Patents

Literature

427 results about "Gel casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

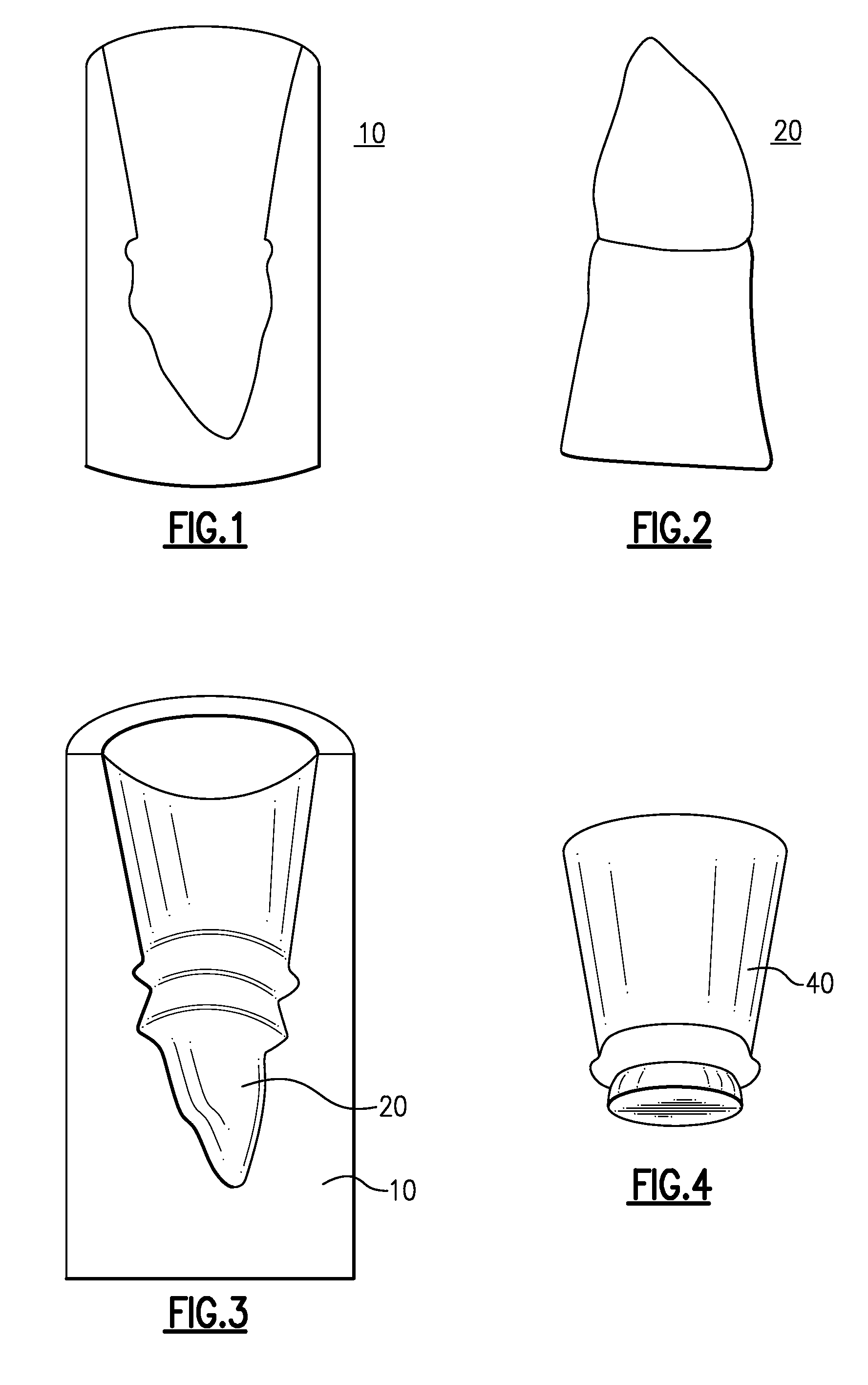

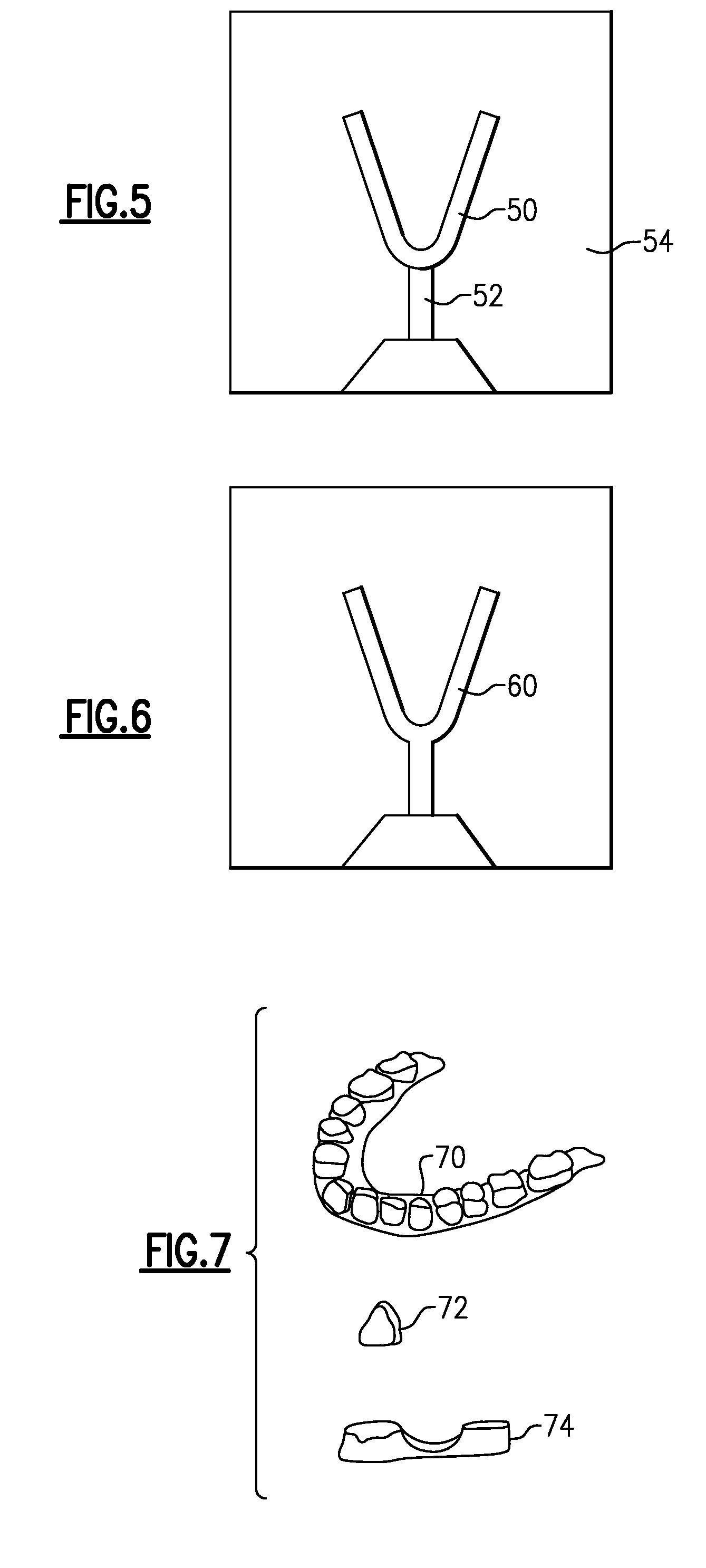

Solid free-form fabrication methods for the production of dental restorations

InactiveUS20050023710A1Improve bindingImpression capsCeramic shaping apparatusPolymer scienceFree form

