Patents

Literature

46results about How to "Improve medium temperature strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

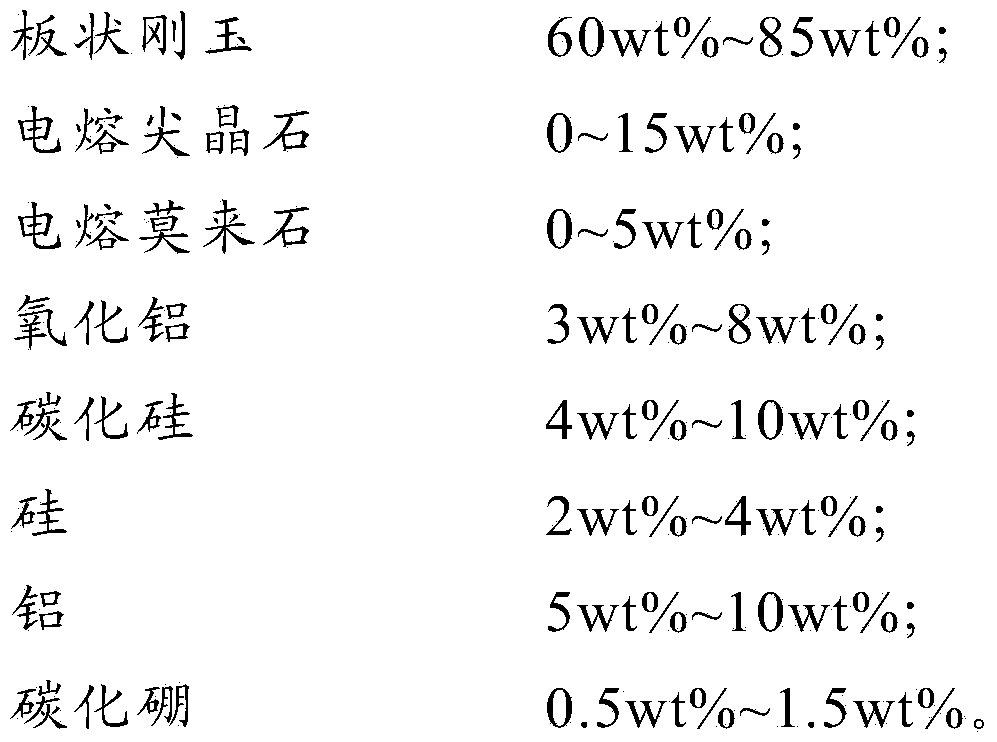

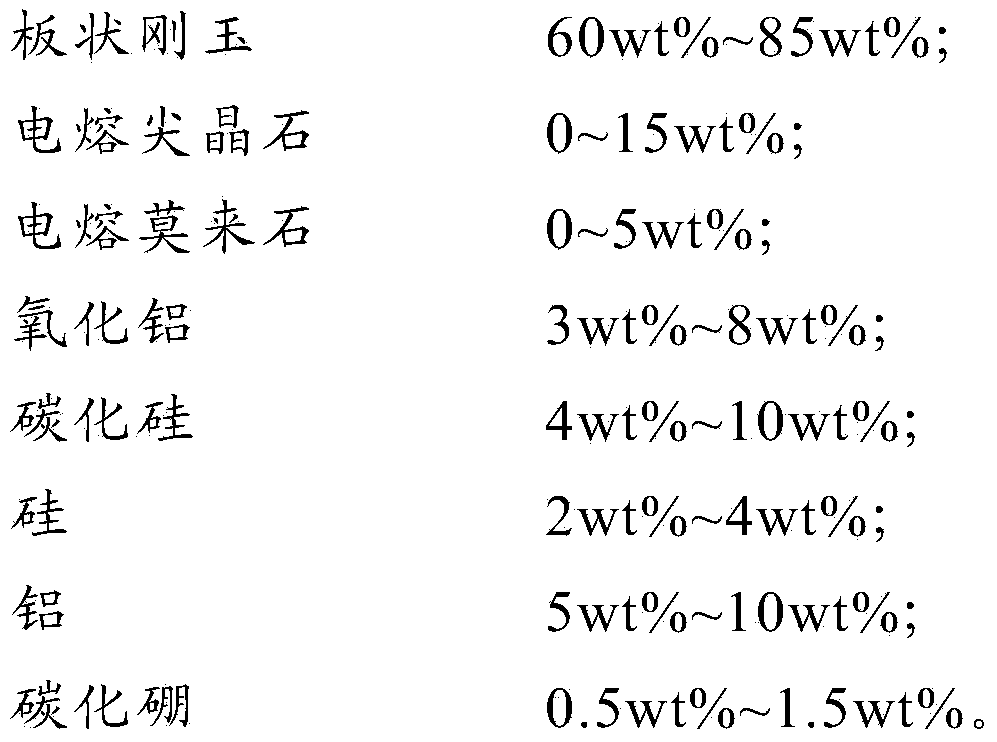

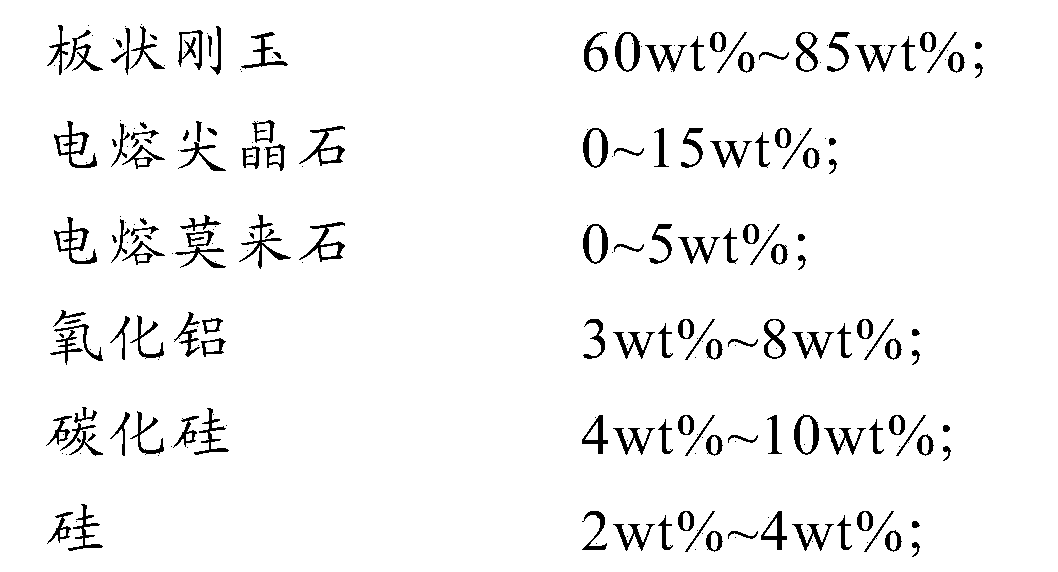

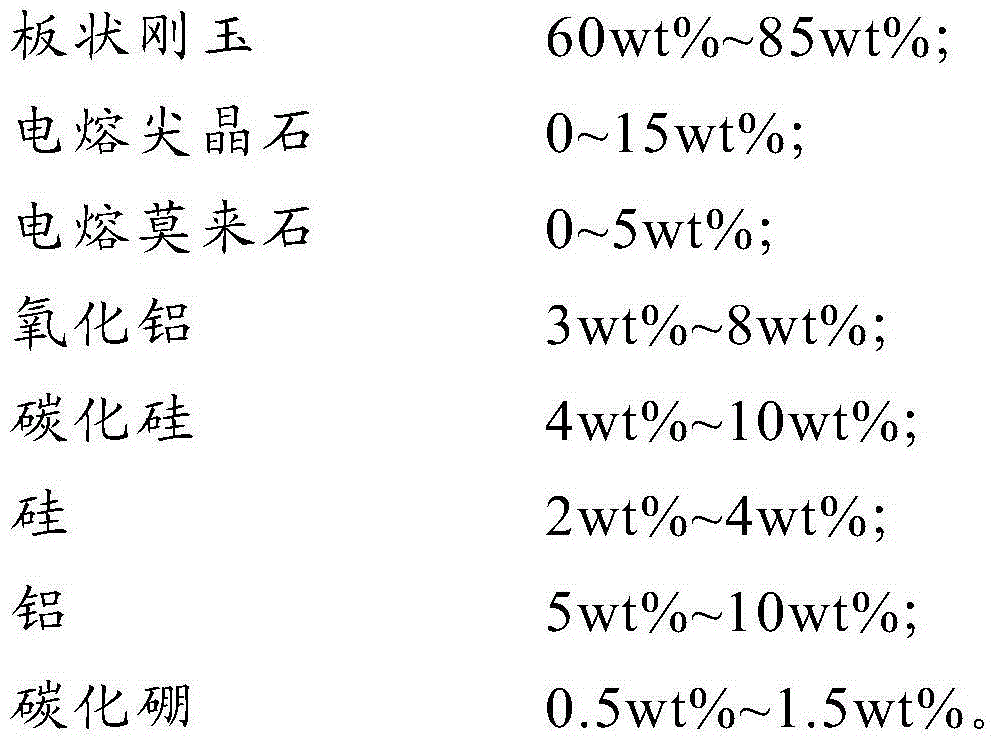

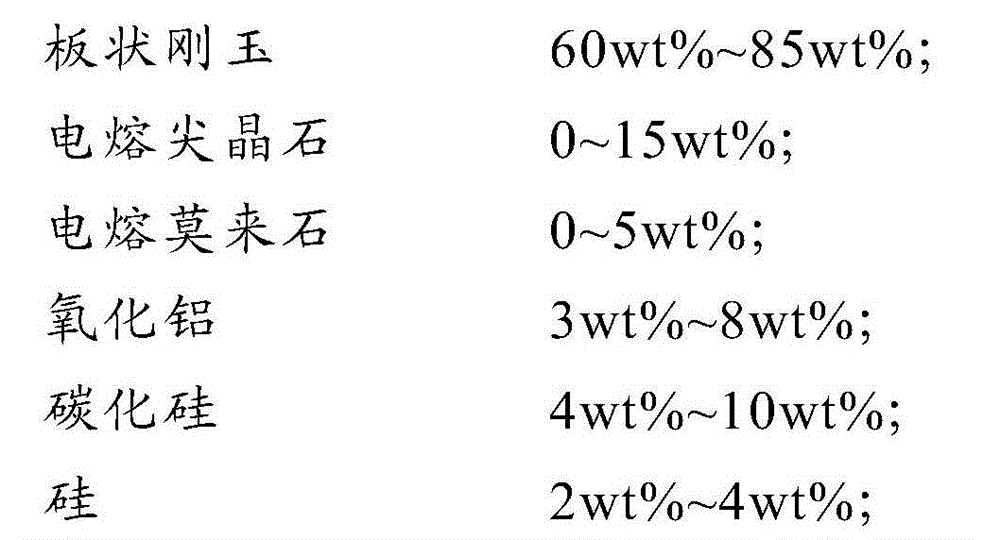

Sliding brick and preparation method thereof

The invention provides a sliding brick and a preparation method thereof. The sliding brick is prepared from a mixture through molding and sintering, wherein the mixture comprises plate-shaped corundum, fused spinel, fused mullite, alumina, silicon carbide, silicon, aluminum and boron carbide. According to the invention, plasticity of both aluminum and silicon is combined together, which is favorable for improvement of density and strength of the sliding brick; meanwhile main materials like plate-shaped corundum are used, so the sliding brick has good high temperature performance, erosion resistance and thermal shock resistance. In the process of preparation of the sliding brick, light roasting or high temperature sintering is employed, so the prepared sliding brick has high hot strength and erosion resistance and good cold strength, anti-scouring performance and oxidation resistance.

