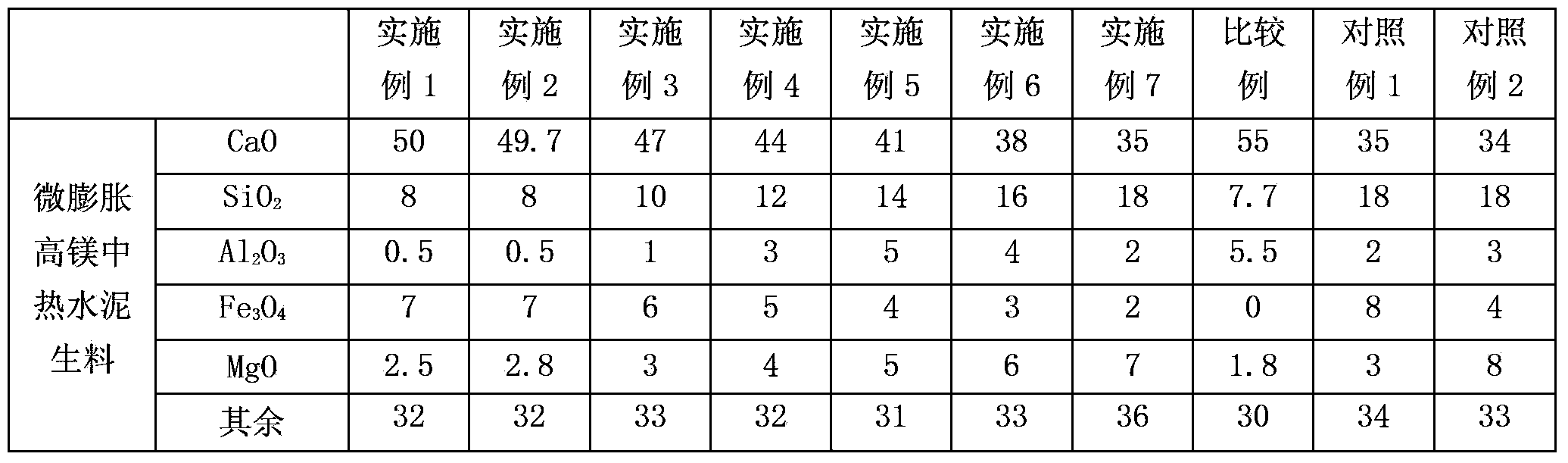

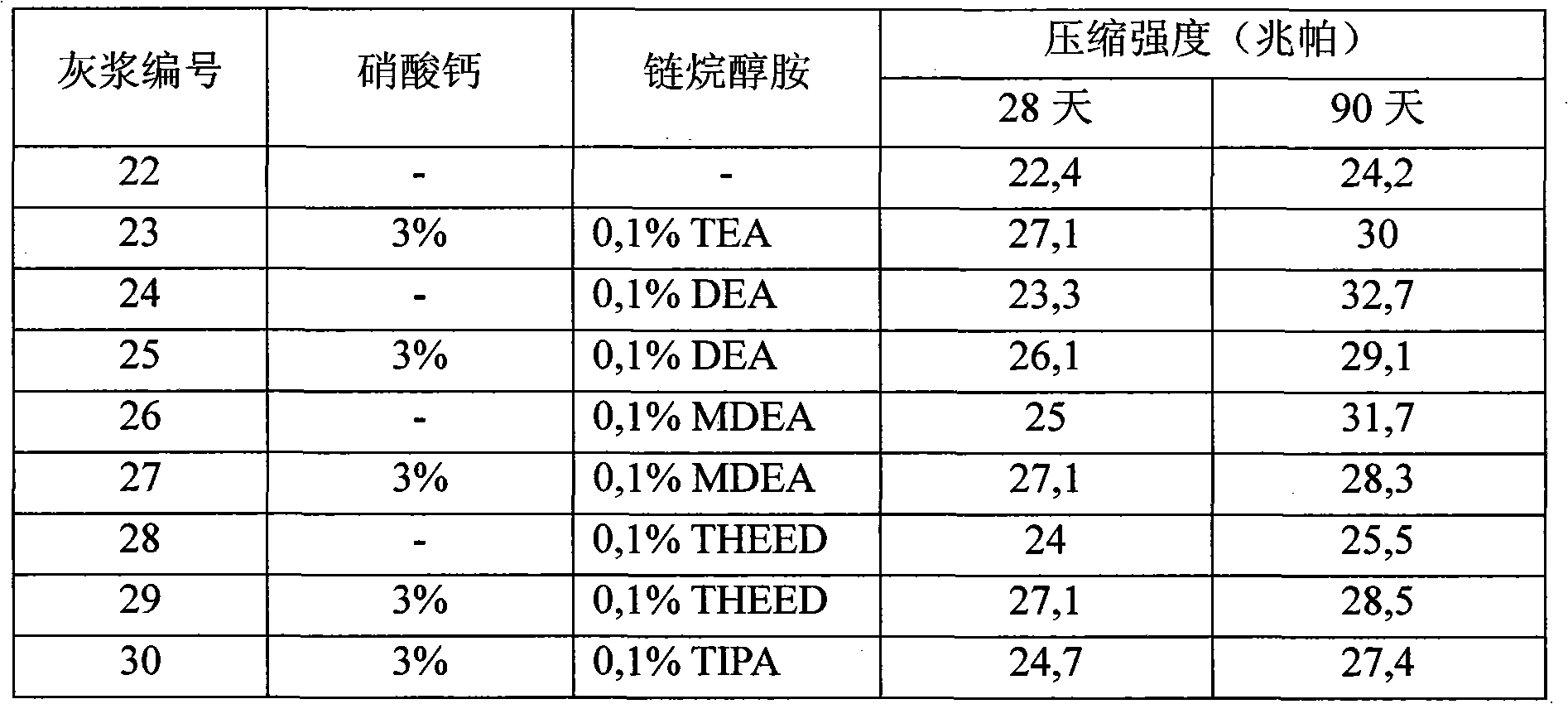

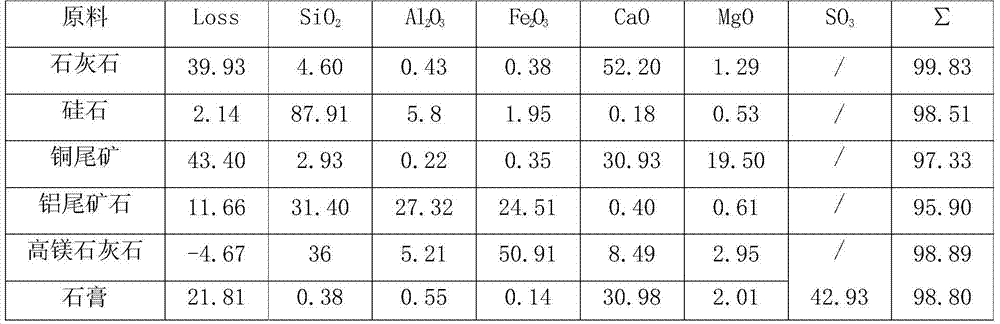

Minimum inflation high magnesium moderate heat cement, production method therefor and applications thereof

The invention discloses a kind of minimum inflation high magnesium moderate heat cement, a production method therefor and applications thereof. The cement is prepared from calcium raw materials, silicon materials, aluminum raw materials, iron raw materials, magnesium raw materials, correction raw materials and clinker activating agents through two-grinding and one-burning process. The content of MgO in the clinkers is raised to 6-9%, the content of periclase is controlled to 2-8%, the minimum inflation performance of periclase can be used fully, the contraction of mass concrete can be compensated, concrete cracks can be decreased, and therefore the volume stability and safety of concrete are raised.