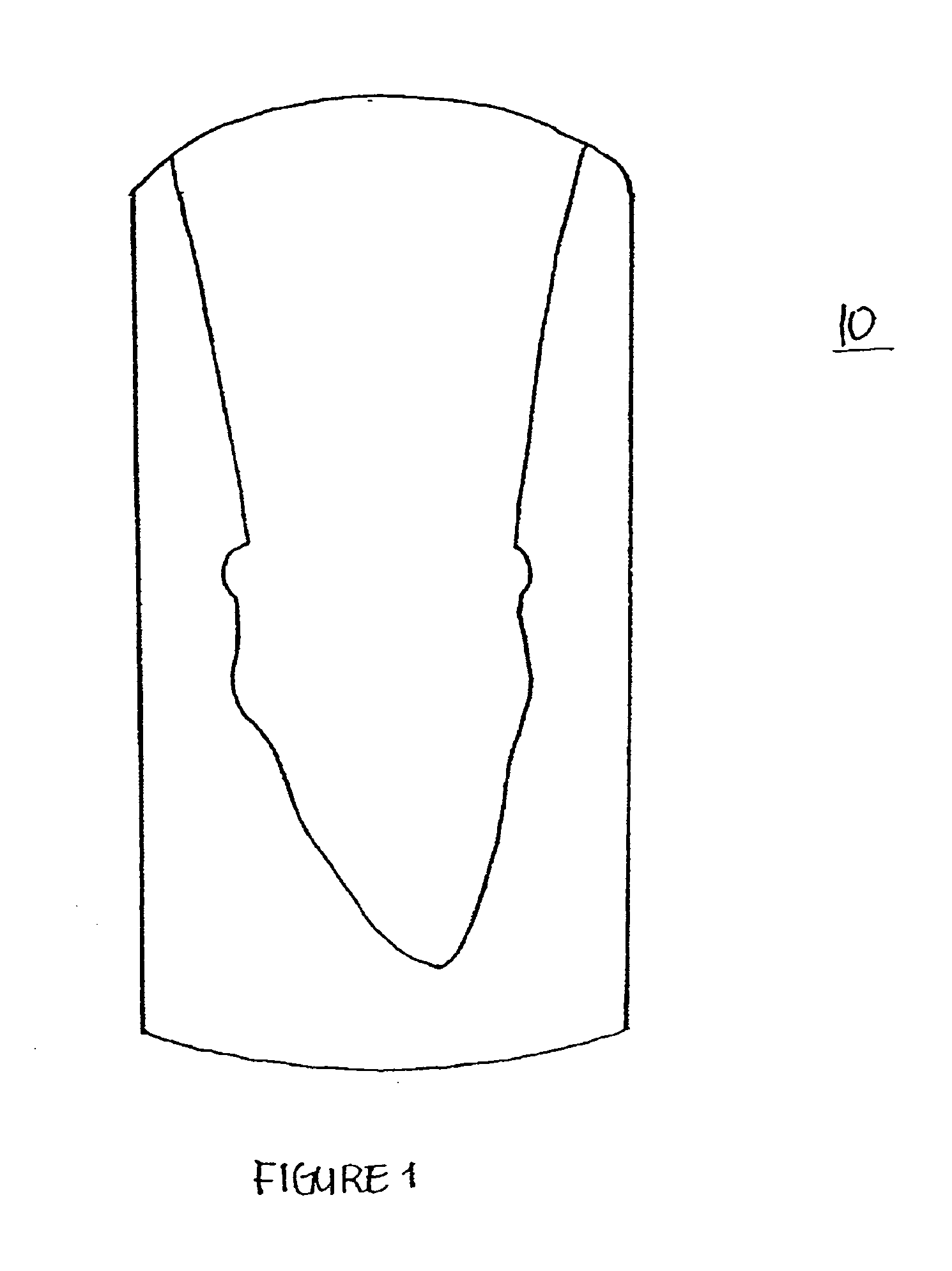

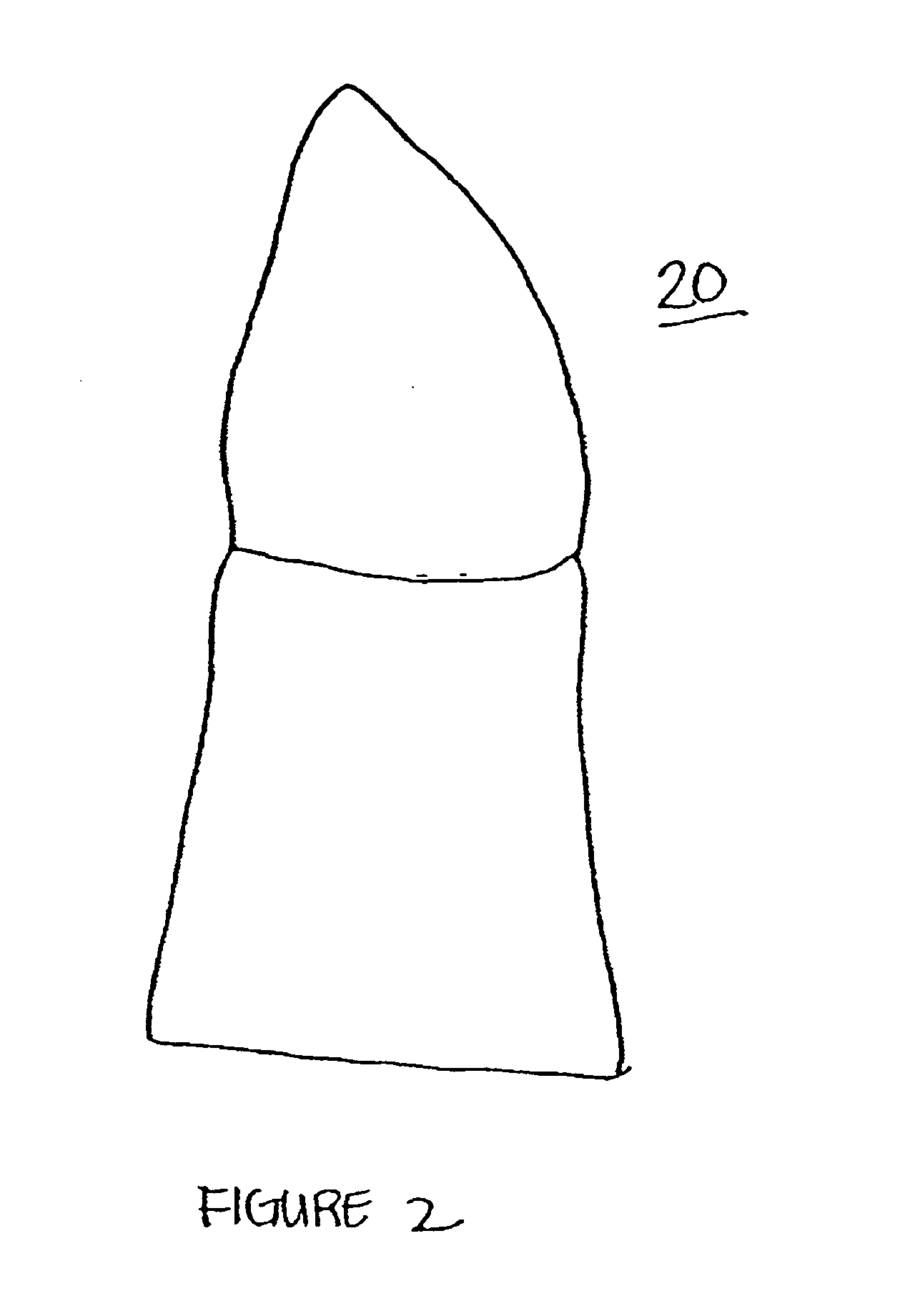

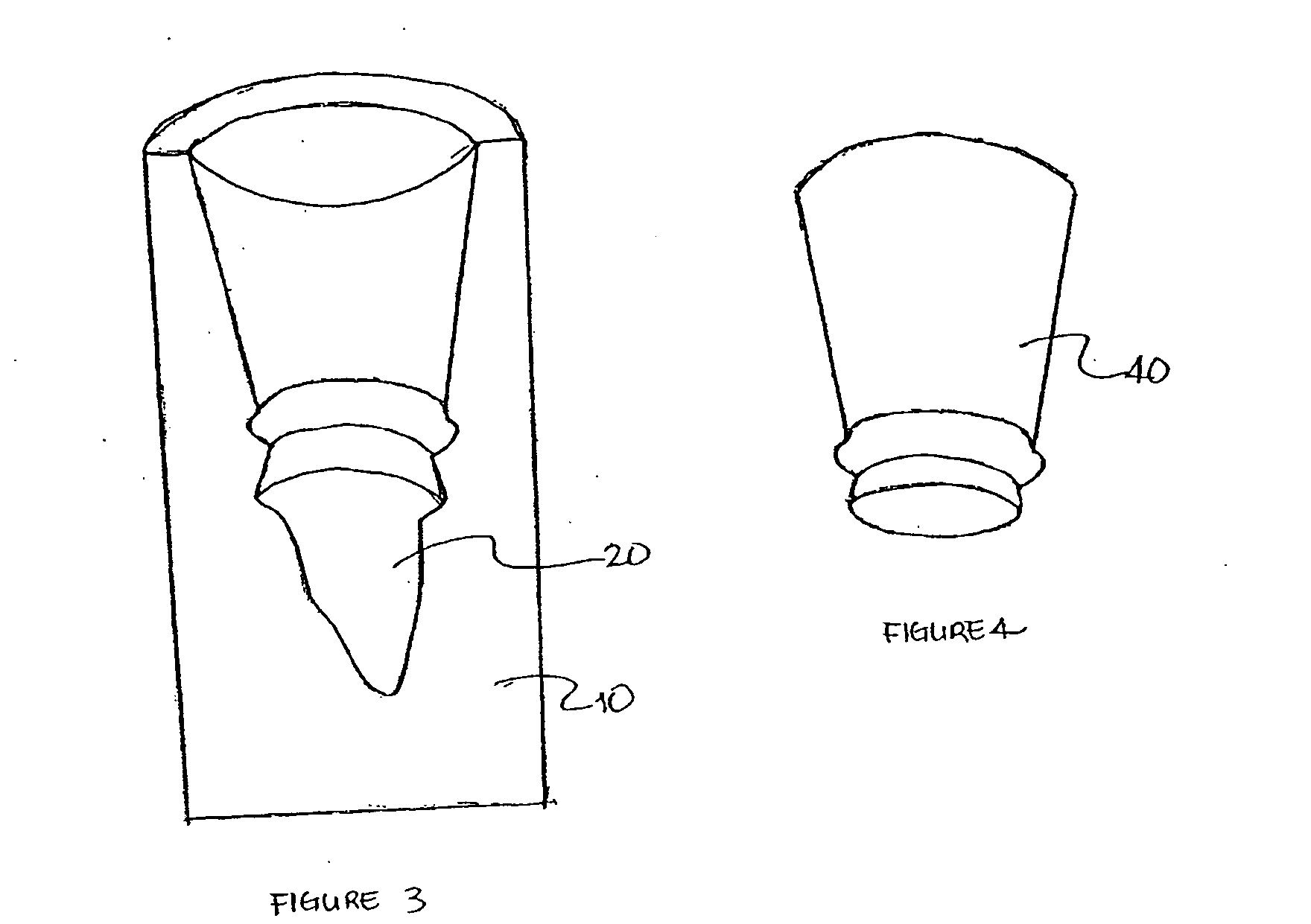

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

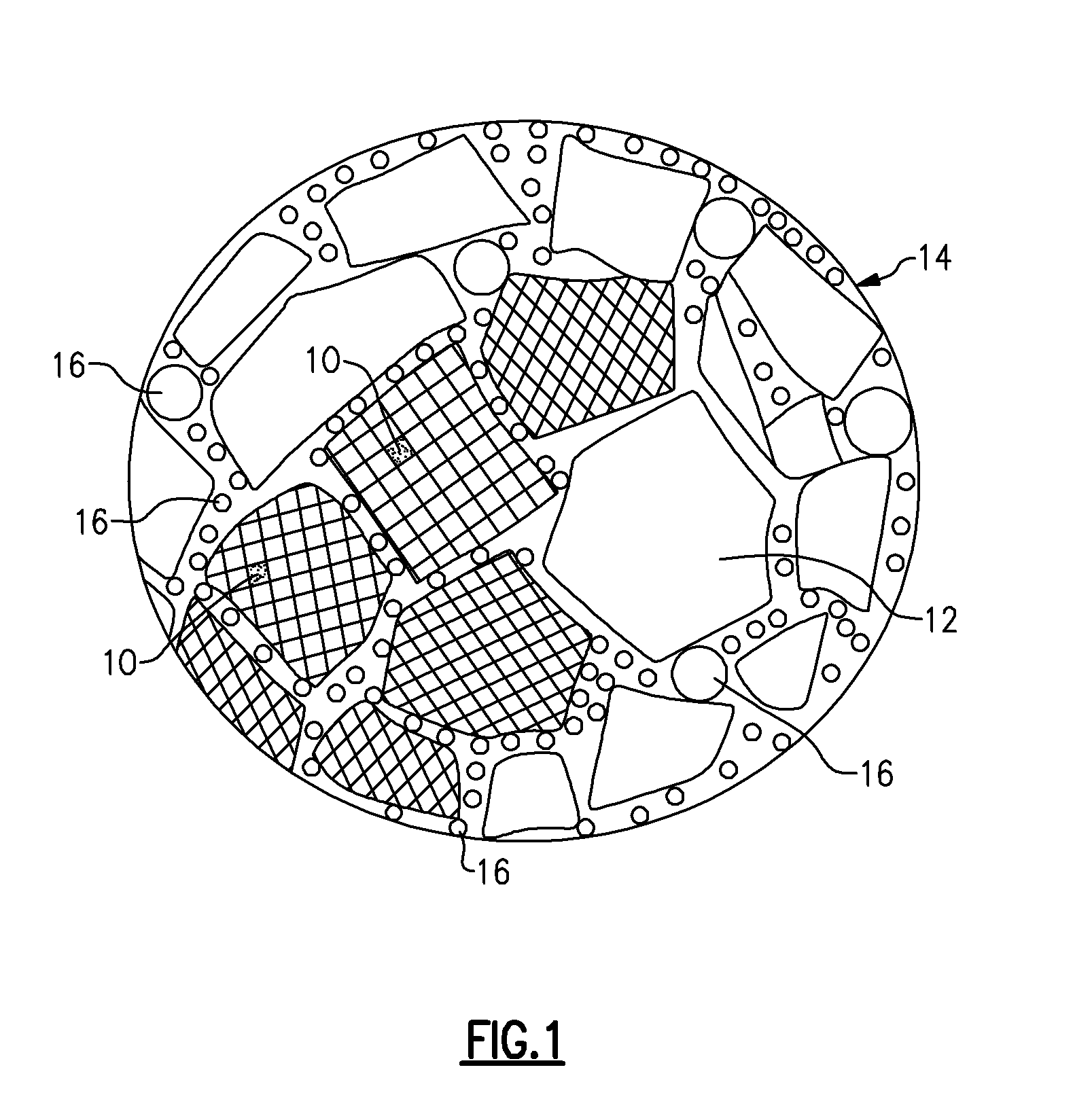

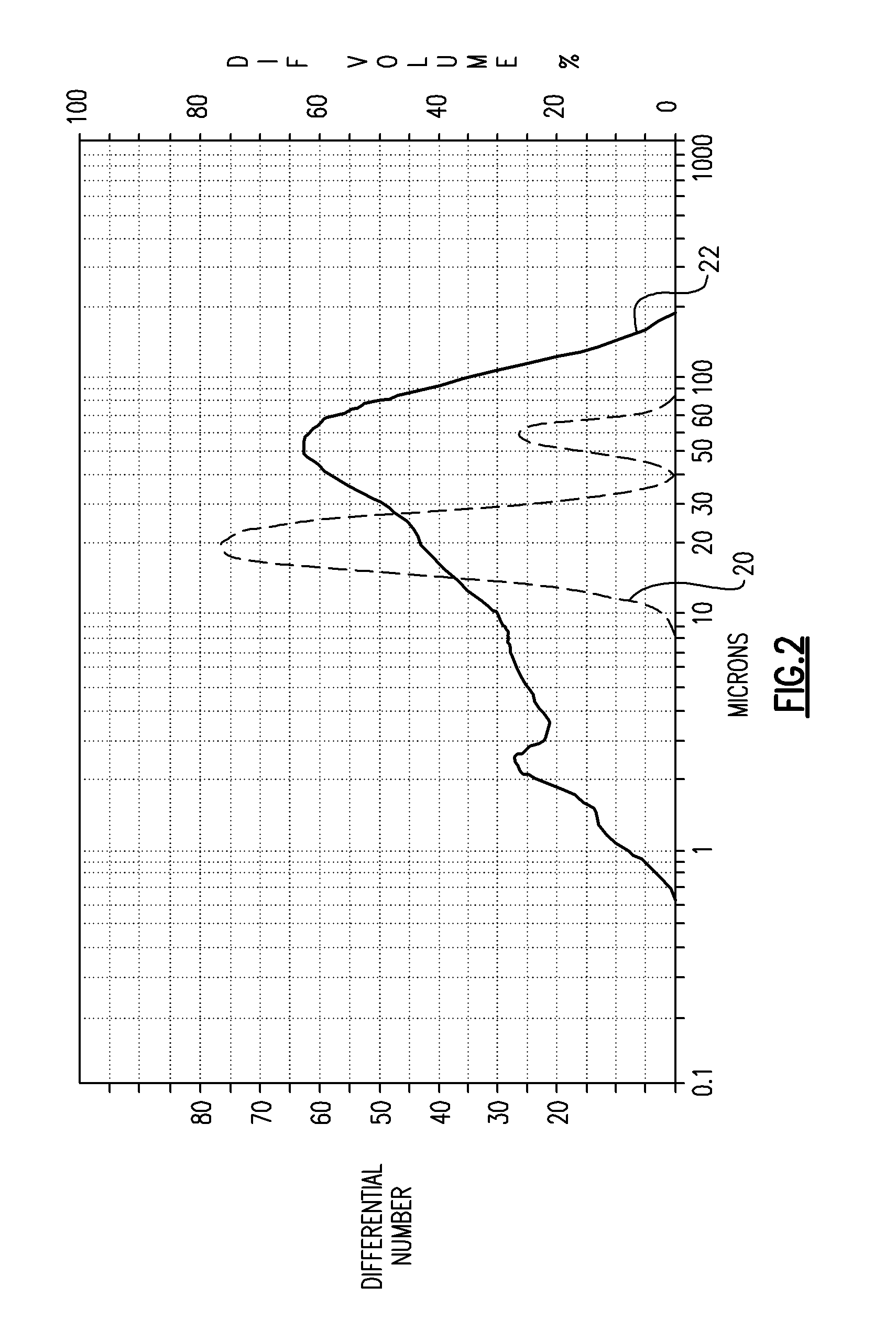

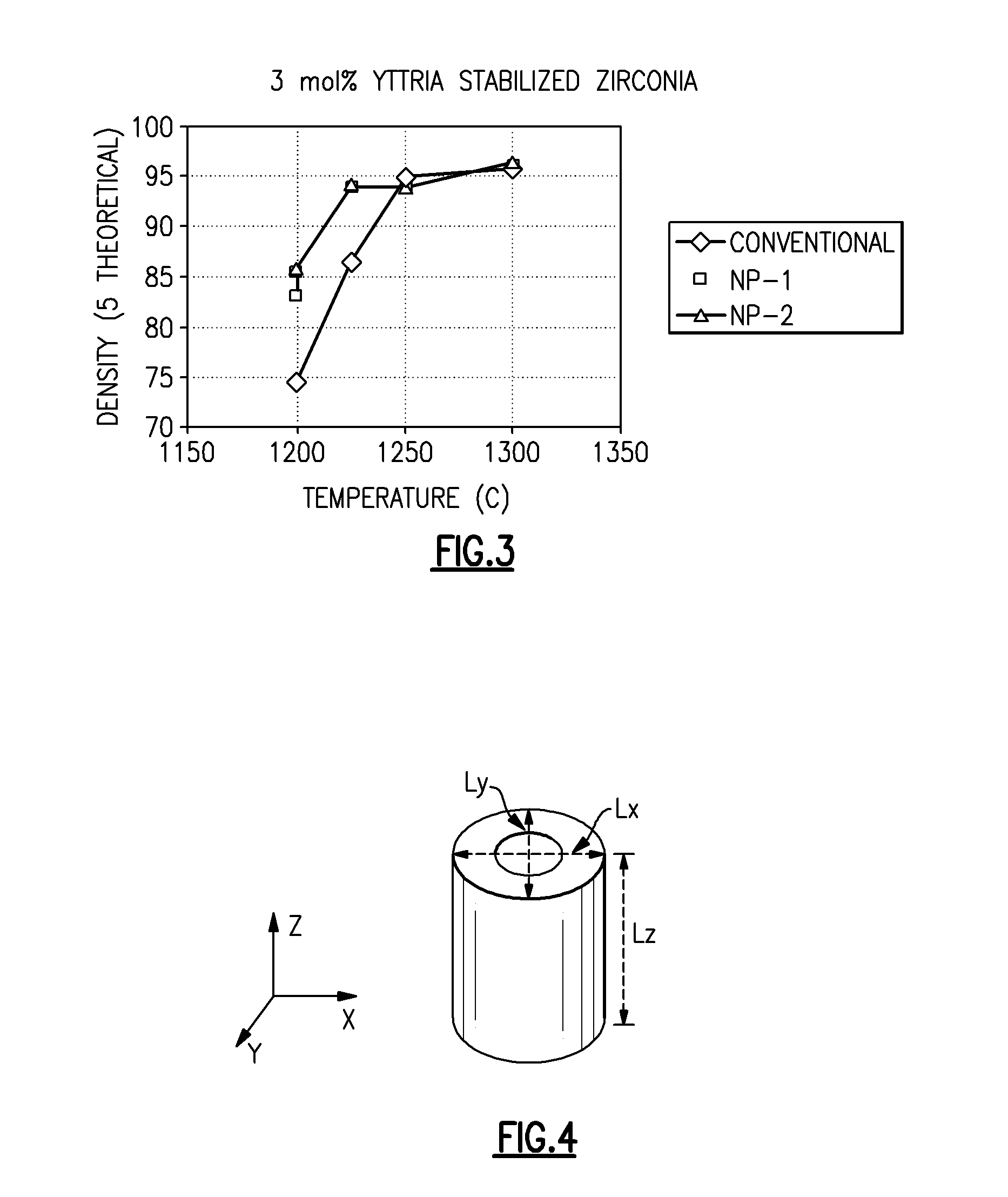

Dental restorations using nanocrystalline materials and methods of manufacture

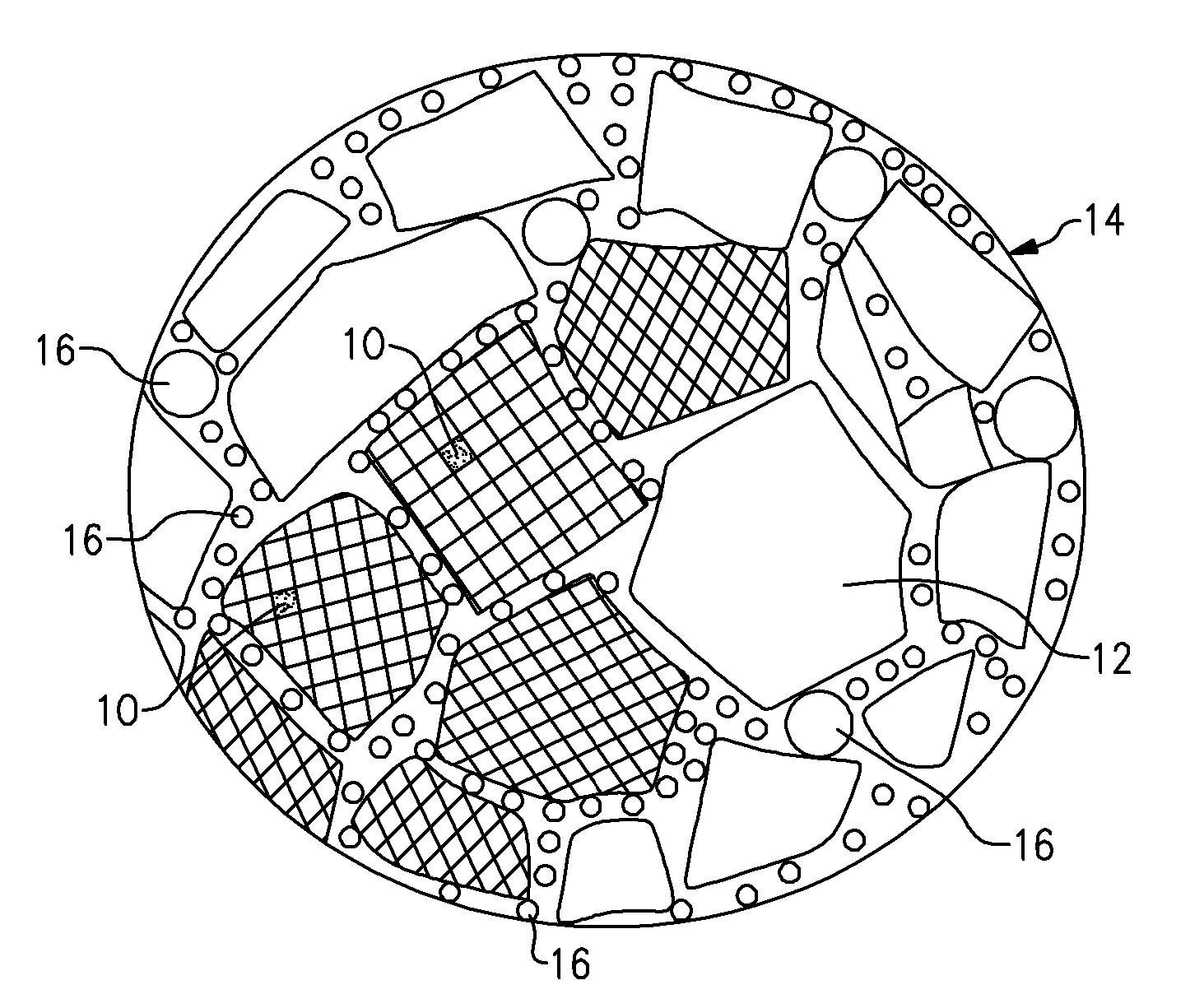

Dental articles are produced using relatively low sintering temperatures to achieve high density dental articles exhibiting strengths equal to and greater than about 700 MPa. Ceramic powders comprised of nanoparticulate crystallites are used to manufacture dental articles. The ceramic powders may include sintering agents, binders and other similar additives to aid in the processing of the ceramic powder into a dental article. The ceramic powders may be processed into dental articles using various methods including, but not limited to, injection molding, gel-casting, slip casting, or electroforming, hand, cad / camming and other various rapid prototyping methods. The ceramic powder may be formed into a suspension, pellet, feedstock material or a pre-sintered blank prior to forming into the dental article.

