Patents

Literature

155results about How to "Meet preparation requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

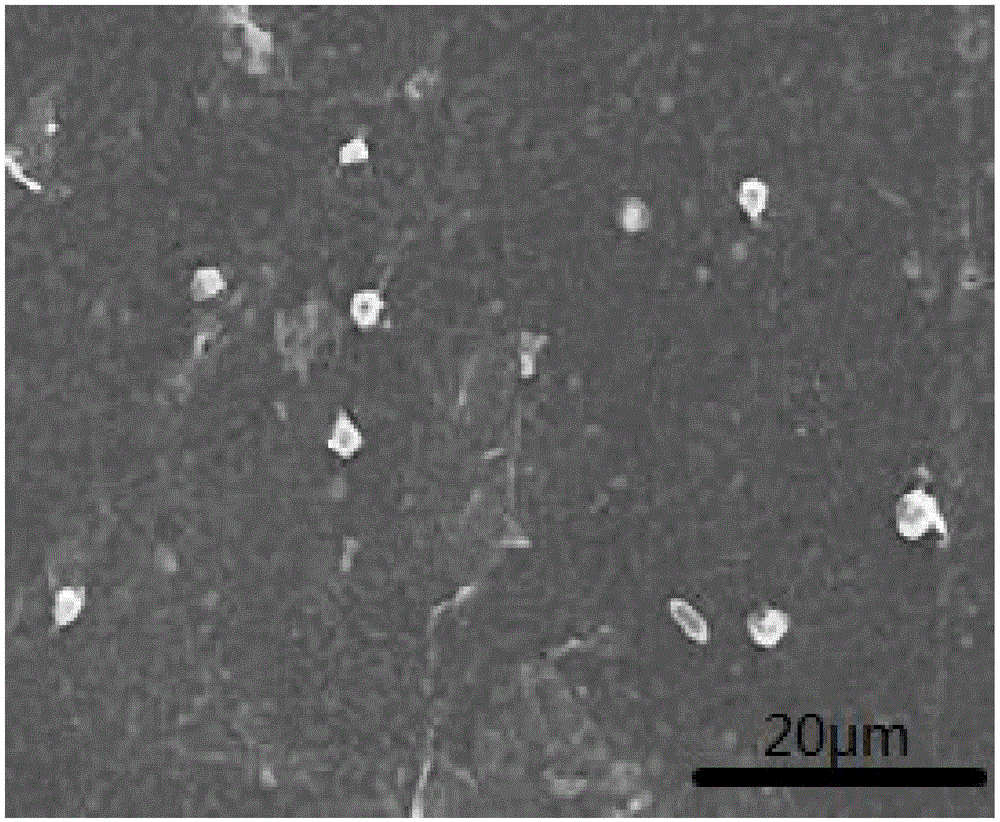

Method of preparing organization bracket performing selectivity laser sintering by using macromolecule microsphere

InactiveCN101138651AParticle size controllableHigh forming precisionBone implantSelective laser sinteringPolymer science

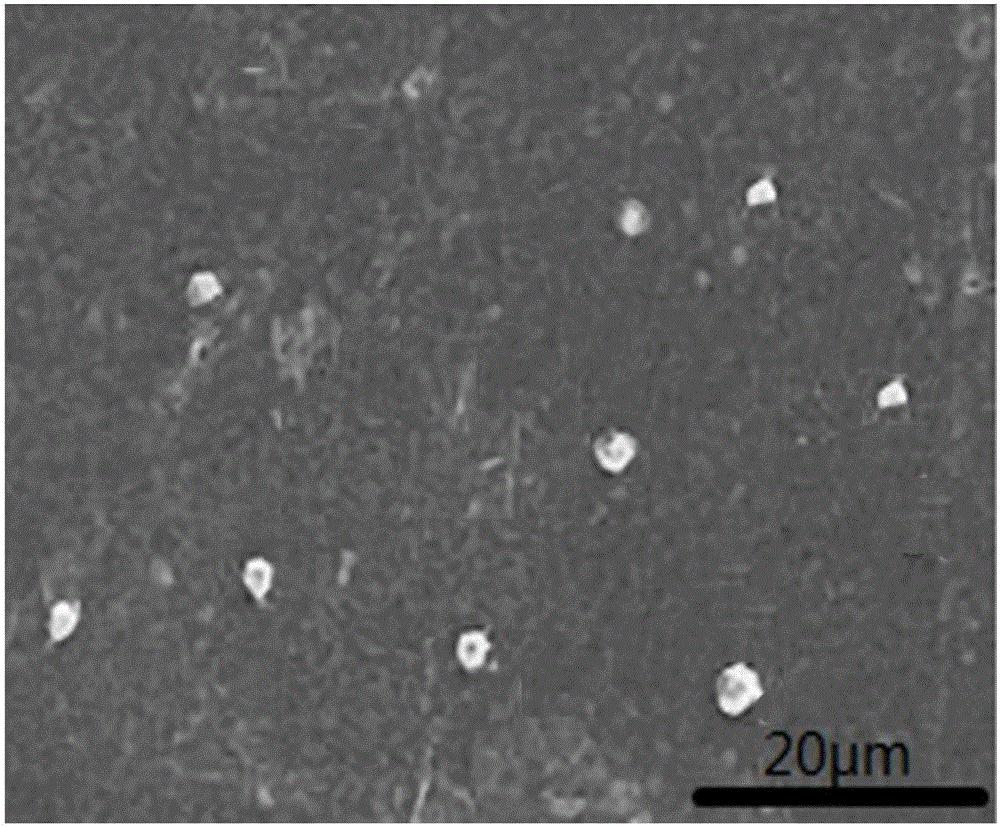

The present invention discloses a manufacture method of a tissue frame, which conducts the selective laser sintering by the polymer micro spheres. The method comprises the following steps. The polymer material dissolved in the solvent is dropped in the dispersant under stirring status at a uniform speed. The polymer micro spheres are obtained after cleaning, ultrasound dispersion and freezing preparation. The mixing powder is obtained after mixing the polymer micro spheres with a pore-foaming agent. A three-dimensional model of the frame is designed by the computer assistant software. The mixing powder is formed by the selective laser sintering according to the three-dimensional model; therefore the frame is produced. The polymer micro spheres produced by the method in the present invention have regular shapes and adjustable particle diameter. The method is simple and practical. The mechanical property of the frame after forming is excellent. The horizontal movement between the layers is small and the forming accuracy is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation device and method for multi-masterbatch, polyergic source and high throughput metal materials

The invention discloses a preparation device and preparation method of a high-flux metal material with multiple master batches and multiple energy sources. The device includes a high-energy electron beam generator, an arc generator, a laser, an arc generator and a high-energy electron beam generator. Converter, reflective laser prism, matrix master batch tank, high-efficiency ball mill-mechanical mixing-turbulent air mass synergistic mixing box, integrated structure of conduit and quality control valve, powder feeding pipe, atmospheric pressure and temperature controllable processing chamber, carrier protective gas , induction heating coil, self-heating three-dimensional motion sample processing platform, high-throughput preparation of new metal materials, using quality control valve to quantitatively distribute pure metal powder to the mixing box according to the calculated design requirements, high-efficiency ball milling-mechanical mixing-turbulent air mass synergy The mixing system thoroughly mixes multiple powders. The invention has wide application range, simple operation and wide range of materials that can be prepared.

Owner:SHANGHAI UNIV

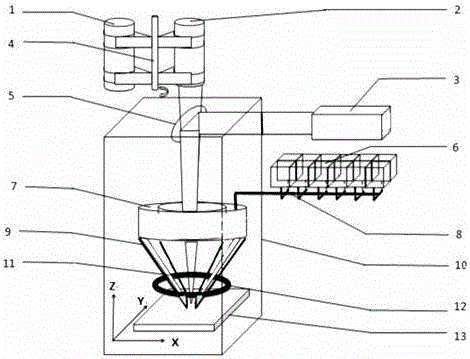

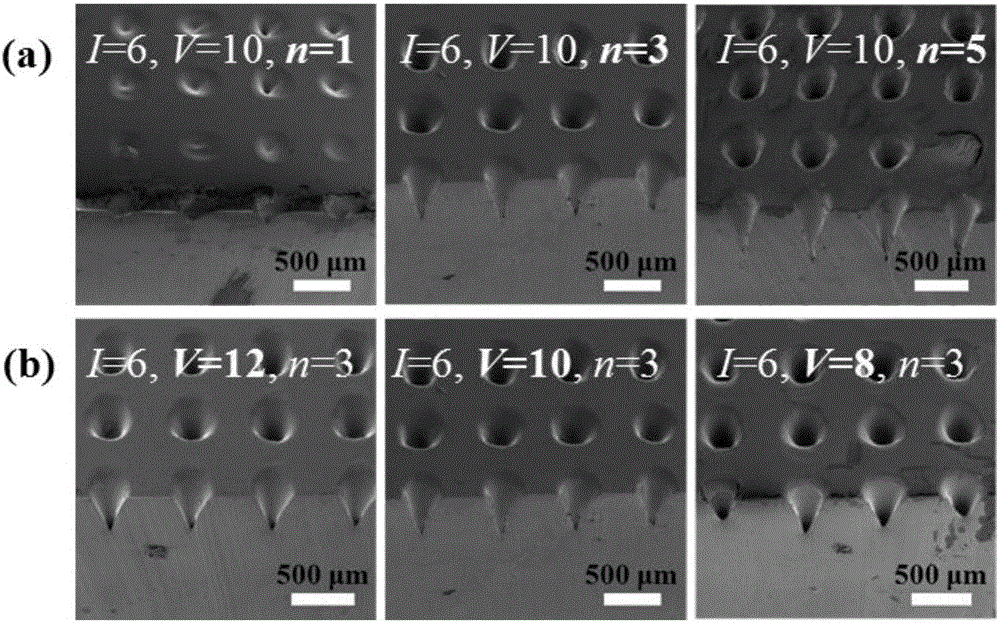

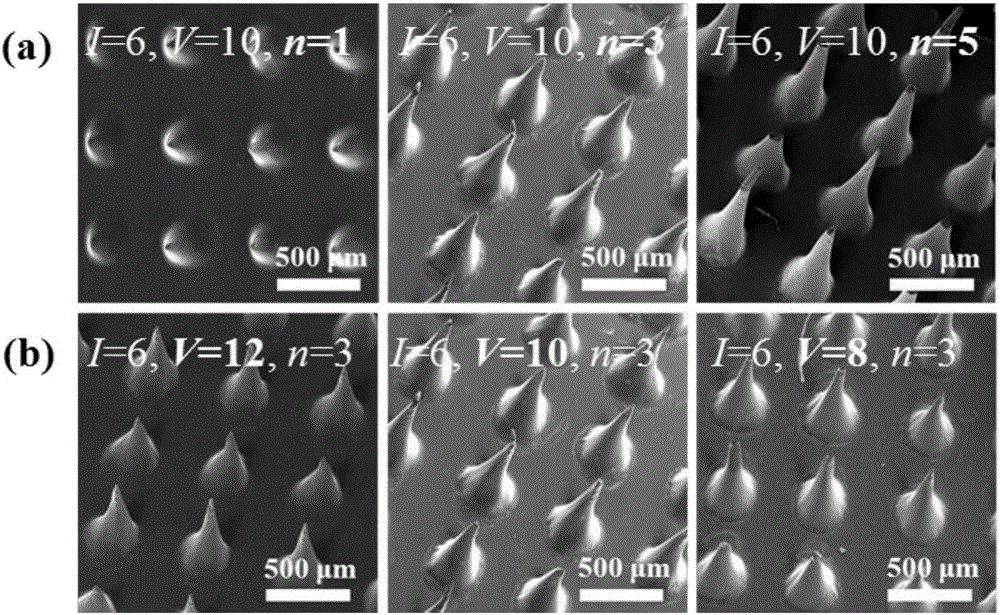

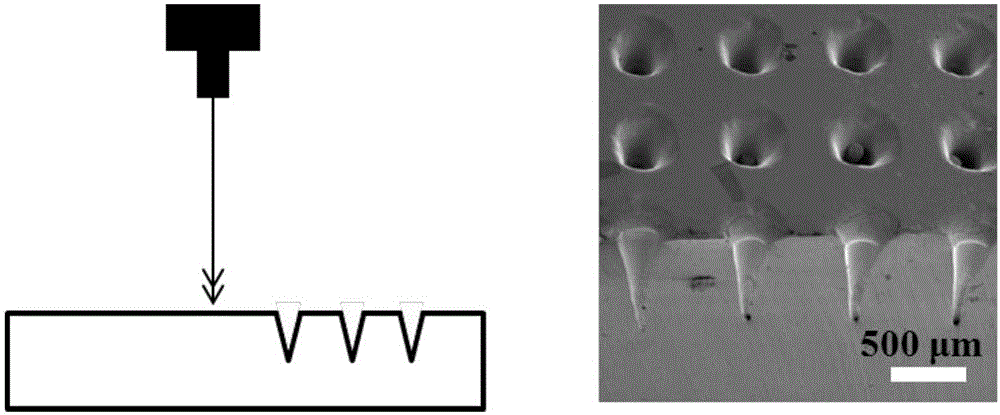

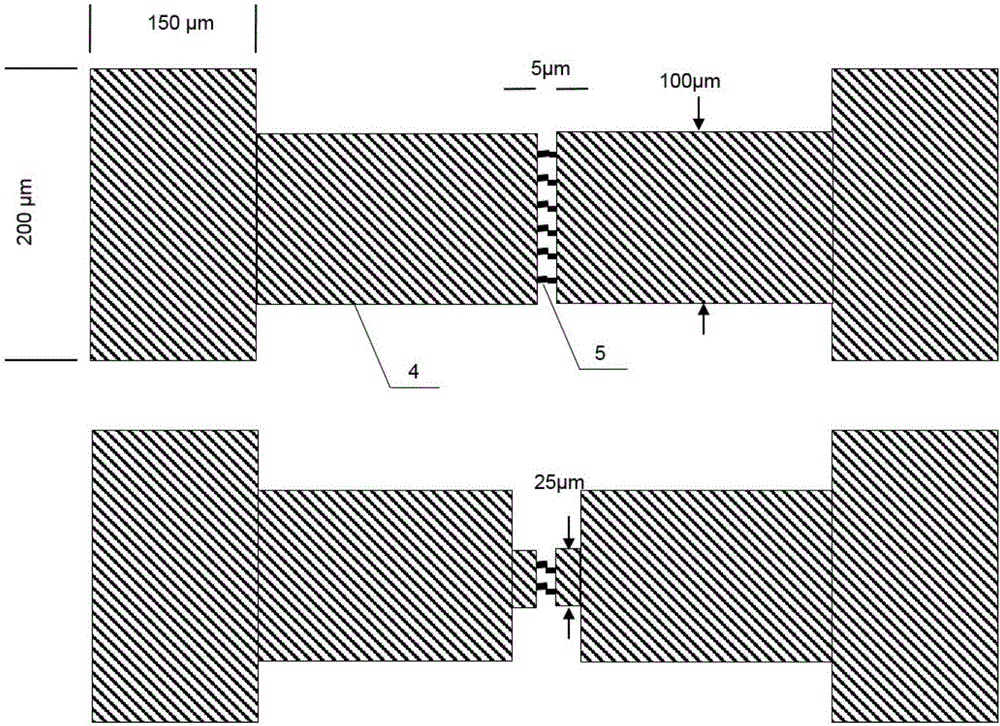

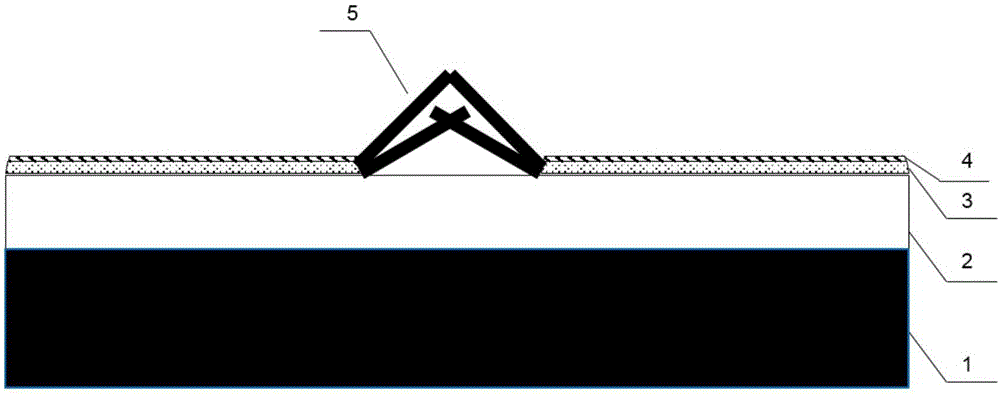

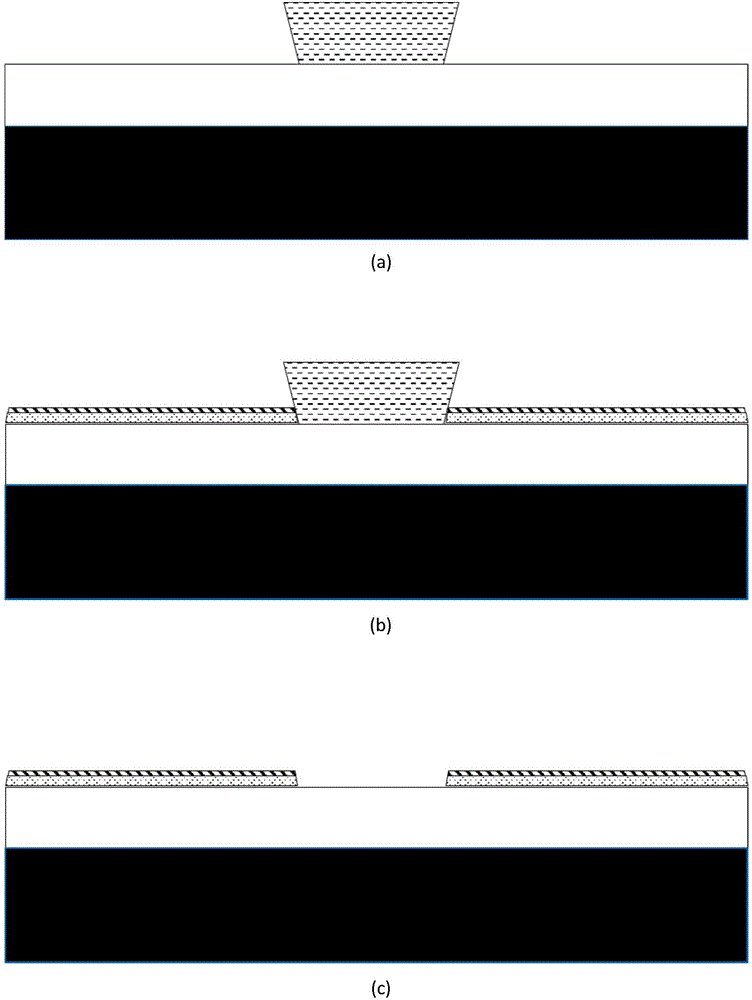

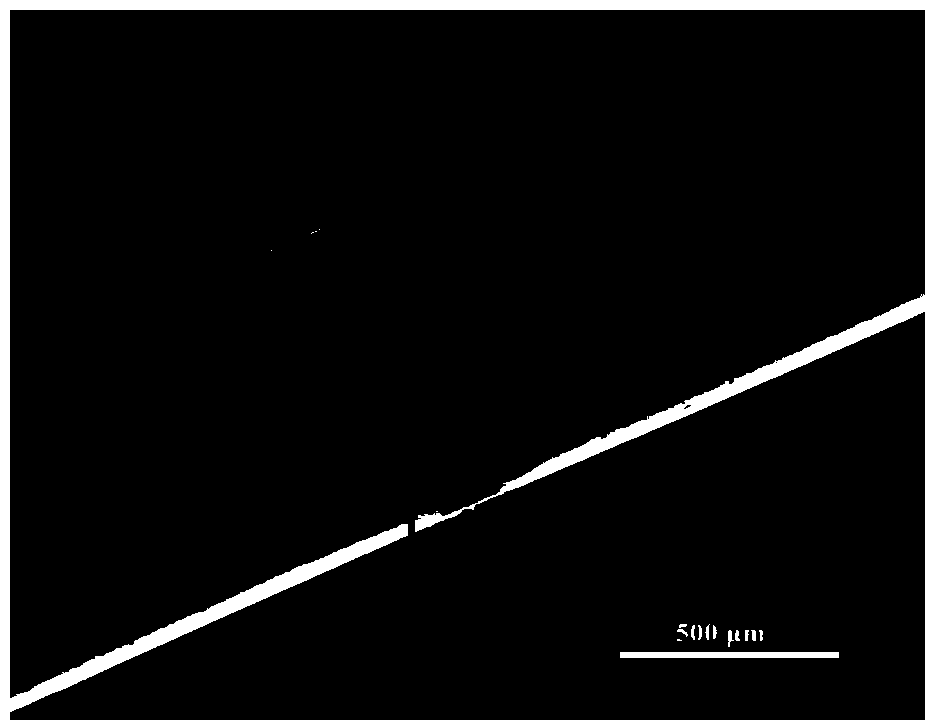

Method for producing micro-needle array templates based on laser etching technology as well as products and application thereof