Owner:HUNAN XIANGGANG RUITAI TECH

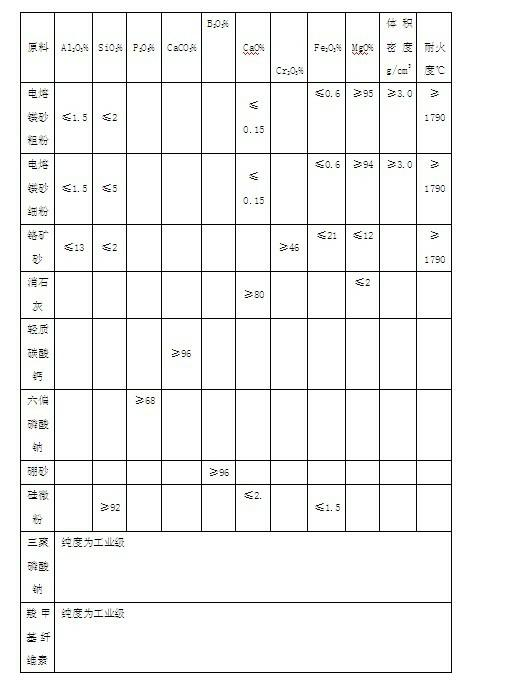

Novel RH gunning refractory

ActiveCN102659432AHigh bonding strengthGood high temperature performanceEnvironmental indexRefractory

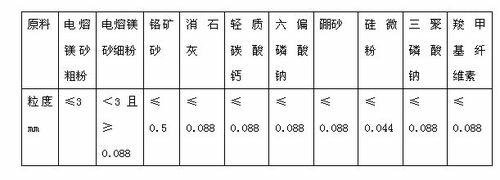

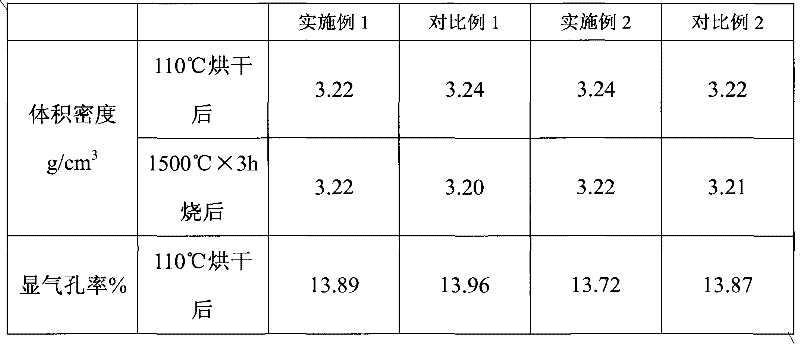

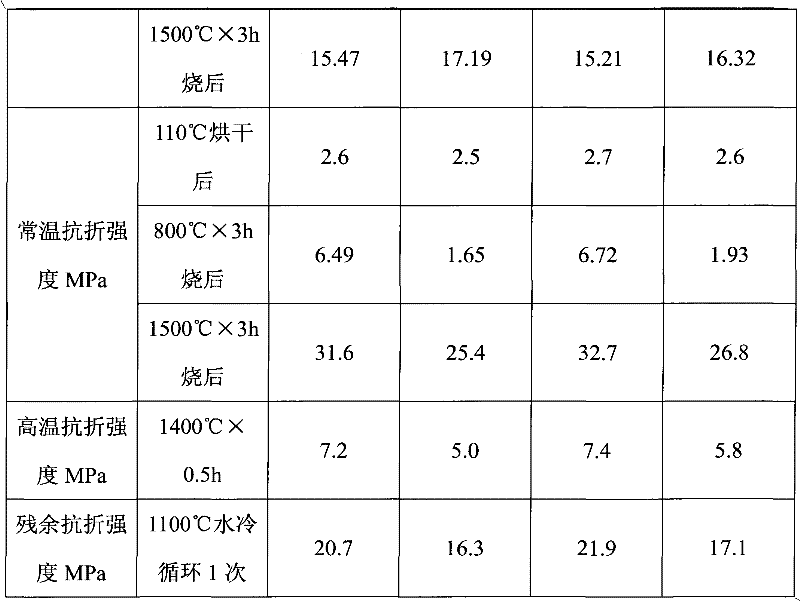

The invention relates to a novel RH gunning refractory belonging to the refractory material field. The gunning refractory comprises the following raw materials in weight percent: 50-60% of fused magnesite crude powder, 15-30% of fused magnesite fine powder, 10-255% of chrome ore, 0.5-2% of slaked lime, 1-5% of light calcium carbonate, 1-4% of sodium hexametaphosphate, 2-55% of borax, 2-4% of silica powder, 0.5-4% of sodium tripolyphosphate and 0.005-0.1% of carboxymethylcellulose; and the raw materials are evenly mixed in a stirring device to obtain a finished product. The RH gunning refractory prepared from the raw materials provided by the invention is low in production cost, resistant to erosion and good in impermeability; an RH insert tube after being subjected to gunning maintainmentcan be used more than 85 times and the RH insert tube can be used for 5-6 furnaces after every time of gunning maintainment; the service life of the RH insert tube is obviously prolonged and the production efficiency is greatly improved; and in the use process, no harmless gas gives out, no peculiar smell is produced and no thick smoke is generated; and therefore the novel RH gunning refractory completely meets specified environmental indexes and utilization requirements..

Owner:攀枝花市银江金勇工贸有限责任公司

Non-cement light alumina magnesia cast material and its prepn process

InactiveCN101066855AImprove medium temperature strengthImprove corrosion resistanceCeramic shaping apparatusRefractorySpinel

The present invention relates to one kind of no-cement light alumina-magnesia cast material and its preparation process. The technological scheme is that the alumina-magnesia cast material is prepared with porous alumina-magnesia ceramic grain in 40-70 wt% and compact alumina-magnesia grain in 0-20 wt% as aggregate, and fine alumina-magnesia powder in 5-50 wt%, fine silica powder in 1-10 wt% and fine active alpha-alumina powder in 1-8 wt% as matrix, and through adding water in the quantity of 8-20 wt % and water reducing agent in 0-3 wt% , stirring, vibrating to form and drying at 110 deg.c for 8-48 hr. The alumina-magnesia cast material has MgO and Al2O3 as main chemical components, and main crystal phases of periclase, spinel and corundum. It may be contacted directly with refractory magnesia material and refractory spinel material at high temperature, and has the features of high porosity, small average pore size, high strength, etc.

Owner:WUHAN UNIV OF SCI & TECH

Method for controlling medium-temperature strength of gel-cast ceramic parts

The invention discloses a method for controlling the medium-temperature strength of gel-cast ceramic parts. The method comprises the steps of firstly, adding organic monomers, a cross-linking agent and a dispersant sodium polyacrylate into diluted silica sol, so as to obtain a premix, then, adding polysiloxane, ceramic powder and polyimide, and carrying out ball milling, so as to obtain ceramic slurry, carrying out in-situ curing, then, carrying out freeze drying, and carrying out degreased pre-sintering, impregnation aftertreatment and final-sintering, thereby obtaining the ceramic parts. According to the method, polyimide has adhesion property due to the high-temperature resistance of polyimide, a reticular structure is formed due to the low-temperature cross-linking of polysiloxane, a role in adhering ceramic granules is played, after freeze drying, silica sol is dehydrated, so as to form a silicon-oxygen bond three-dimensional reticular structure, and the medium-temperature strength of ceramic blanks at a degreasing stage can be remarkably improved due to the synergism of polyimide, polysiloxane and silica sol; the method can be applied to the preparation of the gel-cast ceramic parts, and the medium-temperature strength of the ceramic blanks at the degreasing stage is effectively controlled, so that the integrity of the ceramic parts can be guaranteed.

Owner:XI AN JIAOTONG UNIV

Preparation method for special casting material of ferronickel rotary kiln discharge opening

InactiveCN104150926AImprove corrosion resistanceImprove thermal shock resistanceConventional castingZirconate

The invention discloses a preparation method for a special casting material of a ferronickel rotary kiln discharge opening. The special casting material is prepared from the following materials in percentage: 40-80% of material bauxite or / and adamantine spar aggregate, 5-20% of electric smelting mullite or / and adamantine spar fine powder, 3-10% of alumina micro powder, 3-10% of silicone micro powder, 1-8% of pure calcium aluminate cement and 3-30% of calcium zirconate or / and zirconite. The preparation method has the advantages that corrosion resistance, thermal shock resistance and performance in moderate-temperature intensity can be improved greatly; utilization requirements of the ferronickel rotary kiln discharge opening are met. Compared with the conventional casting materials used by cement kiln discharge openings, the service life of the casting material can be prolonged by three months.

Owner:ZHENGZHOU DONGFANG CERAMIC ENG

A kind of corundum refractory castable

The invention discloses a corundum refractory castable. The raw materials used include a main material and an added organic dispersant. The main material is composed of corundum particles and fine powder, nano zinc oxide, aluminum oxide powder, and a binder. The weight percent of the raw materials is: 80-95wt% of corundum particles and fine powder, 3-15wt% of alumina micropowder, 1-5wt% of binder, 0.2-5wt% of nano-zinc oxide, and the added organic dispersant is the weight of the main material. 0.05-0.3 wt%. The present invention utilizes the characteristics of fine particle size of nano-zinc oxide powder, high activity at high temperature, moderate price and the like to improve the structure of the corundum castable, increase the medium-temperature strength, and prepare a corundum castable with excellent comprehensive performance and moderate price.

Owner:浙江亿维高温材料有限公司

Amorphous periclase-silicon carbide composite fireproof materials and method for preparing same

The present invention relates to one kind of amorphous periclase-SiC refractory material and it production process. The technological scheme includes mixing fused magnesia or sintered magnesia in 50-90 wt%, silicon carbide in 10-50 wt% and fine silica powder in 3-8 wt%; adding water in 4-8 wt% and water reducing agent in 0.1-3 wt% during construction; and forming through stirring, vibration depositing, and roasting at 100-300 deg.c for 2-24 hr. The produced amorphous composite refractory material has high smelting point, high heat conductivity, and especially self-protecting oxidation characteristic, which is that the oxidized SiC forms one layer of protecting silica film to protect the inside from being further oxidized. The present invention substitutes SiC for graphite to raise the antioxidant performance of the material greatly and using fine silica powder as binding agent makes the material possess raised medium temperature strength.