Owner:IVOCLAR VIVADENT AG

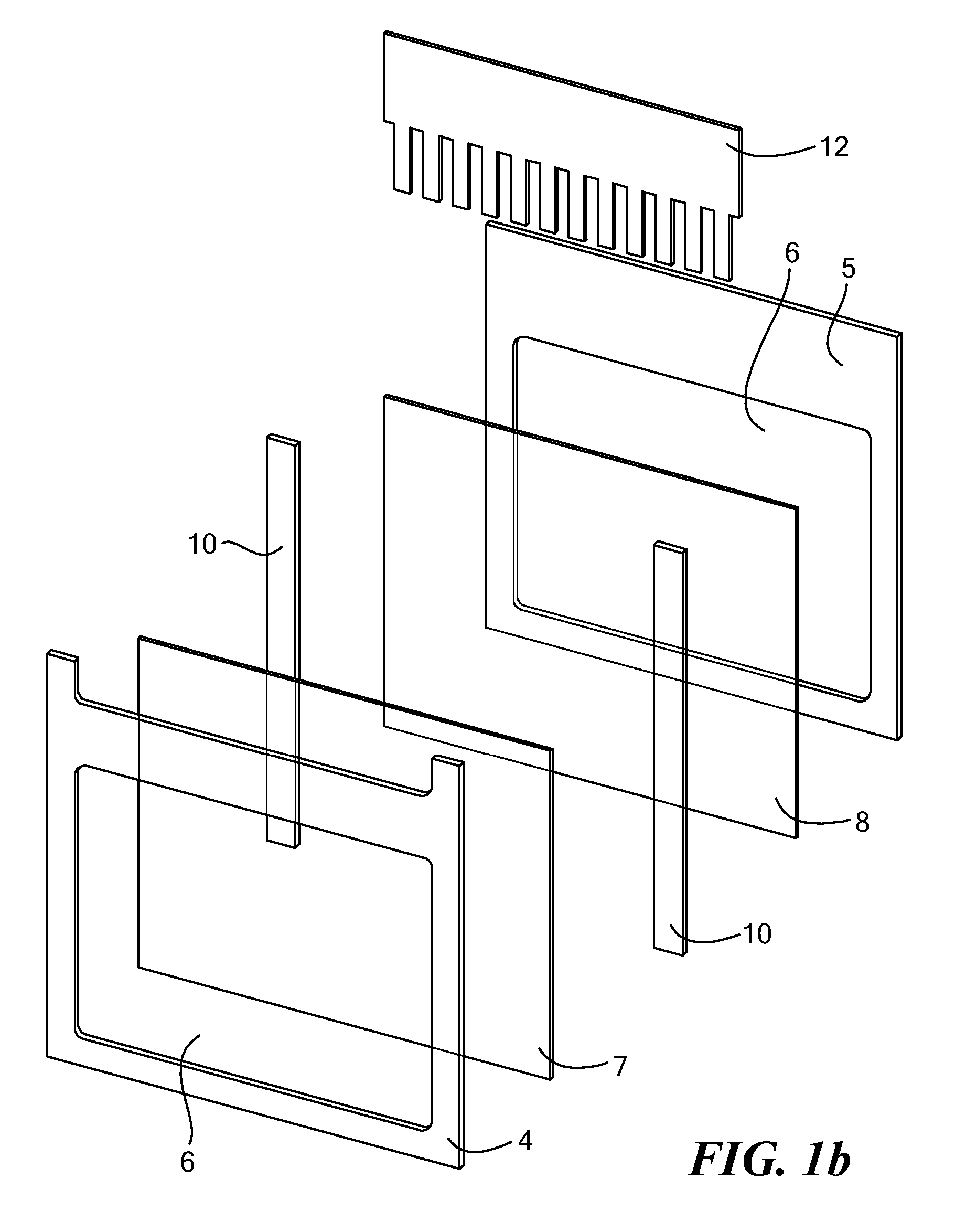

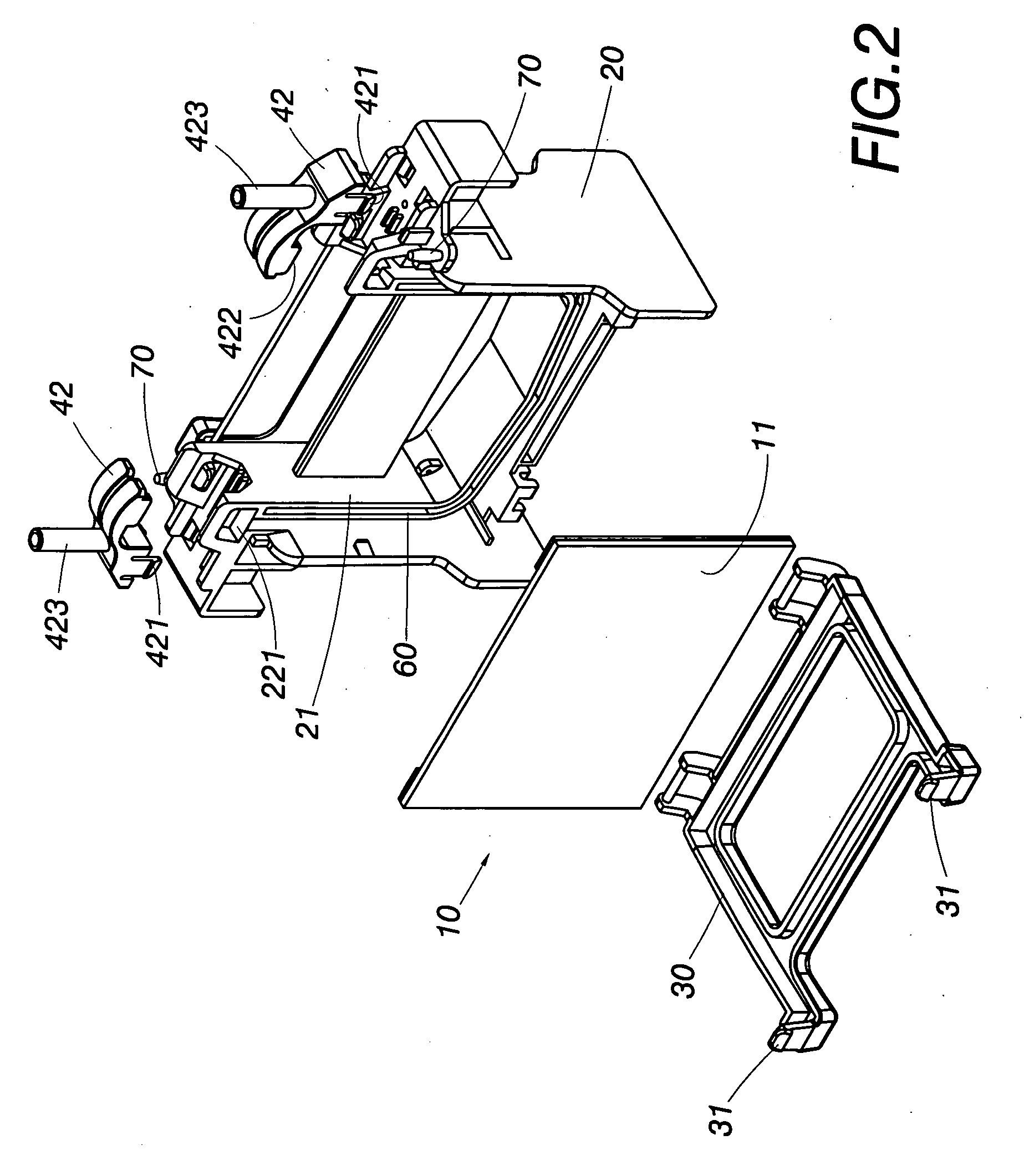

Multifunctional Electrophoresis Cassette

InactiveUS20070284250A1Increase distanceSludge treatmentVolume/mass flow measurementElectroblottingElectrophoresis

Devices and methods are provided for more efficiently performing electrophoresis and electroblotting. A sandwich structure includes an electrophoresis gel affixed to a blotting membrane. A gel casting and / or running frame is used to hold the sandwich. A method and composition that allows separation of the gel and membrane after performing a combined electrophoresis and electroblotting operation so as to allow further operations to be performed individually upon the membrane, gel or both. A uniform electrophoretic field may be created by surrounding the sandwich structure using an insulating fluid; the insulating fluid is then swapped for a conducting fluid to allow application of an electroblotting field. An apparatus automatically manages fluid exchange and actuation of electrophoresis and electroblotting electrodes. A plurality of parallel cavities may be used to hold multiple gels or gel membrane sandwiches.

Owner:SAGE SCI

Methods of Manufacturing Dental Restorations Using Nanocrystalline Materials

Dental articles are produced using relatively low sintering temperatures to achieve high density dental articles exhibiting strengths equal to and greater than about 700 MPa. Ceramic powders comprised of nanoparticulate crystallites are used to manufacture dental articles. The ceramic powders may include sintering agents, binders and other similar additives to aid in the processing of the ceramic powder into a dental article. The ceramic powders may be processed into dental articles using various methods including, but not limited to, injection molding, gel-casting, slip casting, or electroforming, hand, cad / camming and other various rapid prototyping methods. The ceramic powder may be formed into a suspension, pellet, feedstock material or a pre-sintered blank prior to forming into the dental article.

Owner:IVOCLAR VIVADENT AG

Method for forming mould-free gel with metal sizing agents through 3D printing

The invention provides a method for forming mould-free gel with metal sizing agents through 3D printing. A 3D printing technology is combined with a gel forming technology, the metal sizing agents are prepared through a gel forming process, the sizing agents are adopted as the raw materials of 3D printing, then layered printing is carried out through 3D printing equipment according to a data model, the metal sizing agents are solidified fast by controlling the additive number of initiating agents and catalysts, the initiating agents and the catalysts are accumulated layer by layer to form a metal blank, and the metal blank is dried and sintered to obtain a metal part product with a large size and in a complex shape. The method can be used for manufacturing a part including a sealed cavity and a complex inner cavity, the part cannot be manufactured through a traditional gel casting forming mode, the blank is directly formed through the 3D printing technology, mould development cost is saved, the method has obvious advantages in single part production and small scale production, requirements for powder materials are low, the process is stable and reliable, the operability is strong, consumed time is short, efficiency is high, cost is low, and the industrialization of manufacturing the metal part with the large size and in the complex shape through the 3D printing technology is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

Method for manufacturing SiC ceramic-based turbine blade based on photocurable 3D printing

The invention discloses a method for manufacturing a SiC ceramic-based turbine blade based on photocurable 3D printing. The method comprises the following steps of firstly manufacturing a turbine blade resin mold based on the photocurable 3D printing technology, casting the blade resin mold by using a non-water-based gel-casting ceramic slurry, curing and carrying out pyrolysis carbonization process to obtain a porous carbon preform; by an in-situ reaction sintering technology, at 1420-1700 DEG C, carrying out siliconizing and silicon discharge processes on the carbon perform to obtain the porous SiC ceramic-based composites material turbine blade; and finally obtaining the dense SiC ceramic-based composites material turbine blade by a chemical vapor deposition / infiltration method. The method has the characteristics of near-net molding, free molding and complex molding and the purpose that ceramic parts are densified can be achieved at a lower temperature.

Owner:XI AN JIAOTONG UNIV

Preparation method of metal toughened ceramic-based composite material turbine blade

The invention discloses a preparation method of a metal toughened ceramic-based composite material turbine blade. According to the preparation method, the metal 3D (three dimensional) printing technology, the stereolithography rapid molding technology, the chemical vapor deposition technology and the gel-casting molding technology are combined, a metal toughened skeleton with desired structural type is manufactured by the 3D printing technology, and the metal toughened skeleton is embedded into a ceramic product to enhance the toughness of the ceramic turbine blade. By utilizing the preparation method, the metal toughened skeleton is embedded into a ceramic product to greatly improve the toughness of the ceramic product, and a silicon carbide ceramic material prepared by transforming a precursor has high strength. Compared with the conventional metal blade, by utilizing the metal toughened ceramic-based composite material turbine blade, the quality of the blade can be greatly lightened, and the thrust-weight ratio of an engine can be greatly improved.

Owner:XI AN JIAOTONG UNIV

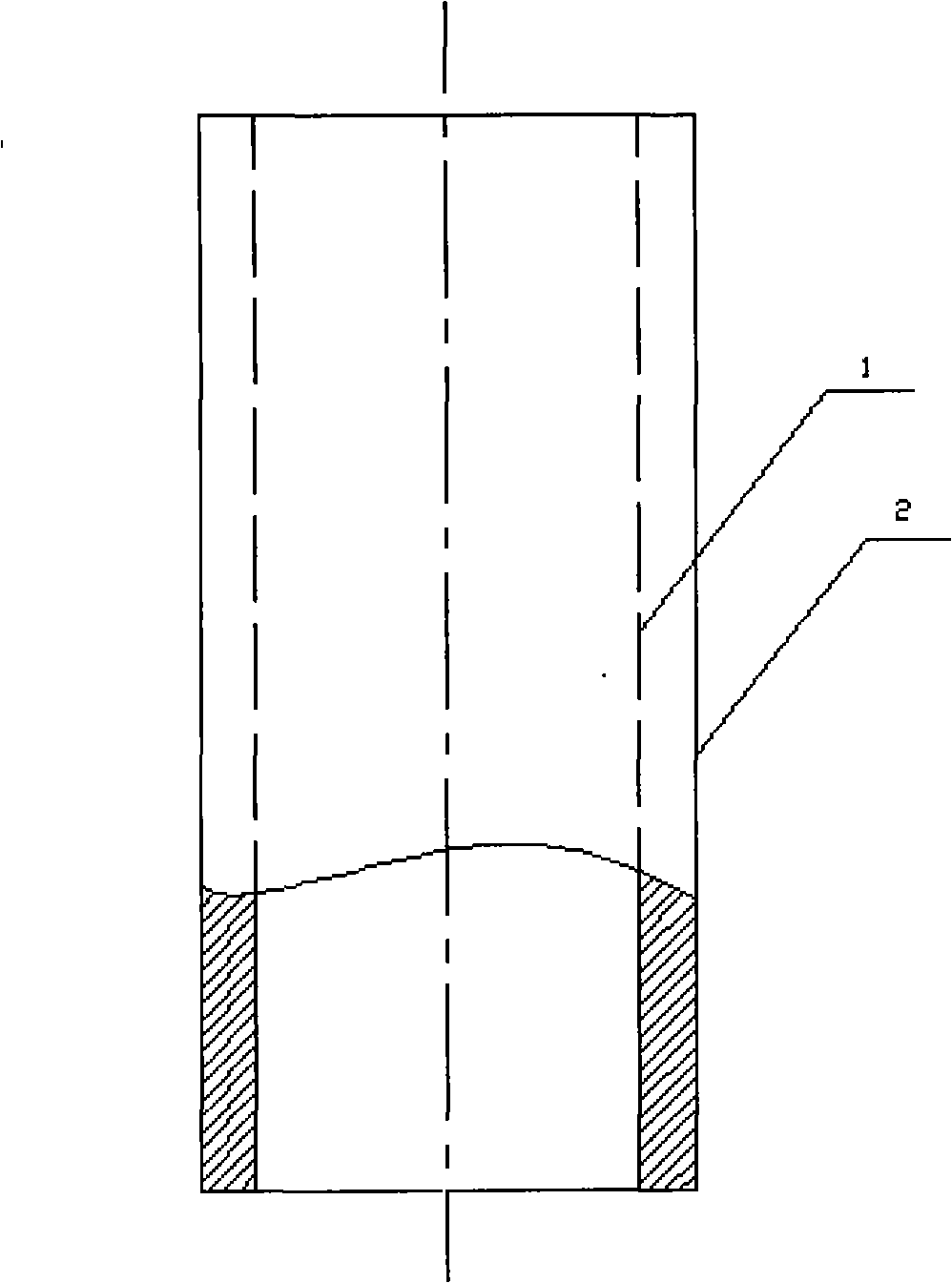

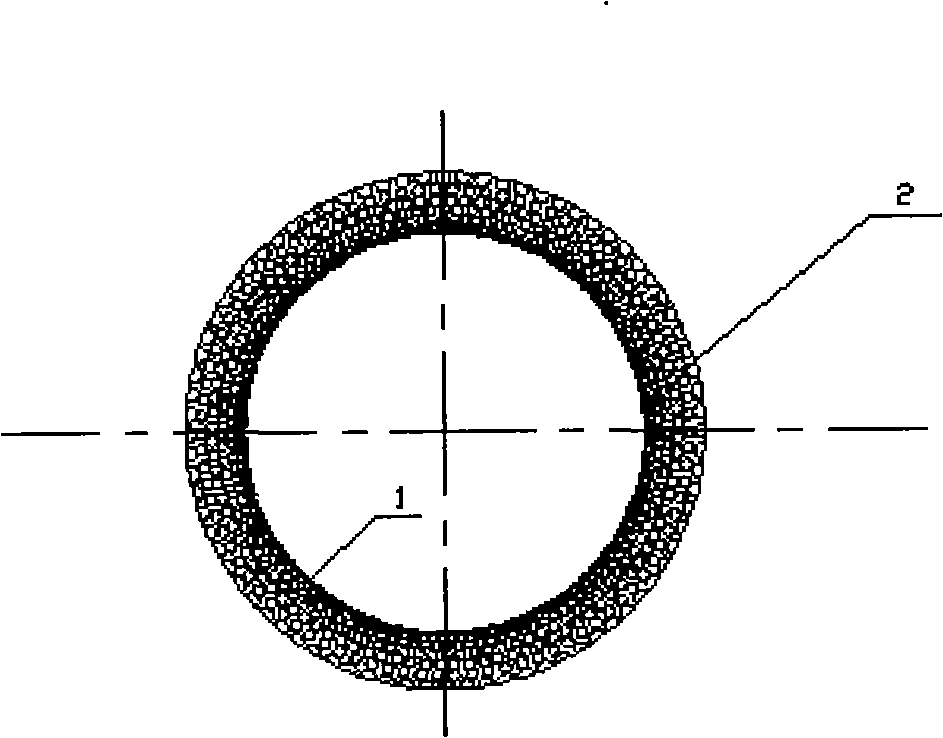

Preparation of continuous hole graded ceramic tube

The invention relates to a preparation method of a gradient ceramic tube with continuous holes, which combines with the advantages of a centrifugal shaping method and gel-casting. Evenly distributed gel-casting suspension is poured into a pattern to carry out centrifugation and gelatinization occurs to the suspended slurry under the effect of centrifugal force and heating to realize solidification and shaping. A wet blank is demoulded, dried and sintered and the gradient ceramic tube with the continuous holes is prepared. The pore diameters of pattern tubes are distributed continuously along the radial direction of the pattern tubes, the pore diameter of an inner surface is the smallest while the bore diameter of an outer surface is the largest; besides, the inner surface is quite flat and smooth without defect, therefore, the ceramic tube can be used both in the process of microfiltration and ultrafiltration and as a good support to further paint film on the inner surface. The preparation method is simple, thus saving the vacuum degassing procedure in traditional gel-casting; the gradient ceramic tube with the continuous holes can be shaped by one step; the pattern tubes with different pore diameters can be prepared by controlling the initial grain sizes of ceramic powders; the blank has high strength and is easy to operate with high efficiency and the yield of pattern tubes is high.