InactiveCN106511257AImprove skin permeabilityImprove the effect of transdermal treatmentSurgeryPharmaceutical delivery mechanismOptoelectronicsTemplate based

The invention discloses a method for producing micro-needle array templates based on a laser etching technology as well as products and application thereof. The method comprises the following steps: (1) curing and cooling PDMS and a curing agent to obtain a PDMS substrate; (2) designing a laser etching mask plate pattern and enabling the pattern to be a concentric circle array; and (3) placing the PDMS substrate in an engraving area of a laser engraving machine and setting condition parameters of laser processing technology, subsequently carrying out laser treatment on the PDMS substrate with reference to the laser etching mask plate pattern so as to obtain the PDMS substrate etched by laser, wherein the PDMS substrate is the micro-needle array template. According to the method, the key laser etching process conditions are improved, so that the problems that the micro-needle array templates are complex in production process, high in cost and poor in structural design, and large-scale production and application of the micro-needle array templates are difficult can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A-D-A type conjugated molecules based on substituted indenothiophene condensed ring unit and preparation method thereof

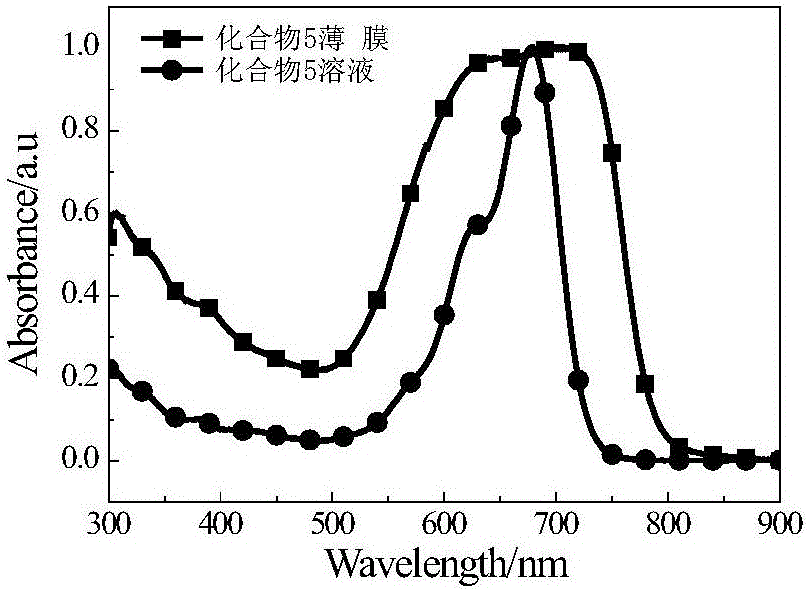

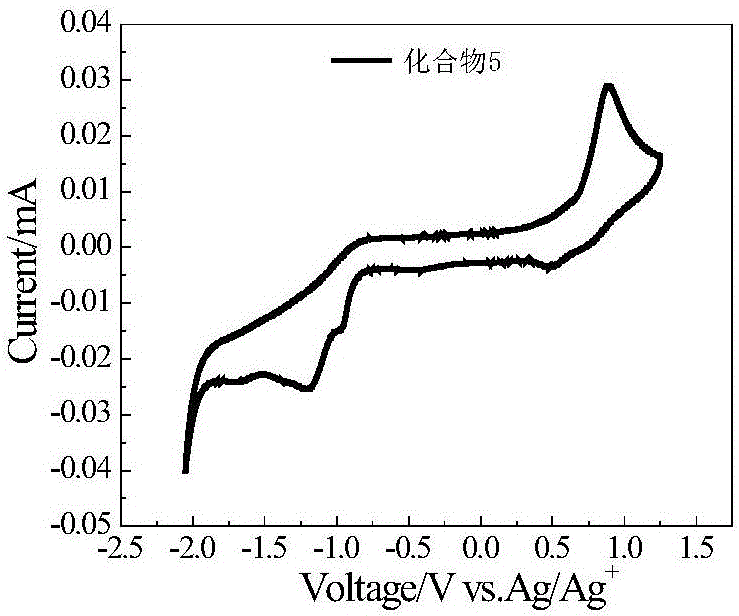

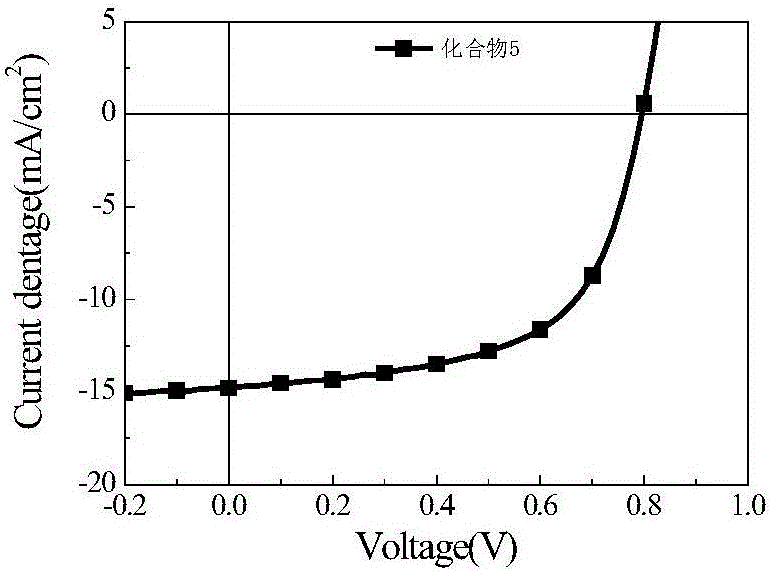

ActiveCN106543201AImprove solubilityEnhance light absorptionOrganic chemistrySolid-state devicesElectronic propertiesActive layer

The invention discloses A-D-A type conjugated molecules based on a substituted indenothiophene condensed ring unit, and a preparation method and an application of the molecules as an active layer material in organic photovoltaic device. The conjugated molecules have the structure represented by the following general formula defined in the specification. Different electrical absorption units alkoxy, fluorine atoms and the like are introduced to an indenothiophene condensed ring unit, the electron withdrawing characteristic of the fluorine atoms and the alkoxy is utilized, the HOMO energy level of the material is adjusted, then the open-circuit voltage of a photovoltaic battery is adjusted, the spectral absorption range is improved, and thus the photoelectric conversion efficiency of the device is improved.

Owner:XIAN MODERN CHEM RES INST

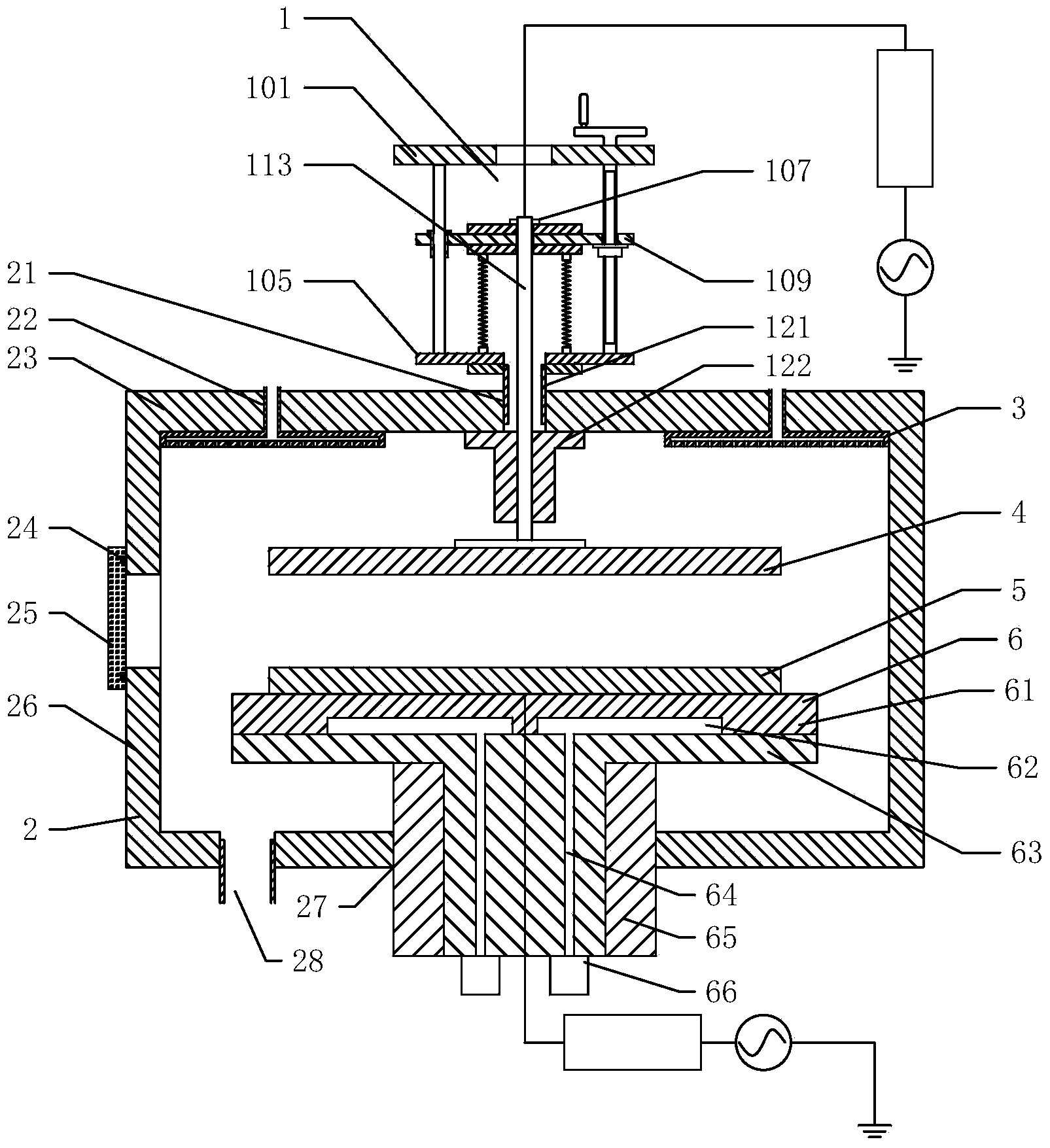

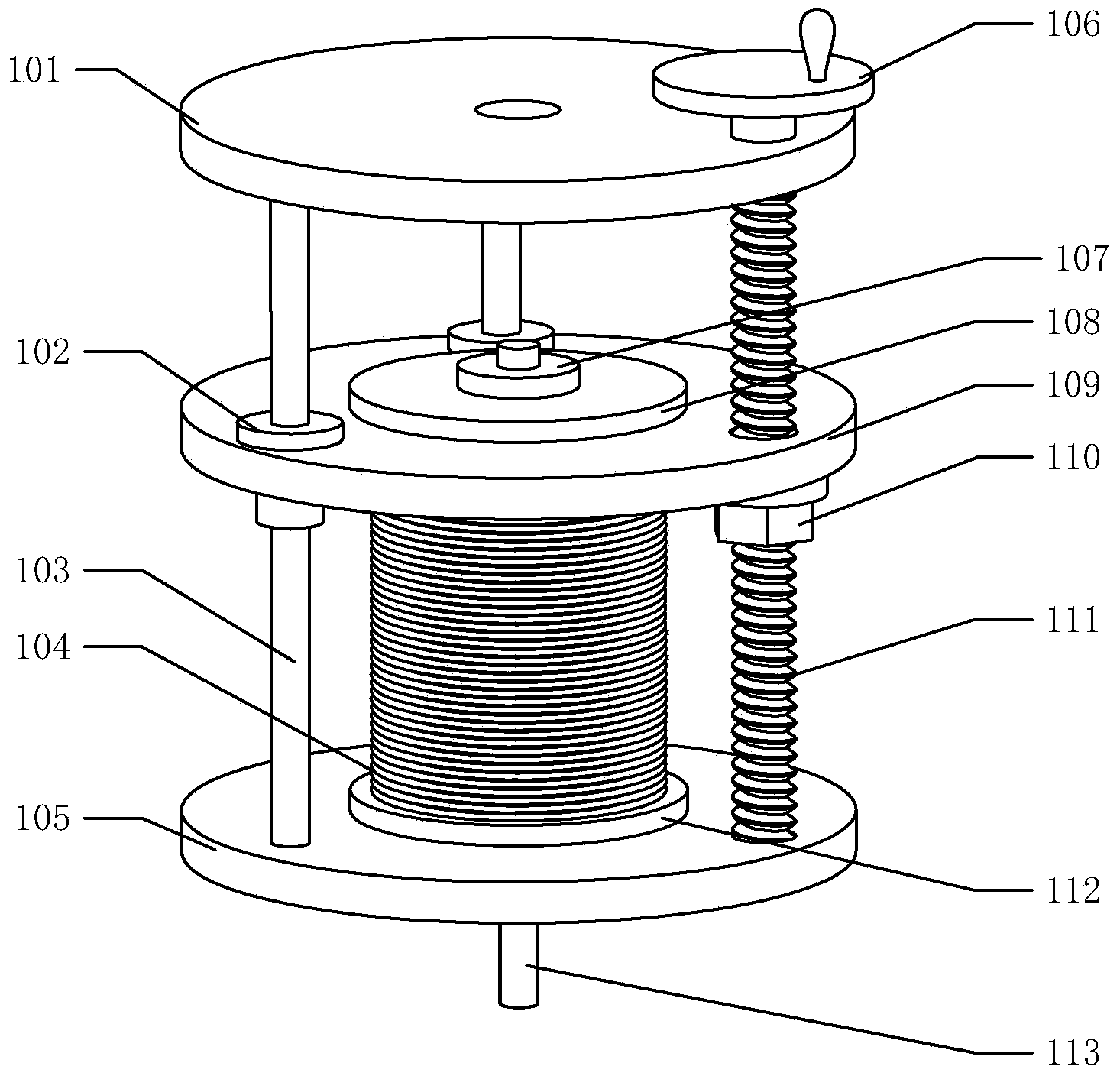

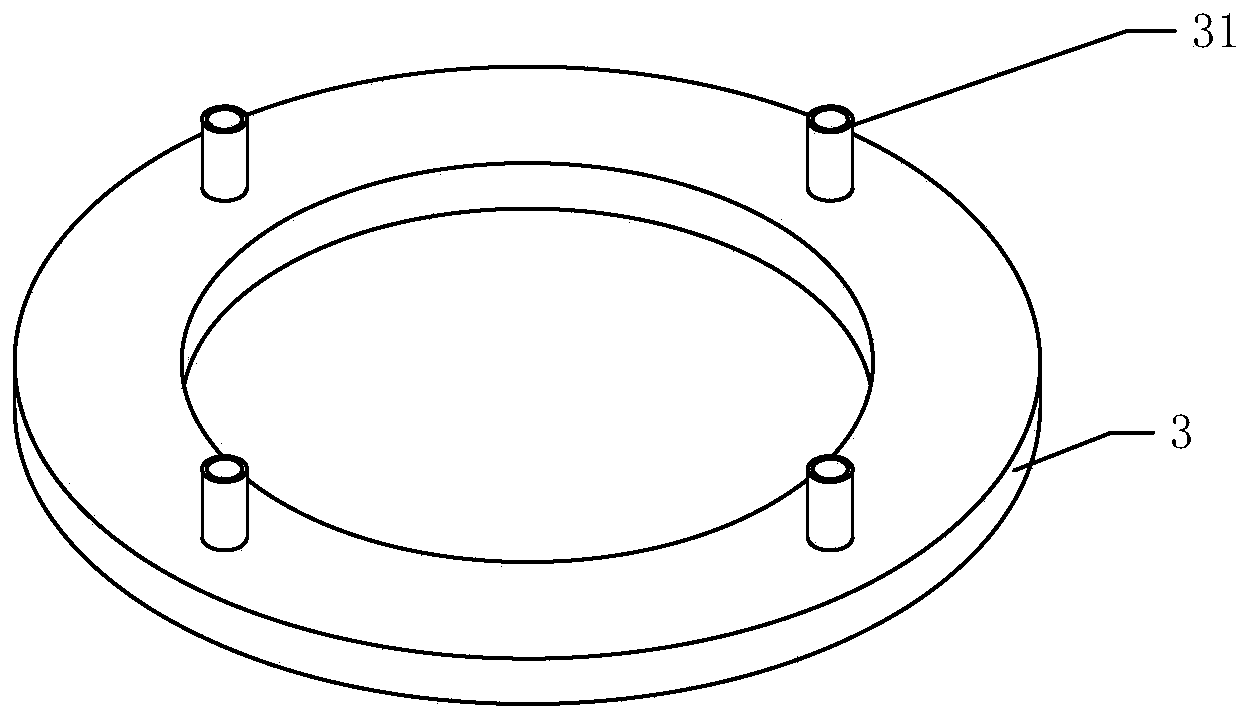

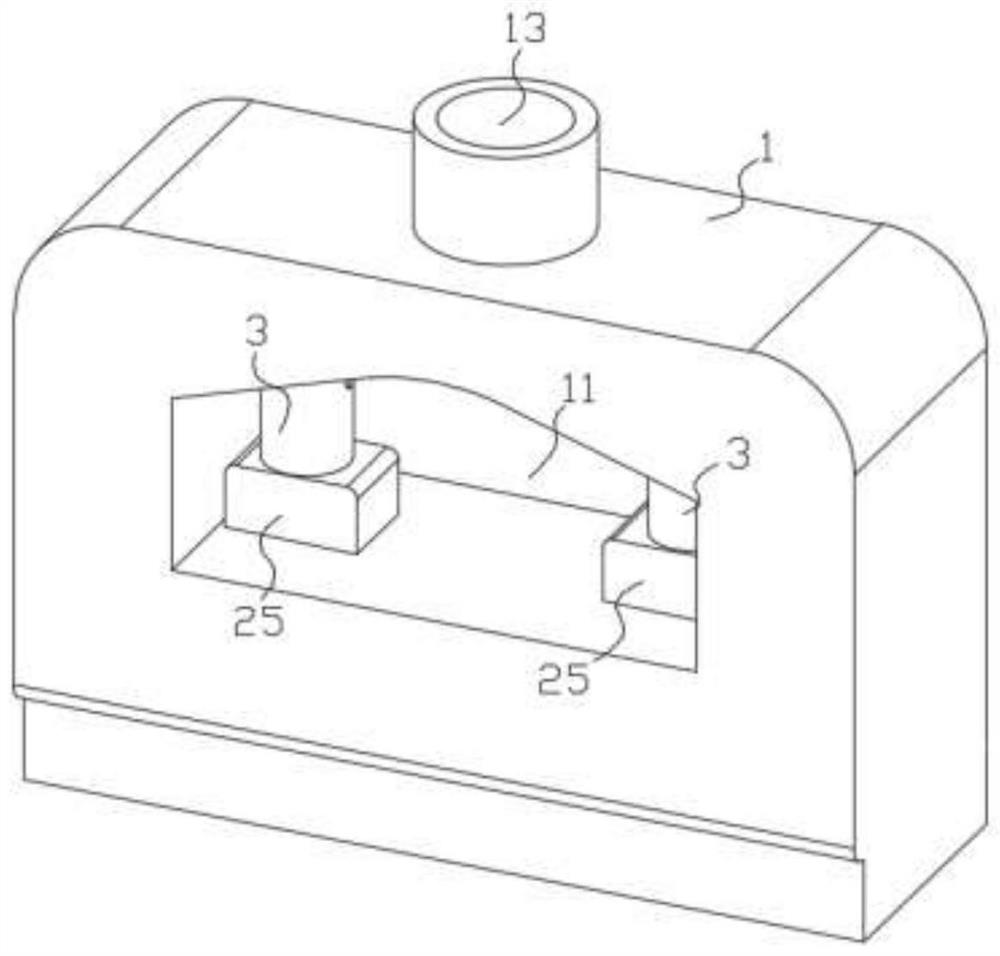

Plasma reaction chamber electrode gap adjusting device and plasma reaction chamber

InactiveCN103972014AMeet preparation requirementsPrecise control of electrode spacingElectric discharge tubesEngineeringPlasma reaction

The invention relates to an electrode gap adjusting device. Electrodes are located in a plasma reaction chamber and include the upper electrode and the lower electrode. The electrode gap adjusting device is characterized by comprising an upper electrode lifting device, the upper electrode lifting device comprises an upper fixing plate, a lifting plate, a lower fixing plate, a guiding supporting rod, a screw and a sliding rod, the upper fixing plate and the lower fixing plate are oppositely arranged in parallel, and the lifting plate is arranged between the upper fixing plate and the lower fixing plate in parallel; the guiding supporting rod and the screw are vertically installed between the upper fixing plate and the lower fixing plate and evenly distributed on the circle with the center of the upper fixing plate as the circle center and the certain distance as the radius; the sliding rod is arranged between the lifting plate and the upper electrode. According to the plasma reaction chamber electrode gap adjusting device and the plasma reaction chamber, the distance between the electrodes can be accurately controlled to achieve the optimal discharging position according to the etching technology requirement, and the technology precision can be better achieved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Customizable high-gain ZnO nanowire array UV detector and preparation method thereof

ActiveCN106409975AImprove uniformitySolve the problem of controllability of growth directionFinal product manufactureSemiconductor devicesUv detectionUv detector

A customizable high-gain ZnO nanowire array UV detector and a preparation method thereof relate to the fields of microelectronic technologies, nanometer technologies and UV detection. On the basis of a synergic theory, nanowires compete for a reaction solute when fluctuation is instable, an in such a competition mechanism, the thinner a seed layer is, the fewer solute resources are needed, and growth time is decided by the growth speed. Based on such a growing principle, the thickness of the seed layer, the solution concentration and growth time are adjusted to obtain nanowires of higher quality, and UV detection devices of different gains are obtained. The method is simple and effective, and the customized devices of different gains can be suitable for UV detection in different environments.