Owner:CHINA BUILDING MATERIALS ACAD

Ceramic material of porous spinel, and preparation method

InactiveCN1915903ASmall average pore sizeHigh purityCeramic shaping apparatusCeramicwarePericlasePore distribution

This invention relates to a method for preparing porous spinel ceramic material. The method comprises: (1) mixing magnesite powder 10-90 wt.%, Al(OH)3 powder 10-90 wt.%, water 2-10 wt.% and adhesive 0-3 wt.%; (2) molding; (3) drying the green bodies at 110 deg.C for 4-24 h; (4) sintering at 1600-1800 deg.C, and keeping the temperature for 1-8 h. The porous spinel ceramic material mainly contains MgO and Al2O3, and has main crystal phase of periclase-spinel, spinel or spinel-corundum. The porous spinel ceramic material can be directly contacted with flame retardant magmesium and spinel materials, and is a lightweight heat-insulating flame retardant with uniform pore distribution and high strength.

Owner:WUHAN UNIV OF SCI & TECH

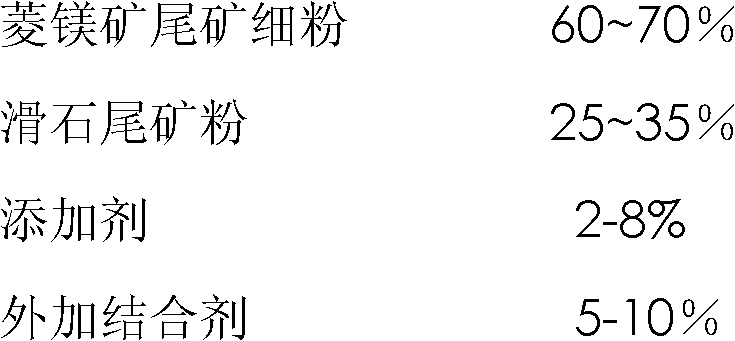

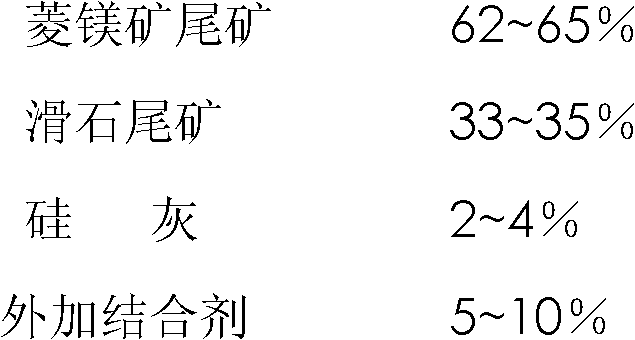

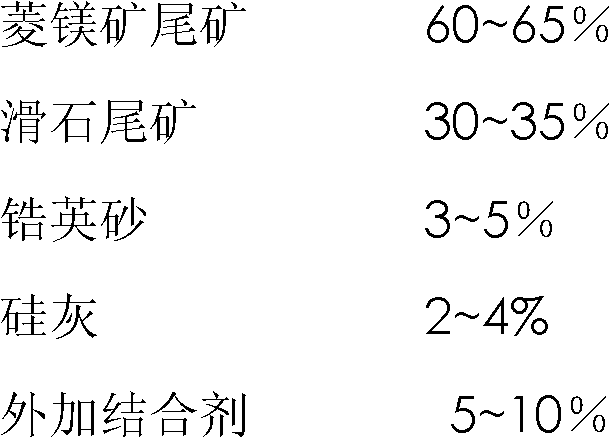

Method for synthesizing high-purity forsterite with magnesite tailings and talc tailings

The invention discloses a method for synthesizing high-purity forsterite by using magnesite tailings and talc tailings, which effectively utilizes tailings resources and can be used to produce high-density refractory materials used under high-temperature conditions above 1600°C. The present invention uses magnesite tailings and talc tailings as the main raw materials, adds additives and binders, and manufactures high-purity forsterite refractory raw materials through batching, mixing, molding, drying, high-temperature synthesis and crushing. The weight percent content of each component is as follows: 60-70% of fine magnesite tailings powder; 25-35% of talc tailings powder; 2-8% of additives; 5-10% of external binder. Using magnesite tailings and talc tailings to synthesize high-purity forsterite refractory raw materials, the use temperature is high (above 1600 ℃), the bulk density is high (greater than 2.55g / cm3), and the combined content of olivine and periclase is greater than 97%. The utility model has wide application field, comprehensive utilization of waste, and low production cost.

Owner:UNIV OF SCI & TECH LIAONING +1

Roasting method for producing sodium chromate using chrome iron ore as raw material

InactiveCN1418823AAvoid scaringSolve the pollution of the environmentChromates/bichromatesBrucitePericlase

The method for preparing sodium chromate by calcining chromite includes the following steps: pulverizing chromite and sieving with 200 mesh sieve, adding sodium carbonate whose added amount is 80-150% of chromite amount, and adding magnesite, baudisserite, periclase, brucite or synthetic magnesium oxide, magnesium hydroxide and magnesium carbonate and calcining them at 1000-1200 deg.c for 10-60 min. under the condition of oxidation atmosphere, then extracting clinker and dissolving sodium chromate so as to obtain the goal of preparing sodium chromate. The conversion rate of chromite can be upto 97-99.5%.

Owner:TIANJIN CHEM RES & DESIGN INST

Bauxite-based nanometer composite oxide ceramic bond A1203-MgO-C unfired product and preparation method thereof

The invention relates to an A1203-MgO-C unfired product with carbon wrapped by nano Al2O3-MgO film and a preparation method thereof. The product uses natural high alumina bauxite (AlOOH) and sintered periclase (MgO) as initial raw material and employs method of sol-gel technology, which comprises following steps, putting superfine high alumina bauxite, carbon dust, water and additive into high speed impact mixer, carrying out coating process so as to let the materials have strong impact and mix with each other to form high density composite sol suspension liquid of carbon and aluminium hydroxide, therefore Al(OH)3 is mightily adsorbed on the surface of carbon, then realizing workmanship of coating powdered carbon by aluminium hydroxide. During the wet-milled process of mixture, the magnesium oxide powder and the mixture water in the matrix powder have hydration reaction to produce magnesium hydroxide sol, and the magnesium hydroxide sol and the aluminium hydroxide sol have situ synthesis reaction to produce nanostructured matrix of carbon-aluminium spinel to prepare A1203-MgO-C unfired product of the invention.

Owner:高树森

Non-cement light alumina magnesia cast material and its prepn process

InactiveCN101066855AImprove medium temperature strengthImprove corrosion resistanceCeramic shaping apparatusRefractorySpinel

The present invention relates to one kind of no-cement light alumina-magnesia cast material and its preparation process. The technological scheme is that the alumina-magnesia cast material is prepared with porous alumina-magnesia ceramic grain in 40-70 wt% and compact alumina-magnesia grain in 0-20 wt% as aggregate, and fine alumina-magnesia powder in 5-50 wt%, fine silica powder in 1-10 wt% and fine active alpha-alumina powder in 1-8 wt% as matrix, and through adding water in the quantity of 8-20 wt % and water reducing agent in 0-3 wt% , stirring, vibrating to form and drying at 110 deg.c for 8-48 hr. The alumina-magnesia cast material has MgO and Al2O3 as main chemical components, and main crystal phases of periclase, spinel and corundum. It may be contacted directly with refractory magnesia material and refractory spinel material at high temperature, and has the features of high porosity, small average pore size, high strength, etc.