Owner:WUHAN UNIV OF SCI & TECH

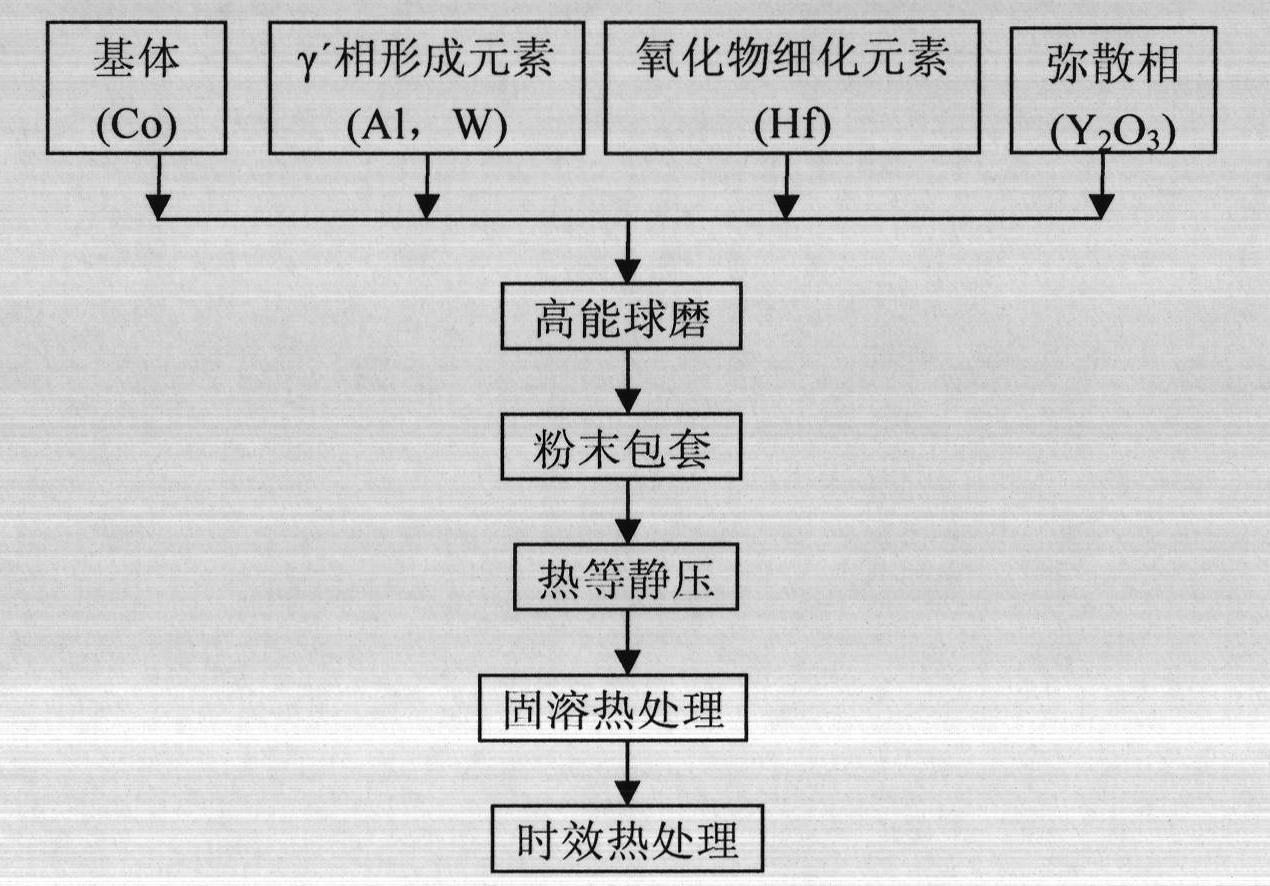

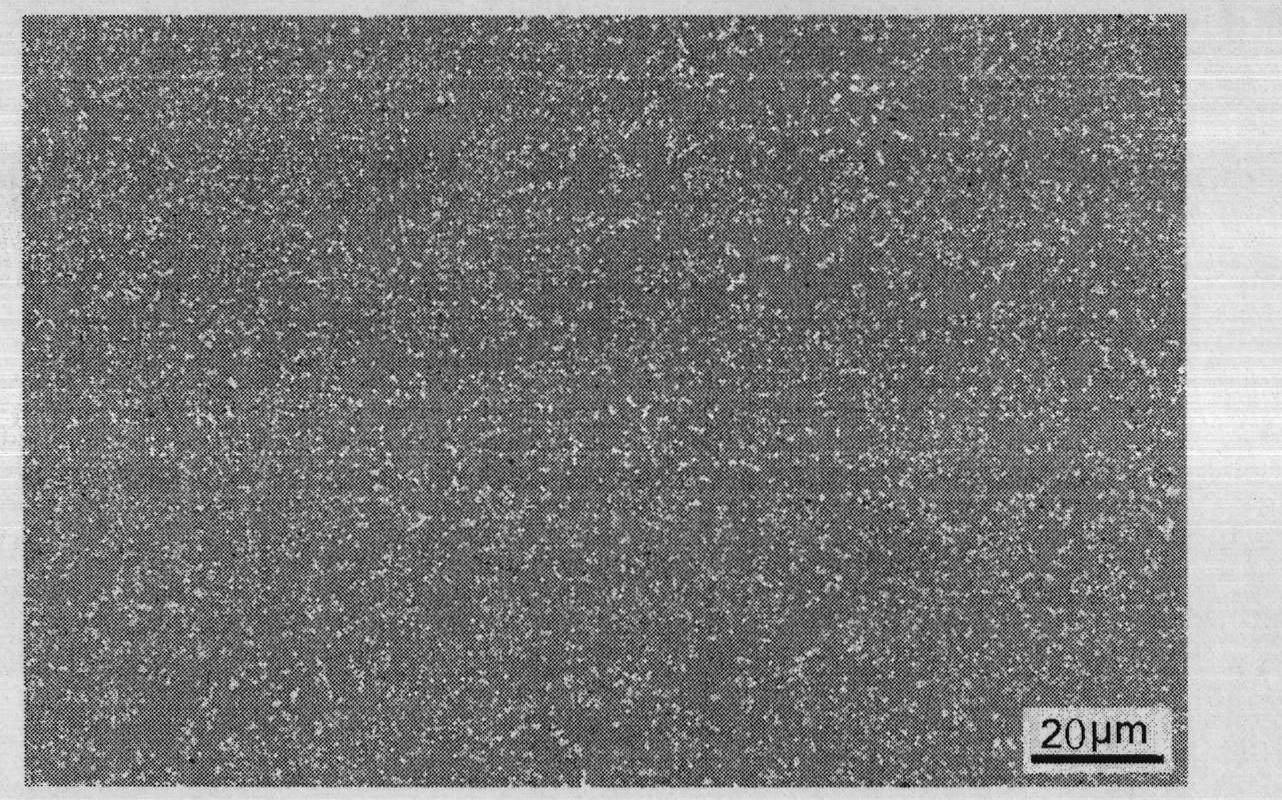

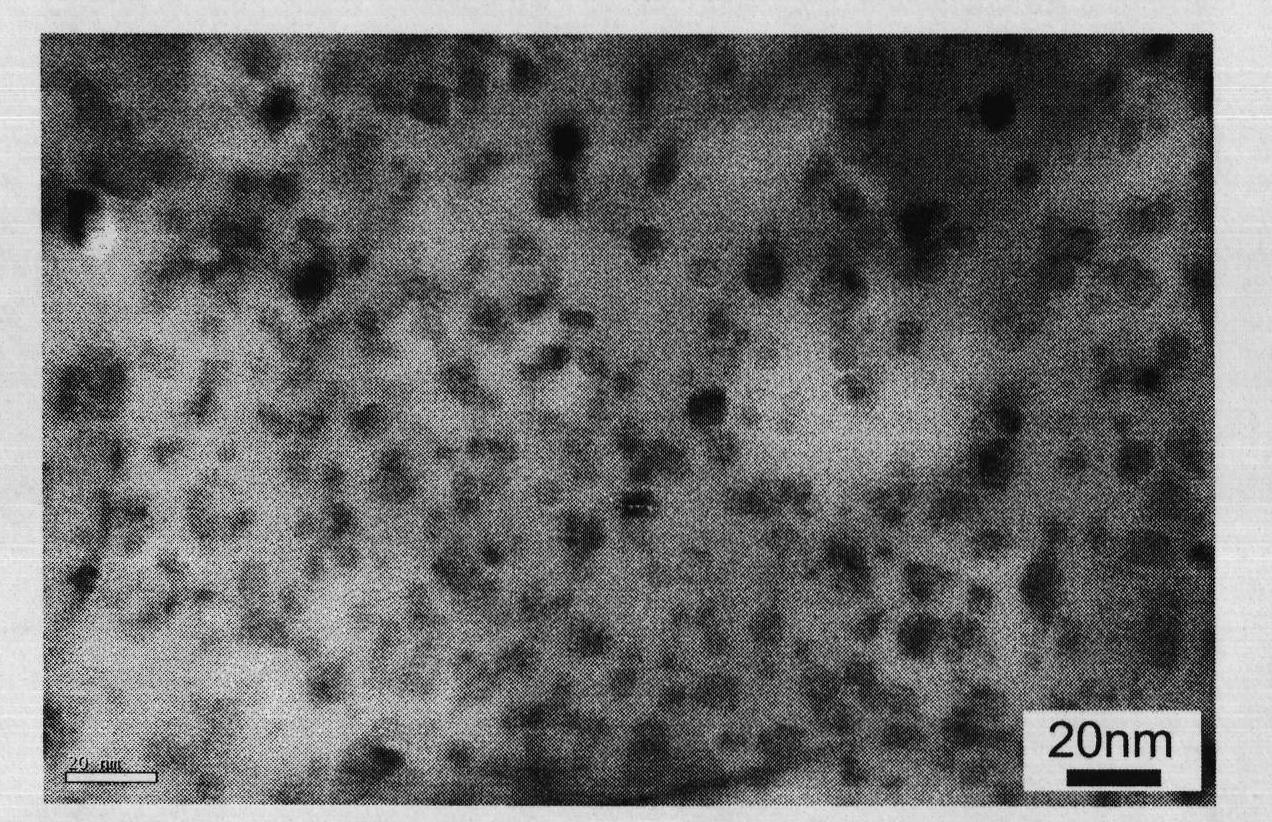

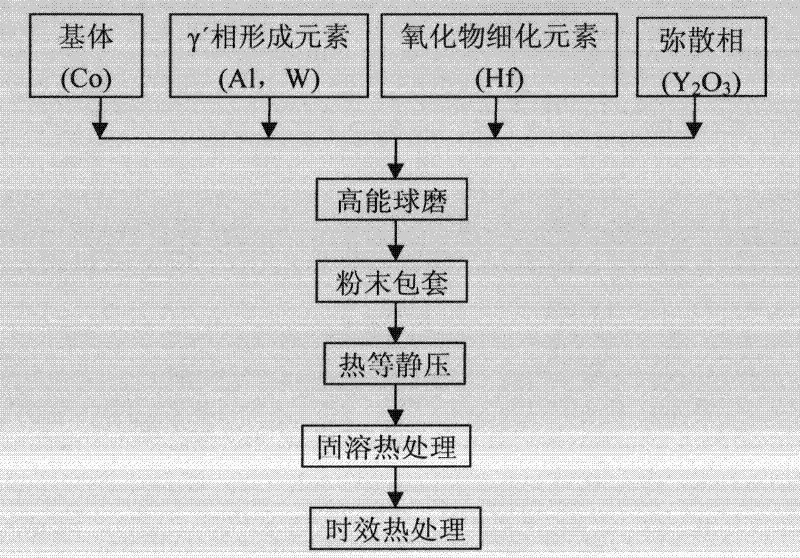

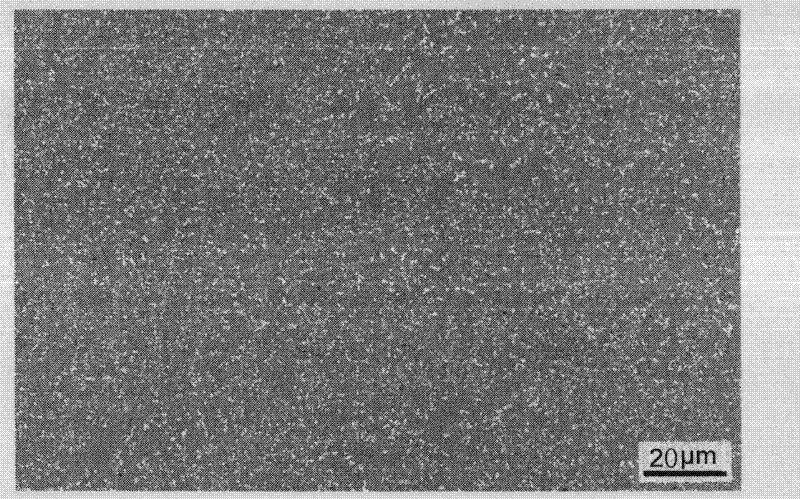

Method for preparing oxide dispersion strengthened cobalt-based super alloy

The invention discloses a method for preparing oxide dispersion strengthened cobalt-based super alloy, and belongs to the field of metal-based composite materials. The preparation method comprises the following steps of: pre-mixing Co powder, gamma-phase forming elements (Al and W), oxide thinning element (Hf) and oxide dispersion phase (Y2O3) with grain diameter of 30 to 30 nanometers uniformly, then uniformly dispersing Y2O3 granules into the Co matrix by high-energy ball milling in a high-purity protective atmosphere, and wrapping the high-energy ball milled alloy powder by using a low-carbon steel ladle and performing hot isostatic pressing at the temperature of between 900 and 1,300 DEG C; and performing solid solution heat treatment (1,000 to 1,300 DEG C) and aging heat treatment (600 to 900 DEG C) on a sample after the hot isostatic pressing to obtain a final nano phase strengthened composite material. The method has the main advantage of solving the problem that the improvement on high-temperature strength is greatly limited because carbide in the traditional cobalt-based alloy is easily roughened or dissolved at a high temperature by simultaneously introducing oxide dispersion strengthening and gamma-phase strengthening into the cobalt-based alloy for the first time.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum-magnesium-zirconium brick for RH impregnating pipe and circulating pipe and preparation method thereof

The invention relates to an aluminum-magnesium-zirconium brick for an RH impregnating pipe and a circulating pipe and a preparation method thereof, and the aluminum-magnesium-zirconium brick is used for an inner pipe of the RH impregnating pipe and the circulating pipe. The aluminum-magnesium-zirconium brick is prepared from the following raw materials in percentage by weight: 25-45% of corundum particles, 15-35% of fused magnesia particles, 15% of corundum fine powder, 10% of alpha-alumina micropowder, 4.85% of zirconia fine powder, 5% of fused magnesia fine powder, 1% of silicon dioxide micropowder, 4% of activated alumina, 0.1% of water reducing agent and 0.05% of dispersant. The aluminum-magnesium-zirconium brick has the advantages of high green strength, no need of sintering, good thermal shock stability and strong resistance to acidic and basic fused slag corrosion.