Owner:BEIJING UNIV OF TECH

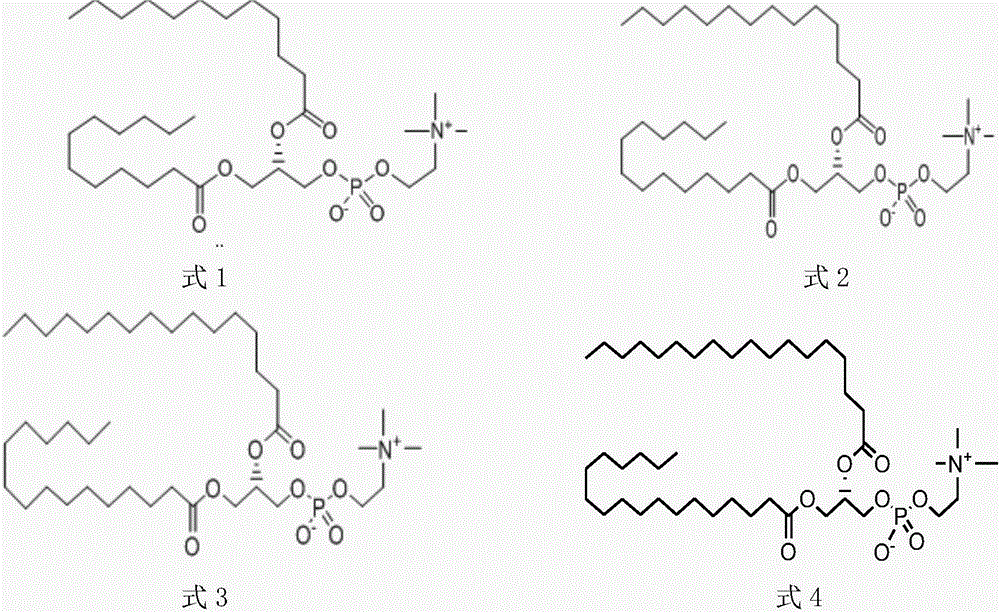

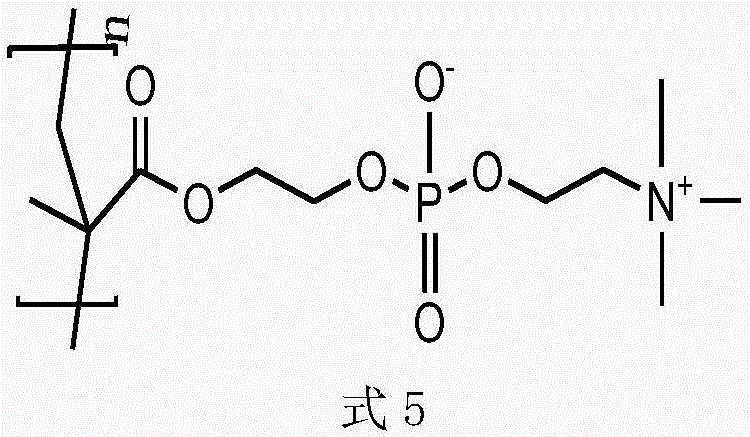

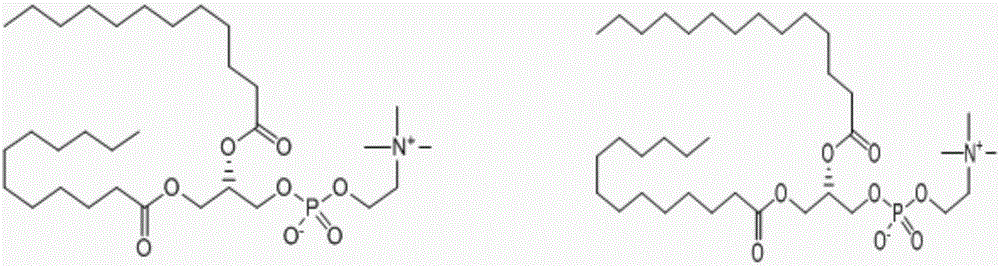

Polyether polyurethane material containing phosphorylcholine group on side chain and preparation method thereof

The invention relates to a polyether polyurethane material containing a phosphorylcholine group on a side chain and a preparation method thereof. The preparation method comprises the following steps: (1) enabling polyether glycol to react with excess diisocyanate to obtain a two-end isocyanate-based prepolymer; (2) performing chain extension on the two-end isocyanate-based prepolymer by taking a bis-amino phosphorylcholine compound as a chain extender to obtain phosphorylcholine modified polyurethane. The process is simple and feasible; moreover, the phosphorylcholine group is positioned on the side chain of a polymer, and is accumulated on the surface of the material when being applied to an organism, so that the biocompatibility of the material is enhanced greatly, and the absorption of proteins and platelets in blood is very low. A membrane prepared from the material has high mechanical strength and flexibility; the used diisocyanate is fat diisocyanate which contains a plurality of urethane groups, so that a degradation product is non-toxic and can be absorbed by the organism.

Owner:南通药享科技有限公司

Aerogel material reinforced by fiber reinforcement and preparation method of aerogel material

InactiveCN106866093ADiffusion is easy to completeEasy to complete distributionSupercritical dryingPolymer science

The invention relates to an airgel material reinforced by fiber reinforcement and its preparation method. The width of the material is 0.5-1.5 meters, and the length is 5-30 meters. Its composition includes silicon dioxide airgel and reinforced continuous fiber, and its weight ratio is 1:0.5-2.5. The present invention also relates to (1), limiting and winding the continuous reinforcing fiber into a winding unit while keeping a certain gap between the continuous fibers; (2), disposing silicon alkoxide, alcohol solvent and basic catalyst according to a certain ratio (3) Immerse the silica sol into the continuous reinforcing fiber winding unit through the impregnation process; (4) After the silica gel is aged for a certain period of time, the surface is treated with a hydrophobizing agent; (5) The silica gel containing silica gel The continuous fiber winding unit of glue is supercritically dried. The material prepared by the invention has large specific surface area and low thermal conductivity, and can be applied in many fields such as fire retardation, sound insulation, gas adsorption and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

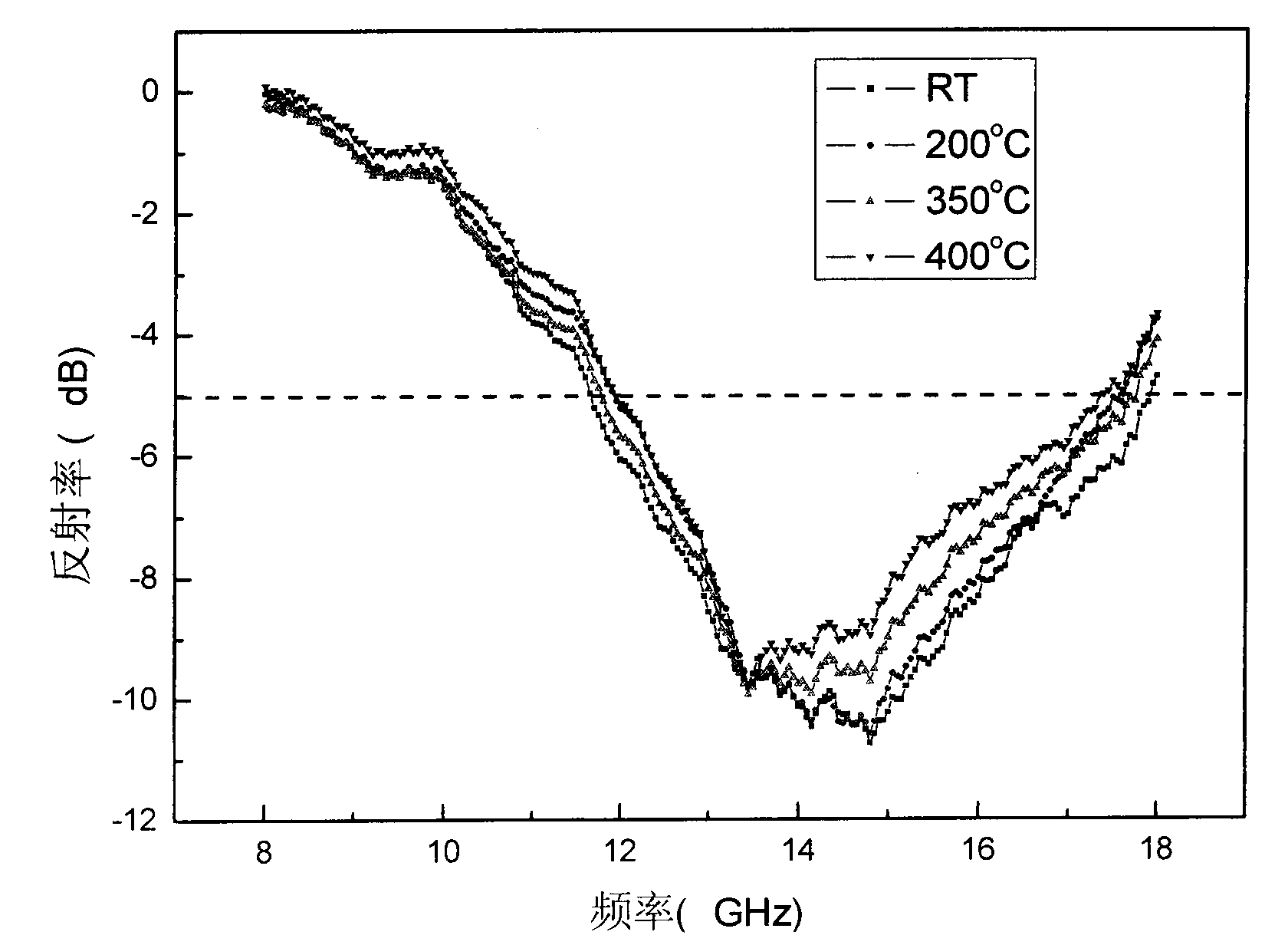

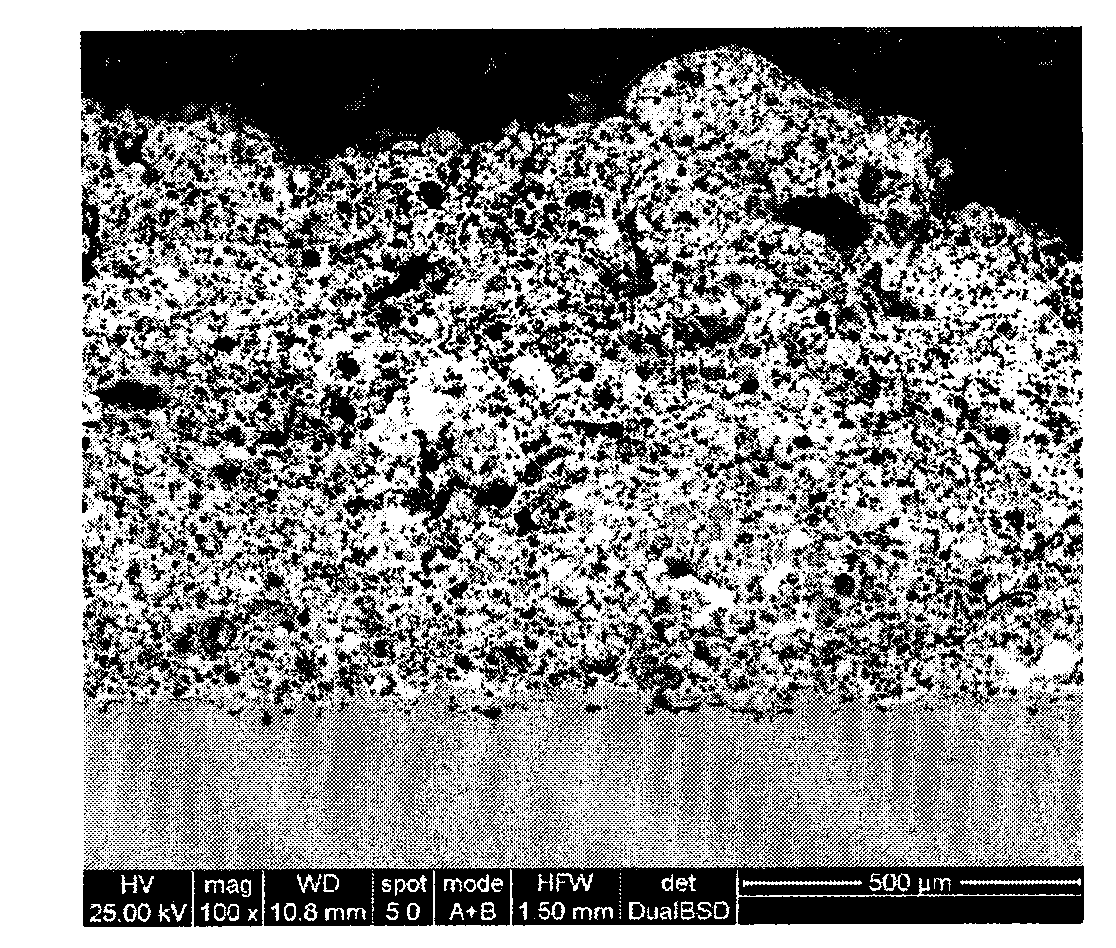

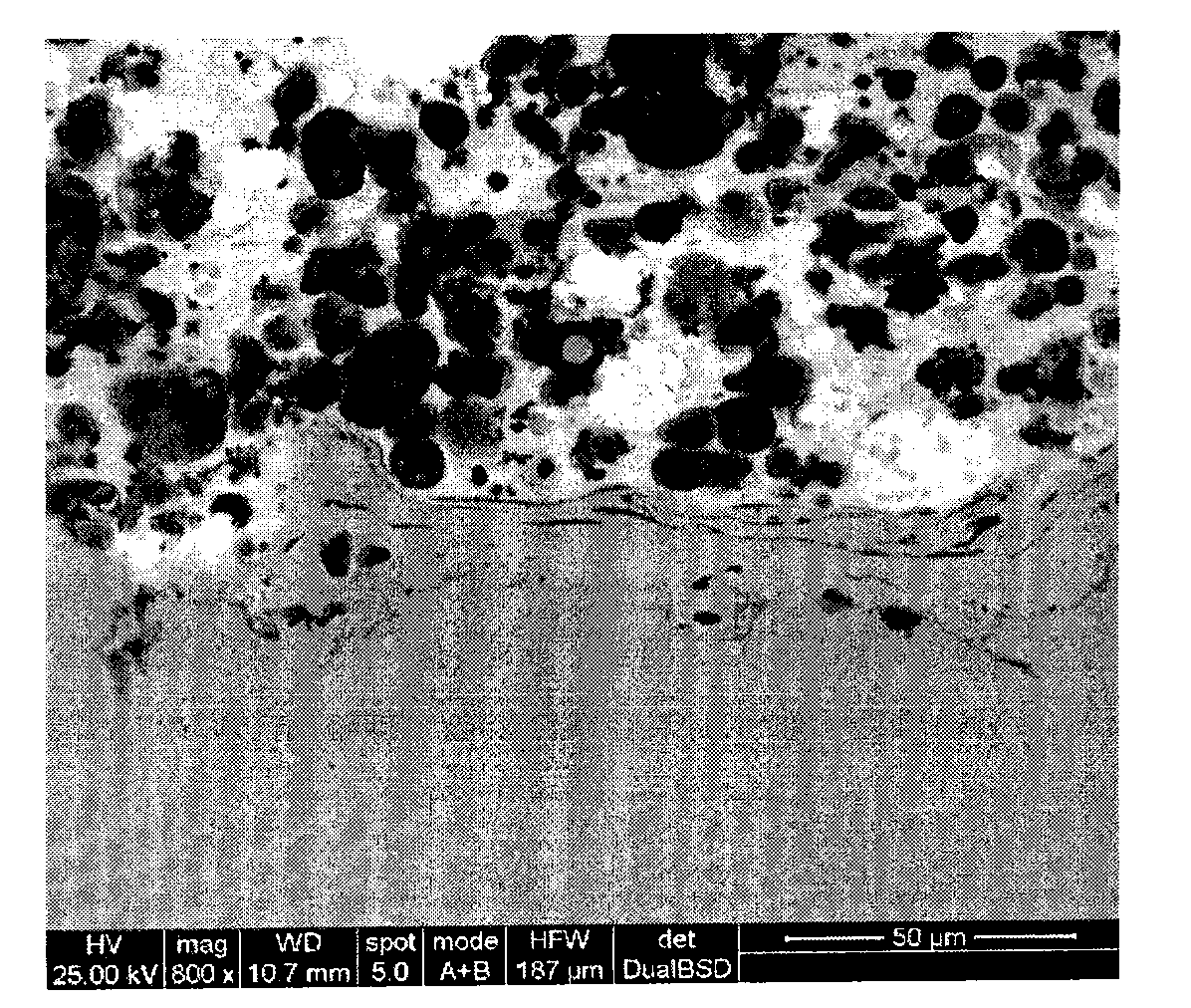

Temperature-resistant thermal-spray radar absorbing coating and preparation method of spraying powder thereof

ActiveCN102758164ASimple preparation processGood mechanical propertiesMolten spray coatingThermal sprayingForming processes

The invention discloses a thermal spraying powder material used in a radar absorbing coating, a thermal-spray radar absorbing coating, and a preparation method thereof. The radar absorbing coating comprises an absorbing agent and an inorganic binder used for binding and dispersing the absorbing coating. The inorganic binder is selected from glass, glaze, or an enamel material. The forming process of the coating is a thermal spraying process. According to the invention, glass, glaze, or the enamel material is adopted as the binder; the temperature resistance of the prepared coating is substantially higher than those of traditional absorbing paints, and can be higher than 300 DEG C. The material has good absorbing performance. The coating has excellent mechanical properties, so that surface coating preparation requirements of different types of parts can be satisfied.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

Preparation method of transparent self-toughening dicyandiamide/epoxy resin-based composite material

The invention belongs to the technical field of application of high performance epoxy resin and particularly relates to a preparation method of a transparent self-toughening dicyandiamide / epoxy resin-based composite material, in particular to a preparation method of a transparent self-toughening epoxy resin composition with low heat release, a heavy-thickness prepreg unidirectional tape and a composite material. The composition comprises the following raw materials in parts by weight: 60-100 parts of liquid epoxy resin, 0-40 parts of solid epoxy resin, 1.0-12 parts of a dicyandiamide curing agent and 0.5-6 parts of an accelerant. The epoxy resin is prepared by adopting a solution reaction manner; compared with a general dicyandiamide / epoxy resin system, a system in the invention has the advantages that the peak heat flux is decreased by 48% or higher, the heat release is decreased by 38% or higher, and the reaction heat is low; moreover, a resin casting body has 3.5% or more of breaking elongation, 80MPa or higher of tensile strength and 24kJ / m<2> of higher impact strength and has good toughness without adding a toughening agent; 130-DEG C medium temperature curing can be realized, and a cured product is transparent.

Owner:AVIC BASIC TECH RES INST

Polyester type polyurethane material with side chain containing phosphorylcholine group and preparation method thereof

The invention relates to a polyester type polyurethane material with a side chain containing a phosphorylcholine group and a preparation method thereof. The preparation method comprises the following steps of: (1) causing polyester glycol react with excessive diisocyanate, thereby acquiring a double-end isocyanate group prepolymer; and (2) adopting a phosphorylcholine compound containing two amino groups for expanding the chain of the double-end isocyanate group prepolymer, thereby acquiring a biodegradable polyurethane material with the side chain containing the phosphorylcholine group. The phosphorylcholine group in the polyurethane material is located on the side chain of the polymer, so that the biocompatibility of the material can be effectively promoted under the condition of low content of the phosphorylcholine group. Soft segments of the material are all made from polyester; the degree of crystallinity is higher; the higher mechanical strength of the material is guaranteed; the main chain is fully hydrophobic; the degradation velocity is low; the polyurethane material, which is used as a tissue engineering repairing holder material, and the like, can be long-term applied to organism; after the material acts, the material can be gradually degraded into non-toxic products and then absorbed by the organism, so that the injury of the second operation can be avoided.