Owner:WUHAN UNIV OF SCI & TECH

Periclase-silicon carbide-carbon composite materials and method for preparing same

InactiveCN1884202AHigh melting pointHigh thermal conductivityCarbon compositesHexamethylenetetramine

The invention discloses a periclase-carborundum-carbon composite material and preparing method, which comprises the following steps: blending 60-90% electric melting or sintered magnesite, 5-35% carborundum, 2-15 % graphite, 0.5-5% carbon black and 0.5-6% additive; mixing 3-9% binder and 0-1%hexamethylenetetramine hardener; stirring; moulding; baking at 150-350 deg.c for 2-24 h. The invention improves oxidation resistance of material and penetrability and aggressivity resistance of melting waste and metal fusion, which fits melting furnace and container liner widely.

Owner:WUHAN UNIV OF SCI & TECH

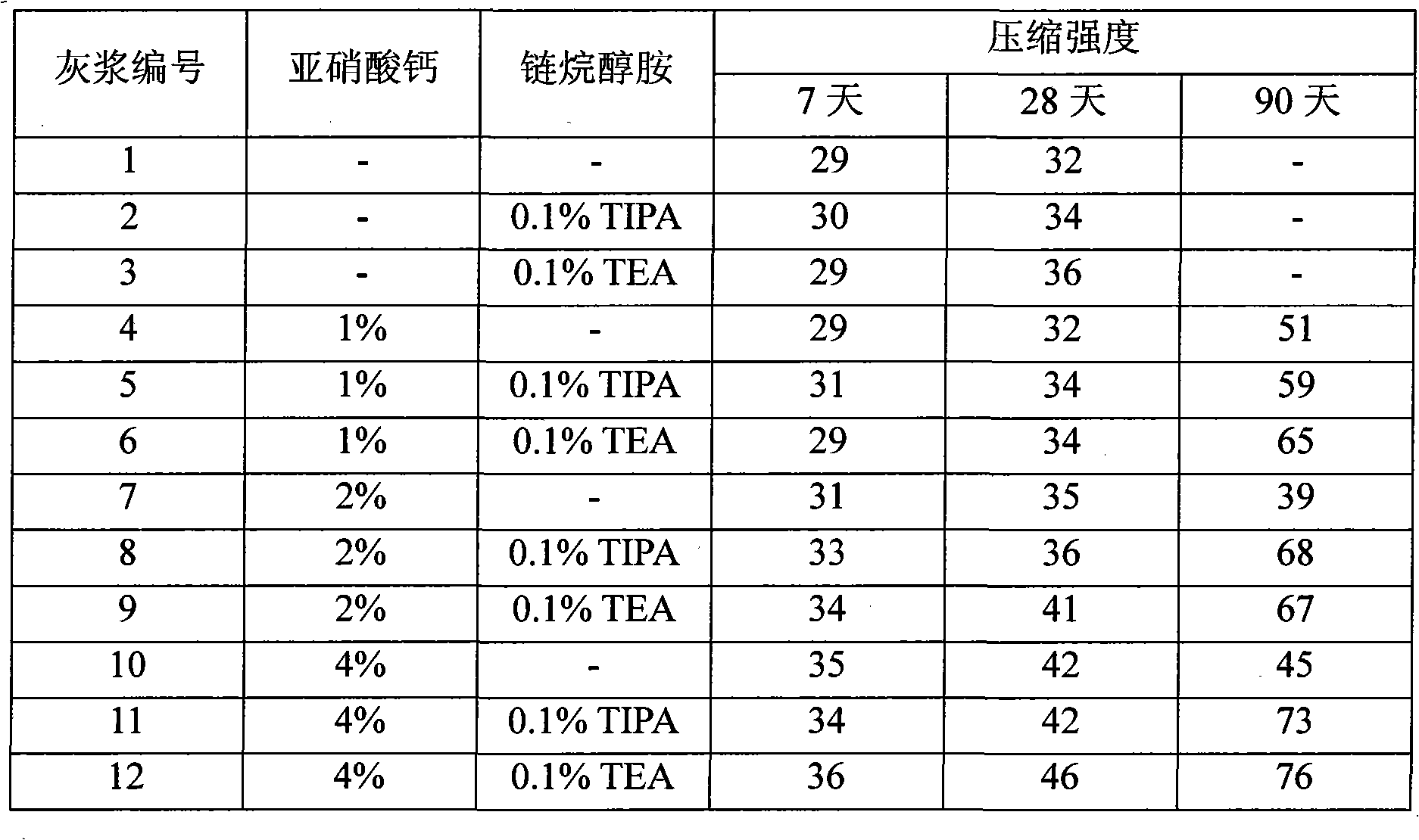

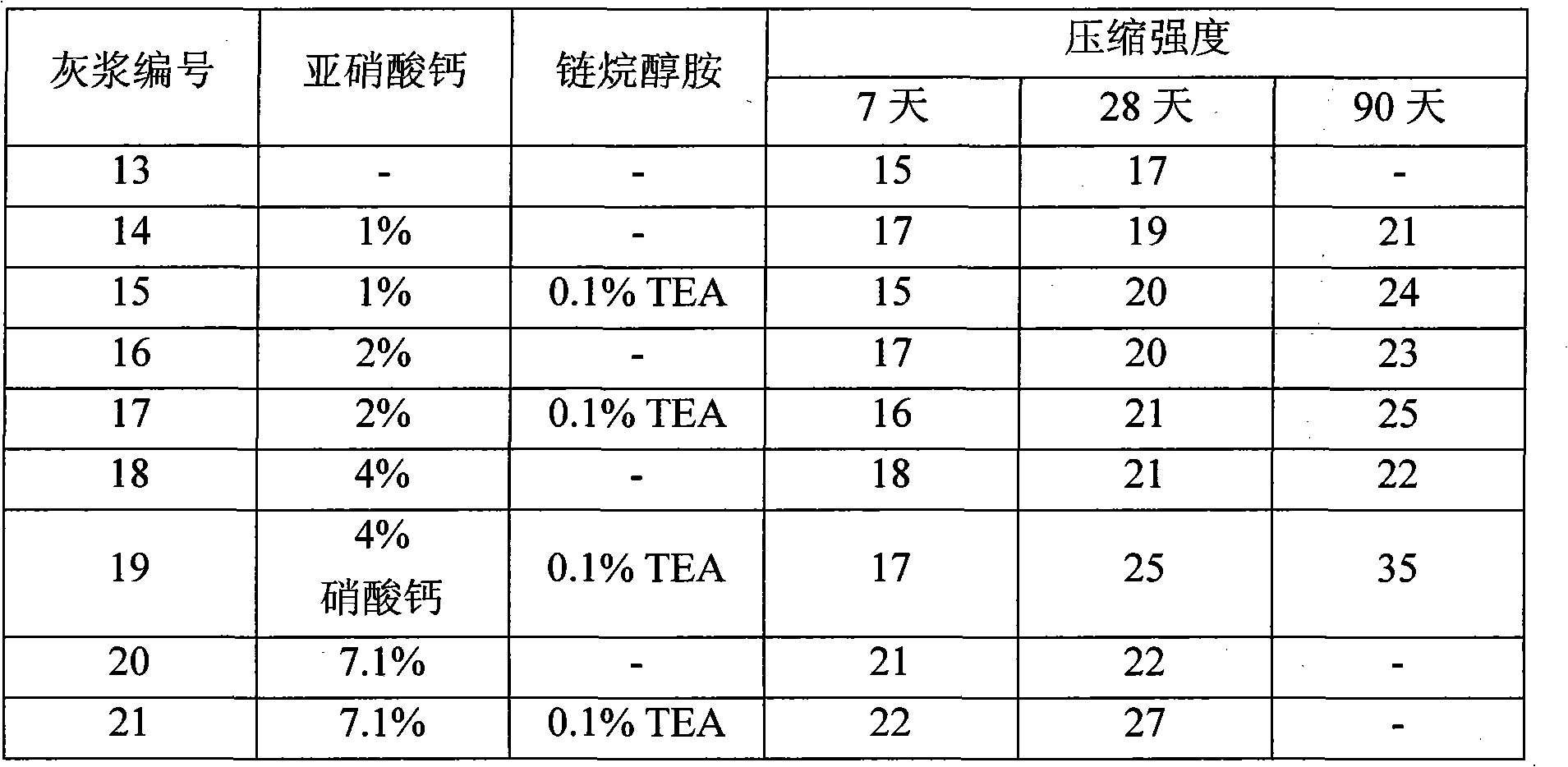

Additives for cement

The invention provides a belite-calcium sulphoaluminate-ferrite (BCSAF) cement composition comprising: a BCSAF clinker which clinker has the following mineralogical composition, based on the total weight of the clinker: 5 to 25%, preferably 10 to 20%, of a calcium aluminoferrite phase having the general formula C2AxF(1-X), wherein X is from 0.2 to 0.8; 15 to 35% of a calcium sulphoaluminate phase; 40 to 75% of belite (C2S); from 0.01 to 10% in total of one or more minor phases selected from calcium sulphates, alkali metal sulphates, perovskite, calcium aluminates, gehlenite, free lime and periclase and / or a vitreous phase; and an alkanolamine.

Owner:HOLCIM

Sagger

The present invention provides a sagger which is used for sintering powder of lithium compound and realizing corrosion resistance improvement for lithium diffusion through containing a magnesium oxide component. Simultaneously, thermal expansion coefficient increase of the sagger can be restrained through containing the magnesium oxide component, thereby effectively preventing a thermal shock performance reduction problem and a product strength reduction problem which are caused by the thermal expansion coefficient increase. The sagger which is used for sintering the powder of the lithium compound according to the invention comprises spinel with grain diameter that is smaller than 1 mm and periclase with grain diameter that is smaller than 0.5 mm. The composition ratio of the crystal phase is as follows: cordierite: periclase: spinel: corundum: mullite=1:(0.1-0.7):(0.03-0.4):(0.01-0.15):(0.06-1.10).

Owner:NGK INSULATORS LTD +1

Amorphous periclase-silicon carbide composite fireproof materials and method for preparing same

The present invention relates to one kind of amorphous periclase-SiC refractory material and it production process. The technological scheme includes mixing fused magnesia or sintered magnesia in 50-90 wt%, silicon carbide in 10-50 wt% and fine silica powder in 3-8 wt%; adding water in 4-8 wt% and water reducing agent in 0.1-3 wt% during construction; and forming through stirring, vibration depositing, and roasting at 100-300 deg.c for 2-24 hr. The produced amorphous composite refractory material has high smelting point, high heat conductivity, and especially self-protecting oxidation characteristic, which is that the oxidized SiC forms one layer of protecting silica film to protect the inside from being further oxidized. The present invention substitutes SiC for graphite to raise the antioxidant performance of the material greatly and using fine silica powder as binding agent makes the material possess raised medium temperature strength.