Owner:NANJING UNIV OF TECH

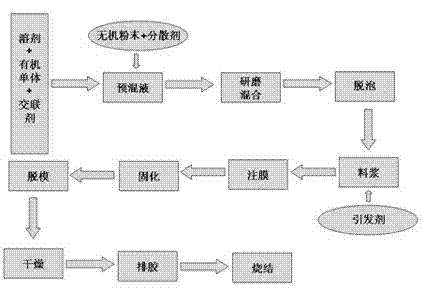

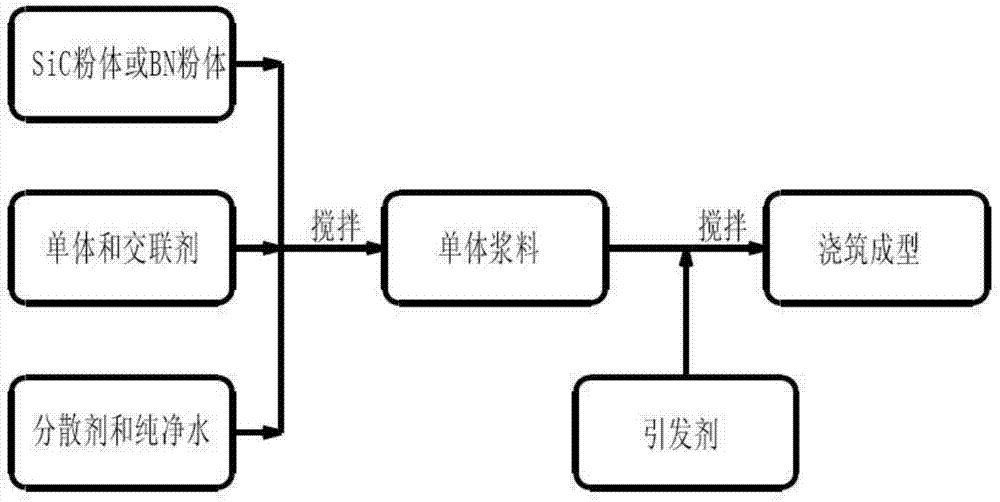

Microwave curing process for ceramic material gel casting

The invention relates to a microwave curing process for ceramic material gel casting, which comprises the following steps: firstly, dissolving organic monomer and crosslinker in sequence in the solvent, adding a dispersant and obtaining pre-prepared liquid; adjusting the pH value of the pre-prepared liquid to be 7-11, adding ceramic powder to the pre-prepared liquid, stirring the mixture stronglyand mechanically for 1h and obtaining even slurry; adding an initiating agent and a catalytic agent to the slurry and mixing evenly; soon afterward, removing the gas in the slurry by vacuum; casting the slurry into a module; placing the module packed with the slurry in a microwave oven for a curing process, and obtaining a gel casting ceramic body; and drying the ceramic body, and then sintering at the temperature of 1200 DEG C-2200 DEG C for 1-6h, and finally obtaining a ceramic product. Compared with the conventional gel casting curing method, the microwave curing process has the advantagesthat the process has fast heating speed and uniform temperature field, reduces the activation energy of reaction, accelerates the reaction rate, causes the polymerization reaction to be finished rapidly and achieves the purpose of high speed and high quality moulding of materials.

Owner:OCEAN UNIV OF CHINA

Carbon fibre enhanced reaction sintering silicon carbide ceramic and preparation method thereof

The present invention relates to a carbon fiber reinforced reaction sintering silicon carbide ceramic and the preparation method, belonging to material technical field. Composite material perform is prepared by using gel-casting technology; the portions of the components include 100 weight portions of silicon carbide, 7-18 weight portions of carbon black and 2-8 weight portions of carbon fiber. The preparation method is that the composite powders of component silicon carbide and carbon black, and carbon fiber are dispersed in the solution of organic monomer and crosslinking agent; the solidified molded perform is fully dried at 60-80 DEG C to get the perform; the perform will then be buried under silicon powders in a sintering furnace for gel removal and thermal insulation at the temperature of 500 to 800 DEG C, and the sintering temperature is 1500 to 1800 DEG C. The reaction sintering silicon carbide ceramic carbon fiber prepared by the invention can be uniformly dispersed in the perform and the fracture toughness of the carbon fiber / reaction sintering silicon carbide composite material is significantly increased compared with that of the matrix.

Owner:山东金鸿集团有限公司

Solid Free-Form Fabrication Methods For The Production of Dental Restorations

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

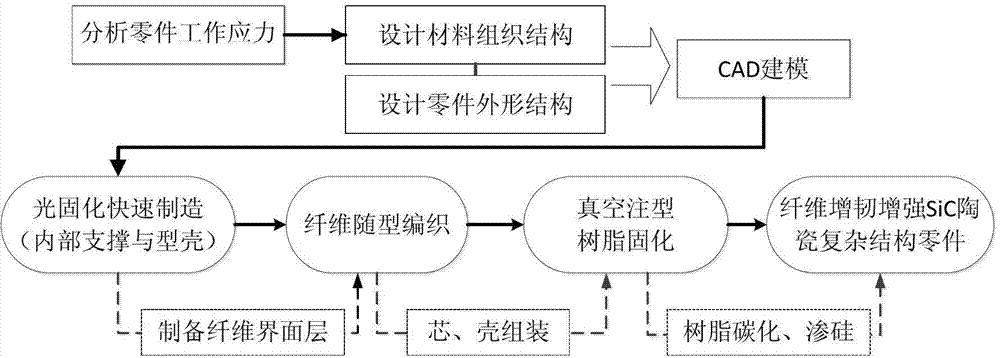

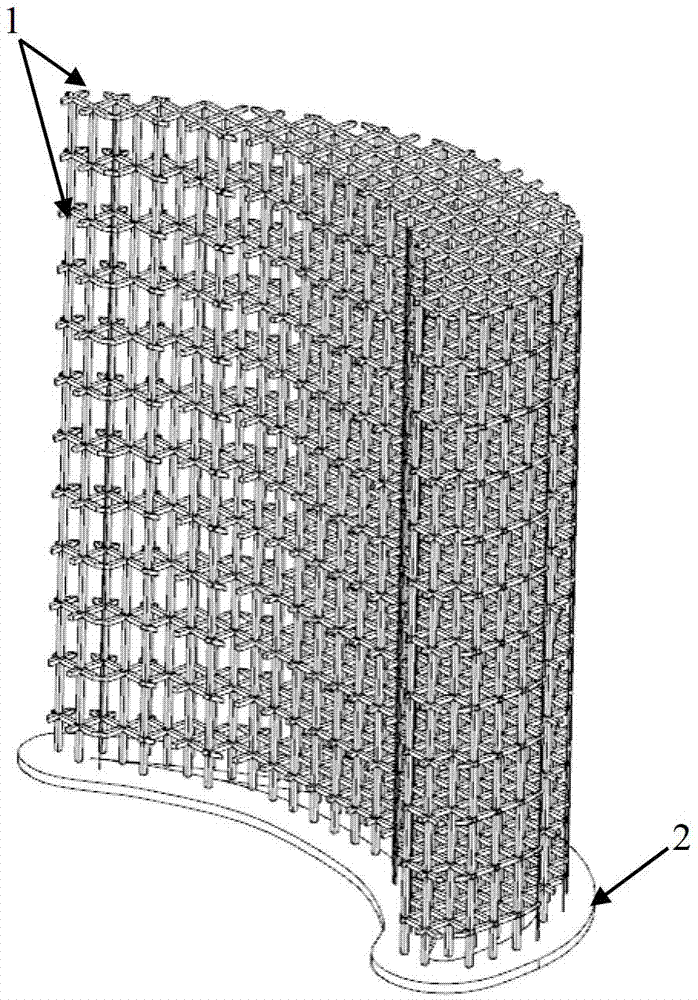

Preparation method of SiCf/SiC ceramic matrix composite turbine blades

InactiveCN103113123AMeet preparation requirementsImprove silicon corrosion resistanceYarnStress distribution

The invention discloses a preparation method of SiCf / SiC ceramic matrix composite turbine blades, which is characterized in that through analyzing the stress distribution of a blade in an application state, based on this point, a performance-controllable SiCf / SiC ceramic matrix composite turbine blade is manufactured through the designing and adopting of processes such as rapid forming, high-performance continuous yarn braiding, gel-casting, reactive sintering, and the like. According to the method, parts such as blades and the like are manufactured by using heterogeneous materials, the contradiction between the uniformity and nonuniform loaded structure of materials is solved, and the performances of materials can be set flexibly according to the bearing needs of manufactured parts; and prepared SiCf / SiC ceramic matrix composite turbine blades have the characteristics of near-net forming variable-cross-section complex structure, controllable material performance, flexible machining, short production cycle, low cost, and the like, and can be applied to the development and manufacturing of high-temperature-resistant complex structured parts for aerospace and the like.

Owner:XI AN JIAOTONG UNIV

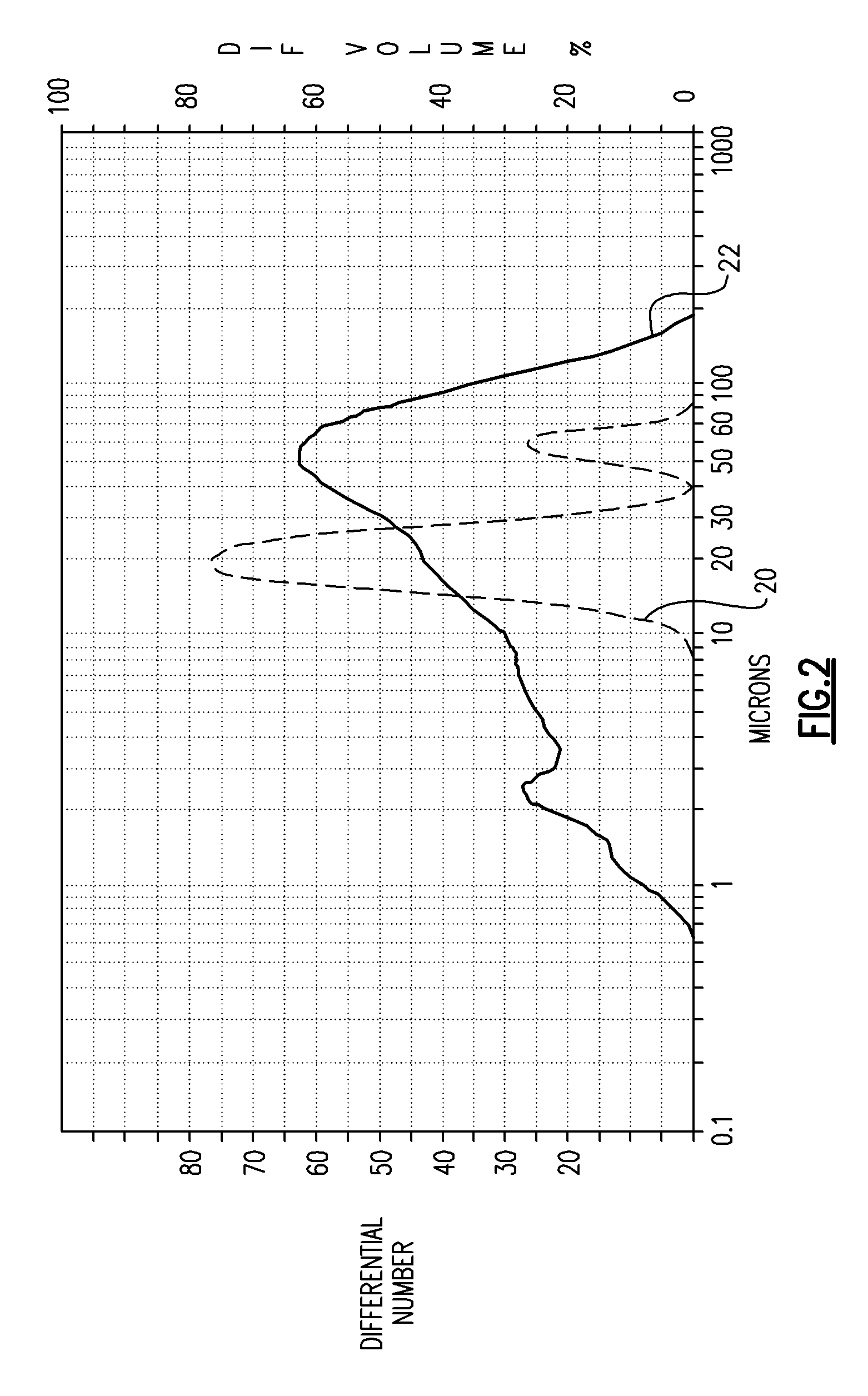

Preparation method of large quartz ceramic crucible

The invention discloses a preparation method of a large quartz ceramic crucible, which is formed based on the method of gel casting molding, and particularly comprises the following steps: a) taking fused quartz with purity of 99.0-99.9% according to the mass percent as a raw material, and carrying out granular grading on the grains of the fused quartz; b) uniformly mixing the raw material proportioned by the step a), adding gel solution, preparing into pulp in a ball mill or a blender; c) injecting or pressure-injecting the prepared pulp prepared by the step b) into a preheated metal mold, and taking out from the metal mold after the pulp is solidified into green bodies; d) naturally drying the green bodies; and e) putting the dried green bodies into a high-temperature furnace, baking toobtian the large quartz ceramic crucible. Raw material grain proportioning and the preparation method, optimized by the invention, can product the quartz ceramic crucible with larger overall dimension and thin wall for fusion of special glass, casting of polycrystalline and calcining of rear earth material.

Owner:洛阳北苑新材料技术有限公司

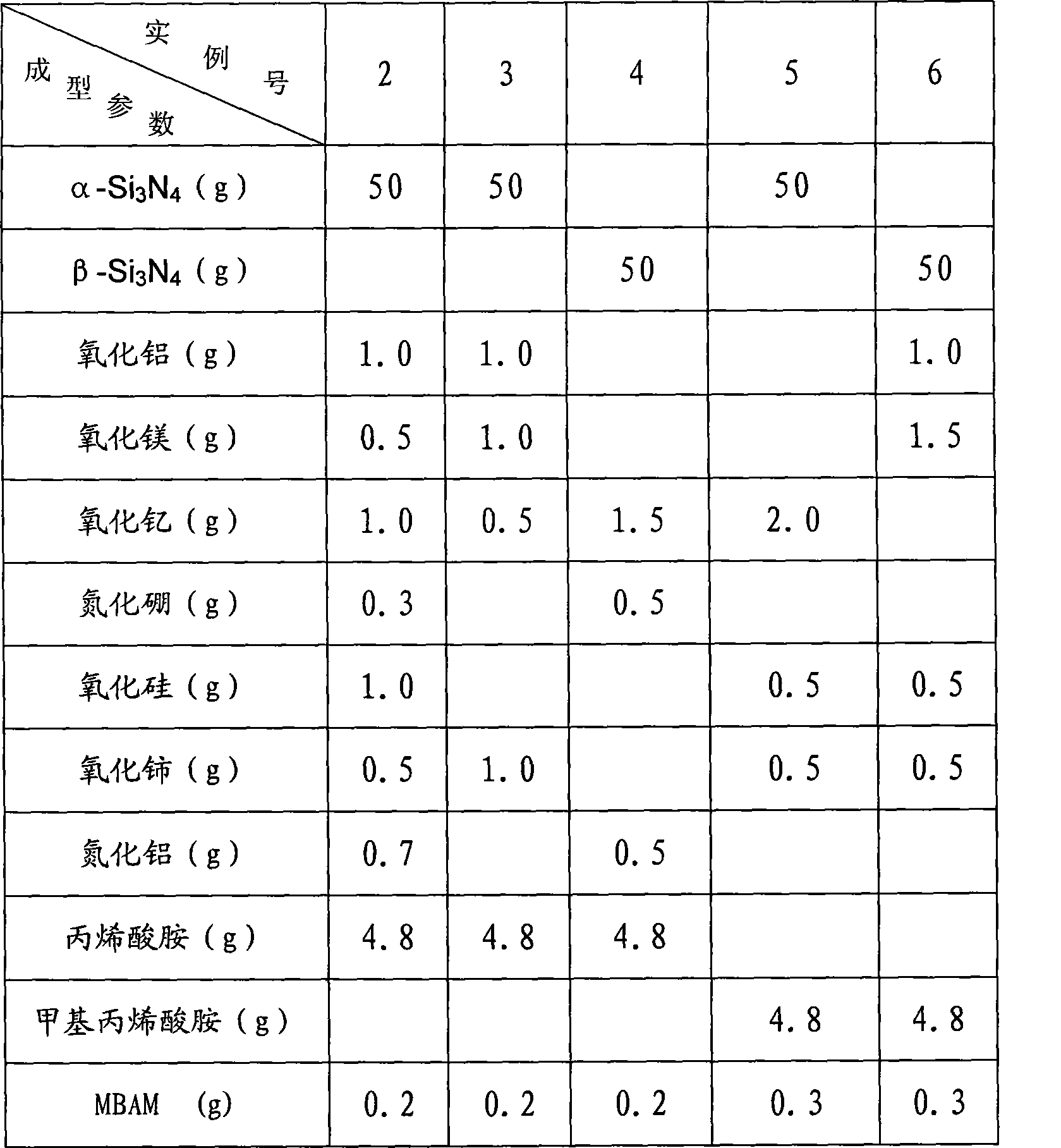

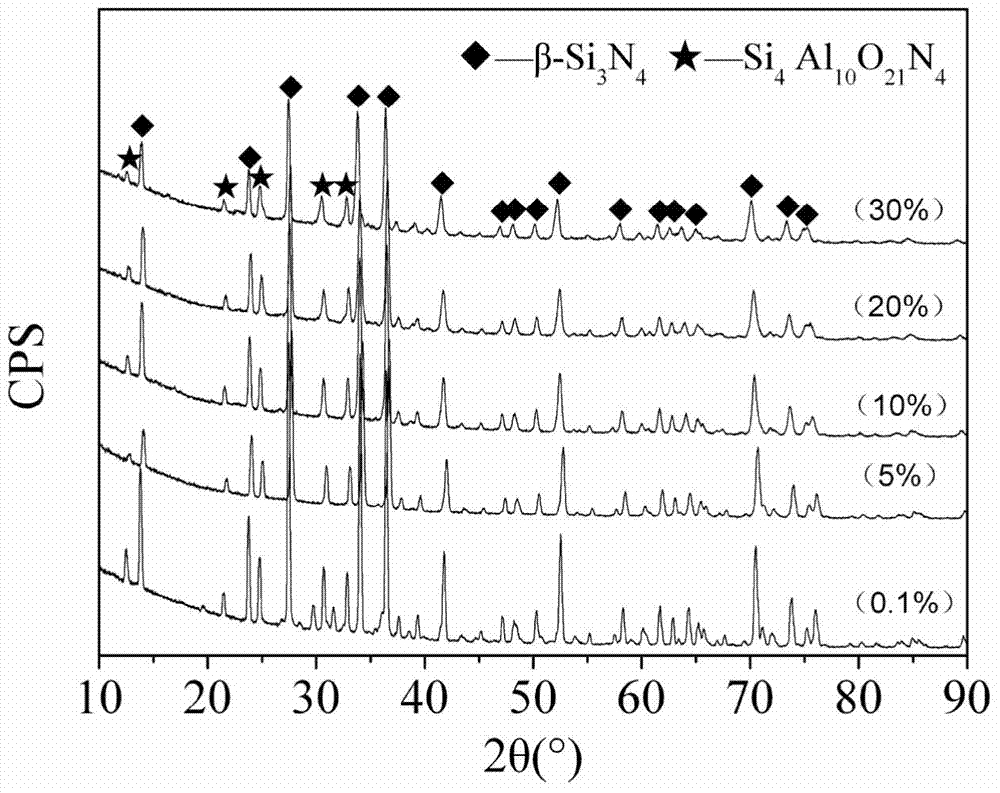

Gel-casting moulding technique for preparing silicon nitride ceramics heating element

InactiveCN101397210AUniform structureImprove dry strengthCeramic shaping apparatusMicrowave ovenCross linker

The invention relates to a gelatin injection molding-shaping method for preparing silicon nitride ceramics heating elements, pertains to the technical field of inorganic material composition and preparation, and is characterized in that the following steps are included: a monomer solution containing an organic monomer and a cross linker is confected, silicon nitride ceramics powder and 4-39% of sintering addition agent are added for preparing suspensoid slurry, and dispersing agent which accounts for 1-3% of the mass of solid-phase powder material is added; the pH value is adjusted to 9-11; the suspensoid slurry is ball-milled for 4-8 hours, and the ceramics slurry with 55-60% of solid phase volume content and 0.7-0.9 Pa.s of viscosity is obtained; 20-50% of initiator and 10-30% of catalyst are added and stirring is carried out in vacuum for 5-15 minutes to remove bubbles; then injection mold, solidification and dryness are carried out; finally the blanker is sintered in a microwave oven at 1550-1800 DEG C. The ceramics blanker obtained by the invention has even structure, the operation is simple, and the production cost is low.