Owner:南通捷事达新材料有限公司

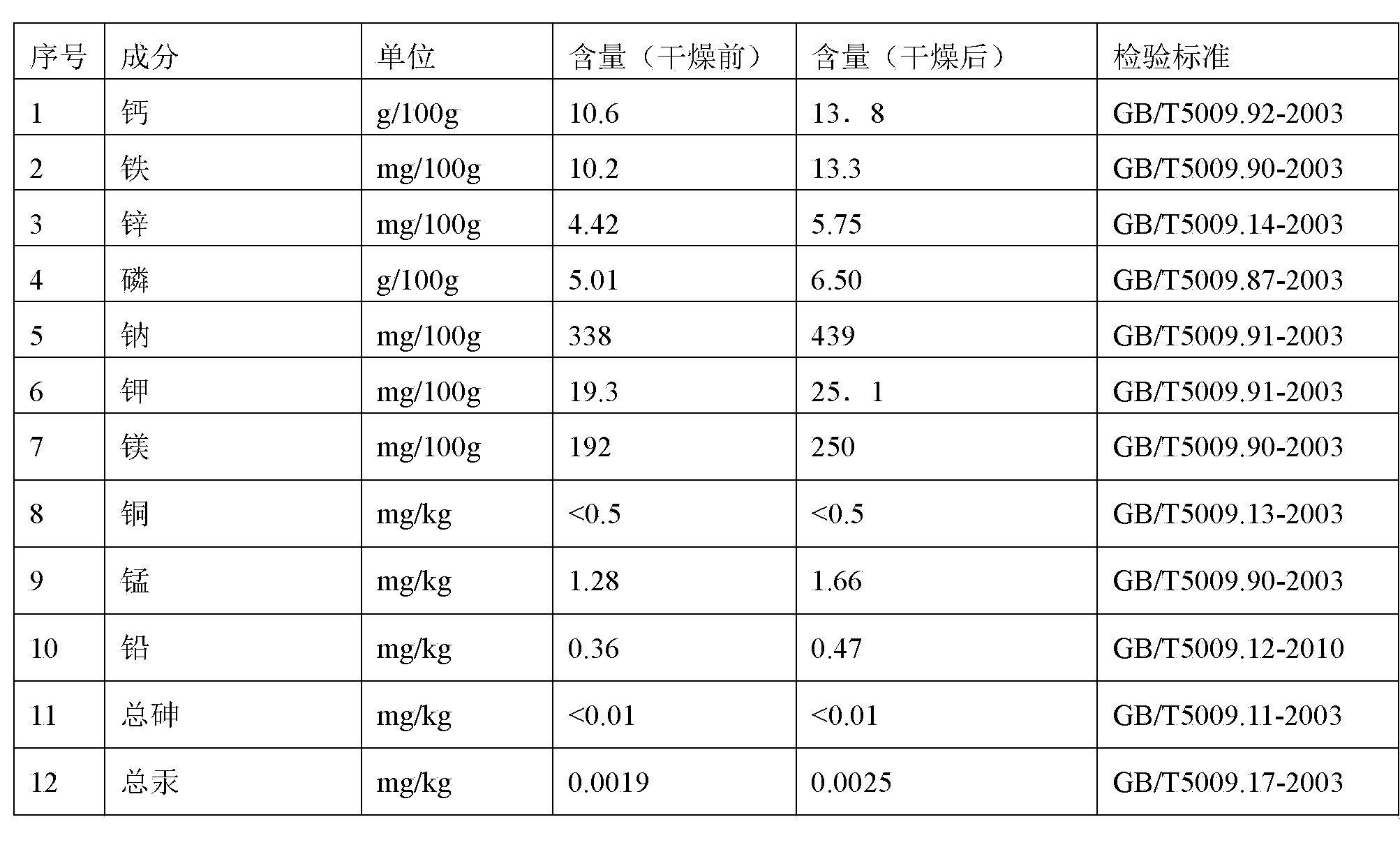

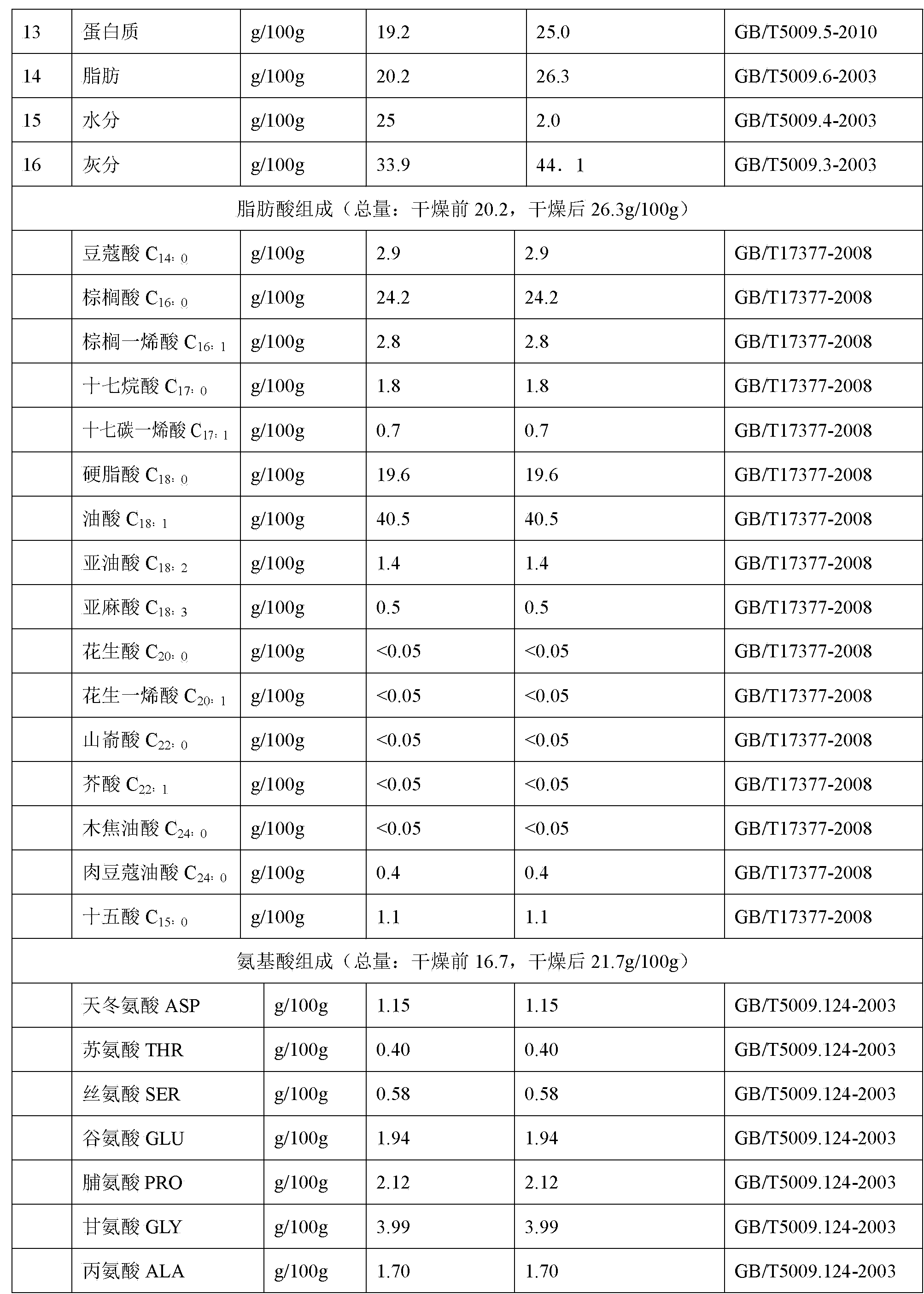

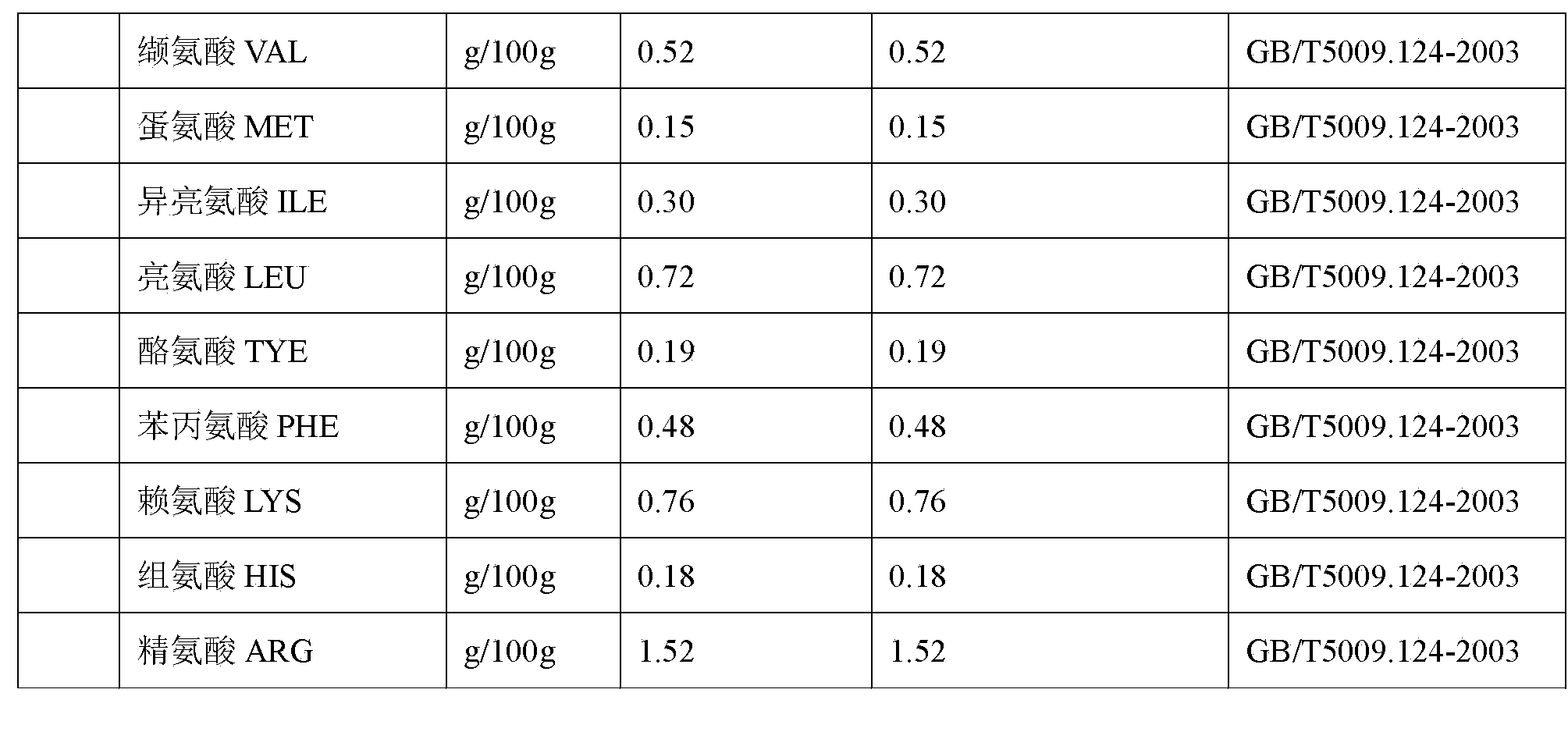

Fresh bone-meat powder, and preparation method and edible method thereof

The invention discloses a fresh bone-meat powder, and a preparation and an edible method thereof, and aims at providing a nutrient, safe and reliable fresh bond-meat powder. The preparation method can be used to process bone and meat at any position of any animals, and the nutrition components can be reserved completely. The product is prepared according to the following steps: 1) crushing a clean and edible fresh bone with meat into coarse fresh bone-meat particles with a diameter of 5.0 mm or less at a temperature of less than 0 DEG; 2) placing the coarse fresh bone-meat particles obtained in the step 1) in a refrigeration pulverizer to crush into micro fresh bone-meat particles with a diameter of 50 mu m or less at a temperature of -150 DEG C; 3) placing the micro fresh bone-meat particles prepared in the step 2) in a low-temperature drier to dry to obtain the fresh bone-meat powder with a water content of 2.0% or less at a temperature of -30 DEG C or less; and 4) packaging the fresh bone-meat powder obtained in the step 3) to obtain the fresh bone-meat powder product. The fresh bone-meat powder and the preparation method and the edible method thereof belong to the technical field of foodstuffs.

Owner:广东骨全能生物食品科技有限公司

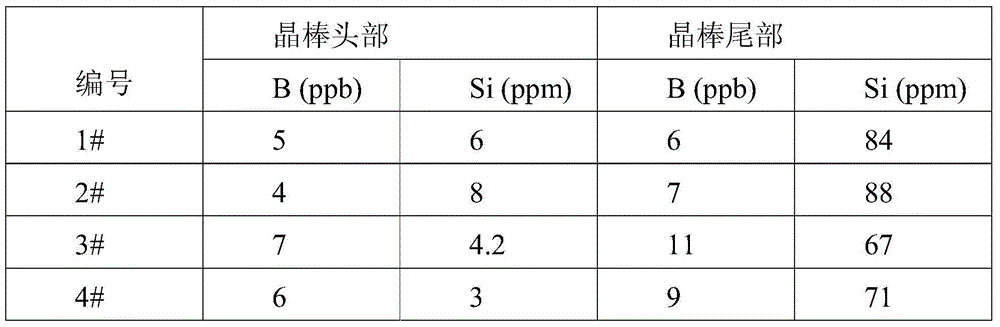

Growing method of gallium arsenide monocrystalline

ActiveCN106319630ASolving the problem of not wetting with quartz cruciblesSolve the problem of low crystal growth ratePolycrystalline material growthFrom frozen solutionsGallium arsenateSeed crystal

The invention provides a growing method of gallium arsenide monocrystalline. The method comprises the following components: (1) a quartz crucible is cleaned; (2) the quartz crucible is placed in a quartz tube which contains gallium of high purity, vacuum-pumping and inflation operation are repeatedly carried out for the quartz tube, and finally inert gas or nitrogen is filled; (3) the quartz tube is heated till the temperature in the quartz tube reaches to 1240 DEG C or above and insulation is carried out, and the quartz tube is cooled to room temperature; (4) the quartz crucible is taken out from the quartz tube and is immersed in acid, deionized water is used for washing, absolute ethyl alcohol is used for carrying out dehydration treatment, and the quartz crucible is placed in a drying box for standby; (5) seed crystal, polycrystalline materials, and the balance being arsenic are placed in the quartz crucible in order according to charging requirements, the quartz crucible is placed in a quartz ampoule, and vacuum-pumping, baking and soldering and sealing treatment are carried out; (6) a traditional VGF method is used for accomplishing the growth of gallium arsenide monocrystalline. PBN crucibles are not used, a liquid sealing agent B2O3 is not used, and GaAs monocrystalline is not polluted by extra introduction of B element from the source.

Owner:广东先导微电子科技有限公司

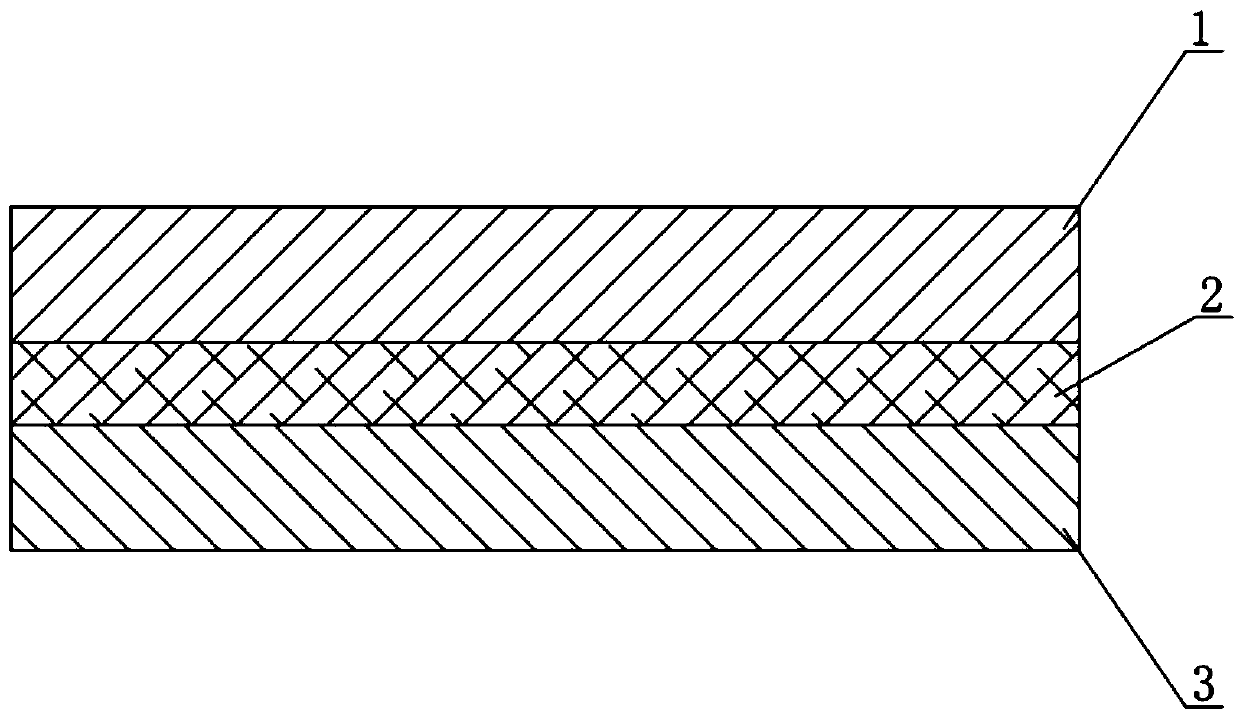

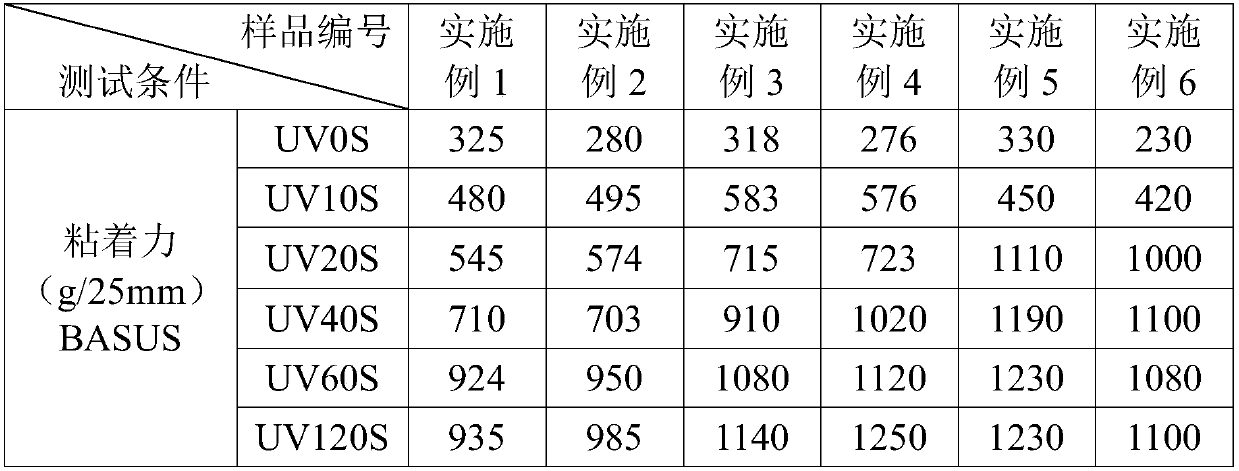

Acrylic pressure-sensitive adhesive, photo-thermal dual curable adhesive film and preparation method thereof

InactiveCN109651961AExcellent adhesionMeet preparation requirementsOrganic non-macromolecular adhesiveFilm/foil adhesives without carriersMethacrylateCross-link

The invention discloses an acrylic pressure-sensitive adhesive, which is prepared by uniform mixing of a polyacrylate prepolymer, a reactive diluent, an organic solvent, a photoinitiator and a crosslinking agent in a weight ratio of 100:(20-50):(30-50):(0.5-3.0):(0.3-3.0). The polyacrylate prepolymer is prepared by: dissolving butyl acrylate, methyl methacrylate and epoxypropyl methacrylate in anorganic solvent, also adding an initiator, and introducing N2 for reaction. The invention also discloses a photo-thermal dual curable adhesive film, which includes an adhesive layer prepared from theabove-mentioned acrylic pressure-sensitive adhesive, and photo-thermal cross-linking treatment is carried out on the adhesive layer. The invention also discloses a preparation method of the photo-thermal dual curable adhesive film. The photo-thermal dual curable adhesive film prepared according to the invention has high cohesiveness and good reworkability, can realize photo-thermal dual curing, shortens the curing time and improves the production efficiency.