Owner:WUHAN UNIV OF SCI & TECH

Chromium-free alkaline brick for cement kiln and preparation thereof

The invention particularly relates to a chromium-free basic brick for a cement kiln and a preparation method thereof. The preparation method adopts the technical proposal that: firstly, mixing 45 to 96 weight percent of magnesia, 2 to 17 weight percent of Al2O3, 1 to 10 weight percent of iron, 0 to 40 weight percent of hercynite or magnesium aluminate spinel and 0 to 10 weight percent of Fe2O3, and adding a water glass solution or a sodium tripolyphosphate solution or a sodium hexametaphosphate solution which is 3 to 6 weight percent of mixed materials; and secondly, performing mixing, forming, roasting and hardening treatment. The preparation method utilizes a high-temperature environment at a temperature of 1,500 DEG C when products are used to generate the hercynite through in-site chemical reaction in the service process of unfired bricks, so that the chromium-free basic brick for the cement kiln has the superior characteristics of periclase-hercynite bricks. The preparation technology is simple, does not require high-temperature firing, and saves energy resources; and metallic combination is formed in green bricks through plastic phase transition of metallic phases under the action of forming pressure, and has the function of reinforcing and plasticizing the green bricks, so that the green bricks have large volume density, high strength and good thermal shock stability.

Owner:WUHAN UNIV OF SCI & TECH +1

Calcic spinel refractory material and preparation method thereof

Owner:WUHAN UNIV OF SCI & TECH +1

Porous periclase-forsterite-spinel composite ceramic material and preparation method thereof

The invention relates to a porous periclase-forsterite-spinel composite ceramic material and a preparation method thereof. The technical scheme is as follows: the method comprises the following steps: mixing the raw materials of 28-90wt% of magnesite powder, 5-20wt% of clay powder and 5-67wt% of Al(OH)3 powder; adding water which is 5-15wt% of the raw materials, evenly stirring and molding the raw materials, and then drying the molded green body under the condition at 110 DEG C for 16-48 hours; carrying out heat preservation under the condition at 1300-1600 DEG C for 3-10 hours, so as to obtain the porous periclase-forsterite-spinel composite ceramic material, wherein the particle sizes of the magnesite powder, the Al(OH)3 powder and the clay powder are smaller than 88mum; molding is molding in a mechanical pressing manner, or molding in a manual ramming manner, or molding in a pouring manner. The porous periclase-forsterite-spinel composite ceramic material has the characteristics of being environment-friendly, controllable in phase composition, controllable in pore size, and controllable in volume; the prepared porous periclase-forsterite-spinel composite ceramic material has high apparent porosity, high strength and good high-temperature performance.

Owner:WUHAN UNIV OF SCI & TECH

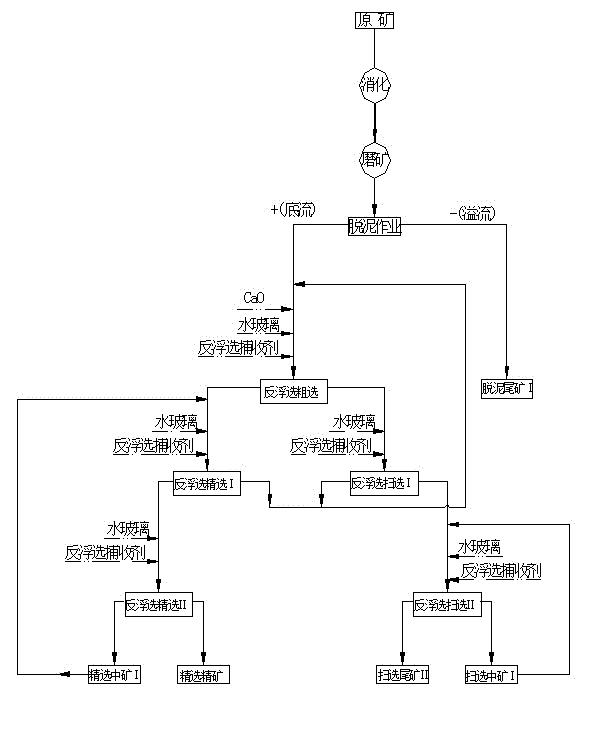

Digestion-desliming-reverse floatation method for treatment of low-grade magnesite high in silicon content and calcium content