Owner:郑州市裕丰耐火材料有限公司

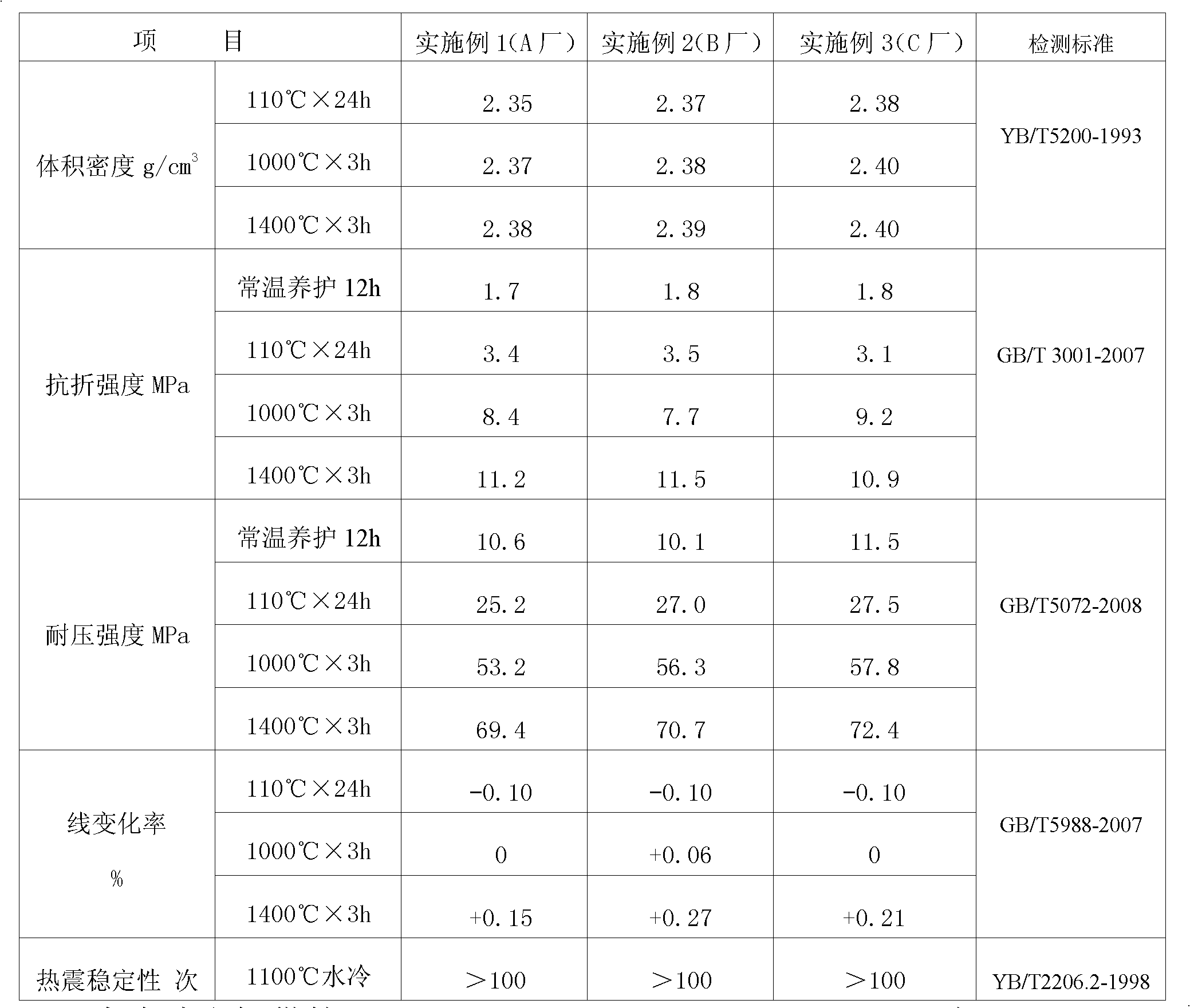

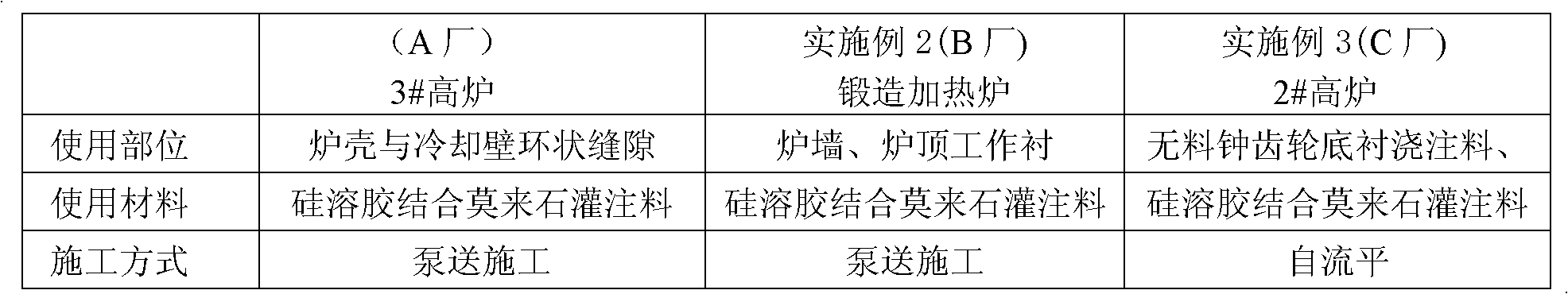

Silica sol-combined mullite perfusion material adapted to rapid repair of industrial furnace

The invention discloses a silica sol-combined mullite perfusion material adapted to rapid repair of an industrial furnace, which belongs to the refractory material technical field. The perfusion material comprises the following raw materials by weight: 50-60% of mullite granules, 10-20 % of mullite powder, 5-10% of white alundum powder, 4-15% of alpha-active alumina micro powder, 0.6-1.0% of magnesium oxide powder, 0.5-0.7% of dextrin, 10-16% of silica sol and 1-2% of dispersing alumina. The silica sol-combined mullite perfusion material is characterized in that the silica sol is individually packaged; other components are weighted according to ratio and mixed through mechanical stirring to uniform aggregates in a dry state; on construction site, the individually packaged silica sol and uniform aggregates in the dry state are weighted according to ratio, and uniformly mixed and stirred and pumped for construction. The perfusion material has the advantages of excellent physical and chemical property and good application property, pumping for construction can be used, manpower and material resources can be saved, rapid repair requirement for various industrial furnaces can be satisfied, and the perfusion material is the excellent repair refractory material with strong adaptability.

Owner:中冶武汉冶金建筑研究院有限公司

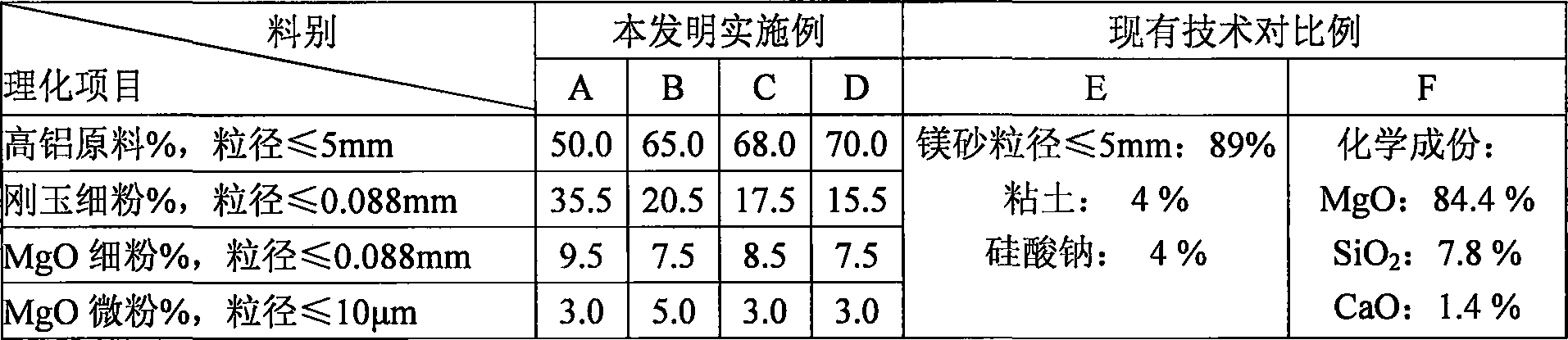

Painting and repairing material in use for wall of casting ladle

A coating material for repairing the wall of pouring ladle is composed of high-Al particles, fine corundum powder, fine powder of magnesium oxide, micro powder of magnesium oxide, micro Si powder, organic fibers and water-reducing agent (sodium or calcium lignosulfonate or carboxymethyl cellulose) proportionally.

Owner:BAOSHAN IRON & STEEL CO LTD

Aluminum silica sol composite combined aluminum silicon carbide castable and preparation method thereof

The invention discloses an aluminum silica sol composite combined aluminum silicon carbide castable and a preparation method thereof. The castable is prepared from the following raw materials in percentage by weight: 25-35% of 12-8mm bauxite aggregate, 10-15% of 8-3mm bauxite aggregate, 15-20% of 3-0mm bauxite aggregate, 15-25% of <88 mu m corundum fine powder or alumina fine powder, 5-12% of <88 mu m SiC fine powder, 1-5% of <5 mu m silicon micropowder and 5-10% of <5 mu m alpha-Al2O3 micropowder. An aluminum silica sol composite binder accounting for 10-15 wt% of all the raw materials is also added. The castable has the characteristics of high moderate-temperature strength, favorable thermal shock resistance and high corrosion resistance, can implement flash baking, and enhances the turnaround efficiency of the iron ladle; and since the service life is doubled, the castable can effectively save the consumption of the refractory material.

Owner:河南竹林耐材有限公司

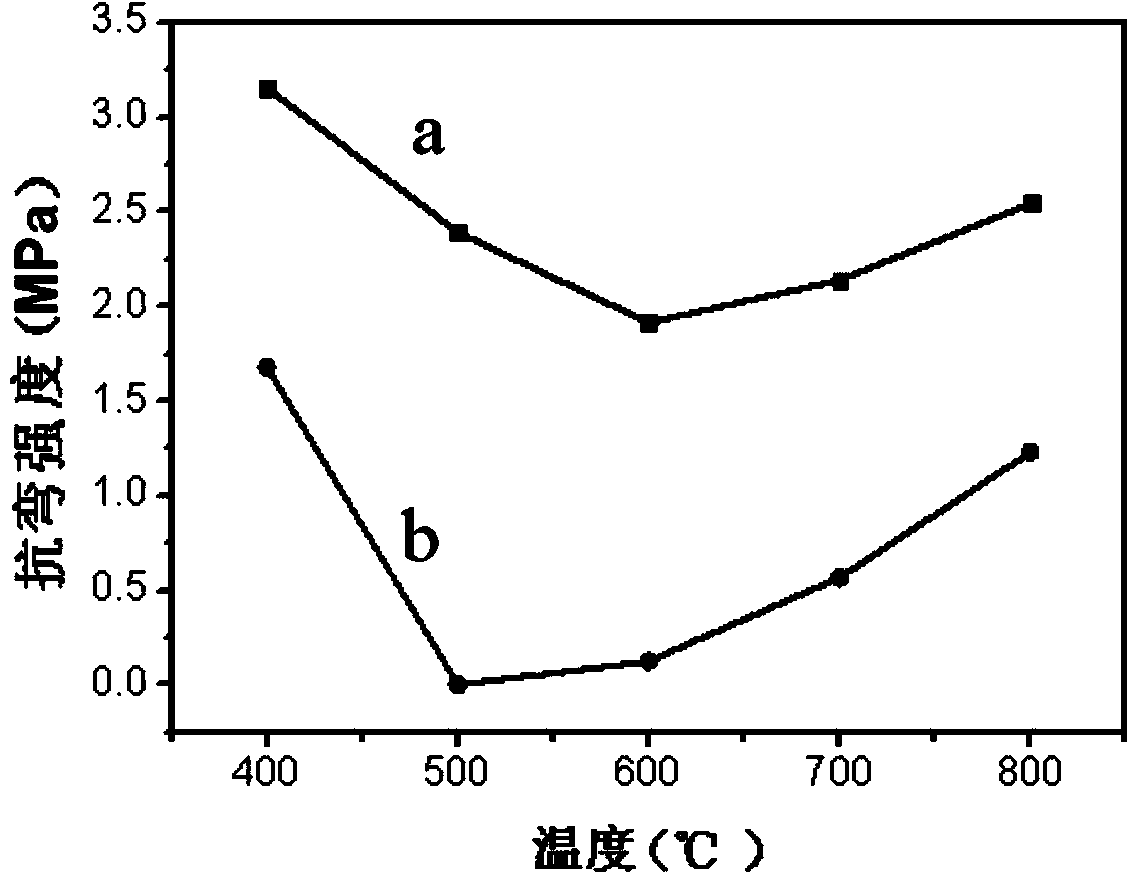

Periclase-silicon carbide composite materials and method for preparing same

The present invention relates to one kind of periclase-silicon carbide composite material and its preparation. The technological scheme includes mixing fused magnesia or sintered magnesia in 60-90 wt%, silicon carbide in 10-40 wt% binding agent in 3-8 wt%, hexamethine tetramine as curing agent in 0-1 wt% through stirring; pressing and forming the mixture; and stoving at 110-350 deg.c for 2-24 hr to prepare the composite material. The prepared composite material has high smelting point, high heat conductivity, and especially self-protecting oxidation characteristic, which is that the oxidized SiC forms one layer of protecting silica film to protect the inside from being further oxidized. The present invention substitutes SiC for graphite to raise the antioxidant performance of material greatly and the material has raised medium temperature strength, so that the material may be used as lining material for metallurgical furnace and container.