Owner:潍坊同有新材料科技有限公司

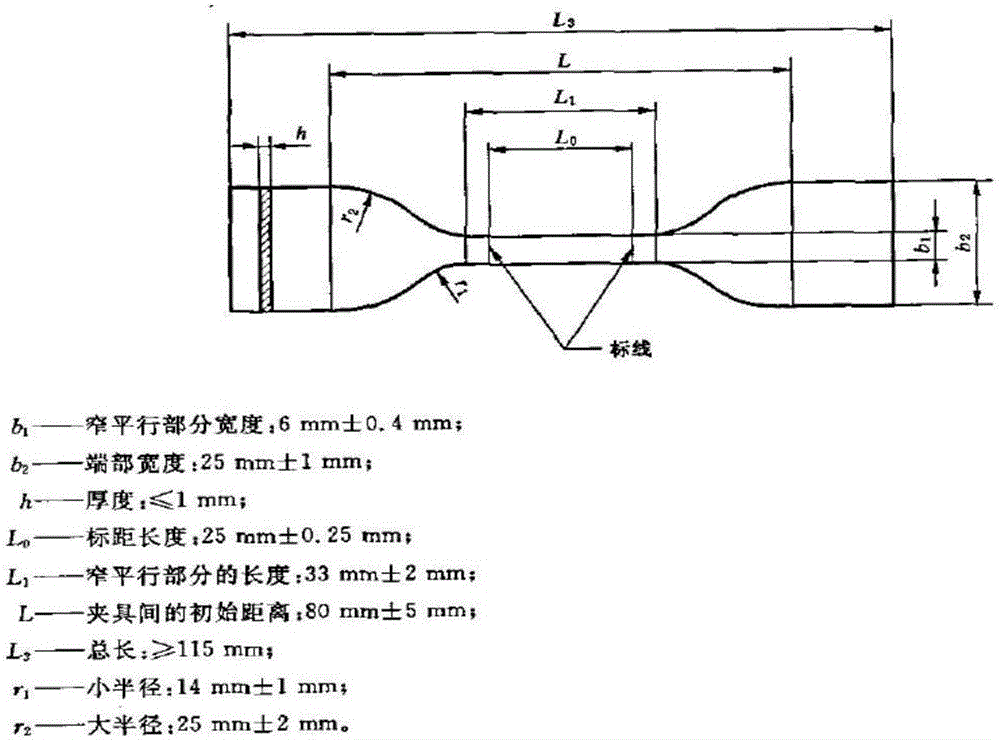

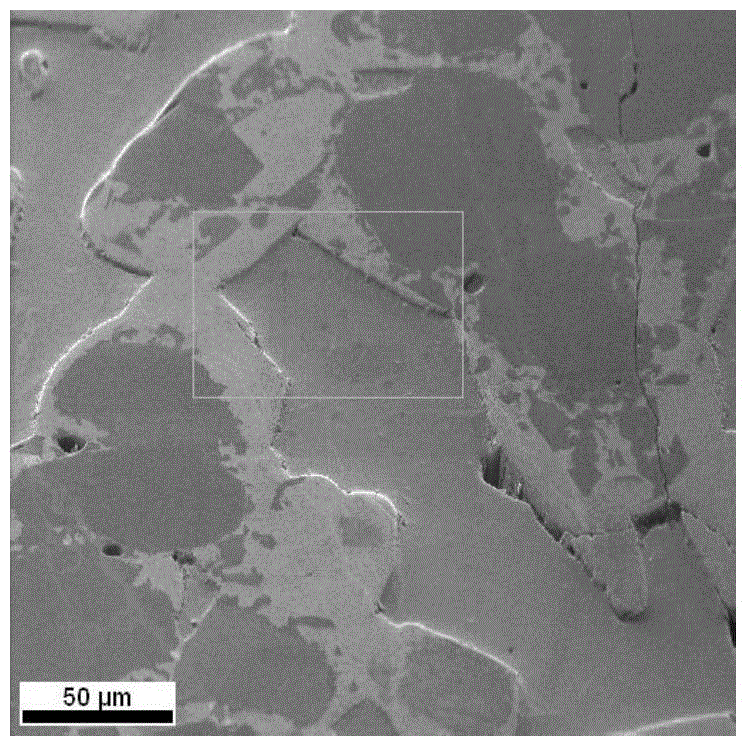

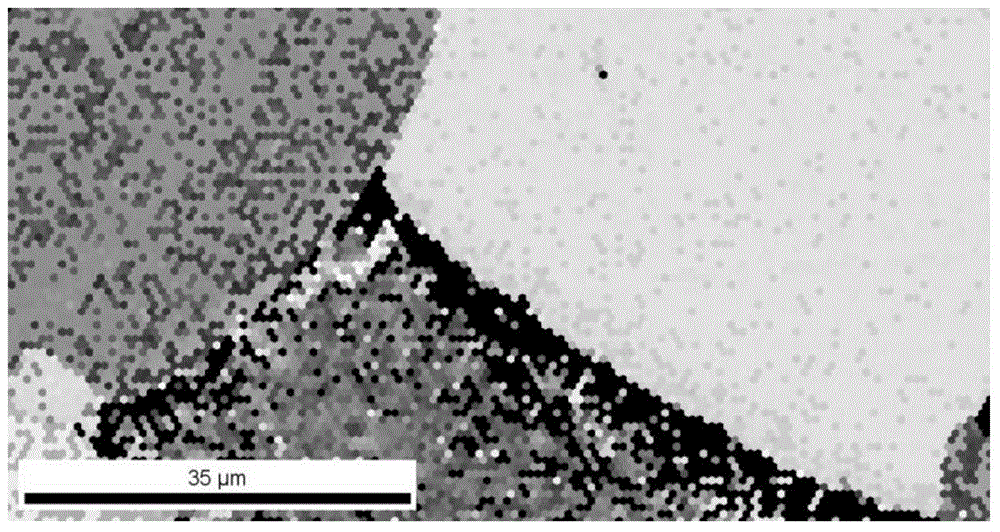

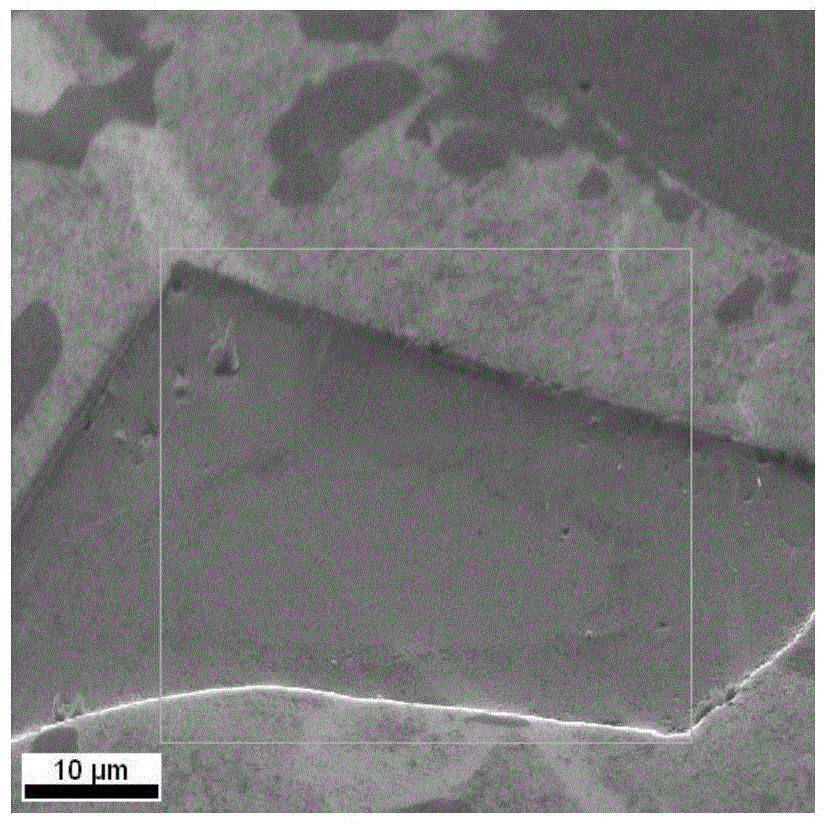

Preparation method for metal matrix composite material sample suitable for EBSD (Electron Backscattered Diffraction) detection

InactiveCN104458373AGuaranteed flatnessReduce stress valueMaterial analysis using wave/particle radiationPreparing sample for investigationHigh surfaceMatrix composition

The invention discloses a preparation method for a metal matrix composite material sample suitable for EBSD (Electron Backscattered Diffraction) detection, and belongs to the field of preparation of detection samples. The preparation method is used for processing a metal matrix composite material with a multiphase structure by utilizing linear cutting, mechanical polishing, and vibration polishing-ion polishing-vibration polishing processes so as to obtain the metal matrix composition material sample suitable for the EBSD detection. The obtained metal matrix composition material sample simultaneously meets requirements on high surface smoothness and a low stress value and the requirement of keeping the original surface stress distribution rule of the sample; the EBSD detection requirements of different-type metal matrix composite materials are met, and preparation requirements of detection samples for performing various detections, such as XRD detection and Raman spectrum detection, on different-type multiphase conducting materials are also met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

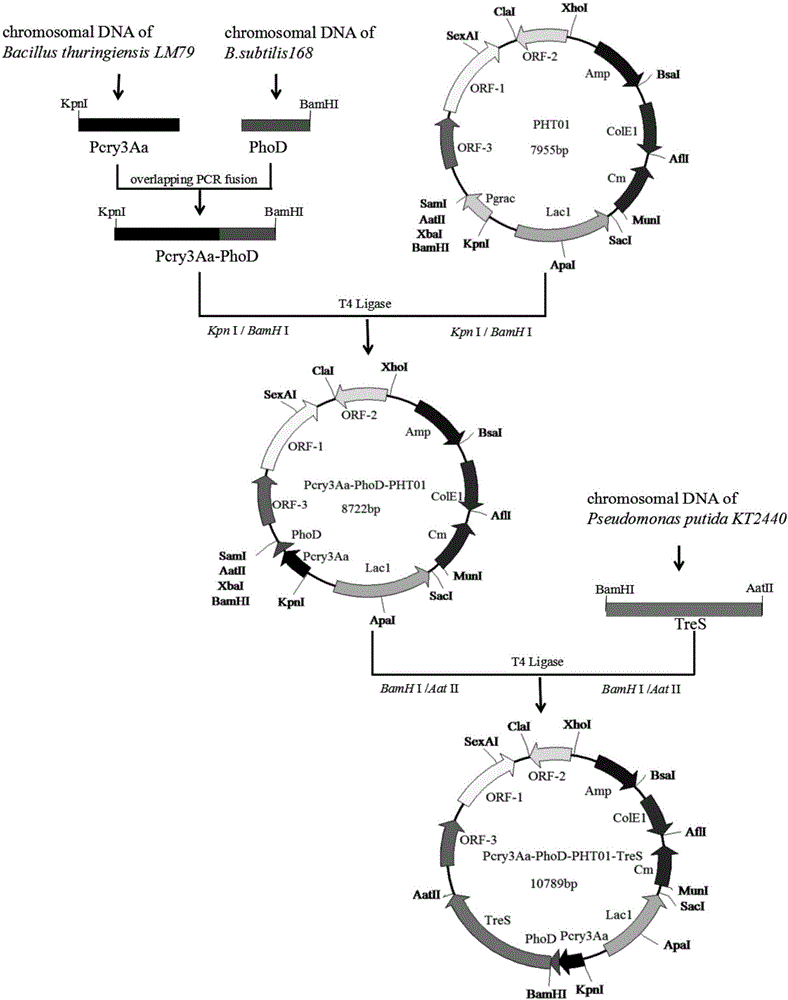

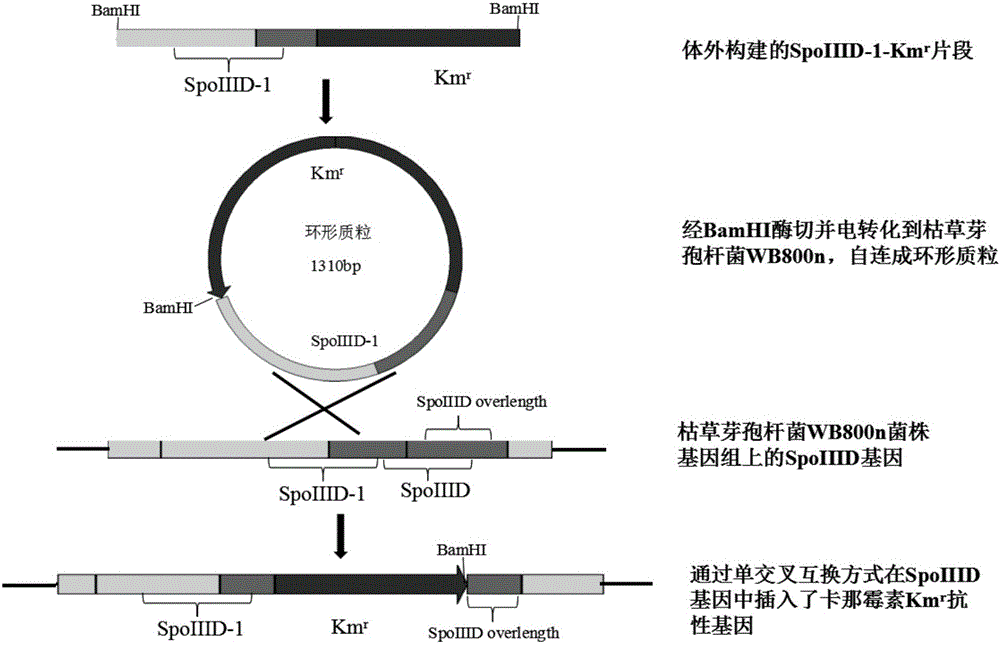

Method for constructing highly expressed trehalose synthase engineering bacteria by using Pcry3Aa promoter

ActiveCN105779489AGood synthesis effectImprove stabilityBacteriaTransferasesSequence signalProtein target

The invention relates to a method for constructing highly expressed trehalose synthase engineering bacteria by using a Pcry3Aa promoter. For a recombinant carrier, a Pcry3Aa-PhoD fragment by which a Pcry3Aa promoter fragment and a PhoD signal peptide fragment are connected by an overlap PCR (Polymerase Chain Reaction) is inserted at the upstream of a restriction enzyme cutting site BamHI of a shuttle plasmid PHT01, and a target protein trehalose synthase TreS fragment is inserted between two restriction enzyme cutting site, i.e., BamHI and AatII. The invention further relates to a method for constructing the highly expressed trehalose synthase engineering bacteria by using the recombinant carrier. According to the method disclosed by the invention, the Pcry3Aa promoter is adopted to naturally induce the synthesis of trehalose synthase; because the Pcry3Aa promoter contains a special STAB-SD structure, the stability of the Pcry3Aa promoter to transcribe mRNA is improved, the half-life period of mRNA is prolonged, the mRNA translation level of a downstream target gene is improved, and therefore the trehalose synthase is highly expressed.

Owner:山东开盾生物科技有限公司

Impact-resistant epoxy resin-based glass fiber composite high in interlaminar fracture toughness

The invention belongs to the technical fields of high-performance epoxy resin and application of high-performance epoxy resin composites, and relates to an impact-resistant epoxy resin-based glass fiber composite high in interlaminar fracture toughness. The impact-resistant epoxy resin-based glass fiber composite comprises, by mass, 60-100 parts of liquid epoxy resin, 0-40 parts of solid epoxy resin, 2-15 parts of nanometer rubber particles, 1.0-12 parts of dicyandiamide curing agent and 0.5-6 parts of accelerator. Epoxy resin is prepared through shearing, dispersion and mixing, the impact strength of the system is 31 kJ / m<2> or above, the highest impact strength can reach 50 kJ / m<2> or above, and the epoxy resin composite is high in impact toughness. The epoxy resin / glass fiber compositeprepared from the epoxy resin system is high in interlaminar toughness and impact resistance, the mode I interlaminar fracture toughness can reach 1706 J / m<2> or above, and compared with a common epoxy resin / glass fiber composite, the mode I interlaminar fracture toughness is increased by 60%; the compression strength of the epoxy resin / glass fiber composite obtained after impact can reach 260 MPaor above, and compared with the common epoxy resin / glass fiber composite, the compression strength is increased by 62%.

Owner:AVIC BASIC TECH RES INST

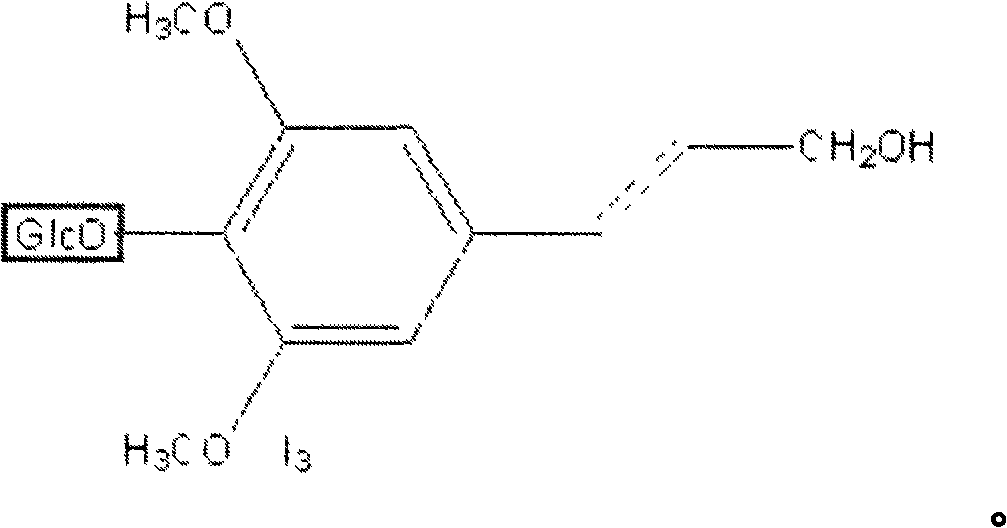

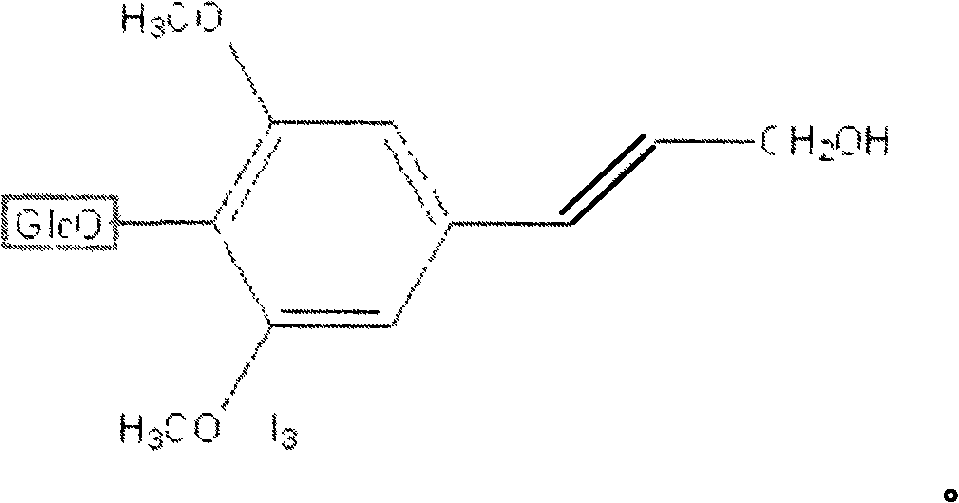

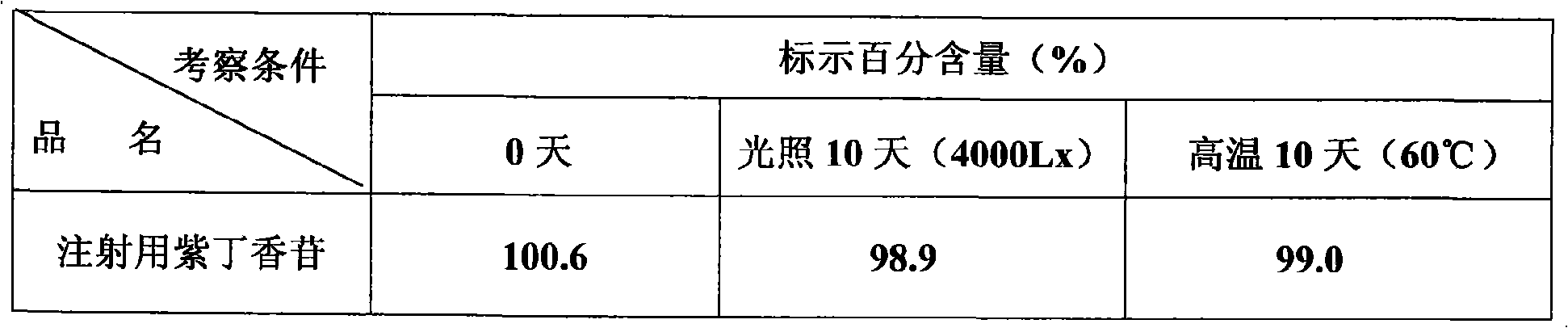

Syringin for injection, preparation method and application thereof

InactiveCN101554370AEasy to useMeet preparation requirementsPowder deliveryOrganic active ingredientsSyringinExcipient

The invention relates to a syringin for injection, a preparation method and the application thereof. The invention can provide an injection that is clinically and safely used and has the pharmacological actions of resisting fatigue, tranquilizing and allaying excitement, expanding blood vessel, reducing blood viscosity, stanching, and the like. The injection contains syringin, pharmacology-permissible pH regulating substance, a stabilizing agent and an excipient. 50-2800 mg dry substance in each injection contains 5-2000 mg of syringin, 0.04-0.8 g of excipient and 0.0001-0.1g of stabilizing agent. Of the above substance, the pH regulating substance has an adding amount for regulating the weight fraction pH value to 3.5-7.5. The product of the invention is used for preparing medicaments for resisting fatigue, tranquilizing and allaying excitement, expanding blood vessel, reducing blood viscosity, stanching, resisting dumps.