ActiveCN104437883AIncrease planktonic diversityRaise the gradeFlotationGrain treatmentsSlurryPericlase

The invention discloses a digestion-desliming-reverse floatation method for treatment of low-grade magnesite high in silicon content and calcium content. The digestion-desliming-reverse floatation method for treatment of the low-grade magnesite high in silicon content and calcium content comprises the following steps that low-grade magnesite raw ore high in silicon content and calcium content is crushed and then is fed into a rotary kiln or a fluidized bed boiler to b roasted; the roasted material is ground by a ball grinder to be fine, and then water is added to the fine material, so that raw ore pump is obtained; the raw ore pulp is placed in a desliming hydrocyclone, so that slurry is removed; the deslimed raw ore pulp is placed in a floating device, the regulator such as sodium carbonate or CaO is added firstly, sodium silicate is added, then a reverse flotation collecting agent is added, stirring is conducted, reverse floatation rough concentration is conducted, rough concentrate is obtained, and tailings containing quartz and dolomite are separated. According to the digestion-desliming-reverse floatation method, through digestion, the floating difference between periclase and dolomite is increased, the effect that a qualified product is obtained at low ore dressing cost is achieved finally through the reverse flotation technology, and industrial production for purification of the low-grade magnesite high in silicon content and calcium content can be achieved easily.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Fireproof fired clay hollow brick and preparation method thereof

InactiveCN105967696AUniform Flame RetardancyUniform fire resistanceCeramic materials productionClaywaresPolyvinyl alcoholSlag

The invention discloses a fireproof fired clay hollow brick and a preparation method thereof. The fireproof fired clay hollow brick is prepared from the following raw materials (by weight): 15-25 parts of Benshan green mud, 17-29 parts of picrite, 7-14 parts of high aluminum fine powder, 9-18 parts of fused magnesite, 13-21 parts of periclase, 10-15 parts of high boron calcium borate, 16-24 parts of petroleum coke slag, 11-19 parts of kyanite ore tailings, 5-10 parts of sodium metaantimonate, 18-26 parts of brown fused alumina slag, 14-22 parts of silica fume, 32-46 parts of attapulgite, 17-23 parts of polyvinyl alcohol, 8-14 parts of magnesium silicate, 12-18 parts of barite, 10-15 parts of chromite slag, 13-21 parts of sawdust, 19-33 parts of fly ash and a proper amount of water. The prepared fired clay hollow brick has both excellent flame retardancy and fire resistance, long-term operation temperature of the fired clay hollow brick is also greatly raised. Actual operation temperature can reach 1350 DEG C and above.