Owner:WUHAN UNIV OF SCI & TECH

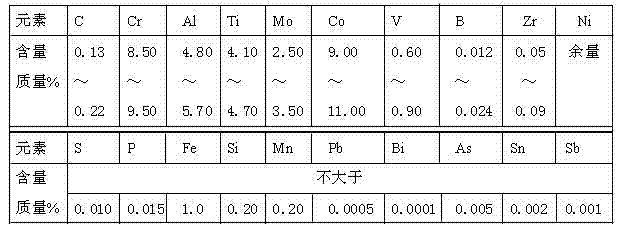

Metallic aluminium and non-silicone low-carbon alumina-zirconia-carbon slide plate for pouring high manganese steel and production method thereof

ActiveCN106699142AReduce C contentWeakened corrosion resistanceMelt-holding vesselsAdditive ingredientBoron carbide

The invention discloses a metallic aluminium and non-silicone low-carbonalumina-zirconia-carbon slide plate for pouring high manganese steel. The metallic aluminium and non-silicone low-carbon alumina-zirconia-carbon slide plate for pouring the high manganese steel is prepared from a main ingredient and an addition agent, wherein the main ingredient is prepared from the following raw materials in percentage by weight: 39 to 50 percent of dense electro-fused alumina, 6 to 10 percent of alpha-aluminum oxide micropowder, 25 to 35 percent of fused alumina zirconia, 4 to 8 percent of silicon carbide, 4 to 6 percent of metal aluminum powder, 2 to 6 percent of zirconium oxide powder, 1 to 3 percent of carbon black, and 0.5 to 1 percent of boron carbide; the addition agent is phenolic resin; the weight of the addition agent is 4 to 6 percent of the total weight of the main ingredient. A production method comprises the steps of weighing the raw materials according to the weight, and uniformly mixing to obtain a clay; extrusion forming, drying for 8 to 10h at the temperature ranging from 190 to 210 DEG C, hooping, grinding, and drying to obtain the slide plate. The product provided by the invention has no need to be subjected to sintering and oil immersing, is simplified in process and short in production cycle, cannot cause pollution to the environment, has excellent oxidation resistance and corrosion resistance, can meet the use requirement on continuous sliding for 3 to 4 times through a research and development experiment, and has a remarkable comprehensive benefit.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

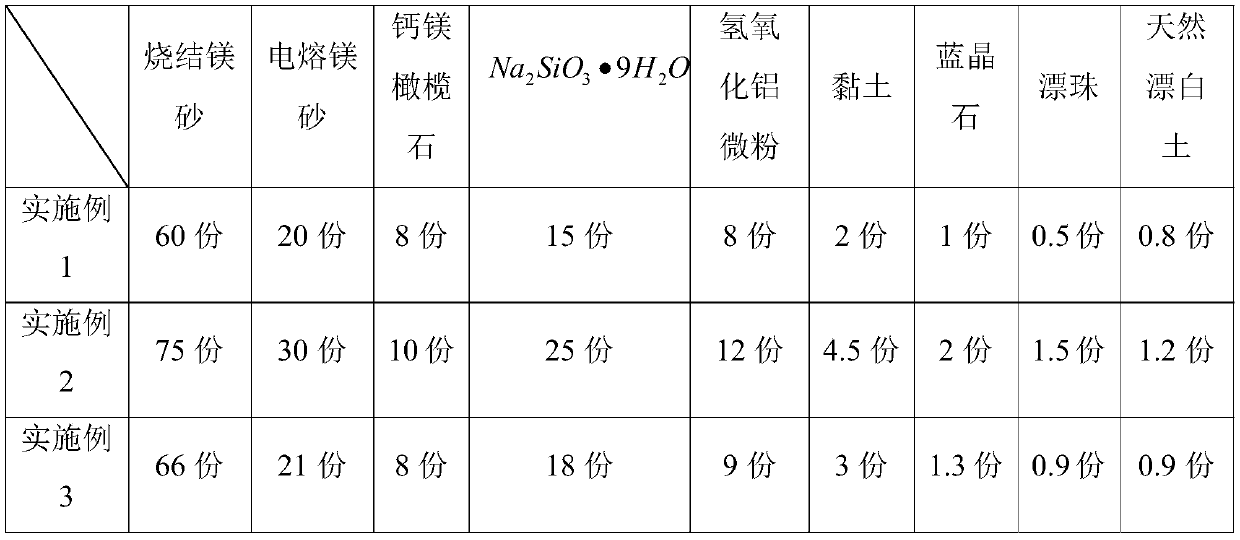

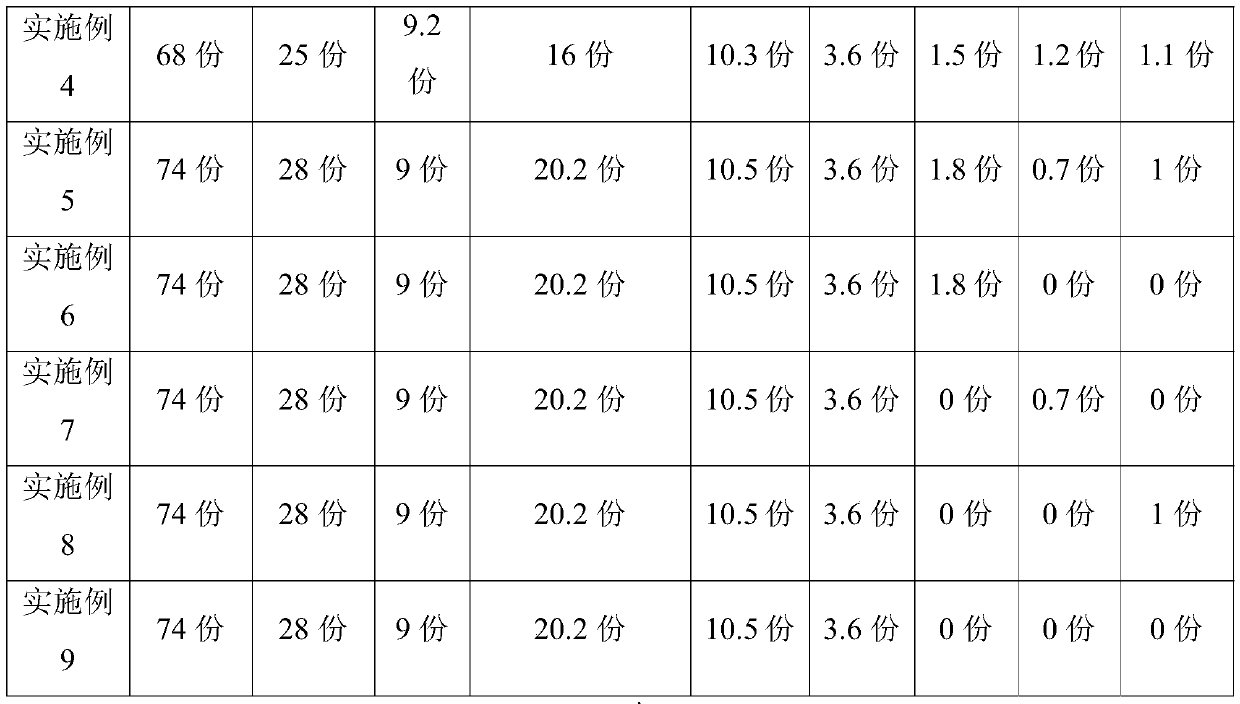

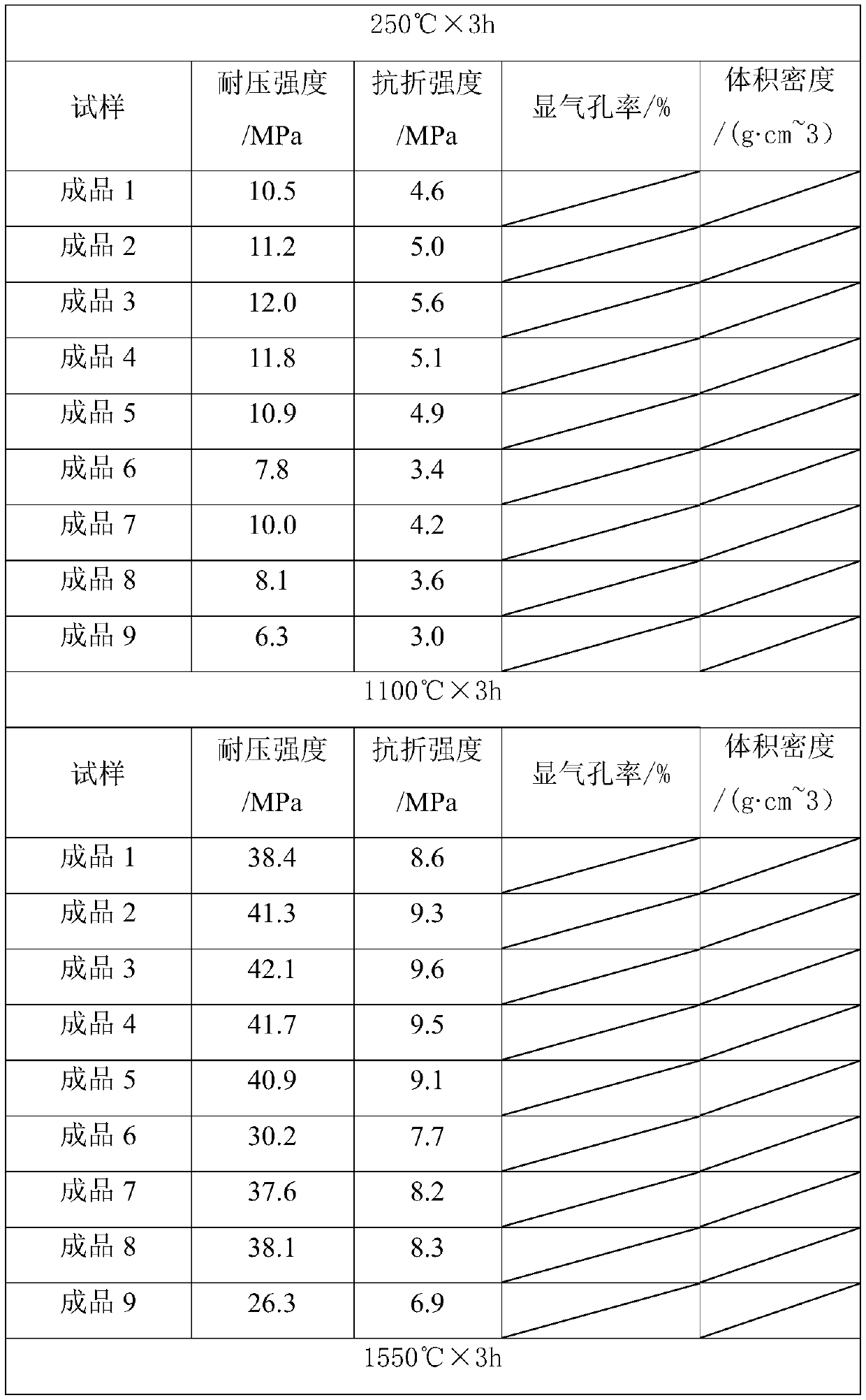

Environment-friendly magnesian dry material and preparation process thereof

An environment-friendly magnesian dry material comprises sintered magnesia, fused magnesia, calcium forsterite, a binding agent, aluminum hydroxide micro powder, a high-temperature sintering agent, anexpanding agent, floating beads and bentonite in a mass ratio of (60-75): (20-30): (8-10): (15-25): (8-12): (2-4.5): (1-2): (0.5-1.5): (0.8-1.2). According to the invention, the proportion of each component of the dry material is optimized; by adopting the environment-friendly binding agent, the problem that the binding agent is decomposed into toxic and harmful substances under a high-temperature condition can be effectively solved, the dry material is more energy-saving and environment-friendly, the hardness requirement of the dry material in the using process can be ensured on the premisethat the dry material has no pungent smell in the using process and is more beneficial to the production environment, and the scouring resistance of the dry material is ensured.