Owner:SHENZHEN JINKE SPECIAL MATERIALS CO LTD

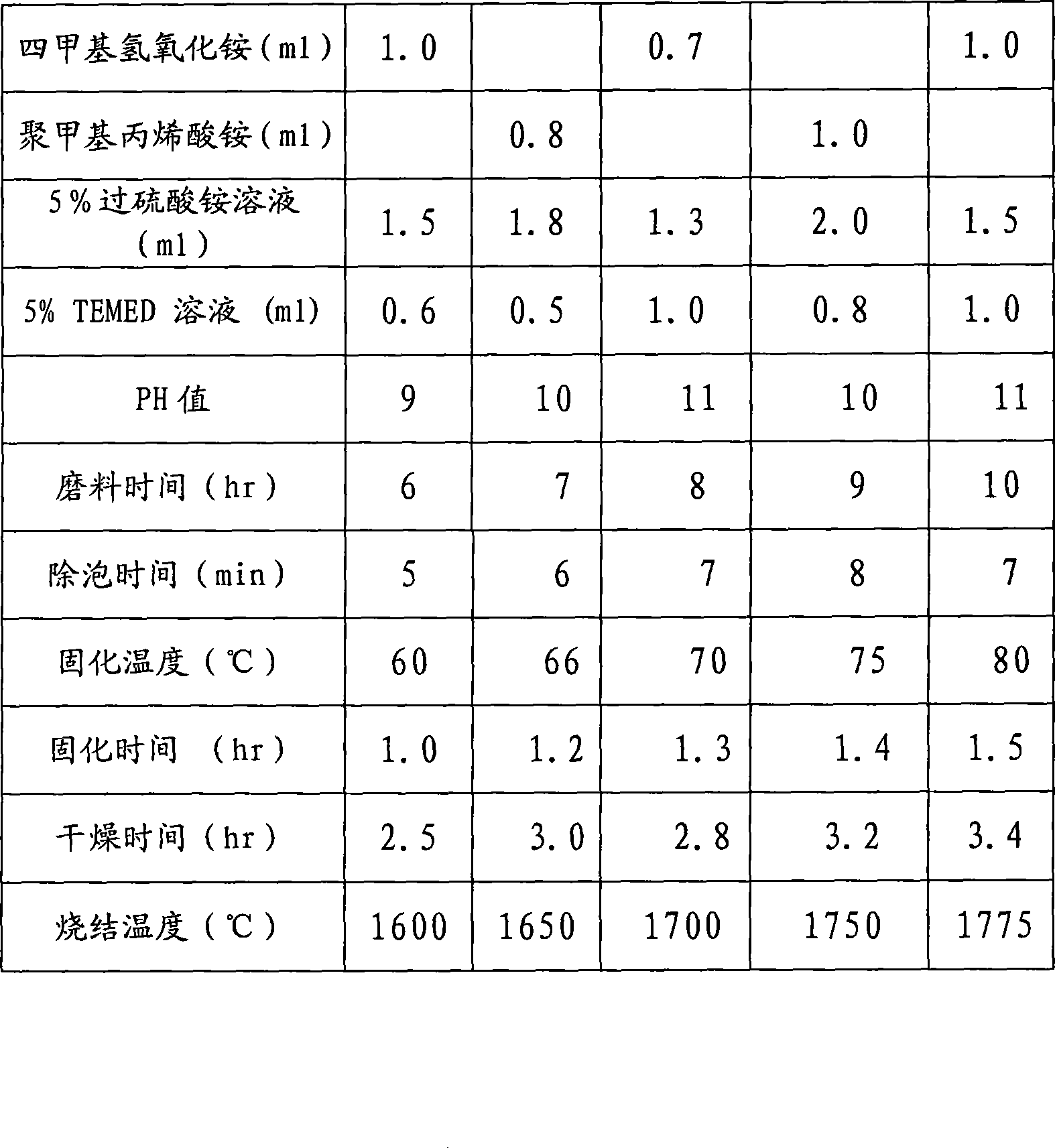

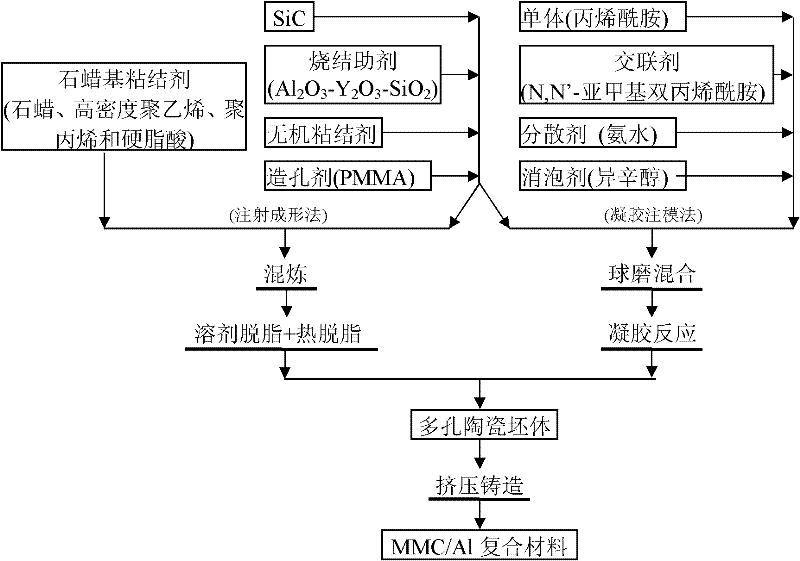

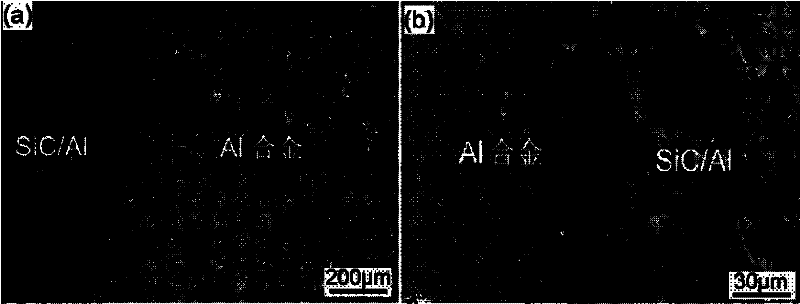

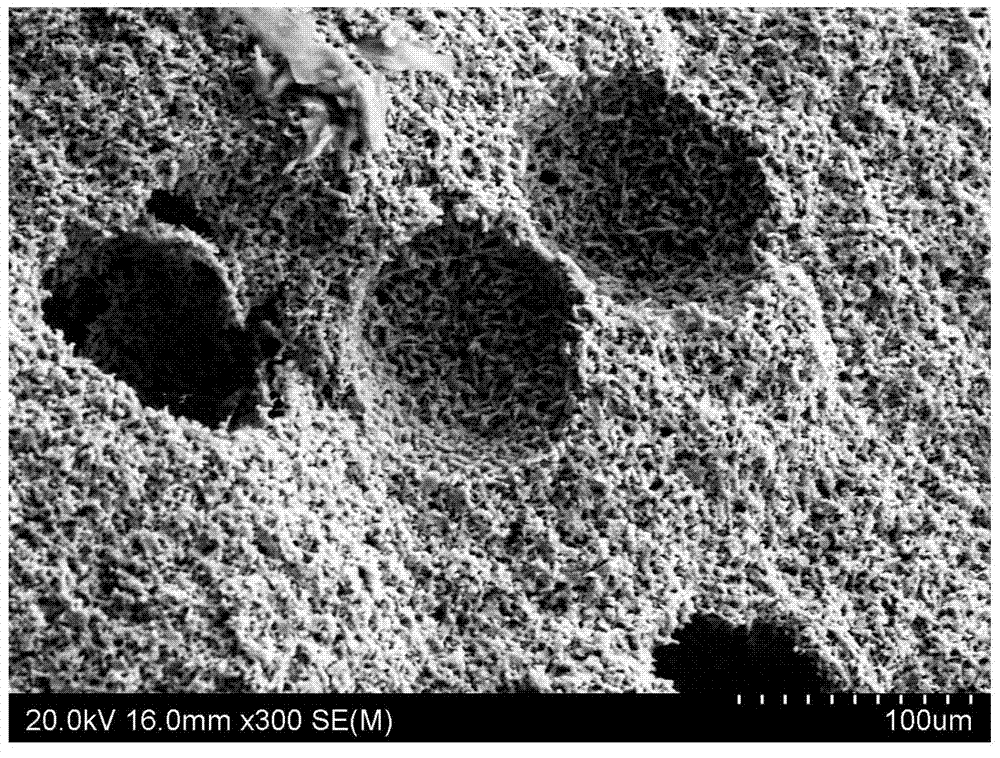

Method for preparing selectively enhanced aluminum-based composite from ceramic particles

The invention relates to a method for preparing selectively enhanced aluminum-based composite from ceramic particles and belongs to the field of metal matrix composites (MMCs). The preparation method comprises the following steps: firstly, preparing porous ceramic blanks; and secondly, putting the porous ceramic blanks at a part needing to be enhanced, injecting molten alloy into a mould at 750-1,100 DEG C, applying pressure of 20-50MPa to forcibly fill the molten alloy into the porous ceramic blanks and a mold cavity, and solidifying, thus obtaining the selectively enhanced aluminum-based composite. The method has the advantages that a foaming technology, an injection molding and a gel casting process are combined, thus leading the porous ceramic blank to have designability; the MMC reinforcement and an aluminum matrix are integrally formed by adopting extrusion casting process, thus fully playing the advantages of high strength and high toughness of the aluminum matrix and wear resistance of the MMC reinforcement. The composite has the advantages of high thermal conductivity, good radiation capability, excellent wear resistance and light weight.

Owner:UNIV OF SCI & TECH BEIJING

Nano ceramic water-base gel casting method

The invention relates to a nano-ceramic water-based gelcasting method. It first models the nano-ceramic powder in the method of gelcasting, and then presses the drying biscuit in the mould to form the model. This invention greatly improves the density of nanometer ceramic biscuit and its microstructure.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

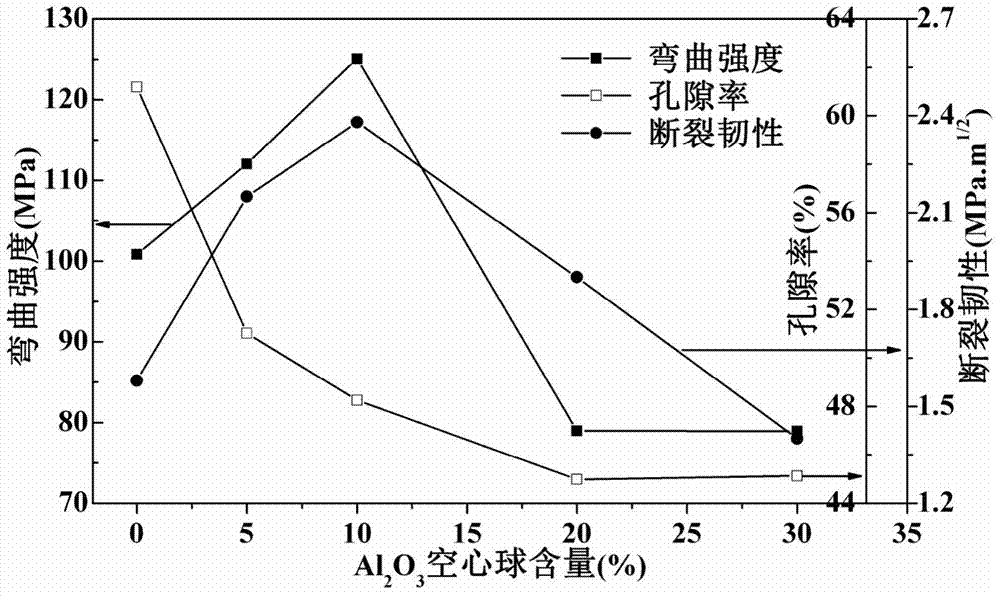

Preparation method for porous silicon nitride ceramic

The invention provides a preparation method for porous silicon nitride ceramic. The preparation method comprises the following steps: preparation of gel; addition of a pore forming agent; molding of a green body; drying of the green body; sintering of the green body; etc. The method combines a gel-casting and a pore forming agent addition process together and has the advantages of simple process, low cost and substantially shortened gel discharge time; and the prepared porous silicon nitride ceramic has great porosity, high bending strength and good mechanical properties.

Owner:HOHAI UNIV

Gel-casting 3D printing preparation method for ceramic gradient material

InactiveCN104493952AImplement gradient distributionImprove work efficiencyCeramic shaping apparatusGradient materialAdditive ingredient

The invention discloses a gel-casting 3D printing preparation method for ceramic gradient material. The gel-casting 3D printing preparation method for the ceramic gradient material includes steps that 1) building a computer three-dimensional sketch map of the ceramic gradient material, slicing, and building a scanning route; 2) calculating ingredient proportions of different positions; 3) setting corresponding printing parameters; 4) preparing ceramic ingredient, organic monomer, cross-linking agent, initiator, catalyst and the like; 5) starting printing equipment to perform sol-gel 3D printing, pouring the ceramic ingredient, organic premixed liquid, initiator and catalyst to a printing head, and printing to form according to a set track and a set speed after mixing; 6) sintering the green body to prepare the ceramic gradient material. The gel-casting 3D printing preparation method for the ceramic gradient material has advantages that the gradient distribution for the ingredients is really realized through using a computer to control the ingredient proportions at different positions; the 3D printing technology belongs to a material increase preparing method, compared with a traditional technique, raw material is saved.