Owner:安徽宏发节能设备有限公司

Magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and production method

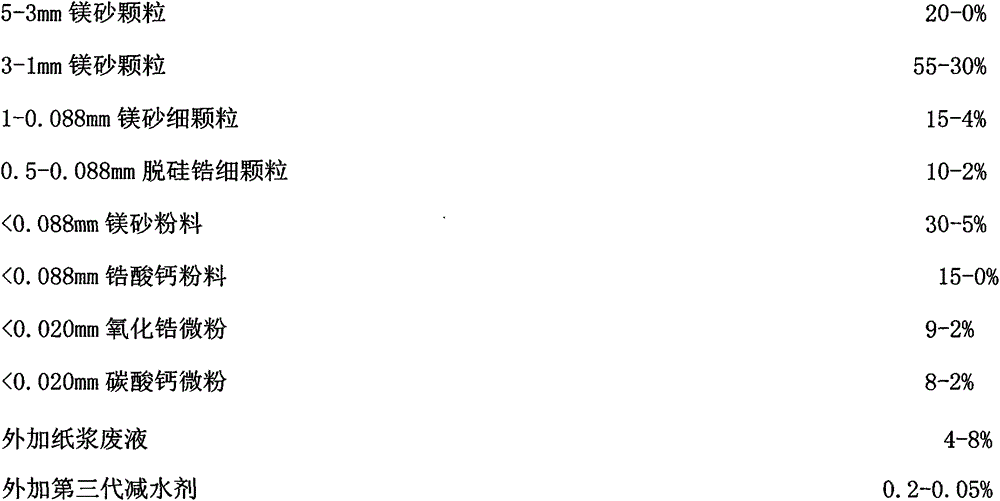

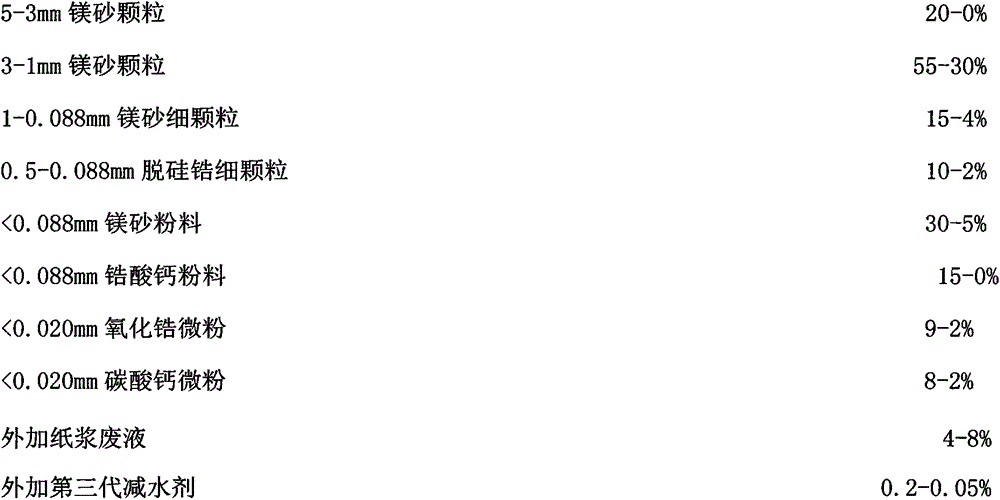

The invention relates to a magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and a production method. During manufacturing, 0-20% of 3 mm-5 mm magnesia particles, 30-55% of 1 mm-3 mm magnesia particles, 4-15% of 0.088 mm-1 mm fine magnesia particles, 2-10% of 0.088 mm-0.5 mm fine desilicated zirconia particles, 5-30% of magnesia powder with the diameter being less than 0.088 mm, 0-15% of calcium zirconate powder with the diameter being less than 0.088 mm, 2-9% of zirconia micro powder with the diameter being less than 0.020 mm, 2-8% of calcium carbonate micro powder with the diameter being less than 0.020 mm, 4-8% of additional waste pulp liquid and 0.2-0.05% of additional third-generation water reducing agents are used; during production, the adopted process includes the steps that firstly, the zirconia micro powder and the calcium carbonate micro powder are premixed; secondly, the 3 mm-5 mm magnesia particles, the 1 mm-3 mm magnesia particles and the 0.088 mm-1 mm fine magnesia particles are added to a mixing mill, and he waste pulp liquid and the third-generation water reducing agents are added to the mixing mill to be mixed; thirdly, magnesia powder with the diameter being less than 0.088 mm, calcium zirconate with the diameter being less than 0.088 mm and premixed zirconia-calcium carbonate micro powder with the diameter being less than 0.020 mm are add and mixed until the mixture is even; finally, forming, drying, 1580-1700 DEG C sintering and checking are conducted on the mixture to obtain a refractory material with periclase-calcium zirconate-baddeleyite as a main crystal phase. The magnesium-calcium-zirconium brick has the advantages of being convenient to manufacture, low in cost, simple to use and excellent in performance, has excellent anti-erosion performance and thermal shock resistance, excellent high-temperature physical and chemical stability, and is competent for the work of secondary refining to make clean steel.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. according to the technical scheme, 75-95wt% of periclase-magnesium aluminate spinel composite material, 4-20wt% of magnesite and 0.5-5wt% of magnesium aluminate spinel are mixed together to obtain a mixture; a binder accounting which is 3-8wt% of the mixture is added to the mixture and mixed evenly, and then the final mixture is mechanically pressed and formed; the formed blank is dried at 110 DEG C for 8-36 hours and then fired at 1500-1650 DEG C, and furthermore, heat is preserved for 4-15 hours, and finally, the periclase-magnesium aluminate spinel refractory material for the rotary cement kiln is obtained. The preparation method of the periclase-magnesium aluminate spinel refractory material for the rotary cement kiln is simple; the periclase-magnesium aluminate spinel refractory material prepared has the characteristic of controllable distribution of magnesium aluminate spinel, and also the characteristics of good coating formation property, good thermal shock resistance and high medium erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

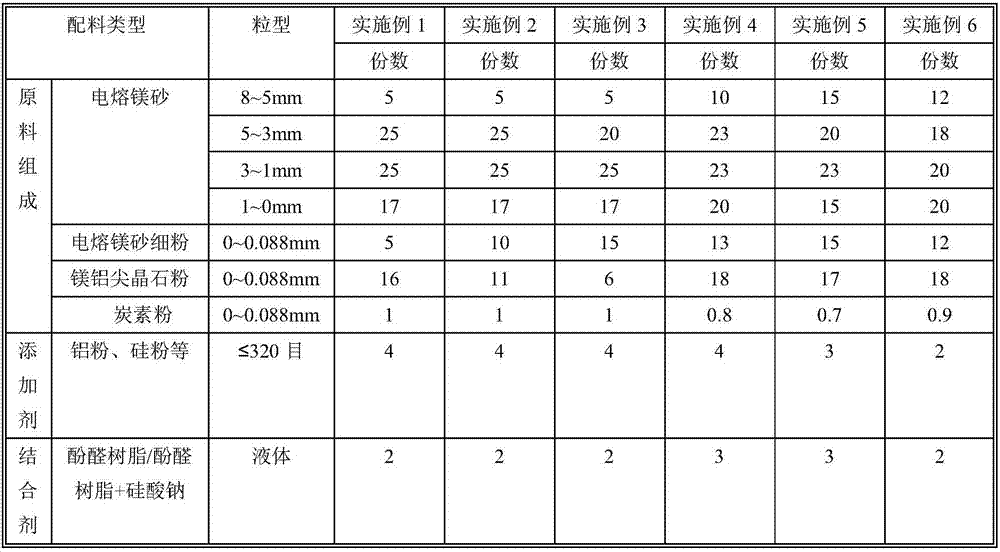

Ultra-low carbon periclase-spinel-carbon brick for steel ladle and preparing method

The invention relates to an ultra-low carbon periclase-spinel-carbon brick for a steel ladle and a preparing method. The ultra-low carbon periclase-spinel-carbon brick is prepared from, by weight, 5-15 parts of fused magnesite with the particle size being larger than or equal to 5 mm and smaller than 8 mm, 5-25 parts of fused magnesite with the particle size being larger than or equal to 3 mm and smaller than 5 mm, 5-25 parts of fused magnesite with the particle size being larger than or equal to 1 mm and smaller than 3 mm, 10-20 parts of fused magnesite with the particle size being smaller than 1 mm, 5-15 parts of fused magnesite fines, 5-20 parts of magnesium aluminate spinel powder, 0-1 parts of carbon powder, 1-3 parts of binding agent and 0-4 parts of additive, wherein the carbon powder and the additive exist in the brick certainly. The ultra-low carbon periclase-spinel-carbon brick has the advantages that the fused magnesite, the magnesium aluminate spinel powder and carbon are used as main raw materials, a small part of carbon powder is used as replacement to ensure that a matrix is not wet by refining slag, and spinel powder high in thermal shock resistance and alkali slag resistance is added to ensure thermal shock resistance of the brick.

Owner:海城利尔麦格西塔材料有限公司

Gunning mix for repairing RH refractory brick

The invention relates to gunning mix for repairing refractory materials, in particular to gunning mix for repairing an RH refractory brick. In order to solve the technical problem of short service life of the RH refractory brick due to falling off in the prior art, the invention creatively discloses the gunning mix for repairing the RH refractory brick, the gunning mix comprises the following raw materials by weight: 35 to 45 % of periclase, 25 to 35 % of magnesite clinker, 13 to 24 % of pure calcium aluminate cement, 6 to 8 % of monox ultrafine powder and 3 to 4 % of aluminium oxide micro powder. The gunning mix disclosed by the invention has the advantages that after the repair of a magnesia-alumina spinel brick of the RH stove, the maintenance period is reduced from the original about 5 times per month to about 2 times per month caused by the cracking or the falling off of the magnesia-alumina spinel brick, and the maintenance cost is reduced; the average service life of the magnesia-alumina spinel brick is prolonged from the original 65 stove times on average to 98 stove times on average after the repairing of the magnesia-alumina spinel brick by the conventional spray-repairing method.

Owner:宝武环科南京资源利用有限公司

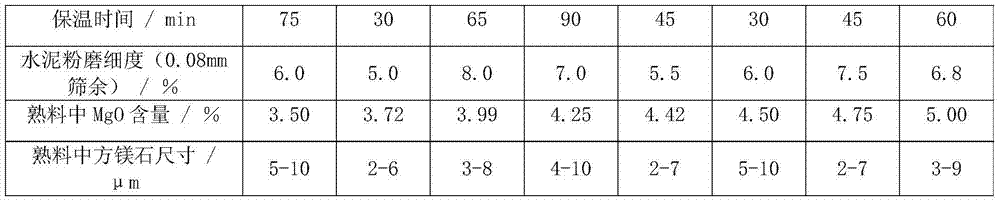

High-magnesium micro-expansive moderate heat Portland cement for water-power engineering and preparation method thereof

ActiveCN103693873ACompensation for temperature drop shrinkageControl of periclase contentHigh magnesiumPortland cement

The invention discloses a high-magnesium micro-expansive moderate heat Portland cement for water-power engineering and a preparation method thereof. Through control on the grinding fineness of raw materials, sintering temperature of a cement clinker, insulation time, cooling system and cement grinding fineness, reasonable control of expansion effect time and expansion size of periclase in the cement clinker is realized, so that the content of MgO is 3.5%-5%, and periclase size is 2-10 mum. Experiments show that the high-magnesium micro-expansive moderate heat Portland cement for water-power engineering has late expansion mainly occurred 28 days after hydration of the cement and has expansion enhancement in 28-180 days of 0.011%-0.020%, and the expansion time basically fits the late temperature drop stage of large-volume concrete in the water-power engineering, so as to effectively compensate for the late thermal shrinkage of concrete in the water-power engineering.