Owner:浙江欣辉耐火材料股份有限公司

Tundish magnesium calcium ladle cover casting materials and preparation method thereof

ActiveCN109095897AImprove medium temperature strengthImproved thermal shock stabilityThermal shockOxide

The invention relates to tundish magnesium calcium ladle cover casting materials. The tundish magnesium calcium ladle cover casting materials comprise the following components in percentage by weight:20-40wt% of magnesium sand granules, 20-40wt% of magnesium calcium sand granules, 5-15wt% of quick lime granules, 10-20wt% of a magnesium sand fine powder, 0.5-3wt% of an organic magnesium compound,1-6wt% of organic calcium, 2-6wt% of a thermoplastic micro powder, 2-8wt% of a magnesium oxide micro powder and 0.1-0.2wt% of a water reducing agent. The invention further relates to a method for preparing the tundish magnesium calcium ladle cover casting materials. According to the tundish magnesium calcium ladle cover casting materials and the preparation method thereof disclosed by the invention, the heat shock stability of fireproof materials is improved, besides, dissipation of heat quantity is effectively reduced, and favorable heat preservation properties and favorable thermal shock resistance of the materials are guaranteed; and when the tundish magnesium calcium ladle cover casting materials are applied to high-quality steel continuous casting tundishes, the temperature of a housing of a tundish ladle cover can be reduced by 10% or above averagely, and the average service life reaches 15 times or above.

Owner:阳泉市庚光高温材料有限公司

Green and environment-friendly magnesia spinel gunning mix for converter as well as preparation and application of green and environment-friendly magnesia spinel gunning mix

PendingCN113666734ASuitable for gunning maintenanceImprove adhesionManufacturing convertersProcess efficiency improvementSteelmakingMetallurgy

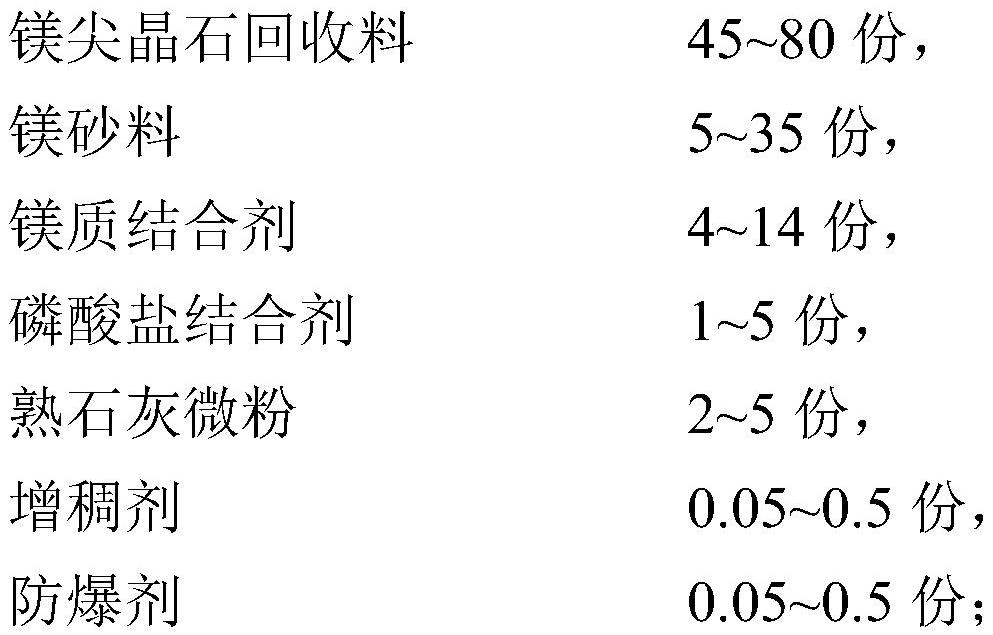

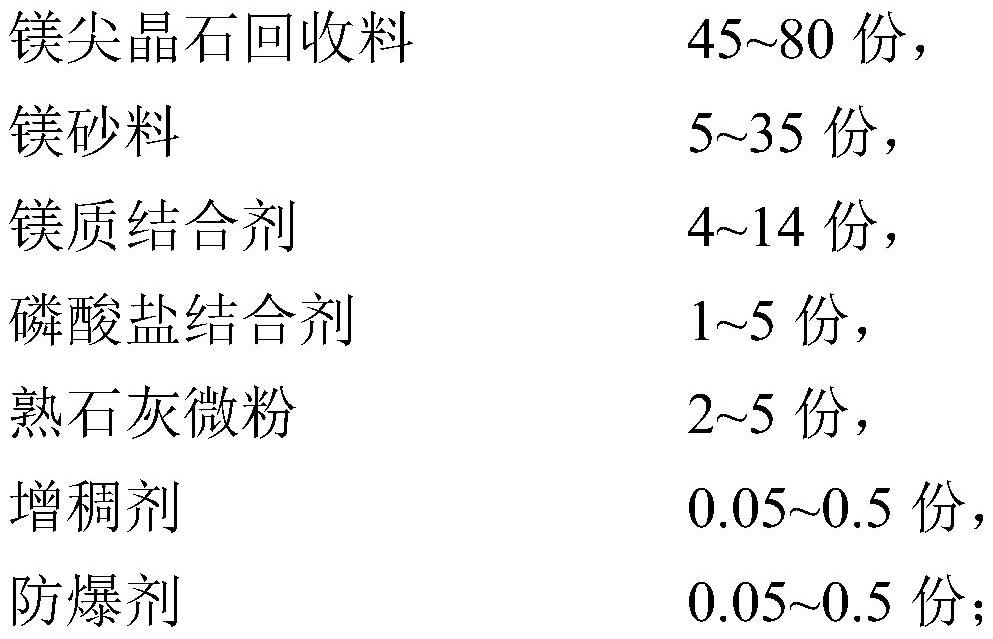

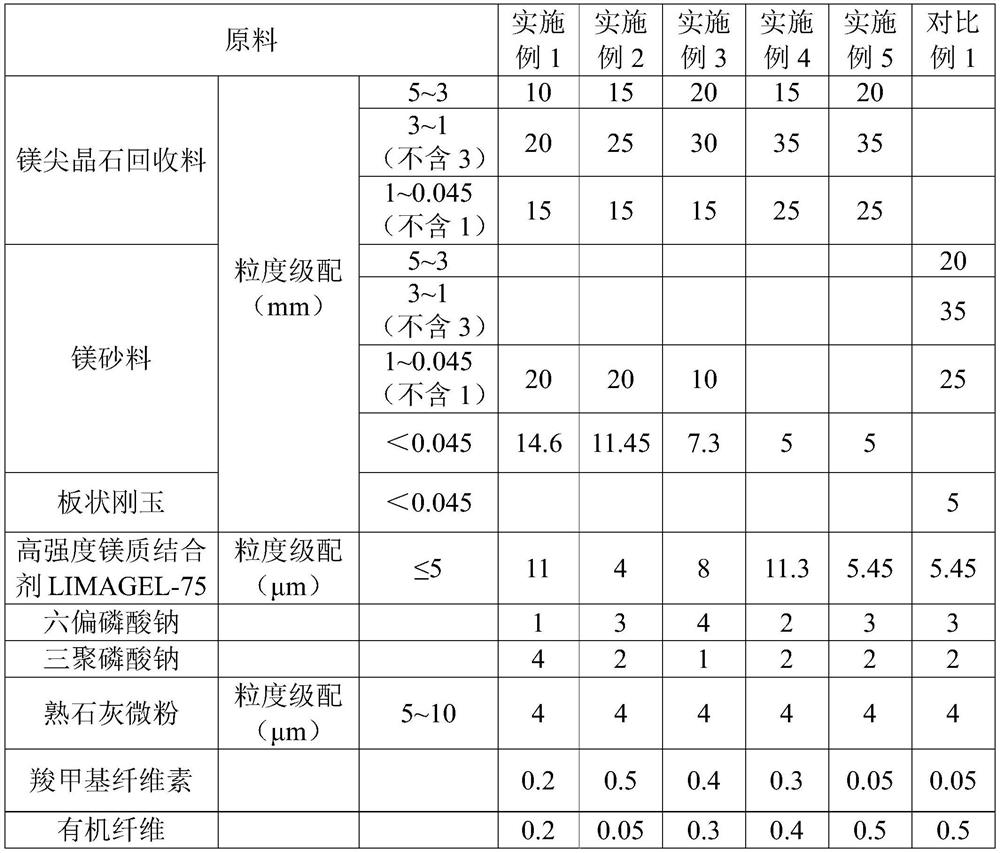

The invention discloses a green and environment-friendly magnesia spinel gunning mix for a converter, a preparation method of the green and environment-friendly magnesia spinel gunning mix and an application of the green and environment-friendly magnesia spinel gunning mix in converter maintenance. The magnesia spinel gunning mix comprises the following raw materials in parts by mass: 45-80 parts of a magnesia spinel reclaimed material, 5-35 parts of a magnesia material, 4-14 parts of a magnesia binding agent, 1-5 parts of a phosphate binding agent, 2-5 parts of slaked lime micro powder, 0.05-0.5 part of a thickening agent and 0.05-0.5 part of an anti-explosion agent. The gunning mix does not contain asphalt and resin, is environment-friendly, and has excellent adhesion and molten steel corrosion resistance by introducing the magnesium spinel reclaimed material and adopting the magnesium binding agent. The waste refractory materials are recycled, the green and environment-friendly development requirement is met, the service life of the gunning material is guaranteed, the steelmaking cost is reduced, and application and popularization are facilitated.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

Sliding brick and preparation method thereof

The invention provides a sliding brick and a preparation method thereof. The sliding brick is prepared from a mixture through molding and sintering, wherein the mixture comprises plate-shaped corundum, fused spinel, fused mullite, alumina, silicon carbide, silicon, aluminum and boron carbide. According to the invention, plasticity of both aluminum and silicon is combined together, which is favorable for improvement of density and strength of the sliding brick; meanwhile main materials like plate-shaped corundum are used, so the sliding brick has good high temperature performance, erosion resistance and thermal shock resistance. In the process of preparation of the sliding brick, light roasting or high temperature sintering is employed, so the prepared sliding brick has high hot strength and erosion resistance and good cold strength, anti-scouring performance and oxidation resistance.

Owner:HUNAN XIANGGANG RUITAI TECH

Novel high strength refractory brick and production method thereof

The invention relates to a novel high strength refractory brick and a production method thereof. The novel high strength refractory brick comprises, by weight, 50-70 parts of corundum, 20-40 parts of mullite, 1-10 parts of first grade clay, and 1-10 parts of an ultrafine powder binder, and also comprises arched CrNi steel fibers, and 100Kg of the CrNi steel fibers are added to 1m<3> of the refractory brick. Compared with refractory bricks in the prior art, the novel high strength refractory brick provided by the invention has the advantages of high refractoriness and high flexural strength.