Owner:HARBIN UNIV OF SCI & TECH

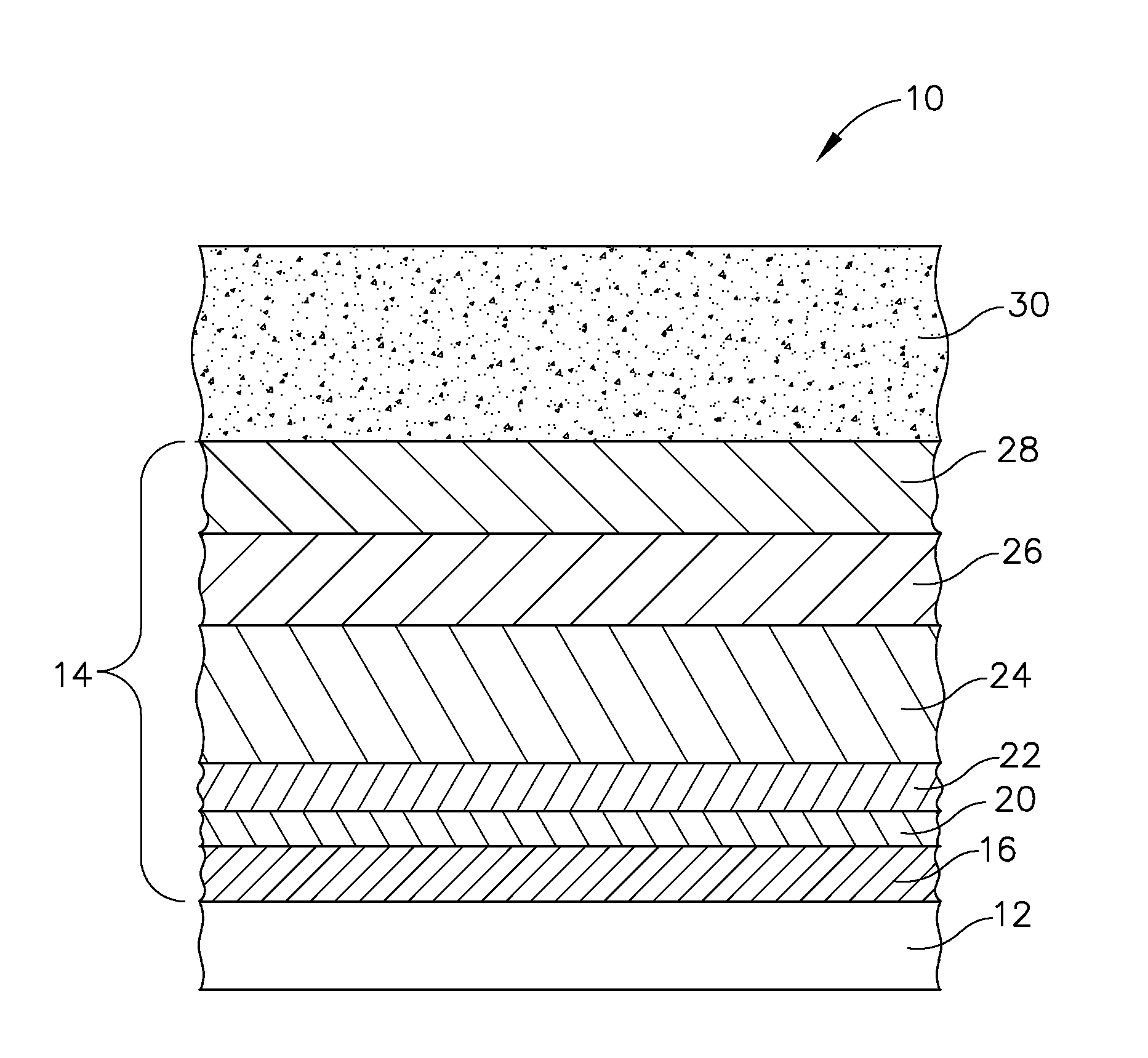

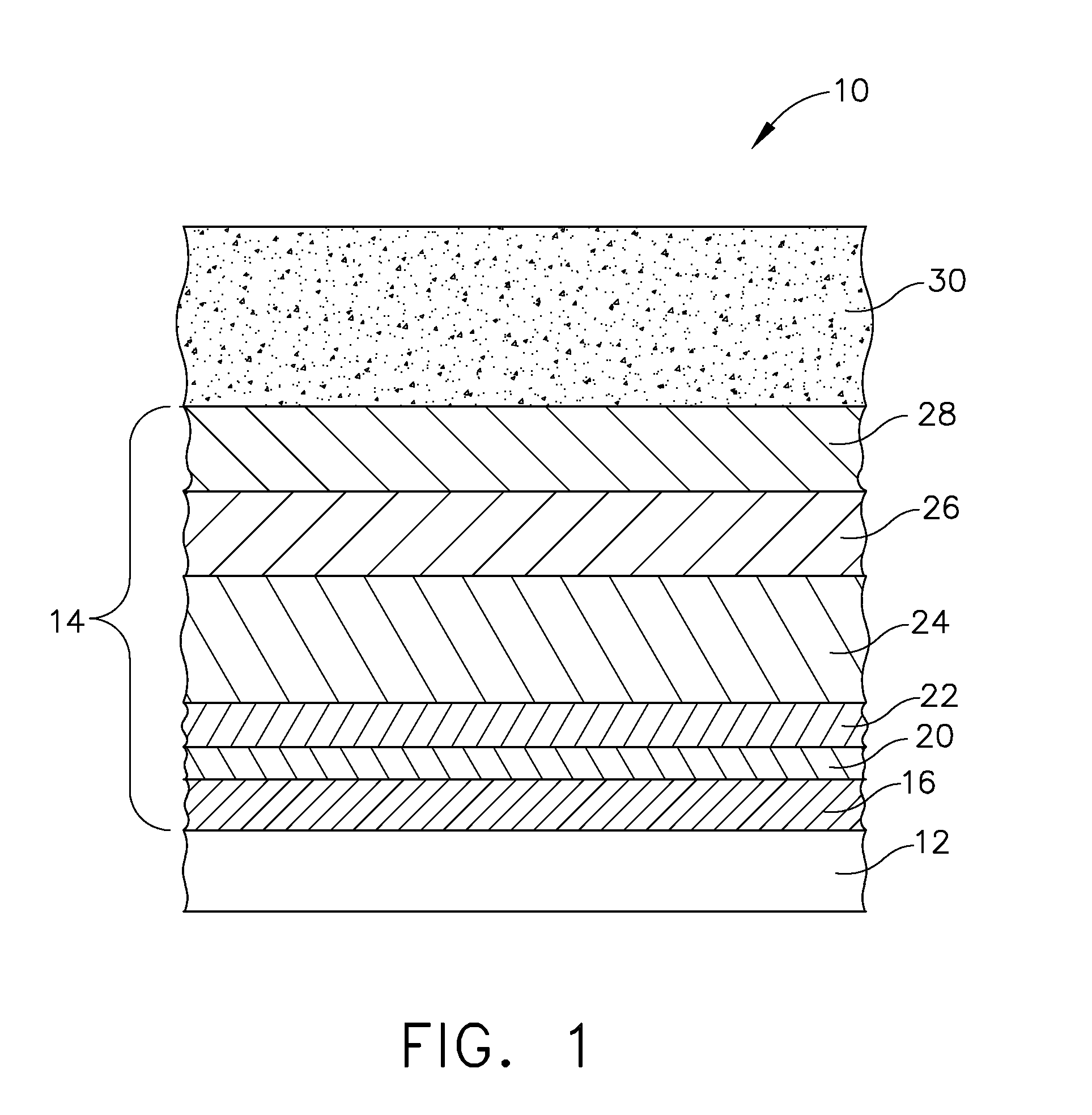

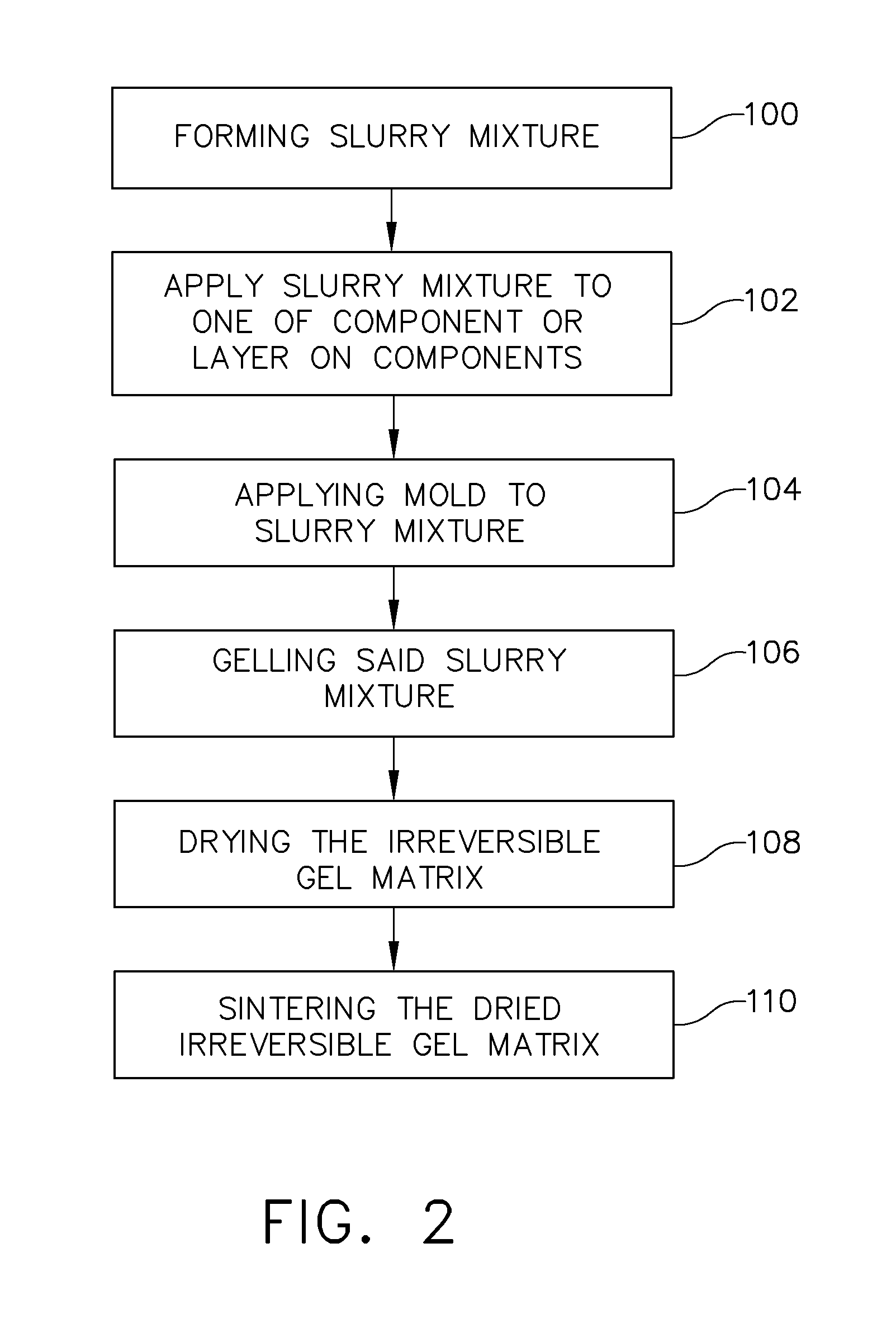

Method of depositing abradable coatings under polymer gels

ActiveUS20160312628A1Avoid Blade DamageAvoid damageEngine fuctionsBlade accessoriesGel castingPolymer gel

Owner:GENERAL ELECTRIC CO

Yttrium-aluminium series small crystal transparent ceramic material and preparation method

The invention relates to an yttrium-aluminum series of transparent ceramic material of small crystal and a preparation method, pertaining to the preparation of Y2O3A12O3 series of transparent ceramic. The method of the invention adopts sol gel, coprecipitation, combustion synthesis and spray pyrolysis to prepare the powder while adopts dry compression, iso-static pressing, slip casting, gel casting or electrophoretic deposition to prepare the bisque. The transparent ceramic with small crystal obtained by adopting vacuum sintering, hydrogen sintering, two-step sintering method, spark plasma sintering method and high pressure low temperature sintering method has the content of Y2O3 from 0 to 100 percent, the content of A12O3 from 100 to 0 percent, and the transparent ceramic pellet, the dimension of which is below 300 nm, thus having good transmittance performance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

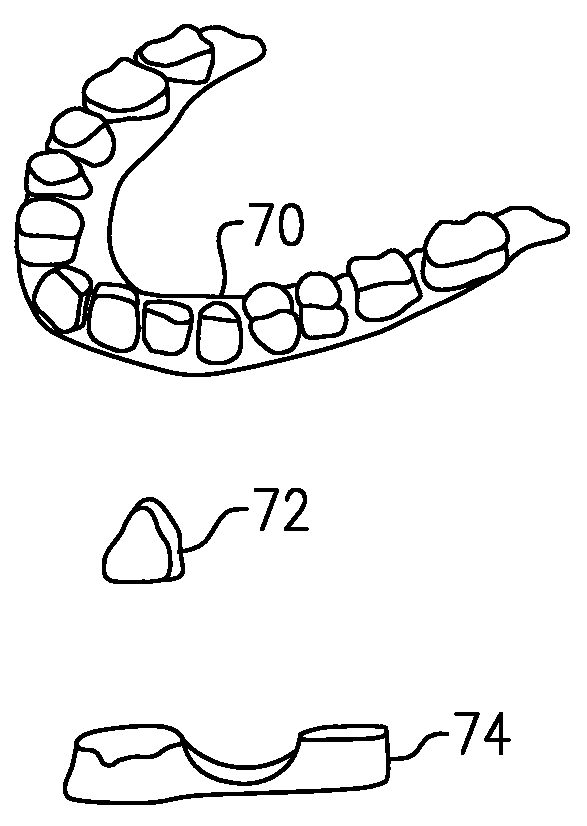

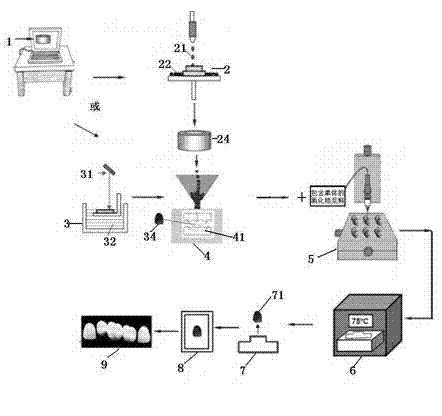

Method for producing zirconia denture through rapid prototype of gel-casting

InactiveCN102755199AHigh material utilizationImprove production efficiencyArtificial teethComputer Aided DesignDentures

The invention discloses a method for producing zirconia denture through rapid prototype of gel-casting. The method comprises the following steps of step one, collecting three-dimensional data of an oral cavity through a computer to generate a three-dimensional computer-aided design (CAD) virtue model of the required denture; step two, producing a male die of the required denture according to the three-dimensional CAD virtue model obtained in the step one; step three, producing a female die by wrapping the male die obtained in the step two; step four, injecting zirconia colloidal slurry into the female die obtained in the step three through a gel-casting process, and performing heating to induce a polymerization reaction to enable the zirconia colloidal slurry to be cured; step five, demoulding and drying the cured zirconia to obtained a blank of the required denture; and step six, sintering the blank to obtain the zirconia denture. The method for producing the zirconia denture through the rapid prototype of the gel-casting has the advantages of being high in material utilization rate, producing efficiency and product density, and good in strength.

Owner:SHANGHAI I DENTAL TECH CO LTD

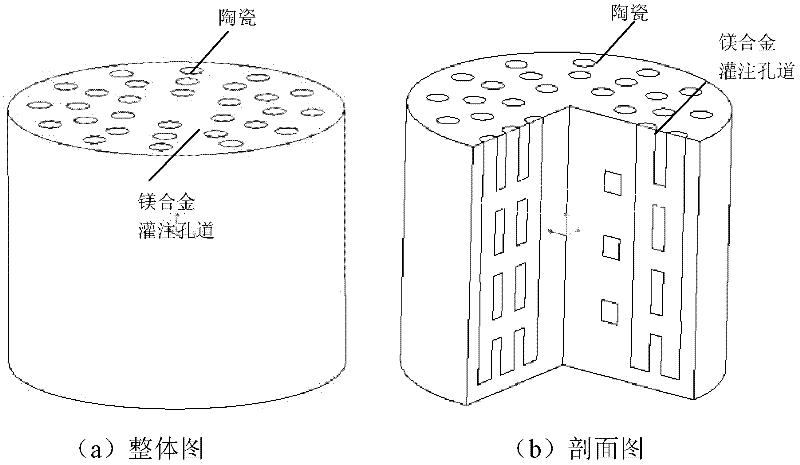

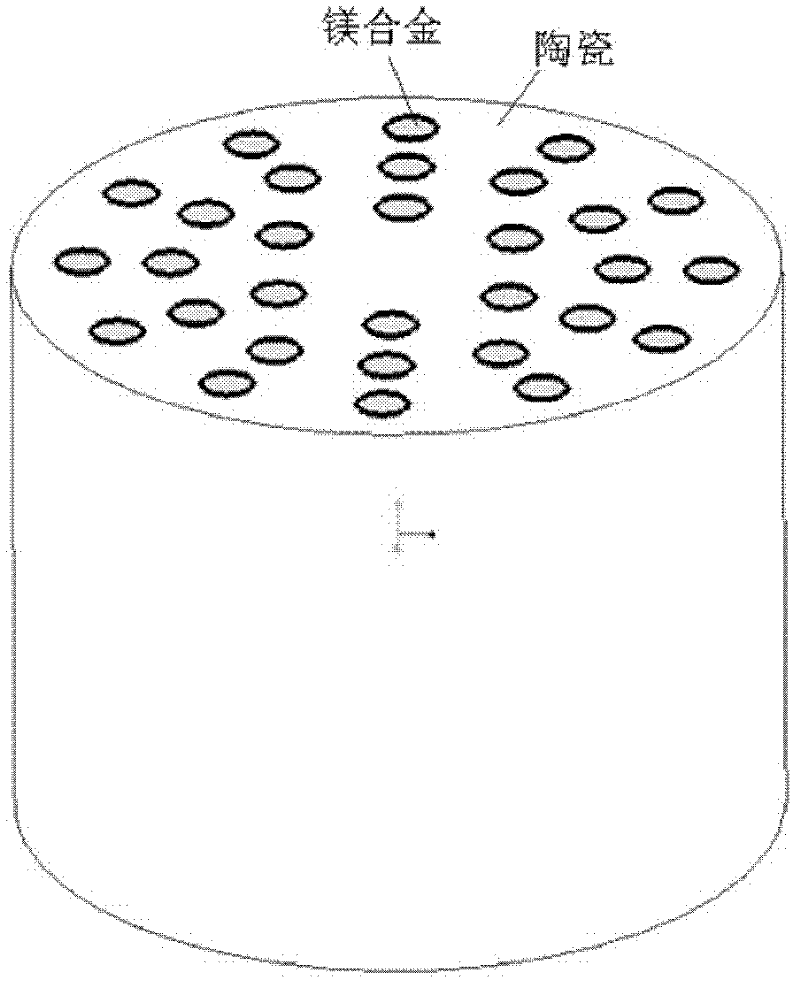

Magnesium alloy/biological ceramic bone bracket based on photocuring and gel casting and forming method of bone bracket

InactiveCN102335460AImprove early mechanical propertiesMeet growthBone implantBiomechanicsGel casting

The invention discloses a magnesium alloy / biological ceramic bone bracket based on photocuring and gel casting and a forming method of the bone bracket. The method comprises the following steps of: establishing computer-aided design (CAD) models of the bracket and a bracket negative model through shape correlation and microstructure simulation by using reverse engineering and CAD according to the structures of different bone defect parts and the analysis results of biomechanics; making a resin bracket negative model by a photocuring technology; filling ceramic slurry into the bracket negative model by a gel casting process, curing and sintering at a high temperature to make a biological activity ceramic framework with mutually-communicated porous pipelines; and casting molten magnesium alloy into the porous pipelines of the biological activity ceramic framework by a vacuum suction casting method, cooling for solidification, and thus obtaining the magnesium alloy / biological ceramic simulation composite structure bone bracket. The internal microstructure of the made bracket consists of the mutually-communicated pipelines, the magnesium alloy is filled in the pipelines to increase the early mechanical property of the composite bracket, and the pipelines filled with the magnesium alloy become mutually-communicated pore passages as the magnesium alloy is corroded and degraded, so that the requirements of organization growth, nutrition and metabolism are met.