Owner:CHINA BUILDING MATERIALS ACAD

Method for preparing periclase-silicon carbide-carbon composite powder through in-situ reaction

The invention relates to a method for preparing periclase-silicon carbide-carbon composite powder through in-situ reaction. The method comprises the following steps of: stirring and mixing 40 to 80 weight percent of periclase powder, 5 to 25 weight percent of monatomic silicon powder, 10 to 30 weight percent of graphite and 1 to 10 weight percent of phenolic resin, performing compression moulding, and naturally drying for 24 hours; performing heat treatment at the temperature of between 110 and 300DEG C for 8 to 24 hours, keeping temperature of between 1,000 and 1,700DEG C for 1 to 12 hours in the reducing atmosphere, and naturally cooling; and crushing into powder of which the granularity is less than 10 mu m. The preparation process is simple, and magnesite raw materials are rich; and the prepared periclase-silicon carbide-carbon composite powder has high melt erosion resistance, permeability and thermal shock resistance, can improve the service performance of high temperature materials and has long service life.

Owner:WUHAN UNIV OF SCI & TECH

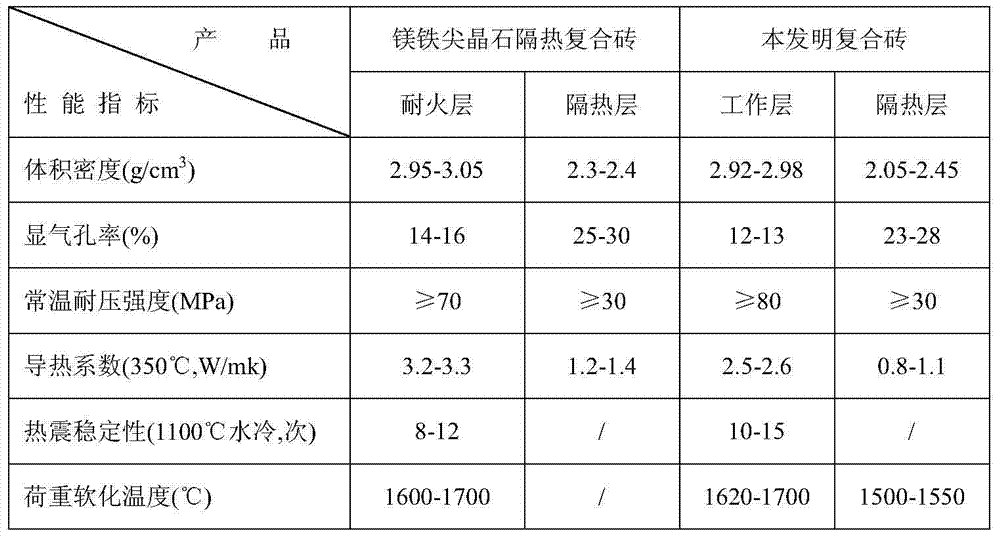

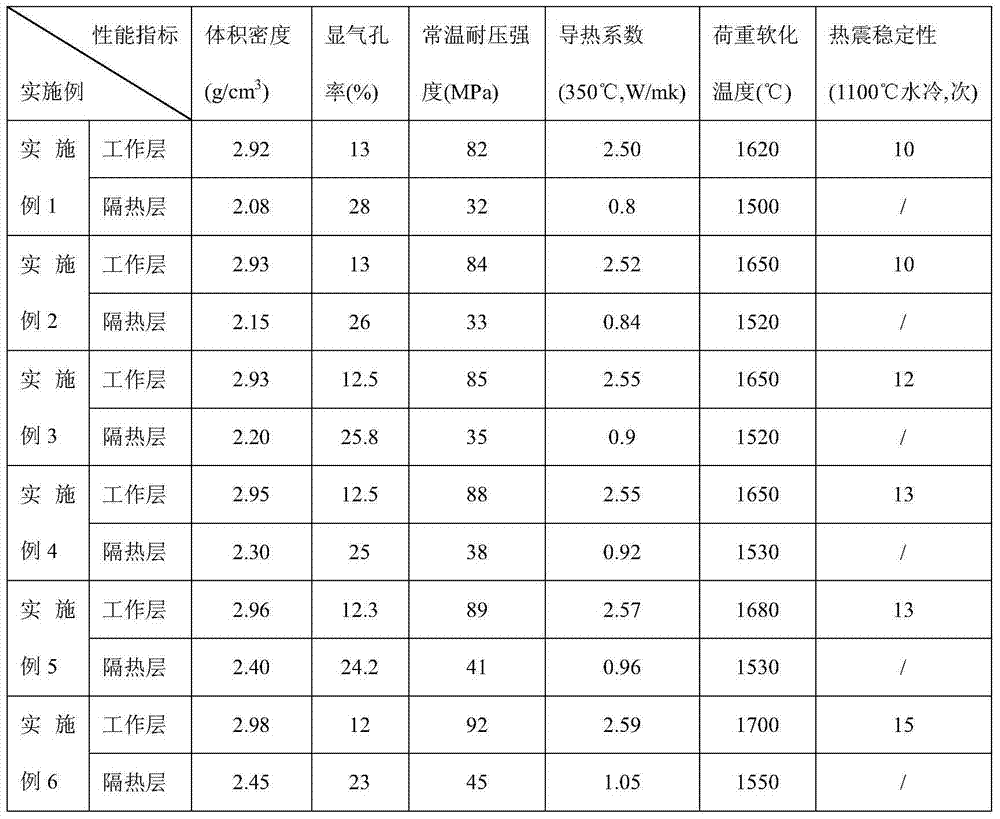

Periclase-pleonaste and hercynite/forsterite composite brick

The invention discloses a periclase-pleonaste and hercynite / forsterite composite brick prepared by compounding a working layer and a heat insulation layer, wherein the working layer is prepared from magnesium-iron sand, hercynite sand and fused magnesite which serve as main raw materials; the heat insulation layer is prepared from medium-heavy synthetic olivine sand, medium-light synthetic boltonite sand, magnesite particles, fine magnesia powder and rice hull ash which serve as main raw materials; and the periclase-pleonaste and hercynite / forsterite composite brick is prepared through the steps of proportioning; mixing; molding; drying; sintering and the like. The working layer of the composite brick disclosed by the invention is strong in erosion resistance, good in thermal shock resistance and low in heat conductivity coefficient and is easily adhered to a kiln coating; the heat insulation layer is favorable in high-temperature volume stability, relatively high in mechanical strength and relatively low in heat conductivity coefficient. Therefore, the composite brick can be used for a high-temperature zone of a rotary cement kiln and is long in service life and capable of remarkably reducing the heat loss of a kiln body and has favorable energy-saving and emission reduction effects.

Owner:河南瑞泰耐火材料科技有限公司

Nano-aperture porous periclase-magnesium aluminate spinel ceramic material and preparation method thereof

The invention relates to a nano-aperture porous periclase-magnesium aluminate spinel ceramic material and a preparation method thereof. The preparation method comprises the steps of sequentially heating magnesite fine powder to 680 to 850 DEG C and 950 to 1250 DEG C, keeping warm, and obtaining magnesium oxide powder with high porosity; putting 70 to 98 weight percent of magnesium oxide powder with high porosity into a vacuum mixer, adding 0.1 to 25 weight percent of solution containing Al<3+> and 0.1 to 10 weight percent of aluminium hydroxide micro powder under 2.0kPa, and stirring to obtain a mixture; keeping warm of the mixture at 110 to 220 DEG C, cooling, mechanical pressing, and drying; then keeping warm at 950 to 1250 DEG C and 1480 to 1620 DEG C respectively, and obtaining the nano-aperture porous periclase-magnesium aluminate spinel ceramic material. The preparation method provided by the invention is low in preparation cost and environmentally-friendly, and the prepared product has a nanoscale pore size, and has the advantages of low air permeability, small volume density, low heat conduction coefficient, and high strength.