Owner:苑立超

Hemostasis needle and preparing method and application thereof

ActiveCN109330654AEffectively blockedEffective synchronous hemostasisSurgical needlesOcculdersCross-linkDrug administration

The invention belongs to the field of biomedical polymer materials, and particularly relates to a hemostasis needle and a preparing method and application thereof. The hemostasis needle comprises a syringe needle and a hemostasis coating for coating the surface of the periphery of the syringe needle, wherein the hemostasis coating is a non-toxic cross-linked polymer which can swell and shed off from the surface of the periphery of the syringe needle when meeting a solvent. The hemostasis needle prepared by means of the method is utilized for puncturing the blood vessels and the visceral organs, after the hemostasis needle is pulled out, the coating is left at the puncturing position to block a puncturing hole, and thus synchronous hemostasis is achieved. The preparing method of the hemostasis needle is easy to operate and low in cost, takes effect quickly, and can be widely applied to the fields such as drug administration, blood sampling, sampling and interventional therapy on patients with normal or abnormal clinical blood coagulation functions. The hemostasis needle is adjustable in size, easy to produce on a large scale, capable of effectively solving the problem that unnecessary hemorrhage is caused when the patients with normal or abnormal clinical blood coagulation functions are subjected to blood vessel and visceral organ puncturing, and free of obvious untoward effects.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of non-vacuum downward-casting copper-zirconium alloy slab ingot

The invention discloses a preparation method of a non-vacuum downward-casting copper-zirconium alloy slab ingot. The preparation method comprises the following steps: S1, carrying out burdening: weighing required raw materials according to percentage; S2, carrying out smelting: installing an electrolytic copper plate into a furnace, adding a covering agent, a copper-magnesium alloy, titanium and rare earth Re in sequence for smelting after the copper plate is molten, preparing molten copper for discharging after smelting is finished, and keeping the temperature of the molten copper at 1,200-1,300 DEG C; S3, adding the alloy: sealing a tundish with a cover plate, starting a heating device, discharging the molten copper, pouring the molten copper into the tundish, calculating a copper-zirconium alloy according to 5-10% of burning loss, and adding the copper-zirconium alloy into the tundish at intervals; and S4, performing continuous casting: performing downward-casting through a slab ingot crystallizer pipe. By adopting the preparation method, the problem that zirconium cannot be continuously added during the preparation of the copper-zirconium alloy is solved, and the problem that the uniformity of zirconium in a substrate is difficult to ensure is solved in a preparation process, so that a final material has uniform performance, the preparation requirement is met, and the material has high reproducibility.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

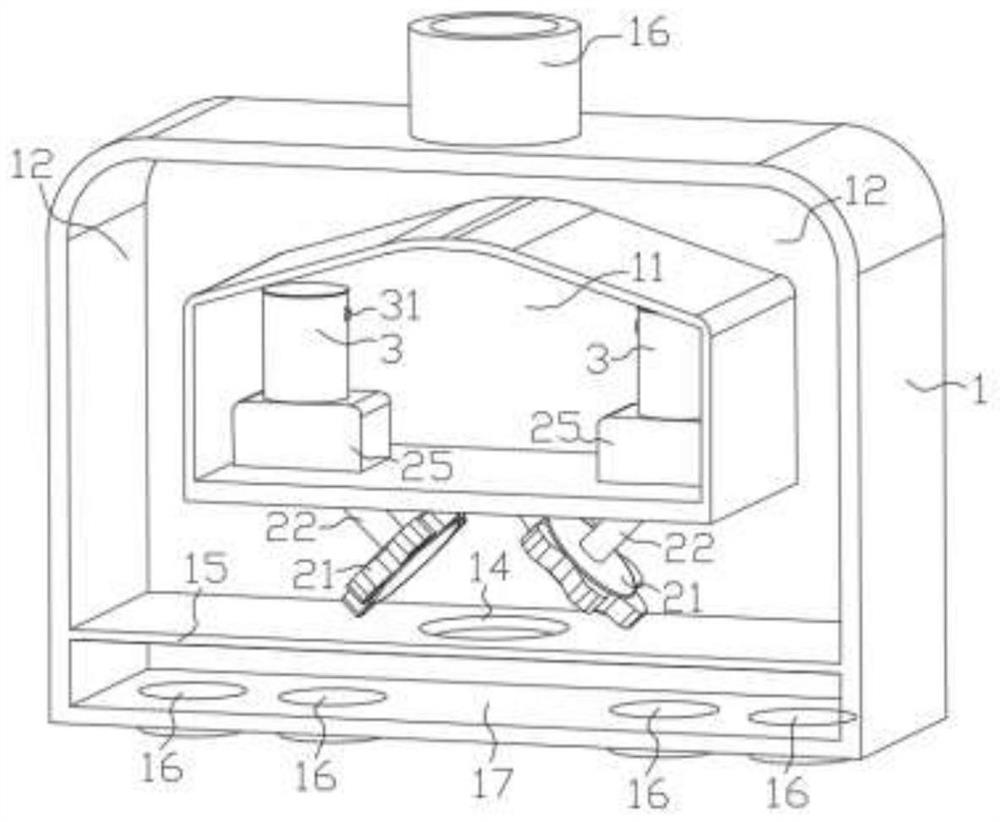

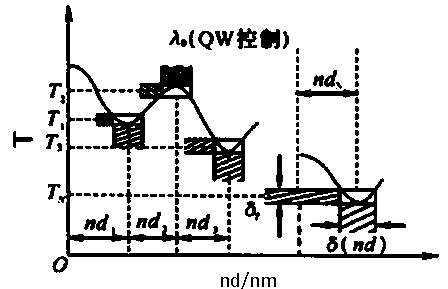

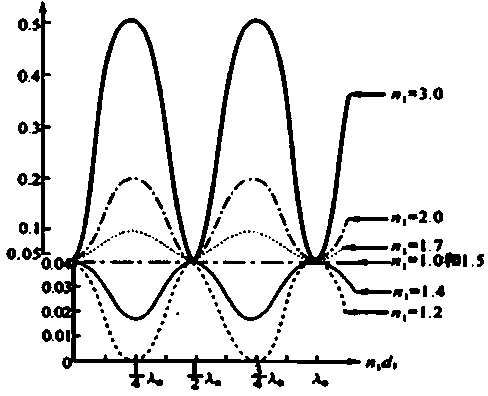

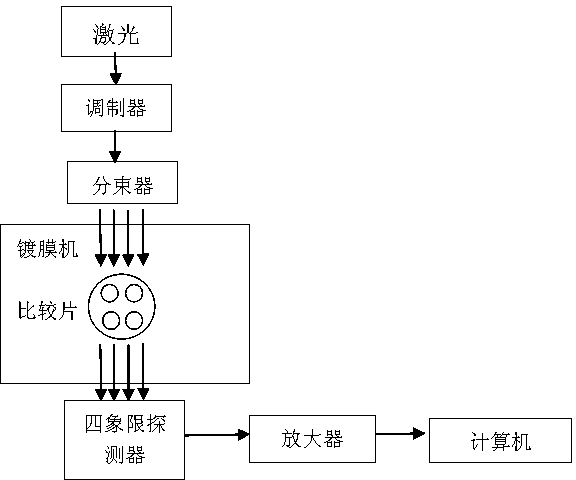

Film thickness monitoring method of optical film and irregular film system optical film thickness instrument

InactiveCN103849850ARealize monitoringGood repeatabilityVacuum evaporation coatingSputtering coatingBeam splitterOptical thin film

The invention relates to a film thickness monitoring method of an optical film and an irregular film system optical film thickness instrument. The prior art has the problems of low precision, difficulty in better repeatability, complicated subsequent treating operation, higher requirement of stabilization degree, and high cost. The film thickness monitoring method of the optical film comprises the steps: preplating by adopting same films; regulating; eliminating direct current components; and obtaining an approximate triangular wave through mathematical treatment. The irregular film system optical film thickness instrument comprises a laser source of a single wavelength, a comparing sheet, a photoelectric detector, an amplifier and a computer, wherein a modulator and a beam splitter are arranged on an emergent light path, four same films are arranged on the comparing sheet for being preplated, and are films with optical thickness difference of lambda / 8; and a four-quadrant detector is adopted as the photoelectric detector. The film thickness monitoring method disclosed by the invention realizes monitoring of an irregular film system; and the irregular film system optical film thickness instrument is high in measurement precision and stable in signal.

Owner:XIAN TECHNOLOGICAL UNIV

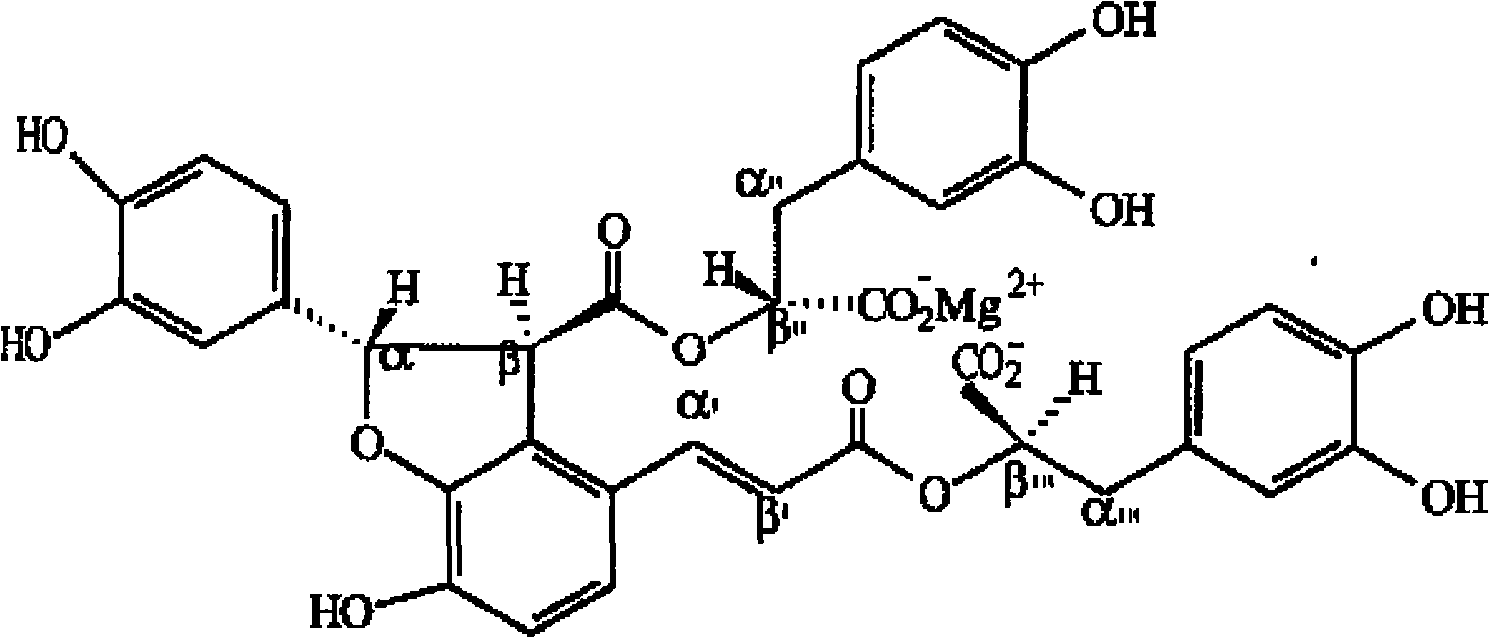

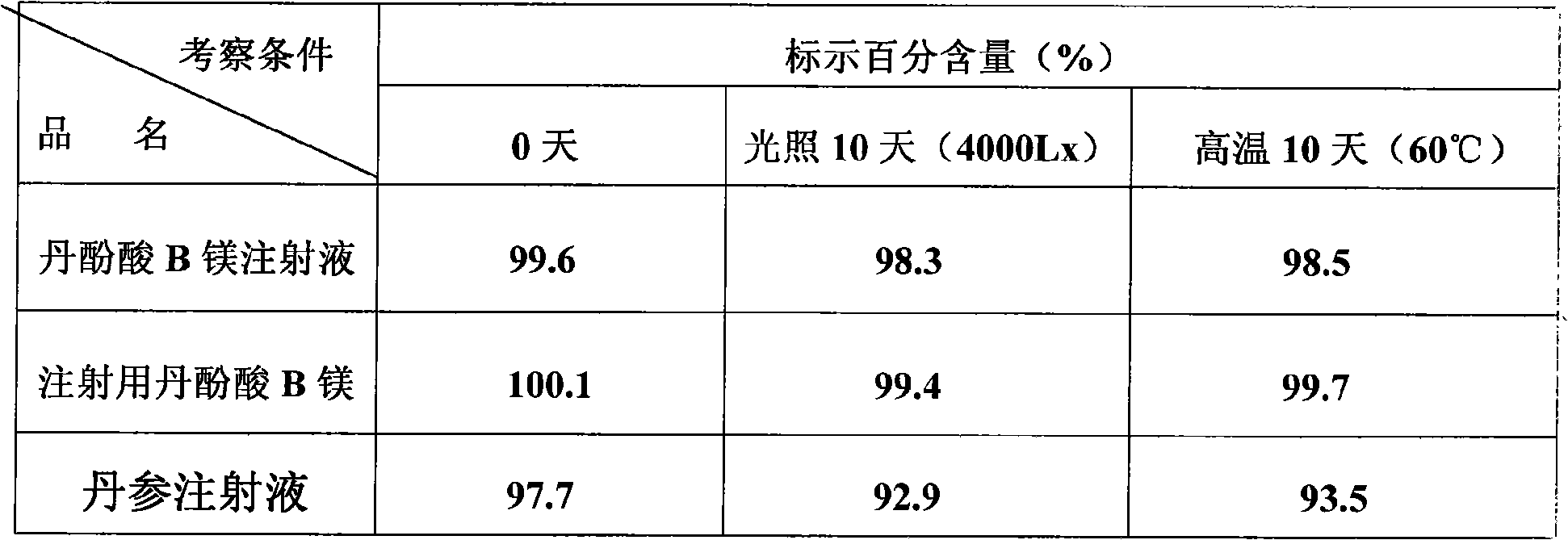

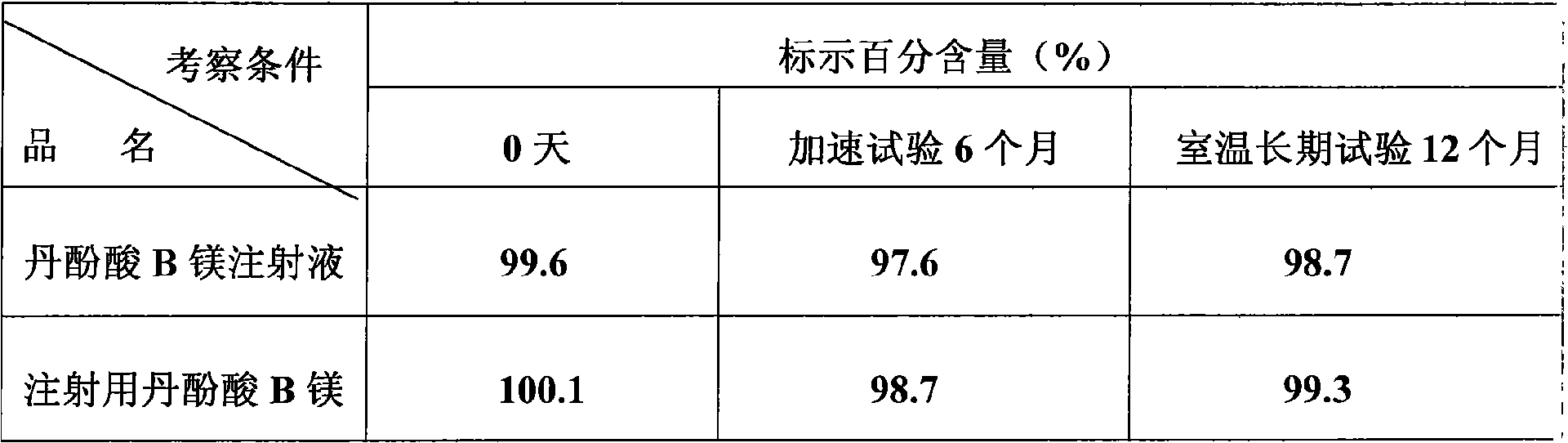

Salvianolic acid B magnesium injection, preparation method and use thereof

InactiveCN101491495AMeet preparation requirementsEasy to useOrganic active ingredientsPowder deliveryDiseaseSalvianolic acid B

The invention relates to a salvianolic acid B magnesium injection and a preparation method and application of the salvianolic acid B magnesium injection. The injection comprises a water injection and a lyophilized powder injection. Currently, relevant salivae miltiorrhizae extract injections only comprise a salivae miltiorrhizae injection, a chambertin injection and other Chinese medicine composite preparations. A product comprises the following compositions: salvianolic acid B magnesium, a pharmacologically allowable pH regulation substance and a stabilizing agent; when the lyophilized powder injection also needs to be added with an excipient, when the injection is in a water injection form, the concentration of the salvianolic acid B magnesium is between 2 and 200mg / ml; in the product, the concentration of the stabilizing agent is between 0.0001 and 0.1g / ml; when the injection is in a lyophilized powder injection form, in each piece, namely each 42 to 1,300 mg of a dry substance, the salvianolic acid B magnesium is between 2 and 400 mg; the addition amount of the excipient is between 0.04 and 0.8 g; the addition amount of the stabilizing agent is between 0.0001 and 0.1g / piece; and in two substances, the addition amount of the pH regulation substance is equal to the addition amount when pH value is regulated to be between 2.5 and 7.5. The salvianolic acid B magnesium injection is used for treating cardiovascular and cerebrovascular diseases and other diseases.