Owner:XI AN JIAOTONG UNIV

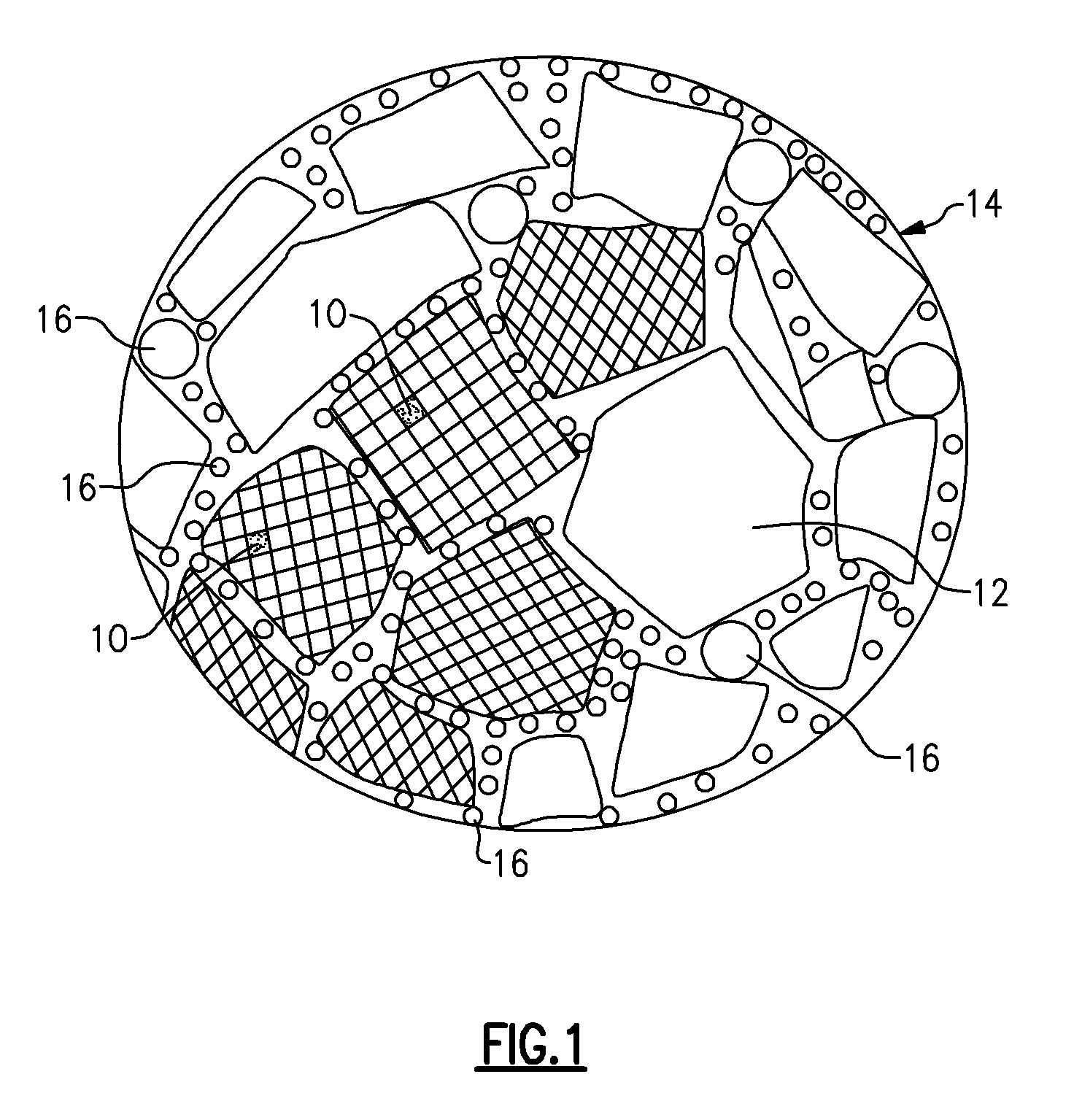

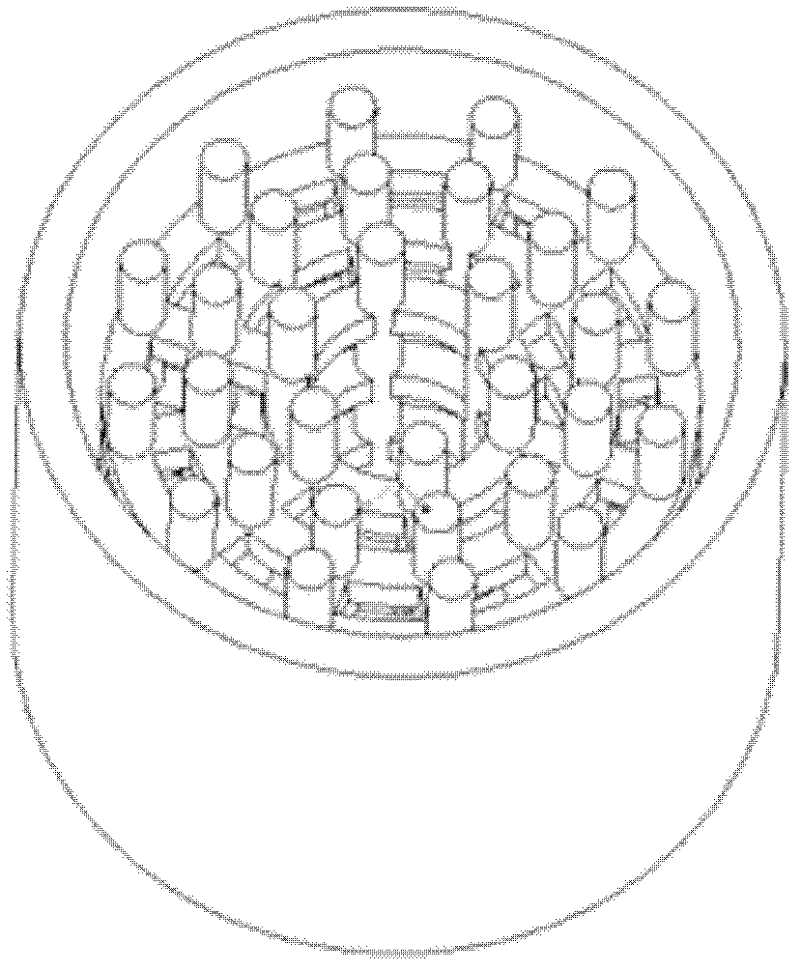

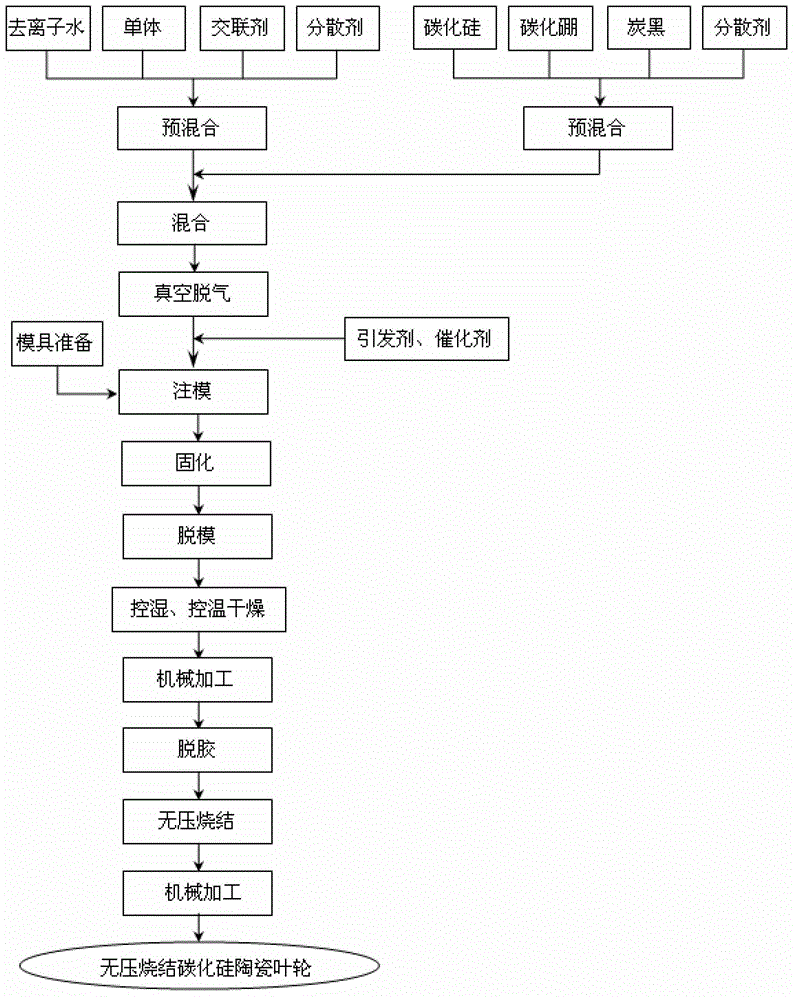

Method for preparing silicon carbide ceramic impeller through gel casting and pressureless sintering

ActiveCN102875150AAvoid uneven dispersionOvercome defects such as uneven curingCarbide siliconGel casting

The invention discloses a method for preparing a silicon carbide ceramic impeller through gel casting and pressureless sintering, and provides a preparation method of a pressureless sintered silicon carbide ceramic impeller with a complex and accurate shape characteristic and an external diameter size capable of reaching over 160 mm. A silicon carbide solid-phase sintering formula system of a boron-containing sintering auxiliary agent and a gel casting and pressureless sintering process are adopted; and the method comprises eight steps of: preparing ceramic slurry; performing injection molding; demolding; drying; machining; degumming; performing pressureless sintering; and machining. According to the method, the technical problems of non-uniform mixing of large-scale ceramic slurry in gel casting, dryness, crack and deformation in a pressureless sintering process and the like are solved, and finally, preparation of the pressureless sintered silicon carbide ceramic impeller is realized. The impeller has good performance such as corrosion resistance, wear resistance, high temperature resistance and the like, and can be widely applied to a centrifugal pump for corrosive liquid conveying of various industries.

Owner:UNIV OF SCI & TECH BEIJING

Method for improving high-temperature performance of alumina-base ceramic core

InactiveCN101955353AHigh apparent porosityGuaranteed impregnation effectTurbine bladeRoom temperature

The invention discloses a method for improving the high-temperature performance of an alumina-base ceramic core, which comprises the following steps of: firstly, preparing an alumina-base ceramic core blank by adopting a gel casting molding process; secondly, preparing an alumina-base ceramic core prefabricated body with a plurality of holes and certain room-temperature anti-bending strength by freezing, drying and pre-sintering; thirdly, allowing penetrating fluid to seep into the alumina-base ceramic core prefabricated body under the conditions of vacuum and external pressure, drying, removing gel and soaking under vacuum and at pressure for three times; and finally, sintering at a high temperature to obtain the required alumina-base ceramic core. The alumina-base ceramic core prepared by the invention has high high-temperature performance and high core-removing property, can meet the process requirements of a hollow turbine blade on directional casting and single-crystal casting and guarantees the qualification rate of blade castings.