Owner:WUHAN UNIV OF SCI & TECH

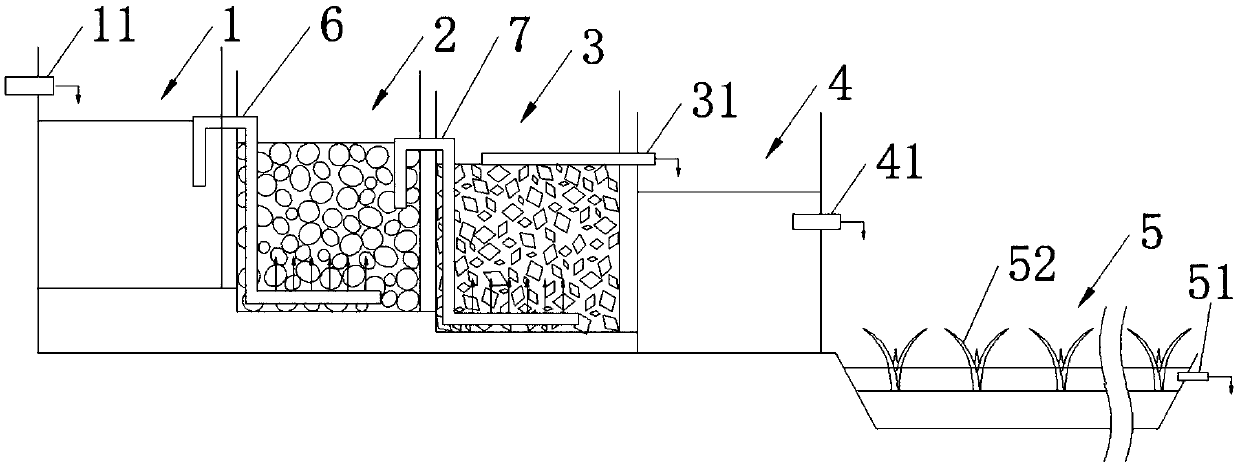

Mine acidic wastewater ecological treatment system and treatment method

PendingCN109607971ASmall footprintEasy to useWater contaminantsMultistage water/sewage treatmentVegetationClass iii

The invention relates to the field of wastewater treatment and discloses a mine acidic wastewater ecological treatment system and treatment method. The system comprises a reservoir, limestone tank, periclase tank, sedimentation tank and aerobic wetland which are sequentially communicated; the limestone tank is filled with a mixture of limestone particles and wood shavings; the periclase tank is filled with periclase particles; and the aerobic wetland is a wetland planted with vegetation. The system has the advantages of low use and maintenance cost and good treatment effect. According to the treatment method, mine acidic wastewater sequentially passes through the reservoir, limestone tank for 90 minutes, periclase tank for 60 minutes, sedimentation tank for 120 minutes and aerobic wetlandof the treatment system. The method has stable process and convenient control, and the treated wastewater reaches the class III standard of surface water.

Owner:HUNAN AGRICULTURAL UNIV

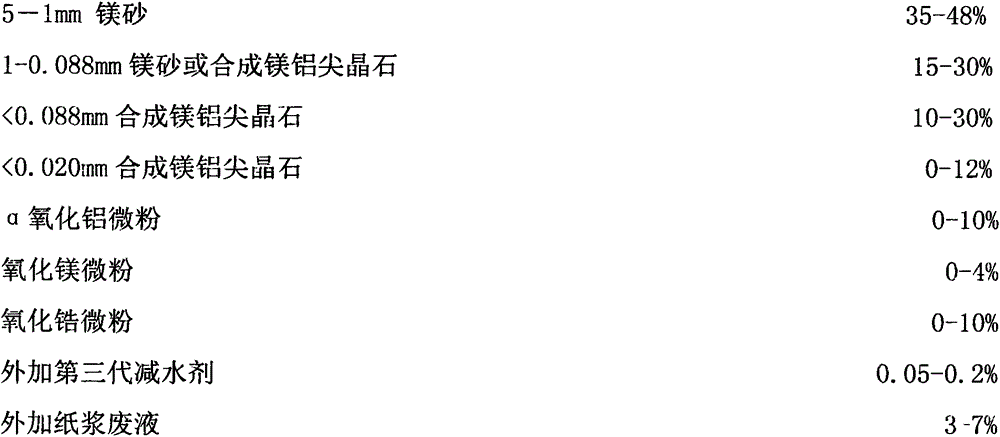

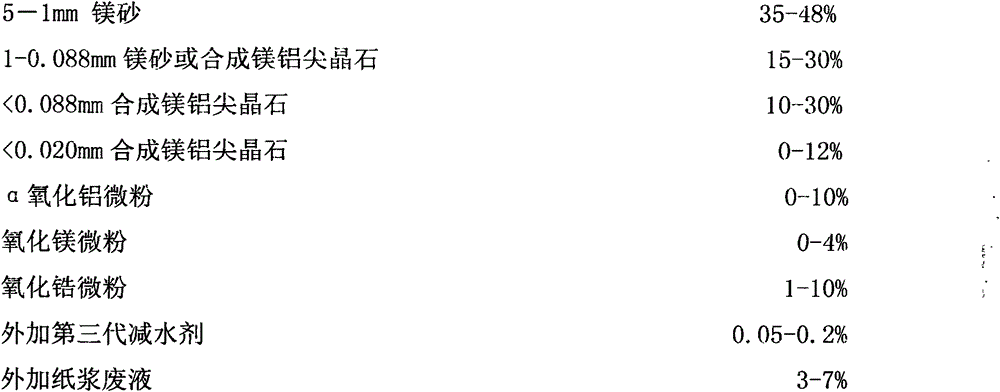

Low-porosity periclase-magnesium aluminate spinel-zirconia sintered composite refractory material and production process thereof

The invention provides a low-porosity periclase-magnesium aluminate spinel-zirconia sintered composite refractory material, which is prepared from the following materials: 35-48% of 5-1mm magnesia, 15-30% of 1-0.088mm magnesia or synthetic magnesium aluminate spinel, 10-30% of less than 0.088mm synthetic magnesium aluminate spinel, 0-12% of less than 0.020mm synthetic magnesium aluminate spinel, 0-10% of G alumina micro powder, 0-4% of magnesium oxide micro-powder, 1-10% of zirconium oxide micro-powder, 0.05-0.2% of external third generation water reducing agent and 3-7% of external sulfite lye. During production, the magnesia is taken as an aggregate, and the composite magnesium aluminate spinel-zirconium oxide is taken as a base material; in the base material, the synthetic magnesium aluminate spinel is taken as coarse particles, while in-situ spinel-zirconium oxide is taken as fine particles; a brick-making material is dispersed in an efficient dispersant and then formed into compact green bricks under high pressure; then the compact green bricks are sintered at high temperature to form the refractory material with a compact structure; according to the proportions of the raw materials, all the raw materials are weighed, blended, mixed, molded and dried, and then sintered in the temperature range from 1650 to 1800 DEG C for 5-10 hours, and finally, the refractory materials is obtained. The refractory material has extremely low apparent porosity, and excellent high-temperature resistance, thermal shock resistance and erosion resistance; therefore, the refractory material is applicable for the grid of the heat accumulating chamber of a glass kiln as an erosion-resistant refractory material.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com