Owner:苑立超

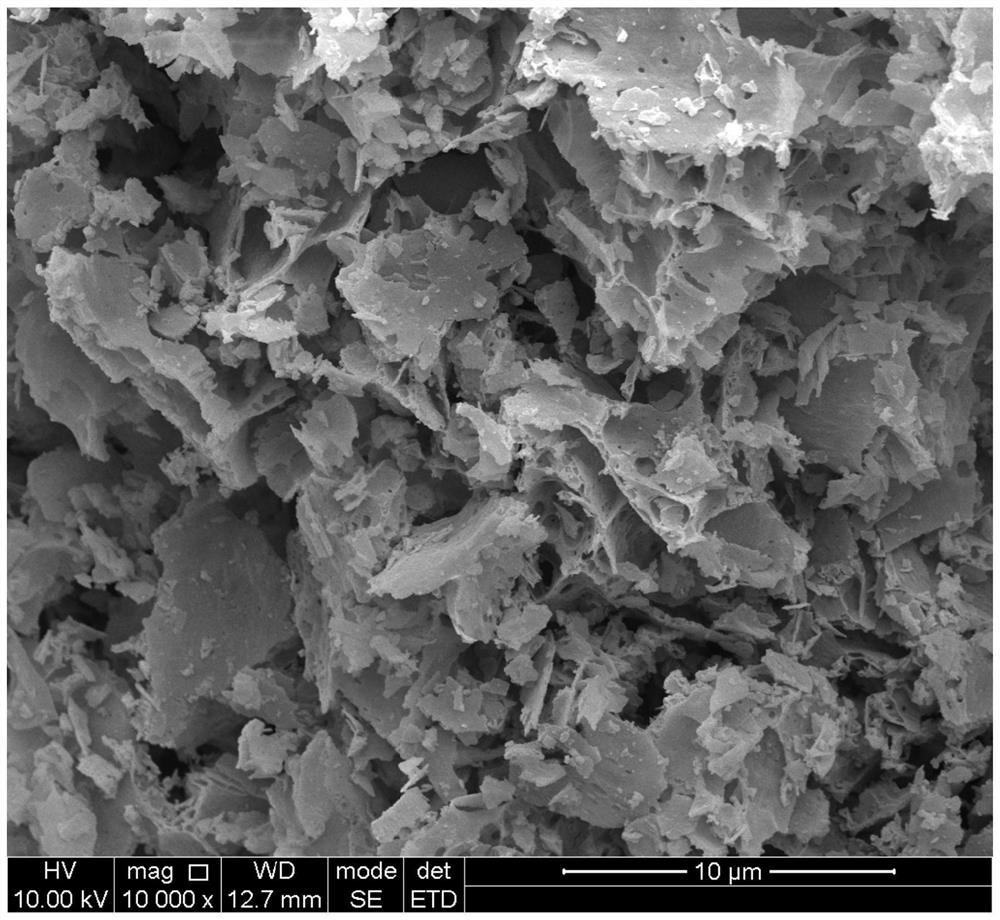

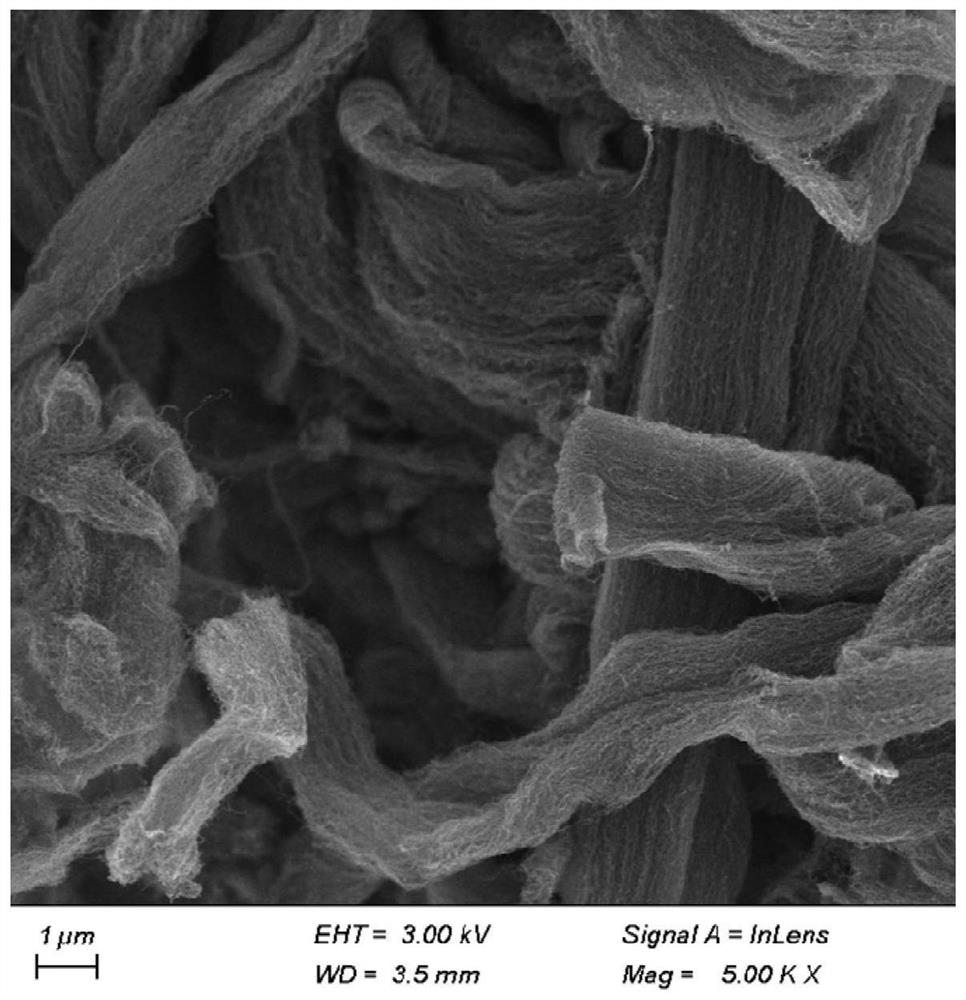

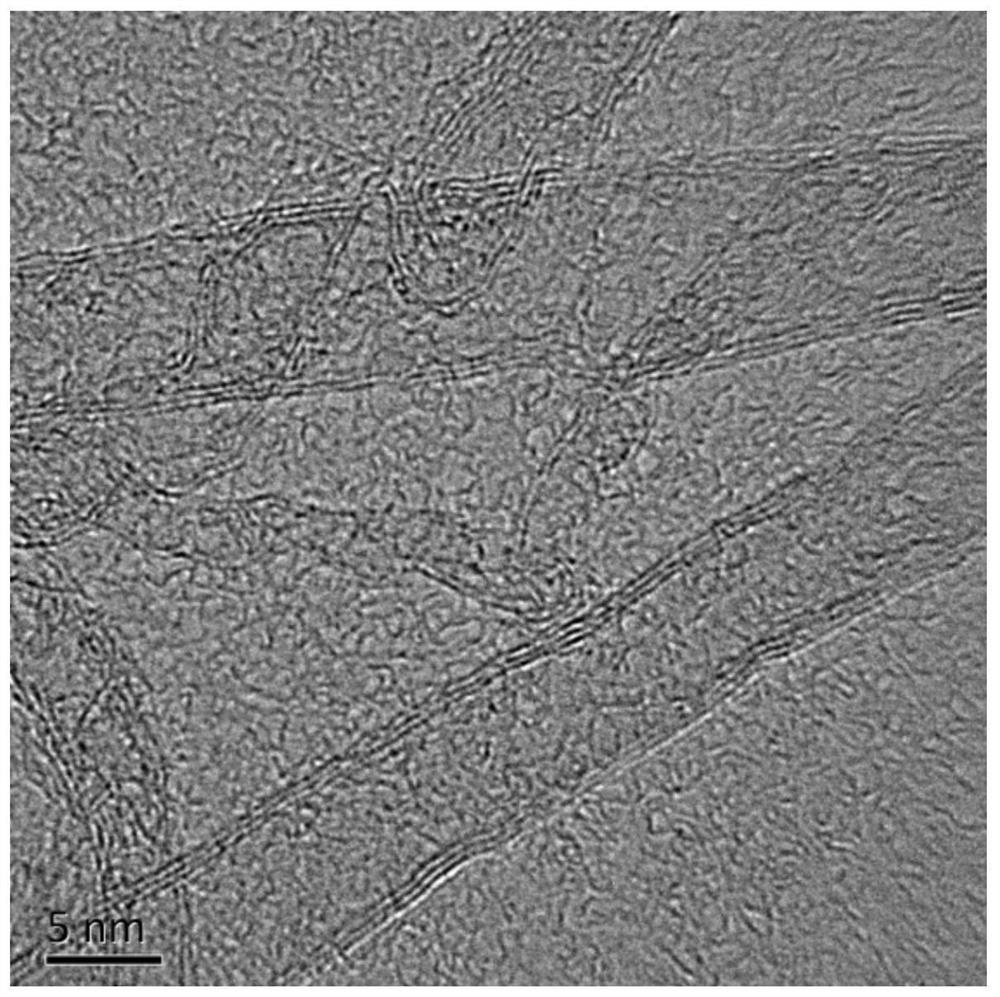

Catalyst for preparing carbon nanotubes as well as preparation method and application thereof

InactiveCN113209969APrevent subsidenceEase of industrial productionCatalyst activation/preparationCarbon nanotubesPtru catalystPorous sheet

The invention discloses a catalyst for preparing carbon nanotubes as well as a preparation method and application thereof. The catalyst comprises a porous sheet-shaped carrier and an active component dispersed on the porous sheet-shaped carrier, wherein the active component comprises a transition metal element. The porous sheet-shaped catalyst provided by the invention is suitable for preparing carbon nanotubes, can meet the preparation requirements of few-wall array carbon nanotubes, can improve the growth rate of carbon nanotubes and improve the industrial production efficiency, and has a wide application prospect.

Owner:佛山市格瑞芬新能源有限公司

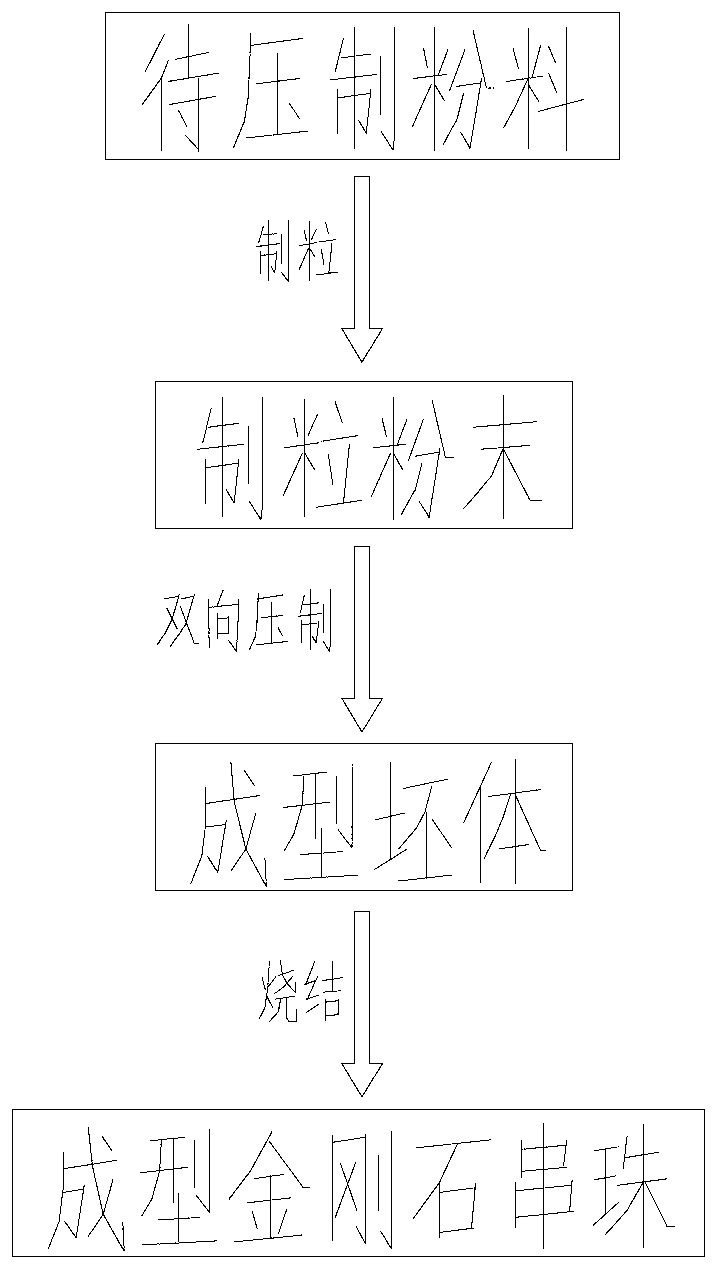

Forming technology of diamond bead cold pressed blank

ActiveCN103263875ANo enrichmentMeet preparation requirementsGranulation by material expressionDisadvantageA diamond

The invention discloses a forming technology of a diamond bead cold pressed blank, comprising the following steps of: (1) pelletizing powder material to be compressed, to obtained pelletized powder; (2) simultaneously and bilaterally compressing the pelletized powder; (3) when compressed, automatically sinking a lower pressure head, to change a final forming position; (4) and sintering after completing compression, and then completing preparation of the diamond beads after stirring. The technology not only can solve disadvantages of traditional manual cold press, simultaneously, but also can provide a diamond bead cold press forming technology with wider adaptability and more stable performances, and further promotes development of a diamond rope saw.

Owner:长沙百通新材料科技有限公司

High temperature methanation catalyst and its preparation method and application

InactiveCN102847540AMeet preparation requirementsImprove catalytic performanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasMethanation

The inventive high temperature methanation catalyst belongs to the technical field of hydrogenation. The invention provides a catalyst with good catalytic performance, in order to overcome the problems of complex composition and preparation method and shorter life of the prior methanation catalyst. The catalyst mainly includes NiO 45%-75%, Cr2O3 0%-10%, and MgO modified carrier 25%-55%. The invention simultaneously provides a method for preparing the catalyst by precipitation method and the application of the catalyst. The catalyst has good activity and stability, and can be used in the application for converting coal-based synthetic gas into urban fuel gas and natural gas.

Owner:孙德标

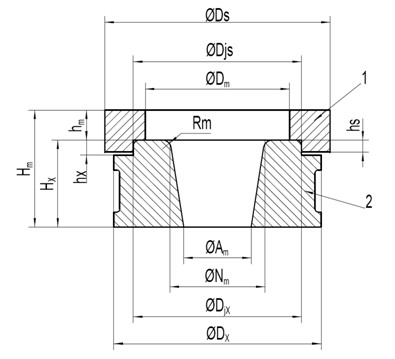

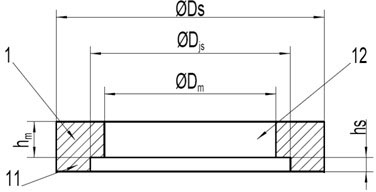

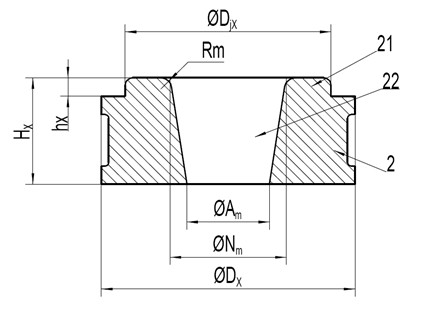

Method for manufacturing large-scale flange forged piece by utilizing combined tyre die

ActiveCN102319850AIncrease production capacityEasy to carryForging/hammering/pressing machinesFlangeElectrical and Electronics engineering

The invention discloses a method for manufacturing a large-scale flange forged piece by utilizing a combined tyre die, and the method comprises the following steps: step 1), setting a combined tyre die stack for storing the combined tyre die and a database; step 2), searching for determining whether the combined tyre die stack is empty or not, if so, turning to the step 5); step 3), finding an upper die enabling Dm to be not less than Dm initial and enabling hm to be not less than hm initial in the tyre die database, finding out all lower dies which can be combined with the upper die, performing pairing treatment on the upper die and the lower dies, screening out the combined tyre die which meets the initial size of a die cavity of the tyre die, calculating the volume of the die cavity, selecting the combined tyre die meeting the requirements as the finally selected combined tyre die and turning to the step 4); if the combined tyre die is not found, turning to the step 5); step 4), using the finally selected combined tyre die to manufacture the large-scale flange forged piece and turning to the step 6); step 5), manufacturing the brand new combined tyre die and manufacturing the large-scale flange forged piece; and step 6), further performing measurement and updating after the upper die and the lower die are used and placing and storing the upper die and the lower die into the combined tyre die stack.