Owner:SHANGHAI HUALIN IND GASES

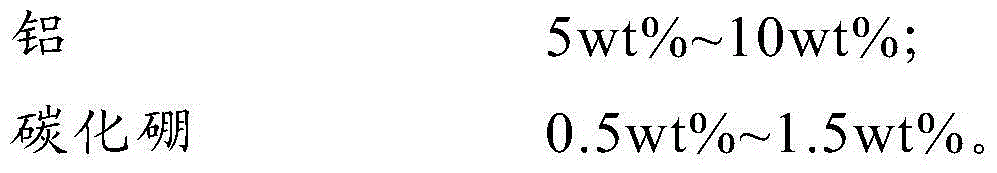

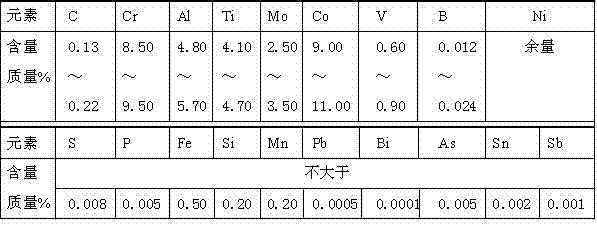

Method for preparing K417G alloy by using DZ417G alloy return material

InactiveCN101994021BImprove plasticityImprove medium temperature strengthProcess efficiency improvementAlloyUltimate tensile strength

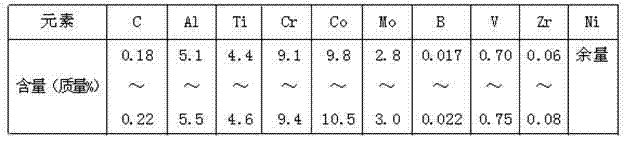

The invention relates to a method for preparing a K417G alloy by using a DZ417G alloy return material. The method comprises the following steps of: smelting the DZ417G alloy return material for the first time after preprocessing the return material, mixing the following materials in mass percent: 0.18-0.22 percent of C, 5.1-5.5 percent of Al, 4.4-4.6 percent of Ti, 9.1-9.4 percent of Cr, 9.8-10.5percent of Co, 2.8-3.0 percent of Mo, 0.017-0.022 percent of B, 0.70-0.75 percent of V, 0.06-0.08 percent of Zr and the balance of Ni, smelting the mixture for the second time to prepare the K417G alloy, refining at temperature ranging from 1550 DEG C to 1590 DEG C for 20min to 30min, and then casting after refining. The invention fully utilizes the DZ417G alloy return material, reduces waste of noble metal resources, and ensures that the prepared K417G alloy has the advantages of good plasticity, high intermediate temperature intensity and good stability through twice smelting. The sigma-phase is not dissolved after being aged for a long time at 850 DEG C, and the K417G alloy can be widely applied to engines of various types.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

No-water stemming material for blast furnace taphole and its prepn

InactiveCN100453509CShorten the blasting timeExtend the tapping timeBlast furnace componentsBlast furnace detailsCarbide siliconSlag

The present invention relates to amorphous refractory material, and is especially one kind of no-water stemming material for blast furnace taphole and its preparation process. The no-water stemming material is prepared with coke powder 15-25 wt%, clay 10-20 wt%, bauxite corundum 20-36 wt%, silicon carbide 10-20 wt%, asphalt 8-16 wt%, sericite 5-9 wt%, additive 1-5 wt% and binding agent 12-22 wt%, and through crushing, sieving, pre-mixing, rolling, kneading and extruding. The no-water stemming material has excellent plasticity and sintering performance, high strength at high and middle temperature and high slag and molten iron flush resistance, and can meet the requirement of high strength smelting in blast furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A metal-aluminum bonded silicon-free low-carbon aluminum-zirconium-carbon slide plate for casting high manganese steel and its production method

ActiveCN106699142BReduce C contentWeakened corrosion resistanceMelt-holding vesselsMetallic aluminumManganese

The invention discloses a metallic aluminium and non-silicone low-carbonalumina-zirconia-carbon slide plate for pouring high manganese steel. The metallic aluminium and non-silicone low-carbon alumina-zirconia-carbon slide plate for pouring the high manganese steel is prepared from a main ingredient and an addition agent, wherein the main ingredient is prepared from the following raw materials in percentage by weight: 39 to 50 percent of dense electro-fused alumina, 6 to 10 percent of alpha-aluminum oxide micropowder, 25 to 35 percent of fused alumina zirconia, 4 to 8 percent of silicon carbide, 4 to 6 percent of metal aluminum powder, 2 to 6 percent of zirconium oxide powder, 1 to 3 percent of carbon black, and 0.5 to 1 percent of boron carbide; the addition agent is phenolic resin; the weight of the addition agent is 4 to 6 percent of the total weight of the main ingredient. A production method comprises the steps of weighing the raw materials according to the weight, and uniformly mixing to obtain a clay; extrusion forming, drying for 8 to 10h at the temperature ranging from 190 to 210 DEG C, hooping, grinding, and drying to obtain the slide plate. The product provided by the invention has no need to be subjected to sintering and oil immersing, is simplified in process and short in production cycle, cannot cause pollution to the environment, has excellent oxidation resistance and corrosion resistance, can meet the use requirement on continuous sliding for 3 to 4 times through a research and development experiment, and has a remarkable comprehensive benefit.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

Aluminum-magnesium-zirconium brick for RH impregnating pipe and circulating pipe and preparation method thereof

The invention relates to an aluminum-magnesium-zirconium brick for an RH impregnating pipe and a circulating pipe and a preparation method thereof, and the aluminum-magnesium-zirconium brick is used for an inner pipe of the RH impregnating pipe and the circulating pipe. The aluminum-magnesium-zirconium brick is prepared from the following raw materials in percentage by weight: 25-45% of corundum particles, 15-35% of fused magnesia particles, 15% of corundum fine powder, 10% of alpha-alumina micropowder, 4.85% of zirconia fine powder, 5% of fused magnesia fine powder, 1% of silicon dioxide micropowder, 4% of activated alumina, 0.1% of water reducing agent and 0.05% of dispersant. The aluminum-magnesium-zirconium brick has the advantages of high green strength, no need of sintering, good thermal shock stability and strong resistance to acidic and basic fused slag corrosion.

Owner:郑州市裕丰耐火材料有限公司

Prefabricated refractory wallboard used for graphitized furnace and manufacture method thereof

Owner:广元市宏益耐火材料有限公司

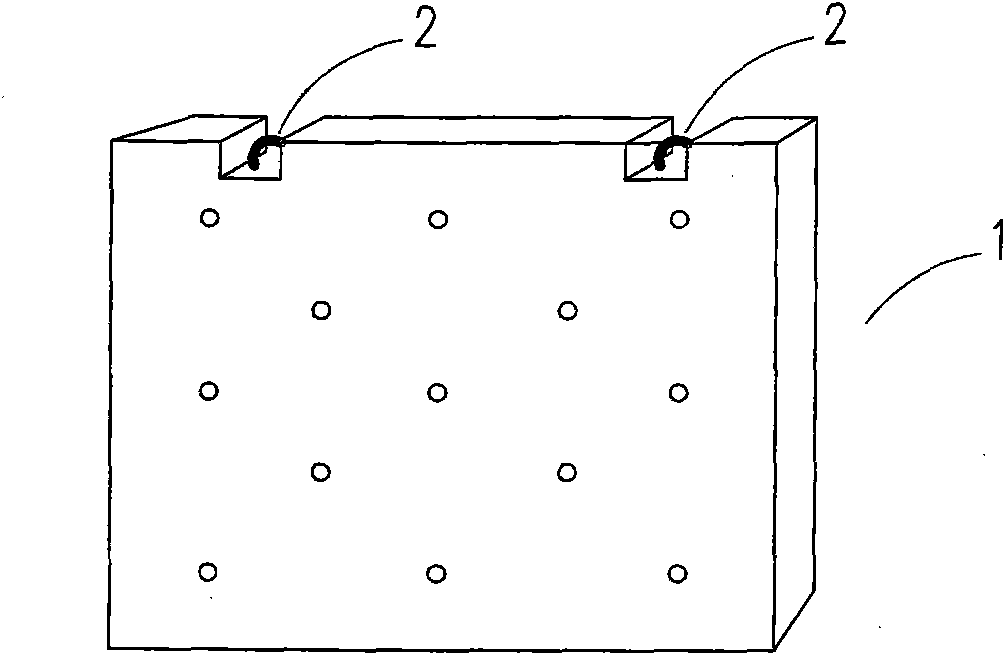

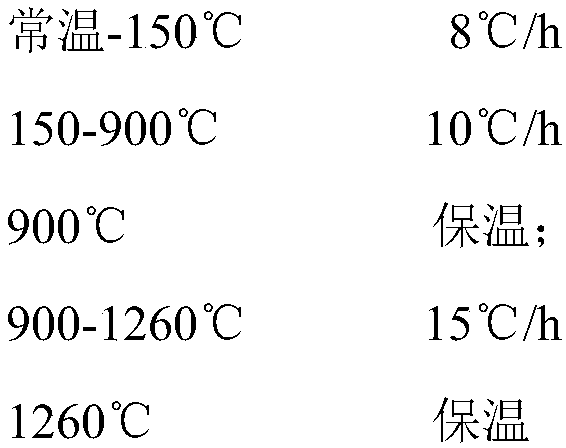

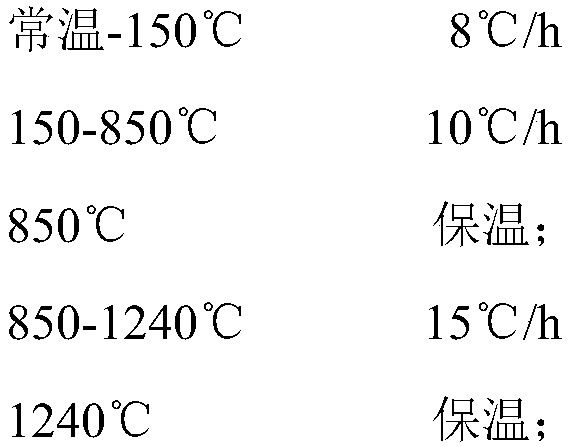

Preparation method of large solid quartz ceramic material

ActiveCN109369163AImprove firing pass rateImprove medium temperature strengthPorosityRoom temperature

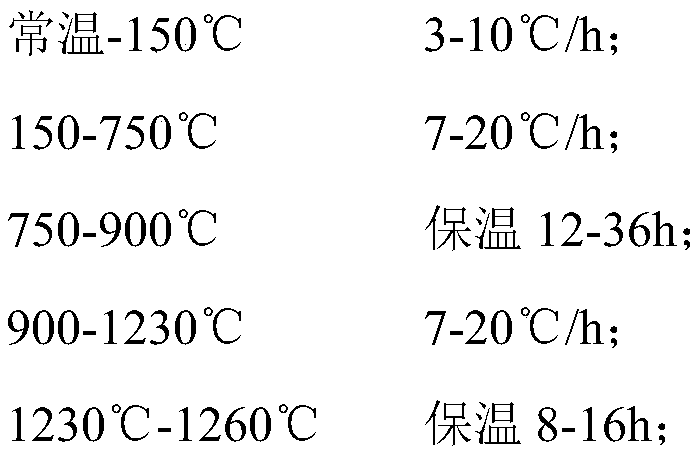

The invention relates to a preparation method of a large solid quartz ceramic material and belongs to the technical field of quartz ceramic products. The preparation method comprises the following steps: preparing a mixed material: weighing the following substances in percent by mass: 15-35% of quartz coarse particles, 20-40% of quartz fine particles, 0.99-5.66% of a bonding agent, 15-30% of quartz fine powder, 8-20% of quartz micropowder and 8-15% of spherical quartz micropowder, and mixing the substances uniformly to form the mixed material; isostatic compaction: filling a rubber mold with the mixed material and vacuumizing the mold, and carrying out compression moulding at an isostatic press of 80-150 MPa to form a blank; and sintering process: sintering the blank in the step 2 according to a firing system, and carrying out furnace cooling to room temperature after fire stopping. The preparation method is scientific and reasonable and simple and feasible and the prepared quartz ceramic material is good in microstructure uniformity and has the characteristics of low porosity, high volume density and high constant temperature pressure resistance.

Owner:ZIBO GT INDAL CERAMICS

A kind of machine-pressed non-burning clay brick and preparation method thereof

The invention discloses a machine-pressed non-burning clay brick and a preparation method thereof, comprising the following components: hard clay, soft clay, quartz sand, pyrophyllite, dispersant, solid binder and liquid binder; Non-fired clay bricks can reach the normal temperature strength of fired clay bricks by drying at 120°C, without high temperature firing, low energy consumption, simple production process, high medium temperature strength, and small volume change at high temperature, which not only saves production The cost also reduces problems such as waste gas pollution caused by firing, omits the firing process of traditional clay bricks, and realizes energy saving and emission reduction of refractory clay bricks.

