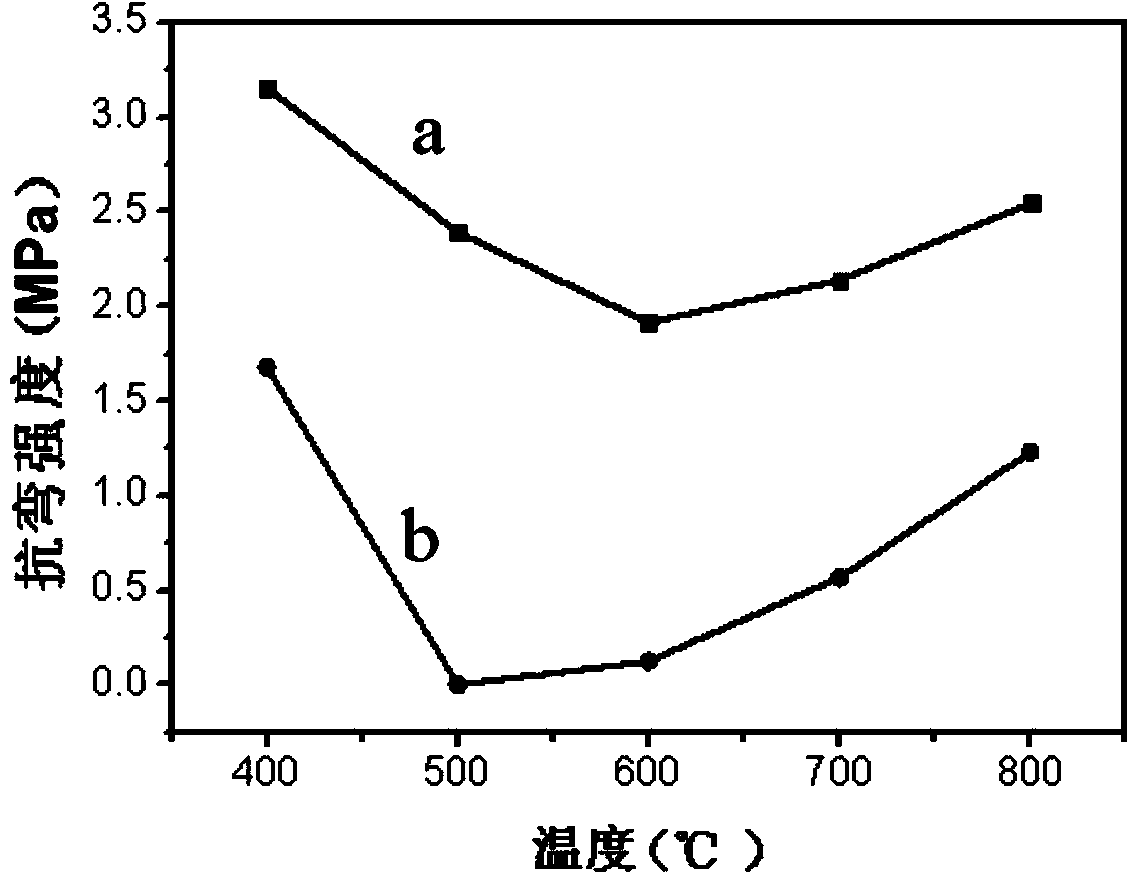

Method for controlling medium-temperature strength of gel-cast ceramic parts

A technology for ceramic parts and gel injection molding, applied in the field of ceramic parts preparation, can solve the problems of low strength and body damage, and achieve the effects of good high temperature resistance, improved strength and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Al 2 o 3 Fabrication of base ceramic parts

[0028] 1) Dilute the silica sol to SiO with deionized water 2 The mass fraction is 30%, and organic monomer acrylamide (AM), crosslinking agent N, N'-methylenebisacrylamide (MBAM) and dispersant sodium polyacrylate (PAANa) are added to the diluted silica sol , stirring and dissolving to obtain a premix; then polysiloxane is added to the premix, and the polysiloxane is uniformly dispersed in the premix by ultrasonic dispersion, and at the same time, a surfactant is added during the ultrasonic dispersion process to promote the dissolution of the polysiloxane. Disperse, then add ceramic powder (including 40 μm alumina, 5 μm alumina and sintering aid magnesium oxide) and polyimide, stir evenly to obtain a mixture, adjust the pH value of the mixture to 9 with ammonia water, and then ball mill the mixture, When ball milling, first add the mixture after adjusting the pH value to the ball milling jar, and then add corun...

Embodiment 2

[0034] Example 2: Preparation of SiC-based ceramic parts

[0035] 1) Dilute the silica sol to SiO with deionized water 2 The mass fraction is 10%, add organic monomer methacrylic acid, crosslinking agent N, N'-methylenebisacrylamide (MBAM) and dispersant sodium polyacrylate (PAANa) to the diluted silica sol, stir Dissolve to obtain a premix; then add polysiloxane to the premix, disperse the polysiloxane evenly in the premix by ultrasonic dispersion, and add a surfactant during the ultrasonic dispersion process to promote the dispersion of polysiloxane, Then add ceramic powder (including SiC powder of 45 μm and 5 μm) and polyimide, stir evenly to obtain a mixture, adjust the pH value of the mixture to 11 with ammonia water, and then ball mill the mixture. During ball milling, first add After adjusting the pH value of the mixture, add corundum balls to the ball mill jar according to the ratio of the mass ratio of the mixture to the balls of 2.5:1, and ball mill and disperse for...

Embodiment 3

[0040] Example 3: SiO 2 Fabrication of base ceramic parts

[0041] 1) Dilute the silica sol to SiO with deionized water 2 The mass fraction is 20%, add organic monomer methacrylamide, crosslinking agent acryl methyl acrylate and dispersant polyacrylic acid sodium (PAANa) in the silica sol after the dilution, stir and dissolve, obtain premix; Then Polysiloxane is added to the premix, and the polysiloxane is uniformly dispersed in the premix by ultrasonic dispersion. 2The ceramic powder raw materials and polyimide of the system are stirred evenly to obtain a mixture, and the pH value of the mixture is adjusted to 10 with ammonia water, and then the mixture is ball-milled. When ball-milling, the mixture after adjusting the pH value is first added to the ball mill tank, Then add corundum balls to the ball mill tank according to the mass ratio of the mixture to the balls at a ratio of 1.5:1, and ball mill and disperse for 30 minutes in a planetary ball mill with a rotating speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com