Owner:NANJING DEV ADVANCED MFG

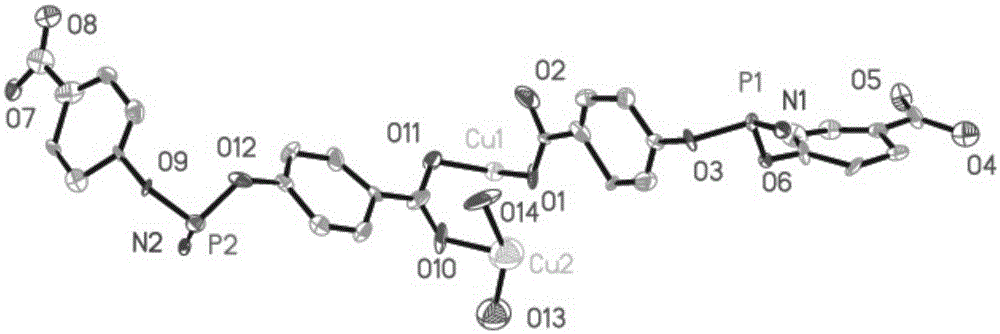

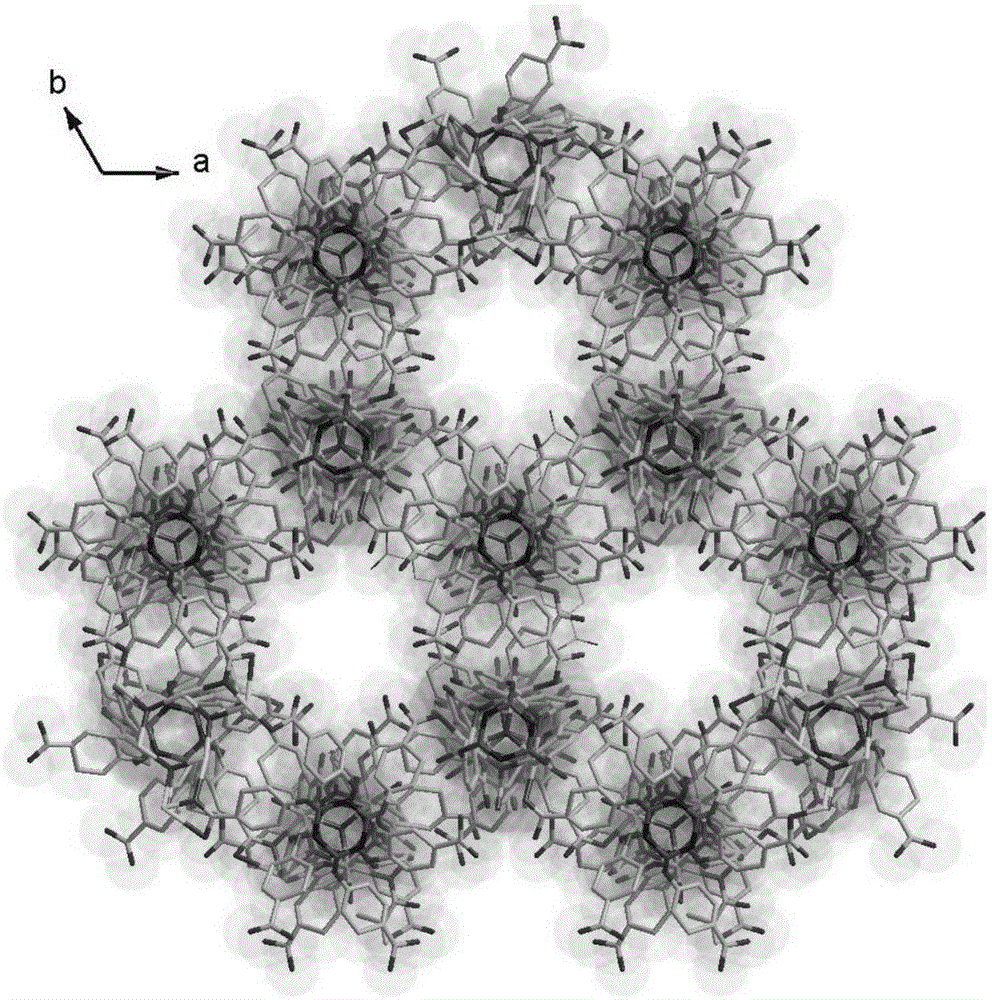

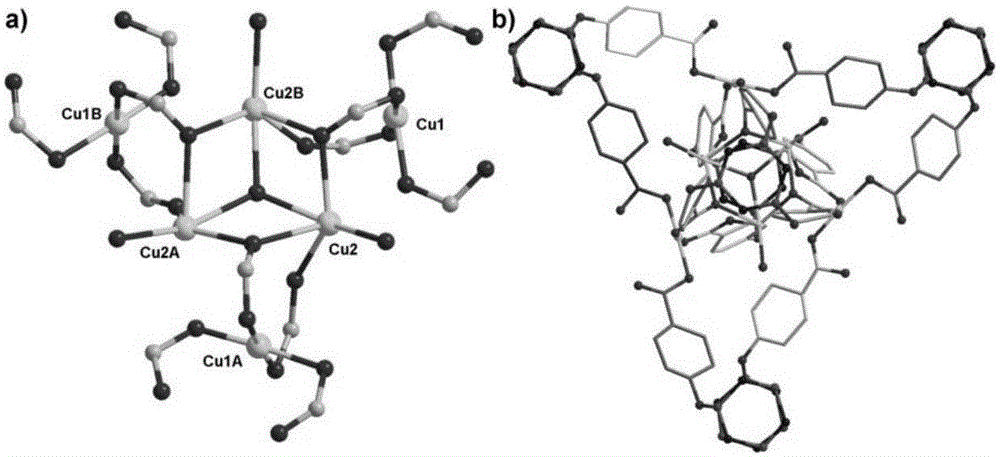

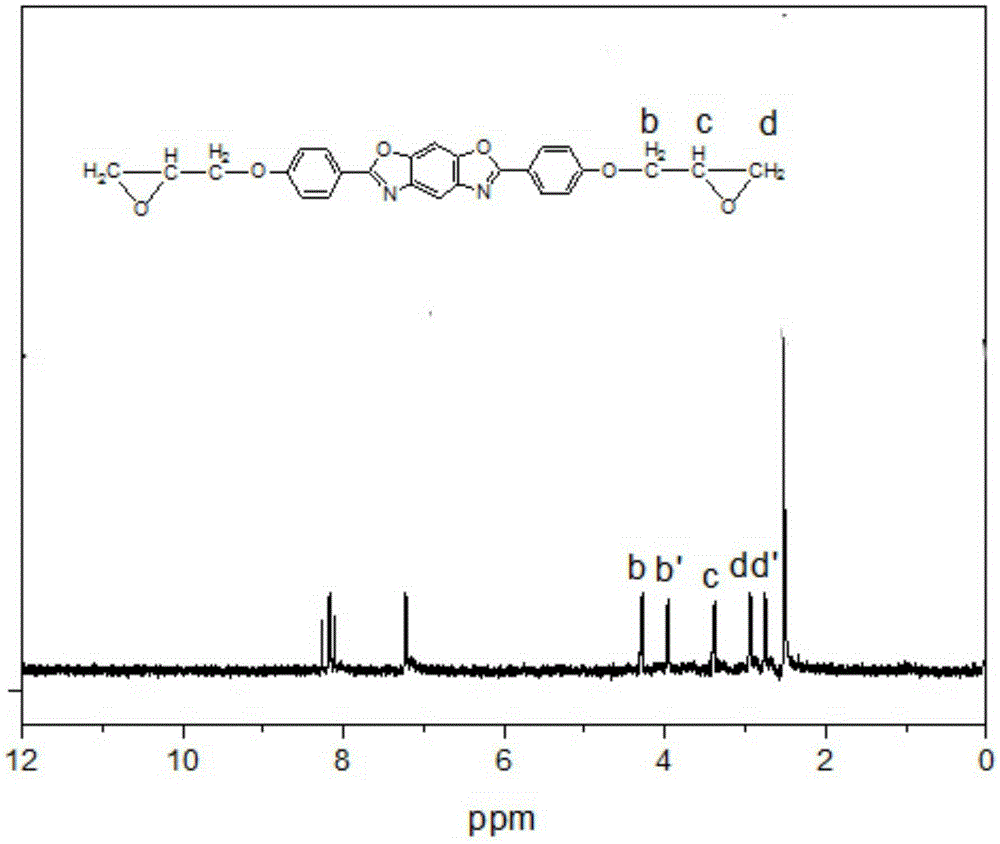

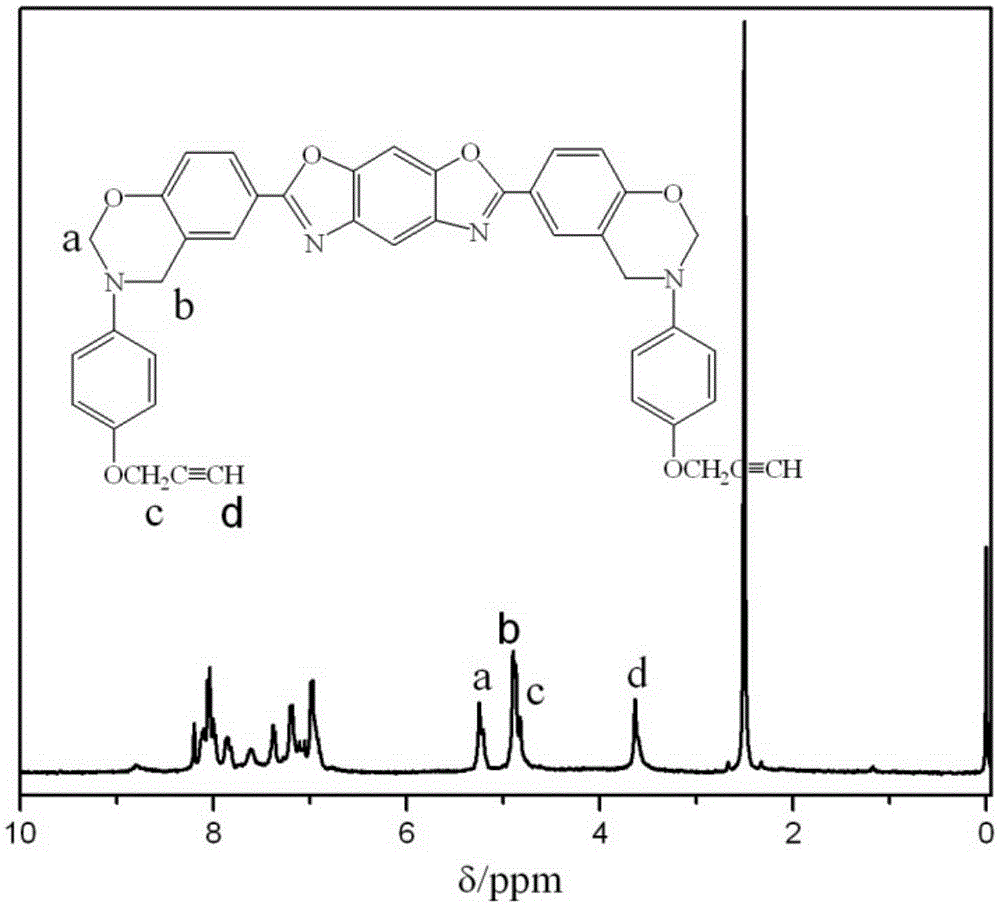

Copper-cyclotriphosphazene hexacarboxylic acid derivative coordination framework material and preparation and application thereof

InactiveCN105153205ANovel topologyImprove stabilityOther chemical processesGroup 5/15 element organic compoundsHEXAAcid derivative

The invention discloses a copper-cyclotriphosphazene hexacarboxylic acid derivative coordination framework material and a preparation method and application thereof. The coordination framework material is formed by adopting raw materials comprising copper ions and a ligand L through reaction, wherein the ligand L is hexa-(4-carboxylate benzoxy) cyclotriphosphazene and the chemical formula is C42H30O18N3P3; in addition, the coordination framework material is a three-dimensional framework material and has one-dimensional linear pore passages. By improving the composition and structure of the coordination framework material, various parameters in the preparation method and the like, the structurally ordered copper-cyclotriphosphazene hexacarboxylic acid derivative coordination framework materials can be obtained, the preparation method of the series of materials can effectively guarantee the reaction yield and the actual application is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

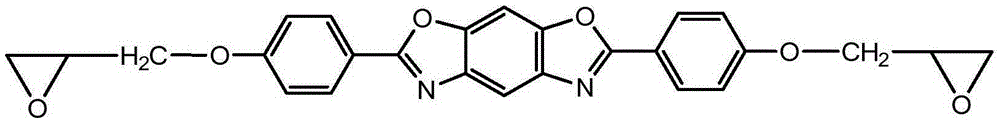

PBO fiber epoxy resin composite material and preparation method thereof

The invention relates to a PBO fiber epoxy resin composite material and a preparation method thereof. The PBO fiber epoxy resin composite material contains the following components in parts by mass: 100 parts of PBO fibers and 50-80 parts of a mixed epoxy resin matrix. The preparation method comprises the following steps: firstly preparing a glue material by virtue of pre-polymerization; carrying out surface modification on the PBO fibers; soaking the PBO fibers into glue material, winding, airing to obtain a prepreg, paving the prepreg into a mold, carrying step heating, pressurization and curing, naturally cooling to the room temperature, and carrying out demolding, so as to obtain the PBO fiber / epoxy resin composite material. Novel epoxy resin and benzoxazine resin which have good compatibility with PBO are adopted in the matrix resin glue material, so that the wettability and cohesive property of the PBO fibers to the matrix resin can be increased, therefore, the interface performance of the resin and the fibers is remarkably improved, and the high strength property of the PBO fibers in the composite material is adequately exerted; and furthermore, the temperature resistance grade of the composite material is substantially increased, the mechanical property of the composite material is substantially improved, and the PBO fiber epoxy resin composite material can be used for preparing high-temperature-resistant composite materials and composite materials with high strength requirements.

Owner:EAST CHINA UNIV OF SCI & TECH

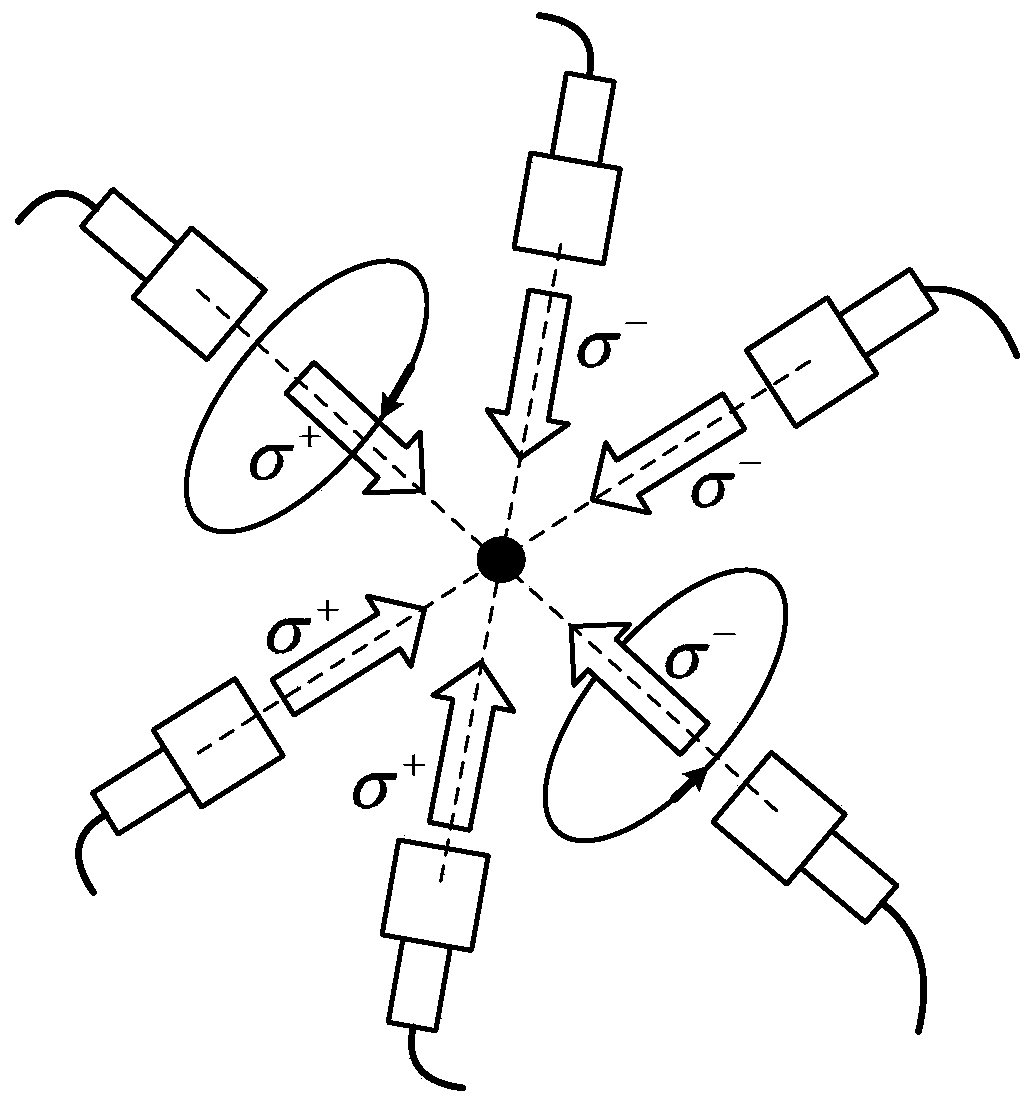

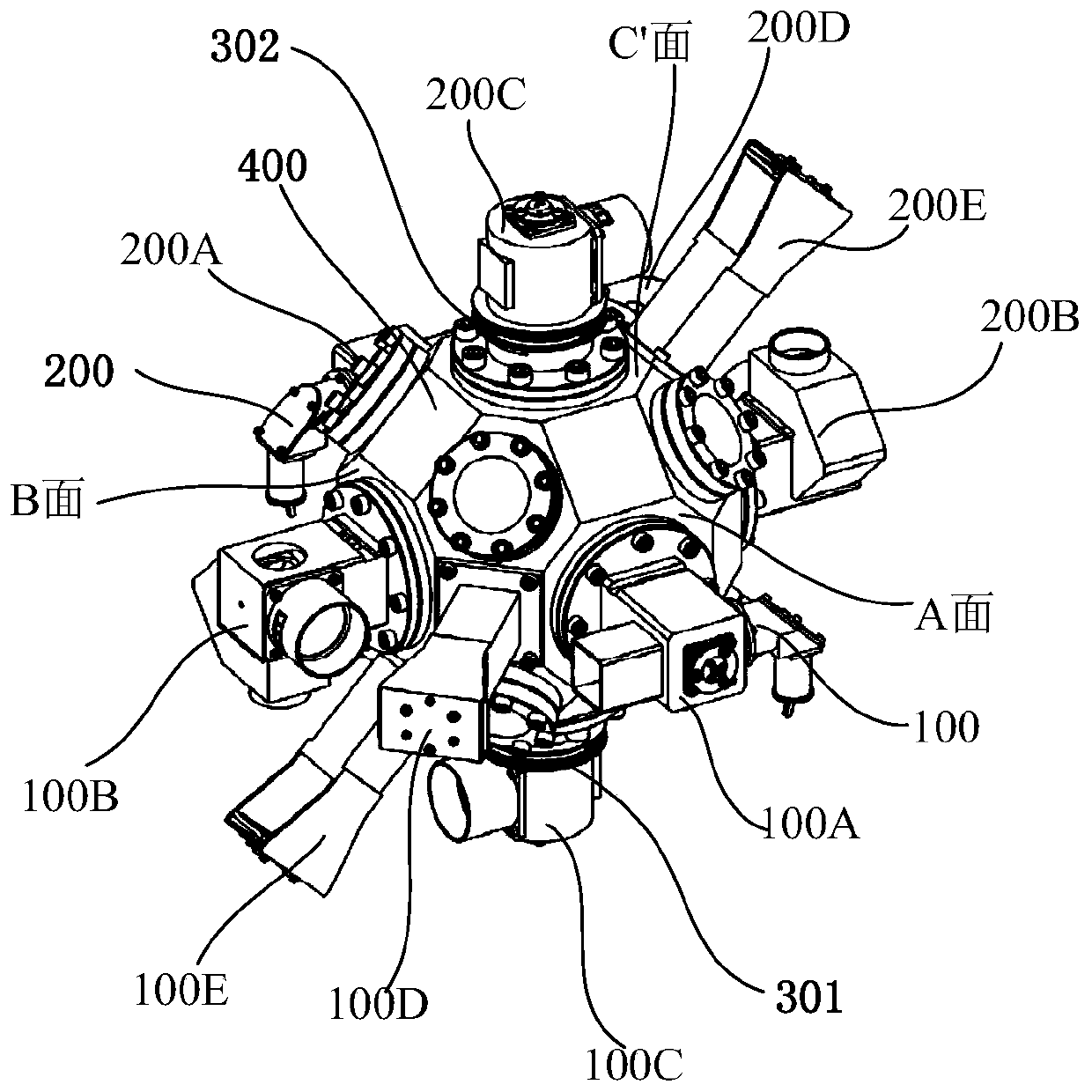

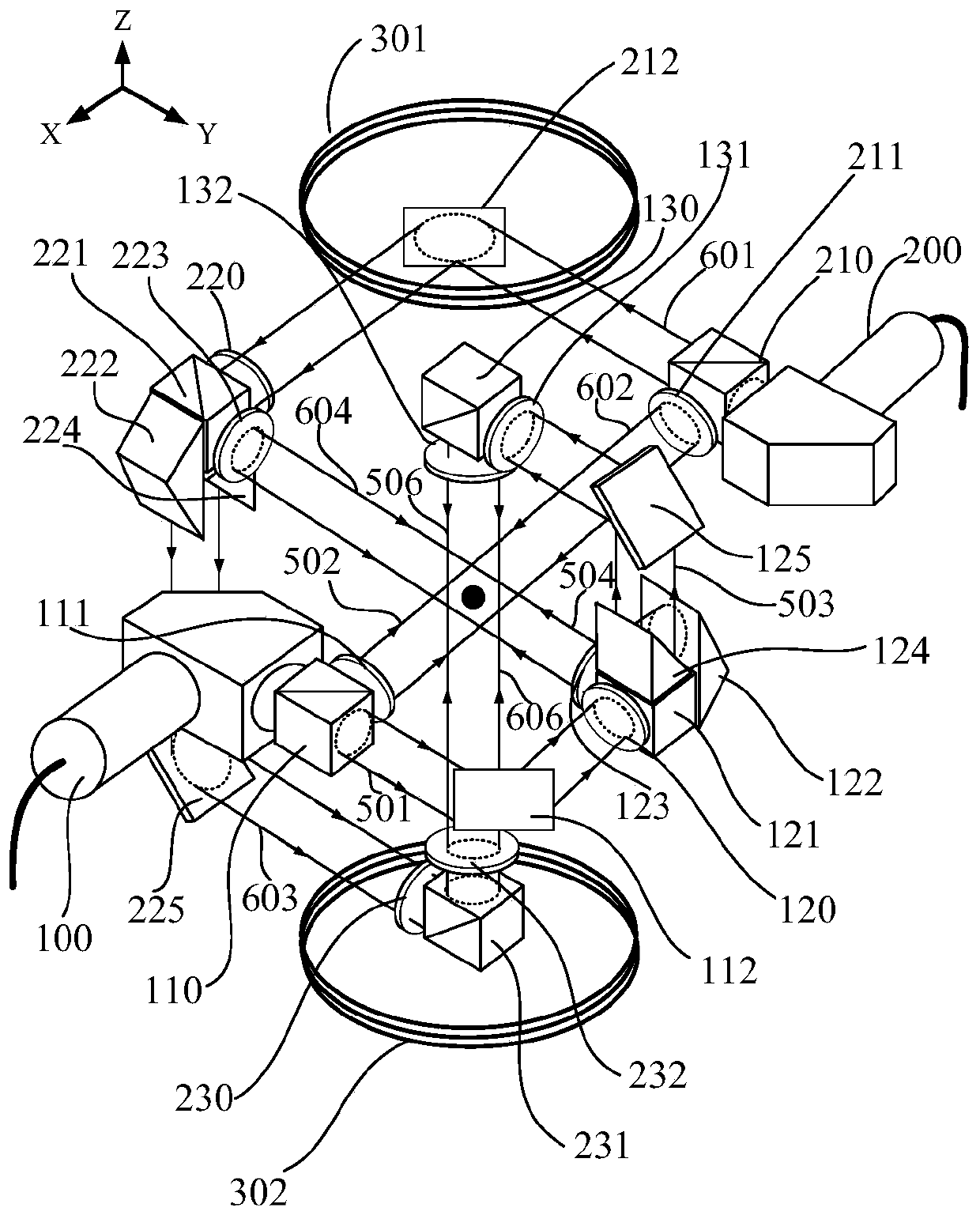

Double-beam input laser cooling atom three-dimensional magneto-optical trap device

ActiveCN111584115AEliminate quality impactImprove performanceNeutron particle radiation pressure manipulationMagneto-optical trapPolarization-maintaining optical fiber

The invention provides a double-beam input laser cooling atom three-dimensional magneto-optical trap device, and aims to overcome the defects that an optical path system of an existing magneto-opticaltrap is easily affected by the external environment, and generated cold atoms have large-amplitude random jitter, and extra errors are introduced although random jittering of cold atom parameters caused by optical fiber factors is reduced. A unique three-dimensional MOT optical path transmission topology is designed, six polarization maintaining optical fibers required originally are reduced to two polarization maintaining optical fibers, and the influence of unstable incident laser polarization degree and light intensity fluctuation on the generated cold atom quality is greatly eliminated; polarization characteristics of laser beams are utilized, multiple times of light beam splitting and reflection are performed, independent adjustment of power and polarization of six beams of laser used for atom cooling is achieved under the condition that only two paths of input light exist, particularly, the power of the six beams of light which are oppositely emitted in pairs at a convergence point can be adjusted to be strictly equal, and the influence caused by inconsistent fluctuation pace of the power of the six beams of light in the working process of the device is greatly reduced.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method for deeply removing fluorine from LiHCO3 solution recycled and leached from waste lithium batteries

ActiveCN112853120AMeet preparation requirementsAvoid decompositionWaste accumulators reclaimingProcess efficiency improvementTitanium zirconiumLithium carbonate

The invention belongs to the technical field of lithium ion battery recovery, and provides a method for deeply removing fluorine from an LiHCO3 solution recycled from waste lithium batteries. The method is used for preparing battery-grade lithium carbonate by taking the LiHCO3 solution as a stock solution. The method comprises the following steps of A, preparing raw materials; B, performing alkali washing on a fluorine removal agent; B, introducing CO2 to regulate and control the pH of a system; D, removing the fluorine from the LiHCO3 solution; and E, regenerating the fluorine removal agent. According to the method, the fluorine removal agent containing elements such as aluminum, titanium, zirconium and nitrogen is added into the LiHCO3 solution, and the CO2 gas is blown to regulate and control the reaction pH, so that the deep fluorine removal effect can be achieved, the LiHCO3 solution system can be ensured to be unchanged, meanwhile, new impurities are not introduced, the subsequent preparation requirements of the battery-grade lithium carbonate are met, and the product quality is improved.

Owner:衢州华友资源再生科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com