Owner:PUYANG REFRACTORIES GRP CO LTD +1

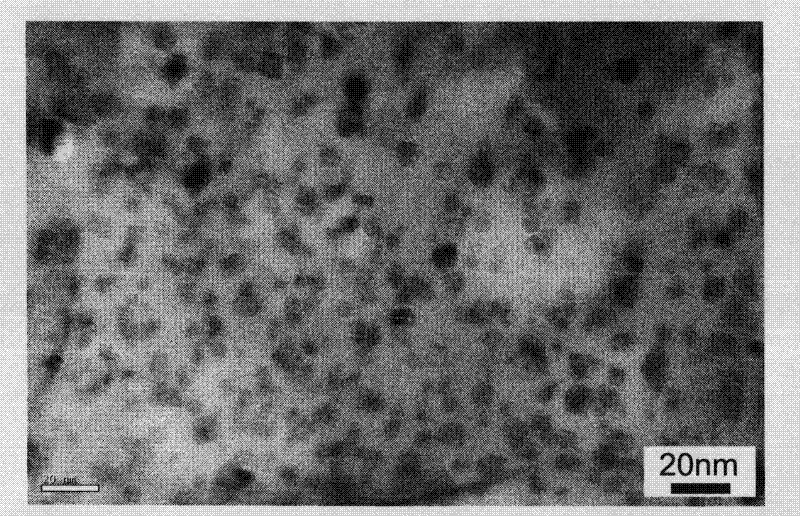

Method for preparing oxide dispersion strengthened cobalt-based super alloy

The invention discloses a method for preparing oxide dispersion strengthened cobalt-based super alloy, and belongs to the field of metal-based composite materials. The preparation method comprises the following steps of: pre-mixing Co powder, gamma-phase forming elements (Al and W), oxide thinning element (Hf) and oxide dispersion phase (Y2O3) with grain diameter of 30 to 30 nanometers uniformly,then uniformly dispersing Y2O3 granules into the Co matrix by high-energy ball milling in a high-purity protective atmosphere, and wrapping the high-energy ball milled alloy powder by using a low-carbon steel ladle and performing hot isostatic pressing at the temperature of between 900 and 1,300 DEG C; and performing solid solution heat treatment (1,000 to 1,300 DEG C) and aging heat treatment (600 to 900 DEG C) on a sample after the hot isostatic pressing to obtain a final nano phase strengthened composite material. The method has the main advantage of solving the problem that the improvement on high-temperature strength is greatly limited because carbide in the traditional cobalt-based alloy is easily roughened or dissolved at a high temperature by simultaneously introducing oxide dispersion strengthening and gamma-phase strengthening into the cobalt-based alloy for the first time.

Owner:UNIV OF SCI & TECH BEIJING

Corundum refractory castable

ActiveCN104311058BImprove medium temperature strengthImprove thermal shock resistanceHydrated aluminaNano zinc oxide

The invention relates to a corundum refractory castable which is prepared from the following components in parts by weight: 15-20 parts of coarse aggregate, 35-40 parts of medium aggregate, 15-30 parts of fine aggregate, 5-10 parts of sodium silicate, 5-10 parts of nano magnesium oxide, 1-5 parts of nano zinc oxide, 10-15 parts of alumina micro powder and 1-6 parts of hydrated alumina, wherein the coarse aggregate is corundum, the medium aggregate comprises dolomite and zirconite, and the fine aggregate is corundum.

Owner:宁夏胜金水泥有限公司

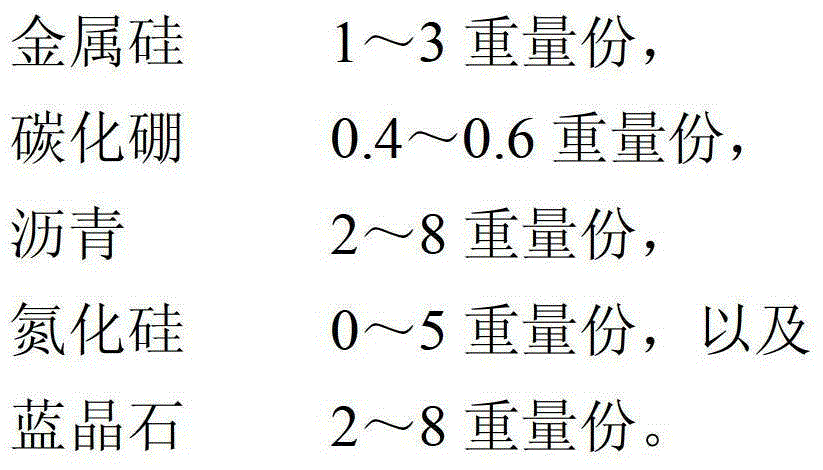

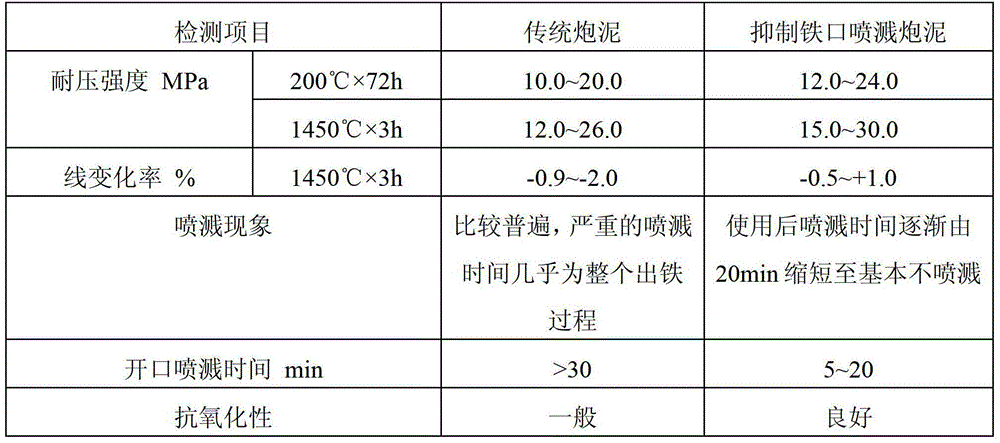

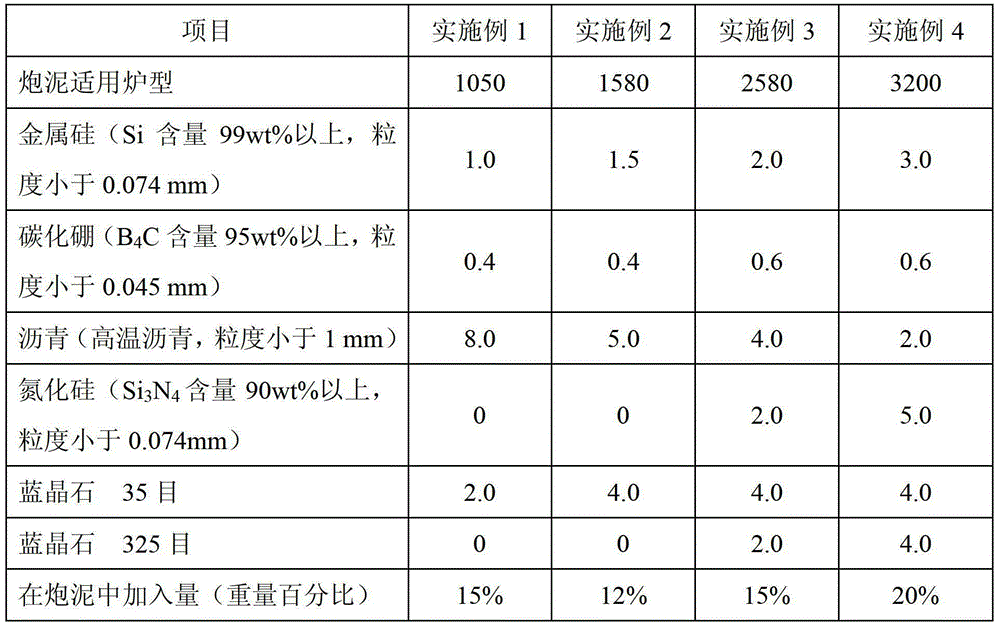

Additives for taphole clay to suppress spattering of iron holes

The invention belongs to the technical field of metallurgical refractory matters and relates to an additive for stemming for inhibiting iron notch splash. The additive comprises the following components in parts by weight: 1-3 parts of silicon metal, 0.4-0.6 part of boron carbide, 2-8 parts of asphalt, 0-5 parts of silicon nitride and 2-8 parts of kyanite. When the additive for stemming for inhibiting iron notch splash disclosed by the invention is added into the stemming, a proper amount of glass phase components can be generated at high temperature, and possible cracks generated in an iron notch channel can be plugged by the glass phase contacted with molten iron under the condition that the high-temperature performance is not influenced, so that splash caused by gas channeling is effectively prevented. Moreover, the additive has the advantages of proper micro expansion effect, medium and high temperature strength, slag iron erosion resistance and oxidation resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

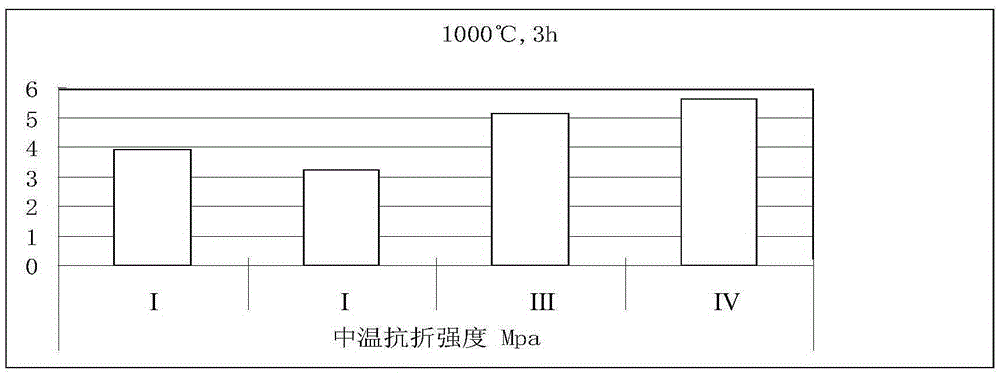

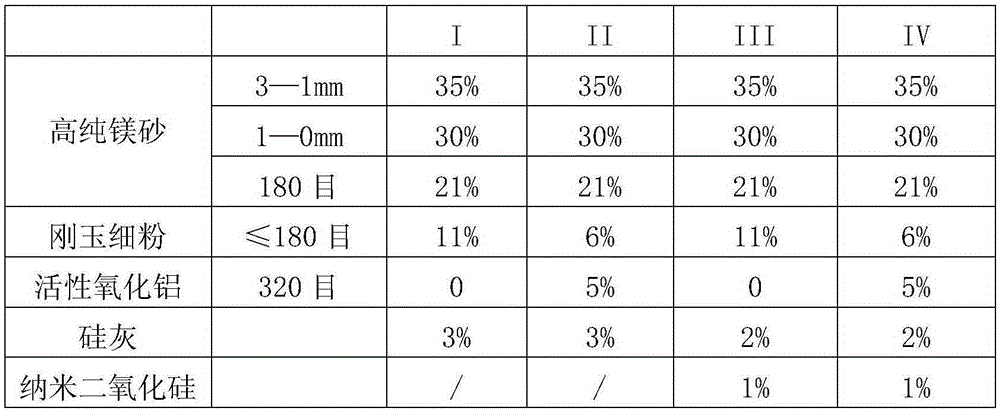

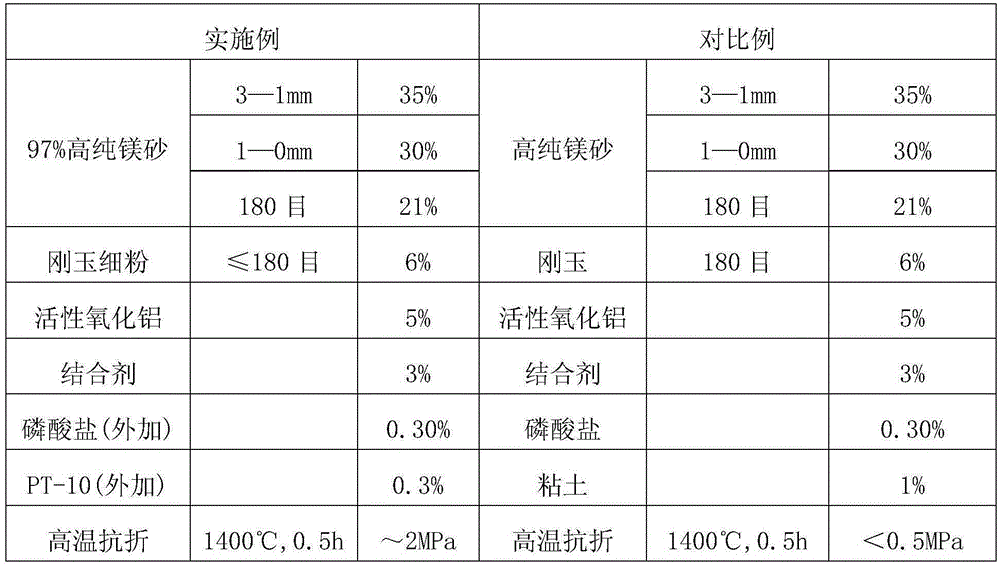

Magnesium-aluminum ramming material for rh furnace

ActiveCN103771887BMeet construction performanceDoes not affect high temperature performancePhosphatePlasticizer

Owner:上海彭浦特种耐火材料厂有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com