Owner:XI AN JIAOTONG UNIV +1

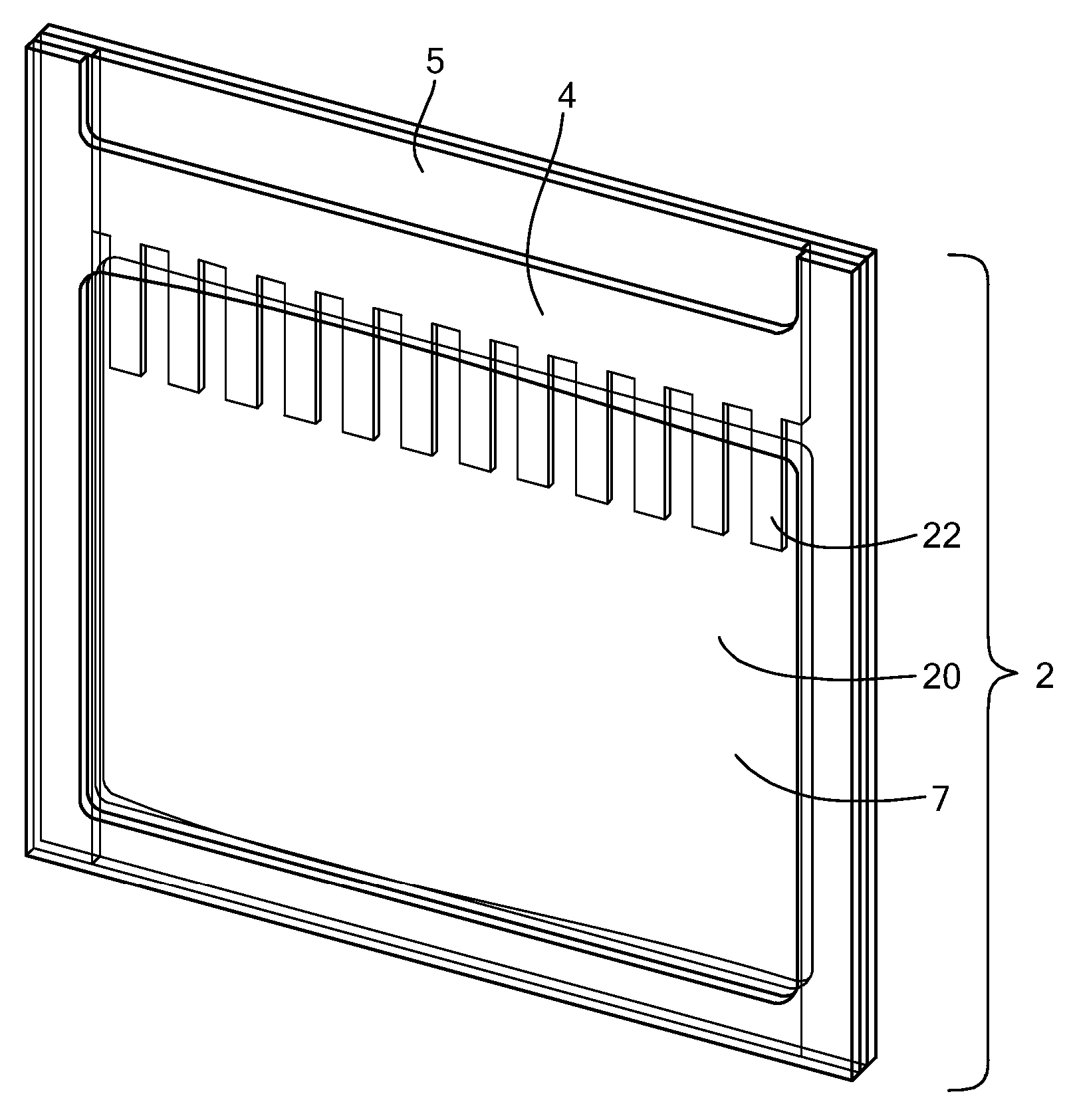

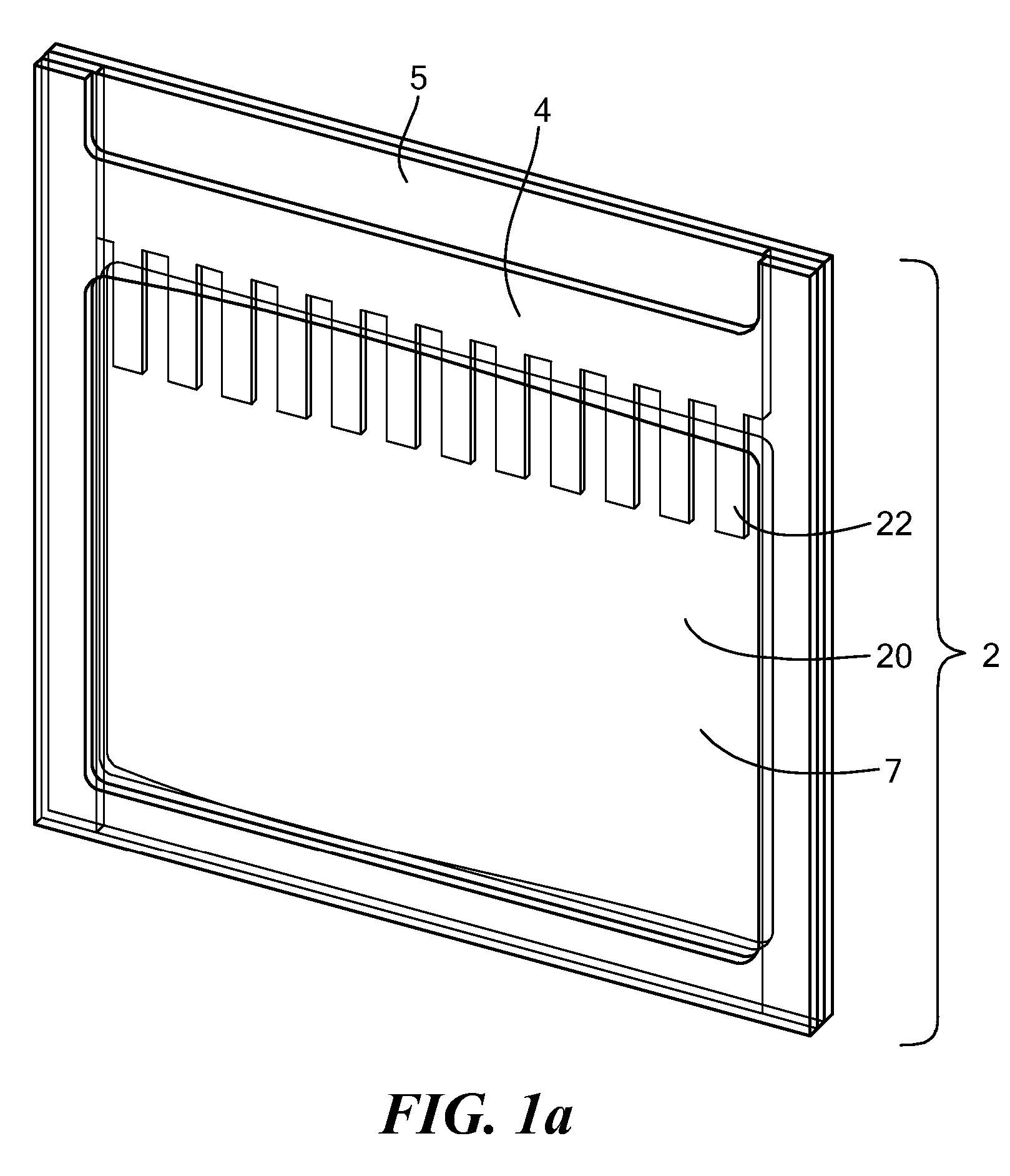

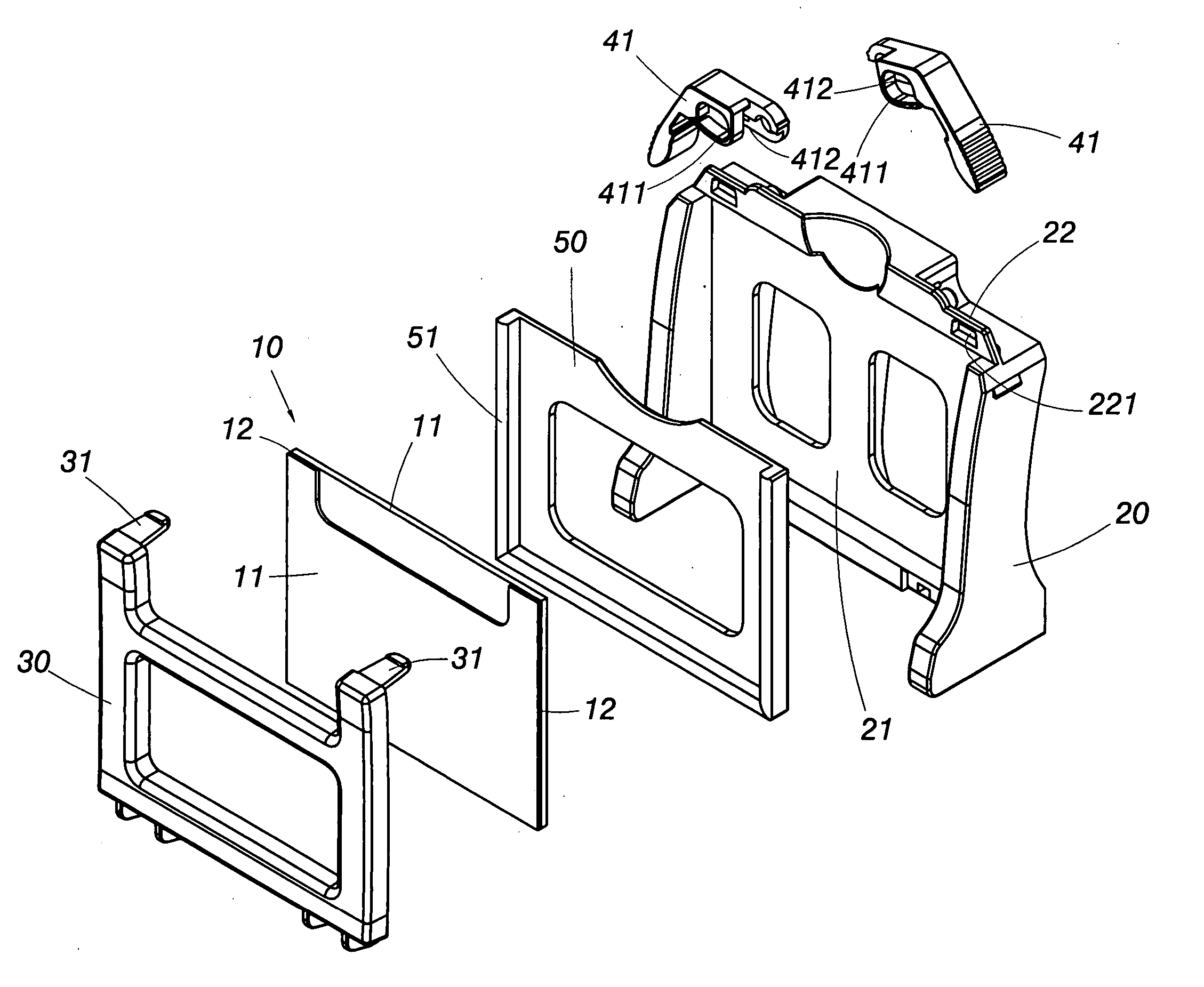

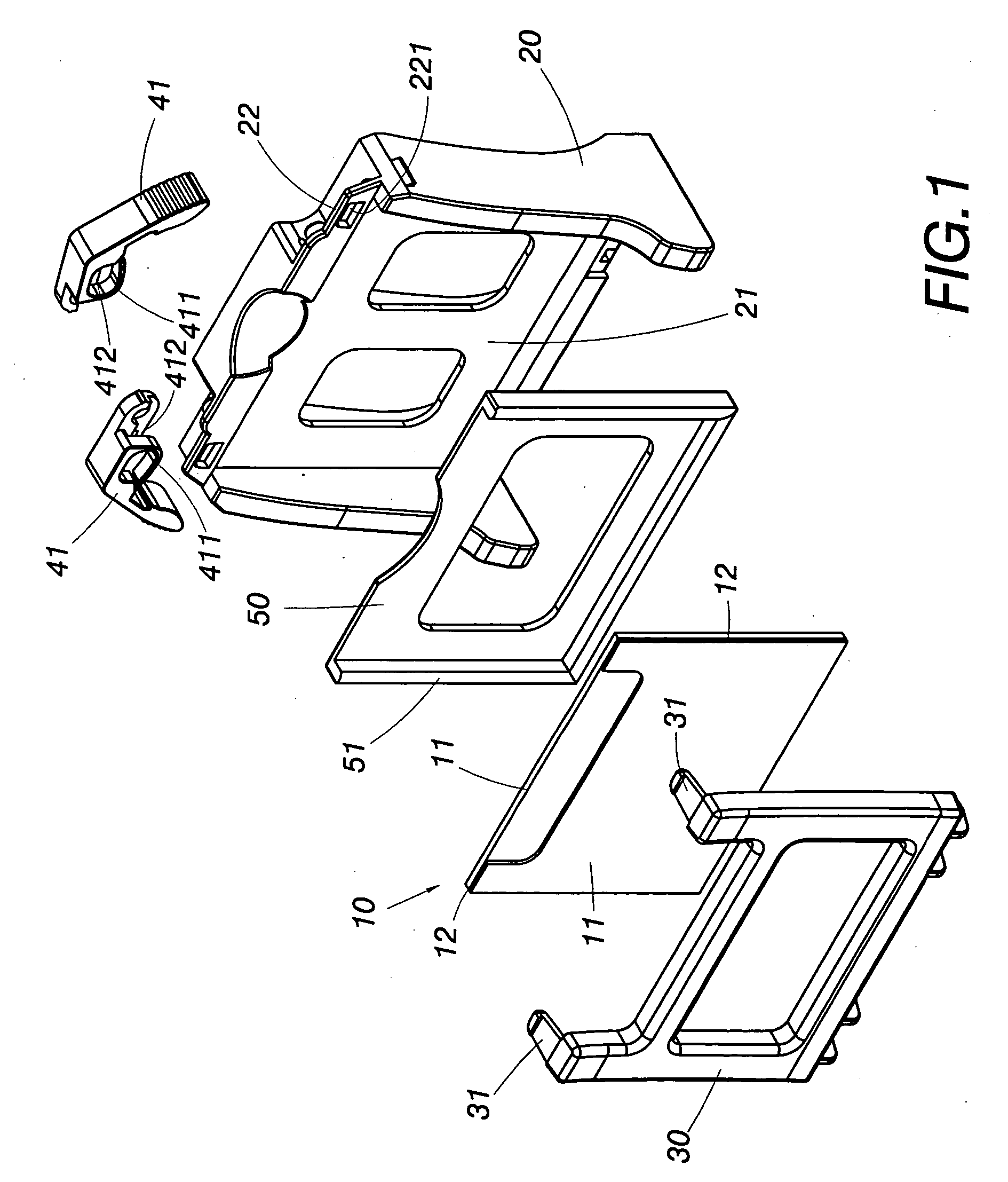

Gel casting module and electrode module of an electrophoresis device

InactiveUS20060278533A1Simple operation modeAvoid breakingCellsSludge treatmentElectrophoresisEngineering

A gel casting module and an electrode module provided on a caster in an electrophoresis device having at least a recess provided for clinging thereto of a flat plate of a gel plate sandwich, a caster lid is provided on the lower side of the recess of the caster and can be turned to press on the recess; the caster is provided on two sides of its shoulder with clasps for fixing or releasing the caster lid, thereby the caster is used as a main-body for the gel casting module and the electrode module to position the gel plate sandwich. When in use, it needs only to do an action of closing the caster lid, the gel plate sandwich can be surely fixed on the caster; this not only increases the convenience of operation, but also largely simplifies the operation procedure for electrophoresis gel casting and running.

Owner:WEALTEC BIOSCI

Preparation method of precision SiC ceramic formed by gel casting based on silicone mold and precision SiC ceramic

ActiveCN106747457AOvercoming Difficult FormingOvercome the technical problems of easy deformationCeramic shaping apparatusFreeze-dryingSilica gel

The invention belongs to the technical field of ceramic materials and discloses a preparation method of precision SiC ceramic formed by gel casting based on a silicone mold and the precision SiC ceramic. The preparation method disclosed by the invention comprises the following steps: firstly, producing a mold seed: determining the size M of the mold seed according to a formula M=P / ((1-a)(1-b)(1-c)); carrying out three-dimensional molding, producing the mold seed and carrying grinding and polishing treatment on the surface of the mold seed; secondly, producing the silicone die; thirdly, preparing ceramic slurry; fourthly, carrying out gel casting; fifthly, carrying out drying treatment on a green body; sixthly, carrying out sintering treatment to obtain a SiC ceramic part. The invention also discloses the precision SiC ceramic prepared by the method. According to the method, the gel casting, freeze drying and reaction sintering are carried out by using the silicone mold with good elasticity, the technical difficult problems of difficulty in deformation and easiness in deformation of the ceramic part with a complex structure are solved, and the preparation of the SiC ceramic with the complex structure and precision dimension is realized.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

Gel casting molding method based on gelose and ceramic slurry mixed solution

ActiveCN106079032ADoes not affect compactnessWith strengthSlip casting mouldsOrganic contentGel casting

The invention discloses a gel casting molding method based on a gelose and ceramic slurry mixed solution. The method comprises the specific steps that firstly, ceramic powder and a dispersing agent are added into water for preparing ceramic slurry with the solid phase volume fraction of 53-59%; then a gelose solution with the concentration of 3-4.5 wt% is added into the ceramic slurry, so that the pH value is regulated to 8-11, and the ceramic slurry is made even by means of ball-milling; the mixed slurry is injected into an imperforate mould for to be heated sufficiently after vacuum bubble removing is conducted; and then ceramic parts are obtained after cooling, drying and sintering are conducted. Due to the fact that the gelose solution and the ceramic slurry are mixed firstly and made even by means of ball-milling, and then are subjected to vacuum bubble removing and casting molding, bubbles are not generated in the process, and ceramic blanks are free of defects. By means of the method, the mixed slurry with the high solid phase content and the low viscosity can be prepared, and the compact ceramic parts in complicated shapes and with different sizes can be obtained after the blanks are sintered. In addition, the gelose is naturally macromoledular, the organic content in the blanks is low, and debonding is not needed; and the ceramic blanks have certain strength and can be processed to a certain extent before being sintered.

Owner:湖北迪洁膜科技有限责任公司

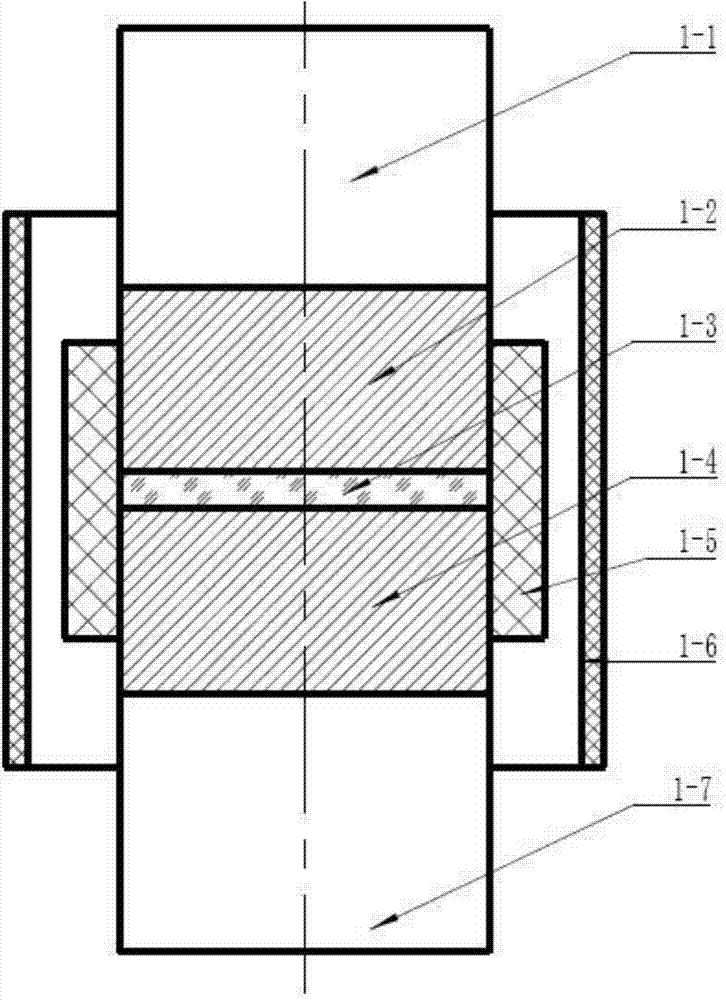

Hot pressed sintering method of ceramic products with high density and complex shapes

ActiveCN103896601AHigh densityComplex shape preservationCeramic shaping apparatusNumerical controlHigh density

The invention belongs to the technical field of preparation and forming methods of ceramic materials and in particular relates to a hot pressed sintering method of ceramic products with high density and complex shapes. In the method, a process for forming ceramic bodies with steel molds, which belongs to traditional hot pressed sintering processes, is abandoned. The method is characterized by firstly preparing a mold material into a required mold with a complex shape through a gel forming process, or firstly preparing a body of the mold material by adopting cold isostatic pressing, secondly machining the body into a required mold with a complex shape by adopting a numerically-controlled machine tool, thirdly preparing the target ceramic powder into slurry with high solid content by adopting the advanced gel forming technology, and injecting the slurry into the mold to form the composite hot-pressed body; or firstly preparing the target ceramic powder into a part body through a gel casting process, secondly injecting the mold material slurry through the gel casting technology to form the composite hot-pressed body, and removing the hot-pressed mold material after sintering, thus finally obtaining the ceramic products with complex structures and high density and properties.

Owner:TSINGHUA UNIV

Alumina fiber reinforced alumina ceramic matrix composite and preparation method thereof

The present invention discloses an alumina fiber reinforced alumina ceramic matrix composite and a preparation method thereof, the alumina fiber reinforced alumina ceramic matrix composite is characterized by comprising the following raw materials by weight: 40-60 parts of alumina, 20-30 parts of clay, 10-15 parts of modified alumina fiber, 2-3 parts of antimony sulfide, 1-3 parts of beryllium oxide, 0.03-0.05 part of methyl ethyl ketone peroxide, 3-5 parts of vinyl acetate, 0.2-0.4 part of silane coupling agent KH550, 1-2 parts of microcrystalline wax, 1-2 parts of carboxymethyl cellulose, 20-30 parts of ethanol, and 30-40 parts of deionized water; the antioxidant treated alumina fiber added in the alumina fiber reinforced alumina ceramic matrix composite is used as a ceramic reinforcing phase, and has the characteristics of ceramic toughness reinforcing properties, mechanical properties, abrasion resistance, hardness and high temperature resistance, the gel casting technology used in the method can reduce the production cost, and improve the material integrity and machinability, and any shape and size of ceramic structural workpieces can be convenient to produce.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

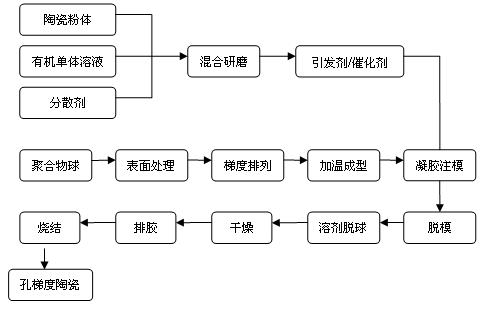

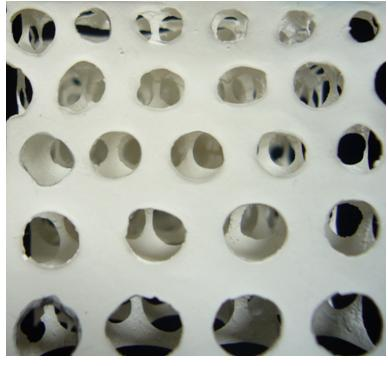

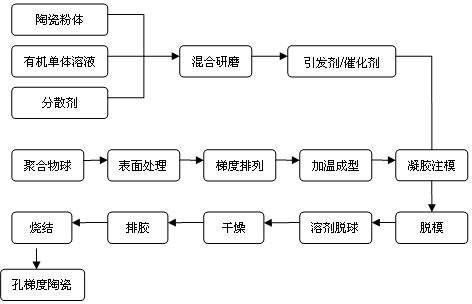

Method for preparing ceramic foams with pore gradient

The invention relates to a method for preparing ceramic foams with pore gradient. The method comprises the following steps: arranging polymers or organic matter spheres to form a template in gradient distribution according to the design requirement, carrying out heating and pressurizing to ensure the spheres to adhere to each other to form a whole, filling the whole into a moulding mould and then injecting slurry for gel casting and removing the mould after drying the spheres to obtain a moulded green body integrating the spheres and solidifying slurry, immersing the green body after removing the mould into a solvent or warming the green body, removing the spheres to obtain a network-shaped body only with the solidifying slurry and obtaining the ceramic foams with pore gradient after binder removal and high-temperature sintering. The ceramic foams prepared according to the technical scheme adopted by the invention have the following advantages: the pore diameters are in gradient distribution; the pore gradient can be designed and controlled; the moulded green body has high strength and can be processed and cut into needed shapes; the sizes and shapes of the products are controllable; the problem that the shapes and sizes of the products as well as the sizes of the pores are usually limited by organic carriers in the process of preparing the ceramic foams is solved; and the shortcomings of less slurry absorbed for moulding, more blind pores and low product strength in the impregnation method are overcome.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com